Page 1

TAC Vista

TAC Pangaea

WorkStation

TAC Xenta 280/300/401

Product Manual

Page 2

Page 3

TAC Vista

TAC Xenta 280/300/401

Product Manual

Page 4

Copyright © 2007-2011 Schneider Electric Buildings AB. All rights reserved.

This document, as well as the product it refers to, is only intended for licensed users. Schneider Electric Buildings AB owns the copyright of

this document and reserves the right to make changes, additions or deletions. Schneider Electric Buildings AB assumes no responsibility for

possible mistakes or errors that might appear in this document.

Do not use the product for other purposes than those indicated in this document.

Only licensed users of the product and the document are permitted to use the document or any information therein. Distribution, disclosure,

copying, storing or use of the product, the information or the illustrations in the document on the part of non-licensed users, in electronic or

mechanical form, as a recording or by other means, including photo copying or information storage and retrieval systems, without the express

written permission of Schneider Electric Buildings AB, will be regarded as a violation of copyright laws and is strictly prohibited.

Trademarks and registered trademarks are the property of their respective owners.

Page 5

TAC Xenta, TAC Xenta 280/300/401 Contents

Contents

INTRODUCTION

1 About this Manual 9

1.1 Structure..................................................................................................................... 9

1.2 Typographic Conventions.......................................................................................... 10

1.3 Prerequisites............................................................................................................... 10

REFERENCE

2 TAC Xenta Components 13

2.1 Hardware Units ................................................................................................ ..... ..... 13

2.2 Configurations............................................................................................................ 14

2.3 Communications ........................................................................................................ 15

3 Technical Description 17

3.1 The TAC Xenta 280 Controller........................................................................ ..... ..... 17

3.1.1 Terminals.................................................................................................................... 17

3.1.2 Jacks........................................................................................................................... 18

3.1.3 LED Indicators and Service pin................................................................................. 19

3.1.4 Technical Data TAC Xenta 280................................................................................. 20

3.2 The TAC Xenta 300 Controller........................................................................ ..... ..... 21

3.2.1 Terminals.................................................................................................................... 21

3.2.2 Jacks........................................................................................................................... 23

3.2.3 LED Indicators and Service pin................................................................................. 23

3.2.4 Technical Data TAC Xenta 300................................................................................. 24

3.3 The TAC Xenta 401 Controller........................................................................ ..... ..... 25

3.3.1 Terminals.................................................................................................................... 25

3.3.2 Jacks........................................................................................................................... 25

3.3.3 LED Indicators and Service pin................................................................................. 26

3.3.4 Technical Data TAC Xenta 401................................................................................. 27

4 Installation 29

4.1 Mounting the Controller............................................................................................. 29

4.2 Electrical Installation ................................................................................................. 30

4.2.1 General Considerations.............................................................................................. 30

4.2.2 Cabinet Connections .................................................................................................. 32

4.2.3 Cables......................................................................................................................... 34

4.3 Terminations .............................................................................................................. 39

4.3.1 The TAC Xenta OP Operator Panel........................................................ ..... .... .......... 42

5 Configuring your System 45

5.1 Overview.................................................................................................................... 45

Schneider Electric Buildings AB, June 2011 5 (74)

04-00067-02-en

Page 6

Contents TAC Xenta, TAC Xenta 280/300/401

5.2 A Single TAC Xenta 280/300/401 Controller............................................................ 46

5.2.1 Initial Check ............................................................................................................... 46

5.2.2 OP Panel Activities..................................................................................................... 47

5.3 Two or more TAC Xenta 280/300/401 Units............................................................. 47

5.3.1 Initial Check ............................................................................................................... 47

5.3.2 Device Configuration ................................................................................................. 47

5.3.3 OP Panel Activities..................................................................................................... 48

5.4 Additional I/O Units................................................................................................... 48

5.4.1 Selecting I/O Modules................................................................................................ 48

5.4.2 Initial Check ............................................................................................................... 49

5.4.3 I/O Module Configuration.......................................................................................... 49

5.5 Setting the Date and Time.......................................................................................... 50

5.6 Clearing the Xenta Application..................................... ..... ........................................ 51

5.7 Lock a Xenta OP to a specific TAC Xenta Controller............................................... 51

5.7.1 Creating the PVI-block in the Xenta.......................................................................... 51

5.7.2 Enabling the function in TAC Xenta OP.................................................................... 52

6 The TAC Xenta Service Menu 53

6.1 Accessing the Service Menu ...................................................................................... 53

6.2 Submenus 1-8............................................................................................................. 54

6.2.1 Submenu 6: Test dial.................................................................................................. 57

APPENDIX

A Appendix A Restart Values 63

B Appendix B Restart Sequences 67

Index 71

6 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 7

INTRODUCTION

1 About this Manual

Page 8

Page 9

TAC Xenta, TAC Xenta 280/300/401 1 About this Manual

1 About this Manual

This manual describes a particular process. For information on certain

products, we refer you to the manual or the Help for the product in question.

For information on how to install software, we refer you to the instructions delivered with the software.

For information on third party products, we refer you to the instructions

delivered with the third party product.

If you discover errors and/or unclear descriptions in this manual, please

contact your Schneider Electric representative.

Note

1.1 Structure

• We are continuously improving and correcting our documentation. This manual may have been updated.

Please check our Docnet site at www.tac.com for the latest version.

The manual is divided into the following parts:

• Introduction

The Introduction section contains information on how this manual

is structured and how it should be used to find information in the

most efficient way.

• Reference

The Reference section contains more comprehensive information

about various parts of the Getting Started section. It also provides

you with information on alternative solutions not covered by the

Getting Started section.

Schneider Electric Buildings AB, June 2011 9 (74)

04-00067-02-en

Page 10

1 About this Manual TAC Xenta, TAC Xenta 280/300/401

!

1.2 Typographic Conventions

Throughout the manual the following specially marked texts may occur.

Warning

• Alerts you that failure to take, or avoid, a specific action might

result in physical harm to you or to the hardware.

Caution

• Alerts you to possible data loss, breaches of security, or other

more serious problems.

Important

• Alerts you to supplementary information that is essential to the

completion of a task.

Note

• Alerts you to supplementary information.

Tip

• Alerts you to supplementary information that is not essential to

Advanced

• Alerts you that the following information applies to complex

1.3 Prerequisites

To be able to profit from the contents in this manual, it is recommended

that you read the following documents:

• TA C Xenta 280 Programmable Controller datasheet

the completion of the task at hand.

tasks or tasks restricted by access.

• TA C Xenta 300 Programmable Controller datasheet

• TA C Xenta 400 Controller, freely programmable datasheet

10 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 11

REFERENCE

2 TAC Xenta Components

3 Technical Description

4 Installation

5 Configuring your System

6 The TAC Xenta Service Menu

Page 12

Page 13

TAC Xenta, TAC Xenta 280/300/401 2 TAC Xenta Components

TAC Xenta 280 or 300 controller

12 13 14 15 16 17 18 20

TAC Xenta 401 controller

Operator panel

12 13 14 15 16 17 18 20

I/O expansion module

2 TAC Xenta Components

2.1 Hardware Units

The TAC Xenta 280/300/400 family consists of the following units:

• The TAC Xenta 280/300/401 controller. The controller contains

the database of the inputs and outputs of the TAC Xenta system. It

also contains the system and application software for all the functions that are to be performed by the controller and the connected

peripheral units.

• TAC Xenta OP. The operator panel includes control buttons while

a screen displays the values and menus. TAC Xenta OP can be

connected to any controller in the network.

I/O expansion modules. These can be used to extend the number of

inputs and outputs on a TAC Xenta 300/401 controller.

The I/O modules are described in a separate manual, TAC Xenta 400 I/

O Modules.

Schneider Electric Buildings AB, June 2011 13 (74)

04-00067-02-en

Fig. 2.1: The basic units of the TAC Xenta: the controller, the operator

panel, and an I/O expansion module

Page 14

2 TAC Xenta Components TAC Xenta, TAC Xenta 280/300/401

Inputs Outputs I/O Modules See section

TAC Xenta 280 3.1

TAC Xenta 281 6 6 none

TAC Xenta 282 8 8 none

TAC Xenta 283 6 6 none

TAC Xenta 300 3.2

TAC Xenta 301 12 8 up to 2

TAC Xenta 302 12 8 up to 2

TAC Xenta 401 none none up to 10 3.3

A number of controllers and I/O modules can form a local network and

exchange data.

The TAC Xenta OP operator panel allows the user to:

• Obtain access to certain parameters

• Monitor the system status

• Adjust setpoints and time channels

• Display alarms (without communicating with a central system)

Up to two OPs may be connected to each controller.

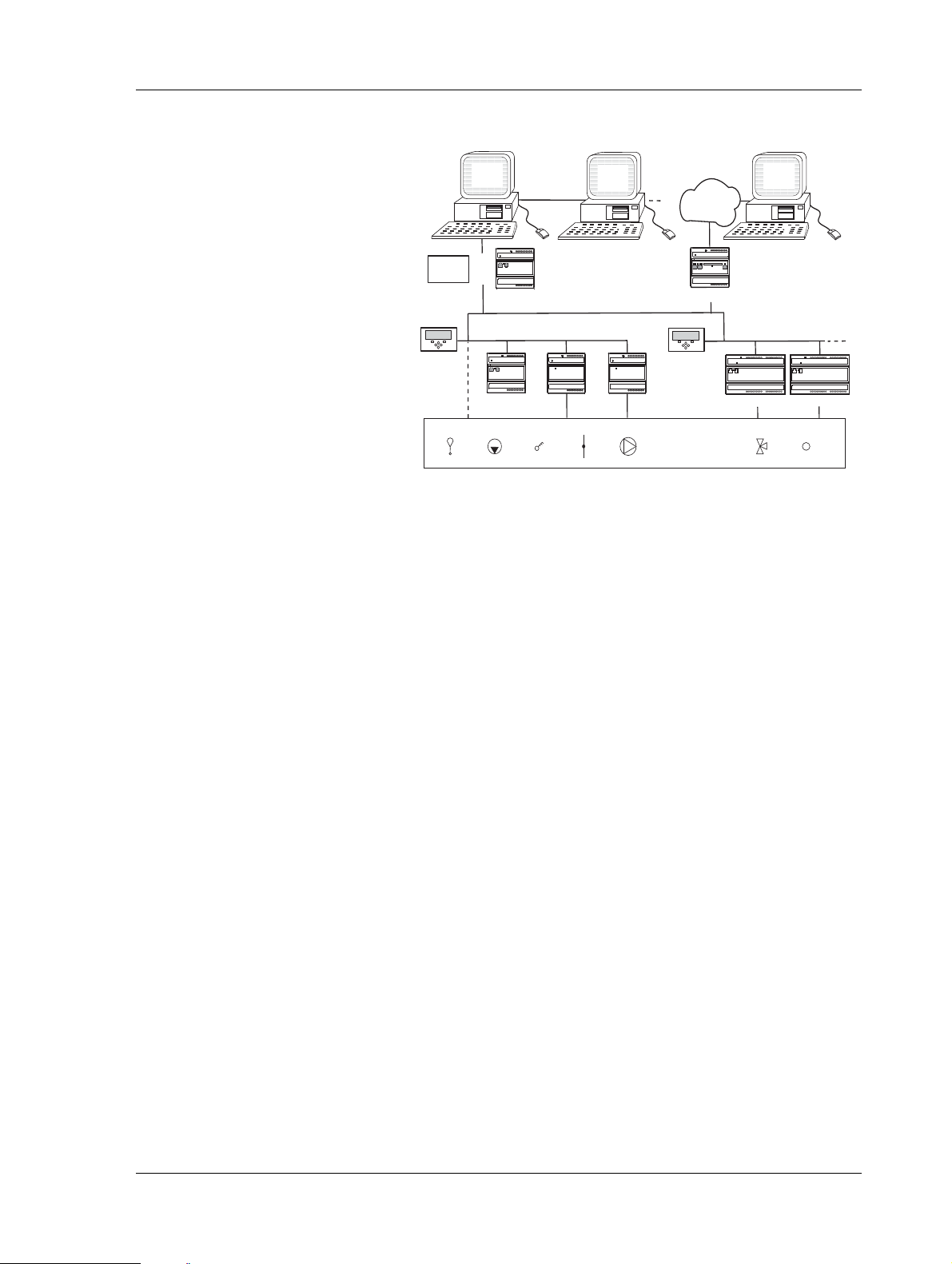

2.2 Configurations

The TAC Xenta controllers can be used in different configurations, for

example:

• As stand-alone units (for a TAC Xenta 401 with at least one I/O

module).

• With controllers and OPs in a network, with extra I/O modules as

required (no I/O modules for the TAC Xenta 280).

• With controllers, OPs, I/O modules and other equipment in a full

network with suitable adapters, possibly with connections to a

TAC Vista Central System.

14 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 15

TAC Xenta, TAC Xenta 280/300/401 2 TAC Xenta Components

+

-

TAC

Vista

TAC Xenta OP

TP/FT-10

TAC Xenta OP

TAC Xenta 401

TAC Xenta 281

TAC Xenta 901

TAC

Vista

TAC Xenta 511

TAC Xenta 301

Management

level

Automation

level

Field

level

I/O ModuleorI/O Module

Web

Browser

IP Network

PCLTA

card

Fig. 2.2: A TAC Xenta network example

2.3 Communications

The TAC Xenta units communicate with each other in a network using

a common bus, Echelon® L

10). Additional I/O units also connect to the network and may be added

as required. An I/O unit can only be associated with one controller.

Explicit L

operator panel and the controller.

The L

defined on foreign equipment.

The Functional Block applications are modeled as true L

troller Objects.

The Network Variable interface (including the Standard Network Variable Types, SNVTs) can be customized, and External Interface Files

(XIFs) can be generated in the field using the TAC Menta tool. Available SNVTs are listed in an appendix to the Engineering Applications

in TAC Menta manual.

When connected to a TAC Vista Central System, the operating conditions of equipment such as fans, pumps, and recovery units can be displayed as graphs on the monitor and printed as reports. All temperatures

and alarms may be read, while setpoints and time settings may be

altered as required

TAC Xenta controllers can be reached from TAC Vista in many ways.

Using LonWorks in the Xenta controller, some examples are:

• From a PCLTA card in some form, directly on the PC.

ONWORKS® Free Topology 78 kbps (FTT-

ONTALK® messages are used in communications between the

ONTALK protocol makes it possible to use Network Variables,

ONMARK Con-

Schneider Electric Buildings AB, June 2011 15 (74)

04-00067-02-en

Page 16

2 TAC Xenta Components TAC Xenta, TAC Xenta 280/300/401

• Via the LTA function in the TAC Xenta 911.

• Via the LTA function in the TAC Xenta 511.

• Using the TAC Xenta 901.

• Via an Ethernet/LON gateway.

Using the serial channel in the Xenta controller, for example:

• Directly connected to a PC serial channel.

• Connected to a PC serial channel via a telephone modem.

• Connected to a PC serial channel via the IP modem function of the

TAC Xenta 911.

Starting from v 3.1, application programs generated in TAC Menta may

be downloaded from TAC Vista via the network.

The TAC Xenta 280/300/401 can communicate as follows:

• It can send alarm and trend logging (versions 3.2 and higher) messages.

• It can answer requests for the status of inputs and outputs.

• It can send/ any of the parameters/variables in the program which

are freely available (“Public signal”).

• It can communicate with other T AC Xenta controllers to exchange

data.

• It can communicate with the Operator Panel, the I/O-modules, and

TAC Vis ta.

For further details, please consult the TAC Vista IV, Engineering Clas-

sic/LNS Network manuals.

RS232

The TAC Xenta 280/300/401 controller has an RS232 port that can be

used to:

• Load the system software.

• Load the application software from the TAC Menta programming

tool.

• Connect to TAC Menta when used as a commissioning tool.

• Connect a specific controller directly to T AC V ista or via a modem

(modem connection not available with TAC Xenta 280).

• Retrieve the “System Error Log File” using the “Xenta System

Error Log Viewer”.

16 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 17

TAC Xenta, TAC Xenta 280/300/401 3 Technical Description

3 Technical Description

3.1 The TAC Xenta 280 Controller

Fig. 3.1: The TAC Xenta 280 controller

3.1.1 Terminals

The TAC Xenta 281, 282 and 283

The TAC Xenta 280 has three I/O configurations, called the TAC Xenta

281, 282, and 283.

No external TAC Xenta 400 I/O modules can be used.

Digital

inputs

Term. notation

TAC Xenta 281 2-43-3

TAC Xenta 282 2244-4

TAC Xenta 283 24 --6-

XBUKVY

Thermistor

inputs

Universal inputs

Relay

outputs

TRIAC

outputs

Analog

outputs

Schneider Electric Buildings AB, June 2011 17 (74)

04-00067-02-en

Page 18

3 Technical Description TAC Xenta, TAC Xenta 280/300/401

20

17

18

16

19

15

12

13

11

14

40

37

38

36

39

35

32

33

31

34

10

7

8

6

9

5

2

3

1

4

30

27

28

26

29

25

22

23

24

21

K2

KC1

K1

Y2

G0

Y1

G

M

X2

M

M

X1

M

U4

U3

U2

C2

U1

M

C1

K3

KC2

0~24 V

AC/DC

}

Comm

{

max 230 V AC

Y3

M

TAC Xenta 281

max 230 V AC

20

17

18

16

19

15

12

13

11

14

40

37

38

36

39

35

32

33

31

34

10

7

8

6

9

5

2

3

1

4

30

27

28

26

29

25

22

23

24

21

K4

KC2

KC1

K2

K1

K3

M

Y4

Y3

Y2

G0

Y1

G

M

X2

M

M

X1

M

B2

M

M

U4

U3

B1

U2

C2

U1

M

C1

0~24 V

AC/DC

}

Comm

{

TAC Xenta 282

20

17

18

16

19

15

12

13

11

14

40

37

38

36

39

35

32

33

31

34

10

7

8

6

9

5

2

3

1

4

30

27

28

26

29

25

22

23

24

21

V2

V6

V5

V1

G0

G

X2

M

M

X1

B3

M

B2

B4

M

M

B1

C2

M

C1

V3

V4

0

~

24 V

AC/DC

}

Comm

{

24 V AC

VC

TAC Xenta 283

Fig. 3.2: The terminals of the TAC Xenta 281, 282, and 283

Inputs

All TAC Xenta 280 controllers have digital inputs (X).

The TAC Xenta 281 and 282 have universal (analog or digital, U)

inputs. The universal inputs can be used for three types of signals:

• TAC thermistor 1.8 kohm at 25 °C (the same as the thermistor

inputs)

• Voltage input 0–10V

• open/closed contact (the same as the digital inputs).

The TAC Xenta 282 also has thermistor inputs (labeled B) for

1.8 kohm.

The TAC Xenta 283 has thermistor inputs (labelled B) that can be used

with either 1.8 kohm or 10 kohm thermistors.

All controller inputs are protected from transients, in compliance with

the EN 50082-1 norm.

Outputs

The TAC Xenta 281 and 282 have the following outputs;

• Analog (Y) — 0–10V DC outputs

• Digital (K) — relay potential-free outputs

While the TAC Xenta 283 has TRIAC (V) — outputs capable of supplying inductive loads.

3.1.2 Jacks

18 (74) Schneider Electric Buildings AB, June 2011

The TAC Xenta 280 has two modular jacks–one for the TAC Xenta OP

operator panel and one for an RS232 connection with TAC Menta.

The socket for the operator panel provides it with 24V AC or DC,

depending on the supply.

04-00067-02-en

Page 19

TAC Xenta, TAC Xenta 280/300/401 3 Technical Description

Service pin

Red service diode

indicates a non-configured

node or a hardware fault

Green status diode indicates that the program is running

At distances greater than 10 m (32 ft.) between the TAC Xenta controller and the OP, an external power supply should be used. In addition, the

communications connection has to follow the same rules as for other

nodes.

Jack for the

RS232/modem

Fig. 3.3: Location of jacks on the TAC Xenta 280 controller

3.1.3 LED Indicators and Service pin

The Service pin can be activated through a small hole on the front. Also

on the front, there are two LED indicators–one red and one green.

Jack for the

Operator panel

Fig. 3.4: LED Indicators and Service Pin

The red service diode is primarily an error indication. It also lights up if

the Service pin is activated.

The green status diode blinks once per second to indicate that the program is running.

Schneider Electric Buildings AB, June 2011 19 (74)

04-00067-02-en

Page 20

3 Technical Description TAC Xenta, TAC Xenta 280/300/401

3.1.4 Technical Data TAC Xenta 280

Note

• For a complete list of updated technical data for the Xenta 280

controller, see the TAC Xenta 280 Programmable Controller

datasheet (003-2248).

Program cycle time min. 1 s

Universal inputs (TAC Xenta 281, 282: U1–U4):

A/D-resolution 12 bits

–as Thermistor Inputs

Supply voltage 0.6V DC

Thermistor inputs (B1–B2, only TAC Xenta 282):

A/D-resolution 12 bits

Accuracy (Measuring range):

–50 °C to –30 °C (–58 °F to –22 °F) ±4 °C (±7.2 °F)

–30 °C to –10 °C (–22 °F to +14 °F) ±2 °C (±3.6 °F)

–10 °C to +10 °C (14 °F to 50 °F) ±1 °C (±1.8 °F)

+10 °C to +30 °C (50 °F to 86 °F) ±0.5 °C (±0.9 °F)

+30 °C to +60 °C (86 °F to 140 °F) ±1 °C (±1.8 °F)

+60 °C to +120 °C (140 °F to 248 °F) ±2 °C (±3.6 °F)

+120 °C to +150 °C (248 °F to 302 °F) ±4 °C (±7.2 °F)

Thermistor inputs (B1–B4, only TAC Xenta 283):

A/D-resolution 10 bits

Accuracy (Measuring range):

–20 °C to –10 °C (–4 °F to +14 °F) ±2 °C (±3.6 °F)

–10 °C to +10 °C (14 °F to 50 °F) ±1 °C (±1.8 °F)

+10 °C to +30 °C (50 °F to 86 °F) ±0,5 °C (±0.9 °F

+30 °C to +60 °C (86 °F to 140 °F) ±1 °C (±1.8 °F)

+60 °C to +90 °C (140 °F to 194 °F) ±2 °C (±3.6 °F)

+90 °C to +120 °C (194 °F to 248 °F) ±4 °C (±7.2 °F

TRIAC outputs (TAC Xenta 283 only, V1–V6)

Load may require auxiliary power

(term. 40) of up to

Pulse length (TAC Menta DOPU

block)

72 VA

min. 0.5 s

Analog outputs (TAC Xenta 281: Y1–Y3, TAC Xenta 282: Y1–

Y4):

D/A-resolution 12 bits

a

:

20 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 21

TAC Xenta, TAC Xenta 280/300/401 3 Technical Description

a. If the active sensor (0–10V), analog actuators and the TAC Xenta con-

troller itself are supplied by the same transformer, the following restrictions will ensure the specified accuracy (for thermistor inputs,

universal inputs, and analog outputs):

Cable length from controller to:

Transformer: 3 m (10 ft.)

Active sensor/actuator: 20 m (65 ft.)

Number of active sensors: max. 4

Number of actuators: max.6

Network communication (C1–C2, polarity insensitive):

Protocol FTT-10, L

ONTALK®

Communication speed 78 kbits/s

Other communication:

TAC Menta RS232, up to 9600 bits/

s, RJ45

TAC Vista (version IV or higher

TP/FT-10, screw term.

required), also for appl.pgm download

TAC Xenta OP TP/FT-10, modular

jack

3.2 The TAC Xenta 300 Controller.

Fig. 3.5: The TAC Xenta 300 controller

3.2.1 Terminals

TAC Xenta 301 and 302

TAC Xenta 300 has two I/O configurations: TAC Xenta 301 and TAC

Xenta 302.

Digital

inputs

Thermistor

inputs

Universal

inputs

Relay

outputs

Analog

outputs

Term. notation

Schneider Electric Buildings AB, June 2011 21 (74)

04-00067-02-en

XB UKY

Page 22

3 Technical Description TAC Xenta, TAC Xenta 280/300/401

Digital

inputs

Thermistor

inputs

Universal

inputs

Relay

outputs

Analog

outputs

TAC Xen ta 301 44 462

TAC Xen ta 302 44 444

max 230 V AC

K4

KC2

K3

K2

KC1

K1

Y4

M

Y3

Y2

M

Y1

G0

G

0

}

19-40 V DC

~

24 V AC or

Comm

X4

20

M

19

X3

18

X2

17

M

16

X1

15

B4

14

M

13

B3

12

B2

11

10

M

9

B1

8

U4

7

M

6

U3

5

U2

4

M

3

U1

2

C2

{

1

C1

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

TAC Xenta 301

max 230 V AC

K4

KC2

K3

K2

KC1

K1

K6

KC3

K5

Y2

M

Y1

0

G0

~

G

24 V AC or

}

19-40 V DC

Comm

X4

20

M

19

X3

18

X2

17

M

16

X1

15

B4

14

M

13

B3

12

B2

11

10

M

9

B1

8

U4

7

M

6

U3

5

U2

4

M

3

U1

2

C2

{

1

C1

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

TAC Xenta 302

Fig. 3.6: The terminals of the TAC Xenta 301 and 302

Inputs

The TAC Xenta 300 controllers have twelve inputs:

• Four thermistor inputs (labeled B1–B4)

• Four universal (analog or digital, U1–U4)

• Four digital (X1–X4).

The universal inputs can be used for three types of signals:

• TAC thermistor 1.8 kohm at 25 °C (the same as the thermistor

inputs)

• Voltage input 0–10V

• Open/closed contact (the same as the digital inputs)

All controller inputs are protected from transients, in compliance with

the EN 50082-1 norm.

