Page 1

Operating

M

a

6

3

m

G

C

e

n

e

r

Incl. EU Declar

anual

ation of Confor

ity

Vacu

VGC08

um

A, VG

aug

083B

Co

troll

tinb29e1 (201

-11)

1

Page 2

Prod

u

V

o

f

r

t

n

T

T

o

W

A

T

mcaIndAtiv

N

u

T

y

d

e

dpm

c

-

-

e

t

e

r

f

e

q

r

B

l

e

n

s

a

m

d

p

m

d

y

U

N

o

e

t

0

e

c

n

d

u

a

e

n

h

O

d

e

u

e

p

r

a

p

r

a

w

w

t

h

p

a

e

f

m

s

i

o

c

s

b

s

a

N

t

o

n

s

e

A

a

s

C

t

n

n

s

b

d

e

p

i

s

a

t

t

1

o

P

m

a

e

c

s

e

o

i

r

a

a

t

e

t

e

m

o

t

d

d

ct Identi

ication

I

all communi

n

meplate:

ations with I

FICON, plea

e specify th

information

n the produc

alid

Imp

ity

rtant Use

Informa

ion

his document

399

399

he part numb

If

not indicated

rrespond to

c

e reserve th

ll dimensions

here are ope

e

lectromechan

a

re a variety o

ent must tak

tion of this e

no event will

mages that

ny examples

e purposes.

p

rticular insta

tual use bas

a

o patent liabil

c

its, equipme

hroughout thi

s

mbols and s

applies to pr

700

701

er (PN) can b

otherwise in

he unit VGC

right to mak

are indicated

ational chara

ical equipme

uses for soli

every preca

uipment is s

INFICON be

esult from th

or diagrams i

Because of t

llation, INFIC

d on the exa

ity is assume

t, or softwar

manual we

fety messag

ducts with p

(VGC083A, use

(VGC083B, use

taken from

he legends, t

83A.They ap

technical ch

in mm.

teristic differ

t. Because o

state equip

tion and sati

fe and used

responsible

use or appli

cluded in thi

e many varia

N cannot as

mples and di

by INFICO

described in

se notes, no

s to make y

rt numbers:

ith BAG050 and

ith BAG051 or B

he product n

e illustration

ly to the VG

nges withou

nces betwee

these differe

ent, all perso

fy themselve

n an accepta

r liable for in

ation of this

manual are

les and requ

ume respon

grams.

with respect

this manual.

ices and appl

u aware of s

PGEG050)

AG052/053 and

meplate.

in this docu

083B by an

prior notice.

n solid state

ces, and be

ns that apply

that the inte

le manner.

irect or cons

quipment.

rovided solel

irements imp

ibility or liabil

to use of info

y internation

fety consider

EG050)

ent

logy.

quipment an

ause there

this equipnded appli-

quential

y for illustra-

sed on any

ty for any

mation cir-

lly recognize

tions.

entifies infor

I

p

hysical hazar

s

rious injury,

ation about

s which, if p

roperty dam

ractices or ci

ecautions are

ge, or econo

cumstances

not taken, co

ic loss.

hat can caus

uld result in d

electrical or

eath or

CA

TION

I

entifies infor

hysical hazar

oderate injur

ation about

s which, if p

, property da

ractices or ci

ecautions are

mage, or eco

cumstances

not taken, co

omic loss.

hat can caus

uld result in

electrical or

inor or

2

tinb29e

(2016-11) VGC083A_B.

m

Page 3

Liability and Warranty

NOTICE

Identifies information that is critical for successful application and understanding of

the product.

SHOCK HAZARD

Labels may be located on or inside the device to alert people that dangerous

voltages may be present.

INFICON assumes no liability and the warranty is rendered null and void if the enduser or third parties

• disregard the information in this document

• use the product in a non-conforming manner

• make any kind of interventions (modifications, alterations etc.) on the product

• use the product with accessories not listed in the corresponding product docu-

mentation.

tinb29e1 (2016-11) VGC083A_B.om 3

Page 4

Contents

Product Identification 2

Validity 2

Important User Information 2

Liability and Warranty 3

1 Introduction / General Information 6

1.1 VGC083A 6

1.2 VGC083B 7

2 Technical Data 8

3 Important Safety Information 11

3.1 Safety Precautions - General 11

3.2 Safety Precautions - Service and Operation 11

3.3 Electrical Conditions 12

3.3.1 Proper Equipment Grounding 13

3.3.2 Electrical Interface and Control 13

3.4 Overpressure and use with hazardous gases 13

3.5 Gases other than Nitrogen / air 13

4 Installation 15

4.1 Mechanical Installation - Controller 15

4.1.1 Panel Mount 15

4.1.2 Rack Mount 15

4.1.3 Mechanical Installation - Ionization Gauge 17

4.1.4 Mechanical Installation - Convection Gauge 17

4.2 Electrical Installation 18

4.2.1 Grounding 18

4.2.2 Installation 19

4.2.3 Connecting the Ionization Gauge Cable 19

4.2.3.1 Standard Nude and Glass IG Cable 20

4.2.3.2 Bakeable Nude IG Cable 21

4.2.3.3 Standard IG Cable Connector Pin Out 22

4.2.4 Connecting the PGE050 - connectors labeled "2" and "3" 23

4.2.5 Power Connection 24

4.2.6 Relay Connection 24

4.2.7 Analog Output Connection 24

4.2.8 Analog Input Connection (Capacitance Diaphragm Gauges, etc.) 24

4.2.9 Digital I/O Connection 25

4.2.10 RS232 / RS485 Serial Communications Connection 26

5 Operation - IG and CG 28

5.1 IG Emission Current 28

5.2 IG Degas 28

5.3 IG Filament Material Selection / Venting the Chamber 28

5.4 IG Over Pressure Shut Down 29

5.5 IG Over Temperature Shut Down 29

5.6 Convection Gauge (CG) Initial Setup 30

6 Setup and programming 31

6.1 Applying Power 31

6.2 Front Panel Display 31

6.3 User Interface Basics 32

6.4 Factory-Set Default Parameters 32

6.5 Programming 34

6.5.1 SETUP UNIT 34

6.5.2 ION GAUGE 35

6.5.3 ION GAUGE 40

6.5.4 RELAYS 40

6.5.5 Analog Output 42

6.5.6 SERIAL COMM 47

6.5.7 DISPLAY 47

4

tinb29e1 (2016-11) VGC083A_B.om

Page 5

7 Analog Output Charts & Equations (Nitrogen/Air Only) 49

7.1 Analog Output wide range measurement for IG - CG1 0.5 - 7V

(Nitrogen / Air only) 49

7.2 Analog Output for IG LOG N - 10 (Nitrogen / Air only) 50

7.3 Analog Output for IG LOG N - 11 (Nitrogen / Air only) 51

7.4 Analog Output for IG LOG N - 12 (Nitrogen / Air only) 52

7.5 Analog Output for IG 1.8 - 8.7 V (Nitrogen / Air only) 53

7.6 Analog Output for IG LINEAR (Nitrogen / Air only) 54

7.7 Analog Output for CG1 or CG2 1 - 8 V (Nitrogen / Air only) 54

7.8 Analog Output for CG1 or CG2 0 - 7 V (Nitrogen / Air only) 56

7.9 Analog Output for CG1 or CG2 NON - LIN (Nitrogen / Air only) 57

7.10 Analog Output for CG1 or CG2 LINEAR (Nitrogen / Air only) 59

8 Using the Gauge with Different Gases 60

8.1 Ion Gauge Display Correction Factors for Selected Gases 60

8.2 Effects of Different Gases on Convection Gauge Display 61

8.3 Effects of Different Gases on Analog Output 64

8.3.1 Ion Gauge Analog Output Correction Factors for Selected Gases 64

8.3.2 IG - CG1 0.5 - 7V Analog Output Correction Factors for Selected Gases 64

8.3.2.1 IG-CG1 0.5 - 7V Analog Output Correction Factors -

Ion Gauge Range 64

8.3.2.2 IG-CG1 0.5 - 7V Analog Output Correction Factors -

Convection Gauge Range 66

8.3.3 Convection gauge analog output for selected gases 66

8.3.3.1 CG1 1 - 8 V or CG2 1 - 8 V Analog Output Correction Factors -

Convection Gauge 67

8.3.3.2 CG1 0 - 7 V or CG2 0 - 7 V Analog Output Correction Factors -

Convection Gauge 68

8.3.3.3 CG1 NON-LIN or CG2 NON-LIN Analog Output Correction Factors -

Convection Gauge 69

9 Communication Protocol (Serial Interface) 70

9.1 Device Specific Serial Communication Info 70

9.2 INFICON RS232 / RS485 Command Protocol Summary 70

9.3 INFICON RS232 and RS485 Command Protocol Summary 71

9.4 RS232 GP 307 and 358 Protocol 74

9.5 RS485 GP 307 and 358 Protocol 75

10 Service 77

10.1 Calibration 77

10.2 Troubleshooting - IG Operation 77

10.3 Troubleshooting - IG Error Messages 78

10.4 Clearing Error Messages - IG 78

10.5 Research Screen 78

10.5.1 Research Screen (Diagnostic Display - IG) 78

10.6 Maintenance 80

11 Repair 81

12 Accessories 81

13 Storage 82

14 Disposal 82

EU Declaration of Conformity 83

For cross-references within this document, the symbol (→ XY) is used; for cross-

references to further documents listed under ‘Literature’, use is made of the symbol

(→ [Z]).

tinb29e1 (2016-11) VGC083A_B.om 5

Page 6

n

V

TcM

i

p

c

n

n

h

u

o

Tsy

T

h

B

o

T

m

P

x

n

G

s

8

O

n

A

e

n

w

n

o

n

n

m

a

e

e

o

G

n

r

G

h

o

8

d

e

u

n

a

t

t

g

o

-

d

t

a

l

u

n

m

c

e

0

p

d

e

d

s

®

m

e

GCo

A

G

&

f

m

u

u

a

o

d

1

s

a

u

a

a

o

o

a

c

d

o

i

d

d

o

f

1 I

1.1

troduct

GC083A

ypical Com

omplete Va

easureme

on / Ge

onents of t

uum Press

t System

eral Inf

e

re

rmatio

he Vacuum

stem which i

•

The VGC0

One INFIC

•

ionization g

One or two

•

Cables to i

•

1)

The VGC083

vacuum gaug

ypical compo

t

e figure belo

AG050 hot io

c

ntrol for up t

auge Control

s comprised

3A Vacuum

N BAG050

auge or othe

INFICON P

terconnect t

will also operate

head.

ents of the c

. The VGC0

n gauge hea

two enhanc

er VGC083A

f the followin

auge Contr

ude UHV EB

brands of nu

E050 convec

e VGC083A

the Granville-Phi

mplete vacu

3A provides

(IG). Additio

d convection

is a vacuum

:

ller

degas Bayar

e UHV EB-d

ion enhance

nd point-of-u

lips® Convectron

m measure

ower and op

ally, it provid

gauges (CG)

ressure mea

-Alpert hot c

egas B-A ga

pirani heads

se devices

convection enh

ent system

erating contr

s power and

.

urement

thode

ges

1)

nced pirani

re shown in

l for the

operating

he VGC083A

e

ither rack or i

h

igh rack-mou

i

portant infor

GE050 Oper

d

vice you int

e

ternal devic

, a controller

strument pa

t panels are

ation about

ting Manual.

nd to connec

s and cables

nit capable o

el mountable

vailable to

he PGE050

Read the Op

to the VGC0

that the VGC

V

B

P

1

controlling

Optional ind

ount the unit i

onvection ga

rating Manu

3A prior to c

83A is inten

C083A Vac

ntroller

G050 Ion G

E050 Conve

2 (CVG 1 &

ultiple gauge

stry standar

nto rack encl

ge please re

ls in their ent

onnecting an

ed to be use

om Gauge

uge

tion Gauges

2)

heads, is

19-inch, 2U

sures. For

er to the

rety for any

using the

with.

6

tinb29e

(2016-11) VGC083A_B.

m

Page 7

1.2 VGC

0

a

e

u

n

t

c

e

g

e

V

u

r

1

e

a

c

n

0

y

l

C

p

a

A

n

n

o

o

/

n

e

M

c

o

r

h

c

C

n

t

o

g

p

u

b

G

t

e

a

5

e

.

n

o

h

t

r

s

B

R

i

v

c

y

g

g

e

V

e

c

e

h

t

e

h

B

r

w

i

o

a

u

G

s

c

g

w

Typic

compl

Meas

83B

l Compone

te Vacuum

rement Sys

ts of the

Pressure

em

The Va

system

which is com

• The

• On

INFICON B

cath

ode ionizatio

gau

• On

• Cab

1)

or two INFIC

les to interco

The

vacu

Typical

components

the figu

BAG05

and op

uum Gauge

VGC083B V

es

GC083B will als

m gauge head.

e below. The

or BAG052

rating control

ontroller VG

rised of the f

cuum Gauge

G051 nude o

gauge or ot

ON PGE050

nect the VG

operate the Gra

f the comple

VGC083B pr

053 ion gau

for up to two

083B is a v

llowing:

Controller

BAG052 / 0

er equivalent

onvection en

083B and po

ville-Phillips® Co

e vacuum m

vides power

e heads (IG)

enhanced co

cuum pressu

3 glass I2R

brands of I

hanced piran

int-of-use de

nvectron® conve

asurement s

and operatin

Additionally,

vection gau

re measurem

ayard-Alpert

2

glass/nude

heads1)

ices

tion enhanced pi

stem are sho

control for e

it provides p

es (CG).

nt

ot

-A

ani

n in

ther the

wer

or

VGC083

Controll

BAG051

BAG052

PGE050

1 & 2 (C

B Vacoom G

r

Ion Gauge

or

/ 053 Ion Ga

Convection

G 1 & 2)

uge

ge

auges

The VG

either r

high ra

importa

PGE05

device

externa

C083B, a co

ck or instrum

k-mount pan

nt information

Operating

ou intend to

l devices and

troller unit ca

ent panel mo

ls are availa

about the P

anual. Read

onnect to th

cables that th

able of contr

ntable. Optio

le to mount t

E050 convec

he Operating

VGC083B p

e VGC083B i

olling multipl

nal industry s

e unit into ra

tion gauge pl

Manuals in t

ior to connec

intended to

gauge head

tandard 19-in

k enclosures

ase refer to t

eir entirety fo

ing and usin

be used with.

, is

h, 2U

. For

he

r any

the

tinb29e1 (2016-11) VGC0

83A_B.om

7

Page 8

2 Technical Data

Measurement range

Display

Functionality

IG sensor control

IG remote input signals

(digital I/O)

Setpoint relays

VGC083A

with BAG050

with PGE050

VGC083B

with BAG051 or BAG052/053

with PGE050

2×10

1×10

4×10

1×10

-11

-4

-10

-4

…1×10-3 Torr

…1000 Torr

…1×10-3 Torr

…1000 Torr

Units of measurement Torr, mbar, Pa (user selectable)

Pressure indication LED - 3 independent pressure display

channels, 3 digit plus 2 digit exponent per

channel

Set-up & programming screen OLED - displays state of all setpoint relays, IG

emission current, error messages for fault

conditions

VGC083A

(IG)

powers & operates one INFICON BAG050

nude UHV EB-Degas B-A hot cathode or other

equivalent brands

, (CG) powers & operates up to 2 INFICON PGE050

VGC083B

(IG)

convection or Granville-Phillips

Convectron

powers & operates one BAG051 or BAG052 /

053 or other equivalent brands of glass or nude

2

I

R B-A hot cathode

®

, (CG) powers & operates up to 2 INFICON PGE050

convection or Granville-Phillips

Convectron

®

®

(GP)

®

(GP)

IG sensor on/off, degas on/off and emission current can all be controlled via front

panel soft-keys, remote input signals (digital I/O) or serial communications. IG sensor can also be automatically turned on/off using measurements from one of the

user selectable convection or alternate gauges.

IG sensor on/off, degas on/off and emission current can also be set by applying

momentary continuity to ground. Also the 9-pin D-sub remote input DIGITAL I/O

connector provides pin-pin compatible signals with the GP 358 controller as well as

compatible signals with the GP 307.

Number 6

single-pole, double-throw (SPDT), user assignable to any of the gauges

Contact rating 5 A at 30 V (dc), 5 A at 250 V (ac), resistive

load

8

tinb29e1 (2016-11) VGC083A_B.om

Page 9

Analog output

Analog input

Serial communications

Status output

IG (Ionization Gauge)

Ambience

Housing

IG analog output

Log-linear

0 … 10 V (dc), 1 V/decade, or

1.7 … 9.3 V (dc) (nominal 1.8 … 8.7 V (dc)),

0.8 V/decade

Linear 0 … 10 V (dc) (useable over 3 decades)

Combination IG + CG analog

Log-linear

CG analog output

Log-linear

0.5 … 7 V (dc), 0.5 V/decade

1 … 8 V (dc), 1 V/decade, or

0 … 7 V (dc), 1 V/decade

Linear 0 … 10 V (dc) (useable over 3 decades)

Non-linear analog S-curve 0.375 … 5.659 V (dc)

CDG one 0 … 10 V (dc) analog input signal from a

CDG when used as an alternate gauge to CG2,

or analog input from one of the following

INFICON modules: PGE300, PGE500,

BAG300

Protocol RS485 / RS232 - ASCII protocol

IG sensor on/off status message is displayed on the front panel, by serial communications and by SPDT relay (DIGITAL I/O Connector) rated at 1 A at 30 V (dc)

resistive, or 1 A at 30 V (ac) non-inductive.

IG degas on/off status or IG error conditions are displayed on the front panel, by

serial communications and by an open collector transistor output (ground emitter)

rated at 40 V max. VCE, 50 mA IC max.

IG filament switching User selectable between filament 1 or 2 using

the front panel soft-keys or RS232 / RS485

serial comm

IG emission current 100 μA, 4 mA, 10 mA or automatic switching of

emission current (auto ranging)

IG degas 40 W, resistive

-3

IG overpressure protection

(turns ion gauge off at the

following factory default settings)

1 × 10

5 × 10

1 × 10

Torr at 100 μA emission current

-4

Torr at 4 mA emission current

-4

Torr at 10 mA emission current

Temperature

Operation

Storage

0 … +40 °C

–40 … +50 °C

Relative humidity 0 … 95, non-condensing

Altitude

Operating

Storage

max. 2500 m (8200 ft.)

max. 12500 m (41000 ft.)

Pollution degree II

Degree of protection IP20

Housing aluminum extrusion - black powder paint finish

tinb29e1 (2016-11) VGC083A_B.om 9

Page 10

M

iVG

WVG

c

G

G

V

C

m

m

2

5

y

2

D

D

D

a

e

0

b

b

1

r

d

o

ains specifi

D

mensions

C083A, V

ations

C083B

oltage

onnectors

IG & CG

Digital I/O

Serial com

RS23

RS48

analog I/O,

power

m (inch)

unications

setpoint rela

s,

20 …

power

gauge

9-pin

9-pin

9-pin

plugg

includ

8 V (dc), 20

reversal and

cable assem

-sub male

-sub female

-sub male

ble terminal

d)

W protected

transient ove

blies provide

lock (mating

against

-voltages

by INFICON

connectors

eight

C083A, V

C083B

.7 kg (1.7 lb.)

0

10

tinb29e

(2016-11) VGC083A_B.

m

Page 11

t

e

t

i

f

t

t

p

r

d

n

F

h

t

e

o

v

o

o

d

A

d

m

A

d

e

e

t

t

b

e

e

a

s

e

d

r

m

i

h

m

m

c

n

o

C

a

A

e

o

n

n

a

A

o

c

n

N

d

w

d

q

r

e

e

e

u

.

o

N

d

o

,

s

n

t

e

m

c

m

q

w

n

e

c

t

e

o

m

o

e

t

s

a

c

w

s

w

y

p

f

h

o

r

a

o

y

h

s

d

h

c

r

i

s

p

y

e

y

f

r

t

d

D

C

c

m

u

r

r

e

d

u

a

u

d

b

s

m

o

n

a

o

h

e

r

m

y

a

n

n

c

o

o

s

N

d

d

e

l

u

o

a

h

c

T

n

u

D

o

a

s

o

n

p

e

i

m

n

h

n

e

3 Impo

3.1 Safe

Gen

rtant Sa

y Precau

ral

ety Info

ions -

mation

INFICO

provide

this ma

To avoi

ment.

bodily

Failure

and int

tomer's

Althoug

INFICO

operati

installat

This de

Hazard

product

tection

provide

N has design

it is installe

ual. Please

WARNI

d serious inj

ailure to co

arm, includ

o comply wit

nded use of t

failure to co

h every atte

N cannot anti

n, or mainte

ion and use

ice meets F

us voltages

should never

f the operato

.

d and tested

and operate

ead and foll

G

ury or death

ply with the

ng death, an

these warni

his instrumen

ply with thes

pt has been

ipate every

ance of the

f this product,

C part 15 re

re present wi

be operated

r from accide

this product t

within the st

w all warnin

follow the s

e safety pr

or propert

gs violates t

. INFICON di

instructions.

ade to consi

ontingency th

odule. If you

please conta

uirements for

th this produ

ith the cove

tal contact w

o provide saf

rict safety gui

gs and instr

fety inform

cedures co

damage.

e safety stan

sclaims all lia

er most pos

at arises fro

have any que

ct INFICON.

an unintenti

t during norm

s removed u

ith hazardous

and reliable

elines provi

ctions.

tion in this

ld result in s

ards of insta

ility for the c

ible installati

various inst

tions about t

nal radiator,

al operation.

less equivale

internal volta

service,

ed in

ocu-

rious

lation

s-

ns,

llations,

e safe

lass A.

he

nt proges is

3.2 Safe

Serv

y Precau

ce and O

ions -

eration

W

the pro

Do not

INFICO

service

use this

W

perform

After se

service

specifie

shock o

product

To redu

moistur

not spill

have b

duct if i

Due to

is possi

that the

equipm

has be

Ensure

ground.

Ensure

electric

Use a p

power

RNING! Th

uct enclosur

odify this pr

N service trai

and repair ce

product if un

RNING! S

ing any servi

rvicing this pr

person. Whe

d by INFICO

r other hazar

will void the

ce the risk of

. These pro

any type of li

en damaged.

is damaged.

he possibility

ble that the p

product be p

nt grounding

n compromis

the enclosur

that the vacu

lly grounded

ower source

upplies.

ere are no op

. Refer servi

duct or subs

ed personne

ter to ensur

uthorized m

urce power

ing.

duct, ensur

replacemen

Substitution

s. Use of un

arranty.

fire or electri

ucts are not

uid onto the

Immediately

of corrosion

oduct’s safet

riodically ins

. Do not use i

d.

of the unit is

m port on w

f 20 … 28 V

rator service

ing to service

itute any part

l. Return the

that all safet

difications ha

ust be remov

that all safet

parts are req

of non-quali

uthorized pa

shock, do no

aterproof an

e products.

ontact INFI

hen used in

could be co

ected for so

the equipme

connected di

ich the vacuu

dc), 200 W o

able parts or

trained pers

without aut

roduct to an

features are

ve been mad

ed from the p

checks are

uired, ensure

ied parts ma

ts or modific

t expose this

careful atte

o not use the

ON to arrang

ertain enviro

promised ov

nd electrical

nt grounding

ectly to a go

m gauge sen

r use INFIOC

djustments i

nnel.

orization of q

NFICON qua

maintained.

.

oduct prior t

ade by a qu

that the part

result in fire,

tions made t

product to rai

tion must be

se products if

return of th

mental cond

r time. It is i

onnections a

r electrical i

d quality eart

ors are mou

series optio

side

alified

lified

o not

lified

are

electric

this

or

aid to

they

pro-

tions, it

portant

nd

sulation

ted is

nal

tinb29e1 (2016-11) VGC0

83A_B.om

11

Page 12

3.3 Electrical NConditio

n

T

Tinvi

D

CtoIf

o

DwEDD

N

wofle

f

xtamTso

h

S

Afie

o

otath

c

y

n

q

a

h

O

r

e

g

m

a

G

s

m

e

g

o

c

m

e

a

B

a

r

G

l

e

i

d

a

t

a

s

c

c

u

n

e

a

d

w

s

G

n

o

o

m

y

i

a

t

d

e

y

r

x

n

h

f

n

g

m

h

a

o

e

r

a

o

r

r

r

p

n

0

s

g

n

u

o

h

e

s

a

a

a

c

t

e

n

T

e

u

l

h

o

a

e

n

m

s

m

e

e

c

0

i

m

m

s

t

m

s

a

u

e

a

s

o

n

r

c

t

c

1

t

N

n

e

e

a

n

t

n

t

o

l

m

p

i

b

o

t

a

e

e

a

m

s

t

d

a

n

v

o

d

s

e

e

n

a

-

o

e

y

-

t

OTICE

s

urn off power

urn off power

g normally a

ce personnel

b

this operati

is important t

It

ctions and e

n

lectrical insul

e

o not use if t

ontact INFIC

INFICON fo

measured pr

nditions, the

c

The pressu

•

The pressu

•

The pressu

•

uring the De

ill turn off but

nsure vacuu

egas of the B

o not attempt

h

re.

ever use an

hen the Ion

other gauge

ading to fila

b

fore pressur

you are usin

I

perating the i

o

e

tended perio

in emission

inated by res

he most com

r or head el

a

ll possible ind

aracterized

c

e

lectrodes, or

ensors that f

fter servicing

d service pe

WARNIN

e

ning electrica

a

re maintained

c

ntact with th

a

gaseous env

rounded con

g

c

ming in cont

ge potential.

e gas inside

to the unit be

to the unit if

cording to thi

for any servi

g manual.

hat the produ

quipment gro

tion has bee

e unit has be

N for return

evaluation.

ssure excee

ion gauge wil

re exceeds 1.

re exceeds 5.

re exceeds 1.

as cycle, if th

the filament

level is less

AG05x serie

to turn the I

uxiliary or co

auge filamen

may not all

ent damage.

is allowed t

dual filamen

n gauge fila

d of time ma

urrent in appl

idual applicat

on cause of

ctrodes. Nois

ications of ga

s either: A) a

) an accumu

il due to cont

these produc

son

! When high

shock hazar

at earth grou

gas contain

ironment ma

uctor of elect

ct with an e

This conditio

he vacuum c

ore attempti

cable or plu

instruction

e or troubles

t be periodic

nding. Do n

compromis

n dropped o

uthorization

s the thresh

l turn off:

00 × 10

-3

Tor

00 × 10-4 Tor

00 × 10-4 Tor

e measured

ill remain tur

than 5.00 x 1

ionization ga

on if the pre

vection gau

t in use is co

w for timely t

Always turn

rise above 1

t IGs, it is hig

ents 1 and 2

result in failu

cations wher

on or proces

all vacuum g

y or erratic re

ge contamin

chemical rea

lation of mate

mination are

s, ensure tha

voltage is pr

may exist u

nd potential.

d in vacuum

couple dang

icity. A perso

posed, ungro

applies to al

amber (vacu

g to service t

is damaged

anual. Cont

ooting condit

lly inspected

t use if the eq

d.

the enclosur

nd instructio

lds that are d

at 100 μA e

at 4 mA emi

at 10 mA e

ressure exce

ed on.

-5

Torr befor

uge heads.

sure is near t

e to automati

structed of tu

rn off of the t

ff the IG filam

.00E-03 (1.0

ly recommen

An inactive f

re of that fila

the filament

related che

uge failures i

dings and to

tion. Conta

tion of proce

rial on the he

not covered

all safety ch

sent in any v

less all expo

his applies t

chambers. A

rous high vol

could be se

nded electri

products tha

um/pressure

e controller.

or the produc

ct qualified I

ion that may

for sound el

uipment grou

has been d

ns for returni

efined under

ission curre

sion current.

ission curren

ds 1.00 × 10

attempting t

he threshold

ally turn off t

ngsten. The

ungsten fila

ent (tungsten

× 10-3) Torr.

ded to period

ilament not o

ent to establ

coating may

istries.

s contaminati

al gauge he

ination can g

ss gases with

d (sensor) el

nder warrant

cks are mad

cuum syste

ed electrical

all products

electrical di

tage directly

riously injure

al conductor

may come i

ontainment

is not operat

FICON serot be covere

ctrical con-

nding or

maged.

g the product

he following

t.

.

-4

Torr, Dega

initiate

imits defined

e Ion Gauge

esponse tim

ent possibly

manually

ically alternat

erating for a

sh and main-

ecome cont

n of the sen

d failures are

nerally be

head / sens

ctrodes.

.

by a quali-

, a life threat

conductors

hat come in

charge within

o any un-

or killed by

t high vol-

contact with

essel).

-

-

r

12

tinb29e

(2016-11) VGC083A_B.

m

Page 13

3.3.1 Pro

p

u

c

p

h

e

m

r

a

s

h

A

h

e

n

d

n

g

e

A

s

i

y

d

n

s

o

A

r

s

e

m

e

c

e

n

o

g

e

A

e

d

e

a

v

r

A

a

y

o

s

A

m

o

e

o

A

z

u

a

q

o

f

m

U

e

A

o

n

a

a

a

A

s

s

q

y

o

s

p

p

h

t

h

o

f

a

e

e

s

b

u

A

o

d

e

o

A

v

u

a

o

g

s

e

t

u

n

c

n

e

c

e

u

r

e

f

y

y

r

a

r

o

e

i

t

r

m

f

c

h

)

e

c

r

w

o

m

a

v

o

o

e

a

e

m

G

o

s

i

m

o

l

t

s

f

k

a

e

s

d

e

p

i

s

x

h

t

o

t

p

w

r

p

i

o

g

n

e

r

a

t

r

s

i

e

e

o

o

b

o

d

l

l

s

f

i

h

s

u

d

e

c

g

w

e

(

e

x

s

u

c

e

i

r

e

o

e

t

y

e

h

e

o

e

u

y

s

v

h

w

e

r

p

v

y

a

l

c

n

e

i

r

p

o

e

n

2

e

e

p

d

r

Gro

3.3.2 Ele

Con

3.4 Over

with

er Equip

nding

trical Inte

trol

pressure

hazardou

ent

face and

nd use

gases

W

present

which t

ground

groundi

intende

any co

earthin

pressur

W

harm,

trical d

It is the

and an

are use

any sig

your sy

taken t

W

pressu

system

In case

implem

an auto

pressur

The va

pressur

sure ins

an isola

sure co

lower; f

the gau

correct

RNING! Ha

in many vac

e ion gauge

d. Consult a

ng. Proper gr

operation o

trol module

conductor.

measurem

RNING! In

hield all con

scharges in

user’s respo

connections

in a safe m

als to autom

tem design

prevent injur

RNING! In

e inside you

component

where an e

nt fail-safe s

matic backfill

s if the pres

uum gauge h

s above 20

ide the senso

tion valve or

ditions. Wit

r example, a

e tube from

d barometric

ardous volta

um processe

nd the conv

ualified Elec

unding of yo

the equipme

ust be conne

se a ground l

nt devices if

rder to prot

ductors whi

or around th

sibility to ens

made to exte

nner. Always

te your proc

nd ensure sa

and propert

tall suitable

vacuum ch

are capable

uipment failu

stem operati

peration wh

ure relief dev

ads used wi

sia (1000 tor

r. If your cha

ressure relie

some fittings

quick-conne

he vacuum c

(atmospheric

es that could

. Verify that t

ction gauges

rician if you a

r equipment

t. The vacuu

ted directly t

ug on the vac

ecessary.

ct personne

h are subjec

vacuum sy

re that the el

nal devices,

double chec

ss. Perform

eguards and

damage.

rotective d

mber to les

of withstan

e could caus

n. For exam

re a malfunct

ce was not in

h this product

); DO NOT e

ber goes to

device to pro

, actual safe

, O-ring com

amber fitting

pressure.

seriously inju

he vacuum c

are mounted

re in doubt a

is essential f

m gauge hea

a good qual

uum connecti

l from electri

t to potentia

stem.

ectrical signa

or example, r

the system

hazardous o

personnel sa

vices that w

than what t

ing.

a hazardous

le, use a pre

ion could res

talled on the

are not inten

ceed 35 psig

igher pressu

tect the gaug

verpressure

ression fittin

with only a fe

re or cause d

nnection por

are electricall

out your equi

r safety as w

s and enclos

ity equipment

on flange of t

c shock and

high voltag

s from this pr

lays and sol

et-up before

peration anal

ety measure

ll limit the le

e vacuum c

condition, al

sure relief d

lt in high inte

chamber.

ed for use at

(< 2 ½ bars)

res, you shou

tube from o

onditions ma

may forcibly

psi over loc

ath are

s on

pment

ll as

ure of

e

bodily

elec-

duct

noids,

sing

sis of

are

el of

amber

ays

vice in

nal

res-

ld install

erpres-

be

release

l un-

3.5 Gas

Nitro

s other t

gen / air

an

C

to incr

sure si

may ca

into th

flamm

of the

ment, c

expose

pressu

W

without

INFICO

Do not

unless

analog

when u

W

of flam

of expl

incand

an expl

UTION! If t

ase above l

e), vacuum

use leaks th

atmospher

ble gases ar

acuum/pres

ould cause

the gauge t

e when usin

RNING! Do

referring to c

N gauges an

ttempt to us

ou have appl

utput to dete

ing convecti

RNING! Do

able gases,

sive or comb

scent temper

sion which c

e internal pr

cal uncorre

ittings may

t would allo

of the surro

examples

ure contain

odily injury

be internal

g hazardous

not attempt t

rrection fact

modules ar

with other g

ied correction

rmine the tru

n gauges to

not use the I

apors or fum

stible gases

tures and co

uld result in

ssure of a v

ted baromet

elease and

the gas ins

nding envir

f hazardous

ent vessel i

nd possible

olume to pre

gases.

use with gas

r data tables.

calibrated fo

ses such as

factors to bo

measured p

easure pres

in an explos

s. Do not us

r gas mixtur

uld become a

erious injury

acuum gaug

ic pressure

ossible over

ide the gaug

nment. To

gases that if

to the atmo

damage to e

ssure above

es other than

direct reado

rgon (Ar) or

h the display

essure. This

ure of gases

ive atmosphe

the IG to m

s. The sens

n ignition sou

or death.

device is a

atmospheri

ressure co

tube to rel

ic, pyrophor

allowed to le

pheric envi

uipment. N

local atmos

nitrogen (N2)

t of nitrogen

arbon dioxid

d pressure a

s particularly

other than N

e or in the pr

asure the pr

r filaments o

rce. This coul

lowed

pres-

ditions

ase

c and

ak out

on-

eve

heric

or air

r air.

(CO2)

d the

critical

/Air.

sence

ssure

erate at

cause

tinb29e1 (2016-11) VGC0

83A_B.om

13

Page 14

eththte

G

m

f

m

o

e

v

s

h

e

g

u

m

v

e

m

o

e

c

1

e

u

s

o

n

y

WARNIN

s

nce of flam

e pressure o

e gauge nor

mperature c

a

nd gas mixtur

o

r death.

! Do not us

able gases,

explosive or

ally operate

uld exceed t

e. This could

the PGE050

apors or fum

combustible

at 125 °C, b

e ignition te

cause an exp

in an explosi

s. Do not us

ases or gas

t if malfuncti

perature of c

osion which

e atmospher

the PGE050

ixtures. The

n should occ

rtain combu

ould result in

or in the pre

to measure

sensor wire i

r, the wire

tible gases

serious injur

-

14

tinb29e

(2016-11) VGC083A_B.

m

Page 15

4 Installation

4.1 Mechanical Installation Controller

4.1.1 Panel Mount

Procedure

The unit is intended for indoor use only. The unit is offered as a space saving half

rack design. It may also be used as a bench top device or easily installed in an

instrument panel. Optional EIA-standard rack mount panels are available for either

full rack or dual, side-by-side rack mount installation. When mounting multiple units

in your rack mount enclosure or mounting the unit below other electronic equipment in your rack, allow at least 1U of space (1.75 in., 45 mm) between the units to

ensure adequate ventilation.

Make a cutout in your rack panel or instrument control panel as shown in

the drawing below. Be sure to allow clearance behind the panel for the instrument as well as connectors and cables at the back of the instrument.

Optional EIA-standard, 19-inch, 2U height rack mount panels are available

from INFICON. The optional rack mount panels are provided with panel cutouts and mounting holes to allow efficient mounting of your VGC083 unit.

Drill four guide holes on each side of the panel cut out (two on each side)

with dimensions as shown in the panel cut-out drawing above.

Slide the unit into the panel hole cut-out. Guide the four studs on the back of

the unit front panel face plate thru the four holes next to the panel cut-out.

Use four # 10-32 Hex Nut (provided with instrument) to tighten the unit to

the panel.

4.1.2 Rack Mount

tinb29e1 (2016-11) VGC083A_B.om 15

Optional EIA-standard 19-inch wide, 2U height rack mount panels available from

INFICON (→ 81):

Page 16

Single cut-out panel

All dimensions in inches.

Single cut-out panel

All dimensions in inches.

The single cut-out and dual cut-out rack mountable panels shown above are available from INFICON. Panel color matches the front panel of VGC083 units. Screws

for mounting to rack enclosure are included.

16

tinb29e1 (2016-11) VGC083A_B.om

Page 17

4.1.3 Mec

z

CVGC

s

u

s

a

h

n

o

e

i

h

s

m

h

s

c

m

g

/

m

t

r

e

h

c

s

s

n

n

h

m

TEb

g

d

h

s

h

n

i

e

m

g

t

p

h

o

s

o

m

.

o

a

s

a

d

0

t

i

c

i

A

y

2

s

e

h

o

g

h

h

o

f

m

r

u

0

s

T

a

n

d

T

t

o

U

l

s

e

b

e

e

b

r

g

s

a

h

m

0

r

p

i

0

s

s

t

N

i

a

C

A

d

o

b

s

a

e

o

b

t

e

m

g

w

e

o

e

b

e

d

s

e

1

A

o

c

p

l

i

n

f

e

r

e

u

u

y

Ioni

VG

hanical In

ation Ga

083A

tallation -

ge

4.1.4 Mec

Con

083B

hanical In

vection G

tallation -

uge

NOTIC

BA

Mount t

ure. Lo

ween y

pressur

may als

The ion

mount t

conden

Do not

Vibratio

chanica

Shield t

or in a

For ele

vacuu

proper

lic-type

Fittings

installat

Use all

pected

For mo

the Op

Mount t

or restri

proces

change

Mounti

and co

cooling,

Mount t

reading

1 Torr,

or

G051

he ionization

g or restricte

ur process c

changes. M

o cause mea

ization gauge

he gauge wit

ation collecti

ount the ion

ns may caus

l stress to co

he ionization

puttering sys

trical safety

chamber. W

rounding. D

flange clamp

Flanges - foll

ion and use.

metal vacuu

o be below 1

e detailed inf

rating Manu

he PGE050a

cted, small di

chamber an

.

g the PGE05

trol instability

such as hea

he PGE050w

errors may o

ounting pos

he VGC083

B-degas Ba

rands of equ

BAG05

auge as clo

, small diam

amber and t

unting the io

urement and

can be moun

port down to

g in the gau

zation gauge

unstable rea

ponents in t

auge near io

em.

urposes the

en using KF

not attempt t

.

w the fitting/

fittings with

00 × 10-7 Tor

rmation abo

l for the PGE

close as po

meter tubing

the gauge.

too close to

. Do not mou

ers or air con

th its main ax

cur above 1

tion has little

can operate

ard-Alpert h

ivalent nude

, BAG053

e as possible

ter tubing wil

e gauge. Thi

nization gaug

control insta

ed in any ori

help minimiz

e.

where it will

ings, measu

e ionization

n or electron

ousing of the

langes, meta

modify your

lange manuf

etal seals w

(1.33 × 10-7

t the PGE05

50.

sible to the p

will create a

his may caus

gas source

t the PGE05

itioning vent

is horizontal (

orr if the uni

o no effect.

one INFICO

t cathode ion

HV EB-deg

The VG

one INFI

or one B

enclose

hot cath

or other

gauges.

to the pressu

l create a pre

may cause

e too close to

ility.

ntation, how

the effect of

e subjected t

rement errors

auge.

ources such

gauge must

l clamps mus

flange in ord

cturer's reco

en operating

mbar, 1.33 ×

convection

essure you

ressure diffe

e a delay in r

inlet may als

near a sourc

.

see diagram

is not mount

BAG050 nu

zation gauge

s B-A gauge

083B can op

ON BAG05

G052/053 gl

I2R Bayard-

de ionization

rands of equ

re you want t

sure differen

delay in res

a gas source

ver, if possib

any particles

excessive v

and possible

as an electro

e grounded t

be used to e

r to use non-

mendations

pressures ar

10-5 Pa).

auge, please

ant to measu

rence betwee

sponse to pr

cause meas

of heating o

elow). Press

d horizontall

e UHV

or other

.

rate

nude

ass

lpert

gauge

ivalent

mease betonse to

inlet

e,

or

bration.

me-

beam

o the

nsure

metal-

or

ex-

refer to

e. Long

n your

ssure

rement

r

re

. Below

tinb29e1 (2016-11) VGC0

83A_B.om

17

Page 18

E

o

MpDtiost

o

w

h

t

o

m

oth

h

E

n

s

o

g

W

h

h

o

a

d

U

d

d

o

r

t

o

w

a

t

h

p

D

a

h

d

v

s

n

e

u

r

e

o

T

w

k

n

w

c

G

e

m

m

s

d

T

g

t

e

h

o

o

h

1

e

b

e

o

g

d

m

m

s

p

a

t

b

s

k

n

o

-

o

y

a

4.2

4.2.1

lectrical

Groundin

Installati

g

n

ount the PG

rticles or co

o not mount t

ns may cau

ress to comp

F

langes/ Fittin

f

llowing:

-

NPT fittings:

a

nt compound

raps of pipe t

g

uge into the

e gauge.

t

Be sure t

g

rounded to pr

fi

tings, especi

p

roduce a goo

c

nnected to.

easurement

t

earth groun

at you conne

e

rth ground c

e green colo

t

050 with por

densation fr

he PGE050

e unstable re

onents in the

s - follow the

hen connec

or wrap the t

hread seal ta

gauge port.

e vacuum g

otect personn

lly those wit

electrical co

se a ground

evice if nece

via a good q

ct a separate

nnection an

ed screw pro

down, if pos

m collecting i

here it will b

dings, meas

PGE050.

manufacture

ing the devic

readed porti

e such as P

o not use a

uges and the

el from shoc

O-rings whe

nnection bet

lug on the va

ssary. The V

uality equipm

12-AWG eart

the location

ided) on the

ible, to help

the gauge.

subjected to

rement error

's recommen

using a NP

n of the tubin

FE (Teflon®)

rench or othe

rest of your v

and injury. B

not used wit

een the gaug

uum connect

C083 control

nt earthing c

ing conduct

arked with t

ack panel of

inimize the

excessive vi

s and possibl

ations and n

fitting, apply

with one-an

tape and han

r tool which

acuum syste

aware that

h metal clam

e and the ch

ion flange of

unit should

onductor. It i

r between a

e earth grou

the VGC083.

ffect of any

ration. Vibra-

mechanical

te the

a thread seal

d-a-half to tw

tighten the

ay damage

are properl

ome vacuum

s, may not

mber it is

he pressure

e connected

encouraged

nown facility

d symbol (vi

18

tinb29e

(2016-11) VGC083A_B.

m

Page 19

4.2.2 Inst

a

e

n

b

e

i

o

e

m

V

i

e

C

O

b

e

e

t

t

g

n

e

e

s

o

a

h

3

t

t

e

O

e

g

h

c

n

e

a

r

e

t

u

w

c

.

e

A

a

o

B

n

c

h

c

c

V

a

a

m

f

b

t

b

o

8

G

c

o

o

o

n

o

c

e

f

e

llation

A good,

necting

on the

recommend

or disconnec

ack panel of

d practice is

ing it. The el

he device as

o remove po

ctrical conne

shown below

er from any

tions for the

.

able prior to

GC083 are l

oncated

4.2.3 Con

Gau

necting th

ge Cable

Ionizatio

Good, r

ing or d

brands

propriat

low) fro

of the

easy or

low-lev

cable w

the BN

CAUTI

trolled

disconn

options

equipm

commended

isconnecting i

f equivalent

e length of io

the ion gau

GC083 label

entation of th

l ion current

ith the BNC c

connector l

N! When c

y the VGC08

ect power to

to devices or

nt damage o

practice is to

t. With INFIC

auges) conn

gauge cabl

e head on t

d "1". The cir

mating con

ignal from th

nnector at th

beled "COL".

anging or m

, you must fi

he VGC083b

removing/ins

r possible inj

remove pow

Ns nude B-

cted to your

(see various

e vacuum ch

ular plastic c

ectors. The

ion collector

e controller e

king cabling

st turn power

fore either c

alling option

ry to personn

r from any c

ionization g

vacuum cha

IG cable con

mber to the

onnector (CP

NC connecto

electrode of

d of your ca

onnections t

to the VGC0

anging cable

ards in the V

el.

ble prior to c

uge head (or

ber, connect

igurations sh

ack panel co

) is keyed t

r is for conne

he head. The

le is connect

any device c

3 OFF. Failu

connections

C083 may r

nnectother

an ap-

wn be-

nector

allow

ting the

coaxial

d at

onre to

rom

sult in

tinb29e1 (2016-11) VGC0

83A_B.om

19

Page 20

1

B

VGC083A:

B

d

A

e

0

a

e

G

P

P

G

mvayo

y

→BAG

b

→

m

n

q

G

G

e

c

G

c

o

a

m

e

n

u

g

n

b

N

a

a

G

d

y

t

e

h

e

n

n

o

1

G

s

S

t

@

i

y

o

VGC083B:

BAG052,

ba

BAG050 c

BAG051,

AG053 cabl

AG051 nud

kable cable 2

ble

IG

0 °C

art numbers

baka

art numbers

le cable 200

BAG

051 nude IG

81.

050 nude I

81.

50 °C

C

able

BA

BAG052

050 nude IG

50 °C

/ 053 glass I

50 °C

able

cable

4.2.3.

Standar

IG Cable

VGC083

Nude and

NOTE

lass

I

Cables not

anufacturers

rious versio

u have any

h

ads using I

F

or the nude I

scribed in th

d

s

stem, conne

anufactured

may be speci

s of the B-A i

uestions reg

cables not

, connect th

e previous pa

t the head e

by INFICON

fically constr

nization gau

rding the co

anufactured

IG cable (P

ge. After inst

d of the IG c

may differ in

cted for the t

e head. Con

nections to b

y INFICON.

→ 81) at t

lling the nud

ble as show

BAG050

connecti

esign. Cable

pe of DEGA

act reachus

made to ion

e VGC083A

IG head on

below.

ude IG head

n

from certain

used in

inficon.com i

zation gauge

controller as

our vacuum

cable

f

20

tinb29e

(2016-11) VGC083A_B.

m

Page 21

VG

k

e

G

e

e

k

t

C

h

e

v

n

i

h

n

i

h

G

d

m

d

o

a

t

h

a

t

h

→

o

h

h

s

a

8

h

s

A

v

s

h

v

d

g

A

e

w

c

C

e

w

G

v

s

e

t

t

V

r

U

g

o

a

i

o

a

C

u

r

B

w

s

t

C083B

For the

describ

system,

For the

describ

system,

glass IG, con

d in the prev

connect the

nude IG, con

d in the prev

connect the

ect the IG c

ous page. Af

ead end of t

ect the IG c

ous page. Af

ead end of t

ble (PN →

er installing t

e IG cable a

Gl

ble (PN →

er installing t

e IG cable a

81) at the VG

e glass IG h

shown belo

ass IG head

81) at the VG

e nude IG h

shown belo

C083B contr

ad on your v

.

able connect

083A contr

ad on your v

.

ller as

cuum

on

ller as

cuum

4.2.3.2 Ba

VG

eable Nud

C083A: BA

IG Cable

050

The ba

connec

Bakeab

for 50 °

with eit

from th

When u

or equi

eable nude I

ion to the nu

le Cable wirin

ambient te

er single or

VGC083A c

sing the bake

alent Nude E

cable (PN

e gauge pins

g information

perature. All

ual filament i

ntroller.

able IG cable

B- degas IG

B

co

81) is pro

(BAG050 pin

below). All ot

IG cables pro

n gauges an

(PN → 81)

ead accordin

G051 nude I

nnection

ided with pu

s) and is bak

er cables lis

vided by INFI

filament swi

connect the

to wire colo

head cable

h-on sockets

able to 200 °

ed above are

CON can be

ching is cont

GC083A to

s listed belo

for

(See

rated

sed

olled

AG050

.

B

G050 nude

eq

uivalent B-A

HV EB-dega

auge pin pat

IG or

ern

tinb29e1 (2016-11) VGC0

83A_B.om

21

Page 22

3

B

d

o

B

a

Cis

i

m

T

o

Bfo

wfrWG

m

q

C

s

i

m

Tcoaw

a

T

Gcath

o

wca

e

u

p

N

o

n

h

e

e

g

0

e

n

e

e

u

p

N

o

n

a

n

p

V

t

i

o

s

c

a

e

e

g

m

m

G

o

e

a

e

n

u

n

e

y

n

e

h

d

e

e

y

c

)

0

.

l

g

c

o

g

h

d

e

e

y

c

s

w

n

e

s

a

e

e

a

u

w

b

e

V

2

u

e

a

u

s

G

a

g

w

l

i

c

1

o

i

t

o

o

v

a

s

o

i

t

n

o

c

r

F

w

e

c

e

e

o

e

m

e

o

hanging cabl

not only bad

u

er of this eq

s

tuation, equi

s from one d

electronics h

ipment, may

ment damag

evice to anot

ndling proce

lead to erron

and possibl

er when pow

ure, it is not

ous measure

operator inju

er is applied t

dvised and,

ment results,

ry.

the module

f done by the

a hazardous

VGC083

: BAG051

CAUTIO

ent before c

he bakeable

c

nnection to t

akeable Cabl

r 50 °C ambi

ith either sin

om the VGC

hen using th

auge accordi

! It is always

nnecting or d

ude IG cabl

he nude gau

e wiring infor

nt temperatu

le or dual fila

83B controlle

bakeable I

ng to wire col

good industr

isconnecting

(PN → 81

e pins (BAG

ation below)

re. All IG cab

ent ion gau

r.

cable conne

rs listed bel

practice to t

ables.

is provided

51 pins) and i

All other cab

es provided

es and filam

t to BAG051

w.

rn off power

ith push-on s

s bakeable t

les listed abo

y INFICON c

nt switching i

or equivalent

o the instru-

ckets for

200 °C (See

e are rated

n be used

controlled

2

nude I

R B-A

4.2.3.

Standar

Connect

I2R Deg

IG Cable

r Pin Out

ase View

BAG051

s - single fila

BAG051 or e

ent

uivalent nud

hanging cabl

i

not only bad

u

er of this eq

tuation, equi

s

CAUTIO

ent before c

he informatio

nnection of

lready have i

ith INFICON

c

ble with the

he pin-out of

auge cables

bles such as

e control unit

c

ntact no. 7 f

s

itch filament

ble and phy

d

sired to swit

I2R (resistiv

s from one d

electronics h

ipment, may

ment damag

! It is always

nnecting or d

presented i

B-A type ion

stalled on yo

roduct desig

GC083.

he CPC con

s shown belo

those for us

, e.g., the VG

r FIL2. This t

s from the co

ically remov

h filaments.

degas) B-A

evice to anot

ndling proce

lead to erron

and possibl

good industr

isconnecting

this section i

ization gauge

r vacuum ve

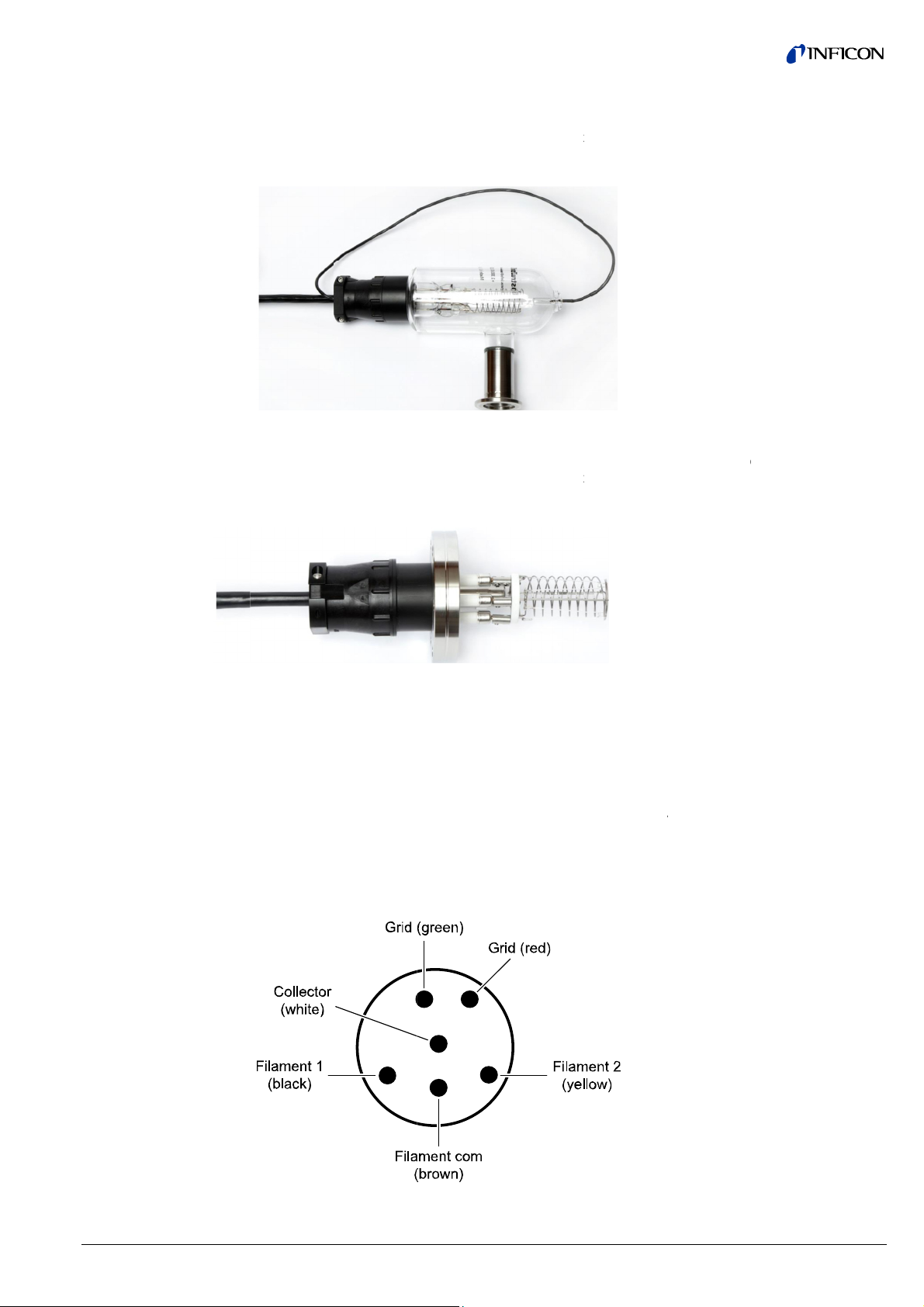

s, and you

ector used o

w. When usin

with controll

083, there i

pe of cable

trol unit - the

, rotate and r

Base

BAG0

I

R Degas - d

auge pin pat

er when pow

ure, it is not

ous measure

operator inju

practice to t

ables.

intended to

head or an I

sel which m

ish to continu

Granville-Ph

INFICON t

rs capable of

an additiona

nd control un

e is no need

connect the

iew

51

al filament

tern

er is applied t

dvised and,

ment results,

ry.

rn off power

address the i

cable that y

y not be dire

e using eithe

illips® and IN

o-filament s

switching th

l pin / socket

it will allow th

to go to the h

able connect

the module

f done by the

a hazardous

o the instru-

stallation /

u may

tly compatibl

that head /

ICON Ion

itch capable

filament fro

onnection at

user to

ad end of th

r when it is

22

tinb29e

(2016-11) VGC083A_B.

m

Page 23

4.2.4 Connecting the PGE050 connectors labeled "2"

and "3"

The view shown below is the CPC connector end of the IG cable:

VGC083 Connector End of Cable View

Pin/Socket

Contact

Description

(compatible with Granville-Phillips® ion gauge cables)

Number

1 Shield, chassis ground

7 FIL 2 (this contact is only present on dual filament IG cables

available from INFICON)

8 FIL COM

11 FIL 1

13 Grid Source (supply)

14 Grid return Used only for I2R degas design using the VGC083B

Not used for VGC083A EB-degas design

PN 399-580 … -582 are a custom cable assemblies provided in different lengths

from INFICON for connecting the VGC083 to INFICON PGE050 gauge or MKS

Instruments / Granville-Phillips® 275 Convectron® vacuum gauge sensor. Connect

the DE-9 D-subminiature connector to VGC083 and PGE050 connectors to "2" or

"3".

For your reference, the wiring chart for the PGE050 cable provided by INFICON is

shown below. In addition to INFICON provided standard cable assembly lengths,

INFICON will provide custom length cable assemblies upon request.

VGC083

pin no.

1

2

3

4

5

6

7

8

9

connects to PGE050 gauge pin no.

(INFICON molded, custom connector)

NC

cable shield

3

3

2

5

1

1

NC

tinb29e1 (2016-11) VGC083A_B.om 23

Page 24

4.2.5

o

n

o

e

e

r

T

o(P

c

A

e

R

Asiva

A

O

TINtaaAin

e

o

e

l

n

Y

o

a

p

b

u

g

o

e

a

p

r

t

P

a

8

t

y

h

h

t

t

a

aAna

d

f

e

V

o

d

C

n

p

e

a

o

d

b

s

l

s

Y

e

u

o

e

e

1

R

0

a

k

p

i

S

)

o

s

8

d

N

C

n

n

t

a

n

l

3

a

B

c

e

g

1

p

r

o

9

a

y

o

C

c

g

aCo

e

o

e

t

c

d

o

o

n

g

"

4.2.6

Power C

Relay Co

nnection

nection

he VGC083 r

e

ch 2-contact

the power c

t

N → 81).

Power

(

ontacts)

+

–

total of six s

p

luggable term

r

lay contactor

LY6. Each re

a

nd I (commo

LY1 thru RL

(contacts)

=

≠

I

quires an in

pluggable te

ntactors. Op

Con

Power input

tpoint relays

inal strip mati

s. The VGC0

lay has a con

).

Y6

Rela

ut power of 2

minal strip m

ional power s

tact Descripti

(20 … 28 V (

ower ground

re provided

ng connector

3 back pane

act labeled =

Contact De

Relay #1 to

(NORMAL

Relay #1 to

(NORMALLY

#1 to Relay

0 … 28 V (dc

ting connect

pplies are al

n

c), 200 W)

y the VGC0

are provide

relay connec

(Normally Op

cription

Relay #6

OPEN)

Relay #6

CLOSED)

#6 (COMMO

, 200 W to o

r is provided

o available f

Anal

Con

3. Two each

for easy con

tors are mark

en), ≠ (Norm

Rela

)

erate. One

for connectio

om INFICON

g Output

nectors

-contact

ection to the

ed RLY1 thru

lly Closed)

Connectors

4.2.7

4.2.8

Analog O

Connecti

Analog In

(Capacita

Gauges,

utput

n

put Conn

nce Diaph

tc.)

ction

agm

total of three

gnals are pro

cuum gauge

a

re provided f

p

nel analog o

h

s a contact l

O1 , AO2, A

(contacts)

+

–

ne analog in

his input can

FICON vacu

ct mating plu

nalog input c

1. Each conn

put ground)

A1

(

contacts)

+

–

D

analog outpu

portional to t

s. Three eac

r connection

utput connec

beled + (an

O3

An

ut is provide

be accepted

um module s

ggable termin

ntactor. The

ector has a c

nd D (power

A

Analog In

D

ts are provid

e displayed p

2-contact pl

o the analog

ors are mark

log output sig

Contact D

log Output #

log Output G

(Signal

by the VGC

rom one cap

ries PGE300

al strip conne

GC083 bac

ntact labeled

etect).

ontact Descri

alog Input (S

ut Ground (

tect (power d

d by the VG

ressure for a

ggable termi

utput contac

d AO1, AO2

nal) and – (a

scription

to #3 (Signa

ound #1 to #

eturn)

83 for using

citance diaph

PGE500 or

tor is provid

panel analo

+ (analog inp

tion

gnal)

ignal Return)

tect)

083. These

y of the user

al strip matin

tors. The VG

and AO3. Ea

alog output

An

l)

s an alternat

ragm gauge

AG302. On

d for connec

input conne

ut signal) an

An

utput voltage

assigned

connectors

083 back

h connector

round).

log Output

nnectors

gauge to "2

r other

each 3-conion to the

tor is marked

– (analog

alog Input

C

nnectors

.

24

tinb29e

(2016-11) VGC083A_B.

m

Page 25

When using a capacitance manometer / diaphragm gauge or INFICON modules

such as the PGE300, PGE500, BAG302 as an ALTERNATE GAUGE, the gauge

must be connected to the VGC083 as shown below. The alternate gauge must be

provided power from an auxiliary power supply capable of providing the power required by the alternate gauge connected to the VGC083. The D contact is used in

this configuration to protect the IG from being turned on at high pressure in case

power to the alternate gauge is lost.

4.2.9 Digital I/O Connection

Signal Type A - Control Input

Signals

Signal Type B - Status Output

Signal

Signal Type C - Status output

Signal

The IG can be controlled manually using the front panel soft-keys, via remote input

signals using the digital I/O connector or RS232/RS485 commands. The VCG083

can also be configured so that the IG sensor on/off is controlled by using the pressure measurements from CG1, CG2 or the alternate gauge. If the user prefers digital I/O as the means of controlling the IG, various control input and status output

signals are available from the 9-pin D-sub male DIGITAL I/O connector. The

DIGITAL I/O Connector also provides pin-pin compatible signals with the GP 358

vacuum gauge controller as well as compatible signals with the GP 307.

The DIGITAL I/O Connector provides three different types of signals as listed

below: