Page 1

T3000

Thermal Power Supply

OVER TEMP

POWER MODE

RESET

OPEN

LOAD

SER - PAR

J1

1

OUT 1 NEG

OUT 1 POS

OUT 2 POS

OUT 2 NEG

User's Manual

518-035 Revision A, Feb 2006

Page 2

instruments

Thermal Power Supply

T3000

Preface

Warranty

SYCON INSTRUMENTS, INC.

Policy

Sycon Instruments, Inc. (Sycon) warrants that all electronic instrumentation

equipment manufactured by Sycon shall be free from defects in materials and workmanship

for a period of 2 years from date of shipment. Mechanical vacuum components such as

feedthroughs, sensors, cables, and shutters shall be warranted for a period of six months

from the date of shipment. For the duration of the warranty period Sycon will, at its option,

either repair or replace any part which is defective in materials or workmanship without

charge to the purchaser. The foregoing shall constitute the exclusive and sole remedy of

the purchaser for any breach by Sycon of this warranty.

This warranty does not apply to any equipment which has not been used in

accordance with the specifications recommended by Sycon for the proper and normal use

of the equipment. Sycon shall not be liable under any circumstances for consequential or

incidental damages in connection with, or arising out of the sale, performance, or use of,

the equipment covered by this warranty.

This warranty is in lieu of all other warranties by Sycon, expressed or implied,

including the implied warranty of merchantability, the implied warranty of fitness for a

particular purpose, and warranty against infringement of any patent.

EQUIPMENT RETURN

Before returning any equipment to Sycon contact the Product Service Department in

your area for instructions. Obtain a Return Authorization (RA) number and indicate this

number on all shipping cartons and correspondence. Ship all items in suitable containers

with adequate protection from outside damage.

Sycon Instruments, Inc.

6757 Kinne Street

East Syracuse, New York

13057-1215

Phone (315) 463-5297

Fax (315) 463-5298

Preface

Page i

Warranty

Page 3

T3000

Thermal Power Supply

instruments

Warranty

Page ii

Preface

Page 4

instruments

Thermal Power Supply

T3000

Table of Contents

PREFACE.....................................................................................................................................I

WARRANTY ......................................................................................................................................I

TABLE OF CONTENTS .......................................................................................................................III

LIST OF TABLES ...............................................................................................................................IV

LIST OF FIGURES..............................................................................................................................V

SECTION 1...................................................................................................................................1-1

INTRODUCTION – DESCRIPTION OF EQUIPMENT .................................................................................1-1

1.1 Purpose and Capabilities .............................................................................................1-1

1.2 Theory of Operation .....................................................................................................1-1

1.3 Technical Characteristics.............................................................................................1-2

1.4 Output Characteristics..................................................................................................1-3

SECTION 2...................................................................................................................................2-1

INSTALLATION ..................................................................................................................................2-1

2.1 Inspection.....................................................................................................................2-1

2.2 Input/Output Connectors..............................................................................................2-1

2.3 Locations and Mounting...............................................................................................2-8

2.4 Wire Sizing...................................................................................................................2-9

2.5 Outline Drawings........................................................................................................2-10

SECTION 3...................................................................................................................................3-1

OPERATING INSTRUCTIONS...............................................................................................................3-1

3.1 Controls and Indicators ................................................................................................3-1

3.2 Basic Operation............................................................................................................3-4

SECTION 4...................................................................................................................................4-1

USE OF THE T3000 WITH THE RS-3000.............................................................................................4-1

4.1 Introduction...................................................................................................................4-1

4.2 Description ...................................................................................................................4-1

4.3 Basic Operation............................................................................................................4-5

4.4 Error Conditions ...........................................................................................................4-6

SECTION 5...................................................................................................................................5-1

CALIBRATION ...................................................................................................................................5-1

5.1 Instructions...................................................................................................................5-1

SECTION 6...................................................................................................................................6-1

MAINTENANCE..................................................................................................................................6-1

6.1 Introduction...................................................................................................................6-1

6.2 Preventive Maintenance...............................................................................................6-1

6.3 Fuses............................................................................................................................6-3

SECTION 7...................................................................................................................................7-1

T3000 CONFIGURATIONS..................................................................................................................7-1

7.1 T3000 Stand-Alone Configuration................................................................................7-1

7.2 T3000 Controlled by RS3000.......................................................................................7-2

7.3 T3000 Controlled by STC.............................................................................................7-3

7.4 T3000 Controlled by STC via RS3000........................................................................7-4

APPENDIX A.................................................................................................................................A-1

RMS RELATIONSHIPS.......................................................................................................................A-1

