Liebherr R974C User Manual

Machine for Industrial Applications R 974 C

litronic`

Operating Weight: 110,300 – 120,600 kg

Engine Output: 400 kW / 543 HP

Technical Data

Engine

Engine

Rating per ISO 9249 400 kW (543 HP) at 1,800 RPM Model Liebherr D 9508

Type 8 cylinder V-engine Bore/Stroke 128/157 mm Displacement 16.16 l

Engine operation 4-stroke diesel Common-rail-injection turbo-charged after-cooled

reduced emissions Cooling water-cooled

Air cleaner dry-type air cleaner with pre-cleaner, primary and safety elements, automatic dust discharge

Fuel tank 1,460 l Electrical system

Voltage 24 V

Batteries 2 x 170 Ah/12 V Starter 24 V/7.8 kW

Alternator three phase current 28 V/80 A

Swing Drive

Swing Drive

Drive by Liebherr swash plate motor with integrated brake valves

Transmission Liebherr compact planetary reduction gear Swing ring Liebherr, sealed single race ball bearing swing

ring, internal teeth Swing speed 0 – 5.9 RPM stepless Swing torque 295 kNm

Holding brake wet multi-disc (spring applied, pressure released) Option pedal controlled positioning brake

Uppercarriage

Uppercarriage

Design torque resistant modular design upper frame Attachment mounting parallel length girders

Catwalks on both sides

Hydraulic System

Hydraulic System

Hydraulic pumps

for attachment and

travel drive 2 Liebherr variable flow swash plate pumps Max. flow 2 x 496 l/min.

Max. hydr. pressure 350 bar

Pump control electro-hydraulic with electronic engine speed sensing regulation over entire RPM range, pressure compensation, flow compensation automatic oil flow optimizer, flow summation

1 reversible swash plate pump, closed-loop circuit

Max. flow 315 l/min. Max. hydr. pressure 350 bar

Hydraulic tank 745 l Hydraulic system 1,350 l

Hydraulic oil filter 2 full flow filters in return line with integrated fine filter area (5 µm), 1 high pressure filter for each main pump

Cooler radiator, consisting of cooling unit for coolant and after-cooler as well as 2nd cooler for hydraulic oil with hydrostatically regulated fan drive

MODE selection adjustment of machine performance and the hydraulics via a mode selector to match application

ECO for especially economical and environmentally friendly operation

POWER for maximum digging power and heavy duty jobs LIFT for lifting

FINE for precision work and lifting through very sensitive movements

RPM adjustment stepless adjustment of engine output via the rpm at each selected mode

Menu for auxiliary functions 4 fixed adjustable oil flow parameters for optional working tools

Hydraulic Controls

Hydraulic Controls

Power distribution via control valves in single block with integrated safety valves

Flow summation to boom stick and bucket cylinders Closed-loop circuit for uppercarriage swing drive

Activation electro-hydraulic control Attachment and swing proportional via joystick levers

Travel proportional via foot pedals or removable hand levers

Additional functions via foot pedals or joystick toggle switch

Operator’s Cab

Operator’s Cab

Cab profiles and deep drawn technology, resiliently mounted, sound insulated, tinted windows. Front window armored glass, door with sliding window

Operator’s seat shock absorbing suspension, adjustable to operator’s weight, 6-way adjustable seat

Joysticks integrated into adjustable seat consoles Monitoring menu driven query of current operating condi-

tions via the LCD display. Automatic monitoring, display, warning (acoustical and optical signal) and saving machine malfunction data, for exam ple, engine overheating, low engine oil pressure or low hydraulic oil level

Heating system standard automatic air conditioning, combined cooler/heater, additional dust filter in fresh air/ recirculated

Noise emission

ISO 6396 LpA (inside cab) = 72 dB(A) 2000/14/EC LWA (surround noise) = 109 dB(A)

Undercarriage

Undercarriage

EW heavy version, long undercarriage, extra wide Drive Liebherr swash plate motors with integrated

brake valves on both sides Transmission Liebherr planetary reduction gears Travel speed low range – 2.1 km/h

high range – 3.6 km/h Drawbar pull max. 867 kN

Track components D 9 G, maintenance-free Track rollers/Carrier rollers 11/2

Track pads double-grouser beveled or flat pads Digging locks wet multi-discs (spring applied, pressure

released)

