Page 1

889 IC Sample Center

Manual

8.889.8001EN

Page 2

Page 3

Metrohm AG

CH-9101 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

889 IC Sample Center

8.889.8001EN

Manual

02/2010 dm

Page 4

Teachware

Metrohm AG

CH-9101 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Instrument description ......................................................... 1

1.1.1 Model versions ........................................................................ 1

1.1.2 Instrument components ........................................................... 2

1.1.3 Intended use ........................................................................... 2

1.2 About the documentation ................................................... 2

1.2.1 Symbols and conventions ........................................................ 2

1.3 Safety instructions ................................................................ 3

1.3.1 General notes on safety ........................................................... 3

1.3.2 Electrical safety ........................................................................ 3

1.3.3 Tubing and capillary connections ............................................. 5

1.3.4 Personnel safety ...................................................................... 5

1.3.5 Flammable solvents and chemicals ........................................... 6

1.3.6 Recycling and disposal ............................................................. 6

Table of contents

2 Overview of the instrument 7

2.1 Front and rear ....................................................................... 7

2.2 Opening the device ............................................................... 8

2.3 Interior view ........................................................................ 10

2.4 Interior ................................................................................. 11

2.5 Cooling option .................................................................... 12

3 Installation 13

3.1 Setting up the instrument .................................................. 13

3.1.1 Packaging .............................................................................. 13

3.1.2 Checks .................................................................................. 13

3.1.3 Location ................................................................................ 13

3.1.4 Removing the device from the packaging .............................. 13

3.2 Connecting a computer ...................................................... 14

3.3 Connecting pump and column .......................................... 15

3.4 Tubing ................................................................................. 16

3.4.1 Tubing guide ......................................................................... 17

3.5 Outlet tubings ..................................................................... 17

4 Functioning 19

889 IC Sample Center

3.6 Rinsing the syringe ............................................................. 18

4.1 Injection modes .................................................................. 19

4.2 Syringe and buffer loop ..................................................... 20

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

4.3 Full loop injection ............................................................... 21

4.4 Partial loopfill injection ...................................................... 24

4.5 Pickup injection .................................................................. 27

5 Handling and maintenance 31

5.1 General ................................................................................ 31

5.2 Care ...................................................................................... 31

5.2.1 Cleaning in general ................................................................ 31

5.3 Maintenance and service ................................................... 32

5.3.1 Sample loop .......................................................................... 32

5.3.2 Replacing the sample needle ................................................. 33

5.3.3 Replacing the air needle ........................................................ 35

5.3.4 Replacing the fuses ................................................................ 36

5.4 Quality Management and validation with Metrohm ....... 37

6 Troubleshooting 38

6.1 Error list .............................................................................. 38

6.1.1 Rack unit ............................................................................... 38

6.1.2 Needle unit ............................................................................ 39

6.1.3 Syringe unit ........................................................................... 40

6.1.4 Injection valve unit ................................................................. 42

6.1.5 Cooling unit .......................................................................... 42

6.1.6 Electronics ............................................................................. 42

6.2 Analytical problems ............................................................ 43

6.2.1 Autosampler .......................................................................... 43

7 Appendix 45

7.1 Samples and sample vials .................................................. 45

7.2 I/O interface ........................................................................ 45

7.2.1 Properties of the I/O interface ................................................ 46

7.2.2 Pin assignment of the remote interface .................................. 46

8 Technical specifications 47

8.1 General ................................................................................ 47

8.2 Sampling .............................................................................. 47

8.3 Analytical characteristics ................................................... 48

8.4 Programming ...................................................................... 48

8.5 Interfaces ............................................................................. 48

8.6 Options (pre-installed) ........................................................ 48

8.7 Mains connection ............................................................... 49

8.8 Safety specifications ........................................................... 49

■■■■■■■■

IV

889 IC Sample Center

Page 7

■■■■■■■■■■■■■■■■■■■■■■

9 Conformity and warranty 51

10 Accessories 55

Index 60

Table of contents

8.9 Electromagnetic compatibility (EMC) ................................ 49

8.10 Ambient temperature ......................................................... 50

8.11 Dimensions .......................................................................... 50

9.1 Declaration of Conformity ................................................. 51

9.2 Warranty (guarantee) ......................................................... 52

9.3 Quality Management Principles ........................................ 53

10.1 Scope of delivery 2.889.0010 ............................................ 55

10.2 Scope of delivery 2.889.0020 ............................................ 57

10.3 Optional accessories 2.889.0010 ...................................... 58

10.4 Optional accessories 2.889.0020 ...................................... 59

889 IC Sample Center

■■■■■■■■

V

Page 8

Table of figures

Table of figures

Figure 1 889 IC Sample Center - front ............................................................. 7

Figure 2 889 IC Sample Center - rear .............................................................. 8

Figure 3 Interior view without covering ......................................................... 10

Figure 4 Interior with sampling device ........................................................... 11

Figure 5 Interior with installed cooling option. .............................................. 12

Figure 6 Unpacking the 889 IC Sample Center .............................................. 13

Figure 7 Connecting pump and column ........................................................ 16

Figure 8 Guiding the rinsing tubing ............................................................... 17

Figure 9 Tubing guide from above ................................................................ 17

Figure 10 Mounting the outlet tubing ............................................................. 17

Figure 11 Mounting the leakage tubing .......................................................... 18

Figure 12 PASA™ injection concept ................................................................ 19

Figure 13 Full loop injection ............................................................................ 21

Figure 14 Replacing the sample needle ........................................................... 33

Figure 15 Pin assignment of I/O socket and plug ............................................. 46

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

VI

889 IC Sample Center

Page 9

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Instrument description

The 889 IC Sample Center is a robust Autosampler for high sample

throughput, optimized for the challenges of the modern analytic laboratory. Its greatest advantages are speed and small sample volumes.

Special features:

■ Control of syringes with high resolution. This enables very high preci-

sion during injections.

■ The control per PC software makes operation readily comprehensible.

A context-sensitive online Help function is available for every window

and every dialog.

■ As a means of enhancing safety, no needle movements are carried out

when the door is open.

■ The optional sample cooling guarantees consistent results.

1 Introduction

Standard micro titer plates (high or low form) or sample racks can be

used. The same plates or racks must be present in the left-hand and righthand loading drawer.

1.1.1 Model versions

2.889.0010 889 IC Sample Center

With:

■ 15 µL injection needle

■ 500 µL syringe

■ 1000 µL buffer loop

■ 100 µL sample loop

2.889.0020 889 IC Sample Center Cool

With:

■ 15 µL injection needle

■ 500 µL syringe

■ 1000 µL buffer loop

■ 100 µL sample loop

■ Accessories for cooling the samples

889 IC Sample Center

■■■■■■■■

1

Page 10

1.2 About the documentation

1.1.2 Instrument components

The 889 IC Sample Center has the following components:

■ 2 sample racks

Each for 48 vials.

■ Needle arm

With air needle and drives for horizontal and vertical positioning.

■ Injection valve

With six connectors and two switching positions (LOAD and INJECT)

■ Syringe module

For aspirating and transferring the samples.

■ Cooling module (optional)

For cooling the samples.

■ USB connector

For the connection to a PC.

■ I/O interface

For output of an inject marker signal.

1.1.3 Intended use

The 889 IC Sample Center is designed for usage as an automation system

in analytical laboratories.

■■■■■■■■■■■■■■■■■■■■■■

This instrument is suitable for processing chemicals and flammable samples. The usage of the 889 IC Sample Center therefore requires that the

user has basic knowledge and experience in the handling of toxic and

caustic substances. Knowledge with respect to the application of the fire

prevention measures prescribed for laboratories is also mandatory.

1.2 About the documentation

Caution

Please read through this documentation carefully before putting the

instrument into operation. The documentation contains information

and warnings which the user must follow in order to ensure safe operation of the instrument.

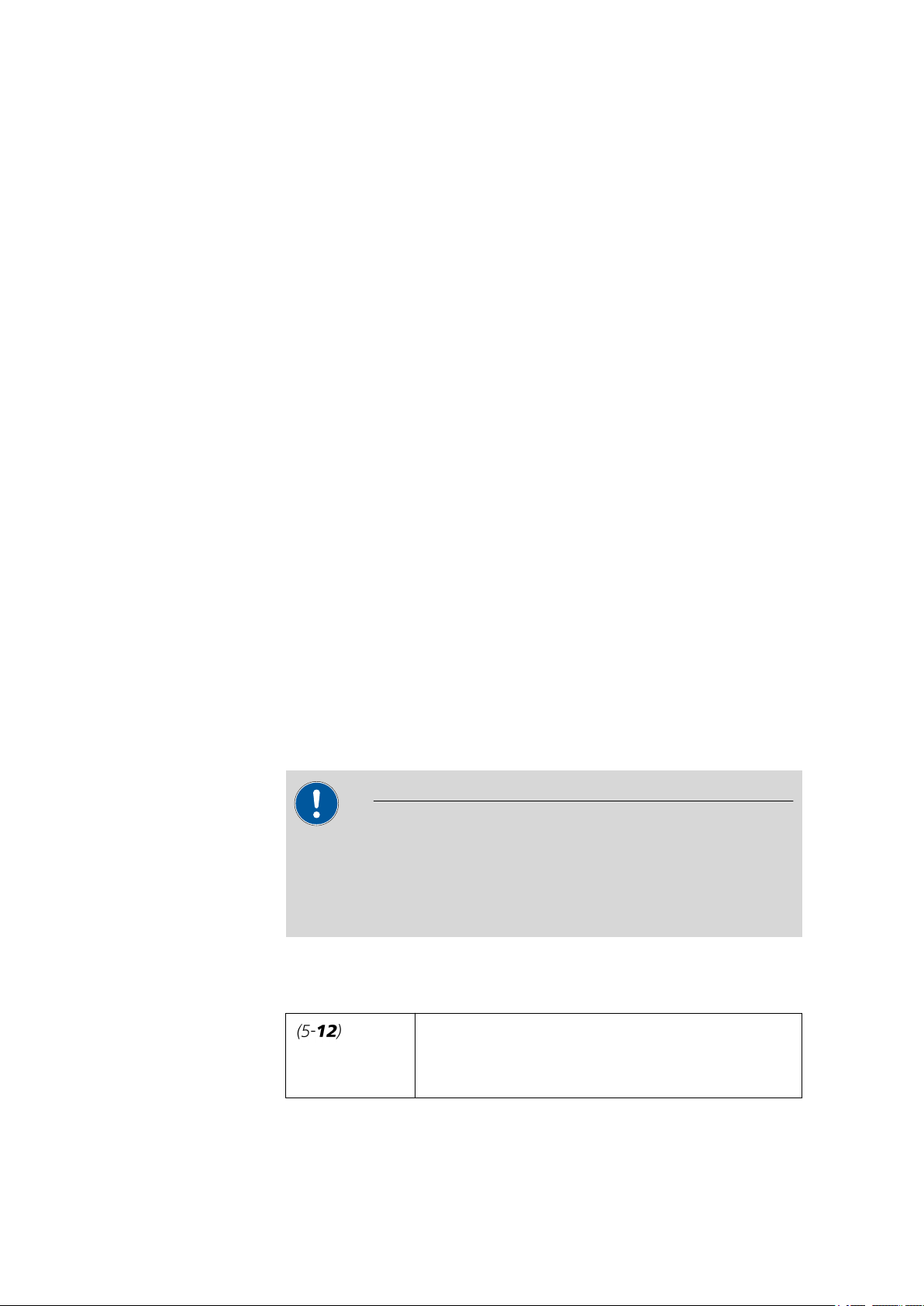

1.2.1 Symbols and conventions

The following symbols and styles are used in this documentation:

Cross-reference to figure legend

■■■■■■■■

2

The first number refers to the figure number, the

second to the instrument part in the figure.

