Page 1

TECHNICAL HANDBOOK

iina70e1-m (1408) Translation of the original handbook

Catalog-No.

UL 1000:

550 - 000A

550 - 001A

550 - 002A

UL 1000 Fab:

550 - 100A

550 - 101A

from software version

UL1000 Fab and

UL1000

Helium Leak Detector

V5.14

Page 2

iina70e content.fm Technical Handbook(1408)

2

Page 3

Table of Contents

1 General Information 7

1.1 Notes on the Use of this Handbook 7

1.1.1 Safety Symbols 7

1.1.2 Indications 8

1.1.3 Symbols of Vacuum Technology 8

1.1.4 Definiton of Terms 8

1.2 Support from INFICON Service 10

1.2.1 Service Centers 11

1.3 Introduction 13

1.3.1 Purpose 13

1.3.2 Technical Data 15

1.3.2.1 Physical Data 15

1.3.2.2 Electrical Data 15

1.3.2.3 Other Data 16

1.3.2.4 Ambient Conditions 16

1.4 Unpacking 16

1.4.1 Supplied Equipment 17

1.4.2 Accessories and Options 18

1.4.2.1 Sniffer line SL200 18

1.4.2.2 Toolbox 18

1.4.2.3 Helium Bottle Holder 18

1.4.2.4 ESD Mat 18

1.4.2.5 RC1000 Remote control 19

1.4.2.6 Test chamber TC1000 20

2 Installation 21

2.1 Transportation 21

2.2 Working Location 23

2.3 Electrical Connections 25

2.3.1 Mains Power 25

2.3.2 Connections for the Data Acquisition Systems 27

2.3.2.1 Accessories 28

2.3.2.2 Digital Out 28

2.3.2.3 Digital In 29

2.3.2.4 Recorder 30

2.3.2.5 RS232 31

2.3.2.6 Remote Control 31

2.4 Vaccum Connections 32

2.4.1 Inlet Port 32

2.4.2 Exhaust 32

2.4.3 Vent 32

2.4.4 Purge-connection (UL1000 Fab) /

Gas ballast (UL1000) 32

2.5 Default parameters 33

iina70e content.fm Technical Handbook(1408)

Table of Contents 3

Page 4

3 First Operation Check 34

3.1 Needed Equipment 34

3.2 Description of the Initial Operation 34

3.2.1 Start up and Measure 34

3.2.2 Internal Calibration 37

3.2.3 Verification 37

4 Description and Working Principle 38

4.1 Introduction 38

4.2 Components of the UL1000 and UL1000 Fab 38

4.2.1 Vacuum System 39

4.2.2 Control Panel 40

4.2.2.1 LC Display 41

4.2.2.2 START Button 41

4.2.2.3 STOP Button 41

4.2.2.4 ZERO Button 41

4.2.2.5 MENU Button 43

4.2.2.6 Soft Keys 43

4.2.2.7 Numerical Entries 43

4.3 Working Modes 45

4.3.1 Vacuum Mode 45

4.3.2 Sniffer Mode 47

4.3.3 Auto Leak Test Mode 47

5 Operation of the UL1000 and UL1000 Fab 48

5.1 Display 48

5.2 The Screen in Run-Up Mode 48

5.3 Display in stand-by mode 49

5.3.1 Purging 49

5.4 The Screen in Measurement Mode 49

5.4.1 Call for Calibration 49

5.4.2 Speaker Volume 50

5.4.3 Status Line in the Display 50

5.4.4 Numerical Display Mode 51

5.4.5 Trend Mode 51

6 Description of the Menu 52

6.1 Main Menu 52

6.2 View 54

6.2.1 Scale linear/logarithmic 55

6.2.2 Display-range auto/manual 55

6.2.3 Time axis 56

6.2.4 Contrast 56

6.2.5 Background in Stand-by 57

6.2.6 Decimal places 57

6.2.7 Lower display limit 58

6.3 Mode 58

6.3.1 Auto Leak Test 59

iina70e content.fm Technical Handbook(1408)

4 Table of Contents

Page 5

6.4 Trigger & Alarms 61

6.4.1 Trigger Level 1 61

6.4.2 Trigger Level 2 62

6.4.3 Volume 62

6.4.4 Units 63

6.4.5 Alarm delay 63

6.4.6 Audio alarm type 64

6.4.6.1 Pinpoint 64

6.4.6.2 Leak rate prop. 64

6.4.6.3 Setpoint 65

6.4.6.4 Trigger alarm 65

6.5 Calibration 65

6.6 Settings 66

6.6.1 Vacuum settings 67

6.6.1.1 Automatic purge (UL1000 Fab only) 67

6.6.1.2 Vent delay 67

6.6.1.3 Vacuum ranges 68

6.6.1.4 Leak rate internal test leak 69

6.6.1.5 Machine factor 69

6.6.1.6 Auto Leak Test adjustments 69

6.6.2 Zero & Background 73

6.6.2.1 Background Suppression 73

6.6.2.2 Zero 73

6.6.3 Mass 74

6.6.4 Interfaces 75

6.6.4.1 Control Location 75

6.6.4.2 RS232 Protocol 76

6.6.4.3 Recorder output 77

6.6.4.4 Scaling Recorder Output 78

6.6.5 Miscellaneous 79

6.6.5.1 Time&Date 79

6.6.5.2 Language 79

6.6.5.3 Leak rate filter 80

6.6.5.4 Mains Frequency 80

6.6.5.5 Service interval exhaust filter 80

6.6.5.6 Service message exhaust filter 81

6.6.6 Parameter save / load 81

6.6.6.1 Load parameter set 81

6.6.6.2 Save parameter set 82

6.6.7 Monitoring functions 82

6.7 Information 85

6.7.1 Service 85

6.8 Access Control 86

6.8.1 Access to CAL function 86

6.8.2 Access to Trigger&Alarme menu 87

6.8.3 Change Device PIN 87

6.8.4 Change Menu-PIN 87

7 Calibration 88

iina70e content.fm Technical Handbook(1408)

7.1 Introduction 88

Table of Contents 5

Page 6

7.2 The calibration routines 88

7.2.1 Internal Calibration 89

7.2.1.1 Automatic Internal Calibration 89

7.2.1.2 Manual Internal Calibration 89

7.2.2 External Calibration 89

7.3 Factor of Calibration - Range of Values 93

8 Error And Warning Messages 94

8.1 Hints 94

8.2 List of Errors & Warnings 95

9 Maintenance Work 99

9.1 General Information 99

9.2 Maintenance or Service at INFICON 100

9.3 Key to the Maintenance Plan 100

9.4 Maintenance Plan 101

9.5 Maintenance Groups 102

9.5.1 1500 Hours Maintenance 102

9.5.2 4000 Hours Maintenance 102

9.5.3 8000 Hours Maintenance 103

9.5.4 16000 Hours Maintenance 103

9.5.5 Notes refering the maintenance of the SplitFlow 80 104

9.6 Description of the Maintenance Work 104

9.6.1 Opening the Instrument for Maintenance Purposes 105

9.7 Checking and Replacing the Filter Insert 106

9.8 Replacing the Exhaust Silencer 108

9.9 Checking/Emptying the Exhaust Filter 109

9.9.1 Replacing the Filter Insert 109

9.10 Monitoring the Oil Level of the D16 B and Topping up the Oil 111

9.11 Oil Change for the D16B 112

9.12 Scroll Pumps (UL1000 and UL1000 Fab only) 114

6 Table of Contents

Appendix 115

A Diagram 115

B Index 116

C Declaration of Conformity 118

iina70e content.fm Technical Handbook(1408)

Page 7

1 General Information

Caution

Warning

STO P

Danger

Skilled personnel

Notice: We recommend that you carefully read this technical handbook to ensure

optimum operating conditions right from the start.

This technical handbook contains important informations on the functions,

installation, start-up and operation of th e UL 10 00 and UL1 0 00 Fa b.

General

We reserve the right to modify the design and the specified data. The illustrations are

not binding.

1.1 Notes on the Use of this Handbook

1.1.1 Safety Symbols

Important remarks concerning operational safety and protection are emphasised as

follows:

Information on correct handling or use. Disregard can lead to malfunctions or minor

equipment damage.

Information on preventing extensive equipment and environmental damage.

Information on preventing any kind of physical injury.

Indicates procedures that must be performed by skilled personnel only.

iina70e 01.fm technical handbook(1408)

General Information 7

Page 8

1.1.2 Indications

Tipp Information on helpful procedures.

Notice: Information on special technical requirements that the user must comply

with.

The references to diagrams consists of the chapter number, figure number and the

item number in this order. F or example : Fig. 2-4/ 7 refers to item 7 in t he figure 4 of

chapter 2.

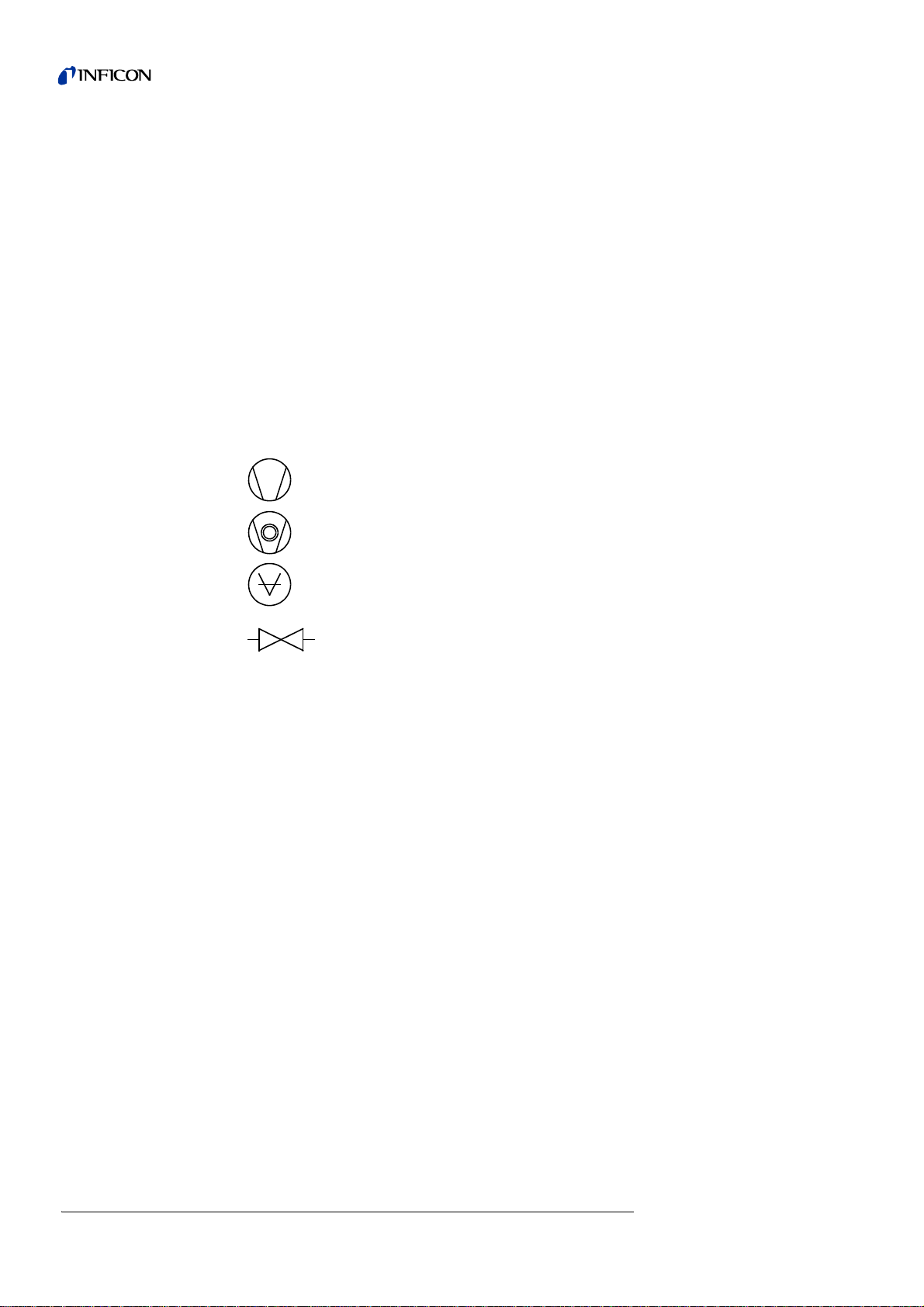

1.1.3 Symbols of Vacuum Technology

Given in the following are some important vacuum symbols which are used in this

manual.

