Page 1

CURSOR TIER 3

SERIES

Industrial application

C10

C10 ENT X

C13

C13 ENT X

CURSOR G-DRIVE

CURSOR 10 TE X

CURSOR 13 TE X

Technical and Repair manual

Page 2

This publication provides unit and relevant component repair

data, specifications, instructions and methodologies.

This publication has been drawn up for qualified and

specialised personnel.

Before performing any operation check that the part relevant

to the unit on which you must work is available along with all

safety devices for accident-prevention, such as, goggles,

helmet, gloves, shoes, etc. and hoisting and transporting

equipment.

Operations are to be performed by following the indications

included here, using the special equipment indicated and

assuring proper repair, compliance with schedule and

operator’s safety requirements.

Each repair must aim to restore operating efficiency and safety

in compliance with the FPT provisions.

FPT cannot be held liable for modifications, alterations or other

interventions non authorised by FPT on the vehicle and if the

unit is warranted the above mentionedinterventions will cause

its expiration.

FPT is not liable for repairing interventions.

FPT will provide further details required to carry out the

interventions and all the instructions that are not included on

this publication.

Data included in this publication may not be up-to-date

therefore subject to Manufacturer’s modifications that can be

added at any time for technical or commercial purposes and

also to meet new law regulations in other Countries.

If issues on this publication differ from what is actually noticed

on the unit, please get in touch with the FPT network before

starting any intervention”.

It is forbidden to copy this text or any of its parts and all

illustrations included.

Publication edited by

FIAT Powerrtrain Technologies

Mkt. Advertising & Promotion

Viale dell’Industria, 15/17

20010 Pregnana Milanese

Milano (Italy)

Print P2D32C003 E -2

nd

Ed. 05.2007

Produced by:

B.U. TECHNICAL PUBLISHING

Iveco Technical Publications

Lungo Stura Lazio, 15/19

10156 Turin - Italy

Page 3

CURSOR ENGINES TIER 3

1

CURSOR ENGINES

Cursor F3A Part 1

Cursor F3B Part 2

Cursor engines application G-Drive Part 3

Print P2D32C003 E Base - May 2007

Page 4

2

CURSOR ENGINES TIER 3

Print P2D32C003 EBase - May 2007

Page 5

RYR

CURSOR ENGINES TIER 3

3

PRELIMINA

Manuals for repairs are split into Parts and Sections, each one of which is marked by a numeral; the contents of these sections are

indicated in the general table of contents.

The sections dealing with things mechanic introduce the specifications, tightening torque values, tool lists, assembly

detaching/reattaching operations, bench overhauling operations, diagnosis procedures and maintenance schedules.

The sections (or parts) of the electric/electronic system include the descriptions of the electric network and the assembly’s

electronic systems, wiring diagrams, electric features of components, component coding and the diagnosis procedures for the

control units peculiar to the electric system.

The manual uses proper symbols in its descriptions; the purpose of these symbols is to classify contained information. In particular,

there have been defined a set of symbols to classify warnings and a set for assistance operations.

EMARKS

SYMBOLS - WARNINGS

Danger for persons

Missing or incomplete observance of these prescriptions can cause serious danger for persons’ safety.

Danger of serious damage for the assembly

Failure to comply, both fully or in part, with such prescriptions will involve serious damage to the assembly and may

sometimes cause the warranty to become null and void.

!

NOTE

General danger

It includes the dangers of above described signals.

Environment protection

Moreover, it describes the correct actions to be taken to ensure that the assembly is used in such a way so as to protect

the environment as much as possible.

It indicates an additional explanation for a piece of information.

Print P2D32C003 E Base - May 2007

Page 6

4

GENERAL WARNINGS

Warnings shown cannot be representativeof all danger situations possibly occurring. Therefore, it is suggested to contact

immediate superiors where a danger situation occurs which is not described.

!

Use both specific and general-purpose toolings according to the prescriptions contained in respective use and

maintenance handbooks. Check use state and suitability of tools not subjected to regular check.

The manual handling of loads must be assessed in advance because it also depends, besides weight, on its size and on

the path.

Handling by mechanical means must be with hoisters proper as for weight as well as for shape and volume. Hoisters,

ropes and hooks used must contain clear indications on maximum carrying capacity acceptable. The use of said means

is compulsorily permitted to authorised personnel only. Stay duly clear of the load, and, anyhow, never under it.

In disassembling operations, always observe provided prescriptions; prevent mechanical parts being taken out from

accidentally striking workshop personnel.

Workshop jobs performed in pairs must always be performed in maximum safety; avoid operations which could be

dangerous for the co-operator because of lack of visibility or of his/her not correct position.

Keep personnel not authorised to operations clear of working area.

You shall get familiar with the operating and safety instructions for the assembly prior to operating on the latter. Strictly

follow all the safety indications found on the assembly.

CURSOR ENGINES TIER 3

Do not leave the running assembly unattended when making repairs.

When carrying out work on the assembly lifted off the ground, verify that the assembly is firmly placed on its supporting

stands, and that the manual/automatic safety devices have been actuated in the event that the assembly is to be lifted

by means of a hoist.

When you h ave to operate on assemblies powered by natural gas, follow the instructions contained in the document,

as well as all the specific safety standards provided for.

Only remove radiator cap when the engine is cold by cautiously unscrewing it in order to let system residual pressure

out.

Inflammable fuel and all inflammable fluidsand liquids must be handled with care, according to what contained on harmful

materials 12-point cards. Refuelling must be performed outdoors with the engine off, avoiding lit cigarettes, free flames

or sparks in order to prevent sudden fires/bursts. Adequately store inflammable, corrosive and polluting fluids and liquids

according to what provided by regulations in force. Compulsorily avoid to use food containers to store harmful liquids.

Avoid to drill or bore pressurised containers, and throw cloths impregnated with inflammable substances into suitable

containers.

Worn out, damaged or consumable parts must be replaced by original spares.

During workshopactivity, always keep the work place clean; timely clear or clean floors from accidentalliquid or oil spots.

Electric sockets and electric equipment necessary to perform r epair interventions must meet safety rules.

Base - May 2007 Print P2D32C003 E

Page 7

CURSOR ENGINES TIER 3

Put on, where required by the intervention, garments and protections provided in accident prevention rules; contact

with moving parts can cause serious injuries. Use suitable, preferably tight-fitted garments, and avoid to use jewels,

scarves, etc.

Do not leave the engine in motion at workshop locations not provided with a pipe to scavenge exhaust gas outside.

Avoid to breathe fumes coming from heating or from paint welding because they can cause damages to health; operate

outdoors or in suitably ventilated areas. Put on proper inspirator if paint powder is present.

Avoid contact with hot water or steam coming from the engine, radiator and pipings because they could cause serious

burns. Avoid direct contact with liquids and fluids present in vehicle systems; where an accidental contact has occurred,

refer to 12-point cards for provisions to make.

Clean the assemblies and carefully verify that they are intact prior to overhauling. Tidy up detached or disassembled

parts with their securing elements (screws, nuts, etc.) into special containers.

Check for the integrity of the parts which prevent screws from being unscrewed: broken washers, dowels, clips, etc.

Self-locking nuts with an insert made of nylon must always be replaced.

Avoid contact of rubber parts with diesel oil, petrol or other not compatible substances.

Before washing under pressure mechanical parts, protect electric connectors, and central units, if present.

5

Tightening screws and nuts must always be according to prescriptions; FPT commercial and assistance network is

available to give all clarifications necessary to perform repair interventions not provided in this document.

Before welding:

- Disconnect all electronic central units, take power cable off battery positive terminal (connect it to chassis bonding)

and detach connectors.

- Remove paint by using proper solvents or paint removers and clean relevant surfices with soap and water.

- Await about 15 minutes before welding.

- Equip with suitable fire resistant protections to protect hoses or other components where fluids or other materials

flow which may catch fire easily on welding.

Should the vehicle be subjected to temperatures exceeding 80°C (dryer ovens), disassemble drive electronic central

units.

The disposal of all liquids and fluids must be performed with full observance of specific rules in force.

Print P2D32C003 E Base - May 2007

Page 8

6

GENERALWARNINGS O N THE ELECTRIC SYSTEM

If an intervention has to be made on the electric/electronic system, disconnect batteries from the system; in this case,

!

always disconnect, as a first one, the chassis bonding cable from batteries negative terminal.

Before connecting the batteries to the system, make sure that the system is well isolated.

Disconnect the external recharging apparatus from the public utility network before taking apparatus pins off battery

terminals.

Do not cause sparks to be generated in checking if the circuit is energised.

Do not use a test lamp in c hecking circuit continuity, but only use proper control apparatuses.

Make sure that the electronic devices wiring harnesses (length, lead type, location, strapping, connection to screening

braiding, bonding, etc.) comply with system and are carefully recovered after repair or maintenance interventions.

Measurements in drive electronic central units, plugged connections and electric connections to components can only

be made on proper testing lines with special plugs and plug bushes. Never use improper means like wires, screwdrivers,

clips and the like in order to avoid the danger of causing a short circuit, as well as of damaging plugged connections, which

would later cause contact problems.

CURSOR ENGINES TIER 3

To start up the engine, do not use fast chargers. Start up must only be performed with either separate batteries or special

truck.

A wrong polarisation of supply voltage in drive electronic central units (for instance, a wrong polarisation of batteries)

can cause them to be destroyed.

Disconnect the batteries from the system during their recharging with an external apparatus.

On connecting, only screw up connector (temperature sensors, pressure sensors etc.) nuts at prescribed tightening

torque.

Before disconnecting the junction connector from an electronic central unit, isolate the system.

Do not directly supply electronic central units servo components at nominal vehicle voltage.

Cables must be arranged such as to result to be parallel to reference plane, i.e. as close as possible to chassis/body

structure.

Once the intervention on the electric system has been completed, recover connectors and wiring harnesses according

to original arrangement.

NOTE

Connectors presentmust be seen from cable side. Connectors views contained in the manual arerepresentative of cable

side.

Base - May 2007 Print P2D32C003 E

Page 9

CURSOR ENGINES TIER 3

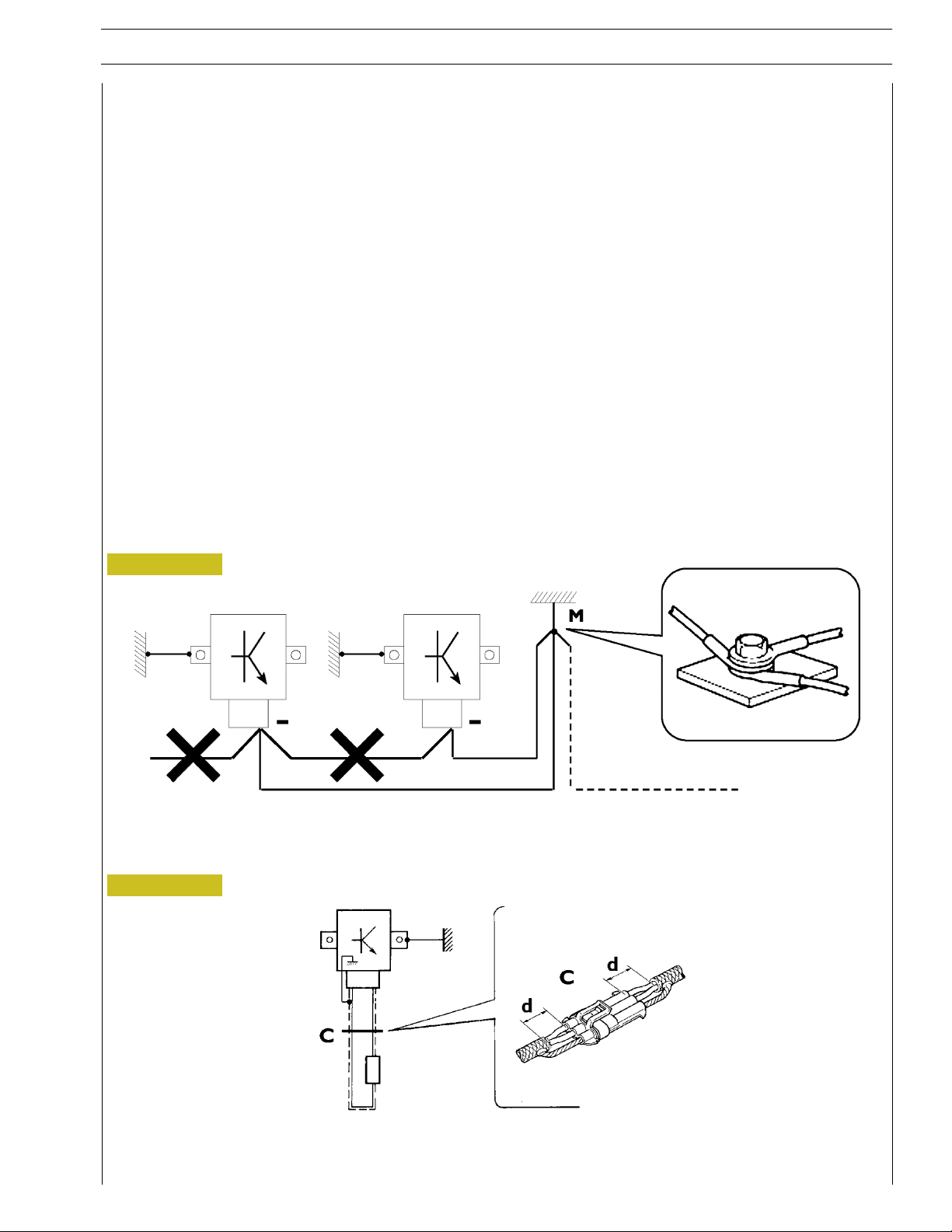

Bonding and screening

Negative leads connected to a system bonded point must be both as short and possible and “star“-connected to each other, trying

then to have their centering tidily and properly made (Figure 1, re. M).

Further, following warnings are to be compulsorily observed for electronic components:

- Electronic central units must be connected to system bonding when they are provided with a metallic shell.

- Electronic central units negative c ables must be connected both to a system bonding point such as the dashboard opening

bonding (avoiding “serial“ or “chain“ connections), and to battery negative terminal.

- Analog bonding (sensors), although not connected to battery negative system/terminal bonding, must have optimal isolation.

Consequently, particularly considered must be parasitic resistances in lugs: oxidising, clinching defects, etc.

- Screened circuits braiding must only electrically contact the end towards the central unit entered by the signal (Figure 2).

- If junction connectors are present, unscreened section d, near them, must be as short as possible (Figure 2).

- Cables must be arranged such as to result to be parallel to reference plane, i.e. as close as possible to chassis/body structure.

7

Figure 1

1. NEGATIVE CABLES “STAR“ CONNECTION TO SYSTEM BONDING M

Figure 2

88039

2. SCREENING THROUGH METALLIC BRAIDING OF A CABLE TO AN ELECTRONIC COMPONENT — C. CONNECTOR

d. DISTANCE ! 0

Print P2D32C003 E Base - May 2007

Page 10

8

CURSOR ENGINES TIER 3

OPTIONAL ELECTRICAL AND MECHANICAL PARTS INSTALLATIONS

Assemblies shall be modified and equipped with additions - and their accessories shall be fitted - in accordance with the assembling

directives issued by FPT.

It is reminded that, especially about the electric system, several electric sockets are provided for as series (or optional) sockets in

order to simplify and normalise the electrical intervention that is care of preparation personnel.

It is absolutely forbidden to make modifications or connections to electric central units wiring harnesses; in particular,

the data interconnection line between central units (CAN line) is to be considered inviolable.

CONVERSIONS BETWEEN THE MAIN UNITS OF MEASUREMENT OF THE INTERNATIONAL SYSTEM AND MOST USED DERIVED QUANTITIES

Power

1 kW = 1.36 metric HP

1 kW = 1.34 HP

1 metric HP = 0.736 kW

1 metric HP = 0.986 HP

1 HP = 0.746 kW

1 HP = 1.014 metric HP

Torque

1 Nm = 0.1019 kgm

1 kgm = 9.81 Nm

Revolutions per time unit

1 rad/s = 1 rpm x 0.1046

1 rpm = 1 rad/s x 9.5602

Pressure

1 bar = 1.02 kg/cm

1 kg/cm

1bar = 10

2

= 0.981 bar

5

2

Pa

Where accuracy is not particularly needed:

- Nm unit is for the sake of simplicity converted into kgm according to ratio 10:1

1 kgm = 10 Nm;

2

- bar unit is for the sake of simplicity converted into kg/cm

2

1 kg/cm

=1bar.

according to ratio 1:1

Temperature

0° C=32° F

1° C = (1 x 1.8 + 32) ° F

Base - May 2007 Print P2D32C003 E

Page 11

CURSOR ENGINES F3A

1

Part 1

CURSOR ENGINES F3A

Section

General specifications

Fuel 2

Duty - Industrial application 3

Overhaul and technical specifications 4

Tools 5

Safety prescriptions Appendix

1

PREFACE TO USER’S GUIDELINE MANUAL

Section 1 describes the F3A engine illustrating its features

and working in general.

Section 2 describes the type of fuel feed.

Section 3 relatesto the specific dutyand is dividedin four separate parts:

1. Mechanical part, related to the engine overhaul,

limited to those components with different characteristics

based on the relating specific duty.

2. Electrical part, concerning wiring harness, electrical

and electronic equipment with different characteristics

based on the relating specific duty.

3. Maintenance planning and specific overhaul.

4. Troubleshooting part dedicated to the operators who,

being entitled to provide technical assistance, shall have simple

and direct instructions to identify the causeof the major inconveniences.

Sections 4 and 5 illustrate the overhaul operations of the engine overhaul on standand the necessary equipment to execute

such operations.

The appendix contains a list of the general safety regulations

to be respected by all installation and maintenance engineers

in order to prevent serious accidents taking place.

Print P2D32C003 E Base - May 2007

Page 12

2

CURSOR ENGINES F3A

Print P2D32C003 EBase - May 2007

Page 13

CURSOR ENGINES F3A

3

SPECIAL REMARKS

Diagrams and symbols have been widely used to give a clearer and more immediate illustration of the subject being dealt with, (see

next page) instead of giving descriptions of some operations or procedures.

Example

∅

Ø 1 = housing for connecting rod small end bush

1

Ø 2 = housing for connecting rod bearings

∅

2

Tighten to torque

Tighten to torque + angular value

α

Print P2D32C003 E Base - May 2007

Page 14

4

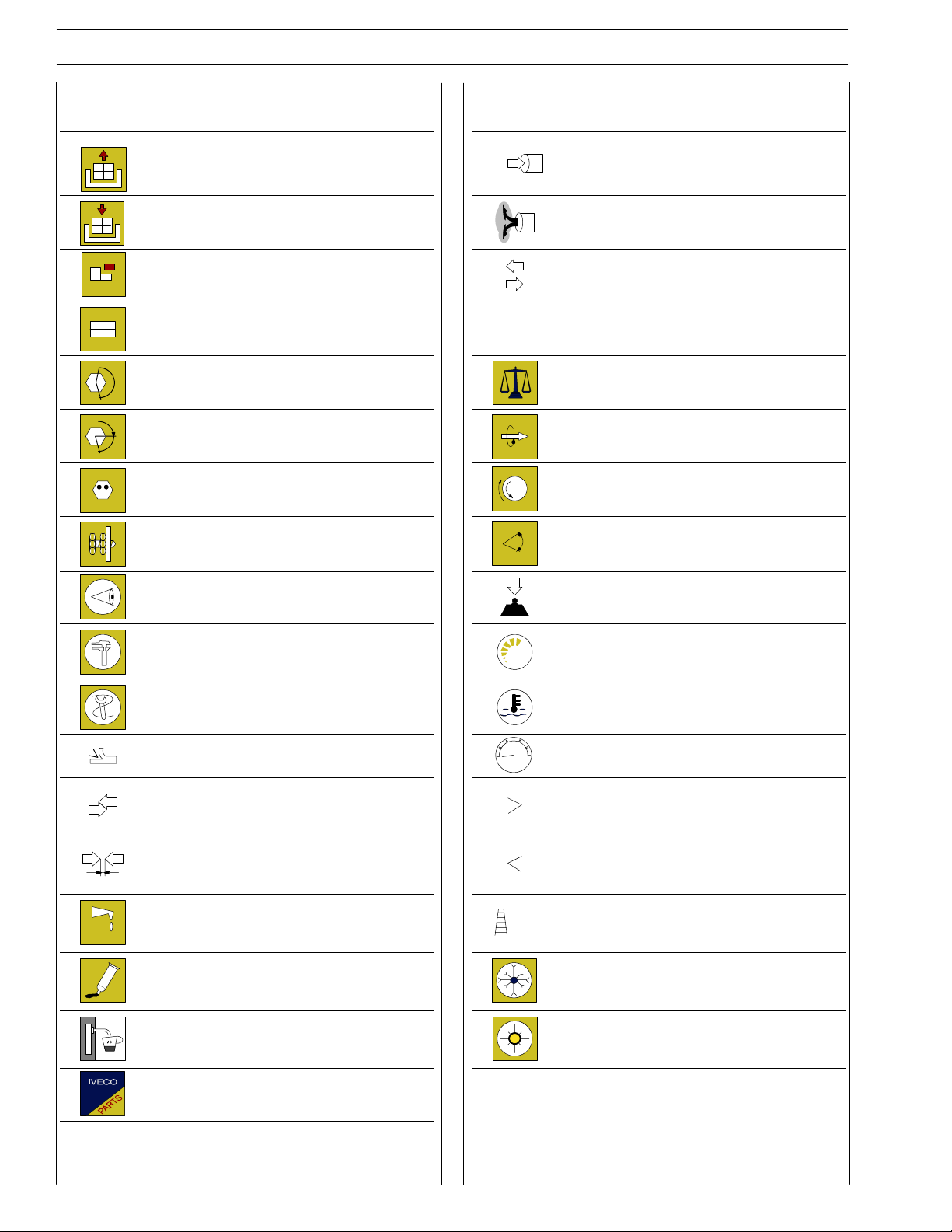

SYMBOLS - ASSISTANCE OPERATIONS

CURSOR ENGINES F3A

Removal

Disconnection

Refitting

Connection

Removal

Disassembly

Fitting in place

Assembly

ρ

Tighten to torque

Tighten to torque + angle value Rolling torque

α

Press or caulk Rotation

Regulation

Adjustment

Visual inspection

Fitting position check

Intake

Exhaust

Operation

Compression ratio

Tolerance

Weight difference

Angle

Angular value

Preload

Measurement

Value to find

Number of revolutions

Check

Equipment Temperature

Surface for machining

Machine finish

Interference

Strained assembly

Thickness

Clearance

Lubrication

Damp

Grease

Sealant

Adhesive

bar

Pressure

Oversized

Higher than….

Maximum, peak

Undersized

Less than….

Minimum

Selection

Classes

Oversizing

Temperature < 0 °C

Cold

Winter

Temperature > 0 °C

Air bleeding

Hot

Summer

Replacement

Original spare parts

Print P2D32C003 EBase - May 2007

Page 15

CURSOR ENGINES F3A

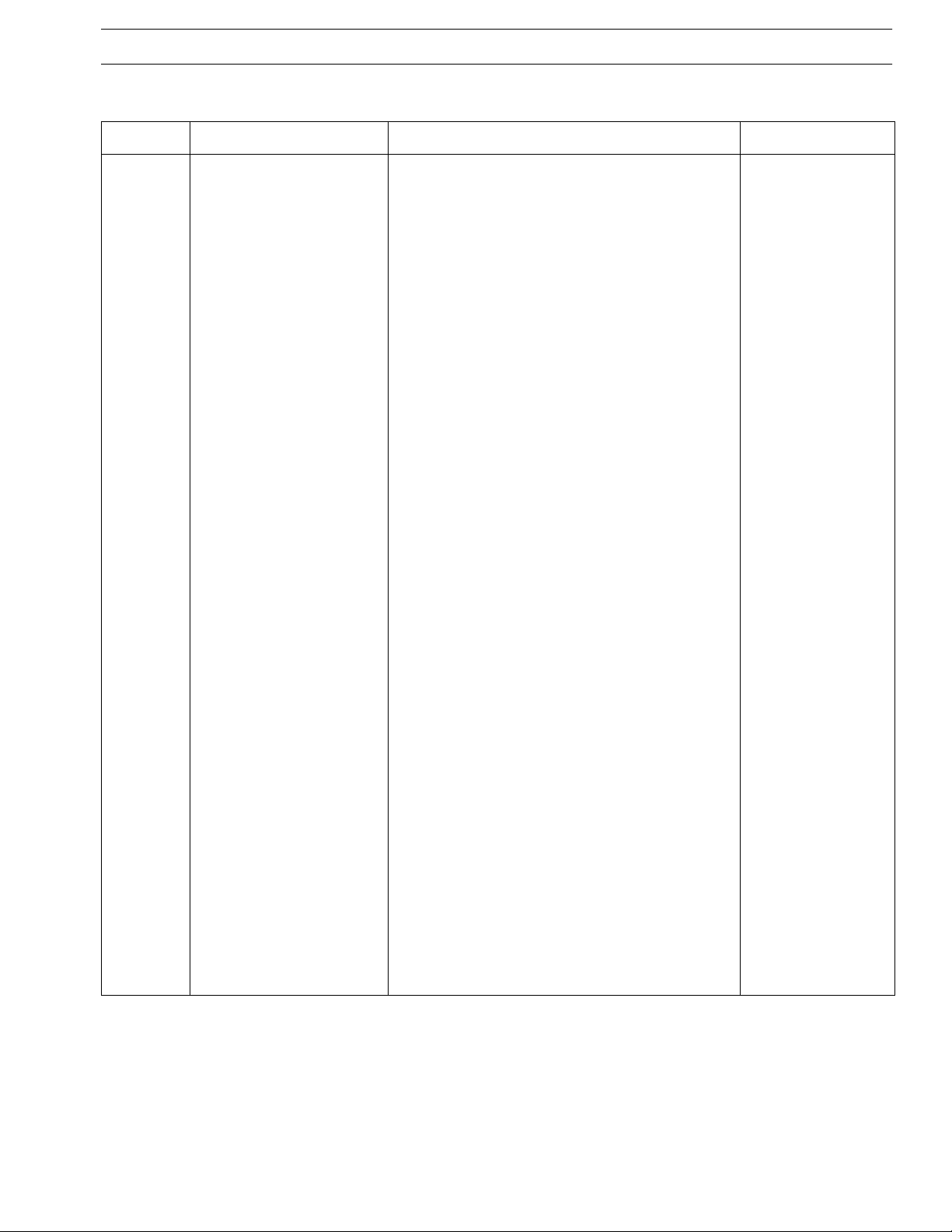

UPDATING

Section Description Page Date of revision

5

Print P2D32C003 E Base - May 2007

Page 16

6

CURSOR ENGINES F3A

Print P2D32C003 EBase - May 2007

Page 17

CURSOR ENGINES F3A

SECTION 1 - GENERAL SPECIFICATIONS

SECTION 1

General Specifications

Page

CORRESPONDENCE BETWEEN TECHNICAL

AND COMMERCIAL CODES 3............

VIEWS OF THE ENGINE

(ONLY FOR TYPE F3AE0684P*E904) 5......

VIEWS OF THE ENGINE (FOR TYPES: F3AE0684P*E906 -

F3AE0684L*E906 - F3AE0684P*E905) 8.....

VIEWS OF THE ENGINE

(ONLY FOR TYPE: F3AE0684N*E907) 11.....

VIEWS OF THE ENGINE

(ONLY FOR TYPE: F3AE0684N*E907) 14.....

LUBRICATION DIAGRAM

(ONLY FOR TYPE: F3AE0684P*E904 ) 16.....

LUBRICATION DIAGRAM

(FOR TYPES: F3AE0684P*E906 - F3AE0684L*E906 -

F3AE0684P*E905) 17.....................

1

LUBRICATION DIAGRAM

(ENGINES F3AE0684N*E907) 18............

- Oil pump 19.............................

- Overpressure valve 19.....................

- Oil pressure control valve 20................

- Heat exchanger (for type: F3AE0684P*E906 -

F3AE0684L*E906 - F3AE0684P*E905 -

F3AE0684N*E907) 20.....................

- Heat exchanger

(only for type: F3AE0684P*E904) 21..........

- By-pass valve 22..........................

- Thermostatic valve 22......................

- Engine oil filters 22........................

COOLING 23.............................

- Description 23...........................

- Operation 23............................

- Water pump 25..........................

- Thermostat 25...........................

TURBOCHARGING 26......................

EGR EXHAUST GAS

RECIRCULATION SYSTEM 27.............

INTERNAL EGR ACTING ON

THEINTAKEVALVES 27..................

Base - May 2007Print P2D32C003 E

Page 18

2

SECTION 1 - GENERAL SPECIFICATIONS

CURSOR ENGINES F3A

Base - May 2007 Print P2D32C003 E

Page 19

CURSOR ENGINES F3A

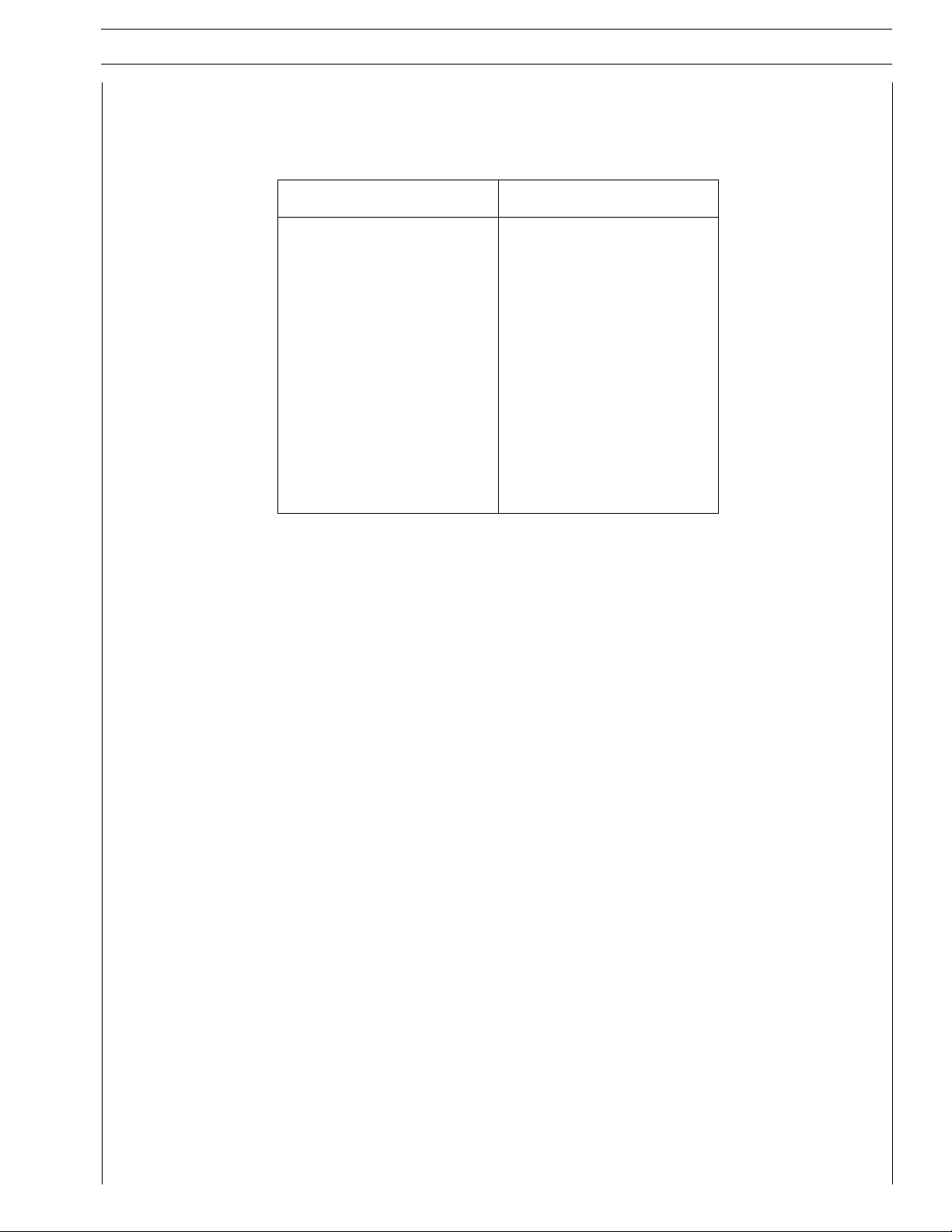

SECTION 1 - GENERAL SPECIFICATIONS

CORRESPONDENCE BETWEEN TECHNICAL AND COMMERCIAL CODES

Technical Code Commerciale Code

F3AE0684P*E904

F3AE0684P*E906

F3AE0684L*E906

F3AE0684P*E905 C10 ENT X

F3AE0684N*E907

F3AE9687A*E001

F3AE9687B*E001

3

F3AE9687C*E001

Base - May 2007Print P2D32C003 E

Page 20

4

SECTION 1 - GENERAL SPECIFICATIONS

CURSOR ENGINES F3A

Base - May 2007 Print P2D32C003 E

Page 21

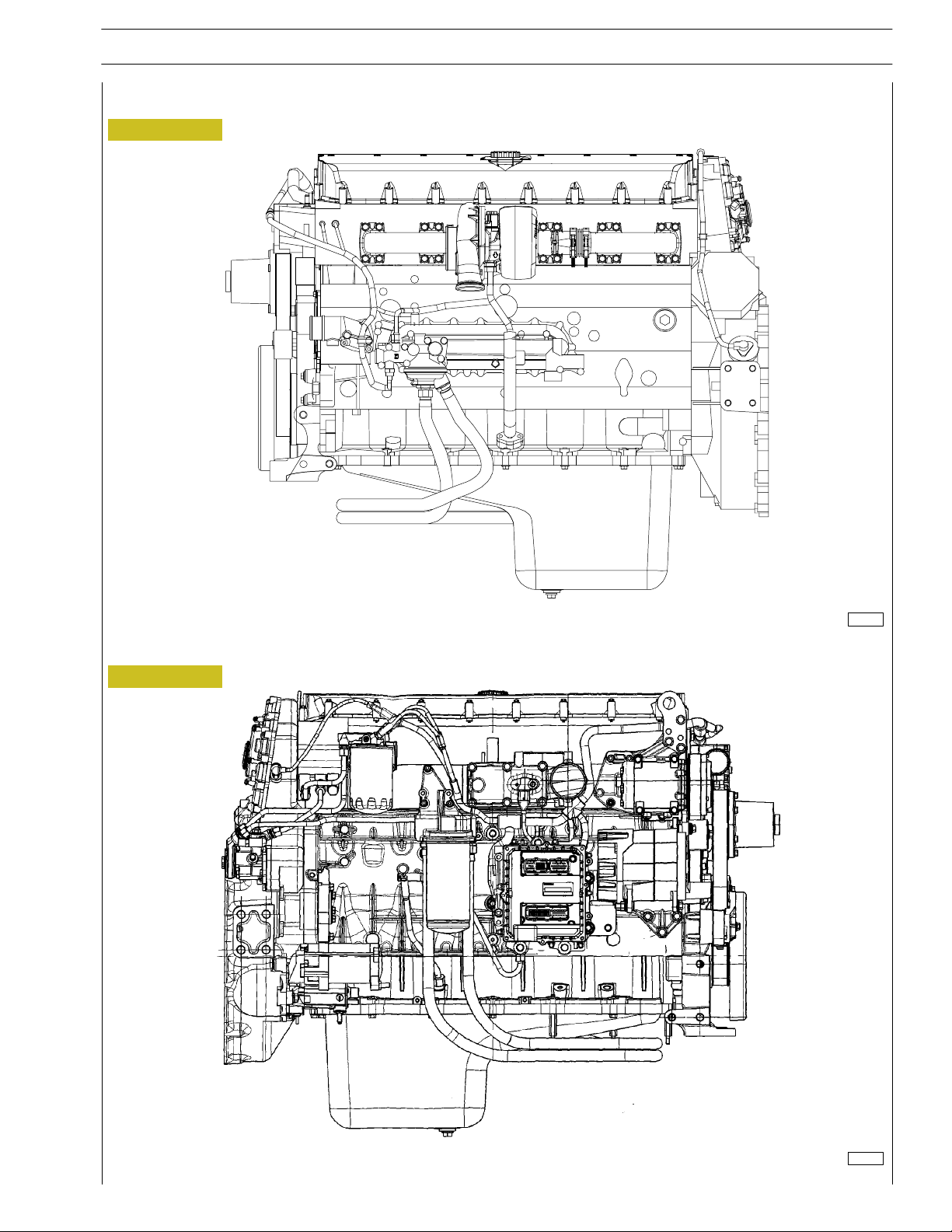

CURSOR ENGINES F3A

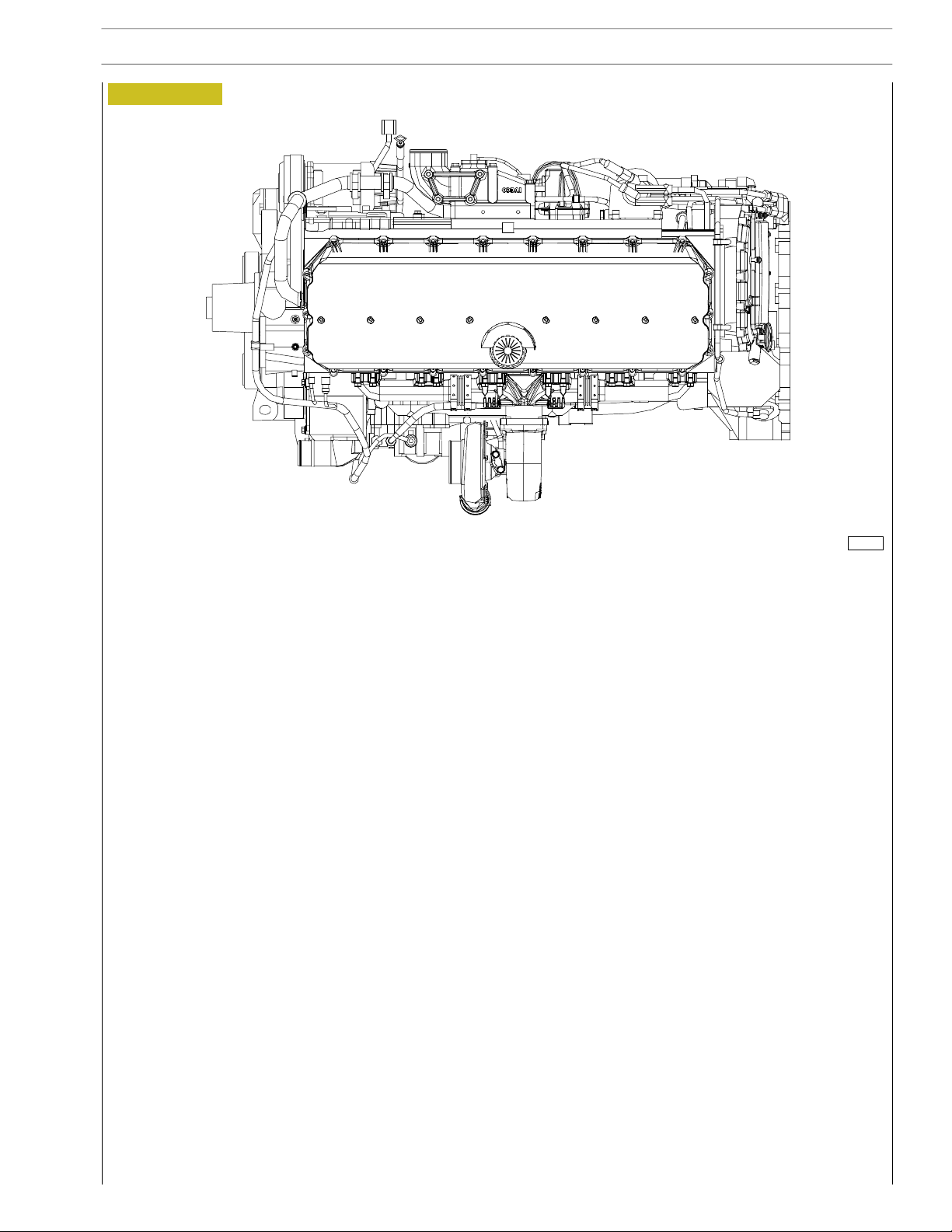

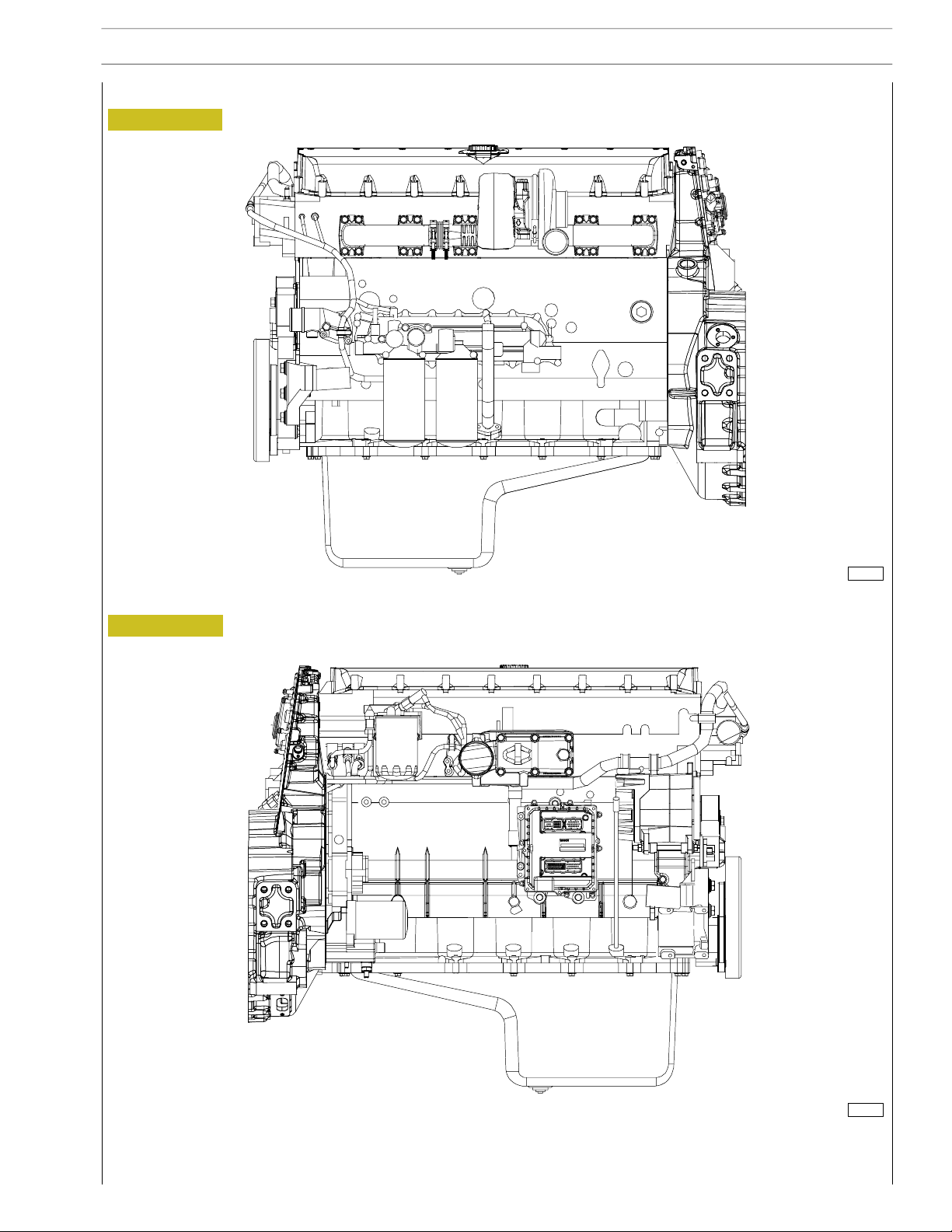

VIEWS OF THE ENGINE (ONLY FOR TYPE F3AE0684P*E904)

Figure 1

SECTION 1 - GENERAL SPECIFICATIONS

5

Figure 2

104224

LEFT-HAND SIDE VIEW

RIGHT-HAND SIDE VIEW

104225

Base - May 2007Print P2D32C003 E

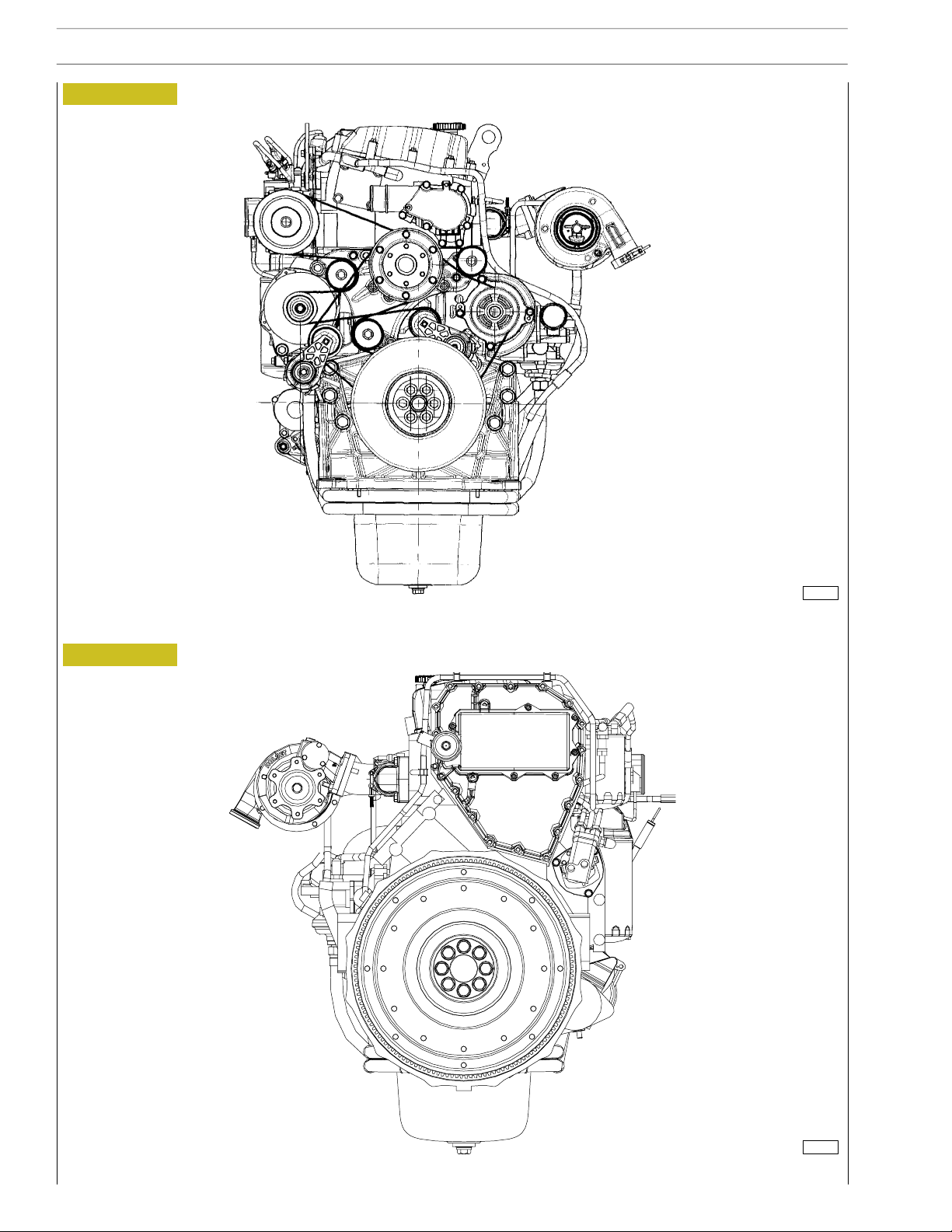

Page 22

6

SECTION 1 - GENERAL SPECIFICATIONS

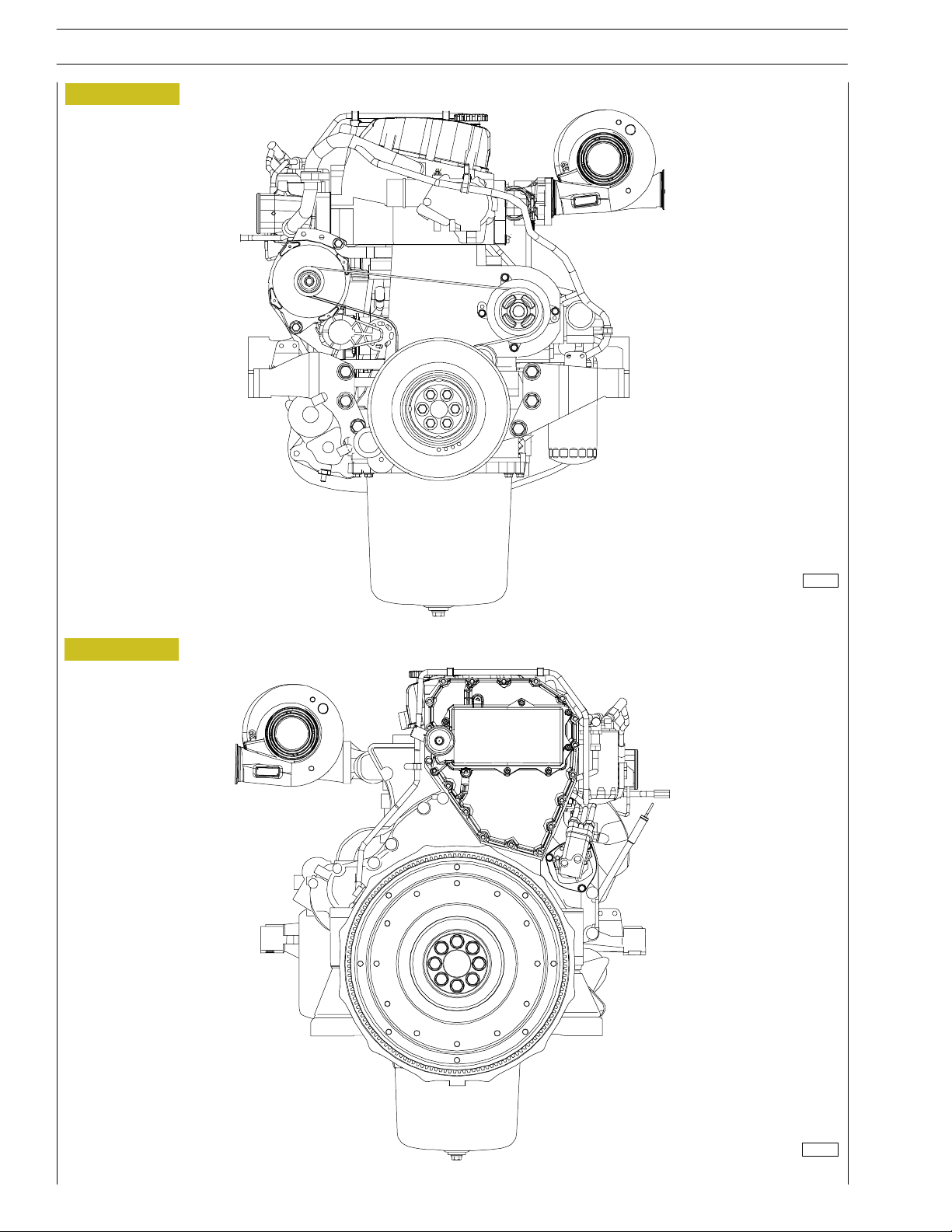

Figure 3

CURSOR ENGINES F3A

Figure 4

104226

FRONT VIEW

104227

REAR VIE W

Base - May 2007 Print P2D32C003 E

Page 23

CURSOR ENGINES F3A

Figure 5

SECTION 1 - GENERAL SPECIFICATIONS

7

TOP VIEW

104228

Base - May 2007Print P2D32C003 E

Page 24

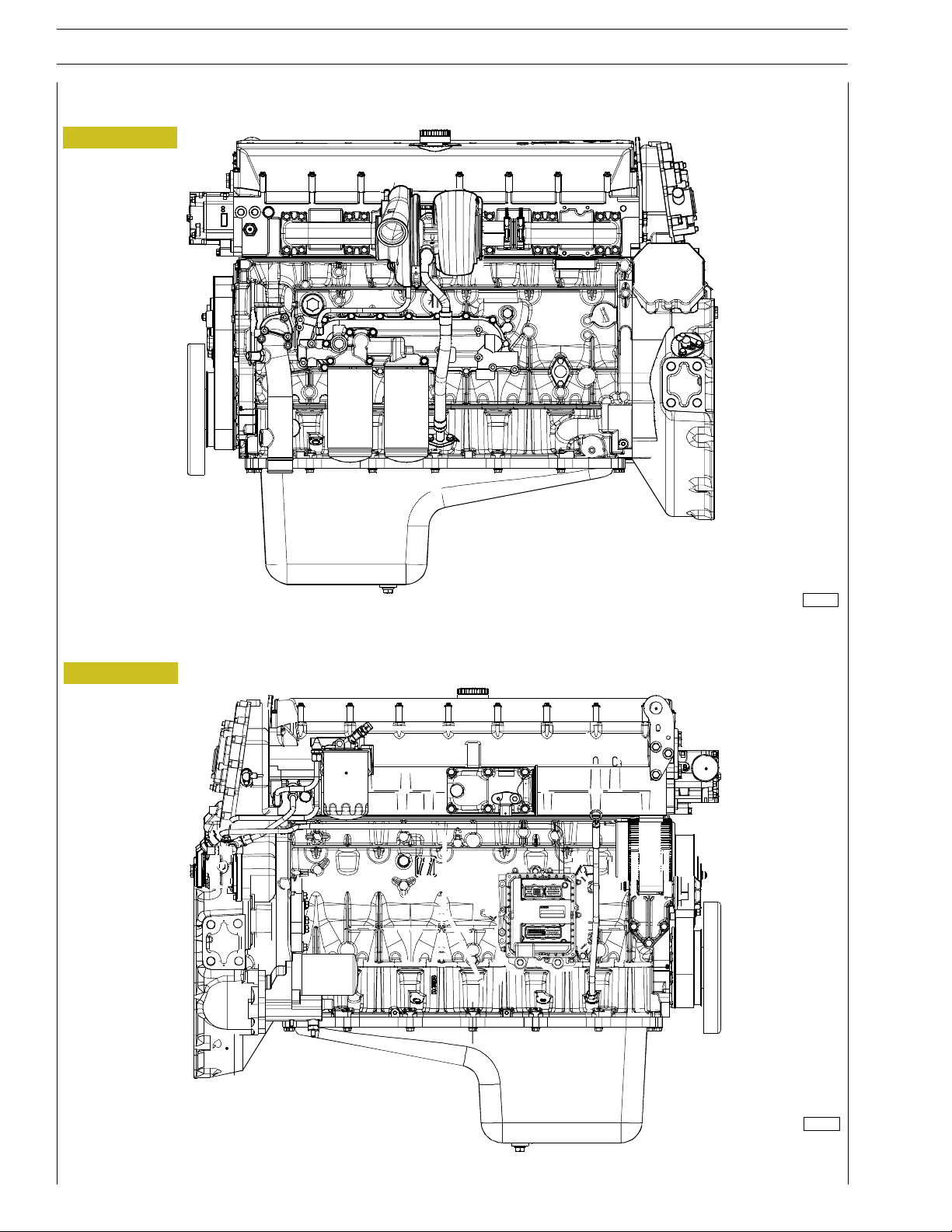

8

SECTION 1 - GENERAL SPECIFICATIONS

CURSOR ENGINES F3A

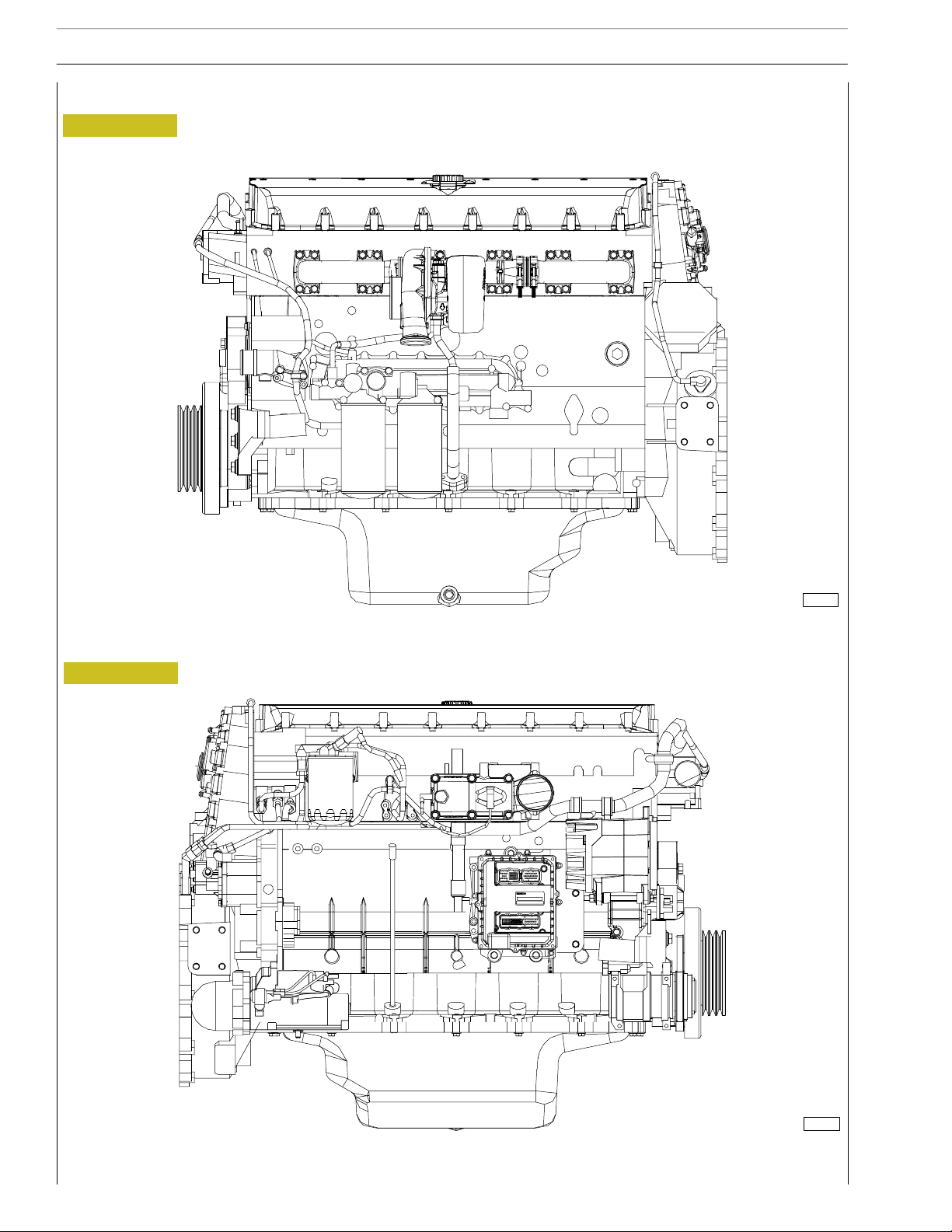

VIEWS OF THE ENGINE (FOR TYPES: F3AE0684P*E906 - F3AE0684L*E906 - F3AE0684P*E905)

Figure 6

Figure 7

104229

LEFT-HAND SIDE VIEW

104230

RIGHT SIDE VIEW

Base - May 2007 Print P2D32C003 E

Page 25

CURSOR ENGINES F3A

Figure 8

SECTION 1 - GENERAL SPECIFICATIONS

9

Figure 9

104231

FRONT SIDE VIEW

REAR SIDE VIEW

104232

Base - May 2007Print P2D32C003 E

Page 26

10

SECTION 1 - GENERAL SPECIFICATIONS

Figure 10

CURSOR ENGINES F3A

TOP SIDE VIEW

104233

Base - May 2007 Print P2D32C003 E

Page 27

CURSOR ENGINES F3A

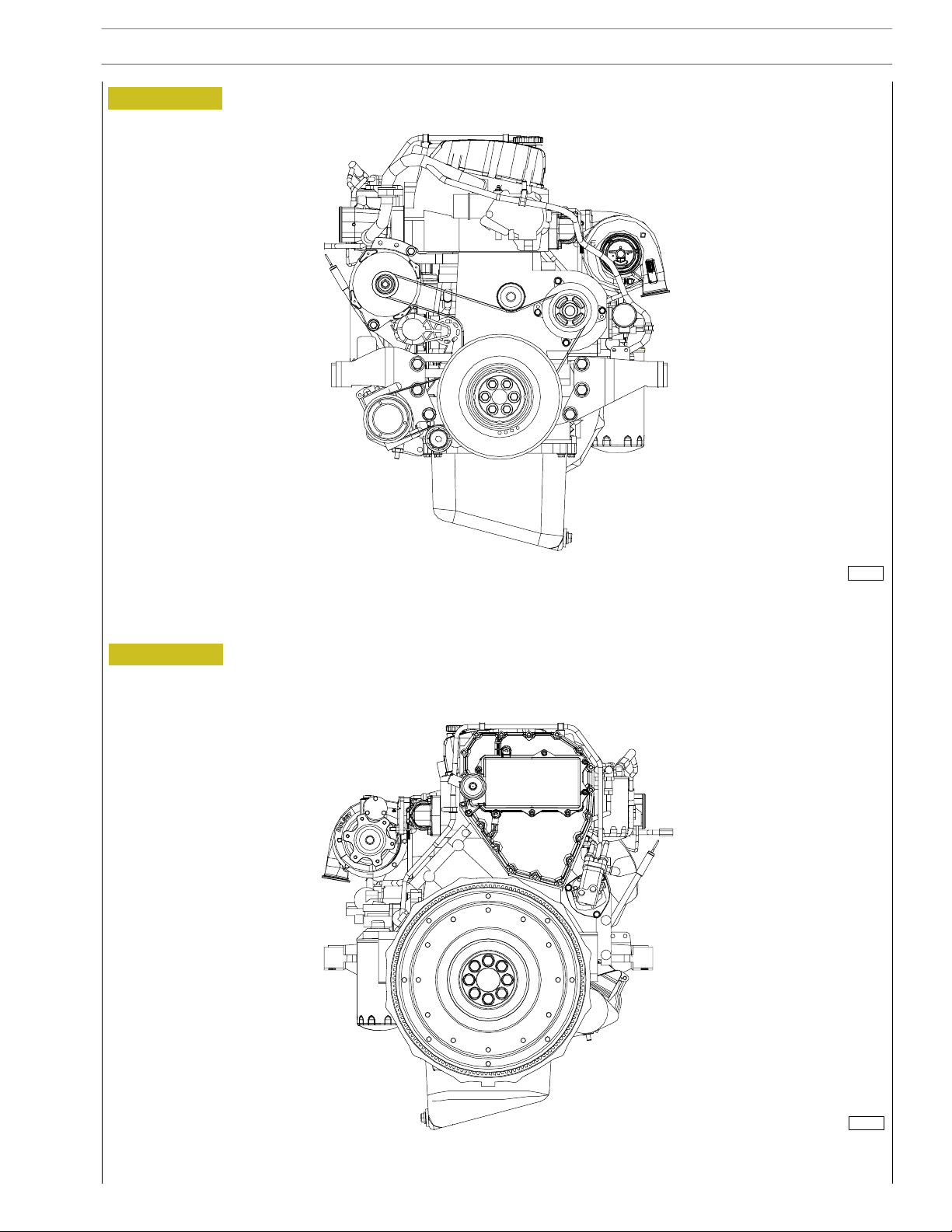

VIEWS OF THE ENGINE (ONLY FOR TYPE: F3AE0684N*E907)

Figure 11

SECTION 1 - GENERAL SPECIFICATIONS

11

Figure 12

104755

LEFT-HAND SIDE VIEW

RIGHT SIDE VIEW

104756

Base - May 2007Print P2D32C003 E

Page 28

12

SECTION 1 - GENERAL SPECIFICATIONS

Figure 13

CURSOR ENGINES F3A

Figure 14

104757

FRONT SIDE VIEW

104758

REAR SIDE VIEW

Base - May 2007 Print P2D32C003 E

Page 29

CURSOR ENGINES F3A

Figure 15

SECTION 1 - GENERAL SPECIFICATIONS

13

TOP SIDE VIEW

104759

Base - May 2007Print P2D32C003 E

Page 30

14

SECTION 1 - GENERAL SPECIFICATIONS

CURSOR ENGINES F3A

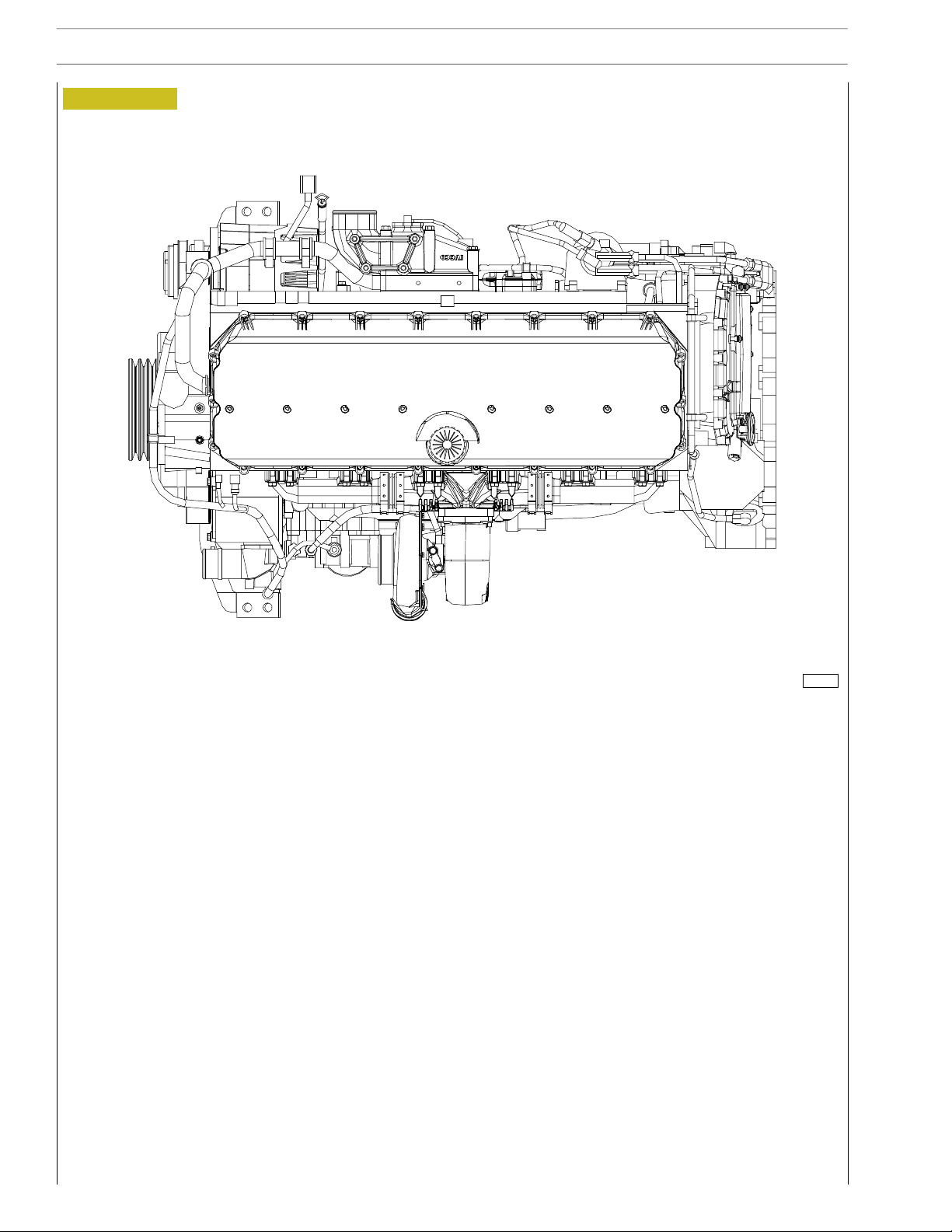

VIEWS OF THE ENGINE (FOR TYPES: F3AE9687A*E001 - F3AE9687B*E001 - F3AE9687C*E001)

Figure 16

Figure 17

116763

LEFT-HAND SIDE VIEW

116764

RIGHT SIDE VIEW

Base - May 2007 Print P2D32C003 E

Page 31

CURSOR ENGINES F3A

Figure 18

SECTION 1 - GENERAL SPECIFICATIONS

15

Figure 19

116761

FRONT SIDE VIEW

TOP SIDE VIEW

116762

Base - May 2007Print P2D32C003 E

Page 32

16

SECTION 1 - GENERAL SPECIFICATIONS

LUBRICATION DIAGRAM (ONLY FOR TYPE: F3AE0684P*E904)

Figure 20

CURSOR ENGINES F3A

Dropping oil

Pressure oil

104234

Base - May 2007 Print P2D32C003 E

Page 33

CURSOR ENGINES F3A

SECTION 1 - GENERAL SPECIFICATIONS

LUBRICATION DIAGRAM (FOR TYPES: F3AE0684P*E906 - F3AE0684L*E906 - F3AE0684P*E905)

Figure 21

17

Dropping oil

Pressure oil

104235

Base - May 2007Print P2D32C003 E

Page 34

18

SECTION 1 - GENERAL SPECIFICATIONS

CURSOR ENGINES F3A

LUBRICATION DIAGRAM (ENGINES F3AE0684N*E907 - F3AE9687A*E001 - F3AE9687B*E001

- F3AE9687C*E001)

Figure 22

Dropping oil

Pressure oil

104760

Base - May 2007 Print P2D32C003 E

Page 35

CURSOR ENGINES F3A

SECTION 1 - GENERAL SPECIFICATIONS

19

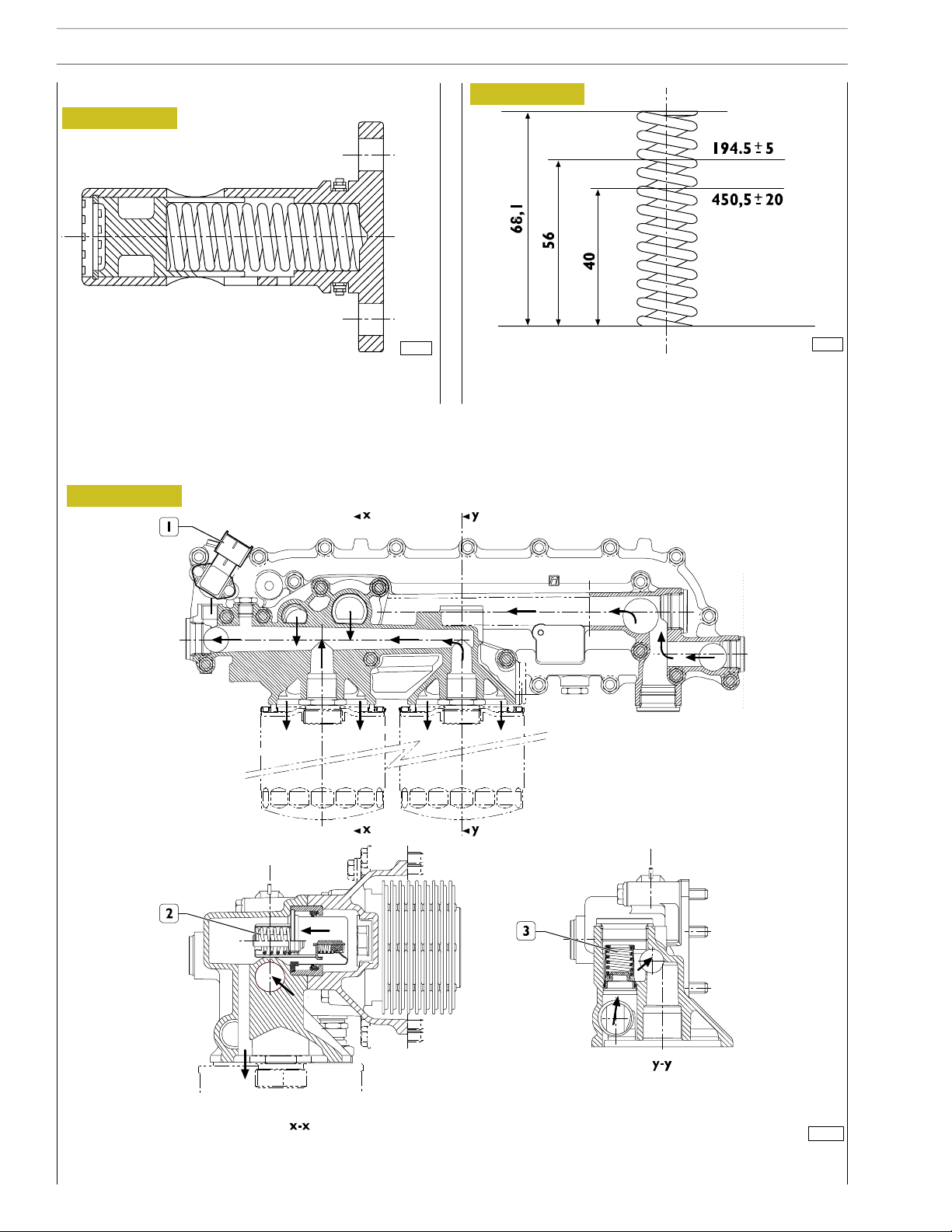

Oil pump

Figure 23

60560

The oil pump (1) cannot be overhauled. On finding any

damage, replace the oil pump assembly.

See under the relevant heading for replacing the gear (2) of

the crankshaft.

Overpressure valve

Figure 25

73540

MAIN DATA TO CHECK THE OVERPRESSURE

VALVE SPRING

Figure 24

1

OIL PUMP CROSS-SECTION

1. Overpressure valve — Start of opening pressure 10.1 ±0.7 bars.

73541

Base - May 2007Print P2D32C003 E

Page 36

20

SECTION 1 - GENERAL SPECIFICATIONS

CURSOR ENGINES F3A

Oil pressure control valve

Figure 27

Figure 26

73542

The oil pressure co ntrol valve is located on the left-hand side

of the c rankcase.

MAIN DATA TO CHECK THE OIL PRESSURE

CONTROL VALVE SPRING

73543

Start of opening pressure 5 bars.

Heat exchanger

(for type: F3AE0684P*E906 - F3AE0684L*E906 - F3AE0684P*E905 - F3AE0684N*E907 F3AE9687A*E001 - F3AE9687B*E001 - F3AE9687C*E001)

Figure 28

104236

HEAT EXCHANGER

The heat exchan ger is fitted with: 1. Oil pressure/temperature sensor - 2. By-pass valve - 3. Heat valve.

Base - May 2007 Print P2D32C003 E

Page 37

CURSOR ENGINES F3A

Heat exchanger (only for type: F3AE0684P*E904)

Figure 29

2

SECTION 1 - GENERAL SPECIFICATIONS

21

104237

HEAT EXCHANGER

The following elements are fitted on the intercooler: 1. By-pass valve - 2. Oil pressure/temperature sensor - 3. Heat valve.

Base - May 2007Print P2D32C003 E

Page 38

22

SECTION 1 - GENERAL SPECIFICATIONS

CURSOR ENGINES F3A

By-pass valve

Figure 30

The valve quickly o pens at a pressure of: 3 bars.

Thermostatic valve

Figure 31

73545

This is a new generation of filters that permit much more

thorough filtration as they are able to holder back a great er

amount of particles of smaller dimensions than those held

back by conventional filters with a paper filtering element.

These high-filtration devices, to date used only in industrial

processes, make it possible to:

- reduce the wear of engine components over time;

- maintain the performance/specifications of the oil and

thereby lengthen the time intervals between changes.

External spiral winding

The filtering elements are closely wound by a spiral so that

each fold is firmly anchored to the spiral with respect to the

others. This produces a uniform use of the element even in

the worst conditions such as cold starting with fluids with a

high viscosity and peaks of flow. In addition, it ensures uniform distribution of the flow over the entire length of the

filtering element, with consequent optimization of the loss of

load and of its working life.

Mount upstream

To optimize flow distribution and the rigidity of the filtering element, this has an exclusive mount composed of a strong mesh

made of nylon and an extremely strong synthetic material.

Start of opening:

- travel 0.1 mm at a temperature of 82 ±2°C

End of opening:

- travel 8 mm at a temperature of 97°C

.

Engine oil filters

Figure 32

Filtering element

73546

Composed of inert inorganic fibres bound with an exclusive

resin to a structure with graded holes, the element is manu-

.

factured exclusively to precise procedures and strict quality

control.

Mount downstream

A mount for the filtering element and a strong nylon mesh

make it even stronger, which is especially helpful during cold

starts and long periods of use. The performance of the filter

remains constant and reliable throughout its working life and

from one element to another, irrespective of the changes in

working conditions.

Structural parts

The o-rings equipping the filtering element ensure a perfect

seal between it and the container, eliminating by-pass risks

and keeping filter performance constant. Strong corrosionproof bottoms and a sturdy internal metal core complete the

structure of the filtering element.

When mounting the filters, keep to the following rules:

- Oil and fit new seals.

- Screw down the filters to bring the seals into contact

with the supporting bases.

- Tighten the filter to a torque of 35-40 Nm.

47447

Base - May 2007 Print P2D32C003 E

Page 39

CURSOR ENGINES F3A

SECTION 1 - GENERAL SPECIFICATIONS

COOLING

Description

The engine cooling system is of the closed-circuit, forced circulation type.

It consists mainly of the following components:

- expansion tank, not supplied;

- a heat exchanger to cool down lubrication oil;

- a water pump with centrifugal system incorporated in the cylinder block;

- fan, not supplied;

- a 2-way thermostat controlling t h e coolant circulation.

Operation

The water pump is actuated by the crankshaft through a poli-V belt and sends coolant to t he cylinder block, especially to the

cylinder head (bigger quantity). When the coolant temperature reaches and overcomes the operating temperature, the

thermostat is opened and from here the coolant flows into the radiator and is cooled down by the fan.

The pressure inside the system, due to temperature change, is adequately controlled t hrough t he expansion vessel.

23

Base - May 2007Print P2D32C003 E

Page 40

24

SECTION 1 - GENERAL SPECIFICATIONS

Figure 33

CURSOR ENGINES F3A

Water flowing out of the thermostat

Water circulating in the engine

Water flowing into the pump

104238

Base - May 2007 Print P2D32C003 E

Page 41

CURSOR ENGINES F3A

SECTION 1 - GENERAL SPECIFICATIONS

25

Water pump

Figure 34

104239

CROSS-SECTION OF THE WATER PUMP

The water pump consists of: rotor, shaft with bearing,

T-gasket and drive pulley with dust sh ield.

Figure 36

TO THE

RADIATOR

TO THE

EXPANSION

TUB

TO THE

FROM

THE ENGINE

BY PASS

60748

Water leaving the thermostat

Check the t hermostat works properly; replace it if in doubt.

Temperature of start of travel 84°C ±2°C.

Minimumtravel15mmat94°C ±2°C.

Check that the pump body has no cracks or water

leakage; if it does, replace the entire water pump.

Thermostat

View of thermostat operation

Figure 35

TO THE

RADIATOR

TO THE

EXPANSION

TUB

FROM

THE ENGINE

Water circulating in the engine

TO THE

BY PASS

60747

Base - May 2007Print P2D32C003 E

Page 42

26

SECTION 1 - GENERAL SPECIFICATIONS

TURBOCHARGING

The turbocharging system consists of:

- air filter;

- Wastegate turbocharger.

Figure 37

CURSOR ENGINES F3A

1. TURBOCHARGER HX55

Exhaust gas

Inlet air

Compressed air (hot )

Intake compressed air

104240

Base - May 2007 Print P2D32C003 E

Page 43

CURSOR ENGINES F3A

SECTION 1 - GENERAL SPECIFICATIONS

EGR EXHAUST GAS RECIRCULATION SYSTEM

The exhaust gases may be partially conveyed back into the cylinders to reduce the maximum combustion temperature responsible for producing nitrogen oxides (NOx).

The exhaust gas recirculation (EGR) system, by reducing the combustion temperature, thus represents an effective NOx emission controlling system.

INTERNAL EGR ACTING ON THE INTAKE VALVES

Through a modification to the design of the intake cams, the internal EGR system enables part of the exhaust gas to be conveyed

back into the engine’s cylinders.

This type of EGR, called internal EGR, has n o electronically controlled elements, the system is always active.

Its configuration requires no additional elements such as control valves, pipes or heat exchangers, so the profile of the engine

remains unchanged.

In addition to the main lobe, the intake cam presents an additional lobe (3) with respect to the configuration without EGR.

During the exhaust stroke of the cylinder concerned, this lobe opens the intake valve slightly earlier (*). In this way, part of the

exhaust gas is trapped in the intake pipe and then, during the int ake stroke of the cylinder, is returned to the load of the cy linder

forthepowerstroke.

Figure 38

27

Y: Lift of valves in mm.

Y: Regulation of engine

shaft in degrees

1. Exhaust cams - 2. Intake cams - 3. EGR lobe - S. Exhaust pipes - A. Intake pipes.

104761

Base - May 2007Print P2D32C003 E

Page 44

28

SECTION 1 - GENERAL SPECIFICATIONS

CURSOR ENGINES F3A

Base - May 2007 Print P2D32C003 E

Page 45

CURSOR ENGINES F3A

SECTION 2- FUEL

SECTION 2

Fuel

FEEDING 3...............................

FUEL SUPPLY DIAGRAM (ALL TYPES) 4.......

- Fuel pump 5............................

- Injector-pump 5.........................

1

Page

Base - May 2007Print P2D32C003 E

Page 46

2

SECTION 2 - FUEL

CURSOR ENGINES F3A

Base - May 2007 Print P2D32C003 E

Page 47

CURSOR ENGINES F3A

FEEDING

Fuel is supplied via a fuel pump, filter and pre-filter, 6

pump-injectors govern ed by the camshaft via rocker arms

and by the electronic control unit.

Figure 1

SECTION 2- FUEL

3

1. Fuel pressure damper - 2. Valve for return circuit, starts opening at 3.5 bars -

3. Valve for return circuit, starts opening at 0.2 bars.

Return circuit

Supply circuit

104241

Base - May 2007Print P2D32C003 E

Page 48

4

SECTION 2 - FUEL

FUEL SUPPLY DIAGRAM (ALL TYPES)

Figure 2

CURSOR ENGINES F3A

104242

1. Temperature sensor - 2. Bleed valve - 3. Secondary fuel filter - 4. By-pass valve (0.3 ÷ 0.4 bar) - 5. Fuel su pply pump -

6. Integrated valve (3.5 bar) - 7. Pressure relief valve (5 bar) - 8. Fuel tan k - 9. Priming pump - 10. Primary fuel filter -

11. Check valve (opening 0.1 bar) - 12. Heater - 13. Electronic control unit - 14. Fuel return union with valve built in

(0.2 bar) - 15. Pump-inject ors.

Base - May 2007 Print P2D32C003 E

Page 49

CURSOR ENGINES F3A

SECTION 2- FUEL

5

Fuel pump

Figure 3

A. Fuel inlet — B. Fuel delivery — C. By-pass nut —

D. Fuel return from the pump-injectors —

E. Pressure relief valve — Opening pressure: 5-8 bars.

Figure 4

CROSS-SECTION OF THE FUEL PUMP

1. Oil and fuel leakage indicator.

Injector-pump

73547

73548

Pumping element

The pumping element is operated by a rocker arm governed

directly by the cam of the camshaft.

The pumping element is able to ensure a high delivery

pressure. The return stroke is made by means of a return

spring.

Nozzle

Garages are authorized to perform fault diagnosis solely on

the entire injection system and may not work inside the

injector-pump, which must only be replaced.

A specific fault-diagnosis program, included in the control

unit, is able to check the operation of each injector (it

deactivates one at a time and checks the delivery of the other

five).

Fault diagnosis makes it possible to distinguish errors of an

electrical origin from ones of a mechanical/hydraulic origin.

It indicates broken pump-injectors.

It is therefore n ecessary to interpret all the control unit error

messages correctly.

Any defects in the injectors are to be resolved by replacing

them.

Solenoid valve

The solenoid, which is energized at each active phase of the

cycle, via a signal from the control unit, controls a slide valve

that shuts off the pumping element delivery pipe.

When the solenoid is not energized, the valve is open, the

fuel is pumped but it flows back into th e return pipe with the

normal transfer pressure of approximately 5 bars.

When the solenoid is energized, the valve shuts and the fuel,

not being able to flow back into the return pipe, is pumped

into the nozzle at high pressure, causing the needle to lift.

The amount of fuel injected depends on the length of time

the slide valve is closed and therefore on the time for which

the solenoid is energized.

The solenoid valve is joined to the injector body and cannot

be removed.

On the top there are two screws securing the electrical

wiring from the c ontrol unit.

To ensure signal transmission, tighten the screws with a torque

wrenchtoatorqueof1.36—1.92Nm(0.136—0.192kgm).

Figure 5

104243

1. Fuel/oil seal — 2. Fuel/diesel seal — 3. Fuel/exhaust gas seal.

The injector-pump is composed of: pumping element, nozzle,

solenoid valve.

Base - May 2007Print P2D32C003 E

Page 50

6

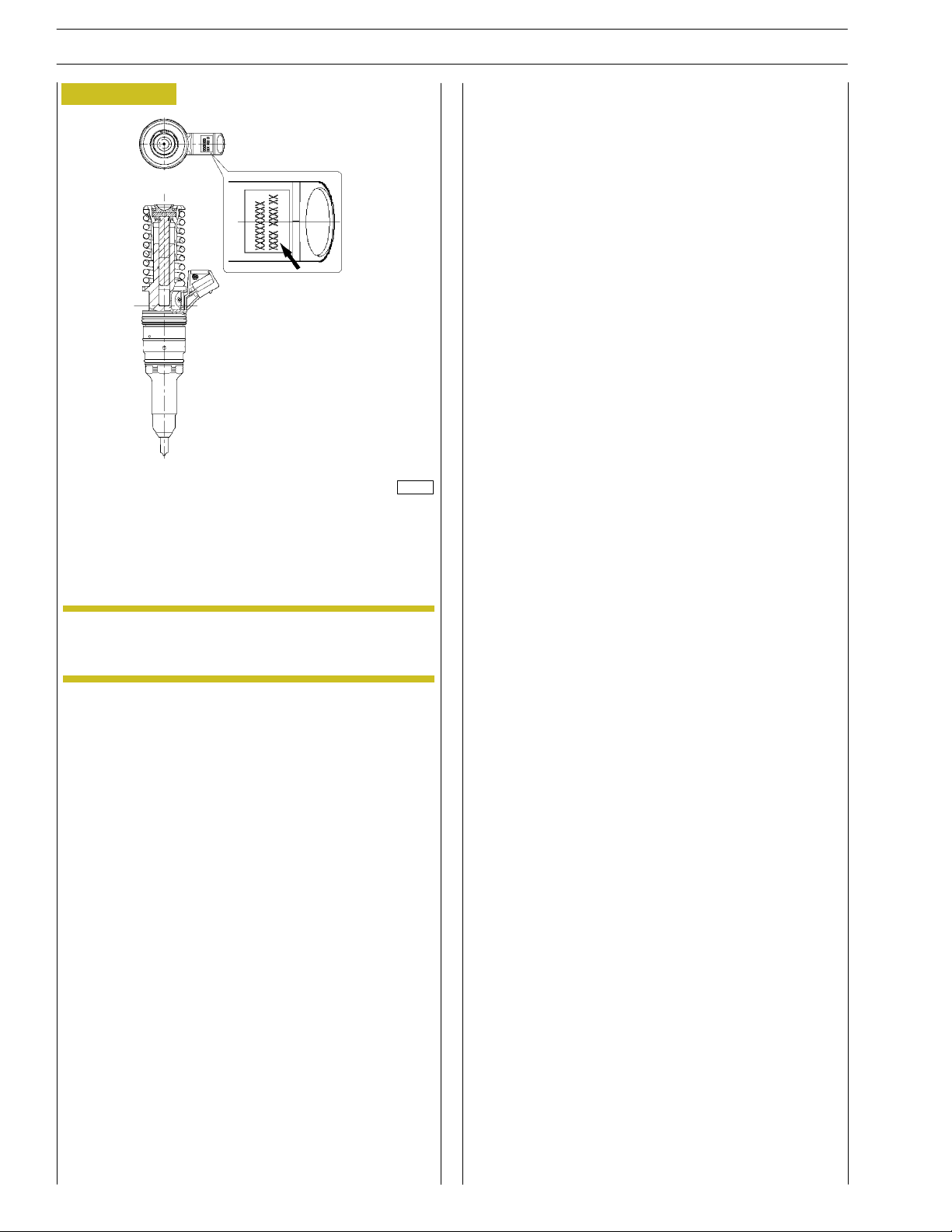

Figure 6

SECTION 2 - FUEL

CURSOR ENGINES F3A

104245

Foreachinjectorreplaced,hook up to the diagnostic station

and, when asked by the program, enter the code punchedon

the injector (→) to reprogram the control unit.

NOTE

When checking the clearance of the rocker arms,

it is important to check the injector-pump pre-load.

Base - May 2007 Print P2D32C003 E

Page 51

CURSOR ENGINES F3A

SECTION 3 - INDUSTRIAL APPLICATION

SECTION 3

Industrial application

CLEARANCE DATA 3.....................

PART ONE -

MECHANICAL COMPONENTS 5.........

ENGINE DISASSEMBLY ASSEMBLY 7.........

ENGINE ASSEMBLY 14......................

ENGINE FLYWHEEL 16.....................

- Fitting engine flywheel 16...................

- Fitting camshaft 17........................

- Fitting pump-injectors 18...................

- Fitting rocker-arm shaft assembly 18..........

1

Page

- Camshaft timing 19.......................

- Phonic wheel timing 21....................

- Intake and exhaust rocker play adjustment and

pre-loading of rockers controlling pump injectors 22

ENGINE COMPLETION 23..................

PART TWO -

ELECTRICAL EQUIPMENT 29.............

- Components on the engine F3A

(For all types except F3AE0684P*E904) 31.....

- Components on the engine F3A

(only for type F3AE0684P*E904) 32..........

- Components on the engine F3A

(only for type F3AE0684N*E907) 33.........

- Components on the engine F3A

(only for type F3AE9687A*E001) 34..........

BLOCK DIAGRAM 35.......................

- EDC 7 UC31 electronic control unit 36.......

- EDC control unit PIN-OUT 37..............

- Pump injector 40.........................

- Engine coolant temperature sensor 41........

- Fuel temperature sensor 42.................

- Flywheel pulse transmitter 43................

- Distribution pulse transmitter 44.............

Base - May 2007Print P2D32C003 E

Page 52

2

SECTION 3 - INDUSTRIAL APPLICATION

-Sensor de temperatura/presión del aire 45.....

-Sensor de presión/temperatura de aceite 45....

-Alt ernator 46............................

-Starting motor 47.........................

-Pre/post-heating resistance 48...............

EDC SYSTEM FUNCTIONS 49................

PART THREE - TROUBLESHOOTING 53......

PREFACE 55...............................

METHODS OF DIAGNOSIS 56...............

-PT-01 56...............................

PT-01 PORTABLE TESTER 57.................

CURSOR ENGINES F3A

Page

-Main functions 57.........................

-Test parameters 57.......................

FAILURE CODES 58........................

Base - May 2007 Print P2D32C003 E

Page 53

CURSOR ENGINES F3A

Typ

e

CLEARANCE DATA

SECTION 3 - INDUSTRIAL APPLICATION 3

F3AE0684

P*E904 P*E906 L*E906 P*E905 N*E907

bar

ρ

Compression ratio 16.5:1

Max. output kW

(HP)

rpm

Max. torque Nm

(kgm)

rpm

Loadless engine

idling rpm

Loadless engine

peak rpm

Borexstroke mm

Displacement cm

SUPERCHARGING

Turbocharger type

LUBRICATION

Oil pressure

(warm engine)

317

(430)

2100

1900

(190)

1500

1000 1000 1000 1000 600

2110 2110 2110 2110 2110

3

317

(430)

2100

1900

(190)

1500

Forced by gear pump, relief valve single action

335

(455)

2100

1900

(190)

1500

125 x 140

10300

Intercooler

Direct injection

HOLSET HX55

oil filter

317

(430)

2100

1900

(190)

1500

291

(395)

2100

1820

(182)

1500

NOTE

- idling bar

- peak rpm bar

COOLING

Water pump control

Thermostat

- start of opening ºC

Data, features and performances are valid only if the setter fully complies with all the installation prescriptions provided

by FPT.

Furthermore, the users assembled by the setter shall always be in conformance to couple, power and number of turns

based on which the engine has been designed.

By means of belt

-

-

Liquid

-

Base - May 2007Print P2D32C003 E

Page 54

4

Typ

e

SECTION 3 - INDUSTRIAL APPLICATION

CLEARANCE DATA

CURSOR ENGINES F3A

F3AE9687

A*E001 B*E001 C*E001

bar

ρ

Compression ratio 16.5:1

Max. output kW

(HP)

rpm

Max. torque Nm

(kgm)

rpm

Loadless engine

idling rpm

Loadless engine

peak rpm

Borexstroke mm

Displacement cm

SUPERCHARGING

Turbocharger type

LUBRICATION

Oil pressure

(warm engine)

315

(428)

2100

1900

(190)

1500

800 800 800

2300 2300 2300

3

DIRECT INJECTION INTERCOOLER

Forced by gear pump, relief valve single action

290

(394)

2100

1800

(180)

1500

125 x 140

10300

HOLSET HX55

oil filter

265

(360)

2100

1700

(170)

1500

NOTE

- idling bar

- peak rpm bar

COOLING

Water pump control

Thermostat

- start of opening ºC

Data, features and performances are valid only if the setter fully complies with all the installation prescriptions provided

by FPT.

Furthermore, the users assembled by the setter shall always be in conformance to couple, power and number of turns

based on which the engine has been designed.

By means of belt

-

-

Liquid

-

Base - May 2007 Print P2D32C003 E

Page 55

CURSOR ENGINES F3A

SECTION 3 - INDUSTRIAL APPLICATION 5

PART ONE -

MECHANICAL COMPONENTS

Base - May 2007Print P2D32C003 E

Page 56

6

SECTION 3 - INDUSTRIAL APPLICATION

CURSOR ENGINES F3A

Base - May 2007 Print P2D32C003 E

Page 57

CURSOR ENGINES F3A

SECTION 3 - INDUSTRIAL APPLICATION 7

ENGINE DISASSEMBLY ASSEMBLY

Handle all parts extremely carefully. Never get your

hands or fingers between pieces.

Wear the required safety clothing such as goggles,

gloves and safety shoes.

Protect the electric parts before doing any washing with

high-pressure jets.

Figure 1

Figure 3

104247

- Remove the engine supports;

- removethedrive(1).

99357

Before securing the engine on the rotary stand, remove:

- the engine electric cable, disconnecting it from the control

unit and from all the sensors/transmitters connected to it;

For all types except F3AE0684P*E904 and F3AE0684N*E907.

- using a suitable tool (3), work in the direction of the arrow

on the tightener and remove the compressor drive belt

(1);

- remove the compressor (2) together with the engine

support.

Figure 2

Figure 4

- Remove the oil pressure adjuster valve (1).

104246

104248

- Secure the engine to the rotary stand with the brackets

993601036.

- Drain the lubricating oil from the sump.

Base - May 2007Print P2D32C003 E

Page 58

8

SECTION 3 - INDUSTRIAL APPLICATION

CURSOR ENGINES F3A

Figure 5

104249

For all types excluding F3AE0684P*E904

- Using a suitabletool (3), work in the direction of the arrow

on the tightener (2) and remove the belt (1).

Figure 6

Figure 8

104251

Remove:

- thermostat assembly (8);

- pipes complete with coolant (6);

- pulley (4);

- water pump (7);

- automatic tightener support (1);

- fixed tightener ( 5);

- damper flywheel (3) and pulley beneath;

- automatic tightener (2);

104250

Only for type F3AE0684P*E904

- Using a suitable tool, operate on the belt take-up units (1)

and (3) in order to remove the belts (2) and (4).

- Remove the compressor (5) and the fan hub (6) with

related supports.

Figure 7

104249/A

Remove:

-alternator(2).

- supports (1 and 3).

Figure 9

99361

with the extractor 99340053 (2) applied as shown in the

figure, extract the seal (4). Undo the screws (3) and take off

the cover (1). Disconnect all the electrical connections and

sensors.

Base - May 2007 Print P2D32C003 E

Page 59

CURSOR ENGINES F3A

SECTION 3 - INDUSTRIAL APPLICATION 9

Figure 10

1

2

On the engine exhaust side, remove the following parts:

- oil delivery pipe (1);

- oil return pipe (4);

- turbocharger (3);

- exhaust manifold (2).

3

4

104252

Figure 12

101960

- using tool 99360314 unscrew the oil filters (1).

Figure 11

99258

Only for type F3AE0684P*E904

- disconnect the oil pipes (3) and (4) and disengage them

from the clamps (←);

- take out the fixing screws (1) and remove the cooler (2);

Figure 13

99362

- Disconnect the pipes (2) from the support (1) disengaging

them from the clamps and remove them.

- Take out the screws (3) and remove the supports (1).

Base - May 2007Print P2D32C003 E

Page 60

10

SECTION 3 - INDUSTRIAL APPLICATION

CURSOR ENGINES F3A

Figure 14

104306

For all types excluding F3AE0684P*E904 only, using tool

99360314 (2), unscrew the oil filters (1).

Figure 16

104253

For all types except F3AE0684N*E907.

Take out the screws (2) and remove the intake manifold (1).

Figure 17

Figure 15

Disconnect the fuel pipes (1) from the fuel pump (2).

Remove:

- the fuel pump (2);

- the fuel filter unit (3) and pipes (1).

104254

Only for type F3AE0684N*E907

104763

Loosen the screws (1) and remove the intake manifold (2).

Figure 18

Remove:

104255

- the starter motor (1);

- the control unit (2) and its support;

- the oil dipstick (3) from the crankcase.

Base - May 2007 Print P2D32C003 E

Page 61

CURSOR ENGINES F3A

SECTION 3 - INDUSTRIAL APPLICATION 11

Figure 19

104256

- Unscrew the screws (1) and remove the heat exchanger (4);

- unscrew the screws (2) and remove the water line (3).

Figure 21

60496

- Unscrew the screws (2) and remove the gear (1) fitted

with phonic wheel.

Figure 20

85480

Remove the rocker arm cover (1), take off the screws (2) and

remove: the cover (3), the filter (5) and the gaskets (4 and 6).

Take off the screws (8) and remove the blow-by case (7).

Figure 22

60497

- Unscrew the screws (1); tighten one screw in a reaction

hole and remove the shoulder plate (2), remove the sheet

gasket.

Base - May 2007Print P2D32C003 E

Page 62

12

SECTION 3 - INDUSTRIAL APPLICATION

CURSOR ENGINES F3A

Figure 23

60498

Unscrew the screws (2) and remove the transmission gear (1).

Figure 24

Figure 26

60501

Unscrew the screws (1) and take down the gearbox (2).

Figure 27

60499

Stop the engine flywheel (3) rotation by means of tool

99360351 (1), unscrew the fixing screws (2) and remove the

engine flywheel.

Figure 25

60500

Apply the extractor 99340054 (2) and pull out the seal

gasket (1).

99364

In sequence, take out the:

- idle gear (1);

- oil pump gear (2).

Figure 28

104257

- Disconnect the electrical connections from the pump

injectors from the pump injector solenoid valves.

- Unscrew the screws (1) fixing the rocker arm shaft.

Base - May 2007 Print P2D32C003 E

Page 63

CURSOR ENGINES F3A

SECTION 3 - INDUSTRIAL APPLICATION 13

Figure 29

116814

Apply tool 99360553 (1) to the rocker holder shaft (2) and

remove the shaft (2) from the cylinder head.

Figure 30

Figure 32

60515

- By means of metal ropes, lift the cylinder head (1).

- Remove the seal (2).

Figure 33

102935

To extract pump injector from cylinder head, use the tool

operating as follows:

- hook tool 99342149 part (3) to pump injector (4);

- mount part (2) on part (3) resting part (2) on cylinder

head;

- screw nut (1) and extract pump injector (4) from cylinder

head.

Figure 31

60514

- Fit the plugs 99360180 (1) instead of injectors.

- Remove the camshaft (2).

- Unscrew the fixing screws on the cylinder head (3).

99268

For all types except F3AE0684P*E904 and F3AE0684N*E907

Undo the screws (2) and remove the engine oil sump (1)

together with the spacer ( 3) and the seal (4).

Figure 34

81871

Only valid for types F3AE0684P*E904 - F3AE0684N*E907 F3AE9687A*E001 - F3AE9687B*E001 - F3AE9687C*E001.

Base - May 2007Print P2D32C003 E

Page 64

14

SECTION 3 - INDUSTRIAL APPLICATION

CURSOR ENGINES F3A

Figure 35

Undo the screws and remove the suction strainer (1).

A. F3AE0684P*E904 - F3AE0684N*E907 -

F3AE9687A*E001 - F3AE9687B*E001 F3AE9687C*E001

B. F3AE0684P*E906 - F3AE0684L*E906

F3AE0684P*E905 - F3AE0684N*E907.

99367

Figure 38

60515

Check that the pistons 1-6 are exactly at the T.D.C.

Put the gasket (2) on the crankcase.

Mount the cylinder head (1) and tighten the screws as shown

in Figs. 38 - 39 - 40.

NOTE

Lubricate the thread of the screws with engine oil

before assembly.

Use new screws every time for head assembly.

ENGINE ASSEMBLY

Figure 36

60563

Using the centring ring 99396035 (2), check the exact position

of the cover (1). If it is wrong, proceed accordingly and lock

the screws (3).

Figure 37

Figure 39

61270

Diagram of the tightening sequence of the screws fixing the

cylinder head.

Figure 40

60564

Key on the gasket (1), mount the key 99346250 (2) and,

screwing down the nut (3), drive in the gasket (1).

Base - May 2007 Print P2D32C003 E

- Pre-tightening with the torque wrench (1):

st

phase: 60 Nm (6 kgm).

1

nd

phase: 120 Nm (12 kgm).

2

60565

Page 65

CURSOR ENGINES F3A

SECTION 3 - INDUSTRIAL APPLICATION 15

Figure 41

α

- Closing to angle with tool 99395216 (1):

rd

3

phase: angle of 120°.

th

phase: angle of 60°.

4

Figure 42

α

60566

NOTE

Figure 44

Mount the gear housing within 10 min. of applying

the sealant.

60567

Mount the oil pump (4), the intermediate gears (2) together

with the link rod (1) and lock the screws (3) in two phases:

pre-tightening 30 Nm.

closing to angle 90°.

Figure 43

60633

Using a torque wrench, tighten the highlighted screws with the

following sequence and tightening torques:

10 screws M12 x 1.75 x 100 63 Nm

2 screws M12 x 1.75 x 70 63 Nm

4 screws M12 x 1.75 x 35 63 Nm

1 screw M12 x 1.75 x 120 63 Nm

2 screws M12 x 1.75 x 193 63 Nm

:

Figure 45

47592

Apply LOCTITE5970 IVECO n˚ 2992644 silicone on the gear

housing, using appropriate tools (1), as shown in the figure.

The sealer string (1) diameter is to be 1,5 ±

0.5

0.2

60568

Key on the gasket (1), mount the keying device 99346251 (2)

and, screwing down the nut (3), drive i n the gasket.

Base - May 2007Print P2D32C003 E

Page 66

16

SECTION 3 - INDUSTRIAL APPLICATION

CURSOR ENGINES F3A

ENGINE FLYWHEEL

Fitting engine flywheel (For types: F3AE0684P*E904 - F 3AE0684P*E906 - F 3AE0684L*E906)

Figure 46

VIEW OF HOLES:

A—B—C

VIEW OF HOLE:

D

60668

DETAIL OF PUNCH MARKS ON ENGINE FLYWHEEL FOR PISTON POSITIONS

A = Hole on flywheel with one reference mark,

corresponding to the TDC of pistons 3-4.

B = Hole on flywheel with one reference mark,

corresponding to the TDC of pistons 1-6.

C = Hole on flywheel with one reference mark,

corresponding to the TDC of pistons 2-5.

D = Hole on flywheel with two reference marks, position

corresponding to 54°.

Fitting engines flywheel (Only for type: F3AE0684N*E907 - F3AE9687A*E001 - F3AE9687B*E001 F3AE9687C*E001)

Figure 47

104764

DETAIL OF PUNCH MARKS ON ENGINE FLYWHEEL FOR PISTON POSITIONS

A = Hole on flywheel with one reference mark,

corresponding to the TDC of pistons 3-4.

B = Hole on flywheel with one reference mark,

corresponding to the TDC of pistons 1-6.

Base - May 2007 Print P2D32C003 E

C = Hole on flywheel with one reference mark,

corresponding to the TDC of pistons 2-5.

D = Hole on flywheel with two reference marks, position

corresponding to 54°.

Page 67

CURSOR ENGINES F3A

If the teeth of the ring gear mounted on the engine

flywheel, for starting the engine, are very damaged,

replace the ring gear. It must be fitted after heatingthe

ring gear to a temperature of approx. 200°C.

Figure 48

α

SECTION 3 - INDUSTRIAL APPLICATION 17

Fitting camshaft

Figure 50

49037

NOTE

The crankshaft has a locating peg that has to couple

with the relevant seat on the engine flywheel.

Position the flywheel (1) on the crankshaft, lubricate the

thread of the screws (2) with engine oil and screw them down.

Lock rotation with tool 99360351 (3). Lock the screws (2) in

three phases.

First phase: pre-tightening with torque wrench (4) to a torque

of 120 Nm (12 kgm).

Figure 49

Position the crankshaft with the pistons 1 and 6 at the top dead

72436

centre (T.D.C.).

This situation occurs when:

1. The hole with reference mark (5) of the engine flywheel

(4) can be seen through the inspection window.

2. The tool 99360612 (1), through the seat (2) of the engine

speed sensor, enters the hole (3) in the engine flywheel (4).

If this condition does not occur, turn the engine flywheel (4)

appropriately. Remove the tool 99360612 (1).

Figure 51

73843

Fit the camshaft (4), positioning it observing the reference

marks (→) as shown in the figure.

Lubricate the seal (3) and fit it on the shoulder plate (2).

Mount the shoulder plate (2) with the sheet metal gasket (1)

and tighten the screws (5) to the required torque.

α

49036

Second and third phase: closing to angle of 60° +30° with tool

99395216 (1).

Figure 52

60570

- Apply the gauge 99395218 (1). Check and adjust the

position of the link rod (3) for the idle gear. Lock the screw

(2) to the required torque.

Base - May 2007Print P2D32C003 E

Page 68

18

SECTION 3 - INDUSTRIAL APPLICATION

CURSOR ENGINES F3A

Figure 53

60571

- Fit the idle gear (1) back on and lock the screws (2) to the

required torque.

Fitting pump-injectors

Figure 55

104243

Fit the seals (1) (2) (3) on the injectors.

Figure 56

Figure 54

5

60572

Position the gear (2) on the camshaft so that the 4 slots are

centred with the holes for fixing the camshaft, without fully

locking the screws (5).

Using the dial gauge with a magnetic base (1), check that the

clearance between the gears (2 and 3) is 0.073 — 0.195 mm;

if this is not so, adjust the clearance as follows:

- Loosen the screws (4) fixing the idle gear (3).

- Loosen the screw (2, Figure 52) fixing the link rod. Shift

the link rod (3, Figure 52) to obtain the required

clearance.

- Lock the screw (2, Figure 52) fixing the link rod and

screws (2, Figure 53) fixing the idle gear to the required

torque.

Mount:

104260

- The injectors (1) and, using a torque wrench, lock the

bracket fixing screws to a torque of 26 Nm.

- The crosspieces (2) on the valve stem, all with the largest

holeonthesameside.

Fitting rocker-arm shaft assembly

Figure 57

NOTE

Apply the tool 99360553 (1) to the rocker arm shaft (2) and

mount the shaft on the cylinder head.

Before refitting the rocker-arm shaft assembly,

make sure that all the adjustment screws have been

fully unscrewed.

116814

Base - May 2007 Print P2D32C003 E

Page 69

CURSOR ENGINES F3A

SECTION 3 - INDUSTRIAL APPLICATION 19

Figure 58

70567A

SCHEME OF SCREW TIGHTENING SEQUENCE

SECURING ROCKER ARMS

Screw screws (1 - 2 - 3) until rocker arms are brought to

contact relating seats on cylinder head, tighten the screws

according to sequence indicated in figure operating in two

steps as indicated in successive figure.

Camshaft timing

Figure 60

71776

Figure 59

α

104261

Apply the tool 99360321 (7) and the spacer 99360325 (6) to

the gearbox (3).

NOTE

The arrow shows the direction of rotation of the

engine when running.

Using the above-mentioned tool, turn the engine

flywheel (1) in the direction of rotation of the

engine so as to take the piston of cylinder no.1 to

approximately the T.D.C. in the phase of

combustion.

This condition occurs when the hole with one

reference mark (4), after the hole with two

reference marks (5) on the engine flywheel (1), can

be seen through the inspection window (2).

Lock the screws (2) fixing the rocker-arm shaft as follows:

st

- 1

- 2

phase: tightening to a torque of 80 Nm (8 kgm) with

thetorquewrench(1);

nd

phase: closing with an angle of 60° using the tool

99395216 (3).

Fit and connect the wiring to the injectors.

Base - May 2007Print P2D32C003 E

Page 70

20

SECTION 3 - INDUSTRIAL APPLICATION

CURSOR ENGINES F3A

Figure 61

71774

The exact position of piston no.1 at the T.D.C. is obtained

when in the above-described conditions the tool 99360612

(1) goes through the seat (2) of the engine speed sensor into

thehole(3)intheengineflywheel(4).

If this is not the case, turn and adjust the engine flywheel (4)

appropriately.

Remove the tool 99360612 (1).

Figure 63

77259

The camshaft is in step if at the cam lift values of 4.44 ±0.05 mm

there are the following conditions:

1) theholemarkedwithanotch(5)canbeseenthroughthe

inspection window;

2) the tool 99360612 (1) through the seat (2) of the engine

speed sensor goes into the hole (3) in the engine

flywheel (4).

Figure 62

60573

Set the dial gauge with the magnetic base (1) with the rod on

the roller (2) of the rocker arm that governs the injector of

cylinder no.1 and pre-load it by 6 mm.

With tool 99360321 (7) Figure 60, turn the crankshaft

clockwise until the pointer of the dial gauge reaches the

minimum value beyond which it can no longer fall.

Reset the dial gauge.

Turn the engine flywheel anticlockwise until the dial gauge gives

a reading for the lift of the cam of the camshaft of 4.44 ±0.05 mm.

Figure 64

60575

If you do not obtain the conditions illustrated in Figure 63 and

described in points 1 and 2, proceed as follows:

1) loosen the screws (2) securing the gear (1) to the camshaft

and utilize the slots (see Figure 65) on the gear (1);

2) turn the engine flywheel appropriately so as to bring about

the conditions described in points 1 and 2 Figure 63, it

being understood that the cam lift must not change at all;

3) lock the screws (2) and repeat the check as described

above.

Tighten the screws (2) to the required torque.

Base - May 2007 Print P2D32C003 E

Page 71

CURSOR ENGINES F3A

SECTION 3 - INDUSTRIAL APPLICATION 21

Figure 65

71778

When the adjustment with the slots (1) is not enough to make

up the phase difference and the camshaft turns because it

becomes integral with the gear (2); as a result, the reference

value of the cam lift varies, in this situation it is necessary to

proceed as follows:

1) lock the screws (2, Figure 64) and turn the engine flywheel

clockwise by approx. 1/2 turn;

2) turn the engine flywheel anticlockwise until the dial gauge

gives a reading of the lift of the cam of the camshaft of 4.44

±0.05 mm;

3) take out the screws (2, Figure 64) and remove the gear (1)

from the camshaft.

Mount the gear (2) Figure 65 with the 4 slots (1) centred with

the fixing holes of the camshaft, locking the relevant screws to

the required tightening torque.

Check the timing of the shaft by first turning the flywheel

clockwise to discharge the cylinder completely and then turn

the flywheel anticlockwise until the dial gauge gives a reading

of 4.44 ±0.05.

Check the timing conditions described in Figure 63.

Phonic wheel timing

Figure 67

Figure 66

72436

Turn the flywheel (4) again to bring about the following

conditions:

- a notch (5) can be seen through the inspection window;

- the tool 99360612 (1) inserted to the bottom of the seat

of the engine speed sensor (2) and (3).

77260

Turn the crankshaft by taking the piston of cylinder no. 1 into

the compression phase at T .D.C.; turn the fly wheel in the

opposite direction to the normal direction of rotation by

approximately 1/4 of a turn.

Again turn the flywheel in its normal direction of rotation until

you see the hole marked with the double notch (4) through

the inspection hole under the flywheel housing. Insert tool

99360612 (5) into the seat of the flywheel sensor (6).

Insert the tool 99360613 (2), via the seat of the phase sensor,

onto the tooth obtained on the phonic wheel.

Should inserting the tool (2) prove difficult, loosen the screws

(3) and adjust the phonic wheel (1) appropriately so that the

tool (2) gets positioned on the tooth c orrectly. Go ahead and

tighten the screws (3).

Base - May 2007Print P2D32C003 E

Page 72

22

g

pumpinj

SECTION 3 - INDUSTRIAL APPLICATION

CURSOR ENGINES F3A

Intake and exhaust rockerplay adjustment andpre-loadingofrockers controllin

Figure 68

ectors

ADJUSTMENT OF INTAKE, EXHAUST AND INJECTION ROCKERS

The adjustment of clearance between the rockers and rods

controlling the intake and exhaust valves, as well as the

adjustment of pre-loading of the rockers controlling pump

injectors, must be carried out carefully.

Take the cylinder where clearance must be adjusted to the

bursting phase; its valves are closed while balancing the

symmetric cylinder valves.

Symmetric cylinders are 1-6, 2-5 and 3-4.

In order to properly operate, follow these instructions and

data specified on the table.

Adjustment of clearance between the rockers and

controlling intake and exhaust

valves:

rods

- use a polygonal wrench to slacken the locking nut (1) of

the rocker arm adjusting screw (2).

- insert the thickness gauge blade (3);

- tighten or untighten the adjustment screw with the

appropriate wrench;

- make sure that the gauge blade (3) can slide with a slight

friction;

- lock the nut (1), by blocking the adjustment screw.

Pre-loading of rockers controlling pump

injectors:

- using a polygonal wrench, l oosen the nut locking the

rocker adjustment screw (5) controlling the pump

injector (6);

104262

- using an appropriate wrench(4), loosenthe adjustment

screw until the pumping element is at the

end-of-stroke;

- tighten the adjustment screw, with a dynamometric

wrench, to 5 Nm tightening torque (0.5 kgm);

- untighten the adjustment screw by 1/2 to 3/4 rotation;

- tighten the locking nut.

FIRING ORDER

Clockwise

start-up

and rotation

1and6atTDC 6 1 5

Adjusting

cylinder

valve no.

1-4-2-6-3-5

Adjusting

clearance

of cylinder

valve no.

Adjusting

pre-loading

of cylinder

injector no.

120º 3 4 1

120º 5 2 4

120º 1 6 2

120º 4 3 6

120º 2 5 3

NOTE

In order to properly carry out the above-mentioned

adjustments, follow the sequence specified in the

table, checking the exact position in each rotation

phase by means of pin 99360612, to be inserted in

th

the 11

hole in each of the three sectors with 18

holes each.

Base - May 2007 Print P2D32C003 E

Page 73

CURSOR ENGINES F3A

SECTION 3 - INDUSTRIAL APPLICATION 23

Figure 69

85480

Fit the distribution cover (1).

NOTE

The valve rocker arm cover fastening screws (1) shall

be tightened according to the sequence shown in

Figure 70.

Fit the blow-by case (7) and its gasket and then tighten the

screws (8) to the prescribed torque.

Install the filter (5) and the gaskets (4 and 6).

ENGINE COMPLETION

Figure 71

99367

Fit the suction strainer (1) and tighten the fixing screws to the

prescribed torque.

A. F3AE0684P*E904 - F3AE0684N*E907 -

F3AE9687A*E001 - F3AE9687B*E001 F3AE9687C*E001

B. F3AE0684P*E906 - F3AE0684L*E906

F3AE0684P*E905.

NOTE

The filter (5) operation is unidirectional, therefore it

must be assembled with the two sight supports as

illustrated in the figure.

Fit the cover (3) and tighten the fastening screws (2) to the

prescribed torque.

NOTE

Apply silicone LOCTITE 5970 IVECO n˚ 2992644

on the blow-by case (7) surface of engines f itted with

P.T.O. according to the procedure described in the

following figure.

Figure 70

17 14 13 1 4 5 8

18

19

20

16 15 12 2 3 6 7

45363

DIAGRAM OF ROCKER ARM CAP FIXING SCREWS

TIGHTENING SEQUENCE

Figure 72

9

10

99268

11

For all types except F3AE0684P*E904 and F3AE0684N*E907

Place gasket (4) on oil sump (1), position spacer (3) and fit the

sumpontheenginebasebytighteningscrews(2)tothe

specified torque, by complying with the tightening sequence

showninFigure74.

Base - May 2007Print P2D32C003 E

Page 74

24

SECTION 3 - INDUSTRIAL APPLICATION

CURSOR ENGINES F3A

Figure 73

81871

Only for types F3AE0684P*E904 and F3AE0684N*E907 F3AE9687A*E001 - F3AE9687B*E001 - F3AE9687C*E001

Figure 74

1

12 11 10 3

913

14

8

Check the state of the flexible elements of the control

unit support and change them if they have

deteriorated.

Figure 76

104763

Only for type F3AE0684N*E907 - F3AE9687A*E001 F3AE9687B*E001 - F3AE9687C*E001

Assemble the intake manifold (2), insert the locking screws (1)

and tighten to the specified torque.

45672

DIAGRAM OF ENGINE OIL SUMP FIXING SCREWS

TIGHTENING SEQUENCE

Figure 75

45362

Figure 77

104255

Tightening the fixing screws to the prescribed torque, mount:

- the starter motor (1);

- the control unit (2) and its support;

- the oil dipstick (3) in the crankcase.

For all types except.

Fit the intake manifold (1) and tighten the fixing screws (2) to the

104253

prescribed torque.

Base - May 2007 Print P2D32C003 E

Page 75

CURSOR ENGINES F3A

SECTION 3 - INDUSTRIAL APPLICATION 25

Figure 78

99362

Only for type F3AE0684P*E904

Mount the support (1) and tighten the fixing screws (3).

Connect the oil pipes (2) to the support (1) tightening the

fittings to the prescribed torque.

Figure 80

99363

For all types excluding F3AE0684P*E904

Mount the oil filters (1) on the support as follows:

- oil the seal;

- screw the filters down for the seals to make contact with

the supporting bases;

- tighten the fil ters to a torque of 35 to 40 Nm.

Figure 79

101960

Fittheoilfilters(1)ontherelevantsupportsasfollows:

- oil the seals;

- screw the filters down for the seals to make contact with

the supporting bases;

- tighten the fil ters to a torque of 35 to 40 Nm.

Figure 81

104254

Fit, with the respective gaskets.

- the fuel pump (2);

- fuel filter unit (3) and pipes (1);

- connect the pipes (1) to the fuel pump (2).

Base - May 2007Print P2D32C003 E

Page 76

26

SECTION 3 - INDUSTRIAL APPLICATION

CURSOR ENGINES F3A

Figure 82

99258

Only for type F3AE0684P*E904

Mount the cooler (2) with the relevant seal and tighten the

fixing screws (1) to the prescribed torque.

Tighten the screws (←) fixing the clamps retaining the pipes

(3 and 4) to the spacer.

Figure 83

Figure 85

18

54852854 11

63 27 63 47 63 27

45359

DIAGRAM OF EXHAUST MANIFOLD FIXING SCREWS

TIGHTENING SEQUENCE

Figure 86

DIAGRAM OF HEAT EXCHANGER FIXING SCREWS

TIGHTENING SEQUENCE

Figure 84

1

2

Mount the following with new seals:

- exhaust manifold (2);

- turbocharger (3);

- oil pipe (1 and 4);

455361

45360

DIAGRAM OF TURBOCHARGER FIXING SCREWS AND

NUTS TIGHTENING SEQUENCE

SEQUENCE: Preliminary tightening 4 - 3 - 1 - 2

Tightening 1-4-2-3

3

4

104252

Base - May 2007 Print P2D32C003 E

Page 77

CURSOR ENGINES F3A

SECTION 3 - INDUSTRIAL APPLICATION 27

Figure 87

Fit, with the following parts:

- automatic tightener support (1);

- automatic tightener (2);

- damper flywheel (3) and pulley beneath;

- fixed tightener ( 5);

- water pump (7);

- the pulley (4);

- pipe comprehensive of coolant (6);

- thermostat assembly (8).

104251

Figure 89

104249

For all types excluding F3AE0684P*E904

Using a suitable tool (3), work in the direction of the arrow on

the tightener (2) and mount the belt (1).

NOTE

The take-up units are of the automatic type;

therefore no further adjustments are required after

assembly.

Figure 88

99360

Mount the following, tightening the screws to the prescribed

torque:

- the supports (1 and 3);

-alternator(2).

Figure 90

101701

DIAGRAM FOR FITTING BELT DRIVING FAN - WATER

PUMP - ALTERNATOR

1. Alternator - 2. Water pump - 3. Crankshaft -

4. Compressor.

Base - May 2007Print P2D32C003 E

Page 78

28

SECTION 3 - INDUSTRIAL APPLICATION

CURSOR ENGINES F3A

Figure 91

104250

Only for type F3AE0684P*E904

Fit the fan hub (6) and the compressor (5) with related

supports.

Using a suitable tool, operate on the belt take-up units (1) and

(3) and fit the belts (2) and (4).

Figure 93

104246

- mount the oil pressure adjuster valve (1).

NOTE

The take-up units are of the automatic type;

therefore no further adjustments are required after

assembly.

Figure 92

104247

Fit the arm 99360585 onto the engine lifting hooks and hook

the arm onto the hoist.

Take out the screws fixing the brackets 99361036 to the

rotary stand.Lift the engine and remove the above-mentioned

brackets from it.

Complete engine assembly with the following parts, tightening

the fixing screws or nuts to the prescribed torque:

- mount the drive (1);

- mount the engine supports;

Figure 94

99357

For all types except F3AE0684P*E904 and F3AE0684N*E907

Fit the engine support together with the air-conditioner

compressor (2).

Using a suitable tool (3), work in the direction of the arrow and

mount the belt (1).

Connect the engine electric cable to the sensors and control

unit.

Refill the engine with lubricating oil of the prescribed gradeand

quantity.

Base - May 2007 Print P2D32C003 E

Page 79

CURSOR ENGINES F3A

SECTION 3 - INDUSTRIAL APPLICATION 29

PART TWO -

ELECTRICAL EQUIPMENT

Base - May 2007Print P2D32C003 E

Page 80

30

SECTION 3 - INDUSTRIAL APPLICATION

CURSOR ENGINES F3A

Base - May 2007 Print P2D32C003 E

Page 81

CURSOR ENGINES F3A

SECTION 3 - INDUSTRIAL APPLICATION 31

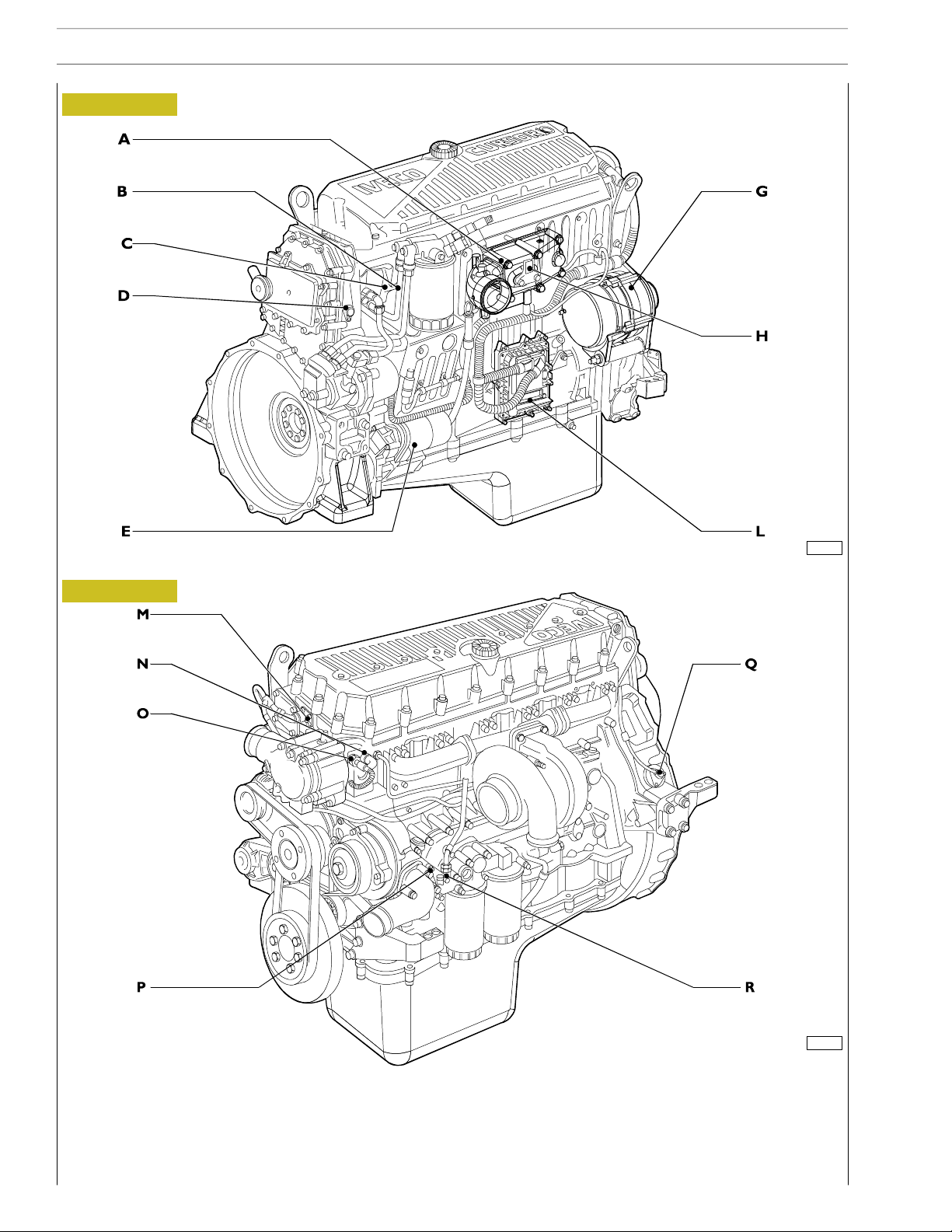

Components on the engine F3A (For all types except F3AE0684P*E904)

Figure 1

ENGINE RIGHT-HAND SIDE VIEW

Figure 2

104263

104264

ENGINE LEFT-HAND SIDE VIEW

A. Resistance for engine warming - B. Fuel filter clogged signalling switch - C. Fuel temperature sensor - D. Engine rpm sensor

on camshaft - E. Starter motor - G. Alternator - H. Air temperature/pressure sensor - I. Conditioner compressor - L. EDC 7

control unit - M. Connector on engine block for connection with electro-injectors - N. Water temperature for EDC 7 -

O. Water temperature sensor - P. Oil pressure/temperature transmitter - Q. Engine speed on flywheel sensor - R. Low oil

pressure transmitter.

Base - May 2007Print P2D32C003 E

Page 82

32

SECTION 3 - INDUSTRIAL APPLICATION

Components on the engine F3A (only for type F3AE0684P*E904)

Figure 3

CURSOR ENGINES F3A

ENGINE RIGHT-HAND SIDE VIEW

Figure 4

104307

ENGINE LEFT-HAND SIDE VIEW

104308

A. Resistance for engine warming - B. Fuel filter clogged signalling switch - C. Fuel temperature sensor - D. Engine rpm sensor