Page 1

WARNING

Reference

NOTICE

CAUTION

WARNING

NOTICE

96M11352

High-speed, High precision, Wide Static

Elimination Blower

SJ-F2000/5000 Series

Instruction Manual

Read this instruction manual before using the product in order to achieve maximum performance.

Keep this instruction manual in a safe place after reading it so that it can be used at any time.

Symbols

The following symbols alert you to important messages. Be sure to read these messages

carefully.

Safety Information on SJ-F2000/5000 Series

General precautions

Precautions on power supply

Precautions specific to the SJ-F2000/5000 Series

It indicates a hazardous situation which, if not avoided, will result in death or

DANGER

serious injury.

It indicates a hazardous situation which, if not avoided, could result in death

or serious injury.

It indicates a hazardous situation which, if not avoided, could result in minor

CAUTION

or moderate injury.

It indicates a situation which, if not avoided, could result in product damage

NOTICE

as well as property damage.

It indicates cautions and limitations that must be followed during operation.

Important

It indicates additional information on proper operation.

Point

It indicates tips for better understanding or useful information.

Indicates the reference pages in this manual or the reference pages in separate manuals.

• Do not use this product for the purpose to protect a human body or a part

of human body.

• This product is not intended for use as explosion-proof product. Do not

WARNING

CAUTION

NOTICE

CAUTION

NOTICE

WARNING

CAUTION

use this product in a hazardous location and / or potentially explosive

atmosphere.

• You must verify that the SJ-F2000/5000 Series is operating correctly in

terms of functionality and performance before the start and during the

operation of the SJ-F2000/5000 series.

• We recommend that you take substantial safety measures to avoid any

damage in the event of a problem occurring.

• KEYENCE never warrants the function or performance of the SJ-F2000/

5000 Series if it is used in a manner that differs from the SJ-F2000/5000

Series specifications contained in this instruction manual or if the

SJ-F2000/5000 Series is modif ied.

• When the SJ-F2000/5000 Series is used in combination with other

instruments, functions and performance maybe degraded, depending on

operating conditions and the surrounding environment.

• Use the power supply with the specified rated voltage and current.

• Do not connect multiple power supplies to a single SJ-F2000/5000 Series

or more than one SJ-F2000/5000 Series connected together, otherwise the

power supplies will be short-circuited , which may result in accidents or

product malfunction.

• Noise conveyed through the power supply line may cause the SJ-F2000/

5000 Series to malfunction. Be sure to use a stabilized DC power supply

with an insulated transformer.

• When using a commercially available switching regulator, be sure to

completely ground the switching regulator's frame ground terminal.

When the SJ-F2000/5000 Series is used in an enclosed space, the generated

ozone may become harmful. Make sure that there is adequate ventilation.

• The appropriate AC power cable for SJ-F5000/SJ-F5500 must be provided

by the user, which complies with the technical regulation and/or standard

in the countries and/or regions for use.

• To avoid the risk of electric shock or product malfunctions, prevent water,

oil, or flammable solvent from splashing onto the SJ-F2000/5000 Series.

• To avoid the risk of injury, electric shock, or product malfunctions, keep

fingers and metallic objects such as tools or wires away from the

SJ-F2000/5000 Series during operation.

• To avoid the risk of electric shock, do not operate the SJ-F2000/5000 Series

with wet hands.

• To avoid the risk of electric shock or product malfunctions, be sure to turn

the power off during maintenance of the SJ-F2000/5000 Series.

• To avoid the risk of injury, do not touch the electrode probes directly with

your hands or fingers during maintenance.

• If any abnormality is observed in the SJ-F2000/5000 Series, immediately

turn off the power and contact the nearest KEYENCE office. Do not try to

repair the SJ-F2000/5000 Series by yourself. This may cause electric shock

or product malfunctions.

• Do not use this unit for any purpose other than eliminating static.

• For proper static elimination, be sure to ground the functional grounding

terminal of the SJ-F2000/5000 Series at a resistance not exceeding 100 Ω.

• Do not use the SJ-F2000/5000 Series in a location in which the temperature

changes suddenly, or where condensation occurs. This may lead to

product breakdown.

• Do not touch the SJ-F2000/5000 Series' electrode probes with hard objects

such as tools. If the electrode probes are damaged, the SJ-F2000/5000

Series does not operate properly, resulting in product malfunctions.

• When the SJ-F2000/5000 Series is used over a long time, dust accumulates

on the electrode probes. Clean the electrode probes when the alarm

indicator flashes. If you continue to use the SJ-F2000/5000 Series with dust

accumulating on the electrode probes, the SJ-F2000/5000 Series will not

operate properly, resulting in product malfunctions. Regular cleaning is

recommended.

• Do not drop the SJ-F2000/5000 Series or subject it to a strong impact. This

may cause product malfunctions.

Locations

To prevent product malfunctions, avoid installing the SJ-F2000/5000 Series in

the following locations.

