Page 1

Programat

®

P300/G2

Operating Instructions

Valid as of

software Version 5.0

s

Page 2

2

Page 3

Table of Contents

Views of the Furnace, List of Parts 4

1. Introduction / Signs and Symbols 8

1.1 Preface

1.2 Introduction

1.3 Notes regarding the Operating Instructions

1.4 Notes on the different voltage versions

2. Safety First 9

.1 Indications

2

2.2 Health and safety instructions

3. Product Description 12

3.1 Components

3.2 Hazardous areas and safety equipment

3.3 Functional description

3.4 Accessories

4. Installation and Initial Start-Up 13

4.1 Unpacking and checking the contents

4.2 Selecting the location

4.3 Assembly

4.4 Dismounting the furnace head

4.5 Initial start-up

4.6 Dehumidification

5. Operation and Configuration 18

5.1 Introduction to the operation

5.2 Explanation of the key functions

5.3 Program structure

5.4 Adjustable parameters and possible value ranges

5.5 Settings / test programs and information

5.6 Explanation of the symbols on the display

5.7 Explanation of the beeper signals

6. Practical Use 23

6.1 Switching on/off

6.2 Firing using an Ivoclar Vivadent program

6.3 Firing using an individual program

6.4 Other options and special features of the furnace

7. Maintenance, Cleaning and Diagnosis 25

7.1 Monitoring and maintenance

7.2 Cleaning

7.3 Special programs

7.4 Temperature calibration

7.5 Service note

7.6 Stand-by

8. What if ... 27

8.1 Error messages

8.2 Technical malfunctions

8.3 Repair

9. Product Specifications 30

9.1 Delivery form

9.2 Technical data

9.3 Acceptable operating conditions

9.4 Acceptable transportation and storage conditions

10. Appendix 31

10.1 Program table

10.2 Menue structure

10.3 Firing curves

3

Page 4

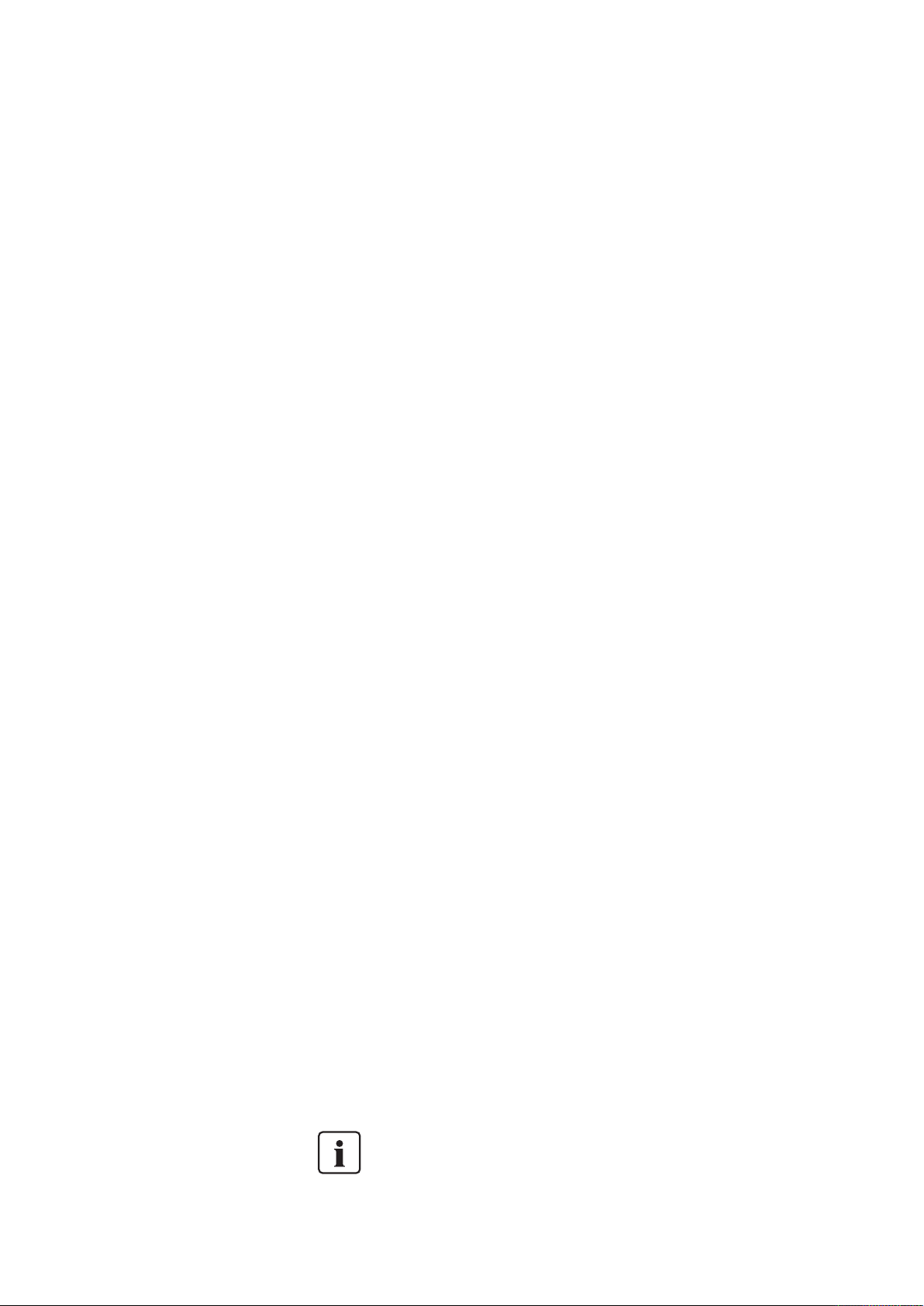

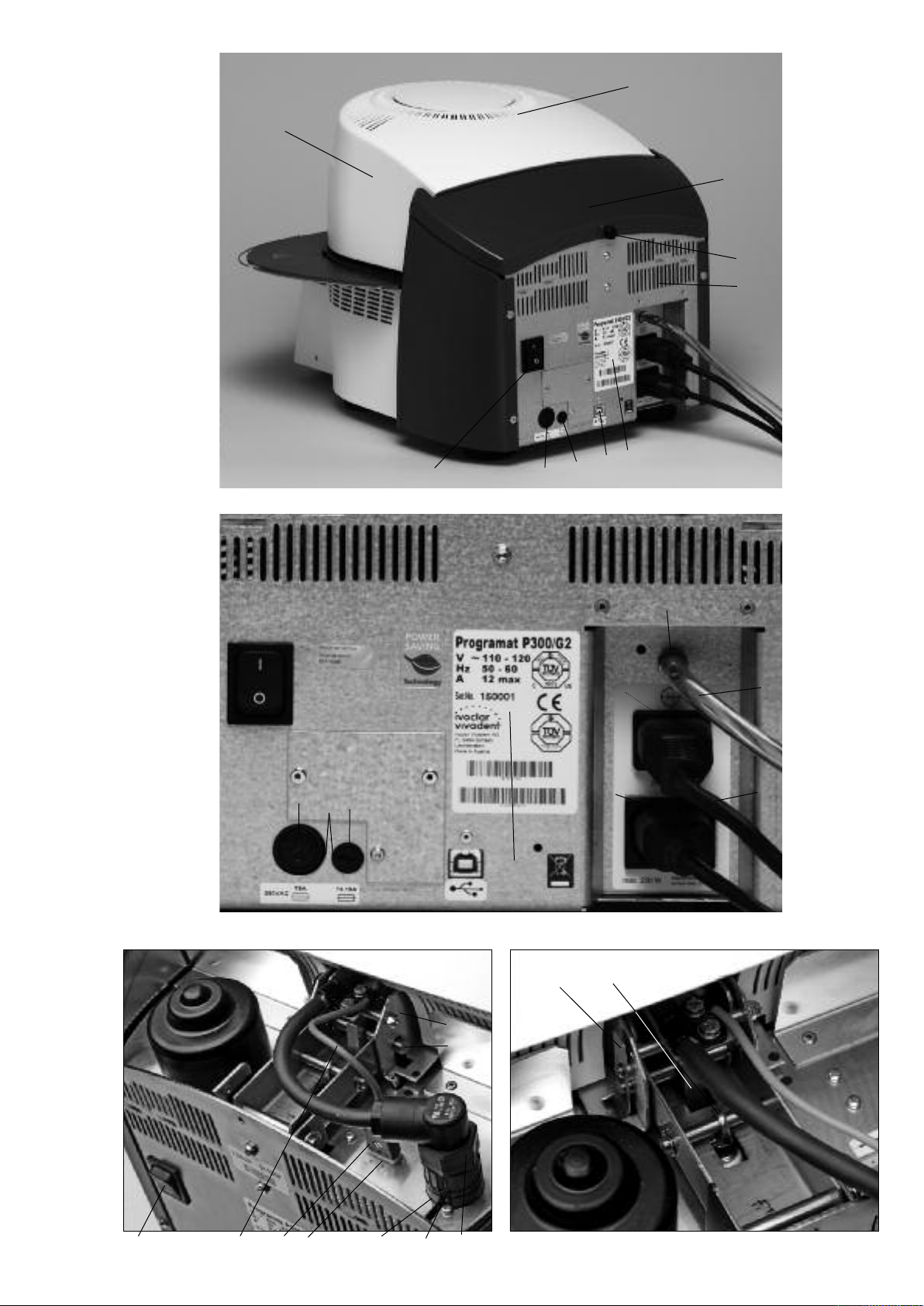

List of parts

Front view:

