Page 1

Press

Abutment Solutions

all ceramic

all you need

instructions for use

Page 2

Table of Contents

3 Product Information

Material

Uses

Composition

6 Fabrication of Hybrid Abutments and Hybrid Abutment Crowns

Treatment/fabrication process

Shade – tooth shade, preparation shade/abutment shade

Model preparation

Selecting a Ti base

Layer thicknesses of the ceramic components

Modeling

Sprueing

Investing

Preheating

Pressing

Divesting

Removing the reaction layer

Finishing

Stain and Characterization firing

Glaze firing

Crown on hybrid abutment

32 Optional: Clinical Try-in

Temporarily securing the pressed object on the Ti base

Clinical try-in

application procedure

37 Permanent Cementation

Pre-treatment of the Ti base

Preparing the pressed object

Cementation with Multilink Implant

43 Seating and Aftercare

Sterilization

Intraoral preparation

Seating the hybrid abutment and crown

Seating the hybrid abutment crown

Care notes – Implant Care

50 General Information

Frequently Asked Questions

Material Selection Table

Press and Firing Parameters

Clinical Cases

2

Page 3

®

IN ST RUC TI ONS FO R U SE

Press

all ceramic

all you need

emax Press-VA 2009-d_emax Press-VA-d.qxd 22.09.11 14:13 Seite 1

e.max

IPS

Press Abutment Solutions

Product Information

Press ceramics have been synonymous with esthetics, accuracy of fit, shape and function for decades. The IPS e.max Press lithium disilicate

(LS2) glass-ceramic additionally offers an outstanding strength of 400 MPa. The already extensive indication range from thin veneers (0.3 mm)

and monolithic molar crowns to anterior and premolar bridges is now expanded to include hybrid abutment restorations.

With IPS e.max Press, you can fabricate such restorations in combination with a titanium base (Ti base). Two different approaches are available:

– Hybrid abutment and separate crown

– Hybrid abutment crown

Both solutions show outstanding function, efficiency and esthetics. The durable bond to the Ti base is achieved by means of the self-curing

Multilink Implant luting composite.

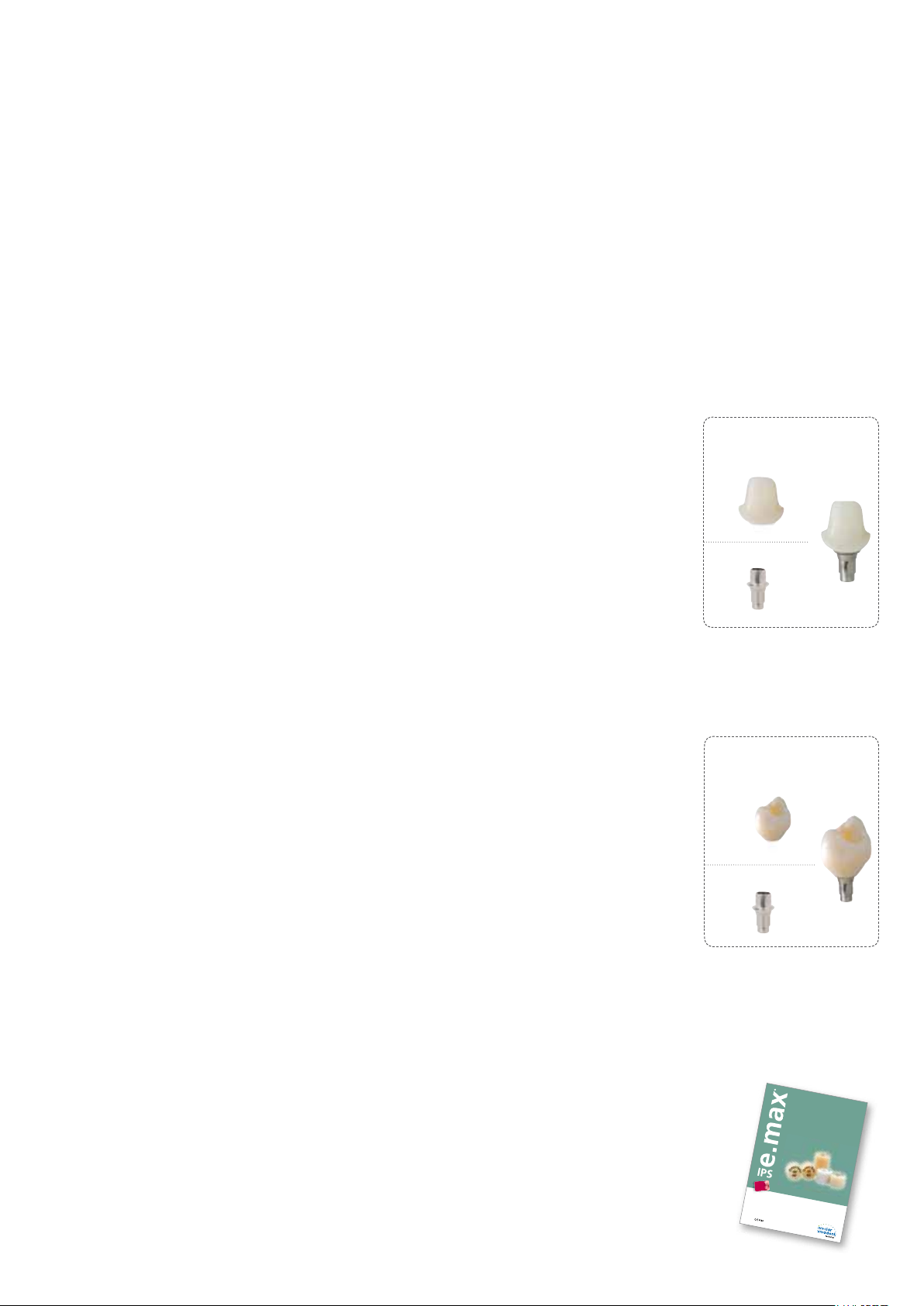

Hybrid abutment

The hybrid abutment is an individually pressed LS2 abutment which is luted to the Ti base. The shape,

emergence profile and esthetic properties of this abutment can be ideally adjusted to the clinical

situation.

Individual esthetics

Given the lifelike appearance of LS2 glass-ceramics, the esthetic possibilities are virtually limitless,

particularly in the anterior region. Due to the individual characterization, a lifelike appearance is

achieved near the root and the transition area to the crown. With the preparation margin of the crown

located on the gingival level, the geometry of the hybrid abutments allows for an easy integration of

the restoration. Excess cementation material is therefore easily removed.

Hybrid abutment

IPS e.max Press LS

AbutmentBase

Ti base

2

Flexibility due to laboratory fabrication

The pressed LS2 abutment is extraorally luted to a Ti base with Multilink Implant, then screwed into

place in the oral cavity and finally provided with a permanent IPS e.max crown. As the hybrid abutment

is conveniently fabricated in the lab, the process is time-saving and flexible.

Hybrid abutment crown

Hybrid abutment crowns are characterized by combining abutment and monolithic crown in one piece.

This is an efficient two-in-one solution made of lithium disilicate (LS2), which is directly luted to a Ti base.

Efficient fabrication due to two-in-one approach

LS2 glass-ceramics provide for strength, durability and efficiency, particularly in the posterior area.

Moreover, the material offers well-known esthetic properties allowing restorations to be simply

characterized with IPS e.max Ceram stains.

Luted extraorally, screwed in intraorally – for improved flexibility

The monolithically pressed hybrid abutment crown is reliably luted to the Ti base by means of Multilink

Implant. Then, the restoration is screwed onto the implant – in one piece. Thus, the bothersome task of

excess cement removal is a thing of the past. Subsequently, the screw access channel is sealed with a

composite material (e.g. Tetric EvoCeram®). If required, the screw can be accessed at any time, which

affords the dental team clincial flexibility.

New possibilities for economically efficient restorations

IPS e.max Press hybrid abutment crowns are a new, economically attractive alternative to conventional

implant-supported restorations, particularly for the posterior area, where strength, durability and convenient clinical handling matter.

Hybrid abutment crown

IPS e.max Press LS

Abutment

Ti base

Base

2

Note regarding the Instructions for Use:

The present Instructions for Use deal only with IPS e.max Press Abutment Solutions and represent a

supplement to the existing IPS e.max Press Instructions for Use. The IPS e.max Press Instructions for Use

contain more detailed descriptions of the material (e.g. ingot concept) and the entire indication range.

In case you do not have the IPS e.max Press Instructions for Use, you can order them from your sales

representative or simply download it from www.ivoclarvivadent.com.

3

Page 4

Material

Uses

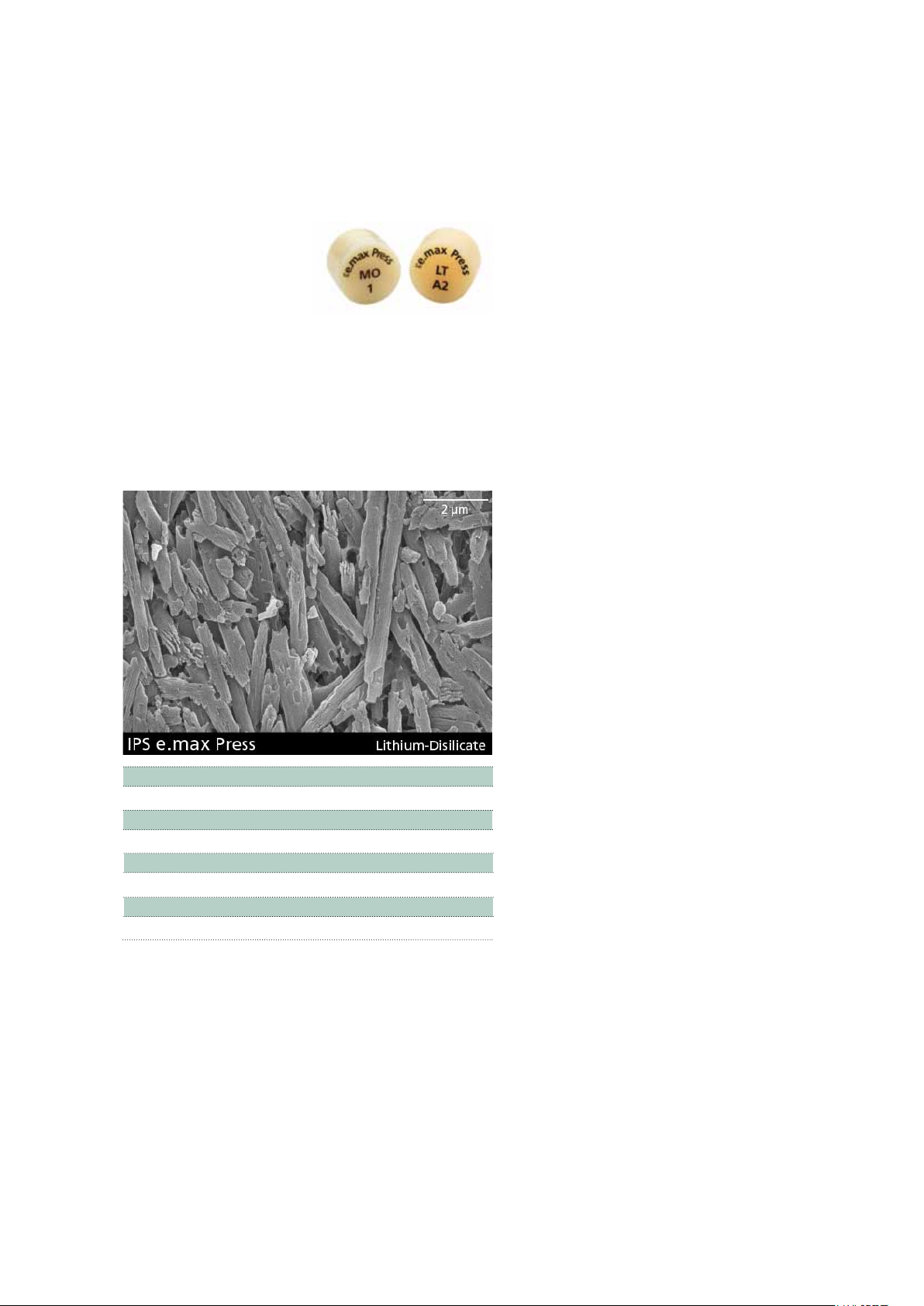

Press ceramic

IPS e.max Press are lithium disilicate glass-ceramic (LS2) ingots for

the press technology. The industrial

production process creates absolutely homogeneous ingots in different translucency levels. For IPS e.max Press Abutment Solutions,

ingots from the exisitng range of products are used.

The ingots feature a strength of 400 MPa and are thus the pressed

ceramic ingots with the highest strength. They are pressed in Ivoclar

Vivadent press furnaces to produce objects with outstanding accuracy

of fit. The pressed, tooth-coloured, highly esthetic restorations are

completed with IPS e.max Ceram.

CTE (100–400°C) [10-6/K] 10.2

CTE (100-500°C) [10-6/K] 10.5

Flexural strength (biaxial) [MPa]* 400

Fracture toughness [MPa m

Modulus of elasticity [GPa] 95

Vickers hardness [MPa] 5800

Chem. solubility [µg/cm2]* 40

Pressing temperature [°C] 915–920

*according to ISO 6872

0.5

] 2.75

Indications

– Hybrid abutments for anterior and posterior single-tooth

restorations

– Hybrid abutment crowns for anterior and posterior restorations

Contraindications

– Use of Ti bases which do not fulfil the geometry requirements.

– Failure to observe the requirements stipulated by the implant

manufacturer for using the selected implant type (diameter and

length of the implant must be approved for the respective position

in the jaw by the implant manufacturer).

– Bruxism

– Failure to observe the permissible maximum and minimum ceramic

wall thicknesses.