• Locations in which the SJ-F2000/5000 Series may be directly subjected to

vibration or impact.

• Locations in which the ambient temperature drops below 0°C or exceeds +

50°C.

• Locations in which the relative humidity drops below 35% or exceeds 65%,

or where condensation occurs.

• Locations in which the temperature changes suddenly.

• Locations in which the SJ-F2000/5000 Series is exposed to a direct breeze

from an air conditioner.

• Locations in which there are volatile or flammable substances, solvents, or

corrosive gases.

• Locations exposed to dust, salt, metal particles, or greasy fumes.

• Locations in which water, oil or chemicals may splash onto the SJ-F2000/

5000 Series.

• Locations in which a strong magnetic or electric field is generated.

Other precautions

Be sure to follow all procedures described in each section of this instruction

manual.

This SJ-F2000/5000 Series uses EEPROM. Do not power off the unit while it

is being set.

Precautions on Regulations and Standards

CE Marking

Keyence corporation has confirmed that SJ-F2000/5000 series complies with the essential

requirements of the applicable EC Directives, based on the following specifications. Be sure to

consider the following specifications when using SJ-F2000/5000 series in the Member States of

European Union.

z EMC Directive

• Applicable Standard EMI : EN61326-1, ClassA

• The length of all input/output cables must be less than or equal to 30m.

Remarks:

These specifications do not give any guarantee that the end-product with this product

incorporated complies with the essential requirements of EMC Directive. The manufacturer

of the end-product is solely responsible for the compliance on the end-product itself

according to EMC Directive.

z Low-Voltage Directive

• Applicable Standard EN61010-1

• When using the AC adapter applicable to SJ-F2500/SJ-F2000, use the AC adapter

(SJ-U1/SJ-U2) specified by KEYENCE.

• SJ-F5000/SJ-F5500 is designed as a Class I equipment. Be sure to connect the protective

earthing terminal on the AC power cable to the protective earthing conductor in the

building installation.

• Use this product at the altitude of 2000 m or less.

• Indoor use only.

CSA Certificate

SJ-F2000/5000 series complies with the following CSA and UL standards and has been certified

by CSA (Class 2252 05/Class 2252 85). Be sure to consider the following specifications when

using this product as a product certified by CSA.

• Applicable standard: CAN/CSA C22.2 No.61010-1

• When using the AC adapter applicable to SJ-F2500/SJ-F2000, use the AC adapter

(SJ-U1/SJ-U2) specified by KEYENCE.

• SJ-F5000/SJ-F5500 is designed as a Class I equipment. Be sure to connect the protective

earthing terminal on the AC power cable to the protective earthing conductor in the

building installation.

• Use this product at the altitude of 2000 m or less.

• Indoor use only.

• When using SJ-F2010/SJ-F5010, use the following power supply.

CSA/UL-listed power supply that provides Class 2 output as defined in the CEC

(Canadian Electrical Code) and NEC (National Electrical Code), or CSA/UL-listed power

supply that has been evaluated as a Limited Power Source as defined in CAN/CSA-C22.2

