Page 1

TECHNICAL HANDBOOK

jina85e1-f (1112)

catalog no.

540-001

540-002

from software version 1.6

T-Guard™

Sensor for Leak Detection

Page 2

Printed in Germany

We reserve the right to alter the design or any data given in this handbook. This is

due to the fact that we are permanently developing ou r pr od u cts .

The illustrations are not binding. If there are divergences between your product and

the Technical Handbook, please contact us.

Reprint, translation and duplication need to be a pproved by INFICON GmbH. Please

contact your sales people for an updated version of the Technical Handbook.

INFICON GmbH

Bonner Straße 498

50968 Cologne

Germany

jina85e 0.fm Technical Handbook(1112)

2

Page 3

Content

1 Operating instructions 4

1.1 How to use this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Warning and danger symbols . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Graphic conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety 7

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Requirements to be fulfilled by the user . . . . . . . . . . . . . . . . . . 7

2.3 Restrictions of use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Description 9

3.1 Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Vacuum diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Wise Technology™ Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5.1 Control unit for desktop operation . . . . . . . . . . . . . . . . . . . . . . 20

3.5.2 19" control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5.3 Connection Cable for Control Unit, 5 m . . . . . . . . . . . . . . . . . 23

3.5.4 Connector set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.5.5 Fore Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.5.6 2m line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.5.7 I•Stick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.5.8 Set of filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.6 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.7 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4 Installation 29

4.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2 Installing Mechanically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.3 Choosing a Fore Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4 Installing Electrically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.5 Connecting the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.6 Connecting a PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.6.1 Selection of functions assigne d to the PLC inputs. . . . . . . . . . 32

4.6.2 Electrical connection of the PLC inputs . . . . . . . . . . . . . . . . . 34

4.6.3 Selection of functions assigned to the PLC outputs. . . . . . . .35

4.6.4 Electrical connection of the PLC outputs . . . . . . . . . . . . . . . . 37

T-Guard EN_jina85IVZ .fm Technical Handbook(1112)

4.6.5 Overview of all settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.7 Connecting a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Content 1

Page 4

5 Operation 39

5.1 Running up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

5.2 Calibrating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

5.2.1 Preparing Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

5.2.2 Start Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

5.3 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

5.3.1 Accumulation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

5.3.1.1 Hints for a good measurement: . . . . . . . . . . . . . . . . . . . . . . . .45

5.3.2 Carrier Gas Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

5.3.2.1 Hints for a good measurement: . . . . . . . . . . . . . . . . . . . . . . . .48

5.3.3 Continuous Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

5.3.4 Switching Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

5.3.5 Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

5.3.6 Helium contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

5.4 Controlling via PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

5.4.1 How to execute an accumulation measurement . . . . . . . . . . .51

5.4.2 How to execute a carrier gas measurement . . . . . . . . . . . . . .51

5.5 Controlling via RS-232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

5.6 Configuring analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

5.7 Using the I-Stick and the parameter sets . . . . . . . . . . . . . . . .53

5.8 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

5.8.1 Menu Structure Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

5.8.2 Explanation of Menu Items . . . . . . . . . . . . . . . . . . . . . . . . . . .56

5.9 F.A.Q. - Frequently asked questions . . . . . . . . . . . . . . . . . . .63

6 Maintenance 66

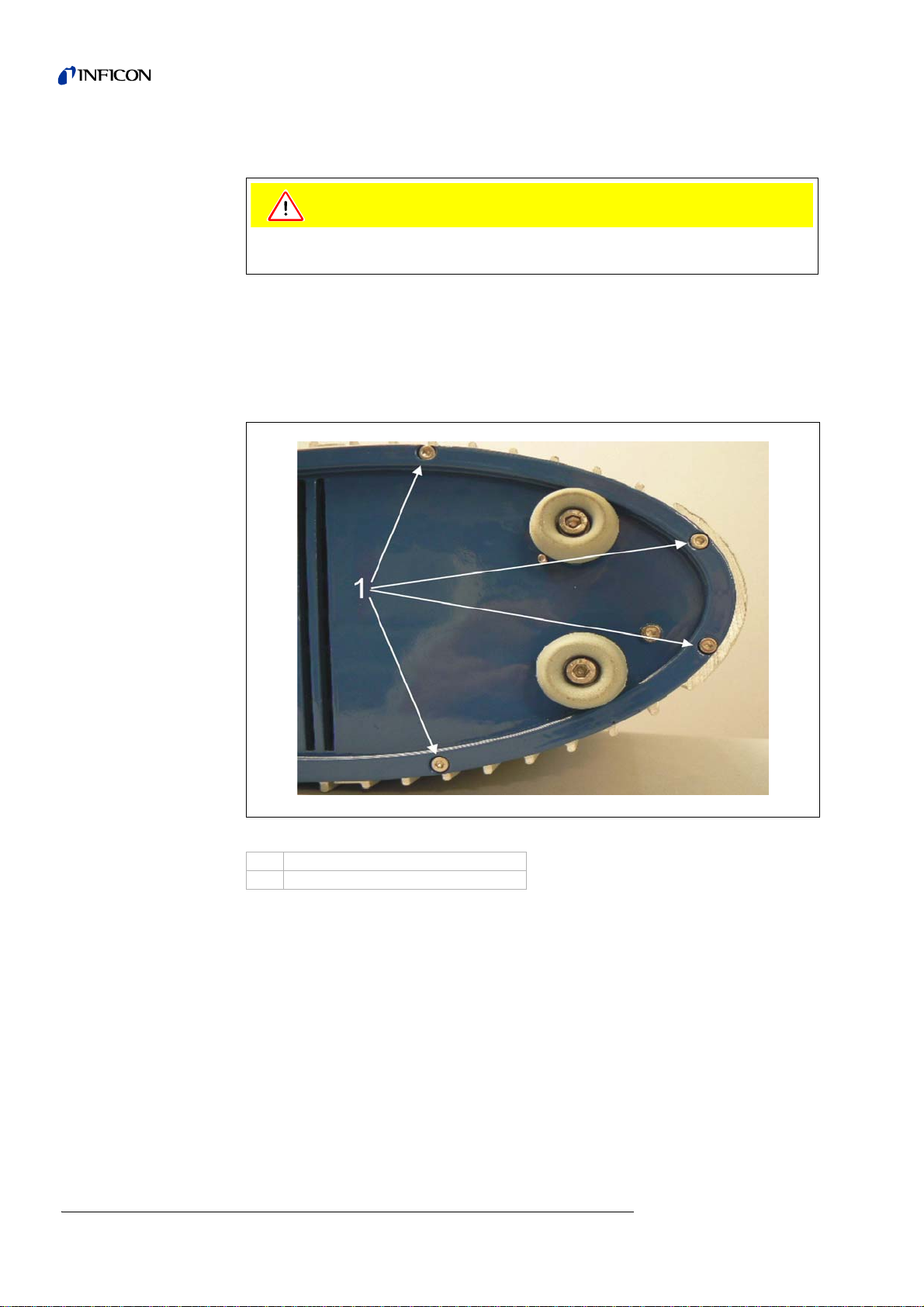

6.1 Replacing the Inlet Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

6.2 Replacing Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

6.3 Replacing the Internal Fuses . . . . . . . . . . . . . . . . . . . . . . . . .68

7 Product Handling 71

7.1 Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

7.1.1 Transporting after Contamination . . . . . . . . . . . . . . . . . . . . . .71

7.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8 Technical Data 72

8.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

8.2 Weight / dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

8.3 Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

8.4 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

8.5 Assembly Drawing for built-in Control Unit . . . . . . . . . . . . . . .73

T-Guard EN_jina85IVZ .fm Technical Handbook(1112)

2 Content

Page 5

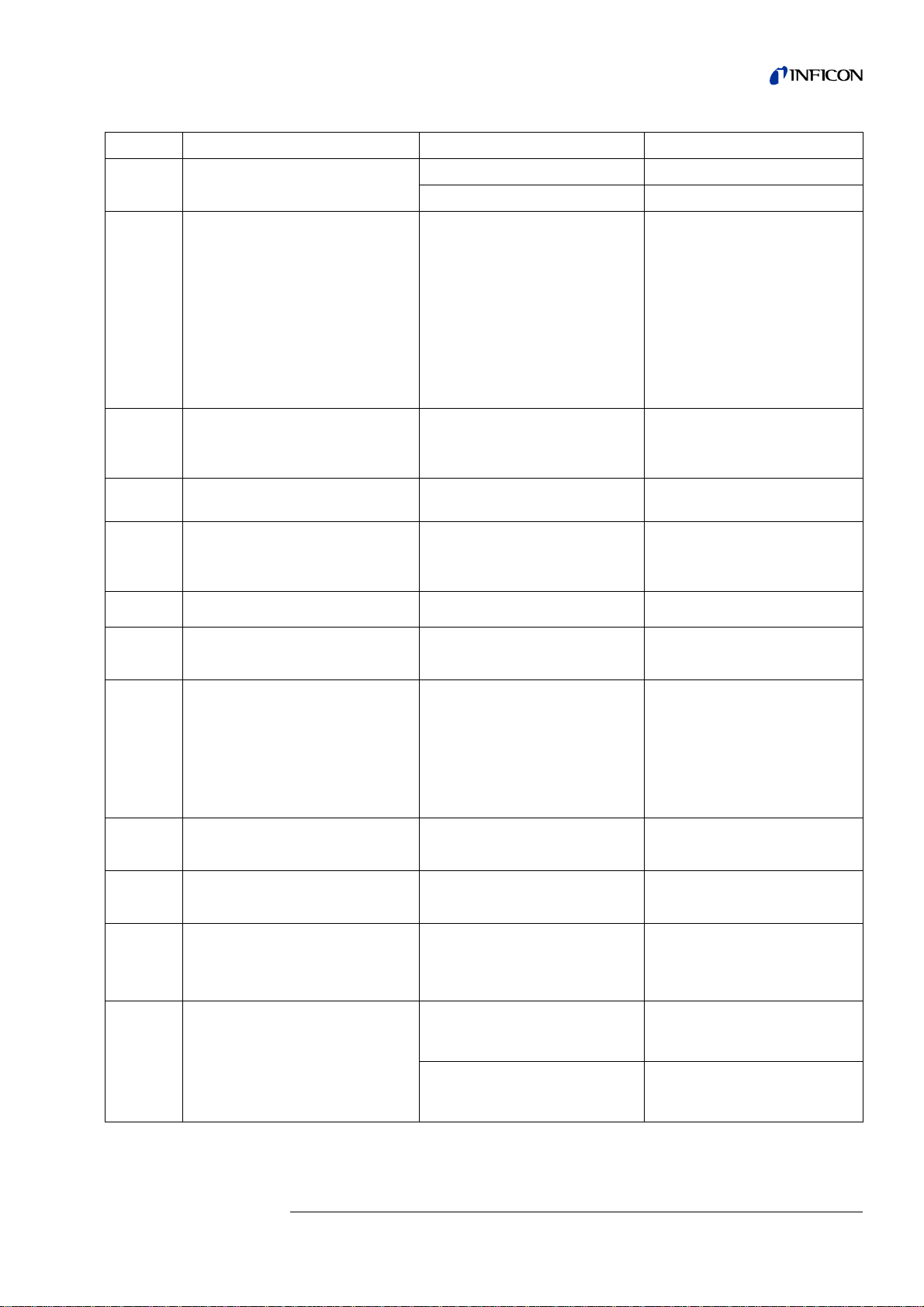

9 Errors and Warnings 74

10 Service Centers World Wide 78

10.1 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

T-Guard EN_jina85IVZ .fm Technical Handbook(1112)

Content 3

Page 6

1 Operating instructions

Warning

Caution

1.1 How to use this manual

• Please read this manual before using the T-Guard™ Leak Detection Sensor.

• Keep the manual in a way that you can use it at any time.

The INFICON T-Guard™ Leak Detection Sensor has been designed for safe and

efficient operation when used properly and in ac cord an ce with this Tec hn ica l

Handbook. It is on the user's own responsibility carefully to read and strictly to

observe all safety precautions described in this chapter and throughout this

Technical Handbook. The T-Guard™ Leak Detection Sensor must only be operated

under the conditions described in this Technical Handbook. It must be operated and

maintained by trained personnel only. Consult local, state, and national authorities

regarding specific requirements and regulations. In case you have any further

queries on safety, operation and/or maintenance, please contact our office nearest

to you.

1.2 Warning and danger symbols

Indicates procedures that must be strictly observed to prevent haza rd s to per sons.

Indicates procedures that must strictly be observed to prevent damage to, or

destruction of T-Guard™ Leak Detection Sensor.

4 Operating instructions

jina85e 1.fm Technical Handbook(1112)

Page 7

1.3 Graphic conventions

Notice Points to very useful pieces of information.

1 Points to an operation that you have to perform.

⇒ Points to the result of an operation you accomplished.

→ Points to the button you have to press.

• Shows a listing.

1.4 Glossary

Sensitivity

Characterises the ratio of the helium signal to the measured signal.

I·Stick

Optional memory extension of the T-Gu ard™ Leak Detection Sensor.

Calibration

Measuring time

Parameter set

RS232

Purge

T-Guard

Equalisation of measured signal and leakage rate.

Time from the beginning of the measurement to the output of the results.

Group of parameters, e.g. measuring time, chamber volume, carrier gas, etc.

Interface standard for data communication between electronic devices.

Removal of excessive helium from the air.

Tracer (Gas) Guard

jina85e 1.fm Technical Handbook(1112)

Operating instructions 5

Page 8

Carrier Gas

Trigger

Background

Zero

Cycle time

Large gas flow which transports a small gas flow.

Limit value of the rejection leakage rate for th e detection of le aks of the test sa mple .

The air contains 5 ppm (0.0005%) of helium by nature. For goo d measurements with

the T-Guard, the helium content in the air must be less than 10 ppm.

"Reset to Zero" is an automatic function of the T-Guard™ Leak Detection Sensor.

Time from the beginning of the measurement to the next possible measurement.

6 Operating instructions

jina85e 1.fm Technical Handbook(1112)

Page 9

2 Safety

Skilled personnel

Warning

Warning

2.1 Intended use

The T-Guard™ Leak Detection Sensor is a helium leak dete ction sensor which does

not need any vacuum chamber. It can find leaks in test samples and quantify them

when they are filled with helium under pressure.

Using the T-Guard™ Leak Detection Sensor, the chamber with the test sa mple does

not have to be evacuated.

Measured at atmospheric pressure, the minimum detectable leak rate is 1×10

l/s. This depends on the chamber volume and the measuring time, the rejection l eak

rate will mostly be between 1·10

Do not let water penetrate into the body or hoses of the T-Guard™ Leak Detection

Sensor. Do not forget to use the external filters.

Only use accessories and spare parts from INFICON.

2.2 Requirements to be fulfilled by the user

-4

and 1·10-2 mbar l/s.

-6

mbar

The T-Guard™ Leak Detection Sensor must only be started and operated by

properly trained staff.

Get used to the functioning of the device. Yo u may only use the device after reading

and understanding the manual.

2.3 Restrictions of use

Disregarding the following precautions could result in serious injury:

For all contacts of the I/O port, a maximum voltage of 60 V DC or 25 V AC must not

be exceeded or reached based on the protective cond uctor or the earthing devices.

Please refer to the information given in the following chapters.

For maintenance work, disconnect the T-Guard™ Leak Detection Se nsor from the

power supply.

jina85e 2.fm Technical Handbook(1112)

Safety 7

Page 10

Warning

Before replacing the fuses, the T-Guard™ Leak Detection Sensor must be

Caution

Caution

Caution

disconnected from the power supply.

Disregarding the following precautions could result in damage to the equipment.

The T-Guard™ Leak Detection Sensor must not be operated while standing in

water or when exposed to drip water. The same applies to all other kinds of liquid.

The T-Guard™ Leak Detection Sensor should only be used inside rooms.

Avoid the T-Guard getting in contact with bases, acids, and solvents, as well as

being exposed to extreme climatic conditions.

Do not suck up liquids into the T-Guard™.

8 Safety

jina85e 2.fm Technical Handbook(1112)

Page 11

3 Description

This chapter describes the exterior design of the T-Guar d™ Leak Detection Sensor,

its accessories and how to use it.

3.1 Housing

The housing of the unit consists of an oval cylinder. On top, there are several

electrical connections and the ventilation opening. On the rear side, ther e are th ree

hose connectors.

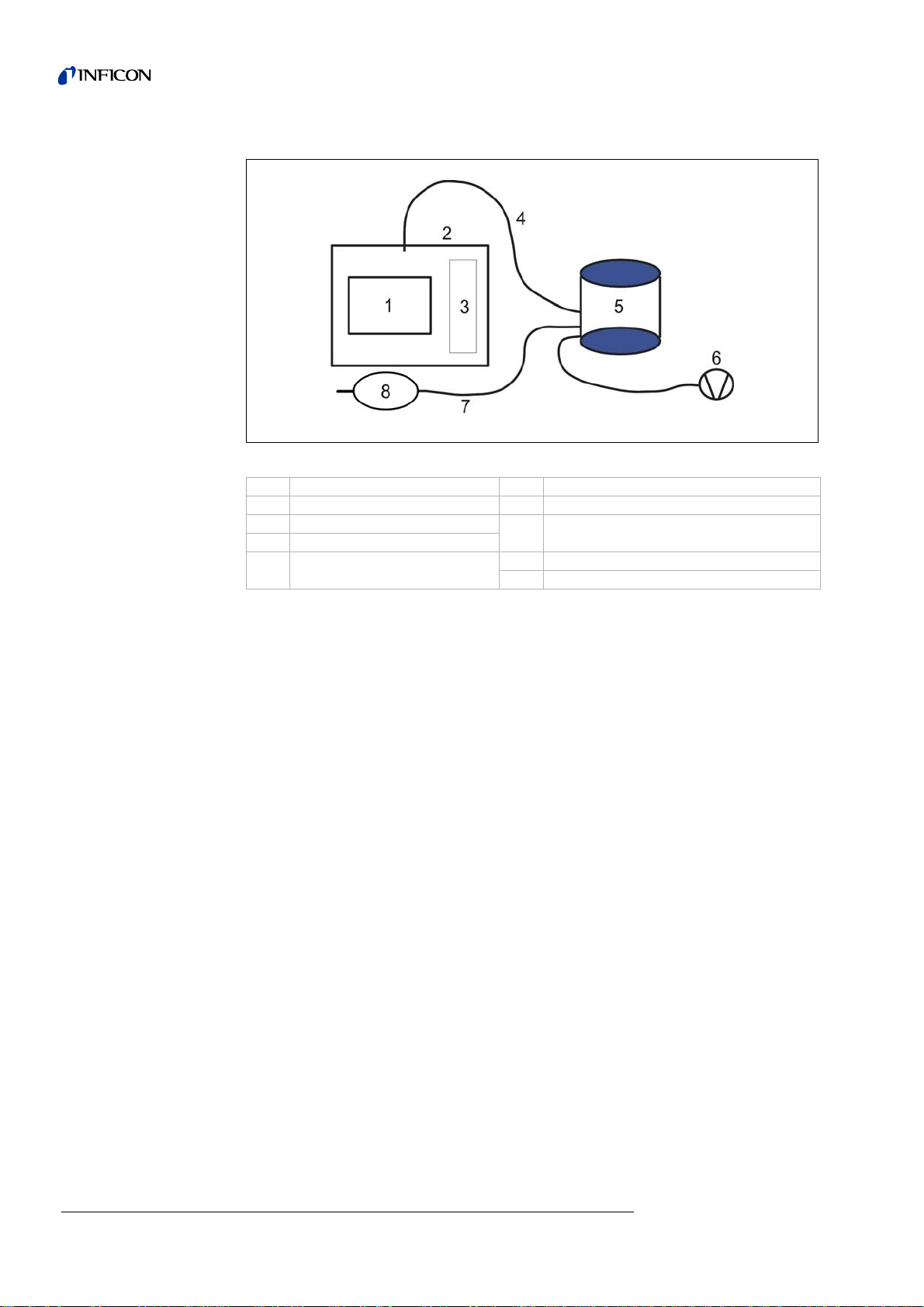

Fig. 4-1 Front view of the T-Guard™ Leak Detection Sensor

Fig. 4-2 Back view of the T-Guard™ Leak Detection Sensor

jina85e 3.fm Technical Handbook(1112)

Description 9

Page 12

3.2 Interfaces

The T-Guard™ Leak Detection Sensor has 5 interfaces for control and information

exchange.

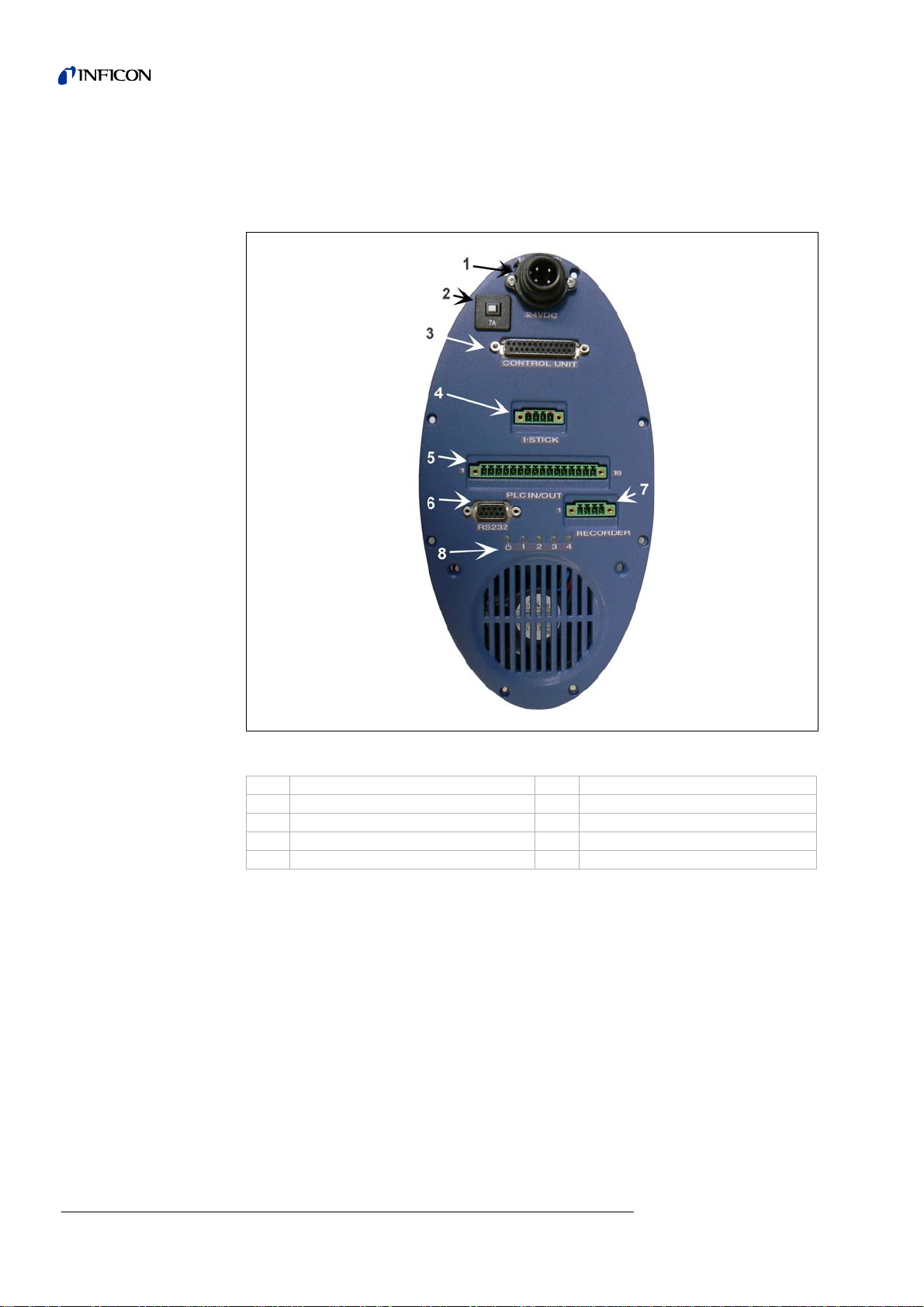

Fig. 4-3

Power Connector

Only two of the four pins are used for the power supply. The plus pole is marked with

„1+“, the minus pole is marked with „2-“.

Fuse

The fuse reacts to reverse polarity and a current exceeding 7 A.

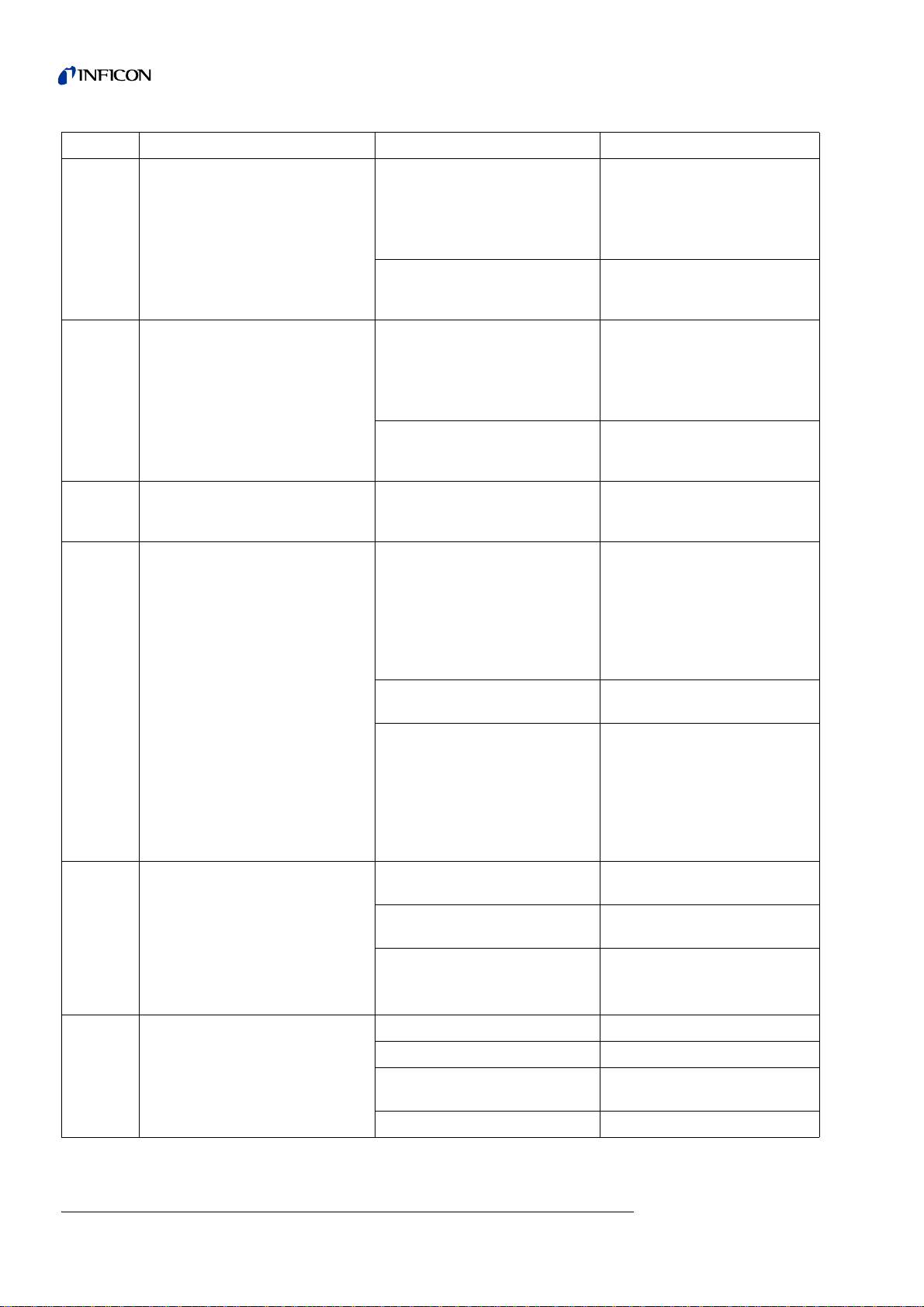

Item Description Item Description

1 Power supply connector 5 PLC-interface

2 Fuse 6 RS232 PC-interface

3 Interface for the control unit 7 Analog Recorder Output

4 I•Stick -connector 8 Status LEDs

jina85e 3.fm Technical Handbook(1112)

10 Description

Page 13

Interface for the control unit

Here, the INFICON control unit (Cat. No. 551-100 or 551-101) is connected via its

connecting cable (Cat. No. 551-102 or 551-103) to control the T-Guard™ Leak

Detection Sensor manually.

Notice The connection cable must only be plugged in or unplugged when the

supply voltage of the T Guard™ is turned off or disconnected.

I•Stick -connector

You can store 25 parameter sets on the INFICON-I-Stick and also download them

from there.

PLC-interface

The T-Guard™ Leak Detection Sensor has 6 configurable digital PLC-Inputs and

8 configurable digital PLC-outputs.

(Refer to 4.6.1 Selection of functions assigned to the PLC inputs. and 4.6.3 Selection

of functions assigned to the PLC outputs..)

RS232 PC-interface

Connect any RS232 capable device here with an uncrossed RS232 cable in order to

control the T-Guard™ Leak Detection Sensor or to read out information. The latter

takes less than 100 ms.

Analog Recorder Output

The T-Guard™ Leak Detection Sensor has two separately configurable analog

recorder outputs (0 - 10 V).

They have a resolution of 16 bit and a hardware limited refresh rate of about 2 Hz.

For a higher refresh rate, please use the RS232 interface.

For detailed Information on how to use the analog output refer to chapter 5.6.

jina85e 3.fm Technical Handbook(1112)

Description 11

Page 14

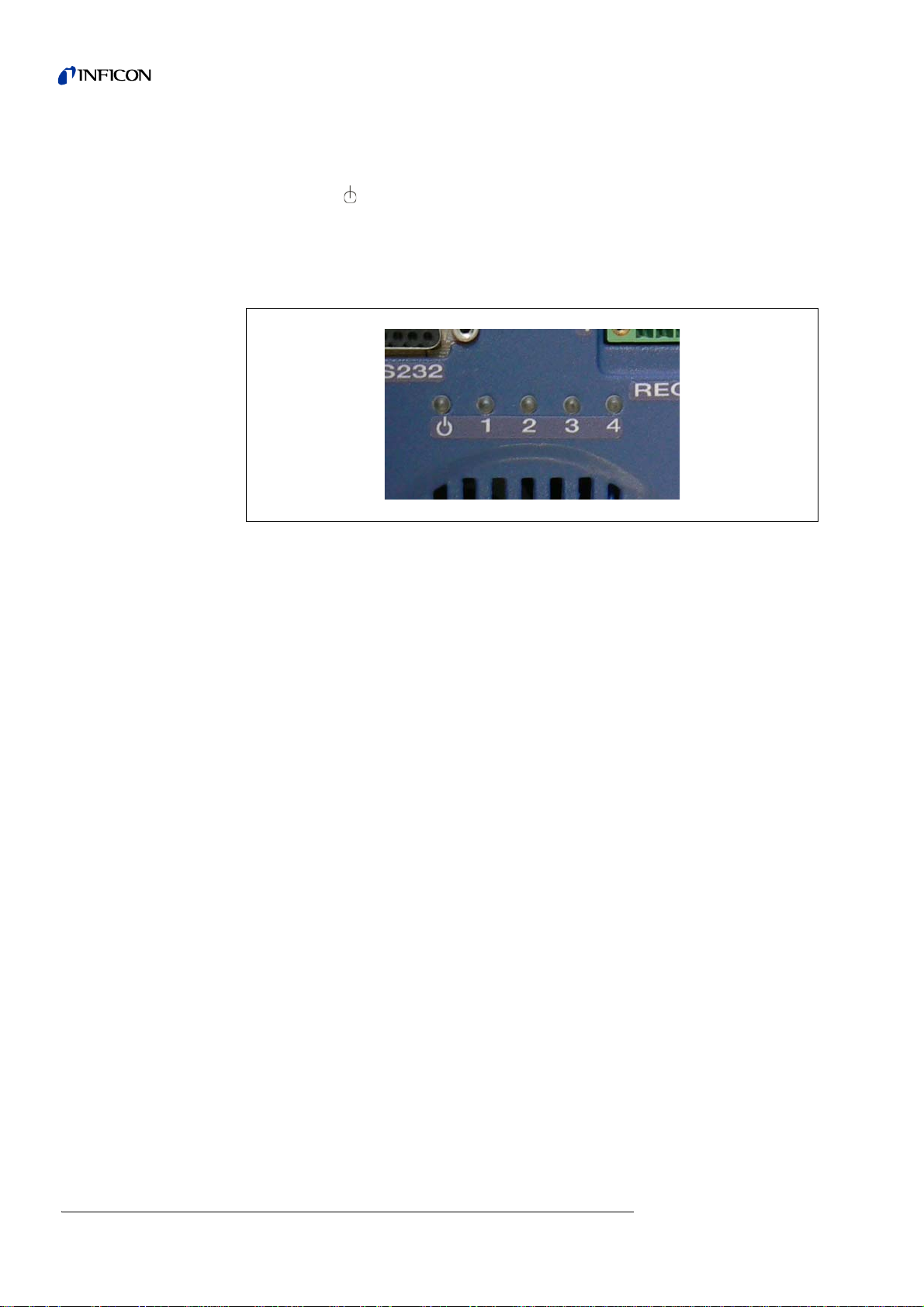

Status LEDs

Certain operating conditions can be indicated by 5 status LEDs:

The first LED : lights up during operation

The four remaining LEDsindicate the status of the configurable digital outputs 1-4.

LED No. 2 is red and in standard setting, it will light up to

indicate an error or a warning. The desired output function

can be set (refer to4.6.3).

