Page 1

C

over Page

OPERATING MANUAL

®

Transpector CPM

Compact Process Monitor

PN 074-641-P1B

Page 2

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

INFICON®, Transpector®, and FabGuard® are registered trademarks and FabGuard Explorer™ is a trademark

of INFICON.

Windows®, Windows NT® and Microsoft® are registered trademarks of Microsoft Corporation.

®

is a registered trademark of DuPont Co.

Teflon

Swagelok

®

is a registered trademark of Swagelok Co.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2016 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 3

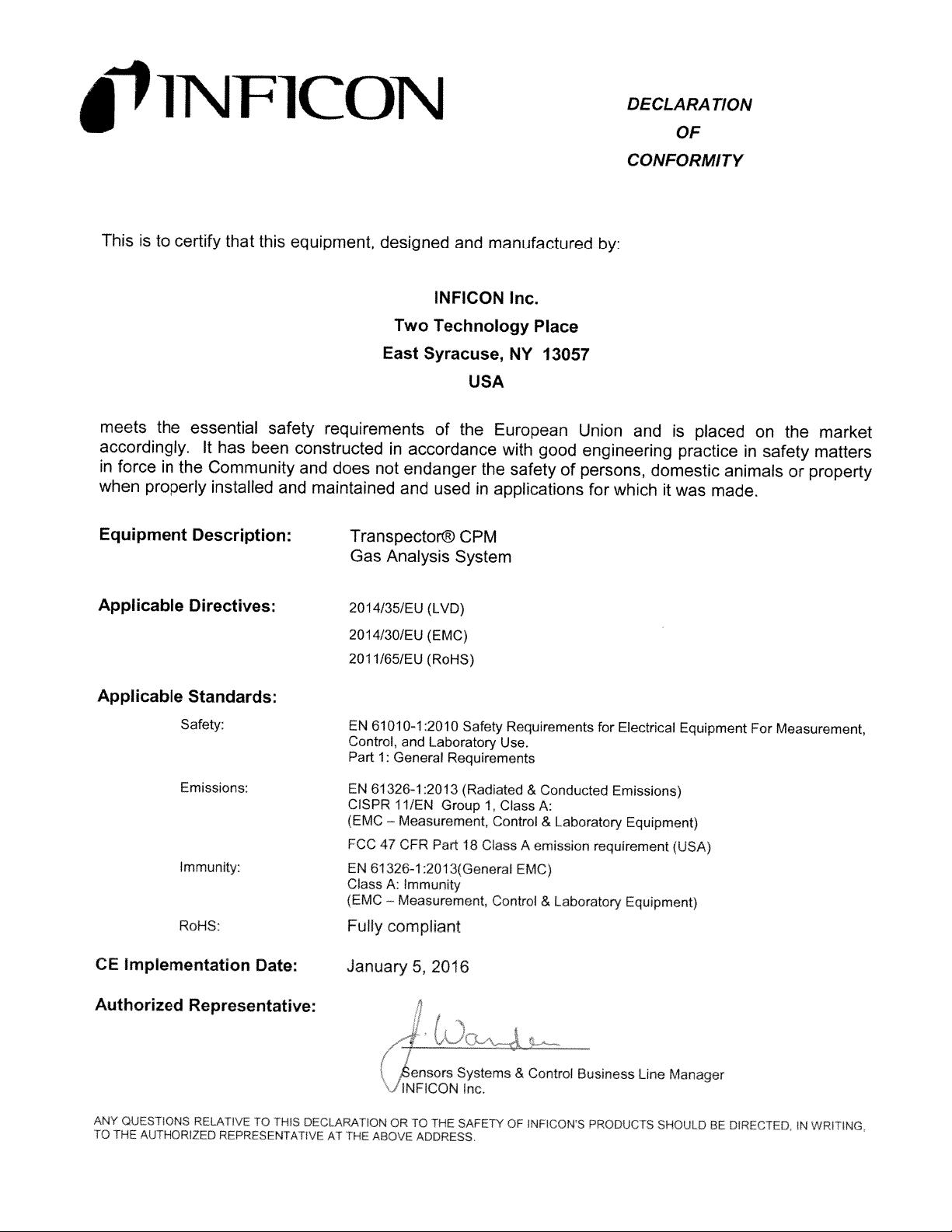

Declaration Of Conformity

Page 1

Page 4

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

one (1) year from the date of shipment thereof by Seller. Seller's liability under this

warranty is limited to such of the above products or parts thereof as are returned,

transportation prepaid, to Seller's plant, not later than thirty (30) days after the

expiration of the period of warranty coverage in respect thereof and are found by

Seller's examination to have failed to function properly because of defective

workmanship or materials and not because of improper installation or misuse and

is limited to, at Seller's election, either (a) repairing and returning the product or

part thereof, or (b) furnishing a replacement product or part thereof, transportation

prepaid by Seller in either case. In the event Buyer discovers or learns that a

product does not conform to warranty, Buyer shall immediately notify Seller in

writing of such non-conformity, specifying in reasonable detail the nature of such

non-conformity. If Seller is not provided with such written notification, Seller shall

not be liable for any further damages which could have been avoided if Seller had

been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

Warranty

www.inficon.com reachus@inficon.com

Standard INFICON One Year

Page 1

Page 5

Transpector CPM Operating Manual

Table Of Contents

Cover Page

Trademarks

Disclaimer

Copyright

Declaration Of Conformity

Warranty

Chapter 1

Getting Started

1.1 General Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Purpose of Transpector CPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2.1 Description of the Transpector CPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Using this Operating Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 How to Contact INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4.1 Returning Transpector CPM to INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5 Transpector CPM Performance Specifications. . . . . . . . . . . . . . . . . . . . . . .1-5

1.5.1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.5.2 Hex Block Orifice Sampling Inlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.5.3 Atmospheric Pressure (Capillary) Sampling. . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.6 Physical Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.6.1 Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.6.2 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.6.3 Ventilation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.7 Electrical Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.7.1 Required Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.7.1.1 Acceptable Supply Voltage Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.7.1.2 Required Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.7.1.3 Power Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1.7.1.4 Fuse Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.7.1.5 Overvoltage Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

1.7.1.6 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.8 Nitrogen Purge Gas (Corrosive System Only) . . . . . . . . . . . . . . . . . . . . . . 1-11

1.9 Exhaust Gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.10 Air Pressure Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1.10.1 Required Air Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

1.10.2 Air Pressure Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

TOC – 1

Page 6

Transpector CPM Operating Manual

1.10.3 Moisture Content of Compressed Air Supply . . . . . . . . . . . . . . . . . . . . . . . 1-13

1.10.4 Air Pressure Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1.11 Vacuum Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.11.1 Required Vacuum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.11.2 Acceptable Range Of Vacuum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.12 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.12.1 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.12.2 Altitude Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.12.3 Maximum Humidity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.12.4 Pollution Degree. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.12.5 Maximum Operating Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.12.6 Minimum Operating Temperatures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.12.7 Clean Room Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.12.8 Anti-Static Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.13 Computer System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.13.1 Operating System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Chapter 2

2.1 Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Transpector Electronics Module, Heat Guard, and Cable Box Installation . 2-2

2.2.1 Attach Transpector Electronics Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.2 Attach Heat Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.3 Attach Cable Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3 Sniffer Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.4 Mounting the Pumping System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.4.1 Installing the Support Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.4.2 Atmospheric Support Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.5 CPM Controller Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.6 Transpector Cable Box Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.7 CPM Foreline Pump Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.8 Software Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Chapter 3

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 General Networking Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.1 IP Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.2 Subnetworking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 Transpector CPM IP Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Installation

Connecting Transpector CPM

TOC – 2

Page 7

Transpector CPM Operating Manual

3.3.1 Using the INFICON Mass Spectrometer Search Utility to

Change the Transpector CPM IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.1.1 Change IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3.1.2 Launch Web UI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.1.3 Find Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3.3.1.4 Show Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3.4 Connecting Transpector CPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.4.1 Connecting a Single Transpector CPM . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3.4.1.1 Single Transpector CPM Direct Connection Installation. . . . . . . . . . . . . . . .3-6

3.4.1.2 Installing a Single Transpector CPM on an Existing Local Network. . . . . . . 3-6

3.4.2 Installing Multiple Transpector CPM Sensors. . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.4.2.1 Installing Multiple Transpector CPM Directly to a Host Computer . . . . . . . . 3-7

3.4.2.2 Installing Multiple Transpector CPM on an Existing Local Network . . . . . . .3-7

3.5 Changing the Computer IP Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.5.1 Windows 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Chapter 4

How the CPM System Works

4.1 CPM Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.3 Instrument Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.3.1 Input/Output (Aux I/O) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3.1.1 CPM Aux I/O Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.3.1.2 Two Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3.1.3 One Status Relay Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.3.1.4 One Analog Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.3.2 Ultra-High Vacuum System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.3.2.1 Foreline Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.3.3 Heater(s) Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.3.4 CPM Controller Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.3.5 Solenoid Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.3.6 Sensor and Transpector Electronics Module Subsystem. . . . . . . . . . . . . . . 4-7

4.4 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4.5 Sample Inlet Systems and Examples of Use . . . . . . . . . . . . . . . . . . . . . . . .4-9

4.5.1 Inlet System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

4.5.2 High Pressure Sampling: Orifice Bypass (V4) . . . . . . . . . . . . . . . . . . . . . . 4-12

4.5.3 Dual-Capillary Sampling Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.6 Advice and Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

4.6.1 Achieving Good Base Pressure in the CPM. . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.6.2 Avoiding Trapped Gas when Sampling Valves are Closed . . . . . . . . . . . . 4-14

TOC – 3

Page 8

Transpector CPM Operating Manual

Chapter 5

Theory and Application Guide

5.1 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2.1 The Ion Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2.2 The Quadrupole Mass Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2.2.1 Scanning Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.2.2.2 The Zero Blast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.2.3 The Ion Detector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.2.3.1 The Electron Multiplier (EM) Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.2.3.2 The Continuous Dynode Electron Multiplier/Faraday Cup Detector. . . . . . . 5-9

5.3 How to Interpret The Result . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.3.1 Qualitative Interpretation Of Mass Spectra . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.3.1.1 Ionization Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.3.1.2 Isotope Ratios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.3.1.3 Electron Energy Effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.3.1.4 A Qualitative Interpretation Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.3.1.5 Dry Etching Chemistries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.3.1.6 Tungsten CVD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.3.1.7 Copper MOCVD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

5.3.2 Quantitative Interpretation of Mass Spectra

(Calculating Partial Pressures). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.3.3 Additional Information For Interpreting Mass Spectra . . . . . . . . . . . . . . . . 5-32

5.3.3.1 Ion Source Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

5.3.3.2 Scanning Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

5.3.3.3 Fragmentation Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

Chapter 6

Operation

6.1 HexBlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.1 HexBlock Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.1.1.1 Hex Block Process Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.1.2 Calibration Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.1.2.1 High Mass FC5311 Tuning Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.1.3 Process Gauge (CDG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.2 Heaters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.3 Pumping System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.3.1 Foreline Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.3.1.1 Foreline Pirani Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

TOC – 4

Page 9

Transpector CPM Operating Manual

6.3.2 Turbo Molecular Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

6.3.2.1 Turbo Molecular Pump Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.4 Nitrogen Purge Valve for the Turbo Molecular Pump on Corrosive Pumping

Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

6.5 Filament Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

6.5.1 Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

6.5.2 Total Pressure Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

6.5.3 Filament Lifetime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

6.6 Pneumatic Digital Pressure Switch and Pressure Gauge . . . . . . . . . . . . . 6-11

6.6.1 Setup Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

6.6.2 How to Test for Proper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.6.3 How to Lock and Unlock the Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Chapter 7

Maintenance

7.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.2 Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2.1 Toxic Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.2.2 Radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.2.3 Electrical Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.3 Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.3.1 Bakeout of Quadrupole. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.3.2 Spare Heating Jacket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.4 General Instructions For All Repair Procedures . . . . . . . . . . . . . . . . . . . . . . 7-4

