Page 1

Lumamat

®

100

Operating Instructions

Page 2

2

Page 3

3

Views of the Unit, List of Parts 5

1. Introduction / Signs and Symbols 6

1.1 Preface

1.2 Introduction

1.3 Sings and symbols

2. Safety First 7

2.1 Indications

2.2 Health and safety instructions

3. Product Description 10

3.1 Components

3.2 Hazardous areas and safety equipment

3.3 Functional description

3.4 Contraindication

4. Installation and Initial Start-Up 11

4.1 Unpacking and checking the contents

4.2 Selecting the location

4.3 Assembly and initial start-up

5. Operation 12

5.1 Introduction to the operation

5.2 Working with Program P1

5.3 Working with Program P2

5.4 Working with Program P3

5.5 Working with Program P4

5.6 Acceptable tempering space

6. Practical Use 14

6.1 Switching on/off

6.2 Curing

6.3 Switching the buzzer on/off

6.4 Buzzer upon premature opening during the cooling phase

7. Maintenance, Cleaning, and Diagnosis 15

7.1 Monitoring and Maintenance

7.2 Cleaning

7.3 Changing the lamps

7.4 Changing the dust filter

7.5 Changing the fuse

7.6 Calibration

7.7 Special configuration modes

8. What If… 18

8.1 Technical malfunctions

8.2 Error messages

8.3 Repair

9. Product Specifications 19

9.1 Delivery form

9.2 Technical data

9.3 Acceptable operating conditions

9.4 Acceptable transportation and storage conditions

Table of Contents

Page 4

4

1

36

28

6

5

22

21

17

2

16

26

70

29

72

73

3

4

13

33

20

1

25

7

9

8

10

11

13

32

29

34

23

24

22

75

71

76

77

19

18

27

30

37

26

38

31

39

15

14

12

Page 5

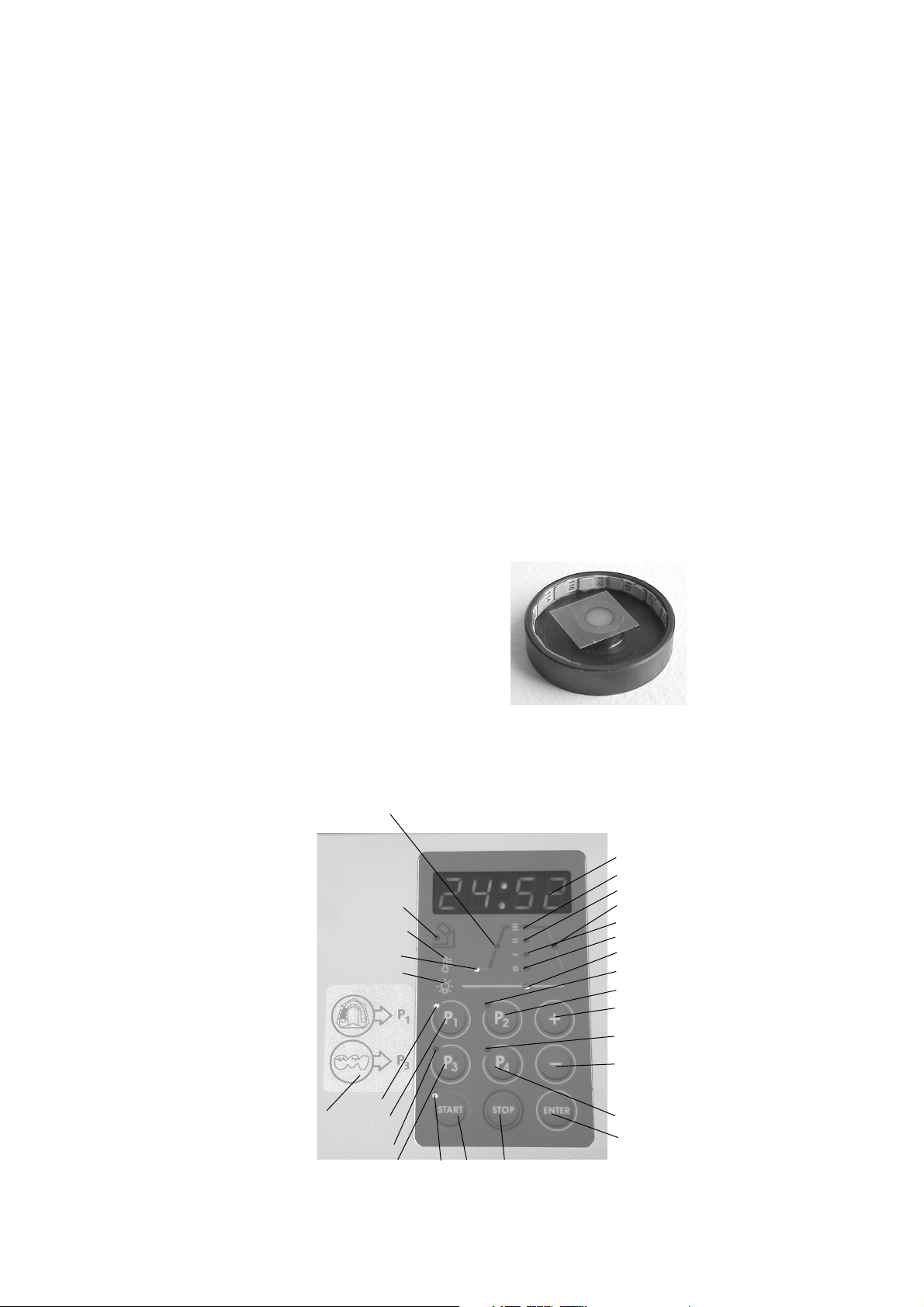

5

Front view

1Viewing window

2 Curing chamber

3 Grip

4 Bottom of unit

5 Housing

6 Keypad

7 Air vents

8 Filter holder

9 Filter pad

10 Power socket

11 Power plug

12 Fuse

13 Power cord

14 Lateral fuse stop

15 Fuse holder

16 Magnetic catch

17 Lamp protection

18 Lamp

19 Lamp socket

20 Swivel arm

21 Air vent with fan

22 On/Off switch

23 Ventilation grating

24 Rubber feet

25 Rating plate

26 Infrared heater

27 Temperature sensor

28 Sealing

29 Recessed grip

30 Light sensor

31 Upper reflector

32 RS-232 interface

33 Spring for gas pressure

34 Rear panel

36 Screws for lamp protection

37 Sensorprint

38 Temperature protector

39 Extra fuse

Electronic controls

40 Indicator for opened unit

41 LED P1

42 P1 key

43 LED P3

44 P3 key

45 LED of Start key

46 Start key

47 Stop key

48 Enter key

49 P4 key

50 LED P4

51 - key

52 + key

53 P2 key

54 LED P2

55 Light indicator

56 Heating indicator (off)

57 Heating indicator Stage 1

58 Heating indicator Stage 2

59 Heating indicator Stage 3

60 Display

61 Indicator for heating

procedure

62 Indicator for procuring

63 Indicator for cooling

procedure

64 Symbol for light

65 Symbol for temperature

66 Information plate

Object holder

70 Tempering space limiter

71 Object holder

