Page 1

Before using this Free-layout Elimination Blower,

be sure to thoroughly read this Instruction Manual.

After you are finished with this Instruction Manual,

be sure to store it in a safe place for quick reference.

High-speed, High-precision

Free-layout Static Elimination Blower

Instruction Manual

300

Series

96M10106

1

Page 2

Preface

This document describes handling, method of operation and precautions when using the High-speed,

High-precision Free-layout Elimination Blower Unit SJ-F300 Series. Before you start to use the SJF300 Series, be sure to thoroughly read this document in order to make full use and safely use the

functions of the SJ-F300 Series.

Store this document in a safe place so that you can retrieve it whenever necessary.

■ Symbols

This manual uses the following symbols to alert you to important information.

Be sure to read below.

Failure to follow these instructions may lead to death or serious injury.

Failure to follow these instructions may lead to injury.

Failure to follow these instructions may lead to physical damage (product

malfunction, etc.).

Provides additional information on precautions and restrictions that must be

followed in operation.

Provides additional information on proper operation.

Indicates useful information or information that aids understanding of text descriptions.

Indicates a reference item or page to be referred to in this manual and a separate manual.

DANGER

WARNING

CAUTION

Important:

Note:

Tip

Safety Precautions

■ General Precautions

• At startup and during operation, be sure to monitor the functions and

performance of the SJ-F300 Series.

• We recommend that you take substantial safety measures to avoid any

damage in the event that a problem occurs.

• Do not modify the SJ-F300 Series or use it in any way other than described

in the specifications. The functions and performance of products used or

modified in this way cannot be assured.

• When the SJ-F300 Series is used in combination with other instruments,

functions and performance may be degraded, depending on operating

conditions and the surrounding environment.

• Do not use the SJ-F300 Series for the purpose of protecting the human

body.

■ SJ-F300 Series Handling Precautions

The SJ-F300 Series is a high-voltage product that is not designed in an explosion-proof structure. Pay

attention to the following when using the SJ-F300 Series.

• To prevent electric shock and to ensure accurate static elimination, be sure

to connect a Class D earth (maximum resistance of 100 Ohms).

• Do not use this product in locations where there is the risk of ignition or

explosion from flammable solvents or dirt and dust.

• High voltage is applied to this product. Prevent it from being splashed with

water, oil, or flammable solvents. Failure to do so may cause insulation

breakdown, which will result in electric shock or malfunction.

• Do not bring your fingers or tools, wire or other metallic objects near this

product. Doing so may cause electric shock or malfunction.

• Do not use this product in a non-ventilated location. The ozone generated

from this product may become toxic. Be sure to ventilate the installation site

when this product is used in a non-ventilated location.

• Do not use this product in locations where sudden changes in temperature

or condensation are likely to occur. Doing so may cause accidents or

malfunction.

• Do not operate this product with wet hands. Doing so may cause electric

shock.

• Before starting maintenance, be sure to turn the power OFF. Failure to do so

may result in electric shock or accidents.

• During maintenance, do not directly touch the electrode needles. Doing so

may cause personal injury.

• If any malfunction is observed in this product, immediately turn it OFF, and

contact your nearest agent. You should never repair this product yourself.

Doing so may cause electric shock or malfunction.

Do not touch the electrode needles with a tool or other hard object. Damage to

the electrode needles will prevent static elimination performance from being

fully demonstrated, and cause accidents or malfunction.

CAUTION

WARNING

CAUTION

• When this product is used for a long period of time, the electrode needles

become dirty due to the adhesion of dust and dirt. If the ion level alarm

indicator or condition alarm indicator lights, clean the electrode needles. If

the electrode needles are used in a dirty or dusty state, the static elimination

performance can no longer be fully demonstrated, resulting in accidents or

malfunction. We recommend periodically cleaning the electrode needles (as

a guideline, once every two weeks in a regular operating environment

though this depends on the installation conditions ).

• Do not drop or subject this product to shock. Doing so may result in

accidents or malfunction.

• Use this product for static elimination only. Do not use it for other purposes.

■ Power Supply Precautions

• Use a DC power supply with rated 24 V output.

• Noise applied to the power supply may cause this product to malfunction. If

this happens, install an insulated transformer.

• When using a switching regulator, be sure to connect a Class D earth to the

Frame Ground terminal.

■ Grounding Precautions

• To ensure safety and appropriate static elimination, be sure to ground this

product.

• Be sure to connect a Class D earth (maximum resistance of 100 Ohms).

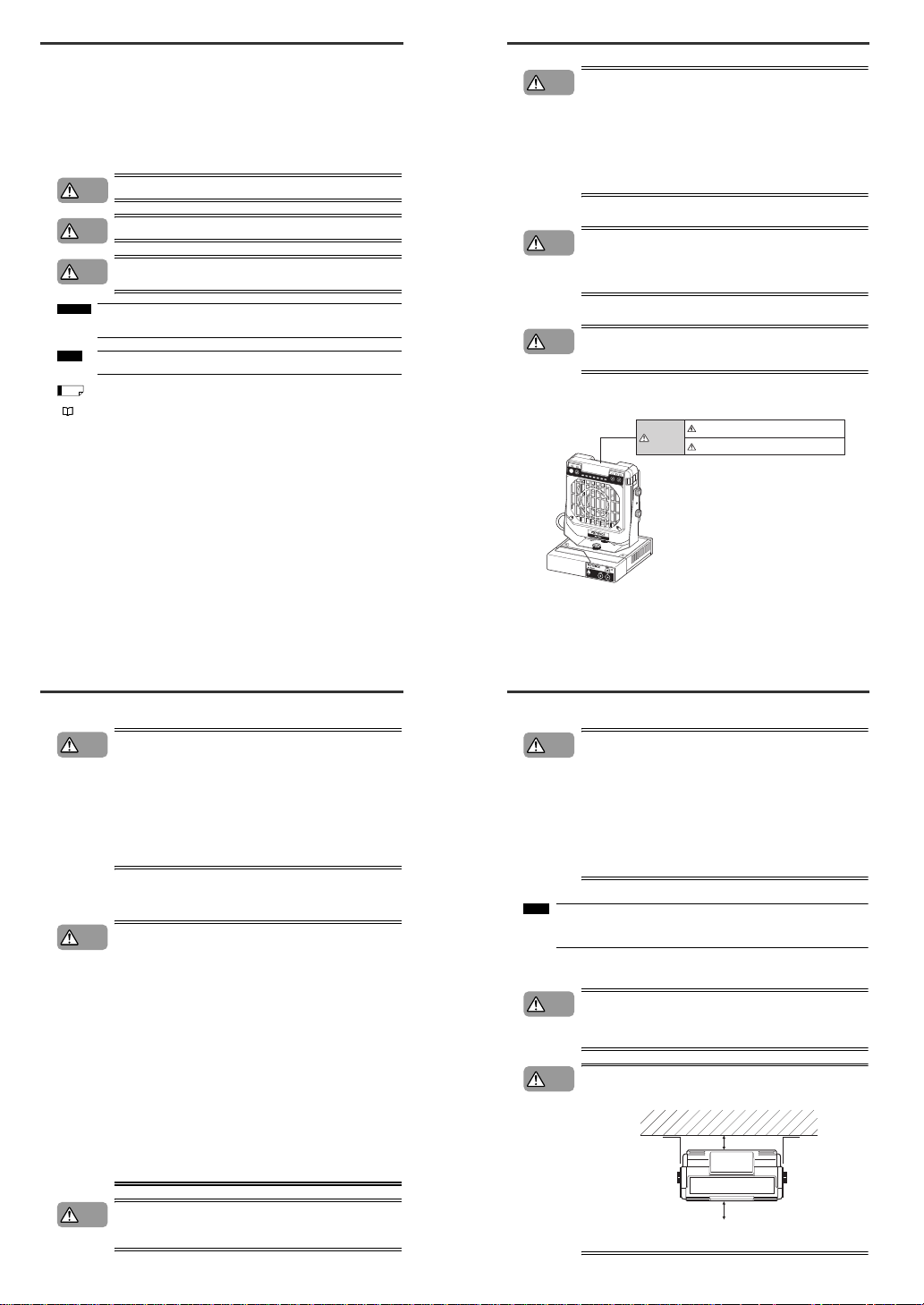

■ SJ-F300 Series Warning Label

A WARNING label is affixed on the SJ-F300 Series to ensure safety.

Read the description on this WARNING label to ensure correct use of the SJ-F300 Series.

CAUTION

CAUTION

CAUTION

Be sure to turn the power off when replacing

the electrode probes. Otherwise, electric shock may occur.

Do not touch electrode probes with your hands

or fingers, as this may cause injury.

WARNING

* WARNING labels in Japanese, German, French, Italian and Chinese:SC

are provided.

Use them as necessary.

STAR

T

/STOP

BALANCE

ION

FAN

COND

IONLEVEL

■ Installation Precautions

Avoid installing the SJ-F300 Series in the following locations as this may

cause accidents.

• Locations directly subject to vibration and shock

• Locations subject to ambient temperature out of the 0°C to +50°C range

• Locations subject to ambient humidity out of the 35 to 65%RH range

(condensation not allowed)

• Locations subject to sudden changes in temperature

• Locations subject directly from blasts from air conditioners

• Locations subject to volatile or flammable substance, solvents or corrosive

gases

• Locations subject to large amounts of dirt, and dust, salt, iron and oil smoke

• Locations that may be splashed with water, oil or chemical mist

• Locations where strong magnetic and electrical fields are generated

■ About Warming Up the SJ-F300 Series

Leave the SJ-F300 Series for about 20 minutes after turning the power ON to allow

the ion balance to stabilize.

The ion balance may be unstable during this warming up period.

■ Other Precautions

•

Be sure to read the WARNINGS and CAUTIONS described in each of the

items in this Instruction Manual.

•

The Static Elimination Blower Unit has a built-in EEPROM. Do not turn the

Static Elimination Blower Unit OFF during the setup.

Refer to the following diagram when installing the SJ-F300 Series.

• Install the Static Elimination Blower Unit away from the wall or surroundin g

objects.

• Install the Static Elimination Blower Unit so that the Electrode Unit can be

removed for replacement.

CAUTION

Note:

CAUTION

CAUTION

50 mm or more

50 mm or more

1

Page 3

Precautions on Regulations and Standards

■ CE Marking

Keyence Corporation has confirmed that this product complies with the essential requirements of the

applicable EC Directive, based on the following specifications.

Be sure to consider the following specifications when using this product in the Member State of

European Union.

● EMC Directive (2004/108/EC)

• Applicable standard EN61326-1

• Be sure to provide a ground when installing the SJ-F300 Series.

• The length of cable (power lead and I/O leads) must be less than or equal to 30 m.

Remarks:

These specifications do not give any guarantee that the end-product with this product incorporated

complies with the essential requirements of EMC Directive. The manufacturer of the end-product is

solely responsible for the compliance on the end-product itself according to EMC Directive.

● Low-Voltage Directive (2006/95/EC)

• Applicable Standard : EN61010-1

• Overvoltage category I

• Use this product under pollution degree 2.

• Use the power supply for the SJ-F300 Series, that satisfies the requirements of the Limited Power

Source specifications stipulated in EN60950-1 and certified by European third-party certification

organization, or a Keyence Corporation AC adapter (SJ-U2). The specifications of the AC adapter

(SJ-U2) are as follows.

• When connecting to an SJ-U2, be sure to use a power cable compliant with European standards.

Applicable standard: EN60950-1

Overvoltage category II

Pollution degree 2

• Be sure to provide a ground when installing the SJ-F300 Series.

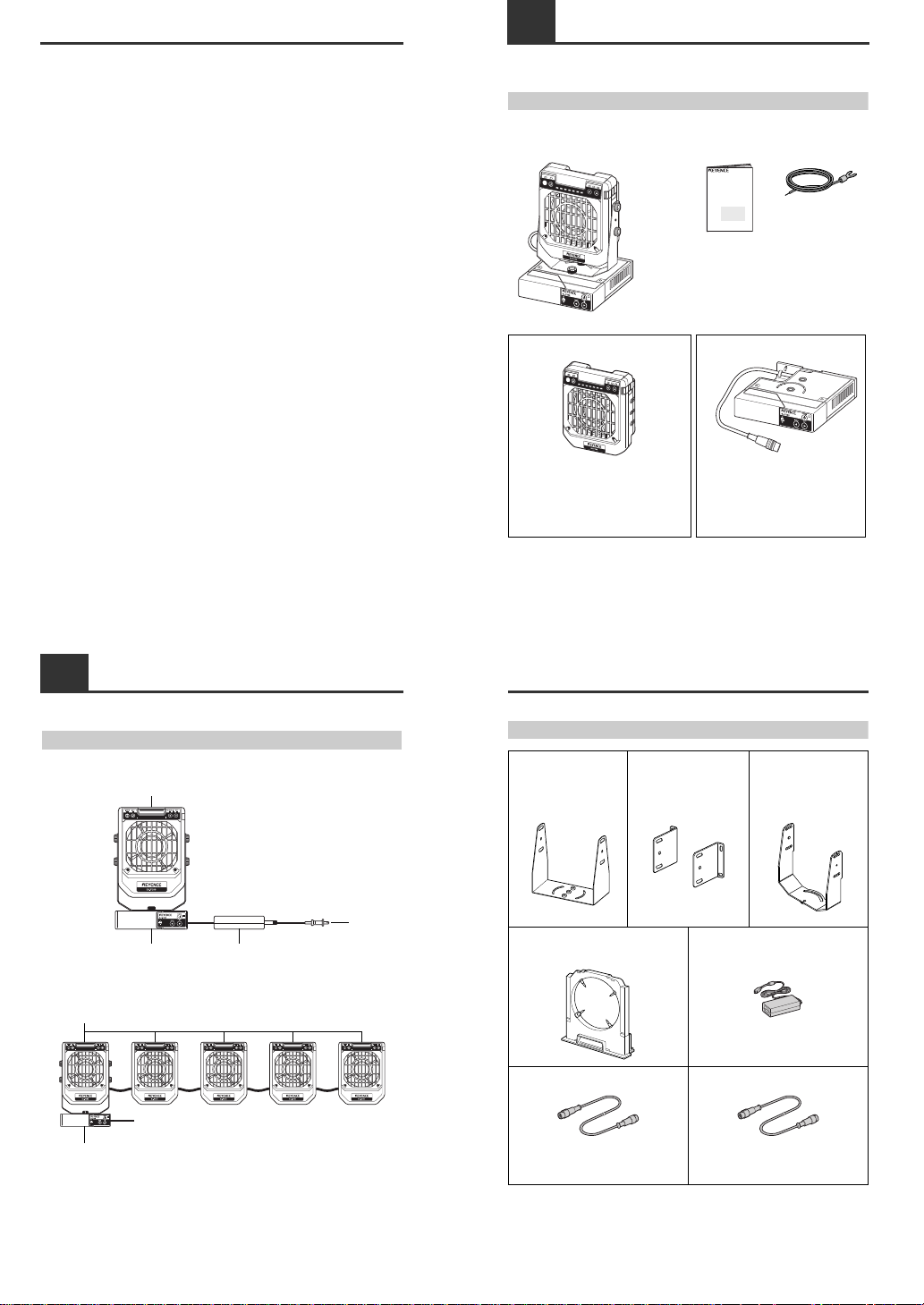

1ABOUT THE STATIC ELIMINATION BLOWER UNIT SJ-F300 SERIES

1-1 System Configuration

This section describes the system configuration of the Static Elimination Blower Unit SJ-F300 Series.

System Configuration

■ When used independently

■ When used in connection

Maximum number of the Static Elimination Blower Units connectable to one Controller Unit is five.

to AC power

Controller Unit AC adapter

Static Elimination Blower Unit

to 24 VDC power

Controller Unit

Static Elimination Blower Units

1-2

Checking the Contents of the Package

The package contains the following components and accessories. Before getting started, make sure

that the package contains everything that it is supposed to contain.

Package Contents

■ When you purchased as a set

■ When you purchased independently

START

/STOP

BALANCE

ION

FAN

COND

IONLEVEL

• Body • Instruction Manual • Earth lead

• Warning label (Japanese, German, French, Italian,

Chinese: SC)

* Use as necessary.

SJ-F

300

Series

High-speed, High-precision

Free-layout Static Elimination Blower

Instruction Manual

Before using this Free-layout Elimination Blower,

be sure to thoroughly read this Instruction Manual.

After you are finished with this Instruction Manual,

be sure to store it in a safe place for quick reference.

Attached to the main

unit when shipped

from the factory.

START

/STOP

BALANCE

ION

FAN

COND

IONLEVEL

• Static Elimination Blower Unit (SJ-F030/F035) • Controller Unit (SJ-F300)

• Warning label

(Japanese, German, French, Italian, Chinese: SC)

* Use as necessary.

* When purchased the Static Elimination Blower

Unit independently, note that a mounting fixture

is not included.

• Earth lead

• Instruction Manual

1-2

Checking the Contents of the Package

Options

* • Total cable length cannot exceed 20 m.

(One unit: 20 m, Two units: 15 m, Three units or more: 10 m)

• To connect the blowers with a cable other than that of 2, 5 and 10m, use the blower-blower extension

cable (SJ-C * P) in combination with a controller-blower extension cable (SJ-C * J).

Mounting fixture A (OP-78476)

Accessory: M4 screw for fixing

the Static

Elimination Blower

Unit x 4

Mounting fixture B (OP-78477)

Accessory: M4 screw for fixing

the Static

Elimination Blower

Unit x 4

Mounting fixture C (OP-78478)

Accessory: M4 fixing screw x 6

Electrode Unit for exchanging (OP-51407) AC adapter (SJ-U2)

Capable of driving up to one fan.

For details of the AC cable, contact the KEYENCE

sales office in your district.

Controller-Blower extension cable * Blower-Blower extension cable *

SJ-C2J Plug-Jack at both ends 2 m

SJ-C5J Plug-Jack at both ends 5 m

SJ-C10J Plug-Jack at both ends 10 m

SJ-C02P Plug-Plug at both ends 0.2 m

SJ-C2P Plug-Plug at both ends 2 m

SJ-C5P Plug-Plug at both ends 5 m

SJ-C10P Plug-Plug at both ends 10 m

2

Page 4

1-3 Names and Functions of Parts

Static Elimination Blower Unit

Electrode Unit

Provided with the electrode needles. Remove from the Static Elimination Blower Unit before attempting

maintenance and servicing work.

Refer to "Performing Maintenance on the Electrode Needles" (page 9) for details about how to

remove the Electrode Unit.

Electrode needle

Generates ions from its tip.

Lock switch

Fixes the Electrode Unit to the Static Elimination Blower Unit.

Fan guard

SJ-F030: Metal

SJ-F035: Resin

■ Operation panel

START

/STOP

BALANCE

ION

FAN

COND

IONLEVEL

Lock switch

Static elimination blower

unit operation panel

Fan guard

Electrode Unit

Electrode needle

[1] Ion level alarm indicator

Lit OFF Normal

Blinking in red Ion level alarm has occurred.