Vacuum pump in general

Turbomolecular pump

Measuring instrument

1.1.4 Definiton of Terms

Autoranging

The range of the preamplifier and the vacuum ranges are selected automatically.

The autoranging feature of the UL1000 Fab covers the entire range or leak rates

depending on the selected operating mode. Not only the leak rate signal, but also the

pressure in the test sample (inlet pressure P1) and the forevacuum pressure (P2) are

used for control purposes. Range switching between the main ranges is performed

via valves. Fine range switching within the m ain ranges is implemen ted by switching

over the gain factor of the preamplifier.

Autotune

Mass alignment

This function automatically aligns the mass spectrometer so that a maximum leak

rate is displayed. The control processor changes the voltage which erates the ions

in the selected mass range until a maximum ion current is detected by the ion

detector. During each calibration the mass alignment is run automatically.

Valve

8 General Information

iina70e 01.fm technical handbook(1408)

Page 9

Auto zero

Measurement and automatic adaptation to the helium background.

This function determines the internal ZERO level of the unit which is then deducted

from the currently measured leak rate signal. This function is enabled by pressing

the Start key provided the UL1000 or UL1000 Fab have ru n at least 20 s in "Standby"

mode or in "Ventilation" mode.

If the before suppressed helium background further decreases and only the display

limit appears, the ZERO-level will be adjusted automatically

Menu

The menu allows the user to program the UL10 00 and UL 100 0 Fab accordin g to his

requirements. The menu has a tree architecture.

Default

Status of the UL1000 and UL1000 Fab when supplie d by the fa cto ry .

GROSS

GROSS is a measurement mode which allows high inlet pressure (1 to 15 mbar).

The smallest detectable leak rate is 1x10

-6

mbar l/s.

FINE

FINE is the medium measurement mode with inlet pressure between 2 and 0,4mbar.

Detection limit is 1x10

-10

mbar l/s.

ULTRA

ULTRA is the most sensitive measuring range with inlet pressures below 0,4 mbar.

The minimum detectable leak rate is 5x10

-12

mbar l/s.

Foreline pressure

Pressure in the foreline between Turbo pump and scroll pump.

Minimum detectable leak rate

The smallest leak rate the UL1000 and UL1000 Fab is able to detect

( 5x10

-12

mbar l/s).

Internal helium background

The existing helium partial pressure in the measurement system. The level of the

internal helium background is measured in the Stand-by mode and subtracted from

the measured signal.

Measure Measurement mode

The UL1000 and UL1000 Fab measures the leak rate of the test sample.

iina70e 01.fm technical handbook(1408)

General Information 9

Page 10

1.2 Support from INFICON Service

INFICON GmbH

Bonner Str. 498,50968 Cologne, Germany

Tel: +49 221 3474 2222 Fax: +49 221 3474 2221

m

zisa01e1-a

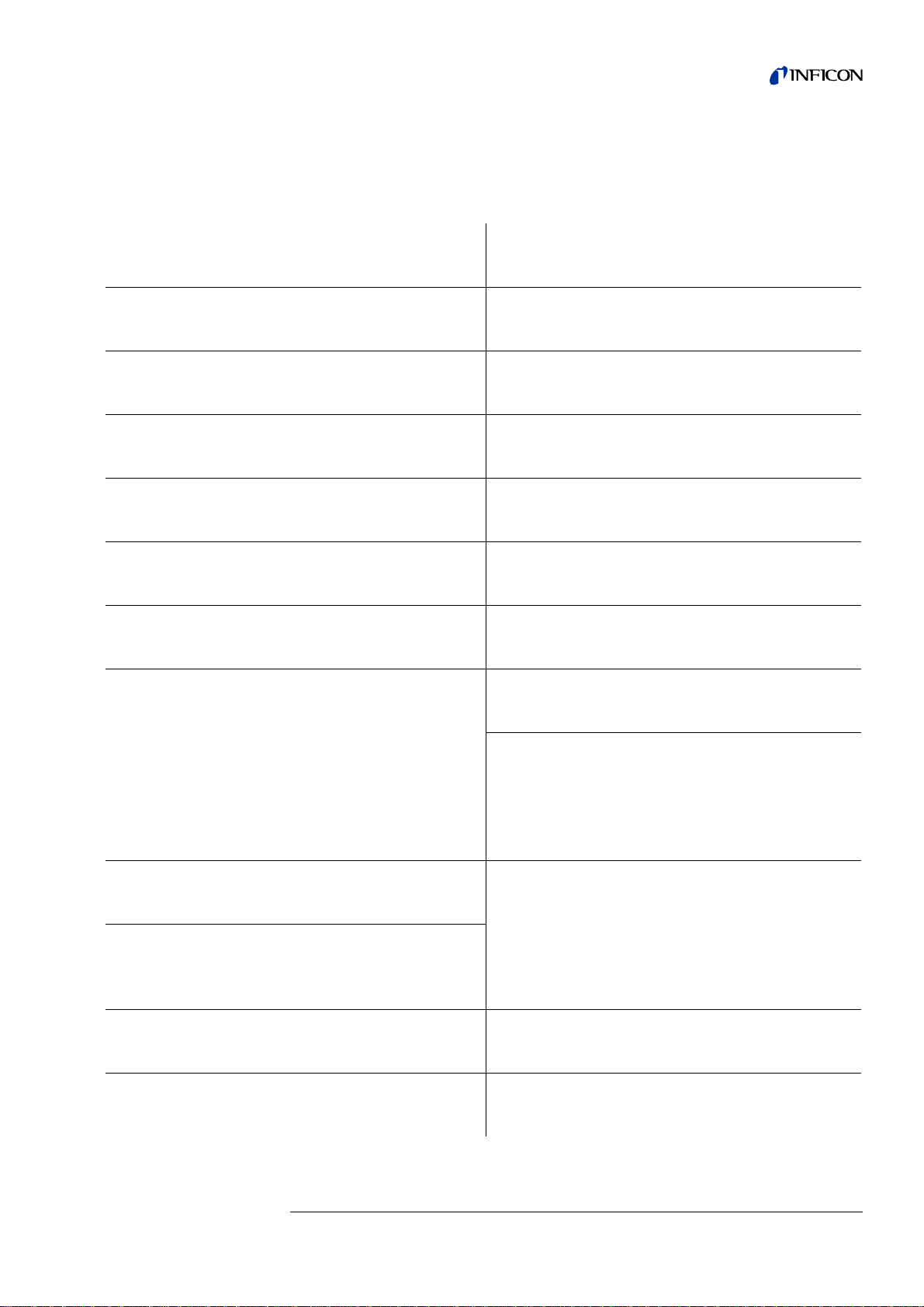

Declaration of Contamination

Legally binding declaration:

I/we hereby declare that the information on this form is complete and accurate and that I/we will assume any further costs that may

arise. The contaminated product will be dispatched in accordance with the applicable regulations.

Organization/company

Address Post code, place

Phone Fax

Email

Name

Date and legally binding signature Company stamp

1) or not containing any amount

of hazardous residues that

exceed the permissible ex posure limits

Process related contamination of product:

toxic no 1) yes

caustic n o 1) yes

biological hazard no

yes 2)

explosive no

yes 2)

radioactive no

yes 2)

other harmful substances no1) yes

The service, repair, and/or disposal of vacuum equipment and components will only be carried out if a correctly completed declaration has

been submitted. Non-completion will result in delay.

This declaration may only be completed (in block letters) and signed by authorized and qualified staff.

Copies:

Original for addressee - 1 copy for accompanying documents - 1 copy for file of sender

Harmful substances, gases and/or by-products

Please list all substances, gases, and by-products which the product may have come into contact with:

Trade/product name

Chemical name

(or symbol)

Precautions associated

with substance

Action if human contact

Description of product

Type

Article Number

Serial Number

Reason for return

Operating fluid(s) used (Must be drained before shipping.)

The product is free of any substances which are damaging to

health yes

This form can be downloaded

from our website.

2) Products thus contam i nated will not be ac cepted without written

evidence of deconta mi nation!

If an instrument is returned to INFICON or an authorised representative of INFICON,

please indicate wether the instrument is free of substances damaging to healths or

wether it is contaminated. If it is contaminated also indicate the nature of the hazard.

INFICON must return any appliances without a Declaration of Contamination to the

sender’s address. A form for stating details as to the type of contamination is

reproduced in Fig. 1-1.

A maintenance and service contract is recommended.

Fig. 1-1: Declaration of Contamination form

www.inficon.com leakdetection.service@inficon.co

iina70e 01.fm technical handbook(1408)

10 General Information

Page 11

1.2.1 Service Centers

In case you urgently need assistance please get in touch with the local INFICON

Service in your country or the service hotline in Cologne, Ge rm a ny:

Algeria jhj@agramkow.dk Finland jhj@agramkow.dk

Agramkow

Sonderborg

Belarus leakdetection.service@inficon.com France Christophe.Zaffanella@oerlikon.com

INFICON GmbH

Cologne

Belgium leakdetection.service@inficon.com Germany leakdetection.service@inficon.com

INFICON GmbH

Cologne

Brazil fernandoz@prestvacuo.com.br Hungary adam.lovics@kon-trade.hu

PV Pest Vácuo Ltda.

Santa de Parnaíba

Bulgaria leakdetection.service@inficon.com India asdash@hotmail.com

INFICON GmbH

Cologne

Canada reachus@vpcinc.ca Ireland reach.unitedkingdom@inficon.com

Vacuum Products Canada Ltd.

Ontario

Central America infoqro@meisa.com Italy davide.giovanetti@inficon.com

MEISA S.a. de C.V.

Querètaro

China reach.china@inficon.com Israel urimark@mark-tec.co.il

INFICON LTD

Hong Kong

INFICON LTD

Beijing

INFICON LTD

Guangzhou

INFICON LTD

Shanghai

Czech Republic filip.lisec@inficon.com Korea reach.korea@inficon.com

INFICON GmbH

Pilsen

Denmark jhj@agramkow.dk INFICON Ltd.

Agramkow

Sonderborg

Egypt jhj@agramkow.dk Latvia leakdetection.service@inficon.com

Agramkow

Sonderborg

Estonia leakdetection.service@inficon.com Lithuania leakdetection.service@inficon.com

INFICON GmbH

Cologne

iina70e 01.fm technical handbook(1408)

Phone: +45 741 236 36

Fax: +45 744 336 46

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +55 114 154 4888

Fax: +55 114 154 4888

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +905.672.7704

Fax: +905.672.2249

Phone: +52 44 22 25 42 80

Fax: +52 44 22 25 41 57

Phone: +852.2862.8863

Fax: +852.2865.6883

Phone: +86.10.6590.0164

Fax: +86.10.6590.0521

Phone: +86.20.8723.6889

Fax: +86.20.8723.6003

Phone: +86.21.6209.3094

Fax: +86.21.6295.2852

Phone +420 734 331 758

Fax: +420 604 203 037

Phone: +45 744 336 36

Fax: +45 744 336 46

Phone: +45 741 236 36

Fax: +45 744 336 46

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Agramkow

Sonderborg

OLV France

Orsay

INFICON GmbH

Cologne

Kontrade

Budaörs

Dashpute

400 064

INFICON

Blackburn

INFICON GmbH

Castelnuovo

Mark Technologies Ltd.

