Page 1

IvoBase® Injector

Operating Instructions

Valid as of

Software Version 2.0

Page 2

Table of Contents

List of parts 3

1. Introduction / Signs and Symbols 6

1.1 Preface

1.2 Introduction

1.3 Notes regarding the Operating Instructions

1.4 Note on the different voltage versions

2. Safety First 7

2.1 Indications

2.2 Health and safety instructions

3. Product Description 10

3.1 Components

3.2 Hazardous areas and safety equipment

3.3 Functional description

4. Installation and Initial Start-Up 11

4.1 Unpacking and checking the contents

4.2 Selecting the location

4.3 Removing the transport protection

4.4 Establishing the connections

4.5 Initial start-up

5. Operation and Configuration 14

5.1 Introduction to the operation

5.2 Explanation of key functions

5.3 Basic meaning of the screens

5.4 Settings and information

5.5 Explanation of the symbols on the display

5.6 Description of the beeper sounds

5.7 Operating status display

6. Practical Use 17

6.1 Switching on the injector

6.2 Loading

6.3 Starting the injection process

6.4 Further possibilities and special features of the injector

7. Maintenance, Cleaning and Diagnosis 19

7.1 Monitoring and maintenance

7.2 Emptying the waste water container

7.3 Replacing the heating

7.4 Replacing the temperature sensor

7.5 Cleaning

7.6 Heater test

7.7 Service Hint

7.8 Information about transport protection

8. What if...? 23

8.1 Error messages

8.2 Resin leaks from the flask

8.3 Resin leaks from the injection head

8.4 Technical malfunctions

8.5 Repair

9. Product Specifications 26

9.1 Delivery form

9.2 Technical data

9.3 Acceptable operating conditions

9.4 Acceptable transportation and storage conditions

10. Appendix 27

10.1 Program structure

2

Page 3

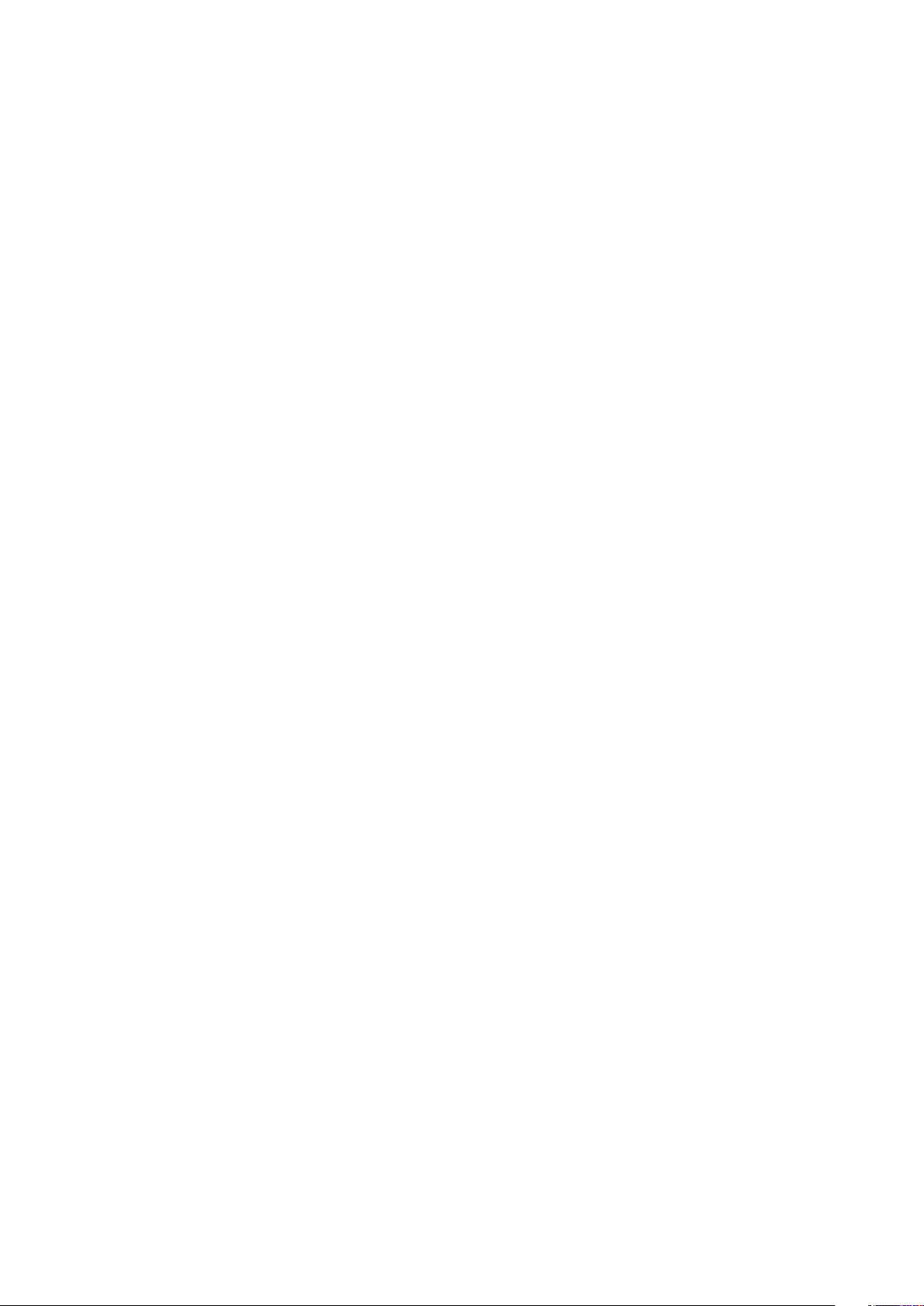

17

16

15

List of Parts

3

2

1

4

5

3

6

7

18

19

14

13

12

11

Injector:

1 Temperature sensor

2 Heater

3 Warnings

4 Operating Status Display (OSD)

5 Warning light

6 Clasps

7 Door handle

8 Polymerization chamber

9 Injection head

10 Operating panel

11 Rubber feet

12 Waste water container

13 Power cord

14 Housing

15 Capsule

16 Safety door

17 Flask

18 Knurled screw for hood

19 Air vents

20 On /Off switch

21 Power socket

22 Recessed grip

23 USB connection

24 Rating plate

25 Flask holder

26 Discharge opening

10

8

9

20

21

18

22

23

24

3

Page 4

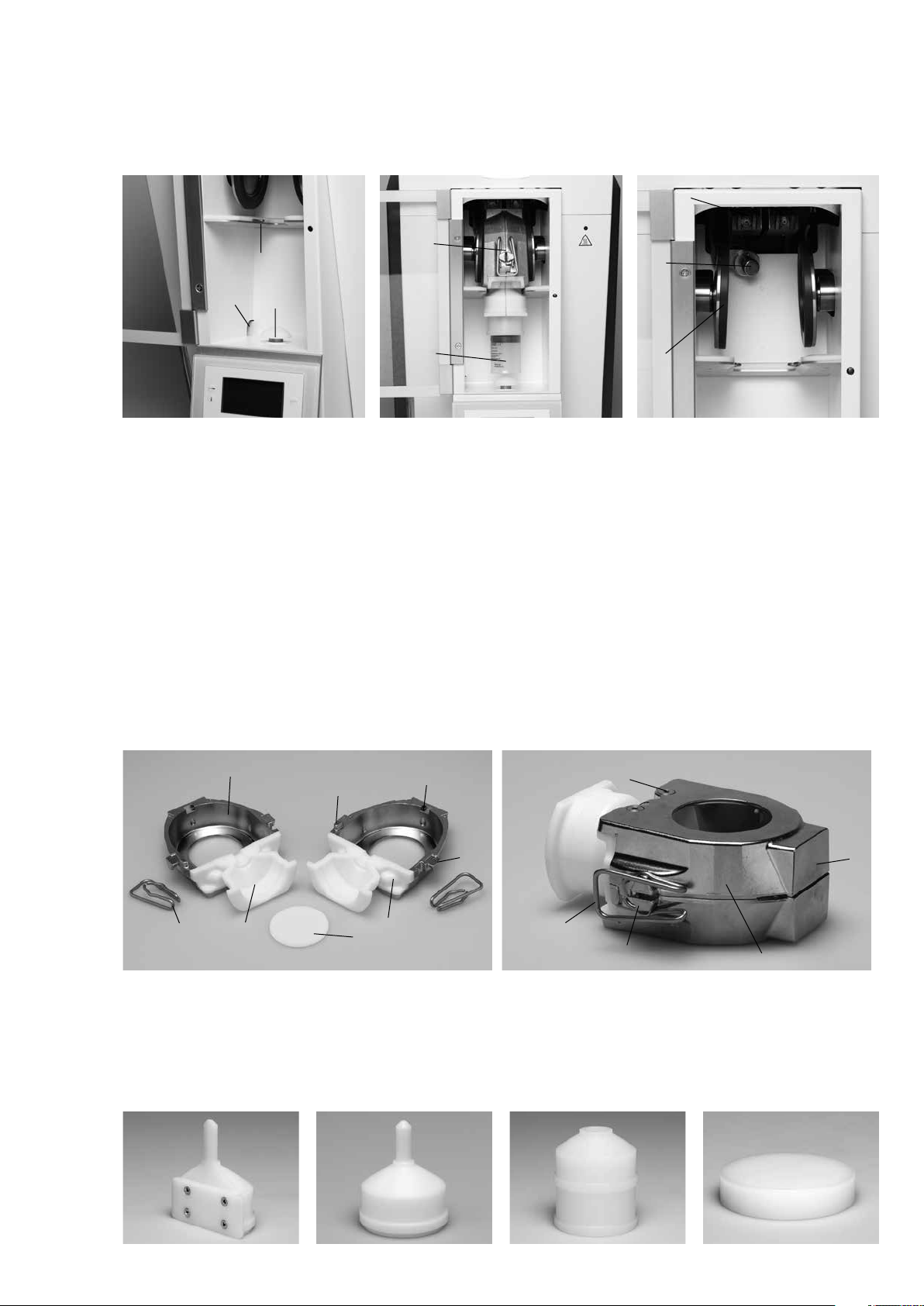

25

2

17

1

26

Flask:

40 Isolating shoulder

41 Centering peg

42 Flask lid

43 Flask housing

44 Locking clasp attachment

9

15

45 Locking clasp

46 Recess for the aeration filter

47 Screws

48 Heating surface

49 Sensor surface

6

43

41

45

61 Access former half 62 Access former full 63 Centring insert 64 Deflasking aid

40

42

40

46

44

45

47

44

49

48

4

Page 5

Operating panel

71 Settings key

72 Information key

73 Right cursor key

74 Left cursor key

75 Program 2 key

76 Program 1 key

77 RMR key

78 – key

79 + key

80 ESC key

81 ENTER key

82 Next Program Number key

83 Program 3 key

84 STOP key

85 START key

86 START LED

100 Thermal glove

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

101 USB download cable

102 Temperature Checking Set

Please note that the list of parts applies

to the entire Operating Instructions.

