Page 1

DP-CL18

ORDER No.KM60503633CE

G0

Color Laser Printer

© 2005 Panasonic Communications Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

DP-CL18

2

Page 3

CONTENTS

Page Page

1 Introduction 5

1.1. Specifications

1.2. Options, Accessories and Supplies

1.3. Printer Panel

1.4. External View

1.5. Main Components Layout

1.6. PCB, Switches and Sensors Identification

2 About Lead Free Solder

2.1. Suggested PbF Solder

2.2. How to recognize that PbF Free solder is used

3 Installation, Setup, and Repacking

3.1. Installation Requirements

3.2. Setup

3.3. Repacking

4 User Mode Operation

4.1. User Mode Printer Panel Operation

4.2. User Mode Main Menu

4.3. Check then Print Selection 1 Menu

4.4. Memory Print Item Menu

4.5. Confidential Print Selection 1 Menu

4.6. System Information Item Menu

4.7. Color Calibration Item Menu

4.8. Maintenance Item Menu

4.9. Tray Item Menu

4.10. Print Item Menu

4.11. PCL Item Menu

4.12. PostScript Item Menu

4.13. N/W Protocol Setup Item Menu

4.14. Receive Setting Item Menu

4.15. Adjust to Media Item Menu

4.16. System Item Menu

4.17. Mono Page Detect Item Menu

5 HDD Maintenance Mode Operation

5.1. HDD Maintenance Mode Operation

5.2. HDD Maintenance Mode Menu Table

5.3. HDD Maintenance Mode Main Menu

5.4. HDD Information Item Menu

5.5. Check Disk Item Menu

5.6. Quick Format Item Menu

5.7. HDD Format Item Menu

5.8. HDD Deletion Item Menu

6 Service Mode Operation

6.1. Service Mode Control Panel Operation

6.2. Service Mode Menu Table

6.3. Service Main Menu

6.4. Print Report Item Menu

6.5. Position Setting Item Menu

6.6. STR Setting Item Menu

6.7. DEV. Bias Item Menu

6.8. FSR Temp. Setting Item Menu

6.9. Maintenance Item Menu

10

11

13

15

15

16

21

21

22

24

30

30

32

33

34

35

36

37

38

39

41

42

43

44

46

47

48

48

49

49

50

51

52

53

54

55

55

56

56

57

65

66

75

76

77

78

79

6.10. ENG Serial Number Item Menu

5

7

8

6.11. Controller Setting Item Menu

6.12. Panel Test Item Menu

6.13. Engine Test Item Menu

6.14. Color Correction Item Menu

6.15. Flag Setting Item Menu

6.16. Printing Network Configuration Report

7 Mechanical Function

7.1. Drive Mechanism General Description

7.2. Accumulator Tension Unit (ATU) Drive Mechanism

7.3. Print Process

8 Removal and Replacement Procedures

8.1. Fuser Unit

8.2. Accumulator Unit (Acc. Unit)

8.3. Front Door Cover and STR (Second Transfer Roller) Bias

Assembly

8.4. Right Cover

8.5. Rear, Left and Top Covers

8.6. Color Registration Sensor

8.7. Engine Control Board, Toner Cartridge Holder, Cartridge

Drive Unit, Paper Pickup Motor, Main Drive Unit, Bias Unit,

Fan Motor and Fan Motor Duct

8.8. LSU (Laser Scanning Unit)

8.9. Paper Exit

8.10. IH (Inductive Heater) Unit

8.11. Paper Feed Unit

8.12. Power Supply Unit (Power Supply Board and IH Power

Board)

8.13. Main Control Board

8.14. High Voltage Board and Reg. Thermistor Sensor

8.15. Accumulator Tension Unit

8.16. Print Cartridge Unit Holder

8.17. Fuser Fan Motor

8.18. Front Door Open Detection and Right Cover Open

Detection Switches

8.19. MPT (Multipurpose Print Tray) Home Position Sensor and

MPT Paper Detection Sensor Boards

8.20. Waste Toner Cartridge Full Sensor

8.21. Standard Paper Cassette

9 Block and Connection Diagrams

9.1. Block Diagram

9.2. Connection Diagram

10 Electrical Circuit General Description

10.1. General Description

10.2. Explanation of Connector

11 Adjustment

11.1. Print Position Calibration

11.2. Color Density Adjustment

11.3. Skew Adjustment

12 Preventative Maintenance

12.1. General

80

81

82

83

93

93

94

95

95

98

108

116

116

117

117

119

119

122

123

133

133

137

140

144

146

147

148

152

153

153

154

154

155

161

161

163

165

165

169

198

198

199

207

210

210

DP-CL18

3

Page 4

DP-CL18

12.2. Recommended Tools 210

12.3. Recommend Cleaning

12.4. Maintenance Tables

13 Tr oubleshooting

13.1. Initial Troubleshooting Flowchart

13.2. Warning/Error Message

13.3. Jam and HDD Error

13.4. Print Quality

13.5. Printer Error (Call Service)

13.6. No Message

13.7. No Printing

14 Replacemen t Parts List with Lubrication Guide

210

211

212

212

213

228

240

256

283

284

287

14.1. Covers

14.2. Left Side Parts

14.3. Right Side Parts

14.4. Front and Top Side Parts

14.5. Rear Side Parts (Power Supply, Main Control and High

Voltage Boards)

14.6. Cassette

14.7. Packing Material

14.8. Toner Cartridge Dummy Case

14.9. Print Cartridge Dummy Case

14.10. PbF Solder Service Part Number

287

290

297

301

307

310

313

313

313

314

4

Page 5

1 Introduction

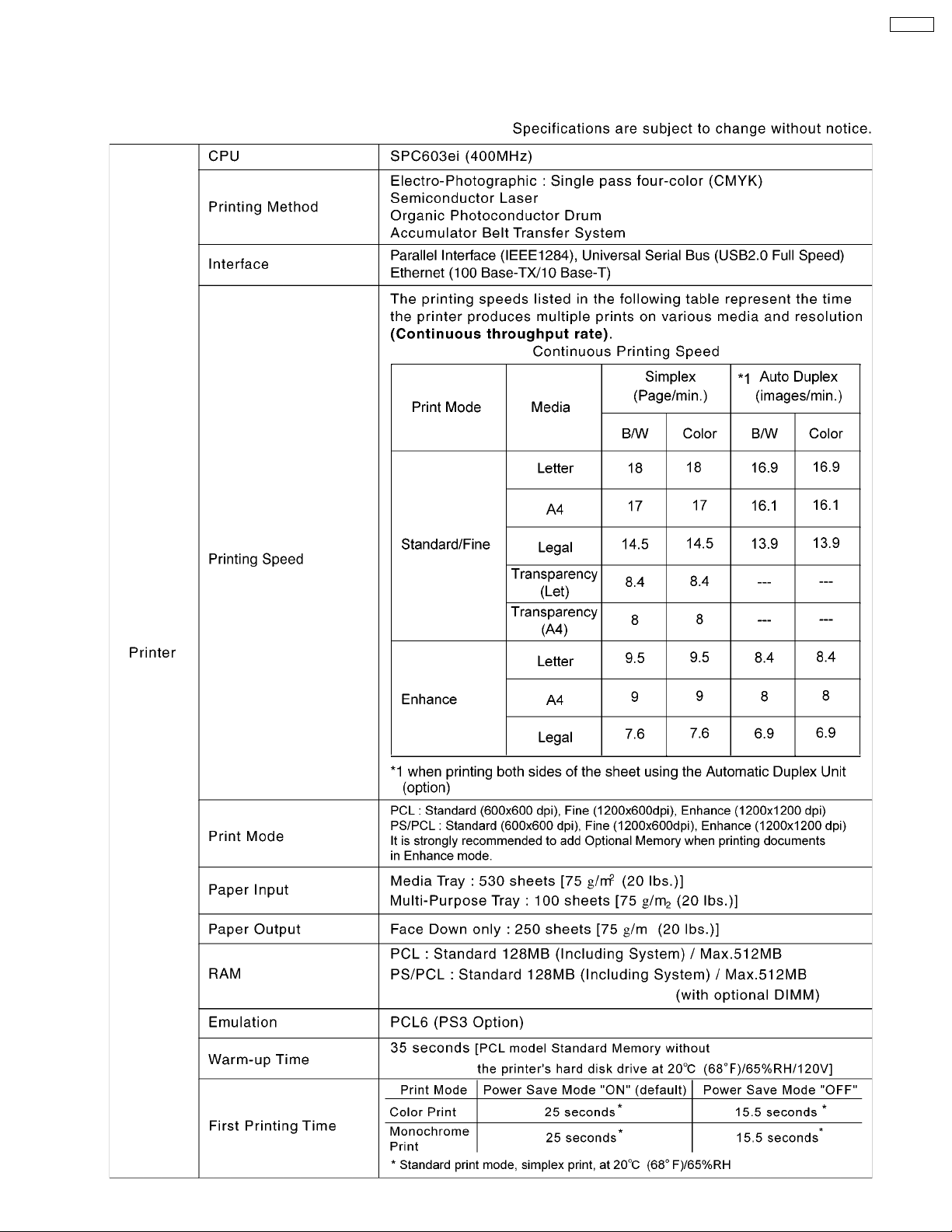

1.1. Specifications

DP-CL18

5

Page 6

DP-CL18

6

Page 7

1.2. Options, Accessories and Supplies

Model No. Description Remarks

DQ-UR3K Black Toner Cartridge 6K Average Life (6,000 pages *1)

DQ-UR3C Cyan Toner Cartridge 6K Average Life (6,000 pages *1)

DQ-UR3M Magenta Toner Cartridge 6K Average Life (6,000 pages *1)

DQ-UR3Y Yellow Toner Cartridge 6K Average Life (6,000 pages *1)

DQ-UR4C Cyan Toner Cartridge 3K Average Life (3,000 pages *1)

DQ-UR4M Magenta Toner Cartridge 3K Average Life (3,000 pages *1)

DQ-UR4Y Yellow Toner Cartridge 3K Average Life (3,000 pages *1)

DQ-UP3K Black Print Cartridge Average Life (15,000 pages *1)

DQ-UP3C Color Print Cartridge Average Life (15,000 pages *1)

DQ-FU3 Fuser Unit Average Life (100,000 pages *1)

DQ-BF3 Waste Toner Cartridge Average Life (14,000 pages *1)

DQ-BE3 Accumulator Unit Average Life (100,000 pages *1)

DQ-BR3 Transfer Roller Average Life (100,000 pages *1)

DA-DS1 Optional Paper Feeder

KX-CLAD1 Automatic Duplex Unit

KX-CLEM3 128MB DIMM

KX-CLEM4 256MB DIMM

KX-CLHD2 Hard Disk Drive

DA-MC2 Upgrade Kit for DP-CL18 (PS3)

DP-CL18

*1

The rated life expectancy of each consumable is based on printing under specific operating conditions such as page coverage

for a particular page size (5% coverage per color at 600 x 600 dpi resolution on A4 size paper). The actual consumable life will

vary depending on its use and other printing variables including page coverage, page size, media type, print resolution,

continues or intermittent printing, number of color planes, ambient temperature and humidity.