Kiriat Ono

Japan reach.japan@inficon.com

INFICON Co. Ltd.

Yokohama

INFICON Ltd.

Sungnam city

Suwon City

INFICON Ltd.

Cheonan City

INFICON GmbH

Cologne

INFICON GmbH

Cologne

Phone: +45 741 236 36

Fax: +45 744 336 46

Phone: +33 476 351 584

Fax: +33 476 351 584

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +36 23 50 38 80

Fax: +36 23 50 38 96

Phone: +91 22 888 0324

Fax: +91 22 888 0324

Phone: +44 1254 678 250

Fax: +44 1254 698 577

Phone: +39 045 6 40 25 56

Fax: +39 045 6 40 24 21

Phone: +972 35 34 68 22

Fax: +972 35 34 25 89

Phone: +81.45.471.3396

Fax: +81.45.471.3387

Phone: +82 312 062 890

Fax: +82 312 063 058

Phone: +82 312 062 890

Fax: +82 312 063 058

Phone: +82 312 062 890

Fax: +82 312 063 058

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

General Information 11

Page 12

Mexico infoqro@meisa.com Spain richard.cunill@leyboldoptics.com

MEISA S.a. de C.V.

Querètaro

Netherlands leakdetection.service@inficon.com Sweden jhj@agramkow.dk

INFICON GmbH

Cologne

Norway jhj@agramkow.dk Syria leakdetection.service@inficon.com

Agramkow

Sonderborg

Poland kamola@vakpol.com Taiwan Susan.Chang@inficon.com

VAK-POL & GAZ Sp. zo.o

Pulawy

Portugal leakdetection.service@inficon.com Tunisia leakdetection.service@inficon.com

INFICON GmbH

Cologne

Republic of South Africa vacuquip@hotmail.com Turkey jhj@agramkow.dk

Vacuquip

Randburg

Russia leakdetection.service@inficon.com Ukraine leakdetection.service@inficon.com

INFICON GmbH

Cologne

Singapore reach.singapore@inficon.com United Kingdom reach.unitedkingdom@inficon.com

INFICON PTE LTD.

Singapur

Slovakia filip.lisec@inficon.com United Arab Emirates leakdetection.service@inficon.com

INFICON GmbH

Pilsen

Slovenia medivak@siol.net USA service.usa@inficon.com

Medivac

Ljubljani

South America except Brazil infoqro@meisa.com Inficon Inc.

MEISA S.a. de C.V.

Querètaro

Phone: +52 442 225 42 80

Fax: +52 442 225 41 57

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +45 741 236 36

Fax: +45 744 336 46

Phone: +48 60 23 15 212

Fax: +48 60 23 15 212

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +27 73 15 78 355 Agramkow

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +65.890.6250

Fax: +65.890.6266

Phone +420 734 331 758

Fax: +420 604 203 037

Phone: +386 15 63 91 50

Fax: +386 17 22 04 51

Phone: +52 44 22 12 36 15

Fax: +52 44 22 12 19 40

Leybold Optics Ibérica

Barcelona

Agramkow

Sonderborg

INFICON GmbH

Cologne

INFICON Company Limited

Chupei City, HsinChu Hsien

INFICON GmbH

Cologne

Sonderborg

INFICON GmbH

Cologne

INFICON

Blackburn

INFICON GmbH

Cologne

Inficon Inc.

East Syracuse, NY

San Jose, CA

Inficon Inc.

Austin, TX

Phone: +34 93 66 60 778

Fax: +34 93 66 64 612

Phone: +45 741 236 36

Fax: +45 744 336 46

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +886.3.5525.828

Fax: +886.3.5525.829

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +45 741 236 36

Fax: +45 744 336 46

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +44 1254 678 250

Fax: +44 1254 698 577

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +1.315.434.1167

Fax: +1.315.434.2551

Phone: +1.408.361.1200

Fax: +1.408.362.1556

Phone: +1.512.448.0488

Fax: +1.512.448.0398

12 General Information

iina70e 01.fm technical handbook(1408)

Page 13

1.3 Introduction

STO P

Danger

Caution

1.3.1 Purpose

The UL1000 and UL1000 Fab are helium leak detectors. These instruments may be

used to detect the location and the size of leaks on objects under test in two different

ways:

• when the test sample has been evacuated first and is sprayed with helium on the

or

• when a helium overpressure is provided in the test sample and the test sample is

Caution: Danger of explosion

Hydrogen forms a highly explosive gas mixture with air.

Great caution is necessary when using hydrogen! No smoking, no naked flames,

avoid sparks.

outside. It is required that a vacuum connection is provided between the UL1000

and UL1000 Fab and the test sample (vacuum mode).

searched from the outside with a sniffer probe which is attached to the inlet port

(sniffer mode).

The UL1000/UL1000 Fab is only allowed to be used as a leak detector. It ma y not

be used as a pump system (especially not for pumping off aggressive or humid

gasses)

For UL1000 use only:

Notice: Pumping condensable gases and steams: When pumping test sample

water vapour that is inside can attain to the fore pump. With the water vapor

that is in the air - especially in humid areas or wh en using humid or wet test

samples - the acceptable compatibility of water vapor or capacity of water

vapor respectively can be exceeded.

The steam in the oil of the pump condenses when the water vapor rises over the

acceptable value. So the attribute of the oil ch anges and danger of corrosion occures

for the pump.

While using the leak detector with condensable gases and steams the oil of the fore

pump has to be controlled regularly. So you can recognize a condensation of water

vapor in the pump. Usually the oil is light and lucent. When water vapor is inside it

gets blear and milky at operating state temperature.

When turning the pump off water vapor condensates and rases the part of water in

the oil.

iina70e 01.fm technical handbook(1408)

General Information 13

Page 14

Warning

The leak detector must not directly be switched off after the process, in which

Caution

Caution

STO P

Danger

condensable gases or steams are pumped, is finished. It must be ru nning (at least

20 minutes) with opend gas ballast valve (see Chapte r 5.3.1) until the oil of the

pump is free from detachted steams.

When not taking care of this instruction there can be a corrosion within the pump.

So damages will occure.

The height of the oil of the pump has to be controlled regularly.

The normal intervalls of changing the oil from the producer have to be taken care

of. See instructions of the rotary vane pump.

Gases that contain halogen melecules (i.e. fluorine, chlorine), i.e. refrigerants and

SF6, should not be pumped by the leak detector in higher contact rations an d over

a longer time period.

The coating layer of the cathodes (at the ion source) can be affected. This could

cause a burn out of the cathodes.

For UL1000 Fab use only:

Condensable gases and steams can attain the inside of the leak detector and

destruct the fore pump.

With the water vapor that is in the air - especially in humid areas or when using

humid or wet test samples - the acceptable compatibility of water vapor or capacity

of water vapor respectively can be exceeded.

Dangerous gases pollute the machine.

So you must not use the machine for detecting toxical, acidity, microbiological,

explosive, radioactive or other noxious matters.

If you plan to detect noxious matters please contact the manufacturer. Rules for

decontamination will be developed then. If the leak detector alreay has been in

contact with dangerous gases please fill the declaration of contamination, too, and

send it to INFICON before you send the parts.

iina70e 01.fm technical handbook(1408)

14 General Information

Page 15

1.3.2 Technical Data

1.3.2.1 Physical Data

Max. inlet pressure 15 mbar

Minimum detectable Helium leak rates

• in vacuum mode (ULTRA) <5×10

limit of detection in sniffer mode <5×10

Maximum displayable helium leak rate in ULTRA 0.1 mbar l/s

Measurement range 12 decades

Time constant of the leak rate signal (blanked off,

63% of the final value)

Pumping speed (Helium) at the inlet

Max. roughing capability 25 m

• in vacuum mode

Detectable masses 2, 3 and 4

Mass spectrometer 180° magnetic sector field

Ion source 2 filaments;

Inlet port DN 25 KF

Run-up time (after starting) 3 min

<1 s

17.6 cfm (50 Hz)

30 m

21.1 cfm (60 Hz)

– GROSS mode 8 l/s

– FINE mode 7 l/s

– ULTRA mode 2.5 l/s

Iridium/Yttria-oxide

-12

mbar l/s

-8

mbar l/s

3

/h (50 Hz)

3

/h (60 Hz)

Hinweis To get down to the minimum detected leak rate range some conditions

must be fulfilled:

• UL1000 and UL1000 Fab has fully warmed up

• Ambient conditions must be stable (temperature, no vibration/accelerations.)

• The part under test has been evacuated long enough (background is no longer

decreasing)

• ZERO must be active

1.3.2.2 Electrical Data

Part no. 550 - 000A, 550 - 100A 230 V 50 Hz

Part no. 550 - 001A, 550 - 101A 115 V 60 Hz

Part no. 550 - 00 2A 100 V 50/60 Hz

Power consumption 1100 VA

Type of protection IP20

Power cords (EU, USA, UK) 3 m

iina70e 01.fm technical handbook(1408)

General Information 15

Page 16

1.3.2.3 Other Data

Valves solenoid

Dimensions (L × W × H) incl. handle in mm 1068 × 525 × 850

Dimensions (L × W × H) incl. handle in inches 42 × 21 × 33

Weight in kg 110

Weight in lbs 242

Noise level dB (A) < 70

Noise level dB (A) 0.5m distance < 56

Audio alarm dB (A) 90

Contamination level (to IEC 60664-1) 2

Overvoltage category (to IEC 60664-1) II

1.3.2.4 Ambient Conditions

For use within buildings

Permissible ambient temperatur e (d ur in g op er at ion) +10 °C … +40 °C

Permissible storage temperature 0 °C … +60 °C

Max. rel. humidity 80% non condensing

Max. permissible height above sea level (during operation) 2000 m

1.4 Unpacking

Unpack the UL1000 and UL1000 Fab immediately after delivery, even if it will be

installed later on.

Examine the shipping container for any external damage. Completely remove the

packaging materials.

Check if the UL1000 and UL1000 Fab is complete (See Chapter 1.4.1) and carefu lly

examine the leak detector visually.

If any damage is discovered, report it immediately to the forwarding agent and

insurer. If the damaged part has to be replaced, please contact the orders

department.

Notice: Before starting up make sure that the transportation fixing is loosened.

(Please refer to chapter 2.1)

Tipp Retain the packaging materials in the event of complaints about damage.

Tipp For unpacking please use the wedge which is part of the packaging.