No. 60950-1/UL60950-1

EMS : EN61326-1

UL61010-1

1

Page 2

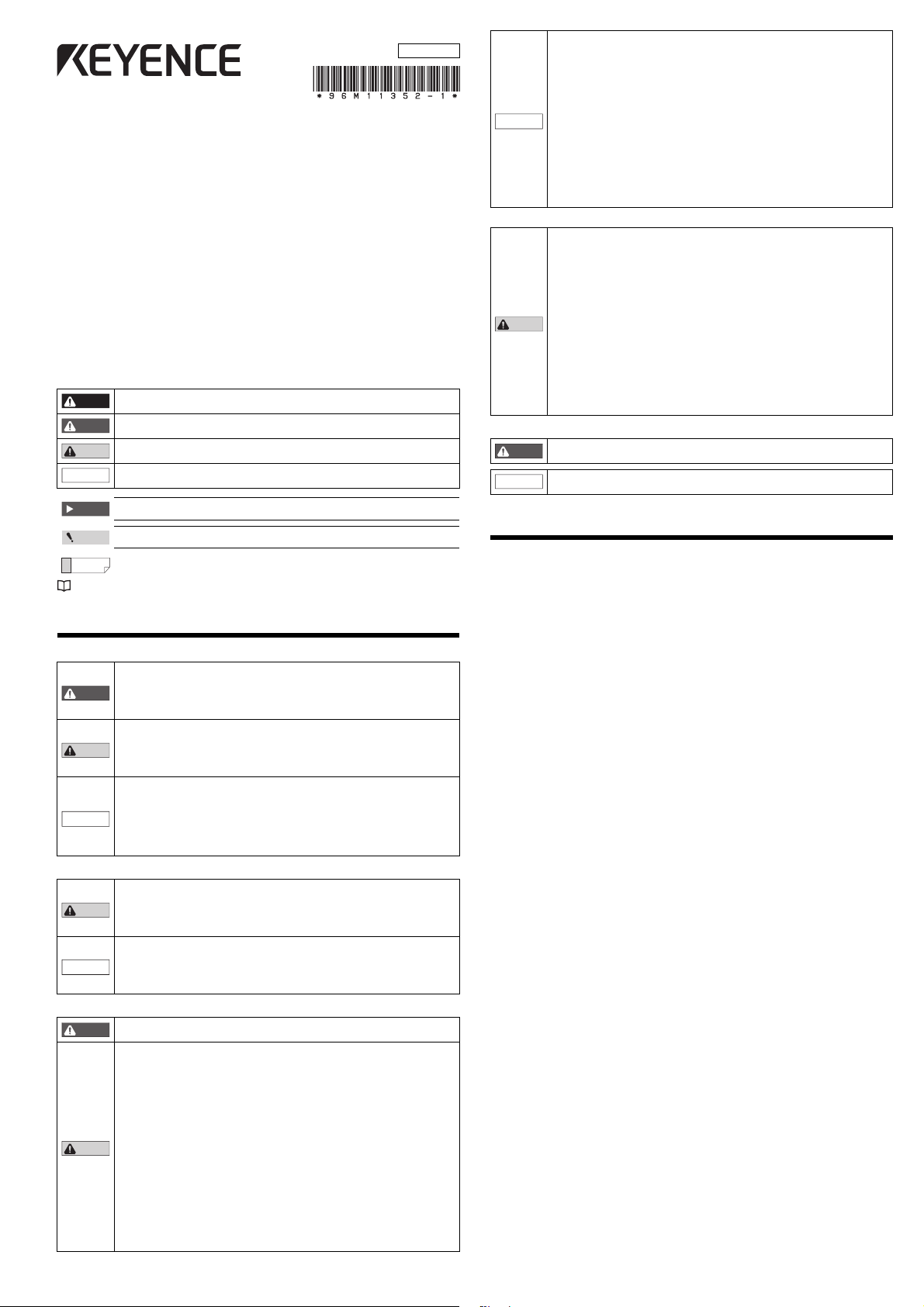

Getting Started

Condition/Ion level

Alarm indicator

Front cover

Lock switch

START/STOP button

Stand

Cursor key

Indicator

5 LEDs for SJ-F5000/SJ-F5010

7 LEDs for SJ-F5500

Rear cover

Air filter

Input/output terminal block

(SJ-F5010 only)

Ground terminal

(SJ-F5000/SJ-F5500 only)

AC power inlet

(SJ-F5000/SJ-F5500 only)

