Page 1

Application

T200 Series

T200 series thermostats provide temperatur e control

on a variety of heating, cooling and single stage heat

pump applications.

The large LCD window displays room temperature

including degree increments indicated by a series of

dashes. The system heat output cycles on a 1 or 2F

degree field selectable differential. The cool output

differential is fixed at 2F degrees. The setpoint is

displayed and changed by pressing one of the setpoin t

buttons up or down. Installation is simplified by having

all of the field wires mounted to the separate wall pla te.

This is a powered thermostat, which must receive

75 mA of power at all times.

T200 Series

Digital, On/Off Thermostat

General Instructions

Features

• LCD window display

• Jumper selectable 5 minute time delay for heating

an

d cooling applications

• Mechanical contact for 40

(optional)

°

F limit freeze protection

Printed in U.S.A. 5/10 © Copyright 2010 Schneider Electric All Rights Reserved. F-27027-5

Page 2

SPECIFICATIONS

Inputs

Outputs

Environment

Table-1 Model Chart.

Power Input: 20 to 32 Vac, 75 mA to 1.2 amps.

Electrical:

Battery, Setpoint backup (Energizer 357 or equivalent).

Mechanical:

Operating Differential, Heati ng 1 or 2F degrees (0.6 or 1.1C degrees), Cooling 2F

degrees (1.1C degrees).

Setpoint Adjustment Range, 50 to 86° F (10 to 30°C). Material, Rigid vinyl. Finish, Off-white.

Temperature limits:

Shipping & Storage, -40 to 125°F (-40 to 52°C).

Operating, 40 to 125°F (5 to 53°C). Humidity: 95% non-condensing. Shipping Weight: 0.4 lbs (170 g). Location: NEMA Type 1.

Model Control Outputs

T201 Heating Only None Heat/Off None No No

T201-FP

T205-FP

T207-FP

a On T20X-FP (freeze protection) models a relay will provide power to a valve or relay if the thermostat fails.

a

T204 Cooling Only On/Auto Cool/Off None No No

T205 Cooling & Heating On/Auto Cool/Off/Heat Manual No No

a

T207 Cooling & Heating On/Auto Cool/Off/Heat Manual No Yes

a

Heating Only None Heat/Off None Yes No

Cooling & Heating On/Auto Cool/Off/Heat Manual Yes No

Cooling & Heating On/Auto Cool/Off/Heat Manual Yes Yes

Fan

Control

System

Switch

Changeover Mechanical Contact

B & O

Terminals

2 © Copyright 2010 Schneider Electric All Rights Reserved. F-27027-5

Page 3

TYPICAL APPLICATION (wiring diagram)

