Page 1

User Manual

Compact I/O Isolated Analog Modules

Catalog Numbers

1769-IF4I, 1769-OF4CI, 1769-OF4VI

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Overview

Installation and Wiring

Table of Contents

Preface

Who Should Use This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . Preface-1

How to Use This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Preface-1

Manual Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Preface-1

Related Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . Preface-2

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . Preface-2

Chapter 1

How to Use Analog I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Hardware Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

General Diagnostic Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

System Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Module Field Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Chapter 2

Compliance to European Union Directives . . . . . . . . . . . . . . . . . . . . 2-1

EMC Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Low Voltage Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Hazardous Location Considerations. . . . . . . . . . . . . . . . . . . . . . . 2-3

Prevent Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Remove Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Reduce Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Protect the Circuit Board from Contamination . . . . . . . . . . . . . . 2-4

System Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Minimum Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Panel Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

DIN-rail Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Replace a Single Module Within a System . . . . . . . . . . . . . . . . . . . . . 2-8

Field Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

System Wiring Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Label the Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Remove the Finger-safe Terminal Block . . . . . . . . . . . . . . . . . . 2-15

Wire the Finger-safe Terminal Block . . . . . . . . . . . . . . . . . . . . . 2-15

Wire the Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Analog Input Module Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Analog Output Modules Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

i Publication 1769-UM014B-EN-P - May 2010

Page 4

ii Table of Contents

Module Data, Status, and Channel

Configuration for the Input Module

Chapter 3

1769-IF4I Input Module Addressing . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1769-IF4I Input Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1769-IF4I Output Image. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1769-IF4I Configuration File . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1769-IF4I Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

1769-IF4I Input Data Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

1769-IF4I Output Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

1769-IF4I Configuration Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Channel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Enable/Disable Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Input Filter Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Input Type/Range Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Input Data Selection Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

1769-IF4I Real Time Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

1769-IF4I Time Stamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

1769-IF4I Process Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Module Data, Status, and Channel

Configuration for the Output

Modules

Chapter 4

1769-OF4CI Output Module Memory Map. . . . . . . . . . . . . . . . . . . . 4-1

1769-OF4VI Output Module Memory Map. . . . . . . . . . . . . . . . . . . . 4-2

1769-OF4CI and -OF4VI Output Data File . . . . . . . . . . . . . . . . . . . 4-3

Channel Alarm Unlatch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

1769-OF4CI and -OF4VI Input Data File . . . . . . . . . . . . . . . . . . . . . 4-4

1769-OF4CI and -OF4VI Data Values . . . . . . . . . . . . . . . . . . . . 4-4

1769-OF4CI and -OF4VI Output Data Loopback/Echo . . . . . 4-6

1769-OF4CI and -OF4VI Configuration Data File . . . . . . . . . . . . . . 4-7

1769-OF4CI and -OF4VI Channel Configuration . . . . . . . . . . . 4-8

1769-OF4CI and -OF4VI Enable/Disable Channel . . . . . . . . . . 4-9

Clamping/Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Clamp/Limit Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Ramping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Hold for Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

1769-OF4CI and -OF4VI Fault Mode (FM) . . . . . . . . . . . . . . . 4-13

1769-OF4CI and -OF4VI Program/Idle Mode (PM). . . . . . . . 4-14

1769-OF4CI and -OF4VI Program/Idle to Fault Enable (PFE) . . .

4-14

1769-OF4CI and -OF4VI Fault Value . . . . . . . . . . . . . . . . . . . . 4-15

1769-OF4CI and -OF4VI Program/Idle Value. . . . . . . . . . . . . 4-16

Publication 1769-UM014B-EN-P - May 2010

Page 5

Module Diagnostics and

Troubleshooting

Table of Contents iii

Chapter 5

Safety Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Activate Devices When Troubleshooting. . . . . . . . . . . . . . . . . . . 5-1

Stand Clear of the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Program Alteration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Safety Circuits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Module Operation versus Channel Operation . . . . . . . . . . . . . . . . . . 5-2

Power Cycle Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Channel Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Out-of-range Detection (Input and Output Modules) . . . . . . . . 5-3

Open-circuit Detection (1769-IF4I Module Only) . . . . . . . . . . . 5-4

Non-critical vs. Critical Module Errors. . . . . . . . . . . . . . . . . . . . . . . . 5-4

Module Error Definition Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Module Error Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Extended Error Information Field . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Module Inhibit Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Contacting Rockwell Automation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Specifications

Module Addressing and

Configuration with MicroLogix

1500

Configuration Using the RSLogix

5000 Generic Profile for

CompactLogix Controllers

Appendix A

General Specifications for 1769-IF4I, -OF4CI, and -OF4VI Modules. .

A-1

1769-IF4I Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

1769-OF4CI Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . A-5

1769-OF4VI Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Appendix B

Input Module Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Input Module’s Input Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Input Module’s Configuration File . . . . . . . . . . . . . . . . . . . . . . . . B-3

Configure Analog I/O Modules in a MicroLogix 1500 System. . . . . B-4

Appendix C

Configure I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Configure Analog Output Modules . . . . . . . . . . . . . . . . . . . . . . . C-7

Configure Analog Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Publication 1769-UM014B-EN-P - May 2010

Page 6

iv Table of Contents

Configure Modules in a Remote

DeviceNet System with a

1769-ADN DeviceNet Adapter

Two’s Complement Binary

Numbers

Index

Appendix D

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Add the DeviceNet Adapter to the Scanlist . . . . . . . . . . . . . . . . . . . D-2

Configure the 1769-IF4I Input Module Example . . . . . . . . . . . . . . D-4

1769-IF4I External Power Example. . . . . . . . . . . . . . . . . . . . . . D-8

Configure the 1769-OF4CI Output Module Example. . . . . . . . . . . D-9

1769-OF4CI External Power Example . . . . . . . . . . . . . . . . . . D-10

1769-OF4CI Output Channels Example . . . . . . . . . . . . . . . . . D-11

Appendix E

Positive Decimal Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Negative Decimal Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Glossary

Publication 1769-UM014B-EN-P - May 2010

Page 7

Preface

Read this preface to familiarize yourself with the rest of the manual. This

preface covers the following topics:

Who should use this manual

How to use this manual

Related publications

Conventions used in this manual

Rockwell Automation support

Who Should Use This Manual

How to Use This Manual

Use this manual if you are responsible for designing, installing, programming,

or troubleshooting control systems that use the Allen-Bradley Compact I/O

system.

As much as possible, we organized this manual to explain, in a task-by-task

manner, how to install, configure, program, operate and troubleshoot a control

system using the 1769 isolated analog I/O modules.

Manual Contents

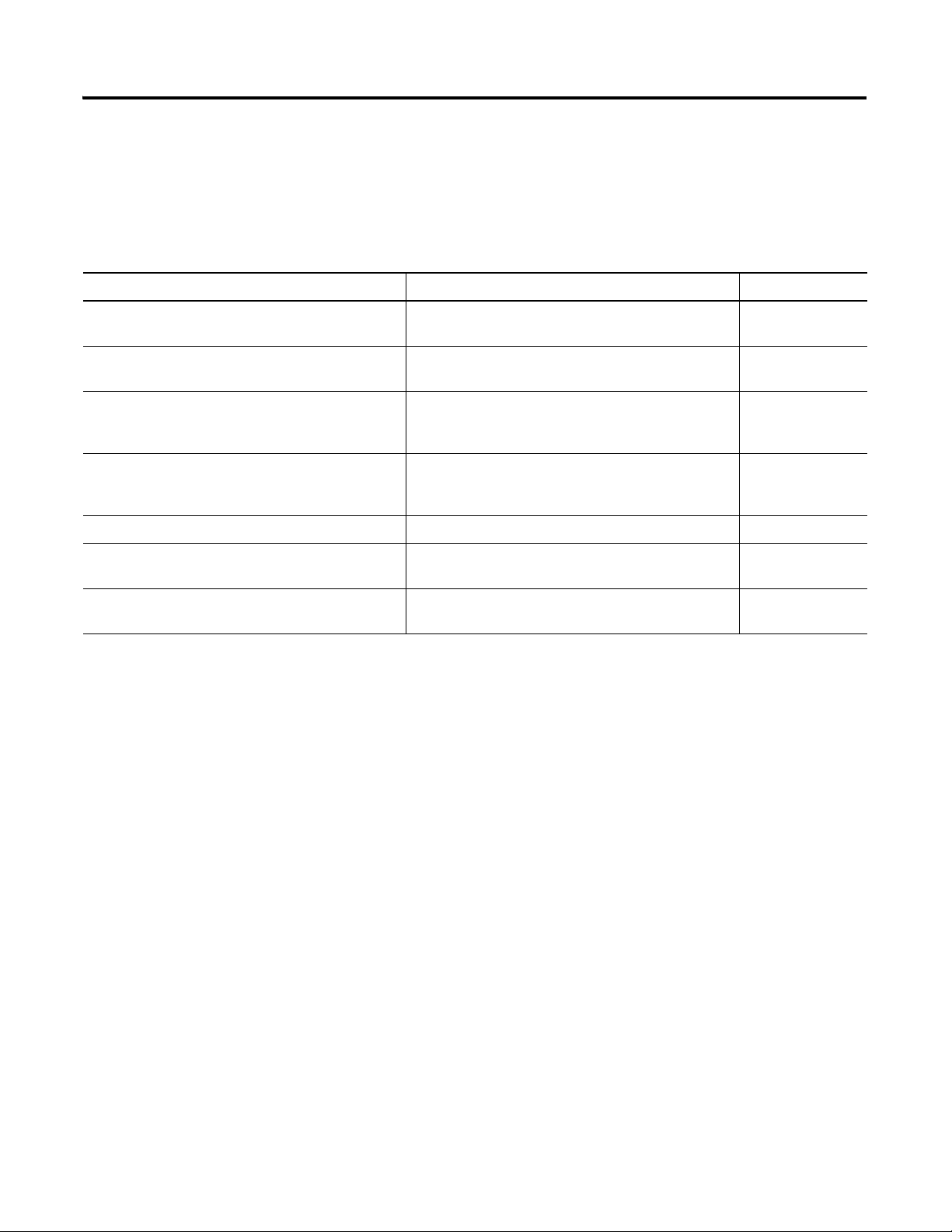

For See

An overview of the analog input and output modules Chapter 1

Installation and wiring guidelines Chapter 2

Input module addressing, configuration, and status information Chapter 3

Output module addressing, configuration, and status information Chapter 4

Information on module diagnostics and troubleshooting Chapter 5

Specifications for the input and output modules Appendix A

Information on addressing and configuration using MicroLogix 1500 and

RSLogix 500 software

Information on configuring the module using CompactLogix and RSLogix

5000 software

Information on configuring the module using the 1769-ADN DeviceNet

adapter and RSNetWorx software

Information on understanding two’s complement binary numbers Appendix E

Definitions of terms used in this manual Glossary

1 Publication 1769-UM014B-EN-P - May 2010

Appendix B

Appendix C

Appendix D

Page 8

2 Preface

Related Documentation

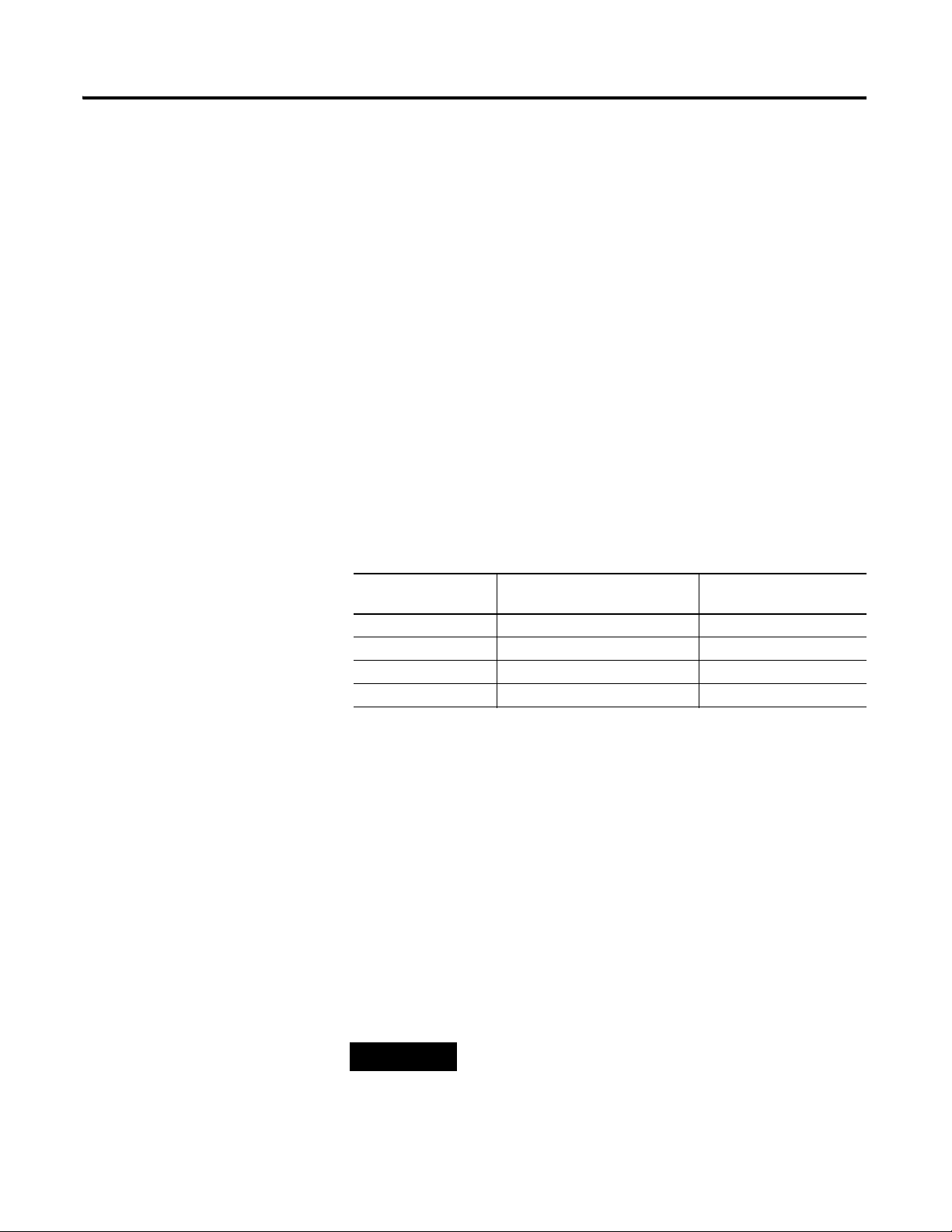

The table below provides a listing of publications that contain important

information about MicroLogix 1500 systems.

For Read this document Document number

A user manual containing information on how to install,

use and program your MicroLogix 1500 controller.

