Page 1

PNOZ s2

Safety relays

Operating Manual-21394-EN-07

Page 2

Preface

This document is the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes. Suggestions and comments for improving this documentation will be

gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®,

SafetyNET p®, the spirit of safety® are registered and protected trademarks of Pilz GmbH

& Co. KG in some countries.

SD means Secure Digital

Page 3

PNOZ s2

PNOZ s2 safety relay

The safety relay provides a safety-related interruption of a safety circuit.

The safety relay meets the requirements of EN 60947-5-1, EN 60204-1 and VDE 0113-1

and may be used in applications with

} E-STOP pushbuttons

} Safety gates

For your safety

} Only install and commission the unit if you have read and understood these operating

instructions and are familiar with the applicable regulations for health and safety at work

and accident prevention.

Ensure VDE and local regulations are met, especially those relating to safety.

} Any guarantee is rendered invalid if the housing is opened or unauthorised modifica-

tions are carried out.

Unit features

} Positive-guided relay outputs:

– 3 safety contacts (N/O), instantaneous

– 1 auxiliary contact (N/C), instantaneous

} Safe separation of safety contacts from all other circuits

} 1 semiconductor output

} Connection options for:

– E-STOP pushbutton

– Safety gate limit switch

– Start button

} A connector can be used to connect 1 PNOZsigma contact expansion module

} Operating modes can be set via rotary switch

} LED indicator for:

– Supply voltage

– Input status, channel 1

– Input status, channel 2

– Switch status of the safety contacts

} Plug-in connection terminals (either spring-loaded terminal or screw terminal)

Operating Manual PNOZ s2

21394-EN-07

– Start circuit

– Errors

3

Page 4

PNOZ s2

Safety features

The relay meets the following safety requirements:

} The circuit is redundant with built-in self-monitoring.

} The safety function remains effective in the case of a component failure.

} The correct opening and closing of the safety function relays is tested automatically in

each on-off cycle.

} The unit has an electronic fuse.

