Page 1

Operation and Safety Manual

Original Instructions - Keep this manual with the machine at all times.

Boom Lift Models

1100SB

ANSI

3121264

July 7, 2010

Page 2

Page 3

FOREWORD

FOREWORD

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and lessees with the precautions and

operating procedures essential for the safe and proper machine operation for its intended purpose.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to make specification changes

without prior notification. Contact JLG Industries, Inc. for updated information.

3121264 – JLG Lift – a

Page 4

FOREWORD

SAFETY ALERT SYMBOLS AND SAFETY SIGNAL WORDS

This is the Safety Alert Symbol. It is used to alert you to the potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death

INDICATES AN IMMINENTLY HAZARDOUS SITUATION. IF NOT

AVOIDED, WILL RESULT IN SERIOUS INJURY OR DEATH. THIS DECAL

WILL HAVE A RED BACKGROUND.

INDICATES A POTENTIALLY HAZARDOUS SITUATION. IF NOT

AVOIDED, COULD

DECAL WILL HAVE AN ORANGE BACKGROUND.

RESULT IN SERIOUS INJURY OR DEATH. THIS

INDICATES A POTENTIALLY HAZARDOUS SITUATION. IF NOT

AVO I DED, MAY RESULT IN MINOR OR MODERATE INJURY. IT MAY

ALSO ALERT AGAINST UNSAFE PRACTICES. THIS DECAL WILL HAVE

A YELLOW BACKGROUND.

INDICATES INFORMATION OR A COMPANY POLICY THAT RELATES

DIRECTLY OR INDIRECTLY TO THE SAFETY OF PERSONNEL OR PROTECTION OF PROPERTY.

b – JLG Lift – 3121264

Page 5

THIS PRODUCT MUST COMPLY WITH ALL SAFETY RELATED BULLETINS. CONTACT JLG INDUSTRIES, INC. OR THE LOCAL AUTHORIZED

JLG REPRESENTATIVE FOR INFORMATION REGARDING SAFETYRELATED BULLETINS WHICH MAY HAVE BEEN ISSUED FOR THIS

PRODUCT.

For:

• Accident Reporting

• Product Safety Publications

• Current Owner Updates

• Questions Regarding

Product Safety

FOREWORD

• Standards and Regulations

Compliance Information

• Questions Regarding Special Product Applications

• Questions Regarding Product Modifications

JLG INDUSTRIES, INC. SENDS SAFETY RELATED BULLETINS TO THE

OWNER OF RECORD OF THIS MACHINE. CONTACT JLG INDUSTRIES,

INC. TO ENSURE THAT THE CURRENT OWNER RECORDS ARE

UPDATED AND ACCURATE.

JLG INDUSTRIES, INC. MUST BE NOTIFIED IMMEDIATELY IN ALL

INSTANCES WHERE JLG PRODUCTS HAVE BEEN INVOLVED IN AN

ACCIDENT INVOLVING BODILY INJURY OR DEATH OF PERSONNEL OR

WHEN SUBSTANTIAL DAMAGE HAS OCCURRED TO PERSONAL PROPERTY OR THE JLG PRODUCT.

Contact:

Product Safety and Reliability Department

JLG Industries, Inc.

13224 Fountainhead Plaza

Hagerstown, MD 21742

or Your Local JLG Office

(See addresses on inside of manual cover)

In USA:

Toll Free: 877-JLG-SAFE (877-554-7233)

Outside USA:

3121264 – JLG Lift – c

Phone: 240-420-2661

Fax: 301-745-3713

E-mail: ProductSafety@JLG.com

Page 6

FOREWORD

Original Issue - July 7, 2010

REVISION LOG

d – JLG Lift – 3121264

Page 7

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

SECTION - 1 - SAFETY PRECAUTIONS

1.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 PRE-OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Operator Training and Knowledge. . . . . . . . . . . 1-1

Workplace Inspection. . . . . . . . . . . . . . . . . . . . . 1-2

Machine Inspection . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Trip and Fall Hazards . . . . . . . . . . . . . . . . . . . . . 1-3

Electrocution Hazards . . . . . . . . . . . . . . . . . . . . 1-4

Tipping Hazards . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Crushing and Collision Hazards. . . . . . . . . . . . . 1-7

1.4 TOWING, LIFTING, AND HAULING . . . . . . . . . . . . .1-8

1.5 ADDITIONAL HAZARDS / SAFETY . . . . . . . . . . . . .1-9

SECTION - 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2.1 PERSONNEL TRAINING . . . . . . . . . . . . . . . . . . . . .2-1

Operator Training . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Training Supervision. . . . . . . . . . . . . . . . . . . . . . 2-1

Operator Responsibility . . . . . . . . . . . . . . . . . . . 2-1

2.2 PREPARATION, INSPECTION, AND

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Pre-Start Inspection . . . . . . . . . . . . . . . . . . . . . . 2-4

Function Check. . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Boom Control System Check Procedure . . . . . . 2-6

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.3 OSCILLATING AXLE LOCKOUT TEST

(IF EQUIPPED) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

SECTION - 3 - MACHINE CONTROLS AND INDICATORS

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 CONTROLS AND INDICATORS . . . . . . . . . . . . . . . 3-1

Ground Control Station . . . . . . . . . . . . . . . . . . . . 3-1

Ground Control Indicator Panel . . . . . . . . . . . . . 3-5

Platform Station . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Platform Control Indicator Panel . . . . . . . . . . . . 3-13

SECTION - 4 - MACHINE OPERATION

4.1 DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 BOOM OPERATING CHARACTERISTICS AND

LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Controlled Arc . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Envelope Tracking. . . . . . . . . . . . . . . . . . . . . . . . 4-3

Controlled Angle . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Swing Speed Proportioning . . . . . . . . . . . . . . . . 4-3

Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

3121264 – JLG Lift – i

Page 8

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

4.3 CAPACITY SELECT . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.4 ENGINE OPERATION . . . . . . . . . . . . . . . . . . . . . . . 4-6

Starting Procedure. . . . . . . . . . . . . . . . . . . . . . . 4-6

Shutdown Procedure . . . . . . . . . . . . . . . . . . . . . 4-7

4.5 TRAVELING (DRIVING) . . . . . . . . . . . . . . . . . . . . . . 4-7

Traveling Forward and Reverse. . . . . . . . . . . . . 4-8

4.6 STEERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.7 EXTENDING THE AXLES . . . . . . . . . . . . . . . . . . . . 4-8

4.8 PLATFORM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Platform Level Adjustment . . . . . . . . . . . . . . . . 4-10

Platform Rotation . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.9 BOOM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Swinging the Boom . . . . . . . . . . . . . . . . . . . . . 4-11

Raising and Lowering the Boom . . . . . . . . . . . 4-11

Telescoping the Boom. . . . . . . . . . . . . . . . . . . 4-11

Swinging the Jib. . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.10 FUNCTION SPEED CONTROL . . . . . . . . . . . . . . . 4-11

4.11 EMERGENCY TOWING . . . . . . . . . . . . . . . . . . . . . 4-12

4.12 SHUT DOWN AND PARK . . . . . . . . . . . . . . . . . . . 4-13

4.13 LIFTING AND TIE DOWN. . . . . . . . . . . . . . . . . . . . 4-13

Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Tie Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.14 STOWING THE JIB FOR TRANSPORT . . . . . . . . .4-14

SECTION - 5 - EMERGENCY PROCEDURES

5.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 INCIDENT NOTIFICATION . . . . . . . . . . . . . . . . . . . .5-1

5.3 EMERGENCY OPERATION . . . . . . . . . . . . . . . . . . .5-1

Operator Unable to Control Machine . . . . . . . . . 5-1

Platform or Boom Caught Overhead . . . . . . . . . 5-2

Boom Movement Prevented By Boom

Control System . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.4 EMERGENCY TOWING PROCEDURES . . . . . . . . .5-2

SECTION - 6 - GENERAL SPECIFICATIONS & OPERATOR

MAINTENANCE

6.1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2 OPERATING SPECIFICATIONS. . . . . . . . . . . . . . . .6-1

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Engine Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Major Component Weights. . . . . . . . . . . . . . . . . 6-7

ii – JLG Lift – 3121264

Page 9

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

6.3 OPERATOR MAINTENANCE . . . . . . . . . . . . . . . . .6-11

6.4 TIRES & WHEELS . . . . . . . . . . . . . . . . . . . . . . . . .6-18

Tire Inflation . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Tire Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Tire Replacement . . . . . . . . . . . . . . . . . . . . . . . 6-18

Wheel Replacement . . . . . . . . . . . . . . . . . . . . . 6-19

Wheel Installation . . . . . . . . . . . . . . . . . . . . . . . 6-19

6.5 SUPPLEMENTAL INFORMATION . . . . . . . . . . . . .6-20

SECTION - 7 - INSPECTION AND REPAIR LOG

LIST OF FIGURES

2-1. Basic Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . .2-7

2-2. Daily Walk-Around Inspection - Sheet 1 of 3 . . . . . .2-8

2-3. Daily Walk-Around Inspection - Sheet 2 of 3 . . . . . .2-9

2-4. Daily Walk-Around Inspection - Sheet 3 of 3 . . . . .2-10

3-1. Ground Control Station . . . . . . . . . . . . . . . . . . . . . .3-2

3-2. Ground Control Indicator Panel. . . . . . . . . . . . . . . .3-5

3-3. Platform Control Console. . . . . . . . . . . . . . . . . . . . .3-8

3-4. Platform Control Indicator Panel . . . . . . . . . . . . . .3-14

4-1. Dual Capacity Decal. . . . . . . . . . . . . . . . . . . . . . . . .4-4

4-2. Position of Least Forward Stability . . . . . . . . . . . . .4-5

4-3. Position of Least Backward Stability . . . . . . . . . . . .4-6

4-4. Grade and Side Slopes . . . . . . . . . . . . . . . . . . . . . .4-9

4-5. Drive Disconnect Hub . . . . . . . . . . . . . . . . . . . . . .4-12

4-6. Lifting and Tie Down Chart - Sheet 1 of 2. . . . . . . 4-15

4-7. Lifting and Tie Down Chart - Sheet 2 of 2. . . . . . . 4-16

4-8. Decal Location Sheet 1 of 5 . . . . . . . . . . . . . . . . . 4-17

4-9. Decal Location Sheet 2 of 5 . . . . . . . . . . . . . . . . . 4-18

4-10. Decal Location Sheet 3 of 5 . . . . . . . . . . . . . . . . . 4-19

4-11. Decal Location Sheet 4 of 5 . . . . . . . . . . . . . . . . . 4-20

4-12. Decal Location Sheet 5 of 5 . . . . . . . . . . . . . . . . . 4-21

6-1. Engine Operating Temperature Specifications - Deutz

- Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6-2. Engine Operating Temperature Specifications - Deutz

- Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6-3. Lubrication and Maintenance Point Location. . . . 6-10

3121264 – JLG Lift – iii

Page 10

TABLE OF CONTENTS

SECTION - PARAGRAPH, SUBJECT PAGE SECTION - PARAGRAPH, SUBJECT PAGE

LIST OF TABLES

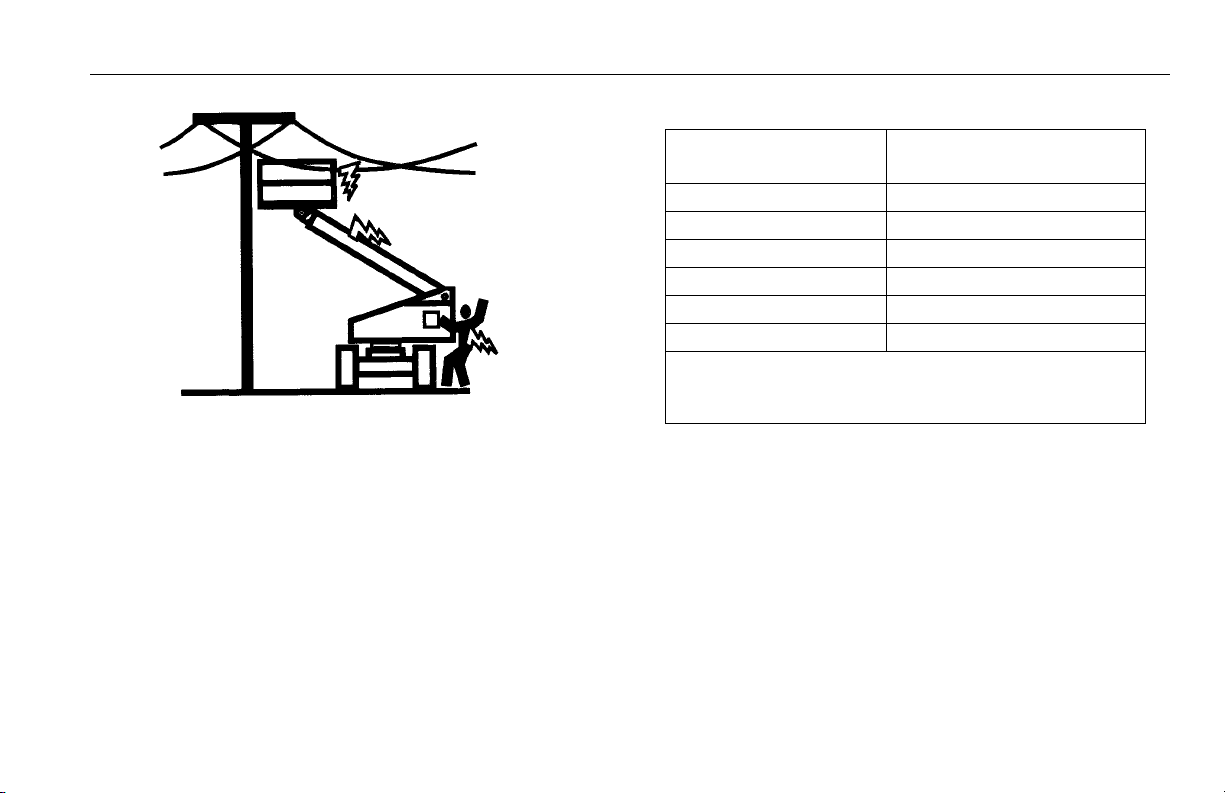

1-1 Minimum Approach Distances (M.A.D.) . . . . . . . . . 1-5

1-2 Beaufort Scale (For Reference Only) . . . . . . . . . . 1-10

2-1 Inspection and Maintenance Table . . . . . . . . . . . . . 2-3

6-1 Operating Specifications . . . . . . . . . . . . . . . . . . . . .6-1

6-2 Dimensional Data. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-3 Chassis Specifications. . . . . . . . . . . . . . . . . . . . . . . 6-2

6-4 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6-5 Tire Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6-6 Deutz TD2011L4 Specifications . . . . . . . . . . . . . . . 6-3

6-7 Hydraulic Oil Specifications. . . . . . . . . . . . . . . . . . . 6-4

6-8 Mobilfluid 424 Specs . . . . . . . . . . . . . . . . . . . . . . . .6-4

6-9 Mobil DTE 13M Specs . . . . . . . . . . . . . . . . . . . . . . . 6-5

6-10 UCon Hydrolube HP-5046. . . . . . . . . . . . . . . . . . . . 6-5

6-11 Mobil EAL H 46 Specs. . . . . . . . . . . . . . . . . . . . . . . 6-6

6-12 Exxon Univis HVI 26 Specs . . . . . . . . . . . . . . . . . . . 6-6

6-13 Component Weights . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6-14 Lubrication Specifications . . . . . . . . . . . . . . . . . . . 6-11

6-15 Wheel Torque Chart. . . . . . . . . . . . . . . . . . . . . . . . 6-20

7-1 Inspection and Repair Log . . . . . . . . . . . . . . . . . . .7-1

iv – JLG Lift – 3121264

Page 11

SECTION 1 - SAFETY PRECAUTIONS

SECTION 1. SAFETY PRECAUTIONS

1.1 GENERAL

This section outlines the necessary precautions for proper

and safe machine operation and maintenance. For proper

machine use, it is mandatory that a daily routine is established based on the content of this manual. A maintenance

program, using the information provided in this manual and

the Service and Maintenance Manual, must also be established by a qualified person and followed to ensure the

machine is safe to operate.

The owner/user/operator/lessor/lessee of the machine

should not operate the machine until this manual has been

read, training is accomplished, and operation of the machine

has been completed under the supervision of an experienced and qualified operator.

If there are any questions with regard to safety, training,

inspection, maintenance, application, and operation, please

contact JLG Industries, Inc. (“JLG”).

FAILURE TO COMPLY WITH THE SAFETY PRECAUTIONS LISTED IN

THIS MANUAL COULD RESULT IN MACHINE DAMAGE, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

1.2 PRE-OPERATION

Operator Training and Knowledge

• Read and understand this manual before operating the

machine.

• Do not operate this machine until complete training is performed by authorized persons.

• Only authorized and qualified personnel can operate the

machine.

3121264 – JLG Lift – 1-1

Page 12

SECTION 1 - SAFETY PRECAUTIONS

• Read, understand, and obey all DANGERS, WARNINGS,

CAUTIONS, and operating instructions on the machine

and in this manual.

• Use the machine in a manner which is within the scope of

its intended application set by JLG.

• All operating personnel must be familiar with the emergency controls and emergency operation of the machine

as specified in this manual.

• Read, understand, and obey all applicable employer,

local, and governmental regulations as they pertain to

operation of the machine.

Workplace Inspection

• The operator is to take safety measures to avoid all hazards in the work area prior to machine operation.

• Do not operate or raise the platform while on trucks, trailers, railway cars, floating vessels, scaffolds or other equipment unless approved in writing by JLG.

• Do not operate the machine in hazardous environments

unless approved for that purpose by JLG.

• Be sure that the ground conditions are able to support the

maximum load shown on the decals located on the

machine.

o

• This machine can be operated in temperatures of 0

o

F (-20o C to 40o C). Consult JLG for operation out-

104

side this range.

F to

Machine Inspection

• Before machine operation, perform inspections and functional checks. Refer to Section 2 of this manual for

detailed instructions.

• Do not operate this machine until it has been serviced and

maintained according to requirements specified in the

Service and Maintenance Manual.

• Be sure the footswitch and all other safety devices are

operating properly. Modification of these devices is a

safety violation.

MODIFICATION OR ALTERATION OF AN AERIAL WORK PLATFORM

SHALL BE MADE ONLY WITH WRITTEN PERMISSION FROM THE MANUFACTURER

• Do not operate any machine on which safety or instruction

placards or decals are missing or illegible.

• Avoid any buildup of debris on the platform floor. Keep

mud, oil, grease, and other slippery substances from footwear and platform floor.

1-2 – JLG Lift – 3121264

Page 13

SECTION 1 - SAFETY PRECAUTIONS

1.3 OPERATION

General

• Do not use the machine for any purpose other than positioning personnel, their tools, and equipment.

• Never operate a machine that is not working properly. If a

malfunctions occurs, shut down the machine.

• Never slam a control switch or lever through neutral to an

opposite direction. Always return switch to neutral and

stop before moving the switch to the next function. Operate controls with slow and even pressure.

• Do not allow personnel to tamper with or operate the

machine from the ground with personnel in the platform,

except in an emergency.

• Do not carry materials directly on platform railing. Contact

JLG for approved material handling accessories.

• When two or more persons are in the platform, the operator shall be responsible for all machine operations.

• Always ensure that power tools are properly stowed and

never left hanging by their cord from the platform work

area.

• Supplies or tools which extend outside the platform are

prohibited unless approved by JLG.

• When driving, always position boom over rear axle in line

with the direction of travel. Remember, if boom is over the

front axle, steer and drive functions will be reversed.

• Do not assist a stuck or disabled machine by pushing,

pulling, or by using boom functions. Only pull the unit

from the tie-down lugs on the chassis.

• Do not place boom or platform against any structure to

steady the platform or to support the structure.

• Stow boom and shut off all power before leaving machine.

Trip and Fall Hazards

During operation, occupants in the platform must wear a full

body harness with a lanyard attached to an authorized lanyard anchorage point. Attach only one (1) lanyard per lanyard anchorage point.

3121264 – JLG Lift – 1-3

Page 14

SECTION 1 - SAFETY PRECAUTIONS

• Before operating the machine, make sure all gates are

closed and fastened in their proper position.

• Keep both feet firmly positioned on the platform floor at all

times. Never use ladders, boxes, steps, planks, or similar

items on platform to provide additional reach.

• Never use the boom assembly to enter or leave the platform.

• Use extreme caution when entering or leaving platform.

Be sure that the boom is fully lowered. It may be necessary to telescope out to position the platform closer to the

ground for entry/exit. Face the machine, maintain “three

point contact” with the machine, using two hands and one

foot or two feet and one hand during entry and exit.

Electrocution Hazards

• This machine is not insulated and does not provide protection from contact or proximity to electrical current.

1-4 – JLG Lift – 3121264

Page 15

SECTION 1 - SAFETY PRECAUTIONS

Table 1-1. Minimum Approach Distances (M.A.D.)

