Page 1

CH-9101 Herisau/Switzerland

E-Mail info@metrohm.com

Internet www.metrohm.com

787 KF Titrino

Program version 5.787.0010

Instructions for Use

8.787.1003 03.2002 / pkl

Page 2

Page 3

Table of contens

Table of contents

1 Introduction ..........................................................................................................1

1.1 Instrument description...........................................................................................1

1.2 Controls and parts................................................................................................. 2

2

Manual operation..................................................................................................6

2.1 Keypad ..................................................................................................................6

2.2 Principle of data input............................................................................................ 7

2.3 Tutorial ................................................................................................................... 8

2.3.1 Entering data, setting the dialog language....................................................8

2.3.2 Titer determination .......................................................................................10

2.3.3 Karl Fischer titration .....................................................................................15

2.3.4 Drift...............................................................................................................16

2.4 Selection of the mode, key <MODE> ................................................................ 18

2.5 Configuration, key <CONFIG>...........................................................................19

2.6 Parameters, key <PARAM> ............................................................................... 22

2.6.1 Parameters for SET ...................................................................................... 22

2.8 Result calculations............................................................................................... 31

2.9 Drift display, key <DRIFT> ................................................................................. 36

2.10 Data output ...................................................................................................... 37

3

Error messages, Troubleshooting.....................................................................39

3.1 Error and special messages................................................................................ 39

3.2 What can you do if the data transfer does not work?.......................................... 41

3.3 Diagnosis............................................................................................................. 42

3.3.1 General......................................................................................................... 42

3.3.2 Procedure..................................................................................................... 42

3.3.3 Equipment required: ....................................................................................43

3.3.4 Diagnosis steps ...........................................................................................43

3.4 Initialise and test RAM ......................................................................................... 52

3.5 Releasing a locked spindle with inserted Exchange Unit.................................... 53

4

Preparations .......................................................................................................53

4.1 Setting up and connecting the instruments ........................................................53

4.1.1 Titrino with Titration Stand or Stirrer .............................................................53

4.1.2 Connection of a printer ................................................................................54

4.1.3 Connection of a balance..............................................................................55

4.1.4 Connection of a KF Oven............................................................................. 57

4.1.5 Connection of the 774 Oven Sample Processor.......................................... 57

4.1.6 Connection of a Sample Changer ...............................................................58

4.1.7 Connection of a recorder ............................................................................. 59

4.1.8 Connection of a computer ........................................................................... 60

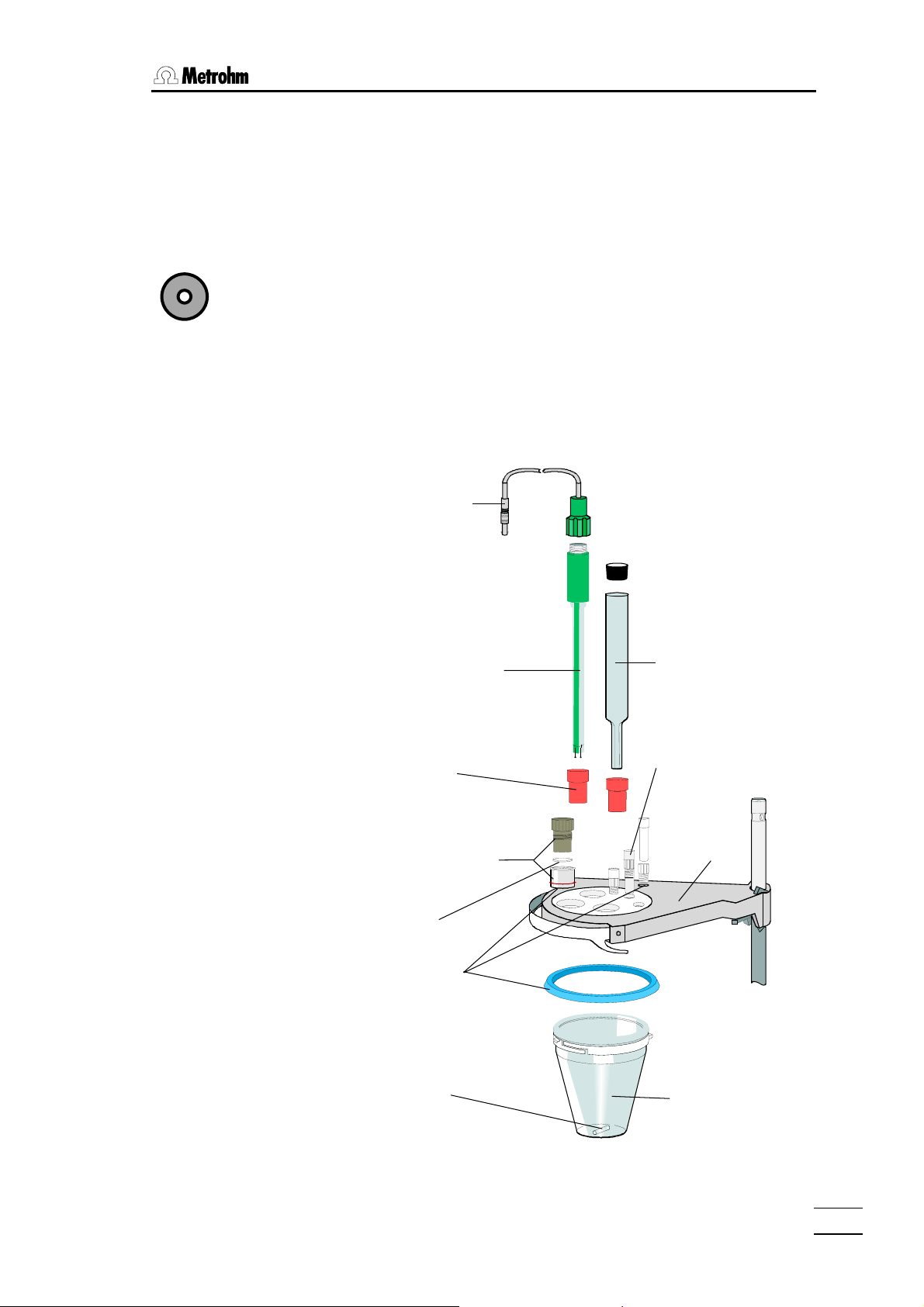

4.2 Connection of electrodes, preparing titration vessel...........................................61

5

Appendix.............................................................................................................63

5.1 Technical specifications ......................................................................................63

5.2 Pin assignment of the "Remote" socket............................................................... 65

5.2.1 Lines of the "Remote" socket during the titration ......................................... 67

5.3 RS232 interface ...................................................................................................68

787 KF Titrino

Page 4

Table of contents

5.4 Validation / GLP................................................................................................... 69

5.5 Warranty and conformity ..................................................................................... 70

5.5.1 Warranty....................................................................................................... 70

5.5.2 EU Declaration of conformity....................................................................... 71

5.5.3 Certificate of Conformity and System Validation ......................................... 72

5.6 Scope of delivery and ordering designations ..................................................... 73

Index...........................................................................................................................77

787 KF Titrino

Page 5

1.1 Instrument description

1 Introduction

1.1 Instrument description

The 787 KF Titrino is a fast and precise titrator for the water determination according to

Karl Fischer.

With the Metrodata VESUV Software determination data can be saved on a PC.

