Page 1

Ivomat IP3

Operating Instructions

Bedienungsanleitung

Mode d’emploi

Istruzioni d’uso

Instrucciones de uso

Instruções de Uso

Page 2

2

Page 3

Ivomat IP3

Table of Contents

1. Introduction / Signs and Symbols

1.1 Preface

1.2 Introduction

1.3 Signs and Symbols

2. Safety First

2.1 Indications

2.2. Health and safety instructions

3. Product Description

3.1 Components

3.2 Functional description

3.3 Hazardous areas and safety equipment

4. Installation

4.1 Unpacking and checking the contents

4.2 Selecting the location

4.3 Connections

4.4 Connecting the return water canister

5. Start-Up

5.1 Switching on/off

5.2 Filling in water

6. Operation

6.1 Placing the objects and starting the program

6.2 End of the program and removing the objects

English

7. Maintenance, Cleaning, and Diagnosis

7.1 Monitoring and maintenance

7.2 Cleaning

7.3 Maintenance

8. What If …

8.1 Power failure

8.2 Repair

8.3 Technical malfunctions

9. Product Specifications

9.1 Delivery form

9.2 Technical data

9.3 Acceptable operating conditions

9.4 Acceptable transportation conditions

3

Page 4

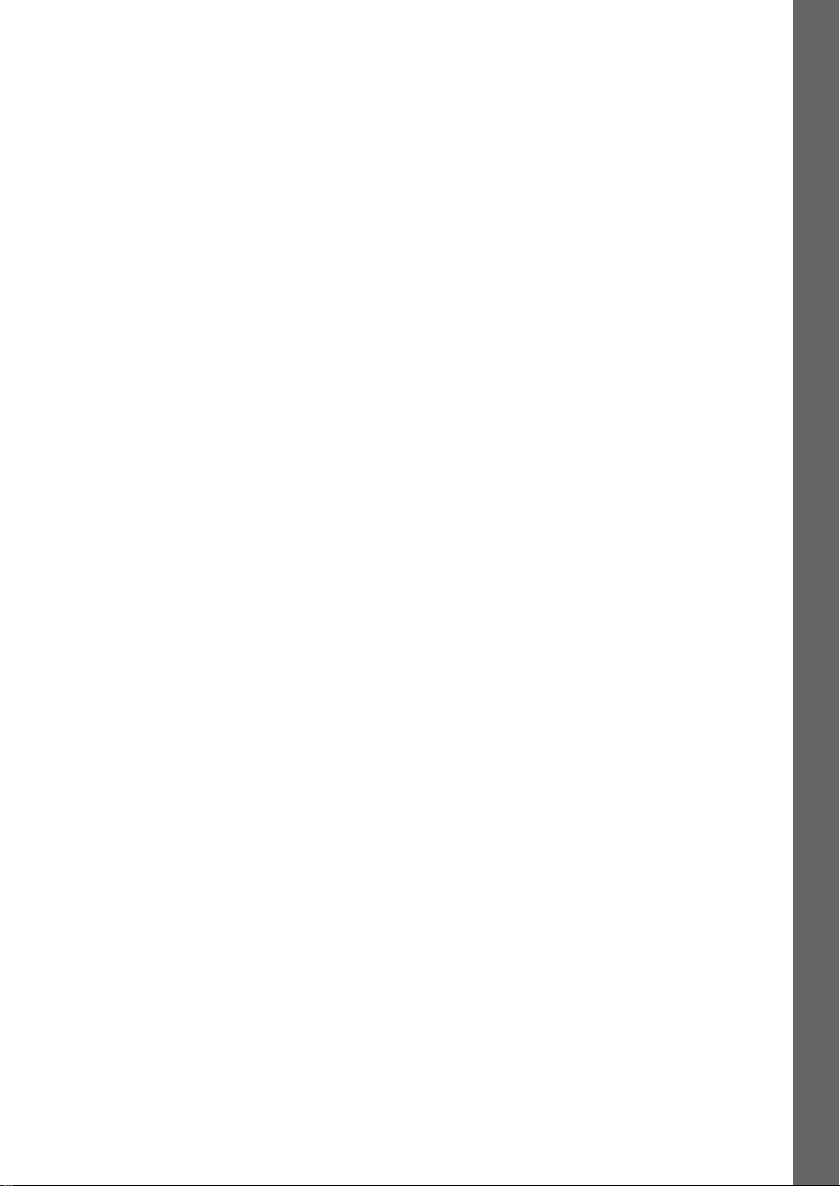

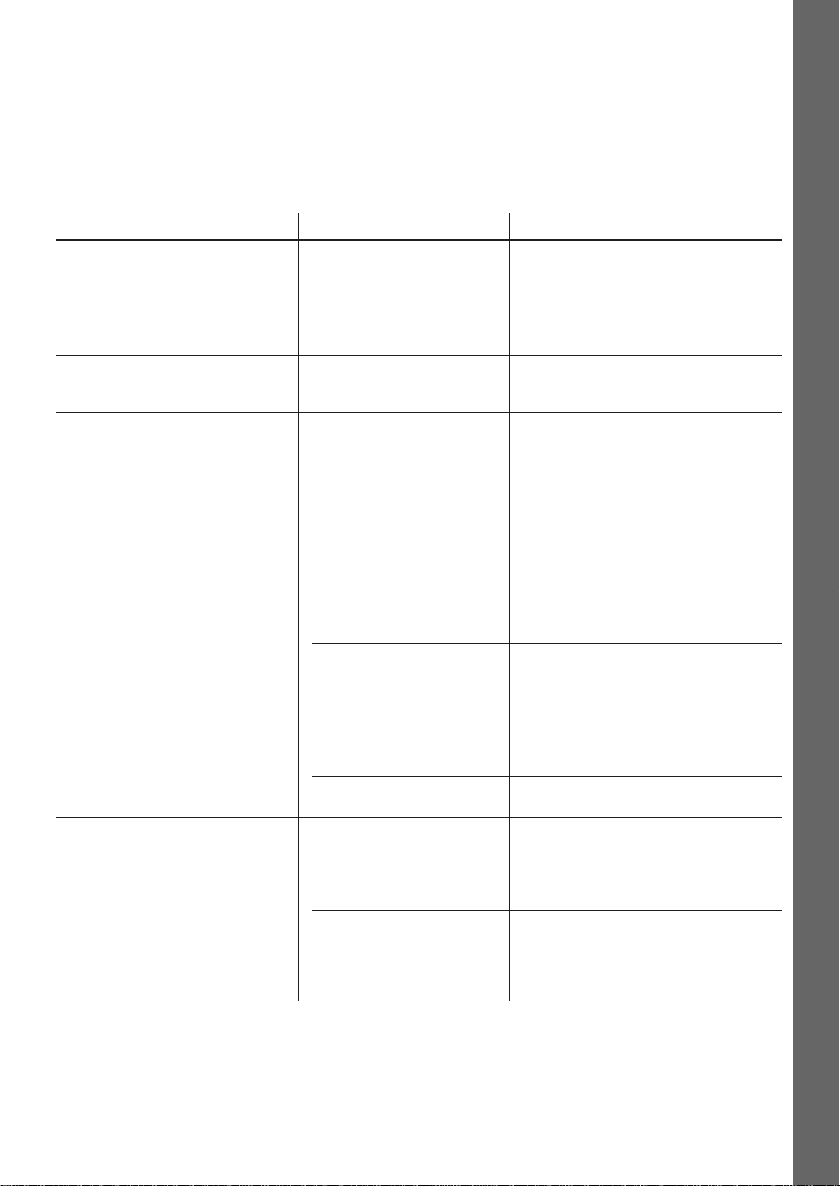

List of Parts

1) Air filter control

1a) Sight glass

1b) Release button

2) Safety lever

3) Bold knob

4) Pressure chamber lid

5) Pressure chamber

6) Thermostat

7) Manometer

8) Timer

9) Mains switch

10) Pilot lamp

11) Non-return valve

12) Compressed air hose

13) Power cord

14) Fuse cap

15) Fuse

16) Safety valve

17) Reset button

18) Water drain hose

19) Canister cap

20) Return water canister

21) Canister hose

22) Sealing washer for sound absorber

23) Sound absorber

24) Collar

25) Air hole

26) Collar screw

27) Polymerization container lid

28) Alligator clips

29) Polymerization container

30) Replenishing cup

4

Page 5

10

2

1

3

4

5

English

9

8

7

27

28

4

3

29

2

5a

5

11

6

30

18

19

21

22

23 20

12

17

1

13

1a

1b

18

14,15

5

16

16a

Page 6

1. Introduction / Signs and Symbols

1.1 Preface

Dear Customer,

Thank you for having purchased the IVOMAT IP3. This

apparatus is a technically advanced product. Please read

these Operating Instructions carefully and use the

IVOMAT IP3 according to the instructions. Should you

have any further questions, please contact your dealer

or Ivoclar Vivadent directly.

1.2 Introduction

Apparatus: IVOMAT IP3

Target group:Dental professionals

The IVOMAT IP3 is suitable for the polymerization of

dental resins.The Operating Instructions ensure safe,

correct, and economic use of the IVOMAT IP3. They are

divided into several, clearly structured chapters.This

should enable you to locate specific topics quickly and

easily.

To inform you about risks, dangers, important

information, and contraindications,these Instructions

contain corresponding signs/symbols to mark important

paragraphs.

We recommend keeping the Instructions in a safe place

near the apparatus to have immediate access to the

information if necessary.

Should you lose the Operating Instructions, extra copies

can be ordered at a normal fee from your local Ivoclar

Vivadent Service Center.

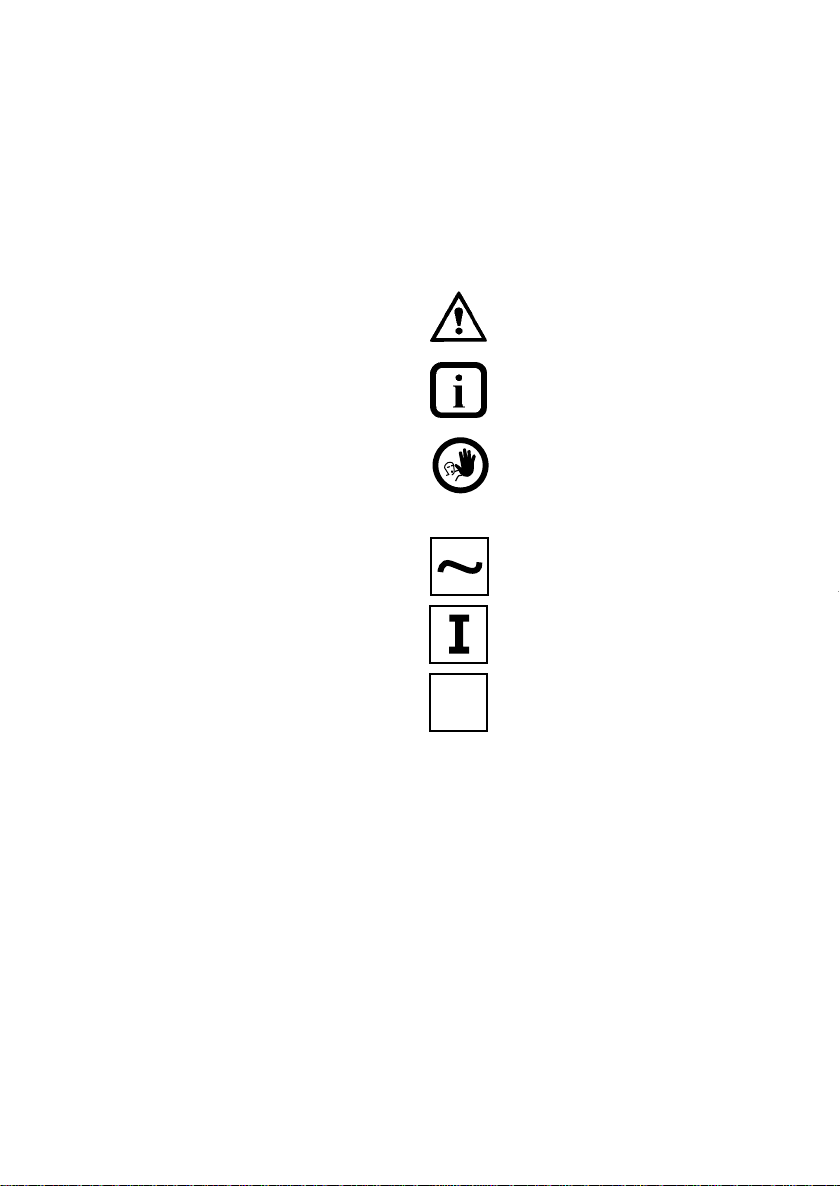

1.3 Signs and symbols

The signs and symbols in these Operating Instructions

facilitate the finding of important points and have the

following meanings:

In the Operating Instructions

Risks and dangers

Information

Contraindication

On the apparatus

Alternating current

On

Off

O

6

Page 7

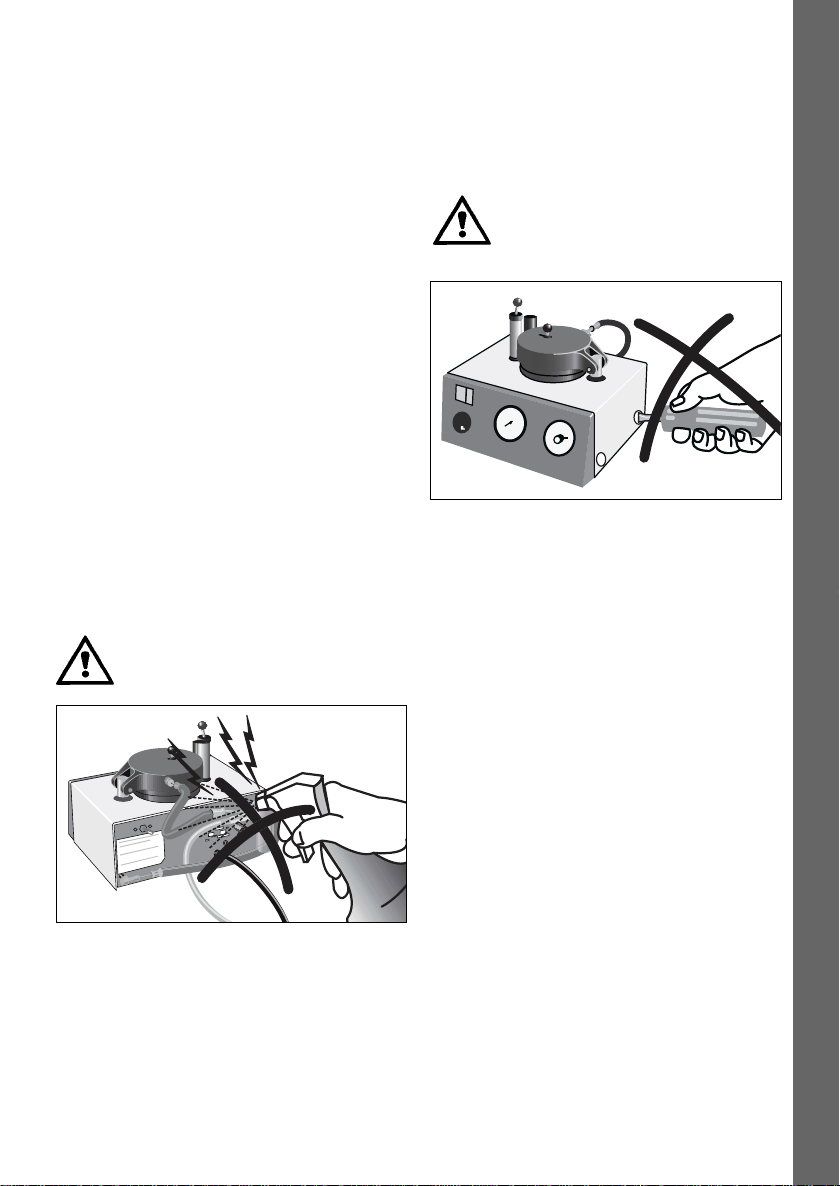

2. Safety First

English

This chapter is especially important for individuals who

work with the IVOMAT IP3 or who have to carry out

maintenance or repair work. This chapter must be read

and the corresponding instructions followed.

2.1 Indications

The IVOMAT IP3 has been especially developed for the

polymerization of dental resins and materials and should

be used for these purposes only.

Uses other than the ones stipulated are contraindicated.

The manufacturer does not assume any liability for

damage resulting from misuse.The user is solely

responsible for any risk resulting from failure to observe

these instructions.

Further instructions to assure proper use of the furnace:

– The instructions,regulations, and notes in these

Operating Instructions must be observed.

– The apparatus must be operated under the indicated

environmental and operating conditions

(see Chapter 9)

– The IVOMAT IP3 must be properly maintained.

2.2.1

Risks and dangers

2.2.2

Risks and dangers

The housing must not be opened while it is connected to

the power supply,since there is a risk of electrical shock.

The connection cover may only be opened by a qualified

service center.

Make sure that no liquids or other foreign objects enter

the air vents, since this may result in an electrical shock.

7

Page 8

3. Product Description 4. Installation

3.1 Components

The IVOMAT IP3 consists of the following components:

– Apparatus with air filter control

– Non-return valve

– 1.5 m compressed air hose

– 1.2 m water drain hose with canister cap

– Canister hose with sound absorber; polymerization

container in pressure chamber, and 3 object clips

secured to removable lid

– 1 return water container

– 1 replenishing cup

Special accessories

– IVOMAT refill container type IN 1

– Wallfixator

3.2 Functional description

The pressure chamber is equipped with a heater.

In this way, the water can be heated to the temperature

required for the corresponding material.

The pressure chamber is impinged with compressed air

to achieve optimum homogeneity of the material. The

polymerization time can be set by means of the timer.

3.3 Hazardous areas and safety equipment

Description of the hazardous areas:

Hazardous area Type of risk

Safety holder Electrical shock

Air vents Electrical shock

4.1 Unpacking and checking the contents

Remove the apparatus from its packaging and check for

possible transportation damage.We recommend keeping

the original packaging for future transportation

purposes. Use only the original packaging for

transportation.

Do not carry the IVOMAT IP3 by means of

the power cord. Support the bottom of the

IVOMAT IP3 with both hands to carry it.

4.2 Selecting the location

Place the apparatus on a flat table using the rubber feet.

Make sure that the apparatus is not placed in the

immediate vicinity of heaters or other sources of heat.

Furthermore, protect the apparatus from direct sunlight.

4.3 Connections

Make sure the voltage indicated on the rating plate

complies with the local power supply.If this is not the

case, the apparatus must not be connected.

Connecting the compressed air hose

Make sure that the hose is properly connected.

Power connection

Make sure that the power cord does not touch any parts

of the apparatus that become hot during use.

The electrical installations of the room where

the apparatus is located must comply with

the national regulations and IEC standards.

Description of the safety equipment

Safety equipment Protective effect

Protective conductor Protection from electrical shock

IP44 (system of protection) Protection from electrical shock

Protective thermal switch Protects the IVOMAT IP3

from overheating

8

Page 9

5. Start-up

English

4.4 Connecting the return water canister

– Fill return water canister (20) to a depth of 3–5 cm.

– Insert the canister hose into the canister and screw

cap on (19).

– Put the canister on the floor in a suitable place.

– Lift the safety lever (2) and engage. Push the bolt to

the right using the knob (3) and lift the lid (4) of the

vessel.

– Remove protective insert used during transportation.

5.1 Switching on / off

Take the polymerization container (29) with lid (27) out

of the pressure chamber. Switch on main (9) (0 to I).The

pilot lamp (10) will light up when the apparatus is ready

for use.

The apparatus may be kept ready for use

throughout the day (mains switch on I), but the

pressure chamber lid (4) should remain either

unbolted or open after each use.

5.2 Filling in water

Fill the pressure chamber with water.

– Maximum filling height: up to the market groove in

the chamber

– Minimum filling height: objects to be polymerized

must be completely under water

9

Page 10

6. Operation

6.1 Placing the objects and starting the program

– Remove the lid (27) from the polymerization contains.

Secure the objects to be polymerized on the alligator

clips (28).

– Slowly insert the polymerization container with lid and

objects, or models held by the Wallfixator,into the

pressure chamber.

– Close chamber lid (4). Bolt the chamber by sliding the

knob (3) to the left. Press safety lever down until it

audibly clicks into place.

Chamber lid

– Set polymerization thermostat (6). Move the red

indicator to the desired temperature.

Timer

– Automatic program:

• The manometer (7) indicates the rise in pressure

(check to make sure that the required operating

pressure has been reached by the time the selected

temperature has been achieved.

Thermostat (°C)

The program automatically begins, once the timer

is set. Note: For times under 5 minutes, first turn

the timer to approximately 10 minutes, then

immediately turn it back to the desired time.

(If required, the time may be returned to zero during the

automatic program in progress.The time may also be

prolonged or shortened.)

Manometer

• The water in the pressure chamber is heated.

The black indicator on the thermostat registers the

current temperature.

• Once the desired temperature is reached, the set

polymerization time begins (timer countdown).

• After the polymerization time, the water is ejected

from the pressure chamber and flows into the canister.

At the same time, the pressure is released (indicated

on the manometer).

10

Page 11

7. Maintenance, Cleaning,

and Diagnosis

English

6.2 End of the program and removing the objects

– Opening the pressure chamber lid:

Do not lift the safety lever before the

manometer needle is at zero and the

black thermostat indicator has fallen

below 110 °C (230 °F). (Any residual

pressure is blown off against the chamber

lid.) The lid can then be safely unbolted by

pushing the knob to the right and the

chamber lid opened.

– Removing the polymerized objects:

Remove the polymerization container

including the lid from the pressure

chamber and allow it to cool for a few

minutes before removing the polymerized

objects. Cooling too quickly may result in

stress within the resin materials.

– Use softened water (not distilled) or

water 4–9° hard (70–160 ppm/°

US = 5-12° Brit.) (Ph 7–8/20 °C).

If tape water of more than 9° hard (16° Fr)

is used, special care must be given to

maintenance and cleaning or

decalcification (see decalcification,

page 11).

– Make sure that no wax enters the

pressure chamber.

– Set the polymerization time only after

bolting the pressure chamber lid.

– Caution: Do not touch hot parts of

the apparatus during use.

For safety reasons,disconnect power

cord for all cleaning and maintenance

procedures.

7.1 Monitoring and maintenance

Keep pressure chamber sealing rim (5a) and sealing ring

clean and undamaged. If using water as prescribed in

point IV, remove the perforated plate and clean the

pressure chamber, heater, outflow filter,and outflow

system at least every three months. (Remove any wax

residue using a suitable wax solvent.)

7.2 Cleaning

Dust the IVOMAT IP3 from time to time. Use,for

example, a vacuum cleaner with a cleaning brush for

that purpose.

Parts Cleaning material

Housing Cloth

Pressure chamber Deliming agent

7.3 Maintenance

Please observe the relevant accident control

regulations and other accepted rules regarding

safety and industrial medicine. The connection

cover, which is marked with the rating plate below

may only be opened by a qualified service

technician and with the power disconnected.

Decalcification

If hard tap water of more than 9° (160 ppm/°US = 5–12°

Brit.) is used, the apparatus must be regularly checked,

according to use about once a week, for possible

calcareous deposits on the heating element. For that

purpose, the perforated plate must be removed from the

pressure chamber.

If there is a visible chalky deposit on the heating

element, the device must be cleaned using a deliming

agent as follows: (customary deliming agents used for

coffee makers,boilers, etc. can be used).

11

Page 12

8. What If …

– Fill the pressure chamber with approx. 0.5 l water and

dissolve the amount of deliming agent recommended

in the corresponding instructions for use.

– Close and bolt the pressure chamber lid.

– Set the thermostat to 80 °C and the timer to

5 minutes.

– Once the program is completed, open the lid and

check the cleaning results.

– Remove any large, loose particles from the chamber.

– If necessary,repeat the procedure until the heating

element and pressure chamber are clean.

– After decalcifying, repeat the procedure with fresh

water to rinse the pressure chamber and the outflow

system. (Once the operating pressure is reached, the

program can be interrupted by setting the timer to 0)

– Empty the return water canister and rinse with fresh

water.

Deliming agents are caustic and toxic.

Avoid contact with skin and eyes. In case

of accidental contact, rinse with copious

amounts of fresh water.

Condensation accumulated in the sight glass (1a) can be

drained off by pushing the release button (1b).

At three-months intervals, unscrew the canister cap (19)

and clean (clear) the small air hole (25) of the canister

hose (21). Access to the hole (25) is gained by loosening

the screw (26) and removing the collar (24).

8.1 Power failure or blown fuse

– In the event of a power failure, the automatic program

is interrupted. Once the power supply returns,the

program will automatically continue.

– To take the objects out of the pressure chamber

during prolonged power failures, proceed as described

under 3a.

– If the fuse (15) of the apparatus is defective, open the

fuse cap and replace the fuse.

If problems arise, which are not mentioned in the

table below, please contact our Customer Service

Department.

8.2 Repair

Repairs may only be carried out by a certified Ivoclar

Vivadent Service Center. Please contact our Customer

Service Department.

12

Page 13

8.3 Technical malfunctions

English

Error or malfunction

1. Objects not fully cured, even though

the program ran normally (Timer

has run to "0", manometer shows

"0").

2. Program fails to continue after

polymerization time has been set.

3. Automatic program has stopped

too soon (Timer has not run to "0",

manometer indicates pressure).

Possible causes

– Too little water in the

pressure chamber, or

– temperature too low,or

– time too short, or

– air pressure too low

Chamber lid not properly closed

and bolted.

No or far to little water in the

pressure chamber (excess heat

protection of the heater

engaged).

Heater and overheating sensor

in the chamber very dirty or

calcareous.

Power failure or defective fuse.

Corrective action

1a) Repeat program (polymerization) with

sufficient water, correct temperature and

time, and stipulated air pressure.

2a) Close and bolt chamber lid according

to the instructions.

3a) Disconnect power. Release pressure by

means of the safety valve.Turn air knob

(16a) at the end of the safety valve (16)

counter-clockwise until the manometer

indicates "0" and the black needle on the

thermostat registers less than 90 °C/194 °F.

Open the chamber lid and allow chamber

to cool for approx. 6 min.Then, turn air

knob clockwise until it stops. Press red

reset button (17) on the back of the

apparatus.

3b) Proceed as described in 3a). Remove

perforated plate from the pressure

chamber and clean it. Clean heater with

overheating sensor and clean or delime the

chamber according to the service

recommendations.

3c) See point 7.

4. Pressure falls abnormally slowly

after the end of the program.

(Manometer shows "0", timer has

run to "0". Polymerization

temperature has been reached.

Outflow filter in the pressure

chamber is partly blocked.

Outflow system partly blocked.

13

4a) Remove perforated plate from the

pressure chamber. Clean outflow filter,

chamber, and heater, or delime according

to the service recommendations.

4b) Clean sound absorber (23). Unscrew

water drain hose (18) from the back of the

apparatus and blow compressed air

through the hoses. Delime if necessary.

Page 14

9. Product Specifications

9.1 Delivery form

The IVOMAT IP3 consists of the following components:

– Apparatus with air filter control

– Non-return valve

– 1.5 m compressed air hose

– 1.2 m water drain hose with canister cap

– Canister hose with sound absorber; polymerization

container in pressure chamber, and 3 object clips

secured to removable lid

– 1 return water container

– 1 replenishing cup

9.2 Technical data

Power supply: Single-phase alternating current

Standard version:

– 220 V / 50 Hz

– 240 V / 50 Hz

Acceptable voltage fluctuations: +10 % to –15 %

Power consumption: 1030 W

Electrical fuses:

100–118 V: 12.5 A, slow. Diameter: 6.3 x 32 mm

220 V: 6.3 A, slow. Diameter: 5 x 20 mm

240 V: 5 A, slow. Diameter 5 x 20 mm

Compressed air:

Operating pressure (already set): approx. 6 bar = 6.10 Pa

(Tolerance:green area of the scale)

System pressure: 6 to max. 12 bar = 6 to max.12.10 Pa

Hose with an inside diameter of 6 mm

9.3 Acceptable operating conditions

Acceptable temperature range

+5 °C to +40 °C (+41 °F to +104 °F)

Acceptable altitude:

The apparatus has been tested for use at altitudes of up

to 2000 m

Atmospheric pressure of 500 mbar to 1060 mbar

9.4 Acceptable transportation and storage

conditions

Acceptable temperature range

–20 °C to +55 °C (-4 °F to +131 °F)

Maximum relative humidity: 80 %

Dimensions of the closed apparatus:

Width: 312 mm, Depth:302 mm

Height: 220 mm

Useful dimensions of pressure chamber:

Diameter: 112 mm, height:98 mm

Max. water capacity 0.78 dm

Weight: 9.75 kg

Safety information:

EN 61010, Part 1, EMC tested

3

(Liter)

14

Page 15

Ivomat IP3

Teileverzeichnis

1. Einleitung und Zeichenerklärung

1.1 Vorwort

1.2 Einleitung

1.3 Zeichenerklärung

2. Sicherheit geht vor

2.1 Bestimmungsgemässe Verwendung

2.2 Sicherheits- und Gefahrenhinweise

3. Produktbeschreibung

3.1 Aufbau des Gerätes

3.2 Funktionsbeschreibung

3.3 Gefahrenstellen und Sicherheitseinrichtungen

4. Installation

4.1 Auspacken und Lieferumfang prüfen

4.2 Standortwahl

4.3 Anschlüsse herstellen

4.4 Rückwasser Kanister anschliessen

5. Inbetriebnahme

5.1 Ein- und Ausschalten des Gerätes

5.2 Wasser einfüllen

6. Bedienung

6.1 Bestückung und Programmstart

6.2 Programmende und Objekt entnehmen

Deutsch

7. Unterhalt, Reinigung und Diagnose

7.1 Kontroll- und Unterhaltsarbeiten

7.2 Reinigungsarbeiten

7.3 Wartungshinweise

8. Was ist, wenn …

8.1 Stromausfall

8.2 Reparaturarbeiten

8.3 Technische Störungen

9. Produktspezifikationen

9.1 Lieferform

9.2 Technische Daten

9.3 Zulässige Betriebsbedingungen

9.4 Zulässige Transportbedingungen

15

Page 16

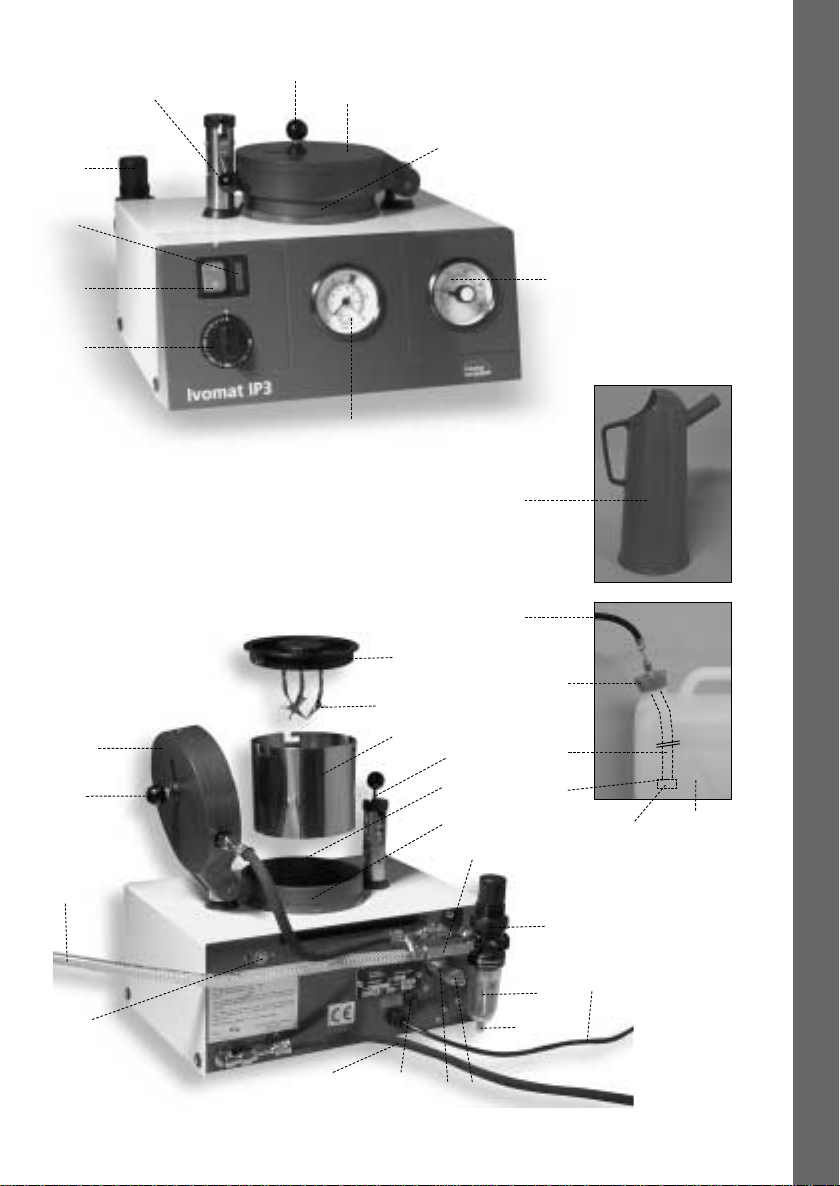

Teileverzeichnis

1) Luftfilterregler

1a) Sichtbehälter

1b) Ablassknopf

2) Nockenhebel

3) Knopf für Riegelbetätigung

4) Kesseldeckel

5) Druckkessel

5a) Druckkessel-Dichtungsrand

6) Temperaturregler

7) Manometer

8) Zeitschaltuhr

9) Netzschalter

10) Kontrollampe

11) Rückschlagventil

12) Druckluftschlauch

13) Netzkabel

14) Verschlusskappe zu Sicherung

15) Sicherung

16) Sicherheitsventil

16a) Anlüftung des Sicherheitsventils

17) Rückstellknopf

18) Abwasserschlauch

19) Kanisterdeckel

20) Rückwasserkanister

21) Kanisterschlauch

22) Dichtscheibe für Schalldämpfer

23) Schalldämpfer

24) Ring

25) Belüftungsbohrung

26) Schraube

27) Deckel des Polymerisationsbehälters

28) Krokodilklemme

29) Polymerisationsbehälter

30) Wasser-Einfüllgefäss

16

Page 17

10

2

3

4

Deutsch

5

1

9

8

7

27

28

4

3

29

2

5a

5

11

6

30

18

19

21

22

23 20

12

17

1

13

1a

1b

18

14,15

17

16

16a

Page 18

1. Einleitung und Zeichenerklärung

1.1 Vorwort

Sehr geehrter Kunde,

Es freut uns, dass Sie sich für den Kauf des IVOMAT IP3

entschieden haben. Bei diesem Gerät handelt es sich um

ein technisch hochstehendes Produkt. Wir bitten Sie, die

Bedienungsanleitung zu lesen und das Gerät analog der

Bedienungsanleitung in Betrieb zu nehmen. Wenn Sie

noch zusätzliche Fragen haben, wenden Sie sich bitte an

das entsprechende Depot oder direkt an Ivoclar Vivadent.

1.2 Einleitung

Zutreffendes Gerät: IVOMAT IP3

Zielgruppe: Zahntechnisches Fachpersonal

Der IVOMAT IP3 eignet sich für das Aushärten von

Dental-Kunststoffen. Die Bedienungsanleitung dient zur

sicheren, sachgerechten und wirtschaftlichen Nutzung

des IVOMAT IP3. Die Bedienungsanleitung ist in mehrere

Kapitel unterteilt, die klar gegliedert sind. Diese

Aufteilung erleichtert ein schnelles Auffinden der

gewünschten Punkte.

Um Sie schnell und übersichtlich über Gefahren, wichtige

Informationen und nicht zulässige Anwendungen

informieren zu können, werden an den Stellen

entsprechende Symbole (Piktogramme) verwendet.

Wir empfehlen Ihnen, die Bedienungsanleitung an einem

geschützten Ort in der Nähe des Gerätes aufzubewahren,

sodass jederzeit ein schneller Informationszugriff möglich

ist. Bei einem eventuellen Verlust können Sie die BA

gegen Schutzgebühr über die entsprechende Ivoclar

Vivadent Servicestelle beziehen.

1.3 Zeichenerklärung

Die Symbole in der Bedienungsanleitung erleichtern

Ihnen das Auffinden wichtiger Punkte und geben Ihnen

folgende Hinweise:

In der Bedienungsanleitung:

Gefahren mit Risiken

Informationen

Nicht zulässige Verwendungen

Auf dem Gerät:

Wechselstrom

Ein

Aus

O

18

Page 19

2. Sicherheit geht vor

Deutsch

Dieses Kapitel ist für alle Personen, die mit dem Gerät

arbeiten oder am Gerät Unterhalts- oder Reinigungsarbeiten durchführen, zwingend zu lesen. Die Hinweise

sind zu befolgen.

2.1 Bestimmungsgemässe Verwendung

Der IVOMAT IP3 ist speziell für die Aushärtung von

Dental-Kunststoffen und Materialien entwickelt worden.

Bitte verwenden Sie dieses Gerät ausschliesslich für

diesen Zweck.

Eine andere oder darüber hinausgehende Benutzung gilt

als nicht bestimmungsgemäss. Für hieraus resultierende

Schäden haftet der Hersteller nicht. Das Risiko trägt

allein der Anwender.

Zur bestimmungsgemässen Anwendung gehören zudem:

– Die Beachtung der Anweisungen,Vorschriften und

Hinweise in der vorliegenden Bedienungsanleitung

– Der Betrieb unter den vorgeschriebenen Umwelt- und

Betriebsbedingungen (siehe Kapitel 9)

– Die korrekte Instandhaltung des Gerätes

2.2.1

Gefahren und Risiken

2.2.2

Gefahren und Risiken

Das Gehäuse darf wegen Stromschlaggefahr nicht

geöffnet werden, wenn das Gerät unter Stromspannung

steht. Den Anschlussdeckel darf nur eine qualifizierte

Servicestelle öffnen.

Es dürfen keine Gegenstände oder Flüssigkeiten in die

Lüftungsschlitze gelangen. Es könnte dadurch Stromschlag verursacht werden.

19

Page 20

3. Produktbeschreibung

4. Installation

3.1 Aufbau des Gerätes

Der IVOMAT IP3 besteht aus folgenden Komponenten:

– Gerät mit Luftfilterregler

– Rückschlagventil

– 1,5 m Druckluft-Schlauch

– 1,2 m Abwasserschlauch mit Kanisterdeckel

– Kanisterschlauch und Schalldämpfer, im Druckkessel

eingesetztem Polymerisationsbehälter mit 3, am

abnehmbaren Deckel befestigten, Objektklemmen.

– 1 Rückwasserkanister

– 1 Wasser-Einfüllgefäss

Sonderzubehör:

– IVOMAT-Nachfüllanlage Typ IN 1

– Wallfixator

3.2 Funktionsbeschreibung

Der Druckbehälter ist mit einer Heizung versehen. Somit

kann das Wasser je nach Bedarf auf die entsprechende

Temperatur aufgeheizt werden,welche für das Material

benötigt wird. Der Drucktopf wird mit Pressluft

beaufschlagt, um eine optimale Materialhomogenität zu

erzielen. Die Aushärtedauer kann mittels dem

Zeitschalter eingestellt werden.

3.3 Gefahrenstellen und Sicherheitseinrichtungen

Bezeichnung der Gefahrenstellen

Gefahrenstelle Art der Gefährdung

Sicherheitshalter Stromschlag

Lüftungsschlitze Stromschlag

Bezeichnung der Sicherheitseinrichtungen

Sicherheitseinrichtung Schutzwirkung

Schutzleiter Schutz vor Stromschlag

IP44 (Schutzart) Schutz vor Stromschlag

Thermoschutzschalter Schützt den IVOMAT IP3 vor

Überhitzung

4.1 Auspacken und Lieferumfang prüfen

Gerät aus der Verpackung nehmen und auf eventuelle

Transportschäden überprüfen.Wir empfehlen, dass Sie

die Originalverpackung für eventuelle Versandzwecke

aufbewahren. Für den Versand verwenden Sie bitte nur

die Originalverpackung.

Tragen Sie den IVOMAT IP3 nicht am

Netzkabel. Tragen Sie den IVOMAT IP3 mit

beiden Händen am Geräte-Unterteil.

4.2 Standortwahl

Stellen Sie das Gerät mit den Gummifüssen auf eine

ebene Ablagefläche. Achten Sie darauf, dass das Gerät

nicht einer direkten Sonnenbestrahlung ausgesetzt ist.

Stellen Sie das Gerät nicht in unmittelbare Nähe von

Heizkörpern oder anderen Wärmequellen.

4.3 Anschlüsse herstellen

Typenschild mit Spannung überprüfen.

Bitte prüfen Sie, ob die auf dem Typenschild angegebene

Spannung mit derjenigen Ihres Netzes übereinstimmt.

Sollte dies nicht der Fall sein, darf das Gerät nicht

angeschlossen werden.

Druckschlauch anschliessen

Bitte prüfen Sie, ob der Schlauch einwandfrei aufgesteckt

ist

Netzanschluss herstellen

Es ist zu beachten, dass das Netzkabel nicht mit heiss

werdenden Geräteteilen in Berührung kommt.

Die elektrischen Installationen des Raumes, in

dem sich das Gerät befindet, müssen den

landesüblichen und den IEC Normen

entsprechen.

20

Page 21

5. Inbetriebnahme

Deutsch

4.4 Rückwasser Kanister anschliessen

– Rückwasserkanister (20) 3–5 cm mit Wasser füllen.

– Kanisterschlauch in Kanister stecken und

Kanisterdeckel (19) verschrauben

– Rückwasserkanister auf dem Boden an geeigneter

Stelle aufstellen.

– Nockenhebel (2) nach oben schwenken und einrasten,

Riegel mit Knopf (3) nach rechts schieben und

Kesseldeckel (4) aufklappen.

– Einlage (Transportschutz) entfernen.

5.1 Ein- und Ausschalten des Gerätes

Polymerisationsbehälter (29) mit Deckel (27) aus Druckkessel nehmen. Netzschalter (9) drücken (von Pos. 0 auf

Pos.I). Die leuchtende Kontrollampe (10) zeigt die

Betriebsbereitschaft des Gerätes an.

Das Gerät kann den ganzen Arbeitstag in Betriebsbereitschaft gehalten werden (Netzschalter I ),

jedoch sollte nach jedem Arbeitszyklus der Kesseldeckel (4) offen oder unverriegelt bleiben.

5.2 Wasser einfüllen

Wasser in den Druckkessel einfüllen:

– Füllhöhe maximal = bis zur Markierungsrille des

Druckkessels

– Füllhöhe minimal = Objekte müssen vollständig im

Wasser sein.

21

Page 22

6. Bedienung

6.1 Bestückung und Programmstart

– Deckel (27) vom Polymerisationsbehälter abnehmen,

Polymerisationsgut an den Krokodilklemmen (28)

befestigen.

– Polymerisationsbehälter mit Deckel und Objekten,

bzw.Modelle mit dem Wallfixator,in den Druckkessel

langsam einsetzen.

– Kesseldeckel (4) schliessen:Riegel mit Knopf (3) nach

links schieben und Nockenhebel (2) nach unten

drücken bis Einrasten hörbar.

3

4

2

Kesseldeckel

– Polymerisationstemperatur am Temperaturregler (6) –

roter Sollwert-Zeiger – einstellen.

8

Zeitschaltuhr

– Automatischer Programmablauf:

• Das Manometer (7) zeigt den Druckaufbau an.

(Prüfen, ob der erforderliche Betriebsdruck nach

Erreichen der Soll-Wert-Temperatur erreicht wird.)

6

Temperatur-Regler (°C)

Nach dem Einstellen beginnt der automatische

Programmablauf. Beachten: Bei Zeiten unter

5 Minuten zuerst auf ca. 10 Minuten «überzeihen» und sogleich auf die gewünschte Zeit

rückstellen! (Falls erforderlich, kann die Zeit während

des automatischen Programmablaufs auf Null

geschaltet, verlängert oder verkürzt werden.)

7

Druckanzeige

• Wasser im Druckkessel wird aufgeheizt

(kontrollierbar am schwarzen Ist-Wert-Zeiger des

Temperaturreglers.)

• Nach Erreichen der Soll-Wert-Temperatur läuft die

eingestellte Polymerisationszeit ab.(Zeitschaltuhr

rückwärtszählend)

• Nach Ablauf der Polymerisationszeit wird das

Wasser aus dem Druckkessel in den Rückwasserkanister befördert. Zugleich erfolgt der Abbau des

Druckes (Manometer-Anzeige).

22

Page 23

7. Unterhalt, Reinigung

und Diagnose

Deutsch

6.2 Programmende und Objekt entnehmen

– Öffnen des Druckkesseldeckels:

Erst wenn der Zeiger des Manometers

auf Null steht und der schwarze IstWert-Zeiger des Temperaturreglers

unter 110°C abgelaufen ist, darf der

Nockenhebel (2) nach oben geschwenkt werden. (Eventuell im Gerät

noch vorhandener Restdruck wird auf die

Geräteabdeckung abgeblasen.) Nun kann

der Riegel mit Knopf (3) gefahrlos nach

rechts geschoben und der Kesseldeckel

aufgeklappt werden.

– Entnahme des Polymerisationsgutes:

Polymerisationsbehälter samt Deckel aus

dem Druckkessel nehmen und vor Entnahme des Polymerisationsgutes einige

Minuten abkühlen lassen. Bei zu schnellem

Abkühlen können im Kunststoff

Spannungen entstehen.

– Enthärtetes Wasser (kein destilliertes)

oder Wasser mit 4 bis 9° d-Härte (7 bis

16° fr) verwenden. (Ph 7 bis 8 / 20° C).

Bei Verwendung von Leitungswasser mit

über 9° d-Härte (16° fr) ist besondere

Wartung – Reinigung, bzw. Entkalkung

erfolderlich! (Siehe Entkalkung, Seite 23).

– Dafür sorgen, dass möglichst kein

Wachs in den Druckkessel gelangt.

– Polymerisationszeit an der

Zeitschaltuhr erst nach Verriegelung

des Kesseldeckels einstellen!

– Vorsicht: Bei der Bedienung des

Gerätes sind heisse Teile berührbar!

Aus sicherheitstechnischen Gründen bei

sämtlichen Wartungs- und Reinigungsarbeiten

den Netzstecker aus der Gerätesteckdose

ziehen.

7.1 Kontroll- und Unterhaltsarbeiten

Druckkessel-Dichtungsrand (5a) und Kesseldichtung

sauber halten und nicht beschädigen. Bei Verwendung

von Wasser, wie unter Punkt 6.2 vorgeschrieben, mindestens vierteljährlich Druckkessel, Heizung,Ablauffilter und

Ablaufsystem nach Herausnehmen des gelochten

Zwischenbodens reinigen. (Wachsrückstände mit

geeigneten Wachslösemitteln entfernen.)

7.2 Reinigungsarbeiten

Den IVOMAT IP3 gelegentlich von Staub befreien.

Verwenden Sie dazu zum Beispiel einen Staubsauger mit

Reinigungspinsel.

Was Womit

Gehäuse Lappen

Drucktopf Entkalkungsmittel

7.3 Wartungshinweise

Beachten Sie bitte die einschlägigen Unfallverhütungs-Vorschriften sowie die sonstigen anerkannten sicherheitstechnischen und arbeitsmedizinischen Regeln. Der Anschlussdeckel,

welcher mit dem untenstehenden Hinweisschild

gekennzeichnet ist, darf nur nach Ziehen des

Netzsteckers (Unterbrechen der Spannungsversorung) vom qualifizierten Servicetechniker geöffnet

werden.

Entkalkung

Wird Leitungswasser mit über 9° d-Härte (16° fr)

verwendet, so muss das Gerät je nach Inanspruchnahme

regelmässig, z.B. wöchentlich, auf eventuelle Kalkablagerungen am Heizkörper überprüft werden! Um dies

festzustellen, muss der Lochblech-Zwischenboden aus

dem Druckkessel entfernt werden.

Hat sich am Heizkörper eine sichtbare Kalkschicht gebildet, muss das Gerät mit einem kalklösenden Mittel

folgendermassen gereinigt werden: (Geeignet sind

handelsübliche Kalkentferner, wie sie zum Entkalken von

Kaffeemaschinen, Boilern etc. verwendet werden.)

23

Page 24

8. Was ist, wenn …

– Ca. 0,5 Liter Wasser in den Druckkessel füllen und die

in der Gebrauchsanweisung des Kalkentferners

empfohlene Menge des Mittels darin auflösen.

– Kesseldeckel schliessen und verriegeln.

– Temperaturregler auf 80° C einstellen.

– Zeitschaltuhr auf 5 Minuten einstellen.

– Nach Beendigung des Programmablaufes Kesseldeckel

öffnen und sich vom Ergebnis der Entkalkung

überzeugen.

– Grobe, abgelöste Kalkpartikel aus dem Druckkessel

entfernen.

– Erforderlichenfalls Entkalkungsvorgang wiederholen,

bis Heizung und Druckkessel sauber sind.

– Nach beendeter Entkalkung Vorgang mit reinem

Wasser durchführen, damit der Druckkessel und das

Ablaufsystem gespült werden. (Ist der Betriebsdruck

erreicht, kann das Programm durch Stellen der

Zeitschaltuhr auf 0 abgebrochen werden.)

– Rückwasserkanister entleeren und mit sauberem

Wasser ausspülen.

Entkalkungsmittel sind ätzend und giftig!

Haut- und Augenkontakt vermeiden!

Bei versehentlichem Kontakt mit viel

Frischwasser spülen!

Im Sichtbehälter (1a) des Luftfilterreglers angesammeltes

Kondensat durch Drücken des Knopfes (1b) ablassen.

Vierteljährlich nach Abschrauben des Kanisterdeckels

(19) kleine Belüftungsbohrung (25) am Anschlussrohr des

Kanisterschlauches (21) säubern (freimachen). Die

Bohrung (25) wird zugänglich nach Lösen der Schraube

(26) und Abziehen des Ringes (24).

8.1 Stromausfall vom Netz her oder infolge

Sicherungsdefekt:

– Bei Stromausfall wird der automatische

Programmablauf unterbrochen. Nach Beendigung der

Störung läuft das Programm automatisch weiter.

– Sofern man bei längeren Stromunterbrechungen die

Objekte aus dem Druckkessel nehmen will, ist wie

unter 3a) beschrieben, vorzugehen.

– Ist die Sicherung (15) des Gerätes defekt, so kann

diese nach Öffnen der Verschlusskappe (14) entfernt

und ersetzt werden.

Bei Fehlern oder Störungen, die in der vorstehenden Aufstellung nicht erhalten sind, fordern

Sie bitte unseren Kundendienst an.

8.2 Reparaturarbeiten

Reparaturarbeiten dürfen nur von einer qualifizierten

Ivoclar-Servicestelle durchgeführt werden. Bitte wenden

Sie sich diesbezüglich an den Kundenservice.

24

Page 25

8.3 Technische Störungen

Deutsch

Fehler oder Störung

1. Polymersationsgut nicht ausgehärtet, obwohl Programmablauf

normal erfolgt ist. (Zeitschaltuhr ist

auf "0" abgelaufen.

Manometer zeigt "0")

2. Kein automatischer Programmablauf nach Einstellen der

Polymerisationszeit

3. Automatischer Programmablauf

hat vorzeitig unterbrochen.

(Zeitschaltuhr ist nicht auf "0"

abgelaufen. Manometer zeigt Druck

an!)

Mögliche Ursachen

– Zu wenig Wasser im Druck-

kessel

oder

– zu niedrige Temperatur,

– zu kurze Zeit,

– zu niedriger Luftdruck

Kesseldeckel nicht ordnungsgemäss geschlossen und

verriegelt

Kein oder viel zu wenig Wasser

in den Druckkessel eingefüllt.

(Übertemperaturschutz der

Heizung hat angesprochen.)

Heizung und Fühler des Übertemperaturschutzes im Kessel

stark verschmutzt oder verkalkt.

Behebung

1a) Arbeitsablauf (Polymerisation) mit

genügend Wasser, vorgeschriebener

Temperatur und Zeit sowie vorgeschriebenem Luftdruck wiederholen

2a) Kesseldeckel laut Anleitung schliessen

und verriegeln (siehe V.f)

3a) Netzstecker ziehen. Druck über

Sicherheitsventil ablassen: Die Anlüftung

(16a) am Ende des Sicherheitsventils (16)

entgegen dem Uhrzeigersinn drehen, bis

das Manometer "0" anzeigt und der

schwarze Zeiger am Temperaturregler

unter 90°C abgesunken ist. Kesseldeckel

öffnen und Kessel ca. 6 Min.auskühlen

lassen. Anlüftung (16a) bis zum Anschlag

im Uhrzeigersinn zudrehen. Den roten

Rückstellknopf (17) an der Geräterückwand kurz drücken.

3b) Wie unter 3a) beschrieben vorgehen.

Dann gelochten Zwischenboden aus Druckkessel nehmen und reinigen. Heizung mit

Fühler des Übertemperaturschutzes und

Kessel reinigen, bzw. entkalken gemäss

Wartungsempfehlung.

4. Druck baut sich nach Ablauf des

Programmes abnormal langsam ab.

(Manometer zeigt "0" an. Zeitschaltuhr ist auf "0" abgelaufen.

Polymerisationstemperatur wurde

erreicht.)

Stromausfall vom Netz her oder

infolge Sicherungsdefekt

Ablauffilter im Druckkessel

teilweise verstopft.

Ablaufsystem teilweise

verstopft.

25

3c) Siehe Punkt 7.

4a) Gelochten Zwischenboden aus Druckkessel nehmen.Ablauffilter samt Kessel

und Heizung reinigen, bzw. entkalken,

gemäss Wartungsempfehlung.

4b) Schalldämpfer (23) reinigen.

Abwasserschlauch (18) an Geräterückwand

abschrauben und Schläuche mit Pressluft

ausblasen. Erforderlichenfalls entkalken.

Page 26

9. Produktspezifikationen

9.1 Lieferform

Der IVOMAT IP3 besteht aus folgenden Komponenten:

– Gerät mit Luftfilterregler

– Rückschlagventil

– 1,5 m Druckluft-Schlauch

– 1,2 m Abwasserschlauch mit Kanisterdeckel

– Kanisterschlauch und Schalldämpfer, im Druckkessel

eingesetztem Polymerisationsbehälter mit 3, am

abnehmbaren Deckel befestigten, Objektklemmen.

– 1 Rückwasserkanister

– 1 Wasser-Einfüllgefäss

9.2 Technische Daten

Elektroanschluss: Einphasenwechselstrom

Normalausführung:

– 220V / 50 Hz

– 240V / 50 Hz

Zulässige Spannungsschwankungen: +10% bis –15%

Leistungsaufnahme: 1030 W

Elektr. Sicherung:

100 – 118 V: 12,5 A, Träge.Durchschnitt 6,3 x 32 mm

220 V: 6,3 A, Träge.Durchschnitt 5 x 20 mm

240 V: 5 A, Träge.Durchschnitt 5 x 20 mm

Druckluft:

Betriebsdruck (bereits fix eingestellt): ca. 6 bar = 6.10 Pa

(Toleranz:Grüner Skalabereich)

Netzdruck: 6 bis max. 12 bar = 6 bis max.12.10 Pa

Schlauch mit 6 mm Innendurchmesser

9.3 Zulässige Betriebsbedingungen

Umgebungstemperaturbereich im Betrieb:

+ 5°C bis 40 °C (+41°F bis 104°F)

Zulässige Höhe:

Das Gerät ist für Höhen bis 2000 m geprüft.

Atmosphärischer Druck von 500 mbar bis 1060 mbar

9.4 Zulässige Transportbedingungen

Umgebungstemperaturbereich:

–20 °C bis +55 °C (–4°F bis 131 °F)

Maximale relative Feuchte: 80 %

Abmessungen des geschlossenen Gerätes:

Breite 312 mm, Tiefe 302 mm,

Höhe 220 mm

Druckkessel-Nutzmasse:

Durchmesser 112 mm, Höhe 98 mm.

Max Wasserfüllung 0.87 Liter

Gewicht: 9.75 kg

Sicherheitshinweise:

EN 61010, Teil 1

EMV geprüft

26

Page 27

Ivomat IP3

Liste des composants

1. Introduction et explication des symboles

1.1 Préambule

1.2 Introduction

1.3 Explication des symboles

2. La sécurité avant tout

2.1 Utilisation appropriée

2.2 Consignes en matière de sécurité et de danger

3. Description du produit

3.1 Montage de l'appareil

3.2 Description du fonctionnement

3.3 Endroits dangereux et dispositifs de sécurité

4. Installation

4.1 Déballage et contrôle de la livraison

4.2 Choix de l'emplacement

4.3 Etablir les branchements

4.4 Brancher le récipient de récupération d'eau

5. Fonctionnement

5.1 Mise en route et arrêt de l'appareil

5.2 Remplissage d'eau

6. Utilisation pratique

6.1 Equipement et mise en marche du programme

6.2 Fin de programme et retirer l'élément

Français

7. Entretien, nettoyage et diagnostic

7.1 Travaux de contrôle et d'entretien

7.2 Travaux de nettoyage

7.3 Notices d'entretien

8. Que faire si …

8.1 Panne de courant

8.2 Travaux de réparation

8.3 Défaillances techniques

9. Spécifications du produit

9.1 Présentation

9.2 Fiche technique

9.3 Conditions d'utilisation

9.4 Conditions de transport

27

Page 28

Liste des composants

1) Filtre détendeur

1a) Récipient de retenue

1b) Bouton de purge

2) Levier de verrouillage

3) loquet de verrouillage

4) couvercle de cuve

5) cuve

5a) rebord d'étanchéité

6) thermostat

7) manomètre

8) minuterie

9) interrupteur général

10) voyant lumineux

11) raccord anti-retour

12) tuyau d'air comprimé

13) fil de branchement électrique

14) capuchon de fusible

15) fusible

16) soupape de sûreté

16a) bouton de décompression

17) bouton de réarmement

18) tuyau d'écoulement de l'eau

19) bouchon du récipient de récupération

20) récipient de récupération

21) tuyau du récipient de récupération

22) joint d'étanchéité du silencieux

23) silencieux

24) bague

25) trou d'aération

26) vis

27) couvercle du récipient de polymérisation

28) pince "crocodile"

29) récipient de polymérisation

30) récipient de remplissage

28

Page 29

10

2

3

4

Français

5

1

9

8

7

27

28

4

3

29

2

5a

5

11

6

30

18

19

21

22

23 20

12

17

1

13

1a

1b

18

14,15

29

16

16a

Page 30

1. Introduction et explication des symboles

1.1 Préambule

Cher Client,

Nous vous remercions d'avoir porté votre choix sur

l'IVOMAT IP3, un appareil de haute technicité.

Nous vous demandons de lire attentivement le mode

d'emploi et d'utiliser l'appareil en suivant le mode

d'emploi.

Si vous avez encore d'autres questions, n'hésitez pas à

contacter votre Dépôt ou directement Ivoclar Vivadent.

1.2 Introduction

Appareil concerné : IVOMAT IP3

Groupe cible : personnel travaillant dans les laboratoires

de prothèse dentaire

L'IVOMAT IP3 est recommandé pour la polymérisation de

résines dentaires.

Le mode d'emploi est un outil indispensable à un emploi

sûr, approprié et économique de l'IVOMAT IP3.

Il est divisé en plusieurs chapitres permettant de trouver

rapidement les différents sujets.

Nous avons utilisé la représentation pictographique pour

vous informer rapidement et clairement sur les dangers,

les informations importantes et les utilisations non

autorisées.

Nous vous conseillons de ranger le mode d'emploi dans

un endroit protégé, à proximité de l'appareil et toujours

accessible.

En cas de perte du mode d'emploi, celui-ci peut être

commandé auprès du point de service après-vente

Ivoclar Vivadent qui le remettra contre paiement d'un

droit.

1.3 Explication des symboles

Les symboles indiqués dans le mode d'emploi vous

permettent de retrouver facilement les points importants

et ont la signification suivante :

Dans le mode d'emploi :

Dangers et risques

Informations

Utilisation non autorisée

Sur l'appareil :

Courant alternatif

Marche

Arrêt

O

30

Page 31

2. La sécurité avant tout

Français

La lecture de ce chapitre est obligatoire pour toutes les

personnes travaillant avec l'appareil ou exécutant des

travaux de maintenance ou de réparation sur l'appareil.

2.1 Utilisation appropriée

L'IVOMAT IP3 est exclusivement destiné à la

polymérisation de résines et matériaux dentaires.

Utiliser l'IVOMAT IP3 uniquement à cet effet.

Tout autre usage est considéré comme inapproprié.Dans

ce cas, le fabricant décline toute responsabilité et seul

l'utilisateur en assume le risque.

Une utilisation appropriée comporte également :

– l'observation des instructions, des directives et des

consignes mentionnées dans le présent mode

d'emploi.

– Le fonctionnement de l'appareil dans le cadre des

conditions stipulées en matière d'environnement et de

fonctionnement (cf. chapitre 9)

– L'entretien correct de l'appareil

2.2.1

Dangers et risques

2.2.2

Dangers et risques

Le moufle-couvercle ne doit pas être ouvert lorsque

l'appareil est encore sous pression. Seul un service

qualifié est autorisé à ouvrir le couvercle.

Veiller à ce qu'aucun liquide ni objet quelconque ne

parvienne dans les évents d'aération, ceci pouvant

provoquer une décharge électrique.

31

Page 32

3. Description du produit 4. Installation

3.1 Montage de l'appareil

L'IVOMAT IP3 se compose des éléments suivants :

– appareil avec filtre détendeur

– raccord anti-retour

– 1,5 m de tuyau de branchement à air comprimé

– 1,2 m de tuyau d'écoulement d'eau avec bouchon de

récipient de récupération

– tuyau du récipient de récupération et silencieux, cuve

de polymérisation avec couvercle muni de 3 pinces

crocodiles à l'intérieur du couvercle amovible

– 1 récipient de récupération d'eau

– 1 récipient de remplissage

Accessoires en option:

– dispositif de remplissage automatique (type IN 1)

– plaque de fixation de clefs

3.2 Description du fonctionnement

La cuve est équipée d'une résistance. L'eau peut ainsi

être chauffée à la température adaptée aux besoins.

De l'air comprimé est injecté dans la cuve de

polymérisation afin d'obtenir une homogénéité optimale

du matériau. La durée de polymérisation peut être réglée

à l'aide de la minuterie.

3.3 Endroits dangereux et dispositifs de sécurité

Description des endroits dangereux

Endroits dangereux Type de danger

Support de fusible décharge électrique

Event d'aération décharge électrique

4.1 Déballage et contrôle de la livraison

Sortir l'appareil de son emballage et contrôler la

présence éventuelle d'avaries de transport. Nous

recommandons de conserver l'emballage d'origine.

Ne pas porter l'IVOMAT IP3 par le câble mais

le saisir par le bas de l'appareil.

4.2 Choix de l'emplacement

Les pieds en caoutchouc doivent reposer sur une surface

plane. Ne pas exposer l'appareil aux rayons solaires

directs et le mettre à proximité de radiateurs ou d'une

autre source de chaleur.

4.3 Etablir les branchements

Contrôler si la tension indiquée sur la plaque

d'identification correspond bien avec la tension du

réseau.

Si ce n'est pas le cas, ne pas brancher l'appareil.

Branchement du tuyau à air comprimé

Contrôler si le tuyau est correctement enfoncé

Etablir le branchement au réseau

Veiller à ce que le câble ne soit pas en contact avec des

parties de l'appareil pouvant chauffer.

Les installations électriques de l'endroit où se

trouve l'appareil, doivent correspondre aux

normes respectives du pays et aux normes

IEC.

Description des dispositifs de sécurité

Dispositif de sécurité Fonction

Terre protège contre la décharge

électrique

IP44 protège contre la décharge

électrique

Commutateur thermique Protège l'IVOMAT IP3 de la

de sécurité surchauffe

32

Page 33

5. Fonctionnement

Français

4.4 Brancher le récipient de récupération d'eau

– Verser de l'eau dans le récipient de récupération

(20) jusqu'à une hauteur de 3 à 5 cm

– Introduire le tuyau d'écoulement dans le récipient et

visser le bouchon (19)

– Placer le récipient de récupération sur le sol

– Basculer le levier de verrouillage (2) vers le haut et

enclencher, pousser le loquet de verrouillage (3) vers

la droite et relever le couvercle de la cuve.

– Retirer la protection mise en place pour le transport.

5.1 Mise en route et arrêt de l'appareil

Retirer le récipient de polymérisation (29) et couvercle

(27) de la cuve.Appuyer sur l'interrupteur général (9), de

position O à position I. Le voyant lumineux (10) indique

la mise sous tension de l'appareil.

L'appareil peut rester sous tension pendant une

journée complète à condition de maintenir ouvert

le couvercle de cuve (4) après chaque cycle de

travail ou non verrouillé.

5.2 Remplissage d'eau

Remplir la cuve en respectant la hauteur de remplissage:

– maximum : jusqu'à la rainure figurant sur la cuve

– minimum : immersion complète des objets à

polymériser

33

Page 34

6. Utilisation pratique

6.1 Equipement et mise en marche du programme

– Retirer le couvercle du récipient de polymérisation

(27) et fixer l'objet aux pinces crocodiles (28)

– Replacer lentement le récipient de polymérisation

avec le couvercle et les objets ou les modèles avec la

plaque de fixation dans la cuve

– Fermer le couvercle de cuve (4) : pousser le loquet de

verrouillage (3) vers la gauche et rabattre le levier de

verrouillage (2) vers le bas jusqu'à son enclenchement

audible

Couvercle de cuve

– régler la température de polymérisation au thermostat

(6) (aiguille rouge)

Minuterie

– Déroulement automatique du programme :

• le manomètre (7) indique le niveau de pression.

(Contrôler si la pression nécessaire est obtenue

après atteinte de la température de consigne)

Thermostat (°C)

Après le réglage, le déroulement automatique du

programme s'active. Pour une durée inférieure à 5

minutes, tourner d'abord le bouton jusqu'à

l'indication de 10 minutes env. puis positionner sur

la durée souhaitée.

(Si cela est nécessaire, le temps peut être réglé sur O,

prolongé ou diminué pendant le déroulement

automatique du programme.

Affichage au manomètre

• l'eau est chauffée dans la cuve (contrôle possible

grâce à l'aiguille noire du thermomètre)

• dès que la température de consigne est atteinte, le

temps de polymérisation programmé s'écoule

(minuterie avec compte à rebours)

• quand le temps de polymérisation est expiré, l'eau

est refoulée de la cuve dans le récipient de

récupération. La pression tombe en même temps

(indication au manomètre)

34

Page 35

7. Entretien, nettoyage

et diagnostic

Français

6.2 Fin de programme et retirer l'élément

– Ouverture du couvercle de la cuve :

Ce n'est que lorsque l'aiguille du

manomètre est revenue à O et que

l'aiguille noire du thermomètre est

inférieure à 110°C, que l'on peut

orienter le levier de verrouillage (2)

vers le haut.

(Il est possible qu'une pression résiduelle

s'échappe encore de l'appareil.) Le loquet

de verrouillage (3) peut alors, sans

danger, être tiré vers la droite et on peut

ouvrir le couvercle de la cuve.

– retrait de l'élément :

Retirer le récipient de polymérisation avec

son couvercle de la cuve et laisser

refroidir quelques minutes avant der

retirer les éléments.(Un refroidissement

trop rapide risque de provoquer des

tensions dans la résine).

– Utiliser de l'eau ayant une dureté

comprise entre 4 et 9° (7 à 16°fr) d'un

PH de 7 à 8 / 20°C). Si l'on utilise de

l'eau du robinet d'une dureté supérieure à

9°(16°fr), prévoir un nettoyage particulier

ou détartrage. (voir détartrage, page 35).

– veiller à ne pas laisser de cire dans la

cuve de polymérisation

– ne régler la minuterie qu'après

verrouillage du couvercle de la cuve

– Attention : en cours de

fonctionnement, certaines parties

de l'appareil sont chaudes.

Eviter leur contact.

Pour des raisons de sécurité, pendant les

travaux d'entretien et de nettoyage, retirer la

fiche-secteur de la prise de courant de

l'appareil.

7.1 Travaux de contrôle et d'entretien

Ne pas endommager et maintenir en parfait état de

propreté le rebord (5a) de la cuve de polymérisation et le

joint de la cuve. Si l’on utilise de l'eau,comme spécifié

sous le point 6.2, nettoyer au moins une fois par

trimestre la cuve, la résistance de chauffe, le filtre et le

système d'écoulement après avoir enlevé le fond perforé

de la cuve. (Eliminer les résidus de cire à l'aide d'une

solution dégraissante adaptée).

7.2 Travaux de nettoyage

Dépoussiérer de temps en temps l'IVOMAT IP3. Utiliser

pour cela un aspirateur et un pinceau à nettoyer.

Quelle pièce : Avec quel moyen :

Carter Chiffon

Cuve Détartrant

7.3 Notices d'entretien

Veiller à respecter les prescriptions en matière

d'accidents du travail ainsi que les règles officielles en

matière de sécurité et de médecine du travail.

Seule une personne qualifiée est autorisée à ouvrir le

carter arrière de l'appareil après avoir retiré la prise.

Détartrage

En cas d'utilisation d'une eau de dureté supérieure à

9°d (16°fr), vérifier régulièrement selon la fréquence

d'emploi (par ex. une fois par semaine) le dépôt éventuel

de calcaire sur la résistance de chauffe. Pour pouvoir le

constater, il faut retirer auparavant le fond perforé de la

cuve.

Si une formation calcaire s'est déposée sur la résistance,

l'appareil doit être nettoyé avec un produit détartrant de

la manière suivante : (les solutions de détartrage pour

cafetières, bouilloires etc.conviennent parfaitement).

35

Page 36

8. Que faire si ...

– remplir la cuve d'environ 0,5 l d'eau et dissoudre la

quantité de détartrant recommandée selon le mode

d'emploi

– fermer le couvercle et verrouiller

– régler le thermostat à 80°C

– régler la minuterie à 5 minutes

– à la fin du programme, ouvrir le couvercle et s'assurer

que l'appareil est correctement détartré

– retirer de la cuve les plaques de tartre importantes

– si c'est nécessaire, répéter le détartrage jusqu'à ce que

la résistance de chauffe et la cuve soient propres

– le détartrage achevé, répéter l'opération à l'eau

propre pour que la cuve et le système d'écoulement

soient rincés. (quand la pression est atteinte, le

programme peut être interrompu en plaçant la

minuterie sur la position 0)

– vider le récipient de récupération et le rincer à l'eau

claire

Les liquides de détartrage sont corrosifs

et toxiques ! Eviter le contact avec les

yeux et la peau ! En cas d'accident, rincer

abondamment à l'eau.

Purger le récipient de retenue (1a) du filtre à air en

appuyant sur le bouton (1b)

Une fois par trimestre, dévisser le bouchon (19) du

récipient de récupération et nettoyer le petit trou

d'aération (25) situé sur le tube de raccordement du

tuyau (21). Le trou d'aération (25) devient accessible en

retirant la vis (26) et l'anneau (24).

8.1 Panne de courant provenant du réseau ou suite

à une défaillance des fusibles

– dans le cas d'une panne de courant, le déroulement

automatique du programme est interrompu. Le

programme redémarre automatiquement dès la mise

sous tension

– Si les pannes de courant sont plus longues, et que l'on

veuille retirer les objets de la cuve, procéder comme

décrit sous 3a)

– Si le fusible (15) de l'appareil est défectueux, ouvrir le

capuchon (14) puis retirer et remplacer le fusible.

Pour les erreurs ou les pannes ne figurant pas dans

la liste ci-après, veuillez contacter notre service

clientèle.

8.2 Travaux de réparation

Seul un personnel qualifié du service après-vente Ivoclar

est autorisé à faire des réparations.Veuillez vous

adresser au Service clientèle.

36

Page 37

8.3 Défaillances techniques

Français

Erreurs ou défaillance

1) Polymérisation défectueuse malgré

un déroulement normal du

programme (minuterie et

manomètre indiquant 0)

2) Le programme ne se déroule pas

automatiquement après le réglage

du temps de polymérisation

3) Interruption prématurée du

programme (la minuterie n'a pas

terminé sa course et le manomètre

indique une pression)

Causes possibles

– niveau d'eau insuffisant dans

la cuve ou

– température trop basse

– durée de polymérisation

insuffisante

– pression d'air insuffisante

Le couvercle de cuve n'est pas

correctement fermé et

verrouillé

Absence ou très peu d'eau dans

la cuve (le disjoncteur

thermique s'est déclenché)

La résistance de chauffe et la

sonde du disjoncteur thermique

sont souillées ou entartrées

Remèdes

1a) Répéter le processus de polymérisation

en respectant la quantité d'eau, la

température, la durée ainsi que la pression

2a) Fermer et verrouiller le couvercle selon

instruction

3a) Débrancher l'appareil du secteur.

Décomprimer la cuve à l'aide de la soupape

de sûreté.Visser dans le sens opposé à celui

des aiguilles d'une montre le bouton de

décompression (16a) situé à l'extrémité de la

soupape de sûreté (16) jusqu'à ce que le

manomètre indique 0 et que l'aiguille noire

du thermostat indique une température

inférieure à 90°C. Ouvrir le couvercle de la

cuve et laisser refroidir la cuve pendant 6

minutes environ. Ensuite revisser le bouton de

décompression dans le sens horaire.Appuyer

sur le bouton rouge de "réarmement" (17)

situé à l'arrière de l'appareil.

3b) Procéder comme décrit sous 3a. Puis

enlever le fond perforé de la cuve et

nettoyer. Nettoyer aussi la résistance de

chauffe,la sonde du disjoncteur thermique

ou détartrer conformément aux

recommandations d'entretien

4) La pression tombe trop lentement

après le déroulement du

programme (Manomètre et

minuterie indiquent "0" et la

température de polymérisation a

été atteinte)

Coupure de courant ou fusible

défectueux

Filtre d'écoulement

partiellement obstrué

Système d'écoulement

partiellement obstrué

37

3c) voir point 7

4a) Retirer le fond perforé de la cuve et

nettoyer la résistance de chauffe et le filtre

ou procéder à un détartrage conformément

aux recommandations d'entretien.

4b) Nettoyer le silencieux (23). Dévisser le

tuyau d'écoulement d'eau (18) de la face

arrière de l'appareil et le souffler à l'air

comprimé. Le cas échéant, détartrer.

Page 38

9. Spécifications du produit

9.1 Présentation

L'IVOMAT IP3 se compose des éléments suivants :

– appareil avec filtre détendeur

– raccord anti-retour

– 1,5 m de tuyau de branchement à air comprimé

– 1,2 m de tuyau d'écoulement d'eau avec bouchon de

récipient de récupération

– tuyau du récipient de récupération et silencieux, cuve

de polymérisation avec couvercle muni de 3 pinces

crocodiles à l'intérieur du couvercle amovible

– 1 récipient de récupération d'eau

– 1 récipient de remplissage

9.2 Fiche technique

Branchement électrique : courant alternatif monophasé

Version standard :

– 220V/50 HZ

– 240V/50 HZ

Tolérance de variation de secteur : +10% à –15%

Puissance : 1030 W

Fusibles électriques :

100–118 V:12,5A, inerte ø 6,3 x 32 mm

220 V : 6,3 A, inerte ø 5 x 20 mm

240 V : 5 A, inerte ø 5 x 20 mm

Pression d'air :

Pression de travail préréglée (déjà réglée)

env.6 bar = 6.10 Pa

(Tolérance :partie verte de la graduation du cadran)

Pression d'arrivée : 6 à 12 bar max. = 6 à 12.10 Pa

Diamètre intérieur du tuyau : 6 mm

9.3 Conditions d'utilisation

Plage de température ambiante :

+5°C à 40 °C (+41°F à 104°F)

Altitude tolérée :

L'appareil s'utilise jusqu'à une altitude de 2000 m

Pression atmosphérique de 500 mbar à 1060 mbar

9.4 Conditions de transport

Plage de température ambiante :

–20 °C à à 55°C (–4°F à 131°F)

Humidité relative maximale : 80%

Encombrement de l'appareil fermé :

Largeur : 312 mm, profondeur :302 mm,

hauteur : 220 mm

Dimension utile de la cuve de polymérisation :

Diamètre : 112 mm, hauteur 98 mm

Remplissage maximum : 0,87 l

Poids : 9,75 kg

Remarques de sécurité :

