Page 1

Operating

M

0

-

r

C

o

3

anual

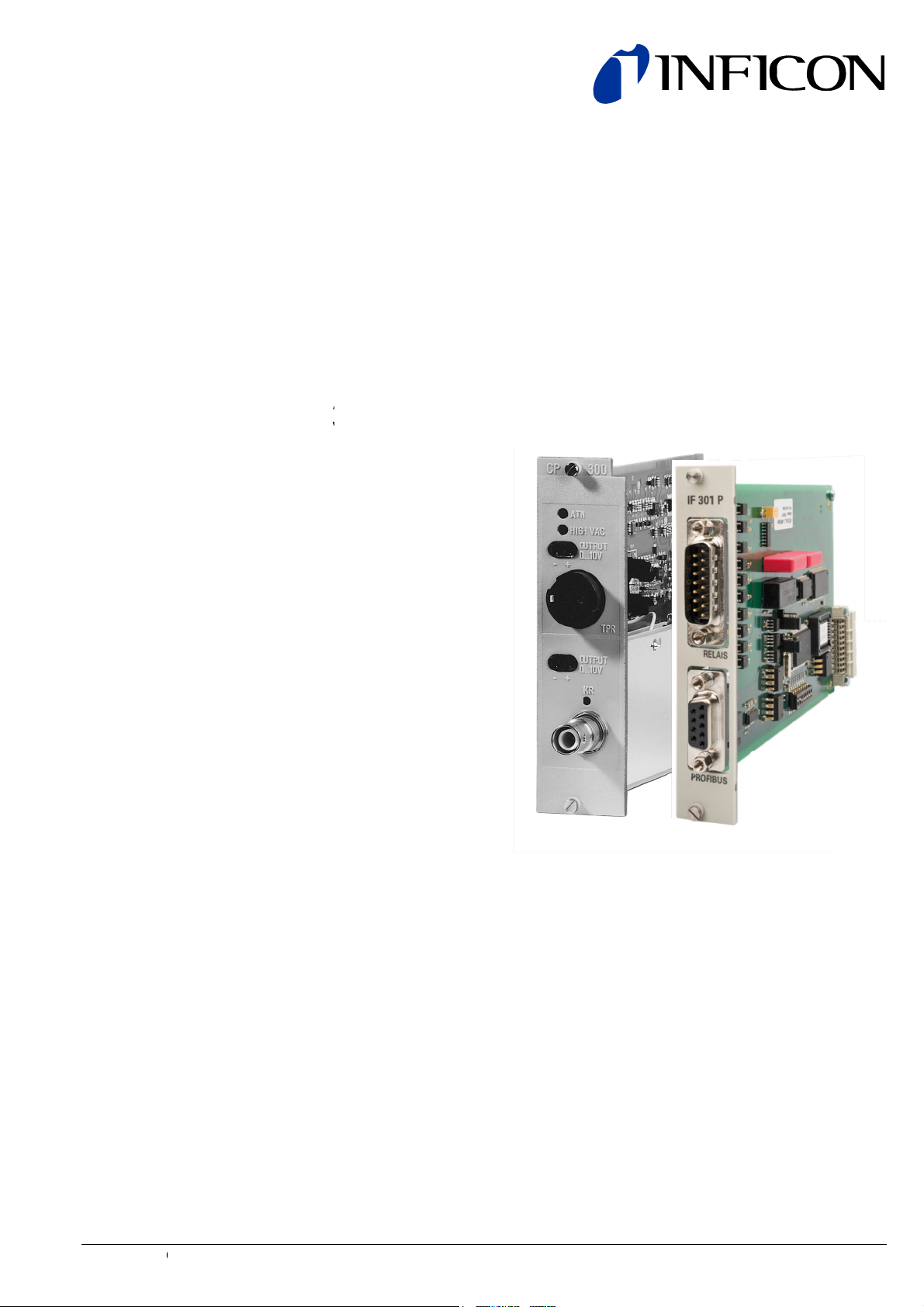

Plug

Cont

CP300

IF300P

In B

oller

9,

ards

TPG

for T

00

otal Pressure Gauge

IG9972BEN (2

017-09)

1

Page 2

About this Document

Validity

This document describes the plug-in boards for the total pressure gauge controller TPG300, intended as a supplement to the documentation of the basic unit

TPG300 (→ [1]).