[2] Condition alarm indicator

Lit OFF Normal

Blinking in red Condition alarm has occurred.

[3] Ion balance indicator When lit, the indicator displays the ion balance.

[4] Ion level indicator When lit, the indicator displays the ion level.

[5] Blow rate indicator When lit, the indicator displays the blow rate setting value.

[6] Monitor

The monitor displays the ion balance, ion level, blow rate setting value in

seven indication levels.

Lights in red when the Static Elimination Blower Unit needs cleaning.

[7] START/STOP key Used for switching start/stop.

[8] ENTER key Used for selecting various setups.

[9] UP/DOWN key Used for selecting and adjusting various setups.

[1]

[6] [9]

[2] [3] [4] [5]

[7] [8]

1-3

Names and Functions of Parts

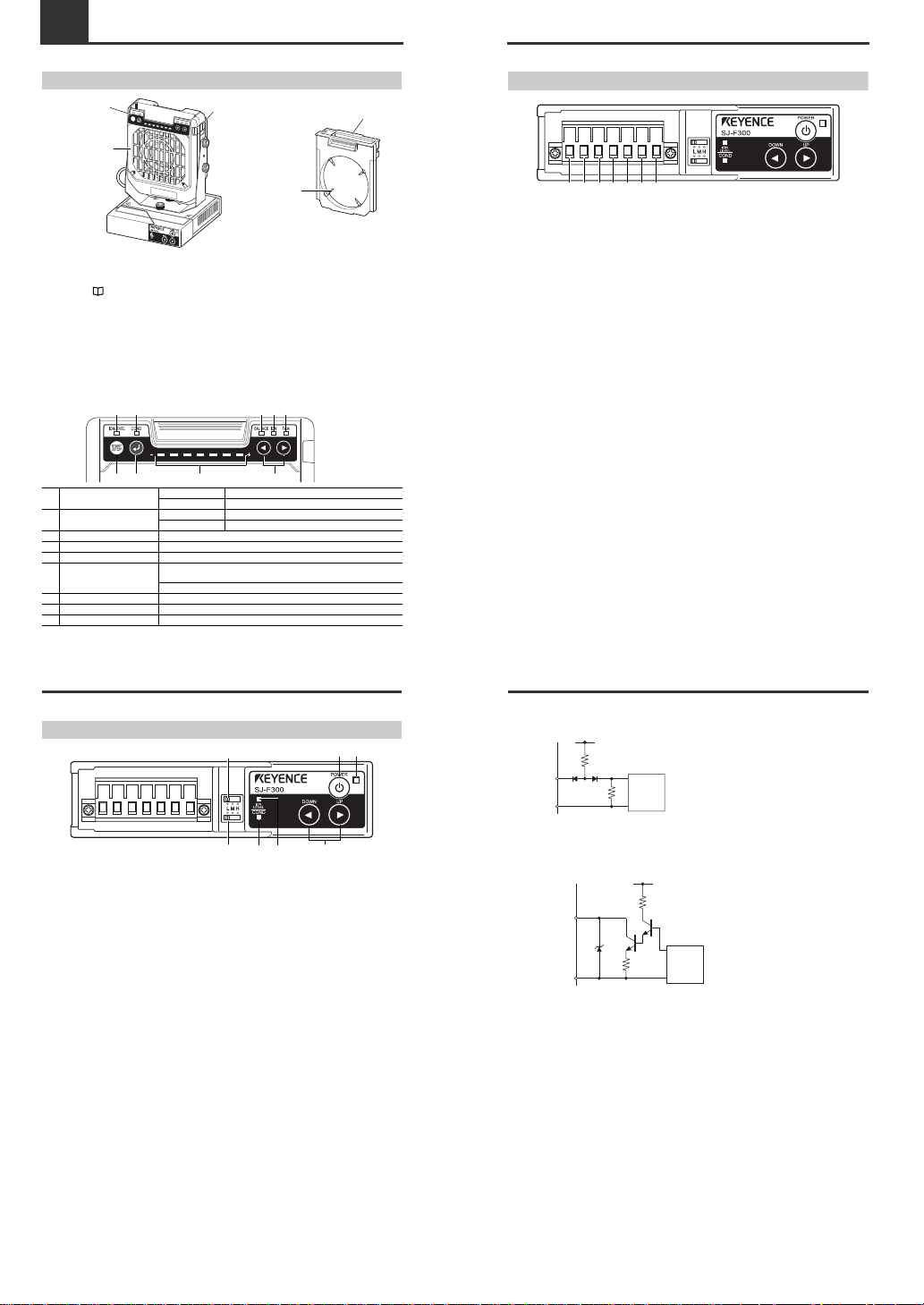

Controller Unit (Operation/Display Section)

[1] Power switch ..... Used for turning ON/OFF the SJ-F300 Series.

[2] Power indicator ..... Displays the power condition ON/OFF.

Lit in green : Normal

Lit OFF : Power OFF

Blinking in green : Static elimination stop inputted.

Blinking in red : Alarm has stopped.

[3] Blow rate adjusting key ..... Used for adjusting the blow rate of the Static Elimination Blower Units

being connected collectively.

[4] Ion level alarm indicator .....Blinks when the ion emission level has dropped below the setting value

due to dirt or wear of the electrode needles.

Lit OFF : Normal

Blinking in red : Ion level alarm has occurred.

Blinking in red : Alarm has stopped.

*

1

Double blinking : Under ion balancing

[5] Condition alarm indicator ....Blinks when the static elimination performance may be influenced by

instability of the installation environment (temperature, humidity,

surrounding metal objects, etc.), for example, when ions are being

absorbed by surrounding metal objects.

Lit OFF : Normal

Blinking in red : Condition alarm has occurred.

Blinking in red : Alarm has stopped.

*

1

[6] Ion level alarm sensitivity setup switch .....Used for changing the threshold value at which ion level

alarm is output.

H: High sensitivity

M: Medium sensit ivity

L: Low sensitivity

[7] Condition alarm sensitivity setup switch ..... Used for changing the threshold value at which condition

alarm is output.

H: High sensitivity

M: Medium sensit ivity

L: Low sensitivity

*

1 Alarm level 2, 3: [2], [4] and [5] blink simultaneously in red.

Alarm level 1: [2] blinks in red.

[6]

[1]

[3][4][5][7]

[2]

1-3

Names and Functions of Parts

Controller Unit (I/O Terminal Section)

[1] Ground terminal ..... Be sure to connect a Class D earth.

[2] DC power terminal ..... 24 VDC ±10%

[3] 0 V terminal ..... 0 V for power and 0 V for I/O

[4] Static elimination stop input terminal ..... Static elimination can be turned ON/OFF by shorting this

terminal with [3] or [5].

[5] 0 V terminal ..... 0 V for power and 0 V for I/O

[6] Alarm output terminal ..... Outputs a signal when alarm condition has occurred.

[7] Condition/Ion level alarm output terminal .... Outputs a signal when the static elimination

performance may be influenced by instability of the

installation environment, or when the ion emission level

has dropped.

[1] [2] [3] [4] [5] [6] [7]