A user manual containing information on how to install,

and use your 1769-ADN DeviceNet adapter.

A user manual containing information on how to install,

use and program your 1769-L20 and -L30 CompactLogix

controllers.

A user manual containing information on how to install,

use and program your 1769-L31, -L32C, -L32E, -L35CR

and -L35E CompactLogix controllers.

An overview of 1769 Compact I/O modules. Compact I/O Selection Guide 1769-SG002

An overview of the MicroLogix 1500 System, including

the 1769 Compact I/O system.

In-depth information on grounding and wiring

Allen-Bradley programmable controllers.

MicroLogix 1500 User Manual 1764-UM001

DeviceNet Adapter User Manual 1769-UM001

CompactLogix User Manual 1769-UM007

CompactLogix System User Manual 1769-UM011

MicroLogix 1500 System Overview 1764-SO001

Allen-Bradley Programmable Controller Grounding and

Wiring Guidelines

1770-4.1

If you would like a manual, you can:

download a free electronic version from the internet at

www.literature.rockwellautomation.com.

purchase a printed manual by contacting your local distributor or

Rockwell Automation representative.

Conventions Used in This Manual

Publication 1769-UM014B-EN-P - May 2010

The following conventions are used throughout this manual.

Bulleted lists (like this one) provide information, not procedural steps.

Numbered lists provide sequential steps or hierarchical information.

Bold type is used for emphasis.

Page 9

Chapter

Controller

Analog I/O

Module

Valve

Level Sensor

Analog Input Wired

to Tank

Analog Output

Wired to Valve

1

Overview

This chapter explains how analog data is used, describes the 1769-IF4I isolated

analog input module, and describes the 1769-OF4CI and 1769-OF4VI isolated

analog output modules. Included is information about:

the use of analog I/O.

the modules’ hardware and diagnostic features.

an overview of the 1769 analog input system operation.

an overview of the 1769 analog output system operation.

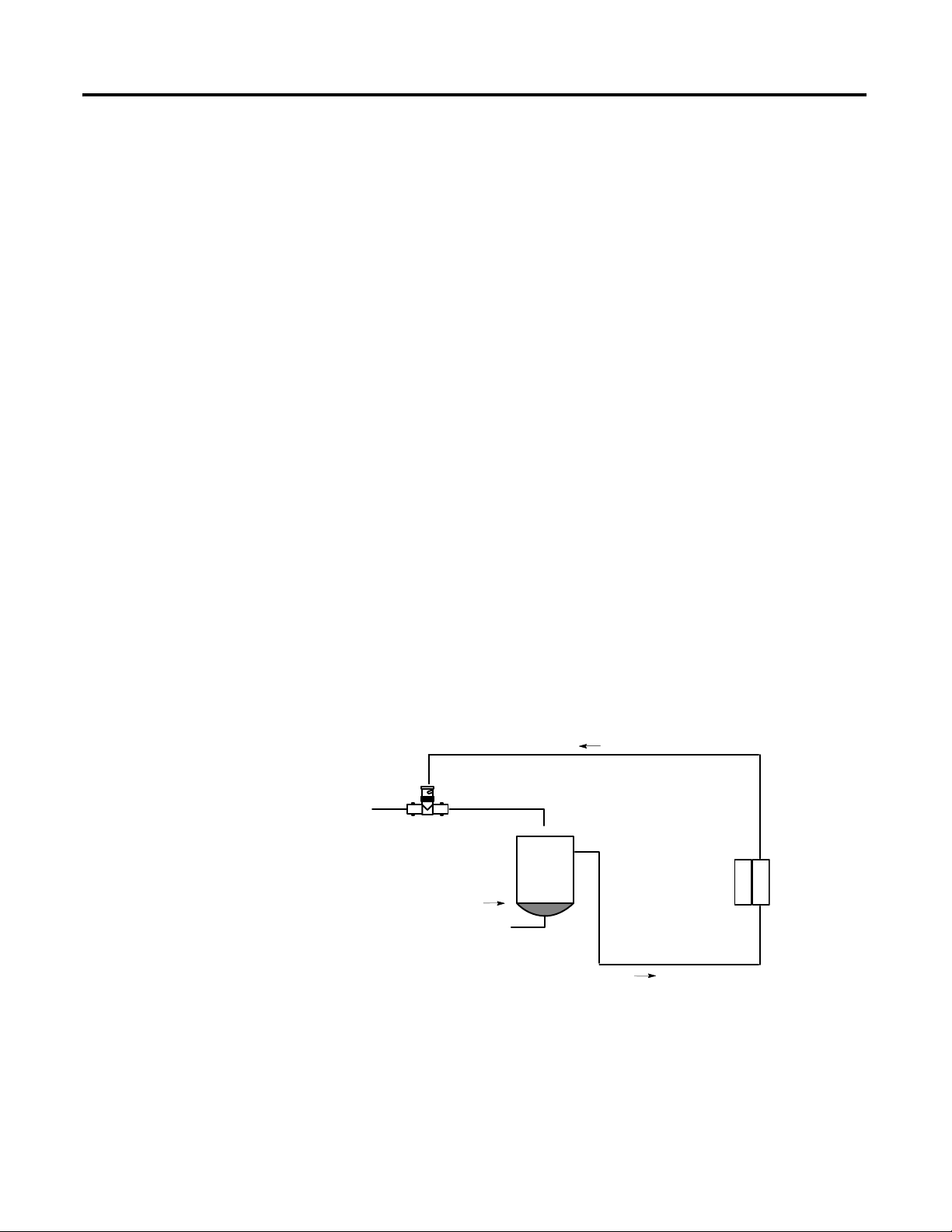

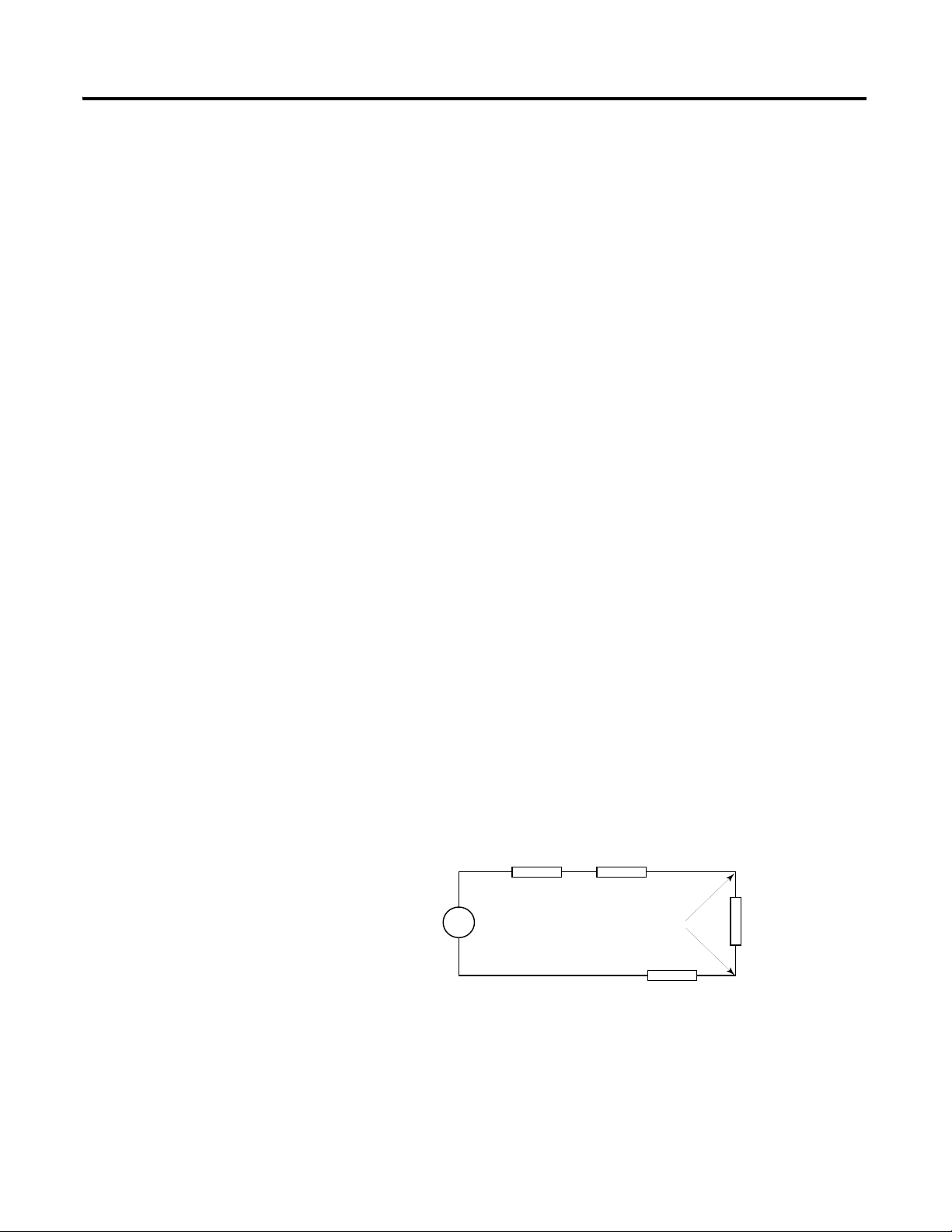

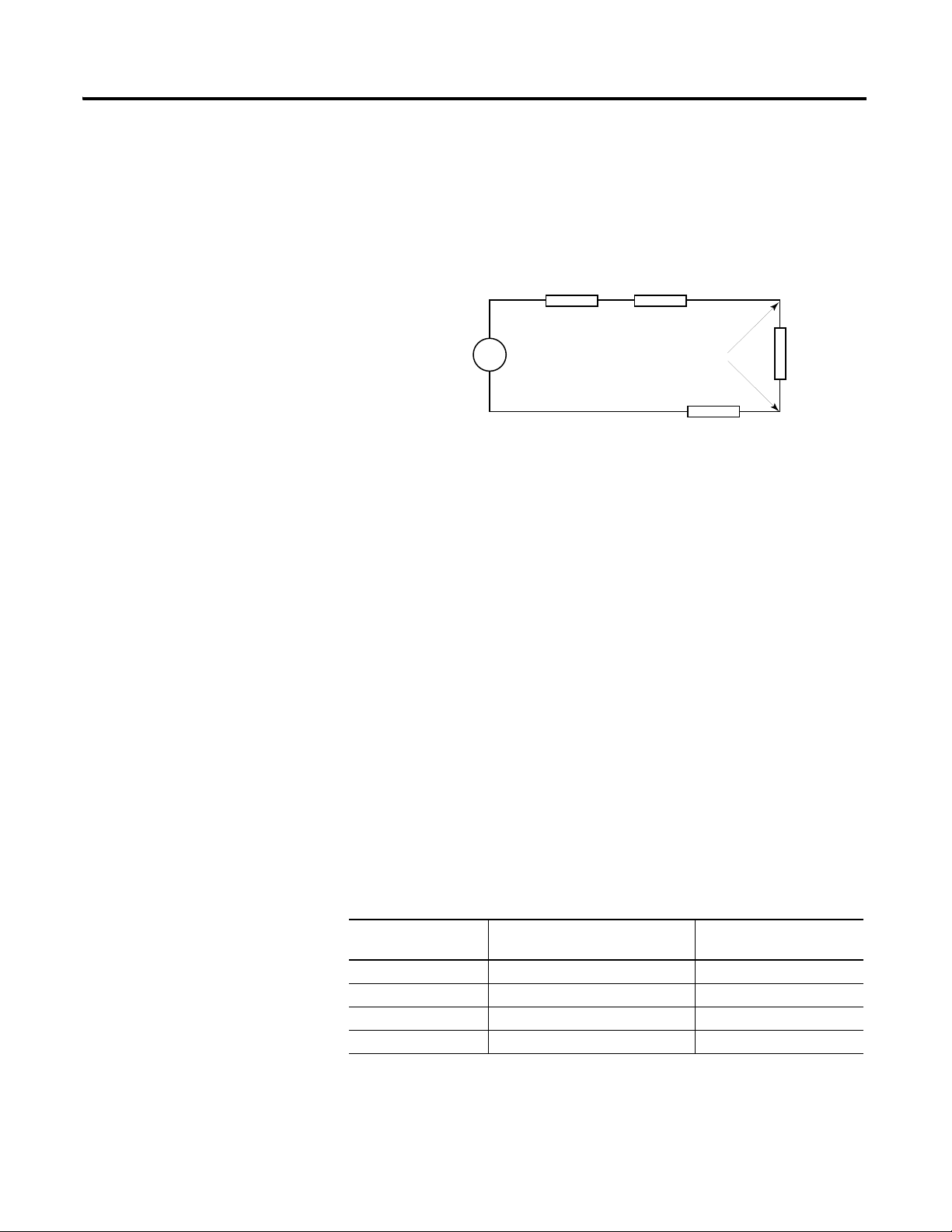

How to Use Analog I/O Data

Analog refers to the representation of numerical quantities by the

measurement of continuous physical variables. Analog applications are present

in many forms. The following application shows a typical use of analog data.

In this application, the controller controls the amount of fluid in a holding

tank by adjusting the valve opening. The valve is initially open 100%. As the

fluid level in the tank approaches the preset point, the controller modifies the

output to close the valve 90%, 80%, and so on, continuously adjusting the

valve to maintain the fluid level.

Figure 1.1 Analog I/O Application Example

1 Publication 1769-UM014B-EN-P - May 2010

Page 10

1-2 Overview

General Description

The 1769-IF4I isolated analog input module converts and digitally stores

analog data for retrieval by controllers, such as the CompactLogix controller or

the MicroLogix 1500 controller. The module supports connections from any

combination of as many as four voltage or current analog sensors. The

1769-IF4I input module provides four, isolated-differential analog input

channels.

The 1769-OF4CI and -OF4VI isolated output modules each provide four,

isolated differential analog output channels.

The modules provide the following input/output types/ranges:

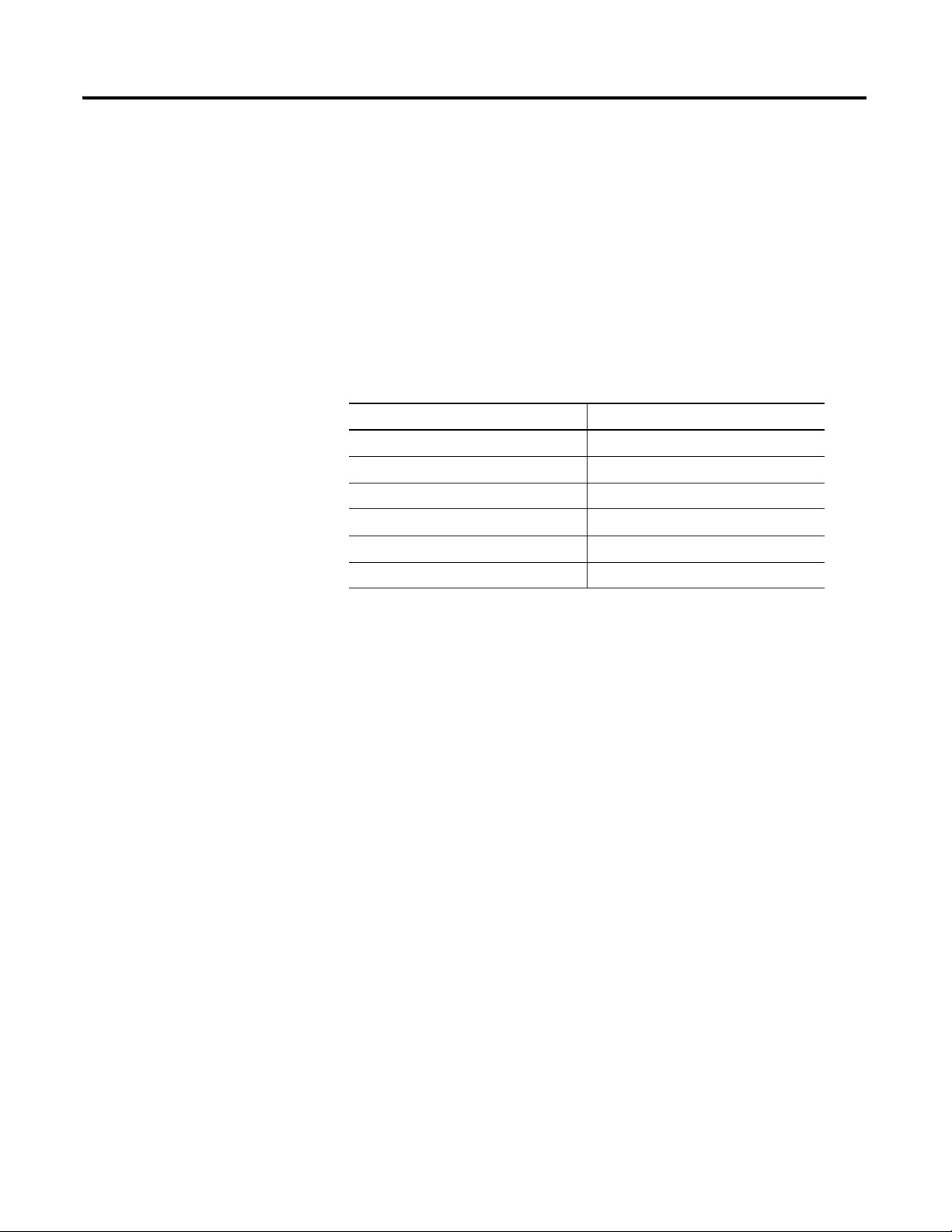

Table 1.1 Normal and Full Ranges

Normal Operating Input Range Full Module Range

±10V dc ± 10.5V dc

1…5V dc 0.5…5.25V dc

0…5V dc -0.5…+5.25V dc

0…10V dc -0.5…+10.5V dc

0…20 mA 0…21 mA

4…20 mA 3.2…21 mA

The data can be configured on board each module as:

engineering Units.

scaled-for-PID.

percent.

raw/proportional data.

Hardware Features

The modules contain removable terminal blocks. The modules’ channels are

isolated from each other and are normally wired as differential inputs or

outputs. Single-ended applications can be supported by wiring the negative

terminal of each channel to the other channel’s negative terminals; however,

this eliminates the channel-to-channel isolation provided by the modules.

Module configuration is normally done via the controller’s programming

software. In addition, some controllers support configuration via the user

program. In either case, the module configuration is stored in the memory of

the controller. Refer to your controller’s user manual for more information.

Publication 1769-UM014B-EN-P - May 2010

Page 11

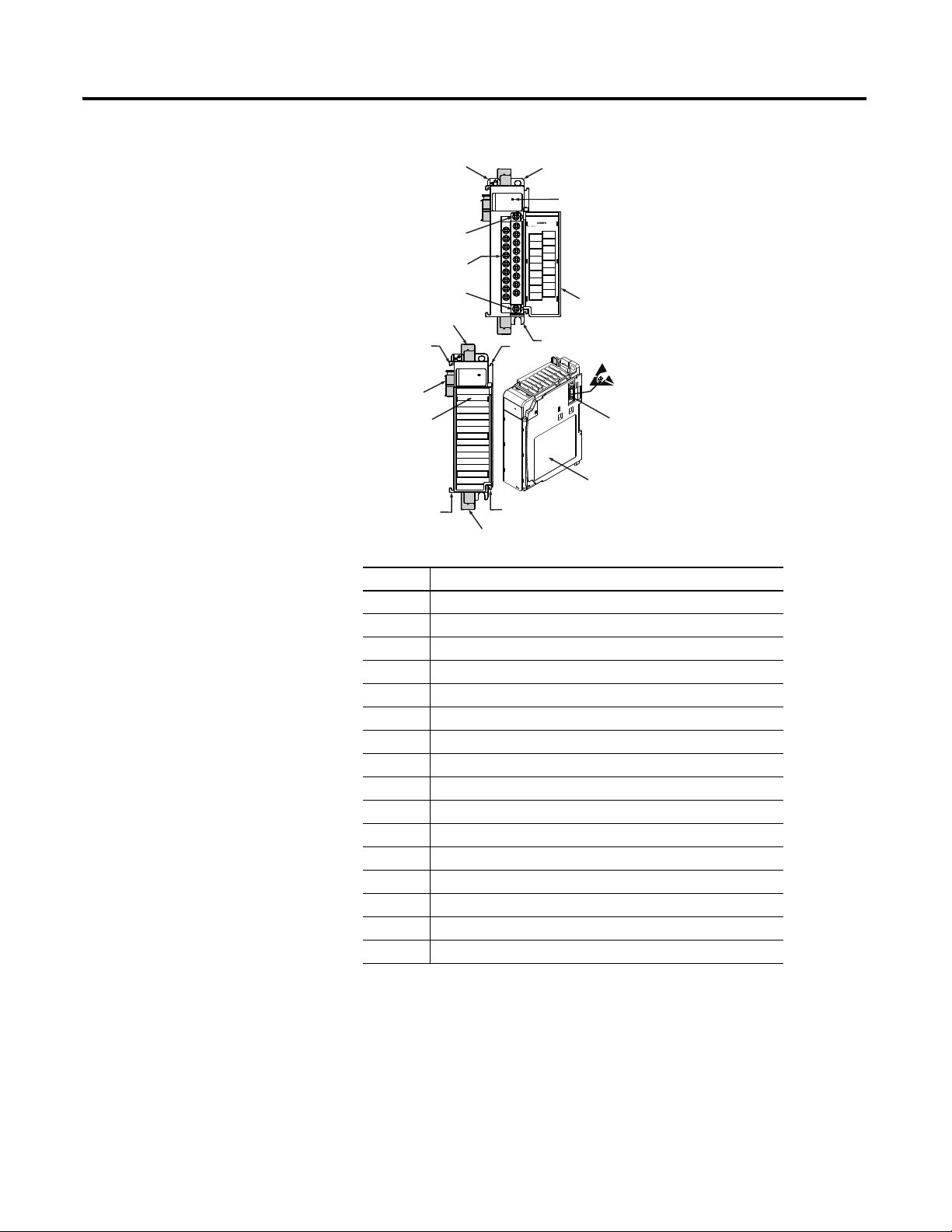

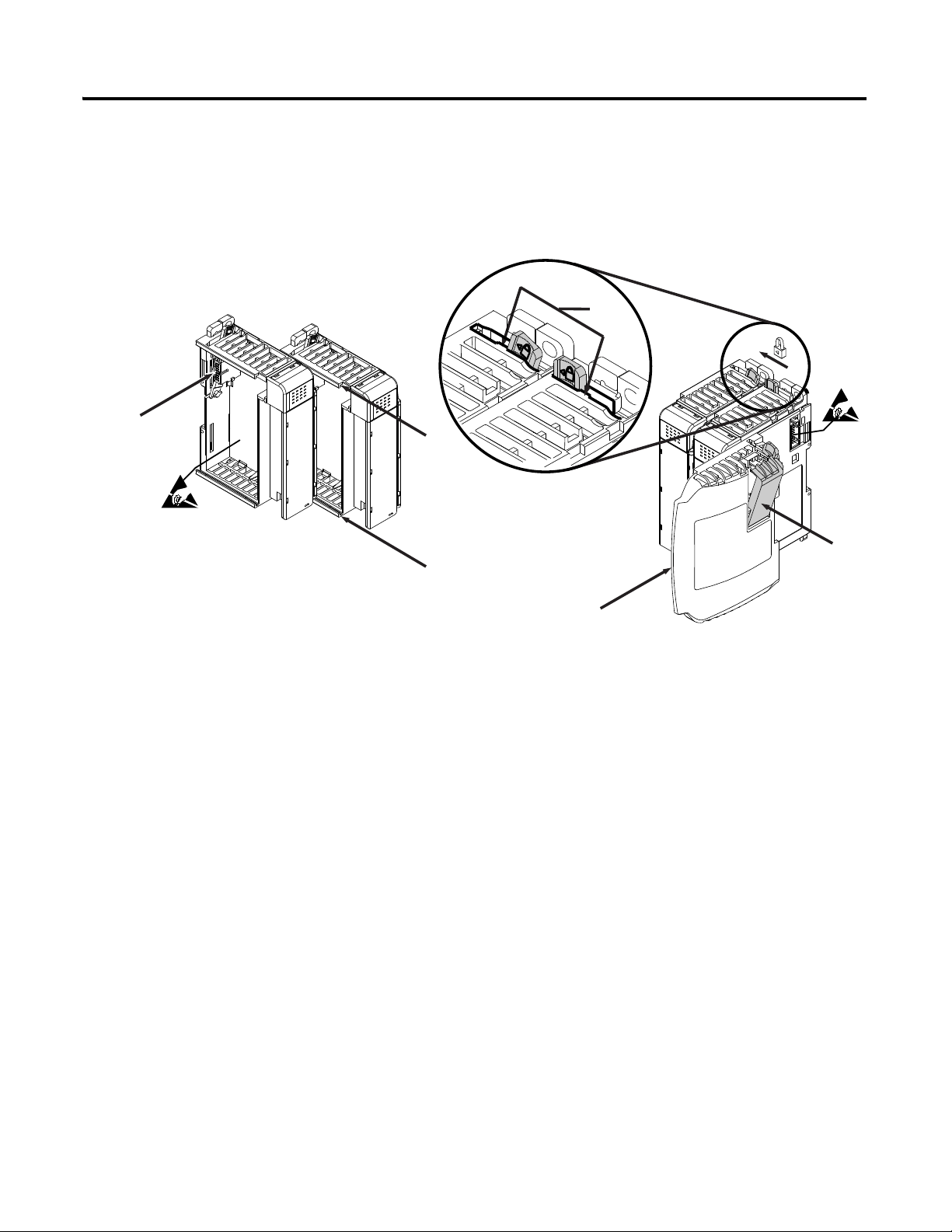

Figure 1.2 Isolated Analog Modules’ Hardware Features

10a

10b

4

10

2b

3

2a

1

5a

9

5b

6

7a

7b

8b

7b

8a

7a

1769-IF

4I

DANGER

Do Not Remove RTB Under Power

Unless Area is Non-Hazardous

Ensure Adjacent

Bus Lever is Unlatched/Latched

Before/After

Removing/Inserting Module

N/C

Ch3+

N/C

Ch3-

Ch1+

Ch1-

N/C

Ch3_iRtn

N/C

Ch0+

Ch0-

Ch2+

Ch2-

Ch0_iRtn

N/C

Ch2_iRtn

N/C

Ch1_iRtn

OK

Analog

OK

Analog

Overview 1-3

Table 1.2 Isolated Modules’ Feature Descriptions

Item Description

1 Bus lever (with locking function)

2a Upper-panel mounting tab

2b Lower-panel mounting tab

3 Module status LEDs

4 Module door with terminal identification label

5a Movable bus connector with female pins

5b Stationary bus connector with male pins

6 Nameplate label

7a Upper tongue-and-groove slots

7b Lower tongue-and-groove slots

8a Upper DIN-rail latch

8b Lower DIN-rail latch

9 Write-on label for user identification tags

10 Removable terminal block (RTB) with finger-safe cover

10a RTB upper retaining screw

10b RTB lower retaining screw

Publication 1769-UM014B-EN-P - May 2010

Page 12

1-4 Overview

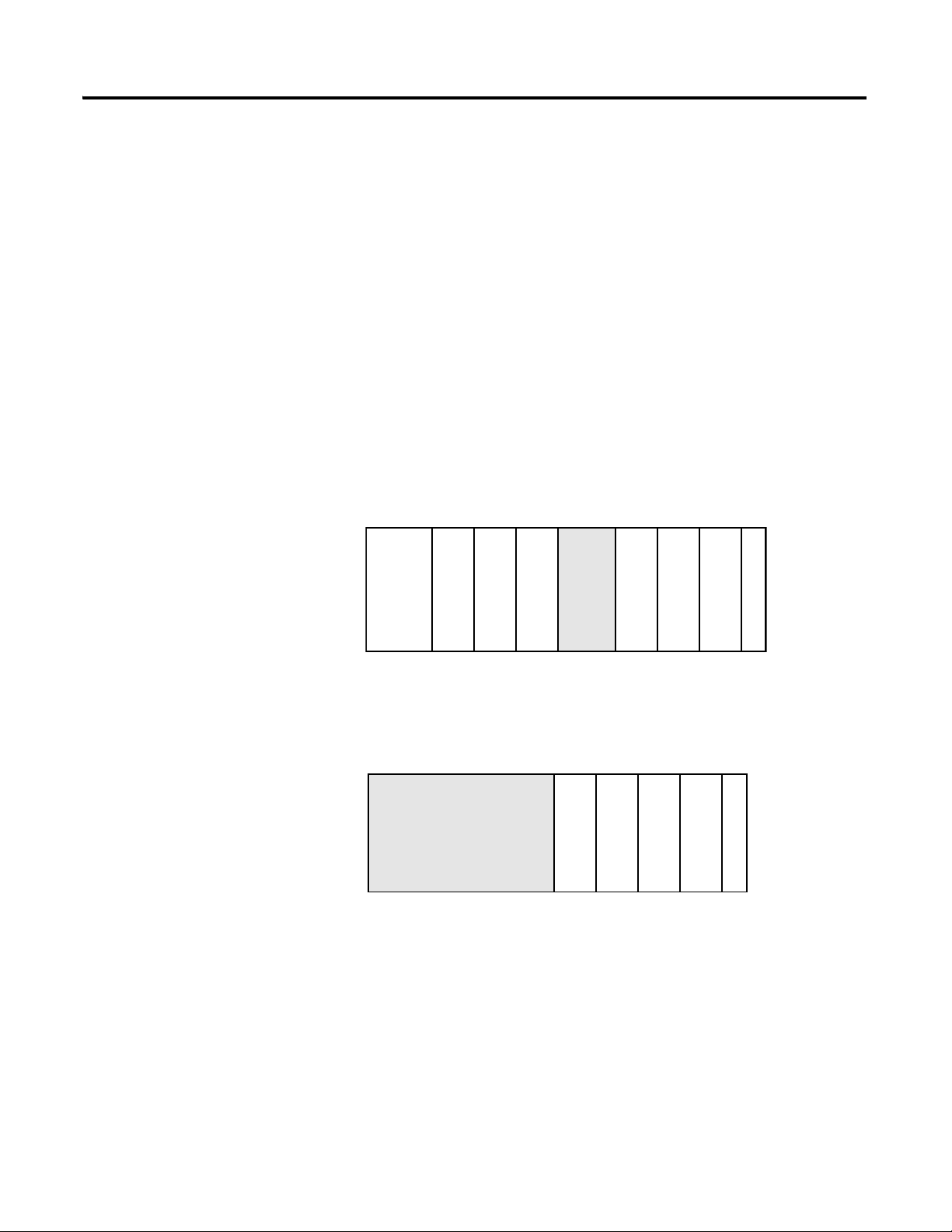

1

1123432

234

System Power Supply

Compact I/O

Compact I/O

Compact I/O

End Cap

CompactLogix Controller

or I/O Communication

Adapter

Compact I/O

Compact I/O

Compact I/O

or

Power Supply Distance

Compact I/O

Compact I/O

Compact I/O

Compact I/O

End Cap

MicroLogix 1500 Controller

with Integrated System

Power Supply

Power Supply Distance

General Diagnostic Features

The analog modules contain diagnostic features that can help you identify the

source of problems that may occur when cycling power or during normal

channel operation.

These power cycle and channel diagnostics are explained in chapter 5.

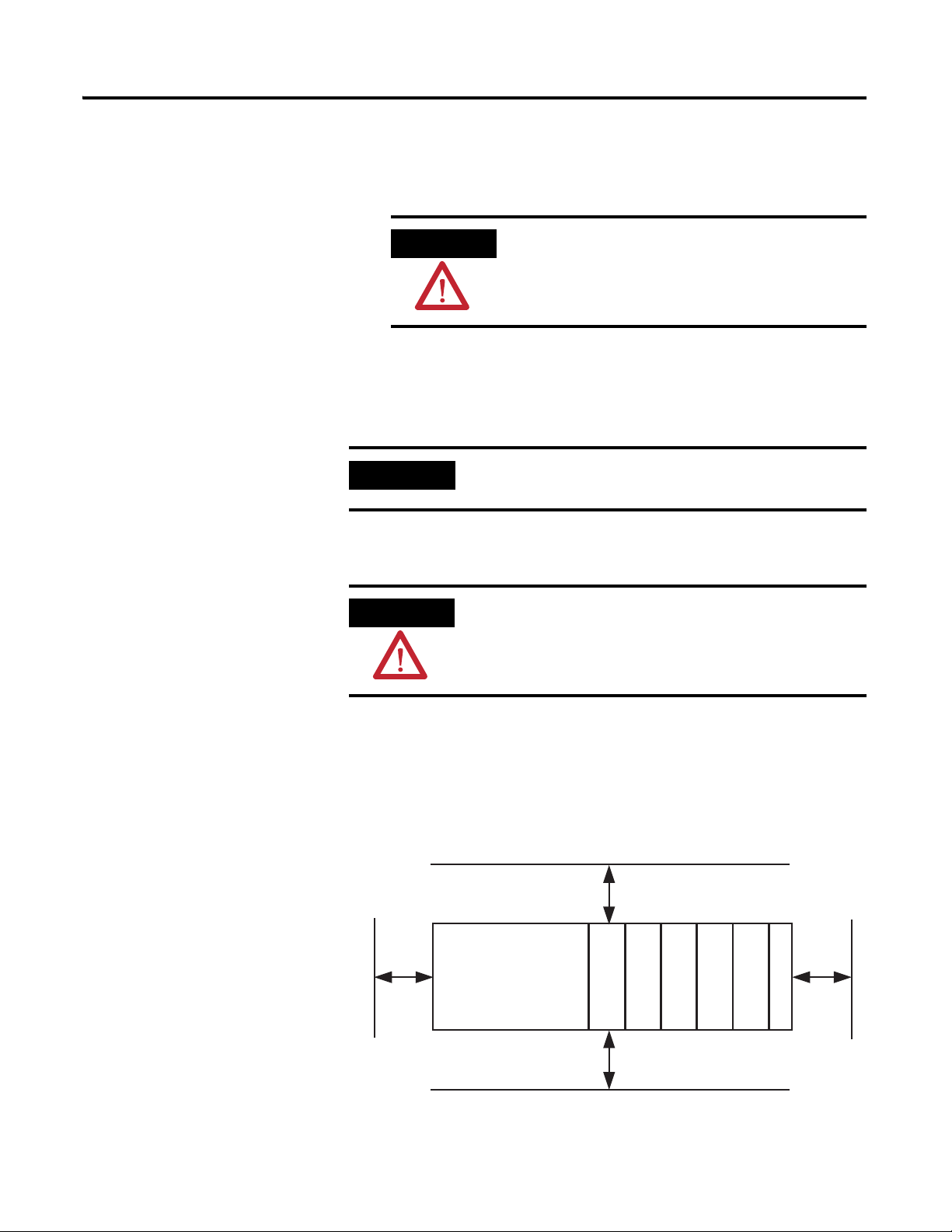

System Overview

The modules communicate to the controller through the bus interface. The

modules also receive 5 and 24V dc power through the bus interface.

You can install as many analog modules as your power supply can support.

However, the modules may not be located more than eight modules away from

the system power supply.

Figure 1.3 Determine Power Supply Distance

Publication 1769-UM014B-EN-P - May 2010

Page 13

Overview 1-5

System Operation

When you cycle power, the module performs a check of its internal circuits,

memory, and basic functions. During this time, the module status OK LED

remains off. If no faults are found during power-cycle diagnostics, the module

status OK LED is turned on.

After power-cycle checks are complete, the module waits for valid channel

configuration data. If an invalid configuration is detected, the module

generates a configuration error. Once a channel is properly configured and

enabled, it begins the analog-to-digital or digital-to-analog conversion process.

Input Modules

Each time a channel is read by the input module, that analog data value is

tested by the module for an over-range or under-range condition. If any of

these conditions are detected, unique bits are set in the channel status word.

The channel status word is described in the 1769-IF4I Input Data File on

page 3-3.

The controller reads the two’s complement binary converted analog data from

the modules. This typically occurs at the end of the program scan or when

commanded by the control program. If the controller and the modules

determine that the bus data transfer was made without error, the data is used

in your control program.

Output Modules

The output modules monitor channels for over-range and under-range

conditions and can also clamp the outputs at designated levels (if enabled by

the user program). If such conditions are detected, a unique bit is set in the

channel status word.

The channel status word is described in the 1769-OF4CI and -OF4VI Output

Data File on page 4-3.

The output modules receive two’s complement binary values from the bus

master. This typically occurs at the end of the program scan or when

commanded by the control program. If the controller and the module

determine that the bus transfer was completed without error, the output

module converts the data to an analog output signal.

Publication 1769-UM014B-EN-P - May 2010

Page 14

1-6 Overview

ADC

OPTO

LED

OPTO

DC / DC

Converter

High

Impendence

Ch0+

Ch0-

Ch0_iRtn

ADC

OPTO

OPTO

DC / DC

Converter

High

Impendence

Ch0+

Ch0-

Ch0_iRtn

CPU

ASIC BUS

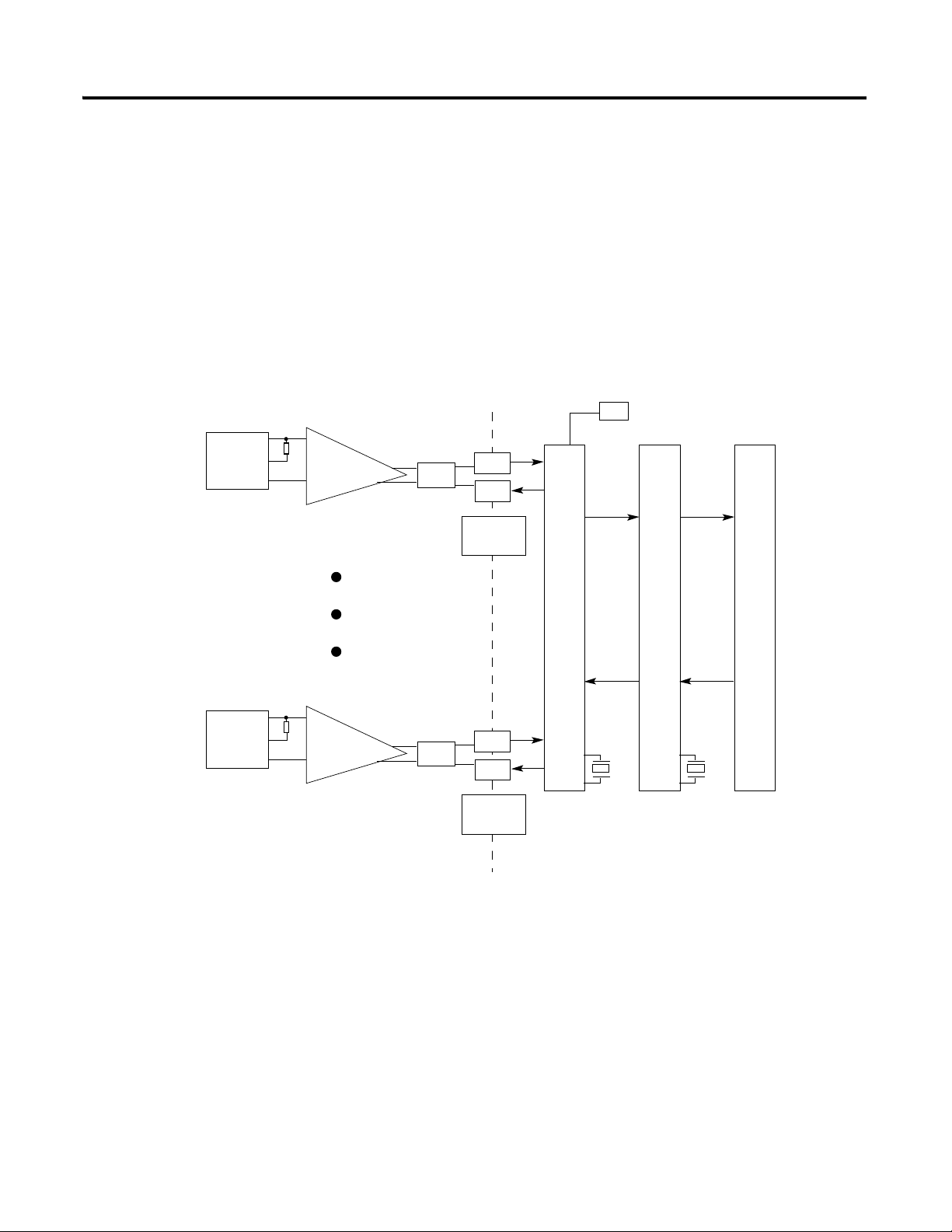

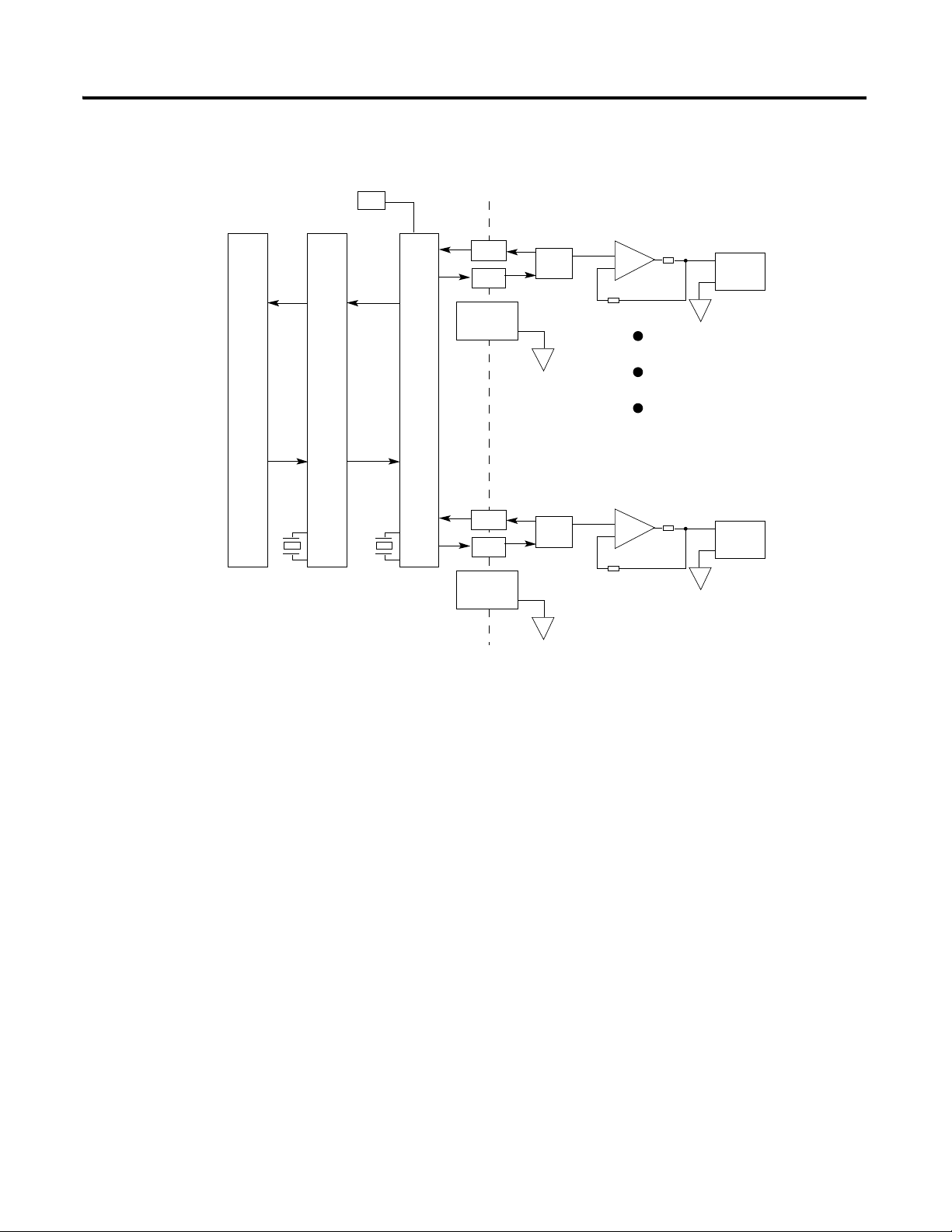

Module Operation

The following sections describe the input and output modules’ block diagrams.

Input Module Block Diagram

The input module’s input circuitry consists of four isolated-differential analog

inputs each with it’s own analog-to-digital (A/D) converter. The A/D

converter reads the selected input signal and converts it to a digital value that is

presented to the controller.

Figure 1.4 1769-IF4I Block Diagram

Publication 1769-UM014B-EN-P - May 2010

Page 15

Overview 1-7

DAC

0

OPTO

LED

OPTO

OPTO

OPTO

DC / DC

Converter

DC / DC

Converter

CPU

ASICBUS

0

Iout0+

Iout0-

+

_

DAC

3

3

Iout3+

Iout3-

+

_

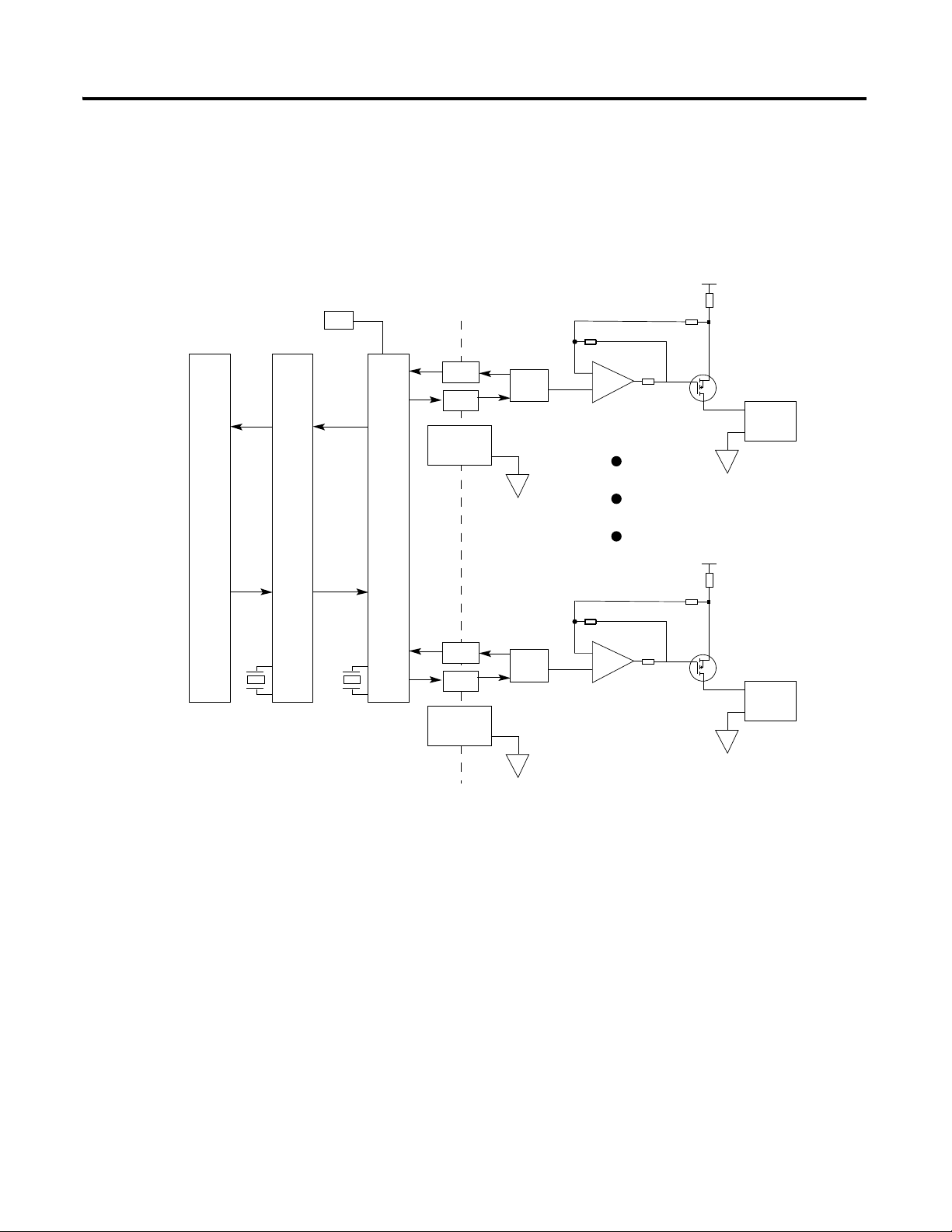

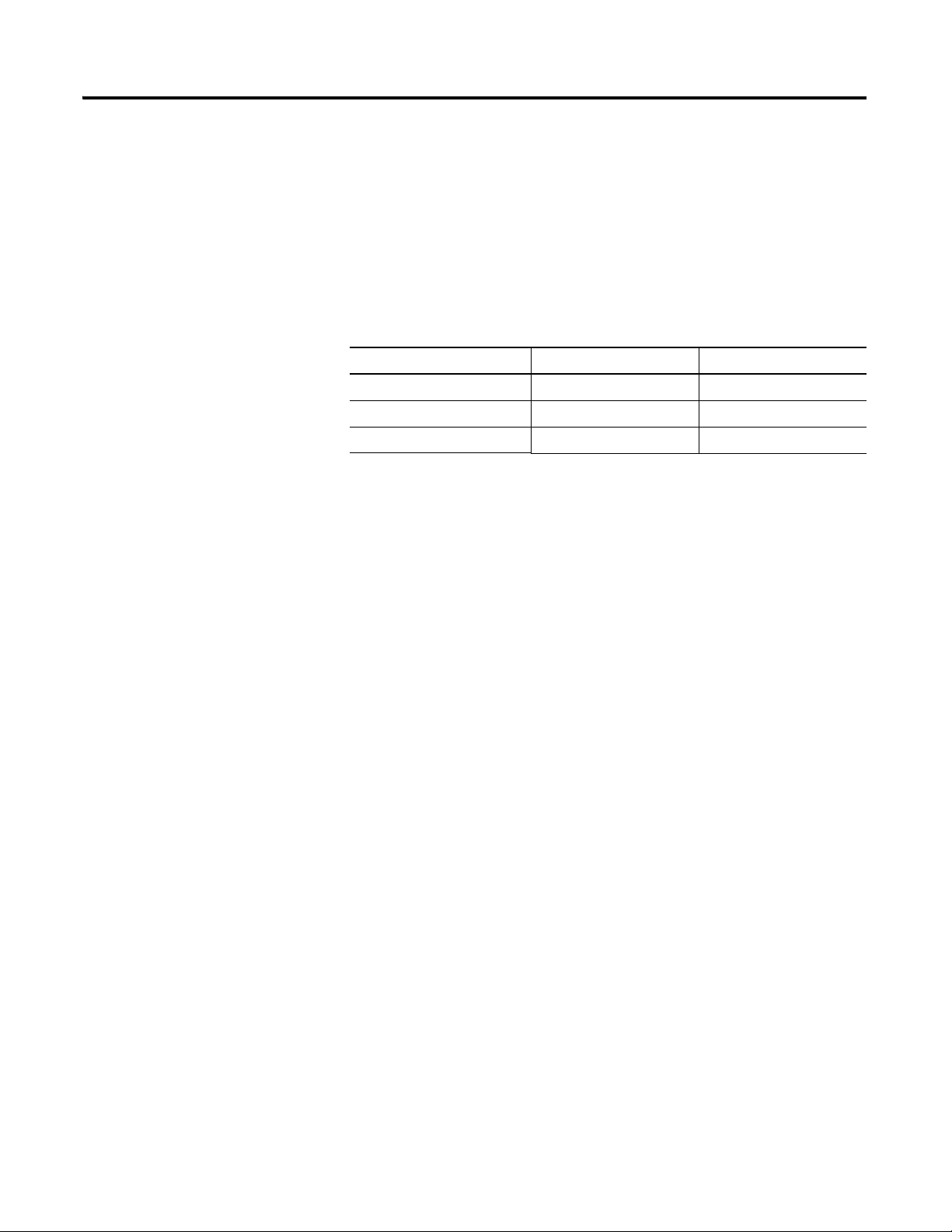

Output Modules Block Diagram

The output modules use one digital-to-analog (D/A) converter per isolated

output channel to convert the digital output data from the controller to an

analog output signal.

Figure 1.5 1769-OF4CI Block Diagram

Publication 1769-UM014B-EN-P - May 2010

Page 16

1-8 Overview

DAC

0

OPTO

LED

OPTO

OPTO

OPTO

DC / DC

Converter

DC / DC

Converter

CPU

ASICBUS

DAC

3

3

Vout3+

Vout3-

+

_

0

Vout0+

Vout0-

+

_

Figure 1.6 1769-OF4VI Block Diagram

Publication 1769-UM014B-EN-P - May 2010

Module Field Calibration

Each isolated analog modules’s calibration is guaranteed by its design. No field

calibration is required.

Page 17

Installation and Wiring

This chapter tells you how to:

determine the power requirements for the modules.

avoid electrostatic damage.

install the module.

wire the module’s terminal block.

wire input devices.

wire output devices.

Chapter

2

Compliance to European Union Directives

This product is approved for installation within the European Union and EEA

regions. It has been designed and tested to meet the following directives.

EMC Directive

The analog modules are tested to meet Council Directive 2004/108/EC

Electromagnetic Compatibility (EMC) and the following standards, in whole

or in part, documented in a technical construction file:

EN 61000-6-4

EMC – Generic Emission Standard, 6-4 - Industrial Environment

EN 61000-6-2

EMC – Generic Immunity Standard, Part 6-2 - Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 2006/95/ECLow Voltage, by

applying the safety requirements of EN 61131-2 Programmable Controllers,

Part 2 – Equipment Requirements and Tests.

For specific information required by EN61131-2, see the appropriate sections

in this publication, as well as the following Allen-Bradley publications:

1 Publication 1769-UM014B-EN-P - May 2010

Page 18

2-2 Installation and Wiring

Industrial Automation, Wiring and Grounding Guidelines for Noise

Immunity, publication 1770-4.1

Automation Systems Catalog, publication B113

Power Requirements

General Considerations

The modules receive power through the bus interface from the +5V dc/+24V

dc system power supply.

Table 2.1 Maximum Current Draw

Module 5V dc 24V dc

1769-IF4I (Series A) 145 mA 125 mA

1769-OF4CI (Series A) 145 mA 140 mA

1769-OF4VI (Series A) 145 mA 75 mA

The Compact I/O system is suitable for use in an industrial environment

when installed in accordance with these instructions. Specifically, this

equipment is intended for use in clean, dry environments (Pollution degree

(1)

) and to circuits not exceeding Over Voltage Category II

2

60664-1).

(3)

(2)

(IEC

Publication 1769-UM014B-EN-P - May 2010

(1)

Pollution Degree 2 is an environment where, normally, only non-conductive pollution occurs except that

occasionally a temporary conductivity caused by condensation shall be expected.

(2)

Over Voltage Category II is the load level section of the electrical distribution system. At this level transient

voltages are controlled and do not exceed the impulse voltage capability of the product’s insulation.

(3)

Pollution Degree 2 and Over Voltage Category II are International Electrotechnical Commission (IEC)

designations.

Page 19

Installation and Wiring 2-3

ATTENTION

ATTENTION

Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or

non-hazardous locations only. The following attention statement applies to use

in hazardous locations.

EXPLOSION HAZARD

Substitution of components may impair suitability for

Class I, Division 2.

Do not replace components or disconnect equipment

unless power has been switched off or the area is

known to be non-hazardous.

Do not connect or disconnect components unless

power has been switched off or the area is known to be

non-hazardous.

This product must be installed in an enclosure.

All wiring must comply with N.E.C. article 501-4(b).

Prevent Electrostatic Discharge

Electrostatic discharge can damage integrated circuits or

semiconductors if you touch analog I/O module bus

connector pins or the terminal block on the input module.

Follow these guidelines when you handle the module:

Touch a grounded object to discharge static potential.

Wear an approved wrist-strap grounding device.

Do not touch the bus connector or connector pins.

Do not touch circuit components inside the module.

Use a static-safe work station, if available.

When it is not in use, keep the module in its

static-shield box.

Publication 1769-UM014B-EN-P - May 2010

Page 20

2-4 Installation and Wiring

ATTENTION

Remove Power

Remove power before removing or inserting this module.

When you remove or insert a module with power applied,

an electrical arc may occur. An electrical arc can cause

personal injury or property damage by:

sending an erroneous signal to your system’s field

devices, causing unintended machine motion.

causing an explosion in a hazardous environment.

Electrical arcing causes excessive wear to contacts on both

the module and its mating connector and may lead to

premature failure.

Reduce Noise

Most applications require installation in an industrial enclosure to reduce the

effects of electrical interference. Analog inputs and outputs are highly

susceptible to electrical noise. Electrical noise coupled to the analog inputs will

reduce the performance (accuracy) of the module.

Group your modules to minimize adverse effects from radiated electrical noise

and heat. Consider the following conditions when selecting a location for the

analog module. Position the module:

away from sources of electrical noise such as hard-contact switches,

relays, and ac motor drives.

away from modules which generate significant radiated heat, such as the

1769-IA16 module. Refer to the module’s heat dissipation specification.

In addition, route shielded, twisted-pair analog input and output wiring away

from any high-voltage I/O wiring.

Protect the Circuit Board from Contamination

The printed circuit boards of the analog modules must be protected from dirt,

oil, moisture, and other airborne contaminants. To protect these boards, the

system must be installed in an enclosure suitable for the environment. The

interior of the enclosure should be kept clean and the enclosure door should

be kept closed whenever possible.

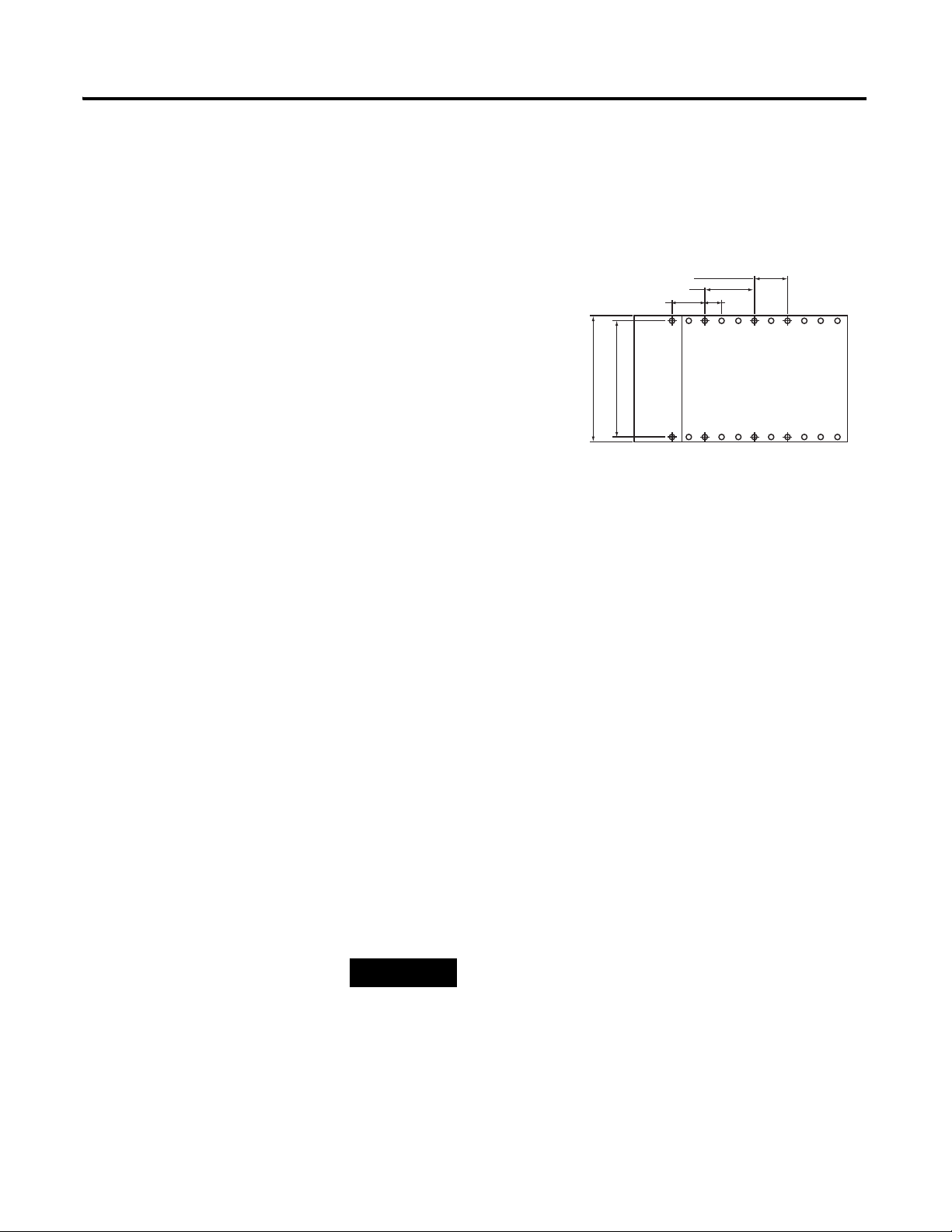

System Assembly

Publication 1769-UM014B-EN-P - May 2010

The module can be attached to the controller or an adjacent I/O module

before or after mounting.

Page 21

Installation and Wiring 2-5

6

5

4

3

1

1

2

For mounting instructions, see Panel Mounting Using the Dimensional

Template on page 2-7, or DIN-rail Mount on page 2-8. To work with a system

that is already mounted, see Replace a Single Module Within a System on page

2-8.

Figure 2.1 Assemble the Compact I/O System

1. Disconnect power.

2. Check that the bus lever of the module to be installed is in the unlocked

(fully right) position.

3. Use the upper and lower tongue-and-groove slots (1) to secure the

modules together (or to a controller).

4. Move the module back along the tongue-and-groove slots until the bus

connectors (2) line up with each other.

5. Push the bus lever back slightly to clear the positioning tab (3). Use your

fingers or a small screwdriver.

Publication 1769-UM014B-EN-P - May 2010

Page 22

2-6 Installation and Wiring

ATTENTION

IMPORTANT

ATTENTION

Host Controller

Compact I/O

Compact I/O

Compact I/O

Compact I/O

Compact I/O

End Cap

Side Side

Top

Bottom

6. To allow communication between the controller and module, move the

bus lever fully to the left (4) until it clicks. Ensure it is locked firmly in

place.

When attaching I/O modules, it is very important

that the bus connectors are securely locked together

to be sure of proper electrical connection.

7. Attach an end cap terminator (5) to the last module in the system by

using the tongue-and-groove slots as before.

8. Lock the end cap bus terminator (6).

A 1769-ECR or 1769-ECL right or left end cap must be

used to terminate the end of the bus.

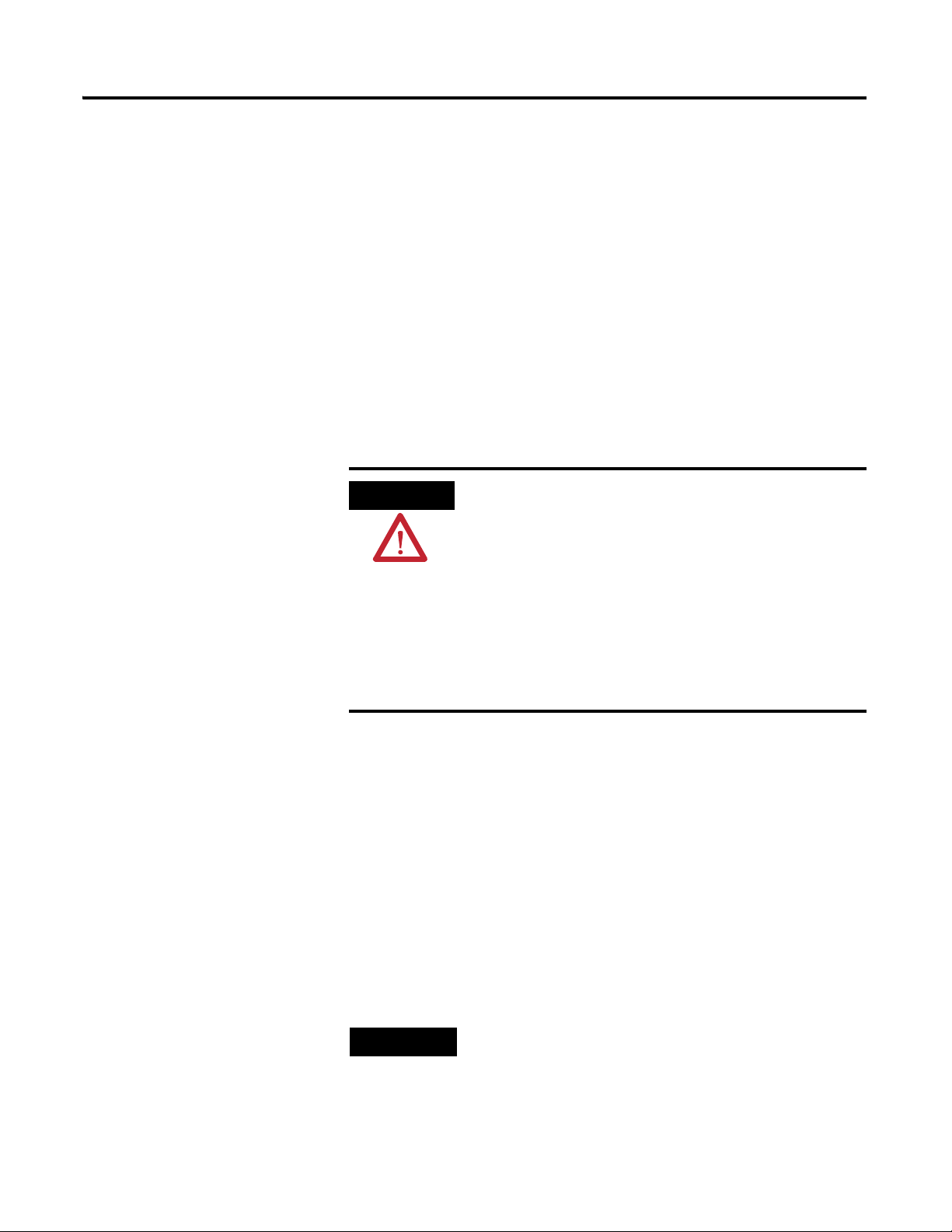

Mount

During panel or DIN rail mounting of all devices, be sure

that all debris (that is, metal chips or wire strands) is kept

from falling into the module. Debris that falls into the

module could cause damage when you cycle power.

Minimum Spacing

Maintain spacing from enclosure walls, wireways, or adjacent equipment.

Allow 50 mm (2 in.) of space on all sides for adequate ventilation.

Figure 2.2 Space Requirements

Publication 1769-UM014B-EN-P - May 2010

Page 23

Installation and Wiring 2-7

TIP

l Mounting

Host Controller

Refer to host controller documentation for this dimension.

Spacing for single-wide modules 35 mm (1.378 in.).

Overall hole spacing tolerance:

±0.4 mm (0.016 in.).

Spacing for one-and-a-half-wide modules 52.5 mm (2.067 in.).

Locate holes every 17.5 mm (0.689 in.) to allow for a

mix of single-wide and one-and-a-half-wide modules

(for example, the 1769-OA16 module).

Panel Mount

Mount the module to a panel using two screws per module. Use M4 or #8

panhead screws. Mounting screws are required on every module.

Figure 2.3 Panel Mounting Using the Dimensional Template

Panel Mounting Procedure Using Modules as a Template

The following procedure allows you to use the assembled modules as a

template for drilling holes in the panel. If you have sophisticated

panel-mounting equipment, you can use the dimensional template provided.

Due to module mounting hole tolerance, it is important to follow these

procedures.

1. On a clean work surface, assemble no more than three modules.

2. Using the assembled modules as a template, carefully mark the center of

all module-mounting holes on the panel.

3. Return the assembled modules to the clean work surface, including any

previously mounted modules.

4. Drill and tap the mounting holes for the recommended M4 or #8 screw.

5. Place the modules back on the panel, and check for proper hole

alignment.

6. Attach the modules to the panel using the mounting screws.

If mounting more modules, mount only the last one of this

group and put the others aside. This reduces remounting

time during drilling and tapping of the next group.

7. Repeat steps 1 to 6 for any remaining modules.

Publication 1769-UM014B-EN-P - May 2010

Page 24

2-8 Installation and Wiring

ATTENTION

TIP

DIN-rail Mount

The module can be mounted using the following DIN rails:

35 x 7.5 mm (EN 50 022 - 35 x 7.5) or 35 x 15 mm (EN 50 022 - 35 x 15).

Before mounting the module on a DIN rail, close the DIN rail latches. Press

the DIN rail mounting area of the module against the DIN rail. The latches

will momentarily open and lock into place.

Replace a Single Module Within a System

The module can be replaced while the system is mounted to a panel (or DIN

rail). Follow these steps in order:

1. Remove power.

Remove power before removing or inserting this module.

When you remove or insert a module with power applied,

an electrical arc may occur. An electrical arc can cause

personal injury or property damage by:

sending an erroneous signal to your system’s field

devices, causing unintended machine motion.

causing an explosion in a hazardous environment.

Electrical arcing causes excessive wear to contacts on both

the module and its mating connector and may lead to

premature failure.

2. On the module to be removed, remove the upper and lower mounting

screws from the module (or open the DIN latches using a flat-blade or

Phillips screwdriver).

3. Move the bus lever to the right to disconnect (unlock) the bus.

4. On the right-side adjacent module, move its bus lever to the right

(unlock) to disconnect it from the module to be removed.

5. Gently slide the disconnected module forward. If you feel excessive

resistance, check that the module has been disconnected from the bus,

and that both mounting screws have been removed (or DIN latches

opened).

It may be necessary to rock the module slightly from front

to back to remove it, or, in a panel-mounted system, to

loosen the screws of adjacent modules.

Publication 1769-UM014B-EN-P - May 2010

Page 25

Installation and Wiring 2-9

6. Before installing the replacement module, be sure that the bus lever on

the module to be installed and on the right-side adjacent module are in

the unlocked (fully right) position.

7. Slide the replacement module into the open slot.

8. Connect the modules together by locking (fully left) the bus levers on

the replacement module and the right-side adjacent module.

9. Replace the mounting screws (or snap the module onto the DIN rail).

Field Wiring Connections

Use the following information to properly make field wiring connections.

Ground

This product is intended to be mounted to a well-grounded mounting surface

such as a metal panel. Additional grounding connections from the module’s

mounting tabs or DIN rail (if used) are not required unless the mounting

surface cannot be grounded. Refer to Allen-Bradley Industrial Automation

Wiring and Grounding Guidelines, publication 1770-4.1, for additional

information.

Publication 1769-UM014B-EN-P - May 2010

Page 26

2-10 Installation and Wiring

System Wiring Guidelines

Consider the following when wiring your system.

General Guidelines

Channels are isolated from each other.

Do not use the analog module’s NC terminals as connection points.

To ensure optimum accuracy, limit overall cable impedance by keeping

your cable as short as possible. Locate the I/O system as close to your

sensors or actuators as your application will permit.

Use Belden 8761, or equivalent, shielded wire.

Keep shield connection to ground as short as possible.

Under normal conditions, the drain wire and shield junction must be

connected to earth ground via a panel or DIN rail mounting screw at

the analog I/O module end.

(1)

Publication 1769-UM014B-EN-P - May 2010

(1)

In environments where high-frequency noise may be present, it may be necessary to directly ground cable

shields to earth at the module end and via a 0.1µF capacitor at the sensor end.

Page 27

Installation and Wiring 2-11

V in

Vs

Ri

Rc

RcRs

+

-

1769-IF4I Input Module Guidelines

If multiple power supplies are used with analog inputs, the power supply

commons must be kept at potentials that do not result in the module’s

working voltage rating being exceeded.

The 1769-IF4I module does not provide loop power for analog inputs.

Use power supplies that match the input transmitter specifications.

Differential analog inputs are more immune to noise than single-ended

analog inputs.

Voltages on Ch+, Ch-, and Ch_IRtn for a single, isolated channel of the

1769-IF4I module must not exceed the module’s maximum overload

levels.

1769-IF4I channels used as current inputs require a jumper to be placed

between a channel’s CH_IRtn and Ch- terminals.

1769-OF4CI and -OF4VI Output Modules Guidelines

Voltage outputs (Vout 0+ to Vout 3+ for 1769-OF4VI) of the output

module are referenced to each channel’s Vout- terminal (channels are

isolated from each other). Load resistance for a voltage output channel

must be equal to or greater than 2 k.

Current outputs (Iout 0+ to Iout 3+ for 1769-OF4CI) of the output

module source current that returns to each channel’s Iout- terminal

(channels are isolated from each other). Load resistance for a current

output channel must remain between 0 and 500 .

Effect of Transducer/Sensor and Cable Length Impedance on Voltage Input

Accuracy

For voltage inputs, the length of the cable used between the transducer/sensor

and the 1769-IF4I module can affect the accuracy of the data provided by the

module.

Figure 2.4 Voltage Input Accuracy

Publication 1769-UM014B-EN-P - May 2010

Page 28

2-12 Installation and Wiring

TIP

Vin

Ri Vs

Rs 2 RcRi++

-------------------------------------------------------

=

%Ai 1

Vin

Vs

---------

–

100=

Vs Vin

Rs 2 RcRi++

Ri

-------------------------------------------------------

=

Where:

Rc = DC resistance of the cable (each conductor) depending on

cable length

Rs = Source impedance of analog transducer/sensor input

Ri = Impedance of the voltage input (1 M for 1769-IF4I)

Vs = Voltage source (voltage at the transducer/sensor input device)

Vin = Measured potential at the module input

%Ai = Percent added inaccuracy in a voltage-based system due

to source and cable impedance.

For example, for Belden 8761 two conductor, shielded cable:

Rc = 16 /1000 ft

Rs = 0 (ideal source)

Table 2.2 Effect of Cable Length on Input Accuracy

Length of Cable,

m(ft)

50 (164) 2.625 0.000525%

100 (328) 5.25 0.00105%

200 (656) 10.50 0.0021%

300 (984) 15.75 0.00315%

DC Resistance of the Cable,

Rc ()

Accuracy Impact at the

Input Module

As input source impedance (Rs) and/or resistance (dc) of the cable (Rc) get

larger, system accuracy decreases. If you determine that the inaccuracy error is

significant, implementing the following equation in the control program can

compensate for the added inaccuracy error due to the impedance of the source

and cable.

Publication 1769-UM014B-EN-P - May 2010

In a current loop system, source and cable impedance do

not impact system accuracy.

Page 29

Installation and Wiring 2-13

V in

Vs

Ri

Rc

RcRs

+

-

Vin

Ri Vs

Rs 2 RcRi++

-------------------------------------------------------=

Effect of Device and Cable Output Impedance on Output Module Accuracy

The maximum value of the output impedance is shown in the example below,

because it creates the largest deviation from an ideal voltage source.

Figure 2.5 Output Module Accuracy

Where:

Rc = DC resistance of the cable (each conductor)

depending on cable length

Rs = Source impedance (1 for 1769-OF4VI)

Ri = Impedance of the voltage input (220 k for 1769-IF4I)

Vs = Voltage at the output of 1769-OF4VI

Vin = Measured potential at the module input

%Ai = Percent added inaccuracy in a voltage-based

system due to source and cable impedance.

For example, for Belden 8761 two conductor, shielded cable and a

1769-OF4CI output module:

Rc = 16 /1000 ft

Rs = 15

Ri = 220 k

Table 2.3 Effect of Output Impedance and Cable Length on Accuracy

Length of Cable (m) dc Resistance of the Cable

Rc ()

50 2.625 0.00919%

100 5.25 0.01157%

200 10.50 0.01634%

300 15.75 0.02111%

Accuracy Impact at the

Input Module

Publication 1769-UM014B-EN-P - May 2010

Page 30

2-14 Installation and Wiring

%Ai 1

Vin

Vs

---------

–

100=

Publication 1769-UM014B-EN-P - May 2010

Page 31

Installation and Wiring 2-15

TIP

Vs Vin

Rs 2 RcRi++

Ri

-------------------------------------------------------

=

Wire the

Finger-safe

Terminal Block

Upper Retaining Screw

Lower Retaining Screw

As output impedance (Rs) and/or resistance (dc) of the cable (Rc) get larger,

system accuracy decreases. If you determine that the inaccuracy error is

significant, implementing the following equation in the control program can

compensate for the added inaccuracy error due to the impedance of the output

module and cable.

In a current loop system, source and cable impedance do

not impact system accuracy.

Label the Terminals

A removable, write-on label is provided with the module. Remove the label

from the door, mark the identification of each terminal with permanent ink,

and slide the label back into the door. Your markings (ID tag) will be visible

when the module door is closed.

Figure 2.6 Terminal Labels

Publication 1769-UM014B-EN-P - May 2010

Page 32

2-16 Installation and Wiring

TIP

SLOT # _____

MODULE TYPE ______

Remove the Finger-safe Terminal Block

When wiring field devices to the module, it is not necessary to remove the

terminal block. If you remove the terminal block, use the write-on label on the

side of the terminal block to identify the module slot location and type. RTB

position can be indicated by circling either the R for right side or L for left

side.

Figure 2.7 Finger-safe Terminal Block

To remove the terminal block, loosen the upper and lower retaining screws.

The terminal block will back away from the module as you remove the screws.

When replacing the terminal block, torque the retaining screws to 0.46 Nm

(4.1 lb-in).

Wire the Finger-safe Terminal Block

When wiring the terminal block, keep the finger-safe cover in place.

1. Loosen the terminal screws to be wired.

2. Begin wiring at the bottom of the terminal block and move up.

3. Route the wire under the terminal pressure plate. You can use the bare

wire or a spade lug. The terminals accept a 6.35 mm (0.25 in.) spade lug.

The terminal screws are non-captive. Therefore, it is

possible to use a ring lug (maximum 1/4 in. o.d. with a

0.139 in. minimum i.d. (M3.5)) with the module.

Publication 1769-UM014B-EN-P - May 2010

Page 33

Installation and Wiring 2-17

TIP

ATTENTION

ATTENTION

4. Tighten the terminal screw making sure the pressure plate secures the

wire. Recommended torque when tightening terminal screws is 0.68 Nm

(6 lb-in).

If you need to remove the finger-safe cover, insert a

screwdriver into one of the square, wiring holes and gently

pry the cover off. If you wire the terminal block with the

finger-safe cover removed, you will not be able to put it

back on the terminal block because the wires will be in the

way.

Wire Size and Terminal Screw Torque

Each terminal accepts up to two wires.

Table 2.4 Terminal Wire Considerations

Wire Type Wire Size Terminal Screw

Solid Cu-90 °C (194 °F) 0.325…2.080 mm

(22…14 AWG)

Stranded Cu-90 °C (194 °F) 0.325…1.310 mm

(22…16 AWG)

Torque

2

0.68 Nm (6 lb-in) 0.46 Nm (4.1 lb-in)

2

0.68 Nm (6 lb-in) 0.46 Nm (4.1 lb-in)

Retaining Screw

Wire the Modules

To prevent shock hazard, care should be taken when wiring

the module to analog signal sources. Before wiring any

analog module, disconnect power from the system power

supply and from any other source to the analog module.

After the analog module is properly installed, follow the wiring procedure

below. To ensure proper operation and high immunity to electrical noise,

always use Belden 8761 (shielded, twisted-pair) or equivalent wire.

Torque

When wiring an analog input, take care to avoid connecting

a voltage source to a channel configured for current input.

Improper module operation or damage to the voltage

source can occur.

Never connect a voltage or current source to an analog

output channel.

Publication 1769-UM014B-EN-P - May 2010

Page 34

2-18 Installation and Wiring

ATTENTION

Cable

Signal Wire

Signal Wire

Drain Wire

Foil Shield

Signal Wire

Signal Wire

Cut foil shield

and drain wire.

Figure 2.8 Belden 8761 Wire

To wire your module follow these steps.

1. At each end of the cable, strip some casing to expose the individual

wires.

2. Trim the signal wires to 2-inch lengths. Strip about 5 mm (3/16 in.) of

insulation away to expose the end of the wire.

Be careful when stripping wires. Wire fragments that

fall into a module could cause damage when you

cycle power.

3. At one end of the cable, twist the drain wire and foil shield together.

Under normal conditions, this drain wire and shield junction must be

connected to earth ground, via a panel or DIN rail mounting screw at

the analog I/O module end. Keep the length of the drain wire as short

as possible.

In environments where high frequency noise may be present, it may be

necessary to ground the cable shields to earth at the module end via a

0.1 µF capacitor at the sensor end for analog inputs and at the load end

for analog outputs.

4. At the other end of the cable, cut the drain wire and foil shield back to

the cable.

5. Connect the signal wires to the terminal block.

Refer to Analog Input Module Wiring on page 2-19 and Analog Output

Modules Wiring on page 2-21.

6. Connect the other end of the cable to the analog input or output device.

7. Repeat steps 1 to 5 for each channel on the module.

Publication 1769-UM014B-EN-P - May 2010

Page 35

Analog Input Module Wiring

N/C

N/C

Ch2-

Ch2_iRtn

Ch2+

N/C

Ch0-

Ch0_iRtn

Ch0+

Ch3-

Ch3_iRtn

Ch3+

N/C

Ch1-

Ch1_iRtn

Ch1+

N/C

N/C

Ch2+

Ch1-

Ch1+

Ch1_iRtn

Ch3-

Ch3+

Ch3_iRtn

N/C

N/C

N/C

Ch0+

N/C

N/C

Ch2-

Ch2_iRtn

N/C

Ch0-

Ch0_iRtn

W ARNING -Do Not

Remove RTB Unless

Area is Non-Hazar

1769-IF4I

Belden 8761 Cable

(or equivalent)

Analog Voltage Source

Analog Current Source

N/C

N/C

N/C

N/C

N/C

N/C

Ch1+

Ch2+

Ch0+

Ch3+

Ch1-

Ch2-

Ch0-

Ch3-

Ch1_iRtn

Ch2_iRtn

Ch0_iRtn

Ch3_iRtn

IMPORTANT

Figure 2.9 1769-IF4I Terminal Layout

Installation and Wiring 2-19

Figure 2.10 1769-IF4I Wiring Differential Inputs

1769-IF4I input channels connected to current sources

must have a jumper wire placed between Ch#_iRtn and the

Ch#- terminals for that channel.

Publication 1769-UM014B-EN-P - May 2010

Page 36

2-20 Installation and Wiring

IMPORTANT

Sensor/

Transmitter

Supply

+

+

+

+

-

Current

Transmitter

Signal

Signal

Voltage Transmitter

Voltage Transmitter

Ground

Signal

Ground

(1)

Ch0+

N/C

Ch0_iRtn

N/C

Ch0-

Ch1+

N/C

Ch1_iRtn

N/C

Ch1-

Ch2+

N/C

Ch2_iRtn

N/C

Ch2-

Ch3+

N/C

Ch3_iRtn

N/C

Ch3-

1769-IF4I Terminal Block

Sensor/

Transmitter

Supply

+

+

+

+

+

-

Current

Transmitter

Signal

Signal

Voltage Transmitter

Voltage Transmitter

Ground

Signal

Ground

Differential

Voltage

Transmitter

Signal

+

_

(1)

Figure 2.11 1769-IF4I Wiring Single-ended Sensor/Transmitter Types

Figure 2.12 1769-IF4I Wiring Mixed Transmitter Types

Publication 1769-UM014B-EN-P - May 2010

(1) The external power supply must be rated Class 2.

1769-IF4I input channels connected to current sources

must have a jumper wire placed between Ch#_iRtn and the

Ch#- terminals for that channel.

Page 37

Analog Output Modules Wiring

N/C

I out 0-

N/C

I out 1-

N/C

I out 2-

N/C

I out 3-

N/C

N/C

I out 3+

N/C

I out 2+

N/C

I out 1+

N/C

I out 0+

N/C

1769-OF4CI

+24V dc

N/C

N/C

I out 0+

I out 1+

N/C

I out 2+

N/C

I out 3+

N/C

N/C

N/C

I out 0-

I out 1-

N/C

I out 2-

N/C

I out 3-

N/C

Ensure Adjacent Bus Lever

Unlatched/Latched Before/

Removing/Inserting Module

DANGER

Do Not Remove RTB Under Powe

Unless Area is Non-Hazardous

Earth Ground

Current Load

Figure 2.13 1769-OF4CI Terminal Layout

Installation and Wiring 2-21

Figure 2.14 1769-OF4CI Wiring Diagram

Publication 1769-UM014B-EN-P - May 2010

Page 38

2-22 Installation and Wiring

N/C

V out 0-

N/C

V out 1-

N/C

V out 2-

N/C

V out 3-

N/C

N/C

V out 3+

N/C

V out 2+

N/C

V out 1+

N/C

V out 0+

N/C

1769-OF4VI

+24V dc

N/C

N/C

V out 0+

V out 1+

N/C

V out 2+

N/C

V out 3+

N/C

N/C

N/C

V out 0-

V out 1-

N/C

V out 2-

N/C

V out 3-

N/C

Ensure Adjacent Bus Lever

Unlatched/Latched Before/

Removing/Inserting Module

DANGER

Do Not Remove RTB Under Powe

Unless Area is Non-Hazardous

Earth Ground

Voltage Load

Figure 2.15 1769-OF4VI Terminal Layout

Publication 1769-UM014B-EN-P - May 2010

Figure 2.16 1769-OF4VI Wiring Diagram

Page 39

Chapter

Slot e

Input Image

File

Output Image

File

Configuration

File

Slot e

Slot e

Input Image

7 Words

Output Image

1 Word

Configuration File

26 Words

Memory Map

Bit 15 Bit 0

Channel 3 Configuration Words Words 20 to 25

Channel 2 Configuration Words Words 14 to 19

Channel 1 Configuration Words Words 8 to 13

Channel 0 Configuration Words Words 2 to 7

Clear Latched Alarm Bits Word 0

High-/Low-alarm & Over-/Under-range Word 6

General Status Bits Word 5

Time Stamp Value Word Word 4

Channel 3 Data Word Word 3

Word 2Channel 2 Data Word

Word 1Channel 1 Data Word

Channel 0 Data Word Word 0

Enable Time Stamp Word 1, bit 15

Real Time Sample Rate Word 0

3

Module Data, Status, and Channel

Configuration for the Input Module

This chapter examines the analog input module’s data table, channel status, and

channel configuration word.

1769-IF4I Input Module Addressing

The1769-IF4I memory map shows the output, input, and configuration tables

for the 1769-IF4I module.

Figure 3.1 1769-IF4I Memory Map

1 Publication 1769-UM014B-EN-P - May 2010

Page 40

3-2 Module Data, Status, and Channel Configuration for the Input Module

TIP

TIP

TIP

1769-IF4I Input Image

The 1769-IF4I input image file represents data words and status bits. Input

words 0 to 3 hold the input data that represents the value of the analog inputs

for channels 0 to 3. These data words are valid only when the channel is

enabled and there are no errors. Input words 5 and 6 hold the status bits. To

receive valid status information, the channel must be enabled.

1769-IF4I Output Image

The 1769-IF4I output image file contains the clear alarm control bits for the

high- and low-alarm bits on each input channel. These bits are used to clear

alarms when alarms are latched.

You can access information in the input image file using

the programming software configuration screen.