Fig. 4-4 Status LEDs

12 Description

jina85e 3.fm Technical Handbook(1112)

Page 15

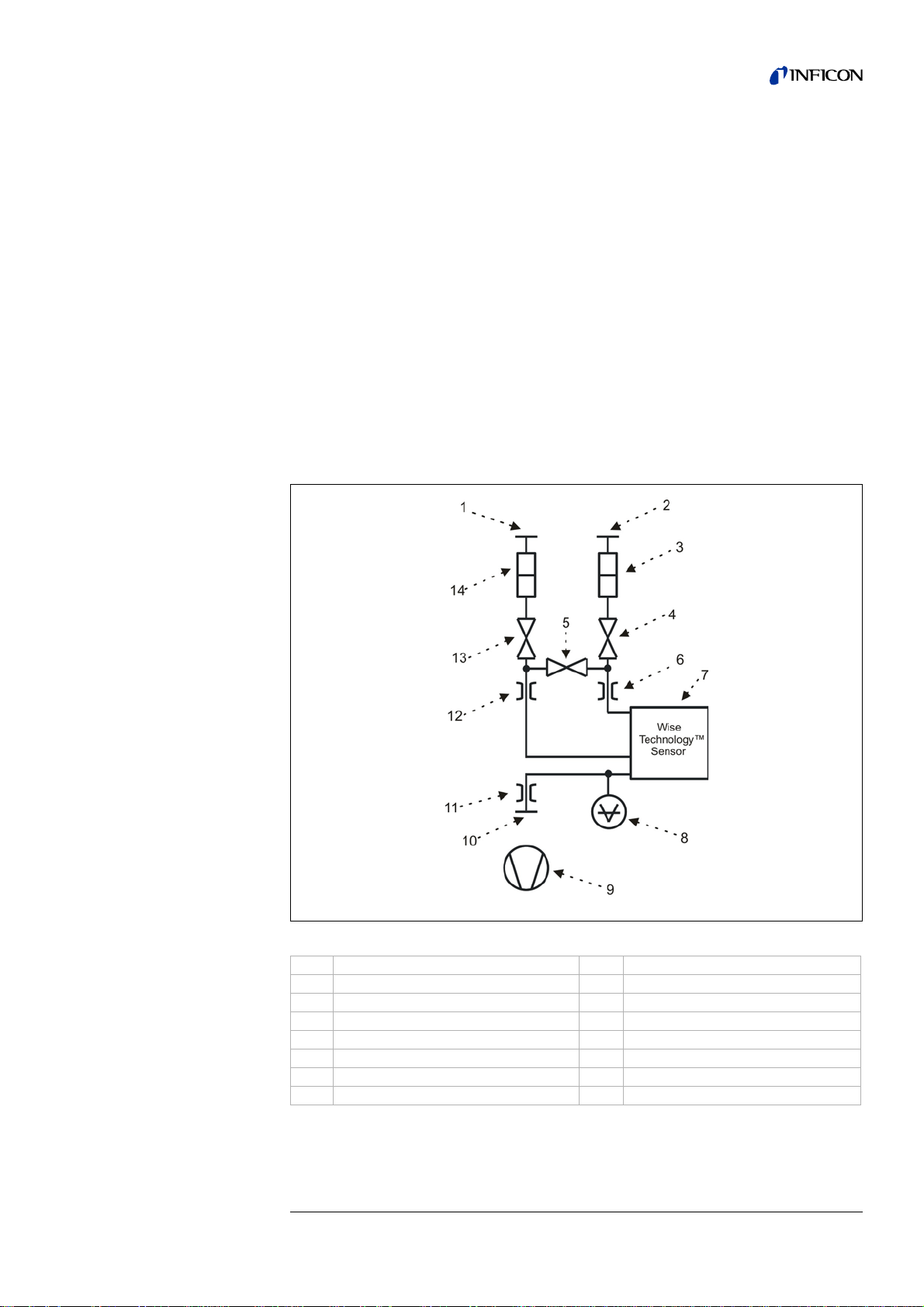

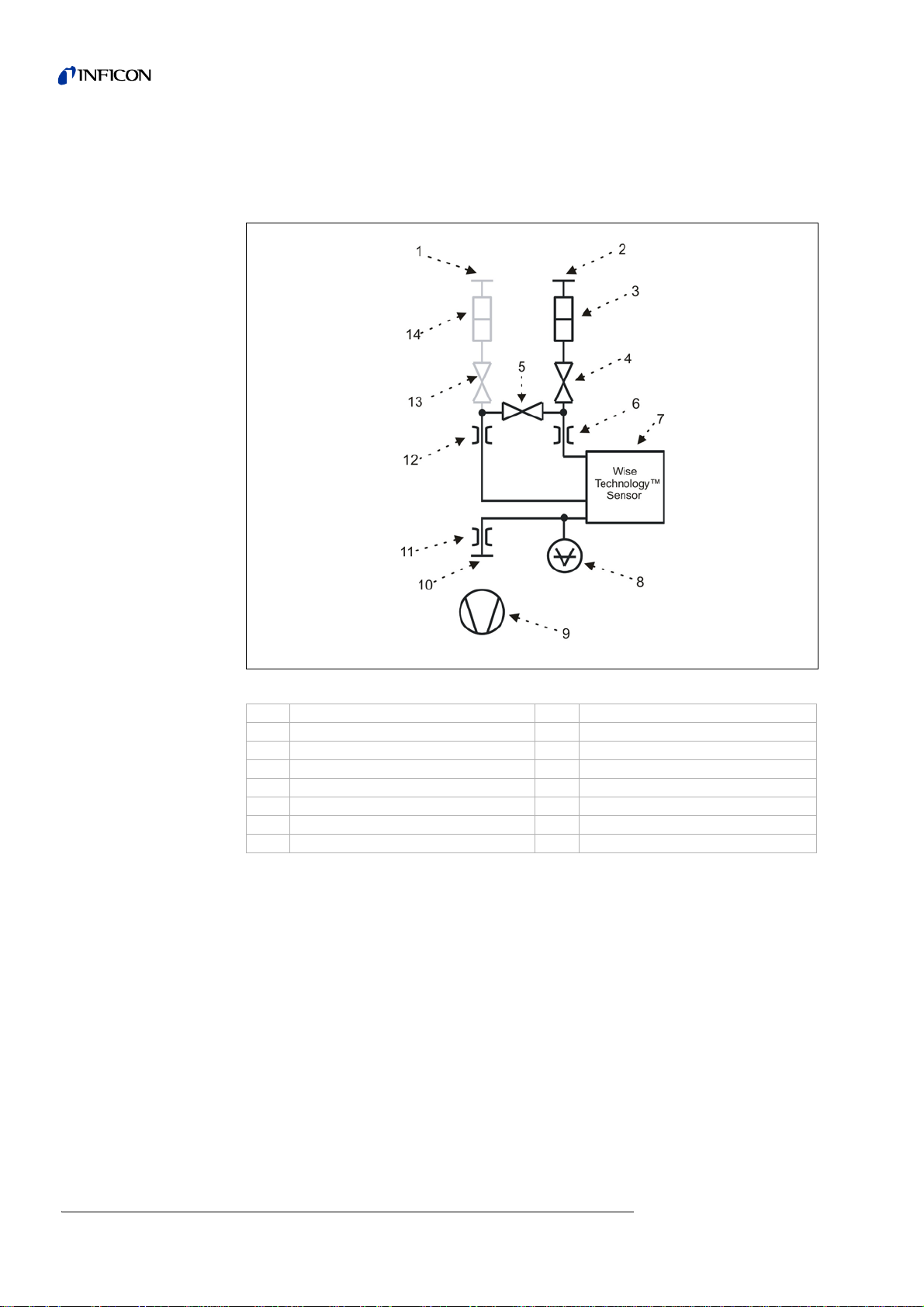

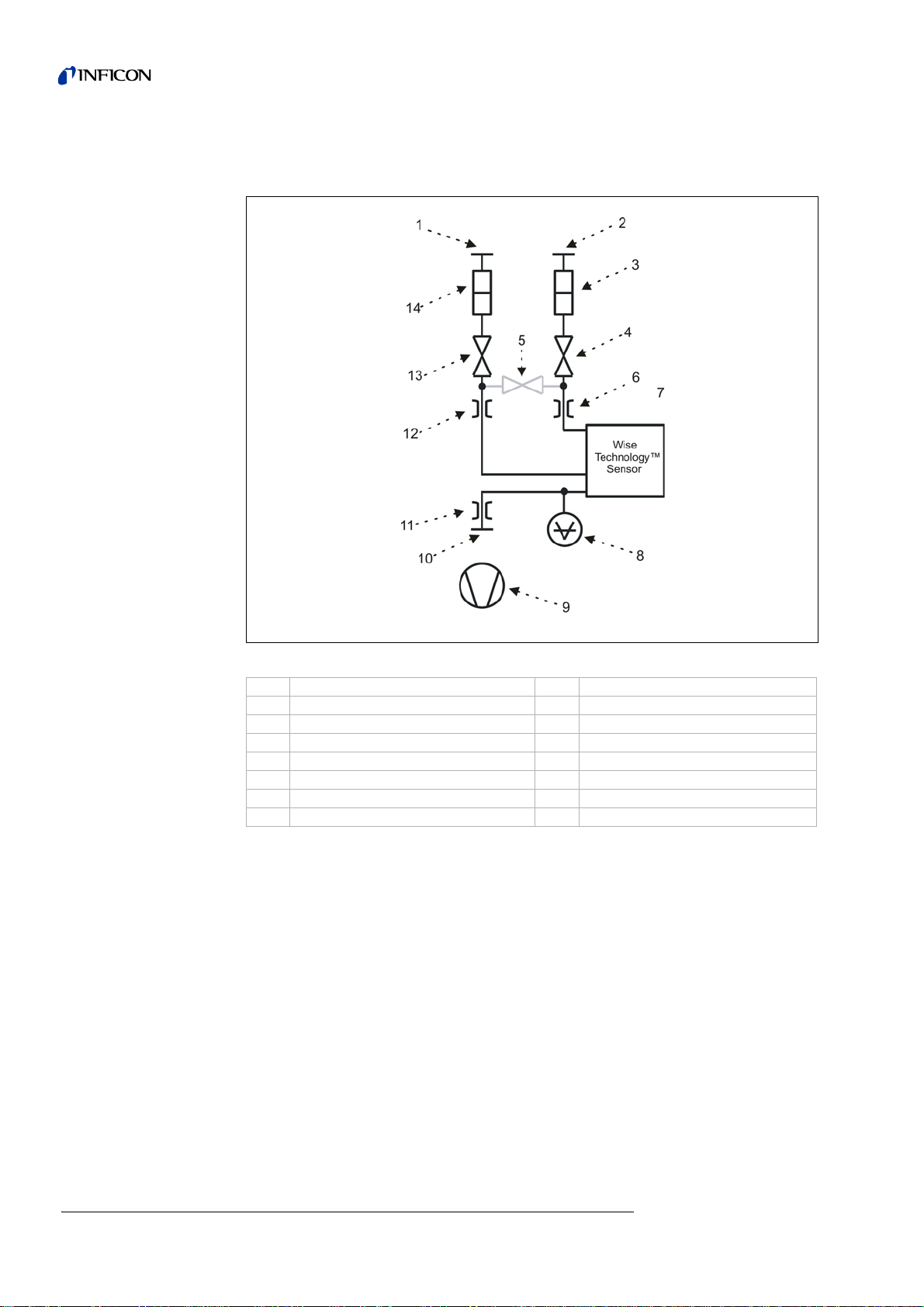

3.3 Vacuum diagram

On top of the vacuum diagram, there are the measurement inlet "IN" and the

reference inlet "Ref". Both inlets are equipped with an external filter to protect TGuard™ Leak Detection Sensor from sucking in dust or fluids. Three valves are

integrated in the T Guard™ Leak Detection Sensor (see Fig. 4-5).

Valve V1 opens and closes the measurement inlet. Valve V3 opens and closes the

reference inlet. Valve V2 opens and closes the connection between V1 and V3.

These three valves are connected to two flow-restricted capillaries which lead to the

Wise Technology™ Sensor.

The upper inlet of the Wise Technology™ Sensor is the fine inlet, the lower one is

the gross inlet, which is less sensitive to helium than the fine inlet.

The Wise Technology™ Sensor detects the heliu m in the gas stream, which passes

by. The total pressure, which is applied to the Wise Technology™ Sensor is detected

by the Pressure Gauge p1.

The fore pump, which provides the gas stream inside T-Guard™ Leak Detection

Sensor is also throttled to produce constant pressure and flow for the Wise Technology™ Sensor.

Fig. 4-5 Vacuum diagram of the T-Guard™ Leak Detection Sensor

Item Description Item Description

1 Inlet “IN” 8 Pressure gauge p1

2 Reference “Ref” 9 Pump

3 Filter 2 10 Pump connector “OUT”

4 Valve V

5 Valve V

6 Throttle 2 13 Valve V

7 Wise Technology™ Sensor 14 Filter 1

jina85e 3.fm Technical Handbook(1112)

3

2

11 Throttle 3

12 Throttle 1

1

Description 13

Page 16

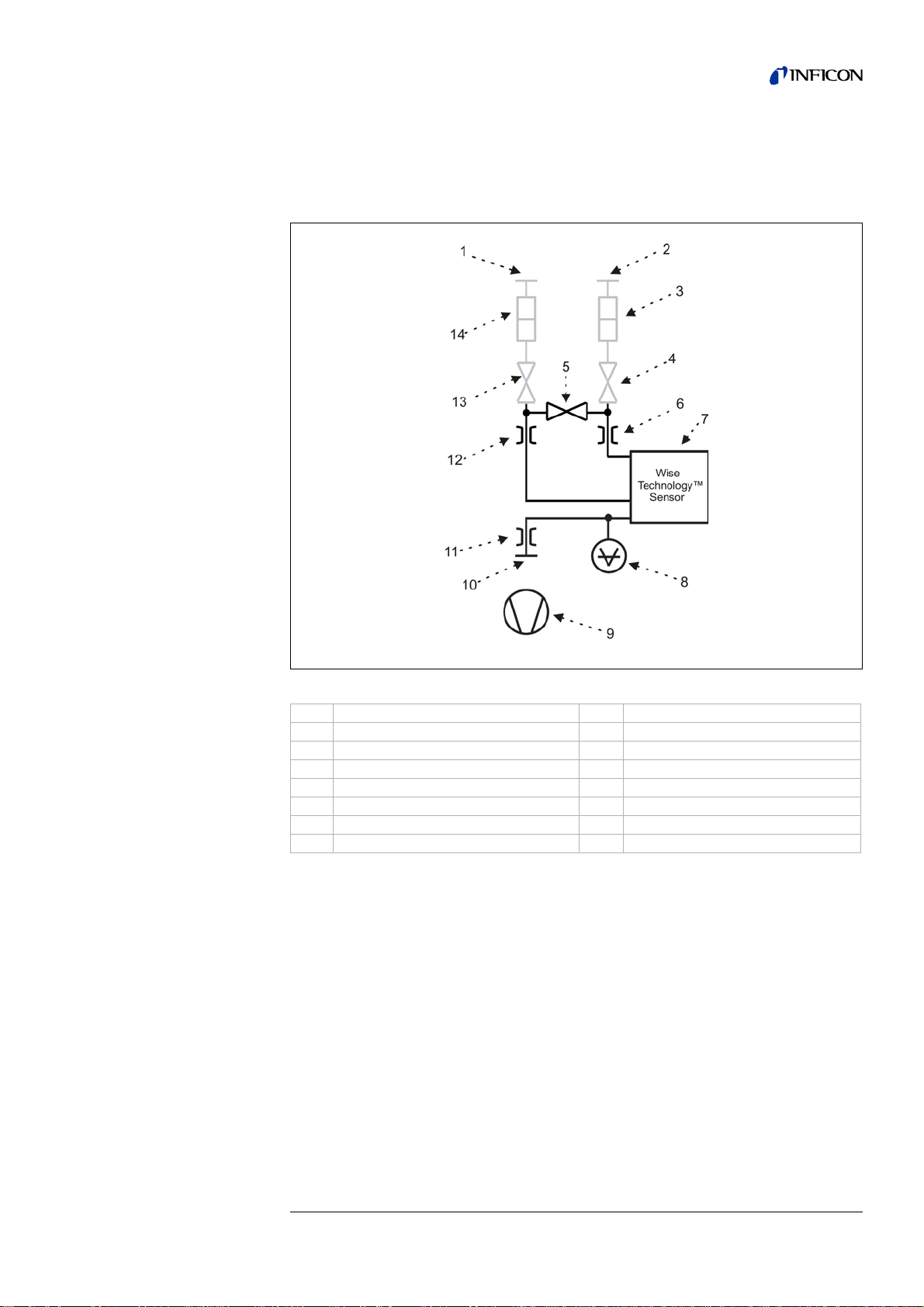

When the T-Guard™ Leak Detection Sensor is not measuring at the moment or is

READY , V2 and V3 are open, V1 is closed (refer to Fig. 4-6). Only gas from the

reference inlet gets to the sensor.

Fig. 4-6 Valve position in READY mode.