7

Page 8

DP-CL18

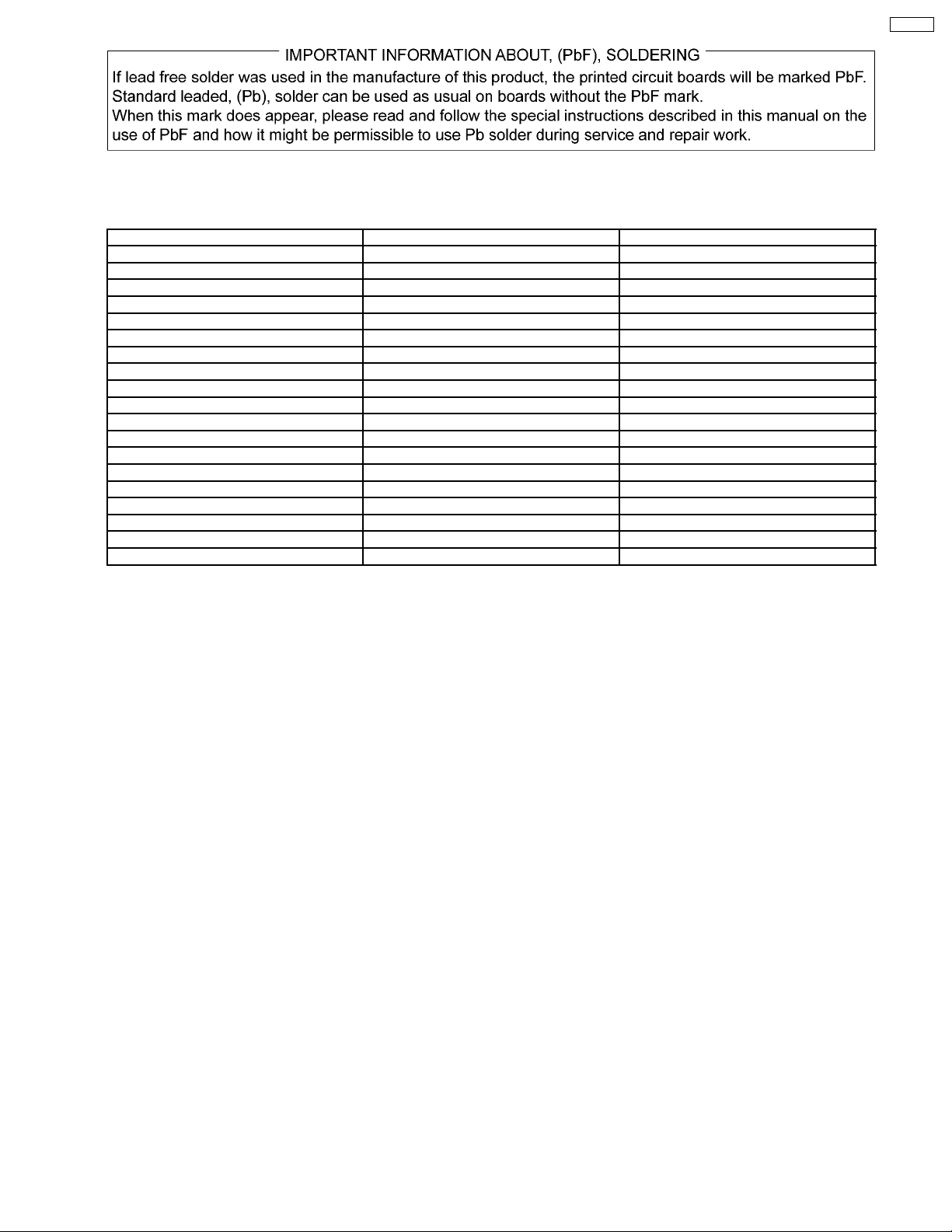

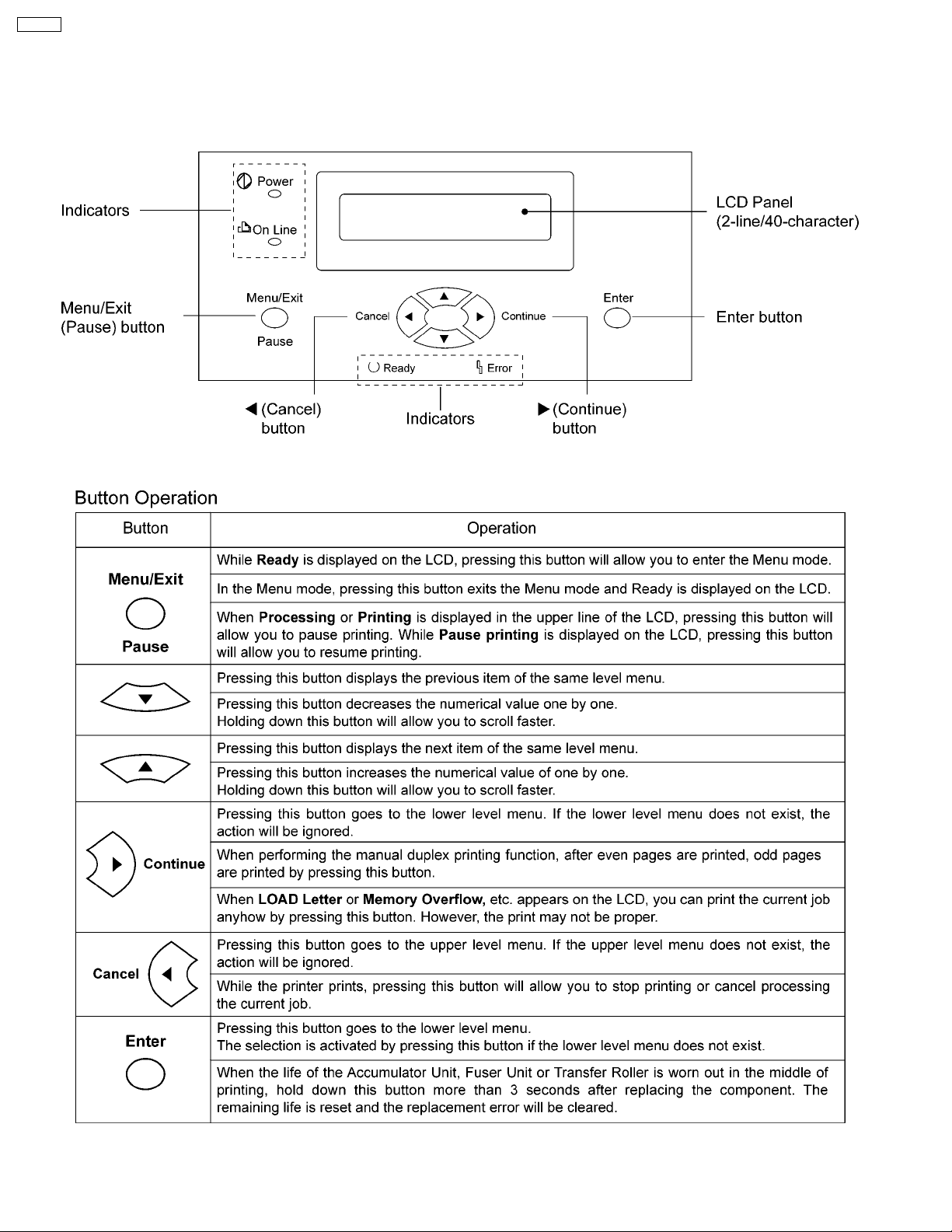

1.3. Printer Panel

1.3.1. Panel Operation

8

Page 9

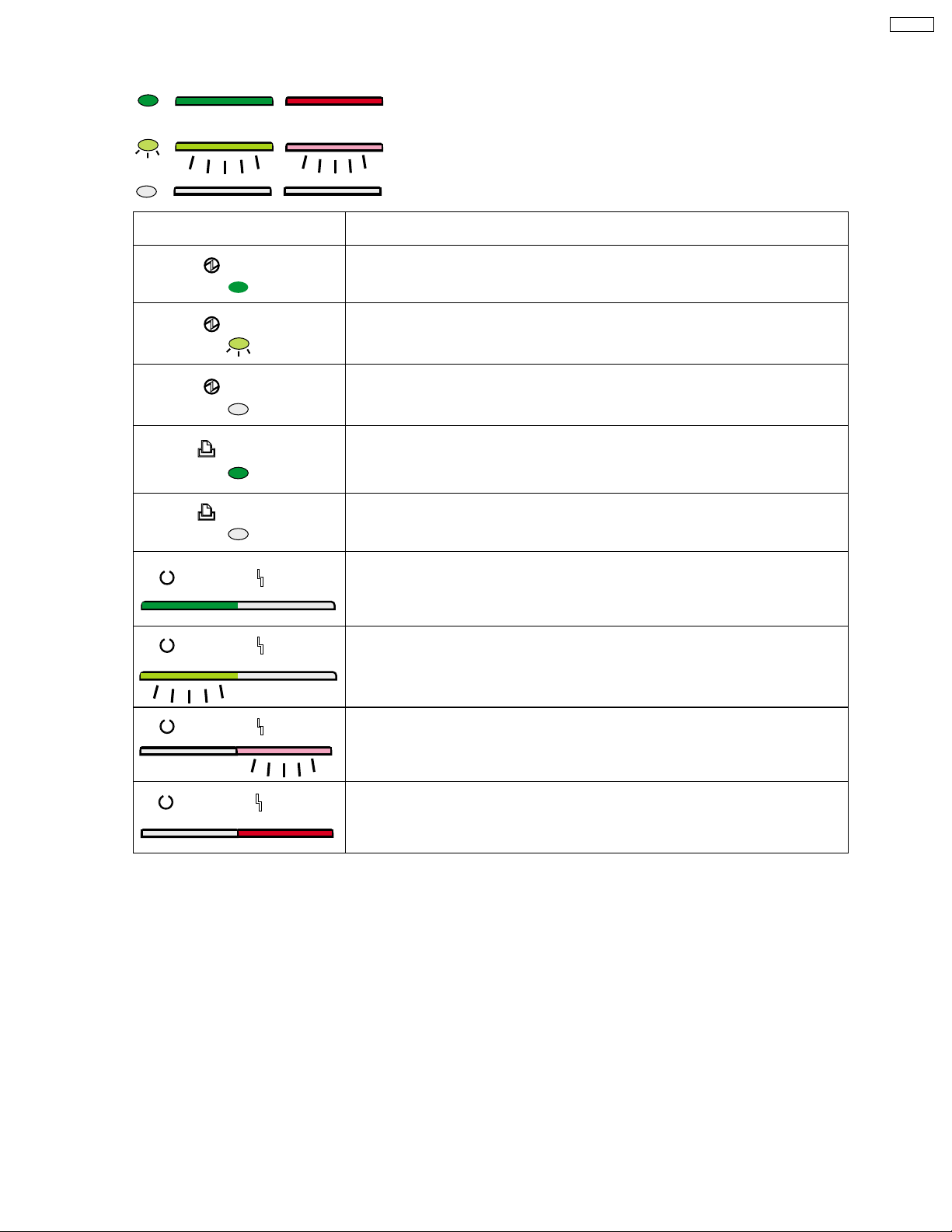

1.3.2. LED Indicator

Three indicators show the following printer’s status:

Indicator Printer Status

DP-CL18

On

Blink

Off

Power

Power

Power

On Line

On Line

Ready Error

Ready Error

Printer is turned on.

Printer is in the Power Save mode.

Printer is turned off.

Printer is ready for printing.

(Printer warms up and starts printing automatically

when it receives print data.)

Printer is in the Off Line.

Printer is in the normal condition.

Printer is not in error conditions.

Printer is receiving data, printing or data remains in the memory.

Printer is in the Menu mode.

Ready Error

Ready Error

Printer recoverable errors (media jam, media empty, etc.)

has occurred.

An internal error (Call for Service Error) has occured.

