LG LM-2164H2L, LM-3064H3L Service manual

Multi Type Room

Air Conditioner

SERVICE MANUAL

MODEL: LM-2164H2L/M

LM-3064H3L/M

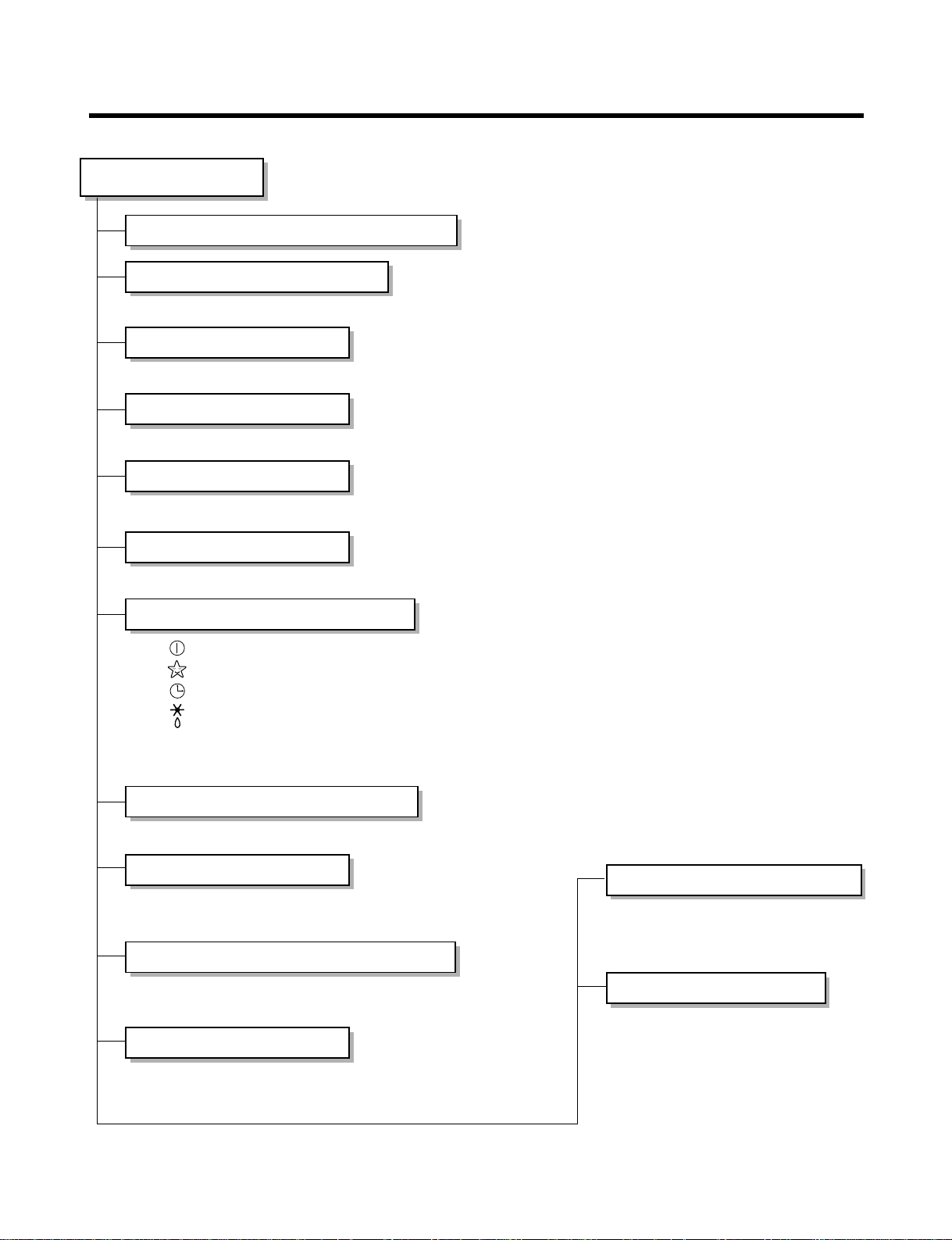

Functions...................................................................................................................................... 3

Product Specifications................................................................................................................ 5

Dimensions................................................................................................................................... 7

Refrigeration Cycle Diagram..................................................................................................... 10

Wiring Diagram .......................................................................................................................... 11

Operation Details ....................................................................................................................... 12

Display Function........................................................................................................................ 19

Self-Diagnosis Function............................................................................................................ 19

Installation.................................................................................................................................. 20

Operation.................................................................................................................................... 34

Disassembly of the parts (Indoor Unit).................................................................................... 36

2-way, 3-way Valve..................................................................................................................... 38

Cycle Troubleshooting Guide ....................................................................................................42

Electronic Parts Troubleshooting Guide.................................................................................. 43

Electronic Control Device ......................................................................................................... 50

Schematic Diagram.................................................................................................................... 53

Exploded View and Replacement Parts List............................................................................ 55

- 2 -

Contents

- 3 -

Functions

• Room temperature sensor. (THERMISTOR)

• Maintains the room temperature in accordance with the Setting Temp.

• Indoor fan is delayed for 5 seconds at the starting.

• Restarting is inhibited for approx. 3 minutes.

• High, Med, Low, Chaos

--- Lights up in operation

--- Lights up in Sleep Mode

--- Lights up in Timer Mode

--- Lights up in Deice Mode(for Heat pump model)

--- Lights up in Compressor operation(for Cooling model)

• Intermittent operation of fan at low speed.

• The fan is switched to low(Cooling), med(Heating) speed.

• The unit will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

• The fan is switched to intermittent or irregular operation

•

The fan speed is automatically switched from high to low speed.

• The louver can be set at the desired position or swing

up and down automatically.

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Operation indication Lamps (LED)

OUT

DOOR

Health Dehumidification Operation

• Both the indoor and outdoor fan

stops during deicing.

• Hot start after deice ends.

• The indoor fan stops until the

evaporator piping temperature will be

reached at 28°C.

Sleep Mode Auto Control

Natural Air Control by CHAOS Logic

Airflow Direction Control

Deice (defrost) control (Heating)

Hot-start Control (Heating)

- 4 -

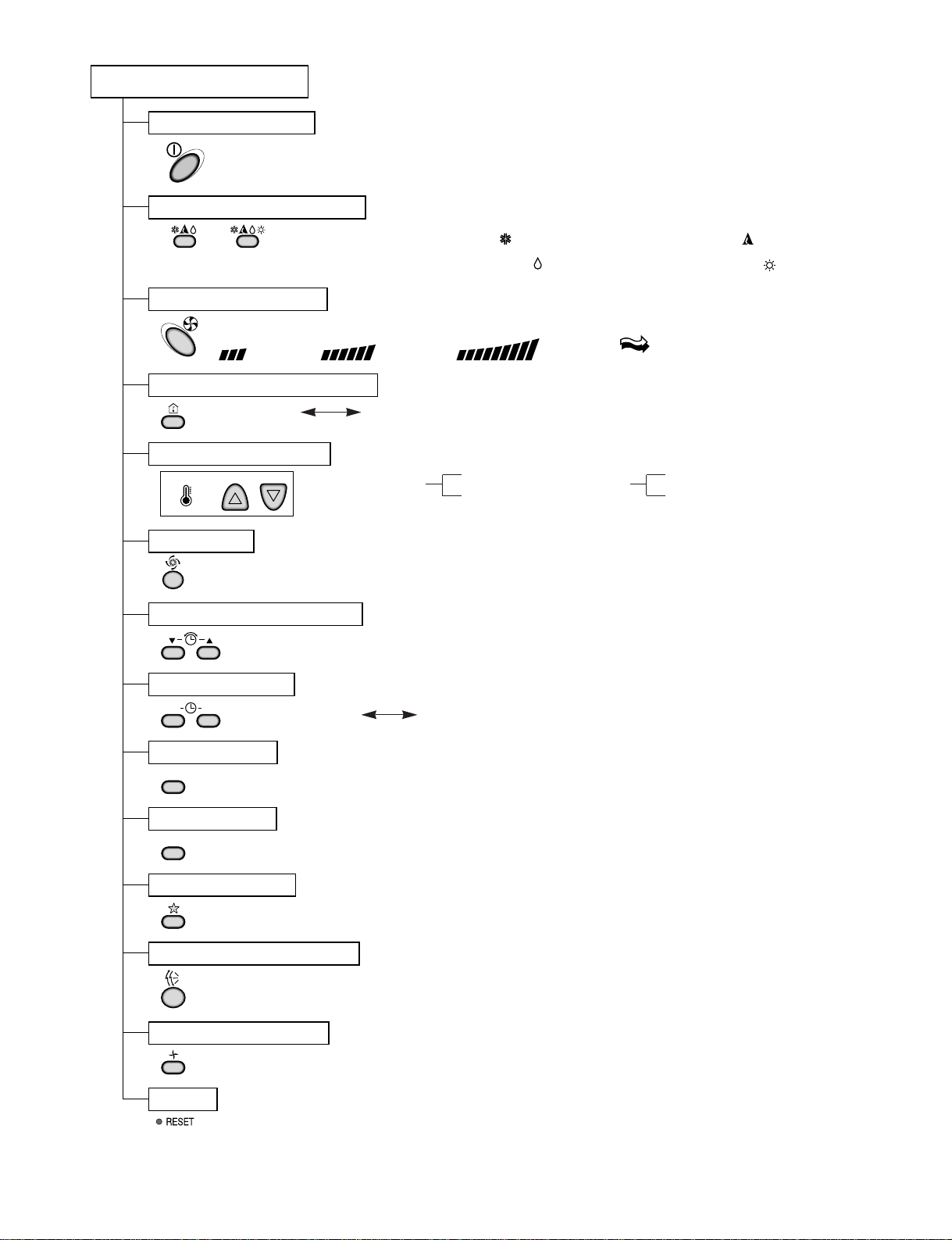

Remote Controller

JET COOL

Healthy Dehumidification Operation Mode.

( )

Operation Mode Selection

(Cooling

model only)

(Heating

model only)

Cooling Operation Mode.( )

Heating Operation Mode.( )

Auto Operation Mode.( )

Sleep Operation

Fan Operation Mode

Room, Temperature Display

Setting the Time or Timer

Airflow Direction Control

Operation ON/OFF

Temperature Setting

TEMPERATURE

LOWHIGH

Timer Selection

ON OFF

Timer Setting

SET

Timer Cancel

CANCEL

Reset

Fan Speed Selection

(Low) (Med) (High) (CHAOS)

: (High: 39°C LOW : 11°C)

Down to 18°C

Up to 30°C

Cooling

: OFF, ON, OFF ON

: Cancel Sleep Mode, Timer ON or Timer OFF

: 1, 2, 3, 4, 5, 6, 7, Off Timer

: Fan Operates without cooling or heating.

Down to 16°C

Up to 30°C

Heating

- 5 -

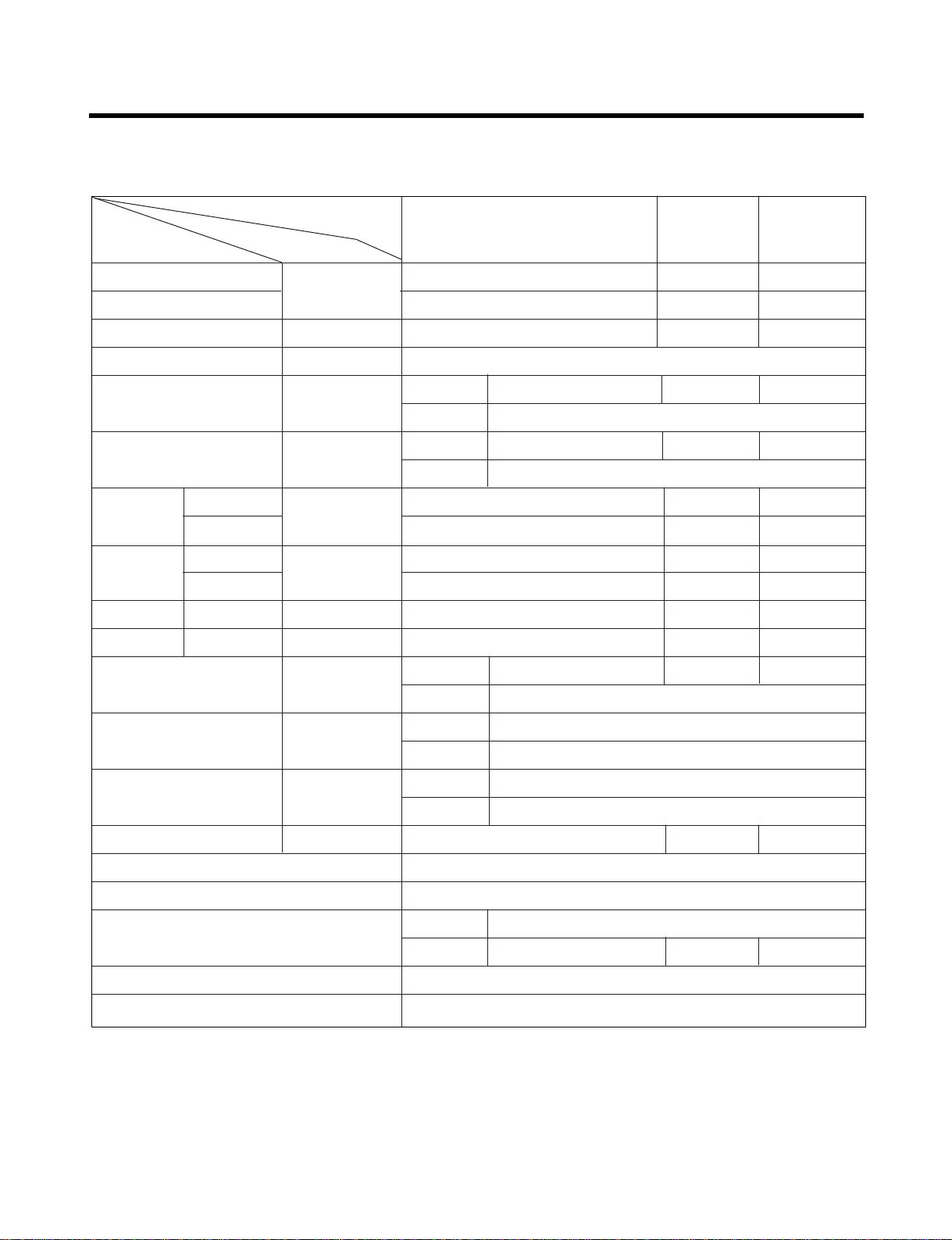

Product Specifications

21,000(5,292) 14,000(3,528) 7,000(1,764)

21,000(5,292) 14,000(3,528) 7,000(1,764)

3.0 2.0 1.0

1Ø, 220-240V, 50Hz

Indoor 10.5 6.5

Outdoor 53

Indoor 41 38

Outdoor 55

2,200 1,420 900

2,200 1,420 830

9.7 6.2 4.0

9.7 6.2 3.8

9.5 9.9 7.8

9.5 9.9 8.4

Indoor 13 7.5

Outdoor 61

Indoor 888 x 287 x 170 / 802 x 262 x 165

Outdoor 870 x 655 x 320

Indoor 10 / 7

Outdoor 62

1,500 990

O

L.C.D Wireless

Liquid 1/4"(6.35)

Gas 1/2"(12.7) 3/8"(9.52)

O

O

Operation

A-Unit OnlyA-Unit + B-Unit B-Unit Only

Unit

Item

Cooling Capacity

Heating Capacity

Moisture Removal §⁄/h

Power Source ø, V, Hz

Air Circulation m

3

/min

Noise Level dB(A)

Input W

A

E.E.R. Btu/h

.

w

C.O.P. -

Motor Output W

Dimensions(W x H x D)

mm

Net. Weight kg

Refrigerant(R-22)(at 7.5m)

g

Airflow Direction Control(Up & Down)

Remocon Type

Service Valve

Sleeping Operation

Drain Hose

Cooling

Heating

Cooling

Heating

Cooling

Heating

Runnig

Current

Btu/h(kcal/h)

