Page 1

OPERATING MANUAL

TEK-Mate

®

Refrigerant Leak Detector

Page 2

Declaration Of Conformity

This is to certify that this equipment, designed and manufactured by INFICON Inc.,

2 Technology Place, East Syracuse, NY 13057 USA meets the essential safety requirements of

the European Union and is placed on the market accordingly. It has been constructed in

accordance with good engineering practice in safety matt ers in force in the Community and

does not endanger the safety of persons, domestic animals or property when properly installed

and maintained and used in applications for which it was made.

Equipment Description . . . . . . . . . . . . . .TEK-Mate® Refrigerant Leak Detector

Applicable Directives . . . . . . . . . . . . . . . 73/23/EEC as amended by 93/68/EEC

Applicable Standards . . . . . . . . . . . . . . .EN 61010-1: 1993 EN55011, Group 1,

CE Implementation Date. . . . . . . . . . . . .March 1, 1997

Authorized Representative . . . . . . . . . . . Duane Wright

Any questions relative to this declaration or to the safety of INFICON's products should be

directed, in writing to the quality assurance department at the above address.

89/336/EEC as amended by 93/68 EEC

2002/95/EC (RoHS)

Class A: 1991 EN50082-1: 1992

Manager, Quality Assurance

INFICON, Inc.

WARNINGWARNINGWARNING

This symbol is intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in the literature

accompanying the instrument.

TEK-Mate®, Toolbox Tough™ and INFICON® are trademarks of INFICON Inc.

DURACELL® is a registered trademark of Duracell Inc.

2

Page 3

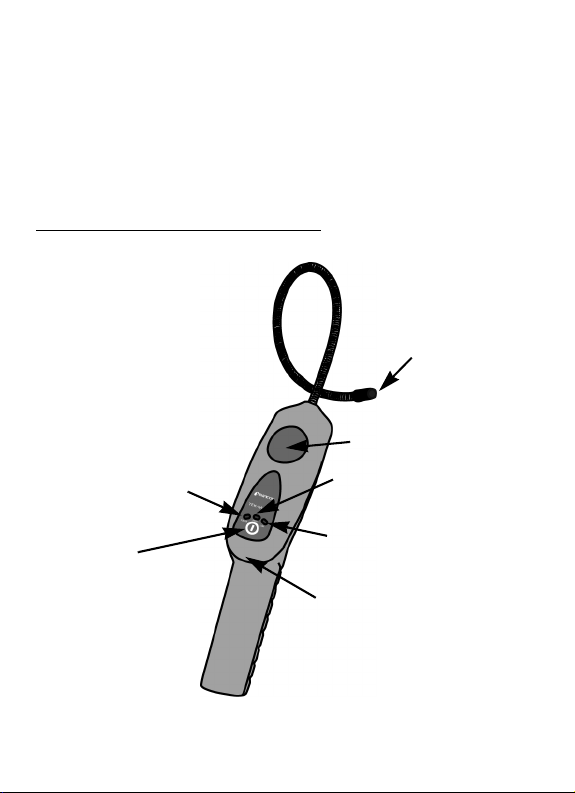

TEK-Mate Features

TEK-Mate combines sophisticated technology with durability for an instrument with outstanding

sensitivity that's Laboratory Accurate, Toolbox Tough™.

Electrochemical heated-diode sensor.

"No-reset" detection of CFCs, HCFCs, and HFCs.

Automatic adjustment ("zeroing") to refrigerants in leak test area.

Rugged flexible probe with a foam filter for sensor protection.

High/Low sensitivity and power in one switch.

To get the best performance from your TEK-Mate Leak Detector, please read this manual

carefully before you start using it. If you have any questions or need additional assistance,

please call 800-344-3304. We'll be ha ppy to help you!

Filter

Sensor Cover

Power/Low Battery LED

Power/Sensitivity Setting Switch

High Sensitivity LED

Low Sensitivity LED

Battery Cover Release Latch

3

Page 4

Getting Started

1. Install the batteries. See How To Install The Alkaline Batteries.

2. Install the sensor. See How To Install Or Change the Sensor.

NOTE: Installation of the batteries and sensor is required before use.