16 General Information

iina70e 01.fm technical handbook(1408)

Page 17

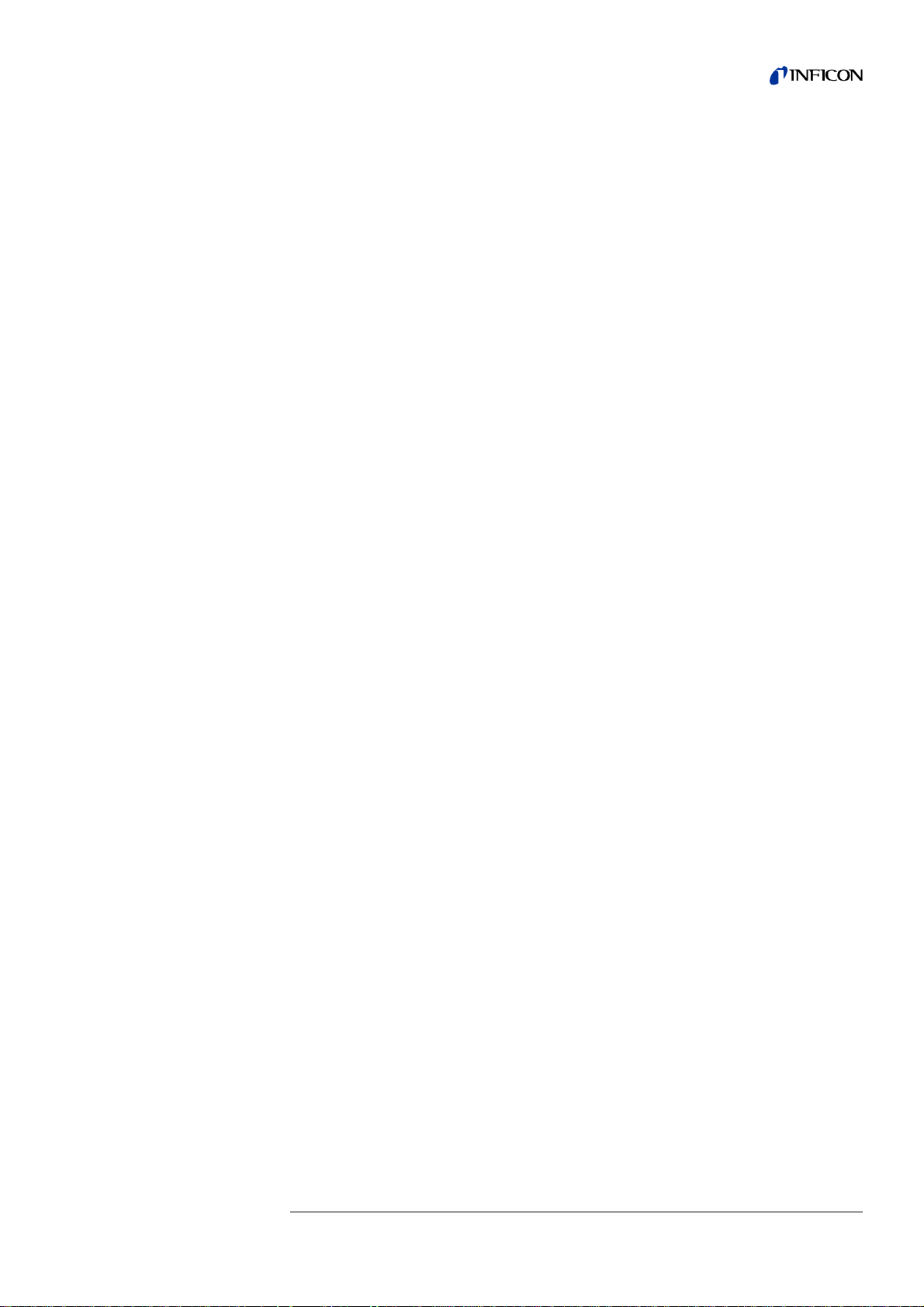

1.4.1 Supplied Equipment

• Helium Leak Detector UL1000 or UL1000 Fab

• Exhaust hose adapter with clamps (see arrow 1)

• power cord fixture

• Set of fuses (see arrow 2)

• Set of tools (see arrow 7)

• Bellow Clips (2 + 2) (see arrow 5)

• Folder with documents

– Technical Handbook UL1000 and UL1000 Fab

– Spare Parts List UL1000 and UL1000 Fab

• hooks to wrap power cord (with screws) (see arrow 6)

• Tool to open the UL1000 and UL1000 Fab (see arrow 7)

• O-Ring with filter (for use at applications with particles)

iina70e 01.fm technical handbook(1408)

Fig. 1-2

General Information 17

Page 18

1.4.2 Accessories and Options

The following parts can be ordered additionally:

• Sniffer Line SL200 14005

• Leak Ware 14090

• Helium Sniffer QUICK-TEST QT100 15594

• Tool Box (detachable) 551-000

• Helium Bottle Holder 551-001

• ESD Mat 551-002

• RC1000 Remote control

• Test chamber TC1000 551-005

• spray gun with hose 16555

• set of plugs 20099024

• LeakWare (software package) 14090

1.4.2.1 Sniffer line SL200

By use of the sniffer line the UL1000 and UL1000 Fab can easily be converted to a

sniffer leak detector. The length of the sniffer line is 4m (i.e. 12 feet).

1.4.2.2 Toolbox

The toolbox is a detachable compartment with a lockable lid. Fittings and small

fixtures can be stored plus the hand set (Please refer to Chapter 1.4.2.5). The

storage volume is approximately 5 l.

The toolbox is placed on the working surface and jammed by the handle.

– RC1000WL wireless version

– RC1000C cable version

– Extension Cable, 8 m

551-015

551-010

14022

1.4.2.3 Helium Bottle Holder

The helium bottle holder allows you to carry a helium reservoir a nd a spray g un with

the UL1000 and UL1000 Fab. Only small and midsize bottles (max 10 l, 200 bar) will

fit without influencing the stability of the UL1000 and UL1000 Fab.

1.4.2.4 ESD Mat

This mat is put on the working surface of the UL1000 and UL1000 Fab and is

clamped and grounded by the inlet port ring. It avoids electrical disch arge s between

the working surface and sensitive test parts.

18 General Information

iina70e 01.fm technical handbook(1408)

Page 19

1.4.2.5 RC1000 Remote control

The RC1000 is a wireless remote control that allows to operate the UL1000 and

UL1000 Fab from distance up to 100 m. It provides the functions START, STOP/

VENT, ZERO and speaker volume, and displays leak rate in bargaraph or in chart

mode. (see also Technical Handbook RC1000.)

Measured values can be stored in an internal memory for up to 24 hours of recording

time. The data can easily be downloaded to a USB stick to save it.

An internal trigger can be set to provide a warning if the limit leak rates are exceeded.

An optical warning is shown on the display and an acoustic warning signal is

sounded on the integrated loudspeaker or the connected headphones.

The RC1000 remote control is housed in a robust housing to enable ergonomic

working. Magnets on the underside of the unit enable it to be attached to horizontal

or vertical metal surfaces.

The RC1000 also enables remote operation of the leak test device in question using

a connection cable of up to 28 metres in length.

Fig. 1-3 RC1000 wireless remote control

iina70e 01.fm technical handbook(1408)

General Information 19

Page 20

1.4.2.6 Test chamber TC1000

This test chamber turns the UL1000 / UL1000 Fab into a workstation to test

hermetically sealed components.

Testing according to MIL-STD 883 can be done easily, fast and accurate. The test

starts automatically when the chamber lid is closed, test parameters like cycle time

and rejectant level can be setted in the menu Auto Leak Test (see 6.6.1.6). The test

cycle runs automatically, the test result is also displayed by red / green LEDs directly

at the chamber.

Fig. 1-4 Test chamber TC1000

20 General Information

iina70e 01.fm technical handbook(1408)

Page 21

2 Installation

Caution

Warning

Caution

Caution

Caution

2.1 Transportation

The UL1000 and UL1000 Fab is not equipped with any crane eyes and must

therefore not be transported using lifting equipment.

The UL1000 and UL1000 Fab must only be pushed or pulled along using the handle

provided for this purpose. Don’t use the handle to lift.

Your feet can be pinched.

Keep your feet away from the rollers. .

Your feet can be run over.

Do not pull the unit, push it

When transporting over longer distances the original pa ckaging must be used . The

castors must not be fixed when the UL1000 and UL1000 Fab is sh ipped in a crate.

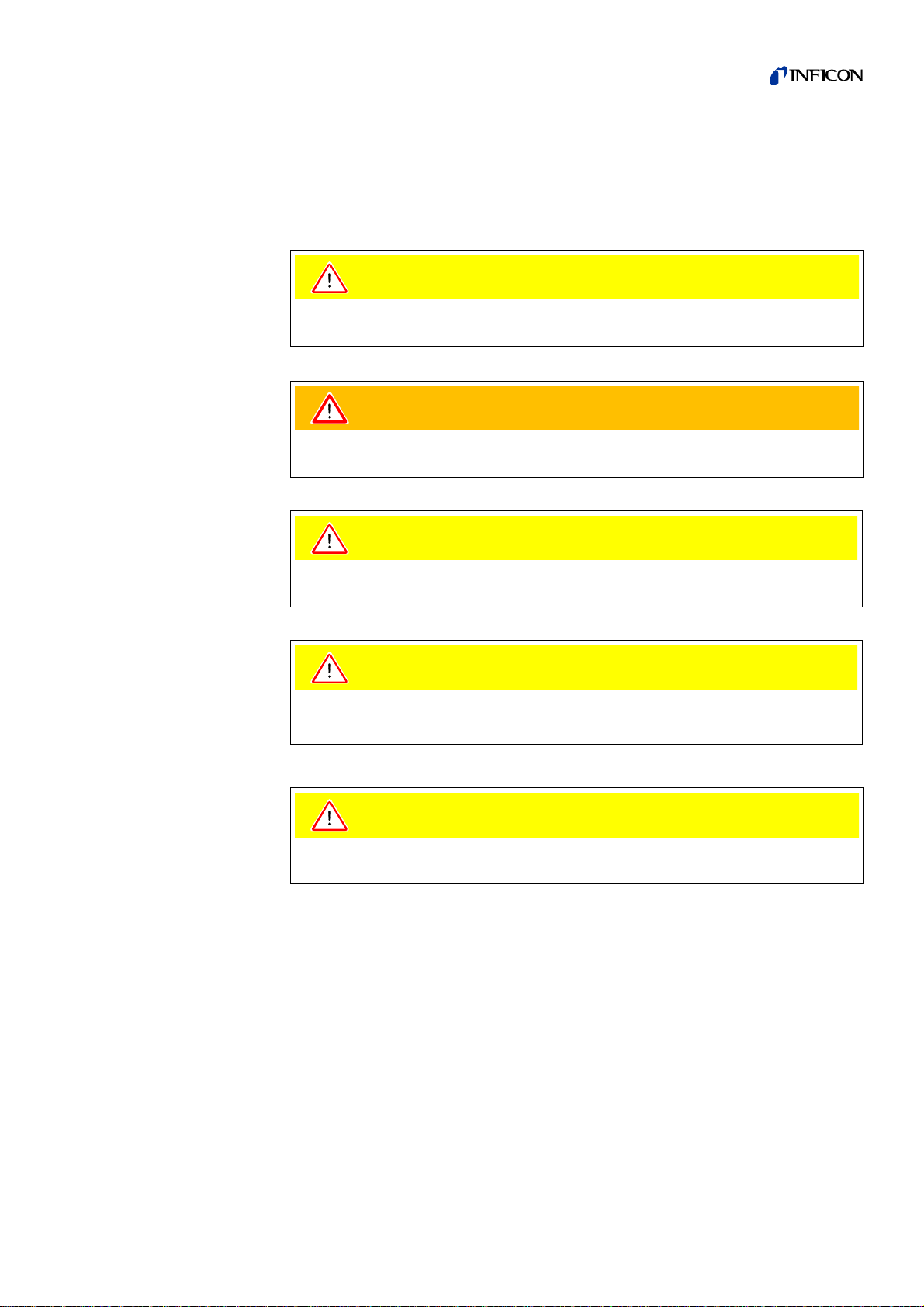

UL1000 Fab with Triscroll TS 620

For transportation the chassis plate where the pump is mounted on has to be

secured by a transportation fixing.

This transportation fixing consists of 2 screws at chassis of the UL1000 Fab (one on

each side).

To get access to these screws remove the side covers of the UL1000 Fab.

