Pfaff 1222 Owner's Manual

I

Welcome

to

the

modern,

efficient

world

at

the

Pfaff

sewing

machine,

You

are

probably

very

anxious

to

try

out

your

new

machine,

but

we

suggest

that

you

first

take

the

time

to

read

this

instruction

booklet

Your

Pfff

sewing

machine

is

very

versatile,

and

we

wnd

like

to

tell

you

about

all

the

wonderful

boicts

you

can

create

with

it.

Instruction

Book

for

the

Push-Button

Pfaff

1221

and

1222

Dear

(new)

Plaff

Customer:

We

reommond

that

you

study

these

sewing

instructions

carefully,

and

hope

that

sewing

wdh

your

Pfff

will

always

be

a

pleasure.

PFAFF

i

aubalrnaschinen

0.

rn

b

H

k,arlsr

ubo.[)

ir

lach

.

WestGorrnooy

We

suggest

that

you

thumb

through

the

booklet

first

and

then

open

it

at

pages

62

and

63,

where

the

roost

essential

parts

of

your

machine

are

illustrated.

By

identifyinq

these

parts

on

your

machine,

you

will

quickly

familiarize

yourself

with

your

Pfaff

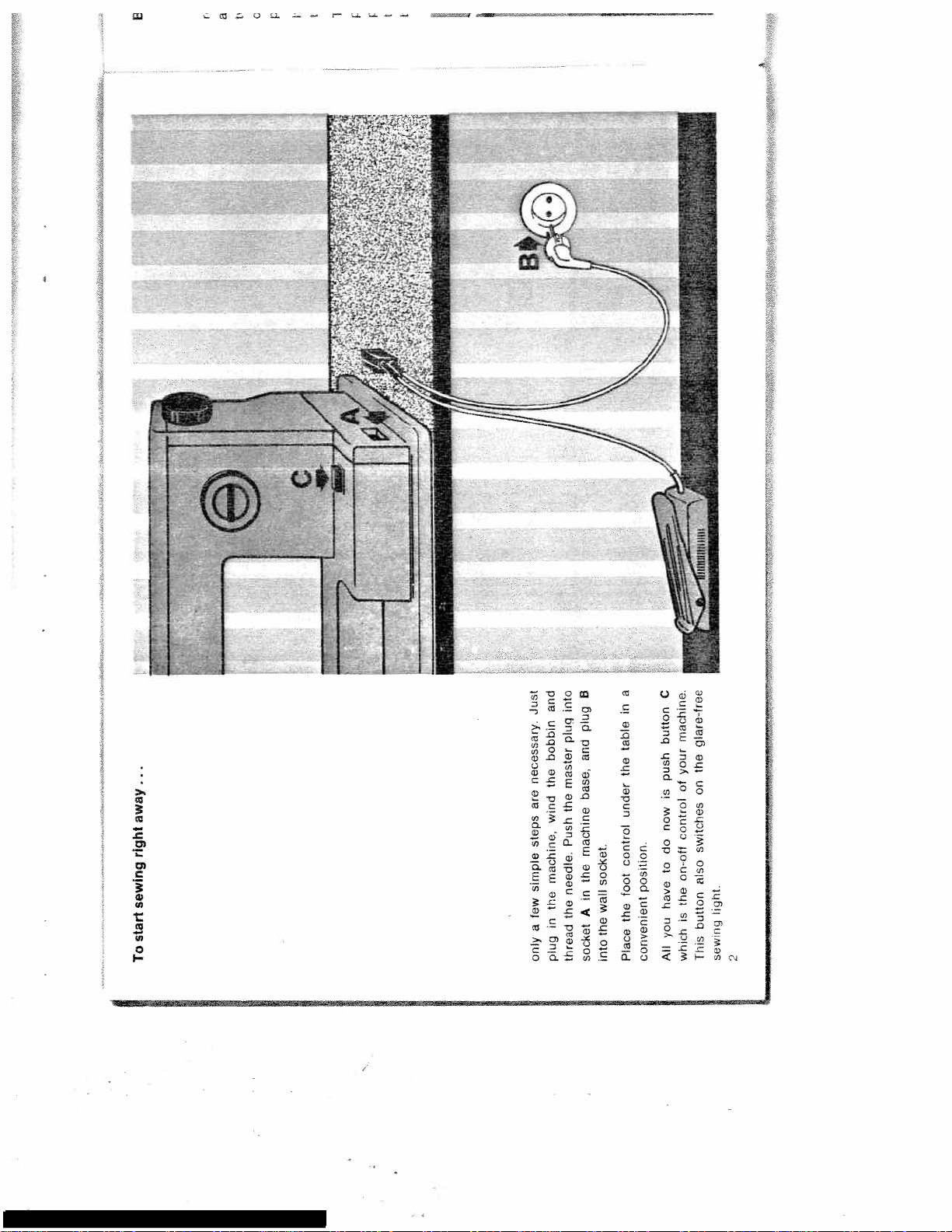

To

start

sewing

right

away.

only

a

few

simple

steps

are

necessary

Just

plug

in

the

machine,

wmd

the

bobbm

and

thread

the

needle

Push

the

master

pluq

into

socket

A

in

the

machine

base,

and

plug

B

into

the

wall

socket

Place the

foot

control

under the

table

in

a

convenient

posWon.

All

you

have

to

do

now

is

push

button

C

which

is

the

onoff

control

of

your

machine.

This

button

al%o

switches

on

the

glarefres

sewing

tight

...

•.

••.:•.

.

..

...,

.

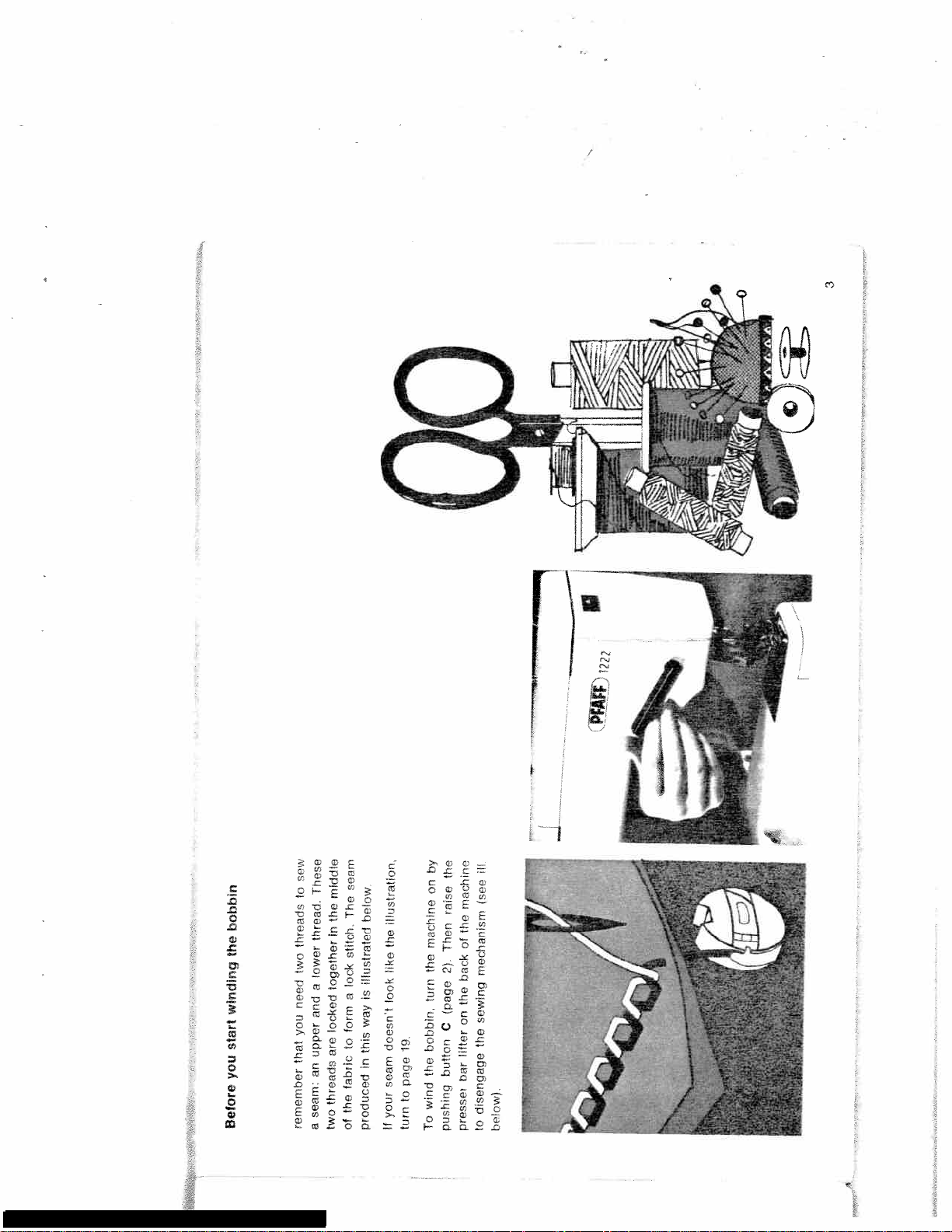

Before

you

start

w[radlnq

the

bobhn

remember

that

you

need

two

threads

to

sew

a

seam:

an

upper

and

a

lower

thread.

These

two

threads

are

locked

together

In

the

middle

of

the

fabric

to

form

i

lock

stitch,

The

seam

produced

in

this

way

is

illustrated

below

If

your

seam

doesnt

look

like

the

illustration.

turn

to

page

19.

To

wind

the

bobbin,

turn

the

machine

on

by

pushing

button

C

(page

2).

