Page 1

BS-120/BS-130/BS-180/BS-190

Chemistry Analyzer

Service Manual

Page 2

i

© 2007-2010 Shenzhen Mindray Bio-medical Electronics Co., Ltd. All rights

Reserved.

For this Service Manual, the issued Date is 2010-04 (Version: 4.0).

Intellectual Property Statement

SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called

Mindray) owns the intellectual property rights to this Mindray product and this manual.

This manual may refer to information protected by copyrights or patents and does not

convey any license under the patent rights of Mindray, nor the rights of others.

Mindray does not assume any liability arising out of any infringements of patents or

other rights of third parties.

Mindray intends to maintain the contents of this manual as confidential information.

Disclosure of the information in this manual in any manner whatsoever without the

written permission of Mindray is strictly forbidden.

Release, amendment, reproduction, distribution, rent, adaption and translation of this

manual in any manner whatsoever without the written permission of Mindray is strictly

forbidden.

, , , , , are the

registered trademarks or trademarks owned by Mindray in China and other countries.

All other trademarks that appear in this manual are used only for editorial purposes

without the intention of improperly using them. They are the property of their

respective owners.

Responsibility on the Manufacturer Party

Contents of this manual are subject to changes without prior notice.

All information contained in this manual is believed to be correct. Mindray shall not be

liable for errors contained herein nor for incidental or consequential damages in

connection with the furnishing, performance, or use of this manual.

Mindray is responsible for safety, reliability and performance of this product only in

the condition that:

all installation operations, expansions, changes, modifications and repairs of this

product are conducted by Mindray authorized personnel;

the electrical installation of the relevant room complies with the applicable

national and local requirements;

the product is used in accordance with the instructions for use.

Upon request, Mindray may provide, with compensation, necessary circuit diagrams,

calibration illustration list and other information to help qualified technician to maintain

and repair some parts, which Mindray may define as user serviceable.

Page 3

ii

Warranty

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR ANY PARTICULAR PURPOSE.

Exemptions

WARNING:

It is important for the hospital or organization that employs this

equipment to carry out a reasonable service/maintenance plan.

Neglect of this may result in machine breakdown or injury of human

health.

NOTE:

This equipment is to be operated only by medical professionals trained

and authorized by Mindray or Mindray-authorized distributors.

Mindray's obligation or liability under this warranty does not include any

transportation or other charges or liability for direct, indirect or consequential

damages or delay resulting from the improper use or application of the product or the

use of parts or accessories not approved by Mindray or repairs by people other than

Mindray authorized personnel.

This warranty shall not extend to:

any Mindray product which has been subjected to misuse, negligence or

accident;

any Mindray product from which Mindray's original serial number tag or product

identification markings have been altered or removed;

any product of any other manufacturer.

Return Policy

Return Procedure

In the event that it becomes necessary to return this product or part of this product to

Mindray, the following procedure should be followed:

Obtain return authorization: Contact the Mindray Service Department and obtain

a Customer Service Authorization (Mindray) number. The Mindray number must

appear on the outside of the shipping container. Returned shipments will not be

accepted if the Mindray number is not clearly visible. Please provide the model

number, serial number, and a brief description of the reason for return.

Freight policy: The customer is responsible for freight charges when this product

is shipped to Mindray for service (this includes customs charges).

Return address: Please send the part(s) or equipment to the address offered by

Customer Service department.

Page 4

iii

Company Contact

Manufacturer: Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

Address:

Mindray Building, Keji 12th Road South, Hi-tech Industrial Park,

Nanshan, ShenZhen 518057, P.R.China,

Tel:

Fax:

+86 755 26582479 26582888

+86 755 26582934 26582500

Page 5

iv

Page 6

Who Should Read This Manual

This manual is geared for service personnel authorized by Mindray.

What Can You Find in This Manual

This manual covers principles, installation procedures, theories, maintenance and

troubleshooting guidelines of the BS-120/BS-130/BS-180/BS-190. Please service the

system strictly as instructed by this manual.

Conventions Used in This Manual

Foreword

This manual uses the following typographical conventions to clarify meanings in the

text.

Bold and Italic font indicates text displayed on the screen, such as Sample

Request.

Safety Symbols

In this manual, the signal words

and NOTE are used regarding safety and other important instructions. The signal

words and their meanings are defined as follows. Please understand their meanings

clearly before reading this manual.

When you see… Then…

WARNING

BIOHAZARD

CAUTION

Read the statement following the symbol. The

statement is alerting you to an operating hazard that

can cause personal injury.

Read the statement following the symbol. The

statement is alerting you to a potentially

biohazardous condition.

Read the statement following the symbol. The

statement is alerting you to a possibility of system

damage or unreliable results.

BIOHAZARD, WARNING, CAUTION

NOTE

Read the statement following the symbol. The

statement is alerting you to information that requires

your attention.

1

Page 7

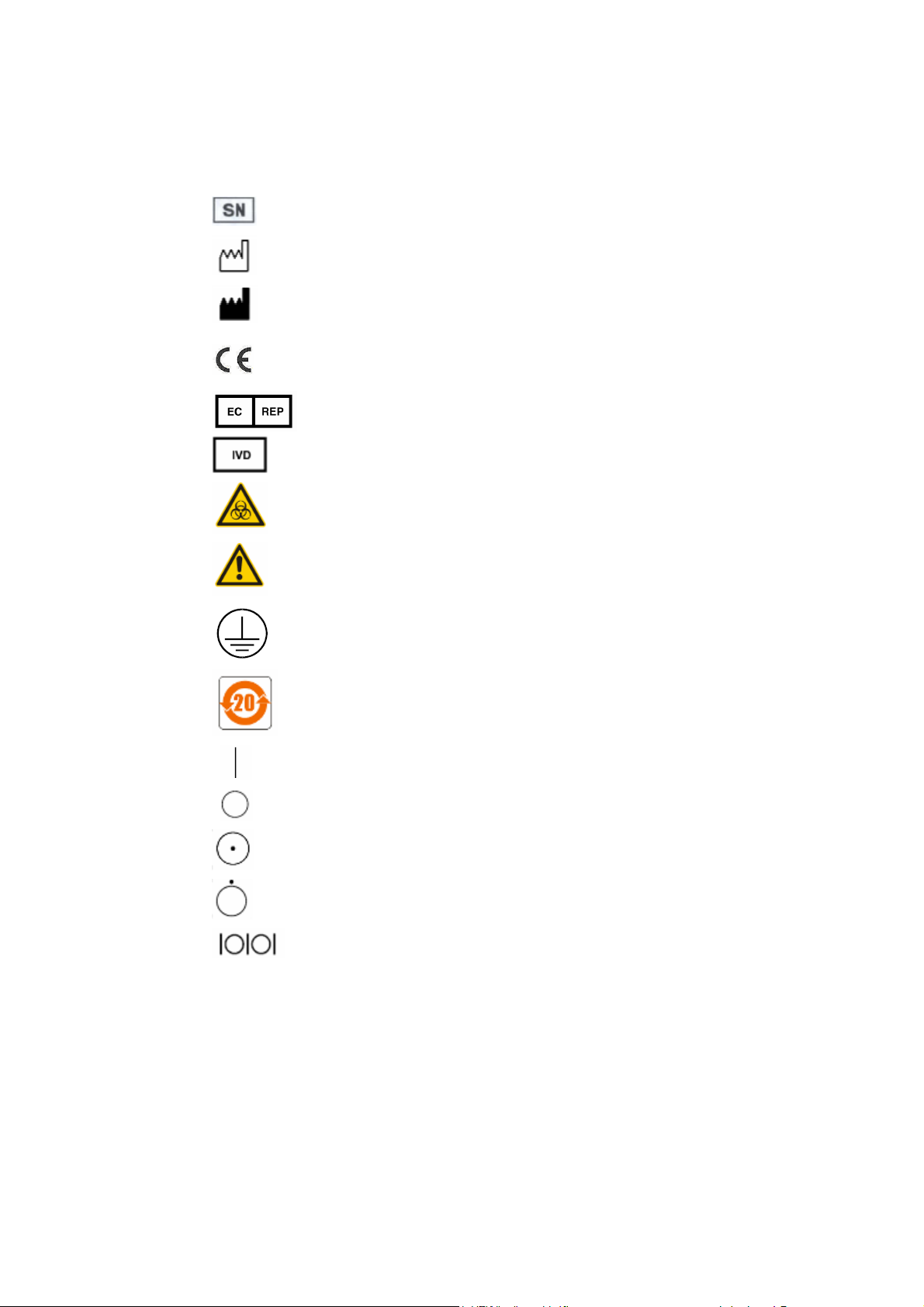

Labels Used On the System

The labels attached to the panels of the system use symbols to clarify the meaning of

the text. The chart below explains the symbols on the labels.

Serial Number

Date of Manufacture

Manufacturer

CE marking. The device is fully in conformity with the Council

Directive Concerning In Vitro Diagnostic Medical Devices

98/79/EC.