Item Description Item Description

1 Inlet “IN” 8 Pressure gauge p1

2 Reference “Ref” 9 Pump

3 Filter 2 10 Pump connector “OUT”

4 Valve V

5 Valve V

3

2

6 Throttle 2 13 Valve V

7 Wise Technology™ Sensor 14 Filter 1

11 Throttle 3

12 Throttle 1

1

14 Description

jina85e 3.fm Technical Handbook(1112)

Page 17

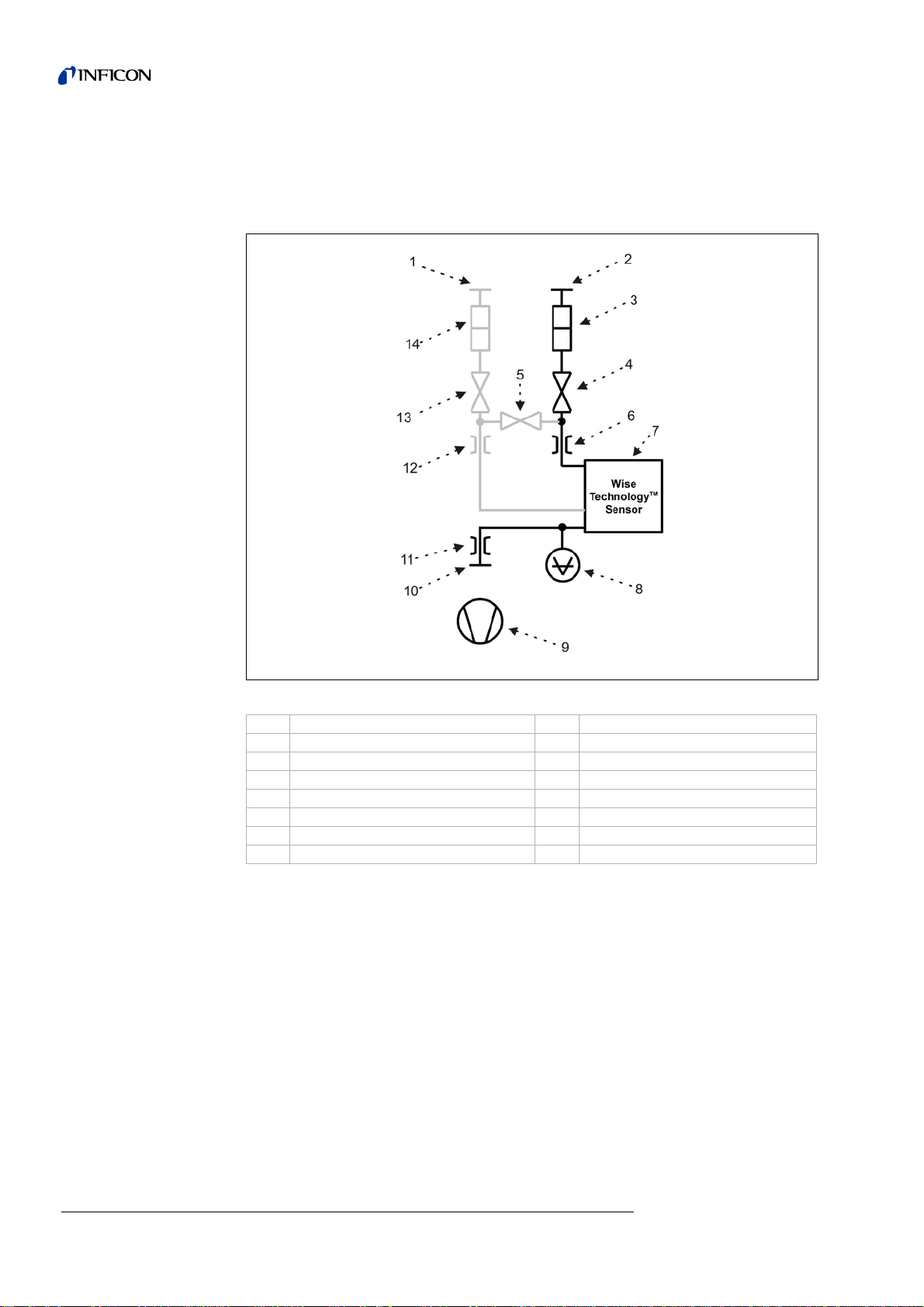

In Standby mode, all valves except V2 are closed and the pressure before the Wise

Technology™ Sensor is equal to the base pressure of the fore pump.

(refer to Fig. 4-7)

Fig. 4-7 Valve configuration in S

TANDBY mode.

Item Description Item Description

1 Inlet “IN” 8 Pressure gauge p1

2 Reference “Ref” 9 Pump

3 Filter 2 10 Pump connector “OUT”

4 Valve V

5 Valve V

3

2

6 Throttle 2 13 Valve V

11 Throttle 3

12 Throttle 1

1

7 Wise Technology™ Sensor 14 Filter 1

jina85e 3.fm Technical Handbook(1112)

Description 15

Page 18

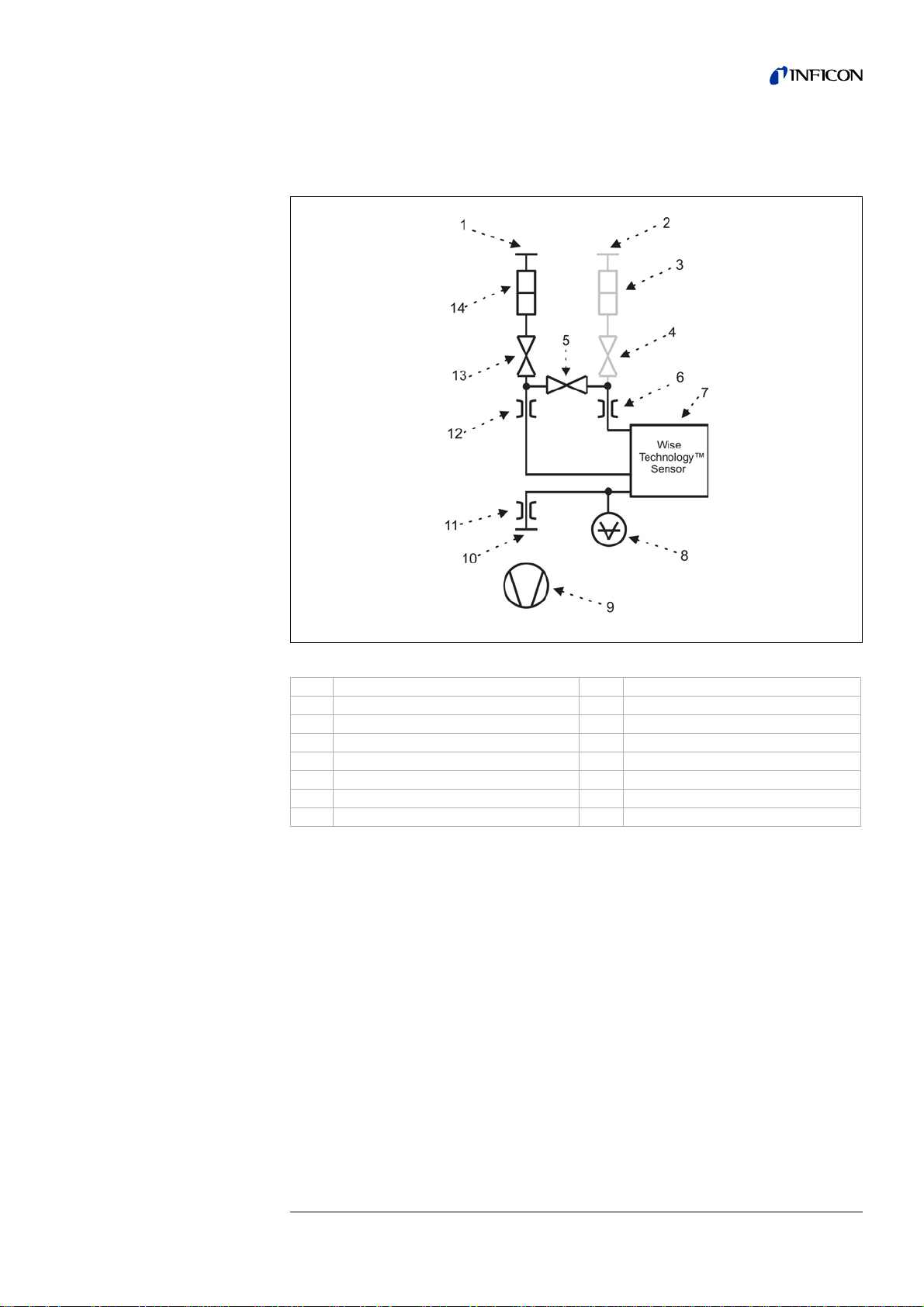

In the rare event that the sensor is contaminated with helium, only the valve V3 to the

reference inlet "Ref" is open, to purge the sensor. In this case, highly pure nitrogen

or external air has to be led to the reference inlet to decontaminate the sensor as fast

as possible.

Fig. 4-8 Valve configuration during decontamination

Item Description Item Description

1 Inlet “IN” 8 Pressure gauge p1

2 Reference “Ref” 9 Pump

3 Filter 2 10 Pump connector “OUT”

4 Valve V

5 Valve V

6 Throttle 2 13 Valve V

7 Wise Technology™ Sensor 14 Filter 1

3

2

11 Throttle 3

12 Throttle 1

1

jina85e 3.fm Technical Handbook(1112)

16 Description

Page 19

In FINE measurement mode, V1 and V2 are open, V3 is closed (see Fig. 4-9). The

sensor receives only gas from the measurement inlet and shows the highest sensitivity to helium from the measurement line.

Fig. 4-9 Valve configuration in FINE mode

Item Description Item Description

1 Inlet “IN” 8 Pressure gauge p1

2 Reference “Ref” 9 Pump

3 Filter 2 10 Pump connector “OUT”

4 Valve V

5 Valve V

3

2

6 Throttle 2 13 Valve V

7 Wise Technology™ Sensor 14 Filter 1

11 Throttle 3

12 Throttle 1

1

jina85e 3.fm Technical Handbook(1112)

Description 17

Page 20

In GROSS measurement mode, V1 and V3 are open, V2 is closed (see Fig. 4-10).

This way, the Wise Technology™ Sensor only receives little helium from the measurement line and normally even less helium from the reference line.

Fig. 4-10 Valve configuration in GROSS mode

Item Description Item Description

1 Inlet “IN” 8 Pressure gauge p1

2 Reference “Ref” 9 Pump

3 Filter 2 10 Pump connector “OUT”

4 Valve V

5 Valve V

6 Throttle 2 13 Valve V

7 Wise Technology™ Sensor 14 Filter 1

3

2

11 Throttle 3

12 Throttle 1

1

Other valve configurations than described above are not used by the software and

cannot be set by the user.

18 Description

jina85e 3.fm Technical Handbook(1112)

Page 21

3.4 Wise Technology™ Sensor

The helium detector (Wise Technology™ Sensor) consists of a closed glass

container with a measurement device for the precise determination of the pressure

inside the glass housing and a membrane chip with a large number of small quartz

windows.

The membrane is permeable only for helium; the membrane avoids all other co mponents of air from entering the glass housing.

The quartz membrane is heated so that the permeation for helium is sufficie ntly high

and fast.

Inside of the glass housing, the total pressure is measur ed precisely. As only helium

can enter the glass housing, the total pressu re is equa l to the pa rtial pressure of

helium.

The determined total pressure inside the housing is p roportional to the helium partial

pressure outside the sensor.

jina85e 3.fm Technical Handbook(1112)

Description 19

Page 22

3.5 Accessories

1

9

12

11

2

3

4

5

14

6

7

8

10

13

In addition to the main unit, two different types of the control panel and the corresponding connection cables are available.

3.5.1 Control unit for desktop operation

Install the control panel on a flat workbench to avoid slipping. It is used to control all

functions and read all values of the T-Guard™ Leak Detection Sensor.

The control panel contains an LC Display, START, S

and also 8 soft keys to navigate in the menu on the display and to enter values.

TOP, ZERO and MENU buttons

Buttons

20 Description

Fig. 4-11 Soft keys of the control unit

Item Description Item Description

1 LC Display 8 Soft key No. 5

2 Soft key No. 1 9 Soft key No. 6

3 Soft key No. 2 10 Soft key No. 7

4 Soft key No. 3 11 Soft key No. 8

5 Soft key No. 4 12 MENU button

6 START button with LED 13 STOP / VENT button with LED

7 Control Unit 14 Z

START button

Notice All 3 LEDs in the buttons are inactive with T-Guard™ Leak Detec tio n

ERO button with LED

Sensor.

jina85e 3.fm Technical Handbook(1112)

Page 23

Press the START button to start a measurement using the selected method. The

measurement will then finish automatically.

STOP button

Press the STOP button to cancel the measurement immediately.

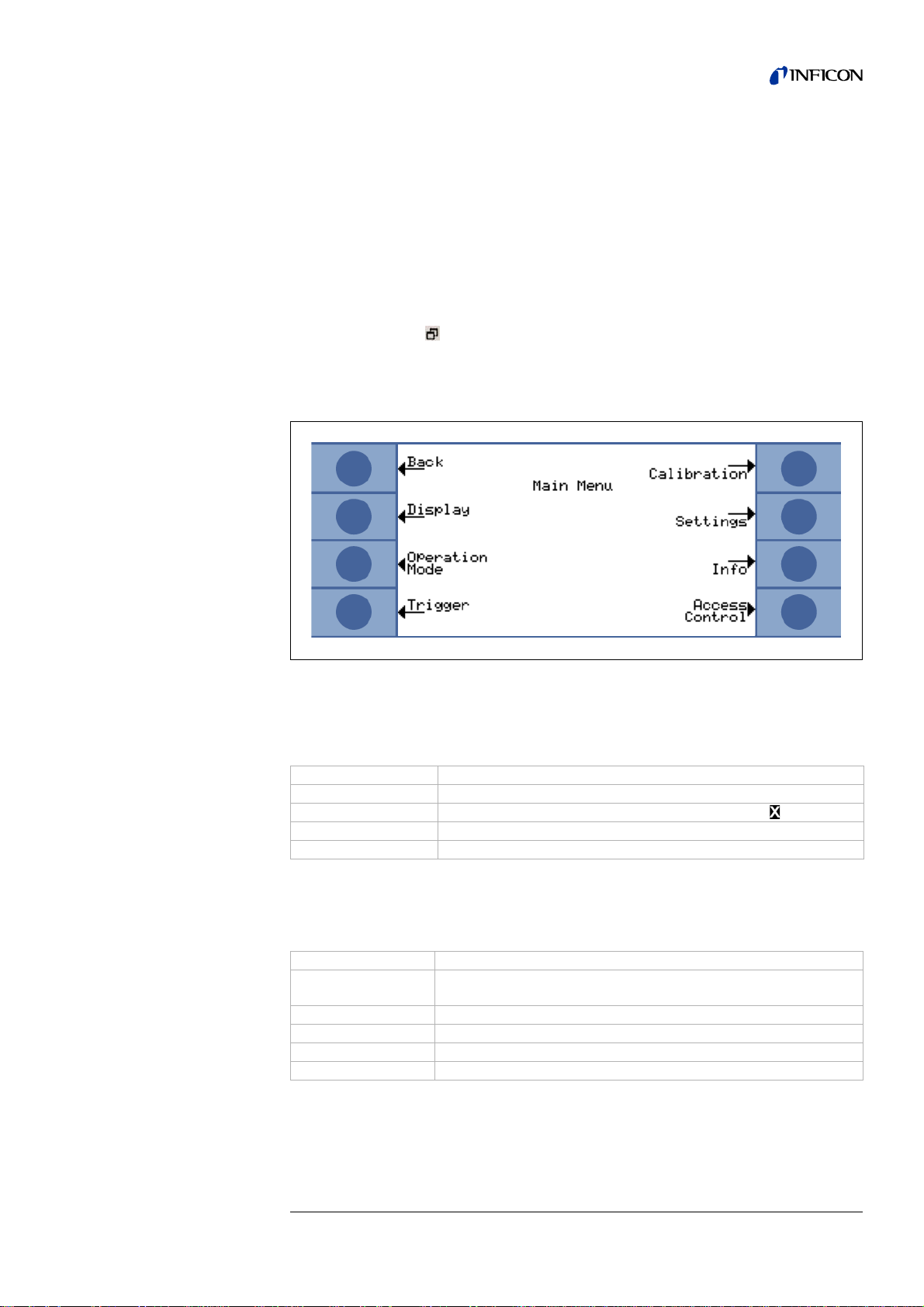

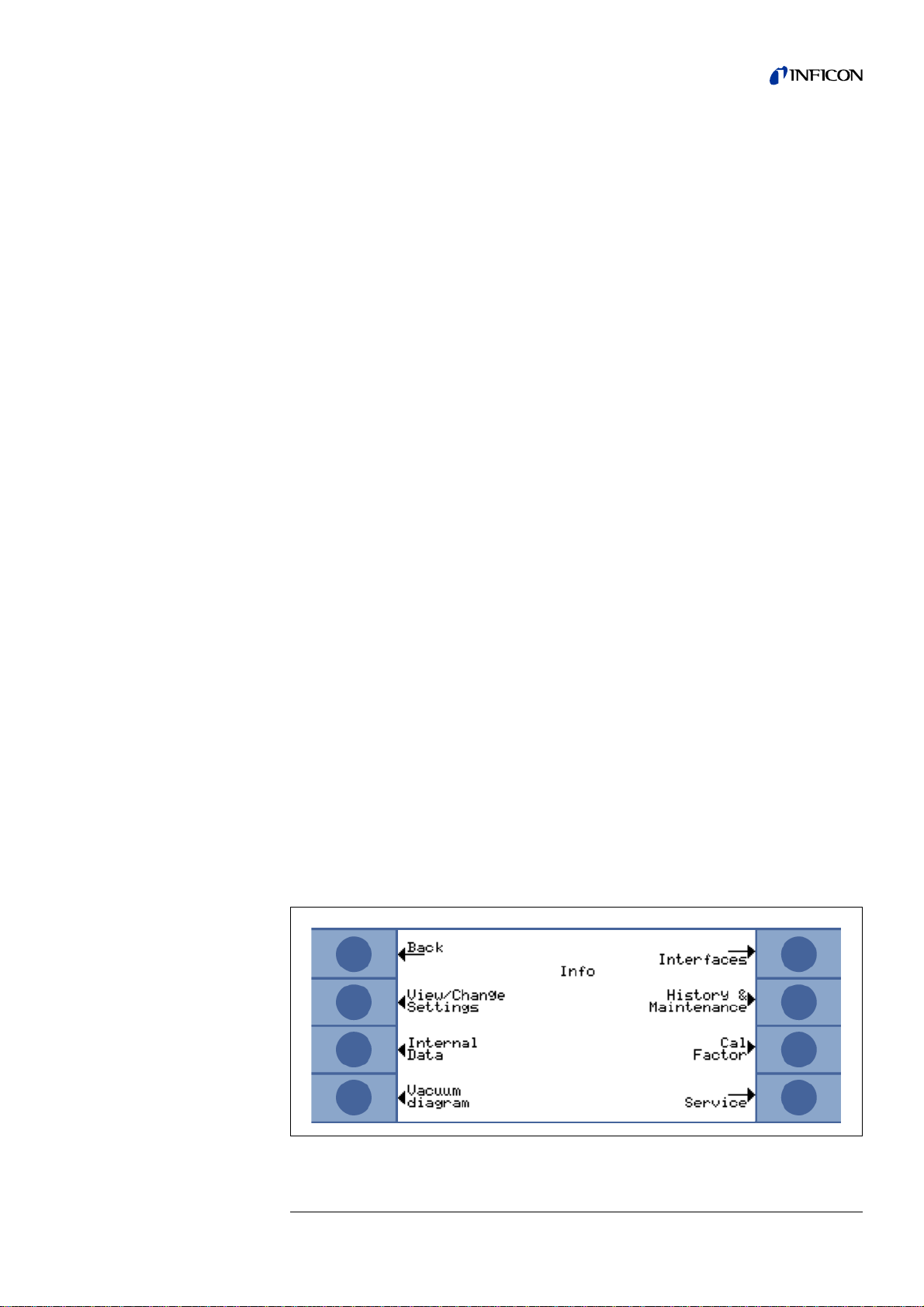

MENU button

In order to change the settings or to read information about T-Gua rd™ Leak Detection Sensor, open the menu by pressing the MENU button or the Soft Key (No.4) with

the MENU symbol ( ).

