Page 1

User Manual

POINT I/O and ArmorPOINT I/O 2 Port EtherNet/IP

Adapters

Catalog Numbers

1734-AENTR, 1738-AENTR, Series A

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Automation, POINT I/O, ArmorPOINT I/O, RSLo gix, RSLinx, RSL ogix 5000, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Preface

Read this preface to familiarize yourself with the rest of the manual. It provides

information concerning:

• who should use this manual

• the purpose of this manual

• related documentation

• conventions used in this manual

Who Should Use this Manual

Purpose of this Manual

Use this manual if you are responsible for designing, installing, programming, or

™

troubleshooting control systems that use Series A 1734 POINT I/O

™

1738 ArmorPOINT I/O

2 Port EtherNet/IP Adapter Modules.

or

This manual is a reference guide for the 1734-AENTR, 1738-AENTR Series A

POINT I/O™ 2 Port EtherNet/IP and ArmorPOINT I/O 2 Port EtherNet/IP

Adapters, communications adapters for POINT I/O modules. It describes the

procedures you use to install, wire, configure, troubleshoot, and use these

modules.

ATTENTION: You must use series C POINT I/O modules with the

adapter. Series A or B POINT I/O modules do not work with the adapter.

Related Documentation

The following documents contain additional information concerning Rockwell

Automation products. To obtain a copy, contact your local Rockwell Automation

office or distributor

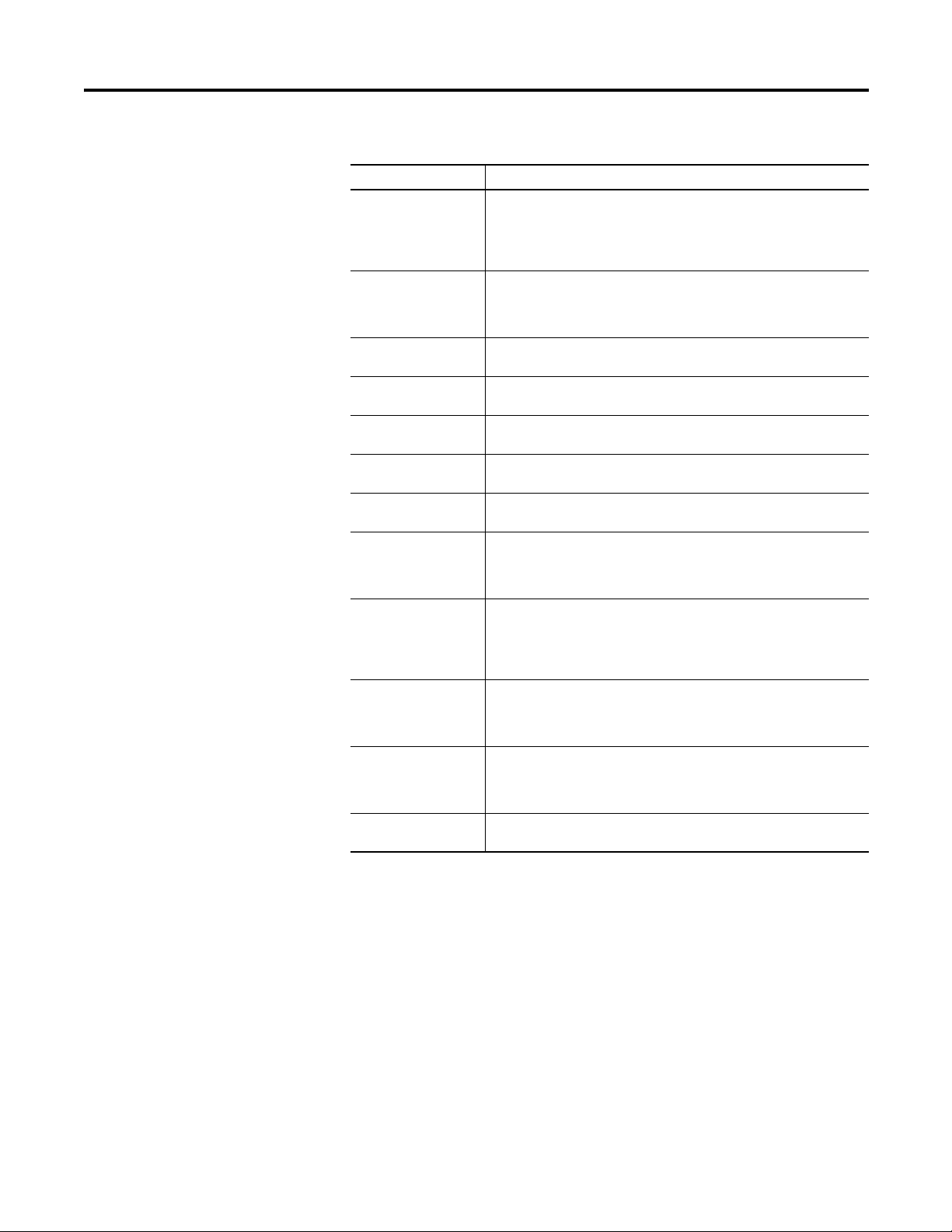

For Information About See This Publication Publication Number

1734-series I/O modules and compatible control platforms. POINT I/O™ Selection Guide 1734-SG001

Using EtherNet/IP for industrial control EtherNet/IP Design Considerations Reference Manual ENET-RM002

ControlLogix Ethernet communication interface modules ControlLogix EtherNet/IP Bridge Module Installation Instructions 1756-IN019

EtherNet/IP Modules in Logix5000 Control Systems User Manual ENET-UM001

ControlLogix chassis and power supplies installation ControlLogix Chassis and Power Supplies Installation Instructions 1756-IN005

ControlLogix systems ControlLogix System User Manual 1756-UM001

RSLinx RSLinx Classic Getting Results Guide LINX-GR001

1734-AENTR adapter installation POINT I/O 2 Port EtherNet/IP Adapter Installation Instructions 1734-IN040

1738-AENTR adapter installation ArmorPoint I/O 2-Port EtherNet/IP Adapter Installation Instructions 1738-IN028

Installing an EtherNet/IP network EtherNet/IP Media Planning and Installation Manual ODVA

Rockwell Automation Publication 1734-UM014B-EN-P - May 2013 i

Page 4

Common Techniques Used in this Manual

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Italic type is used for emphasis.

Rockwell Software products contain extensive tutorials and help screens. We

recommend that you use these tutorials and help screens to learn about the

products.

For more information about Rockwell Software products, visit the Rockwell

Software website at

http://www.rockwellautomation.com/software/.

ii Rockwell Automation Publication 1734-UM014B-EN-P - May 2013

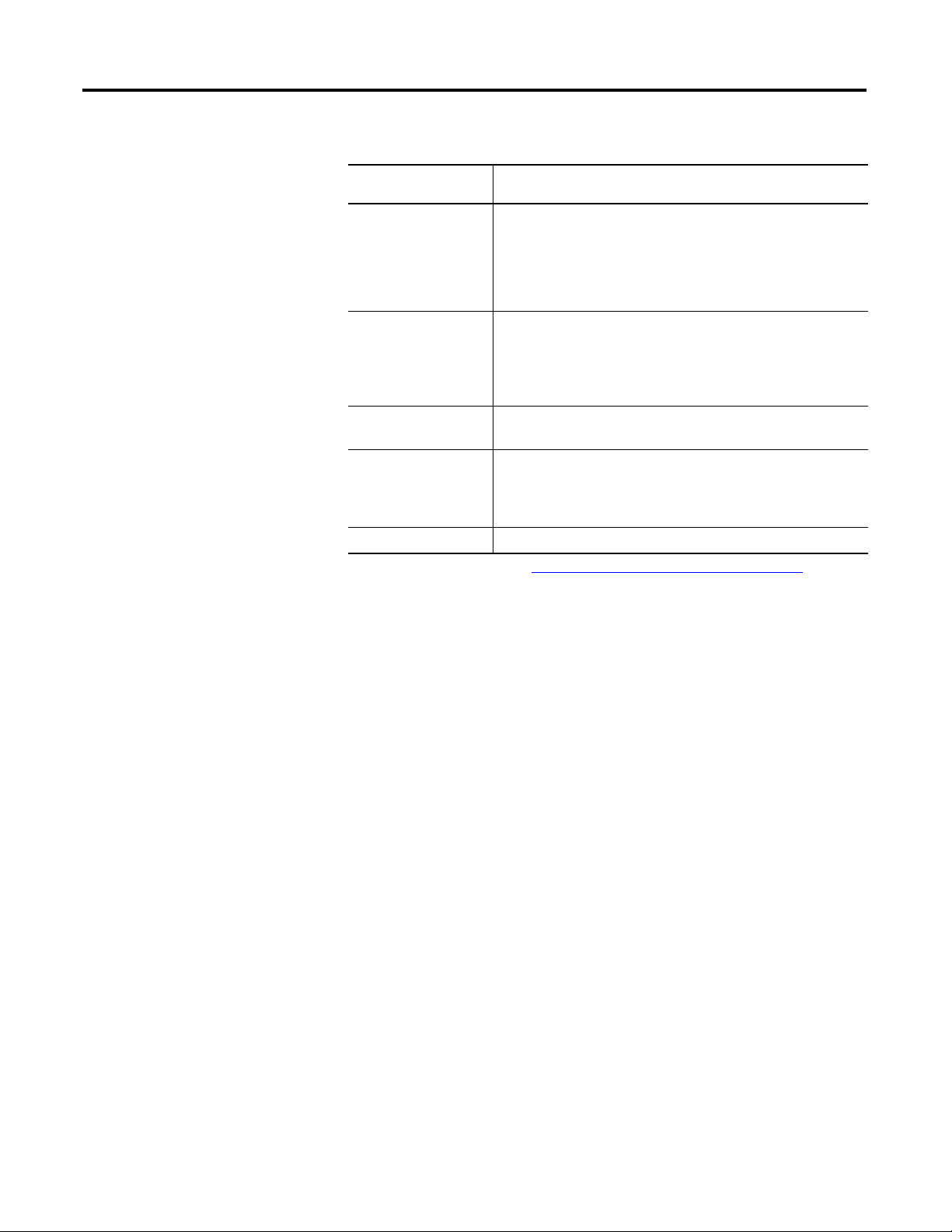

Page 5

About the Adapters

Table of Contents

Preface

Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Related Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Common Techniques Used in this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . ii

Chapter 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Important Adapter Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About the POINT I/O and ArmorPOINT I/O

2 Port Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Set the Chassis Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Adapter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Empty Slots and RIUP Situations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Power Up a System for the First Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Adapter Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

What the Adapter Does . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Hardware/Software Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Use of the Common Industrial Protocol (CIP) . . . . . . . . . . . . . . . . . . . . . . . 5

Understand the Producer/Consumer Model . . . . . . . . . . . . . . . . . . . . . . . . . 5

Specify the Requested Packet Interval (RPI) . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Support of Rack-optimized and Direct Connections . . . . . . . . . . . . . . . . . . 6

Mixing Rack-optimized and Direct Connections. . . . . . . . . . . . . . . . . . 7

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 2

Install Your Adapter

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Identify Adapter Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Mount the I/O Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mount the POINT I/O Adapter on a DIN Rail. . . . . . . . . . . . . . . . . 11

Mount the ArmorPOINT I/O Adapter and Base on a Wall or Panel

12

Install the POINT I/O Adapter Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Install the ArmorPOINT I/O Adapter Module. . . . . . . . . . . . . . . . . . . . . 14

Wire the POINT I/O Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wire the ArmorPOINT I/O Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 3

Configure the Adapter for Your

EtherNet/IP Network

Rockwell Automation Publication 1734-UM014B-EN-P - August 2013 iii

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Configuration Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Page 6

Table of Contents

Set the Network Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Use the Rockwell BootP/DHCP Utility. . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Use DHCP Software to Configure Your Adapter . . . . . . . . . . . . . . . . . . . 26

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 4

Configure the Adapter for Direct

Connection in RSLogix 5000

Software

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Set Up the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Create the Example Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Configure the I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Add the POINT I/O Adapter to the I/O Configuration. . . . . . . . . . . . . 33

Add the Relay Output Module 36

Add the Digital Output Module 38

Edit the Controller Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Create the Ladder Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Download the Program to the Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Verify the Module Chassis Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Configure the Adapter with Fixed IP Address. . . . . . . . . . . . . . . . . . . . . . . 45

Recover From an Overloaded Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Gateway Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Subnet Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Set the Network Address for POINT I/O Adapter . . . . . . . . . . . . . . 21

Set the Network Address for ArmorPOINT I/O Adapter. . . . . . . . 22

Save the Relation List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Add the Local EtherNet/IP Bridge to the I/O Configuration. . . . . 30

Add the POINT I/O Modules to the I/O Configuration . . . . . . . . 35

Chapter 5

Configure the Adapter for Direct

Connection and Rack

Optimization in RSLogix 5000

Software

iv Rockwell Automation Publication 1734-UM014B-EN-P - August 2013

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Set Up the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Set Up the POINT I/O Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Create the Example Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Configure the I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Add the Local EtherNet/IP Bridge to the I/O Configuration. . . . . 50

Add the I/O Adapter to the I/O Configuration . . . . . . . . . . . . . . . . . 52

Add the POINT I/O Module and Configure for Rack-optimized

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Add the POINT I/O Module and Configure For Direct Connection

58

Download the Program to the Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Verify the Module Chassis Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Access Module Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Page 7

Chapter 6

Table of Contents

Troubleshoot the Adapter

EtherNet/IP I/O Adapter

Specifications

Adapter Web Dialogs

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Interpret the Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Status Indicators for POINT I/O Adapter. . . . . . . . . . . . . . . . . . . . . . 65

Status Indicators for ArmorPOINT I/O Adapter . . . . . . . . . . . . . . . 68

Appendix A

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Appendix B

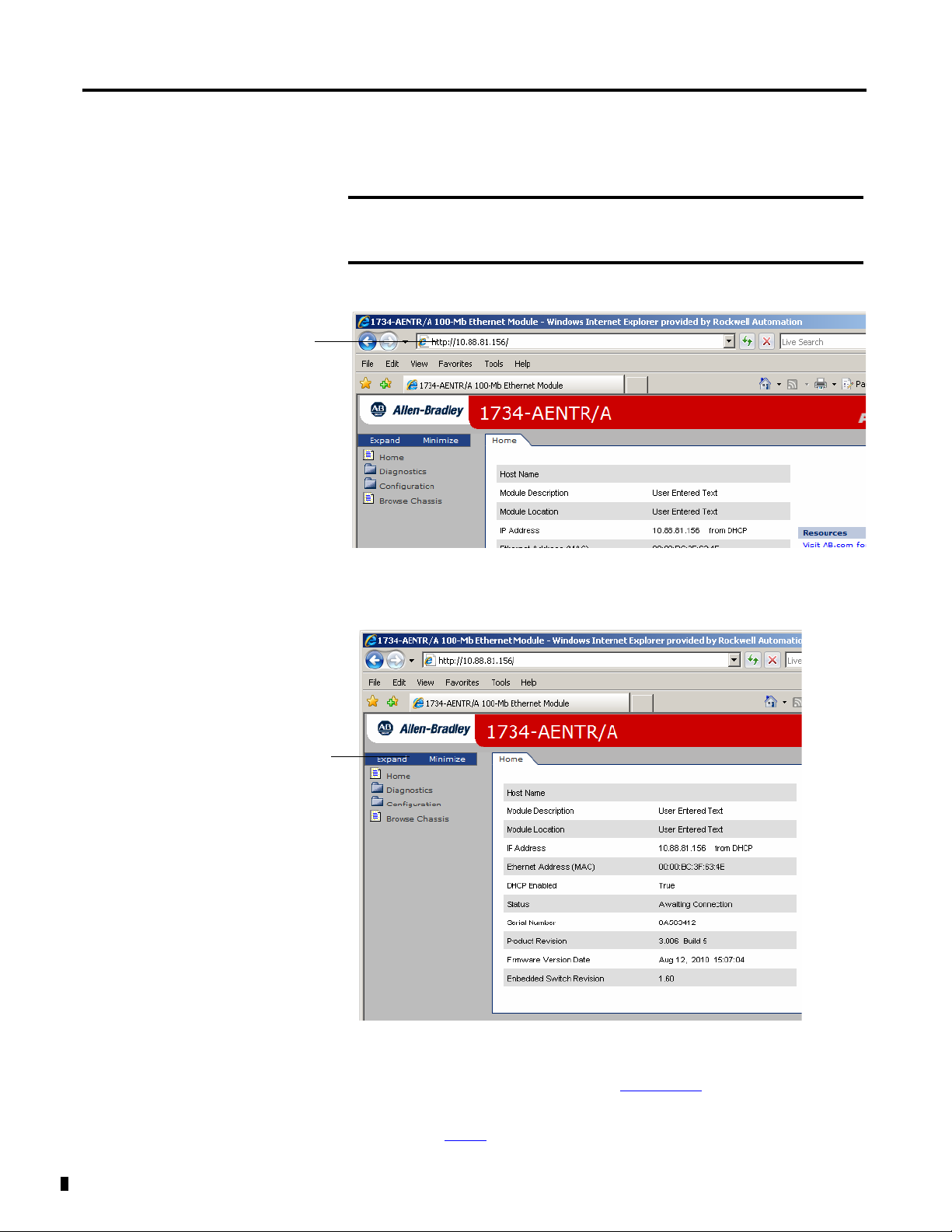

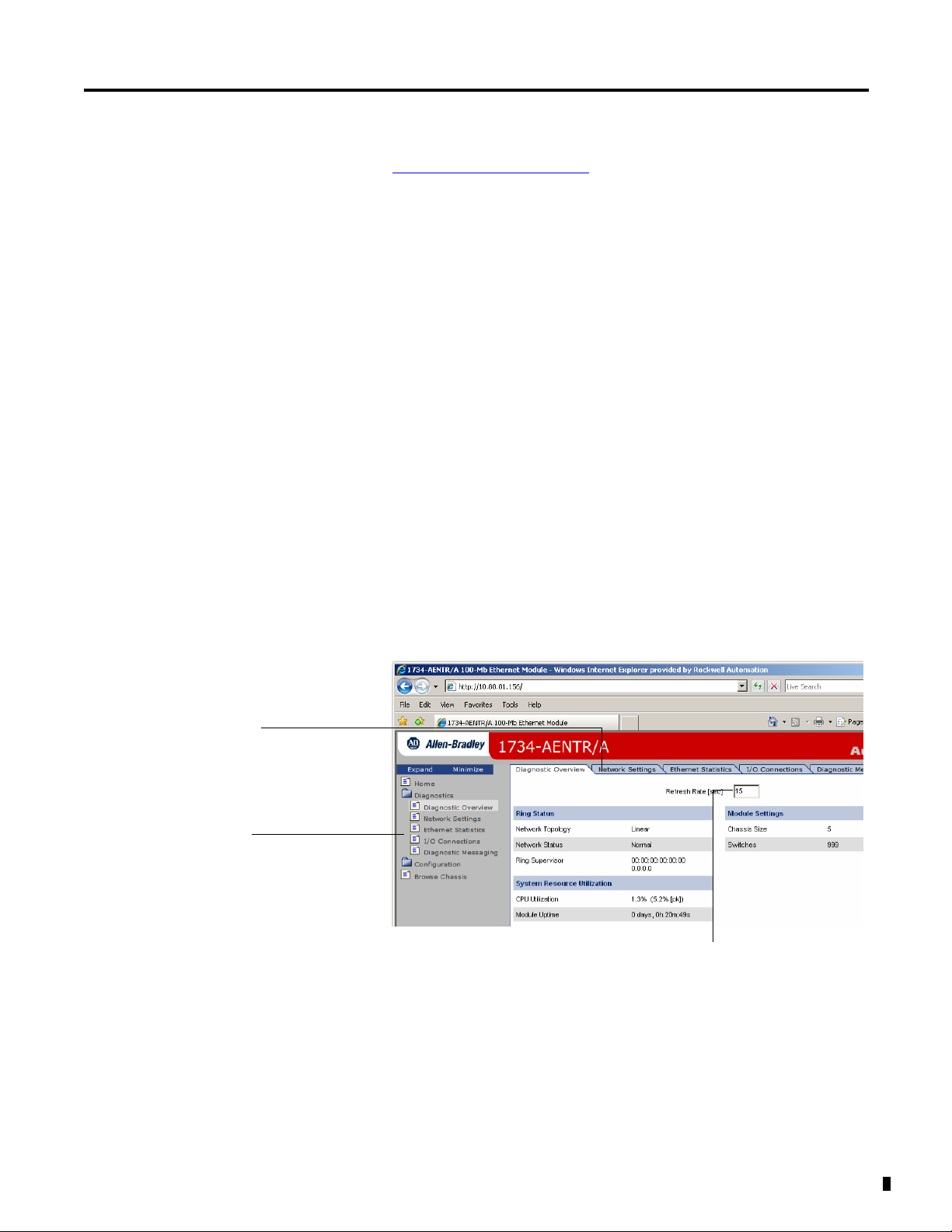

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Work with the Home Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

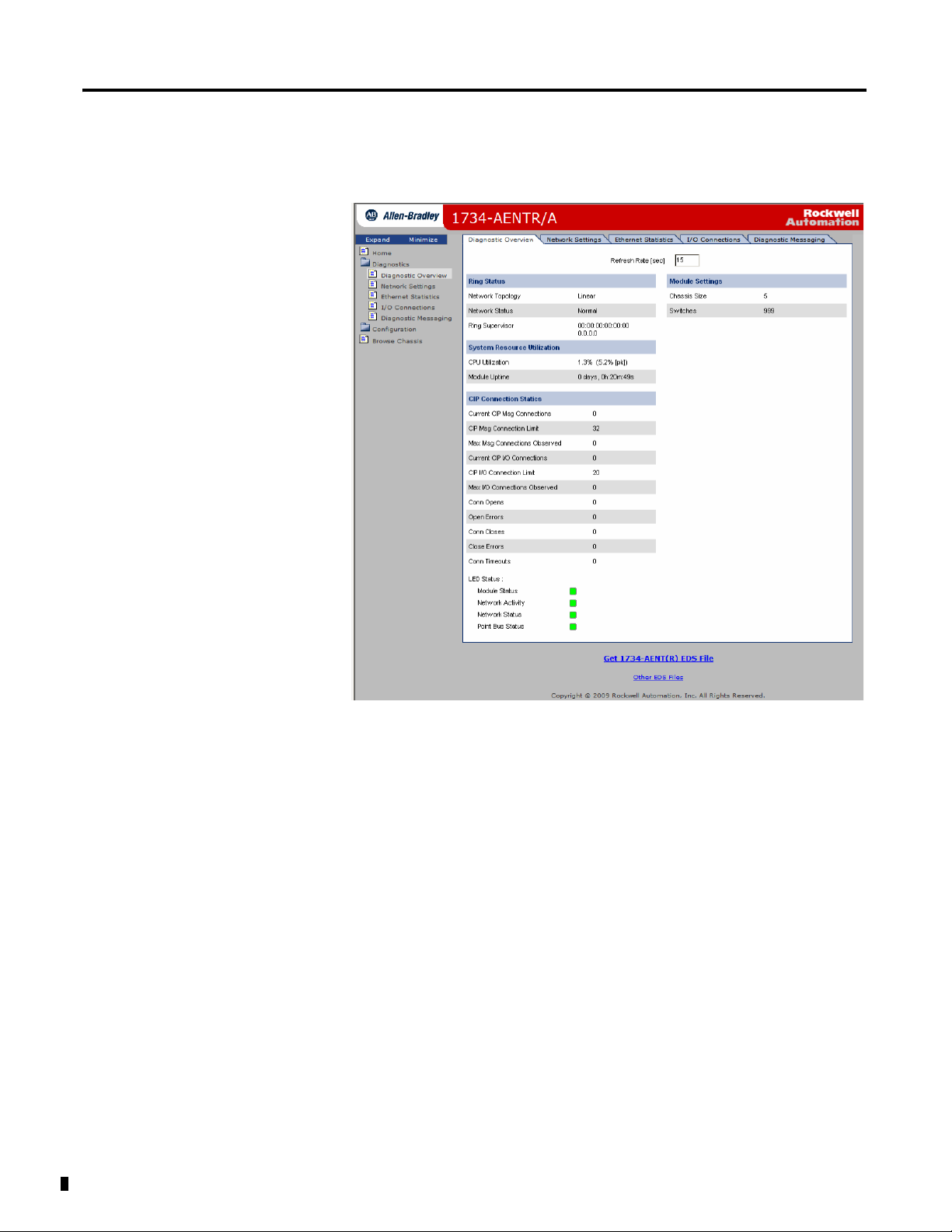

Work with the Diagnostics Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Use the Diagnostic Overview Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

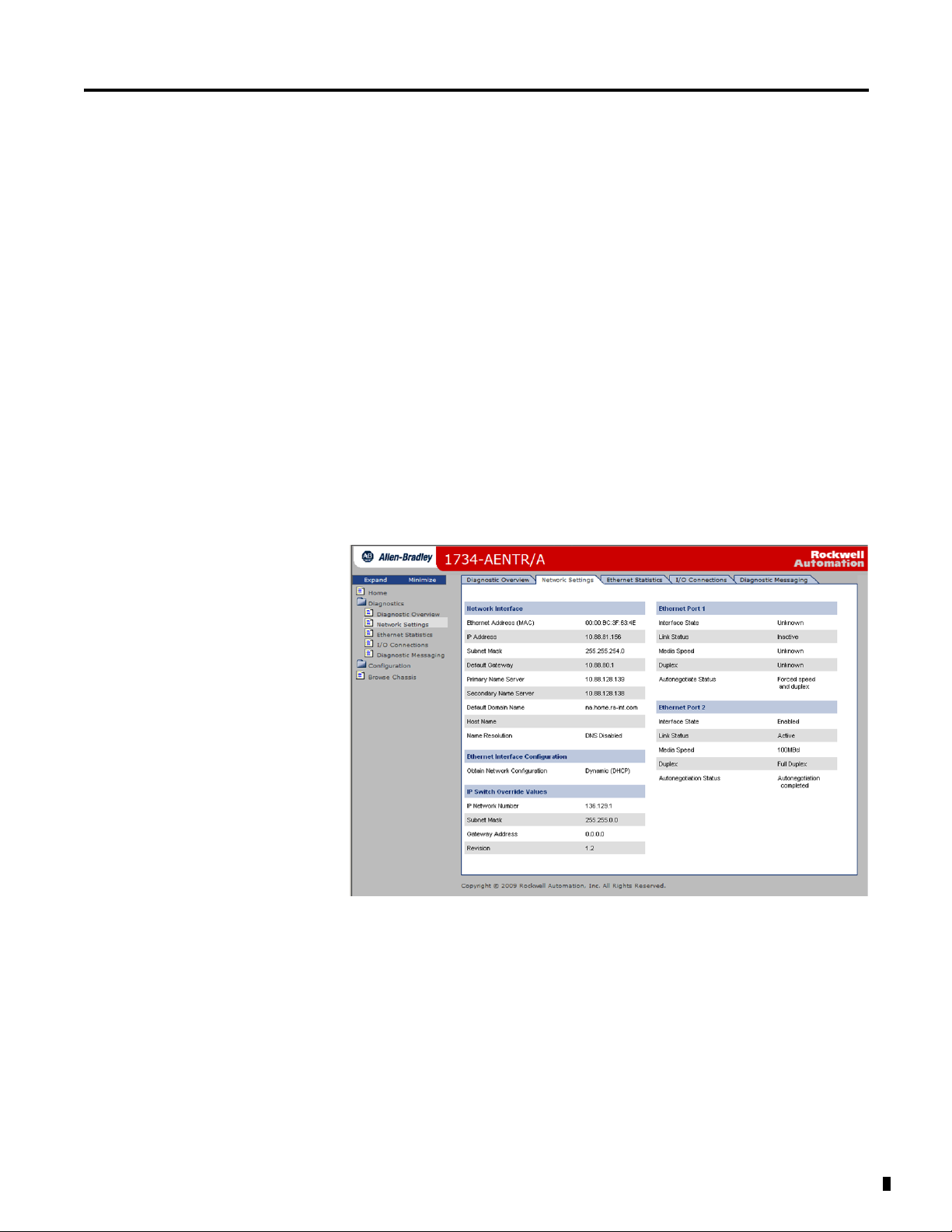

Use the Network Settings Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Use the Ethernet Statistics Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Use the I/O Connections Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Use the Diagnostic Messaging Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

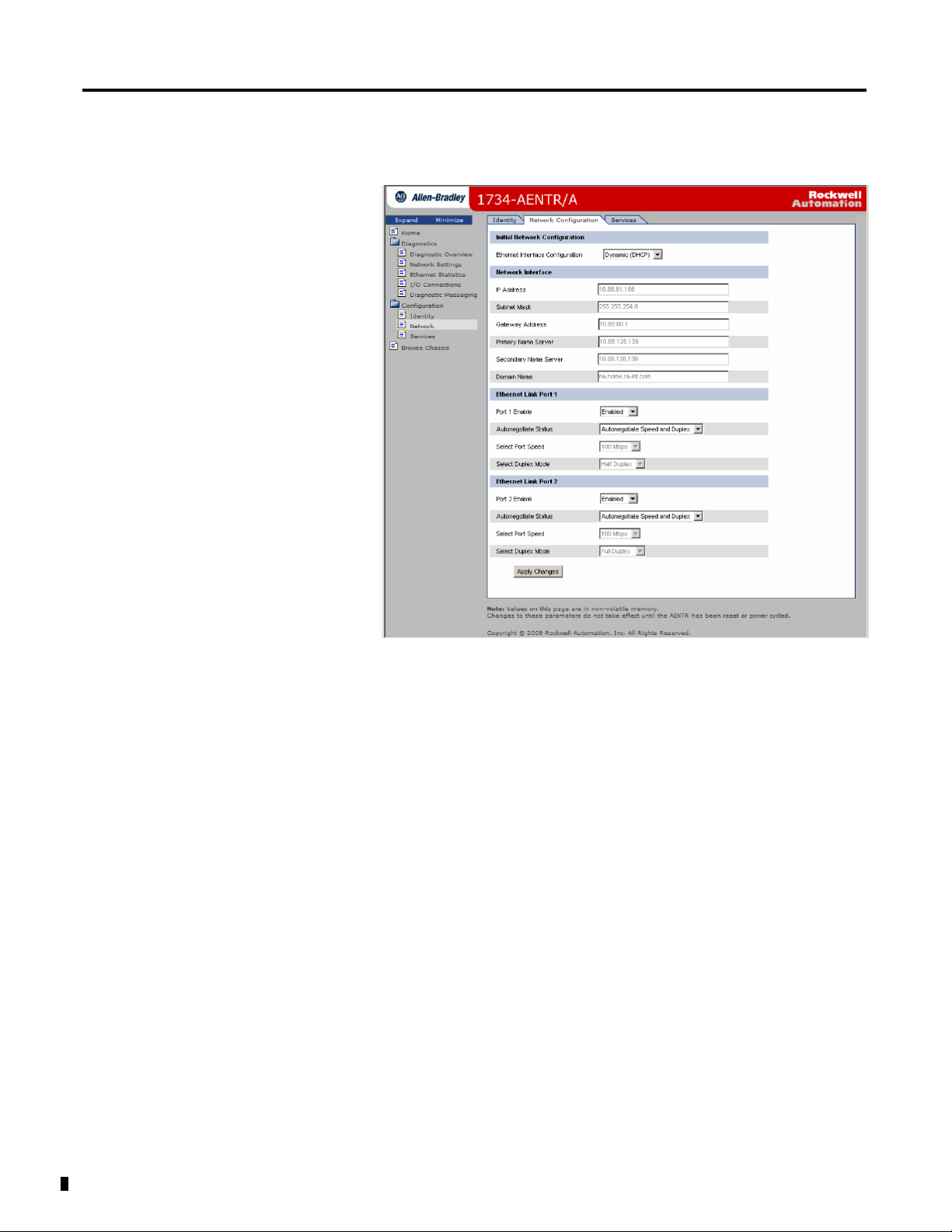

Work with the Configuration Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Use the Identity Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Use the Network Configuration Page . . . . . . . . . . . . . . . . . . . . . . . . . . 87

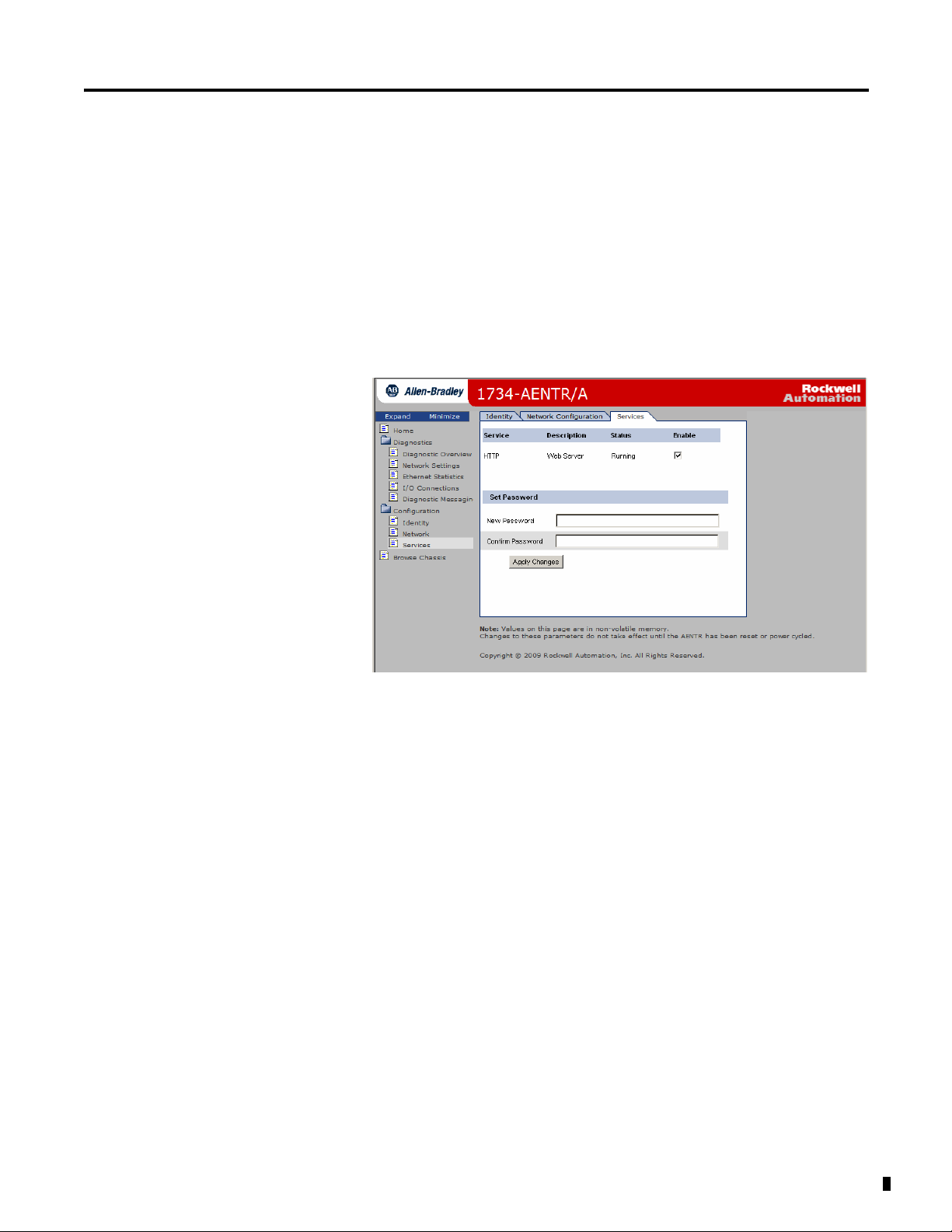

Use the Services Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

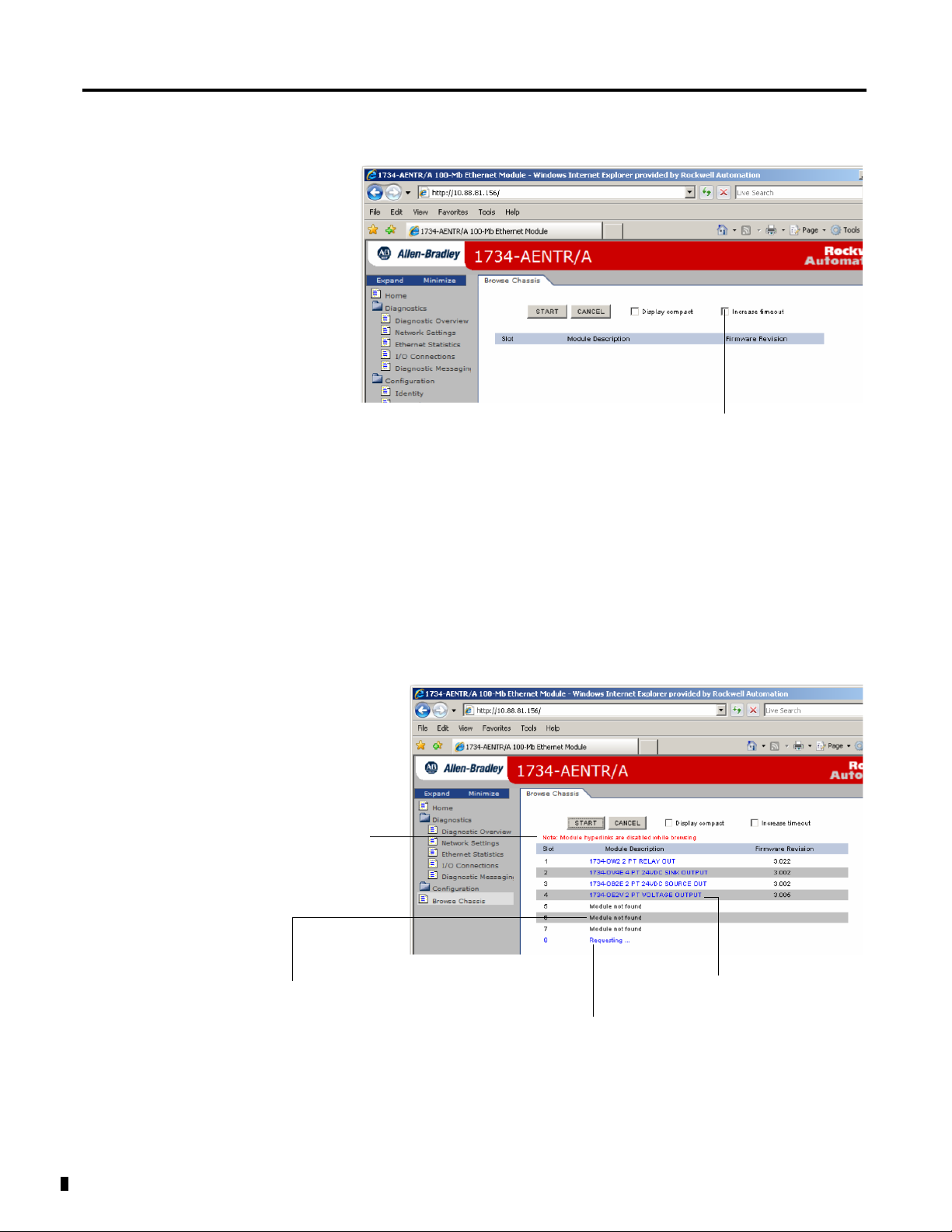

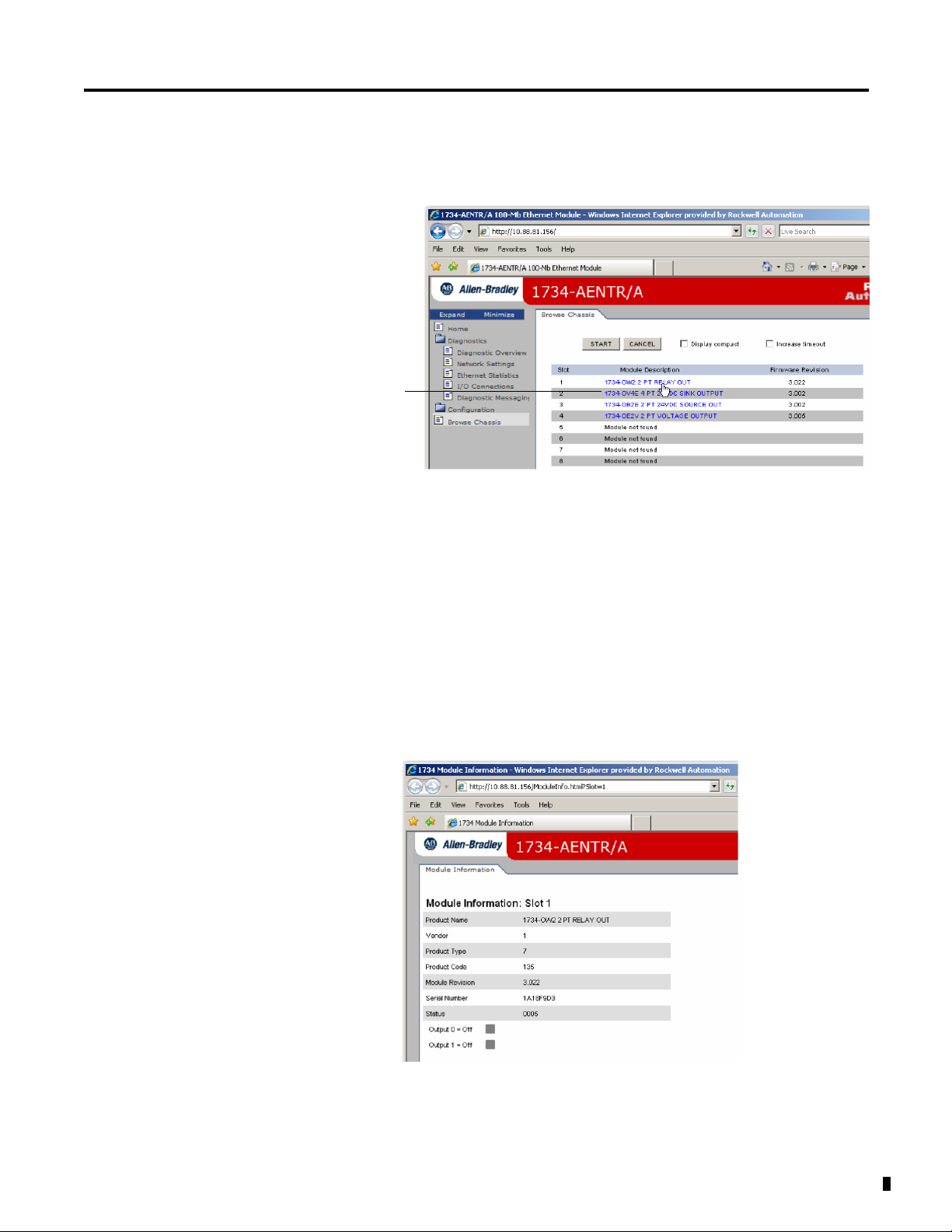

Work with the Browse Chassis Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Configure the RSLinx Ethernet

Communication Driver

Index

Appendix C

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Install the RSLinx Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Configure the AB_ETH Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Configure the AB_ETH/IP Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Rockwell Automation Publication 1734-UM014B-EN-P - August 2013 v

Page 8

Table of Contents

vi Rockwell Automation Publication 1734-UM014B-EN-P - August 2013

Page 9

About the Adapters

Chapter

1

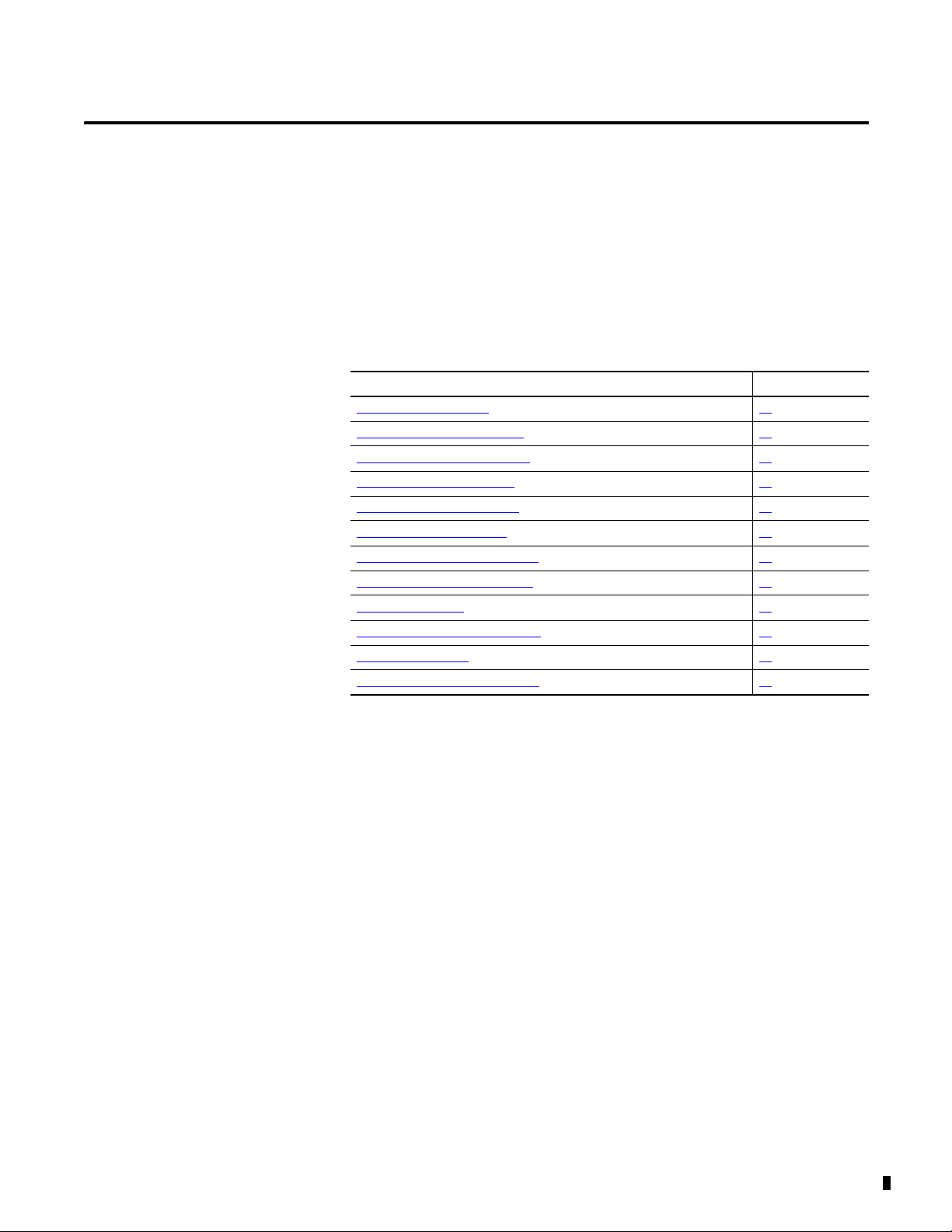

Overview

This chapter provides an overview of the Series A1734-AENTR POINT I/O

and 1738-AENTR ArmorPOINT I/O EtherNet/IP adapters, their primary

features, and how to use them.

You need to understand the concepts discussed in this chapter to configure your

adapter and use it in an EtherNet/IP control system.

This table lists where to find specific information.

Topic Page

Important Adapter Considerations

About the POINT I/O and ArmorPOINT I/O 2 Port Adapters 1

Adapter Replacement 2

Empty Slots and RIUP Situations 2

Power Up a System for the First Time 3

Adapter Features 4

Hardware/Software Compatibility 5

What the Adapter Does 4

Use of the Common Industrial Protocol (CIP) 5

Understand the Producer/Consumer Model 5

Specify the Requested Packet Interval (RPI) 6

Support of Rack-optimized and Direct Connections 6

Mixing Rack-optimized and Direct Connections 7

1

Important Adapter Considerations

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 1

Before you begin using your adapter, note the following important

considerations.

ATTENTION: You must use series C POINT I/O modules with the

adapter. Series A or B POINT I/O modules do not work with the adapter.

Page 10

Chapter 1 About the Adapters

About the POINT I/O and ArmorPOINT I/O 2 Port Adapters

The POINT I/O and ArmorPOINT I/O adapters provide connectivity to

EtherNet/IP networks for POINT I/O and ArmorPOINT I/O modules

respectively.

The POINT I/O adapter is for the I/O backplane that provides connectivity

through two RJ-45 connectors for 2-port pass-through support of daisy chain or

ring, and the existing star and tree network topologies.

Likewise, the ArmorPOINT I/O adapter provides the same connectivity

through two M12 Ethernet-keyed connectors. It ships with a terminating base for

use in the last I/O module on the backplane.

Set the Chassis Size

The I/O adapters for EtherNet/IP require configuration of their chassis size

before you can make any I/O connections. The factory default setting for the

chassis size is one slot, which represents the adapter by itself.

You must set the chassis size to a number equaling one slot for the adapter plus

one slot for each I/O module present in the backplane of the adapter.

For example, a POINT I/O system consisting of a 1734-AENTR adapter, one

1734-IB8, one 1734-OB8, and one 1734-OB8S POINT Guard I/O module uses

a chassis size of 4. The adapter stores this chassis size setting in non-volatile

memory.

Each time the adapter is powered up, the adapter compares the number of I/O

modules present on its backplane to the chassis size value from non-volatile

memory. The adapter does not allow any I/O connection until the number of I/

O modules present equals the chassis size value minus one for the adapter itself.

Adapter Replacement

Note that during a connection request from the controller, the chassis size setting

is not communicated to the adapter. You must always set this chassis size using a

separate operation. This includes situations when you are replacing an adapter.

The adapter does not allow any I/O connections until it is configured with the

appropriate chassis size and the proper number of POINT I/O or

ArmorPOINT I/O modules are present.

Empty Slots and RIUP Situations

The POINT I/O system cannot detect an empty terminal base. For this reason,

there are numerous situations in which you can potentially configure a system

that is unusable or one that exercises unintended control.

2 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 11

About the Adapters Chapter 1

In an attempt to address these situations, you must observe the following rules for

I/O system construction and the

removal and reinsertion of modules.

• A correct I/O system does not have any empty terminal bases.

• After you cycle power, the adapter will not allow any I/O connections

until the number of modules comprising the chassis plus one for the

adapter equals the stored chassis size.

– It cannot assume any safe operation until there is a match between the

number of modules indicating their presence in the chassis and what the

adapter has saved in non-volatile memory because it cannot detect

empty terminal bases.

– Actual module identification (such as, electronic keying) is done when

connection establishment requests are received from the controller or

controllers.

• A POINT I/O module removed under power does not disrupt operation

of the other I/O modules. On the other hand, ArmorPOINT I/O

modules are not intended to be removed under power.

– When you remove a module, the adapter detects what changed.

– Whenever you remove a module with an active connection from the

POINT I/O system, the adapter indicates this by flashing the

POINTBus Status LED red and reports a minor recoverable fault.

• If more than one contiguous module is removed under power, connections

to all modules in the contiguous missing module set are disallowed until all

modules are replaced. Because the adapter cannot detect an empty base, it

does not know the physical positioning of the modules until all the missing

modules are replaced.

• If a module separating two sets of contiguous missing modules is removed,

the two sets merge into a single set. All the modules must be replaced

before connections are permitted to any module in the set.

• If modules of different types are removed and returned to the wrong

locations, attempts to connect to these modules will fail during verification

of the electronic ID (providing that keying has not been disabled).

• If modules of the same type are removed and returned to the wrong

locations, they accept connections from the controller or controllers and

reconfigure with the correct data once they pass their electronic keying

check.

• These removal and return situations exist whether the system is under

power or not. If the system is under power, the situation arises immediately.

If the system is not under power, the situation arises in the next power

cycle.