Authorized Representative in the European Community

In Vitro diagnostic equipment

Biohazard warning: Risk of potentially biohazardous infection

Warning: Risk of personal injury or equipment damage

Protective ground terminal

Time limit in use for environmental protection (20 years)

ON (Main Power)

OFF (Main Power)

ON (Power)

OFF (Power)

Serial communication port

Graphics

All graphics, including screens and printout, are for illustration purposes only and

must not be used for any other purpose.

2

Page 8

EC Representative

Name: Shanghai International Holding Corp. GmbH(Europe)

Address:

Eiffestrasse 80 D-20537 Hamburg Germany

Tel:

Fax:

+49 40 2513174

+49 40 255726

3

Page 9

Safety Precautions

Observe the following safety precautions when using the Chemistry Analyzer.

Ignoring any of these safety precautions may lead to personal injury or equipment

damage.

WARNING

If the system is used in a manner not specified by Mindray, the

protection provided by the system may be impaired.

Preventing Electric Shock

Please observe the following instructions to prevent electric shock.

WARNING

When the Main Power is on, users must not open the rear cover or

side cover.

Spillage of reagent or sample on the analyzer may cause equipment

failure and even electric shock. Do not place sample and reagent on

the analyzer.

Preventing Personal Injury Caused by Moving Parts

Please observe the following instructions to prevent personal injury caused by

moving parts.

WARNING

Do not touch the moving parts when system is in operation. The

moving parts include sample probe, mixing bar, sample/reagent disk

and reaction disk.

Do not put your finger or hand into any open part when the system is

in operation.

Preventing Personal Injury Caused by Photometer Lamp

Please observe the following instructions to prevent personal injury caused by

photometer lamp.

WARNING

Light sent by the photometer lamp may hurt your eyes. Do not stare

into the lamp when the system is in operation.

If you want to replace the photometer lamp, first switch off the Main

Power and then wait at least 15 minutes for the lamp to cool down

before touching it. Do not touch the lamp before it cools down, or you

may get burned.

4

Page 10

Preventing Infection

Please observe the following instructions to protect against the biohazardous

infection.

BIOHAZARD

Inappropriately handling samples, controls and calibrators may lead

to biohazardous infection. Do not touch the sample, mixture or waste

with your hands. Wear gloves and lab coat and, if necessary,

goggles.

In case your skin contacts the sample, control or calibrator, follow

standard laboratory safety procedure and consult a doctor.

Handling Reagents and Wash Solution

WARNING

Some reagents and wash solution may be corrosive to human skins.

Plaase handle the reagents and concentrated wash solution carefully

and avoid direct contact.In case your skin or clothes contact the

reagents or wash solution, wash them off with water. In case the

reagents or wash solution spill into your eyes, rinse them with much

water and consult an oculist.

Treating Waste Liquids

Please observe the following instructions to prevent environmental pollution and

personal injury caused by waste.

BIOHAZARD

Some substances in reagent, control, enhanced wash solution and

waste are subject to regulations of contamination and disposal.

Dispose of them in accordance with your local or national guidelines

for biohazard waste disposal and consult the manufacturer or

distributor of the reagents for details.

Wear gloves and lab coat and, if necessary, goggles.

Treating Waste Analyzer

Please observe the following instructions to dispose of the waste analyzer.

WARNING

Materials of the analyzer are subject to contamination regulations.

Dispose of the waste analyzer in accordance with your local or

national guidelines for waste disposal.

5

Page 11

Preventing Fire or Explosion

Please observe the following instructions to prevent fire and explosion.

WARNING

Ethanol is flammable substance. Please exercise caution while using

the ethanol.

6

Page 12

Precautions on Use

To use the BS-120/BS-130/BS-180/BS-190 Chemistry Analyzer safely and

efficiently, please pay much attention to the following operation notes.

Intended Use

WARNING

The BS-120/BS-130/BS-180/BS-190 is a fully-automated and

computer-controlled chemistry analyzer designed for in vitro

quantitative determination of clinical chemistries in serum, plasma,

urine and CSF samples. Please consult Mindray first if you want to

use the system for other purposes.

To draw a clinical conclusion, please also refer to the patient’s clinical

symptoms and other test results.

Operator

WARNING

The BS-120/BS-130/BS-180/BS-190 is to be operated only by

clinical professionals, doctors or laboratory experimenters trained by

Mindray or Mindray-authorized distributors.

Environment

CAUTION

Please install and operate the system in an environment specified by

this manual. Installing and operating the system in other environment

may lead to unreliable results and even equipment damage.

Preventing Interference by Electromagnetic Noise

CAUTION

Electromagnetic noise may interfere with operations of the system.

Do not install devices generating excessive electromagnetic noise

around the system. Do not use such devices as mobile phones or

radio transmitters in the room housing the system. Do not use other

CRT displays around the system.The electromagnetic noise might

lead to system failures.

Do not use other medical instruments around the system that may

generate electromagnetic noise to interfere with their operations.

7

Page 13

Operating the System

CAUTION

Operate the system strictly as instructed by this manual.

Inappropriate use of the system may lead to unreliable test results or

even equipment damage or personal injury.

Before using the system for the first time, run the calibration program

and QC program to make sure the system is in normal status.

Be sure to run the QC program every time you use the system,

otherwise the result may be unreliable.

Do not open the covers of the sample/reagent disk cover when the

system is in operation.

Do not open the reaction disk cover when system is in operation.

The RS-232 port on the analyzing unit is to be used for connection

with the operation unit only. Do not use it for other connections. Only

use the supplied cable for the connection.

The operation unit is a personal computer with the

BS-120/BS-130/BS-180/BS-190 operating software installed.

Installing other software or hardware on this computer may interfere

with the system operation. Do not run other software when the

system is working.

Computer virus may destroy the operating software or test data. Do

not use this computer for other purposes or connect it to the Internet.

Do not touch the display, mouse or keyboard with wet hands or

hands with chemicals.

Do not place the Main Power to ON again within 10 seconds since

placing it to OFF; otherwise the system may enter protection status.

If it does so, switch off the Main Power and switch it on again.

Service and Maintenance

CAUTION

Maintain the system strictly as instructed by this manual.

Inappropriate maintenance may lead to unreliable results, or even

equipment damage and personal injury.

Dust may accumulate on the system surface when the system is

exposed to the outside for a long time.To wipe off dust from the

system surface, use a soft, clean and wet (not too wet) cloth, soaked

with mild soap solution if necessary, to clean the surface. Do not use

such organic solvents as ethanol for cleaning. After cleaning, wipe

the surface with dry cloth.

Switch off all the powers and unplug the power cord before cleaning.

Take necessary measures to prevent water ingression into the

system, otherwise it may lead to equipment damage or personal

injury.

Replacement of such major parts as lamp, photometer, sample

probe, mixer and syringe plunger assembly must be followed by a

calibration.

8

Page 14

Setting up the System

CAUTION

To define such parameters as sample volume, reagent volume and

wavelength, follow the instructions in this manual and the package

insert of the reagents.

Samples

CAUTION

Use samples that are completely free of insoluble substances like

fibrin, or suspended matter; otherwise the probe may be

blocked.Medicines, anticoagulants or preservative in samples may

lead to unreliable results.

Medicines, anticoagulants or preservative in the samples may lead to

unreliable results.

Hemolysis, icterus or lipemia in the samples may lead to unreliable

test results, so a sample blank is recommended.

Store the samples properly. Improper storage may change the

compositions of the samples and lead to unreliable results.

Sample volatilization may lead to unreliable results. Do not leave the

sample open for a long period.

Some samples may not be analyzed on the

BS-120/BS-130/BS-180/BS-190 based on parameters the reagents

claim capable of testing. Consult the reagent manufacturer or

distributor for details.

Certain samples need to be processed before being analyzed by the

system. Consult the reagent manufacturer or distributor for details.

The system has specific requirements on the sample volume. Refer

to this manual for details.

Load the sample to correct position on the sample disk before the

analysis begins; otherwise you will not obtain correct results.

9

Page 15

10

Reagents, Calibrators and Controls

CAUTION

Use appropriate reagents, calibrators and controls on the system.

Select appropriate reagents according to performance characteristic

of the system. Consult the reagent suppliers, Mindray or

Mindray-authorized distributor for details, if you are not sure about

your reagent choice.

Store and use reagents, calibrators and controls strictly as instructed

by the suppliers. Otherwise, you may not obtain reliable results or

best performance of the system.

Improper storage of reagents, calibrators and controls may lead to

unreliable results and bad performance of the system even in validity

period.

Perform a calibration after changing reagents. Otherwise, you may

not obtain reliable results.

Contamination caused by carryover among reagents may lead to

unreliable test results. Consult the reagent manufacturer or

distributor for details.