1. LM-2164H2L/M

- 6 -

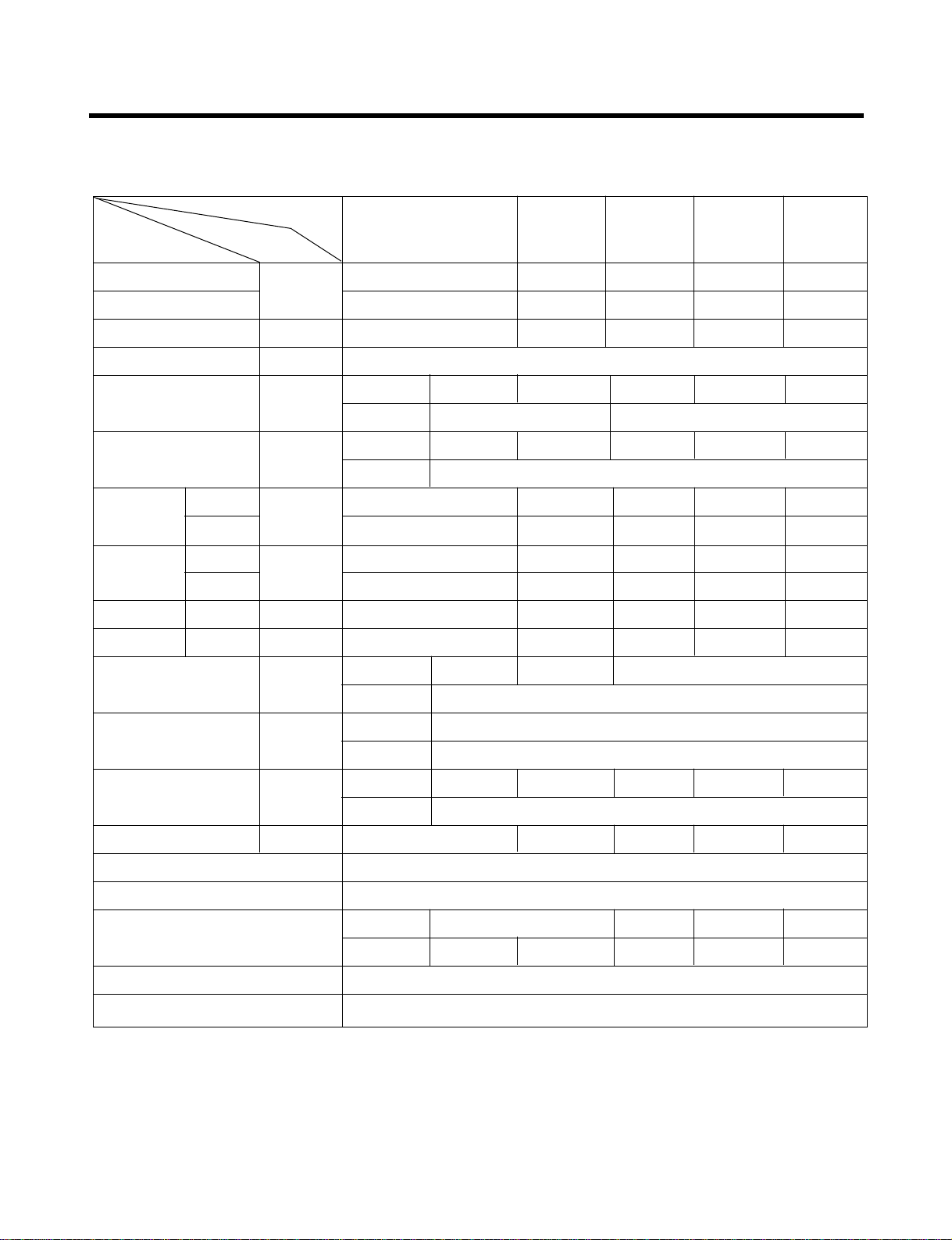

14,000(3,528)

10,000(2,520) 24,000(6,048) 14,000(3,528) 28,000(7,056)

14,000(3,528)

10,000(2,520) 24,000(6,048) 14,000(3,528) 28,000(7,056)

2.0 1.5 3.4 2.0 4.0

1Ø, 220-240V, 50Hz

10.5 6.5 – – –

58 – – –

41 38 – – –

60

1,520 1,400 2,750 1,520 2,870

1,550 1,460 2,840 1,320 2,700

6.7 6.2 12.3 6.7 12.8

6.8 6.4 8.7 5.8 12.0

9.2 7.1 8.5 9.2 9.8

9.0 6.8 8.5 10.6 10.4

13 7.5

101.5

888

x 287 x 170 / 802 x 262 x 165

870 x 800 x 320

10 7 – – –

83

1,170 1,220 – – –

O

L.C.D Wireless

1/4"(6.35) – – –

1/2"(12.7) 3/8"(9.52) – – –

O

O

Operation

A-Unit

B or C-Unit A+B or C

B+C A+B+C

Unit

Item

Cooling Capacity

Heating Capacity

Moisture Removal §⁄/h

Power Source ø, V, Hz

Air Circulation m

3

/min

Noise Level dB(A)

Input W

A

E.E.R. Btu/h

.

w

C.O.P. -

Motor Output W

Dimensions(W x H x D)

mm

Net. Weight kg

Refrigerant(R-22)(at 7.5m)

g

Airflow Direction Control(Up & Down)

Remocon Type

Service Valve

Sleeping Operation

Drain Hose

Cooling

Heating

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Liquid

Gas

Cooling

Heating

Cooling

Heating

Runnig

Current

Btu/h(kcal/h)

2. LM-3064H3L/M

- 7 -

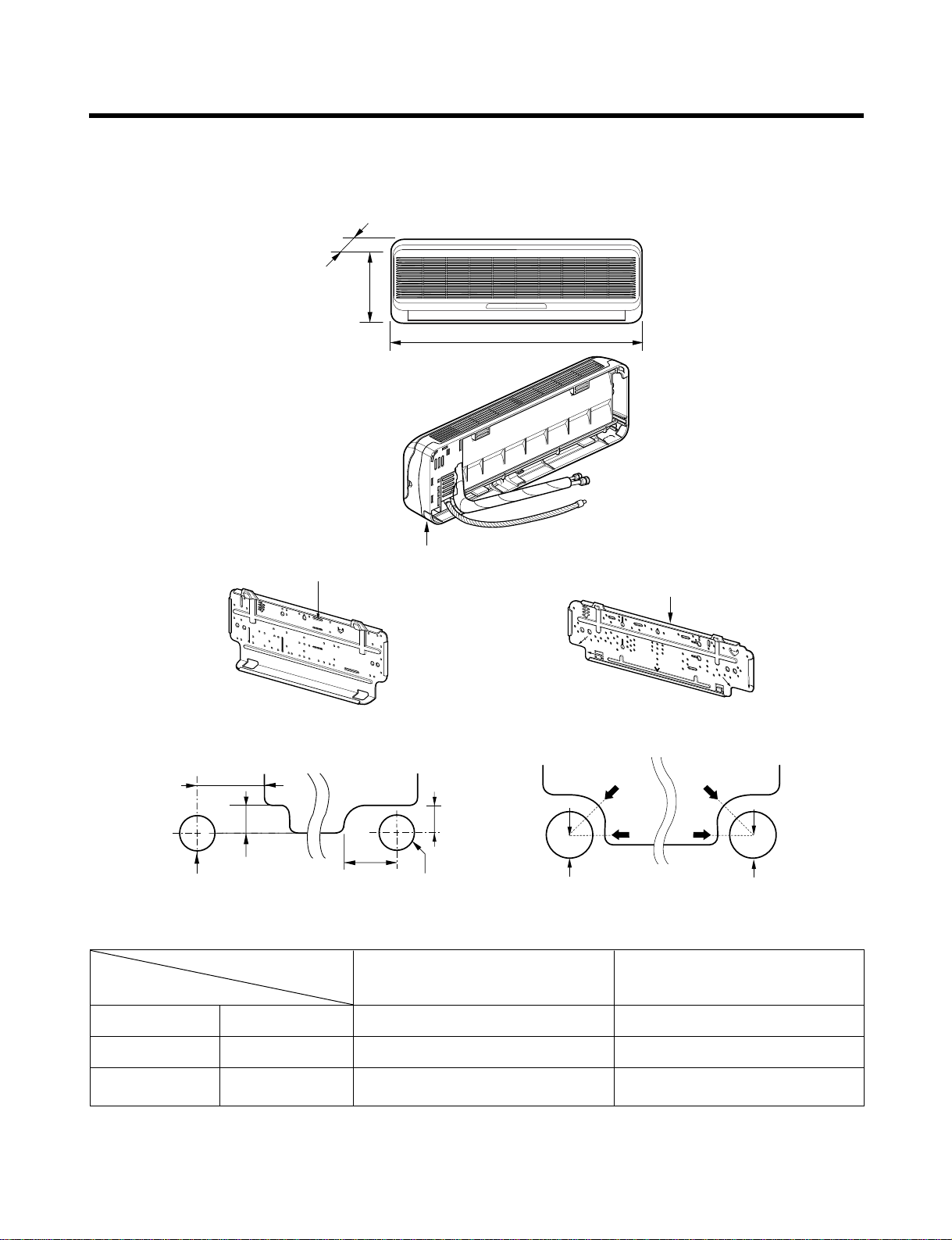

Dimensions

Installation plate

Installation plate

Right rear piping

Left rear piping

ø70mm

ø70mm

50mm

20mm

20mm

80mm

A

A

ø70mm

Center

Center

ø70mm

Left rear piping Right rear piping

A

A

D

H

W

Tubing hole cover

W mm 802 888

H mm 262 287

D mm 165 170

7K Btu Series

14K Btu Series

MODEL

DIM

(7K)

(7K)

(14K)

(14K )