You can access information in the output image file using

the programming software configuration screen.

1769-IF4I Configuration File

The configuration file contains information that you use to define the way a

specific channel functions.

The configuration file is explained in more detail in 1769-IF4I Configuration

Data File on page 3-6.

Not all controllers support program access to the

configuration file. Refer to your controller’s user manual.

Publication 1769-UM014B-EN-P - May 2010

Page 41

Module Data, Status, and Channel Configuration for the Input Module 3-3

1769-IF4I Input Data File

The input data table lets you access analog input module read data for use in

the control program, via word and bit access. The data table structure is shown

in the table below. For each input module, slot x, words 0 to 3 in the input data

file contain the analog values of the inputs.

Table 3.1 1769-IF4I Input Data Table

Bit Position

1514131211109876543210

Word

0 SGN Analog Input Data Channel 0

1 SGN Analog Input Data Channel 1

2 SGN Analog Input Data Channel 2

3 SGN Analog Input Data Channel 3

4 Nu Time Stamp Value

5 Nu NuNuNuNuNuNuNuNuNuNuNuS3 S2S1S0

6 L3 H3U3O3L2H2U2O2 L1H1U1O1 L0H0U0O0

1769-IF4I Input Data Values

Words 0 to 3 contain the converted analog input data from the field device.

The most significant bit (MSB) is the sign bit, which is in two’s complement

format. (Nu indicates not used with the bit set to 0.)

General Status Bits (S0 to S3)

Word 5, bits 0 to 3 contain the general operational status bits for input

channels 0 to 3. If set (1), these bits indicate an error associated with that

channel. The over- and under-range bits and the high- and low-alarm bits for

channels 0 to 3 are logically ORed to the appropriate general status bit.

Low Alarm Flag Bits (L0 to L3)

Word 6, bits 3, 7, 11, and 15 contain the low alarm flag bits for input channels

0 to 3. If set (1), these bits indicate the input signal is outside the user-defined

range. The module continues to convert analog data to minimum full-range

values. The bit is automatically reset (0) when the low alarm condition clears,

unless the channel’s alarm bits are latched. If the channel’s alarm bits are

latched, a set (1) low alarm flag bit clears via the corresponding Clear Alarm

Latch bit in your output data file.

Publication 1769-UM014B-EN-P - May 2010

Page 42

3-4 Module Data, Status, and Channel Configuration for the Input Module

High Alarm Flag Bits (H0 to H3)

Word 6, bits 2, 6, 10, 14 contain the high alarm flag bits for input channels 0 to

3 and applies to all input types. If set (1), the input signal is outside the

user-defined range. The module continues to convert analog data to maximum

full-range values. The bit is automatically reset (0) when the high alarm

condition clears, unless the channel’s alarm bits are latched. If the channel’s

alarm bits are latched, a set (1) high alarm flag bit clears via the corresponding

Clear Alarm Latch bit in your output data file.

Over-Range Flag Bits (O0 to O3)

Over-range bits for channels 0 to 3 are contained in Word 6, bits 0, 4, 8, 12.

They apply to all input types. When set (1), this bit indicates input signals

beyond the normal operating range. However, the module continues to

convert analog data to the maximum full range value. The bit is automatically

reset (0) by the module when the over-range condition is cleared and the data

value is within the normal operating range.

Under-Range Flag Bits (U0 to U3)

Under-range bits for channels 0 to 3 are contained in Word 6, bits 1, 5, 9, 13.

They apply to all input types. When set (1), this bit indicates input signals

below the normal operating range. It may also indicate an open circuit

condition, when the module is configured for any voltage range or the 4 to 20

mA range. However, the module continues to convert analog data to the

minimum full range value. The bit is automatically reset (0) by the module

when the under-range condition is cleared and the data value is within the

normal operating range.

Time Stamp Value (Word 4)

The 1769-IF4I supports a 15-bit rolling timestamp that is updated during each

new update of the analog input values. The timestamp has a 1 ms resolution.

The timestamp value is placed in the Input Data file, word 4, for each module

input data update (if the timestamp function is enabled). Enable and/or

disable this timestamp in word 1, bit 15 of the Configuration Data file.

Publication 1769-UM014B-EN-P - May 2010

Page 43

Module Data, Status, and Channel Configuration for the Input Module 3-5

1769-IF4I Output Data File

0

(1)

(2)

(3)

The output data table lets you access analog output module write data for use

in the control program, via word and bit access.

Table 3.2 1769-IF4I Output Data Table

Bit Position

15 141312111098 7 6 543210

Word

(1)

Nu

Nu = Not used. Bit must be set to 0.

ULx = Unlatch Low Process Alarm Latch x. This lets you individually cancel each low process alarm latch. Cancel = 1.

UHx = Unlatch High Process Alarm Latch x. This lets you individually cancel each high process alarm latch.

Nu Nu Nu Nu Nu Nu Nu

UL3

(2)

(3)

UL2 UH2 UL1 UH1 UL0 UH0

UH3

These bits are written during run mode to clear any latched low- and

high-process alarms. The alarm is unlatched when the unlatch bit is set (1) and

the alarm condition no longer exists. If the alarm condition persists, then the

unlatch bit has no effect until the alarm condition no longer exists. You need

to keep the unlatch bit set until verification from the appropriate input channel

status word that the alarm status bit has cleared (0). Then you need to reset (0)

the unlatch bit. The module will not latch an alarm condition if a transition

from no alarm to alarm occurs while a channel’s clear latch bit is set.

Publication 1769-UM014B-EN-P - May 2010

Page 44

3-6 Module Data, Status, and Channel Configuration for the Input Module

1769-IF4I Configuration

The configuration file lets you determine how each individual input channel

will operate. Parameters such as the input type and data format are set up using

Data File

this file. This data file is writable and readable. The default value of the

configuration data table is all zeros.

Table 3.3 1769-IF8 Configuration Data Table

Bit Position

Word

0 Real Time Sample Value

1 ETS Reserved

2EC ReservedEAAL

3 Reserved Inpt Dta Fm Chl0 Reserved Inpt Tp/RngeSel Chl0

4 S Process Alarm High Data Value Channel 0

5 S Process Alarm Low Data Value Channel 0

6 S Alarm Dead Band Value Channel 0

7 Reserved

8EC ReservedEAAL

9 Reserved Inpt Dta Fm Chl1 Reserved Inpt Tp/RngeSel Chl1

10 S Process Alarm High Data Value Channel 1

11 S Process Alarm Low Data Value Channel 1

12 S Alarm Dead Band Value Channel 1

13 Reserved

14 EC Reserved EA AL

15 Reserved Inpt Dta Fm Chl2 Reserved Inpt Tp/RngeSel Chl2

16 S Process Alarm High Data Value Channel 2

17 S Process Alarm Low Data Value Channel 2

18 S Alarm Dead Band Value Channel 2

19 Reserved

20 EC Reserved EA AL

21 Reserved Inpt Dta Fm Chl3 Reserved Inpt Tp/RngeSel Chl3

22 S Process Alarm High Data Value Channel 3

23 S Process Alarm Low Data Value Channel 3

24 S Alarm Dead Band Value Channel 3

25 Reserved

(1)

CompactLogix L43 controllers will be able to support these interrupts.

15 14 13 1211109 8 76543210

(1)

EI

(1)

EI

(1)

EI

(1)

EI

Reserved Input Filter Sel Chl0

Reserved Inpt Filter Sel Chl1

Reserved Input Filter Sel Chl2

Reserved Input Filter Sel Chl3

Publication 1769-UM014B-EN-P - May 2010

The configuration file is typically modified using the programming software

configuration screen.

For information on configuring the module using MicroLogix 1500 and

RSLogix 500 software, see Appendix B; for CompactLogix and RSLogix 5000

software, see Appendix C; for 1769-ADN DeviceNet adapter and RSNetWorx

software, see Appendix D.

The configuration file can also be modified through the control program, if

supported by the controller. The structure and bit settings are shown in

Channel Configuration on page 3-7.

Page 45

Module Data, Status, and Channel Configuration for the Input Module 3-7

Channel Configuration

Each channel’s configuration words consist of bit fields, the settings of which

determine how the channel operates. See the table below and the descriptions

that follow for valid configuration settings and their meanings. The default bit

status of the configuration file is all zeros.

Table 3.4 Bit Definitions for Channel Configuration Words

Define To Select Make these bit settings

151413121110987…43210

Input Filter

Selection

Enable

Interrupt

Enable

Process

Alarm

Latch

Enable

Process

Alarms

Enable

Channel

(1)

CompactLogix L43 controllers will be able to support these interrupts.

60 Hz

50 Hz

28.5 Hz

300 Hz

360 Hz

(1)

Enable

Disable 0

Enable

1

Disable 0

Enable

1

Disable 0

Enable 1

Disable 0

0000

0001

0010

0011

0100

1

Table 3.5 Bit Definitions for Input Range and Input Data

Define Indicate this These bit settings

15…11109 8 7…4 3210

Input

Range

Select

-10…+10V dc

0…5V dc

0…10V dc

4…20 mA

1…5V dc

0…20 mA

Input

Data

Format

Select

Raw/Proportional

Counts

Engineering Units 0 0 1

Scaled for PID 0 1 0

000

Percent Range 0 1 1

Publication 1769-UM014B-EN-P - May 2010

0000

0001

0010

0011

0100

0101

Page 46

3-8 Module Data, Status, and Channel Configuration for the Input Module

TIP

Enable/Disable Channel

This configuration selection lets each channel to be individually enabled.

Input Filter Selection

The input filter selection field lets you select the filter frequency for each

channel and provides system status of the input filter setting for analog input

channels 0 to 3. The filter frequency affects the noise rejection characteristics,

as explained below. Select a filter frequency considering acceptable noise and

step response time.

Noise Rejection

The 1769-IF4I module uses a digital filter that provides noise rejection for the

input signals. The filter is programmable, allowing you to select from five filter

frequencies for each channel. A lower frequency (60 Hz versus 300 Hz) can

provide better noise rejection but it increases channel update time. Transducer

power supply noise, transducer circuit noise, or process variable irregularities

may also be sources of normal mode noise.

When a channel is not enabled (0), no voltage or current

input is provided to the controller by the A/D converter.

Common Mode Rejection is better than 60 dB at 50 and 60 Hz, with the 50

and 60 Hz filters selected, respectively. The module performs well in the

presence of common mode noise as long as the signals applied to the user plus

and minus input terminals do not exceed the working voltage rating of the

module. Improper earth ground may be a source of common mode noise.

Channel Step Response

The selected channel filter frequency determines the channel’s step response.

The step response is the time required for the analog input signal to reach

100% of its expected final value. This means that if an input signal changes

faster than the channel step response, a portion of that signal will be

attenuated by the channel filter.

Publication 1769-UM014B-EN-P - May 2010

Page 47

Module Data, Status, and Channel Configuration for the Input Module 3-9

Module Update Time and Scanning Process

The module update time is defined as the time required for the module to

sample and convert the input signals of all enabled input channels and provide

the resulting data values to the controller. For the 1769-IF4I, each input

channel is continuously sampled at an independent rate determined by the

filter setting selected for each channel. The module’s Input Data file is updated

on a channel-by-channel basis at a rate corresponding to the sample rate for

each enabled channel.

The Filter Frequency and Update Times table shows the channel update times

associated with each input channel filter setting. Selecting a filter setting for a

channel will set the indicated update time for that channel in the Input Data

file.

The Real Time Sampling function can be used to set a pre-determined module

update time. When a valid Real Time Sample rate is set by the user, the module

will update the Input Data file with the most recently sampled value from each

input channel at the interval (module update time) set by the Real Time Sample

rate. The Input Data file values are left unchanged between update times, but

the input channels continue to be sampled at the fastest rate allowed by each

channel’s filter setting.

Table 3.6 Filter Frequency and Update Times

Filter Frequency Update Time per Channel Update Time per

Module

28.5 Hz 108 ms Not applicable

50 Hz 62 ms Not applicable

60 Hz 52 ms Not applicable

300 Hz 12 ms Not applicable

360 Hz 10 ms Not applicable

(1)

If you use real-time sampling, the user-configured sample rate is used as the module update time.

(1)

Input Type/Range Selection

This selection along with proper input wiring lets you configure each channel

individually for current or voltage ranges and provides the ability to read the

configured range selections.

Publication 1769-UM014B-EN-P - May 2010

Page 48

3-10 Module Data, Status, and Channel Configuration for the Input Module

Input Data Selection Formats

This selection configures channels 0 to 3 to present analog data in any of the

following formats.

Raw/Proportional Data

Engineering Units

Scaled-for-PID

Percent Range

Raw/Proportional Data

The value presented to the controller is proportional to the selected input and

scaled into the maximum data range allowed by the bit resolution of the A/D

converter and filter selected. The full range for a ±10V dc user input is -32767

to +32767.

See Valid Input Data on page 3-11.

Engineering Units

The module scales the analog input data to the actual current or voltage values

for the selected input range. The resolution of the engineering units is

dependent on the range selected and the filter selected.

See Valid Input Data on page 3-11.

Scaled-for-PID

The value presented to the controller is a signed integer with zero representing

the lower user range and 16383 representing the upper user range.

Allen-Bradley controllers, such as the MicroLogix 1500, use this range in their

PID equations. The amount over and under user range (full scale range -410 to

16793) is also included.

See Valid Input Data on page 3-11.

Percent Range

The input data is presented as a percentage of the user range. For example, 0V

to 10V dc equals 0% to 100%.

Publication 1769-UM014B-EN-P - May 2010

See Valid Input Data on page 3-11.

Page 49

Module Data, Status, and Channel Configuration for the Input Module 3-11

Valid Input Data Word Formats/Ranges

The following table shows the valid formats and min./max. data ranges

provided by the module.

Table 3.7 Valid Input Data

1769-IF4I

Normal

Operating

Input Range

-10…+10V dc +10.5…-10.5V -32767…

0…5V dc -0.5…5.25V -32767…

0…10V dc -0.5…10.5V -32767…

4…20 mA 3.2…21 mA

1.0…5V dc 0.5…5.25V 500…5250 -2048…

0…20 mA 0…21 mA 0…21000 0…17202 0.00…

Full Range

(includes amounts

over and under

normal operating

range)

Raw/Proportional

Data

+32767

+32767

+32767

-32767…

+32767

Engineering

Units

Full Range Normal

-10500…

+10500

-500…5250 -1638…

-500…

10500

3200…

21000

Scaled-for-PID Percent

Full Range Normal

Operating

Range

-410…16793 -100…

17202

-819…17202 -5.00…

0…16383

-819…

+17407

17407

Operating

Range

+100%

0…100%

Full Range

-105.00…

105.00%

-10.00…

105.00%

105.00%

-5.00…

+106.25%

-12.50…