Page 1

be certain.

m

Series 215 Rotary Actuator

Product Information

011-199-001 C

Page 2

Copyright information © 1996, 2000, 2008 MTS Systems Corporation. All rights reserved.

Trademark information MTS is a registered trademark of MTS Systems Corporation within the United

States. This trademark may be protected in other countries.

DTE is a registered trademark of Mobil Corporation.

Tellus is a registered trademark of Shell Oil Corporation.

Molykote is a registered trademark of Dow Chemical Corporation.

Publication information

Manual Part Number Publication Date

011-199-001 A

011-199-001 B

011-199-001 C

April 1996

June 2000

March 2008

2

Manual Template 4.3

Page 3

Contents

Technical Support 5

How to Get Technical Support 5

Before You Contact MTS 5

If You Contact MTS by Phone 6

Problem Submittal Form in MTS Manuals 7

Preface 9

Before You Begin 9

Conventions 10

Documentation Conventions 10

Introduction 13

Functional Description 13

Optional Equipment 13

Closed-Loop Rotary Actuator Systems 15

Actuator Specifications 16

Options Specifications 19

Reaction Brackets 22

Reaction Bases 23

Diaphragm Flexures 24

Flange Adapters 25

Safety Information 27

Hazard Placard Placement 27

Series 215 Rotary Actuator Product Manual

3

Page 4

Installation 31

Actuator Installation 32

Reaction Bracket and Torque Cell Installation 32

Diaphragm Flexure Installation 34

Aligning Force Train Components 34

Component Alignment on an MTS Base Plate 35

Component Centerline Alignment 35

Adjusting Actuator and Torque Cell Centerline Height 35

Adjusting Actuator and Torque Cell Concentricity 36

Adjusting Actuator and Torque Cell Centerline Angularity 37

Operation 39

Thrust and Side Load Characteristics 39

Definition of Useful Mathematical Terms 40

Test Setup Using No Flexures 42

Test Setup Using Standard Flexures 46

Test Setup Using Diaphragm Flexures 50

Summary of Side Load Calculations 54

Rotational Inertial 57

Determining Maximum Rotational Inertia (JT) 57

Rotational Inertia Control Options 60

Maintenance 61

Routine Maintenance 61

Actuator Performance Checks 61

Actuator Inspection 64

4

Series 215 Rotary Actuator Product Manual

Page 5

Technical Support

How to Get Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

MTS web site

www.mts.com

E-mail techsupport@mts.com

Telephone MTS Call Center 800-328-2255

Fax 952-937-4515

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes MTS software, look

for online help and README files that contain additional product information.

If you cannot find answers to your technical questions from these sources, you

can use the internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact MTS in one of the

following ways.

The MTS web site gives you access to our technical support staff by means of a

Technical Support link:

www.mts.com > Contact Us > Service & Technical Support

Weekdays 7:00 A.M. to 5:00 P.M., Central Time

Please include “Technical Support” in the subject line.

Before You Contact MTS

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your site

number and system

number

Series 215 Rotary Actuator Product Manual Technical Support

The site number contains your company number and identifies your equipment

type (material testing, simulation, and so forth). The number is usually written on

a label on your MTS equipment before the system leaves MTS. If you do not

have or do not know your MTS site number, contact your MTS sales engineer.

Example site number: 571167

When you have more than one MTS system, the system job number identifies

which system you are calling about. You can find your job number in the papers

sent to you when you ordered your system.

Example system number: US1.42460

5

Page 6

If You Contact MTS by Phone

Know information from

prior technical

If you have contacted MTS about this problem before, we can recall your file.

You will need to tell us the:

assistance

• MTS notification number

• Name of the person who helped you

Identify the problem Describe the problem you are experiencing and know the answers to the

following questions:

• How long and how often has the problem been occurring?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

• What are the model numbers of the suspect equipment?

• What model controller are you using (if applicable)?

• What test configuration are you using?

Know relevant

computer information

If you are experiencing a computer problem, have the following information

available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive in which the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

Know relevant

For software application problems, have the following information available:

software information

• The software application’s name, version number, build number, and if

available, software patch number. This information is displayed briefly

when you launch the application, and can typically be found in the “About”

selection in the “Help” menu.

• It is also helpful if the names of other non-MTS applications that are

running on your computer, such as anti-virus software, screen savers,

keyboard enhancers, print spoolers, and so forth are known and available.

If You Contact MTS by Phone

Your call will be registered by a Call Center agent if you are calling within the

United States or Canada. Before connecting you with a technical support

specialist, the agent will ask you for your site number, name, company, company

address, and the phone number where you can normally be reached.

Technical Support

6

Series 215 Rotary Actuator Product Manual

Page 7

Problem Submittal Form in MTS Manuals

If you are calling about an issue that has already been assigned a notification

number, please provide that number. You will be assigned a unique notification

number about any new issue.

Identify system type To assist the Call Center agent with connecting you to the most qualified

technical support specialist available, identify your system as one of the

following types:

• Electromechanical materials test system

• Hydromechanical materials test system

• Vehicle test system

• Vehicle component test system

• Aero test system

Be prepared to

Prepare yourself for troubleshooting while on the phone:

troubleshoot

• Call from a telephone when you are close to the system so that you can try

implementing suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

Write down relevant

Prepare yourself in case we need to call you back:

information

• Remember to ask for the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions to be followed, such as data recording

or performance monitoring.

After you call MTS logs and tracks all calls to ensure that you receive assistance and that action

is taken regarding your problem or request. If you have questions about the status

of your problem or have additional information to report, please contact MTS

again and provide your original notification number.

Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems you are experiencing

with your MTS software, hardware, manuals, or service which have not been

resolved to your satisfaction through the technical support process. This form

includes check boxes that allow you to indicate the urgency of your problem and

your expectation of an acceptable response time. We guarantee a timely

response—your feedback is important to us.

The Problem Submittal Form can be accessed:

• In the back of many MTS manuals (postage paid form to be mailed to MTS)

• www.mts.com > Contact Us > Problem Submittal Form (electronic form to

be e-mailed to MTS)

Series 215 Rotary Actuator Product Manual Technical Support

7

Page 8

Problem Submittal Form in MTS Manuals

Technical Support

8

Series 215 Rotary Actuator Product Manual

Page 9

Before You Begin

Preface

Before You Begin

Safety first! Before you attempt to use your MTS product or system, read and understand the

Safety manual and any other safety information provided with your system.

Improper installation, operation, or maintenance of MTS equipment in your test

facility can result in hazardous conditions that can cause severe personal injury or

death and damage to your equipment and specimen. Again, read and understand

the safety information provided with your system before you continue. It is very

important that you remain aware of hazards that apply to your system.

Other MTS manuals In addition to this manual, you may receive additional MTS manuals in paper or

electronic form.

If you have purchased a test system, it may include an MTS System

Documentation CD. This CD contains an electronic copy of the MTS manuals

that pertain to your test system, including hydraulic and mechanical component

manuals, assembly drawings and parts lists, and operation and preventive

maintenance manuals. Controller and application software manuals are typically

included on the software CD distribution disc(s).

Series 215 Rotary Actuator Product Manual Preface

9

Page 10

Conventions

DANGER

WARNING

CAUTION

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions As necessary, hazard notices may be embedded in this manual. These notices

contain safety information that is specific to the task to be performed. Hazard

notices immediately precede the step or procedure that may lead to an associated

hazard. Read all hazard notices carefully and follow the directions that are given.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

Note For general safety information, see the safety information provided with

your system.

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury, equipment damage, or

endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Illustrations Illustrations appear in this manual to clarify text. It is important for you to be

Electronic manual

conventions

Preface

10

aware that these illustrations are examples only and do not necessarily represent

your actual system configuration, test application, or software.

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

Series 215 Rotary Actuator Product Manual

Page 11

Documentation Conventions

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers, are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

Series 215 Rotary Actuator Product Manual Preface

11

Page 12

Documentation Conventions

12

Preface

Series 215 Rotary Actuator Product Manual

Page 13

Introduction

Functional Description

Functional Description

MTS Series 215 Rotary Actuators are heavy-duty, torque-generating actuators

that operate under precision servovalve control. When coupled with an

appropriate MTS servovalve and transducer, Series 215 Actuators provide the

rotational motion and torque required to torsion test materials and components.

These actuators receive drive power from a hydraulic power unit via a servovalve

which is manifold-mounted to the top of the actuator.

Series 215 Actuators have a maximum static displacement of 100° or ±50°. The

maximum dynamic displacement is 90˚ or ±45° with hydraulic cushions in the

last 5° of displacement.

Series 215 Rotary Actuator

The preceding figure shows a Series 215 Rotary Actuator with an attached

Servovalve/Servovalve manifold, flange adapter, and foot mounting assembly.