889 IC Sample Center

Page 11

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

Instruction step

Carry out these steps in the sequence shown.

Warning

This symbol draws attention to a possible life hazard

or risk of injury.

Warning

This symbol draws attention to a possible hazard due

to electrical current.

Warning

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

Warning

This symbol draws attention to a possible biological

hazard.

1.3 Safety instructions

1.3.1 General notes on safety

Warning

This instrument may only be operated in accordance with the specifications in this documentation.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

Caution

This symbol draws attention to a possible damage of

instruments or instrument parts.

Note

This symbol marks additional information and tips.

1.3.2 Electrical safety

The electrical safety when working with the instrument is ensured as part

of the international standard IEC 61010.

889 IC Sample Center

■■■■■■■■

3

Page 12

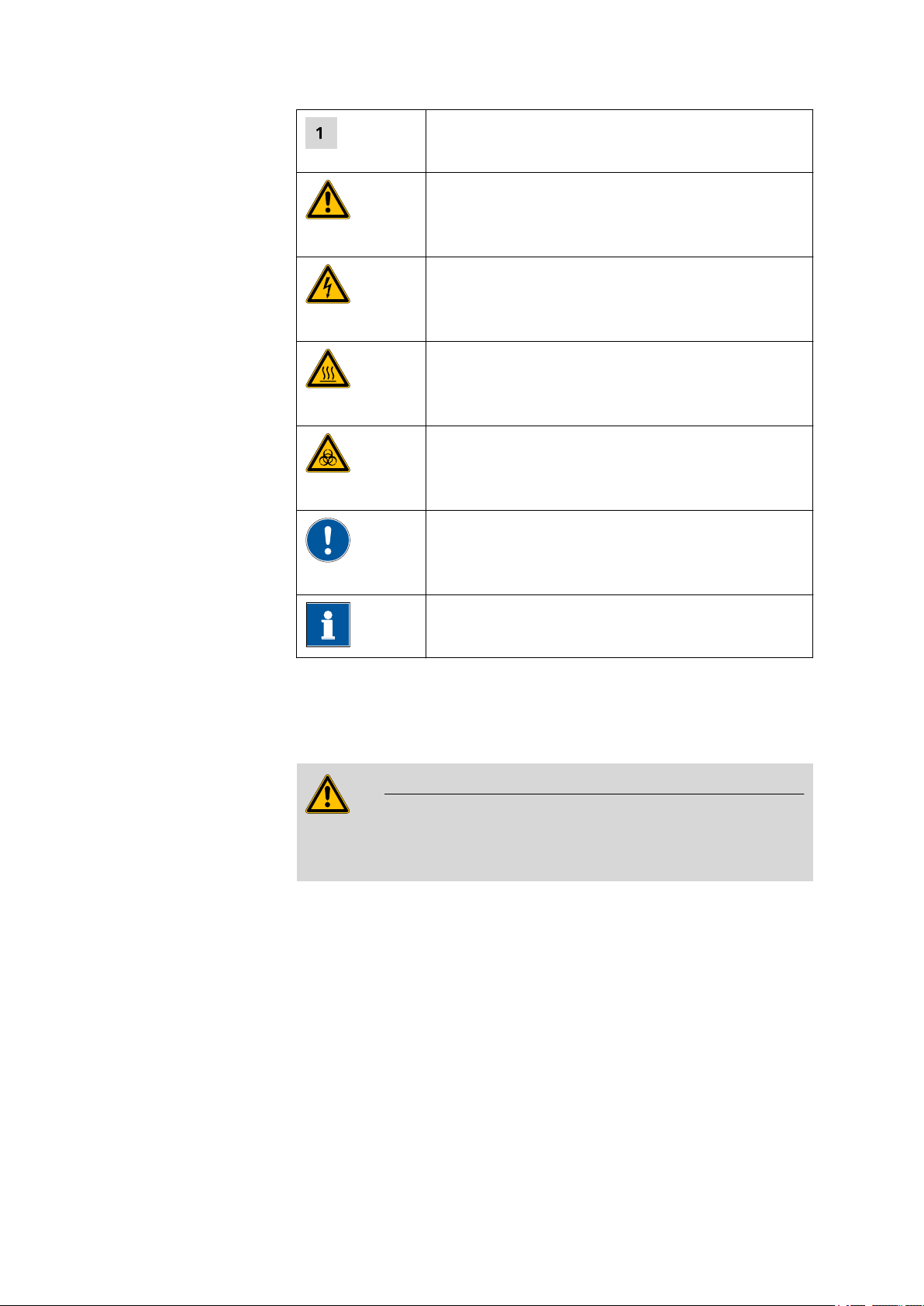

1.3 Safety instructions

■■■■■■■■■■■■■■■■■■■■■■

Warning

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

Warning

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

Mains voltage

Warning

An incorrect mains voltage can damage the instrument.

Only operate this instrument with a mains voltage specified for it (see

rear panel of the instrument).

Mains cable

Warning

Replace or repair defective or frayed insulation of the mains cable.

Protection against electrostatic charges

Warning

Electronic components are sensitive to electrostatic charges and can be

destroyed by discharges.

Always pull the mains cable out of the mains connection socket before

connecting or disconnecting electrical appliances on the rear panel of

the instrument.

■■■■■■■■

4

889 IC Sample Center

Page 13

■■■■■■■■■■■■■■■■■■■■■■

Fuses

Warning

Replaced burned fuses only with new fuses of the same size and the

same type, as specified next to the fuse holder or in the accessories list

in this manual.

1.3.3 Tubing and capillary connections

Caution

Leaks in tubing and capillary connections are a safety risk. Tighten all

connections well by hand. Avoid applying excessive force to tubing

connections. Damaged tubing ends lead to leakage. Appropriate tools

can be used to loosen connections.

Check the connections regularly for leakage. If the instrument is used

mainly in unattended operation, then weekly inspections are mandatory.

1 Introduction

1.3.4 Personnel safety

Wear protective goggles and working clothes suitable for laboratory

work while operating the 889 IC Sample Center. It is also advisable to

wear gloves when caustic liquids are used or in situations where glass

vessels could break.

Personnel are not permitted to reach into the working area of the

instrument while operations are running!

A considerable risk of injury exists for the user.

Warning

Warning

889 IC Sample Center

■■■■■■■■

5

Page 14

1.3 Safety instructions

Warning

In the event of a possible jamming of a drive, the mains plug must be

pulled out of the socket immediately. Do not attempt to free jammed

sample vessels or other parts while the instrument is switched on.

Blockages can only be cleared when the instrument is in a voltage-free

status; this action generally involves a considerable risk of injury.

1.3.5 Flammable solvents and chemicals

Warning

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location.

■ Keep all sources of flame far from the workplace.

■ Clean up spilled liquids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

■ Dispose of solvents and chemicals according to good professional

practice.

■■■■■■■■■■■■■■■■■■■■■■

1.3.6 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

■■■■■■■■

6

889 IC Sample Center

Page 15

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4

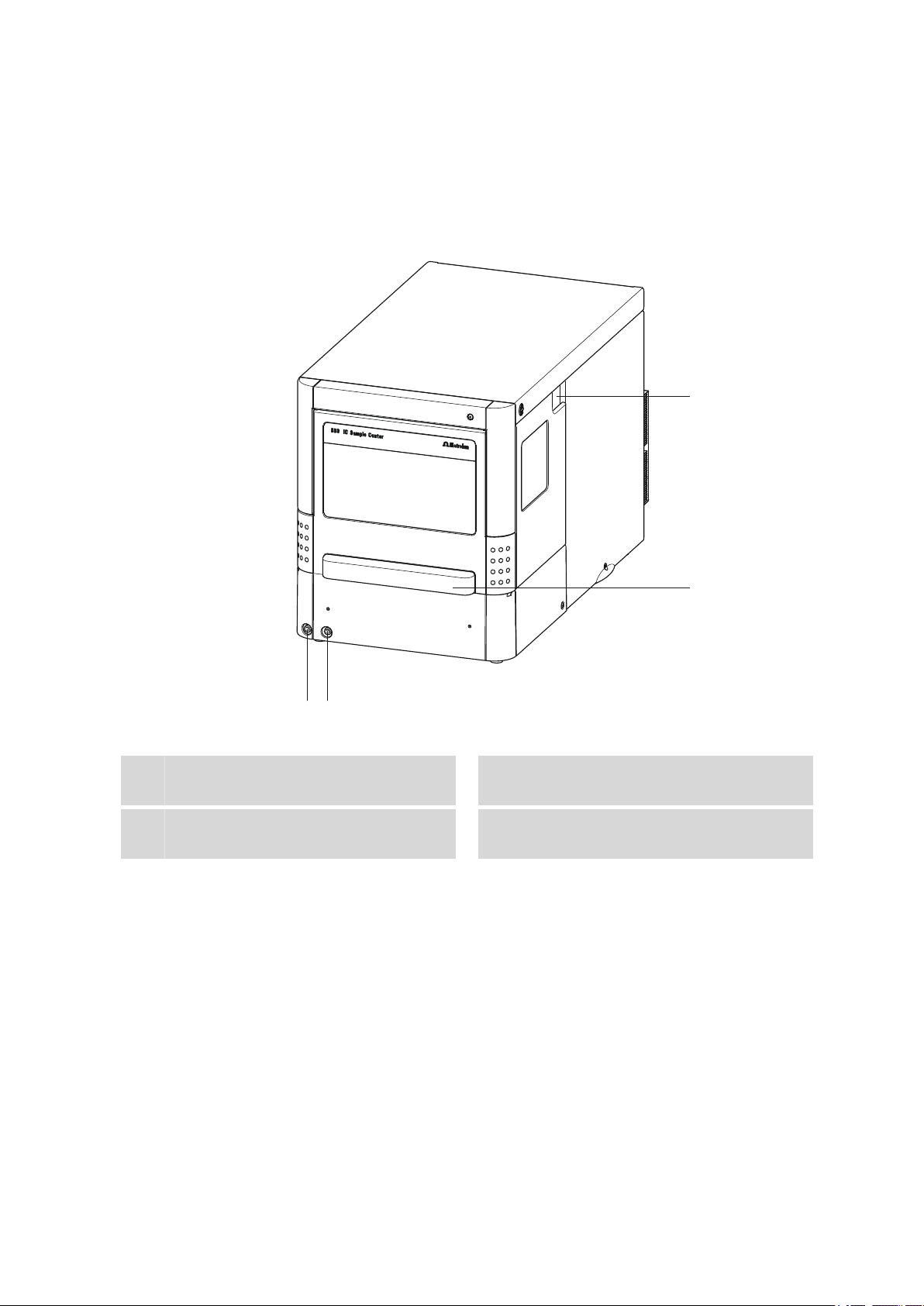

2 Overview of the instrument

2.1 Front and rear

2 Overview of the instrument

Tubing guide

1

For capillaries and tubings.