1 Sealing surface

2 Furnace head sealing ring

3 Insulation

4 Thermocouple

5 Firing plate

6 Display

7 Frame plate

8 QTK heating muffle

9 Furnace housing

10 Keypad

11 On/Off switch

12 Heating element fuse

13 Vacuum pump fuse

15 Fuse holder

16 Power cord

17 Power socket

18 Vacuum pump socket

19 Rating plate

21 Vacuum hose connection

23 Rubber feet

25 Furnace head housing

26 Thermocouple plug

27 Plug fuse

28 Heater plug

29 Heater plug socket

30 Thermocouple plug socket

32 Leaf spring

33 Air vents (base)

34 Cooling tray

35 Screw for cooling tray

36 Hood

37 Knurled screw for hood

38 Air vents furnace head

39 Air vents rear panel

40 Warnings

41 Furnace head mounting mark

42 Furnace base mounting mark

43 Furnace head mounting

44 Quartz-glass tube

46 Vacuum hose

47 Silicone washer

48 Firing plate holder

49 Thermocouple cable

50 Connecting rod

51 Plug-in console

53 USB interface

Please note that the list of parts applies to the entire

Operating Instructions. These parts and their numbers are

often referred to in later chapters.

4

Page 5

40

10

25

6

47

35

33

4

3

2

5

7

1

23

34

8

9

5

Page 6

25

11

12

13

53

38

36

37

39

19

12

15

13

51

50

19

32

18

43

17

21

46

16

49 26 30 29

27 2811

6

Page 7

3

8

1

5

0

5

4

1

4

42

44

Control unit:

70 Program key

71 ESC key

72 ENTER key

73 START key

74 Start LED

75 STOP key

76 + key

77 – key

78 Information / Settings

79 Cursor key right

80 Cursor key left

81 Stand-by temperature

82 Closing time

83 Temperature increase

84 Holding temperature

85 Holding time

86 Vacuum on

87 Vacuum off

88 Long-term cooling

89 Power saving key

90 Open furnace head

91 Close furnace head

92 Numeric keys

93 Home key

78

93

89

82

87

86

83

81

84

80

79

85

70

71

77

76

72

90

91

88

75

73

74

92

100 Programat firing tray

101 Metal pin A

102 Metal pin B

103 Metal pin C

100

102

103

101

7

Page 8

1. Introduction / Signs and Symbols

1.1 Preface

Dear Customer

Thank you for having purchased

the Programat P300/G2. It is a

state-of-the-art furnace for

dental applications.

The furnace has been designed

according to the latest industry

standards. Inappropriate use

may damage the equipment and

be harmful to personnel. Please

observe the relevant safety

instructions and read these

Operating Instructions carefully.

Enjoy working with the

P300/G2.

1.2 Introduction

The signs and symbols in these

Operating Instructions facilitate

the finding of important points

and have the following

meanings:

Risks and dangers

Important

information

Contraindication

Burn hazard

Risk of crushing

The Operating

Instructions must

be read.

1.3 Notes regarding the

Operating Instructions

Furnace concerned:

Programat P300/G2

Target group:

Dental technologists

These Operating Instructions

facilitate the correct, safe and

economical use of the

Programat P300/G2 furnace.

Should you lose the Operating

Instructions, extra copies can be

ordered at a nominal fee from

your local Ivoclar Vivadent

Service Centre or downladed

from www.ivoclarvivadent.com.

1.4 Notes on the different

voltage versions

The furnace is available with

different voltage versions.

– 110–120 V / 50–60 Hz

– 200–240 V / 50–60 Hz

In the Operating Instructions,

the furnace is described in the

200-240 V voltage version.

Please note that the voltage

range shown on the images

(e.g. rating plate) may differ

depending on the voltage

version of your furnace.

8

Page 9

2. Safety First

This chapter is especially important for personnel who work with the

Programat P300/G2 or who have to carry out maintenance or repair

work. This chapter must be read and the corresponding instructions

followed.

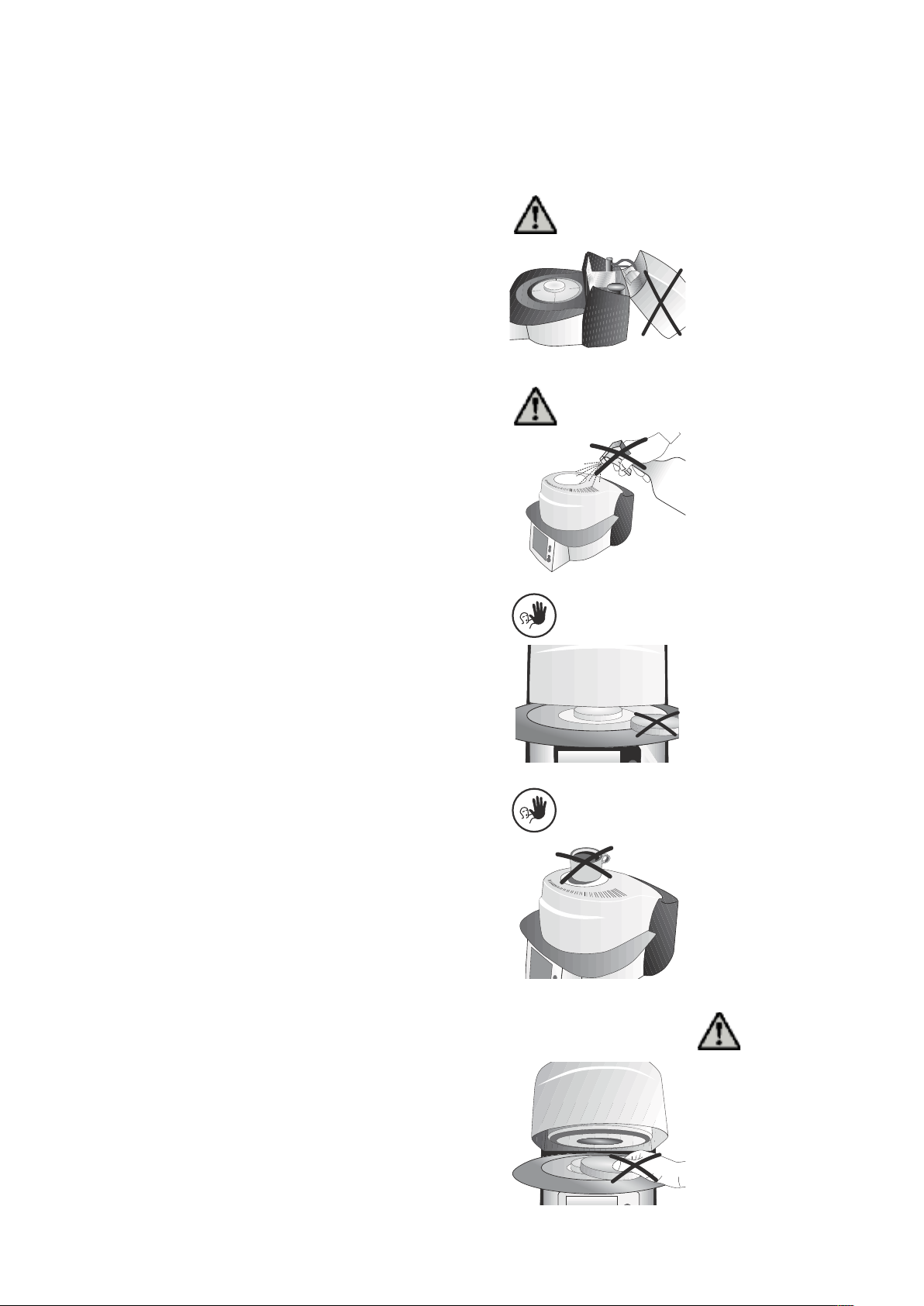

2.1 Indications

The Programat P300/G2 must only be used to fire dental ceramic

materials and it should be used for this purpose only. Other uses

than the ones stipulated, e.g. cooking of food, firing of other

materials, etc. are contraindicated. The manufacturer does not

assume any liability for damage resulting from misuse. The user is

solely responsible for any risk resulting from failure to observe these

Instructions.

Further instructions to assure proper use of the furnace:

– The instructions, regulations and notes in these Operating Instruc-

tions must be observed.

– The instructions, regulations and notes in the material’s Instruc-

tions for Use must be observed.

– The furnace must be operated under the indicated environmental

and operating conditions (Chapter 9).

– The Programat P300/G2 must be properly maintained.

2.1.1

Risks and dangers

The furnace head should not be

removed from the furnace base as

long as the furnace head is

connected by means of the

heater cable.

2.1.2

Risks and dangers

Make sure that no liquids or other

foreign objects enter the furnace.

2.1.3

Contraindication

Firing trays must not be placed in

the area surrounding the firing

table, since this will obstruct the

closing of the furnace head.

2.1.4

Contraindication

2.1.5

Risks and dangers

Foreign objects must not be

placed on the furnace head or the

air vents. Make sure that no

liquids or other foreign objects

enter the air vents, since this may

result in an electrical shock.