Power switch

SJ-F5500 / SJ-F5000 only

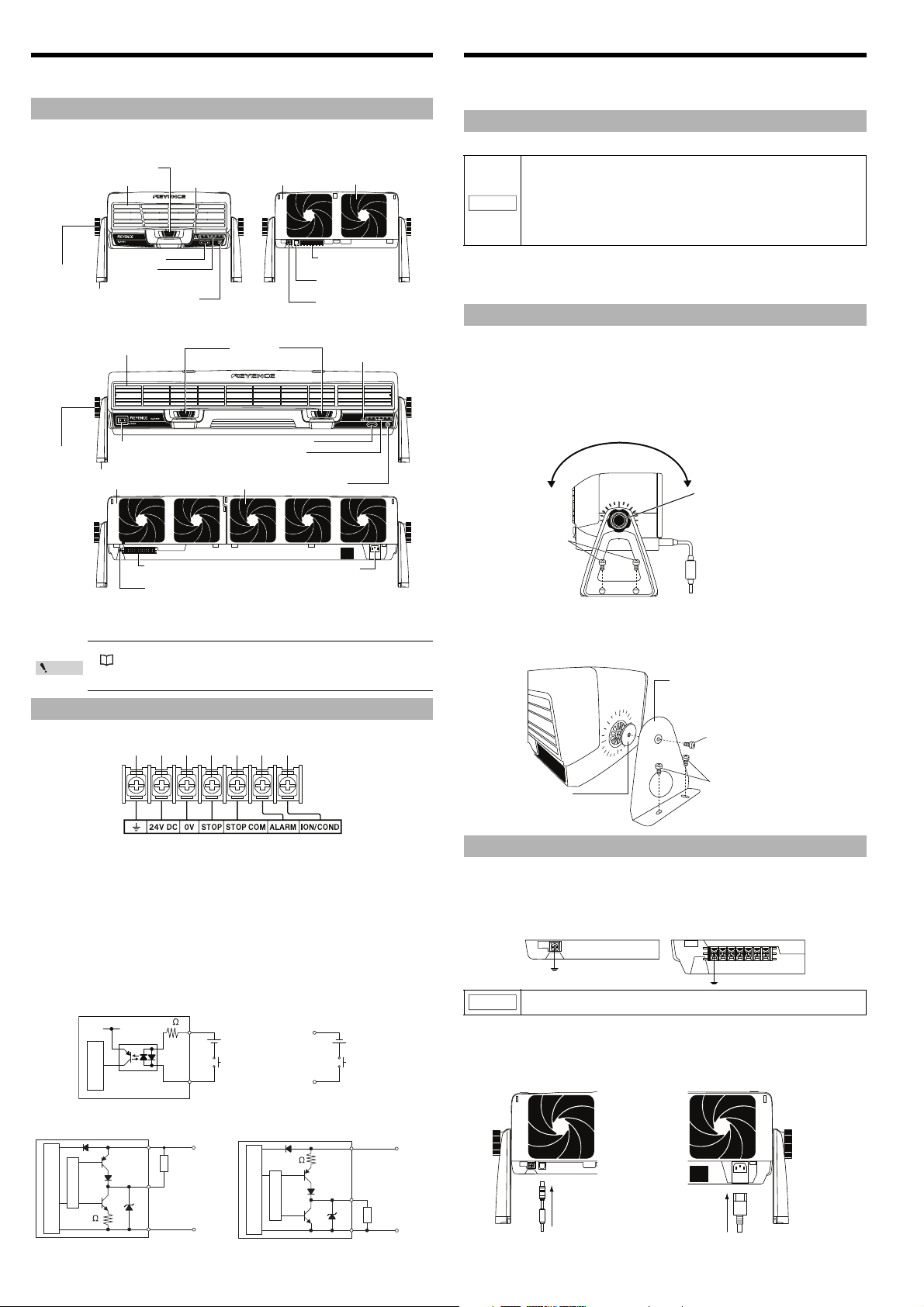

Angle fixing

knob

Point

[4] Static elimination

interruption input

[4] Static elimination

interruption input

[5] COM for static elimination

interruption input

[5] COM for static elimination

interruption input

or

+24 V

+24 V

Main circuit

2 k

NPN open collector output PNP open collector output

[2] 24 V DC

terminal

Main circuit

Overcurrent

protection circuit

24V DC

0V

[3] 0V terminal

*

*

[6] Alarm

[7] Condition/ion level alarm

24V DC

0V

2.4

Main circuit

[3] 0V terminal

*

[2] 24 V DC

terminal

2.4

* [6] Alarm

[7] Condition/ion level alarm

Overcurrent

protection circuit

Load

Load

Loosen the angle fixing knob

to adjust the angle.

M4 screw

L-type mounting bracket

SJ-F2000 series: OP-87147

SJ-F5000 series: OP-87148

Buffer rubber

M5 screw

SJ-F2000 series: M5 screw

SJ-F5000 series: M8 screw

For SJ-F2000/SJ-F5000

SJ-F2500/SJ-F5500

For SJ-F2010/SJ-F5010

Installation and Connection

The package of SJ-F2000/5000 Series includes the following items. Ensure that these items are

included in your package before using the Unit. The name of each part is as follows.

Package content and part names

• Static Elimination Blower Unit

SJ-F2000 series

Angle fixing

knob

SJ-F5000 series

Lock switch

Front cover

Cursor key

Indicator

5 LEDs for SJ-F2000/SJ-F2010

7 LEDs for SJ-F2500

Stand

START/STOP button

Condition/Ion level

Alarm indicator

Rear cover

Air filter

Input/output terminal

block (SJ-F2010 only)

24 V DC IN connector

(SJ-F2000/SJ-F2500 only)

Ground terminal

(SJ-F2000/SJ-F2500 only)

This section explains how to set up and install the SJ-F2000/5000 Series.

Before installation, carefully verify the installation precautions for the SJ-F2000/5000 Series

and confirm the distance to the target object.

Precautions for installation

Installation location

• Keep a space of at least 50 mm around the front and the rear of the

SJ-F2000/5000 Series.

• Keep a space of at least 20 mm around the bottom of the SJ-F5000 series.

• The installation location should withstand a load of at least 8 kg for the

NOTICE

Interference

SJ-F2000/5000 Series may not operate properly if multiple SJ-F2000/5000 Series are

installed close together, or if there are electrical conductors in the vicinity. Provide at least

SJ-F2000 series, and 20 kg for the SJ-F5000 series.

• Keep a tightening torque of no more than 1.5 N•m for the included stand,

the L-type mounting bracket, and the U-type mounting bracket (The

recommended tightening torque is 1.0 - 1.2 N•m).

50 mm of space when installing the unit.

Installing SJ-F2000/5000 Series

There are two ways to install the SJ-F2000/5000 Series. The first is by using the stand

provided with this product, and the other is by using the L-type mounting bracket (SJ-F2000

series: OP-87147, SJ-F5000 series: OP-87148) or U-type mounting bracket (SJ-F2000 series:

OP-87149, SJ-F5000 series: OP-87150).

Installation method

z Using the stand

Drill and tap (M4) the location where the SJ-F2000/5000 Series is to be installed, and

then use the M5 screw to secure the included stand.