1-3

Names and Functions of Parts

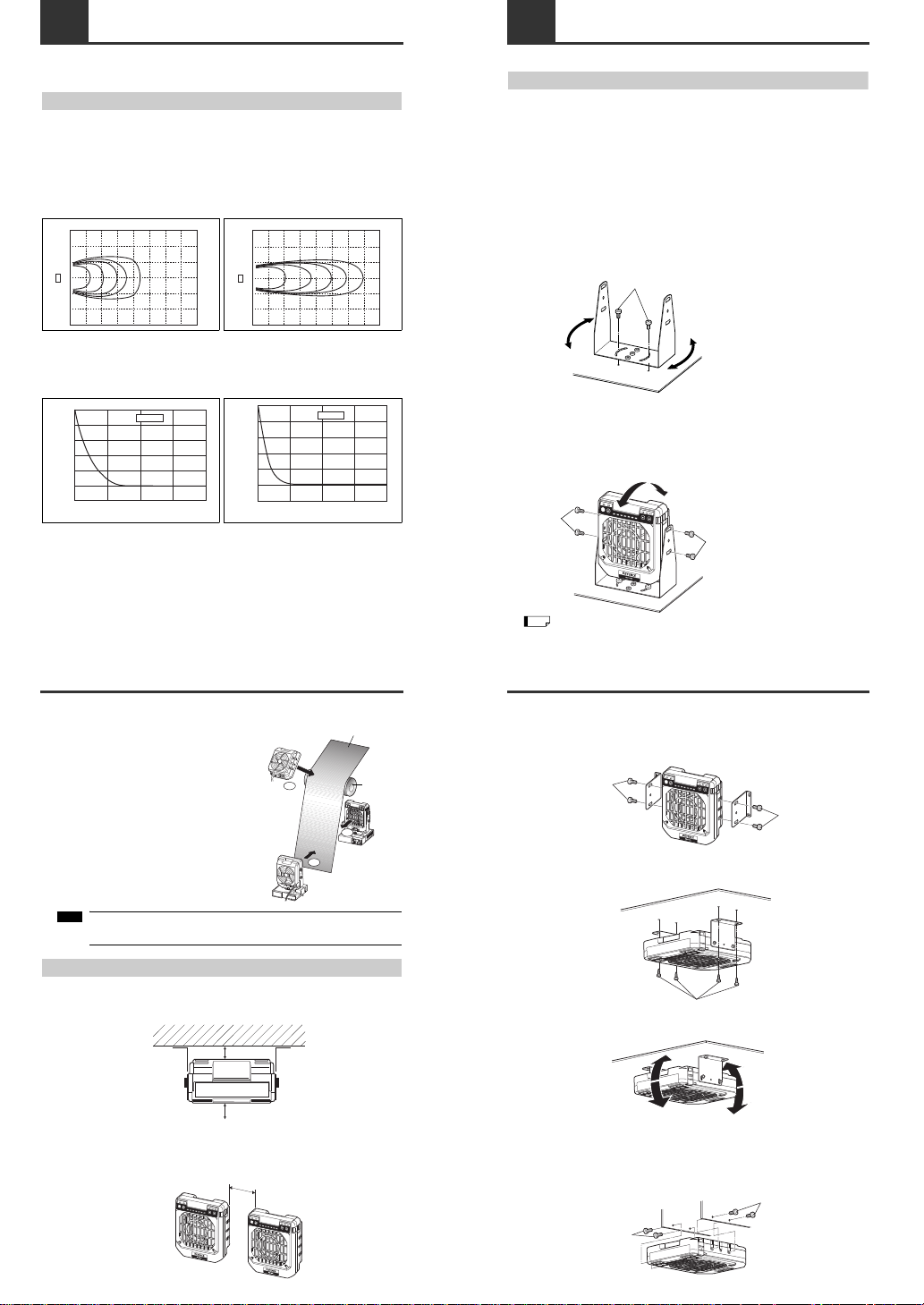

■ Input circuit diagram

[4] Static elimination stop input

■ Output circuit diagram

Open collector output

[6] Alarm output, [7] Condition/Ion level alarm output

+5 V

Internal

Circuit

470 Ω

10 kΩ

INPUT[4]

0 V[3], [5]

Input zero-voltage contact (relay, etc.) or NPN open

collector to INPUT or 0 V.

5 V

47 V

180 Ω

4.7 Ω

OUTPUT[6], [7]

40 VDC

100 mA

0 V[3], [5]

Internal

Circuit

3

Page 5

2CONNECTION AND INSTALLATION

2-1 Before Installation

Before you install this product, examine carefully the distance between the Static Elimination Blower

Unit and the target object and the time required for static elimination.

About Static Elimination Performance

The following shows a typical example where static is eliminated from an aluminum plate (20 pF)

150 mm x 150 mm square charged to +1000 V by this product.

The blow rate of the blower is set at maximum (FAST).

■ Static elimination area

The following graphs show the relationship between the time required for eliminating static from a target

object charged from +1000 V to +100 V and the distance from the charged object up to the Static

Elimination Blower Unit.

■ Static elimination time

The following graphs show the relationship between the time required for eliminating static at the

maximum blow rate from a target object charged at +1000 V positioned 300 mm apart from the Static

Elimination Blower Unit and the charged level.

200 400 800 1000 1200 1400 1600mm600

600mm

600mm

0

1s 2s 3s 4s 5s

SJ-F030

200 400 800 1000 1200 1400 1600mm600

600mm

600mm

0

1s 3s 4s 5s

SJ-F035

2s

01234

1

0.8

0.6

0.4

0.2

0

-0.2

Time required for static elimination (sec)

Charged level (kV)

SJ-F030

01234

1

0.8

0.6

0.4

0.2

0

-0.2

Time required for static elimination (sec)

Charged level (kV)

SJ-F035

2-1

Before Installation

■ Appropriate static elimination method

Pay attention to the following points to ensure that static

elimination is performed appropriately.

Static elimination cannot be performed accurately at

locations where the target object is touching a metallic

body (earthed body).

Eliminate static from the target body at locations where it is

not directly touching metallic bodies (earthed body).

Static will be eliminated from only the surface of the

insulated body (film, sheet, etc.) that is facing the Static

Elimination Blower Unit.

When eliminating static from both sides of a target body,

install two Static Elimination Blower Units as one unit must

be installed on either side of the target body.

Install the Static Elimination Blower Unit so that it can be easily accessed, for

example, for replacement of parts and cleaning.

Installation Precautions

■ Installation site

Refer to the following diagram when installing the SJ-F300 Series.

• Install the Static Elimination Blower Unit away from the wall or surrounding objects.

• Install the Static Elimination Blower Unit so that the Electrode Unit can be removed for replacement.

■ Interference

The Static Elimination Blower Unit may not function properly if two or more units are used close to each other.

In such an installation, refer to the following diagram and maintain the indicated distance between units.

START

/STO

P

BA

L

A

NC

E

ION

FAN

COND

I

O

N

L

E

VEL

OK

OK

NG

Film, sheet or other electrically charged object

Metal roller

Note:

50 mm or more

50 mm or more

STAR

T

/S

TOP

STAR

T

/S

TOP

15 mm or more

2-2 Connection and Installation

Installing the SJ-F300 Series

Install the SJ-F300 Series at locations where static electricity is generated or is likely to be generated.

When installing the Static Elimination Blower Unit separately from the Controller Unit, refer to

"■ Installing the Static Elimination Blower Unit" below.

■ Installing the Static Elimination Blower Unit

There are two ways of installing the Static Elimination Blower Unit, with or without the mounting fixtures.

Each installation method is shown below.

● When using mounting fixture A (OP-78476):

1 Tap M4 screw holes where the Static Elimination Blower Unit is to be installed, and fasten

mounting fixture A (OP-78476) with M4 screws.

You can adjust the horizontal angle of the Static Elimination Blower Unit by using the semi-circled

cutout holes on the base of mounting fixture A.

M4 screws for fastening mounting fixture A at the installation location must be provided separately.

2 Install the Static Elimination Blower Unit on mounting fixture A.

You can adjust the vertical angle of the Static Elimination Blower Unit by using the semi-circled cutout

holes on the base of mounting fixture A.

M4 screws for fastening mounting fixture A to the Static Elimination Blower Unit are provided with

mounting fixture A.

When using the accessory mounting fixture, also fasten it with screws as shown above.

M4 screws

STAR

T

/STOP

BALANCE

ION

FAN

COND

IONLEVEL

M4 screws

M4 screws

Tip

2-2

Connection and Installation

● When using mounting fixture B (OP-78477):

1 Install mounting fixture B (OP-78477) on the Static Elimination Blower Unit.

M4 screws for fastening the Static Elimination Blower Unit to mounting fixture B are provided with

mounting fixture B.

2 Tap M4 screw holes where the Static Elimination Blower Unit is to be installed, and fasten

mounting fixture B (OP-78477) with M4 screws.

M4 screws for fastening mounting fixture B to the installation location must be provided separately.

3

Loosen the screws mounted on the Static Elimination Blower Unit, and adjust the installation

angle. Then, fasten with the screws again.

● When mounting fixtures are not used:

Drill holes of diameter 4.2 mm or more at the location where the Static Elimination Blower Unit is to be

installed, and fasten with M4 screws.

M4 screws must be provided separately.

STAR

T

/STOP

BALANCE

ION

FAN

COND

IONLEVEL

M4 screws

M4 screws

START

/STOP

M4 screws

START

/STOP

S

T

A

R

T

/

ST

O

P

M4 screws

M4 screws

4

Page 6

2-2

Connection and Installation

Connecting Cables

When you have finished with installation, connect the earth lead, the connection cable for the Static

Elimination Blower Unit and the power supply.

■ Connecting the earth lead

Connect the accessory earth lead to the earth connection terminal on the side panel of the Controller

Unit, to conduct grounding.

Alternatively, you can connect the earth lead to the input terminal section on the front panel of

the Controller Unit.

(Refer to "Controller Unit (I/O Terminal Section)" on page 3)

To prevent electric shock and to ensure accurate static elimination, be sure to

connect a Class D earth.

■ Connecting the cable

Connect the connection cable of the Controller Unit to the input terminal [IN] of the Static Elimination

Blower Unit.

Turn off the power before connecting the connection cable.

When installing the Controller Unit separately from the Static Elimination Blower Unit, use the optional

extension cable (SJ-C2J, SJ-C5J and SJ-C10J).

Tip

Ground terminal

Hook

Hang the earth lead on the hook.

WARNING

2-2

Connection and Installation

■ Connecting the power supply

Connect the power supply according to one of the following methods.

24 VDC power supply

Connect a 24 VDC output power supply having sufficient power capacity margin to the power terminals

(terminals [2] and [3]).

AC adapter (SJ-U2)

Connect the AC adapter to the power connector on the side of the Controller Unit. The AC adapter is

available as an option.

When using an AC adapter, use one Static Elimination Blower Unit.

When using plural Static Elimination Blower Units in connection, use a 24 VDC output

power supply.

[1] [2]

[3] [4] [5] [6] [7]

Note:

2-2

Connection and Installation

■ Installing an additional Static Elimination Blower Unit

Connect the output terminal [OUT] of the Static Elimination Blower Unit with the input terminal [IN] of a

Static Elimination Blower Unit to add using a blower-blower extension cable.

When using plural Static Elimination Blower Units in connection, connect a 24 VDC

output power supply having sufficient power capacity margin to the power output

terminals (Refer to "Connecting the power supply" on page 5).

Current/Power consumption by the number of blower units being connected

Static Elimination Blower Unit to add

Blower-Blower extension cable

Input terminal

[IN]

Output terminal

[OUT]

Number of units Max current

consumption

Max power

consumption

1 unit 1.2 A 29 W

2 units 2.4 A 58 W

3 units 3.6 A 87 W

4 units 4.8 A 116 W

5 units 6 A 144 W

Note:

Tip

2-2

Connection and Installation

■ Installing the Controller Unit

The Controller Unit can be mounted on the DIN rail.