Outputs

The TAC Xenta 300 controllers have eight outputs:

• Analog — 0–10V DC outputs

• Digital — relay potential-free outputs

22 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 23

TAC Xenta, TAC Xenta 280/300/401 3 Technical Description

3.2.2 Jacks

The TAC Xenta 300 has two modular jacks–one for the TAC Xenta OP

operator panel and one for an RS232 connection with TAC Menta.

The socket for the operator panel provides it with 24V AC or DC,

depending on the supply.

At distances greater than 10 m (32 ft.) between the TAC Xenta controller and the OP, an external power supply should be used. In addition, the

communications connection has to follow the same rules as for other

nodes.

Jack for the

RS232/modem

Fig. 3.7: Location of jacks on the TAC Xenta 280 controller

3.2.3 LED Indicators and Service pin

The Service pin can be activated through a small hole on the front. Also

on the front are two LED indicators–one red and one green.

Red service diode

indicates a non-configured

node or a hardware fault

Jack for the

Operator panel

Service pin

Green status diode indicates that the program is running

Fig. 3.8: LED Indicators and Service Pin

The red service diode is primarily an error indication. It also lights up if

the Service pin is activated.

The green status diode blinks once per second to indicate that the program is running.

Schneider Electric Buildings AB, June 2011 23 (74)

04-00067-02-en

Page 24

3 Technical Description TAC Xenta, TAC Xenta 280/300/401

3.2.4 Technical Data TAC Xenta 300

Note

• For a complete list of updated technical data for the Xenta 300

controller, see the TAC Xenta 300 Programmable Controller

datasheet (003-1302).

Real-time clock:

Power outage TAC Xenta 301 2

Program cycle time min. 1 s

Universal inputs (U1–U4):

Quantity 4

–as Thermistor Inputs

Supply voltage 0.6V DC

Thermistor inputs (B1–B4):

A/D-resolutiony 12 bits

Accuracy (Measuring range):

–50 °C to –30 °C (–58 °F to –22 °F) ±4 °C (±7.2 °F)

–30 °C to –10 °C (–22 °F to +14 °F) ±2 °C (±3.6 °F)

–10 °C to +10 °C (14 °F to 50 °F) ±1 °C (±1.8 °F)

+10 °C to +30 °C (50 °F to 86 °F) ±0.5 °C (±0.9 °F)

+30 °C to +60 °C (86 °F to 140 °F) ±1 °C (±1.8 °F)

+60 °C to +120 °C (140 °F to 248 °F) ±2 °C (±3.6 °F)

+120 °C to +150 °C (248 °F to 302 °F) ±4 °C (±7.2 °F)

Digital outputs (K1–K6 or K1–K4):

Control voltage, relay outputs to be protected by max. 10 A fuse

Pulse length (TAC Menta DOPU

block)

Analog outputs (Y1–Y2 or Y1–Y4)

Quantity

D/A-resolution 12 bits

Network communication (C1–C2, polarity insensitive):

Protocol FTT-10, L

Communication speed 78 kbits/s

¨

min. 0.5 s

1

ONTALK®

1

If the active sensor (0–10V), analog actuators, and the TAC Xenta controller itself are supplied by the same transformer, the following restrictions will ensure the specified accuracy (for thermistor inputs, universal

inputs, and also for analog outputs):

24 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 25

TAC Xenta, TAC Xenta 280/300/401 3 Technical Description

12 13 14 15 16 17 18 20

Cable length from controller to:

Transformer: 3 m (10 ft.)

Active sensor/actuator: 20 m (65 ft.)

Number of active sensors: max. 4

Number of actuators: max. 6

3.3 The TAC Xenta 401 Controller

Fig. 3.9: The TAC Xenta 401 controller

3.3.1 Terminals

3.3.2 Jacks

The TAC Xenta 401 controller uses four of the screw terminals–two for

power supply and two for network communication.

24 V AC

(19-40 V DC)

Comm

}

}

~ 0

G G0 C1C2

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 19 20

Fig. 3.10: The terminals of the TAC Xenta 401

The TAC Xenta 401 has two modular jacks–one for the TAC Xenta OP

operator panel and one for an RS232 connection with TAC Menta.

The socket for the operator panel provides it with 24V AC or DC,

depending on the supply.

At distances greater than 10 m (32 ft.) between the TAC Xenta controller and the OP, an external power supply should be used. In addition, the

Schneider Electric Buildings AB, June 2011 25 (74)

04-00067-02-en

Page 26

3 Technical Description TAC Xenta, TAC Xenta 280/300/401

Jack for the

RS232/modem

Jack for the

Operator panel

Service pin

Red service diode

indicates a non-configured

node or a hardware fault

Green status diode indicates that the program is running

communications connection has to follow the same rules as for other

nodes.

Fig. 3.11: Location of jacks on the TAC Xenta 280 controller

3.3.3 LED Indicators and Service pin

The Service pin can be activated through a small hole on the front. Also

on the front, there are two LED indicators–one red and one green.

Fig. 3.12: LED Indicators and Service Pin

The red service diode is primarily an error indication. It also lights up if

the Service pin is activated.

The green status diode blinks once per second to indicate that the program is running.

26 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 27

TAC Xenta, TAC Xenta 280/300/401 3 Technical Description

3.3.4 Technical Data TAC Xenta 401

Note

• For a complete list of updated technical data for the Xenta 280

controller, see the TAC Xenta 400 Controller, freely programma-

ble datasheet (003-1629).

Program cycle time min. 1 s

Network communication (C1–C2; polarity insensitive):

Protocol FTT-10, L

Communication speed 78 kbits/s

ONTALK®

Schneider Electric Buildings AB, June 2011 27 (74)

04-00067-02-en

Page 28

3 Technical Description TAC Xenta, TAC Xenta 280/300/401

28 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 29

TAC Xenta, TAC Xenta 280/300/401 4 Installation

4 Installation

4.1 Mounting the Controller

The TAC Xenta 280/300/401 controller is designed to be mounted on a

DIN rail inside a cabinet. The controller can also be mounted directly

on a wall. A wide range of standard enclosures meeting DIN 43 880,

with different enclosure ratings, are available for wall mounting.

The enclosure primarily consists of a terminal part containing screw terminals, and an electronics part where the printed circuit boards are situated. The enclosure is designed in such a way that the entire electrical

installation can be connected to the screw terminals of the terminal part

when mounted on a DIN rail or on a wall.

Fig. 4.1: The terminal part (left) and the electronics part (right) of the

TAC Xenta 401

The operator panel can be mounted in the front of the cabinet or on top

of a TAC Xenta controller, or it can be held in the hand.

Fig. 4.2: The TAC Xenta 280/300 controller and the TAC Xenta OP

operator panel mounted on a DIN rail

Schneider Electric Buildings AB, June 2011 29 (74)

04-00067-02-en

Page 30

4 Installation TAC Xenta, TAC Xenta 280/300/401

148 – 2.0 (5.83 – 0.08)

4.0

(0.16)

48 – 0,5

(1.89–0.02)

16.1

(0.63)

180 (7.09)

77.4 (3.05)

45

(1.77)

110

(4.33)

180 + 0.4 (7.09 + 0.02) to the next TAC Xenta 280/300/3000

174 + 0.4 (6.85 + 0.02) to the next TAC Xenta 400/500/900

70 –2.0 (2.76 –0.08)

10.1

(0.40)

90 (3.54)

77.4 (3.05)

45

(1.77)

2 3 4 5 6 7 8 10

12 13 14 15 16 17 18 20

90 + 0.4 (3.54 + 0.02) to the next TAC Xenta 400/500/900

96 + 0.4 (3.78 + 0.02) to the next TAC Xenta 280/300/3000

4.0

(0.16)

48 – 0,5

(1.89–0.02)

110

(4.33)

Fig. 4.3: Mounting distances for TAC Xenta 280/300

Fig. 4.4: Mounting distances for TAC Xenta 401

4.2 Electrical Installation

4.2.1 General Considerations

The installation is normally treated as a CAT III category (IEC 664), in

30 (74) Schneider Electric Buildings AB, June 2011

principle entailing permanent connection to a 230V AC mains supply.

For the TAC Xenta 280/300 and the I/O modules, this is only applicable

to the relay outputs.

All equipment connected to the controller has to comply with the following standards:

• EN 60 742 (or other relevant safety standard; for example ETL

listing UL 3111-1, first version and CAN/CSA C22.2 No. 1010.1-

04-00067-02-en

Page 31

TAC Xenta, TAC Xenta 280/300/401 4 Installation

~ 0

24 V AC

(19-40 V DC)

}

1 2 3 4 5 6 7 8 9 10

G G0 C1C2

Comm

}

92) for the device(s) that provide an ELV-type power supply (normally 24V AC) to the controller and other connected equipment.

• EN 61 010 or IEC 950 (or other relevant safety standard) for computers, modems, and other equipment supplied by 230V mains.