• Instruction Manual x 1

• Grounding cable x 1

• A power supply is necessary to use SJ-F2000/5000 Series.

See "Installation and Connection" (page 2)

• The 0V and ground terminals for the 24 V DC IN connector of the SJ-F2000/

SJ-F2500 are non-insulated.

Input/output terminals (SJ-F2010/5010 only)

Layout of the input/output terminal block

[1] Ground terminal: Be sure to ground at a resistance not exceeding 100 Ω.

[2] 24 V DC terminal: DC24 ±10%

[3] 0V terminal: 0V for power and various alarm output

[4] Static elimination interruption input: To turn static elimination on/off, connect the DC24 V

voltage between [4] and [5].

[5] COM for static elimination interruption: COM terminal for static elimination interruption

[6] Alarm output terminal: Output when there is an alarm.

[7] Condition/Ion level alarm output terminal:

Output when the installation environment prevents static elimin ation from being properly executed or causes the

ion generation amount to decrease.

* The ground connection terminal [1] and the 0V terminal [3] are internally isolated.

Input/output circuit and the wiring method (SJ-F2010/5010 only)

z Input circuit [static elimination interruption input]

[1] [2] [3] [4] [5] [6] [7]

z Using L-type mounting bracket for the SJ-F2000/5000 series

(SJ-F2000 series: OP-87147, SJ-F5000 series: OP-87148)

Mount the SJ-F2000/5000 Series on the L-type mounting bracket for the SJ-F2000/5000

series. Drill and tap (M5) the location where the SJ-F2000/5000 Series is to be installed,

and then secure the bracket.

Connecting the SJ-F2000/5000 Series

Connecting the grounding cable

Connect the provided grounding cable to the rear ground terminal, and then connect the

cable to the ground. For SJ-F2010/SJ-F5010, connect the provided grounding cable to the

ground connection terminal of the input/output terminal block.

For proper static elimination, be sure to ground the SJ-F2000/5000 Series at a

NOTICE

resistance not exceeding 100 Ω.

Connecting to the power supply

To connect to the power supply, use one of the following methods.

.

For SJ-F2000/2500

Connect the AC adapter to the 24 VDC IN connector.

If a 24V power supply is being used, make sure

to use the 24VDC IN cable (OP-87152).

.

For SJ-F5000/5500

Connect the AC cordset to the

AC power supply inlet.

z Output circuit [Alarm, condition ion level alarm output]

2

Page 3

.

Reference

.

SJ-F2500/SJ-F5500

.

SJ-F2000/SJ-F2010/SJ-F5000/SJ-F5010

Reference

.

For SJ-F2000/SJ-F5000/SJ-F2010/SJ-F5010

Red Red

Orange Green Orange

Red Red

Red

Orange Green Orange

Red

· SJ-F2500/SJ-F5500 ·

SJ-F2000/SJ-F2010/SJ-F5000/SJ-F5010

.

Keylock ON

.

Keylock OFF

CAUTION

NOTICE

Push the stopper

towards the outside.

Pull out the

board.

For SJ-F2010/5010

Connect a DC24 V power supply (Class 2 or LPS) with sufficient output capacity to the power terminals ([2] and [3]).

[1] [2] [3] [4] [5] [6] [7]

For the power source, use a DC power supply with sufficient marginal output

at a rated voltage of 24 V (output capacity per each blower must exceed the

NOTICE

following values; SJ-F2000: 0.9 A, SJ-F2500: 1.2 A, SJ-F2010: 1.0 A, SJ-F5010:

1.9 A).

Before using the unit, wait approx. 20 minutes after the unit is turned on.

Point

Otherwise, the ion balance may not be stabilized.

Operation and Function

Display and output specifications

Status

Power OFF

Normal operation

Static elimination

interrupted

Ion amount decreased

Condition abnormal

Ion amount decreased

and condition abnormal

<Alarm level 1>

Front cover removed

<Alarm level 2>

Internal memory value abnormal

Abnormal discharge Fan damaged

Static elimination

interruption input

-- -OPENOPEN

Open

Short

-

-

-

-

-

Indicator

Indicates the

electric charge level

Left and right edge

red LED illuminate

Indicates the

electric charge level

Indicates the

electric charge level

Indicates the

electric charge level

Three middle LEDs flash

(ON OFF ON OFF)

All LEDs flash

(ON OFF ON OFF)

Condition/ion

level alarm

indicator

Tur n o ff Sh or t OP EN

Tur n o ff OP EN OP EN

Red LED flashes

(ON OFF ON OFF)

Red LED flashes

(ON ON OFF ON ON OFF)

Red LED flashes

(ON OFF ON OFF)

Tur n o ff OP EN OP EN

Tur n o ff OP EN OP EN

Alarm

output

Short Short

Short Short

Short Short

Ion level

condition

alarm output

Initialization

Returns all of the settings to the factory defaults. While pressing the and cursor keys simultaneously,

turn on the power. The indicators illuminate, as shown below. Release the keys to start operation.