Connector for the outlet tubing

3

889 IC Sample Center

Figure 1 889 IC Sample Center - front

Door to the sample chamber

2

With handle.

Connector for the condensation and

4

leakage tubing

■■■■■■■■

7

Page 16

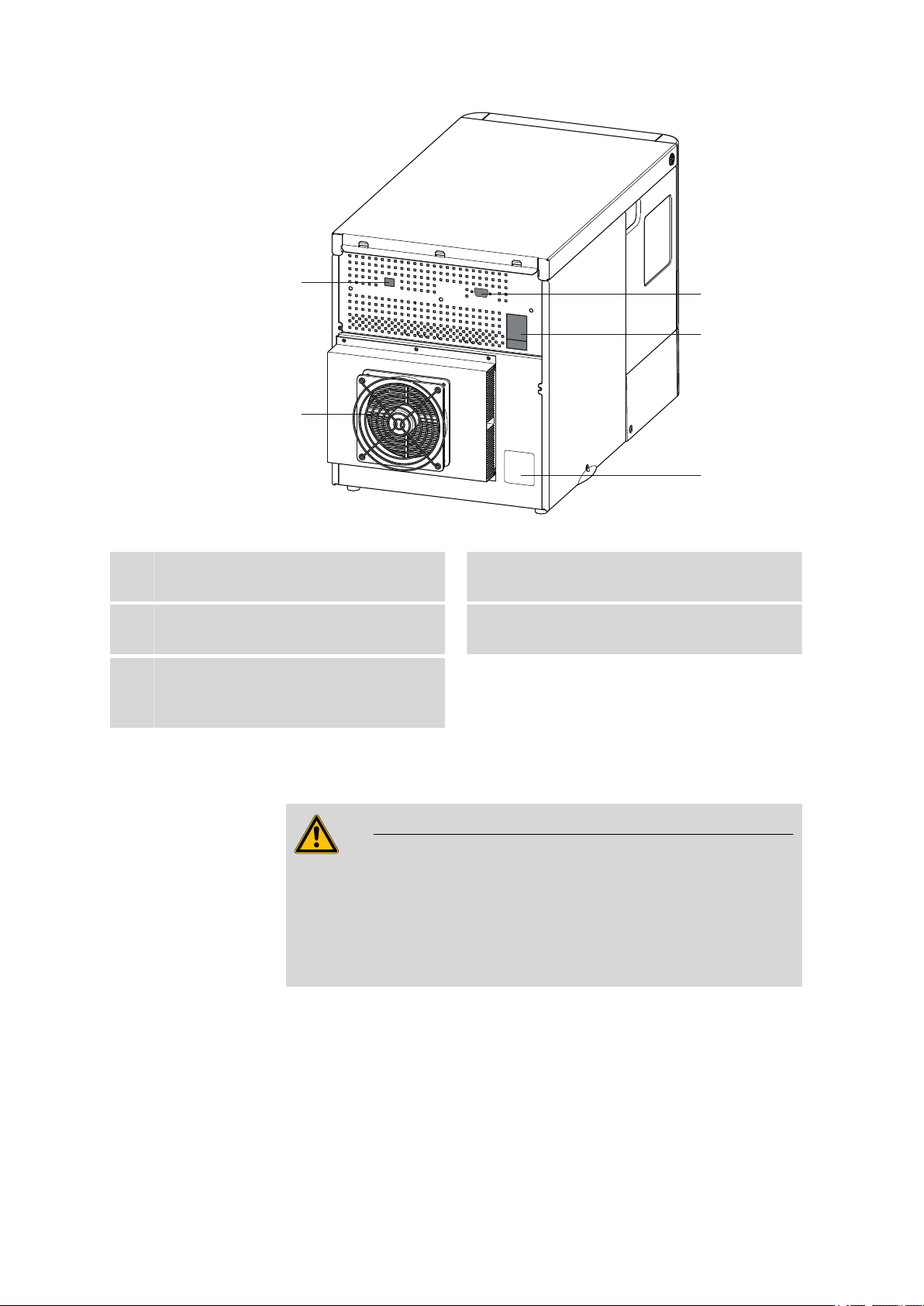

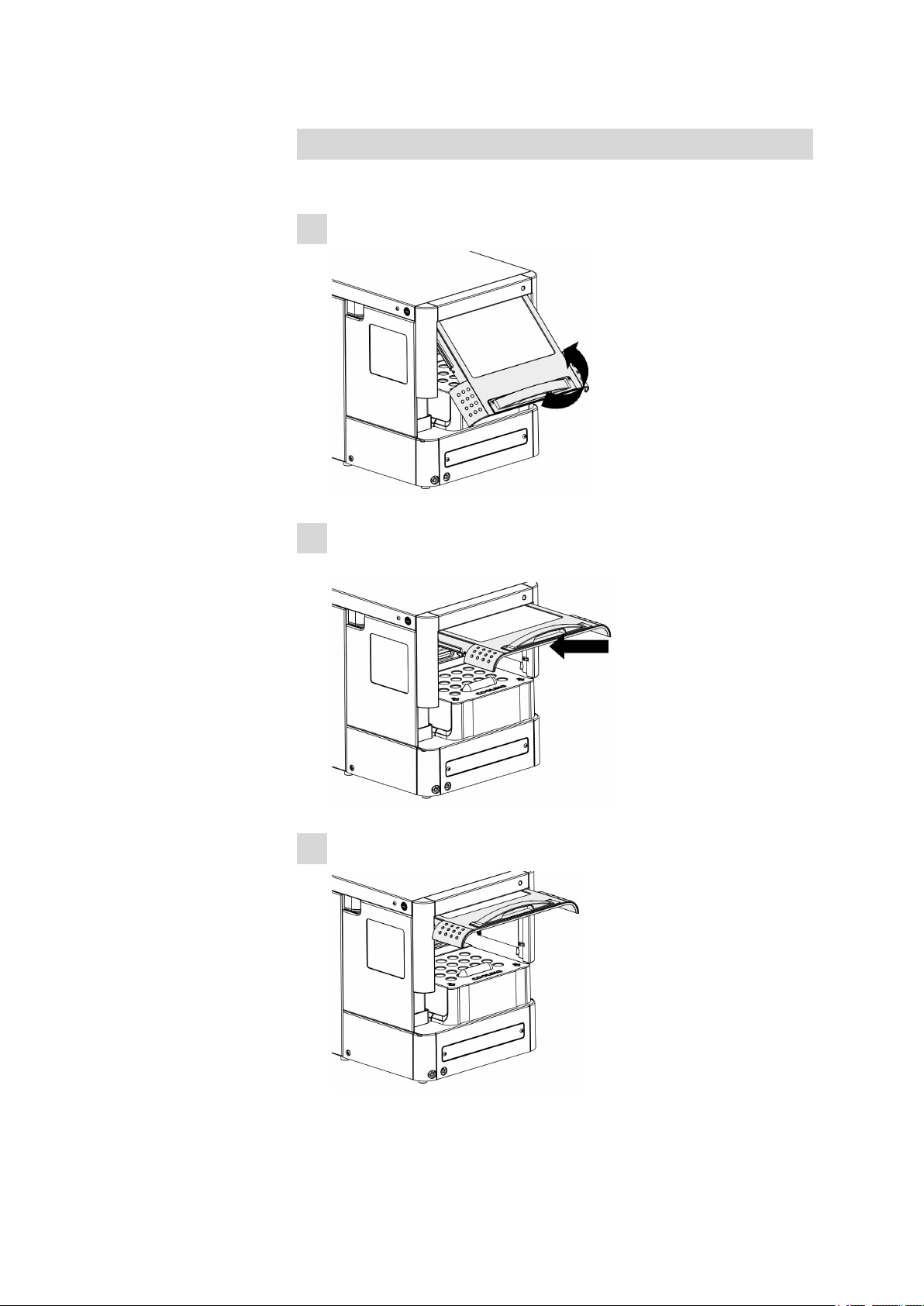

2.2 Opening the device

1

2

3

4

5

■■■■■■■■■■■■■■■■■■■■■■

Figure 2 889 IC Sample Center - rear

USB connector

1

For the connection to a PC.

I/O connector

3

For output of an inject marker signal.

Type plate

5

Contains specifications concerning mains

voltage and serial number.

2.2 Opening the device

Warning

Mobile parts are to be found in the interior of the 889 IC Sample Center. Reaching into the interior during operation puts personnel at a serious risk of injury. Open the door only if the device is in idle mode. Due

to safety considerations, no needle movements are carried out by the

device when the door is open.

Fan

2

For the cooling unit. Do not cover!

Mains connection socket

4

With mains switch and fuse holder.

■■■■■■■■

8

889 IC Sample Center

Page 17

■■■■■■■■■■■■■■■■■■■■■■

2 Overview of the instrument

Opening the door

Proceed as follows:

Grip the door handle:

1

Carefully pull out the door and press it upwards until it is in a hori-

2

zontal position.

889 IC Sample Center

Slide the door into the housing.

3

■■■■■■■■

9

Page 18

2.3 Interior view

■■■■■■■■■■■■■■■■■■■■■■

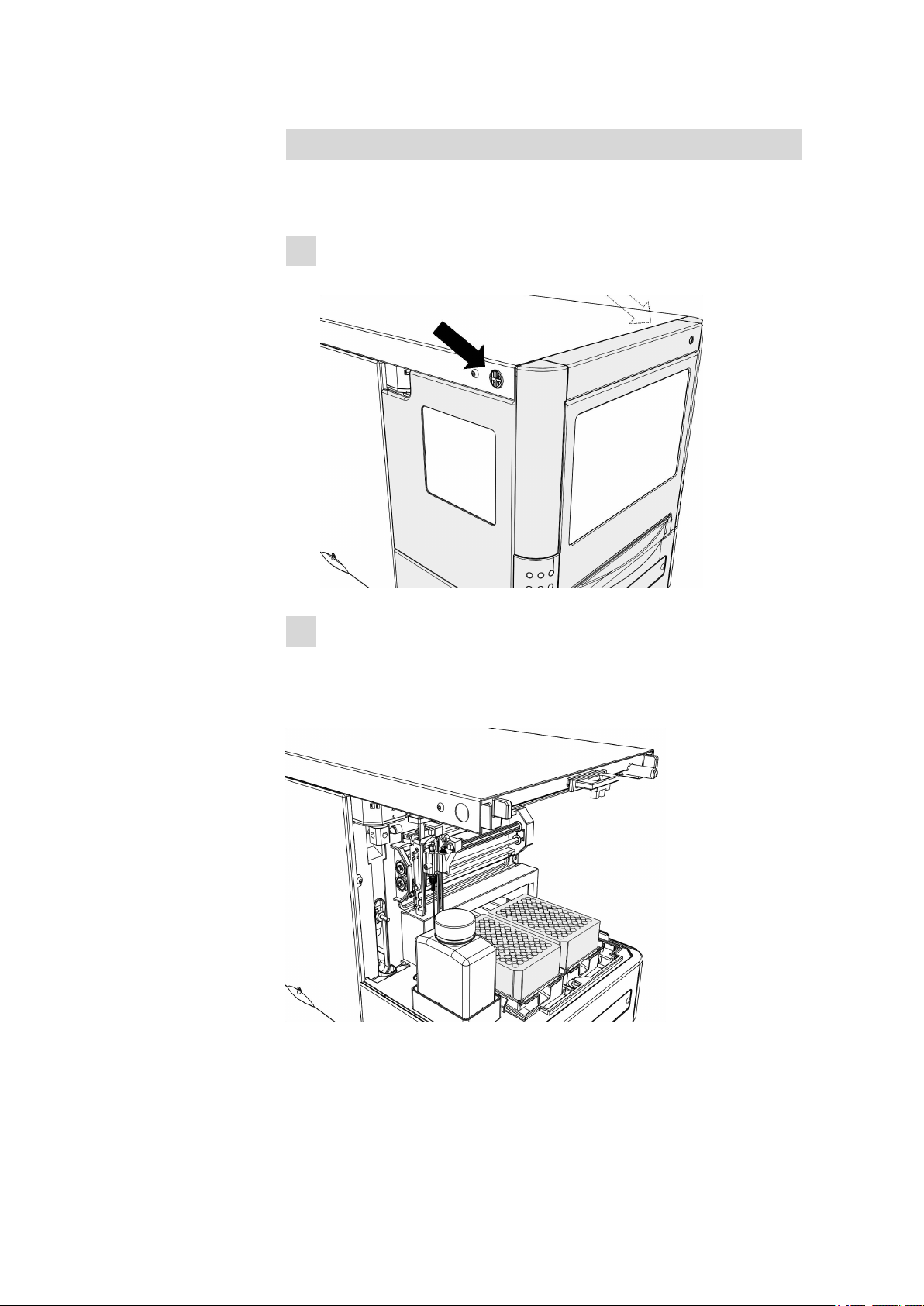

Removing the covering

You can remove the covering on the housing in order to make the interior

more readily accessible:

Press the two black buttons on the sides of the housing (above)

1

simultaneously.

Carefully pull out the covering towards the front.

2

2.3 Interior view

Figure 3

Interior view without covering

■■■■■■■■

10

889 IC Sample Center

Page 19

■■■■■■■■■■■■■■■■■■■■■■

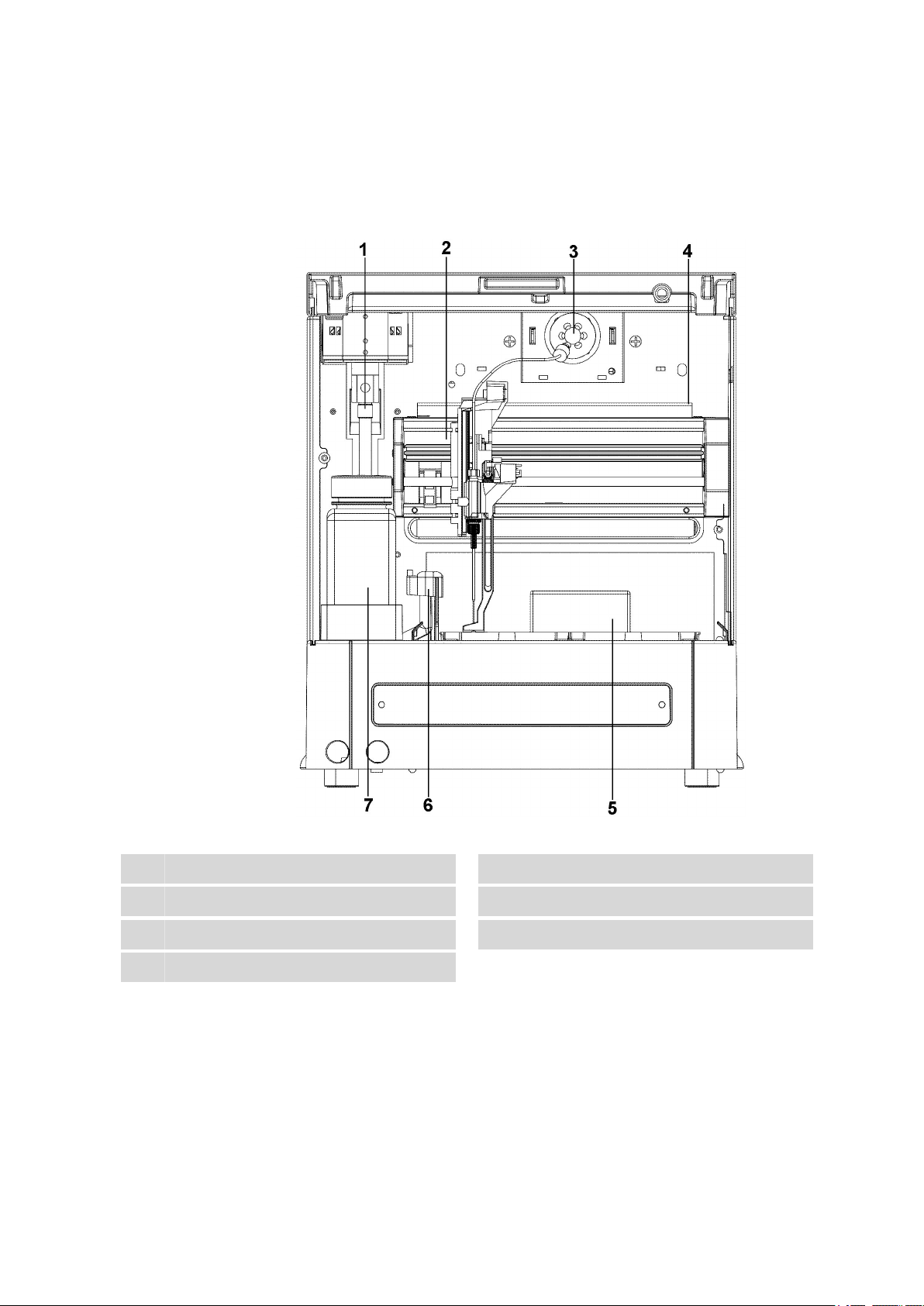

2.4 Interior

2 Overview of the instrument

The following parts are to be found in the interior of the 889 IC Sample

Center:

Syringe

1

Injection valve

3

Sample chamber

5

Washing bottle

7

889 IC Sample Center

Figure 4 Interior with sampling device

Needle arm

2

Sample drip pan

4

Needle washing position

6

■■■■■■■■

11

Page 20

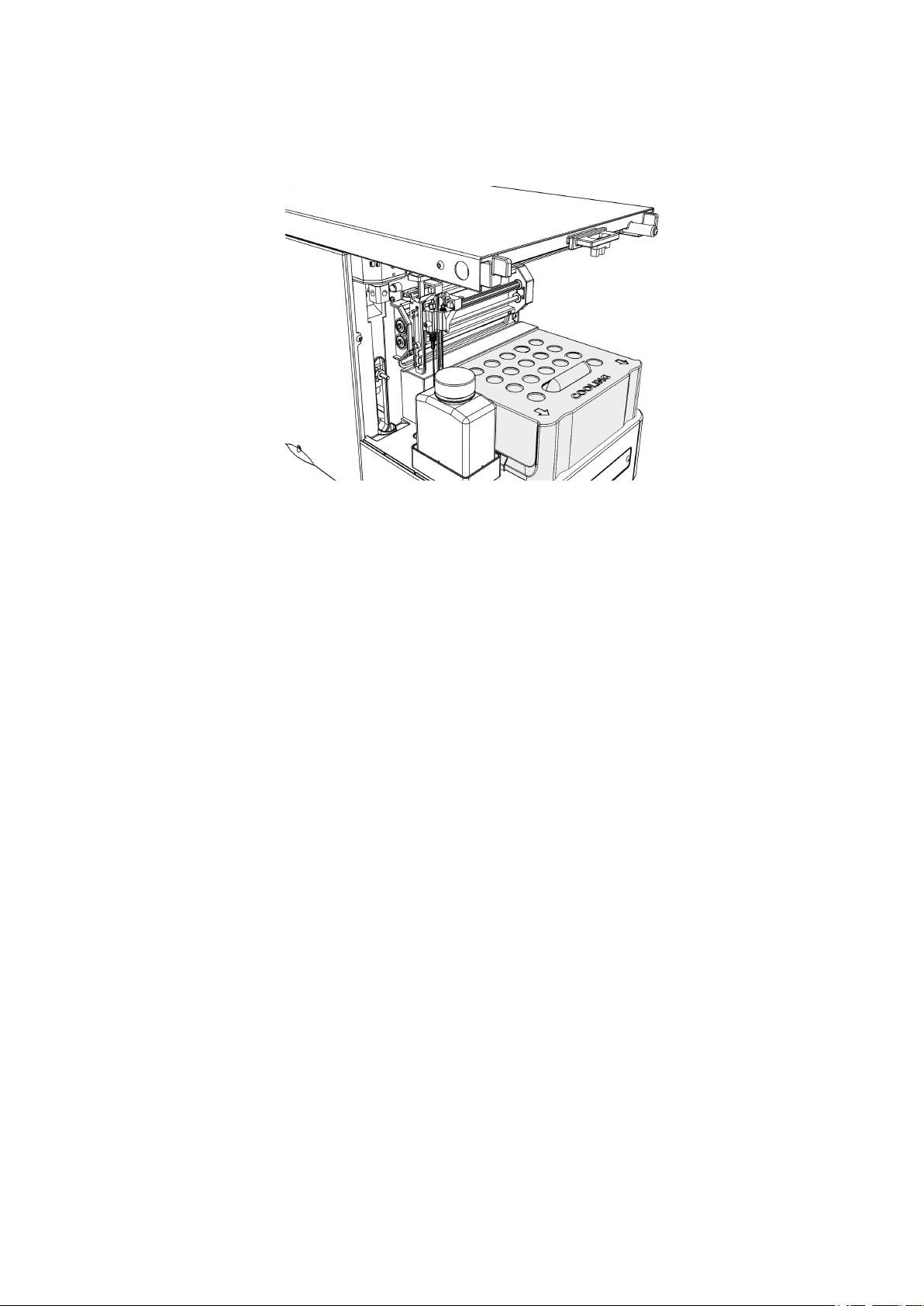

2.5 Cooling option

2.5 Cooling option

Figure 5 Interior with installed cooling option.

■■■■■■■■■■■■■■■■■■■■■■

If the cooling option is installed, pull the covering of the cooling option off

towards the front. Now you can place the sample racks or micro titer

plates.

■■■■■■■■

12

889 IC Sample Center

Page 21

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

3.1 Setting up the instrument

3.1.1 Packaging

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

3.1.2 Checks

Immediately after receipt, check whether the shipment has arrived complete and without damage by comparing it with the delivery note.

3.1.3 Location

The instrument has been developed for operation indoors and may not be

used in explosive environments.

3 Installation

Place the instrument in a location of the laboratory suitable for operation

and free of vibrations, if possible protected from corrosive atmospheres

and contamination by chemicals.

The instrument should be protected against excessive temperature fluctuations and direct sunlight.

3.1.4 Removing the device from the packaging

Grip the device at the positions marked with arrows and lift it out of the

packaging.

Figure 6

Unpacking the 889 IC Sample Center

889 IC Sample Center

Grip the device underneath with both hands when you are transporting it.

Always hold the device in an upright position.

Before you switch on the 889 IC Sample Center, allow the device to stand

for at least one hour in order to adapt to the room temperature.

■■■■■■■■

13

Page 22

3.2 Connecting a computer

Warning

Take care to ensure that the ventilation openings on the rear side of the

device are not covered. Note that blocked ventilation openings could

have an influence on the performance of the device, in particular on its

cooling output.

Objects placed on the device could also impair the cooling output.

Objects can be placed at the sides of the 889 IC Sample Center. If an

object is placed on only one side, then a minimum clearance of 5 cm must

be maintained. In the case of more than one sides, a minimum clearance

of 10 cm applies.

3.2 Connecting a computer

The 889 IC Sample Center requires a USB connection to a computer in

order to be able to be controlled by a PC software. When a 6.2151.020

cable USB A - USB B is used, the instrument can be connected directly,

either to a USB socket on a computer, to a connected USB hub or to a

different Metrohm control instrument.

■■■■■■■■■■■■■■■■■■■■■■

Cable connection and driver installation

A driver installation is required in order to ensure that the 889 IC Sample

Center is recognized by the PC software. To accomplish this, you must

comply with the procedures specified. The following steps are necessary:

1

Installing software

■ Insert the MagIC Net™ PC software installation CD and carry

out the installation program directions.

■ Exit the program if you have started it after the installation.

2

Establishing cable connections

■ Check whether the fuse and the supply voltage which are speci-

fied on the rear side of the device also match the prevailing circumstances.

■ Connect the 889 IC Sample Center to the mains supply.

■ Connect the instrument to a USB connector (Type A) of your com-

puter (see manual of your computer). The 6.2151.020 cable

USB A - USB B is used for this purpose. The USB connector of

the 889 IC Sample Center is located on the rear of the instrument.

■■■■■■■■

14

889 IC Sample Center

Page 23

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

Switch on the instrument using the mains switch on the rear of the

3

instrument.

For Windows 2000: the instrument is recognized and the driver is

installed automatically.

For Windows XP: the instrument is recognized and the installation

assistant for the driver is started automatically. Select the option

"Install software automatically" and click on [Next]. Exit the assistant

with [Finish].

For Windows Vista: the instrument is recognized and the installation assistant for the driver is started automatically. Select the option

"Find and install driver software". Agree to all of the requests that

follow. The installation assistant will be exited automatically.

Registering and configuring the instrument in the PC software

The instrument must be registered in the configuration of MagIC Net™ .

Once that has been done, you can then configure it according to your

requirements. Proceed as follows:

1

Setting up the instrument

■ Start MagIC Net™ .

The instrument is recognized automatically. The configuration dialog for the instrument is displayed.

■ Make configuration settings for the instrument.

More detailed information concerning the configuration of the

instrument can be found in the documentation of MagIC Net™ .

3.3 Connecting pump and column

The 889 IC Sample Center is supplied with the necessary mounted hose

and capillary connections. Connect the high pressure pump and the separation columns to the still unoccupied ports 1 and 6 on the injection valve

with one suitable PEEK capillary each (6.1831.010). Observe the following

illustration.

889 IC Sample Center

■■■■■■■■

15

Page 24

3.4 Tubing

1

2

3

4

5

6

4

2

5

3

1

■■■■■■■■■■■■■■■■■■■■■■

Figure 7 Connecting pump and column

Connection to the syringe module

1

Port 3 of the injection valve.

Connection to the high pressure pump

3

Port 1 of the injection valve.

Sample loop

5

Port 2 and 5 of the injection valve.

3.4 Tubing

The 889 IC Sample Center is equipped with the following standard tubing:

Tubing/Capillary

Standard sample needle and

capillary (15 µL)

Buffer tubing from the high

pressure valve to the syringe

valve (1000 µL)

Connection to the needle

2

Port 4 of the injection valve.

Connection to the separation column

4

Port 6 of the injection valve.

Material/Dimensions

SS (inert-coated): 97 mm x 0.8 mm

OD x 0.25 mm ID

ETFE (Tefzel): 200 mm x 1/16" OD x

0.25 mm ID

ETFE (Tefzel): 1275 mm x 1/16" OD x

1.0 mm ID

Tubing from the syringe valve

to the washing bottle

Tubing from the syringe valve

PTFE: 400 mm x 1/18" OD x 1.6 mm

ID

PTFE: 400 mm x 1/8" OD x 1.6 mm ID

to the outlet tubing

Observe the following when mounting new tubing or capillaries:

■ Do not tighten the connectors excessively. This could block the flow

path.

■ Make sure that you always use tubing volumes which are suitable for

the other components in the flow path.

16

■■■■■■■■

889 IC Sample Center

Page 25

■■■■■■■■■■■■■■■■■■■■■■

3.4.1 Tubing guide

In order to prevent the rinsing tubing from hindering the horizontal movement of the needle unit, use the tubing guide in the collection pan under

the injection valve:

Figure 8 Guiding the rinsing tubing

3 Installation

Figure 9 Tubing guide from above

3.5 Outlet tubings

Set up the following tubing connections for the disposal of waste fluids:

General waste

Connect one outlet tubing (included in the scope of delivery) on the lefthand tubing connector on the front of the 889 IC Sample Center. Guide

the other end into a waste container underneath the 889 IC Sample Center.

Figure 10

All of the liquid which is conveyed to the washing position will be channeled through this outlet. Sample liquid which was not injected will also

be disposed of through this outlet.

Mounting the outlet tubing

889 IC Sample Center

■■■■■■■■

17

Page 26

3.6 Rinsing the syringe

Condensation and leakage outlet

All leakage liquid and condensation water (from the cooling module) will

be channeled through the right-hand tubing connector. If the cooling

option is used, it is advisable to connect this connector with a waste container underneath the 889 IC Sample Center.

Figure 11 Mounting the leakage tubing

3.6 Rinsing the syringe

The syringe must be rinsed bubble-free prior to the start-up of the 889 IC

Sample Center.

Fill the washing bottle with isopropanol.

■■■■■■■■■■■■■■■■■■■■■■

Warning

Do not use any saline or buffer solutions. Crystals could block or damage the entire system.

Proceed as follows:

Immerse the end of the tubing for the washing bottle into the vessel.

1

Open the manual control in MagIC Net™.

2

Select 889 IC Sample Center in the device selection (all devices).

3

On the tab General, carry out the function Washing.

4

The syringe, the needle and the tubing are rinsed thoroughly.

If needed, carry out the function a second time until the syringe no

5

longer contains any bubbles and the tubing is filled.

Repeat the washing procedure with ultra pure water or possibly with

6

eluent.

■■■■■■■■

18

889 IC Sample Center

Page 27

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4

5

4 Functioning

4.1 Injection modes

Three different injection modes can be utilized:

■ Full loop injection: for full precision

■ Partial loopfill injection: for full flexibility

■ Pickup injection: for smallest loss of sample

The sample loop injection with pressure-assisted sample aspiration =

PASA™ can be used with all three injection modes. This is a tried and tested concept which combines high accuracy with simplicity and reliability.

■ No movement of the sample needle

■ Reduced risk of bubbles in the sample intake

■ No wearing or contamination of the injection port

4 Functioning

Buffer loop

1

Separation column

3

Compressed air

5

889 IC Sample Center

Figure 12

PASA™ injection concept

High pressure pump

2

Sample loop

4

The syringe aspirates the sample out of the sample vessel and into the

sample loop. The buffer loop between the syringe and the injection valve

■■■■■■■■

19

Page 28

4.2 Syringe and buffer loop

prevents the contamination of the syringe. Washing solution is required in

order to:

■ remove the sample from the buffer loop and the sample needle.

■ rinse the buffer loop and the sample needle.

4.2 Syringe and buffer loop

The following range of sample volumes can be covered with the various

injection modes using the 500 µL syringe, in combination with the standard buffer loop (1000 µL) and the standard sample loop (100 µL):

■ Full loop: 100 µL

■ Partial loopfill: 1…50 µL

■ Pickup: 1…27 µL

The maximum injection volume is calculated in accordance with the following formulas:

■ Full loop: injection volume = sample loop volume

■ Partial loopfill: max. injection volume = 0.5 × sample loop volume

■ Pickup: max. injection volume = (sample loop volume – 3 × needle vol-

ume) / 2

■■■■■■■■■■■■■■■■■■■■■■

The full loop injection yields the maximum possible reproducibility < 0.3%,

but not the maximum accuracy, because the loop volume is specified as

being with an accuracy of ±10%. The minimum sample loss is 230 µL (2 ×

(sample loop overfilling + rinsing volume) for one 15 µL needle).

The partial loopfill injection yields a maximum accuracy and reproducibility

better than 0.5% relative standard deviation (RSD) for injection volumes

> 10 µL. The minimum sample loss (rinsing volume is equal to 30 µL.

30 µL is the recommended minimum rinsing volume. Smaller rinsing volumes can be programmed, but reproducibility will be reduced as a result.

The pickup injection offers maximum accuracy (the same as with partial

loopfill) and no loss of sample, but somewhat lower reproducibility,

namely a relative standard deviation (RSD) better than 1% for injection

volumes > 10 µL.

■■■■■■■■

20

889 IC Sample Center

Page 29

■■■■■■■■■■■■■■■■■■■■■■

4.3 Full loop injection

The sample loop is filled completely (quantitatively) with sample. This type

of injection results in excellent reproducibility.

1

Initial situation

4 Functioning

Figure 13 Full loop injection

The injection valve is in INJECT position. The sample needle penetrates the vial with the air needle. An overpressure channeled in

through the air needle ensures that no air or steam bubbles form

during the aspiration of the sample.

2

Rinsing the aspirating line

889 IC Sample Center

■■■■■■■■

21

Page 30

4.3 Full loop injection

■■■■■■■■■■■■■■■■■■■■■■

The syringe aspirates a rinsing volume of sample solution out of the

sample vial and fills the sample line with sample. The rinsing liquid is

expelled.

3

Switching the injection valve to LOAD

The injection valve is switched over to the LOAD position. This causes an homogenous sample plug to be present at the inlet to the

sample loop.

4

Filling the sample loop

■■■■■■■■

22

The sample loop is quantitatively filled by a multiple of the loop volume being pumped through the loop.

■ 3 × loop volume with sample loops ≤ 100 µL

889 IC Sample Center

Page 31

■■■■■■■■■■■■■■■■■■■■■■

■ 2 × loop volume with sample loops 100...500 µL

■ 1.5 × loop volume with sample loops ≥ 500 µL

5

Switching the injection valve to INJECT

4 Functioning

The injection valve switches to the INJECT position. The sample loop

is now part of the flow path of the eluent; the sample is transported

to the separation column. The determination is started.

A washing cycle is performed after each injection.

Air segment with the full loop injection

A 5 µL air segment can be used in order to reduce the necessary volume

of sample solution. The air segment must be located at the head of the

rinsing volume and will not be injected.

In the case of a standard needle, the rinsing volume with air segment

must be at least 30 µL for one injection, and at least 35 µL for injections

without air segments. In the case of high-viscosity samples, larger rinsing

volumes must be programmed and the speed of the syringe stroke must

be reduced in order to improve reproducibility.

889 IC Sample Center

■■■■■■■■

23

Page 32

4.4 Partial loopfill injection

4.4 Partial loopfill injection

The switchover sequence for the partial loopfill injection is as follows:

1

Initial situation

■■■■■■■■■■■■■■■■■■■■■■

The injection valve is in INJECT position. The sample needle penetrates the vial with the air needle. An overpressure channeled in

through the air needle ensures that no air or steam bubbles form

during the aspiration of the sample.

2

Rinsing the aspirating line

■■■■■■■■

24

889 IC Sample Center

Page 33

■■■■■■■■■■■■■■■■■■■■■■

4 Functioning

The syringe aspirates a rinsing volume of sample solution out of the

sample vial and fills the sample line with sample. The rinsing liquid is

expelled.

3

Switching the injection valve to LOAD

The injection valve is switched over to the LOAD position. This causes an homogenous sample plug to be present at the inlet to the

sample loop.

4

Filling the sample loop partially

889 IC Sample Center

The programmed injection volume is now aspirated into the sample

loop.

■■■■■■■■

25

Page 34

4.4 Partial loopfill injection

■■■■■■■■■■■■■■■■■■■■■■

5

Switching the injection valve to INJECT

The injection valve switches to the INJECT position. The sample loop

is now part of the flow path of the eluent; the sample is transported

to the separation column. The determination is started.

Air segment with the partial loopfill injection

An air segment can be used in order to reduce the necessary volume of

sample solution. The air segment must be located at the head of the rinsing volume and will not be injected.

In the case of a standard needle, the rinsing volume with air segment

must be at least 30 µL for one injection, and at least 35 µL for injections

without air segments. In the case of high-viscosity samples, larger rinsing

volumes must be programmed and the rate of the syringe stroke must be

reduced in order to improve reproducibility.

■■■■■■■■

26

889 IC Sample Center

Page 35

■■■■■■■■■■■■■■■■■■■■■■

4.5 Pickup injection

The switchover sequence for the pickup injection is as follows:

Initial situation

1

4 Functioning

The injection valve is in INJECT position. The sample needle is in

washing position.

2

Rinsing the washing reservoir

The washing reservoir is filled several times (the number of times can

be programmed) with the syringe volume. This takes place after a

washing sequence or after the buffer tubing has been emptied. The

injection valve remains in INJECT position. Note that the transport

solution must be compatible with the eluent.

3

Filling the aspirating line with transport solution

For the first injection, the syringe aspirates a segment of transport

solution in order to fill the sample line with transport solution.

889 IC Sample Center

■■■■■■■■

27

Page 36

4.5 Pickup injection

■■■■■■■■■■■■■■■■■■■■■■

4

Switching the injection valve to LOAD

The needles switches from the washing position to the sample vial.

The injection valve switches to the LOAD position.

5

Aspirating sample

■■■■■■■■

28

The programmed injection volume is aspirated from the sample vial.

889 IC Sample Center

Page 37

■■■■■■■■■■■■■■■■■■■■■■

4 Functioning

6

Transporting sample into the sample loop

The sample needle moves back to the washing position. A second

segment of transport solution is aspirated. The sample is transported

quantitatively into the sample loop.

7

Switching the injection valve to INJECT

889 IC Sample Center

The injection valve switches to the INJECT position. The sample loop

is now part of the flow path of the eluent; the sample is transported

to the separation column. The determination is started.

This sequence is repeated for each injection.

■■■■■■■■

29

Page 38

4.5 Pickup injection

■■■■■■■■■■■■■■■■■■■■■■

Air segment in the pickup injection

If an air segment was programmed, this will appear at the beginning of

the first segment of the transport solution and at the beginning of each

sample segment.

The following is to be observed for this injection technique:

Note

The air segment at the beginning of the sample segment is injected

onto the separation column.

Note

No overpressure is permitted to be applied in the sample vessel,

because the air segment would expand during the change from sample

position to transport position. This could lead to a considerable error

with respect to the injection volume of the sample.

■■■■■■■■

30

889 IC Sample Center

Page 39

■■■■■■■■■■■■■■■■■■■■■■

5 Handling and maintenance

5.1 General

The 889 IC Sample Center requires appropriate care. Excess contamination

of the instrument may result in functional disruptions and a reduction in

the service life of the sturdy mechanics and electronics of the instrument.

Severe contamination can also have an influence on the measured results.

Regular cleaning of exposed parts can prevent this to a large extent.

Spilled chemicals and solvents must be removed immediately. In particular,

the mains plug should be protected from contamination.

Note

It is not necessary to disconnect the device from the electricity source

for care and maintenance work. This means that it is possible to continue to operate the device with the control software. Use Manual

operation in MagIC Net™ to check the functioning of the individual

device components.

5 Handling and maintenance

5.2 Care

The following applies for all care and maintenance work:

Open the door of the 889 IC Sample Center.

1

If the cooling option is installed, remove the covering of the cooling

2

option by pulling it towards the front.

Press the two buttons on the sides of the device simultaneously.

3

Remove the covering by pulling towards the front.

4

5.2.1 Cleaning in general

Generally speaking, the 889 IC Sample Center requires little upkeep. Clean

the outside of the housing with a soft cloth and a mild cleaning fluid.

Other parts which require regular care include:

■ Valve drip pan. A special drip pan is fitted underneath the injection

valve. Clean this with a soft cloth and a mild cleaning fluid.

889 IC Sample Center

■■■■■■■■

31

Page 40

5.3 Maintenance and service

■ Sample rack. If sample has been spilled on the sample rack, clean this

with a soft cloth and a mild cleaning fluid.

■ Drainage lines. Rinse the drainage tubing regularly in order to pre-

vent blockage and to ensure the drainage of liquids and condensation

water.

5.3 Maintenance and service

5.3.1 Sample loop

The 889 IC Sample Center is equipped as standard with a 100 µL sample

loop. Other sample loops can be mounted. Please note however that the

correct combination of syringe and buffer loop is required in order to achieve good results.

Observe the following when mounting a sample loop:

■ Mount the sample loop at Port 2 and Port 5 of the injection valve.

■ Adjust the configuration settings in the control software for the

changed sample loop volume.

■■■■■■■■■■■■■■■■■■■■■■

Note

The maximum injection volume is calculated in accordance with the following formulas:

Full loop: Injection volume = Loop volume

Partial loopfill: max. injection volume = 0.5 × loop volume

µL Pickup: max. injection volume = (loop volume – 3 × needle volume)

/ 2

■■■■■■■■

32

889 IC Sample Center

Page 41

■■■■■■■■■■■■■■■■■■■■■■

5.3.2 Replacing the sample needle

5 Handling and maintenance

889 IC Sample Center

Figure 14 Replacing the sample needle

Replace the sample needle as follows:

Open the Manual control in MagIC Net™ .

1

Under device selection, 889 IC Sample Center, select the tab Nee-

2

dle. Under Position/Input, select Exchange position and click on

[Start].

Now a message window is displayed.

Remove the sample rack and click on [OK].

3

■■■■■■■■

33

Page 42

5.3 Maintenance and service

■■■■■■■■■■■■■■■■■■■■■■

The needle moves into the exchange position.

Open the door of the 889 IC Sample Center.

4

If working with the cooling option, remove the covering of the cool-

5

ing option by pulling it towards the front.

Press the two buttons on the sides of the device simultaneously.

6

Remove the covering by pulling towards the front.

7

Loosen the nut 3 of the capillary connection.

8

Undo the tubing connection at Port 4 on the injection valve.

9

Remove the sample needle by pulling it upward and out of its seat.

10

Load a new sample needle. Ensure while doing so that the seal sur-

11

rounds the needle.

Tighten the sample needle with the connection nut.

12

Mount the other end of the capillary connection to port 4 of the

13

injection valve. Do not screw too tightly. This may block the tubing

connection.

Put the device covering back into position.

14

If working with the cooling option, replace the covering of the cool-

15

ing option.

Close the door of the 889 IC Sample Center.

16

Select the General tab in the manual control and start the Reset

17

device function.

■■■■■■■■

34

The sample needle moves back to the starting position.

889 IC Sample Center

Page 43

■■■■■■■■■■■■■■■■■■■■■■

5 Handling and maintenance

Note

If you are using the sample racks with 12 or 48 vials, then you

must adjust the setting of the needle height to > 2 mm. This will

prevent the needle from touching the bottom of the vial.

Perform a rinsing procedure in order to clean the new needle. Start

18

the Wash function. To interrupt the rinsing procedure, click on

Stop.

19

Note

The needle settings may need to be adjusted.

In MagIC Net™, open the configuration settings of the 889 IC Sam-

ple Center and select the Needle tab.

Perform the necessary setting.

5.3.3 Replacing the air needle

Replace the air needle as follows:

Replace the sample needle, (see Chapter 5.3.2, page 33).

1

Undo the fastening nut (made of chrome) for the air needle.

2

Undo the fastening nut (made of chrome) for the adjusting screw.

3

Remove the air needle.

4

Tighten the height adjustment nut on the fixing nut (made of

5

chrome). The thread of the height adjustment nut must match the

lower part of the fixing nut. The O-ring must be properly seated in

the fixing nut.

Insert the air needle.

6

Mount the sample needle.

7

Select the correct needle height for the new needle in the manual

8

operation feature of MagIC Net™ on the Needle tab.

889 IC Sample Center

■■■■■■■■

35

Page 44

5.3 Maintenance and service

If you are using the sample racks with 12 or 48 vials, then you

must adjust the setting of the needle height to > 2 mm. This will

prevent the needle from touching the bottom of the vial.

Perform a rinsing procedure in order to clean the new needle. On the

9

General tab, under Wash, click on Start. To interrupt the rinsing

procedure, click on Stop.

5.3.4 Replacing the fuses

The fuses installed in the 889 IC Sample Center are of the type

2 × 2.5 A

■■■■■■■■■■■■■■■■■■■■■■

Note

Warning

The device must be disconnected from the electricity source before the

fuses are replaced.

Make sure that the fuses to be installed correspond to the correct type

and the correct power load.

The fuses are located in the fuse holder at the rear of the device.

Note

Contact a service technician in the event of repeated problems with the

fuses.

■■■■■■■■

36

889 IC Sample Center

Page 45

■■■■■■■■■■■■■■■■■■■■■■

5 Handling and maintenance

5.4 Quality Management and validation with Metrohm

Quality Management

Metrohm offers you comprehensive support in implementing quality management measures for instruments and software. Further information on

this can be found in the brochure «Quality Management with

Metrohm» available from your local Metrohm agent.

Validation

Please contact your local Metrohm agent for support in validating instruments and software. Here you can also obtain validation documentation

to provide help for carrying out the Installation Qualification (IQ) and

the Operational Qualification (OQ). IQ and OQ are also offered as a

service by the Metrohm agents. In addition, various application bulletins

are also available on the subject, which also contain Standard Operat-

ing Procedures (SOP) for testing analytical measuring instruments for

reproducibility and correctness.

Maintenance

Electronic and mechanical functional groups in Metrohm instruments can

and should be checked as part of regular maintenance by specialist personnel from Metrohm. Please ask your local Metrohm agent regarding the

precise terms and conditions involved in concluding a corresponding

maintenance agreement.

Note

You can find information on the subjects of quality management, validation and maintenance as well as an overview of the documents currently available at www.metrohm.com/com/ under Support.

889 IC Sample Center

■■■■■■■■

37

Page 46

6.1 Error list

6 Troubleshooting

The 889 IC Sample Center is controlled by the MagIC Net™ PC software.

If a problem occurs which is directly related to the 889 IC Sample Center,

then an error number will be identified in a message window. The significance of the error numbers is listed in the following chapter.

6.1 Error list

6.1.1 Rack unit

Problem

Cause Remedy

■■■■■■■■■■■■■■■■■■■■■■

Error 294 The Home sensor of the

rack holder has not been

activated.

Error 295 The current position of the

rack holder deviates more

than 2 mm from the Home

position.

Error 296 The Home sensor has not

been deactivated.

1. Switch off sample changer.

2. Slide the rack holder carefully back and

forth and remove possible obstacles.

3. If possible, slide the rack holder backwards

right to the stop.

4. Switch on sample changer.

If the error occurs again, please call the

Metrohm Service.

1. Switch off sample changer.

2. Slide the rack holder carefully back and

forth and remove possible obstacles.

3. If possible, slide the rack holder backwards

right to the stop.

4. Switch on sample changer.

If the error occurs again, please call the

Metrohm Service.

■ If in one of the following steps the rack

holder has to be moved: first switch off the

sample changer.

■ Ensure that the transport safeguard (foam

material) has been removed from the sample chamber.

■ Remove other possible obstacles in the

area of the rack holder.

■■■■■■■■

38

If the error occurs again, please call the

Metrohm Service.

889 IC Sample Center

Page 47

■■■■■■■■■■■■■■■■■■■■■■

Problem Cause Remedy

6 Troubleshooting

Error 297 The Home sensor of the

rack holder has unexpectedly been activated.

Error 298 The rack is located in an

undefined position.

6.1.2 Needle unit

Problem

Error 303 The needle is located in an

Error 304 The Home sensor for the

Cause Remedy

undefined horizontal position.

horizontal movement of

the needle has not been

activated.

Call the Metrohm Service.

Carry out the function [Reset device] in the

Manual Control of the sample changer.

If the error occurs again, please call the

Metrohm Service.

Carry out the function [Reset device] in the

Manual Control of the sample changer.

If the error occurs again, please call the

Metrohm Service.

1. Check whether the horizontal movement

of the needle is obstructed.

2. If possible, remove possible obstacles.

If the error occurs again, please call the

Metrohm Service.

Error 306 The Home sensor for the

horizontal movement of

the needle has not been

deactivated.

Error 307 The Home sensor for the

horizontal movement of

the needle has unexpectedly been activated.

Error 308 In order to reach the hori-

zontal Home position of

the needle, the expected

number of steps has not

been carried out.

Error 312 The needle is located in an

undefined vertical position.

1. Check whether the horizontal movement

of the needle is obstructed.

2. If possible, remove possible obstacles.

If the error occurs again, please call the

Metrohm Service.

Call the Metrohm Service.

1. Check whether the horizontal movement

of the needle is obstructed.

2. If possible, remove possible obstacles.

If the error occurs again, please call the

Metrohm Service.

Carry out the function [Reset device] in the

Manual Control of the sample changer.

889 IC Sample Center

■■■■■■■■

39

Page 48

6.1 Error list

Problem Cause Remedy

If the error occurs again, please call the

Metrohm Service.

■■■■■■■■■■■■■■■■■■■■■■

Error 313 The Home sensor for the

vertical movement of the

needle has not been activated.

Error 315 The Home sensor for the

vertical movement of the

needle has not been deactivated.

Error 316 The Home sensor for the

vertical movement of the

needle has been unexpectedly activated.

Error 317 When moving the needle

unit vertically the needle

deflector has not recognized a rack, nor a wash or

waste position.

1. Check whether the vertical movement of

the needle unit is obstructed.

2. If possible, remove possible obstacles.

If the error occurs again, please call the

Metrohm Service.

1. Check whether the vertical movement of

the needle unit is obstructed.

2. If possible, remove possible obstacles.

If the error occurs again, please call the

Metrohm Service.

Call the Metrohm Service.

If the error has occurred during moving to a

rack position: ensure that there is a rack with

vials or a micro titer plate on the rack holder.

If the error occurs again, please call the

Metrohm Service.

Error 318 When moving the needle

unit vertically the needle

deflector is blocked.

Error 319 The sample needle arm is

located in an undefined

vertical position.

6.1.3 Syringe unit

Problem

Error 324 The syringe valve has not

Error 330 The Home sensor of the

Cause Remedy

reached the required port.

syringe has not been activated.

1. Check whether the movement of the needle deflector is obstructed.

2. If possible, remove possible obstacles.

If the error occurs again, please call the

Metrohm Service.

Call the Metrohm Service.

Call the Metrohm Service.

1. Check whether the flow path is kinked or

blocked in on one or more places.

2. If possible, free the flow path of blockages.

■■■■■■■■

40

889 IC Sample Center

Page 49

■■■■■■■■■■■■■■■■■■■■■■

Problem Cause Remedy

If the error occurs again, please call the

Metrohm Service.

6 Troubleshooting

Error 331 The Home sensor of the

syringe has unexpectedly

been activated.

Error 332 The required load volume

of the syringe is too high.

Error 333 The required unload vol-

ume of the syringe is too

high.

Call the Metrohm Service.

The permitted load volume is limited by the

maximum syringe volume. The load volume

currently possible depends additionally on the

current position of the syringe plunger.

■ Ensure that the required load volume of

the syringe is lower or the same as the

maximum syringe volume.

■ Check whether the required load volume

can be reached from the current position

of the syringe piston.

■ Before loading the syringe eject enough

volume first or enter a lower load volume.

The permitted unload volume is limited by the

maximum syringe volume. The unload volume

currently possible depends additionally on the

current position of the syringe plunger.

Error 334 The syringe plunger is loca-

ted in an undefined position.

Error 335 The spindle of the syringe

cannot be rotated correctly.

■ Ensure that the required unload volume of

the syringe is lower or the same as the

maximum syringe volume.

■ Check whether the required unload volume

is possible assuming the current position of

the syringe piston.

■ Before unloading the syringe aspirate

enough volume first or enter a lower

unload volume.

Carry out the function [Reset device] in the

Manual Control of the sample changer.

If the error occurs again, please call the

Metrohm Service.

1. Check whether the flow path is kinked or

blocked in on one or more places.

2. If possible, free the flow path of blockages.

If the error occurs again, please call the

Metrohm Service.

889 IC Sample Center

■■■■■■■■

41

Page 50

6.1 Error list

6.1.4 Injection valve unit

Problem Cause Remedy

■■■■■■■■■■■■■■■■■■■■■■

Error 340 The injection valve has not

reached the required port.

Error 341 The consumption warning

limit of the injection valve

has been reached.

Error 342 The sensor of the injection

valve has provided an

unexpected value.

6.1.5 Cooling unit

Problem

Error 347 When switching on the

Cause Remedy

cooling a temperature of

over 48 °C has been measured.

6.1.6 Electronics

Problem

Error 280, 282, 283,

284

Cause Remedy

An electronic error has

occurred in the EEPROM.

Call the Metrohm Service.

Call the Metrohm Service.

Call the Metrohm Service.

Have a look at the technical specifications in

the device manual of the sample changer and

ensure that the range of the operating temperature has not been exceeded.

1. Switch off sample changer.

2. Wait a few seconds.

3. Switch on sample changer.

Error 290 When initializing the sam-

ple changer at least one

critical malfunction has

been found. No injections

can be carried out.

If the error occurs again, please call the

Metrohm Service.

1. Exit MagIC Net.

2. Switch off sample changer.

3. Ensure that the cable between the sample

changer and the PC is connected correctly.

4. Switch on sample changer.

5. Start MagIC Net.

If the error occurs again, please call the

Metrohm Service.

■■■■■■■■

42

889 IC Sample Center

Page 51

■■■■■■■■■■■■■■■■■■■■■■

6.2 Analytical problems

Analytical problems such as poor reproducibility and carry-over can occur

in any chromatography system. The cause is usually difficult to find. First

of all, you should attempt to determine whether the problem is caused by

the Autosampler or another component of the system.

Please take into consideration the fact that analytical problems can also be

caused by external influences such as temperature or light-sensitive sample. Make sure that the application was able to be performed previously

without problems and that no changes have been made to the system.

Some causes and possible solutions for analytical problems are listed

below. Contact your service point for additional help.

6.2.1 Autosampler

Problem

Cause Remedy

6 Troubleshooting

The reproducibility

does not correspond

to the specifications.

A peak which is too

high occurs with a

blank.

There is air in the flow

path.

The syringe is leaking. ■ If the leakage occurs on the upper end of

The syringe valve is leaking. Check the valve or replace it.

The rotor seal is worn out. Replace the seal and check the stator.

There is a dead volume in

the tubing connections.

There is air in the syringe. Rinse the syringe (see Chapter 3.6, page 18).

The sample properties and

the hardware do not correspond.

Carry out a standard washing procedure (in

MagIC Net™ under Manual control).

the syringe, check the correct assembly of

the syringe.

■ If the leakage occurs on the lower end of

the syringe, replace the piston tip or the

entire syringe.

Reinstall the connections with new pressure

screws.

Check the hardware:

■ Needle — Carry out the standard washing

procedure (in order to rinse the needle on

the in- and the outside).

■ Valve — Replace rotor by another type.

■ Capillary connections — Replace capillary

between Autosampler and column or use

another washing solution.

889 IC Sample Center

■■■■■■■■

43

Page 52

6.2 Analytical problems

Problem Cause Remedy

The blank is contaminated. ■ Use a new blank.

■ Do not fill the sample vessel completely in

order to avoid contamination of the air

needle.

The cause is not clear. Examine the problem more closely by varying

the washing solution.

There is no injection. The flow path is blocked. 1. Loosen the needle from the valve.

2. Carry out a standard washing procedure.

3. If washing solution is flowing out of the

injection port, check the needle. If no

washing solution is flowing out of the

injection port, remove the buffer tubing

from the valve.

4. Carry out a standard washing procedure.

5. If washing solution is flowing out of the

open end, check the rotor seal. If not, then

check the entire flow path to determine

whether the connections have been tightened too firmly.

If the problem persists, undo the buffer

tubing from the syringe valve.

6. Carry out a standard washing procedure.

7. If washing solution is flowing out of the

syringe valve, check the buffer tubing. If

not, check the syringe valve.

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

44

The injection valve is leaking.

1. Remove the needle connection and the

buffer tubing.

2. Connect the injection port 1 to a high pressure pump.

3. Seal port 6.

4. Start the pump with a low flow rate.

5. Check port 3 and 4 for leakage.

6. If the ports 3 and 4 are leaking, check the

rotor sealing. If not, manually test the valve

again.

Warning

Observe the maximum pressure of 350 bar in order to avoid any valve

leakage.

889 IC Sample Center

Page 53

■■■■■■■■■■■■■■■■■■■■■■

7 Appendix

7.1 Samples and sample vials

Note the following points:

■ The following types of racks or micro titer plates are supported:

– 12 samples

– 48 samples

– 96 samples (low form, low)

– 96 samples (high form, high)

– 384 samples (low form, low)

■ Fill the standard vials with a pipette in order to ensure that any air bub-

bles that may appear can escape during filling.

■ Do not fill sample vessels up to the edge. Doing so would cause the

sample liquid to be pressed into the air needle. This could cause a

cross-contamination of the samples and a contamination of the needle.

■ It is important that the sealing caps and septa be air-tight in order to

prevent the formation of air bubbles and the evaporation of volatile

samples.

We recommend the following types of seals:

– For standard micro titer plates (low) sealing tape

– For deep well plates (high): pierceable sealing mats (pre-slit or

made of silicone) or sealing tape

– For vials: thin standard septa; no vials with hard caps which are

not designed for being punctured by an injection needle.

■ If you use unsealed vials or micro titer plates, the precision of the injec-

tion will not be in accordance with the specifications.

7 Appendix

7.2 I/O interface

The manufacturer assumes no liability for damage which is either

directly or indirectly caused by connections between the 889 IC Sample

Center and devices which do not meet the relevant safety standards.

889 IC Sample Center

Caution

■■■■■■■■

45

Page 54

7.2 I/O interface

1

5

6

9

5

1

9

6

7.2.1 Properties of the I/O interface

When the injection valve switches from LOAD to INJECT, an Inject

Marker signal (Contact closure) will be generated at the output lines of

the I/O interface for 0.1…2.0 s.

■■■■■■■■■■■■■■■■■■■■■■

■ V

■ I

= 28 V

max

= 0.25 A

max

DC

/V

AC

7.2.2 Pin assignment of the remote interface

Figure 15 Pin assignment of I/O socket and plug

Table 1 Inputs and outputs of the I/O interface

Pin No. Assigment

1 Output - Common (COM)

2 Output - Normally open (NO)

3 Input 1 (TTL)

4 Input 2 (TTL)

5 GND

6 Output - Normally close (NC)

7 +5 volts

8 GND

9 GND

■■■■■■■■

46

889 IC Sample Center

Page 55

■■■■■■■■■■■■■■■■■■■■■■

8 Technical specifications

8.1 General

8 Technical specifications

Noise pressure

level

Safety and EMC

compatibility

Altitude up to 2000 m above sea level.

Maximum weight

load

Viscosity range 0.1…5 cP

Leq < 70 dB

According to CE guidelines, CSA (UL) certified

65 kg

8.2 Sampling

Sample capacity

Vial/plate dimensions (including

cover)

Sample loop volume

2 micro titer plates according to the SBS standard, with 96 cavities

(high/low shape) and 384 cavities (low shape), 48 vial- or 12 vial-racks.

Maximum plate/vial height: 47 mm (including septum or cap)

1…5000 µL programmable, 10 mL sample loop optional

Dispensing syringe 500 µL standard

Vial recognition Sensor for missing vials

Headspace pressure

Switching time of

the injection valve

Needle puncture

accuracy

Washing solution Integrated container for the washing solution

Moistened materials in the flow

path

Injection cycle

time

889 IC Sample Center

Built-in compressor, only for vials with septum

electrical < 100 ms

± 0.6 mm

PTFE, TEFZEL, PEEK

< 60 s, in all injection modes for 1 injection≤ 100 µL including 300 µL

wash cycle

■■■■■■■■

47

Page 56

8.3 Analytical characteristics

■■■■■■■■■■■■■■■■■■■■■■

8.3 Analytical characteristics

Injection modes Full-Loop, Partial Loopfill, Pickup mode, PASA™ (pressure-assisted

sample aspiration)

Reproducibility Relative standard deviation ≤ 0.3% for the Full-Loop injection.

Relative standard deviation ≤ 0.5% for the Partial Loopfill injection,

injection volume > 10 µL.

Relative standard deviation ≤ 1.0% for the Pickup injection, injection

volume > 10 µL.

Memory effect < 0.05 % with programmable needle rinsing

8.4 Programming

Injection modes

Injection volume 1…5000 µL (with 1 µL increment), depending on the system settings.

Max. injection volume

Full-Loop, Partial Loopfill, Pickup Mode

■ Full Loop = Sample loop volume

■ Partial Loopfill = 0.5 x Sample loop volume

■ Pickup = (Sample loop volume - 3 x Needle volume)/2

8.5 Interfaces

Output signal

Data interface USB connector, type B (for the connection to a PC)

1 programmable relay outlet as injection mark

8.6 Options (pre-installed)

Cooling for the

sample rack

Built-in Peltier element

Range: 4 °C to 3 °C below ambient temperature

Air temperature in the sample vessel: 4 °C ±2 °C (at the temperature

sensor)

(Temperature at 80% relative humidity and ambient temperature of

25°C)

■■■■■■■■

48

889 IC Sample Center

Page 57

■■■■■■■■■■■■■■■■■■■■■■

8.7 Mains connection

Voltage 100…240 V ±10 %

Frequency 50 / 60 Hz

8 Technical specifications

Power consump-

200 VA

tion

Fuse 2.5 ATH

8.8 Safety specifications

Design and testing

Safety instructions This document contains safety instructions which have to be followed

According to EN/IEC 61010-1, UL 61010-1, CAN/CSA-C22.2 No.

61010-1, protection class I.

by the user in order to ensure safe operation of the instrument.

8.9 Electromagnetic compatibility (EMC)

Emission

Standards fulfilled:

■ EN/IEC 61326-1

■ EN/IEC 61000-6-3

■ FCC 47 CFR Part 15

■ EN/IEC 61000-3-2

■ EN/IEC 61000-3-3

Immunity Standards fulfilled:

■ EN/IEC 61326-1

■ EN/IEC 61000-6-2

■ EN/IEC 61000-4-2

■ EN/IEC 61000-4-3

■ EN/IEC 61000-4-4

■ EN/IEC 61000-4-5

■ EN/IEC 61000-4-6

■ EN/IEC 61000-4-8

■ EN/IEC 61000-4-11

889 IC Sample Center

■■■■■■■■

49

Page 58

8.10 Ambient temperature

8.10 Ambient temperature

■■■■■■■■■■■■■■■■■■■■■■

Nominal function

range

Humidity 20…80 % relative humidity

Storage -25…+60 °C

+10…+40 °C

8.11 Dimensions

Width

Height 360 mm

Depth

1.889.0010 510 mm

1.889.0020 575 mm

Weight

1.889.0010 19 kg

1.889.0020 21 kg

Material of housing

Cover Steel

Base Steel

Side panels PC/ABS (UL 94 V0)

Front PC/ABS (UL 94 V0)

Panes PMMA

300 mm

■■■■■■■■

50

889 IC Sample Center

Page 59

■■■■■■■■■■■■■■■■■■■■■■

9 Conformity and warranty

9.1 Declaration of Conformity

This is to certify the conformity to the standard specifications for electrical

appliances and accessories, as well as to the standard specifications for

security and to system validation issued by the manufacturing company.

9 Conformity and warranty

Name of commodity

Electromagnetic

compatibility

Safety specifications EN/IEC 61010-1: 2001, UL 61010-1: 2004,

889 IC Sample Center

Autosampler for usage in ion chromatography systems.

This instrument has been built and has undergone final type testing

according to the standards:

Emission: EN/IEC 61326-1: 2006, EN/IEC 61000-6-3: 2006,

EN 55011: 2007, FCC 47 CFR Part 15,

EN/IEC 61000-3-2: 2006,

EN/IEC 61000-3-3: 2005

Immunity: EN/IEC 61326-1: 2006, EN/IEC 61000-6-2: 2005,

EN/IEC 61000-4-2: 2001,

EN/IEC 61000-4-3: 2006,

EN/IEC 61000-4-4: 2004,

EN/IEC 61000-4-5: 2001,

EN/IEC 61000-4-6: 2001,

EN/IEC 61000-4-8: 2001,

EN/IEC 61000-4-11: 2004

CAN/CSA-C22.2 No. 61010-1: 2004, protection class I

This instrument meets the requirements of the CE mark as contained in

the EU directives 2006/95/EC (LVD), 2004/108/EC (EMC). It fulfils the following specifications:

EN 61326-1 Electrical equipment for measurement, control

and laboratory use – EMC requirements

EN 61010-1 Safety requirements for electrical equipment for

measurement, control and laboratory use

Manufacturer Metrohm Ltd., CH-9101 Herisau/Switzerland

889 IC Sample Center

■■■■■■■■

51

Page 60

9.2 Warranty (guarantee)

■■■■■■■■■■■■■■■■■■■■■■

Metrohm Ltd. is holder of the SQS certificate ISO 9001:2000 Quality management system for development, production and sales of instruments

and accessories for ion analysis.

Herisau, 10 Mai, 2009

D. Strohm

Vice President, Head of R&D

9.2 Warranty (guarantee)

Metrohm guarantees that the deliveries and services it provides are free

from material, design or manufacturing errors. The warranty period is 36

months from the day of delivery; for day and night operation it is 18

months. The warranty remains valid on condition that the service is provided by an authorized Metrohm service organization.

Glass breakage is excluded from the warranty for electrodes and other

glassware. The warranty for the accuracy corresponds to the technical

specifications given in this manual. For components from third parties that

make up a considerable part of our instrument, the manufacturer's warranty provisions apply. Warranty claims cannot be pursued if the Customer

has not complied with the obligations to make payment on time.

During the warranty period Metrohm undertakes, at its own choice, to

either repair at its own premises, free of charge, any instruments that can

be shown to be faulty or to replace them. Transport costs are to the Customer's account.

A. Dellenbach

Head of Quality Management

■■■■■■■■

52

Faults arising from circumstances that are not the responsibility of

Metrohm, such as improper storage or improper use, etc. are expressly

excluded from the warranty.

889 IC Sample Center

Page 61

■■■■■■■■■■■■■■■■■■■■■■

9.3 Quality Management Principles

Metrohm Ltd. holds the ISO 9001:2000 Certificate, registration number

10872-02, issued by SQS (Swiss Association for Quality and Management

Systems). Internal and external audits are carried out periodically to assure

that the standards defined by Metrohm’s QM Manual are maintained.

The steps involved in the design, manufacture and servicing of instruments

are fully documented and the resulting reports are archived for ten years.

The development of software for PCs and instruments is also duly documented and the documents and source codes are archived. Both remain

the possession of Metrohm. A non-disclosure agreement may be asked to

be provided by those requiring access to them.

The implementation of the ISO 9001:2000 quality management system is

described in Metrohm’s QM Manual, which comprises detailed instructions on the following fields of activity:

Instrument development

The organization of the instrument design, its planning and the intermediate controls are fully documented and traceable. Laboratory testing

accompanies all phases of instrument development.

9 Conformity and warranty

Software development

Software development occurs in terms of the software life cycle. Tests are

performed to detect programming errors and to assess the program’s

functionality in a laboratory environment.

Components

All components used in the Metrohm instruments have to satisfy the quality standards that are defined and implemented for our products. Suppliers of components are audited by Metrohm as the need arises.

Manufacture

The measures put into practice in the production of our instruments guarantee a constant quality standard. Production planning and manufacturing

procedures, maintenance of production means and testing of components, intermediate and finished products are prescribed.

Customer support and service

Customer support involves all phases of instrument acquisition and use by

the customer, i.e. consulting to define the adequate equipment for the

analytical problem at hand, delivery of the equipment, user manuals, training, after-sales service and processing of customer complaints. The

Metrohm service organization is equipped to support customers in implementing standards such as GLP, GMP, ISO 900X, in performing Opera-

889 IC Sample Center

■■■■■■■■

53

Page 62

9.3 Quality Management Principles

■■■■■■■■■■■■■■■■■■■■■■

tional Qualification and Performance Verification of the system components or in carrying out the System Validation for the quantitative determination of a substance in a given matrix.

■■■■■■■■

54

889 IC Sample Center

Page 63

■■■■■■■■■■■■■■■■■■■■■■

10 Accessories

Note

Subject to change without notice.

10.1 Scope of delivery 2.889.0010

10 Accessories

Qty.

Order no. Description

1 1.889.0010 IC Sample Center