1. Indoor Unit

- 8 -

W

D

L1

L2

L9

L4

L3

H

L10

L10

L10

L8

Gas side

3-Way valve

Liquid side

2-Way valve

L7L5L6

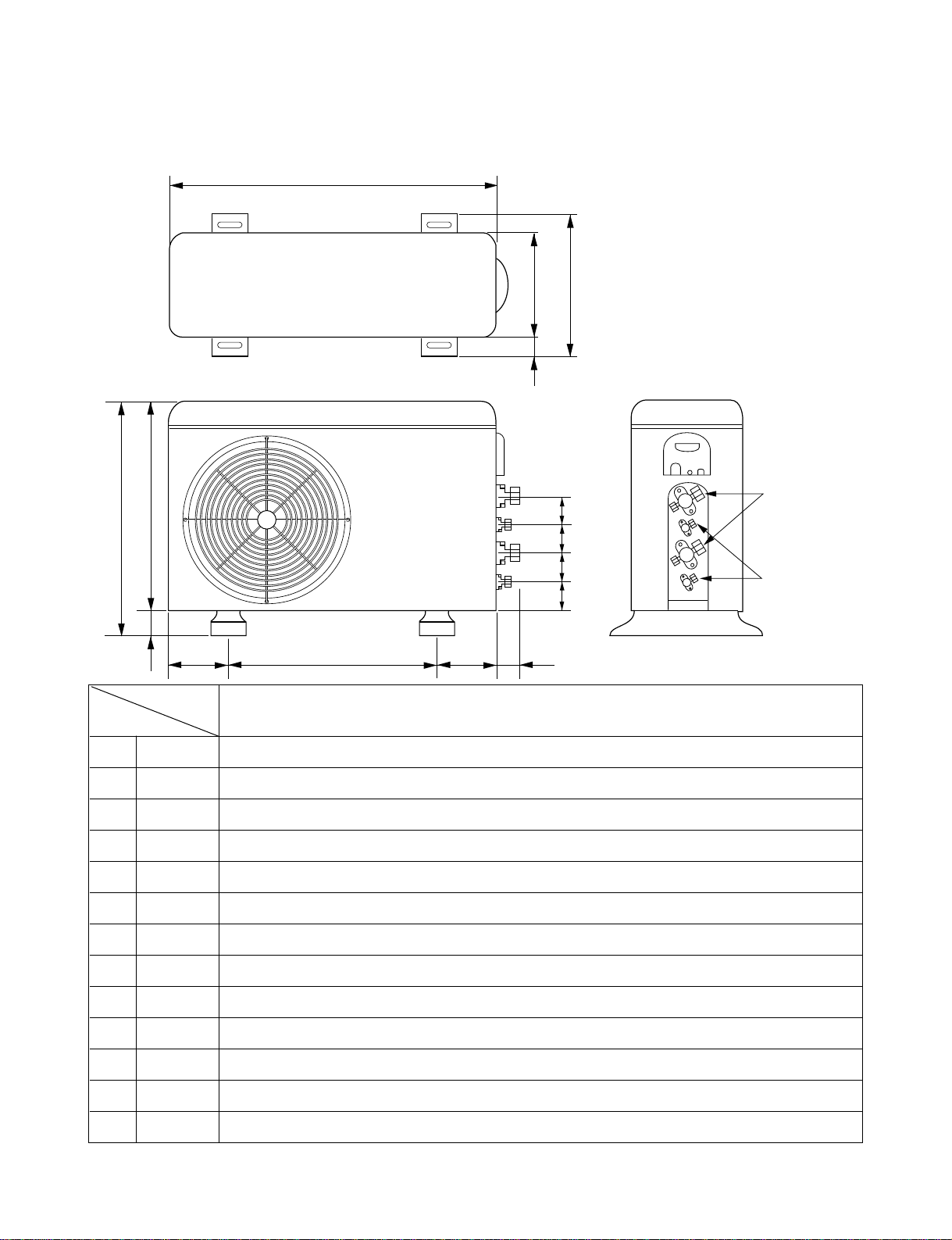

2. Outdoor Unit

2-1. LM-2164H2L/M

W mm 870

H mm 655

D mm 320

L1 mm 370

L2 mm 25

L3 mm 630

L4 mm 25

L5 mm 546

L6 mm 160

L7 mm 160

L8 mm 64

L9 mm 76.5

L10 mm 50

LM-2164H2L/M

MODEL

DIM

- 9 -

W

L5L6 L7 L8

L3

H

D

L1

L2

L4

L10L9

Gas side

3-way valve

Liquid side

2-way valve

L10L10L10L10

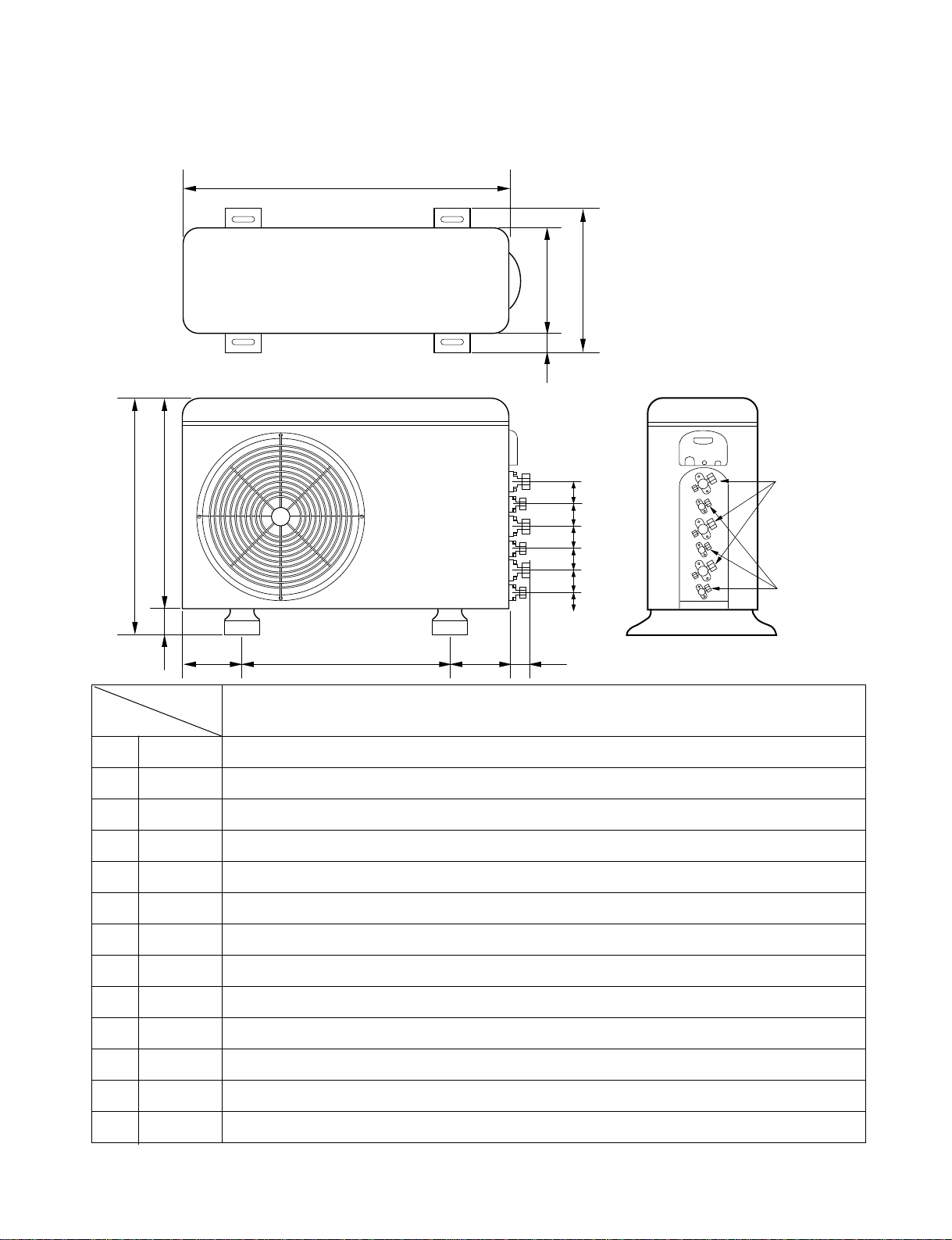

2-2. LM-3064H3L/M

W mm 870

H mm 800

D mm 320

L1 mm 370

L2 mm 25

L3 mm 775

L4 mm 25

L5 mm 546

L6 mm 160

L7 mm 160

L8 mm 64

L9 mm 76.5

L10 mm 50

LM-3064H3L/M

MODEL

DIM

- 10 -

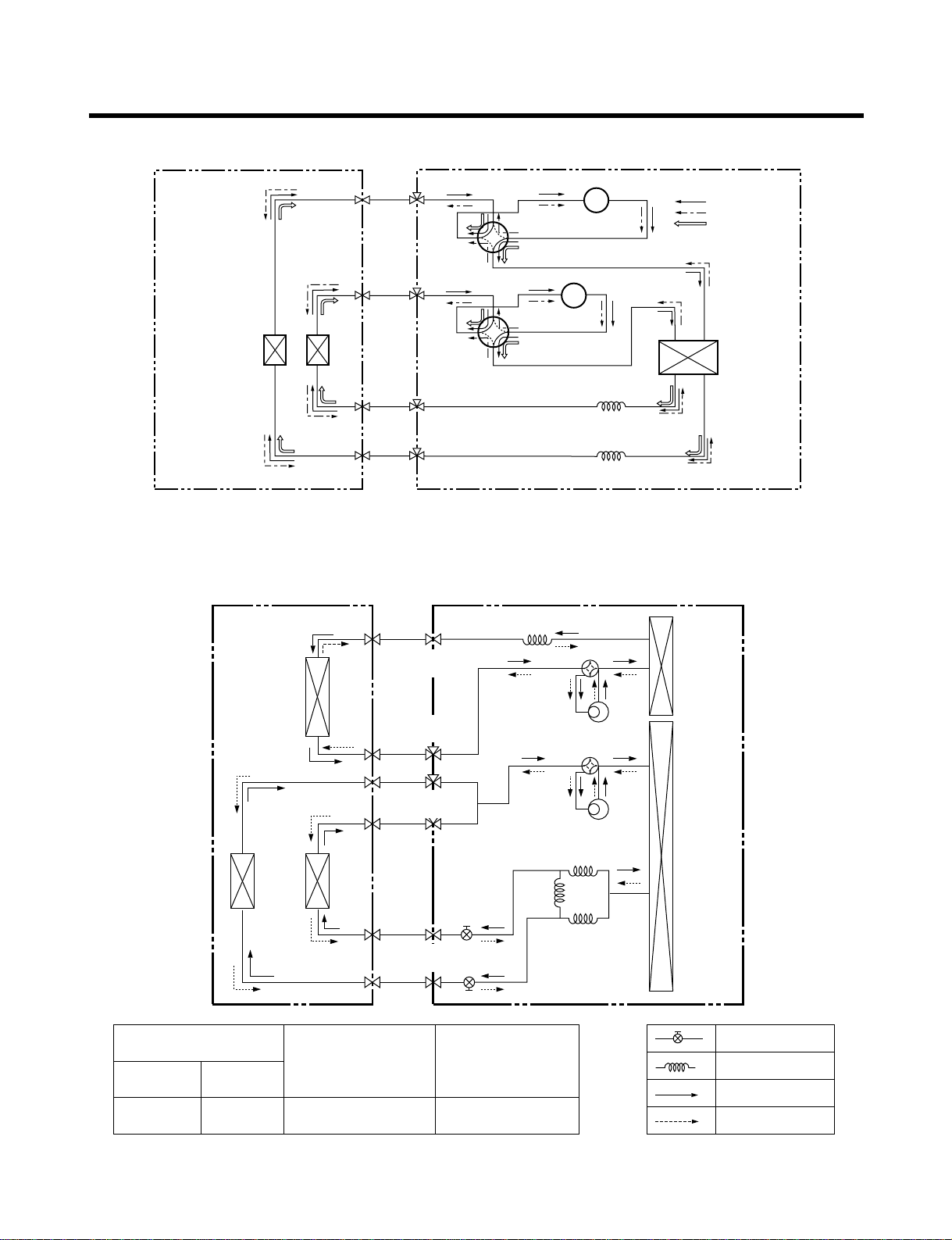

Refrigeration Cycle Diagram

1. LM-2164H2L/M

2. LM-3064H3L/M(Cooling & Heating models)

HEAT

EXCHANGER

COOLING

HEATING

DEICE

HEAT

EXCHANGER

CAPILLARY TUBE

COMPRESSOR-B

COMPRESSOR-A

CAPILLARY TUBE

2-WAY

VALVE

4-WAY

VALVE

B-UNITA-UNIT

3-WAY

VALVE

4-WAY

VALVE

Pipe Size (Diameter : inch)

Max.

piping length

(m)

Max.

piping elevation

(m)