Then

raise

the

pressei

bar

lifter

on

the

hack

of

the

machine

to

disengage

the

sewing

mechanism

(see

iii

helcw)

3

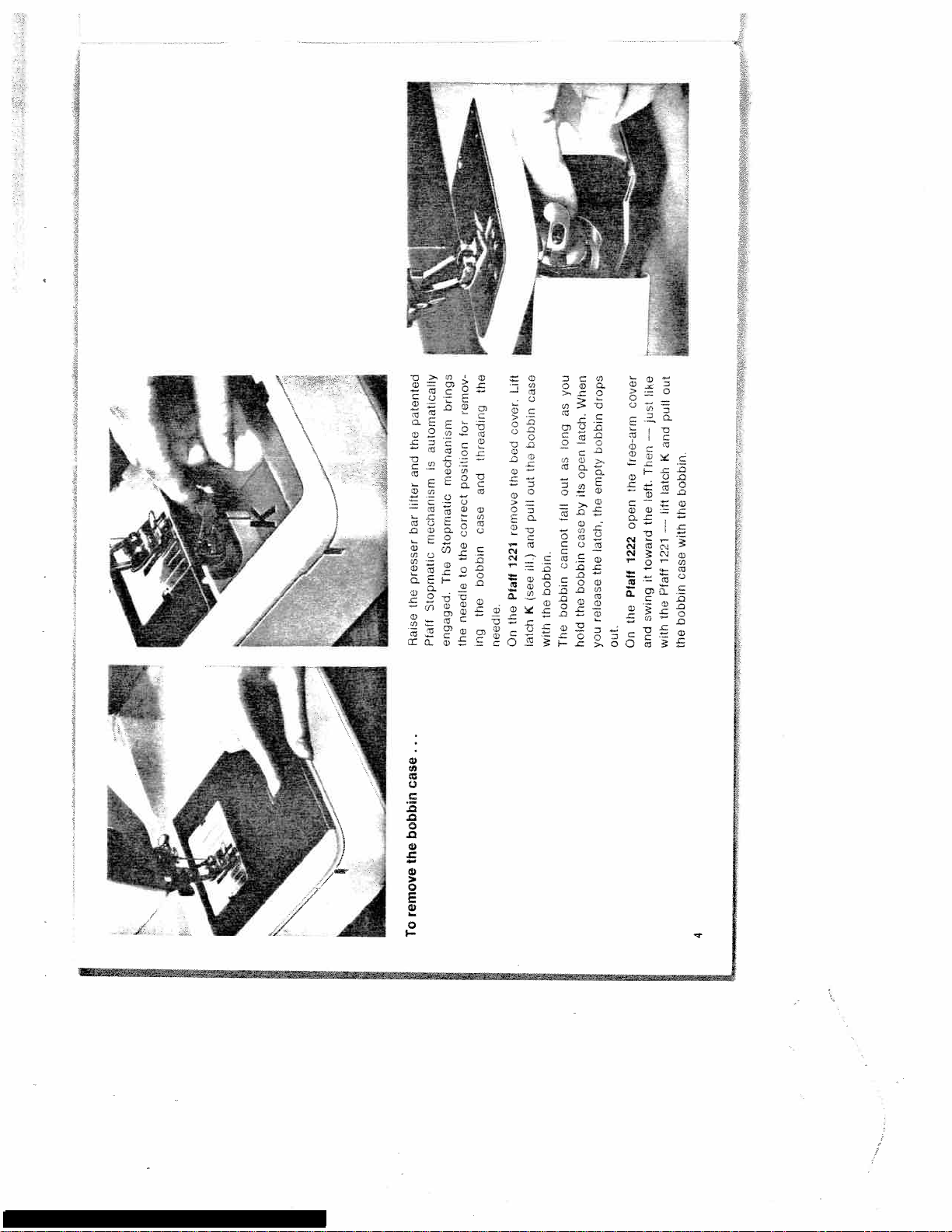

Rais

thu

presser

bar

lifter

and

th

patented

Ptatf

Siopnistw

tiiechiiiSin

iS

aiitutalicolIy

engaged.

The

Stoprnatic

rnechuncni

hr

ings

the

needle

to

the

correct

posihon

tor

iemov

ing

the

bobbin

case

and

tiietdiiq

the

needle.

On

the

Ptati

1221

remose

the

bed

ovur

Lilt

latch

K

(see

ill

)

and

pull

out

tho

bobbin

cae

with

the

bobbin.

The

bobbin

cannot

tall

Out

aio

ig

Os

OU

hold

the

bobbin

case

by

its

opi

ii

latch

When

you

release

the

latch,

the

empty

bobbin

drops

out

On

the

Ptatt

1222

open

the

Ii

Cu-di

in

cover

and

swing

it

toward

the

left.

Thci

just

like

with

the

Ptatf

1221

lilt

laid

K

and

pull

out

the

bobbin

case

with

the

bobbin

N

To

remove

the

bobbin

case

4

4

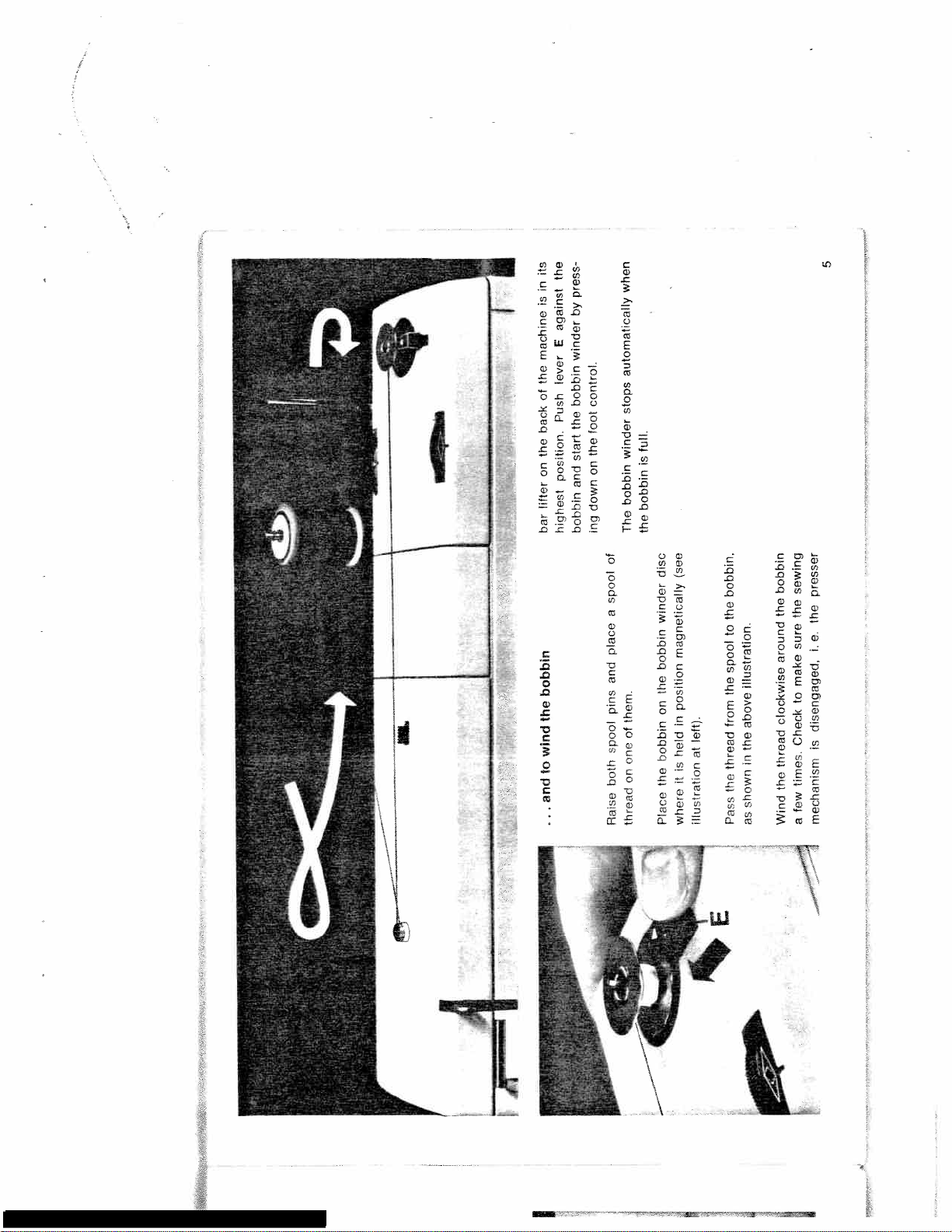

and

to

wind

the

bobbin

—

bar

lifter

on

the

back

of

the

machine

is

in

its

highest

position.

Push

lever

E

against

the

bohhin

and

start

the

bobbin

winder

by

press

ing

down

on

the

foot

control.

I

...

I

Raise

both

spool

pins

and

place

a

spool

of

thread

on

one

of

them.

The

bobbin

winder

stops

automatically

when

the

bobbin

is

full,

Place

the

bobbin

on

the

bobbin

winder

disc

where

it

is

held

in

position

magnetically

(see

illustration

at

left).

Pass

the

thread

from

the

spool

to

the

bobbin,

as

shown

in

the

above

illustration.

Wind

the

thread

clockwise

around

the

bobbin

a

few

times.

Check

to

make

sure

the

sewing

mechanism

is

disengaged,

i.

e.

the

presser

5

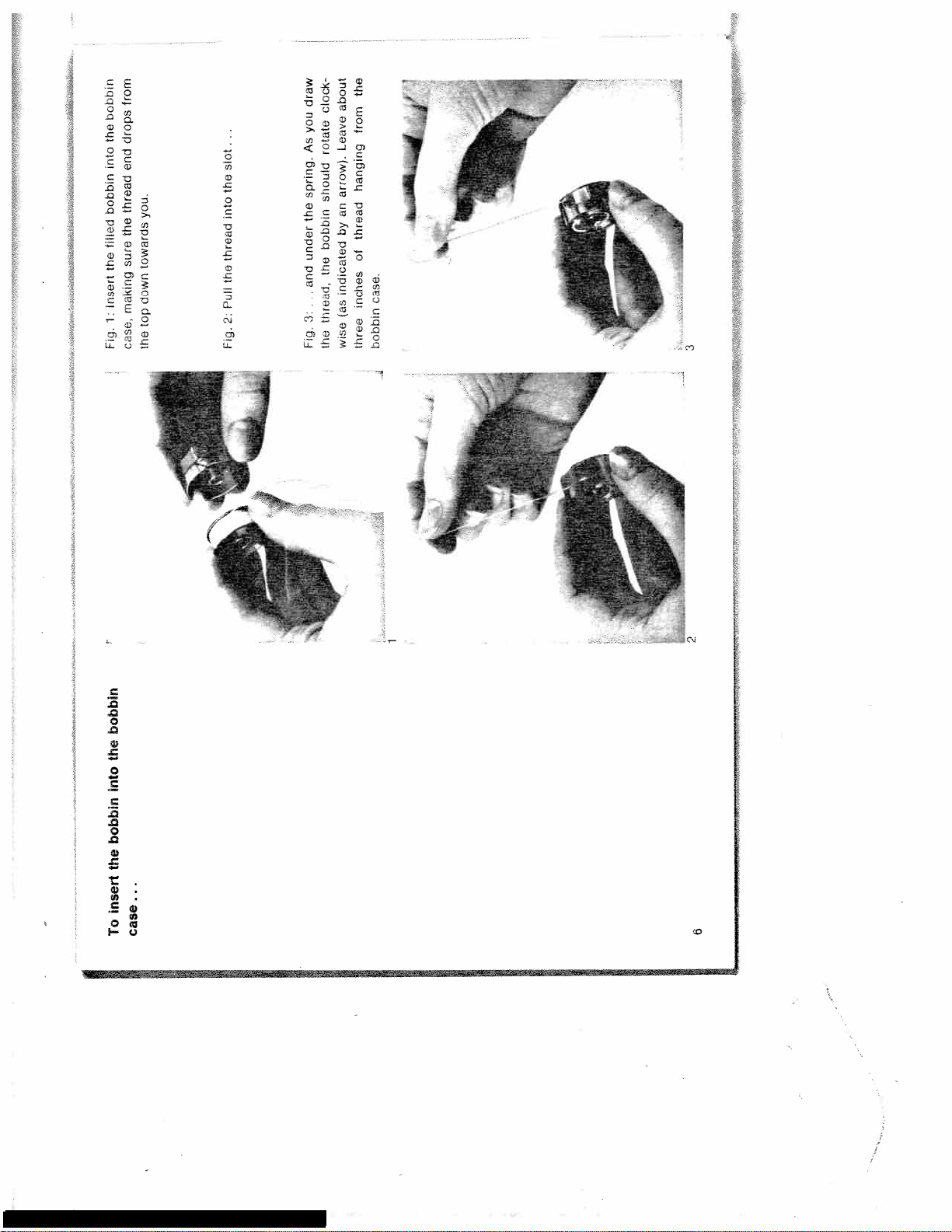

Fig.