9

Page 10

DP-CL18

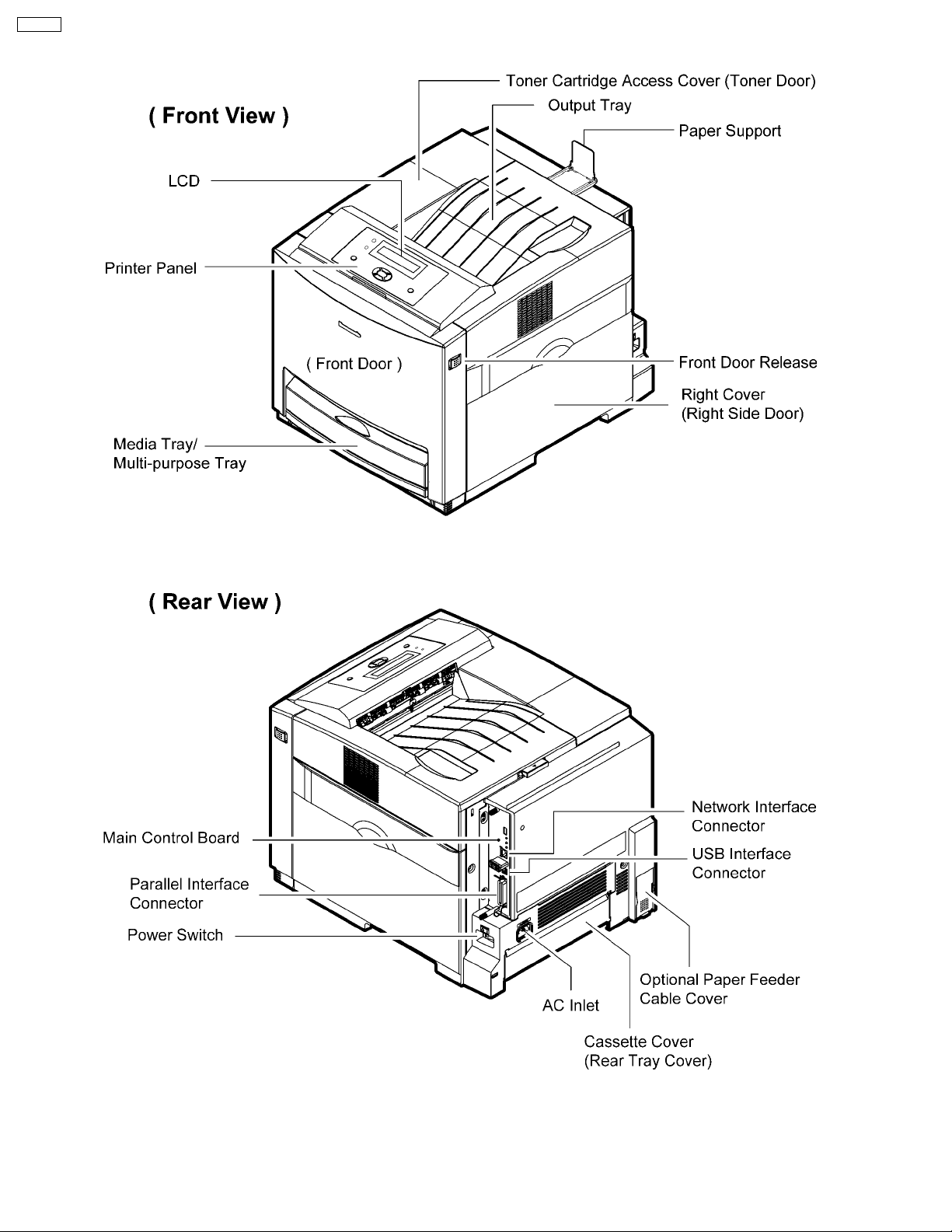

1.4. External View

10

Page 11

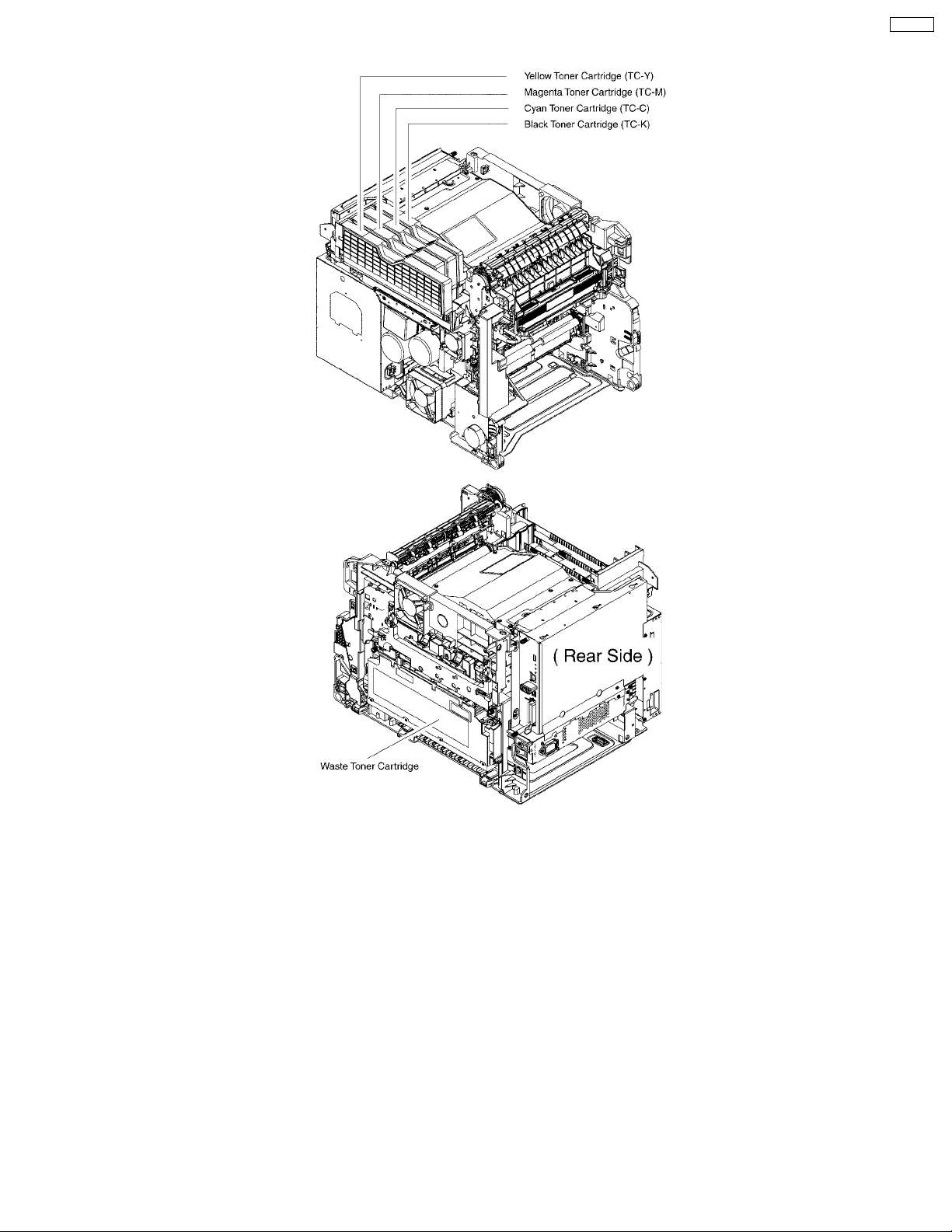

1.5. Main Components Layout

DP-CL18

11

Page 12

DP-CL18

12

Page 13

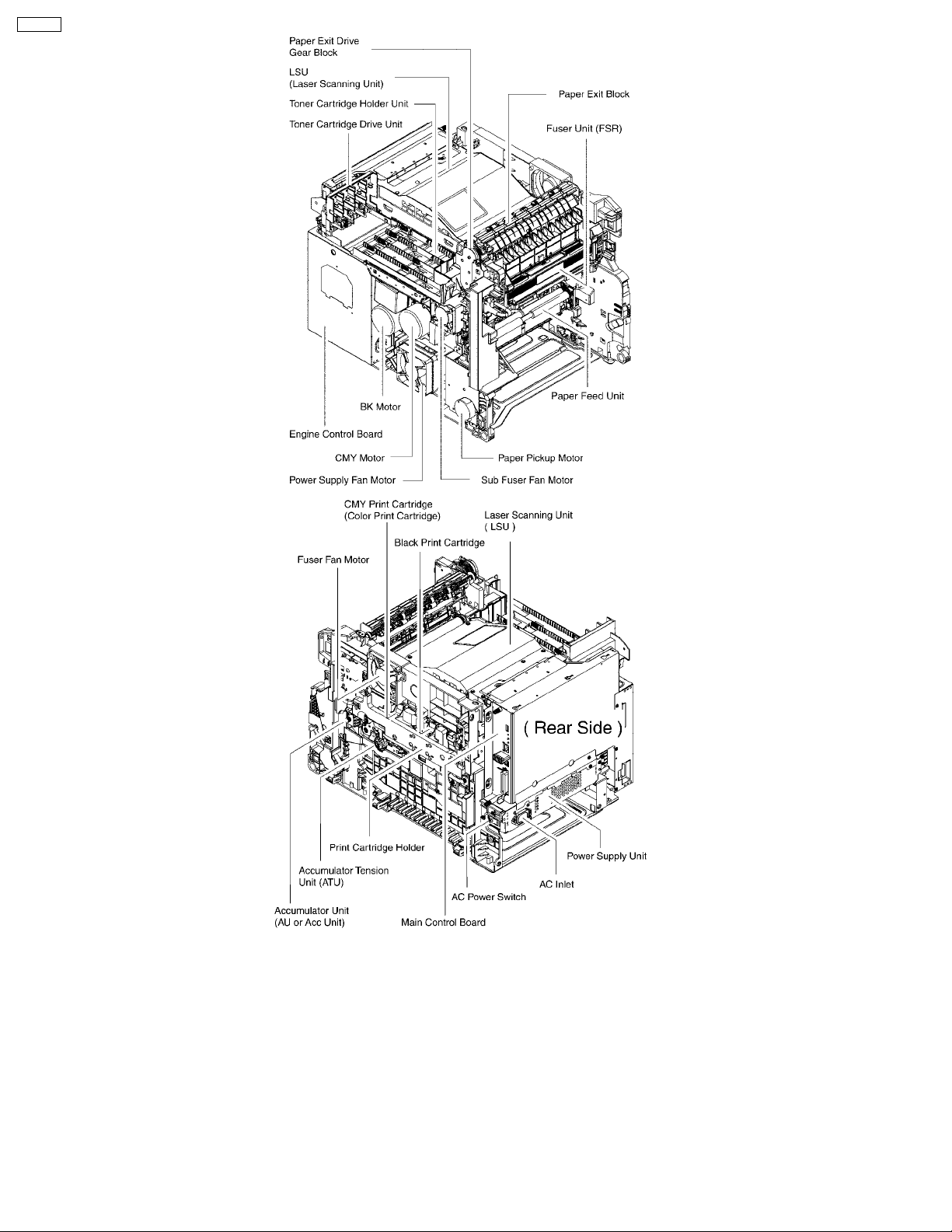

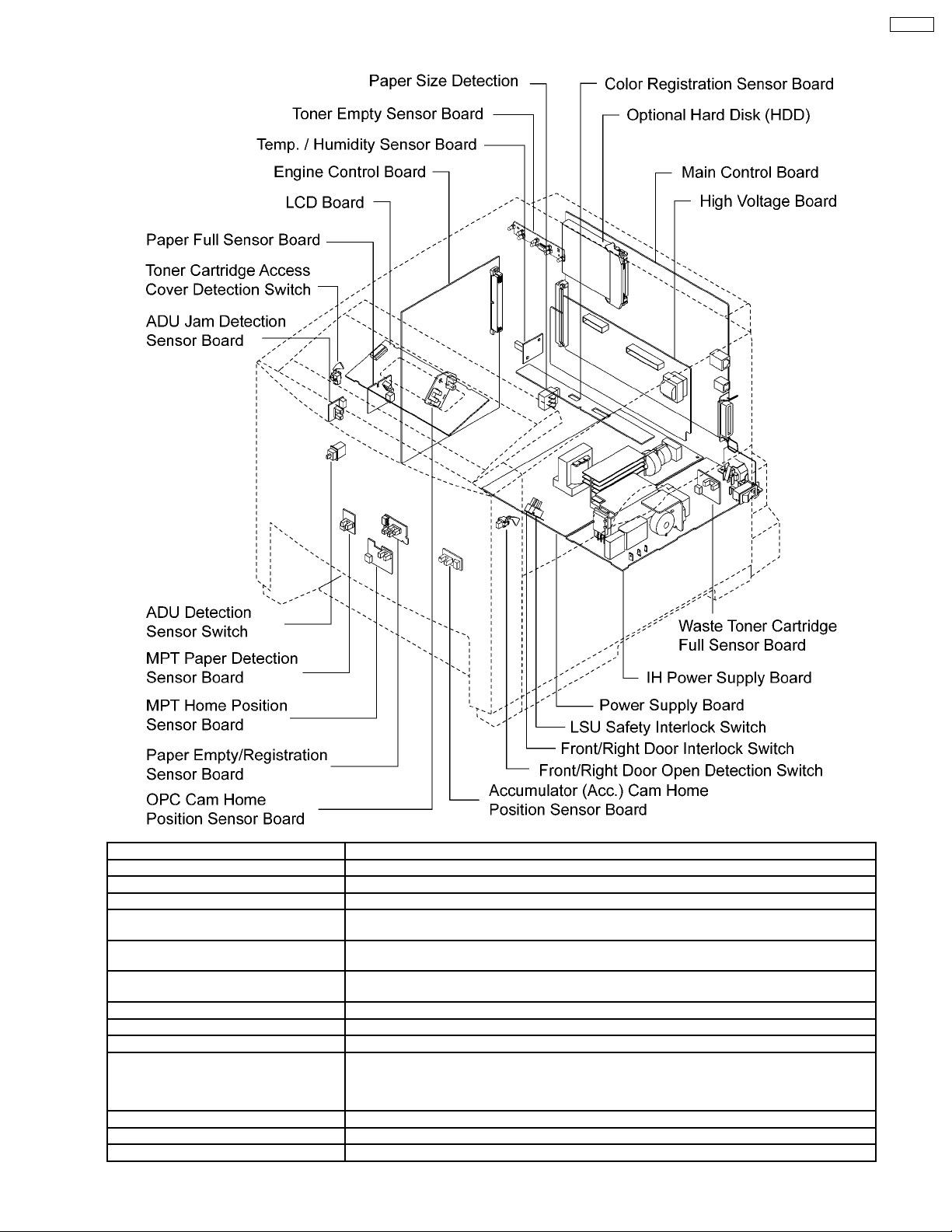

1.6. PCB, Switches and Sensors Identification

DP-CL18

Sensor/Switch/Board Name Description

Paper Size Detection For detecting the current selected paper size at the standard paper cassette.

Toner Empty Sensor Board For detecting whether the toner is low (or empty) or not.

Temp./Humidity Sensor Board For sensing the ambient temperature and humidity.

Paper Full Sensor Board This board has the paper full sensor. The paper full sensor is fo r detecting whether the output

Toner Cartridge Access Cover Detection

Switch

ADU Jam Detection Sensor Board For detecting whether the paper is ejected from the ADU (Option Automatic Duplex Unit) within

ADU Detection Sensor Switch For detecting whether the ADU is installed.

MPT Paper Detection Sensor Board For detecting whether the paper is set on the MPT (multi-purpose paper tray).

MPT Home Position Sensor Board For detecting the home position of the MPT pickup roller.

Paper Empty/Registration Sensor Board This board has the paper empty and registration sensors. The paper empty sensor is for

OPC Cam Home Position Sensor Board For detecting the home position of the OPC drum.

Acc. Cam Home Position Sensor Board For detecting the home position of the accumulator cam and controlling the printing process.

Front/Right Door Open Detection Switch For detecting whether the front door or right cover is opened.

paper tray is full.

For detecting whether the toner cartridge access cover is closed. If the toner cartridge access

cover is opened, printing is not possible.

the proper time.

detecting whether the paper is set on the standard paper cassette. The registration sensor is for

detecting whether the sheet of paper arrived at the registration roller after being properly picked

and traveling through the paper feed rollers.

13

Page 14

DP-CL18

Sensor/Switch/Board Name Description

LSU Safety Interlock Switch When the front door or right cover is opened (or both are opened), the power that is supplied to

the laser diode drive circuit in the laser unit is shut off because this switch is opened

Front/Right Door Interlock Switch When the front door or right cover is opened (or both are opened), the printing is not done

because this switch is opened.

Waste Toner Cartridge Full Sensor Board For detecting whether the waste toner cartridge is full.

Color Registration Sensor Board For reading the Color Registration Check Pattern to calculate adjustment for the fine Color

Registration Adjustment.

14

Page 15

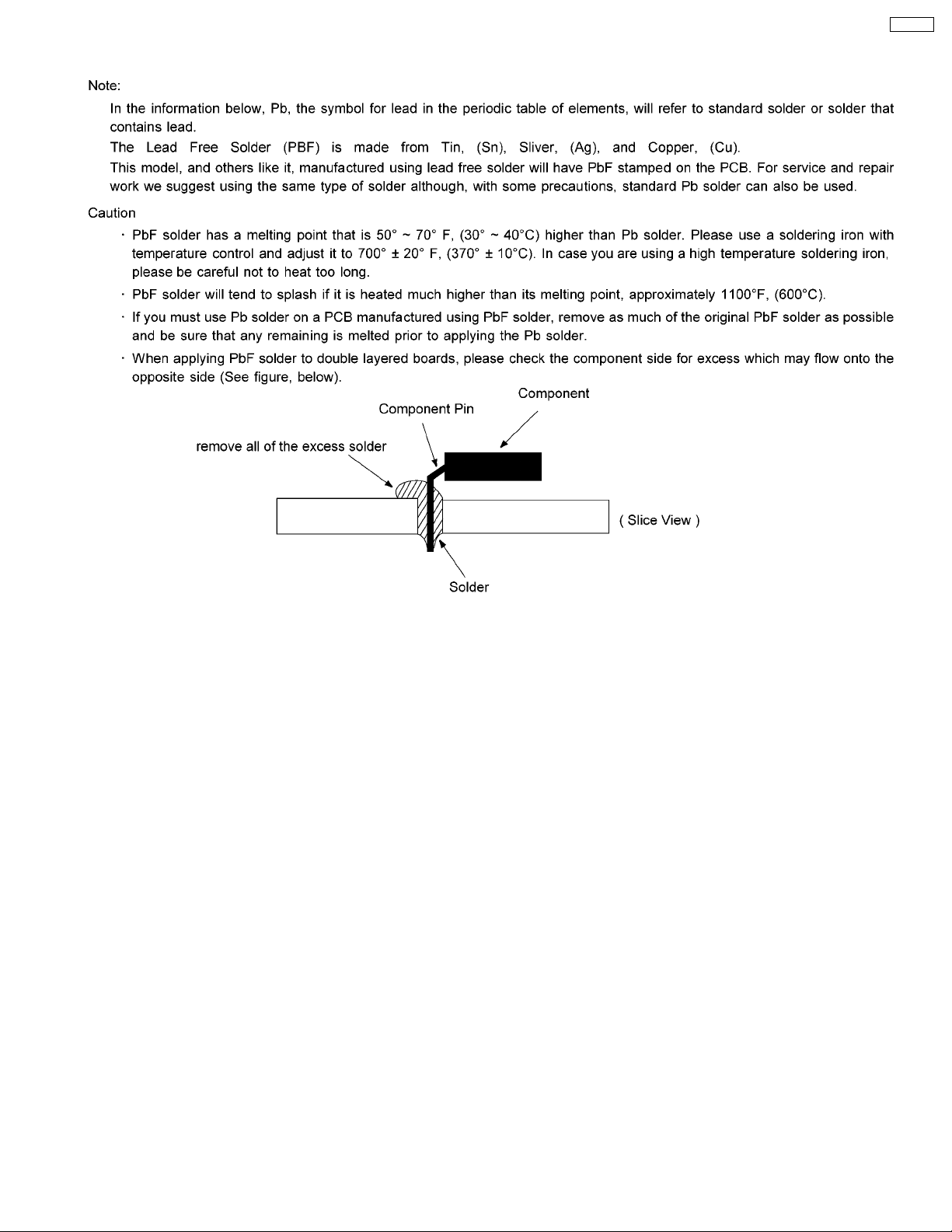

2 About Lead Free Solder

DP-CL18

2.1. Suggested PbF Solder

We recommend you to use the following solder when re-soldering component for repair. Before using other Pb free solder than the

following solder, be sure to confirm a solder maker you appoint has made license agreements to be required when using Pb free

solder legally.

Supplier: Senju Metal Industry Co., Ltd. (http://www.senju-m.co.jp)

Part Description in Senju: ECO SOLDER RMA02 P3 M705 Series

Note:

When the recommended PbF solder is not available at Senju Metal Industry Co., Ltd., see section 14.10 PbF Solder Service

Part Number.