7.5 Required Tools, Materials, or Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.5.1 Tools for Replacing the Filament Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.5.2 Tools for Replacing the Ion Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

7.5.3 Tools for Replacing the Electron Multiplier . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.5.4 Parts Required For Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.6 Changing Diaphragms in the Foreline Pump . . . . . . . . . . . . . . . . . . . . . . . .7-6

7.6.1 Replacement Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7.6.2 Diaphragm kit PN 923-418-G1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

7.6.3 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

7.7 Transpector Sensor Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

7.7.1 How to Determine if a Filament Kit Replacement is Required . . . . . . . . . . 7-17

7.7.2 Transpector Sensor Filament Replacement . . . . . . . . . . . . . . . . . . . . . . . . 7-18

7.7.3 Transpector Sensor Ion Source Replacement . . . . . . . . . . . . . . . . . . . . . .7-20

7.7.4 Electron Multiplier Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

7.8 HexBlock Inlet Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

7.8.1 Valve and Orifice Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

TOC – 5

Page 10

Transpector CPM Operating Manual

Chapter 8

Diagnosing Problems

8.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Communication Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.3 CPM Symptom—Cause— Remedy Chart . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.4 If You Cannot Resolve Your Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8.5 Event Log Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Chapter 9

Recommended Parts List

9.1 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 CPM Consumable Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.3 Preventative Maintenance Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.4 Replacement Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Chapter 10

FabGuard Explorer Operation

10.1 Operation (FabGuard Explorer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.2 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.3 Connecting to Transpector CPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.4 RGA Configuration—CPM tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

10.4.1 Valves and Orifices pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10.4.1.1 Inlet LP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10.4.1.2 Inlet HP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10.4.1.2.1 Inlet HC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10.4.1.2.2 Inlet Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10.4.1.2.3 Inlet Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

10.4.2 Gauges pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

10.4.2.1 Process Gauge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

10.4.3 Bypass Delay - Interlock between V2 and V4 . . . . . . . . . . . . . . . . . . . . . . 10-7

10.5 CPM Configuration Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

10.6 CPM Sensor Acquisition Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

10.6.1 What to Acquire (RGAs). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

10.6.1.1 Acquisition Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

10.6.1.1.1 Spectrum Mode Acquisition Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 10-14

10.6.1.2 Selected Masses Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-15

10.6.1.2.1 Existing Masses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-16

10.6.1.2.2 Adding Masses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-17

10.6.2 How to Acquire (CPM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-20

10.6.2.1 Ionizer Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-21

TOC – 6

Page 11

Transpector CPM Operating Manual

10.6.2.2 Start Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-21

10.6.2.2.1 Start Mode Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-21

10.6.2.2.2 Data Threshold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

10.6.2.2.3 Emission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

10.6.2.2.4 Multiplier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

10.6.2.2.5 Relay 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

10.6.2.3 Stop Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-23

10.6.2.3.1 Stop Mode Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-23

10.6.2.3.2 Data Threshold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-23

10.6.2.3.3 Maximum Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-24

10.6.2.3.4 Emission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-24

10.6.2.3.5 Multiplier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-24

10.6.2.3.6 Relay 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-25

10.6.2.4 Dwell. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-25

10.6.2.4.1 Dwell Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-25

10.6.2.4.2 Dwell Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-26

10.6.2.5 Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-26

10.6.2.5.1 Delay Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-26

10.6.2.5.2 Time Between Scans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-27

10.6.2.5.3 Stabilization Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-27

10.6.2.6 Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-27

10.6.2.6.1 Baseline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-27

10.6.2.6.2 Peak Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-28

10.6.2.7 Inlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-28

10.6.2.7.1 Close After . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-29

10.6.2.7.2 Duty Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-29

10.6.2.8 Heater. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-29

10.6.2.8.1 Off After . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-29

Chapter 11

Glossary

Chapter 12

Bibliography

TOC – 7

Page 12

Chapter 1

WARNING

WARNING - Risk Of Electric Shock

WARNING - Risk Of Electric Shock

WARNING - Risk Of Electric Shock

Getting Started

1.1 General Safety Information

Transpector CPM is not for use in a manner not specified

by INFICON.

There are no user serviceable components within the

Transpector CPM case.

Transpector CPM Operating Manual

Potentially lethal voltages are present when the line cord

is connected to Transpector CPM.

Refer all Transpector CPM maintenance to qualified

personnel.

1–1

Page 13

1.2 Purpose of Transpector CPM

Transpector CPM samples a representative fraction of a process environment and

directs the gas sample to a Residual Gas Analyzer (RGA). The CPM can detect

levels of impurities in process gases at sub-ppm levels.

1.2.1 Description of the Transpector CPM

Transpector CPM is comprised of:

®

FabGuard

control and status information. It includes a full array of basic residual gas

analyzer (RGA) features, including Spectrum or Selected Peaks scanning,

Leak Detection and Recipe Generation.

Quadrupole Sensor analyzes gases by: (1) ionizing the gas molecules,

(2) separating the ions by their mass-to-charge ratio, and (3) measuring the

quantity of ions at each mass. The sensor can indicate the partial pressures of

gases characteristic of processes occurring within a vacuum or other vessel,

and is used to investigate the nature of a process or to monitor process

conditions.

Electronics Module (Transpector

module and quadrupole sensor are a matched set. The electronics module

attaches to and is supported by the sensor.

or FabGuard Explorer™ software provides automatic or manual

Transpector CPM Operating Manual

®

) controls the sensor. The electronics

CPM Controller consolidates control functions into a single device. The CPM

controller works in conjunction with the Transpector electronics module to

control valve activation, heaters, pumps, and power to all elements of the

system.

Pumping System provides process sampling from 1.5 atmospheres to high

vacuum.

Inlet Valves, a HexBlock™ inlet provides several sampling ranges, a

calibration reference, and a process pressure gauge.

1–2

Page 14

1.3 Using this Operating Manual

CAUTION

WARNING

WARNING - Risk Of Electric Shock

Before using this manual, please take a moment to understand the Cautions and

Warnings used throughout. They provide pertinent information that is useful in

achieving maximum instrument efficiency while ensuring personal safety.

NOTE: Notes provide additional information about the current topic.

HINT: Hints provide insight into product usage.

Failure to obey these messages could result in damage

to the sensor.

Failure to obey these messages could result in personal

injury.

Transpector CPM Operating Manual

Potentially lethal voltages are present.

1–3

Page 15

1.4 How to Contact INFICON

To contact INFICON regarding Transpector CPM, please use the following contact

information:

INFICON, Inc.

Two Technology Place

East Syracuse, NY 13057

USA

Tel: +315.434.1100

Fax: +315.437.3803

E-mail: reachus@inficon.com

Worldwide customer support information is also available at www.inficon.com

under Contact >> Support Worldwide

Sales and Customer Service

Technical Support

Repair Service

If experiencing a problem with Transpector CPM, please have the following

information readily available:

Transpector CPM Operating Manual

The Transpector CPM serial number

A description of the problem

An explanation of any attempts at corrective action

The exact wording of any error messages received

1.4.1 Returning Transpector CPM to INFICON

Do not return any component of the Transpector CPM to INFICON without first

speaking with a Customer Support Representative. A Return Material

Authorization (RMA) number must be obtained from the Customer Support

Representative.

If a package is delivered to INFICON without an RMA number, the package will be

held and customer contact will be made. This will result in delays in servicing

Transpector CPM.

Prior to being given an RMA number, a Declaration Of Contamination (DOC) form

may need to be completed if the sensor has been exposed to process materials.

DOC forms must be approved by INFICON before an RMA number is issued.

INFICON may require that the sensor be sent to a designated decontamination

facility, not to the factory.

