Page 1

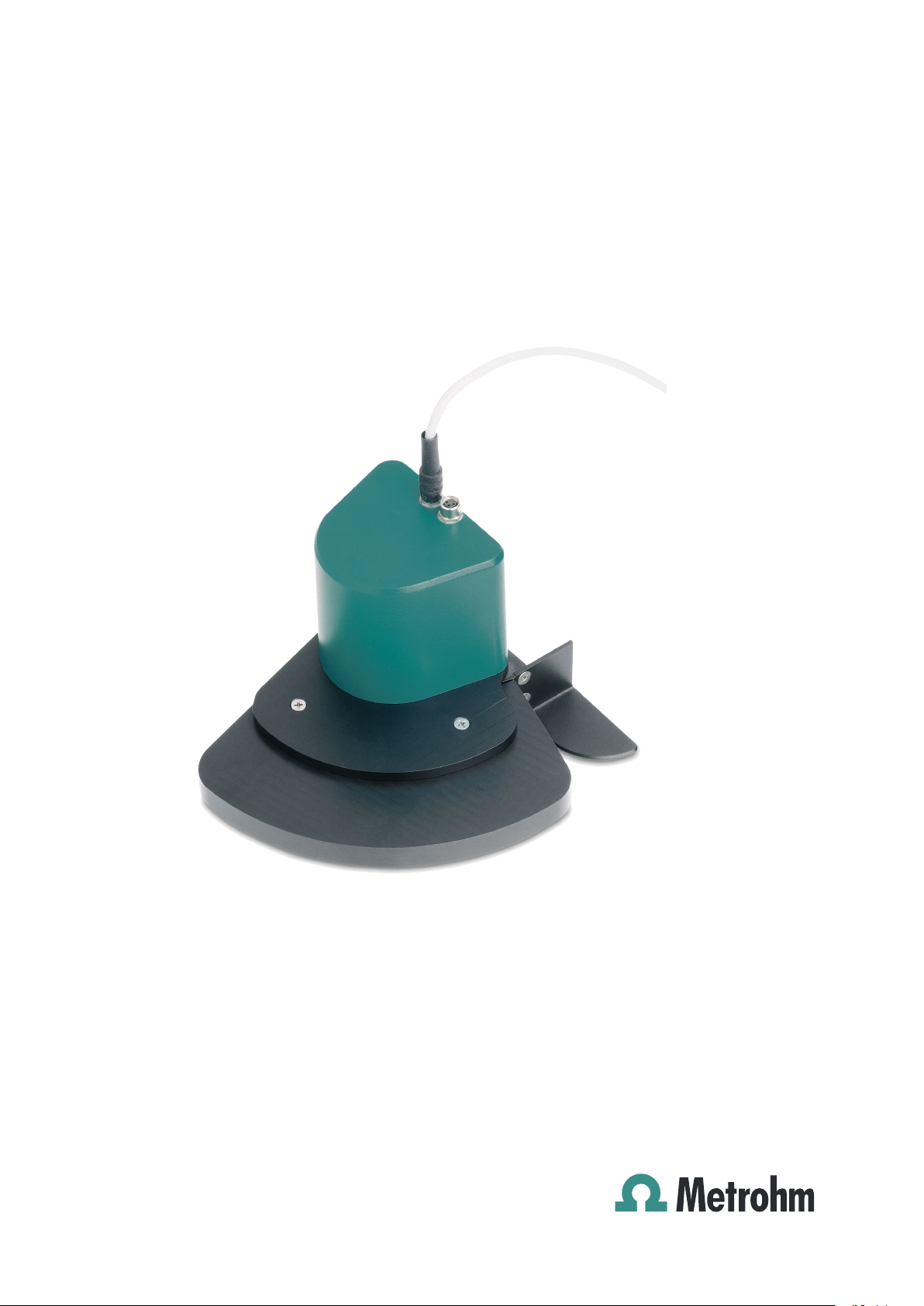

786 Swing Head

Manual

8.786.8001EN

Page 2

Page 3

Metrohm AG

CH-9101 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

786 Swing Head

Manual

8.786.8001EN 01/2010 dm

Page 4

Teachware

Metrohm AG

CH-9101 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although

with great care, errors cannot be entirely excluded. Should you notice any

mistakes please send us your comments using the address given above.

all the information given in this documentation has been checked

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

Table of contents

1 Introduction

1.1 Instrument description ......................................................... 1

1.2 Model versions ...................................................................... 1

1.3 Intended use ......................................................................... 2

1.4 About the documentation ................................................... 2

1.4.1 Symbols and conventions ........................................................ 2

1.5 Safety instructions ................................................................ 3

1.5.1 General notes on safety ........................................................... 3

1.5.2 Electrical safety ........................................................................ 3

1.5.3 Tubing and capillary connections ............................................. 4

1.5.4 Personnel safety ...................................................................... 4

1.5.5 Flammable solvents and chemicals ........................................... 5

1.5.6 Recycling and disposal ............................................................. 5

1

2 Overview of the instrument 6

3 Installation 8

3.1 Packaging .............................................................................. 8

3.2 Checks .................................................................................... 8

3.3 Mounting the Swing Head to the Sample Processor ........ 8

3.3.1 Mounting the Swing Head ....................................................... 8

3.3.2 Guide chain for cables and tubing ......................................... 11

3.3.3 Mounting the robotic arm reinforcement ............................... 12

3.4 Configuring the robotic arm .............................................. 13

3.5 Mounting the robotic arm ................................................. 16

3.6 Robotic arms with beaker sensor ..................................... 18

4 Handling and maintenance 20

4.1 General ................................................................................ 20

4.2 Quality Management and validation with Metrohm ....... 20

5 Troubleshooting 21

5.1 Robotic arm ......................................................................... 21

6 Appendix 23

6.1 Robotic arms ....................................................................... 23

6.1.1 Robotic arms for titration ....................................................... 23

6.1.2 Robotic arms for sample preparation ..................................... 25

6.1.3 Robotic arms for special applications ..................................... 26

786 Swing Head

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

7 Technical specifications

7.1 786 Swing Head ................................................................. 28

7.2 Supply connection .............................................................. 28

7.3 Safety specifications ........................................................... 28

7.4 Electromagnetic compatibility (EMC) ................................ 28

7.5 Ambient temperature ......................................................... 29

7.6 Reference conditions .......................................................... 29

7.7 Dimensions .......................................................................... 29

28

8 Conformity and warranty 30

8.1 Declaration of Conformity ................................................. 30

8.2 Warranty (guarantee) ......................................................... 31

8.3 Quality Management Principles ........................................ 32

9 Accessories 34

9.1 Scope of delivery 2.786.0010 ............................................ 34

9.2 Scope of delivery 2.786.0020 ............................................ 35

9.3 Scope of delivery 2.786.0030 ............................................ 36

9.4 Scope of delivery 2.786.0040 ............................................ 38

9.5 Optional accessories 2.786.0040 ...................................... 39

9.6 Scope of delivery 2.786.0240 ............................................ 40

9.7 Optional accessories 2.786.0240 ...................................... 41

Index 42

■■■■■■■■

IV

786 Swing Head

Page 7

■■■■■■■■■■■■■■■■■■■■■■

Table of figures

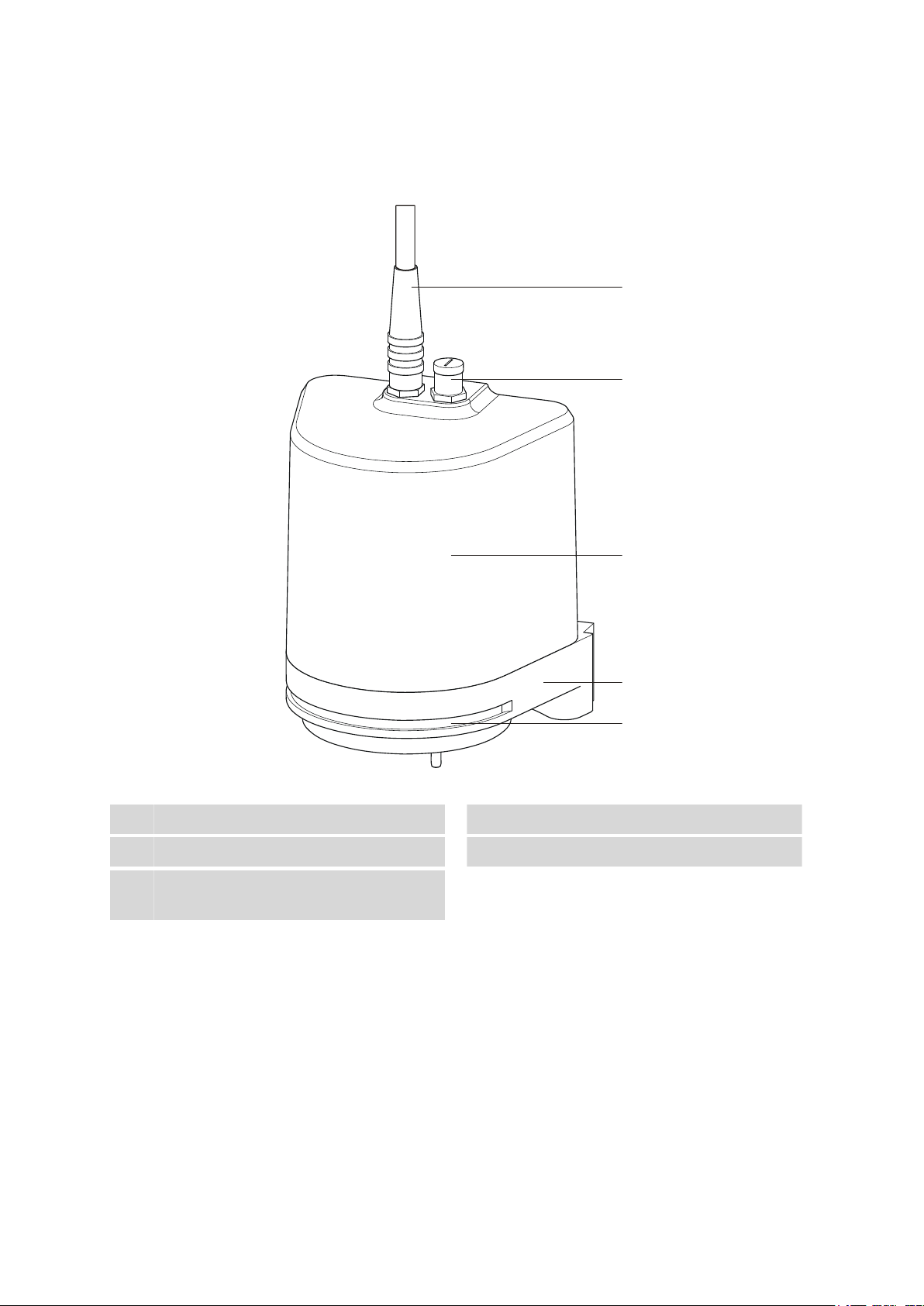

Figure 1 Front 786 Swing Head ...................................................................... 6

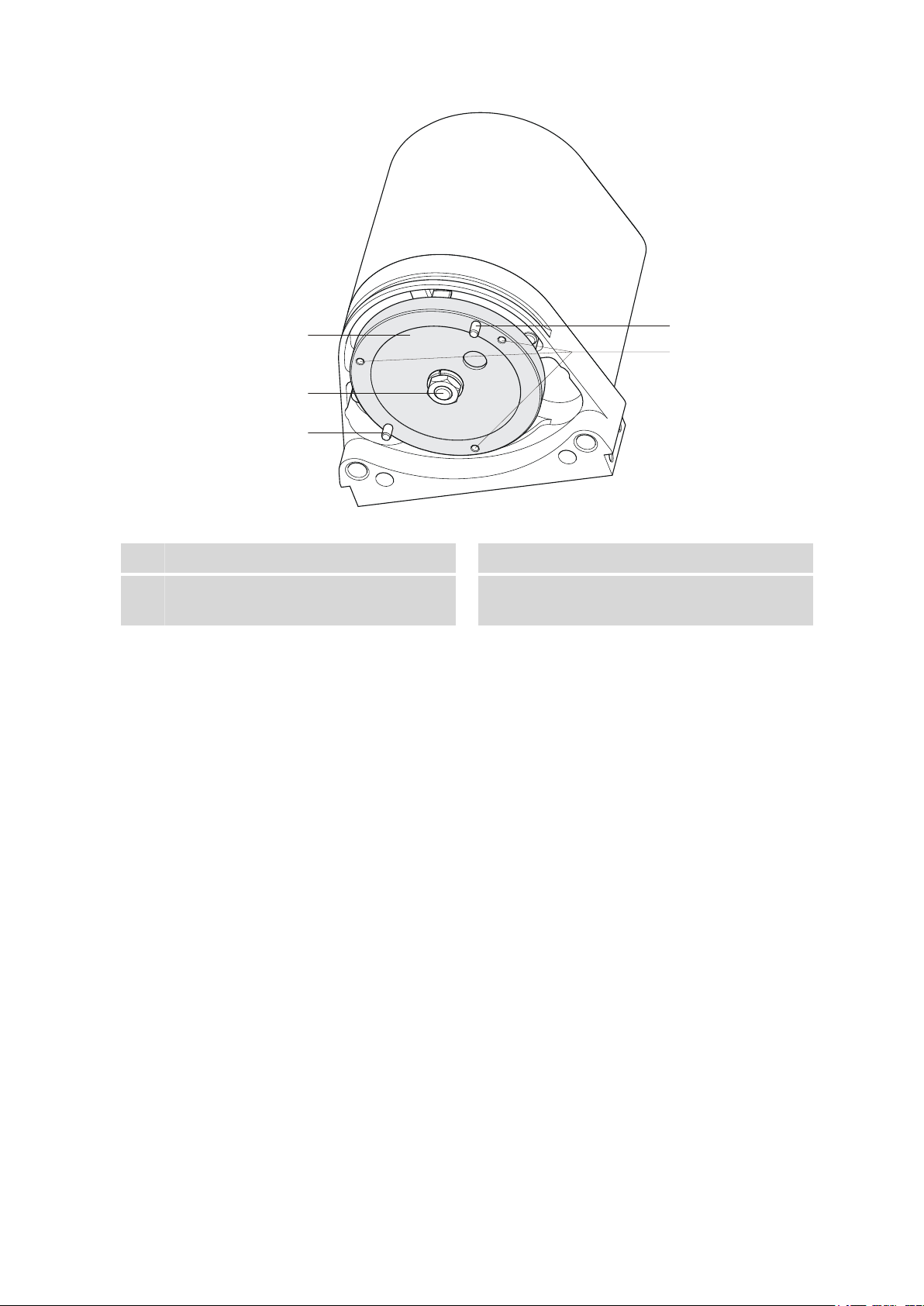

Figure 2 Underside 786 Swing Head ............................................................... 7

Figure 3 Connecting Swing Head .................................................................... 9

Figure 4 Mounting the tower extension ........................................................ 10

Figure 5 Mounting the Swing Head to the tower extension ........................... 11

Figure 6 Guide chain - Opening chain links ................................................... 12

Figure 7 Mounting the 6.2058.090 robotic arm reinforcement ..................... 13

Figure 8 Robotic arms - standard model versions: ......................................... 14

Figure 9 Configuration data of the robotic arms ............................................ 15

Figure 10 Limitation screw at the robotic arm ................................................. 16

Figure 11 Mounting the robotic arm ............................................................... 17

Figure 12 Connecting a beaker sensor (for example 6.1462.150) .................... 18

Table of figures

786 Swing Head

■■■■■■■■

V

Page 8

Page 9

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Instrument description

The 786 Swing Head is an auxiliary drive for the Sample Processors from

Metrohm, e.g. the 815 USB Robotic Sample Processor XL. It extends the

capabilities

precisely to any given position on a sample rack. The working area of the

Sample Processors is now being expanded even further. Now, even positions

outside of the sample rack can be moved to as a result. It is thus possible to

transfer samples from the sample rack into separate working stations in just

a few simple steps.

This is a high-precision motor drive, which is mounted on the tower of a

Sample Processor. Robotic arms of different construction types are available

for assembly on the 786 Swing Head. Equipped with the corresponding

accessories, these can be used for applications requiring a high degree of

flexibility or very complex working steps.

of these automation systems to include the possibility of moving

1 Introduction

1.2 Model versions

786 Swing Head with transfer robotic arm left (2.786.0010)

Additional equipment for the Sample Processors for transferring/pipetting

liquid samples out of smaller-sized sample vessels and into larger titration

vessels on the rack or into an external titration cell which is mounted to the

left of the workplace.

786 Swing Head with transfer robotic arm right (2.786.0020)

Additional equipment for the Sample Processors for transferring/pipetting

liquid samples from smaller-sized sample vessels and into larger titration

vessels on the rack or into an external titration cell which is mounted to the

right of the workplace.

786 Swing Head with titration robotic arm (2.786.0030)

Additional equipment for the Sample Processor for the purpose of direct

titration into sample vessels 75 mL in size and larger.

786 Swing Head without robotic arm (2.786.0040)

Additional equipment for the Sample Processor without titration or transfer

robotic arm.

786 Swing Head

786 Swing Head with reinforcement right (2.786.0240)

Reinforced Swing Head for assembly on Sample Processors.

■■■■■■■■

1

Page 10

1.3 Intended use

1.3 Intended use

■■■■■■■■■■■■■■■■■■■■■■

The 786

lytical laboratories. It is not suitable for usage in biochemical, biological or

medical environments in its basic equipment version.

This instrument is suitable for transferring chemicals and flammable solvents.

The usage of the 786 Swing Head therefore requires that the user has basic

knowledge and experience in the handling of toxic and caustic substances.

Knowledge with respect to the application of the fire prevention measures

prescribed for laboratories or production plants is also mandatory.

Swing Head is designed for usage in an automation system in ana-

1.4 About the documentation

Caution

Please read through this documentation carefully before putting the

instrument

warnings which have to be followed by the user in order to ensure safe

operation of the instrument.

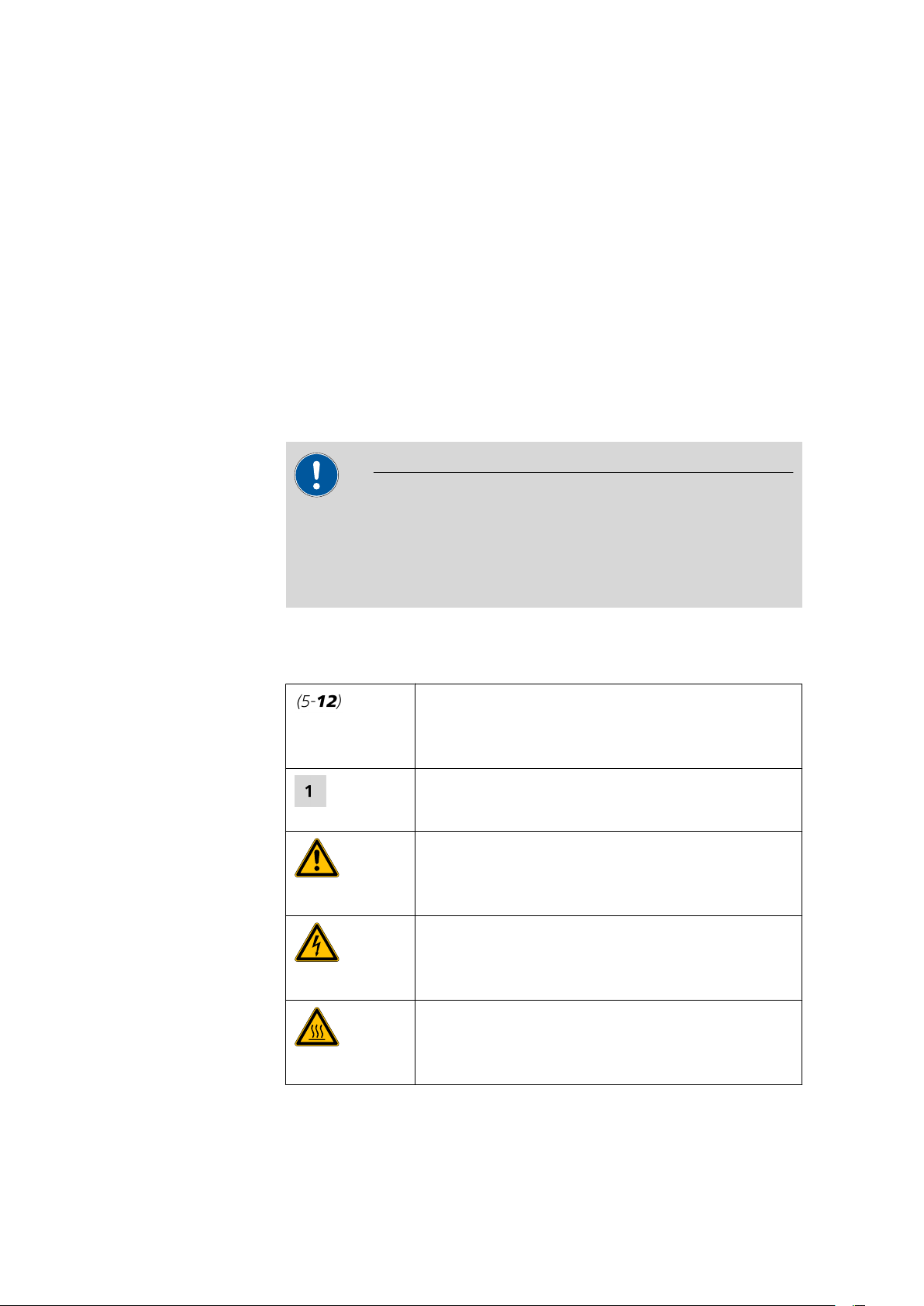

1.4.1 Symbols and conventions

The following symbols and styles are used in this documentation:

into operation. The documentation contains information and

Cross-reference to figure legend

The first number refers to the figure number, the second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

Warning

This symbol draws attention to a possible life hazard

or risk of injury.

Warning

This symbol draws attention to a possible hazard due

to electrical current.

Warning

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

■■■■■■■■

2

786 Swing Head

Page 11

■■■■■■■■■■■■■■■■■■■■■■

1.5 Safety instructions

1.5.1 General notes on safety

Warning

This instrument may only be operated in accordance with the specifications in this documentation.