If equipment using 230 V mains is connected to one of the relay output

terminals on the controller, then low-voltage equipment connected to

the other relay terminals on the controller must provide at least basic

insulation on all touchable parts.

Caution

• We strongly recommend that switches be installed to make it

possible to separate the external equipment when the relay output

terminals control equipment using the 230V mains.

Terminals G, G0 and C1, C2

• Mount the terminal part of the

T AC Xenta 280, 300, or 40 1 on a DIN

rail.

• Connect the cables to the correct terminals (see figure below).

• For the TAC Xenta 401, put the electronics part of the controller

on to the terminal part (the remaining terminals are not used).

Fig. 4.5: Terminals for power supply and network communication

Remaining terminals (TAC Xenta 280 and 300)

For information on the remaining terminal connection, see the

datasheets:

• TAC Xenta 280 Programmable Controller (003-2248)

• TAC Xenta 300 Programmable Controller (003-1302)

Note

• Do not use the unlabeled terminals!

Schneider Electric Buildings AB, June 2011 31 (74)

04-00067-02-en

Page 32

4 Installation TAC Xenta, TAC Xenta 280/300/401

1 2

G G0 U1 M U2 Y1 M Y2 B1 M B2 M U3

G1 G G0

G G0 M X

G G0 MX X1

TAC Xenta 280, 300 or 400 I/O module(s)

PU

230

VAC

G

G0

N

1 2 1 2

G G0 M S

G G0 M S

R =500 Ω

Insulated

signal

ground rail

Cabinet

terminals

R

min 1.5 mm

2

(14 AWG), max 2 m (6.5 ft)

Cabinet

ground

rail

4.2.2 Cabinet Connections

When cabinet mounting is used, jumpers may be used between M (measurement neutral) terminal pairs, as shown in the figure below. All G0

points have to be connected to protective ground.

Fig. 4.6: Skeleton diagram for cabinet connections

When connecting G0 to ground, each TAC Xenta unit has to its own

connection with the ground rail, that is, jumpers cannot be used for the

G0 terminals. Please refer to the figure on the next page.

Several units may share the same ground rail, but every unit with measuring inputs and/or analog outputs has to have all its gr ound connec-

32 (74) Schneider Electric Buildings AB, June 2011

tions with the same ground rail.

In other words, a discontinuity in the ground rail cannot be allowed to

split a controller or separate it from the connected units.

04-00067-02-en

Page 33

TAC Xenta, TAC Xenta 280/300/401 4 Installation

(14 AWG)

TR

G0

2

TAC Xenta 1

G0

PU

G0

TAC Xenta 2

G0

PU

G0

min 1.5 mm

Fig. 4.7: Connections between insulated signal ground rails and the

cabinet ground rail

When a Wall Module (ZS101–105) is connected to the TAC Xenta 280

or 300, the following terminals can be used (term. B2: v 3.0 or later).

2

(14 AWG),

TAC Xenta 282 or 300

G G0 C2 C1 M B1 B2

G

X1 M K1 KC1

Insulated

signal

ground rail

230

VAC

min 1.5 mm

max 2 m (6.5 ft)

G0

N

Cabinet

ground

Cabinet

terminals

rail

ZS 101-105

F0 F1 F2 F3G0 G C2 C1 1 2 3 4 5 6 7 8

2

1

0

3

470 Ω

10 kΩ

(24 V AC)

Fig. 4.8: Skeleton diagram for the connection of Wall Module ZS 101–

105 to TAC Xenta 282 or 300

Schneider Electric Buildings AB, June 2011 33 (74)

04-00067-02-en

Page 34

4 Installation TAC Xenta, TAC Xenta 280/300/401

4.2.3 Cables

G and G0 (Power supply):

G, min. cross-sectional area 0.75 mm² (18 AWG)

G0 to TAC Xenta, min. cross-sectional

area

C1 and C2 (network):

The FTT-10 system allows the user to wire the control devices with

virtually no topology restrictions.

Min. cross-sectional area 0.65 mm² (18 AWG)

Note that the max. wire distance in one segment depends on the type

of wire and the topology.

The wires are polarity insensitive, but they have to be a twisted-pair.

Terminals X (Digital inputs):

Min. cross-sectional area 0.25 mm² (22 AWG)

Max. cable length 200 m (660 ft.)

Terminals U (Universal inputs as digital inputs):

Min. cross-sectional area 0.25 mm² (22 AWG)

Max. cable length 200 m (660 ft.)

Terminals U (Universal inputs, device powered via

the same transformer as the base unit):

Min. cross-sectional area 0.75 mm² (18 AWG)

Max. cable length 20 m (65 ft.)

Terminals U (Universal inputs, measurement device powered via

their own transformer, external or internal):

Min. cross-sectional area 0.25 mm² (22 AWG)

Max. cable length 200 m (660 ft.)

Terminals B, U (as thermistor inputs):

Min. cross-sectional area 0.75 mm² (18 AWG)

Max. cable length

up to 75 °C, cross-sectional area 0.75 mm²75 m (250 ft.)

up to 75 °C, cross-sectional area 1.5 mm²150 m (500 ft.)

up to 150 °C, cross-sectional area 1.5 mm²75 m (250 ft.)

Terminals K1–K6 (Relay outputs):

Cross-sectional area 0.75 – 1.5 mm² (18–14

Max. cable length 200 m (660 ft.)

Terminals V1–V6 (TRIAC outputs):

Cross-sectional area 0.75 – 1.5 mm² (18–14

1.5 mm² (14 AWG)

AWG)

AWG)

34 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 35

TAC Xenta, TAC Xenta 280/300/401 4 Installation

Max. cable length 200 m (660 ft.)

Terminals Y (Analog outputs, for actuator powered via

the same transformer as the base unit):

Min. cross-sectional area 0.75 mm² (18 AWG)

Max. cable length 20 m (65 ft.)

Some actuators allow greater cable length, for example:

EM52 0.5 mm².(20 AWG)80 m(260 ft.)three wires

EM15LBB0.75 mm²(18 AWG)80 m(260 ft.)three wires

EM420.75 mm²(18 AWG)80 m(260 ft.)four wires

TAC Forta0.75 mm²(18 AWG)80 m(260 ft.)four wires

Terminals Y (Analog outputs, for actuator powered via

their own transformer, ext. or int.; or when the outputs have isolated

converters):

Min. cross-sectional area 0.25 mm² (22 AWG)

Max. cable length 200 m (660 ft.)

TP/FT-10 Free Topology & Bus Topology Segments

Five cable types have been validated for the TP/FT-10 channel (for use

with the FTT-10A Free Topology Transceiver and LPT-10 Link Power

Transceiver). These cable types are:

Cable Bus Topology Free Topology

Type AWG

Belden 8471

(PVC Jacket)

or equivalent

Belden 85102

(PVC Jacket)

or equivalent

Category 5 24AWG 0.5 900 3 450 250

Level IV cable 22AWG 0.65 1400 3 500 400

JY (st)

Y 2X2X0.8

16AWG 1.3 2700 3 500 400

16AWG 1.3 2700 3 500 500

20.4AWG 0.8 900 3 500 320

Diameter

(mm)

If a Loop is used, the bus polarity has to be observed:

Length

(m)

Stub

(m)

Length

(m)

Stub

(m)

Schneider Electric Buildings AB, June 2011 35 (74)

04-00067-02-en

Page 36

4 Installation TAC Xenta, TAC Xenta 280/300/401

Fig. 4.9: Bus polarity within a loop

TP/XF-1250 Bus Topology Segment

Two cable types have been validated for the TP/XF-1250 channel (for

use with the TPT/XF-1250 Bus Topology Transceiver). These cable

types are:

Cable Type AWG Diameter Bus

TIA 568A

Category 5 Cable

Level IV Cable 22AWG 0.65 mm 130 m 0.3 m

24AWG 0.5 mm 130 m 0.3 m

For the TP/FX-1250 Channel operating in a bus topology, the maximum

bus length of TIA 568A Category 5 cabling is 130 meters, with a maximum stub length of 0.3 meters. There are topology restrictions associated with the use of this channel - refer to www.echelon.com.

Note

• If a shielded cable is used in TP/FT-10, the shield shall be connected to link power source that is ground to a 470kW, 1/4Watt,

> 10%, metal film resistor to prevent static charge buildup.

A gas discharge tube can be connected in parallel with the resistor for

lightning protection.

A restriction for TP/XF-1250 is the 8-in-16 rule, which says that the

number of nodes in an arbitrary 16-meter section of the cable cannot

exceed eight.

If circumstances require that more nodes have to be gathered at a certain

part, this can be done in two ways, while still observing the rule.

1 Add more cable between suitable nodes; remember, though, that

the maximum length of the bus is still 130 m.

2 Split the channel in two by inserting a router in such a way that the

rule is observed for each part.

