Page 1

MicroLogix™ 1500

Programmable

Controllers

Bulletin 1764

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown

in this guide are intended solely for purposes of example. Since there

are many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellectual property liability) for actual use based upon

the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole

or part, without written permission of Rockwell Automation, is

prohibited.

Throughout this publication, notes may be used to make you aware of

safety considerations. The following annotations and their

accompanying statements help you to identify a potential hazard,

avoid a potential hazard, and recognize the consequences of a

potential hazard:

WARNING

Identifies information about practices or

circumstances that can cause an explosion in a

hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

!

ATTENTION

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage, or economic loss.

!

IMPORTANT

Identifies information that is critical for successful

application and understanding of the product.

MicroLogix, Compact I/O, and RSLogix are trademarks of Rockwell Automation.

Page 3

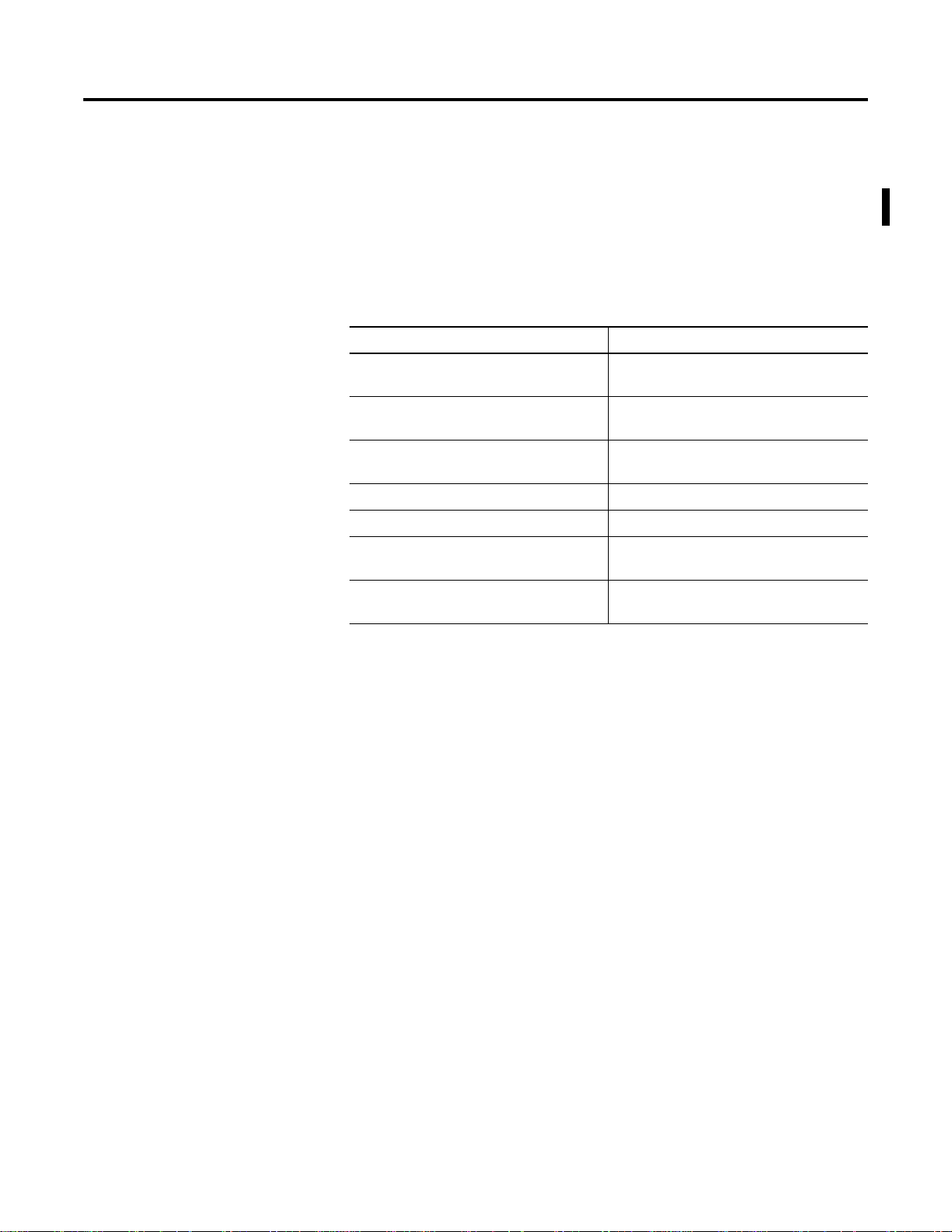

Summary of Changes

The information below summarizes the changes to this manual since

the last printing.

To help you find new and updated information in this release of the

manual, we have included change bars as shown to the right of this

paragraph.

The table below lists the sections that document new features and

additional or updated information on existing features.

For this information: See

Series C support for up to 16 expansion I/O

modules

List of controller series, OS FRN numbers,

and RSLogix versions

Updated list of recommended surge

suppressors

Ethernet Connectivity Page 4-23

Typical CPU hold-up time Page A-1

Updated system loading and heat

dissipation worksheets

System loading graphs for 1769 power

supplies, including 1769-PA4 and 1769-PB4

Chapter 1

Page 1-5

Page 3-6

Appendix F

pages F-5 through F-7

iii Publication 1764-UM001B-EN-P - March 2002

Page 4

Summary of Changes iv

Publication 1764-UM001B-EN-P - March 2002

Page 5

Hardware Overview

Table of Contents

Preface

Who Should Use this Manual. . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Common Techniques Used in this Manual . . . . . . . . . . . . . P-3

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . P-3

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . P-3

Your Questions or Comments on this Manual . . . . . . . . P-4

Chapter 1

Hardware Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

MicroLogix 1500 Component Descriptions . . . . . . . . . . . . . 1-2

Base Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Processors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Data Access Tool (Catalog Number 1764-DAT) . . . . . . . 1-3

Memory Modules/Real-Time Clock . . . . . . . . . . . . . . . . 1-4

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Communication Options . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Compact™ Expansion I/O . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

End Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Expansion Power Supply and Cables . . . . . . . . . . . . . . 1-7

System Requirements for Using Expansion Modules . . . 1-7

Adding an I/O Bank . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Addressing Expansion I/O . . . . . . . . . . . . . . . . . . . . . . 1-11

Expansion I/O Power Failure . . . . . . . . . . . . . . . . . . . . 1-11

Chapter 2

Installing Your Controller

v Publication 1764-UM001B-EN-P - April 2002

Agency Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Compliance to European Union Directives . . . . . . . . . . . . . 2-1

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installation Considerations. . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Hazardous Location Considerations . . . . . . . . . . . . . . . 2-3

Disconnecting Main Power. . . . . . . . . . . . . . . . . . . . . . 2-4

Safety Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Power Distribution. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Periodic Tests of Master Control Relay Circuit . . . . . . . . 2-5

Power Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Isolation Transformers . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Power Supply Inrush . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Loss of Power Source. . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Page 6

Table of Contents vi

Input States on Power Down . . . . . . . . . . . . . . . . . . . . 2-6

Other Types of Line Conditions . . . . . . . . . . . . . . . . . . 2-7

Preventing Excessive Heat. . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Master Control Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Using Emergency-Stop Switches . . . . . . . . . . . . . . . . . . 2-9

Schematic (Using IEC Symbols) . . . . . . . . . . . . . . . . . . 2-10

Schematic (Using ANSI/CSA Symbols). . . . . . . . . . . . . . 2-11

Base Unit Mounting Dimensions . . . . . . . . . . . . . . . . . . . . 2-12

Controller Spacing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Mounting the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Using a DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Base Unit Panel Mounting . . . . . . . . . . . . . . . . . . . . . . 2-16

Installing Controller Components. . . . . . . . . . . . . . . . . . . . 2-17

Prevent Electrostatic Discharge . . . . . . . . . . . . . . . . . . . 2-17

Processor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Data Access Tool (DAT). . . . . . . . . . . . . . . . . . . . . . . . 2-19

Memory Module/Real-Time Clock. . . . . . . . . . . . . . . . . 2-20

Compact I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Wiring Your Controller

Communication Connections

Chapter 3

Wiring Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Wiring Recommendation . . . . . . . . . . . . . . . . . . . . . . . 3-2

Using Surge Suppressors . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Recommended Surge Suppressors . . . . . . . . . . . . . . . . 3-6

Grounding the Controller . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Miswiring - 1764-28BXB Only. . . . . . . . . . . . . . . . . . . . 3-8

Terminal Block Layouts . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Terminal Groupings. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Sinking and Sourcing Input Circuits . . . . . . . . . . . . . . . . . . 3-10

1764-24AWA Wiring Diagram . . . . . . . . . . . . . . . . . . . . 3-11

1764-24BWA Wiring Diagram with Sinking Inputs . . . . . 3-12

1764-24BWA Wiring Diagram with Sourcing Inputs . . . . 3-13

1764-28BXB Wiring Diagram with Sinking Inputs . . . . . 3-14

1764-28BXB Wiring Diagram with Sourcing Outputs . . . 3-15

Controller I/O Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Minimizing Electrical Noise. . . . . . . . . . . . . . . . . . . . . . 3-16

Transistor Output Transient Pulses . . . . . . . . . . . . . . . . 3-16

Chapter 4

Default Communication Configuration . . . . . . . . . . . . . . . . 4-1

Communications Toggle Push Button. . . . . . . . . . . . . . . . . 4-2

Connecting to the RS-232 Port . . . . . . . . . . . . . . . . . . . . . . 4-3

DF1 Full-Duplex Communication Parameters . . . . . . . . 4-3

Making a DF1 Full-Duplex Point-to-Point Connection . . 4-3

Publication 1764-UM001B-EN-P - April 2002

Page 7

Using Trim Pots and the Data

Access Tool (DAT)

Table of Contents vii

Using a Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Isolated Modem Connection. . . . . . . . . . . . . . . . . . . . . 4-5

Connecting to a DF1 Half-Duplex Network. . . . . . . . . . 4-7

Connecting to a DH-485 Network . . . . . . . . . . . . . . . . . . . 4-10

DH-485 Configuration Parameters. . . . . . . . . . . . . . . . . 4-12

Recommended Tools . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

DH-485 Communication Cable . . . . . . . . . . . . . . . . . . . 4-12

Communication Cable Connection to the

DH-485 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Connecting the AIC+ . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Connecting to DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Cable Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Connecting to Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Ethernet Connections. . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

RS-232 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Chapter 5

Trim Pot Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Trim Pot Information Function File. . . . . . . . . . . . . . . . 5-2

Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Data Access Tool (DAT) . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

DAT Keypad and Indicator Light Functions. . . . . . . . . . 5-2

Power-Up Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

DAT Function File . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Power Save Timeout (PST) Parameter. . . . . . . . . . . . . . 5-4

Understanding the DAT Display . . . . . . . . . . . . . . . . . . 5-5

Entering Bit Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Entering Integer Mode . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Monitoring and Editing. . . . . . . . . . . . . . . . . . . . . . . . . 5-6

F1 and F2 Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Working Screen Operation . . . . . . . . . . . . . . . . . . . . . . 5-7

Non-Existent Elements . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Controller Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Using Real-Time Clock and

Memory Modules

Chapter 6

Real-Time Clock Operation . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Removal/Insertion Under Power. . . . . . . . . . . . . . . . . . 6-1

Real-Time Clock Function File . . . . . . . . . . . . . . . . . . . 6-1

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Writing Data to the Real-Time Clock. . . . . . . . . . . . . . . 6-2

RTC Battery Operation . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Memory Module Operation . . . . . . . . . . . . . . . . . . . . . . . . 6-3

User Program and Data Back-Up . . . . . . . . . . . . . . . . . 6-3

Program Compare . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Publication 1764-UM001B-EN-P - April 2002

Page 8

Table of Contents viii

Specifications

Replacement Parts

Data File Download Protection. . . . . . . . . . . . . . . . . . . 6-4

Memory Module Write Protection . . . . . . . . . . . . . . . . . 6-5

Removal/Insertion Under Power. . . . . . . . . . . . . . . . . . 6-5

Memory Module Information File . . . . . . . . . . . . . . . . . 6-5

Appendix A

Controller Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Choosing a Power Supply . . . . . . . . . . . . . . . . . . . . . . A-2

Transistor Output Transient Pulses . . . . . . . . . . . . . . . . A-8

Controller Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Compact I/O Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Panel Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

End Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Appendix B

MicroLogix 1500 Replacement Kits. . . . . . . . . . . . . . . . . . . B-1

Lithium Battery (1747-BA) . . . . . . . . . . . . . . . . . . . . . . . . B-2

Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Battery Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Disposing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Replacement Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . B-5

Replacement Doors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Base Terminal Door (1764-RPL-TDR1) . . . . . . . . . . . . . B-6

Processor Access Door (1764-RPL-CDR1) . . . . . . . . . . . B-6

Base Comms Door

(included in 1764-RPL-DR) . . . . . . . . . . . . . . . . . . . . . . B-6

Trim Pots/Mode Switch Cover Door

(included in 1764-RPL-DR) . . . . . . . . . . . . . . . . . . . . . . B-6

Troubleshooting Your System

Publication 1764-UM001B-EN-P - April 2002

Appendix C

Understanding Controller LEDs . . . . . . . . . . . . . . . . . . . . . C-1

When Operating Normally . . . . . . . . . . . . . . . . . . . . . . C-2

When an Error Exists . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Controller Error Recovery Model . . . . . . . . . . . . . . . . . . . . C-3

Identifying Controller Faults . . . . . . . . . . . . . . . . . . . . . . . C-4

Automatically Clearing Faults . . . . . . . . . . . . . . . . . . . . C-4

Manually Clearing Faults Using the Fault Routine . . . . . C-4

Fault Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Calling Rockwell Automation for Assistance . . . . . . . . . . . . C-5

Page 9

Upgrading Your Operating System

Understanding Communication

Protocols

Table of Contents ix

Appendix D

Preparing for Upgrade. . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Performing the Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Missing/Corrupt OS LED Pattern . . . . . . . . . . . . . . . . . . . . D-2

Appendix E

RS-232 Communication Interface . . . . . . . . . . . . . . . . . . . . E-1

DF1 Full-Duplex Protocol . . . . . . . . . . . . . . . . . . . . . . . . . E-1

DF1 Half-Duplex Protocol . . . . . . . . . . . . . . . . . . . . . . . . . E-2

DF1 Half-Duplex Operation . . . . . . . . . . . . . . . . . . . . . E-2

Considerations When Communicating as a DF1 Slave

on a Multi-drop Link . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Using Modems with MicroLogix 1500

Programmable Controllers . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Dial-Up Phone Modems . . . . . . . . . . . . . . . . . . . . . . . . E-4

Leased-Line Modems . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

Radio Modems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

Line Drivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

DH-485 Communication Protocol. . . . . . . . . . . . . . . . . . . . E-5

DH-485 Network Description . . . . . . . . . . . . . . . . . . . . E-5

DH-485 Token Rotation . . . . . . . . . . . . . . . . . . . . . . . . E-6

DH-485 Configuration Parameters. . . . . . . . . . . . . . . . . E-6

Devices that Use the DH-485 Network . . . . . . . . . . . . . E-7

Important DH-485 Network Planning Considerations. . . E-8

Modbus RTU Slave Communication Protocol

(MicroLogix 1764-LSP and 1764-LRP Series B and

later processors only) . . . . . . . . . . . . . . . . . . . . . . . . . . . E-13

ASCII Protocol (MicroLogix 1500 1764-LSP

and 1764-LRP Series B and later Processors only) . . . . . . . E-13

System Loading and Heat

Dissipation

Appendix F

System Loading Limitations . . . . . . . . . . . . . . . . . . . . . . . . F-1

System Expansion Calculations . . . . . . . . . . . . . . . . . . . . . F-1

Selecting System Devices . . . . . . . . . . . . . . . . . . . . . . . F-2

Verifying the System Loading . . . . . . . . . . . . . . . . . . . . F-4

Calculating Heat Dissipation . . . . . . . . . . . . . . . . . . . . . . . F-9

Glossary

Index

Publication 1764-UM001B-EN-P - April 2002

Page 10

Table of Contents x

Publication 1764-UM001B-EN-P - April 2002

Page 11

Preface

Read this preface to familiarize yourself with the rest of the manual. It

provides information concerning:

• who should use this manual

• the purpose of this manual

• related documentation

• conventions used in this manual

• Rockwell Automation support

Who Should Use this Manual

Purpose of this Manual

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting control systems that use

MicroLogix 1500 controllers.

You should have a basic understanding of electrical circuitry and

familiarity with relay logic. If you do not, obtain the proper training

before using this product.

This manual is a reference guide for MicroLogix 1500 controllers. It

describes the procedures you use to install, wire, and troubleshoot

your controller. This manual:

• explains how to install and wire your controllers

• gives you an overview of the MicroLogix 1500 controller system

Refer to publication 1762-RM001, MicroLogix 1200 and MicroLogix

1500 Programmable Controllers Instruction Set Reference Manual for

the MicroLogix 1200 and 1500 instruction set and for application

examples to show the instruction set in use. Refer to your

programming software user documentation for more information on

programming your MicroLogix 1500 controller.

Related Documentation

P-1 Publication 1764-UM001B-EN-P - April 2002

The documents listed on page P-2 contain additional information

concerning Rockwell Automation products. If you would like a copy,

you can:

• download a free electronic version from the internet:

www.ab.com/micrologix or www.theautomationbookstore.com

• purchase a printed manual by:

– contacting your local distributor or Rockwell Automation

representative

– visiting www.theautomationbookstore.com and placing your

order

– calling 1.800.963.9548 (USA/Canada)

or 001.330.725.1574 (Outside USA/Canada)

Page 12

Preface P-2

For Read this Document Document Number

A technical overview of the MicroLogix 1500 and related

products

Information on the MicroLogix 1500 Controllers instruction set MicroLogix 1200 and 1500 Programmable

MicroLogix 1500 Programmable Controllers

Technical Data

1764-TD001

1762-RM001

Controllers Instruction Set Reference Manual

Information on mounting and wiring the MicroLogix 1500 Base

Units, including a mounting template for easy installation

MicroLogix 1500 Programmable Controllers

Base Unit Installation Instructions

1764-IN001

An overview of Compact I/O Compact I/O System Overview 1769-SO001

More information on Compact I/O Power Supplies and Cables 1769 Compact I/O Power Supplies and

1769-TD001

Communication Bus Expansion Cables

Technical Data

More information on Compact Analog I/O and Temperature Input

Modules

Compact Analog I/O and Temperature Input

Modules Technical Data

1769-TD004

Detailed information on using Compact I/O Analog Modules Compact I/O Analog Modules User Manual 1769-UM002

Detailed information on installing, configuring, and using

1769-IT6 Thermocouple/mV Input Modules

Detailed information on installing, configuring, and using

1769-IR6 RTD/Resistance Input Modules

Detailed information on installing, configuring, and using

1769-HSC High Speed Counter Modules

A description on how to install and connect an AIC+. This

manual also contains information on network wiring.

Compact I/O 1769-IT6 Thermocouple/mV

Input Module User Manual

Compact I/O 1769-IR6 RTD/Resistance Input

Module User Manual

Compact 1769-HSC High Speed Counter

Module User Manual

Advanced Interface Converter (AIC+) User

Manual

1769-UM004

1769-UM005

1769-UM006

1761-6.4

Information on how to install, configure, and commission a DNI DeviceNet™ Interface User Manual 1761-6.5

Information on installing, connecting, and configuring an ENI Ethernet Interface User Manual 1761-UM001

Information on installing, configuring, and using a DeviceNet

Scanner

Information on DF1 open protocol. DF1 Protocol and Command Set Reference

Compact™ I/O 1769-SDN DeviceNet Scanner

User Manual

1761-UM009

1770-6.5.16

Manual

In-depth information on grounding and wiring Allen-Bradley

programmable controllers

A description of important differences between solid-state

programmable controller products and hard-wired

Allen-Bradley Programmable Controller

Grounding and Wiring Guidelines

Application Considerations for Solid-State

Controls

1770-4.1

SGI-1.1

electromechanical devices

An article on wire sizes and types for grounding electrical

equipment

A complete listing of current documentation, including ordering

National Electrical Code - Published by the National Fire Protection

Association of Boston, MA.

Allen-Bradley Publication Index SD499

instructions. Also indicates whether the documents are available

on CD-ROM or in multi-languages.

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation Glossary AG-7.1

Publication 1764-UM001B-EN-P - April 2002

Page 13

Preface P-3

Common Techniques Used in this Manual

Rockwell Automation Support

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not

procedural steps.

• Numbered lists provide sequential steps or hierarchical

information.

• Italic type is used for emphasis.

Rockwell Automation offers support services worldwide, with over 75

Sales/Support Offices, 512 authorized Distributors and 260 authorized

Systems Integrators located throughout the United States alone, plus

Rockwell Automation representatives in every major country in the

world.

Local Product Support

Contact your local Rockwell Automation representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

Before you contact Rockwell Automation for technical assistance, we

suggest you please review the troubleshooting information contained

in this publication first.

Publication 1764-UM001B-EN-P - April 2002

Page 14

Preface P-4

If the problem persists, call your local Rockwell Automation

representative or contact Rockwell Automation in one of the following

ways:

Phone United

States/Canada

Outside United

States/Canada

Internet

⇒

1.440.646.5800

You can access the phone number for your

country via the Internet:

1. Go to http://www.ab.com

2. Click on

(http://support.automation.rockwell.com)

3. Under

Information

1. Go to http://www.ab.com

2. Click on

(http://support.automation.rockwell.com)

Product Support

Support Centers

Product Support

, click on

Contact

Your Questions or Comments on this Manual

If you find a problem with this manual, or you have any suggestions

for how this manual could be made more useful to you, please

contact us at the address below:

Rockwell Automation

Automation Control and Information Group

Technical Communication, Dept. A602V

P.O. Box 2086

Milwaukee, WI 53201-2086

Publication 1764-UM001B-EN-P - April 2002

or visit our internet page at:

http://www.rockwellautomation.com

For the latest information on MicroLogix controllers, visit

www.ab.c

om/micrologix

Page 15

Hardware Overview

Chapter

1

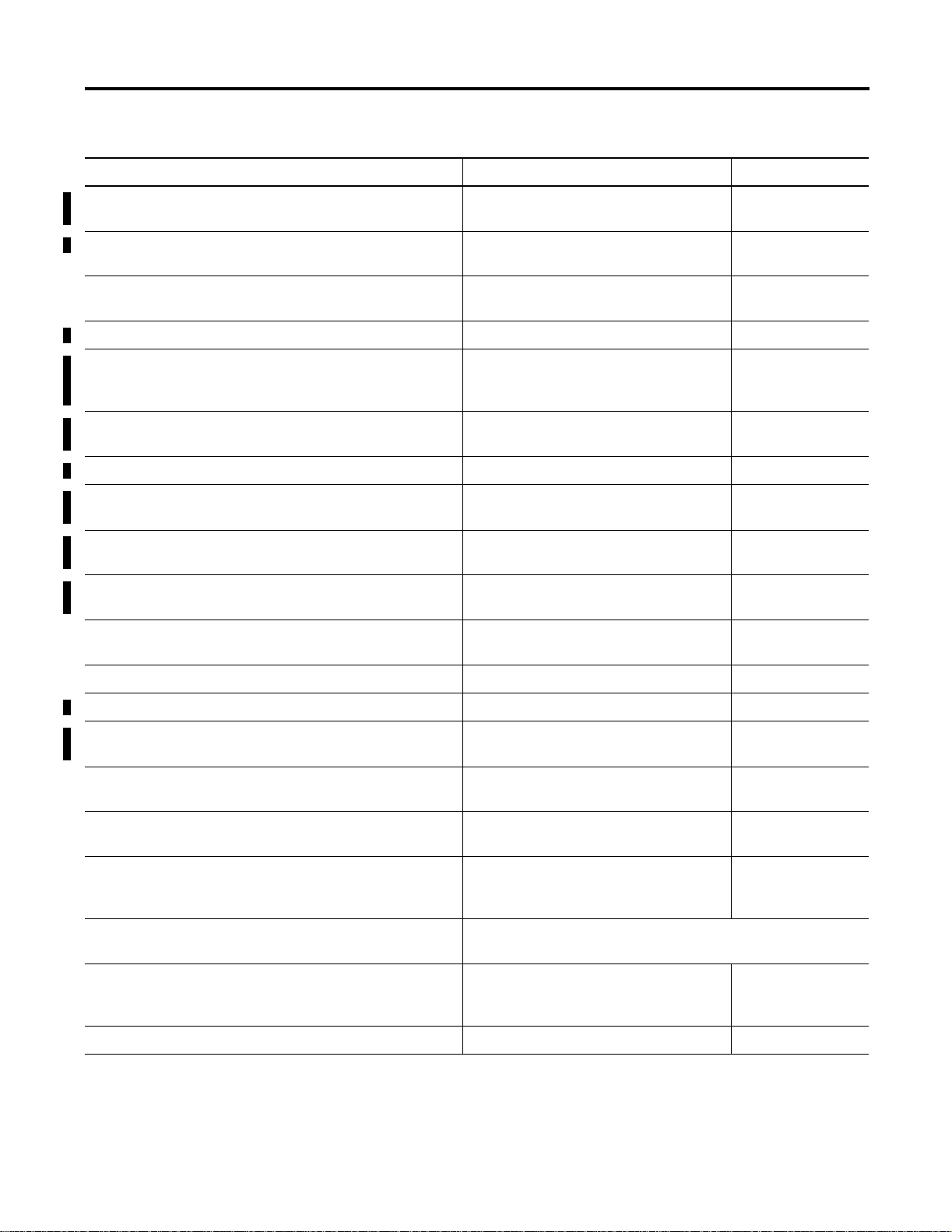

Hardware Features

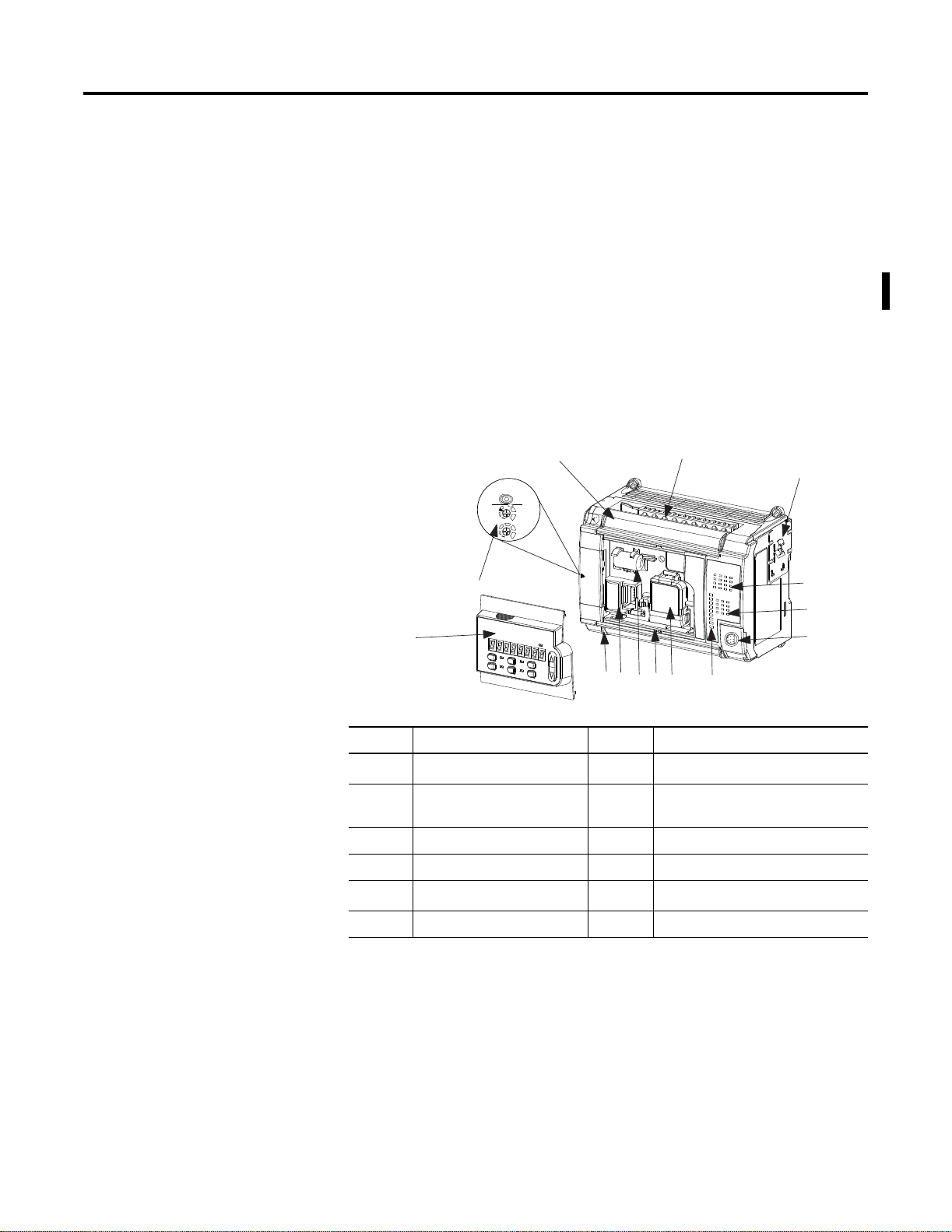

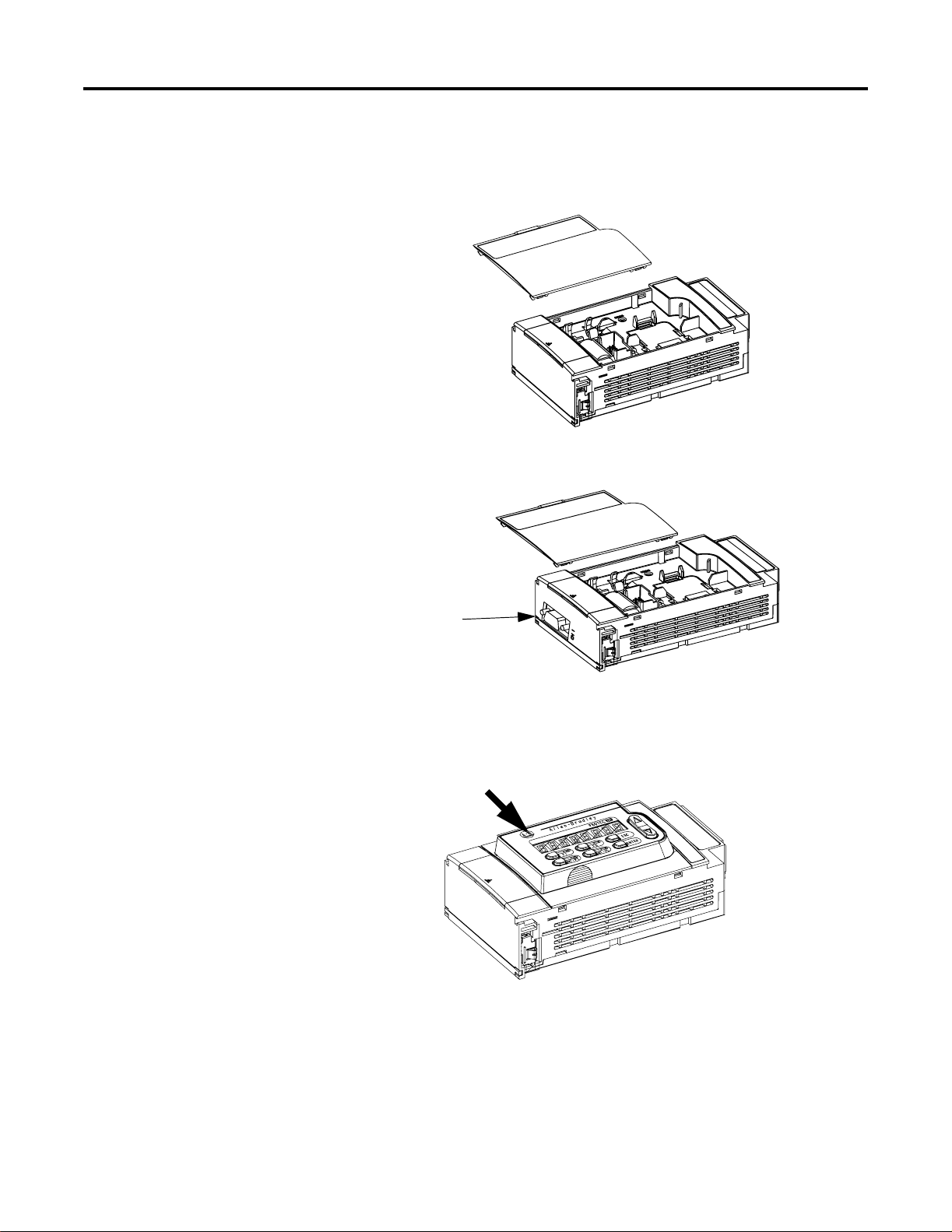

The MicroLogix 1500 programmable controller is composed of a base

unit, which contains a power supply, input and output circuits, and a

processor. The controller is available with 24 or 28 points of

embedded I/O. Additional I/O may be added using Compact™ I/O.

The hardware features of the controller are:

1

2

3

4

5

1

6

7

11

12

REM

RUN PROG

10

10

9

8

Feature Description Feature Description

1 Removable Terminal Blocks 7

2 Interface to Expansion I/O,

Removable ESD Barrier

3 Input LEDs 9 Battery

4 Output LEDs 10 Terminal Doors and Label

5 Communication Port 11

6 Status LEDs 12 Mode Switch, Trim Pots

(1) Optional.

1 Publication 1764-UM001B-EN-P - April 2002

8

Memory Module/Real-Time Clock

Replacement Battery

Data Access Tool

(1)

(1)

(1)

Page 16

1-2 Hardware Overview

MicroLogix 1500 Component Descriptions

A controller is composed of a processor (1764-LSP or enhanced

1764-LRP with RS-232 port) and one of the base units listed below.

The FET transistor outputs are available on the 1764-28BXB base only.

Base Units

Catalog

Number

1764-24AWA 120/240V ac (12) 120V ac (12) Relay, 2 isolated relays

1764-24BWA 120/240V ac (8) Standard 24V dc

1764-28BXB 24V dc (8) Standard 24V dc

Line Power Inputs Outputs High Speed I/O

n/a

(4) 20 kHz input

(8) 20 kHz input

(2) 20 kHz output

(4) Fast 24V dc

(8) Fast 24V dc

per unit

(12) Relay, 2 isolated relays

per unit

(6) Relay, 2 isolated relays

per unit

(4) Standard 24V dc FET

(2) Fast 24V dc FET

Publication 1764-UM001B-EN-P - April 2002

Page 17

Processors

Processor (Catalog Number 1764-LSP)

Processor (Catalog Number 1764-LRP)

Hardware Overview 1-3

Communications Port

• DTE (male) 9-pin D-shell

connector

• 30V dc isolation

Data Access Tool (Catalog Number 1764-DAT)

1764-DAT

mounted on

1764-LSP

processor.

Publication 1764-UM001B-EN-P - April 2002

Page 18

1-4 Hardware Overview

Memory Modules/Real-Time Clock

Memory module

mounted on

1764-LSP

processor.

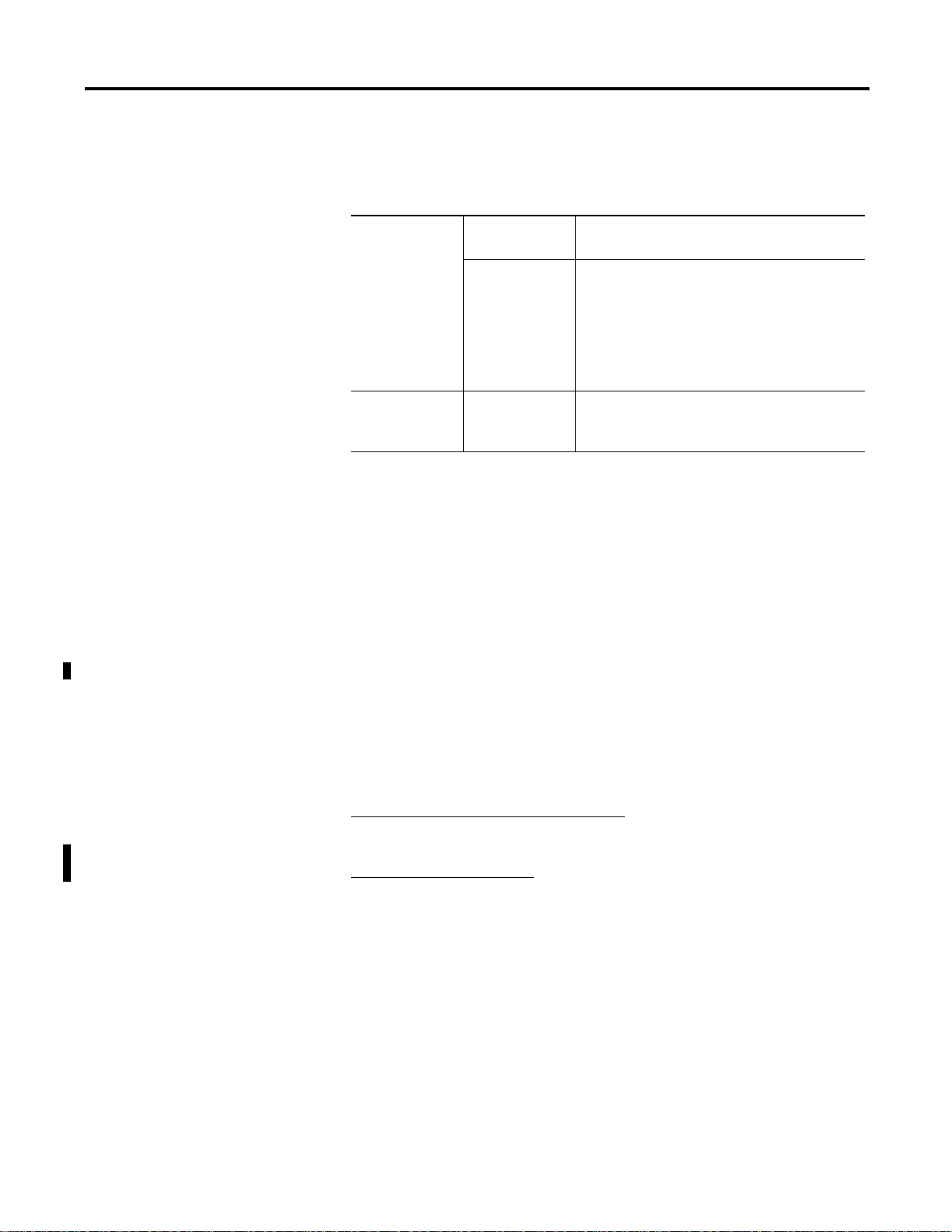

The following memory modules and real-time clock modules are

available:

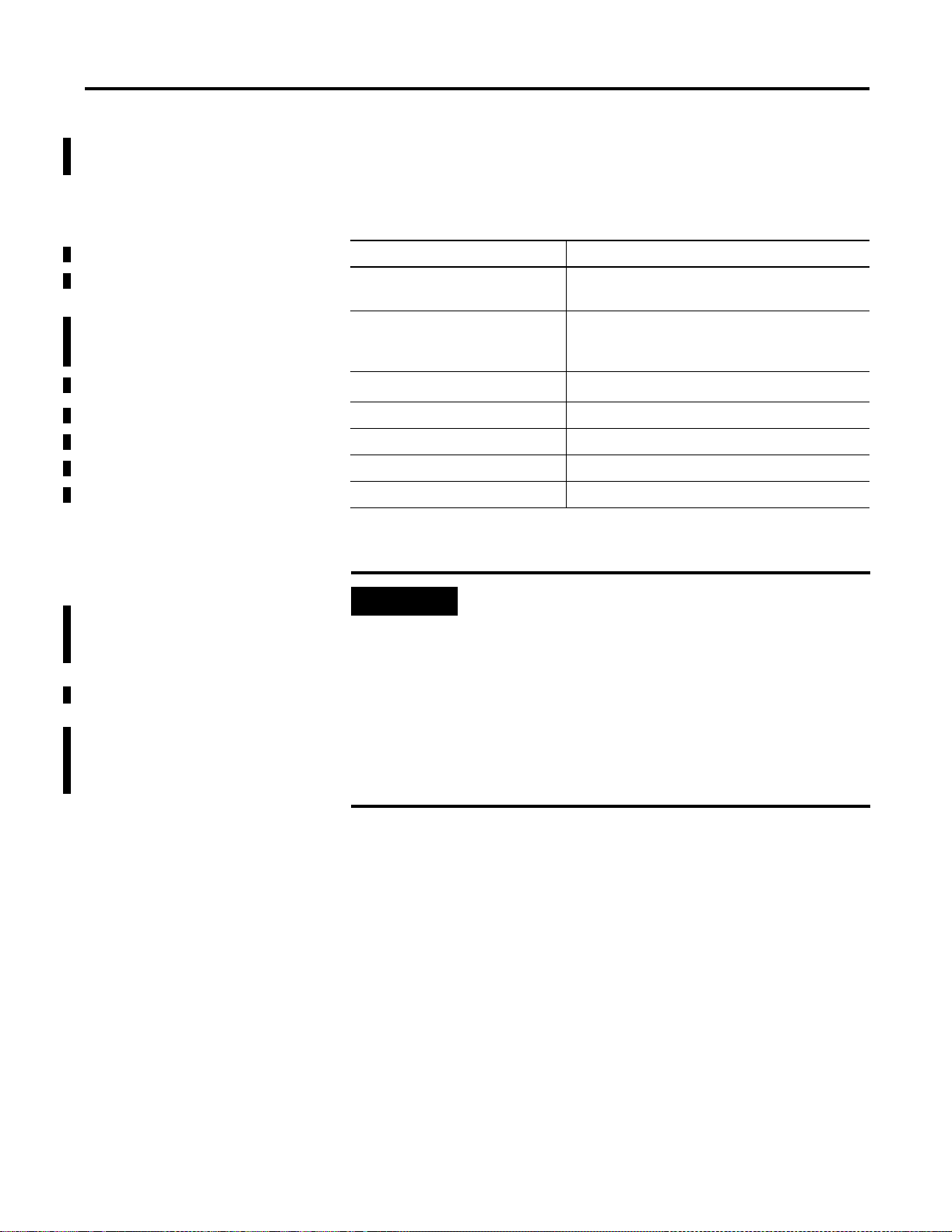

Catalog Number Function Memory Size

1764-RTC Real-Time Clock not applicable

1764-MM1 Memory Module 8K

1764-MM1RTC Memory Module and Real-Time Clock 8K

1764-MM2

1764-MM2RTC

(1) For 1764-LRP programs greater than 8k, use the 1764-MM2 or 1764-MM2RTC.

(1)

(1)

Memory Module 16K

Memory Module and Real-Time Clock 16K

Cables

Use only the following communication cables in Class I, Division 2

hazardous locations.

Table 1.1 Cables for Use in Class I, Division 2 Hazardous Environment

1761-CBL-PM02 Series C or later 2707-NC8 Series B or later

1761-CBL-HM02 Series C or later 2707-NC9 Series B or later

1761-CBL-AM00 Series C or later 2707-NC10 Series B or later

1761-CBL-AP00 Series C or later 2707-NC11 Series B or later

Publication 1764-UM001B-EN-P - April 2002

Page 19

Hardware Overview 1-5

Programming

Programming the MicroLogix 1500 programmable controller is done

using RSLogix™ 500, Rev. 4.0 or later. Certain features are only

available when using the most current version of the software, as

noted in System Requirements for Using Expansion Modules on page

1-7.

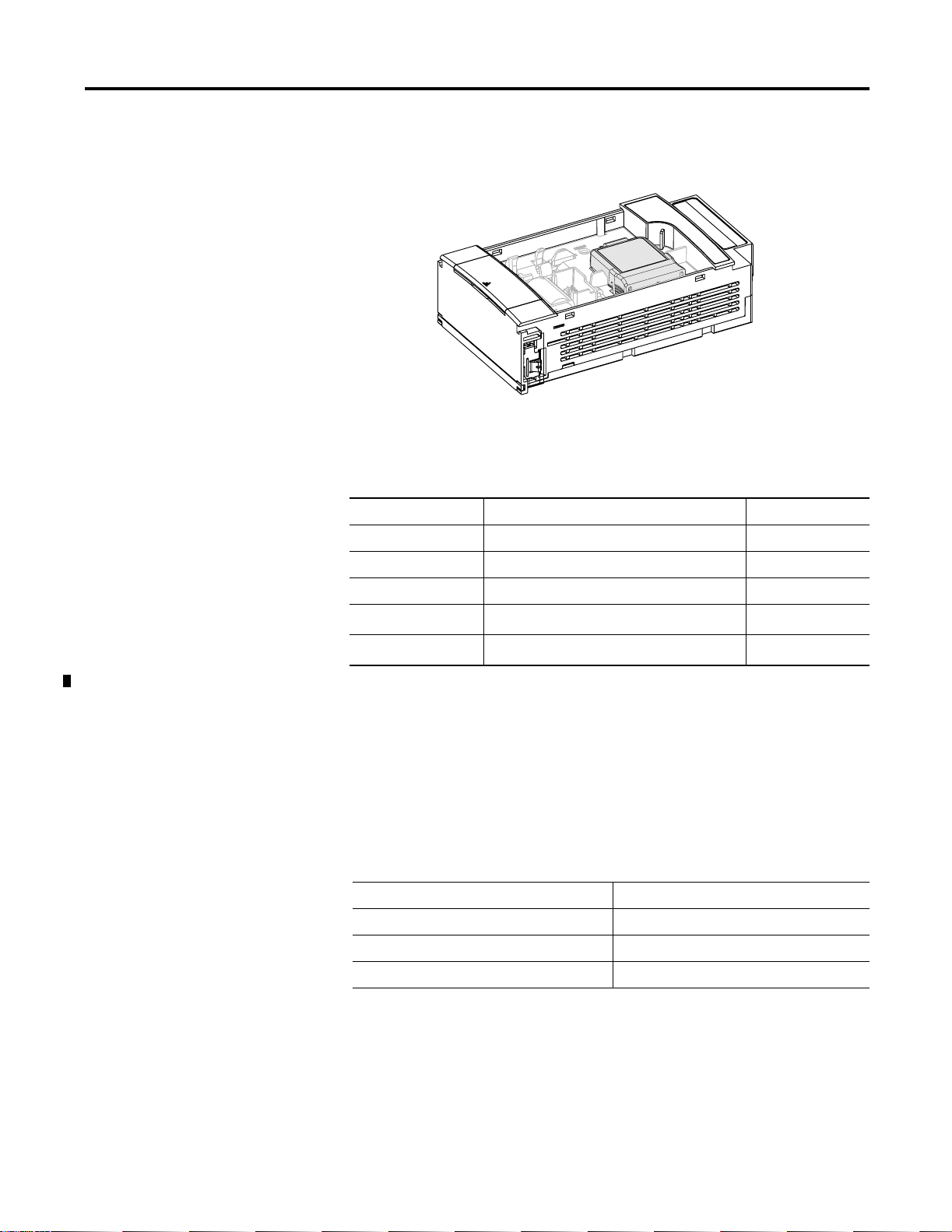

The following table lists the firmware release numbers, feature and

functionality enhancements, and the required version of RSLogix 500

and RSLogix 500 Starter software.

Table 1.B Required Software Version by FRN Number

Controller Firmware

Release

Initial

Release

Enhancement October

Series B

Release

1764-LSP

Enhancement October

Available

for Sale

Date

February

1999

1999

March

2000

2000

Catalog

Number

Series

AB

AC

BA

BB

Catalog

Number

Revision

OS FRN

Number

2 Initial Release 3.01.00

3 Power Supply and Expansion Cable

4 String Data File Type,

5 PTO Controlled Stop,

Feature and Functionality

Changes

Compatibility

ASCII Instruction Set,

Modbus RTU Slave Protocol,

Ramping (when using PWM outputs),

Static Data File Protection,

RTC Messaging

Memory Module Program Compare Bit

Enhancement

Required

Version of

RSLogix

500/RSLogix

500 Starter

Software

3.01.00

4.00.00

4.50.00

1764-LRP

Series C

Release

Initial

Release

Enhancement October

Series C

Release

September

2001

March

2000

2000

September

2001

CA

BA

BB

CA

6 Floating Point Data File Support,

Programmable Limit Switch (PLS),

Real Time Clock Adjust (Copy Word),

Absolute Value,

Gray Code,

Recipe,

Message Instruction Support for

1769-SDN

4 Initial Release - Same Functionality as

1764-LSP

5 PTO Controlled Stop,

Memory Module Program Compare Bit

Enhancement

6 Floating Point Data File Support,

Programmable Limit Switch (PLS),

Real Time Clock Adjust (Copy Word),

Absolute Value,

Gray Code,

Recipe,

Message Instruction Support for

1769-SDN

Publication 1764-UM001B-EN-P - April 2002

5.10.00

4.00.00

4.50.00

5.10.00

Page 20

1-6 Hardware Overview

Communication Options

Compact™ Expansion I/O

The MicroLogix 1500 can be connected to a personal computer. It can

also be connected to the DH-485 network using an Advanced

Interface Converter (1761-NET-AIC), to an Ethernet network using an

Ethernet Interface (1761-NET-ENI), or to a DeviceNet™ network using

a DeviceNet Interface (1761-NET-DNI) or through the DeviceNet

Scanner module (1769-SDN). The controller can also be connected to

Modbus™ SCADA networks as an RTU slave. See Communication

Connections on page 4-1 for more information on connecting to the

available communication options.

The 1764-LRP processor provides an additional communication port.

Each of the communications ports can be independently configured

for any supported communication protocol. (Channel 0 is on the base

unit and Channel 1 is on the 1764-LRP processor.)

Compact expansion I/O (Bulletin 1769) can be connected to the

MicroLogix 1500 Controller. A maximum of either 8 or 16 expansion

I/O modules can be used, depending upon your system. See System

Requirements for Using Expansion Modules on page 1-7.

See System Loading and Heat Dissipation on page F-1 for more

information on system configurations.

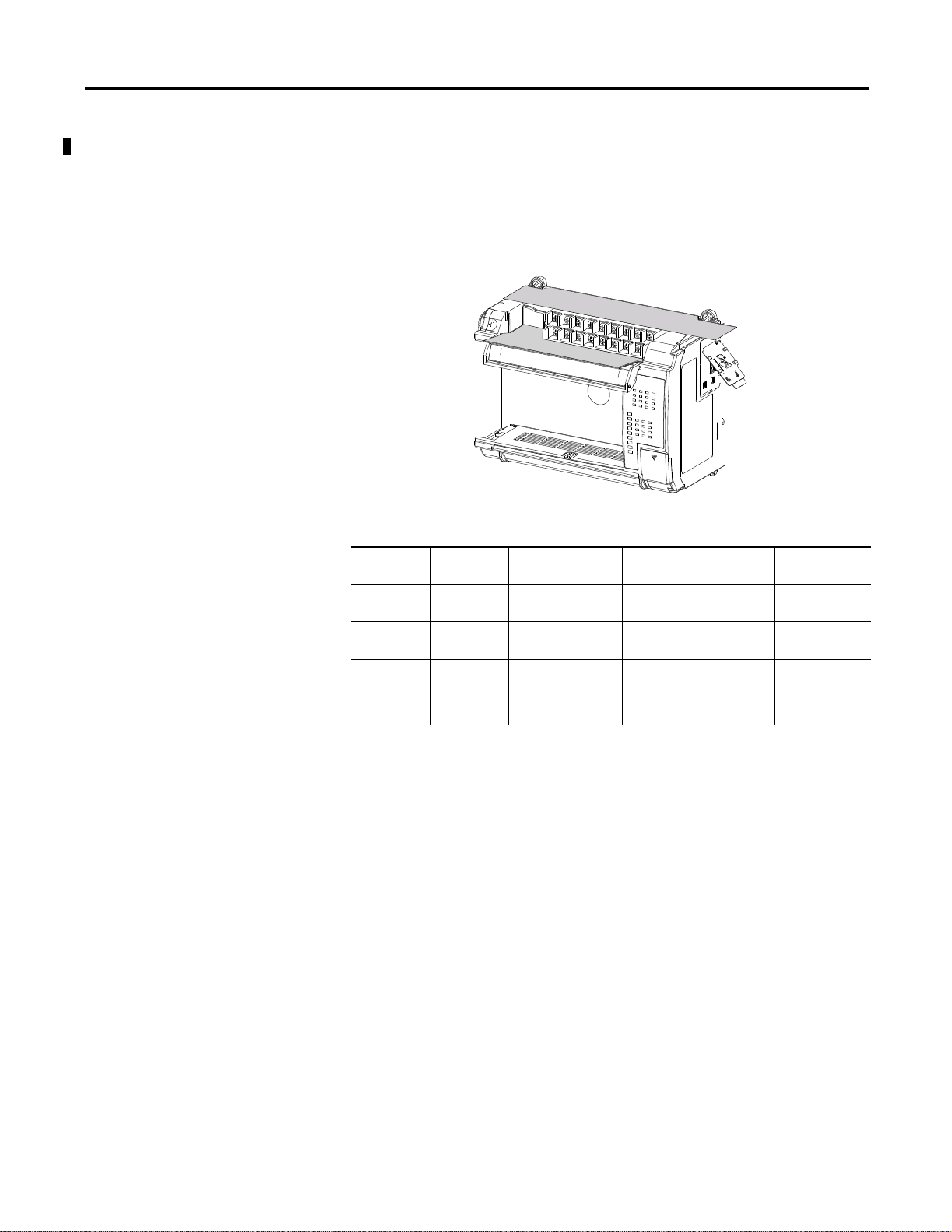

End Cap

An end cap terminator (catalog number 1769-ECR or 1769-ECL) must

be used at the end of the group of I/O modules attached to the

MicroLogix 1500 Controller. The end cap terminator is not provided

with the base or processor units. It is required when using expansion

I/O.

This illustration shows the right end cap (1769-ECR ). The left end cap

(1769-ECL) is shown on page 1-10.

Publication 1764-UM001B-EN-P - April 2002

Page 21

Hardware Overview 1-7

Expansion Power Supply and Cables

With Operating System Revision Number (FRN) 3 or higher, you can

connect an additional bank of I/O to your controller. Using an

expansion power supply increases the system’s capacity for adding

expansion I/O modules. The additional I/O bank is connected to the

controller via a specially designed cable. The additional I/O bank

must include a power supply and an end cap.

TIP

Depending on the system configuration, each

controller can support up to 16 expansion I/O

modules. See the System Requirements for Using

Expansion Modules below. Also see System

Guidelines on page 1-9 for system limitations and

illustrations of expansion I/O banks.

System Requirements for Using Expansion Modules

To support a maximum of 8 I/O modules in an additional I/O bank,

you must have the following:

Table 1.3 Requirements to Support a Maximum of 8 I/O Modules

Product Catalog Number

MicroLogix 1500

Processor

MicroLogix 1500

Base Unit

Operating System

Version

1764-LSP, Series A, Revision C or higher

1764-LSP, Series B or higher

1764-LRP, Series B or higher

1764-24AWA, Series A or higher

1764-24BWA, Series A or higher

1764-28BXB, Series A or higher

Firmware Revision Number (FRN) 3 or higher

1764-LSP, Series A RSLogix 500, Version 3.01.09 or higher,

(1)

Programming

Software

1 Power Supply

(optional)

1 Cable (optional) 1769-CRL1, 1769-CRL3, 1769-CRR1, 1769-CRR3

1 End Cap (required) 1769-ECL, 1769-ECR

(1) You can check the FRN by looking at word S:59 (Operating System FRN) in the Status File.

1764-LSP, Series B

1764-LRP, Series B

1764-LSP, Series C

1764-LRP, Series C

1769-PA2, 1769-PA4

1769-PB2, 1769-PB4

RSLogix 500, Version 4.00.00 or higher.

RSLogix 500, Version 5.00.00 or higher.

Publication 1764-UM001B-EN-P - April 2002

Page 22

1-8 Hardware Overview

To support a maximum of 16 I/O modules in an additional I/O bank,

you must have the following:

Table 1.4 Requirements to Support a Maximum of 16 I/O Modules

Product Catalog Number

MicroLogix 1500 Processor 1764-LSP, Series C or higher

1764-LRP, Series C or higher

MicroLogix 1500 Base Unit 1764-24AWA, Series B or higher

1764-24BWA, Series B or higher

1764-28BXB, Series B or higher

Operating System Version

Programming Software RSLogix 500, Version 5.10.00 or higher.

1 Power Supply (optional) 1769-PA2, 1769-PA4, 1769-PB2, 1769-PB4

1 Cable (optional) 1769-CRL1, 1769-CRL3, 1769-CRR1, 1769-CRR3

1 End Cap (required) 1769-ECL, 1769-ECR

(1) You can check the FRN by looking at word S:59 (Operating System FRN) in the Status File.

Firmware Revision Number (FRN) 6 or higher

(1)

IMPORTANT

If your processor is at an older revision, you must

upgrade the operating system to FRN 3 or higher

to use an expansion cable and power supply (or to

FRN 6 or higher to allow up to 16 expansion

modules). On the Internet, go to

http://www.ab.com/micrologix to download the

operating system upgrade. Navigate to MicroLogix

1500 for further instructions and downloads.

MicroLogix 1500 base units are not field upgradeable

from Series A to Series B.

Publication 1764-UM001B-EN-P - April 2002

Page 23

Hardware Overview 1-9

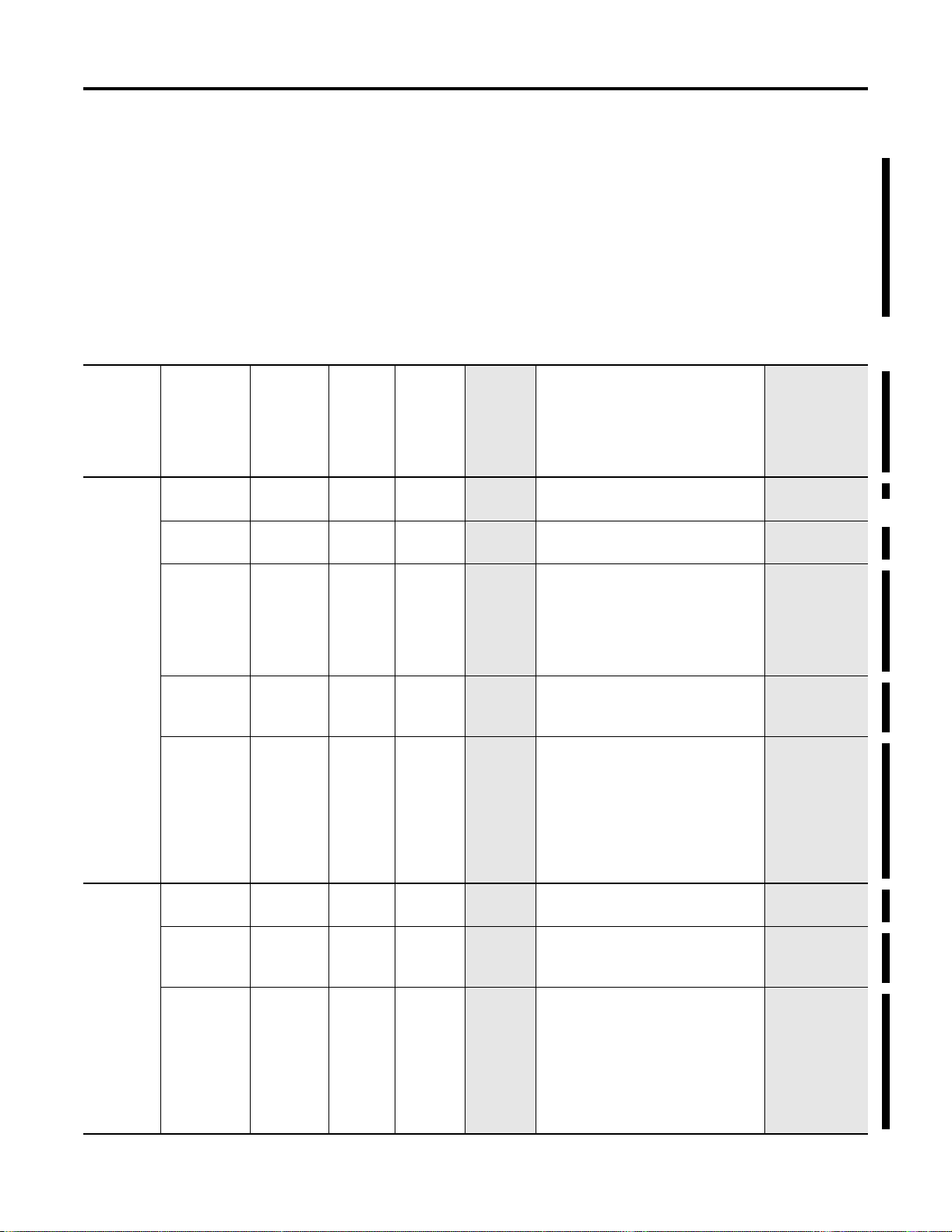

Adding an I/O Bank

System Guidelines

A maximum of one 1769 Expansion Cable can be used in a

MicroLogix 1500 system, allowing for two banks of I/O modules (one

connected directly to the controller, and the other connected via the

cable). Each I/O bank requires its own power supply (Bank 1 uses the

controller’s embedded power supply).

ATTENTION

!

ATTENTION

!

LIMIT OF ONE EXPANSION POWER SUPPLY

The expansion power supply cannot be connected

directly to the controller. It must be connected using

an expansion cable. Only one power supply

(embedded in the base unit or an expansion power

supply) may be used on an I/O bank. Exceeding

these limitations may damage the power supply and

result in unexpected operation.

REMOVE POWER

Remove system power before making or breaking

cable connections. When you remove or insert a

cable connector with power applied, an electrical arc

may occur. An electrical arc can cause personal

injury or property damage by:

• sending an erroneous signal to your system’s field

devices, causing unintended machine operation

• causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on

both the module and its mating connector.

IMPORTANT

Refer to your power supply and I/O module’s

documentation for instructions on how to set up

your system.

See the System Requirements for Using Expansion

Modules on page 1-7 to determine the maximum

number of expansion I/O modules you can use in

your MicroLogix system.

Also see System Loading and Heat Dissipation on

page F-1 for more information on system

configurations.

Publication 1764-UM001B-EN-P - April 2002

Page 24

1-10 Hardware Overview

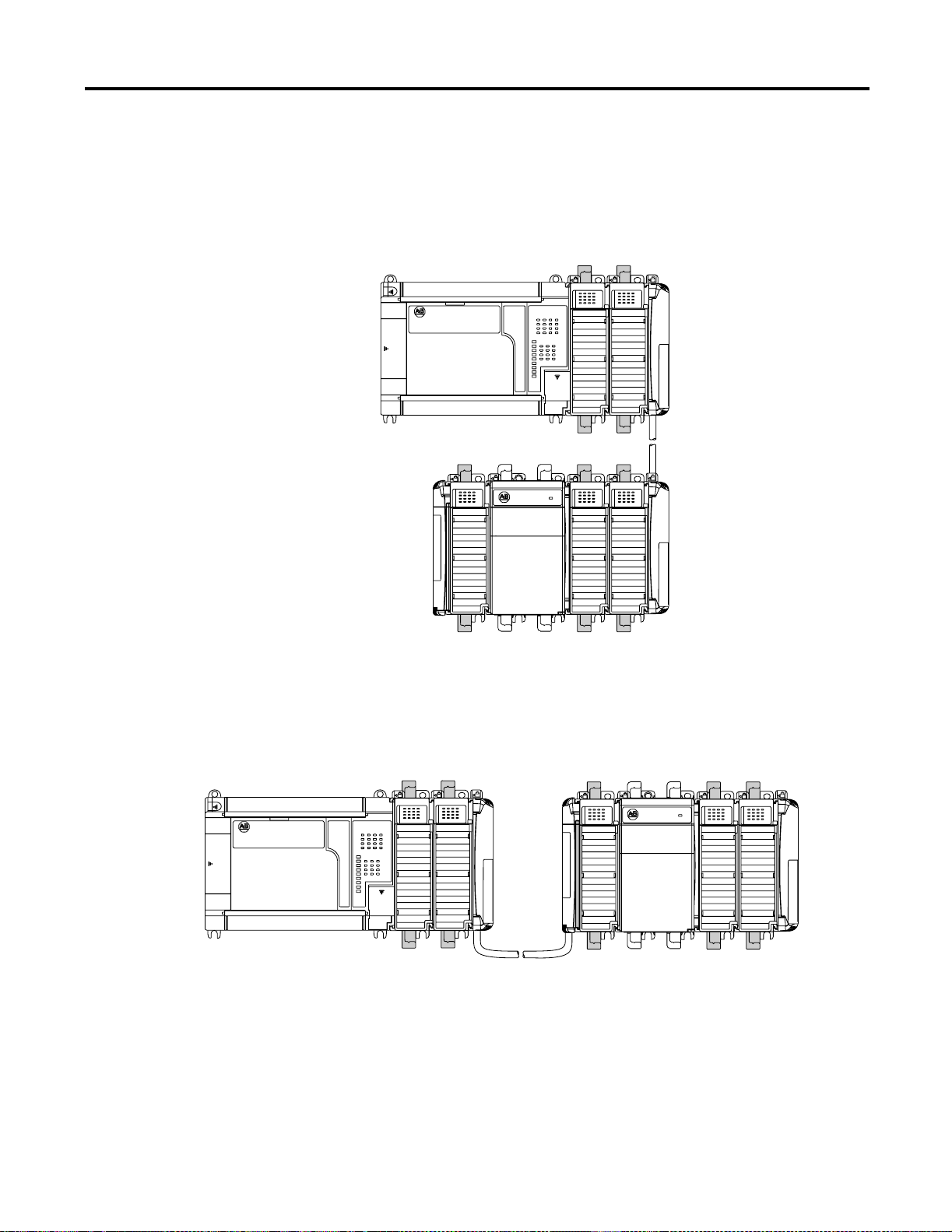

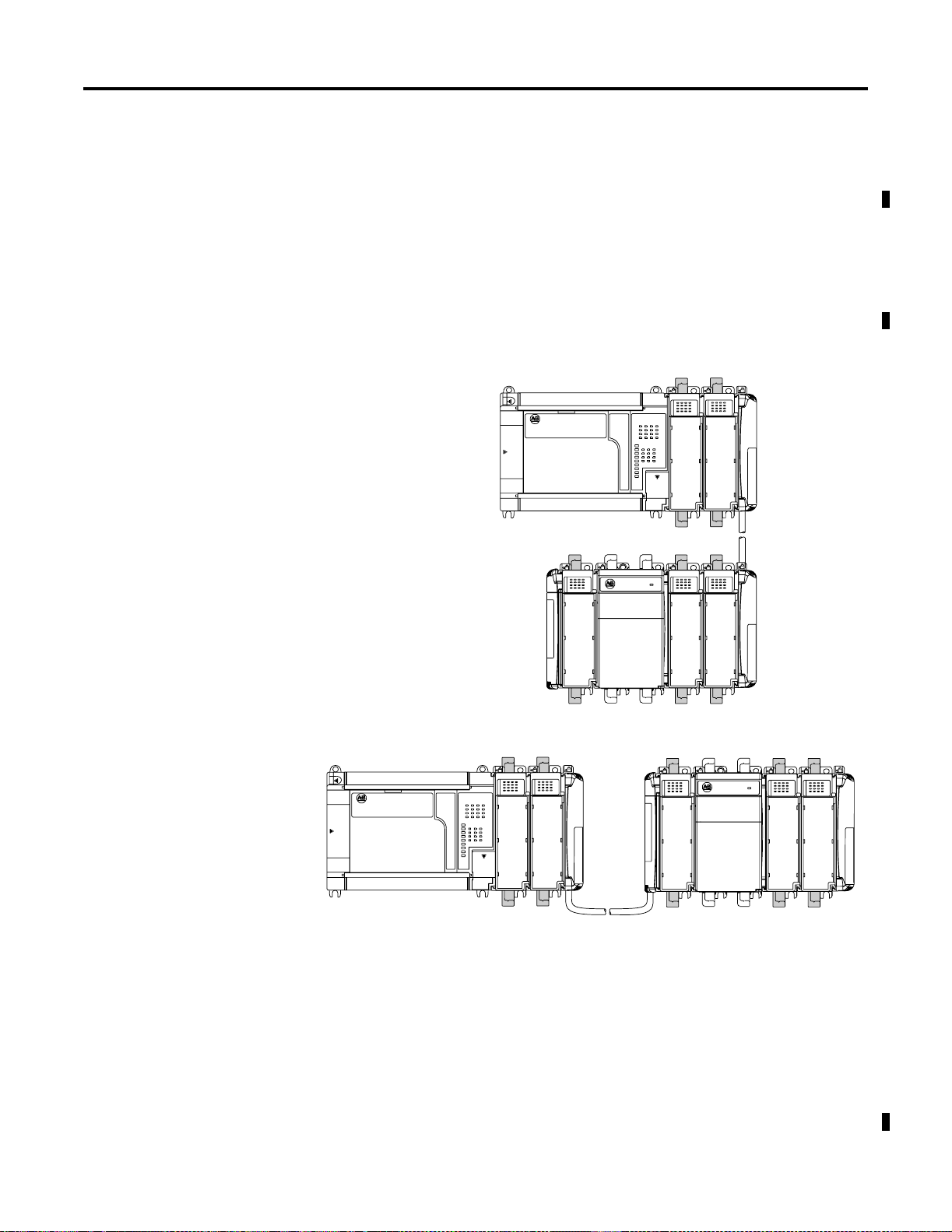

The following illustrations show a MicroLogix 1500 with an expansion

I/O bank.

Vertical Orientation

Expansion

I/O Bank 1

1769-CRRx

Expansion Cable

1769-ECL

End Cap

(1) The x in this catalog number can be either a 1 or a 3 representing the length of the cable:

1 = 1 foot (305 mm) and 3 = 3.28 feet (1 meter).

(1)

Expansion

I/O Bank 2

Horizontal Orientation

1769-ECR

End Cap

Publication 1764-UM001B-EN-P - April 2002

Expansion

I/O Bank 1

(1) The x in this catalog number can be either a 1 or a 3 representing the length of the cable:

1 = 1 foot (305 mm) and 3 = 3.28 feet (1 meter).

1769-CRLx

Expansion Cable

(1)

Expansion

I/O Bank 2

Page 25

Hardware Overview 1-11

Addressing Expansion I/O

The expansion I/O is addressed as slots 1 through 16 (the controller’s

embedded I/O is addressed as slot 0). Power supplies and cables are

not counted as slots. Modules are counted from left to right on each

bank as shown in the illustrations below. For more information on

addressing, refer to the MicroLogix 1200 and MicroLogix 1500

Programmable Controllers Instruction Set Reference Manual,

publication 1762-RM001.

Vertical Orientation

Expansion

Embedded

I/O = Slot 0

Slot 1

I/O Bank 1

Slot 2

Horizontal Orientation

Embedded

I/O = Slot 0

Slot 1

Slot 2

Expansion I/O Bank 1 Expansion I/O Bank 2

Expansion I/O Power Failure

Expansion

I/O Bank 2

Slot 3

Slot 4

Slot 3

Slot 5

Slot 4

Slot 5

Expansion I/O errors represent failures of the I/O bus or the modules

themselves. The error codes are listed in the MicroLogix 1200 and

MicroLogix 1500 Programmable Controllers Instruction Set Reference

Manual, publication 1762-RM001.

Publication 1764-UM001B-EN-P - April 2002

Page 26

1-12 Hardware Overview

Publication 1764-UM001B-EN-P - April 2002

Page 27

Chapter

2

Installing Your Controller

This chapter shows you how to install your controller system. The

only tools you require are a Flat or Phillips head screwdriver and drill.

Topics include:

• agency certifications

• compliance to European Union Directives

• using in hazardous locations

• master control relay

• power considerations

• preventing excessive heat

• controller spacing

• mounting the controller

Agency Certifications

Compliance to European Union Directives

• UL 508

• C-UL under CSA C22.2 no. 142

• Class I, Division 2, Groups A, B, C, D

(UL 1604, C-UL under CSA C22.2 no. 213)

• CE compliant for all applicable directives

This product has the CE mark and is approved for installation within

the European Union and EEA regions. It has been designed and tested

to meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in

whole or in part, documented in a technical construction file:

• EN 50081-2

EMC - Generic Emission Standard, Part 2 - Industrial

Environment

• EN 50082-2

EMC - Generic Immunity Standard, Part 2 - Industrial

Environment

This product is intended for use in an industrial environment.

1 Publication 1764-UM001B-EN-P - April 2002

Page 28

2-2 Installing Your Controller

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of EN 61131-2

Programmable Controllers, Part 2 - Equipment Requirements and

Tests.

For specific information required by EN 61131-2, see the appropriate

sections in this publication, as well as the following Allen-Bradley

publications:

• Industrial Automation Wiring and Grounding Guidelines for

Noise Immunity, publication 1770-4.1

• Guidelines for Handling Lithium Batteries, publication AG-5.4

• Automation Systems Catalog, publication B111

Installation Considerations

Most applications require installation in an industrial enclosure

(1)

(Pollution Degree 2

(Over Voltage Category II

your controller as far as possible from power lines, load lines, and

other sources of electrical noise such as hard-contact switches, relays,

and AC motor drives. For more information on proper grounding

guidelines, see the Industrial Automation Wiring and Grounding

Guidelines publication 1770-4.1.

ATTENTION

) to reduce the effects of electrical interference

(2)

) and environmental exposure. Locate

Vertical mounting of the controller is not

recommended due to heat build-up considerations.

!

ATTENTION

!

Be careful of metal chips when drilling mounting

holes for your controller or other equipment within

the enclosure or panel. Drilled fragments that fall into

the base or processor unit could cause damage. Do

not drill holes above a mounted controller if the

protective debris strips are removed or the processor

is installed.

Publication 1764-UM001B-EN-P - April 2002

(1) Pollution Degree 2 is an environment where normally only non-conductive pollution occurs except that

occasionally temporary conductivity caused by condensation shall be expected.

(2) Overvoltage Category II is the load level section of the electrical distribution system. At this level transient

voltages are controlled and do not exceed the impulse voltage capability of the products insulation.

Page 29

Installing Your Controller 2-3

Safety Considerations

Safety considerations are an important element of proper system

installation. Actively thinking about the safety of yourself and others,

as well as the condition of your equipment, is of primary importance.

We recommend reviewing the following safety considerations.

Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B,

C, D or non-hazardous locations only. The following WARNING

statement applies to use in hazardous locations.

WARNING

!

EXPLOSION HAZARD

• Substitution of components may impair suitability

for Class I, Division 2.

• Do not replace components or disconnect

equipment unless power has been switched off.

• Do not connect or disconnect components unless

power has been switched off, or the area is

known to be non-hazardous.

• This product must be installed in an enclosure. All

cables connected to the product must remain in

the enclosure or be protected by conduit or other

means.

• All wiring must comply with N.E.C. article

501-4(b).

WARNING

!

When installing any peripheral device (for example,

push buttons, lamps) into a hazardous environment,

ensure that they are Class I, Division 2 certified, or

determined to be safe for the environment.

Publication 1764-UM001B-EN-P - April 2002

Page 30

2-4 Installing Your Controller

Use only the following communication cables in Class I, Division 2

hazardous locations.

Table 2.1 Cables for Use in Class I, Division 2 Hazardous Environment

1761-CBL-PM02 Series C or later 2707-NC8 Series B or later

1761-CBL-HM02 Series C or later 2707-NC9 Series B or later

1761-CBL-AM00 Series C or later 2707-NC10 Series B or later

1761-CBL-AP00 Series C or later 2707-NC11 Series B or later

Disconnecting Main Power

WARNING

EXPLOSION HAZARD

Do not replace components or disconnect

equipment unless power has been switched off.

!

The main power disconnect switch should be located where operators

and maintenance personnel have quick and easy access to it. In

addition to disconnecting electrical power, all other sources of power

(pneumatic and hydraulic) should be de-energized before working on

a machine or process controlled by a controller.

Safety Circuits

WARNING

EXPLOSION HAZARD

Do not connect or disconnect connectors while

circuit is live.

Publication 1764-UM001B-EN-P - April 2002

!

Circuits installed on the machine for safety reasons, like overtravel

limit switches, stop push buttons, and interlocks, should always be

hard-wired directly to the master control relay. These devices must be

wired in series so that when any one device opens, the master control

relay is de-energized, thereby removing power to the machine. Never

alter these circuits to defeat their function. Serious injury or machine

damage could result.

Page 31

Installing Your Controller 2-5

Power Distribution

There are some points about power distribution that you should

know:

• The master control relay must be able to inhibit all machine

motion by removing power to the machine I/O devices when

the relay is de-energized. It is recommended that the controller

remain powered even when the master control relay is

de-energized.

• If you are using a dc power supply, interrupt the load side rather

than the ac line power. This avoids the additional delay of

power supply turn-off. The dc power supply should be powered

directly from the fused secondary of the transformer. Power to

the dc input and output circuits should be connected through a

set of master control relay contacts.

Power Considerations

Periodic Tests of Master Control Relay Circuit

Any part can fail, including the switches in a master control relay

circuit. The failure of one of these switches would most likely cause

an open circuit, which would be a safe power-off failure. However, if

one of these switches shorts out, it no longer provides any safety

protection. These switches should be tested periodically to assure they

will stop machine motion when needed.

The following explains power considerations for the micro controllers.

Isolation Transformers

You may want to use an isolation transformer in the ac line to the

controller. This type of transformer provides isolation from your

power distribution system to reduce the electrical noise that enters the

controller and is often used as a step-down transformer to reduce line

voltage. Any transformer used with the controller must have a

sufficient power rating for its load. The power rating is expressed in

volt-amperes (VA).

Publication 1764-UM001B-EN-P - April 2002

Page 32

2-6 Installing Your Controller

Power Supply Inrush

During power-up, the MicroLogix 1500 power supply allows a brief

inrush current to charge internal capacitors. Many power lines and

control transformers can supply inrush current for a brief time. If the

power source cannot supply this inrush current, the source voltage

may sag momentarily.

The only effect of limited inrush current and voltage sag on the

MicroLogix 1500 is that the power supply capacitors charge more

slowly. However, the effect of a voltage sag on other equipment

should be considered. For example, a deep voltage sag may reset a

computer connected to the same power source. The following

considerations determine whether the power source must be required

to supply high inrush current:

• The power-up sequence of devices in a system.

• The amount of the power source voltage sag if the inrush

current cannot be supplied.

• The effect of voltage sag on other equipment in the system.

If the entire system is powered-up at the same time, a brief sag in the

power source voltage typically will not affect any equipment.

Loss of Power Source

The power supply is designed to withstand brief power losses without

affecting the operation of the system. The time the system is

operational during power loss is called “program scan hold-up time

after loss of power.” The duration of the power supply hold-up time

depends on the type and state of the I/O, but is typically between 10

milliseconds and 3 seconds. When the duration of power loss reaches

this limit, the power supply signals the processor that it can no longer

provide adequate dc power to the system. This is referred to as a

power supply shutdown. The processor then performs an orderly

shutdown of the controller.

Input States on Power Down

Publication 1764-UM001B-EN-P - April 2002

The power supply hold-up time as described above is generally

longer than the turn-on and turn-off times of the inputs. Because of

this, the input state change from “On” to “Off” that occurs when

power is removed may be recorded by the processor before the

Page 33

Installing Your Controller 2-7

power supply shuts down the system. Understanding this concept is

important. Write the user program, taking this effect into account.

Other Types of Line Conditions

Occasionally the power source to the system can be temporarily

interrupted. It is also possible that the voltage level may drop

substantially below the normal line voltage range for a period of time.

Both of these conditions are considered to be a loss of power for the

system.

Preventing Excessive Heat

For most applications, normal convective cooling keeps the controller

within the specified operating range. Ensure that the specified

temperature range is maintained. Proper spacing of components

within an enclosure is usually sufficient for heat dissipation.

In some applications, a substantial amount of heat is produced by

other equipment inside or outside the enclosure. In this case, place

blower fans inside the enclosure to assist in air circulation and to

reduce “hot spots” near the controller.

Additional cooling provisions might be necessary when high ambient

temperatures are encountered.

TIP

Do not bring in unfiltered outside air. Place the

controller in an enclosure to protect it from a

corrosive atmosphere. Harmful contaminants or dirt

could cause improper operation or damage to

components. In extreme cases, you may need to use

air conditioning to protect against heat build-up

within the enclosure.

Publication 1764-UM001B-EN-P - April 2002

Page 34

2-8 Installing Your Controller

Master Control Relay

A hard-wired master control relay (MCR) provides a reliable means for

emergency machine shutdown. Since the master control relay allows

the placement of several emergency-stop switches in different

locations, its installation is important from a safety standpoint.

Overtravel limit switches or mushroom-head push buttons are wired

in series so that when any of them opens, the master control relay is

de-energized. This removes power to input and output device circuits.

Refer to the figures on pages 2-10 and 2-11.

ATTENTION

Never alter these circuits to defeat their function

since serious injury and/or machine damage could

result.

!

TIP

If you are using an external dc power supply,

interrupt the dc output side rather than the ac line

side of the supply to avoid the additional delay of

power supply turn-off.

The ac line of the dc output power supply should be

fused.

Connect a set of master control relays in series with

the dc power supplying the input and output

circuits.

Place the main power disconnect switch where operators and

maintenance personnel have quick and easy access to it. If you mount

a disconnect switch inside the controller enclosure, place the switch

operating handle on the outside of the enclosure, so that you can

disconnect power without opening the enclosure.

Whenever any of the emergency-stop switches are opened, power to

input and output devices should be removed.

When you use the master control relay to remove power from the

external I/O circuits, power continues to be provided to the

controller’s power supply so that diagnostic indicators on the

processor can still be observed.

The master control relay is not a substitute for a disconnect to the

controller. It is intended for any situation where the operator must

quickly de-energize I/O devices only. When inspecting or installing

terminal connections, replacing output fuses, or working on

Publication 1764-UM001B-EN-P - April 2002

Page 35

Installing Your Controller 2-9

equipment within the enclosure, use the disconnect to shut off power

to the rest of the system.

TIP

Do not control the master control relay with the

controller. Provide the operator with the safety of a

direct connection between an emergency-stop switch

and the master control relay.

Using Emergency-Stop Switches

When using emergency-stop switches, adhere to the following points:

• Do not program emergency-stop switches in the controller

program. Any emergency-stop switch should turn off all

machine power by turning off the master control relay.

• Observe all applicable local codes concerning the placement

and labeling of emergency-stop switches.

• Install emergency-stop switches and the master control relay in

your system. Make certain that relay contacts have a sufficient

rating for your application. Emergency-stop switches must be

easy to reach.

• In the following illustration, input and output circuits are shown

with MCR protection. However, in most applications, only

output circuits require MCR protection.

The following illustrations show the Master Control Relay wired in a

grounded system.

TIP

In most applications input circuits do not require

MCR protection; however, if you need to remove

power from all field devices, you must include MCR

contacts in series with input power wiring.

Publication 1764-UM001B-EN-P - April 2002

Page 36

2-10 Installing Your Controller

L1

L2

230V ac

Disconnect

Schematic (Using IEC Symbols)

Fuse

MCR

230V ac

I/O

Circuits

Isolation

Transformer

115V ac

X1

or 230V ac

Fuse

X2

Operation of either ofthese contacts will

remove power from the external I/O

circuits, stopping machine motion.

Emergency-Stop

Push Button

(Lo) (Hi)

Line Terminals:

Connect to terminals of Power Supply

(1764-24AWA and 1764-24BWA).

Overtravel

Limit Switch

Stop

Line Terminals: Connect to 24V dc

terminals of Power Supply.

Start

MCR

MCR

dc Power Supply.

Use IEC 950/EN 60950

_

+

Master Control Relay (MCR)

Cat. No. 700-PK400A1

MCR

Suppr.

115V ac or

230V ac

I/O Circuits

24V dc

MCR

I/O

Circuits

Suppressor

Cat. No.

700-N24

Publication 1764-UM001B-EN-P - April 2002

Page 37

Schematic (Using ANSI/CSA Symbols)

Installing Your Controller 2-11

L1

230V ac

Disconnect

Isolation

Transformer

115V ac or

X1 X2

230V ac

Fuse

L2

Operation of either ofthese contacts will

remove power from the external I/O

Emergency-Stop

Push Button

Overtravel

Limit Switch

Stop

Fuse

Start

MCR

MCR

Master Control Relay (MCR)

Cat. No. 700-PK400A1

MCR

115V ac or

230V ac

I/O Circuits

MCR

Suppr.

230V ac

Output

Circuits

Suppressor

Cat. No.

700-N24

(Lo) (Hi)

Line Terminals:

Connect to 1764-24AWA or

1764-24BWA terminals.

dc Power Supply.

Use NEC Class 2

_

+

Line Terminals: Connect to 24V

dc terminals of Power Supply.

MCR

24 V dc

I/O

Circuits

Publication 1764-UM001B-EN-P - April 2002

Page 38

2-12 Installing Your Controller

Base Unit Mounting Dimensions

A

Controller Spacing

B

(1)

Dimension

Height (A) DIN latch open: 138 mm (5.43 in.), DIN latch closed: 118 mm (4.65 in.)

Width (B) 168 mm (6.62 in.)

Depth (C) 87 mm (3.43 in.)

(1) See Controller Dimensions on page A-9 for more dimensional information.

1764-24AWA 1764-24BWA 1764-28BXB

C

The base unit is designed to be mounted horizontally, with the

Compact™ expansion I/O extending to the right of the base unit.

Allow 50 mm (2 in.) minimum of space on all sides for adequate

ventilation, as shown below.

To p

Publication 1764-UM001B-EN-P - April 2002

Side

Controller

Compact I/O

Bottom

Compact I/O

Compact I/O

Compact I/O

Compact I/O

Side

End Cap

Page 39

Mounting the Controller

ATTENTION

!

Installing Your Controller 2-13

Do not remove protective debris strips until after the

base and all other equipment in the panel near the

base is mounted and wiring is complete. The debris

strips are there to prevent drill fragments, wire

strands and other dirt from getting into the controller.

Once wiring is complete, remove protective debris

strips and install processor unit. Failure to remove

strips before operating can cause overheating.

Protective

Debris Strips

ESD Barrier

ATTENTION

!

ATTENTION

!

Be careful of metal chips when drilling mounting

holes for your controller or other equipment within

the enclosure or panel. Drilled fragments that fall

into the controller could cause damage. Do not drill

holes above a mounted controller if the protective

debris strips have been removed.

Electrostatic discharge can damage semiconductor

devices inside the base unit. Do not touch the

connector pins or other sensitive areas.

Publication 1764-UM001B-EN-P - April 2002

Page 40

2-14 Installing Your Controller

TIP

If additional I/O modules are required for the

application, remove the ESD barrier to install

expansion I/O modules. A maximum of 16 I/O

modules may be connected to the base. (See page

1-7 for system requirements.) The I/O module’s

current requirements and power consumption may

further limit the number of modules connected to

the base. See System Loading and Heat Dissipation

on page F-1. An end cap terminator (catalog number

1769-ECR or 1769-ECL) is required at the end of the

group of I/O modules attached to the base.

Using a DIN Rail

The base unit and expansion I/O DIN rail latches lock in the open

position so that an entire system can be easily attached to or removed

from the DIN rail. The maximum extension of the latch is 15 mm (0.67

in.) in the open position. A flat-blade screw driver is required for

removal of the base unit. The base can be mounted to

EN50022-35x7.5 or EN50022-35x15 DIN rails. DIN rail mounting

dimensions are shown below.

Publication 1764-UM001B-EN-P - April 2002

B

A

DIN Rail Latch

Dimension Height

A DIN latch open: 138 mm (5.43 in.), DIN latch closed: 118 mm (4.65 in.)

B 47.6 mm (1.875 in.)

C 47.6 mm (1.875 in) DIN latch closed

54.7 mm (2.16 in.) DIN latch open

C

Page 41

Installing Your Controller 2-15

To install your base unit on the DIN rail:

1. Mount your DIN rail. (Make sure that the placement of the base

unit on the DIN rail meets the recommended spacing

requirements, see Controller Spacing on page 2-12. Refer to the

mounting template from the inside back cover of the MicroLogix

1500 Programmable Controller Base Units Installation

Instructions, publication 1764-IN001.

2. Hook the top slot over the DIN rail.

3. While pressing the base unit down against the top of the rail,

snap the bottom of the base unit into position. Ensure DIN

latches are in the up (secured) position.

4. Leave the protective debris strip attached until you are finished

wiring the base unit and any other devices.

To remove your base unit from the DIN rail:

1. Place a flat-blade screwdriver in the DIN rail latch at the bottom

of the base unit.

2. Holding the base unit, pry downward on the latch until the latch

locks in the open position. Repeat this procedure with the

second latch. This releases the base unit from the DIN rail.

DIN Rail Latch

Publication 1764-UM001B-EN-P - April 2002

Page 42

2-16 Installing Your Controller

Base Unit Panel Mounting

Mount to panel using #8 or M4 screws.

Mounting Template

To install your base unit using mounting screws:

1. Remove the mounting template from the inside back cover of

the MicroLogix 1500 Programmable Controller Base Units

Installation Instruction, publication 1764-IN001.

2. Secure the template to the mounting surface. (Make sure your

base unit is spaced properly, see Controller Spacing on page

2-12).

3. Drill holes through the template.

4. Remove the mounting template.

5. Mount the base unit.

6. Leave the protective debris strips attached until you are finished

wiring the base unit and any other devices.

Publication 1764-UM001B-EN-P - April 2002

Page 43

Installing Your Controller 2-17

Installing Controller Components

Prevent Electrostatic Discharge

ATTENTION

!

Electrostatic discharge can damage integrated circuits

or semiconductors if you touch bus connector pins.

Follow these guidelines when you handle any

module:

• Touch a grounded object to discharge static

potential.

• Wear an approved wrist-strap grounding device.

• Do not touch the bus connector or connector

pins.

• Do not touch circuit components inside the

module.

• If available, use a static-safe work station.

When not in use, keep the module in its static-shield

bag.

ATTENTION

!

Processor

Be sure the base unit is free of all metal fragments

before removing protective debris strips and

installing the processor unit. Failure to remove strips

before operating can cause overheating.

Publication 1764-UM001B-EN-P - April 2002

Page 44

2-18 Installing Your Controller

1. Be sure base unit power is off.

2. Slide the processor into the base unit using the guide rails for

alignment.

3. Push until a click is heard. Be careful not to push on the

connector when installing the 1764-LRP processor.

IMPORTANT

It is critical that the processor is fully engaged

and locked into place.

4. Make sure the actuator is pushed closed.

5. To remove the processor from the base unit, make sure base

unit power is off. Push the actuator to the open position until

the processor is ejected slightly. Once the processor has been

ejected, it can be removed from the base unit.

Publication 1764-UM001B-EN-P - April 2002

Page 45

Installing Your Controller 2-19

Data Access Tool (DAT)

1. Remove cover from processor.

2. Holding the DAT in the proper orientation (as shown), place the

DAT onto processor. Align DAT port on the processor with the

plug on the DAT.

3. Firmly seat DAT on processor; make sure it seats into place.

Publication 1764-UM001B-EN-P - April 2002

Page 46

2-20 Installing Your Controller

4. To remove DAT, grasp using finger areas and pull upward.

Memory Module/Real-Time Clock

1. Remove the cover (or DAT if installed) from the processor as

shown below.

Publication 1764-UM001B-EN-P - April 2002

ATTENTION

!

Electrostatic discharge can damage semiconductor

devices inside the base and processor units. Do not

touch the connector pins or other sensitive areas.

Page 47

Installing Your Controller 2-21

2. Align connector on the memory module with the connector pins

on the processor.

3. Firmly seat the memory module in the processor making sure

the locking tabs click into place.

4. Replace the cover (or DAT if used).

Publication 1764-UM001B-EN-P - April 2002

Page 48

2-22 Installing Your Controller

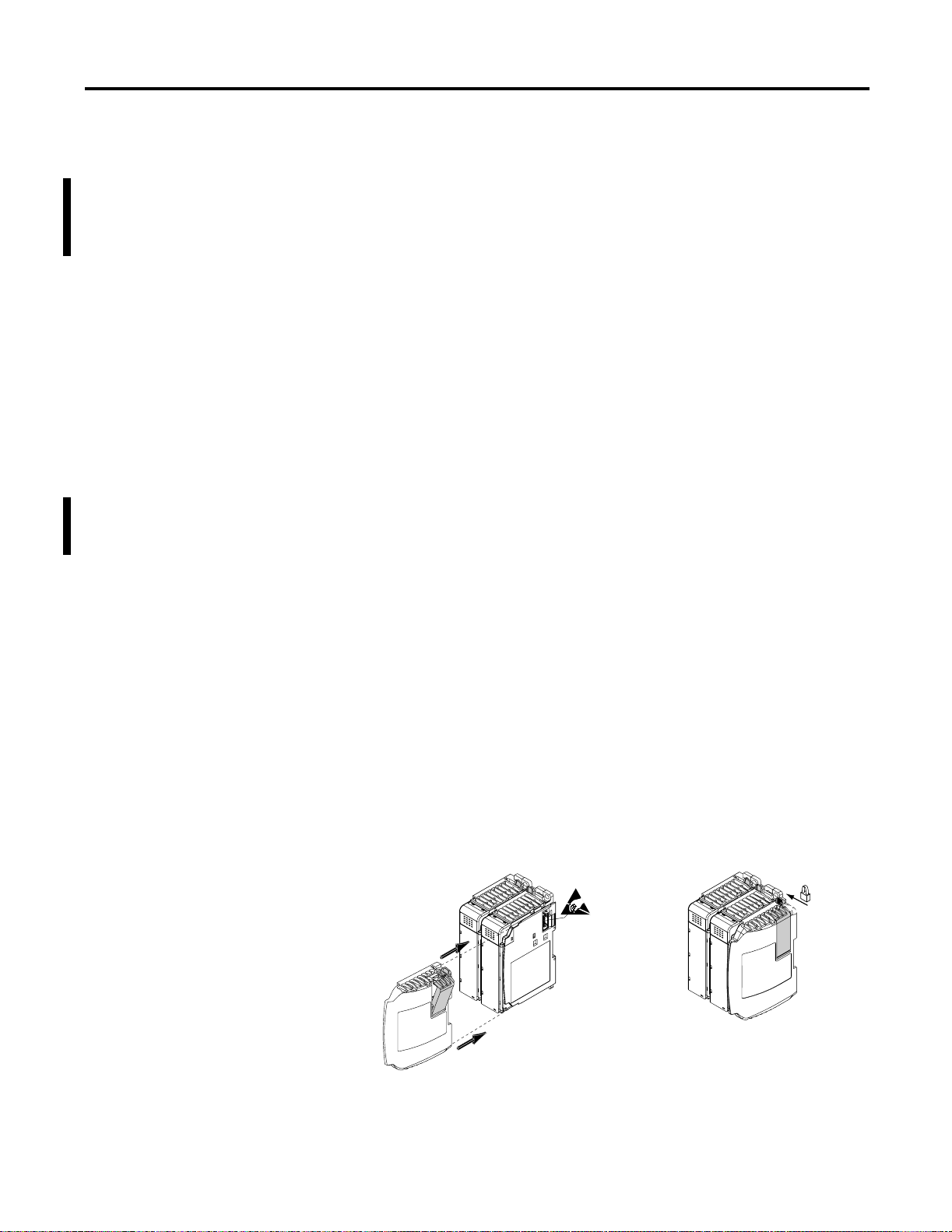

Compact I/O

Attach and Lock Module (Module-to-Controller or Module-to-Module)

A Compact I/O module can be attached to the controller or an

adjacent I/O module before or after mounting to the panel or DIN rail.

The module can be detached and replaced while the system is

mounted to a panel or DIN rail.

ATTENTION

!

ATTENTION

!

Remove power before removing or inserting an I/O

module. When you remove or insert a module with

power applied, an electrical arc may occur. An

electrical arc can cause personal injury or property

damage by:

• sending an erroneous signal to your system’s field

devices, causing the controller to fault

• causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on

both the module and its mating connector. Worn

contacts may create electrical resistance, reducing

product reliability.

When attaching I/O modules, it is very important that

they are securely locked together to ensure proper

electrical connection.

Publication 1764-UM001B-EN-P - April 2002

Page 49

Installing Your Controller 2-23

3

4

1

1

To attach and lock modules:

TIP

1. Disconnect power.

2. Check that the bus lever of the module to be installed is in the

unlocked (fully right) position.

3. Use the upper and lower tongue-and-groove slots (1) to secure

the modules together (or to a controller).

Remove ESD barrier when attaching I/O modules to

a MicroLogix 1500 base unit.

2

6

5

4. Move the module back along the tongue-and-groove slots until

the bus connectors (2) line up with each other.

5. Push the bus lever back slightly to clear the positioning tab (3).

Use your fingers or a small screw driver.

6. To allow communication between the controller and module,

move the bus lever fully to the left (4) until it clicks. Ensure it is

locked firmly in place.

ATTENTION

When attaching I/O modules, it is very important

that the bus connectors are securely locked

together to ensure proper electrical connection.

!

Publication 1764-UM001B-EN-P - April 2002

Page 50

2-24 Installing Your Controller

7. Attach an end cap terminator (5) to the last module in the

system by using the tongue-and-groove slots as before.

8. Lock the end cap bus terminator (6).

IMPORTANT

A 1769-ECR right end cap (or a 1769-ECL left end cap

if I/O bank is located below the controller) must be

used to terminate the end of the serial

communication bus.

See Controller Dimensions on page A-9 for mounting dimensions.

Publication 1764-UM001B-EN-P - April 2002

Page 51

Chapter

Wiring Your Controller

This chapter describes how to wire your controller. Topics include:

• wiring requirements

• using surge suppressors

• grounding guidelines

• sinking and sourcing circuits

• wiring diagrams, input voltage ranges, and output voltage

ranges

• minimizing noise

3

Wiring Requirements

Wire Type

Solid Cu-90°C (194°F) #14 to #22 AWG 1.13 Nm (10 in-lb) rated

Stranded Cu-90°C (194°F) #14 to #22 AWG

(1) Two wires maximum per terminal screw.

ATTENTION

!

Be careful when stripping wires. Wire fragments that

fall into the controller could cause damage. Once

wiring is complete, be sure the base unit is free of all

metal fragments before removing protective debris

strips and installing the processor unit. Failure to

remove strips before operating can cause

overheating.

Wire Size

(1)

Wiring Torque

1.3 Nm (12 in-lb) maximum

1 Publication 1764-UM001B-EN-P - April 2002

Page 52

3-2 Wiring Your Controller

Wiring Recommendation

ATTENTION

Before you install and wire any device, disconnect

power to the controller system.

!

ATTENTION

!

• Allow for at least 50 mm. (2 in.) between I/O wiring ducts or

terminal strips and the controller.

• Route incoming power to the controller by a path separate from

the device wiring. Where paths must cross, their intersection

should be perpendicular.

Calculate the maximum possible current in each

power and common wire. Observe all electrical

codes dictating the maximum current allowable for

each wire size. Current above the maximum ratings

may cause wiring to overheat, which can cause

damage.

United States Only: If the controller is installed within

a potentially hazardous environment, all wiring must

comply with the requirements stated in the National

Electrical Code 501-4 (b).

Publication 1764-UM001B-EN-P - April 2002

TIP

• Separate wiring by signal type. Bundle wiring with similar

electrical characteristics together.

• Separate input wiring from output wiring.

• Label wiring to all devices in the system. Use tape,

shrink-tubing, or other dependable means for labeling purposes.

In addition to labeling, use colored insulation to identify wiring

based on signal characteristics. For example, you may use blue

for dc wiring and red for ac wiring.

Do not run signal or communications wiring and

power wiring in the same conduit. Wires with

different signal characteristics should be routed by

separate paths.

Page 53

Wiring Your Controller 3-3

Wiring without Spade Lugs

When wiring without spade lugs, it is recommended to keep the

finger-safe covers in place. Loosen the terminal screw and route the

wires through the opening in the finger-safe cover. Tighten the

terminal screw making sure the pressure plate secures the wire.

Finger-Safe Cover

terminal screw torque:

1.13 Nm (10 in-lbs) rated

1.3 Nm (12 in-lbs) max.

Wiring with Spade Lugs

The diameter of the terminal screw head is 5.5 mm (0.220 in.). The

input and output terminals of the MicroLogix 1500 base unit are

designed for a 6.35mm (0.25 in.) wide spade (standard for #6 screw

for up to 14 AWG) or a 4 mm (metric #4) fork terminal.

When using spade lugs, use a small, flat-blade screwdriver to pry the

finger-safe cover from the terminal blocks as shown below. Then

loosen the terminal screw.

Finger-Safe

terminal screw torque:

1.13 Nm (10 in-lbs) rated

1.3 Nm (12 in-lbs) max.

Cover

Publication 1764-UM001B-EN-P - April 2002

Page 54

3-4 Wiring Your Controller

Using Surge Suppressors

Inductive load devices, such as motor starters and solenoids, require

the use of some type of surge suppression to protect and extend the

operating life of the controller’s output contacts. Switching inductive

loads without surge suppression can significantly reduce the life

expectancy of relay contacts. By adding a suppression device directly

across the coil of an inductive device, you prolong the life of the

output or relay contacts. You also reduce the effects of voltage

transients and electrical noise from radiating into adjacent systems.

The following diagram shows an output with a suppression device.

We recommend that you locate the suppression device as close as

possible to the load device.

ac or dc

Outputs

+dc or L1

VAC/D

Out 0

Out 1

Out 2

Out 3

Out 4

Out 5

Out 6

Out 7

COM

Suppression

Device

dc COM or L2

If the outputs are dc, we recommend that you use an 1N4004 diode

for surge suppression, as shown below.

+24V dc

VAC/D

Out 0

Out 1

Relay or Solid

State dc Outputs

Out 2

Out 3

Out 4

Out 5

Out 6

Out 7

COM

IN4004 Diode

24V dc common

Suitable surge suppression methods for inductive ac load devices

include a varistor, an RC network, or an Allen-Bradley surge

suppressor, all shown below. These components must be

appropriately rated to suppress the switching transient characteristic of