Only the Controller Unit can be mounted on the DIN rail. Do not mount the

Controller Unit on the DIN rail with the Static Elimination Blower Unit fixed to

it.

Install the Controller Unit away from the wall or surrounding objects.

CAUTION

Important:

30 mm30 mm

30 mm

30 mm

5

Page 7

3FUNCTION AND OPERATION

3-1 Flow of Operation

The following chart shows the operational flow from installing the SJ-F300 Series, connecting cables to

starting/stopping static elimination of the target object.

Conduct connection and installation

Page 4

Turn on the power Page 6

Start static elimination Page 6

Turn off static elimination Page 8

Adjusting blow rate of the Static Elimination Blower Unit

Page 6

Adjusting sensitivity of ion level alarm

Adjusting sensitivity of condition alarm

Adjusting ion balance

Page 7

Page 7

Page 7

Setup

Confirming charged state and static eliminated state

Confirming ion level

Confirming blow rate of the Static Elimination Blower Unit

Page 8

Page 8

Page 8

Confirmation

3-2 List of Setup and Display Functions

This section describes the setup and display functions of the Controller Unit and the Static Elimination

Blower Unit of the SJ-F300 Series.

Controller Unit

Static Elimination Blower Unit

* In the startup of the second time or later, the state when the power turned off is in memory.

Function name Description Default

Page to

refer to

Power

Turns ON or OFF the main power supply. Collectively

controls the power supplies of the Static Elimination

Blower Units being in connection.

6

Collective blow rate

adjustment

Increases or decreases the blow rate of the blower.

Collectively adjusts the blow rates of the Static

Elimination Blower Units being in connection.

MIN 6

Alarm output

Blinks the indicator and outputs an alarm signal (N.C.)

when trouble occurs.

8

Ion level alarm output

Blinks the indicator and outputs an alarm signal (N.O.)

when the ion emission level drops below the setting

value. When such trouble occurs even in one of the

Static Elimination Blower Units being in connection,

blinks the indicator and outputs an alarm signal (N.O.).

8

Ion level alarm sensitivity

Alarm sensitivity can be adjusted in three stages. The

same setting is applied to all the Static Elimination

Blower Units being in connection.

Low 7

Condition alarm output

Blinks the indicator and outputs an alarm signal (N.O.)

when static elimination performance is influenced by the

installation environment or surrounding metal objects.

When such trouble occurs even in one of the Static

Elimination Blower Units being in connection, blinks the

indicator and outputs an alarm signal (N.O.).

9

Condition alarm

sensitivity

Alarm sensitivity can be adjusted in three stages. The

same setting is applied to all the Static Elimination

Blower Units being in connection.

Low 7

Abnormal discharge

detection

Stops the operation of static elimination and executes

alarm output when abnormal discharge is detected.

9

Collective ion balance

adjustment

Collectively adjusts the ion balances of the Static

Elimination Blower Units being in connection.

0 V 7

Static elimination stop

input

Stops the operation of static elimination of all the Static

Elimination Blower Units being in connection through

terminal input.

8

Function name Description Default

Page to

refer to

Individual start/stop of

static elimination

Starts or stops ion emission and fan rotation. ON * 6, 8

Monitor

Displays the charge monitor (charged state and static

eliminated state of the target object), ion level (emitted

ion amount), and blow rate.

Charge monitor 8

Individual adjustment of

ion balance

Adjusts the balance of ions emitted from the Static

Elimination Blower Unit.

0 V 8

Individual adjustment of

blow rate

Adjusts the blow rate of the Static Elimination Blower

Unit.

MIN 7

3-3 Operation

Operation of Power Supply

This section describes how to operate the power supply of the Controller Unit and the Static Elimination

Blower Unit.

■ Turning on the power

Press and hold on the Controller Unit for about two

seconds, then the power indicator lights in green and the

power for the Controller Unit and the Static Elimination Blower

Unit is turned on.

• In the default setting, turning on the power starts static elimination automatically.

• Connecting (supplying) the power starts static elimination automatically.

■ Turning off the power

Press and hold on the Controller Unit for about two

seconds, then the power for the Controller Unit and the Static

Elimination Blower Unit is turned off.

Starting Static Elimination

Turning on the power of the fan of the Static Elimination Blower Unit and applying voltage to the

electrode needles generates ions to start static elimination. This section describes how to start static

elimination.

In the default setting, turning on the power starts static elimination automatically.

If static elimination is stopped before turning off the power in the initial use of this product,

turning on the power next time will not start static elimination automatically.

■ Starting static elimination

Press and hold on the Static

Elimination Blower Unit for about two

seconds, then static elimination starts.

Power indicator

Tip

Tip

3-3

Operation

Adjusting Blow Rate of the Static Elimination Blower Unit

This blow rate adjustment enables static elimination from a wider area.

Follow one of the procedures below to adjust the blow rate of the Static Elimination Blower Unit.

• Blow rate adjustment using the Controller Unit

• Blow rate adjustment using the Static Elimination Blower Unit

This section describes each adjustment procedure.

■ Blow rate adjustment using the Controller Unit

Every pressing of

or for one second increases or

decreases blow rate by one stage.

* Blow rates of all the Static Elimination Blower Units being

connected at the same time are increased or decreased

collectively (Collective adjustment of blow rate).

• Every pressing of or for about one second increases or decreases blow rate by one

stage.

• When two or more Static Elimination Blower Units having different blow rates used in

connection, the blow rates increase or decrease with the difference maintained. Note that

when the blow rate reaches a maximum or minimum value, the blow rate will be the same at

that value.

• Pressing and holding or enables continuous adjustment of blow rate.

Increases blow ra te.

Decreases blow rate.

Tip

6

Page 8

3-3

Operation

■ Blow rate adjustment using the Static Elimination Blower Unit

This allows individual blow rate adjustment of each Static Elimination Blower Unit.

1 Press or

to select the blow

rate indicator.

The blow rate indicator lights in red.

2 Press and hold for about two

seconds to select the adjustment

mode.

The blow rate indicator blinks in red.

3 Press or to adjust blow

rate.

The monitor LED lights to indicate

the blow rate selected.

• Pressing and holding or enables continuous adjustment of blow rate.

4 Press to complete the blow

rate setup.

Increases blow rate.

Decreases blow rate.

Blow rate indicator

Tip

3-3

Operation

Adjusting Ion Level Alarm Sensitivity

This adjustment allows you to be alerted when the ion emission level has dropped below the setting

value due to dirt or wear of the electrode needles in the connection units by causing the ion level alarm

indicator to blink and an alarm signal (control output [N.O.]) to output.

This section describes how to adjust ion level alarm sensitivity.

Refer to "Ion level alarm output function" (page 8) for indicated states during an alarm output.

■ Adjusting sensitivity

Use the ion level alarm sensitivity setup switch on the Controller

Unit to adjust the sensitivity.

The default setting for the ion level alarm sensitivity switch is "L (Low)".

Static elimination is active during ion level alarm output. Be sure to turn the power

OFF before attempting maintenance on the electrode needles.

Adjusting Condition Alarm Sensitivity

This feature allows you to be alerted when static elimination performance is influenced by the

installation environment (temperature, humidity, surrounding metal objects, etc.) or when ions are

absorbed by surrounding metal objects in the connection units by causing the condition alarm output

indicator to blink and an alarm signal (control output (N.O.)) to output.

This section describes how to adjust condition alarm sensitivity.

Refer to "Condition alarm output function" (page 9) for indicated state during an alar m output.

■ Adjusting sensitivity

Use the condition alarm sensitivity setup switch on the Controller

Unit to adjust the sensitivity.

The default setting for the condition alarm sensitivity switch is "L (Low)".

Ion level alarm sensitivity setup switch

H : High sensitivity

M : Medium sensitivity

L : Low sensitivity

Tip

Important:

Condition alarm sensitivity setup switch

H : High sensitivity

M : Medium sensitivity

L : Low sensitivity

Tip

3-3

Operation

Adjusting Ion Balance

The SJ-F300 Series senses the charged amount of the target object by the I.C.C. function to

automatically control the emission (balance) of plus and minus ions.

The zero point, the point for reference for the I.C.C. function, is adjusted before shipment. However, in

some environments, the zero point sometimes drifts. If this reference zero point drifts, adequate static

elimination cannot be maintained.

The SJ-F300 Series allows arbitrary adjustment of ion balance.

Follow one of the procedures below to adjust ion balance.

• Ion balance adjustment using the Controller Unit

• Ion balance adjustment using the Static Elimination Blower Unit

This section describes each adjustment procedure.

■ Ion balance adjustment using the Controller Unit

1 Press and hold and for about two seconds

simultaneously.

The ion level alarm indicator blinks and the ion balance

adjustment mode is selected.

2 Press or for about one second to adjust the ion

balance.

3 Press and simultaneously to complete the

setup.

• It takes about 30 seconds for the ion balance setting to be reflected after the setup

completed.

• In the case of adjustment using the Controller Unit, the ion balances of all the Static

Elimination Blower Units being in connection are adjusted collectively.

• In the case where two ore more Static Elimination Blower Units each having

different ion balance are connected, the difference is maintained during the

adjustment. Note that when the ion level reaches the threshold of the zero point,

the setting value will be the same at that value.

Every pressing for about one second moves the

zero point to the + side.

Every pressing for about one second moves the

zero point to the - side.

Ion level alarm indicator

Note:

3-3

Operation

■ Ion balance adjustment using the Static Elimination Blower Unit

1 Press or to select the ion

balance indicator.

The ion balance indicator lights in red.

2 Press and hold for about two

seconds.

The ion balance indicator blinks in

red and the ion balance adjustment

mode is selected.

