Page 1

890 Titrando

Manual

8.890.8002EN / 2014-06-06

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

890 Titrando

8.890.8002EN / 2014-06-06

Manual

ek

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://documents.metrohm.com.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 The Titrando system ............................................................. 1

1.2 Instrument description ......................................................... 2

1.3 Titration modes – Measuring modes – Dosing com-

1.4 About the documentation ................................................... 3

1.4.1 Symbols and conventions ........................................................ 3

1.5 Safety instructions ................................................................ 4

1.5.1 General notes on safety ........................................................... 4

1.5.2 Electrical safety ........................................................................ 4

1.5.3 Working with liquids ................................................................ 5

1.5.4 Flammable solvents and chemicals ........................................... 6

1.5.5 Recycling and disposal ............................................................. 6

Table of contents

mands .................................................................................... 2

2 Overview of the instrument 7

3 Installation 9

3.1 Setting up the instrument .................................................... 9

3.1.1 Packaging ................................................................................ 9

3.1.2 Checks .................................................................................... 9

3.1.3 Location .................................................................................. 9

3.2 Connecting a controller ........................................................ 9

3.2.1 Operation ................................................................................ 9

3.3 Connecting MSB devices .................................................... 13

3.3.1 Connecting a dosing device ................................................... 14

3.3.2 Connecting a stirrer or titration stand .................................... 15

3.3.3 Connecting a Remote Box ..................................................... 16

3.4 Connecting USB devices ..................................................... 17

3.4.1 General ................................................................................. 17

3.4.2 Connecting a USB hub ........................................................... 18

3.4.3 Connecting a printer .............................................................. 18

3.4.4 Connecting a balance ............................................................ 19

3.4.5 Connecting a PC keyboard (only for operation with Touch

Control) ................................................................................. 20

3.4.6 Connecting a barcode reader ................................................. 21

890 Titrando

3.5 Connecting sensors ............................................................ 22

3.5.1 Connecting a polarizable electrode ........................................ 22

4 Working with the exchange unit 23

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

5 Operation and maintenance 25

5.1 General notes ...................................................................... 25

5.1.1 Care ...................................................................................... 25

5.1.2 Maintenance by Metrohm Service .......................................... 25

5.2 Quality management and qualification with Metrohm .. 26

6 Troubleshooting 27

6.1 General ................................................................................ 27

6.2 Karl Fischer titration .......................................................... 28

6.2.1 ............................................................................................. 28

7 Appendix 30

7.1 Remote interface ................................................................ 30

7.1.1 Pin assignment of the remote interface .................................. 30

8 Technical specifications 34

8.1 Measuring interface ........................................................... 34

8.1.1 Temperature .......................................................................... 34

8.1.2 Polarizer ................................................................................ 34

8.2 Internal dosing device ........................................................ 35

8.3 Power connection ............................................................... 35

8.4 Safety specifications ........................................................... 35

8.5 Electromagnetic compatibility (EMC) ................................ 36

8.6 Ambient temperature ......................................................... 36

8.7 Reference conditions .......................................................... 36

8.8 Dimensions .......................................................................... 37

8.9 Interfaces ............................................................................. 37

9 Warranty (guarantee) 38

10 Accessories 40

Index 42

■■■■■■■■

IV

890 Titrando

Page 7

■■■■■■■■■■■■■■■■■■■■■■

Table of figures

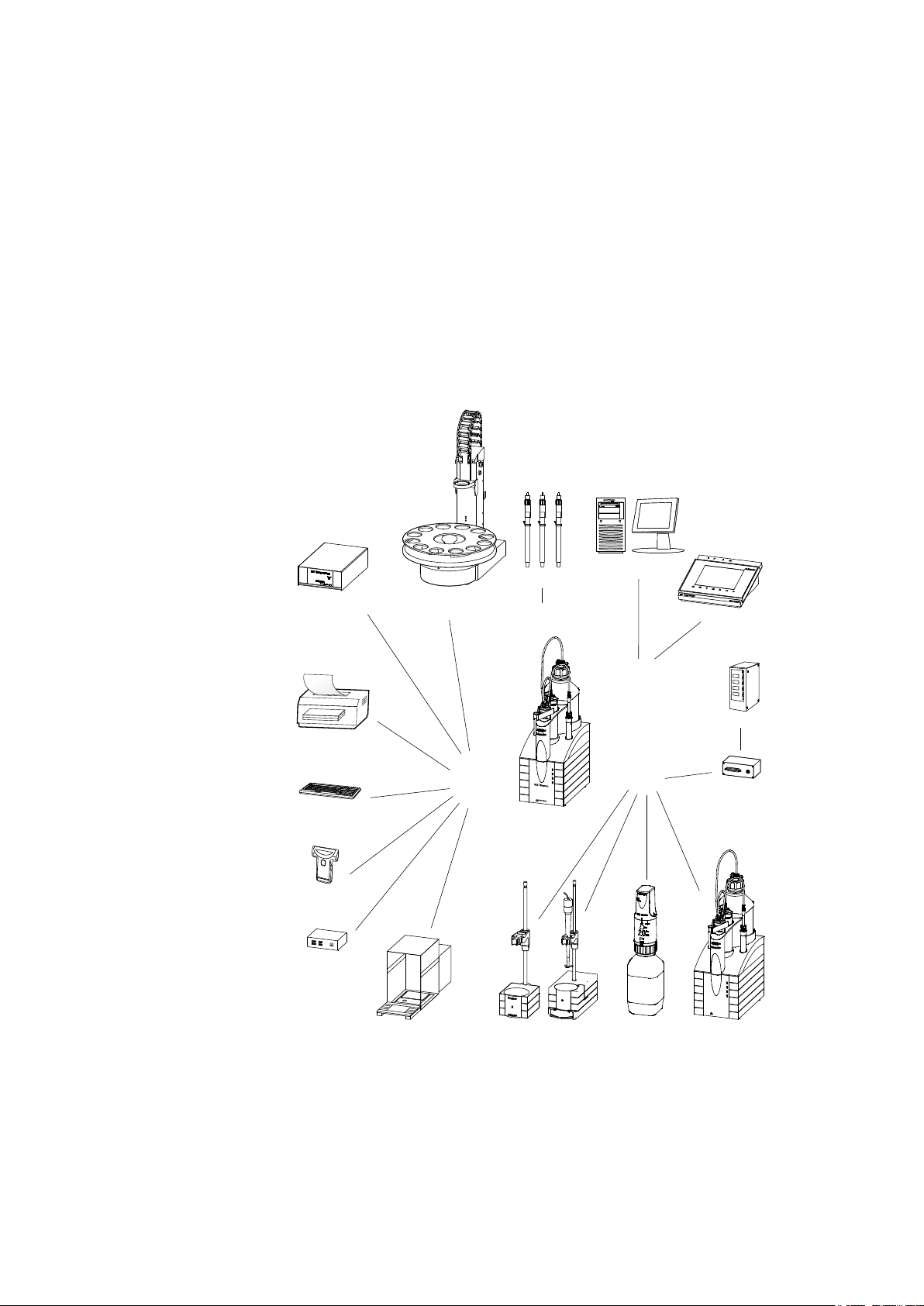

Figure 1 The Titrando system .......................................................................... 1

Figure 2 Front 890 Titrando ............................................................................ 7

Figure 3 Rear 890 Titrando ............................................................................. 8

Figure 4 Connecting the Touch Control ......................................................... 10

Figure 5 Connecting the computer ................................................................ 12

Figure 6 MSB connections ............................................................................ 13

Figure 7 Connecting a dosing device ............................................................. 15

Figure 8 Connecting an MSB stirrer ............................................................... 16

Figure 9 Connecting the propeller stirrer to the titration stand ...................... 16

Figure 10 Connecting the Remote Box ............................................................ 17

Figure 11 Connecting a printer ....................................................................... 19

Figure 12 Connecting a polarizable electrode .................................................. 22

Figure 13 Attaching the exchange unit ........................................................... 23

Figure 14 Connectors of the Remote Box ........................................................ 30

Figure 15 Pin assignment of remote socket and remote plug .......................... 30

Table of figures

890 Titrando

■■■■■■■■

V

Page 8

Page 9

■■■■■■■■■■■■■■■■■■■■■■

MSB

USB

Controller

Input 1 / 2

Sensors

PC keyboard

Barcode

reader

USB hub

USB/RS-232 Converter

Balance

Touch Control

USB Sample Processor

Robotic Titrosampler

Printer

Relay Box

Remote Box

Dosing Interface

Stirrer / Ti Stand Dosino Dosimat

On

Status

8

05

D

o

s

i

m

a

M

e

t

r

o

h

Titrando

Computer

On

Status

1 Introduction

1.1 The Titrando system

The Titrando is the heart of the modular Titrando system. Operation is carried out either by Touch Control with a touch-sensitive screen ("standalone titrator") or by a computer with a corresponding software.