• Maintain distance from electrical lines, apparatus, or any

energized (exposed or insulated) parts according to the

Minimum Approach Distance (MAD) as shown in Table 1-

1.

• Allow for machine movement and electrical line swaying.

Voltage Range

(Phase to Phase)

0 to 50 KV 10 (3)

Over 50KV to 200 KV 15 (5)

Over 200 KV to 350 KV 20 (6)

Over 350 KV to 500 KV 25 (8)

Over 500 KV to 750 KV 35 (11)

Over 750 KV to 1000 KV 45 (14)

NOTE: This requirement shall apply except where

employer, local or governmental regulations

are more stringent.

• Maintain a clearance of at least 10 ft. (3m) between any part

of the machine and its occupants, their tools, and their

equipment from any electrical line or apparatus carrying up

to 50,000 volts. One foot additional clearance is required for

every additional 30,000 volts or less.

MINIMUM APPROACH DISTANCE

in Feet (Meters)

3121264 – JLG Lift – 1-5

Page 16

SECTION 1 - SAFETY PRECAUTIONS

• The minimum approach distance may be reduced if insulating barriers are installed to prevent contact, and the barriers

are rated for the voltage of the line being guarded. These

barriers shall not be part of (or attached to) the machine. The

minimum approach distance shall be reduced to a distance

within the designed working dimensions of the insulating

barrier. This determination shall be made by a qualified person in accordance with the employer, local, or governmental

requirements for work practices near energized equipment

DO NOT MANEUVER MACHINE OR PERSONNEL INSIDE PROHIBITED

ZONE (MAD). ASSUME ALL ELECTRICAL PARTS AND WIRING ARE

ENERGIZED UNLESS KNOWN OTHERWISE.

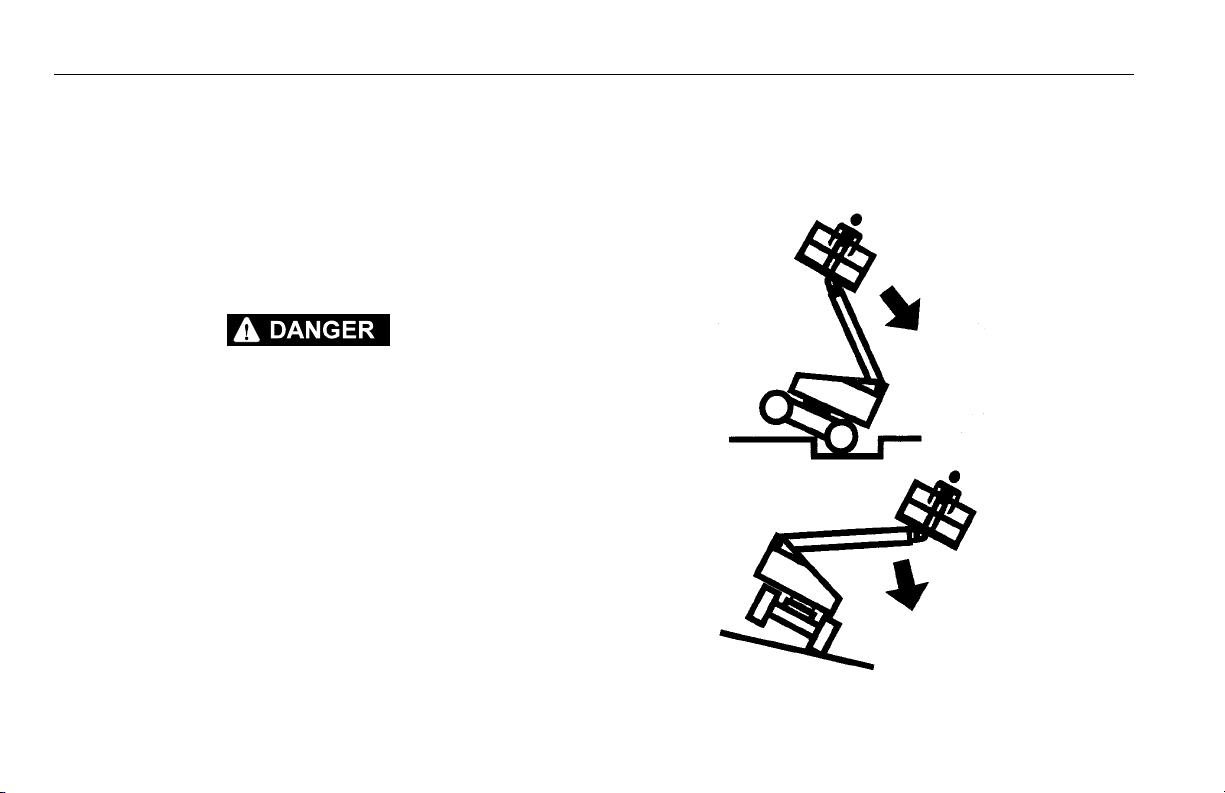

Tipping Hazards

• The user must be familiar with the surface before driving.

Do not exceed the allowable sideslope and grade while

driving.

1-6 – JLG Lift – 3121264

Page 17

SECTION 1 - SAFETY PRECAUTIONS

• Do not elevate platform or drive with platform elevated

while on a sloping, uneven, or soft surface.

• Before driving on floors, bridges, trucks, and other surfaces, check allowable capacity of the surfaces.

• Never exceed the maximum platform capacity. Distribute

loads evenly on platform floor.

• Do not raise the platform or drive from an elevated position unless the machine is on firm, level (up to the rated 3

degrees) and smooth surfaces.

• Keep the chassis of the machine at least 2 ft. (0.6m) from

holes, bumps, drop-offs, obstructions, debris, concealed

holes, and other potential hazards on the floor/surface.

• Do not push or pull any object with the boom.

• Never attempt to use the machine as a crane. Do not tieoff machine to any adjacent structure.

• Do not operate the machine when wind conditions exceed

28 mph (12.5 m/s). Refer to Table 1-2, Beaufort Scale (For

Reference Only).

• Do not increase the surface area of the platform or the

load. Increase of the area exposed to the wind will

decrease stability.

• Do not increase the platform size with unauthorized deck

extensions or attachments.

• If boom assembly or platform is in a position that one or

more wheels are off the ground, all persons must be

removed before attempting to stabilize the machine. Use

cranes, forklift trucks, or other appropriate equipment to

stabilize machine.

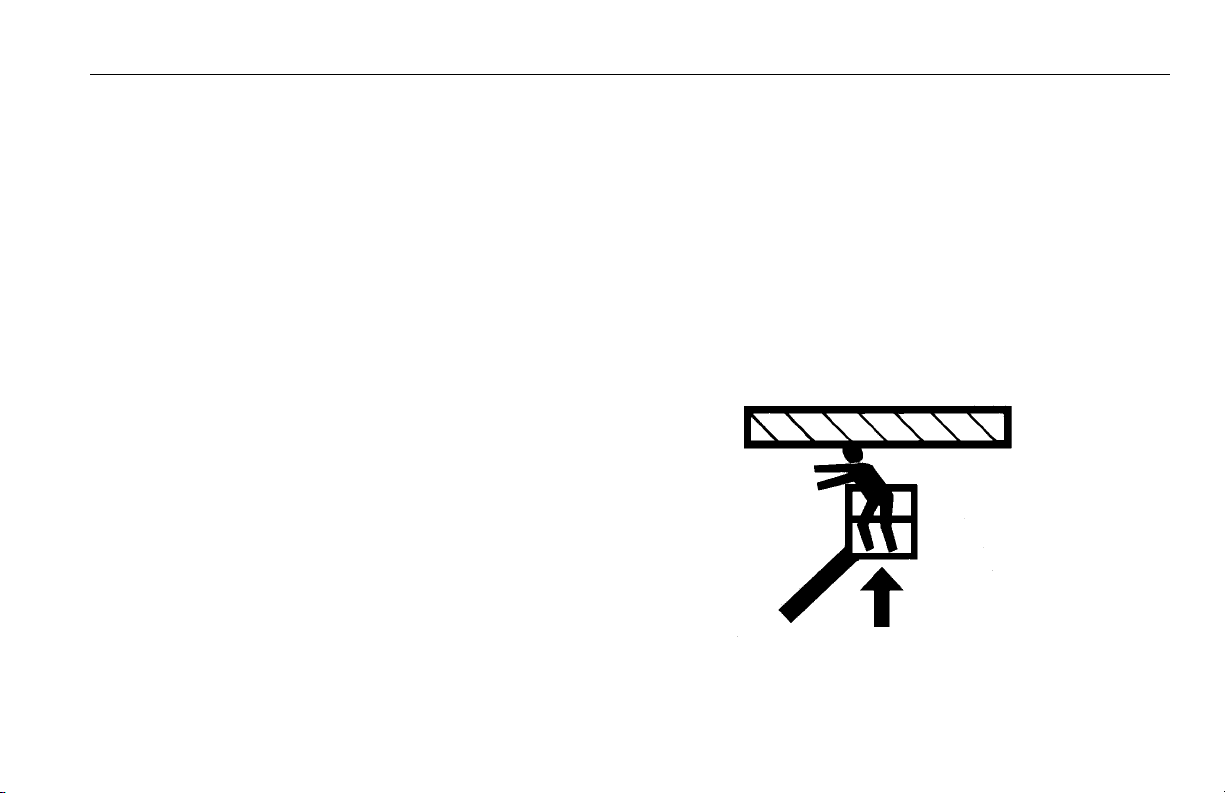

Crushing and Collision Hazards

• Approved head gear must be worn by all operating and

ground personnel.

• Check work area for clearances overhead, on sides, and

bottom of platform when lifting or lowering platform, and

driving.

• During operation, keep all body parts inside platform railing.

3121264 – JLG Lift – 1-7

Page 18

SECTION 1 - SAFETY PRECAUTIONS

• Use the boom functions, not the drive function, to position

the platform close to obstacles.

• Always post a lookout when driving in areas where vision

is obstructed.

• Keep non-operating personnel at least 6 ft. (1.8m) away

from machine during all driving and swing operations.

• Limit travel speed according to conditions of ground surface, congestion, visibility, slope, location of personnel,

and other factors which may cause collision or injury to

personnel.

• Be aware of stopping distances in all drive speeds. When

driving in high speed, switch to low speed before stopping. Travel grades in low speed only.

• Do not use high speed drive in restricted or close quarters

or when driving in reverse.

• Exercise extreme caution at all times to prevent obstacles

from striking or interfering with operating controls and persons in the platform.