1 Introduction

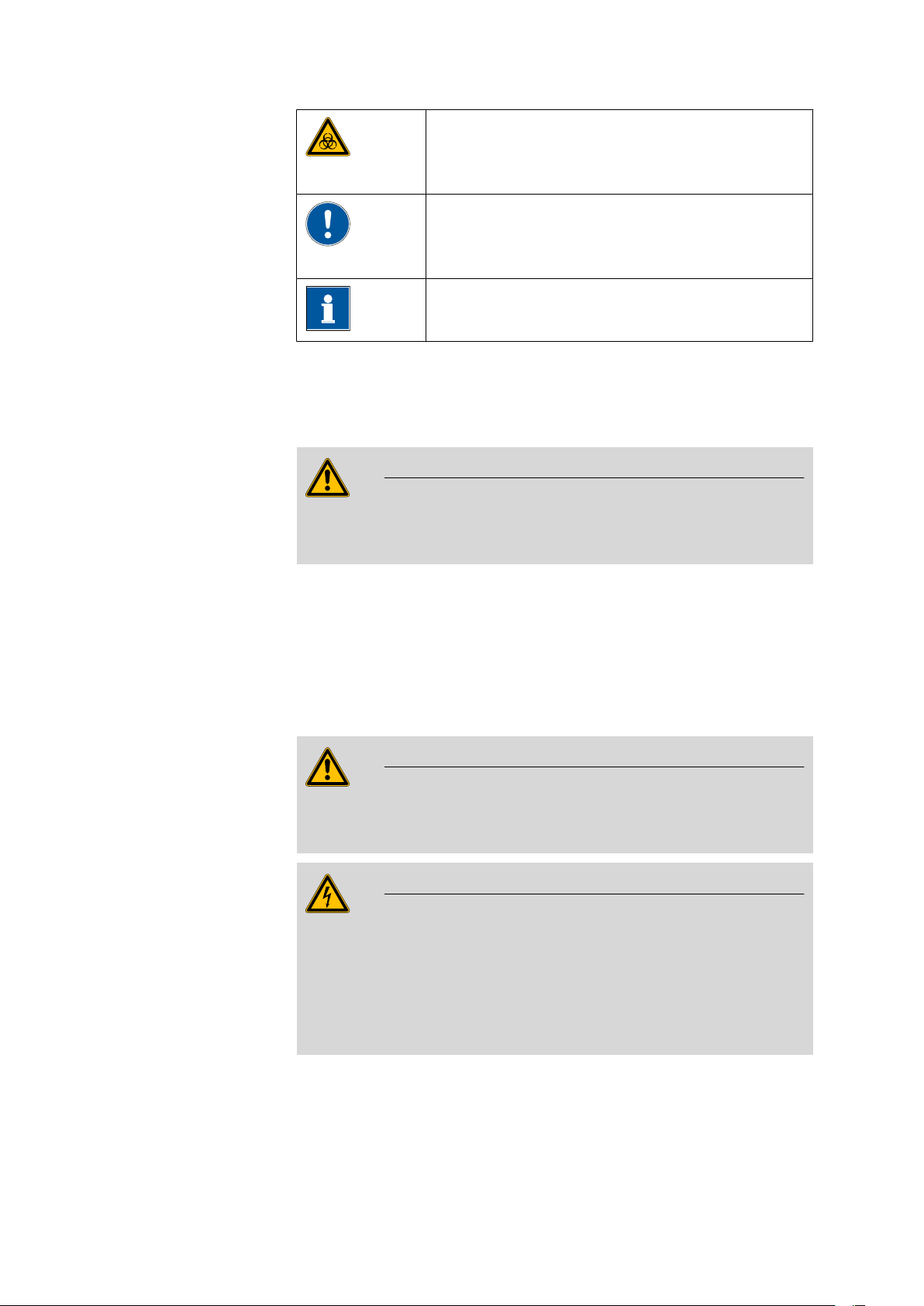

Warning

This symbol draws attention to a possible biological

hazard.

Caution

This symbol draws attention to a possible damage of

instruments or instrument parts.

Note

This symbol marks additional information and tips.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

1.5.2 Electrical safety

electrical safety when working with the instrument is ensured as part of

The

the international standard IEC 61010.

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

Never open the housing of the instrument. The instrument could be damaged by this. There is also a risk of serious injury if live components are

touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

Warning

Warning

786 Swing Head

■■■■■■■■

3

Page 12

1.5 Safety instructions

1.5.3 Tubing and capillary connections

Caution

Leaks in tubing and capillary connections are a safety risk. Tighten all

connections well by hand. Avoid applying excessive force to tubing connections. Damaged tubing ends lead to leakage. Appropriate tools can

be used to loosen connections.

Check the connections regularly for leakage. If the instrument is used

mainly

in unattended operation, then weekly inspections are mandatory.

1.5.4 Personnel safety

Warning

Wear protective goggles and working clothes suitable for laboratory work

while operating the 786 Swing Head. It is also advisable to wear gloves

when caustic liquids are used or in situations where glass vessels could

break.

■■■■■■■■■■■■■■■■■■■■■■

Warning

Always install the safety shield supplied with the equipment before using

the instrument for the first time. Pre-installed safety shields are not

allowed to be removed.

The 786 Swing Head may not be operated without a safety shield!

Warning

Personnel are not permitted to reach into the working area of the instrument while operations are running!

A considerable risk of injury exists for the user.

Warning

In the event of a possible blockage of a drive, the mains plug must be

pulled out of the socket immediately. Do not attempt to free jammed

sample vessels or other parts while the device is switched on. Blockages

can only be cleared when the instrument is in a voltage-free status; this

action generally involves a considerable risk of injury.

■■■■■■■■

4

786 Swing Head

Page 13

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

Warning

The 786

Swing Head is not suitable for utilization in biochemical, biolog-

ical or medical environments in its basic equipment version.

Appropriate protective measures must be implemented in the event that

potentially infectious samples or reagents are being processed.

1.5.5 Flammable solvents and chemicals

Warning

All relevant safety measures are to be observed when working with flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location.

■ Keep all sources of flame far from the workplace.

■ Clean up spilled liquids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

1.5.6 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

More details about the disposal of your old equipment can be obtained from

your local authorities, from waste disposal companies or from your local

dealer.

786 Swing Head

■■■■■■■■

5

Page 14

2 Overview of the instrument

1

2

3

4

5

■■■■■■■■■■■■■■■■■■■■■■

1

3

5

■■■■■■■■

6

Figure 1 Front 786 Swing Head

Connection cable

Housing

Guide slot

For the robotic arm reinforcement.

Connector for beaker sensor

2

Fastening plate

4

786 Swing Head

Page 15

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

3

4

2 Overview of the instrument

Figure 2 Underside 786 Swing Head

1

3

Drive disc

Drive pin

Swing axis

2

M2 bore holes

4

For fastening a robotic arm.

786 Swing Head

■■■■■■■■

7

Page 16

3.1 Packaging

1

1

2

3 Installation

3.1 Packaging

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

3.2 Checks

■■■■■■■■■■■■■■■■■■■■■■

Immediately

and without damage by comparing it with the delivery note.

after receipt, check whether the shipment has arrived complete

3.3 Mounting the Swing Head to the Sample Processor

3.3.1 Mounting the Swing Head

Dismounting the titration head holder

■■■■■■■■

8

Loosen the screws of the holder on both sides.

1

Loosen and remove the holder from the holder plate of the guide chain.

2

Use the hexagon key provided. The screws will be needed again later.

786 Swing Head

Page 17

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4

3 Installation

Connecting the Swing Head

The connection socket (Mini DIN) for the Swing Head drive is each located

on the rear of the tower next to the stirrer connector.

Figure 3 Connecting Swing Head

Connect the Swing Head as follows:

1

Plug in the cable

■ Guide the connection cable of the Swing Head through the guide

chain of the tower (see Chapter 3.3.2, page 11).

■ Plug the Mini DIN plug into the socket 'Swing Head'.

Mounting the Swing Head

Screw the Swing Head tightly to the holder plate of the guide chain.

1

Clamp the Swing Head between the guide jaws.

2

Screw the Swing Head to the guide jaws with the screws previously

3

loosened.

786 Swing Head

■■■■■■■■

9

Page 18

3.3 Mounting the Swing Head to the Sample Processor

1

Place the connection cable into the guide chain (see Chapter 3.3.2,

4

page 11).

Mounting the Swing Head with tower extension

For certain applications, it may be necessary to mount the 786 Swing

Head

at a higher position. A 6.2058.010 tower extension can be moun-

ted on the lift for this purpose.

First, remove the titration head holder from its mount (see Chapter 3.3.1,

page 8). Proceed afterwards as follows:

Fasten the tower extension to the lift guide of the Sample Processor in

1

accordance with the following illustration and fix it in place with the

screws provided.

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

10

Figure 4 Mounting the tower extension

Mount the Swing Head to the holder plate of the guide chain.

2

786 Swing Head

Page 19

■■■■■■■■■■■■■■■■■■■■■■

2

3

3 Installation

Figure 5 Mounting the Swing Head to the tower extension

Screw the Swing Head tightly to the upper end of the tower extension.

3

3.3.2 Guide chain for cables and tubing

Tubings and cables can be placed into the guide chain.

You can open the individual chain links with a screwdriver as follows.

1

Open the guide chain

■ Insert a screwdriver into the groove located on the side of a chain

link.

■ Loosen the clip with a forceful leverage movement.

■ Pull the clip out of the chain by hand.

■ Repeat the above actions for each chain link.

786 Swing Head

■■■■■■■■

11

Page 20

3.3 Mounting the Swing Head to the Sample Processor

Figure 6 Guide chain - Opening chain links

2

Insert into the guide chain

■ Place the required tubings or cables into the guide chain.

3

Close the guide chain

■ Close the clip for each chain link again by hand and apply forceful

pressure to snap them into place.

■■■■■■■■■■■■■■■■■■■■■■

Caution

Take care to ensure when mounting tubing and cables that there is no

traction on the drives while moving the lift or swiveling the robotic arm.

This could lead to overloading of and possible damage to the drive.

Remove

the clips of the two lowest chain links when you install the rinsing

and aspiration tubing.

3.3.3 Mounting the robotic arm reinforcement

In cases in which it is necessary to take up or strip off a filter or a pipetting

tip on the robotic arm, you must mount a 6.2058.090 robotic arm rein-

forcement. The reinforcement provides the robotic arm with stable resistance when picking up or stripping the tools used and prevents it from

bending.

The reinforcement has to be placed before mounting a robotic arm. Proceed

as follows:

■■■■■■■■

12

786 Swing Head

Page 21

■■■■■■■■■■■■■■■■■■■■■■

2

1

6.2058.090

Figure 7 Mounting the 6.2058.090 robotic arm reinforcement

Shift the reinforcement from the front over the holder plate of the

1

Swing Head.

Screw the reinforcement to the lift guide with the screws provided.

2

3 Installation

3.4 Configuring the robotic arm

A variety of differently constructed robotic arms is available for enabling a

range of applications. They differ from one another in their geometric

wide

sizes, e.g. swing radius or maximum permissible swing angle. The configuration data must be entered in the Sample Processor or in the control

software prior to the assembly of the robotic arm. The data required

is engraved on the underside of the robotic arm. Examples of the most

common robotic arms are shown in the illustration below.

786 Swing Head

■■■■■■■■

13

Page 22

3.4 Configuring the robotic arm

321

4 5

Figure 8 Robotic arms - standard model versions:

■■■■■■■■■■■■■■■■■■■■■■

Transfer robotic arm (6.1462.030)

1

For sample transfer, left-swinging.

Titration robotic arm (6.1462.050)

3

With titration head, left-/right-swinging *).

Macro robotic arm (6.1462.070)

5

With holder for a 6.1458.XXX titration head

insert, right-swinging.

*) can be mounted in two ways

A detailed list of the available robotic arms, along with the necessary

configuration data, can be found in Chapter Robotic arms, page 23ff.

The following figure illustrates the most important configuration data that

needs

to be set in the control software to ensure correct usage of a robotic

arm (left-swinging, here).

Note

Transfer robotic arm (6.1462.040)

2

For sample transfer, right-swinging.

Macro robotic arm (6.1462.060)

4

With holder for a 6.1458.XXX titration head

insert, left-swinging.

■■■■■■■■

14

786 Swing Head

Page 23

■■■■■■■■■■■■■■■■■■■■■■

2

3

4

5

1

3 Installation

Figure 9 Configuration data of the robotic arms

Swing axis

1

This runs through the middle of the Swing

Head drive.

Source axis

3

runs from the swing axis to the midpoint

This

of the sample rack and marks the initial position of the robotic arm.

Max. swing angle

5

This stands for the swing range that the

robotic arm can reach. The range runs from

the source axis to the maximum possible

robotic arm position.

Swing direction

Left-swinging (swing direction +) or right-swinging (swing direction –)

model

versions are available as different types of robotic arms. Left-swinging

Swing radius

2

is determined by the length of the robotic

This

arm. The radius runs from the axis of rotation

to the midpoint of the tip of the robotic arm.

Swing offset

4

determines the 0° position of the robotic

This

arm.

786 Swing Head

■■■■■■■■

15

Page 24

3.5 Mounting the robotic arm

1

2

means swinging from the initial position (pointing towards the middle of the

rack) outwards to the left.

In

the case of a Sample Processor with two towers, a right-swinging robotic

arm must be mounted on Tower 1, a left-swinging robotic arm on Tower 2.

If the alignment is incorrect, the two robotic arms could possibly come into

contact with one another, resulting in damage to the drives.

3.5 Mounting the robotic arm

Depending on the model, robotic arms can be mounted as either rightswinging or left-swinging. The position of the limitation screw of the robotic

arm must be taken into account during assembly. The limitation screw must

face the tower of the Sample Processor during the mounting of the robotic

arm. The following illustration shows on the left the position of the limitation

screw at a right-swinging robotic arm (Position 1) and on the right with a

left-swinging robotic arm (Position 2).

■■■■■■■■■■■■■■■■■■■■■■

Figure 10 Limitation screw at the robotic arm

For robotic arms which can be mounted in two different ways (e.g.

6.1462.050), the limitation screw can be fitted in accordance with the

required assembly direction (see above).

Note

The configuration data of a robotic arm must be configured in the control

software before it is mounted (see Chapter 3.4, page 13).

Mounting the robotic arm

The mounting of a robotic arm on the Swing Head is described here, taking

as an example a 6.1462.070 robotic arm for titration and a 6.1458.040

titration head insert. Initialize the Sample Processor before performing the

mounting sequence.

After the initialization of the Sample Processor, the drive disc of the Swing

Head

is positioned as though the robotic arm were located in the outermost

position.

16

■■■■■■■■

786 Swing Head

Page 25

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

Figure 11 Mounting the robotic arm

Mount the robotic arm as follows:

Place the 6.1458.040 titration head insert in the opening of the robotic

1

arm and screw tight with the supplied screws.

Hold the robotic arm in such a way that the opening faces to the right.

2

While doing so, rotate the robotic arm outwards as far as possible,

i.e. towards the tower - see above. Slip the robotic arm from below

over the guide pins of the drive disc of the Swing Head.

3 Installation

786 Swing Head

Note

Take care to ensure that you do not twist the drive disc, thus causing

pressure against the drive.

Screw the robotic arm to the Swing Head tightly with the screws and

3

washers provided.

■■■■■■■■

17

Page 26

3.6 Robotic arms with beaker sensor

6.1462.150

1

2

3

3.6 Robotic arms with beaker sensor

For

safety reasons, the presence of a beaker on the sample rack of a Sample

Processor can be detected. Some robotic arm model versions are therefore

equipped with a beaker sensor.

■■■■■■■■■■■■■■■■■■■■■■

Figure 12 Connecting a beaker sensor (for example 6.1462.150)

Plug of the connection cable

1

Beaker sensor

3

Contact sensor in accordance with the Piezo

principle

Connection socket on the 786 Swing

2

Head

A robotic arm with beaker sensor is mounted as described on page 16. The

connection of the sensor cable must take place while the instrument is

switched off.

beaker sensor is automatically recognized when switching on the instru-

The

ment.

Functioning of the beaker sensor

If the beaker sensor of the robotic arm is activated, then the lift of the Sample

Processor will move automatically into its work position after a MOVE command. The presence of the sample vessel is checked by the robotic arm

setting down on top of it.

■■■■■■■■

18

786 Swing Head

Page 27

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

No separate LIFT command is required in such cases.

Note

The work position of the lift must be configured in such a way that the

robotic arm is in place on the sample vessel. The robotic arm must bend

slightly while doing so, so that the Piezo sensor will generate a signal.

very

786 Swing Head

■■■■■■■■

19

Page 28

4.1 General

■■■■■■■■■■■■■■■■■■■■■■

4 Handling and maintenance

4.1 General

The

786 Swing Head requires appropriate care. Excess contamination of the

instrument may result in functional disruptions and a reduction in the service

life of the sturdy mechanics and electronics of the instrument.

Severe contamination can also have an influence on the measured results.

Regular cleaning of exposed parts can prevent this to a large extent.

Spilled chemicals and solvents must be removed immediately.

4.2 Quality Management and validation with Metrohm

Quality Management

Metrohm offers you comprehensive support in implementing quality management measures for instruments and software. Further information on

this can be found in the brochure «Quality Management with

Metrohm» available from your local Metrohm agent.

Validation

Please contact your local Metrohm agent for support in validating instruments and software. Here you can also obtain validation documentation to

provide help for carrying out the Installation Qualification (IQ) and the

Operational Qualification (OQ). IQ and OQ are also offered as a service

by the Metrohm agents. In addition, various application bulletins are also

available on the subject, which also contain Standard Operating Proce-

dures (SOP) for testing analytical measuring instruments for reproducibility

and correctness.

Maintenance

Electronic and mechanical functional groups in Metrohm instruments can

and should be checked as part of regular maintenance by specialist personnel from Metrohm. Please ask your local Metrohm agent regarding the

precise terms and conditions involved in concluding a corresponding maintenance agreement.

Note

You can find information on the subjects of quality management, valida-

and maintenance as well as an overview of the documents currently

tion

available at www.metrohm.com/com/ under Support.

■■■■■■■■

20

786 Swing Head

Page 29

■■■■■■■■■■■■■■■■■■■■■■

5 Troubleshooting

5.1 Robotic arm

Problem Cause Remedy

5 Troubleshooting

The robotic arm moves

all the way outward

and buzzes.

Sample Processor – The Swing

Head is not correctly configured.

Sample Processor – Robotic

arm is wrongly mounted.

1. Immediately remove the mains plug

and close the control software.

2.

Dismount the robotic arm.

3. Plug in the mains plug again and

restart the control software.

4. In the control software under "Configuration" (or under "Device manager" for Touch Control), enter the

correct value for the Swing offset.

5. Initialize the instrument.

6. Remount the robotic arm.

1. Immediately remove the mains plug

and close the control software.

Dismount the robotic arm.

2.

3. Plug in the mains plug again and

restart the control software.

4. Check the configuration of the robotic

arm and correct it if necessary (leftswinging ⇔ right-swinging).

5. Initialize the instrument.

6. Mount the robotic arm correctly.

The Swing Head either

misses the rack positions totally or is inaccurate

786 Swing Head

Sample Processor – The Swing

Head is not correctly configured.

Sample Processor – The axial

distance is not correctly configured.

Sample Processor – The wrong

rack table is being used.

1. In the control software under "Configuration" (or under "Device manager" for Touch Control), enter the

correct values for the Swing radius,

Swing offset etc.

2.

Initialize the instrument.

1. In the control software under "Configuration" (or under "Device manager" for Touch Control), enter the

correct value for the Axial distance.

2.

Initialize the instrument.

Initialize the rack using the function Ini-

tialize rack in the "Manual control".

■■■■■■■■

21

Page 30

5.1 Robotic arm

Problem Cause Remedy

■■■■■■■■■■■■■■■■■■■■■■

Swing Head – The Swing Head

drive is defective.

Contact the Metrohm Service.

■■■■■■■■

22

786 Swing Head

Page 31

■■■■■■■■■■■■■■■■■■■■■■

6.1462.050

6.1462.060

6.1462.070

6.1462.260

6 Appendix

6.1 Robotic arms

6.1.1 Robotic arms for titration

Table 1 Configuration data of the titration robotic arms

Type 6.1462.050 6.1462.060 6.1462.070 6.1462.260

6 Appendix

Swing direction +/– + – +

Swing offset 0° –8° –8° –8°

Max. swing angle 84° 73° 73° 105°

Swing radius 110 mm 127 mm 127 mm 110 mm

6.1462.050

6.1462.060

Robotic arm with titration head, left or right-swinging

For titration in 75 mL sample vessels and larger.

The arm can be equipped with two microelectrodes, one propeller stirrer

and three spray nozzles. Two buret tips with anti-diffusion valve and one

aspiration

arm.

Material: PP

Robotic arm with holder for a titration head, left-swinging

The arm can be modified to create the desired titration robotic arm by means

of the installation of a titration head 6.1458.xxx.

Material: PP

tip with connections for M6 tubing are already retracted into the

6.1462.070

786 Swing Head

Robotic arm with holder for a titration head, right-swinging

■■■■■■■■

23

Page 32

6.1 Robotic arms

6.1462.150

6.1462.160

6.1462.170

■■■■■■■■■■■■■■■■■■■■■■

The arm can be modified to create the desired titration robotic arm by means

of the installation of a titration head 6.1458.xxx.

Material: PP

6.1462.260

Robotic arm with holder for a titration head, left-swinging, external

The

arm can be modified to create the desired titration robotic arm by means

of the installation of a titration head 6.1458.xxx. The cutout permits movement to external positions near the rack, e.g. an external rinsing station.

Material: PVC

Table 2 Configuration data of the robotic arms with beaker sensor

Type 6.1462.150 6.1462.160 6.1462.170

Swing direction +/– + –

Swing offset 0° –8° –8°

Max. swing angle 84° 73° 73°

Swing radius 110 mm 127 mm 127 mm

6.1462.150

Robotic arm with titration head and beaker sensor, left or rightswinging

For titration in 75 mL sample vessels and larger.

The arm can be equipped with two microelectrodes, one propeller stirrer

and three spray nozzles. Two buret tips with anti-diffusion valve and one

aspiration

tip with connections for M6 tubing are already retracted into the

arm.

Material: PP

6.1462.160

Robotic arm with holder for a titration head and beaker sensor,

left-swinging

■■■■■■■■

24

786 Swing Head

Page 33

■■■■■■■■■■■■■■■■■■■■■■

6.1462.030

6.1462.040

6.1462.090

6.1462.240

6 Appendix

The arm can be modified to create the desired titration robotic arm by means

of the installation of a titration head 6.1458.xxx.

Material: PP

6.1462.170

Robotic arm with holder for a titration head and beaker sensor,

right-swinging

The

arm can be modified to create the desired titration robotic arm by means

of the installation of a titration head 6.1458.xxx.

Material: PP

6.1.2 Robotic arms for sample preparation

Table 3 Configuration data of the robotic arms for sample preparation

Type 6.1462.030 6.1462.040 6.1462.090 6.1462.240

Swing direction + – – –

Swing offset 8° 8° 8° –8.6°

Max. swing angle 117° 117° 117° 122°

Swing radius 112 mm 112 mm 112 mm 149.8 mm

6.1462.030

Robotic arm with transfer head, left-swinging

Robotic

arm for fully automated pipetting or dilution of liquid samples with

Sample Processor Systems.

Material: PP

6.1462.040

Robotic arm with transfer head, right-swinging

Robotic arm for fully automated pipetting or dilution of liquid samples with

Sample Processor Systems.

Material: PP

6.1462.090

Robotic arm with Luer lock adapter, right-swinging

For the connection of hollow needles with Luer lock connection. Suitable

for the transfer of samples from sealed vials with septum seal.

Material: PP

786 Swing Head

■■■■■■■■

25

Page 34

6.1 Robotic arms

6.1462.250

6.1462.080

■■■■■■■■■■■■■■■■■■■■■■

6.1462.240

Robotic arm with transfer head, bent, right-swinging

The transfer head can, when equipped with 6.1808.220 adapter, be used

as a holder for various tools with Luer connection on multirow racks.

Material: PP

6.1.3 Robotic arms for special applications

Table 4 Configuration data of the special robotic arms

Type 6.1462.250 6.1462.080

Swing direction + +

Swing offset 0° 8°

Max. swing angle 115.5° 117°

Swing radius 110 mm 112 mm

6.1462.250

Robotic arm as holder for a Polytron, left-swinging

The

robotic arm makes it possible to use the Polytron for sample preparation

on multirow sample racks. It contains one retracted buret tip for adding

solvents and three spray nozzles for cleaning.

Material: PP

6.1462.080

Robotic arm DIS-COVER, left-swinging

■■■■■■■■

26

786 Swing Head

Page 35

■■■■■■■■■■■■■■■■■■■■■■

6 Appendix

Robotic arm for placing and removing sample vessel covers (75 and 250 mL)

covers

6.2037.050 und 6.2037.060) on the sample rack of a Robotic Sample

Processor.

Material: PP

786 Swing Head

■■■■■■■■

27

Page 36

7.1 786 Swing Head

7 Technical specifications

7.1 786 Swing Head

■■■■■■■■■■■■■■■■■■■■■■

Load

Rate

Beaker sensor

Approx. 15 N

10…55 angular degree/s

For the robotic arm with sensor

socket

7.2 Supply connection

Connector plug

9-pin Mini DIN plug

For connecting to a Sample Processor (Swing Head socket)

7.3 Safety specifications

Design and testing

Safety instructions

According to EN/IEC/UL 61010-1, EN/IEC 61010-2-081, CSA-C22.2 No.

61010-1, protection class ⅠⅠⅠ

This document contains safety instructions which have to be followed by

the user in order to ensure safe operation of the instrument.

7.4 Electromagnetic compatibility (EMC)

Emission

Immunity

■■■■■■■■

28

Standards fulfilled

■ EN/IEC 61326-1

■ EN/IEC 61000-6-3

■ EN 55022 / CISPR 22

■ EN/IEC 61000-3-2

Standards fulfilled

■ EN/IEC 61326-1

■ EN/IEC 61000-6-2

■ EN/IEC 61000-4-2

■ EN/IEC 61000-4-3

■ EN/IEC 61000-4-4

■ EN/IEC 61000-4-5

■ EN/IEC 61000-4-6

■ EN/IEC 61000-4-8

■ EN/IEC 61000-4-11

■ EN/IEC 61000-4-14

■ NAMUR

786 Swing Head

Page 37

■■■■■■■■■■■■■■■■■■■■■■

7.5 Ambient temperature

7 Technical specifications

Nominal function

range

Storage

Transport

5…45 °C

Humidity < 80 %

–20…60 °C

–40…60 °C

7.6 Reference conditions

Ambient temperature

Relative humidity

25 °C (±3 °C)

≤60 %

7.7 Dimensions

Width

Height

Depth

Weight (without

accessories)

0.10 m

0.15 m

0.09 m

0.97 kg

Material

Housing

Metal housing, surface-treated

786 Swing Head

■■■■■■■■

29

Page 38

8.1 Declaration of Conformity

8 Conformity and warranty

8.1 Declaration of Conformity

This is to certify the conformity to the standard specifications for electrical

appliances and accessories, as well as to the standard specifications for

security and to system validation issued by the manufacturing company.

■■■■■■■■■■■■■■■■■■■■■■

Name of commodity

Electromagnetic compatibility

786 Swing Head

The

786 Swing Head is a motor drive for robotic arms which can be used

with Metrohm Sample Processors.

This instrument has been built and has undergone final type testing according to the standards:

Emission: EN/IEC 61326-1: 2002, EN/IEC 61000-6-3: 2001,

EN 55022 / CISPR 22: 2006

EN/IEC 61000-3-2: 2000

Immunity: EN/IEC 61326-1: 2002, EN/IEC 61000-6-2: 2001,

EN/IEC 61000-4-2: 2001,

EN/IEC 61000-4-3: 2002,

EN/IEC 61000-4-4: 2004,

EN/IEC 61000-4-5: 2001,

EN/IEC 61000-4-6: 2001,

EN/IEC 61000-4-8: 2001,

EN/IEC 61000-4-11: 2004,

EN/IEC 61000-4-14: 2004, NAMUR: 2004

,

Safety specifications

■■■■■■■■

30

EN/IEC 61010-1, protection class III

This instrument meets the requirements of the CE mark as contained in the

EU directives

specifications:

EN 61326-1 Electrical equipment for measurement, control and

EN 61010-1 Safety requirements for electrical equipment for

EN 61010-2-081 Particular requirements for automatic and semi-

2006/95/EC (LVD), 2004/108/EC (EMC). It fulfils the following

laboratory use – EMC requirements

measurement, control and laboratory use

automatic laboratory equipment for analysis and

other purposes

786 Swing Head

Page 39

■■■■■■■■■■■■■■■■■■■■■■

8 Conformity and warranty

Manufacturer

Metrohm Ltd., CH-9101 Herisau/Switzerland

Metrohm Ltd. is holder of the SQS certificate ISO 9001:2000 Quality management

system for development, production and sales of instruments and

accessories for ion analysis.

Herisau, 31 March, 2003

D. Strohm

Vice President, Head of R&D

8.2 Warranty (guarantee)

Metrohm

material, design or manufacturing errors. The warranty period is 36 months

from the day of delivery; for day and night operation it is 18 months. The

warranty remains valid on condition that the service is provided by an

authorized Metrohm service organization.

guarantees that the deliveries and services it provides are free from

A. Dellenbach

Head of Quality Management

Glass breakage is excluded from the warranty for electrodes and other

glassware. The warranty for the accuracy corresponds to the technical specifications given in this manual. For components from third parties that make

up a considerable part of our instrument, the manufacturer's warranty provisions apply. Warranty claims cannot be pursued if the Customer has not

complied with the obligations to make payment on time.

During the warranty period Metrohm undertakes, at its own choice, to either

repair at its own premises, free of charge, any instruments that can be shown

to be faulty or to replace them. Transport costs are to the Customer's

account.

Faults arising from circumstances that are not the responsibility of Metrohm,

such as improper storage or improper use, etc. are expressly excluded from

the warranty.

786 Swing Head

■■■■■■■■

31

Page 40

8.3 Quality Management Principles

8.3 Quality Management Principles

Metrohm Ltd. holds the ISO 9001:2000 Certificate, registration number

10872-02, issued by SQS (Swiss Association for Quality and Management

Systems). Internal and external audits are carried out periodically to assure

that the standards defined by Metrohm’s QM Manual are maintained.

The steps involved in the design, manufacture and servicing of instruments

are fully documented and the resulting reports are archived for ten years.

The development of software for PCs and instruments is also duly documented

possession of Metrohm. A non-disclosure agreement may be asked to be

provided by those requiring access to them.

The implementation of the ISO 9001:2000 quality management system is

described in Metrohm’s QM Manual, which comprises detailed instructions

on the following fields of activity:

Instrument development

The organization of the instrument design, its planning and the intermediate

controls are fully documented and traceable. Laboratory testing accompanies all phases of instrument development.

and the documents and source codes are archived. Both remain the

■■■■■■■■■■■■■■■■■■■■■■

Software development

Software development occurs in terms of the software life cycle. Tests are

performed to detect programming errors and to assess the program’s functionality in a laboratory environment.

Components

All components used in the Metrohm instruments have to satisfy the quality

standards that are defined and implemented for our products. Suppliers of

components are audited by Metrohm as the need arises.

Manufacture

The measures put into practice in the production of our instruments guarantee a constant quality standard. Production planning and manufacturing

procedures, maintenance of production means and testing of components,

intermediate and finished products are prescribed.

Customer support and service

Customer support involves all phases of instrument acquisition and use by

the customer, i.e. consulting to define the adequate equipment for the analytical problem at hand, delivery of the equipment, user manuals, training,

after-sales service and processing of customer complaints. The Metrohm

service organization is equipped to support customers in implementing

standards such as GLP, GMP, ISO 900X, in performing Operational Qualifi-

■■■■■■■■

32

786 Swing Head

Page 41

■■■■■■■■■■■■■■■■■■■■■■

8 Conformity and warranty

cation and Performance Verification of the system components or in carrying

out

the System Validation for the quantitative determination of a substance

in a given matrix.

786 Swing Head

■■■■■■■■

33

Page 42

9.1 Scope of delivery 2.786.0010

9 Accessories

Note

Subject to change without notice.

9.1 Scope of delivery 2.786.0010

Qty. Order no. Description

1 1.786.0010 786 Swing Head

Additional drive for a Sample Processor required for the usage of a

robotic arm.

■■■■■■■■■■■■■■■■■■■■■■

1 6.1462.030 Robotic arm with transfer head for 786

Swing Head, left swinging

Transfer robotic arm for liquid handling purposes

Material: PP (black)

1 6.1562.100 Pipetting tubing / 10 mL

Pipetting tubing for fully automated liquid transfer.

Material: FEP

Length (m): 3.8

Volume (mL): 10

1 6.1823.010 Guiding shaft to Pipetting tubing

Used with the Transfer Arm of the Robotic Sample Processor

Outer diameter (mm): 6

Length (mm): 163

■■■■■■■■

34

786 Swing Head

Page 43

■■■■■■■■■■■■■■■■■■■■■■

Qty. Order no. Description

1 6.2621.120 Hexagon key 1.5 mm

2 V.024.4012 Counter sunk screw

1 8.786.8001EN 786 Swing Head Manual

9.2 Scope of delivery 2.786.0020

9 Accessories

Qty. Order no. Description

1 1.786.0010 786 Swing Head

Additional drive for a Sample Processor required for the usage of a

robotic arm.

1 6.1462.040 Robotic arm with transfer head for 786

Swing Head, right swinging

Transfer robotic arm for liquid handling purposes

Material: PP (black)

1 6.1562.100 Pipetting tubing / 10 mL

Pipetting tubing for fully automated liquid transfer.

Material: FEP

Length (m): 3.8

Volume (mL): 10

786 Swing Head

■■■■■■■■

35

Page 44

9.3 Scope of delivery 2.786.0030

Qty. Order no. Description

1 6.1823.010 Guiding shaft to Pipetting tubing

Used with the Transfer Arm of the Robotic Sample Processor

Outer diameter (mm): 6

Length (mm): 163

1 6.2621.120 Hexagon key 1.5 mm

■■■■■■■■■■■■■■■■■■■■■■

2 V.024.4012 Counter sunk screw

1 8.786.8001EN 786 Swing Head Manual

9.3 Scope of delivery 2.786.0030

Qty. Order no. Description

1 1.786.0010 786 Swing Head

Additional drive for a Sample Processor required for the usage of a

robotic arm.

■■■■■■■■

36

786 Swing Head

Page 45

■■■■■■■■■■■■■■■■■■■■■■

Qty. Order no. Description

1 6.1462.050 Robotic arm with titration head for 786

Swing Head, left or right swinging

Titration head for Swing Head

Material: PP (black)

1 6.1808.040 Thread adapter M6 outer / M8 inner

Outer thread M6, inner thread M8.

Material: PTCFE

9 Accessories

1 6.1909.030 Stirring propeller / 104 mm

Propeller stirrer with PP shaft, PVDF tip. Length from the SGJ: 104 mm.

For KF applications with 722, 802 Rod Stirrer

Material: PP

2 6.2042.030 Buret tip clip (rod stirrer)

Clip for proper alignment of buret tips, dosing or aspiration tubings

using a rod stirrer in the titration beaker of a sample changer

Material: PEEK

786 Swing Head

■■■■■■■■

37

Page 46

9.4 Scope of delivery 2.786.0040

Qty. Order no. Description

1 6.2621.120 Hexagon key 1.5 mm

2 V.024.4012 Counter sunk screw

1 8.786.8001EN 786 Swing Head Manual

9.4 Scope of delivery 2.786.0040

■■■■■■■■■■■■■■■■■■■■■■

Qty. Order no. Description

1 1.786.0010 786 Swing Head

Additional drive for a Sample Processor required for the usage of a

robotic arm.

1 6.2621.120 Hexagon key 1.5 mm

2 V.024.4012 Counter sunk screw

1 8.786.8001EN 786 Swing Head Manual

■■■■■■■■

38

786 Swing Head

Page 47

■■■■■■■■■■■■■■■■■■■■■■

9.5 Optional accessories 2.786.0040

Order no. Description

6.1462.240 Transfer head for 786 Swing Head, bent and right

swinging

Transfer head, bent and right swinging, for 786 Swing Head. In combination with

the

6.1808.220 Adapter the transfer head can be used on multi-row racks to pick

up tools with luer connection.

Material: PP (black)

9 Accessories

6.1462.250

Swing arm for Polytron and 786 Swing Head, left swinging, with one buret tip for

the

additiona of solvent or titrant and three spray nozzles for cleaning. The swing

arm allows the usage of the Polytron for sample preparation on multi row racks.

Material: PP (black)

Material 2: Metal

6.1462.260

Titration head holder to 786 Swing Head with possibility to swing to external

positions

Material: PVC

Swing arm for Polytron and 786 Swing Head, left

swinging

Robotic arm with holder for titration head, left swinging, external

786 Swing Head

■■■■■■■■

39

Page 48

9.6 Scope of delivery 2.786.0240

Order no. Description

6.2058.040 Swing arm enhancement for Swing Head 786

The swing arm enhancement is for stabilizing the swing arm connected to the 786

Swing Head and working with various tools

Material: Aluminum

9.6 Scope of delivery 2.786.0240

Qty. Order no. Description

1 1.786.0110 786 Swing Head

■■■■■■■■■■■■■■■■■■■■■■

Additional drive for a Sample Processor required for the usage of a

robotic arm.

1 6.2058.090 Verstärkung zu SwingHead R

1 6.2621.120 Hexagon key 1.5 mm

2 V.024.4012 Counter sunk screw

1 8.786.8001EN 786 Swing Head Manual

■■■■■■■■

40

786 Swing Head

Page 49

■■■■■■■■■■■■■■■■■■■■■■

9.7 Optional accessories 2.786.0240

Order no. Description

6.1462.240 Transfer head for 786 Swing Head, bent and right

swinging

Transfer head, bent and right swinging, for 786 Swing Head. In combination with

the

6.1808.220 Adapter the transfer head can be used on multi-row racks to pick

up tools with luer connection.

Material: PP (black)

9 Accessories

786 Swing Head

■■■■■■■■

41

Page 50

Index

Index

■■■■■■■■■■■■■■■■■■■■■■

B

Beaker sensor ..................... 18, 24

D

DIS-COVER ............................... 26

Drive disc ............................. 7, 16

Drive pin .................................... 7

G

GLP .......................................... 20

Guarantee ................................ 31

Guide chain ........................ 10, 11

Guide pins ................................ 17

L

Left-swinging. .......................... 14

Limitation screw ....................... 16

Luer lock adapter ..................... 25

M

Max. swing angle ..................... 15

Mini DIN .................................... 9

Model versions ........................... 1

P

Polytron ................................... 26

Q

Quality Management ................ 20

R

Right-swinging.. ....................... 14

Robotic arm

Beaker sensor ............... 18, 24

Bent ................................... 26

Configuration data

......................... 14, 23, 25, 26

Configuring ........................ 13

Left-swinging ..................... 15

Luer lock adapter ................

Model versions ............. 13, 23

Mounting ........................... 16

Right-swinging ................... 15

Titration head ..................... 23

Transfer head ..................... 25

Robotic arm reinforcement ....... 12

Robotic arms

Model versions ................... 25

S

Safety instructions ...................... 3

Sample preparation .................. 25

25

Service ....................................... 3

Service Agreement ................... 20

Swing axis ............................ 7, 15

Swing direction ........................ 15

Swing Head

Connect ............................... 9

Mounting ............................. 9

Swing offset ............................. 15

Swing radius ............................ 15

T

Titration head ........................... 23

Titration head holder .................. 8

Tower extension ....................... 10

Transfer head ........................... 25

Troubleshooting ....................... 21

V

Validation ................................. 20

W

Warranty .................................. 31

■■■■■■■■

42

786 Swing Head

Loading...

Loading...