15

Page 16

DP-CL18

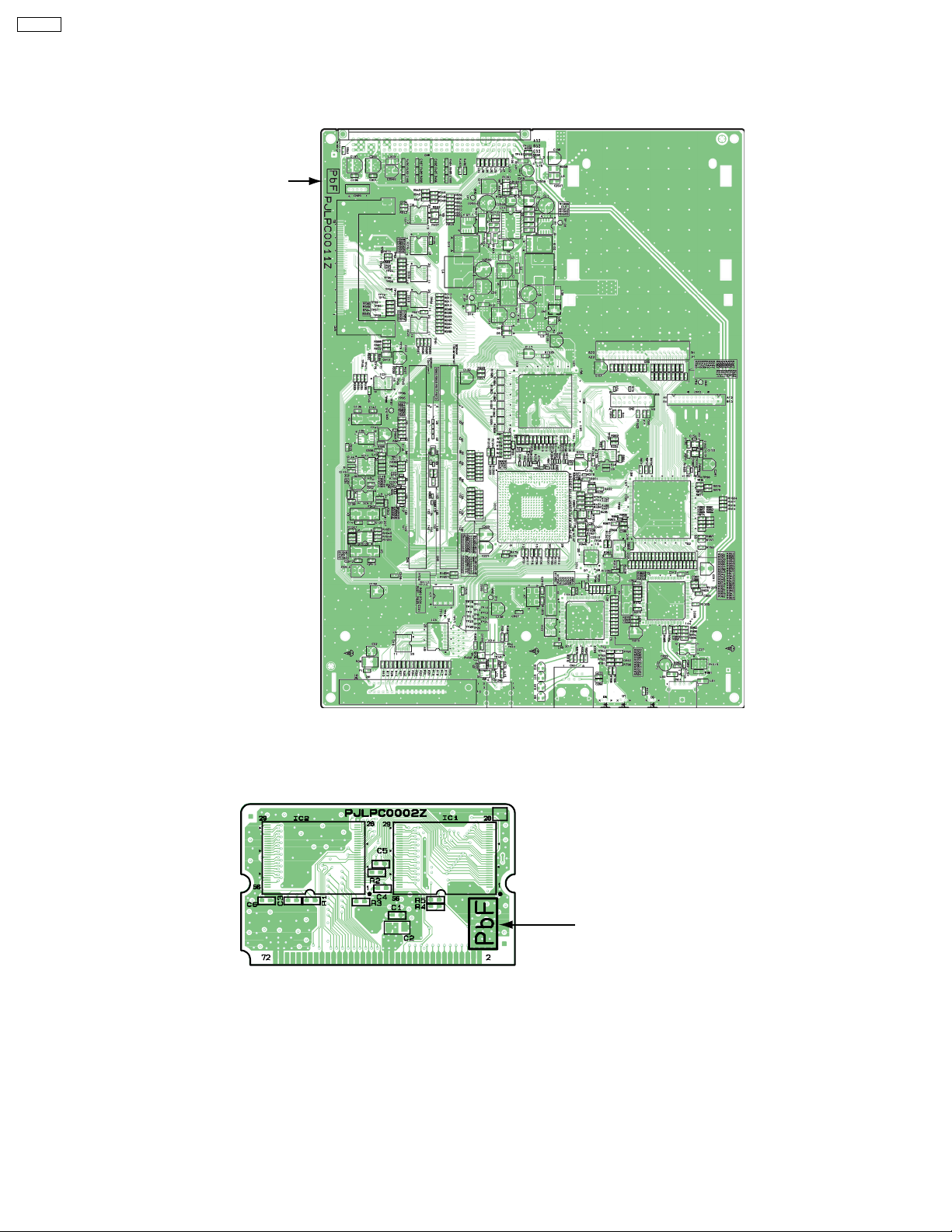

2.2. How to recognize that PbF Free solder is used

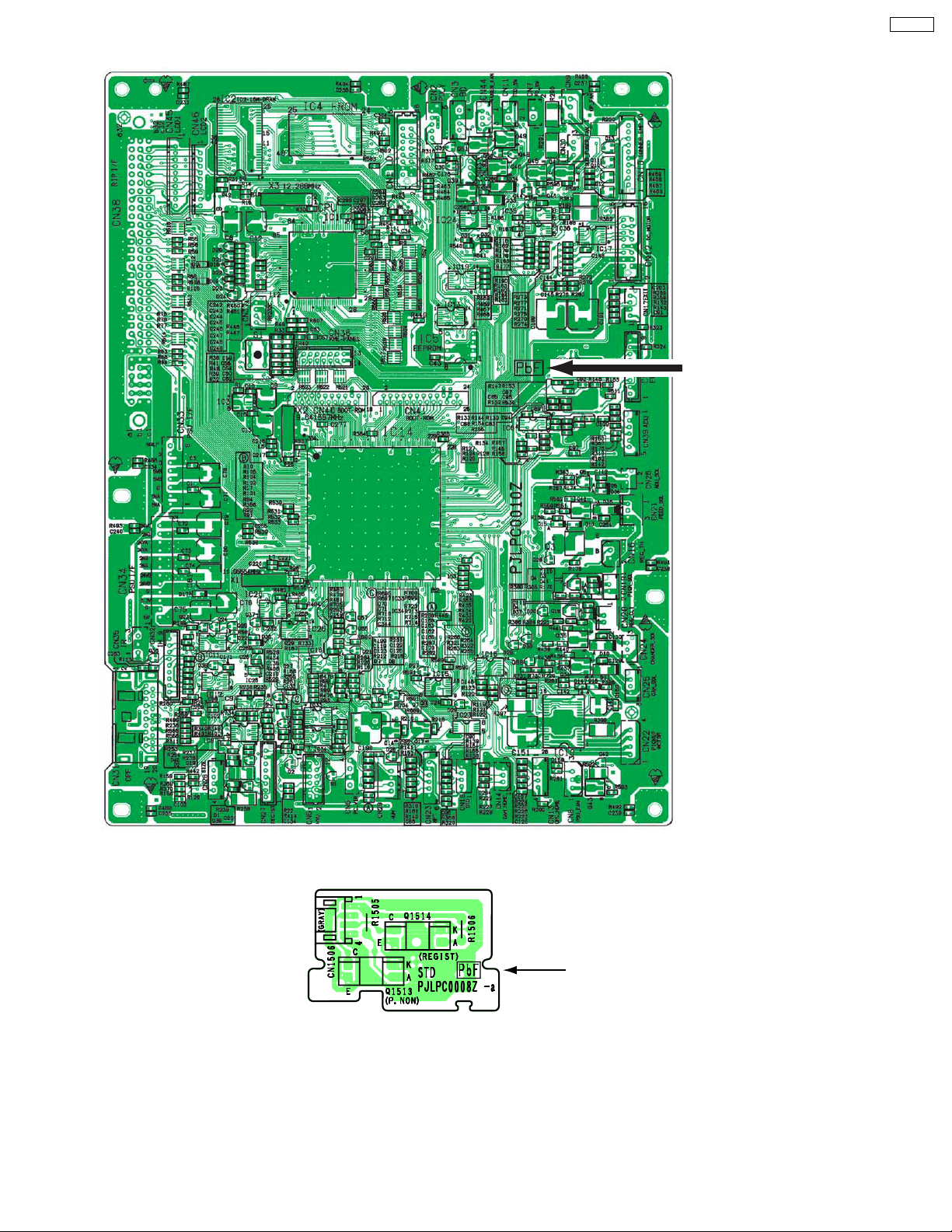

2.2.1. Main Control Board

(Top View)

Marked PbF

2.2.2. ROM Board

(Top View)