1

Insert

the

tilled

bobbin

into

the

bobbin

case,

making

sure

the

thread

end

drops

from

the

top

down

towards

you

Fig.

3

and

under

the

spring,

As

you

draw

th

thread,

the

bobbin

should

rotate

clock

wise

(as

indicated

by

an

arrow).

Leave

about

three

inches

of

thread

hanging

from

the

bobbin

case

To

insert

the bobbin

into

the

bobbin

case.

.

-

Fig.

2

Pull

the

thiead

into

the

slot

6

2

3

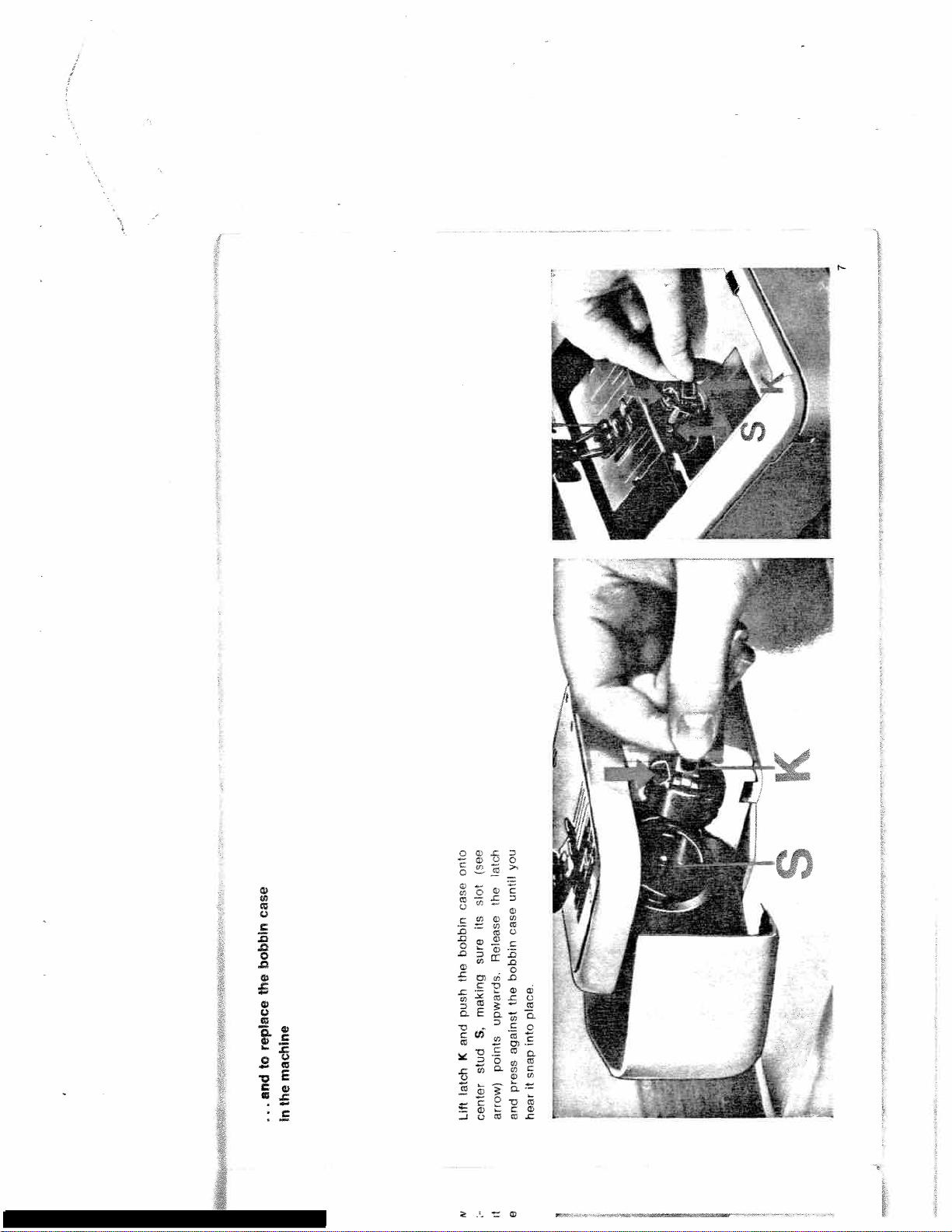

nd

to

repace

the

bobbhi

case

n

the

mach3ne

Lift

latch

K

and

push

the

bobbin

case

onto

center

stud

S.

rnakinq

sure

its

slot

(see

arrow)

points

upwards,

Release

the

latch

and

press

against

the

bobbin

case

until

you

hear

it

snap

into

place.

7

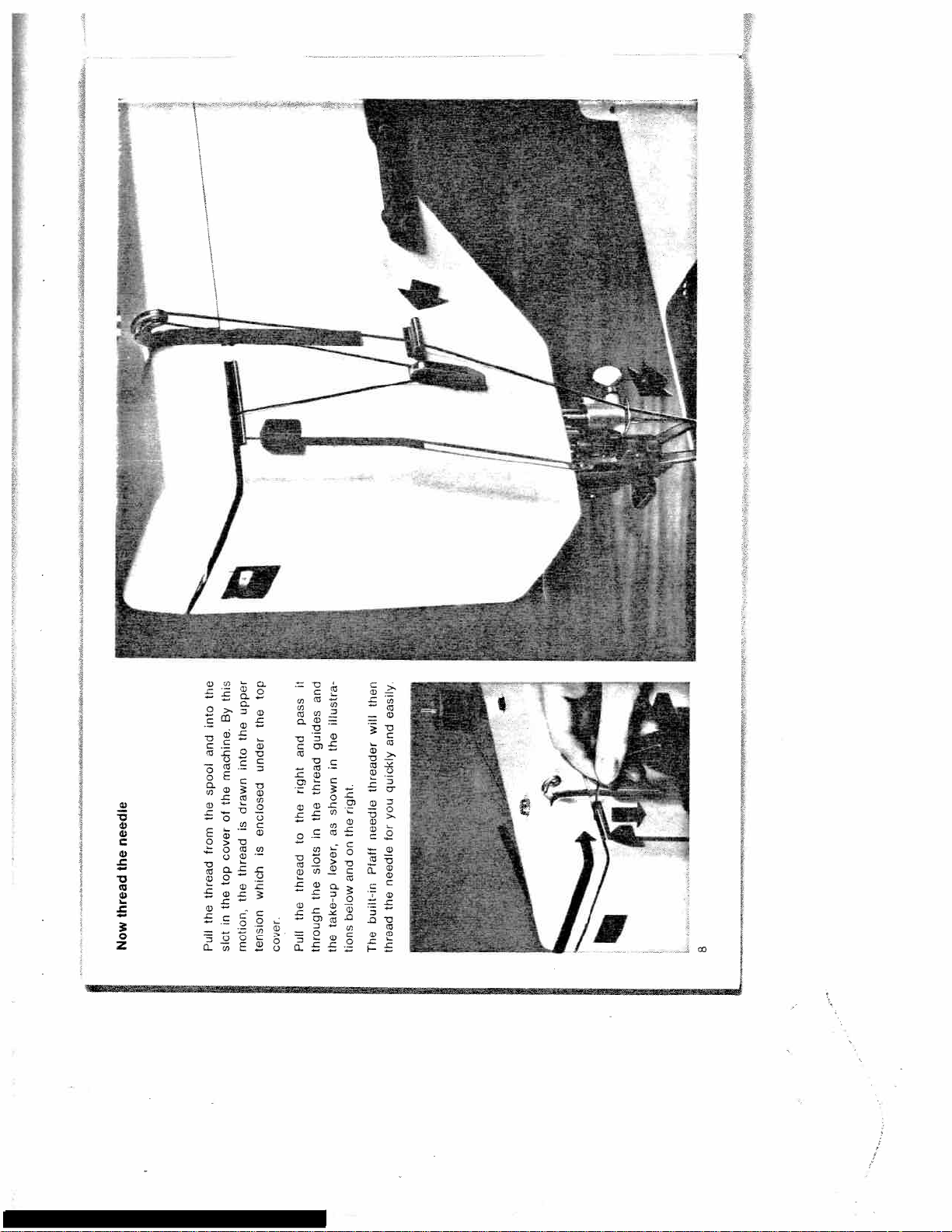

Now

thread

the

needle

Pull

the

thread

from

the

spool

and

into

the

slot

in

the

top

cover

of

the

machine.

By

this

motion,

the

thread

is

drawn

into

the

upper

tension

which

is

enclosed

under

the

top

cover

Pull

th

thread

to

the

right

and

pass

it

through

the

slots

in

the

thread

guides

and

the

take-up

lever,

as

shown

in

the

illustma

tions

below

and

on

the

right

The

built-in

Pfaff

needle

threader

will

then

thread

the

needle

for

you

quickly

and

easily.

8

a

a

New

push

the

needle

threader

contml

down

completely

and

draw

the

needk

thoad

under

the

threader

prong.

Release

the

needle

threader

control

slightly

until

the

prong

reverses

and

pulls

the

thread

through

the

needle

eye

Fully

release

the

control,

take

hold

of

the

thread

loop

and

pull

the

thread

through

the

needle

eye

eom

pletely.