Gas Liquid

3/8"(1/2") 1/4" 10~15 5~7

ex)

Solenoid Valve

Capillary

Cooling & Deice

Heating

Indoor Unit Outdoor Unit

Heat

Exchanger

A-Unit

Heat

Exchanger

Comp-A

B-Unit

C-Unit

Heat

Exchanger

2- WAY

Valve

3- WAY

Valve

2- WAY

Valve

3- WAY

Valve

Comp-B

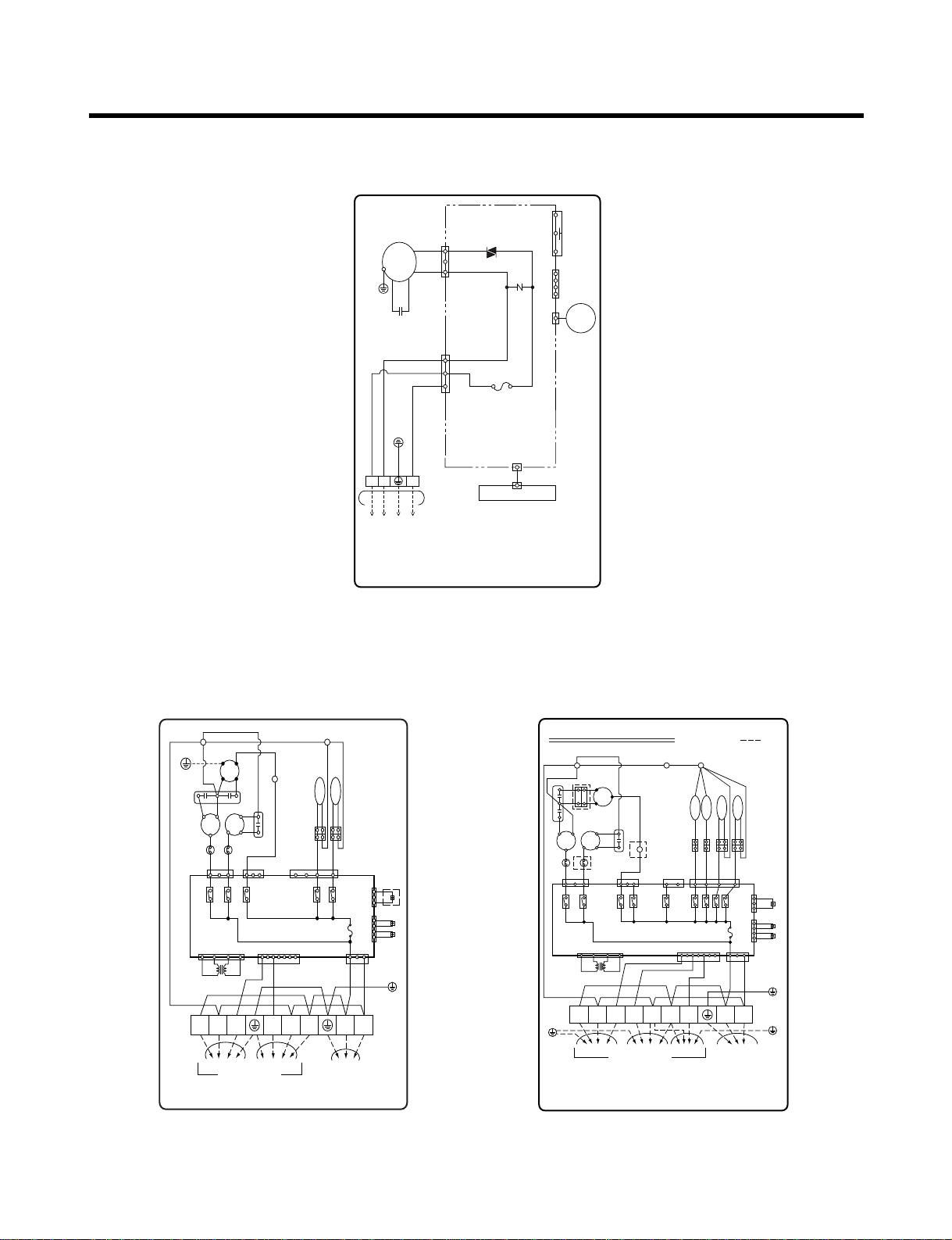

3854A20023B

INDOOR WIRING DIAGRAM

CN-DISP1

CN-U/D

FUSE

AC250V/T2A

CN-TH

SSR

SH-CAPA.

BR

YL

OR

BK

CN-POWER CN-FAN

ZNR

THERMISTOR

FORCED

OPERATION

AUTO

RESTART

REMOTE

CONTROL

STEP

MOTOR

MOTOR

MAIN PCB

ASM

DISPLAY PCB ASM

TO OUTDOOR UNIT

PILLAR

TERMINAL

BR

BL

YL

1

(

L

)

2

(

N

)

3

OUTDOOR WIRING DIAGRAM

MOTOR

MAIN PCB ASSY

TO INDOOR UNIT

A-UNIT B-UNIT C-UNIT

MAIN

POWER

TERMINAL

BLOCK

CN-TRANS

BK

BR

BL

BK BK

BK

BK

"A"

COMP

BL

BK

WH RD BL YL

BL BL BK BK

BL BL BK BK

RD

RD

S R

C

OLP

C

R

BR

BK

YL

S

BK

BK

YL

OR

OPTION

BK(Hi)

BK

T/B2 T/B3

OPTION

T/B1

T/B4

7

1 3

1 3

5 3 1 3 1

BK

WH

BK

WH

RD WH BK

GN/YL

CN-COM

CN-TH1 CN-TH2

CN

-

POWER

RY8

RY9

RY3

RY2

RY1

CN

-

FAN CN

-

BYPASSCN

-

COMP

CAPA.