787 KF Titrino

1

Page 6

1.2 Controls and parts

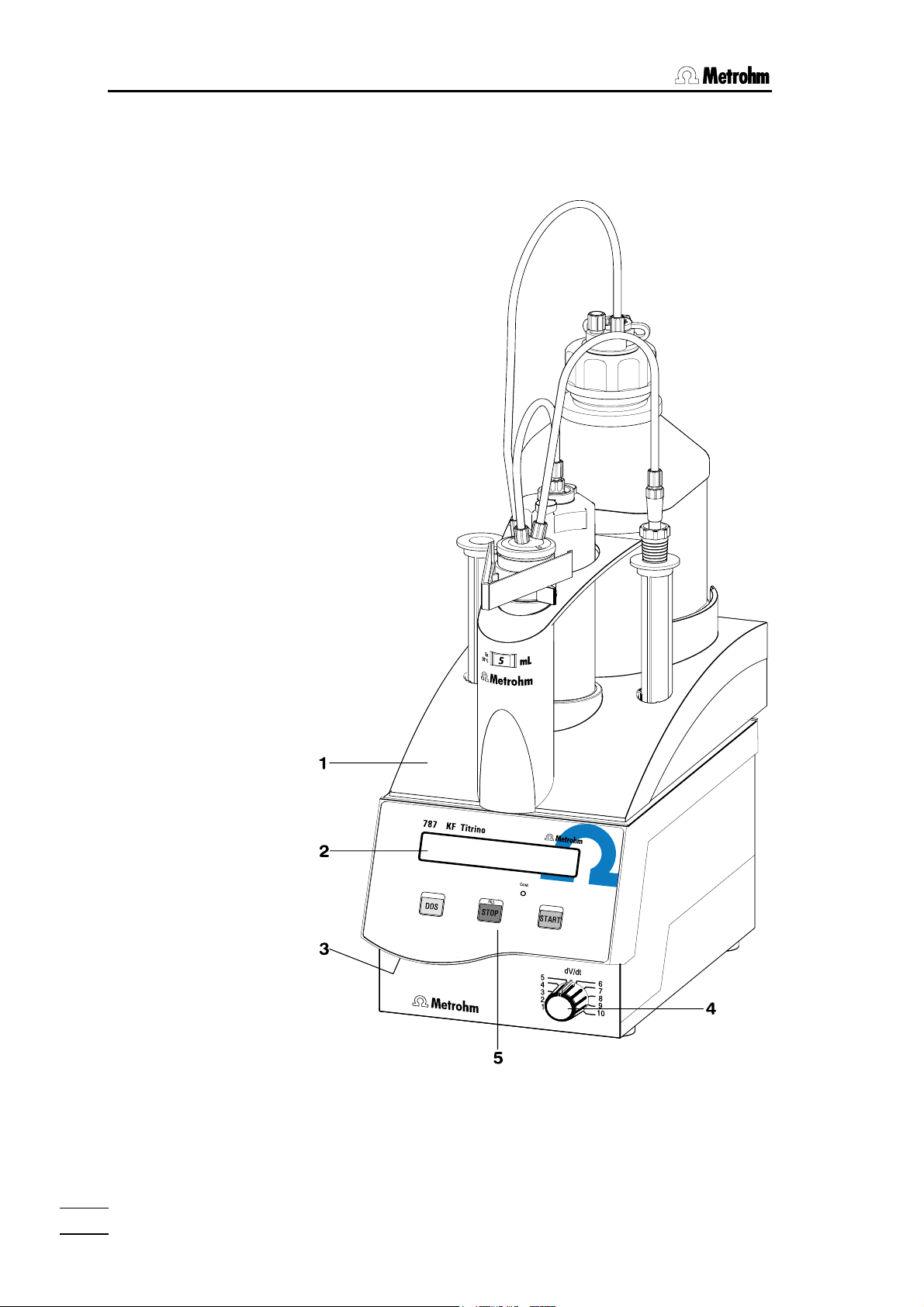

1.2 Controls and parts

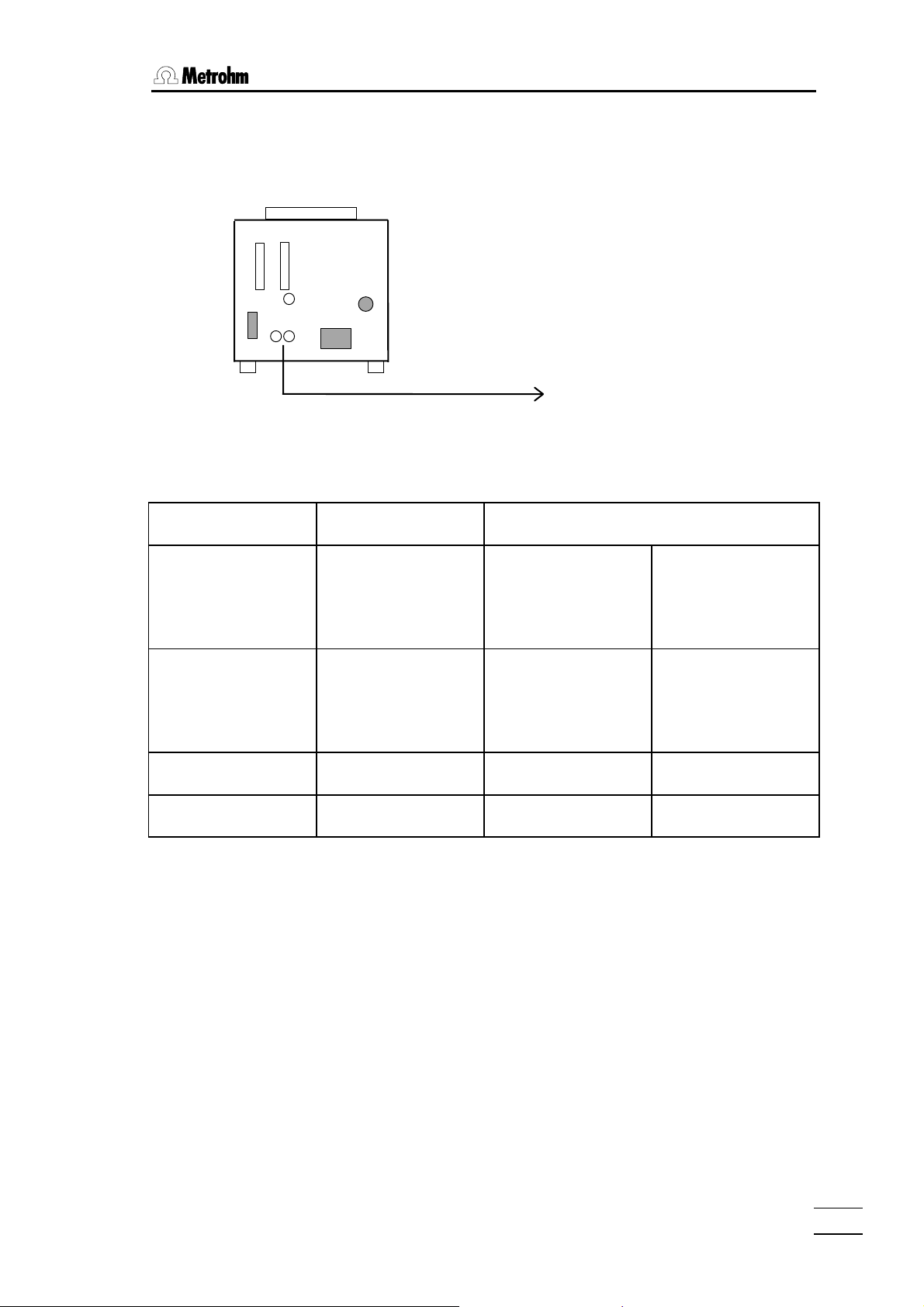

Front view of instrument:

787 KF Titrino

2

Page 7

1.2 Controls and parts

1 Exchange Unit

2 Display

3 Setting of display contrast

4 Controls the dosing rate during manual dosing with <DOS> and subse-

quent filling

5 Control keys and indicator lamps on the Titrino

Key <DOS> Dosing key. Dispensing is performed as long as <DOS> is being

pressed. Used e.g. to prepare the Exchange Unit. The dispensing

rate can be set with potentiometer (4).

Key <STOP/FILL> - Stops procedures, e.g. titrations, conditioning.

- Filling after manual dosing with <DOS>.

Key <START> Starts procedures, e.g. titrations, conditioning.

Identical with key <START> of the separate keypad.

Indicator lamp:

"Cond." Lamp flashes during conditioning. Lamp is on when the titration

cell is conditioned.

787 KF Titrino

3

Page 8

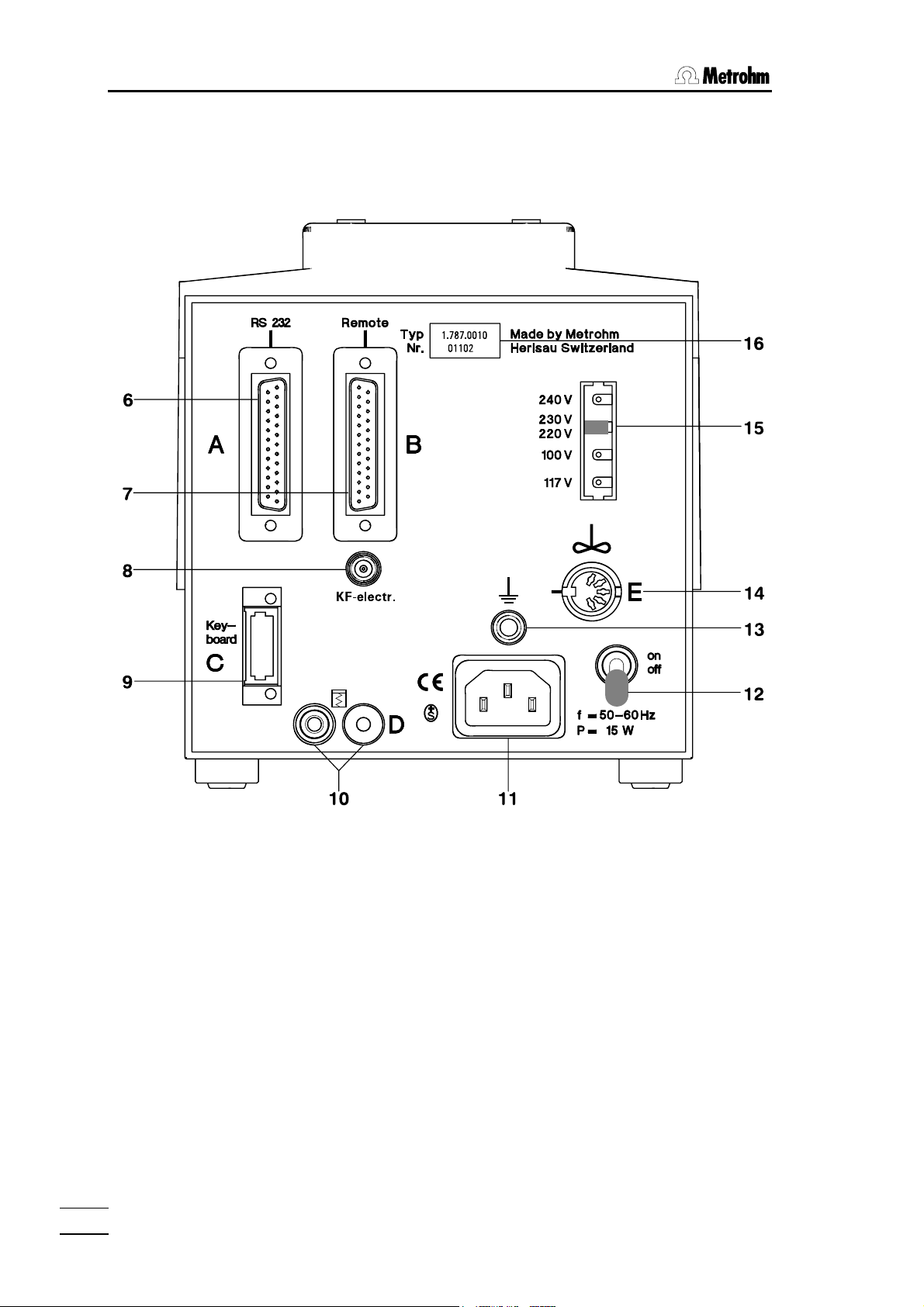

1.2 Controls and parts

Rear view of instrument:

787 KF Titrino

4

Page 9

1.2 Controls and parts

6 RS232 interface

for the connection of printer, balance or a computer

7 Remote lines

(input/output)

for the connection of Sample Changers, robots etc.

8 Connection for the KF electrode

9 Connection for separate keypad

10 Analog output for the connection of a recorder

11 Connection for power cable

With power supplies where the voltage is subject to severe HF disturbances, the Titrino should be operated via an additional power filter, e.g. Metrohm 615 model.

12 Mains switch

13 Earthing socket

14 Connection for Ti Stand or stirrer

703 Ti Stand or 728 Magnetic Stirrer

Supply voltage: 9 VDC (I ≤ 200 mA)

15 Display of the set mains voltage

Before switching on for the first time, check that the set mains voltage matches the

voltage of your power supply. If this is not the case, disconnect mains cable and

change voltage.

16 Rating plate

with fabrication, series and instrument number

787 KF Titrino

5

Page 10

2.1. Keypad

2 Manual operation

2.1 Keypad

CONFIG Configuration, see page 19.

PARAM Parameters, see page 22.

CALC DATA Result calculation, see page 31.

These keys are opening the corresponding menus.

For the principle of data input see page 7.

DRIFT ON/OFF switching of the drift display,

see page 36.

UNIT Unit of result and sample size, see

page 34.

SELECT Selection of special values (dialog

marked with ":")

MODE Mode selection, see page 18.

PRINT Printing of reports, see page 37.

CLEAR Clears values, set special values.

ENTER Stores values.

STOP Stops methods.

QUIT Quits inquiries, waiting times, printing.

START Starts methods.

787 KF Titrino

6

Page 11

2.2 Principle of data input

2.2 Principle of data input

KFT ********

KFT ********

>KF device settings

KFT ********

>peripheral units

KFT ********

send to: IBM

KFT ********

>auxiliaries

KFT ********

• The first line of the display always shows the active

mode (in this case "KFT") and the state of the Titrino.

"********" means the Titrinos is in its standby state.

• The keys <CONFIG>, <PARAM> and <CALC

DATA> are opening the corresponding menus.

• Pressing one of this keys shows the first group of

inquiries of the corresponding menu in the second

line of the display.

Example key <CONFIG>:

You opened the configuration menu, the second line

of the display shows the first group of inquiries of

this menu ">KF device settings".

• By pressing <CONFIG> repeatedly you can move

to the other titles of this menu. With pressing

<CONFIG> 2 times you go to the group of inquiries

"peripheral units".

• If a dialog text is marked with ">", it contains a

group of inquiries. You branch into this group by

pressing <ENTER>.

• Example first inquiry of the group "peripheral units":

Now you opened the first inquiry of the group peripheral units in the configuration menu and you can

change the setting.

If a dialog text of an inquiry is marked with ":", you

can select a value with the key <SELECT>.

• A value is stored with <ENTER> and the cursor

moves to the next inquiry.

• Repeated pressing of <ENTER> moves you

through the inquiries of the group ">peripheral

units“, after the last inquiry of this group you leave

this group and return to the level above.

The next group of the menu "configuration“ appears:

">auxiliaries“

• With key <QUIT> you leave an inquiry or a group of

inquiries, it always

• In this example you leave the menu "configuration"

by pressing <QUIT> and return to the standby

state with the display of the titration mode.

moves you one level up.

787 KF Titrino

7

Page 12

2.3. Tutorial

2.3 Tutorial

This short operating course teaches you to work quick and efficient with the 787 KF Titrino, by means of the most important applications.

Set up your Titrino and connect the peripheral devices needed, see chapter 4.

2.3.1 Entering data, setting the dialog language

We can thus make a start and first take a look at the fundamentals of the entry of data.

We change the dialog language.

KFT ********

<CONFIG>

KFT ********

>KF device settings

3 × <CONFIG>

KFT ********

>auxilliaries

<ENTER>

KFT ********

dialog: english

<SELECT>

KFT ********

dialog: español

<ENTER>

KFT ********

fecha 2002-03-27

• Switch on the Titrino. It is now in the standby state, it

shows you the active mode.

• Press the key <CONFIG>, the display shows:

This is the title of the group "KF device settings".

This group contains various inquiries for the KF titraton.

• Press <CONFIG> 3 times. You see the titles of the

other groups of inquiries in the configuration menu.

The display shows

This "auxiliaries" group contains the inquiry for the

dialog language.

• Pressing the <ENTER> key takes you to the inquiries of the group "auxiliaries". Note the ">" sign. All titles of inquiry groups are prefixed by this sign.

This is the first inquiry of the "auxiliaries" group: the

selection of the dialog language.