Optional Equipment

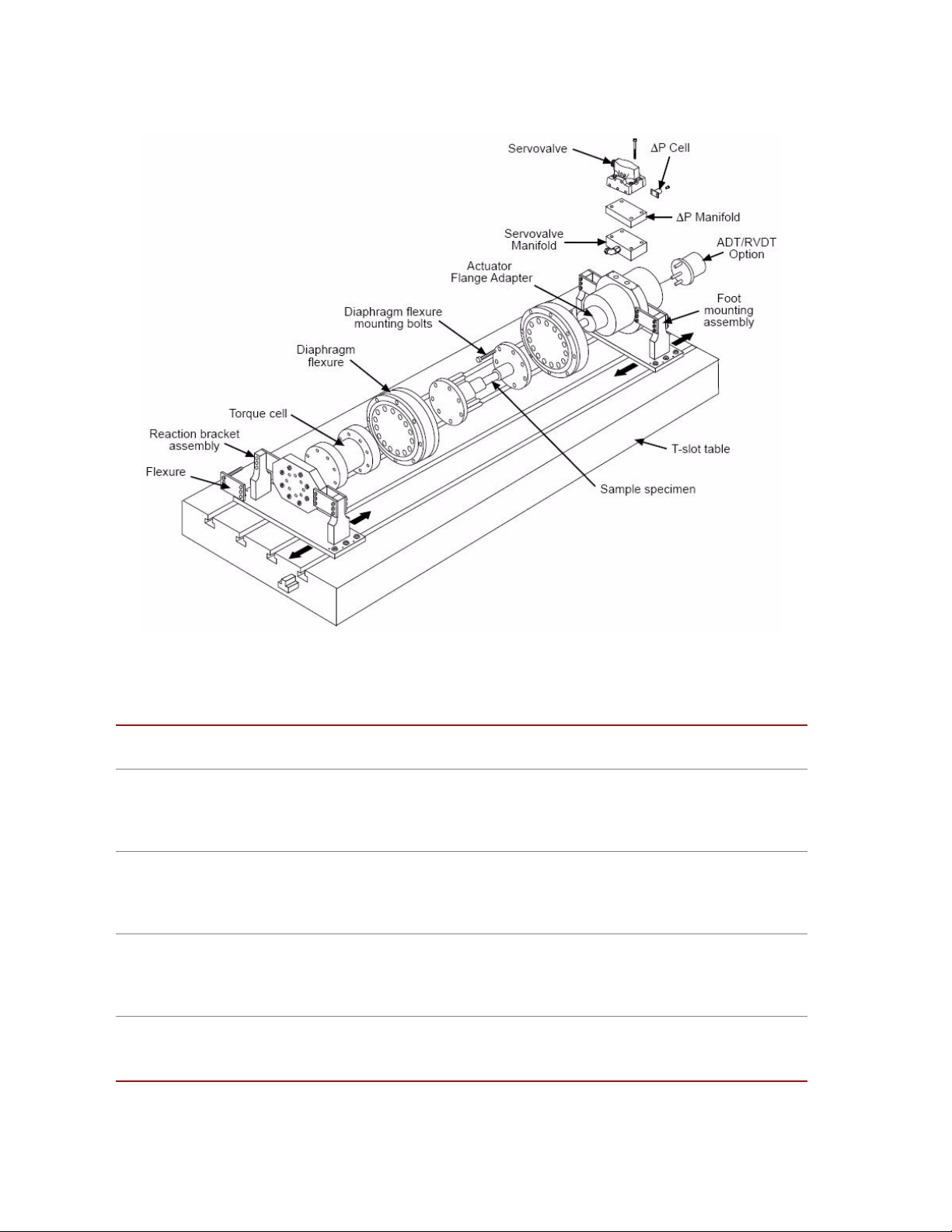

A variety of options are available for the Series 215 Rotary Actuators. The

following figure and table show a test system containing a rotary actuator and the

available optional components.

Series 215 Rotary Actuator Product Manual Introduction

13

Page 14

Optional Equipment

Rotary Actuator Test System with Optional Equipment

Optional Equipment for Series 215 Rotary Actuators

PTION FUNCTION

O

Reaction base plate or

T-slot table

A reaction base plate or T-slot table is used with the rotary actuator for two

purposes; (1) it provides a mounting surface for the actuator and drive train

components; (2) it provides a structure which can react the large forces generated

by the rotary actuator.

Flange adapter

The flange adapter (located behind the diaphragm flexure in the photograph) is

secured to the actuator rotor shaft by a split flange clamp assembly. It provides a

coupling surface between the actuator and specimen adapter plate or diaphragm

flexure.

Diaphragm flexures

Diaphragm flexures should be used at both ends of the specimen if large axial and

angular deflections are generated during testing. If reaction forces exceed stated

actuator operating limits, diaphragm flexures help reduce the thrust and side loads

experienced by the actuator.

Reaction bracket

The reaction bracket attaches securely to the reaction base plate or T-slot table and

provides a mounting surface for the torque cell. Each reaction bracket is designed

to restrain a specific model torque cell.

14

Introduction

Series 215 Rotary Actuator Product Manual

Page 15

Torque cell

Closed-Loop Rotary Actuator Systems

Optional Equipment for Series 215 Rotary Actuators (Continued)

A torque cell provides a precise electrical feedback signal that is proportional to

the torque applied to the specimen. For more information on MTS torque cells,

refer to the appropriate MTS product specification.

ADT

An angular displacement transducer (ADT) connected to the rear shaft of the

actuator produces a DC electrical signal that is proportional to the angular position

of the actuator. Rotation of the actuator will generate a feedback signal

(0 V DC to ±10 V DC) from the ADT to the transducer conditioner. Rotation is

continuous with no reactive torque induced. The ADT is a precision differential

capacitor coupled to a solid state oscillator, demodulator, and amplifier to yield

DC input - DC output performance.

RVDT

A rotary variable differential transformer (RVDT) attached to the rear shaft of the

actuator provides an AC feedback signal proportional to the angular position of

the actuator. As the actuator rotates, a feedback signal is sent to the transducer

conditioner. An RVDT converts a mechanical angular displacement into an

electrical output by means of an electrical input carrier. It consists of a rotor

assembly to which the mechanical input is applied, and a stator assembly in which

the windings are contained.

Differential pressure

cell

The differential pressure (∆P) cell is a single-unit, dual port, bonded strain gage

pressure sensor. Depending on the specific application, the ∆P cell is used to

stabilize or control actuator force output. The ∆P cell (located beneath the

servovalve) provides a feedback signal to a controller monitoring fluid pressure

within the actuator housing. For more information on MTS ∆P cells, refer to the

appropriate MTS product specification.

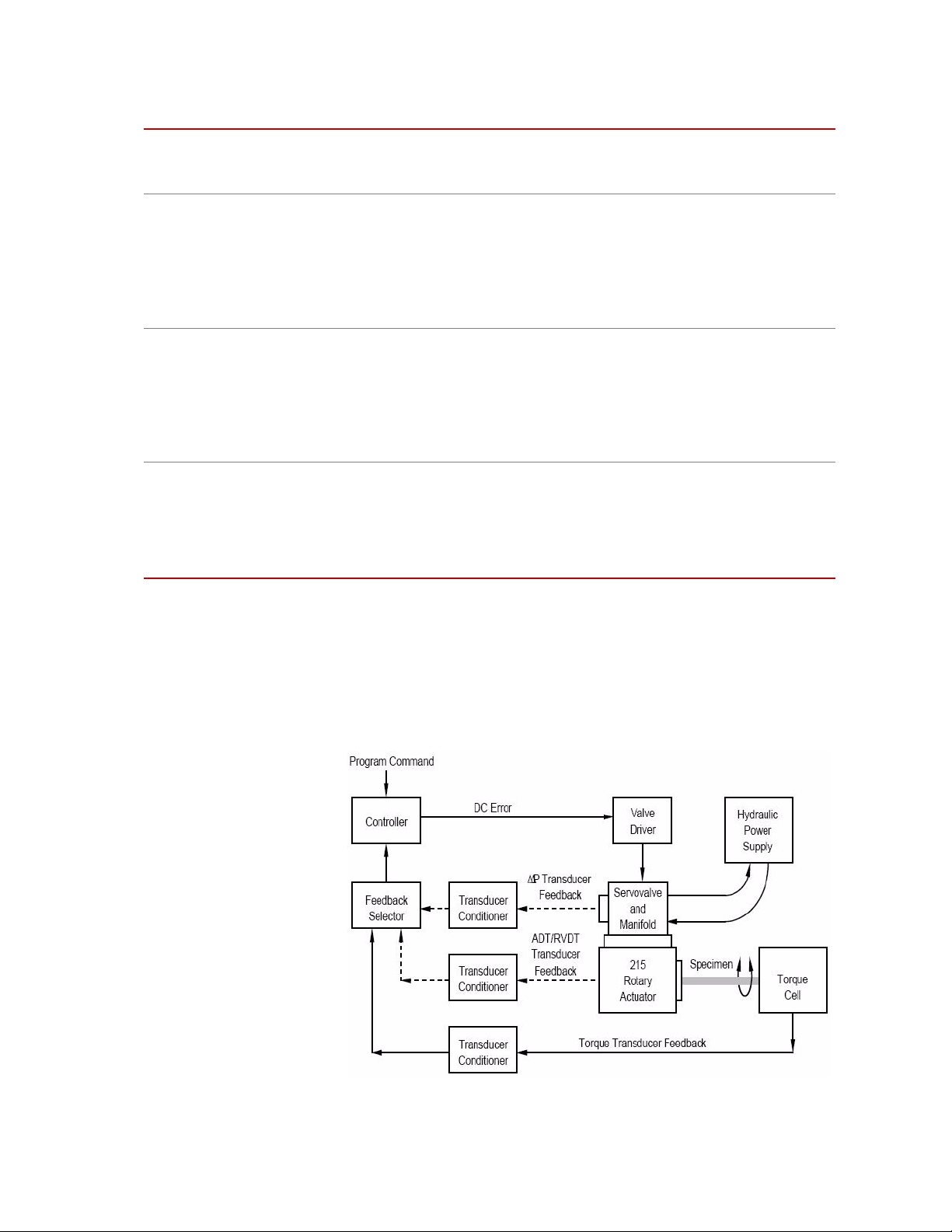

Closed-Loop Rotary Actuator Systems

In a closed-loop control system containing a rotary actuator, a command signal

sent to the actuator servovalve is compared to a feedback signal received from an

actuator transducer. The following figure shows a block diagram of the major

components in a typical rotary actuator closed-loop control system.

Block Diagram of a Testing System Using a Rotary Actuator

Series 215 Rotary Actuator Product Manual Introduction

15

Page 16

Actuator Specifications

Actuator Specifications

Series 215 Rotary Actuator Ratings by Model

M

ODEL RATED

TORQUE*

As the block diagram shows, a program command signal is input to the

controller. The command signal is compared to the feedback signal from one of

the actuator transducers. If the command signal equals the feedback signal from

the transducer conditioner, no DC error is present and the valve driver circuit

produces little or no servovalve control signal. If the command signal does not

equal the feedback signal, a DC error signal is sent to the valve driver circuit.

The valve driver circuit uses this signal to generate a servovalve control signal.

The servovalve control signal causes the servovalve spool to open in a direction

and by an amount necessary to direct a regulated flow of hydraulic fluid to the

actuator’s pressure or return ports. The actuator moves in response to the flow of

hydraulic fluid. The constant feedback of the closed-loop system enables the

controller to maintain precise control of actuator torque or movement.

Series 215 Rotary Actuators are available in six models. This section lists

specifications for both the Series 215 Actuator and its options.

ISPLACEMENT THRUST LOAD

D

Q (MAXIMUM)

IDE

S

LOAD†

P (M

AXIMUM)

ENDING

B

M

OMENT

M (MAXIMUM)

lbf·in. N·m in.3/rad cm3/rad lbf kN lbf kN lbf·in. N·m

215.32 2000 226 0.80 13.1 750 3.3 1500 6.67 3600 405

215.35 5000 565 1.9 31.1 750 3.3 3500 15.57 15,400 1732

215.41 10,000 1130 3.7 60.6 750 3.3 3500 15.57 15,400 1732

215.42 20,000 2260 7.2 117.9 750 3.3 3500 15.57 17,300 1946

215.45 50,000 5650 19.0 311.3 1200 5.3 5700 25.36 43,000 4837

215.51 100,000 11,300 38.0 622.7 1200 5.3 6500 28.92 50,000 5625

* Actuator is designed for cyclic use at rated torque: rated at maximum differential pressure at 21 MPa

(3000 psi).

† P and M are interdependent: if P is at maximum, M must be zero; if P = 75% of maximum, M may

be up to 25% of its maximum value.

‡ If these values are to be exceeded, additional internal or external cushions are required; contact

MTS.

§ w = rotational velocity in rad/sec and J or I = rotational inertia in lbm-in.

from rotary actuator, flange, flexure, and 1/2 of test specimen (lbm = pounds mass).

¶ Does not include flange adapter.

2

or kg-m2 including inertias

16

Introduction

Series 215 Rotary Actuator Product Manual

Page 17

Series 215 Rotary Actuator Ratings by Model

w

260

J

---------=

w

4.4

I

-------=

w

305

J

---------=

w

5.2

I

-------=

w

385

J

---------=

w

6.6

I

-------=

w

840

J

---------=

w

14.4

I

----------=

w

970

J

---------=

w

16.6

I

----------=

w

1525

J

------------=

w

26.1

I

----------=

M

ODEL MAX VELOCITY

CUSHION LIMITATION‡

Actuator Specifications

OTARY ACTUATOR ROTATIONAL INERTIA¶

R

U.S.

Customary

rad/sec

215.32 11.67 0.00342

215.35 18.54 0.00544

215.41 20.23 0.00594

215.42 29.04 0.00852

215.45 171 0.0500

215.51 284 0.0831

* Actuator is designed for cyclic use at rated torque: rated at maximum differential

pressure at 21 MPa (3000 psi).

† P and M are interdependent: if P is at maximum, M must be zero; if P = 75% of

maximum, M may be up to 25% of its maximum value.

‡ If these values are to be exceeded, additional internal or external cushions are

required, contact MTS.

§ w = rotational velocity in rad/sec and J or I = rotational inertia in lbm-in.2 or kg-m2

including inertias from rotary actuator, flange, flexure, and 1/2 of test specimen (lbm =

pounds mass).

¶ Does not include flange adapter.

SI Metric

rad/sec

lbm-in.