3 Press or to adjust ion balance.

4 Press to complete the ion

balance setup.

■ Confirmation and clear of the ion balance setting value

1 Press and hold for about two

seconds with the ion balance

displayed.

The ion balance indicator blinks in

red and the ion balance adjustment

mode is selected.

2 Press and or

simultaneously on the Static

Elimination Blower Unit.

The monitor displays the ion

balance setting. You can

confirm the adjusted state from

the color and the position of the

LED that lights up. Pressing

and holding and or

simultaneously for about three

seconds clears the adjustment

values.

3 Press on the Static Elimination Blower Unit to complete the adjustment.

The zero point moves to the

+ side.

The zero point moves to the

- side.

Ion balance indicator

Ion balance indicator

Without adjustment

Lit in green

Adjustment in the

+ direction

Lit in green

Full adjustment in

the + direction

Lit in red

<Example when adjusted in the + direction>

7

Page 9

3-3

Operation

Turning Off Static Elimination

Static elimination can be turned off using the Controller Unit or the Static Elimination Blower Unit in a

powered ON state.

This section describes each adjustment procedure to turn off static elimination.

■ Operation using the Controller Unit

Shorting the static elimination stop

input terminal [4] and the 0 V terminal

[5] turns off static elimination.

When static elimination turned off,

the power indicator on the Controller Unit blinks in green.

■ Operation using the Static Elimination Blower Unit

Pressing and holding for about two seconds turns off static elimination.

When static elimination turned off, the center LED of the monitor lights in red.

If static elimination is turned off before turning off the power in the initial use of this product,

turning on the power next time will not start static elimination automatically.

Refer to "Starting Static Elimination" (page 6) for details about how to start static

elimination.

[1][2][3][4] [5][6][7]

Power indicator

Tip

3-4 About Display Function

Monitor Display Function

The monitor on the Static Elimination Blower Unit allows you to confirm the following states by

indication of LED.

■ Displaying charge monitor

Press or to select the ion

balance indicator to display the charge

monitor.

The LED lights up towards the + side or

the - side to indicate the charged level

of the target object.

The LED lit closer to the end (red)

indicates higher charged level.

When static elimination is completed,

the center LED of the monitor lights in

green.

■ Displaying ion level monitor

Press or to select the ion level

indicator to display the ion level

monitor.

The amount of plus ions being emitted

is indicated on the + side; and the

amount of minus ions is indicated on

the - side.

The LED lit closer to the end (green)

indicates higher ion level. When ions

are emitted to the full, the LEDs on the

both ends light in green.

Charge monitor

Charged state and static eliminated state of

the target object

Ion level monitor

Amount of ion emitted from the Static

Elimination Blower Unit

Blow rate setting value

monitor

Blow rate setting value of the Static

Elimination Blower Unit

Red Red

Green

OrangeOrange OrangeOrange

Ion balance indicator

Green Green

Red

Orange

Green Green

Orange

Ion level indicator

3-4

About Display Function

■ Displaying blow rate setting value monitor

Press or to select the blow

rate indicator to display the blow

rate setting value monitor.

The LED lit closer to the + side

indicates higher blow rate; and the

LED lit closer to the - side indicates

lower blow rate.

Alarm Output Display Function

■ Alarm output function

This function causes the following LED to light or blink and an alarm signal (control output [N.C.]) to

output when internal circuits are damaged or abnormal discharging occurs in the connection units.

• This alarm output stops static elimination.

• An alarm is output when static elimination is turned off in all the Static Elimination

Blower Units being connected.

Green GreenGreenGreenGreen GreenGreen

Blow rate indicator

Controller Unit

Power indicator: Blinking in red

Ion level alarm indicator: Blinking in red

Condition alarm indicator: Blinking in

red

Static Elimination

Blower Unit

Monitor: All seven LEDs blinking in red

Ion level alarm indicator

Condition alarm indicator

Power indicator

Monitor

Note:

3-4

About Display Function

■ Ion level alarm output function

This function causes the ion level alarm indicator to blink and an alarm signal (control output [N.O.]) to

output when the ion emission level has dropped below the setting value due to dirt or wear of the

electrode needles in the connection units.

Refer to "Adjusting Ion Level Alarm Sensitivity" (page 7) for details about ion level alarm

sensitivity setup.

This alarm output will not stop static elimination. Be sure to turn the power OFF

before starting maintenance on the electrode needles.

• Once this alarm has been output, the alarm is kept output until the power is turned

off, static elimination is turned off, or the ion level alarm se nsitivity is reset.

• In the case where the Static Elimination Blower Units are used in connection, the

alarm signal is output when ion level alarm condition occurs even in one of these

units.

Ion level alarm indicator

Tip

Important:

Note:

Ion level alarm indicator

8

Page 10

3-4

About Display Function

■ Condition alarm output function

This function causes the condition alarm output indicator to blink and an alarm signal (control output

[N.O.]) to output when ions are being absorbed by surrounding metal objects or when static elimination

performance is influenced by the installation environment (temperature, humidity, surrounding metal

objects, etc.).

Refer to "Adjusting Condition Alarm Sensitivity" (page 7) for details about condition alarm

sensitivity setup.

• The display and output of condition alarm are automatically turned off when the

cause of the alarm condition is removed.

• In the case where the Static Elimination Blower Units are used in connection, the

alarm signal is output when alarm condition occurs in one of these units.

Condition alarm indicator

Condition alarm indicator

Tip

Note:

3-5 Other Functions

Abnormal Discharge Detection Function

To prevent trouble, this function causes the ion emission to stop when it detects abnormal discharging

caused by condensation on the electrode needle tips or adhesion of debris. At this time, the ion level

alarm indicator and the condition alarm indicator on the Controller Unit and all monitor LEDs on the

Static Elimination Blower Unit light up in red to inform you that an abnormality has occurred.

Refer to "Table of Indicated States" (page 12) for indicated states of the Controller Unit.

About Function When Static Elimination Blower Units Are Used in Connection

In the case where the Static Elimination Blower Units are used in connection, the blow rates and the ion

balances of all the units can be adjusted collectively from the Controller Unit.

■ Blow rate collective adjustment function

This function allows the blow rates of all the units being in connection to be increased or decreased

collectively.

Increasing the blow rate enables static elimination from a wider area.

Refer to "Adjusting Blow Rate of the Static Elimination Blower Unit" (page 7) for details about how to

adjust blow rate collectively.

■ Ion balance collective adjustment function

This function allows the ion balances of all the units being in connection to be adjusted collectively.

The SJ-F300 Series senses the charged amount of the target object by the I.C.C. function to

automatically control the emission (balance) of plus and minus ions.

The zero point, the point for reference for the I.C.C. function, is adjusted before shipment. However, in

some environments, the zero point sometimes drifts. If this reference zero point drifts, adequate static

elimination cannot be maintained. For this reason, it is necessary to adjust the SJ-F300 Series to a

desired zero point using this function.

Refer to "Adjusting Ion Balance" (page 7) for details about how to adjust ion balance collectively.

4MAINTENANCE

4-1 About Maintenance

Maintenance must be performed periodically to ensure that the static elimination performance of the

SJ-F300 Series is fully demonstrated. For maintenance, be sure to thoroughly read the descriptions

under "Safety Precautions" ( page 1), and pay attention to the following points.

About Maintenance

• The SJ-F300 Series uses high voltage. Before starting maintenance, be sure to turn

the power OFF. Failure to do so may result in electric shock or malfunction.

•

Do not directly touch the electrode needles.

Take care not to touch these needles even if

the power is turned OFF. Directly touching

these needles may cause personal injury.

When the SJ-F300 Series is used for a long period of time, the electrode needles become dirty due to

the adhesion of dust and dirt.

If the ion level alarm indicator lights, clean the electrode needles. If the electrode needles are used in a

dirty or dusty state, the static elimination performance can no longer be fully demonstrated, resulting in

accidents or malfunction. We recommend periodically cleaning the electrode needles (as a guideline,

once every two weeks in a regular operating environment though this depends on the installation

conditions).

If cleaning the electrode needles does not improve the static elimination performance, or the ion level

alarm indicator frequently lights, replace the Electrode Unit.

WARNING

START

/STOP

BALANCE

ION

FAN

COND

IONLEVEL

4-2

Performing Maintenance on the Electrode Needles

When the SJ-F300 Series is used for a long period of time, the electrode needles become dirty due to

the adhesion of dust and dirt.

If the electrode needles are used in a dirty or dusty state, the static elimination performance can no

longer be fully demonstrated, resulting in accidents or malfunction. Be sure to periodically perform

maintenance on the electrode needles.

Performing Maintenance on the Electrode Needles

• Before removing the Electrode Unit, turn the SJ-F300 Series OFF.

• Do not directly touch the electrode needles with your hands. Doing so may

cause personal injury. Pay attention to this when performing maintenance

on the electrode needles.

1 Remove the Electrode Unit.

Unlock the lock switch on the Static

Elimination Blower Unit, and pull out the

Electrode Unit in the direction of the

arrow.

2 Clean the electrode needles.

Clean the electrode needles with a cotton wool

bud moistened with alcohol.

WARNING

STAR

T

/STOP

BALANCE

ION

FAN

COND

IONLEVEL

BALANCE

ION

FAN

COND

IONLEVEL

STAR

T

/STOP

9

Page 11

4-2

Performing Maintenance on the Electrode Needles

3 Install the Electrode Unit.

Make sure that the lock switch on the

Static Elimination Blower Unit is unlocked,

and then insert the Electrode Unit.

Make sure that the Electrode Unit is

slowly inserted all the way, and then lock

the lock switch to fasten the Electrode

Unit in place.