Marked PbF

16

Page 17

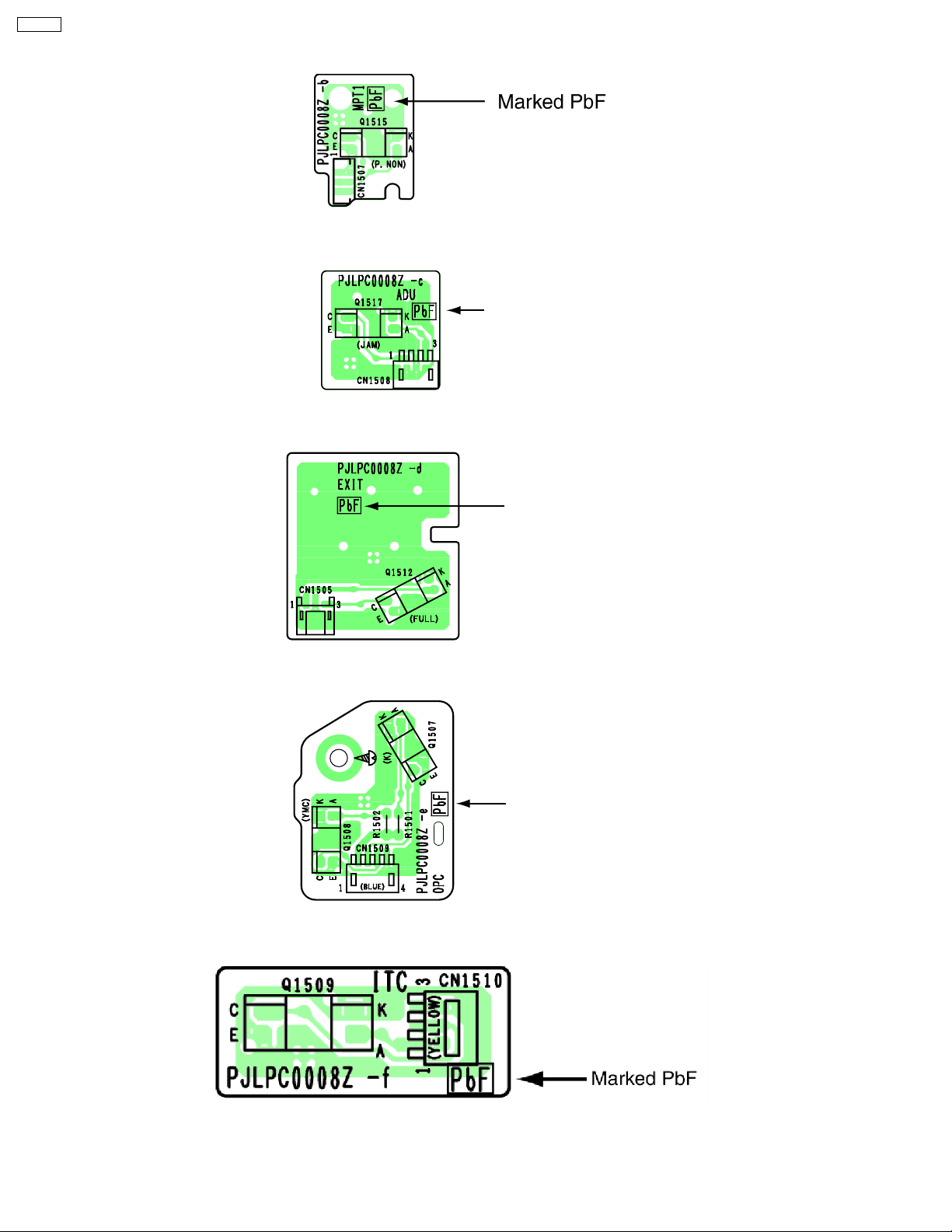

2.2.3. Engine Control Board

Marked PbF

DP-CL18

2.2.4. Paper Empty/Registration Sensor Board

17

Marked PbF

Page 18

DP-CL18

2.2.5. Multi-purpose (MPT) Paper Detection Sensor Board

2.2.6. ADU Jam Detection Sensor Board

Marked PbF

2.2.7. Paper Full Sensor Board

Marked PbF

2.2.8. OPC Cam Home Sensor Board

Marked PbF

2.2.9. Accumulator Cam Home Position Sensor Board

18

Page 19

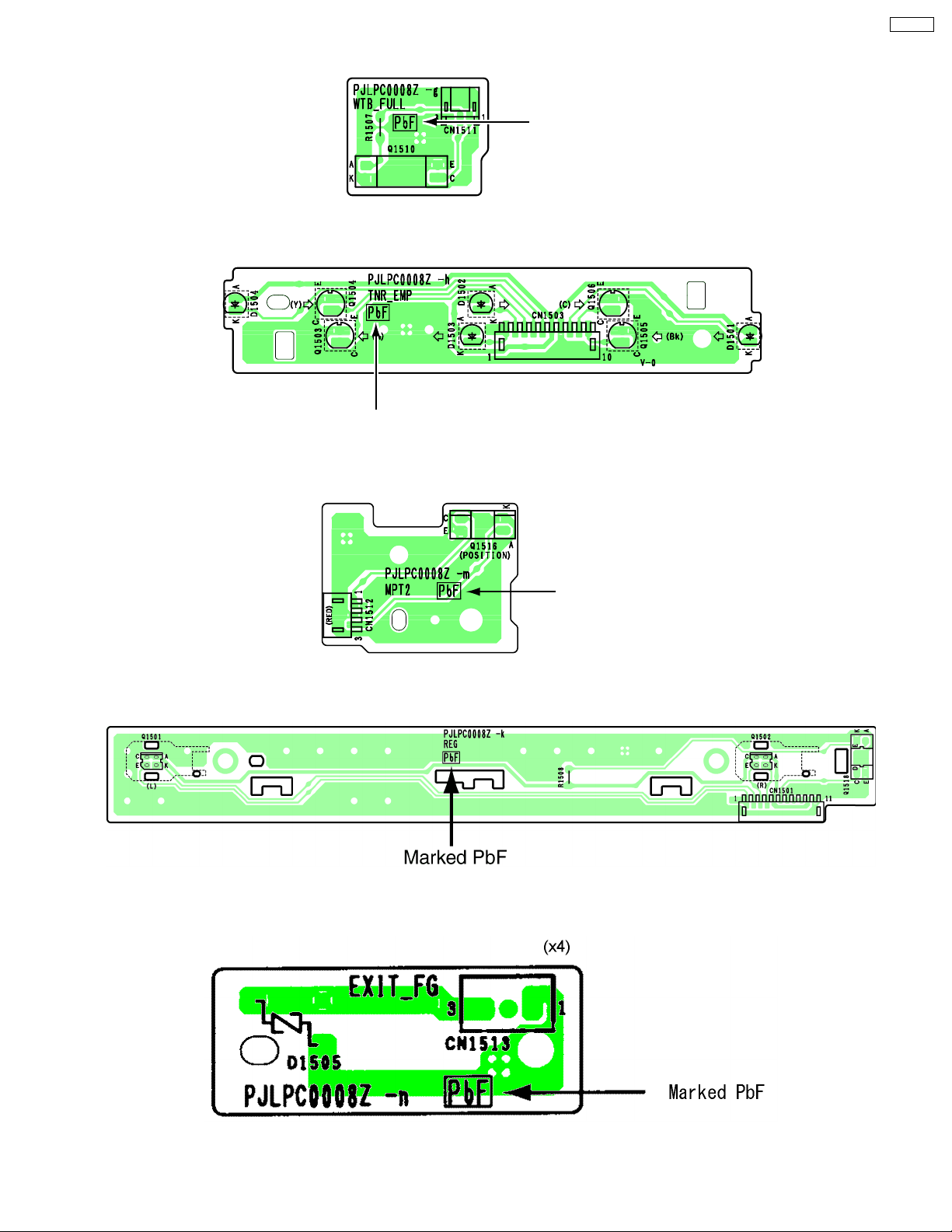

2.2.10. Waste Toner Full Detection Board

Marked PbF

2.2.11. Toner Empty Sensor Board

Marked PbF

2.2.12. Multi-purpose (MPT) Home Position Sensor Board

DP-CL18

2.2.13. Color Registration Sensor Board

2.2.14. Exit FG Board

Marked PbF

19

Page 20

DP-CL18

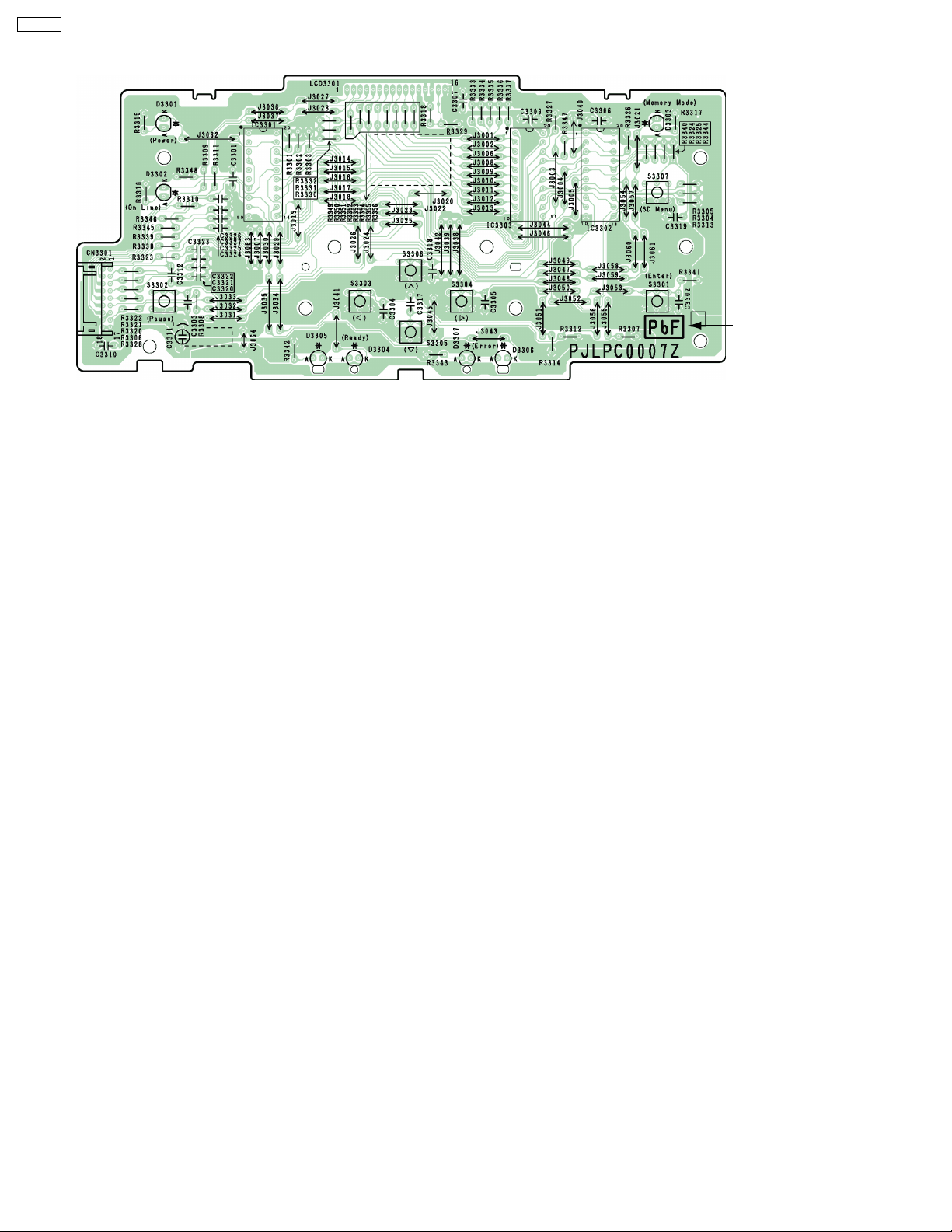

2.2.15. LCD Board

Marked PbF

20

Page 21

3 Installation, Setup, and Repacking

3.1. Installation Requirements

3.1.1. Environment

1. Temperature Range :10 °C - 32.5 °C(50°F - 90.5 °F) (Temperature fluctuation ± 10 °C per hour or less)

2. Humidity Range :20% RH - 80% RH (Humidity fluctuation ± 20 °C per hour or less)

3. Weight : Gross; Approx. 33 kg (72.77 lbs.), Net; Approx. 30 kg (66.15 lbs) excluding packing material

4. Place the unit on a stable, level surface.

5. Do not install the unit under the following conditions.

a. Extremely high or low temperature

b. Extremely high or low humidity

c. Direct exposure to sunlight

d. Areas of high dust concentration

e. Areas of poor ventilation

f. Areas exposed to chemical fumes

g. Areas with extreme vibration

h. Directly in air conditioning flow

DP-CL18

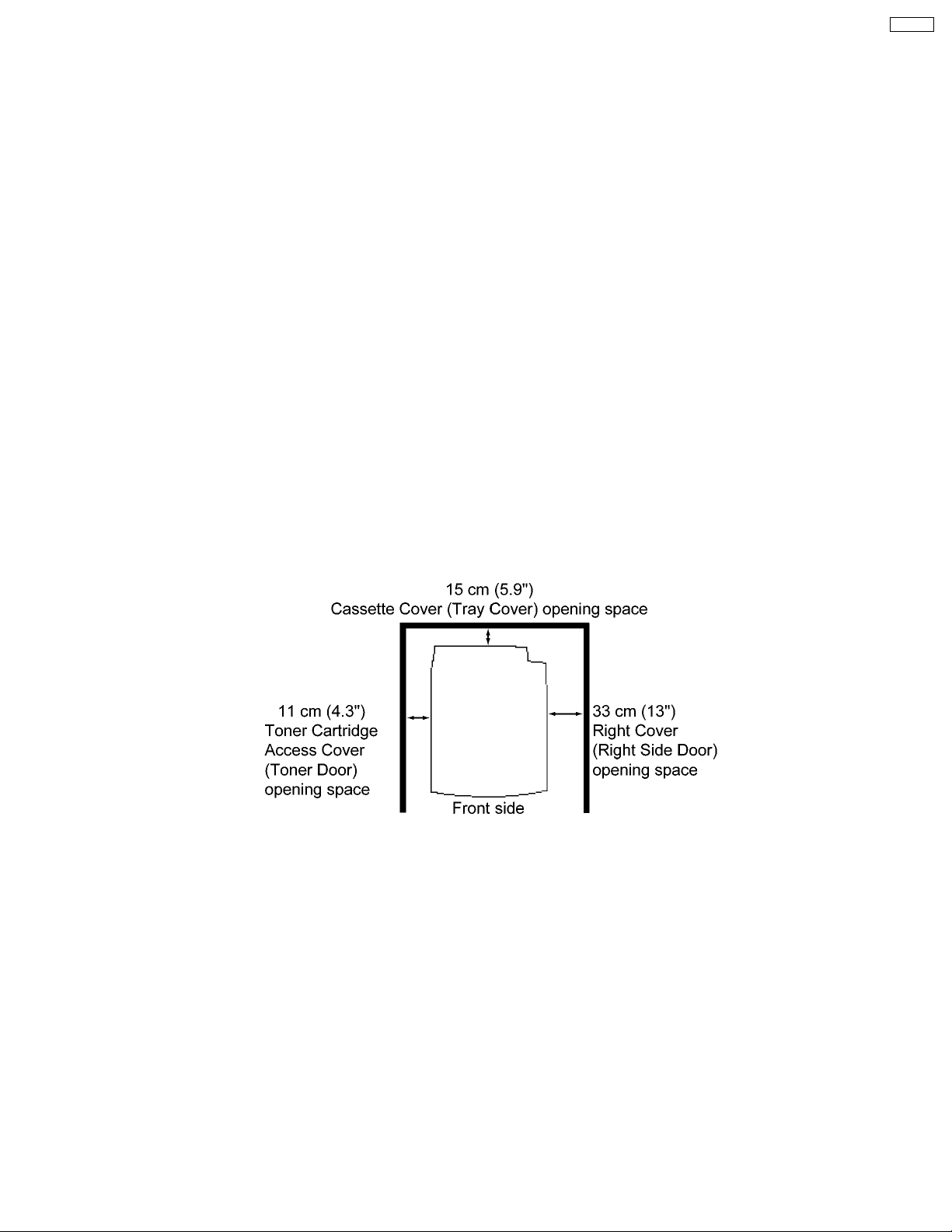

3.1.2. Minimum Space Requirements

1. Right : 33 cm (13")

2. Left : 11 cm (4.3")

3. Rear : 15 cm (5.9")

Note:

When you install a consumable component or replace it with a new one, additional space may be required.

21

Page 22

DP-CL18

3.2. Setup

3.2.1. Removing the Packing Material

1. Remove the plastic bag from the printer.

2. Remove any adhesive tape.

Note:

Please do not throw away the packing materials. They may be required to ship or transport the printer. To provide optimum print

quality, the unit must be kept upright and level at all times.

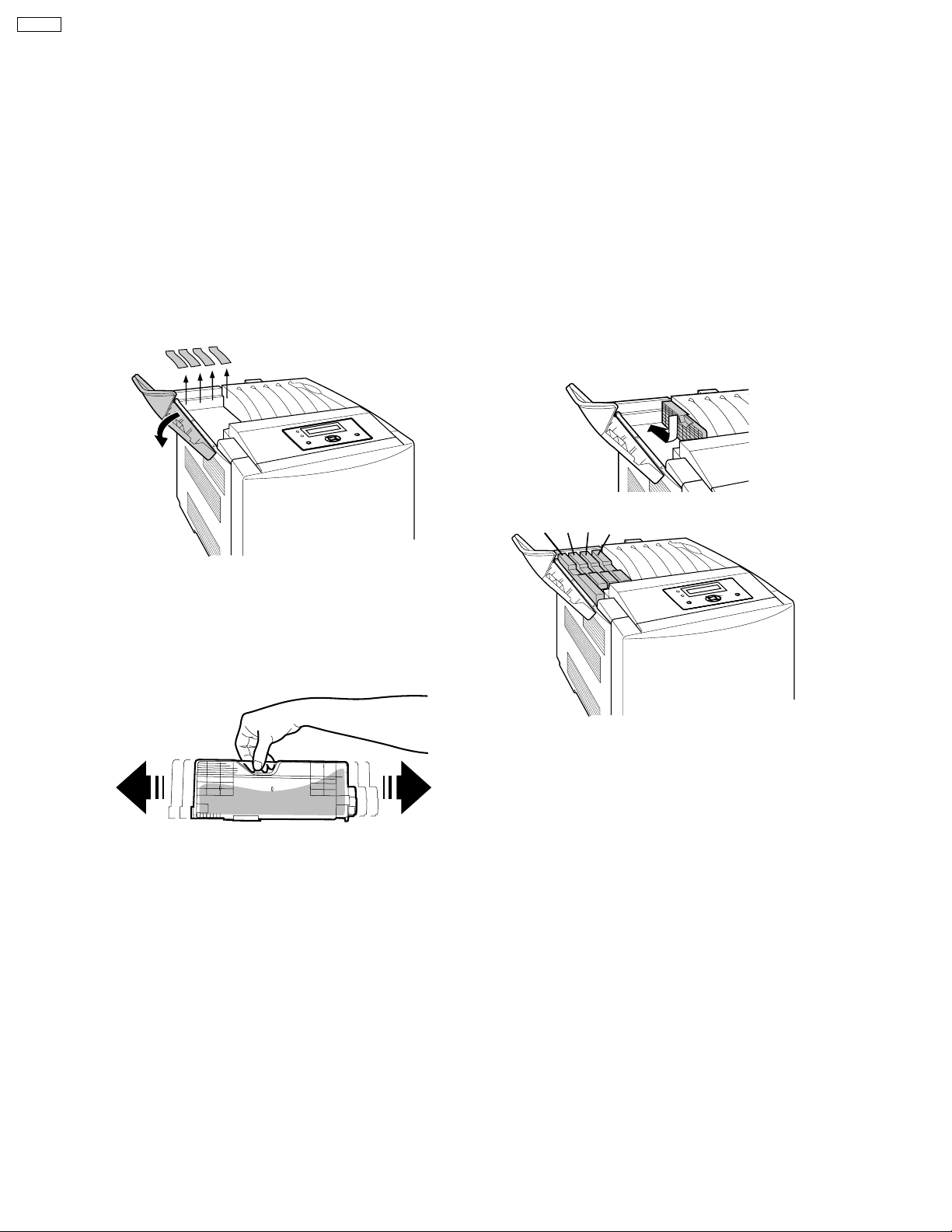

3.2.2. Installing the Toner Cartridge

1.Open the toner cartridge access cover

( toner door) and remove the sealing

tapes.

2.Open the plastic bags and take out the

toner cartridges. Shake the toner

cartridges several times.

3.Insert the toner cartridges in the appropriately

labeled slots. From right to left, the order of the

color toner cartridges is Black (1), Cyan (2),

Magenta (3), Yellow (4).

(4) (3) (2) (1)

4.Close the toner cartridge access cover ( toner

door).