A Titrando system can contain numerous kinds of a variety of instruments.

The following figure provides an overview of the peripheral devices you

can connect to the 890 Titrando.

1 Introduction

890 Titrando

Figure 1

The Titrando system

■■■■■■■■

1

Page 10

1.2 Instrument description

Up to three control instruments (Titrando, Dosing Interface, USB Sample

Processor, etc.) can be controlled via USB connection during operation

with the 900 Touch Control.

You can request information on special applications in the "Application

Bulletins" and "Application Notes", available free of charge through the

responsible Metrohm representative. Various monographs on the subjects

of titration techniques and electrodes are also available.

Updating the device software is described in the Help for the corresponding PC software.

1.2 Instrument description

The 890 Titrando has the following characteristics:

■ Operation

Operation is carried out by means of a touch-sensitive Touch Control

or with high-performance PC software.

■ Dosing

An internal dosing drive for exchange units.

■ MSB connectors

Four MSB connectors (Metrohm Serial Bus) for connecting dosing devices (Dosimat with exchange unit or Dosino with dosing unit), stirrers,

titration stands and Remote Boxes.

■ USB connectors

Two USB connectors, through which devices such as printers, PC keyboards, barcode readers or additional control instruments (USB Sample

Processor, Titrando, Dosing Interface, etc.) can be connected.

■ Measuring interface

One measuring input for a polarizable electrode.

■■■■■■■■■■■■■■■■■■■■■■

1.3 Titration modes – Measuring modes – Dosing commands

The 890 Titrando supports the following titration modes, measuring

modes and dosing commands:

■ KFT

Volumetric water content determination according to Karl Fischer.

Measuring modes:

– Ipol (voltametric measurement with selectable polarization cur-

rent)

– Upol (amperometric measurement with selectable polarization

voltage)

■■■■■■■■

2

890 Titrando

Page 11

■■■■■■■■■■■■■■■■■■■■■■

■ MEAS

The following measuring modes can be selected for measurements:

– Ipol (voltametric measurement with selectable polarization cur-

rent)

– Upol (amperometric measurement with selectable polarization

voltage)

■ Dosing commands

The following commands for dosing can be selected:

– PREP (rinsing the cylinder and tubings of an exchange unit or

dosing unit)

– EMPTY (emptying the cylinder and tubings of a dosing unit)

– ADD (dosing a specified volume)

1.4 About the documentation

CAUTION

1 Introduction

Please read through this documentation carefully before putting the

instrument into operation. The documentation contains information

and warnings which the user must follow in order to ensure safe operation of the instrument.

1.4.1 Symbols and conventions

The following symbols and formatting may appear in this documentation:

Method Dialog text, parameter in the software

File ▶ New Menu or menu item

[Next] Button or key

Cross-reference to figure legend

The first number refers to the figure number, the second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

WARNING

890 Titrando

This symbol draws attention to a possible life-threatening hazard or risk of injury.

WARNING

This symbol draws attention to a possible hazard due

to electrical current.

■■■■■■■■

3

Page 12

1.5 Safety instructions

1.5 Safety instructions

■■■■■■■■■■■■■■■■■■■■■■

WARNING

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

WARNING

This symbol draws attention to a possible biological

hazard.

CAUTION

This symbol draws attention to possible damage to

instruments or instrument parts.

NOTE

This symbol highlights additional information and

tips.

1.5.1 General notes on safety

WARNING

This instrument may only be operated in accordance with the specifications in this documentation.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

1.5.2 Electrical safety

The electrical safety when working with the instrument is ensured as part

of the international standard IEC 61010.

WARNING

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

■■■■■■■■

4

890 Titrando

Page 13

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

WARNING

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

Mains voltage

WARNING

An incorrect mains voltage can damage the instrument.

Only operate this instrument with a mains voltage specified for it (see

rear panel of the instrument).

Protection against electrostatic charges

WARNING

Electronic components are sensitive to electrostatic charges and can be

destroyed by discharges.

Do not fail to pull the mains cable out of the mains connection socket

before you set up or disconnect electrical plug connections at the rear

of the instrument.

1.5.3 Working with liquids

CAUTION

Periodically check all system connections for leaks. Observe the relevant

regulations in respect to working with flammable and/or toxic fluids

and their disposal.

890 Titrando

■■■■■■■■

5

Page 14

1.5 Safety instructions

1.5.4 Flammable solvents and chemicals

WARNING

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location (e.g. fume cup-

board).

■ Keep all sources of flame far from the workplace.

■ Clean up spilled liquids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

1.5.5 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

■■■■■■■■■■■■■■■■■■■■■■

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

■■■■■■■■

6

890 Titrando

Page 15

■■■■■■■■■■■■■■■■■■■■■■

2 Overview of the instrument

2 Overview of the instrument

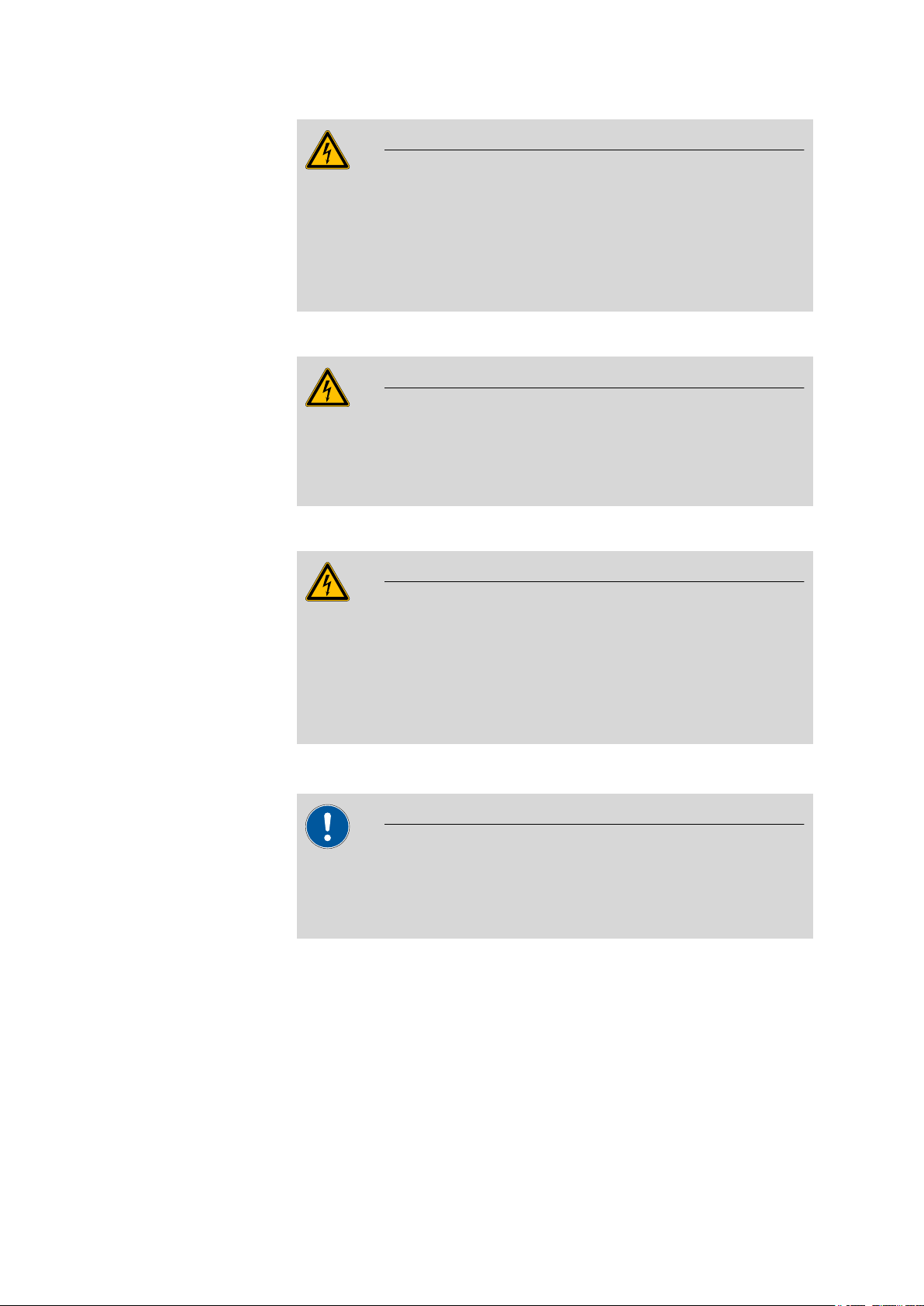

Figure 2 Front 890 Titrando

Guide openings

1

For centering the exchange unit.