72 Object holder support

73 Bottom reflector

74 Space limiter grid

75 Alligator clip

76 Object holder small

77 Object holder large

Test set

80 Sample holder

81 Temperature stripe

82 Test material

83 Protection foil

List of Parts

40

41

42

43

44 45 46

47

48

49

51

50

52

53

54

55

56

57

58

59

60

61

65

62

64

63

66

80

Page 6

6

1. Introduction / Signs and Symbols

1.1 Preface

Dear Customer,

Thank you for having purchased

the Lumamat 100.

It is a high quality technical

product. The Lumamat 100 has

been especially developed for

the SR Adoro material from

Ivoclar Vivadent. The integrated

infrared heater permits

tempering of the SR Adoro

material.

The Lumamat 100 has been

designed according to the latest

industry standards. Inappropriate

use may damage equipment and

be harmful to personnel. Please

observe the relevant safety

instructions in Chapter 2.

You must read

these Operating

Instructions!

1.2 Introduction

The Lumamat 100 has been

developed for use in dental lab

technology and is equipped with

state-of-the-art electronic

components.

The Operating Instructions are

divided into several chapters to

help you find specific topics

quickly and easily.

1.3 Signs and symbols

The signs and symbols in these

Operating Instructions and on

the Lumamat 100 facilitate the

finding of important points and

have the following meanings:

Operating Instructions:

Risks and dangers

This symbol marks

safety instructions

that must be

followed to prevent

injury or death.

Furthermore, damage

to the unit and/or

laboratory may thus

be avoided.

Important

information

This symbol marks

additional

information for

correct and economic

use of the

Lumamat 100.

Contraindication

Burn hazard

Unit:

Alternating current

On

Off

Burn hazard

Risk of crushing

Page 7

7

2. Safety First

This chapter is especially important for personnel

who work with the Lumamat 100 or who have to

carry out maintenance or repair work. This chapter

must be read and the corresponding instructions

followed.

2.1 Indications

The Lumamat 100 must only be used to cure and

temper SR Adoro materials and should be used for

this purpose only. Other uses than the one

stipulated are contraindicated. The manufacturer

does not assume any liability for damage resulting

from misuse. The user is solely responsible for any

risk resulting from failure to observe these

Instructions.

Further instructions to assure

proper use of the Lumamat 100:

– The instructions, regulations,

and notes in these Operating

Instructions must be

observed.

- The Lumamat 100 must be

used under the stipulated

environmental and operating

conditions (see Chapter 9).

– The unit must be properly

maintained.

2.1.1

Contraindication

Burn hazard

2.1.2

Contraindication

Risk of crushing

The heater must not be touched,

as there is a burn hazard.