CAPA.

FUSE T3.15A

THERMISTOR

THERMISTOR

TRANS-

FORMER

OLP

OPTION

OPTION

2 1

RY10

RY7

RY5

RY4

"B"

COMP

1(L) 1(L)2(N) 1(L) 2(N)2(N)

3 3 3

H C F

B-S.V

C-S.V

A 4-WAY

B 4-WAY

4 3 2 1

CN-SV

OUTDOOR WIRING DIAGRAM

3854AP3911C

MAIN PCB ASSY

TO INDOOR UNIT

A-UNIT B-UNIT

MAIN

POWER

TERMINAL

BLOCK

CN-TRANS

BK BK

BR

BL

BL YL

BK BK

BK

BK

BK

BK

OR

H C F

YL

BK

BK

"A"

COMP

BL

BK

RD

RD

S R

C

OLP

C

R

BR

BK

YL

S

BK

BK

T/B2

T/B1

T/B3

GN/YL

MOTOR

BK

7

4 33 11 3 2 1

5 3 1 3 1

BK

WH

WH BK

GN/YL

GN/YL

WH

CN-COM

CN-TH1 CN-TH2

CN-POWER

CN-SV

RY9

RY3

RY2

RY1

RY10

CN-FANCN-COMP

CAPA.

CAPA.

FUSE T3.15A

THERMISTOR

THERMISTOR

TRANS-

FORMER

OLP

"B"

COMP

1(L) 1(L)2(N) 1(L) 2(N)2(N)

3 3

A 4-WAY

B 4-WAY

OPTION

- 11 -

Wiring Diagram

1. Indoor Unit

• LM-2164H2L/M

• LM-3064H3L/M

2. Outdoor Unit

• LM-2164H2L/M • LM-3064H3L/M

Operation Details

■ MAIN UNIT FUNCTION

• DISPLAY

1) Cooling Only Model

Operation Indicator

• On while in appliance operation, off while in appliance pause

• Flashing while in disconnection or short in Thermistor (3 sec off / 0.5 sec on)

Sleep Timer Indicator

• On while in sleep timer mode, off when sleep timer cancel or appliance operation pause

Timer Indicator

• On while in timer mode (on/off), off when timer mode is completed or canceled.

Comp. Running Incidator

• While in appliance operation, on while in outdoor unit compressor running, off while in compressor off

2) Heat Pump Model

Operation Indicator

• On while in appliance operation, off while in appliance pause

• Flashing while in disconnection or short in Thermistor (3 sec off / 0.5 sec on)

Sleep Timer Indicator

• On while in sleep timer mode, off when sleep timer cancel or appliance operation pause

Timer Indicator

• On while in timer mode (on/off), off when timer mode is completed or canceled

Defrost Indicator

• Off except when hot start during heating mode operation or while in defrost control

■ Cooling Mode Operation

• When the intake air temperature reaches 0.5°C below the setting temp, the compressor and the outdoor fan

stop.

• When it reaches 0.5°C above the setting temp, they start to operate again.

Compressor ON Temp ➲ Setting Temp+0.5°C

Compressor OFF Temp ➲ Setting Temp-0.5°C

• While in compressor running, operating with the airflow speed set by the remote control. While in compressor

not running, operating with the low airflow speed regardless of the setting.

■ Healthy Dehumidification Mode

• When the dehumidification operation input by the remote control is received, the intake air temperature is

detected and the setting temp is automatically set according to the intake air temperature.

26°C ≤ Intake Air Temp ➲ 25°C

24°C ≤ Intake Intake Air Temp<26°C ➲ Intake Air Temp-1°C

18°C ≤ Intake Intake Air Temp<24°C ➲ Intake Air Temp-0.5°C

Intake Air Temp<18°C ➲ 18°C

-12-

• While in compressor off, the indoor fan repeats low airflow speed and pause.

• While the intake air temp is between compressor on temp. and compressor off temp., 10-min dehumidifica-

tion operation and 4-min compressor off repeat.

Compressor ON Temp. ➲ Setting Temp+0.5°C

Compressor OFF Temp. ➲ Setting Temp-0.5°C

• In 10-min dehumidification operation, the indoor fan operates with the low airflow speed.

■ Heating Mode Operation(Heat Pump models)

• When the intake air temp reaches +3°…above the setting temp, the compressor is turned off. When below

the setting temp, the compressor is turned on.

Compressor ON Temp. ➲ Setting Temp.

Compressor OFF Temp. ➲ Setting Temp.+3°C

• While in compressor on, the indoor fan is off when the indoor pipe temp. is below 20°C, when above 28°C , it

operates with the low or setting airflow speed. When the indoor pipe temp is between 20°C and 28°C, it oper-

ates with Super-Low(while in sleep mode, with the medium airflow speed).

• While in compressor off, the indoor fan is off when the indoor pipe temp is below 33°C, when above 35°C , it

operates with the low airflow speed.

• If overloaded while in heating mode operation, in order to prevent the compressor from OLP operation, the

outdoor fan is turned on/off according to the indoor pipe temp.

• While in defrost control, both of the indoor and outdoor fans are turned off.

■ Defrost Control(Heat Pump models)

• Defrost operation is controlled by timer and sensing temperature of outdoor pipe.

• The first defrost starts only when the outdoor pipe temperature falls below -6°C after 60 minutes passed from

starting of heating operation and more than 10 minutes operation of compressor.

• Defrost ends after 12 minutes passed from starting of defrost operation or after the outdoor fan operates with-

in max. 2 minutes 30 seconds when the outdoor pipe temperature rises over 12°C even it before 12 minutes.

• The second defrost starts only when the outdoor pipe temperature falls below -6°C after 60 minutes passed

from ending of the first defrost and more than 10 minutes operation of compressor.

■ Cooling overload

• Control indoor fan by sensing outdoor pipe temperature.

• One step down from setting fan speed if pipe temperature is oven 50°C and if below 45°C, operate on setting

temperature.

■ Heating overload(Heat Pump models)

• Outdoor fan ON/OFF by sensing outdoor pipe temperature.

• Outdoor fan is OFF if pipe temperature is over 6.5°C and outdoor fan is ON if pipe temperature is below 0°C.

• Outdoor fan is off if any one part is heating overload condition.

-13-

-14-

■ Fuzzy Operation (Cooling Only Model)

• According to the temperature set by Fuzzy rule, when the intake air temp is 0.5°C or more below the setting

temp, the compressor is turned off. When 0.5°C or more above the setting temp, the compressor is turned on.

Compressor ON Temp ➲ Setting Temp + 0.5°C

Compressor OFF Temp ➲ Setting Temp + 0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

26°C ≤ Intake Air Temp ➲ 25°C

24°C ≤ Intake Air Temp < 26°C ➲ Intake Air Temp + 1°C

22°C ≤ Intake Air Temp < 24°C ➲ Intake Air Temp + 0.5°C

18°C ≤ Intake Air Temp < 22°C ➲ Intake Air Temp

Intake Air Temp<18°C ➲ 18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is automatically selected according to the

temperature.

■ Fuzzy Operation (Heat Pump Models)

• When any of operation mode is not selected like the moment of the power on or when 3 hrs has passed since

the operation off, the operation mode is selected.

• When determining the operation mode, the compressor, the outdoor fan, and the 4 way valve are off and only

the indoor fan is operated for 15 seconds. Then an operation mode is selected according to the intake air

temp at that moment as follows.

24°C ≤ Inatake Air Temp ➲ Fuzzy Operation for Cooling

21°C ≤ Inatake Air Temp<24°C ➲ Fuzzy Operation for Dehumidification

Inatake Air Temp<21°C ➲ Fuzzy Operation for Heating

• If any of the operation modes among cooling / dehumidification / heating mode operations is carried out for 10

sec or longer before Fuzzy operation, the mode before Fuzzy operation is operated.

1) Fuzzy Operation for Cooling

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 0.5°C or more below

the setting temp, the compressor is turned off. When 0.5°C or more above the setting temp, the compressor

is turned on.

Compressor ON Temp ➲ Setting Temp +0.5°C

Compressor OFF Temp ➲ Setting Temp + 0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

26°C≤ Intake Air Temp ➲ 25°C

24°C≤ Intake Air Temp<26°C ➲ Intake Air Temp + 1°C

22°C≤ Intake Air Temp<24°C ➲ Intake Air Temp + 0.5°C

18°C≤ Intake Air Temp<22°C ➲ Intake Air Temp

Intake Air Temp<18°C ➲ 18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is automatically selected according to the tem-

perature.

-15-

2) Fuzzy Operation for Dehumidification

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 0.5°C or more below

the setting temp, the compressor is turned off. When 0.5°C or more above the setting temp, the compressor

is turned on.