Powe r on

z For the SJ-F2000 series, SJ-F5010

Connect the power supply. The power turns on automatically.

z For the SJ-F5000 series (Except SJ-F5010)

Connect the power supply, and then turn on the power switch of the blower.

Start/stop static elimination

Static elimination starts automatically when the power is turned on.

Static elimination starts or stops when the START/STOP button is pressed and held down for

approx. 1 second during operation.

The indicator turns on when static elimination is interrupted, as shown below.

* The airflow stabilizes approx. 20 seconds after operation starts.

External interruption of static elimination (SJ-F2010/5010 only)

To save energy when 24 V DC voltage is connected between rear terminals [4] and [5], static

elimination and the fan can be interrupted while the power is on.

See "Input/output circuit and the wiring method (SJ-F2010/5010 only)" (page 2).

Control the airflow

Adjust the airflow by using the or

cursor keys.

The indicator LED flashes in response to the

airflow change.

Reduces airflow

Increases airflow

Press and hold down or

to continue adjusting the

airflow.

After you release the cursor key, the set value indicated by the LED flashes for approx. 5 seconds

and returns to the display that indicates the electric charge level. To set the airflow to the initial

value, press and hold down both cursor keys simultaneously for approx. 2 seconds.

Electric charge level display function

Confirms the electric charge level of the target.

The plus and minus side LEDs of the indicator will illuminate in response to the current charge

level of the target.

The further away from the center the illuminated LED is, the higher the electric charge level.

When static elimination is finished, the green LED in the middle of the indicator will be illuminated.

Alarm output/display function

The LED illuminates or flashes to indicate the current status.

SJ-F2010/5010 outputs the signal from the rear input/output terminal block.

The main indicator displays any decreases or abnormalities in ion generation.

Keylock function

While using the keylock function, operations other than using the START/STOP buttons can be

locked to prevent the accidental operation of buttons.

While pressing the cursor key, turn on the power. The indicators illuminate, as shown below.

After you release the cursor key, the display switches to the electric charge level display and

static elimination begins. To turn keylock off, repeat the above procedure.

* Operate with the front cover closed.

Output verification (SJ-F2010/5010 only)

The alarm, the ion level alarm, and the condition alarm are turned on and off manually. (to verify

output terminal operation)

While pressing the START/STOP button and the and cursor keys simultaneously, turn on

the power. The indicators illuminate, as shown below.

For various outputs, while pressing the cursor key, turn on the power, and while pressing the

cursor key, turn off the power. Static elimination is interrupted while output is being verified.

Power ON again to restart static elimination.

* Operate with the front cover closed.

NPN/PNP output switching (SJ-F2010/5010 only)

The PNP and NPN output are used to switch the output circuit. The initial setting is NPN.

* Operate with the front cover closed.

•NPN

While pressing the cursor key and the

START/STOP button simultaneously, turn on the

power.

Release the buttons to start static elimination.

•PNP

While pressing the cursor key and the

START/STOP button simultaneously, turn on the

power.

Release the buttons to start static elimination.

Maintenance of Electrode Probes

When the SJ-F2000/5000 Series is used for a long period, the electrode probes become dirty due

to the accumulation of dust.

If you continue to use the SJ-F2000/5000 Series with dust accumulating on the electrode probes,

the static elimination ability may deteriorate, resulting in an accident or product breakdown.

Therefore, be sure to clean the electrode probes periodically.

Maintenance of electrode probes

• Turn off the SJ-F2000/5000 Series before the maintenance of the electrode probes.

• Do not touch the electrode probes directly with your hand or fingers, as

this may cause injury. Be extremely careful when cleaning them.

Be sure to mount the electrode probes so that they are facing in the correct

direction, as described here.

Cleaning the electrode probes

Use a cotton swab soaked in alcohol to softly wipe the electrode probes.

1 Slide the lock switch located on the face of the

front cover. After you slide the lock switch,

press the tab at the upper part of the front

cover, and then pull the front cover towards

you to remove it.

2 Push the stopper, which is to the right of the

slot, towards the outside. This is the stopper

used to set the board for the electrode probes.

Pull out the board for the electrode probes.

* To mount the board, perform the above procedure in

the reverse order.

3

Page 4

Copyright (c) 2010 KEYENCE CORPORATION. All rights reserved.

11352E 1060-1 96M11352

Printed in Japan

Changing the electrode probes

Power supply

Static elimination

interruption input

(Input terminal)

Static elimination

interruption input

(START/STOP button)

Ion generation

status

Alarm output

(Output terminal)

Normally

ON

Normally

OFF

NormallyONForced

OFF

NormallyONNormally

OFF

NormallyONForced OFF Normally

ON

150ms 150ms 150ms 150ms

MAX

150ms

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Replace the electrode probe if the static elimination capability fails to recover after you clean the

electrode probe, or if the red alarm for the condition/ion level indicator flashes (ON OFF ON OFF)

frequently. Prepare the optional electrode unit for replacement (SJ-F2000 series: OP-87153,

SJ-F5000 series: OP-87154).

To mount an electrode probe, perform the cleaning procedure in the reverse order. Follow the

steps described in "Start/stop static elimination" (page 3) and resume static elimination.

Cleaning the rear air filter

If the airflow level for the static elimination blower decreases, or if the air filter becomes dirty, take

out the rear cover and use cleaner or a similar agent to remove the dust from the inside filter.

Changing the fuse

When the fuse blows, replace the fuse in the fuse holder located under the AC inlet. Be sure to use a

fuse rated 250V, 1.6A, Time lag. (Recommended fuse: ET series manufactured by SOC Corporation)

Timing Charts

* The static elimination interruption input (input terminal) and the alarm output (output terminal)

are only for SJ-F2010/5010).

Warnings and Remedies

Refer to the following list for troubleshooting and remedies before sending out the unit for repairs.

Problem Inspection Remedy

Neither the indicator

nor the pilot lamp turns

ON.

No static elimination is

performed.

Ion level (ION LEVEL)

alarm is illuminated and

output.

The power is ON but

the fan does not rotate.

The condition (COND)

alarm is illuminated and

output.

Control output is not

output correctly.

Static elimination

interrupt input is not

input properly.

There is little airflow.

The three middle

indicators flash.

All indicators flash.

Check that the power supply cable is

connected correctly.

Check that the power supply is within

the rated range.

Check that the electrode probes are

not worn out or dirty.

Check that static elimination is not

interrupted.

Check that the electrode probes are

not worn out or dirty.

Check that there is no conductive object

within 50 mm of the ele ctrode probes.

Check that the wiring is correct.

Check that static elimination has not

been interrupted.

Check that there is no conductive

object or another Static Eli minator Unit

close to the SJ-F2000/5000 Series.

Check that the cable is wired correctly.

Check that the cable is wired correctly.

Check that the airflow setting is not

too low.

Check that the rear filter is not clogged. Remove the dust and contaminant clogged in the filter.

Check that the front cover has not

been removed.

Abnormal discharge from the tip of

the electrode probe

Ground cable is not c onnected Verify that the ground cable is actually connected.

Abnormal value for the internal

memory

Fan is damaged Contact the nearest KEYENCE office.

Follow the steps in "Connecting to the power

supply" (page 2) to correctly connect the cable.

Use power supply within the rated range.

Follow the steps in "Maintenance of Electrode

Probes" (page 3) to perform maintenance or

replace electrode probes.

Follow the steps in "Operation and Function"

(page 3) to start static elimination.

Follow the steps in "Maintenance of Electrode

Probes" (page 3) to perform maintenance or

replace electrode probes.

Make sure there are no electrically conductive objects

within 50 mm of the front of the Static Eliminator Unit.

Follow the steps in "Connecting the grounding cable"

(page 2) to correctly connect the grounding cable.

Follow the steps in "Operation and Function"

(page 3) to start static elimination.

Keep the SJ-F2000/5000 Series away from the

conductive object or the Static Eliminator Unit.

Check the output circuit and make sure that the

wiring is correct.

Verify the input circuit and the wiring and

connect correctly according to "Input/output

circuit and the wiring method (SJ-F2010/5010

only)" (page 2).

Follow the steps in "Control the airflow" (page

3) to verify the settings.

Correctly mount the front cover, and then press and

hold the START/STOP button for approx. 2 seconds.

Turn off the power and perform maintenance on the

electrode probe. If the alarm persists even after you

perform maintenance, remove any conductive

objects that may be near the Static Eliminator Unit.

Follow the steps described in "Initiali zation"

(page 3) and initialize the SJ-F2000/5000 Series.

If the alarm persists even after the initiali zation,

contact the nearest KEYENCE office.

Specifications

Static Eliminator Unit main body

Control

input

Control

output

Rating

Environ

ment

*1 Measured at a distance of 300 mm from the front side of the fan

*2

Measured at a distance of 300 mm from the front side of the fan, using the maximum air flow rate

WARRANTIES AND DISCLAIMERS:

(1) KEYENCE warrants the Products to be free of defects in materials and workmanship for a

period of one (1) year from the date of shipment. If any models or samples were shown to

Buyer, such models or samples were used merely to illustrate the general type and quality of

the Products and not to represent that the Products would necessarily conform to said models

or samples. Any Products found to be defective must be shipped to KEYENCE with all

shipping costs paid by Buyer or offered to KEYENCE for inspection and examination.

Upon examination by KEYENCE, KEYENCE, at its sole option, will refund the purchase price

of, or repair or replace at no charge any Products found to be defective.