J

2

kg-m

I

2

Series 215 Rotary Actuator Product Manual Introduction

17

Page 18

Actuator Specifications

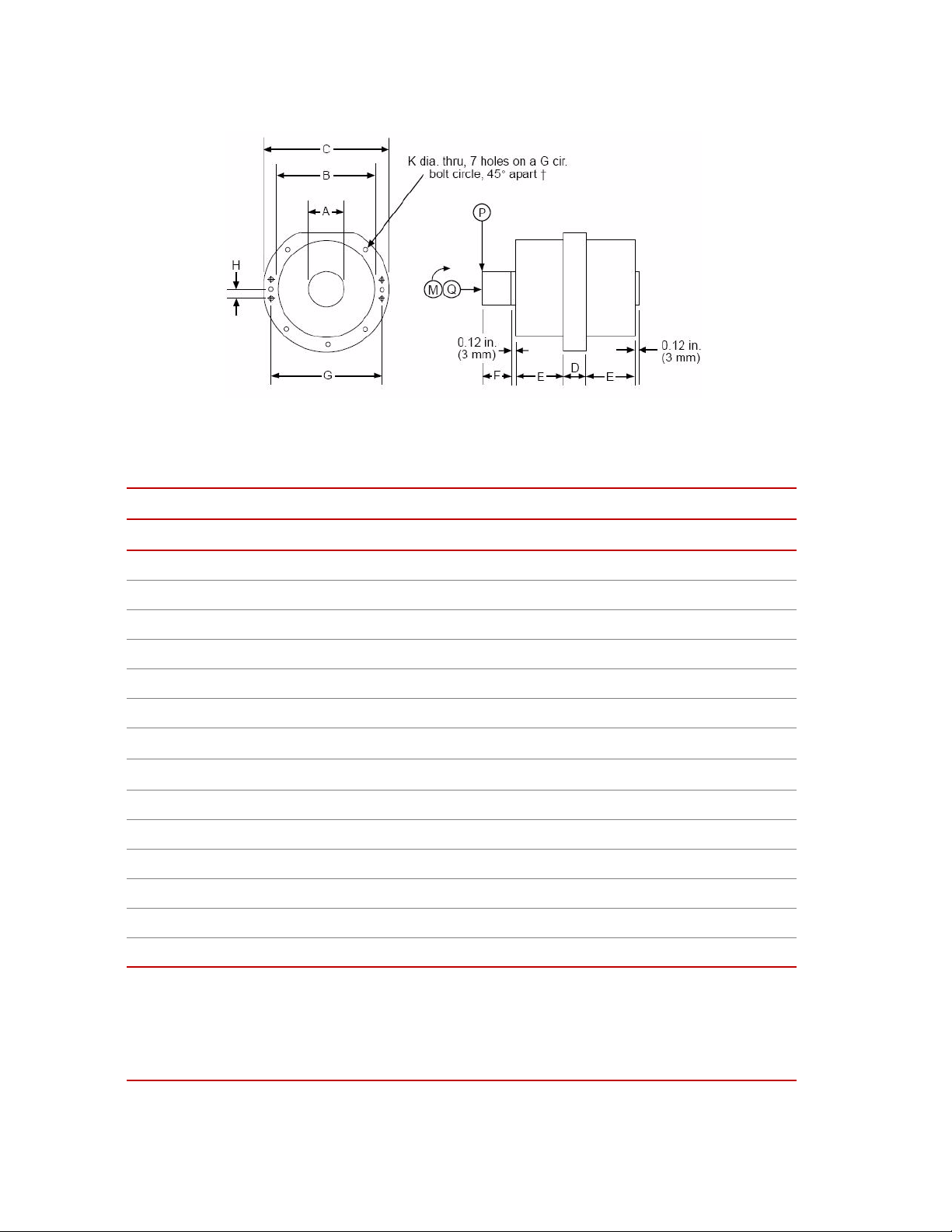

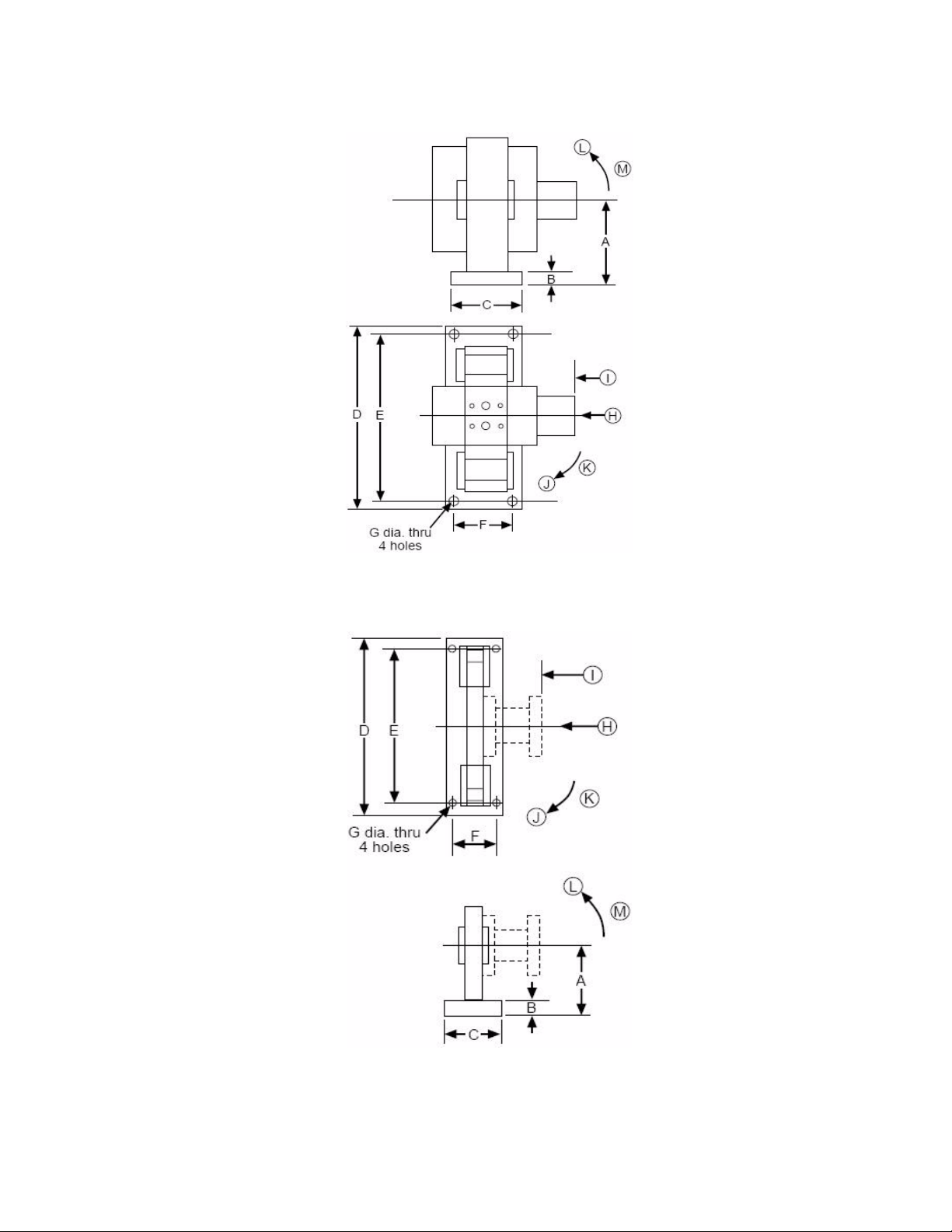

ABC DE

Actuator Dimensional Drawing

Actuator Dimensions and Weights

M

ODEL IN. MM IN. MM IN. MM IN. MM IN. MM

215.32 1.50 38.1 7.875 200.0 10.00 254 1.175 29.8 3.130 79.5

215.35 2.251 57.1 7.875 200.0 10.00 254 2.275 57.8 3.130 79.5

215.41 2.251 57.1 7.875 200.0 10.00 254 2.275 57.8 3.130 79.5

215.42 2.251 57.1 7.875 200.0 10.00 254 3.275 83.2 3.130 79.5

215.45 3.751 95.3 9.875 250.8 12.25 311 2.775 74.5 4.137 105.1

215.51 3.751 95.3 9.875 250.8 12.25 311 5.553 141.0 4.137 105.1

FGH KWEIGHT

MODEL IN. MM IN. MM IN. MM IN. MM LB KG

215.32 2.50 63.5 9.000 228.6 1.000 25.4 0.406 10.3 100 45

215.35 2.50 63.5 9.000 228.6 1.000 25.4 0.406 10.3 130 59

215.41 2.50 63.5 9.000 228.6 1.000 25.4 0.406 10.3 130 59

215.42 2.99 75.9 9.000 228.6 1.000 25.4 0.406 10.3 150 70

215.45 3.49* 88.6* 11.000 279.4 1.000 25.4 0.656 16.7 270 125

215.51 5.12* 130.0* 11.000 279.4 1.000† 25.4† 0.656 16.7 365 165

* Contains a 3.0 mm (0.12 in.) shoulder that is 0.25 mm (0.01 in.) larger in diameter than Dimension

'A'.

† 215.51 pattern has more bolt holes, not evenly spaced.

Dimensions and weights are subject to change without notice. Contact MTS for dimensions and weights crit-

ical to your needs.

18

Introduction

Series 215 Rotary Actuator Product Manual

Page 19

Options Specifications

Foot Mounting The foot mounting option is used for easy attachment of the actuator to a reaction

Options Specifications

Specifications for the most common options available for use with the Series 215

Rotary Actuators are described below.

base and also provides some flexure capability.

Series 215 Rotary Actuator Product Manual Introduction

19

Page 20

Options Specifications

Foot Mounting Dimensions and Ratings

M

ODEL ABCD

IN. MM IN. MM IN. MM IN. MM

215.32 6.25 158.8 0.75 19 5.00 127 17.00 432

215.35 6.25 158.8 0.75 19 5.00 127 17.00 432

215.41 6.50 166.4 1.00 25 5.00 127 19.50 495

215.42 6.50 166.4 1.00 25 5.00 127 19.50 495

215.45 7.75 196.8 1.50 38 6.00 152 22.00 559

215.51 7.75 196.8 1.50 38 6.00 152 22.00 559

MODEL EFGTHRUST LOAD*

IN. MM IN. MM IN. MM LBF N

215.32 12.00 304.8 3.75 92.3 0.781 19.8 100 445

215.35 12.00 304.8 3.75 92.3 0.781 19.8 100 445

H (M

AXIMUM)

215.41 18.00 457.2 3.50 88.9 0.781 19.8 150 670

215.42 18.00 457.2 3.50 88.9 0.781 19.8 150 670

215.45 18.00 457.2 4.00 101.6 0.781 19.8 500 2200

215.51 18.00 457.2 4.00 101.6 0.781 19.8 500 2200

MODEL THRUST

D

EFLECTION

I (MAXIMUM)

IN. MM LBF-IN.N-MRAD LBF-IN.N-M RAD

215.32 0.03 0.76 200 22 0.004 4500 508 0.003

215.35 0.03 0.76 200 22 0.004 4500 508 0.003

215.41 0.07 1.8 400 45 0.008 9000 1000 0.003

215.42 0.07 1.8 400 45 0.008 9000 1000 0.003

215.45 0.06 1.5 2000 225 0.006 20,000 2260 0.0008

215.51 0.06 1.5 2000 225 0.006 35,000 3960 0.0004

* Thrust load (H) and bending moments (J and L) are interdependent. H ratings assume J =

0 and L = 0. J and L ratings assume H = 0. Ratings must be decreased in proportion to other

loads present, for example, if H = 75% of rating, J and L must not total 25% of rating.

Dimensions and ratings are subject to change without notice. Contact MTS for verification of

critical dimensions and ratings.

ORIZONTAL

H

B

ENDING

M

OMENT*

J (M

AXIMUM)

A

NGULAR

D

EFLECTION

K

ERTICAL*

V

M

OMENT L

(M

AXIMUM)

BENDING

A

NGULAR

DEFLECTION

M

20

Introduction

Series 215 Rotary Actuator Product Manual

Page 21

Options Specifications

Foot Mounting Specification Drawing

Reaction Bracket Specification Drawing

Series 215 Rotary Actuator Product Manual Introduction

21

Page 22

Reaction Brackets

Reaction Brackets

Reaction brackets provide a torsionally rigid connection between the torque cell

and the reaction base. Brackets provide some flexural capability and readily

accept MTS torque cells.

Reaction Bracket Dimensions and Ratings

M

ODEL ABCD E F

IN. MM IN. MM IN. MM IN. MM IN. MM IN. MM

215.32 6.25 158.8 0.75 19 5.00 127 17.00 432 12.00 304.8 3.75 92.3

215.35 6.25 158.8 0.75 19 5.00 127 17.00 432 12.00 304.8 3.75 92.3

215.41 6.50 166.4 1.00 25 5.00 127 19.50 495 18.00 457.2 3.50 88.9

215.42 6.50 166.4 1.00 25 5.00 127 19.50 495 18.00 457.2 3.50 88.9

215.45 7.75 196.8 1.50 38 6.00 152 22.00 559 18.00 457.2 4.00 101.6

215.51 7.75 196.8 1.50 38 6.00 152 22.00 559 18.00 457.2 4.00 101.6

MODEL GTHRUST LOAD*

H (M

AXIMUM)

IN. MM LBF N IN. MM LBF·IN

HRUST

T

D

EFLECTION

I (MAXIMUM)

ORIZONTAL

H

B

ENDING

M

OMENT*

J (M

AXIMUM)

A

NGULAR

D

EFLECTION

K

ERTICAL*

V

B

M

(M

M RAD LBF·IN.N·M RAD

N·

ENDING

OMENT L

AXIMUM)

A

NGULAR

D

EFLECTI

ON

M

.

215.32 0.781 19.8 100 445 0.03 0.76 200 22 0.004 3500 395 0.003

215.35 0.781 19.8 100 445 0.03 0.76 200 22 0.004 3500 395 0.003

215.41 0.781 19.8 150 670 0.07 1.8 400 45 0.008 9000 1000 0.003

215.42 0.781 19.8 150 670 0.07 1.8 400 45 0.008 9000 1000 0.003

215.45 0.781 19.8 500 2200 0.06 1.5 2000 225 0.006 20,0002260 0.0012

215.51 0.781 19.8 500 2200 0.06 1.5 2000 225 0.006 35,0003960 0.0012

* Thrust load (H) and bending moments (J and L) are interdependent. H ratings assume J = 0 and L = 0.

J and L ratings assume H = 0. Ratings must be decreased in proportion to other loads present, for

example, if H = 75% of rating, J and L must not total 25% of rating.

Dimensions and ratings are subject to change without notice. Contact MTS for verification of dimensions

and ratings critical to your needs.

22

Introduction

Series 215 Rotary Actuator Product Manual

Page 23

Reaction Bases

Reaction bases are constructed of heavy-duty steel and designed for high

torsional stiffness. They readily accept MTS rotary actuators and reaction

brackets. When used with MTS reaction brackets and foot mounting options, the

stiffness/flexural capability is adequate to prevent excessive actuator side loads.

(However, a review of thrust loads should be made.) When purchased as a

system, the specimen length is fully adjustable (within the specified limits)

without requiring realignment of the actuator and reaction bracket. If required,

legs are available to raise the bases to any specified height.

Reaction Base Dimensions and Ratings

M

ODEL LENGTH§WIDTH HEIGHT*MAXIMUM SPACE†

IN. MM IN. MM IN. MM IN. MM

Reaction Bases

215.32

215.35

215.41

215.42

215.45

215.51

ODEL WEIGHT TORSIONAL STIFFNESS‡

M

215.32

215.35

215.41

215.42

215.45

215.51

45 1143 15 380 4.7 120 28.50 724

45 1143 15 380 4.7 120 28.00 711

54 1370 22 560 5.7 144 33.50 851

54 1370 22 560 5.7 144 29.75 756

60 1525 22 560 20 508 34.50 876

60 1525 22 560 20 508 30.25 768

LB KG LBF·IN./RAD N·M/RAD

375 170

375 170

800 363

800 363

1125 510

1125 510

55 x 10

55 x 10

122 x 10

122 x 10

742 x 10

742 x 10

6

6

6

6

6

6

6.2 x 10

6.2 x 10

13.7 x 10

13.7 x 10

83.8 x 10

83.8 x 10

6

6

6

6

6

6

* Without legs.