Compressor ON Temp ➲ Setting Temp + 0.5°C

Compressor OFF Temp ➲ Setting Temp+0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

26°C ≤ Intake Air Temp ➲ 25°C

24°C ≤ Intake Air Temp<26°C ➲ Intake Air Temp+1°C

22°C ≤ Intake Air Temp<24°C ➲ Intake Air Temp+0.5°C

18°C ≤ Intake Air Temp<22°C ➲ Intake Air Temp

Intake Air Temp<18°C ➲ 18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan repeats the low airflow speed or pause as in

dehumidification operation.

3) Fuzzy Operation for Heating

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 3°C or more above

the setting temp, the compressor is turned off. When below the setting temp, the compressor is turned on.

Compressor ON Temp ➲ Setting Temp

Compressor OFF Temp ➲ Setting Temp + 3°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

20°C≤Intake Air Temp ➲ Intake Air Temp + 0.5°C

Intake Air Temp<20°C ➲ 20°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is set to the high or the medium according to the

intake air temperature and the setting temperature.

■ Airflow Speed Selection

• The airflow speed of the indoor fan is set to high, medium, low, or chaos (auto) by the input of the airflow

speed selection key on the remote control.

■ On-Timer Operation

• When the set time is reached after the time is input by the remote control, the appliance starts to operate.

• The timer LED is on when the on-timer is input. It is off when the time set by the timer is reached.

• If the appliance is operating at the time set by the timer, the operation continues.

-16-

■ Off-Timer Operation

• When the set time is reached after the time is input by the remote control, the appliance stops operating.

• The timer LED is on when the off-timer is input. It is off when the time set by the timer is reached.

• If the appliance is on pause at the time set by the timer, the pause continues.

■ Off-Timer <=> On-Timer Operation

• When the set time is reached after the on/off time is input by the remote control, the on/off-timer operation is

carried out according to the set time.

■ Sleep Timer Operation

• When the sleep time is reached after <1,2,3,4,5,6,7,0(cancel) hr> is input by the remote control while in appli-

ance operation, the operation of the appliance stops.

• While the appliance is on pause, the sleep timer mode cannot be input.

• While in cooling mode operation, 30 min later since the start of the sleep timer, the setting temperature

increases by 1°C. After another 30 min elapse, it increases by 1°C again.

• When the sleep timer mode is input while in cooling cycle mode, the airflow speed of the indoor fan is set to

the low.

• When the sleep timer mode is input while in heating cycle mode, the airflow speed of the indoor fan is set to

the medium.

■ Chaos Swing Mode

• By the Chaos Swing key input, the upper/lower vane automatically operates with the Chaos Swing or they are

fixed to the desired direction.

• While in Chaos Swing mode, the angles of cooling and heating cycle operations are different.

■ Chaos Natural Wind Mode

• When the Chaos Natural Wind mode is selected and then operated, the high, medium, or low speed of the air-

flow mode is operated for 2~15 sec. randomly by the Chaos Simulation.

■ Jet Cool Mode Operation (Cooling Only Model)

• If the Jet Cool key is input at any operation mode while in appliance operation, the Jet Cool mode operates.

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature, 18°C

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has the priority.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode and then

operated in order that the air outflow could reach further.

■ Jet Cool Mode Operation (Heat Pump Models)

• While in heating mode or Fuzzy operation, the Jet Cool key cannot be input. When it is input while in the other

mode operation (cooling, dehumidification, ventilation), the Jet Cool mode is operated.

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature, 18°C.

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has the priority.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode and then

operated in order that the air outflow could reach further.

-17-

■ Auto Restarting Operation

• When the power is restored after a sudden power failure while in appliance operation, the mode before the

power failure is kept on the memory and the appliance automatically operates in the mode on the memory.

• The slide switch on the main unit of the appliance should be on the Auto Restarting position in order that the

Auto Restarting operation is available.

• Operation Mode that is kept on the memory

- State of Operation ON/OFF

- Operation Mode/Setting Temp/Selected Airflow Speed

- Sleep Timer Mode/Remaining Time of Sleep Timer (unit of hour)

• If no input by the remote control or no switching of the slide switch within 7 hr after the appliance operates by

the Auto Restarting operation, the appliance is forced to stop at the moment of 7-hr elapse.

Slide Switch

FORCED

OPERATION

AUTO

RESTART

REMOTE

CONTROL

■ Forced Operation (Cooling Only Model)

• To operate the appliance by force in case that the remote control is lost, the forced operation selection switch

is on the main unit of the appliance to operate the appliance in the standard conditions.

• When the power is supplied while the slide switch is on the forced operation position, or when the slide switch

position is switched to the Auto Restarting position (or test operation) or switched from the remote control posi-

tion to the forced operation position while the power is on, the forced operation is carried out.

• When the slide switch position is switched from the forced operation position to the Auto Restarting position or

the remote control position, the forced operation is canceled and the appliance stops operating.

• The forced operation is carried out in cooling mode with the setting temperature 22°C and the high speed of

airflow.

• While in forced operation, the key input by the remote control has no effect and the buzzer sounds 10 times to

indicate the forced operation.

■ Forced Operation (Heat Pump Models)

• To operate the appliance by force in case that the remote control is lost, the forced operation selection switch

is on the main unit of the appliance to operate the appliance in the standard conditions.

• When the power is supplied while the slide switch is on the forced operation position, or when the slide switch

position is switched to the Auto Restarting (or test operation) position or switched from the remote control posi-

tion to the forced operation position while the power is on, the forced operation is carried out.

• When the slide switch position is switched from the forced operation position to the Auto Restarting position or

the remote control position, the forced operation is canceled and the appliance stops operating.

•

The forced operation is carried out in cooling mode with the setting temperature 22°C and the high speed of airflow.

• In the forced operation mode, the indoor fan is operated at low speed for around 15 sec and then the operation

condition is set according to the intake air temperature as follows.

24°C≤Intake Air Temp ➲ Cooling Mode Operation, 22°C, High Speed

21°C≤Intake Air Temp<24°C ➲ Dehumidification Operation, 23°C, High Speed

Intake Air Temp<21°C ➲ Heating Mode Operation, 24°C, High Speed

-18-

■ Remote Control Operation Mode

• When the remote control is selected by the slide switch on the main unit, the appliance operates according to

the input by the remote control.

■ Protection of the evaporator pipe from frosting

• If the indoor pipe temp is below 0°C in 7 min. after the compressor operates without any pause while in cool-

ing cycle operation mode, the compressor and the outdoor fan are turned off in order to protect the indoor

evaporator pipe from frosting.

• When the indoor pipe temp is 7°C or higher after 3 min. pause of the compressor, the compressor and the

outdoor fan is turned on according to the condition of the room temperature.

■ Buzzer Sounding Operation

• When the appliance-operation key is input by the remote control, the short "beep-beep-" sounds.

• When the appliance-pause key is input by the remote control, the long "beep—" sounds.

• When a key is input by the remote control while the slide switch on the main unit of the appliance is on the

forced operation position, the error sound "beep-beep-beep-beep-beep-" is made 10 times to indicate that the

remote control signal cannot be received.