EN 61010, Partie 1, Contrôle CEM

38

Page 39

Ivomat IP3

Elenco particolari

1. Introduzione e spiegazione dei simboli

1.1 Premessa

1.2 Introduzione

1.3 Spiegazione dei simboli

2. La sicurezza innanzitutto

2.1 Utilizzo secondo le prescrizioni

2.2 Avvertenze di sicurezza e di pericolo

3. Descrizione prodotto

3.1 Costruzione dell’apparecchio

3.2 Descrizione delle funzioni

3.3 Punti di pericolo e dispositivi di sicurezza

4. Installazione

4.1 Disimballaggio e controllo del contenuto

4.2 Scelta del luogo di installazione

4.3 Allacciamenti

4.4 Collegamento della tanica di scarico

5. Messa in funzione

5.1 Accensione e spegnimento dell’apparecchio

5.2 Riempimento con acqua

6. Utilizzo

6.1 Inserimento ed avvio dell’apparecchio

6.2 Fine programma e prelievo dell’oggetto

Italiano

7. Manutenzione, pulizia e diagnosi

7.1 Manutenzione e controlli

7.2 Lavori di pulizia

7.3 Avvertenze di manutenzione

8. Cosa succede, se …

8.1 Interruzioni di corrente

8.2 Riparazioni

8.3 Disturbi tecnici

9. Specifiche del prodotto

9.1 Presentazione

9.2 Dati tecnici

9.3 Condizioni ammesse per il funzionamento

9.4 Condizioni ammesse per il trasporto

39

Page 40

Elenco particolari

1) regolatore filtro d’aria

1a) contenitore trasparente

1b) valvola di scarico

2) leva con eccentrico

3) manopola del chiavistello

4) coperchio della camera di polimerizzazione

5) camera di polimerizzazione

5a) bordo a chiusura ermetica della camera di

polimerizzazione

6) regolatore di temperatura

7) manometro

8) temporizzatore

9) interruttore generale

10) spia di controllo

11) valvola di ripercussione

12) tubo d’aria compressa

13) cavo di allacciamento

14) cappuccio per fusibile

15) fusibile

16) valvola di sicurezza

16a) vite per scarico pressione

17) pulsante per il limitatore di temperatura

18) tubo di scarico

19) tappo della tanica di scarico

20) tanica di scarico

21) tubo della tanica

22) guarnizione per silenziatore

23) silenziatore

24) anello

25) foro di areazione

26) vite

27) coperchio del contenitore di polimerizzazione

28) morsetto a pinza

29) contenitore di polimerizzazione

30) contenitore per riempimento acqua

40

Page 41

10

2

1

3

4

5

Italiano

9

8

7

27

28

4

3

29

2

5a

5

11

6

30

18

19

21

22

23 20

12

17

1

13

1a

1b

18

14,15

41

16

16a

Page 42

Introduzione e spiegazione dei simboli

1.1 Premessa

Egregio Cliente,

La ringraziamo per la preferenza accordataci con

l’acquisto dell’Ivomat IP3. Questo apparecchio è un

prodotto d'elevata qualità tecnica. La preghiamo di

leggere attentamente le istruzioni d’uso e di utilizzare

l’apparecchio seguendone le indicazioni. In caso di

ulteriori domande, si rivolga al Suo concessionario di

fiducia o direttamente alla Ivoclar Vivadent.

1.2 Introduzione

Apparecchio: Ivomat IP3

Destinatari: personale odontotecnico specializzato

Ivomat IP3 è indicato per la polimerizzazione di resine

dentali. L’istruzione d’uso serve ad un uso sicuro,

appropriato ed economico dell’apparecchio Ivomat IP3.

Le istruzioni d’uso sono suddivise in diversi capitoli per

una semplice visualizzazione degli argomenti ed un facile

ritrovamento dei punti desiderati.

Per poter informare rapidamente in merito ai pericoli,

informazioni importanti ed impieghi non ammessi,

vengono impiegati i relativi simboli (pittogrammi).

Si consiglia di conservare le istruzioni d’uso in un luogo

protetto nelle vicinanze dell’apparecchio in modo da

averle sempre a portata di mano. In caso di smarrimento

potrà richiederne una copia al Servizio Assistenza Ivoclar

Vivadent.

1.3 Spiegazione dei simboli

I simboli nelle istruzioni d’uso facilitano il ritrovamento

di punti importanti e avvertono in merito a:

Nelle istruzioni d’uso:

pericoli e rischi

informazioni

impieghi non ammessi

Sull’apparecchio:

corrente alternata

accensione

spegnimento

O

42

Page 43

2. La sicurezza innanzitutto

Italiano

Questo capitolo deve essere letto da tutte le persone che

lavorano con l’apparecchio o che eseguono lavori di

manutenzione o pulizia sull’apparecchio. Le avvertenze

devono essere rispettate.

2.1 Utilizzo secondo le prescrizioni

L’Ivomat IP3 è stato sviluppato appositamente per la

polimerizzazione di resine e materiali dentali. Si prega di

utilizzare l’apparecchio soltanto a questo scopo.

Un utilizzo diverso è da ritenere non conforme alle

disposizioni. Per i danni ivi risultanti il produttore non si

assume alcuna responsabilità. Il rischio è a totale carico

dell’utilizzatore. Per un uso corretto sono inoltre

necessari:

– il rispetto delle indicazioni, prescrizioni ed avvertenze

della presente istruzione d’uso

– l’impiego secondo le condizioni ambientali e di

funzionamento previste (vedi capitolo 9)

– la corretta manutenzione dell’apparecchio.

2.2.1

Pericoli e rischi

2.2.2

Pericoli e rischi

A causa del pericolo di scossa elettrica la carcassa

dell'apparecchio non deve essere aperta quando

l’apparecchio è sotto tensione. La carcassa

dell’apparecchio può essere aperta soltanto da

personale qualificato del Servizio Assistenza.

Nelle fessure d'aerazione non devono penetrare oggetti

o liquidi. Si potrebbe causare una scossa elettrica.

43

Page 44

3. Descrizione prodotto

4. Installazione

3.1 Montaggio dell’apparecchio

L’Ivomat IP3 si compone di:

– apparecchio con regolatore del filtro d’aria

– valvola di scarico

– tubo dell’aria 1,5 m

– tubo di scarico acqua 1,2 m con coperchio della tanica

– tubo della tanica e silenziatore, contenitore della

polimerizzazione inserito nella camera di

polimerizzazione con 3 morsetti portalavoro fissati al

coperchio estraibile

– 1 tanica dell’acqua di scarico

– 1 tanica di riempimento

Accessori (disponibili separatamente)

– impianto di riempimento Ivomat tipo IN 1

– Wallfixator (portamascherine)

3.2 Descrizione delle funzioni

La camera di polimerizzazione è provvista di resistenza.

In tal modo l’acqua può essere riscaldata alla

temperatura necessaria al materiale. Il contenitore di

polimerizzazione viene pressurizzato per ottenere

un’ottimale omogeneità del materiale. La durata della

polimerizzazione può essere regolata per mezzo del

temporizzatore.

3.3 Punti di pericolo e dispositivi di sicurezza

Descrizione dei punti di pericolo

Punti di pericolo Tipo di pericolo

Supporto di sicurezza Scossa elettrica

Fessure di aerazione Scossa elettrica

Descrizione dei dispositivi di sicurezza

Dispositivo di sicurezza Effetto protettivo

Conduttore di sicurezza protezione da scosse

elettriche

IP44 (tipo di protezione) protezione da scosse

elettriche

Interruttore da surriscaldo protegge l’Ivomat IP3 da

surriscaldo

4.1 Disimballaggio e controllo del contenuto

Prelevare l’apparecchio dalla confezione e controllare

l’eventualità di danni dovuti al trasporto. Si consiglia di

conservare l’imballaggio originale per eventuali trasporti

successivi. Per il trasporto si prega di utilizzare soltanto

l’imballaggio originale.

Non sorreggere l’Ivomat IP3 tramite i cavi

d'allacciamento. Sorreggere l’apparecchio

tenendolo alla base con entrambe le mani.

4.2 Scelta del luogo di installazione

Posizionare l’apparecchio con i piedini in gomma su di

una superficie piana. Fare attenzione che l’apparecchio

non sia esposto direttamente ai raggi solari. Non

posizionare l’apparecchio nelle dirette vicinanze di

termosifoni o altre fonti di calore.

4.3 Allacciamenti

Controllare la targhetta del voltaggio. Controllare che la

tensione indicata sulla targhetta corrisponda a quella

della rete. Nel caso in cui non corrisponda,l’apparecchio

non deve essere collegato.

Allacciamento del tubo di pressione

Controllare che il tubo della pressione sia collegato

correttamente.

Allacciamento elettrico

Controllare che il cavo di corrente non venga a contatto

con parti dell’apparecchio soggette a riscaldamento.

L’impianto elettrico del locale in cui si trova

l’apparecchio deve corrispondere alle norme

locali vigenti ed alle norme IEC.

44

Page 45

5. Messa in funzione

Italiano

4.4 Allacciamento della tanica di scarico

– riempire la tanica di scarico (20) con 3–5 cm di acqua.

– inserire il tubo della tanica nella tanica ed avvitare il

coperchio (19)

– posizionare la tanica sul pavimento in luogo idoneo

– orientare la leva con eccentrico (2) verso l’alto fino

all’arresto, spostare a destra la manopola del

chiavistello (3) e sollevare il coperchio della camera di

polimerizzazione (4)

– Togliere l’inserto (protezione per il trasporto).

5.1 Accensione e spegnimento dell’apparecchio

Prelevare il contenitore di polimerizzazione (29) con il

coperchio (27) dalla camera di polimerizzazione.

Premere l’interruttore (9) (da posizione 0 a posizione I).

La lampada di controllo accesa dimostra che

l’apparecchio è in funzione.

L’apparecchio può essere mantenuto in funzione

per tutto il giorno (interruttore I) tuttavia dopo

ogni ciclo di lavoro il coperchio della camera di

polimerizzazione (4) dovrebbe rimanere aperto o

non bloccato.

5.2 Riempimento con acqua

Versare l’acqua nella camera di polimerizzazione:

– livello massimo = fino alla demarcazione della camera

di polimerizzazione

– livello minimo = gli oggetti devono essere

completamente immersi nell’acqua

45

Page 46

6. Utilizzo

6.1 Completamento ed avvio del programma

– Togliere il coperchio (27) dal contenitore di

polimerizzazione, fissare l’oggetto da polimerizzare

con il morsetto a pinza (28).

– Inserire lentamente il contenitore di polimerizzazione

con coperchio ed oggetto rispettiv.modello con il

portamascherine Wallfixator nella camera di

polimerizzazione.

– Chiudere il coperchio (4): spingere la manopola del

chiavistello a sinistra e premere la leva con eccentrico

(2) verso il basso fino a percepire lo scatto di chiusura.

Coperchio della camera di polimerizzazione

– Impostare la temperatura di polimerizzazione con

l’apposito regolatore (6) (indicatore) rosso del valore

nominale.

Temporizzatore

– Decorso automatico del programma:

• il manometro (7) indica la pressione (controllare se

è stata raggiunta la pressione richiesta).

Manometro

Regolatore della temperatura (°C)

In seguito all’impostazione inizia il decorso

automatico del programma. Attenzione: in caso di

tempi inferiori ai 5 minuti, “portare” prima a

ca. 10 minuti e poi ridurre impostando il tempo

desiderato! (Se necessario, durante il decorso

automatico del programma il tempo può essere portato

a zero, prolungato oppure abbreviato).

• L’acqua nella camera di polimerizzazione viene

riscaldata (controllabile sulla lancetta nera del

regolatore di temperatura).

• A raggiungimento della temperatura nominale

decorre il tempo di polimerizzazione scelto (sul

temporizzatore inizia il conto alla rovescia).

• Terminata la polimerizzazione l’acqua si scarica

nella tanica ed il manometro segna la diminuzione

della pressione in camera (visualizzazione sul

manometro).

46

Page 47

7. Manutenzione, pulizia

e diagnosi

Italiano

6.2 Fine programma e prelievo dell’oggetto

– Apertura della camera di polimerizzazione:

soltanto quando il manometro è a zero

e la temperatura è scesa sotto i 110°C

spingere verso l’alto la leva con

eccentrico (2). (Un’eventuale pressione

residua si scaricherà al momento

dell’apertura in direzione della carcassa.) A

questo punto si può spostare verso destra

la manopola del chiavistello (3) senza

rischi ed aprire il coperchio della camera di

polimerizzazione.

– Prelievo del manufatto polimerizzato:

estrarre il recipiente con il coperchio dalla

camera di polimerizzazione lasciandolo

raffreddare per alcuni minuti. In caso di

raffreddamento troppo rapido possono

formarsi tensioni nella resina.

– Utilizzare acqua depurata (non

distillata) oppure acqua con una

durezza d da 4 a 9° (7 – 16 °fr)