Brake valves integrated into travel motor

Attachment |

Type box-type, combination of resistant steel plates and cast steel components

Hydraulic cylinders Liebherr cylinders with special seal-system, shock absorbed

Pivots sealed, low maintenance Pivots bucket-to-stick

bucket-to-link O-ring sealed and completely enclosed Lubrication automatic central lubrication system

Hydraulic connections pipes and hoses equipped with SAE split-flange connections

2 R 974 C Litronic Machine for Industrial Applications

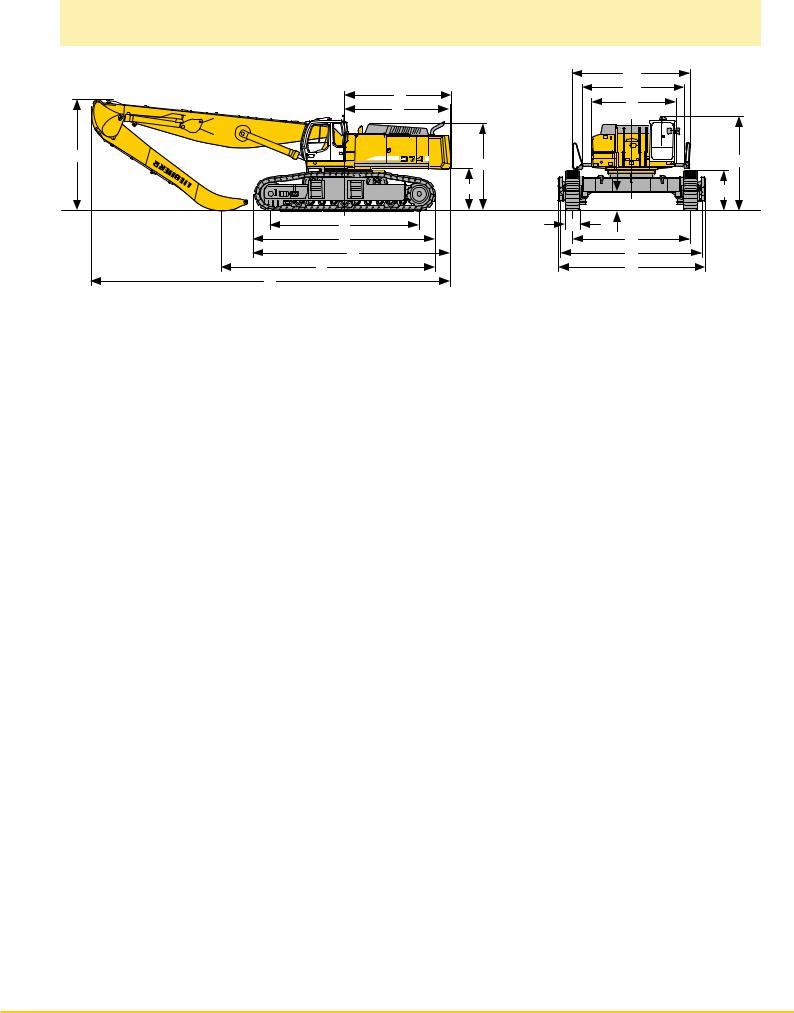

Dimensions |

|

|

|

|

|

|

|

|

A2 |

|

E |

|

|

A1 |

|

|

|

A |

|

|

D |

|

|

|

|

|

|

|

|

W |

|

|

H |

C |

|

|

|

||

|

|

|

|

|

|

|

K |

|

P |

|

|

|

|

|

|

|

|

|

Q |

L |

|

|

|

N |

U |

|

|

|

S |

Z |

|

|

|

B |

V |

|

|

|

G |

X |

|

|

|

|

|

|

|

mm |

|

Industrial-Type Straight Boom 10.00 m |

|

||

A |

|

|

3,605 |

|

and Industrial Stick 7.50 m |

mm |

||

A1 |

|

|

4,365 |

|

V |

|

9,050 |

|

A2 |

|

|

5,000 |

|

W |

|

4,750 |

|

C |

|

|

3,995 |

|

X |

|

15,250 |

|

D |

|

|

4,500 |

|

|

|

|

|

E |

|

|

4,540 |

|

Industrial-Type Straight Boom 12.00 m |

|

||

H |

|

|

3,710 |

|

and Industrial Stick 9.00 m |

mm |

||

K |

|

|

1,790 |

|

V |

|

10,000 |

|

L |

|

|

6,320 |

|

W |

|

6,250 |

|

P |

|

|

1,680 |

|

X |

|

17,100 |

|

Q |

|

|

780 |

|

|

|

|

|

S |

|

|

5,000 |

|

Industrial-Type Gooseneck Boom 12.00 m |

|

||

U |

|

|

7,720 |

|

and Industrial Stick 9.00 m |

mm |

||

N |

600 750 |

1,000 |

|

V |

|

9,250 |

||

B |

6,000 |

6,000 |

6,000 |

|

W |

|

4,750 |

|

G |

6,290 |

6,290 |

6,290 |

|

X |

|

17,250 |

|

Z |

|

|

8,370 |

|

|

|

|

|

|

|

|

|

|

Industrial-Type Straight Boom 14.00 m |

|

||

|

|

|

|

|

and Industrial Stick 10.50 m |

mm |

||

|

|

|

|

|

V |

|

10,900 |

|

|

|

|

|

|

W |

|

7,700 |

|

|

|

|

|

|

X |

|

18,850 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Industrial-Type Gooseneck Boom 14.00 m |