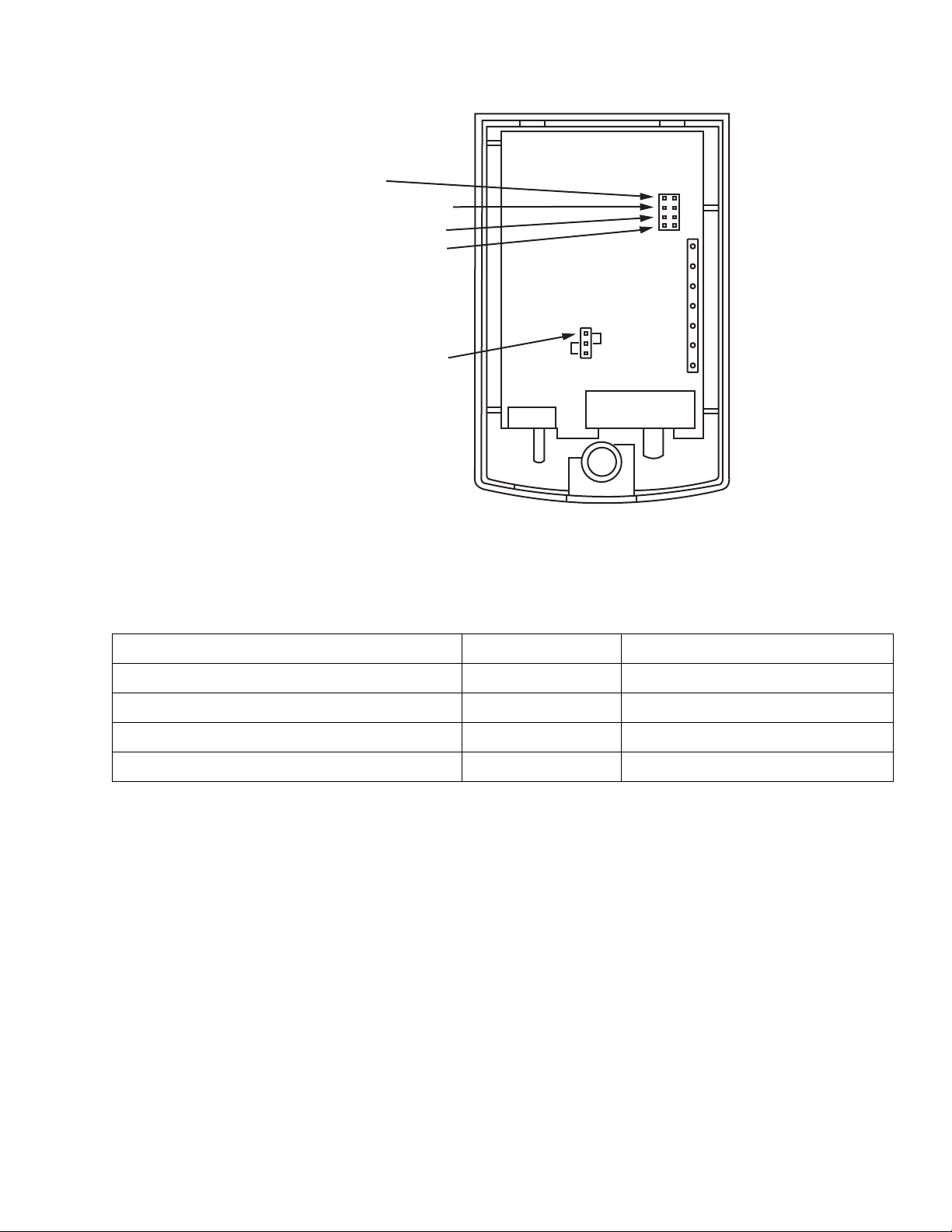

Figure-1 Terminal Identification.

DISPLAY

HEATING OPERATING

DIFFERENTIAL

HEAT CONTROL

COOL CONTROL

AUTO

FAN

CONTROL

HC

TH

RH

RC

W

Y

G

B

O

Table-2 Field Selectable Jumper Options.

Feature Jumpered Not Jumpered

1. Display Celsius Fahrenheit

2. Heating operation differential 2 degrees 1 degree

3. Heat control No delay 5 minute delay

4. Cool control* No delay 5 minute delay

* T201, heat only model, only has jumper options 1 thru 3. A fourth jumper location exists but is non-functional in heat only models.

F-27027-5 © Copyright 2010 Schneider Electric All Rights Reserved. 3

Page 4

RH

Figure-2 T201 Typical Wiring to Heating System With Single Transformer.

24 V AC

TRANSFORMER

24 V AC

120 V AC

FAN

RELAY

COOLING

RELAY

RC

Y

G

Optional 250 Ohm 5 watt resistor is needed

only if power drops below 75 milliamps.

1

1

1

Figure-3 Typical T204 Wiring to Cooling System With Single Transformer.

Figure-4 Typical T205 Wiring to Heating/Cooling System With Single Transformer.

W

24 VAC

1

HEATING

RELAY

24 VAC

TRANSFORMER

120 VAC

1

Optional 250W 5 watt resistor is needed

only if power drops below 75 milliamps.