• You select the various dialog languages with the

<SELECT> key. Press <SELECT> repeatedly until

"español" appears in the display.

Note the sign ":". It appears if the values can be selected with the key <SELECT>.

• Accept the new "value" with <ENTER>.

The next inquiry "fecha" (date) of the group "ajustes

varios" (auxiliaries) is shown.

You can open this inquiry by pressing <ENTER>

too and go through all the inquiries of this group this

787 KF Titrino

8

Page 13

2.3 Tutorial

<QUIT>

KFT ********

>ajustes varios

<QUIT>

KFT ********

way.

Because this inquiry follows no colon ":" the value

can't be selected by <SELECT>, the date "fecha"

has to be entered with the numeric keys.

• Exit the inquiries with <QUIT>. You are one level

higher in the "configuration" menu showing the title

"ajustes varios" (auxiliaries).

• Press <QUIT> once again to exit the "configuration"

menu and return to the standby state.

All the dialog texts will now be displayed in Spanish.

If you prefer English as the displayed dialog language, proceed as before and select "English".

787 KF Titrino

9

Page 14

2.3. Tutorial

2.3.2 Titer determination

Set up your titration vessel, see page 61f and plug your KF electrode into the measuring

input ('KF electr.').

Put a Exchange Unit with KF reagent on the Titrino and rinse the tubing and the buret tip

with <DOS>. Fill the buret again with <STOP/FILL>.

Fill your titration vessel with solvent, put a stirrer bar in the titration vessel and switch on

the stirrer.

For the titer determination you need water and a syringe that allows the exact dispensing

of 30 µL.

Selection of the mode

<MODE>

KFT ********

TITER with H2O or Std.

<ENTER>

TITER ********

Briefly check a few settings under the <PARAM> key:

2 × <PARAM>

TITER ********

>preselections

<ENTER>

TITER ********

conditioning: ON

<ENTER>

TITER ********

req.ident: OFF

<ENTER>

TITER ********

req.smpl size: ON

<ENTER>

TITER ********

report: OFF

• Press <MODE> repeatedly until "TITER with H2O or

std." appears in the display.

• Confirm "TITER with H2O or std." with <ENTER>.

The mode "TITER" is active and instrument is in its

standby state

• Press <PARAM> twice so that the title "preselections" appears in the display:

View the individual inquiries of this group with

<ENTER>. The following values should be set:

Automatic drying of the titration cell before and between titrations: "ON".

Request of the sample identification after the titration

start: "OFF".

Request of the sample size after the titration start:

"ON".

If no printer is attached, the report printout after the

titration must be switched off.

787 KF Titrino

10

Page 15

2.3 Tutorial

or

TITER ********

report: short

With a connected printer, the short report, for example,

can be selected.

<ENTER>

If you have to alter one of these settings, you can do this with the <SELECT> key.

Your titration vessel already contains solvent. Start with <START>. First the titrations cell

is dried. The display shows

TITER wait

as long as the vessel is still wet and the green "Cond." lamp flashes. As soon as the titration vessel is dry and hence ready for operation, this is shown by

TITER conditioning

an the "Cond."-LED lights continuously.

To determine the titer we shall perform several titrations and store the mean value as

"titer".

Calculating the mean value and standard deviation

Check that the mean value calculation is switched on:

2 × <CALC DATA>

TITER ********

>statistics

<ENTER>

TITER ********

mean: n= 20

2 × <QUIT>

• Press <CALC DATA> twice until the display shows

the title of the group is "statistics". Press <ENTER>.

Number of single determinations for the calculation of

the mean value. Since the mean value is recalculated

after every determination, the maximum value can remain set at 20. The mean calculation is terminated

when the operating mode is changed.

• Exit the inquiry.

787 KF Titrino

11

Page 16

2.3. Tutorial

Determination

<START>

KFR volume 0.000 ml

smpl size 1.0 g

0.03

<ENTER>

KFR volume ↑ 1.426 ml

#======

KFR volume 5.632 ml

titer 5.3267 mg/ml

• Now prepare the sample, e.g. 30 µL water and start

the titration with <START>. The display shows

• Inject the sample and enter the weight in g:

If you have connected a balance, you can also backweigh the syringe.

The titration now runs.

The first line of the display shows the current volume. In

addition, a "↑" appears when dispensing is being performed.

A "control bar" appears on the second line and shows

the control deviation of the current measured value

from the set endpoint.

On completion of the titration, the first line shows the

dispensed volume and the second the calculated titer.

If you have connected a printer, a report is also printed:

date 2002-03-27 time 13:55:10 3

smpl size 0.03 g

titer 5.3267 mg/ml

============

Perform another determination.

On completion of the titration, the mean value of the two determinations is calculated. The

report on the printer has the following appearance:

date 2002-03-27 time 13:55:10 3

smpl size 0.03 g

titer 5.3686 mg/ml

mean (2) 5.3477 mg/ml

+/-s 0.02973 mg/ml

s(rel) 0.56 %

============

787 KF Titrino

12

Page 17

2.3 Tutorial

Viewing the statistics data

If you have not connected a printer, you can view the statistics data on the display with

<SELECT>.

KFR volume 5.676 ml

titer 5.3686 mg/ml

<SELECT>

KFR volume 5.676 ml

mean (2) 5.3477 mg/ml

<SELECT>

KFR volume 5.676 ml

+/-s 0.02973 mg/ml

<SELECT>

KFR volume 5.676 ml

s(rel) 0.56 %

<SELECT>

• From the result display "titer", switch to the display of

the mean value with <SELECT>.

Mean value of 2 determinations.

• Press <SELECT> again and the standard deviation

is shown.

Absolute standard deviation.

• Pressing <SELECT> once more leads to the

relative standard deviation.

• <SELECT> returns you to the result display.

Repeat the titer determination once more.

With a connected printer you may want a printout of the single results that are used for the

statistics calculation: press the key sequence <PRINT><1><ENTER>.

Let us assume that you have discovered that one of the values is an "outlier" and you

would like to delete it.

Deleting a result in the mean value calculation

2 × <CALC DATA>

KFR volume 5.676 ml

>statistics

2× <ENTER>

KFR volume 5.676 ml

res.tab: original

<SELECT>

KFR volume 5.676 ml

res.tab: delete n

<ENTER>

787 KF Titrino

In our example, the deviation of the second result is

excessive. We thus wish to delete it:

• Press <CALC DATA> twice. The display shows:

• Open with <ENTER> the inquiry of the result table

"res.tab:"

• Press <SELECT> to display "delete n". This means

that you wish to delete a single result with the index

n in the result table.

13

Page 18

2.3. Tutorial

KFR volume 5.676 ml

delete n= 1

<2>

<ENTER>

2 × <QUIT>

• Enter the index of the result you wish to delete, in

our case the second:

• Exit the inquiry with <QUIT>.

Mean value and standard deviation are recalculated

and can be viewed in the display.

If you have connected a printer, a new report is printed

out.

Following this titer determination, you now decide to perform Karl Fischer determinations.

The titer just determined will be automatically used here.

787 KF Titrino

14

Page 19

2.3 Tutorial

2.3.3 Karl Fischer titration

<MODE>

KFR volume 5.676 ml

KFT

<ENTER>

KFT conditioning

<CALC DATA>

3 × <ENTER>

KFT conditioning

titer 5.3326 mg/ml

2 × <QUIT>

Now prepare your sample and titrate it.

• Select the "KFT" mode: Press <MODE> repeatedly

until the display shows

• Accept this mode with <ENTER>

The instrument is in the KFT mode and the titration

cell is ready for operation.

• Check briefly that the titer just determined has also

been adopted: Press <CALC DATA>, branch to the

group "calculation" with <ENTER> and then press

<ENTER> two times more to display the following

inquiry.

• Exit the inquiry by pressing <QUIT> twice.

Result calculation and unit of the result

The result is calculated by the following formula:

=

)content(water

<UNIT>

KFT volume 3.459 ml

result unit: %

2 × <SELECT>

<ENTER>

KFT volume 3.459 ml

result unit: mg/ml;3

<1>

<ENTER>

• Change the unit of the result to mg/mL: Press

<UNIT>. The display shows:

• You wish to have your result in mg/mL. Press

<SELECT> repeatedly until "mg/ml" appears in the

display.

• Press <ENTER>. The number of decimal places is

shown after the separator ";". The "3" flashes to show

you that you can now enter a number. Enter here,

e.g. 1 decimal place and exit the inquiry by pressing

<QUIT> twice.

<QUIT>

The result is outputted in the new unit.

××−

factortiter)blank)KFR(volume(

×

divisorsmplsize

787 KF Titrino

15

Page 20

2.3. Tutorial

It is now necessary to match the factor to the new result unit. A table with a selection of

matched quantities for factor, divisor and unit of the sample size can be found in the

quick reference.

<CALC DATA>

4 × <ENTER>

KFT volume 3.459 ml

factor 0.1

<1>

<ENTER>

KFT volume 3.459 ml

divisor 1

<ENTER>

2 × <QUIT>

• Enter a new factor: Press <CALC DATA> and enter

the inquiries of the "calculation" group with

<ENTER>. Proceed with 3 times <ENTER> to the

display:

• Enter "1".

• As divisor enter the density of the sample.

• Exit the inquiry by pressing <QUIT> twice. The re-

sult is recalculated and outputted.

2.3.4 Drift

The drift is measured in µL/min. It specifies how much KF reagent is consumed per unit

time to keep the titration cell dry. The reagent is needed,

• to titrate moisture in the titration cell.

• to compensate the iodine consumption of slow side reactions.

The drift value is generally of the order of a few µL/min for "dry conditioned" titration cells.

Checking the condition of the solvent

The drift can be displayed during the conditioning of the titration cell with the <DRIFT>

key:

<DRIFT>

Drift 4.3 µl/min

<DRIFT>

• Press <DRIFT>. The first line of the display shows

You can follow the progress of the drift. In fresh solvent

the drift value should drop to less than 10 µL/min after

a few minutes.

• Pressing <DRIFT> once again switches the drift

display off.

787 KF Titrino

16

Page 21

2.3 Tutorial

Drift correction of the results

You can correct your results by the drift. This is primarily necessary if you wish to determine very small amounts of moisture or when you have very long titration times.

For the correction "drift value ∗ titration time" is subtracted form the dispensed volume:

corrected volume = dispensed volume – (drift value ∗ titration time)

The drift value can be determined automatically or entered manually. In the automatic

determination the current drift value at the start of the titration is stored and used for the

correction. In the manual entry you yourself enter a fixed value, e.g. the stable drift value

that you have read off from the display during conditioning.

<CALC DATA>

7 × <ENTER>

KFT volume 3.459 ml

drift corr.: OFF

2 × <SELECT>

<ENTER>

KFT volume 3.459 ml

drift value 0.0 µl/min

2.2

<ENTER>

<QUIT>

KFT-Vol -d 2.365 ml

• Activate the drift correction: Press <CALC DATA>

and enter the inquiries of the "calculation" group with

<ENTER>. Proceed with <ENTER> until the display shows:

• Make your selection with <SELECT>, e.g. "man.".

• Enter a drift value, e.g. 2.2 µL/min and exit the in-

quiry.

The result is recalculated and the first line of the display

shows

-d means that a drift correction has been performed.

If you have connected a printer, the full report provides

you with all data for recalculation of the result:

date 2002-03-27 time 13:55:10 3

smpl size 0.03 g

KFR volume 3.459 ml

drift man. 2.2 µl/min

(-d)time 1.03

water 922.2 mg/ml

============

787 KF Titrino

17

Page 22

2.4. Selection of the mode, key <MODE>

2.4 Selection of the mode, key <MODE>

MODE

–

Press key <MODE> until the desired mode is

displayed and confirm with <ENTER>.

The following modes can be selected:

• KFT:

Karl Fischer titration

• TITER with H2O or std.:

Titer determination with water or water-containing

standard.

• TITER with Na2Tart*2H2O:

titer determination with sodium tartrate.

• BLANK determination:

determination of the blank value

The set values under the <CONFIG> and <PARAM>

keys apply to all modes, whereas the calculations differ

for each mode. Once values have been set they remain

effective even if the instrument is switched off.