This warranty does not apply to any defects resulting from any action of Buyer, including but

not limited to improper installation, improper interfacing, improper repair, unauthorized

modification, misapplication and mishandling, such as exposure to excessive current, heat,

coldness, moisture, vibration or outdoors air. Components which wear are not warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various Products. They are only

suggestions, and it is Buyer's responsibility to ascertain the fitness of the Products for Buyer’s

intended use. KEYENCE will not be responsible for any damages that may result from the use

of the Products.

(3) The Products and any samples ("Products/Samples") supplied to Buyer are not to be used

internally in humans, for human transportation, as safety devices or fail-safe systems, unless their

written specifications state otherwise.

Should any Products/Samples be used in such a manner or misused in any way, KEYENCE

assumes no responsibility, and additionally Buyer will indemnify KEYENCE and hold KEYENCE

harmless from any liability or damage whatsoever arising out of any misuse of the Products/

Samples.

(4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE PROVIDED WITH NO

OTHER WARRANTIES WHATSOEVER. ALL EXPRESS, IMPLIED, AND STATUTORY

WARRANTIES, INCLUDING, WITHOUT LIMITATION, THE WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT

OF PROPRIETARY RIGHTS, ARE EXPRESSLY DISCLAIMED.

IN NO EVENT SHALL KEYENCE AND ITS AFFILIATED ENTITIES BE LIABLE TO ANY

PERSON OR ENTITY FOR ANY DIRECT, INDIRECT, INCIDENTAL, PUNITIVE, SPECIAL OR

CONSEQUENTIAL DAMAGES (INCLUDING, WITHOUT LIMITATION, ANY DAMAGES

RESULTING FROM LOSS OF USE, BUSINESS INTERRUPTION, LOSS OF INFORMATION,

LOSS OR INACCURACY OF DATA, LOSS OF PROFITS, LOSS OF SAVINGS, THE COST OF

PROCUREMENT OF SUBSTITUTED GOODS, SERVICES OR TECHNOLOGIES, OR FOR ANY

MATTER ARISING OUT OF OR IN CONNECTION WITH THE USE OR INABILITY TO USE THE

PRODUCTS, EVEN IF KEYENCE OR ONE OF ITS AFFILIATED ENTITIES WAS ADVISED OF A

POSSIBLE THIRD PARTY’S CLAIM FOR DAMAGES OR ANY OTHER CLAIM AGAINST

BUYER. In some jurisdictions, some of the foregoing warranty disclaimers or damage

limitations may not apply.

BUYER'S TRANSFER OBLIGATIONS:

If the Products/Samples purchased by Buyer are to be resold or delivered to a third party, Buyer

must provide such third party with a copy of this document, all specifications, manuals, catalogs,

leaflets and written information provided to Buyer pertaining to the Products/Samples.

Item Specifications

Model SJ-F2500 SJ-F2000 SJ-F5500 SJ-F5000 SJ-F2010 SJ-F5010

Voltage application method Pulse AC method

Applied voltage ±7000 V

Ion balance control method I.C.C.

Static elimination time

Operating distance More than 50 mm

Maximum air speed

Maximum air flow rate 4.0 m

Ozone concentration Less than 0.005 ppm

*1

Ion balance

Static elimination

interruption input

NPN open

Alarm/Ion

level alarm/

Condition

collector

PNP open

alarm

collector

Power supply DC24 V ±10%

Current consumption 1.2 A 0.9 A 90 VA 65 VA 1.0 A 1.9 A

Ambient temperature 0°C - 50°C

Relative humidity 35% - 65%

Overvoltage category II

Pollution degree 2

Weight About 2 kg About 2 kg About 5 kg About 5 kg About 2 kg About 4 kg

About

*2

*1

About

0.6 sec

1.0 sec

5.7 m/s 3.5 m/s 5.7 m/s 3.5 m/s 3.5 m/s 3.5 m/s

3

/min 2.5 m3/min

±5 V

About

About

0.6 sec

1.0 sec

10.0 m3/min

6.2 m3/min 2.5 m3/min 6.2 m3/min

- DC24 V input

-

-

AC100 - 240 V

(50/60 Hz)

100 mA (Less than 40 V)

(Residual voltage 1 V or less)

(Residual voltage 3 V or less)

About

About

1.0 sec

1.0 sec

100 mA (24 V ±10%)

DC24 V ±10%

External Dimensions

Main body (with stand attached)

D

E

C

φ

A

183.5

135.5

B

Item SJ-F2500 SJ-F2000 SJ-F2010 SJ-F5500 SJ-F5000 SJ-F5010

A 115 135

B 68.5 48.5

C35 45

D 302.9 638.8

E 252 582

F 126 153.7/428.3

G 287 617

H 50 65.5

F (Lever center)

10.6

G (φ4.5 hole pitch)

Removable

front cover

50 133 50

(70.5)

113

φ

4.5 hole × 4

50 (φ4.5 hole pitch)

69

Rotatable

360 degrees

Removable

filter

H

(Cable projection

distance)

<Unit: mm>

4

Loading...

Loading...