§ Longer bases available on request.

† Maximum space between mounting surfaces of actuator output flange and torque cell (with the

MTS reaction bracket supporting the torque cell).

‡ Torsional stiffness over entire length. Stiffness increases proportionately as the actuator and

reaction bracket are moved toward each other.

Dimensions and ratings are subject to change without notice. Contact MTS for verification of

dimensions and ratings critical to your needs.

Series 215 Rotary Actuator Product Manual Introduction

23

Page 24

Diaphragm Flexures

Diaphragm Flexures

As described in the “Test Setup Considerations” section, one or two diaphragm

flexures are used when large thrust and side loads are encountered on test setups

having both the rotary actuator and the reaction bracket rigidly mounted to the

reaction base. The flange adapter option is required to attach the diaphragm

flexure to the actuator. The flexure attaches readily to torque cells. The rotational

inertia of the diaphragm flexure must be included when determining the actuator

performance.

Diaphragm Flexure Dimensions and Ratings

M

ODEL AB C DE F G

IN. MM IN. MM IN. MM THREAD

S

IZE

215.32 4.00 101 9.75 248 2.00 51 5/16-18 0.88 22 0.344 8.7 0.41 10

215.35 5.00 127 9.75 248 2.00 51 3/8-16 0.86 22 0.406 10.3 0.40 10

215.41 5.00 127 12.25 311 2.03 52 3/8-16 0.89 23 0.406 10.3 0.42 11

215.42 8.00 203 12.25 311 2.93 74 5/8-11 1.33 34 0.656 16.6 0.39 10

215.45 8.00 203 15.25 387 2.99 76 5/8-11 1.36 35 0.656 16.6 0.42 11

215.51 9.75 248 15.25 387 3.49 89 3/4-10 1.62 41 0.781 19.8 0.42 11

MODEL HTHRUST LOAD

J (MAXIMUM)

IN

. MM LBF N IN. MM LBF·IN.N·M RAD

215.32 3.25 82.55 100 450 0.15 3.81 100 11.3 0.028 85 0.0249

215.35 4.25 107.95 100 450 0.15 3.81 100 11.3 0.025 95 0.0278

215.41 4.25 107.95 150 670 0.15 3.81 100 11.3 0.025 210 0.0614

EFLECTION

D

K (MAXIMUM)

. MM IN. MM IN. MM

IN

ENDING

B

M

OMENT

L (MAXIMUM)

NGULAR

A

DEFLECT

M

OTATIONAL

R

INERTIA

·IN.

LBM

2

KG·M

2

215.42 6.50 165.10 150 670 0.17 4.32 300 33.9 0.015 460 0.135

215.45 6.50 165.10 500 2200 0.25 3.81 400 45.2 0.015 960 0.281

215.51 8.00 203.20 500 2200 0.15 3.81 400 45.2 0.015 1400 0.410

Dimensions and ratings are subject to change without notice. Contact MTS for verification of

dimensions and ratings critical to your needs.

24

Introduction

Series 215 Rotary Actuator Product Manual

Page 25

Flange Adapters

Flange Adapters

Diaphragm Flexure Specification Drawing

A flange adapter may be used to mount the specimen to the actuator. Adapter

mounting position is adjustable. The actuator shaft may extend beyond the

adapter, be flush with it, or be recessed into it. Diameter A may be used as a

shallow pilot.

Flange Adapter Dimensions and Inertia

M

ODEL ABCD

IN. MM IN. MM IN. MM IN. MM

215.32 2.2511 57.2 4.00 102 2.25 57 2.99 75.9

215.32 2.2511 57.2 5.00 127 2.25 57 2.99 75.9

215.41 2.2511 57.2 5.00 127 2.00 51 2.99 75.9

215.42 2.2511 57.2 8.00 203 2.00 51 2.99 75.9

215.45 3.7400 95.0 8.00 203 3.25 83 3.68 93.5

215.51 3.7400 95.0 9.75 248 4.88 124 5.31 134.9

Series 215 Rotary Actuator Product Manual Introduction

25

Page 26

Flange Adapters

ODEL EF G ROTATIONAL INERTIA

M

THREAD

IN

. MM IN. MM LBM·IN.

2

KG·M

2

SIZE

215.32 5/16-18 0.63 16.0 3.25 82.5 14.4 0.00421

215.32 3/8-16 0.75 19.1 4.25 107.9 21.8 0.00639

215.41 3/8-16 0.75 19.1 4.25 107.9 21.8 0.00639

215.42 5/8-11 0.75 19.1 6.50 165.1 208 0.0608

215.45 5/8-11 1.25 31.8 6.50 165.1 273 0.0799

215.51 3/4-10 1.50 38.1 8.00 203.2 737 0.216

Dimensions are subject to change without notice. Contact MTS for verification of

dimensions critical to your needs.

26

Introduction

Flange Adapter Dimension Drawing

Series 215 Rotary Actuator Product Manual

Page 27

Safety Information

4

(27.6 MPa).

2

4

Hazard Placard Placement

Hazard placards contain specific safety information and are affixed directly to the

system so they are plainly visible.

Each placard describes a system-related hazard. When possible, international

symbols (icons) are used to graphically indicate the type of hazard and the

placard label indicates its severity. In some instances, the placard may contain

text that describes the hazard, the potential result if the hazard is ignored, and

general instructions about how to avoid the hazard.

The following labels and icons may be found on an actuator.

L

ABEL DESCRIPTION

Hazard Placard Placement

Part #46-140-101

Part #46-140-201

WA RN I NG

Hydraulic pressure above 3000 psi can rupture

components. Can cause severe personal injury

or damage to equipment.

Do not exceed 3000 psi (20.7 MPa).

Read instructions before operating or

servicing.

WA RN I NG

Hydraulic pressure above 4000 psi can rupture

components. Can cause severe personal injury

or damage to equipment.

Do not exceed 4000 psi (27.6 MPa).

Read instructions before operating or

servicing.

Series 215 Rotary Actuator Product Manual Safety Information

27

Page 28

Hazard Placard Placement

L

ABEL DESCRIPTION

CAUTION

High drain pressure can cause rod seal damage

and hydraulic oil leakage.

Remove drain line shipping cap and connect

drain hose before operating.

Part # 045-283-501

Attached mass warning.

Do not exceed maximum attached mass.

Part # 057-230-041

Part # 700-004-198

Hydraulic Actuator ID tag lists the following:

• Model number

• Serial number

• Assembly number/Rev

• Force

• Effective Area

• Static Stroke

• Dynamic Stroke

• Hydrostatic/Non-Hydrostatic

• Maximum attached mass

Safety Information

28

Series 215 Rotary Actuator Product Manual

Page 29

L

ABEL DESCRIPTION

Hydraulic Actuator ID tag lists the following:

• Model number

• Serial number

• Assembly number/Rev

• Force

• Effective Area

• Static Stroke

Hazard Placard Placement

Part # 037-588-801

Part # 57-237-711

Part # 57-238-5xx

• Dynamic Stroke

• Hydrostatic/Non-Hydrostatic

Pressure icon.

Can be used alone, or in conjunction with

pressure rating label (Part # 57-238-5xx).

Pressure rating. Actual rating listed on this

label will vary. This label is used in

conjunction with the Pressure icon (Part #

57237711). Located directly beneath pressure

icon on actuator.

Series 215 Rotary Actuator Product Manual Safety Information

29

Page 30

Hazard Placard Placement

Safety Information

30

Series 215 Rotary Actuator Product Manual

Page 31

Installation

This section describes the procedures for installing the Series 215 Rotary

Actuator and optional equipment onto a base plate or T-slot table. It also includes

instructions for aligning the components of the rotary actuator test system after

they have been installed or moved.

Though the Series 215 Rotary Actuator can be installed onto any suitable base

plate or T-slot table that conforms to the specifications listed in the Diaphragm

Flexure Dimensions and Ratings table, these instructions assume that an MTS

supplied base plate or T-slot table will be used.

Typical Test System Configuration (Using T-slot Table)

Series 215 Rotary Actuator Product Manual Installation

31

Page 32

Actuator Installation

Actuator Installation

Typically, the Series 215 Rotary Actuator is first bolted to a foot mounting

assembly, then positioned on a base plate or T-slot table and secured with lightly

lubricated mounting bolts. The foot mounting dimensions and ratings must match

the actuator in use. After completing the alignment of force train components,

torque the bolts to the correct values.

Actuator Mounting Bolt Torque Values

M

ODEL ACTUATOR ASSEMBLY TO FOOT

M

OUNTING

·FT N·MLBF·FT N·M

LBF

215.32, 215.35 35 47 150 204

FOOT MOUNTING TO BASE PLATE OR T-SLOT

T

ABLE

215.41, 215.42

215.45, 215.51

80 110 150 204

Reaction Bracket and Torque Cell Installation

The reaction bracket should be positioned at the opposite end of the base plate or

T-slot table from the actuator. Ensure that it is oriented with the smooth vertical

surface facing the actuator.

Lightly lubricate the reaction bracket mounting bolts and hand-tighten them to

secure the position of the reaction bracket. The reaction bracket mounting bolts

should not be fully tightened until the force train components are aligned. Refer

to the appropriate table for the reaction bracket force ratings and the torque

values used when installing the reaction bracket and torque cell.

In most cases the selected torque cell bolts directly to the surface of the reaction

bracket. When possible, the side of the torque cell that attaches to the center

collar should be bolted to the reaction bracket. This configuration will cause the

least movement of the torque cell electrical cable. The torque cell and reaction

bracket should be bolted together with the correct torque value. It may be

necessary to temporarily tighten the reaction bracket mounting bolts to keep it

from moving while the torque cell is bolted in place.