There are orange labels on the bottom part pointing to the screws:

iina70e 02.fm technical handbook(1408)

Installation 21

Page 22

Fig. 2-1

For transportation fixing the screws are tightened to the chassis plate. For oper ation

of the UL1000 Fab the screws should be loosened.

To loosen the screws first loosen the counter nut that is accessible from und erneath:

22 Installation

Fig. 2-2

iina70e 02.fm technical handbook(1408)

Page 23

Loosen the screws approximately 10 mm above the chassis plate and tighten then

STO P

Danger

Caution

the counter nuts again:

Fig. 2-3

For transportation tighten the screws again and fix them by the counter nuts.

2.2 Working Location

Move the UL1000 and UL1000 Fab to the desired position and arrest the castors.

Caution: Exhaust gases and fumes:

Exhaust gases and fumes from oil-sealed pumps may be harmful to health.

For operation in poorly ventilated rooms, an exhaust pipe should be connected to

exhaust connection 5 depending on the application and gases used.

Make sure that you can always reach the mains plug.

iina70e 02.fm technical handbook(1408)

Installation 23

Page 24

Warning

The UL1000 and UL1000 Fab must not be operated while standing in water or

Warning

Warning

Caution

Caution

when exposed to drip water. The same applies to all other kinds of liquids.

Avoid contact with bases, acids or solvents as well as exposure to extreme climatic

conditions.

The UL1000 and UL1000 Fab is designed for indoor use only.

Ensure a sufficient air cooling. The air inlet as well the air discharg e openings must

never be obstructed.

The UL1000 and UL1000 Fab can be locked by arresting the castors of the front

wheels to avoid movements on skewness.

It is recommended that you check all major helium sources in the vicinity of the

UL1000 and UL1000 Fab within a radius of about 10 m for the presence of any big

leaks. You may use the sniffer probe for this.

iina70e 02.fm technical handbook(1408)

24 Installation

Page 25

2.3 Electrical Connections

Warning

STO P

Danger

2.3.1 Mains Power

Notice: Generally the local regulations for electrical connections m ust be observed.

Before connecting the UL1000 and UL1000 Fab to the mains you mu st make sure

that the mains voltage rating of the UL1000 and UL1000 Fab coincides with the

locally available mains voltage. The instrument must exclusively be connected to a

single phase supply with fuses for installation (Circuit breaker 16A max. according

to IEC/EN 60898 with tripping characteristic B).

The mains voltage rating for the UL1000 and UL1000 Fab can be read off from the

name plate beneath the mains socket Fig. 2-6/7 at the back side. This vo ltage is fixed

and can not be changed.

A separate fuse for each of the mains conductors has been integ rated into the mains

switch.

The mains voltage is applied to the instrument via the detachable mains ca ble which

is supplied with the instrument. A mains socket Fig. 2-6/7 is available for this purpose

at the back side of the instrument.

Caution: mains voltage:

Improperly grounded or fused products can lead to fatal injuries.

Only 3-core mains cables having a protection ground conductor must be used.

Operation of the UL1000 and UL1000 Fab where the ground conductor has been

left unconnected is not permissible.

Notice: The cable can be secured like shown in the following Figure.

iina70e 02.fm technical handbook(1408)

Installation 25

Page 26

Fig. 2-4 secure fixture power cord

Notice: If the machine is not operating the cable can be stored at the cable holders.

Fig. 2-5 storing power cord

26 Installation

iina70e 02.fm technical handbook(1408)

Page 27

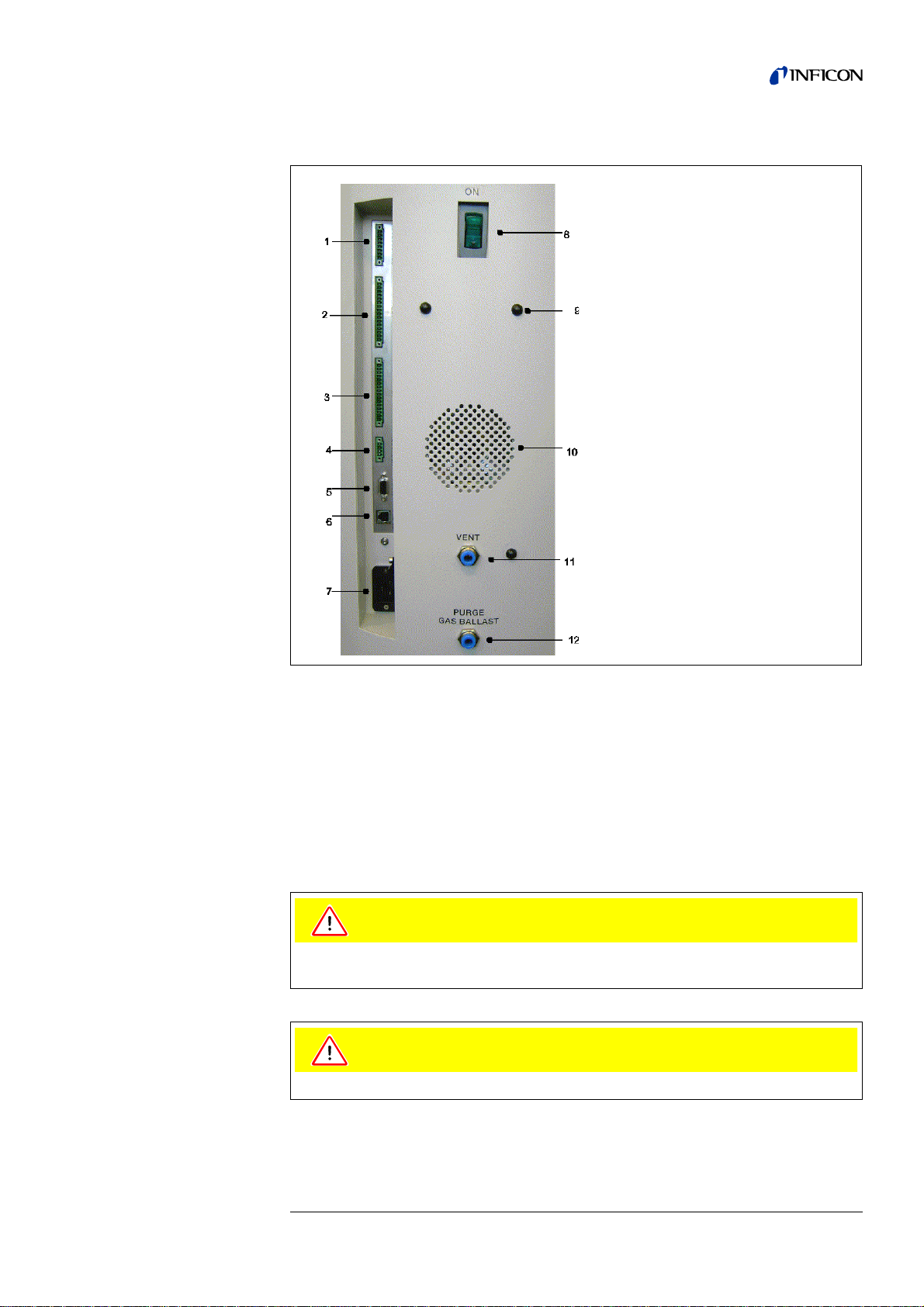

2.3.2 Connections for the Data Acquisition Systems

Caution

Caution

1. Accessories

2. Digital Out

3. Digital In

4. Recorder

5. RS232

6. Remote Control /

Wireless transmitter

7. Mains Socket

8. Mains Switch

9. Hole to mount cable hooks.

10. Speaker

11. Vent

12. Purge (UL1000 Fab) /

Gas ballast (UL1000)

Fig. 2-6

Tipp The sockets: Accessories, Digital Out, Digital In and Recorder have pin 1

on top. The pin numbers are counted downwards. The socket 2 and 3 are

coded mechanically to avoid a confusion with the counter plug. For the

connection with the counter plug (set of plugs 20099024) remove the

plastic pins at the plug, accordingly the plug fits the socket.

Tipp The connections for external devices are safely seperated from the mains

and safe low voltage.

The electronic of the device can be destroyed. So just connect de vices to the le ak

detector that are seperated from the mains.

Just connect devices that don’t excess 25V AC/Amp.

iina70e 02.fm technical handbook(1408)

Installation 27

Page 28

2.3.2.1 Accessories

2.3.2.2 Digital Out

The following accessories may be connected to the sniffer line SL200 (P lease refe r

to Chapter Fig. 2-6/1) or the test chamber TC1000:

Contact pins 1 and 3 are fused with a 0.8 A slow-blow fuse. The amount of power

which can be drawn is limited to 10 W. The contacts are numbered from top to

bottom.

Pin Assignment

1 +24 V, constantly applied, power supply for the sniffer line SL200.

2 GND24

3, 6 Input

4, 5, 7, 8 Output

The following relay outputs are available for further signal processing. The maximum

rating for the relay contacts is 60V AC/1A.

Pin Assignment

1 +24V, bridged with pin 1 of socket „Digital In“

2 GND_24V

3 Trigger 1

4 Trigger 2

5Free

6 Zero active

7 Ready

8 CAL active

9 Cal request

10 Error

11 Warning

12 Purge

13 Measure

14 Recorder Strobe

15 Common dig. out

16 Free

28 Installation

Description of the operation mode of the Digital Out.

Trigger 1:

Is open in case Trigger Level 1 is exceeded or the machine is not in condition of

measuring.

Trigger 2:

Is open in case Trigger Level 2 is exceeded or the machine is not in condition of

measuring.

Zero active:

Is closed in case Zero function is running.

Ready:

Is closed in case machine is ready for measurement (Emission on, no error).

CAL active

Closed when machine is in calibrating routine.

iina70e 02.fm technical handbook(1408)

Page 29

2.3.2.3 Digital In

CAL Request

Is opend in case of calibration request. During external calibration a open output

indicates that the external calibrated leak has to be clos ed .

Error

Open when an error is shown.

Warning

Open when a warning is shown.

Purge

Closed when purge is active.

Measure

Closed in case a machine is in measure mode.

Recorder Strobe

Closed in case recorder output is invalid. Only used when record output is set on

„leak rate“.

These inputs can be used to control the UL1000 and UL1000 Fab with a

programmable logic control (PLC).

Pin Assignment

1 +24V, bridged with pin 1 of socket „Digital Out“

2 GND_24V

3Start

4Stop

5Zero

6CAL

7 Clear

8 Purge

9Free

10 Free

11 Common dig

12 Free

13 Free

14 Free

15 Free

16 Free

Description of operation mode of the Digital In.

Zero:

Change from low to high: activate zero

Change from high to low: deactivate zero

Start:

Change from low to high: activate START

Stop:

Change from low to high: activate STOP

When this inlet is longer high than anounced in chapter 6.6.1.2 then ventilate it

additionaly.

iina70e 02.fm technical handbook(1408)

Installation 29

Page 30

2.3.2.4 Recorder

Purge:

Change from low to high: activate purge

Change from high to low: deactivate purge

Clear:

Change from low to high: confirm error message

CAL:

Change from low to high:

When machine is in stand-by mode: start internal calibration. In case machine is

measurement mode: start external calibration. (Premise: external calibration test

leak has to be open and leak rate signal is stable)

Change from high to low:

External calibration: approve that external test leak is closed and leak rate signal is

stable.

High means: U > 13 V(approximately 7mA)

Low means: U < 7 V

The level of the logic signals must not exceed 35V.

Notice: Signals at these inputs are only accepted if the location of control is set to

„PLC“ or „Local and PLC“. Refer to Chapter 6.6.4.1

The recorder output see Fig. 2-6/4 may be used to log th e leak rate, the inlet pressure

and the forevacuum pressure.