You will go back to the position in the menu you left before.

By pressing the M

ENU button again you will get back to the m easurement menu. By

pressing the MENU button for two seconds you will get into the main menu.

Fig. 4-12 Main Menu appearance

Soft Keys

The functions of the 8 soft keys depend on the currently opened menu.

Soft key No. 1 Description

1 and 8 very often have the functions B

4 often has the function to completely leave the menu ( )

ACK / ESC and OK, in this order,

MENU button Enter/Leave the menu

Entering values and units

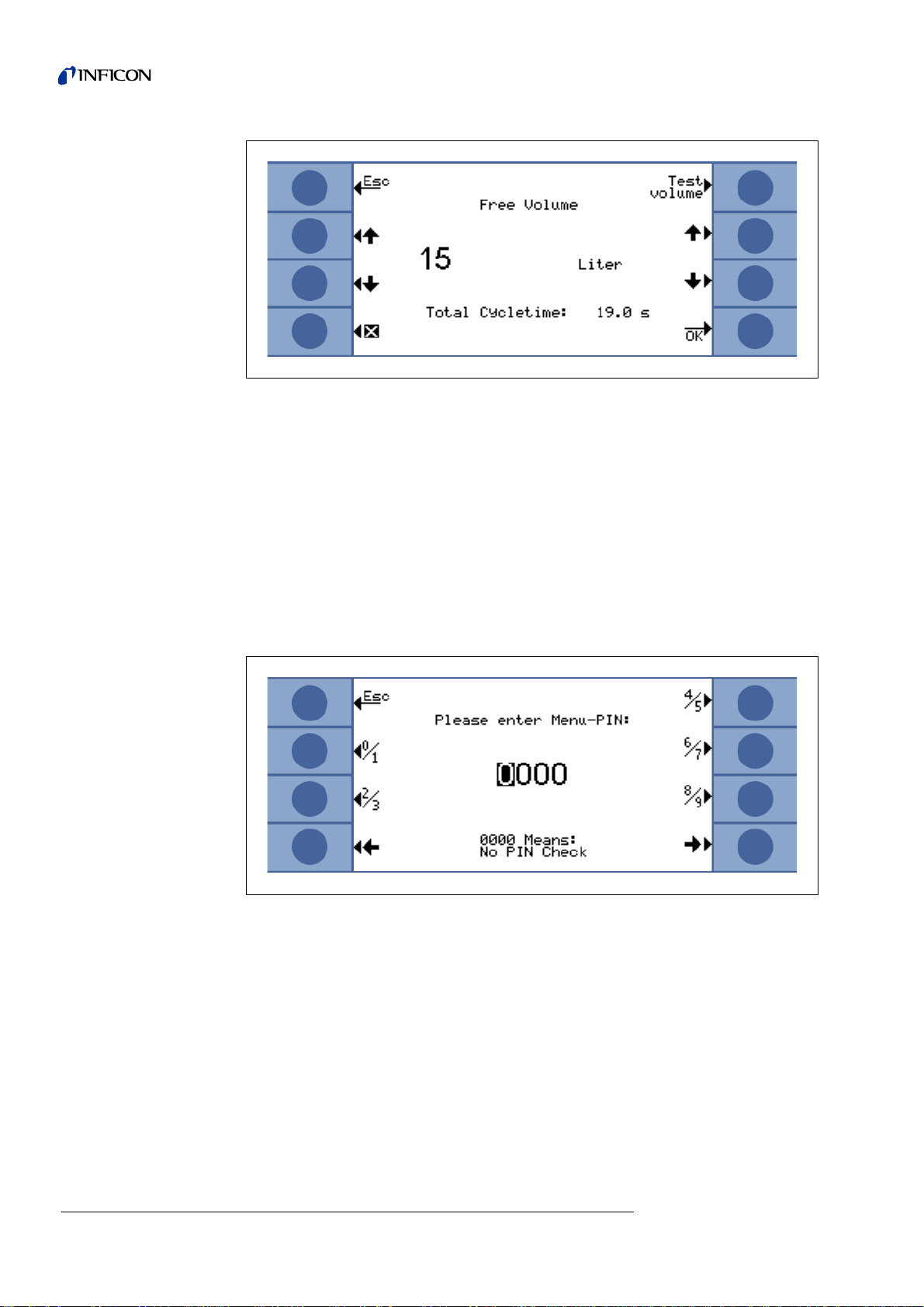

The numerical values are entered in the the MENU page as follows:

Soft key No. 1 Description

SC-button)

1 (E

2( ↑ ) increments the numerical value.

3( ↓ ) decrements the numerical value.

6 and 7( ↑ and ↓ ) changes the unit

8 (OK) saves the entered value.

jina85e 3.fm Technical Handbook(1112)

leave this menu page and return to the previous menu page. The

value will not be changed.

Description 21

Page 24

Fig. 4-13 You can change the value and the unit on this menu page

Entering the Menu-PIN

1 Press the ESC-button (soft key No.1) to leave this menu page and to return to the

previous menu page. The Menu-PIN will then neither be changed nor be entered.

2 Pressing a number button opens a submenu where you can select one of these two

numbers. After that, the cursor moves to the next digit to the right.

3 You can move the cursor to the left or to the right using the soft keys No. 4 and 8.

( ← and → ).

4 OK appears for soft key No. 8 when the last digit has been reached.

5 Pressing OK causes the PIN to be stored.

Status Line in the Display

22 Description

Fig. 4-14 Entering the Menu-PIN

The lowest line of the display is the status line. It shows general information, for

instance, the actual measurement mode.

jina85e 3.fm Technical Handbook(1112)

Page 25

3.5.2 19" control unit

You can insert this control unit in a 19’’ rack or in a panel cut-out as shown in Section

8.5.

This control panel is used in the same way as it is for the desktop control unit, only

the START, STOP and ZERO buttons are at other positions.

Fig. 4-15 Control unit for the installation in a 19"-rack

On its front side, the 19"-control unit refers to protection class IP40.

3.5.3 Connection Cable for Control Unit, 5 m

This cable connects the control unit and the T-Guard™ Leak Detection Sensor.

Fig. 4-16 Connection cable for control unit, cat. No. 551-102

jina85e 3.fm Technical Handbook(1112)

Description 23

Page 26

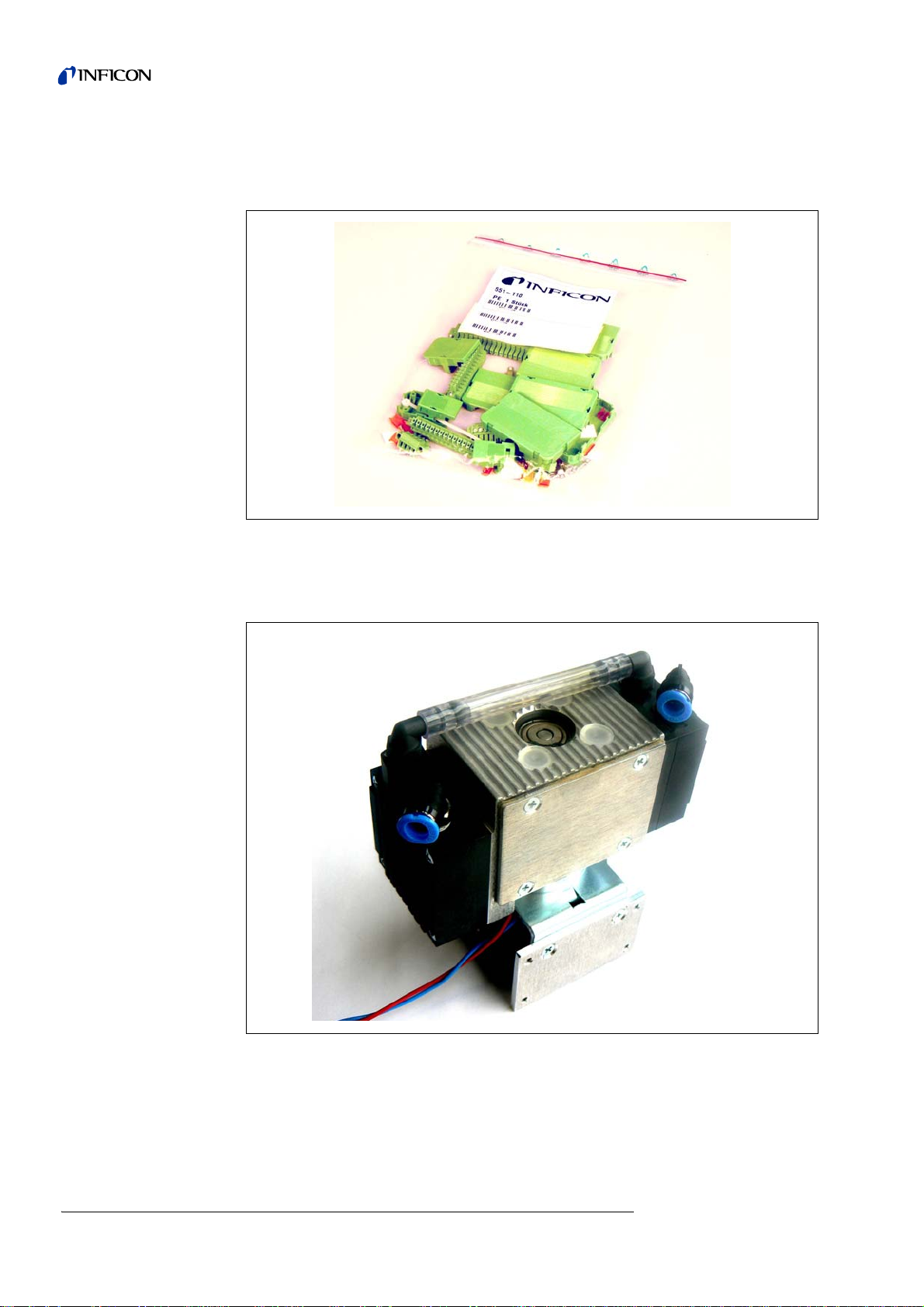

3.5.4 Connector set

The connector set includes all Phoenix connectors for connecting the electrica l interfaces.

Fig. 4-17 Connector set, cat. No. 551-110

3.5.5 Fore Pump

24 Description

Fig. 4-18 Fore pump, cat No. 200 002 929

This fore pump has two stages, is brushless and runs with a supply voltage of

24 V DC.

jina85e 3.fm Technical Handbook(1112)

Page 27

3.5.6 2m line

Fig. 4-19 2m line, cat. No. 200 002 793

In case your chamber is more than 50 cm away from the T-Guard, you must use

these 2m lines and shorten them if necessary. Both lines must have the same length.

Lines longer than 2m cause measurement errors.

3.5.7 I•Stick

Fig. 4-20 I Stick, cat. No. 200 001 997

Chapter 5.7 describes how to use the I Stick.

jina85e 3.fm Technical Handbook(1112)

Description 25

Page 28

3.5.8 Set of filters

Fig. 4-21 Filter set, cat. No. 200 001 680

Plugged filters cause pressure warnings. Check the filters every 6 months and

replace them no later than every 2 years.

3.6 Scope of delivery

• Main unit of the T-Guard™ Leak Detection Sensor

• Reference and measurement line with filters

26 Description

Fig. 4-22 Reference and measurement line with filters

jina85e 3.fm Technical Handbook(1112)

Page 29

3.7 Ordering Information

Description Cat. no.

T-Guard™ Leak Detection Sensor 540-001

T-Guard™ Leak Detection Sensor, version profibus 540-002

Control Unit for Desktop Operation 551-100

Control unit for the installation in a 19"-Rack 551-101

Connecting cable for the control unit, 5 m 551-102

Connecting cable for the control unit, 1 m 551-103

Set of connectors 551-110

I•Stick 200 001 997

Set of fuses 200 002 489

Set of filters 200 001 680

I/O test box 200 002 490

Power supply connection 200 002 496

Chamber connector 200 002 615

Measuring line 210 x 2 x 2 m 200 002 793

Fore pump, 24 V, two-step, brushless 200 002 929

jina85e 3.fm Technical Handbook(1112)

Description 27

Page 30

28 Description

jina85e 3.fm Technical Handbook(1112)

Page 31

4 Installation

Caution

Caution

Caution

4.1 Unpacking

Unpack the T-Guard™ Leak Detection Sensor immediately after receipt even if it is

to be put into operation at some later date.

Examine the shipping container for any external damage.

Completely remove all packaging materials.

Notice The three hose connectors are protected by plugs. Please only remove the

Notice Retain the shipping container and the packaging materials. Perhaps it will

Check if the T-Guard™ Leak Detection Sensor is complete (see Section 3.6) and

carefully subject it to a visual inspection. If any damage is discovered, please

immediately inform the forwarding agent and the insurers. If it is necessary to

exchange the damaged part, please contact our orders department.

After unpacking T-Guard™ Leak Detection Sensor, you have to care for a proper

installation:

plugs when you connect the hoses to the T-Guard™.

be required in the event of claims for compensation.

4.2 Installing Mechanically

Ensure sufficient ventilation.

In order to ensure adequate ventilation of the T-Gu ard™ Leak Detection Sensor, a

gap of at least 20 cm must be provided on top. Avoid heat sources being in the

vicinity of the T-Guard™ Leak Detection Sensor.

Do not block the ventilation inlets and outlets of the T-Guard™. Doing so could

damage the device.

Do not forget to attach the filters on the ends of the test an d re fe re nc e line s. T he y

protect the hoses from clogging and the sensor from dust contamination.

Notice T-Guard™ Leak Detection Sensor must be isolated from any vibration.

Vibration may lead to false measurement results!

jina85e 4.fm Technical Handbook(1112)

Installation 29

Page 32

The T-Guard™ Leak Detection Sensor can be used in each orientation. You can

Caution

unscrew the rubber feet and use these holes to fasten the main unit.

Please only remove the plugs when you connect the hoses to the T-Guard™. At the

time of delivery, the T-Guard is filled with helium-free nitrogen. This avoids helium to

penetrate into the sensor.

The T-Guard™ Leak Detection Sensor must be installed near the test chamber,

since the standard measuring line is only 50 cm long (measur ing line 2m leng th see

3.5.6).

Notice Changing the length or inner diameter of the test line affects the

measurement speed and results.

Notice Apply grease to the outside of the ends of the gr een measurement lines in

a thin film to be able to slide them into the connections until they snap in.

Otherwise it can happen that they are not deep enough in the connector

and measuring errors can appear.

4.3 Choosing a Fore Pump

The T-Guard™ Leak Detection Sensor stops working when oil penetrates into it

from one of the fore pumps.

Arrange the pumps with oil seal below the T-Guard™ Leak Detection Sensor.

You can use any vacuum pump with a gas flow of more than 200 sccm at a base

pressure of less than 50 mbar.

Connect the vacuum pump with a 6 mm tube to the tube connector labelled with

"

OUT" .

30 Installation

jina85e 4.fm Technical Handbook(1112)

Page 33

4.4 Installing Electrically

Caution

The T-Guard requires a 24 V DC power supply (tolerance ± 10 %).

A wrong polarity triggers the fuse.

The power supply should be able to supply a current of maximum 6 A. Typically, the

T-Guard needs 70W.

The following maximum cable lengths have to be met:

0.75 mm² 8.5 m

AWG 18 10 m

1mm² 10m

AWG 16 15 m

1.5 mm² 17.5 m

AWG 14 25 m

Notice Do not power up the power supply before having attached all other cables

you need!

Power Connector

Only two of the four pins are used for the power supply. The plus po le is marked with

„1+“, the minus pole is marked with „2-“.

4.5 Connecting the control unit

The CONTROL UNIT output of the T-Guard™ can be damaged when the cable is

disconnected or connected during operation.

Only plug or pull the cables when the T-Guard™ is switched off.

Attach one end of the control unit cable to the connector CONTROL UNIT of the TGuard™ Leak Detection Sensor and the other end to the control unit itself. Now TGuard™ Leak Detection Sensor can be operated via the control unit.

jina85e 4.fm Technical Handbook(1112)

Installation 31

Page 34

4.6 Connecting a PLC

4.6.1 Selection of functions assigned to the PLC inputs.

Select the PLC inputs as follows:

Main Menu

In the sub-menu S

of the I/O-connector (suitable for PLC-inputs) shall be assigned to which command.