32

Installation

Series 215 Rotary Actuator Product Manual

Page 33

Reaction Bracket and Torque Cell Installation

MTS Base Plate and Reaction Bracket

Reaction Bracket Ratings and Mounting Bolt Torque Value

M

ODEL REACTION BRACKET RATING TORQUE CELL TO REACTION

B

RACKET TORQUE VALUE

·FT.N·MLBF·FT.N·MLBF·FT.N·M

LBF

215.32 2000 0.226 18 24.0 150 204

215.35 5000 0.560 35 47.0 150 204

215.41 10,000 1.130 35 47.0 150 204

215.42 20,000 2.260 170 230.0 150 204

215.45 50,000 5.650 170 230.0 150 204

215.51 100,000 11.300 280 380.0 150 204

REACTION BRACKET TO BASE OR TS

LOT TABLE TORQUE VALUE

Series 215 Rotary Actuator Product Manual Installation

33

Page 34

Diaphragm Flexure Installation

Diaphragm Flexure Installation

Depending upon user requirements, the end of the actuator rotor shaft can extend

beyond the flange, be flush with it, or be recessed into the flange adapter to allow

the use of the inside diameter as a pilot diameter.

Diaphragm flexures are used to reduce the potentially damaging effects of large

axial and lateral deflections of the actuator rotor shaft. Perform the necessary

calculations for determining whether or not diaphragm flexures are required by

the specific test system.

Mount the flexure(s) to either the flange adapter or the torque cell.

The following table lists the flexure ratings and mounting bolt torques for the

available flexure diaphragms.

Flange Adapter and Diaphragm Flexure Rating

FLANGE AND DIAPHRAGM FLEXURE RATING MOUNTING BOLT TORQUE

M

ODEL

·N.N·MLBF·IN.N·M

LBF

215.32 2000 226 18 24

215.35 5000 565 35 47

215.41 10,000 1130 35 47

215.42 20,000 2260 170 230

215.45 50,000 5650 170 230

215.51 100,000 11,300 280 380

Aligning Force Train Components

After the actuator, reaction bracket, and torque cell have been positioned on the

base plate or T-slot table, they must be aligned. The goal of the alignment process

is to ensure that the actuator and torque cell share the same centerline.

If the test system utilizes a base plate supplied by MTS, the actuator and reaction

bracket will have been pre-aligned at the factory. The combination of an MTS

base plate and reaction bracket enables the operator to easily move the reaction

bracket/torque cell assembly and simplifies the alignment procedure.

If the test system does not utilize an MTS base plate or T-slot table, the torque

cell has been separated from the reaction bracket, or the actuator has been moved,

then the “Component Centerline Alignment Procedure” must be performed in

order to ensure proper alignment of the components of the test system. If the

reaction bracket, torque cell, and actuator have not been moved and were

properly aligned when installed, then it is not necessary to perform the alignment

procedures.

34

Installation

The diaphragm flexure assemblies are self-centering.

Series 215 Rotary Actuator Product Manual

Page 35

Note In each of the following procedures the base plate or T-slot table must be

flat to within 0.015 mm/m (0.002 in./ft).

Component Alignment on an MTS Base Plate

Rotary actuator testing systems equipped with an MTS base plate and reaction

bracket combination are pre-aligned. The following procedure describes the

alignment process used when you wish to increase or decrease the distance

between the actuator and the torque cell.

Note If the actuator has been moved or the torque cell has been separated

from the reaction bracket, the “Component Centerline Alignment

Procedure” must be completed before attempting this procedure.

1. To move the reaction bracket and torque cell assembly, loosen the lateral

clamping bolts located on the left side of the reaction bracket.

2. Loosen the vertical clamping bolts on the reaction bracket.

3. Slide the reaction bracket and torque cell assembly to the desired position.

4. Tighten the lateral clamping bolts on the left side of the reaction bracket to

assure alignment.

Component Alignment on an MTS Base Plate

5. To secure the reaction bracket and torque cell assembly, lubricate and

tighten each of the lateral clamping bolts to 3.9 N·m (35 lbf·in.).

6. Lubricate and tighten each of the vertical clamping bolts to 84.7 N·m (750

lbf·in.). Alignment is complete.

Component Centerline Alignment

If the test system does not utilize an MTS base plate or T-slot table, or the torque

cell has been separated from the reaction bracket, or the actuator has been moved,

then this procedure must be performed in order to ensure proper alignment of the

components of the test system. In each of the steps, it is assumed that the bolts

used to install the actuator and reaction bracket to the base plate or T-slot table

are hand tight unless otherwise specified.

The purpose of this procedure is to ensure that the actuator and torque cell share

the same centerline. The procedure is composed of three groups of steps covering

the following operations:

• Adjusting actuator and torque cell centerline height,

• Adjusting actuator and torque cell concentricity, and

• Adjusting for actuator and torque cell centerline angularity.

Adjusting Actuator and Torque Cell Centerline Height

This procedure describes the steps necessary to adjust the centerline height of the

torque cell with respect to the actuator. The procedure requires a dial indicator,

magnetic V-block, extension rod, and clamps.

1. Attach a dial indicator to the actuator rotor shaft using a magnetic V-block

as the base.

Series 215 Rotary Actuator Product Manual Installation

35

Page 36

Adjusting Actuator and Torque Cell Concentricity

2. Rotate the V-block around the rotor shaft circumference while

simultaneously reading the pilot diameter runout on the face of the torque

cell flange. Check the reading at top and bottom positions.

A. Variation between the actuator reading and the torque cell flange face

must differ by less than 0.0508 mm (0.002 in.).

B. Height adjustments are made by loosening and repositioning the torque

cell. When the proper position has been achieved, re-tighten the torque

cell mounting bolts to the appropriate torque values.

3. Repeat Steps 1 and 2 to ensure that the adjustment was not altered when the

torque cell was re-torqued.

Adjusting Actuator and Torque Cell Concentricity

While centerline heights may be identical and parallel to the base plate or T-slot

table mounting surface, the actuator and torque cell can be eccentric in a lateral

direction. There are two ways to correct for actuator/torque cell eccentricity. The

most appropriate method depends on the type of specimen to be tested. Both

methods are listed below.

Rigid specimen If the current test application makes use of a rigid specimen, then the specimen

itself can be used to facilitate the alignment process. Because the presumed goal

of the alignment process is to mount the specimen without exerting any

unintentional forces upon it, it may be simplest to loosen the bolts securing the

reaction bracket to the table and then place the specimen in position.

Flexible or fragile

specimen

When installing the mounting bolts, ensure that there are no gaps between the

specimen, flexures, and torque cell. Only after checking that both ends of the

specimen contact the mounting surfaces should the mounting bolts be torqued.

This technique allows the specimen configuration to control the “at rest” position

of the reaction bracket. Once the specimen is securely positioned, the reaction

bracket bolts may be torqued to the proper value. Do not use the mounting bolts

to pull

the reaction bracket into position.

If the current test application uses a flexible or fragile specimen, then the

following procedure must be used to correct for actuator/torque cell eccentricity.

1. Attach a dial indicator to the actuator rotor shaft using a magnetic V-block

for the base.

2. Rotate the V-block around the rotor shaft circumference while

simultaneously reading the pilot diameter runout on the torque cell flange.

3. Adjust the torque cell position for an acceptable level of eccentricity by

loosening the reaction bracket. The acceptable level of eccentricity is

determined by the test requirements.

4. After positioning the torque cell, re-tighten the mounting bolts to the

appropriate torque values.

5. Recheck the centerline height and adjust as required.

36

Installation

Series 215 Rotary Actuator Product Manual

Page 37

Adjusting Actuator and Torque Cell Centerline

Adjusting Actuator and Torque Cell Centerline Angularity

The final alignment procedure adjusts for centerline angularity deviations

between the actuator rotor shaft and the torque cell flange face.

Do not apply hydraulic pressure to the system unless the servovalve command

(DC error) has been zeroed.

If the servovalve command (DC error) does not equal zero when hydraulic

pressure is applied to the system, equipment damage or personal injury can

result.

Always ensure that the DC error is zero before applying hydraulic pressure to the

system.

1. Adjust the system controller for zero DC error and apply system hydraulic

pressure according to applicable system procedures.

2. Attach a dial indicator to the actuator rotor shaft using a magnetic V-block

for the base. Set the dial indicator to read the runout of the torque cell flange

face, outside the bolt circle area.

3. Use the Set Point control on the controller to rotate the actuator rotor shaft

while simultaneously reading the indication from the face of the torque cell

flange.

4. To obtain a reading over a wider range of motion, reposition the V-block on

the opposite side of the actuator rotor shaft and repeat Step 3.

5. Adjust the torque cell position for an acceptable level of angularity by

loosening and moving the reaction bracket. The acceptable level of

angularity is determined by the test requirements.

6. After positioning the torque cell, re-tighten the reaction bracket mounting

bolts to the appropriate torque.

7. Turn off system hydraulic pressure.

8. Repeat the “Actuator and Torque Cell Centerline Height” and “Actuator and

Torque Cell Concentricity” procedures to ensure that all measurements

conform to the requirements of the test.

Series 215 Rotary Actuator Product Manual Installation

37

Page 38

Adjusting Actuator and Torque Cell Centerline

38

Installation

Series 215 Rotary Actuator Product Manual

Page 39

Operation

CAUTION

Thrust and Side Load Characteristics

This section discusses the calculations and precautions that must be considered in

order to produce accurate test results and help protect equipment and personnel.

Though some of the calculations included in this section may not be required by

specific test situations, it is recommended that you read each section and ensure

that the actuator will be operated within the limits of its thrust load, side load, and

rotational inertia ratings.

Do not exceed the thrust load, side load, or rotational inertia ratings of the

actuator.

Exceeding the thrust load, side load, or rotational inertia ratings of the

actuator can damage equipment, injure personnel, and void any warranty in

effect on the Series 215 Rotary Actuator.

Ensure that the thrust load, side load, and rotational inertia ratings for the actuator

exceed the anticipated test forces. This section contains calculations for deriving

the anticipated test forces.