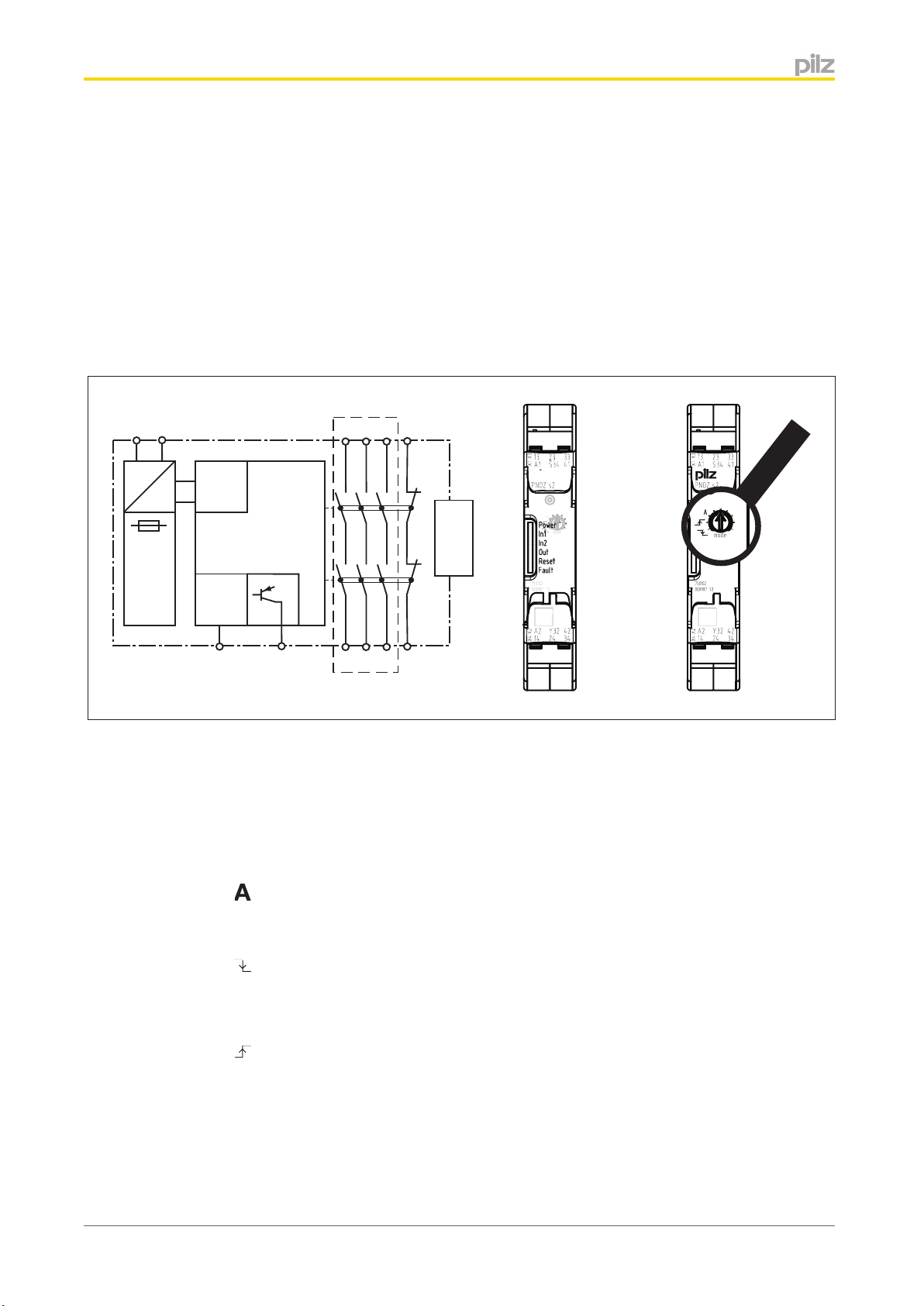

Block diagram/terminal configuration

A1 A2

13

23 33 41

Input

Power

Reset/

Start

S34

Centre: Front view with cover, right: Front view without cover

*Safe separation in accordance with EN 60947-1, 6 kV

Function description

} Single-channel operation: no redundancy in the input circuit, earth faults in the reset

and input circuit are detected.

Y32

K1

K2

14

Interface

24 34 42

unit

expansion

}

} Manual start: Unit is active once the input circuit is closed and then the start circuit is

}

}

} Increase in the number of available instantaneous safety contacts by connecting con-

Operating Manual PNOZ s2

21394-EN-07

Automatic start: Unit is active once the input circuit has been closed.

closed.

Monitored start with falling edge: Unit is active once

– the input circuit is closed and then the start circuit is closed and opened again.

– the start circuit is closed and then opened again once the input circuit is closed.

Monitored start with rising edge: Unit is active once the input circuit is closed and

once the start circuit is closed after the waiting period has elapsed (see technical details).

tact expander modules or external contactors/relays;

A connector can be used to connect 1 PNOZsigma contact expander module.

4

Page 5

PNOZ s2

Installation

Install base unit without contact expansion module:

} Ensure that the plug terminator is inserted at the side of the unit.

Connect base unit and PNOZsigma contact expansion module:

} Remove the plug terminator at the side of the base unit and at the contact expansion

module.

} Connect the base unit and the contact expansion module to the supplied connector be-

fore mounting the units to the DIN rail.

Installation in control cabinet

} The safety relay should be installed in a control cabinet with a protection type of at least

IP54.

} Use the notch on the rear of the unit to attach it to a DIN rail (35 mm).

} When installed vertically: Secure the unit by using a fixing element (e.g. retaining brack-

et or end angle).

} Push the device upwards or downwards before lifting it from the DIN rail.

Wiring

Please note:

} Information given in the "Technical details" must be followed.

} Outputs 13-14, 23-24, 33-34 are safety contacts; output 41-42 is an auxiliary contact

(e.g. for display).

} Auxiliary contact 41-42 and semiconductor output Y32 should not be used for safety

circuits!

} To prevent contact welding, a fuse should be connected before the output contacts (see

technical details).

} Calculation of the max. cable length l

R

= max. overall cable resistance (see technical details)

lmax

/ km = cable resistance/km

R

l

} Use copper wire that can withstand 60/75 °C.

} Sufficient fuse protection must be provided on all output contacts with capacitive and in-

ductive loads.

in the input circuit:

max

Operating Manual PNOZ s2

21394-EN-07

5

Page 6

PNOZ s2

Preparing for operation

Operating modes

The operating mode is set via the rotary switch on the unit. You can do this by opening the

cover on the front of the unit.

CAUTION!

Do not adjust the rotary switch during operation, otherwise an error message will appear, the safety contacts will open and the unit will not be ready

for operation until the supply voltage has been switched off and then on

again.

Set operating modes

} Switch off supply voltage.

} Select operating mode via the operating mode selector switch "mode".

} If the operating mode selector switch "mode" is in its start position (vertical position), an

error message will appear.