Please find a complete list of the input commands and their meanings below:

Command Explanation

START Starts a measuring cycle.

STOP Stops a measurement cycle. You will not get a valid leak rate.

START/STOP Starts and stops a measurement cycle if switched to HIGH or

CAL Starts a calibration.

PROOF Starts checking the calibration with the proof leak rate.

CLEAR Clears errors and warnings. T-Guard™ Leak Detection

READY Wakes up the T-Gu ar d™ Lea k De te ctio n Sen so r from

STANDBY Puts the T-Guard™ Leak Detection Sensor on Standby

GROSS / FINE Switches between GROSS and FINE measurement.

PURGE Purges the measurement line as long as input is high. The

INV START electrically inverted START command

INV STOP electrically inverted STOP command

STOP/START Stops and starts a measurement cycle, if switched to HIGH

INV CAL electrically inverted CAL command

INV PROOF electrically inverted PROOF command

INV CLEAR electrically inverted CLEAR command

INV READY electrically inverted READY command

INV STANDBY electrically inverted STANDBY command

FINE / GROSS Switches between FINE and GROSS. Only available in Conti-

INV PURGE electrically inverted PURGE command

→

Settings → Interfaces → Select PLC Inputs.

ELECT PLC INPUTS, you can set which pin

If the T-Guard™ Leak Detection Sensor was in STANDBY the

start will be delayed by some seconds.

LOW , respectively.

A successful calibration changes the calibration factor.

Sensor restarts in case of an error.

Standby mode.

mode. This enlarges the sensor lifetime.

Only available in Continuous Mode.

helium sensor signal will be ignored.

Only available if auto-purge is off.

and LOW, respectively.

nuous Mode.

32 Installation

To change the commands assigned to the input- pins, select the appropriate pin using

the UP and DOWN arrows on the left side of the display.

Then select the desired command from the list of commands using the UP and

jina85e 4.fm Technical Handbook(1112)

Page 35

DOWN buttons on the right side of the display.

Press OK to save your settings. A screen with all selected settings will be displayed

for your reference.

Confirm with OK again.

Notice Most PLC functions are activated when the input signal rises. Having a

High-signal when starting the T-Guard™ Leak Detection Sensor is not

enough.

Fig. 5-1 Selecting the PLC Inputs

jina85e 4.fm Technical Handbook(1112)

Installation 33

Page 36

4.6.2 Electrical connection of the PLC inputs

Caution

1

2

3

4

5

6

7

PLC IN/OUT

24V

The default setting is as follows:

Pin Command Explanation

1Start

2Stop

3Cal

4Proof

5 Clear:

6 Standby

7 Common Common negative pole for all PLC inputs.

Connect to the negative pole of the power supply.

Max. permissible input voltage of the digital inputs: 28 V.

Signal level:

24 V (low-resistance) means High,

0 V (high-resistance) means Low,

Change from LOW to HIGH:

The programmed command for the input is enabled (edge controlled).

Fig. 5-2 Electrical connection of the PLC inputs

34 Installation

jina85e 4.fm Technical Handbook(1112)

Page 37

4.6.3 Selection of functions assigned to the PLC outputs.

Main menu→Settings→Interfaces→Define PLC outputs

In the sub-menu D

of the I/O connector (suitable for PLC outputs) shall be assig ned to which command.

Signal Explanation

OPEN low-resistance, for testing purposes

CLOSE: high-resistance, for testing purposes

TRIGGER 1 low-resistance means Trigger 1 was exceeded

TRIGGER 2 low-resistance means Trigger 2 was exceeded

READY low-resistance means the T-Guard™ is ready for the next

CYCLE ACTIVE low-resistance means the T-Guard™ Leak Detection Sensor is

STANDBY low-resistance means that the T-Guard™ Leak Detection

ERROR low-resistance means an error has occurred

WARNING low resistance means there is an outstanding warning

ERROR / WARN low-resistance means an error has occurred or there is an

CAL ACTIVE low-resistance means a calibration is running right now

REC. STROBE low-resistance means the recorder output is invalid for 300 ms

MEASURE low-resistance means that the T-Guard™ Leak Detection

GROSS / FINE low-resistance means that the T-Guard™ Leak Detection

GROSSLEAK low-resistance means the highest trigger value was exceeded

CONTAMINATED low-resistance means the sensor was contaminated with too

INV TRIGGER 1 high-resistance means Trigger1 was exceeded

INV TRIGGER 2 high resistance means Trigger2 was exceeded

INV READY high-resistance means the T-Guard™ is ready for the next

EFINE PLC OUTPUTS, you can set which pin

measurement. In Continuous Measurement mode, the TGuard measures the reference line.

just performing a measurement cycle This includes automatic

purging and reference measurement in Carrier Gas mode.

There is no measuring cycle in Continuous Measurement

mode. That is the reason why the output is always high-resistive.

Sensor is just in Standby mode

outstanding warning

because of changing the decade of LR Mantissa and LR

Exponent.

Sensor is just measuring. The leak rate of the last measurement is on when this output and also the REC STROBE output

are high-resistive.

Sensor is just in GROSS mode

by at least the factor 5.

much helium. In this case, immediately purge the reference

line with external air or nitrogen to decontaminate the sensor.

measurement. In Continuous Measurement mode, the TGuard measures the reference line.

jina85e 4.fm Technical Handbook(1112)

Installation 35

Page 38

Signal Explanation

INV CYCLE ACTIVE high-resistance means that the T-Guard™ Leak Detection

Sensor is performing a measurement cycle. This includes

automatic purging and reference measurement in Carrier Ga s

mode. There is no measuring cycle in Continuous Measurement mode. That is the reason why the output is always highresistive.

INV STANDBY high-resistance means that the T-Guard™ Leak Detection

Sensor is just in Standby mode

INV ERROR high-resistance means an error has occurred

INV WARNING high resistance means there is an outstanding warning

INV ERROR / WARN high-resistance means an error has occurred or there is an

outstanding warning

INV CAL ACTIVE high-resistance means a calibration is running right now

INV REC. STROBE high-resistance means the recorder output is invalid for 300 ms

because of changing the decade of LR Mantissa and LR

Exponent.

INV MEASURE high-resistance means that the T-Guard™ Leak Detection

Sensor is just measuring. The leak rate of the last measure-

ment is on when this output and also the REC STROBE output

are high-resistive.

FINE / GROSS high-resistance means that the T-Guard™ Leak Detection

Sensor is just in GROSS mode

INV GROSS LEAK high-resistance means the highest trigger value was exce eded

by at least the factor 5.

INV CONTAMI-

NATED

high-resistance means the sensor was contaminated with too

much helium. In this case, immediately purge the reference

line with external air or nitrogen to decontaminate the sensor.

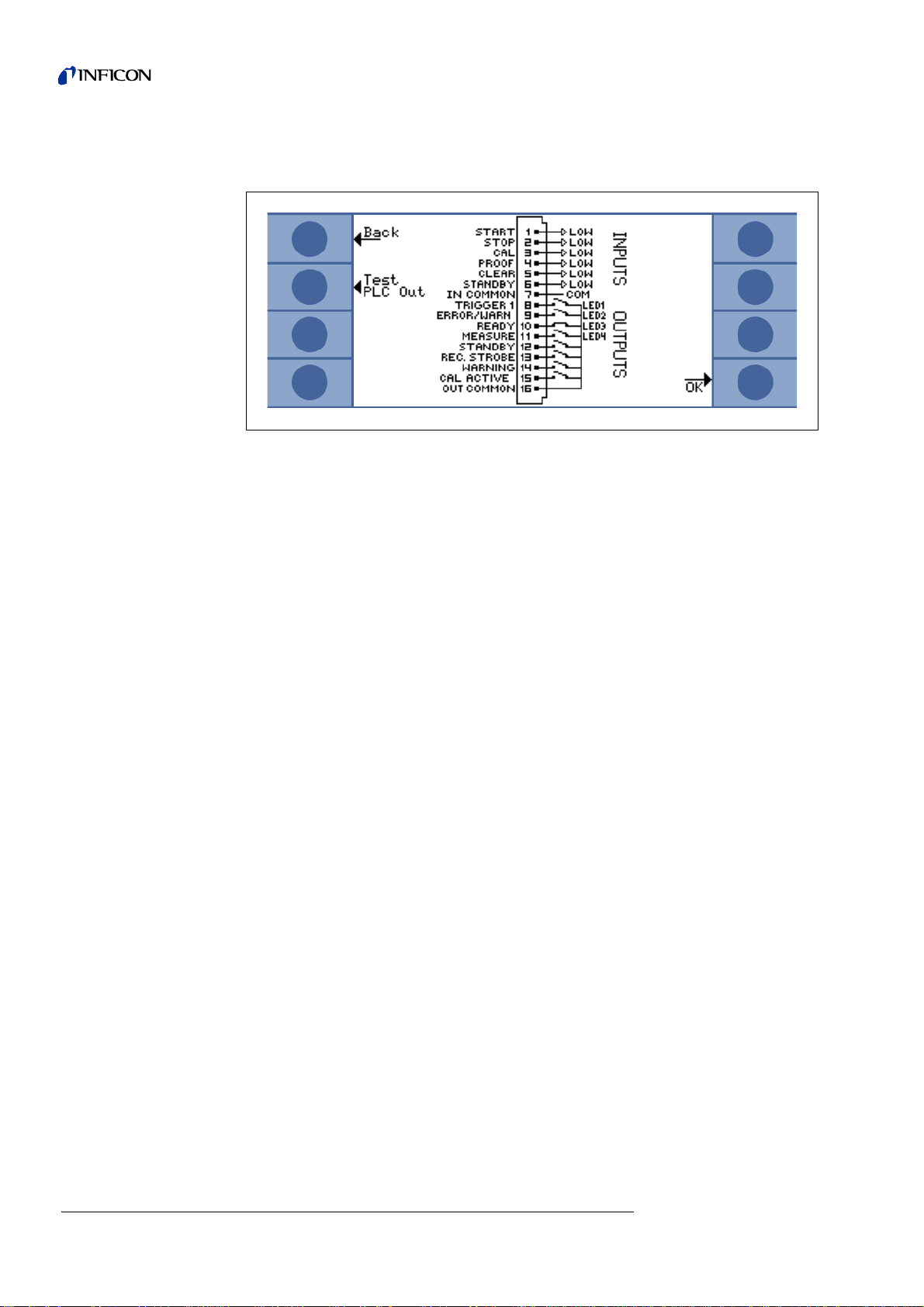

To change these settings, select the appropriate pin with the UP and DOWN arrows

on the left side of the display.

Then select the desired setting from the list of settings with the UP and DOWN

buttons on the right side of the display. Press OK to save your settings.

A graphic with all selected settings will be displayed for your reference.

Confirm with OK again.

Fig. 5-3 Selecting the PLC Outputs

jina85e 4.fm Technical Handbook(1112)

36 Installation

Page 39

4.6.4 Electrical connection of the PLC outputs

Caution

16

8

9

10

11

12

13

24V

14

15

PLC IN/OUT

The default setting is as follows:

Pin Command Explanation

8 Trigger 1

9 Error/Warning

10 Ready

11 Measure

12 Standby

13 Rec. Strobe

14 Warning

15 Cal active

16 Common Common connection for all PLC outputs.

This contact can be used as the positive or the negative

pole.

The maximum permissible voltage for the output signals is 28 V.

The maximum total current for the output pins 8 - 11 is 0.75 A.

The maximum total current for the output pins 12 - 15 is also 0,75 A.

Permissible output current Max. 125 mA per output

Load resistance of outputs Min. 130 ohm per output

Supply voltage of

outputs

24 V DC

jina85e 4.fm Technical Handbook(1112)

Fig. 5-4 Electrical connection of the PLC outputs

Installation 37

Page 40

4.6.5 Overview of all settings

This screen shows the actual selected set-up of all input and output signals

Fig. 5-5 Overview of Inputs and Outputs

4.7 Connecting a PC

A computer can control the T-Guard™ Leak Detection Sensor via a standard RS232

cable (not a null modem cable) connected with the RS232 connector. The Inter face

Description document (iins85e1-a) explains how to do this in detail.

38 Installation

jina85e 4.fm Technical Handbook(1112)

Page 41

5 Operation

Caution

In order to work with the T-Guard™ Leak Detection Sensor, you need at least:

• Main unit with 3 hoses and two dust filters

• Fore pump

• Power supply unit 24 V / 6A

• Control unit with cabling (INFICON control unit, PC or PLC)

• Chamber

•Fan

• Test sample which has been filled with helium under pressure

To avoid early ageing of the sensor, prevent the re fere nce line from th e ingress of

helium!

If possible, lead external air to the reference line.

5.1 Running up

After switching on the T-Guard™ Leak Detection Sensor, the following display will

appear:

Fig. 6-1 Start screen

The T-Guard™ Leak Detection Sensor will start up when 24 V are applied to the

power supply connector.

jina85e 5.fm Technical Handbook(1112)

Operation 39

Page 42

Fig. 6-2 Estimated remaining time of the run-up period

The run-up process takes longer than 3 minutes if the device was turned off for a long

time. Once the T-Guard™ is ready for the measurement, the current measured value

of the leakage rate is displayed on the screen. Otherwise the device is activated with

a warning after 30 minutes at the latest.

The name of the current parameter set is displayed in the top line of the Leak Rate

screen. If the parameter set is changed later, there will be an asterisk befo re the

name of the parameter set.

Fig. 6-3 The T-Guard™ is now ready for measurement.

Changing Contrast

40 Operation

Notice If the T-Guard™ Leak Detection Sensor has been switched off for several

days, the initial sensor current may be too high to measure with the hig hest

sensitivity. In this case, apply external air to the reference inlet and wait for

two hours.

Then, the T-Guard™ Leak Detection Sensor will meet its specification.

Using external air, the unit will display "Background OK".

You can change the image contrast of the display during the run-up phase by

pressing Menu

→

Display→Contrast.

(The default value is 30)

jina85e 5.fm Technical Handbook(1112)

Page 43

5.2 Calibrating

3 x chamber volume (in ccm)

Carrier gas flow (in ccm per seconds)

-------------------------------------------------------------------------------------------------- -

Before you measure, you should set-up the unit according to your measuring

arrangement and calibrate it. This ensures that the unit will really be able to measure

what you want to.

5.2.1 Preparing Calibration

Before calibrating the T-Guard™, you should follow these steps in the described

order:

For the Carrier Gas mode:

1 Input the carrier gas flow (e.g from the mass flow controller, 30,000 sccm in

Settings

2 Change Trigger 1

3 Change the measuring time, when required (a shorter measuring time causes a

lower repeatability).

4 Enter the Calibration Leak Rate (must be higher than half of the trigger level)

5 Place the calibrated leak inside the chamber.

6 Close the chamber

7 Wait for a certain time which is calculated by:

→

Measurement Settings → Carrier Gas Flow)

8 Start the calibration (refer to Chapter 5.2.2)

For the Accumulation mode:

1 Enter the net volume (chamber volume minus sample volume)

2 Set Trigger 1

3 Change the measuring time, when required (a shorter measuring time causes a

lower repeatability).

4 Enter the Calibration Leak Rate (must be higher than half the trigger level)

5 Place the calibrated leak inside the chamber.

6 Close the chamber

7 Start the calibration (refer to Chapter 5.2.2)

Notice You can also view and edit all settings on one page in:

Main menu

Most important settings are on top, least important settings are on

the bottom of this table.

→

Info → View/Edit settings

jina85e 5.fm Technical Handbook(1112)

Operation 41

Page 44

5.2.2 Start Calibration

You can calibrate the T-Guard™ Leak Detection Sensor by selecting the following

submenu:

Main Menu

→

Calibration → Start Calibration.

Fig. 6-4 M

After the calibration routine, you can accept the new calibration factor by pressing

OK or cancel the calibration by pressing Esc. A calibration factor of less than 0.2 or

more than 5 will result in a warning instead of a successful calibration. Refer to

Chapter 9for possible causes of errors and warnings.

The ideal calibration factor you can get is 1. If the calibration factor is smaller than

0.5 or greater than 2, you can confirm but you will receive a warning as hint that you

can improve your measuring arrangement.

Notice You have to recalibrate for every change of free volume in accumulation

AIN MENU Calibration

mode and for every change of the carrier gas flow in Carrier Gas Mode.

This ensures a reliable measurement.

42 Operation

jina85e 5.fm Technical Handbook(1112)

Page 45

5.3 Measuring

Each measurement is started by the START button. A progress bar is displayed

during the measurement. When the measurement has finished, the display shows

the leak rate or an error message. The measurement can be cancelled at any time

by pressing STOP-button. The then displayed leak rate is a provisional value.

