Kenwood DPF-1030, DPF-1030-E, DPF-1030-S, DPF-2030, DPF-2030-E Service manual

...

COMPACT DISC PLAYER |

|

DPF-1030/1030E/1030-S |

|

DPF-2030/2030E/2030-S |

|

SERVICE MANUAL |

© 2000-3/B51-5603-00 (K/K) 2100 |

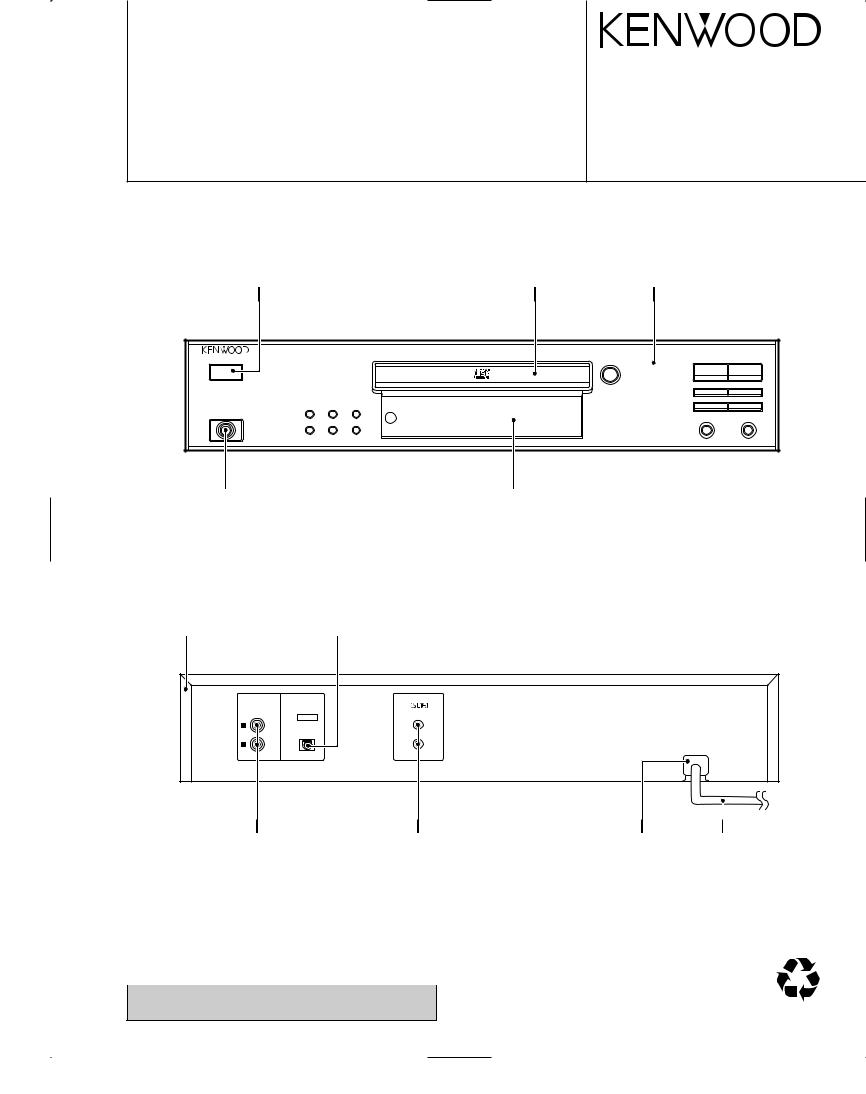

Power Knob * |

|

Tray cover * |

|

Front cab ass'y* |

(K29-) |

|

(A21-) |

|

(A60-) |

POWER |

OPEN/CLOSE |

|

|

0 |

7 |

6 |

|

|

|

|

|

- ON – OFF |

|

|

|

|

|

|

|

4 |

¢ |

P.MODE |

CHECK PEAK SEARCH |

|

1 |

¡ |

PHONES |

|

|

REPEAT |

RANDOM |

EDIT |

CLEAR TIME DISPLAY |

|

||

|

|

|

H/P jack |

FL window |

(E11-0345-08) |

(B10-3611-08) |

Top cabinet * |

Digital output jack |

(A01-) |

(W02-2752-08) |

OUTPUT |

SYSTEM CONTROL |

L

R

Pin jack |

|

System jack |

|

AC power cord bushing |

|

AC power cord * |

(E63-1081-08) |

|

(E11-0188-05) |

|

(J42-0083-05) |

|

(E30-) |

|

|

|

|

|

|

|

* Refer to parts list on page 14.

In compliance with Federal Regulations, following are repro- |

|

KENWOOD-Corp. certifies this equipment conforms to DHHS |

|

ductions of labels on, or inside the product relating to laser |

|

Regulations No. 21 CFR 1040. 10, Chapter 1, Subchapter J. |

|

product safety. |

|

DANGER : Laser radiation when open and interlock defeated. |

|

|

|

70% |

|

|

|

||

Refer to DP-3080MKΙΙ /3090 Service manual (B51-5349-00), |

AVOID DIRECT EXPOSURE TO BEAM. |

|

|

|

|

||

if you require disassembly for repair.

DPF-1030/2030

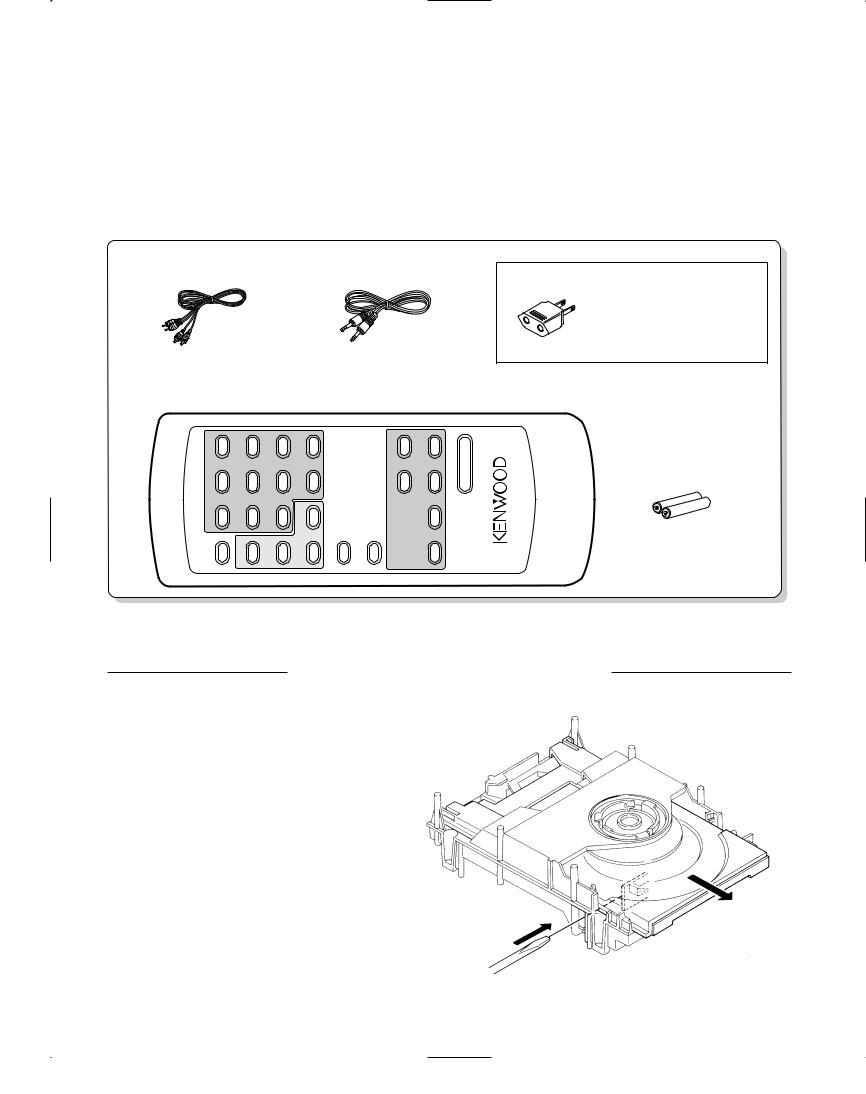

CONTENTS / ACCESSORIES

Contents

CONTENTS / ACCESSORIES .................................. |

2 |

DISASSEMBLY FOR REPAIR.................................... |

2 |

CIRCUIT DESCRIPTION ............................................ |

3 |

ADJUSTMENT ............................................................ |

4 |

PC BOARD ................................................................ |

5 |

SCHEMATIC DIAGRAM |

............................................ 7 |

EXPLODED VIEW .................................................... |

12 |

PARTS LIST.............................................................. |

14 |

SPECIFICATIONS ...................................... |

Back cover |

Accessories

Audio cord .................. |

(1) |

System control cord ...... |

(1) |

|

(E30-2913-08) |

|

(E30-2912-08) |

AC plug adaptor .............. |

(1) |

|

|

|

(E03-0115-05) |

|

Use to adapt the plug on the power cord to the shape of the wall outlet.

(Accessory only for regions where use is necessary.)

Remote control unit ......... |

(1) |

(A70-1414-08) : RC-P0715 |

|

(DPF-2030 only) |

Battery cover : (A09-1190-08) |

2 3 |

5 6 |

8 9 |

0 +10 |

|

|

7 6 |

4 ¢ |

DOWN UP |

OUTPUT LEVEL |

UNIT RC-P0715 |

1 |

4 |

7 |

CHECK |

|

|

|

¡ |

|

|

CONTROL |

TIME DISP |

P.MODE |

EDIT |

CLEAR |

RANDOM |

REPEAT |

|

1 |

|

|

REMOTE |

Batteries (R6/AA)........ |

(2) |

(DPF-2030 only) |

|

DISASSEMBLY FOR REPAIR

1. How to open tray when tray not come out.

1.Insert the screw driver to left side hole of mechanism ass'y.

2.While pushing the rack gear fully right wards, then the tray pull.

2

1. Pin description of microprocessor

|

Pin No. |

Pin Name |

I/O |

Description |

|

1-6 |

6G-1G |

O |

FL grid control port. |

|

7 |

NC |

- |

Unused. |

|

8 |

VDD |

- |

Power supply(+5V). |

|

9-11 |

- |

- |

Connected to ground. |

|

12 |

C-RESET |

O |

DSP signal output. |

|

13 |

S-MUTE |

O |

Muting signal output for system. |

|

14 |

NC |

- |

Unused. |

|

15 |

TEXT |

I |

Text copy detection. |

|

16 |

- |

- |

Connected to ground. |

|

17 |

RESET |

I |

Hardware reset signal input. |

|

18 |

LD CLOSE |

O |

Tray motor control. |

|

19 |

LD OPEN |

O |

Tray motor control. |

|

20 |

AVSS |

- |

Connected to ground. |

|

21 |

- |

- |

Connected to ground. |

|

22 |

PU IN SW |

I |

Pickup location. |

|

23 |

OPEN SW |

I |

Tray open switch input. |

|

24 |

CLOSE SW |

I |

Tray close switch input. |

|

25-28 |

KEYO-3 |

I |

Key input port. |

|

29 |

AVDD |

- |

Power supply(+5V). |

|

30 |

AVREF |

- |

Reference voltage(+5V). |

|

31,32 |

XT1,2 |

- |

Connected to ground. |

|

33 |

VSS |

- |

Connected to ground. |

|

34,35 |

XO,1 |

- |

X'tal 4.19MHz. |

|

36 |

WRQ |

I |

Sub code Q output. |

|

37 |

COIN |

O |

Command data to DSP. |

|

38 |

16BIT |

- |

Unused. |

|

39 |

HF |

- |

Connected to ground. |

|

40 |

NC |

- |

Unused. |

|

41 |

CQCK |

O |

Clock output to DSP. |

|

42 |

SQOUT |

I |

SQ data to dsp. |

|

43 |

RWC |

O |

Reading/writing control port. |

|

44 |

GND |

- |

Connected to ground. |

|

45 |

S BUSY |

I/O |

System control data. |

|

46 |

S DATA |

I/O |

System control status. |

|

47 |

RMC |

I |

Remote control signal input. |

|

48 |

GND |

- |

Connected to ground. |

|

49 |

TRY L/H |

O |

Tray motor speed control. |

|

50 |

SL- |

O |

Sled motor control port(reverse). |

|

51 |

SL+ |

O |

Sled motor control port(forward). |

|

52 |

VDD |

- |

Power supply(+5V). |

|

53-59 |

NC |

- |

Unused. |

|

60 |

DRF |

I |

CD focus OK signal input. |

|

61 |

NC |

- |

Unused. |

|

62-70 |

a-j |

O |

FL segment(a-j) control port. |

|

71 |

VLOAD |

- |

Power supply(-30V). |

|

72,73 |

k,l |

O |

FL segment(k,l) control port. |

|

74-77 |

NC |

- |

Unused. |

|

78-80 |

9G-7G |

O |

FL grid(9G-7G) control port. |

3 |

|

|

|

|

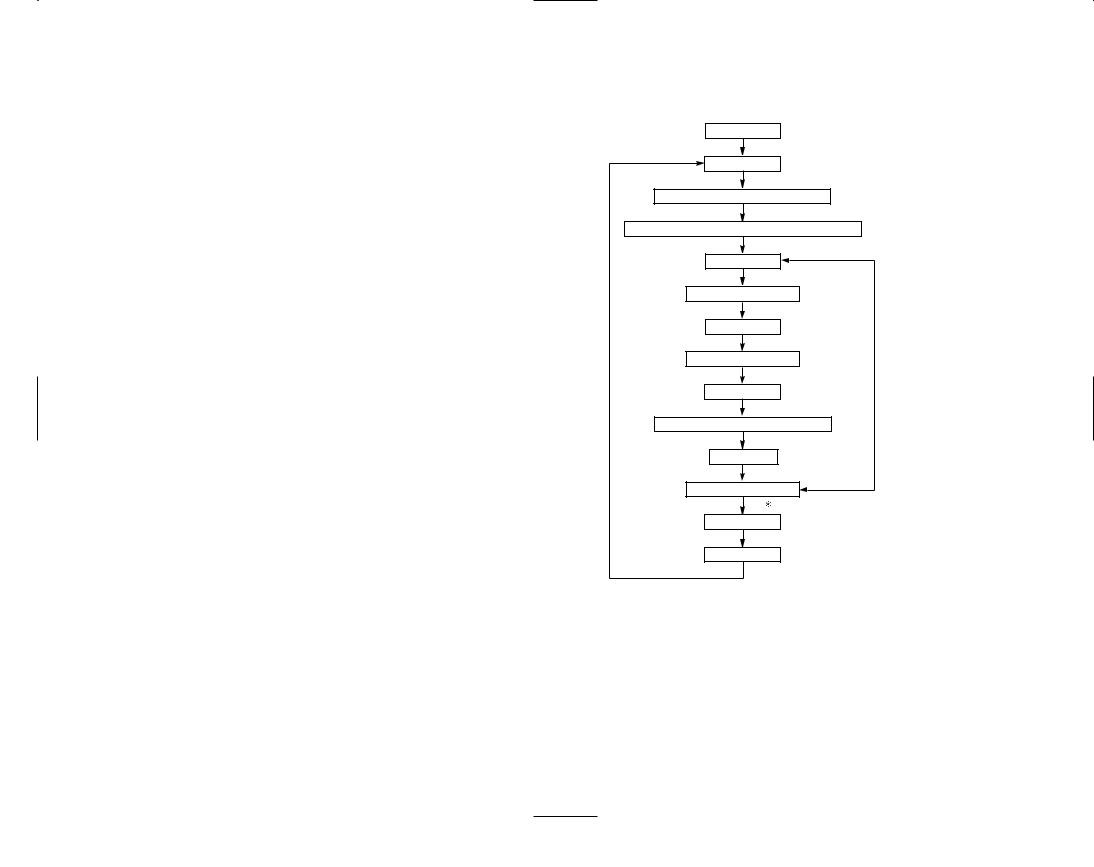

2. Test mode

Setting the test mode

: While pressing the STOP key, press the POWER switch.

START

FL LIGHT UP ALL

Tray open/close enable (display no change)

For move Pick-up, UP and DOWN key enable only stop mode

Key in PLAY |

|

|

Laser ON , Display [LD ON] |

|

|

Key in Play |

|

|

Focus ON, Display [FS ON] |

|

|

Key in PLAY |

|

STOP key enable |

|

If key in STOP, |

|

|

|

|

|

|

return to start |

PLAY (Track servo OFF) Display [Sb OFF] |

stage. |

|

|

||

Key in PLAY |

|

|

Play (Track servo ON) |

|

|

|

WITH TIME DISPLAY |

|

Key in STOP |

When play mode, UP key enable |

|

but only track jump. |

|

|

|

|

|

STOP |

|

|

Test mode will be cancelled by pressing the |

||

POWER switch key in the stop mode. |

||

3. Key function in test mode

No. |

INPUT KEY |

FUNCTION |

DISPLAY |

1 |

PLAY(1ST) |

LASER ON |

LD ON |

2 |

PLAY(2ND) |

FOCUSING SERVO ON |

FS ON |

3 |

PLAY(3RD) |

PLAY(TRACKING SERVO OFF) |

Sb off |

4 |

PLAY(4TH) |

PLAY(TRACKING SERVO ON) |

TN0. And Time |

5 |

UP |

In the stop mode. Moves the pickup slightly |

|

|

|

toward the outer position disc. |

– |

|

|

When tracking servo is ON, set the track number up. |

|

6 |

DOWN |

In the stop mode. Moves the pickup slightly |

|

|

|

toward the inner position disc. |

– |

|

|

When tracking servo is ON, set the track number up. |

|

7 |

STOP |

Laser off, focusing servo off, tracking servo off. |

All segments |

8 |

OPEN/CLOSE |

In the stop mode, Tray is opened or closed. |

All segments |

1030/2030-DPF DESCRIPTION CIRCUIT

DPF-1030/2030

ADJUSTMENT

CD section

Since this CD system incorporates the following automatic adjustment function, when the pickup is replaced, it is not necessary to readjust it

Since this CD unit does not need adjustment, the combination of PWB and laser pickup unit is not restricted.

•Automatic adjustment item

1.Focus offset(Fig.1)

2.Tracking offset(Fig.2)

3.E/F balance (Tracking error balance) (Fig.3)

4.RF level AGC function (HF level : constant)

5.RF level automatic follow-up of the tracking gain

This automatic adjustment is performed each time a disc is changed. Therefore, each disc is played back using the optimal settings

Fig.4 Checking points

4

Loading...

Loading...