36 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 37

TAC Xenta, TAC Xenta 280/300/401 4 Installation

TAC Xenta 1

C1 C2

C1 C2

C1 C2

C1 C2

TAC Xenta 1

TAC Xenta 2

TAC Xenta 2

470 kΩ

¼ W

If a shielded communication cable is used, the shield can only be

grounded at one point.

Redundant wires (second pair of Siemens J-Y(st)Y) are cut at the end of

the shield.

Fig. 4.10: Connecting the communication cable

Schneider Electric Buildings AB, June 2011 37 (74)

04-00067-02-en

Page 38

4 Installation TAC Xenta, TAC Xenta 280/300/401

5

4

3

2

1

9

8

7

6

GND (Red)

RxD-TxD (Green)

TxD-RxD (Y ellow)

1 3 5 7

2 4 6 8

~10 cm

(4")

TAC Xenta

Modular jacks, 8/8 male,

emission damper and cable

Modular jack, female

(from inside of adapter)

D9, female

(from inside of adapter)

TAC Xenta

RS232 RS232

PC

TxD

RxD

GND

G0G

0 V

230 V

24 V

Earth current

in GND wire

Transformer

Transformer

RS232

Modular jack for RS232 serial comm. portmax. 10 m (32 ft.)

Fig. 4.11: RS232 cable connections and adaptor for PC

Caution

• The G terminal of the TAC Xenta should never be connected to

protective ground. This may cause a short-circuit via a Laptop,

where the earth of the RS232 port is directly connected to protective ground in the power supply.

Fig. 4.12: Incorrect G, G0 connection, short-circuited via the RS232

connection.

38 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 39

TAC Xenta, TAC Xenta 280/300/401 4 Installation

13

12

11

10

9

8

7

6

5

4

3

2

1

25

24

23

22

21

20

19

18

17

16

15

14

1 3 5 7

2 4 6 8

DCD

GND

DSR

CTS

RTS

RxD

TxD

DTR

Modular jack, female

(from inside of adapter)

D25 male

This type of connection has to be avoided. One way to protect the circuits is to use battery power on the laptop if you are uncertain of the connections.

TAC Xenta

RS232 RS232

G0G

24 V

TxD

RxD

GND

Fig. 4.13: Correct G, G0 connection

PC

230 V

0 V

4.3 Terminations

Schneider Electric Buildings AB, June 2011 39 (74)

04-00067-02-en

Fig. 4.14: RS232 connection between the TAC Xenta controller and a

modem

Each network segment requires a termination for proper data transmission performance. The terminations are connected differently, depend-

Page 40

4 Installation TAC Xenta, TAC Xenta 280/300/401

To Network

C1

+

R1

C2

+

C1, C2: 100 mF, >50 V

R1: Resistance: see the text

1%, 0,125 W

ing on the network topology. Terminations are sometimes built into a

node in, for example, a linked power supply.

Free Topology Segment

In a Free Topology segment only one termination is required and can be

placed anywhere on the segment.

If there is a router or a repeater, it is convenient to put the termination

near it, generally on the “downstream” side.

If there is a supervisory PC in the segment equipped with a PCLTA

board, a termination on the board can be connected for this segment.

Doubly Terminated Bus Topology Segment

In a doubly terminated bus topology, exactly two terminations are

required – one at each end of the segment – at the true endpoints.

TP/FT-10

The termination is built from the following components, where a total

termination impedance of approximately 53

Ω is required.

Fig. 4.15: Network Terminator for a TP/FT-10 connection

Observe polarity shown for C1 and C2. These capacitors are recommended.

Free topology: one termination with R1 = 52,3 W

Doubly terminated bus topology: two terminations, one on each end of

the segment, each with R1 = 105 W.

A LonWorks termination device (single/double) is available from

Schneider Electric, part no. 007309051.

40 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 41

TAC Xenta, TAC Xenta 280/300/401 4 Installation

.15 μF 10%

.33 μF 10%

59

Ω

1%

340

Ω

1%

102

Ω

1%

TP/XF-1250

Doubly terminated bus topology. The termination has a different circuit

diagram from that of TP/FT-10.

Fig. 4.16: Network Terminator for a TPT/XF-1250 connection

With the free topology, connections may be made anywhere on the segment and only one terminator is required.

The total length of all wires of the segment, can be up to 500 m under

optimal conditions. Stub length 3 m.

With the bus topology two terminations - one at each end - are required.

When a TP/FT-10A channel is used, the total length of all wires of the

segment can be up to 2700 m, under optimal conditions. If a TP/XF1250 channel is used, the total length of all wires of the segment can be

up to 130 m, under optimal conditions. Stub length 0.3 m.

Schneider Electric Buildings AB, June 2011 41 (74)

04-00067-02-en

Page 42

4 Installation TAC Xenta, TAC Xenta 280/300/401

4

3

21

C1 C2 G G0

Socket and screw terminals for

TAC Xenta controller connection

TAC Xenta

controller

Socket for connection

to operator panel

4.3.1 The TAC Xenta OP Operator Panel

Cable between the controller and the operator panelmax. 10 m (32 ft.)

There are two ways to connect the operator panel (see figures below):

• Use the modular socket on the front of the TAC Xenta controller

and on the back of the operator panel. A modular jack 4/4 cable is

supplied with the OP for this purpose.

• Use the screw terminals, labeled 1–4, located on the back of the

operator panel. T erminals 1 and 2 are used for communication and

terminals 3 and 4 for 24V AC.

Fig. 4.17: The OP panel

To adjust the contrast of the display, use the potentiometer on the rear

of the operator panel.

Normally, there is a logout time once you have logged into the OP.

It is, however, possible to override this timeout and obtain a permanent

display by setting a bit in the SYSREG block. Please refer to the TAC

Vista IV, Engineering Applications in TAC Menta manual.

42 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 43

TAC Xenta, TAC Xenta 280/300/401 4 Installation

Options for connecting the OP to the Controller

Modular jack

G0 G C2 C1

4321

TAC Xenta OP

C1 C2 G G0

4321

Fig. 4.18: Modular jack for connection of TAC Xenta OP to TAC Xenta

280/300/401 or to a separate jack

max. 10 m (32 ft.)

TAC Xenta Controller TAC Xenta OP

G0 22

G21

C2 2

C1 1

G0 4

G3

C2 2

C1 1

Fig. 4.19: Terminal connection TAC Xenta 280/300/401 - TAC Xenta OP,

power supply from controller

230 V / 24 V

TAC Xenta Controller TAC Xenta OP

G0 22

G21

C2 2

C1 1

0

~

G0 4

G3

C2 2

C1 1

Fig. 4.20: Terminal connection TAC Xenta 280/300/401 (or the network

directly) - TAC Xenta OP, local power supply

Schneider Electric Buildings AB, June 2011 43 (74)

04-00067-02-en

Page 44

4 Installation TAC Xenta, TAC Xenta 280/300/401

44 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 45

TAC Xenta, TAC Xenta 280/300/401 5 Configuring your System

PC

TAC Menta:

- Address allocation

- Download application

- Online simulation

TAC Xenta controller

(Part no.

0-073-0920)

RS232

5 Configuring your System

5.1 Overview

A TAC Xenta 280/300/401 controller is delivered as a freely programmable controller. A customer-specific application is created using the

programming tool TAC Menta.

A PC that has TAC Menta installed and running is connected, using the

Programming Serial Kit cable (part no. 007309200), to the RS232 port

of the TAC Xenta controller to be loaded. How this is done is described

in the Engineering Applications in TAC Menta manual.

During the customizing process, the online/simulation mode of TAC

Menta can also be used to monitor the input and output status of the

TAC Xenta controller. Parameter tuning can also be done from TAC

Menta.

Note

• Starting from TAC Xenta v 3.1, the application program download may also be done from TAC Vista via the network.

However, the online/simulation mode in TAC Menta still has to use the

RS232 port.

Fig. 5.1: Commissioning tool (principle of operation)

Devices have to be configured in the following situations:

• When there are I/O modules (see sections 5.3 and 5.4 of this manual)

• When there are several controllers (see section 5.5 of this manual)

Schneider Electric Buildings AB, June 2011 45 (74)

04-00067-02-en

Page 46

5 Configuring your System TAC Xenta, TAC Xenta 280/300/401

5.2 A Single TAC Xenta 280/300/401 Controller

5.2.1 Initial Check

Caution

• TAC Xenta 280/300: It is important that the electronics part has

the same input/output configuration as the terminal part.

After the wires have been connected, but before the electronics part has

been mounted on the terminal part, perform these checks:

1 Turn on the power.

2 Check that the supply voltage, 24V AC or 19–40V DC, is con-

nected to the proper terminals G and G0.

3 T AC Xenta 280/300: Check that the voltage levels of the input and

output terminals are appropriate, bearing in mind their use and

possible preset values.