Operating mode selector switch "mode"

Automatic/manual

start

Monitored start rising

edge

without detection of

shorts across contacts

Connection

} Supply voltage

Supply voltage AC DC

Monitored start falling

edge

Operating Manual PNOZ s2

21394-EN-07

6

Page 7

PNOZ s2

} Input circuit

Input circuit Single-channel Dual-channel

Emergency stop

without detection of shorts

across contacts

Safety gate

without detection of shorts

across contacts

} Start circuit/feedback loop

Start circuit/feedback loop Start circuit Feedback loop

Automatic start

Manual/monitored start

} Semiconductor output

*Connect together the 0V connections on all the external power supplies

Information

If a base unit and a contact expansion module from the PNOZsigma range

are connected via the connector, no additional wiring is necessary.

Operating Manual PNOZ s2

21394-EN-07

7

Page 8

PNOZ s2

Operation

The unit is ready for operation when the Power LED is permanently lit.

LEDs indicate the status and errors during operation:

LED on

LED flashes

Information

Status indicators and error indicators may occur independently. In the case

of an error display, the "Fault" LED will light or flash (exception: "Supply

voltage too low"). An LED that is also flashing indicates the potential cause

of the error. An LED that is lit and is static indicates a normal operating status. Several status indicators and error indicators may occur simultaneously.

Status indicators

Power, In1, In2

Input circuit is closed.

Out

Safety contacts are closed and semiconductor output Y32 carries a high signal.

Reset

24 V DC is present at S34.

Error indicators

Fault

Diagnostics: Plug terminator not connected

} Remedy: Insert plug terminator, switch supply voltage off and then on

again.

Fault

Diagnostics: Internal error, unit defective

} Remedy: Switch supply voltage off and then on again, change unit if neces-

sary.

Operating Manual PNOZ s2

21394-EN-07

Power

Diagnostics: Supply voltage too low

} Remedy: Check the supply voltage.

8

Page 9

PNOZ s2

Reset

Fault

Diagnostics: Position of rotary switch is not permitted or rotary switch was adjusted during operation.

} Remedy: Switch supply voltage off and then on again.

Power, In1, In2, Out, Reset, Fault

Diagnostics: The operating mode selector switch "mode" is in its start position

(vertical position)

} Remedy: Switch off the supply voltage and set the required operating mode

on operating mode selector switch "mode".

Faults - malfunctions

} Contact malfunctions: If the contacts have welded, reactivation will not be possible after

the input circuit has opened.

Service life graph

The service life graphs indicate the number of cycles from which failures due to wear must

be expected. The wear is mainly caused by the electrical load; the mechanical load is negligible.

Operating Manual PNOZ s2

21394-EN-07

9

Page 10

PNOZ s2

Example

} Inductive load: 0,2 A

} Utilisation category: AC15

} Contact service life: 2,000,000 cycles

Provided the application requires fewer than 2,000,000 cycles, the PFH value (see technical details) can be used in the calculation.

To increase the service life, sufficient spark suppression must be provided on all output

contacts. With capacitive loads, any power surges that occur must be noted. With contactors, use freewheel diodes for spark suppression.

Technical Details

General 750102 751102

Approvals CCC, CE, GOST, KOSHA, TÜV,

cULus Listed

Electrical data 750102 751102

Supply voltage

Voltage 24 V 24 V

Type DC DC

Voltage tolerance -15 %/+10 % -15 %/+10 %

Output of external power supply

2,0 W 2,0 W

(DC)

Residual ripple DC 20 % 20 %

Continuous duty 100 % 100 %

Max. inrush current impulse

Reset circuit 0,50 A 0,50 A

Feedback loop 0,50 A 0,50 A

Max. overall cable resistance Rlmax

Single-channel at UB DC 30 Ohm 30 Ohm

Voltage at

Input circuit DC 24,0 V 24,0 V

Reset circuit DC 24,0 V 24,0 V

Feedback loop DC 24,0 V 24,0 V

Current at

Input circuit DC 75,0 mA 75,0 mA

Reset circuit DC 7,0 mA 7,0 mA

Feedback loop 7,0 mA 7,0 mA

Number of output contacts

Instantaneous safety contacts

3 3

(N/O)

