Page 1

Service & Maintenance Manual

Model(s)

DVL &

DVSP

Series

P/N - 3121136

September 27, 2005

Page 2

Page 3

INTRODUCTION - MAINTENANCE SAFETY PRECAUTIONS

MAINTENANCE SAFETY PRECAUTIONS

A. GENERAL

This section contains the general safet y precautions

which must b e o bs erved d uri ng mai nt ena nce o f th e a er ial

platform. It is of utmost importance that maintenance personnel pay strict attention to these warnings and precautions to avoid possible i njury to them selves or ot hers or

damage to the equipment. A maintenance program must

be established by a qualified person and must be followed

to ensure that the machine is safe to operate.

MODIFICATION OF THE MACHINE WITHOUT CERTIFICATION BY

A RESPONSIBLE AUTHORITY THAT THE MACHINE IS AT LEAST

AS SAFE AS ORIGINALLY MANUFACTURED IS A SAFETY VIOLATION.

The specific precautions to be observed during machine

maintenance are inserted at the appropriate point in the

manual. These precautions are, for the most part, those

that apply when servicing hydraulic and larger machine

component parts.

Your safety, and that of others, is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of component weight and never attempt to

move heavy parts without the aid of a mechanical device.

Do not allow heavy objects to rest in an unstable position.

When raising a portion of the equipment, ensure that adequate support is provided.

SINCE THE MACHINE MANUFACTURER HAS NO DIRECT CONTROL OVER THE FIE LD INSPECTION AND MAINTENANC E,

SAFETY IN THIS AREA IS THE RESPONSIBILITY OF THE OWNER/

OPERATOR.

C. MAINTENANCE

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN

THIS SECTION COULD RESULT IN MACHINE DAMAGE, PERSONNEL INJURY OR DEATH AND IS A SAFETY VIOLATION.

• REMOVE ALL RINGS, WATCHES, AND JEWELRY

WHEN PERFORMING ANY MAINTENANCE.

• DO NOT WEAR LONG HAIR UNRESTRAINED, OR

LOOSE FITTING CLOTHING AND NECKTIES WHICH

ARE APT TO BECOME CAUGHT ON OR ENTANGLED

IN EQUIPMENT.

• OBSERVE AND OBEY ALL DANGER, WARNING, CAUTION AND OTHER INSTRUCTIONS ON MACHINE

AND IN SERVICE MANUAL.

• KEEP STANDING SURFACES AND HAND HOLDS

FREE OF OIL, GREASE, WATER, ETC.

• NEVER WORK UNDER AN ELEVATED PLATFORM

UNTIL PLATFORM HAS BEEN SAFELY RESTRAINED

FROM ANY MOVEMENT BY BLOCKING OR OVERHEAD SLING.

• BEFORE MAKING ADJUSTMENTS, LUBRICATING OR

PERFORMING ANY OTHER MAINTENANCE, SHUT

OFF ALL POWER CONTROLS.

•BATTERY SHOULD ALWAYS BE DISCONNECTED

DURING REPLACEMENT OF ELECTRICAL COMPONENTS.

• KEEP ALL SUPPORT EQUIPMENT AND ATTACHMENTS STOWED IN THEIR PROPER PLACE.

• USE ONLY APPROVED, NONFLAMMABLE CLEANING

SOLVENTS.

B. HYDRAULIC SYSTEM SAFETY

1. It should be particularly noted that the machines

hydraulic systems operate at extremely high and

potentially dangerous pressures. Every effort should

be made to relieve any system pressure prior to disconnecting or removing any portion of the system.

2. Relieve system pressure by activating the lift DOWN

control with the platform completely lowered to

direct any line pressure back into the return line to

the reservoir. Pressure feed lines to system components can then be disconnected with minimal fluid

loss.

3121136 – JLG Lift – a

Page 4

INTRODUCTION - REVISION LOG

October 4, 2001 – Original Issue of Manual

October 25, 2001 – Manual Revised

November 12, 2001 – Manual Revised

December 13, 2001 – Manual Revised

February 22, 2002 – Manual Revised

October 29, 2002 – Manual Revised

January 22, 2003 – Manual Revised

Feburary 18, 2003 – Manual Revised

July 18, 2003 – Manual Revised

October 1, 2003 – Manual Revised

August 16, 2004 – Manual Revised

September 27, 2005 – Manual Revised

REVISION LOG

b – JLG Lift – 3121136

Page 5

TABLE OF CONTENTS

TABLE OF CONTENTS

SUBJECT - SECTION, PARAGRAPH PAGE NO.

MAINTENANCE SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A

A GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A

B HYDRAUL IC SYSTEM SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A

C MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A

REVISION LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B

SECTION 1 - MACHINE SPECIFICATIONS

1.1 CAPACITIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

System Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Drive Motor GearBox (gear oil) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 COMPONENT DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Hydraulic Pump/ Pump Motor Assembl y. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Rear Wheel Drive Mot ors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Batteries/Batt e ry Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.3 PERFORMANCE DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Platform Capacit ies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Platform Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Machine Height (platform stowed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Base Footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.4 TORQUE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.5 LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Lubrication Spec ifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.6 HYDRAULIC PR ESSURE SETTINGS AND ADJU STMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Hydraulic Pressure Gauge Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

After Filter Pre s su re Che c k . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.7 CYLINDER SPECI FI CATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.8 SERIAL NUMBER LOCA TI ON S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

SECTION 2 - GENERAL

2.1 MACHINE PREPARATION, INSPECTION, AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Preparation, Inspection, and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Pre-Start Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Pre-Delivery Inspection and Frequent Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Annual Machine Ins pection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Preventative Ma intenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 PREVENTIVE MAINTENANCE AND INSPECTION SCHEDULE . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Inspection and M a intenance Codes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Footnotes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.3 SERVICING AND MAINTEN ANCE GUIDELINES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Safety and Workma ns hip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Cleanliness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

3121136 – JLG Lift – i

Page 6

TABLE OF CONTENTS

Components Remov al and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Component Disas s e mbly and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Pressure-Fit Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Bearings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 -6

Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Bolt Usage and Torque Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Hydraulic Line s and Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Lubricatio n and Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 -7

Mast Chain Inspection Proc edure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.4 LUBRICATION INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Changing Hyd ra u lic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Lubricatio n Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

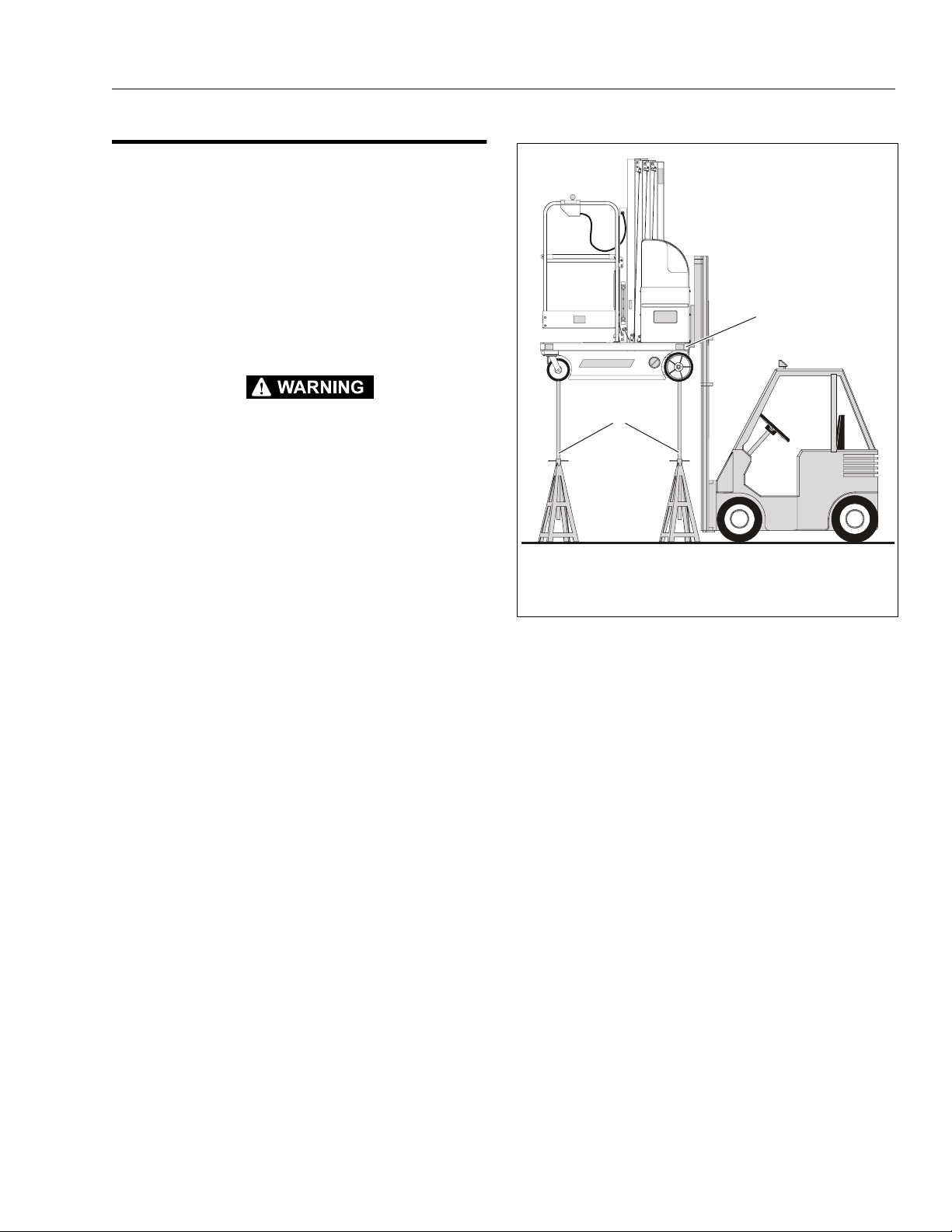

2.5 POSITIONING LIFT FOR ACCESS TO COMPONENTS LOCATED UNDER THE BASE FRAME. .2-9

SECTION 3 - BASE COMPONENTS

3.1 BASE ASSEMBLY COMPON EN TS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 BASE FR A M E COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Drive Motor Cover - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Battery Charger Cover - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.3 DRIVE AN D CASTER WHEELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Drive Motor Wheel (Std.) - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Caster Wheels - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Wheel Retention for Rough Terrain Drive Wheel (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.4 DRIVE M O TOR COMPONENT - SERVICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Torque Limiting Clutch Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Visual Inspection and Limiting Torque Checking Procedure . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Check Clutch Torque Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Torque Limiting Clutch Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Drive Wheel Alignment - (Machines built prior to S/N-0130005271) . . . . . . . . . . . . . . . . . . .3-5

3.5 DRIVE MOTOR ASSEMBLY - SERVICING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Drive Motor Assembly - Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Drive Motor Bra k e Removal and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Brake Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Brake Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1 2

Checking/Adjusting Armature Plate Gap Se t t ing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -12

Brake Assembly Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Drive Motor Boo t As sembly Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Drive Motor Brush Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Brush Cleaning and Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Brush Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Brush Reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Gear Box Disassembly/Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Gear/Pinion Shaft Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Drive Shaft As s e mbly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Final Gear Box Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

3.6 POT HOLE PROTECTION SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3.7 BATTER Y /BATTERY CHARGER - SERVICE PROC E D U RES. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -22

Battery Low Volt age Warning Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2 2

Battery Condi t i on Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

ii – JLG Lift – 3121136

Page 7

Battery Replacem e nt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Battery Charger Ge neral Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Battery Charger Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Battery Charge/ Fl ash Code LED Indicator on Pla t form Control Console . . . . . . . . . . . . . .3-24

Battery Charging Stat us Indicators Mounted on Ground Control St ation Cover . . . . . . . . .3-24

Wet/VRLA Battery - Charging Profile Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

General Component Installation Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

Battery Charger Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

Cover Installa t ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

AC Line Fuse Install ation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

Interlock Relay Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Wet/VRLA Switch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Shunt Assembly Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

SCR Rectifier Ins t al la t ion (Either Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Transformer Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Printed Circuit Board Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

DC Circuit Breaker/Voltage Select Switch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

SECTION 4- CONTROL COMPONENTS

4.1 CONTROL COMPONENTS OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2 CONTROLS COVER INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Battery Cover Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 2

Center, Left and Rig ht Lo we r Cove rs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.3 CONTROL COMPONENTS - INS TAL L A TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Ground Control Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Traction Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Platform Control Console Installati o n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Battery Instal l at ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Horn Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Alarm Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Battery Instal la t ion (EE Spec Machines Onl y ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Fuse Box - (EE Spec Machines Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Master Disconnect Switch - (EE Spec Machines Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.4 GROUND CONTROL MO DU L E - SERVICE PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Cover Removal/In s t allation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Power Selector /EStop Switch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

4.5 GROUND CONTROL MO DU L E - PROGR AM M IN G. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Programming Le v e l s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Activating Programming Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Entering Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Programming Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Selecting Programmable Item to Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Adjusting Programmable Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Service Programming Mode - (Level-2 ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Operator Programming Mode - (Level-3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

4.6 PLATFORM CONTROL CONSOLE - SERVICE PROCEDURES -

(MACHINES S/N - 0130007616 TO PRESENT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Remove Platform Control Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Display/Controller Module Electrical Connectio ns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Mounting Bracke t - Inst all/Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Rear Cover - Install/Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Display/Cont roller Module - Inst al l /Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Drive/Lift Mod e Switch - Install/R e move . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Horn Button Switc h - Install/Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

TABLE OF CONTENTS

3121136 – JLG Lift – iii

Page 8

TABLE OF CONTENTS

Key Switch - Install/Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

E-Stop/Shut D own Switch - Install/Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -17

Joystick Assembly - Install/Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 1 7

4.7 PLATFORM CONTROL CONSOLE - SERVICE PROCEDURES -

(MACHINES PRIOR TO S/N - 0130007616) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Remove Platform Control Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Upper/Lower Shell Attach Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Emergency Sto p Switch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -19

Upper/Lower Sh ell Component Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Button Pad Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Joystick Assembly Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Joystick Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

4.8 PUMP-M OT O R ASSEMBLY - SERVICE PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Inline Hydraulic Filter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Pump/Motor/Tank Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Motor Cap/Motor I nstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Motor Brush Ins t allation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Brush Housin g F inal Assembly Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 2 3

Tank Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

Pump Installati on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4- 2 4

Filter Screen Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

Pressure Adjust V al v e Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

Pressure Check Valve Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

4.9 OBSTRU CTION SENSOR SYSTEM - SERVICE P RO CEDURE (DVSP - OPTION) . . . . . . . . . . . .4-2 6

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

Transducer Sensor Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

OSS Component Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

SECTION 5 - MAST COMPONENTS

5.1 MAST COMPONENTS OVER VI EW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 MAST CHAINS AND SEQUENCING CABLES ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Mast Chain/Cable Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Sequencing Cab l e Adj us t ment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.3 SEQUENCE CABLE REPLACEMENT KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Remove Old Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Replacement Ca bl e Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Clamp Installat i on (Drum/Socket Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.4 HYDRAUL IC LIFT CYLINDER - REMOVAL , IN SPECTION AND REBUILD . . . . . . . . . . . . . . . . . . .5-7

Lift Cylinder Re moval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Cylinder Disa s s e mbly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Lift Cylinder Component Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Cylinder Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Cylinder Insta l lation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

5.5 MAST ASSEMBLY INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Mast Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Mast Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

5.6 MAST A SSE M BLY AND DISASSEMBLY PROC ED URES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

Mast Disassembly Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

Mast Assembly - DVL/DVSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

5.7 DVSP - STOCKPICKER PLATFORM - INSTALL A TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 -24

5.8 DVSP - STOCKPICKER PLATFORM - MID-GATE I N T ER L O CK INSTALLATION. . . . . . . . . . . . . .5-25

5.9 MAST BEACON - INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-25

iv – JLG Lift – 3121136

Page 9

SECTION 6- TROUBLESHOOTING

6.1 GENER AL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2 TROUBLESHOOTING INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.3 HYDRAULIC CIRCUIT CHECKS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.4 ELECTRICAL CIRCUIT CHECKS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Ground Control Module LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.5 TROUBLESHOOTING TABLES INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Specifications For Various Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Special Pin Extract or Tools F or Ele c t r ic al Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Fault Code Troub le s hooting Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Main Power Circuit Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Mast Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Hydraulic Leak Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Base Frame Components Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Drive System Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

6.6 SPECIFICATION S FOR VARIOUS COM PONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6.7 SPECIAL PIN EXTRACTOR TOOL S FOR ELECTRICAL CONNECTORS . . . . . . . . . . . . . . . . . . .6-10

6.8 FAULT CODE TROUBLESH OOTI N G TABL ES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

Machine in Drive Spee d Cut- Back (Turtle) Mode All The Tim e . . . . . . . . . . . . . . . . . . . . . .6-11

Obstruction Sensor System - Detectio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

Battery Voltage Low - Warning Level 3 - Three (3) LED/LCDs lit. . . . . . . . . . . . . . . . . . . . .6-12

Code 02 - Left PHP Bar - UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

Code 03 - Right PHP Bar - UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

Code 04 - Tilt Condit ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

Code 05 - Reserved . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

Code 06 - Reserved . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

Code 07- Left Drive Mo t or - D is c onnected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

Code 08 - Right Drive Mot o r - D is connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Code 09 - Left Brake - Dis co n nected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Code 10 - Right Brake - Dis connected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Code 11 - Left Drive Motor - Shor t Circ uit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

Code 12 - Right Drive Motor - Sh ort Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

Code 13 - Traction Mod ul e - In Fol d Back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

Code 14 - Pump Motor - Dis connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

Code 15 - Lift Down Val v e - Disc onnected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

Code 16 - Lift Down Val v e - Sho r t Circ uit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

Code 17 - Ground Cont rol M odule - In Fold Back. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

Code 18 - Alarm - Short Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

Code 19 - Alarm - Disconnected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

Code 20 - Beacon - Short Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

Code 21 - Beacon - Disc onnected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-20

Code 22 - Horn - Short Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-20

Code 23 - Horn - Disconnected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

Code 24 - Auxiliary #1 Circui t - Sh ort Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

Code 25 - Auxiliary #1 Circu it - Di s co n nected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

Code 26 - Auxiliary #2 - Sh ort Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

Code 27 - Auxiliary #2 - Dis connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

Code 28 - Reserved . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

Code 29 - Reserved . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

Code 30 - Traction Mod ul e - No Com m unication with Ground Control Module. . . . . . . . .6-24

Code 31 - Platform Control Con sol e - No Communication with Ground Control Module .6-25

Code 32 - Pump Motor - Over Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

Code 33 - Both PHP Bars - UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

Code 38 - Battery Volt age Low - Warning Level 2 - Two (2 ) LED/LCDs lit . . . . . . . . . . . . .6-26

TABLE OF CONTENTS

3121136 – JLG Lift – v

Page 10

TABLE OF CONTENTS

Code 39 - Battery Vo l t age Low - Warning Level 3 - One (1) LED/LCDs lit . . . . . . . . . . . . .6-26

Code 40 - Obstruction Sensor System - No Communication with Ground Control Module6-27

Codes 41 thru 46 - OSS - Se nsor 1 through 6 - Fault Conditi on . . . . . . . . . . . . . . . . . . . . .6-28

Codes (100 - 199) Ground Control Module - Fault Condition . . . . . . . . . . . . . . . . . . . . . . .6-29

Codes (200 - 299) Platform Control Console - Fault Condition. . . . . . . . . . . . . . . . . . . . . .6-30

Codes (300 - 399) Traction Control Module - Fault Condition. . . . . . . . . . . . . . . . . . . . . . .6-31

6.9 MAIN POW E R CIRCUIT TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-32

Machine Will Not Power Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-32

6.10 M AST TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-33

Platform Will Not Lower Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-33

Platform Lift Up And Down Jerky . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-33

Mast Noisy When L if t ing And Lowering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-34

Platform (Mast ) Wo n’t Stay Elevated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-35

Platform (Mast ) Descends Too Slowly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-35

6.11 H Y D RAULIC LEAK TROUBLESHOO TING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-36

Miscellaneous Hydraulic Leak Troubles hooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-36

6.12 B A SE FRAME COMPONENTS TROUBL ESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-37

Caster Wheels No t Operating Freely. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-37

Pot Hole Protecti on (PHP) Bars will not Lower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-37

6.13 DRIVE SYSTEM TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-38

Won’t Climb Grade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-38

Machine Drive s in Opposite Direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3 9

Machine Won’t Drive Straight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-40

Noise From Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-41

vi – JLG Lift – 3121136

Page 11

TABLE OF CONTENTS

LIST OF FIGURES

FIGURE NO. TITLE PAGE NO.

1-1. Hydraulic Pressure Adjustment Screw . (M achine Rear Covers Removed) . . . . . . . . . . . . . . . . . .1-3

1-2. Typical Hydraulic Pres s ure Gaug e In stallation (Hydraulic Filter Removed).. . . . . . . . . . . . . . . . .1-4

1-3. Typical Hydraulic Pre s s ure Gaug e Installation (After Hydraulic Filter).. . . . . . . . . . . . . . . . . . . . .1-4

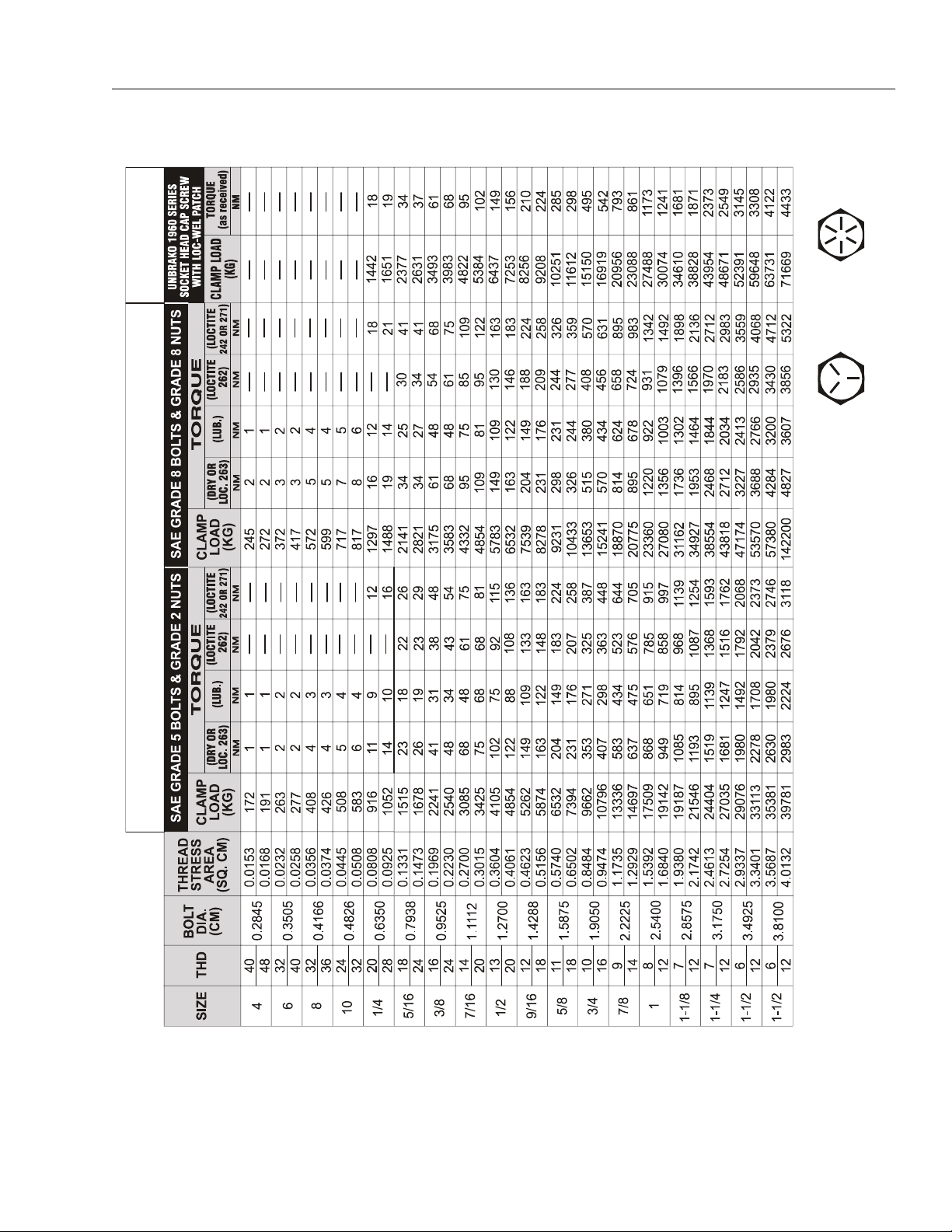

1-4. Torque Chart. (ANSI Spec.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

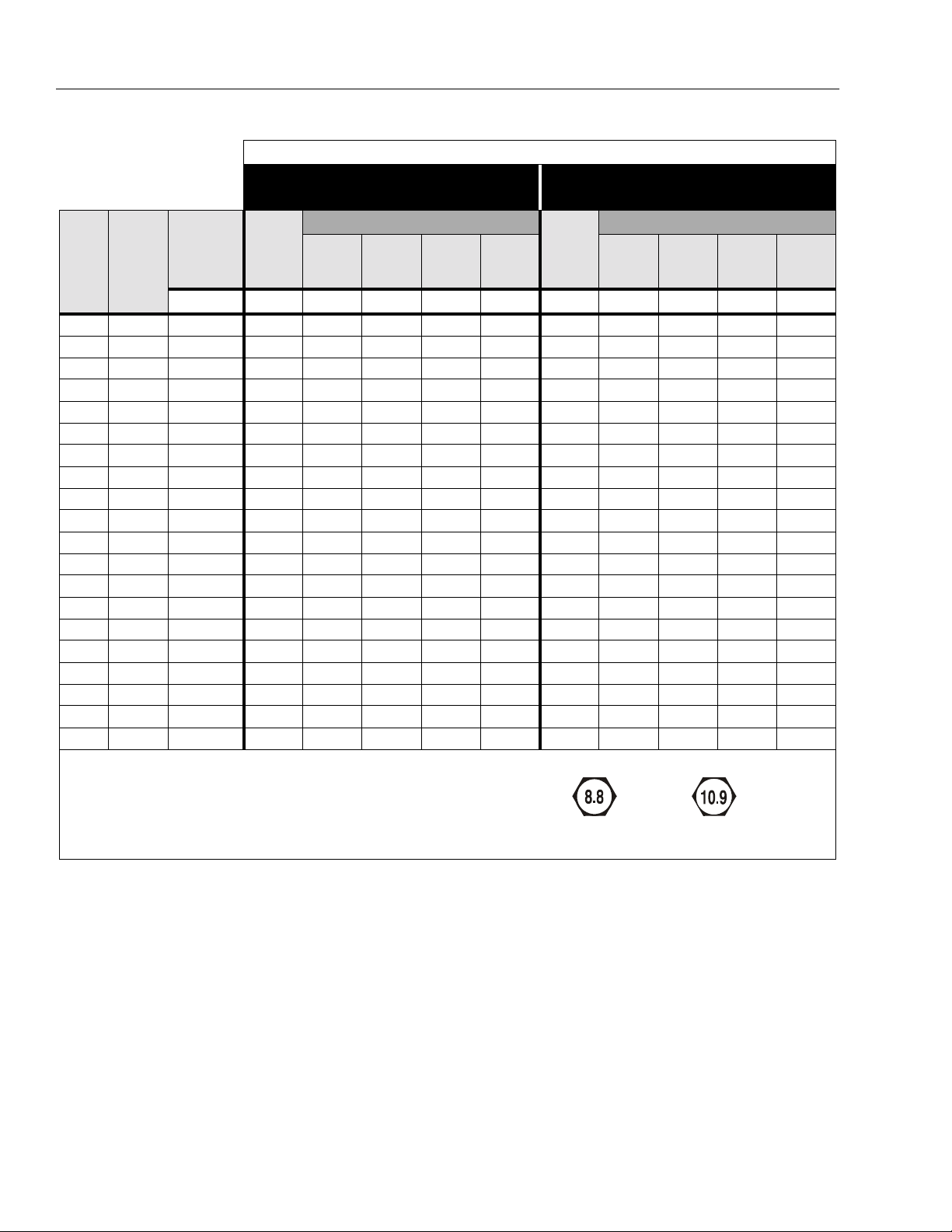

1-5. Torque Chart. (ANSI t o M E TRI C Conversion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

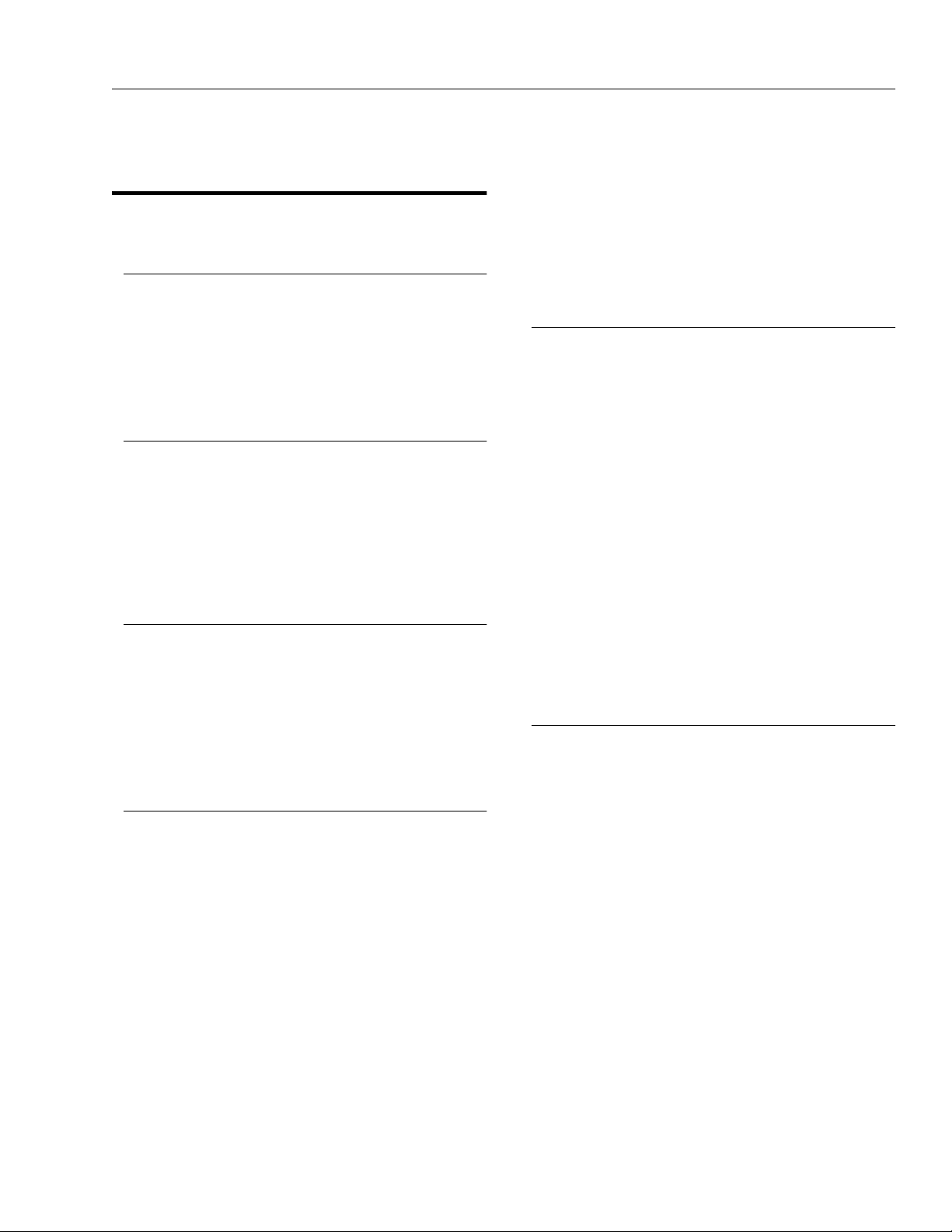

1-6. Torque Chart (Metric Class Fasteners) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

2-1. Accessing Machin e Un de rs id e Components by Liftin g wit h a Fork Truc k.. . . . . . . . . . . . . . . . . .2-9

3-1. Base Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3-2. Drive Motor Assembly Components. (Mach ines built prior to S/N-0130005271). . . . . . . . . . . . .3-7

3-3. Drive Motor Assembly Components. (Mach ines built since S/N-0130005271) . . . . . . . . . . . . . .3-7

3-4. Drive Motor Component Assembly (Mach i nes bui lt prior to S/N-0130005271) . . . . . . . . . . . . . .3-9

3-5. Drive Motor Component Assembly (Mach i nes bui lt since S/N-0130005271). . . . . . . . . . . . . . . .3-10

3-6. Torque Limiting Clutch Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3-7. Brake Assembly Com ponents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

3-8. Drive Motor Gear Box Assem bly - DV L /D VSP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

3-9. Pot-Hole-Prote c t ion Sys t e m Com ponents.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3-10. DVL/DVSP - SCR Dual Voltage - Battery Charger Wiring Diagram.. . . . . . . . . . . . . . . . . . . . . . . .3-28

4-1. Control Components Location - DVL/DVSP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4-2. Component Electrical Connections.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4-3. Ground Control Module Components.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4-4. Platform Control Console Component s.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

4-5. Platform Control Console Component s.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

5-1. Mast Component s . (D VL/DVSP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5-2. DVL/DVSP - Mast Chain and Sequence Cable Adjustment Com ponents. . . . . . . . . . . . . . . . . . .5-3

5-3. Machine Positio ne d fo r Cy l inder Re m ov al.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

5-4. Lift Cylinder Component Cross-Section (DVL/DVSP ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

5-5. Mast Section - Assembly Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

5-6. Mast Chain Routin g D iagram. - DVL/DVSP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

5-7. Mast Bottom End - Slid e Pa d Installation (Typical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

5-8. Mast Top End - Slide Pa d Installation (Typical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

5-9. DVSP - StockPicker Plat form Ins t all ation.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-24

6-1. Component Electrical Connections.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6-2. Overview of Electr ic al Sys t e m Components. (DVL /D VSP) (Sheet 1 of 2) . . . . . . . . . . . . . . . . . . .6-42

6-3. Electrical Diagram . (DVL/DVSP) (Sheet 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 -44

6-4. Electrical Diagram - (with Load Sensing System) (DVL/DVSP ) (S hee t 2 ) . . . . . . . . . . . . . . . . . . .6-46

6-5. Hydraulic Diagram . ( D VL /DVSP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-48

LIST OF TABLES

TABLE NO. TITLE PAGE NO.

1-1 DVL and DVSP - Machine Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1-2 Hydraulic Oil Operat ing Rang e. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-3. Lubrication Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-4. Cylinder Speci f ic at ions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-5 Lubrication Interv al s for Vario us Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

2-1 Inspection and Mai nt e nance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2-2 DVL/DVSP - Preventive Maintenance & Inspection Schedule.. . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2-3 Chain Stretch Tolera nce . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

3-1 Battery Low Voltage Warning Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

4-1 DVL/DVSP Ground Control Module - Field Programmable Settings and Factory Preset.. . . . . . .4-13

4-2 Obstruction Se ns or Sys tem Components (Platform Cutawa y ) . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

5-1 DVL/DVSP Mast Component Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

6-1 LCD Display - Service Fault Code Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

3121136 – JLG Lift – vii

Page 12

TABLE OF CONTENTS

6-2 Ohm Ratings for Various Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6-3 Amper age Draw for Various Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6-4 Speci a l Pin Extractor Tools for Elect rical Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6-5 Machine In Drive Speed Cut-Back (Turtle) Mode All The Time . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

6-6 Obstr uction Sensor System - Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

6-7 Code 02 - L e f t PH P Bar - UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

6-8 Code 03 - Right PHP Bar - UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

6-9 Code 04 - T il t Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

6-10 Code 07 - Left Dri v e Mo t or - Disconnected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

6-11 Code 08 - Right Dr iv e M otor Disconnected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

6-12 Code 0 9 - Left Brake - Disconnected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

6-13 Code 10 - Right Brake - Disconnected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

6-14 Code 11 - Left Dri v e Mot or - Short Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

6-15 Code 12 - Right Dr iv e M otor - Short Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

6-16 Code 13 - Tractio n M odule - In Fold Back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

6-17 Code 14 - Pump Motor - Disconnected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

6-18 Code 15 - Lift Dow n V al v e - D is connected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

6-19 Code 16 - Lift Down Valve - Short Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

6-20 Code 17 - Ground Co nt r ol Module - In Fold Back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

6-21 Code 18 - Alarm - Short Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-18

6-22 Code 19 - Alarm - Disconnected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

6-23 Code 20 - Beacon - Short Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

6-24 Code 21 - Beacon - Sh or t D isconnected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 -20

6-25 Code 2 2 - Horn - Short Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6- 20

6-26 Code 23 - Horn - Disconnected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

6-27 Code 24 - Auxil iary #1 Circuit - Short Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

6-28 Code 25 - Auxil ia ry #1 Circuit - Disconnected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

6-29 Code 2 6 - Auxil iary #2 - Short Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

6-30 Code 2 7 - Auxil iary #2 - Disconnected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

6-31 Code 30 - Tractio n Module - No Communication with Grou nd Control Module . . . . . . . . . . . . . .6-24

6-32 Code 31 - Platfor m Control Console - No Communica t ion with Ground Control Modu le. . . . . . .6-25

6-33 Code 32 - Pump Motor - Over Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

6-34 Code 33 - Both PHP Bars - UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

6-35 Code 40 - OSS - No Communication with Ground Control Module . . . . . . . . . . . . . . . . . . . . . . .6-27

6-36 Codes 4 1 th ru 46 - OSS - Sensor 1 through 6 - Faul tCondition . . . . . . . . . . . . . . . . . . . . . . . . . .6-28

6-37 Codes (100 - 199) Ground Cont rol Mo dule - Fa ult Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-29

6-38 Code (200 - 299) Platform Control Console - Fault Condition. . . . . . . . . . . . . . . . . . . . . . . . . . . .6-30

6-39 Codes ( 30 0 - 3 9 9) Traction Control Module - Fault Conditio n. . . . . . . . . . . . . . . . . . . . . . . . . . . .6-31

6-40 Machine Will Not Power UP.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-32

6-41 Platform Will Not Lower Manually. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-33

6-42 Platform Lift Up and Down Jerky . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-33

6-43 Mast Noisy when Lifting and Lowering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-34

6-44 Platform (Mast) Won’t Stay Elevated.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-35

6-45 Platform (Mast) Descends Too Slowly.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-35

6-46 Hydra ul ic Leak Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-36

6-47 Caster Wheels Not Operating Freely.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-37

6-48 Pot Hole Protect ion (PHP) Bars will not Lower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-37

6-49 Won’t Climb Grade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-38

6-50 Machine Dri v e in Opp os i t e D ire ction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-39

6-51 Machine Won’t Drive Straight.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4 0

6-52 Noise from Drive Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-41

viii – JLG Lift – 3121136

Page 13

SECTION 1 - MA CHINE SPECIFICATIONS

SECTION 1. MACHINE SPECIFICATIONS

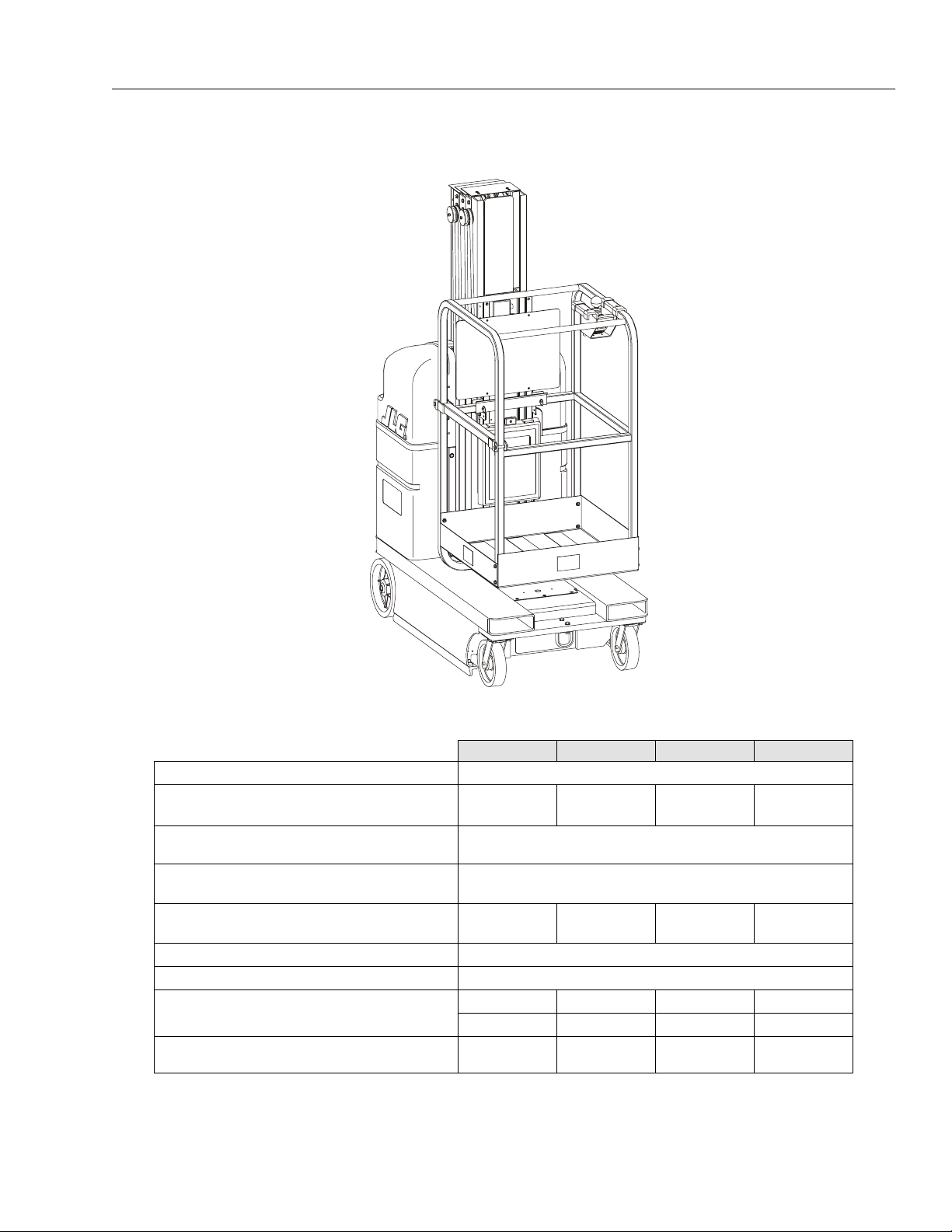

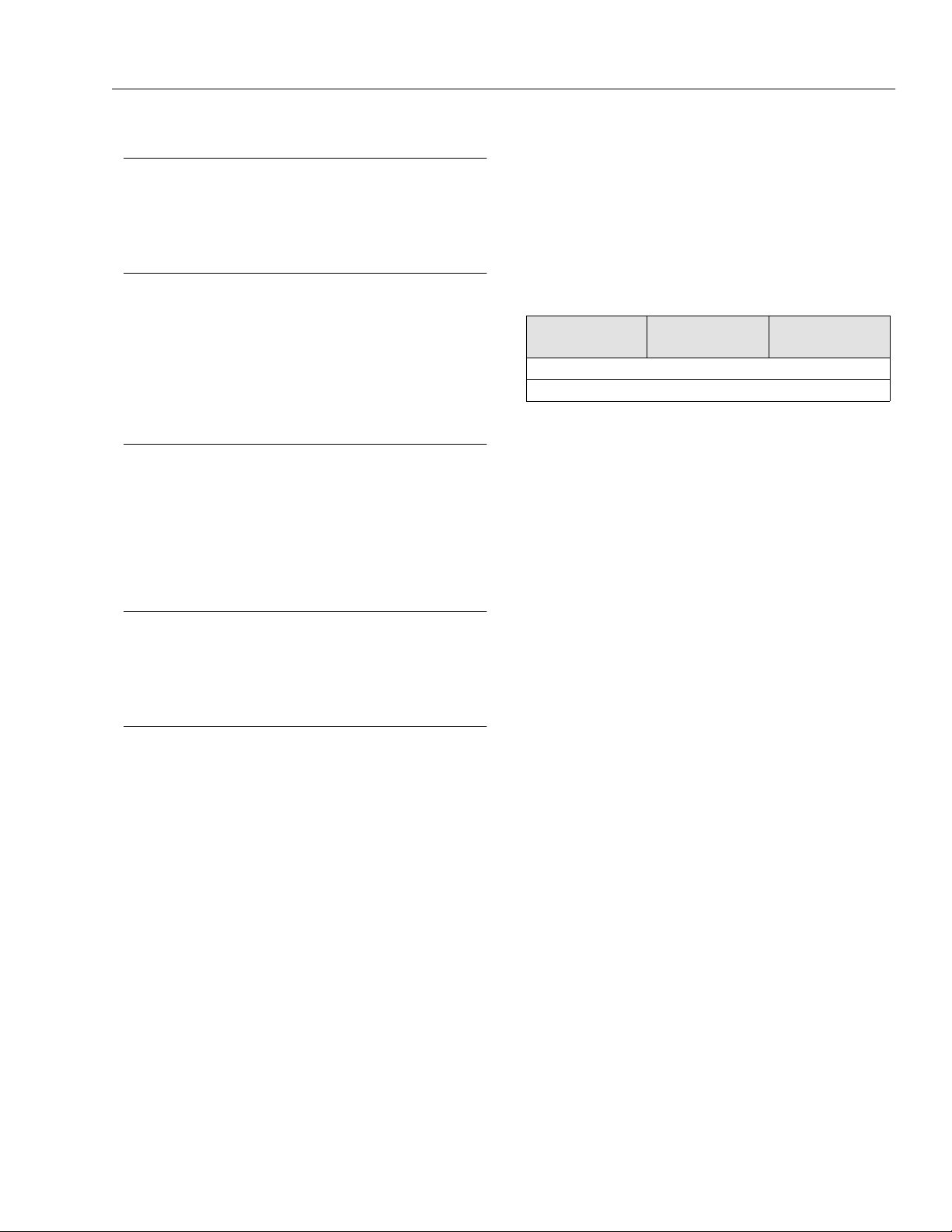

Table 1-1. DVL and DVSP - Machin e Spec i fications

15DVL 20DVL 15DVSP 20DVSP

Maximum Occupants: 1

Maximum W ork Load (Capacity) :

(DVL-Std. Platform / DVSP - Stockpicker Platform)

Maximum T r avel Grade (Gradeabilit y):

(Platform STOWED ONL Y)

Maximum T ravel Grade (Side Slope):

(Platform STOWED ONL Y)

Maximum Vertical Platform Height:

500 lb.

(230 kg)

15 ft.

(4.57 m)

350 lb.

(160 kg)

19.5 ft.

(5.94 m)

500 lb.

(230 kg)

20%

5°

15 ft.

(4.57 m)

Maximum Wheel Load (Per Wheel): 800 lb. (360 kg)

Maximum Drive Speeds (Operator Variabl e): 0.5 - 2 mph (0.8 - 3.2 kph)

Max. Platform Speeds (w/Max. Load): Platform Up:

Platform Down:

Gross Machine Weight (Platform Empty):

20 sec. 22.5 sec. 20 sec.

15 - 21 sec. 21 - 26 sec. 15 - 21 sec. 21 - 26 sec.

2,105 lb.

(955 kg)

2,105 lb.

(955 kg)

2,150 lb.

(975 kg)

400 lb.

(180 kg)

19.5 ft.

(5.94m)

22.5 sec.

2,150 lb.

(975kg)

3121136 – JLG Lift – 1-1

Page 14

SECTION 1 - MACHINE SPECIFICATIONS

1.1 CAPACITIES

System Voltage

All Models – 24 Volt DC

Hydraulic System

All Models – 5 qts. U.S. (4.7 L)

Drive Motor GearBox (gear oil)

All Models – 6 oz. (175cc)

1.2 COMPONENT DATA

Hydraulic Pump/Pump Motor Assembly

Pump Motor - 24 Volt DC motor, Standard Duty

Pump Displacement –

DVL/DVSP – .098 cu. in./rev. (1.6cc/rev.)

Pump Output (Max.) –

DVL/DVSP - 1.20 gpm @ 2200 psi @ 23.5 volts and 105

amps @ 45 centistrokes (200 SSU)

Reservoir Capacity –

DVL/DVSP - 1 Gallon (3.78 L)

Rear Wheel Drive Motors

Drive Motors -

1/2 HP, 24 Volt DC, Variable

Right Angle, Sealed Gear Box, 40:1 ratio

Brake Shaft and Drive Shaft - Integral to Moto r

Parking Brake ( m ust be released for pushing)

Batteries/ Battery Charger

Batteries (2) – 12 Volt / 100 Amp Hour –

Deep Cycle Marine - RV

Weight – 65.7 lb. (29.8 Kg) - Per Battery

1.3 PERFORMANCE DATA

Platform Cap a cities

Standard - 15DVL - 500 lb. (230kg)

20DVL - 350 lb. (160kg)

StockPicker - 15DVSP - 500 lb. (230kg)

20DVSP - 400 lb. (180kg)

Extendible - 15DVL/ 15DVSP - 500 lb. (230kg )

20DVL Series - 350 lb. (160kg)

Molded - 15DVL/15DVSP - 500 lb. (230kg)

20DVL Series - 350 lb. (160kg)

NOTE: Distribute weight evenly in platform when loading.

Reference the c apa city de cal on th e machi nes’ de cal

billboard mounted on mast.

Platform Size

Standard - 26in.-W x 26 in.-L (66cm) x (66cm)

Stockpicker - 28in.-W x 48in.-L (71cm x 122cm)

Extendible - 26in.-W x 49in.-L (66cm x 124cm)

Moulded - 25in.-W x 26in.-L (64cm x 66cm)

Machine Height (platform stowed)

DVL/DVSP - 78 in. (198cm) height

Base Footprin t

DVL/DVSP - 29.25in.-W x 52in.-L (74cm) x (132cm)

1.4 TORQUE REQUIREMENTS

When maintenance becomes necessary or a fastener has

loosened, refer to the applicable Torque Chart in this section

of the manual, to determine proper torque values.

Battery Charger –

Microprocessor Controlled/SCR Circuit Monitor

120/240 Volt A.C. Selectable / 50/60 Hz input

24 volt, 20 amp output - with 2 amp finish

Reset Circuit Breaker

Automatic Charge Circuit

Plug Interlock Circuit

Wet/VRLA Battery Switch

NOTE: The batteries on DVL/DVSP machines require

approximately five (5) hours to fully charge when

drained to LOW BATTERY VOLTAGE warning on the

Ground Control Module LCD display.

1-2 – JLG Lift – 3121136

Page 15

SECTION 1 - MA CHINE SPECIFICATIONS

1.5 LUBRICATION

Hydraulic Oil

Hydraulic oils must have anti-wear qualities at least to API

Service Classification GL-3, and sufficient chemical stability for mobile hydraulic system service. JLG Industries,

recommends Mob ilfluid 424 hydr aulic oil, which has an

SAE viscosity of 10W-30 and a viscosity index of 152.

For cold weather applications, i.e. when temperatures

remain consistently below +20°F (–7°C) JLG recommends using Mobil DTE 13 hydraulic oil.

Aside from JLG recommendations, it is not advisable to

mix oils of different brands or types, as they may not contain the same required add itives o r be of comp arable vis cosities. If use of hydraulic oil other than Mobilfluid 424 is

desired, contact JLG Industr ies for pr oper recommen dations.

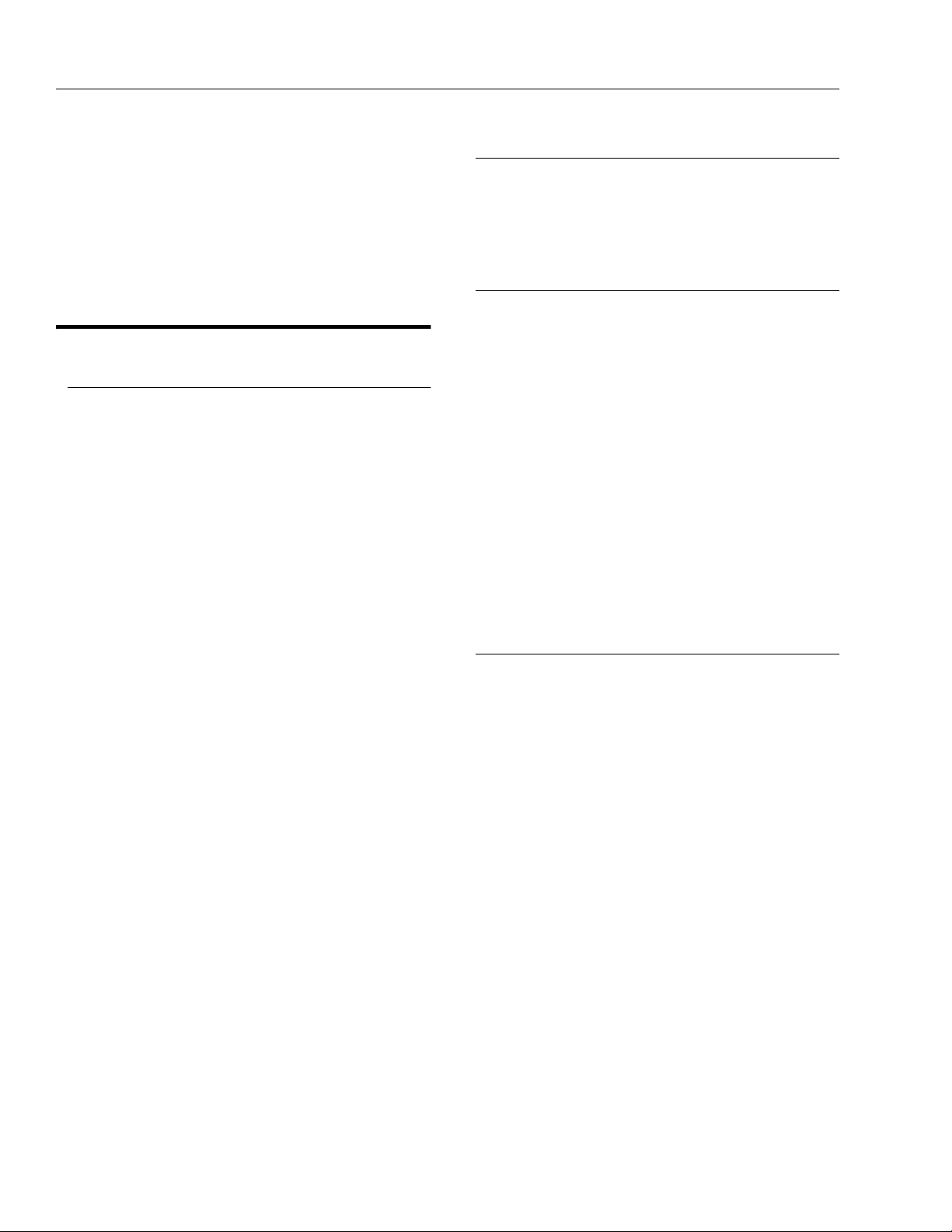

Table 1-2. Hydraulic Oil Operating Range

HYDRAULIC SYSTEM OPERATING

TEMPERATURE RANGE

+0˚ F to +180˚ F

(-18˚ C to +83˚ C)

+0˚ F to +210˚ F

(-18˚ C to +99˚ C)

+50˚ F to +210˚ F

(+10˚ C to +99˚ C)

SAE VISCOSITY

GRADE

10W

10W-20, 10W-30

20W-20

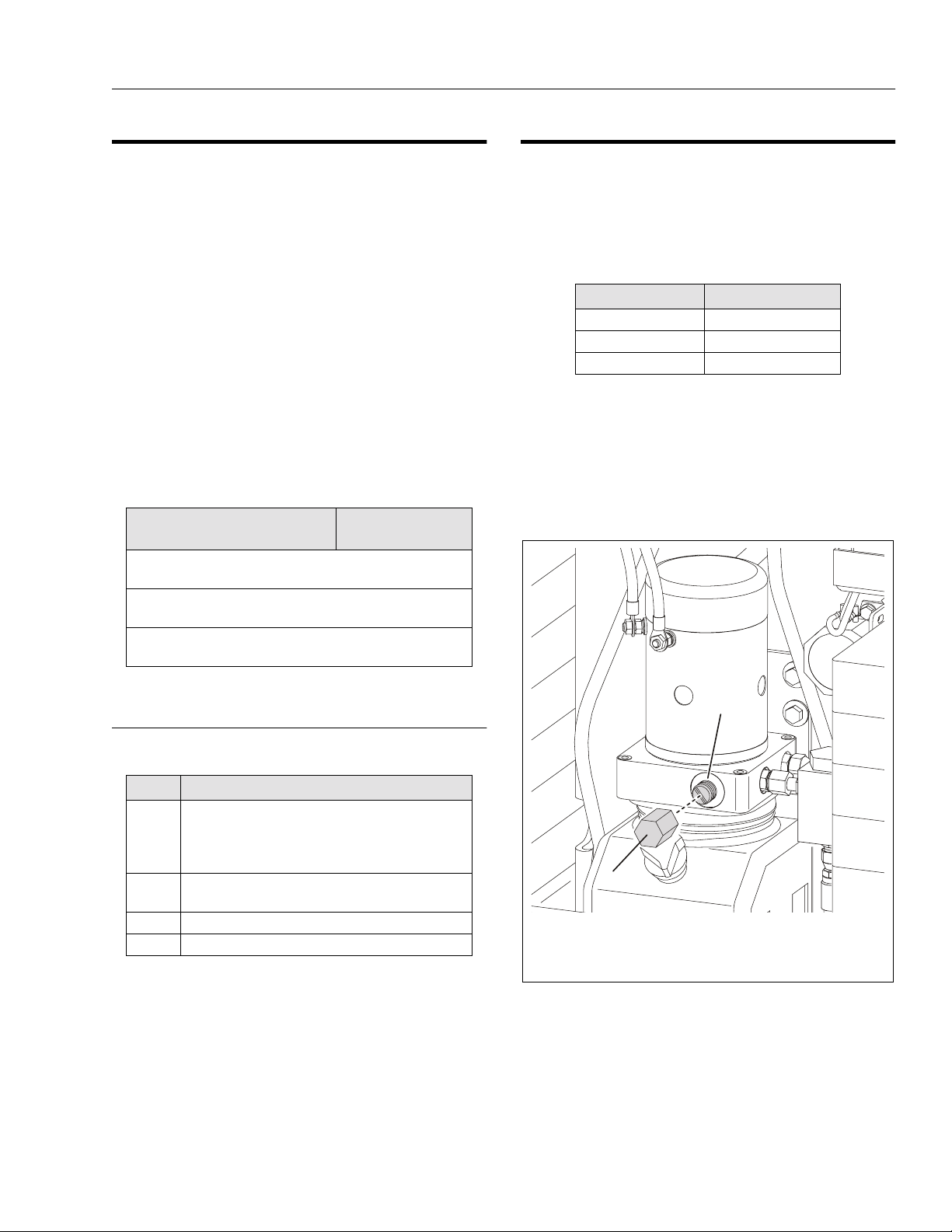

1.6 HYDRAULIC PRESSURE SETTINGS AND ADJUSTMENT

Adjust system pressure so that p latform will rai se with ma ximum rated capacity in platform.

The following pressure setting are factory recommended

(initial) settings;

MODEL PRESSURE SETTING

15DVL/15DVSP 2600 PSI

20DVL 1800 PSI

20DVSP 2800 PSI

Turning adjustment screw clockwise increases sy stem

pressure, turning screw counterclockwise decreases system pressure. (See Figure 1-1., Hydraulic Press ure Adjust-

ment Screw. (Machine Rear Covers Removed))

Perform pressure ad justment with oil at normal operat ing

temperature. If pressure is set when oil is cold, platform may

not raise rated load after soil has warmed.

Lubrication Specifications

Table 1-3. Lubrication Specifications

KEY SPECIFICATIONS

MPG - Multipurpose Grease having a minimum dripping point

of 350° F . Excellent water resistance and adhesive qualities, and being of extreme pressure type. (Timken OK

40 pounds minimum.)

EPGL - Extreme Pressure Gear Lu be (oil) meeting AP I service

classification GL-5 or MIL -Spec MIL -L-2105.

HO - Hydraulic Oil. ISO- Vg grade 32, 46.

CL - Chain Lube. Use a good quality chain lubricant.

2

1

1. Remove Adjust Screw Cap 2. P ressure Ad justment Screw

Note: Machine rear covers must be removed to access pump motor.

Figure 1-1. Hydraulic Pressure Adjustment Screw.

(Machine Rear Covers Removed)

3121136 – JLG Lift – 1-3

Page 16

SECTION 1 - MACHINE SPECIFICATIONS

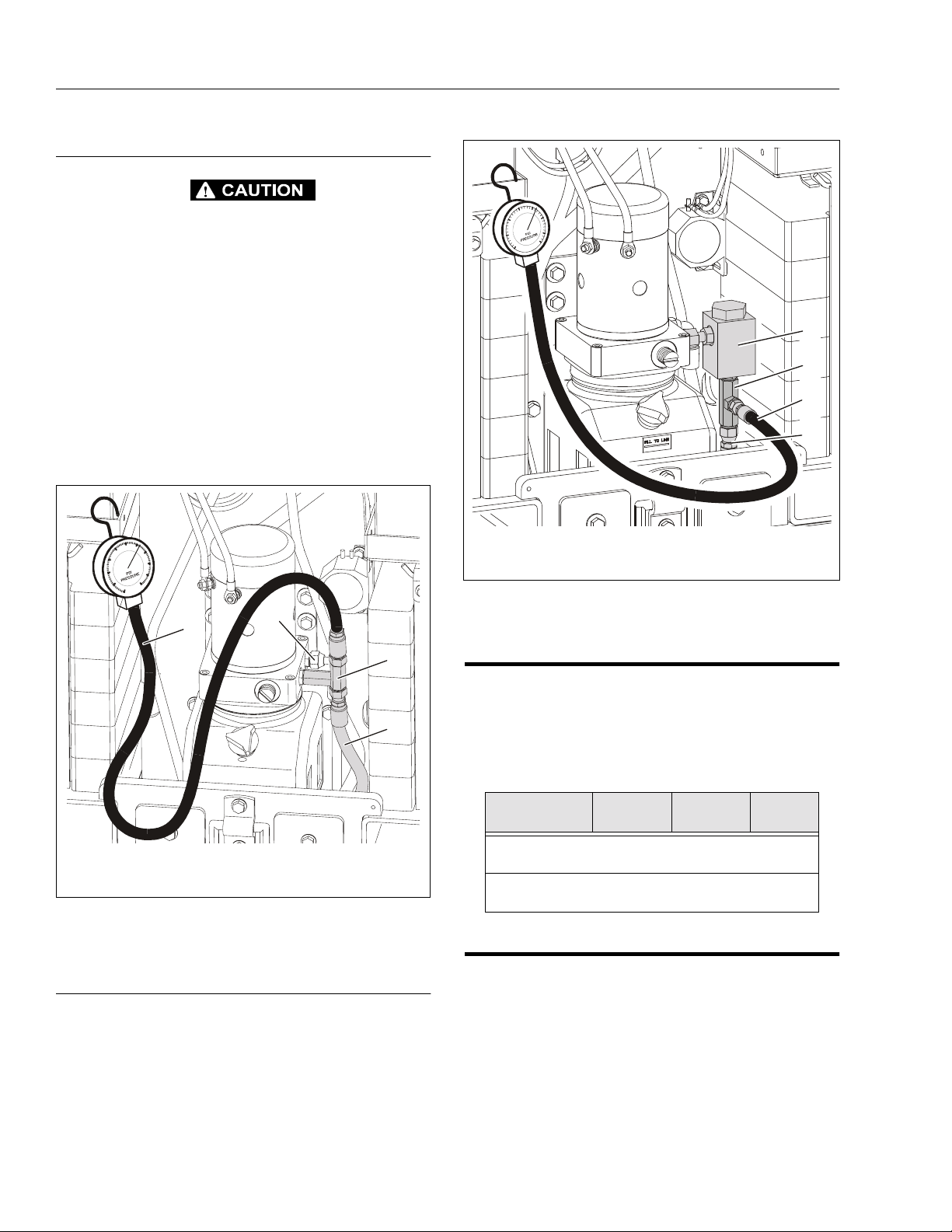

Hydraulic Press u r e Gaug e Connection

ONLY OPEN HYDRAULIC SYSTEM LINES WITH THE MAST FULLY

LOWERED TO RELIEVE PRESSURE IN THE SYSTEM. CAREFULLY

LOOSEN REQUIRED FITTINGS, WEAR SAFETY PROTECTION

EQUIPMENT WHEN WORKING WITH HYDRAULIC SYSTEMS.

Remove the hydraulic oil filter and ins tall a t-fitting between

the pump and the extend line to connect a hydraulic pressure gauge as shown in Figure 1-2., Typical Hydraulic Pressure Gauge Installation (Hydraulic Filter Removed).

CHECK, and if necessary, ADJUST the hydraulic pressure to

initial settings shown in table at the beginning of this section.

Cycle the hydraulic system several times with the maximum

load capacity in the platform, then recheck pressure setting.

When pressure has stabilized continue to "After Filter Pressure Check" following.

1

2

3

4

1

4

3

2

1. Pressure Gauge Assembly 3. T- Fitting

2. Extend Line 4. Return Line

Figure 1-2. Typical Hydrauli c P re s s ure Gauge

Installation (Hydraulic Filter Removed).

After Filter Pressure Check

Reinstall the hydraulic oil filter and install the t-fitting

between the hydraulic filter and the extend line to the cylinder. Recheck the hydraulic pressure and compare with the

previous r eadings when filter wa s removed. If a signi ficant

drop in pressure reading has occurred, replace the hydraulic filter and recheck the "after filter" pressure reading.

1. Hydraulic Oil Filter 3. Pressure Gauge Assembly

2. T- Fitting 4. Extend Line

Figure 1-3. Typical Hydraulic Pressure Gauge

Installation (After Hydraulic Filter).

1.7 CYLINDER SPECIFICATIONS

NOTE: All dimensions are given in inches (in), with the met-

ric equivalent, centimeters (cm), given in parentheses.

Table 1-4. Cylinder Specifications

DESCRIPTION

15DVL/15DVSP Lift Cylinder

20DVL/20DVSP Lift Cylinder

BORE

in./(cm)

1.63

(4.10)

1.63

(4.10)

STROKE

in./(cm)

41.50

(105.4)

54.0

(137.1)

ROD DIA.

in./(cm)

1.375

(3.49)

1.375

(3.49)

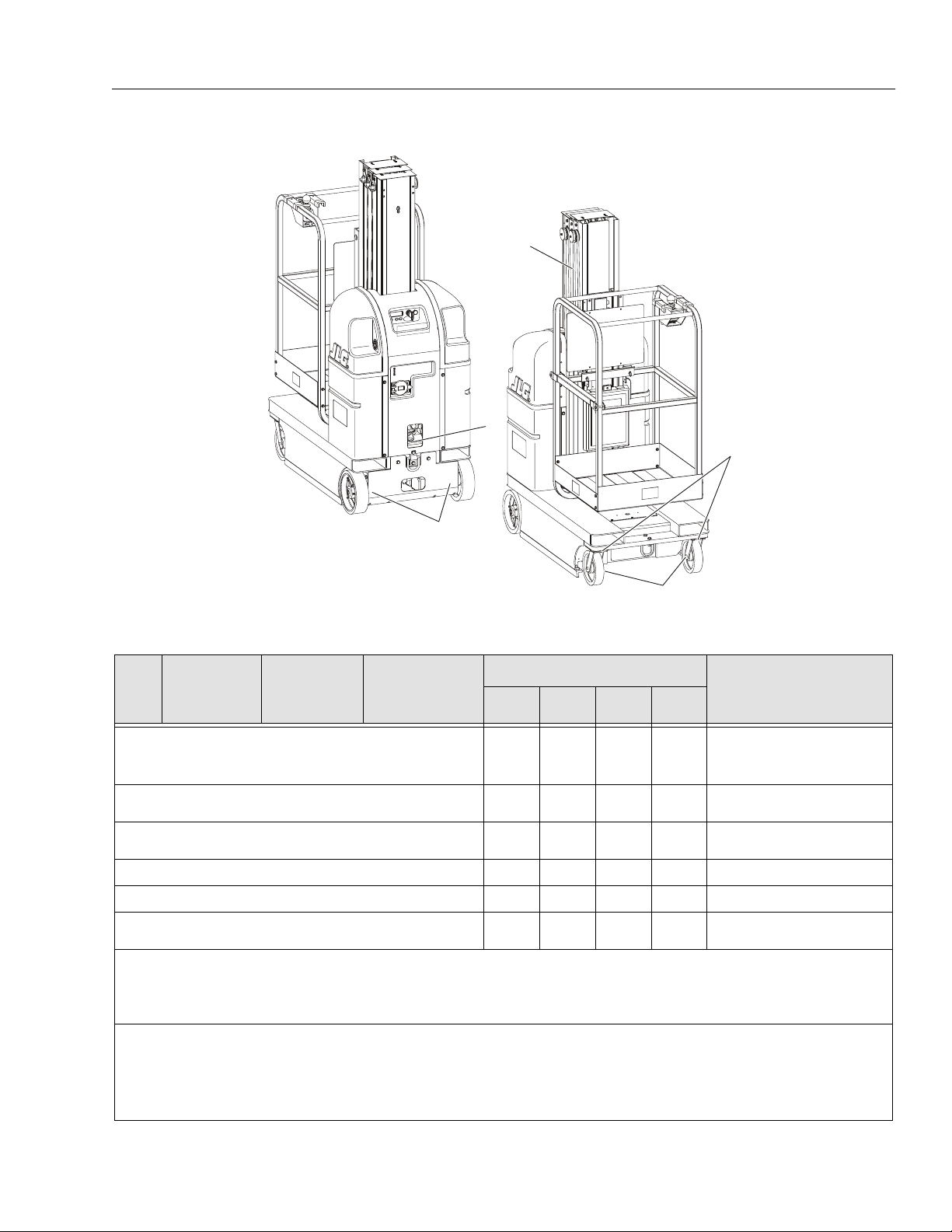

1.8 SERIAL NUMBER LOCATIONS

For machine identification, a serial number plate is affixed to

the machine. The plate is located on the back of the mast,

just above the mast support column.

1-4 – JLG Lift – 3121136

Page 17

SECTION 1 - MA CHINE SPECIFICATIONS

4

3

5

1

Table 1-5.Lubrication Intervals for Various Components

ITEM COMPONENT

1Hydraulic Oil

Drive Wheel

2

Bearings

Drive Wheel

3

Gear Box

4 Cas ter Axles 2 - Grease Fittings MPG - Pressure Gun

5 Swivel Raceways 2 - Front Casters MPG - Pressure Gun

6Mast Chains 2 - Per Section

Key to Lubr icants: MPG - Multipurpose Grease

HO - Hydraulic Oil - ISO-Vg grade 32, 46.

GEAR OIL - Good Quality Worm Gear Oil - SAE 90 - AGMA# 5 - EP Compounded

CL - Chain Lube. Use a good quality chain lubricant

NO/TYPE

LUBE POINTS

Fill T o Line on

Reservoir

5 Qt. Rese rvoir

2 - Gear Boxe s G ear Oil

(a)

LUBE/METHOD

HO - Check Hyd. Oil

Level

HO - Change Hyd. Oil

— — Permanently Sealed.

Chain Lube - Brush or

Spray

2

INTERVAL

3

MONTHS6MONTHS1YEAR2YEARS

(b)

COMMENTS

Check fluid level every day .

✔

Change hydraulic oil every 2

years.

Change only when serviced

requires 6 oz. (175 cc’s) to fill.

(c)

✔

✔

✔

Inspect, lubricate if dry or rusting.

Notes: (a) Be certain to lubricate like items on each side of the machine.

such as a high number of cycles, location, corrosive/dirty environment, etc., user must adjust lubricating requirements accordingly.

(b) Recommended lubricating intervals are based on normal use. If machine is subjected to severe operating conditions,

(c) Prior to checking hydraulic oil level, operate machine through one complete cycle of lift function (full up and down). F ailure to do so

will result in incorrect o il level readi ng on the hydrau lic reservoir .

3121136 – JLG Lift – 1-5

Page 18

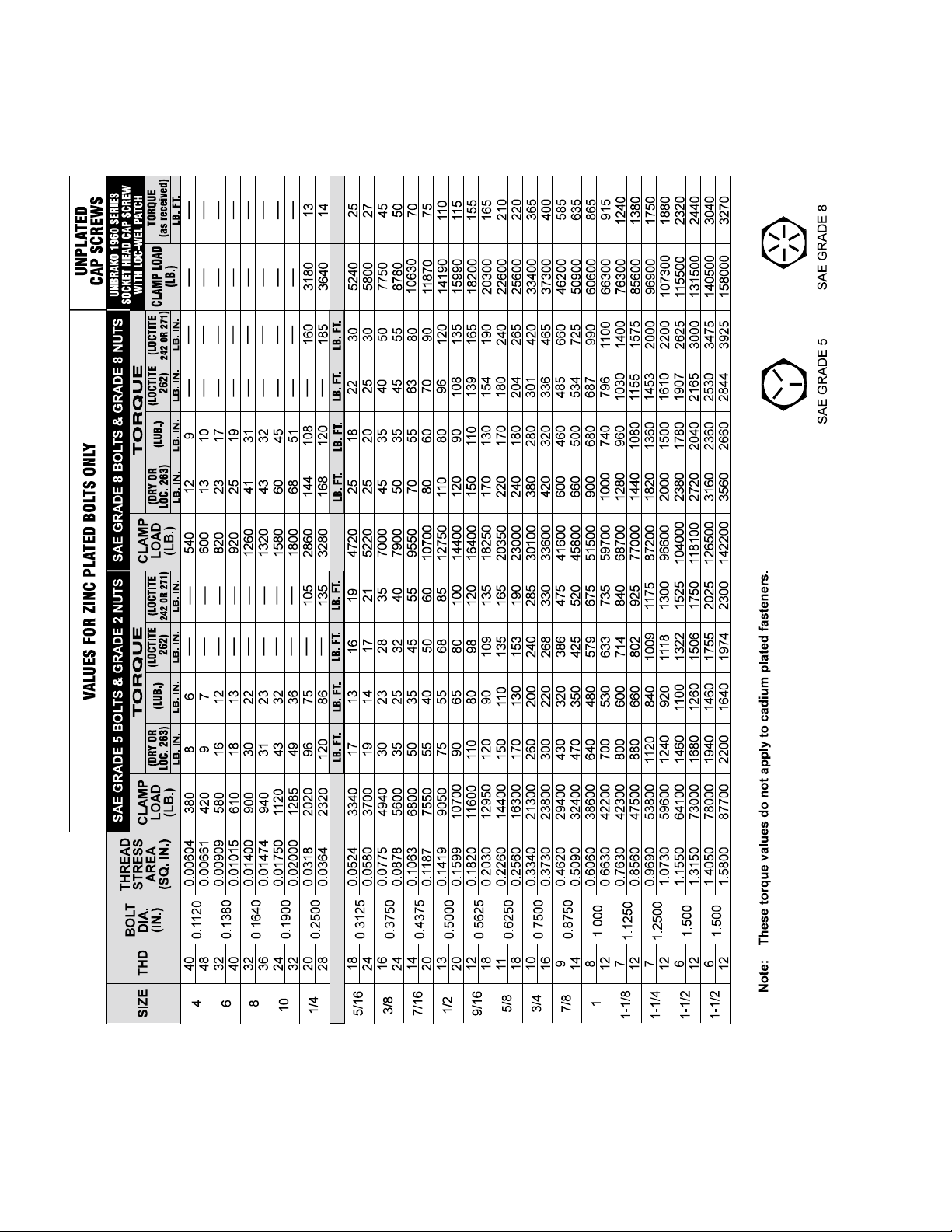

SECTION 1 - MACHINE SPECIFICATIONS

Figure 1-4. Torque Chart. (ANSI Spec.)

1-6 – JLG Lift – 3121136

Page 19

UNPLATED

CAP SCREWS

SECTION 1 - MA CHINE SPECIFICATIONS

SAE GRADE 5 SAE GRADE 8

VALUES FOR ZINC PLATED BOLTS ONLY

Note: These torque values do not apply to cadium plated fasteners.

Figure 1-5. T orque Chart. (ANSI to METRIC Conversion)

3121136 – JLG Lift – 1-7

Page 20

SECTION 1 - MACHINE SPECIFICATIONS

VALUES FOR ZINC PLATED / YELLOW CHROMATE FASTENERS ONLY

CLASS 8.8 ME TRIC BOLTS &

CLASS 8 METRIC NUTS

TORQUE

LUB

LOCTITE

262

LOCTITE

242 OR

271

CLAMP

SIZE PITCH

TENSILE

STRESS

AREA

CLAMP

LOAD

DRY OR

LOCTITE

263

sq. mm KN N, m N, m N, m N, m KN N, m N, m N, m N, m

3 .5 5.03 2.19 1.3 1.0 1.2 1.4 3.13 1.9 1.4 1.5 2.1

3.5 .6 6.78 2.95 2.1 1.6 1.9 2.3 4.22 3.0 2.2 2.4 3.3

4 .7 8.78 3.82 3.1 2.3 2.8 3.4 5.47 4.4 3.3 3.5 4.8

5 .8 14.2 6.18 6.2 4.6 5.6 6.8 8.85 8.9 6.6 7.1 9.7

6 1 20.1 8.74 11 7.9 9.4 12 12.5 15 11 12 17

7 1 28.9 12.6 18 13 16 19 18 25 19 20 28

81.2536.615.92519232822.837272940

10 1.5 58.0 25.2 50 38 45 55 36.1 72 54 58 79

12 1.75 84.3 36.7 88 66 79 97 52.5 126 95 101 139

14 2 115 50.0 140 105 126 154 71.6 200 150 160 220

16 2 157 68.3 219 164 197 241 97.8 313 235 250 344

18 2.5 192 83.5 301 226 271 331 119.5 430 323 344 473

20 2.5 245 106.5 426 320 383 469 152.5 610 458 488 671

22 2.5 303 132.0 581 436 523 639 189.0 832 624 665 915

24 3 353 153.5 737 553 663 811 220.0 1060 792 845 1170

27 3 459 199.5 1080 810 970 1130 286.0 1540 1160 1240 1690

30 3.5 561 244.0 1460 1100 1320 1530 349.5 2100 1570 1680 2310

33 3.5 694 302.0 1990 1490 1790 2090 432.5 2600 2140 2280 2860

36 4 817 355.0 2560 1920 2300 2690 509.0 3660 2750 2930 4020

42 4.5 1120 487.0 4090 3070 3680 4290 698.0 5860 4400 4690 6440

CLASS 10.9 METRIC BOLTS &

CLASS 10 METRIC NUTS

LOAD

DRY OR

LOCTITE

263

LUB

TORQUE

LOCTITE

262

LOCTITE

242 OR

271

Note: These torque value s do not apply to cadmium plated fa steners.

METRIC CLASS 8.8 METRIC CLASS 10.9

Figure 1-6. Torque Chart (Metric Class Fasteners)

1-8 – JLG Lift – 3121136

Page 21

SECTION 2. GENERAL

SECTION 2 - GENERAL

2.1 MACHINE PREPARATION, INSPECTION, AND MAINTENANCE

General

This section provides the necessary information needed

by those personnel that are responsible to place the

machine in operation readiness and maintain its safe

operating condition. For maximum service life and safe

operation, ensure that all the necessary inspections and

maintenance have been completed before placing the

machine into service.

Preparation, Inspection, and Maintenance

It is important to establish and conform to a comprehensive inspection and preventive maintenance program. The

following table outlines the periodic machine inspections

and maintenance recommended by JLG Industries, Inc.

Consult your national, regional, or local regu lat io ns for further requirements for aerial work platforms. The frequenc y

of inspections and maintenance must be increased as

environment, severity and frequency of usage requires.

Pre-Start Inspection

It is the User’s or Operator’s primary responsibility to perform a Pre-Start Inspection of the machine prior to use

daily or at each change of operator. Reference the Operator’s and Safety Manual for completion procedures for the

Pre-Start Inspection. The Operator and Safety Manual

must be read in its entirety and understood prior to performing the Pre-Start Inspection.

Pre-Delivery Inspection and Frequent Inspection

The Pre-Delivery Inspection and Frequent Inspection shall

be performed by a qualified JLG equipment mechanic.

JLG Industries, Inc. recognizes a qualified JLG equipment

mechanic as a person who, by possession of a recognized degree, certificate, extensive knowledge, tra ini ng, or

experience, has successfully demonstrated the ability and

proficiency to service, repair, and maintain the subject

JLG product model.

The Pre-Delivery Inspection and Frequent Inspection procedures are performed in the same manner, but at different times. The Pre-Delivery Inspection shall be performed

prior to each sale, lease, or rental delivery. The Frequent

Inspection shall be accomplished for each machine in service for 3 months; out of service for a period of more than

3 months; or when purchased used. The frequency of this

inspection must be increased as environment, severity

and frequency of usage requires.

Reference the JLG Pre-Delivery and Frequent Inspection

Form and the Inspection and Preventative Maintenance

Schedule for items requirin g inspection during the performance of these inspections. Reference the appropriate

areas of this manual for servicing and maintenance procedures.

Annual Machine Inspection

The Annual Machine Inspection must be performed by a

qualified JLG equipment m echan ic on an annual b asis, n o

later than thirteen (13) months from the date of the prior

Annual Machine Inspection. JLG Industries, Inc. recognizes a qualified JLG equipment mechanic as a person

who has successfully completed the JLG Servic e Training

School for the subject JLG product model. Reference the

machine Service and Maintenance Manual and appropriate JLG inspection form for performance of this inspection.

Reference the JLG Annual Machine Inspection Form and

the Inspection and Preventative Maintenance Schedule for

items requiring inspection during the performance of this

inspection. Reference the appropriate areas of this manual for servicing and maintenance procedures.

For the purpose of receiving safety-related bulletins, it is

important that JLG Industries, Inc. has updated ownership

information for each machine. When performing each

Annual Machine Inspection, notify JLG Industries, Inc. of

the current machine ownership.

Preventative Maintenance

In conjunction with the specified inspections, maintenance shall be p erformed by a qualifie d JLG equipment

mechanic. JLG Industries, Inc. recognizes a qualified JLG

equipment mechan ic as a pe rson who, by p osse ssio n of a

recognized degree, certificate, extensive knowledge, training, or experience, has successfully demonstrated the

ability an d profici ency to service , repair, and mainta in the

subject JLG product model .

Reference Table 2-2, DVL/DVSP - Preventive Maintenance

& Inspection Schedule., and the approp riate areas of this

manual for servicing and maintenance procedures. The

frequency of service and maintenance must be increased

as environment, severity and frequency of usage requires.

3121136 – JLG Lift – 2-1

Page 22

SECTION 2 - GENERAL

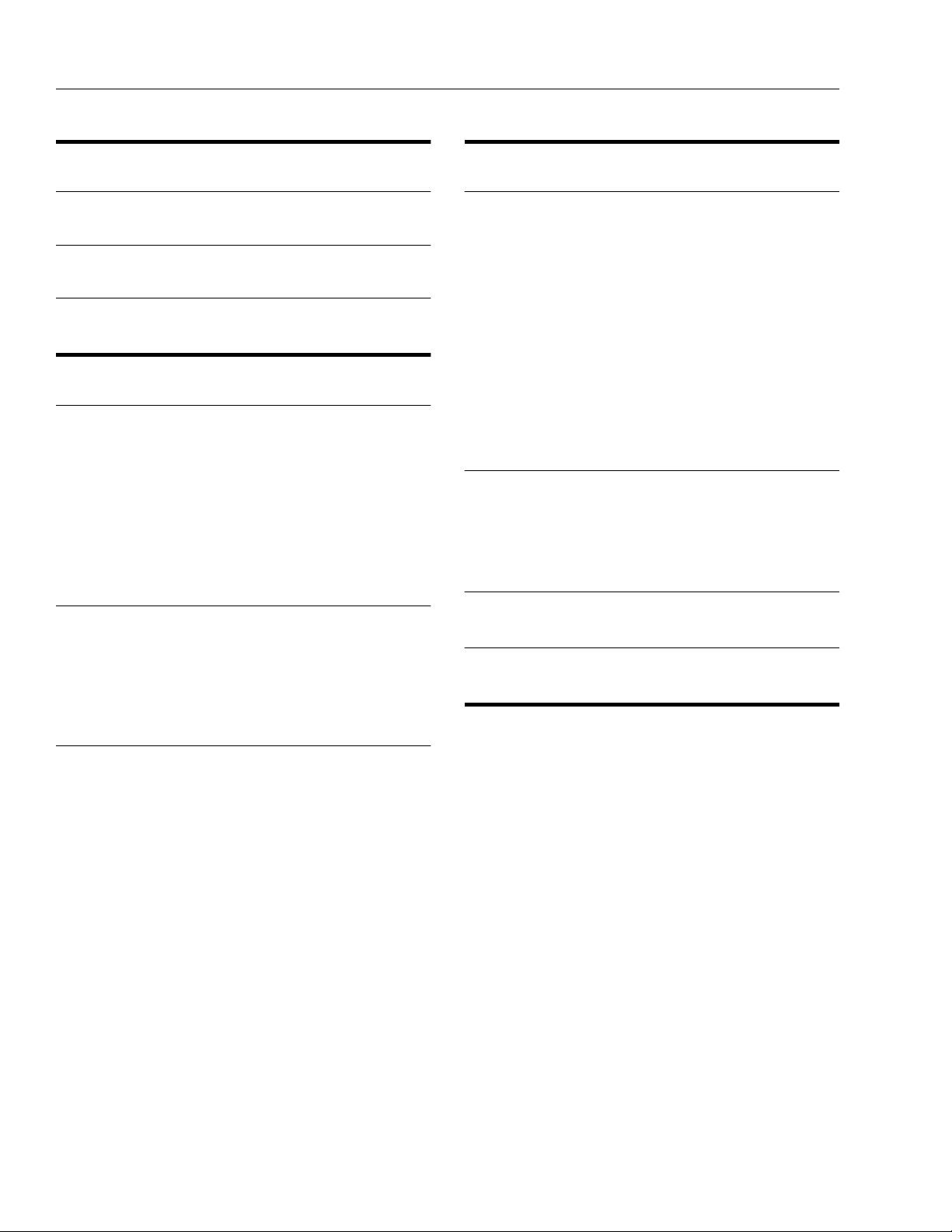

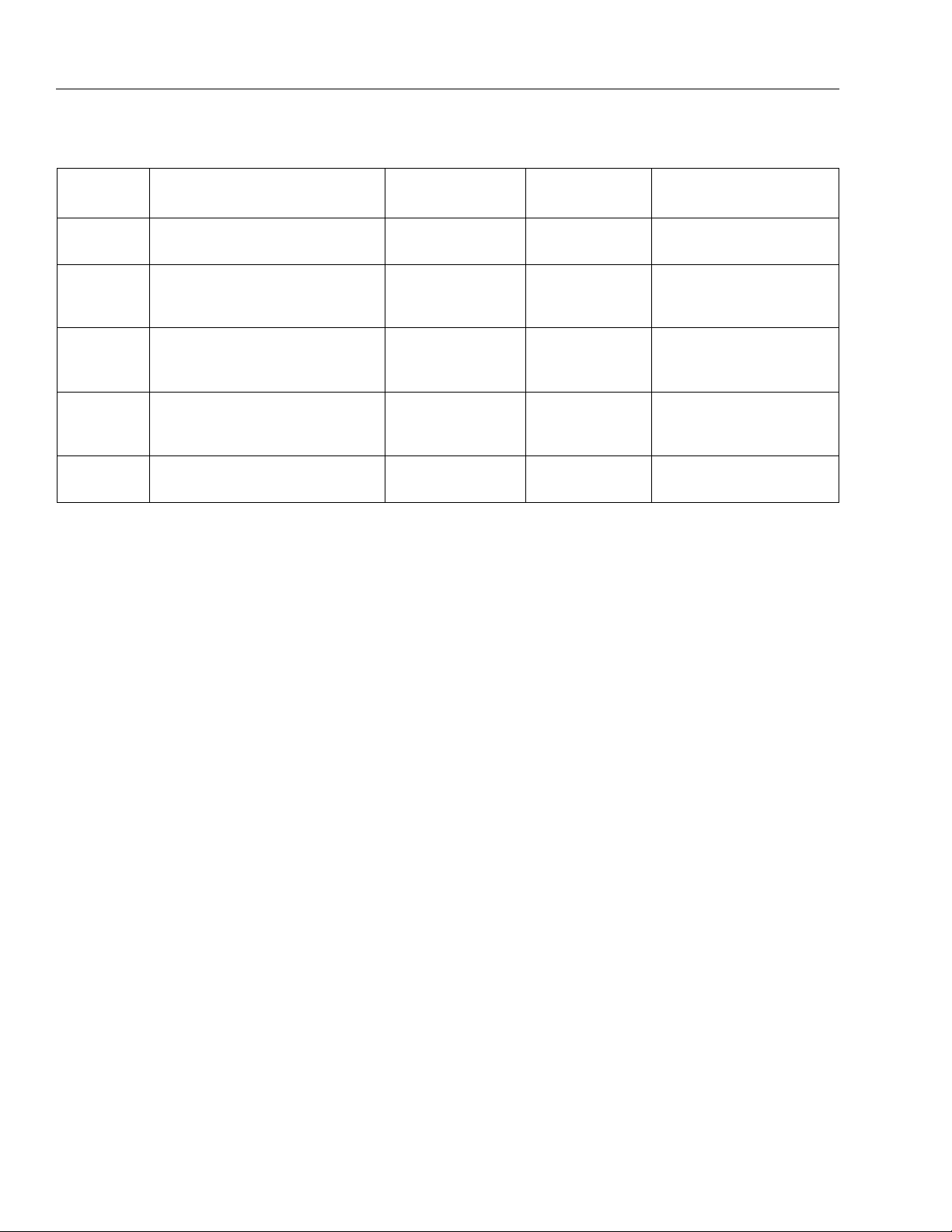

Table 2-1. Inspection and Maintenance

Type Frequency

Pre-Start

Inspection

Pre-Delivery

Inspection

Frequent

Inspection

Annual

Machine

Inspection

Preventative

Maintenance

Prior to use each day; or

At each Operator change.

Prior to each sale, lease, or

rental delivery.

In service for 3 months; or Out of service

for a period of more than 3 months; or Purchased used.

Annuall y, no lat er than 13 months from the

date of the prior inspecti on.

At intervals as specified in the Service and

Maintenance Manual.

Primary

Responsibility

User or Operator User or Operator Operator and Safety Manual

Owner , Dealer , or User Qualified JLG

Owner , Dealer , or User Qualified JLG

Owner , Dealer , or User Qualified JLG

Owner , Dealer , or User Qualified JLG

Service

Qualification

Mechanic

Mechanic

Mechanic

Mechanic

Reference

Service and Maintenance Manual and applicable JLG ins pection form.

Service and Maintenance Manual and applicable JLG ins pection form.

Service and Maintenance Manual and applicable JLG ins pection form.

Service and Maintenance Manual

2-2 – JLG Lift – 3121136

Page 23

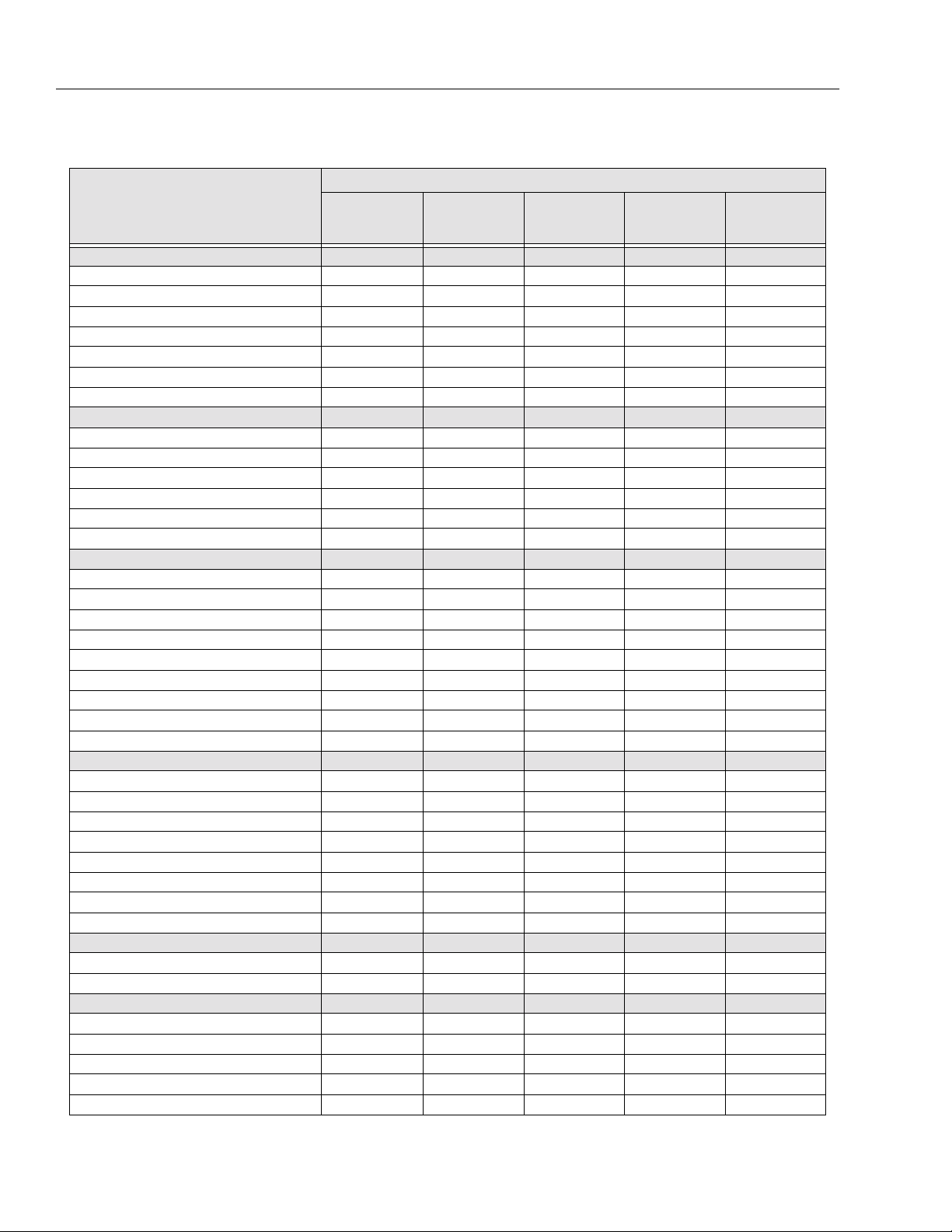

2.2 PREVENTIVE MAINTENANCE AND INSPECTION SCHEDULE

(See T able 2-2.)

The preventive maintenance and inspection checks are

listed and defined in the following table. This table is

divided into t wo basic parts, the “AREA” to be inspected

and the “INTERVAL” at which the inspection is to take

place. Under the “AREA” portion of the table, the various

systems along with the components that make up that

system are listed. The “INTERVAL” portion of the table is

divided into five col umn s repr ese ntin g t he vari ous i nspe ction time periods. The numbers listed within the interval

column represent the applicable inspection code for

which that component is to be checked.

The checks and services listed in this schedule are not

intended to replace any local or regional regulations that

may pertain to this type of equipment nor should the lists

be considered as all inclusive. Variances in interval times

may occur due to climate and/or c ondition s and de pending on the location and use of the machine.

SECTION 2 - GENERAL

3121136 – JLG Lift – 2-3

Page 24

SECTION 2 - GENERAL

a

Table 2-2. DVL/DVSP - Preventive Maintena nce & Inspection Schedule.

INTERVAL

AREA ON MACHINE

PRE-START (a)

INSPECTION

3 MONTH

PREVENTATIVE

MAINTENANCE

MAST ASSEMBL Y 7

Mast Sections 2, 5 2, 5

Chain Systems 14 3, 14 14, 25

Sequence Cable Systems 31, 2, 3

Covers or Shields 1

Sheave Systems 1, 2 1, 2

Bearings 1, 2

Slide Pads 1, 2

PLATFORM ASSEMBLY 7

Platform 11

Guard Rails 1, 2, 4 1, 2, 4

Gate 1, 5 1, 5

Floor 1, 2 1, 2

Extension Deck Assembly 1, 5 1, 5

Lanyard Anch orage Point 1, 4 1, 4

CHASSIS ASSEMBL Y 7

Pot Hole Protection System 55

Battery and Valve Covers or Doors 1, 7 1, 7

Static Strap

Caster Wheels 1, 2 14 1, 2 1, 2

Drive Wheels/Axle Assembly 22

Gear Box Assembly *

Drive Motor Brushes 2, 20

T orque Limit Clutch ** 1, 7 3

Brake Release 55

FUNCTIONS/CONTROLS 7

Platform Controls 5, 6, 7 5, 6, 7

Ground Controls 5, 6 5, 6, 14

Functi on Control Lo cks, Guards, o r Detents 55

Function Enable System

Emergency Stop Switches (Ground & Platform) 5

Functi on Limit or Cuto ut Switch Syste ms 5

Drive Brakes 5

Manual Descent or Auxiliary Power 55

POWER SYSTEM

Batteries 19 9 18

Battery Charger 5

HYDRAULIC/ELECTRIC SYSTEM 9

Hydraulic Pump 1, 2, 9 1, 2, 5, 9

Hydraulic Cylinder 2, 7, 9 2, 9

Cylinder Attachment Pins and Pin Retainers 1, 2 1, 2

Hydraulic Hoses, Lines, and Fittings 1, 9 1, 9

Hydraulic R eservoir , Cap, and Breather 5, 7 5, 7

6 MONTH

PREVENTATI VE

MAINTENANCE

PRE-DELIVERY (b)

OR FREQUENT (c )

INSPECTION

ANNUAL (d)

(YEARLY)

INSPECTION

2-4 – JLG Lift – 3121136

Page 25

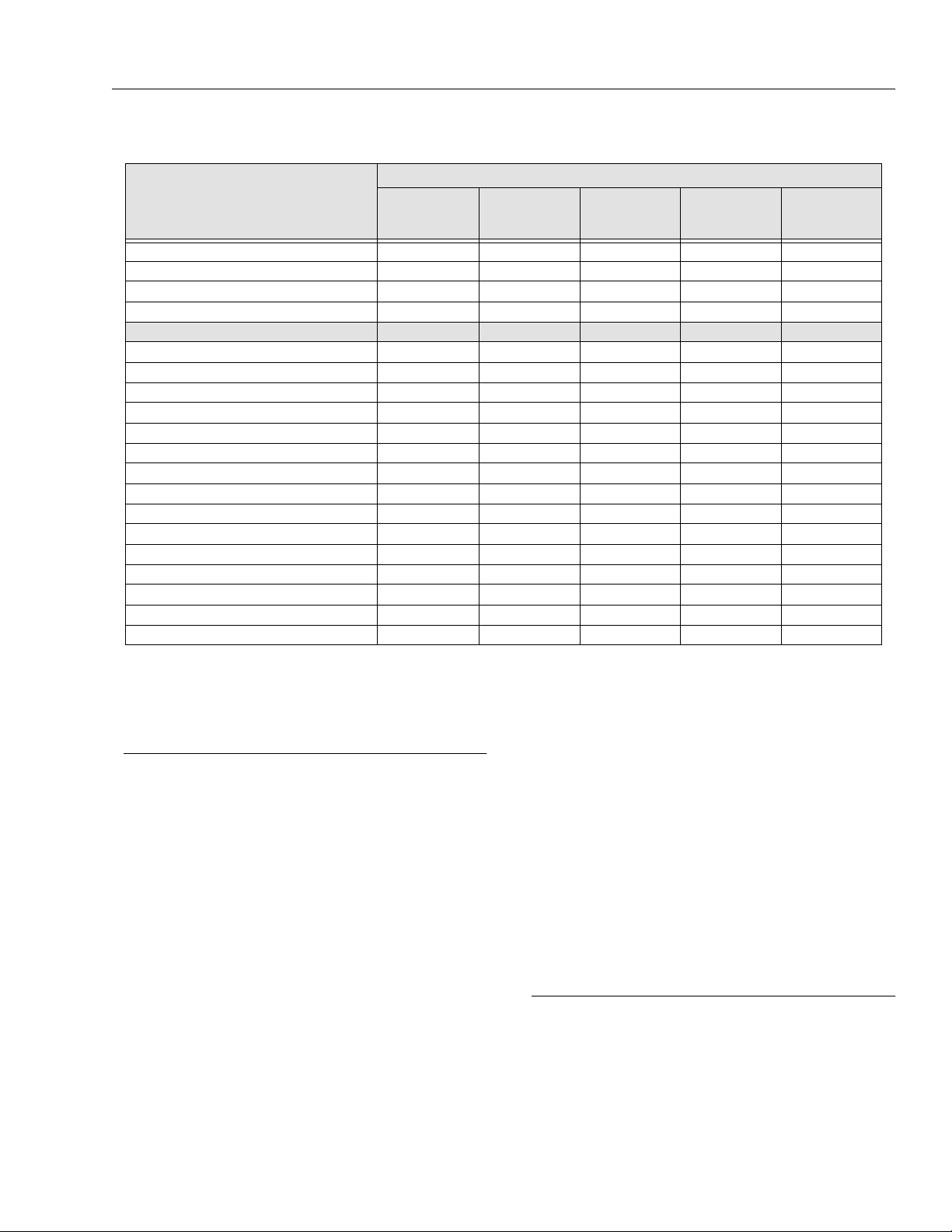

SECTION 2 - GENERAL

Table 2-2. DVL/DVSP - Preventive Maintenance & Inspection Schedule. (Continued)

INTERVAL

AREA ON MACHINE

PRE-START (a)

INSPECTION

3 MONTH

PREVENTATIVE

MAINTENANCE

Hydraulic Filter

Hydraulic Fluid *** 11 11 11

Electrical Connections 20 20

Instruments, Gauges, Switches, Lights, Ho rn 5

GENERAL

Operator and Safety Manuals in Storage Box 21 21 21

ANSI and EMI M anuals/Handbooks I nstalled 21 21 21

Capacity Decals Ins talled, Secure, Legible 21 21 21

All Decals/Placards In stalled, Secure, Legible 21 21 21

"Walk-Around" Inspection Performed 22

Annual Machine Inspection Due 21

No Unauthorized Modifications or Additions 21 21

All Relevant Saf ety Publications Incorporat ed 21 21, 22

General Structural Condition and Welds 2, 4 2, 4

All Fasteners, Pins , Shields, and Covers 1, 2

Grease and Lubricate to Specifications 22 22

Function Test of All Systems 22 22

Paint and Appearance 77

Stamp Inspec tion Date on Fra me 22