1–4

Page 16

Transpector CPM Operating Manual

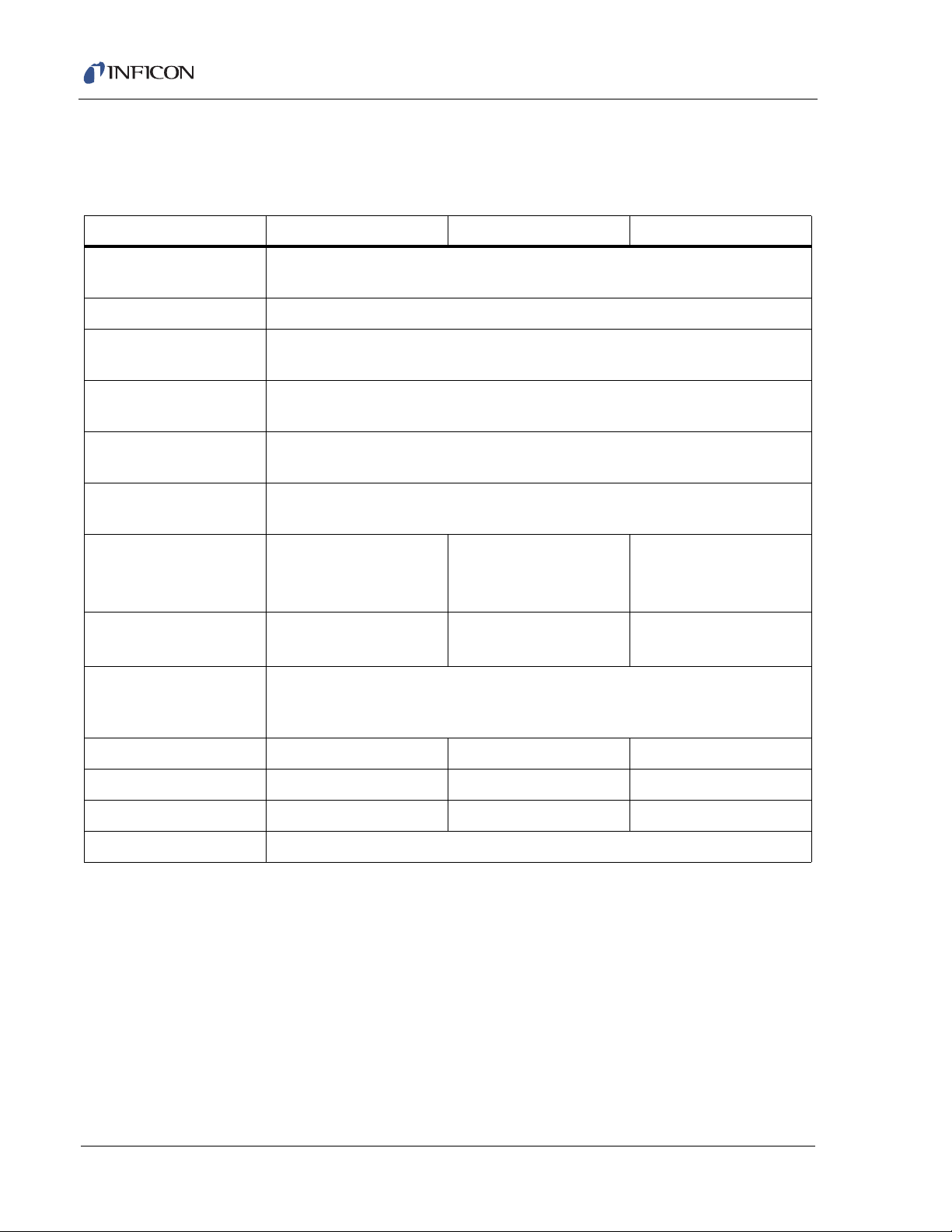

1.5 Transpector CPM Performance Specifications

1.5.1 General Specifications

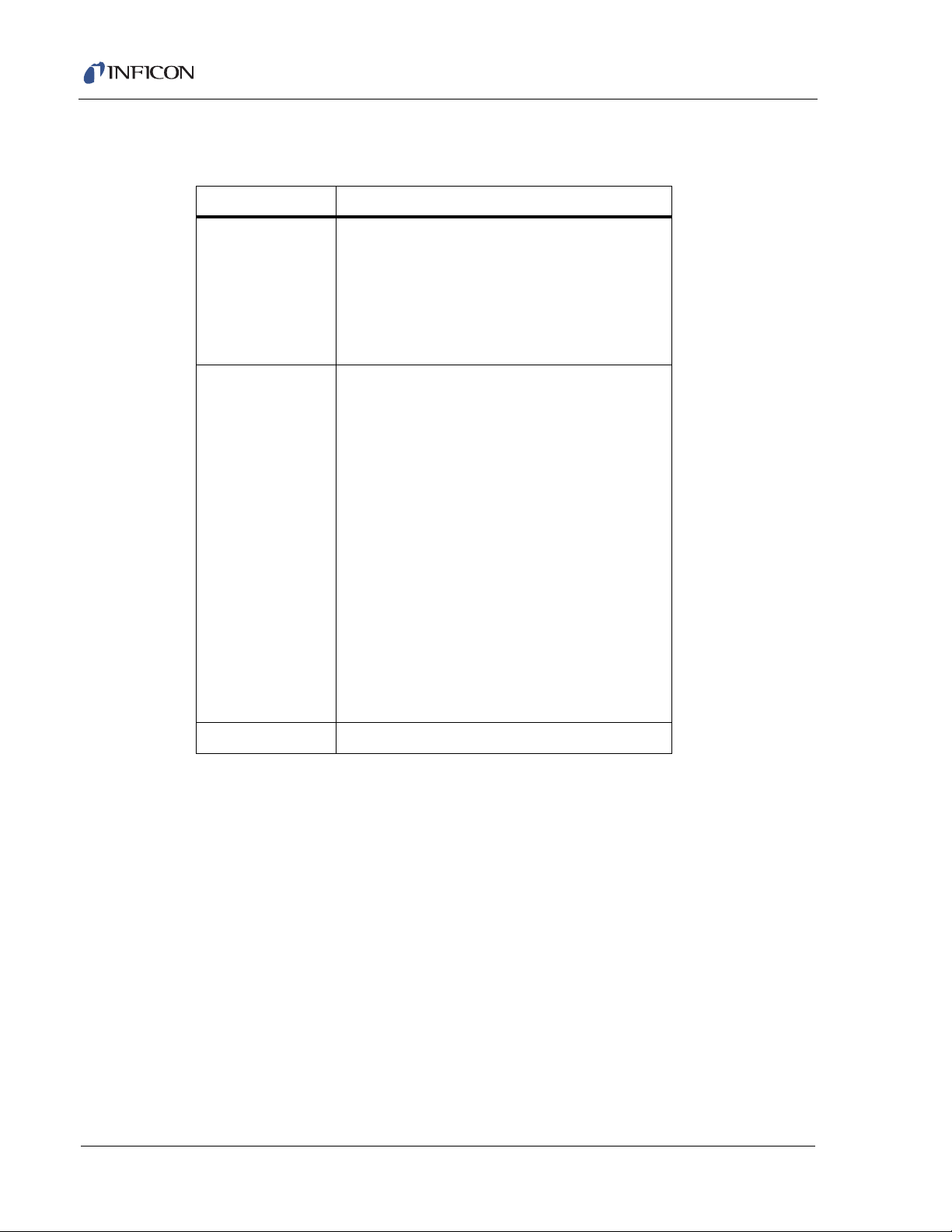

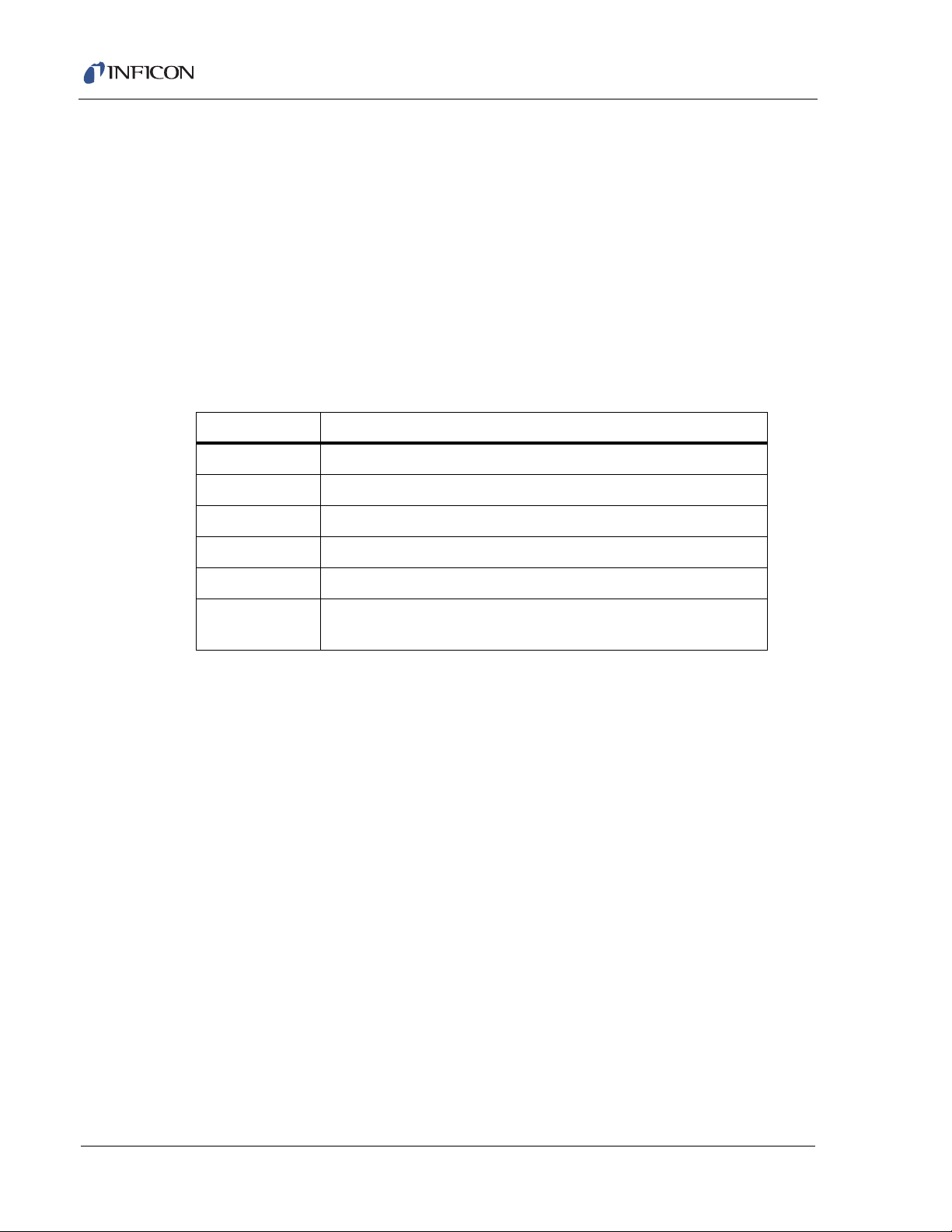

Table 1-1 General specifications

Mass Range (AMU) 1 – 100 1 – 200 1 – 300

Resolution <1 AMU wide @ 10% peak height over entire mass range

(per AVS 1993 recommended practice)

Total Pressure Range

Total Pressure

Accuracy

1

2

5x10-7–1x10-3 Torr (6.6x10-7–1.3x10-3 mbar)

±25% 1x10

-6

–1x10-3 Torr (1.3x10-6–1.3x10-3 mbar)

Maximum Ion Source

Operating Pressure

Nominal Operating

Pressure

4

System Operating

Pressure

Sensitivity

@ Low Emission

@ High Emission

Minimum Detectable

Partial Pressure

5

Maximum Data Rate

(analog scans OR

selected peaks)

Abundance Sensitivity

Zero Blast

Detection Limit

Linearity

7

8

9

3

-8

Torr (1.3x10-8 mbar)–1.2 atmospheres (with proper inlet configuration)

1x10

Amps/Torr (Amps/mbar)

-6

>4x10

>2x10

(1.3x10

6

(>3x10-6)

-5

(>1.5x10-5)

-13

1x10

-13

<5 ppm <10 ppm <100 ppm

<2 ppm <25 ppm <200 ppm

<1 ppm <2 ppm <4 ppm

Torr

mbar)

1x10-3 Torr (1.3x10-3 mbar)

2x10-4 Torr (2.6x10

-4

mbar)

Amps/Torr (Amps/mbar)

-6

-5

2x10

(2.6x10

(>1.5x10-6)

(>7.6x10-6)

-13

To rr

-13

mbar)

>2x10

>1x10

1.8 ms per point

(555 data points per second)

±20%

Amps/Torr (Amps/mbar)

-6

-6

4x10

(5.3x10

(>7.6x10-7)

(>3.8x10-6)

-13

Torr

-13

mbar)

>1x10

>5x10

1–5

Page 17

Transpector CPM Operating Manual

Table 1-1 General specifications (continued)

Mass Range (AMU) 1 – 100 1 – 200 1 – 300

Minimum Background

Pressure

Maximum Sensor and

1x10-8 Torr

(1.3x10

150°C

-8

mbar)

Inlet Temperature

1

Ion source pressure reading @ low emission using total pressure lens

2

Total pressure accuracy @ low emission

3

Maximum ion source operating pressure @ low emission

4

-4

2x10

5

MDPP at the ion source with EM on and 1 s dwell time

6

Mass 40 contribution onto 41 AMU

7

Zero blast contribution onto 2 AMU

8

Minimal detectable concentration with Krypton in air @ a 1 s dwell time

9

For 1 Torr orifices and lower. Linearity @ low emission at 0.1 to 2 times the nominal orifice pressure