Contact pins

3

For the data chip.

"On" LED

5

Lights up when the Titrando is ready for

operation.

Piston rod

2

Moves the piston of the exchange unit up

and down.

Coupling

4

For switching the flat stopcock.

"Status" LED

6

Shows the current status of the internal dosing drive.

890 Titrando

■■■■■■■■

7

Page 16

■■■■■■■■■■■■■■■■■■■■■■

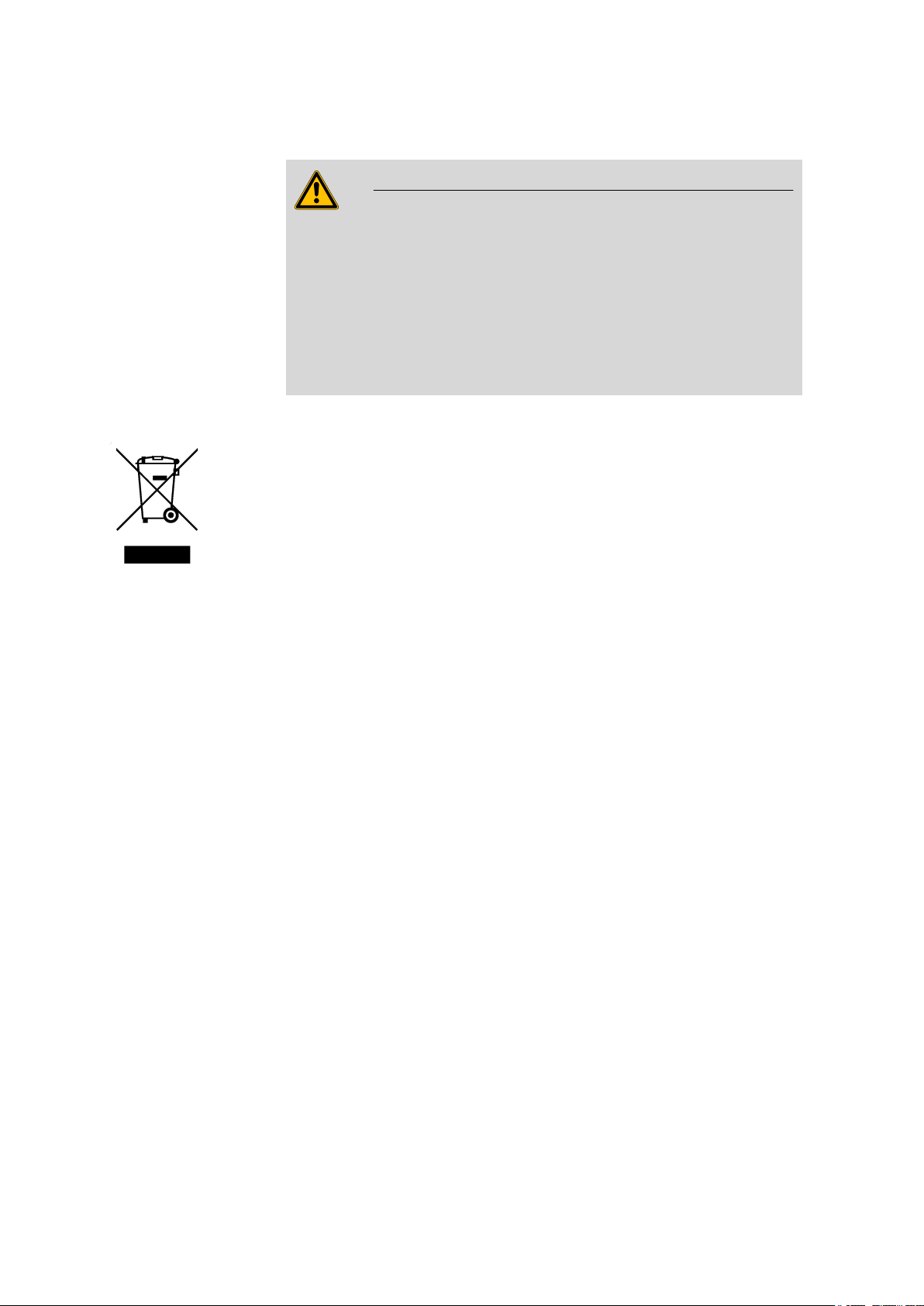

Figure 3 Rear 890 Titrando

Type plate

1

Contains specifications concerning supply

voltage, instrument type and serial number.

Connector (Controller)

3

For connecting a Touch Control or a PC with

installed PC software. Mini DIN, 9-pin.

Power socket

5

Electrode connector (Pol.)

7

For connecting polarizable electrodes, e.g.

double Pt wire electrodes. Socket F.

USB connector (USB 1 and USB 2)

2

USB ports (type A) for connecting printer,

keyboard, barcode reader, additional Titrandos, USB Sample Processor, etc.

MSB connector (MSB 1 to MSB 4)

4

Metrohm Serial Bus. For connecting external

dosing devices, stirrers or Remote Boxes.

Mini DIN, 9-pin.

Measuring interface 1 (Input 1)

6

■■■■■■■■

8

890 Titrando

Page 17

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

3.1 Setting up the instrument

3.1.1 Packaging

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

3.1.2 Checks

Immediately after receipt, check whether the shipment has arrived complete and without damage by comparing it with the delivery note.

3.1.3 Location

The instrument has been developed for operation indoors and may not be

used in explosive environments.

3 Installation

Place the instrument in a location of the laboratory which is suitable for

operation, free of vibrations, protected from corrosive atmosphere, and

contamination by chemicals.

The instrument should be protected against excessive temperature fluctuations and direct sunlight.

3.2 Connecting a controller

3.2.1 Operation

Two different versions are available for operating the 890 Titrando:

■ A Touch Control with touch-sensitive screen. It forms a "stand-alone

instrument" together with the 890 Titrando.

■ A computer enables operation of the 890 Titrando with the help of a

PC software, e.g. tiamo.

CAUTION

Take care to ensure that the power supply cable is pulled out of the

power socket before either setting up or disconnecting connections

between the instruments.

890 Titrando

■■■■■■■■

9

Page 18

3.2 Connecting a controller

3.2.1.1 Connecting a Touch Control

NOTE

The plug is protected against accidental disconnection of the cable by

means of a pull-out protection feature. If you wish to pull out the plug,

you will first need to pull back the outer plug sleeve marked with

arrows.

Connect the Touch Control as follows:

■ Insert the plug of the Touch Control connection cable into the

1

Controller socket.

■■■■■■■■■■■■■■■■■■■■■■

Figure 4 Connecting the Touch Control

■ Connect the MSB devices (see Chapter 3.3, page 13).

2

■ Connect the USB devices (see Chapter 3.4, page 17).

■ Connect the Titrando to the power supply.

3

■ Switch on the Touch Control.

4

The Touch Control power supply is supplied through the Titrando.

Automatic system tests are performed on both instruments at the

time of activation. The On LED on the front of the Titrando lights up

when the system test has been completed and the instrument is

ready for operation.

■■■■■■■■

10

890 Titrando

Page 19

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

CAUTION

The Touch Control must be shut down properly by deactivation with

the power switch on the rear of the instrument before the power supply is interrupted. If this is not done, then there is a danger of data loss.

Because of the fact that the power supply for the Touch Control is provided through the Titrando, you must never disconnect the Titrando

from the power supply (e.g. by deactivating with a connector strip)

before you have deactivated the Touch Control.

If you would prefer not to position the Touch Control directly next to the

Titrando, then you can lengthen the connection with the 6.2151.010

cable. The maximum connection length permitted is 5 m.

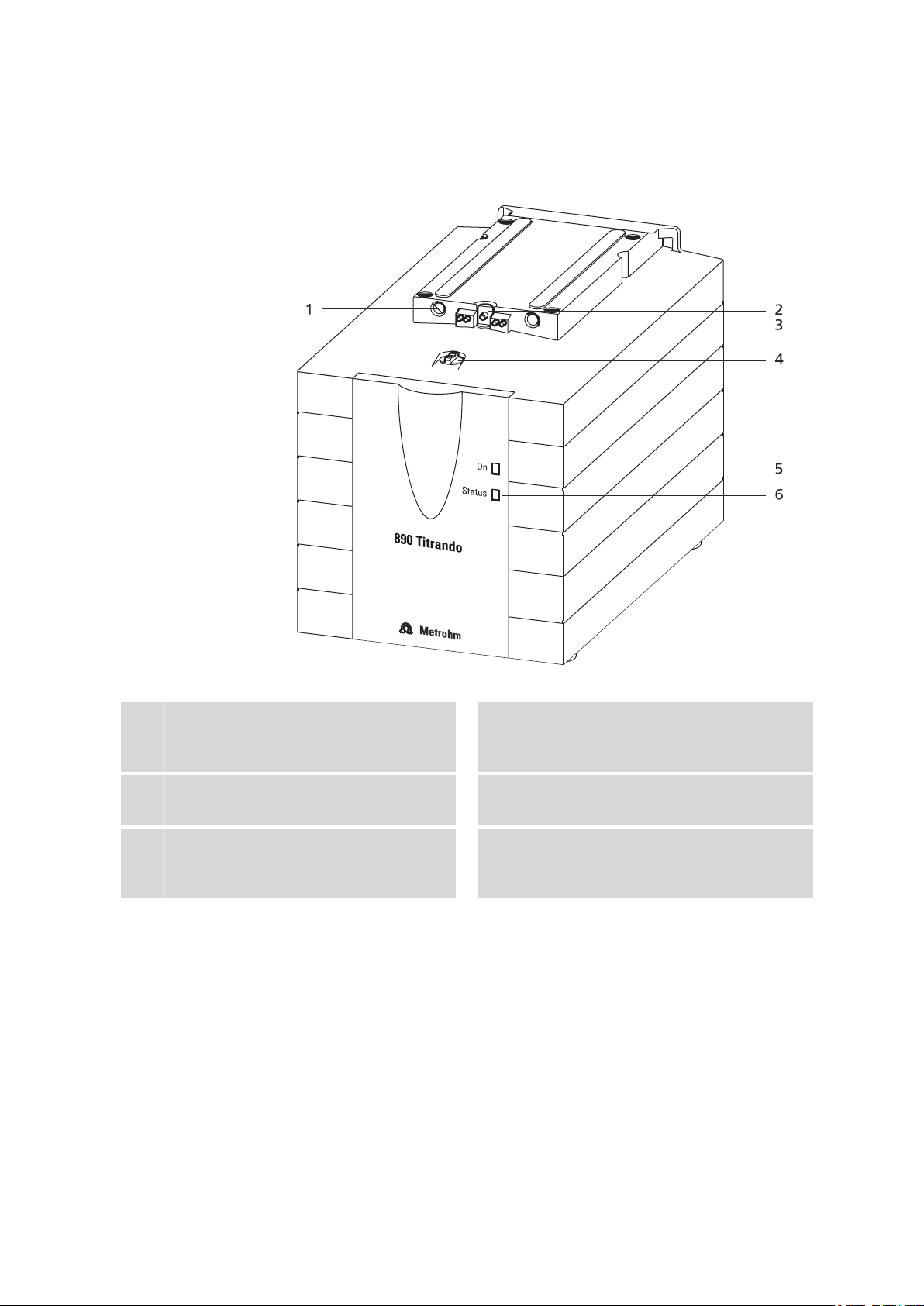

3.2.1.2

Connecting a computer

The 890 Titrando requires a USB connection to a computer in order to be

able to be controlled by a PC software. Using a 6.2151.000 controller

cable, the instrument can be connected directly, either to a USB socket on

a computer, to a connected USB hub or to a different Metrohm control

device.

You need administrator rights for the installation of driver software and

control software on your computer.

Cable connection and driver installation

A driver installation is required in order to ensure that the 890 Titrando is

recognized by the PC software. To accomplish this, you must comply with

the procedures specified. The following steps are necessary:

1

Installing the software

■ Insert the PC software installation CD and carry out the installa-

tion program directions.

■ Exit the program if you have started it after the installation.

2

Establishing the cable connections

■ Connect all peripheral devices to the instrument, see Chapter 3.3,

page 13 and see Chapter 3.4, page 17.

■ Connect the instrument to the power supply if you have not

already done this.

The "On" LED on the 890 Titrando is not yet illuminated!

■ Connect the instrument to a USB connector (Type A) of your com-

puter (see manual of your computer). The 6.2151.000 cable is

used for this purpose.

890 Titrando

■■■■■■■■

11

Page 20

3.2 Connecting a controller

6.2151.000

■■■■■■■■■■■■■■■■■■■■■■

Figure 5 Connecting the computer

The instrument is recognized. Depending on the version of the Windows operating system used, the driver installation proceeds differently afterwards. Either the necessary driver software is installed

automatically or an installation wizard is started.

Follow the instructions of the installation wizard.

3

The "On" LED on the 890 Titrando lights up when the driver installation has been completed and the instrument is ready for operation.

If problems should occur during installation, contact your company's IT

support team.

NOTE

The plug on the instrument end of the 6.2151.000 controller cable is

protected against accidental disconnection by means of a pull-out protection feature. If you wish to pull out the plug, you will first need to

pull back the outer plug sleeve marked with arrows.

Registering and configuring the instrument in the PC software

The instrument must be registered in the configuration of your PC software. Once that has been done, you can then configure it according to

your requirements. Proceed as follows:

■■■■■■■■

12

890 Titrando

Page 21

■■■■■■■■■■■■■■■■■■■■■■

MSB

Stirrer / Ti Stand

Dosimat / Dosino

Dosimat

Remote Box

Dosino / Dosimat

Dosino

Relay Box

Ti Stand / Stirrer

1

Setting up the instrument

■ Start the PC software.

The instrument is automatically recognized. The configuration dialog for the instrument is displayed.

■ Make configuration settings for the instrument and its connec-

tors.

More detailed information concerning the configuration of the

instrument can be found in the documentation for the respective PC

software.

3.3 Connecting MSB devices

In order to connect MSB devices, e.g. stirrers or dosing devices, Metrohm

instruments are equipped with up to a maximum of four connectors on

what is referred to as the Metrohm Serial Bus (MSB). Various kinds of

peripheral devices can be connected in sequence (in series, as a

"daisy chain") at a single MSB connector (8-pin Mini DIN socket) and controlled simultaneously by the respective control instrument. In addition to

the connection cable, stirrers and the Remote Box are each equipped with

their own MSB socket for this purpose.

3 Installation

The following figure provides an overview of the instruments that can be

connected to an MSB socket, along with a number of different cabling

variations.

Figure 6

MSB connections

The control instrument determines which peripheral devices are supported.

890 Titrando

■■■■■■■■

13

Page 22

3.3 Connecting MSB devices

■■■■■■■■■■■■■■■■■■■■■■

NOTE

When connecting MSB devices together, the following must be

observed:

■ Only one device of the same type can be used at a single MSB con-

nector at one time.

■ Type 700 Dosino and 685 Dosimat dosing devices cannot be con-

nected together with other MSB instruments on a shared connector.

These dosing devices must be connected separately.

CAUTION

Exit the control software before you plug in MSB instruments. When it

is switched on, the control instrument automatically recognizes which

device is connected to which MSB connector. The operating unit or the

control software enters the connected MSB devices into the system

configuration (device manager).

MSB connections can be extended with the 6.2151.010 cable. The maximum connection length permitted is 15 m.

3.3.1 Connecting a dosing device

Three dosing devices can be connected to the instrument (MSB 2 to

MSB 4).

The types of dosing devices that are supported are:

■ 800 Dosino

■ 700 Dosino

■ 805 Dosimat

■ 685 Dosimat

Proceed as follows:

1

Connecting a dosing device

■ Exit the control software.

■ Connect the connection cable of the dosing device to one of the

sockets marked with MSB on the rear of the control instrument.

■ Start the control software.

■■■■■■■■

14

890 Titrando

Page 23

■■■■■■■■■■■■■■■■■■■■■■

Figure 7 Connecting a dosing device

3.3.2 Connecting a stirrer or titration stand

You can use the following instruments:

3 Installation

■ With built-in magnetic stirrer (stirring "from below"):

– 801 Stirrer

– 803 Ti Stand

■ Without built-in magnetic stirrer (stirring "from above"):

– 804 Ti Stand with propeller stirrer 802 Stirrer

Connect a stirrer or a titration stand as follows:

1

Connecting the stirrer or titration stand

■ Exit the control software.

■ Connect the connection cable of the magnetic stirrer or of the

titration stand to one of the sockets marked with MSB on the

rear of the control instrument.

■ 804 Ti Stand only: Connect the propeller stirrer to the stirrer con-

nector (socket with stirrer symbol) of the titration stand.

■ Start the control software.

890 Titrando

■■■■■■■■

15

Page 24

3.3 Connecting MSB devices

■■■■■■■■■■■■■■■■■■■■■■

Figure 8 Connecting an MSB stirrer

Figure 9 Connecting the propeller stirrer to the titration stand

3.3.3 Connecting a Remote Box

Instruments that are controlled via remote lines and/or that send control

signals via remote lines can be connected via the 6.2148.010 Remote Box.

In addition to Metrohm, other instrument manufacturers also use similar

connectors that make it possible to connect different instruments

together. These interfaces are also frequently given the designations "TTL

Logic", "I/O Control" or "Relay Control" and generally have a signal level

of 5 volts.

Control signals are understood to be electrical line statuses or electrical

pulses (> 200 ms) which display the operating status of an instrument or

which trigger or report an event. Sequences on a variety of instruments

can thus be coordinated in a single complex automation system. No

exchange of data is possible, however.

Proceed as follows:

1

Connecting the Remote Box

■ Exit the control software.

■■■■■■■■

16

890 Titrando

Page 25

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

■ Connect the Remote Box connection cable to one of the sockets

marked with MSB on the rear of the control instrument.

■ Start the control software.

Figure 10 Connecting the Remote Box

You can, for example, connect an 849 Level Control (fill level monitoring

in a canister) or a 731 Relay Box (switch box for 230/110 volt alternating

current sockets and low-voltage direct current outlets). The Remote Box

also has an MSB socket at which a further MSB device, e.g. a dosing

device or a stirrer, can be connected.

You will find precise information concerning the pin assignment of the

interface on the Remote Box in the appendix.

3.4 Connecting USB devices

3.4.1 General

The 890 Titrando has two USB connectors (type A sockets) for peripheral

devices with USB interfaces. The Titrando functions as a USB hub (distributor) no matter how it is operated. If you wish to connect more than two

devices to the USB, you can also use an additional, commercially available

USB hub.

CAUTION

If you operate the 890 Titrando with the aid of the Touch Control, take

care to ensure that the Touch Control is switched off when you set up

or disconnect connections between the various instruments. If you use

a PC software to control the 890 Titrando, you should exit the program

before you set up or disconnect the USB connections.

890 Titrando

■■■■■■■■

17

Page 26

3.4 Connecting USB devices

3.4.2 Connecting a USB hub

If you wish to connect more than two devices to the USB connector of the

890 Titrando, you can also use an additional commercially available USB

hub (distributor). If you operate the 890 Titrando with the help of the

Touch Control, then you should use a USB hub with its own power supply.

Connect the USB hub as follows:

Switch off the Touch Control and/or exit the PC software.

1

With the aid of the 6.2151.020 cable, connect the USB connector of

2

the 890 Titrando (type A) with the USB connector of the hub (type B,

see manual for the hub).

Switch on the Touch Control.

3

The USB hub is recognized automatically.

■■■■■■■■■■■■■■■■■■■■■■

3.4.3 Connecting a printer

Printers that are connected to the 890 Titrando with Touch Control must

meet the following requirements:

■ Printer languages: HP-PCL (PCL 3 to 5, PCL 3GUI), Canon BJL Com-

mands or Epson ESC P/2

■ Printer resolution: 300 dots/inch or 360 dots/inch (Epson)

■ Paper size: A4 or Letter, single-sheet feed.

Connect the printer as follows:

Switch off the Touch Control.

1

With the aid of the 6.2151.020 cable, connect the USB connector of

2

the 890 Titrando (type A) with the USB connector of the printer (type

B, see manual for the printer).

Switch on the printer first, then the Touch Control.

3

Configure the printer in the device manager of the Touch Control

4

(see Touch Control manual).

■■■■■■■■

18

890 Titrando

Page 27

■■■■■■■■■■■■■■■■■■■■■■

Figure 11 Connecting a printer

3.4.4 Connecting a balance

■ Operation with a PC software:

– Connect the balance directly to the serial connector (COM) of

the computer. This is usually 9-pin and marked with the symbol

IOIOI.

■ Operation with Touch Control:

– You will need the 6.2148.050 USB/RS-232 adapter to connect a

balance.

3 Installation

The following table offers an overview of the balances that you can use

together with the 890 Titrando and of which cable you will need for connection to the RS-232 interface:

Balance

AND ER, FR, FX with RS-232 inter-

Cable

6.2125.020 + 6.2125.010

face (OP-03)

Mettler AB, AG, PR (LC-RS9) In the scope of delivery for the

balance

Mettler AM, PM, PE with interface

option 016

or

Mettler AJ, PJ with interface

option 018

6.2146.020 + 6.2125.010

Also from Mettler: ME 47473

adapter and either ME 42500

hand switch or ME 46278 foot

switch

Mettler AT 6.2146.020 + 6.2125.010

Also from Mettler: ME 42500

hand switch or ME 46278 foot

switch

890 Titrando

Mettler AX, MX, UMX, PG, AB-S,

PB-S, XP, XS

6.2134.120

■■■■■■■■

19

Page 28

3.4 Connecting USB devices

■■■■■■■■■■■■■■■■■■■■■■

Balance Cable

Mettler AE with interface option

011 or 012

6.2125.020 + 6.2125.010

Also from Mettler: ME 42500

hand switch or ME 46278 foot

switch

Ohaus Voyager, Explorer, Analyti-

Cable AS017-09 from Ohaus

cal Plus

Precisa balances with RS-232-C

6.2125.080 + 6.2125.010

interface

Sartorius MP8, MC, LA, Genius,

6.2134.060

Cubis

Shimadzu BX, BW 6.2125.080 + 6.2125.010

Operation with Touch Control

Connect the balance as follows:

Plug in the USB plug of the USB/RS-232 adapter at the USB connec-

1

tor of the 890 Titrando.

Connect the RS-232 interface of the USB/RS-232 adapter with the

2

RS-232 interface of the balance (see table for cable).

Switch on the Touch Control.

3

Switch on the balance.

4

Activate the RS-232 interface of the balance if necessary.

5

Configure the RS-232 interface of the USB/RS-232 adapter in the

6

device manager of the Touch Control (see Touch Control manual).

3.4.5 Connecting a PC keyboard (only for operation with Touch Control)

The PC keyboard is used as an aid for text and numerical input.

Connect the PC keyboard as follows:

Insert the USB plug of the keyboard into one of the USB sockets of

1

the 890 Titrando.

■■■■■■■■

20

890 Titrando

Page 29

■■■■■■■■■■■■■■■■■■■■■■

Switch on the Touch Control.

2

The keyboard is recognized automatically and entered in the device

manager.

Configure the keyboard in the device manager of the Touch Control

3

(see Touch Control manual).

3.4.6 Connecting a barcode reader

The barcode reader is used as an aid for text and numerical input. You can

connect a barcode reader with USB interface.

Operation with Touch Control

Connect the barcode reader as follows:

Insert the USB plug of the barcode reader into one of the USB sock-

1

ets of the 890 Titrando.

Switch on the Touch Control.

2

3 Installation

The barcode reader is recognized automatically and entered in the

device manager.

Configure the barcode reader in the device manager of the Touch

3

Control (see Touch Control manual).

Settings on the barcode reader:

Program the barcode reader as follows (see also the manual for the barcode reader):

Switch the barcode reader to programming mode.

1

Specify the desired layout for the keyboard (USA, Germany, France,

2

Spain, German-speaking Switzerland).

This setting must match the setting in the device manager (see the

Touch Control manual).

Make sure that the barcode reader is set in such a way that Ctrl char-

3

acters (ASCII 00 to 31) can be sent.

890 Titrando

■■■■■■■■

21

Page 30

3.5 Connecting sensors

Program the barcode reader in such a way that the ASCII character

4

02 (STX or Ctrl B) is sent as the first character. This first character is

normally referred to as the "Preamble" or "Prefix Code".

Program the barcode reader in such a way that the ASCII character

5

04 (EOT or Ctrl D) is sent as the last character. This last character is

normally referred to as the "Postamble", "Record Suffix" or "Postfix

Code".

Exit the programming mode.

6

3.5 Connecting sensors

The measuring interface contains the following measuring inputs:

■ Pol. for a polarizable electrode

3.5.1 Connecting a polarizable electrode

Connect the polarizable electrode as follows:

Plug the electrode plug into the Pol. socket of the 890 Titrando.

1

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

22

Figure 12 Connecting a polarizable electrode

NOTE

The electrode cable is protected against accidental disconnection

of the cable by means of a pull-out protection. If you wish to pull

out the plug again, you will first need to pull back the outer plug

sleeve.

890 Titrando

Page 31

■■■■■■■■■■■■■■■■■■■■■■

4 Working with the exchange unit

The exchange unit (806 Exchange Unit) has an integrated data chip that

makes it possible to store data about the exchange unit and for the

reagent. The data is edited in the Touch Control or in the PC software.

The start-up of the exchange unit is described in the manual for the

exchange unit.

4 Working with the exchange unit

890 Titrando

Figure 13 Attaching the exchange unit

Proceed as follows to attach the exchange unit:

Attach the exchange unit from the front onto the 890 Titrando and

1

push it all the way to the rear.

It must snap in audibly.

If the exchange unit is attached correctly, its initialization is activated

by a microswitch which is triggered by the guide bolts of the

exchange unit. The exchange unit is recognized and the data is read

out automatically from the data chip. The 890 Titrando carries out an

■■■■■■■■

23

Page 32

■■■■■■■■■■■■■■■■■■■■■■

automatic rotation of the flat stopcock and then returns it to the

exchange position (dosing position). The Status LED will be continuously illuminated once this has been accomplished.

The following table contains a summary of which operating statuses of

the internal dosing device are displayed by the Status LED:

Status of the

Description

"Status" LED

off No exchange unit is attached.

constant illumination

The exchange unit has been correctly attached

and recognized and can now be used for dosing

and titration. The flat stopcock is in the exchange

position, i.e. the exchange unit can be removed.

slow flashing ■ The exchange unit is currently being used for

dosing or filling.

■ An intelligent exchange unit has been

attached and the data on the integrated data

chip is currently either being read out or written.

rapid flashing Error on the dosing drive, consult the "Trouble-

shooting" chapter.

■■■■■■■■

24

890 Titrando

Page 33

■■■■■■■■■■■■■■■■■■■■■■

5 Operation and maintenance

5.1 General notes

5.1.1 Care

The 890 Titrando requires appropriate care. Excess contamination of the

instrument may result in functional disruptions and a reduction in the service life of the otherwise sturdy mechanics and electronics.

Spilled chemicals and solvents should be removed immediately. Above all,

the plug connections on the rear of the instrument (in particular the

power socket) should be protected from contamination.

CAUTION

Although this is largely prevented by design measures, the power plug

should be unplugged immediately if aggressive media have found their

way into the interior of the instrument to prevent serious damage to

the instrument electronics. In such cases, Metrohm Service must be

informed.

5 Operation and maintenance

5.1.2 Maintenance by Metrohm Service

Maintenance of the 890 Titrando is best carried out as part of annual service, which is performed by specialist personnel from Metrohm. A shorter

maintenance interval may be necessary if you frequently work with caustic

and corrosive chemicals.

Metrohm Service offers every form of technical advice for maintenance

and service of all Metrohm instruments.

890 Titrando

■■■■■■■■

25

Page 34

5.2 Quality management and qualification with Metrohm

■■■■■■■■■■■■■■■■■■■■■■

5.2 Quality management and qualification with

Metrohm

Quality management

Metrohm offers you comprehensive support in implementing quality management measures for instruments and software.

Qualification

Please contact your local Metrohm representative for support in qualification of instruments and software. The Installation Qualification (IQ)

and Operational Qualification (OQ) are offered by Metrohm representatives as a service. They are carried out by trained employees using standardized qualification documents and in accordance with the currently

applicable requirements of the regulated industry.

Maintenance

The electronic and mechanical functional groups of Metrohm instruments

can and should be checked by specialist personnel from Metrohm as part

of a regular preventive maintenance schedule. Please ask your local

Metrohm representative regarding the precise terms and conditions

involved in concluding a corresponding maintenance agreement.

For detailed information on this topic, please visit www.metrohm.com.

■■■■■■■■

26

890 Titrando

Page 35

■■■■■■■■■■■■■■■■■■■■■■

6 Troubleshooting

6.1 General

Problem Cause Remedy

6 Troubleshooting

The "On" LED is not

illuminated, even

though the instrument is connected

to the power supply.

It is not possible to

attach the exchange

unit.

The exchange unit

can not be removed

and the "Status"

LED is flashing

slowly.

Die "Status" LED

does not light up,

even though an

exchange unit is

attached.

The Touch Control or the

computer has not been

switched on yet or the

plugs are not correctly

plugged in.

The flat stopcock of the

exchange unit is not in the

exchange position.

The piston rod in the

exchange unit is not in the

correct position.

The exchange unit is currently being used for dosing or filling.

The exchange unit has not

been attached correctly.

1. Check the plug connections.

2. Switch on the Touch Control or the computer.

Move the green switching lever to the right

until it stops.

Move the piston rod into the correct position

(see the manual for the exchange unit).

■ Wait until the procedure has been comple-

ted.

■ Cancel the procedure manually.

Remove the exchange unit and then attach it

once again (it must snap in audibly). The LED

flashes while data is read out from an intelligent exchange unit (806 Exchange Unit) and

lights up constantly if the exchange unit has

been recognized correctly.

The "Status" LED

flashes rapidly.

890 Titrando

The dosing drive is overloaded because the flat stopcock is jammed.

The dosing drive is overloaded because the piston is

jammed.

1. Switch off the Touch Control or exit the PC

software.

2. Check whether the exchange unit can be

removed.

a. If not, move the green switching

lever to the right until it stops.

3. Attempt once more to remove the

exchange unit; perform maintenance on it

afterwards (see the manual for the

exchange unit).

1. Switch the control instrument off and then

back on again.

■■■■■■■■

27

Page 36

6.2 Karl Fischer titration

Problem Cause Remedy

2. Remove and clean the exchange unit (see

the chapter in the manual for the exchange

unit, "Care and upkeep").

3. Contact your local Metrohm Service

department if necessary.

■■■■■■■■■■■■■■■■■■■■■■

The data of the exchange

unit can no longer be read.

The data chip is damaged,

either mechanically or by

chemical action.

6.2 Karl Fischer titration

Problem

The drift is very high

during conditioning.

The drift becomes

greater after each

titration.

Cause Remedy

The titration cell is leaking. ■ Check the seals and the septum. Replace if

The sample releases water

very slowly.

A side reaction is taking

place.

■ Contact your local Metrohm Service

department to have the data chip replaced.

■ If necessary, remove the data chip yourself

so that the exchange unit can continue to

be used in the meantime.

necessary.

■ Replace the molecular sieve.

■ Adjust the method.

■ Add solubility promoter.

■ Increase the temperature (possibly using a

KF oven).

■ See technical literature.

■ Use special reagents.

■ Adjust the method (increase/decrease the

temperature, external extraction).

■ See technical literature.

The titration will not

be finished.

■■■■■■■■

28

The pH value is no longer

Add buffer (see technical literature).

in the optimum range.

The titration cell is leaking. ■ Check the seals and the septum. Replace if

necessary.

■ Replace the molecular sieve.

The minimum increment is

too low.

Select the user-defined titration rate and

increase the minimum volume increment (see

manual/help of the software used).

The stop criterion is unsuitable.

Adjust the control parameters (see manual/

help of the software used):

■ Increase the stop drift.

890 Titrando

Page 37

■■■■■■■■■■■■■■■■■■■■■■

Problem Cause Remedy

■ Select a short delay time.

See also: The drift becomes

greater after each titration.

6 Troubleshooting

The sample is overtitrated.

The solution

becomes darker

after each titration.

The increments at the end

of the titration are too

high.

The amount of methanol in

the working medium is too

low.

The electrode may be covered.

The electrode may be covered.

■ Select the user-defined titration rate and

reduce the dosing rate (see manual/help of

the software used).

The following experiment provides a clue

for the optimum dosing rate: During conditioning, display the drift and add sample

without starting the titration. Select a value

below the highest drift as dosing rate.

■ Stir faster.

■ Replace the working medium.

■ Reduce the amount of solubility promoter,

if working with solvent mixtures, see technical literature.

Wipe off the electrode with ethanol or a suitable solvent.

Replace the working medium.

Wipe off the electrode with ethanol or a suitable solvent.

The endpoint is

reached too quickly.

The titration times

with volumetric

titration are constantly longer.

The electrode has a short

circuit.

The dosing rate outside the

control range is too high.

The buffer capacity of the

solvent may be exhausted

with two-component

reagents.

1. Check the Pt wires.

2. Activate the electrode check.

Select the user-defined titration rate and

reduce the dosing rate (see manual/help of the

software used).

Replace the working medium.

890 Titrando

■■■■■■■■

29

Page 38

7.1 Remote interface

1

2

3

13

1

14

25

1

13

14

25

7 Appendix

7.1 Remote interface

The 6.2148.010 Remote Box allows devices to be controlled which cannot

be connected directly to the MSB interface of the Titrando.

■■■■■■■■■■■■■■■■■■■■■■

Figure 14 Connectors of the Remote Box

Cable

1

For connecting to the Titrando.

Remote connector

3

For connecting instruments with a remote

interface.

MSB connector

2

Metrohm Serial Bus. For connecting external

dosing devices or stirrers.

7.1.1 Pin assignment of the remote interface

Figure 15

The above figure of the pin assignment applies for all Metrohm instruments with 25-pin D-Sub remote connector.

Pin assignment of remote socket and remote plug

■■■■■■■■

30

890 Titrando

Page 39

■■■■■■■■■■■■■■■■■■■■■■

+5 V

t

p

t

p

7 Appendix

Inputs

approx. 50 kΩ Pull-up

tp > 20 ms

active = low, inactive = high

Outputs

Open Collector

tp > 200 ms

active = low, inactive = high

IC = 20 mA, V

CEO

= 40 V

+5 V: maximum load = 20 mA

The following tables offer information concerning the assignment of the

individual pins and their function:

Table 1

Assignment Pin No. Function

Inputs and outputs of the remote interface

*

Input 0 21 Start

Input 1 9 Stop

Input 2 22

Input 3 10 Quit

Input 4 23 –

Input 5 11

Input 6 24

Input 7 12

Output 0 5 Ready

Output 1 18 Conditioning OK

Output 2 4 Determination

Output 3 17 EOD

Output 4 3

Output 5 16 Error

Output 6 1

Output 7 2 Warning

890 Titrando

■■■■■■■■

31

Page 40

7.1 Remote interface

■■■■■■■■■■■■■■■■■■■■■■

Assignment Pin No. Function

*

Output 8 6

Output 9 7

Output 10 8

Output 11 13

Output 12 19

Output 13 20

0 volts / GND 14

+5 volts 15

0 volts / GND 25

* Signal activated only for operation with Touch Control.

Table 2

Explanation of the individual functions

Function Explanation

Start The current method is started at the time of acti-

vation.

t

> 100 ms

pulse

Stop The current method is canceled (Stop) at the time

of activation.

t

> 100 ms

pulse

Quit The current command in the determination run

will be canceled at the time of activation.

t

> 100 ms

pulse

Ready The instrument is ready to receive a start signal.

Conditioning OK The line is set when Conditioning with SET titra-

tion and KFT titration is at OK. The line remains

set until the determination is started with

[START].

Determination The instrument performs a data-generating

determination.

EOD End of Determination.

Pulse (t

= 200 ms) after a determination or

pulse

after a buffer/standard solution during calibration

using a Sample Processor.

■■■■■■■■

32

Error The line is set for error message display.

890 Titrando

Page 41

■■■■■■■■■■■■■■■■■■■■■■

7 Appendix

Function Explanation

Warning The line is set for warning message display.

890 Titrando

■■■■■■■■

33

Page 42

8.1 Measuring interface

8 Technical specifications

8.1 Measuring interface

The 890 Titrando has one measuring input for polarizable electrodes.

The measuring cycle is 100 ms for all measuring modes.

8.1.1 Temperature

A measuring input (Temp.) for temperature sensors of the Pt1000 or NTC

type with automatic temperature compensation.

R (25 °C) and B value can be configured for NTC sensors.

Measuring range

Pt1000 –150 - +250 °C

NTC –5 - +250 °C

(R (25 °C) = 30,000 Ω and B (25/50) = 4,100 K)

■■■■■■■■■■■■■■■■■■■■■■

Resolution

Pt1000 0.1 °C

NTC 0.1 °C

Measuring accuracy

Pt1000 ±0.2 °C

(Applies for measuring range –20 - +150 °C; ±1 digit; without sensor

error, under reference conditions)

NTC ±0.6 °C

(Applies for measuring range +10 - +40 °C; ±1 digit; without sensor

error, under reference conditions)

8.1.2 Polarizer

One measuring input (Pol.) for polarizable electrodes.

Measuring mode

Ipol

Polarization

current

Measuring

range

Resolution 0.1 mV

Determination with adjustable polarization current

–122.5 - +122.5 µA (increment: 0.5 µA)

–125.0 - +125.0 µA: non-guaranteed values, dependent on reference

voltage +2.5 V

–1,200 - +1,200 mV

■■■■■■■■

34

890 Titrando

Page 43

■■■■■■■■■■■■■■■■■■■■■■

8 Technical specifications

Measuring

accuracy

Measuring mode

±0.2 mV

(±1 digit, without sensor error, under reference conditions)

Determination with adjustable polarization voltage

Upol

Polarization

voltage

–1,225 - +1,225 mV (increment: 25 mV)

–1,250 - +1,250 mV: non-guaranteed values, dependent on reference

voltage +2.5 V

Measuring

–120 - +120 µA

range

Resolution 0.1 µA

8.2 Internal dosing device

Cylinder volume of

the exchange unit

Resolution 20,000 steps per cylinder volume

1 mL, 5 mL, 10 mL, 20 mL or 50 mL

8.3 Power connection

Supply voltage

100 - 240 V

Frequency 50 - 60 Hz

Power consump-

Maximum 45 W

tion

Fuse Electronic overload protection

8.4 Safety specifications

Design and testing

Safety instructions The documentation contains safety instructions which have to be fol-

■ EN/IEC 61010-1

■ UL 61010-1

■ CSA-C22.2 No. 61010-1

■ Protection class I

lowed by the user in order to ensure safe operation of the instrument.

890 Titrando

■■■■■■■■

35

Page 44

8.5 Electromagnetic compatibility (EMC)

8.5 Electromagnetic compatibility (EMC)

Emission Standards fulfilled:

■ EN/IEC 61326-1

■ EN/IEC 61000-6-3

■ EN/IEC 61000-6-4

■ EN 55022 / CISPR 22

Immunity Standards fulfilled:

■ EN/IEC 61326-1

■ EN/IEC 61000-6-2

■ EN/IEC 61000-4-2

■ EN/IEC 61000-4-3

■ EN/IEC 61000-4-4

■ EN/IEC 61000-4-5

■ EN/IEC 61000-4-6

■ EN/IEC 61000-4-11

■ EN/IEC 61000-4-14

■ NAMUR

■■■■■■■■■■■■■■■■■■■■■■

8.6 Ambient temperature

Nominal function

range

Storage –20 - +60 °C

Transport –40 - +60 °C

+5 - +45 °C

8.7 Reference conditions

Ambient temperature

Relative humidity ≤ 60%

Instrument status Instrument in operation at least 30 min

Validity of the

data

+25 °C (± 3 °C)

After adjustment

■■■■■■■■

36

890 Titrando

Page 45

■■■■■■■■■■■■■■■■■■■■■■

8.8 Dimensions

Width 142 mm

Height 227 mm

Depth 231 mm

Weight 2,817 g

Material (housing) Poly(butylene terephthalate) (PBT)

8.9 Interfaces

USB connectors

USB ports

Controller port

Touch Control With integrated Touch Control cable.

Computer With 6.2151.000 cable.

2 USB downstream ports (type A sockets), 500 mA each, for connecting peripheral devices such as printers, keyboards, barcode readers or

RS-232/USB boxes (Metrohm order no. 6.2148.020).

Connector "Controller"

USB upstream port with auxiliary power supply (Mini DIN socket) for

connecting Touch Control or computer for controlling the 890

Titrando.

8 Technical specifications

MSB connectors (Metrohm Serial Bus)

Dosing device

Stirrer Connector for a maximum of four stirrers.

Remote Box Connector for a maximum of four Remote Boxes. Remote Boxes can

Connector for a maximum of three external dosing devices, models

Dosimat or Dosino (MSB 2 to MSB 4).

Stirrer control: switching on/off manually or coordinated with the titration sequence.

Speed in 15 steps and shift direction can be selected.

be used to actuate and monitor external devices.

890 Titrando

■■■■■■■■

37

Page 46

9 Warranty (guarantee)

Metrohm guarantees that the deliveries and services it provides are free of

defects in materials, design or manufacturing.

The general warranty period is 36 months (exclusions below) from the

date of delivery, or 18 months in the event of continuous operation. The

warranty remains valid on the condition that the servicing is provided by a

service organization authorized by Metrohm at defined intervals and with

a defined scope.

The warranty period for anion suppressors of the type "MSM" is 120

months from the date of delivery or 60 months in the case of continuous

operation.

The warranty period for IC separation columns is 90 days after start-up.

For third-party components that are recognizable as such, the manufacturer's warranty regulations apply.

■■■■■■■■■■■■■■■■■■■■■■

For instruments sold under the Metrohm NIRSystems brand, a full 16month warranty is applicable. In the event of continuous operation, the

warranty period is reduced by half.

Consumables and materials with limited storage life and glass breakage in

the case of electrodes or other glass parts are excluded from the warranty.

Warranty claims cannot be asserted if the ordering party has failed to

meet its payment obligations according to schedule.

During the warranty period, Metrohm undertakes either to replace free of

charge or to credit the purchaser for any modules or components that can

be shown to be faulty. Any transport or customs fees that may apply are

the responsibility of the ordering party.

The precondition for this is that the ordering party has to specify the article number, the article designation, an adequate error description, the

delivery date and (if applicable) the serial number or chip data in the Support Tracker. Metrohm then decides whether a replacement or a credit

note is to be issued or whether the faulty part has to be returned using

the Return Material Authorization (RMA). If a replacement or credit note is

issued, the ordering party undertakes to store the faulty part for at least

24 months in accordance with the current storage directives (in compliance with ESD guidelines) and to hold it in readiness for onsite inspection

or for return shipment to Metrohm. Metrohm reserves the right to invoice

the ordering party for these articles, including retroactively, in the event of

noncompliance with these preconditions.

■■■■■■■■

38

890 Titrando

Page 47

■■■■■■■■■■■■■■■■■■■■■■

9 Warranty (guarantee)

The same warranty periods that are specified for a corresponding new

part apply to parts that are replaced or repaired within the above-mentioned warranty periods. However, replacement or repair of a part does

not extend the warranty period of the entire system.

Deficiencies arising from circumstances that are not the responsibility of

Metrohm, such as improper storage or improper use, etc., are expressly

excluded from the warranty.

Metrohm also offers a 120-month spare parts availability guarantee and a

60-month PC software support warranty, calculated from the date on

which the product is withdrawn from the market. The content of this warranty is the ability of the customer to obtain functioning spare parts or

appropriate software support at market prices during the time of the warranty period. This does not apply for software products sold under the

Metrohm NIRSystems brand.

If Metrohm AG is unable to meet this obligation due to circumstances

beyond the control of Metrohm AG, then the ordering party shall be

offered alternative solutions at preferential conditions.

890 Titrando

■■■■■■■■

39

Page 48

10 Accessories

Up-to-date information on the scope of delivery and optional accessories

for your instrument can be found on the Internet.

When you receive your new instrument, we recommend downloading

the accessories list from the Internet, printing it out and keeping it

together with the manual for reference purposes.

Instruments currently sold

If you do not know the article number of your instrument, proceed as follows:

Downloading the accessories list

■■■■■■■■■■■■■■■■■■■■■■

NOTE

Go to the Metrohm website http://www.metrohm.com/com.

1

2

Click on .

The Search webpage will be displayed.

Enter a search term relating to the instrument into the search field

3

and click on Find.

The search results will be displayed.

In the search results, select the Devices tab (if it is not already

4

selected) and then click on the Metrohm article number of the

required instrument (e.g. 2.852.0050).

The page with information pertaining to the searched article is displayed.

Select the Parts tab.

5

The complete list of accessories with the scope of delivery and the

optional accessories will be displayed.

6

Click on .

■■■■■■■■

40

890 Titrando

Page 49

■■■■■■■■■■■■■■■■■■■■■■

10 Accessories

The Partslists webpage will be displayed.

Select the desired output language.

7

With the article number entered, click on the command Generate

8

PDF.

The PDF file with the accessories data will be created in the language

selected.

Direct access for all instruments

If you are unable to find your instrument using the search as described

above, this may be due to the instrument not being sold anymore. Using

the article number, you can download accessories lists for all instruments

as follows:

Downloading the accessories list

Type http://partslists.metrohm.com into your Internet browser.

1

The Partslists webpage will be displayed.

Select the desired output language.

2

Enter the article number and click on the Generate PDF command.

3

The PDF file with the accessories data will be created in the language

selected.

890 Titrando

■■■■■■■■

41

Page 50

Index

Index

■■■■■■■■■■■■■■■■■■■■■■

Numbers/Symbols

6.2151.000 controller cable ..... 11

685 Dosimat ............................ 14

700 Dosino .............................. 14

800 Dosino .............................. 14

801 Stirrer ................................ 15

803 Ti Stand ............................. 15

804 Ti Stand ............................. 15

805 Dosimat ............................ 14

A

ADD ........................................... 3

B

Balance .................................... 19

Barcode reader

Connect ............................. 21

C

Computer

Connect ............................. 11

Connect

Balance .............................. 19

Barcode reader ................... 21

Computer ........................... 11

Dosing device ..................... 14

MSB devices ....................... 13

PC keyboard ....................... 20

Printer ................................ 18

Remote Box ........................ 16

Stirrer ................................. 15

Titration stand .................... 15

Touch Control .................... 10

USB hub ............................. 18

Connector

MSB ..................................... 2

USB ...................................... 2

Controller

Connector ............................ 8

D

Device software

Update ................................. 2

Dosing command ....................... 2

ADD ..................................... 3

EMPTY ................................. 3

PREP ..................................... 3

Dosing device

Connect ............................. 14

Driver software

Install ................................. 11

E

Electrode

Connect ............................. 22

Electrostatic charge .................... 5

EMPTY ....................................... 3

Exchange unit ........................... 23

G

Guarantee ................................ 38

I

Installation

Driver software ................... 11

Installation qualification ............ 26

Instrument description ................ 2

Instrument type .......................... 8

K

Keyboard

Connect ............................. 20

KFT ............................................ 2

L

LED

On ...................................... 27

Status ........................... 24, 27

M

Mains voltage ............................. 5

Maintenance ............................ 25

Maintenance agreement .......... 26

MEAS ......................................... 3

Measuring interface ................ 2, 8

Measuring mode ........................ 2

MEAS ................................... 3

Metrohm Serial Bus MSB, see also

"MSB" ...................................... 13

MSB

Connect devices ................. 13

Connector ............................ 8

MSB connector ........................... 2

O

Operational qualification .......... 26

Overview of the instrument ........ 7

P

PC keyboard

Connect ............................. 20

Pin assignment ......................... 30

Power connection ...................... 8

PREP ........................................... 3

Printer ...................................... 18

Q

Quality management ................ 26

R

Remote

Interface ............................. 30

Pin assignment ................... 30

Remote Box

Connect ............................. 16

S

Safety instructions ...................... 4

Sensor

Connect ............................. 22

Serial number ............................. 8

Service ....................................... 4

Stirrer

Connect ............................. 15

System test ............................... 10

T

Temperature sensor

Connect ............................. 22

Titrando system .......................... 1

Titration mode ............................ 2

KFT ....................................... 2

Titration stand

Connect ............................. 15

Touch Control

Connect ............................. 10

U

Update

Device software .................... 2

USB

Connector ............................ 8

USB connector ........................... 2

USB hub

Connect ............................. 18

W

Warranty .................................. 38

■■■■■■■■

42

890 Titrando

Loading...

Loading...