4 TAC Xenta 280/300: Check the voltage, both AC and DC,

between G0 and the other (labeled) terminals.

5 Repeat step 4 with G as the reference terminal.

6 Turn off the power and mount the electronics part on the terminal

part.

7 Turn on the power again.

8 If previously unloaded, load the program, using TAC Menta,

according to the method described in the Engineering Applications

in TAC Menta manual.

9 Check that the green status LED on the front starts to blink, indi-

cating that the internal program is running.

Service pin

Red service diode indicates

a non-configured node or a hardware fault

Green status diode indicates

that the program is running

Neuron ID

(on the rear)

Fig. 5.2: LEDs and service pin in the controller

10 If additional I/O-units are used, follow the steps in section 5.4.

46 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 47

TAC Xenta, TAC Xenta 280/300/401 5 Configuring your System

Network address:

- Subnet no. 1

- Node no. 10

TAC Xenta

Device name:

CU_1

PC

RS232

Device Configuration

tool

Device name:

CU_2

Network address:

- Subnet no. 1

- Node no. 20

TAC Xenta

TAC Xenta

controller

5.2.2 OP Panel Activities

1 Connect the TAC Xenta OP to the TAC Xenta unit.

2 TAC Xenta 280/300: Select the Temp & Status menu (or equiva-

lent) to check that all inputs have appropriate values.

5.3 Two or more TAC Xenta 280/300/401 Units

5.3.1 Initial Check

Perform the steps described in section 5.2.1.

5.3.2 Device Configuration

Before it can start to communicate, each TAC Xenta unit has to be

assigned a network address (a subnet/node address and a device name).

This is done using a separate Device Configuration programming tool.

The tool is either run on a PC and started from TAC Menta or it is run

as a stand-alone tool.

The procedure is fully explained in the Engineering Applications in

TAC Menta manual.

If two or more units have the same Device name, they have to be given

unique names. This is also done using the Device Configuration tool.

The figure below indicates some of the parameters that are involved.

The use of network addresses is explained in the TAC Vista IV, Engi-

neering Classic/LNS Networks manuals.

Fig. 5.3: Device Configuration parameters (example)

Schneider Electric Buildings AB, June 2011 47 (74)

04-00067-02-en

Page 48

5 Configuring your System TAC Xenta, TAC Xenta 280/300/401

5.3.3 OP Panel Activities

When an operator panel is connected to a network that includes a number of TAC Xenta controllers, the following will happen:

1 The operator panel (OP) will send a request to the network for any

TAC Xenta controller that is not occupied to start acting as a

server and send texts to the operator panel.

2 The first available Xenta controller will send a list of all the

groups in the network. These will be shown on the OP and when

one of them has been selected, the TAC Xenta controllers of the

group will be shown on the operator panel. As all TAC Xenta controllers know which other TAC Xenta controllers are present in

the network, an operator panel can be served by any TAC Xenta

controller in the network.

3 From this list, the desired TAC Xenta controller will be chosen by

the user, and the controller that first acted as a server will be

released from its duties.

4 The selected TAC Xenta controller will then supply the operator

panel with the menu on the highest level in the program.

5 TAC Xenta 280/300: Select the Temp & Status menu (or equiva-

lent) to check that all inputs have reasonable values.

6 Now select another controller from the top menu and repeat steps

5-6, as many times as required.

5.4 Additional I/O Units

5.4.1 Selecting I/O Modules

There are two types of I/O modules:

• Configured (older, for older versions of the Base unit)

• Unconfigured (newer, for Base units of version 3.2 or higher)

Note

• The TAC Xenta 280 does not use extra I/O modules.

48 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 49

TAC Xenta, TAC Xenta 280/300/401 5 Configuring your System

Service pin

Neuron ID

(on the side)

Service LED: red ind. =

hardware fault

Comm. status LED, green flashing light:

• once every other sec: communication with Base unit

• faster: the unit is off-line

5.4.2 Initial Check

Note

• It is important that the electronics part has the same input/output

configuration as the terminal part.

Perform these checks after the wires have been connected to the I/O

modules, but before the electronics part has been mounted on the terminal part.

1 Turn on the power.

2 Check that the supply voltage, 24V AC or 19–40V DC, is con-

nected to the proper terminals (G and G0).

3 Check that the voltage levels of the input and output terminals are

appropriate, bearing in mind their use and possible preset values.

4 Check the voltage, both AC and DC, between G0 and all the other

terminals.

5 Repeat steps 1-4 with G as the reference terminal.

6 Turn off the power and mount the electronics part on the terminal

part.

7 Turn on the power again.

8 Check the LEDs for the following:

• The red service LED on the front will now blink once.

• The green communication status LED on the front starts

flashing rapidly (about 2-3 Hz), indicating that the unit is offline.

Fig. 5.4: LEDs and service pin of the I/O modules

5.4.3 I/O Module Configuration

Schneider Electric Buildings AB, June 2011 49 (74)

04-00067-02-en

An I/O module always belongs to a specific TAC Xenta controller.

Before the module can be utilized, it has to be linked to that controller

by using the Device Configuration programming tool. The tool is either

run on a PC and started from TAC Menta or it is run as a stand-alone

tool.

Page 50

5 Configuring your System TAC Xenta, TAC Xenta 280/300/401

The procedure is described in the manual Engineering Applications in

TAC Menta.

In some versions of TAC Xenta OP, these items can also be set from the

Service menu. This is described in chapter 6 (‘IO Module Config’) of

this manual. Please note that this menu can only be reached from the

Service access level.

The figure below indicates some of the parameters that are involved.

The use of network addresses is described in the TAC Vista IV, Engi-

neering Classic/LNS Networks manuals.

Device Configuration

PC

tool

RS232

TAC Xenta

I/O

Module no.: 1

Module type: 421

I/O

Module no.: 2

Module type: 411

Network address:

- Subnet no. 1

- Node no. 10

Network address:

- Subnet no. 1

- Node no. 13

Fig. 5.5: I/O module configuration parameters (example)

About 45 seconds after the configuration procedure has completed, the

green LED should start to blink at a rate of about once every other second. This will indicate that the unit is communicating with the application in the Base unit.

5.5 Setting the Date and Time

Set the current date and time from TAC Menta during commissioning

(Online mode). The setting affects only the controller that is connected

to TAC Menta. Please refer to the Engineering Applications in TAC

Menta manual for further details.

Date and time can also be set from the TAC Xenta OP, if the operator

has logged on at the appropriate access level (usually the medium level).

For details, refer to the TAC Xenta OP Handbook.

If the controllers are connected to a supervisory system like TAC Vista,

the date and time can be set in all units with one command from TAC

Vista.

Network address:

- Subnet no. 1

- Node no. 14

A TAC Xenta Master unit broadcasts its clock time once every

24 hours.

In both cases, the date and time are sent periodically. This will ensure

that even if some units are offline when the time data is sent, they will

eventually be updated with the values from the central system or, with

regards to standalone, from the Master.

50 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 51

TAC Xenta, TAC Xenta 280/300/401 5 Configuring your System

1 3 5 7

2 4 6 8

DTR CTSDCD

Modular jack

(seen from the underside,

with the fastening flap)

2 DCD

3 DTR

7 CTS

TAC Vista sends the time in GMT format. The time value is transformed in each separate TAC Xenta to the valid time zone and the current standard or daylight saving time.

5.6 Clearing the Xenta Application

If a Xenta 280/300/401 application has crashed and refuses to accept a

new download, both from Vista and Menta, there is a way to clear the

application (Xenta version 3.61 or higher).

1 Manufacture a jack with the following pins short-circuited.

Fig. 5.6: A “Clear application” device

2 Turn off power to the controller.

3 Put the jack in the RS232 port.

4 Turn on power to the controller; a forced Clear Application will be

made.

5 Remove the jack.

5.7 Lock a Xenta OP to a specific TAC Xenta Controller

You can lock a Xenta OP to a specific TAC Xenta 280/300/401 controller.

To be able to do this you have to enable the function by adding a PVI

block in the Menta application in the Xenta and enable the function in

the Xenta OP.

5.7.1 Creating the PVI-block in the Xenta

1 Create a Public PVI-block with the name XENTASYSREG and

set this block’s initial value to 8.

Schneider Electric Buildings AB, June 2011 51 (74)

04-00067-02-en

Page 52

5 Configuring your System TAC Xenta, TAC Xenta 280/300/401

Fig. 5.7: XENTASYSREG With the initial value to 8

If you have multiple TAC Xenta OP panels in the network, each one

connected to a specific Xenta Controller, you have to create this special

PVI block in every one of these Xenta Controller’s Menta code.