Never place objects in

the firing chamber by hand, since

there is a burn hazard. Always use

the tongs (accessories) supplied

for this purpose. Never touch the

hot surface of the furnace head,

as there is a burn hazard. Please

also refer to the warnings on the

furnace.

9

Page 10

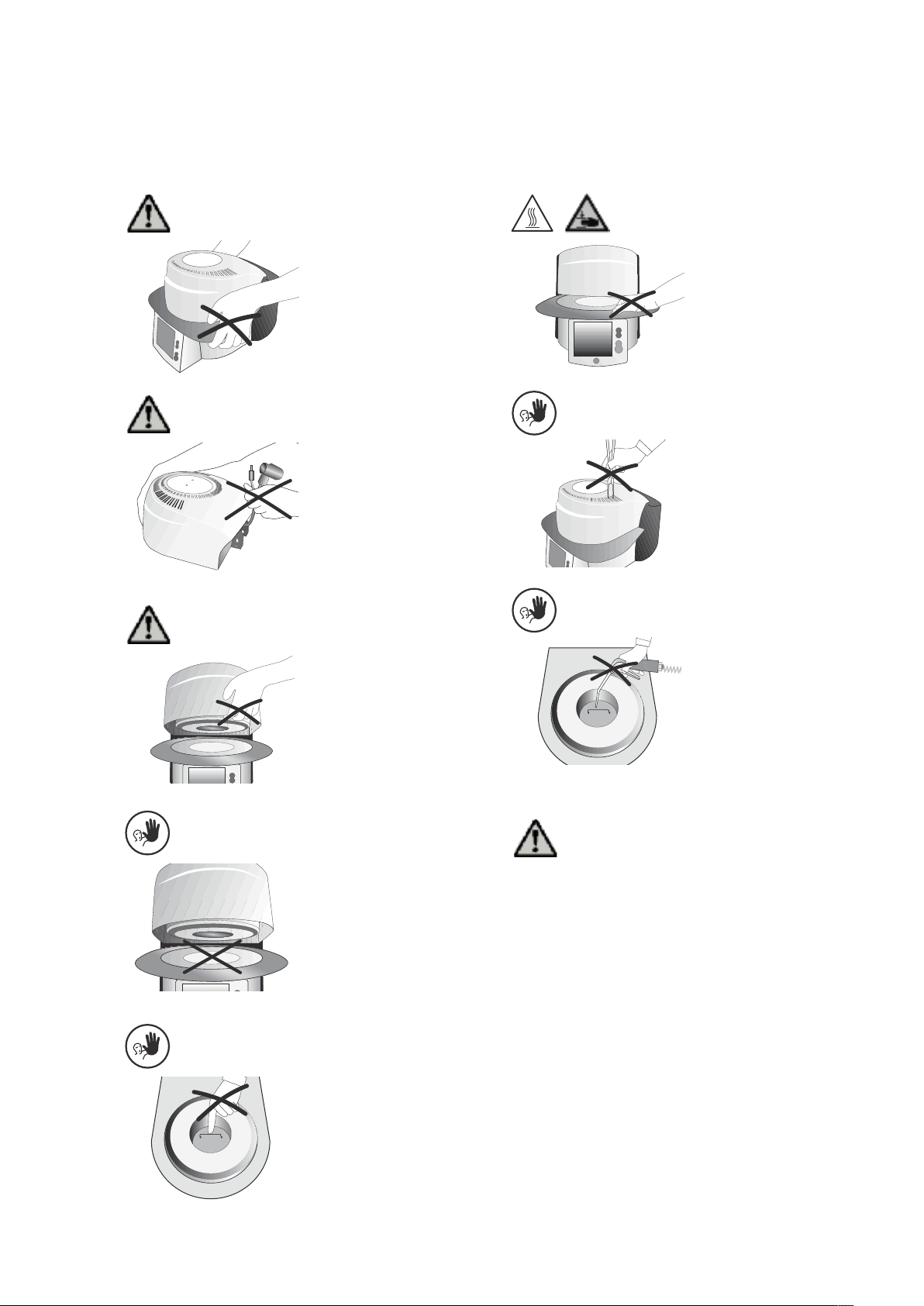

2.1.6

2.1.11

2.1.7

2.1.8

Risks and dangers

Risks and dangers

Risks and dangers

Do not carry the furnace by the

cooling tray.

Do not carry the furnace head by

the cables, since the cables and

connections may be damaged.

The furnace has an electric drive

and must be operated by means

of the electronic controls. Never

open the furnace head by hand,

since the mechanism will be

damaged.

Risk of crushing and burn hazard

Never reach under the furnace

head with the hand or other parts

of the body during operation,

since there is a risk of crushing

and a burn hazard.

2.1.12

Contraindication

Do not insert any foreign objects

into the air vents. There is a risk of

electrical shock.

2.1.13

Contraindication

This product contains ceramic

fibres and may release fibre dust.

Do not use compressed air on the

furnace, thus distributing the dust

in the environment, and observe

the additional notes on page 11.

2.1.9

2.1.10

Contraindication

Contraindication

Never use the furnace without a

firing table.

Do not touch the thermocouple

and the quartz tube in the firing

chamber. Avoid contact with the

skin (grease contamination), as

the parts will be prematurely

damaged.

2.1.14

Risks and dangers

The furnace must not be operated if the quartz tube in the

firing chamber is damaged. There is a risk of electric shock

upon contact with the heating wire.

Avoid damage of the insulation by contact with the

investment tongs or firing tongs.

10

Page 11

2.2 Health and safety instructions

This furnace has been designed according to EN 61010-1 and has

been shipped from the manufacturer in excellent condition as far as

safety regulations are concerned. To maintain this condition and to

assure risk-free operation, the user must observe the notes and

warnings contained in these Operating Instructions.

– Place furnace on a fire-proof table (observe local regulations, e.g.

distance to combustible substances or objects, etc.).

– Always keep the air vents at the rear and the side of the furnace

free from obstruction.

– Do not touch any parts that become hot during the operation of

the furnace. There is a burn hazard!

– Clean furnace only with a dry or slightly moist cloth. Do not use

any solvents! Disconnect power before cleaning.

– Use original packaging for transportation purposes.

– The furnace must be cool before it is packed for transportation

purposes.

– The user must especially become familiar with the warnings and

the operating conditions to prevent injury to personnel or damage

to materials. The manufacturer is not responsible for damage

resulting from misuse or failure to observe the Operating

Instructions. Warranty claims cannot be accepted in such cases.

– Before switching on the furnace, make sure that the voltage

indicated on the rating plate complies with your local power

supply.

– The power socket must be equipped with a residual current circuit

breaker.

– The furnace must be plugged into a socket with protected

contacts.

– Before calibration, maintenance, repair or exchange of parts, the

power must be disconnected if the furnace is to be opened.

– If calibration, maintenance, or repair has to be carried out with

the power connected and the furnace open, only qualified

personnel who are familiar with the risks and dangers may

perform these procedures.

– After maintenance, the required safety tests (high voltage

resistance, protective conductor, etc.) have to be carried out.

– Ensure that only fuses of the indicated type and rated current are

used.

– If it is assumed that safe operation is no longer possible, the

power must be disconnected to avoid accidental operation.

Safe operation is no longer possible if

– the furnace is visibly damaged;

– the furnace does not work;

– the furnace has been stored under;

unfavourable conditions over an extended period of time.

– Use only original spare parts.

– The temperature range for faultless operation is +5 °C to +40 °C

(+41 °F to +104 °F).

– If the furnace has been stored at very low temperatures or high

atmospheric humidity the head has to be opened and the unit

dried or left to adjust to room temperature for approx. 1 hour (do

not connect the power yet).

– The furnace has been tested for use at altitudes of up to 2000 m

above sea level.

– The furnace may only be used indoors.

Any disruption of the protective conductor either inside or

outside the furnace or any loosening of the protective

conductor connection may lead to danger for the user in

case of malfunction. Deliberate interruptions are not

tolerated. Materials developing harmful gases must not

be fired.

Warnings regarding the dismounting of the heating muffle

This product contains ceramic fibres and may release fibre

dust. Fibre dust has proved to be carcinogenic in animal

experiments. The corresponding EU Safety Data Sheet

must be observed.

The heat insulation of the firing chamber in the Programat P300/G2

consists of ceramic fibres. After prolonged use of ceramic fibres at

temperatures of over 900 °C (1652 °F), silicogenic substances

(Cristobalite) may be produced. In certain cases, e.g. upon changing

of the heating muffle, the possible resulting dust exposure may

cause irritation of the skin, eyes, and respiratory organs. Therefore,

proceed as follows when changing the heating muffle:

– Make sure the corresponding staff wears long-sleeved clothing as

well as headgear, goggles and gloves.

– Place suction equipment at the source of the dust or, if not

possible, provide the staff with FFP3 facemasks or similar items.

– Once the procedure has been completed, any dust possibly

adhering to exposed skin must first be rinsed off with cold water.

Only after that should soap and warm water be used.

– The corresponding work clothes should be washed separately.

Warning

The insulation on this product contains refractory ceramic fibres (RCF)

which pose a possible cancer hazard, if agitated and inhaled. May be

irritating to the skin, eyes or respiratory tract if insulation is cracked

or corrupted.

California Proposition 65

Warning: ”This product contains Refractory Ceramic Fibres, a

substance known to the State of California to cause cancer.”

Disposal:

The furnaces must not be disposed of in the normal

domestic waste. Please correctly dispose of old

furnaces according to the corresponding EU council

directive. Information on the correct disposal may

also be found on your local Ivoclar Vivadent homepage.

11

Page 12

3. Product Description

3.1 Components

The Programat P300/G2

comprises the following

components:

– Furnace base with electronic

controls

– Furnace head with firing

chamber

– Firing table

– Cooling tray

– Power cord and hose for

vacuum pump

– Vacuum pump (accessory)

3.2 Hazardous areas and safety equipment

Description of the risk areas of the furnace:

Hazardous area

Description of the safety equipment of the furnace:

Safety equipment Protective effect

Type of risk

Risk of burningFiring chamber

Risk of crushingOpening/closing mechanism

Risk of electrical shockElectrical components

Protection from electrical shockProtective conductor

Protection from electrical shockElectrical fuses

3.3 Functional description

The firing chamber may be heated up to max.

1200 °C (2192 °F) by means of a heating element.

Furthermore, the firing chamber has been

designed in such a way that a vacuum may be

created with a vacuum pump. The firing process is

controlled with the corresponding electronic controls and a software. Moreover, the set and actual

temperatures are continuously compared.

3.4 Accessories

(not part of the delivery form)

– Silver Wire Test Set

– Programat Accessories Set (large and small firing

trays, firing tongs, Temperature Checking Set)

– Vacuum pump

12

Page 13

4. Installation and Initial Start-Up

4.1 Unpacking and checking the contents

The packaging provides the following advantages:

– Reusable packaging

– Closing mechanism with integrated transportation grips

– Ideal protection by Styrofoam inserts

– Easy handling / optimum unpacking

– The packaging may be used in several ways (modules)

Remove the furnace components from their packaging and place

them on a suitable table. Please observe the instructions on the

outer packaging.

There are no special transportation grips on the furnace. Support the

bottom of the furnace to carry it.

4.2 Selecting the location

Place the furnace on a flat table using the rubber feet. Make sure

that the furnace is not placed in the immediate vicinity of heaters or

other sources of heat. Make sure that air may properly circulate

between the wall and the furnace.

Also ensure that there is enough space between the furnace and the

user, as the furnace releases heat during the opening of the furnace

head.

The furnace should neither be placed nor operated in areas

where there is an explosion hazard.

4.3 Assembly

Make sure the voltage indicated on the rating plate (19) complies

with the local power supply. If this is not the case, the furnace must

not be connected.

Check the delivery for completeness (see delivery form in Chapter 9)

and transportation damage. If parts are damaged or missing, contact

your local Ivoclar Vivadent Service Center.

Packing and shipping of individual components:

The packaging of the P300/G2 permits simple and safe shipping of

individual components. Simply use the corresponding inserts. Fold

the side flaps (2) and combine the two packaging parts by means of

the transportation flaps. The packaging may be disposed of with the

regular household refuse.

19

Step 1:

Assembling the cooling tray (34)

Remove both screws (35) including the silicone rest (47) for the

cooling tray (34).

35

35

47

47

We recommend keeping the original packaging for future

service and transportation purposes.

13

Page 14

Place the cooling tray (34) on the frame plate (7).

Make sure that the cooling tray (34) is correctly

positioned on the frame plate (7).

Secure the cooling tray (34) with the two screws

(35) including the silicone washer (47).

4

3

7

Step 2:

Placing the firing plate (5)

Place the firing plate (5) on the firing plate holder

(48).

35

47

5

48

14

Page 15

Step 3:

Mounting the furnace head

The complete furnace head is best mounted with

the rear panel of the furnace pointing towards the

user. Lift the furnace head with both hands (see

picture) and carefully position it on the furnace

head mounting (43).

Ensure that the furnace head mounting mark (41)

is aligned with the furnace base mounting mark

(42).

Make sure that the firing plate (5) is

not damaged by mounting the furnace

head.

51

Step 4:

Connections

Connect the cables of the furnace head with the

furnace base. Proceed as follows:

– Insert the thermocouple plug (26) (make sure

that the polarity of the plug is correct)

– Insert the heater plug (28)

50

41

42

28

15

26

30

27

Page 16

Secure the heater plug (28) with the plug fuse (27)

by turning it until the heater plug (28) has been

secured.

27

28

Step 5:

Mounting the hood (36)

Once all cables are properly connected to the

furnace base, the hood (36) can be mounted.

Subsequently, secure the hood with the knurled

screw (37).

The furnace may only be operated with

the hood mounted.

Step 6:

Establishing additional connections

Power connection

Please make sure that the voltage indicated on the

rating plate complies with the local power supply.

Connect the power cord (16) with the power

socket (17) of the furnace.

Vacuum pump connection

Connect the vacuum pump plug with the vacuum

pump socket (18).

6

3

7

3

21

46

17

We recommend using only the VP3 easy or VP4

vacuum pumps from Ivoclar Vivadent, since these

pumps are especially coordinated with the furnace.

If other pumps are used, please observe and do not

exceed the maximum power consumption.

18

16

16

Page 17

.4 Removing the furnace head

4

Before the hood (36) is removed, the furnace has

to be switched off and the power cord (16)

disconnected from the power socket (17).

1. Loosen and remove the knurled screw (37) of

the hood (36)

2. Remove the hood (36)

3. Disconnect the thermocouple plug (26)

4. Disconnect the heater plug (28)

5. Press the leaf spring (32) with a finger, lift off

the furnace head at the same time and

remove it

Make sure the furnace head

has completely cooled down

before it is removed (fire

hazard).

4.5 Initial start-up

1. Connect the power cord (16) with the wall

socket.

2. Put the On/Off switch (11) at the rear of the

furnace on position “I”.

Stand-by mode

After program selection (Ivoclar Vivadent or

individual programs), the stand-by display is

shown.

The furnace will now automatically conduct a selftest. The performance of all furnace components is

automatically checked. The display shows the

following indications during the self-test:

3

1

2

4

1 Status bar

2 Firing hours

3 SW version

4 Current supply voltage

If any component is defective, the corresponding

error number (Error xxx) will be indicated in the

display. If all components work properly, the

display shows the program selection.

91

90

94

92

93

90 Program number and program group

91 Current temperature

92 Temperature increase (t)

93 Holding temperature (T)

94 Possible key options

4.6 Dehumidification

Before the first firing, the firing chamber should be

dehumidified using the dehumidification program.

17

Page 18

5. Operation and Configuration

5.1 Introduction to the operation

The Programat P300/G2 is equipped with a graphic display with

backlighting. Moreover, the keypad features a parameter firing curve

with the parameter keys, where the parameters can be selected. The

enter keys and the command keys can be used to program and

control the furnace.

84

8

7

93

89

87

86

83

81

2

8

79

80

70

85

71

77

76

2

9

72

5.2 Explanation of key functions

(see page 7 ”Control unit”)

– T = Holding temperature (84)

Indicates the holding temperature (actual firing temperature).

–H= Holding time (85)

Indicates the holding time (actual firing time).

–S= Closing time (82)

Indicates the closing time of the furnace head (pre-drying time).

–B= Stand-by temperature (81)

Indicates the stand-by temperature.

–t➚ = Temperature increase (83)

Indicates the temperature increase per minute for heating up.

– V1 Vacuum on temperature (86)

Indicates the temperature level at which the vacuum is switched

on.

– V2 Vacuum off temperature (87)

Indicates the temperature level at which the vacuum is switched

off.

If this temperature equals the holding temperature T, the vacuum

is maintained during the entire holding time.

Specific case: If the temperature V2 is exactly 1 °C (or 1 °F) higher

than the holding temperature T during activated long-term

cooling, the vacuum is maintained during the entire long-term

cooling (e.g. recommended for the cleaning program).

–L= Long-term cooling temperature (88)

Indicates the temperature level at which the furnace head starts to

open after the end of the holding time and free or controlled (tL)

cooling.

– tL = Controlled cooling temperature gradient (°C or °F / min)

– Information / Settings (78)

After pressing the key (78) (2 cogwheels), a selection (information/

settings) is displayed. You can then toggle between Information

and Settings by means of the cursor keys. The selection is

confirmed by pressing the Enter key

– Cursor keys (79, 80)

The current cursor position is indicated by means of a fix (nonblinking) frame around the value.

– Enter keys (76, 77, 92)

The values can be entered by using the + / – keys or the numeric

keys.

Each value entered by means of the + or – key will be immediately

accepted (as long as the value ranges are observed) without

separately confirming the entered value (pressing the key once will

adjust the value by + or – 1). An active entry by means of the

numeric keys will blink until the value has been confirmed or the

process aborted.

90

Each entry via the numeric keys can be confirmed with the Enter

key. However, the Program key, the START key or the parameter

91

keys can be used to confirm an entry by means of the numeric

keys. Therefore, a program can be edited considerably faster (less

88

keystrokes required).

If an invalid entry is made (outside the current value range), the

invalid entry continues to blink after confirmation.

5

7

As an error message (Entry error: entry outside the value range) an

exclamation mark will blink in the bottom line until a new value is

entered and the entry is either confirmed or the process aborted

3

7

with the ESC key. If the process is aborted with ESC, the old valid

value will reappear. Please refer to the respective parameter details

4

7

for the value range.

– START key (73)

The program is started by pressing this key.

– STOP key (75)

Pressing this key once (program paused)

Pressing this key twice (program will be interrupted and vacuum

flooded).

– Power-saving key (89)

Power-saving function activated (only possible with the furnace

head closed and the furnace on idle). The display shows the

power-saving icon. Pressing any key ends the power-saving

function.

– Open furnace head key (90)

The furnace head is opened (not possible during a program in

progress).

– Close furnace head key (91)

The furnace head is closed (not possible during a program in

progress).

– P = Program and parameter key (70) with triple function

It is possible to switch from the stand-by mode (or firing curve

display) to the parameter list and remaining time display.

– Home key (93)

Return to ”Program selection Indication".

18

Page 19

5.3 Program structure

The furnace offers two types of programs:

a. Ivoclar Vivadent programs for Ivoclar

Vivadent materials

b. Individual programs

All programs are equivalent and therefore fullfledged programs. In each program, all the

parameters can be adjusted.

a) Ivoclar Vivadent programs for Ivoclar

Vivadent materials (see chapter 10.1)

Refer to enclosed Program table

b) Individual programs

Free, individually adjustable programs

When the furnace is delivered ex

works, the Ivoclar Vivadent programs

already contain the recommended

material parameter settings.

However, the parameters can be changed and

overwritten at any time, if required, if the

programs are to be used for other purposes.

Therefore, the 50 programs are also available as

individual programs.

The programs are designed in such a way that

they can be either used as conventional, one-stage

programs or as two-stage programs, if required.

The mode can be changed via the symbol (one- or

two-stage program) by using the + or – key.

5.4 Adjustable parameters and possible value ranges

Symbol Parameter Value range Value range

P Program number P 1–300

B

S Closing time (min : sec) 00:18–30:00

➚ Temperature increase rate 30–140 °C/min 54–252 °F/min

t

T Holding temperature 100–1200 °C 212–2192 °F

H Holding time (min : sec) 00:01–60:00

1 Vacuum on 0 or 1–1200 °C 0 or 34–2192 °F

V

V2 Vacuum off 0 or 1–1200 °C 0 or 34–2192 °F

➚ Temperature increase rate

t

t2➚ 2ndstage 30–140 °C/min 54–252 °F/min

T

H

V1 (V1 2) Vacuum on

2 (V2 2) Vacuum off

V

L Long-term cooling 0 or 50–1200 °C 0 or 122–2192 °F

L Cooling temperature rate 0 or 1–50 0 or 32–90

t

Stand-by temperature 100–700 °C 212–1292 °F

Holding temperature

2ndstage 100–1200 °C 212–2192 °F

Holding time

n

d

2

stage (min : sec) 00.01–60:00

tage 0 or 1–1200 °C 0 or 34–2192 °F

2nds

n

d

2

stage 0 or 1–1200 °C 0 or 34–2192 °F

Automatic plausibility check

The furnace is equipped with an automatic plausibility check function. The parameters

(e.g. T 960 but L 1000) are checked upon each program start. In case of contradictory

parameter combinations, the program stops automatically and the respective error

number is indicated.

19

Page 20

5.5 Settings / configuration and information

By pressing the "Information / Settings" key (78), the following

menu is displayed:

ettings

Information

S

Settings

Write protection

Display Short description

After entry of the

user code (6725) the

+ and – keys can be

used to switch on

the write protection.

(For further

information see

chapter 6.4.2)

The cursor position (frame around the symbol) can be changed by

means of the cursor keys. To view the required Settings or

Information, press the Enter key.

5.5.1 Settings / Configuration

Settings

Contrast

Display Short description

The contrast can be

set by means of the

+ or – keys

Temperature mode

The + and – keys can

be used to switch

from °C to °F

User calibration

value

This program is

suitable to conduct

the temperature

calibration by means

of the Temperature

Checking Set Type 2.

The furnace head

opens automatically

if the Enter key is

pressed. Place the

test into the firing

chamber and start

the program by

means of the START

key.

Volume

The desired volume

can be set by means

of the + or – keys

Beeper tune

The tune can be set

by means of the + or

– keys

Time

The time can be

entered by using the

numeric keys

”Ivoclar Vivadent

optimized

temperature control

function“

Power-saving mode

Service interval

Protocolling

Vacuum test

program

Heating muffle test

program

Key test

Cleaning program

Dehumidification

program

Only after entry of

the STD code.

The automatic powersaving mode can be

activated and deactivated with the +

or – key (for additional information, see

section 6.4.7)

Here you can set the

interval for the service notes to be displayed (Hint 1700).

The automatic protocol function can

be activated or

deactivated with the

+ or – key.

Allows to check the

vacuum quality of

the system

Allows to check the

heating muffle. The

result is shown in

graphical form after

the end of the

program

Allows to check the

keypad

The program is used

to clean the heating

muffle and the

insulation materials

by a heat process.

Permits the

dehumidification of

the furnace

Date

The date can be

selected by using the

numeric keys

20

Page 21

Settings

Selection of factory

settings

Reset firing hours

Display Short description

With this setting, all

values and parameters can be reset

to the factory

settings.

Attention:

All individual programs which have

been created and

saved will be deleted

with this function.

Only after entry of

the user code.

The firing hour count

can be reset to 0.

Only after entry of

the user code.

5.5.2 Information

Settings

Serial number

Software version

Furnace head

firing hours

Display Short description

Serial number of the

furnace

Reset vacuum pump

hours

Important information

The user code (6725) is required for some settings.

The operating hour

count of the vacuum

pump can be reset to

0. Only after entry of

the user code.

Operating hours

furnace

Operating hours

vacuum pump

Latest start of

calibration program

Calibration value

Supply voltage

Error table

Shows the current

supply voltage

21

Page 22

5.6 Symbols in the display

Symbol name

“One-stage

program”

“Two-stage

program”

“Two-stage

program”

“Standard opening

of the furnace

head” (can be

switched with the

+ / – key)

Meaning

Indicates that a

conventional, onestage program is

used

Indicates that a

specific, two-stage

program is used. The

bold line indicates the

values for the first

stage

Indicates that a

specific, two-stage

program is used. The

bold line indicates the

values for the second

stage

Indicates that the

furnace head is

opened at normal

speed after firing.

Symbol

5.7 Explanation of the speaker signals

Basically, all the acoustic signals are played in the melody and at the

volume selected by the user.

The signal transmitter can only be ended with the STOP key.

1 After the self-test is completed

To inform the user that the automatic self-test has been

successfully completed, the selected melody is played.

2 Furnace head open and temperature below 550 °C / 1022 °F

To inform the user that the temperature in the open furnace head

has dropped below 550 °C / 1022 °F, the selected melody is

played (5 seconds). In other words, the furnace head is basically

cool enough for the next program start.

3 Furnace head open and temperature below 320 °C / 608 °F

To inform the user that the temperature in the open furnace head

has dropped below 320 °C / 608 °F, the selected melody is played.

If the first playback (10 seconds) is not acknowledged with the

STOP key, a second playback sounds after 5 minutes (for

5 minutes). After that, no further signal is played.

If one of the two playbacks is acknowledged with the STOP key,

the signal transmitter is switched off immediately and no further

signals indicating the cooled furnace head will be sounded.

4 For error messages

Error messages are acoustically supported with the ”error melody”

(endless beep). The signal transmitter may be switched off with

the STOP key, while the error message still remains visible. If the

error message is acknowledged with the ESC key, the signal

transmitter is also switched off.

“Quick opening of

the furnace head”

(can be switched

with the + / – key)

Pre-drying

”Thermo Shock

Protection“

”Standard closing of

the furnace head”

Indicates that the

furnace head is

quickly opened after

firing.

Indicates that the

option “Pre-drying”

has been activated

Thermo Shock

Protection active

Pre-drying/TSP

inactive

22

Page 23

6. Practical Use

The operating procedure for the Programat P300/G2 will be

explained with the help of two examples: one Ivoclar Vivadent and

one individual program.

6.1 Switching on/off

Put ON/OFF switch (11) on position “I”. The furnace conducts an

automatic self-test, which will be indicated in the beginning.

Subsequently, a status bar shows that the self-test is being

conducted. Make sure that the furnace is not manipulated during

this time.

6.1.1 Stand-by mode

The stand-by display is shown after the successful self-test and the

program selection (see section 4.5).

A program can be selected by

pressing the + or - key or by

entering the required program

number using the numeric keys.

The parameter list is displayed by

pressing the P key.

6.1.2 List of parameters

The list shows all the parameters.

One-stage program

If a two-stage program is used, the parameters are displayed for the

first and the second stage in a separate screen. The P key is used to

switch back and forth between the two screens. Please note the

appropriate symbol (first or second stage).

6.1.3 Operating indicator: Firing curve

If the program is started with the START key, the firing curve display

with the vacuum status is shown.

c)

e)

b)

)

d

The following information is always displayed:

a) Program number and program group

b) Remaining time

c) Current temperature

d) Status of vacuum

e) Status bar

If a two-stage program is selected,

two stages are shown.

The remaining time can be

displayed or the parameter list

accessed for information purposes

at any time during a firing cycle by

pressing the P key. The parameters

can be modified only if the program

is stopped or in the stand-by mode.

6.1.4 Operating indicator: Remaining time

If the P key is pressed while the

firing curve is being displayed, the

remaining time will be shown.

The remaining time indicator

informs the user about the time

that is left until the process is completed even from a distance. The

remaining time is displayed in the centre of the screen in large

characters.

)

a

a) stage 1 b) stage 2

Two-stage program

stage 1 is shown stage 2 is shown

If the cursor is on the symbol for the program stage, you can toggle

between a one- and a two-stage program by means of the + or –

key.

Starting a program is possible at any time, even if the input screen

for the second stage is still being displayed.

Special variant: Conducting a one-stage program in which only part

of the holding time is fired with a vacuum (requirement: holding

temperature 1 = holding temperature 2).

6.2 Firing using an Ivoclar Vivadent program

Step 1:

Select the desired program (1 to 50) according to the firing table

(Chapter 10).

Step 2:

Open the furnace head with the “Open furnace head” key (90) and

place the object on the firing tray in the furnace.

Step 3:

Press the START key (73) to start

the program. The green Start LED

starts flashing. The process is

indicated in the firing curve display.

23

Page 24

6.3 Firing using an individual program

Step 1:

Switch to the program selection by pressing the Home key (93).

Select Individual programs with the right cursor key. Select a free

program.

Step 2:

Press the desired parameter (e.g.

temperature increase). The input

mask appears. In the lower field,

you will find information about the

acceptable temperature range (min.

and max.). This will facilitate the

entry and prevents input errors.

Step 3:

Press the START key (73) to start

the program. The process is

indicated in the firing curve display.

6.4 Further possibilities and special features of the

furnace

6.4.1 Illogical values or incorrect entry

If an illogical value is entered by means of the numeric keys

(outside the current value range), the invalid entry still blinks after

confirmation.

As error message (entry error: entry

outside the value range), an exclamation mark blinks in the bottom

line until the next value is entered

and successfully confirmed or the

process is aborted with ESC. The

old, valid value reappears. Please

refer to the parameter details for the value range.

6.4.2 Program write protection

If the program write-protection is activated in the Settings, all Ivoclar

Vivadent programs are write-protected. This is indicated by a closedlock icon in the stand-by display and the parameter list.

Only Ivoclar Vivadent programs can be protected with the

program write-protection. This function is not available for

individual programs.

6.4.3 Stopping the running program

Press the STOP key once to pause a running program. The green LED

in the START key blinks. Press the STOP key twice to completely stop

the program or press START to continue. The current temperature is

maintained.

6.4.4 Changing the parameters while the program is running

All parameters of the program which have not yet been executed,

can be changed while the program is stopped (green LED blinks).

6.4.6 Closing of the furnace head

Various functions are available for the

closing of the furnace head. If the cursor

is on the spot in the parameter list shown

in the figure, you can toggle between the

following functions by using the + or –

key:

– Thermo Shock Protection

– Pre-drying

– no function activated

– TSP – Thermo Shock Protection

The TSP function prevents the object from too high of

temperatures during the closing process. For this purpose, the TSP

function gauges the temperature of the firing chamber in the furnace head upon start of the firing program. If required, the closing

path within the set closing time S is adjusted. TSP is only active if

no active predrying has been selected or if the temperature in the

firing chamber is too high when the program is started. In

addition, TSP works only if the stand-by temperature of

B = 403 °C/757 °F required for Ivoclar Vivadent materials is used.

The active TSP function is shown on the display by means of the

symbol "TSP". If programs are started with a temperature of more

than 680 °C / 1256 °F, an error message is produced.

– Pre-drying

If the pre-drying function is activated, the furnace heats to the

specified stand-by temperature.

6.4.7 Power-save mode

If the power-save mode is activated and the furnace head closed,

this function is automatically activated after 30 minutes if the furnace is idle and no key is pressed during this time. The Power Saving

icon appears on the display. The power-save mode is terminated by

pressing any key.

6.4.8 Protocolling

If the protocol function is activated (see section 5.5.1), a firing

protocol can be copied to a PC at the end of the firing program by

means of the included software. Subsequently, the protocols can be

edited and managed on the PC.

The furnace saves the 15 firing programs that were last

conducted for protocolling. Copying the protocols to a PC

will automatically erase the saved entries on the furnace.

6.4.9 Software update

The user will be able to conduct a software update by PC and download cable. For that purpose, the software download mode of the

furnace is activated by pressing two special keys simultaneously

while the power supply is switched on. For further details, please

refer to the Software Update Instructions

(www.ivoclarvivadent.com/downloadcenter).

Please note that the individual programs are being erased

upon a software update. We therefore recommend that

you carry out a data backup (e.g. using the Programat

PrograBase 2 PC software).

6.4.5 Quick opening of the furnace head

By switching the symbol “standard opening of the furnace head”

for the currently loaded program, the user may activate a ”quick

opening of the furnace head” at the end of the program.

24

Page 25

7. Maintenance, Cleaning and Diagnosis

This chapter describes the user maintenance and cleaning procedures

for the Programat P300/G2. All the other tasks must be performed

by qualified service personnel at a certified Ivoclar Vivadent Service

Centre.

7.1 Monitoring and maintenance

The time for these maintenance procedures depends on the

frequency of use and the working habits of the users. For that

reason, the recommended times are only approximations.

What Part

be replaced by a certified Ivoclar Vivadent Service Center. Fine hairline cracks on the

surface of the insulation are harmless and do not influence the function of the

furnace in a negative fashion.

Check if the sealing rims of the furnace head and the furnace base are clean and

undamaged.

expected.

The expendable parts are as follows:

– Heating muffle

– Insulation material

Expendable parts are not covered by the warranty. Please also

observe the shorter service and maintenance intervals.

This furnace has been developed for typical use in dental

laboratories. If the product is used in a production

enterprise, for industrial applications and for continuous

use, premature ageing of the expendable parts has to be

Var. external connectionsCheck all plug-in connections for correct fit

Opening mechanismCheck if the furnace head opens smoothly and without excessive noise.

Thermocouple (4)Check if the thermocouple is straight and in the right place.

head (2) and the furnace base

(1)

When

weekly

monthly

weekly

monthlyInsulation (3)Check the insulation for cracks and damages. If the insulation is worn down it has to

weeklySealing rims of the furnace

by a certified Ivoclar Vivadent Service Centre.

Use the temperature checking set to check and adjust the temperature in the

furnace.

Check if there is condensate in the vacuum hose or firing chamber.

In general, the furnace head should not be replaced since the components

(furnace head and furnace base) have been coordinated with each other.

However, if the furnace head must be replaced for maintenance reasons,

subsequent temperature calibration is required.

7.2 Cleaning

The furnace may only be cleaned when it is cool, since

there is a burn hazard. Do not use any cleaning solutions.

The following parts have to be cleaned from time to time:

Item: Frequency: Cleaning material:

Housing (9) and furnace if required soft, dry cloth

head (25)

Keypad (10) weekly soft, dry cloth

Cooling tray daily cleaning brush *

(34)

Firing chamberCheck temperature.

Firing chamber

weeklyKeypad (10)Check the keypad for visible damage. If the keypad is damaged, it has to be replaced

twice a

year

daily Firing chamberCheck the quartz glass cylinder to make sure the quartz glass is not defective.

monthlyVacuum hose

Insulation (3) daily cleaning brush *

Sealing rim of the furnace daily cleaning brush and

head (2) and sealing a soft cloth

surface (1)

*Never clean with compressed air!

25

Page 26

7.3 Special programs

Press the ”cogwheel” key (Settings/Information).

Vacuum pump test program

With the program, the vacuum performance of the furnace vacuum

system can be automatically tested. For that purpose, the achieved

(minimum) pressure in mbar is measured and indicated. If the

pressure value is below 80 mbar (hPa), the vacuum performance of

the system is adequate.

Keypad test

Each time the keypad is pressed, a short beep sounds. The keypad

test can be ended by pressing ESC.

Heating muffle test program

The quality of the heating muffle may be automatically checked by

means of the heater test (duration: approximately 7 minutes).

The heater test should only be conducted with the empty

firing chamber, since an object in the chamber (e.g. firing

tray) may influence the test result. Conduct the heater test

immediately after switching on the furnace and before any

actual firing procedures are conducted. If the furnace is too hot, an

incorrect heating muffle quality will be indicated. If the heating

element quality falls below 50 %, replacing the heating element is

recommended.

Dehumidification program

The condensation of water in the insulation of the firing chamber

and the vacuum pump will result in a lower vacuum and thus to

impaired firing results. For that reason, the furnace head should be

kept closed when the furnace is switched off, in order to prevent the

absorption of humidity. Start the dehumidification program if

required (humidity in the insulation).

Cleaning Program

The cleaning program is used to "clean" the heating muffle

(duration: approximately 17 minutes). After a cleaning program, it is

recommended to calibrate the furnace. In case of problems with

discolouration of the ceramic, we recommend replacing the firing

table or the firing tray material.

7.4 Calibration

Furnace calibration (Silver Test)

The sheathed thermocouple may be subject to changes

with affect the furnace temperature, depending on the

mode of operation. Check furnace temperature with the

”Silver Test” at least once a year and adjust if necessary.

For that purpose, the furnace features a special calibration program.

Procedure:

a) The Furnace must be at operating temperature (switched on for

at least 60 minutes) and have a stand-by temperature of 403 °C

(757 °F).

b) You can access the Settings menu by pressing the "Information /

Settings" key.

Subsequently, press and hold

the right cursor key (79) until

the following display appears.

To select the calibration program press the ENTER key.

The following is displayed:

c) Insert silver wire into the Ivoclar Vivadent sample holder.

d) Place the sample holder with the silver strip in the centre of the

firing plate (6).

e) Press START (if error message Error 14 appears, the furnace

temperature is still too high fort he ”Silver Test”

(>410 °C/770 °F)). The furnace closes automatically at the correct

temperature and the program starts.

If the silver wire has started to melt (and has a ”pitted”

appearance) at the end of the program, the furnace

temperature is correctly calibrated (Figure B). If not,

recalibration is necessary.

Recalibration

A change in temperature of

Sample holder

silver wire

”+/-” 100 °C (180 °F) is possible in

the Programat P300/G2. Select the

calibration program to activate the

iring plate (6)

F

calibration keys + and –. The

program must not be started for

this purpose. The latest calibration

value is indicated on the display.

– If the silver wire has not started

Fig. A Temperature too low

to melt after the Silver Test,

recalibrate using the + key

(Figure A)

– If the silver wire has melted

down to a ball after the Silver

Test, recalibrate using the – key

(Figure C).

ig. B Temperature just right

F

Every time a calibration key is

pressed, the set temperature

changes by 1 °C (1.8 °F)

Experience has shown that a

recalibration of 5 °C (9 °F) is

appropriate, which means pressing

the relevant key five times.

Fig. C Temperature too high

While the calibration keys are in use, the calibration value in °C (°F)

is shown in the Display. Entering the calibration value does not have

to be confirmed with ENTER. We recommend that you do not

recalibrate the furnace immediately before it reached the holding

temperature or during the holding time of the Silver Test program.

Repeat the Silver Test until the silver wire starts to melt correctly

(Figure B).

7.5 Service note

When the service note (Hint 1700) appears for the first time, two

years have passed or the heating muffle has more than 1200 firing

hours. For that reason, Ivoclar Vivadent recommends to have the furnace serviced. Please see your Equipment Service Pass for further

information. The interval until the next service note can be selected

once in the advanced settings (see Chapter 5.5.1).

7.6 Stand-by

We recommend keeping the furnace head closed, especially if the

temperature drops below 150 °C (302 °F).

26

Page 27

8. What if …

This chapter will help you to recognize malfunctions and take

appropriate measures or, if possible and acceptable, to perform

some simple repairs.

8.1 Error messages

The furnace continuously checks

all functions during operation.

If an error is detected, the

respective error message is

displayed.

In case of an error, the heater switches off for safety reasons.

The following error messages may be displayed. If there are any questions, please contact the Ivoclar Vivadent After Sales Service.

Error Conti- Error Error Message Text

int nuation

H

No. possible

2 T < B Enter a logical value for T

8 L > T Enter a logical value for long-term cooling L

9

0 V2x > Tx + 1°C Change either the vacuum values or the holding time T

1

1

1

3 Current temperature after Excess temperature! Program aborted, furnace head opens to allow the furnace to cool down.

1

*, ** Start > Tx + 80 °C

14 Temperature in the firing chamber Temperature too high for calibration; the furnace cools down! Start the program again later!

* > 410 °C at the start of the calibration

6 T2 < T1 Enter a lower value for T1 or a higher value for T2.

1

17 Power failure > 10 s during

18 T1 > V12 Enter a lower value for T1 or a higher value for V12

20 no Error in the heating system Check the heater fuse. If the fuse is i.o. contact your Service Centre.

**

23 Heating muffle very old The heating muffle is very old. It is recommended to replace it. After the error message has been

24 Heating muffle defective The condition of the muffle is so poor that is has to be replaced immediately.

26 T is > B + 160 °C at the start of a Firing chamber too hot to start a firing program.

27 no Furnace head cannot The furnace head cannot be moved to the final position. It might be blocked by an external mechanical

**, ***

28 The furnace head does not The furnace head does not open/close correctly. The furnace head was manually moved or is obstructed.

** reach the target position The furnace head must only be moved using the keys intended for this purpose!

32 no The vacuum is not released The vacuum cannot be released. The vacuum valve might be dirty or stuck. Contact your Service Center.

**

33

110 HV > H (H2) Enter a lower value for HV or a higher value for H (H2)

702 Brief power failure during a program A program in progress was interrupted by a brief power failure. The program is continued!

800 Final vacuum value not reached The required final vacuum value cannot be reached. Check the vacuum pump.

801 Vacuum drop An unacceptable vacuum drop has occurred.

802 The vacuum does not increase No vacuum increase could be measured. Check the following points: Is the firing chamber tight (no

1510 Temperature > VT at the start of a The temperature in the firing chamber is higher than the pre-drying temperature. Press START to continue

1700 Service note Two years have passed or the heating muffle has been in use for more than 1200 firing hours since the last

V2x <= V1x Enter a logical value for the vacuum-on temperature Vx1 or the vacuum-off temperature Vx2

ncorrect values for V1x, V2x

I

rogram, i.e. too high

p

program in progress

firing program

be initialized source! If not, contact your Service Centre.

Necessary vacuum (xxxmbar)

reached within 1 min. pump fuse.

in progress

(self-test) contamination on the sealing surfaces)? Is the vacuum hose connected? Is the vacuum pump connected?

firing program the program despite the error message.

a firing

is not The vacuum cannot be established. Check the seal of the firing chamber, vacuum hose, vacuum pump,

nter a logical value for V1x, V2x

E

A firing program in progress was interrupted for more than 10 s. The program cannot be continued!

acknowledged, a firing program may still be started.

Is the fuse F1 o.k.?

inspection of the furnace. Ivoclar Vivadent therefore recommends that your furnace should be inspected.

Please refer to the Equipment Service Passport or the Operating Instructions for further information. The

interval until the next appearance of the note can be set in the Settings.

* Furnace head opens when this error occurs.

** A program in progress is stopped.

*** The error cannot be acknowledged; the programs cannot be started.

27

Page 28

Please contact the Ivoclar Vivadent After Sales Service, if one of the

following error messages is being displayed:

25, 29

43, 44, 45, 46, 47, 48

54, 56

103, 107

143, 144, 145, 146, 147, 148

700, 701, 703, 704, 705, 706, 707

1010, 1011, 1012, 1013, 1014, 1015, 1016

1024, 1025, 1026, 1028

1143, 1144, 1145, 1146, 1147, 1148

1202, 1203, 1204, 1205, 1206, 1207

1400, 1401, 1402

1500

28

Page 29

8.2 Technical malfunctions

These malfunctions may occur without an error message being displayed:

* If there are any questions, please contact the Ivoclar Vivadent After Sales Service.

escription Double-check Action

D

Vacuum is not released Is the vacuum released within Wait until the vacuum is released, remove object.

or only very slowly. approximately 30 seconds? Switch the furnace on and off again. *

ndication on display incomplete. *

I

riting in the display is very Is the contrast properly set? Adjust contrast.

W

hard to read.

Display not illuminated Is the furnace properly connected according Correctly connect the furnace and switch it on.

uzzer does not sound. Is the buzzer switched off Select tune 1–5.

B

Furnace head does not open. Was the furnace head moved manually? Open the furnace head only by using the

Vacuum pump does not start working. Is the vacuum pump fuse defective? Check fuse and replace if necessary.

Final vacuum is not reached. Is the vacuum hose OK? Check vacuum hose and hose connection.

Incorrect or illogical temperature indication Is the thermocouple bent or fractured? *

Hairline cracks in the heating muffle Are the cracks very small and insignificant Small cracks in the muffle are normal and do not

Cracks in the insulation Are the cracks very small and insignificant Small cracks in the insulation do not negatively influence

Cracks in the quartz glass / heating element Are there cracks in the quartz glass or is the Switch off the furnace. *

o the Operating Instructions and switched

t

n?

o

(Tune 0)?

orresponding keys. Switch the furnace on and off

c

again.

Has the vacuum already been released? Is the program still running? Wait until the program is

Was the maximum power consumption Use only the vacuum pump recommended by

exceeded? Ivoclar Vivadent.

Is the vacuum pump plug correctly connected? Correctly connect the vacuum pump

Is the pump output OK? Start the vacuum test program.

Humidity/condensation in the vacuum hose? Start dehumidification program.

Is the thermocouple correctly connected? Correctly connect thermocouple.

Is the thermocouple plug defective? *

(hairline cracks)? negatively influence the function of the furnace.

Are the cracks large or have parts of the *

heating muffle broken off?

(hairline cracks)? the furnace.

Are the cracks large or have parts of the *

insulation broken off?

quartz glass sheathing the heating wire broken?

omplete. Switch furnace off and on again. If it still does

c

ot work properly, contact your local Ivoclar Vivadent

n

Service Centre.

to the furnace base.

8.3 Repair

Repairs may only be carried out by a certified Ivoclar

Vivadent Service Centre. Please refer to the addresses on

the last page of these Operating Instructions.

If repairs during the warranty period are not carried out by a certified

Ivoclar Vivadent Service Centre, the warranty will expire immediately.

Please also refer to the corresponding warranty regulations.

29

Page 30

9. Product Specifications

9.1 Delivery form

– Programat P300/G2

– Power cord

– USB data cable

– Vacuum hose

– Calibration Test Pack

– Programat Firing Tray Kit

– Operating Instructions

– Service Passport Equipment

9.1.2 Recommended accessories

– Programat Accessories Set

– Temperature Checking Set 2

– Vacuum Pump VP4 / VP3 easy

9.2 Technical data

Power supply 110–120 V / 50–60 Hz

200–240 V / 50–60 Hz

Overvoltage category II

Contamination level 2

Tolerated voltage fluctuations +/- 10%

Max. power consumption 12 A at 110–120 V

8.5 A at 200–240 V

Acceptable data for vacuum pump of other manufacturers

Max. output: 250 W / max. leakage current 0.75 mA

Final vacuum: < 50 mbar

Use only tested pumps

Electrical fuses: 110–120 V:

250 V / T 15 A (heating circuit)

250 V / T 5 A (vacuum pump)

200–240 V:

250 V / T 8 A (heating circuit)

250 V / T 3.15 A (vacuum pump)

Dimensions of electrical fuses 110–120 V:

Diameter 6.3 x 32 mm

200–240 V:

Diameter 5 x 20 mm

Dimensions of the closed furnace

Depth: 430 mm / width: 305 mm / 410 mm (with Cooling tray)

Height: 320 mm

Usable size of the firing chamber Diameter 80 mm

Height 48 mm

Max. firing temperature 1200 °C (2192 °F)

Weight Furnace base: 12.0 kg

Furnace head: 4.5 kg

9.3 Acceptable operating conditions

Acceptable ambient temperature range:

+5 °C to +40 °C (+41 °F to +104 °F)

Acceptable humidity range:

80 % maximum relative humidity for temperatures up to 31 °C

(87.8 °F) gradually decreasing to 50 % relative humidity at 40 °C

(104 °F); condensation excluded.

Acceptable ambient pressure:

The furnace is tested for use at altitudes of up to 2000 m above sea

level.

9.4 Acceptable transportation and storage conditions

Acceptable temperature range -20 °C to +65 °C (-4 °F to +149 °F)

Acceptable humidity range Max. 80 % relative humidity

Acceptable ambient pressure 500 mbar to 1060 mbar

Use only original packaging of the Programat P300/G2 together with

the respective foam material for shipping purposes.

Safety information

The P300/G2 complies with the following guidelines:

– IEC 1010-1/EN 61010, Part 1

– UL and cUL standards

Radio protection / electromagnetic compatibility EMC tested

30

Page 31

10.1 Program table

Two program tables (°C / °F) are enclosed to these Operating Instructions. If not, please contact your local Service Centre.

Important information

The current program table is also available at:

www.ivoclarvivadent.com/downloadcenter

The program tables can be downloaded from the internet as PDF

files. Please make sure that your program table complies with the

software version you use, as the table is coordinated with the

respective software version.

10. Appendix

31

Page 32

10.2 Menu structure

10.2.1 Possibilities of the program selection

32

Page 33

10.2.2 Information / Settings

33

Page 34

10.3 Firing curves

10.3.1 Vacuum during both stages

10.3.3 Pre-drying

10.3.2 Vacuum during long-term cooling

10.3.4 Controlled long-term cooling

34

Page 35

Page 36

Ivoclar Vivadent – worldwide

Ivoclar Vivadent AG

endererstrasse 2

B

L-9494 Schaan

F

Liechtenstein

Tel. +423 235 35 35

ax +423 235 33 60

F

ww.ivoclarvivadent.com

w

Ivoclar Vivadent Pty. Ltd.

– 5 Overseas Drive

1

.O. Box 367

P

oble Park, Vic. 3174

N

Australia

el. +61 3 979 595 99

T

ax +61 3 979 596 45

F

www.ivoclarvivadent.com.au

Ivoclar Vivadent GmbH

remschlstr. 16

B

Postfach 223

A-6706 Bürs

Austria

el. +43 5552 624 49

T

Fax +43 5552 675 15

www.ivoclarvivadent.com

Ivoclar Vivadent Ltda.

ua Geraldo Flausino Gomes,

R

8 – 6.º andar Cjs. 61/62

7

Bairro: Brooklin Novo

CEP: 04575-060 São Paulo – SP

razil

B

Tel. +55 11 3466 0800

Fax +55 11 3466 0840

www.ivoclarvivadent.com.br

Ivoclar Vivadent Inc.

2785 Skymark Avenue, Unit 1

Mississauga

Ontario L4W 4Y3

Canada

Tel. +1 905 238 5700

Fax +1 905 238 5711

www.ivoclarvivadent.us

Ivoclar Vivadent Marketing Ltd.

Rm 603 Kuen Yang

International Business Plaza

No. 798 Zhao Jia Bang Road

Shanghai 200030

China

Tel. +86 21 5456 0776

Fax +86 21 6445 1561

www.ivoclarvivadent.com

Ivoclar Vivadent Marketing Ltd.

alle 134 No. 7-B-83, Of. 520

C

ogotá

B

Colombia

Tel. +57 1 627 33 99

ax +57 1 633 16 63

F

ww.ivoclarvivadent.com

w

Ivoclar Vivadent SAS

.P. 118

B

-74410 Saint-Jorioz

F

rance

F

Tel. +33 450 88 64 00

ax +33 450 68 91 52

F

ww.ivoclarvivadent.fr

w

Ivoclar Vivadent GmbH

Dr. Adolf-Schneider-Str. 2

-73479 Ellwangen, Jagst

D

Germany

Tel. +49 (0) 79 61 / 8 89-0

Fax +49 (0) 79 61 / 63 26

ww.ivoclarvivadent.de

w

Ivoclar Vivadent Marketing Ltd.

(Liaison Office)

503/504 Raheja Plaza

5 B Shah Industrial Estate

1

eera Desai Road, Andheri (West)

V

Mumbai, 400 053

India

el. +91 (22) 2673 0302

T

Fax +91 (22) 2673 0301

www.ivoclarvivadent.com

Ivoclar Vivadent s.r.l. & C. s.a.s

Via Gustav Flora, 32

39025 Naturno (BZ)

Italy

Tel. +39 0473 67 01 11

Fax +39 0473 66 77 80

www.ivoclarvivadent.it

Ivoclar Vivadent K.K.

1-28-24-4F Hongo

Bunkyo-ku

Tokyo 113-0033

Japan

Tel. +81 3 6903 3535

Fax +81 3 5844 3657

www.ivoclarvivadent.jp

Ivoclar Vivadent S.A. de C.V.

v. Mazatlán No. 61, Piso 2

A

ol. Condesa

C

06170 México, D.F.

Mexico

el. +52 (55) 5062-1000

T

ax +52 (55) 5062-1029

F

ww.ivoclarvivadent.com.mx

w

voclar Vivadent Ltd.

I

2 Omega St, Albany

1

O Box 5243 Wellesley St

P

Auckland, New Zealand

el. +64 9 914 9999

T

ax +64 9 814 9990

F

www.ivoclarvivadent.co.nz

Ivoclar Vivadent

olska Sp. z.o.o.

P

Al. Jana Pawla II 78

00-175 Warszawa

Poland

el. +48 22 635 54 96

T

Fax +48 22 635 54 69

www.ivoclarvivadent.pl

Ivoclar Vivadent Marketing Ltd.

erbenevskaja Nabereshnaya 11, Geb. W

D

15114 Moscow

1

Russia

Tel. +7 495 913 66 19

ax +7 495 913 66 15

F

www.ivoclarvivadent.ru

Ivoclar Vivadent Marketing Ltd.

171 Chin Swee Road

#02-01 San Centre

Singapore 169877

Tel. +65 6535 6775

Fax +65 6535 4991

www.ivoclarvivadent.com

Ivoclar Vivadent S.L.U.

c/ Emilio Muñoz Nº 15

Entrada c/ Albarracin

E-28037 Madrid

Spain

Tel. + 34 91 375 78 20

Fax + 34 91 375 78 38

www.ivoclarvivadent.es

Ivoclar Vivadent AB

alvägen 14

D

-169 56 Solna

S

Sweden

Tel. +46 (0) 8 514 93 930

ax +46 (0) 8 514 93 940

F

ww.ivoclarvivadent.se

w

Ivoclar Vivadent Liaison Office

hi Evran Caddesi No 1

A

olaris Is Merkezi Kat: 7

P

0670 Maslak

8

Istanbul

urkey

T

el. +90 212 346 04 04

T

Fax +90 212 346 04 24

www.ivoclarvivadent.com

voclar Vivadent Limited

I

Ground Floor Compass Building

Feldspar Close

Warrens Business Park

nderby

E

Leicester LE19 4SE

United Kingdom

Tel. +44 116 284 78 80

Fax +44 116 284 78 81

ww.ivoclarvivadent.com

w

Ivoclar Vivadent, Inc.

175 Pineview Drive

mherst, N.Y. 14228

A

USA

Tel. +1 800 533 6825

Fax +1 716 691 2285

www.ivoclarvivadent.us

Version: 1

Date information prepared: 10/2010

Valid as of Software V5.0

This apparatus has been developed solely for use in dentistry. Start-up and

operation should be carried out strictly according to the Operating Instructions.

Liability cannot be accepted for damages resulting from misuse or failure to

observe the Instructions. The user is solely responsible for testing the apparatus

for its suitability for any purpose not explicitly stated in the Instructions.

Descriptions and data constitute no warranty.

Printed in Austria

© Ivoclar Vivadent AG, Schaan/Liechtenstein

635578/1010/e

Loading...

Loading...