|

||

|

|

|

|

|

and Industrial Stick 10.50 m |

mm |

||

|

|

|

|

|

V |

|

|

10,000 |

|

|

|

|

|

W |

|

|

5,450 |

|

|

|

|

|

X |

|

|

19,200 |

R 974 C Litronic Machine for Industrial Applications 3

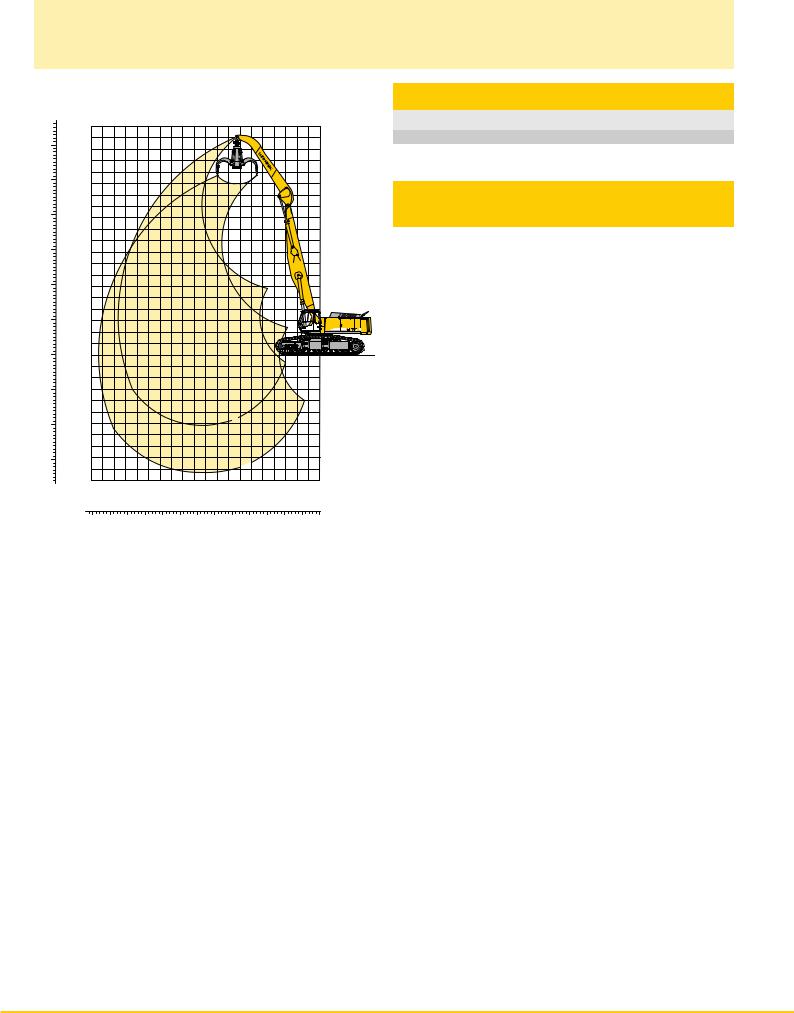

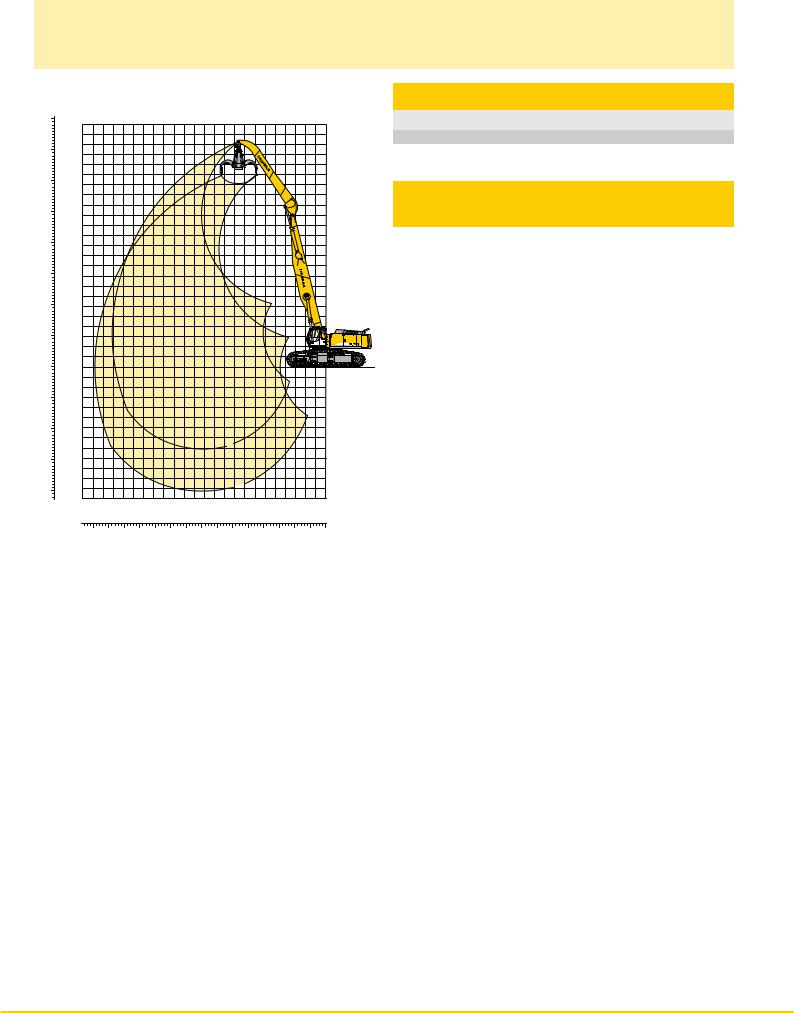

Industrial Attachment

with Industrial-Type Straight Boom 10.00 m

ft |

m |

|

|

|

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

60 |

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 |

|

|

|

|

|

|

|

|

|

|

|

40 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

20 |

6 |

|

|

|

|

|

|

|

|

|

|

|

10 |

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

-10 |

-2 |

|

|

|

|

|

|

|

|

|

|

|

-4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-20 |

-6 |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

-8 |

|

|

|

|

|

|

|

|

|

|

|

-30 |

-10 |

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

18 |

16 |

14 |

12 |

10 |

8 |

6 |

4 |

2 |

0 |

m |

|

|

60 |

50 |

|

40 |

30 |

|

20 |

|

10 |

0 |

ft |

Attachment Envelope

1 with industrial stick 7.50 m

2 with industrial stick 7.50 m and grapple model 75 B

Operating Weight

and Ground Pressure

The operating weight includes basic machine with counterweight 18.0 t, industrial-type straight boom 10.00 m, industrial stick 7.50 m and grapple model 75 B with 5 open tines 3.00 m3.