FACTORY

INSTALLED

JUMPER

RH

RC

W

G

24 VAC HEATING

1

TRANSFORMER

24 VAC

Y

HEATING

RELAY

COOLING

RELAY

FAN

RELAY

120 VAC

1

If one of the secondary sides

of both transformers are grounded,

grounded sides must be connected

together.

4 © Copyright 2010 Schneider Electric All Rights Reserved. F-27027-5

Page 5

24 VAC HEATING

TRANSFORMER

24 VAC

120 VAC

24 VAC COOLING

TRANSFORMER

120 VAC

FAN

RELAY

COOLING

RELAY

RC

RH

Y

W

G

HEATING

RELAY

1

11If one of the secondary sides

of both transformers are grounded,

grounded sides must be connected

together.

FAC TORY

INSTALLED

JUMPER

Figure-5 Typical T205 Wiring to Heating/Cooling System With Dual Transformer.

24 VAC HEATING

TRANSFORMER

24 VAC

120 VAC

FAN

RELAY

COOLING

RELAY

RC

RH

Y

W

G

B

O

HEATING

RELAY

REVERSING

VALVE

1

1

Either the B or O output

will be connected to the

reversing valve. Terminal

O supplies 24V on a call

for cooling. Terminal B

supplies 24V on a call for

heat.

FACTORY

INSTALLED

JUMPER

Figure-6 Typical T207 Wiring To Heating/Cooling System With Single

Transformer & Reversing Valve.

INSTALLATION

Inspection

F-27027-5 © Copyright 2010 Schneider Electric All Rights Reserved. 5

Inspect the package for damage. If damaged, notify the appropriate carrier immediately.

If undamaged, open the package and inspect the device for obvious damage.

Return damaged products.

Requirements

• Tools (not provided)

— Writer’s Note: Need list.

• Training: Installer must be a qualified, experienced technician

• Other accessories as appropriate

Page 6

Precautions

]

W A R N I N G

]

C A U T I O N

N O T E

N O T E

]

W A R N I N G

General

• Electrical shock hazard! Disconnect power before installation to prevent electrical shock

or equipment damage.

• Make all connections in accordance with the electrical wiring diagram and in accordance

with national and local electrical codes.

• Avoid locations where excessive moisture, corrosive fumes, explosive vapors, or vibra-

tion are present.

• Avoid electrical noise interference. Do not install near large conductors, electrical

machinery, or welding equipment.

Federal Communications Commission (FCC)

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in residential installations. This equipment generates, uses, and can radiate radio frequency energy and may cause harmful interference if

not installed and used in accordance with the instructions. Even when instructions are followed, there is no guarantee that interference will not occur in a particular installation. If this

equipment causes harmful interference to radio and television reception—which can be

determined by turning the equipment off and on—the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment to an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio/television technician for help.

Canadian Department of Communications (DOC)

This class B digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numerique de la classe B respecte toutes les exigences du Reglement sur le

material broilleur du Canada.

European Standard EN 55022

This is a class B (European Classification) product. In a domestic environment this product

may cause radio interference in which case the user may be required to take adequate measures.

6 © Copyright 2010 Schneider Electric All Rights Reserved. F-27027-5

Page 7

Mounting

N O T E

Wiring

Mount the T200 series to a suitable surface. The T200 is shipped with an adapter plate

(4-1/4 x 4-3/4 in.) that covers the mounting blemishes of a previous thermostat. New

installation will not need the adapter plate. Do not mount on a surface that exceeds 125°F

(52°C).

• The T200 series is a powered thermostat which must receive 75 mA of power at all times.

• Some systems may require a 250 ohm, 5 watt resistor (included) to be installed across

the "W" and "C" terminals of the furnace or boiler control board (Figure-2) to assure

proper current draw for the thermostat. Install the resistor if the thermostat setpoint

cannot be adjusted, if the heating relay cycles too often (1-15 seconds), or if the heating

relay will not cycle.