If cleaning the electrode needles does not improve the static elimination

performance, or the ion level alarm indicator frequently lights, a probable cause is

that the electrode needles have reached the end of their service life. Replace the

Electrode Unit.

An optional Electrode Unit for exchanging (OP-51407) is available.

START

/STOP

START

/STOP

BALANCE

ION

FAN

COND

IONLEVEL

BALANCE

ION

FAN

COND

IONLEVEL

Note:

4-3

Performing Maintenance on the Air Filter

When the blow rate of the static elimination blower has decreased or the air filter has got dirty, perform

maintenance on the air filter on the back panel of the Static Elimination Blower Unit.

Performing Maintenance on the Air Filter

1 Remove the air filter.

Pull the tab on the bottom of the air filter in the direction of

the arrow to remove the air filter together with the cover.

•

Be sure to turn off the main power of the Static Elimination Blower Unit

before attempting maintenance. If not, there may be a risk of electric shock

or accidents.

2 Clean the air filter.

Clean the air filter of dust and dirt.

If the dirt is hard to remove, rinse the filter and dry completely

before use.

3 Attach the air filter.

Fit the air filter to the cover and attach them to the back

panel of the Static Elimination Blower Unit.

•

Do not operate the blower without the air filter attached. This may cause

malfunction.

WARNING

CAUTION

5SPECIFICATIONS

5-1 Timing Charts

■ Ion generation control timing chart

* When all the connected Static Elimination Blower Units stop static elimination, alarm output turns ON.

Indicator states when static elimination is OFF

■ Input response timing chart

Normally ON

Normally OFF

Normally ON Forced OFF Normally ON

Normally OFF

Normally ON

Forced OFF

Normally ON

Static elimination

stop input (terminal)

ON

OFF

Static elimination

stop input (static

elimination blower)

ON

OFF

Ion emission state

Unit indicator

Emitting

No

emissions

Alarm output

ON

OFF

Normal static elimination OFF <during static elimination stop input (via terminal)>

The center LED of the monitor lights in red.

Static elimination

stop input (unit)

ON

OFF

Ion emission

state

Emitting

No

emissions

MAX3.5s MAX1.5s

5-1

Timing Charts

■ Ion level alarm output timing chart

■ Condition alarm output timing chart

■ Alarm output timing chart

Power

ON

OFF

Static elimination

stop input

ON

OFF

Alarm indicator

Blinking

OFF

Alarm output

(N.C.)

ON

OFF

Ion emission

Emitting

No

emissions

Ion level

indicator

Max. 6.5 s

Blinking

OFF

Ion level alarm

output (N.O.)

ON

OFF

When the ion level alarm is output,

removing the cause of the alarm can

restore the normal state. One way of

restoring the normal state is to

perform maintenance on the

electrode needles.

For details on electrode needle

maintenance, see "Performing

Maintenance on the Electrode

Needles" ( page 9).

Power

ON

OFF

Static elimination

stop input

ON

OFF

A

larm indicator

Blinking

OFF

A

larm output

(N.C.)

ON

OFF

Ion emission

Emitting

No

emissions

Condition

indicator

Blinking

OFF

Condition alarm

output (N.O.)

ON

OFF

When the condition alarm is output,

removing the cause of the alarm can

restore the normal state. One way of

restoring the normal state is to

enhance the installation

environment.

Max. 6.5 s

Power

ON

OFF

Alarm indicator

ON

OFF

Static elimination

stop input

Blinking

OFF

Alarm output

(N.C.)

ON

OFF

Ion emission

Emitting

No

emissions

When the alarm is output, the

normal state can be restored by

performing one of the two available

restore methods depending on the

cause of alarm output.

For details on how to restore the

normal state, see "During an alarm

(levels 1, 2)" ( page 13).

Max. 6.5 s

10

Page 12

5-2 Specifications

■ Controller Unit/Static Elimination Blower Unit

■ AC ada pte r

Static elimination stop input

Alarm output

Ion level alarm output

Condition alarm output

Power voltage

Current consumption

Operating ambient temperature

Operating ambient humidity

Static Elimination Blower Unit

Controller Unit

Voltage application method

Applied voltage

Ion balance control method

Static elimination time

*1

Ion balance

*1

Max. fan speed

*2

Max. blow rate

Ozone concentration

Control input

Variable DC

±7000 V max.

I.C.C. method

3.1 m

3

/min

0.005 ppm max.

NPN open collector or no-voltage contact signal

NPN open collector

100 mA (40 V max.)

24 VDC±10%

1.2 A max.

0 to +50°C

35 to 65%RH (condensation not allowed)

Approx. 620 g

Approx. 320 g

Approx. 2 sec

±5 V

0.8 m/s

Approx. 0.7 sec

±10 V

3.5 m/s

Model

Control output

Rating

Environmental

resistance

Weight

Controller Unit

Static Elimination Blower Unit

SJ-F300

*1 Values obtained by measurement 300 mm from the front of the Static Elimination Blower Unit

(SJ-F030: Blow rate min./SJ-F035: Blow rate max.)

*2 Values obtained by measurement 300 mm from the front of the Static Elimination Blower Unit

SJ-F030 (Wide type) SJ-F035 (High speed type)

Rated input

Rated output

Operating ambient temperature

Operating ambient humidity

* The power cable supplied with SJ-U2 is 125V rated power voltage.

100 to 240 VAC (50/60 Hz)

24 VDC 2.65 A

0 to +35°C

20 to 80% (condensation not allowed)

Approx. 250 g

Model

Rating

Environmental

resistance

Weight

SJ-U2

5-3 External Dimensions

■ Body

When the Controller Unit and the Static Elimination Blower Unit integrated

Controller Unit

(139)

22.6

SJ-F030 67

SJ-F035 72

103.7

30°

(109)

(50)

45

φ15

120

(Fixing part 121)

140.7

211.7

(2)

37.8

120

103.7

35.9

φ6 Cable length 300 mm

Min. bend radius 15

2-M4 to depth 3

φ15

φ15

31

41.7

30.7

(2)

(62)

5-3

External Dimensions

Static Elimination Blower Unit

■ Mounting fixture

106

(5)

2x2 M4 to depth 6

12.2

11.7

45

64.5

SJ-F030 61.5

SJ-F035 66.5

5.5

(50)

1

(121.6)

158

87

120

(Fixing part 121)

R35

4.5

3-M6

80°

30°

26

121

φ11

2.3

35

50

4

110

138

70

10

4.5

5.5

17

t = 3.2

60

4.5

98.5

83

5.5

40

40°

Mounting fixture A (OP-78476) Mounting fixture B (OP-78477)

5-3

External Dimensions

■ Extension cable (SJ-C * J)

■ Extension cable (SJ-C * P)

■ AC adapter (SJ-U2)

* For details of the AC cable, contact the KEYENCE sales office in your district.

6 mm dia. cable length SJ-C2J 2 m

SJ-C5J 5 m

SJ-C10J 10 m

49

φ15.5

51

φ15

6 mm dia. cable length SJ-C02P 0.2 m

SJ-C2P 2 m

SJ-C5P 5 m

SJ-C10P 10 m

5151

φ15

φ15

(37.5)

7

ø16

(10.3)

(16.3)

(12.5)

(14)

28

ø3.5

1800

114.5

50.5

11

Page 13

AAPPENDICES

1 Troubleshooting

This appendix describes troubles that may occur during the use of this product and troubleshooting

methods. Check the following table before sending in your SJ-F300 Series for repair.

Symptom Check Item Remedy

Are the power cable and the

extension cable connected properly?

Is a power supply within specification

being used?

Is the power turned off?

Is there sufficient power capacity?

Is static elimination turned off?

Are the electrode needles worn or dirty?

Is static elimination stop currently set?

Is the abnormal discharge detection

function operating?

Are conductors or other Static Elimination Blower

Units located near the Static Elimination Blower Unit?

Is the blow rate adjustment setting

set to low?

Is the filter on the back panel of the

blower clogged?

Are the electrode needles worn or dirty?

Are conductive objects located in the area

within 50 mm in front of the electrode needles?

Are conductors or other Static Elimination Blower

Units located near the Static Elimination Blower Unit?

Are the electrode needles worn or dirty?

-

Is wiring correct?

Is wiring correct?

Connect the power cable and the

extension cable correctly.

Use a power supply that is within

specification.

Refer to "1-3 Names and Functions of

Parts" ( page 3) of this manual.

The number of blower unit that the optional AC

adapter (SJ-U2) can drive is only one. If you attempt

to use two or more blower units in connection, use a

DC power supply with sufficient capacity.

Turn on static elimination by following the instructions of

"Starting Static Elimination" ( page 6) of this manual.

Perform maintenance on the electrode

needles or replace the electrode unit.

Cancel the static elimination stop input

of the SJ-F300 Series.

Check the electrode unit for any

conductive substances (e.g. oil droplets).

Keep the Static Elimination Blower Unit away from

conductors or other Static Elimination Blower Units.

Refer to the "Adjusting Blow Rate of the Static

Elimination Blower Unit" ( page 6) of this manual.

Clean the clogging duct and refuse off

the filter.

Perform maintenance on the electrode

needles or replace the electrode unit.

Keep the conductive objects away from the area

within 50 mm in front of the electrode needles.

Keep the Static Elimination Blower Unit away from

conductors or other Static Elimination Blower Units.

Perform maintenance on the electrode

needles or replace the electrode unit.

Refer to "During an alarm (levels 1, 2)"

( page 13) of this manual.

Check the output circuit and wiring,

and connect correctly.

Check the input circuit and wiring, and

connect correctly.