– All uses not stated as indications are contraindicated.

Important processing restrictions

Failure to observe the following restrictions may compromise the

results achieved with IPS e.max Press:

– If hybrid abutment crowns are fabricated, the opening of the

screw channel must not be located in the area of contact points

and areas with masticatory function. If this is not possible, a

hybrid abutment with a separate crown would be preferred.

– No extension units; only single-tooth restorations

– Layering with a veneering ceramic other than IPS e.max Ceram

– Pressing of two or more IPS e.max Press ingots in one investment

ring

– Pressing of IPS e.max Press in the IPS Investment System 300 g

– Use of a luting composite other than Multilink® Implant to lute

IPS e.max Press to the Ti base

– Temporary cementation of the crown on the hybrid abutment.

– Failure to observe the manufacturer's instructions regarding the

processing of the Ti base.

Side effects

If the patient is known to be allergic to any of the components,

IPS e.max Press Abutment Solutions should not be used.

Ti base

For IPS e.max Press Abutment Solutions, customary Ti bases made of

titanium or titanium alloys are used.

Please observe the instructions for use and processing of the manufacturer of the Ti bases used.

4

Page 5

Composition

IPS e.max Press ingots and accessories required in conjunction with

IPS e.max Press Abutment Solutions consist of the following main

components:

– IPS e.max Press ingots

Components: SiO2

Additional components: Li2O, K2O, MgO, ZnO, Al2O3, P2O5 and

other oxides

– IPS Alox Plunger

Components: Al

– IPS Alox Plunger Separator

Components: Boron nitride

– IPS e.max Press Invex Liquid

Components: Hydrofluoric acid and sulphuric acid in water

– IPS PressVEST Powder

Components: SiO2, MgO and NH4H2PO4

– IPS PressVEST Liquid

Components: Colloidal silicic acid in water

2O3

Warning

– Do not inhale ceramic dust during finishing – use exhaust air

discharge and mouth protection.

– IPS Ceramic Etching Gel contains hydrofluoric acid. Contact with

skin, eyes and clothing must be prevented at all costs, since the

material is extremely toxic and corrosive. The etching gel is intended

for professional use only and must not be applied intraorally

(inside the mouth).

– IPS PressVEST Speed Powder

Components: SiO2, MgO and NH4H2PO4

– IPS PressVEST Speed Liquid

Components: Colloidal silicic acid in water

– IPS Object Fix Flow

Components: Oxides, water, thickening agent

– IPS Ceramic Etching Gel

Components: Hydrofluoric acid (approx. 5%)

– Virtual Extra Light Body Fast Set

Components: Addition-reaction silicone, vinyl polysiloxane,

methylhydrogensiloxane, organoplatinic complex, silica

– Monobond Plus

Components: Alcohol solution of silane methacrylate, phosphoric

acid methacrylate and sulphide methacrylate

– Multilink Implant

Components: Dimethacrylate, HEMA, barium glass, ytterbium tri-

fluoride, spheroid mixed oxide

5

Page 6

®

e.max

IPS

Press Abutment Solutions

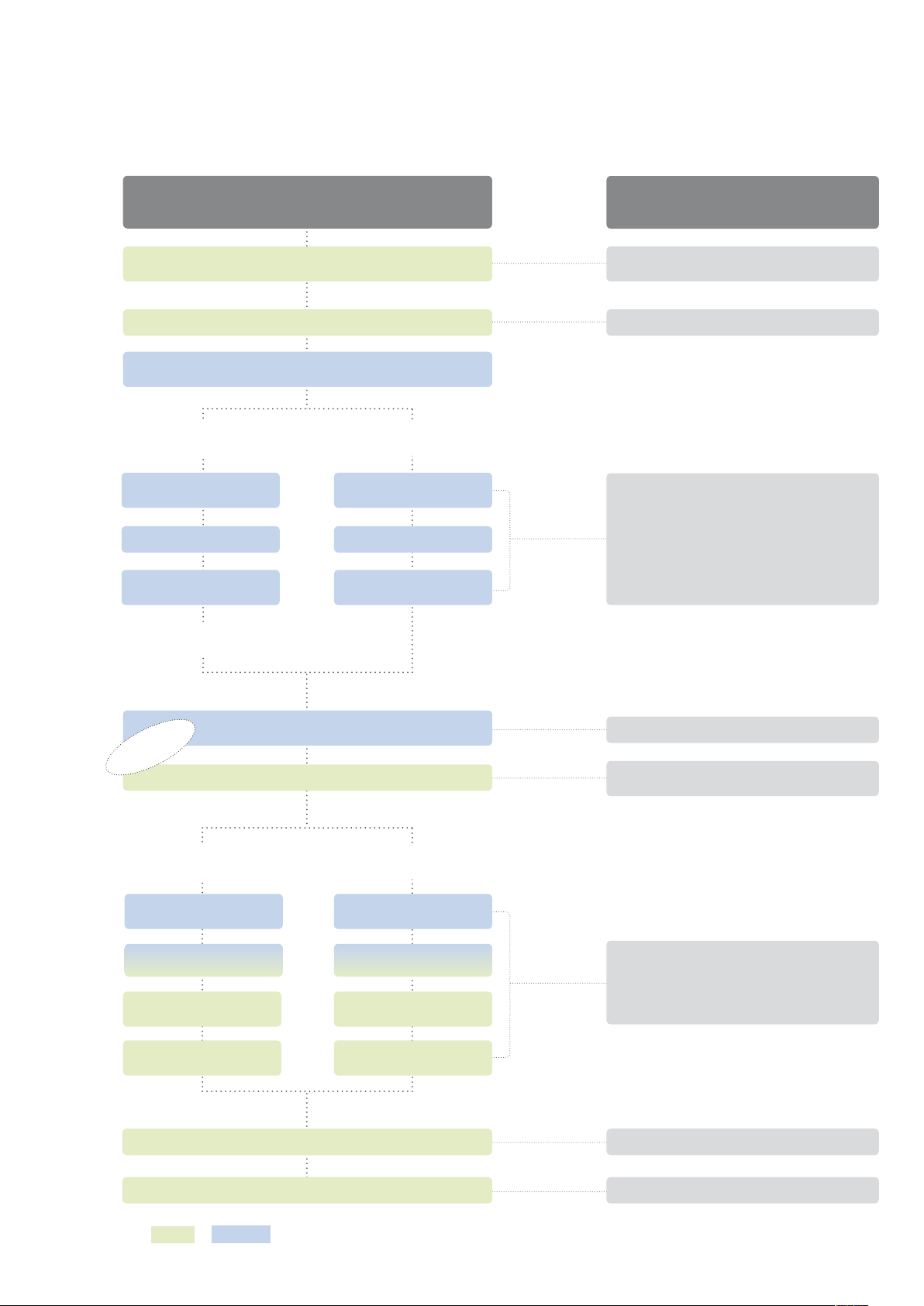

Treatment/Fabrication Process

Implantation, healing phase,

Shade determination, impression-taking

Hybrid

abutment

Contouring

and Investing

Pressing

Characterization, glaze

Optional: Polishing

Crown made of

IPS e.max Press

Working steps

gingiva shaping

Model fabrication,

selection of Ti base

Hybrid

abutment crown

Contouring

and investing

Pressing

Characterization, glaze

Ivoclar Vivadent

All the products

Cervitec Plus, Cervitec Liquid,

Telio system

OptraGate, Virtual

IPS Investment Ring System 100g, 200g

IPS PressVEST, IPS PressVEST Speed

IPS e.max Press

Programat EP 3000, EP5000

IPS Alox Plunger

IPS Alox Plunger Separator

IPS e.max Ceram

Programat P300, P500, P700

Temporarily securing

pressed object – Ti base

Optional

Hybrid

abutment

Cementing

pressed object – Ti base

Preparing for

intraoral cementation

Screwing in the hybrid abut-

ment intraorally

Cementation

IPS e.max Press crown

Checking the articulation/occlusion

Clinical try-in

pressed object – Ti base

intraoral cementation

Screwing in the hybrid abut-

ment crown intraorally

Virtual Extra Light Body Fast Set

OptraGate, Virtual Extra Light Body Fast Set,

Liquid Strip

Hybrid

abutment crown

Cementing

Preparing for

IPS Ceramic Etching Gel, Monobond Plus,

Multilink Implant, Liquid Strip,

Tetric EvoCeram, bluephase

Sealing

the screw channel

OptraFine, OptraPol, AstroPol

Practice

Laboratory

Recall

Implant Care

6

The range of available products may vary from country to country.

Page 7

Shade – tooth shade, preparation shade/abutment shade

Optimum integration in the oral cavity of the patient is the prerequisite for a true-to-nature all-ceramic

restoration. To achieve this, the following guidelines and notes must be observed by both the dentist and

the laboratory.

With IPS e.max Press Abutment Solutions, you can imitate not only the clinical crown of a natural tooth,

but also a part of the "root". By defining/determining the "root shade" you can adjust the shade of the

IPS e.max Press Abutment Solution restoration accordingly. This allows you to achieve a highly esthetic

implant-supported restoration which retains its lifelike appearance also in the case of gingiva recession.

Hybrid abutment and separate crown

Restoration shade

(pressed ceramic LS

characterization)

,

2

(crown on hybrid abutment)

Shade luting material

Shade hybrid abutment

(Ti base, luting material, pressed

ceramic LS2)

Hybrid abutment crown

Shade hybrid abumtent crown

(Ti base, luting material, pressed ceramic LS

, characterizations)

2

Please refer to the table on page 52 for the selection of the suitable IPS e.max Press ingot.

Application procedure – Fabrication Hybrid Abutment and Hybrid Abutment Crown

7

Page 8

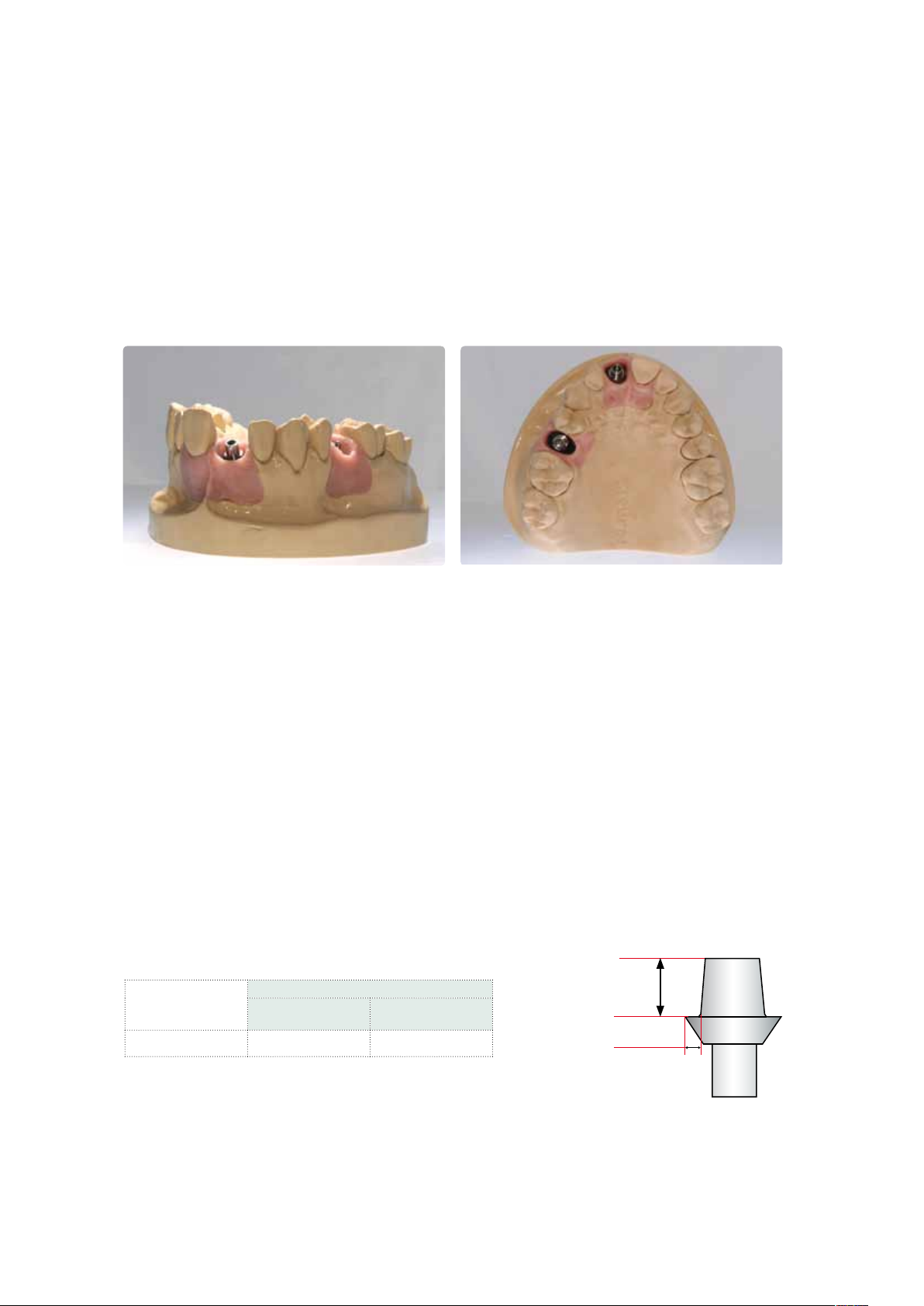

Model preparation

For the fabrication of an IPS e.max Press Abutment Solutions restoration, a model with gingiva mask is fabricated.

– Select the suitable model analog according to the implant system used.

– Fabricate a model with gingiva mask.

Prepared model with gingiva mask

Selecting a Ti base

The following paragraphs outline the selection criteria for a suitable Ti base. As a general rule, the instructions of the

respective manufacturer regarding the use of the Ti base have to be observed.

– Only bases consisting of Ti or Ti alloys must be used.

– Select a Ti base with a size that matches the clinical situation and the chosen implant system. The geometry

requirements must be observed.

– The rotation lock must be designed in such a way that stress concentrations on the pressed object are avoided.

– Ti bases with undercuts, e.g. retention grooves, are suitable to some extent.

– Check the available space for the pressed object taking the geometry of the Ti base into account on the model (e.g.

silicone key).

– Observe the instructions of the manufacturer when modifying the Ti base.

Height H

Minimum dimensions

Height H

(bonding surface)

Ti

Shoulder width S

Ti base HTi min. 4.0 mm STi min. 0.6 mm

Ti

Ti

(luted area)

Marginal shoulder

width S

Ti

8

Page 9

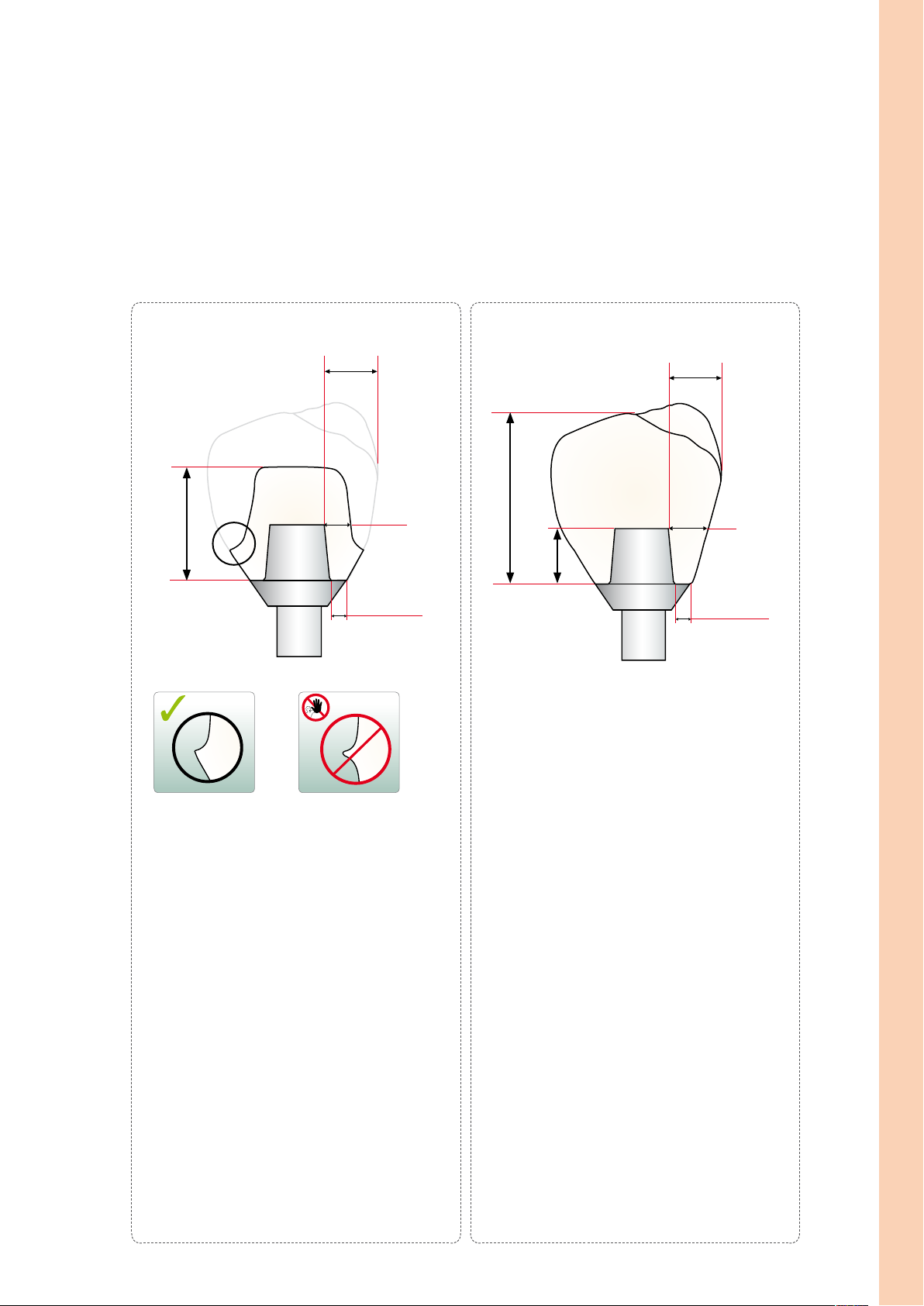

Layer thicknesses of the ceramic components

Observing the geometry requirements of the pressed objects made of IPS e.max Press material is the key to success for a

durable restoration. The more attention given to the design, the better the final results and the clinical success will turn out

to be. The following basic guidelines have to be observed:

Hybrid abutment

Width abutment crown B

A

Height H

Wall thickness W

Marginal

shoulder width S

AK

AK

Height H

A

A

Hybrid abutment crown

Height

Ti base

Width abutment crown B

Wall thickness W

Marginal

shoulder width S

AK

AK

Application procedure – Fabrication Hybrid Abutment and Hybrid Abutment Crown

A

– The marginal shoulder width SA must be at least

0.6 mm.

– Create an emergence profile with a right angle at

the transition to the crown (see picture).

– The wall thickness WA must be at least 0.5 mm.

– The height HA must not exceed twice the height of

the Ti base HTi.

– The hybrid abutment should be designed in a simi-

lar way as a prepared natural tooth:

– Circular epi-/supragingival shoulder with rounded

inner edges or a chamfer.

– In order for the crown to be cemented to the

hybrid abutment using a conventional/self-

adhesive cementation protocol, retentive surfaces

and a sufficient "preparation height" must be

observed.

– The width BAK of the crown is limited to 6.0 mm

from the axial height of contour to the screw

channel of the hybrid abutment.

– The marginal shoulder width S

must be at least

A

0.6 mm.

– The wall thickness WAK must be larger than 1.5 mm

for the entire circumference.

– The opening of the screw channel must not be

located in the contact point areas or areas with a

masticatory function. If this is not possible, a hybrid

abutment with a separate crown should be

preferred.

– The width of the hybrid abutment crown BAK is

limited to 6.0 mm from the axial height of contour

to the screw channel.

– The height HAK must not exceed twice the height of

the Ti base by more than 2 mm.

9

Page 10

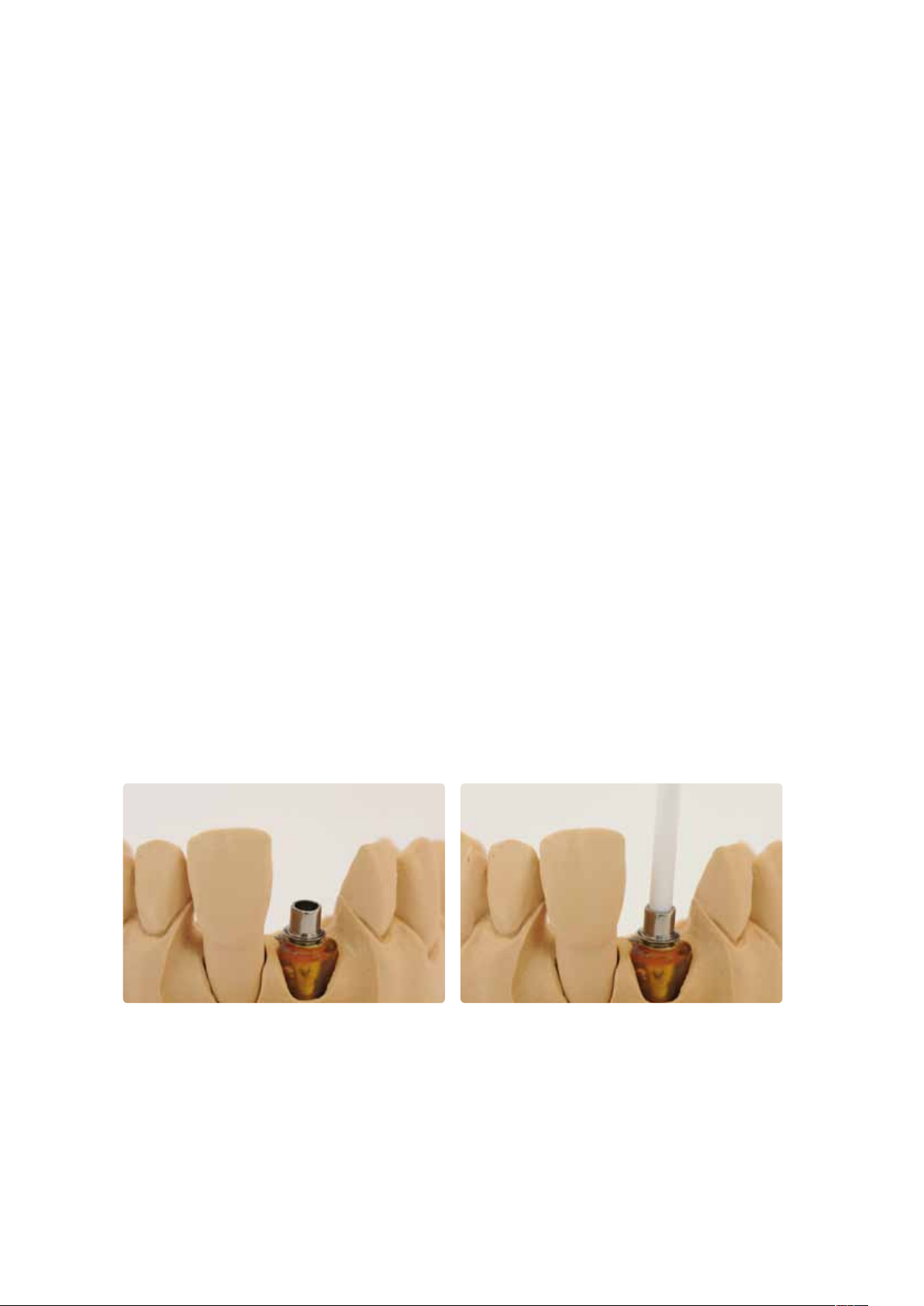

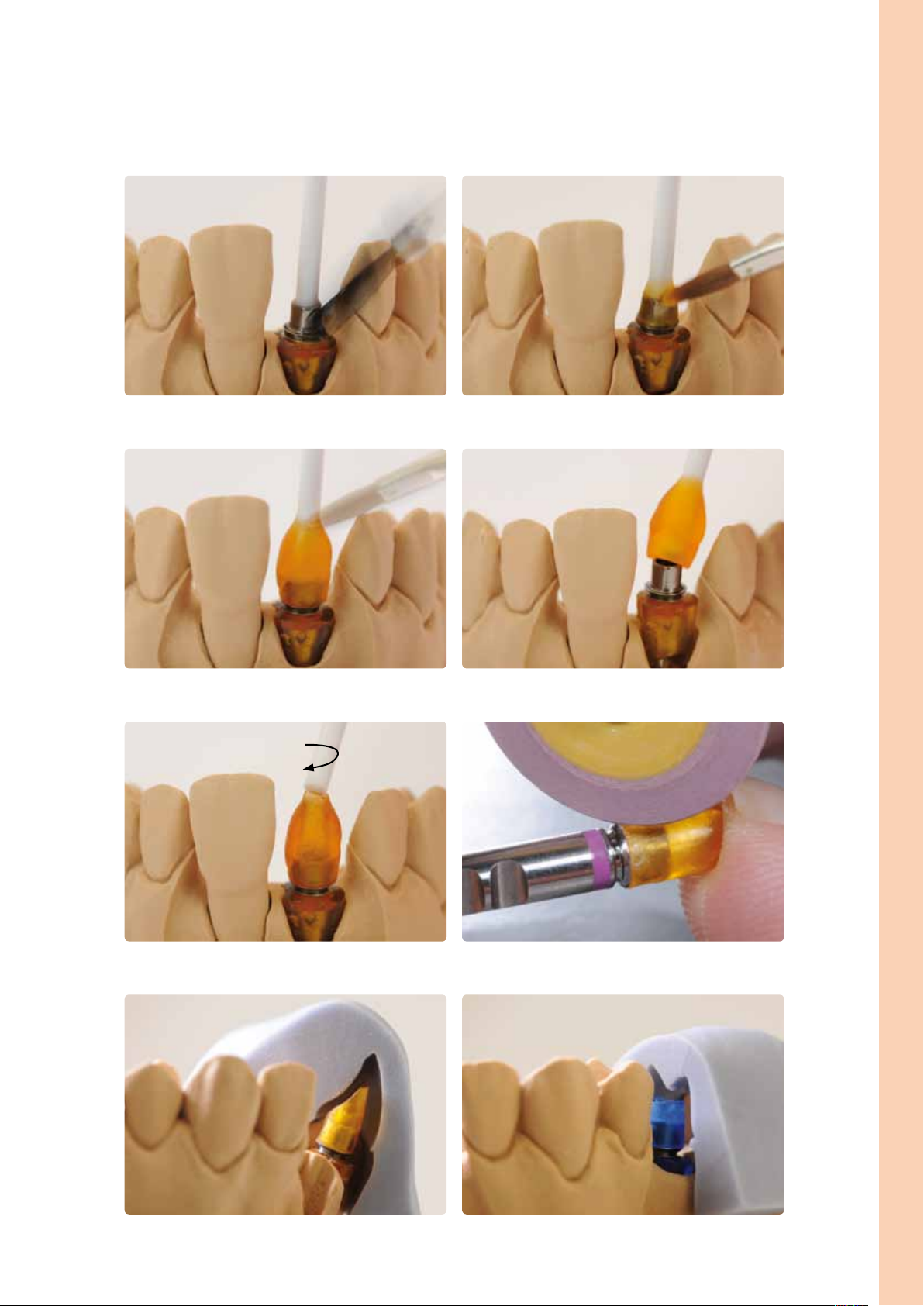

Modeling

Fabrication of a resin coping

To prepare the wax-up, a resin coping is prepared if both hybrid abutments and hybrid abutment crowns

are fabricated. Please observe the following procedure:

– Check the implant position and inclination with regard to the position of the screw channel.

– Screw the Ti base onto the model analog with the corresponding screw.

– Tip: Make sure that an additional model analog is available as this will facilitate some steps.

– Clean the Ti base with a steam cleaner.

– Insert a pin with the same diameter as the screw channel to "seal" and "extend" the screw channel.

– Do not apply die spacer.

– Isolate the Ti base and the pin with a thin application of separator. If too much separator is used, this

might result in uneven areas on the inner aspect of the pressed object.

– In order to achieve a sound fit and to facilitate the subsequent wax-up, a coping is first fabricated on

the Ti base with modelling resin. Design the coping in such a way that it can subsequently be completely covered with modelling wax. Please observe the instructions of the manufacturer regarding the

processing of modelling resin.

– Remove the Ti base from the model.

– Eliminate possible over-contoured areas of the resin coping at the transition area to the Ti base by

means of rubber polishers. Do not damage the Ti base.

– Remove the resin coping together with the pin from the T i base.

– Loosen and remove the pin by rotating the resin coping.

– Screw the Ti base onto the model analog again.

– Place the resin coping back on the Ti base and check the fit and dimension (e.g. silicone key). If

necessary, adjust the coping by means of rotary instruments.

Screw the Ti base onto the model analog with the corresponding screw. – Insert a pin with the same diameter as the screw channel to "seal" and "extend"

10

the screw channel.

Page 11

Isolate the Ti base and the pin with a thin application of separator.

Apply the modelling resin to the Ti base in increments.

Application procedure – Fabrication Hybrid Abutment and Hybrid Abutment Crown

Design the resin coping on the entire Ti base.

Loosen and remove the pin by rotating the resin coping.

Remove the resin coping together with the pin from the Ti base.

Eliminate possible over-contoured areas of the resin coping at the transition area to

the Ti base by means of rubber polishers.

Place the resin coping back on the Ti base and check the fit and dimension (e.g. silicone key). If necessary, adjust the coping by means of rotary instruments.

Design the coping in such a way that it can subsequently be covered with modelling wax.

11

Page 12

Wax-up

Please observe the following notes with regard to modelling:

– Observe the stipulated layer thicknesses.

– Create an accurate model of the restoration, particularly at the transition area to the Ti base.

– Do not over-contour the margins, since this would require time-consuming and risky fitting procedures after pressing.

– Use an organic wax for modelling to ensure that it burns out without leaving residue in the investment ring.

Procedure for hybrid abutments

– Before creating the wax object, re-insert the isolated pin into the screw channel.

– Design the emergence profile by flooding the area between the gingiva mask and the resin coping with wax.

– Contour the hybrid abutment to a reduced tooth shape. The hybrid abutment should be designed in such a way that the

required layer thicknesses are met in the crown that is fabricated. Check by means of the silicone key and in relation to

the opposing dentition.

– Determine the crown margins in relation to the gingiva level.

– Design a chamfer on which the crown is subsequently seated.

– Remove the object together with the Ti base from the model and check the emergence profile. If necessary, make

adjustments.

– Check the transition to the Ti base and remove excess wax.

– Check the required minimum thicknesses (page 9) prior to attaching the sprue.

Design the emergence profile by flooding the area between the gingiva mask and the

resin coping with wax.

Check the dimensions by means of the silicone key and in relation to the opposing

dentition.

Design the hybrid abutment with a reduced tooth shape and determine the crown

Remove the object together with the Ti base from the model and check the emergence

profile. If necessary, make adjustments. Check the transition to the Ti base and

12

margin in relation to the gingiva level.

thoroughly remove excess wax.

Page 13

Procedure for hybrid abutment crowns:

– If required, re-insert the isolated pin into the screw channel before creating the wax object.

– Design the emergence profile by flooding the area between the gingiva mask and the resin coping with wax.

– Design the abutment crown to full contour according to functional and esthetic criteria. Check in relation to the

opposing dentition.

– Make sure to take a slightly reduced occlusal relief into consideration during the wax-up, since the application of the

Stains and Glaze results in a slight increase in vertical dimensions.

– Remove the object together with the Ti base from the model and check the emergence profile. If necessary, make

adjustments.

– Check the transition to the Ti base and remove possible excess wax.

– Check the required thicknesses (page 9) prior to attaching the sprues.

Application procedure – Fabrication Hybrid Abutment and Hybrid Abutment Crown

Design the emergence profile by flooding the area between the gingiva mask and the

resin coping with wax. If necessary, re-insert the pin prior to modelling.

Design the abutment crown to full contour according to functional and esthetic

criteria. Check the object in relation to the opposing dentition.

13

Page 14

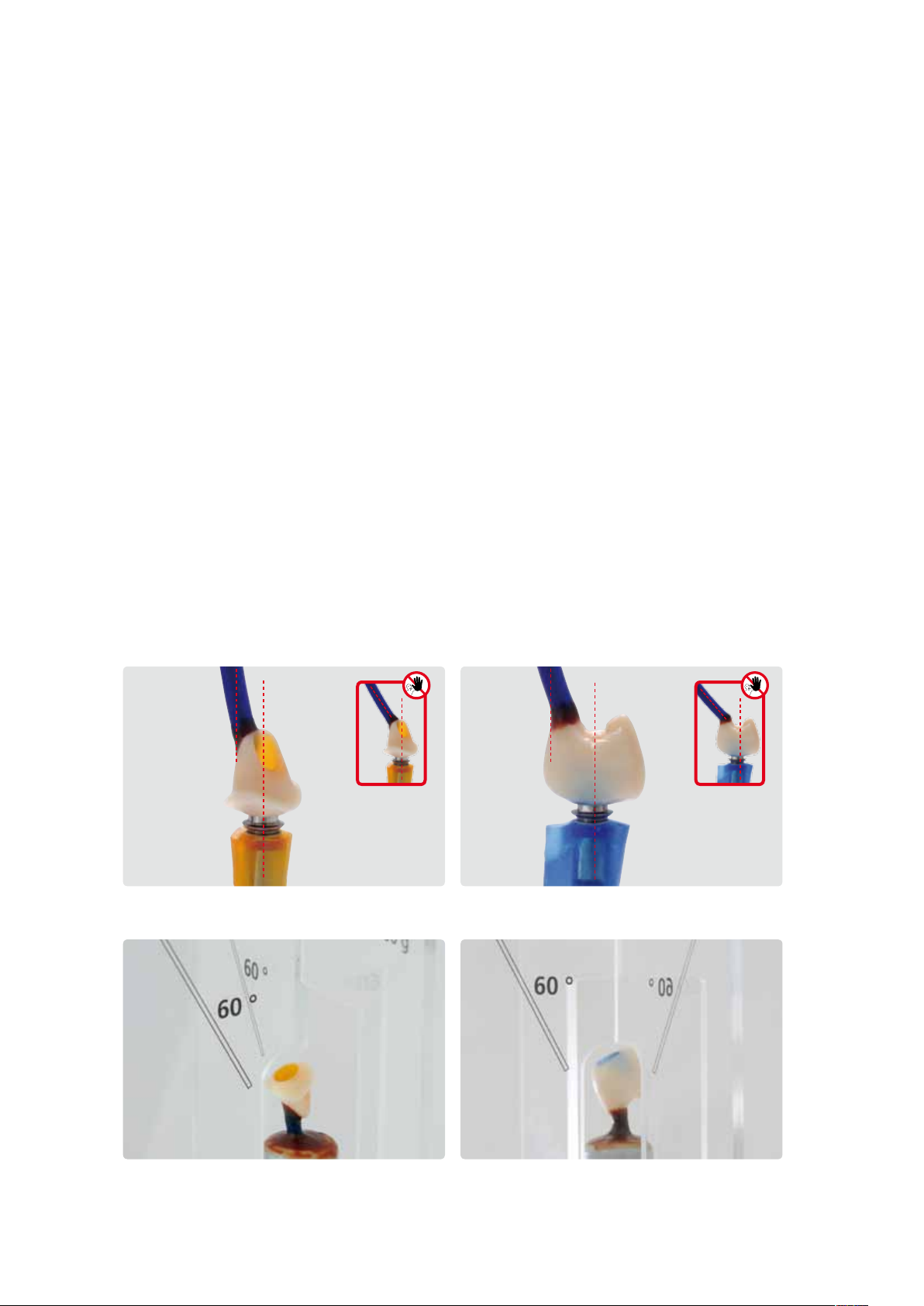

Sprueing

Please observe the following notes when attaching the sprues to the abutment or the abutment crown:

– Depending on the number and size of the objects to be invested, either the 100 g or 200 g IPS Investment Ring System

is selected. Before sprueing, weigh the ring base and record the weight (seal the opening of the ring base with wax).

Please note that the mixing ratio of the investment material is different for the various restoration types (e.g. inlays,

crowns, abutments).

– Use a 2.5 mm wax wire for sprueing.

– For abutments, the sprue is attached to an axial surface.

– For abutment crowns, the sprue is attached to a cusp.

– Align the wax wire as parallel as possible to the screw channel in order to prevent the investment material

from fracturing in the screw channel.

– The maximum length (object + sprue) of 16 mm must not be exceeded.

– Place the object on the investment ring base in such a way that the screw channel is parallel to the outer wall of the

investment ring. As a result, the investment material can subsequently be filled evenly and in a controlled manner. The

objects could be placed in a tilted position on the investment ring base, but this may lead to difficulties during investing

(e.g. bubbles in the screw channel).

– Observe a distance of at least 10 mm between the object and the silicone ring.

– If only one object is invested and pressed in an EP500 furnace, a second short (blind) sprue must be placed. This ensures

that the switch-off function of the furnace works properly at the end of the pressing procedure.

ø 2.5 mm ø 2.5 mm

Attach the sprue to a circular area of the abutment model and as parallel as possible

to the screw channel. Use a 2.5 mm wax wire.

Attach the sprue to an oral cusp of the abutment crown and as parallel as possible to

the screw channel. Use a 2.5 mm wax wire.

Place the object on the investment ring base in such a way that the screw channel is parallel to the outer wall of the investment ring.

Furthermore, this reduces the risk of the investment material breaking in the screw channel while the ceramic material is pressed.

As a result, the investment material can subsequently be filled evenly and in a controlled manner.

14

Page 15

Investing

Investing is carried out with either IPS PressVEST or IPS PressVEST Speed. The corresponding IPS Silicone Ring with the

matching ring gauge is used for investment.

Determine the weight of the object before investing.

– Position the wax objects on the ring base and attach them with wax and weigh.

– The difference between the empty and the loaded ring base is the definitive wax weight.

Small Ingot Large Ingot (L)

Wax weight up to max. 0.75 g up to max. 2 g

Investment Ring System 100 g and 200 g only 200 g

Please refer to the Instructions for Use of the corresponding investment material regarding the detailed processing

parameters. The following basic procedure is recommended:

– Do not use a debubblizer on the wax objects.

– Carefully place the IPS Silicone Ring on the ring base without damaging the objects. The silicone ring must sit flush on

the ring base.

– The processing temperature of the investment material is 18– max. 23 °C / 64 °F – max. 73 °F. Higher or lower

processing temperatures substantially affect the setting behaviour.

– Mix the investment material. Note: The investment material contains quartz powder. Therefore, avoid the inhalation of

dust.

– Important: Pour the investment material slowly into the investment ring, so that the material continuously

fills the screw channel. If the material does not sufficiently fill the screw channel, use an instrument to

carefully apply additional investment material to the screw channel from the top.

– Carefully fill the investment ring with investment material up to the marking on the silicone ring and position the ring

gauge with a hinged movement.

– Allow the investment ring to set without manipulating it.

– To prevent crystallization of the IPS PressVEST investment material, the invested ring must be processed within 24 hours.

– If IPS PressVest Speed is used, make sure that the investment ring is placed in the preheating furnace after a setting time

of at least 30 and maximum 45 minutes.

Application procedure – Fabrication Hybrid Abutment and Hybrid Abutment Crown

Investment material: Liquid concentration and quantity

IPS PressVEST IPS PressVEST Speed

Indication

Investment Ring

Liquid : dist. water

200 g

Investment Ring

Liquid : dist. water

100 g

Investment Ring

Liquid : dist. water

200 g

Investment Ring

Liquid : dist. water

100 g

IPS e.max Press

Hybrid abutment

Hybrid abutment crown

Mixing time

(under vacuum at approx. 350 rpm)

Liquid concentration: The data contained in the table are approximative values. Depending on the geometry of the Ti

base and the materials used for the wax-up, these values may be individually changed. However, the concentrated Liquid

content must not be lower than 50% in relation to distilled water.

Important: The total quantity of liquid (Liquid + dist. water) must not be altered.

16 ml : 6 ml 32 ml : 12 ml 20 ml : 7 ml 40 ml : 14 ml

60 seconds

If a high-speed mixer is used, the mixing time under

2.5 minutes

vacuum has to be reduced.

15

Page 16

Correctly sprued abutment (left) and abutment crown (right). The screw channel is in a

vertical position and parallel with the wall of the investment ring.

Continue to carefully fill the investment ring up to the marking and position the ring gauge with a hinged movement.

Pour the investment material slowly into the investment ring, so that the material can

continuously fill the screw channel.

16

Page 17

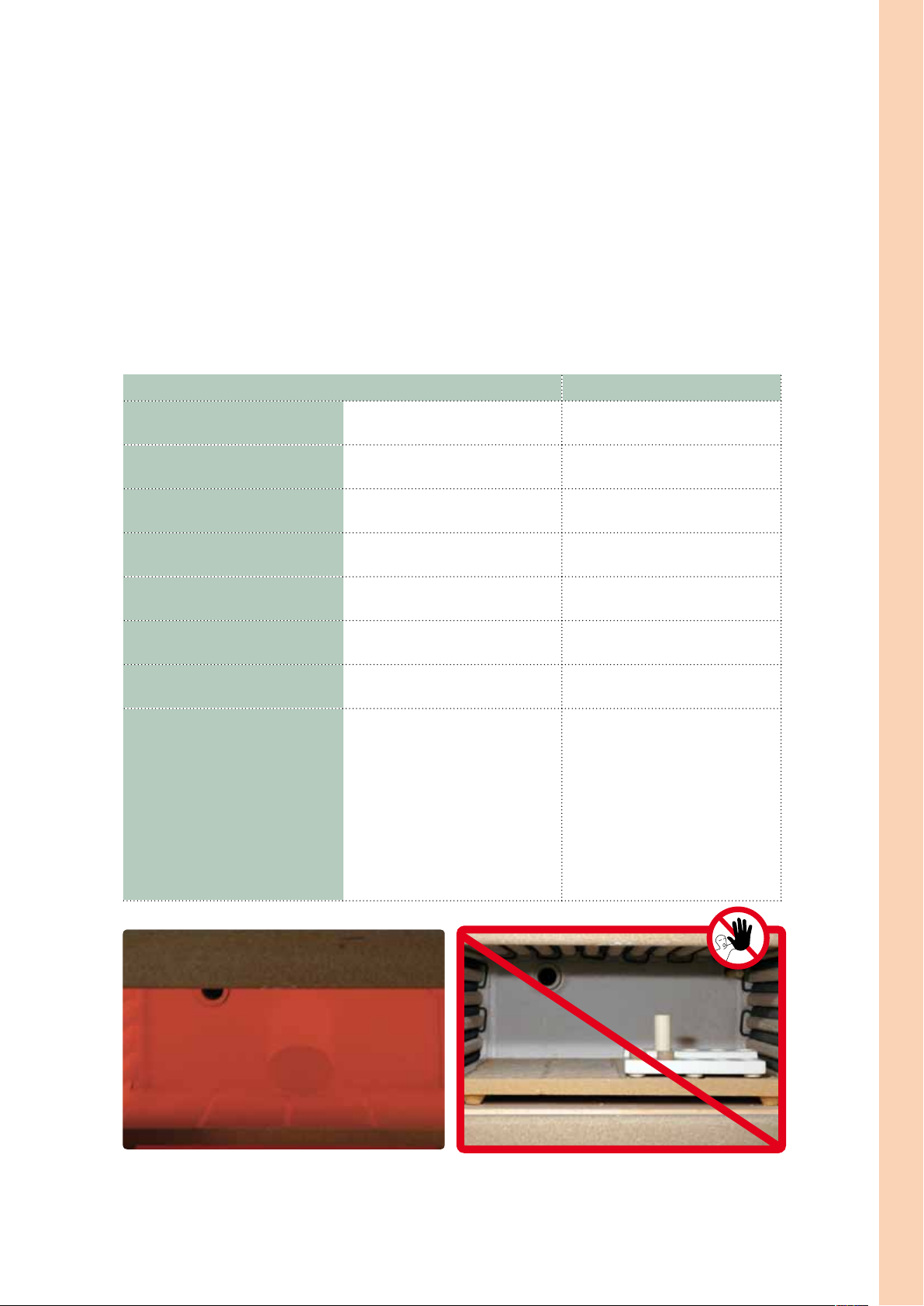

Preheating

After the stipulated setting time of the respective investment material (IPS PressVEST or IPS PressVEST Speed), the investment ring is prepared for preheating as follows:

– Remove the ring gauge with a turning movement.

– Carefully push the investment ring out of the IPS Silicone Ring.

– Remove the ring base with a turning movement.

– Remove rough spots on the bottom surface of the investment ring with a plaster knife. Check the 90° angle. Investment

material residue must not enter the sprues. Blow into the sprues if necessary.

– If several investment rings are preheated together, mark them accordingly.

IPS PressVEST IPS PressVEST Speed

Setting time min. 60 min, max. 24 hrs min. 30 min, max. 45 min

Temperature of the preheating furnace

when placing the investment ring

Position of the investment ring in the

preheating furnace

Final temperature for preheating the

investment ring

Holding time of the investment ring at

final temperature

IPS e.max Press ingots no preheating no preheating

IPS Alox Plunger no preheating no preheating

Important If several Speed investments are to be

Towards the rear wall, tipped with the

Room temperature

opening facing down

850 °C / 1562 °F 850 °C / 1562 °F

min. 60 min

850 °C / 1562 °F; switch on the

preheating furnace in time.

Towards the rear wall, tipped with the

opening facing down

100 g investment ring – min. 45 min

200 g investment ring – min. 60 min

conducted, they should be invested

consecutively and placed into the pre-

heating furnace at an interval of

approx. 20 minutes. Make sure that

the furnace temperature does not

drop too much when placing the

investment rings into the preheating

furnace. The stipulated holding time

counts from the point when the pre-

heating temperature has been reached

again.

Application procedure – Fabrication Hybrid Abutment and Hybrid Abutment Crown

Towards the rear wall, tipped with the opening facing down Do not preheat the IPS e.max Press ingot and Alox Plunger.

In order to ensure smooth working procedures in the laboratory on a daily basis, impeccable functioning of the infrastructure, particularly the preheating furnaces, is essential. This includes their maintenance, cleaning with a vacuum cleaner in a

cool state as well as regular checks of the temperature controls and heating elements, etc., by the manufacturer.

17

Page 18

Pressing

Carry out the following preparatory steps for pressing before the preheating cycle for the investment ring has been

completed:

– Provide a cold IPS Alox Plunger and a cold IPS e.max Press ingot in the desired shade (please refer to the material

selection table on page 52).

– Dip the cold IPS Alox Plunger into the opening of the IPS Alox Plunger Separator and keep it ready for use.

– Turn on the press furnace (e.g. Programat EP 5000) in time so that the self-test and preheating phase are completed.

– Select the press program for IPS e.max Press and the desired investment ring size.

Remove the investment ring from the preheating furnace immediately after completion of the preheating cycle. This step

may take max. 30 seconds to prevent the investment ring from cooling down too much.

– Place the cold IPS e.max Press ingot into the hot investment ring.

– Insert the ingots in the investment ring with the non-imprinted side facing down. The imprinted side faces up to check

the ingot shade.

– Place the side of the cold IPS Alox Plunger which has been coated with Separator into the hot investment ring.

– Use the investment ring tongs to place the loaded investment ring in the centre of the hot press furnace.

– The selected press program is started by pressing START.

After the end of the press cycle (optical and/or acoustic signal) proceed as follows:

– Remove the investment ring from the press furnace using the investment ring tongs immediately after pressing.

– Place the investment ring on a cooling grid to cool in a place protected from draft.

– Do not speed up cooling, e.g. by blasting with compressed air.

100 g Investment Ring 200 g Investment Ring

1 small ingot

1 small ingot

IPS e.max Press ingots cold ingot cold ingot

IPS Alox Plunger cold plunger cold plunger

IPS Alox Plunger Separator

Ingots: select one large or one small ingot according to the determined wax weight!

✓ ✓

or

1 large ingot

Provide a cold isolated IPS Alox Plunger and a cold IPS e.max Press ingot in the

desired shade.

Place the cold IPS e.max Press ingot into the hot investment ring with the imprinted

18

side facing up.

Page 19

Then, place the side of the IPS Alox Plunger which has been coated with Separator

into the hot investment ring.

Place the hot and loaded investment ring in the centre of the hot press furnace using

the IPS Investment Ring Tongs.

Application procedure – Fabrication Hybrid Abutment and Hybrid Abutment Crown

Press START to start the selected program. Once the press program is completed, place the hot investment ring on the cooling

grid using the Investment Ring Tongs and allow it to cool to room temperature.

Press parameters for IPS e.max Press

Programat EP 3000

Select the press program in accordance with the selected ingot to be pressed

and the investment ring size used.

The press parameters for HO, MO, LT and HT are integrated

starting with software V 6.1.

Programat EP 5000

Select the press program in accordance with the selected ingot to be pressed

and the investment ring size used.

The press parameters for HO, MO, LT and HT are integrated starting

with software V 6.1.

The press parameters for older-generation Ivoclar Vivadent press furnaces

are listed on page 53 under Press Parameters.

19

Page 20

Divesting

After cooling to room temperature (approximately 60 minutes), the investment ring may show cracks, which developed

during the cooling phase (immediately around the Alox plunger). This is the result of the different CTEs of the various

materials (Alox Plunger, investment material and press ingot) and does not compromise the press results.

Divest the investment ring as follows:

– Mark the length of the Alox Plunger on the cooled investment ring.

– Separate the investment ring using a separating disc. This predetermined breaking

point enables reliable separation of the Alox Plunger and the ceramic material.

– Break the investment ring at the predetermined breaking point using a plaster knife.

– Always use polishing beads to divest the pressed objects (rough and fine divestment).

Do not use Al2O3.

– Rough divestment is carried out with polishing beads at 4 bar (58 psi) pressure.

– Fine divestment is carried out with polishing beads at 2 bar (29 psi) pressure.

– Observe the blasting direction and distance to prevent damage to the object margins

during divestment.

– Same as the outer surfaces, thoroughly blast the screw channel with polishing beads

at 2 bar (29 psi) pressure.

– Remove possible ceramic residue from the Alox Plunger with type 100 Al2O3.

Mark the length of the Alox Plunger.

Separate the investment ring using a separating disc and break it at the predetermined breaking point.

Tip

Pull out the plunger with pliers from the separated segment using a rotating movement.

This also removes any possible ceramic residue from the Alox plunger.

20

Page 21

Rough divesting with polishing beads at 4 bar (58 psi) pressure until the object

becomes visible.

Fine divestment of the abutment is carried out with polishing beads

at 2 bar (29 psi) pressure.

Application procedure – Fabrication Hybrid Abutment and Hybrid Abutment Crown

Fine divestment of the abutment crown is carried out with polishing beads at 2 bar

(29 psi) pressure.

Completely divested IPS e.max Press objects.

21

Page 22

Removing the reaction layer

After fine divestment, the reaction layer formed during the press procedure is removed using IPS e.max Press Invex Liquid.

The procedure is carried out as follows:

– Pour the Invex Liquid into a plastic cup.

– Immerse the pressed object in the Invex Liquid and clean in an ultrasonic cleaner for at least 10 min and at most 30 min.

Make sure that the objects are completely covered with Invex Liquid.

– Use the sieve insert to remove the restoration from the Invex Liquid and clean the object under running water and blow

dry.

– Carefully remove the white reaction layer with type 100 Al2O3 at max. 1–2 bar (15–29 psi) pressure.

– Make sure that the reaction layer is completely removed, both from the screw channel and the outer side of the object

(repeat the procedure, if necessary).

– If the reaction layer is not completely removed, problems may occur in the further course of the fabrication process.

– Replace the IPS e.max Invex Liquid after 20 applications or after sedimentation of the Liquid.

To remove the reaction layer, immerse the pressed objects in IPS e.max Press Invex ... ... and place in an ultrasonic cleaner for at least 10 and at most 30 minutes.

Using Al

and a pressure of at most 1–2 bar (15–29 psi) pressure, carefully remove

2O3

the reaction layer from the outer side ...

... and the screw channel.

Warning

– The Invex Liquid contains < 1% hydrofluoric acid.

– It is harmful when inhaled, swallowed and when it comes into contact with the skin. Furthermore, it is corrosive.

– Keep the container tightly sealed and store it in a well-ventilated place (acid cabinet).

– If the material comes into contact with the eyes, immediately rinse with copious amounts of water and see an ophthalmologist

immediately.

– In case of accidental contact with skin, immediately wash with plenty of water.

– Use suitable protective clothing, gloves and goggles when working.

– In case of an accident or physical discomfort, see a physician immediately, and take the Invex label with you, if possible.

Disposal

– Neutralize the Invex Liquid before disposal!

– Use the IPS Ceramic Neutralization Powder to neutralize the Invex Liquid.

– For 50 ml Invex Liquid, approx. 3–4 g of IPS Ceramic Neutralization Powder are required.

– Note: strong foam development during neutralization.

– Carefully add the neutralization powder to the Invex Liquid in small portions until foam is no longer formed; then allow a

reaction time of 5 minutes.

– If larger quantities are disposed of, check the liquid with litmus paper (must show an alkaline reaction).

– After the reaction time, pour the neutralized solution into the sink, flushing it with running water.

22

Page 23

Finishing

It is of critical importance to use the correct grinding instruments for finishing and adjusting high-strength glass-ceramics

(please refer to the Ivoclar Vivadent Flow Chart "Recommended grinding instruments for glass-ceramics"). If unsuitable

grinding instruments are used, chipping of the edges and local overheating may occur.

Observe the following procedure for finishing IPS e.max Press restorations:

– Adjustment by grinding of pressed IPS e.max Press restorations should be kept to a minimum.

– Overheating of the ceramic must be avoided. Low speed and light pressure is recommended.

– Make sure that the minimum thicknesses are maintained even after the minor adjustments.

Fitting to the Ti base

The fit of the abutment or abutment crown is checked on the Ti base before the sprue is separated.

– Before the object is fitted, the inner aspect of the object (screw channel) is checked for bubbles in the ceramic. If

required, the bubbles are removed with suitable instruments.

– Carefully position the abutment or abutment crown on the Ti base. Note: Apply only light pressure to secure the pressed

object on the Ti base in order to prevent chipping of the ceramic. Observe the position of the rotation lock.

– Possible rough spots interfering with the fit of the pressed object on the Ti base cause greyish-black markings on the

screw channel. Carefully remove such markings with suitable grinding instruments. The diameter of the grinding

instrument must be smaller than that of the screw channel. As an alternative to marking the rough spots, an occlusion

spray can also be used.

– Carefully remove possible rough spots until an optimum fit between the Ti base and the pressed object is achieved.

Repeat the procedure, if required.

Application procedure – Fabrication Hybrid Abutment and Hybrid Abutment Crown

Check the screw channel for bubbles ...

Possible rough spots interfering with the fit on the Ti Base cause stains on the screw

channel of the pressed object, ...

Carefully position the abutment or abutment crown on the Ti base.

... which can be carefully removed by means suitable grinding tools.

23

Page 24

After possible rough spots have been removed, an optimum fit between the hybrid

abutment ...

... or the abutment crown and the Ti base is achieved.

Finishing

Once an optimum fit between the abutment or the abutment crown and the Ti base has been achieved, please proceed as

follows for the finishing steps:

– Separate the sprue using a separating disc. Avoid overheating.

– Smooth out the attachment point of the sprue. Make sure that the minimum thicknesses are maintained.

– Check the emergence profile and the fit on the model.

– In the case of abutment crowns, additionally check the occlusion and articulation. Adjust by grinding, if necessary, and

create surface textures.

– To clean the abutment crown, briefly blast the outer side with Al2O3 at 1 bar (15 psi) pressure and clean with the steam

cleaner. Some blasting devices may require different pressure settings to accomplish this procedure.

Separate the sprues using a separating disc. Avoid overheating.

Smooth out the attachment point of the sprue.

Check the emergence profile and the fit on the model.

24

Page 25

Stain and Characterization firing

IN S T R U C T I O N S

FO R

US E

Ceram

all ceramic

all you need

The following paragraphs will explain the steps of optional staining and characterizing with IPS e.max Ceram Shades and

Essences. On abutments, only the emergence profile is characterized for the individual patient. This characterization may

also take place at a later stage, i.e. when the crown is characterized.

Application procedure – Fabrication Hybrid Abutment and Hybrid Abutment Crown

If abutments are fabricated, only the area of the emergence profile is characterized

with IPS e.max Ceram Shades and Essences.

If abutment crowns are fabricated, the entire outer surface may be individually

characterized.

The Stains and Characterization firing is conducted with IPS e.max Ceram Shades and Essences. For further

information, please refer to the IPS e.max Ceram Instructions for Use.

– IPS e.max Ceram Shades are ready-to-use stains in syringes.

– IPS e.max Ceram Essences are intensively shaded powdered stains, which are mixed with IPS e.max Ceram

Glaze and Stain Liquid.

The following steps must be observed:

– Clean the pressed object with a steam cleaner to remove any contaminations and grease

residue. Any contamination after cleaning must be prevented.

– Tip: For the characterization, place the abutment or the abutment crown on the Ti base using a little IPS e.max Ceram

Glaze and Stain Liquid. This allows you to assess the effect of the Ti base on the shade.

– For better wetting of the stains, a small quantity of IPS e.max Ceram Glaze and Stain Liquid may be slightly rubbed into

the area that needs to be characterized.

– Mix the pastes or powders with the IPS e.max Ceram Glaze and Stain Liquids (allround or longlife) until the desired

consistency is achieved.

– More intensive shades are achieved by several staining procedures and repeated firing, not by applying thicker layers.

– To imitate the incisal area and translucency of the abutment crown in the incisal and occlusal third, IPS e.max Ceram

Shade Incisal may be used.

– The cusps and fissures can be individualized using Essences.

– If abutments are fabricated, only the area of the emergence profile is characterized with IPS e.max Ceram Shades and

Essences. Do not apply materials to the bonding surface to the crown, as this might compromise the fit and the bond.

– Important: Make sure that absolutely no materials are applied to the screw channel and the interface to the Ti base in

order not to compromise the fit and bond.

– Conduct the Stain and Characterization firing on a honey-comb firing tray using the stipulated firing parameters. Please

observe the special firing parameters.

– Remove restoration from the furnace after completion of the firing cycle (wait for the acoustic signal of the furnace).

– Allow the objects to cool to room temperature in a place protected from draft.

– Do not touch the hot objects with metal tongs.

25

Page 26

Apply IPS e.max Ceram Shade Incisal to imitate the incisal area.

Enhance the chroma of the buccal surface.

Individual characterization of the emergence profile with IPS e.max Ceram Essences.

Conduct the Stain and Characterization firing on a honey-comb firing tray.

Firing parameters for the Stain and Characterization firing

IPS e.max Ceram on IPS e.max Press

Abutment Solutions

B

°C

S

mint°C/min

T

°C

H

min

V

1

°C

Stain and Characterization firing 403 6:00 60 770 01:00 450 769 500

V

2

°C

Additional Stain and Characterization firing cycles can be conducted with the same firing parameters.

Note:

If the layer thickness is less than 2 mm on the entire pressed object, long-term cooling (L) is not required to

produce a tension-free condition.

L

°C

26

Page 27

Glaze firing

Glaze firing is conducted with powder or paste glaze. On abutments, only the emergence profile is glazed.

Glaze firing may also take place at a later stage, i.e. when the crown is glazed. On abutment crowns, glaze

is applied to the entire outer surface.

The following procedure is recommended:

– Mix the glazing material (IPS e.max Ceram Glaze Paste or Powder) with the IPS e.max Ceram Glaze and Stain Liquids

allround or longlife to the desired consistency.

– Apply an even layer of glazing material covering all areas that are to be glazed.

– If required, the fluorescence may be increased by applying a fluorescing glazing materal (paste or powder).

– Important: Make sure that absolutely no materials are applied to the screw channel and the interface to the Ti base in

order not to compromise the fit.

– Make sure that no glaze material is present on the interface of abutments and abutment crowns prior to the firing cycle.

If necessary, carefully remove the glaze material.

– Conduct the Glaze firing on a honey-comb firing tray using the stipulated firing parameters. Please observe the special

firing parameters.

– Remove restoration from the furnace after completion of the firing cycle (wait for the acoustic signal of the furnace).

– Allow the objects to cool to room temperature in a place protected from draft.

– Do not touch the hot objects with metal tongs.

– If adjustments are required after Glaze firing (e.g. contact points), they may be applied using IPS e.max Ceram Add-on

(see page 28).

Application procedure – Fabrication Hybrid Abutment and Hybrid Abutment Crown

Apply an even layer of glaze material to the emergence profile of the abutment. Make

sure that no glaze material enters the screw channel.

Make sure that no glaze material is present on the interface of abutments and

abutment crowns prior to the firing cycle. If necessary, carefully remove the glaze

material.

Apply the glazing material evenly on the outer surface of the abutment crown. Make

Conduct the Glaze firing on a honey-comb firing tray with the corresponding

27

sure that no glaze material enters the screw channel.

parameters.

Page 28

Firing parameters for the Glaze firing

IPS e.max Ceram on IPS e.max Press

Abutment Solutions

Glaze firing 403 6:00 60 770

B

°C

S

mint°C/min

°C

T

H

min

1:00–

2:00

V

1

°C

450 769 500

V

2

°C

If the gloss is unsatisfactory after the first Glaze firing, further Glaze firing procedures may be conducted

using the same firing parameters.

Note:

If the layer thickness is less than 2 mm on the entire pressed object, long-term cooling (L) is not required to

produce a tension-free condition.

L

°C

Completely glazed and characterized abutment and abutment crown

Adjustments with IPS e.max Ceram Add-On

Use IPS e.max Ceram Add-On Dentin and/or Incisal to make adjustments to the abutment or

abutment crown after Glaze firing. Please observe the following procedure for processing:

– Mix IPS e.max Ceram Add-On Dentin or Incisal with IPS e.max Ceram Build-Up Liquid soft or

allround and apply on the corresponding areas.

– Fire with the stipulated parameters for the "Add-On after Glaze firing". Observe long-term cooling!

If necessary, polish the adjusted areas to a high gloss after firing.

Firing parameters IPS e.max Ceram Add-On after Glaze firing.

IPS e.max Ceram on IPS e.max Press

Glaze firing 403 6:00 50 700 01:00 450 699 500

B

°C

S

min.t°C/min

28

T

°C

H

min

V

1

°C

V

2

°C

L

°C

Page 29

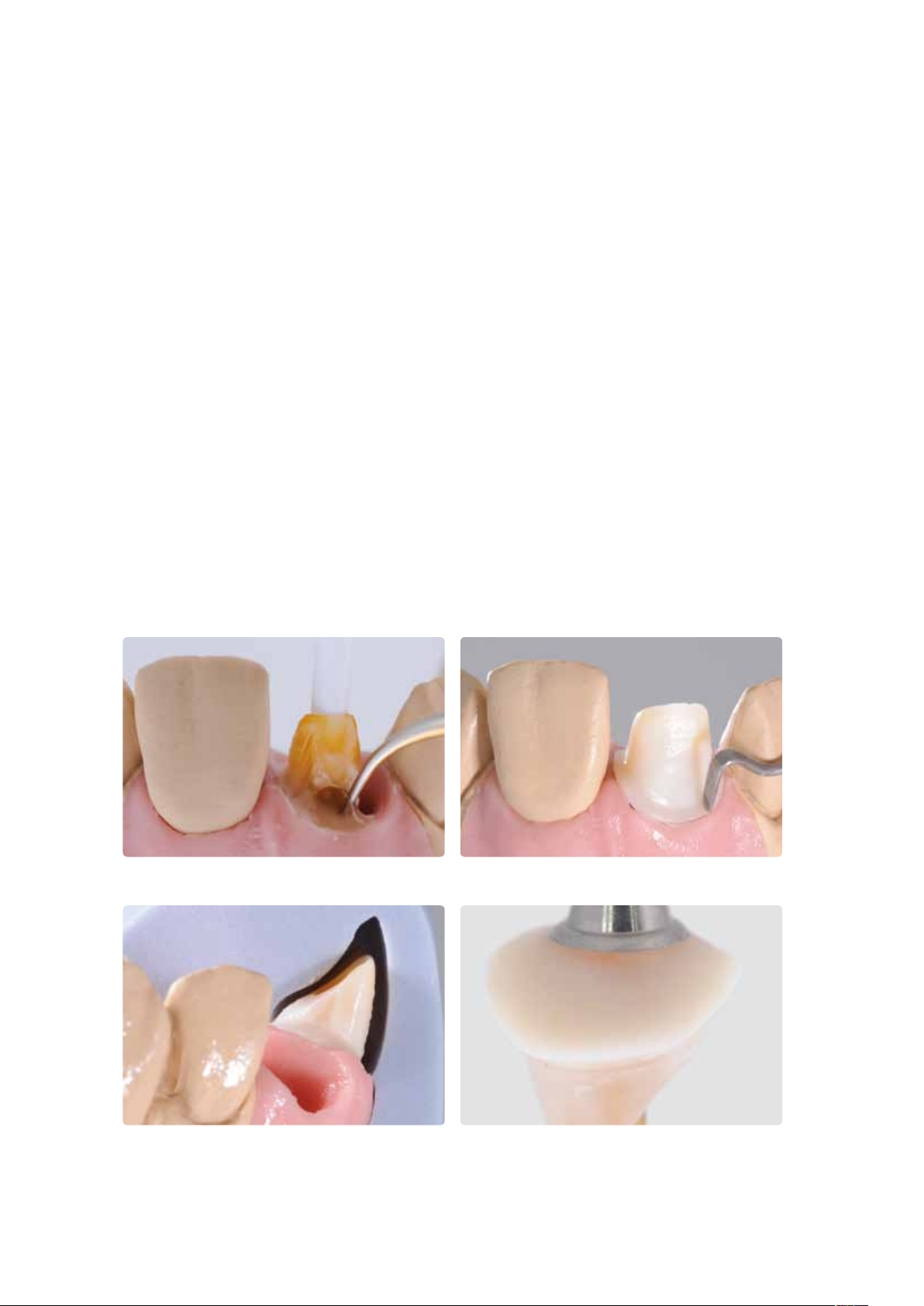

Optional: Polishing the emergence profile of the abutment

If no characterizations and no glaze firing of the abutment are required, the emergence profile may be

manually polished. Please remember that polishing results in a slight reduction of the emergence profile,

which might influence the fit to the gingiva in certain situations.

Please observe the following procedure for polishing:

– Clean the pressed object with a steam cleaner to remove any contaminations.

– Place the pressed object onto the Ti base for processing.

– Overheating of the glass-ceramic must be avoided. Observe the recommendations of the manufacturer of the grinding

tool.

– Pre-polish the emergence profile with a diamond-coated rubber polisher. Note: The Ti base should not be modified.

– Fine polishing of the emergence profile with a high-gloss rubber polisher.

– High-gloss polishing with brushes and polishing paste.

– Clean the abutment with an ultrasonic or steam cleaner.

Application procedure – Fabrication Hybrid Abutment and Hybrid Abutment Crown

Pre-polish the emergence profile with a diamond-coated rubber polisher.

Then clean the abutment with ultrasonic ...

High-gloss polishing with brushes and polishing paste.

... or with steam.

29

Page 30

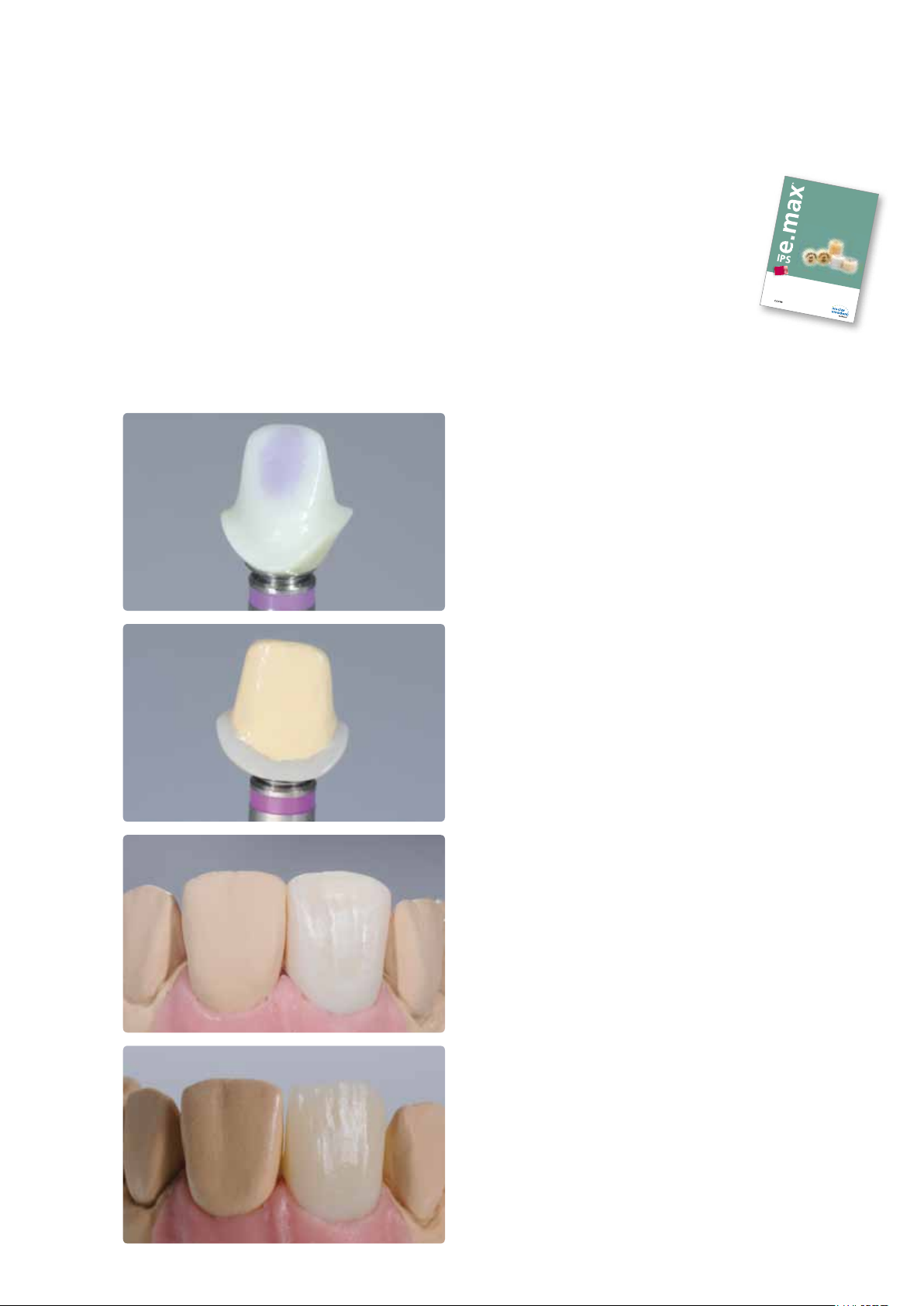

Crown on hybrid abutment

IN STR UC TIO NS F OR U SE

Press

all ceramic

all you need

emax Press-VA 2009-d_emax Press-VA-d.qxd 22.09.11 14:13 Seite 1

Preferably, a crown made of IPS e.max Press is seated on an IPS e.max Press hybrid abutment. Depending on your

preference, the staining, cut-back or layering technique may be applied for this. For a detailed description of the

fabrication, please refer to the IPS e.max Press Instructions for Use.

The following paragraphs describe the working steps which deviate from the procedure applied for the fabrication of

restorations on prepared teeth. In this example, an IPS e.max Press crown is fabricated in the cut-back technique.

Screw the Ti base onto the model analog with the

corresponding screw. If required, the abutment

can be secured on the Ti base by means of Virtual

Extra Light Body Fast Set.

Seal the screw channel (e.g. with silicone).

Before contouring the crown, apply a spacer up to

approx. 1 mm from the cervical crown margin.

Isolate the abutment and then contour the crown

with wax.

Finally, the restoration is pressed with IPS e.max

Press material.

Pressed IPS e.max Press crown with cut-back after

divesting and finishing.

30

Page 31

Complete the anatomical shape of the reduced

areas using IPS e.max Ceram layering materials,

such as Incisal and Opal.

Finish the restoration with diamonds and give it a

true-to-nature shape and surface structure.

Finally, conduct the Stain and Glaze firing with

IPS e.max Ceram Shades, Essences and Glaze.

Application procedure – Fabrication Hybrid Abutment and Hybrid Abutment Crown

Abutment and matching crown after Characterization and Glaze firing.

31

Page 32

®

e.max

IPS

Press Abutment Solutions

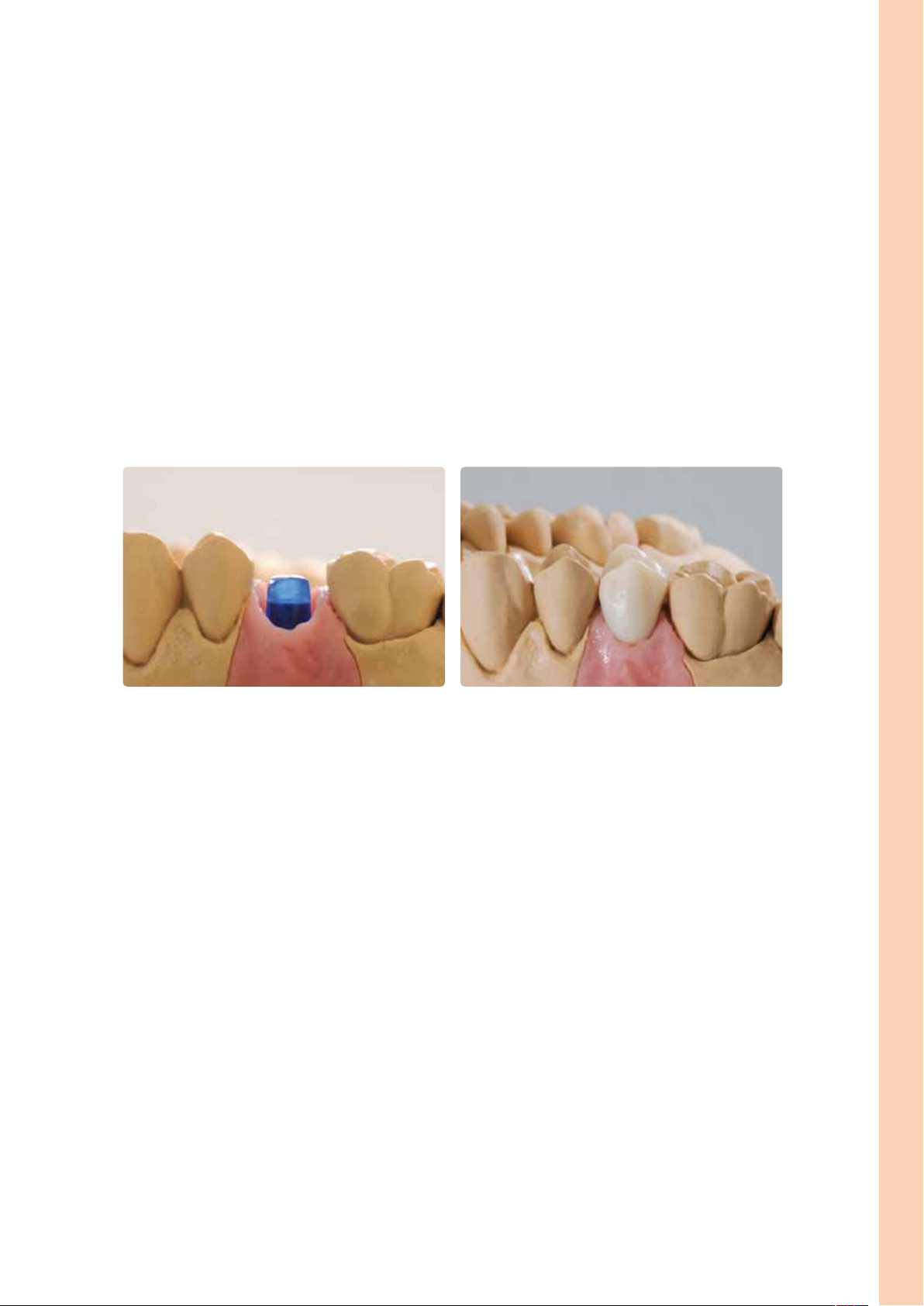

Optional: Clinical Try-in

Temporarily securing the pressed object on the Ti base

Before the abutment or abutment crown is permanently luted to the Ti base, a clinical try-in may be performed. To

facilitate the intraoral handling, the components are temporarily arttached to one another with silicone material,

e.g. Virtual® Extra Light Body Fast Set.

Please observe the following procedure to temporarily secure the components in place:

– Clean the non-pre-treated Ti base and the pressed object (abutment or abutment crown) with steam and blow dry.

– Place the pressed object on the Ti base (which is screwed to the model analog) and mark the relative position of the

components. This facilitates the achievement of the correct position when the parts are subsequently temporarily

assembled.

– Seal the screw channel with a foam pellet.

– Insert the Virtual cartridge into the dispenser and remove the protective cap.

– Screw on the mixing tip and attach the Oral Tip to the mixing tip.

– Apply Virtual Extra Light Body Fast Set both to the Ti base and directly into the pressed object.

– Insert the Ti base into the pressed object. Observe the relative position of the objects (rotation lock/marking).

– Hold the parts in the correct relative position for 2:30 minutes until the Virtual Extra Light Body Fast Set has set.

– Carefully remove protruding excess material with a suitable instrument, e.g. a scalpel.

Cleaned, non-pre-treated pressed objects (abutment or abutment crown)

Seal the screw channel with a foam pellet.

Place the abutment or abutment crown onto the Ti base and mark the relative position.

Insert the Virtual cartridge into the dispenser, screw on the mixing tip and attach the

32

Oral Tip.

Page 33

Application procedure – Optional: Clinical try-in

Apply Virtual Extra Light Body Fast Set both to the Ti base ...

Insert the Ti base into the pressed object. In doing so, observe the relative position of

the two components (rotation lock/marking). Hold the components in place for

approx. 2:30 minutes until the Virtual Extra Light Body Fast Set material has set.

... and directly into the pressed object (abutment/abutment crown).

Carefully remove protruding excess material with a suitable instrument, e.g. a scalpel.

Remove excess Virtual Extra Light Body Fast Set material from the screw channel with

an instrument.

33

Page 34

Clinical try-in

Hybrid abutment

Important note: Any intraoral checking of the occlusion/articulation and possible adjustments by grinding may only be

performed if the objects have been attached to one another by means of Virtual Extra Light Body Fast Set. During try-in,

the Virtual material acts as a buffer, particularly if grinding is necessary, and prevents chipping in the transition area

between the hybrid abutment and the crown.

Please observe the following procedure for the clinical try-in:

– Have the clean prepared hybrid abutment (temporarily secured) and the matching clean crown ready at hand.

– Remove the temporary restoration.

– Manually screw in the hybrid abutment with the matching screw.

– Check the geometry of the hybrid abutment (e.g. fit, gingival anaemia) with regard to the gingival margin.

– If required, seal the screw channel on the hybrid abutment with a foam pellet.

– Tip: Isolate the inner aspect of the crown with glycerin gel, e.g. Try-in paste, Liquid Strip

– Place the crown intraorally onto the hybrid abutment to check and adjust the proximal contacts, if necessary.

Note: No occlusal functional checks must be performed at this stage.

– For the functional check, the crown has to be secured on the hybrid abutment with Virtual Extra Light Body

Fast Set. Do not use Try-in paste for this purpose, as this material is not sufficiently resistant against the

compressive forces.

– Insert the Virtual cartridge into the dispenser and remove the protective cap.

– Screw on the mixing tip and attach the Oral Tip to the mixing tip.

– Apply Virtual Extra Light Body Fast Set to the inner aspect of the crown.

– Use your finger to press the crown to the hybrid abutment until the final position has been achieved. Hold the crown in

the final position until the Virtual material has set.

– Remove excess Virtual material.

– Check the occlusion/articulation and make required adjustments with suitable grinding instruments (see separate

IPS e.max Recommended grinding instruments for ceramics – use in the dental practice). If adjustments have been made

by grinding, conduct another polishing cycle or glaze firing.

– Carefully remove the crown from the hybrid abutment and the hybrid abutment (including Ti base).

– Insert the temporary restoration.

Manually screw in the hybrid abutment with the matching screw. Check the geometry

of the hybrid abutment (e.g. fit, gingival anaemia) with regard to the gingival margin.

If required, seal the screw channel of the hybrid abutment with a foam pellet.

34

Page 35

Application procedure – Optional: Clinical try-in

Tip: Isolate the inner aspect of the crown with glycerine gel.

Apply Virtual Extra Light Body Fast Set to the inner aspect of the crown.

Place the crown intraorally onto the hybrid abutment to check and adjust the proximal

contacts, if necessary. Note: No occlusal functional checks must be performed

Use your finger to press the crown to the hybrid abutment until the final position has

been achieved. Hold the crown in the final position until the Virtual material has set.

at this stage.

Remove excess Virtual material.

Carefully remove the crown from the hybrid abutment and remove the

Virtual Extra Light Body Fast Set material.

Check the occlusion/articulation and use suitable grinding instruments to make

possibly required adjustments.

Unscrew the hybrid abutment.

35

Page 36

Hybrid abutment crown

Please observe the following procedure for the clinical try-in:

– Have the cleaned hybrid abutment crown (temporarily secured with Virtual Extra Light Body Fast Set) at hand.

– Remove the temporary restoration.

– Place the hybrid abutment crown intraorally onto the implant to check and possibly adjust the proximal

contacts. Note: No occlusal functional checks must be performed at this stage.

– Manually screw in the hybrid abutment crown with the matching screw.

– Check the geometry of the hybrid abutment crown (e.g. fit, gingival anaemia) with regard to the gingiva.

– Check the occlusion/articulation and make possibly required adjustments with suitable grinding instruments (see separate

IPS e.max Recommended grinding instruments for ceramics – use in the dental practice). If adjustments have been made

by grinding, conduct another polishing cycle or glaze firing.

– Carefully remove the hybrid abutment crown (including Ti base).

– Rinse the implant site e.g. with Cervitec Liquid (antibacterial mouth wash with chlorhexidine) to clean and disinfect it.

– Insert the temporary restoration.

Place the hybrid abutment crown intraorally onto the implant to check and possibly

adjust the proximal contacts. Note: No occlusal functional checks must be

performed at this stage.

Manually screw in the hybrid abutment crown with the matching screw.

Check the geometry of the hybrid abutment crown (e.g. fit, gingival anaemia) with

regard to the gingiva.

Check the occlusion/articulation and use suitable grinding instruments to make

possibly required adjustments.

Carefully remove the hybrid abutment crown (including Ti base).

36

Page 37

®

e.max

IPS

Press Abutment Solutions

Permanent Cementation

Careful preparation of the bonding surface is a prerequisite for an optimum adhesive cementation of the

Ti base and the pressed object. The following paragraphs outline the required procedures. The procedure is

the same for hybrid abutments and hybrid abutment crowns.

IPS e.max Press Abutment Solutions

Abutment,

abutment crown

Blasting –

Etching

Conditioning/silanating

Adhesive cementation Multilink

Covering the cementation joint Glycerine gel, e.g. Liquid Strip

The bonding area with

®

Ceramic Etching Gel for 20 s

IPS

with Monobond

The bonding area

®

The bonding area with Al

®

Plus for 60 s

Implant MO 0

Ti base

at low pressure

–

2O3

Application procedure – Permanent Cementation

Curing

Polishing the cementation joint Customary polishers for ceramic/resin materials

All the materials that are required for permanent cementation

and for clinical try-in are contained both in the IPS e.max Press

Abutment Solutions Basic Kit A–D* and the IPS e.max

Abutment Solutions Cem Kit*.

* The range of available products may vary from country to country.

(optionally in a light-curing device)

7-minute curing

37

Page 38

Pre-treatment of the Ti base

To prepare the Ti base for cementation with the pressed object, please observe the following procedure:

– Observe processing instructions of the manufacturer of the Ti base.

– Clean the Ti base in an ultrasonic cleaner and blow dry or use a steam cleaner.

– Screw Ti base onto a model analog.

– Place the pressed object on the Ti base and mark the relative position of the components. This facilitates locating the

correct position when the parts are assembled at a later stage.

– The emergence profile of the Ti base must not be blasted or modified in any way. To protect the emergence profile,

hard modelling wax is applied, as this material can be easily removed later on.

– Seal the screw channel with wax.

– Carefully blast the bonding area with Al2O3 (50–100 µm) at low pressure until an even mat surface has been achieved.

– Clean with an instrument and steam cleaner. Make sure that any wax residue is carefully removed.

– After cleaning, any contamination of the bonding surface must be prevented, since contaminations negatively influence

the bond.

– Apply Monobond Plus on the cleaned bonding surface and allow to react for 60 seconds. After the reaction time, dry

the remaining residue with water- and oil-free air.

– Seal the screw channel with a foam pellet or wax. Make sure that the bonding surface is not contaminated.

Screw Ti base onto a model analog. Mark the relative position to the

pressed object.

Carefully blast the bonding area with Al

mat surface has been achieved.

(50–100 µm) at low pressure until an even

2O3

Apply wax to protect the emergence profile. In addition, seal also the screw channel

Clean with an instrument and steam cleaner. Make sure that any

38

wax residue is carefully removed.

with wax.

Page 39

Application procedure – Permanent Cementation

Apply Monobond Plus on the cleaned bonding surface and allow to react for

60 seconds. After the reaction time, dry the remaining residue with water-

and oil-free air.

Seal the screw channel with a foam pellet or wax.

Make sure that the bonding surface is not contaminated.

Preparing the pressed object

To prepare the pressed object for cementation onto the Ti base, please observe the following procedure:

– Do not blast the IPS e.max Press object to prepare it for cementation.

– Clean the pressed object in an ultrasonic cleaner and blow dry or use a steam cleaner.

– After cleaning, any contamination of the bonding surface must be prevented, since contaminations negatively influence

the bond.

– To protect the outer surfaces or the glazed areas, wax may be applied.

– Etch the bonding surface with 5% hydrofluoric acid gel (IPS Ceramic Etching Gel) for 20 seconds.

– Subsequently, thoroughly rinse the bonding surface under running water and dry with oil-free air.

– Apply Monobond Plus on the cleaned bonding surface and allow to react for 60 seconds. After the reaction time, dry

the remaining residue with water and oil-free air.

Do not blast IPS e.max Press object Etch with IPS Ceramic Etching Gel for 20 seconds. Allow Monobond Plus to react for 60 seconds

39

and dry with air.

Page 40

Cementation with Multilink® Implant

For an optimum bond between the IPS e.max Press object and the Ti base, use the self-curing luting composite Multilink®

Implant with light-curing option. Read the respective Instructions for Use for more detailed information.

Please observe the following procedure for cementation:

– Keep the cleaned and conditioned components that are to be luted (pressed objects, Ti base) at hand.

– The subsequent cementation procedure must be carried out quickly and without interruption. The working

time of Multilink Implant is 90 (± 15) seconds at 23 °C (± 1 °C) or 73 °F (± 1.8 °F).

– As a general rule, attach a new mixing tip to the Multilink Implant syringe prior to each use.

– Apply Multilink Implant directly from the mixing tip in a thin layer on the bonding surface of the Ti base and the

bonding surface of the pressed object.

– Leave the mixing tip attached to the Multilink Implant syringe until the next application. As the material will cure in the

mixing tip, it will serve as a seal.

– Position the pressed object above the Ti base in such a way that the position markings are aligned.

– Use even and low pressure to join the parts and check the correct relative position of the components when they are in

their final position (transition Ti base/pressed object).

– Subsequently, tightly press the components together for 5 seconds.

– Carefully remove excess in the screw cavity, e.g. with Microbrush or brush, using a rotary movement.

– Remove excess at the transition to the Ti base carefully in its ductile state, e.g. with a foam pellet, while applying slight

pressure to hold the components in place.

– Apply a glycerine gel (e.g. Liquid Strip) to the cementation joint to prevent the formation of a inhibition layer.

– After that, completely polymerize the luting composite for 7 minutes in a light-polymerization device.

– Important: Do not move the objects until the Multilink Implant material has completely cured and hold them

in place without allowing for any motion, e.g. with diamond-coated tweezers.

– After completion of the polymerization, rinse off the glycerine gel with water.

– Smooth out and polish the cementation joint with rubber polishers.

– If there are any cement residues in the screw channel, remove them using suitable rotary instruments.

– Clean with a steam cleaner.

Keep the cleaned and conditioned components that are to be luted at hand. Attach a new mixing tip to the Multilink Implant syringe prior to each use.

40

Page 41

Application procedure – Permanent Cementation

Apply Multilink Implant directly from the mixing tip in a thin layer on the bonding

surface of the Ti base.

Position the pressed object above the Ti base in such a way that the position markings

are aligned.

Apply Multilink Implant directly from the mixing tip in a thin layer on the bonding

Join the components using even and light pressure. Subsequently, tightly press the

surface of the pressed object.

components together for 5 seconds.

Carefully remove excess in the screw cavity, e.g. with a Microbrush or a brush, using a

rotary movement.

Apply a glycerine gel (e.g. Liquid Strip) to the cementation joint to prevent the

formation of a inhibition layer.

Remove excess carefully in its ductile state, e.g. with a foam pellet, while applying

Polymerize the luting composite for 7 minutes (optionally in a light-curing unit).

Important: Do not move the objects until the material has completely

cured and hold them in place without allowing for any motion.

slight pressure to hold the components in place.

41

Page 42

After completion of the polymerization, rinse off the glycerine gel with water.

Smooth out and polish the cementation joint with rubber polishers.

If there is any cement residue in the screw channel, remove using suitable rotary

instruments. Do not damage the Ti base.

Completed hybrid abutment and hybrid abutment crown after cementation.

42

Page 43

®

e.max

IPS

Press Abutment Solutions

Seating and Aftercare

Sterilization

We recommend sterilizing hybrid abutments or hybrid abutment crowns before seating

them in the patient's mouth.

– The sterilization time is 15 minutes at 121 °C / 250 °F.

– Only devices which comply with the standards EN 13060 and EN 285 should be

used for sterilization. The sterilization processes are validated according to

EN ISO-17664:2004.

Intraoral preparation

Please observe the following procedure to prepare for the permanent cementation of the implant-supported restoration:

– Remove the temporary restoration.

– Clean the implant site.

– Check the periimplant tissue (emergence profile).

Application procedure – Seating and Aftercare

Seating the hybrid abutment and crown

Preparing/conditioning the hybrid abutment and crown

Conditioning of the ceramic surface, i.e. the bonding surface, in preparation for cementation is critical for generating a

sound bond between the cementation material and the all-ceramic material.

The following steps must be observed:

– Do not blast the IPS e.max Press hybrid abutment or the IPS e.max Press crown with Al2O3 or glass polishing beads prior

to seating.

– Ideally, conduct the clinical try-in before etching in order not to contaminate the bonding surface.

– Thoroughly clean the hybrid abutment and the crown with water and blow dry.

– Etch the bonding surfaces with 5% hydrofluoric acid gel (IPS Ceramic Etching Gel) for 20 seconds. Make sure that no

etching gel comes into contact with the emergence profile or the outer side of the crown. Important: Do not use the

IPS Ceramic Etching Gel intraorally.

– Thoroughly rinse off the etching gel with water and dry with oil- and water-free air.

– If an adhesive or self-adhesive cementation protocol is used, apply Monobond Plus to the bonding surfaces,

allow to react for 60 seconds and then dry with oil- and water-free air.

Do not blast IPS e.max Press objects. Etch the bonding surfaces with IPS Ceramic Etching Gel

for 20 seconds.

43

Apply Monobond Plus to the bonding areas,

allow to react for 60 s and blow dry.

Page 44

Seating the hybrid abutment and crown

For the permanent seating of the hybrid abutment and the crown, please observe the following working steps. Please also

observe the Instructions for Use of the selected luting material.

– Do not use phenolic mouth washes, as such products negatively influence the bond between the ceramic and the

composite.

– Insert the hybrid abutment intraorally into the implant.

– Manually screw in the matching implant screw.

– Tighten the implant screw with a torque wrench (observe the instructions of the manufacturer).

– Insert a cotton or foam pellet into the screw channel.

– Seal the screw channel with a temporary composite (e.g. Telio® CS Inlay). This serves to ensure access to the screw at a

later stage.

– Check the bonding area for contamination/moisture and clean or dry with an air syringe, if necessary.

– Apply the luting material, e.g. SpeedCEM®, into the conditioned crown.

– Place the crown onto the hybrid abutment and secure in place in the final position.

– Conduct the pre-polymerization using the four-quarter technique.

– Remove excess luting material.

– Cover the cementation joint with glycerine gel (e.g. Liquid Strip).

– Polymerize with an LED curing light (e.g. bluephase®).

– Rinse off the glycerine gel with water.

– Check the occlusion and articulation and make adjustments, if necessary. If adjustments are made to the restoration by

grinding, these areas must subsequently be polished to a high gloss, e.g. using OptraFine.

– Polish restoration margins and the cementation joint with silicone polishers (e.g. Astropol®, OptraFine).

– Apply Cervitec Plus in the area of the gingival margin.

Insert the hybrid abutment intraorally into the implant.

Tighten the implant screw with a torque wrench (observe the instructions of the

manufacturer).

Manually screw in the matching implant screw.

Seal the screw channel, for instance with a cotton or foam pellet

44

and a temporary composite material.

Page 45

Application procedure – Seating and Aftercare

Apply the luting material, e.g. SpeedCEM, into the conditioned crown.

Conduct the pre-polymerization using the four-quarter technique.

Place the crown onto the hybrid abutment and secure in place.

Remove excess luting material.

Cover the restoration margin with glycerine gel (e.g. Liquid Strip).

Rinse off the glycerine gel with water. Check the occlusion and articulation and make adjustments, if necessary.

Polymerize with an LED curing light (e.g. bluephase).

45

Page 46

Polish restoration margins and the cementation joint with polishers (e.g. Astropol,

OptraFine).

Completed IPS e.max Press hybrid abutment and crown.

46

Page 47

Seating the hybrid abutment crown.

Preparing/conditioning the hybrid abutment crown

Please observe the following notes to prepare for the intraoral sealing of the screw channel:

– As a general rule, do not blast IPS e.max Press hybrid abutment crowns with Al2O3 or glass polishing beads.

– Thoroughly clean the the hybrid abutment crown with water and blow dry.

– Etch the screw channel from the occlusal side with 5% hydrofluoric acid gel (IPS Ceramic Etching Gel) for 20 seconds.