Thrust and Side Load Characteristics

The thrust and side loads that may be encountered during testing are generally

the result of the following factors:

• Specimen shortening or lengthening due to torsional force

• Specimen shortening or lengthening due to temperature

• Misalignment of the test specimen when initially mounted

• Base plate or T-slot table twisting

• Permanent deformation of the specimen due to torsional force

Thrust loads The following table lists the maximum allowable thrust load (Q) that can be

applied to the actuator rotor shaft. Because thrust loads can be induced by a wide

variety of experimental conditions, this manual will not attempt to define or

predict the forces that can result from specific testing situations. If there is a

possibility that the maximum thrust load rating of the actuator will be exceeded

during testing, steps should be taken to minimize the load. One way of reducing

the effect of thrust loads on the actuator bearings is to install diaphragm flexures.

Thrust loads can have a significant effect on actuator bearings. These effects are a

function of specimen geometry, material, and temperature as shown in the

following example:

Increase the temperature of a steel shaft 25.4 mm (1 in.) in diameter and 1,270

mm (50 in.) in length by 22˚C (40˚F). The increase in specimen temperature

causes the shaft to expand by approximately 0.305 mm (0.012 in.). If the shaft is

Series 215 Rotary Actuator Product Manual Operation

39

Page 40

Definition of Useful Mathematical Terms

mounted in a force train using a 215 Rotary Actuator, the shaft expansion would

exert a resultant force of 6,000 lbs. on the actuator bearings.

To confine the resultant force to an acceptable maximum requires the addition of

diaphragm flexures to the force train. Multiplying the stiffness of the diaphragm

flexure by the amount of specimen expansion will give the thrust load imposed

on the actuator bearings.

Use the following formula to calculate the maximum thrust load applied to the

actuator bearings when using diaphragm flexures:

Flexure Stiffness (Flexure’s Maximum Thrust Deflection) = Maximum Thrust

Load

Side loads Side loads, which are normally induced by specimen misalignment or base plate

or T-slot table compliance, may be active at the same time thrust loads are active.

If the specimen is soft, such as a length of rubber hose, side loads on the actuator

are relatively small. This is because the specimen bends easily and exerts little

resistance to the deflection caused by base plate twisting. However, if the

specimen is stiffer (steel for example), the increased resistance of the specimen to

bending exerts substantial side loads on the actuator bearings and torque cell due

to the restraining characteristics of the test setup. As in the test setup for thrust

loads, diaphragm flexures can be used to reduce the side loads to a practical limit.

Note The service life of the actuator is normally reduced by significant thrust

and side loads. For this reason, the use of flexure diaphragms and a rigid

base plate is recommended even when the actuator’s thrust and side

load ratings are sufficient for the test situation.

Definition of Useful Mathematical Terms

The following terms are listed in alphabetical order and defined in both U.S.

Customary and SI Metric units of measure.

Mathematical Terms (part 1 of 3)

ERM DEFINITION TERM DEFINITION

T

a Distance from actuator's center line to

center of reaction base plate’s solid

height (mm) (in.).

β 0.333 - 0.21 (d/b) k

b Width of reaction base plate (mm) (in.). k

k2 Lateral stiffness of a solid cylindrical

specimen (kN/mm) (lbf/in.)

12 ET IL2 3

F1

F2

Angular horizontal stiffness of actuator and

reaction bracket flexures (N·m/rad) (lbf·in./

rad).

M

F1/θF1

Lateral stiffness of diaphragm flexures (lbfin./rad).

d Thickness of reaction base plate (mm)

(in.). Measurement of solid metal only.

Do not include T-slot depth.

Operation

40

=MF2/θ

L

1

Length of base plate or T-slot table subjected

to twisting (mm) (in.).

F2

Series 215 Rotary Actuator Product Manual

Page 41

Mathematical Terms (part 2 of 3)

T

ERM DEFINITION TERM DEFINITION

Definition of Useful Mathematical Terms

E

E

I

k

Μ

M

S

Modulus of elasticity of the base plate or

T-slot table, shear (N/m2) (lb/in.2)

L

2

Length of test specimen (mm) (in.). Do not

include specimen adapter plates unless their

compliance is equal to or greater than that of

the specimen.

T

Modulus of elasticity of the specimen,

tension (N/m2) (lb/in.2).

Moment of inertia for a round solid (mm

4

(in.

)

πr4/4

1

Torsional stiffness of a thin flat plate (Nm./rad) (lbf-in./rad)

L

F

Distance between flexing points of

diaphragm flexures.

4

M Bending moment on test specimen with no

)

flexures (N·m) (lbf·in.).

PL 22

M

1

Bending moment on actuator and reaction

bracket with standard flexures installed (Nm) (lbf-in.).

Es (β)bd3 /L

2

Bending moment on test specimen with

1

θ

k

F1

T Applied torque (N-m) (lbf-in.)

standard flexures or diaphragm flexures

installed (N-m) (lbf-in.).

(Standard Flexures)

(Diaphragm Flexures)

F

1

Maximum lateral bending capacity of

standard flexures (N-m) (lbf-in.)

u Distance from front bearing to specimen

(mm) (in.). Include specimen adapter plates

if they are less compliant than the specimen.

M

F

2

Maximum horizontal bending capacity of

W Load on front actuator bearing (kN) (lbf)

diaphragm flexures (N-m) (lbf-in.)

P Side load imposed on test specimen and

actuator.

∆ Centerline offset between actuator and

reaction bracket mountings due to twisting of

base plate or T-slot table (mm) (in.).

=k2k1aT1 + k2k1a2

∆ =

r Radius of test specimen (mm) (in.) q Angle of flex imposed on flexures (rad).

(Standard Flexures)

(Diaphragm Flexures)

Series 215 Rotary Actuator Product Manual Operation

41

Page 42

Test Setup Using No Flexures

Mathematical Terms (part 3 of 3)

T

ERM DEFINITION TERM DEFINITION

s Distance between front and rear

bearings (mm) (in.).

S

B

Bending stress on test specimen due to

base plate twisting (N/m2) (psi).

MrI Without Flexures

M2rI With Flexures

θ

F

1

θ

F

2

Maximum horizontal angular deflection of

standard flexures (rad).

Maximum angular deflection of diaphragm

flexures (rad).

Test Setup Using No Flexures

The following figure illustrates an example of a test setup having no flexures. If

diaphragm flexures will not be used in the rotary actuator test system, special

attention should be paid to the side loads that will be imposed on the specimen

and actuator by twisting of the base plate or T-slot table.

Side load calculations The following side load calculation procedure is used to determine side loads due

to the base plate or T-slot table torsional compliance. When side loads are

unacceptable as determined from these calculations, optional components are

required in the force train to reduce the load imposed on the actuator and torque

sensor.

Loads on an Actuator and Specimen due to base plate twist (excludes thrust loads)

42

Operation

Series 215 Rotary Actuator Product Manual

Page 43

Test Setup Using No Flexures

Sample calculation The previous figure illustrates the forces and measurements pertinent to the

calculations. Refer to the appropriate tables for ratings and dimensions of the

Model 215.45 Rotary Actuator used in the example.

The following procedure uses sample values. When performing the calculations

to determine the anticipated test forces, the values appropriate to your specific

test should be substituted for the sample values. In addition, the example uses

U.S. Customary units of measure.

Calculate the side load (P) and compare P to the actuator's side load rating in the

actuator ratings table. If P exceeds or approaches the side load rating, two

flexures must be used in the test setup.

Also calculate SB, the bending stress on the specimen under test. If SB is above

the determined maximum tolerable value, two flexures must be used in the test

setup.

Example

: Suppose a Model 215.45 Rotary Actuator is mounted to a T-slotted

steel reaction base, resulting in the following parameters:

Base: 48 in. x 24 in. x 6 in.

T-slot depth: 2 in.

Height (A from Table 1-4): 7.75 in. (Actuator centerline to base of foot

mounting)

Actuator torque capacity (T): 50,000 lbf-in.

Length of base subjected to twisting (L

Specimen material: Steel (E

Specimen length (L

): 10 in.

2

= 12 x 106, ET = 29 x 106)

S

): 37 in.

1

Specimen radius (r): 1 in.

Calculate side load Calculate the side load (P) imposed on the test specimen and actuator bearing as

a result of base plate twist using the following formula:

A. To calculate P, it is first necessary to calculate k

, d, β, k2, I, a, and T as

1

follows:

Series 215 Rotary Actuator Product Manual Operation

43

Page 44

Test Setup Using No Flexures

Then:

B. Calculate the value of k

, the lateral stiffness of a solid cylindrical

2

specimen, by using the formula:

C. Substitute the calculated values for k

, k2, and the example values into

1

the original equation to compute the side load (P).

44

Operation

Series 215 Rotary Actuator Product Manual

Page 45

Test Setup Using No Flexures

The value of 862 lbf is the side load (P) imposed on the test specimen and

actuator by base plate twist.

Calculate bending

moment

Calculate specimen

stress

Calculate the bending moment (M) on the test specimen with no flexures

installed by using the following formula:

The value of 4310 lbf-in. is the bending moment exerted on the actuator shaft and

specimen.

For this example, P = 862 or 12% of side load capacity, and M = 4310 or 10% of

bending moment capacity. The sum is less than 100% at capacity, so flexures are

not necessary.

Calculate SB as the final step:

The value 5488 psi represents the amount of stress experienced by the specimen

under test. Typically, in a torsion test, stress caused by reaction base or T-slot

table twist should be zero or as close to zero as possible. In the sample

calculation, the excessive specimen stress loading introduces unfavorable loads

Series 215 Rotary Actuator Product Manual Operation

45

Page 46

Test Setup Using Standard Flexures

on the test specimen which can invalidate the test results or cause premature

failure of the specimen. To reduce these loads requires the use of flexure options

or a stiffer mounting surface.

Test Setup Using Standard Flexures

The following figure shows an example of a test setup in which flexures are

integral on both the actuator foot mounting and the reaction bracket. Flexures are

used to reduce excessive side load forces applied to an actuator or specimen.

It is important to determine if standard flexures are adequate for your test setup

or if diaphragm flexures need to be used. This subsection describes calculations

that help make this determination.

46

Operation

Forces Resulting from Base Plate Twisting (Integral Flexures)

∆ = Center line offset between actuator and reaction bracket mountings due to

base plate twisting or T-slot table (in.) (mm):

θ = Angle of flex imposed on actuator and reaction bracket flexures (rad):

θ

1

F

= Maximum horizontal angular deflection of standard flexures (rad).

Series 215 Rotary Actuator Product Manual

Page 47

Test Setup Using Standard Flexures

k

= Angular horizontal stiffness of actuator and reaction bracket (N·m/rad)

F1

(lbf·in./rad):

M

= Bending moment on actuator and reaction bracket with standard flexures

1

installed (N·m) (lbf·in.):

= Maximum horizontal bending capacity of standard flexures (N·m)

M

F1

(lbf·in.).

M

= Bending moment on specimen with standard flexures installed (lbf·in.)

2

(N·m):

Calculate centerline

offset

SB = Bending stress on test specimen due to base plate twisting (N/m

2

) (psi):

The previous figure illustrates the forces and measurements pertinent to the

calculations. Refer to the appropriate tables for ratings and dimensions of the

Model 215.45 Rotary Actuator used in the example.

The following procedure uses sample values. When performing the calculations

to determine the anticipated test forces, the values appropriate to your specific

test should be substituted for the sample values. In addition, the example uses

U.S. Customary units of measure.

Use the following values and formulas to calculate Δ (centerline offset) and then

θ (angle of flex on flexures). If θ is not greater than θ

, the standard flexures are

F

1

adequate.

Also calculate SB, the bending stress on the specimen under test. If SB is above

the determined maximum tolerable value, diaphragm flexures must be used in the

test setup.

Calculate the centerline offset (D) between the actuator and reaction bracket

mountings due to base plate twist by using the following formula:

Series 215 Rotary Actuator Product Manual Operation

47

Page 48

Test Setup Using Standard Flexures

Calculate angle of flex Calculate the angle of flex (q) imposed on foot mounting and reaction bracket

flexures by using the following formula:

Compare angular

deflection

Calculate lateral

stiffness

Compare the maximum horizontal angular deflection of the standard flexures

value (K = qF1= 0.006 rad.) with the calculated angle of flex imposed on foot

mounting and reaction bracket flexures (q=0.000107 rad.) to determine if the

flexures are adequate.

θ < θ

F

1

In the case of the sample calculation, the flexures are adequate. If the flexures are

not adequate, additional flexural capability is required or base plate stiffness

must be increased. Consult MTS Systems for assistance.

Calculate the lateral stiffness (k

) of the foot mounting and reaction bracket

F

1

flexures by using the following formula:

48

Operation

Series 215 Rotary Actuator Product Manual

Page 49

Test Setup Using Standard Flexures

Calculate bending

moment (M1)

Calculate bending

moment (M2)

Calculate specimen

stress

Calculate the bending moment (M1) that is applied to the actuator and reaction

bracket when equipped with standard flexures.

Calculate the bending moment (M2) induced in the test specimen with standard

flexures installed by using the following formula:

Calculate the additional stress (SB) induced in the specimen due to base plate

twist by using the following formula:

The value 12.2 psi represents the amount of stress experienced by the specimen

under test and is an acceptable stress level. Typically, in a torsion test, stress

caused by reaction base or T-slot table twist should be zero or as close to zero as

possible. Specimen stress loading introduces unfavorable loads on the test

Series 215 Rotary Actuator Product Manual Operation

49

Page 50

Test Setup Using Diaphragm Flexures

specimen which can invalidate the test results or cause premature failure of the

specimen.

Test Setup Using Diaphragm Flexures

If the values derived from the calculations in “Test Setup Using Standard

Flexures” section indicate that diaphragm flexures must be used to reduce side

loads to acceptable levels, then the following calculations should be performed to

ensure that the selected diaphragm flexures are adequate. In addition, this

subsection contains the equations necessary for calculating the stress experienced

by the specimen when diaphragm flexures are installed in the test system.

The following figure shows an example of a test setup in which diaphragm

flexures are mounted at both ends of the test specimen. These would be required

on test setups where both the rotary actuator and the reaction bracket are rigidly

mounted to the reaction base.

50

Operation

Forces Resulting from Base Plate Twisting (Diaphragm Flexures)

Series 215 Rotary Actuator Product Manual

Page 51

Test Setup Using Diaphragm Flexures

Sample calculation The previous figure illustrates the forces and measurements pertinent to the

calculations. Refer to the appropriate tables for ratings and dimensions of the

Model 215.45 Rotary Actuator used in the example. The following calculations

use values derived from the sample calculations performed previously.

Using the preceding formulas and following values calculate Δ (centerline offset)

and then θ (angle of flex on flexures). If θ is not greater than θ

adequate (from Table 1-7, θ

Calculate S

and determine if it is within acceptable limits for the specific

B

= M).

F2

test.

a = 11.75 in. (Distance from actuator center line to base plate center)

k

= 148.5 x 106 lbf-in./rad. (Torsional stiffness of thin flat plate)

1

L

= 43 in. (Length of base plate subjected to twisting)

1

Note Length of base plate subject twist has been changed from 37 in. to 43 in.

This was necessary because using diaphragm flexures at the ends of a

specimen increases the distance between the foot mounting and

reaction bracket. Refer to “Diaphragm Flexure Dimensions and Ratings”,

dimension C.

L

F =

13 in. (

Distance between flexing points of the diaphragm

flexures) (from Diaphragm Flexure Dimensions and Ratings, rating L)

, the flexures are

F2

M

= 400 lbf·in (Maximum lateral bending capacity of the diaphragm

F2

flexure) (from Diaphragm Flexure Dimensions and Ratings, rating M)

= 0.015 rad (Maximum angular deflection of the diaphragm

θ

F2

flexure)

T = 50,000 lbf·in. (Applied torque)

Series 215 Rotary Actuator Product Manual Operation

51

Page 52

Test Setup Using Diaphragm Flexures

Calculate centerline

offset

Calculate the center line offset (∆) between actuator and reaction bracket due to

base plate twist by using the following formula:

Calculate flex angle Calculate the angle of flex (q) imposed on each diaphragm flexure by using the

following formula:

Compare angular

Calculate lateral

Operation

52

deflection

stiffness

Compare the maximum horizontal angular deflection of the diaphragm flexures

(qF2=0.015 rad.) with the calculated angle of flex imposed on foot mounting and

reaction bracket flexures (q=0.000305rad.) to determine if the flexures are

adequate.

θ < θ

F

2

In the case of the sample calculation, the flexures are adequate. If the flexures are

not adequate, additional flexural capability is required or base plate stiffness

must be increased. Consult MTS Systems for assistance.

Calculate the lateral stiffness (k

) of the diaphragm flexures by using the

F

1

following formula:

Series 215 Rotary Actuator Product Manual

Page 53

Test Setup Using Diaphragm Flexures

Calculate bending

moment (M2)

Calculate specimen

stress

Calculate the bending moment (M2) that is induced in the test specimen with

diaphragm flexures installed by using the following formula:

Calculate the additional stress (SB) induced in the specimen due to base plate

twist by using the following formula:

The value 10.4 psi represents the amount of stress experienced by the specimen

under test and is an acceptable stress level. Typically, in a torsion test, stress

caused by reaction base or T-slot table twist should be zero or as close to zero as

possible. Specimen stress loading introduces unfavorable loads on the test

specimen which can invalidate the test results or cause premature failure of the

specimen.

Series 215 Rotary Actuator Product Manual Operation

53

Page 54

Summary of Side Load Calculations

Summary of Side Load Calculations

This section contains a brief summary of side load calculations made before

beginning a test.

Side load calculations

excluding flexures

The following formulas are used in preliminary calculations to determine if

forces generated exceed the actuator rating, thus requiring the addition of

flexures.

1. Calculate the side load (P) imposed on the test specimen and actuator

bearing as a result of base plate twist using the following formula:

A. Calculate the value of k

, the torsional stiffness of a thin flat plate, by

1

using the formula:

Note In the above formula, is used in place of J (polar

momentary inertia) due to warpage that occurs in thin flat plates under

torque.

B. Calculate the value of ks, the lateral stiffness of a solid cylindrical

specimen, by using the formula:

2. Calculate the bending moment (M) on the test specimen by using the

following formula:

3. Calculate the stress (S

) induced in the specimen due to base plate twist by

B

using the following formula:

54

Operation

Series 215 Rotary Actuator Product Manual

Page 55

Summary of Side Load Calculations

Side load calculations

when using standard

flexures

The following calculations are used when flexures are installed on the foot

mounting and reaction bracket.

1. Calculate the center line offset (∆) between the actuator and reaction bracket

due to base plate twist by using the following formula:

2. Calculate the angle of flex (θ) imposed on standard flexure by using the

following formula:

3. Compare the maximum horizontal angular deflection of the standard

flexures in use with the calculated angle of flex imposed on the flexures.

This will determine if the flexures are adequate. The relationship should be:

4. Calculate the lateral stiffness (k

) of the diaphragm flexures by using the

F

2

following formula:

5. Calculate the bending moment (M

) that is applied to the actuator and

1

reaction bracket with standard flexures installed.

6. Calculate the bending moment (M2) that is applied to the test specimen with

standard flexures installed.

Series 215 Rotary Actuator Product Manual Operation

55

Page 56

Summary of Side Load Calculations

7. Calculate the stress (SB) induced in the specimen due to base plate twist by

using the following formula:

Side load calculations

using diaphragm

flexures

The following calculations are used when diaphragm flexures are coupled to the

ends of a specimen.

1. Calculate the center line offset (∆) between actuator and reaction bracket

due to base plate twist by using the following formula:

2. Calculate the angle of flex (θ) imposed on each diaphragm flexure by using

the following formula: