Page 1

Assembly Connections for POINT I/O

and ArmorPOINT I/O EtherNet/IP

Adapters

Catalog Numbers Bulletins 1734 and 1738

User Manual

Page 2

Important User Information

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (publication SGI-1.1

http://literature.rockwellautomation.com

) describes some important differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated

with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and

diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from your local Rockwell Automation sales office or online at

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to: personal injury or death, property damage, or

economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Labels may be on or inside the equipment, such as a drive or motor, to alert people that dangerous voltage may be present.

Labels may be on or inside the equipment, such as a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

Allen-Bradley, Rockwell Automation, POINT I/O, ArmorPOINT I/O, RSView, RSLinx, RSLogix 5000 and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents Preface

Why Read This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Who Should Use This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

About the Vocabulary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Related Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Common Techniques Used in this Manual. . . . . . . . . . . . . . . . . . . . . . vi

Chapter 1

Introduction

About Assembly Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Choose a Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Data Headers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Listen Only Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Connection Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2

Configuration

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Configure the Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chassis Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Data Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Individual Module Configuration Options. . . . . . . . . . . . . . . . . . . . 7

Module Configuration Sent with the Connection Request . . . . . . . 8

Module Configuration with RSNetWorx for DeviceNet. . . . . . . . . 8

Calculate the Connection Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connection Size Calculation Example . . . . . . . . . . . . . . . . . . . . . . . 9

Troubleshooting Connection Size Errors. . . . . . . . . . . . . . . . . . . . 10

Table of Contents

Using an Assembly Connection

Assembly Structure

1734/1738 I/O Module Assembly

Information

Chapter 3

Use an Assembly Connection with RSNetWorx for EtherNet/IP . . . 13

Use an Assembly Connection with RSLogix5000 . . . . . . . . . . . . . . . . 16

Add the Hardware to the I/O Configuration Tree . . . . . . . . . . . . 17

Enter the Connection Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . 18

Build the Configuration Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 4

Assembly Structure Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Byte, Word, and Double Word Alignment. . . . . . . . . . . . . . . . . . . 23

Fixed Size per Slot Alignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 5

Module Assembly Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Discrete Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Analog and Specialty I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . 32

Data Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Module Specific Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Two-channel Discrete Input Modules . . . . . . . . . . . . . . . . . . . . . . 34

iii Publication 1734-UM016A-EN-P - October 2010

Page 4

iv Table of Contents

Four-channel Discrete Input Modules . . . . . . . . . . . . . . . . . . . . . . 35

Eight-channel Discrete Input Modules. . . . . . . . . . . . . . . . . . . . . . 35

Two-channel Discrete Output Modules with Status . . . . . . . . . . . 37

Two-channel Discrete Output Modules. . . . . . . . . . . . . . . . . . . . . 38

Four-channel Discrete Output Modules with Status . . . . . . . . . . . 38

Four-channel Discrete Output Modules. . . . . . . . . . . . . . . . . . . . . 39

Eight-channel Discrete Output Modules with Status . . . . . . . . . . 40

Eight-channel Discrete Output Modules . . . . . . . . . . . . . . . . . . . . 41

Four-channel Discrete Diagnostic Input Modules. . . . . . . . . . . . . 41

Two-channel Relay and AC Output Modules . . . . . . . . . . . . . . . . 43

Four-channel Relay and AC Output Modules . . . . . . . . . . . . . . . . 43

Sixteen-channel Discrete Diagnostic Input Modules. . . . . . . . . . . 43

Sixteen-channel Discrete Output Modules. . . . . . . . . . . . . . . . . . . 44

Eight-channel Configurable Discrete Input/Output Modules . . . 45

Very High Speed Counter Modules . . . . . . . . . . . . . . . . . . . . . . . . 46

Counter Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Two-channel Analog Input Modules . . . . . . . . . . . . . . . . . . . . . . . 50

Four-channel Analog Input Modules . . . . . . . . . . . . . . . . . . . . . . . 51

Eight-channel Analog Input Modules. . . . . . . . . . . . . . . . . . . . . . . 54

Two-channel Analog Output Modules. . . . . . . . . . . . . . . . . . . . . . 59

Four-channel Analog Output Modules. . . . . . . . . . . . . . . . . . . . . . 61

Two-channel RTD Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . 64

Two-channel Thermocouple Input Modules . . . . . . . . . . . . . . . . . 65

Synchronous Serial Interface Modules . . . . . . . . . . . . . . . . . . . . . . 67

Address Reserve Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

ASCII Interface Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Publication 1734-UM016A-EN-P - October 2010

Index

Page 5

Preface

Read this preface to familiarize yourself with the rest of the manual. It provides

information concerning:

• the purpose of this manual

• related documentation

• conventions used in this manual

Why Read This Manual

Who Should Use This Manual

About the Vocabulary

This manual is a reference guide for using Assembly Connections with

POINT I/O and ArmorPOINT I/O modules.

You must be able to program and configure industrial automation controllers

and I/O to use the connections specified in this manual. You should also be

familiar with the POINT I/O or ArmorPOINT I/O families of product to

use these connections.

We assume that you are familiar with the material presented in this manual. If

you are not, refer to product-specific documentation before you attempt to use

this manual. Related documentation for Rockwell Automation products is

listed in the table below.

In this manual, we refer to the:

• 1734 family as POINT I/O modules

• 1738 family as ArmorPOINT I/O modules

Related Documentation

The following documents contain additional information concerning Rockwell

Automation products.

Resource Description

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Application Considerations for Solid-State Controls

SGI-1.1

Allen-Bradley Industrial Automation Glossary AG-7.1

Getting Results with RSNetWorx for DeviceNet,

publication DNET-GR001D-EN-E

RSLogix 5000 software online help An online help system that accompanies the RSLogix 5000 programming

v Publication 1734-UM016A-EN-P - October 2010

In-depth information on grounding and wiring Allen-Bradley programmable

controllers.

A description of important differences between solid-state programmable

controller products and hard-wired electromechanical devices.

A glossary of industrial automation terms and abbreviations.

A getting results guide on how to effectively use the RSNetWorx for DeviceNet

software and how to access and navigate the online help.

software package.

Page 6

vi Preface

Resource Description

POINT I/O and ArmorPOINT I/O module publications Publications for POINT I/O and ArmorPOINT I/O modules are available from the

Rockwell Automation Literature Library.

National Electrical Code - Published by the National Fire

Protection Association of Boston, MA.

You can view or download publications at

http://www.literature.rockwellautomation.com

technical documentation, contact your local Rockwell Automation distributor

or sales representative.

Common Techniques Used in this Manual

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Italic type is used for emphasis.

An article on wire sizes and types for grounding electrical equipment.

. To order paper copies of

Publication 1734-UM016A-EN-P - October 2010

Page 7

Introduction

Chapter

1

About Assembly Connections

This document describes Assembly connections, a new connection type for

POINT I/O and ArmorPOINT I/O EtherNet/IP adapters. These adapters

currently support Rack Optimized connections between ControlLogix or

CompactLogix controllers and the discrete I/O modules in the chassis.

They are also capable of bridging direct connections between any

EtherNet/IP-capable connection originator and the I/O modules, via

the backplane. This new functionality being presented will permit the exchange

of data between an originator and all POINT I/O modules present in the

chassis in one connection.

This new Assembly connection is mutually exclusive to other connection

types, for example, Rack Optimized or Direct to module connections. In other

words, if this connection is in use by one connection originator, other

originators are prevented from making Rack Optimized or Direct Connections

to the modules in the same chassis. Furthermore, the connection is

all-inclusive; every module present in the backplane participates in the

connection.

The I/O data that is exchanged with the adapter takes the following form:

Adapter Data Exchange

T → O produced I/O data O → T consumed I/O data

64-bit Status header Run/Idle header

Slot 1 data Slot 1 data

Slot 2 data Slot 2 data

::

::

(1)

Slot N

data

(1)

N is the number of I/O modules

The 64-bit Status header is optional and the packing of the data is dependant

on the selected alignment choice. The exact method for determining the data

structure is covered in the following sections.

Choose a Connection

1 Publication 1734-UM016A-EN-P - October 2010

The Assembly connection supports an optional 64-bit status header and also

supports requests from listen-only originators.

Slot N data

Page 8

2 Introduction

Data Headers

In the Target to Originator (T → O) direction, the adapter can be configured

to produce a status header for the connection. The header consists of an

8-byte bitmap, where bits 1 - 63 indicate the health of each of the 63 possible

backplane connections. This is similar to existing Rack Optimized

connections. A "1" indicates that a module is not connected or that slot is not

populated. A "0" indicates that the module is actively participating in the

connection. Currently, Bit 0 is reserved and should be ignored.

When the header is used, modules may be removed and reinserted without

breaking the I/O connection to the adapter. Modules not present or that are

failed are reflected in the status header.

If the optional status header is not included, the adapter cannot support RIUP

without breaking the I/O connection. If any one I/O module fails or is

removed, the adapter will break the connection to the connection originator.

Since no status is provided, this is the only way to reflect the fact that a

problem exists with the I/O modules on the backplane.

In the Originator to Target (O → T) direction the adapter supports the 4-byte

Run/Idle header. Sending a "1" indicates that the controller is in the Run mode

and that the adapter should apply the data that was just received. Sending a "0"

indicates that the controller is in program or idle mode and that the adapter

should put the I\O modules in their idle mode.

Listen Only Connections

Using an Assembly connection will allow multiple originators to consume data

from the POINT I/O system. However, only one owner of the connection is

permitted. That one owner will control all output devices present in the chassis

as well as the configuration of the connection.

Connection Points

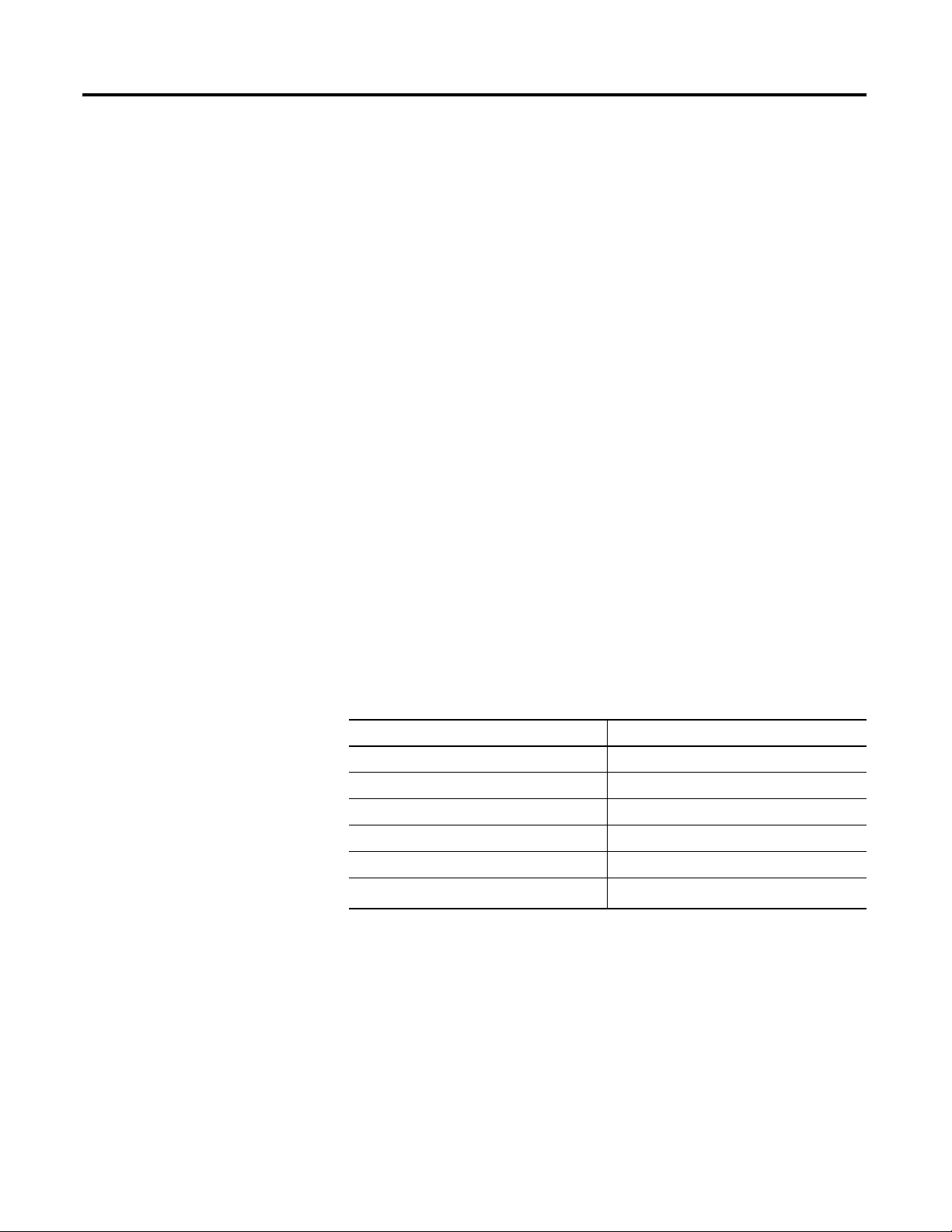

The following table lists the connection points that are supported for the

different connection styles discussed.

Publication 1734-UM016A-EN-P - October 2010

Page 9

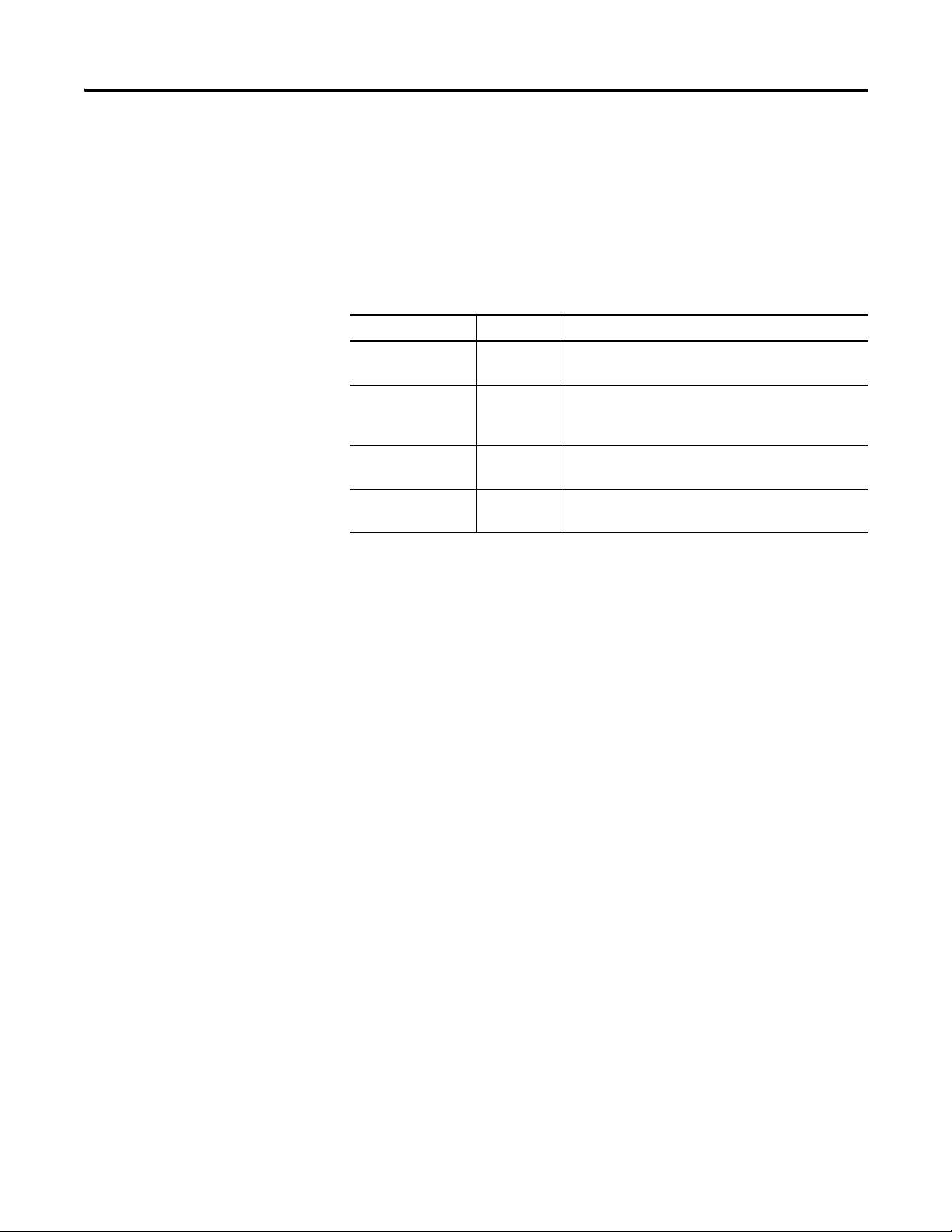

Supported Connection Points for Connection Styles

Introduction 3

Connection Configuration

Connection Point

Consumed

Connection Point

Produced

Connection Point

Exclusive Owner 102 100 101

Listen-only 102 191 101

Input-only 102 190 101

Owning with no status header 102 100 103

Listen-only with no status header 102 191 103

Input-only with no status header 102 190 103

Publication 1734-UM016A-EN-P - October 2010

Page 10

4 Introduction

Notes:

Publication 1734-UM016A-EN-P - October 2010

Page 11

Configuration

Chapter

2

About This Chapter

This chapter describes the various configuration options that you can use to

set up assembly connections.

Configure the Connection

This connection is accepted with or without a configuration assembly present.

If a configuration assembly is present, it must contain the following minimum

information.

Minimal Adapter Configuration Assembly

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Config 0 Reserved (Set to 0)

Config 1 Reserved (Set to 0)

Config 2 Reserved (Set to 0)

Config 3 Reserved (Set to 0)

Config 4 Chassis size (Low Byte)

Config 5 Chassis size (High Byte)

Config 6 Alignment for Produced Assembly (T → O)

Config 7 Size per slot (T→ O) (in Bytes)

Config 8 Alignment for Consumed Assembly (O → T)

Config 9 Size per slot (O → T) (in Bytes)

Chassis Size

Before establishing I/O connections, you must configure the 1734 adapters

for chassis size. This ensures that the correct number of modules are present

in the chassis at power up. The chassis size must include 1 count for the

adapter (Chassis Size = number of I/O modules + 1).

5 Publication 1734-UM016A-EN-P - October 2010

Page 12

6 Configuration

TIP

TIP

Data Alignment

Some computing devices require data to be aligned on boundaries that are

proper for their data type. There are several alignment options available to

reduce or prevent shifting operations in the originator:

Byte Boundaries

Each node's I/O data is mapped at the next available byte. Byte data can

appear at any address.

Word Boundaries

If a node's I/O data is one byte in length, it is mapped at the next available

byte. Otherwise the previous data is padded so that the node's data starts on a

16-bit boundary.

This does not mean that every slot occupies two bytes in the image.

Word data can only begin on even addresses, for example, 0, 2, 4, 8,

0xA, or 0xC.

Double Word Boundaries

If a node's I/O data is one byte in length, it is mapped at the next available

byte. If a node's data is two bytes in length, padding is added to ensure that it is

mapped to an even address. If a node's data is greater than 2 bytes in length,

padding is added to ensure that the data is mapped to a Double Word

boundary.

This does not mean that every slot occupies 4 bytes in the image.

Double Word data and array data larger than 2 bytes in size must be

aligned on addresses ending in 0, 4, 8, and 0xC.

Fixed Boundaries

The fixed boundary allows you to choose the fixed "size per slot" that each

module occupies in the I/O data. Mapping size ranges from 1…24 bytes.

The alignment choices are independently selected for each direction; O → T

and T

→ O. If Fixed Boundaries are selected, the Size per Slot choice

determines how many bytes are reserved for each slot in the I/O packet. If the

size selected is larger than a module's data, that module's data is padded with

0's out to the size selected. If the size selected is smaller than a module's data,

that module's data is truncated at the size selected.

Publication 1734-UM016A-EN-P - October 2010

Page 13

Configuration 7

When Fixed Boundaries are selected, the formula for mapping is:

H+(N-1)(size per slot), where N = slot position and H is the size of the

optional status header (8 if used, 0 if not used).

The choice of alignment is highly dependent on the originator used and

application-specific requirements.

• If data size is at a premium, Byte alignment is the most efficient choice.

• If the originator can only process data on DINT boundaries (as is the

case with RSLogix controllers), then Double Word alignment should be

used.

• If ease of programming is desired, the Fixed Boundaries option allows

for easy location of the data within the data packet. Additionally the use

of Fixed Boundaries along with the 1734-ARM module will allow

modules to be added later without having the location of any slot's data

change. The ARM module will reserve data space for future modules.

Since each slot occupies the same size in the data image, when the ARM

module is replaced with a future module, the data boundaries are

preserved.

Individual Module Configuration Options

The request for an Assembly connection is accepted with or without a

configuration assembly present. If a configuration assembly is present, it must

contain the minimum information presented in the Configuring the

Connection section. See TableMinimal Adapter Configuration Assembly on

page 5. If individual module configuration is required, it can be appended to

the end of the minimum configuration structure for any or all modules that

require configuration. The construction of this configuration data structure is

a manual process.

Alternatively any tool that is capable of sending CIP packets can configure the

parameters of individual POINT I/O modules. The configuration is stored

locally in the module's non-volatile storage. When the configuration is sent

from the connection originator via the connection request, the adapter also

stores a copy of this configuration and restores it if that module is ever

replaced. This is similar to the Automatic Device Replacement feature of

DeviceNet scanners. If the configuration is sent from the connection

originator via the connection request, the configuration assembly size is

limited to the maximum packet size of 510 bytes. This may be an issue in larger

systems that require module configuration. Configuring modules through a

separate tool will allow the configuration to be sent to modules individually,

effectively eliminating the packet size limitation. Furthermore, the

configuration tool of choice may provide a rich graphical user interface,

reducing the possibility that configuration is incorrectly entered. One such tool

is RSNetWorx for DeviceNet.

Publication 1734-UM016A-EN-P - October 2010

Page 14

8 Configuration

Module Configuration Sent with the Connection Request

Individual module configuration must be manually constructed and appended

to the minimal configuration assembly specified in the table Minimal Adapter

Configuration Assembly on page 5. For each module that needs to be

configured, the following information must be provided:

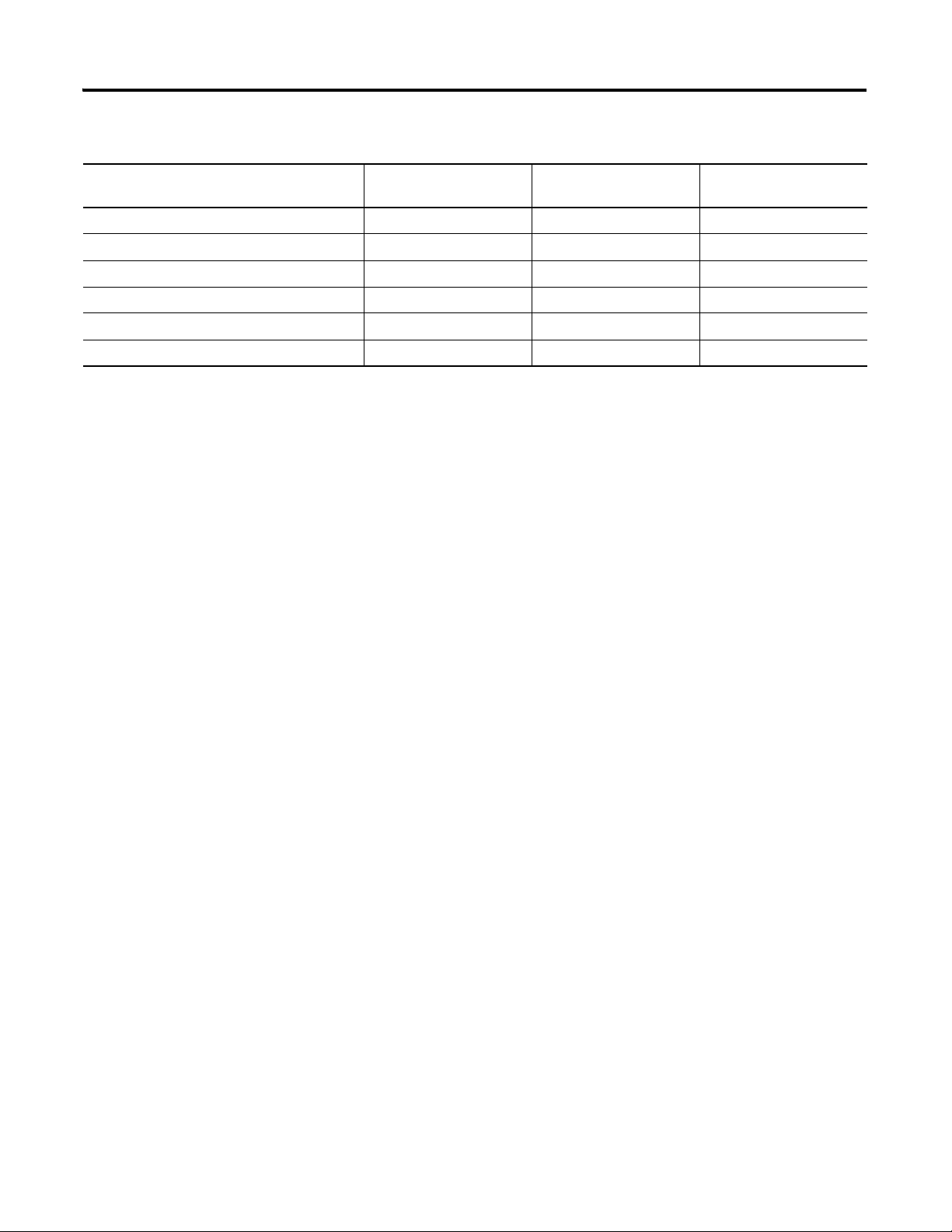

Module Configuration Information

Field Data Type Description

Slot number USINT The slot number to identify modules that require

configuration data.

Configuration size USINT The size, in bytes, of the Configuration Data for the

given module. It does not include the size of the first

three fields shown here.

Configuration

assembly instance

Configuration data Array of

UINT The adapter reads this field to access the module

configuration assembly’s instance number.

The configuration assembly data as defined by the

BYTE

module's EDS file.

This structure may be repeated for as many modules as necessary until the

whole assembly exceeds 509 bytes. The module order is not important as long

as all module configuration follows the minimal header information from the

table Minimal Adapter Configuration Assembly on page 5.

If any part of the configuration assembly is wrong (either the minimal

assembly or a portion directed to an I/O module), the connection request will

be rejected with the General Return Code indicating an Error in the Data

Segment (0x09). The Extended Error code will indicate the byte offset into the

configuration data segment where the error was detected. The Configuration

assembly details for all of the 1734 and 1738 I/O modules are presented in

Module Assembly Information on page 31.

Module Configuration with RSNetWorx for DeviceNet

Publication 1734-UM016A-EN-P - October 2010

RSNetWorx for DeviceNet provides a rich parameter-based configuration user

interface. The POINT I/O and ArmorPOINT I/O adapters have the

capability to present their backplane as a DeviceNet subnet to RSLinx. The

subnet can be used to bridge configuration data from RSNetWorx for

DeviceNet to backplane devices. With this method, all configuration for a

POINT I/O backplane can be stored to the DeviceNet network file (.DNT)

and restored via this file if necessary.

Page 15

Configuration 9

Cat # A

E

N

T

I

B

8

I

E

2

C

O

B

4

E

Slot # 0 1 2 3

Module Tx size Rx size

IB8 1 – byte 0

OB4E 1 – byte 1 – byte

IE2C 6

- int

- int

- byte

- byte

0

Calculate the Connection Size

The I/O assembly size is limited to the maximum size that can be specified in

the standard Forward_Open service (509 bytes). The size needs to be manually

calculated based on the alignment choices, inclusion of the optional status

header, and the I/O sizes for the modules present in the chassis. The adapter

validates the connection size in the forward open against what it calculates

from the backplane and the alignment choice. If the two do not match, the

connection request is rejected with extended error code 0x0109, Invalid

Connection Size.

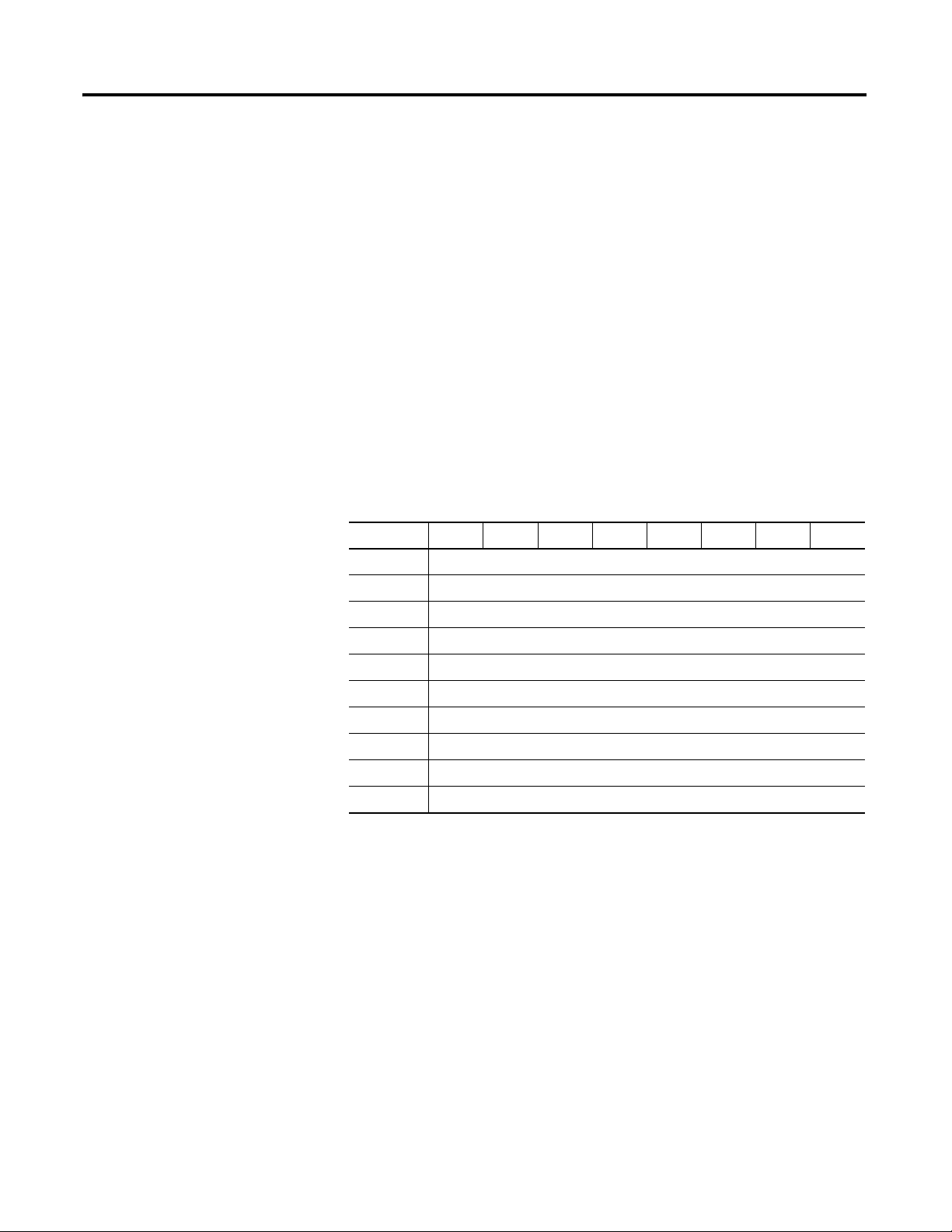

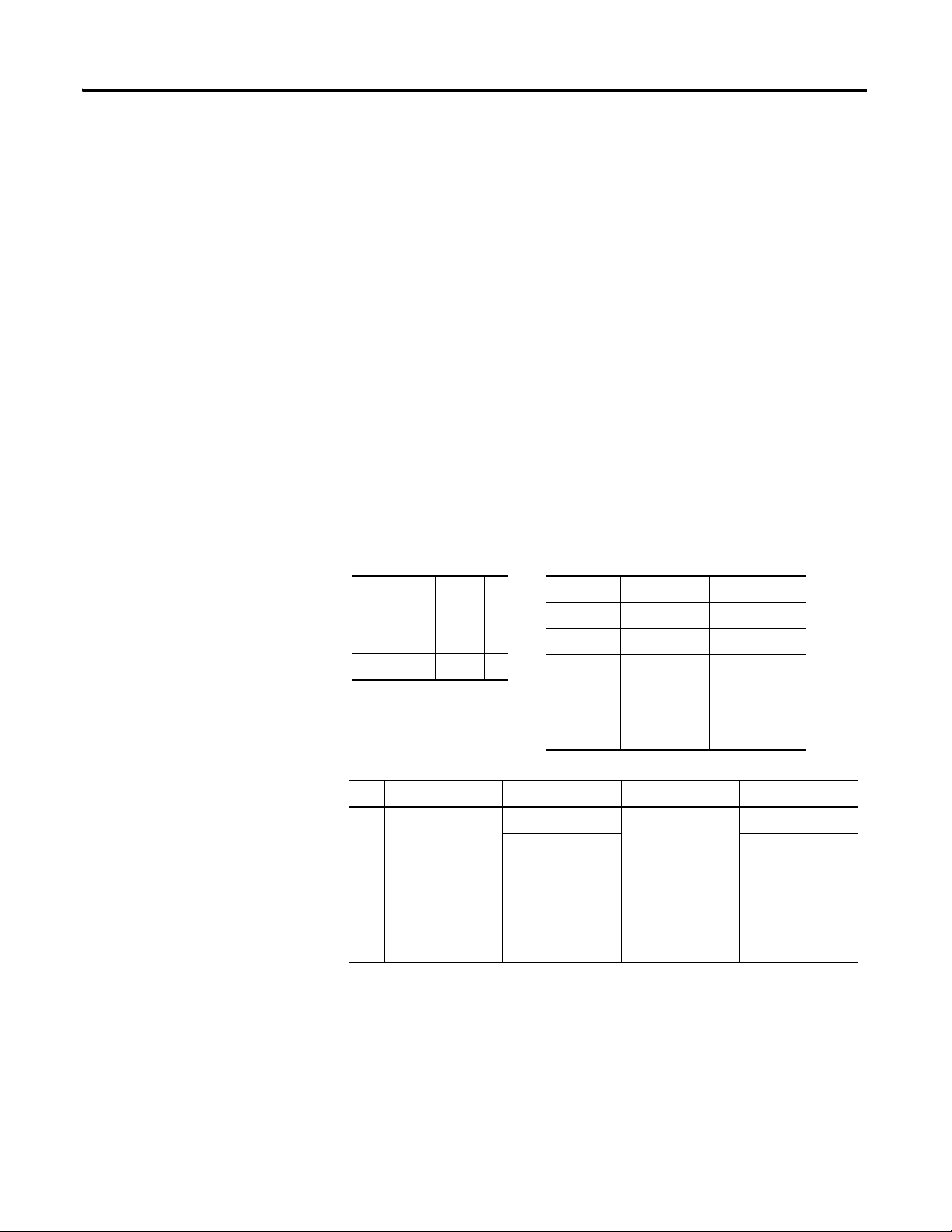

Connection Size Calculation Example

The following system will be used to demonstrate the connection size

calculation. The adapter's produced size (T

optional status header is included. In some software the consumed size

(O

→T) does not need to account for the 4 byte Run/Idle header as it is

assumed and already included. For the example both header sizes have been

included.

POINT I/O system example

→ O) must include 8 bytes if the

T → O alignment T → O size O → T alignment O → T size

1 Byte 16 bytes Byte 5 bytes

status 8 bytes

slot 1 byte

slot 2 int

slot 2 int

slot 2 byte

slot 2 byte

slot 3 byte

Publication 1734-UM016A-EN-P - October 2010

run /idle 4 bytes

slot 3 byte

Page 16

10 Configuration

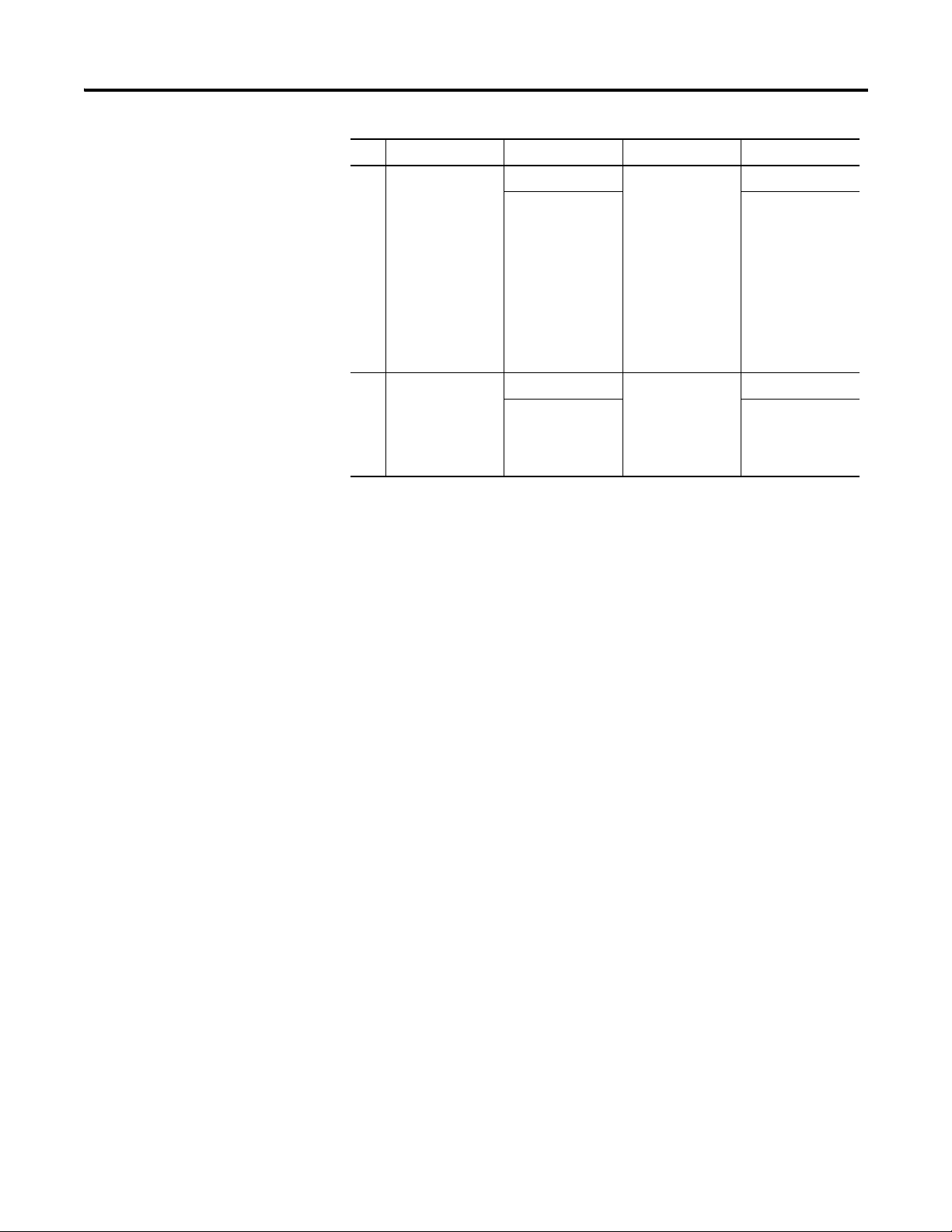

T → O alignment T → O size O → T alignment O → T size

2 Double Word 19 bytes Double Word 5 bytes

status 8 bytes

slot 1 byte

slot 1 pad

slot 1 pad

slot 1 pad

slot 2 int

slot 2 int

slot 2 byte

slot 2 byte

slot 3 byte

3 6 bytes per slot 26 bytes 1 byte per slot 7 bytes

run / idle 4 bytes

slot 3 byte

status 8 bytes

slot 1 6 bytes

slot 2 6 bytes

slot 3 6 bytes

run /idle 4 bytes

slot 1 byte

slot 2 byte

slot 3 byte

In row 1, the data is packed on byte boundaries. This is the most efficient data

representation when alignment is not a concern.

In row 2 the data for slot 1 is padded so that slot 2's data began on a Double

Word bound ary.

In row 3 every slot takes up the selected size per slot regardless of whether that

module has any data to produce.

This section touches briefly on data alignment. More comprehensive examples

of data alignment are provided in Assembly Structure Examples on page 23.

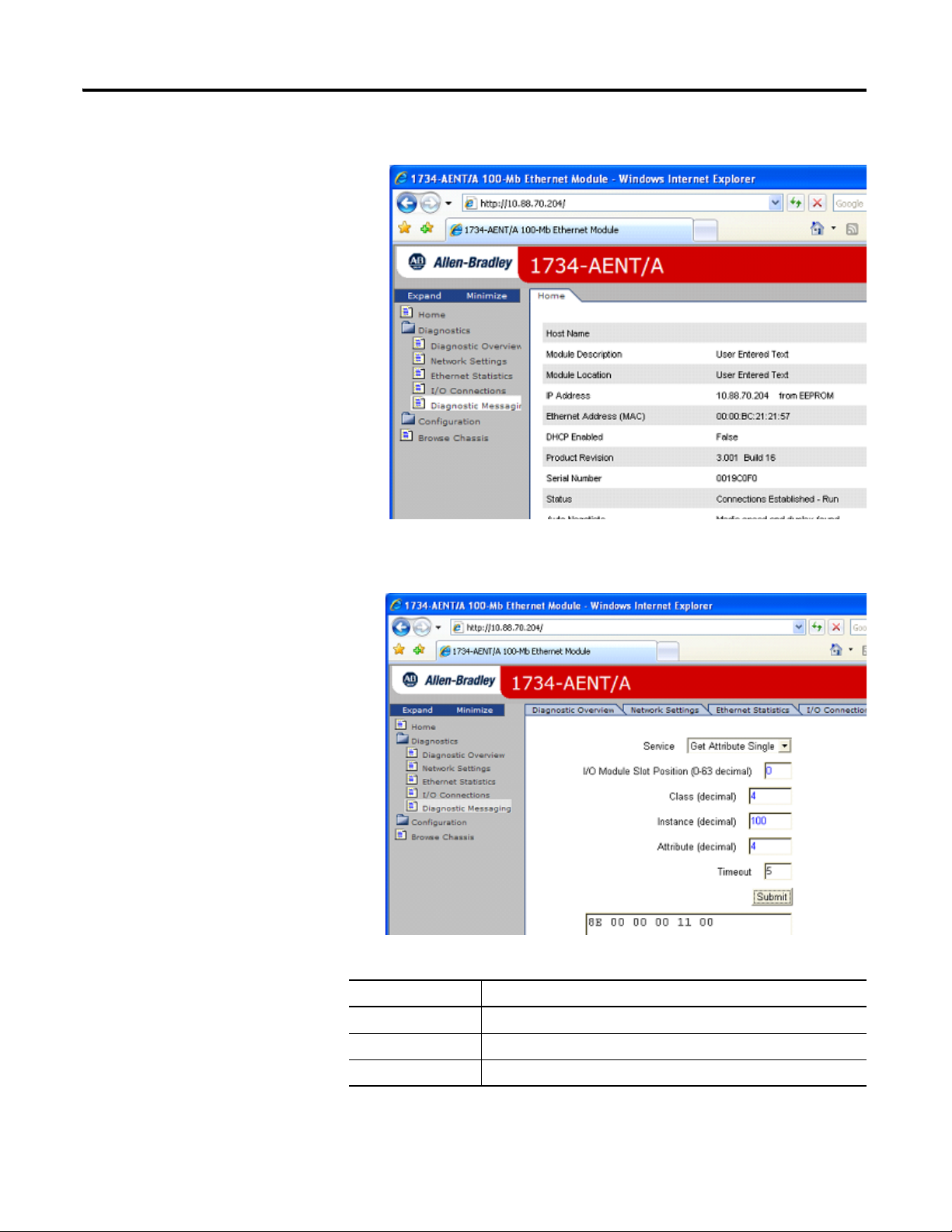

Troubleshooting Connection Size Errors

If the adapter returns the Invalid Connection Size error in response to a

connection request, it is possible to query the adapter for its calculated size.

Publication 1734-UM016A-EN-P - October 2010

This section highlights a technique that can be used to help resolve connection

size errors.

The adapter cannot validate connection sizes until the request to open the

connection is received. It is within that request that the adapter receives the

alignment choice and status election. Based on all the information in the

request and the modules present, the request may be rejected by the adapter

because of a size error.

Page 17

Configuration 11

1. Open the adapter's web page and select the Diagnostics folder.

2. On the Diagnostic Messaging tab, enter the Slot, Class, Instance, and

Attribute to get the adapter's calculated connection sizes.

Diagnostic Messaging Field Description

Field Description

Service Get Attribute Single

Slot Position 0

Class 4

Publication 1734-UM016A-EN-P - October 2010

Page 18

12 Configuration

Diagnostic Messaging Field Description

Field Description

Instance 100 (O → T data)

101 (T → O data with status)

103 (T → O data without status)

Attribute 4

Response 8E 00 00 00 xx xx

8E 00 — Indicates message was processed successfully

00 00 — 0 = success. Non-zero indicates an error code

xx xx — Indicates size (Little Endian format)

(1)

in Little Endian format, the least significant byte is shown first. A returned value of A2 01 should be interpreted

as 0x01A2 hex (418 decimal).

(1)

Once you have the sizes from the adapter, return to your calculations to

resolve the differences between your expected size and the size from the

adapter.

Publication 1734-UM016A-EN-P - October 2010

Page 19

Using an Assembly Connection

Chapter

3

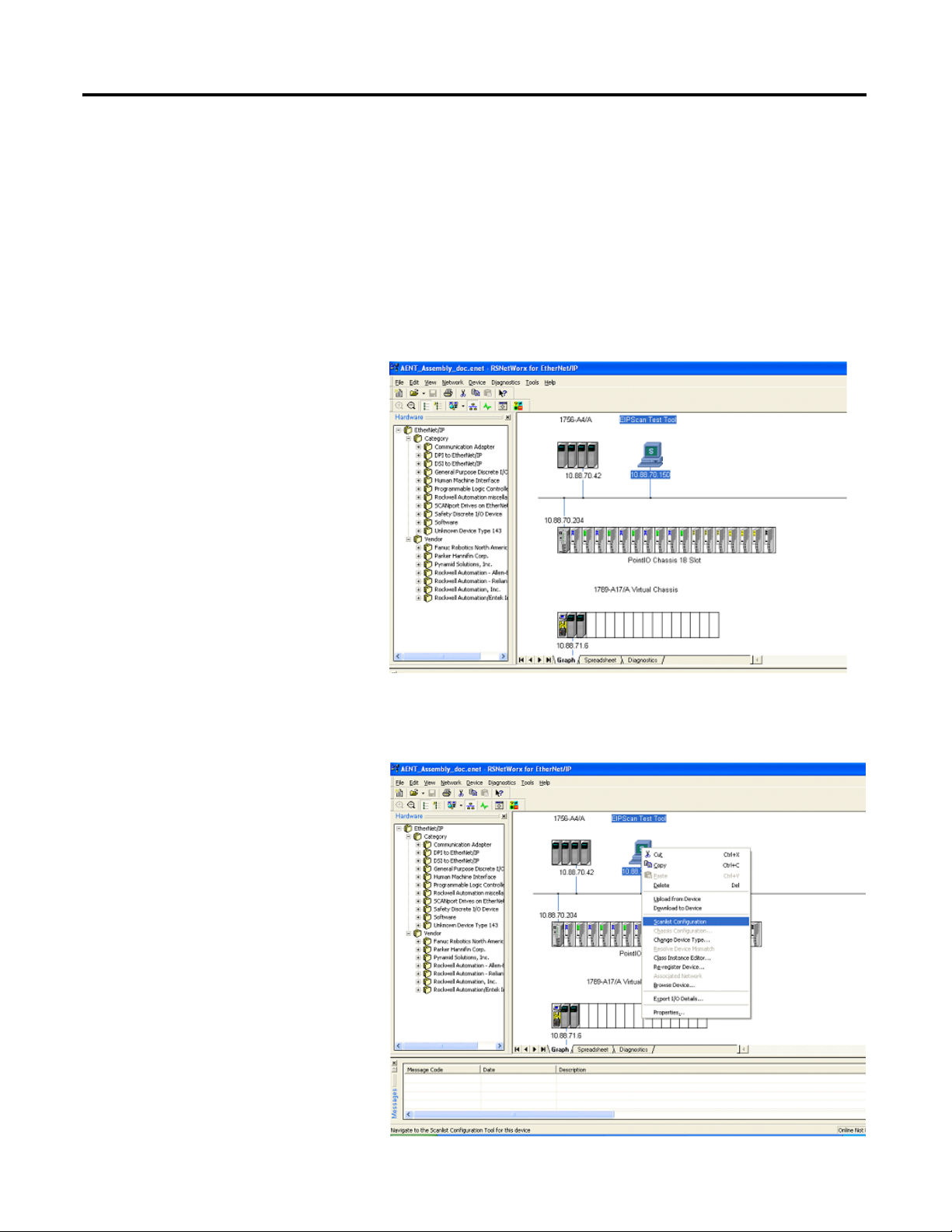

Use an Assembly Connection with RSNetWorx for EtherNet/IP

This section provides an illustration of the steps needed to configure the

Assembly connection using RSNetWorx for EtherNet/IP.

1. Browse the EtherNet/IP network.

2. Select the connection originator that will make the connection to the

1734-AENT. Right click that device and select Scanlist Configuration to

launch the Scanlist Configuration tool.

13 Publication 1734-UM016A-EN-P - October 2010

Page 20

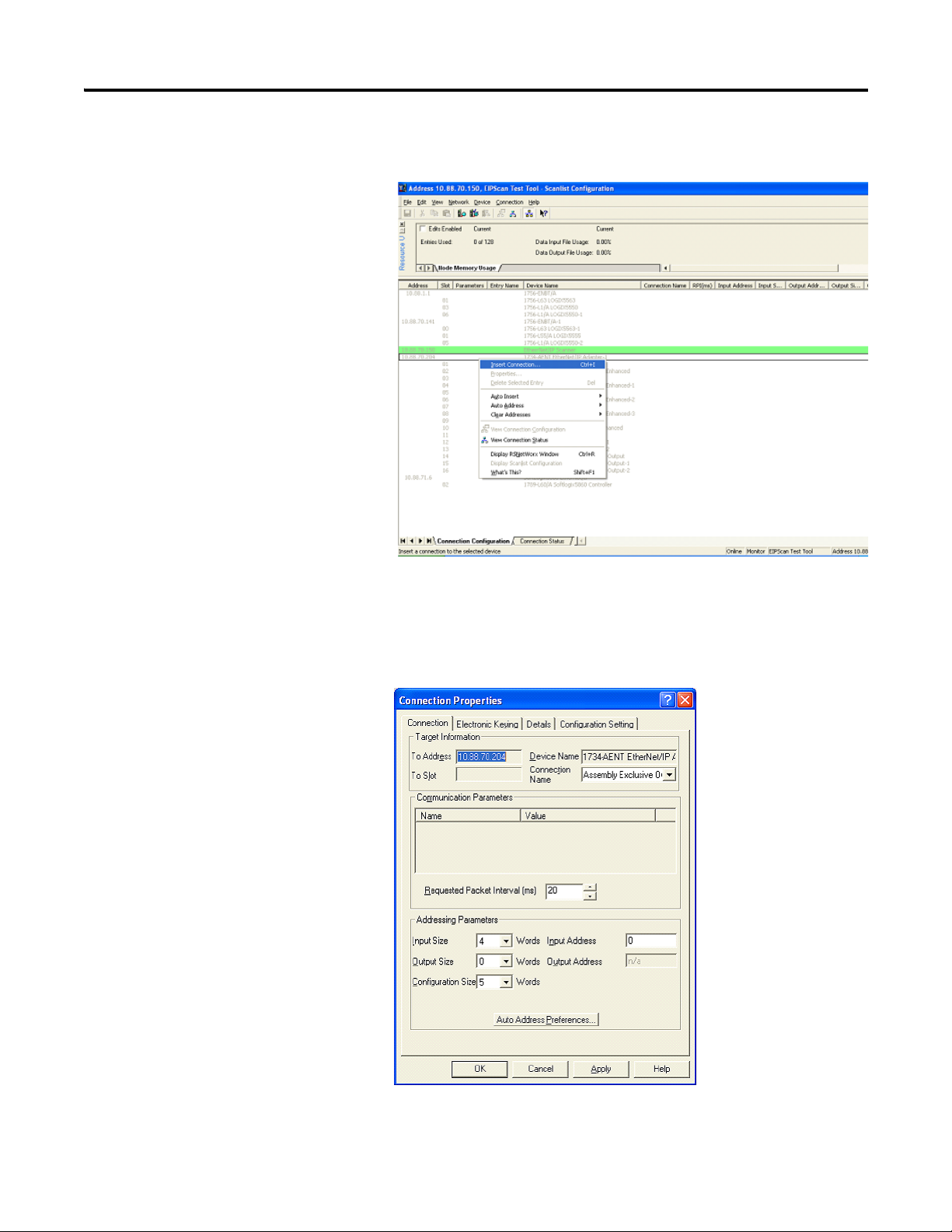

14 Using an Assembly Connection

3. Right click the targeted adapter and select Insert Connection to display

the Connection Properties dialog.

4. On the Connection tab of this dialog, select the connection from the

Connection Name pull-down (for example, Exclusive Owner and

Listen-Only connections). Listen-Only connections are only accepted if

an Exclusive Owner connection already exists.

Publication 1734-UM016A-EN-P - October 2010

Page 21

Using an Assembly Connection 15

TIP

You can also select the Requested Packet Interval and connection sizes.

For a full discussion on connections sizes, refer to the Configuration

Setting tab step that follows and Calculate the Connection Size. The

defaults reflect an empty system (with the adapter only).

In RSNetWorx, the 4-byte Run/Idle header is not considered when

calculating the Output Size. When you enter the connection size on

this dialog, make sure to subtract 4 bytes from your calculated size.

Also note that this dialog expresses the size in Words. If your

calculation was performed in Bytes, you must divide by 2.

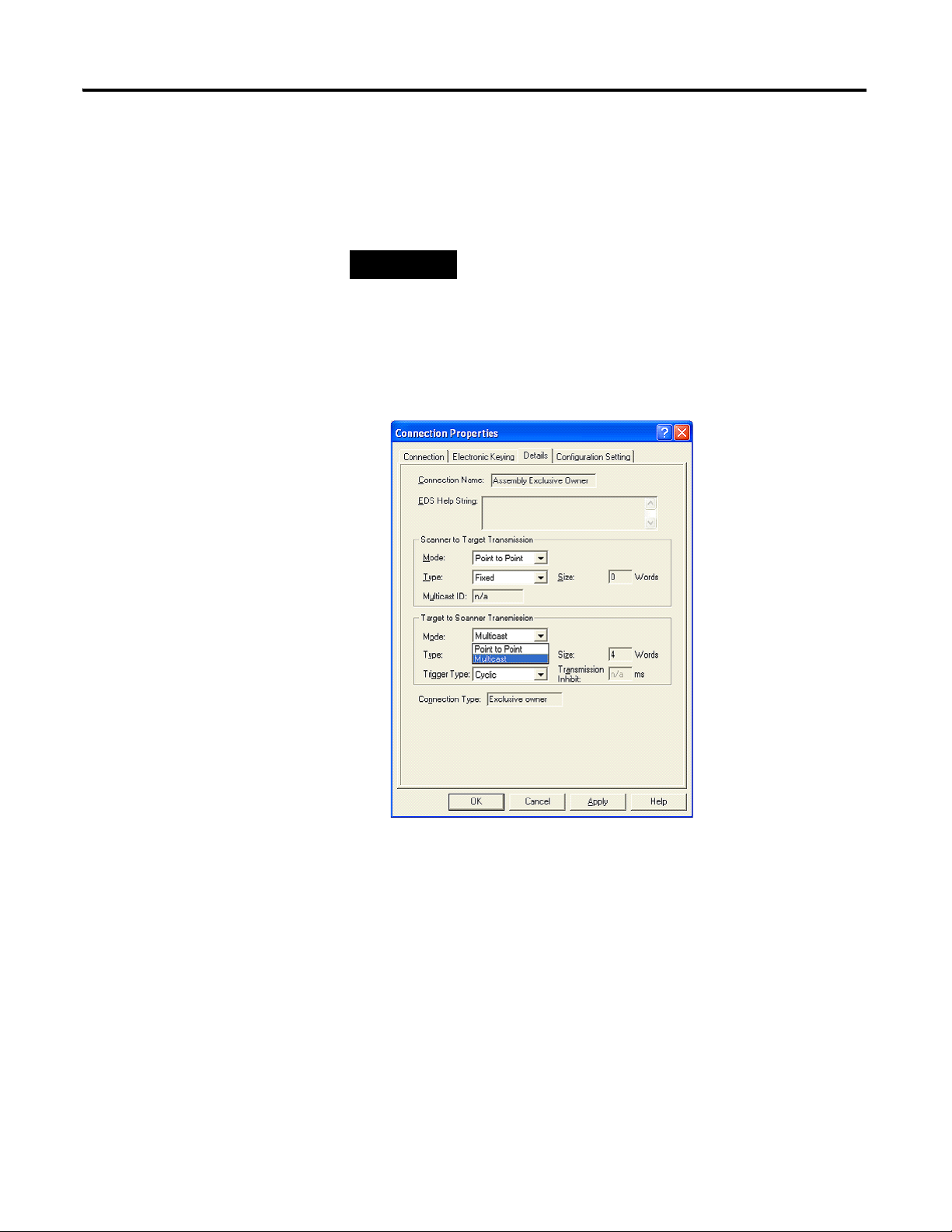

5. In the Details tab, you can select between Point to Point and Multicast

for the Target to Scanner data.

Publication 1734-UM016A-EN-P - October 2010

Page 22

16 Using an Assembly Connection

TIP

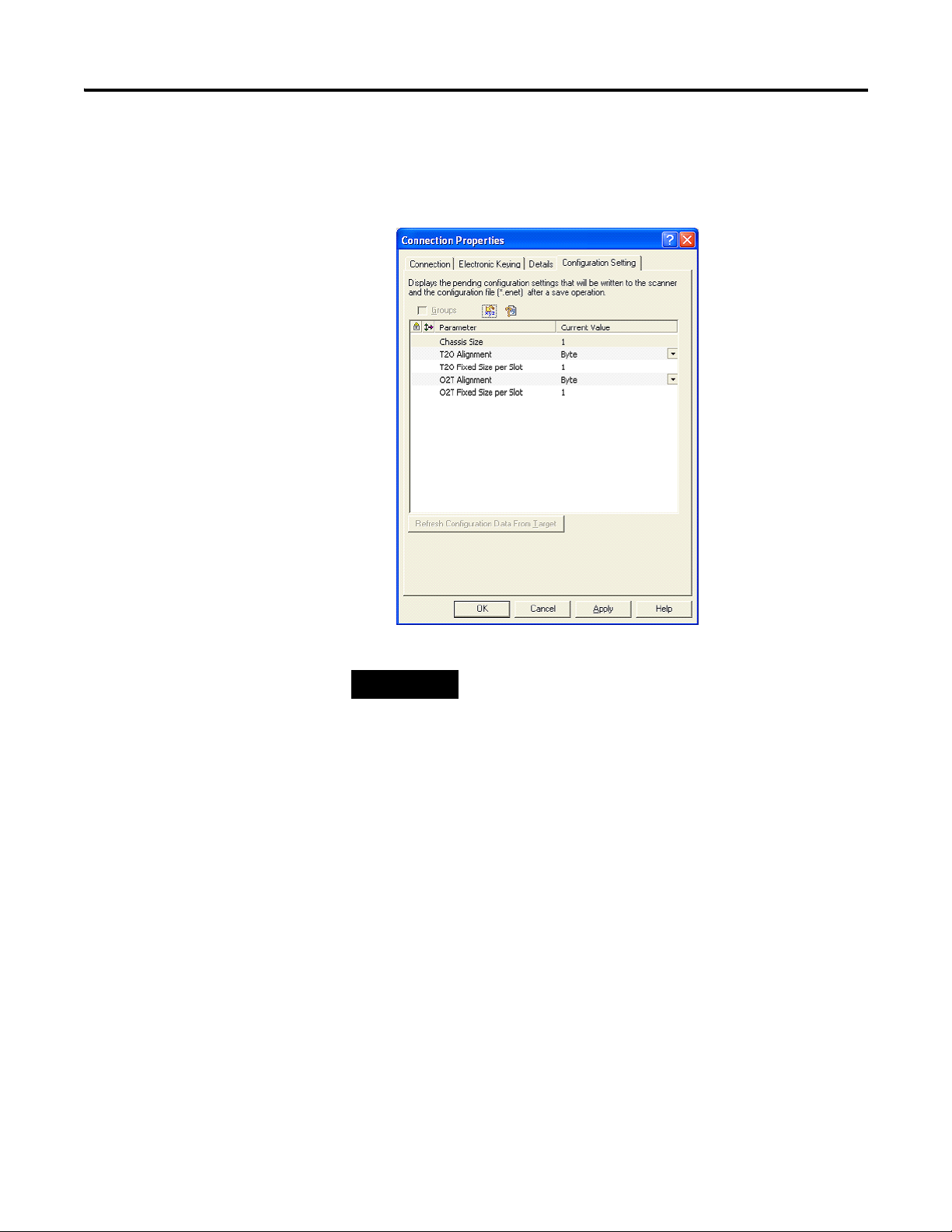

6. The Configuration Setting tab displays the configuration options for the

connection. Here, you can specify the Chassis Size and Data Alignment.

The terms T2O and O2T are abbreviations for Target to Originator and

Originator to Target.

Use an Assembly Connection with RSLogix5000

Remember when specifying the Chassis Size to include 1 for the

adapter.

See Data Alignment for alignment choices.

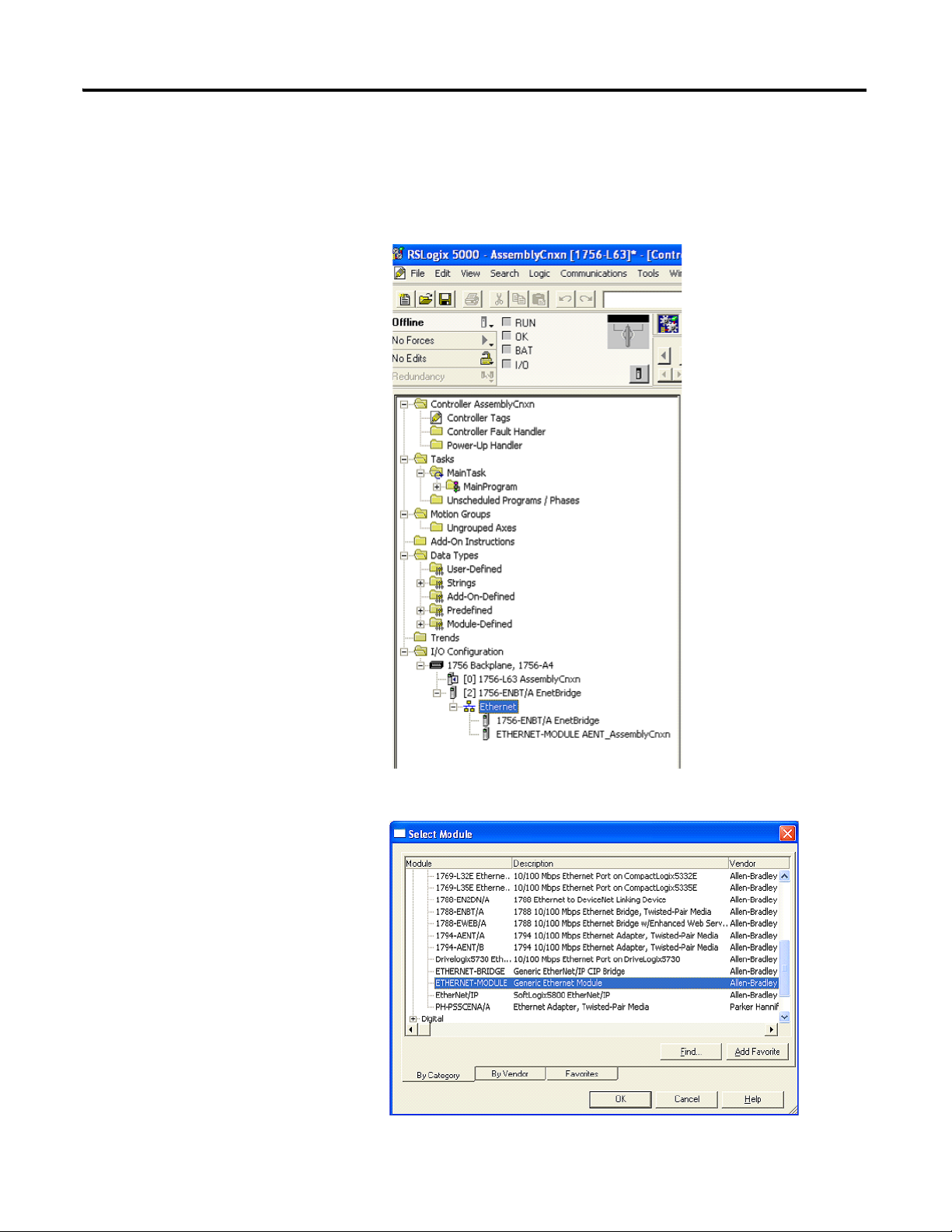

The Assembly connection can be used with RSLogix5000 and the Generic

EtherNet/IP profile. When this connection is used in RSLogix5000, there are

no intelligent Tags created for the adapter. All Input, Output, and

Configuration data are in unstructured Tag arrays.

Publication 1734-UM016A-EN-P - October 2010

Page 23

Using an Assembly Connection 17

Add the Hardware to the I/O Configuration Tree

1. Add a new module to the Ethernet network in the I/O Configuration

section of the Controller Organizer pane.

2. Select a Generic Ethernet Module.

Publication 1734-UM016A-EN-P - October 2010

Page 24

18 Using an Assembly Connection

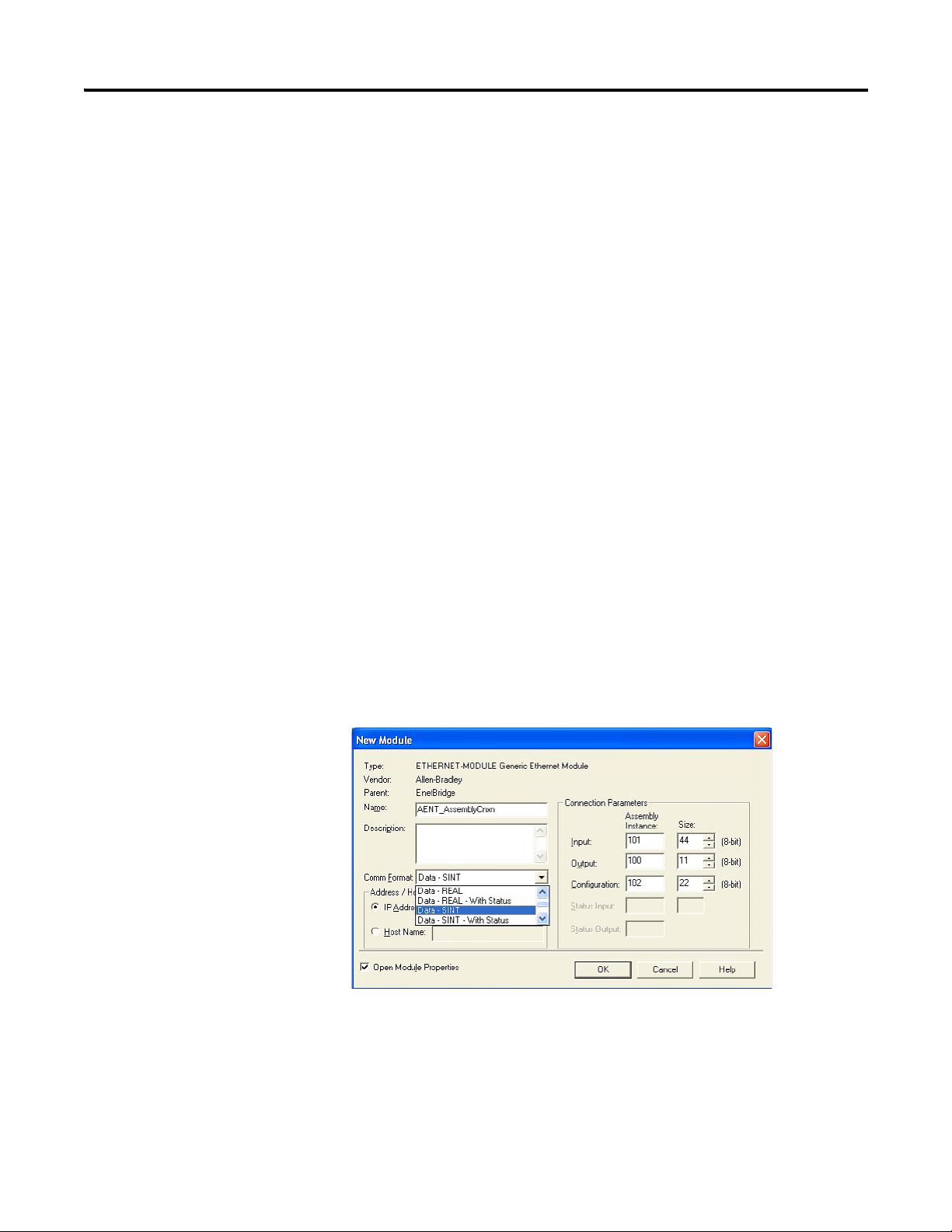

Enter the Connection Parameters

In the New Module Properties dialog, enter Connection Parameters, the

Comm Format, the module's IP Address, and a name.

Enter a Name for the module that RSLogix 5000 uses in the tags that are

created for this module. The Data - SINT Comm Format should be selected,

indicating that all sizes are to be interpreted as a number of bytes. If this

connection is a Listen only connection, select the Input Data - SINT Comm

Format since it is otherwise not possible to enter an Output config assembly

size of 0.

Next, enter the Assembly Instances for the desired connection as

described in Connection Points. Enter the sizes (in bytes) for the Input and

Output instances per your calculations. See Calculate the Connection Size for

details on obtaining the sizes. If the optional status header is being used, its

size (8 bytes) must be included in the Input Size. For RSLogix 5000 the Output

Size does not include the Run/Idle header. Here the terms Input and Output

refer to the adapter's Produced and Consumed data respectively.

It is possible to make the connection without sending any

configuration data. The adapter's Chassis Size can be set from its web

page and the adapter will align produced and consumed data by

default on byte boundaries. If these options and the default configuration of all

I/O modules are acceptable, a 0 can be entered for the Configuration Size on

the Module Properties dialog. The configuration Assembly Instance must be

entered even if the size is 0. The following section will describe the steps taken

when configuration is needed.

Publication 1734-UM016A-EN-P - October 2010

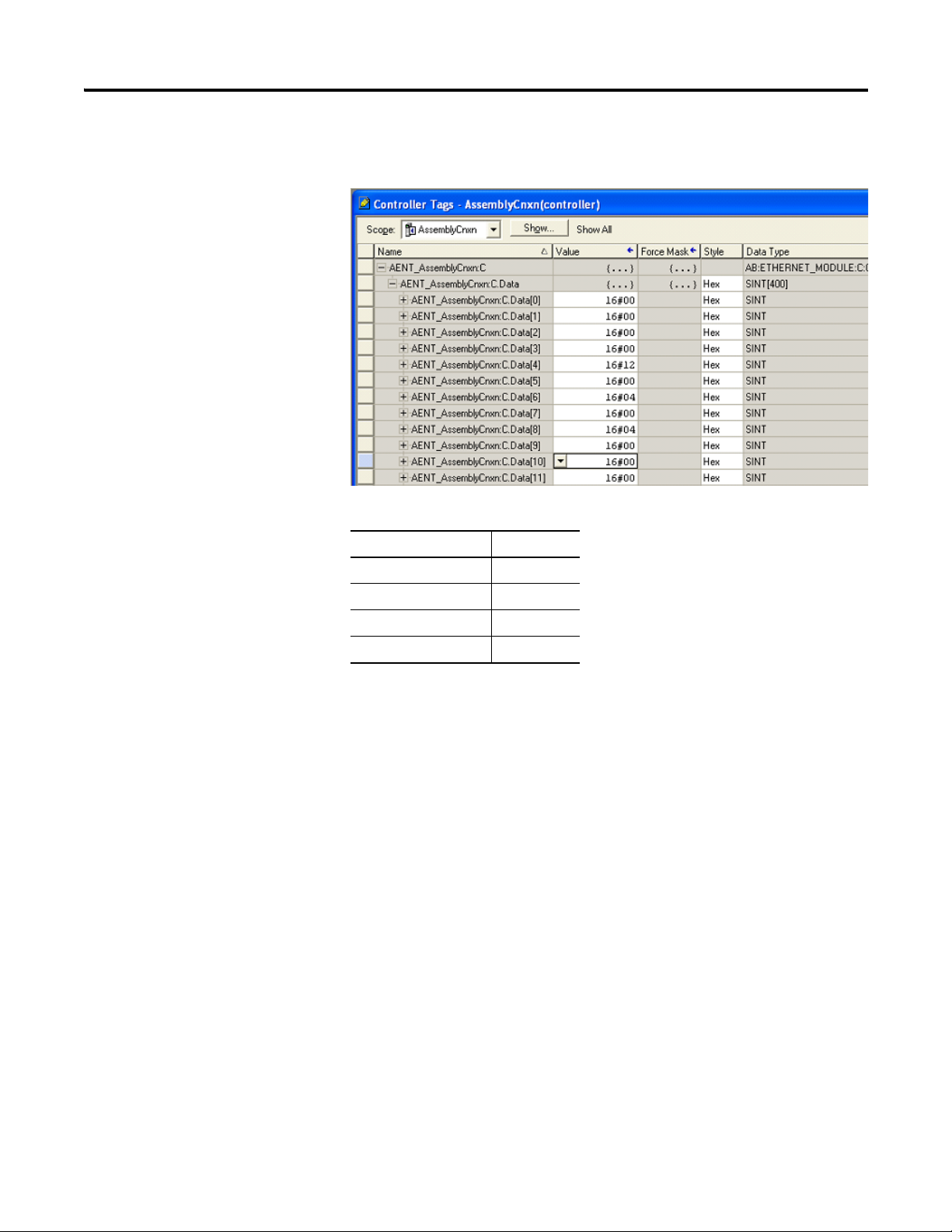

Build the Configuration Tag

If any configuration is required, the minimum configuration header must be

sent and then any individual module configuration may follow. Open the

Page 25

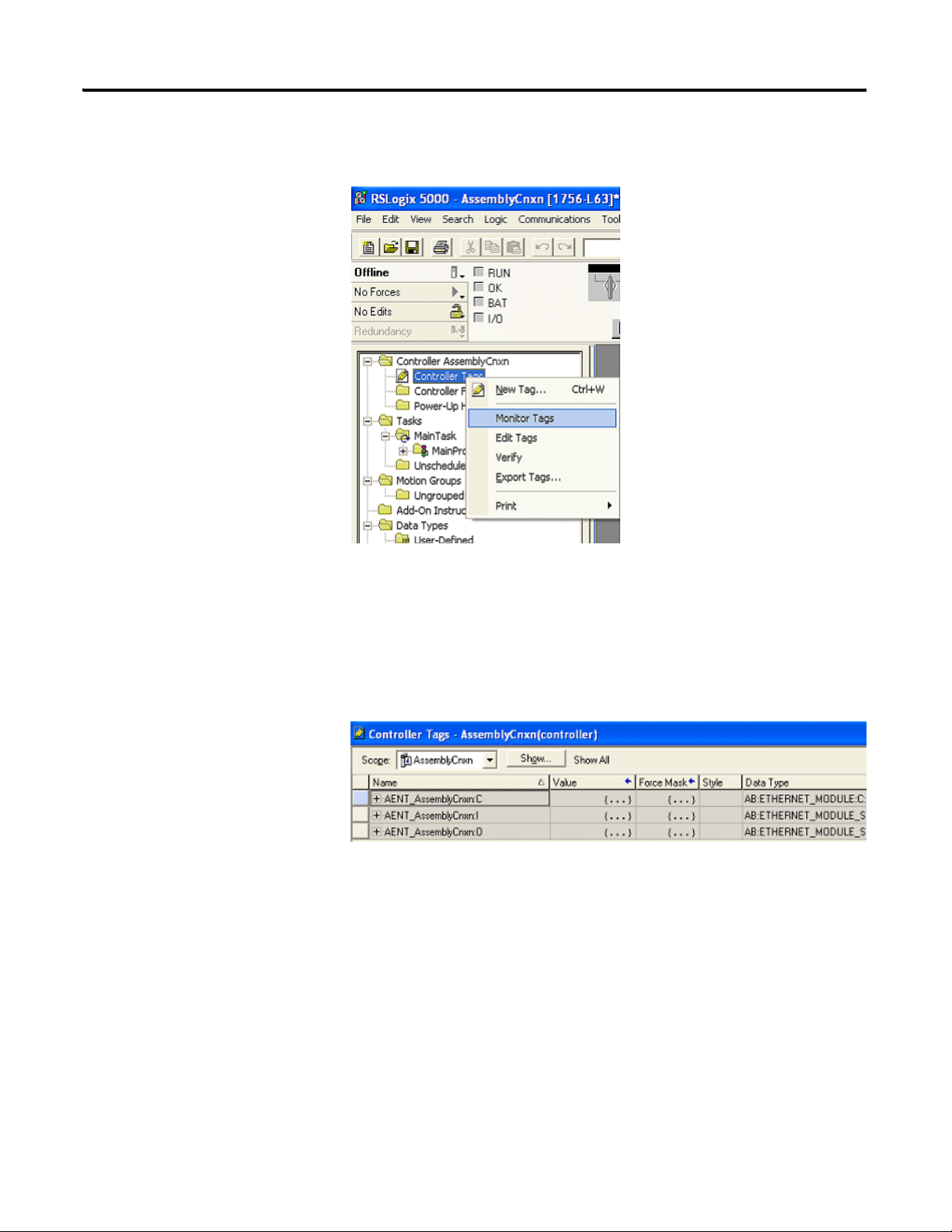

Using an Assembly Connection 19

Controller Tags by right-clicking the Controller Tags option from the

Controller Organizer pane. Select Monitor Tags.

Monitor Tags

You should see three Tags with the module's name. They will have an C, I, or

O suffix denoting Configuration, Input, or Output respectively. Note that the I

and O Tags are sized according to the sizes that were entered on the properties

page. The C Tag always has 400 bytes allocated for it regardless of the size

specified.

Add Configuration Header

Bytes 0…9 must contain the minimum configuration header information

described in Minimal Adapter Configuration Assembly. As can be seen from

the figure below, the Chassis Size is set to 0x12 (18 decimal). The produced

Publication 1734-UM016A-EN-P - October 2010

Page 26

20 Using an Assembly Connection

and consumed alignment choice is Double Word alignment which is

enumerated as a 4. See the following table for valid alignment values.

Alignment choices for configuration header

Alignment Choice Value

Byte 0

Word 2

Double Word 4

Fixed size per slot 0xFF

Add I/O Module Configuration

If individual module configuration is required, it can be appended to

the configuration header. In the example shown below a 1734-OB4E module

is being configured. Byte 10 indicates that the data is to be sent to slot 2. Byte

11 specifies the size of the data as 8 bytes. Bytes 12 and 13 specify the OB4E

module configuration assembly instance 0x7B. The instance number is entered

in little endian (least significant byte first). In byte 16 the value of 7 indicates

that when the module is in Idle mode, Hold Last State should be enabled for

channels 0, 1, and 2 but not channel 3. If more module configuration is

needed, it could begin at byte 22 with the slot number of the next module to

be configured.

Publication 1734-UM016A-EN-P - October 2010

Page 27

Using an Assembly Connection 21

For more information on configuration, see 1734/1738 I/O Module

Assembly Information.

After the configuration has been entered into the tag, remember to

save the RSLogix 5000 project. The tags are only retained upon a save. Also

remember that any configuration added here must be reflected in the

Configuration Size of the Connection Parameters entered on the Module

Properties dialog.

If any part of the configuration assembly is wrong (either the minimal

assembly or a portion directed to an I/O module), the connection request will

be rejected with the General Return Code indicating an Error in the Data

Segment (0x09). The Extended Error code will indicate the byte offset into the

configuration data segment where the error was detected.

Publication 1734-UM016A-EN-P - October 2010

Page 28

22 Using an Assembly Connection

The error shown above was created by entering an invalid configuration

assembly size on the Module Properties page. A size of 18 bytes was entered.

The error here points to an offset of 0x000b (11 decimal). If we return to the

configuration tag, byte 0x000b is the location that contains the size of the I/O

module configuration. The header is 10 bytes and the module has 8 bytes of

configuration. However, we have neglected to add the 4 bytes of overhead

needed to describe the slot 2 configuration. When the adapter parsed the

configuration assembly to byte 0x000b it saw that it needed 8 more bytes of

information. It had already parsed through byte 11, therefore 18 would not be

an adequate size. The adapter returns the offset of the first byte where the

error is detected (0x000b).

Publication 1734-UM016A-EN-P - October 2010

Page 29

Assembly Structure

Chapter

4

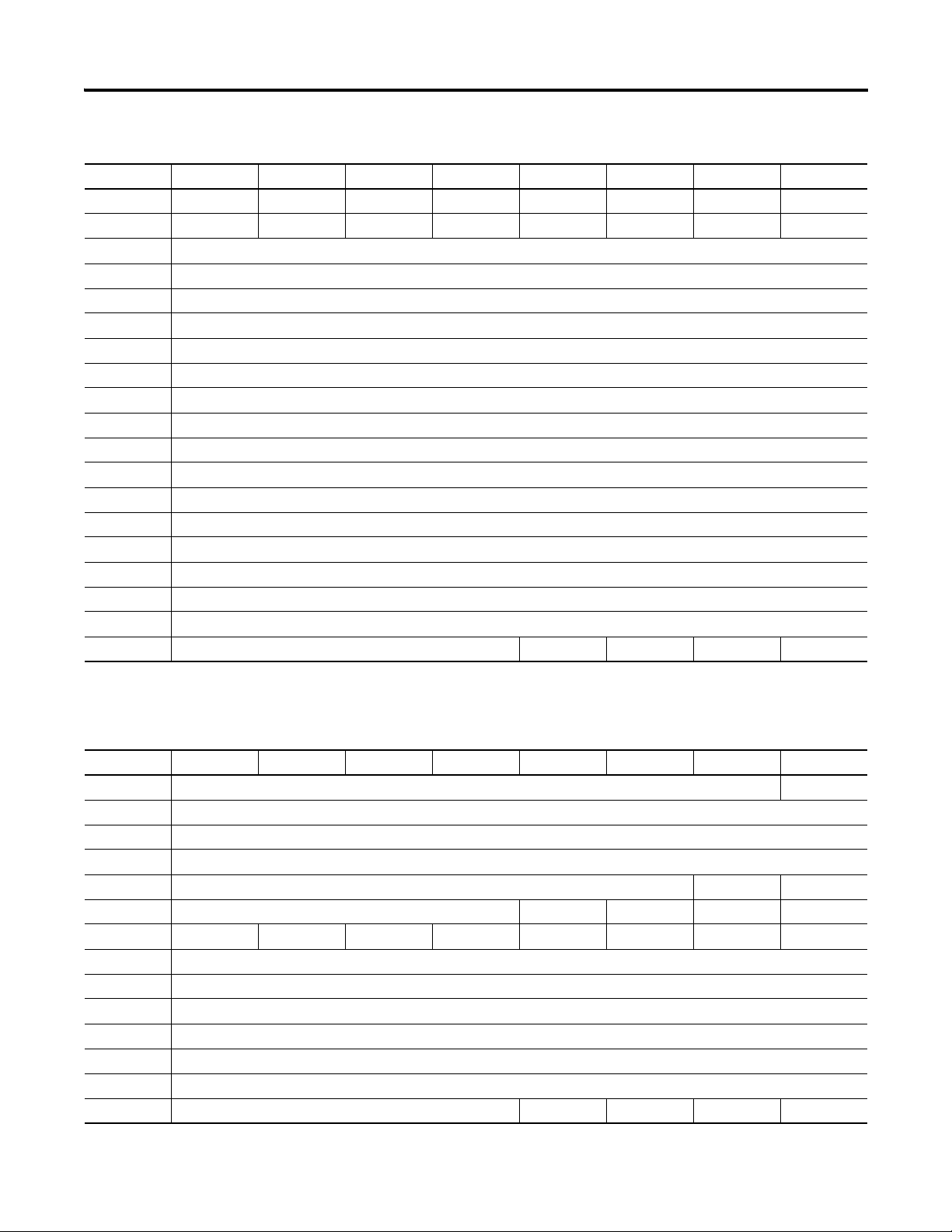

Assembly Structure Examples

Produced Assembly, Byte Aligned

Byte, Word, and Double Word Alignment

The following chassis is used to demonstrate how the data is aligned for the

Byte, Word, and Double Word alignment options. This chassis was

intentionally assembled as shown to demonstrate as many use cases as

possible. Discrete and analog modules are intermixed. An ARM module is

used to reserve space for a future device. The 1734-IB4D module in slot 8 is

configured to produce 2 bytes while the IB4D module in slot 7 is configured

to produce 1 byte. The ASCII module in slot 10 is configured to produce

9 bytes.

Example POINT system

A

A

O

W

4

I

B

4

3

I

I

Cat # A

B

E

4

N

T

Slot # 0 1234567891011121

I

B

B

8

2

O

O

S

R

E

B

B

B

B

B

C

M

2

4

4

8

4

2

C

D

D

E

E

E

I

I

I

O

Byte Bit 7 Bit 6 Bit5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Produce 0 Slot 7 status Slot 6 status Slot 5 status Slot 4 status Slot 3 status Slot 2 status Slot1 status Slot 0 status

Produce 1 Slot 15 status Slot 14 status Slot 13 status Slot 12 status Slot 11 status Slot 10 status Slot 9 status Slot 8 status

Produce 2 Slot 23 status Slot 22 status Slot 21 status Slot 20 status Slot 19 status Slot 18 status Slot 17 status Slot 16 status

Produce 3 Slot 31 status Slot 30 status Slot 29 status Slot 28 status Slot 27 status Slot 26 status Slot 25 status Slot 24 status

Produce 4 Slot 39 status Slot 38 status Slot 37 status Slot 36 status Slot 35 status Slot 34 status Slot 33 status Slot 32 status

Produce 5 Slot 47 status Slot 46 status Slot 45 status Slot 44 status Slot 43 status Slot 42 status Slot 41 status Slot 40 status

Produce 6 Slot 55 status Slot 54 status Slot 53 status Slot 52 status Slot 51 status Slot 50 status Slot 49 status Slot 48 status

Produce 7 Slot 63 status Slot 62 status Slot 61 status Slot 60 status Slot 59 status Slot 58 status Slot 57 status Slot 56 status

Produce 8 Reserved Slot 1 Bit 3 Slot 1 Bit 2 Slot 1 Bit 1 Slot 1 Bit 0

Produce 9 Slot 2 Bit 7 Slot 2 Bit 6 Slot 2 Bit 5 Slot 2 Bit 4 Slot 2 Bit 3 Slot 2 Bit 2 Slot 2 Bit 1 Slot 2 Bit 0

Produce 10 Reserved Slot 3 Bit 1 Slot 3 Bit 0

Produce 11 Reserved Slot 4 Bit 1 Slot 4 Bit 0

Produce 12 Reserved Slot 5 Bit 3 Slot 5 Bit 2 Slot 5 Bit 1 Slot 5 Bit 0

Produce 13 Slot 6 Bit 7 Slot 6 Bit 6 Slot 6 Bit 6 Slot 6 Bit 4 Slot 6 Bit 3 Slot 6 Bit 2 Slot 6 Bit 1 Slot 6 Bit 0

Produce 14 Slot 7 Bit 7 Slot 7 Bit 6 Slot 7 Bit 5 Slot 7 Bit 4 Slot 7 Bit 3 Slot 7 Bit 2 Slot 7 Bit 1 Slot 7 Bit 0

23 Publication 1734-UM016A-EN-P - October 2010

Page 30

24 Assembly Structure

Produced Assembly, Byte Aligned

Byte Bit 7 Bit 6 Bit5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Produce 15 Slot 8 Bit 7 Slot 8 Bit 6 Slot 8 Bit 5 Slot 8 Bit 4 Slot 8 Bit 3 Slot 8 Bit 2 Slot 8 Bit 1 Slot 8 Bit 0

Produce 16 Slot 8 Bit 15 Slot 8 Bit 14 Slot 8 Bit 13 Slot 8 Bit 12 Slot 8 Bit 11 Slot 8 Bit 10 Slot 8 Bit 9 Slot 8 Bit 8

Produce 17 Slot 9 Channel 0 - Low Byte

Produce 18 Slot 9 Channel 0 - High Byte

Produce 19 Slot 9 Channel 1 - Low Byte

Produce 20 Slot 9 Channel 1 - High Byte

Produce 21 Slot 9 Channel 0 - Status

Produce 22 Slot 9 Channel 1 - Status

Produce 23 Slot 10 ASCII Data 1

Produce 24 Slot 10 ASCII Data 2

Produce 25 Slot 10 ASCII Data 3

Produce 26 Slot 10 ASCII Data 4

Produce 27 Slot 10 ASCII Data 5

Produce 28 Slot 10 ASCII Data 6

Produce 29 Slot 10 ASCII Data 7

Produce 30 Slot 10 ASCII Data 8

Produce 31 Slot 10 ASCII Data End of String Delimiter

Produce 32 Slot 11 ARM - Reserved Byte

Produce 33 Reserved Slot 13 Bit 3 Slot 13 Bit 2 Slot 13 Bit 1 Slot 13 Bit 0

Consumed Assembly, Byte Aligned

Byte Bit 7 Bit 6 Bit5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Consume 0 Reserved Run/Idle

Consume 1 Reserved

Consume 2 Reserved

Consume 3 Reserved

Consume 4 Reserved Slot 4 Bit 1 Slot 4 Bit 0

Consume 5 Reserved Slot 5 Bit 3 Slot 5 Bit 2 Slot 5 Bit 1 Slot 5 Bit 0

Consume 6 Slot 6 Bit 7 Slot 6 Bit 6 Slot 6 Bit 5 Slot 6 Bit 4 Slot 6 Bit 3 Slot 6 Bit 2 Slot 6 Bit 1 Slot 6 Bit 0

Consume 7 Slot 10 ASCII Data 1

Consume 8 Slot 10 ASCII Data 2

Consume 9 Slot 10 ASCII Data 3

Consume 10 Slot 10 ASCII Data 4

Consume 11 Slot 10 ASCII Data 5

Consume 12 Slot 10 ASCII Data End of String Delimiter

Consume 13 Reserved Slot 12 Bit 3 Slot 12 Bit 2 Slot 12 Bit 1 Slot 12 Bit 0

Publication 1734-UM016A-EN-P - October 2010

Page 31

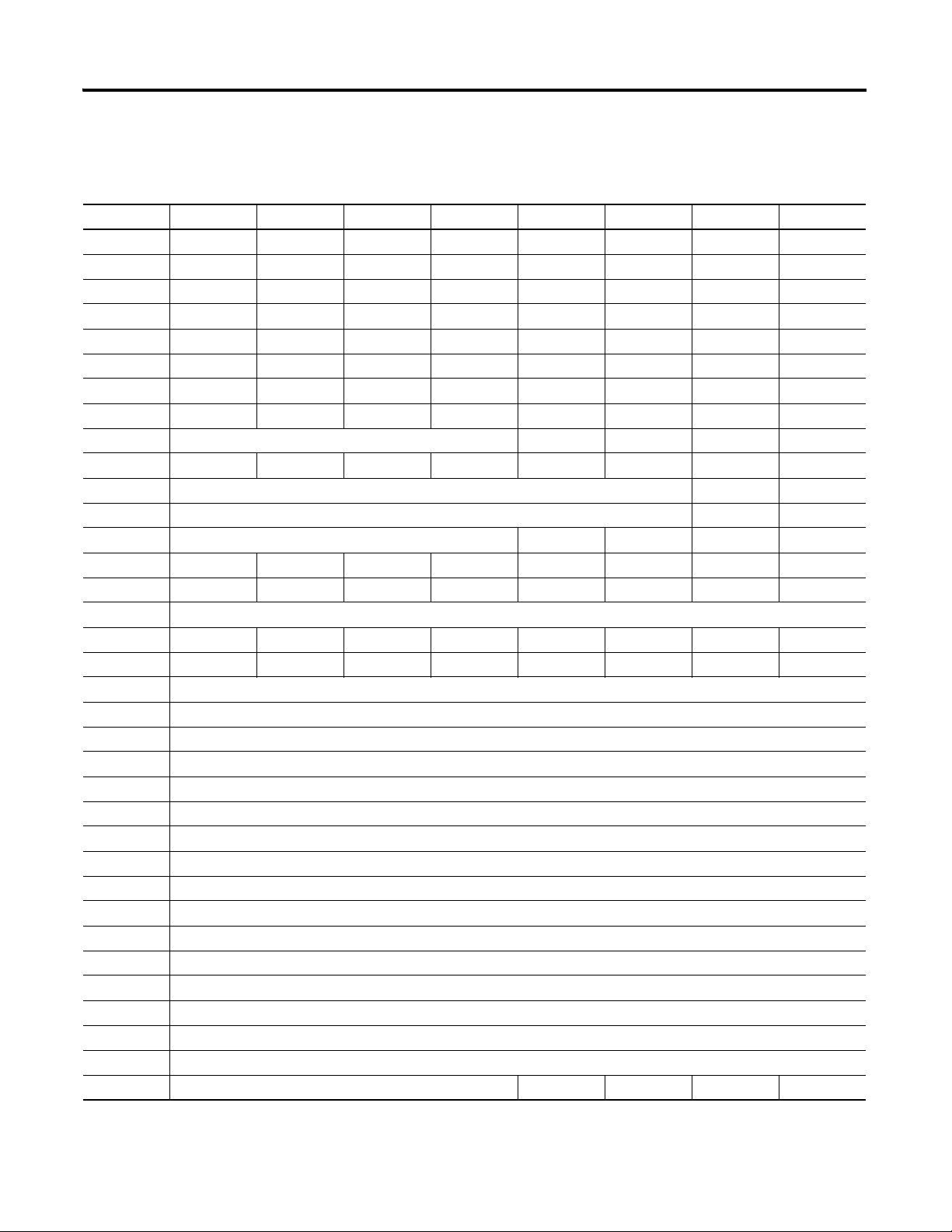

Assembly Structure 25

Produced Assembly, Word Aligned

Byte Bit 7 Bit 6 Bit5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Produce 0 Slot 7 status Slot 6 status Slot 5 status Slot 4 status Slot 3 status Slot 2 status Slot1 status Slot 0 status

Produce 1 Slot 15 status Slot 14 status Slot 13 status Slot 12 status Slot 11 status Slot 10 status Slot 9 status Slot 8 status

Produce 2 Slot 23 status Slot 22 status Slot 21 status Slot 20 status Slot 19 status Slot 18 status Slot 17 status Slot 16 status

Produce 3 Slot 31 status Slot 30 status Slot 29 status Slot 28 status Slot 27 status Slot 26 status Slot 25 status Slot 24 status

Produce 4 Slot 39 status Slot 38 status Slot 37 status Slot 36 status Slot 35 status Slot 34 status Slot 33 status Slot 32 status

Produce 5 Slot 47 status Slot 46 status Slot 45 status Slot 44 status Slot 43 status Slot 42 status Slot 41 status Slot 40 status

Produce 6 Slot 55 status Slot 54 status Slot 53 status Slot 52 status Slot 51 status Slot 50 status Slot 49 status Slot 48 status

Produce 7 Slot 63 status Slot 62 status Slot 61 status Slot 60 status Slot 59 status Slot 58 status Slot 57 status Slot 56 status

Produce 8 Reserved Slot 1 Bit 3 Slot 1 Bit 2 Slot 1 Bit 1 Slot 1 Bit 0

Produce 9 Slot 2 Bit 7 Slot 2 Bit 6 Slot 2 Bit 5 Slot 2 Bit 4 Slot 2 Bit 3 Slot 2 Bit 2 Slot 2 Bit 1 Slot 2 Bit 0

Produce 10 Reserved Slot 3 Bit 1 Slot 3 Bit 0

Produce 11 Reserved Slot 4 Bit 1 Slot 4 Bit 0

Produce 12 Reserved Slot 5 Bit 3 Slot 5 Bit 2 Slot 5 Bit 1 Slot 5 Bit 0

Produce 13 Slot 6 Bit 7 Slot 6 Bit 6 Slot 6 Bit 6 Slot 6 Bit 4 Slot 6 Bit 3 Slot 6 Bit 2 Slot 6 Bit 1 Slot 6 Bit 0

Produce 14 Slot 7 Bit 7 Slot 7 Bit 6 Slot 7 Bit 5 Slot 7 Bit 4 Slot 7 Bit 3 Slot 7 Bit 2 Slot 7 Bit 1 Slot 7 Bit 0

Produce 15 Pad

Produce 16 Slot 8 Bit 7 Slot 8 Bit 6 Slot 8 Bit 5 Slot 8 Bit 4 Slot 8 Bit 3 Slot 8 Bit 2 Slot 8 Bit 1 Slot 8 Bit 0

Produce 17 Slot 8 Bit 15 Slot 8 Bit 14 Slot 8 Bit 13 Slot 8 Bit 12 Slot 8 Bit 11 Slot 8 Bit 10 Slot 8 Bit 9 Slot 8 Bit 8

Produce 18 Slot 9 Channel 0 - Low Byte

Produce 19 Slot 9 Channel 0 - High Byte

Produce 20 Slot 9 Channel 1 - Low Byte

Produce 21 Slot 9 Channel 1 - High Byte

Produce 22 Slot 9 Channel 0 - Status

Produce 23 Slot 9 Channel 1 - Status

Produce 24 Slot 10 ASCII Data 1

Produce 25 Slot 10 ASCII Data 2

Produce 26 Slot 10 ASCII Data 3

Produce 27 Slot 10 ASCII Data 4

Produce 28 Slot 10 ASCII Data 5

Produce 29 Slot 10 ASCII Data 6

Produce 30 Slot 10 ASCII Data 7

Produce 31 Slot 10 ASCII Data 8

Produce 32 Slot 10 ASCII Data End of String Delimiter

Produce 33 Slot 11 ARM - Reserved Byte

Produce 34 Reserved Slot 13 Bit 3 Slot 13 Bit 2 Slot 13 Bit 1 Slot 13 Bit 0

Publication 1734-UM016A-EN-P - October 2010

Page 32

26 Assembly Structure

Consumed Assembly, Word Aligned

Byte Bit 7 Bit 6 Bit5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Consume 0 Reserved Run/Idle

Consume 1 Reserved

Consume 2 Reserved

Consume 3 Reserved

Consume 4 Reserved Slot 4 Bit 1 Slot 4 Bit 0

Consume 5 Reserved Slot 5 Bit 3 Slot 5 Bit 2 Slot 5 Bit 1 Slot 5 Bit 0

Consume 6 Slot 6 Bit 7 Slot 6 Bit 6 Slot 6 Bit 5 Slot 6 Bit 4 Slot 6 Bit 3 Slot 6 Bit 2 Slot 6 Bit 1 Slot 6 Bit 0

Consume 7 Pad

Consume 8 Slot 10 ASCII Data 1

Consume 9 Slot 10 ASCII Data 2

Consume 10 Slot 10 ASCII Data 3

Consume 11 Slot 10 ASCII Data 4

Consume 12 Slot 10 ASCII Data 5

Consume 13 Slot 10 ASCII Data End of String Delimiter

Consume 14 Reserved Slot 12 Bit 3 Slot 12 Bit 2 Slot 12 Bit 1 Slot 12 Bit 0

Produced Assembly, Double Word Aligned

Byte Bit 7 Bit 6 Bit5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Produce 0 Slot 7 status Slot 6 status Slot 5 status Slot 4 status Slot 3 status Slot 2 status Slot1 status Slot 0 status

Produce 1 Slot 15 status Slot 14 status Slot 13 status Slot 12 status Slot 11 status Slot 10 status Slot 9 status Slot 8 status

Produce 2 Slot 23 status Slot 22 status Slot 21 status Slot 20 status Slot 19 status Slot 18 status Slot 17 status Slot 16 status

Produce 3 Slot 31 status Slot 30 status Slot 29 status Slot 28 status Slot 27 status Slot 26 status Slot 25 status Slot 24 status

Produce 4 Slot 39 status Slot 38 status Slot 37 status Slot 36 status Slot 35 status Slot 34 status Slot 33 status Slot 32 status

Produce 5 Slot 47 status Slot 46 status Slot 45 status Slot 44 status Slot 43 status Slot 42 status Slot 41 status Slot 40 status

Produce 6 Slot 55 status Slot 54 status Slot 53 status Slot 52 status Slot 51 status Slot 50 status Slot 49 status Slot 48 status

Produce 7 Slot 63 status Slot 62 status Slot 61 status Slot 60 status Slot 59 status Slot 58 status Slot 57 status Slot 56 status

Produce 8 Reserved Slot 1 Bit 3 Slot 1 Bit 2 Slot 1 Bit 1 Slot 1 Bit 0

Produce 9 Slot 2 Bit 7 Slot 2 Bit 6 Slot 2 Bit 5 Slot 2 Bit 4 Slot 2 Bit 3 Slot 2 Bit 2 Slot 2 Bit 1 Slot 2 Bit 0

Produce 10 Reserved Slot 3 Bit 1 Slot 3 Bit 0

Produce 11 Reserved Slot 4 Bit 1 Slot 4 Bit 0

Produce 12 Reserved Slot 5 Bit 3 Slot 5 Bit 2 Slot 5 Bit 1 Slot 5 Bit 0

Produce 13 Slot 6 Bit 7 Slot 6 Bit 6 Slot 6 Bit 6 Slot 6 Bit 4 Slot 6 Bit 3 Slot 6 Bit 2 Slot 6 Bit 1 Slot 6 Bit 0

Produce 14 Slot 7 Bit 7 Slot 7 Bit 6 Slot 7 Bit 5 Slot 7 Bit 4 Slot 7 Bit 3 Slot 7 Bit 2 Slot 7 Bit 1 Slot 7 Bit 0

Produce 15 Pad

Produce 16 Slot 8 Bit 7 Slot 8 Bit 6 Slot 8 Bit 5 Slot 8 Bit 4 Slot 8 Bit 3 Slot 8 Bit 2 Slot 8 Bit 1 Slot 8 Bit 0

Publication 1734-UM016A-EN-P - October 2010

Page 33

Assembly Structure 27

Produced Assembly, Double Word Aligned

Byte Bit 7 Bit 6 Bit5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Produce 17 Slot 8 Bit 15 Slot 8 Bit 14 Slot 8 Bit 13 Slot 8 Bit 12 Slot 8 Bit 11 Slot 8 Bit 10 Slot 8 Bit 9 Slot 8 Bit 8

Produce 18 Pad

Produce 19 Pad

Produce 20 Slot 9 Channel 0 - Low Byte

Produce 21 Slot 9 Channel 0 - High Byte

Produce 22 Slot 9 Channel 1 - Low Byte

Produce 23 Slot 9 Channel 1 - High Byte

Produce 24 Slot 9 Channel 0 - Status

Produce 25 Slot 9 Channel 1 - Status

Produce 26 Pad

Produce 27 Pad

Produce 28 Slot 10 ASCII Data 1

Produce 29 Slot 10 ASCII Data 2

Produce 30 Slot 10 ASCII Data 3

Produce 31 Slot 10 ASCII Data 4

Produce 32 Slot 10 ASCII Data 5

Produce 33 Slot 10 ASCII Data 6

Produce 34 Slot 10 ASCII Data 7

Produce 35 Slot 10 ASCII Data 8

Produce 36 Slot 10 ASCII Data End of String Delimiter

Produce 37 Slot 11 ARM - Reserved Byte

Produce 38 Reserved Slot 13 Bit 3 Slot 13 Bit 2 Slot 13 Bit 1 Slot 13 Bit 0

Consumed Assembly, Double Word Aligned

Byte Bit 7 Bit 6 Bit5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Consume 0 Reserved Run/Idle

Consume 1 Reserved

Consume 2 Reserved

Consume 3 Reserved

Consume 4 Reserved Slot 4 Bit 1 Slot 4 Bit 0

Consume 5 Reserved Slot 5 Bit 3 Slot 5 Bit 2 Slot 5 Bit 1 Slot 5 Bit 0

Consume 6 Slot 6 Bit 7 Slot 6 Bit 6 Slot 6 Bit 5 Slot 6 Bit 4 Slot 6 Bit 3 Slot 6 Bit 2 Slot 6 Bit 1 Slot 6 Bit 0

Consume 7 Pad

Consume 8 Slot 10 ASCII Data 1

Consume 9 Slot 10 ASCII Data 2

Consume 10 Slot 10 ASCII Data 3

Publication 1734-UM016A-EN-P - October 2010

Page 34

28 Assembly Structure

Consumed Assembly, Double Word Aligned

Byte Bit 7 Bit 6 Bit5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Consume 11 Slot 10 ASCII Data 4

Consume 12 Slot 10 ASCII Data 5

Consume 13 Slot 10 ASCII Data End of String Delimiter

Consume 14 Reserved Slot 12 Bit 3 Slot 12 Bit 2 Slot 12 Bit 1 Slot 12 Bit 0

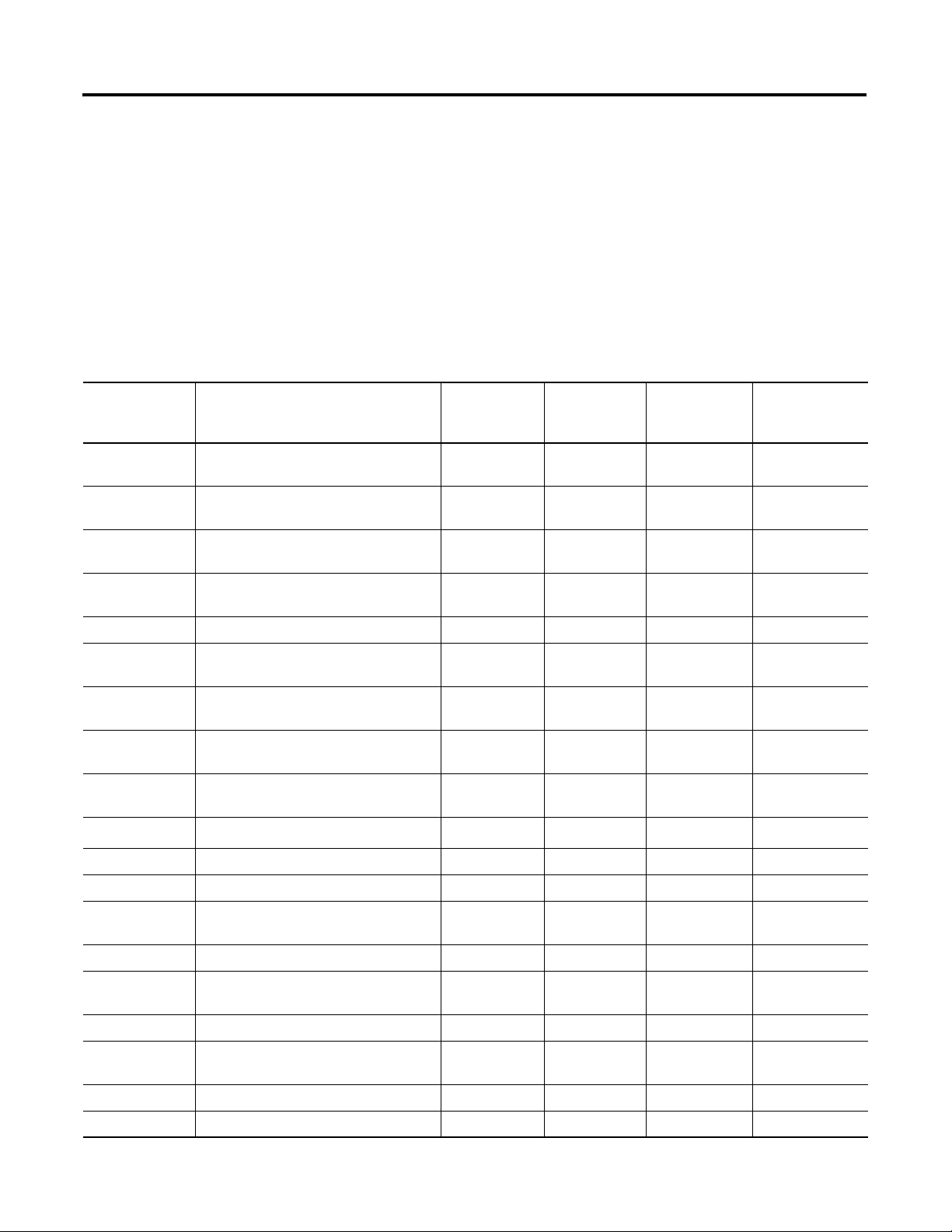

Fixed Size per Slot Alignment

The following chassis is used to demonstrate how the Fixed Size per Slot

alignment option might be used. This chassis is built to show a machine that

sometimes uses 5 analog modules, but usually only needs 3 modules. In order

to maintain data structure consistency (and therefore the same control logic),

Fixed Size per Slot alignment of 6 bytes is used and the unused slots are

populated with Address Reserve Modules.

Example POINT system with unused slots

A

A

I

I

I

I

Cat # A

Slot # 012345678

Produced Assembly, Fixed Size per Slot Alignment

Byte Bit 7 Bit 6 Bit5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Produce 0 Slot 7 status Slot 6 status Slot 5 status Slot 4 status Slot 3 status Slot 2 status Slot1 status Slot 0 status

Produce 1 Slot 15 status Slot 14 status Slot 13 status Slot 12 status Slot 11 status Slot 10 status Slot 9 status Slot 8 status

Produce 2 Slot 23 status Slot 22 status Slot 21 status Slot 20 status Slot 19 status Slot 18 status Slot 17 status Slot 16 status

Produce 3 Slot 31 status Slot 30 status Slot 29 status Slot 28 status Slot 27 status Slot 26 status Slot 25 status Slot 24 status

Produce 4 Slot 39 status Slot 38 status Slot 37 status Slot 36 status Slot 35 status Slot 34 status Slot 33 status Slot 32 status

Produce 5 Slot 47 status Slot 46 status Slot 45 status Slot 44 status Slot 43 status Slot 42 status Slot 41 status Slot 40 status

Produce 6 Slot 55 status Slot 54 status Slot 53 status Slot 52 status Slot 51 status Slot 50 status Slot 49 status Slot 48 status

Produce 7 Slot 63 status Slot 62 status Slot 61 status Slot 60 status Slot 59 status Slot 58 status Slot 57 status Slot 56 status

Produce 8 Slot 1 Channel 0 - Low Byte

Produce 9 Slot 1 Channel 0 - High Byte

Produce 10 Slot 1 Channel 1 - Low Byte

Produce 11 Slot 1 Channel 1 - High Byte

Produce 12 Slot 1 Channel 0 - Status

Produce 13 Slot 1 Channel 1 - Status

I

R

R

M

B

4

E

E

E

E

M

2

2

2

N

C

C

C

T

I

B

B

4

4

Publication 1734-UM016A-EN-P - October 2010

Page 35

Assembly Structure 29

Produced Assembly, Fixed Size per Slot Alignment

Byte Bit 7 Bit 6 Bit5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Produce 14 Slot 2 Channel 0 - Low Byte

Produce 15 Slot 2 Channel 0 - High Byte

Produce 16 Slot 2 Channel 1 - Low Byte

Produce 17 Slot 2 Channel 1 - High Byte

Produce 18 Slot 2 Channel 0 - Status

Produce 19 Slot 2 Channel 1 - Status

Produce 20 Slot 3 Channel 0 - Low Byte

Produce 21 Slot 3 Channel 0 - High Byte

Produce 22 Slot 3 Channel 1 - Low Byte

Produce 23 Slot 3 Channel 1 - High Byte

Produce 24 Slot 3 Channel 0 - Status

Produce 25 Slot 3 Channel 1 - Status

Produce 26 Slot 4 ARM - Reserved Byte

Produce 27 Slot 4 ARM - Reserved Byte

Produce 28 Slot 4 ARM - Reserved Byte

Produce 29 Slot 4 ARM - Reserved Byte

Produce 30 Slot 4 ARM - Reserved Byte

Produce 31 Slot 4 ARM - Reserved Byte

Produce 32 Slot 5 ARM - Reserved Byte

Produce 33 Slot 5 ARM - Reserved Byte

Produce 34 Slot 5 ARM - Reserved Byte

Produce 35 Slot 5 ARM - Reserved Byte

Produce 36 Slot 5 ARM - Reserved Byte

Produce 37 Slot 5 ARM - Reserved Byte

Produce 38 Reserved Slot 6 Bit 3 Slot 6 Bit 2 Slot 6 Bit 1 Slot 6 Bit 0

Produce 39 Pad

Produce 40 Pad

Produce 41 Pad

Produce 42 Pad

Produce 43 Pad

Produce 44 Slot 7 Bit 3 Slot 7 Bit 2 Slot 7 Bit 1 Slot 7 Bit 0

Produce 45 Pad

Produce 46 Pad

Produce 47 Pad

Produce 48 Pad

Produce 49 Pad

Produce 50 Slot 8 Bit 3 Slot 8 Bit 2 Slot 8 Bit 1 Slot 8 Bit 0

Produce 51 Pad

Publication 1734-UM016A-EN-P - October 2010

Page 36

30 Assembly Structure

Produced Assembly, Fixed Size per Slot Alignment

Byte Bit 7 Bit 6 Bit5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Produce 52 Pad

Produce 53 Pad

Produce 54 Pad

Produce 55 Pad

Publication 1734-UM016A-EN-P - October 2010

Page 37

Chapter

5

1734/1738 I/O Module Assembly Information

Module Assembly

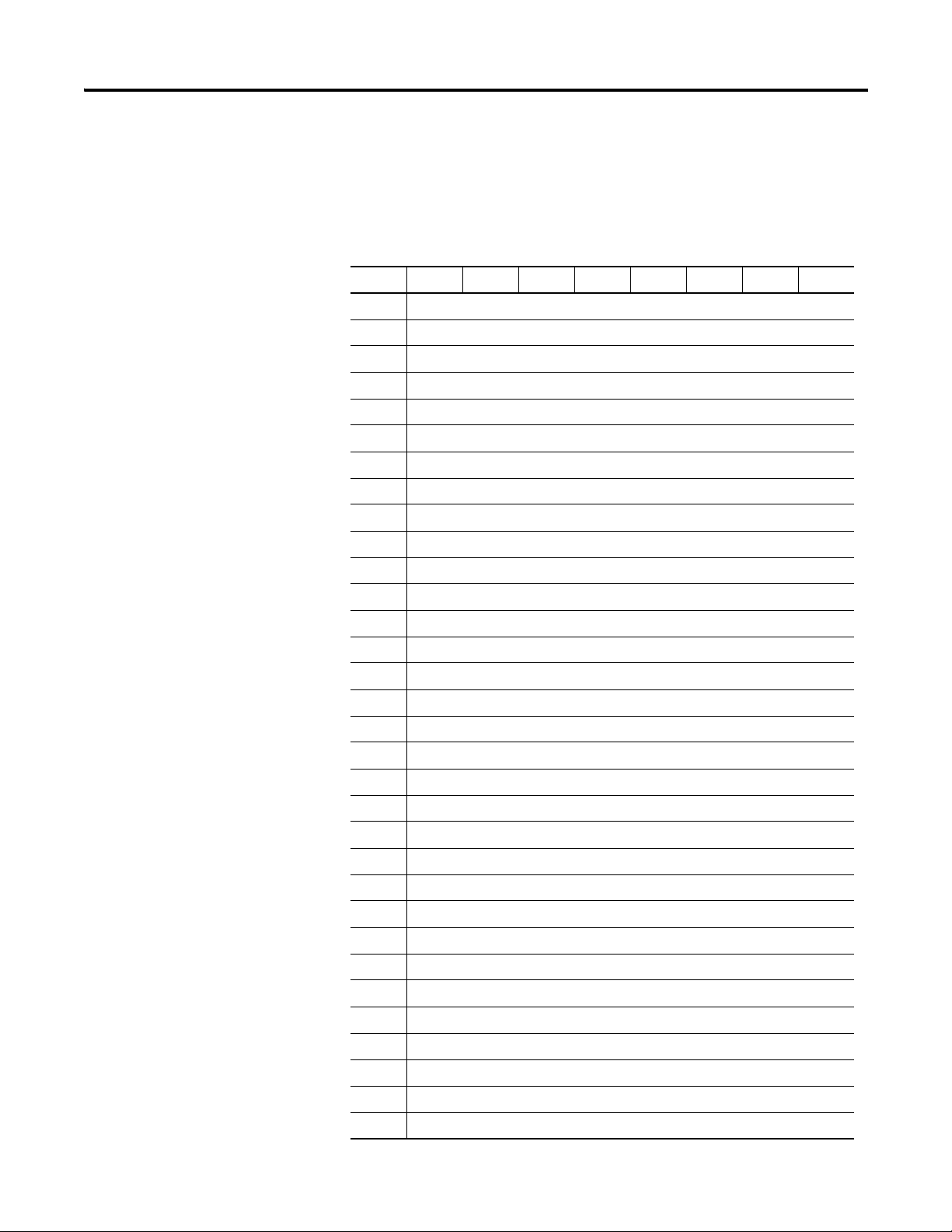

Discrete Modules

Information

POINT I/O and ArmorPOINT I/O Discrete I/O modules

Cat. No Description Configuration

Assembly

Instance

1734-IB2

1738-IB2

1734-IB4

1738-IB4

1734-IB4D

1738-IB4D

1734-IB8

1738-IB8

1734-IV2 2 point DC source input 103 8 1 0

1734-IV4

1738-IV4

1734-IV8

1738-IV8

1734-OB2E

1738-OB2E

2 point DC sink input 103 8 1 0

4 point DC sink input 103 16 1 0

2 point DC sink input with diagnostics 103 18 2,1 0

8 point DC sink input 103 32 1 0

4 point DC source input 103 16 1 0

8 point DC source input 103 32 1 0

2 point DC source output 123 8 1 1

Configuration

Size

Produced Size Consumed Size

1734-OB4E

1738-OB4E

1734-OB2 2 point DC source output 123 8

1734-OB4 4 point DC source output 123 8 1 1

1734-OB8 8 point DC source output 123 8 1 1

1734-OB8E

1738-OB8E

1734-OW2 2 point relay output 103 4 0 1

1734-OW4

1738-OW4

1734-OV2E 2 point 24V DC sink output 123 8 1 1

1734-OV4E

1738-OV4E

1734-OV8E 8 point 24V DC sink output 123 8 1 1

1734-OX2 2 point Form C Relay output 103 4 0 1

31 Publication 1734-UM016A-EN-P - October 2010

4 point DC source output 123 8 1 1

(1)

1

8 point DC source output 123 8 1 1

4 point relay output 103 4 0 1

4 point 24V DC sink output 123 8 1 1

1

Page 38

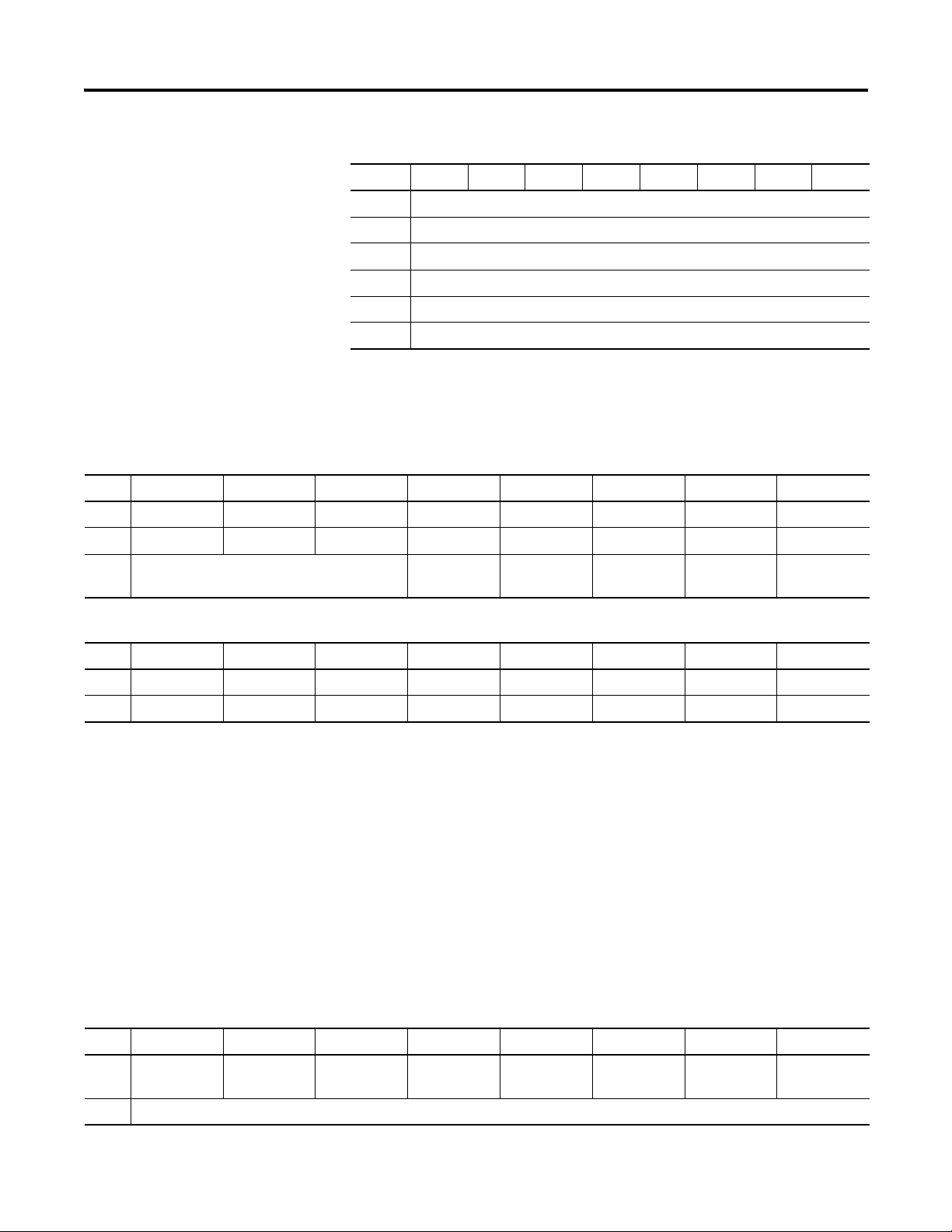

32 1734/1738 I/O Module Assembly Information

POINT I/O and ArmorPOINT I/O Discrete I/O modules

Cat. No Description Configuration

Assembly

Configuration

Size

Produced Size Consumed Size

Instance

1734-OB2EP

2 point 24V DC 2A Protected output 123 8 1 1

1738-OB2EP

1734-IA2

2 point 120V AC input 103 8 1 0

1738-IA2

1734-IA4 4 point 120V AC input 103 16 1 0

1734-IM2 2 point 220V AC input 103 8 1 0

1734-IM4 4 point 220V AC input 103 16 1 0

1734-OA2

2 point 120V/220V AC output 103 4 0 1

1738-OA2

1734-OA4 4-channel 120V/220V AC output 103 4 0 1

1738-IB16 16 point 24V DC sink input 103 6 2,3 0

1738-OB16 16 point 24V DC source input 123 2 1 2

1734-8CFG

1738-8CFG

(1)

While these modules (OB2, OB4, and OB8) have no meaningful data, they return a byte of 0 to be compatible with the "E" modules. In this manner they can be interchanged.

Also these modules expect the same 8-byte configuration assembly even though only the first 4 bytes are meaningful.

8 point 24V DC configurable sink

input/source output

103 8 1 1

Analog and Specialty I/O Modules

POINT and ArmorPOINT Analog and Specialty I/O modules

Cat. No Description Configuration

Assembly

Instance

1734-VHSC5 1 point 5V, 2 out very high speed counter 108 54 6 2,2,4

1734-VHSC24

1 point 24V, 2 out very high speed counter 108 54 6 2,2,4

1738-VHSC24

1734-IJ

1 point 5V counter 123 18 6 1

1738-IJ

1734-IK 1 point 24V counter 123 18 6 1

1734-IE2C

2 point analog current input 123 38 6 0

1738-IE2C

1734-IE4C

4 point analog current input 123 74 12 0

1738-IE4C

1734-IE8C 8 point analog current input 123 146 24 0

1734-OE2C

2 point analog current output 123 36 2 4

1738-OE2C

Configuration

Size

Produced Size Consumed Size

Publication 1734-UM016A-EN-P - October 2010

Page 39

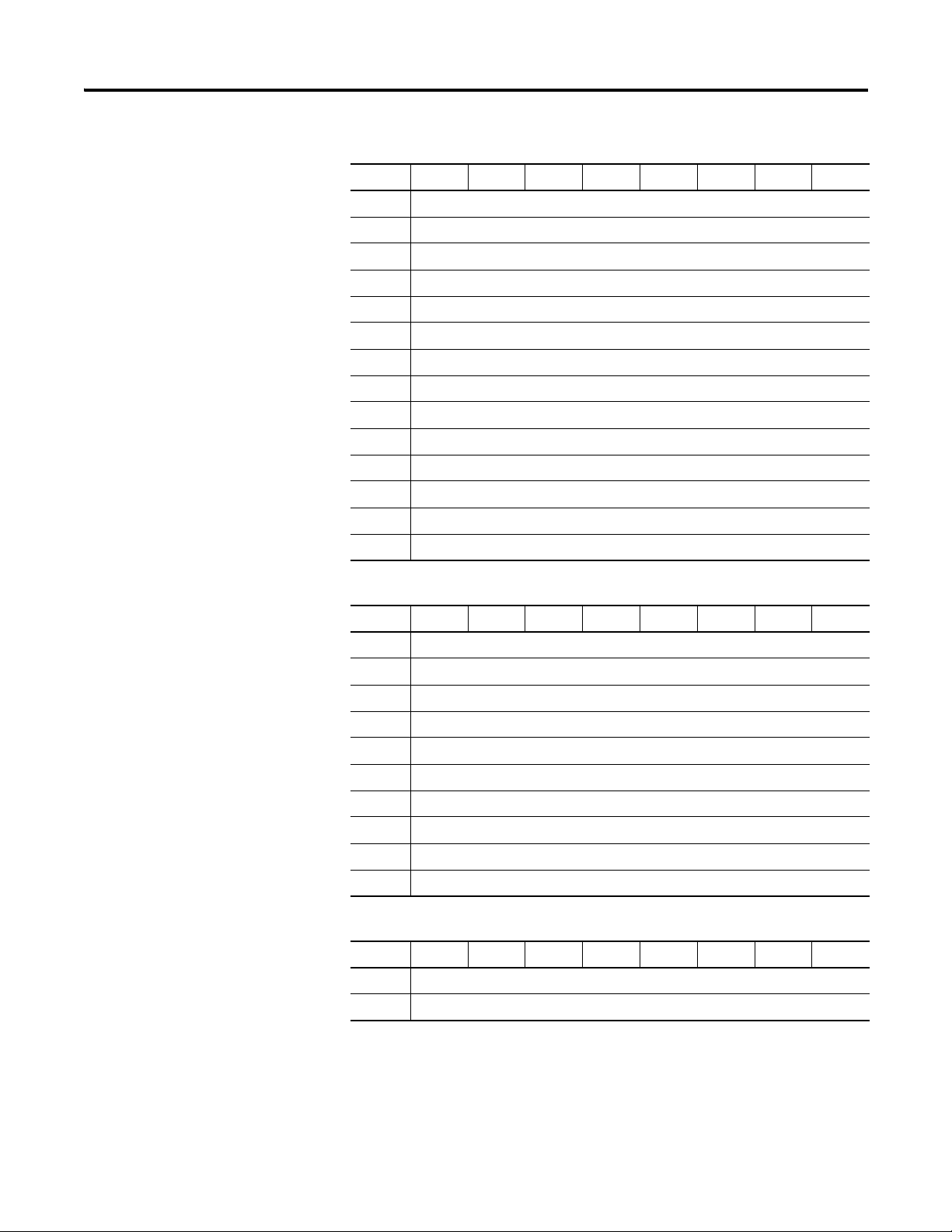

POINT and ArmorPOINT Analog and Specialty I/O modules

1734/1738 I/O Module Assembly Information 33

Cat. No Description Configuration

Assembly

Instance

1734-OE4C

1738-OE4C

1734-IT21

1738-IT21

1734-IR2

1738-IR2

1734-IR2E 2 point enhanced RTD input 123 38 6 0

1734-IE2V

1738-IE2V

1734-OE2V

1738-OE2V

1734-SSI

1738-SSI

1734-232ASC

1738-232ASC

1734-485ASC

1738-485ASC

1734-ARM Address reserve N/A 0 1 0

4 point analog current output 123 72 4 8

2 point thermocouple input 103 46 8 0

2 channel, 2point RTD input 123 38 6 0

2 point analog voltage input 123 38 6 0

2 point analog voltage output 123 36 2 4

POINT I/O synchronous serial interface

POINT I/O RS232 ASCII interface

POINT I/O RS485 ASCII interface

123 26 10 2

103 18 4…132

103 18 4…132

Configuration

Size

Produced Size Consumed Size

default = 24

default = 24

4…132

default = 24

4…132

default = 24

Data Format

The POINT I/O products specify multi-byte data values in little endian

format. The term little endian refers to the ordering method in which:

• The least significant byte of a data item is ordered first.

• The most significant byte of a data item is ordered last

• All bytes in between are ordered sequentially, from least significant byte

to most significant byte.

Layout for 16 bit numbers:

TagName[Low Byte]

TabName[High Byte]

Layout for 32 bit numbers:

TagName[Low Byte]

TagName

Publication 1734-UM016A-EN-P - October 2010

Page 40

34 1734/1738 I/O Module Assembly Information

TagName

TabName[High Byte]

Layout for Array data:

TagName[0]

TagName[1]

TagName[2]

: :

TabName[N]

Module Specific Details

Two-channel Discrete Input Modules

All two-channel discrete input modules use the same configuration and input

assemblies. Use the tables shown below for the following modules:

• 1734-IB2 or 1738-IB2

• 1734-IV2 or 1738-IV2

• 1734-IA2 or 1738-IA2

• 1734-IM2 or 1738-IM2

Configuration Assembly Instance 103

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Input 0 Off to On Filter Low Byte

1 Input 0 Off to On Filter High Byte

2 Input 0 On to Off Filter Low Byte

3 Input 0 On to Off Filter High Byte

4 Input 1 Off to On Filter Low Byte

5 Input 1 Off to On Filter High Byte

6 Input 1 On to Off Filter Low Byte

Publication 1734-UM016A-EN-P - October 2010

7 Input 1 On to Off Filter High Byte

Produced Input Data Assembly 2

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Reserved Ch 1 Ch 0

Page 41

1734/1738 I/O Module Assembly Information 35

Four-channel Discrete Input Modules

All four channel discrete input modules use the same configuration and input

assemblies. Use the tables shown below for the following modules:

• 1734-IB4 or 1738-IB4

• 1734-IV4 or 1738-IV4

• 1734-IA4 or 1738-IA4

• 1734-IM4 or 1738-IM4

Configuration Assembly Instance 103

ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Input 0 Off to On Filter Low Byte

1 Input 0 Off to On Filter High Byte

2 Input 0 On to Off Filter Low Byte

3 Input 0 On to Off Filter High Byte

4 Input 1 Off to On Filter Low Byte

5 Input 1 Off to On Filter High Byte

6 Input 1 On to Off Filter Low Byte

7 Input 1 On to Off Filter High Byte

8 Input 2 Off to On Filter Low Byte

9 Input 2 Off to On Filter High Byte

10 Input 2 On to Off Filter Low Byte

11 Input 2 On to Off Filter High Byte

12 Input 3 Off to On Filter Low Byte

13 Input 3 Off to On Filter High Byte

14 Input 3 On to Off Filter Low Byte

15 Input 3 On to Off Filter High Byte

Produced Input Data Assembly 3

ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Reserved Ch 3 Ch 2 Ch 1 Ch 0

Eight-channel Discrete Input Modules

All eight-channel discrete input modules use the same configuration and input

assemblies. Use the tables shown below for the following modules:

Publication 1734-UM016A-EN-P - October 2010

Page 42

36 1734/1738 I/O Module Assembly Information

• 1734-IB8 or 1738-IB8

• 1734-IV8 or 1738-IV8

Configuration Assembly Instance 103

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Input 0 Off to On Filter Low Byte

1 Input 0 Off to On Filter High Byte

2 Input 0 On to Off Filter Low Byte

3 Input 0 On to Off Filter High Byte

4 Input 1 Off to On Filter Low Byte

5 Input 1 Off to On Filter High Byte

6 Input 1 On to Off Filter Low Byte

7 Input 1 On to Off Filter High Byte

8 Input 2 Off to On Filter Low Byte

9 Input 2 Off to On Filter High Byte

10 Input 2 On to Off Filter Low Byte

11 Input 2 On to Off Filter High Byte

12 Input 3 Off to On Filter Low Byte

13 Input 3 Off to On Filter High Byte

14 Input 3 On to Off Filter Low Byte

15 Input 3 On to Off Filter High Byte

16 Input 4 Off to On Filter Low Byte

17 Input 4 Off to On Filter High Byte

18 Input 4 On to Off Filter Low Byte

19 Input 4 On to Off Filter High Byte

20 Input 5 Off to On Filter Low Byte

21 Input 5 Off to On Filter High Byte

22 Input 5 On to Off Filter Low Byte

23 Input 5 On to Off Filter High Byte

24 Input 6 Off to On Filter Low Byte

25 Input 6 Off to On Filter High Byte

26 Input 6 On to Off Filter Low Byte

27 Input 6 On to Off Filter High Byte

28 Input 7 Off to On Filter Low Byte

29 Input 7 Off to On Filter High Byte

Publication 1734-UM016A-EN-P - October 2010

30 Input 7 On to Off Filter Low Byte

31 Input 7 On to Off Filter High Byte

Page 43

Configuration Assembly Instance 123

1734/1738 I/O Module Assembly Information 37

Produced Input Data Assembly 4

ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Ch 7 Ch 6 Ch 5 Ch 4 Ch 3 Ch 2 Ch 1 Ch 0

Two-channel Discrete Output Modules with Status

All two-channel "enhanced" discrete output modules use the same

configuration and I/O assemblies. Use the tables shown below for the

following modules:

• 1734-OB2E or 1738-OB2E

• 1734-OV2E or 1738-0V2E

• 1734-OB2EP or 1738-OB2EP

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Reserved Fault State 1 Fault State 0

1 Reserved Fault Value 1 Fault Value 0

2 Reserved Idle State 1 Idle State 0

3 Reserved Idle Value 1 Idle Value 0

4 Reserved Enable No Load 1 Enable No Load 0

5 Reserved Reset mode 1 Reset mode 0

6 Reserved Enable Latched Alarms 1 Enable Latched Alarms 0

7 Pad

Produced Input Data Assembly 42

ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Reserved Ch 1

Status

Consumed Output Data Assembly 32

ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Reserved Ch 1 Ch 0

Ch 0

Status

Publication 1734-UM016A-EN-P - October 2010

Page 44

38 1734/1738 I/O Module Assembly Information

Two-channel Discrete Output Modules

Use the tables shown below for the following modules:

• 1734-OB2 or 1738-OB2

Configuration Assembly Instance 123

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Reserved Fault State 1 Fault State 0

1 Reserved Fault Value 1 Fault Value 0

2 Reserved Idle State 1 Idle State 0

3 Reserved Idle Value 1 Idle Value 0

4 Reserved (Set to 0)

5 Reserved (Set to 0)

6 Reserved (Set to 0)

7 Pad

Produced Input Data Assembly 42

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Reserved

Consumed Output Data Assembly 32

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Reserved Ch 1 Ch 0

Four-channel Discrete Output Modules with Status

All four-channel "enhanced" discrete output modules use the same

configuration and I/O assemblies. Use the tables shown below for the

following modules:

• 1734-OB4E or 1738-OB4E

• 1734-OV4E or 1738-0V4E

Publication 1734-UM016A-EN-P - October 2010

Page 45

1734/1738 I/O Module Assembly Information 39

Configuration Assembly Instance 123

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Reserved Fault State 3 Fault State 2 Fault State 1 Fault State 0

1 Reserved Fault Value 3 Fault Value 2 Fault Value 1 Fault Value 0

2 Reserved Idle State 3 Idle State 2 Idle State 1 Idle State 0

3 Reserved Idle Value 3 Idle Value 2 Idle Value 1 Idle Value 0

4 Reserved Enable No Load 3 Enable No Load 2 Enable No Load 1 Enable No Load 0

5 Reserved Reset mode 3 Reset mode 2 Reset mode 1 Reset mode 0

6 Reserved Enable Latched

Alarms 3

7 Pad

Produced Input Data Assembly 43

ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Reserved

Consumed Output Data Assembly 33

ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Reserved Ch 3 Ch 2 Ch 1 Ch 0

Four-channel Discrete Output Modules

Use the tables shown below for the following modules:

• 1734-OB4 or 1738-OB4

Enable Latched

Alarms 2

Enable Latched

Alarms 1

Enable Latched

Alarms 0

Configuration Assembly Instance 123

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Reserved Fault State 3 Fault State 2 Fault State 1 Fault State 0

1 Reserved Fault Value 3 Fault Value 2 Fault Value 1 Fault Value 0

2 Reserved Idle State 3 Idle State 2 Idle State 1 Idle State 0

3 Reserved Idle Value 3 Idle Value 2 Idle Value 1 Idle Value 0

4 Reserved (Set to 0)

5 Reserved (Set to 0)

6 Reserved (Set to 0)

7 Pad

Publication 1734-UM016A-EN-P - October 2010

Page 46

40 1734/1738 I/O Module Assembly Information

Produced Input Data Assembly 43

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Reserved

Consumed Output Data Assembly 33

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Reserved Ch 3 Ch 2 Ch 1 Ch 0

Eight-channel Discrete Output Modules with Status

All eight-channel "enhanced" discrete output modules use the same

configuration and I/O assemblies. Use the tables shown below for the

following modules:

• 1734-OB8E or 1738-OB8E

• 1734-OV8E or 1738-OV8E

Configuration Assembly Instance 123

ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Fault State 7 Fault State 6 Fault State 5 Fault State 4 Fault State 3 Fault State 2 Fault State 1 Fault State 0

1 Fault Value 7 Fault Value 6 Fault Value 5 Fault Value 4 Fault Value 3 Fault Value 2 Fault Value 1 Fault Value 0

2 Idle State 7 Idle State 6 Idle State 5 Idle State 4 Idle State 3 Idle State 2 Idle State 1 Idle State 0

3 Idle Value 7 Idle Value 6 Idle Value 5 Idle Value 4 Idle Value 3 Idle Value 2 Idle Value 1 Idle Value 0

4 Enable No

Load 7

5 Reset Mode 7 Reset Mode 6 Reset Mode 5 Reset Mode 4 Reset Mode 3 Reset Mode 2 Reset mode 1 Reset mode 0

6 Enable

Latched

Alarms 7

7 Pad

Enable No

Load 6

Enable

Latched

Alarms 6

Enable No

Load 5

Enable

Latched

Alarms 5

Produced Input Data Assembly 44

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Ch 7

Enable No

Load 4

Enable

Latched

Alarms 4

status

Ch 6

status

Enable No

Load 3

Enable

Latched

Alarms 3

Ch 5

status

Enable No

Load 2

Enable

Latched

Alarms 2

Ch

status

Ch 3

status

Enable No

Load 1

Enable

Latched

Alarms 1

Ch 2

status

Ch 1

status

Enable No

Load 0

Enable

Latched

Alarms 0

Ch 0

status

Publication 1734-UM016A-EN-P - October 2010

Consumed Output Data Assembly 34

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Ch 7 Ch 6 Ch 5 Ch 4 Ch 3 Ch 2 Ch 1 Ch 0

Page 47

1734/1738 I/O Module Assembly Information 41

Eight-channel Discrete Output Modules

Use the tables shown below for the following modules:

• 1734-OB8 or 1738-OB8

Configuration Assembly Instance 123

ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Fault State 7 Fault State 6 Fault State 5 Fault State 4 Fault State 3 Fault State 2 Fault State 1 Fault State 0

1 Fault Value 7 Fault Value 6 Fault Value 5 Fault Value 4 Fault Value 3 Fault Value 2 Fault Value 1 Fault Value 0

2 Idle State 7 Idle State 6 Idle State 5 Idle State 4 Idle State 3 Idle State 2 Idle State 1 Idle State 0

3 Idle Value 7 Idle Value 6 Idle Value 5 Idle Value 4 Idle Value 3 Idle Value 2 Idle Value 1 Idle Value 0

4 Enable No

Load 7

5 Reset Mode 7 Reset Mode 6 Reset Mode 5 Reset Mode 4 Reset Mode 3 Reset Mode 2 Reset mode 1 Reset mode 0

6 Enable

Latched

Alarms 7

7 Pad

Enable No

Load 6

Enable

Latched

Alarms 6

Enable No

Load 5

Enable

Latched

Alarms 5

Enable No

Load 4

Enable

Latched

Alarms 4

Enable No

Load 3

Enable

Latched

Alarms 3

Enable No

Load 2

Enable

Latched

Alarms 2

Enable No

Load 1

Enable

Latched

Alarms 1

Enable No

Load 0

Enable

Latched

Alarms 0

Produced Input Data Assembly 44

ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Reserved

Consumed Output Data Assembly 34

ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Ch 7 Ch 6 Ch 5 Ch 4 Ch 3 Ch 2 Ch 1 Ch 0

Four-channel Discrete Diagnostic Input Modules

Use the tables shown below for the following modules:

• 1734-IB4D or 1738-IB4DM12

Publication 1734-UM016A-EN-P - October 2010

Page 48

42 1734/1738 I/O Module Assembly Information

Configuration Assembly Instance 103

ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Input 0 Off to On Filter Low Byte

1 Input 0 Off to On Filter High Byte

2 Input 0 On to Off Filter Low Byte

3 Input 0 On to Off Filter High Byte

4 Input 1 Off to On Filter Low Byte

5 Input 1 Off to On Filter High Byte

6 Input 1 On to Off Filter Low Byte

7 Input 1 On to Off Filter High Byte

8 Input 2 Off to On Filter Low Byte

9 Input 2 Off to On Filter High Byte

10 Input 2 On to Off Filter Low Byte

11 Input 2 On to Off Filter High Byte

12 Input 3 Off to On Filter Low Byte

13 Input 3 Off to On Filter High Byte

14 Input 3 On to Off Filter Low Byte

15 Input 3 On to Off Filter High Byte

16 Autobaud

Disable

17 Produced Assembly Instance

Enable Open

Wire Detect 3

Enable Open

Wire Detect 2

Enable Open

Wire Detect 1

Enable Open

Wire Detect 0

This POINT I/O input module produces 1 or 2 bytes of input data based on

which produced assembly is selected. The default assembly (instance 101) is 2

bytes. This module does not consume I/O data.

Produced Diagnostic Input Data Assembly 101

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Fault 3 Fault 2 Fault 1 Fault 0 Input 3 Input 2 Input 1 Input 0

1 Short

Circuit 3

Produced Input Data Assembly 23

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Fault 3 Fault 2 Fault 1 Fault 0 Input 3 Input 2 Input 1 Input 0

Short

Circuit 2

Short

Circuit 1

Short

Circuit 0

Off

Wire 3

Off

Wire 2

Off

Wire 1

Off

Wire 0

Publication 1734-UM016A-EN-P - October 2010

Page 49

1734/1738 I/O Module Assembly Information 43

Two-channel Relay and AC Output Modules

All two-channel relay and AC output modules use the same Consumed I/O

assembly. There are no Produced or Configuration assemblies for these

modules. Use the table shown below for the following modules:

• 1734-OW2

• 1734-OX2

• 1734-OA2 or 1738-OA2M12AC3

Consumed Output Data Assembly 32

Byte Bit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Reserved Ch 1 Ch 0

Four-channel Relay and AC Output Modules

All four channel relay and AC output modules use the same Consumed I/O

assembly. There are no Produced or Configuration assemblies for these

modules. Use the table shown below for the following modules:

• 1734-OW4

• 1734-OW4M12 or 1738-OW4M12AC

• 1734-OA4

Consumed Output Data Assembly 32

Byte Bit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Reserved Ch 3 Ch 2 Ch 1 Ch 0

Sixteen-channel Discrete Diagnostic Input Modules

Use the table shown below for the following modules:

• 1738-IB16DM12

Publication 1734-UM016A-EN-P - October 2010

Page 50

44 1734/1738 I/O Module Assembly Information

Configuration Assembly Instance 103

Byte Bit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Input Off to On Filter Low Byte

1 Input Off to On Filter High Byte

2 Input On to Off Filter Low Byte

3 Input On to Off Filter High Byte

4 Produced Assembly

5 Reserved = 0

This POINT I/O input module produces 2 or 3 bytes of input data based on

which produced assembly is selected. The default assembly instance 101 is 3

bytes. This module does not consume I/O data.

Produced Diagnostic Input Data Assembly Instance 101

ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Ch 7 Ch 6 Ch 5 Ch 4 Ch 3 Ch 2 Ch 1 Ch 0

1 Ch 15 Ch 14 Ch 13 Ch 12 Ch 11 Ch 10 Ch 9 Ch 8

2 Reserved Fault LED

State

SSV Fault

12…15

SSV Fault

8…11

SSV Fault

4…7

SSV Fault

0…3

Produced Input Data Assembly Instance 5

ByteBit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0

0 Ch 7 Ch 6 Ch 5 Ch 4 Ch 3 Ch 2 Ch 1 Ch 0