3. Press the control button to power on the TEK-Mate.

4. Wait for the TEK-Mate to warm up. All three LEDs will illuminate during warm up. When the

High sensitivity LED starts flashing and a chirping sound is heard, the TEK-Mate is ready to

find leaks.

The INFICON TEK-Mate Refrigerant Leak Detector provides similar responses to all CFC's,

HCFC's, HFC's and refrigerant blends (e.g. R-410A, R407c) as well as SF6.

How To Install The Alkaline Batteries

1. Remove the battery cover by releasing the latch and sliding the cover down and off the

handle.

2. Install two “D” size alkaline batteries as shown in Figure 1.

3. Reinstall the battery cover by aligning it with the handle and sliding it up until the latch

engages.

When the batteries reach the end of their life, the green Low Battery indicator will start flashing.

While the batteries may operate the TEK-Mate up to one hour after the Low Battery indicator

starts flashing, the batteries should be replaced as quickly as possible.

Figure 1. Properly Installed Alkaline Batteries

+

+

-

-

Disposing Of The Alkaline Batteries

At the end of the life of a set of alkaline batteries, please dispose of them according to

applicable state and local regulations. In the absence of such regulations, INFICON encoura ges

customers to recycle and/or dispose of the cells through voluntary waste recycling programs.

4

Page 5

How To Install Or Change the Sensor

A new TEK-Mate is shipped with its sensor packed separately. The sensor must be installed

before use. This specialized sensor will operate for about 100 hours befor e it will need to be

replaced.

1. Remove the rubber sensor cover by lifting at the outer edge.

2. If you are replacing a worn out sensor, remove the worn out sensor by pulling it straight out

of the socket and discard it.

WARNINGWARNINGWARNING

IF YOU ARE REPLACING THE SENSOR, THE WORN OUT SENSOR

MAY BE HOT.

3. Remove the new sensor from its packaging and carefully align the three sensor leads (small

wires coming out of the bottom of the “can”) with the three holes in the sensor socket. Insert

the leads into the holes by gently pressing straight down on the sensor until the sensor leads

contact the bottom of the socket. Be careful not to bend the sensor leads. See Figure 2.

4. Reinstall the rubber sensor cover by pressing it down firmly around the edges. Be sure the

edges of the cover are flat against the surface of the detector.

Figure 2. Installing the Sensor

5

Page 6

Using Your INFICON TEK-Mate

WARNINGWARNINGWARNING

DO NOT OPERATE THIS INSTRUMENT IN THE PRESENCE OF GASOLINE,

NATURAL GAS, PROPANE, OR IN OTHER COMBUSTIBLE ATMOSPHERES.

How To Find Leaks

NOTE: A sudden whipping of the leak detector probe or blowing into the sensor tip will affect the

air flow over the sensor and cause the instrument to alarm.

1. Place the tip of the leak-detector probe as close as possible to the site of the suspected leak.

Try to position the probe within 1/4 inch (5 mm) of the possible leak source.

2. Slowly (approximately 1 to 2 inches/second (25 to 50 mm/second)) move the probe past

each possible leak point.

NOTE: It is important to move the tip of the probe past the leak. If held on a leak, the auto

3. When the instrument detects a leak, it will emit a different tone and the LED flash rate will

4. When the TEK-Mate signals a leak, pull the probe away from the leak for a moment, then

5. Return sensitivity to HIGH before searching for additional leaks.

6. When you've finished leak-testing, turn OFF the instrument.

zero feature will gradually zero out the leak signal.

increase to signal the leak.

bring it back to pinpoint the location. If the leak is large, set the sensitivity switch to LOW, by

quickly pressing the main control button, to make it easier to find the exact site of the leak.