22

Page 23

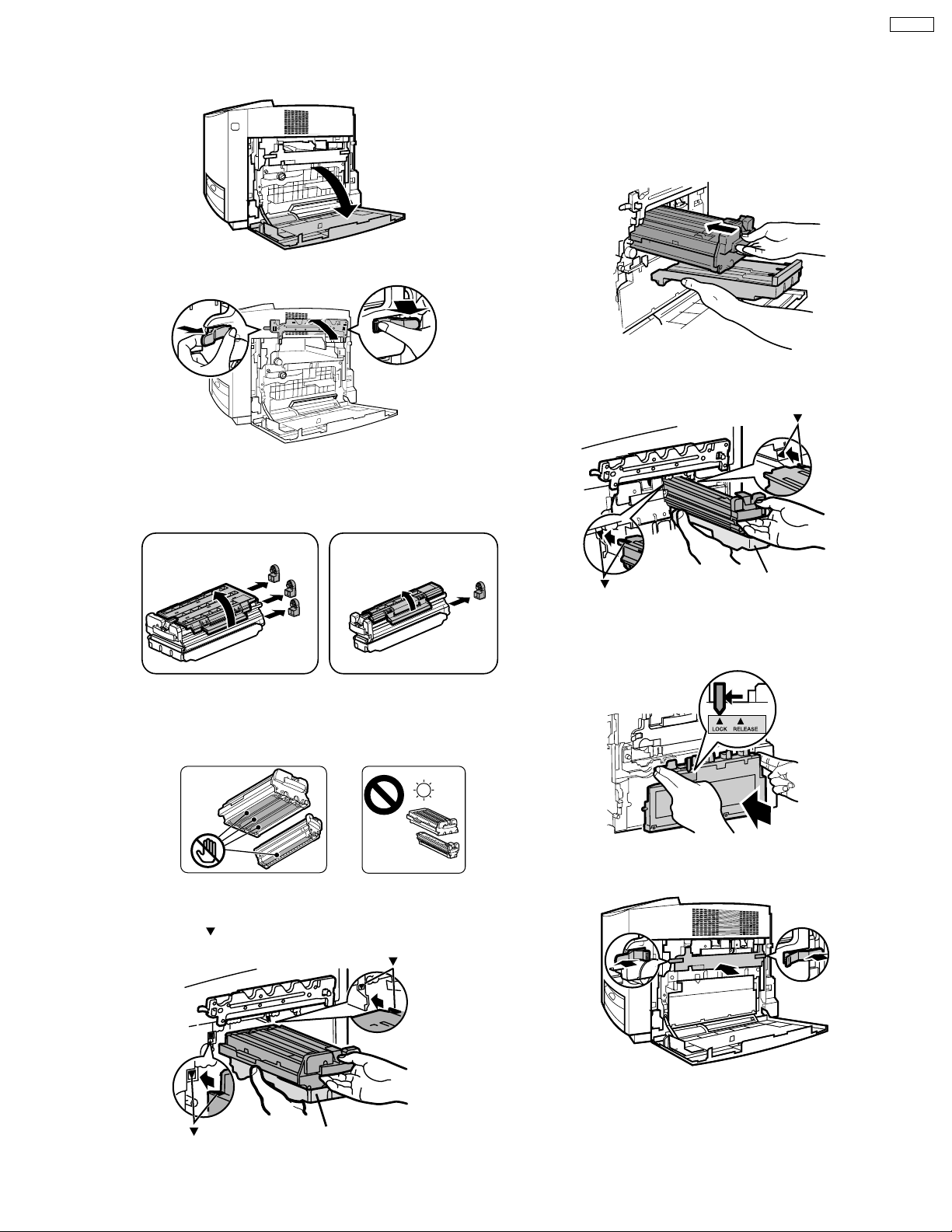

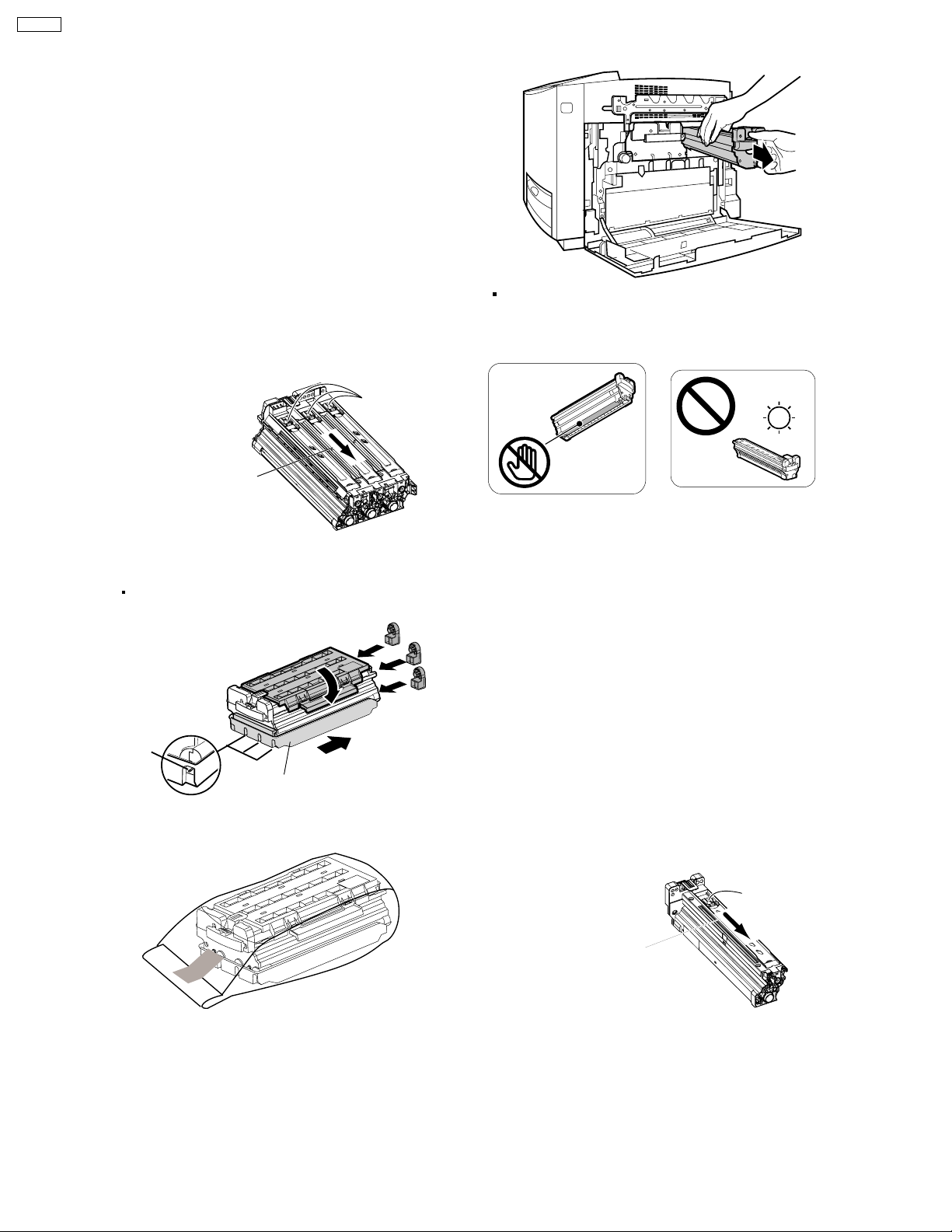

3.2.3. Installing the Print Cartridge

1.Open the right cover (right side door).

2.Unlock and open the print cartridge

holder.

Note:

To prevent damage to the print cartridge,

• Do not touch the green drum surface.

• Do not expose to light for more than 45 sec.

• Do not expose to direct sunlight.

4.Remove the seal covers.

5.Holding the color print cartridge with

the protective tray, match the arrow

marks ( ) then insert the color print

cartridge half way into the printer.

6.Firmly push the color print cartridge

until it snaps into place.

• Store the protective tray, seal covers,

packing materials and cartons for

repacking in future.

10.Close the right side cover (door).

3.Open the plastic bags and take out

the print cartridges.

Black print cartridge

Color print cartridge

Green

drum

Protective tray

( )

( )

7.Repeat steps 4 - 6 for the black print

cartridge.

( )

( )

Protective tray

1

2

9.Close the print cartridge holder until it

clicks (1) and locks it (2).

1

2

2

2

1

2

3

4

21

8.Install the waste toner cartridge (1)

and slide the green lever (2).

DP-CL18

23

Page 24

DP-CL18

3.3. Repacking

Prepare the unit before shipping.

Note:

It is highly recommended that users keep the original carton and All packing materials. Please follow these instructions when

moving the printer.

· Please use the original carton and all of the original packing material.

· Improper repacking of the printer may result in a charge to repair the unit or a cleaning charge to remove spilled toner.

· Since the printer uses dry toner, extreme care must be taken when handling. The printer should be handled in the upright

(vertical) position.

· Original carton and packing materials

· Newspaper or drop cloth

· Shipping tape and scissors

24

Page 25

DP-CL18

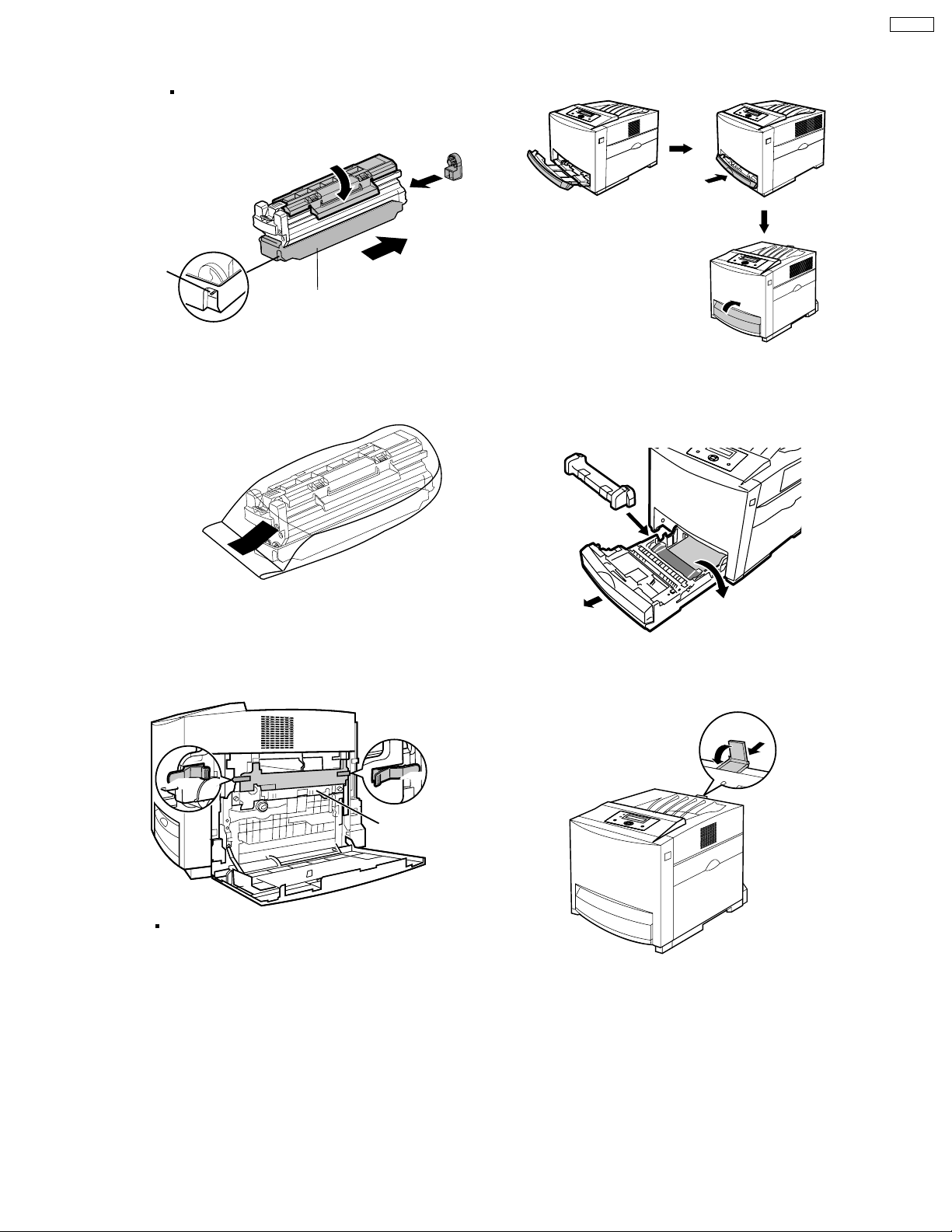

1

Turn off the printer, remove the power code and all

interface cables.

2

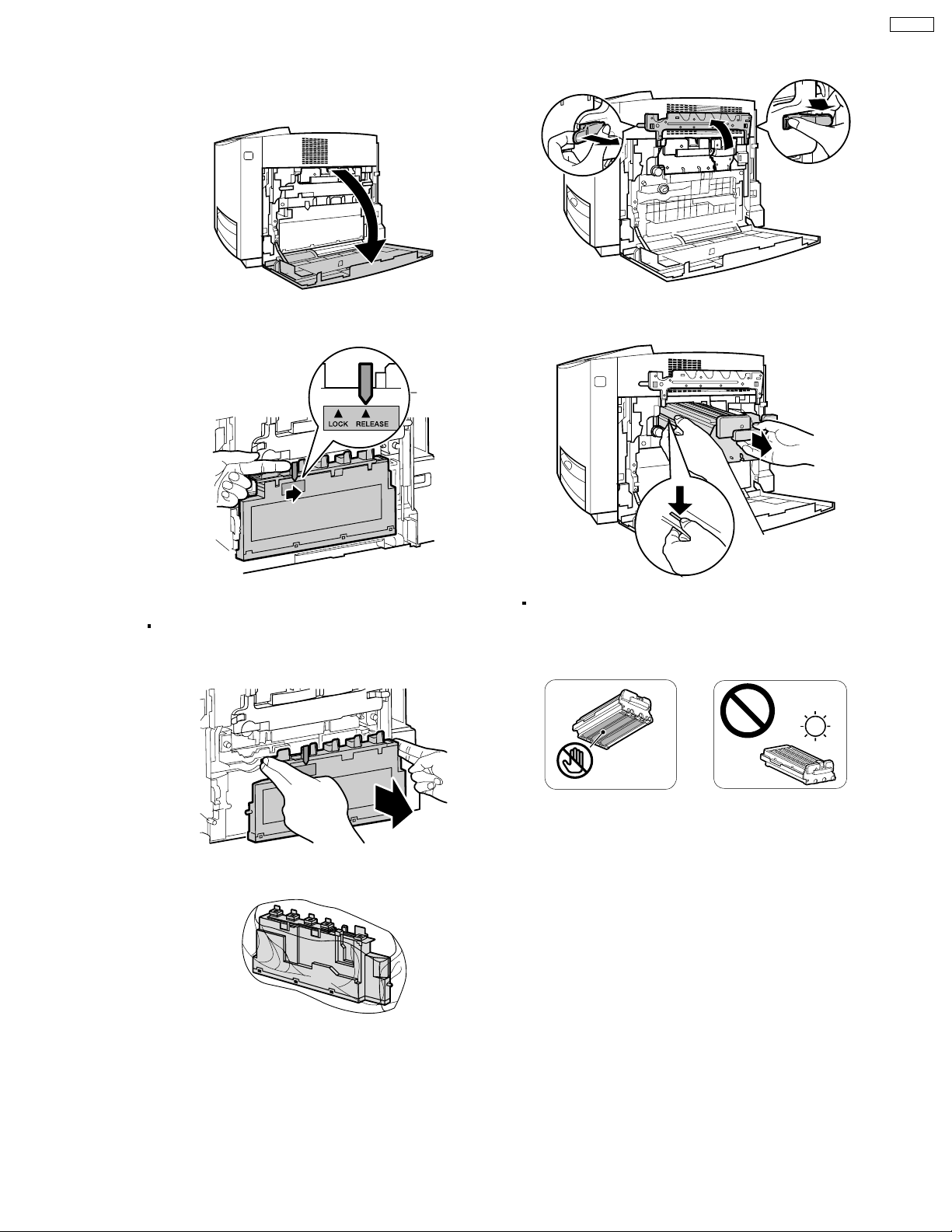

Open the right cover (right side door).

3

Slide the green lever for the waste toner cartridge to

the right (RELEASE).

6

Unlock the two levers (1) and open the print

cartridge holder (2).

1

2

1

7

Pull out the color print cartridge halfway and remove

it (2) while pressing the green stopper (1) on the left

side.

2

1

4

Remove the waste toner cartridge.

Be sure the green lever is in the RELEASE position so

that upper openings to waste toner cartridge are

completely closed.

5

Insert the waste toner cartridge into a plastic bag

and seal the end of the bag tightly.

Note:

To prevent damage to the print cartridge;

- Do not touch the green drum surface.

- Do not expose to light for more than 45 minutes.

- Do not expose to direct sunlight.

25

Page 26

4

DP-CL18

8

Close the PC shutter and wipe off any loose toner on

the color print cartridge using a toner vacuum. Do not

use a standard office vacuum; the toner will not be

retained by typical vacuum dust collectors.

Caution 1:

If replacing the upper seal cover though the

toner is on the color print cartridge, the toner

will be scattered when removing the upper

seal cover. The scattered toner may be

attached to the OPC drum and the poor print

quality will be caused.

Caution 2:

If the print cartridge is wiped using a toner

vacuum when the PC shutter is opening, the

toner in the print cartridge is sucked and

charged. This charge is discharged to the

OPC drum and the OPC drum may be

damaged. Wipe off the toner on the print

cartridge using care that the PC shutter is

not opened.

Move the PC shutter in

this arrow direction to

close the PC shutter.

Replace the protective tray (1), upper seal covers (2-4)

9

and protective caps (5).

Be sure the three sealing levers of the print cartridge

are exposed through the lower seal cover.

PC Shutter

5

Lever

10

Insert the color print car tridge into the black plastic

bag and seal the end of the bag tightly with adhesive

tape.

1

Lower Seal Cover

11

Pull out the black print cartridge.

Note:

To prevent damage to the print cartridge;

- Do not touch the green drum surface.

- Do not expose to light for more than 45 minutes.

- Do not expose to direct sunlight.

12

Close the PC shutter and wipe off any loose toner on

the black print cartridge using a toner vacuum. Do

not use a standard office vacuum; the toner will not

be retained by typical vacuum dust collectors.

Caution 1:

If replacing the upper seal cover though the

2

3

4

Caution 2:

toner is on the black print cartridge, the toner

will be scattered when removing the upper

seal cover. The scattered toner may be

attached to the OPC drum and the poor print

quality will be caused.

If the print cartridge is wiped using a toner

vacuum when the PC shutter is opening, the

toner in the print cartridge is sucked and

charged. This charge is discharged to the

OPC drum and the OPC drum may be

damaged. Wipe off the toner on the print

cartridge using care that the PC shutter is

not opened.

26

PC Shutter

Move the PC shutter in

this arrow direction to

close the PC shutter.

Page 27

DP-CL18

13

Replace the protective tray (1), upper seal cover (2)

and protective cap (3).

Be sure the sealing lever of the print cartridge is

exposed through the lower seal cover .

32

Lever

Lower Seal Cover

14

Insert the black print cartridge into the black plastic

bag and seal the end of the bag tightly with

adhesive tape.

1

16

Remove the media from the multi-purpose tray.

Push the multi-purpose tray (1) and close the tray

cover (2).

1

2

17

Pull the media tray (1) out of the printer. Remove the

media (2) from the media tray and install the tray pad

(3) into the media tray.

15

Close the print cartridge holder [(1)-(2)] and lock it.

Close the right cover (3) (right side door).

11

22

33

Note:

Be sure the accumulator unit is kept in the printer.

22

Accumulator unit

3

1

18

Install the media tray into the printer.

19

Close (1) and insert (2) the paper support into the

printer.

2

1

2

20

Confirm all toner cartr idges are completely installed

in the printer.