• Be sure that operators of other overhead and floor level

machines are aware of the aerial work platform’s presence. Disconnect power to overhead cranes.

• Warn personnel not to work, stand, or walk under a raised

boom or platform. Position barricades on floor if necessary.

1.4 TOWING, LIFTING, AND HAULING

• Never allow personnel in platform while towing, lifting, or

hauling.

• This machine should not be towed, except in the event of

emergency, malfunction, power failure, or loading/unloading. Refer to the Emergency Procedures section of this

manual for emergency towing procedures.

• Ensure boom is in the stowed position and the turntable

locked prior to towing, lifting or hauling. The platform must

be completely empty of tools.

• When lifting machine, lift only at designated areas of the

machine. Lift the unit with equipment of adequate capacity.

• Refer to the Machine Operation section of this manual for

lifting information.

1-8 – JLG Lift – 3121264

Page 19

SECTION 1 - SAFETY PRECAUTIONS

1.5 ADDITIONAL HAZARDS / SAFETY

• Do not use machine as a ground for welding.

• When performing welding or metal cutting operations,

precautions must be taken to protect the chassis from

direct exposure to weld and metal cutting spatter.

• Do not refuel the machine with the engine running.

• Battery fluid is highly corrosive. Avoid contact with skin

and clothing at all times.

• Charge batteries only in a well ventilated area.

3121264 – JLG Lift – 1-9

Page 20

SECTION 1 - SAFETY PRECAUTIONS

DO NOT OPERATE THE MACHINE WHEN WIND CONDITIONS EXCEED 28

MPH (12.5 M/S).

Table 1-2. Beaufort Scale (For Reference Only)

Beaufort

Number

0 0 0-0.2 Calm Calm. Smoke rises vertically

1 1-3 0.3-1.5 Light air Wind motion visible in smoke

2 4-7 1.6-3.3 Light breeze Wind felt on exposed skin. Leaves ru stle

3 8-12 3.4-5.4 Gentle breeze Leaves and smaller twigs in constant motion

4 13-18 5.5-7.9 Moderate breeze Dust and loose paper raised. Small branches begin to move.

5 19-24 8.0-10.7 Fresh breeze Smaller trees sway.

6 25-31 10.8-13.8 Strong breeze Large branches in motion. Whistling heard in overhead wires.

7 32-38 13.9-17.1 Near Gale/Moderate Gale Whole trees in motion. Effort needed to walk against the wind.

8 39-46 17.2-20.7 Fresh Gale Twigs broken from trees. Cars veer on road.

9 47-54 20.8-24.4 Strong Gale Light structure damage.

Wind Speed

mph m/s

Description Land Conditions

Umbrella use becomes difficult.

1-10 – JLG Lift – 3121264

Page 21

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

SECTION 2. USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2.1 PERSONNEL TRAINING

The aerial platform is a personnel handling device; so it is

necessary that it be operated and maintained only by trained

personnel.

Persons under the influence of drugs or alcohol or who are

subject to seizures, dizziness or loss of physical control must

not operate this machine.

Operator Training

Operator training must cover:

1. Use and limitations of the controls in the platform and at

the ground, emergency controls and safety systems.

2. Control labels, instructions, and warnings on the

machine.

3. Rules of the employer and government regulations.

4. Use of approved fall protection device.

5. Enough knowledge of the mechanical operation of the

machine to recognize a malfunction or potential malfunction.

6. The safest means to operate the machine where overhead obstructions, other moving equipment, and obstacles, depressions, holes, drop-offs, etc. exist.

7. Means to avoid the hazards of unprotected electrical

conductors.

8. Specific job requirements or machine application.

Training Supervision

Training must be done under the supervision of a qualified

person in an open area free of obstructions until the trainee

has developed the ability to safely control and operate the

machine.

Operator Responsibility

The operator must be instructed that he/she has the responsibility and authority to shut down the machine in case of a

malfunction or other unsafe condition of either the machine

or the job site.

3121264 – JLG Lift – 2-1

Page 22

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2.2 PREPARATION, INSPECTION, AND MAINTENANCE

The following table covers the periodic machine inspections

and maintenance required by JLG Industries, Inc. Consult

local regulations for further requirements for aerial work platforms. The frequency of inspections and maintenance must

be increased as necessary when the machine is used in a

harsh or hostile environment, if the machine is used with

increased frequency, or if the machine is used in a severe

manner.

JLG INDUSTRIES, INC. RECOGNIZES A FACTORY-TRAINED SERVICE

TECHNICIAN AS A PERSON WHO HAS SUCCESSFULLY COMPLETED

THE JLG SERVICE TRAINING SCHOOL FOR THE SPECIFIC JLG PRODUCT

MODEL.

2-2 – JLG Lift – 3121264

Page 23

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

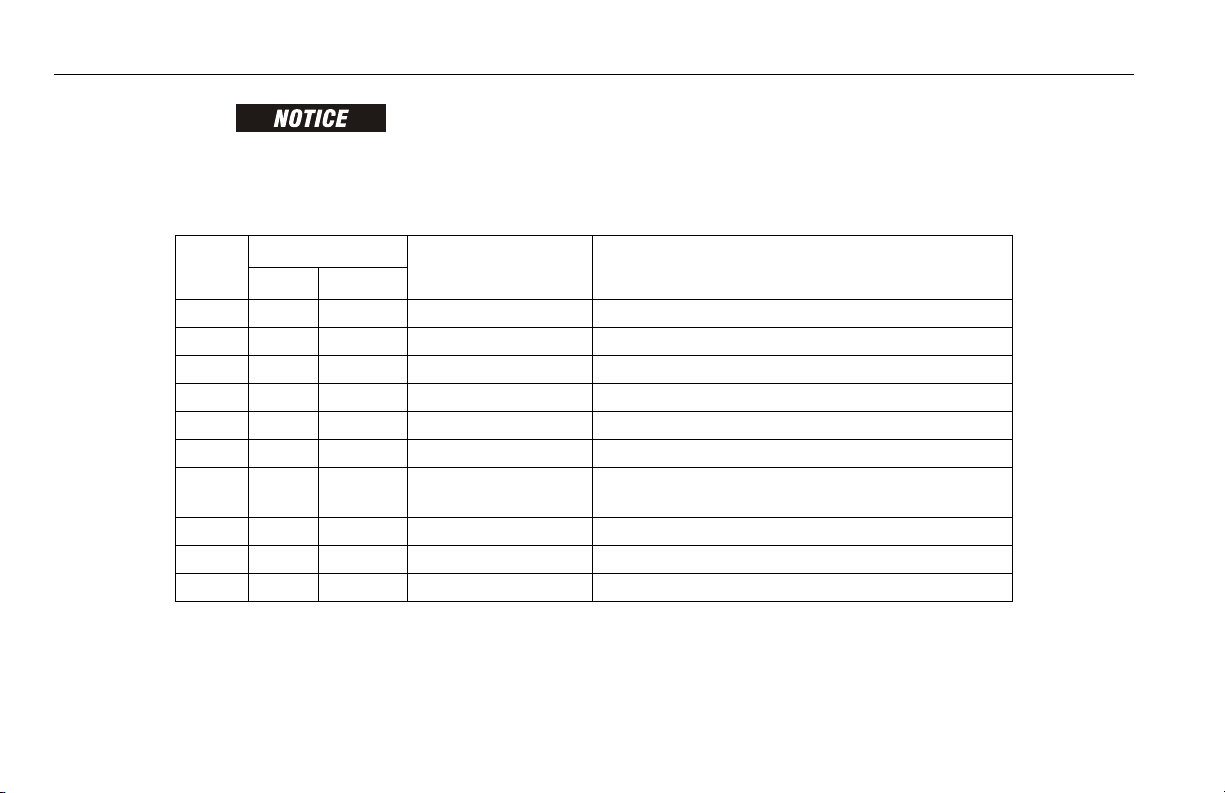

Table 2-1.Inspection and Maintenance Table

Type Frequency

Pre-Start Inspection Before using each day; or

whenever there’s an Operator change.

Pre-Delivery Inspection

(See Note)

Frequent Inspection

(See Note)

Annual Machine Inspection

(See Note)

Preventative Maintenance At intervals as specified in the Ser vice and Main-

NOTE: Inspection forms are available from JLG. Use the Service and Maintenance Manual to perform inspections.

Before each sale, lease, or rental deliver y. Owner, Dealer, or User Qualified JLG

In service for 3 months or 150 hours, whichever

comes first;

o r

Out of service for a period of more than 3 months;

o r

Purchased used.

Annually, no later than 13 months from the date of

prior inspection.

tenance Manual.

Primary

Responsibility

User or Operator User or Operator Operator and Safety Manual

Owner, Dealer, or User Qualified JLG

Owner, Dealer, or User Factory-Trained

Owner, Dealer, or User Qualified JLG

Service

Qualification

Mechanic

Mechanic

Service Technician

(Recommended)

Mechanic

Reference

Service and Maintenance

Manual and applicable JLG

inspection form

Service and Maintenance

Manual and applicable JLG

inspection form

Service and Maintenance

Manual and applicable JLG

inspection form

Service and Maintenance

Manual

3121264 – JLG Lift – 2-3

Page 24

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

Pare nt Metal C rack Weld Cr ack

Pre-Start Inspection

The Pre-Start Inspection should include each of the following:

1. Cleanliness – Check all surfaces for leakage (oil, fuel,

or battery fluid) or foreign objects. Report any leakage to

the proper maintenance personnel.

2. Structure - Inspect the machine structure for dents,

damage, weld or parent metal cracks or other discrepancies.

3. Decals and Placards – Check all for cleanliness and

legibility. Make sure none of the decals and placards are

missing. Make sure all illegible decals and placards are

cleaned or replaced.

4. Operators and Safety Manuals – Make sure a copy of

the Operator and Safety Manual, AEM Safety Manual

(ANSI markets only), and ANSI Manual of Responsibili-

ties (ANSI markets only) is enclosed in the weather

resistant storage container.

5. “Walk-Around” Inspection – Refer to Figure 2-2. and

Figure 2-3.

6. Battery – Charge as required.

7. Fuel (Combustion Engine Powered Machines) – Add the

proper fuel as necessary.

8. Engine Oil Supply - Ensure the engine oil level is at the

Full mark on the dipstick and the filler cap is secure.

9. Hydraulic Oil – Check the hydraulic oil level. Ensure

hydraulic oil is added as required.

10. Accessories/Attachments - Reference the Operator

and Safety Manual of each attachment or accessory

installed upon the machine for specific inspection, operation, and maintenance instructions.

11. Function Check – Once the “Walk-Around” Inspection

is complete, perform a functional check of all systems in

an area free of overhead and ground level obstructions.

Refer to Section 4 for more specific operating instructions.

12. Boom Control System Check - Perform a check of the

boom control system as specified in this section.

2-4 – JLG Lift – 3121264

Page 25

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

IF THE MACHINE DOES NOT OPERATE PROPERLY, TURN OFF THE

MACHINE IMMEDIATELY! REPORT THE PROBLEM TO THE PROPER

MAINTENANCE PERSONNEL. DO NOT OPERATE THE MACHINE UNTIL

IT IS DECLARED SAFE FOR OPERATION.

Function Check

Perform the Function Check as follows:

1. From the ground control panel with no load in the platform:

a. Check that all guards protecting the switches or

locks are in place;

b. Operate all functions and check all limiting and cut-

out switches;

c. Check auxiliary power (or manual descent);

d. Ensure that all machine functions are disabled

when the Emergency Stop Button is activated.

2. Check the Boom Control System. Refer to Boom Control

System Check Procedure below.

3. From the platform control console:

a. Ensure that the control console is firmly secured in

the proper location;

b. Check that all guards protecting the switches or

locks are in place;

c. Operate all functions and check all limiting and cut-

out switches;

d. Check that drive is disabled when the boom is ele-

vated more than 15 degrees above horizontal or

telescoped out beyond transport mode;

e. Ensure that all machine functions are disabled

when the Emergency Stop Button is pushed in.

4. With the platform in the (stowed) position:

a. Drive the machine on a grade, not to exceed the

rated gradeability, and stop to ensure the brakes

hold;

b. Check the tilt sensor alarm to ensure proper opera-

tion.

c. Check that the boom telescope (beyond transport

mode) and lift up (more than 15° above horizontal)

functions are disabled with the axles retracted.

5. Swing the boom over either of the rear tires and ensure

that the Drive Orientation indicator illuminates and that

the Drive Orientation Override switch must be used for

the drive function to operate.

3121264 – JLG Lift – 2-5

Page 26

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

Boom Control System Check Procedure

Perform the following check with no load (personnel or material) in the platform from the ground control station.

1. Extend all axles fully.

2. With the boom fully retracted, raise the boom off the

boom rest to horizontal.

3. Position the jib horizontal, jib straight, and platform level.

4. Extend the boom until it stops.

5. Boom must stop on colored stripe matching the capac-

ity indicator. If the boom does not stop on the correct

stripe, the system must be repaired by JLG authorized

Service Personnel before the machine can be used.

6. Push and hold the gray Boom Control System Test Button on the ground control panel. The lighting of the

green Boom Control System Calibrated indicator indicates the system is functioning properly. No indicator

light or the lighting of the red Boom Control System

Warning indicator indicates the system must be repaired

by JLG authorized Service Personnel before the

machine can be used.

2-6 – JLG Lift – 3121264

Page 27

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

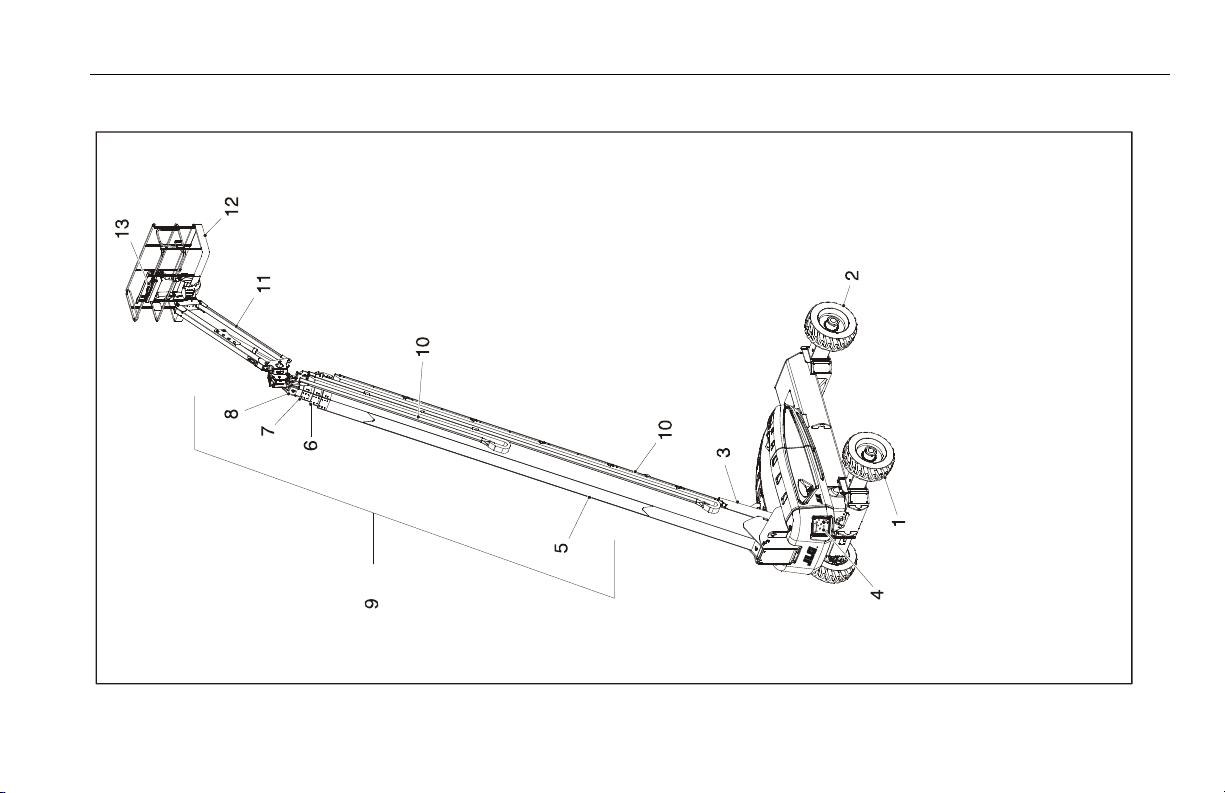

Figure 2-1. Basic Nomenclature

1 . F r on t St e e r W h ee l s

2. Rear Drive Wheels

3 . L i f t C y l in d er

4. Ground Control Console

5 . B a s e B o om S ec t io n

6 . I n n er M id B oo m Se c t io n

7 . O u te r M id B oo m Se c t io n

8 . F l y B o om S ec t io n

9 . B oo m As se m bl y

10. Power Track

11. Jib

12. Platform

13. Platform Control Console

3121264 – JLG Lift – 2-7

Page 28

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

1

2

13

14

3

9

4

7

7

5

5

55

6

6

6

6

9

9

9

9

8

2

11

11

12

11

11

10

9

Figure 2-2. Daily Walk-Around Inspection - Sheet 1 of 3

2-8 – JLG Lift – 3121264

Page 29

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

General

Begin the "Walk-Around Inspection" at Item 1, as noted on

the diagram. Continue to the right (counterclockwise viewed

from top) checking each item in sequence for the conditions

listed in the following checklist.

TO AVOID POSSIBLE INJURY, BE SURE MACHINE POWER IS OFF.

DO NOT OPERATE MACHINE UNTIL ALL MALFUNCTIONS HAVE BEEN

CORRECTED.

INSPECTION NOTE: On all components, make sure there

are no loose or missing parts, that they are securely fastened, and no visible damage, leaks or excessive wear exists

in addition to any other criteria mentioned.

1. Platform Assembly and Gate - Footswitch works properly, not modified, disabled or blocked. Latch, stop, and

hinges in working condition.

2. Platform & Ground Control Consoles - Switches and

levers return to neutral, decals/placards secure and

legible, control markings legible.

3. Boom Sections/Uprights/Turntable - See Inspection

Note.

4. Swing Drive - No evidence of damage.

5. Wheel/Tire Assemblies - Properly secured, no missing

lug nuts. Inspect for worn tread, cuts, tears or other discrepancies. Inspect wheels for damage and corrosion.

6. Drive Motor, Brake, and Hub - No evidence of leakage.

7. Hood Assemblies - See Inspection Note.

8. Auxiliary Hydraulic Pump - See Inspection Note.

9. All Hydraulic Cylinders - No visible damage; pivot

pins and hydraulic hoses undamaged, not leaking.

10. Turntable Bearing - Evidence of proper lubrication. No

evidence of loose bolts or looseness between bearing

and machine.

11. Steering Spindles and Sensors - See Inspection

Note.

Figure 2-3. Daily Walk-Around Inspection - Sheet 2 of 3

3121264 – JLG Lift – 2-9

Page 30

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

12. Main Hydraulic Pump - See Inspection Note.

13. Platform Rotator - See Inspection Note.

14. Jib Rotator - See Description.

Figure 2-4. Daily Walk-Around Inspection - Sheet 3 of 3

2-10 – JLG Lift – 3121264

Page 31

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

2.3 OSCILLATING AXLE LOCKOUT TEST (IF EQUIPPED)

The front axles will oscillate when the boom is in the transport

position (i.e. when the boom is less than 15° above horizontal

and not extended beyond 12" (30.4 cm).

LOCKOUT SYSTEM TEST MUST BE PERFORMED QUARTERLY, ANY TIME

A SYSTEM COMPONENT IS REPLACED, OR WHEN IMPROPER SYSTEM

OPERATION IS SUSPECTED.

NOTE: Ensure the axles are extended and the boom is fully

retracted, lowered, and centered between the rear

wheels prior to beginning lockout cylinder test.

1. Place a 6 inch (15.2 cm) high block with ascension ramp

in front of left front wheel.

2. From platform control station, start engine.

3. Place the Drive control lever to the forward position and

carefully drive machine up ascension ramp until left front

wheel is on top of block.

4. Carefully extend the boom just enough to get it out of

the transport position.

5. With boom in this position, place Drive control lever to

Reverse and carefully drive machine off of block and

ramp.

6. Have an assistant check to see that left front or right rear

wheel remains elevated in position off of the ground.

7. Carefully return the boom to the transport position.

When boom reaches the transport position, carefully

activate Drive to release cylinders. The lockout cylinders

should release and allow the wheel to rest on ground.

8. Repeat the procedure for the right oscillation cylinder

checking to see that the right front or left rear wheel

remains elevated in position off of the ground.

9. If lockout cylinders do not function properly, have qualified personnel correct the malfunction prior to any further operation.

3121264 – JLG Lift – 2-11

Page 32

SECTION 2 - USER RESPONSIBILITIES, MACHINE PREPARATION, AND INSPECTION

NOTES:

2-12 – JLG Lift – 3121264

Page 33

SECTION 3 - MACHINE CONTROLS AND INDICATORS

SECTION 3. MACHINE CONTROLS AND INDICATORS

3.1 GENERAL

THE MANUFACTURER HAS NO DIRECT CONTROL OVER MACHINE

APPLICATION AND OPERATION. THE USER AND OPERATOR ARE

RESPONSIBLE FOR CONFORMING WITH GOOD SAFETY PRACTICES.

This section provides the necessary information needed to

understand control functions.

3.2 CONTROLS AND INDICATORS

NOTE: This machine is equipped with control panels that use

symbols to indicate control functions. Refer to decal

located on the control box guard in front of the control

box or by the ground controls for these symbols and the

corresponding functions.

TO AVOID SERIOUS INJURY, DO NOT OPERATE MACHINE IF ANY CONTROL LEVERS OR TOGGLE SWITCHES CONTROLLING PLATFORM

MOVEMENT DO NOT RETURN TO THE OFF POSITION WHEN RELEASED.

Ground Control Station

NOTE: The Function Enable switch must be held

down in order to operate Telescope, Swing,

Main Lift, Jib Lift, Platform Level Override,

and Platform Rotate functions.

(See Figure 3-1., Ground Control Station)

1. Indicator Panel

The LED Indicator Panel contains indicator lights that

signal problem conditions or functions operating during

machine operation.

2. Boom Control System Test Button

The push button is used to test the boom control system

and confirm that it is working properly.

3. Tel es co p e C o n tr ol

Provides extension and retraction of the boom when

positioned to IN or OUT.

3121264 – JLG Lift – 3-1

Page 34

SECTION 3 - MACHINE CONTROLS AND INDICATORS

1706911 A

1

13

3

2

4

5

6

7

8

9

10

11

12

Figure 3-1. Ground Control Station

1. Indicator Panel

2. Boom Control System Test Button

3. Telescope

4. Swing

5. Lift

6. Platform/Ground Select Switch

7. Hourmeter

8. Power/Emergency Stop

9. Engine Start/Auxiliar y Power/Function Enable

10. Articulating Jib

11. Platform Leveling Override

12. Platform Rotate

13. Jib Swing

3-2 – JLG Lift – 3121264

Page 35

SECTION 3 - MACHINE CONTROLS AND INDICATORS

4. Swing Control

Provides 360 degrees continuous turntable rotation.

5. Lift Control

Provides raising and lowering of the main boom.

NOTE: With PLATFORM/GROUND SELECT switch in the center

position, power is shut off to controls at both operating

stations.

6. Platform/Ground Select Switch

A three position, key operated switch supplies power to

the platform control console when positioned to PLATFORM. With the switch key held in the GROUND position, power is shut off to platform and only ground

controls are operable.

7. Hourmeter

Registers the amount of time the machine has been in

use, with engine running. By connecting into the oil

pressure circuit of the engine, only engine run hours are

recorded. The hourmeter registers up to 9,999.9 hours

and cannot be reset.

NOTE: When Power/Emergency Stop switch is in the “ON” posi-

tion and engine is not running, an alarm will sound, indicating Ignition is “ON”.

WHEN THE MACHINE IS SHUT DOWN THE MASTER/EMERGENCY STOP

SWITCH MUST BE POSITIONED TO THE “OFF” POSITION TO PREVENT

DRAINING THE BATTERY.

8. Power/Emergency Stop Switch

A two-position red mushroom shaped switch furnishes

power to PLATFORM/GROUND SELECT switch when

pulled out (on). When pushed in (off), power is shut off

to the PLATFORM/GROUND SELECT switch.

3121264 – JLG Lift – 3-3

Page 36

SECTION 3 - MACHINE CONTROLS AND INDICATORS

NOTE: Auxiliary power only works if there is no engine oil pres-

sure, and is disabled if engine is running.

Functions will operate at a slower than normal rate

because of the lesser flow of hydraulic fluid delivered.

WHEN USING AUXILIARY POWER, DO NOT OPERATE MORE THAN ONE

FUNCTION AT A TIME. (SIMULTANEOUS OPERATION CAN OVERLOAD

THE AUXILIARY PUMP.

9. Engine Start/ Auxiliary Power Switch /Function Enable

To start the engine, the switch must be held

"UP" until the engine starts.

To use auxiliary power, the switch must be

held “DOWN” for duration of auxiliary pump

use. Aux power can only be used if the engine

is not running.

The enable switch must be held "DOWN" to

enable all boom controls when the engine is

running.

10. Articulating Jib

This switch provides raising and lowering of the jib.

ONLY USE THE PLATFORM LEVELING OVERRIDE FUNCTION FOR

SLIGHT LEVELING OF THE PLATFORM. INCORRECT USE COULD CAUSE

THE LOAD/OCCUPANTS TO SHIFT OR FALL. FAILURE TO DO SO COULD

RESULT IN DEATH OR SERIOUS INJURY.

11. Platform Leveling Override

This switch allows the operator to adjust the automatic

self leveling system. This switch is used to adjust platform level in situations such as ascending/descending a

grade.

12. Platform Rotate

This switch permits rotation of the platform.

13. Jib Swing

This switch allows the operator to swing the jib to the left

and right.

3-4 – JLG Lift – 3121264

Page 37

SECTION 3 - MACHINE CONTROLS AND INDICATORS

1. Battery Charging

2. Low Engine Oil Pressure

3. High Engine Coolant Temp.

4. High Engine Oil Temp.

5. Axles Set

6. Platform Capacity

7. Platform Overload

8. Boom Control System Warning

9. Boom Control System Calibrated

Figure 3-2. Ground Control Indicator Panel

Ground Control Indicator Panel

(See Figure 3-2., Ground Control Indicator Panel)

1. Battery Charging Indicator

3121264 – JLG Lift – 3-5

Indicates a problem in the battery or charging circuit,

and service is required.

2. Low Engine Oil Pressure Indicator

Indicates that engine oil pressure is below normal and

service is required.

3. High Engine Temperature Indicator

Indicates that engine coolant temperature is abnormally

high and service is required.

4. Engine Oil Temperature Indicator

Indicates the temperature of the engine oil, which also

serves as engine coolant, is abnormally high and service is required.

5. Axles Set Indicator

Indicates that the axles are fully extended. The indicator

will flash as the axles are extending or retracting and be

on solid when fully extended. The light will go out when

the axles are fully retracted.

6. Platform Capacity Indicator

Indicates which capacity range is selected. This capacity can only be selected at the platform control console.

Page 38

SECTION 3 - MACHINE CONTROLS AND INDICATORS

7. Platform Overload Indicator (If Equipped)

Indicates the platform has been overloaded.

8. Boom Control System Warning Indicator

Indicates the platform is outside the operating area and

operation of certain boom functions may be disabled

(i.e. lift, telescope). Attempts to use the disabled functions cause the indicator to flash and an alarm to sound.

Immediately return the platform to the ground. If the indicator remains lit, a boom control system fault or failure

has been detected. If a fault or failure is discovered, the

system must be repaired by JLG authorized service personnel before the machine can be used.

9. Boom Control System Calibrated Indicator

When the Boom Control System Test Button is pushed,

illuminates to indicate that the Boom Control System is

calibrated properly.

Platform Station

(See Figure 3-3., Platform Control Console)

TO AVOID SERIOUS INJURY, DO NOT OPERATE MACHINE IF ANY CONTROL LEVERS OR TOGGLE SWITCHES CONTROLLING PLATFORM

MOVEMENT DO NOT RETURN TO THE OFF OR NEUTRAL POSITION

WHEN RELEASED.

1. Power/Emergency Stop

A two-position red mushroom shaped switch furnishes

power to PLATFORM Controls when pulled out (on).

When pushed in (off), power is shut off to the platform

functions.

Within about 2 seconds of pulling the switch out, the

machine will perform a diagnostic check of the various

electrical circuits, and if everything is OK, the platform

alarm will beep once. During this time the lights on the

indicator panel will also blink once as a bulb check.

3-6 – JLG Lift – 3121264

Page 39

SECTION 3 - MACHINE CONTROLS AND INDICATORS

2. Start/Auxiliary Power

When pushed forward, the switch energizes the starter

motor to start the engine.

When pushed back, it energizes the electrically operated hydraulic pump. (Switch must be held ON for duration of auxiliary pump use.)

The auxiliary pump functions to provide sufficient oil flow

to operate the basic machine functions should the main

pump or engine fail. The auxiliary pump will operate

platform rotate, jib lift, jib swing, platform level override,

main boom lift, main telescope and swing.

3. Capacity Select

This switch allows the operator to select between an

operating envelope with a 500 lb. (230 kg) capacity

restriction or a 1000 lb. (450 kg) capacity restriction.

4. Drive Orientation Override

When the boom is swung over the rear tires or further in

either direction, the Drive Orientation indicator will illuminate when the drive function is selected. Push and

release the switch, and within 3 seconds move the

Drive/Steer control to activate drive or steer. Before driving, locate the black/white orientation arrows on both

the chassis and the platform controls and match the

control direction arrow to the intended chassis direction.

NOTE: To operate the Drive Joystick, pull up on the locking ring

below the handle.

NOTE: The DRIVE control levers are spring-loaded and will auto-

matically return to neutral (OFF) position when released.

5. Drive/Steer

The DRIVE joystick provides for driving either forward or

backward. The controller is ‘ramped’ to allow variable

drive speed.

Steering is controlled by a thumb operated switch on

top of the joystick.

3121264 – JLG Lift – 3-7

Page 40

SECTION 3 - MACHINE CONTROLS AND INDICATORS

1. Power/Emergency Stop

2. Engine Start / Aux Power

3. Capacity Select

4. Drive Orientation Override

5. Drive/Steer

6. Telescope

7. Lights

8. Jib Lift

9. Soft Touch Override

10. Jib Swing

11. Axle Extend/Retract

12. Soft Touch Indicator

13. Platform Rotate

14. Jib Stow Override

15. Function Speed Control

16. Main Lift / Swing

17. Drive Speed / Torque Select

18. Steer Select

19. Platform Level Override

20. Horn

21. Indicator Panel

22. Boom Control Select

Figure 3-3. Platform Control Console

3-8 – JLG Lift – 3121264

Page 41

SECTION 3 - MACHINE CONTROLS AND INDICATORS

6. Main Telescope

This control allows extension and retraction of the main

boom.

7. Lights (If Equipped)

This switch operates accessory light packages if the

machine is so equipped.

8. Jib Lift

Provides for raising or lowering of the jib by positioning

up/down.

9. Soft Touch Override Switch (If equipped)

This switch enables the functions that were cut out by

the Soft Touch system to operate again at creep speed,

allowing the operator to move the platform away from

the obstacle that caused the shutdown situation.

NOTE: The Jib Swing function is not operable when the Capacity

Select control is in the 1000 lb. (450 kg) position.

10. Jib Swing

This switch allows the operator to swing the jib to the left

or right.

11. Axle Extend/Retract

This switch allows the operator to extend or retract the

axles. The axles can only be extended or retracted while

the machine is being driven forward or reverse.

12. Soft Touch Indicator (If Equipped)

Indicates the Soft Touch bumper is against an object. All

controls are cut out until the override button is pushed,

at which time controls are active in the Creep Mode.

13. Platform Rotate

This switch allows the operator to rotate the basket to

the left or right.

3121264 – JLG Lift – 3-9

Page 42

SECTION 3 - MACHINE CONTROLS AND INDICATORS

14. Jib Stow Override

This switch allows the operator to rotate the jib to the

right past the electronic stop to stow the jib under the

boom for transport.

15. Function Speed Control

This control affects the speed of telescope, main lift and

jib lift. Turning the knob all the way counterclockwise

until it clicks puts drive, main lift and swing into creep

mode.

NOTE: To operate the Main Lift/Swing Joystick, pull up on the

locking ring below the handle.

NOTE: The MAIN LIFT/SWING control lever is spring-loaded and

will automatically return to neutral (OFF) position when

released.

16. Main Lift/Swing Controller

An infinitely proportional dual axis joystick is provided

for main lift and swing. Push forward to lift up, pull backward to lift down. Move right to swing right, move left to

swing left.

NOTE: When boom is positioned above transport position or tele-

scoped out and any of the following switches, DRIVE

SPEED/TORQUE SELECT or FUNCTION SPEED, are positioned to HIGH, high function speeds are automatically

cut out and the machine continues to operate at a lower

speed.

DO NOT OPERATE MACHINE IF DRIVE SPEED /TORQUE SELECT or

FUNCTION SPEED SWITCHES OPERATE WHEN BOOM IS MORE THAN

15° ABOVE HORIZONTAL.

17. Drive Speed/Torque Select

The forward position gives maximum drive speed by

shifting the drive motors to minimum displacement and

giving high engine when drive controller is moved. The

back position gives maximum torque for rough terrain

and climbing grades by shifting the wheel motors to

maximum displacement and giving high engine speed

when drive controller is moved. The center position

allows the machine to be driven as quietly as possible

by leaving the engine at mid speed and the drive motors

in maximum displacement.

3-10 – JLG Lift – 3121264

Page 43

18. Steer Select

SECTION 3 - MACHINE CONTROLS AND INDICATORS

The action of the steering system is operator selectable.

The center switch position gives conventional front

wheel steering with the rear wheels unaffected. This is

for normal driving at maximum speeds. The forward

position is for “crab” steering. When in this mode both

front and rear axles steer in the same direction, which

allows the chassis to move sideways as it goes forward.

This can be used for positioning the machine in aisle

ways or against buildings. The back switch position is

for “coordinated” steering. In this mode the front and

rear axles steer in the opposite directions to produce the

tightest turning circle for maneuvering in confined areas.

To re-synchronize the front and rear axles, position the

rear drive wheels to the forward drive position by selecting either crab or compound steer, then select front

steer (center switch position) to operate the normal

steering function.

ONLY USE THE PLATFORM LEVELING OVERRIDE FUNCTION FOR

SLIGHT LEVELING OF THE PLATFORM. INCORRECT USE COULD CAUSE

THE LOAD/OCCUPANTS TO SHIFT OR FALL. FAILURE TO DO SO COULD

RESULT IN DEATH OR SERIOUS INJURY.

19. Platform Leveling Override

A three position switch allows the operator to adjust the

automatic self leveling system. This switch is used to

adjust platform level in situations such as ascending/

descending a grade.

20. Horn

If pressed, this switch supplies power to the horn.

3121264 – JLG Lift – 3-11

Page 44

SECTION 3 - MACHINE CONTROLS AND INDICATORS

21. Indicator Panel

The LED Indicator Panel contains indicator lights that

signal problem conditions or functions operating during

machine operation.

22. Boom Control Select

Automatic Mode:

When the Boom Control is positioned to

Automatic, lift and telescope movements are

coordinated by the JLG control system and

the automatic platform leveling feature is

active during lift, telescope, swing, and drive movements.

NOTE: • While operating lift up, the boom may also telescope

out.

• While operating lift down, the boom may also telescope

in.

• While operating swing or drive, the boom may lift up or

lift down.

• While operating telescope in, the boom may lift down

when at high boom angles and the creep light is flashing.

Manual Mode:

When the boom control is positioned to

Manual, lift and telescope movements are

controlled separately by the operator and

the automatic platform leveling feature is

active only during lift functions.

NOTE: When positioned to Manual, boom functions will be

stopped when the envelope limits are reached. When this

occurs, operate a different function or select the automatic position.

NOTE: Depending upon the angle of the chassis and the angle of

the boom, swing left or swing right may be disallowed

while in the Manual mode. The BCS light will illuminate

and further attempts to swing in the disallowed direction

will cause the BCS to flash. When this occurs the only

choices are to swing in the opposite direction or switch to

automatic mode.

3-12 – JLG Lift – 3121264

Page 45

SECTION 3 - MACHINE CONTROLS AND INDICATORS

Platform Control Indicator Panel

(See Figure 3-4., Platform Control Indicator Panel)

NOTE: The platform control indicator panel uses different shaped

symbols to alert the operator to different types of operational situations that could arise. The meaning of those

symbols are explained below.

Indicates a potentially hazardous situation, which if

not corrected, could result in serious injury or

death. This indicator will be red.

Indicates an abnormal operating condition, which if

not corrected, may result in machine interruption or

damage. This indicator will be yellow.

Indicates important information regarding the operating condition, i.e. procedures essential for safe

operation. This indicator will be green with the

exception of the capacity indicator which will be

green or yellow depending upon platform position.

1. Level System Fault Indicator

Indicates a fault in the electronic leveling system. The

fault indicator will flash and an alarm sound. All functions will default to creep if the boom is extended past

transport mode (12 inches [30.5 cm]) or elevated more

than 15° above horizontal.

IF THE LEVEL SYSTEM FAULT INDICATOR IS ILLUMINATED, SHUT

DOWN THE MACHINE, RECYCLE THE EMERGENCY STOP, AND RESTART

THE MACHINE. IF THE FAULT PERSISTS, RETURN THE PLATFORM TO

THE STOWED POSITION, USING MANUAL LEVELING AS REQUIRED,

AND HAVE LEVELING SYSTEM REPAIRED.

2. AC Generator

Indicates the generator is in operation.

3. Platform Overload Indicator (If Equipped)

Indicates the platform has been overloaded.

4. Platform Capacity Indicator

Indicates the maximum platform capacity selected for

the platform.

One of the capacity lights should be on at all times. Both

lights will flash and an alarm will sound if the platform is

out of the operating envelope for the selected capacity.

3121264 – JLG Lift – 3-13

Page 46

SECTION 3 - MACHINE CONTROLS AND INDICATORS

1. Level System

2. AC Generator

3. Platform Overload

4. Platform Capacity

5. Tilt Alarm Warning

6. Glow Plug

7. Enable

8. Fuel Level

9. Creep Speed

10. System Distress

11. Cable Service

12. Drive Orientation

13. Axles Set

14. Boom Control System Warning

Figure 3-4. Platform Control Indicator Panel

3-14 – JLG Lift – 3121264

Page 47

SECTION 3 - MACHINE CONTROLS AND INDICATORS

5. Tilt Alarm Warning Light and Alarm

Indicates that the chassis is on a slope. An alarm will

also sound when the chassis is on a slope and the

boom is above transport position. If lit when the boom is

raised or extended, retract and lower to below horizontal

then re-position machine so that it is level (within the

rated 3 degrees) before continuous operation. If the

boom is above transport position or telescoped, out and

the machine is on a slope, the tilt alarm warning light will

illuminate and an alarm will sound and CREEP is automatically activated.

IF ILLUMINATED WHEN BOOM IS RAISED OR EXTENDED, RETRACT AND

LOWER TO BELOW HORIZONTAL THEN REPOSITION MACHINE SO THAT

IT IS LEVEL BEFORE EXTENDING BOOM OR RAISING BOOM MORE

THAN 15 DEGREES ABOVE HORIZONTAL.

6. Glow Plug Indicator

Indicates the glow plugs are operating. After turning on

ignition, wait until light goes out before cranking engine.

7. Footswitch/Enable Indicator

To operate any function, the footswitch must be

depressed and the function selected within seven seconds. The enable indicator shows that the controls are

enabled. If a function is not selected within seven seconds, or if a seven second lapse between ending one

function and beginning the next function, the enable

light will go out and the footswitch must be released and

depressed again to enable the controls.

Releasing the footswitch removes power from all controls and applies the drive brakes.

TO AVOID SERIOUS INJURY, DO NOT REMOVE, MODIFY OR DISABLE

THE FOOTSWITCH BY BLOCKING OR ANY OTHER MEANS.

FOOTSWITCH MUST BE ADJUSTED IF FUNCTIONS ACTIVATE WHEN

SWITCH ONLY OPERATES WITHIN LAST 1/4" OF TRAVEL, TOP OR BOTTOM.

3121264 – JLG Lift – 3-15

Page 48

SECTION 3 - MACHINE CONTROLS AND INDICATORS

8. Fuel Level Indicator

Indicates the level of fuel in the fuel tank.

9. Creep Speed Indicator

When the Function Speed Control is turned to the creep

position, the indicator acts as a reminder that all functions are set to the slowest speed. The light flashes if the

control system puts the machine into creep speed and

will be on continuously if the operator selects creep

speed.

10. System Distress Indicator

The light indicates that the JLG Control System has

detected an abnormal condition and a Diagnostic Trouble Code has been set in the system memory. Refer to

the Service Manual for instructions concerning the trouble codes and trouble code retrieval.

The system distress indicator light will illuminate for 2-3

seconds when the key is positioned to the on position to

act as a self test.

11. Cable Service Indicator

When illuminated, the light indicates the boom cables

are loose or broken and must be repaired or adjusted

immediately.

12. Drive Orientation Indicator

When the boom is swung beyond the rear drive tires or

further in either direction, the Drive Orientation indicator

will illuminate when the drive function is selected. This is

a signal for the operator to verify that the drive control is

being operated in the proper direction (i.e. controls

reversed situations).

13. Axles Set Indicator

Indicates that the axles are fully extended. The indicator

will flash as the axles are extending or retracting and be

on solid when fully extended. The light will go out when

the axles are fully retracted.

3-16 – JLG Lift – 3121264

Page 49

14. Boom Control System Warning Indicator

Indicates the platform is outside the operating area and

operation of certain boom functions may be disabled

(i.e. lift, telescope). Attempts to use the disabled functions cause the indicator to flash and an alarm to sound.

Immediately return the platform to the ground. If the indicator remains lit, a boom control system fault or failure

has been detected. If a failure is discovered, the system

must be repaired by JLG authorized service personnel

before the machine can be used.

SECTION 3 - MACHINE CONTROLS AND INDICATORS

3121264 – JLG Lift – 3-17

Page 50

SECTION 3 - MACHINE CONTROLS AND INDICATORS

NOTES:

3-18 – JLG Lift – 3121264

Page 51

SECTION 4 - MACHINE OPERATION

SECTION 4. MACHINE OPERATION

4.1 DESCRIPTION

This machine is a self-propelled hydraulic lift equipped with a

work platform on the end of an elevating and rotating boom.

The primary operator control station is in the platform. From

this control station, the operator can drive and steer the

machine in both forward and reverse directions. The operator can raise or lower the upper or lower boom or swing the

boom to the left or right. Standard boom swing is 360 degree

continuous left and right of the stowed position. The machine

has a Ground Control Station which will override the Platform

Control Station. Ground Controls operate Boom Lift and

Swing, and are to be used in an emergency to lower the platform to the ground should the operator in the platform be

unable to do so.

4.2 BOOM OPERATING CHARACTERISTICS AND LIMITATIONS

Capacities

The boom can be raised more than 15° above horizontal with

or without any load in platform, if:

1. Machine is positioned on a smooth, firm and level (up to

the rated 3 degrees) surface.

2. Axles are extended.

3. Load is within manufacturer’s rated capacity.

4. All machine systems are functioning properly.

5. Proper tire pressure.

6. Machine is as originally equipped from JLG.

3121264 – JLG Lift – 4-1

Page 52

SECTION 4 - MACHINE OPERATION

Controlled Arc

When the Boom Control Select switch is in the automatic

mode, the boom control system automatically controls lift

and telescope when the lift function is selected to move the

platform through a predetermined arc, equivalent to the percentage of extension. (i.e. If you start at 70% boom extension, you will end up at approximately 70% boom extension

no matter where you stop in the arc). This means that when

lifting down, telescope in will function automatically, or when

lifting up, telescope out will function automatically.

When the Boom Control Switch is in the manual mode, lift

and telescope functions are independent functions controlled by the operator.

4-2 – JLG Lift – 3121264

Page 53

SECTION 4 - MACHINE OPERATION

BUFFER LINE

ENVELOPE

SLOWDOWN LINE

BUFFER

ZONE

SLOWDOWN

ZONE

Envelope Tracking

When the platform approaches the edges of the operating

envelope all machine functions are slowed down automatically by the boom control system to reduce machine

motions.

NOTE: Boom Control System in Automatic Mode: When the

boom is completely elevated along the edge of the backward stability region and the telescope in function is activated, lift down will automatically function until the boom

is away from the edge of the backward stability region.

Boom Control System in Manual Mode: The boom will

stop when the end of the envelope is reached and the

operator must activate lift and/or telescope, in the proper

direction, to bring the boom back into the envelope.

Controlled Angle

The control system automatically maintains a constant elevated boom angle when swinging the turntable. If the boom

angle is at 30 degrees, swing engaged by itself shall add lift

to maintain the relative boom angle at 30 degrees.

Swing Speed Proportioning

The boom control system sensors sense the distance the

platform is extended from the turntable, allowing higher

swing speeds with the boom retracted and gradually slower

swing speeds as the boom is extended.

3121264 – JLG Lift – 4-3

Page 54

SECTION 4 - MACHINE OPERATION

Figure 4-1. Dual Capacity Decal

Stability

Machine stability is based on two (2) conditions which are

called FORWARD and BACKWARD stability. The machine’s

position of least FORWARD stability is shown in (See Figure

4-2.), and its position of least BACKWARD stability is shown

in (See Figure 4-3.)

TO AVOID FORWARD OR BACKWARD TIPPING, DO NOT OVERLOAD

MACHINE OR OPERATE THE MACHINE ON A SURFACE OUT-OF-LEVEL

MORE THAN THE RATED 3 DEGEES.

4.3 CAPACITY SELECT

The Boom Control System allows the operator to select operation in a 500 pound (230 kg) capacity restriction envelope or a

1000 pound (450 kg) capacity restriction envelope. The operator selects the desired capacity restriction by positioning the

Capacity Select switch on the platform console. The Capacity

Indicator shows the capacity selected, and both capacity lights

will flash and an alarm sound if the platform is out of the

selected capacity range.

NOTE: Operation in the 1000 pound (450 kg) envelope requires

the jib to be fixed in the centered position.

4-4 – JLG Lift – 3121264

Page 55

SECTION 4 - MACHINE OPERATION

Figure 4-2. Position of Least Forward Stability

3121264 – JLG Lift – 4-5

Page 56

SECTION 4 - MACHINE OPERATION

Figure 4-3. Position of Least Backward Stability

.

4.4 ENGINE OPERATION

NOTE: Initial starting should always be performed from the

Ground Control station.

Starting Procedure

IF ENGINE FAILS TO START PROMPTLY, DO NOT CRANK FOR AN

EXTENDED TIME. SHOULD ENGINE FAIL TO START AGAIN, ALLOW

STARTER TO “COOL OFF” FOR 2-3 MINUTES. IF ENGINE FAILS AFTER

SEVERAL ATTEMPTS, REFER TO ENGINE MAINTENANCE MANUAL.

NOTE: Diesel engines only: After turning on ignition, operator

must wait until glow plug indicator light goes out before

cranking engine.

1. Turn key of SELECT switch to GROUND. Position

POWER/EMERGENCY STOP switch to ON, then push

the ENGINE START switch until engine starts.

ALLOW ENGINE TO WARM-UP FOR A FEW MINUTES AT LOW SPEED

BEFORE APPLYING ANY LOAD.

2. After engine has had sufficient time to warm up, shut

engine off.

4-6 – JLG Lift – 3121264

Page 57

SECTION 4 - MACHINE OPERATION

3. Turn SELECT switch to PLATFORM.

4. From Platform, pull POWER/EMERGENCY STOP switch

out, then push the ENGINE START switch until engine

starts.

NOTE: Footswitch must be in released (up) position before

starter will operate. If starter operates with footswitch in

the depressed position, DO NOT OPERATE MACHINE.

Shutdown Procedure

IF AN ENGINE MALFUNCTION CAUSES AN UNSCHEDULED SHUTDOWN, DETERMINE THE CAUSE AND CORRECT IT BEFORE RESTARTING THE ENGINE.

1. Remove all load and allow engine to operate at low

speed for 3-5 minutes; this allows further reduction of

internal engine temperature.

2. Push POWER/EMERGENCY STOP switch in.

3. Turn MASTER switch to Off.

Refer to Engine Manufacturer’s manual for detailed information.

4.5 TRAVELING (DRIVING)

NOTE: When the boom is raised approximately 15 degrees

above horizontal, all drive functions will be disabled.

DO NOT DRIVE WITH BOOM ABOVE HORIZONTAL EXCEPT ON A

SMOOTH, FIRM AND LEVEL (UP TO THE RATED 3 DEGREES) SURFACE.

TO AVOID LOSS OF TRAVEL CONTROL OR “TIP OVER”, DO NOT DRIVE

MACHINE ON GRADES EXCEEDING THOSE SPECIFIED IN THE OPERATING SPECIFICATIONS SECTION OF THIS MANUAL.

DO NOT DRIVE ON SIDESLOPES WHICH EXCEED 5 DEGREES.

USE EXTREME CAUTION WHEN DRIVING IN REVERSE AND AT ALL

TIMES WHEN THE PLATFORM IS ELEVATED.

3121264 – JLG Lift – 4-7

Page 58

SECTION 4 - MACHINE OPERATION

BEFORE DRIVING, LOCATE THE BLACK/WHITE ORIENTATION ARROWS

ON BOTH THE CHASSIS AND THE PLATFORM CONTROLS. MOVE THE

DRIVE CONTROLS IN A DIRECTION MATCHING THE DIRECTIONAL

ARROWS.

Traveling Forward and Reverse

1. At Platform Controls, pull out Emergency Stop switch,

start engine, and activate footswitch.

2. Position Drive controller to FORWARD or REVERSE as

desired.

This machine is equipped with a Drive Orientation Indicator.

The yellow light on the platform control console indicates

that the boom is swung beyond the rear drive tires and the

machine may Drive/Steer in the opposite direction from the

movement of the controls. If the indicator is illuminated,

operate the Drive function in the following manner:

1. Match the black and white direction arrows on both platform control panel and the chassis to determine the

direction the machine will travel.

2. Push and release the Drive Orientation Override switch.

Within 3 seconds, slowly move the Drive control toward

the arrow matching the intended direction of machine

travel. The indicator light will flash during the 3 second

interval until the drive function is selected.

4.6 STEERING

Position thumb switch on Drive/Steer controller to RIGHT for

steering right, or to LEFT for steering left.

4.7 EXTENDING THE AXLES

NOTE: The operator must be driving the machine (forward or

reverse) in order to extend the axles.

Position the Axle Extend switch to extend the axles or to

retract to retract the axles.

4-8 – JLG Lift – 3121264

Page 59

SECTION 4 - MACHINE OPERATION

G

R

A

D

E

LEVEL

S

I

D

E

S

L

O

P

E

Figure 4-4. Grade and Side Slopes

3121264 – JLG Lift – 4-9

Page 60

SECTION 4 - MACHINE OPERATION

4.8 PLATFORM

Platform Level Adjustment

ONLY USE THE PLATFORM LEVELING OVERRIDE FUNCTION FOR

SLIGHT LEVELING OF THE PLATFORM. INCORRECT USE COULD CAUSE

THE LOAD/OCCUPANTS TO SHIFT OR FALL. FAILURE TO DO SO COULD

RESULT IN DEATH OR SERIOUS INJURY.

NOTE: When the Boom Control Select Switch is in the Manual

mode, Platform leveling only functions during Main Lift

operation. When the Boom Control Select Switch is in the

Automatic mode, Platform Leveling is active during all

functions except during telescope operation. Also, when

in the Manual mode, the Controlled Angle system is not

active.