How To Change The Filter

The foam filter at the probe tip should be replaced if it becomes plugged with water or oil. To

replace the filter, simply pull out the old filter (with a paper clip or similar device). Then, push in

the new filter.

Cleaning The TEK-Mate's Housing

The TEK-Mate's plastic housing can be cleaned with standard household detergent or isopropyl

alcohol. Care should be taken to prevent the cleaner from entering the instrument. Since

gasoline and other solvents may damage the plastic, protect your INFICON TEK-Mate from

contact with these substances.

6

Page 7

Troubleshooting

Except for the batteries and the sensor, the internal parts of the TEK-Mate Leak Detector are

not user serviceable. If you experience a problem with your TEK-Mate, see the Troubleshooting

Table below to determine how to remedy the problem. If you can not remedy the problem, take

your TEK-Mate to your wholesaler for evaluation.

PROBLEM CAUSE REMEDY

1. Poor sensitivity. The

TEK-Mate does not find

leaks.

2. The TEK-Mate

responds slowly to a leak.

3. Will not power up. 3a. Batteries are worn out. 3a. Install a new set of batteries.

4. False alarms - the

TEK-Mate alarms when

the probe is moved or

bumped.

1a. Sensor has reached

the end of its useful life.

1b. Sensitivity set to LOW

instead of HIGH

2a. Dirty or wet filter. 2a. Replace the filter. See page 6.

2b. Failure in the pumping

system.

2c. The sensor cover is

not sealing.

3b. Batteries have been

improperly installed.

4a. Sensor leads are bent. 4a. Remove the sensor and

4b. Moisture was

absorbed by the sensor

during a long period

without use.

1a. Replace the sensor.

See page 5.

1b. Set the Sensitivity to HIGH and

scan for the leak again.

2b. Turn the TEK-Mate on and

listen for a high-pitched motor

sound. If you do not hear the

motor, return the TEK-Mate to your

wholesaler for evaluation.

2c. Make sure the sensor cover is

properly installed. See step 5 on

page 5.

See page 4.

3b. Check battery installation as

shown in Figure 1 on page 4.

inspect the leads. Straighten the

leads with needle nose pliers, if

necessary, and reinstall the

sensor.

4b. Run the TEK-Mate for at least

20 minutes. The absorption of

moisture does not affect the life or

sensitivity of the sensor.

7

Page 8

Return Authorization Procedure

All defective TEK-Mates should be returned to your wholesaler for warranty evaluation. If you

have any questions, please contact INFICON at 800-344-3304.

NOTE: Do not return your defective unit directly to the factory without first contacting your

wholesaler.

Specifications

Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Indoor or Outdoor

Minimum sensitivity to R22, R134a, R404A, R410A . . . . . . . . . . . . .0.25 oz/yr (high sensitivity)

Operating temperature range . . . . . . . . . . . . . . . . . . . . . . . . .+32 °F to 122 °F (0 °C to +50 °C)

Storage temperature range. . . . . . . . . . . . . . . . . . . . . . . . +14 °F to + 140 °F (-10 °C to +60 °C)

Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95% RH NC Max.

Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6500' (2000 m)

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Two “D” cell alkaline batteries

Battery Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Approximately 16 hours

Pollution degree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Overvoltage category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Weight (with power cells) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.28 lb (0.58kg)

1

May be operated for a limited time in lower temperature environments.

2.0 oz/yr (low sensitivity)

Replacement Parts and Accessories

Replacement parts and accessories for your INFICON TEK-Mate Refrigerant Leak Detector are

available through the same dealer from whom you bought the instrument.

Plastic storage case . . . . . . . . . . . . . . . .705-401-P2

Replacement sensor. . . . . . . . . . . . . . . . 703-020-G1

Tip filters, package of 20. . . . . . . . . . . . . 705-600-G1

1

8

Page 9

Warranty and Liability

INFICON warrants your TEK-Mate Refrigerant Leak Detector to be free from defects of

materials or workmanship for two years from the date of purchase. INFICON does not warrant

items that deteriorate under normal use, including power cells, sensors and filters. In addition,

INFICON does not warrant any instrument that has been subjected to misuse, negligence, or

accident, or has been repaired or altered by anyone other than INFICON.