This document applies to plug-in boards listed below

Type Description Part number

CP300C9 Pirani / cold cathode measurement board IO441000

IF300P Interface and relay Board (Profibus) IO441395

The part number (No) can be taken from the product nameplate.

2 IG9972BEN (2017-09) Plug-In Boards.om

Page 3

Contents

About this Document 2

Validity 2

1 Safety 4

1.1 General Safety Information 4

1.2 Symbols Used 4

1.3 General Stipulations 4

2 Description 5

2.1 Pirani / Cold Cathode Measurement Board CP300C9 5

2.2 Interface and Relay Board IF300P 5

2.3 Pirani Measurement 5

2.4 Cold Cathode Measurement 5

3 Technical Data 6

3.1 Pirani / Cold Cathode Measurement Board CP300C9 6

3.2 Interface and Relay Board IF300P 7

4 Installation 8

4.1 Installing / Removing the Plug-In Boards 8

4.2 Connecting the Pirani Gauge 8

4.3 Connecting the Cold Cathode Gauge 9

4.4 Connecting the <OUTPUT> Analog Signal 10

4.5 Connecting the Relays of the IF300P 10

4.6 Connecting the Profibus-DP Interface to the IF300P 11

5 Adjustment 12

5.1 Adjusting the Pirani Measurement Circuit 12

6 Troubleshooting 13

6.1 Operating and Adjustment Problems 13

6.2 Defects 13

6.3 Problems with the RS232C Interface 13

6.4 Problems with the Profibus-DP Interface 14

7 Accessories 15

7.1 Gauges 15

7.2 Measurement Cables and Cable Connectors 15

Appendix 17

A: Output Signals of the Measurement Boards 17

B: Gas Type Dependence 19

C: Literature 21

IG9972BEN (2017-09) Plug-In Boards.om 3

Page 4

1 Safety

1.1 General Safety

Information

1.2 Symbols Used

a) Take the necessary precautions when doing installation work.

It may be necessary implement additional protective measures in the system.

b) Before connecting any external elements, check that they are compatible with

the technical data in this document.

c) Take the necessary precautions when doing maintenance or repair work.

Danger:

Information on preventing any kind of personal injury or extensive

equipment damage.

Caution:

Special information on damage prevention.

Note:

Special information on cost-effective use.

1.3 General Stipulations

Skilled Personnel:

This work may only be carried out by persons with suitable technical

training and the necessary experience.

Waiting time, reaction time, duration of test

<

… > Marking

→ See page …

→ See document …

Since the individual components are delicate, appropriate measures must be taken

to protect them from static electricity. Store modules in antistatic bags or containers.

Damage resulting from incorrect handling may lead to a revocation of the

guarantee.

INFICON accepts no responsibility nor warranty if the user or third parties

• utilize the product not according to the defined use

• make any kind of changes (modifications, alterations, etc.) to the product.

4 IG9972BEN (2017-09) Plug-In Boards.om

Page 5

2 Description

2.1 Pirani / Cold Cathode

Measurement Board

CP300C9

Pirani measurement circuit

Cold cathode measurement

circuit

2.2 Interface and Relay

Board IF300P

2.3 Pirani Measurement

2.4 Cold Cathode

Measurement

The CP300C9 board is a combined board containing one Pirani and one cold

cathode measurement circuit.

The Pirani measurement circuit has one gauge cable connector, two trimmer potentiometers and one analog signal output. When the control unit is on, the Pirani

measurement circuit is in continuous operation. The analog signal is constantly

available, independent of what is shown on the pressure display.

The cold cathode measurement circuit for the measurement of high and ultra high

vacuum has one gauge cable connector and one analog signal output. When the

gauge is turned on, the analog signals are constantly available, independent of

what is shown on the pressure display.

This measurement board contains special electronics to limit the measurement

current to 100 µA, a feature that considerably extends the lifetime of the gauge.

The IF300P board contains a RS232C interface and a Profibus-DP interface. The

board has five relays with one floating changeover contact each.

Within certain limits the thermal conductivity of gases is a function of the pressure.

Pirani thermal conductivity vacuum gauges exploit this phenomenon for pressure

measurements.

The measurement element consists of a thin filament with a high temperature coefficient. The resistance of the wire and consequently its temperature are maintained at a constant value by means of a suitable control circuit. The electrical

power supplied to the filament is, therefore, a measure of the thermal conductivity

and consequently the gas pressure.

The current flowing in a self-sustained gas discharge with a cold cathode (inverted

magnetron) depends on the applied voltage, the gas composition, and the pressure. A magnetic field that penetrates the measurement chamber has the effect

that the electrons move along a spiral trajectory from the cathode to the anode and

thereby cause even at low gas densities a sufficient number of ionizing impacts for

maintaining the discharge. If (with a known gas type) the anode voltage and magnetic field are kept constant, the discharge current is a measure of the pressure.

IG9972BEN (2017-09) Plug-In Boards.om 5

Page 6

3 Technical Data

3.1 Pirani / Cold Cathode

Measurement Board

CP300C9

Number of measurement circuits 1 each

Gauges TPR018, IKR085 (both ITER)

Display range (signal output) 1)

Pirani

Cold cathode

mbar

mbar

5×10-4 … 1000

-9

… 1×10-2

5×10

Measurement range 1)

Pirani

Cold cathode

mbar

mbar

1×10-2 … 100

-8

… 5×10-3

1×10

Cable length

Pirani, max.

Cold cathode, max.

m

m

100

60

2)

… 100

Power supply cold cathode gauges

Operating voltage

Measurement current

kV

µA

3.3

≤600

Signal output

Measured value, analog

Error message

Current, max.

Output resistance

Reaction time (10 90%) for sudden

V

V

mA

Ω

0 … +10

>11.5

2

400

pressure step

Pirani

-3

<10

103 mbar

Cold cathode

-9

⇔ 10-6 mbar

10

ms

ms

<50

<100

Connection, equipment side

Pirani gauge

Cold cathode gauge

Signal output

Weight kg

female

female

female

Amphenol C91E, 6-pin

SHV coaxial

ø2 mm

≈0.21

1)

N2-equivalent

2)

when using the lower measurement range limit (→ 9)

6 IG9972BEN (2017-09) Plug-In Boards.om

Page 7

3.2 Interface and Relay

Board IF300P

Relay

Number 5

Contact type 1 change over contact each

floating

max. 50 V (ac) relative to other

contacts and ground

Characteristic data (ac)

Switching voltage, max.

Switching current, max.

Switching power, max.

30 V (dc), 50 V (ac)

1.5 A

45 W, 75 VA

Characteristic data (dc)

Switching current, max. switching voltages >50 V (dc) are

inadmissible for safety reasons

0.6 A at 50 V (dc)

0.8 A at 40 V (dc)

1.5 A at 30 V (dc)

Connection, equipment side

Type D-sub connector, 15-pin, male

Transition resistance with socket

125 mΩ

Interface

Type Profibus-DP

Baud rates <12Mbaud

Data format

Profibus-DP interface → [2]

Connection, equipment side D-sub connector, 9 pin, male

Cable length, max.

Weight

→ [2]

≈0.16 kg

Before connecting any external elements, check that they conform to the

above technical data and the controller is switched off for at least

15 seconds.

IG9972BEN (2017-09) Plug-In Boards.om 7

Page 8

4 Installation

General

4.1 Installing / Removing

the Plug-In Boards

Use screened cables only (connect screen to barrel of connector). If both

ends of the screen are connected to ground, compensating currents must

be prevented (e.g. by connecting all involved units to a common power

distributor).

In a Profibus-DP installation (IF300P board), use the recommended special

cable only (→ [2]).

For safety reasons, vacant slots should always be covered with blank

panels.

Disconnect all cables from the unit before installing / removing any plugin modules.

Procedure

4.2 Connecting the Pirani

Gauge

Modules should only be handled on an ESD protected bench.

• Switch off the unit and wait one minute

• Remove all cables (power cable last)

• Unscrew the blind plate / plug-in module

• Insert / remove plug-in module

• Screw on the plug-in module / blind plate

• Connect the cables (mains cable first)

• Switch on the unit again

To ensure correct operation, check that the screws of the plug-in

modules are tightened.

Additional protective measures must be taken if certain processes in the

vacuum system (e.g. flashovers) can cause hazardous voltages on the

gauge terminals.

Although the gauge cables are screened, they should not be routed in

parallel to lines producing strong electrical noise.

Connect the gauge to the <TPR> connector on the rear panel. The connectors are

locked so that they cannot be separated accidentally.

8 IG9972BEN (2017-09) Plug-In Boards.om

Page 9

4.3 Connecting the Cold

Cathode Gauge

Additional protective measures must be taken if certain processes in the

vacuum system (e.g. flashovers) can cause hazardous voltages on the

gauge terminals.

Although the gauge cables are screened, they should not be routed in

parallel to lines producing strong electrical noise.

Connect the gauge to the <IKR> connector. Coaxial cables normally suffice. The

following diagram indicates the conditions under which a triaxial cable is required.

The maximum length of 100 m for coaxial cables is specified by

EN 61010. Greater lengths are not admissible without additional protective measures.

If the gauge is not grounded via the vacuum chamber, it must be

grounded separately.

If the cable length is >100 m (only admissible with triaxial cable), the

connectors must be protected against unintentional separation and

contact of the center conductor. The cable must only be plugged in or

detached while the unit is switched off for at least 15 seconds.

IG9972BEN (2017-09) Plug-In Boards.om 9

Page 10

4.4 Connecting the

<OUTPUT>

Analog Signal

4.5 Connecting the Relays

of the IF300P

Pin Assignment

Protection against unintentional separation of the triaxial connector.

Each measurement circuit is equipped with an analog

signal output. Matching connectors are included with

each measurement board.

The relay connector on the rear of the IF300P has the following pin assignment:

15

Relay 1

8

(Switching function 1)

7

14

Relay 2

6

(Switching function 2)

13

5

Relay 3

12

(Switching function 3)

4

11

Relay 4

3

(Switching function 4)

10

2

Relay 5

1

(Error status)

9

15

9

IF 300P

1

8

Screen

Contacts shown de-energized

Pin location

10 IG9972BEN (2017-09) Plug-In Boards.om

Page 11

4.6 Connecting the

Profibus-DP Interface to

the IF300P

Pin Assignment

In a Profibus-DP installation, use the recommended special cable only

(→ [2]).

The interface connector on the rear of the IF300P has the following pin assignment:

Pin

1

Screen

2

3

4

5

6

Do not connect

RxD/TxD-P (B wire)

CNTR-P (optional)

DGND

VP (Only necessary

IF 300P

a bus end devices)

7

8

9

Do not connect

RxD/TxD-N (A wire)

Do not connect

9

6

5

1

IG9972BEN (2017-09) Plug-In Boards.om 11

Page 12

5 Adjustment

5.1 Adjusting the Pirani

Measurement Circuit

Pirani measurement circuits are factory-adjusted to the standard gauge. Due to

manufacturing tolerances, contamination of the gauges, and different cable

lengths, deviations are inevitable.

Cold cathode measurement circuits are factory-adjusted and require no readjustment.

Two trimmer potentiometers are available for compensating the gauge tolerances, gauge contamination, or

different cable lengths, within certain limits.

Adjustment at High Vacuum

Adjustment at Atmospheric

Pressure

The adjustment should only be performed

after the equipment has attained operating

temperature (≈10 minutes).

• With gauge connected, lower the vacuum chamber pressure to <1×10-4 hPa

• Select the measurement circuit to be adjusted (»sensor« mode)

-4

• With the <HIGH VAC> potentiometer adjust the display to 8.0×10

hPa

• Turn the potentiometer clockwise by 90°

• «ur 10-4» should now be displayed (→ [1]).

• Expose the gauge to atmospheric pressure (vent the vacuum chamber)

• Turn the <ATM> potentiometer to obtain a reading of 1.0×103 hPa

• Decrease the pressure to <1×10-4 hPa

• Check the high vacuum reading and readjust, if necessary.

12 IG9972BEN (2017-09) Plug-In Boards.om

Page 13

6 Troubleshooting

6.1 Operating and

Adjustment Problems

6.2 Defects

6.3 Problems with the

RS232C Interface

In addition to the guidelines below, take the documentation of the other system

components into account (→ Literature 21).

Problem Possible cause Correction

Pirani reading too high Pirani gauge contami-

nated

Adjust Pirani measurement circuit (→ 12)

Clean gauge (→ [3])

Replace gauge

Cold cathode reading

too high

Air humidity

Connector insulation

contaminated or moist

Clean insulation or replace connector

Keep the air humidity low

( leakage current)

Keep the equipment in

constant operation

Cold cathode reading

too low

Cold cathode gauge

contaminated

Clean gauge

(→ [4])

Replace ionization

chamber

Pirani can not be

adjusted

Incorrect combination

measurement board –

Select correct

combination (→ 8)

gauge – cable

Gauge severely contami-

nated

Clean or replace gauge

(→ [3])

Problem Possible cause Correction

Cold cathode constantly

indicates « »

Short circuit in the cold

cathode cable / gauge

Replace or repair the

cable / gauge

(overrange), (even

though

the pressure is within the

measuring range)

Cold cathode measurement board defective

Replace the cold cathode

measurement

board(→ 8)

Cold cathode indicates

No IKR gauge connected Connect the gauge

« » (underrange),

even though the pressure

is within the measuring

range

Cold cathode gauge

Cold cathode measure-

Interruption in cold

cathode cable

defective

ment board defective

Replace or repair the

cable

Replace the gauge

(→ [4])

Replace the cold cathode

measurement board

(→ 8)

Problem Possible cause Correction

No communication Pin 2 and 3 of the inter-

Use the correct cable

face cable not crossed

Incorrect Baud rate Match Baud rate

Incorrect data format Adhere to the format

specified for the TPG300

(→ [1])

IG9972BEN (2017-09) Plug-In Boards.om 13

Page 14

6.4 Problems with the

Profibus-DP Interface

Problem Possible cause Correction

No communication Incorrect Baud rate 1) Set Baud rate to

19200 Baud

Incorrect data format Adhere to the standardized

Profibus-DP data format

(→ [2])

Cycle time >100 ms Incorrect firmware Firmware TPG300:

302-654

Firmware Profibus: V1.5

Incorrect Baud rate

1)

Set Baud rate to

19200 Baud

1)

At the controller TPG300, firmware 302-654 or higher

14 IG9972BEN (2017-09) Plug-In Boards.om

Page 15

7 Accessories

A

7.1 Gauges

7.2 Measurement Cables

and Cable Connectors

Pirani Measurement cables

Pirani cable connectors

controller side

Pirani cable connectors

gauge head side

Gauge Compatible to

Vacuum connection Ordering number

measurement board:

TPR018

→ [3]

IKR085

→ [4]

CP300C9 DN 16 ISO-KF

DN 40 CF-F

CP300C9 DN 40 ISO-KF

DN 40 CF-F

IO G15 020

IO G15 024

PT R18 772

PT R18 773

With Amphenol C91 and Lemo (standard plugs on each side).

Length [m] 80 °C

Pirani Measurement

cables for TPR018

Measurement cables, high

temperature version for TPR0181)

250 °C

3 ITC548308 ITC548414

5 – ITC548465

10 ITC548456 ITC448047

15 ITC548457 ITC448043

20 ITC548458 ITC448044

25 ITC548459 ITC120025

30 ITC548460 ITC120030

35 ITC548461 ITC120035

40 ITC548462 ITC120040

45 ITC548463 ITC120045

50 ITC548464 ITC120050

1)

Pirani measurement cable for TPR018:

4

2

1

5

LEMO

female

mphenol C91E

male

4

2

1

5

3

Connectors controller side Ordering Number

Amphenol C91 IT4722125

Crimp contact C91 plug connector IT4722841

Connectors gauge head side Ordering Number

Lemo 4.3 – 5.2 mm IT4722062

Lemo 5.3 – 6.2 mm IT4722063

IG9972BEN (2017-09) Plug-In Boards.om 15

Page 16

Cold Cathode Measurment

Cables

Cold cathode cable

connectors controller side

Cold cathode cable

connectors gauge head side

With SHV and Triax Lemo (standard plugs on each side).

(Test voltage: 6 kV (dc))

Length

[m]

80 °C

Pirani Measurement

cables for IKR085

250 °C

Measurement cables, high

temperature version for IKR0851)

3 ITC220003 ITC230003

5 ITC220005 ITC230005

10 ITC220010 ITC230010

15 ITC220015 ITC230015

20 ITC220020 ITC230020

25 ITC220025 ITC230025

30 ITC220030 ITC230030

35 ITC220035 ITC230035

40 ITC220040 ITC230040

45 ITC220045 ITC230045

50 ITC220050 ITC230050

Connectors controller side Ordering Number

SHV-50-Peek IT4726605

SHV-50-Capton IT4728606

Connectors gauge head side Ordering Number

Triax IT1001030

Coax IT100103116

16 IG9972BEN (2017-09) Plug-In Boards.om

Page 17

Appendix

A: Output Signals of the

Measurement Boards

Pirani Gauge

TPR018 with CP300C9

IG9972BEN (2017-09) Plug-In Boards.om 17

Page 18

Cold Cathode Gauge

IKR085 with CP300C9

18 IG9972BEN (2017-09) Plug-In Boards.om

Page 19

B: Gas Type Dependence

Pirani Gauge TPR018

Indicated pressure (instrument calibrated for air)

IG9972BEN (2017-09) Plug-In Boards.om 19

Page 20

Cold Cathode Gauge IKR085

Indicated pressure (Instrument calibrated for air)

(Mean values, deviations possible depending on degree of contamination).

Reference gauge: Hot cathode ionization gauge

20 IG9972BEN (2017-09) Plug-In Boards.om

Page 21

C: Literature

[1] www.inficon.com

Operating Manual

Total Pressure Gauge Controller TPG300

IG9970BEN

INFICON AG, LI–9496 Balzers, Liechtenstein

[2] www.inficon.com

Communication Protocol

Profibus-DP Interface Board IF300P

IG9973BEN

INFICON AG, LI–9496 Balzers, Liechtenstein

[3] www.inficon.com

Operating Manual

Pirani Gauge TPR018

BG9976BEN

INFICON AG, LI–9496 Balzers, Liechtenstein

[4] www.inficon.com

Operating Manual

Cold Cathode Gauge IKR085

IG9048BEN

INFICON AG, LI–9496 Balzers, Liechtenstein

IG9972BEN (2017-09) Plug-In Boards.om 21

Page 22

LI–9496 Balzers

Liechtenstein

Tel +423 / 388 3111

Fax +423 / 388 3700

Original: English reachus@inficon.com

i g9972ben

www.inficon.com

Loading...

Loading...