787 KF Titrino

18

Page 23

2.5 Configuration, key <CONFIG>

2.5 Configuration, key <CONFIG>

CONFIG

KFT ********

>KF device settings

>KF device settings

limit KF reag. OFF ml

actual KF reag. 0 ml

polarizer: I(pol)

I(pol) 50 µA

EP 250 mV

cond.

U(pol) 400 mV

EP 25 µA

cond.

Key <CONFIG> serves to enter device specific data.

The set values apply to all modes. The quantities

marked with "cond." are also accessible during the

conditioning

KF device settings:

Settings for the monitoring of the reagent supply, the

measuring input, the endpoint and the filling rate.

peripheral units:

Selection of printer, balance and the curve at the analog output.

auxiliaries:

e.g. setting of dialog language, date, time, etc.

RS232 settings:

RS parameters for the COM interface.

The display texts of the Titrino are shown to the left.

The values are the default values.

KF device settings for all modes

KF reagent volume counter (0...999 mL, OFF)

is used for monitoring of the

• reagent supply

• the buffer capacity of the solvent with 2-component

reagents

<CLEAR> sets "OFF".

If the KF reagent volume counter is activated, the

inquiry of the current counter status follows.

Current counter status (0...999 mL)

Selection of the polarization mode (I(pol), U(pol))

Polarization current(-127...127 µA)

Endpoint voltage(-1500 mV...1500 mV)

Polarization voltage(-1270...1270 mV, in steps of 10 mV)

Endpoint current (-150...150 µA)

787 KF Titrino

19

Page 24

2.5. Configuration, key <CONFIG>

filling rate max. ml/min

cond.

>RS232 settings

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: HWs

RS control: ON

>peripheral units

send to: IBM

balance: Sartorius

record: V vs. t

Filling rate after the titration (0.01...150 mL/min, max.)

<CLEAR> sets "max.".

The maximum rate depends on the Exchange unit:

Exchange unit max.

5 mL 15 mL/min

10 mL 30 mL/min

20 mL 60 mL/min

50 mL 150 mL/min

Settings of RS232 interface

see also page 68.

Baud rate (300, 600, 1200, 2400, 4800, 9600)

Data bit (7, 8)

Stop bit (1, 2)

Parity (even, odd, none)

Handshake (HWs, HWf, SWline, SWchar, none)

see page 68.

Control via RS232 interface (ON, OFF)

"OFF" means that the receipt of commands via the

RS232 interface is blocked. Data output

is possible.

Settings for peripheral units

Selection of printer (Epson, Seiko, IBM) at the Titrino

RS232 interface.

"Epson", for Epson Mode, e.g. Epson LX 300+,

Citizen iDP 562 RS, Custom DP40-S4N

"Seiko", e.g. for DPU-414

"IBM", e.g. for HP DeskJet types, for all printers with

IBM character set Table 437 and IBM graphics, as well

as for the data transmission to a computer with

Metrodata software VESUV.

Selection of balance (Sartorius, Mettler, AND, Precisa)

Sartorius: Models MP8, MC1

Mettler: Models AT, AM, PM, AX, MX, UMX and

balances with 011, 012, or 016 interface

AND: Models ER-60, 120, 180, 182, FR-200, 300

and FX-200, 300, 320

Precisa: Models with RS232C interface

Selection of the curve for the output at the analog

output (V vs. t, dV/dt vs. t, U vs. t, -U vs. t)

V vs. t: Volume vs. time curve

dV/dt vs. t: Drift vs. time curve

U vs. t: Control deviation (current value – EP) vs.

time curve

787 KF Titrino

20

Page 25

2.5 Configuration, key <CONFIG>

>auxiliaries

dialog: english

date 2001-03-27

time 08:13

run number 0

electrode test: ON

display KFR vol.: ON

device label

program 787.0010

General settings

Selection of dialog language (english, deutsch,

francais, español)

Current date (YYYY-MM-DD)

Format: Year-month-day, entry with leading zeros.

Current time (HH-MM)

Format: Hours-minutes, entry with leading zeros.

Current run number for result output (0...999)

The sample number is set to 0 when the instrument is

switched on and incremented on every determination.

Electrode test (ON, OFF)

Test for polarized electrodes. Performed on

changeover from the inactive state to a measurement.

"OFF" means that the test is not performed.

Display the dispensed KFR volume in the result display

(ON, OFF)

"ON" means the dispensed KFR volume will be

displayed in the result output on the first line.

Individual identification of devices (up to 8 ASCII

characters)

Display of program version

787 KF Titrino

21

Page 26

2.6. Parameters, key <PARAM>

p

2.6 Parameters, key <PARAM>

The key <PARAM> is used for the entry of values that

PARAM

determine the titration sequence. Values marked with

"cond." are accessible during the conditioning. "**titr."

means that these values can be changed during the

titration. They influence the ongoing determination.

Other values can only be changed in the inactive state.

The display texts of the Titrino are shown to the left.

The values are the default values.

2.6.1 Parameters

KFT ********

>titration parameters

>titration parameters

extr.time 0 s

**titr.

stop crit: drift

**titr.

stop drift 20 µl/min

**titr.

t(delay) 10 s

**titr.

stop V 99.99 ml

**titr.

start V: 0.00 ml

cond.

titration parameters

are valid for the global titration sequence.

preselections:

ON/OFF of various auxiliary functions such as automatic requests after the start and report.

General titration parameters

Extraction time (-9999.. 9999 s)

for

- that evolve sample slowly

- work with KF oven

With positive extraction times, titration is performed

continuously during this time; with negative values no

titrant is added during the extraction time. The

extraction time can be aborted with <QUIT>.

Type of stop criteria (drift, time)

Titration stops if EP is and stop drift is reached. (1...999

µL/min)

Titration stops if there is no dosing during t(delay).

(0...99 s)

Switch off when the end point is reached and the set

time after the last dispensing has elapsed.

Stop volume (0...99.99 mL, OFF)

Safety stop, e.g. if no endpoint is found.

<CLEAR> sets "OFF".

Start volume (0.00…99.99 mL.)

Performed and inquired only in KFT mode.

Start volume is dis

ensed before titration start. In the

787 KF Titrino

22

Page 27

2.6 Parameters, key <PARAM>

dos.rate max. ml/min

**titr.

max.rate 10.0 ml/min

**titr.

min.volume incr. min. µl

**titr.

case of a negative extraction time, it is dispensed after

the extraction time has elapsed.

If a start volume has been entered, an inquiry appears

regarding the dosing rate:

Dosing rate for start volume

(0.01...150 mL/min, max.)

<CLEAR> sets "max.".

The maximum rate depends on the Exchange Unit:

Exchange Unit max.

5 mL 15 mL/min

10 mL 30 mL/min

20 mL 60 mL/min

50 mL 150 mL/min

Maximum titration rate (0.01...150 mL/min, max.)

<CLEAR> sets "max.".

This parameter determines primarily the addition rate

outside the control range, see also page 26.

The maximum rate depends on the Exchange Unit:

Exchange Unit max.

5 mL 15 mL/min

10 mL 30 mL/min

20 mL 60 mL/min

50 mL 150 mL/min

Minimum volume increment in the titration (0.01...999.9

µL/min, min.)

<CLEAR> sets "min.".

This parameter determines the addition rate right at the

start and the end of the titration, see also page 26.

This parameter influences the titration speed and

therefore its accuracy very strongly: A smaller min.rate

results in a slower titration.

The minimum increment depends on the Exchange

Unit:

Exchange Unit min.

5 mL 0.5 µL

10 mL 1.0 µL

20 mL 2.0 µL

50 mL 5.0 µL

787 KF Titrino

23

Page 28

2.6. Parameters, key <PARAM>

>preselections

conditioning: OFF

req.ident: OFF

req.smpl size: OFF

report: OFF

cond.

Preselections for the sequence

Automatic conditioning of titration vessel. (ON, OFF)

If conditioning is "on", between the titrations the titration

solution is constantly maintained at the end point.

When conditioning is performed, the volume drift can

be displayed during the conditioning with <DRIFT>,

see page 36.

Request of the sample identification after start of

titration (ON, OFF)

After start, the sample identification can be requested

automatically.

Not performed or inquired in the "BLANK" mode.

Request of sample size after start of titration (ON, OFF)

Not performed or inquired in the "BLANK" mode.

Selection of the result report on titration completion

(short, full, OFF)

See also page 38.

787 KF Titrino

24

Page 29

2.6 Parameters, key <PARAM>

Titration sequence of KFT

<START>

(Preconditioning)

(<START>

(Request smpl size)

(Request ident.)

(Start volume)

(Extraction time)

Titration with test of

stop criterion

Calculations

Data output

(Reconditioning)

If conditioning is on, the sample solution is titrated until

the EP is reached. The display shows then

KFT conditioning

The vessel is now conditioned. The titration can be started

with <START>.

The sample size ant the sample identification are requested.

The start volume is dispensed.

The titration is executed. If the extraction time is not yet

over when the endpoint has been reached, the titration will

only be terminated after the extraction time is over.

Calculations are carried out.

Data are outputted.

Conditioning is carried out.

787 KF Titrino

25

Page 30

2.6. Parameters, key <PARAM>

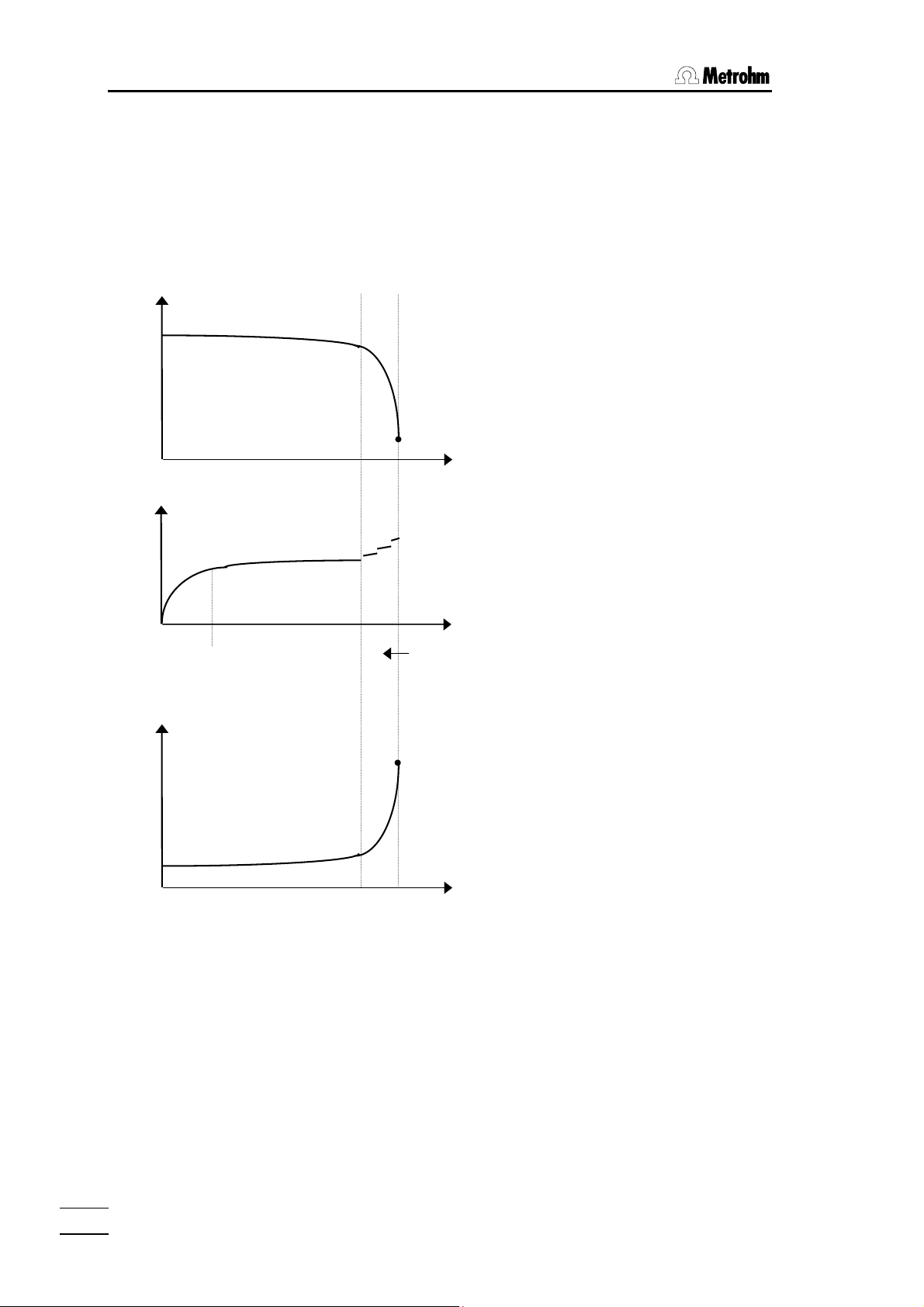

Titration parameters for KFT

The titration parameters can be set according to your samples. The default parameters

are already set to get satisfactory results. Optimize the control parameters for specific

samples only.

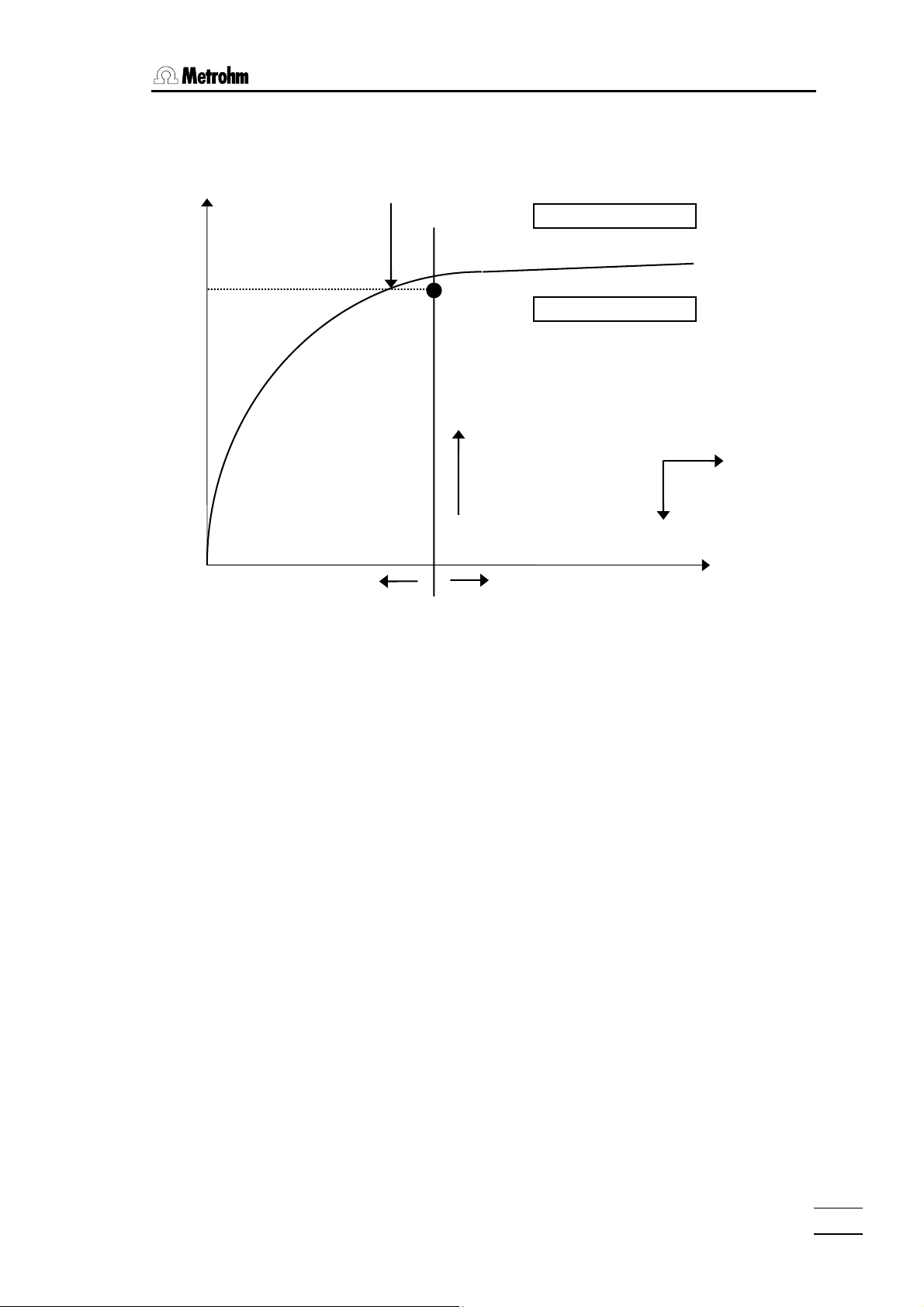

During the titration, reagent dosing is carried out in 3 phases:

U/mV

Ipol

1. Initial dosing:

Here the dosing rate

increases constantly up to

"max.rate".

2. Continuous dosing:

Dosing is performed at the

maximum rate "max.rate"

EP

V/mL

t/s

until the control range

(dynamics) is reached.

3. Control range (dynamics):

In this range, dosing is

performed in single steps.

The last dosing steps are

controlled by the

parameter "min.volume

incr.".

Initial

dosing

Continuous

dosing

V/mL

Control

range

I/uA

EP

Upol

V/mL

Remarks:

• Titer determination should have the same parameters as the sample titrations.

• In most cases the preset default parameters provide precise and reproducible results.

• Ipol gives relatively steep curves. They are flatter with Upol.

787 KF Titrino

26

Page 31

2.6 Parameters, key <PARAM>

Mechanisms of the KFT parameters in Ipol mode

U/mV

+

Titration

(direct titration)

Excess H2O

EP at U

Excess Iodine

Titration

(Back titration)

darker

solution

I(pol)

+

I/µA

• The position and curve characteristics of the line between the ranges of excess water

or excess iodine depends on the type of sample and the ingredients of the working

media.

• The endpoint has to be set close to the range margin, but always within the iodine

excess range. If the endpoint is set too close to the limit, an overdose of KF reagent

may be dispensed. The steeper the curve at the preset polarization current I(pol), the

more delicate it is to titrate to a steady and reproducible endpoint. For the titration of

troublesome samples, the particular conditions must be optimized by trial and error.

Always mind the color of the working medium at the end point as your guideline.

Remark: In most cases the preset default parameters provide precise and

reproducible results.

• If you select negative values for a polarization, you should choose negative values for

all other parameters too in order to have compatible parameter sets.

• In measurements with the setting "Upol", all parameters work in a similar manner as in

measurements with the setting " Ipol".

787 KF Titrino

27

Page 32

2.6. Parameters, key <PARAM>

Relation between the stop criteria "time" and "drift"

The stop criterion "time", t(delay), means that the end point must be exceeded for a

certain period of time. In other words, after the last dosed increment, time t is allowed to

elapse before the titration is stopped. The size of this last increment depends on the

volume of the Exchange Unit used. With a 20 mL Exchange Unit, the smallest possible

increment is 2 µL. With a t(delay) = 5 s, the last 2 µL reagent must thus suffice for 5 s or

longer. This results in a drift of ≤ 2 µL/5 s = 24 µL/min (the drift can be less than 24

µL/min as it is not known whether the last increment would also suffice for 10 s). If you

have been working up to this point with a 20 mL Exchange Unit and a t(delay) = 5 s, you

can set a value of ≤ 24 µL/min as stop drift. The following table shows several values for

the maximum stop drift.

t(delay)

min.incr. (Exchange Unit)

0.5 µL (5 mL) 6 µL/min 3 µL/min 1.5 µL/min

1 µL (10 mL) 12 µL/min 6 µL/min 3 µL/min

2 µL (20 mL) 24 µL/min 12 µL/min 6 µL/min

5 s 10 s 20 s

5 µL (50 mL) 60 µL/min 30 µL/min 15 µL/min

Same t(delay) with a range of extremely small volume increments means different switchoff points. In case the stop criterion "drift" is used, the stopping point remains the same.

The determination of the free water is easily done, as far as the specifications of the

reagent manufacturer regarding the "water capacity" of the reagents are considered.

Problems may occur with specific sample matrices. The relevant literature contains many

precise analysis instructions. Here, we give you some useful hints for the sample addition.

Sample addition

For sample addition various accessories are available, for example injection syringes,

weighing spoons etc.

It is a good idea to apply the back-weighing technique, except when you are disposing

small amounts of liquids with a micro-syringe. Fill the syringe or the weighing spoon with

your sample just before the titration (e.g. during conditioning) and tare it on a balance

with an appropriate precision, which ideally is connected to the Titrino. Sample size

request should always be switched on (see page 24). Add the sample during the request

for the sample size, and weigh the syringe or weighing spoon again to evaluate the

weight difference. Use the transfer of balance data to enter the correct sample size if

possible. The weight has to be transmitted in gram. If you transfer the sample size from

the balance, the sample size request is confirmed automatically, and the titration is

started at once. Otherwise use the keypad to enter the weight.

If the sample size request is switched off, and preconditioning is set, you are explicitly

prompted to add your sample. For six seconds, the message "add sample" is displayed

after which the titration is started by the Titrino itself.

787 KF Titrino

28

Page 33

2.6 Parameters, key <PARAM>

Solid samples

Use the glass weighing spoon 6.2412.000 and dispose the sample through the opening

for the septum stopper.

Liquid samples

Use a disposable syringe (2...20 mL) or a micro-syringe with a long needle attached.

Puncture the septum and dispose the sample carefully. When using disposable syringes,

add the liquid sample carefully without dipping into the solvent. Draw back the last drop

of sample into the syringe before you redraw the needle. For disposing an exact, small

volume of liquid sample, use a micro-syringe. Proceed as described above, but dip the

needle into the preconditioned solvent and dispose the sample carefully. Here drawing

back of solvent or sample adhering to the needle is not recommended.

Always keep in mind to exchange the septum as soon as it shows any large punctures

impairing the tightness of the titration cell.

Pasty, viscous samples

For samples which cannot be disposed with a needle because of their high viscosity, you

can handle your samples with disposable syringes with a large volume without using a

needle. Dispose your sample through the opening of the septum stopper. Back-weigh the

syringe after addition of the sample. Be sure to wipe off any adhering excess sample

substance of the syringe before taring it.

In any case, pay attention to prevent the penetration of atmospheric moisture into the

titration vessel when you are disposing the sample. If you still have to open the titration

cell for any reason, determine a blank value and take it into account for the calculation of

the titration result (see page 34).

787 KF Titrino

29

Page 34

2.6. Parameters, key <PARAM>

In the following table we attempt to show you solutions related more to the instrument's

side:

What to do if ...

Problem Possible causes and remedial action

Dosing at end too long and

increments too small. "Is never

finished!"

The increments at the end of the

titration are too large.

"Overshoots".

Solution becomes too brown at

the end of the titration.

Solution becomes darker with

every titration.

• Increase "min.volume incr.".

• Change stop criterion. Try to increase stop drift or

use a short stopping time as stop criterion, e.g.

• For problematic samples change solvents with

ketones or aldehydes in 2-methoxyethanol or with

amines mixture in methanol/glacial acetic, e.g., see

literature.

• Lower "max.rate". The following experiment gives you

a reference point for the optimum max.rate: Drift

display during conditioning and add sample without

starting the titration. Select a value below the

maximum drift as "max.rate".

• Optimize setup of electrode and buret tip and

improve stirring.

• The methanol fraction in the solvent is too low.

Change the solvent.

• Electrode could be coated; wipe off with acetone.

• Renew solvent.

• Electrode could be coated; wipe off with acetone.

The drift increases with every

titration.

The endpoint is reached "too

rapidly".

The titration times become

longer and longer.

• Does your sample evolve water extremely sluggishly?

Work with the KF oven.

• Are acids esterified in your sample? Change solution

more frequently. Increase buffer capacity of the

solvent.

• Does your sample contain ketones or aldehydes?

Use special reagents suitable for ketones and

aldehydes.

• Reduce "max.rate".

• With 2-component reagents the buffer capacity of the

solvent can be exhausted. Change solution.

• If the drift increases at the same time, see above.

787 KF Titrino

30

Page 35

2.8 Result calculations

2.8 Result calculations

Key <CALC DATA>

CALC

DATA

KFT ********

>calculation

>calculation

smpl size 1.0 g

**titr.

ident.

**titr.

titer 5 mg/ml

cond.

factor 0.1

cond.

The key <CALC DATA> is used to enter the values for

the calculations. The data of this key are method

specific to a sample (sample size and identification) or

to a mode (titer, factor, blank, mean value) and the drift

correction applies to all modes. On exit the result is

always recalculated. Values marked with "cond." are

accessible during the conditioning. "**titr." means that

these values can be changed during the titration. They

influence the ongoing determination.

calculation:

Values for result calculations.

statistics:

Calculation of mean values and standard deviation.

The display texts of the Titrino are shown to the left.

The values are the default values.

Assignments for the result calculation

Sample size (6-digit number ±X.XXXXX)

Entry using keypad, via balance.

Sample sizes that are inquired automatically in the

titration sequence can be viewed and modified with the

<CALC DATA> key. For calculation the absolute

sample size is used (negative signs that appear, e.g. in

backweighing are ignored).

No inquiry of sample size in the "BLANK" mode.

Sample identification (up to 8 ASCII characters)

Entry using keypad, via balance.

Sample sizes that are inquired automatically in the

titration sequence can be viewed and modified with the

<CALC DATA> key.

No inquiry of sample size in the "BLANK" mode.

Titer(0.0...99.9991 mg/mL)

The titer is written in automatically from the titer

determination modes.

Request only in the "KFT" mode.

±

Factor (

1000000)

in the numerator of the formula. Entries for factors with

different units for results and sample size, see page

33f.

787 KF Titrino

31

Page 36

2.8. Result calculations

divisor 0.1

cond.

blank 0.0 ml

cond.

drift corr.: auto

cond.

drift value 0.0 µl/min

cond.

>statistics

mean n= 20

cond.

res.tab: original

cond.

delete n= 1

cond.

±

Divisor (

1000000)

in the denominator of the calculation formula. Used

mainly for the density, see page 33.

Request only in the "KFT" mode.

Blank (0.0...99.9991 mL)

The blank value is written in automatically from the

blank determination mode. Values that are corrected

by a blank value are flagged with "-b".

Request only in the "KFT" mode.

Drift correction for the result (auto, man., OFF)

With the drift correction switched on, the value

(drift*titration time) is subtracted from the KFR volume.

Values that has been corrected by the drift are flagged

with "-d".

auto: The drift value at the start of the titration is

subtracted.

man: A fixed value of the drift is entered and

subtracted.

If the drift correction is set to "man.", the drift value is

requested:

Drift value for the manual drift correction (0...99.9

µL/min)

Statistics calculation

Mean value calculation from n single results (2...20)

Result table (original, delete n, delete all)

"original": The original table is used. Deleted

individual results are again incorporated in

the evaluation.

"delete n": Deletion of single results with the index n.

"delete all": The entire table is deleted.

Delete data from sample number n (1...20)

The deleted result is removed from the statistics

calculation.

787 KF Titrino

32

Page 37

2.8 Result calculations

Calculation formula and units

The calculation formulas are preset and depend on the selected mode.

Formula for the KFT mode

)content(water

=

divisorsmplsize

×

factortiter)blank)KFR(volume(

××−

Factor and divisor are used for the conversion of the result to different units.

Unit of result Sample size in... Factor Divisor

% g

0.1 1

% mg 100 1

% ml 0.1 density of sample [g/mL]

ppm g 1000 1

ppm ml 1000 density of sample [g/mL]

ppm µl 1 density of sample [g/mL]

mg/ml g 1 density of sample [g/mL]

mg/ml ml 1 1

mg 1 1 1

ml 1 1 1000 * density H

O [g/mL] ≈ 1000

2

mg/pc pc 1 1

The unit of the result can be selected with the <UNIT> key, see the following page.

Formula for the titer determination modes

TITER

titer

=

×

factorsmplsize

)KFR(volume

The factor is used to enter the water content of the standard.

Standard used Sample size in... Factor

Water g 1000

Water µl density H

O [g/mL] ≈ 1

2

Methanol ml content of methanol [g/mL]

Methanol µl 0.001 * content of methanol [g/mL]

Na

Tart*2H2O g 156.6

2

Na

Tart*2H2O mg 0.1566

2

787 KF Titrino

33

Page 38

2.8. Result calculations

Formula for the blank determination BLANK

factor)KFR(volumeblank

×=

If the blank is determined with an excessive solvent volume, the result can be

converted to the amount used subsequently with the aid of the factor.

If the drift correction is switched on, the "volume(KFR)" is corrected in all modes as

follows:

volume(KFR) – d = volume(KFR) – (drift value * (-d)time)

"(-d)time" corresponds to the time during which control is exerted (i.e. during the positive

extraction time and during the titration time, but not during the dispensing of the start

volume and during negative extraction times).

With manual drift correction, the entered drift value is reconciled in the result calculation,

whereas with automatic drift correction the drift value at the start of the titration is used.

The drift correction is used when the ingress of moisture during the titration needs to be

compensated. A drift correction is appropriate when the ratio

drift ∗ titration time

volume(KFR)

is large.

Key <UNIT>

UNIT

result unit: %

result unit: %;2

smpl size unit: %

The <UNIT> key can be used to select the unit of the

result in the KFT mode and of the sample size. It is

accessible during the conditioning and in the standby

state.

In the modes "TITER" and "BLANK", the result unit can

be viewed only but not changed.

The display texts of the Titrino are shown to the left.

The values are the default values.

Unit of the result in the KFT mode (%, ppm, mg/mL, g,

mg, mL, mg/pc, no unit)

Number of decimal places (0...9)

The number of decimal places in the result output

follows the separator ";". The number flashes to draw

attention to the fact that this value can now be entered.

Unit for the sample size (g, mg, mL, µL, pc, no unit)

787 KF Titrino

34

Page 39

2.8 Result calculations

Statistics calculations

If the mean value is active, the following quantities are calculated:

• mean

• standard deviation

• relative standard deviation

These values are printed out in the result report or they can be viewed with the

<SELECT> key:

Press the <SELECT> key repeatedly until the desired value appears in the display. The

following are displayed in succession, see also page 13.

• current result

• mean

• standard deviation

• relative standard deviation

A table of the single results can be printed out with the key sequence

<PRINT><1><ENTER>.

Remarks:

• If the number of single results n has been reached, the statistics calculation

begins anew at the next start.

• When the mode is changed, the statistics instructions of the previous mode come

to an end (res.tab. deleted) and the instructions of the new mode are followed.

• Old results that are no longer needed for the statistics calculation can be deleted

with "delete all".

• Recalculated single results are immediately incorporated in the statistics

calculation.

• If a result can not be calculated, the run counter is incremented. The counter for

the number of reconciled single results remains unchanged, however.

787 KF Titrino

35

Page 40

2.9. Drift display, key <DRIFT>

2.9 Drift display, key <DRIFT>

DRIFT

8

During the conditioning, the <DRIFT> key can be

used to switch the display of the current drift on and

off.

The value provides an idea for

• the condition of the titration cell.

• whether a drift correction should occur and the

magnitude of the drift value.

• the sample matrix. Do side reactions take place?

Does the sample contain ketones or aldehydes?

etc.

• the magnitude of the stop drift as a stop criterion

(value above basic drift).

787 KF Titrino

36

Page 41

2.10 Data output

2.10 Data output

Reports for the output at the end of a determination

PARAM

2

× <PARAM>

4

× <ENTER>

>preselections

report: OFF

Meaning of the report blocks:

full Full result report with raw results, calculations and statistics.

short Short result report with calculations and statistics.

Original reports which are put out automatically at the end of the titration and after every

recalculation of the result.

Original reports have double dashes ==== at the end, whereas recalculations are

marked by single dashes

----.

Report outputs can be stopped with <QUIT>.

With <PARAM>, the report sequence at the end of the

determination is defined.

See also page 24.

report:

Definition of report blocks to be printed automatically at

the end of the determination.

The display texts of the Titrino are shown to the left.

The values are the default values.

Preselections

Report sequence: full, short, OFF

Select a block with <SELECT>.

787 KF Titrino

37

Page 42

2.10. Data output

Example of reports:

Full result report

date 2002-03-27 time 08:33:42 4

smpl size 1.0 g ident. 08-4

KFR volume 2.278 ml

blank 0.0315 ml

titer 5.0 mg/ml

drift auto 1.9 µl/min

(-d)time 0:43

water 1.14 %

mean(4) 1.13 %

+/-s 0.005 %

s(rel) 0.44 %

============

- date, time, current run number.

- sample size, identification.

- The blank is printed out only if the value is ≠ 0 mL.

- The drift and the (-d)time are printed out only it the drift

correction has been set to "OFF".

- result

- statistics

Short result report

date 2002-03-27 time 08:35:42 5

smpl size 1.0 g ident. 08-5

(-d)time 0:45

water 1.14 %

mean(5) 1.13 %

+/-s 0.005 %

s(rel) 0.44 %

============

- date, time, current run number.

- result

- mean value with 5 single results

- standard deviation

- relative standard deviation

Additional possibilities for report outputs

In addition to the reports which are printed at the end of the titration, various other reports

can be put out. There are 2 possibilities to select the reports:

<PRINT><keyX><ENTER> key X is the key under which the appropriate data

are entered.

List of reports:

Report <Key X>

Configuration report CONFIG

Parameter report PARAM

Calculation data CALC DATA

Table of the individual results for statistics

1

calculation

Result display without a printer

Results can also be viewed in the display. After a determination the calculated result and

the single results of the statistics calculations can be displayed with <SELECT>.

<SELECT> switches to the next result, view also page 13.

787 KF Titrino

38

Page 43

3.1 Error and special messages

3 Error messages, Troubleshooting

Data transfer inoperative See measures on page 41.

3.1 Error and special messages

change solvent The limit volume of the reagent volume counter "limit KF reag."

has been reached..

Exit: Change solvent and press <CLEAR>.

check electrode

There is a break or short circuit. Possible causes and

rectification of the fault:

- the electrode is not plugged in ⇒ plug it in

- the electrode is not immersed in the solution ⇒ immerse it

- the electrode is defective ⇒ use new electrode.

- the electrode cable is defective ⇒ use new cable.

The electrode test can be switched off under the <PARAM>

key.

Exit: Rectify fault or <STOP>.

check exchange unit The Exchange Unit is not mounted (properly).

Exit: Mount Exchange Unit (properly) so that the coupling

engages or <STOP>.

cylinder empty! During dispensing with <DOS> an entire cylinder ahs been

dispensed.

Exit: Press <STOP/FILL>.

division by zero The result could not be calculated as a divisor in the formula

was equal to zero.

Exit: Enter appropriate value.

stop V reached The determination has been stopped as the stop volume has

been reached.

system error 3 The instrument adjustment data have been overwritten.

Exit: <CLEAR>. Default adjustment data are set. The error

message appears each time the instrument is switched on

until it has been readjusted (Metrohm service).

???? The result exceeds the valid data range or too many decimal

places are needed to display.

787 KF Titrino

39

Page 44

3.1. Error and special messages

Error messages in connection with the data transfer

If neither a computer nor a printer is attached, the report output at the end of the titration

must be switched off:

Receive errors:

E36 Parity

Exit: <QUIT> and set corresponding quantity the

same on both instruments

E37 Stop bit

Exit: <QUIT> and set corresponding quantity the

same on both instruments

E38 Overrun error. At least 1 character could not be read.

Exit: <QUIT>

E39 Overflow of the receive buffer of the Titrino (> 82

characters).

Exit: <QUIT>

Send errors:

E40 DSR=OFF

E41 DCD=OFF

E42 CTS=OFF

Handshake unsatisfactory for more than 1 s.

Exit: <QUIT> Is the receiver switched on and ready

to receive?

E43 The transmission of the Titrino has been interrupted

with XOFF for at least 3 s.

Exit: <QUIT>.

E44 The RS interface parameters are no longer the same

for both instruments.

787 KF Titrino

40

Page 45

3.2 What can you do if the data transfer does not work?

3.2 What can you do if the data transfer does not work?

Problem Questions for remedial action

No characters can be

received on a connected

printer.

No data transmission and the

display of the Titrino shows

an error message.

The received characters are

garbled.

Wrong line spacing.

- Are the instruments switched on and cables plugged

in correctly?

- Is the printer set to ”on-line”?

- Are baud rate, data bit and parity the same on both

instruments?

- Is the handshake set properly?

If everything seems to be ok, try to print a report with the

key sequence <PRINT><CALC DATA><ENTER>. If

this report is printed out correctly, check if reports are

defined in key <PARAM>.

- error 42: Transmission error. Is the printer set to "online"? Is the connection cable properly wired?

- error 43: Data output of the Titrino disabled for

longer than 6 s by XOFF.

- error 36-39: Receive error. Are the RS settings the

same on both devices?

- Are the RS settings the same on both devices?

- Has the correct printer been selected?

The printer does not emulate completely the preset

mode. Usually these problems arise with the IBM mode.

Set the printer to a different mode (e.g. Epson).

787 KF Titrino

41

Page 46

3.3. Diagnosis

r

3.3 Diagnosis

3.3.1 General

The 787 KF Titrino is a very precise and reliable instrument. Thanks to its rugged construction it is virtually impossible for external mechanical or electrical influences to have

an adverse effect on its functions.

Although the occasional fault in the instrument can not be excluded completely, it is certainly much more likely that malfunctions are caused by wrong operation or handling or

through improper connections and operation with non-Metrohm instruments.

It is advisable in each case to isolate the fault with the rapid and easy to perform diagnostic tests. The customer thus need not call METROHM service until there is a true fault in

the instrument. In addition, with the aid of the numbering in the diagnostic program he

can provide the service engineer with much more accurate information.

In inquiries always quote the manufacturing (page 4) and program number (see configuration, page 21) and specify possible error displays..

3.3.2 Procedure

• The diagnostic steps must be performed in sequence and compared with the reactions of the 787 KF Titrino (indented). In the "yes" case, continue with the next instruction.

• If the instrument does not show the expected reaction ("no" case), the appropriate

diagnostic step must be repeated to exclude an operating error. With repeated

wrong reactions, however, there is a strong possibility that a malfunction exists.

• The diagnostic steps allow re-entry into the test routine for repetition if the following

display appears:

diagnose press key 0...9

If the instrument is in a subprogram of the diagnostic routine: Press <Clear>.

If need be, switch the power off then on again after a few seconds. At the same time press key

<9> until the above display appears.

• If <Clear> has been pressed during the display of 'diagnose press key 0...9', the in-

strument returns to the user program.

• Error display: An error is shown in the display as follows:

error XX

error numbe

• If a fault causes the burette drive to stick at the top or bottom end of the cylinder,

see page 52, point 3.5.

787 KF Titrino

42

Page 47

3.3. Diagnosis

3.3.3 Equipment required:

− voltage calibrator, e.g. 1.773.0010 Metrohm pH Simulator

or 1.767.0010 Calibrated Reference for mV, pH, Ω µS, °C

− highly insulated interconnection cable

− cable 3.496.5070

− exchange units, if possible with different cylinder volumes (or 3.496.0070 dummy exchange unit)

− stop watch or watch with second hand

− digital or analogue voltmeter (if need be, connect a calibrated recorder)

− 2 connecting cables with 4 mm banana plugs

− test plug 3.496.8510 (necessary only if plug ‘Remote’ should be checked)

− test plug 3.496.8480 (necessary only if plug ‘RS 232’ should be checked)

6.2108.060

3.3.4 Diagnosis steps

1 Prepare instruments for diagnostic test

• Power off.

• Disconnect all external connections (cables at rear, except mains cable and key-

board).

• Remove exchange unit.

• Power on and immediately press and hold the <9> key until the power up test pat-

tern disappears.

diagnose press key 0...9

2 Perform display test

• Press <2>.

display test

• Press <Enter>.

Characters for a visual check of the display are generated on the eight lines.

Test sequence:

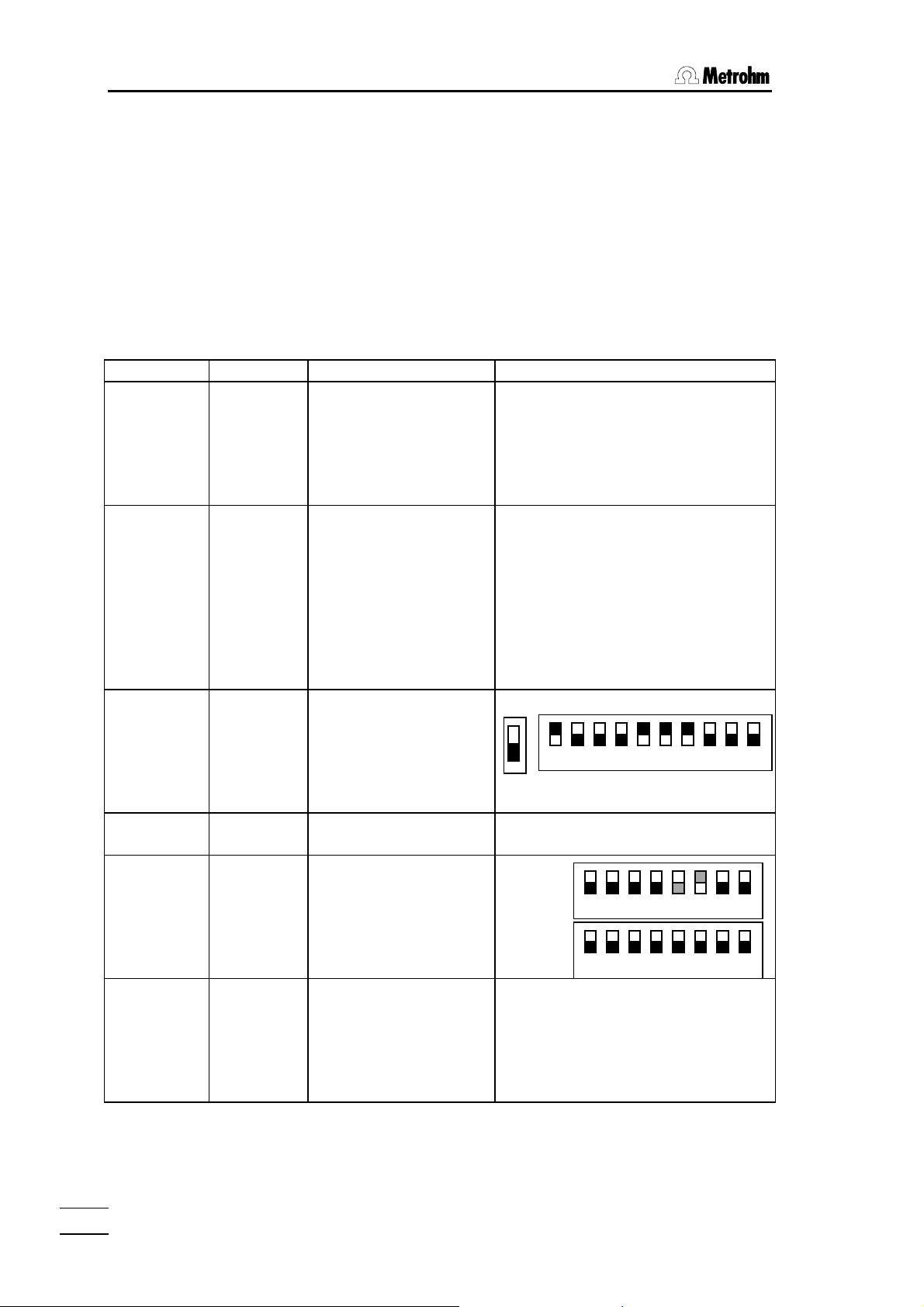

a) The display is cleared and overwritten from the left to the right with a dot pattern

( ▓ ▓ ▓ ▓ ▓ ▓ ▓ ▓ ).

b) The display is cleared and both lines are written into with the letters A, B, C,…Z.

c) The complete character set is shown as a moving display. At the same time with mov-

ing display the LED „Cond.“ are switches on and off.

• The test sequence can be held and then continued at any time by pressing <5>.

• Block 2 is quit by pressing <Clear>.

diagnose press key 0...9

787 KF Titrino

43

Page 48

3.3. Diagnosis

3 Keypad test

• Press <1>.

keys test

• Press <Enter>.

keys test

matrix code

• If any key is now pressed (on the 6.2130.060 keypad or on the front panel of the

787), the appropriate matrix code appears in the display.

Fig. 2 Front panel 787

Fig. 1 Keypad 787

• Block 1 is quit by pressing the <Clear> key twice.

