MOTOROLA

SEMICONDUCTOR TECHNICAL DATA

1:6 Differential Clock

Distribution Chip

The MC10E/100E211 is a low skew 1:6 fanout device designed

explicitly for low skew clock distribution applications. The device can be

driven by either a differential or single-ended ECL or, if positive power

supplies are used, PECL input signal (PECL is an acronym for Positive

ECL, PECL levels are ECL levels referenced to +5V rather than ground).

If a single-ended input is to be used the VBB pin should be connected to

the CLK

supply is designed to act as the switching reference for the input of the

E211 under single-ended input conditions, as a result this pin can only

source/sink up to 0.5mA of current.

• Guaranteed Low Skew Specification

• Synchronous Enabling/Disabling

• Multiplexed Clock Inputs

• V

• Internal 75kΩ Input Pulldown Resistors

• Common and Individual Enable/Disable Control

• High Bandwidth Output Transistors

• Extended 100E V

of a lower speed scan or test clock along with the high speed system

clock. When LOW (or left open in which case it will be pulled LOW by the

input pulldown resistor) the SEL pin will select the differential clock input.

input and bypassed to ground via a 0.01µF capacitor. The V

Output for Single-Ended Use

BB

Range of –4.2V to –5.46V

EE

The E21 1 features a multiplexed clock input to allow for the distribution

BB

MC10E211

MC100E211

1:6 DIFFERENTIAL

CLOCK DISTRIBUTION CHIP

FN SUFFIX

PLASTIC PACKAGE

CASE 776-02

Both a common enable and individual output enables are provided. When asserted the positive output will go LOW on the next

negative transition of the CLK (or SCLK) input. The enabling function is synchronous so that the outputs will only be

enabled/disabled when the outputs are already in the LOW state. In this way the problem of runt pulse generation during the

disable operation is avoided. Note that the internal flip flop is clocked on the falling edge of the input clock edge, therefore all

associated specifications are referenced to the negative edge of the CLK input.

The output transitions of the E211 are faster than the standard ECLinPS edge rates. This feature provides a means of

distributing higher frequency signals than capable with the E111 device. Because of these edge rates and the tight skew limits

guaranteed in the specification, there are certain termination guidelines which must be followed. For more details on the

recommended termination schemes please refer to the applications information section of this data sheet.