27

Page 28

DP-CL18

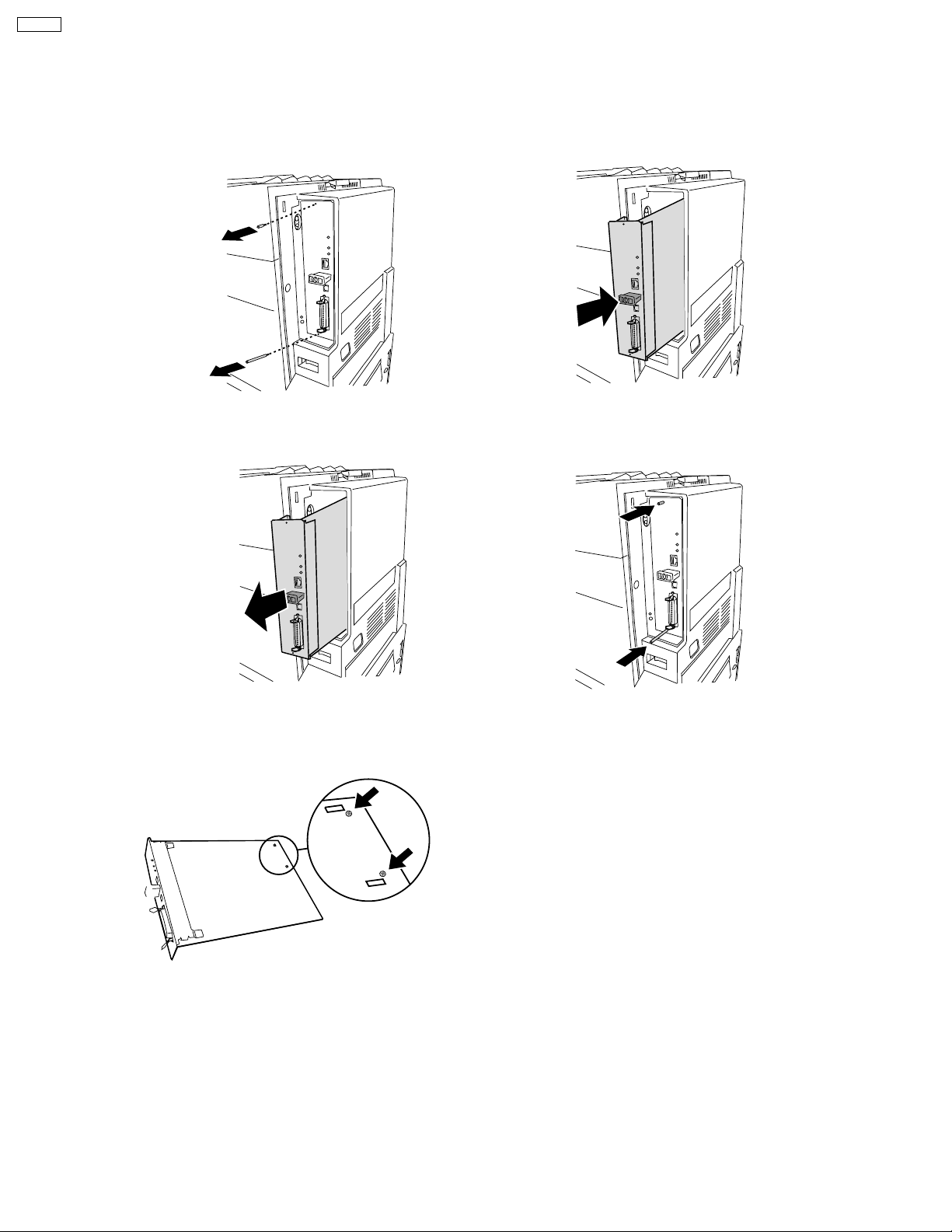

If the hard disk drive option has been installed in the printer, confirm the hard disk

drive is fastened with two screws provided. If it is not installed, proceed to step 26.

21

Remove the two thumb screws from the main

control board.

22

Pull out the main control board while holding the

green handle.

Install the main control board back into the

24

printer, as shown.

Tighten the two thumb screws.25

23

Reconfirm the hard disk drive is fastened with two

screws. If it is not fastened, fasten it with two

screws.

28

Page 29

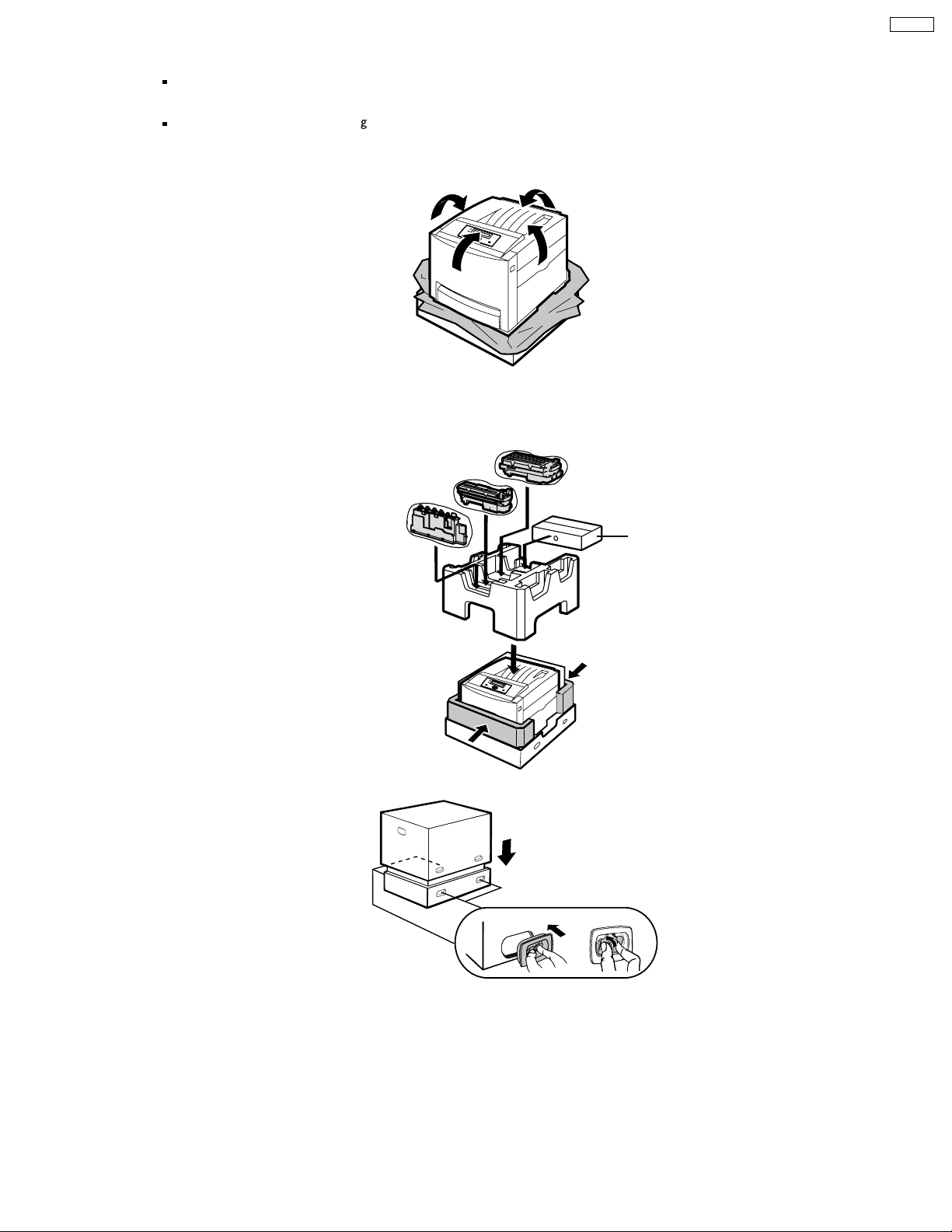

26

Repack the printer in the original shipping box.

Make sure that you keep the printer upright and level when moving.

SAFETY CAUTION

The printer weighs about 30 K (66 lbs.).

It must be handled by two people.

Place the printer in the plastic bag on the lower cushion and wrap the printer with the plastic bag.(1)

(2)

Place the middle on the lower cushion, upper cushion on the printer and middle cushion.

Place the waste toner cartridge, black print cartridge and color print car tridge and accessory box on the

(3)

upper cushion.

Color print cartridge

Black print cartridge

DP-CL18

Waste toner cartridge

Accessory Box

Place the top carton and install the 4 joints.(4)

1

2

3

29

Page 30

DP-CL18

4 User Mode Operation

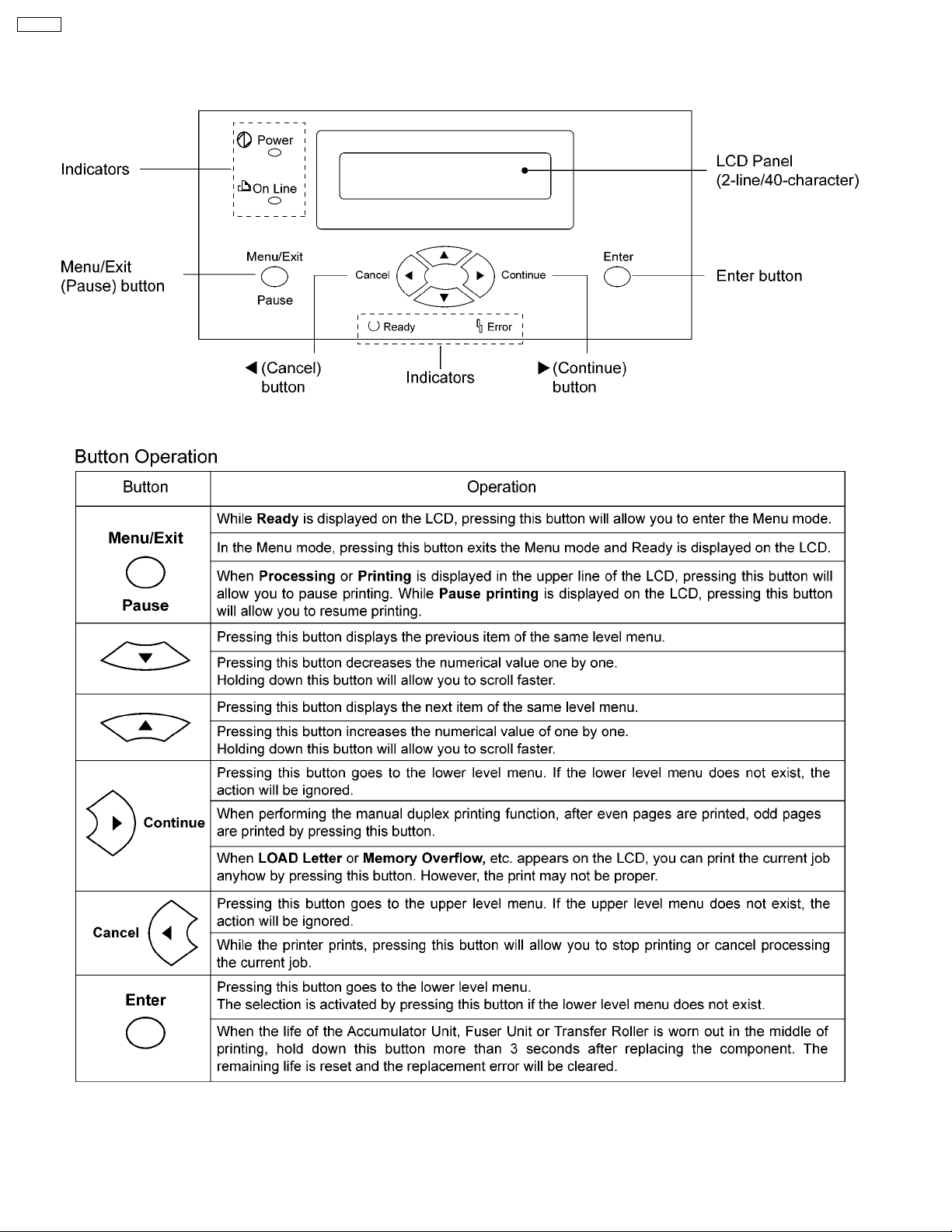

4.1. User Mode Printer Panel Operation

4.1.1. Panel Operation

30

Page 31

4.1.2. LED Indicator

Three indicators show the following printer’s status:

Indicator Printer Status

DP-CL18

On

Blink

Off

Power

Power

Power

On Line

On Line

Ready Error

Ready Error

Printer is turned on.

Printer is in the Power Save mode.

Printer is turned off.

Printer is ready for printing.

(Printer warms up and starts printing automatically

when it receives print data.)

Printer is in the Off Line.

Printer is in the normal condition.

Printer is not in error conditions.

Printer is receiving data, printing or data remains in the memory.

Printer is in the Menu mode.

Ready Error

Ready Error

Printer recoverable errors (media jam, media empty, etc.)

has occurred.

An internal error (Call for Service Error) has occured.

31

Page 32

DP-CL18

4.2. User Mode Main Menu

This section covers the basic operation of this model.

1 Plug in the power cord and connect an interface cable to the laser printer.

2 Turn on the power switch. The LCD displays “Initializing”, then “Ready or Ready (PCM*)”

If the Optional Hard Disk Drive is installed, the LCD displays the “Initializing” and “HDD Accessing” alternately.

3 When Ready or Ready (PCM*) is displayed in the upper line of the LCD, press the Menu/Exit (Pause) button to enter the Menu Mode.

*: Print Count Manager is turned on.

The following chart shows all functions of MENU Mode that are displayed when selecting functions.

32

Page 33

4.3. Check then Print Selection 1 Menu

DP-CL18

33

Page 34

DP-CL18

4.4. Memory Print Item Menu

34

Page 35

4.5. Confidential Print Selection 1 Menu

DP-CL18

35

Page 36

DP-CL18

4.6. System Information Item Menu

36

Page 37

4.7. Color Calibration Item Menu

DP-CL18

37

Page 38

DP-CL18

4.8. Maintenance Item Menu

38

Page 39

4.9. Tray Item Menu

DP-CL18

39

Page 40

DP-CL18

4.9.1. Position Setting Selection 1 Menu

40

Page 41

4.10. Print Item Menu

DP-CL18

41

Page 42

DP-CL18

4.11. PCL Item Menu

42

Page 43

4.12. PostScript Item Menu

DP-CL18

43

Page 44

DP-CL18

4.13. N/W Protocol Setup Item Menu

44

Page 45

DP-CL18

45

Page 46

DP-CL18

4.14. Receive Setting Item Menu

46

Page 47

4.15. Adjust to Media Item Menu

DP-CL18

47

Page 48

DP-CL18

4.16. System Item Menu

4.17. Mono Page Detect Item Menu

48

Page 49

5 HDD Maintenance Mode Operation

5.1. HDD Maintenance Mode Operation

The HDD Maintenance mode has the following functions:

1. Displaying information of printer’s hard disk drive

- Volume Label

- Total Size

-FreeSize

2. Checking the printer’s hard disk drive

3. Formatting the printer’s hard disk drive

- Quick Format: Bad sectors are not checked.

- HDD Format (Physical Format): It will take more time than the Quick Format because bad sectors are checked.

- HDD Deletion:

This feature is used f or disposing of a printer’s hard disk drive for security purposes. All sectors of the hard disk drive will be initialized.

(It will take about 2 hours for 40 GB HDD.)

DP-CL18

The HDD Maintenance Mode is entered by turning on the power while pressing the Continue button until “Initializing...” is

displayed.

49

Page 50

DP-CL18

5.2. HDD Maintenance Mode Menu Table

The following table is shown when a hard disk drive is installed. If it is not installed, “HDD is not Installed” is displayed on the LCD

Panel.

50

Page 51

5.3. HDD Maintenance Mode Main Menu

DP-CL18

51

Page 52

DP-CL18

5.4. HDD Information Item Menu

52

Page 53

5.5. Check Disk Item Menu

DP-CL18

53

Page 54

DP-CL18

5.6. Quick Format Item Menu

54

Page 55

5.7. HDD Format Item Menu

DP-CL18

5.8. HDD Deletion Item Menu

55

Page 56

DP-CL18

6 Service Mode Operation

6.1. Service Mode Control Panel Operation

6.1.1. How to enter the Service Mode

To enter the “Service Mode”, turn on the power while pressing the and buttons at the same time, and keep the pressing

the

the Power Save is off. After warming up, “Service Mode” is displayed in the LCD. This service mode is canceled by turning off the

printer. The printer has a two-line, 40 character LCD (2 x 20 characters). The menus in the following Service Mode flowchart

(sections 6.3 ~ 6.15) are displayed in the lower line.

and buttons until “Initializing” is displayed. The Service Mode will be activated. The Service Mode is accessible when

6.1.2. How to print the Network Configuration Report

Turn on the power while pressing the Enter button and keep the pressing the Enter button until “Initializing...” is displayed. The

Network Configuration Report will be printed. When completing the printing the Network Configuration Report, the printer’s LCD will

display “Ready”. The printing examples are indicated in the section 6.16 “Printing Network Configuration Report”.

56

Page 57

6.2. Service Mode Menu Table

DP-CL18

57

Page 58

DP-CL18

58

Page 59

DP-CL18

59

Page 60

DP-CL18

60

Page 61

DP-CL18

61

Page 62

DP-CL18

62

Page 63

DP-CL18

63

Page 64

DP-CL18

64

Page 65

6.3. Service Main Menu

DP-CL18

65

Page 66

DP-CL18

6.4. Print Report Item Menu

Menu Name Description

Service Report 1 Information regarding JAMs, Service Error Log, etc. is printed.

Service Report 2 Information regarding the life count values of consumable s and basic setting of engine is printed.

Configuration Page General information regarding printer settings or configuration is printed.

NW Config. Page General information regarding the basic setting regarding network configuration is printed.

ENG eeprom Dump Hex Dump of the engine board EEPROM is printed.

CONT eeprom Dump Hex Dump of the main control board EEPROM is printed.

66

Page 67

6.4.1. Printing Example of Service Report 1

The following is an example of what is printed when performing the “Service Report 1” menu.

DP-CL18

67

Page 68

DP-CL18

6.4.2. Printing Example of Service Report 2

The following is an example of what is printed when performing the “Service Report 2” menu.

68

Page 69

6.4.3. Printing Example of Configuration Page

The following is an example of what is printed when performing the “Configuration Page” menu.

DP-CL18

69

Page 70

DP-CL18

70

Page 71

6.4.4. Printing Example of ENG eeprom Dump

DP-CL18

71

Page 72

DP-CL18

6.4.5. Printing Example of CONT eeprom Dump

72

Page 73

6.4.6. Printing Example of NW Config. Page

The following is an example of what is printed when performing the “NW Config. Page” menu.

DP-CL18

73

Page 74

DP-CL18

74

Page 75

6.5. Position Setting Item Menu

Menu Name Description

Top This mode is used to adjust the top print position, primarily when moving the printer, installing the optional paper feeder,

replacing the laser scanning unit or replacing the engine board.

Tray 1 Left This mode is used to adjust the left print position of the printed media loaded in the Tray 1, primarily when moving the printer,

installing the optional paper feeder, replacing the laser scanning unit or replacing the engine board.

Tray 2 Left This mode is used to adjust the left print position of the printed media loaded in the Tray 2, primarily when moving the printer,

installing the optional paper feeder, replacing the laser scanning unit or replacing the engine board.

Tray 3 Left This mode is used to adjust the left print position of the printed media loaded in the Tray 3, primarily when moving the printer,

installing the optional paper feeder, replacing the laser scanning unit or replacing the engine board.

MPT Left This mode is used to adjust the left print position o f the printed media loaded in the multi-purpose tray, primarily when moving

the printer, installing the optional paper feeder, replacing the laser scanning unit or replacing the engine board.

Duplex Left This mode is used to adjust the left print position of the printed media on the back the page, primarily when moving the printer,

installing the optional paper feeder, replacing the laser scanning unit or replacing the engine board.

Test Print The lines to check the top, left and back side left print positions are printed.

DP-CL18

75

Page 76

DP-CL18

6.6. STR Setting Item Menu

The following service menus are used to adjust the toner density for each media (Plain, Thin Paper, Transparency, Label, Coated

Paper, Thick Paper, Card Stock, Envelope, JP Postcard and JP Postcard 2nd).

76

Page 77

6.7. DEV. Bias Item Menu

The following service menus are used to adjust the toner density for all color toner (Cyan, Magenta, Yellow, Black).

DP-CL18

77

Page 78

DP-CL18

6.8. FSR Temp. Setting Item Menu

The following service menus are used to adjust the fusing temperature for each media (Plain, Thin, Transparency, Label, Coated

Paper, Thick, Card, Envelope, JP Postcard and JP Postcard 2nd.)

78

Page 79

6.9. Maintenance Item Menu

Menu Name Description

New TC-C? Cyan Toner Cartridge counter is reset.

New TC-M? Magenta Toner Cartridge counter is reset.

New TC-Y? Yellow Toner Cartridge counter is reset.

New TC-K? Black Toner Cartridge counter is reset.

New AU? Accumulator Unit counter is reset.

New TR? Second Transfer Roller counter is reset

New FSR? Fuser Unit counter is reset.

Error Counter Clr All counters, printed by the Print Report in the service mode, are reset.

JAM Error Log Clr All JAM Error Logs, printed by the Print Report in the service mode, are reset.

Service Err.Log Clr All Service Error Logs, printed by the Print Report in the service mode, are reset.

DP-CL18

79

Page 80

DP-CL18

6.10. ENG Serial Number Item Menu

The Engine Serial Number (eleven figures) is input using this menu.

80

Page 81

6.11. Controller Setting Item Menu

Menu Name Description

Country Application area/country is set.

Print Format Default Paper Size is set.

Language Default Language is set.

PCL Symbol Set Default Symbol Set is set.

Power Save Level Default Power Save Level is set.

DP-CL18

81

Page 82

DP-CL18

6.12. Panel Test Item Menu

This menu is used to check the LCD. Select the “Panel Test “and press the Enter button. Confirm that the LCD messages/patterns

shown in the following table are displayed.

82

Page 83

6.13. Engine Test Item Menu

DP-CL18

83

Page 84

DP-CL18

6.13.1. Solenoid TEST

84

Page 85

6.13.2. Regist Clutch TEST

DP-CL18

85

Page 86

DP-CL18

6.13.3. Motor TEST

86

Page 87

6.13.4. Paper Detect Sensor TEST

DP-CL18

87

Page 88

DP-CL18

6.13.5. Cassette Sensor Test

88

Page 89

6.13.6. Temp & Humidity Sensor

DP-CL18

89

Page 90

DP-CL18

6.13.7. WTC & Toner Sensor

90

Page 91

6.13.8. Door Sensor

DP-CL18

91

Page 92

DP-CL18

6.13.9. Other Sensor

92

Page 93

6.14. Color Correction Item Menu

DP-CL18

6.15. Flag Setting Item Menu

If “Yes” is selected on this menu, the printer will be filled with toner about 5 minutes after turning on the printer the next time.

93

Page 94

DP-CL18

6.16. Printing Network Configuration Report

The following is an example of what is printed when performing the Printing Network Configuration Report (refer to the section 6.1.2

“How to print the Network Configuration Report”.).

94

Page 95

7 Mechanical Function

7.1. Drive Mechanism General Description

DP-CL18

Three motors (CMY motor, BK motor, paper pickup motor)

supply drive to each mechanical block within the engine. The

CMY motor (DC servomotor) supplies drive to the color print

cartridge (CMY PC). The BK motor (DC servomotor) supplies

drive to the black print cartridge (Black PC), four color toner

cartridges, accumulator unit (Acc Unit or AU), accumulator

tension unit (ATU), paper feed unit and fuser unit.

The paper pickup motor (stepping motor) supplies drive to the

multi-purpose paper feeder and option Auto Duplex Unit (ADU).

95

Page 96

DP-CL18

7.1.1. CMY Motor Rotation Travel

Cyan Print Cartridge (Developer)

Magenta Print Cartridge (OPC)

Magenta Print Cartridge (Developer)

Yellow Print Cartridge (OPC)

Yellow Print Cartridge (Developer)

(CMY Motor Rotation Travel)

Cyan Print Cartridge (OPC)

(5)

(4)

(3)

(2)

(9)

(1)

(8)

(12)

(11)

(10)

(7)

(6)

(14)

(13)

CMY Motor

The CMY Motor Rotation is transmitted in the following number order :

(2)

(1)

(3) (4) (5)

(7)

(8) (9)

(6)

To Yellow Print Cartridge (Developer)

To Yellow Print Cartridge (OPC)

To Magenta Print Cartridge (Developer)

To Magenta Print Cartridge (OPC)

(10)

(11) (12) (13)

96

(14)

To Cyan Print Cartridge (Developer)

To Cyan Print Cartridge (OPC)

Page 97

7.1.2. BK Motor Rotation Travel

The Motor Rotation is transmitted to the Toner Cartridge

Holder Unit through this gear.

The Motor Rotation is transmitted to the Black Print Cartridge

(Developer) through this gear.

The Motor Rotation is transmitted to the Black Print Cartridge

(OPC) through this gear.

The Motor Rotation is transmitted to the

fuser through this gear.

(BK Motor Rotation Travel)

The Motor Rotation is

transmitted to the Toner

Cartridge Drive Unit through

this gear.

BK Changer Gear

with Solenoid

(15)

(14)

DP-CL18

(12)

(13)

(25)

(26)

The Motor Rotation is transmitted to

the Accumulator Tension Unit and

Paper Feed Unit through this gear .

(23)

(24)

(27)

(16)

(22)

(1)

(17)

(18)

(5)

(3)

(2)

BK Motor Gear

(BK Changer Gear Solenoid)

The BK Motor Rotation is transmitted in order the following numbers :

The rotation transmission to the black print cartridge

is controlled by the BK Changer Gear Solenoid.

When the BK Changer Gear Solenoid is turned on,

the BK clutch arm is unlatched from the Gear (A). As

a result, the BK motor rotation is not transmitted from

(18) to (19) ~ (21) and black print cartridge.

Gear (A)

(21)

(19)

(4)

(20)

(11)

(10)

(9)

(8)

(6)

(7)

The Motor Rotation is

transmitted to the

Accumulator Unit through

this gear.

21

20

19

18

(1)

(16)

(2)

(17) (18) (19) (20) (21)

(3)

(4) (5) (6) (7)

(8)

(9) (10) (11)

(25)

(22) (23) (24)

(26)

97

BK Changer

Gear Solenoid

(12)

(14)

(27)

BK Clutch Arm

To Black Print Cartridge (Developer)

To Black Print Cartridge (OPC)

To Accumulator Unit

(13)

(15)

To Toner Cartridge Drive Unit

To Toner Cartridge Holder Unit

To Fuser Unit

To Accumulator Tension Unit

and Paper Feed Unit

Page 98

DP-CL18

7.2. Accumulator Tension Unit (ATU) Drive Mechanism

The accumulator tension unit is for operating the function of

accumulator unit and depositing waste toner in the waste toner

cartridge.

The accumulator unit consists of “ATU Drive Clutch”, “Taking

Figure-1

STR

(Second T r ansfer Roller)

up accumulator belt slack”, “Contacting STR Roller to

Accumulator Belt”, “Selecting of FTR Roller”, “lifting up FTR

Roller” and “Waste Toner Cartridge Stirring” mechanisms.

(4)

Acc. Unit

(Accumulator Unit)

(1)

(5)

(3)

(5)

(6)

ATU

(Accumulator Tension Unit)

(1) ATU Drive Clutch

(2) Taking up Accumulator Belt Slack

(3) Contacting STR Roller to Accumulator Belt

(4) Lifting up FTR Roller

(5) Selecting of FTR Roller

(6) Waste Toner Cartridge Stirring

(2)

98

Page 99

7.2.1. ATU Drive Clutch

The ATU drive clutch is used to turn on and off the rotation from the BK motor to the cam shaft. See the following figure-1. The ATU

drive clutch consists of the cam ratchet, cam ratchet wheel, cam ratchet wheel gear, 4 planetary gears and accumulator cam

switching solenoid. The rotation from the BK motor is transmitted to the cam ratchet wheel or cam ratchet wheel gear through the

double teeth gear and 4 planetary gears.

In standby mode, the cam ratchet wheel cannot rotate because hook (A) of the cam ratchet engages with the detent of the cam

ratchet wheel, and the cam ratchet wheel gear is free to rotate because the hook (B) is not engaged with the teeth of the cam

ratchet wheel gear. With this mechanism, the rotation from the BK motor is transmitted to the cam ratchet wheel gear and rotates

in the arrow (C) direction.

When the accumulator switching solenoid is turned on for a predetermined time (150 ~ 200 msec) to perform the printing process,

the hook (B) moves in the arrow (B) direction and is engaged with the teeth of cam ratchet wheel gear. The rotation of the cam

ratchet wheel gear is stopped, then the hook (A) moves in the arrow (A) direction and is released from the detent of the cam ratchet

wheel. As a result, the cam ratchet wheel is free and the cam ratchet wheel is rotated in the arrow (D) by the rotation transmitted

from the BK motor through the double teeth gear and 4 planetary gears. After this, the hook (A) engages with the detent (B) and

the cam ratchet wheel is locked by hook (A). The rotation from the BK motor is transmitted to the cam ratchet wheel gear and is

not transmitted to the cam shaft.

DP-CL18

After hook (A) engages detent (C) and detent (D) the same way, hook (A) engages detent (A) again.

99

Page 100

DP-CL18

There are 4 statuses of the accumulator tension unit for controlling the printing process. These 4 statuses are set by the 4 detents

of the cam ratchet wheel.

· Accumulator Belt Cleaning Position:

When the hook (A) engages with the detent (B), the slack in the accumulator belt is taken up by the “Accumulator belt slack”

mechanism. The cleaning of the accumulator belt is done.

· Toner Transfer Position:

When the hook (A) engages with the detent (C), the FTR roller(s) is (are) raised and come in contact with the accumulator belt

by the “Lift FTR Roller” mechanism for transferring the toner from the OPC drum to the accumulator belt, and the STR roller is

engaged with the accumulator belt by the “STR Roller to Accumulator Belt” mechanism for transferring the toner to the paper.

· FTR Roller Release Position:

When the hook (A) engages with the detent (D), the FTR bias roller(s) is (are) released from the accumulator belt by the “Lift

FTR Roller” mechanism.

· Home Position:

When the hook (A) engages with the detent (A), the tension is released in the accumulator belt and the STR roller is removed

from the accumulator belt.

The accumulator cam home position sensor and sensor tab are for detecting whether the status of the accumulator tension unit is

shifted from one position to next within predetermined time or not. if the status of the accumulator tension unit is not shifted to the

next position within the predetermined time, Error Message “Printer Error 24” is displayed on the LCD display. The following chart

figure-4 indicates the relation between the sensor tab and accumulator cam home position sensor at each position.

100

Loading...

Loading...