Undercarriage |

|

|

EW |

|

|

|

|

|

|

Pad width |

mm |

600 |

750 |

1,000* |

Weight |

kg |

110,300 |

111,800 |

117,200 |

Ground pressure |

kg/cm2 |

1.45 |

1.18 |

0.93 |

* flat pads

4 R 974 C Litronic Machine for Industrial Applications

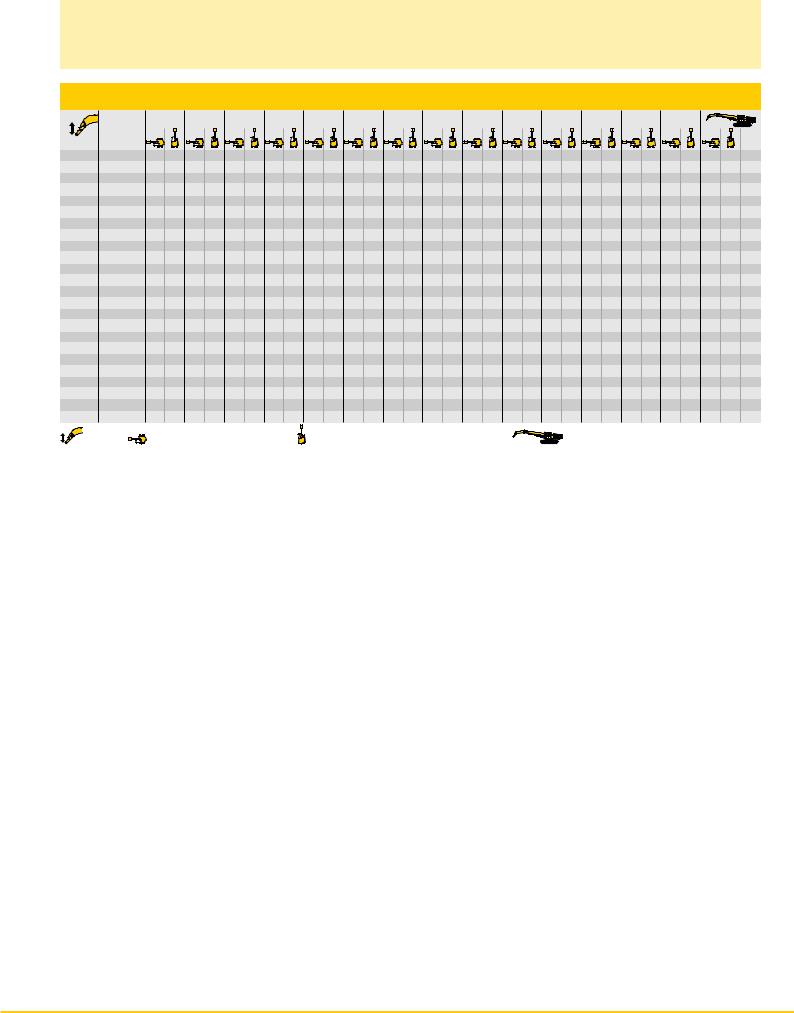

Lift Capacities |

|

with Industrial-Type Straight Boom 10.00 m |

|

Industrial Stick 7.50 m |

|

4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m 22.5 m 24.0 m |

|

Under- |

|

m carriage |

m |

24.0 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22.5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21.0 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