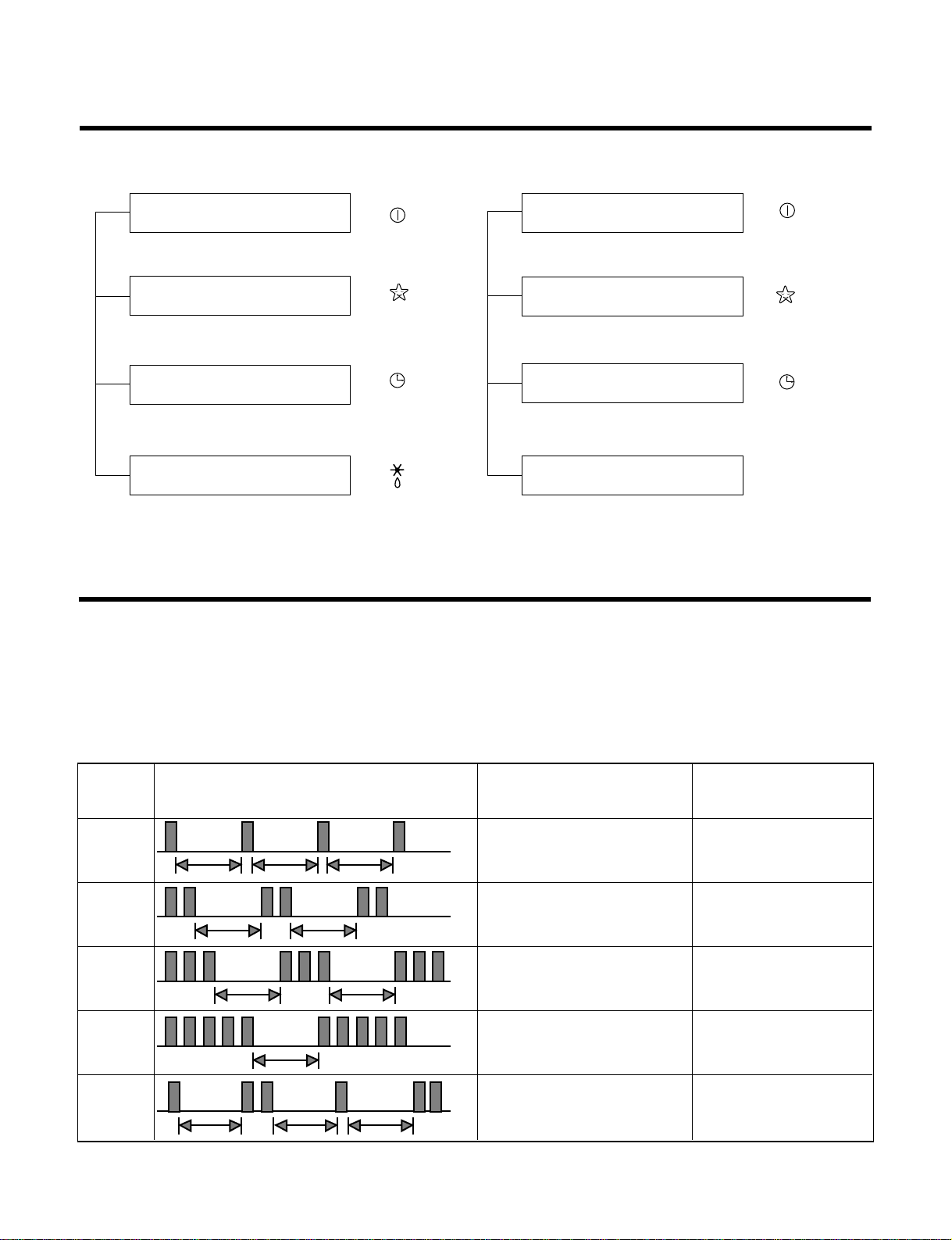

Display Function

1. Heating Model 2. Cooling Model

• Cooling, Soft Dry, Fan, Heating • Cooling, Soft Dry, Fan

• Sleep Mode • Sleep Mode

• Timer Mode • Timer Mode

• Hot-start, Defrost

Self-diagnosis Function

■ Error Indicator

• The function is to self-diagnoisis airconditioner and express the troubles identifically if there is any trouble.

• Error mark is ON/OFF for the operation LED of evaporator body in the same manner as the following table.

• If more than two troubles occur simultaneously, primarily the highest trouble fo error code is expressed.

• After error occurrence, if error is released, error LED is also released simultaneously.

• To operate again on the occurrence of error code 12, be sure to pull out power cord and then re-insert.

• Having or not of error code is different from Model.

Operation Indicator

Timer Indicator

Sleep Timer Indicator

Defrost Indicator

-19-

Operation Indicator

Timer Indicator

Sleep Timer Indicator

Compressor on Indicator

OUT

DOOR

1

(once)

(once)

(twice)

(twice)

(5times)

(once)

(twice)

(3times)

3sec 3sec

3sec

3sec 3sec

3sec

3sec

3sec 3sec

3sec

3sec

2

3

5

12

Error

Code

Error LED

(Indoor body operation LED)

Error contents SVC check point

• Indoor suction temperature

thermistor open/short.

• Indoor pipe temperature

thermistor open/short.

• Indoor TH ass'y check

• Outdoor TH ass'y

check

• Resetting of remocon

operating mode

• Communication

line/circuit check

• Primarily check

refrigerant pressure

• Connecting pipe check

• Connecting cable check

• Outdoor suction temperature

thermistor open/short.

• Outdoor pipe temperature

thermistor open/short.

• Abnormal operation of multi

product.

(Simultanueous operation of

cooling and heating)

• Misconnection of connecting

cables

• Poor communication

- 20 -

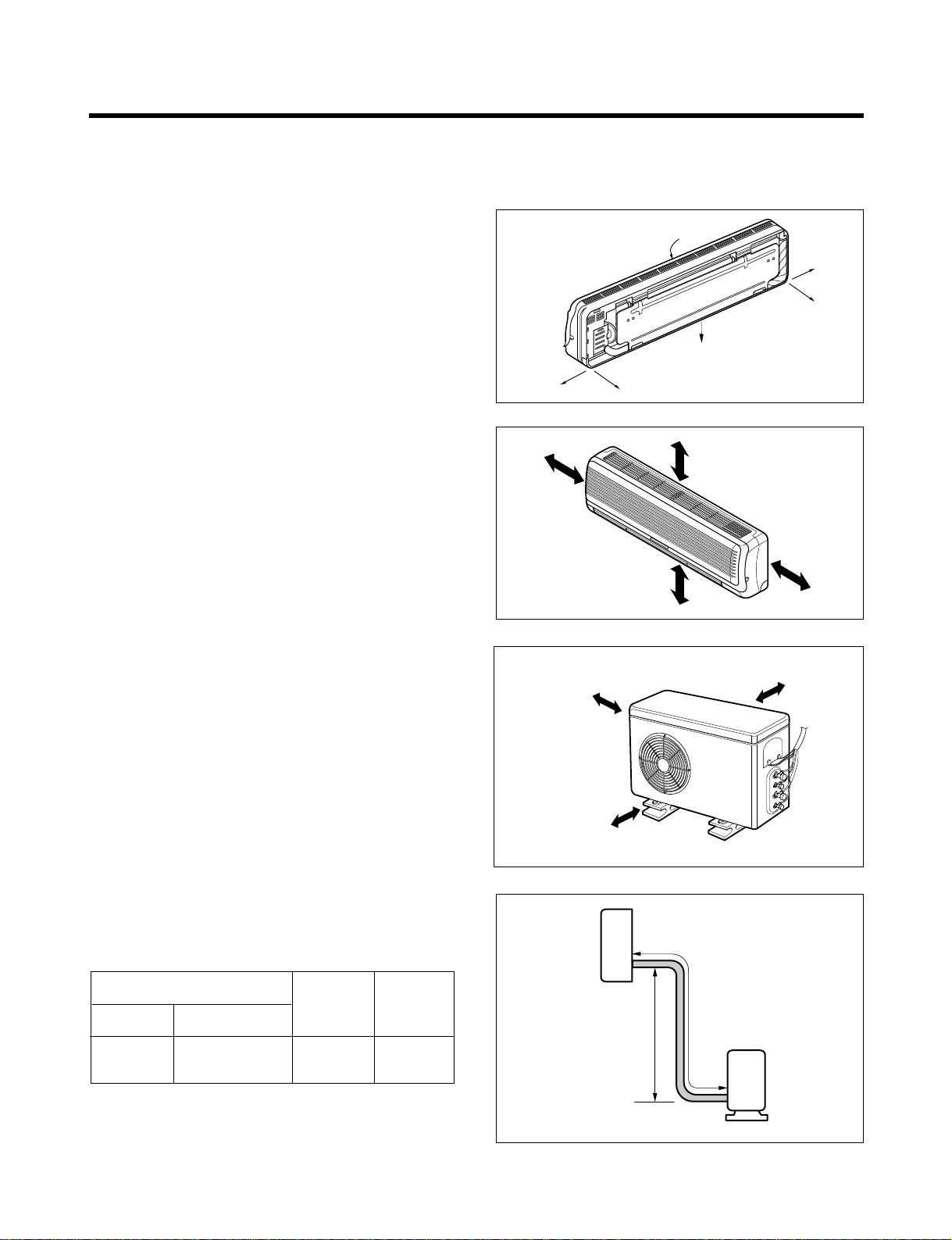

Installation

Front

Right Rear right

Rear left

Down right

Left

More than 5 cm

More than eye-level

More than

5 cm

More than

5 cm

More than 10 cm

More than 10 cm

More than 70 cm

A

B

Indoor unit

Outdoor unit

1) Selection of the best location

1. Indoor unit

• There should not be any heat source or steam

near the unit.

• There should not be any obstacles to prevent

the air circulation.

• A place where air circulation in the room will be

good.

• A place where drainage can be easily obtained.

• A place where noise prevention is taken into

consideration.

• Do not install the unit near the door way.

• Ensure the spaces indicated by arrows from

the wall, ceiling, fence, or other obstacles.

2. Outdoor unit

• If an awning is built over the unit to prevent

direct sunlight or rain exposure, be careful that

heat radiation from the condenser is not

restricted.

• There should not be any animals or plants

which could be affected by hot air discharged.

• Ensure the spaces indicated by arrows from

the wall, ceiling, fence, or other obstacles.

3. Piping length and the elevation

Pipe Size

GAS LIQUID

Max. piping

length

A (m)

Max.

Elevation

B (m)

1/2"(3/8") 1/4" 10~15 5~7

(1) Installation of Indoor, Outdoor unit

Loading...

Loading...