Auxiliary contacts (N/C) 1 1

Inputs 750102 751102

Number 1 1

CCC, CE, GOST, KOSHA, TÜV,

cULus Listed

Operating Manual PNOZ s2

21394-EN-07

10

Page 11

PNOZ s2

Semiconductor outputs 750102 751102

Number 1 1

Voltage 24,0 V 24,0 V

Current 20 mA 20 mA

Relay outputs 750102 751102

Max. short circuit current IK 1 kA 1 kA

Utilisation category

In accordance with the standard EN 60947-4-1 EN 60947-4-1

Auxiliary contacts, AC1 at 240 V 240 V

Min. current 0,01 A 0,01 A

Max. current 6,0 A 6,0 A

Max. power 1500 VA 1500 VA

Auxiliary contacts, DC1 at 24 V 24 V

Min. current 0,01 A 0,01 A

Max. current 6,0 A 6,0 A

Max. power 150 W 150 W

Safety contacts, AC1 at 240 V 240 V

Max. current 6,0 A 6,0 A

Min. current 0,01 A 0,01 A

Max. power 1500 VA 1500 VA

Safety contacts, DC1 at 24 V 24 V

Max. current 6,0 A 6,0 A

Min. current 0,01 A 0,01 A

Max. power 150 W 150 W

Utilisation category

In accordance with the standard EN 60947-5-1 EN 60947-5-1

Auxiliary contacts, AC15 at 230 V 230 V

Max. current 5,0 A 5,0 A

Auxiliary contacts, DC13 (6 cy-

24 V 24 V

cles/min) at

Max. current 5,0 A 5,0 A

Safety contacts, AC15 at 230 V 230 V

Max. current 5,0 A 5,0 A

Safety contacts, DC13 (6 cycles/

24 V 24 V

min) at

Max. current 5,0 A 5,0 A

Contact fuse protection, external

safety contacts

In accordance with the standard EN 60947-5-1 EN 60947-5-1

Blow-out fuse, quick 10 A 10 A

Blow-out fuse, slow 6 A 6 A

Circuit breaker, 24V AC/DC,

6 A 6 A

characteristic B/C

Contact fuse protection, external

auxiliary contacts

Blow-out fuse, quick 10 A 10 A

Blow-out fuse, slow 6 A 6 A

Circuit breaker, 24 V AC/DC,

6 A 6 A

characteristic B/C

Operating Manual PNOZ s2

21394-EN-07

11

Page 12

PNOZ s2

Relay outputs 750102 751102

Contact material AgCuNi + 0,2 µm Au AgCuNi + 0,2 µm Au

Conventional thermal current

750102 751102

while loading several contacts

Ith per contact at UB DC

Conv. therm. current with 1 con-

6,00 A 6,00 A

tact

Conv. therm. current with 2 con-

6,00 A 6,00 A

tacts

Conv. therm. current with 3 con-

5,00 A 5,00 A

tacts

Times 750102 751102

Switch-on delay

With automatic reset typ. 75 ms 75 ms

With automatic reset max. 250 ms 250 ms

With automatic reset after power

75 ms 75 ms

on typ.

With automatic reset after power

250 ms 250 ms

on max.

With manual reset typ. 75 ms 75 ms

With manual reset max. 250 ms 250 ms

With monitored reset with rising

75 ms 75 ms

edge typ.

With monitored reset with rising

250 ms 250 ms

edge max.

With monitored reset with falling

55 ms 55 ms

edge typ.

With monitored reset with falling

70 ms 70 ms

edge max.

Delay-on de-energisation

With E-STOP typ. 50 ms 50 ms

With E-STOP max. 70 ms 70 ms

With power failure typ. 50 ms 50 ms

With power failure max. 70 ms 70 ms

Recovery time at max. switching

frequency 1/s

After E-STOP 100 ms 100 ms

After power failure 100 ms 100 ms

Waiting period with a monitored reset

With rising edge 100 ms 100 ms

With falling edge 110 ms 110 ms

Min. start pulse duration with a

monitored reset

With rising edge 100 ms 100 ms

With falling edge 100 ms 100 ms

Supply interruption before de-ener-

10 ms 10 ms

gisation

Operating Manual PNOZ s2

21394-EN-07

12

Page 13

PNOZ s2

Environmental data 750102 751102

Climatic suitability EN 60068-2-78 EN 60068-2-78

Ambient temperature

Temperature range -10 - 55 °C -10 - 55 °C

Storage temperature

Temperature range -40 - 85 °C -40 - 85 °C

EMC EN 60947-5-1, EN 61000-6-2, EN

61000-6-4

EN 60947-5-1, EN 61000-6-2, EN

61000-6-4

Vibration

In accordance with the standard EN 60068-2-6 EN 60068-2-6

Frequency 10,0 - 55,0 Hz 10,0 - 55,0 Hz

Max. amplitude 0,35 mm 0,35 mm

Airgap creepage

In accordance with the standard EN 60947-1 EN 60947-1

Overvoltage category III III

Pollution degree 2 2

Rated insulation voltage 250 V 250 V

Rated impulse withstand voltage 6,00 kV 6,00 kV

Protection type

Mounting (e.g. cabinet) IP54 IP54

Housing IP40 IP40

Terminals IP20 IP20

Mechanical data 750102 751102

Mounting position Any Any

Mechanical life 10,000,000 cycles 10,000,000 cycles

Material

Bottom PC PC

Front PC PC

Top PC PC

Cross section of external conduc-

tors with screw terminals

1 core flexible 0,25 - 2,50 mm², 24 - 12 AWG –

2 core with the same cross sec-

0,25 - 1,00 mm², 24 - 16 AWG –

tion, flexible with crimp connec-

tors, no plastic sleeve

2 core with the same cross sec-

0,20 - 1,50 mm², 24 - 16 AWG –

tion, flexible without crimp con-

nectors or with TWIN crimp con-

nectors

Torque setting with screw terminals 0,50 Nm –

Connection type Screw terminal Spring-loaded terminal

Mounting type plug in plug in

Cross section of external conduc-

– 0,20 - 2,50 mm², 24 - 12 AWG

tors with spring-loaded terminals:

flexible with/without crimp connector

Spring-loaded terminals: Terminal

– 2

points per connection

Stripping length – 9 mm

Operating Manual PNOZ s2

21394-EN-07

13

Page 14

PNOZ s2

Mechanical data 750102 751102

Dimensions

Height 98,0 mm 100,0 mm

Width 17,5 mm 17,5 mm

Depth 120,0 mm 120,0 mm

Weight 175 g 175 g

The standards current on 2009-12 apply.

Safety characteristic data

Operating

mode

Safety contacts, instantaneous

EN ISO

13849-1:

2006

PL

EN ISO

13849-1:

2006

Category

EN IEC

62061

SIL CL

EN IEC

62061

[1/h]

PFH

D

IEC 61511

SIL

IEC 61511

PFD

EN ISO

13849-1:

2006

T

M

PL e Cat. 4 SIL CL 3 2,50E-09 SIL 3 2,13E-05 20

All the units used within a safety function must be considered when calculating the safety

characteristic data.

Information

A safety function's SIL/PL values are not identical to the SIL/PL values of

the units that are used and may be different. We recommend that you use

the PAScal software tool to calculate the safety function's SIL/PL values.

ATTENTION!

It is essential to consider the relay's service life graphs. The relay outputs'

safety-related characteristic data is only valid if the values in the service life

graphs are met.

[year]

The PFH value depends on the switching frequency and the load on the relay output. If the

service life graphs are not accessible, the stated PFH value can be used irrespective of the

switching frequency and the load, as the PFH value already considers the relay's B10d value as well as the failure rates of the other components.

Operating Manual PNOZ s2

21394-EN-07

14

Page 15

PNOZ s2

Order reference

Order reference

Product type Features

PNOZ s2 24 V DC

PNOZ s2 C 24 V DC

Terminals

Screw terminals 750 102

Spring-loaded terminals 751 102

EC declaration of conformity

This product/these products meet the requirements of the directive 2006/42/EC for machinery of the European Parliament and of the Council. The complete EC Declaration of Conformity is available on the Internet at www.pilz.com/downloads.

Representative: Norbert Fröhlich, Pilz GmbH & Co. KG, Felix-Wankel-Str. 2, 73760 Ostfildern, Germany

Order

no.

Operating Manual PNOZ s2

21394-EN-07

15

Page 16

© Pilz GmbH & Co. KG, 2011

of the equipment. We accept no responsibility for the validity, accuracy and entirety of the text and graphics presented in this information. Please contact our Technical Support if you have any questions.

Back cover

Sachnummer Printed in Germany

21394-EN-07, 2013-05 Printed in Germany

© Pilz GmbH & Co. KG, 2011

...

In many countries we are

represented by our subsidiaries

and sales partners.

Please refer to our homepage

for further details or contact our

headquarters.

Technical support

+49 711 3409-444

support@pilz.com

are registered and protected trademarks

®

, the spirit of safety

®

, SafetyNET p

®

, SafetyEYE

®

, SafetyBUS p

®

, PVIS

®

, PSS

®

, PSEN

®

, Primo

®

, PNOZ

®

, PMI

®

Pilz GmbH & Co. KG

Felix-Wankel-Straße 2

73760 Ostfildern, Germany

Telephone: +49 711 3409-0

Telefax: +49 711 3409-133

E-Mail: pilz.gmbh@pilz.de

Internet: www.pilz.com

, PMCprotego

®

, PIT

®

, Pilz

®

of Pilz GmbH & Co. KG in some countries. We would point out that product features may vary from the details stated in this document, depending on the status at the time of publication and the scope

InduraNET p

Loading...

Loading...