19.5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18.0 |

EW |

|

|

|

|

|

17.9* |

17.9* |

|

|

|

|

|

|

|

|

|

|

16.0* |

16.0* |

9.42 |

16.5 |

EW |

|

|

|

|

|

|

|

18.0* |

18.0* |

|

|

|

|

|

|

|

|

13.8* |

13.8* |

11.52 |

15.0 |

EW |

|

|

|

|

|

|

|

18.2* |

18.2* |

17.4* |

17.4* |

|

|

|

|

|

|

12.6* |

12.6* |

13.09 |

13.5 |

EW |

|

|

|

|

|

|

|

17.8* |

17.8* |

17.2* |

17.2* |

16.1* |

16.1* |

|

|

|

|

11.8* |

11.8* |

14.33 |

12.0 |

EW |

|

|

|

|

|

|

|

17.9* |

17.9* |

17.1* |

17.1* |

16.5* |

16.5* |

13.4* |

13.4* |

|

|

11.3* |

11.3* |

15.32 |

10.5 |

EW |

|

|

|

|

|

|

|

18.3* |

18.3* |

17.4* |

17.4* |

16.6* |

16.6* |

16.0* |

16.0* |

|

|

10.9* |

10.9* |

16.10 |

9.0 |

EW |

|

|

|

|

|

|

|

19.1* |

19.1* |

17.9* |

17.9* |

16.9* |

16.9* |

16.1* |

16.1* |

12.4* |

12.4* |

10.8* |

10.8* |

16.70 |

7.5 |

EW |

|

|

|

|

|

22.2* |

22.2* |

20.2* |

20.2* |

18.6* |

18.6* |

17.4* |

17.4* |

16.2 |

16.3* |

13.8 |

15.4* |

10.7* |

10.7* |

17.15 |

6.0 |

EW |

|

33.8* |

33.8* |

28.0* |

28.0* |

24.2* |

24.2* |

21.5* |

21.5* |

19.5* |

19.5* |

17.9* |

17.9* |

16.0 |

16.7* |

13.7 |

15.6* |

10.7* |

10.7* |

17.45 |

4.5 |

EW |

|

39.6* |

39.6* |

31.4* |

31.4* |

26.3* |

26.3* |

22.9* |

22.9* |

20.4* |

20.4* |

18.4 |

18.6* |

15.7 |

17.1* |

13.6 |

15.8* |

10.8* |

10.8* |

17.62 |

3.0 |

EW |

|

29.2* |

29.2* |

34.4* |

34.4* |

28.3* |

28.3* |

24.2* |

24.2* |

21.3* |

21.3* |

18.0 |

19.1* |

15.4 |

17.4* |

13.4 |

15.9* |

11.0* |

11.0* |

17.65 |

1.5 |

EW |

|

16.4* |

16.4* |

36.7* |

36.7* |

29.9* |

29.9* |

25.3 |

25.3* |

20.9 |

22.0* |

17.7 |

19.6* |

15.2 |

17.6* |

13.3 |

15.9* |

11.3* |

11.3* |

17.56 |

0 |

EW |

6.5* 6.5* |

15.1* |

15.1* |

35.9* |

35.9* |

30.8 |

30.8* |

24.7 |

26.0* |

20.5 |

22.5* |

17.4 |

19.8* |

15.0 |

17.7* |

13.2 |

15.6* |

11.8* |

11.8* |

17.33 |

– 1.5 |

EW |

9.4* 9.4* |

16.5* |

16.5* |

31.8* |

31.8* |

30.2 |

31.1* |

24.3 |

26.2* |

20.2 |

22.6* |

17.2 |

19.8* |

14.9 |

17.4* |

13.2 |

14.9* |

12.4* |

12.4* |

16.96 |

– 3.0 |

EW |

12.5* 12.5* |

18.9* |

18.9* |

32.0* |

32.0* |

30.0 |

30.5* |

24.1 |

25.8* |

20.0 |

22.2* |

17.1 |

19.2* |

14.9 |

16.6* |

|

|

13.2* |

13.2* |

16.44 |

– 4.5 |

EW |

|

21.8* |

21.8* |

34.4* |

34.4* |

29.0* |

29.0* |

24.1 |

24.6* |

20.0 |

21.1* |

17.2 |

18.0* |

14.9* |

14.9* |

|

|

14.7* |

14.7* |

15.07 |

– 6.0 |

EW |

|

|

|

|

|

26.4* |

26.4* |

22.5* |

22.5* |

19.0* |

19.0* |

|

|

|

|

|

|

18.9* |

18.9* |

12.06 |

– 7.5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 9.0 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 10.5 |

EW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Height |

Can be slewed through 360° |

|

In longitudinal position of undercarriage |

Max. reach * Limited by hydr. capacity |

|||||||||||||||||

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities are valid for 600 mm wide double grouser pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of the load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load diagram and automatic check valves on the hoist cylinders, when they are used for lifting operations which require the use of lifting accessories.

R 974 C Litronic Machine for Industrial Applications 5

Industrial Attachment

with Industrial-Type Straight Boom 12.00 m

ft |

m |

|

|

|

|

|

|

|

|

|

|

|

|

|

80 |

24 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

70 |

22 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

60 |

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

40 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

-10 |

-2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

-4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-20 |

-6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-8 |

|

|

|

|

|

|

1 |

|

|

|

|

|

|

-30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-40 |

-12 |

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

24 |

22 |

20 |

18 |

16 |

14 |

12 |

10 |

8 |

6 |

4 |

2 |

0 |

m |

|

|

70 |

|

60 |

50 |

|

40 |

30 |

20 |

|

10 |

0 |

ft |

|

Attachment Envelope

1 with industrial stick 9.00 m

2 with industrial stick 9.00 m and grapple model 75 B

Operating Weight

and Ground Pressure

The operating weight includes basic machine with counterweight 18.0 t, industrial-type straight boom 12.00 m, industrial stick 9.00 m and grapple model 75 B with 5 open tines 2.50 m3.

Undercarriage |

|

|

EW |

|

|

|

|

|

|

Pad width |

mm |

600 |

750 |

1,000* |

Weight |

kg |

111,900 |

113,400 |

118,800 |

Ground pressure |

kg/cm2 |

1.48 |

1.20 |

0.94 |

* flat pads

6 R 974 C Litronic Machine for Industrial Applications

Loading...

Loading...