Torr in the ion source will produce about 1x10

-5

Torr in the quadrupole region

1–6

Page 18

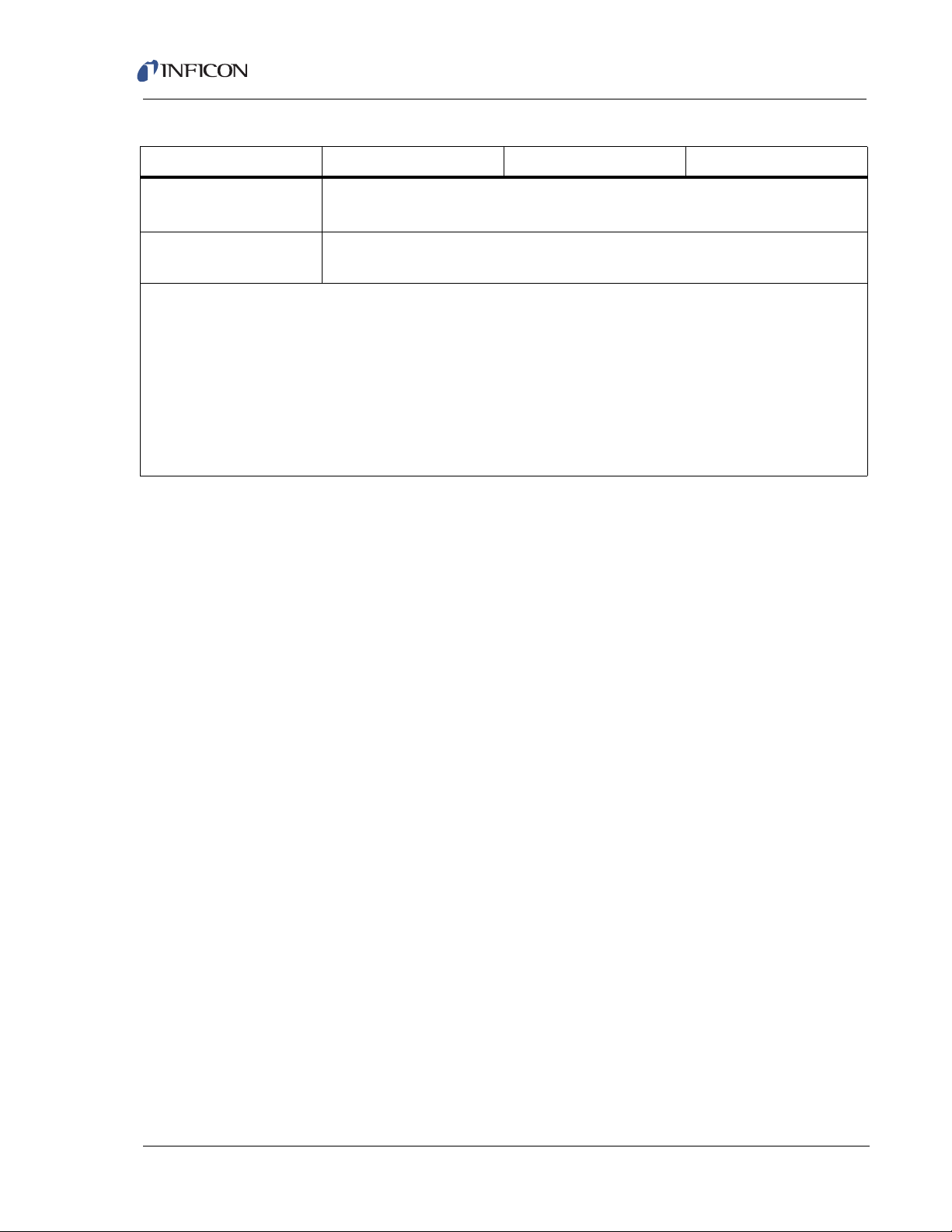

1.5.2 Hex Block Orifice Sampling Inlets

Table 1-2 HexBlock inlets and available orifices (maximum nominal pressure for orifice)

Inlet Orifices

V1 (LP) 3 mTorr (no orifice)

V2 (HP) 3 mTorr (no orifice)

10 Torr (bypass)

30 Torr (bypass)

1 Torr Sniffer (bypass)

3 Torr Sniffer (bypass)

7 Torr Sniffer (bypass)

10 Torr Sniffer (bypass

30 Torr Sniffer (bypass)

100 Torr Sniffer (bypass)

Transpector CPM Operating Manual

10 mTorr

15 mTorr

100 mTorr

360 mTorr

1 Torr

10 mTorr

15 mTorr

100 mTorr

360 mTorr

1 Torr (bypass)

3 Torr (bypass)

1–7

V3 (HC) 1 mTorr (High Conductance)

Page 19

1.5.3 Atmospheric Pressure (Capillary) Sampling

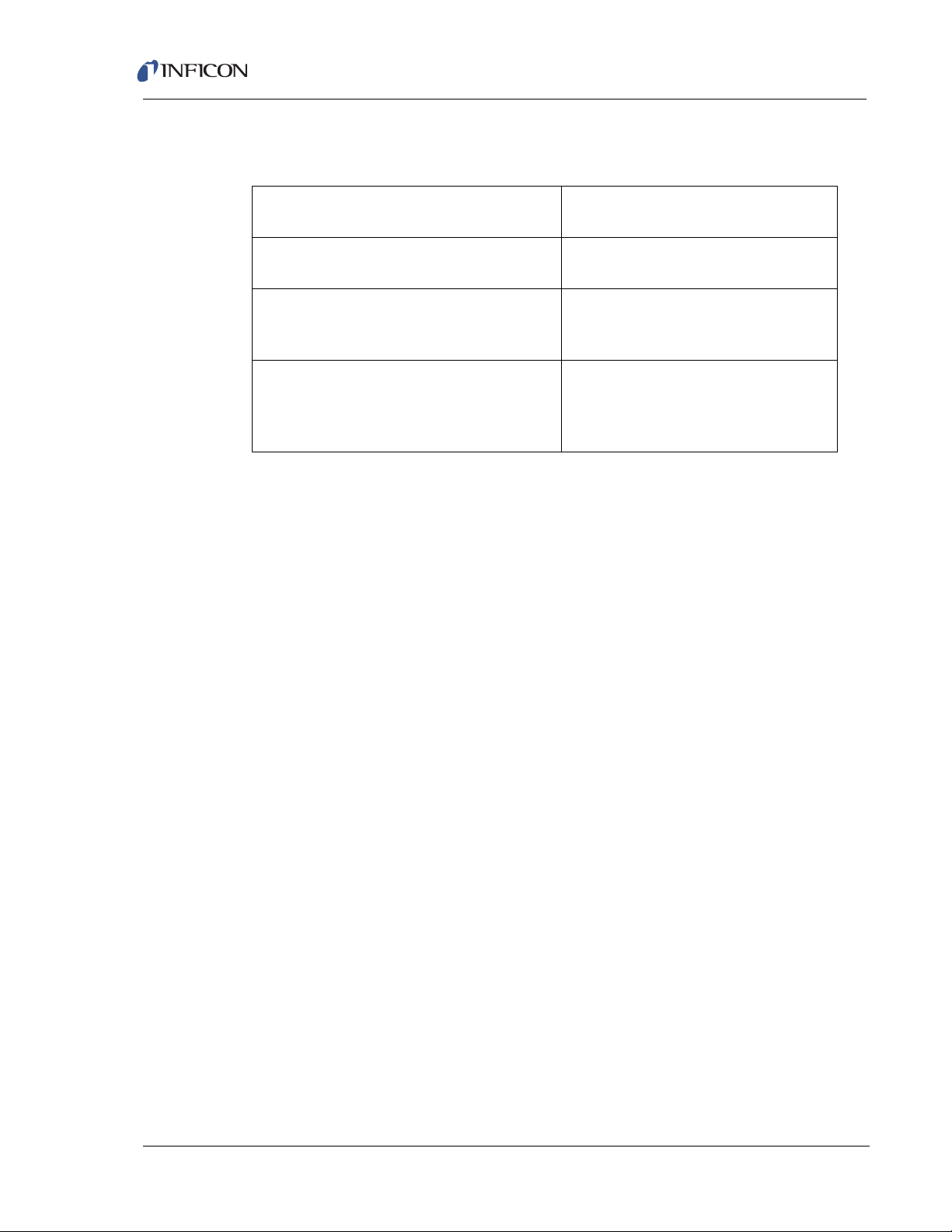

Table 1-3 Capillary sampling option

Transpector CPM Operating Manual

Process Pressure Range

o

(23

C ambient, no purge)

Capillary Size and Lengths 1/16 in. OD x 1.5 m SS capillary

Process Gas Consumption 2.6 sccm @ 300 Torr (400 mbar)

Response Time for Composition

Changes (response to normal inert

gases)

300 to 900 Torr (400 to 1199 mbar)

1/16 in. OD x 3.0 m SS capillary

17 sccm @ 760 Torr (1013 mbar)

30 sccm @ 900 Torr (1199 mbar)

Capillary Delay: t(1.5m) = 0.3 s

t(3.0m) = 1 s

Intermediate Volume Tau = 0.7 s

CPM Isolation time constant = 75 s

1–8

Page 20

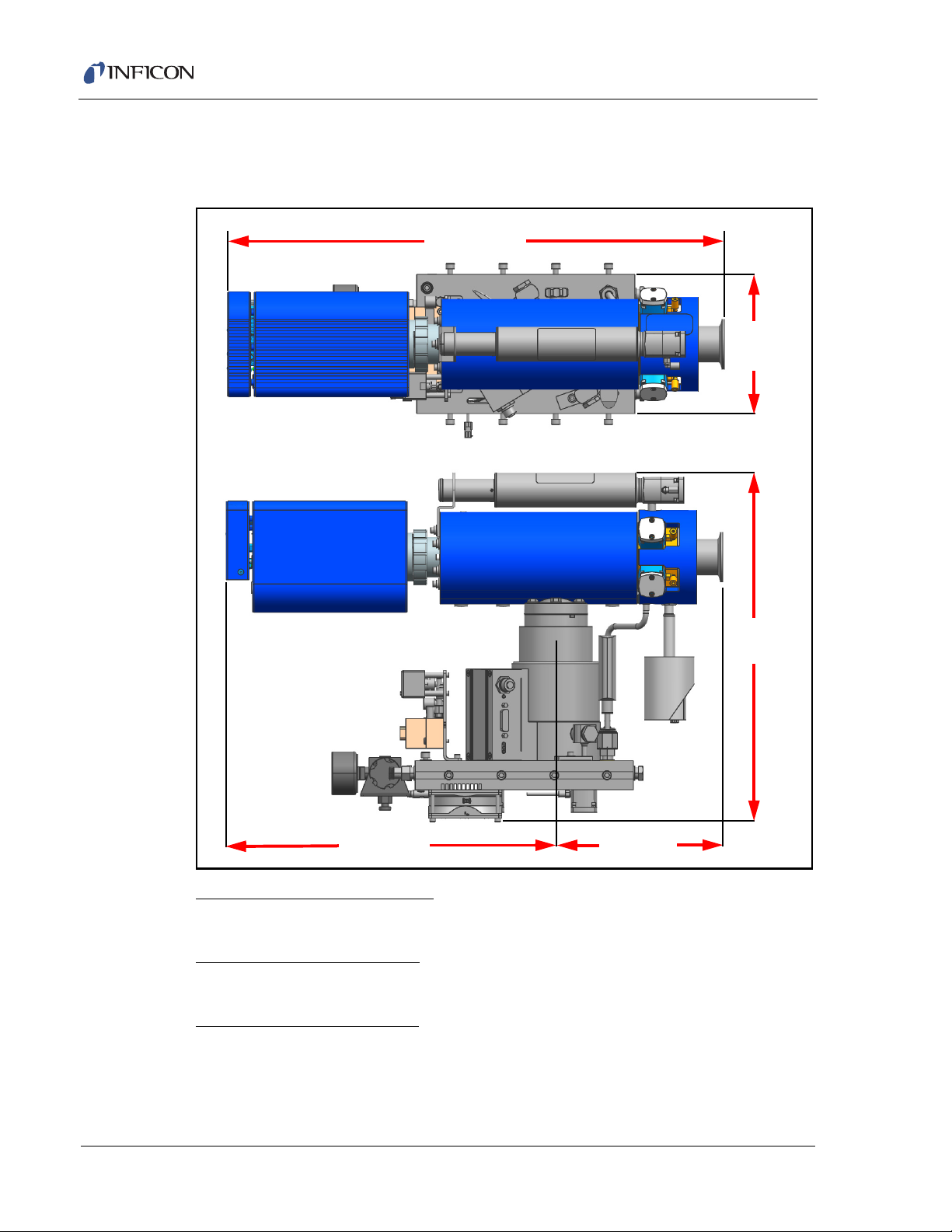

1.6 Physical Requirements

183 mm

362 mm

(7.2 in.)

(14.3 in.)

378 mm

(14.9 in.)

545 mm

(21.5 in.)

152 mm

(6.0 in.)

1.6.1 Physical Dimensions

Figure 1-1 Pumping system dimensions

Transpector CPM Operating Manual

Pumping System dimensions

545 x 152 x 378 mm (21.5 x 6.0 x 14.9 in.)

CPM Controller dimensions

195 x 207 x 89 mm (7.7 x 8.1 x 3.5 in.)

Foreline Pump dimensions

1–9

218 x 150 x 147 mm (8.6 x 5.9 x 5.8 in.)

NOTE: See Figure 2-8 on page 2-10 for cable connections.

Page 21

1.6.2 Weight

CAUTION

The approximate weight of Transpector CPM (without the Foreline Pump and the

CPM controller) is 15.5 kg (34 lb.).

NOTE: This weight does not include connecting cables.

1.6.3 Ventilation Requirements

For adequate ventilation, maintain at least 25.4 mm (1 in.)

clearance around the Transpector electronics module,

the CPM heaters and the pumping system.

If enclosing Transpector CPM, the enclosure must be large enough or ventilated to

provide adequate cooling airflow to the fan on the Transpector CPM pumping

system and the fan in the Transpector CPM controller.

Transpector CPM Operating Manual

1.7 Electrical Power Requirements

The CPM system components that require AC power input are:

CPM controller . . . . . . . . . . . . . . . . . Universal input, any voltage in the range

Personal computer . . . . . . . . . . . . . . Universal input, any voltage in the range

1.7.1 Required Supply Voltage

Except for the AC power input, the CPM controller supplies all required voltages.

1.7.1.1 Acceptable Supply Voltage Range

The AC power input must be 100, 120, or 230 V

NOTE: If the input power is less than 100 V

reach their nominal temperature will be increased.

1.7.1.2 Required Frequency

50 or 60 Hz, ±5%

specified in section 1.7.1.1 is acceptable.

specified in section 1.7.1.1 is acceptable.

~, ±10%

~, the time required for the heaters to

1.7.1.3 Power Rating

CPM controller—500 VA

1–10

Page 22

1.7.1.4 Fuse Rating

CAUTION

Transpector CPM Operating Manual

3.15 A @ 250 V

Interrupt Current 35 A @ 250 V~

Type T (5 x 20 mm)

1.7.1.5 Overvoltage Category

Overvoltage Category II (per EN61010-1:2010)

Short Term: 1440 V < 2 seconds

Long Term: 490 V < 5 seconds

1.7.1.6 Electrical Connections

One of the following:

110 V

230 V

NOTE: Do not replace power cord with an inadequately rated cord. Cord must be

~, three-pronged, grounded plug

~, European style, two-pronged plug with ground contact

rated 10 A or higher.

~

1.8 Nitrogen Purge Gas (Corrosive System Only)

The corrosive service Turbo Molecular Pump requires 10 to 25 sccm nitrogen

purge gas flow through its bearings to protect the bearings from corrosion and loss

of lubricant by evaporation. The CPM nitrogen regulator range is

10–15 psi (gauge). It is set for 10 sccm flow at the factory.

The corrosive service Turbo Molecular Pump (CVD/Etch),

requires nitrogen purge gas flow whenever the system is

operational.

Normally, dry nitrogen is supplied at the acceptable pressure range for the air

pressure. (See section 1.10.1 on page 1-13). In this manner, dry nitrogen can be

supplied directly to the solenoid valve block and to the pressure regulator via the

supplied 6.35 mm (1/4 in.) tee. The regulator supplies dry nitrogen at a reduced

pressure for the purge.

1–11

Page 23

Figure 1-2 Compressed air supply connection

WARNING

CAUTION

Dry Compressed Air

Dry nitrogen

58–100 psi (gauge)

58–100 psi (gauge)

Bearing Purge

Corrosive System Only

Recommended Setting

is 75-80 psi (gauge)

Transpector CPM Operating Manual

The pressure range is 58–100 psi (gauge) (4–6.9 bar) [400–690 kPa].

Recommended setting is 75-80 psi (gauge) (5.17 to 5.52 bar) [517 kPa to

552 kPa].

1.9 Exhaust Gas

Exhausting gas from the Turbo Molecular Pump is required for corrosive

applications. With non-corrosive applications, exhaust the Turbo Molecular Pump

in accordance with the facility's requirements. The dry Foreline Pump has a

6.35 mm (1/4 in.) Swagelok

Nitrogen pressure must not exceed 100 psi (gauge)

(6.9 bar) [690 kPa].

Nitrogen pressure must be at least 58 psi (gauge)

(4 bar) [400 kPa].

®

tube adapter for an exhaust fitting.

1–12

Page 24

1.10 Air Pressure Requirements

WARNING

CAUTION

CAUTION

1.10.1 Required Air Pressure

Dry compressed air (or dry nitrogen) is used to operate the electro-pneumatic inlet

valves. The minimum air pressure required to operate the inlet valves is

58 psi (gauge) (4 bar) [400 kPa]. Recommended setting is 75-80 psi (gauge)

(5.17 to 5.52 bar) [517 kPa to 552 kPa].

1.10.2 Air Pressure Range

The air pressure range is 58–100 psi (gauge) (4–6.9 bar) [400–690 kPa].

Recommended setting is 75-80 psi (gauge) (5.17 to 5.52 bar) [517 kPa to

552 kPa].

Air pressure must not exceed 100 psi (gauge)

(6.9 bar) [690 kPa].

Transpector CPM Operating Manual

Air pressure must be at least 58 psi (gauge) (4 bar)

[400 kPa].

1.10.3 Moisture Content of Compressed Air Supply

The compressed air supply used for inlet valve operation must be dried to the

extent that changes in compressed air pressure during operation will not produce

condensation in lines, solenoids or valve actuators.

Moisture condensation can cause corrosion.

1.10.4 Air Pressure Connections

The compressed air supply connects to the CPM solenoid with 6.35 mm (1/4 in.)

polymer hose. The 6.35 mm (1/4 in.) connector is a friction-lock, right-angle fitting

to adapt the supply hose to the solenoid base.

1–13

Page 25

1.11 Vacuum Requirements

CAUTION

1.11.1 Required Vacuum

The Turbo Molecular Pump and Foreline Pump create vacuum. The Foreline Pump

must provide <10 Torr (13 mbar) when there is up to 30 sccm of nitrogen purge plus

process gas bypass flow.

Do not exceed 10 Torr (13 mbar) Foreline Pump pressure.

1.11.2 Acceptable Range Of Vacuum

The CPM manifold can achieve <1x10-8 Torr (1.33x10-8 mbar) of base pressure (no

sample flow) after bakeout and cool down. This level of vacuum requires a foreline

pressure of <10 Torr (13 mbar).

Transpector CPM Operating Manual

1.12 Environmental Requirements

1.12.1 Use

Indoor use only.

1.12.2 Altitude Range

Up to an altitude of 2000 m (6561 ft.)

Contact INFICON for operation at higher altitudes.

1.12.3 Maximum Humidity

80% relative humidity (no condensation)

1.12.4 Pollution Degree

Pollution Degree 2 (per EN61010-1:2001)

1.12.5 Maximum Operating Temperature

50°C (122°F) Transpector Electronics Module

35°C (95 °F) for the turbo pump under maximum gas load

1.12.6 Minimum Operating Temperatures

20°C (68°F)

1–14

Page 26

1.12.7 Clean Room Requirements

The CPM is clean room compatible (including silicone rubber heaters).

1.12.8 Anti-Static Conditions

CPM passes standard EN 61326-1:2013.

1.13 Computer System Requirements

The minimum system requirements for FabGuard® Explorer Operating Software

are listed in Table 1-4:

Table 1-4 Minimum computer requirements for FabGuard Explorer

Parameters FabGuard Explorer Requirements

Processor 2.4+ GHz Dual Core

Memory 4+ GB

Transpector CPM Operating Manual

Hard Drive

Resolution 1024 X 768 16-bit color or greater

Ethernet Port One free Ethernet port for connection to Transpector CPM

Operating

System

INFICON can supply a controller to run the software that operates

Transpector CPM System. (Refer to section 1.4 on page 1-4.)

1.13.1 Operating System

FabGuard Explorer software requires either Windows 7 or Windows 8 for proper

operation.

See Chapter 10 or the FabGuard Explorer CD for FabGuard Explorer software

operation.

SATA 80 GB to 1 TB 7200+ RPM

Windows 7

®

or Windows 8

®

1–15

Page 27

Chapter 2 Installation

2.1 Installation Overview

The Transpector CPM system is partially disassembled for shipping and must be

re-assembled prior to operation. The Transpector sensor is shipped inside the

CPM manifold tee, but the remaining components such as the Transpector

electronics module, cable box, CPM controller, diaphragm foreline pump and all

connecting cables will need to be installed per the instructions in this chapter:

1 Install the Transpector electronics module, heat guard, and cable box. (See

section 2.2 on page 2-2.)

2 Install sniffers, if applicable. (See section 2.2 on page 2-2.)

3 Mount CPM to process tool, if applicable. (See section 2.4 on page 2-5.)

4 Install the CPM controller and connect communications cables from the CPM

controller to the Transpector cable box (See Figure 2-6 on page 2-8.)

Transpector CPM Operating Manual

5 Connect cables on the Transpector cable box to the various CPM sub systems,

and the control computer. (See Figure 2-8 on page 2-10.)

6 Install the CPM Foreline Pump. (See section 2.7 on page 2-11.)

7 Install the software. (See section 2.8, Software Installation, on page 2-11.)

2–1

Page 28

Transpector CPM Operating Manual

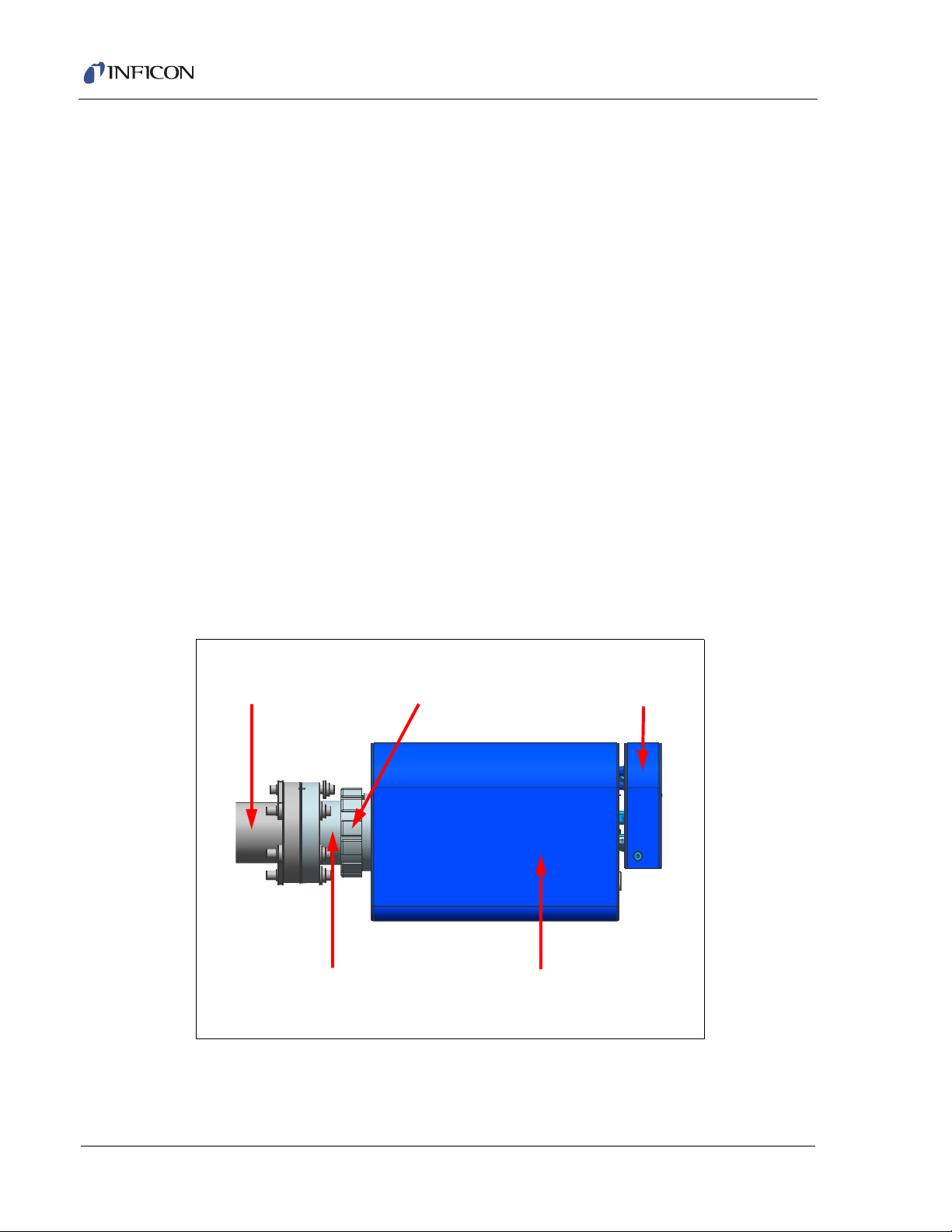

Mounting Nut

CPM Manifold Tee

Transpector Electronics Module

Cable Box

Transpector Sensor

2.2 Transpector Electronics Module, Heat Guard, and Cable Box Installation

The Transpector electronics module and cable box must be mounted in an area

where the ambient temperature does not exceed 50°C (122°F) and there is ample

air flow. Best performance is achieved when the electronics module is not exposed

to wide temperature variations.

2.2.1 Attach Transpector Electronics Module

The Transpector sensor is typically already installed inside the CPM Manifold Tee.

The Transpector electronics module must be mounted onto the sensor:

1 The Transpector sensor mounting connector assembly includes a mounting nut

and an O-ring. Place the nut over the end of the sensor and roll the O-ring back

to the groove on the sensor. When the mounting nut is tightened, the O-ring

compresses making a tight fit on the sensor housing.

2 Note the recessed area on the sensor feedthrough and the ground tab on the

Transpector electronics module. Match the recessed area of the feedthrough

to the ground tab and carefully slide the Transpector electronics module fully

onto the sensor.

3 Finger tighten the mounting nut on the Transpector sensor.

Figure 2-1 Transpector electronics module dimensions

2–2

Page 29

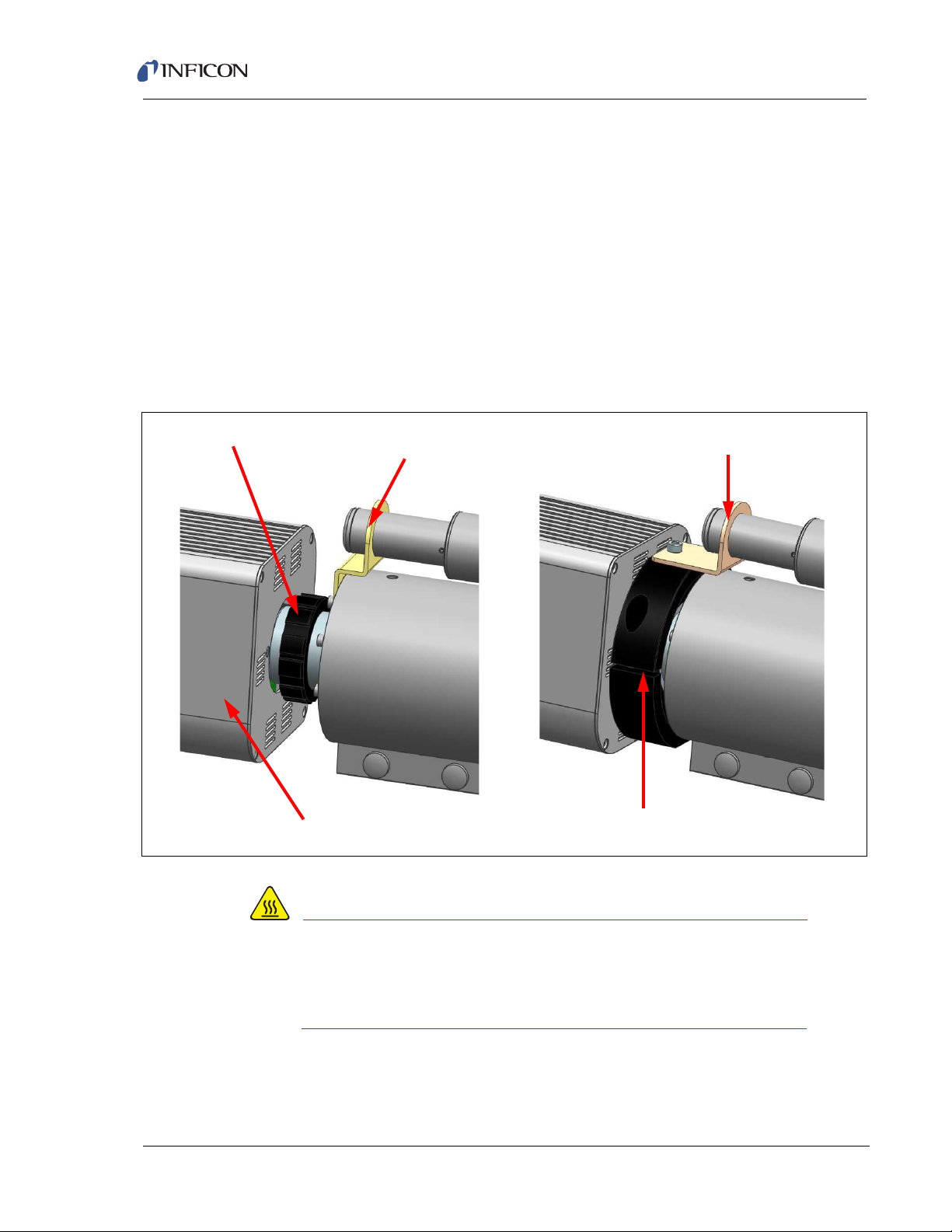

2.2.2 Attach Heat Guard

WARNING - High Temperature

Calibration Reference

Shipping Bracket

Heat Guard

Calibration Reference

Standard Bracket

Transpector Electronics Module

Mounting Nut

To decrease the risk of burns when the heating jacket is on, a heat guard is

provided for the metal surfaces between the Transpector electronics box and the

CPM manifold tee.

1 Loosen the single screw that attaches the calibration reference shipping

bracket to remove the bracket. Replace the screw.

2 Attach heat guard between the Transpector electronics module and the

mounting nut using the two screws provided.

3 Attach calibration reference standard bracket to the heat guard and secure the

bracket to the heat guard with the provided screw.

Figure 2-2 Heat Guard and Calibration Reference Bracket

Transpector CPM Operating Manual

Metal surfaces will be hot when heating jacket is on.

Attach heat guard to avoid risk of burns from metal

surfaces between Transpector electronics module and

CPM manifold tee.

2–3

Page 30

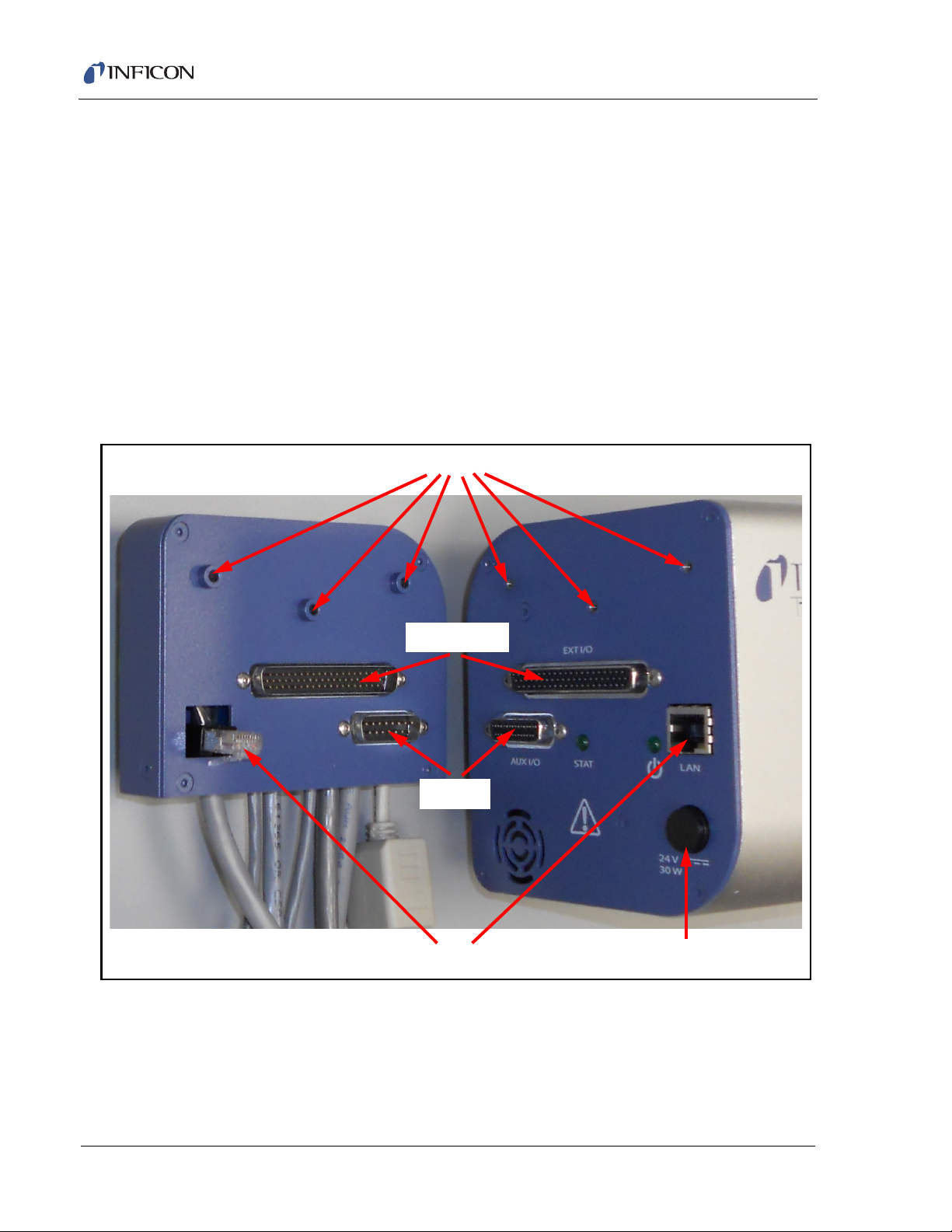

2.2.3 Attach Cable Box

Screw Holes

Ethernet Connection

Extended I/O

Aux I/O

Transpector 24V Input

The cable box and Transpector electronics module are connected via an Ethernet

connection, a 15-pin Aux I/O connection, and a 62-pin extended I/O connection.

Three screws are used to stabilize the cable box on the electronics module.

(See Figure 2-3.)

To connect the cable box to the electronics module:

1 Insert the Ethernet jack on the cable box into the Ethernet port on the

electronics module.

2 Carefully insert the 15-pin Aux I/O and 62-pin extended I/O connectors until

they are secure and the Ethernet connector snaps into place.

3 Secure the cable box on the electronics module with the three provided screws.

Figure 2-3 Transpector electronics module and cable box

Transpector CPM Operating Manual

2–4

Page 31

WARNING - Risk Of Electric Shock

DO NOT remove the cover from the Transpector 24 V

CAUTION

input. 24V is supplied to the Transpector electronics box

from the controller.

2.3 Sniffer Installation

Install the sniffer into the Swagelok® fitting on the hexblock using the 1/4 in.

(6.35 mm) nut and vespel ferrule supplied with the sniffer.

2.4 Mounting the Pumping System

The Transpector CPM system typically mounts directly to a process chamber via

the CF or KF process connection at the end of the Hexblock inlet. Normally there

is no need to use an additional isolation valve between the Hexblock and the

process chamber.

Transpector CPM Operating Manual

If an isolation valve is needed and the CPM does not have a CDG interlock for the

Hexblock inlet, it is essential to pump down the volume between the Hexblock and

isolation valve from the process side before the CPM is turned on. If this volume is

not pumped down properly filament failure can be the result.

If an isolation valve is used ensure and trapped volumes

are pumped out in order to avoid filament failure.

A support kit is supplied for CPM configurations with a standard process

connection. The support kit, PN 922-209-G1, consists of two 1.22 m (4 ft.) support

legs, two adjustable feet and mounting hardware.

2–5

Page 32

2.4.1 Installing the Support Kit

1 Measure the support leg to make sure there is ample room for installation. The

leg may be cut to size.

NOTE: One end of the support leg has a threaded hole for the adjustable foot.

When cutting the leg, make sure that the threaded hole end is used for

the support.

2 Screw the adjustable foot fully into the bottom of the support leg. (See Figure

2-4.)

3 Install the right angle bracket onto the support leg using the T-nut and bolts

provided. Finger tighten.

4 Install the second bolt and T-nut into the bracket, leaving it loose.

5 Slide the T-nut into the CPM foreline block groove and adjust the position of the

leg so that it is perpendicular to the floor with the adjustable foot about 12.7 mm

(1/2 in.) from the floor.

6 Tighten all hardware.

7 Install the safety cap.

Transpector CPM Operating Manual

Figure 2-4 Adjusting leg position

2–6

8 Unscrew the adjustable foot until it supports Transpector CPM and relieve

pressure from the flange.

9 Tighten the lock nut on the adjustable foot against the support leg.

Page 33

2.4.2 Atmospheric Support Frame

Atmospheric Transpector CPMsystems do not need the standard support legs. An

atmospheric system is mounted to a support frame, which also houses the CPM

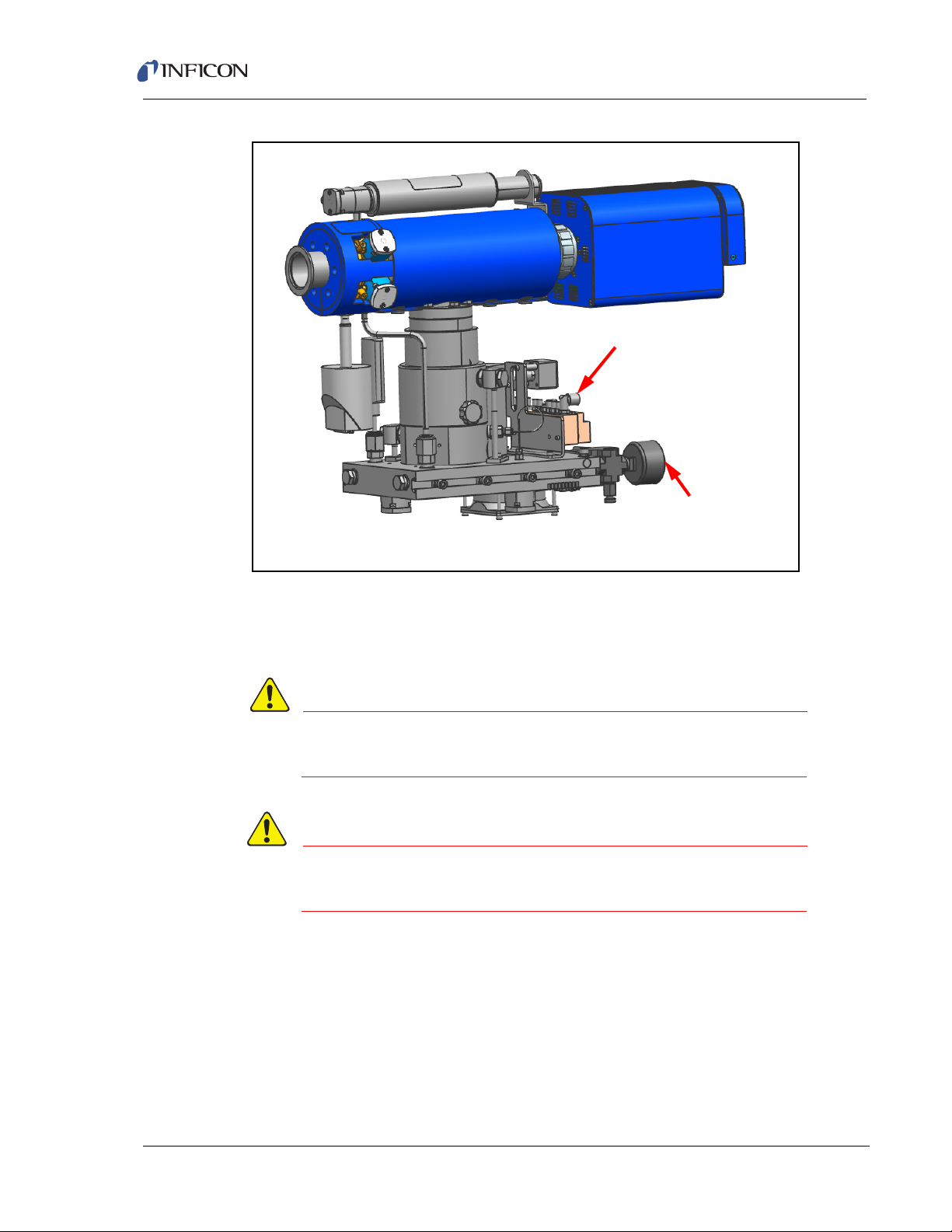

controller. (See Figure 2-5.)

Figure 2-5 CPM configured with support frame for atmospheric sampling

Transpector CPM Operating Manual

2.5 CPM Controller Installation

The CPM controller is standard 1/2 rack, 2U height rack mountable. The CPM

controller is provided with feet and can sit on the floor or table.

Cable connections on the CPM controller are:

Cable bundle that includes the CPM interface cable (connects to the cable box on

the back of the Transpector electronics module), heater cable, and ground strap

Foreline pump power cable

CPM Controller power cable

2–7

Page 34

Transpector CPM Operating Manual

CPM Interface

Foreline

Power

Heater

Fuse

Main Power

Electrical

Input

On/Off

Ground

The back panel of the CPM controller is shown in Figure 2-6. Connections are

shown in Figure 2-8.

Figure 2-6 CPM controller rear panel

2–8

Page 35

2.6 Transpector Cable Box Connections

The cable box mounted on the back of the Transpector electronics module makes

cable connections to most of the subcomponents of the CPM System. (See Figure

2-7. Cable connections for the entire CPM system are shown in Figure 2-8.)

Short Ethernet cable with port (600-1485-P1) attaches to the supplied RJ45,

Cat5e Ethernet cable, which then connects to the control computer. For

networking information, see Chapter 3, Connecting Transpector CPM.

Aux I/O cable (600-1486-P1) is available for User I/O. See section 4.3.1.1 on

page 4-3 for additional information about Aux I/O.

Turbo pump cable (600-1475-P1) connects to the turbo pump controller.

Pirani cable (600-1474-P1) connects to the foreline Pirani gauge.

Solenoid cable (600-1476-P1) connects to the solenoid valve block as well as

the digital pressure switch.

CDG cable (600-1473-P1) connects to the CDG gauge.

CPM cable (600-1472-P1) connects to the CPM interface cable in the cable

bundle from the CPM controller.

Figure 2-7 Cable box and cables

Transpector CPM Operating Manual

(600-1485-P1)

MMSP CPM Ethernet Cable

Turbo Cable (600-1475-P1)

MMSP Aux I/O Cable (600-1486-P1)

Foreline Gauge Cable (600-1474-P1)

CDG Cable (600-1473-P1)

CPM Control Cable (600-1472-P1)

Valve Manifold Cable (600-1476-P1)

2–9

Page 36

Figure 2-8 CPM cable connections

r

r

r

CPM Sensor

Heater Jacket

Hex

Block

Inlet

Transpector CPM Operating Manual

Cable Box (Bottom View)

Transpector CPM

Cable Box

CDG

Pirani

Foreline Block

Transpector CPM Controlle

Forepump

CPM

Interface

Powe

15 9

Turbo

Molecula

Pump

600-1473-P1

1, 3, 5 Or 10 m

Cable Bundle

600-1477-Gx

AC In

Htr

Turbo

Gnd

Ctrl

600-1474-P1

Pressure

Switch

Valve

Block

Fan

600-1130-PX

600-1475-P1

600-1154-PX

600-1155-P5

600-1476-P1

600-1480-PX

922-205-GX

Ethernet

Foreline Pump

600-1475-P1

600-1485-P1

600-1486-P1

600-1474-P1

IO

600-1472-P1

600-1473-P1

600-1476-P1

2–10

Page 37

2.7 CPM Foreline Pump Installation

WARNING

CAUTION

Foreline

Connection

Exhaust Port

Foreline Power

Cable

The 24 V (dc) dry Foreline Pump has the following connections:

Electrical connection to the CPM controller

Foreline hose connection from the UHV Turbo Molecular Pump foreline block

Exhaust port connection—required for corrosive or toxic gas sampling. Refer

to appropriate standards such as

Proper exhaust connections must be installed when

sampling toxic, corrosive or any hazardous gases to

protect the environment from lethal levels of gas.

Transpector CPM Operating Manual

SEMI S6-0707E for exhaust gas guidelines.

If a customer-supplied foreline pump is used, it must

provide a continuous pressure below 10 Torr.

Figure 2-9 Two-stage foreline pump components

2.8 Software Installation

Refer to the FabGuard Explorer Operating Manual for information regarding

software installation.

2–11

Page 38

Chapter 3

CAUTION

Connecting Transpector CPM

3.1 Introduction

Transpector CPM communicates via Ethernet. Devices on an Ethernet network

have two identifying addresses: an IP address and a MAC address.

IP addresses are assigned to identify individual devices on a network. Each

device on an Ethernet network must have a unique IP address.

IP addresses can be reassigned to other devices on the network as long as

each device has a unique IP address.

MAC addresses are unique for each device. MAC addresses are never

duplicated.

3.2 General Networking Information

3.2.1 IP Addresses

Transpector CPM Operating Manual

IP addresses can be either static or dynamic.

Static (manual) IP addresses are set by the user and are changeable by the

user. Static IP addresses are preferred.

Dynamic (automatic) IP addresses are automatically set by a host or by a

server on a network. Dynamic IP addresses can be set through Dynamic Host

Communication Protocol (DHCP).

NOTE: When using Static IP addresses on a large network (e.g., on a company

network), a block of addresses should be reserved for static IP address

use and prohibited from being assigned by the DHCP server (host). This

will avoid duplicate IP address conflicts.

Use static IP addresses with Transpector CPM. Using

DHCP, the host server may generate a new IP address if

Transpector CPM is taken offline and then returned

online or if there is an IP address conflict on the network.

If the Transpector CPM IP address is randomly changed

during data acquisition, FabGuard will not reconnect to

the new sensor IP address, which will result in a loss of

communication and loss of data.

3–1

Transpector CPM follows the IPv4 IP address convention. An example IP address

is

192.168.1.100. Each of the four parts is referred to as an “octet”. The

IP address consists of a Network Prefix and a Host Protocol.

Page 39

3.2.2 Subnetworking

An IP network can be split into multiple subnets. Subnetting sets a region of the

IP address as a Network Prefix for all IP addresses inside the subnet through a

subnet mask. The subnet mask determines which octets of the IP address are

used as the network prefix. (See Table 3-1.)

In order for two network devices to communicate, they must be on the same

subnet, be connected to the same internet network and have the same network

prefix.

NOTE: If two devices have different network prefixes, the two devices are on

different subnets.

Table 3-1 Subnetting

IP address 192.168.1.104 192.168.1.105 192.168.1.150

Subnet mask 255.255.255.0 255.255.0.0 255.255.255.192

Transpector CPM Operating Manual

Example 1 Example 2 Example 3

Network prefix 192.168.1.0 192.168.0.0 192.168.1.128

Host Protocol 0.0.0.104 0.0.1.105 0.0.0.22

3.3 Transpector CPM IP Address

The default Transpector CPM IP address is 192.168.1.100 with a subnet

mask of

NOTE: When connecting to an existing local network, there must be a static

Two methods of changing the Transpector CPM IP address are available.

INFICON Mass Spectrometer Search Utility. (See section 3.3.1.)

Transpector Web UI. (See section 3.3.1.2 on page 3-5.)

255.255.0.0.

IP address for each Transpector RGA. Contact the network administrator

for IP address assignments.

3–2

Page 40

Transpector CPM Operating Manual

3.3.1 Using the INFICON Mass Spectrometer Search Utility to

Change the Transpector CPM IP Address

The INFICON Mass Spectrometer Search Utility (IMSSU) is located on the

software installation disk and the RGA Manuals CD. The IMSSU does not need to

be installed. Double-click INFICONMassSpecSearch.exe. The IMSSU will

display. (See Figure 3-1.)

Figure 3-1 INFICON mass spectrometer search utility

3–3

The IMSSU detects every Transpector RGA installed on the network regardless of

IP address. The IMSSU will run automatically, or it can be manually started by

clicking Search (Clears List). The display shows:

Genus (MPCPM for Transpector CPM sensors)

Serial Number

Current IP address

MAC address

DHCP status (On or Off)

Description (user editable)

Page 41

Right-click on a sensor to display the menu shown in Figure 3-2.

CAUTION

Figure 3-2 IMSSU right-click menu

3.3.1.1 Change IP Address

1 Right-click on the sensor and select Change IP Address. The TCP/IP

Properties window will display. (See Figure 3-3.)

Figure 3-3 TCP/IP Properties window

Transpector CPM Operating Manual

The TCP/IP Properties window displays the:

Transpector CPM MAC Address

Transpector CPM IP address

Change To text box, to enter a new Transpector CPM IP address

DHCP On or DHCP Off selection

Set DHCP Off so the IP address cannot be automatically

assigned.

2 Type the new IP address in the Change To text box.

3 Click Apply. Transpector CPM will automatically reboot and will return online

with the new IP address.

4 Launch Web UI.

3–4

Page 42

3.3.1.2 Launch Web UI

Transpector Web UI can be launched from inside of the IMSSU. (Refer to the

074-581-P1 Transpector Web UI Operating Manual.)

3.3.1.3 Find Device

Find Device On will flash the power indicator on the device. The indicator will flash

for up to 60 seconds and then illuminate.

Find Device Off selected within 60 seconds after selecting Find Device On will

stop the search.

3.3.1.4 Show Settings

Click Show Settings to display multiple settings useful for troubleshooting.

The display shows:

Serial Number

Gateway

IP Address

DHCP Status

MAC Address

Transpector CPM Operating Manual

Description

Subnet Mask

Name

Description

Structure Version

Name

Box Type

Port

Firmware Version

TCP/IP Source

3–5

Page 43

3.4 Connecting Transpector CPM

Before connecting Transpector CPM, decide:

Is Transpector CPM going to be on:

a private network (installed directly on either a computer or a router that is

not hooked up to the internet), or

an internal network where multiple computers are connected with acce ss to

the internet?

Is more than one Transpector CPM sensor being installed at the same time?

3.4.1 Connecting a Single Transpector CPM

3.4.1.1 Single Transpector CPM Direct Connection Installation

When installing a single Transpector CPM on a private network or directly

connected to a computer, changing the IP address of Transpector CPM is

necessary only if the computer being used to connect to Transpector CPM has a

different network prefix than Transpector CPM.

Transpector CPM Operating Manual

The network prefix of Transpector CPM is

host computer used to control Transpector CPM must have a subnet mask of

192.168.x.x. The IP address of the

255.255.0.0 and a network prefix of 192.168.x.x.

If this is not the case, change the computer IP address to match the network prefix

of Transpector CPM. For example, giving the computer an IP address of

192.168.1.101 will allow Transpector CPM to communicate directly with the

computer. (See section 3.5, Changing the Computer IP Address, on page 3-8.)

3.4.1.2 Installing a Single Transpector CPM on an Existing Local Network

When installing a single Transpector CPM on an existing local network, the default

IP address of Transpector CPM may not be compatible with the network.

Transpector CPM can have either a Static IP address (recommended) or a

Dynamic IP address set by DHCP (not recommended).

Contact the network administrator for information regarding valid IP addresses and

ask the administrator to assign an IP address for Transpector CPM. (Refer to

section 3.3.1, Using the INFICON Mass Spectrometer Search Utility to Change the

Transpector CPM IP Address, on page 3-3.)

3–6

Page 44

Transpector CPM Operating Manual

CAUTION

CAUTION

3.4.2 Installing Multiple Transpector CPM Sensors

Each Transpector CPM is shipped with an identical default IP address. When

installing multiple Transpector CPM, the IP address of each Transpector CPM

must be changed one at a time so that each Transpector CPM has a unique

IP address. (Refer to section 3.3.1, Using the INFICON Mass Spectrometer Search

Utility to Change the Transpector CPM IP Address, on page 3-3.)

Do not connect multiple Transpector CPM to a network

without first changing the IP addresses. Otherwise, there

will be IP address conflicts on the network.

3.4.2.1 Installing Multiple Transpector CPM Directly to a Host Computer

A private local network must be created when multiple Transpector CPM sensors

are connected to a single host computer instead of an existing local area network.

Transpector CPM must be installed on either a router or Ethernet switch. The

router or switch is connected to the host computer through the LAN port of the

router/switch.

3.4.2.2 Installing Multiple Transpector CPM on an Existing Local Network

Use an Ethernet switch instead of a router when multiple Transpector CPM

sensors are connected to an existing local network.

Routers can cause conflicts with local networks because

the router will attempt to set IP addresses for all network

connected devices.

Since Transpector CPM sensors are network connected devices, each sensor

must have an IP address assigned to it by a network administrator. After changing

each IP address manually, connect all of the sensors to the Ethernet switch and

connect the switch to the local network.

3–7

Page 45

3.5 Changing the Computer IP Address

An alternative to changing the Transpector CPM IP address is to change the host

computer’s IP address to allow for communication between the host computer and

Transpector CPM.

3.5.1 Windows 7

NOTE: Changing the IP address of the host computer requires administrator

rights.

1 Click Start, then click Control Panel. (See Figure 3-4.)

Figure 3-4 Start menu

Transpector CPM Operating Manual

2 In the Network and Internet group. click View network status and tasks.

(See Figure 3-5.)

Figure 3-5 View network status and tasks

3–8

Page 46

Transpector CPM Operating Manual

3 On the network status and tasks window, click Change adapter settings.

(See Figure 3-6.)

Figure 3-6 Change adapter settings

4 If the host computer is connected directly to Transpector CPM through the

Ethernet port of the computer, right-click Local Area Connection and select

Properties. (See Figure 3-7.)

Figure 3-7 Changing adapter settings

3–9

Page 47

Transpector CPM Operating Manual

5 Click Internet Protocol Version 4 (TCP/IPv4).

6 Click Properties. (See Figure 3-8.)

Figure 3-8 TCP/IPv4

7 On the TCP/IPv4 properties window, click Use the following IP address.

(See Figure 3-9.)

Figure 3-9 Use the following IP address

3–10

Page 48

Transpector CPM Operating Manual

8 In IP address, type 192.168.1.XXX. The last octet can be any number as

long as it is unique to the network and is not the same as the Transpector CPM

IP address. (See Figure 3-10.)

9 In Subnet mask, type 255.255.0.0.

10 Click OK.

Figure 3-10 Changing the computer IP address

11 The IP address will now be set to the manual IP address chosen in step 7.

12 Exit all menus.

13 Connect to Transpector CPM.

14 To change the IP address back to its default settings, follow steps 1 through 6

and reset the properties to their original settings.

3–11

Page 49

Chapter 4

7

5

4

3

2

1

14

12

11

9

10

6

1 . . . . . .Process Pressure Gauge

2 . . . . . .Process Connection (CF40, KF40 or KF25)

3 . . . . . .HexBlock™ Inlet

4 . . . . . .Optional Calibration Reference

5 . . . . . .CPM Sensor (inside manifold)

6 . . . . . .Sensor Manifold and Heater

7 . . . . . .CPM Transpector Electronics Module

8 . . . . . .Pressure Switch

9 . . . . . .Valve Solenoids

10 . . . . .Nitrogen Regulator (for nitrogen purge and valve operation)

11 . . . . .Integrated Foreline Block

12 . . . . .UHV Turbo Molecular Pump

13 . . . . .Foreline Pirani Gauge

14 . . . . .Bypass Connection for High Pressure Applications

8

13

How the CPM System Works

4.1 CPM Components

A fully configured CPM corrosive pumping system is illustrated in Figure 4-1. (The

CPM controller and foreline diaphragm pump are not shown.)

Figure 4-1 CPM pumping system components

Transpector CPM Operating Manual

4–1

Page 50

4.2 Theory of Operation

CAUTION

Many gas analysis applications involving pressures too high for direct exposure to

the quadrupole sensor (pressures greater than 1.0E-4 Torr/mbar) require a

pressure converter to reduce the pressure and keep the sensor at high vacuum.

With a pressure converter, a quadrupole sensor may be used for high pressure

applications such as sputtering, Chemical Vapor Deposition (CVD), etch, vacuum

furnace analysis, and laser gas analysis.

Transpector CPM pressure is the pressure inside the closed ion source (CIS). The

nominal operating pressure inside the closed ion source is approximately

2E-4 Torr. Since the conductance between the closed source and the sensor

manifold is 0.7 L/s and given the effective pumping achieved using the turbo

molecular pump attached to this manifold, the pressure in the mass analyzer region

is approximately 23 times lower than in the closed source. Thus, with the source at

~2E-4 Torr, the pressure in the manifold is approximately 1.0E-5 Torr.

Pressure converters use orifices and/or capillaries to reduce the partial pressure of

the gas-mixture, typically by a fixed proportion, with minimum mass discrimination.

An orifice, a small disk with a defined hole, acts as a conductance limitation. When

both the volume and the high vacuum pump speed are constant, the orifice hole

size determines the pressure at the sensor. Orifices are available in various sizes

to cover various pressure ranges.

Transpector CPM Operating Manual

FabGuard Explorer and FabGuard display total pressure

inside the closed ion source.

Optimum performance is obtained when the total

pressure display reads ~2x10

energy mode (40 eV, 200 A).

Operation in high energy mode (70eV, 2000 A) will give

an inaccurate total pressure reading.

4.3 Instrument Overview

4.3.1 Input/Output (Aux I/O)

This section describes the available input and output (I/O) for Transpector CPM.

See Figure 4-2 for a pinout diagram.

Transpector CPM has two digital inputs for manual emission control, one digital

relay output for emission status, and one analog input.

-4

Torr measured in low

4–2

Page 51

4.3.1.1 CPM Aux I/O Connector

CAUTION

User I/O is through a 15 pin DSUB connector on the cable box attached to the back

of the Transpector electronics module. (See Figure 2-8 on page 2-10.)

A mating DB15 Male connector is supplied in the ship kit for connecting to the

Transpector CPM Aux I/O connections.

4.3.1.2 Two Digital Inputs

Logic Inputs 1 and 2 are by default set to remotely control emission status.

(See Table 4-1.)

Connecting Pin 14 (Logic Input 1) to Pin 15 (Ground) will turn on the emission.

Connecting Pin 13 (Logic Input 2) to Pin 15 (Ground) will turn off the emission.

Table 4-1 Digital inputs

Emission ON PIN 14

Emission OFF PIN 13

Ground PIN 15

Transpector CPM Operating Manual