5.7.2 Enabling the function in TAC Xenta OP

1 Open the TAC Xenta OP local service menu.

2 Press and hold the “escape” and “enter” buttons for a few seconds.

3 Enter the bottom command: “11 OP connects to”.

4 Enter this sub-command, and then type in, using “+” or “-“, the

specific T AC Xenta controller’ s subnet and node you want t his OP

to be “locked” to.

The TAC Xenta controller subnet and node addresses can easily be

found in TAC Vista Workstation; select “properties” for the TAC Xenta

controller and the subnet / node will be displayed.

Note

• When you select, in the OP panel’s new menu, the node number

and press enter the TAC Xenta OP will restart and seek for the

selected TAC Xenta controller.

• It will still be possible to access the TAC Xenta controller from

another T AC Xenta OP in the network if the TAC Xenta OP is of

a version prior to 3.70 or if the lock-function is not enabled in the

TAC Xenta OP. Ho wever doing t his, you will only h ere also “see

the local Xenta controller”. In this case you will be able to exit

this TAC Xenta controller again by pressing “escape”. While in

the locked TAC Xenta OP you will not be able to exit from the

TAC Xenta controller it is locked to.

52 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 53

TAC Xenta, TAC Xenta 280/300/401 6 The TAC Xenta Service Menu

TAC Service menu

1. Name

2. LON Address

3. Wink

4. Restart

5. IO Module Config

6. Test Dial

7. System info

6 The TAC Xenta Service Menu

6.1 Accessing the Service Menu

When a TAC OP is connected to a TAC Xenta controller 280, 300, or

401, menus appear on the display.

Use the password-protected Service menu for system information and

actions.

Schneider Electric Buildings AB, June 2011 53 (74)

04-00067-02-en

Fig. 6.1: Connecting TAC Xenta OP (left) to the controllers 300 or 401

(right).

The Service menu has the following options (the frame symbolizes the

four-line display window of the OP):

Page 54

6 The TAC Xenta Service Menu TAC Xenta, TAC Xenta 280/300/401

AHU2: West

Status

Temperature

Alarm

.

.

Password

Password

CODE:

Enter code to

extend menu

.

.

Status

Password

Service menu

To access the Service menu, press “Enter” ( ) directly after startup. The menu will look something like this:

Move the cursor to Password and press Enter to get:

Enter the code ”1919” by using + or – , Enter and finally “Home”

( ). The Start-up menu reappears.

The bottom line will now include the Service menu option.

6.2 Submenus 1-8

Submenu 1: Device Name and

Submenu 2 Lon address

To get the Name and address of a specific controller:

1 Disconnect the controller from the network.

2 Connect the OP to this unit and select the Service menu, where the

name and address can be checked. Please note that this menu is

only available from the “Service” access level.

3 Select submenu “

1. Name” or ”2. LON address”:

54 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 55

TAC Xenta, TAC Xenta 280/300/401 6 The TAC Xenta Service Menu

Name

LON address

Subnet: 1

Node : 10

Wink node

While pressing HOME,

LED stays ON for

3 seconds.

Restart type: _

0:No restart

1:Warm 2:Cold

3:Orig. appl.

• Reconnect the unit to the network.

• Repeat steps 1–4, as many times as required.

Submenu 3: Wink node

In some cases, it may be necessary to know which physical unit corresponds to a certain node address. Select submenu “

3. Wink”:

1:Warm

2:Cold

3:Orig. appl.

When you press the Home key ( ), the green status diode of the

selected Base unit will light up for about three seconds.

Submenu 4: Restart

There are different types of restarts. These are selected from submenu

“

4. Restart”:

Upon restarting, parameters and values will be retrieved as follows (also

refer to Appendix 1, Restart Values):

Most values according to the ones already present in RAM.

Most values are reset to the original, downloaded application, except

for saved PV Block values, Public parameters,

and certain OPT values.

Resets all values to the original, downloaded application.

Submenu 5: IO module Config, Configuring I/O modules

via the OP

Schneider Electric Buildings AB, June 2011 55 (74)

04-00067-02-en

Chapter 5 contains information about configured and unconfigured I/O

modules, as well as instructions for “Initial checks” on the newly connected units.

Page 56

6 The TAC Xenta Service Menu TAC Xenta, TAC Xenta 280/300/401

T AC Xent a

I/O

I/O

Module no.: 1

Module type: 421

LonTalk

protocol

Module no.: 2

Module type: 411

Network address:

- Subnet no. 1

- Node no. 10

Network address:

- Subnet no. 1

- Node no. 13

Network address:

- Subnet no. 1

- Node no. 14

IO Module Config

Module No: 1

Node Addr.: 13

Valid Service Pin: 0

An I/O module always belongs to a specific TAC Xenta controller (the

Base unit). Before an I/O module can be utilized, it has to be linked to

that controller.

To do this, go to menu “

5. IO Module Config”.

The I/O modules will automatically get the same Subnet number as the

base unit. Normally, this is the number that should be used.

The figure below indicates the parameters that are involved.

Fig. 6.2: I/O module configuration parameters (example)

1 On the operator panel, select the list of controllers on the network.

2 Select the TAC Xenta to configure.

3 Select submenu “5. IO Module Config” and enter the address

value:

4 Press the service pin on the corresponding unit (see diagram

below). Following this, Valid Service Pin: 0 should change to 1.

5 Press Enter to confirm the configuration within 20 seconds or so.

6 About 45 seconds after configuration has finished, the green LED

will start blinking slowly , showing that the unit is communicating

with the Base unit.

7 Repeat steps 3–6 if there is a second I/O module.

8 Repeat steps 2-7 for all the listed controllers with I/O modules.

56 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 57

TAC Xenta, TAC Xenta 280/300/401 6 The TAC Xenta Service Menu

Service pin

Red service diode indicates

a non-configured node or a hardware fault

Neuron ID

(on the rear)

Green status diode indicates

that a program is running

Please note the angle of the screwdriver

being used to activate the service pin!

Upon activation, the red service diode

will flash momentarily.

Service pin

Neuron ID

(on the side)

Comm. status LED, green flashing light:

• once every other sec: communication with Base unit

• faster: the unit is off-line

Fig. 6.3: LEDs and service pin of the controller (Base unit)

Fig. 6.4: Activating the service pin of the controller or the I/O module

Fig. 6.5: LEDs and service pin of the TAC Xenta 400 I/O modules

6.2.1 Submenu 6: Test dial

This function is used in dial-up systems (not applicable to the

TAC Xenta 280) and is explained in the TAC Vista IV, Engineering

Classic/LNS Networks manuals.

Schneider Electric Buildings AB, June 2011 57 (74)

04-00067-02-en

Page 58

6 The TAC Xenta Service Menu TAC Xenta, TAC Xenta 280/300/401

Test dial

Dial 0

Status 08

0000 0000 0010 0100

9 Select “6. Test dial” and the following menu will appear:

10 On Dial use:

•The value 0 for the normal telephone number

or toggle to

•The value 1 for the alternative telephone number

11 Press Enter to initiate a dial-up between the controller and a super-

visory system.

The two Status lines will display codes containing information about the

procedure as described below.

(Dynamic) Status (upper integer value) shows the progress of the dial-up sequence.

Code Meaning

IDLE 00 This is the state before any attempts to dial have been made.

LINE_BLOCKED 01 The line was blocked.

NO_DIAL_STRING 02 No dial string was defined, so no dial attempt was made.

SENDING_DIAL_STR. 03 We are either in the process of sending the dial string to the modem or

waiting for the response.

BUSY 04 The line was busy.

NO_ANSWER 05 No one picked up the phone at the other end.

NO_CARRIER 06 There was no modem at the other end which could answer.

ERROR 07 Something was wrong with the dial string.

NO_DIAL_TONE 08 No normal dial tone.

TIMEOUT 09 The modem did not reply to the dial string at all.

CONNECT 10 We are connected to the remote modem.

NO_LOGIN_REPLY 11 Attempting to log in, but no reply from TAC Vista.

LOGIN_FAIL 12 Our password (and/or network ID) was not accepted by TAC Vista.

LOGIN_OK 13 Connection established!

58 (74) Schneider Electric Buildings AB, June 2011

04-00067-02-en

Page 59

TAC Xenta, TAC Xenta 280/300/401 6 The TAC Xenta Service Menu

Date: 2002-02-11

Ver: X300 3.50

By: TAC

302NP (Neuron ID: 12 chars)

(Static)

Status (lower 16-bit string) pertains to the modem and communication envi-

Code Meaning

---- ---- ---- ---1

---- ---- ---- --1-

---- ---- ---- -1--

---- ---- ---- 1---

ronment, that is, the availability of the modem and other communication issues.

DSR is set when TAC Xenta detects that the modem is driving the

Data Set Ready line. Possible reasons for DSR being low: modem not

connected, modem not powered on, DSR line not connected in the

cable.

AT OK is set when TAC Xenta has sent an AT command to the