Page 1

–

TGF10

TRACER GAS FILLER

nine69e4-b (1111) - All information can be modified without prior notice

Publication: INFICON AB

User‘s manual

Manuel de l’utilisateur

Benutzerhandbuch

Manual del usario

Page 2

Page 3

User‘s manual

TGF10

TRACER GAS FILLER

Page 4

EN

Contents

1.1.

General .......................................................................................................................................... 3

1.2. Installation ..................................................................................................................................... 4

1.3. Operation ....................................................................................................................................... 5

1.4. Pneumatic diagram ........................................................................................................................ 6

1.5. Specifications ................................................................................................................................ 7

2 INFICON – User’s manual TGF10

Page 5

TRACER GAS FILLER TGF10

1.1. General

Tracer Gas Filler TGF10 evacuates and fills an

object subject to leak detection.TGF10 is an

accessory to Hydrogen Leak Detector Sensistor

ISH2000 and can be used together with most of

INFICON probes.

Evacuation and filling is time controlled by the

APC system in the Sensistor ISH2000 Leak

Detector.

TGF10 feature:

The air in the test object is pumped out by a

built in venturi pump before tracer gas is

injected. This is done to make sure that the

tracer gas completely fills the test object. Preevacuation is particularly important on very

long objects e.g. pipes or heat exchangers.

EN

Sequence:

1) Press the start button.

a) Test object is evacuated.

The “Pre Evac Time” is set and adjusted

by a timer in Sensistor ISH2000.

NOTE! Setting a timer equal to zero

(0,0) means that entire line is skipped,

and outputs are not changed.

b) Evacuation ends.

c) Test object is filled with tracer gas.

Filling pressure is controlled by the

gasbottle regulator.

(Test object is ready for leak detection).

2) Press stop button.

a) Test object is evacuated.

The “Post Evac Time” is set by a timer in

Sensistor ISH2000.

b) Evacuation stops and test object is

refilled with air to atmospheric pressure

INFICON – User’s manual TGF10 3

Page 6

EN

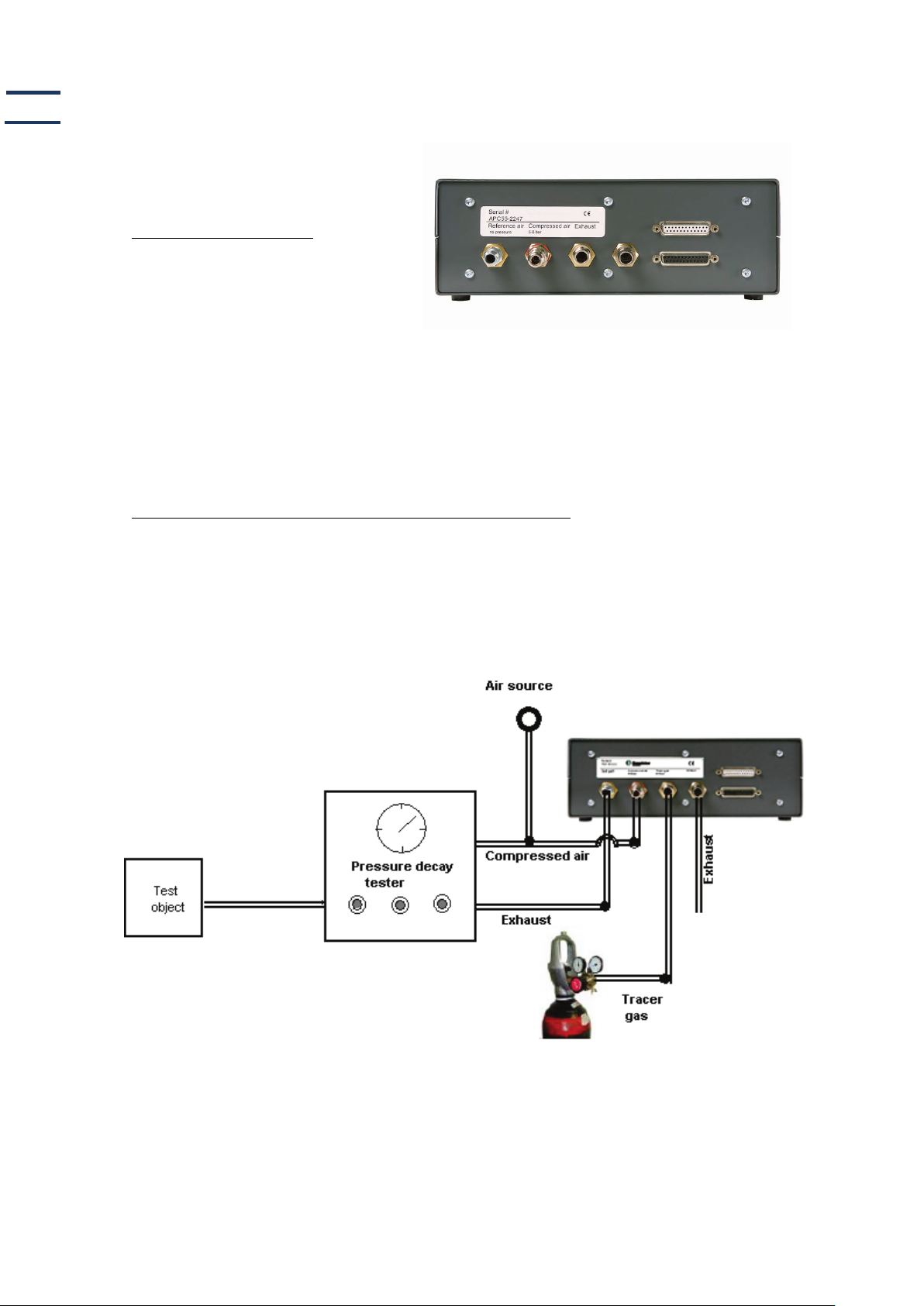

1.2. Installation

Independent leak test station:

1. Connect TGF10 to Leak Detector

Sensistor ISH2000.

2. Connect compressed air to compressed

air port.

3. Connect Tracer gas port to gas bottle.

4. Connect a large hose (∅ 12 mm. or more) to the exhaust port. Remote end of hose should be placed in

a ventilation stud carrying out of the building.

NOTE: Maximum length for a 12 mm hose is 5m. Use bigger diameter if longer hose is needed. Too

high resistance in the exhaust hose will severely reduce capacity of venturi pump.

5. Connect Test port to test object or fixture.

Adding leak detection equipment to an existing pressure decay station:

1 - 4 As above.

5 Connect test port to exhaust port of pressure decay tester.

NOTE. Test port of TGF10 is open to exhaust in standby mode. This means that the pressure decay

instrument can operate normally with the TGF10 instrument connected.

4 INFICON – User’s manual TGF10

Page 7

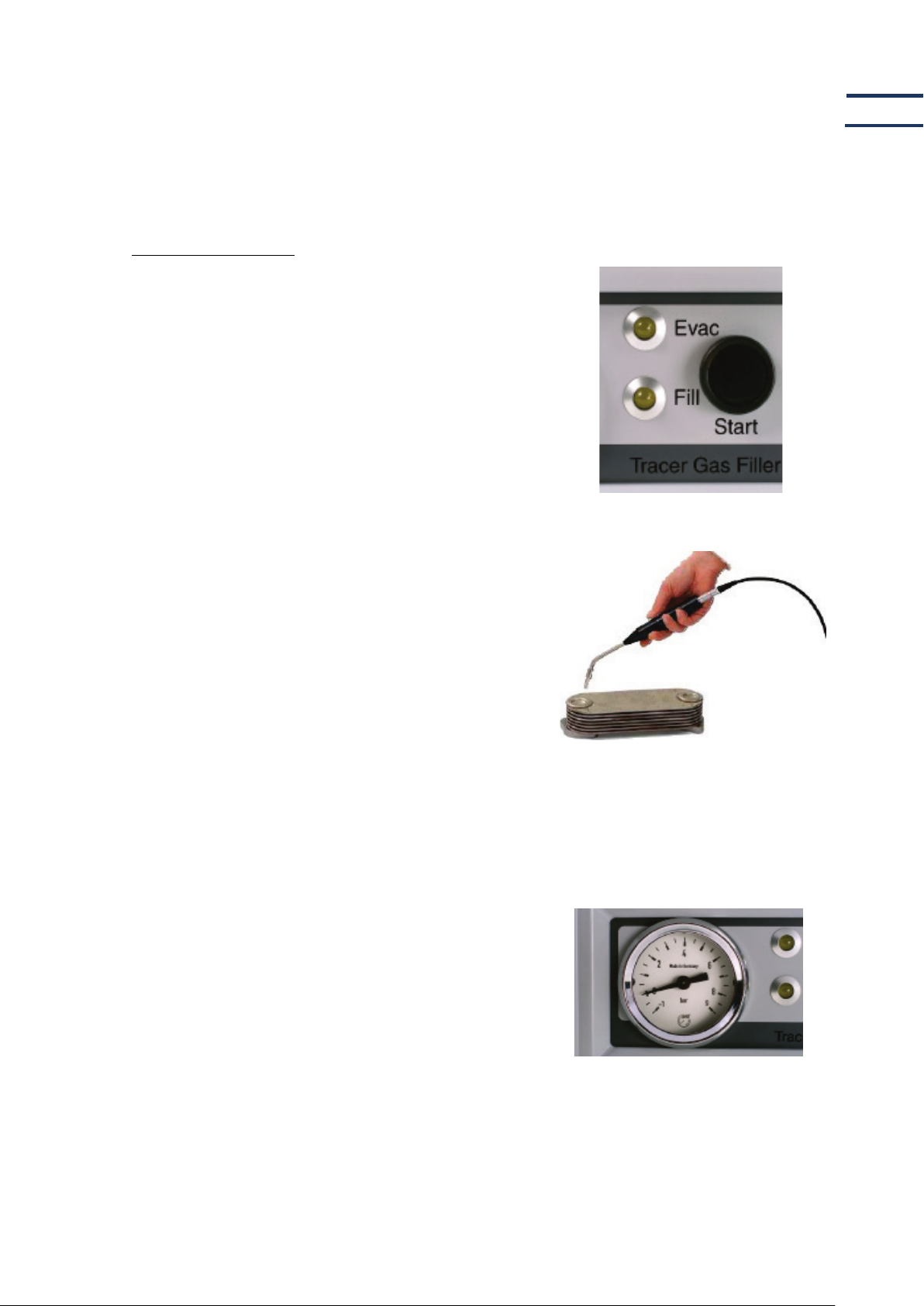

1.3. Operation

Leak Detection Sequence:

1) Press the start button.

a) The “Evac” diode comes on and the test object is evacuated.

Pre fill evacuating time is set and adjusted by a timer in Sensistor

ISH2000.

b) The “Fill” diode comes on and the “Evac” diode goes off.

Note: The “Evac” diode goes off shortly after the “Fill” diode

has come on.

Test object is now filled with tracer gas. Filling pressure is

controlled by the gas bottle regulator.

2) Search and locate leak(s).

3) Press stop button.

a) The “Evac” diode comes on and the test object is evacuated.

b) After test evacuation time is set by a timer in Sensistor

ISH2000.

c) Evacuation stops and Test object is refilled with air to

atmospheric pressure

EN

INFICON – User’s manual TGF10 5

Page 8

EN

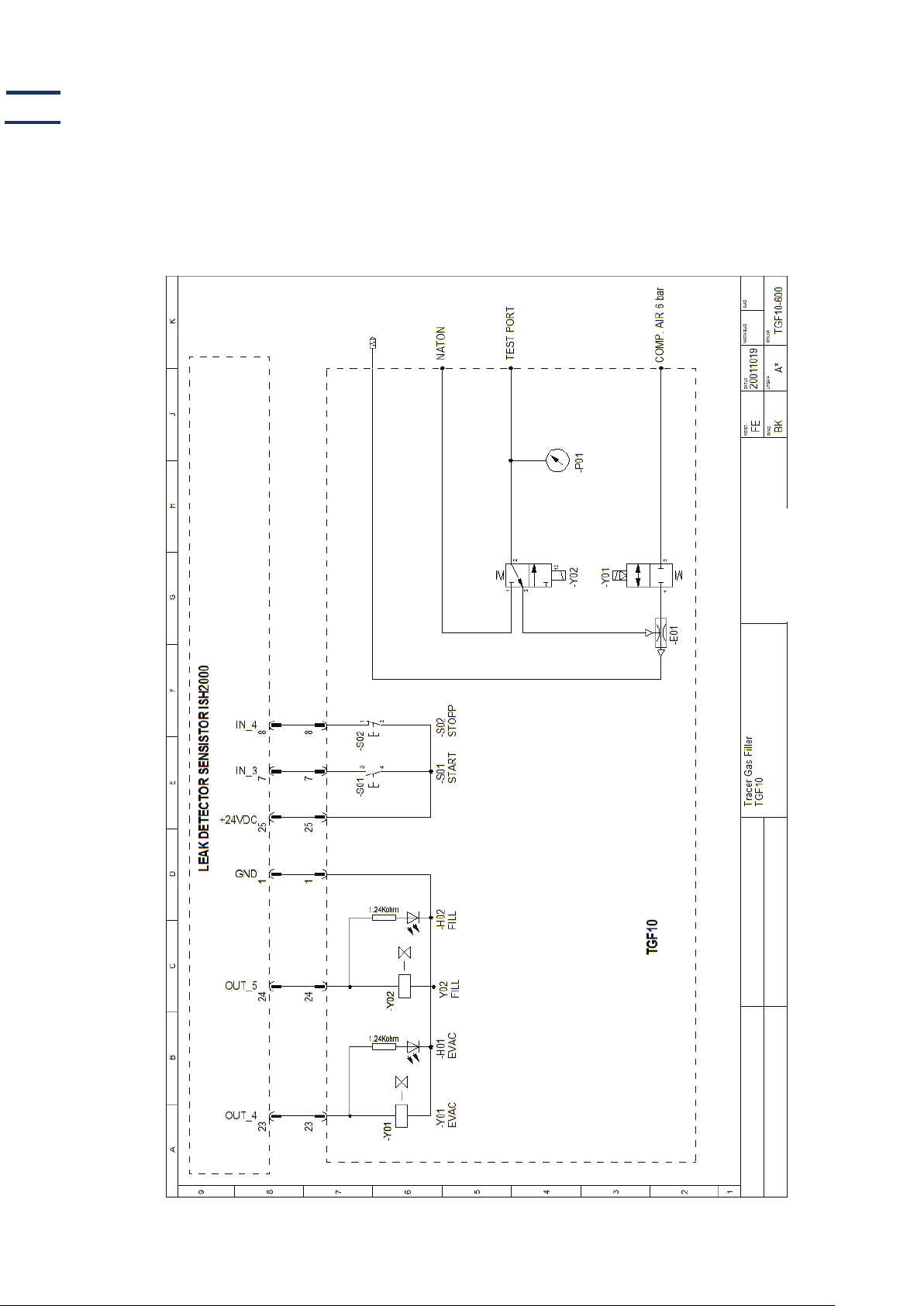

1.4. Pneumatic diagram

6 INFICON – User’s manual TGF10

Page 9

1.5. Specifications

Connections: 4 ea. ISO G1/4”

Manometer: - 1 to + 9 bar

Supplies:

Tracer Gas: 5% Hydrogen in 95% Nitrogen 5% H2 / 95% N2

Tracer Gas Pressure: 0 – 900 kPa (0 – 9 bar, 0-130 PSI)

Compressed air supply: 400 – 800 kPa (4 – 8 bar, 58-116 PSI)

Compressed Air Filtered to 40 mm

EN

Capacity:

Evacuation: 70 std l / min free flow

Ultimate vacuum: - 0.85 bar (-12,3 PSI)

Evacuation time: 0.7 s / l to - 0.5 bar (-7,2 PSI)

1.6 s / l to - 0.7 bar (-10,2 PSI)

3.0 s / l to - 0.8 bar (-11,6 PSI)

Filling: 600 std l / min free flow

Typically 1.0 s / l

Dimensions:

Weight: 4,7 kg

Dementions: 100 x 275 x 205 mm

INFICON – User’s manual TGF10 7

Page 10

EN

Disposal of product when taken out of service.

According to EU legislation, this product must be recovered for

separation of materials and may not be disposed of as unsorted

municipal waste.

If you wish you can return this INFICON product to the

manufacturer for recovery.

The manufacturer has the right to refuse taking back products that

are inadequately packaged and thereby presents safety and/or health

risks to the staff. The manufacturer will not reimburse you for the

shipping cost.

Shipping address:

INFICON AB

Westmansgatan 49

582 16 Linköping

Sweden

8 INFICON – User’s manual TGF10

Page 11

TGF10

D

ISPOSITIF DE

R

EMPLISSAGE DE

T

RAÇAGE

G

AZ DE

Manuel de l’utilisateur

Page 12

FR

Table des matières

1.1.

Généralités .................................................................................................................................... 3

1.2. Installation ..................................................................................................................................... 4

1.3. Fonctionnement ............................................................................................................................. 5

1.4. Schéma ......................................................................................................................................... 6

1.5. Caractéristiques ............................................................................................................................. 7

2 INFICON – Manuel de l’utilisateur TGF10

Page 13

DISPOSITIF DE REMPLISSAGE

DE GAZ DE TRAÇAGE TGF10

1.1. Généralités

Le dispositif de remplissage de gaz de traçage

TGF10 évacue et remplit de gaz de traçage un

objet à tester afin qu’il soit ensuite possible d’y

localiser des fuites. TGF10 est un accessoire du

détecteur de fuites d’hydrogène Sensistor

ISH2000 et peut être utilisé avec la plupart des

sondes à hydrogène INFICON.

Les temps d’évacuation et de remplissage sont

prédéfinis par le système APC du détecteur de

fuites Sensistor ISH2000.

Fonction du TGF10:

L’objet du test est vidé de son air au moyen

d’une pompe venturi intégrée avant l’injection

du gaz de traçage. Ceci garantit une distribution

rapide du gaz de traçage dans toutes les parties

de l’objet du test. La pré-évacuation est

particulièrement importante sur les objets très

longs tels que les tuyaux ou les échangeurs de

chaleur.

Lisez attentivement ce guide et tous les guides

connexes avant toute utilisation de l’appareil.

FR

Séquence:

1) Appuyes sur le bouton “Start” (démarrer).

a) L’objet à tester est evacuee.

Le temps de pré-évacuation “Pre

Evac Time” est predefine et réglé par

une minuterie dans le Sensistor

ISH2000.

REMARQUE ! Lorsqu’une minuterie

est réglée sur une valeur nulle (0,0),

la totalité de la ligne est ignorée et les

sorties ne sont pas modifiées.

b) L’évacuation est terminée.

c) L’objet du test est rempli de gaz de

traçage. La pression de remplissage est

réglée sur le régulateur de la bouteille de

gaz.

(L’objet à tester est prêt pour la détection

de fuites).

2) Appuyez sur le bouton “Stop”

a) L’objet du test est évacué. Le temps de

post-évacuation, “Post Evac Time”,

est réglé par une minuterie dans

Sensistor ISH2000.

L’évacuation est terminée et l’objet du test est à

nouveau rempli d’air à la pression

atmosphérique.

INFICON – Manuel de l’utilisateur TGF10 3

Page 14

FR

Test de chute

Échappement

Air comprimé

Gaz de traçage

Air comprimé

1.2. Installation

Station d’essai d’étanchéité autonome:

1. Connectez le TGF10 au détecteur de

fuites Sensistor ISH2000 (connecteur

25 pts).

2. Raccordez l’air comprimé à l’orifice

“Compressed Air” du TGF10

3. Connectez la bouteille de gaz de traçage à l'orifice “Tracer gas” du TGF10.

4. Raccordez un grand gros diamètre (∅ 12 mm ou plus) à l’orifice d’échappement “Exhaust” du

TGF10. L’autre extrémité du tuyau doit être placée dans un circuit d’aération donnant sur l’extérieur

du bâtiment.

5. REMARQUE : Le tuyau de 12 mm de diamètre ne doit pas dépasser 5 m de long. Utilisez un

diamètre plus grand si un tuyau plus long est requis. Une résistance trop élevée dans le tuyau

d’échappement réduit considérablement les performances de la pompe venturi.

6. Connectez la prise d’essai “Out” à l’objet ou à la fixation du test.

Ajout d’un appareil de détection de fuites à un équipement de chute de pression :

1- 4 Voir la procédure ci-dessus.

5 Connectez la prise d’essai à l’orifice d’échappement de l’équipement de chute de pression.

REMARQUE. La prise d’essai « Out » du TGF10 est ouverte sur l’échappement en mode veille. Cela

signifie que l’équipement de chute de pression peut fonctionner normalement lorsque l’appareil TGF10

est connecté

L’objet

du test

4 INFICON – Manuel de l’utilisateur TGF10

Page 15

1.3. Fonctionnement

Séquence de détection des fuites:

1) Appuyez sur le bouton “Start”

a) Le voyant d’évacuation ”Evac” s’allume et l’objet du test est

èvacué.

Le temps d’évacuation de pré-remplissage est predefine et réglé

par une minuterie dans le Sensistor ISH2000.

b) Le voyant de remplissage “Fill” s’allume et le voyant

d’évacuation “Evac” s’éteint. (Remarque : Le voyant

d’évacuation “Evac” s’éteint peu après l’allumage du voyant de

remplissage “Fill”).

L’objet du test est à présent rempli de gaz de traçage.

La pression de remplissage est réglée sur le détendeur de la

bouteille de gaz.

2) Recherchex et localisez les fuites éventuelles.

3) Appuyez sur le bouton “Stop”

a) Le voyant d’évacuation “Evac” a’allume et l’objet du test est

evacuee.

Le temps d’évacuation après essai est predefine par une minuterie

dans le Sensistor ISH2000.

b) L’évacuation est terminée et l’objet du test est à nouveau rempli

d’air à la pression atmosphérique.

FR

INFICON – Manuel de l’utilisateur TGF10 5

Page 16

FR

1.4. Schéma

6 INFICON – Manuel de l’utilisateur TGF10

Page 17

1.5. Caractéristiques

Raccordements : 4 ISO G de 1/4”

Manomètre : - 1 à + 9 bar

Fournitures :

Gaz de traçage : 5% d’hydrogène dans 95% d’azote (5% H2 / 95% N2)

Pression du gaz de traçage: 0 – 900 kPa (0 – 9 bar, 0-130 PSI)

Air comprimé : 400 – 800 kPa (4 – 8 bar, 58-116 PSI)

Air comprimé : filtré à 40 microns

FR

Capacité :

Évacuation : 70 l/min std. flux libre

Vide final : - 0,85 bar (-12,3 PSI)

Temps d’évacuation : 0,7 s/l à -0,5 bar (-7,2 PSI)

1,6 s/l à -0,7 bar (-10,2 PSI)

3,0 s/l à -0,8 bar (-11,6 PSI)

Remplissage : 600 l/min std flux libre ;

type 1,0 s/l

Remarque : La capacité est fonction du raccordement à l’objet du test. Les valeurs ci-dessus sont basées

sur un tuyau d’une longueur de 1,5 m et d’un diamètre intérieur de 5,5 mm.

Autres caractéristiques :

Poids : 4,7 kg

Dimensions : 100 x 275 x 205 mm

INFICON – Manuel de l’utilisateur TGF10 7

Page 18

FR

Recyclage d’un produit à mettre au rebut

Conformément à la Directive EU relative aux déchets électriques et

électroniques, ce produit doit être recyclé en fin de service et ne peut

donc pas être jeté comme déchet domestique.

Vous pouvez, si vous le désirez, retourner ce produit INFICON au

fabricant qui assumera la responsabilité de son recyclage.

Le fabricant retient le droit de refuser de reprendre un produit dont

l’emballage pourrait représenter un risque pour la santé et/ou la

sécurité de son personnel.

Le fabricant ne compensera pas vos frais d’expédition.

INFICON AB

Westmansgatan 49

582 16 Linköping

Suède

8 INFICON – Manuel de l’utilisateur TGF10

Page 19

Benutzerhandbuch

TGF10

SPURENGASFÜLLEINHEIT

Page 20

DE

Inhalt

1.1.

Allgemeines .................................................................................................................................. 3

1.2. Installation ..................................................................................................................................... 4

1.3. Betrieb ........................................................................................................................................... 5

1.4. Schaltplan ...................................................................................................................................... 6

1.5. Technische Daten .......................................................................................................................... 7

2 INFICON – Benutzerhandbuch TGF10

Page 21

SPURENGASFÜLLEINHEIT TGF10

1.1. Allgemeines

Die Spurengasfülleinheit TGF10 evakuiert und

befüllt ein Objekt, an dem eine Lecksuche

durchgeführt werden soll. Der TGF10 ist ein

Zusatzgerät zum Wasserstoff-Lecksuchgerät

Sensistor ISH2000. Er kann zusammen mit

verschiedenen INFICON Messköpfen eingesetzt

werden.

Das Evakuieren und Befüllen erfolgt

zeitgesteuert durch das APC-System im

Lecksuchgerät Sensistor ISH2000.

Leistungsmerkmale des TGF10:

Die Luft im Testobjekt wird von einer

integrierten Venturi-Pumpe abgepumt, bevor

Spurengas eingefüllt wird. Dadurch wird

sichergestellt, dass das Testobjekt vollständig

mit Spurengas befüllt ist. Bei sehr langen

Objekten, beispielsweise Rohrleitungen oder

Wärmetauschern, ist eine Vorevakuierung

besonders wichtig.

Lesen Sie dieses Handbuch sowie alle weiteren

zugehörigen Handbücher vor dem Arbeiten mit

dem System aufmerksam durch.

DE

Ablauf:

1) Drücken Sie die Starttaste.

a. Das Testobjekt wird evakuiert. Die

„Vorevakuierungszeit“ wird von einem

Timer im Sensistor ISH2000 eingestellt.

HINWEIS! Wenn Sie einen Timer auf

Null (0,0) setzen, wird der betreffende

Schritt übersprungen, und die Ausgänge

werden nicht verändert.

b. Die Evakuierung wird beendet.

c. Das Testobjekt wird mit Spurengas

befüllt. Der Befüllungsdruck wird vom

Druckregler an der Flasche geregelt.

(Das Testobjekt ist bereit für die

Lecksuche.)

2) Drücken Sie die Stopptaste.

a. Das Testobjekt wird evakuiert. Die

„Nachevakuierungszeit“ wird von einem

Timer im Sensistor ISH2000 eingestellt.

b. Die Evakuierung wird gestoppt, und das

Testobjekt wird mit Luft unter

atmosphärischem Druck befüllt.

INFICON – Benutzerhandbuch TGF10 3

Page 22

DE

Abluft

Luftversorgung

Spurengas

Druckluft

Druckabfall-

1.2. Installation

Als eigenständige Lecksuchstation:

1. Schließen Sie den TGF10 an den

Lecksucher Sensistor ISH2000 an.

2. Schließen Sie die Druckluft an den

Druckluftanschluss an.

3. Schließen Sie den

Spurengasanschluss an die Gasflasche an.

4. Schließen Sie einen Schlauch (∅ mindestens 12 mm) an den Abluftanschluss an. Das andere

Schlauchende sollte in einen Abluftkanal geführt werden, der aus dem Gebäude herausführt.

HINWEIS! Ein Schlauch mit einem Durchmesser von 12 mm darf höchstens 5 m lang sein. Falls Sie

einen längeren Schlauch benötigen, muss ein Schlauch mit einem größeren Durchmesser verwendet

werden. Bei zu hohem Widerstand im Abluftschlauch verringert sich die Leistung der Venturi-Pumpe

beträchtlich.

5. Schließen Sie den Testanschluss an das Testobjekt oder die Montagevorrichtung an.

Verbindung mit einem vorhandenen Druckabfallmessgerät:

1 - 4 Wie oben.

5 Schließen Sie den Testanschluss des TGF10 an den Abluftanschluss des Druckabfall-messgeräts

an.

HINWEIS. Der Testanschluss des TGF10 ist im Bereitschaftsbetrieb zum Abluftanschluss hin

geöffnet. Das bedeutet, dass das Druckabfallmessgerät normal arbeitet, wenn der TGF10

angeschlossen ist.

Testobjekt

4 INFICON – Benutzerhandbuch TGF10

Page 23

1.3. Betrieb

Lecksuche:

1) Drücken Sie die Starttaste.

a. Die LED „Evac“ leuchtet, und das Testobjekt wird

evakuiert. Die „Evakuierungsdauer vor der

Befüllung“ wird von einem Timer im Sensistor

ISH2000 eingestellt.

b. Die LED „Fill“ leuchtet, und die LED „Evac“

erlischt.

(Hinweis: Die LED „Evac“ erlischt kurz nach

Aufleuchten der LED „Fill“.)

Das Testobjekt wird jetzt mit Spurengas befüllt. Der

Befüllungsdruck wird vom Druckregler an der

Gasflasche geregelt.

2) Suchen und lokalisieren Sie Lecks

3) Drücken Sie die Stopptaste.

a. Die LED „Evac“ leuchtet, und das Testobjekt wird

evakuiert. Die Evakuierungsdauer nach der Prüfung

wird von einem Timer im Sensistor ISH2000

eingestellt.

b. Die Evakuierung wird gestoppt, und das Testobjekt

wird unter Luft mit atmosphärischem Druck befüllt.

DE

INFICON – Benutzerhandbuch TGF10 5

Page 24

DE

1.4. Schaltplan

6 INFICON – Benutzerhandbuch TGF10

Page 25

1.5. Technische Daten

Anschlüsse: 4 Stck. ISO G1/4“

Manometer: -1 bis +9 bar

Versorgungsleitungen:

Spurengas: 5 % Wasserstoff in 95 % Stickstoff 5% H2 / 95% N2

Spurengasdruck: 0 - 900 kPa (0 - 9 bar, 0-130 PSI)

Druckluftzufuhr: 400 - 800 kPa (4 - 8 bar, 58-116 PSI)

Druckluft Gefiltert auf 40 μm

DE

Leistung:

Evakuierung: 70 Nl/min bei freiem Durchfluss

Endvakuum: -0,85 bar (-12,3 PSI)

Evakuierungszeit: 0,7 s/l bis auf -0,5 bar (-7,2 PSI)

1,6 s/l bis auf -0,7 bar (-10,2 PSI)

3,0 s/l bis auf -0,8 bar (-11,6 PSI)

Befüllung: 600 Nl/min bei freiem Durchfluss typisch 1,0 s/l

Hinweis: Die Leistungswerte hängen vom Anschluss an das Testobjekt ab. Die vorstehenden Werte

beziehen sich auf einen Schlauch mit einer Länge von 1,5 m und einem Innendurchmesser von 5,5 mm.

Abmessungen:

Gewicht: 4,7 kg

Abmessungen: 100 x 275 x 205 mm

INFICON – Benutzerhandbuch TGF10 7

Page 26

DE

Entsorgung des Gerätes

Gemäß geltender EU Gesetzgebung muss dieses Produkt einem

Materialrecycling zugeführt werden und darf nicht in den

kommunalen, unsortierten Müll entsorgt werden.

Zur fachgerechten Entsorgung können Sie dieses INFICON Produkt

an den Hersteller zurück schicken.

Dieser hat das Recht die Annahme von Produkten, die nicht

ordnungsgemäß verpackt sind und somit ein Sicherheits- bzw.

Gesundheitsrisiko für die Mitarbeiter darstellen, zu verweigern.

In diesem Fall wird Ihnen der Hersteller die Frachtkosten nicht

erstatten.

Lieferadresse:

INFICON AB

Westmansgatan 49

582 16 Linköping

Schweden

8 INFICON – Benutzerhandbuch TGF10

Page 27

Manual del usario

TGF10

ALIMENTADOR DE GAS

INDICADOR

Page 28

SP

Índice

1.1. General .......................................................................................................................................... 3

1.2. Instalación ..................................................................................................................................... 4

1.3. Functionamiento ............................................................................................................................ 5

1.4. Esquema ........................................................................................................................................ 6

1.5. Especificaciones ............................................................................................................................ 7

2 INFICON – Manual del usario TGF10

Page 29

ALIMENTADOR DE GAS

INDICADOR TGF10

1.1. General

El alimentador de gas indicador TGF10 evacua

y llena el objeto sometido a la detección de

fugas. El TGF10 es un accesorio del detector de

fugas por hidrógeno Sensistor ISH2000 y puede

usarse junto con la mayoría de las sondas de

hidrógeno de Adixen. El tiempo de evacuación

y llenado se controla mediante el sistema APC

del detector de fugas Sensistor ISH2000.

Característica del TGF10:

Mediante una bomba Venturi incorporada se

extrae el aire del objeto de comprobación antes

de inyectar el gas indicador. Esto se hace para

asegurarse de que el gas indicador llena

completamente el objeto de comprobación. La

evacuación previa es particularmente importante

en objetos muy largos, por ejemplo, tuberías o

termointercambiadores.

Lea esta guía y todos los manuales relevantes

antes de usar el equipo.

SP

Secuencia:

1) Pulse el botón de arranque.

a. Elobjeto de comprobación es evacuado. El

tiempo de evacuación previa (“Pre Evac

Time”) se fija y ajusta en el Sensistor

ISH200 mediante un temporizador.

¡NOTA! El ajuste del temporizador a cero

(0,0) significa que se saltará la línea entera

y las salidas no habrán cambiado.

b. La evacuación finaliza.

c. El objeto de comprobación se llena de gas

indicador. La presión de llenado se controla

mediante el regulador de la botella de gas.

(El objeto de comprobación está listo para la

detección de fugas).

2) Pulse el botón de parada.

a. El objeto de comprobación es evacuado.

El tiempo posterior a la evacuación

(“Post Evac Time”) se ajusta en el

Sensistor ISH2000 mediante un

temporizador.

La evacuación se detiene y el objeto de

comprobación se rellena con aire a presión

atmosférica.

INFICON – Manual del usario TGF10 3

Page 30

SP

Exhaustación

Aire comprimido

Gas indicador

Aire

Objeto

1.2. Instalación

Estación de prueba de fugas independiente:

1. Conecte el TGF10 al detector de fugas

Sensistor ISH2000.

2. Conecte aire comprimido al puerto de aire

comprimido.

3. Conecte el puerto del gas indicador a la

botella de gas.

4. Conecte una manguera grande (∅ de 12 mm

o más) al puerto de exhaustación. El extremo

remoto de la manguera debe colocarse en un

soporte de ventilación que la lleve fuera del

edificio.

NOTA: La longitud máxima de una manguera de

12 mm. es de 5 m. Use un diámetro superior si

necesita una manguera más larga. Una

excesiva resistencia en la manguera de

exhaustación reducirá gravemente la

capacidad de la bomba Venturi. .

5. Conecte el puerto de prueba al objeto o

accesorio de comprobación.

Cómo agregar un equipo de detección de fugas a

una estación de disminución de preción

existente:

1 - 4 Igual al anterior.

5 Conecte el puerto de prueba al puerto de

exhaustación del analizador de disminución de

presión.

NOTA. El puerto de prueba del TGF10 está

abierto a la exhaustación en el modo de

espera. Esto significa que el instrumento de

disminución de presión puede funcionar

normalmente con el instrumento TGF10

conectado.

de

compro-

4 INFICON – Manual del usario TGF10

Controlador de

disminución de la

comprimido

Page 31

1.3. Functionamiento

Secuencia de detección de una fuga:

1) Pulse el boutón de arranque.

a. El diodo „Evac“ se enciende y el

objeto de comprobación es

evacuado.

El tiempo de evacuación del

prellenado se fija y ajusta en el

Sensistor ISH2000 mediante un

temporizador.

b. El diodo „Fill“ (llenar) se

enciende y el „el diodo evac“ se

apaga.

(Nota: El diodo „Evac“ se apaga

brevemente después de que el

diodo « Fill » se haya encendido).

A continuación, el objeto de

comprobación se llena de gas

indicador. La presión de llenado

se controla mediante el regulador

de la botella de gas.

2) Busque y localice la(s) fuga(s)

3) Pulse el botón de parada.

a. El diodo “Evac” se enciende y el

objeto de comprobación es

evacuado. Después de la prueba,

el tiempo de evacuación se ajusta

en el Sensistor ISH2000 mediante

un temporizador.

b. La evacuación se detiene y el

objeto de comprobación se rellena

con aire a presión atmosférica.

SP

INFICON – Manual del usario TGF10 5

Page 32

SP

1.4. Esquema

6 INFICON – Manual del usario TGF10

Page 33

1.5. Especificaciones

Conexiones: 4 ea. ISO G1/4”

Manómetro: - 1 a + 9 bar

Suministros:

Gas indicador: 5% hidrógeno en 95% de nitrógeno 5% H2 / 95% N2

Presión del gas indicador: 0 – 900 kPa (0 – 9 bar, 0-130 PSI)

Suministro de aire comprimido: 400 -800 kPa (4 - 8 bar, 58-116 PSI)

SP

Aire comprimido: filtrado a 40 mm

Capacidad:

Evacuación: 70 std l / flujo libre mínimo.

Vacío último: - 0,85 bar (-12,3 PSI)

Tiempo de evacuación: 0,7 s / l a –0,5 bar (-7,2 PSI)

1,6 s / l a - 0,7 bar (-10,2 PSI)

3,0 s / l a -0,8 bar (-11,6 PSI)

Llenado: 600 std l / flujo libre mínimo

Típicamente 1,0 s / l

Nota: La capacidad depende de la conexión al objeto de comprobación. Las cifras dadas son para una

manguera de 1,5 m.con un diám. interior de 5,5 mm.

Dimensiones:

Peso: 4,7 kg

Dimensiones: 100 x 275 x 205 mm

INFICON – Manual del usario TGF10 7

Page 34

SP

Desecho del producto cuando esté fuera de

servicio.

De acuerdo a la legislación de la UE, este producto debe ser

recuperado para la separación de materiales y no debe ser desechado

como un desperdicio municipal sin clasificar.

Si lo desea, puede devolver este producto INFICON al fabricante

para que realice su recuperación.

El fabricante tiene el derecho de rechazar productos que estén

empacados en forma inadecuada y que por lo tanto representen

riesgos de seguridad o salud para el personal.

El fabricante no le reembolsará los gastos de transporte.

Dirección de envío:

INFICON AB

Westmansgatan 49

582 16 Linköping

Suecia

8 INFICON – Manual del usario TGF10

Page 35

Page 36

www.inficon.com E-mail: reach.sweden@inficon.com

INFICON AB, Box 76, SE-581 02 Linköping, Sweden

Phone: +46 (0) 13 35 59 00 Fax: +46 (0) 13 35 59 01

Loading...

Loading...