Backing up Data

NOTE

The system can automatically store data to the built-in hard disk of

the PC. However, data loss is still possible due to mis-deletion or

physical damage of the hard disk. Mindray recommends you to

regularly back up the data to portable storage device.

Computer and Printer

NOTE

Refer to the operation manuals of computer and printer for details.

External Equipment

WARNING

External equipment connected to the system, such as PC and printer,

shall be consistent with IEC 60950/EN 60950/ GB4943, EN55022

(Class B) /GB 9254 (Class B) and EN55024/ GB-T 17618.

Page 16

Contents

Intellectual Property Statement ........................................................................................... i

Responsibility on the Manufacturer Party............................................................................ i

Warranty..............................................................................................................................ii

Return Policy .......................................................................................................................ii

Foreword .......................................................................................................................................1

Who Should Read This Manual..........................................................................................1

What Can You Find in This Manual....................................................................................1

Conventions Used in This Manual......................................................................................1

Safety Precautions .............................................................................................................4

Precautions on Use ............................................................................................................7

Contents.........................................................................................................................................I

1

System Description..........................................................................................................1-1

1.1 Overview...............................................................................................................1-1

1.2 System Components ............................................................................................1-1

1.3 Functions ..............................................................................................................1-3

2

System Performace and Workflow ..................................................................................2-1

2.1 Technical Specifications........................................................................................2-1

2.1.1 System Specifications..............................................................................2-1

2.1.2 Specifications for Sample System...........................................................2-2

2.1.3 Specifications for Reagent System..........................................................2-3

2.1.4 Specifications of Reaction System ..........................................................2-4

2.1.5 Specifications of Operation......................................................................2-5

2.1.6 Installation Requirements ........................................................................2-5

2.1.7 Optional Modules.....................................................................................2-6

2.2 Workflow (BS-120/BS-130)...................................................................................2-6

2.2.1 Overview..................................................................................................2-6

2.2.2 Timing......................................................................................................2-6

2.2.3 Test Workflow...........................................................................................2-9

2.2.4 Measuring Points................................................................................... 2-11

2.3 Workflow (BS-180/BS-190).................................................................................2-11

2.3.1 Overview................................................................................................2-11

2.3.2 Timing......................................................................................................2-8

2.3.3 Test Workflow...........................................................................................2-9

3

Installation........................................................................................................................3-1

3.1 Environmental Requirements ...............................................................................3-1

3.2 Installation Requirements.....................................................................................3-2

3.2.1 Space and Accessibility Requirements....................................................3-2

3.2.2 Power Requirements ...............................................................................3-2

3.2.3 Water Supply and Drainage Requirements.............................................3-3

3.3 Installation Procedures.........................................................................................3-3

3.3.1 Unpacking................................................................................................3-3

3.3.2 Installation................................................................................................3-5

3.3.3 Operating Software Installation................................................................3-7

3.3.4 Run Operating Software ..........................................................................3-9

3.3.5 Setting up the System............................................................................3-10

3.3.6 Test ........................................................................................................3-14

Contents I

Page 17

3.3.7 Exit the System......................................................................................3-15

4

Units Description .............................................................................................................4-1

4.1 Enclosure and Panel Unit.....................................................................................4-1

4.1.1 Components.............................................................................................4-1

4.1.2 Dismounting/Mounting of Enclosure Unit ................................................4-2

4.2 Probe Unit.............................................................................................................4-5

4.2.1 Function Introduction ...............................................................................4-5

4.2.2 Components of Probe Unit ......................................................................4-5

4.2.3 Dismounting/mounting Sample Probe Unit..............................................4-6

4.3 Sample/Reagent Disk Unit .................................................................................4-10

4.3.1 Function Introduction .............................................................................4-10

4.3.2 Components of Sample/Reagent Disk Unit...........................................4-10

4.3.3 Dismounting Sample/Reagent Disk Unit ............................................... 4-11

4.4 Reaction Disk Unit ..............................................................................................4-17

4.4.1 Function Introduction .............................................................................4-17

4.4.2 Components of Reaction Disk Unit........................................................4-18

4.4.3 Dismounting Reaction Disk Unit ............................................................4-19

4.5 Mixing Unit..........................................................................................................4-22

4.5.1 Function Introduction .............................................................................4-22

4.5.2 Components of Mixing Unit....................................................................4-22

4.5.3 Dismounting Mixing Unit........................................................................4-23

4.6 Photometric Unit .................................................................................................4-26

4.6.1 Introduction............................................................................................4-26

4.6.2 Components of Photometric Unit...........................................................4-26

4.6.3 Dismounting and Mounting Photometric Unit........................................4-30

4.6.4 Adjustment of Photometer .....................................................................4-32

4.7 Power Supply Unit ..............................................................................................4-38

4.7.1 Function and Components.....................................................................4-38

4.7.2 Dismounting Power Supply Unit............................................................4-38

4.8 ISE Unit (Optional)..............................................................................................4-39

4.8.1 Introduction............................................................................................4-39

4.8.2 Components of ISE Unit ........................................................................4-39

4.8.3 Installling and Removing ISE Unit .........................................................4-40

5

Fluid System....................................................................................................................5-1

5.1 Main Functions .....................................................................................................5-1

5.2 Functional Structure..............................................................................................5-1

5.3 Fluid System Chart ...............................................................................................5-2

5.4 Major Components and Their Functions ..............................................................5-3

5.5 Connectors ...........................................................................................................5-4

5.6 Tubing...................................................................................................................5-5

5.7 Fluid System Connections and Layout.................................................................5-6

5.8 External DI Water Tank and Waste Tank ..............................................................5-8

5.9 Key Components ..................................................................................................5-9

5.9.1 Solenoid Valve.............................................................................................5-9

5.9.2 Check Valve.................................................................................................5-9

5.9.3 Liquid Level Float ......................................................................................5-10

5.9.4 Syringe Assembly......................................................................................5-10

5.9.5 Diaphragm Pump.......................................................................................5-11

5.9.6 Probe .........................................................................................................5-11

5.9.7 Filter.......................................................................................................5-12

6

Hardware System............................................................................................................6-1

6.1 Overview...............................................................................................................6-1

II

Contents

Page 18

6.2 Safety Precautions................................................................................................6-1

6.3 Circuit boards........................................................................................................6-2

6.4 Layout of the Boards.............................................................................................6-4

6.5 Detaching and Assembling Circuit Boards ...........................................................6-4

6.6 Function of the Boards .........................................................................................6-5

6.6.1 Control Framework ..................................................................................6-5

6.6.2 Main Board ..............................................................................................6-5

6.6.3 Drive Board..............................................................................................6-6

6.6.4 Pre-amp Board ........................................................................................6-7

6.6.5 AD Conversion Board..............................................................................6-7

6.6.6 Reagent Refrigeration Board...................................................................6-8

6.6.7 Level Detection Board .............................................................................6-8

6.6.8 Reaction Disk Temperature Sampling Board...........................................6-9

6.6.9 Three Probes Connection Board.............................................................6-9

6.6.10 ISE Power Board ...................................................................................6-9

6.6.11 Heater Voltage Selecting Board.............................................................6-9

6.7 On Board LED Indication......................................................................................6-9

6.8 Power Supply Unit ..............................................................................................6-11

6.8.1 Features of Power Supply Unit..............................................................6-12

6.8.2 Protective Function of Power Supply Unit.............................................6-13

6.8.3 Block Diagram .......................................................................................6-13

6.9 Connection Diagram...........................................................................................6-14

7

Service and Maintenance................................................................................................7-1

7.1 Preparation ...........................................................................................................7-1

7.1.1 Tools.........................................................................................................7-2

7.1.2 Wash Solution..........................................................................................7-2

7.1.3 Others......................................................................................................7-2

7.2 Daily Maintenance ................................................................................................7-3

7.2.1 Checking Remaining Deionized Water....................................................7-3

7.2.2 Emptying Waste Tank ..............................................................................7-3

7.2.3 Checking Connection of Deionized Water...............................................7-4

7.2.4 Checking Connection of Waste Water.....................................................7-4

7.2.5 Checking Syringe.....................................................................................7-4

7.2.6 Checking/Cleaning Sample Probe...........................................................7-5

7.2.7 Checking/Cleaning Mixing Bar ................................................................7-6

7.2.8 Checking Printer/Printing Paper ..............................................................7-6

7.2.9 Checking ISE Unit (Optional)...................................................................7-6

7.3 Weekly Maintenance ............................................................................................7-8

7.3.1 Cleaning Sample Probe...........................................................................7-8

7.3.2 Cleaning Mixing Bar.................................................................................7-9

7.3.3 Cleaning Sample/Reagent Compartment..............................................7-10

7.3.4 Cleaning Panel of Analyzing Unit ..........................................................7-11

7.3.5 Washing Deionized Water Tank.............................................................7-11

7.3.6 Washing Waste Tank .............................................................................7-12

7.4 Monthly Maintenance..........................................................................................7-13

7.4.1 Cleaning Wash pool of Probe................................................................7-13

7.4.2 Cleaning Wash pool of Mixing Bar.........................................................7-14

7.4.3 Cleaning Sample/Reagent Rotor...........................................................7-15

7.5 Three-month Maintenance .................................................................................7-15

7.5.1 Washing Dust Screen............................................................................7-15

7.5.2 Replacing Filter Assemby......................................................................7-17

7.6 Irregular Maintenance.........................................................................................7-18

7.6.1 Checking photoelectric system performance.........................................7-18

Contents III

Page 19

7.6.2 Replacing the lamp................................................................................7-18

7.6.3 Replacing the Filter................................................................................7-21

7.6.4 Unclogging Sample Probe.....................................................................7-23

7.6.5 Replacing Probe ....................................................................................7-29

7.6.6 Replacing Mixing Bar.............................................................................7-30

7.6.7 Replacing Plunger Assembly of Syringe................................................7-32

7.6.8 Removing Air Bubbles ...........................................................................7-35

7.6.9 Replacing Dust Screen..........................................................................7-36

7.6.10 Replacing Waste Tubing......................................................................7-36

7.7 Maintaining ISE Module (Optional).....................................................................7-36

7.7.1 Replace Reagent Pack..........................................................................7-36

7.7.2 Replacing Electrodes.............................................................................7-37

7.7.3 Replacing Tubing...................................................................................7-38

7.7.4 Storage of ISE Module (Optional)..........................................................7-38

8

Test and Maintenance Software......................................................................................8-1

8.1 Basic Operations ..................................................................................................8-1

8.1.1 Installation................................................................................................8-1

8.1.2 Overview..................................................................................................8-1

8.2 Operating Commands...........................................................................................8-3

8.2.1 Main Unit..................................................................................................8-4

8.2.2 Mixing Unit...............................................................................................8-4

8.2.3 Reagent Unit............................................................................................8-5

8.2.4 Sample Unit .............................................................................................8-6

8.2.5 Reaction Unit ...........................................................................................8-7

8.2.6 ISE Module ..............................................................................................8-8

8.2.7 Temperature Unit...................................................................................8-10

8.3 Parameter...........................................................................................................8-12

8.3.1 The Precondition for Parameter Configuration......................................8-13

8.3.2 Detailed Operations...............................................................................8-15

8.4 Temperature........................................................................................................8-17

8.4.1 Functions ...............................................................................................8-17

8.4.2 Operation Details...................................................................................8-17

8.5 Photoelectric.......................................................................................................8-18

8.5.1 Filter Offset ............................................................................................8-18

8.5.2 Photoelectric Gain .................................................................................8-19

8.5.3 Light Source Background ......................................................................8-20

8.5.4 Dark Current Test...................................................................................8-21

8.5.5 Other Functions of the Photoelectric Test..............................................8-22

8.6 Macro Instructions ..............................................................................................8-22

8.6.1 Function.................................................................................................8-22

8.6.2 Detailed Operations...............................................................................8-22

9

Troubleshooting...............................................................................................................9-1

9.1 Error Message Classification................................................................................9-1

9.2 Classification of Error Messages..........................................................................9-2

9.3 Operation Unit Error..............................................................................................9-5

9.4 Analyzing Unit Error............................................................................................9-12

9.4.1 Main Unit................................................................................................9-12

9.4.2 Sample/Reagent Unit.............................................................................9-14

9.4.3 Reaction Disk Unit .................................................................................9-19

9.4.4 Temperature Unit...................................................................................9-23

9.4.5 Mixing Unit.............................................................................................9-25

9.4.6 ISE Unit..................................................................................................9-28

9.4.7 Other Units Failures...............................................................................9-49

IV

Contents

Page 20

10 Caculation Methods.......................................................................................................10-1

10.1

Reaction Type.................................................................................................10-1

10.1.1 Endpoint...............................................................................................10-1

10.1.2 Fixed-Time...........................................................................................10-2

10.1.3 Kinetic..................................................................................................10-3

10.2

Calculation Process ........................................................................................10-4

10.2.1 Calculating Absorbance.......................................................................10-5

10.2.2 Calculating Response..........................................................................10-6

10.2.3 Calculating Calibration Parameters.....................................................10-8

10.2.4 Calculating Concentration.................................................................. 10-11

10.2.5 QC Rule.............................................................................................10-12

Contents V

Page 21

Page 22

1

System Description

1.1 Overview

The BS-120/BS-130/BS-180/BS-190 is a fully-automated and

computer-controlled chemistry analyzer designed for in vitro quantitative

determination of clinical chemistries in serum, plasma, urine and CSF

(Cerebrospinal fluid) samples. BS-120/BS-130/BS-180/BS-190 Chemistry

Analyzer consists of the analyzing unit (analyzer), operation unit (personal

computer), output unit (printer) and consumables.

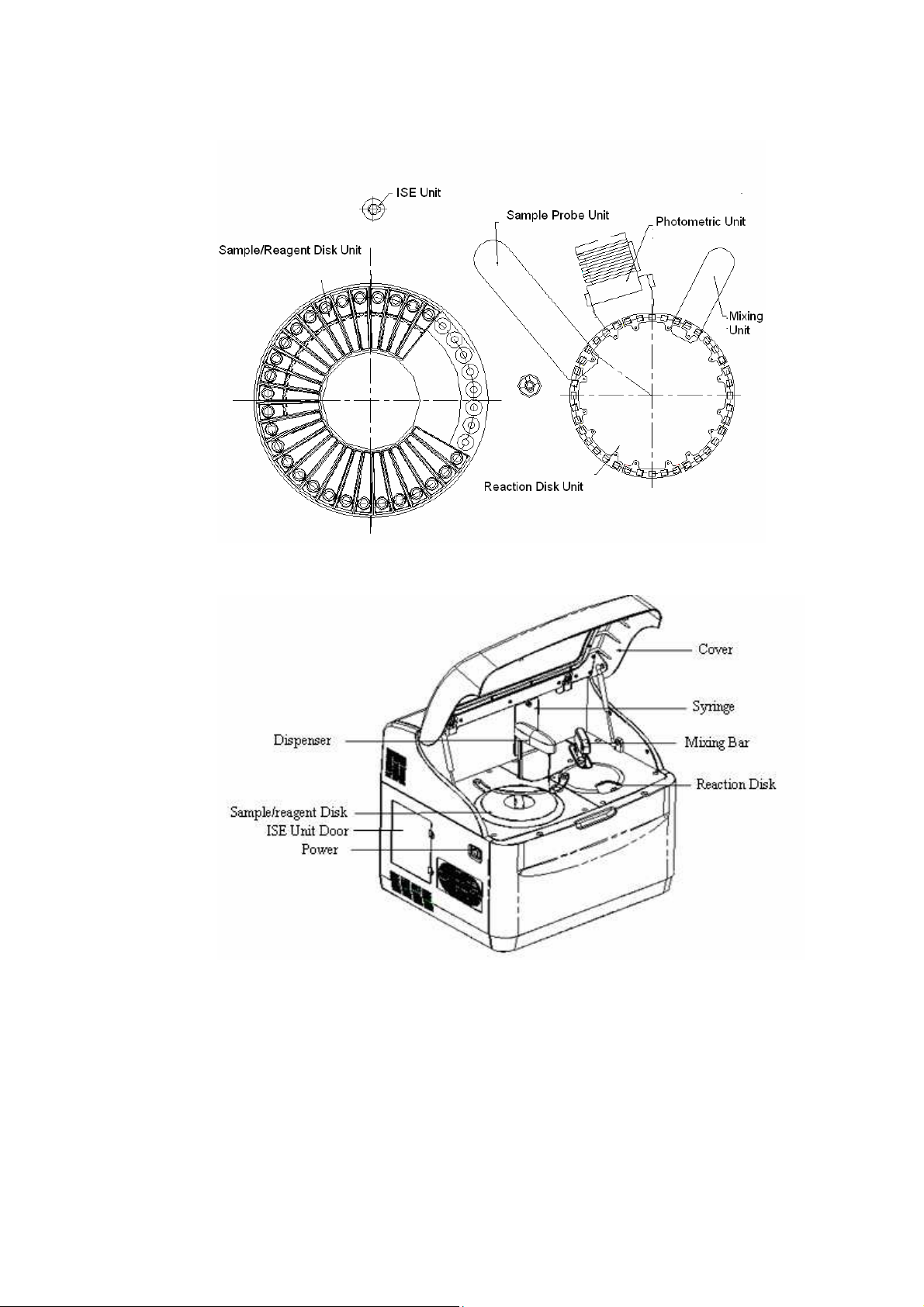

1.2 System Components

BS-120/BS-130/BS-180/BS-190 Chemistry Analyzer realizes the ”two-disk +

one-probe + one-mixing bar” scheme, which means one reaction disk, one

sample/reagent disk, one sample probe and one mixing bar. Reaction disk is

where cuvettes are placed; sample/reagent disk is where sample and reagent

containers are placed; sample probe is used for dispensing R1/R2/S; mixing

bar is used for mixing after S or R2 has been added. The photometric system

adopts filter wheel photometer. The cuvettes are replaced manually after the

tests are finished.

1 System Description 1-1

Page 23

Figure1-1 Layout of the System Panel

Figure 1-2 System Structure-Front View

1 System Description 1-2

Page 24

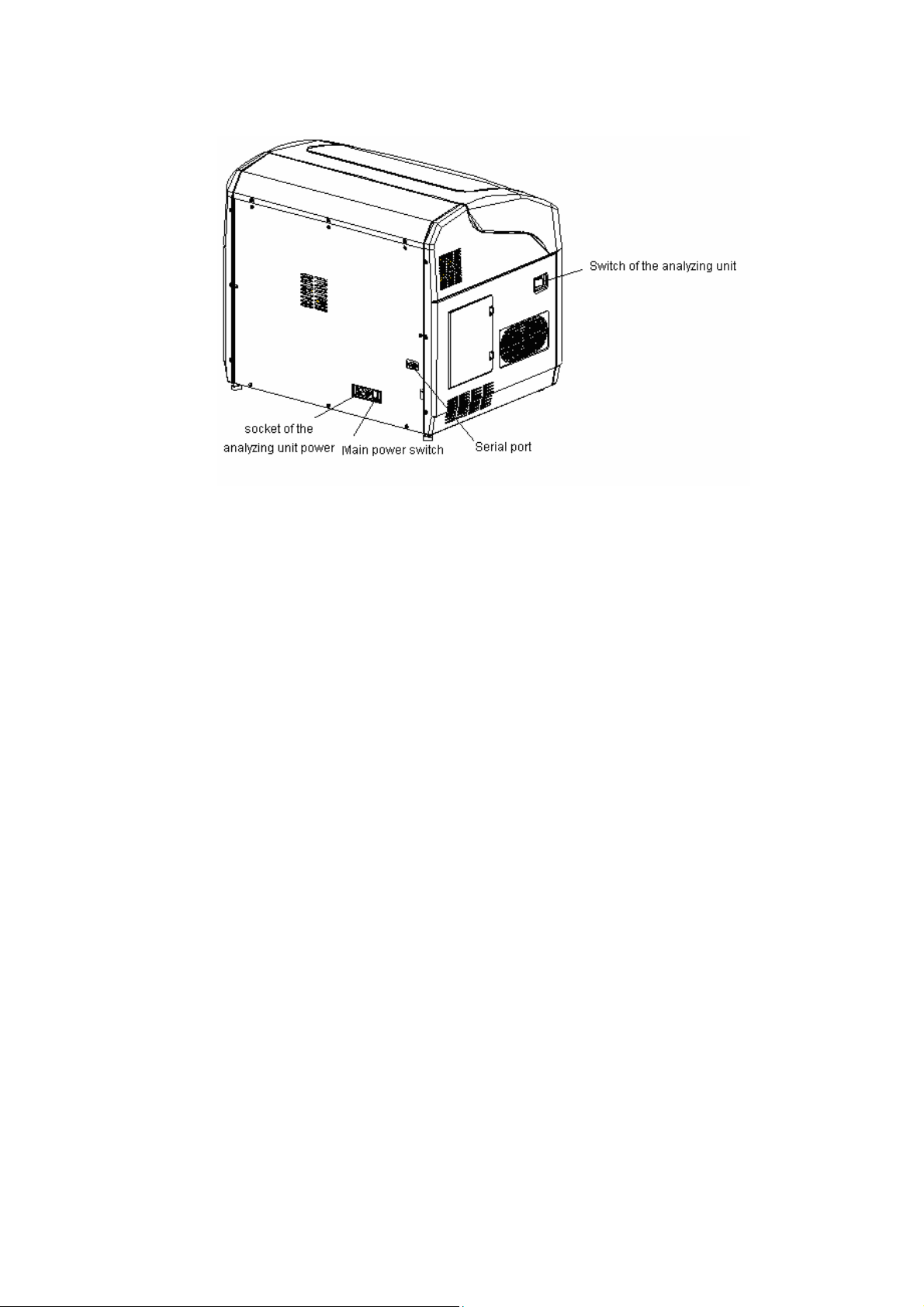

Figure 1-3 System Structure-left Panel View

1.3 Functions

The general working procedure of the BS-120/BS-130/BS-180/BS-190 is as

follows:

1. All mechanical units are initialized.

2. The sample/reagent disk rotates to R1 aspirating position, and the probe

aspirates reagent from a bottle on the sample/reagent disk.

3. The reaction disk carries the cuvettes to the sample/reagent dispensing

position, and the probe dispenses reagent to a cuvette.

4. R1 is incubated in reaction cuvette for several periods.

5. The sample/reagent disk rotates to sample aspirating position, and the

reaction disk carries the cuvettes to the sample/reagent dispensing

position, then the probe dispenses the sample in the reaction cuvette.

6. With sample dispensed, the reaction cuvette rotates to mixing position for

stirring.

7. In case of single-reagent tests, the reaction begins. When defined time is

over, the reaction ends.

8. In case of double-reagent tests, when sample is dispensed and sirred, the

sample/reagent disk rotates to the R2 aspirating position, and the probe

aspirates reagent from the specified bottle on the reagent disk.

9. The reaction disk carries the cuvettes to the sample/reagent dispensing

position, and the probe dispenses reagent to a cuvette.

10. With R2 dispensed, the reaction cuvette is carried to the mixing position

for stirring.

11. During the first and second rotation of each period, the reaction cuvette

receives photometric measurement.

1 System Description 1-3

Page 25

12.

When a batch of analysis is finished or all the cuvettes are used up,

replace the cuvettes manually.

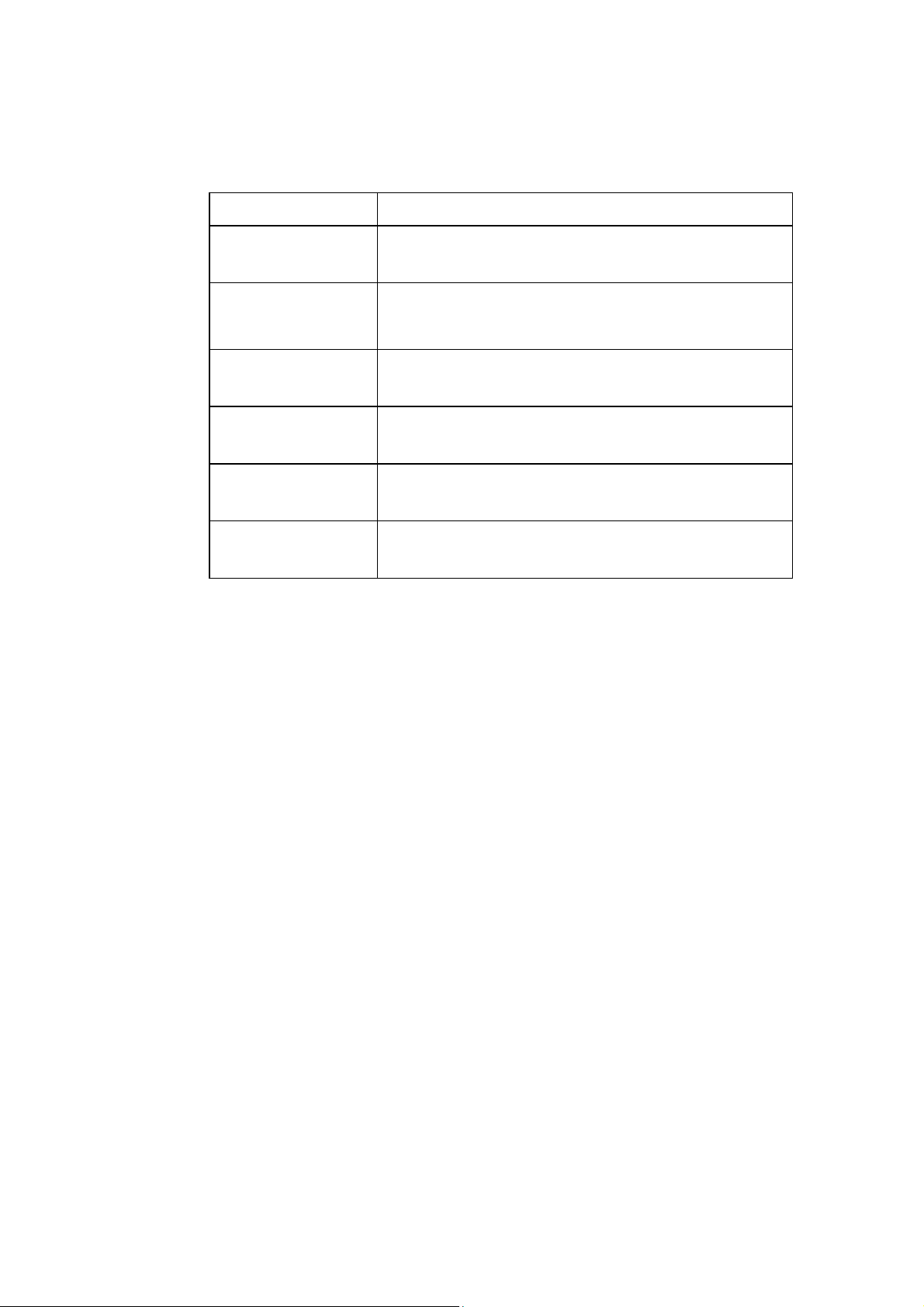

Table 1-1 Functions of System Units

UNIT NAME DESCRIPTION

Sample probe unit

Sample/Reagent

Disk Unit

Reaction Disk Unit

Mixing Unit

Photometric Unit

ISE Unit (optional)

Aspirates and dispenses samples and reagents for all

chemical and ISE tests.

36 positions.

Default: 1~8# sample position; 9~36# reagent position.

Able to hold 40 cuvettes. It provides an environment in

which sample reacts with reagents.

Used to stir the mixture in reaction cuvette when

sample or R2 is dispensed.

Adopts filter wheel structure and performs photometric

measurement (absorbance reading) at 8 wavelengths.

ISE (Ion Selective Electrode) module (not installed on

domestic product).

1 System Description 1-4

Page 26

2

System Performace and

2.1 Technical Specifications

2.1.1 System Specifications

System

Random, multi-channel, multi-test

Sample type

Serum, urine, plasma and CSF (Cerebrospinal fluid)

Number of simultaneous measurements

Workflow

13/26 single-/double-reagent tests

Throughput

BS-120/BS-130: 100 tests/hour, or 300 tests/hour with ISE unit.

BS-180/BS-190: 220 tests/hour, or 440 tests/hour with ISE unit.

Reaction types

Endpoint, Kinetic, Fixed-time; single-/double-reagent test;

single-/double-wavelength test

Reaction time

Maximum 10 minutes for single-reagent analysis; maximum 5 minutes for

double-reagent analysis.

2 System Performance and Workflow

2-1

Page 27

Reaction liquid volume

BS-120/BS-130: 180-500µl

BS-180/BS-190: 150-500µl

Reaction temperature

37℃

Test scope

Clinical chemistries, immunoassays, TDM (Treatment Drug Monitoring)

Auto dilution

Dilution ratio 4~150; dilution is done in reaction cuvette.

Operation mode

System and tests are configured via the operating software. Profiles and

calculation tests are allowed.

Calibration method

Linear (one-point, two-point and multi-point), Logit-Log 4p, Logit-Log 5p, Spline,

Exponential, Polynomial and Parabola

Programming Controls

Westgard Multi-rule, Cumulative sum check, Twin plot

Data processing

Capable of storing and outputting various data and tables/graphs, and calculating

among different tests

Dimensions

l×b×h:690 mm×570 mm×595 mm.

Weight

≤75kg

Emergent samples

Emergent samples can be inserted during test at any time.

Network connection

Able to be connected with LIS (Laboratory Information Management System)

2.1.2 Specifications for Sample System

Sample tube type

Microtube: Φ10×37mm, Φ12×37mm;

Blood collecting tube: Φ12×68.5mm, Φ12×99, Φ12.7×75, Φ12.7×100, Φ13×75,

Φ13×100;

2-2

2 System Performance and Workflow

Page 28

Plastic tube: Φ12×68.5mm, Φ12×99, Φ12.7×75, Φ12.7×100, Φ13×75,

Φ13×100.

Minimum sample volume

Minimum sample volume=dead volume of the sample+total sample volume

needed for all the tests

Dead volume of the sample: Microtube ≤300, Blood collecting tube≤500ul, Plastic

tube≤500ul.

Sample position

Sample and reagent share one sample/reagent disk which is of single-circle

structure. No.1-No.8 are sample positions which can be set as routine, QC, STAT

positions.

STAT sample

Emergent samples can be inserted during test at any time and then run with high

priority.

Sample volume

3µl-45µl, with increment of 0.5µl

Sample probe

Sample and reagent share one probe, which is capable of detecting liquid level,

protecting the probe against collision in the vertical direction and tracking liquid

level.

Sample probe washing

Inside and outside of the probe are washed with carryover less than 0.1%.

Sample input mode

Enter manually

When hand-held bar code system is installed, the sample information can be

entered by using the bar code. Refer to the documents accompanying the

optional hand-held bar code reader.

2.1.3 Specifications for Reagent System

Reagent refrigeration

24 hours non-stop refrigeration, refrigeration temperature: 4-15℃

Reagent dispensing

Reagent is aspirated and dispensed precisely by syringes.

Reagent types

1 to 2 reagent types, R1 and R2

2 System Performance and Workflow

2-3

Page 29

Reagent volume

30µl-450µl, with increment of 1µl

Reagent position assignment

Sample and reagent share one sample/reagent disk which is of single-circle

structure. No.9-No.36 are reagent positions and No. 35 is fixed for wash solution

and No. 36 is fixed for dilution.Other positions can be assigned for R1 or R2. If

ISE module is installed, No.34 is fixed for ISE wash solution.

Reagent input mode

Enter manually

When hand-held bar code system is installed, the reagent information can be

entered using the bar code. Refer to the documents accompanying the optional

hand-held bar code reader.

Reagent probe

Sample and reagent share one probe, which is capable of detecting liquid level,

protecting the probe against collision in the vertical direction and tracking liquid

level.

Reagent probe washing

Inside and outside of the probe are washed with carryover less than 0.1%.

2.1.4 Specifications of Reaction System

Optical path of reaction cuvette

5mm

Material of reaction cuvette

5mm×6mm×30mm, disposable reaction cuvette

Number of reaction cuvettes

40

Mixing method

One mixing bar, which starts to stir after adding a samples or R2

Photometric System

Filter wheel optical system

2-4

Wavelength

8 wavelengths:340nm、405nm、450nm、510nm、546nm、578nm、630nm、

670nm

Wavelength accuracy

±2nm

2 System Performance and Workflow

Page 30

5

Light source

12V, tungsten-halogen lamp, 20W

Photometric measurement method

Photodiode

Measurement range

0~3.5A(for 10mm optical path)

2.1.5 Specifications of Operation

Display

17/15’’ LCD and CRT, resolution: 1024×768, refresh rate: 70Hz

Operating System

Windows XP, Windows Vista

Communication interface

RS-232

Printer

Ink jet printer, laser printer (black-white) and stylus printer

Input device

Keyboard, hand-held barcode scanner connected to the network (optional)

Output device

Display, printer and LIS host

Storage device

Hard disk, USB port

2.1.6 Installation Requirements

Power requirement

100V-130V, 200V-240V

Power frequency

50/60Hz (±3Hz fluctuation)

Power of analyzing unit

350VA

Water consumption

Less than 2.5L/hour

2 System Performance and Workflow

2-

Page 31

6

Environment

Storage temperature: 0~40℃

Storage humidity: 30%RH-85%RH, without condensation

Above-sea-level height (storage): -400~5500 meters

Operating temperature: 15~30℃

Operating humidity: 35%RH-85%RH, without condensation

Above-sea-level height (operation): -400~2000 meters

2.1.7 Optional Modules

ISE (Ion Selective Electrode) module

Hand-held barcode reader

2.2 Workflow (BS-120/BS-130)

2.2.1 Overview

Figure 2-1 General Test Procedure of the BS-120/BS-130

2.2.2 Timing

2.2.2.1 Timing for Main Components

The working period of BS-120/BS-130 is 36 seconds, so its throughput is 100

tests/hour (3600/36). During each working period, the reaction disk rotates three

times and stops three times. During each stop, the sample probe can dispense

sample, first reagent and second reagent respectively. Therefore, the throughput

is not affected no matter it is single-reagent test or double-reagent test because

both of them have the same test efficiency. The practical throughput is affected

by reaction time and cuvettes replacement.

The system collects photometric data two times during each period. Therefore,

the interval between two absorbance readings is 18 seconds for each test.

The movements of major moving parts are shown in the following table.

2-

2 System Performance and Workflow

Page 32

7

finish

Table 2-1 Timing of Major Moving Parts

Components Expected actions

Rotating continuously to

finish photometric

Reaction disk Stop

Sample probe

Mixing bar Mixing R2 Washing mixing bar Mixing S Washing mixing bar Stop Stop

Photometric

system

Aspirating and

dispensing S

Filter wheel rotating

slowly, not

performing

photometric

measurement

measuring of all the

cuvettes and stopping

at the R1 dispensing

position

Washing sample probe

and aspirating R1

Filter wheel stops each

filter on the measuring

position in turn to

photometric measuring

Stop

Dispensing R1

Filter wheel rotating

slowly, not

performing

photometric

measurement

Rotating continuously to

finish photometric

measuring of all the

cuvettes and stopping

at the R2 dispensing

position

Washing sample probe

and aspirating R2

Filter wheel stops each

filter in the measuring

position in turn to finish

photometric measuring

Stop

Dispensing R2

Filter wheel rotating

slowly, not

performing

photometric

measurement

rotating and

stopping after

passing 9 cuvettes

Washing sample

probe

Filter wheel rotating

slowly, not

performing

photometric

measurement

2 System Performance and Workflow 2-

Page 33

8

2.2.2.2 Timing for Sample Probe

a. Lifting up from the wash pool

b. Rotating to the position above the sample/reagent disk

c. Lowering down to the sample tube

d. Aspirating sample and dispensing back a little

e. Lifting up from the sample tube

f. Rotating to the position above the reaction disk

g. Lowering down to the reaction cuvette

h. Dispensing the sample

i. Lifting up from the reaction cuvette

j. Rotating to the position above the wash pool

k. Lowering down to the wash pool

l. Washing inside and outside of the sample probe

2.2.2.3 Timing for Reagent Probe

The timing of dispensing R1 and R2 are basically the same, with slight difference

in the reagent dispensed.Therefore, only the timing of dispensing R1 is shown in

the following:

a. Lifting up from the wash pool

b. Rotating to the position above the sample/reagent disk

c. Lowering down to the reagent bottle

d. Aspirating R1

e. Lifting up from the reagent bottle

f. Rotating to the position above reaction disk

g. Lowering down to the reaction cuvette

h. Dispensing R1

i. Lifting up from the reaction cuvette

j. Rotating to the position above the wash pool

k. Lowering down to the wash pool

l. Washing inside and outside of the reagent probe

2.2.2.4 Timing for Mixing Bar

a. Lifting up from the wash pool and moving into the reaction cuvette

2-

2 System Performance and Workflow

Page 34

b. Sirring reaction liquid

c. Lifting up from the reaction cuvette and moving into the wash pool

d. Washing mixing bar

2.2.2.5 Timing for Reaction Disk

The reaction disk can hold 40 reaction cuvettes. In each working period, the

reaction disk rotates clockwise. It rotates and stops for 3 times respectively, and

passes 41 cuvettes(9+23+9), which means the reaction disk finally stops at the

next position clockwise.

Figure 2-2 Timing of Reaction Disk

2.2.3 Test Workflow

A complete test work flow is show in the following figure.

2 System Performance and Workflow

2-9

Page 35

9

cuvettes

rotating N circles

+9 cuvettes to

Figure 2-3 Workflow for Single-/Double-reagent Tests

finish the photoelectric collection and

stopping the reaction disk at R1 dispensing

Reaction

disk

Period

N=1 R1 33#cuvette

……

N=7

N=8

N=9

N=10

N=11

N=12

N=13

N=14

N=15

N=16

N=17

N=18

N=19

N=20

N=21

N=22

N=23

N=24

N=25

N=26

N=27

Stop

MIX R2

Double-reagent

reaction starts

position)

RB2

……

RB12

RB14

RB16

P2

P4

P6

P8

P10

P12

P14

P16

P18

P20

P22 P23

P24

P28

P30

P32

P34

23 cuvettes (rotating N circles +23 cuvettes to

finish the photoelectric collection and stopping

the reaction disk at R2 dispensing position)

RB1

RB3

RB13

……

MIX SS

Single-reagent

reaction starts

P29

P31

P33

P35

RB15

RB17

P13

P15

P17

P19

P21

P25

P27P26

End

……

P11

9 cuvettes

StopStop

P1

P3

P5

P7

P9

R2

Stop

Position

34#cuvetteN=2

……

39#cuvette

40#cuvette

1#cuvette

2#cuvette

3#cuvette

4#cuvette

5#cuvette

6#cuvette

7#cuvette

8#cuvette

9#cuvette

10#cuvette

11#cuvette

12#cuvette

13#cuvette

14#cuvette

15#cuvette

16#cuvette

17#cuvette

18#cuvette

19#cuvette

36.0

In the figure above, RB1-RB17 are the 17 reagent blank points measured after

R1 is dispensed and before S is dispensed.P1-P35 are the 35 measuring points

after sample is dispensed and mixed to the time when the test with the longest

reaction time is finished.The measuring point, at which sample is dispensed but

not mixed, is invalid and not used in calculation.

2-10

2 System Performance and Workflow

Page 36

2.2.4 Measuring Points

Figure 2-4 Measuring Points for Single-reagent Tests

Figure 2-5 Measuring Points for Double-reagent Tests

2.3 Workflow (BS-180/BS-190)

2.3.1 Overview

Figure 2-6 General Test Procedure of the BS-180/BS-190

2 System Performance and Workflow

2-11

Page 37

2.3.2 Timing

2.3.2.1 Timing for Main Components

The working period of BS-180/BS-190 is 16 seconds, so its throughput is 225

tests/hour (3600/16). During each working period, the reaction disk rotates two

times and stops two times. During each stop, the sample probe dispenses R1

and sample and stirs the sample, and dispensing R2 is done in a single period.

Therefore, the throughput is affected by single or double reagent tests. The

practical throughput is affected by reaction time and cuvettes replacement.

The system collects photometric data two times during each period. Therefore,

the interval between two absorbance readings is 16 seconds for each test.

The movements of major moving parts are shown in the following table.

2.3.2.2 Timing for Sample Probe

a. Lifting up from the wash pool

b. Rotating to the position above the sample/reagent disk

c. Lowering down to the sample tube

d. Aspirating sample and dispensing back a little

e. Lifting up from the sample tube

f. Rotating to the position above the reaction disk

g. Lowering down to the reaction cuvette

h. Dispensing the sample

i. Lifting up from the reaction cuvette

j. Rotating to the position above the wash pool

k. Lowering down to the wash pool

l. Washing inside and outside of the sample probe

2-8

2 System Performance and Workflow

Page 38

2.3.2.3 Timing for Reagent Probe

The timing of dispensing R1 and R2 are basically the same, with slight difference

in the reagent dispensed.Therefore, only the timing of dispensing R1 is shown in

the following:

a. Lifting up from the wash pool

b. Rotating to the position above the sample/reagent disk

c. Lowering down to the reagent bottle

d. Aspirating R1

e. Lifting up from the reagent bottle

f. Rotating to the position above reaction disk

g. Lowering down to the reaction cuvette

h. Dispensing R1

i. Lifting up from the reaction cuvette

j. Rotating to the position above the wash pool

k. Lowering down to the wash pool

l. Washing inside and outside of the reagent probe

2.3.2.4 Timing for Mixing Bar

a. Lifting up from the wash pool and moving into the reaction cuvette

b. Sirring reaction liquid

c. Lifting up from the reaction cuvette and moving into the wash pool

d. Washing mixing bar

2.3.2.5 Timing for Reaction Disk

The reaction disk can hold 40 reaction cuvettes. In each working period, the

reaction disk rotates clockwise. In a routine period, the reaction disk rotates and

stops at the sample dispensing position, and then rotates for 9 cuvette positions

and stops for stirring and R1 dispensing.

2.3.3 Test Workflow

A complete test work flow is show in the following figure.

2 System Performance and Workflow

2-9

Page 39

9

cuvettes

rotating N circles

+9 cuvettes to

Figure 2-7 Workflow for Single-/Double-reagent Tests

finish the photoelectric collection and

stopping the reaction disk at R1 dispensing

Reaction

disk

Period

N=1 R1 33#cuvette

……

N=7

N=8

N=9

N=10

N=11

N=12

N=13

N=14

N=15

N=16

N=17

N=18

N=19

N=20

N=21

N=22

N=23

N=24

N=25

N=26

N=27

Stop

MIX R2

Double-reagent

reaction starts

position)

RB2

……

RB12

RB14

RB16

P2

P4

P6

P8

P10

P12

P14

P16

P18

P20

P22 P23

P24

P28

P30

P32

P34

23 cuvettes (rotating N circles +23 cuvettes to

finish the photoelectric collection and stopping

the reaction disk at R2 dispensing position)

RB1

RB3

RB13

……

MIX SS

Single-reagent

reaction starts

P29

P31

P33

P35

RB15

RB17

P13

P15

P17

P19

P21

P25

P27P26

End

……

P11

9 cuvettes

StopStop

P1

P3

P5

P7

P9

R2

Stop

Position

34#cuvetteN=2

……

39#cuvette

40#cuvette

1#cuvette

2#cuvette

3#cuvette

4#cuvette

5#cuvette

6#cuvette

7#cuvette

8#cuvette

9#cuvette

10#cuvette

11#cuvette

12#cuvette

13#cuvette

14#cuvette

15#cuvette

16#cuvette

17#cuvette

18#cuvette

19#cuvette

36.0

In the figure above, P1a and P1b are collected at different wavelengths in the same

period.

2-10

2 System Performance and Workflow

Page 40

3

Installation

3.1 Environmental Requirements

The system is for indoor use only.

The bearing platform should be leveled with gradient less than 1/200.

The bearing platform should be able to bear 75Kg weight.

The bearing platform should be 500mm-800mm high.

The installation site should be well ventilated.

CAUTION

The system radiates heat when running. A well-ventilated

environment helps keeping the room temperature stable. Use

ventilation equipment if necessary. Do not expose the system to

direct draft that may lead to unreliable results.

The installation site should be free of dust as much as possible.

The installation site should not be under the direct sun.

The installation site should not be close to a heat or draft source.

The installation site should be free of corrosive gas and flammable gas.

The bearing platform should be free of vibration.

The installation site should not be disturbed by large noise or power supply.

The system should not be placed near brush-type motors and electrical

contacts that are frequently powered on and off.

3 Installation 3-1

Page 41

Do not use devices such as mobile phones or radio transmitters near the

system. Electromagnetic waves generated by those devices may interfere

with operation of the system.

The altitude height of the installation site should be lower than 2000 meters.

Ambient temperature: 15℃-30℃, with fluctuation less than ±2℃/H.

Relative humidity: 35%RH-85%RH, without condensation

CAUTION

Operating the system in an environment other than the specified

may lead to unreliable test results.

If the temperature or relative humidity does not meet the

requirements mentioned above, be sure to use air-conditioning

equipment.

3.2 Installation Requirements

3.2.1 Space and Accessibility Requirements

Figure 3-1 Space and Accessibility Requirements

3.2.2 Power Requirements

Power supply: 100-130V/200-240V, 50/60Hz, three-wire power cord and

properly grounded.

The system should be connected to a properly grounded power socket.

3 Installation 3-2

Page 42

The distance between the power socket and the system should be less than

3 meters.

WARNING

Make sure the power socket is grounded correctly. Improper

grounding may lead to electric shock and/or equipment damage.

Be sure to connect the system to a power socket that meets the

requirements mentioned above and has a proper fuse installed.

3.2.3 Water Supply and Drainage Requirements

The supplied water must meet requirements of the CAP Type II water, with

specific resistance no less than 0.5(MΩ.cm@25℃).

The water temperature should be within 5℃-32℃.

BIOHAZARD

Dispose of waste liquids according to your local regulations.

CAUTION

The supplied water must meet requirements of the CAP Type II

water; otherwise insufficiently-purified water may result in

misleading measurement.

3.3 Installation Procedures

3.3.1 Unpacking

Check the delivery list before unpacking. Besides PC and printer box, there

are three boxes for analyzing unit, accessory and deionized water tank,

waste tank and used-cuvette bucket.

The gross weight of the analyzing unit is about 95Kg. 3-4 people are needed

to lay the wooden case containing the analyzing unit on the gound. Use fork

truck, if possible.

Use special tools to unpack the top cover and the side plate.

3 Installation 3-3

Page 43

Figure 3-2 Unpack the Top Cover of the Wooden Case

Figure 3-3 Remove the side plate of the wooden case

Prize the fixing parts around

the top cover, then remove

the top cover.

Prize the fixing parts around

the side plate, then remove

all the side plates

Remove the plastic bag, and use the adjustable wrench to remove the four

plates fixing the feet.

3 Installation 3-4

Page 44

5

Figure 3-4 Remove the Fixing Plate

3.3.2 Installation

Remove the

package

plates of the

front and back

feet.

Fix the analyzer: after the analyzer is placed on the target installation site,

adjust the two front fixing bolts to ensure the four of them have the same

height (the two behind are not adjustable).

Remove the plastic cover and fixing bandage, and install the sample probe

and mixing bar. Do not install the arm cover of the sample probe before

calibrating the level detection board.

• Place the ANALYZING UNIT POWER to ON while ensuring that the sample

probe is not attaching any conducting .object, such as hands.

• Calibrate the sample probe manually. Check if indicator D2 (yellow) is

lightened within 2 seconds when the ANALYZING UNIT POWER to ON. Press

the switch S2 on the level detection board and then release it, then check if

indicator D2 is first extinguished and then lightened. If it is, that means the

calibration succeeds.

Exercise caution to prevent the sample probe from attaching any conducting

object during the calibration.

• Place the ANALYZING UNIT POWER to OFF.

NOTE::::

Remember to install the washer when installing the sample probe.

Use syringe to inject water into the filter and connect the filter to the cap assembly of

the DI water tank. Connect the liquid tubes as indicated in the following figure.

3 Installation 3-

Page 45

6

Figure 3-5 the liquid tubes connecting

CAUTION

Install ISE module(optional):Please refer to 4.8.3 Installing and Removing ISE

Unit.

When placing the deionized water tank and waste tank, ensure the

height difference between the top of the tank and the bottom of the

upper cabinet is within 500-800mm.

Ensure the deionized water pickup tube and waste tank tube are not

blocked, bent, or twisted.

CAUTION

When ISE module electrodes are installed, the power of ISE

module should always be turned on. If the power has been turned

off for more than 0.5 hour, please follow the instructions

demonstrated in the section 7.7.4 Storage of ISE Module.

3 Installation 3-

Page 46

3.3.3 Operating Software Installation

Installation preparation

Configuration:

Operating System: Windows XP Home, Windows Vista Business.

Memory: above 1G;

Graphic Card: above 16 colors;

Resolution: 1024*768

Installation procedure: (Take BS-120 as an example)

1)Double-click the Setup.exe file to start the installation. Select the installation

language.

2)Click Next.

3)Click Change… to modify the installation directory or click Next to enter the next

screen.

3 Installation 3-7

Page 47

4)Click Back to return to the last step to modify the previous setup. Click Install to

start the installation.

5) Click Finish to complete the installation.

3 Installation 3-8

Page 48

3.3.4 Run Operating Software

Turn on Main Power and the Power.

Turn on the printer.

Make sure the liquid tubes are well connected and there is enough deionized water

in the deionized water tank and enough space in the waste tank.

After logging on the Windows operating system, double-click the shortcut icon of the

operating software on the desktop or select the BS-120/BS-130/BS-180/BS-190

operating software program from [Start] to start up the

BS-120/BS-130/BS-180/BS-190 operating software.

After start-up, the analyzer will automatically conduct the following procedures:

checking the operating system and the screen resolution, closing the screen saver,

checking the color configuration, initializing the database and examining the printer.

NOTE

The screen resolution must be 1024x768. The color

configuration must be at least 8 bits.

If all checkings are passed, the following dialog box is displayed. Enter the

username and password, and then click OK. For service personnels, log in with the

maintenance username. Username: bs120, Password: Bs120@Mindray!.

NOTE

While entering the username and the password, pay attention to

the letter case. Capital letters and small letters are different.

The username and password are for service personnels. Do not

release them to customers. Users can only use Admin or other

usernames set by Admin users to log in.

3 Installation 3-9

Page 49

10

Figure 3-6 User Log-in Dialog Box

Enter the username and password, and then click OK to initialize the system and

then operate according to the prompting screen until the main screen of the

operating software is displayed.

After that, wait about 20 minutes until the light source is stable and the reaction disk

temperature reaches 37℃, then the tests can be run. When the lamp is stable, enter

the Maitenance screen and click . Operate as the software instructs to complete

refreshing of the lamp background.

3.3.5 Setting up the System

Before requesting tests, perform the following steps to finish the settings:

To set the options regarding the basic parameters of the system, click Setup

System.

To set the options regarding the hospital and doctor information, click Setup

Hospital.

To set the options regarding parameters of calibrators, click Calibration

Calibrator.

To set the options regarding parameters of controls, click QC Control.

To set the options regarding test parameters, reference, calibration rule and

quality control (QC) rule, click Parameter Test.

To set the options regarding the reagent parameters, click Reagent.

To set the options regarding the carryover information among tests, click

Parameter Carryover.

To set the options regarding the printing parameters, click Setup Print.

The Test screen is where you can set test parameters, reference ranges,

calibration and QC rules of tests.The Test screen includes the following tabs:

Parameters, Reference, Calibration, QC. The Parameters will be explained in

the following figure.

3 Installation 3-

Page 50

Figure 3-7 Parameters Screen

The following table explains the parameters on the Parameters screen.

NOTE

Please set parameters according to instructions of reagents.

Improper settings may lead to unreliable test results.

Parameter Description

Test Name of the test.

No. No. of the test. It cannot be edited.

Full Name Full name of the test. It can be void.

Standard No. Standard No. of the test. It can be void.

Reac. Type Analyzing method, including Endpoint, Fixed-time and

Kinetic.

Pri. Wave. Primary wavelength to be used on the test.