Furthermore, the life cycle of the

heater is considerably shortened

by hand sweat.

The sensorprint must not be

touched for the same reasons.

There is a risk of crushing when

the curing chamber is being

closed. Make sure that the

necessary space is available.

Foreign objects must not be

placed on the air vents. Make

sure that no liquids or other

foreign objects enter the air

vents, since this may result in an

electrical shock.

Please also refer to section

3.2 in Chapter 3.

2.1.3

Risks and dangers

2.1.4

Contraindication

The unit must not be carried by

holding the swivel arm. Carry the

unit only when it is closed. The

recessed grips (29) are located at

the rear panel (34) and in the

front area of the bottom plate.

Page 8

8

2.1.5

Contraindication

Objects must not be placed outside the acceptable tempering

space.

Models that are too high and

thus extend beyond the

tempering space limiter (70)

must not be placed on the

object holder. Furthermore,

thermoplastic model materials

must not be used.

2.1.6

Contraindication

Page 9

9

2.2 Health and safety

instructions

This unit has been designed

according to EN 61010-1 and

has been shipped from the

manufacturer in excellent condition as far as safety regulations

are concerned. To maintain this

condition and to assure risk-free

operation, the user must observe

the notes and warnings

contained in the Operating

Instructions.

– Do not place the unit in the

immediate vicinity of heaters

or other sources of heat.

– Place the apparatus on a fire-

proof table (observe local

regulations, e.g. distance to

combustible objects, etc.).

– Always keep the air vents at

the rear of the apparatus free

from obstruction.

– Make sure that no foreign

objects may enter the air

vents.

– Do not touch any parts that

become hot (lamp, heater)

during the operation of the

unit. There is a burn hazard.

– Clean unit only with a dry or

slightly moist cloth. Do not

use any solvents! Disconnect

power before cleaning.

– Use original packaging for

transportation purposes.

– The user must especially

become familiar with the

warnings and the operating

conditions to prevent injury to

personnel or damage to

materials. The manufacturer is

not responsible for damage

resulting from misuse or failure to observe the Operating

Instructions. Warranty claims

cannot be accepted in such

cases.

– Before switching on, make

sure that the voltage indicated

on the rating plate complies

with your local power supply.

– The power plug may only be

inserted into sockets with

protected contacts.

– Before calibration,

maintenance, repair, or

exchange of parts, the power

must be disconnected if the

unit is to be opened.

– If calibration, maintenance, or

repair has to be carried out

with the power connected

and the unit open, only

qualified personnel, who are

familiar with the risks and

dangers, may perform these

procedures.

– After maintenance, the

required safety tests (high

voltage resistance, protective

conductor test, etc.) have to

be carried out.

– It must be ensured that only

fuses of the indicated type

and rated current are used.

– If it is assumed that safe ope-

ration is no longer possible,

the power must be disconnected to avoid accidental operation. Safe operation is no longer possible if

– the unit is visibly damaged

– the unit does not work

– the unit has been stored

under unfavourable

conditions over an extended

period of time.

– Use only original spare parts.

– The temperature range for

faultless operation is +5 °C to

+40 °C (41–104 °F).

– If the unit has been stored at

very low temperatures or high

atmospheric humidity it has to

be dried or left to adjust to

the room temperature for

approx. 1 hour (do not

connect to power yet).

– Note: Do not work with

liquids near the unit. Should a

liquid accidentally enter the

unit, disconnect power and

consult Customer Service. Do

not operate the unit.

– The unit has been tested for

use at altitudes of up to

2000 m above sea level.

– The unit must be used

indoors.

– Operating the unit without a

dust filter or with a dirty one

influences temperature regulation. Adequate tempering

according to Ivoclar Vivadent

standards is not assured without a dust filter.

Warnings

– Any disruption of the protec-

tive conductor either inside or

outside the unit or any

loosening of the protective

conductor connection may

lead to danger for the user in

case of malfunction. Deliberate interruptions are not

tolerated.

– Direct view into the light or

reflecting surfaces without a

filter is uncomfortable for the

eyes. Prolonged exposure may

lead to eye damage.

Therefore, we recommend

looking at the object only

through the tinted viewing

window of the unit. Protective

goggles absorbing light or

wavelengths below 500 nm

can also be used.

– This is especially applicable for

persons who work with the

unit or in its vicinity for

extended periods of time, or

for people who have undergone eye surgery.

– Persons who are generally

light-sensitive, or who take

medication against lightsensitivity or photo-sensitivity

should not be exposed to the

light of the unit.

– Hot surface. There is a burn

hazard. Do not touch the

heater or the lamps when they

are hot.

– Do not use this unit to cook

food.

– The user is responsible for

cleaning and decontamination

measures, if hazardous

materials spill in the unit or

hazardous gases develop

during operation of the unit

(e.g. incorrect material).

In this case, the user must

contact the local Ivoclar

Vivadent Service Center.

Furthermore, the unit must no

longer be used.

Page 10

10

3. Product Description

3.1 Components

The Lumamat 100 consists of the

following components:

– Base housing with electronic

controls

– Swivel arm with curing

chamber (lamps and heater)

3.2 Hazardous areas and safety

equipment

Description of the hazardous areas:

Risk of burningOuter surfaces of the curing chamber

Risk of eye damageLamp

Risk of electrical shockElectrical components

Risk of crushingOpening / closing mechanism

Risk of burningHeater

Type of riskHazardous area

Description of the safety equipment:

The program is stopped when the apparatus is

opened

Safety switch

Prevents eye damageTinted viewing window

Protection from electrical shockProtective conductor

Protective effectSafety equipment

Also refer to Chapter 2.

3.3 Functional description

The lamp radiates light at 400-580 nm, which

initiates curing of the material. The integrated

heater may be set on three different stages and is

used for tempering the material. Please observe the

recommended values in the Instructions for Use of

the material. The apparatus is thus especially

suitable for tempering the SR Adoro material.

3.4 Contraindication

– Curing of restorations mounted in an articulator.

– Curing of restorations on plaster models heavier

than 400 g

– Curing of restorations on plaster model

exceeding a height of 70 mm

– Curing of restorations on plaster models with a

diameter of more than 80 mm

– Curing of restorations on resin models and

thermoplastic materials

– Curing of temperature sensitive materials

Page 11

11

4. Installation and Initial Start-Up

4.3 Assembly and initial start-up

– Power connection:

Make sure that the voltage indicated on

the rating plate (25) complies with the

local power supply.

Should this not be the case, you must not

connect the unit.

Connect the power cord (13) with the

power socket (10) of the unit and with the

power supply.

–Tempering space limiter (70)

The tempering space limiter is an optical

auxiliary device, defining the acceptable

tempering space for objects, together with

the mounted object holder. These

dimensions must be observed when

placing objects in the curing chamber,

since otherwise parts of the unit will be

damaged.

4.1 Unpacking and checking the

contents

Remove components from their packaging

and place the unit on a suitable table. There

are special transportation grips. The unit is

carried with one hand holding the grip at the

rear of the apparatus and the other hand

supporting the unit at the bottom, where

there is a recessed grip.

Never carry the unit by

holding the swivel arm.

Check the delivery for completeness (see

‘Delivery Form’ in Chapter 9) and transportation damage. If certain parts are missing or

damaged, contact Ivoclar Vivadent Customer

Service. We recommend keeping the original

packaging for future transportation

purposes. Make sure to place the

corresponding transportation safety devices

before transporting the unit.

4.2 Selecting the location

Place the unit on a flat surface using the

rubber feet (24). Make sure it is not placed in

the immediate vicinity of heaters or other

sources of heat. Furthermore, protect the

unit from direct sunlight. Make sure the air

may properly circulate between the wall and

the unit.

Remove the transportation safety

devices from the unit:

1. Safety tape

Check if all lamps are tightly fixed in their

sockets. Push the lamps upwards for that

purpose.

Position the unit in such a way that glare-free

working is ensured and no direct view into

the lamps is possible.

Make sure that there is enough space for the

swivel arm to prevent obstruction of the

swivel mechanism. The unit should neither

be placed nor operated in areas where there

is an explosion hazard.

Initial start-up

The unit may only be switched on or off with

the On/Off switch:

Switched on

Switched off

70

Page 12

12

5. Operating Instructions

5.1 Introduction to the operation

Programs can be selected with P1, P2, P3,

and P4 keys. The respective LED will then be

illuminated.

The parameters are shown in the display. The

program is started by pressing Start. The

display then indicates the remaining time of

the program. The program can be interrupted by pressing Stop.

5.2 Working with Program P1 (set

program with plaster model)

Tempering program for SR Adoro materials

(light/heat), which are polymerized/tempered

on a plaster model (the parameters are set by

the manufacturer and cannot be altered).

If the restorations are placed in the curing

chamber together with a plaster model,

Program P1 must be used (see also sticker on

the apparatus).

When tempering partial models

(e.g. 1/4 models, single or multiple

cores), please refer to the additional instructions in the SR Adoro

Instructions for Use.

5.3 Working with Program P2

(set program)

Light polymerization program for light-curing

resins (light). (The parameters are set by the

manufacturer and cannot be altered).

5.4 Working with Program P3 (set

program without plaster model)

Tempering program for SR Adoro materials

(light/heat), which are polymerized/tempered

without a plaster model (the parameters are

set by the manufacturer and cannot be

altered).

If the restorations are placed in the curing

chamber without the plaster model, Program

P3 must be used (see also sticker on the

apparatus).

5.5 Working with Program P4

(individual program)

The parameters for Program P4 can be set as

desired (see also 6.2.2).

Program Table

No

1

2

3

4

Program

SR Adoro tempering

program (with plaster

model)

Light-curing

program

SR Adoro tempering

program (without

plaster model)

Individual curing

program

VB min

10:00

––––

10:00

0:00 to

10:00***

HP

set

****

––––

set

****

set

****

BP min

––––

10:00

––––

0:00 to

30:00**

VG min

7:00

––––

7:00

0:00 to

30:00***

Stage

3

––––

3

0 – 3

AP min

5:00

****

1:00

****

5:00

****

****

1:00/5:00*

VB

HP

VG

AP

BP

Stage 0

Stage 1

Stage 2

Stage 3

* depending on the heating stage; ** only at stage 0, *** only at stage 1, 2, 3,

**** cannot be set

VB = Precuring, HP = Heating, VG = Tempering, AP = Cooling, BP = Curing

Heat performance:*

Stage 0 = Heater off

Stage 1 = approx. 80 °C / 176 °F

Stage 2 = approx. 95 °C / 203 °F

Stage 3 = approx. 104 °C / 219 °F

* The temperatures were measured with a reference tooth

(typical value) with a plaster model (P1) and without

plaster model (P3).

Page 13

13

5.6 Acceptable tempering space

The parameters (light and temperature)

necessary for adequate curing and

tempering are only ensured within the

acceptable tempering space. The acceptable

tempering space is defined by the tempering

space limiter (70). The objects must be

placed within the acceptable tempering

space.

The necessary parameters (light and

temperature) are only ensured if the

plaster models used meet the following

requirements:

– Lighter than 400 g

– Height below 70 mm

– Diameter smaller than 80 mm

Acceptable tempering space

70

Page 14

14

6. Practical Use

6.1 Switching on/off

Switching on

Put On/Off switch (22) on position 'I'.

Indication of lamp operating hours

After being switched on, the apparatus

performs a brief self-test. During this test,

the display and the LEDs briefly light up.

After that, the display will show four

numbers (e.g. 0823). This means 823 lamp

operating hours. After three seconds, the

indication of the lamp operating hours

changes to the stand-by indication.

Stand-by indication

(- --)

The display shows three dashes and one

empty field. The empty field is moving.

Switching off

Put On/Off switch (22) on position '0'.

6.2 Curing

6.2.1 Standard program

Step 1

Place the object in the curing chamber.

Observe the acceptable tempering space.*

Step 2

Close the unit.

The indicator for opened unit (40) must not

be illuminated as otherwise the program

cannot be started.

Step 3

Select the program by pressing P1 (42), P2

(53), or P3 (44).

Step 4

Press Start (46). Then, the remaining program

time will be indicated on the display.

Step 5

Once the program has been completed,

open the unit and remove the object.

Burn hazard

Please note that the objects may

become very hot. Use tongs or

tweezers to remove the objects.

*

The object must not surpass the

acceptable tempering space. If

this is not observed, the object or

the unit will be damaged when

the unit is closed.

6.2.2 Individual program (P4)

Step 1

Place the object in the curing chamber.

Observe the acceptable tempering space.*

Step 2

Close the unit.

The indicator for opened unit (40) must not

be illuminated as otherwise the program

cannot be started.

Step 3

Select the program.

Press P4 (49). The set parameters will appear

on the display. If changing of the parameters

is not necessary you may proceed with

pressing Start (46). If the parameters have to

be changed, proceed with Step 4.

Step 4

Press Enter (48).

Step 5

Select the heating stage with the '-' or '+'

keys and confirm with Enter. Now the next

parameter to be set starts to blink on the

display. Set the required values for the

individual parameters (observe the values in

the enclosed table) and confirm with Enter.

Now the set parameters light up.

Step 6

Press Start (46) and wait until the program

starts. After that, the remaining program

time will be indicated in the display.

Step 7

Once the program has been completed,

open the unit and remove the object.

Burn hazard

Please note that the objects may

become very hot. Use tongs or

tweezers to remove the objects.

*

The object must not surpass the

acceptable tempering space. If

this is not observed, the object or

the unit will be damaged when

the unit is closed.

6.3 Switching the buzzer on/off

The buzzer can be switched on or off as

desired.

6.3.1 Switching on

To activate the buzzer, proceed as follows:

1. Switch off the unit (put On/Off switch

on position '0')

2. Press Start and hold down the key

3. Put On/Off switch on position 'I'

4. Release Start key

Switching off

To deactivate the buzzer, proceed as

follows:

1. Switch off the unit (put On/Off switch on

position '0'

2. Press Stop and hold down the key

3. Put On/Off switch on position 'I'

4. Release Stop key

6.4 Buzzer upon premature

opening during the cooling

phase

If the chamber is prematurely opened

during the cooling phase, a warning

buzzer sounds. This signal cannot be

acknowledged. As soon as the hood is

closed again, the program (cooling phase)

continues and the buzzer stops.

Wait until the cooling phase (5 min.) has

finished.

On premature interruption of

the program (e.g. power

failure), the curing chamber

must be allowed to cool down

as otherwise the starting

temperature is too high.

Page 15

15

7. Maintenance, Cleaning, and Diagnosis

Item Frequency Cleaning material/measure

Dust filter Monthly Batting or replacing

Housing surfaces If required Cloth

Magnet and counterpiece If required Cloth

Reflector If required Cloth

7.2 Cleaning

The unit may only be

cleaned when it is

cool, since there is

burn hazard. Do not

use any cleaning solutions. The

heater must not be touched, as

hand sweat considerably

shortens the life cycle of the

unit.

What Part Frequency

Check all plug-in connections for correct fit. Power plug Weekly

Check the switch-off mechanism by opening the curing chamber during Interlock Weekly

program operation. If the fan continues to work, the safety switch

(interlock) is defective. In this case, contact your local Ivoclar Vivadent

Service Center.

Check the infrared heater (26) for damage of the glass. Infrared heater (26) Before the first

operation. Weekly

Check temperature and light performance Test Set Every 6 months

This chapter describes the user maintenance

and cleaning procedures. All other tasks

must be performed by qualified service

personnel at a certified Ivoclar Vivadent

Service Center.

7.1 Monitoring and maintenance

The time for these maintenance procedures

depends on the frequency of use and the

working habits of the users. For that

reason, the recommended times are only

approximates.

Disconnect power before maintenance

and cleaning, since there is a risk of

electrical shock.

The following parts have to be cleaned from time to time:

Use only original Ivoclar Vivadent dust

filters.

Page 16

16

7.3 Changing the lamps

The unit is equipped with a sensor that automatically checks the performance of the

lamps. As soon as the performance drops

below a certain value, the display indicates a

corresponding Error message, e.g. Er11,

Er12, Er13. Then, the lamps have to be

replaced.

One defective lamp

For technical reasons, the lamps

are arranged in two groups

consisting of four lamps each.

That means that all four lamps stop working

if one lamp is defective. The defective groups

can be determined by observing the lamps

through the viewing window (1).

Acceptable lamp operating hours

If all eight lamps light up, although Er11 or

Er14 has been displayed, the light

performance is inadequate and the lamps

have reached the end of their life cycle.

Replace all lamps.

Disconnect power during chan-

ging of the lamps and if the unit

has to be opened.

Make sure that the lamp

protection is correctly mounted,

since otherwise the unit cannot

be correctly closed.

Description of how to change the lamps

Step 1

Disconnect power.

Step 2

Remove the eight screws (36) of the lamp

protection.

Step 3

Remove the first lamp of the defective group

from its socket (19) and position the new

one.

Step 4

Close swivel arm with the curing chamber.

Step 5

Connect power.

Step 6

Start Program P2.

Step 7

Look through the viewing window to make

sure that the correct lamp has been replaced.

If all lamps light up, continue with Step 11.

Step 8

If one group of lamps still remains dark,

interrupt the program by pressing Stop.

Step 9

Disconnect power.

Step 10

Repeat Steps 4 to 10 until the defective lamp

has been found.

Step 11

Interrupt program by pressing Stop (47)

Step 12

Disconnect power.

Step 13

Mount the lamp protection (17) with the

corresponding screws (36).

Step 14

Connect power.

36

17

19

18

26

Page 17

17

7.4 Changing the dust filter

Remove filter (8) from the unit with a firm

tug. Clean filter pad (9) or replace it.

Remount the filter..

The unit may only be operated

with the dust filter.

7.5 Changing the fuse

Disconnect power cord (13). The fuse holder

(15) is located in the power socket of the

unit (10). Push the lateral fuse stop (14) in

the direction of the arrow using a screwdriver. The fuse holder (15) is thus released

and may be removed from the unit. Check

fuse (12). Replace defective fuse and insert

the new fuse with its holder into the power

socket (10) until it snaps into place.

Important

Use only fuses with test labels

according to the respective values

specified in ‘Technical Data’

(Chapter 9.2).

9

8

23

7.7 Special configuration modes

With these special modes (functions of the

unit), certain configuration procedures may

be performed and information shown on the

display.

The desired mode is activated as follows:

Press the two keys according to the table

below, while simultaneously switching on the

unit. The display now briefly (3 seconds)

indicates the corresponding mode.

7.6 Calibration

In order to ensure optimum tempering even

after prolonged periods of time, the required

light performance and the corresponding

tempering temperature should be reached.

The temperature sensor of the unit may be

subject to small changes after prolonged use,

which affect the tempering temperature. The

lamps are also subject to a certain aging process, which may compromise the light performance.

These two parameters can be checked any

time by the user with the help of the Test Set

specifically developed for that purpose.

12

15

39

Mode

(Function)

1

2

3

Key Combination

P1 and P2

P3 and P4

START and STOP

Indication on the

Display

The current number of

lamp operating hours is

indicated.

The current calibration

value of the tempering

temperature is indicated.

Within 3 seconds, the 3

software versions of the

unit are indicated one

after the other.

Function

After changing the

lamps, the counter has

to be reset to 0 using

the '-' key.

If the Test Set results

have shown an incorrect

tempering temperature,

the temperature can be

adjusted using key '-'

and '+'. The new

calibration value has to

be confirmed with Enter.

Information about the

software version.

The active mode may only be ended by switching off the unit.

Therefore, we recommend checking the light

performance and tempering temperature

using the Test Set every six months.

The application of the Test Set is described in

the corresponding note accompanying the

Test Set (81). Please observe these

instructions when performing the calibration.

Procedure in case of negative test results:

– If the light performance is inadequate,

change all the lamps.

– If the tempering temperature is

inadequate, adjust the temperature with

the help of the special mode (No. 2).

Please observe the table in Chapter 7.7

for that purpose.

Mode (M)

no meaning

e.g. Mode 2

Page 18

18

8. What if...

8.1 Technical malfunctions

This chapter will help you to recognize

malfunctions and take appropriate measures,

or, if possible, to perform some repairs.

8.2 Error messages

In case of a technical defect, the display will

indicate an Error message with a number.

The Error messages are explained in the

following table:

8.3 Repairs

Repairs may only be carried out by a certified

Ivoclar Service Center. Please refer to the

addresses at the end of these Instructions.

If repairs during the warranty period are not

carried out by a certified Ivoclar Service

Center, the warranty will expire immediately.

Please also read the safety information in

Chapter 2.

Description Double-check Action

Display does not work Is the fuse for the electronic Check fuse.

controls OK?

Display does not work Is the power cord correctly Check power cord for

connected? correct fit

Error Number

10

11

12

14

21

22

23

50

97

98

99

Description

Swivel arm not correctly closed

Light performance too low

No light

Maximum number of acceptable lamp

operating numbers has been surpassed

Temperature in the curing chamber is too

high

Heater does not heat up

Electronics

Possible Causes

Curing chamber does not entirely close (e.g.

something is placed on the bottom of the

unit), or the swivel arm has been opened

during a program in progress (P1).

– At least one lamp is not correctly mounted

in its socket

– At least one lamp per group (group of four)

is defective

– The maximum number of acceptable lamp

operating hours has been surpassed

– Unacceptably high ambient temperature

– Unacceptably low supply voltage

– At least one lamp per group (group of four)

is not correctly mounted in its socket

– At least one lamp per group (group of four)

is defective

– Light sensor or electronic controls defective

Maximum number of acceptable lamp

operating numbers has been surpassed

– Dust filter is dirty

– Air vents are blocked

– Fan is defective

– Unsuitable location of the unit

– Heaters are defective

–Temperature sensor is defective

– Error in the electronic components

Measures

– Remove item

– Do not open the swivel arm during a

program in progress

– Secure lamp correctly in its socket (see Point

7.3)

– Replace defective lamp (see Point 7.3)

– Replace all lamps

– Secure lamp correctly in its socket (see

Point 7.3)

– Replace defective lamp (see Point 7.3)

– Contact your local Ivoclar Vivadent Service

Center

Replace all lamps with new ones (see Point

7.3) and reset the counter for the lamp

operating house to 0 using ‘Mode 1’.

Until the new lamps are available, error message 14 may be acknowledged by pressing

'STOP'. After that, the unit may

temporarily be used again. However, error

message 14 will reappear each time the unit

is switched on to remind the user of the

required lamp replacement.

– Clean dust filter (see Point 7.4)

– Remove obstacle from air vents

– Contact the Service Center

– Select a suitable location (see Point 4.2)

– Contact the Service Center

– Contact the Service Center

–Switch off the unit, wait for 1 minute, and

switch on again

– Contact the Service Center

Page 19

19

9. Product Specifications

Lumamat 100

This chapter contains all the

relevant product specification.

9.1 Delivery form

1 Lumamat 100

1 Power cord

1 Extra fuse

1 Extra lamp

1 Screw driver

1 Operating Instructions

1 Warranty card

1 Standard accessories set

1Test set

Colours:

Standard colour:

White RAL 9016

Special colours:

Salmon RAL 3014

Aquamarine RAL 5014

Turquoise RAL 6027

9.2 Technical data

Power supply

Single-phase alternating current:

220–230 V / 50–60 Hz

100 V / 50–60 Hz

110 V / 50–60 Hz

120 V / 50–60 Hz

Tolerated voltage fluctuations:

+/– 10 %

Power consumption:

max. 750 W

Type of lamp:

Fluorescent lamps (only use

Ivoclar Vivadent lamps)

Electrical fuses:

Value for all voltage versions:

For 220–230 V: T 5A

Has to comply with IEC 127

For 100–120 V: T 8A

Has to be UL and CSA listed.

Dimensions of fuses:

Diameter 5 x 20 mm

Dimensions:

Width: 323 mm

Depth: 440 mm

Height:

closed 272 mm

open 540 mm

Lightwave range:

400–580 nm

Weight:

13.4 Kg

Safety information

This apparatus has been

constructed according to the

following directives:

– Directive 73/336/EEC, low-

voltage guidelines

– Directive 89/336/EEC, radio

protection /electromagnetic

compatibility

Furthermore, the following

standards were observed:

– IEC 61010-1

– UL 3101-1

– CSA 1010.1

9.3 Acceptable operating

conditions

Acceptable temperature range

5–40 °C / 41–104 °F

Acceptable humidity range

Maximum relative humidity at

31 °C (87 °F), gradually

decreasing to 50 % at 35 °C

(95 °F), condensation excluded.

Acceptable ambient pressure

The unit has been tested for use

at altitudes of up to 2000 m

above sea level.

9.4 Acceptable

transportation and

storage conditions

Acceptable temperature range

-30 – +80 °C (-22 – +176 °F)

Acceptable humidity range

Maximum relative humidity at

31 °C (87 °F) gradually decreasing to 50 % at 40 °C (104 °F),

condensation excluded.

Acceptable ambient pressure

500-1060 mbar.

Use only original packaging with

the respective foam material for

shipping purposes.

Page 20

This apparatus has been developed solely for use in

dentistry. Start-up and operation should be carried

out strictly according to the Instructions for Use. Liability cannot be accepted for damages resulting

from misuse or failure to observe the Instructions.

The user is solely responsible for testing the apparatus for its suitability for any purpose not explicitly

stated in the Instructions. Descriptions and data constitute no warranty of attribute and are not binding.

Printed in Liechtenstein

© Ivoclar Vivadent AG, Schaan/Liechtenstein

573351/0303/e

Version: 1

Edition: 03/2003

Ivoclar Vivadent – worldwide

Ivoclar Vivadent AG

Bendererstrasse 2

FL-9494 Schaan

Liechtenstein

Tel. +423 235 35 35

Fax +423 235 33 60

www.ivoclarvivadent.com

Ivoclar Vivadent Pty. Ltd.

1 – 5 Overseas Drive

P. O. Box 367

Noble Park,Vic. 3174

Australia

Tel. +61 3 979 595 99

Fax +61 3 979 596 45

Ivoclar Vivadent Ltda.

Rua Maestro João Gomes de

Araújo 50; Salas 92/94

Sao Paulo, CEP 02332-020

Brasil

Tel. +55 11 69 59 89 77

Fax +55 11 69 71 17 50

Ivoclar Vivadent, Inc.

23 Hannover Drive

St. Catharines, Ont. L2W 1A3

Canada

Tel. +1 800 263 8182

Fax +1 905 988 5411

Ivoclar Vivadent Marketing

Ltd.

Calle 134 No. 13-83, Of. 520

Bogotá

Colombia

Tel. +57 1 627 33 99

Fax +57 1 633 16 63

Ivoclar Vivadent SAS

B.P. 118

F-74410 Saint-Jorioz

France

Tel. +33 450 88 64 00

Fax +33 450 68 91 52

Ivoclar Vivadent GmbH

Dr. Adolf-Schneider-Str. 2

D-73479 Ellwangen, Jagst

Germany

Tel. +49 (0) 79 61 / 8 89-0

Fax +49 (0) 79 61 / 63 26

Ivoclar Vivadent UK Limited

Meridian South

Leicester

LE3 2WY

Great Britain

Tel. +44 116 265 40 55

Fax +44 116 265 40 59

Ivoclar Vivadent s.r.l.

Via dell’Industria 16

I-39025 Naturno (BZ)

Italy

Tel. +39 0473 67 01 11

Fax +39 0473 66 77 80

Ivoclar Vivadent S.A. de C.V.

Av. Mazatlán No. 61, Piso 2

Col. Condesa

06170 México, D.F.

Mexico

Tel. +52 (55) 55 53 00 38

Fax +52 (55) 55 53 14 26

Ivoclar Vivadent Ltd

12 Omega St, Albany

PO Box 5243 Wellesley St

Auckland, New Zealand

Tel. +64 9 630 52 06

Fax +64 9 630 61 48

Ivoclar Vivadent Polska Sp.

z.o.o.

ul. Jana Pawla II 78

PL-01-501 Warszawa

Poland

Tel. +48 22 635 54 96

Fax +48 22 635 54 69

Ivoclar Vivadent S.A.

c/Valderribas 82

E-28007 Madrid

Spain

Tel. +34 91 513 10 08

Fax +34 91 552 64 07

Ivoclar Vivadent AB

Dalvägen 16

S-169 56 Solna

Sweden

Tel. +46 8 514 93 930

Fax +46 8 514 93 940

Ivoclar Vivadent, Inc.

175 Pineview Drive

Amherst, N.Y. 14228

USA

Tel. +1 800 533 6825

Fax +1 716 691 2285

Loading...

Loading...