References are made to the parts and /

or the numbering in later chapters.

5

Page 6

1. Introduction / Signs and Symbols

1.1 Preface

Dear Customer

Thank you for having purchased the IvoBase Injector. It is a modern

injection device for dental applications. The injector has been

designed according to the latest industry standards. Inappropriate

use may damage the equipment and be harmful to personnel.

Please observe the relevant safety instructions and read the Operating Instructions carefully.

Enjoy working with the IvoBase Injector.

1.2 Introduction

The signs and symbols in these Operating Instructions and on the

injector facilitate the finding of important information and have the

following meanings:

Risks and dangers

Important

information

Contraindication

1.3 Notes regarding the Operating Instructions

– Device concerned: IvoBase Injector

– Target group: Dental technologists

These Operating Instructions facilitate the correct, safe and economic use of the IvoBase Injector. Should you lose the Operating

Instructions, extra copies can be ordered at a nominal fee from your

local Ivoclar Vivadent Service Centre or downloaded in the Download Center at www.ivoclarvivadent.com/downloadcenter.

1.4 Note on the different voltage versions

The injector is suitable for the following voltage range:

100 – 120 V / 50 Hz – 60 Hz

200 – 240 V / 50 Hz – 60 Hz

No manual switch-over is necessary to use the individual voltage

versions. Please make sure that the voltage indicated on the rating

plate complies with the local power supply before setting the injector into operation.

Burn hazard

Risk of crushing

Fire hazard

The Operating Instructions must be read.

6

Page 7

2. Safety First

This chapter is especially important for individuals who

work with the IvoBase Injector or who have to carry out

maintenance or repair work. This chapter must be read

and the corresponding instructions followed!

2.1 I n d ication s

The IvoBase Injector is solely intended for the processing of special

resins for dental applications. It should be used for this purpose

only. Uses other than the ones stipulated, e.g. injection of other

materials, etc., are contraindicated. The manufacturer does not

assume any liability for damage resulting from misuse. The user is

solely responsible for any risk resulting from failure to observe these

Instructions.

Further instructions to assure proper use of the injector:

– The instructions, regulations and notes in these Operating

Instructions must be observed.

– The instructions, regulations and notes in the material's Instruc-

tions for Use must be observed.

– The injector must be operated under the indicated environmental

and operating conditions (see Chapter 9).

– The IvoBase Injector must be properly maintained.

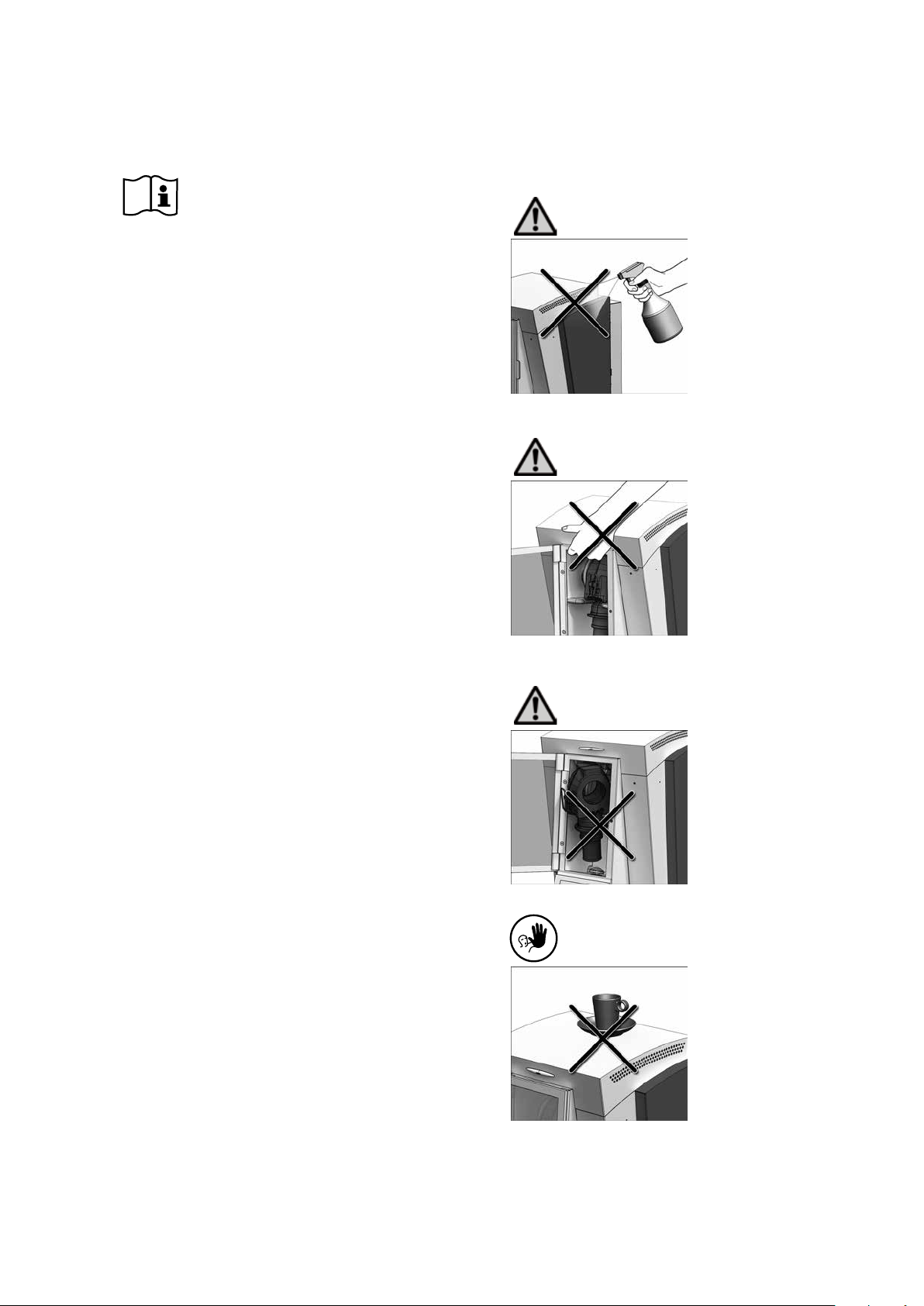

2.1.1

Risks and dangers

Make sure that no liquids or other

foreign substances enter the

injector during cleaning.

2.1. 2

Risks and dangers

The injector may only be carried

by supporting the bottom under

the operating field and by the

recessed grip at the rear of the

injector.

2.1.3

Risks and dangers

2.1. 4

Contraindication

Make sure that the flask is

correctly positioned.

The injection program must not

be started if the flask is

incorrectly positioned.

Foreign objects must not be

placed on the injector.

7

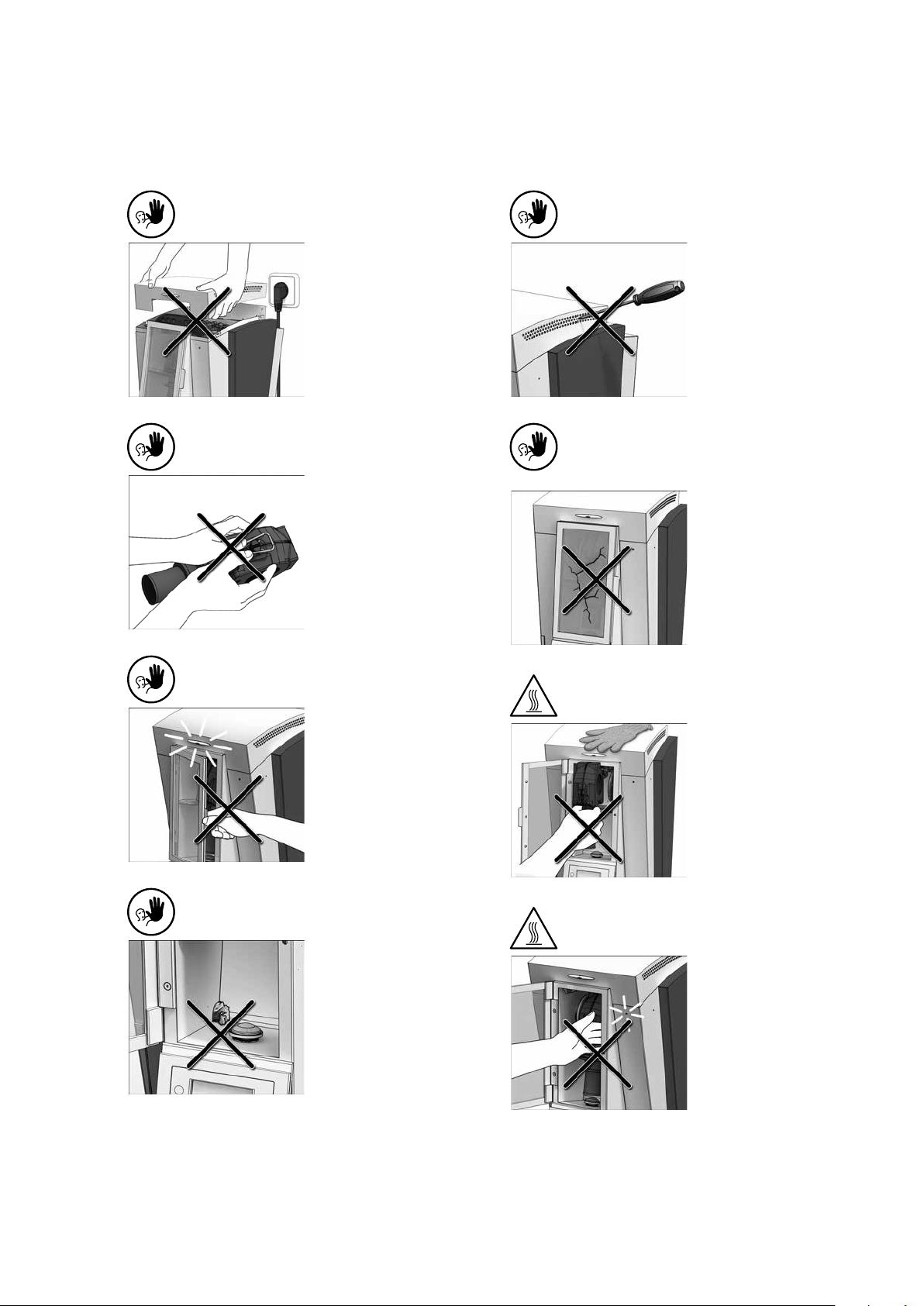

Page 8

2.1. 5

Contraindication

2.1. 9

Contraindication

2.1. 6

Contraindication

2.1.7

Contraindication

The hood may only be removed

while the injector is switched off

and the power plug disconnected.

The locking clasp may only be

removed from the flask by rotating, rather than pushing it.

The safety door must not be

opened while a program is in

progress.

Foreign objects must not enter

the air vents.

2.1.10

Contraindication

The injector must not be operated

if it shows visible damage, for

example, at the heater, safety

door or clasps, etc.

2.1.11

Burn hazard

The flask must not be loaded or

removed from the injector without thermal glove.

2.1. 8

Contraindication

If the discharge outlet is clogged,

the injector must not be operated.

2.1.12

Burn hazard

Do not reach into the hot

injector!

Do not reach into the injector

while the red warning light is still

on. When switched off, the injector may still be hot even if the

warning light is not on.

8

Page 9

2.2 Health and safety instructions

This injector has been designed according to EN 61010-1 and has

been shipped from the manufacturer in excellent condition as far as

safety regulations are concerned. To maintain this condition and to

ensure risk-free operation, the user must observe the notes and

warnings contained in these Operating Instructions.

– It is important that the user becomes familiar with the warnings

and operating conditions to prevent injury to personnel or

damage to materials. The manufacturer is not responsible for

damage resulting from misuse or failure to observe the Operating

Instructions. Warranty claims cannot be accepted in such cases.

– Before switching on the injector, make sure that the voltage indi-

cated on the rating plate complies with your local power supply.

– The mains socket must be equipped with a residual current

operated device (FI).

– The power plug may only be inserted into sockets with protected

contacts.

– Place injector on a fire-proof table. Observe local regulations (e.g.

distance to combustible substances or objects, etc.).

– Always keep the air vents unobstructed.

– Do not touch any parts that become hot during operation of the

injector. Burn hazard!

– Clean injector only with a dry, soft cloth. Do not use any

solvents! Disconnect power before cleaning and allow the

injector to cool down!

– The injector must be cool before it is packed for transportation.

– Use original packaging for transportation purposes.

– Before calibration, maintenance, repair or change of parts, the

power must be disconnected and the injector has to be cool if it

has to be opened.

– If calibration, maintenance or repair has to be carried out with

the power connected and injector open, only qualified personnel

who are familiar with the risks and dangers may perform the procedures.

– After maintenance, the required safety tests (high voltage

resistance, protective conductor, etc.) must be carried out.

– Make sure that only fuses of the indicated type and rated current

are used.

– If it is assumed that safe operation is no longer possible, the

power must be disconnected to avoid accidental operation

– if the injector is visibly damaged.

– if the injector does not work.

– if the injector has been stored under unfavourable conditions

over an extended period of time.

– Use only original spare parts.

– Observe the correct temperature range to ensure faultless opera-

tion (see section 9.2 Technical data).

– If the injector has been stored at very low temperatures or high

atmospheric humidity, it must be dried or left to adjust to the

room temperature for approx. 4 hours prior to connecting power.

– The injector is tested for use at altitudes of up to 2000 m

(6562 ft) above sea level.

– The injector may only be used indoors.

Any disruption of the protective conductor either inside

or outside the injector or any loosening of the protective

conductor may lead to danger for the user in case of a

malfunction. Deliberate interruptions are not permissible.

Material developing harmful gases must not be

processed.

Monomer is used in the processing of denture base

material in the IvoBase Injector. This substance contains

methyl methacrylate (MMA), which is highly flammable.

Please handle this substance with care and avoid direct

skin contact. Please observe the detailed health and safety

instructions contained in the Instructions for Use of the

respective material.

Disposal:

The apparatus must not be disposed of in the normal

domestic waste. Please correctly dispose of old devices

according to the corresponding EU council directive.

Information regarding disposal can be found on the

respective national Ivoclar Vivadent website.

9

Page 10

3. Product Description

3.1 Components

The IvoBase Injector comprises the following components:

– Basic injector with polymerization chamber and operating panel

– Flask

– Waste water container

– Power cord

3.2 Hazardous areas and safety equipment

Description of the hazardous areas of the injector:

Hazardous area Type of risk

Polymerization chamber Burn hazard

Polymerization chamber Risk of crushing

Electrical components Risk of electrical shock

Description of the safety equipment of the injector:

Safety equipment Protective effect

Protective conductor Protection from electrical shock

Electrical fuses Protection from electrical shock

Housing and end caps Protection from electrical

shock, burning and crushing

Red warning light (5) Warns against hot components

in the polymerization chamber

3.3 Functional description

The IvoBase Injector has been developed for the IvoBase System and

allows an automated and controlled injection process. The injector

may be used for both self-curing and heat-curing polymers. The

integrated heater permits the flask to be heated up to 120 °C

(248 °F). With the controlled and automated injection, high-quality

products with outstanding physical properties can be fabricated.

The injection process taking place in the IvoBase Injector can be

basically divided into four stages (see image):

1. Dough stage: During this stage, the material changes to an

injectable consistency.

2. Injection phase: During this stage, the material is injected into the

flask by means of a forward movement of the injection head.

3. Polymerization stage: The controlled heat supply initiates the

polymerization with shrinkage compensation.

4. Cooling stage: During the cooling stage, the system normalizes

the temperature and the tension.

1. Dough

stage

2. Inje ction stage 3. Poly meriz ation stage

4. Cool ing

stage

(optional)

Temperature Injection force

10

Page 11

4. Installation and Initial Start-Up

3

2

3

4.1 Unpacking and checking the contents

The packaging provides the following advantages:

– Reusable packaging

– Closing mechanism with integrated transportation grips

– Ideal protection by Styrofoam inserts

– Easy handling during unpacking

– The packaging may be used in several ways (modules).

Remove the injector from the packaging and place it on a suitable

table. Please observe the instructions on the outer packaging.

Please keep in mind

that the IvoBase

Injector is very heavy.

It should always be

lifted and carried by

at least two people

(see image).

The IvoBase Injector is equipped with a special recessed grip at the

back and can conveniently be held at the operating panel at the

front.

4.2 Selecting the location

Place the injector on a flat table on the rubber feet. Make sure that

the injector is not placed in the immediate vicinity of heaters or

other sources of heat. Make sure that air may properly circulate

between the wall and the injector.

Also ensure that there is enough space between the injector and

the user, as the injector releases heat during the opening of the

sa fe ty d oor.

The injector should neither be placed nor operated in areas

where there is an explosion hazard.

4.3 Removing the transport protection

Once the injector has been set up, the transport protection

(adhesive tape) at the safety door and the waste water container

can be removed.

1

3

Check the delivery for completeness (see delivery form in Chapter 9)

and transportation damage. If parts are damaged or missing, contact your local Ivoclar Vivadent Service Centre.

Packing and shipping

The packaging may be discarded with the regular house-

hold refuse. However, we recommend keeping the original packaging for future service and transportation

purposes.

The packaging permits simple and safe shipping. Simply

use the corresponding plastic inserts and fold the side

flaps.

2

11

Page 12

4.4 Establishing the connections

Power connection

Please make sure that the voltage indicated on the rating plate

complies with the local power supply. Subsequently, connect the

power cord (13) with the power socket of the injector (21).

Connect the USB download cable.

If required, e.g. for software updates, connect the injector with a

laptop/PC using the USB cable (101) and the respective USB slot (23).

12

Page 13

4.5 Initial start-up

1. Connect the power cord (13) with the wall socket.

2. Put the On /Off switch (20) on position "I".

Immediately after switching on, the display shows the start screen

for a few seconds.

The injector now conducts an automatic self-test. During the test,

the performance of all injector components is automatically

checked. The display shows the following indications during the

self-test:

a)

b)

c) d)

a) Software version

b) Progress bar

c) Power supply voltage

d) Number of injections performed

If the program recognizes an error or a hint, the corresponding

information (e.g. "Hint 1700") appears on the display. If all

components are in order, the display will go to stand-by mode and

an acoustic signal will sound.

Make sure that the safety door is always closed during

the self-test.

Stand-by indicator

The stand-by indicator is shown after the self-test, and the last

program used before switching off will be loaded.

a)

b)

d)

c)

a) Status of the injector

b) Program number

c) Possible key strokes

d) Program name

13

Page 14

5. Operation and Configuration

5.1 Introduction to the operation

The IvoBase Injector is equipped with a graphic display with backlighting. The injector can be operated by means of the membranesealed keypad. The input and command keys can be used to

program and control the injector.

71

72

73

74

75

76

Key Function

77

78

79

80

81

82

83

84

85

86

Information

Serial number, software versions, etc.

ENTER, ESC keys

ENTER

Confirmation of the set numeric value.

ESC

– Ends an entry without accepting the

value.

– Return from the current to the previous

screen.

– Acknowledgement of error messages.

STOP

– A program in progress can be aborted

by pressing this key twice.

– The beeper can be confirmed by

pressing the STOP key.

START (Start LED)

Starts the selected program. The green LED

indicates that a program is running.

RMR (Residual Monomer Reduction)

With this function, the residual monomer

content can be reduced to below 1%

(acc. to ISO 20795-1).

5.2 Description of the key functions

Key Function

Program 1 key

Pressing results in the direct change to

Program 1.

Program 2 key

Pressing results in the direct change to

Program 2.

Program 3 key

Pressing results in the direct change to

Program 3.

Next Program Number key

Pressing results in the direct change to the

next higher program number.

Cursor keys left, right

These keys are used to move the cursor.

Minus/Plus keys

These keys are used to change the numeric

value.

Settings

Settings, programming, special programs,

etc.

5.3 Basic meaning of the screens

– Stand-by

Injector and /or

program status

Recommendation area

– Program progress screen

Program status

Currently selected

program

Program or

material name

Progress bar

Status area

The most important information is displayed in the

main screen.

The most likely nex t

action is indicated here.