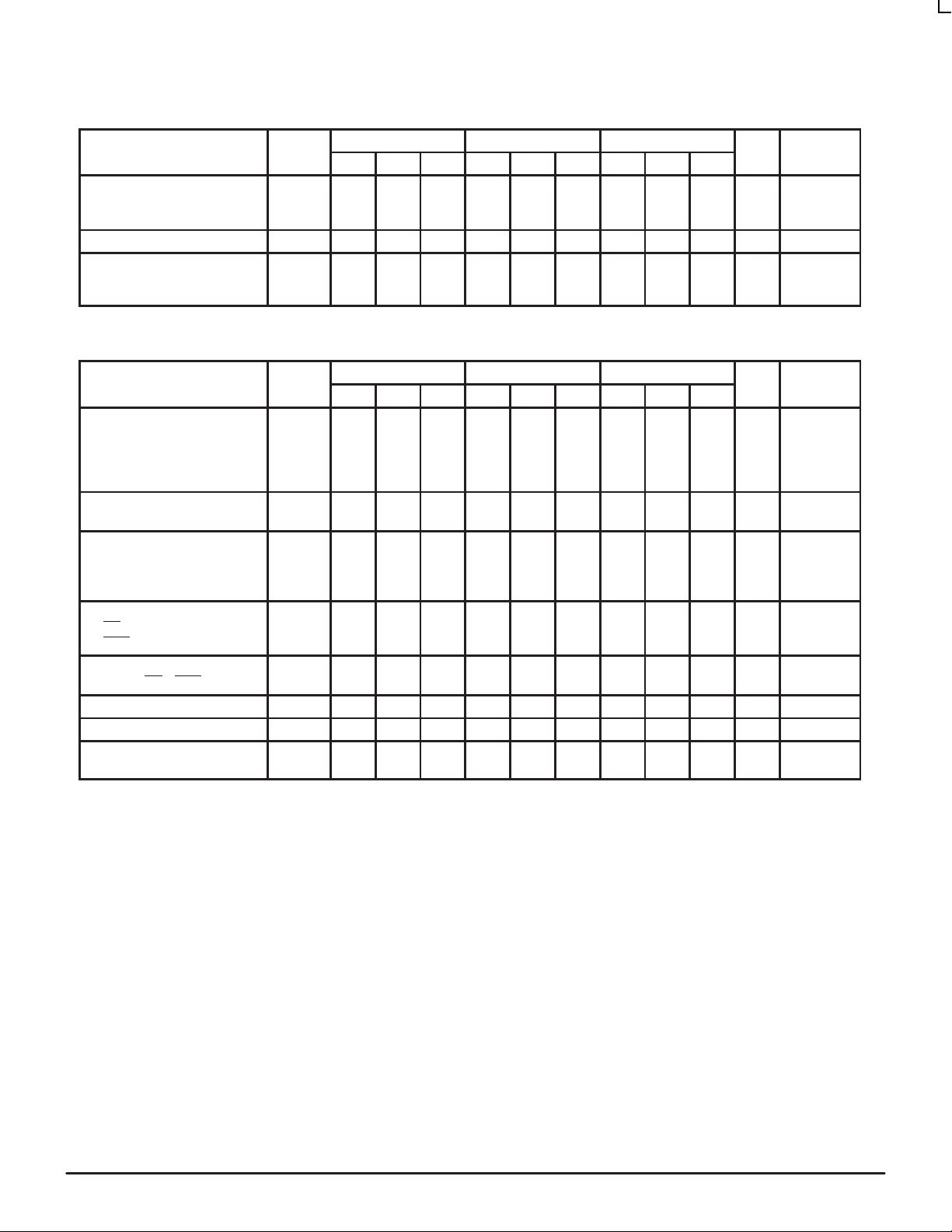

FUNCTION TABLE

CLK SCLK SEL ENx Q

H/L

X

Z*

* Z = Negative transition of CLK or SCLK

X

H/L

Z*

L

H

X

L

L

H

CLK

SCLK

L

ECLinPS is a trademark of Motorola Inc.