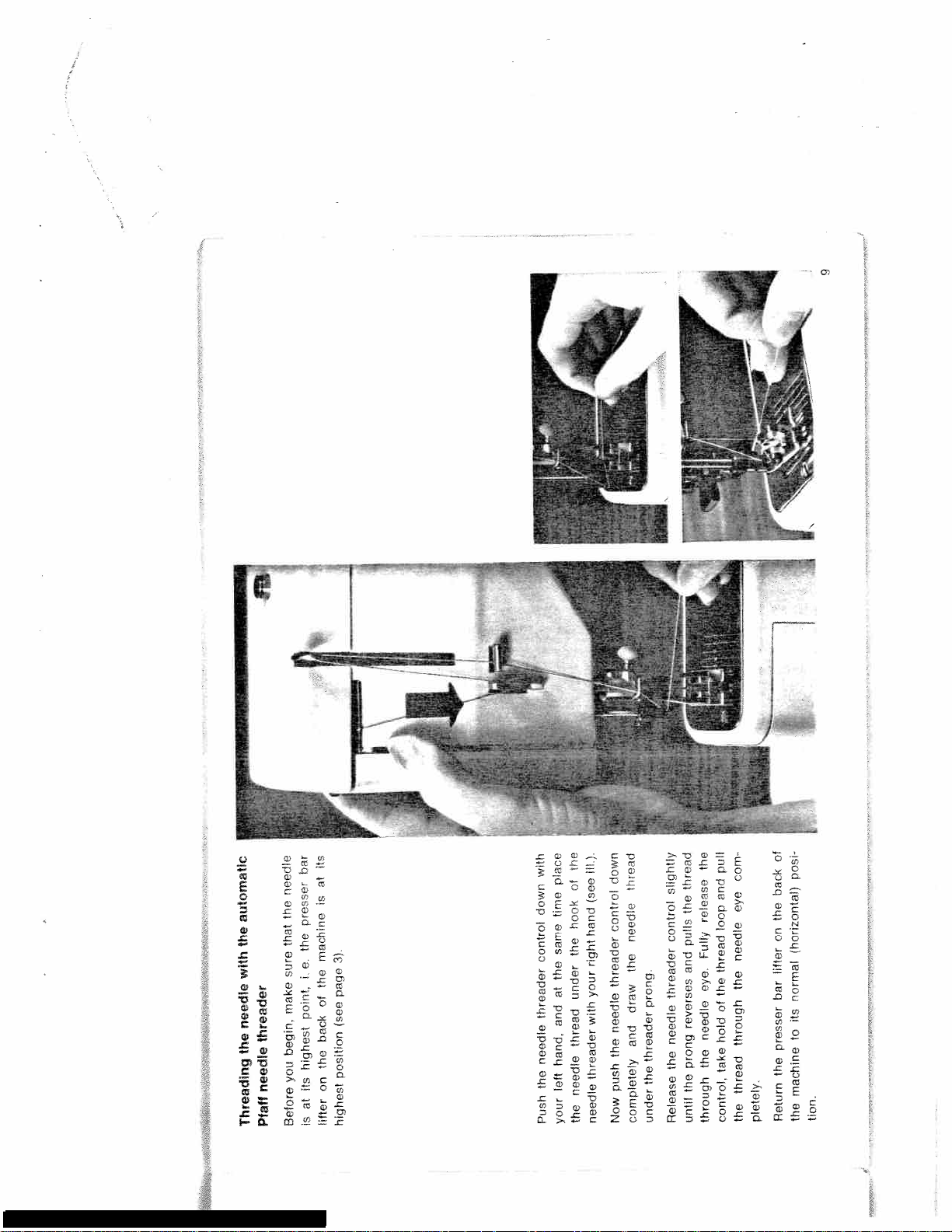

Threading

the

needle

with

the

automatic

Plait

needle

threader

Before

you

begirt.

make

sure

that

lh

needle

is

at

its

highest

point,

I

e.

the

presser

bar

lifter

on

the

back

of

the

machine

is

at

its

highest

position

(see

page

3).

Push

the

needle

threader

control

down

with

your

left

hand,

and

at

the

same

time

place

the

needle

thread

under

the

hook

of

the

needle

threader

with

your

right

hand

(see

Ill

tion.

Return

the

presser

bar

lifter

on

the

back

of

the

machine

to

its

normal

(horizontal)

posh

11

9

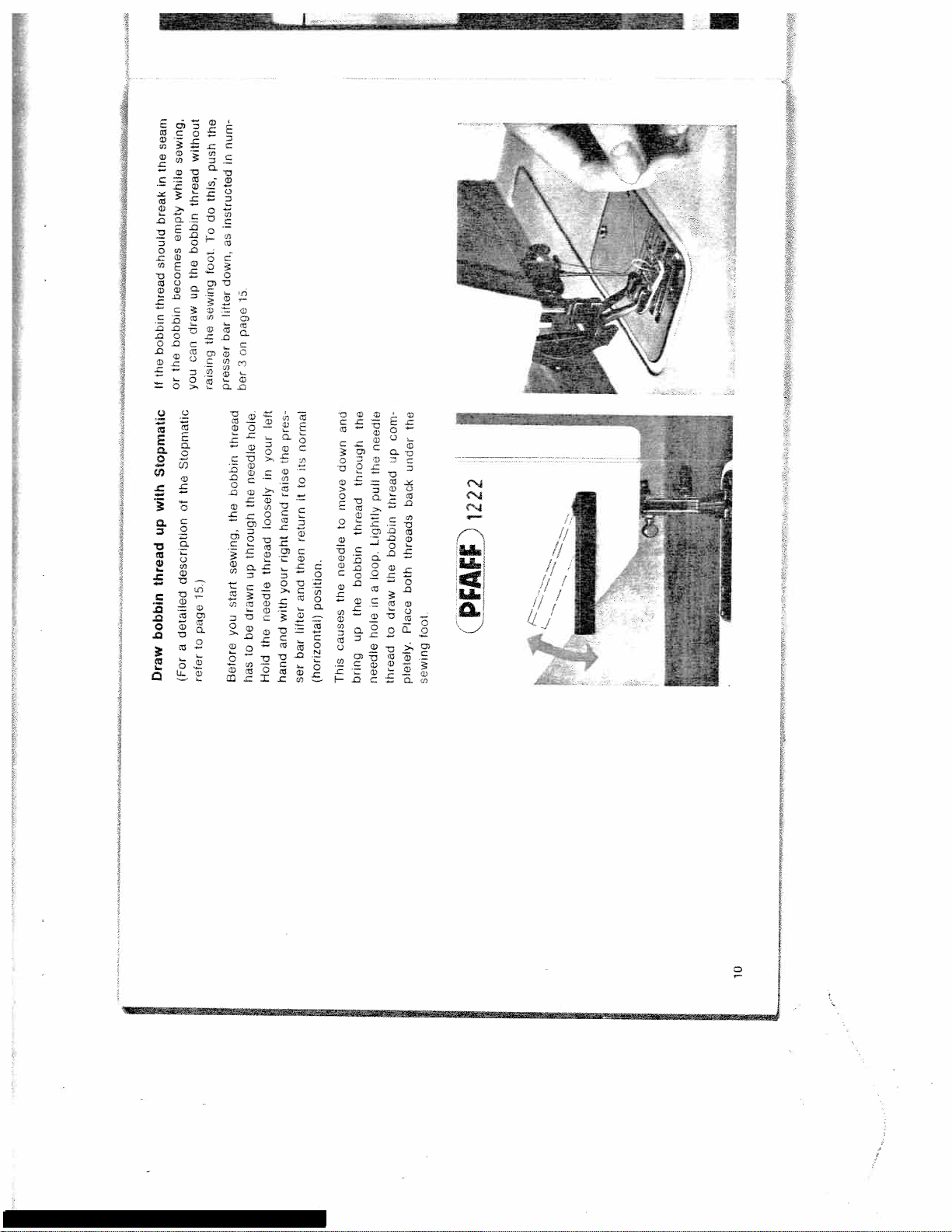

Draw

bobbin

thread

up

with

Stopmatic

(For

a

detailed

description

of

the

Stopniatic

refer

to

page

16)

Before

you

start

sewing,

the

t)ObbiIi

ttireau

has

to

he

drawn

up

tnraugn

the

eodie

hub

Hold

the

needle

thread

loosely

in

your

left

hand

and

with

your

right

hand

raise

the

pre.

ser

bar

lifter

aria

then

return

it

to

ta

normal

(horizontal)

position.

This

causes

the

needle

to

move

uown

and

bring

up

the

bobbin

thrcad

throogh

the

needle

hole

in

a

loop.

Ligritly

pull

tl

neudle

thread

to

draw

the

bobbin

ttrread

ap

oni

pletely.

Place

both

threads

back

under

the

sewing

tool

If

the

bobbin

thread

should

break

in

the

seam

or

the

bobbin

becomes

empty

while

sewing,

you

c

rr

r

ciraw

up

too

bobbin

thread

without

r

ensinig

the

sowing

fool

to

do

this,

push

the

presaur

bar

lnttr

down,

as

instructed

in

nom

her

3

ann

pagi..

lb.

I

PFAFF)

1222

10

•

Reverse-feed

contro!

3

must

be

in

its

hod

zontal

position

and

must

show

the

forward-reverse

sewing

symbol

on

its

top

surface.

•

For

straight

and

zigzag

sewing,

the

de

corative

and

functional-stitch

mechanism

must

he

disengaged.

To

make

sure

it

is,

push

button

4

on

the

top

cover

of

your

machine.

•

The

knob

of

Ultra-Matic

stitch

selector

S

must

be

positioned

horizontally

with

the

buttonhole

symbol

located

at

the

left.

•

Pattern

length

dial

6,

which

you

need

for

decorative

stitching,

must

be

turned

to

this

symbol:

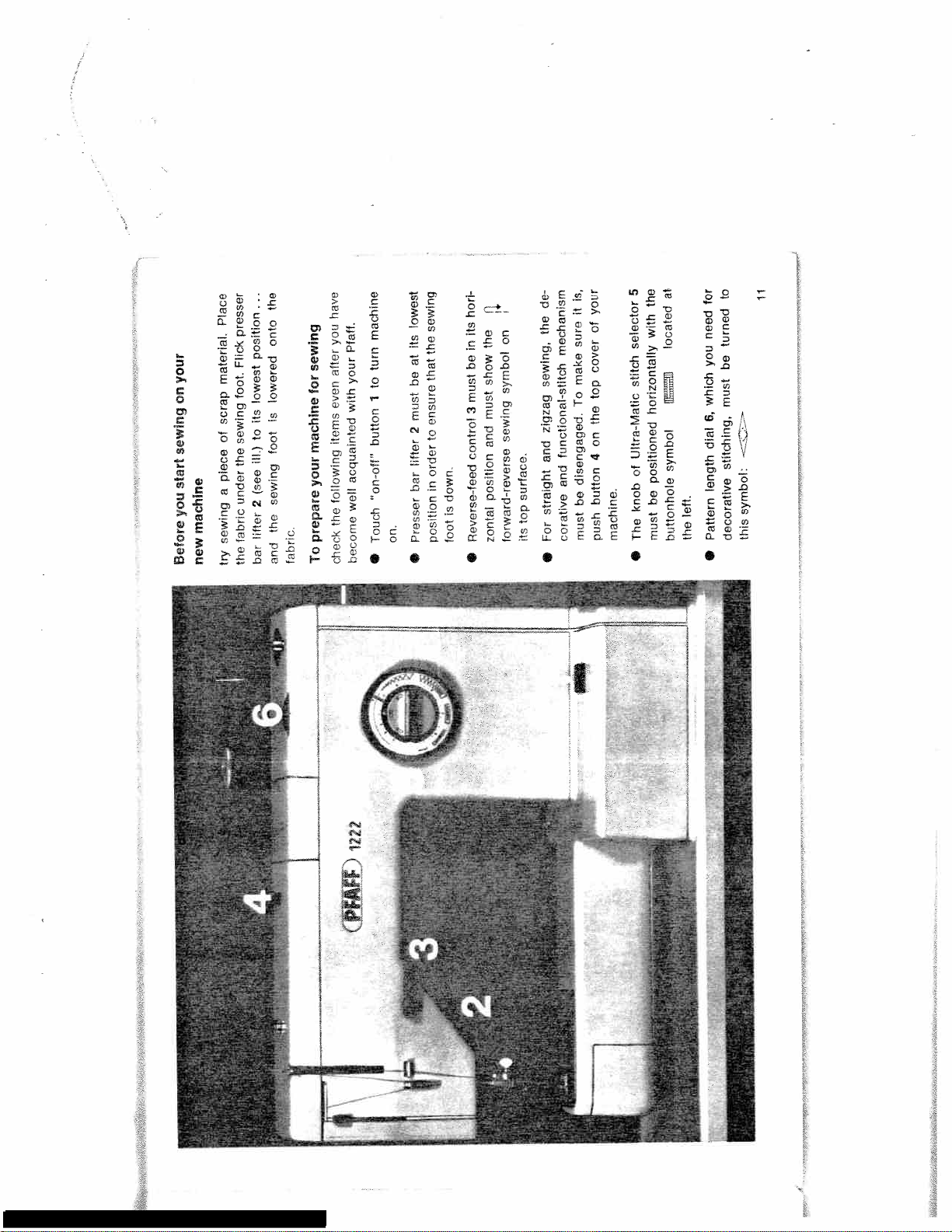

Before

you

start

sewing

on

your

new

machine

try

sewing

a

piece

of

scrap

material.

Place

the

fabric

under

the

sewing

foot.

Flick

presser

bar

lifter

2

(see

ill,)

to

its

lowest

position

and

the

sewing

foot

is

lowered

onto

the

fabric,

To

prepare

your

machine

for

sewing

chock

the

foilowing

items

even

after

you

have

bocome

well

acquainted

with

your

Pfaff.

•

Touch

on-off

button

1

to

turn

machine

on.

•

Presser

bar

lifter

2

must

be

at

Its

lowest

position

in

order

to

ensure

that

the

sewing

foot

is

down.

ii

12

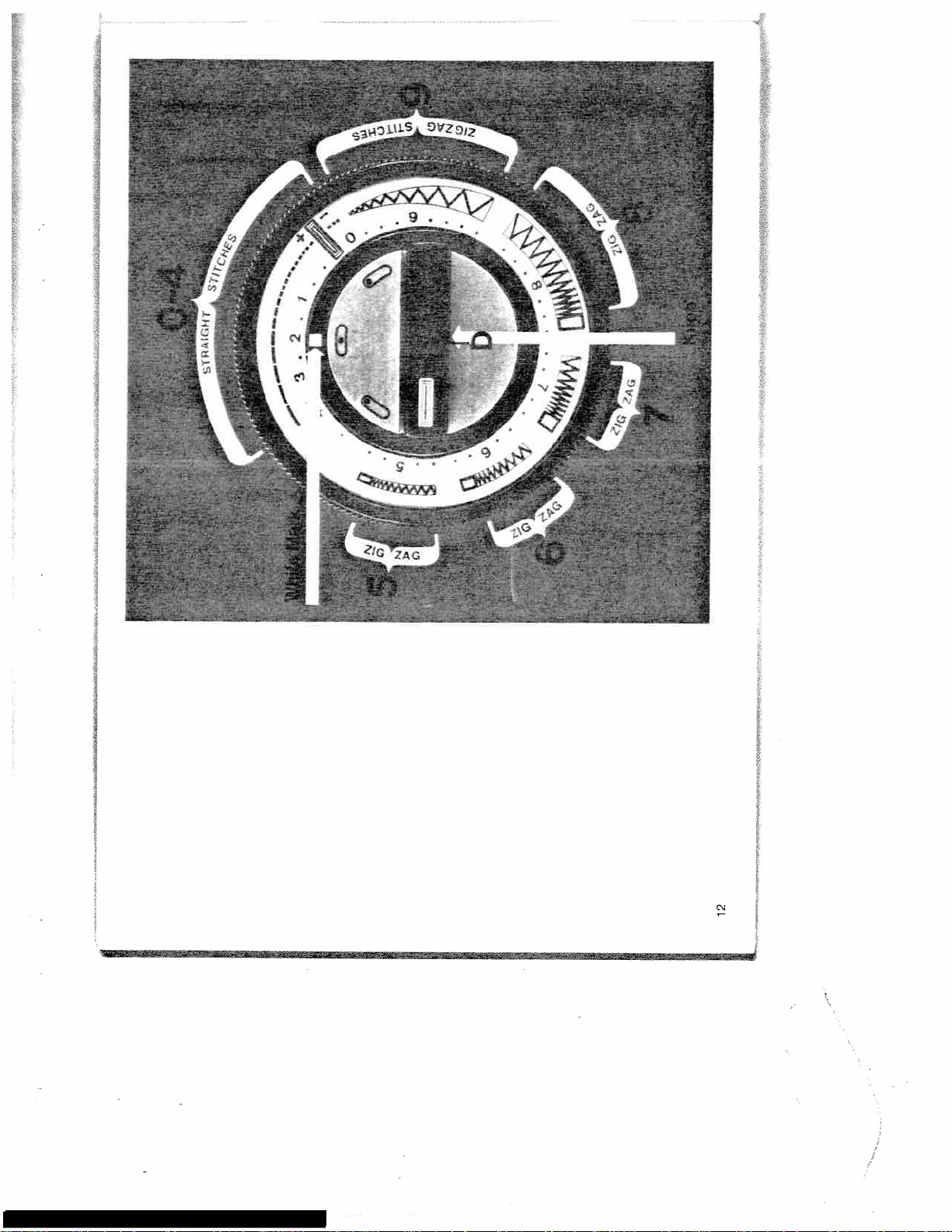

The

Ultra-Mafia

stftch

seector

Note:

The

needle

must never

be

in

the

mate

del when

you

turn

the

Ultra-Matic

stitch

selector,

The

Ultra-Matic

stitch

selector

sets

your

ma

chine

for

straight.

and

zigzag

stitching.

The

different

stitch

ranges

are

marked

by

numbers.

For

instance,

the range

from

0

to

4

comprises straight

stitches

of

different

lengths.

Turn

the

outer

ring

of

the

stitch

selector

until

the

symbol

of

the

stitch

desired

is

opposite

the

white

mark,

ln

the

illustration

on

the

left,

the

stitch

selector

is

set

for

sewing

straight

stitches

about

2

mm

long

(about

12

stitches

per

inch),

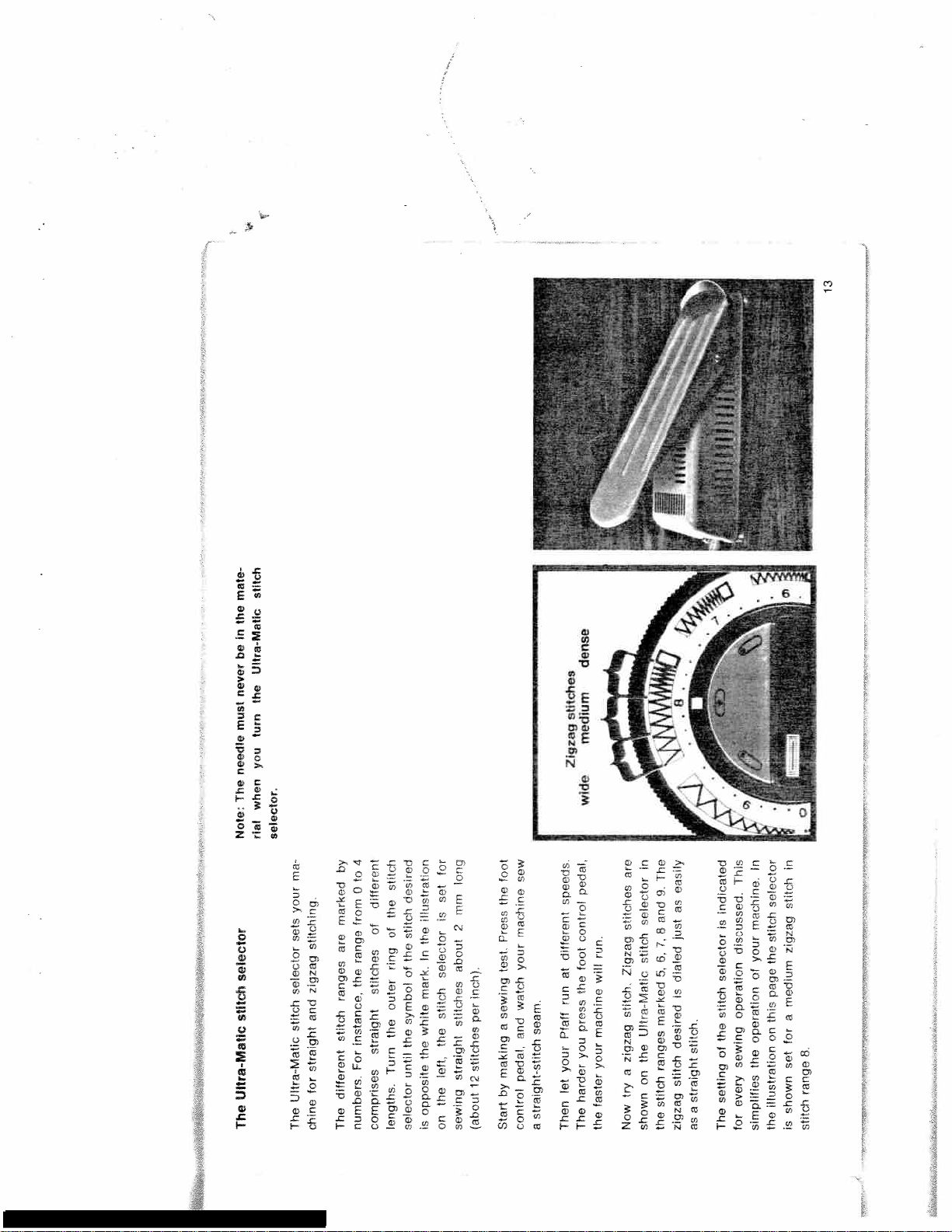

Start

by

making

a

sewing

test..