diagnose press key 0...9

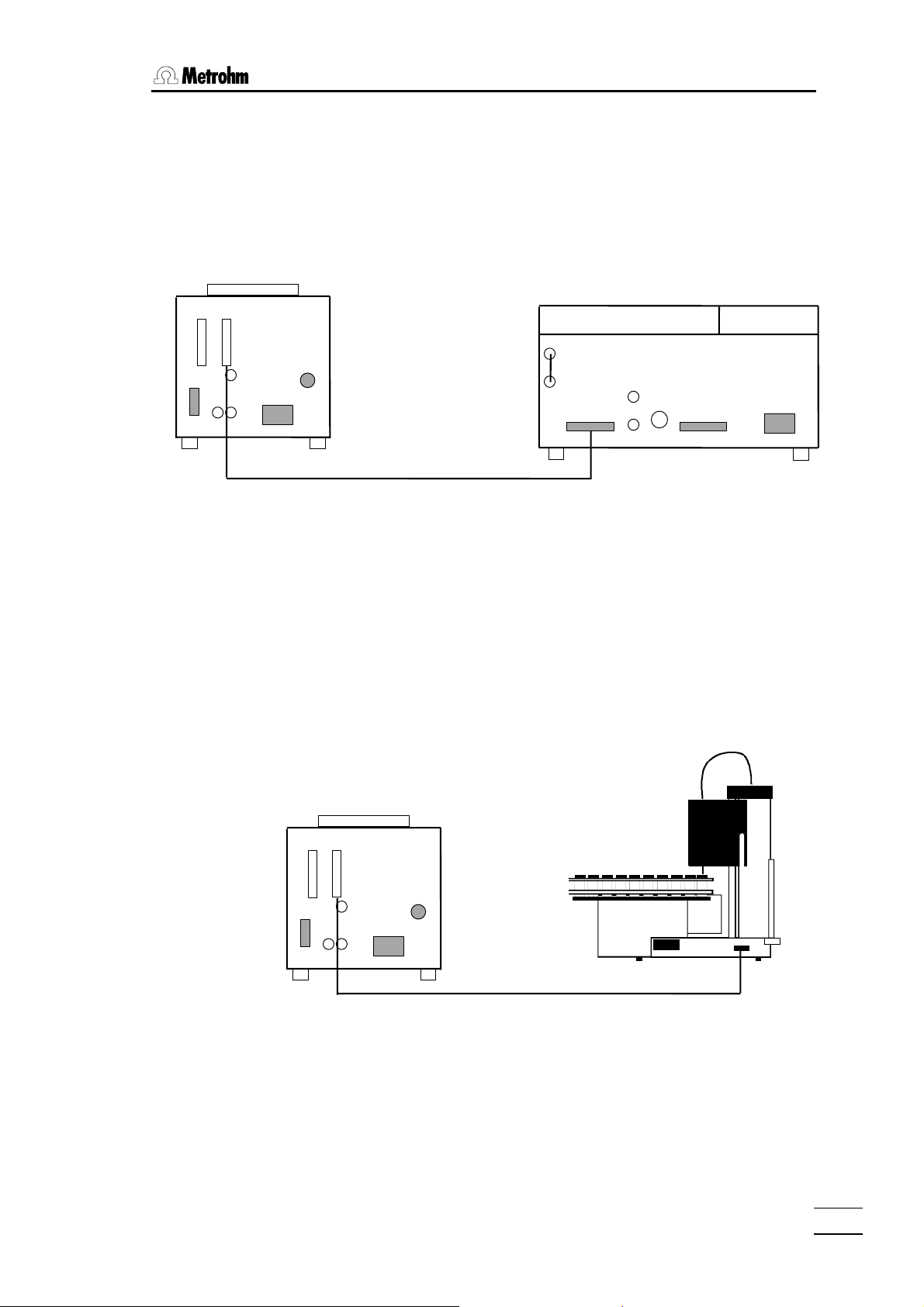

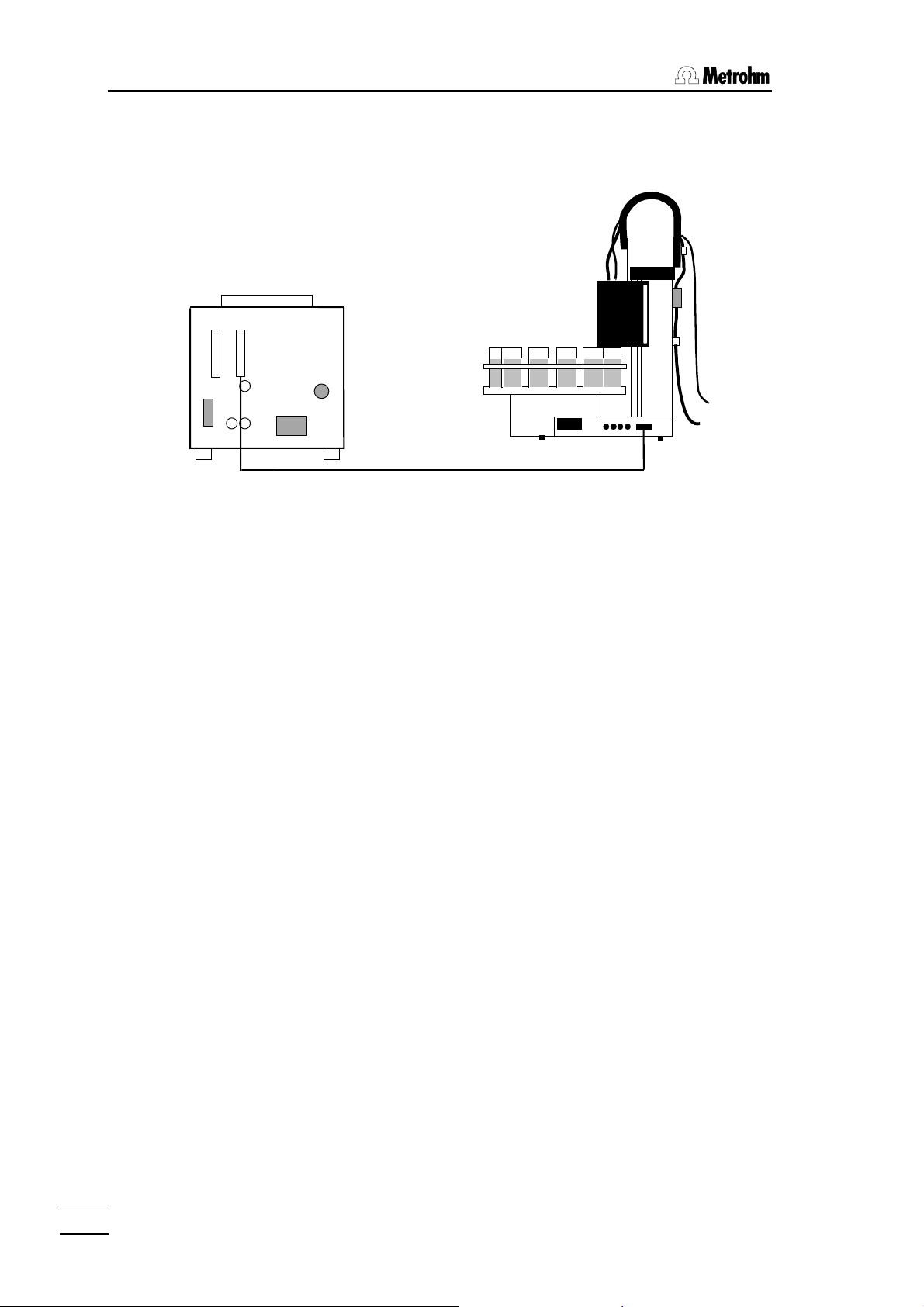

4 Cylinder code, date, time

• Put exchange unit or dummy on the Titrino and put the burette tip into a collecting

receptacle.

787 KF Titrino

44

Page 49

3.3. Diagnosis

• Press <0>.

date/time

cylinder code

• Press <Enter>.

activat ed dosing uni t

date XX-XX-XX

code:D0 XX ml

XX:XX:XX

mL-code

• Check date and time.

• Check whether the ml-code does correspond with the exchange unit placed or not.

For the sake of completeness, different exchange units can be inserted to check their ml code. If desired, the exchange unit can be removed again. If no exchange unit is inserted display does not show the ml-code but „check

exchange unit !“.

• Press <Clear>.

diagnose press key 0...9

5 Analogue output test

A voltage can be set at the analog output (sockets at D) using the keypad. But this should not exceed ± 2000 mV. This voltage can also be used for the calibration of a connected recorder.

• Connect a voltage measuring instrument (voltmeter, DVM, recorder) to the analogue output (10).

• Press <3>.

analog output-1 test

• Press <Enter>.

analog output-1 test

V-out = XXmV

Enter a voltage value in the range

been pressed, this value appears as a voltage at the analog output..

Read off value an the connected voltmeter and compare with the mV value on the display.

(Tolerance

±

2 mV)

±

2000 mV using the keypad. After the <ENTER> key has

• Press <Quit>.

• Disconnect voltmeter.

6 Motor timer test

• Press <6>.

motor-timer test

• Press <Enter>.

787 KF Titrino

45

Page 50

3.3. Diagnosis

pot.meter dV/dt 10?

• Turn knob ‘dV/dt’ to the right stop and press <Enter>.

Test sequence:

a) In a first step, the frequency of the RC oscillator (analogue rate) is tested over a period

of 1 second.

b) In a second step, the frequency of the quartz oscillator (digital rate) is tested over a

period of 1 second.

c) If no error is found, after about 3 s it appears

motor-timer test o.k.

• Press <Clear>.

diagnose press key 0...9

7 Polarizer test

• Press <7>.

polarizer test

• Press <Enter>.

dummy resistor 14.3kΩ ?

• Connect resistor switch-box (or suitable resistor 14.3 kΩ 0.1%) using 3.496.5070

cable to ‘Pol’ socket. Switch-box to 14.3 kΩ.

• Press <Enter>.

Test sequence:

1. An asterisk flashes during the test.

2. In case of an error an error message appears. (If for example the switch-box is not

connected,

3. If no error is found, after about 15 s display shows

polarizer test o.k.

error 100

appears).

• Press <Clear>.

diagnose press key 0...9

• Remove cable and resistor switch-box.

787 KF Titrino

46

Page 51

3.3. Diagnosis

8 External inputs and outputs

This test is meaningful only if the 787 KF Titrino is used interconnected with other instruments via the 'Remote' connection. In addition, a 3.496.8510 test plug normally used in the repair service is required for this test. However, this

plug can also be purchased by customers under the above number.

For the sake of completeness, the procedure is described here. If a diagnostic test of the external inputs and outputs

is not required, continue with point 9.

PIN PIN PIN PIN

1

2

3

3

24 5

12 9

23 10

22 11

21

18

17

16

Fig. 3 Connections in the 3.496.8510 test plug

• Press <4>

extern input/output test

• Press <ENTER>.

I/O-test-connector?

• Insert the 3.496.8510 test plug in port B 'Remote'. (Do not switch off instrument!)

• Press <ENTER>.

Test sequence:

1. In case of an error an error message is displayed. If for example no test plug is con-

nected, error message error 50 01HEX

2. If no error is found, after about 1 s display shows

appears).

• Remove test plug.

• Press <CLEAR>.

787 KF Titrino

extern input/output o.k.

diagnose press key 0...9

47

Page 52

3.3. Diagnosis

9 RS 232 test

A 3.496.8480 test plug normally used in the repair service is required for this test. However, this plug can also be

purchased by customers under the above number.

For the sake of completeness, the procedure is described here. If a diagnostic test of the RS 232 interface is not required, continue with point 10.

2

TxD

3

RxD

8

DCD

20

DTR

6

DSR

4

RTS

5

CTS

Fig. 4 Connections in the 3.496.8480 plug

• Press <5>.

RS232 test

• Press <ENTER>.

RS232 test-connector?

• Insert the 3.496.8480 test plug in 'RS 232' port.

• Press <Enter>.

Test sequence:

1. In case of an error an error message is displayed. If for example no test plug is connected, error message

2. If no error is found, after about 5 s display shows

RS232 test o.k.

error 68

appears).

• Remove test plug.

• Press <Clear>.

diagnose press key 0...9

787 KF Titrino

48

Page 53

3.3. Diagnosis

p

10 Spindle drive and stopcock changeover

• Press <Clear>.

The Titrino fills (only if an exchange unit is inserted)

The Titrino gets out of the diagnosis menu and returns to the user program.

• Remove exchange unit.

• Check spindle zero position, see Fig. 5.

0.2 - 0.6 mm

Fig. 5 Fig. 6

The spindle must be 0.2 - 0.6 mm below the edge of the sliding plate.

The bar of the stopcock coupling must be exactly parallel to the lateral edges of the MPT

Titrino, see Fig.6.

• Reinsert Exchange Unit.

Titrino fills.

The display of before reappears.

• Knob 'dV/dt' to right stop.

• Press the <DOS> key (on instrument) until the piston rod reaches the top and at the

same time measure the time from start to end.

XXX X ********

Spindle remains at maximum position. The transit time of the spindle is 20 s.

cylinder em

ty !

mind selected language!

• Measure spindle lifting (can be performed only if the 3.496.0070 Dummy Exchange

Unit is inserted or the locking switch (in right hole) is carefully operated with a

screwdriver after removal of the Exchange Unit).

From the start point, the spindle travels 80 mm. Instead of the spindle height, the expelled

volume can be measured (corresponds to max. vol. of Exchange Unit used).

• Press <FILL> (on instrument) and simultaneously measure the time until the Titrino is

again in the 'ready' position.

Times for filling: per stop cock cycle 1 s

for filling 20 s (Tolerance: 10 %)

The following generally holds: Spindle and stopcock must move at a constant speed

(noise!). In the filling setting, the stopcock coupling must position the lever of the Exchange

Unit correctly at the left stop (with virtually no play and without sticking).

• Set potentiometer 'dV/dt' to left stop.

• Press <DOS> (on instrument) at same time and use a stopwatch to measure the

time for 1/10 of the cylinder volume to be expelled. The time should be ca. 90 ... 110

s.

787 KF Titrino

49

Page 54

3.3. Diagnosis

• Set potentiometer 'dV/dt' to right stop.

• Press <FILL>.

11 Setting up original arrangement

Reconnect all peripherals disconnected at the start of the diagnostic routine and perform

a short function test with these.

787 KF Titrino

50

Page 55

3.4. Initialise and test RAM

3.4 Initialise and test RAM

On the odd occasion large disturbing signals (e.g. mains spikes, lightning, etc.) can have

an adverse effect on the processor functions and hence lead to a system crash. After

such a crash the RAM area must be initialised. Although the basic instrument data remain

stored, the RAM initialisation should be performed only when necessary since the stored

user data (configuration, parameters, calculation variables, etc.) are cleared as a result.

• Power OFF

• Power ON and simultaneously press keys <DOS> and <STOP/FILL>.

RAM Init.

• Press <START>.

confirm RAM Init.

• Press <START>.

RAM Init. activ

RAM is tested and initialised. Subsequently a warm start is executed.

The lost data of the user memory must now be reentered.

If 'system error 3' appears in the display, <Clear>can be used to return to the instrument

program. The initialisation values are loaded automatically. The instrument thus remains