• The T200 series cannot operate with a millivolt automatic self-powered gas heating

system unless an isolation relay and a separate 24 Vac transformer are used. Install an

isolation relay if the ignition blower runs continuously or if the furnace will not shut off

when the thermostat reaches the set temperature. Another symptom is that the furnace

may not turn on.

T201

The T201 models are a heat only model with a "HEAT/OFF" system switch and no fan

control. Applications include hydronic and radiant floor heating systems as well as gas and

electric forced air heating systems. Refer to Figure-2.

T204

The T204 model is a cool only model with a "COOL/OFF" system switch and a "FAN

ON/AUTO" fan switch. Applications include direct expansion cooling only systems. Refer to

Figure-3.

T205

The T205 models are heat/cool models with manual changeover. The unit consists of a

"COOL/OFF/HEAT" system switch and a "FAN/ON/AUTO" fan switch. Applications include

hydronic heating and radiant floor heating systems as well as gas and electric forced air

heating with conventional air conditioning systems. Refer to Figure-4 and Figure-5.

T207

The T207 models are heat/cool models with manual changeover and B (powered on heat

demand) and O (powered on cool demand) terminals. The unit consists of a

"COOL/OFF/HEAT" system switch and a "FAN ON/AUTO" fan switch. Applications include

all of the T205 applications plus single stage heat pumps and forced air zoning systems that

require B and O outputs. Refer to Figure-6.

For field selectable jumper options see Table-2.

For jumper and terminal locations see Figure-1.

Auto Fan Control (HC/TH)

A three-pin jumper (Figure-1) is set to enable the HC or TH mode.

The HC mode is used in electric heat applications to energize the fan relay at the same time

the heating relay is energized. The TH mode is used in fossil fuel applications where the

furnace, not the thermostat, controls the fan directly. In this application, a call for heat only

energizes the heating relay.

Optional Freeze Protection

When the T200 thermostat is ordered with the FP option a limit switch is wired in parallel with

the terminals R and W. This will provide power to a heating valve or relay if the thermostat

fails. This provides freeze protection to 40

source.

F-27027-5 © Copyright 2010 Schneider Electric All Rights Reserved. 7

°

F (4°C) as long as heat is available from the heat

Page 8

On October 1st, 2009, TAC be came the Buildings business of its parent com pany Schneider Electric. This document re flects the visual identity of Schneider Electric,

however there remains references to TAC as a corporate brand in the body copy. As each document is updated, the body copy will be changed to ref lec t ap propriate

CHECKOUT

7272

3-1/4

(81)

1-7/16

(36)

4-3/4

(121)

2-1/2

(64)

4-1/4

(108)

SYSTEM

SWITCH

FAN

SWITCH

Figure-7 T200 Series Dimensions.

MAINTENANCE

1. Verify jumper pin selections.

2. Verify that the T200 is wired correctly to your heating and or cooling loads.

3. Confirm that 75 milliamps are available at all times. To measure the current draw

connect an ammeter (set to measure milliamps) in series with the heat or cool output.

If power value is below 75 milliamps install a 250 ohm 5 watt resistor in parallel across

the switched load. Recheck for 75 milliamps. The T200 thermostats must have 75

milliamps to function properly.

4. Verify system Heat/Cool/Fan outputs:

Heating — Connect a voltmeter in parallel across the heat output terminal, W, and

common of the power source.

Cooling — Connect a voltmeter in parallel across the cooling output terminal, Y, and

common of the power source.

Fan — Connect a voltmeter in parallel across the fan terminal, G, and common of the

power source.

5. The display will show the current room temperature as a number. Up to five dashes will appear under the number. Each dash represents 1/5 of a degree. The thermostats ON/OFF switching is based on whole degrees.

The T200 series requires no maintenance. Replace defective modules.

Regular maintenance of the total system is recomended to assure sustained, optimum

performance.

FIELD REPAIR

DIMENSIONAL DATA

Replace battery with Energizer 357 or equivalent as needed. Replace any damaged or failed

components with functional replacements.

corporate brand changes.

Copyright 2010, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-27027-5

Loading...

Loading...