Remaining time indicator

Graphic

status information

14

Page 15

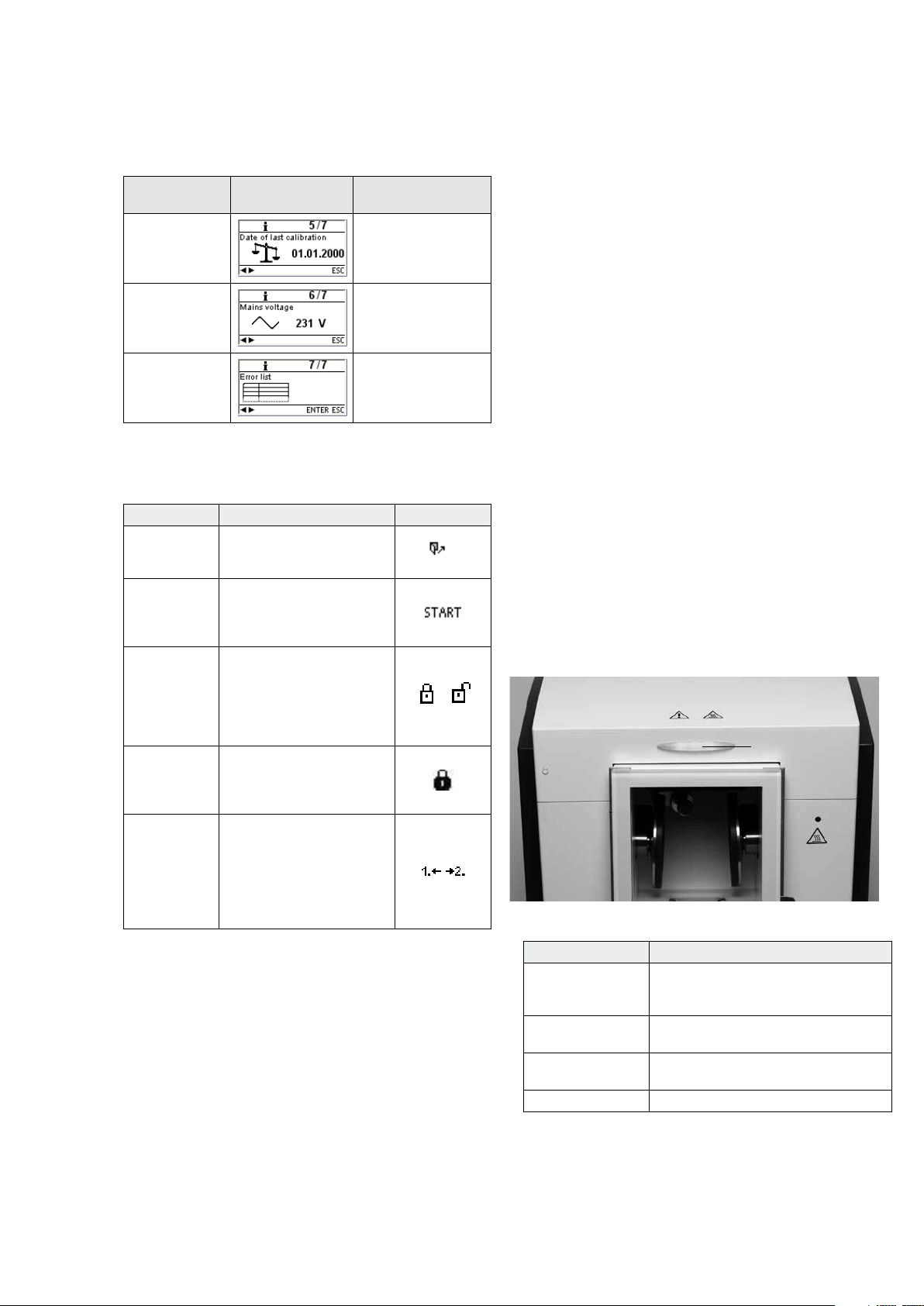

5.4 Settings and information

By pressing the "Settings" key (71) you can access the

settings screen (the latest selected settings will be indicated).

The cursor keys (73, 74) can be used to toggle between possible

settings. This screen can be exited with the ESC key (80) or any of

the program keys (75, 76, 83).

5.4.1 Settings

Settings marked with "*" are protected by Ivoclar

Vivadent with a code. The code is communicated if

changes become necessary.

Settings

Contrast

Temperature unit

Language

selection

Volume

Melody

Programming *

Indication on

display

Short description

The contrast can be

changed by means of

– or +.

The – and + keys can

be used to toggle

between °C and °F.

Enables the language

selection.

The volume can be

adjusted by means of

– or +.

The desired tune can

be set using – or +.

Allows the parameters

of the currently selected program to be set.

Settings

General write

protection

Keypad test

Heater test

Transport

protection

Service interval

Load factory

settings

5.4.2 Information

By pressing the "Information" key (72) you can access the information screen (the latest selected information will be indicated). The

cursor keys (73, 74) can be used to toggle between the possible

information. This screen can be exited with the ESC key (80) or any

of the program keys (75, 76, 83).

Information

Serial number

Indication on

display

Indication on

display

Short description

Permits activation or

deactivation of the

general write protection (using – or +)

once the user password has been

entered. The general

write protection

applies to all the

programs.

Permits checking the

keypad.

Permits the examination

of the heater system.

See Chapter 7.6

Heater test for details.

Activates the transport

protection.

See Chapter 7.8

Select the interval for

the next reminder. The

interval is set in

months.

Resets all the values

and parameters to the

factory settings.

Short description

Serial number of the

device

Renaming *

Time

Date

Permits renaming of

the currently selected

program.

Permits renaming the

material.

The time can be set

using the – or + keys.

The date can be set

using the – or + keys.

Software version

Program cycles

Operating hours

15

Currently installed

software version

Sum of all the executed program cycles

(injections)

Page 16

Settings

Date of the latest

calibration

Supply voltage

List of errors

Indication on

display

Short description

Shows the current

supply voltage.

5.5 Explanation of the symbols on the display

Symbol name Explanation Symbol

Shows that the door is open.

Door open

Start possible

Program write

protection

General write

protection

Page selection

The door must be closed in

order to start a program.

Shows that the injector is

ready to use. The door is

closed and a program can be

started.

A closed lock indicates that

the program write protection

is active. With an open lock,

this protection is inactive

(adjustable with the – or +

key).

If this symbol is displayed, the

general write protection is

active. This protection applies

to all injector programs.

Program parameters are

available on two pages. By

selecting the appropriate

symbol with the cursor key

and by pressing ENTER, the

program changes to the

respective page.

5.6 Description of the beeper sounds

Basically, the beeper tune and volume set by the user are used for

all acoustic signals. The acoustic signal can be stopped by pressing

STOP.

1. After the self-test has been completed

The set beeper tune briefly sounds to inform the user that the

automatic self-test has been successfully completed.

2. In the case of error messages

Error messages are indicated with the error beeper tune (endless

beeping). The beeper can be confirmed by pressing the STOP key,

while the error message still remains visible. If the error message

is confirmed by pressing the ESC key, the beeper is also ended.

3. At the end of an injection program

The set beeper tune briefly sounds to inform the user that the

current program has been completed.

4. Upon opening of the safety door during an injection program in

progress

If the safety door is opened while an injection program is

running, the user is warned by the error tune (endless beeping).

The acoustic signal can be stopped by closing the safety door.

5.7 Operating status display

The integrated optical operating status display (OSD) indicates the

different operating statuses of the injector.

13

The following activities are indicated:

Colour Activities

green The injector is ready for operation (with

the door closed and the self-test

completed).

white The injector is in the preparation stage

(with the door open).

red The injection process is active; injector is

busy.

yellow (flashing) Information, note or error message.

16

Page 17

6. Practical Use

6.1 Switching on the injector

Put the On/Off switch (20) on position "I". The injector now conducts an automatic self-test. Make sure that the injector is not

manipulated during that time.

6.1.1 Stand-by screen

If the self-test has been successfully completed, the stand-by

screen is displayed. Now the desired program can be selected with

the program or cursor keys.

Once the flask has been placed in

the injector and the safety door

has been closed, the START

symbol appears in the recommendation section. The selected program is started by pressing START.

6.1.2 Program progress screen

After the program has been started, the program progress screen is

displayed.

Program status

Currently selected

program

Program or

material name

Progress bar

Remaining time indicator

Graphic

status information

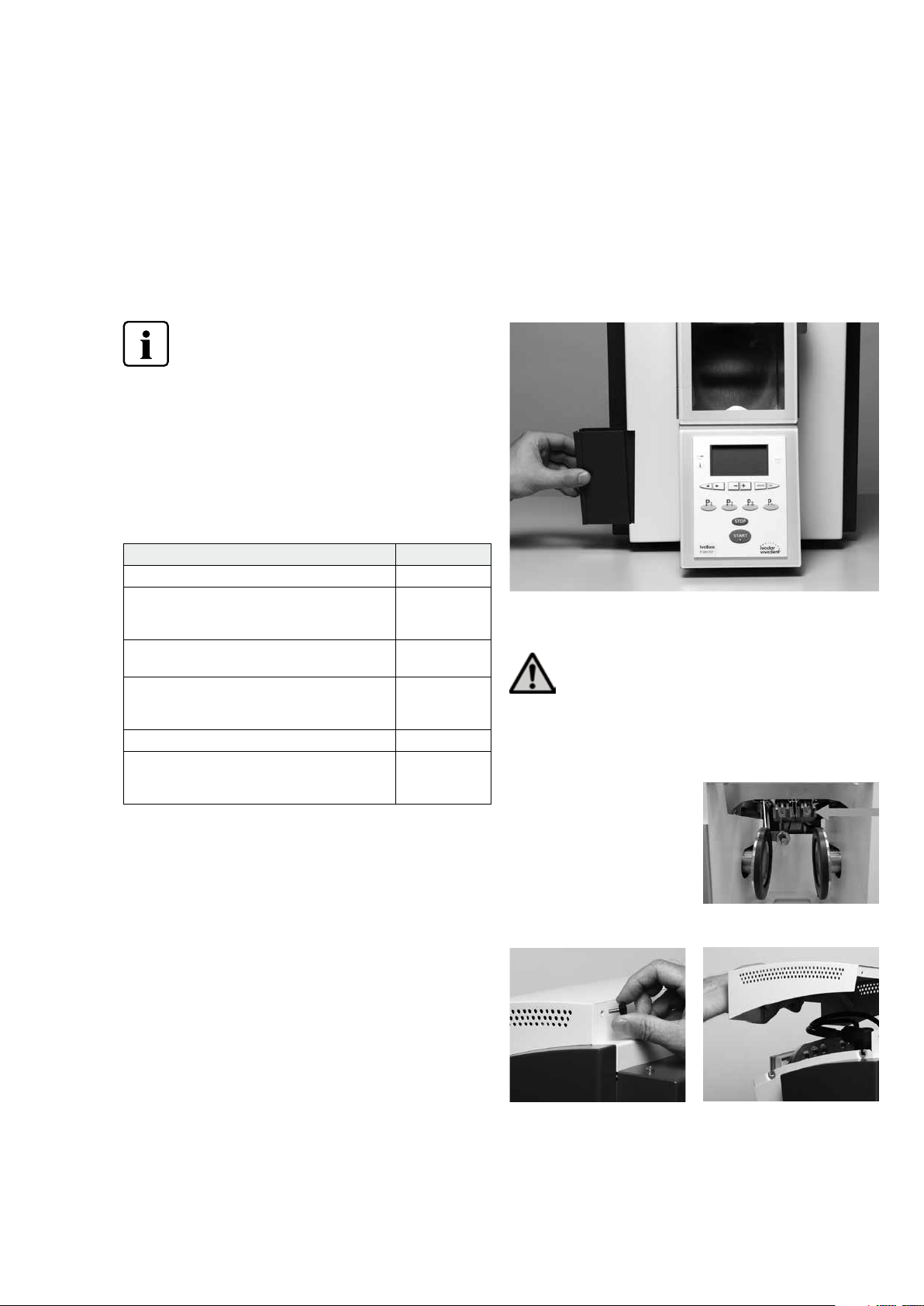

6.2 Loading

To load the IvoBase Injector, proceed as follows:

Please read the following processing notes

carefully.

– Make absolutely sure that both flask halves have cooled to room

temperature before injection. A temperature of >30 °C (>86 °F)

jeopardizes controlled polymerization and might lead to

inaccuracies of fit.

– When working with self-curing materials, make sure that as little

time as possible lies between mixing the material and injection.

A lit warning light (5) indicates that the injector tempera-

ture is high during loading or removal and, therefore,

there is a burn hazard (>45 °C/>113 °F).

Always use the thermal glove supplied when

removing the flask from the injector!

6.3 Starting the injection process

For practical use, please observe the Instructions for Use

of the respective material!

Step 1:

Select the desired program (P1 to P20) using the program or cursor

keys.

Step 2:

Open the safety door and insert the flask into the injector. The flask

perceptibly snapping into place indicates the correct position.

Step 1:

Open the safety door (16).

Step 2:

Slide the flask into the holder intended for this purpose as shown in

the picture.

Make sure that the flask is securely placed and that it has

been inserted until it stops. The flask perceptibly

snapping into place indicates the correct position.

Step 3:

Close the door. If the OSD lights up green, the injector is ready for

the process.

Step 3:

Close the safety door. The injector cannot be started if the door is

open. Press Start to start the program.

The course of the program can be observed on the program

progress indicator.

6.4 Further possibilities and special features of the

injector

6.4.1 General write protection

If the programs are write protected as a whole, a closed, solid lock

is displayed in the parameter list. The setting "Renaming" cannot be

selected if the write protection is active. A hint in the form of closed

lock is shown next to the keyboard symbol.

6.4.2 Stopping the running program

Pressing STOP once results in the

program abort screen being displayed.

You can now abort the program

by pressing the STOP key again, or

you can press ESC and the program abort screen disappears and the program is resumed.

17

Page 18

If the safety door is opened while an injection pro-

gram is running, the program is stopped for safety

reasons. While the program is interrupted, the

green LED in the START key flashes. The process is

automatically resumed once the door has been

closed.

6.4.3 RMR function (Residual Monomer Reduction)

Pressing the RMR key (77) activates the RMR function. This means

that the residual monomer content of the processed material can be

reduced to below 1%.

6.4.6 Software update

The user will be able to conduct a software update via PC and USB

download cable. For that purpose, the software download mode is

activated by pressing two special keys simultaneously while the

power supply is switched on. For further details, please refer to the

Software Update Instructions in the Download Center

(ww w.ivoclarvivadent.com /downloadcenter).

18

Page 19

7. Maintenance, Cleaning, Diagnosis

This chapter describes the user maintenance and cleaning procedures for the IvoBase Injector. Only those tasks are listed that may

be performed by dental professionals. All other tasks must be performed by qualified service personnel at a certified Ivoclar Vivadent

Service Centre.

The time for these maintenance procedures depends on the frequency of use and the working habits of the users. For that reason,

the recommended times are only approximations.

This injector has been developed for typical use in dental

laboratories. If the product is used for continuous operation, premature ageing of the expendable parts has to

be expected.

Expendable parts are, for instance:

– Heater

– Clasps

Expendable parts are not covered by the warranty.

Please also observe the shorter service and maintenance intervals.

7.1. Monitoring and maintenance

What: When:

Check all plug-in connections for correct fit. weekly

Check the water level in the waste water container and empty it, if necessary (see 7.2 for

details).

Check if the heater is dirty or damaged (see 7.3

for details).

Check if the temperature sensor in the polymerization chamber is dirty or damaged (see

7.4 for details).

Check if the safety door is dirty or damaged. daily

Check the keypad for visible damage. If the keypad is damaged, it has to be replaced by a

certified Ivoclar Service Centre.

daily

weekly

weekly

weekly

7.2 Emptying the waste water container

During the polymerization process, condensation develops within

the injector, which is discharged via a drain outlet. Check the water

level at regular intervals and empty the waste water container, if

necessary.

The waste water container can be removed from and replaced in

the injector as shown in the picture.

7.3 Replacing the heater

Before replacing the heater, disconnect the injector from

the power supply.

The heater system of the IvoBase Injector has been developed in

such a way that users may replace it by themselves, if required

(cleaning, defect).

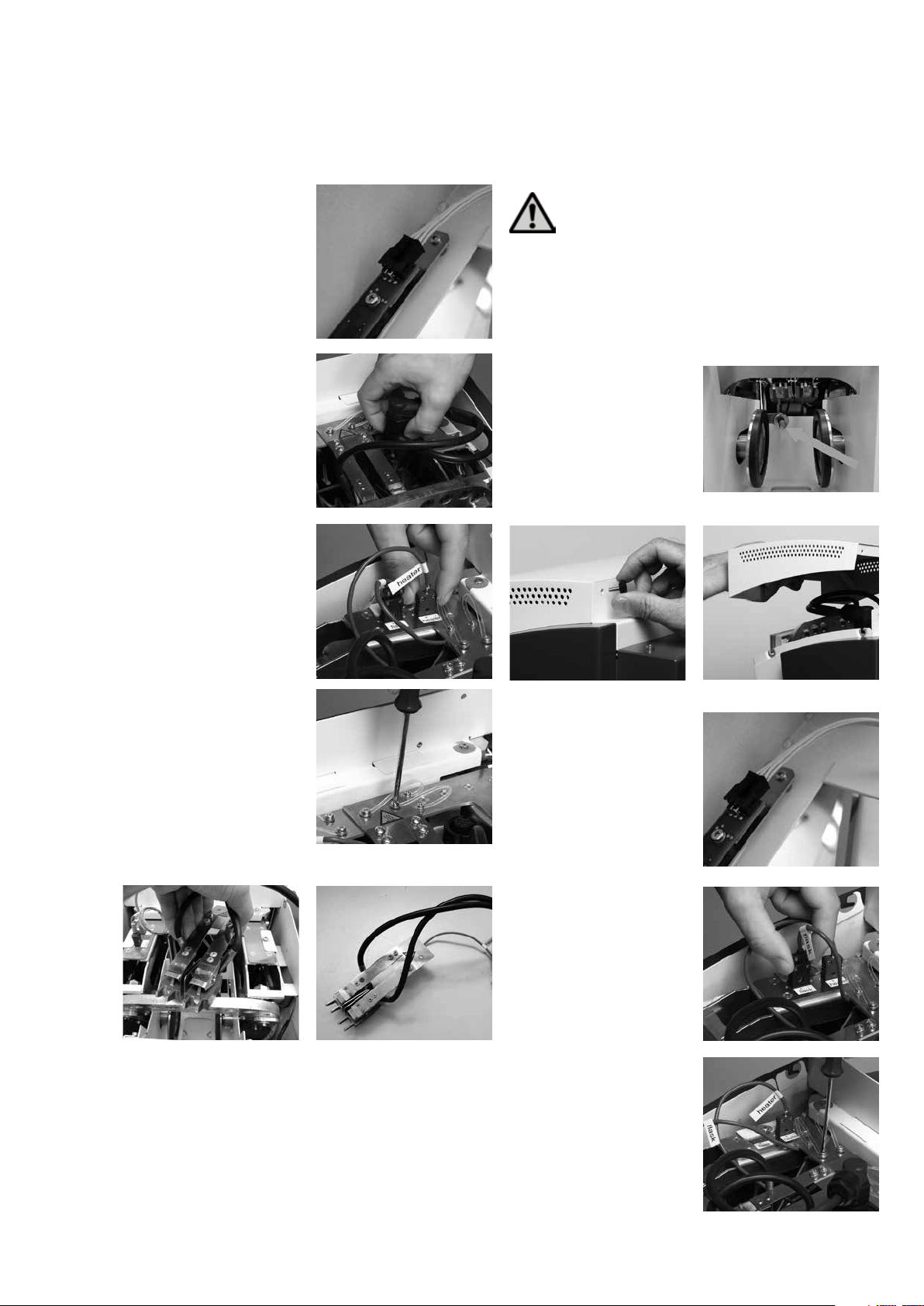

Dismounting the heater:

To dismount the heater, please

proceed as follows:

Step 1:

Remove the two knurled screws at the rear and remove the hood.

19

Page 20

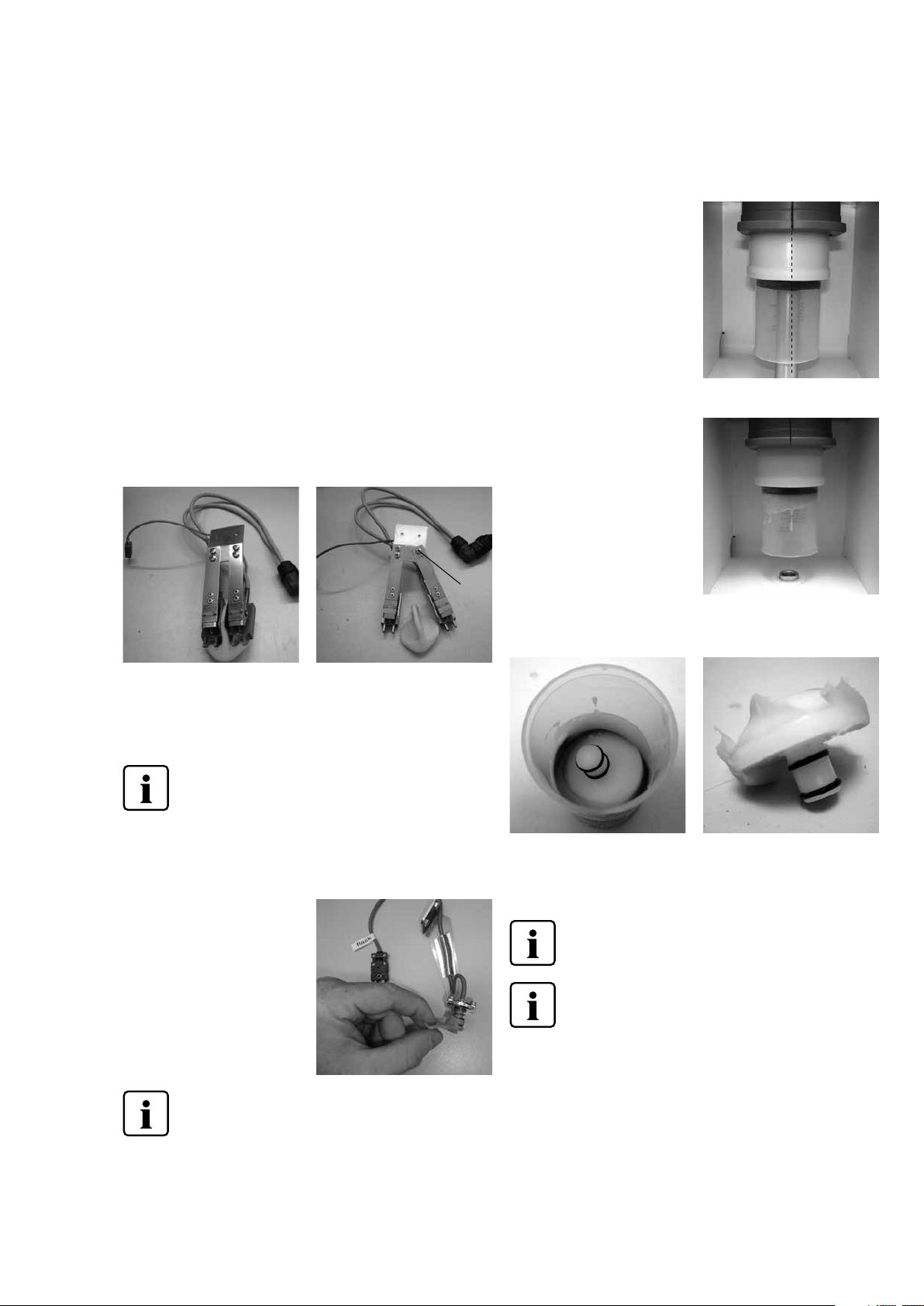

Step 2:

Unplug the cable for the OSD.

Step 3:

Unplug the heater plug.

Step 4:

Unplug the plug with the label

"heater".

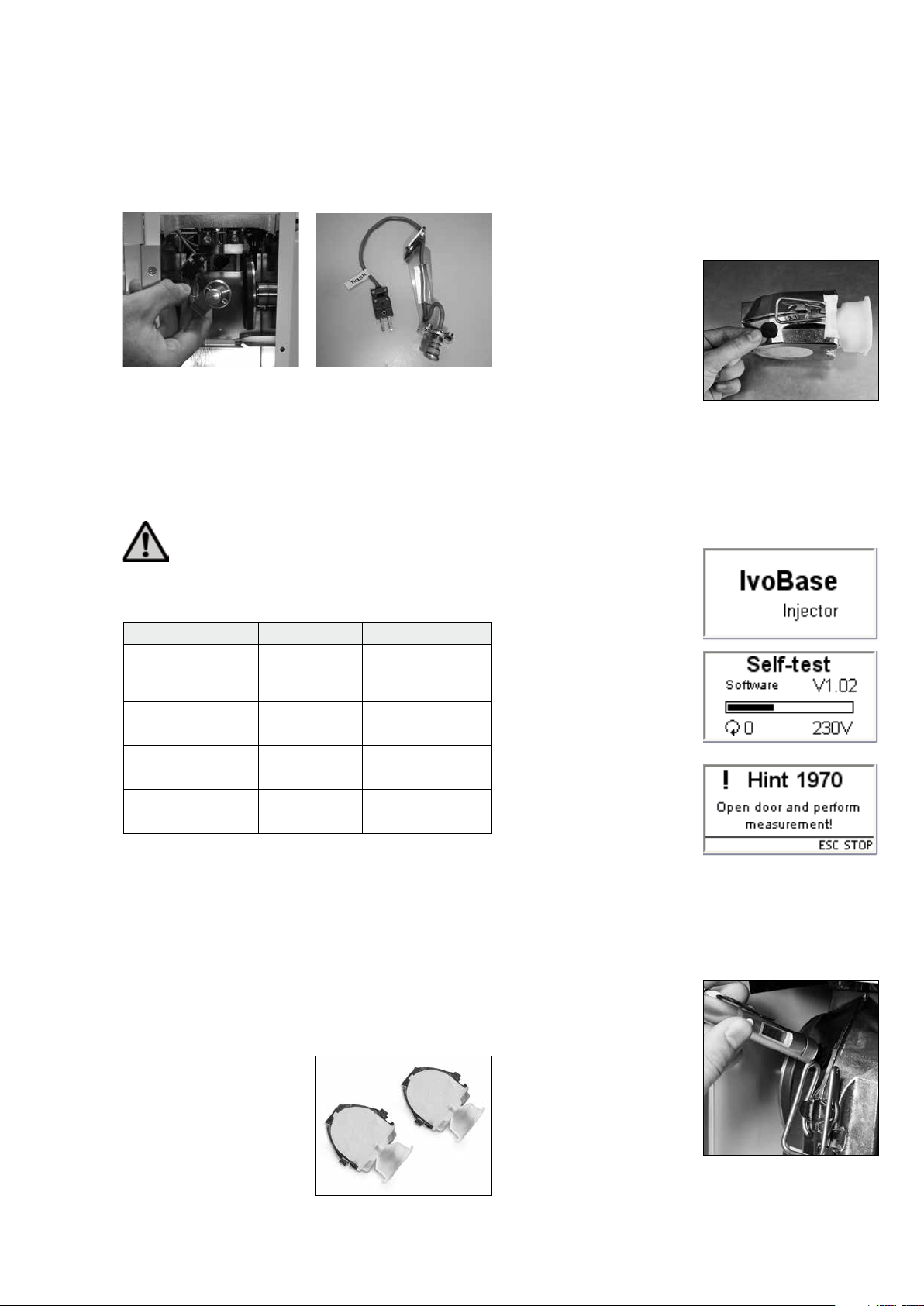

7.4 Replacing the temperature sensor

Before replacing the temperature sensor, disconnect the

injector from the power supply.

The temperature sensor of the IvoBase Injector has been developed

in such a way that users may replace it by themselves, if required

(cleaning, defect).

Check weekly if the temperature sensor is damaged and/or bent.

Also, check it for correct fit or other damage.

Dismounting the temperature sensor:

To dismount the temperature

sensor, please proceed as follows:

Step 1:

Remove the two knurled screws at the rear and remove the hood.

Step 5:

Remove the screws of the

he at er.

Step 6:

Remove the heater. Dismounted heater.

Mounting the heater:

Place the heater back in its original position (align the heater in the

centre with the help of an inserted flask) and secure it in place with

the screws. (The heater is mounted in the same way as it is dismounted. Follow the Steps 6 to 1.)

Step 2:

Unplug the cable for the OSD.

Step 3:

Unplug the plug with the label

"fla s k ".

Step 4:

Remove the screws of the

sensor.

20

Page 21

Step 5:

Remove the sensor. Dismounted sensor:

Mounting the temperature sensor:

Mounting the temperature sensor is carried out in the same way as

dismounting. Simply reverse the order of the above steps (Step 5 to

Step 1).

7.5 Cleaning

The injector may only be cleaned when it is cool, since

there is a burn hazard. Do not use any cleaning

solutions. Disconnect the power to the injector before

cleaning.

The following parts have to be cleaned from time to time:

What When Cleaning material

Injector housing and

membrane-sealed keypad

Safety door if required soft cloth

if required soft, dry cloth

Step 2:

Clean the IvoBase polymerization chamber, heater and temperature

sensor while they are cold. Please make sure that the contact surfaces of the heater and the temperature sensor are clean.

Step 3:

Close the flask with the locking

clamps and attach a measuring

point to the spot on the left flask

half shown in the picture (see

picture). It is important that the

exact position is observed. Only in

this way can correct measuring

values be achieved.

Step 4 :

Load the IvoBase Injector with the test flask and close the safety

do or.

Step 5:

Select the heater test program with the „Settings“ key. Confirm

your selection with the Enter key.

Step 6:

Start the test program using the

Start key. The flask is heated to

100 °C / 212 °F for approximately

10 minutes. The remaining time is

indicated in the display. The

Operating Status Display is not

illuminated during the heating

phase.

Important: The door must not be

opened during the test. If this is

not observed, the test program is

immediately aborted.

Polymerization

chamber

Flask and flask

accessories *

* The flask housing may show a dark discolouration, for instance,

when plaster material is left in the flask for a longer period. This

oxide layer can be removed by means of pumice flour. This dark

layer does not influence the usability of the flask in any way.

if required soft cloth

after every use water

7.6 Heater test

The heater test is used to check the observance of the temperature

in the IvoBase Injector independently and at regular intervals.

For that purpose, proceed as follows:

Step 1:

Fabricate a test flask that is

exclusively filled with stone

(without model – see Fig. 1). If the

stone in the flask set a longer

while ago and is dry, the flask has

to be soaked in water before the

test.

Step 7:

After the program is completed,

the message „Hint 1970“ appears

in the display, with the prompt to

determine the temperature now.

The acoustic signal can be

switched off with the ESC key.

Step 8 :

Open the safety door and conduct the measurement. In order to

obtain the most reliable result, conduct several measurements in

close succession. The available time window for that purpose is

60 seconds. This time must not be exceeded, since the flask would

cool down too much and the measurement would be skewed.

Important: The sensor of the

IR thermometer must be held as

closely as possible to the

measuring point (see picture).

However, a small air gap should

be present. Measurements directly

on the metal surface without

measuring point are not

admissible, since these

measurement can be skewed by

reflections.

21

Page 22

Step 9:

Analyze the measurement. The measuring results must be in the

following temperature range:

– Min.: 90 °C / 194 °F

– Max.: 110 °C / 230 °F

If the measured value is not within this range, please contact your

Ivoclar Vivadent Service Centre.

Step 10 :

Press the Stop key to end the test. After that, remove the

flask from the injector and remove the measuring point.

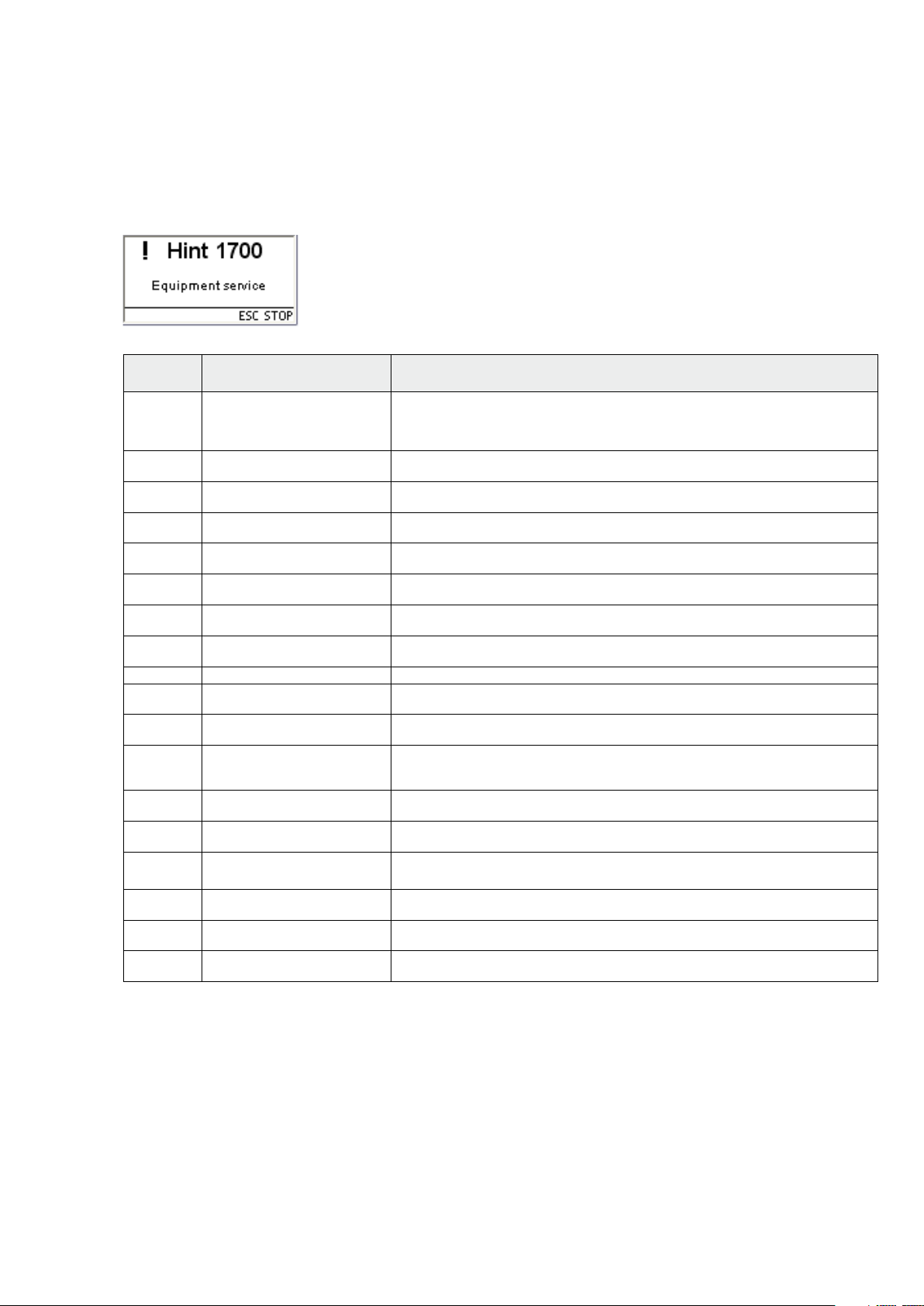

7.7 Service Hint

When the Service Hint is displayed for the first time ( Hint 1700),

3 years have passed or 10,000 cycles have been carried out. Therefore, Ivoclar Vivadent recommends having a maintenance procedure

performed on the injector. The interval until the next appearance of

the Service Hint can be changed in the Settings (see Section 5.4.1).

7.8 Information about transport protection

In order to transport the Ivobase Injector, the clamps must be

brought into a transport position. This function can be activated in

the Settings (see Chapter 5.4 Settings and information).

22

Page 23

This chapter will help you to recognize malfunctions and take appropriate measures.

8.1 Error messages

During operation, the injector continuously monitors all the functions. If an error is

detected, the respective error message is displayed.

8. What if....?

Error / Hint

No.

170 0 Service reminder Three years have passed since the last technical inspection of the injector. Therefore,

190 0 Door is open. Once a program has been started, the door must remain closed. Close the door. The program will

1901

**

1913

**

1914

**

1917 Power failure A program in progress will automatically resume, irrespective of the duration of the power failure.

1920

**, ***

1921

**, ***

1928 Checking the start temperature The flask is too hot to start a program. Press START to start the program any way.

1930

**, ***

1935

**,***

1936 Low amount of material in capsule The injection motor has reached the maximum travelling distance. The amount of material in the

1941

**

196 0

**

1970 Open door and conduct measure-

1971

**

1972 Heater test completed At the end of the heater test, the temperature of the flask must be determined within one minute.

198 0 Switch off device At the end of the transport protection program, the IvoBase Injector can be transported safely. The

** A program in progress is aborted. *** Error cannot be acknowledged; programs cannot be started.

Error Text Error Message

Ivoclar Vivadent recommends having a maintenance procedure performed on the injector. For further

information, please refer to the Equipment Ser vice Passport or the Operating Instructions. The inter val

until the nex t appearance of the Service Hint can be changed in the Settings.

automatically resume.

Hood is missing. The injector hood may only be removed for maintenance purposes. The

Insert the flask. Insert a flask into the injector and start the program again.

Insert the capsule. Insert a flask including a material capsule into the injector and start the program again.

Technical malfunction heater/sensor No temperature increase in the flask was noted during the polymerization phase.

Technical malfunction heater/sensor No temperature increase of the heater was noted during the polymerization phase.

Technical malfunction heater/sensor The function of the heater is checked during the self-test. No temperature increase is noticeable.

Technical defec t; service The press motor has exceeded the permitted travelling distance.

Press force too low! The press force which squeezes the flask halves together is too low (sudden pressure drop).

The door is open during the self-test. The door must be closed during the self-test. Close the door and switch the injector off and on

ment

Heater test aborted If the door is opened during the heater test or the cover removed from the injector, the test pro -

injector must be turned off beforehand. The injector cannot be started without the hood in place.

capsule is low. Reasons for this could be: There is not sufficient material in the capsule for the dental

lab work. Material leaks from a flask.

again.

At the end of the heater test, open the door and use the supplied IR thermometer to determine the

temperature of the flask.

gram is aborted. Manual abortion is also possible by pressing Stop t wice.

After a longer waiting time, the flask has cooled down too much.

device can now be switched off.

If one of the following error codes is displayed, please contact the Ivoclar Vivadent After Sales Service directly.

25, 29,

54, 56,

103, 107,

700, 701, 705, 706 707,

1010, 1011, 1012, 1013, 1014, 1015, 1016, 1028

1202, 1203, 1204, 120 6 , 12 07

140 0, 1401, 1402

150 0

1910, 1911, 1912, 1931, 1935, 1950, 1951, 1952, 19 53

23

Page 24

8.2 Resin leaks from the flask

Under certain circumstances – e.g. if the filter component was forgotten to be placed in the flask (see Instructions for Use of the

corresponding materials) – resin may leak from the flask during

injection. This results in contamination of the heating shoes or the

temperature sensor. Please proceed as follows in such cases:

8.2.1 Cleaning the heater

Step 1:

Dismounting the heater: Proceed as described in section 7.3 of

these Operating Instructions.

Step 2:

The heater consists of two heating elements. Loosen both screws

on one of the two heating elements. One screw (a) must be completely loosened and removed. Subsequently, this heating element

can simply be swivelled away from the the remaining element.

Polymerized resin material can then be easily removed from the

heater (see image).

a)

Step 3:

After having cleaned the heater, mount it in the injector again.

Swivel the heating element back to its original position and tighten

the screw that was previously removed (see image). To insert the

heater, proceed as described in Section 7.3.

8.3 Resin leaks from the injection head

In case of a malfunction, resin may

leak from the material capsule

during injection (e.g. if the plunger is tilted in the material capsule

– see image). If leaked and

polymerized material is deposited

in the material capsule, the injection head may get stuck in the

capsule, since it is not fixedly connected with the plunger.

If this is the case, proceed as

follows:

Step 1:

Wait until the program has

ended and the plunger has

moved all the way down.

Step 2:

Remove the injection head of the material capsule and completely

remove the material.

Wait until the material has completely set /

polymerized before removing it.

8.2.2 Cleaning the temperature sensor

Step 1:

Dismounting the temperature sensor. Proceed as described in section 7.4 of these Operating Instructions.

Step 2:

Carefully remove the material

from the temperature sensor.

Step 3:

Remount the temperature sensor

in the injector (see 7.4)

Wait until the material is completely set/

polymerized before removing it.

Step 3:

Replace the injection head in the plunger. The head is pushed in –

there is no screw connection to the plunger.

Wait until the material has completely set /

polymerized before removing it.

To insert the injection head in the plunger, dampen

the rubber rings of the injection head.

24

Page 25

8.4 Technical malfunctions

These malfunctions may occur without an error message being displayed:

Error Double-check Measure

Display incomplete Contact Ivoclar Vivadent After Sales Service.

Text on the display is difficult to read. Is the contrast set correctly? Adjust the contrast.

Display is not illuminated. Has the injector been correctly connected

and switched on according to the Operating

Instructions?

Buzzer does not sound. Is the beeper switched off (Volume = 0)? Set the volume from 1–5.

Correctly connect and switch on the injector.

8.5 Repair

Repairs may only be carried out by a certified Ivoclar

Vivadent Service Centre. Please refer to the addresses on

the last page of these Operating Instructions.

If repairs during the warranty period are not carried out by a

certified a Ivoclar Service Centre, the warranty will expire

immediately. Please also refer to the corresponding warranty

regulations.

25

Page 26

9. Product Specifications

9.1 Delivery form

– IvoBase Injector

– Power cord

– USB download cable

– 2 Sets of flasks

– Thermal glove

– Temperature Checking Set

– var. accessories

– Warranty Card, Operating Instructions, Service Passport

9.2 Technical data

Nominal voltage 100 – 120 V / 200 – 240 V

Nominal frequency 50 Hz – 60 Hz

Acceptable voltage fluctuations +/– 10%

Nominal output 450 W

Protection category I

Overvoltage category II

Contamination level 2

Dimensions Depth: 400 mm

Width: 340 mm

Height: 560 mm

Max. temperature 300 °C (572 °F)

Weight 35.6 kg

9.3 Acceptable operating conditions

Acceptable ambient temperature:

+5 °C to +40 °C / +41°F to +104 °F

Acceptable humidity range:

Relative humidity 80% for temperatures up to 31 °C / 87.8 °F

gradually decreasing to 50% relative humidity at 40 °C / 104 °F

condensation excluded.

Acceptable ambient pressure:

The injector is tested for use at altitudes of up to 2000 m ( 6562 ft)

above sea level.

9.4 Acceptable transportation and storage conditions

Acceptable temperature range: –20 °C to +65 °C / –4 °F to +149 °F

Acceptable humidity range: Max. 80% relative humidity

Acceptable ambient pressure: 500 mbar to 1060 mbar

Use only the original packaging together with the corresponding

foam material for shipping purposes.

Safety notes

The IvoBase Injector complies with the following guidelines:

– IEC 61010-1:2001

– EN 61010 -1:2001

– UL 61010 -1:200 4

– CAN/CSA-C22.2 No. 61010 -1:2004

– IEC 61010-2-010 :2003

– EN 61010 -2- 010:20 03

– CAN/CSA-C22.2 No. 61010-2-010:20 04

Radio protection / electromagnetic compatibility EMC tested

26

Page 27

10.1 Program structure

10. Appendix

Program

No.

1 IvoBase Hybrid

2 IvoBase High Impact

3 SR Ivocap High Impact

4 SR Ivocap Clear

5 SR Ivocap Elastomer Program for the polymerization of the SR Ivocap Elastomer material 65 min

6–20 Ivoclar Vivadent – Spare Space for future Ivoclar Vivadent injection programs.

Name Description Duration

Program for the polymerization of the IvoBase Hybrid material,

residual monomer <= 1.5%

Program for the polymerization of the IvoBase Hybrid material with additional

RMR, residual monomer <= 1.0%

Program for the polymerization of the IvoBase High Impact material,

residual monomer <= 1.5%

Program for the polymerization of the IvoBase High Impact material with additional RMR, residual monomer <= 1.0%

Program for the polymerization of the SR Ivocap High Impact material, residual

monomer <= 1.5%

Program for the polymerization of the SR Ivocap High Impact material with

additional RMR, residual monomer <= 1.0%

Program for the polymerization of the SR Ivocap Clear material, residual

monomer <= 1.5%

Program for the polymerization of the SR Ivocap Clear material with additional

RMR, residual monomer <= 1.0%

35 min

45 min

50 min

60 min

55 min

65 min

55 min

65 min

27

Page 28

Ivoclar Vivadent – worldwide

Ivoclar Vivadent AG

Bendererstrasse 2

9494 Schaan

Liechtenstein

Tel. +423 235 35 35

Fax +423 235 33 60

www.ivoclarvivadent.com

Ivoclar Vivadent Pty. Ltd.

1 – 5 Overseas Drive

P.O. Box 367

Noble Park, Vic. 3174

Australia

Tel. +61 3 9795 9599

Fax +61 3 9795 9645

www.ivoclarvivadent.com.au

Ivoclar Vivadent Ltda.

Alameda Caiapós, 723

Centro Empresarial Tamboré

CEP 06460-110 Barueri – SP

Brazil

Tel. +55 11 2424 7400

Fax +55 11 3466 0840

www.ivoclarvivadent.com.br

Ivoclar Vivadent Inc.

1-6600 Dixie Road

Mississauga, Ontario

L5T 2Y2

Canada

Tel. +1 905 670 8499

Fax +1 905 670 3102

www.ivoclarvivadent.us

Ivoclar Vivadent Shanghai

Trading Co., Ltd.

2/F Building 1, 881 Wuding Road,

Jing An District

200040 Shanghai

China

Tel. +86 21 6032 1657

Fax +86 21 6176 0968

www.ivoclarvivadent.com

Ivoclar Vivadent Marketing Ltd.

Calle 134 No. 7-B-83, Of. 520

Bogotá

Colombia

Tel. +57 1 627 3399

Fax +57 1 633 1663

www.ivoclarvivadent.co

Ivoclar Vivadent SAS

B.P. 118

F-74410 Saint-Jorioz

France

Tel. +33 4 50 88 64 00

Fax +33 4 50 68 91 52

www.ivoclarvivadent.fr

Ivoclar Vivadent GmbH

Dr. Adolf-Schneider-Str. 2

D-73479 Ellwangen, Jagst

Germany

Tel. +49 7961 889 0

Fax +49 7961 6326

www.ivoclarvivadent.de

Wieland Dental + Technik

GmbH & Co. KG

Schwenninger Strasse 13

D-75179 Pforzheim

Germany

Tel. +49 7231 3705 0

Fax +49 7231 3579 59

www.wieland-dental.com

Ivoclar Vivadent Marketing (India)

Pvt. Ltd.

503/504 Raheja Plaza

15 B Shah Industrial Estate

Veera Desai Road, Andheri (West)

Mumbai, 400 053

India

Tel. +91 22 2673 0302

Fax +91 22 2673 0301

www.ivoclarvivadent.in

Ivoclar Vivadent s.r.l.

Via Isonzo 67/69

40033 Casalecchio di Reno (BO)

Italy

Tel. +39 051 6113555

Fax +39 051 6113565

www.ivoclarvivadent.it

Ivoclar Vivadent K.K.

1-28-24-4F Hongo

Bunkyo-ku

Tokyo 113-0033

Japan

Tel. +81 3 6903 3535

Fax +81 3 5844 3657

www.ivoclarvivadent.jp

Ivoclar Vivadent Ltd.

12F W-Tower, 1303-37

Seocho-dong, Seocho-gu,

Seoul 137-855

Republic of Korea

Tel. +82 2 536 0714

Fax +82 2 596 0155

www.ivoclarvivadent.co.kr

Ivoclar Vivadent S.A. de C.V.

Av. Insurgentes Sur No. 863,

Piso 14, Col. Napoles

03810 México, D.F.

México

Tel. +52 55 5062 1000

Fax +52 55 5062 1029

www.ivoclarvivadent.com.mx

Ivoclar Vivadent BV

De Fruittuinen 32

2132 NZ Hoofddorp

Netherlands

Tel. +31 23 529 3791

Fax +31 23 555 4504

www.ivoclarvivadent.com

Ivoclar Vivadent Ltd.

12 Omega St, Rosedale

PO Box 303011 North Harbour

Auckland 0751

New Zealand

Tel. +64 9 914 9999

Fax +64 9 914 9990

www.ivoclarvivadent.co.nz

Ivoclar Vivadent Polska Sp. z o.o.

Al. Jana Pawla II 78

00-175 Warszawa

Poland

Tel. +48 22 635 5496

Fax +48 22 635 5469

www.ivoclarvivadent.pl

Ivoclar Vivadent Marketing Ltd.

Prospekt Andropova 18 korp. 6/

office 10-06

115432 Moscow

Russia

Tel. +7 499 418 0300

Fax +7 499 418 0310

www.ivoclarvivadent.ru

Ivoclar Vivadent Marketing Ltd.

Qlaya Main St.

Siricon Building No.14, 2

Office No. 204

nd

Floor

P.O. Box 300146

Riyadh 11372

Saudi Arabia

Tel. +966 11 293 8345

Fax +966 11 293 8344

www.ivoclarvivadent.com

Ivoclar Vivadent S.L.U.

C/ Ribera del Loira nº 46, 5ª planta

28042 Madrid

Spain

Tel. + 34 913 757 820

Fax + 34 913 757 838

www.ivoclarvivadent.es

Ivoclar Vivadent AB

Dalvägen 14

S-169 56 Solna

Sweden

Tel. +46 8 514 939 30

Fax +46 8 514 939 40

www.ivoclarvivadent.se

Ivoclar Vivadent Liaison Office

: Tesvikiye Mahallesi

Sakayik Sokak

Nisantas’ Plaza No:38/2

Kat:5 Daire:24

34021 Sisli – Istanbul

Turkey

Tel. +90 212 343 0802

Fax +90 212 343 0842

www.ivoclarvivadent.com

Ivoclar Vivadent Limited

Ground Floor Compass Building

Feldspar Close

Warrens Business Park

Enderby

Leicester LE19 4SE

United Kingdom

Tel. +44 116 284 7880

Fax +44 116 284 7881

www.ivoclarvivadent.co.uk

Ivoclar Vivadent, Inc.

175 Pineview Drive

Amherst, N.Y. 14228

USA

Tel. +1 800 533 6825

Fax +1 716 691 2285

www.ivoclarvivadent.us

Version : 3

Date of issue: 2014-01

Valid as of Software 2.0

The appara tus has been dev eloped sol ely for use in den tistry. Star t-up and

operation should be carried out strictly according to the Operating Instructions.

Liabilit y cannot be acce pted for damage s resulting fro m misuse or failure t o

observ e the Instruc tions. The u ser is solel y responsibl e for testing the a pparatus

for its suit ability for any p urpose not e xplicitly s tated in the Ins truction s.

Descript ions and data co nstitute no war ranty of attr ibutes and are n ot binding.

Printed in Aus tria

© Ivoclar Vivadent AG, Schaan/ Liechtenstein

6420 03/en /2014-01-29

Loading...

Loading...