Monitor LEDs or

indicators are not

lit.

Power will not be

turned on.

Power is turned on but

the fan will not rotate.

Static is not

eliminated.

Static elimination is not

performed properly.

The blow rate is

reduced.

The ion level

alarm is output or

displayed.

The condition

alarm is output or

indicated.

The alarm

indicator lights up.

Control output is

not output correctly.

Static elimination stop

input is not input correctly.

2 Table of Indicated States

This appendix describes the various indicated states of the SJ-F300 Series.

■ Indicated states when the power is turned ON

Lit State Description

After the power indicator lit in green and the center

LED of the monitor lit in red, and then the monitor

LEDs light from side to side, static elimination is

performed. The state (charge monitor, ion level

monitor or blow rate setup monitor) that was active

before the power was turned OFF is displayed.

After the power indicator lit in green and the

center LED of the monitor lit in red, and then the

monitor LEDs light from side to side, the state

(charge monitor, ion level monitor or blow rate

setup monitor) that was active before the power

was turned OFF is displayed.

2

Table of Indicated States

■ Indicated states during setting change, confirmation and operation

(excluding when the power is turned ON)

Two monitor LEDs on the + side and - side,

respectively, and the ion level indicator light in red.

One monitor LED and the blow rate indicator light in red.

Ion level monitor display

This displays the amount of ions that are being

emitted by the SJ-F300 Series.

This displays the setting value of the blow rate of

the Static Elimination Blower Unit.

The center LED of the monitor lights in red.

Static elimination stop input (I/O terminal section)

The center LED of the monitor lights in red when

static elimination is turned off by shorting the static

elimination stop input terminal and the 0 V terminal.

Static elimination stop input (Blower section)

The center LED of the monitor lights in red when

static elimination is stopped by pressing for

about two seconds.

One monitor LED and the ion balance indicator

light in red.

Charge monitor display

This displays the charged level of the target

object. When there is a plus charged object, the

LED on the + side lights, and when there is a

minus charged object, the LED on the - side lights

to indicate the charged level.

The state (charge monitor, ion level monitor or

blow rate setup monitor) that was active before

static elimination was turned OFF is displayed.

Static elimination stop input canceling

(Operation/Display section)

Pressing and holding for about two seconds

after static elimination is turned off using

cancels the static elimination stop input. The state

(charge monitor, ion level monitor or blow rate

setup monitor) that was active before the static

elimination was stopped is restored.

Note that when an alarm condition occurs, the

LED blinks to indicate the cause of the alarm.

Refer to "Turning Off Static Elimination"

( page 8) for details about how to conduct

static elimination stop input from the Controller

Unit (Operation/Display section).

Refer to "During an alarm (levels 1, 2)"

( page 13) for indicated states during an alarm.

Lit State Description

2

Table of Indicated States

Lit State Description

Ion balance manual setup

In ion balance manual setup, press and hold or

000to set the zero point, when the monitor LED

lights up to indicate the setting value.

Refer to "Adjusting Ion Balance" ( page 7) for

details about how to start ion balance manual

setup.

One of the monitor LEDs lights.

Condition alarm indicator blinks in red.

Condition alarm

The condition alarm indicator blinks in red when

the ion balance is unstable due to influence of the

installation environment.

Ion balance indicator blinks.

Ion balance manual setup start

Pressing and holding for about two seconds

while the ion balance indicator lights up starts ion

balance manual setup, when the ion balance

indicator starts blinking.

Ion balance indicator blinks fast.

Ion balance manual setup completion

After ion balance manual setup is finished,

pressing completes the setup, when the

charged level monitor is displayed.

Refer to "Adjusting Ion Balance" ( page 7) for

details about how to start ion balance manual

setup.

12

Page 14

2

Table of Indicated States

Description

The power indicator on the Controller Unit and

three center LEDs of the monitor on the Static

Elimination Blower Unit blink in red.

During an alarm (level 1)

The power indicator on the Controller Unit and

three center LEDs of the monitor on the Static

Elimination Blower Unit blink in red under the

following conditions.

Remove the cause of alarm condition, and then

press and hold and on the Static

Elimination Blower Unit for about three seconds

simultaneously.

The alarm condition will be cancelled. You can

turn on the power.

Cause of alarm condition

· The lock switch on the Static Elimination Blower

Unit is disengaged.

· The rear cover or the front cover of the Static

Elimination Blower Unit is not properly attached.

During an alarm (level 2)

The power monitor LEDs, ion level alarm indicator,

condition alarm indicator on the Controller Unit,

and all the monitor LEDs on the Static Elimination

Blower Unit blink in red under the following

conditions.

Remove the cause of alarm condition to cancel the

alarm by following the instructions below.

If the alarm is output repeatedly, please contact

your nearest KEYENCE sales office.

Cause of alarm condition

· Discharged abnormally

· Internal memory value trouble

· Electrode unit not attached

· Fan trouble

How to cancel the alarm

· When discharged abnormally, turn on the power

again.

· When some trouble occurred in the internal

memory, press and hold and for about

three seconds.

Ion level alarm indicator blinks in red.

Ion level alarm

The ion level alarm indicator blinks in red when the

ion level decreases lower than the setting value.

Lit State

The power indicator, ion level alarm indicator,

condition alarm indicator on the Controller Unit,

and all the monitor LEDs on the Static Elimination

Blower Unit blink in red.

2

Table of Indicated States

Description

During an alarm (level 3)

The power indicator, ion level alarm indicator,

condition alarm indicator on the Controller Unit, and

all the monitor LEDs of the Static Elimination Blower

Unit blink in red and the power supply to the Static

Elimination Blower Unit is stopped under the

following conditions.

Remove the cause of alarm condition to cancel the

alarm by following the instructions below.

Cause of alarm condition

· Excessive number of Static Elimination Blower

Units connected

· Lead broken or disconnected

· Internal circuit damaged

How to cancel the alarm

· Take appropriate measures against excessive

number of Static Elimination Blower Units

connected and lead broken or disconnected,

and then turn on the power again.

* When the internal circuit has been damaged,

please contact your nearest KEYENCE sales

office.

Lit State

The power indicator, ion level alarm indicator,

condition alarm indicator on the Controller Unit,

and all the monitor LEDs on the Static Elimination

Blower Unit blink in red.

WARRANTIES AND DISCLAIMERS

(1) KEYENCE warrants the Products to be free of defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any models or samples were shown to Buyer, such models or samples were

used merely to illustrate the general type and quality of the Products and not to represent that the Products

would necessarily conform to said models or samples. Any Products found to be defective must be shipped to

KEYENCE with all shipping costs paid by Buyer or offered to KEYENCE for inspection and examination. Upon

examination by KEYENCE, KEYENCE, at its sole option, will refund the purchase price of, or repair or replace

at no charge any Products found to be defective. This warranty does not apply to any defects resulting from

any action of Buyer, including but not limited to improper installation, improper interfacing, improper repair,

unauthorized modification, misapplication and mishandling, such as exposure to excessive current, heat,

coldness, moisture, vibration or outdoors air. Components which wear are not warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various Products. They are only suggestions, and it

is Buyer's responsibility to ascertain the fitness of the Products for Buyer’s intended use. KEYENCE will not be

responsible for any damages that may result from the use of the Products.

(3) The Products and any samples ("Products/Samples") supplied to Buyer are not to be used internally in

humans, for human transportation, as safety devices or fail-safe systems, unless their written specifications

state otherwise. Should any Products/Samples be used in such a manner or misused in any way, KEYENCE

assumes no responsibility, and additionally Buyer will indemnify KEYENCE and hold KEYENCE harmless from

any liability or damage whatsoever arising out of any misuse of the Products/Samples.

(4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE PROVIDED WITH NO OTHER

WARRANTIES WHATSOEVER. ALL EXPRESS, IMPLIED, AND STATUTORY WARRANTIES, INCLUDING,

WITHOUT LIMITATION, THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, AND NON-INFRINGEMENT OF PROPRIETARY RIGHTS, ARE EXPRESSLY DISCLAIMED. IN

NO EVENT SHALL KEYENCE AND ITS A FFILIATED ENTITIES BE LIABLE TO ANY PERSON OR ENTITY

FOR ANY DIRECT, INDIRECT, INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES

(INCLUDING, WITHOUT LIMITATION, ANY DAMAGES RESULTING FROM LOSS OF USE, BUSINESS

INTERRUPTION, LOSS OF INFORMATION, LOSS OR INACCURACY OF DATA, LOSS OF PROFITS,

LOSS OF SAVINGS, THE COST OF PROCUREMENT OF SUBSTITUTED GOODS, SERVICES OR

TECHNOLOGIES, OR FOR ANY MATTER ARISING OUT OF OR IN CONNECTION WITH THE USE OR

INABILITY TO USE THE PRODUCTS, EVEN IF KEYENCE OR ONE OF ITS AFFILIATED ENTITIES WAS

ADVISED OF A POSSIBLE THIRD PARTY’S CLAIM FOR DAMAGES OR ANY OTHER CLAIM AGAINST

BUYER. In some jurisdictions, some of the foregoing warranty disclaimers or damage limitations may not

apply.

BUYER'S TRANSFER OBLIGATIONS:

If the Products/Samples purchased by Buyer are to be resold or delivered to a third party, Buyer must provide

such third party with a copy of this document, all specifications, manuals, catalogs, leaflets and written

information provided to Buyer pertaining to the Products/Samples.

E 1110-2

Copyright (c) 2009 KEYENCE CORPORATION. All rights reserved.

10106E 1120-2 96M10106

Printed in Japan

13

Loading...

Loading...