Fig. 6-5 Fine measurement, progress bar

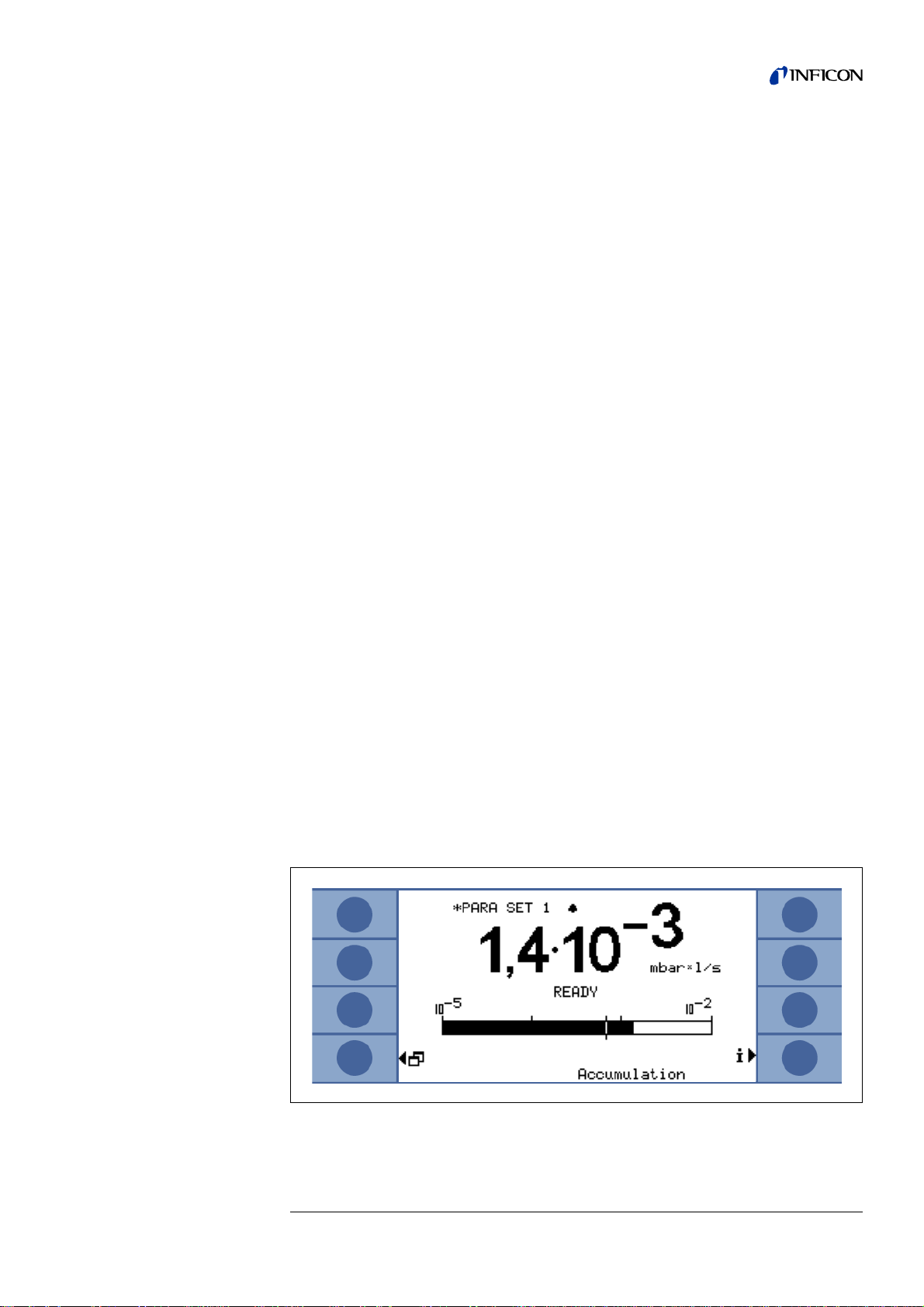

5.3.1 Accumulation Mode

When you put a leak test sample filled with helium under pressure in an enclosed

chamber, the helium level in this chamber will rise over time. This is called "accumulation " (of helium). The difference of the helium levels at two different times reflects

the leak rate.

Fig. 6-6 Display of leak rate in Accumulation mode with information on the helium

background of the sensor and the environment.

jina85e 5.fm Technical Handbook(1112)

Operation 43

Page 46

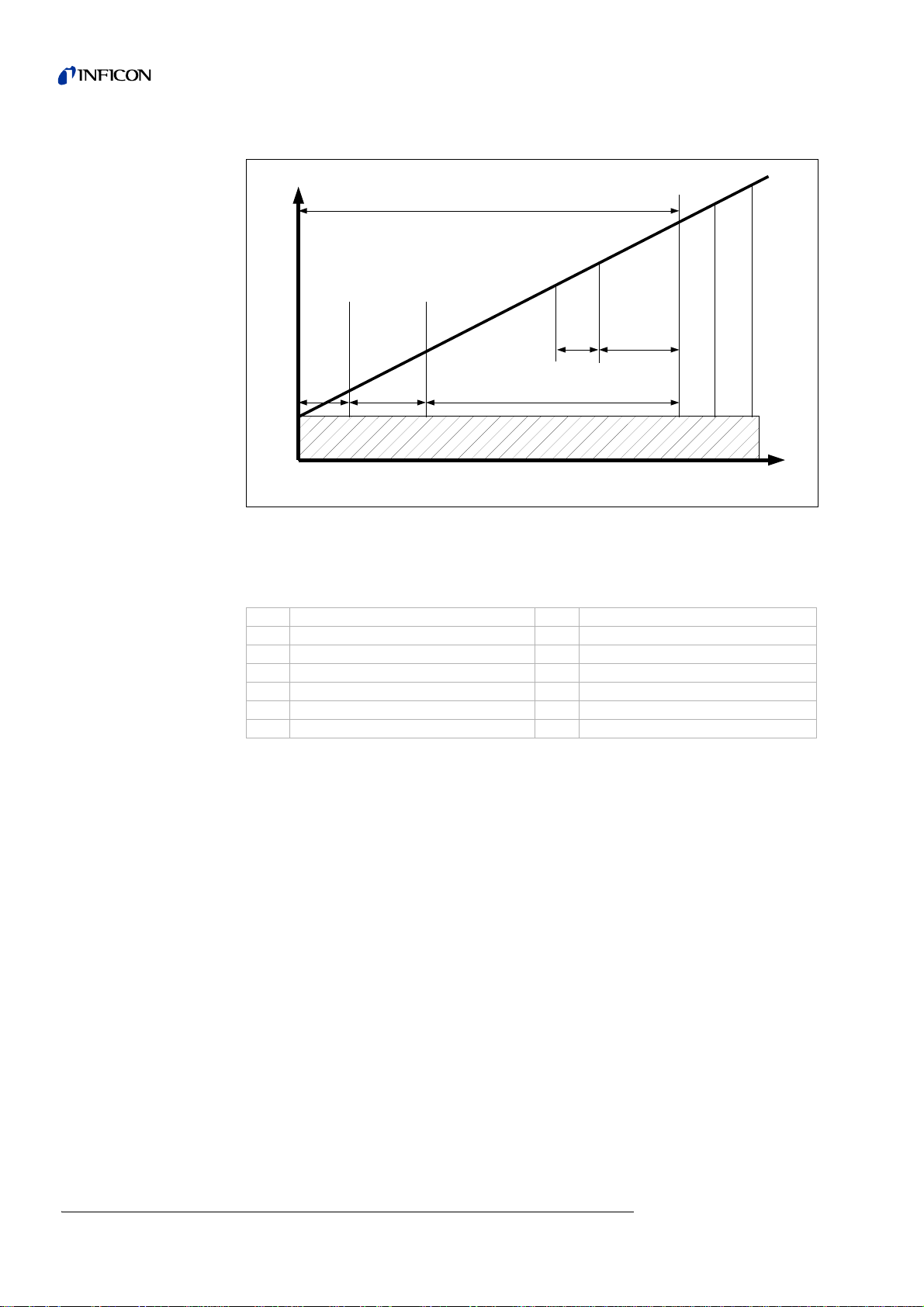

Accumulation Measurement

Fig. 6-7 Typical helium concentration in an enclosed chamber with a leaky test

sample over time. Due to ambient helium, the helium level is never zero.

The helium level rises linearly with time. The T-Guard™ Leak Detection

Sensor measures the helium concentration in the chamber four times.

Item Description Item Description

1 Helium concentration 7 Accumulation time

2 Start 8 Second gross measurement

3 Ambient helium 9 Second fine measurement

4 Time 10 Wait time purge

5 First gross measurement 11 Purge time

6 First fine measurement 12 Measuring time

In Accumulation mode, the T-Guard™ Leak Detection Sensor starts with the G

leak test. If, at the beginning of the test, the helium concentration in the chamber is

much higher (approx. 1000 ppm) than in the environment, the test sample has a

gross leak.

In this case, the T-Guard™ stops the measurement cycle and displays a leak rate o f

a hundred times the highest trigger value.

If the test sample passes the GROSS -leak test, the T-Guard™ Leak Detection

Sensor takes an air sample from the chamber and measures it in F

If, during this first

tration rises too fast, it will stop the measurement and report a leakage rate of five

times the highest trigger level.

After the first

GROSS measurement will be carried out to check if the test sample has exploded.

After that, it takes the next air sample in FINE-mode. From the difference of the two

F

INE-measurements, the T-Guard™ Leak Detection Sensor ca lculates the leak rate.

FINE measurement, the T-Guard™ detects that the helium concen-

FINE-measurement, it will wait for a certain time. Then, the second

INE-mode.

ROSS

jina85e 5.fm Technical Handbook(1112)

44 Operation

Page 47

Notice If the trigger value is higher than 1x10-3mbar l/s per litre of the net volume,

both test samples will be measured in GROSS-mode. Then you must use

outside air to purge the chamber. The h elium background on the reference

line must be really stable for GROSS-mode. If this is not possible, a bigger

chamber or diluted helium has to be used to measure in FINE-mode.

Notice If the T-Guard™stops the measurement due to a too high signal in G

mode, it reports a leakage rate of a hundred times the highest trigger level.

If it stops in F

trigger level.

In both cases, the PLC output "GROSSLEAK" is active.

After each accumulation measurement and waiting for a certain time, the chamber

will be purged. You can generally turn this automatic purge process off; it must then

be initiated with a control command every time.

5.3.1.1 Hints for a good measurement:

• Use fans inside the chamber to have a perfect mixture of helium and air

everywhere inside the chamber! The gas flow of the fans should be at least once

the chamber volume per second!

• Purge the test chamber before measurement!

An insufficient chamber purge is indicated with the warning W45.

• For best and repeatable results you must apply outside air to the reference inlet.

In order to have a more stable background on the reference inlet, put it loosely

into a tightly closed buffer volume. This buffer volume reduces the helium

background variations.

• Apply external air on the measurement line during the purge time in order to clean

it.

• You should purge the chamber after every measurement, then purge the

measurement line for at least 4 s, then wait for 2 s before performing the next

measurement. This removes the residual helium, which could affect the following

measurements, from the measurement system.

ROSS

INE mode for the same reason, it reports five times the highest

• The chamber must have neither slots nor holes. It must be sealed with rubber

gaskets. Only then are the measurements free from external influences.

Fig. 6-8 Display after finished measurement in Accumulation mode

jina85e 5.fm Technical Handbook(1112)

Operation 45

Page 48

INFICON recommends this kind of set-up for Accumulation mode:

Fig. 6-9 Recommended settings for Accumulation mode

Item Description Item Description

1 Test sample 5 T-Guard™ Leak Detection Sensor

2 Testing chamber

3Fan

4 Measuring line connected

to the chamber

6 Fore pump exhaust air far apart from the

chamber

7 Reference line

8 Buffer volume > 4 litres

5.3.2 Carrier Gas Mode

In addition to the gas flow, which the T-Guard™ Leak Detection Sensor takes out of

a chamber, more air can be sucked through the chamber using a fa n or a pump.

This additional gas flow quickly carries the helium from the leak to T-Guard™ Leak

Detection Sensor. This way of leak detection is called Carrier Gas mode.

In Carrier Gas mode, the T-Guard™ Leak Detection Sensor measures the helium

content in the gas stream for a certain time. The helium signal from the end of the

measurement will be used in order to calculate the leak rate.

Carrier Gas mode can be used to detect bigger leaks faster than in Accumulation

mode.

The Carrier Gas mode is very sensitive to fluctuations of the helium background. An

elevated helium background is usually not stable.

46 Operation

jina85e 5.fm Technical Handbook(1112)

Page 49

Carrier Gas Measurement

Fig. 6-10 Typical helium concentration in an enclosed chamber with a leaky test

sample over time.

Item Description Item Description

1 Helium signal 4 Time

2 Start 5 Rising signal

3 Ambient helium 6 Stable signal, final value

Fig. 6-11 Display of leak rate in Carrier Gas mode with information on the helium

background of the sensor and the environment.

The bigger the chamber and the smaller the total gas flow through it, the longer it

takes for the signal to reach its final value.

The time you need to get a constant signal in Carrier Gas mode de pends on the total

gas flow and the volume of the chamber. The time it takes to see 63 % of the signal

is the volume of the chamber divided by the total gas flow.

For example: With a volume of 2 litres and a total gas flow of 20 l/s, you see 63 % of

the signal after 0.1 seconds. After waiting three times as long, you see 95 % of the

signal (0.3 s in this example). After five times as long, you will see 99 % of the signal

jina85e 5.fm Technical Handbook(1112)

Operation 47

Page 50

(0.5 seconds in this example). By increasing the total gas flow, the measurement will

3 x chamber volume (in ccm)

Carrier gas flow (in ccm per seconds)

-------------------------------------------------------------------------------------------------- -

be quicker but for the price of a lower sensitivity. The smallest displayable leakage

rate increases when the total gas flow is increased.

In order to save time, you can calibrate and measure with a shorter time than nee ded

for the final leak rate value. But then the completely identical timing for calibration

and each measurement is very important. This method is called Dynamic Measurement.

Like in the Accumulation mode, a GROSS measurement will be done before the

FINE measurement of the leak rate to avoid helium contamination of the Wise

Technology™ Sensor.

5.3.2.1 Hints for a good measurement:

• Minimize the chamber volume but do not let the test sample touch the walls.

• Place the inlet for external air in the chamber opposite the connection of TGuard™ Leak Detection Sensor.

• Use fans inside the chamber to have a good mixture of helium and air

everywhere.

• Do not make the outside air inlet too big. Helium must not leave the chamber

there.

• Lead the same ambient air into the chamber and the reference line.

• For a trigger leak rate of 1·10

sccm. For a trigger leak rate of 1·10

30,000 sccm. For a trigger leak rate of 1·10

higher than 300,000 sccm.

-5

mbar l/s, do not use a total flow higher than 3000

-4

mbar l/s, do not use a total flow higher than

-3

mbar l/s, do not use a total flow

• After closing the chamber and applying helium to the test object, wait for a cer tain

time, which amounts to:

INFICON strongly recommends this kind of set-up for Carrier Gas Measurement:

48 Operation

jina85e 5.fm Technical Handbook(1112)

Page 51

Fig. 6-12 Recommended set-up for Carrier Gas mode

Item Description Item Description

1 1,000 - 100,000 sccm 6 Air inlet, outside air

2 Dry pump or 7 Test sample

3 Pump exhaust far away from chamber 9 Testing chamber

4 Fore pump exhaust air far away from the

5 Reference line 11 T-Guard™

5.3.3 Continuous Mode

The Continuous mode is only developed for experts in the field of helium leak

detection.

Notice Use the STOP switch or even Standby mode when you do not need a

In Continuous mode, you are able to get a continuous signal from the Wise Technology™ Sensor after pressing START. Pressing STOP switches the valves in a way

that the reference line will be measured. G

selected by the user. The T-Guard™ Leak Detection Sensor will not deliver a leak

rate signal in this mode. Therefore, it will not be possible to set trigger values in Continuous mode.

It is in the duty of the user to interpret the cu rrent signal. The sensor current changes

by 1.5 x 10

Flow controlled fan 8 Fan

10 Measuring hose connected to

chamber

pump outlet

Leak Detection Sensor

measurement signal from T-Guard™ Leak Detection Sensor. Standby

mode will further clean up the Wise Technology™ Sensor and enlarge its

lifetime.

ROSS and FINE modes can and must be

-7

A per mbar of helium before the sensor.

jina85e 5.fm Technical Handbook(1112)

Operation 49

Page 52

Fig. 6-13 Display of the reference value in Continu o us mode.

Caution

5.3.4 Switching Off

You do not need to actively switch off the T-Guard™ Leak Detection Sensor. Just

switch off the power supply after usage.

5.3.5 Standby

The T-Guard™ Leak Detection Sensor will switch to standby mode automatically

after an adjustable time when it is not used. In addition to that, it is possible to switch

to standby mode manually via control unit, RS232 or digital input.

Do not switch off the power supply when the T-Guard™ Leak Detection Sensor is

contaminated with helium. This would reduce the sensor lifetime and increase the

time of the next run-up. Please wait until the T -Guar d is in Stan dby mod e or r eady

to measure (leak rate is displayed) before switching off the power supply.

5.3.6 Helium contamination

By default, the T-Guard™ Leak Detection Sensor uses its GROSS mode before each

measurement. Every time, when the T-Guard™recognises that the measured leak

rate exceeds five times the highest trigger value, it will stop the measurement cycle

instantly.

Due to these two facts, it is extremely unlikely that the sensor is contaminated with

helium.

If, nevertheless, the T-Guard™ should be contaminated, highly-pure nitrogen or

external air has to be pumped into the reference inlet to recover the sensor as fast

as possible.

The recovery time depends on the helium content of the air provided on the reference

inlet and the limit value of contamination. The lower the limit value of contamination

the faster the T.Guard will be ready for measurement again.

50 Operation

jina85e 5.fm Technical Handbook(1112)

Page 53

Notice When using the continuous measurement mode, a tr igg er le ve l canno t be

set. That is why you have to stop the measurement yourself as soon as you

see that the sensor current gets too high. In Continuous mode, the TGuard™ Leak Detection Sensor switches over to the reference line when

the sensor flow is greater than 1x10

5.4 Controlling via PLC

Basic functions and values of T-Guard™ Leak Detection Sensor can be controlled

and read by a PLC. Refer to chapter 4.6 for a detailed listing of all PLC commands

and signals.

Select PLC inputs in:

Main Menu

Select PLC outputs in:

→

-8

A.

Settings →Interfaces →Select PLC Inputs.

Main Menu

PLC outputs 1 - 4 are connected to the LEDs 1 - 4.

The measured leak rate is available at the

→

Settings→Interfaces→Define PLC-outputs

RECORDER output.

5.4.1 How to execute an accumulation measurement

You can start the measurement when READY is low-resistive.

During the measurement, the MEASURE output is low-resistive.

After the measurement, the MEASURE output is high-resistive. When the REC.

STROBE output will be high-resistive again, you can read the analog outputs. This

will happen after about 300 ms.

If the AUTOMATIC PURGING is enabled. READY will be low-resistive after purging.

Only then, the next measurements can be started.

5.4.2 How to execute a carrier gas measurement

You can start the measurement when READY is low-resistive.

During the measurement, the MEASURE output is low-resistive.

After the measurement, the MEASURE output is high-resistive. When the REC.

STROBE output will be high-resistive again, you can read the analog outputs. This

will happen after about 300 ms.

After the reference measurement, the READY output will be low-resistive again. This

takes as long as the FINE-measurement time. Only after the cycle has been finished,

the next measurement can be started.

5.5 Controlling via RS-232

Nearly everything that can be done with the control unit can also be done via the

jina85e 5.fm Technical Handbook(1112)

RS232 connection to a PC.

The Interface Description document explains how to do this (iins85e1-a).

Operation 51

Page 54

5.6 Configuring analog output

You can configure the analog output in the menu screen

Main Menu

in Analog Output and Analog Scale

Fig. 6-14 Configuration of analog outputs.

→

Settings→Interfaces

52 Operation

Fig. 6-15 Configuration of the scale of the analog outputs.

• In the setting "LR Exponent", the exponent results from the voltage as follows:

Exponent = (voltage x 2) -14

For example: A voltage of 4.5 V results in an exponent of (4.5 x 2) - 14 = -5.

• In the setting "LR Log.", the leak rate is calculated as follows:

Leak rate = final value x (10^((U - 10)/(volts/decade)) )

For example: With a final value of 10-1 mbar l/s and 2 V per decade, a voltage of 3.7

V results in a leak rate of 10

-1

10

mbar l/s x 7,08x10-4 = 7,08x10-5 mbar l/s.

For "Current Log.", it is similar for current instead of leak rate.

-1

mbar l/s x 10^((3.7-10)/2) = 10-1 mbar l/s x 10

-3,15

=

jina85e 5.fm Technical Handbook(1112)

Page 55

• In the setting "LR Linear", the leak rate is calculated as follows:

Leak rate = final value/10x voltage

For example: 10 V refer to the final value, e.g. 10-3 mbar l/s, then, 3.7 V refer to, e.g.

-4

3.7x10

For "Current Lin.", it is similar for current instead of leak rate.

The final value and the increase (volts/decade) have to be set separately in the

mbar l/s.

Main Menu

for the outputs 1..2 and 3..4.

The increase volts/ decade does not apply for linear values.

→

Settings→ Interfaces→Analog Scale

5.7 Using the I-Stick and the parameter sets

The I•Stick (Cat-No. 200001997) can be used to save up to 25 parameter sets and

to be able to copy them easily from one device to the other.

A parameter set comprises all settings except the language and the RS232 protocol.

Copying takes place as follows:

Fig. 6-16 Menu screen "Copy Parameters"

1 Go to Main Menu

→

Settings→Copy Parameters

2 On the left side, select your required parameter set . You can select between the

options Default Parameter Set, Current Parameter Set, three internal parameter sets

and up to 25 parameter sets on the I•Stick. If no I•Stick is connected, Copy does not

work. If the memory on the I•Stick is empty, the default parameter set will be copied.

3 On the right side, select the destination which the parameter set is to be copied to .

4 Now use "Copy" for copying the parameter set or "Edit name" to copy the parameter

set with a new name to the right side.

5 Before copying, the differences of the parameter sets are displayed from the right

and the left side for confirmation.

6 If copying was successful, you will return to the "Settings" menu, if not, you will

receive an error message and the "Copy Parameter" menu will be displayed again.

jina85e 5.fm Technical Handbook(1112)

Operation 53

Page 56

7 The name of the current parameter set is displayed in the top line of the leak rate

screen. If the parameter set is being changed later, a star will be written before the

name of the parameter set.

Notice Only insert or disconnect the I•Stick when the device is switched off. If the

I•Stick is connected or disconnected during operation, the device s canno t

recognize it.

Notice With the first use, the I•Stick is initialized. Switch the T-Guard off and on

again to be able to use the I•Stick

5.8 Settings

All Settings referring the configuration of the T-Guard™ Leak Detection Sensor are

provided in the menu structure.

5.8.1 Menu Structure Diagram

Starting in the Main Menu, all menu screens are arranged like a tree structure.

54 Operation

Fig. 6-1 Main Menu

Please find the menu structure of the T-Guard™ Leak Detection Sensor on the

following page.

In this diagram, all operations are listed.

Please find the descriptions of the individual menu items on the following pages.

jina85e 5.fm Technical Handbook(1112)

Page 57

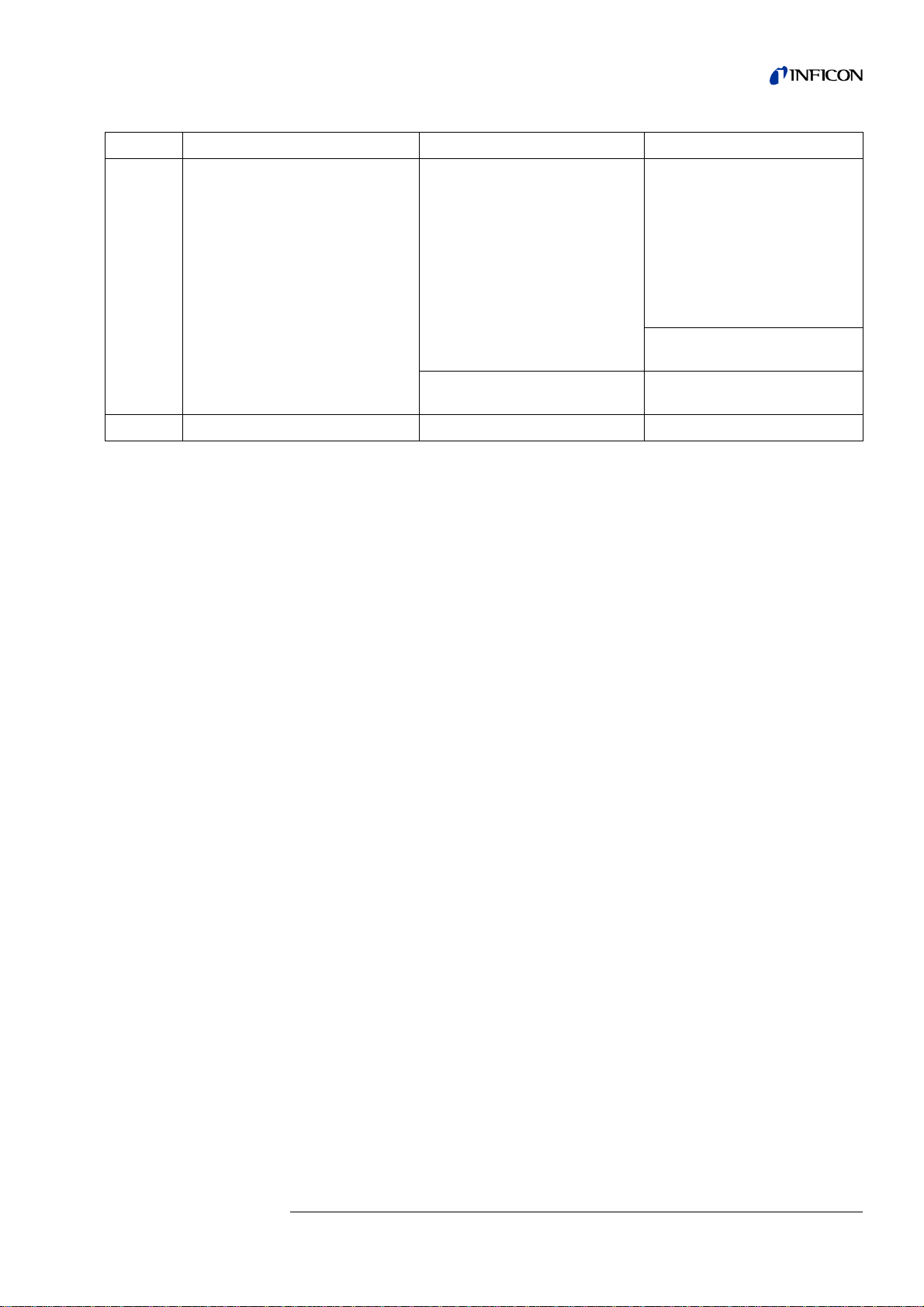

Menu Structure T-Guard™

Back

Display

Operating Mode

Trigger

Calibration

Settings

Main menu T-Guard™ Leak Detection Sensor

Info

Access control

Contrast Invert display

Displayed limit

Accumulation

Carrier gas

Continuous Mode

Standby

Trigger level 1

Trigger level 2 Enabled

Leak rate ext. Proof leak

Start Proof Function

Proof Leak Rate

Start Calibration

Miscellaneous

Interfaces

Measurement Settings

Copy Parameters

Monitoring

View / Change Settings

Internal Data

Vacuum diagram

Interfaces

History & Maintenance

Cal Factor Set to 1

Service

Access to CAL Function

Change Menu PIN

Language

Time & date

Control location

RS232 Protocol

Select PLC Inputs

Define PLC Outputs

Analog Output

Analog Scale

He concentration

Standby time

Flow of Carrier Gas Test Flow

Line length

Set Times

Accumulation Volume Test Volume

Pressure Unit

Change name

Copy

Contamination Limit

Pressure Limits

Measurement list

Display error list

Maintenance History

Calibration History

On

Off

PLC

RS232

All

Local and PLC

Local and RS232

Local

ASCII

Binary

Print automatically

Baud rate

Analogue Output 1 .. 2

Analogue Output 3 .. 4

Set Times Automatic

Measuring time

Wait Time Purge

Purge time (+ on/off)

High

Normal

Low

jina85e 5.fm Technical Handbook(1112)

Operation 55

Page 58

5.8.2 Explanation of Menu Items

The menu items the explanation refers to are written in bold letters.

Main Menu →

Back

Returns to the previous page, does not alter any setting.

Main menu → Display →

Contrast

Here, you can change the image contrast of the display.

Possible values: 0 to 99.

Default setting: 25.

Contrast → Invert display

Inverts dark characters and light background to light characters and dark

background.

Lower Limit

Raises the lowest leak rate displayed.

Increase by factor 1 to 100 possible. Default setting: 2

Main menu → Operating mode →

Accumulation

Chooses Accumulation as operation mode after confirming it with OK.

Carrier gas

Chooses Carrier Gas mode for operation after confirming it with OK.

Continuous Mode

Chooses Continuous mode for operation after confirming it with OK.

Standby

Elongates sensor life time. Press START to restart.

Main menu → Trigger →

Trigger level 1

Enter the reject leak rate here.

This setting determines the measuring time and decides between gross and fine

measurement.

Possible values: 5E-6 mbar l/s to 9.9E-2 mbar l/s.

Default setting: 2E-5 mbar l/s.

Trigger level 2

jina85e 5.fm Technical Handbook(1112)

56 Operation

Page 59

Enter an additional trigger leak rate.

This setting strongly influences the measurement, if enabled. For instance, you can

extend the displayed range upwards by setting the trigger limit 2 to the five-fold value

of the trigger limit 1.

Possible values: 5E-6 mbar l/s to 9.9E-2 mbar l/s.

Default setting: 2E-5 mbar l/s.

Trigger level 2→ Enabled

Enables the use of the additional reject leak rate.

Default setting: Disabled.

Main menu → Calibration →

Leak rate ext. Proof leak

Enter the leak rate for verifying the calibration.

Possible values: 5E-6 mbar l/s to 9.9E-2 mbar l/s.

Default setting: 2E-5 mbar l/s.

Start Test Function

Connect a leak with the proof leak rate to check the calibration. In this procedure, the

calibration factor is only checked but not written newly. The proof leak rate may

deviate from the test leak rate and therefore, it has to be input separately.

Test Leak Rate

Enter the leak rate for checking the calibration.

Possible values: 5E-6 mbar l/s to 9.9E-2 mbar l/s.

Default setting: 2E-5 mbar l/s.

Start

Calibration

Use a leak with a calibration leak rate and start the calib ration. For a successful calibration, the determined calibration factor must be between 0 .2 and 5. If the calibration

factor is between 0.2 and 0.5, or 2 and 5, a warning will be output, however, also after

the confirmed calibration.

Main menu → Settings →

Measurement settings → He concentration

Here, you can set the helium concentration in the test sample which is applied for

filling. T-Guard™ changes the automatic measuring time accordingly and displays

the real leak rate of the leakage.

Possible values: 10% to 100%.

Default setting: 100%.

Measurement settings → Standby time

If the T-Guard™ Leak Detection Sensor is not in use within this time frame, it will

switch to Standby mode automatically.

jina85e 5.fm Technical Handbook(1112)

Operation 57

Page 60

Possible values: 10 s, 30 s, 1 min, 2 min, 5 min, 10 min, 30 min, 60 min, disabled.

Default setting: 10 min .

Measurement Settings → Carrier gas flow

This item is only available in Carrier Gas mode.

Enter the total gas flow in Carrier Gas mode here. T-Guard™ Leak Detection Sensor

itself uses a probe gas flow of 180 sccm in Fine mode and 90 sccm in Gross mode.

Possible values: 60 sccm to 1000000 sccm.

Default setting: 1000 sccm

Measurement settings → Carrier gas flow →

This item is only available in Carrier Gas mode.

The T-Guard™ Leak Detection Sensor can measure the total flow in Carrier Gas

mode if the proof leak rate is applied during setting.

Measurement settings

Here, you can set the length of the measuring line between 50 and 250.

For lengths longer than 50 cm, a set-up time of up to one second is set before the

real measurement starts.

This ensures that, for the gross test, the measuring signal is already on the sensor.

The the default value is 50 cm.

Measurement Settings

Here, you can enter several time values for the measurement.

Measurement Settings

Depending on the smallest trigger value and the total gas flo w/accumulation volume,

the T-Guard™ Leak Detection Sensor selects reasonable times for measurement.

→

Line length

→

Set Times

→

Set Times→Set Times Automatic

Flow test

58 Operation

Measurement times →

Enter the total measuring time here. The cycle time of the T-Guard™ Leak detection

Sensor is longer than the total measurement time.

Possible values: 9 s to 300 s (accumulation), 3 s to 66.7 s (carrier gas). Default

setting: automatic measuring time.

Measurement settings → Set times → Waiting time Purge

This item is only available in Accumulation mode.

After every accumulation measurement, the chamber will be purged after a certain

time after the measurement. Enter this waiting time here.

Possible values: 0.1 s to 300 s.

Default setting: 4 s.

Σετ Τιμεσ

→ Measuring time

jina85e 5.fm Technical Handbook(1112)

Page 61

Measurement settings → Set time → Purge time

This item is only available in Accumulation mode.

Enter here, how long the purge will take after the accumulation measurement The

automatic purging can be switched automatically in this screen. Only then, it is

possible to start purging by a command.

Possible values: 1 s to 50 s.

Default setting: 4 s.

Measurement settings → Accumulation vol. → Test Volume

This item is only available in Accumulation mode.

T-Guard™ Leak Detection Sensor can measure the accumulation volume in

Accumulation mode when the test leak rate is applied during setting up.

Measurement Settings → Accumulation Volume → Volume

This item is only available in Accumulation mode.

Enter the net chamber volume (chamber volume minus test sample volume) here.

Possible values: 0.01 l to 10000 l.

Default setting: 1 l.

Measurement settings → Pressure unit

Choose your favourite pressure unit.

Possible values: atm, Torr, PSI, Pa, mbar.

Default setting: mbar.

Main menu → Settings →

Interfaces → Control location

Select how the T-Guard™ Leak Detection Sensor shall be controlle d.

Possible values: PLC, RS232, all, local and PLC, local and RS232, local.

Default setting: All.

"Local" (control unit) means that neither the PLC nor the RS232 may start or stop a

device.

"RS232" means that neither the control unit nor th e PLC may start or stop a device.

"PLC" means that neither the control unit nor the RS232 may start or stop a device.

The operating unit is always allowed to be configured.

Use the Menu PIN to avoid it.

(Access control → Edit Menu PIN)

RS232 is always allowed to read values.

The PLC outputs are always active.

Interfaces → RS232 Protocol → ASCII

The ASCII protocol can be used to communicate with the T-Guard™ Leak Detection

Sensor by typing commands in a terminal program like Microsoft Hyperterm and

getting a human readable answer.

jina85e 5.fm Technical Handbook(1112)

This record is pre-set as standard.

Operation 59

Page 62

Interfaces → RS232 Protocol → Binary

The binary protocol can be used to communicate with T-Guard™ Leak Detection

Sensor by software, written by a programmer. This method of communication is very

fast. It is, for example, the fastest way to read a leak rate from the T-Guard™ Leak

Detection Sensor.