5/95

Motorola, Inc. 1996

2–1

REV 3

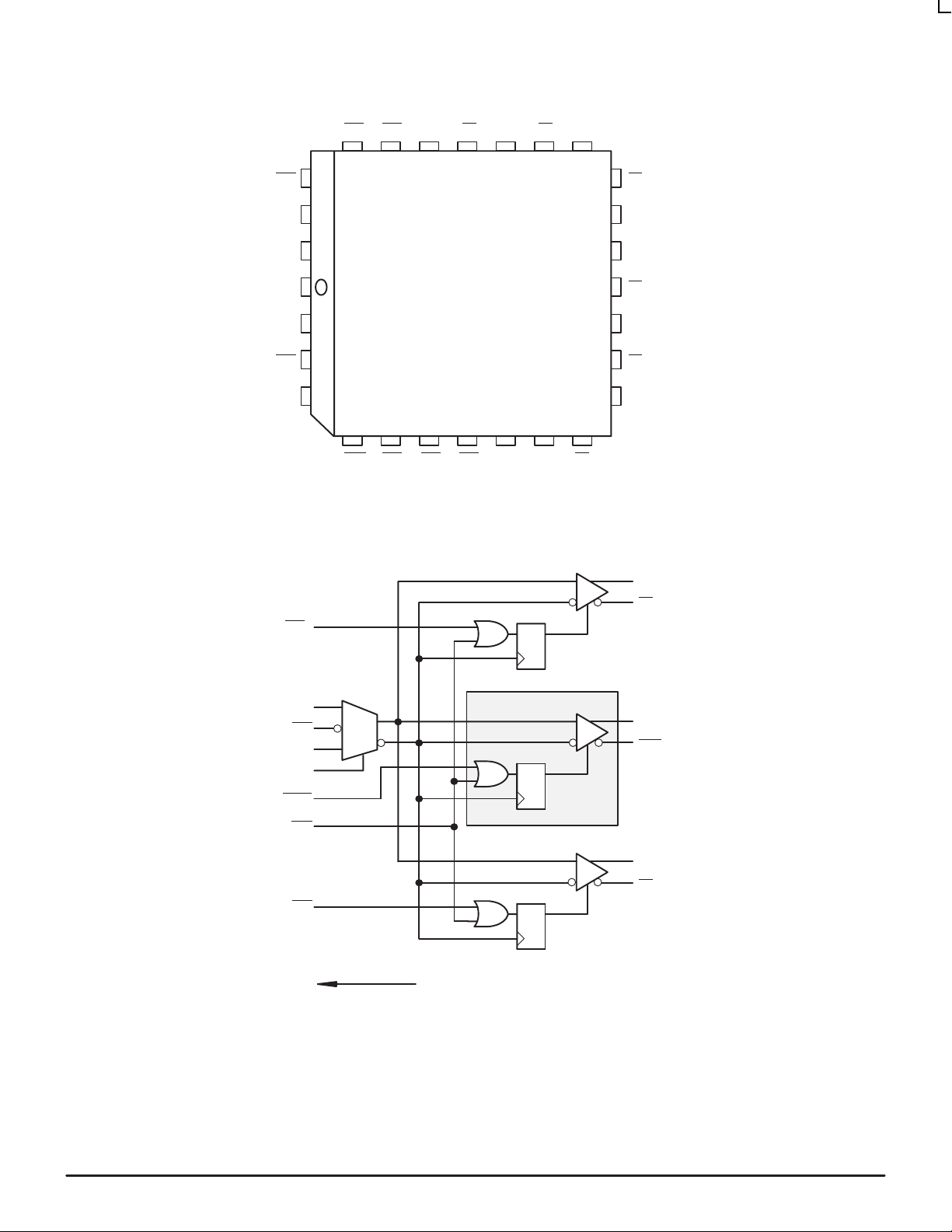

MC10E211 MC100E211

EN3

SEL

SCLK

V

CLK

CLK

V

BB

EE

EN0

EN4 EN5 V

25

26

27

28

1

2

3

4

5

CEN

24

6

EN2

Q5 Q5 Q4 Q4

CC0

22

23

7

8

EN1

EN0

Pinout: 28-Lead PLCC (Top View)

21

CC0

19

20

18

Q3

17

Q3

16

V

CC

Q2

15

14

Q2

Q1

13

12

Q1

11109

Q0

Q0V

Q0

Q0

QD

CLK

CLK

SCLK

SEL

EN1-4

CEN

EN5

V

BB

0

1

BITS 1-4

Q1-4

Q1-4

QD

Q5

Q5

QD

Logic Diagram

MOTOROLA ECLinPS and ECLinPS Lite

2–2

DL140 — Rev 4

MC10E211 MC100E211

DC CHARACTERISTICS (VEE = VEE(min) to VEE(max); VCC = V

0°C 25°C 85°C

Characteristic Symbol Min Typ Max Min Typ Max Min Typ Max Unit Condition

Output Reference Voltage

10E

100E

Input High Current I

Power Supply Current

10E

100E

AC CHARACTERISTICS (V

Characteristic Symbol Min Typ Max Min Typ Max Min Typ Max Unit Condition

Propagation Delay to Output

CLK to Q (Diff)

CLK to Q (SE)

SCLK to Q

SEL to Q

Disable Time

CLK or SCLK to Q

Part–to–Part Skew

CLK (Diff) to Q

CLK (SE), SCLK to Q

Within-Device Skew

Setup Time

EN

x to CLK

to CLK

CEN

Hold Time

CLK to EN

Minimum Input Swing (CLK) V

Com. Mode Range (CLK) V

Rise/Fall Times

20 – 80%

1. Within-Device skew is defined for identical transitions on similar paths through a device.

2. Setup, Hold and Disable times are all relative to a falling edge on CLK or SCLK.

3. Minimum input swing for which AC parameters are guaranteed. Full DC ECL output swings will be generated with only 50mV input swings.

4. The range in which the high level of the input swing must fall while meeting the VPP spec. The lower end of the range is VEE dependent and

can be calculated as VEE + 2.4V.

x, CEN

V

BB

–1.38

–1.38

IH

I

EE

= VEE(min) to VEE(max); VCC = V

EE

t

PLH

t

PHL

t

PHL

t

skew

t

s

t

h

PP

CMR

t

r

t

f

119

119

0°C 25°C 85°C

795

930

745

930

650

900

745

970

600 800 600 800 600 800

50

200

–100

200

900 600 900 160 900 600

0.25 1.0 0.25 1.0 0.25 1.0 V 3

–0.4 Note –0.4 Note –0.4 Note V 4

150 400 150 400 150 400

0

–1.27

–1.35

–1.26

–1.38

150 150 150 µA

160

160

CCO

1065

1115

1085

1195

805

755

650

755

270

370

75

200

200

= GND)

CCO

119

119

= GND)

940

940

910

980

50

–100

–1.25

–1.31

–1.26

–1.38

160

160

1075

1125

1095

1205

0

825

775

650

775

270

370

75

200

200

119

137

960

960

930

1000

–100

0

–1.19

–1.26

160

164

1095

1145

1115

1225

270

370

75

V

mA

ps

ps

2

ps

1

ps

2

ps

2

ps

DL140 — Rev 4

2–3 MOTOROLAECLinPS and ECLinPS Lite

MC10E211 MC100E211

APPLICATIONS INFORMATION

General Description

The MC10E/100E211 is a 1:6 fanout tree designed

explicitly for low skew high speed clock distribution. The

device was targeted to work in conjunction with the E111

device to provide another level of flexibility in the design and

implementation of clock distribution trees. The individual

synchronous enable controls and multiplexed clock inputs

make the device ideal as the first level distribution unit in a

distribution tree. The device provides the ability to distribute a

lower speed scan or test clock along with the high speed

system clock to ease the design of system diagnostics and

self test procedures. The individual enables could be used to

allow for the disabling of individual cards on a backplane in

fault tolerant designs.

Because of lower fanout and larger skews the E211 will

not likely be used as an alternative to the E1 11 for the bulk of

the clock fanout generation. Figure 1 shows a typical

application combining the two devices to take advantage of

the strengths of each.

E211

Q0

Q5

E111

BACKPLANE

E111

Q0

Q8

Q0

Q8

Figure 1. Standard E211 Application

Using the E211 in PECL Designs

The E21 1 device can be utilized very effectively in designs

utilizing only a +5V power supply . Since the internal switching

reference levels are biased off of the VCC supply the input

thresholds for the single-ended inputs will vary with VCC. As a

result the single-ended inputs should be driven by a device

on the same board as the E21 1. Driving these inputs across a

backplane where significant differences between the VCC’s of

the transmitter and receiver can occur can lead to AC

performance and/or significant noise margin degradations.

Because the differential I/O does not use a switching

reference, and due to the CMR range of the E211, even

under worst case VCC situations between cards there will be

no AC performance or noise margin loss for the differential

CLK inputs.

For situations where TTL clocks are required the E21 1 can

be interfaced with the H641 or H643 ECL to TTL Clock

Distribution Chips from Motorola. The H641 is a single supply

1:9 PECL to TTL device while the H643 is a 1:8 dual supply

standard ECL to TTL device. By combining the superior skew

performance of the E211, or E111, with the low skew

translating capabilities of the H641 and H643 very low skew

TTL clock distribution networks can be realized.

Handling Open Inputs and Outputs

All of the input pins of the E211 have a 50kΩ to 75kΩ

pulldown resistor to pull the input to VEE when left open. This

feature can cause a problem if the differential clock inputs are

left open as the input gate current source transistor will

become saturated. Under these conditions the outputs of the

CLK input buffer will go to an undefined state. It is

recommended, if possible,that the SCLK input should be

selected any time the differential CLK inputs are allowed to

float. The SCLK buffer, under open input conditions, will

maintain a defined output state and thus the Q outputs of the

device will be in a defined state (Q = LOW). Note that if all of

the inputs are left open the differential CLK input will be

selected and the state of the Q outputs will be undefined.

With the simultaneous switching characteristics and the

tight skew specifications of the E211 the handling of the

unused outputs becomes critical. To minimize the noise

generated on the die all outputs should be terminated in

pairs, ie. both the true and compliment outputs should be

terminated even if only one of the outputs will be used in the

system. With both complimentary pairs terminated the

current in the VCC pins will remain essentially constant and

thus inductance induced voltage glitches on VCC will not

occur. VCC glitches will result in distorted output waveforms

and degradations in the skew performance of the device.

The package parasitics of the 28-lead PLCC cause the

signals on a given pin to be influenced by signals on adjacent

pins. The E211 is characterized and tested with all of the

outputs switching, therefore the numbers in the data book are

guaranteed only for this situation. If all of the outputs of the

E21 1 are not needed and there is a desire to save power the

unused output pairs can be left unterminated. Unterminated

outputs can influence the propagation delay on adjacent pins

by 15ps - 20ps. Therefore under these conditions this 15ps 20ps needs to be added to the overall skew of the device.

Pins which are separated by a package corner are not

considered adjacent pins in the context of propagation delay

influence. Therefore as long as all of the outputs on a single

side of the package are terminated the specification limits in

the data sheet will apply.

MOTOROLA ECLinPS and ECLinPS Lite

2–4

DL140 — Rev 4

APPLICATIONS INFORMATION

MC10E211 MC100E211

Differential versus Single-Ended Use

As can be seen from the data sheet, to minimize the skew

of the E21 1 the device must be used in the dif ferential mode.

In the single-ended mode the propagation delays are

dependent on the relative position of the VBB switching

reference. Any VBB offset from the center of the input swing

will add delay to either the T

PLH

or T

and subtract delay

PHL

from the other. This increase and decrease in delay will lead

to an increase in the duty cycle skew and thus part-to-part

skew. The within-device skew will be independent of the V

BB

and therefore will be the same regardless of whether the

device is driven differentially or single-endedly.

For applications where part-to-part skew or duty cycle

skew are not important the advantages of single-ended clock

distribution may lead to its use. Using single-ended

interconnect will reduce the number of signal traces to be

routed, but remember that all of the complimentary outputs

still need to be terminated therefore there will be no reduction

in the termination components required. T o use the E21 1 with

a single-ended input the arrangement pictured in Figure 2b

should be used. If the input to the differential CLK inputs are

AC coupled as pictured in Figure 2a the dependence on a

centered VBB reference is removed. The situation pictured

will ensure that the input is centered around the bias set by

the VBB. As a result when AC coupled the AC specification

limits for a differential input can be used. For more

information on AC coupling please refer to the interfacing

section of the design guide in the ECLinPS data book.

pulse. On initial power up the enable flip flops will randomly

attain a stable state, therefore precautions should be taken

on initial power up to ensure the E21 1 is in the desired state.

IN

0.001µF

IN

50Ω

0.01µF

V

BB

Figure 2a. AC Coupled Input

IN

IN

Using the Enable Pins

Both the common enable (CEN

enables (ENx

) are synchronous to the CLK or SCLK input

) and the individual

depending on which is selected. The active low signals are

clocked into the enable flip flops on the negative edges of the

E211 clock inputs. In this way the devices will only be

disabled when the outputs are already in the LOW state. The

internal propagation delays are such that the delay to the

output through the distribution buffers is less than that

through the enable flip flops. This will ensure that the

disabling of the device will not slice any time off the clock

0.01µF

V

BB

Figure 2b. Single-Ended Input

DL140 — Rev 4

2–5 MOTOROLAECLinPS and ECLinPS Lite

MC10E211 MC100E211

-N-

-L-

28 1

OUTLINE DIMENSIONS

FN SUFFIX

PLASTIC PLCC PACKAGE

CASE 776–02

ISSUE D

SNSM

G1

–M

SNSM

–M

0.010 (0.250) T L

–M

SNSS

0.007 (0.180) T L

Y BRK

B

0.007 (0.180) T L

U

D

Z

-M-

D

W

V

X

VIEW D-D

Z

C

G

G1

0.010 (0.250) T L

0.007 (0.180) T L

A

0.007 (0.180) T L

R

E

0.004 (0.100)

J

PLANE

SEATING

-T-

VIEW S

SNSS

–M

NOTES:

1. DATUMS -L-, -M-, AND -N- DETERMINED

WHERE TOP OF LEAD SHOULDER EXITS

PLASTIC BODY AT MOLD PARTING LINE.

2. DIM G1, TRUE POSITION TO BE MEASURED

AT DATUM -T-, SEATING PLANE.

3. DIM R AND U DO NOT INCLUDE MOLD FLASH.

ALLOWABLE MOLD FLASH IS 0.010 (0.250)

PER SIDE.

4. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

5. CONTROLLING DIMENSION: INCH.

6. THE PACKAGE TOP MAY BE SMALLER THAN

THE PACKAGE BOTTOM BY UP TO 0.012

(0.300). DIMENSIONS R AND U ARE

DETERMINED AT THE OUTERMOST

EXTREMES OF THE PLASTIC BODY

EXCLUSIVE OF MOLD FLASH, TIE BAR

BURRS, GATE BURRS AND INTERLEAD

FLASH, BUT INCLUDING ANY MISMATCH

BETWEEN THE TOP AND BOTTOM OF THE

PLASTIC BODY.

7. DIMENSION H DOES NOT INCLUDE DAMBAR

PROTRUSION OR INTRUSION. THE DAMBAR

PROTRUSION(S) SHALL NOT CAUSE THE H

DIMENSION TO BE GREATER THAN 0.037

(0.940). THE DAMBAR INTRUSION(S) SHALL

NOT CAUSE THE H DIMENSION TO BE

SMALLER THAN 0.025 (0.635).

–M

–M

SNSM

SNSM

H

0.007 (0.180) T L

–M

SNSM

K1

K

SNSM

0.007 (0.180) T L

F

–M

VIEW S

INCHES MILLIMETERS

MIN MINMAX MAX

DIM

A

0.485

B

0.485

C

0.165

E

0.090

F

0.013

G

0.050 BSC

H

0.026

J

0.020

K

0.025

R

0.450

U

0.450

V

0.042

W

0.042

X

0.042

Y

—

Z

2°

G1

0.410

K1

0.040

0.495

0.495

0.180

0.110

0.019

0.032

0.456

0.456

0.048

0.048

0.056

0.020

10°

0.430

12.32

12.57

12.32

12.57

4.20

4.57

2.29

2.79

0.33

0.48

1.27 BSC

0.66

0.81

0.51

0.64

11.43

11.43

1.07

1.07

1.07

10.42

1.02

—

—

11.58

11.58

1.21

1.21

1.42

—

0.50

2°

10°

10.92

—

—

—

—

MOTOROLA ECLinPS and ECLinPS Lite

2–6

DL140 — Rev 4

MC10E211 MC100E211

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE/Locations Not Listed: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, 6F Seibu–Butsuryu–Center,

P.O. Box 20912; Phoenix, Arizona 85036. 1–800–441–2447 or 602–303–5454 3–14–2 Tatsumi Koto–Ku, Tokyo 135, Japan. 03–81–3521–8315

MFAX: RMF AX0@email.sps.mot.com – T OUCHTONE 602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://Design–NET .com 51 Ting Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

MC10E211/D

DL140 — Rev 4

◊

2–7 MOTOROLAECLinPS and ECLinPS Lite

*MC10E211/D*

Loading...

Loading...