Press

the

foot

control

pedal,

and

watch

your

machine

sew

a

straight’stitch

seam.

Then

lot

your

Pfaff

run

at

diffe

rent

speeds.

The

harder

you

press

the

foot

control

pedal,

the

faster

your

machine

will

run.

Now

try

a

zigzag

stitch,

Zigzag

stitches

are

shown

on

the

UitraMatic

stitch

selector

In

the

stitch

ranges

marked

5,

6,

7,

8

and

9.

The

zigzag

stitch

desired

is

dialed

just

as

easily

as

a

straight

stitch,

The

setting

of

the

stitch

selector

is

indicated

for

every

sewing

operation

discussed,

This

simplifies

the

operation

of

your

machine,

In

the

illustration

on

this

page

the

stitch

selector

is

shown

set

for

a

medium zigzag

stitch

in

stitch

range

8.

13

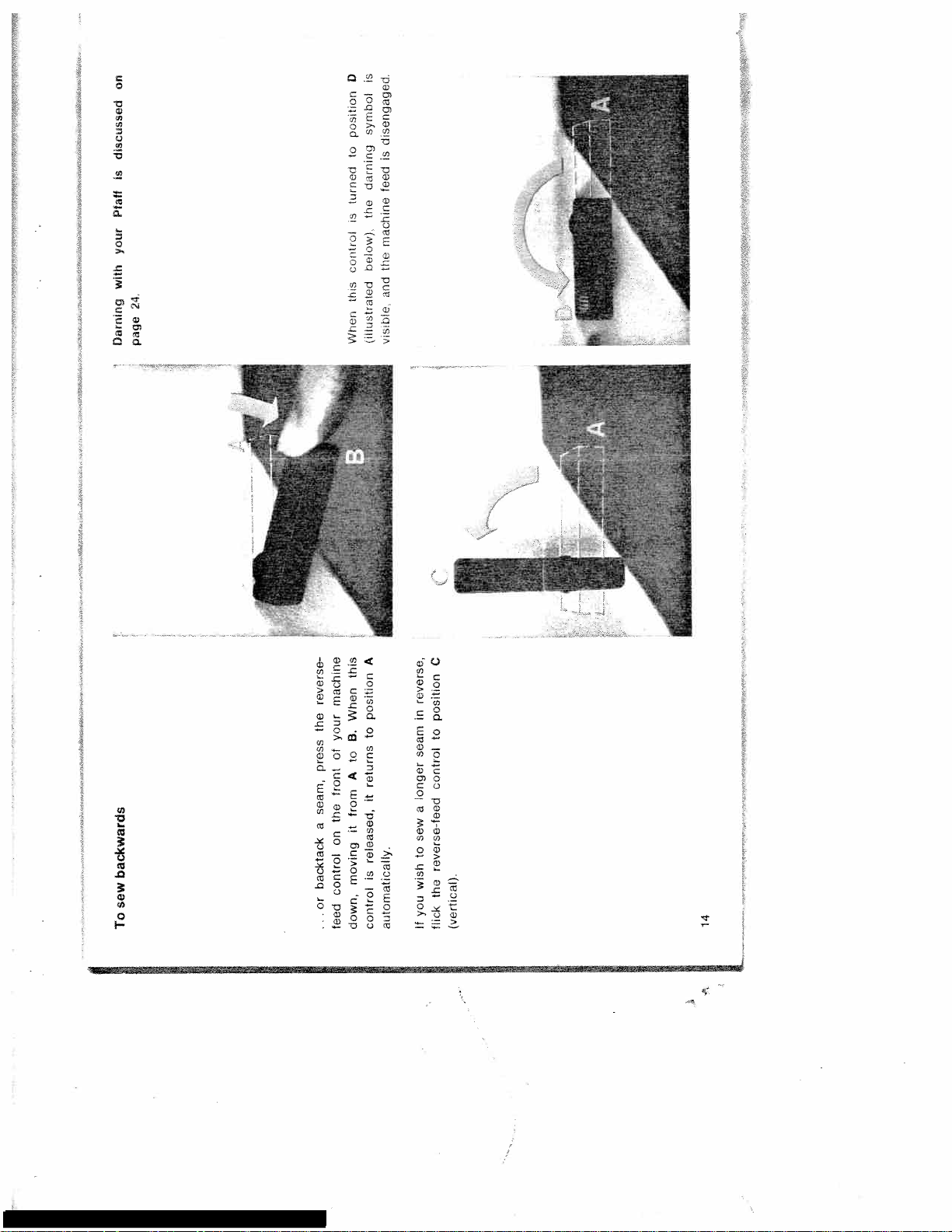

To

sew

backwards

or

backtack

a

seam,

press

the

reverse-

feed

control

on

the

front

of

your

machine

down, moving

it

from

A

to

B.

When

this

control

is

released,

it

returns

to

position

A

automatically.

If

you

wish

to

sew

a

longer

seam

in

roverse,

flick

the

reverse-feed

cuntiol

to

position

C

(vertical),

Darntng

with

your

Pfatt

is

discussed

on

page

24.

/frur

i

this

cuiti

ci

is

fur

nod

to

pusrtiori

0

(illustrated

below),

the

darrrrrrj

symbol

is

\isrDfe

and

the

niachirie

teed

is

disengaged.

14

When

you’ve

finished

sewing

flick

the

presser

bar

litter

to

its

highest

pnsi

tion.

Since

this

lever

has

been

menttoned

repeatedly

so

far,

were

now

going

to

tell

you

how

it

works

when

set

at

its

various

posi

tions

1

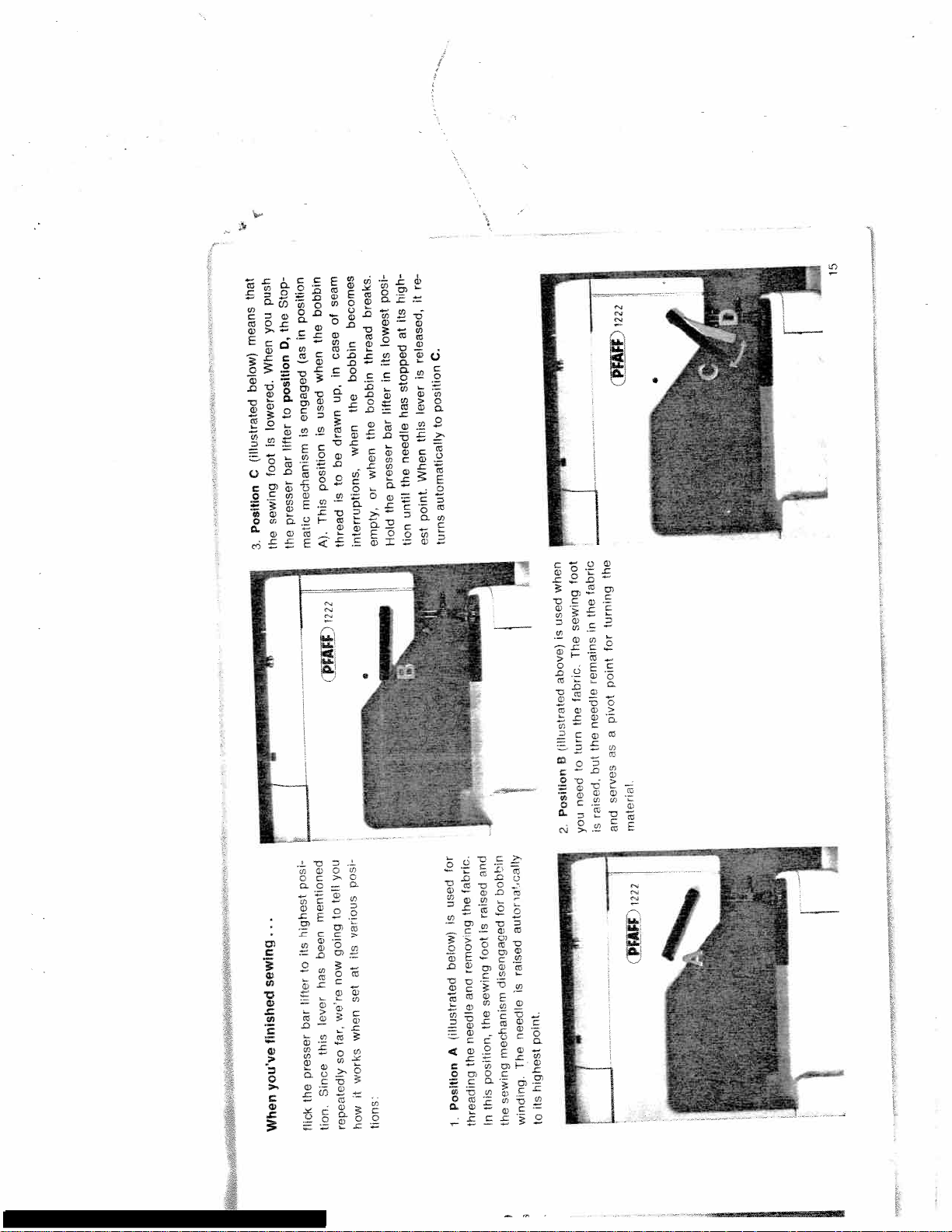

PositIon

A

lillustrrited

belowt

is

used

for

threadinq

the

needle

500

removing

the

fnhrin,

In

this

position,

the

sewing

foot

is

raised

and

the

sewing

mechanism

disengaged

for

bobbin

winding.

The

needle

is

raised

autorni,caIty

to

its

highest

point.

I

‘

3.

Position

C

(illustrated

below)

means

that

the

sewing

foot

Is

lowered.

When

you

push

the

presser

bar

litter

to

position

0,

the

Stop

matic

mechanism

is

engaged

(as

in

position

A).

This

position

is

used

when

the

bobbin

thread

is

to

be

drawn

up,

in

case

of

seam

interruptions,

when

the

bobbin

becomes

empty,

or

when

the

bobbin

thread

breaks.

Hold

the

presser

bar

lifter

in

its

lowest

posi

tion

until

the

needle

has

stopped

at

its

high

est

point.

When

this

lover

is

released,

it

re

turns

automatically

to

position

C.

.J:

.

.

—‘r—

—--

1

2

PosItion

B

(illustrated

above)

is

used

when

you

need

to

turn

the

fabric.

The

sewing

foot

is

raised.

hot

the

needip

remains

in

the

fabric

and

serves

as

a

pivot

point

for

turning

the

material.

(i,F4FF)

1222

Two

pieces

of

fabric

wUl

match

pertectly,

no

matter

how

iong

the

seam

may

be.

Your

Pfaff

is

the

only

home

sewing

machine

in

the

world

featuring

a

Matchmaker

sewing

toot.

This

toot

is

used

tor

sewing

long

seams

and

for

perfectly

matching

plaids,

striped

and

patterned

fabrics.

The

Matchmaker

sewing

toot

is

also

used

for

sewing

over

thick

cross

seams

To

engage

the

Matchmaker

sewnig

toot

simply

push

it

down

in

the

slot

ot

the

raised

sewing

foot

until

it

snaps

into

place

(see

arrow

in

illustraOon

at

bottom

lutt.

To

disengage

this

loot,

push

it

down

,liqhiIy,

then

pull

it

up

out

of

the

51.0

fl

tue

sewinj

toot

$

Other

feet

which

can

be

used

with

the

Match

maker

sewing

foot

include

the

hemmer

toot,

blindstitch

foot

and

felling

foot.

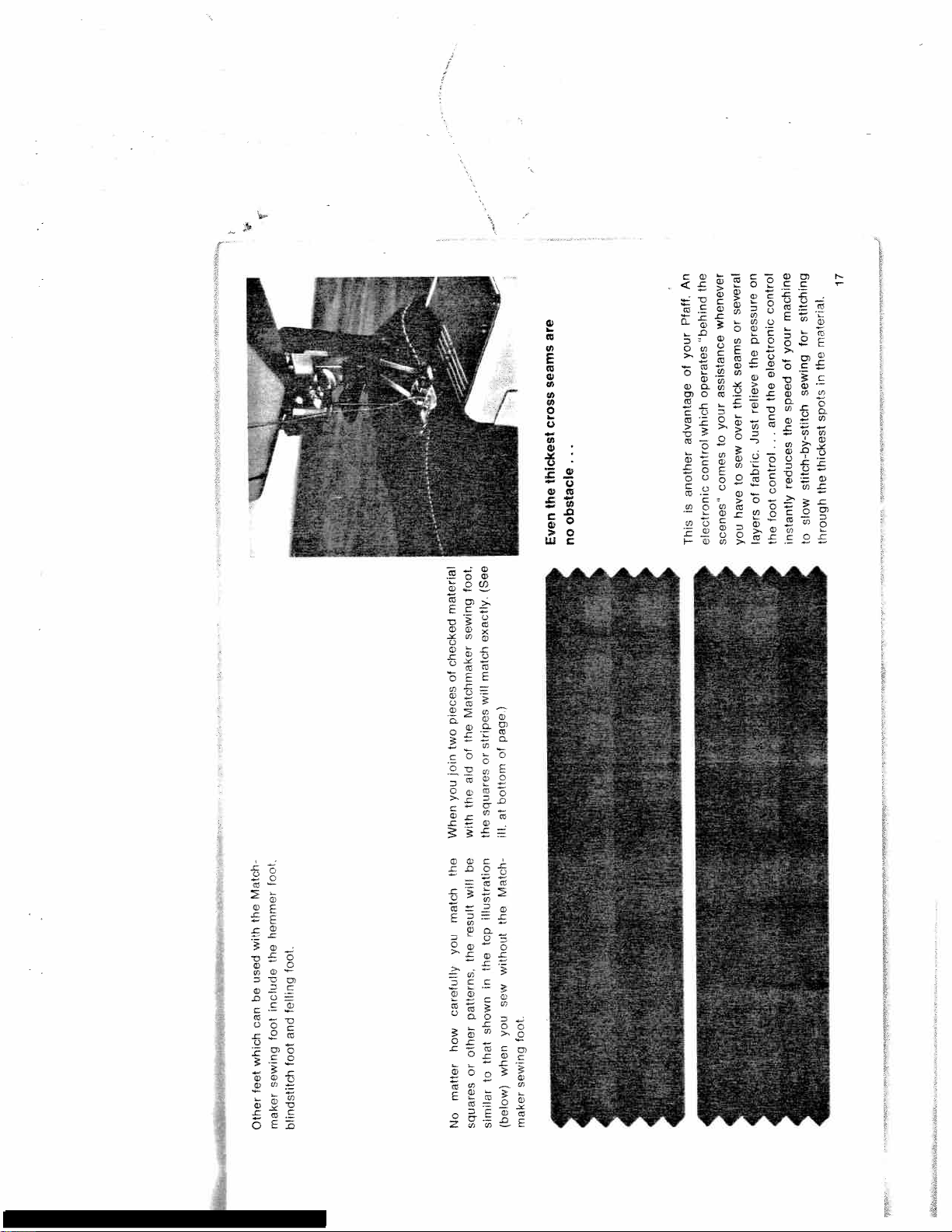

No

matter

how

carefully

you

match

the

squares

or

other

patterns,

the

result

will

be

similar

to

that

shown

in

trio

top

illustration

(below)

when

you

sow

without

the

Match

maker

sewing

foot.

When

you

join

two

pieces

of

checked

material

with

th

aid

of

the

Matchmaker

sewing

foot.

the

squares

nr

stripes

will

match

exactly.

(See

ill

at

bottom

0

f

page

1

Even

the

thickest

cross

seams

are

no

obstacle.

This

is

another

advantage

of

your

Pfaff,

Art

electronic

control

which

operates

“behind

the

scenes

comes

to

your

assistance

whenever

you

have

to

sew

over

thick

seams

or

several

layers

of

fabric.

Just

relieve

the

pressure

on

the

foot

control

,

and

the

electronic

control

instantty

reduces

the

speed

of

your

machine

to

stow

stitchby-stitch

sewing

for

stitching

through

the

thickest

spots

in

the

material.

17

Changing

the

needle

or

sewing

foot

is

easy.

Vanous

sewing

operations

require

different

size

needles

or

special

needles.

A

detailed

Needle

and

Thread

Chart

is

shown

on

page

61.

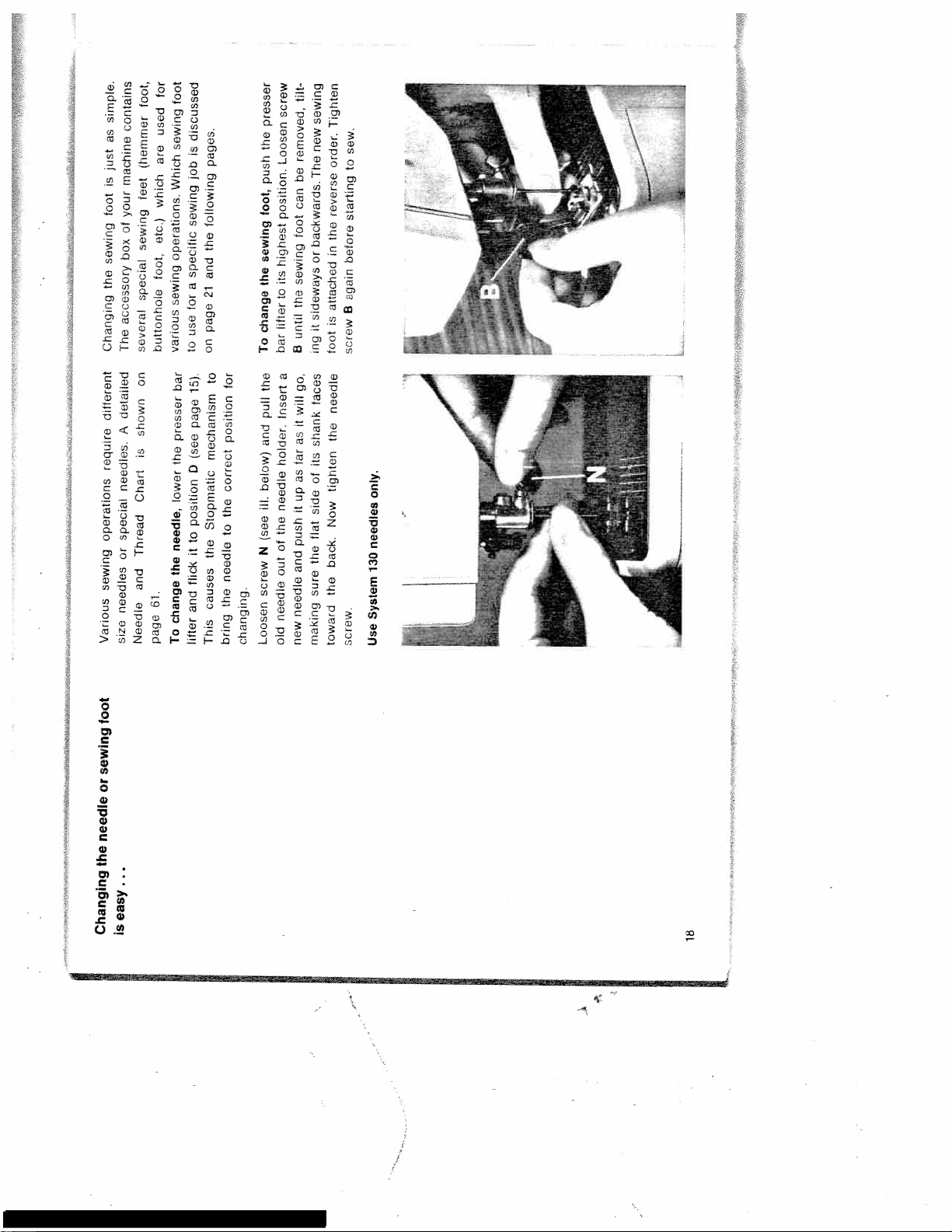

To

change

the

needle,

lower

the

presser

bar

lifter

and

hick

it

to

position

D

(see

page

15)

This

causes

the

Stopmatic

mechanism

to

bring

the

needle

to

the

correct

position

for

changing.