INFICON's liability is limited to instruments returned to INFICON, transportation prepaid, not

later than thirty (30) days after the warranty period expires, and which INFICON judges to have

malfunctioned because of defective materials or workmanship. INFICON's liability is limited to,

at its option, repairing or replacing the defective instrument or part.

This warranty is in lieu of all other warranties, express or implied, whether of merchantability or

of fitness for a particular purpose or otherwise. All such other warranties are expressly

disclaimed. INFICON shall have no liability in excess of the price paid to INFICON for the

instrument plus return transportation charges prepaid. INFICON shall have no liability for any

incidental or consequential damages. All such liabilities are excluded.

Special Information For Automotive Technicians

INFICON's TEK-Mate Refrigerant Leak Detector Model #705-202-G1 is design certified by MET

Laboratories, Inc. to meet SAE J1627, “Rating Criteria for Electronic Refrigerant Leak

Detectors” for R12, R22, and R134a. The following SAE Recommended Practice applies to this

instrument and to the use of generally available electronic leak detection methods to service

motor vehicle passenger compartment air conditioning systems.

1. The electronic leak detector shall be operated in accordance with the equipment

manufacturer's operating instructions.

2. Leak test with the engine not in operation.

3. The A/C system shall be charged with sufficient refrigerant to have a gauge pressure of at

least 50 PSI (340 kPa) when not in operation. At temperatures below 59 °F (15 °C) leaks

may not be measurable, since this pressure may not be reached.

4. Take care not to contaminate the detector probe tip if the part being tested is contaminated.

If the part is particularly dirty, it should be wiped off with a dry shop towel or blown off with

shop air. No cleaners or solvents shall be used, since many electronic detectors are sensitive

to their ingredients.

5. Visually trace the entire refrigerant system, and look for signs of air conditioning lubricant

leakage, damage, and corrosion on all lines, hoses, and components. Each questionable

area shall be carefully checked with the detector probe as well as all fittings, hose-to-line

couplings, refrigerant con trols, service ports with caps in place, brazed or welde d areas, and

areas around attachment points and hold-downs on lines and components.

6. Always follow the refrigerant system around in a continuous path so that no areas of potential

leaks are missed. If a leak is found, always continue to test the remainder of the system.

7. At each area checked, the probe shall be moved around the location, at a rate no more than

1 to 2 inches/second (25 to 50 mm/second) and no more than 1/4 inch (5 mm) from the

surface completely around the position. Slower and closer movement of the probe greatly

improves the likelihood of finding a leak.

9

Page 10

8. An apparent leak shall be verified at least once by blowing shop air into the area of the

suspected leak, if necessary, and repeating the check of the area. In cases of very large

leaks, blowing out the area with shop air often helps locate the exact position of the leak.

9. Leak testing of the evaporator core while in the air conditioning module shall be

accomplished by turning the air conditioning blower on high for a period of 15 seconds

minimum, shutting it off, then waiting for the refrigerant to accumulate in the case for time

specified in step 10, then inserting the leak detector probe into the blower resistor-block or

condensate drain-hole if no water is present, or into the closest opening in the HVAC case

to the evaporator, such as the heater duct or a vent duct. If the detector alarms, a leak

apparently has been found.

10. The accumulation time for evaporator testing is 13 minutes.

11. Following any service to the refrigerant system of the vehicle, and any other service which

disturbs the refrigerant system, a leak test of the repair and of the service ports of the

refrigerant system shall be done.

10

Page 11

NOTE

11

Page 12

TWO TECHNOLOGY PLACE

EAST SYRACUSE, NY 13057-9714 USA

Phone: +315.434.1100

Fax: +315.437.3803

E-Mail: service.tools@inficon.com

www.inficon.com

074-477-P1C

Loading...

Loading...