The measured values are provided by way of an analogu e signal in the ran ge of 0 V

… 10 V. The resolution is limited to 10 mV. The instrument which is connected to the

recorder output (e. g. X(t) chart recorder) should have an input resistance of no less

than 2.5 k. The measured values are available through pins 1 and 4. The reference

potential (GND) is available at pins 2 and 3. The contacts are numbered from top to

bottom.

Tipp A diagramm showing pressures and leakrate versus voltage is attach ed in

the appendix.

Notice: The chart recorder outputs are electrically isolated from other plugs. If, in

spite of this, hum interference is apparent it is recommended to operate the

UL1000 and UL1000 Fab and the chart recorder from the same mains

phase. If this is not possible, you must make sure that the frame ground of

both instruments is kept at the same potential.

Pin Assignment

1 Analog 1

2GND

3GND

4 Analog 2

iina70e 02.fm technical handbook(1408)

30 Installation

Page 31

2.3.2.5 RS232

This RS232 C interface Fig. 2-6/5 is wired as data communication equipment (DCE)

and permits the connection of a personal computer (PC) for monitoring and data

logging. The connection is made through a 9 pin sub-D socket. For more information

refer to the Interface Description.

2.3.2.6 Remote Control

This Remote Control interface Fig. 2-6/6 is a serial interface to control the UL1000

and UL1000 Fab by the RC1000. The RC1000 Remote Control can be connected via

the wireless transmitter or via an extension cable with a RJ45 plug. Refer to the

RC1000 Technical Handbook for more information.

Pin Assignment

2RXD

3TXD

5GND

7RTS

8CTS

Pin Assignment

2 +24V (fuse 0.8 A time lag)

30V

4 RXD (intern. RS232)

5 TXD (intern. RS232)

iina70e 02.fm technical handbook(1408)

Installation 31

Page 32

2.4 Vaccum Connections

Warning

Warning

2.4.1 Inlet Port

The inlet port is located on the top of the UL1000 and UL1000 Fab. The size of the

flange is DN 25 KF.

Risk of injury due to sucking connection flange.

If the Vacuum-Mode of the UL1000 is activated, the connection flange may suck

bodily parts around the connection flange. Keep bodily parts off the connection

flange.

A test object or a test chamber has to be connected to the inlet port if the vacuum

mode is chosen (See Chapter 6.3).

The inlet port is also used for the connection of the sniffer line.

2.4.2 Exhaust

The exhaust Fig. 2-6/12 flange is located underneat h the UL1000 and UL 1000 Fab

at the back side. The size of the flange is DN 16 KF.

Depending on the chamber the UL1000 and UL100 0 Fab is attached to and the gas

inside the chamber lethal gases can be spoiled into the air through the exhaust.

When shipped only the exhaust filter body is preassembled. The filter cartridge is

supplied together with the leak detector and can be installed at the exhaust.

Instead of this an exhaust line can be connected to the exhaust by the exhaust

adapter.

2.4.3 Vent

Usually the parts under test are vented with ambient air when the test is finished. If

it is required the parts can be vented with a different gas (i. e. fresh air, dry air,

nitrogen, …) at max. 1050 mbar pressure. In this case a vent hose has to be

connected to the hose coupling Fig. 2-6/10.

2.4.4 Purge-connection (UL1000 Fab) /

Gas ballast (UL1000)

For purge modes it is recommended to use Helium-free gases at atmospheric

pressure. Ambient air can be contaminated with Helium due to

In this case a gas supply line (i. e. nitrogen, fresh air, …) should be connected to the

hose coupling Fig. 2-6/11. The pressure of these gas line must not exceed

1050 mbar.

The connector 11 and 12 in Fig. 2-6 are quick connectors for hose diameters of 8/

6 mm.

spraying or charging .

iina70e 02.fm technical handbook(1408)

32 Installation

Page 33

2.5 Default parameters

The following parameters are set like shown when in the menu of the UL1000 and

UL1000 Fab under Settings Parameters load/save, „load default values“ is

chosen.

Auto-scaling: On

Scaling logarithmic

Display range: 4 decades

Time axis: 32 seconds

LCD invers: OFF

Background in stand by mode: OFF

Automatic calibration request: OFF

Mass: 4 (helium)

Recorder Output: leak rate

Volume: 2

Leak rate unit: mbar l/s

Mode: Vacuum

Trigger level 1: 1E-9 mbar l/s

Trigger level 2: 1E-8 mbar l/s

Leak rate external test leak (Vacuum): 1E-7 mbar l/s

Leak rate external test leak (Sniffer): 1E-5 mbar l/s

Vent delay: 2 seconds

Automatic purge: OFF

Pressure unit: mbar

Minimum volume: 0

Beep: ON

Maximum evacuation time: 30 minutes

Audio Alarm Typ: Trigger Alarm

Maximum inlet pressure when sniffing: 1 mbar

Minimum Inlet pressure when sniffing: 0,1 mbar

Number of decimal place at leak rate displayed: 1

Scroll display: On

Particle protection: Off

Direct access to calibration: On

Contamination protection: Off

Switch off limit for contamination protection: 1E-3 mbar l/s

Control location: Local

Alarm delay: 30 seconds

Leak rate filter: I•Cal

Zero: enabled

iina70e 02.fm technical handbook(1408)

Installation 33

Page 34

3 First Operation Check

Warning

Caution

The steps for an initial operation are described in this chapter. It is explained how to

switch on the UL1000 and UL1000 Fab, how to measure and how to carry out an

internal calibration.

Notice: If anything unexpected happens during the initial operation or the leak

detector acts in a strange way the UL1000 and UL1000 Fab can be

switched off by the mains switch at any time.

3.1 Needed Equipment

The following parts will be needed:

• A blind flange 25 KF (if not preassembled at the inlet port).

• A helium test leak with a DN 25 KF adapter (optional).

3.2 Description of the Initial Operation

Please proceed the following description step by step to start the initial operation.

Refer to Chapter 5 Operation of the UL1000 and UL1000 Fab for a more detailed

description.

3.2.1 Start up and Measure

1 Unpack the UL1000 and UL1000 Fab and in spect it for any externa l damage (Refer

to Chapter 1.4 Unpacking).

2 Connect the instrument to the mains power (Refer to Chapter 2.3.1 Mains Power).

3 Switch on the leak detector by using the mains switch Fig. 2-6/8.

Caution: Abrupt movements.

Abrupt movements can damage the runnin g tur b o pu mp .

Avoid abrupt movement and vibration of the instrument (e.g. running over cables,

door sills) during operation and up to 4 minutes after switching off since the turbo

pump can be damaged.

Don’t switch the UL1000 and UL1000 Fab on when ambient temperature is below

10°C.

34 First Operation Check

iina70e 03.fm technical handbook(1408)

Page 35

After power on a welcoming picture appears on the screen of the control panel Fig.

3-1/1, then status information on the speed of the turbo pu mp, the forelin e pressure,

the emission and the active filament are given.

The start up procedure takes about 3 minutes and the end is indicated by a beep.

The UL1000 and UL1000 Fab is in Stand-by mode now.

Fig. 3-1: Top view of the Standards

Pos. Description Pos. Description

1 Control Panel 2 Inlet Port

4 Check if the inlet port Fig. 3-1/2 is blanked off. If not, please mount a blind flange with

O-Ring on the inlet port.

5 Press the START Button Fig. 3-2/6. The inlet will be evacuated and the measured

leak rate will be displayed a moment later.

This is the measurement mode. If a test part was connected you wo uld start spraying

Helium to identify leaks.

iina70e 03.fm technical handbook(1408)

First Operation Check 35

Page 36

Fig. 3-2: Control Panel

Pos. Description Pos. Description

1 LC Display 8 Soft Key no. 5

2 Soft Key no. 1 9 Soft Key no. 6

3 Soft Key no. 2 10 Soft Key no. 7

4 Soft Key no. 3 11 Soft Key no. 8

5 Soft Key no. 4 12 MENU Button

6 START Button 13 STOP Button

7 Control Panel 14 ZERO Button

6 To correct for any background signal (residual Helium in the part under test) you may

press the ZERO Button Fig. 3-2/14. To undo ZERO please press the ZERO Button

for 2 … 3 seconds.

7 Press the STOP Button Fig. 3-2/13, the Standards will go to Stand-by. If you press

STOP a few seconds the inlet of the Standards will be vented.

8 To finish the startup procedure please proceed with #16. For calibration proceed with

#9.

36 First Operation Check

iina70e 03.fm technical handbook(1408)

Page 37

3.2.2 Internal Calibration

9 Proceed the internal calibration (Please refer to Chapter 7.2.1 Internal Calibration).

For better quantitative measurements please allow the unit to warm up (15 … 20

minutes).

•Press Calibration (Soft Key no. 5 Fig. 3-2/8) to get into the calibration menu.

• Select internal (Soft Key no. 4 Fig. 3-2/5) to choose the internal calibration.

• Select automatic (Soft Key no. 8 Fig. 3-2/11). The automatic procedure of the

internal calibration is started and takes about 30 seconds.

10 Press the STOP Button Fig. 3-2/13 until the message STAND-BY / VENTED appears

on the display. The inlet is vented now.

3.2.3 Verification

To verify the accuracy please proceed through the following steps. A test leak is

required. If a test leak is not available please continue with #16.

11 Remove the blind flange from the inlet port and connect the ope n helium test leak to

the inlet port.

12 Press the START Button Fig. 3-2/6 again. The inlet will be evacuated and the leak

rate of the test leak will be measured and displayed.

13 Press the STOP Button Fig. 3-2/13 to interrupt the measurement. The Stand-by

mode will be displayed.

14 Press the STOP Button Fig. 3-2/13 again until the message STAND-BY vented

appears an the display. The inlet is vented now.

15 Remove the helium test leak from the inlet port and put a blind flange onto the inlet

port again.

16 Switch off the leakdetector by using the mains switch Fig. 2-6/8.

The first operation is finished.

iina70e 03.fm technical handbook(1408)

First Operation Check 37

Page 38

4 Description and Working Principle

4.1 Introduction

The UL1000 and UL1000 Fab basically is a helium leak detector for vacuum

applications, i.e. the part under test is evacuated while the test is performed. The

vacuum is achieved with a pumping system that is part of the UL1000 and UL1000

Fab. In addition the vacuum can be generated by pumps with are set up in parallel

to the leak detector.

Another operating mode of the UL1000 and UL1000 Fab is the Sniff mode which can

only be used when a sniffer line (See Chapter 1.4.2 Accessories and Options) is

hooked up.

4.2 Components of the UL1000 and UL1000 Fab

The UL1000 and UL1000 Fab is a self-contained unit in a metal housing on wheels.

This housing contains the entire vacuum system and the according power supplies.

On top of the unit is the inlet port and the display.

38 Description and Working Principle

iina70e 04.fm technical handbook(1408)

Page 39

4.2.1 Vacuum System

The vacuum diagram below shows the major components inside the UL1000 and

UL1000 Fab:

Fig. 4-1: Vacuum Diagramm UL1000 and UL1000 Fab

Pos. Description

1 MS: Mass Spectrometer, Helium sensor (180° magnetic field mass

spectrometer)

2 Turbomolecular Pump (TMP, provides high vacumm conditions in the MS)

3 V1a … V8: Electromagnetic Valves to control the gas flows

4 Scroll pump (provides the fo reline pressu re for the TMP und pum ps down th e

parts under test)

5Inlet Port

The mass spectrometer is mainly composed of the ion source, the magnetic

separator and the ion collector.

Gas molecules getting into the mass spectrometer are ionized by the ion source.

These positively charged particles are acceler ated into the magnetic fie ld following a

circular path, the radius of which depends on the mass-to-charge ratio of the ions.

Only helium ions can pass this filter and reach the ion collector where the stream of

the ions is measured as a electrical current.

For operation the mass spectrometer requires a vacuum level in the range of

-4

1×10

iina70e 04.fm technical handbook(1408)

in turn is backed up by a scroll pump.

mbar and lower. This pressure is provided by the tu rbomolecular pump which

Description and Working Principle 39

Page 40

Besides maintaining the pressure in the mass spectrometer the pump system is used

to evacuate the test parts. It is made sure that the pressure in the m ass spectrometer

is low enough under all circumstances. The valves V1a, V1b, V2, V4a, V4b control

the gas flows when measuring. Valves V5 (only UL1000), V6, and V8 are used to

vent the system and the Turbo pump. Valve V7 opens and closes the internal test

leak during calibration.

With the pressure in the test part being lower than ambient pressure sprayed he lium

can penetrate into the part in case of a leakage. As soon as the pressure conditions

allow it one of the valves to the TMP opens. Now Helium can penetrate in to the mass

spectrometer contrary to the pumping direction of the TMP.

See Chapter 4.3 Working Modes for details.

4.2.2 Control Panel

The Control Panel Fig. 4-2/7 contains a liquid chrystal display (LC Display), the

START, STOP, ZERO and MENU buttons and also eight Soft Keys for the different

menus and inputs.

The control panel itself is rotable.

Fig. 4-2: Control Panel

Pos. Description Pos. Description

1 LC Display 8 Soft Key no. 5

2 Soft Key no. 1 9 Soft Key no. 6

3 Soft Key no. 2 10 Soft Key no. 7

4 Soft Key no. 3 11 Soft Key no. 8

5 Soft Key no. 4 12 MENU Button

6 START Button 13 STOP Button

7 Control Panel 14 ZERO Button

40 Description and Working Principle

iina70e 04.fm technical handbook(1408)

Page 41

4.2.2.1 LC Display

4.2.2.2 START Button

4.2.2.3 STOP Button

4.2.2.4 ZERO Button

The LC Display Fig. 4-2/1 is the communication interface to the operator. It displays

the leak rates, the status report of the machine, messages, warnings and errors.

Pushing the START Button Fig. 4-2/6 enables the UL1000 and UL1000 Fab to start

the measure procedure. If the START button is pushed again in measurement mo de,

the maximum leak rate indicator („hold“ function) is acitvated. This indicator shows

the maximum leak rate since „START“. By pressing the START-button again the

„hold“ function will be started.

Pushing the STOP Button Fig. 4-2/13 interupts the measure procedur e. If the button

is pressed longer the inlet is vented according to the conditions defined in the menu

Vent delay. Please refer to chapter 6.6.1.2 Vent delay to select the time parameters

of the venting.

Pushing the ZERO Button Fig. 4-2/14 enables the zero mode.

When pressing ZERO the currently measured leak rate is taken as a background

signal and is subtracted from all further measurements. As a result the displayed leak

rate then is

•1×10

•1×10

•1×10

-6

in GROSS

-10

in FINE

-12

in ULTRA

To reverse the ZERO function please keep the button pressed for about 3 seconds.

After pressing ZERO the decreasing background is fitted to the course automatically.

So it is possible to recognize leaks even when the signal is decreasing rapidly.

Please also refer to the pictures below.

iina70e 04.fm technical handbook(1408)

Description and Working Principle 41

Page 42

Fig. 4-3 decreasing background

When the measurement signal declines below the saved underground value the

underground value will automatically be equated with the measurement signal. As

soon as the measurement signal is increasing again the saved decreasing value

remains constant. Increasings of the signal are displayed clearly as a leak.

Fig. 4-4 undo ZERO

When you want to see the measurement signal (includin g underground) please press

the ZERO button about 3 seconds. The saved value will be reset to zero. The

underground signal will not be suppressed anymore.

Notice: The ZERO functions can be selected to a special mode that allows to use

it only when the signal of the falling background becomes stable (see

Chapter 6.6.2.2).

42 Description and Working Principle

iina70e 04.fm technical handbook(1408)

Page 43

4.2.2.5 MENU Button

4.2.2.6 Soft Keys

Special Functions

When pressing the MENU button (Fig. 4-2/12) the selecting menu is shown at the

display. This function is not depending on the operating mode when calibrating.

If the menu is opened during the current session the operator will lead to the last

screen before the menu was left.

Pushing the MENU button again leads back to th e screen of the previous working

mode. The software shows the last screen that was used before.

The function of the eight Soft Keys Fig. 4-2/2 … /5 and /8 … /11 depends on the

current menu. Only key 1 and 8 very often have the functions Back/Cancel (Softkey

no. 1) and OK (Softkey no. 8.).

When inputs are allowed or when settings can be selected in a submenu two of the

Soft Keys always have the same function:

• Soft Keys no. 1 Fig. 4-2/2 is Cancel.

It allows to escape from the submenu without any changes of the present settin gs

and return to the previous menu page.

• Soft Keys no. 8 Fig. 4-2/11 is OK.

The selected settings or edited values will be stored and the previous menu page

will be displayed again.

4.2.2.7 Numerical Entries

If you have opened a menu page where anumber can be changed please proceed

in the following way:

• If you don’t want to change anything, press Soft Key no. 1 Cancel.

• The digit that can be changed is displayed inverted. With the arrows (Soft

• To change a digit to a specific number press the corresponding pair of numbers.

Having reached the last digit all corrections have to be confirmed by OK (Soft Key

no. 8).

Key no. 8) and (Soft Key no. 4) you can choose which digit you need to

change.

A submenu opens and the desired number can be selected. The submenu closes

automatically and the next digit of the total number no w is inve rte d .

iina70e 04.fm technical handbook(1408)

Description and Working Principle 43

Page 44

Example

To change the trigger level 1.0x10

-7

(Soft Key no. 3) Fig. 4-5.

Fig. 4-5: Numerical entry of the Trigger Level 1

In the submenu press 3 (Soft Key no. 4) Fig. 4-6.

mbar l/s to 3x 10-7mbar l/s please press 2/3

44 Description and Working Principle

iina70e 04.fm technical handbook(1408)

Page 45

4.3 Working Modes

V4a

V4b

p

2

V2

MS

V6

V7

p

1

V1b

V1a

V5

TL

V8

V5

V4a

V4b

p

2

V2

MS

V6

V7

p

1

V1b

V1a

V5

TL

V8

V5

4.3.1 Vacuum Mode

As mentioned (Please refer to Chapter 4.2.1 Vacuum System) the sample has to be

evacuated to allow Helium which is sprayed on the outside to enter through any leaks

due to the pressure difference.

When pressing the START Button Valves V1a and V1b open and the sample is

pumped down by the roughing pump (UL1000) or scroll pump (UL1000 Fab). At the

same time valve V2 is closed to avoid an unacceptable pressure increase in the turbo

pump and the mass spectrometer. With valve V2 being closed the turbomolecular

pump is operated without being backed up by the scroll pump. Since the mass

spectrometer is already under vacuum no further gas is pumped. Th us th e pr essure

p

remains constant or increases only slowly.

2

If the pressure p

process), then the evacuation will be broken (V1a and V1b closed) at p

and V2 will open shortly to restore an appropriate foreline (p

The following diagrams show the gas flow during evacuation and during the modes

GROSS, FINE and ULTRA.

even though increases (e.g because of a very long pumping down

2

<1mbar).

2

>10mbar

2

Fig. 4-6: left: Evacuation (no measurement), right: GROSS Mode

The condition for the evacuation process described is maintained until the inlet

pressure p

has dropped below 15 mbar. Now valve V2 opens. Possibly present

1

helium may now flow upstream against the pumping direction of the turbo molecular

pump into the mass spectrometer where it is detected. This mode is called GROSS,

the detection limit is 1×10

iina70e 04.fm technical handbook(1408)

-6

mbar l/s.

Description and Working Principle 45

Page 46

Since the scroll pump continues to evacuate the test sample the inlet pressure p1 will

V4a

V4b

p

2

V2

MS

V6

V7

p

1

V1b

V1a

V5

TL

V8

V4a

V4b

p

2

V2

MS

V6

V7

p

1

V1b

V1a

V5

TL

V8

continue to drop. Below 2 mbar the UL1000 and UL1000 Fab will switch to FINE

mode, i.e. V4a will open and V1b will close. The gas stream enters the turbo pump

at an intermediate level. The sensitivity of the system now is higher, the detection

limit is 1×10

-10

mbar l/s.

Fig. 4-7: left: FINE Mode, right: ULTRA Mode

Now the lower part of the turbo pump further evacuates the sample and after the

pressure p

has reduced below 0.4 mbar the UL1000 and UL1000 Fab switch es into

1

ULTRA mode, i.e. V1a and V4a close and V4b opens. The entrance into the turbo

pump is on a higher level now. The pumping speed at the inlet port is now 2.5 l/s, the

detection limit is 5×10

-12

mbar l/s.

Tipp A special set up of the UL1000 and UL1000 Fab stopps the autoranging

procedure as described above. With th e mode FINE ONLY (Please refer to

Chapter 6.3 Mode) the unit will stay in FINE Mode Fig. 4-7 (left) regardless

the inlet pressure. The valve V1a is closed.

46 Description and Working Principle

iina70e 04.fm technical handbook(1408)

Page 47

4.3.2 Sniffer Mode

In sniff mode a sniffer line (preferably the INFICON standard sniffer line 14005) is

connected to the inlet port. When pressing the START Button the system starts to

pump air through the sniffer line. Due to the constant gas flow through the sniffer line

the software will range directly into FINE mode and stay there. The inlet pressure will

not drop further down. By measuring the inlet pressure the system software makes

sure that the flow through the sniffer line is at the right level. Otherwise warning

messages are generated. The detection limit in sniff mode is <1×10

INFICON’s sniffersystem QT100 may also be used to sniff. Since the QT100

provides a lower inlet pressure it is recommended to keep the system in vacuum

mode to avoid a wrong generation of pressure warnings. The machine factor has to

be adjusted to value 400.

4.3.3 Auto Leak Test Mode

In this mode the test of hermetically sealed testing objects can be performed

automatically. By use of the optional test chamber TC1000 this test mode starts

automatically when closing the chamber lid. Fast test results within seconds are

achieved by using the internal test leak of the UL1000 or UL1000 Fab for a dynamic

calibration, matched to the required test cycle. Leak rates in the 10-9 mbar l/s rang e

can be detected within 5 seconds.

-7

mbar l/s.

iina70e 04.fm technical handbook(1408)

Description and Working Principle 47

Page 48

5 Operation of the UL1000 and UL1000 Fab

The UL1000 and UL1000 Fab is switched on by pushing the mains switch (Please

refer to Chapter 3.2.1 Start up and Measure). After less than 3 minutes, the start up

is completed; the leak detector is then ready to be used for measurements (Standby

mode).

Please connect the part to be tested to the inlet port and press START. The UL1000

and UL1000 Fab starts to evacuate the part. The evacuation time depends on the

volume of the test part. During evacuation the screen shows the inlet pressure online.

Once the pressure of 15 mbar (11 Torr or 1500 Pa) is reached the unit switches to

measurement mode. The corresponding leak rate is displayed. For further

explanations of the screen please refer to Fig. 5-1.

The displayed leak rate corresponds to the helium background concentration in the

part under test. Since the UL1000 and UL1000 Fab continues to pump down the part

this background leak rate will further reduce. As soon as the leak rate is low enough

in respect to your requirements you may start spraying Helium to search for possible

leaks.

When you are finished please press STOP and hold the button a fe w seconds to vent

the part under test.

5.1 Display

The display is used to either show leak rate signals or program specific set-ups and

get information by means of the software menu (Please refer to Chapter 6

Description of the Menu). In addition messages and maintenance instructions are

displayed on the screen (Please refer to Chapter 8 Error And Warning Messages).

5.2 The Screen in Run-Up Mode

In run-up mode the display shows:

• Speed of the number of revo lu tio ns

• Foreline pressure

• State of emission

• Active filament

• A bar graph which shows the run-up progress

Notice: If the display is too bright or too dark you can cha nge the contrast. Ple ase

see Chapter 6.2.4. During run-up phase the menu button can be pushed

(see Chapter 4.2.2.5) to get to the selection menu.

48 Operation of the UL1000 and UL1000 Fab

iina70e 05.fm technical handbook(1408)

Page 49

5.3 Display in stand-by mode

In stand by mode the states are shown in the lower edge of the display (see Chapter

5.4.3). Furthermore calibration (Please refer to Chapter 7) can also be started in

stand by mode and purging, too (see Chapter 5.3.1)

5.3.1 Purging

Every time when the UL1000 Fab changes into stand by mode it can start purging

automatically after 20 seconds. During this purging the scroll pump is flushed through

purge connection (See Fig. 2-6/11).

When the machine is in stand by mode this operation also can be activated manually

(Key 7). By pressing the key again the purging will be discontinued. By pressing

START the activity will be discontinued, too.

5.4 The Screen in Measurement Mode

In measurement mode the leak rates can be diplayed in two different modes:

• Numerically, combined with a bargrap h Fig. 5- 1

• Trend mode (leak rate versus time) Fig. 5-2

In the lower right corner of the display (next to the Soft Key no. 8) you will find a

symbol that allows to switch between the display modes by pressing Soft Key no. 8.

Please refer to chapters 5.4.4 Numerical Display Mode and 5.4.5 Tren d Mode for

explanations of the different display modes.

Access to calibration (Soft Key no. 5) and access to the speaker volume (Soft Keys

no. 2 and no. 3) is the same in all modes. Also the status icons in the bottom line are

in common in all display modes.

Fig. 5-1: Display, measurement mode

5.4.1 Call for Calibration

In all modes the Soft Key no. 5 is used to get to the calibration routine. Refer to

Chapter 7 Calibration for further information regarding calibration.

iina70e 05.fm technical handbook(1408)

Operation of the UL1000 and UL1000 Fab 49

Page 50

5.4.2 Speaker Volume

STO P

Danger

The hearing can be harmed by the audio alarm.

The accoustic output can exceed a level of 85dB(A).

Do only expose to the audio alarm for a short time or use ear protection.

On the left hand side two loud speaker symbols are shown, combined with the signs

+ and -. By pressing the corresponding softkeys (Soft Keys no. 2 and no. 3) the

volume can be adjusted for convenient loudness. In the bottom line of the display

another loud speaker symbol is shown, combined with a number. This number

indicates the level of the current loudness (ranges from 0 to 15).

Refer to Chapter 6.4.3 Volume for information on loudness, alarms, and sound

tracks.

5.4.3 Status Line in the Display

The status line at the bottom of the display informs about (reading from left to right):

Symbol of display Meaning Explanation

S1 • Trigger 1

S2 • Trigger 2

•• • Detected mass

• Volume level

• Warning triangle

Please refer to Chapter 5.4.2

Speaker Volume.

If the trigger values are exceeded

these signs are inverted. (White on

black background.)

see: Trigger 1

Number of dots indicates the mass

number (4 dots = Helium,

2 dots = Hydr o ge n)

Please refer to Chapter 8.1

VAC • Working mode

ULTRA • Vacuum area

ZERO • ZERO

COR • corrected leak rate

Auto Leak Test • Auto Leak Test

I•ZERO • I•ZERO

STABLE • Signal stable

50 Operation of the UL1000 and UL1000 Fab

VAC or SNIFF indicate which

working mode was selected (Please

refer to Chapter 6.3 Mode).

Depending on the inlet pressure the

UL1000 and UL1000 Fab may be in

GROSS, FINE or ULTRA, which is

indicated here (Chapter 4.3 Working

Modes)

Indicates if ZERO-function is active.

Indicates if the leak rate is displayed

as air equivalent.

Indicates if this mode is active

Indicates if I•ZERO function is active.

Indicates if background signal is

stable (see Chapter 6.6.2.2)

iina70e 05.fm technical handbook(1408)

Page 51

5.4.4 Numerical Display Mode

The display shows the leak rate in big digital figures, see Fig. 5-1. The unit of the leak

rate is shown, too. Underneath the leak rate the inlet pressure is displayed in smaller

digits. The units of leak rate and pressure can be defined in the menu (See Chapter

6.4.4 Units).

Below this the same leak rate is shown graphically as a bar. The scale of this bar, i.e.

the number of decades included in this bar can be defined in the menu (Please refer

to Chapter 6.2.2 Display-range auto/manual). The programmed trigger levels

(Please refer to Chapters 6.4.1 and 6.4.2) are indicated at the bar by short vertical

lines: a straight line for trigger 1 and a dotted line for trigger 2.

In addition the inlet pressure is displayed in smaller figures above the bargraph.

5.4.5 Trend Mode

In trend mode the leak rates are displayed over time Fig. 5-2. In addition the actual

leak rate and inlet pressure also are displayed digitally. The time a xis can be defined

in the menu (Please refer to Chapter 6.2.3 Time axis). The intensity axis (y-axis) is

defined the same way as the bargraph (Please refer to Chapter 6.2.1 Scale linear/

logarithmic ff).

Fig. 5-2: Display, trend mode

iina70e 05.fm technical handbook(1408)

Operation of the UL1000 and UL1000 Fab 51

Page 52

6 Description of the Menu

By pressing the MENU push button Fig. 6-1 the main menu will be displayed

regardless of the current working mode.

Fig. 6-1: The Main Menu

The main menu Fig. 6-1 leads the operator to several submenus described in the

following chapters.

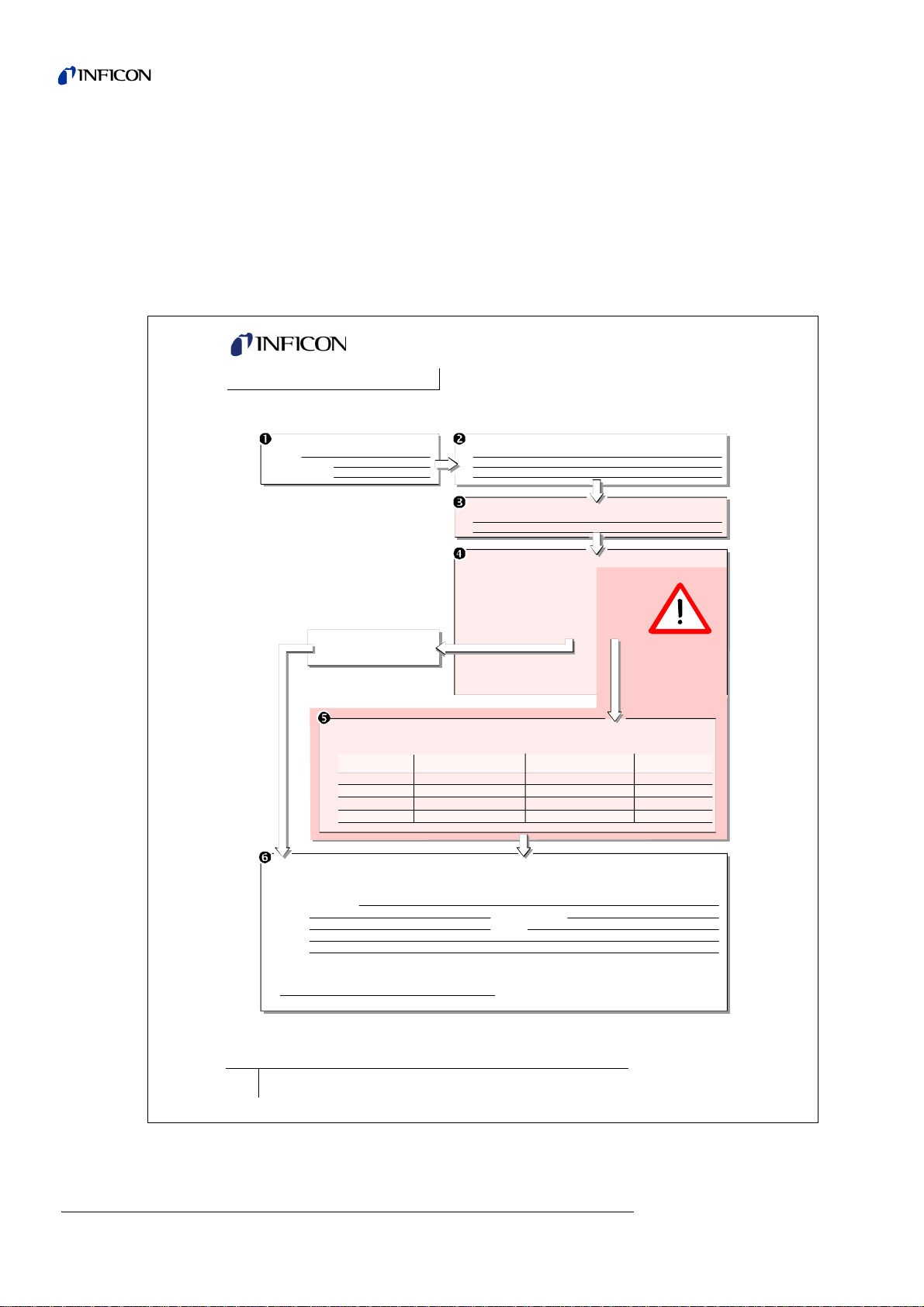

6.1 Main Menu

The main menu shows 7 sub-menus. In these sub-menus groups of technical

features are put together logically. From here the next levels of the menu tree can be

reached.

Tipp All following chapters show the path to get to the described me nu line right

underneath the headline. This path is indicated by a dot (•).

Key No. Name Description

1 Back Return to the previous screen.

Display settings like scaling, contrast, system

2 View

3 Mode

4 Trigger & Alarms

5 Calibration

6 Settings

7 Information

8 Access Control

background.

Please refer to Chapter 6.2.

Selection of different working modes like

Vacuum, Sniff

Please refer to Chapter 6.3.

Settings of units, trigger levels and alarms.

Please refer to Chapter 6.4.

Calibration of the UL1000 and UL1000 Fab.

Please refer to Chapter 6.5.

Settings of internal machine parameters.

Please refer to Chapter 6.6.

Information on the UL1000 and UL1000 Fab

(electrical and vacuum data) and servcie menu.

Please refer to Chapter 6.7.

Access restrictions.

Please refer to Chapter 6.8.

The next page gives an overview of the entire menu architecture Fig. 6-2.

iina70e 06.fm technical handbook(1408)

52 Description of the Menu

Page 53

1. Level 2. Level 3. Level

Scale linear/logarithmic

Display-range auto/manual

Time axis

View (See 6.2)

Mode (See 6.3 ) Sniff/Vacuum / Auto Leak Test

Trigger & Alarms (See 6.4 )

Calibration (See 6.5 )

Main Menu

Settings (See 6.6 )

Information (See 6.7)

Access Control (See 6.8)

Contrast

Background in Stand-by

Decimal places

Lower display limit

Trigger Level 1

Trigger Level 2

Volume

Units

Alarm delay

Audio alarm type

internal

external

Vacuum settings

Zero & Background

Mass

Interfaces

Miscellaneous

Parameter save / load

Monitoring functions

View settings

View internal data

Vacuum diagram

View error list

Calibration history

Calibration factors

Service

Access to CAL function

Change Device PIN

Change Menu-PIN

manual

automatic

Edit leakrate

Start