Page 1

Service Manual

Page 2

Service Manual

Page 3

CapnoLine® is a U.S. registered trademark of Oridion Medical Ltd.

Copyright © Mindray DS USA, Inc., 2009. All rights reserved. Contents of this publication may not be reproduced in any

form without permission of Mindray DS USA, Inc.

DRYLINE

Durasensor

Edwards

FilterLine

LNCS

LNOP

Masimo SET

Max-Fast

miniMediCO

Microstream

Navigator

Nellcor

NIV Line

Oxiband

™

is a trademark of Artema Medical AB

®

is a U.S. registered trademark of Nellcor Puritan Bennett Inc.

®

is a U.S. registered trademark of Edwards Lifesciences Corp.

®

is a U.S. registered trademark of Oridion Medical Ltd.

®

is a U.S. registered trademark of Masimo Corp.

®

is a U.S. registered trademark of Masimo Corp.

®

is a U.S. registered trademark of Masimo Corp.

™

is a trademark of Nellcor Puritan Bennett Inc.

®

is a U.S. registered trademark of Oridion Medical Ltd.

2

®

is a U.S. registered trademark of Oridion Medical Ltd.

™

is a U.S. trademark of Mindray DS USA, Inc.

™

is a U.S. trademark of Nellcor Puritan Bennett Inc.

™

is a trademark of Oridion Medical Ltd.

®

is a U.S. registered trademark of Nellcor Puritan Bennett Inc.

™

OxiMax

Oxisensor

Passport V

Velcro

Viewstation OR

Windows

is a U.S. trademark of Nellcor Puritan Bennett Inc.

®

is a U.S. registered trademark of Nellcor Puritan Bennett Inc.

™

is a U.S. trademark of Mindray DS USA, Inc.

®

is a registered trademark of Velcro Industries B.V.

™

is a U.S. trademark of Mindray DS USA, Inc.

®

is a registered trademark of Microsoft Corp.

Passport V™ Service Manual 0070-10-0705

Page 4

Tabl e o f Co nt en ts

Foreword....................................................................................................................................................... v

Warnings, Cautions, and Notes .......................................................................................................................v

Warnings ......................................................................................................................................................v

Cautions ........................................................................................................................................................v

Notes ............................................................................................................................................................vi

Theory of Operation ......................................................................................................... 1 - 1

Introduction.................................................................................................................................................... 1 - 1

System Connections ........................................................................................................................................1 - 2

Mounting the Patient Monitor ....................................................................................................................1 - 2

Connectors for Peripheral Devices .............................................................................................................1 - 2

Main Unit ......................................................................................................................................................1 - 3

Input System ........................................................................................................................................... 1 - 4

Output System.........................................................................................................................................1 - 4

Processing and Communications System..................................................................................................... 1 - 6

Power Management System ......................................................................................................................1 - 6

Equipment Interface System.......................................................................................................................1 - 8

Parameter modules ..................................................................................................................................1 - 10

Block Diagrams ................................................................................................................ 2 -1

Introduction.................................................................................................................................................... 2 - 1

Block Diagram................................................................................................................................................ 2 - 2

Repair Information ........................................................................................................... 3 - 1

Introduction.................................................................................................................................................... 3 - 1

Safety Precautions...........................................................................................................................................3 - 1

Troubleshooting Guidelines ..............................................................................................................................3 - 2

Special Tools Required ....................................................................................................................................3 - 2

Disassembly Instructions................................................................................................................................... 3 - 2

Removal of the Key Panel and Keys ...........................................................................................................3 - 3

Removal of the Front Housing Assembly .....................................................................................................3 - 4

Removal of the Main Board ......................................................................................................................3 - 5

Removal of the Inverter.............................................................................................................................3 - 6

Removal of the LCD Panel......................................................................................................................... 3 - 7

Removal of the Keyboard .........................................................................................................................3 - 8

Removal of the Alarm LED Board ...............................................................................................................3 - 9

Removal of the Encoder............................................................................................................................3 - 9

Removal of the Multi-parameter Board Assembly .........................................................................................3 - 10

Removal of the Parameter Front Panel Assembly .......................................................................................... 3 - 12

Removal of the Multi-parameter board........................................................................................................3 - 13

Removal of the CO

Removal of the Masimo SpO

Removal of the Nellcor SpO

Removal of the NIBP Assembly ..................................................................................................................3 - 15

Removal of the Recorder Assembly ............................................................................................................3 - 15

Removal of the Recorder Cover (if needed) ................................................................................................. 3 - 16

Removal of the Main Frame and Multi-parameter Board Assembly ................................................................. 3 - 16

Removal of the Speaker Assembly .............................................................................................................3 - 17

Removal of the Fan Assembly.................................................................................................................... 3 - 18

Removal of the CF Card Assembly.............................................................................................................3 - 19

Removal of the Power Board .....................................................................................................................3 - 19

Removal of the Li-ion Battery Interface Board Assembly................................................................................. 3 - 21

Removal of the Interface Board Assembly ...................................................................................................3 - 23

Removal of the Wireless AP ...................................................................................................................... 3 - 25

Nurse Call Cable............................................................................................................................................3 - 27

Module..................................................................................................................... 3 - 13

2

Module ....................................................................................................... 3 - 14

2

Module ........................................................................................................ 3 - 14

2

Passport V™ Service Manual 0070-10-0705 i

Page 5

Tabl e o f Co nt ent s

P/N 8000-21-10361 ..............................................................................................................................3 - 27

Analog Output Cable ......................................................................................................................................3 - 27

P/N 6100-20-86360 ..............................................................................................................................3 - 27

Defib Synch Cable ..........................................................................................................................................3 - 28

P/N 6100-20-86361 ..............................................................................................................................3 - 28

Serial Port to Gas Module 3 Cable ...................................................................................................................3 - 29

P/N 0012-00-1276-XX ............................................................................................................................3 - 29

Null Modem Cable ......................................................................................................................................... 3 - 30

P/N 0012-00-1275-01............................................................................................................................3 - 30

Universal ECG Lead Wires .............................................................................................................................. 3 - 31

P/N 0012-00-1503-XX ............................................................................................................................3 - 31

ECG Cable, 3/5-lead (ESIS and Non ESIS)........................................................................................................ 3 - 32

P/N 0012-00-1745-XX ............................................................................................................................3 - 32

12-pin 3-lead Neo ECG Trunk Cable (IEC/AHA) ................................................................................................3 - 32

P/N 040-000072-00 ..............................................................................................................................3 - 32

IBP Cable....................................................................................................................................................... 3 - 33

P/N 040-000052-00 ..............................................................................................................................3 - 33

P/N 040-000053-00 ..............................................................................................................................3 - 33

P/N 040-000054-00 ..............................................................................................................................3 - 33

P/N 040-000096-00 ..............................................................................................................................3 - 34

Temperature Cable .........................................................................................................................................3 - 34

1.15.1 P/N 040-000055-00 ...................................................................................................................3 - 34

P/N 040-000056-00 ..............................................................................................................................3 - 34

P/N 040-000057-00 ..............................................................................................................................3 - 35

P/N 040-000058-00 ..............................................................................................................................3 - 35

P/N 040-000091-00 ..............................................................................................................................3 - 35

P/N 040-0000100-00 ............................................................................................................................3 - 36

P/N 040-000224-00 ..............................................................................................................................3 - 36

Troubleshooting Menus.................................................................................................................................... 3 - 37

ECG Troubleshooting ...............................................................................................................................3 - 37

NIBP Troubleshooting...............................................................................................................................3 - 39

Troubleshooting..............................................................................................................................3 - 40

SpO

2

Temperature Troubleshooting ....................................................................................................................3 - 42

Resp Troubleshooting ............................................................................................................................... 3 - 43

IBP Troubleshooting .................................................................................................................................3 - 44

Troubleshooting ...............................................................................................................................3 - 45

CO

2

Gas Module Troubleshooting ....................................................................................................................3 - 48

Trends Troubleshooting............................................................................................................................. 3 - 50

Printer/Recorder Troubleshooting .............................................................................................................. 3 - 50

Monitor/Display Troubleshooting ..............................................................................................................3 - 52

Remote View Troubleshooting ...................................................................................................................3 - 52

Installation Menu ............................................................................................................................................3 - 53

Installation Mode.....................................................................................................................................3 - 53

Advanced Installation Setup Menu.............................................................................................................3 - 56

Options Menu......................................................................................................................................... 3 - 57

Trend Storage ................................................................................................................................................ 3 - 57

Software Download ........................................................................................................................................3 - 58

Isometric Drawings and Parts List ..................................................................................... 4 - 1

Introduction.................................................................................................................................................... 4 - 1

Top Level Assembly .........................................................................................................................................4 - 2

Main Unit Assembly ........................................................................................................................................ 4 - 4

Front Housing Sub-assembly .............................................................................................................................4 - 5

ii 0070-10-0705 Passport V™ Service Manual

Page 6

Tabl e o f Co nt en ts

Rear Housing Sub-assembly ............................................................................................................................. 4 - 6

Main Chassis Sub-assembly .............................................................................................................................4 - 7

Interface Connector PCB Assembly....................................................................................................................4 - 9

Parameter Sub-assembly ..................................................................................................................................4 - 10

Patient Connector Sub-assembly........................................................................................................................4 - 11

NIBP Module Assembly ...................................................................................................................................4 - 12

Microstream CO

DPM CO

Masimo SpO

Nellcor SpO

Module Assembly .................................................................................................................4 - 13

2

Module Assembly............................................................................................................................ 4 - 14

2

PCB Assembly........................................................................................................................... 4 - 15

2

Module Assembly .......................................................................................................................4 - 16

2

Calibration Procedure ....................................................................................................... 5 - 1

Introduction.................................................................................................................................................... 5 - 1

Warnings and Guidelines................................................................................................................................ 5 - 1

Test Equipment and Special Tools Required........................................................................................................ 5 - 2

Services......................................................................................................................................................... 5 - 2

ECG Channels Check ..............................................................................................................................5 - 3

NIBP Maintenance...................................................................................................................................5 - 4

NIBP Accuracy Test .........................................................................................................................5 - 4

NIBP Leakage Test ...........................................................................................................................5 - 5

NIBP Calibration ............................................................................................................................. 5 - 5

IBP Calibration........................................................................................................................................ 5 - 6

Calibration .....................................................................................................................................5 - 6

CO

2

Gas Calibration ......................................................................................................................................5 - 8

Monitor Log ............................................................................................................................................5 - 11

Verification ....................................................................................................................................................5 - 12

Initial Set-up............................................................................................................................................5 - 12

ECG ......................................................................................................................................................5 - 13

Initialization .................................................................................................................................... 5 - 13

Leads OFF ...................................................................................................................................... 5 - 13

Pacer Detect ................................................................................................................................... 5 - 13

Performance Test ............................................................................................................................. 5 - 14

IBP 1 and IBP 2 Verification ......................................................................................................................5 - 14

Temperature Verification........................................................................................................................... 5 - 14

Verification....................................................................................................................................5 - 14

SpO

2

NIBP Verification .....................................................................................................................................5 - 14

Battery Operation Verification................................................................................................................... 5 - 15

Operation Verification......................................................................................................................5 - 15

CO

2

Leakage Current Tests ..............................................................................................................................5 - 15

Preventative Maintenance................................................................................................. 6 - 1

User Preventative Maintenance Introduction .......................................................................................................6 - 1

Preventative Maintenance Schedule .................................................................................................................. 6 - 2

Mechanical / Physical / Visual Inspection - Annually ...................................................................................6 - 2

Visual test ...............................................................................................................................................6 - 2

Power on test ..........................................................................................................................................6 - 2

Perform NIBP Verification and Calibration – Annually ..................................................................................6 - 2

Perform CO

Perform IBP Verification and Calibration – Annually..................................................................................... 6 - 2

Perform ECG Verification – Annually..........................................................................................................6 - 2

Perform Verification and Gas Calibration – Annually ...................................................................................6 - 3

Temperature Perform Verification – Annually ...............................................................................................6 - 3

SpO

2

Electrical Safety Tests – Annually ...............................................................................................................6 - 3

Verification and Calibration -- Annually................................................................................... 6 - 2

2

Perform Verification – Annually ........................................................................................................6 - 3

Passport V™ Service Manual 0070-10-0705 iii

Page 7

Tabl e o f Co nt ent s

Care and Cleaning of the Monitor .................................................................................................................... 6 - 4

Decontamination of the Monitor ................................................................................................................6 - 4

Care and Cleaning of SpO

Cleaning and Re-use of a Nellcor

Cleaning CO

Sensors, Adapters and Sampling Components ..............................................................................6 - 6

2

Sensors................................................................................................................. 6 - 5

2

®

Sensor.................................................................................................. 6 - 5

Sterilization and Cleaning of Cuffs....................................................................................................................6 - 7

Reusable Cuffs with Bladders ....................................................................................................................6 - 7

Reusable Bladderless Cuffs .......................................................................................................................6 - 8

Disposable Blood Pressure Cuffs................................................................................................................ 6 - 8

Care and Cleaning of Gas Module................................................................................................................... 6 - 9

Care and Cleaning of 3- and 5-lead ECG Cables and Leadwires .........................................................................6 - 10

Battery Replacement and Maintenance ..............................................................................................................6 - 11

Battery Replacement ................................................................................................................................6 - 11

Battery Maintenance ................................................................................................................................6 - 11

Recorder Maintenance ....................................................................................................................................6 - 12

Cleaning the Recorder Printhead ...............................................................................................................6 - 12

Recorder Paper Replacement ....................................................................................................................6 - 12

Care and Storage of Thermal Chart Paper.................................................................................................. 6 - 12

Warranty Statements....................................................................................................................................... 6 - 14

USA, Canada, Mexico, and Puerto Rico.....................................................................................................6 - 14

International (excluding North America) .....................................................................................................6 - 15

Phone Numbers and How To Get Help ......................................................................................................6 - 16

Manufacturer’s Responsibility ....................................................................................................................6 - 16

iv 0070-10-0705 Passport V™ Service Manual

Page 8

Foreword Introduction

Foreword

The Passport V Service Manual is intended as a guide for technically qualified personnel

during repair and calibration procedures. This publication may have been updated to reflect

product design changes and/or manual improvements.

Warnings, Cautions, and Notes

Please read and adhere to all warnings, cautions, and notes listed here and in the

appropriate areas throughout this manual.

A WARNING is provided to alert the user to potential serious outcomes (death, injury, or

serious adverse events) to the patient or the user.

A CAUTION is provided to alert the user to use special care necessary for the safe and

effective use of the device. They may include actions to be taken to avoid effects on patients

or users that may not be potentially life threatening or result in serious injury, but about which

the user should be aware. Cautions are also provided to alert the user to adverse effects on

this device of use or misuse and the care necessary to avoid such effects.

A NOTE is provided when additional general information is applicable.

Warnings

WARNING: The Passport V operates on line voltages. Therefore, an

electric shock hazard may exist when the instrument covers

are removed. Repair and calibration procedures should only

be performed by qualified personnel who proceed with care

and follow proper servicing techniques. Warnings are given

in various chapters, as well as in other appropriate

locations.

WAR N I NG: In t e rnal El e c trical S hock Ha zard - This unit does not contain

any user-serviceable parts. Do not remove instrument

covers. Refer Servicing to qualified personnel.

WAR N I NG: Wh e n ever th e monito r is open e d for c a l ibratio n or rep a i r, a

risk (leakage) current safety check and a verification of

basic functions of all parameters should be performed

before the monitor is returned to Clinical use. See

“Verification” on page 5-12.

WAR N I NG: Do n ot clea n the mon i tor while it is powered on and/or

plugged in.

WAR N I NG: Pe r f o rm t h e d e contami n ation process with the unit powered

off and the power cord removed.

Cautions

CAUTION: Calibration is not to be performed while monitoring a

patient.

CAUTION: A functional tester cannot be used to assess the accuracy of

the pulse oximeter probe or a pulse oximeter monitor.

Passport V™ Service Manual 0070-10-0705 v

Page 9

Introduction Notes

CAUTION: When cleaning the monitor, do not allow cleaning solutions

CAUTION: When cleaning sensors, do not use excessive amounts of

CAUTION: Some disinfectants may cause skin irritation. Please rinse

CAUTION: Using dark colored soaks may stain the cuffs. Test a single

CAUTION: When ironing or pressing the cuffs, be aware that the

CAUTION: Disposable cuffs can be cleaned using a mild soap solution

CAUTION: Do not clean the Gas Module while it is on and/or plugged

CAUTION: The internal sampling system of the Gas Module does not

into the vent openings.

liquid. Wipe the sensor surface with a soft cloth dampened

with cleaning solution. Do not attempt to sterilize.

cuff thoroughly with water to remove any residual

disinfectants.

cuff to ensure that no damage will occur.

®

Vel c ro

(162°C).

and dried with a clean cloth.

in.

need to be cleaned or sterilized. There is no reverse flow

back to the patient. If the internal sampling system is

suspected to be clogged or dirty, the module should be

serviced by an authorized service person only.

fasteners can melt at temperatures above 325°F

CAUTION: To avoid permanent damage, do not expose metal

components (e.g., pins, sockets, snaps) to disinfectants,

soaps, or chemicals.

CAUTION: Recharge batteries in the Passport V.

CAUTION: Remove the batteries if the Passport V is not likely to be

used for an extended period of time.

CAUTION: Never pull the recorder paper with force when a recording

is in process; it may cause damage to the recorder.

CAUTION: Do not leave the recorder door open unless reloading paper

or troubleshooting.

Notes

NOTE: Unauthorized servicing may void the remainder of the

warranty. Check with the factory or with a local authorized

representative to determine the warranty status of a

particular instrument.

vi 0070-10-0705 Passport V™ Service Manual

Page 10

1.0

Theory of Operation

1.1 Introduction

This patient monitor is intended to be used for monitoring, displaying, reviewing, storing,

and transferring of multiple physiological parameters including: ECG, respiration (Resp),

temperature (Temp), SpO

blood pressure (IBP), End tidal CO

pediatric, and neonatal patients.

, pulse rate (PR), non-invasive blood pressure (NIBP), invasive

2

value (EtCO2) and anesthetic gas (AG) of single adult,

2

FIGURE 1-1 The Passport V Monitor

Passport V™ Service Manual 0070-10-0705 1 - 1

Page 11

System Connections Theory of Operation

Additional Passport V features:

•Provides audible and visual alarm indications.

•Incorporates multiple input devices such as a keypad and knob.

•Enables program upgrade over the network.

1.2 System Connections

1.2.1 Mounting the Patient Monitor

The Passport V can be mounted on a wall mount bracket, a rolling stand, or a bedrail

hook, which can be ordered optionally. Each type of mounting solution is delivered with a

complete set of mounting hardware and instructions. Refer to the documentation delivered

with the mounting hardware for instructions on assembling mounts.

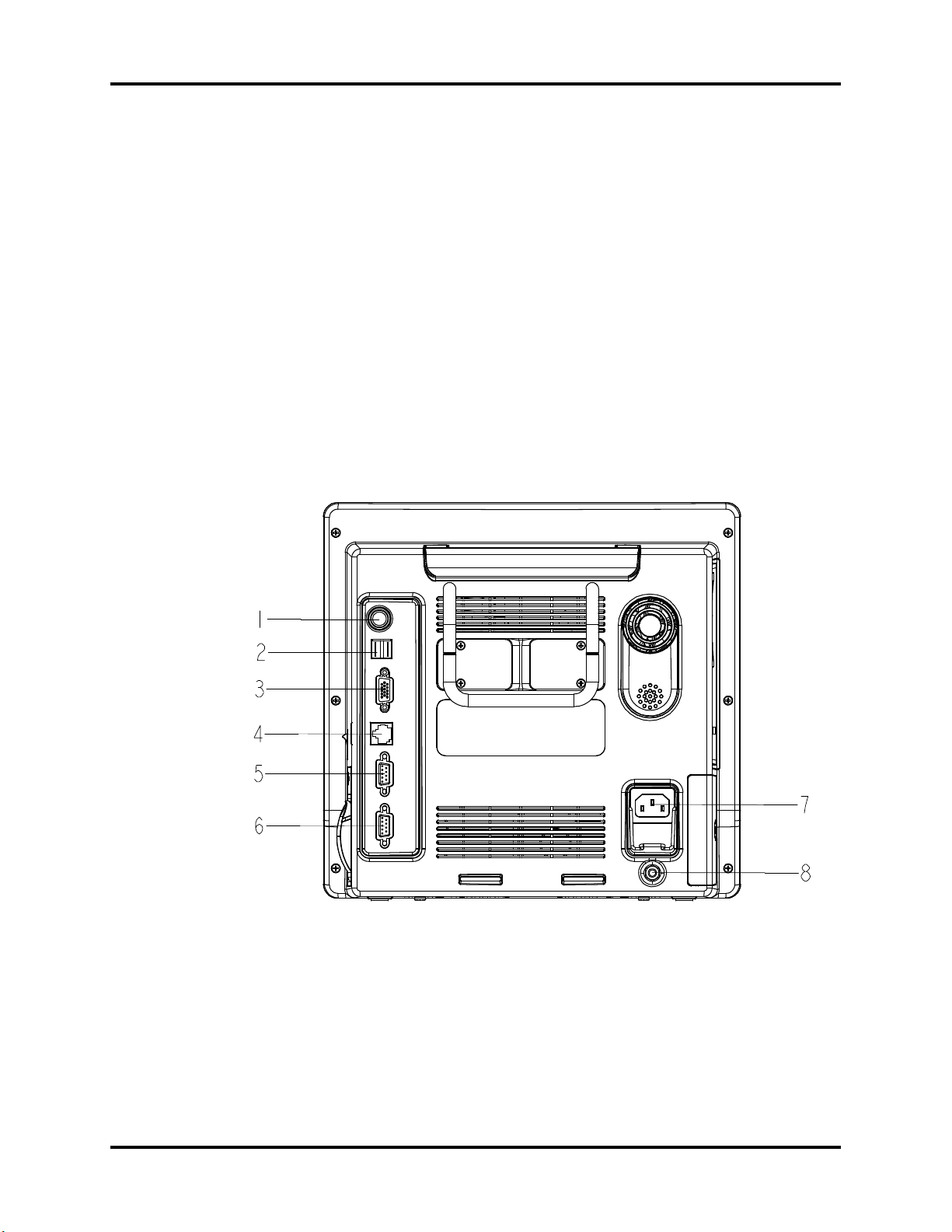

1.2.2 Connectors for Peripheral Devices

On the back of the Passport V are the connectors for peripheral devices.

FIGURE 1-2 Connectors for Peripheral Devices

1 - 2 0070-10-0705 Passport V™ Service Manual

Page 12

Theory of Operation Main Unit

1. Auxiliary Output

A standard BNC connector, through which defibrillator synchronization signals, analog

output signals, and nurse call signals can be outputted, depending on how the monitor is

configured.

2. SB Connector

A connector for an external storage device.

3. VGA Connector

A connector for a standard SVGA color monitor.

4. Network Connector

An RJ45 connector, through which an Ethernet network or a PC can be connected.

5. RS232 serial port

A DB9 connector, used to connect a PC for data or a Gas Module 3, depending on how

the monitor is configured.

6. RS232 serial port

A DB9 connector, used to connect a PC for data or a Gas Module 3, depending on how

the monitor is configured.

7. AC Power Connector

A connector for an AC power source (100 to 240 VAC, 50/60Hz).

8. Equipotential lug

A connector for common ground with other equipment.

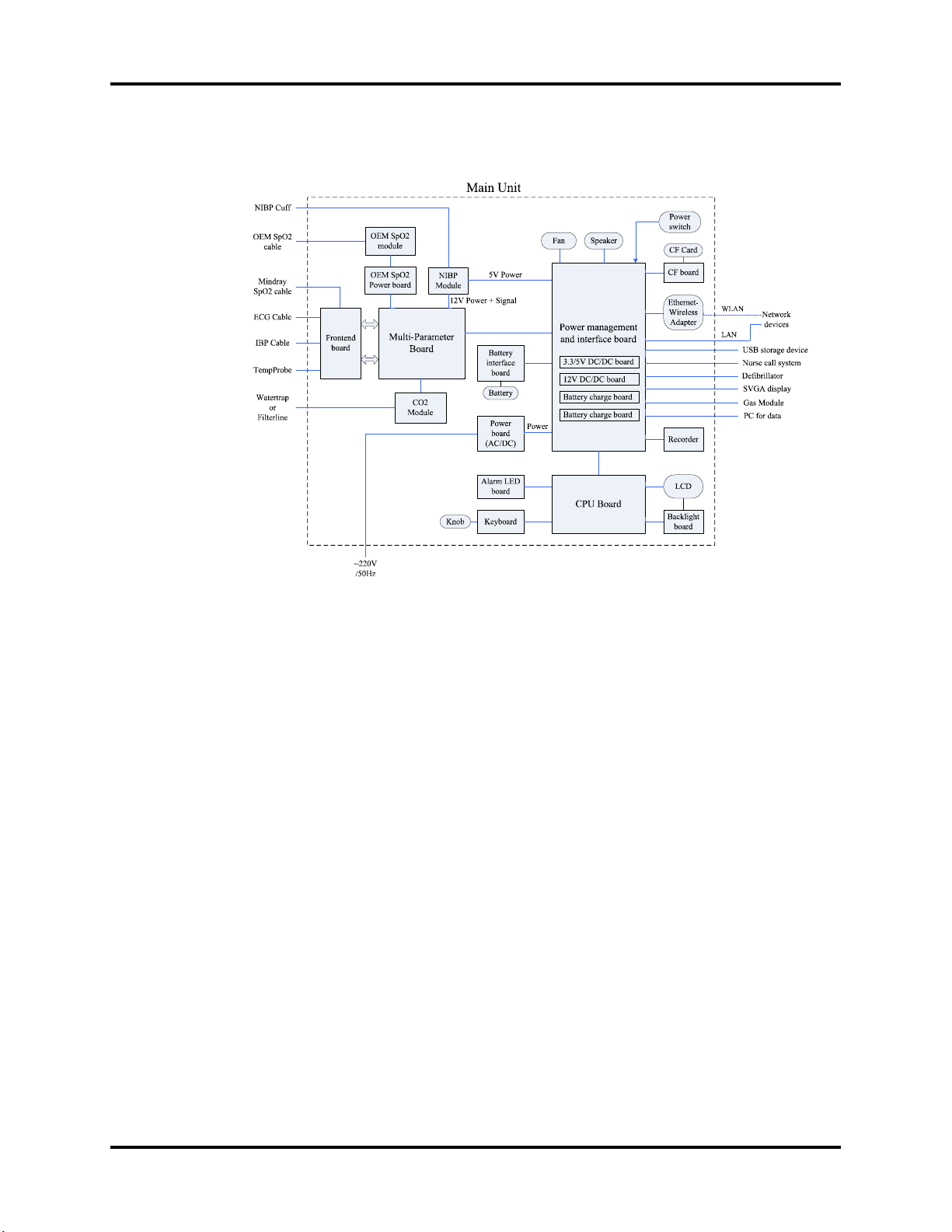

1.3 Main Unit

The Passport V consists of the following:

• Input system:

keypad, knob, and power switch.

• Output system:

LCD panel, alarm LED board, recorder, speaker, AC/battery status LEDs).

• Processing and communications system:

CPU board, Power management and interface board.

• Power management system:

battery, battery interface board, power board (AC/DC), Power management and

interface board.

• Equipment interface system:

power management and interface board, Ethernet-wireless adapter.

• Parameter modules:

multi-parameter board, CO

Additionally, the patient monitor can also connect a DPM SB storage device, a Gas

Module 3, or a PC for data transfer.

module, OEM SpO2 module, NIBP module.

2

Passport V™ Service Manual 0070-10-0705 1 - 3

Page 13

Main Unit Theory of Operation

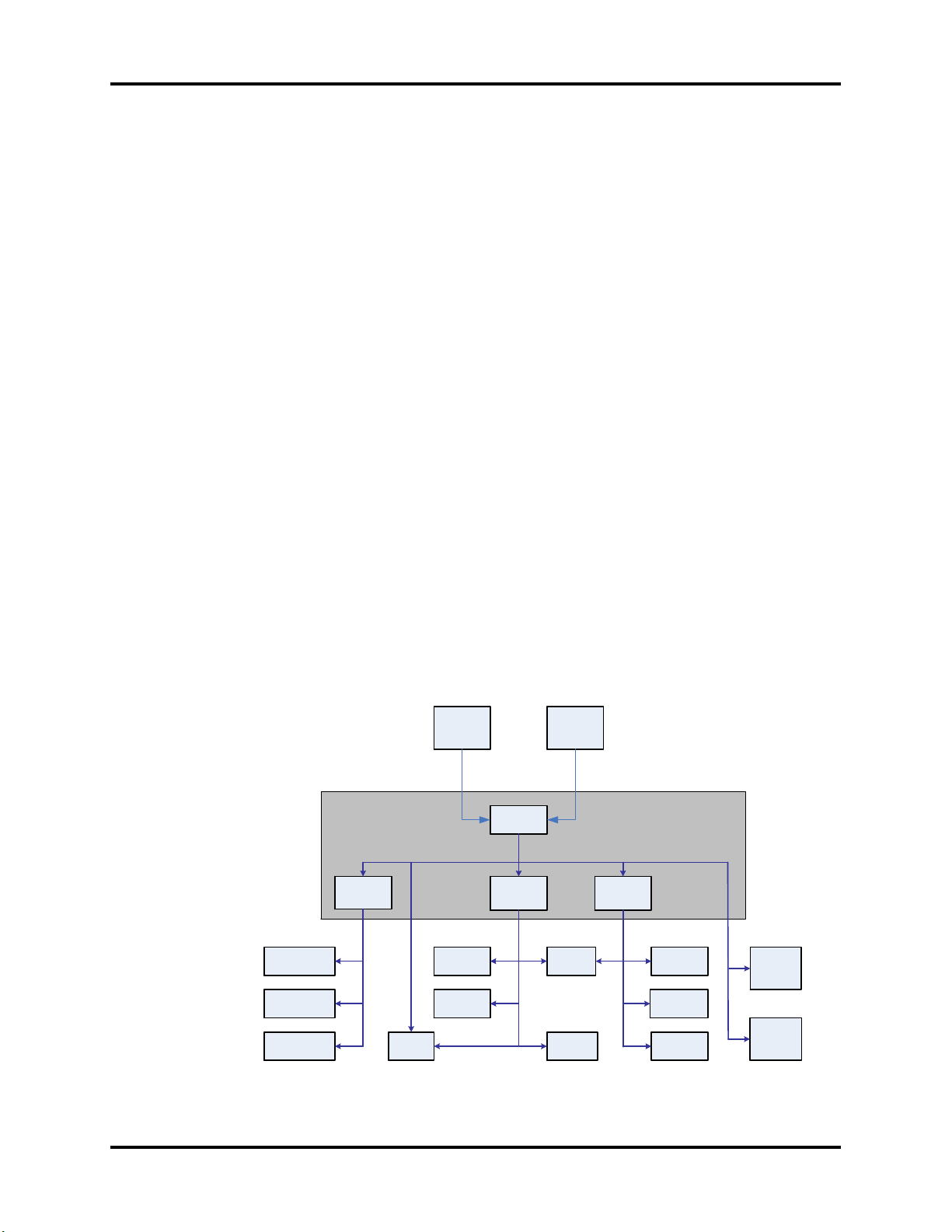

The following diagram illustrates the structure of the patient monitor.

FIGURE 1-3 Patient monitor structure

1.3.1 Input System

Keypad

The keypad, located at the lower part of the monitor’s front panel, contains 18 keys, AC

status LED and battery status LED, and also provides a connection for the knob to the CPU

board.

Knob

The knob can be pressed, or rotated either clockwise or counter-clockwise. It connects to the

keypad.

Power switch

The power switch, located at the right side of the monitor, is a single-throw rocker switch.

Pressing it will power the monitor on or off. The power switch’s status is detected by the

power management and interface board.

1.3.2 Output System

LCD Panel

The monitor uses an LCD panel with a resolution of 800x600, which runs power and gets

digital signals from the CPU board. The backlight is powered by the backlight board, which

is powered by the CPU board.

1 - 4 0070-10-0705 Passport V™ Service Manual

Page 14

Theory of Operation Main Unit

MAIN BOARD

POWER

MODULE

CPU

DRIVE

CIRCUIT

RECORDER

KEY BOARD

FPC INTERFACE

THERMAL PRINT HEAD

MOTOR

CONTROL

POWER

SUPPLY

CONTROL

POWER

SUPPLY

INTERFACE

KEY & LED

INTERFACE

SIGNAL

INTERFACE

Alarm Lamp

The monitor has an alarm lamp on the front panel. The alarm LED board converts the electric

signals into visual signals and then sends the visual signals to the alarm lamp through a light

pipe. The alarm lamp illuminates either red or yellow, depending on how the alarm is

configured.

Recorder

The recorder receives data coming from the CPU board through a UART and then sends them

to the thermal print head for printing. The recorder has a hard key (starting/stopping

recordings) and a green LED on its front. It connects to the power management and interface

board.

The following diagram shows its operating principle.

FIGURE 1-4 Operating principle

MODULE DESCRIPTION

Power supply interface Introduces a DC from the CPU board.

Power module Converts the input power into voltages that fit each module and

CPU Controls the communications between modules.

Signal interface Controls the communications between the CPU board and the

Drive circuit Receives control signals from the CPU and then forwards them to

Recorder key board Sends key commands to the CPU and receives commands from

FPC interface Sends the thermal print head information to the CPU and

Passport V™ Service Manual 0070-10-0705 1 - 5

then forwards them to each module.

recorder CPU.

the stepper motor.

the CPU to control the LED on the recorder.

receives commands from the CPU to control the thermal print

head.

Page 15

Main Unit Theory of Operation

Speaker

The speaker provides sound for alarms, key strokes, heart beats, pulse, and so on. It is driven

directly by the CPU board.

AC and battery status LEDs

The AC status LED and the battery status LED, located at the keypad, are controlled by the

MCU on the power management and interface board. The driving signals come from the

power management and interface board and then go to the keypad via the CPU board.

1.3.3 Processing and Communications System

CPU board

The CPU board is the heart of the patient monitor. It implements a series of tasks including

input and output control, data storage and processing, display processing, system control,

communication management, print management, alarming, etc.

The CPU board has a CPU system comprising the CPU, FLASH, memory, real-time clock,

EEPROM, FPGA, etc. Among them, FPGA deals with audio, video, and interfacing signals.

Also, it provides interfaces to other boards, modules, and devices.

Connections and communications with other components are implemented via the CPU

board, which provides interfaces to:

•A built-in display

•The power management and interface board. Between this board and the CPU board,

the signals of USB+Network+UART+SVGA+I2C+Speaker+GPIO are communicated.

Among them, UART signals finally go to the parameter boards.

•The keypad. Between the keypad and the CPU board, there are two signal wires: one is

the UART signal wire and another is the AC power and battery status signal wire.

•The alarm LED board

Power management and interface board

The power management and interface board is a multi-functional board. It transmits UART

signals to several boards and modules (e.g., multi-parameter board, CO

SpO

module, NIBP module, recorder module, etc.).

2

1.3.4 Power Management System

Battery

The monitor uses two rechargeable lithium-ion batteries (11.1 V, 4400 mAh). The battery

compartment door is located at the left-bottom of the patient monitor. The battery power is

introduced to the power module via the battery interface board, and then processed and

distributed to each component by the power management and interface board.

module, OEM

2

Battery interface board

The battery interface board serves as an interface between the batteries and the power

management and interface board.

1 - 6 0070-10-0705 Passport V™ Service Manual

Page 16

Theory of Operation Main Unit

DC source

11.1V

16.8V/11.1V

5V

DC/DC

3.3V

DC/DC

Recorder

5V

Wireless

Adapter

CF control

board

NIBP

CO2

modul e

CPUboard

digital circuit

Interfaceboard

digital circuit

LCD digital

circuit

3.3V

12V

DC/DC

Multi-

Parameter

board

OEM SpO2

module

Backlight

board

Alarm

indicator

Knob

Power

board

(AC/DC)

Battery

interface

board

16.8V

12V

Power management

and interface board

auto-select

Power board (AC/DC)

The power board (AC/DC) converts the input AC power to DC power (16.8V DC), which

then serves as the input of the power management and interface board.

Power management and interface board

This board is responsible for power management and interfaces. Power management can

perform the functions below:

1. Auto-select the DC source between the power board and the two batteries.

2. Convert the DC source into 12V, 5V, and 3.3V DC and then output them to other boards

and modules.

3. Provide over-voltage and under-voltage protection for 12V, 5V, and 3.3V DC.

4. Detect the power switch status and control power on/off.

5. Detect the battery capacity and control battery charge/discharge.

6. Control the LED for battery and AC status.

7. Control the fan and detect its running status (the complex control algorithm is

implemented via the CPU board).

8. Detect the internal temperature of the patient monitor.

On this board there are four sub-boards: 3.3V and 5V DC board, 12V DC board, and two

battery charge boards. The 3.3V and 5V DC board converts the DC source into 5V and

3.3V. The 12V DC board converts the DC source into 12V DC. Both of them have an over-

current protection mechanism. Each of the two battery charge boards controls the charging

of a battery.

The DC power system is illustrated below:

FIGURE 1-5 DC power system

Passport V™ Service Manual 0070-10-0705 1 - 7

Page 17

Main Unit Theory of Operation

1.3.5 Equipment Interface System

Power management and interface board

This board is also responsible for digital interfaces.

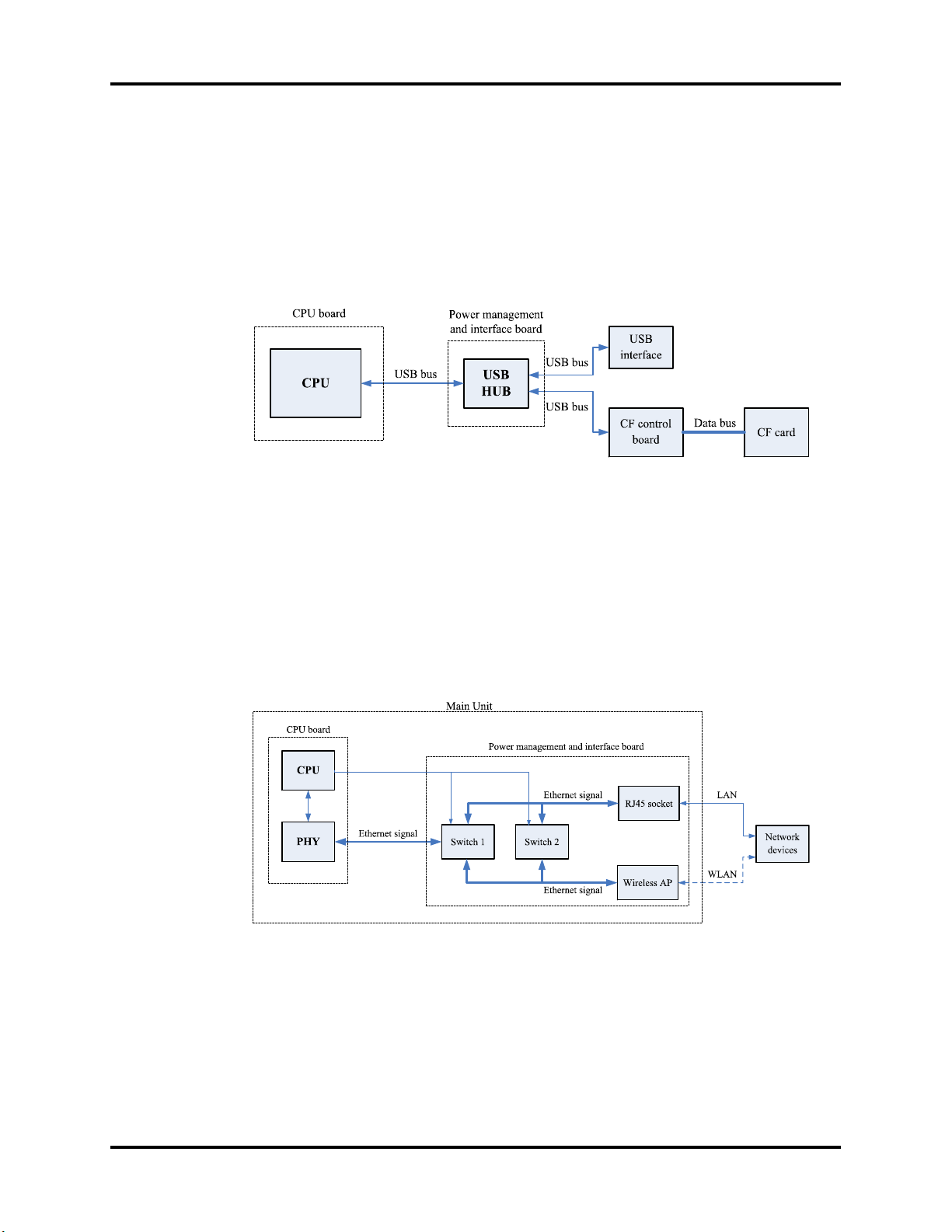

A USB HUB is located at the board. It receives USB signals from the CPU and then distributes

them to three USB ports, of which two connect the USB sockets, and the other connects the

CF control board.

FIGURE 1-6 The USB hub

This board provides connections for both wired network and wireless adapter. In the figure

below, switch 2 always stays off during normal use. The operator can switch between wired

network and wireless adapter through the software UI. Then, the CPU applies the operator’s

selection by controlling switch 1. In configuration mode, the CPU turns off switch 1 and then

turns on switch 2 so that the operator can connect a PC to the wired network to configure the

wireless adapter.

The Ethernet wireless adapter enables the patient monitor to go wireless.

FIGURE 1-7 The ethernet wireless adapter

1 - 8 0070-10-0705 Passport V™ Service Manual

Page 18

Theory of Operation Main Unit

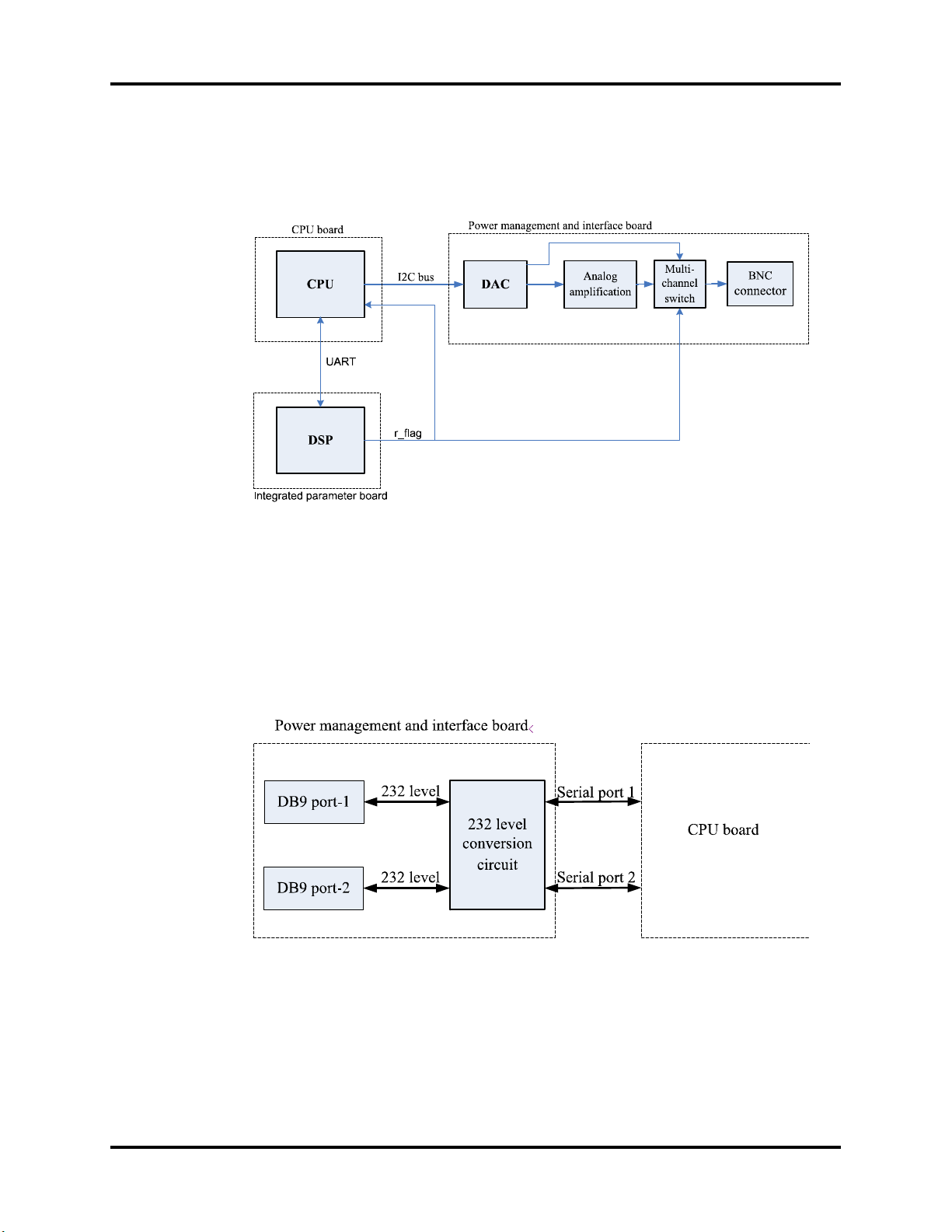

The CPU generates analog signals by controlling the DAC chip on the power management

and interface board via the I2C bus. The analog signals are transmitted to the BNC socket

via the amplifier circuit.

FIGURE 1-8 The amplifier circuit

The signal r_flag from the multi-parameter board goes to the power management and

interface board. The CPU can select the source of defibrillator synchronization signals by

controlling the output of the DAC. The signal r_flag also goes to the CPU for a self-test.

Two UART interfaces (serial port 1 and serial port 2) from the CPU board are extended as

two RS232-level ports via the power management and interface board. Both interfaces can

be configured to accommodate a PC for data or an AG module.

FIGURE 1-9 The serial ports

Passport V™ Service Manual 0070-10-0705 1 - 9

Page 19

Main Unit Theory of Operation

1.3.6 Parameter modules

Multi-Parameter board

The multi-parameter board incorporates multiple parameters, such as ECG, RESP, DPM

SPO

, 2-channel IBP, TEMP, etc. Details include the following:

2

•The multi-parameter board employs a high-speed DSP, making digital filtering, arrhythmia

analysis, and ST analysis faster and more effective.

• The DSP is in charge of 3- and 5-lead ECG monitoring, arrhythmia and ST analysis, RESP

monitoring, and communicating with the CPU board.

•The multi-parameter board also employs an MCU, which supports 1-channel temperature

measurement, DPM SpO

measurement data to the DSP.

•Respiration rate is monitored using the impedance method and can only be measured

with two ECG leads.

•The multi-parameter board integrates the DPM SpO2 circuit. If a monitor is configured

with an OEM SpO

CO2 Module

, and 2-channel IBP measurement. The MCU transfers all the

2

module, then DPM SpO2 functions are overridden.

2

•There are two types of CO2 modules: DPM CO2 and Microstream CO2.

•The DPM CO2 module measures the CO2 concentration using the NDIR technology. It

performs a zero calibration periodically to ensure accurate measurements for a long

period of time. An appropriate compensation can be applied according to the patient

environment, thus preventing measurements from being influenced by interfering gases.

•The Microstream CO

module ensures that measurements will not be affected by other

2

gases and the accuracy can be maintained without any gas compensation. Additionally,

the module has a very low sample flow rate, reducing its effect on the patient and the

environment to a minimum.

OEM SpO

There are two types of OEM SpO

Module

2

modules: Masimo-2013 SpO2 module and Nellcor SpO2

2

module.

An isolation power board is attached to each of them and used to isolate the DC power and

the UART signal of the OEM SpO

modules from other circuits in the main unit. The UART

2

signal comes from the CPU board and passes through the power management and interface

board.

1 - 10 0070-10-0705 Passport V™ Service Manual

Page 20

Theory of Operation Main Unit

CUFF

PRESSURE

SENSOR

PRESSURE

SENSOR

FOR

PROTECT

PRESSURE

SIGNAL

AMPLIFIER

CIRCUITS

PRESSURE

SIGNAL

AMPLIFIER

CIRCUITS

FOR

PROTECT

CPU

ASYCHRONOUS

SERIAL

COMMUNICATION

WATCHDOG

OVER

PRESSURE

PROTECT

CIRCUIT

A/D

CONVERTER

PRESSURE

SIGNAL

MOTOR CONTROL

FEEDBACK SIGNAL

PUMP AND

VALVE

CONTROL

CIRCUIT

FLASH DRAM

MANIFOLD

VALV ES

AND PUMP

NIBP Module

The figure below shows the NIBP module parameter board diagram.

FIGURE 1-10 The NIBP module parameter board

The Passport V calculates NIBP values using the oscillometric method of noninvasive blood

pressure measurement. These measurements correspond to comparisons with auscultatory

values, measured using the fifth Korotkoff sound within ANSI/AAMI SP10 standards for

accuracy.

Passport V™ Service Manual 0070-10-0705 1 - 11

Page 21

Main Unit Theory of Operation

This page intentionally left blank.

1 - 12 0070-10-0705 Passport V™ Service Manual

Page 22

2.0

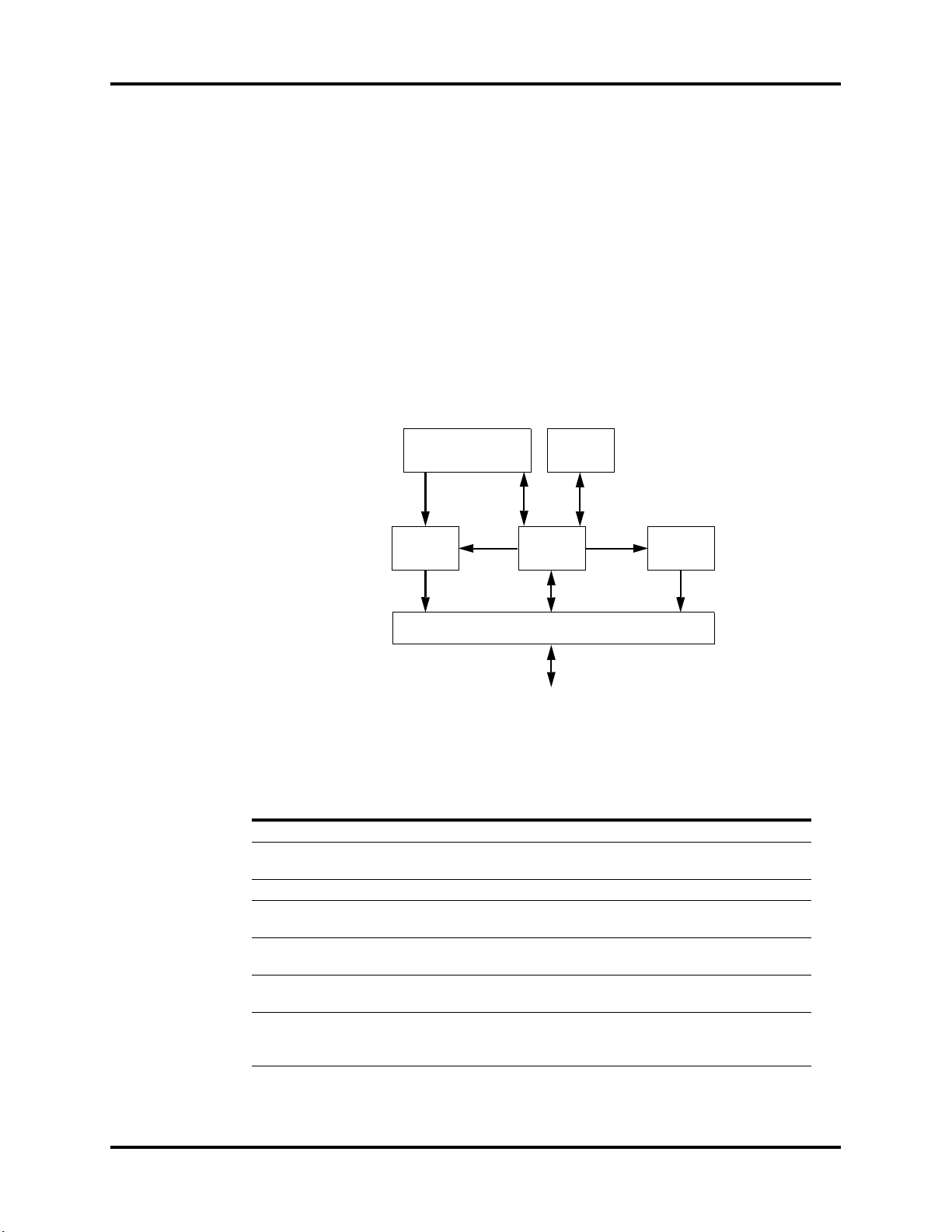

Block Diagrams

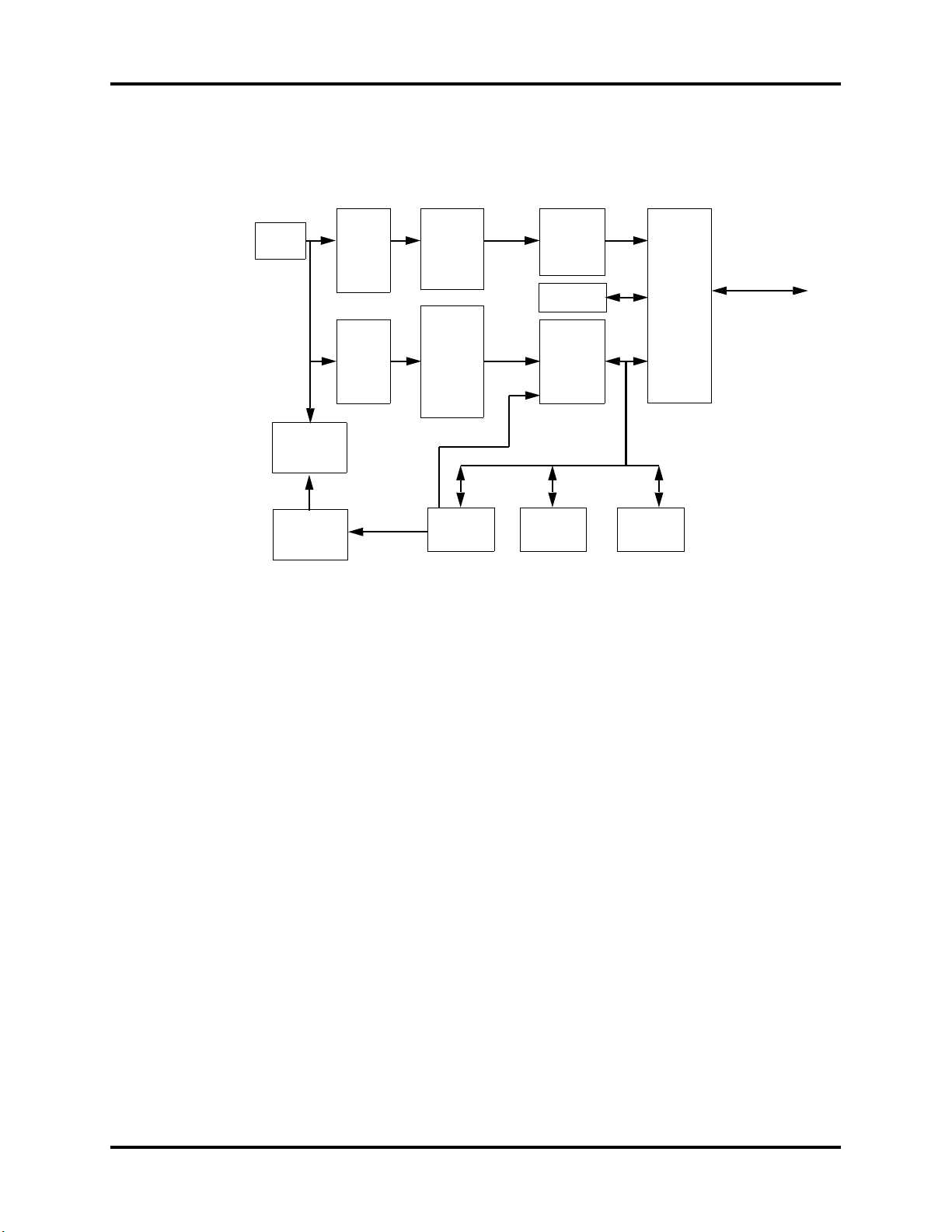

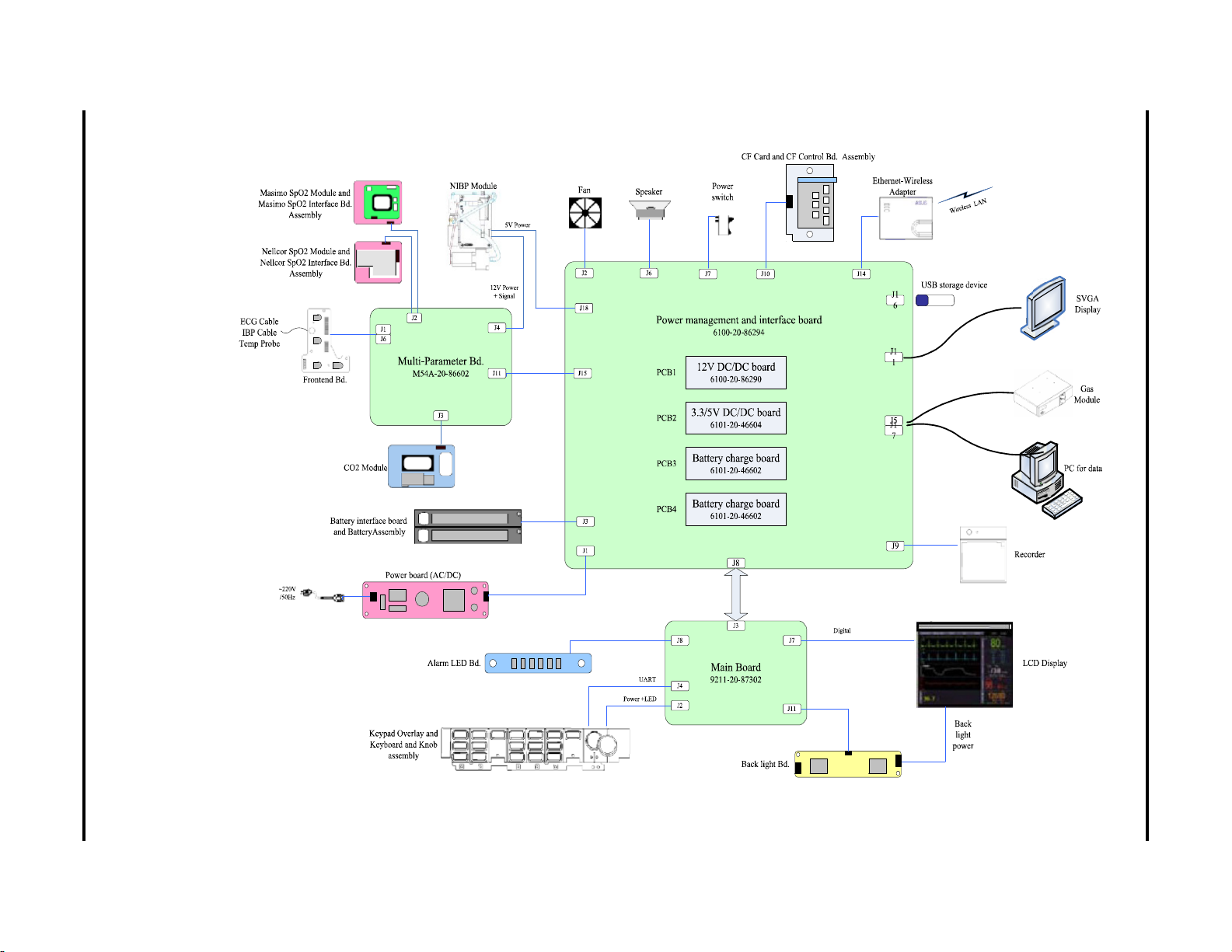

2.1 Introduction

The Block Diagrams indicate the internal organization of the instrument. The block diagrams are used to

gain both familiarity with the instrument and to locate malfunctioning PC boards as readily as possible.

DESCRIPTION PART NUMBER

NIBP Module 6100-30-86329

Masimo SpO

Nellcor SpO2 Module 6100-30-86336

Microstream CO

DPM CO

Power board(AC/DC) 9211-30-87311

Alarm LED Board 9211-30-87306

Battery interface board assembly 9211-30-87331

Keypad Overlay 6100-20-86264-XX or

Keypad 6100-20-86265-XX

Main board 9211-20-87303

Power management and interface board 6100-20-86294

Back light board 022-000001-00

LCD Display 0000-10-11092

Recorder 6101-30-46619

Wireless AP Module 6100-30-86332

CF card assembly 6100-30-86330

Power Switch with Cable Assembly 6100-21-86306

Speaker 020-000001-00

Fan Assembly 6100-21-86315

Module 6100-30-86335

2

Module 6100-30-86333

2

Module 6100-30-86334

2

6100-20-86341-XX

NOTE: See Isometric Drawings and Parts List for a complete list of

Part Numbers.

Passport V™ Service Manual 0070-10-0705 2 - 1

Page 23

2 - 2 0070-10-0705 Passport V™ Service Manual

Block Diagram Block Diagrams

2.2 Block Diagram

FIGURE 2-1 Passport V Block Diagram

Page 24

3.0

Repair Information

3.1 Introduction

This chapter provides the necessary technical information to perform repairs on the

Passport V. The most important prerequisites for effective troubleshooting are a thorough

understanding of the instrument functions as well as understanding the theory of operation.

3.2 Safety Precautions

In the event the instrument covers are removed, observe the following warnings and

guidelines.

1. Do not short component leads together.

2. The instrument covers must not be removed by anyone other than qualified technical

personnel who have received supplementary instructions regarding maintenance of

medical equipment or have equivalent experience in this area.

WAR N I NG: In t e rnal El e c trical S hock Ha zard - This unit does not contain

any user-serviceable parts. Do not remove instrument

covers. Refer Servicing to qualified personnel.

WAR N I NG: Wh e n ever th e monito r is open e d for c a l ibratio n or rep a i r, a

risk (leakage) current safety check and a verification of

basic functions of all parameters should be performed

before the monitor is returned to Clinical use. See

“Verification” on page 5-12.

Passport V™ Service Manual 0070-10-0705 3 - 1

Page 25

Troubleshooting Guidelines Repair Information

3.3 Troubleshooting Guidelines

1. Identify the problem

Due to the wide variety of potential symptoms, certain problems may be more subtle

than others. One approach to troubleshooting is to set up the instrument as described in

Chapter 5.0. Following the guidelines of the tests will help determine the problem if one

exists.

2. Avoid shorting component leads

During repair procedures, it can become tempting to make a series of quick

measurements. Always turn the power off before connecting and disconnecting the test

leads and probes. The accidental shorting of leads can easily stress the components and

cause a second failure (aside from the safety risk).

3. Use the Proper equipment

The equipment listed below is suggested to fulfill a wide range of troubleshooting

requirements. It is imperative to use the designated equipment in order to ensure proper

results of any and all test procedures.

4. Clean up the repair area

After any repair, especially after any soldering or desoldering, clean off the repair area

with alcohol and a stiff brush. This will remove any residual solder flux, in turn allowing

the instrument to return to its original appearance.

3.4 Special Tools Required

•Digital Voltmeter

•Digital Mercury Manometer – 0 to 300 mmHg

•Safety Analyzer

•Patient Simulator

•Test Chamber / Dummy Cuff (P/N 0138-00-0001-01 (700 cc) or -03 (500 cc))

•Desktop PC or notebook PC.

•Microsoft Windows 2000/XP operating system

•Intel Pentium CPU, above 500MHz

•Above 128M memory

•At least one network card and at least one USB port

•CAT-5 crossover cable

• USB cable or DPM SB storage device

3.5 Disassembly Instructions

Before disassembling the unit, perform the following:

•Power down the unit and remove the line cord.

•Remove all cable assemblies from the left side, right side, and rear of the unit.

•Remove any batteries that were installed.

•Perform all work on a properly grounded ESD workstation.

3 - 2 0070-10-0705 Passport V™ Service Manual

Page 26

Repair Information Disassembly Instructions

3.5.1 Removal of the Key Panel and Keys

1. Place the unit on a protective surface.

2. Carefully remove the knob with a pair of pliers that have protection on the jaws. Some

pliers may damage the knob.

FIGURE 3-1 Remove the knob

3. Release the key panel’s four clips from the bottom of the unit with a flat-bladed

screwdriver.

FIGURE 3-2 Release the key panel clips

4. Remove the key panel from the front.

5. Remove the keys and place to the side with the key panel.

Passport V™ Service Manual 0070-10-0705 3 - 3

Page 27

Disassembly Instructions Repair Information

3.5.2 Removal of the Front Housing Assembly

1. Place the unit face down on a protective surface.

2. Remove the six screws from the rear of the unit.

FIGURE 3-3 Remove the screws from the rear of the unit

3. Turn the unit over and carefully separate the front housing assembly and rear housing

assembly.

4. Disconnect the 50-pin ribbon cable from the front housing assembly.

FIGURE 3-4 Disconnect the ribbon cable from the front housing assembly

5. Remove the front housing assembly.

3 - 4 0070-10-0705 Passport V™ Service Manual

Page 28

Repair Information Disassembly Instructions

3.5.3 Removal of the Main Board

1. Remove the front housing assembly as stated in “Removal of the Front Housing

Assembly” on page 3-4.

2. Remove the keyboard cable.

3. Remove the inverter cable.

4. Remove the LCD panel cable.

5. Remove the alarm LED board cable.

6. Remove the five screws that secure the main board to the front housing bracket.

7. Remove the main board carefully.

FIGURE 3-5 Remove the main board

Passport V™ Service Manual 0070-10-0705 3 - 5

Page 29

Disassembly Instructions Repair Information

3.5.4 Removal of the Inverter

1. Remove the front housing assembly as stated in “Removal of the Front Housing

Assembly” on page 3-4.

2. Remove the inverter cable.

3. Remove the two backlight board cable from the inverter.

4. Remove the two screws that secure the inverter to the front housing bracket.

5. Remove the inverter carefully.

FIGURE 3-6 Remove the inverter

3 - 6 0070-10-0705 Passport V™ Service Manual

Page 30

Repair Information Disassembly Instructions

3.5.5 Removal of the LCD Panel

1. Remove the front housing assembly as stated in “Removal of the Front Housing

Assembly” on page 3-4.

2. Remove the two backlight board cables from the inverter.

3. Remove the keyboard cable.

4. Remove the alarm LED board cable.

5. Remove the LCD panel cable.

6. Remove the eight screws that secure the front housing bracket.

7. Remove the front housing bracket and place to the side.

FIGURE 3-7 Remove the LCD panel

Passport V™ Service Manual 0070-10-0705 3 - 7

Page 31

Disassembly Instructions Repair Information

8. Remove the four screws that secure the LCD panel.

9. Remove the LCD panel carefully.

FIGURE 3-8 Remove the LCD panel

3.5.6 Removal of the Keyboard

1. Remove the front housing assembly as stated in “Removal of the Front Housing

Assembly” on page 3-4.

2. Remove the keyboard cable.

3. Remove the encoder cable.

4. Remove the four screws that secure the keyboard to the front housing.

5. Remove the four keyboard pads.

6. Release the clip on the right side of the keyboard and remove the keyboard carefully.

FIGURE 3-9 Remove the Keyboard

3 - 8 0070-10-0705 Passport V™ Service Manual

Page 32

Repair Information Disassembly Instructions

3.5.7 Removal of the Alarm LED Board

1. Remove the front housing assembly as stated in “Removal of the Front Housing

Assembly” on page 3-4.

2. Remove the alarm LED board cable.

3. Remove the two screws that secure the board to the front housing.

4. Remove the alarm LED board and light conducting pipe carefully.

FIGURE 3-10 Remove the alarm LED board

3.5.8 Removal of the Encoder

1. Remove the front housing assembly as stated in “Removal of the Front Housing

Assembly” on page 3-4.

2. Remove the encoder cable from the keyboard.

FIGURE 3-11 Disconnect the encoder cable

Passport V™ Service Manual 0070-10-0705 3 - 9

Page 33

Disassembly Instructions Repair Information

3. Carefully remove the knob with a pair of pliers that have protection on the jaws. Some

pliers may damage the knob.

4. Remove the nut that secures the encoder.

5. Remove the encoder carefully.

FIGURE 3-12 Remove the encoder

3.5.9 Removal of the Multi-parameter Board Assembly

1. Remove the front housing assembly as stated in “Removal of the Front Housing

Assembly” on page 3-4.

2. Disconnect the 50-pin ribbon cable from the interface board.

3. Disconnect the cable from J15 of the interface board.

4. Disconnect the NIBP communication cable from the interface board.

FIGURE 3-13 Disconnect the cables from the multi-parameter board

3 - 10 0070-10-0705 Passport V™ Service Manual

Page 34

Repair Information Disassembly Instructions

5. Remove the four screws that secure the assembly to the rear housing and main frame.

6. Disconnect the CO

tubing and cable from the multi-parameter board assembly (if CO2

2

module is configured).

7. Remove the multi-parameter board assembly carefully.

FIGURE 3-14 Remove the multi-parameter board assembly

Passport V™ Service Manual 0070-10-0705 3 - 11

Page 35

Disassembly Instructions Repair Information

3.5.10 Removal of the Parameter Front Panel Assembly

1. Remove the multi-parameter board assembly as stated in “Removal of the Multi-

parameter Board Assembly” on page 3-10.

2. Unplug the tubing from the NIBP connector.

FIGURE 3-15 Unplug the tubing from the NIBP connector

3. Unfasten the two screws that secure the SpO

connector and then remove the connector

2

(if Masimo or Nellcor SpO2 module is configured).

FIGURE 3-16 Masimo SpO

2

FIGURE 3-17 Nellcor SpO

4. Remove the three screws that secure the parameter front panel.

5. Remove the parameter front panel.

2

FIGURE 3-18 Remove the parameter front panel

3 - 12 0070-10-0705 Passport V™ Service Manual

Page 36

Repair Information Disassembly Instructions

3.5.11 Removal of the Multi-parameter board

1. Remove the parameter front panel assembly as stated in “Removal of the Parameter

Front Panel Assembly” on page 3-12.

2. Remove the three screws that secure the multi-parameter board.

3. Remove the multi-parameter board.

FIGURE 3-19 Remove the multi-parameter board

3.5.12 Removal of the CO2 Module

1. Remove the multi-parameter board assembly as stated in “Removal of the Multi-

parameter Board Assembly” on page 3-10.

2. Remove the two screws that secure the module to the main frame.

3. Remove the CO

FIGURE 3-20 DPM CO2 FIGURE 3-21 Microstream CO

module.

2

2

4. Remove the water trap connector assembly or microstream CO

assembly from the parameter front panel assembly (if necessary).

Passport V™ Service Manual 0070-10-0705 3 - 13

connector fixture

2

Page 37

Disassembly Instructions Repair Information

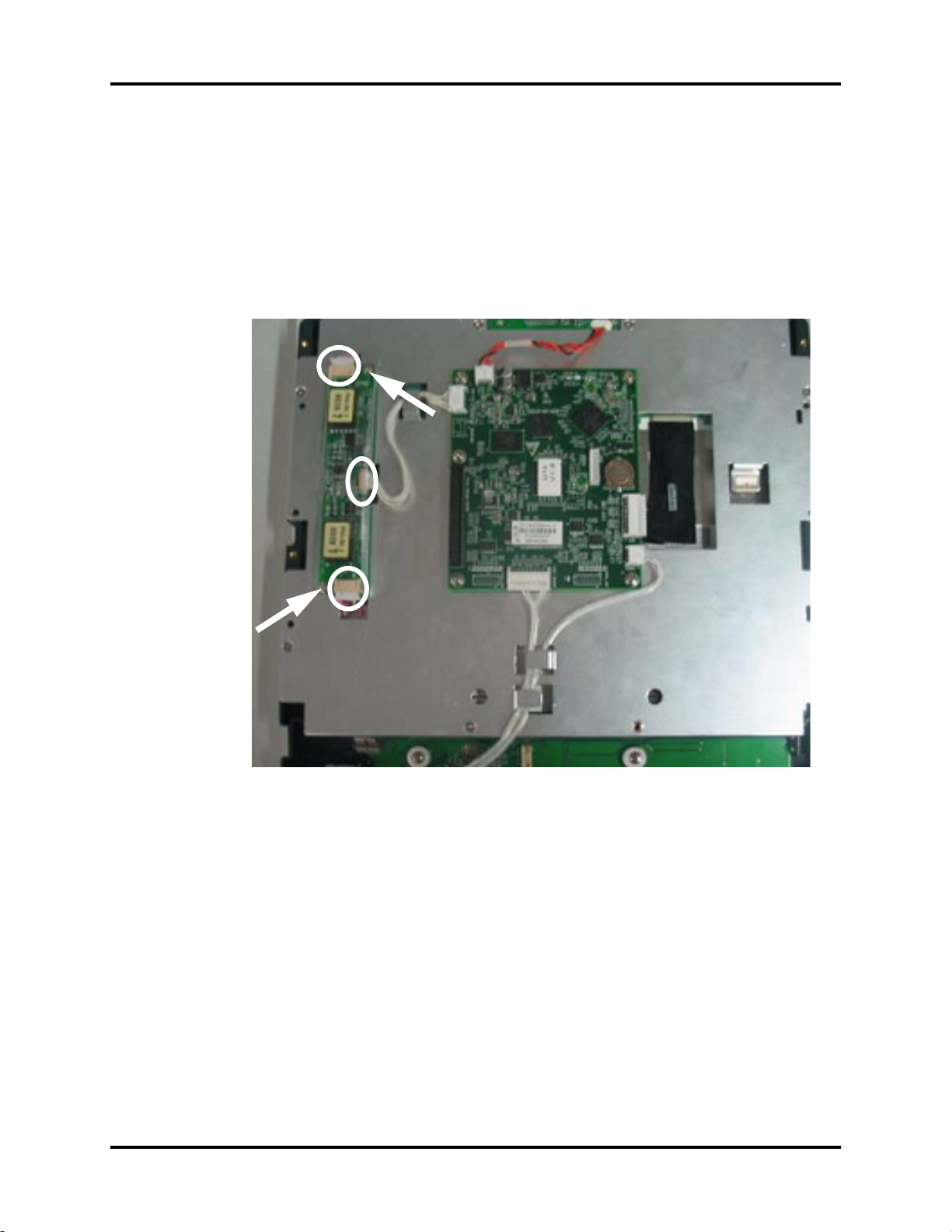

3.5.13 Removal of the Masimo SpO2 Module

1. Remove the multi-parameter board assembly as stated in “Removal of the Multi-

parameter Board Assembly” on page 3-10.

2. Disconnect the SpO2 communication cable from the multi-parameter board.

3. Cut the tie of flexible cable.

4. Unfasten the screw that secures the Masimo SpO2 module to the multi-parameter board

installation frame.

5. Unfasten the two screws that secure the Masimo SpO2 connector.

6. Remove the Masimo SpO2 module.

FIGURE 3-22 Remove the Masimo SpO2 module

3.5.14 Removal of the Nellcor SpO2 Module

1. Remove the multi-parameter board assembly as stated in “Removal of the Multi-

parameter Board Assembly” on page 3-10.

2. Disconnect the SpO2 communication cable from the multi-parameter board.

3. Cut the tie of flexible cable.

4. Unfasten the screw that secures the Nellcor SpO

installation frame.

5. Unfasten the two screws that secure the Nellcor SpO2 connector.

6. Remove the Nellcor SpO2 module.

module to the multi-parameter board

2

FIGURE 3-23 Remove the Nellcor SpO

3 - 14 0070-10-0705 Passport V™ Service Manual

module

2

Page 38

Repair Information Disassembly Instructions

3.5.15 Removal of the NIBP Assembly

1. Remove the multi-parameter board assembly as stated in “Removal of the Multi-

parameter Board Assembly” on page 3-10.

2. Unplug the tubing from the NIBP gas nipple.

3. Disconnect the NIBP communication cable from the NIBP board.

4. Unfasten the screws that secure the NIBP assembly to the multi-parameter board

installation frame.

5. Remove the NIBP assembly.

FIGURE 3-24 Remove the NIBP assembly

3.5.16 Removal of the Recorder Assembly

1. Remove the two screws that secure the recorder.

2. Release the two clips and pull out the recorder.

FIGURE 3-25 Remove the recorder assembly

3. Disconnect the recorder cable.

4. Remove the recorder.

Passport V™ Service Manual 0070-10-0705 3 - 15

Page 39

Disassembly Instructions Repair Information

3.5.17 Removal of the Recorder Cover (if needed)

1. Pry up the recorder cover with a flat-bladed screwdriver.

FIGURE 3-26 Remove the recorder cover

3.5.18 Removal of the Main Frame and Multi-parameter Board Assembly

1. Remove the front housing assembly as stated in “Removal of the Front Housing

Assembly” on page 3-4.

2. Remove the recorder assembly (if installed) as stated in “Removal of the Recorder

Assembly” on page 3-15.

3. Disconnect the power switch cable from the interface board.

4. Remove the eight screws that secure the main frame and multi-parameter board

assembly to the rear housing.

FIGURE 3-27 Remove the screws and cables from the main frame

3 - 16 0070-10-0705 Passport V™ Service Manual

Page 40

Repair Information Disassembly Instructions

5. Remove the two screws that secure the main frame from the bottom.

6. Remove the main frame and multi-parameter board assembly.

FIGURE 3-28 Remove the main frame and multi-parameter board assembly

3.5.19 Removal of the Speaker Assembly

1. Remove the main frame and multi-parameter board assembly as stated in “Removal of

the Main Frame and Multi-parameter Board Assembly” on page 3-16.

2. Cut the clamp that secures the speaker cable.

3. Disconnect the speaker cable from the interface board.

FIGURE 3-29 Disconnect the speaker cable from the interface board

4. Remove the three screws that secure the speaker.

5. Remove the speaker assembly.

FIGURE 3-30 Remove the speaker assembly

Passport V™ Service Manual 0070-10-0705 3 - 17

Page 41

Disassembly Instructions Repair Information

3.5.20 Removal of the Fan Assembly

1. Remove the main frame and multi-parameter board assembly as stated in “Removal of

the Main Frame and Multi-parameter Board Assembly” on page 3-16.

2. Cut the clamp that secures the fan cable.

3. Disconnect the fan cable from the interface board.

FIGURE 3-31 Disconnect the fan cable from the interface board

4. Remove the fan EVA cushion.

5. Remove the two screws that secure the fan.

FIGURE 3-32 Remove the fan assembly

6. Remove the fan.

3 - 18 0070-10-0705 Passport V™ Service Manual

Page 42

Repair Information Disassembly Instructions

3.5.21 Removal of the CF Card Assembly

1. Remove the main frame and multi-parameter board assembly as stated in “Removal of

the Main Frame and Multi-parameter Board Assembly” on page 3-16.

2. Remove the two screws that secure the CF card assembly.

3. Disconnect the CF card cable.

4. Remove the CF card assembly.

FIGURE 3-33 Remove the CF card assembly

3.5.22 Removal of the Power Board

1. Remove the main frame and multi-parameter board assembly as stated in “Removal of

the Main Frame and Multi-parameter Board Assembly” on page 3-16.

2. Remove the two screws that secure the recorder connecting board and then remove the board.

FIGURE 3-34 Remove the screws securing the recorder connecting board

Passport V™ Service Manual 0070-10-0705 3 - 19

Page 43

Disassembly Instructions Repair Information

3. Disconnect the power board connecting cable from the interface board.

FIGURE 3-35 Disconnect the power board connecting cable

4. Remove the three screws that secure the power socket support from the back of the main

frame.

5. Remove the screw that secures the grounding wire.

FIGURE 3-36 Remove the screws that secure the power socket

3 - 20 0070-10-0705 Passport V™ Service Manual

Page 44

Repair Information Disassembly Instructions

6. Disconnect the power socket cable from the power board.

7. Remove the four screws that secure the power board.

8. Remove the power board.

FIGURE 3-37 Remove the power board

3.5.23 Removal of the Li-ion Battery Interface Board Assembly

1. Remove the front housing assembly as stated in “Removal of the Front Housing

Assembly” on page 3-4.

2. Remove the recorder assembly (if installed) as stated in “Removal of the Recorder

Assembly” on page 3-15.

3. Remove the two screws that secure the recorder connecting board and then remove the

board.

FIGURE 3-38 Remove the screws securing the recorder connecting board

Passport V™ Service Manual 0070-10-0705 3 - 21

Page 45

Disassembly Instructions Repair Information

4. Disconnect the Li-ion battery interface board cable from the interface board.

FIGURE 3-39 Disconnect the Li-ion battery interface board cable

5. Remove the four nuts that secure the Li-ion battery interface board assembly.

6. Remove the Li-ion battery interface board assembly.

FIGURE 3-40 remove the Li-ion battery interface board assembly

3 - 22 0070-10-0705 Passport V™ Service Manual

Page 46

Repair Information Disassembly Instructions

3.5.24 Removal of the Interface Board Assembly

1. Remove the multi-parameter board assembly as stated in “Removal of the Multi-

parameter Board Assembly” on page 3-10.

2. Remove the recorder assembly (if installed) as stated in “Removal of the Recorder

Assembly” on page 3-15.

3. Disconnect the power switch cable from the interface board.

4. Remove the six screws that secure the main frame to the rear housing.

FIGURE 3-41 Remove the screws from the main frame

5. Remove the two screws that secure the main frame from the bottom.

6. Remove the main frame assembly and place to the side.

FIGURE 3-42 Remove the screws securing the main frame

7. Disconnect the Li-ion battery interface board cable from the interface board.

8. Disconnect the power cable from the interface board.

9. Disconnect the recorder cable from the interface board.

Passport V™ Service Manual 0070-10-0705 3 - 23

Page 47

Disassembly Instructions Repair Information

FIGURE 3-43 Disconnect the cables from the interface board

10. Disconnect the speaker cable from the interface board.

11. Disconnect the fan cable from the interface board.

12. Disconnect the CF card cable from the interface board.

13. Disconnect the wireless AP (if installed) cable from the interface board.

FIGURE 3-44 Disconnect the cables from the interface board

14. Remove the two screws that secure the interface board assembly to the main frame.

15. Remove the interface board assembly.

FIGURE 3-45 Remove the interface board assembly

3 - 24 0070-10-0705 Passport V™ Service Manual

Page 48

Repair Information Disassembly Instructions

3.5.25 Removal of the Wireless AP

1. Remove the multi-parameter board assembly as stated in “Removal of the Multi-

parameter Board Assembly” on page 3-10.

2. Remove the recorder assembly (if installed) as stated in “Removal of the Recorder

Assembly” on page 3-15.

3. Disconnect the power switch cable from the interface board.

4. Remove the six screws that secure the main frame to the rear housing.

FIGURE 3-46 Remove the screws from the main frame

5. Remove the two screws that secure the main frame from the bottom.

6. Remove the main frame assembly.

FIGURE 3-47 Remove the screws securing the main frame

Passport V™ Service Manual 0070-10-0705 3 - 25

Page 49

Disassembly Instructions Repair Information

7. Remove the nut that secures the wireless AP to the main frame.

FIGURE 3-48 Remove the nut securing the wireless AP to the main frame

8. Disconnect the wireless AP cable from the wireless AP.

9. Remove the wireless AP.

FIGURE 3-49 Disconnect the cables from the wireless AP

3 - 26 0070-10-0705 Passport V™ Service Manual

Page 50

Repair Information Nurse Call Cable

3.6 Nurse Call Cable

3.6.1 P/N 8000-21-10361

FIGURE 3-50 Nurse Call Cable

3.7 Analog Output Cable

3.7.1 P/N 6100-20-86360

FIGURE 3-51 Analog Output Cable

Passport V™ Service Manual 0070-10-0705 3 - 27

Page 51

Defib Synch Cable Repair Information

3.8 Defib Synch Cable

3.8.1 P/N 6100-20-86361

FIGURE 3-52 Defib Synch Cable

3 - 28 0070-10-0705 Passport V™ Service Manual

Page 52

Repair Information Serial Port to Gas Module 3 Cable

3.9 Serial Port to Gas Module 3 Cable

3.9.1 P/N 0012-00-1276-XX

DESCRIPTION DASH NUMBER

12" 9-pin mini-D serial to 25-pin D-shell -01

72" 9-pin mini-D serial to 25-pin D-shell -02

FIGURE 3-53 Serial Port to Gas Module 3 Cable

Passport V™ Service Manual 0070-10-0705 3 - 29

Page 53

Null Modem Cable Repair Information

3.10 Null Modem Cable

3.10.1 P/N 0012-00-1275-01

FIGURE 3-54 Null Modem Cable

3 - 30 0070-10-0705 Passport V™ Service Manual

Page 54

Repair Information Universal ECG Lead Wires

3.11 Universal ECG Lead Wires

3.11.1 P/N 0012-00-1503-XX

DESCRIPTION DASH #

10 24", snap, 5-lead set, Domestic -02

11 24", snap, 3-lead set, Domestic -05

12 24", snap, 5-lead set, International -11

13 24", snap, 3-lead set, International -14

FIGURE 3-55 Universal ECG Lead Wires

Passport V™ Service Manual 0070-10-0705 3 - 31

Page 55

ECG Cable, 3/5-lead (ESIS and Non ESIS) Repair Information

3.12 ECG Cable, 3/5-lead (ESIS and Non ESIS)

3.12.1 P/N 0012-00-1745-XX

FIGURE 3-56 ECG Cable, 3/5-lead (ESIS and Non ESIS)

3.13 12-pin 3-lead Neo ECG Trunk Cable (IEC/AHA)

3.13.1 P/N 040-000072-00

FIGURE 3-57 12-pin 3-lead Neo ECG Trunk Cable (IEC/AHA)

3 - 32 0070-10-0705 Passport V™ Service Manual

Page 56

Repair Information IBP Cable

3.14 IBP Cable

3.14.1 P/N 040-000052-00

FIGURE 3-58 5-pin IBP Cable (IM2301, Hospira)

3.14.2 P/N 040-000053-00

FIGURE 3-59 5-pin IBP Cable (IM2302, BD)

3.14.3 P/N 040-000054-00

FIGURE 3-60 5-pin IBP Cable (IM2303, Edwards)

Passport V™ Service Manual 0070-10-0705 3 - 33

Page 57

Temp era tu re C ab le Repair Information

3.14.4 P/N 040-000096-00

FIGURE 3-61 IBP Adapter Cable (5-pin to 6-pin)

3.15 Temperature Cable

3.15.1 1.15.1 P/N 040-000055-00

FIGURE 3-62 5-pin Esophageal/Rectal Temp Probe (Adult)

3.15.2 P/N 040-000056-00

FIGURE 3-63 5-pin Esophageal/Rectal Temp Probe (Pediatric/Infant)

3 - 34 0070-10-0705 Passport V™ Service Manual

Page 58

Repair Information Tem pe ra tu re C ab le

3.15.3 P/N 040-000057-00

FIGURE 3-64 5-pin Skin Temp Probe (Adult)

3.15.4 P/N 040-000058-00

FIGURE 3-65 5-pin Skin Temp Probe (Pediatric/Infant)

3.15.5 P/N 040-000091-00

FIGURE 3-66 5-pin Temp Cable for 400 Series Disposable Sensor

Passport V™ Service Manual 0070-10-0705 3 - 35

Page 59

Temp era tu re C ab le Repair Information

3.15.6 P/N 040-0000100-00

FIGURE 3-67 5-pin Temp Adapter Cable (5-pin to 6.35 Phone)

3.15.7 P/N 040-000224-00

FIGURE 3-68 5-pin Temp Cable for MRS Disposable Sensor (5.5 DC Jack)

3 - 36 0070-10-0705 Passport V™ Service Manual

Page 60

Repair Information Troubleshooting Menus

3.16 Troubleshooting Menus

3.16.1 ECG Troubleshooting

MESSAGE/PROBLEM REASON SOLUTION

Noisy ECG traces 1 Loose or dry electrodes.

2Defective electrode wires.

3Patient cable or leads are

routed too close to other

electrical devices.

Excessive Electro-surgical

Interference

Muscle Noise 1 Inadequate skin

Excessive alarms: heart rate,

lead fault

ECG Noise 1 External interference.

No ECG Waveform 1 Gain set too low.

1Wrong ECG cable used. 1Use ESIS ECG cable with

preparation prior to