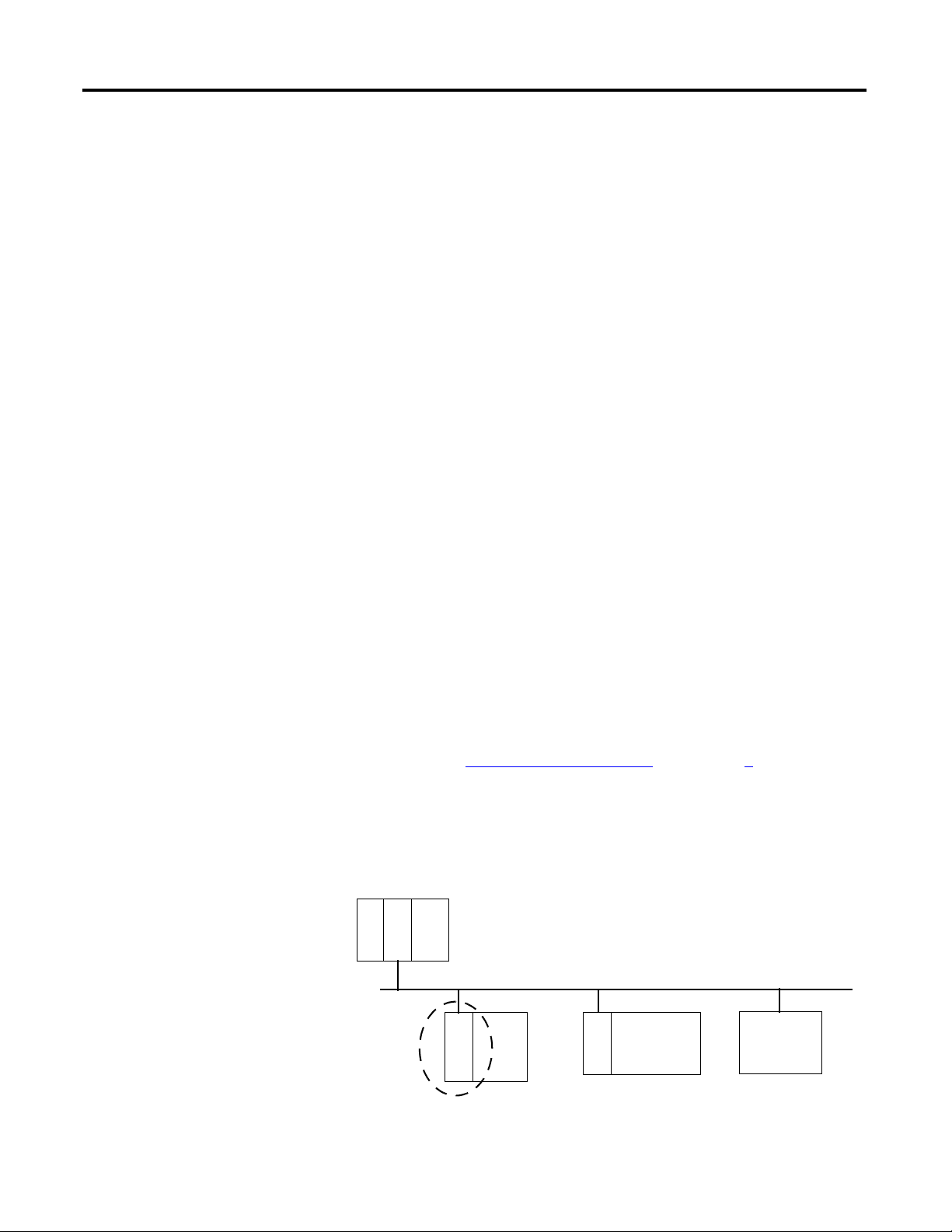

Power Up a System for the First Time

When you power the I/O for the first time, the adapter must assign slot addresses

to every module in the backplane. All I/O modules ship configured at the same

address.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 3

Page 12

Chapter 1 About the Adapters

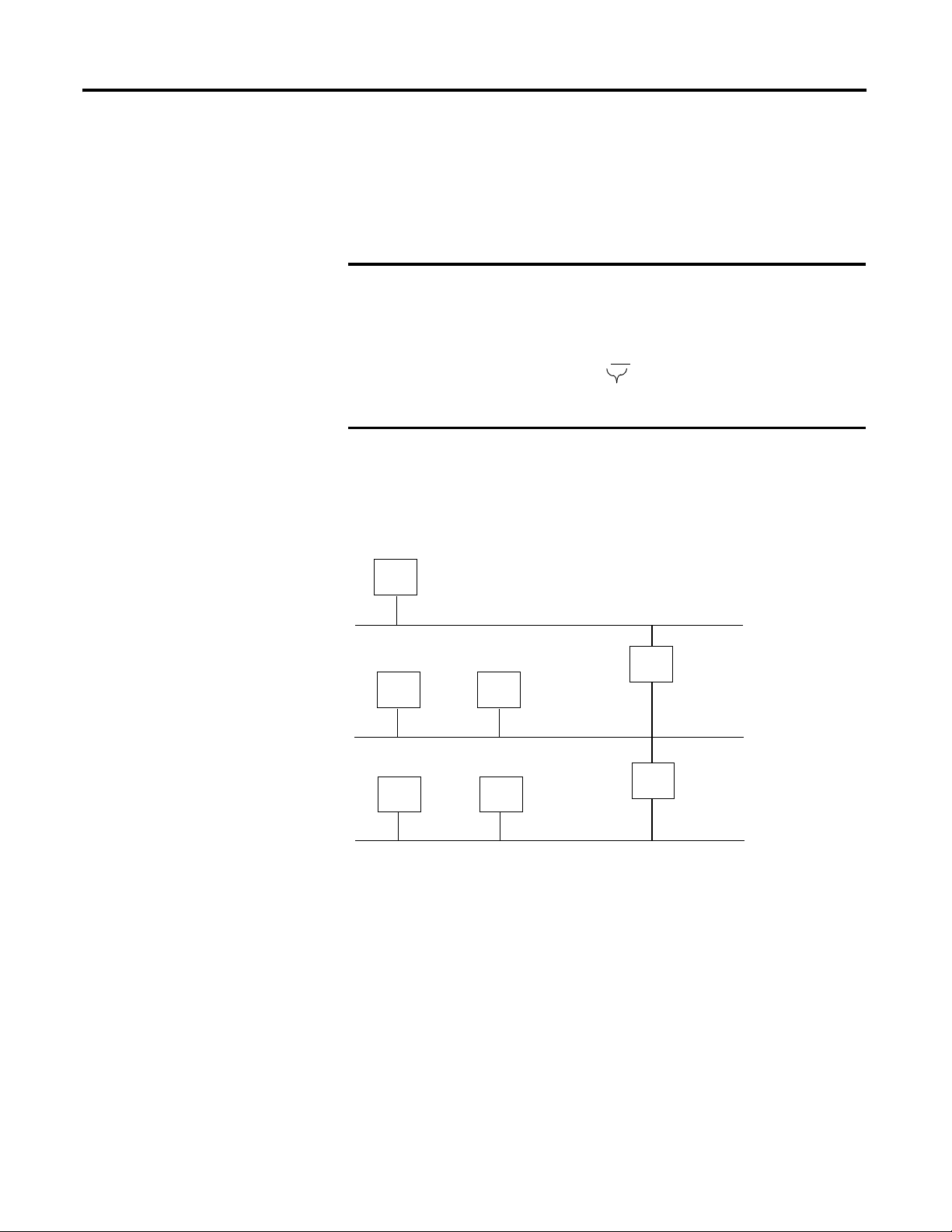

L

5

5

5

5

EtherNet/IP Network

E

N

B

T

Other

Network

Devices

A

E

N

T

R

POINT

I/O

E

N

B

T

ControlLogix

I/O

When you first apply power, we expect that all but one module on the backplane

exhibits a solid red Module Status LED.

One by one the adapter resets these modules and addresses them appropriately.

The amount of time that this operation takes is proportional to the size of your I/

O system.

Adapter Features

Features of the adapters include:

• Use of EtherNet/IP messages encapsulated within standard TCP/UDP/IP

protocol

• Common application layer with ControlNet and DeviceNet networks

• Interfacing via Category 5 rated twisted pair cable

• Half/full duplex 10 Mbit or 100 Mbit operation

• DIN rail mounting for 1734-AENTR adapter/Wall or panel mounting for

1738-AENTR adapter

• Communication to and from other I/O modules on the same DIN rail for

1734-AENTR adapter/Communication to and from other I/O modules

in the chassis for 1738-AENTR adapter

• Communication supported by RSLinx software

• IP address assigned via standard BootP or DHCP tools

• I/O configuration via RSLogix 5000 software

• No network scheduling required

• No routing tables required

• Support of connections from multiple controllers simultaneously

You must use RSLogix 5000 to configure these features. For more details on

configuration, see Configuration Requirements

on in chapter 3.

What the Adapter Does

The I/O adapters perform the following primary tasks:

• Control of real-time I/O data (also known as implicit messaging) - the

adapter serves as a bridge between I/O modules and the network

• Support of messaging data for configuration and programming

information (also known as explicit messaging)

4 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 13

About the Adapters Chapter 1

Hardware/Software Compatibility

Use of the Common Industrial Protocol (CIP)

The I/O adapters and the applications described in this manual are compatible

with the following firmware revisions and

Contact Rockwell Automation if you need software or firmware upgrades to use

this equipment

Product Firmware Revision/ Software Release

1734-AENTR; 1738-AENTR adapters 3.xx or later

1756-ENBT 2.3 or later

Logix controller 11 or later

RSLogix 5000 software 11 or later

RSLinx software 2.3.1 or later

The adapter uses the Common Industrial Protocol (CIP). CIP is the application

layer protocol specified for EtherNet/IP, the Ethernet Industrial Protocol, as well

as for ControlNet and DeviceNet networks. It is a message-based protocol that

implements a relative path to send a message from the producing device in a

system to the consuming devices.

The producing device contains the path information that steers the message along

the proper route to reach its consumers. Since the producing device holds this

information, other devices along the path simply pass this information; they do

not store it.

software releases.

Understand the Producer/ Consumer Model

This has the following significant benefits:

• You do not need to configure routing tables in the bridging modules,

which greatly simplifies maintenance and module replacement.

• You maintain full control over the route taken by each message, which

enables you to select alternative paths for the same end device.

The CIP producer and consumer networking model replaces the old source and

destination (master and slave) model. The producer and consumer model reduces

network traffic and increases speed of transmission. In traditional I/O systems,

controllers poll input modules to obtain their input status. In the CIP system,

input modules are not polled by a controller. Instead, they produce (multicast or

unicast) their data either upon a change of state (COS) or periodically.

Multicast is the default mode for version 17 Logix and earlier controllers and

unicast is the default for version 18 with multicast as a selectable option.

The frequency of update depends upon the options chosen during configuration

and where on the network the input module resides. The input module,

therefore, is a producer of input data, and the controller is a consumer of the data.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 5

Page 14

Chapter 1 About the Adapters

The controller also produces data for other controllers to consume. The

produced and consumed data is accessible by multiple controllers and other

devices over the EtherNet/IP network. This data exchange conforms to the

producer and consumer model.

Specify the Requested Packet Interval (RPI)

Support of Rack-optimized and Direct Connections

The Requested Packet Interval or RPI is the update rate specified for a particular

piece of data on the network. The RPI can be specified for the adapter and

include all of the I/O modules in the I/O system (using a rack-optimized

connection) or specified for a particular module (using direct connection).

When you add a module or an adapter to the I/O configuration of a controller,

you must enter the RPI as a parameter. This value specifies how often to produce

the data for that device. For example, if you specify an RPI of 50 ms, it means that

every 50 ms the device should send its data to the controller and the controller

should send the consumed (output) data to the device.

Use RPIs only for devices that exchange data. For example, a ControlLogix

EtherNet/IP bridge module in the same chassis as the controller does not require

an RPI, because it is not a data-producing member of the system. Its use is only as

a bridge to remote racks.

The I/O adapters supports both direct and rack-optimized connections. A direct

connection is a real-time data transfer link between the controller and the module

occupying the slot that the configuration data references.

Direct I/O connections occur at a cyclic rate specified by the RPI during

configuration. A rack-optimized connection is a grouping of data from one or

more digital I/O modules into a single block of data sent over a single connection

at the same data rate.

Analog, safety, and speciality modules cannot participate in the rack-optimized

connection; these modules require a direct I/O connection.

Rack-optimized connections reduce the total number of connections needed to

transfer data when using many digital I/O modules in a system. The following

example illustrates the benefit of rack-optimized connections.

Assume you set up a system that contains eight digital I/O modules interfaced to

an adapter. If you use direct connections to transfer data to each of the these I/O

modules, you need eight connections to transfer all of the data, one to each of the

6 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 15

About the Adapters Chapter 1

IMPORTANT

eight I/O modules. If you use a rack-optimized connection to transfer the data,

you only need a single connection – the connection to the I/O adapter.

Although rack-optimized connections offer an efficient way to use

resources, there are a few limitations on their use:

• You can use only rack-optimized connections to send data to and

from digital I/O modules. Analog or speciality I/O requires direct

connections.

• All data is sent at the same time as the RPI rate of the I/O adapters.

If the update rate required for a digital module is different from the

RPI of the rack-optimized connection, a direct connection to that

digital I/O module is required.

See the EtherNet/IP Design Considerations Reference Manual,

publicationENET-RM002

for more information on connections.

Mixing Rack-optimized and Direct Connections

Chapter Summary

You can mix communication formats for different I/O modules communicating

through the same adapter. I/O modules set up to use rack optimization

communicate at the rate of the RPI configured for the adapter. I/O modules

configured for direct communication communicate at their own individual RPIs

and ignore the rack-optimized RPI.

In this chapter, you were introduced to the features of the POINT I/O and

ArmorPOINT I/O Adapters, and considerations for installation and usage.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 7

Page 16

Chapter 1 About the Adapters

Notes:

8 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 17

Install Your Adapter

Chapter

2

Overview

This chapter describes how to physically install the Series A POINT I/O and

ArmorPOINT I/O 2 Port EtherNet/IP adapters; and how to connect the

adapter to the EtherNet/IP network. The only tools you require are a flat or

Phillips head screwdriver and a drill.

This table lists where to find specific information.

Topic Page

Identify Adapter Components 10

Mount the I/O Adapter 11

Mount the POINT I/O Adapter on a DIN Rail 11

Mount the ArmorPOINT I/O Adapter and Base on a Wall or Panel 12

Install the POINT I/O Adapter Module 13

Install the ArmorPOINT I/O Adapter Module 13

Wire the POINT I/O Adapter 14

Wire the ArmorPOINT I/O Adapter 15

ATTENTION: You must use series C POINT I/O modules with the

adapter. Series A or B POINT I/O modules do not work with the adapter.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 9

Page 18

Chapter 2 Install Your Adapter

1734-AENTR

Module

Status

Network

Activity

Network

Status

Point Bus

Status

System

Power

Field

Power

POINT I O

02

0

2

Link 2

Activity/

Status

3

4

5

6

7

Link 1

Activity/

Status

44849

Status indicators

RTB removal handle

Removable Terminal

Block (RTB)

DIN rail locking screw

(orange)

Ethernet network

RJ-45 connectors

Network

address

thumbwheel

1738-AENTR

EtherNet I/P

Adapter

Status

Network

Activity

Network

Status

PointBus

Status

System

Power

Adapter

Power

conformance tested

™

PWR

IP ADDRESS

Link 2

Activity/

Status

Link 1

Activity/

Status

44830

M12 connectors

Mini Style 4-Pin

in Male

Connector

Network address

switches

Status indicators

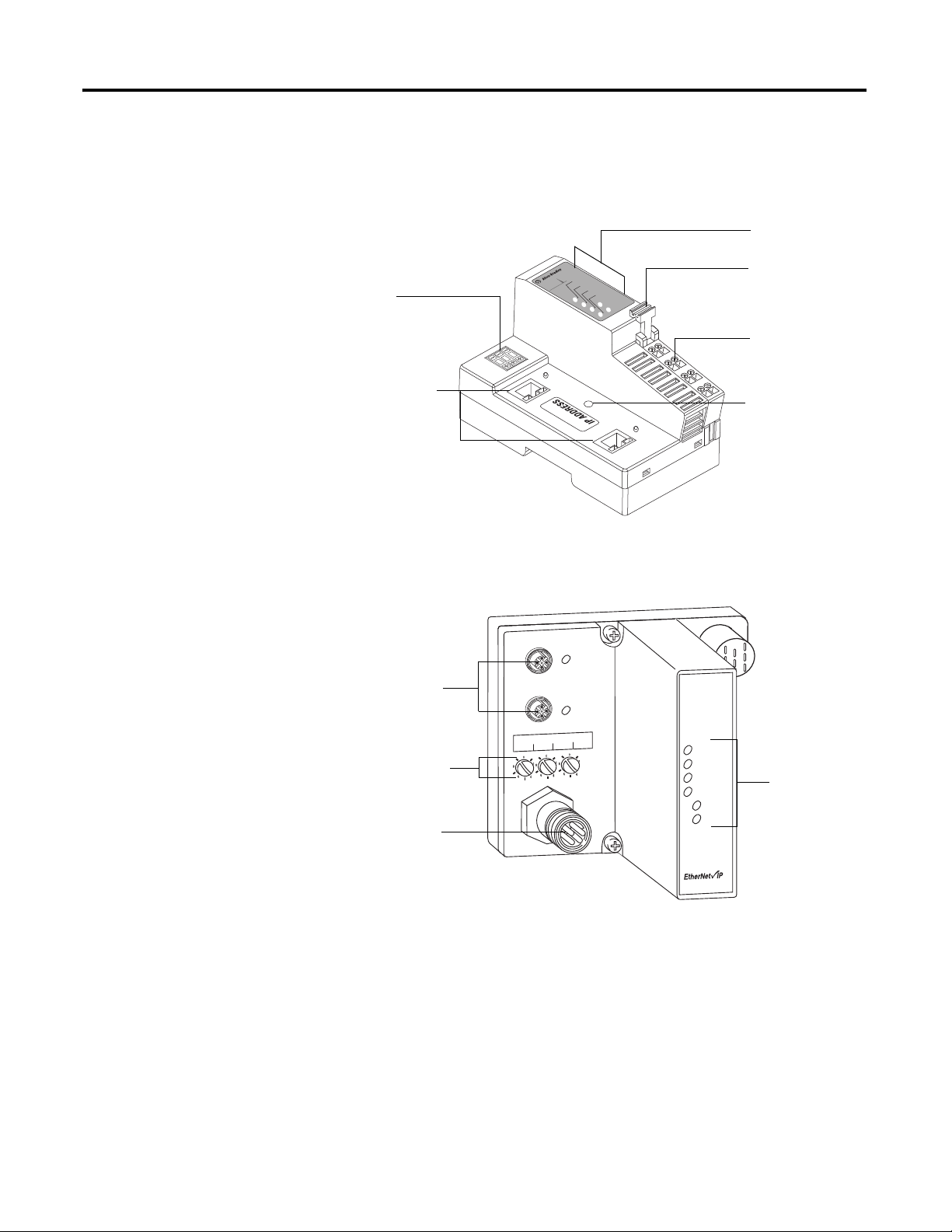

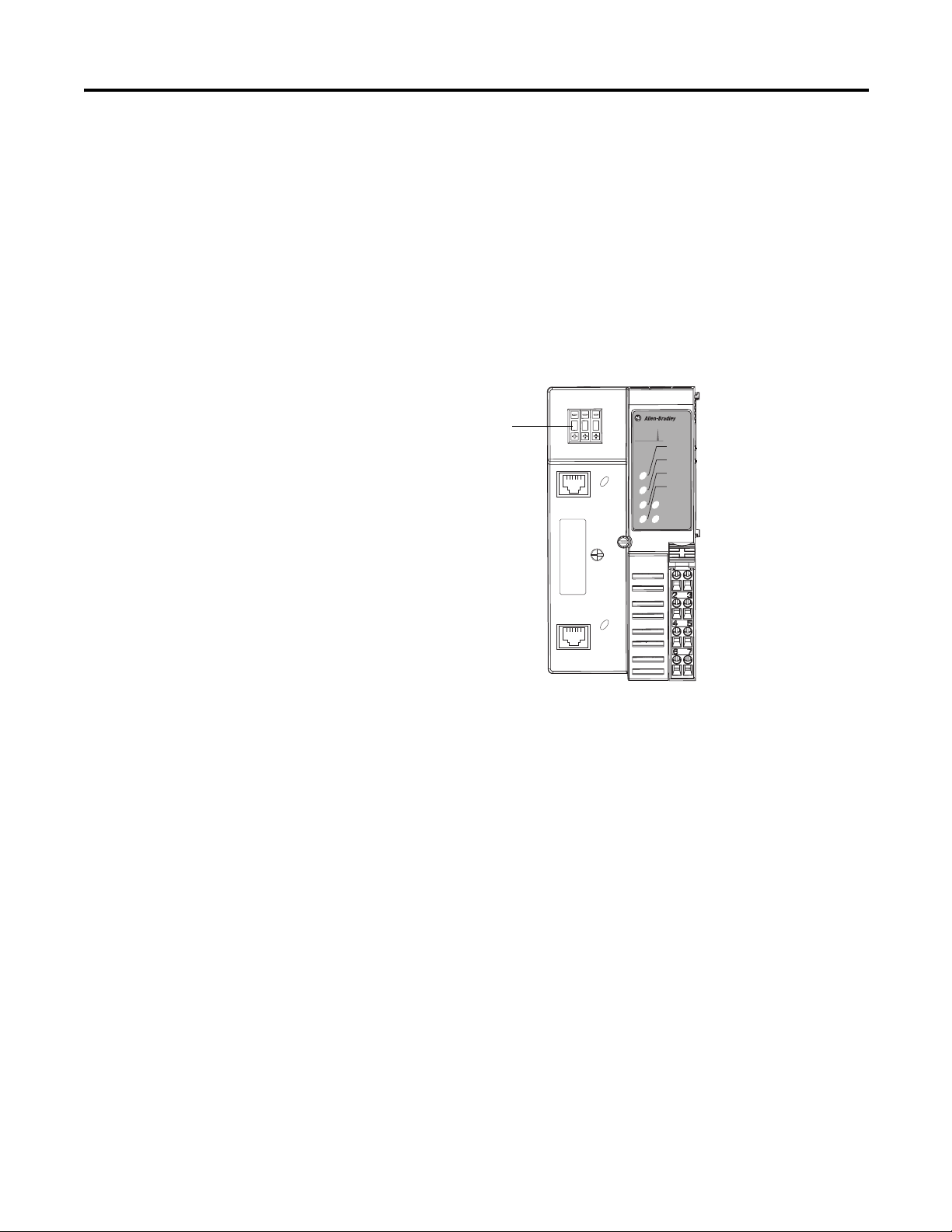

Identify Adapter Components

Use the figures to identify the external features of your I/O adapters.

Physical Features of the 1734-AENTR Adapters

Physical Features of the 1738-AENTR Adapters

10 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 19

Install Your Adapter Chapter 2

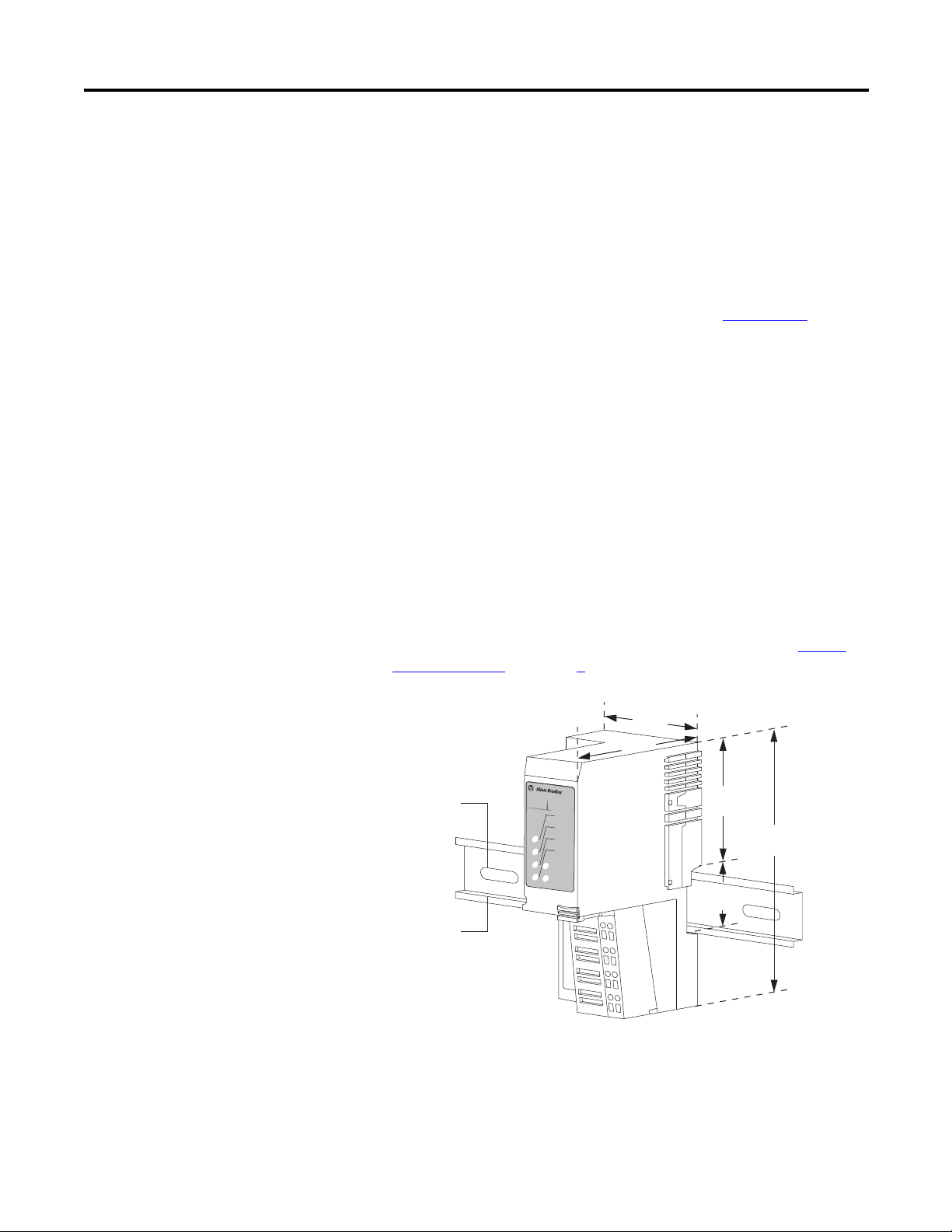

1734-AENTR

Module

Status

Network

Activity

Network

Status

Point Bus

Status

System

Powe

r

Field

Powe

r

POINT I O

75.30

(2.96)

74.00

(2.91)

132.72

(5.23)

52.23

(2.06)

35.55

(1.40)

A

B

45174

A = DIN rail

B = Secure DIN rail approximately every 200 mm (7.8 in.)

Mount the I/O Adapter

Use the following procedures to mount the I/O adapters on a new system before

you install any I/O modules.

Mount a 1734-FPD module in the slot next to the I/O adapter when applying

field power. You can also use the 24V DC to power the adapter to supply field

power, where no FPD is necessary. Refer to Point I/O Field Potential

Distribution Module Installation Instructions, publication 1734-IN059

for more

information.

Mount the POINT I/O Adapter on a DIN Rail

Position the I/O adapters vertically above the DIN rail.

1. Make sure the DIN rail locking screw (orange) is in horizontal position.

2. Position the adapter vertically above an IEC standard (35 x 7.5 x 1 mm)

top-hat DIN rail at a slight angle (DIN rail: Allen-Bradley part number

199-DR1; 46277-3).

3. Press down firmly to install the adapter on the DIN rail, noting that the

locking mechanism locks the adapter to the DIN rail.

4. Set the network address thumbwheel switches to the desired value.Set the

network address thumbwheel switches to the desired value. See Set the

Network Address in chapter 3 for more details on setting the IP address.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 11

Page 20

Chapter 2 Install Your Adapter

IMPORTANT

45175

5. Slide the safety end cap up to remove it, exposing the backplane and power

interconnections.

WARNING: If you connect or disconnect the Ethernet cable with power

applied to this module or any device on the network, an electrical arc

can occur. This could cause an explosion in hazardous location

installations. Be sure that power is removed or the area is nonhazardous

before proceeding.

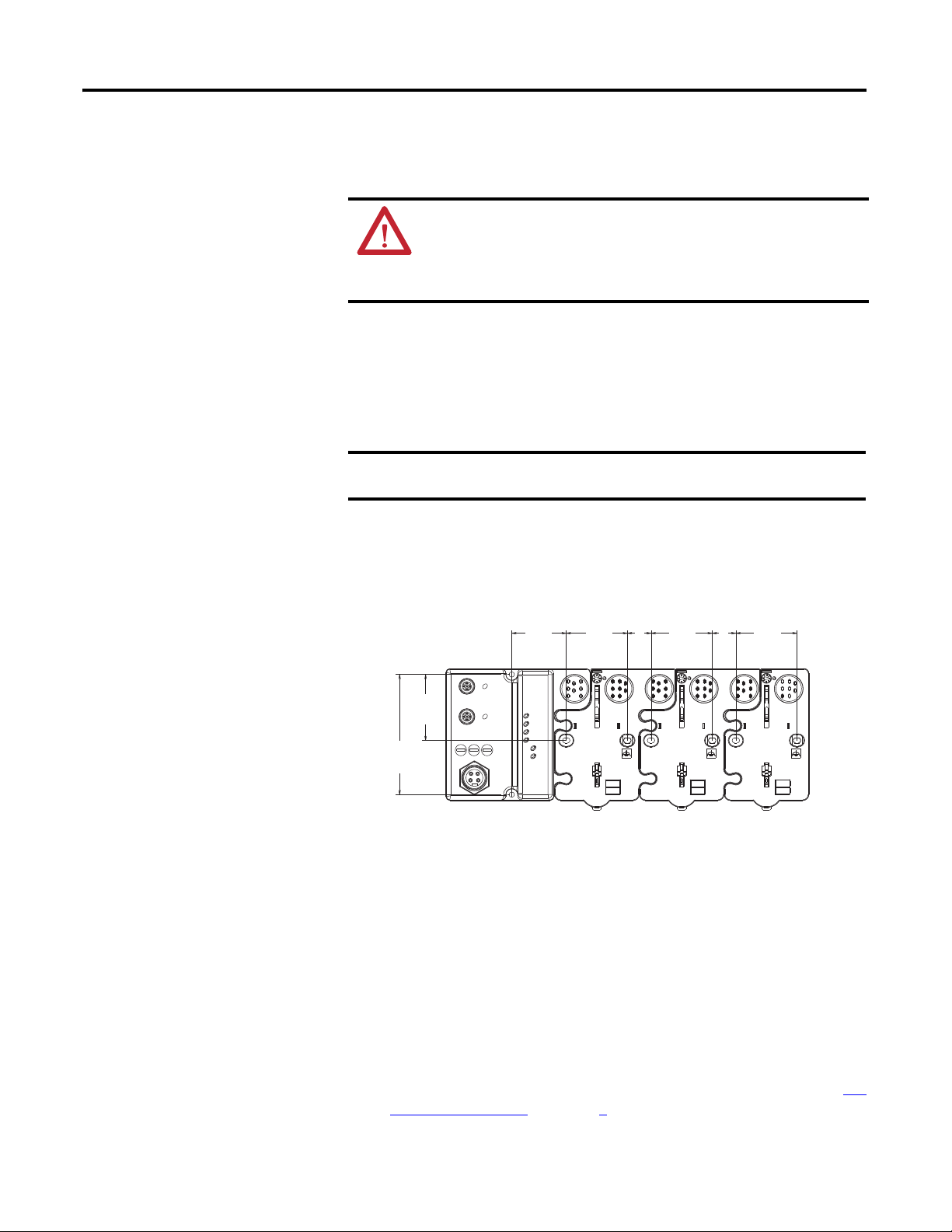

Mount the ArmorPOINT I/O Adapter and Base on a Wall or Panel

To mount the ArmorPOINT I/O adapter on a wall or panel, use the screw holes

provided in the adapter module

The ArmorPOINT I/O adapter must be mounted on a grounded

metal mounting plate or other conductive surface.

.

Refer to the drilling dimensions illustration for the ArmorPOINT I/O adapter

with I/O bases to guide you in mounting the adapter and I/O bases.

Drilling Dimensions

46.25mm

(1.82in)

56.00mm

(2.20in)

102.0mm

(4.01in)

51.90mm

(2.04in)

20.10mm

(0.79in)

51.90mm

(2.04in)

20.10mm

(0.79in)

51.90mm

(2.04in)

Install the mounting base as follows:

1. Lay out the required points as shown in the drilling dimension drawing.

2. Drill the necessary holes for #8 (M4) machine or self-tapping screws.

3. Mount the adapter using #8 (M4) screws.

4. Ground the system using the ground lug connection in the I/O base. The

ground lug connection is also a mounting hole.

5. Mount the terminating base that was shipped with the adapter as the last

base in the backplane instead of the base that was shipped with the

I/O module.

6. Set the network address thumbwheel switches to the desired value. See Set

the Network Address in chapter 3 for more information on setting the IP

address.

12 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 21

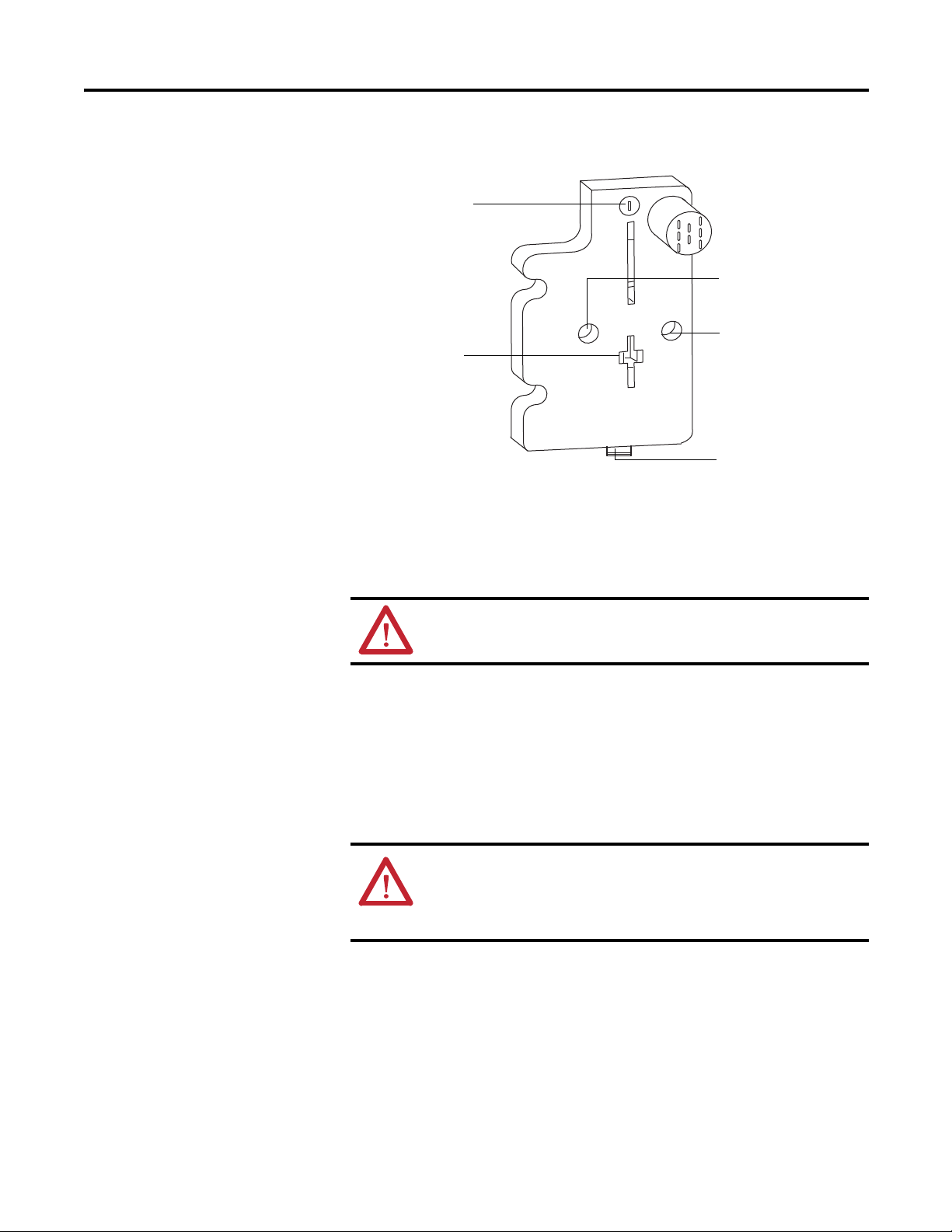

Terminating Base

43787

Mounting hole

Latching mechanism release

Ground connection

Keyswitch

Latching

mechanism hole

Install Your Adapter Chapter 2

Install the POINT I/O Adapter Module

To install the adapter on the DIN rail prior to installing other base units:

ATTENTION: Allow 25.4 mm (1.0 in.) of space between adjacent

equipment for adequate ventilation.

1. Position the adapter vertically above the DIN rail.

2. Press down firmly to install the adapter on the DIN rail, noting that a

locking mechanism locks the adapter to the DIN rail.

3. Set the network address on the network address thumbwheel.

4. Slide the safety end cap up to remove it, exposing the backplane and power

interconnections

ATTENTION: Do not discard the end cap. Use this end cap to cover the

exposed interconnections on the last mounting base on the DIN rail.

Failure to do so could result in equipment damage or injury from electric

shock.

.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 13

Page 22

Chapter 2 Install Your Adapter

NC

C

V

NC

Chas

Gnd

C

V

NC = No Connection

Chas Gnd = Chassis Ground

C = Common

V = Supply

0

4

2

6

Chas

Gnd

12/24V DC

This DC supply connects

to the internal power bus.

1

5

3

7

V DC

Install the ArmorPOINT I/O Adapter Module

To install the ArmorPOINT I/O adapter module:

1. Using a bladed screwdriver, rotate the keyswitch on the mounting base

clockwise until the appropriate number for the I/O module you are

installing aligns with the notch in the base.

Refer to the installation instructions for each module to determine what

this number must be. See Related Documentation

on page i for a list of

these installation instructions.

2. Position the module vertically above the mounting base.

The module bridges two bases.

3. Push the module down until it engages the latching mechanism.

You hear a clicking sound when the module is properly engaged. The

locking mechanism locks the module to the base.

Wire the POINT I/O Adapter

Refer to the following illustration to wire the adapter.

14 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

ATT ENTI ON: Do not connect 120/240V AC power to the V DC supply.

ATT ENTI ON: Do not wire more than two conductors on any single

terminal.

ATTENTION: Make sure all connectors and caps are securely tightened

to properly seal the connections against leaks and maintain IP67

requirements.

Page 23

Install Your Adapter Chapter 2

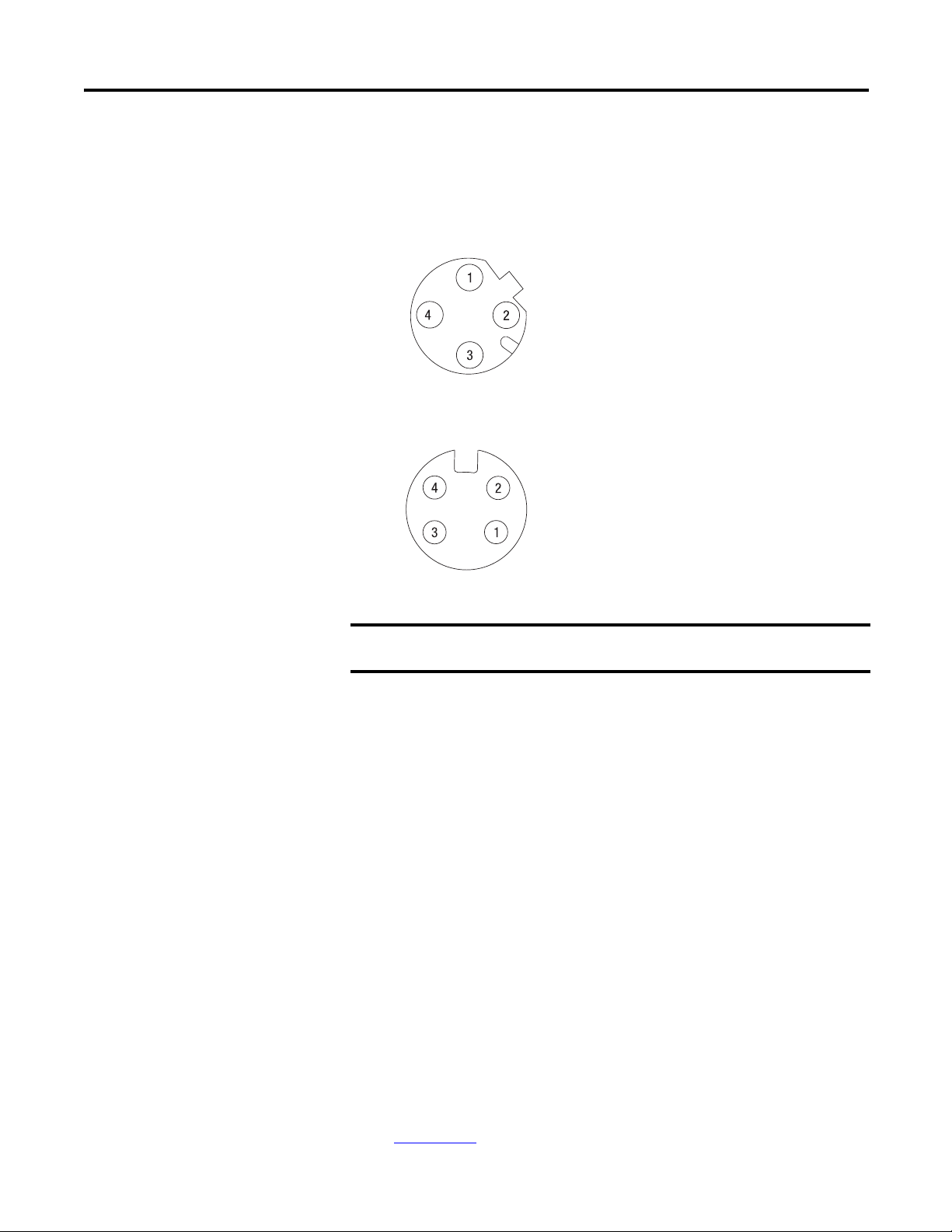

IMPORTANT

(view into connector)

Pin 1 - Tx +

Pin 2 - Rx +

Pin 3 - Tx Pin 4 - Rx -

M12 Female In Connector

43765

43587

Mini Style 4-Pin in Male Connector

(view into connector)

Pin 1 - User Power +

Pin 2 - Adapter Power +

Pin 3 - Adapter Power Pin 4 - User Power -

Wire the ArmorPOINT I/O Adapter

Wire the EtherNet/IP and auxiliary power connectors on the adapter as shown.

EtherNet/IP Connectors

Chapter Summary

Auxiliary Power Connector

(1)

Analog modules have earth grounded metal rings. This should be

considered when choosing shielded cables and grounding techniques.

In this chapter, you learned how to install and wire your POINT I/O or

ArmorPOINT adapter module. The following chapter describes how to

configure your POINT I/O or ArmorPOINT I/O adapter module to

communicate on the EtherNet/IP network by providing an IP address, gateway

address, and Subnet mask.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 15

(1) Auxiliary power cable: standard cordset (single-ended), for example Allen-Bradley part number 889N-F4AFC-6F or 889N-R4AFC6F; or standard patchcord (double-ended), for example, Allen-Bradley part number 889N-F4AFNU-6F or 889N-F4AFNV-6F. Refer to

publication M117-CA001A-EN-P

for more information.

Page 24

Chapter 2 Install Your Adapter

Notes:

16 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 25

Chapter

Configure the Adapter for Your EtherNet/

IP Network

3

Overview

Before using your adapter in an EtherNet/IP network, you need to configure it

with an IP address, subnet mask, and optional Gateway address. This chapter

describes these configuration requirements and the procedures for providing

them. Here are ways you can do this:

• Use the Rockwell BootP/DHCP utility, version 2.3 or later, that ships

with RSLogix 5000 or RSLinx software.

– You can also use this utility to reconfigure a device with an IP address

you must change.

• Use a

• Use the Network Address thumbwheel switches.

• Have your network administrator configure the adapter via the network

See the table for a list of where to find information in this chapter.

Topic Page

Configuration Requirements 18

IP Address 18

Gateway Address 19

Subnet Mask 20

Set the Network Address 21

Set the Network Address for POINT I/O Adapter 21

Set the Network Address for ArmorPOINT I/O Adapter 22

Use the Rockwell BootP/DHCP Utility 22

Save the Relation List 25

Use DHCP Software to Configure Your Adapter 26

third party DHCP server.

DHCP server.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 17

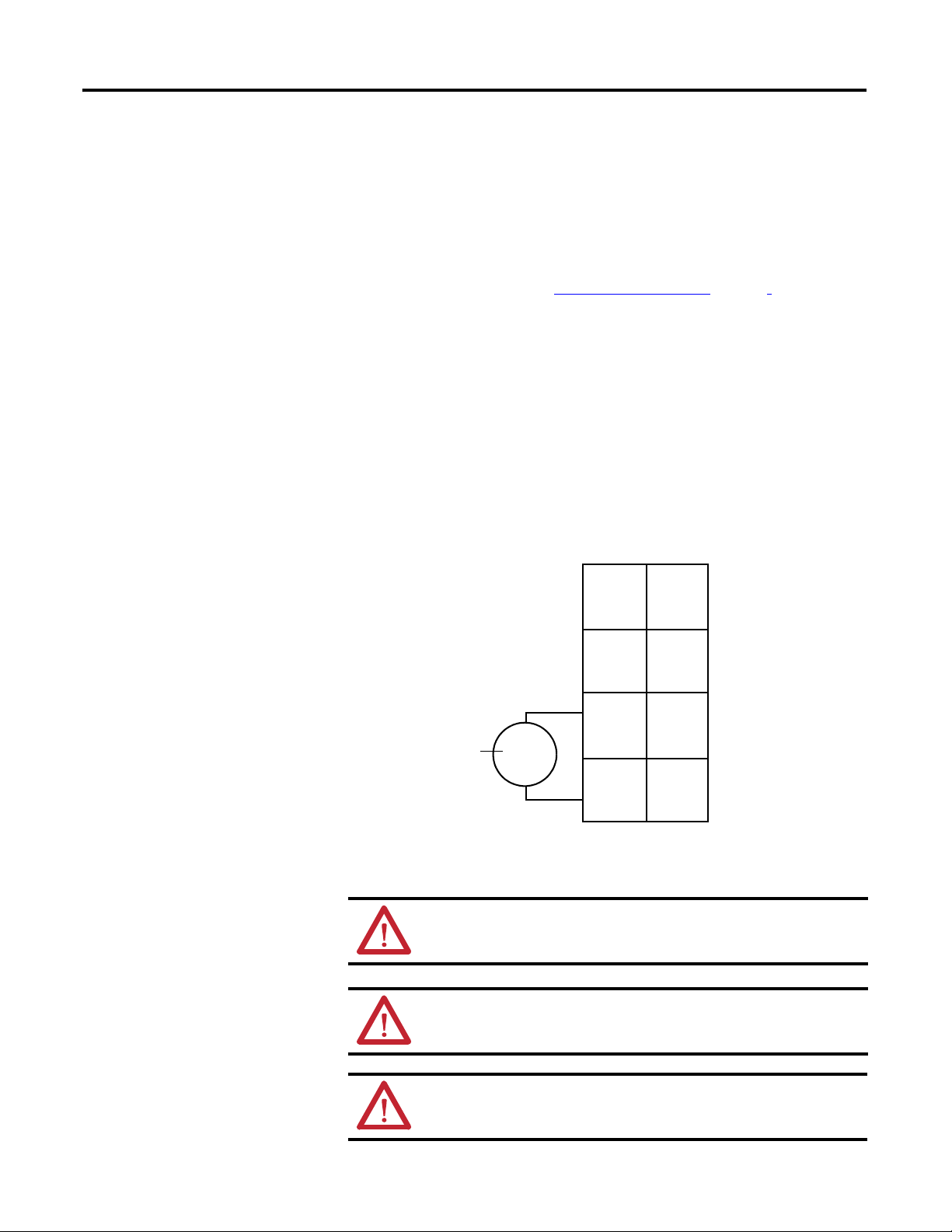

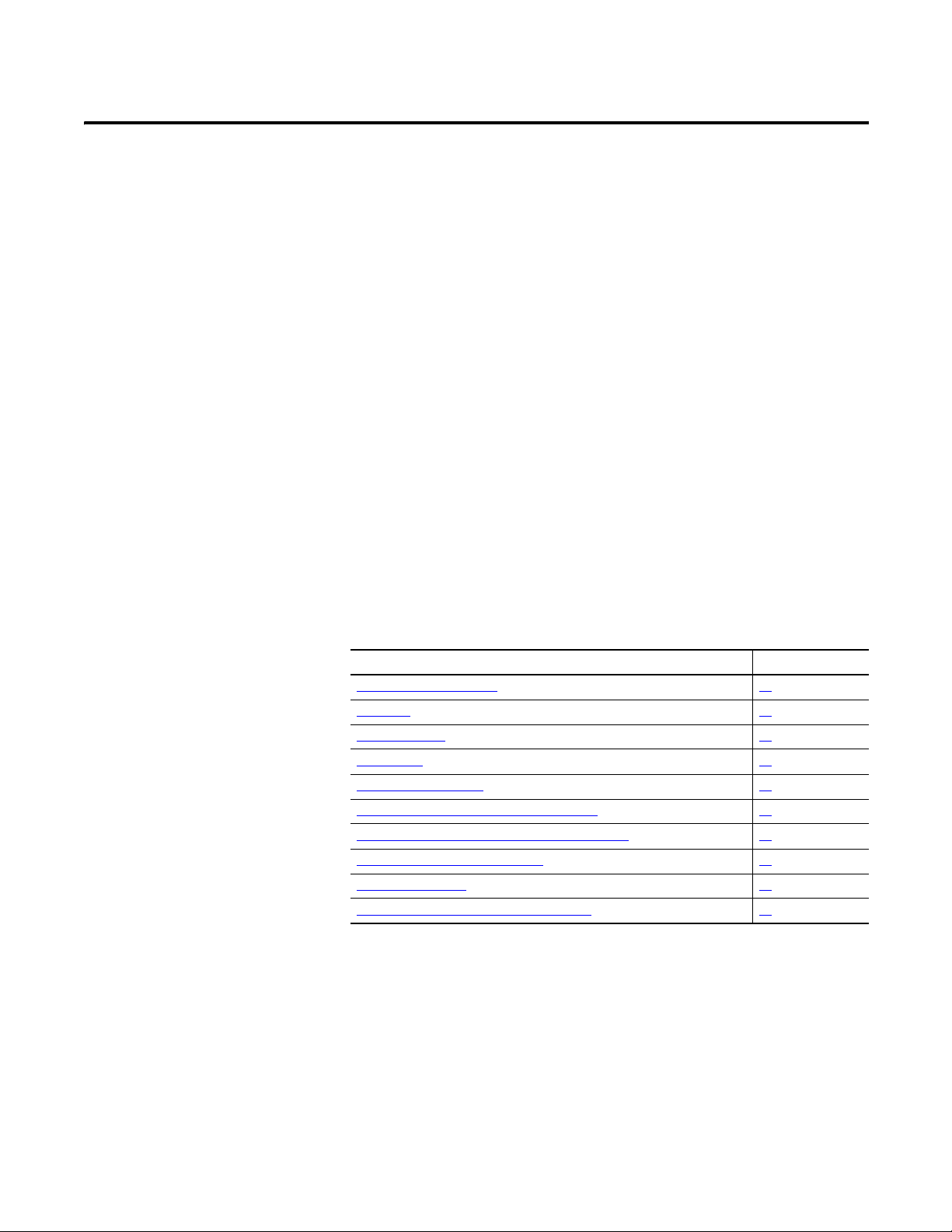

Page 26

Chapter 3 Configure the Adapter for Your EtherNet/IP Network

Class A

Class B

Class C

Network ID

Host ID

Host ID

Host ID

0

0

0

10

0

110

78

15 16

31

31

3123 24

Network ID

Network ID

EXAMPLE

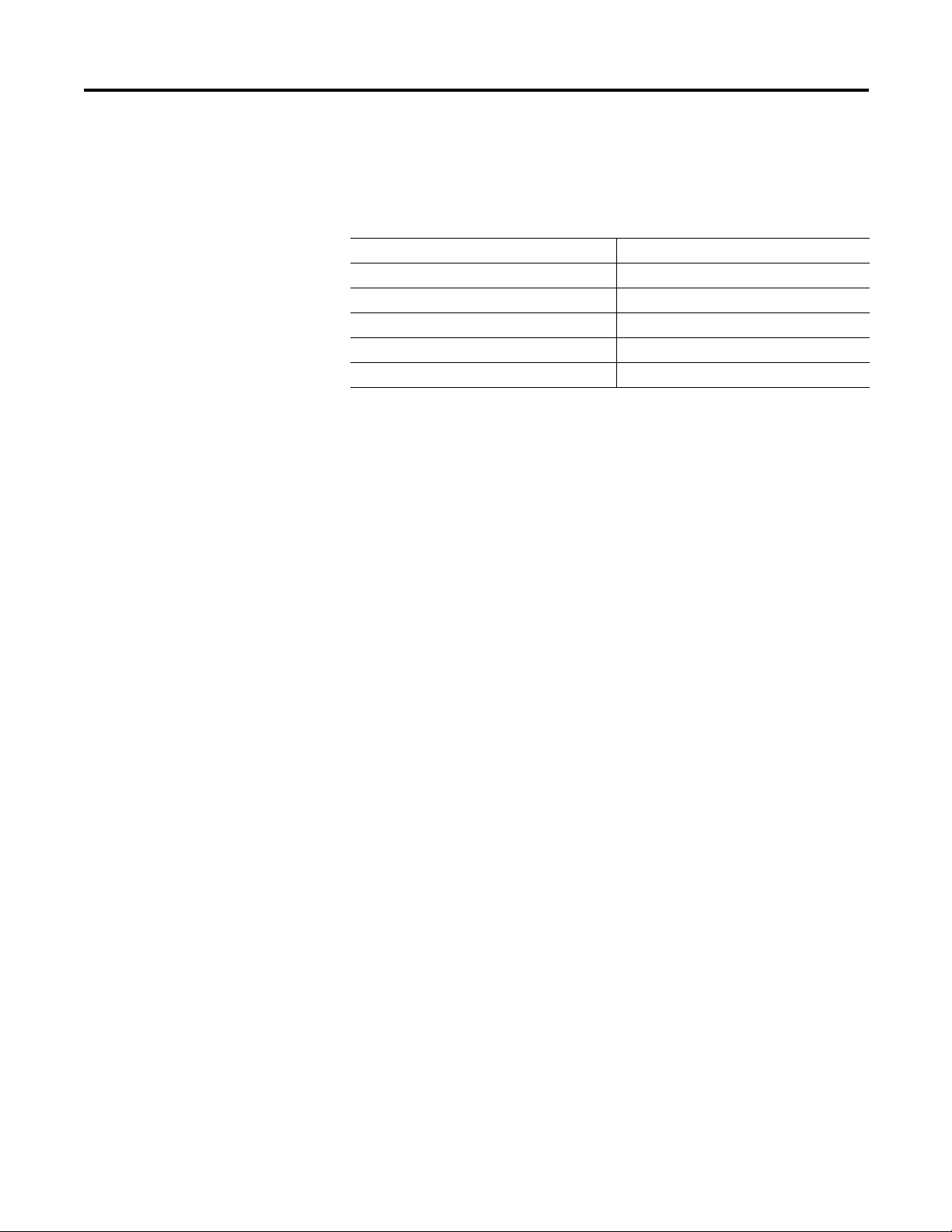

Configuration Requirements

Before you can use your adapter, you must configure its IP address, its subnet

mask, and, optionally, a gateway address. You can use the Rockwell BootP utility,

version 2.3 or later, to perform the

configuration. You can also use a DHCP

server or the network address switches to configure these parameters.

ATTENTION: You must use series C POINT I/O modules with the

adapter. Series A or B POINT I/O modules do not work with the adapter.

If you need to reset the adapter to factory defaults, see Work with the

Configuration Pages in Appendix B.

IP Address

The IP address identifies each node on the IP network (or system of connected

networks). Each TCP/IP node on a network (including the adapter) must have a

unique IP address.

The IP address is 32 bits long and has a Network ID part and Host ID part.

Networks are classified A, B, C, (or other). The class of the network determines

how an IP address is formatted

.

You can distinguish the class of the IP address from the first integer in its dotteddecimal IP address as follows:

Range of first integer Class Range of first integer Class

0 1…127 A 192…223 C

128…191 B 224… 255 other

Each node on the same physical network must have an IP address of the same

class and must have the same network ID. Each node on the same network must

have a different Host ID thus giving it a unique IP address.

IP addresses are written as four decimal integers (0…255) separated by periods

where each integer gives the value of one byte of the IP address

.

For example, the 32-bit IP address:

10000000 00000001 00000000 00000001 is written as

128.1.0.1

18 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 27

Configure the Adapter for Your EtherNet/IP Network Chapter 3

Network 1

Network 2

128.1.0.1

128.2.0.1 128.2.0.2 128.2.0.3

128.1.0.2

A

B

G

C

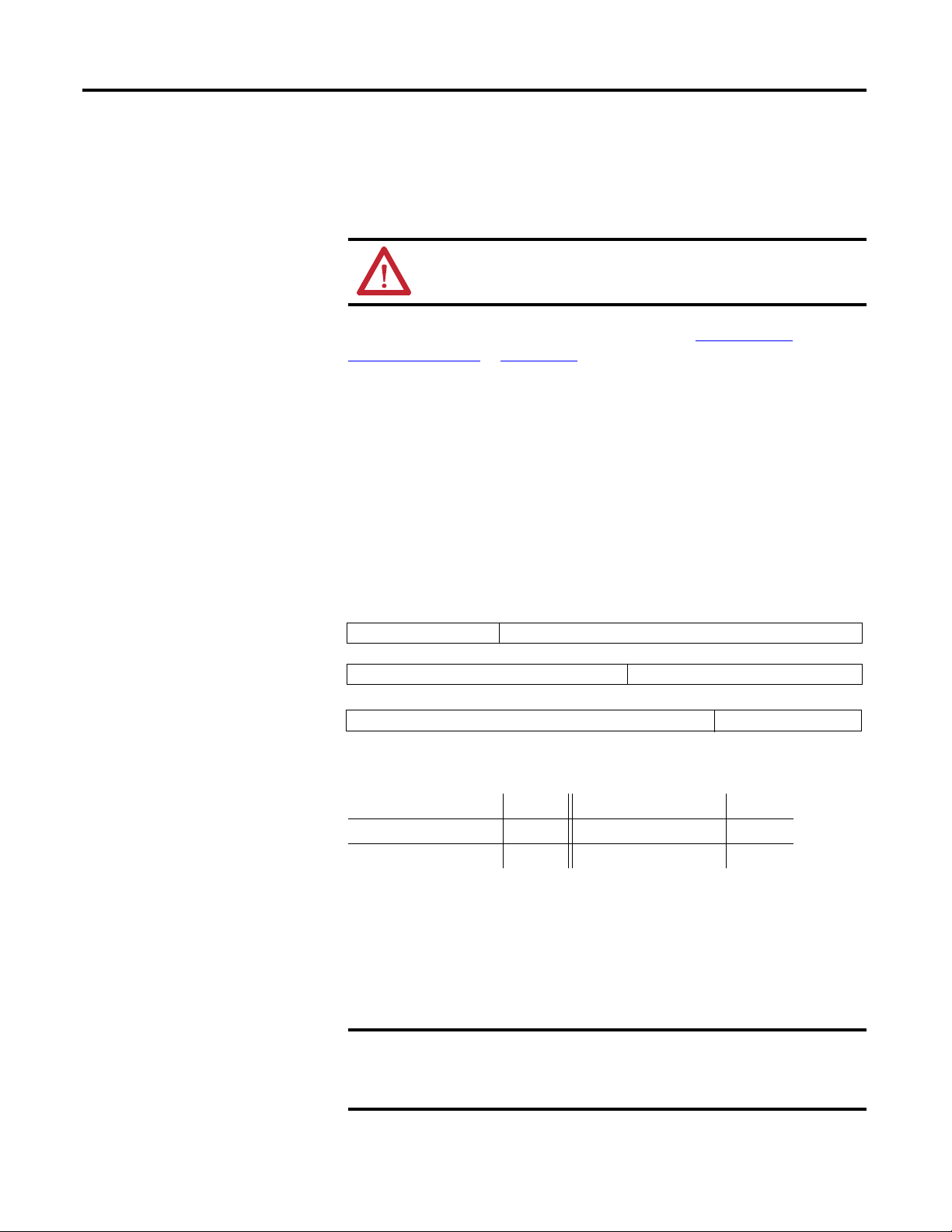

Gateway Address

This section applies to multi-network systems. If you have a single network

system, refer to the next section.

The Gateway Address is the default address of a network. It provides a single

domain name and point of entry to the site. Gateways connect individual physical

networks into a system of networks.

When a node needs to communicate with a node on another network, a gateway

transfers the data between the two networks. The figure shows gateway G

connecting Network 1 with Network 2.

When host B with IP address 128.2.0.1 communicates with host C, it knows

from C’s IP address that C is on the same network. in an Ethernet environment, B

can then resolve C’s IP address into a hardware address (MAC address) and

communicate with C directly.

When host B communicates with host A, it knows from A’s IP address that A is

on another network (the network IDs are different). In order to send data to A, B

must use the IP address of the gateway connecting the two networks. In this

example, the gateway’s IP address on Network 2 is 128.2.0.3.

The gateway has two IP addresses (128.1.0.2 and 128.2.0.3). The first must be

used by hosts on Network 1 and the second must be used by hosts on Network 2.

To be usable, a gateway of a host must be addressed using a network ID matching

its own.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 19

Page 28

Chapter 3 Configure the Adapter for Your EtherNet/IP Network

EXAMPLE

These two bits of the Host ID are used to

extend the netdwork ID.

Network 1

Network 2.1

Network 2.2

A

BC

DE

128.1.0.2

128.1.0.1

128.2.64.3

128.2.128.2

128.2.64.1 128.2.64.2

128.2.128.3

128.2.128.1

G2

G

Subnet Mask

The subnet mask is used for splitting IP networks into a series of subgroups, or

subnets. The mask is a binary pattern that is matched up with the IP address to

turn part of the Host ID address field into a field for subnets

Two bits of the Class B host ID are used to extend the network ID. Each unique

combination of bits in the part of the Host ID where subnet mask bits are 1

specifies a different physical network.

.

Take Network 2 (a Class B network) in the previous

example and add another physical network. Selecting the

following subnet mask would add two additional

network ID bits, allowing for four physical networks:

11111111 11111111 11

000000 00000000 = 255.255.192.0

The new configuration is:

A second network with Hosts D and E was added. Gateway G2 connects

Network 2.1 with Network 2.2.

Hosts D and E will use Gateway G2 to communicate with hosts not on

Network 2.2.

Hosts B and C will use Gateway G to communicate with hosts not on

Network 2.1.

20 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

When B is communicating with D, G (the configured Gateway for B) will route

the data from B to D through G2.

Page 29

Configure the Adapter for Your EtherNet/IP Network Chapter 3

44848

Network address thumbwheel

Press either the + or - buttons

to change the number and

assign the IP address.

02

0

1734-AENTR

Module

Status

Network

Activity

Network

Status

Point Bus

Status

System

Power

Field

Power

POINT I O

Link 1

Activity/

Status

Link 2

Activity/

Status

IP ADDRESS

Set the Network Address

The adapters ship DHCP-enabled and with the switches set to 999. To change

the network address, do the following.

Set the Network Address for POINT I/O Adapter

• Use the thumbwheel switches located on the adapter. Press either the + or -

buttons to change the number.

• Use a Dynamic Host Configuration Protocol (DHCP) server, such as

Rockwell Automation BootP/DHCP.

• Retrieve the IP address from non-volatile memory.

The adapter reads the thumbwheel switches first to determine if the switches are

set to a valid number. You set the node address by using the 3-position

thumbwheel switch. Press the + or - buttons to change the number. Valid settings

range from 001…254.

When you use the thumbwheel to assign an address and set it to 001, the adapter

gateway address is set to 0.0.0.0. and the subnet mask is 255.255.255.0 . When

you use the thumbwheel to assign an address and set it between 002...254, the

adapter gateway address is set to 192.168.1.1.

The adapter does not have a host name assigned, or use any Domain Name

System when using the thumbwheel settings.

If DHCP is not enabled, the adapter uses the IP address, along with other TCP

configurable parameters, stored in non-volatile memory.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 21

Page 30

Chapter 3 Configure the Adapter for Your EtherNet/IP Network

44831

This example shows the network address

set at 163.

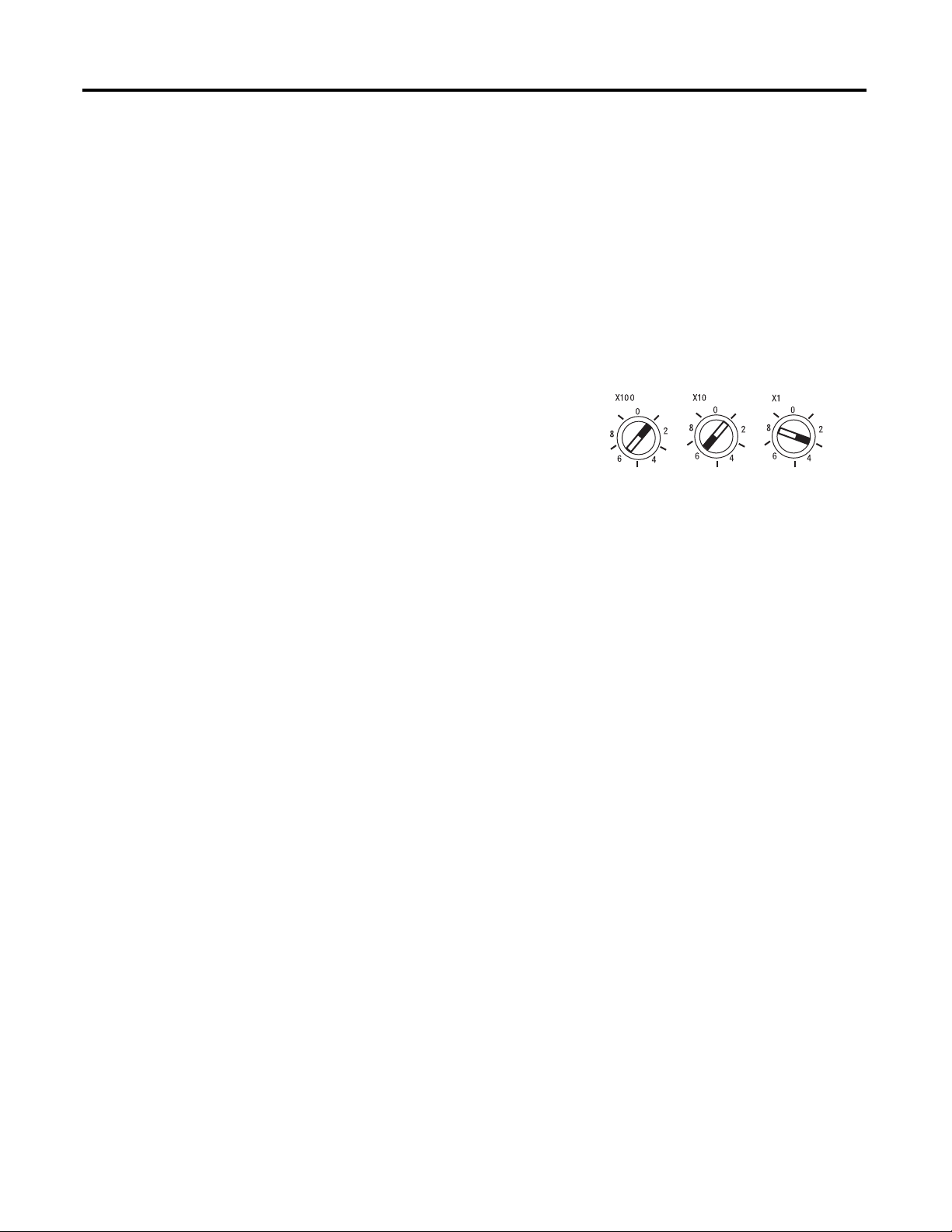

Set the Network Address for ArmorPOINT I/O Adapter

• Adjust the switches in front of the module

• Use a Dynamic Host Configuration Protocol (DHCP) server such as

Rockwell Automation BootP/DHCP

• Retrieve the IP address from non-volatile memory

The adapter reads the switches first to determine if the switches are set to a valid

number. Set the network address by adjusting the three switches on the front of

the adapter.

Network Address Example

Use a small blade screwdriver to rotate the switches. Line up the small notch on

the switch with the number setting you wish to use. Valid settings range from

001…254.

Use the Rockwell BootP/ DHCP Utility

When you use the switches to assign an address and set it to 001, the adapter

gateway address is set to 0.0.0.0. and the subnet mask is 255.255.255.0 . When

you use the switches to assign an address and set it to a valid number between

002...254, the adapter gateway address is set to 192.168.1.1.

If the switches are set to an invalid number (for example, 000 or a value greater

than 254 excluding 888), the adapter checks to see if DHCP is enabled. If DHCP

is enabled, the adapter requests an address from a DHCP server. The DHCP

server also assigns other Transport Control Protocol (TCP) parameters.

If DHCP is not enabled, the adapter uses the IP address, along with other TCP

configurable parameters, stored in non-volatile memory.

The Rockwell BootP/DHCP utility is a standalone program that incorporates

the functionality of standard BootP software with a user friendly graphical

interface. It is located in the Utils directory on the RSLogix5000 software

installation CD. The adapter must have DHCP enabled (factory default and the

network address switches set to an invalid value) to use the utility.

22 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 31

Configure the Adapter for Your EtherNet/IP Network Chapter 3

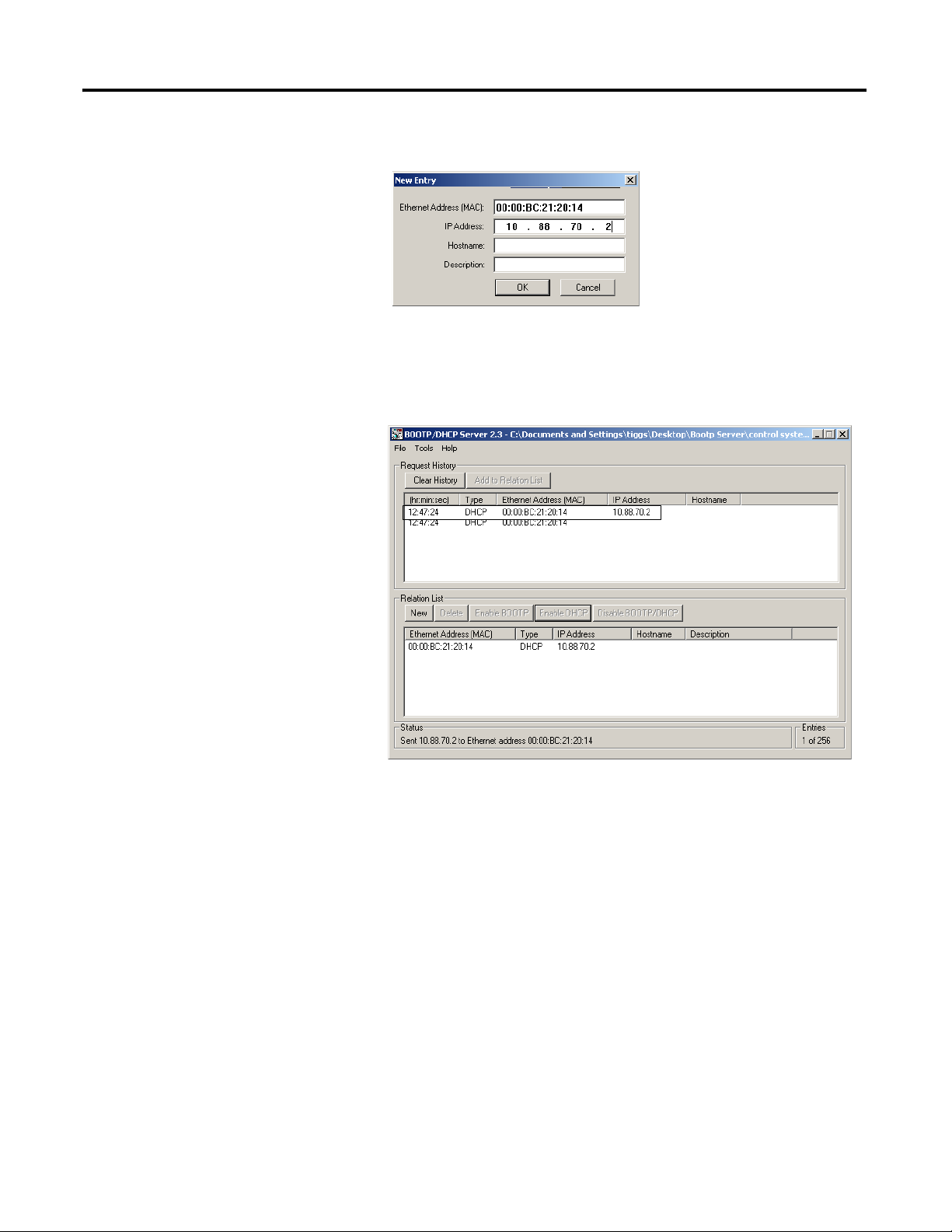

To configure your adapter using the BootP utility, perform the following steps:

1. Run the BootP software.

In the BOOTP Request History panel you see the hardware addresses of

devices issuing BootP requests.

2. Double-click the hardware address of the device you want to configure.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 23

Page 32

Chapter 3 Configure the Adapter for Your EtherNet/IP Network

The New Entry dialog appears with the device’s Ethernet Address (MAC).

3. Enter the IP Address you want to assign to the device and click OK. The

device is added to the Relation List, displaying the Ethernet Address

(MAC) and corresponding IP Address, Hostname, and Description (if

applicable).

When the address displays in the IP Address column in the Request History

section, the IP address assignment has been made.

4. To make this configuration static in the device, highlight the device in the

Relation List panel, and click the Disable BOOTP/DHCP button.

When power is cycled to the device, it uses the configuration saved in nonvolatile memory and will not issue a DHCP request.

5. To enable DHCP for a device with DHCP disabled, highlight the device

in the Relation List, and click the Enable DHCP button.

You must have an entry for the device in the Relation List panel to reenable DHCP.

24 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 33

Configure the Adapter for Your EtherNet/IP Network Chapter 3

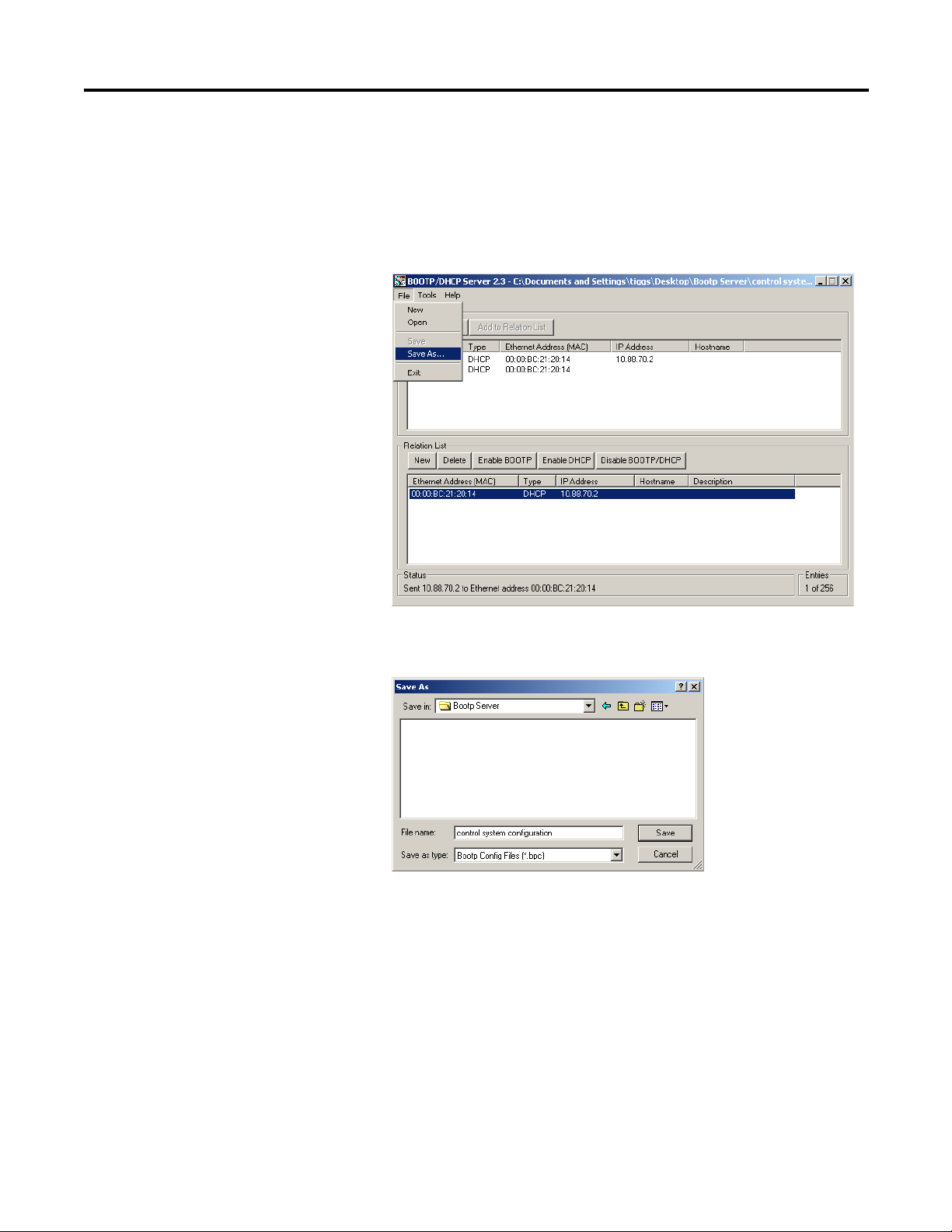

Save the Relation List

You can save the Relation List for later use. To save the Relation List, perform the

following steps:

1. Select Save As... from the File menu.

The Save As dialog appears.

2. Select the folder where you want to save the Relation List.

3. Enter a File name for the Relation List, for example, control system

configuration, and click Save.

You can leave the Save as type at the default setting: Bootp Config Files

(*.bpc).

You now have the option to open the file containing the Relation List at a

later session.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 25

Page 34

Chapter 3 Configure the Adapter for Your EtherNet/IP Network

Use DHCP Software to Configure Your Adapter

DHCP (Dynamic Host Configuration Protocol) software automatically assigns

IP addresses to client stations logging onto a TCP/IP network.

DHCP is based on BootP and maintains some backward compatibility. The main

difference is that BootP was designed for manual configuration, while DHCP

allows for dynamic allocation of network addresses and configurations to newly

attached devices.

Be cautious about using DHCP software to configure your adapter. A DHCP

server typically assigns a finite lease time to the offered IP address.

When 50% of the leased time has expired, the adapter attempts to renew its IP

address with the DHCP server.

The possibility exists that the adapter will be assigned a different IP address,

which would cause the adapter to cease communicating with the ControlLogix

controller. See Configure the Adapter with Fixed IP Address

more details on how to configure an adapter with a fixed IP address.

ATT ENTI ON: To avoid unintended control or loss of control, the

I/O adapter must be assigned a fixed IP address. A dynamically

provided IP address should be used only at initial configuration. If a

DHCP server is used, it must be configured to assign the same IP

address to your adapter.

Failure to observe this precaution may result in unintended machine

motion or loss of process control.

in Chapter 4 for

Chapter Summary

This chapter provided instructions on how to configure POINT and

ArmorPOINT Adapter modules through the RSLogix 5000 software and

included information on configuration requirements and setting the network

address.

26 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 35

Chapter

4

Configure the Adapter for Direct Connection

in RSLogix 5000 Software

Overview

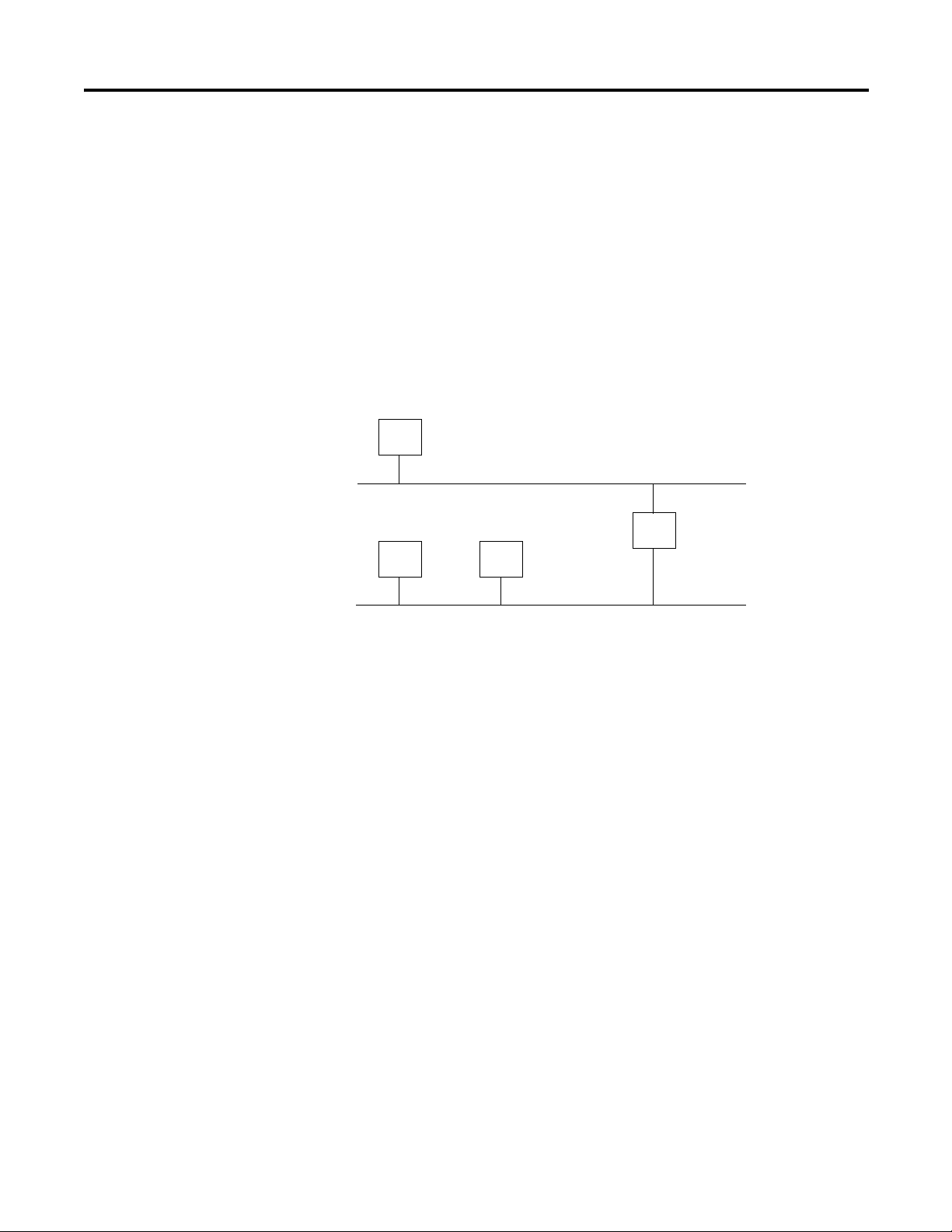

In this example, a ControlLogix controller communicates with I/O modules via

the adapter using a direct connection.

The adapter makes a direct connection to each of the modules referenced by the

data. The modules presented in this chapter use RSLogix 5000 software, revision

11 and above.

ATTENTION: You must use series C POINT I/O modules with the adapter.

Series A or B POINT I/O modules do not work with the adapter.

Topic Page

Set Up the Hardware 27

Create the Example Application 29

Configure the I/O 30

Add the Local EtherNet/IP Bridge to the I/O Configuration 30

Add the POINT I/O Adapter to the I/O Configuration 33

Add the POINT I/O Modules to the I/O Configuration 35

Edit the Controller Tags 40

Create the Ladder Program 41

Download the Program to the Controller 41

Verify the Module Chassis Size 42

Configure the Adapter with Fixed IP Address 45

Recover From an Overloaded Adapter 46

Set Up the Hardware

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 27

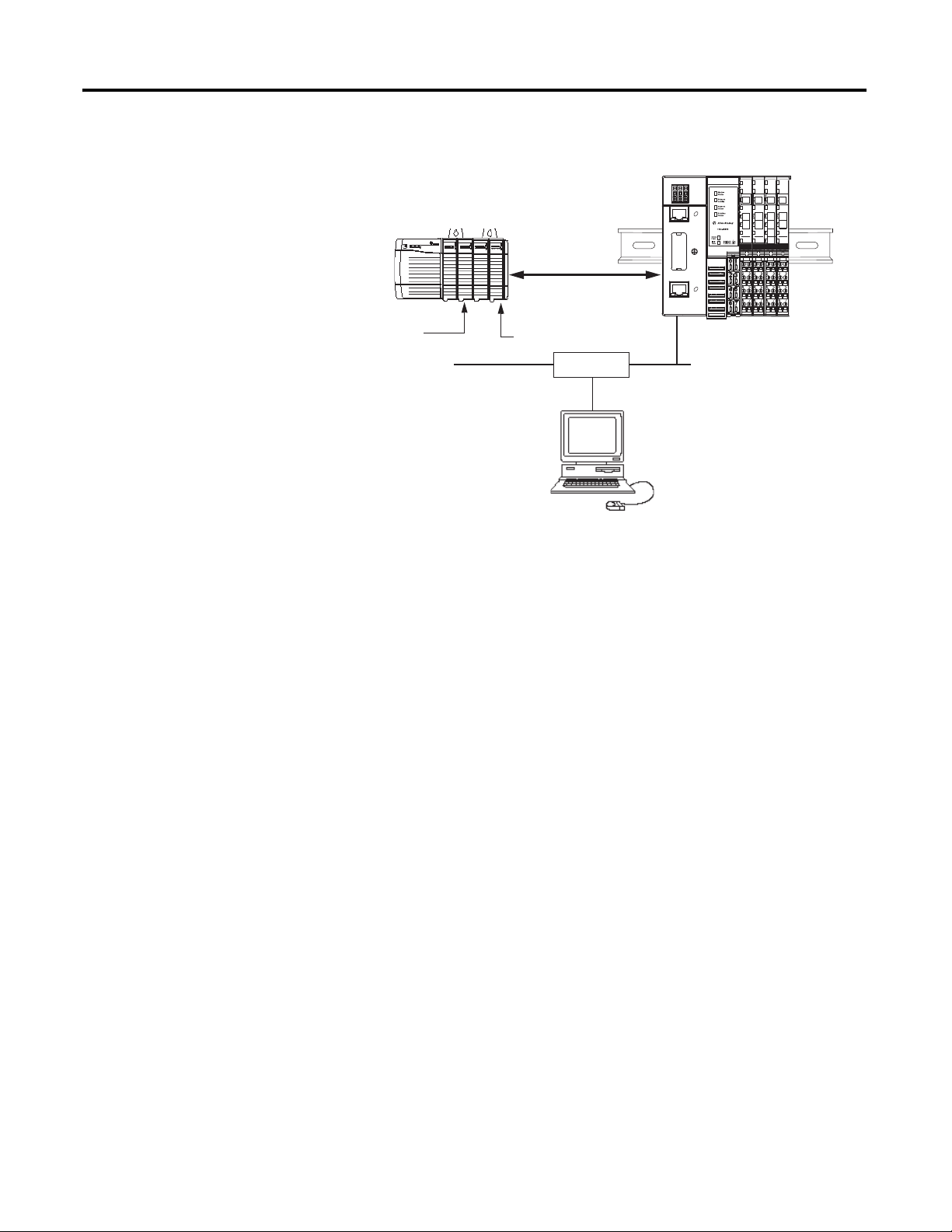

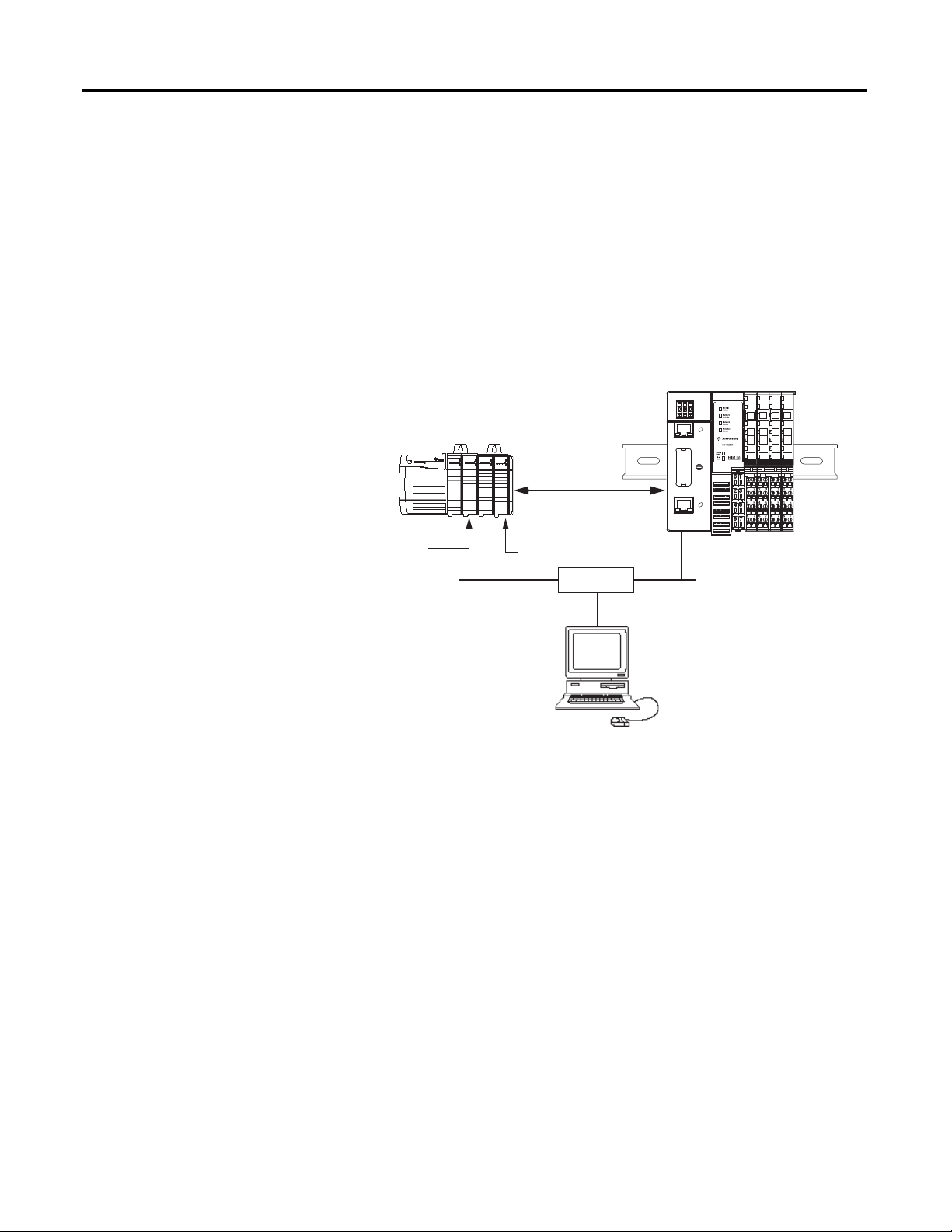

In this example, a ControlLogix chassis contains the L63 controller in slot 1 and a

1756-ENBT bridge module in slot 3. The 1734-AENTR adapter is mounted on

a DIN rail in slot 0, with a 1734-OW2/C relay output module in slot 1, a 1734OV4E/C sink output module in slot 2, and a power supply (not shown).

Page 36

Chapter 4 Configure the Adapter for Direct Connection in RSLogix 5000 Software

45176

To work along with this example, set up your system as shown in the figure.

Slot 0 1 2 3

1734-AENTR

10.88.70.2

Link 1

Activity/

Status

POINT I/O

Local

chassis

L63

controller (slot 1)

Data

1756-ENBT

10.88.70.4 (slot 3)

Link 2

Activity/

Status

Slot 0 1 2 3 4

Switch

10.88.70.26

Programming

terminal

• In the example application, we assume that the L63 controller and 1756-

ENBT module (firmware revision 2.3, or later) are in the slots shown in

the figure.

• Verify the IP addresses for your programming terminal, 1756-ENBT

module, and adapter.

• Verify the position (slot) of the I/O modules on the DIN rail.

• Verify that you connected all wiring and cabling properly.

• Be sure you configured your communication driver (for example,

AB_ETH-1 or AB-ETHIP-1) in RSLinx software, as described in

Appendix of this manual.

28 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 37

Configure the Adapter for Direct Connection in RSLogix 5000 Software Chapter 4

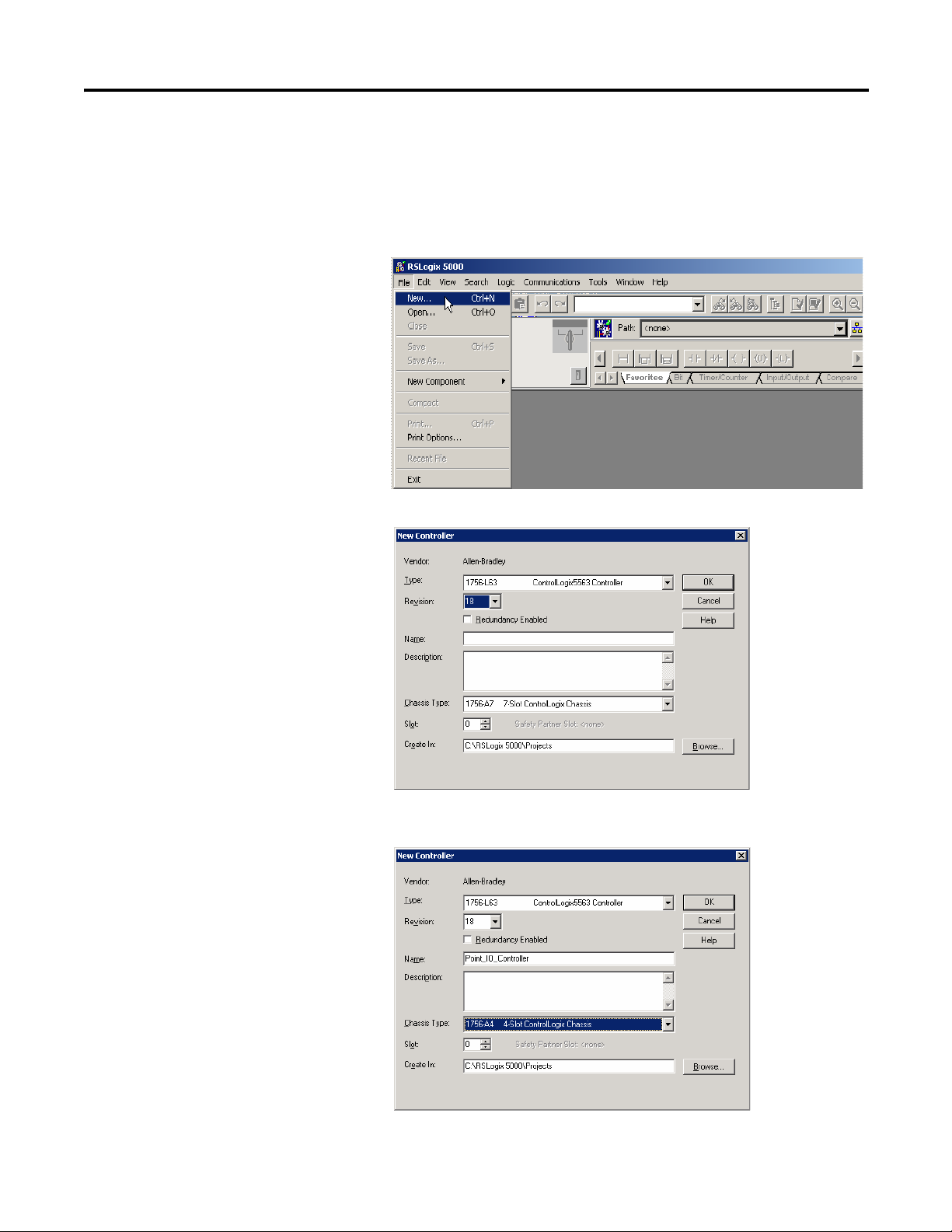

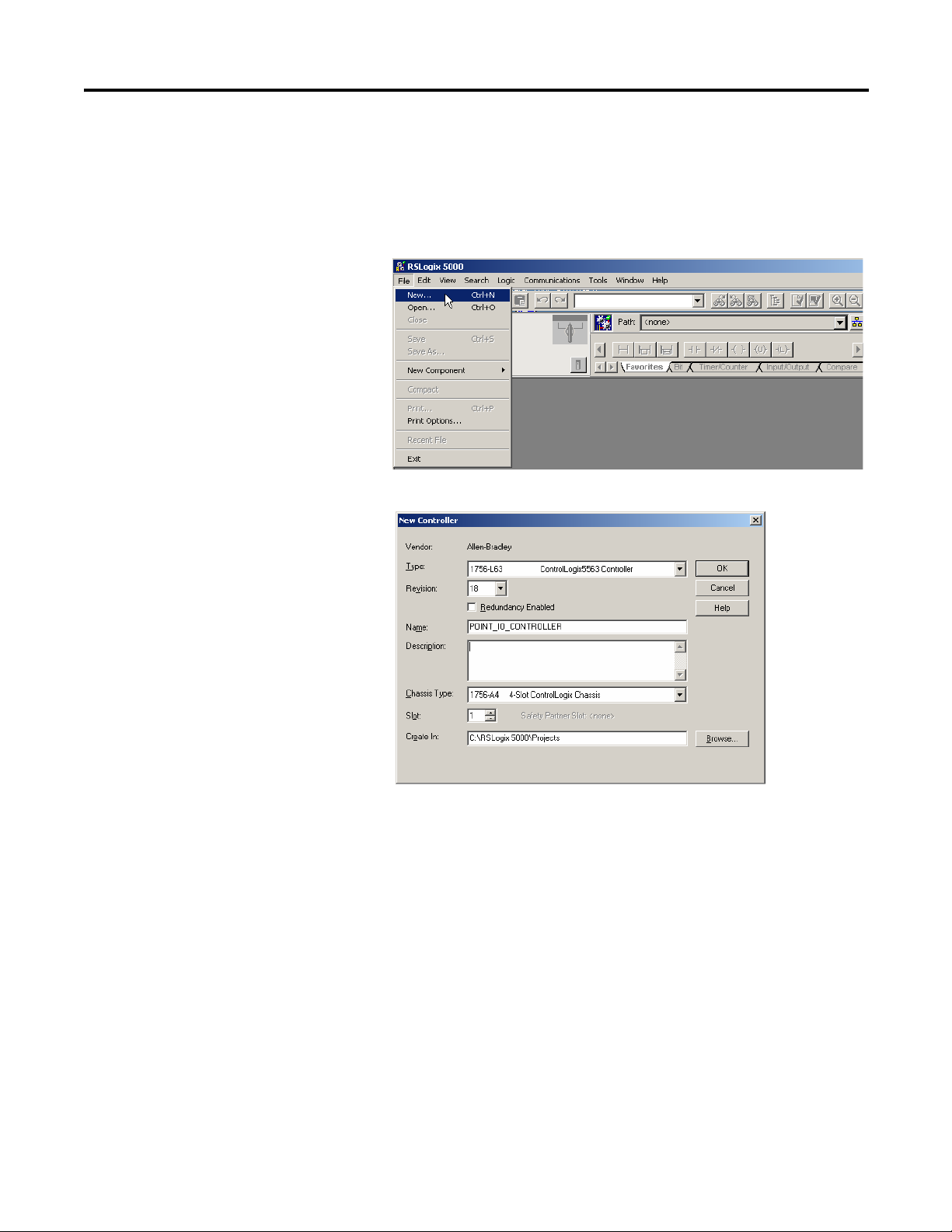

Create the Example Application

Perform the following steps to create the example application:

1. Start RSLogix 5000 Enterprise Series software to open the RSLogix 5000

main dialog.

2. From the File menu, select New.

3. The New Controller dialog opens.

4. Enter an appropriate Name for the Controller, for example,

POINT_IO_Controller.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 29

Page 38

Chapter 4 Configure the Adapter for Direct Connection in RSLogix 5000 Software

IMPORTANT

5. Select the correct Version, Chassis Type, and Slot number of the L63

controller, and the folder where you want to save the RSLogix 5000 file

(Create In). The Description is optional.

RSLogix 5000 software version 18 lets you enable redundancy. To use

redundancy in your system, check the Redundancy Enabled checkbox

when using the said version or later.

6. Click OK.

Configure the I/O

You now add the POINT I/O modules to the controller’s I/O configuration

performing these procedures:

• Add the local 1756-ENBT module to the I/O configuration.

• Add the 1734-AENTR adapter as a child of the 1756-ENBT module on

the Ethernet network.

• Add the POINT I/O modules as children of the AENTR adapter.

Click the Help button on the configuration dialogs shown in this

section if you need assistance in selecting and setting the

parameters.

.

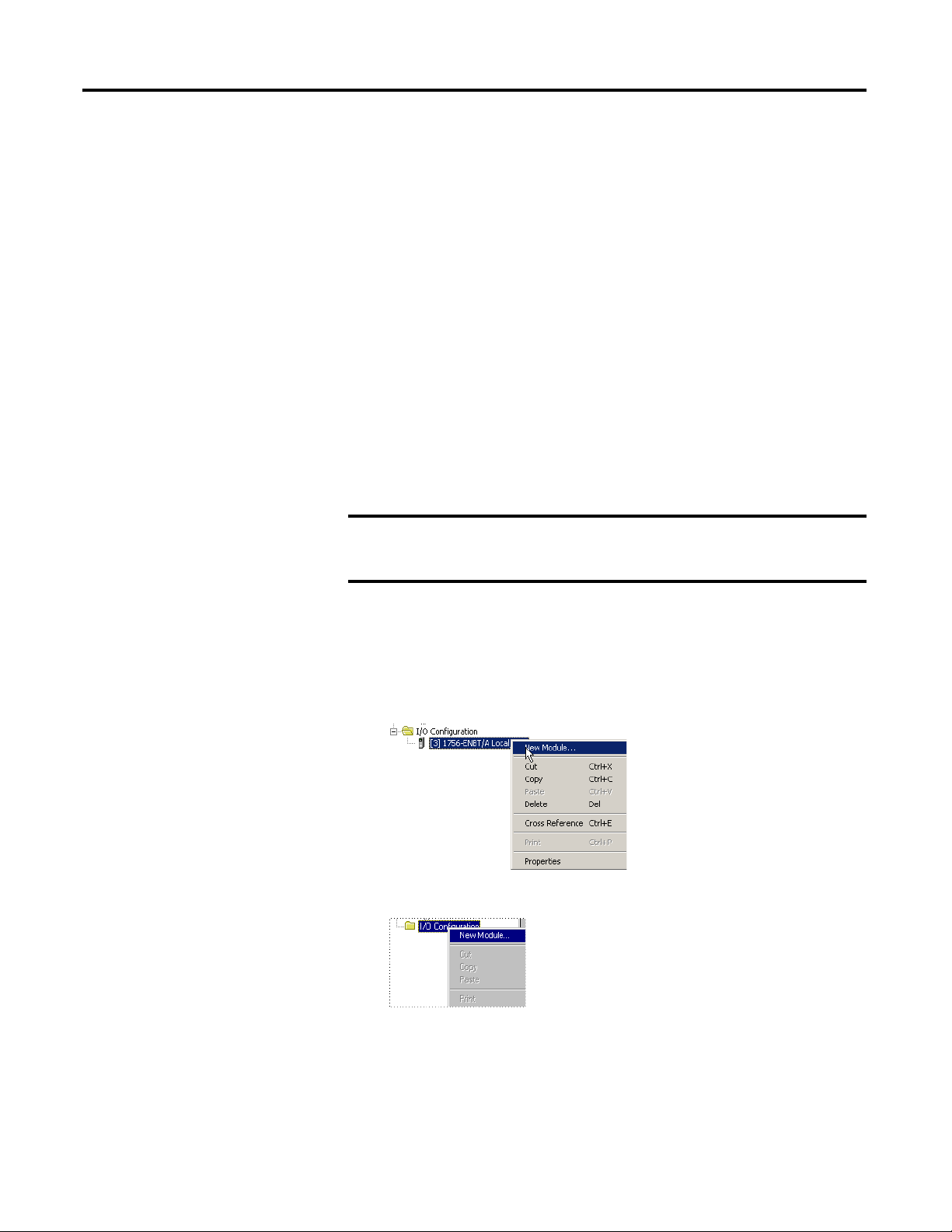

Add the Local EtherNet/IP Bridge to the I/O Configuration

1. Select the I/O Configuration folder in the project dialog, and click the

right mouse button. A menu opens.

2. Choose New Module.

30 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 39

Configure the Adapter for Direct Connection in RSLogix 5000 Software Chapter 4

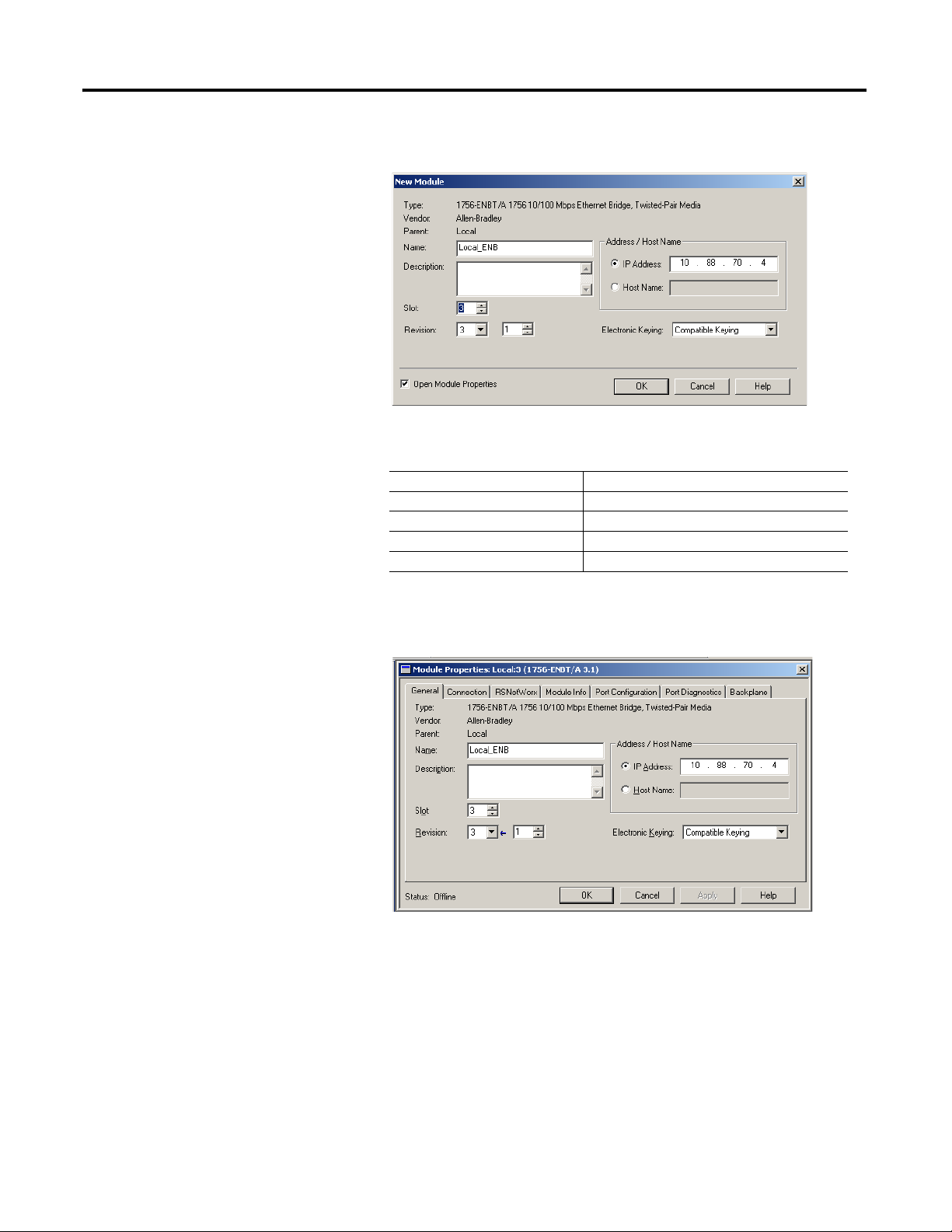

The Select Module dialog opens.

3. Expand the Communications tree as in the following dialog.

4. Select the 1756-ENBT EtherNet/IP Bridge and click OK.

The Select Major Revision dialog opens.

5. Select the number for Major Revision and click OK.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 31

Page 40

Chapter 4 Configure the Adapter for Direct Connection in RSLogix 5000 Software

The New Module dialog opens.

6. Enter values for Name, IP Address, Slot, Electronic Keying, and Revision,

noting that we used the following values:

Name Local_ENBT

IP Address 10.88.70.4

Slot 3

Electronic Keying Compatible Keying

Revision 3.1

7. Click OK to accept the configuration.

The Module Properties dialog opens.

32 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 41

Configure the Adapter for Direct Connection in RSLogix 5000 Software Chapter 4

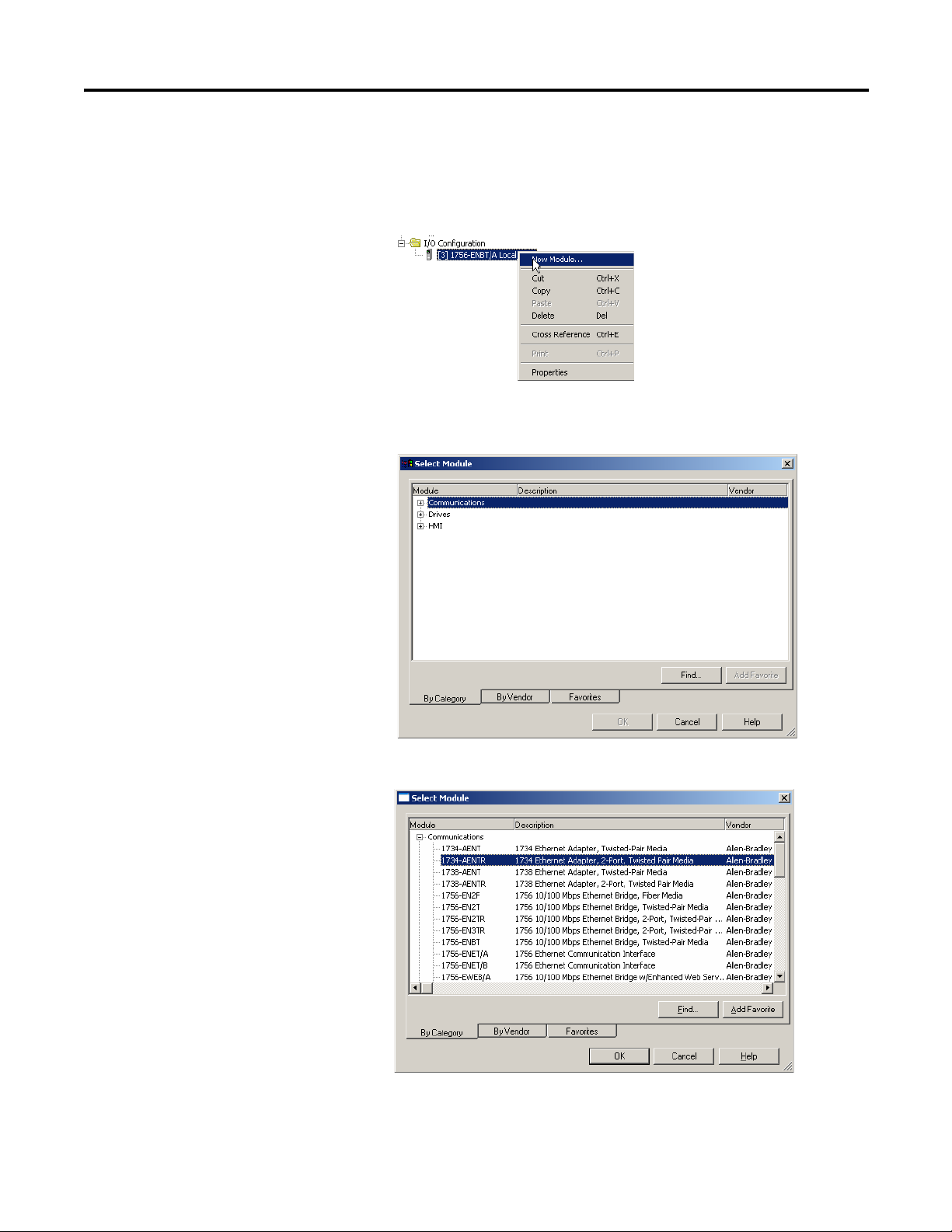

Add the POINT I/O Adapter to the I/O Configuration

Next, you must add the adapter as a child of the local 1756-ENBT module.

1. In the Project dialog, right-click the local 1756-ENBT module under the

I/O Configuration folder, and select New Module from the dialog.

The Select Module dialog opens.

2. Expand the Communications tree.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 33

Page 42

Chapter 4 Configure the Adapter for Direct Connection in RSLogix 5000 Software

IMPORTANT

3. Select your adapter from the list, and click OK, noting that we entered

these values on the General Tab of the New Module dialog.

Name POINT_IO_Adapter

IP Address 10.88.70.2

The Slot field appears grey because the slot is automatically 0 for

the 1734-AENTR adapter.

The New Module dialog opens.

.

4. Click Change...

The Module Definition dialog opens.

5. Choose values for Connection, Chassis Size, Electronic Keying and

Revision, noting that we used the following values:

Connection None

Chassis Size 3

Electronic Keying Compatible Module

Revision 3.1

34 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 43

Configure the Adapter for Direct Connection in RSLogix 5000 Software Chapter 4

IMPORTANT

The chassis size value equals 1 for the adapter plus the number of I/O

modules installed (physically present on the I/O backplane).

Connection choices are the following:

• None – the adapter only makes a direct connection to each of the

modules referenced by the data.

• Rack optimization – digital I/O data is collected into a rack image. This

rack image does not include analog or specialty I/O modules.

• Listen only - rack optimization – read or verify input data only, but does

not control the modules. When you have multiple controllers, one

controller is used to control and the other controllers are used to

monitor. When the owning controller of rack-optimized connection

closes the connection, the Listen-Only data will also stop.

6. Choose None as Connection, because we are only making direct

connections, then click OK. There is no need to have a rack-optimized

connection if all I/O connections to the POINT I/O modules are directly

connected.

A dialog box opens.

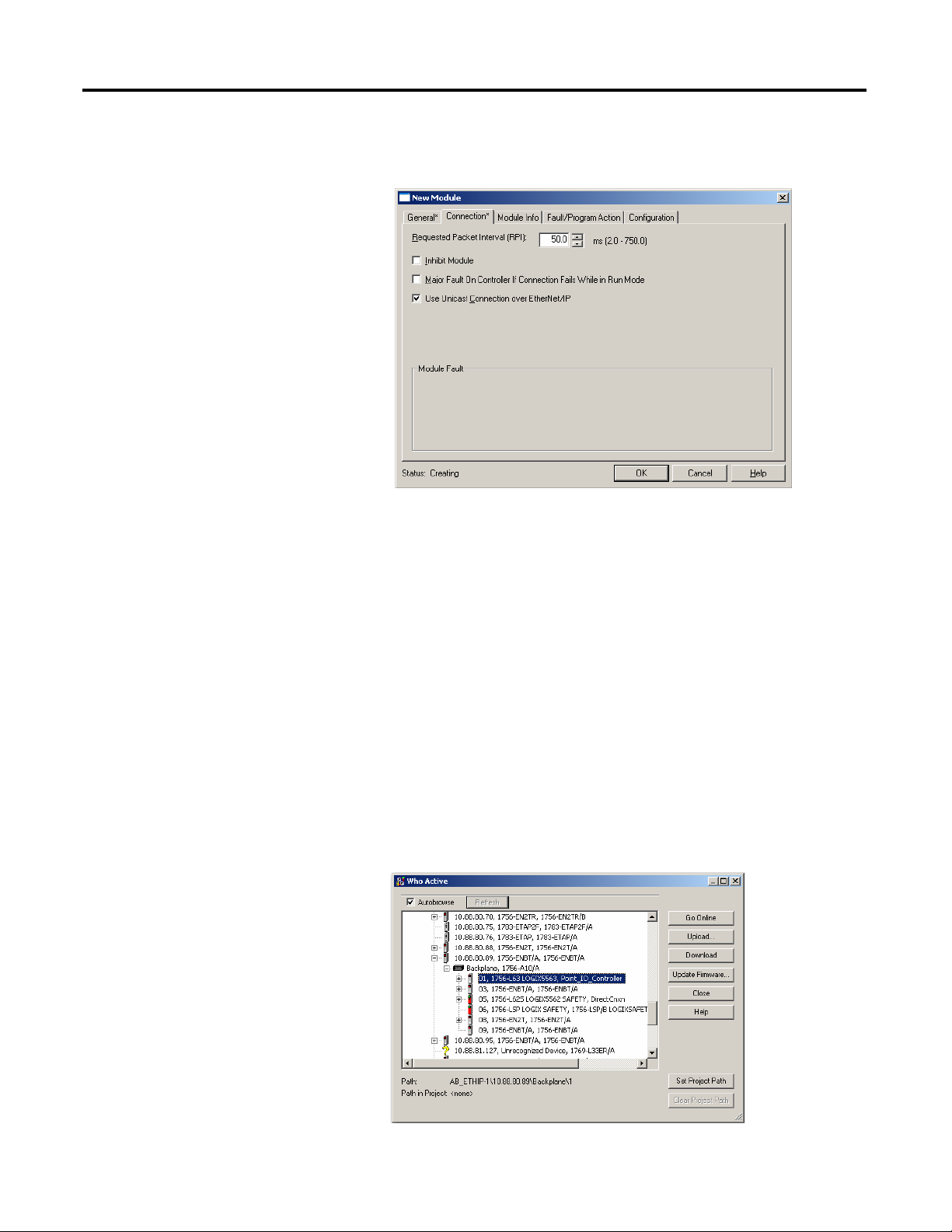

The requested packet interval (RPI) is disabled because you have chosen

None as the Connection.

7. Click OK to accept the configuration.

The name of your adapter appears in the Ethernet folder.

Add the POINT I/O Modules to the I/O Configuration

You now add POINT I/O modules to the I/O Configuration List under the

adapter.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 35

Page 44

Chapter 4 Configure the Adapter for Direct Connection in RSLogix 5000 Software

TIP

In this example, you add a 1734-OW2 relay output and a 1734-OV4E sink

output modules with standard configurations. Use these steps as a guide when

configuring different I/O modules for your system.

This example application uses I/O module default

configurations. For more information, refer to the

POINT I/O Selection Guide, publication

Add the Relay Output Module

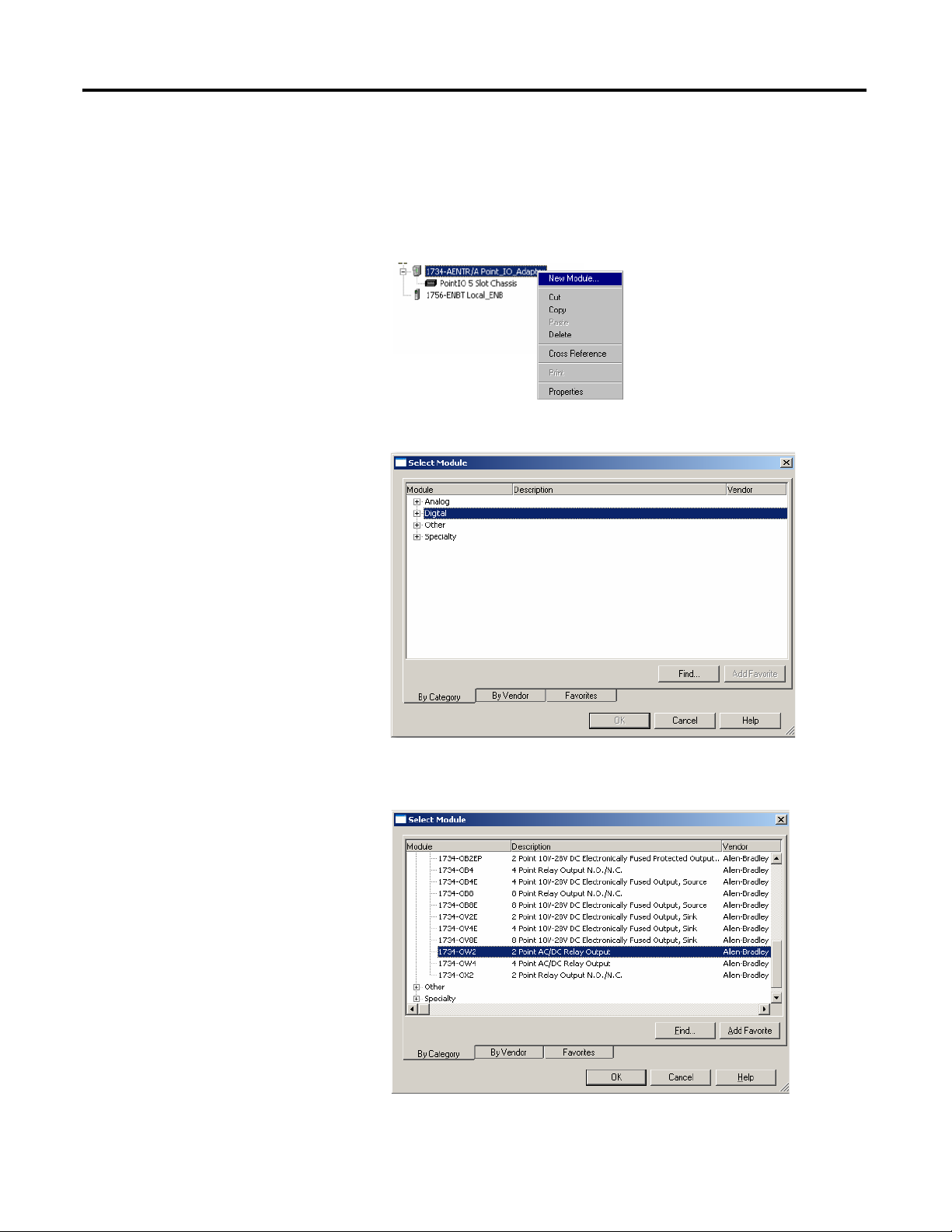

1. Right-click the name of the remote adapter under the I/O Configuration

folder and select New Module.

The Select Module dialog opens.

1734-SG001.

2. Expand the Digital tree.

3. Select the 1734-OW2 relay output module from the list and click OK.

36 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 45

Configure the Adapter for Direct Connection in RSLogix 5000 Software Chapter 4

IMPORTANT

The New Module dialog opens.

4. Enter values for Name and Slot, noting that we used the following values.

Name POINT_Relay_Output

Slot 1

5. Choose Connection.

The RPI is selectable since it is a direct connection.

6. Enter 50 for requested packet interval (RPI) to set how often you exchange

data with the I/O adapters.

To avoid overloading the I/O adapters, we recommend that RPI be no

less than 10 ms for rack connections and 50 ms for direct

connections.

7. Click OK to save the configuration.

The relay output module appears under Ethernet.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 37

Page 46

Chapter 4 Configure the Adapter for Direct Connection in RSLogix 5000 Software

Add the Digital Output Module

1. Right-click the name of the I/O adapter and select New Module.

The Select Module dialog opens.

Expand the Digital tree

.

2. Select the 1734-OV4E digital output module from the list.

38 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 47

Configure the Adapter for Direct Connection in RSLogix 5000 Software Chapter 4

3. Click OK.

The New Module dialog opens.

Enter values for Name and Slot, noting we used the following.

Name POINT_Digital_Output

Slot 2

4. On the Connection tab, enter 10 ms as the RPI for the 1734-OV4E

module.

5. Click OK.

The I/O Configuration in the Project dialog should look similar to the

following

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 39

Page 48

Chapter 4 Configure the Adapter for Direct Connection in RSLogix 5000 Software

Tags created by the system

Enter the new tag here

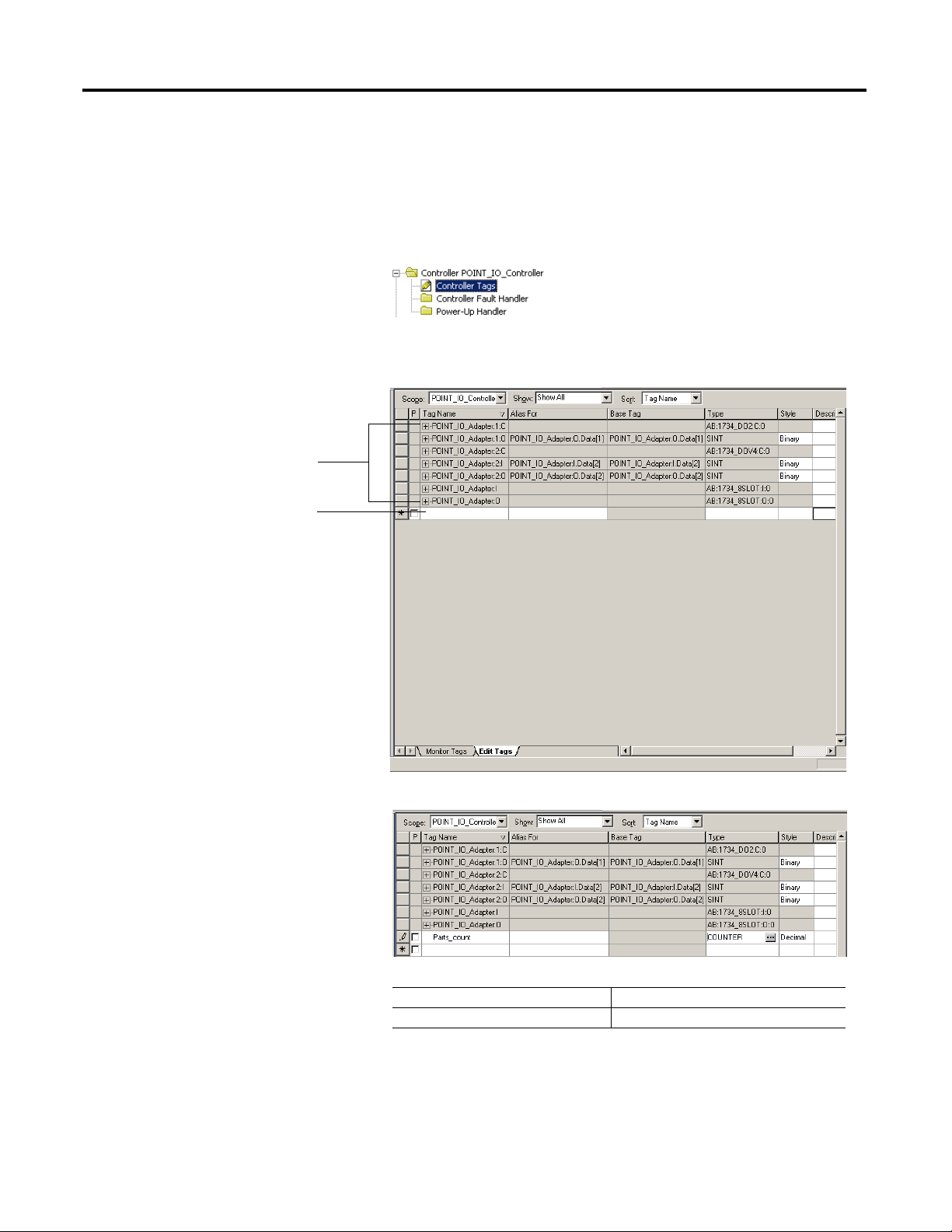

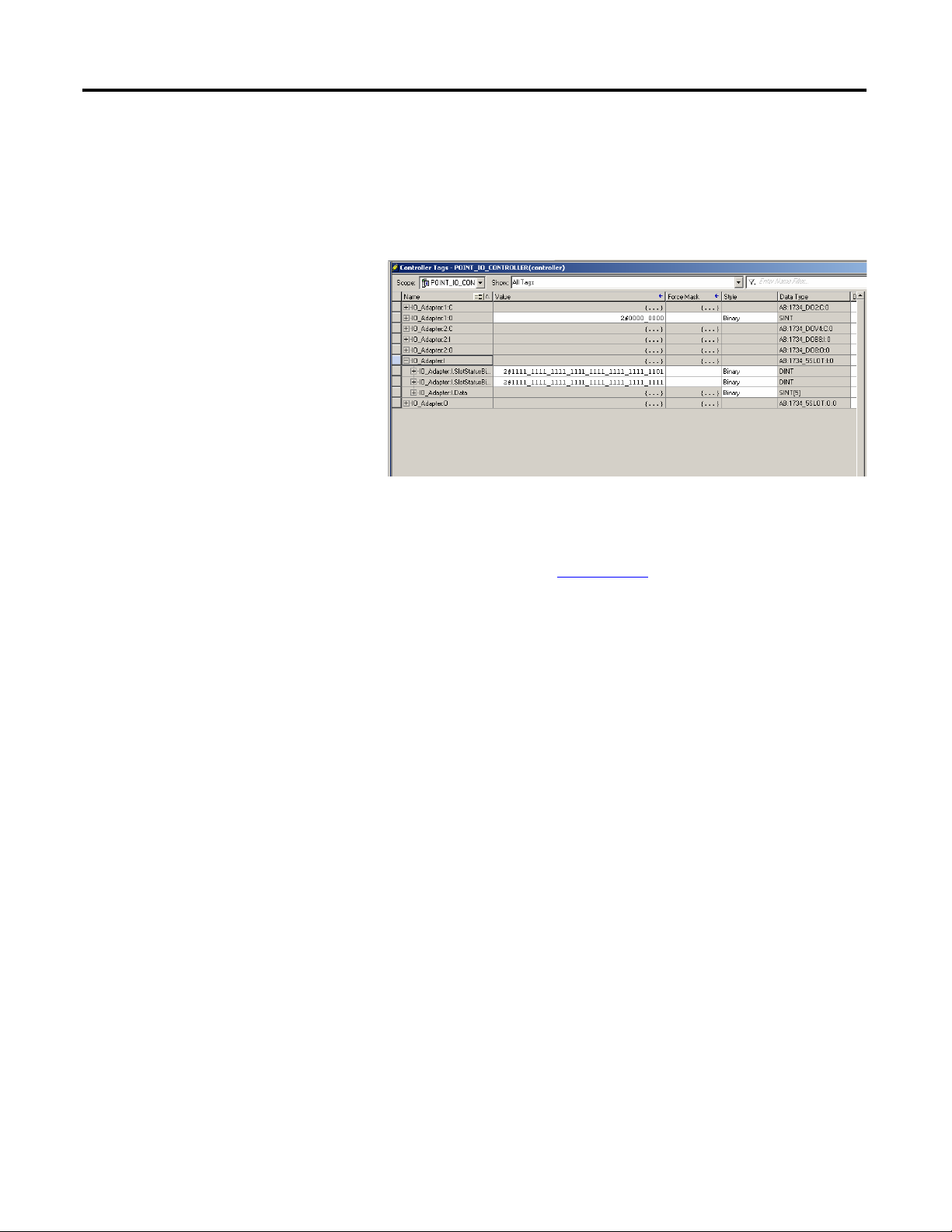

Edit the Controller Tags

When you add modules to the I/O configuration the system creates tags for those

modules to use in the application program.

For the example application you need to add one more controller tag.

1. Double-click the Controller Tags folder in the project dialog.

The Controller Tags dialog opens. You see the tags created for the 1734AENTR adapter and its digital I/O modules.

40 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

2. Click the Edit Tags tab at the bottom of the Controller Tags dialog.

3. Create the following tag:

Tag Typ e

Parts_Count Counter

4. Close the Controller Tags dialog.

Page 49

Configure the Adapter for Direct Connection in RSLogix 5000 Software Chapter 4

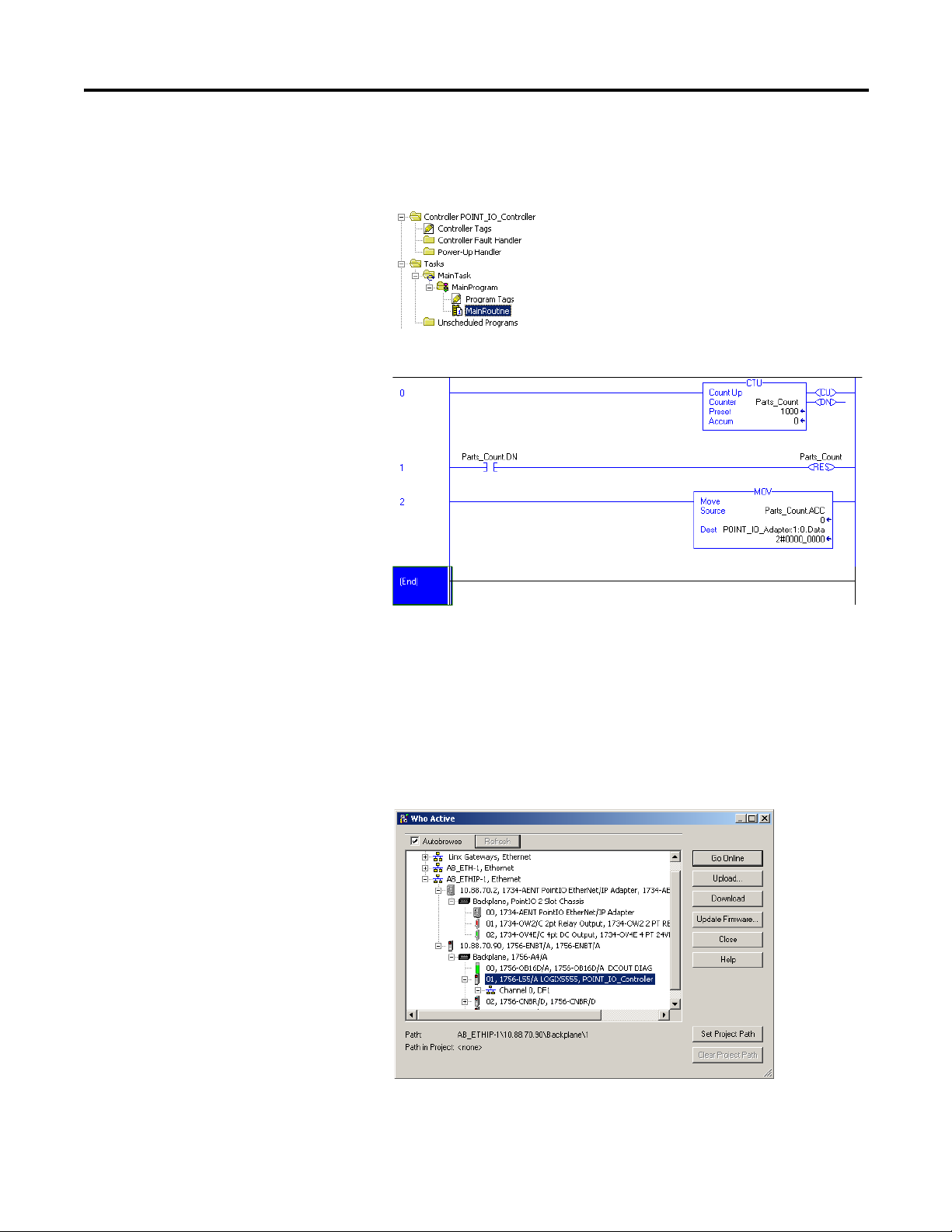

Create the Ladder Program

Create the example ladder program to test the I/O.

1. Under the Main Program folder, double-click Main Routine.

2. Enter the following ladder program using the tags previously created.

Download the Program to the Controller

3. Save the program.

Follow this procedure to download the program you just saved to the

ControlLogix controller.

1. From the main menu, choose Communications>Who-Active.

The Who Active dialog opens.

2. Navigate to select the slot where the controller is located in the chassis.

3. Choose Set Project Path.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 41

Page 50

Chapter 4 Configure the Adapter for Direct Connection in RSLogix 5000 Software

4. Choose Download.

The Download dialog opens with a reminder of the following.

• The controller is in Remote Run mode.

• The mode changes to Remote Program prior to download.

5. From the Download dialog, choose Download

The RSLogix 5000 software dialog opens.

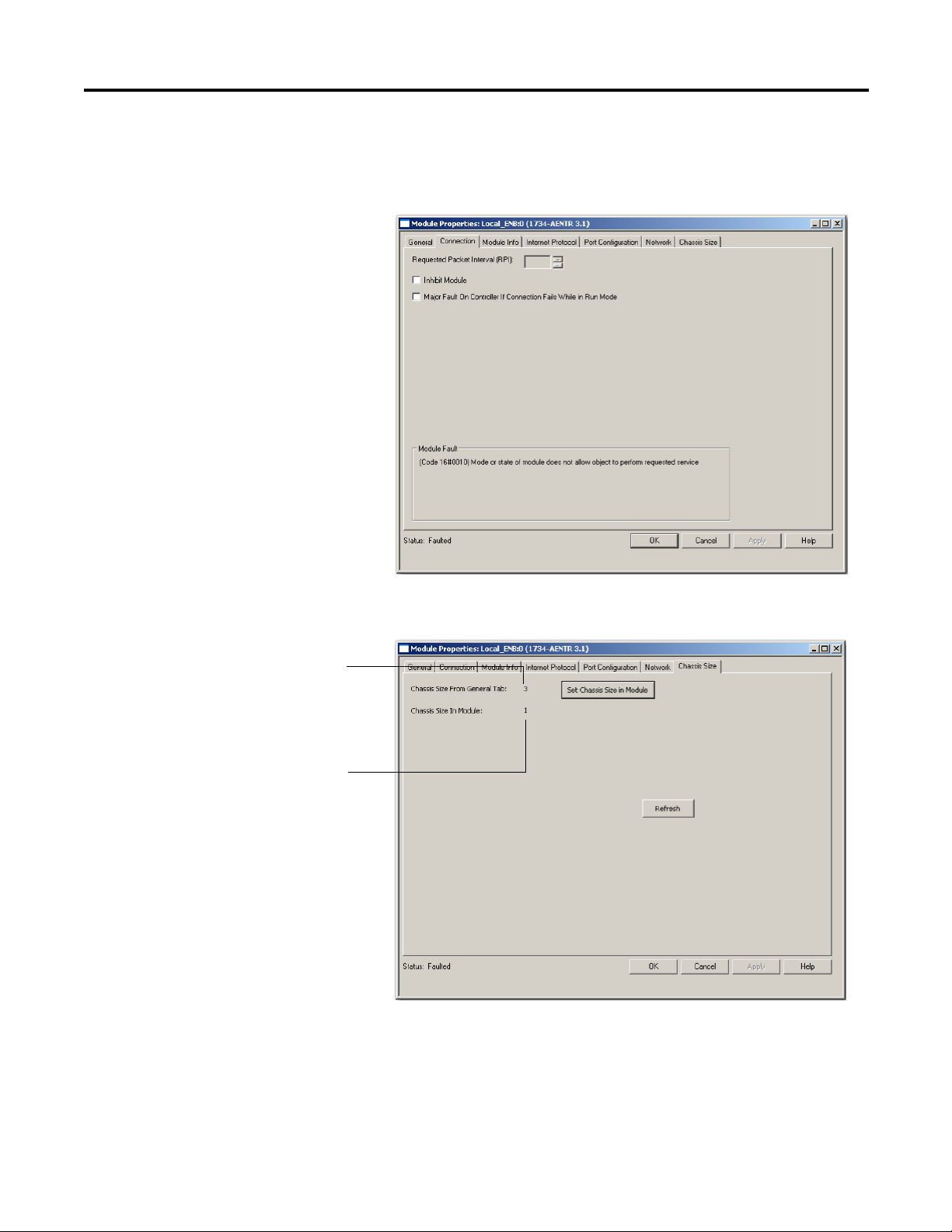

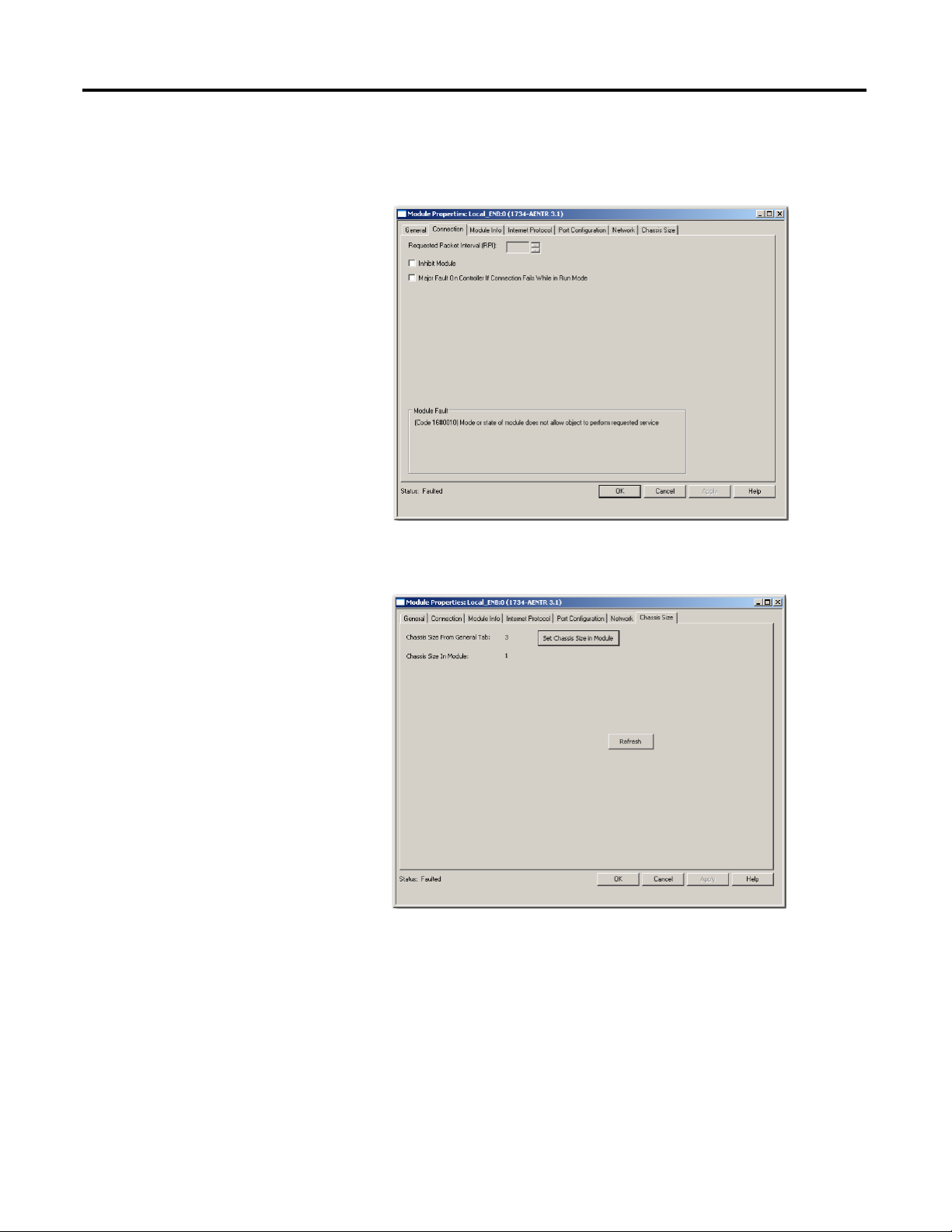

Verify the Module Chassis Size

6. Notice that the 1756-ENBT Bridge is now online.

If yellow triangles are present, see the following section.

You have now built the I/O tree in the RSLogix 5000 software, and the

RSLogix 5000 software used the chassis size from the 1734-AENTR General tab.

Now you need to download this new chassis size value into the 1734-AENTR

adapter hardware. This procedure synchronizes the chassis size value from the

RSLogix 5000 software into the 1734-AENTR adapter hardware.

1. Verify that the RSLogix 5000 software is online.

2. In the Project dialog, right-click the 1734-AENTR adapter under I/O

Configuration.

42 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 51

Configure the Adapter for Direct Connection in RSLogix 5000 Software Chapter 4

Value from

Module Properties

General Tab

Value currently

stored in 1734AENTR

adapter

3. Select Properties.

4. Click the Connection tab.

The Module Fault error code displays.

5. Click the Chassis Size tab.

6. Click Set Chassis Size in Module.

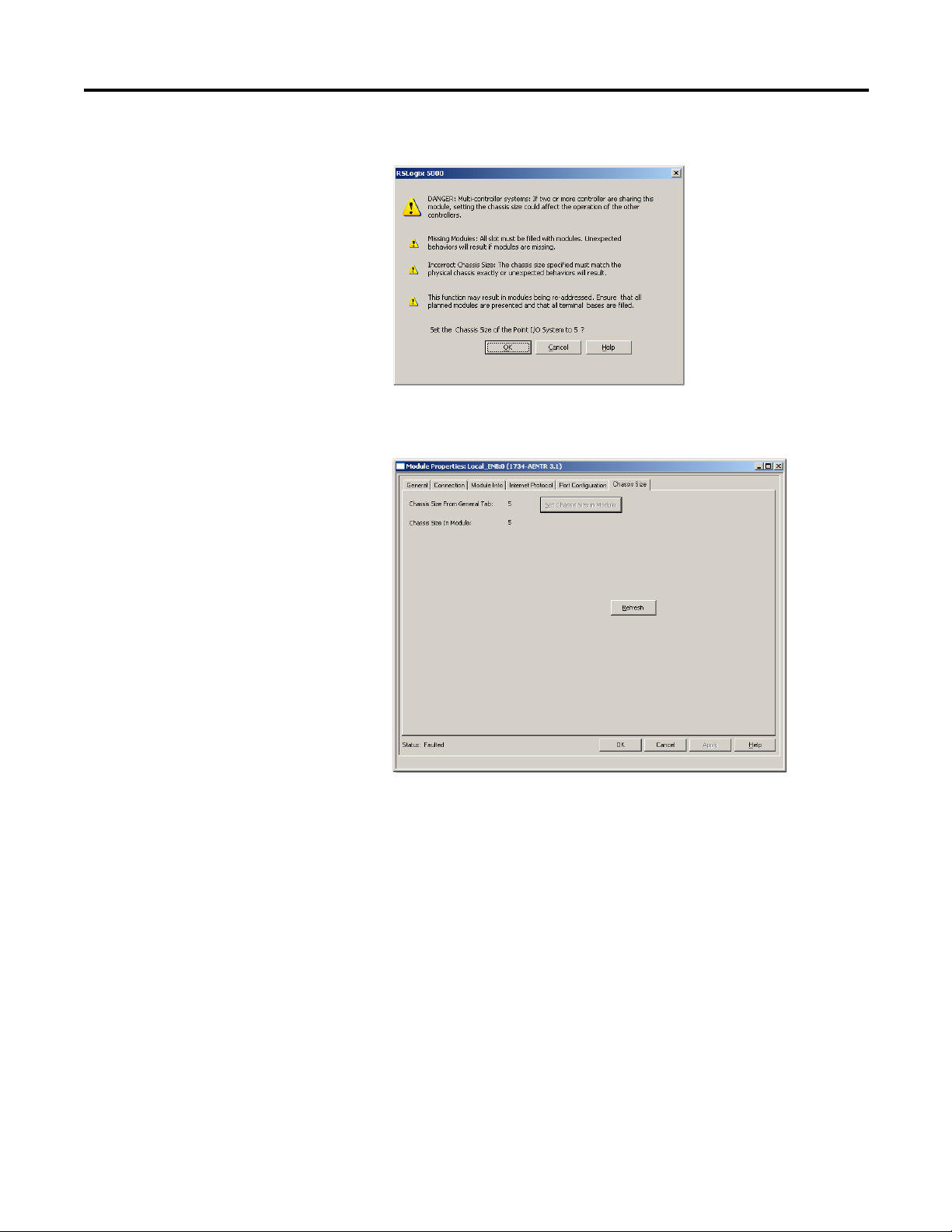

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 43

Page 52

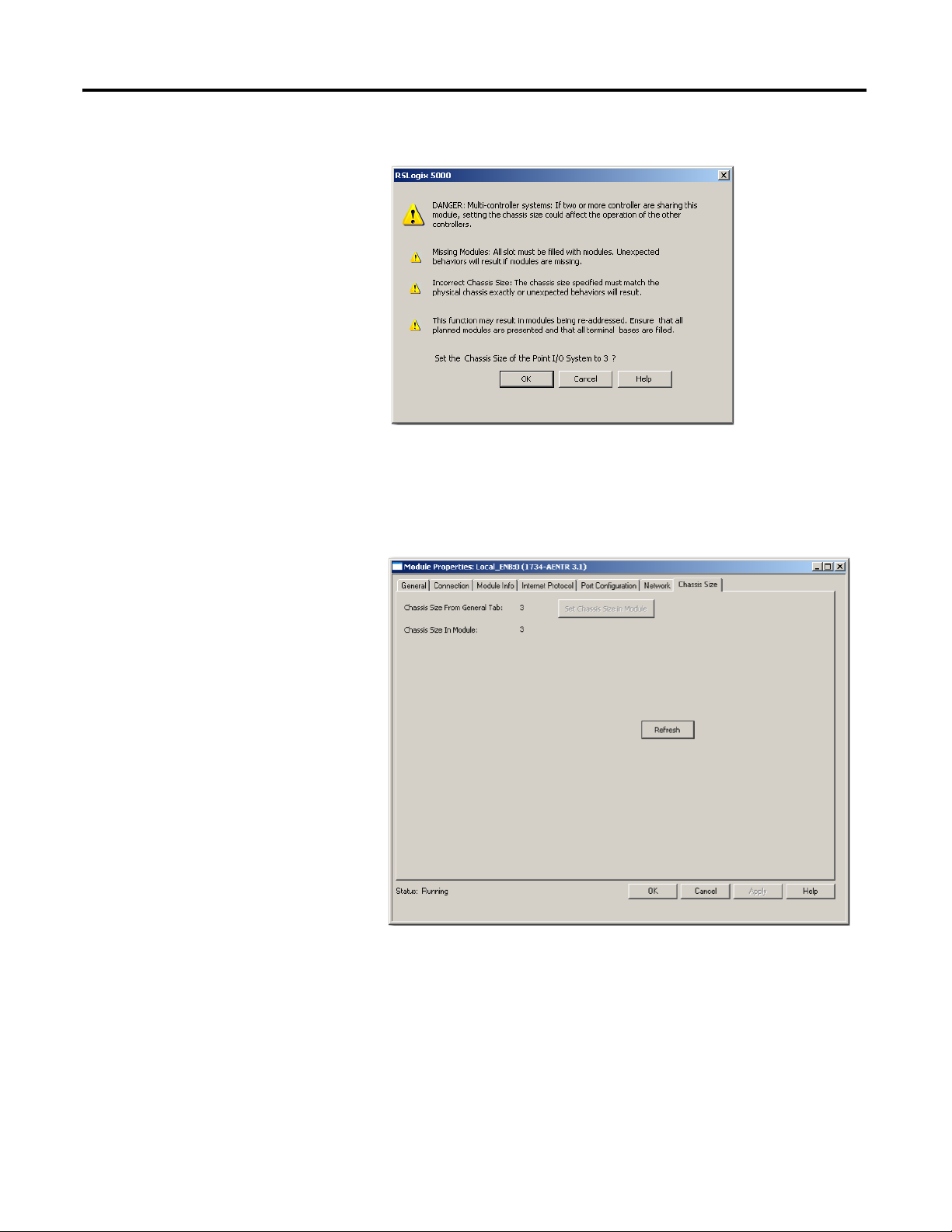

Chapter 4 Configure the Adapter for Direct Connection in RSLogix 5000 Software

7. Read and acknowledge the warning dialog.

8. Click OK to continue.

Notice the chassis size stored in the module has been changed to 3.

At this point, your POINTBus status LED should be solid green. All the

yellow triangles in your I/O configuration should be gone.

9. Click OK.

44 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

Page 53

Configure the Adapter for Direct Connection in RSLogix 5000 Software Chapter 4

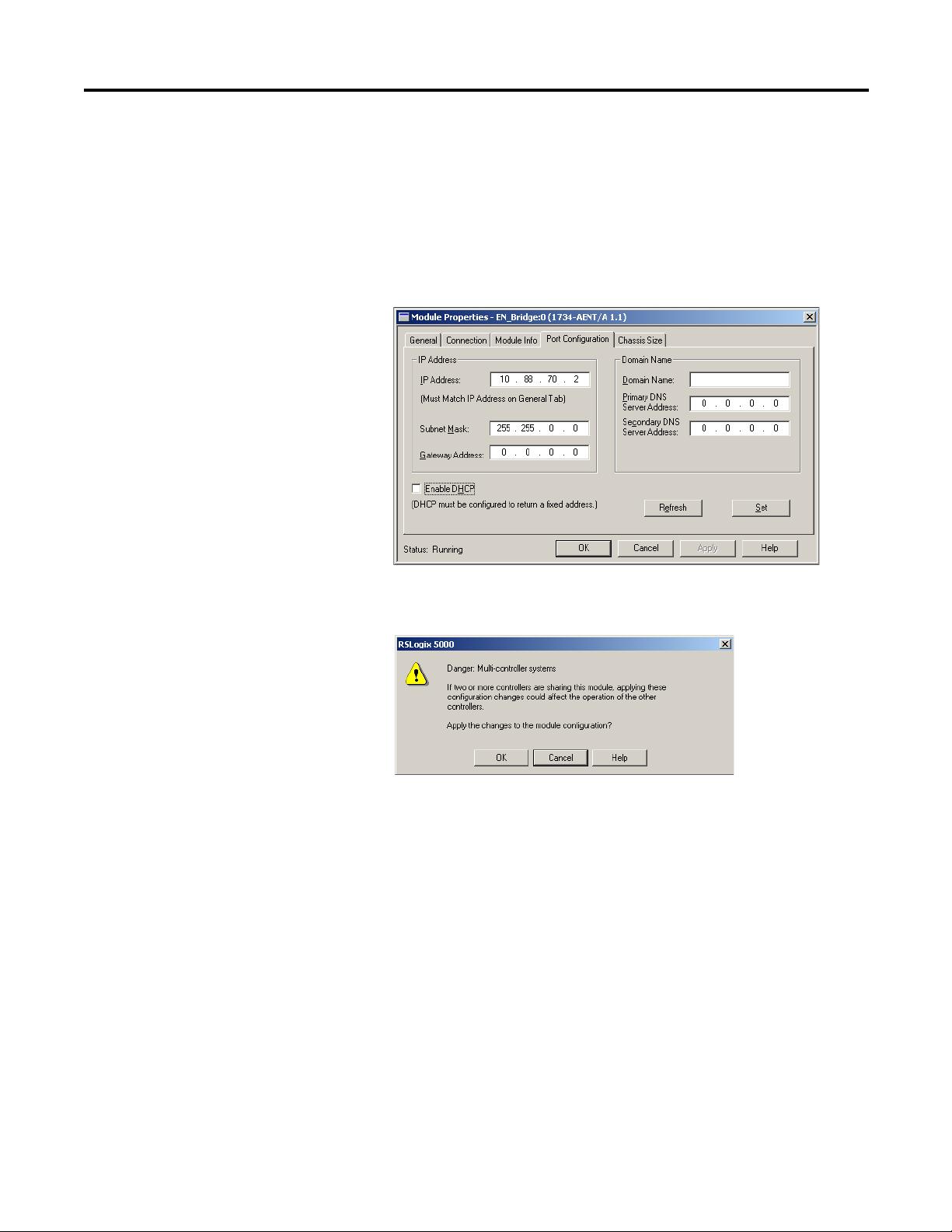

Configure the Adapter with Fixed IP Address

To configure the adapter with a fixed IP address to prevent the adapter from

ceasing to communicate with the ControlLogix controller:

1. All controllers with I/O connections to the AENTR and/or the modules

in its backplane need to be in program mode.

2. In the Module Properties dialog, click the Port Configuration tab.

3. Unselect the Enable DHCP box.

4. Click the Set button.

5. Read and acknowledge the warning.

6. Click OK.

7. Click the Refresh button to verify the changes.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 45

Page 54

Chapter 4 Configure the Adapter for Direct Connection in RSLogix 5000 Software

Recover From an Overloaded Adapter

Each I/O connection established with the I/O adapter consumes a portion of

microprocessor bandwidth. The amount of bandwidth used by a connection

depends on several variables, such as the requested packet interval (RPI), number

of I/O modules involved in the connection, and rate of change of the I/O.

The AENTR adapter continuously monitors this bandwidth and rejects requests

for new I/O connections when there is insufficient bandwidth available to

support the new connection.

The condition where the I/O adapters cannot support the connection due to a

limit of the bandwidth of the microprocessor is shown on the Connection tab of

the Module Properties dialog.

If you encounter this condition, the only action you can take is to alter the

existing connections to reduce the amount of microprocessor bandwidth

consumed. The most likely fixes for this condition include the following:

• Increase the RPI.

• Decrease the number of connections.

• Remove modules from the rack-optimized I/O connection.

• Remove the rack-optimized connection if there are no modules

participating in it.

Chapter Summary

46 Rockwell Automation Publication 1734-UM014B-EN-P - June 2013

This chapter provided instructions on how to configure the POINT I/O

Adapter for Direct Connection through the the RSLogix 5000 software. It

included information about setting up the hardware and configuring the I/O,

adding the adapter to the configuration, and configuring the adapter with a fixed

IP address.

Page 55

Chapter

5

Configure the Adapter for Direct Connection

and Rack Optimization in RSLogix 5000

Software

Overview

This chapter guides you through the steps required to configure your AENTR

adapter with both direct and rack-optimized I/O connections using

RSLogix 5000 software.

You can mix I/O connection formats for different I/O modules communicating

through the same adapter. I/O modules set up to use rack optimization

communicate at the rate of the RPI configured for the adapter.

I/O modules controlled by a direct I/O connection communicate at their own set

RPI. The RPI of the rack-optimized I/O connection has no bearing on the direct

I/O connections. The modules presented in this chapter have a configuration

using RSLogix 5000 software, revision 11. The chapter contains the following

main sections

Topic Page

Set Up the Hardware 48

Create the Example Application 49

Configure the I/O Modules 50

Add the Local EtherNet/IP Bridge to the I/O Configuration 50

Add the I/O Adapter to the I/O Configuration 52

Add the POINT I/O Module and Configure for Rack-optimized Connection 56

Add the POINT I/O Module and Configure For Direct Connection 58

Download the Program to the Controller 60

Verify the Module Chassis Size 61

Access Module Data 64

.

ATTENTION: You must use series C POINT I/O modules with the

adapter. Series A or B POINT I/O modules do not work with the adapter.

Rockwell Automation Publication 1734-UM014B-EN-P - June 2013 47

Page 56

Chapter 5 Configure the Adapter for Direct Connection and Rack Optimization in RSLogix 5000 Software

45176

Set Up the Hardware

The following section describe how to set up the I/O Hardware.

Set Up the POINT I/O Hardware

In this example, a ControlLogix chassis contains the L63 controller in slot 1 and a

1756-ENBT bridge module in slot 3. In this example, we mounted the

1734-AENTR adapter on a DIN rail in slot 0, with a 1734-OW2/C relay output

module in slot 1, a 1734-OV4E/C sink output module in slot 3, and two other

POINT I/O modules which will not be controlled by this Logix controller in

slots 2 and 4.

1734-AENTR

Local

chassis