Loosen

screw

N

(see

ill.

below)

and

pull

the

old

needle

out

of

the

needle

holder

Insert

a

new

needle

and

push

it

up

as

far

as

it

will

go,

making

sure

the

flat

side

of

its

shank

tacos

toward

the

back.

Now

tighten

the

needle

screw

Changing

the

sewing

foot

is

Just

CS

simple.

The

acctssory

box

of

your

macnine

contains

several

special

sewing

feet

(hemmer

foot,

buttonhole

foot,

etc

)

which

are

used

for

venous

sewing

operations.

Which

sewing

toot

to

use

for

a

secrfrc

ewrrtg

job

is

discussed

on

page

21

and

the

following

pages.

To

change

the

sewIng

foot,

push

the

presser

bar

lifter

to

ifs

highest

position.

Loosen

screw

B

until

the

sewing

foot

can

be

removed,

tilt

rug

it

sideways

or

backwards.

The

new

sewing

tnot

is

attached

in

me

reverse

order.

Tighten

screw

B

again

betore

starting

to

sew.

Use

System

130

needles

only.

18

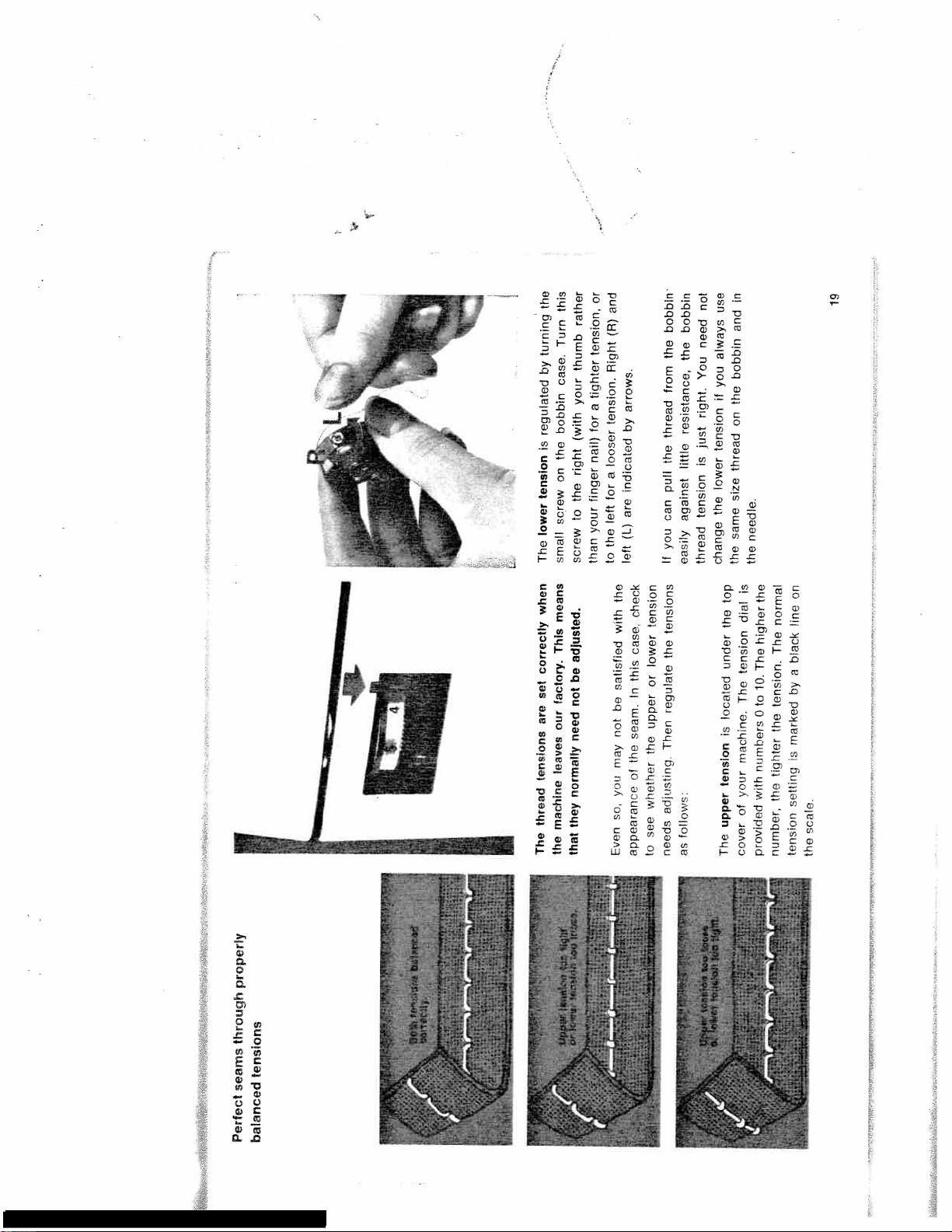

Perfect

seams

through

property

balanced

tensions

Even

so,

you

may

not

be

satisfied

with

the

appearance

of

the

seam.

In

this

case,

check

to

see

whether

the

upper

or

lower

tension

needs

adjusting

Then

regulate

the

tensions

as

follows:

The

upper

tension

is

located

under

the

top

cover

of

your

machine,

The

tension

dial

is

provided

with

numbers

0

to

10.

The

higher

the

number,

the

tighter

the

tension,

The

normal

tension

setting

s

marked

by

a

black

line

on

the

scale.

If

you

can

pull

the

thread

from

the

bobbin’

easily

against

little

resistance,

the

bobbin

thread

tension

is

just

right.

You

need

not

change

the

lower

tension

if

you

always

use

the

same

size

thread

on

the

bobbin

and

in

the

needle,

I

‘V

The

thread

tensions

are

set

correctly

when

the

machine

leaves

our

factory.

This

means

that

they

normally

need

not

be

adjusted.

The

lower

tension

is

regulated

by

turning

the

small

screw

on

the

bobbin

case.

Turn

this

screw

to

the

right

(with

your

thumb

rather

than

your

finger

nail)

for

a

tighter

tension,

or

to

the

left

for

a

looser

tension.

Right

(R)

and

left

(L)

are

indicated

by

arrows,

19

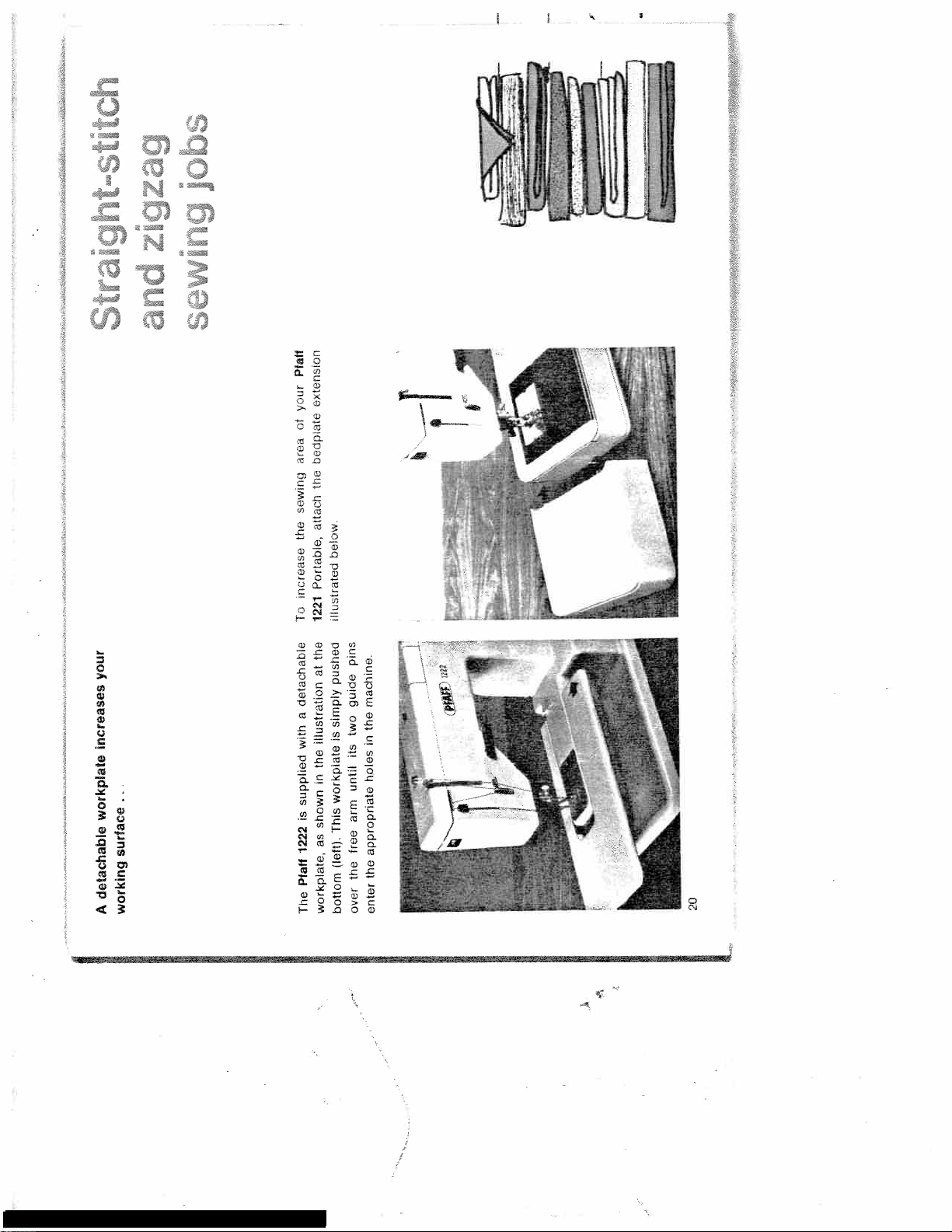

A

detachaWe

workpate

nareases

your

workEng

surface

The

Platl

1222

is

supplied

with

a

detachable

workplate,

as

shown

in

the

illustration

at

the

bottom

(left>.

This

worKpiate

is

simply

pushed

over

the

tree

arm

until

its

two

guide

pins

enter

the

appropriate

holes

in

the

machine.

lo

increase

the

sowing

ama

of

your

Pfaft

1221

Portable,

attach

tie

bedpate

extcnsion

Ilustrated

below.

Loading...

Loading...