Preface

Page iii

Table of Contents

Page 5

T3000

Thermal Power Supply

instruments

List of Tables

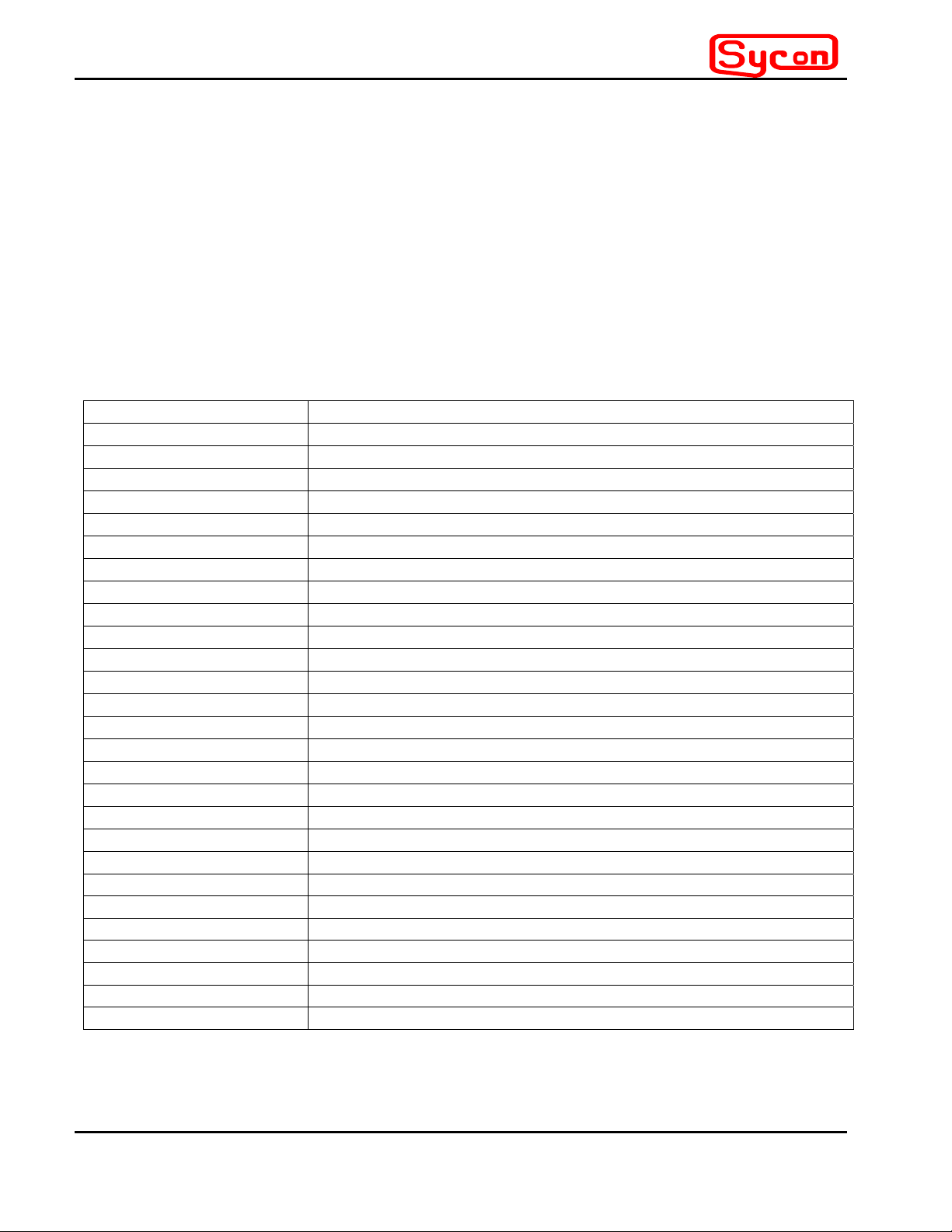

Table 1-1 Specifications .........................................................................................................................1-2

Table 2.2-1 T3000 External Connections...............................................................................................2-1

Table 2.2-2 T3000 Connection Interface................................................................................................2-2

Table 2.4-1 Minimum Wire Size Table ...................................................................................................2-9

Table 3.1-1 T3000 Indicator and Control Description.............................................................................3-1

Table 3.1-2 T3000 LED Mode Indication Summary...............................................................................3-2

Table 3.2-1 T3000 Connector J1 Pin Assignments................................................................................3-5

Table 6-1 Preventive Maintenance Schedule.........................................................................................6-1

Table 6-2 Inspection and Corrective Action............................................................................................6-2

Table A-1 Harmonic Levels & RMS Estimate Error............................................................................... A-2

List of Tables

Page iv

Preface

Page 6

instruments

Thermal Power Supply

T3000

List of Figures

Figure 1-1 Maximum Voltage-Current Profile for Series and Parallel Hookup........................................ 1-3

Figure 2.2-1 AC Line and Frame Ground Connections.............................................................................. 2-4

Figure 2.2-2 Bus Bar Identification For The Two Output Sections............................................................. 2-5

Figure 2.2-3 Bus Bar Jumpers Connect Two Output Sections In Parallel ................................................. 2-6

Figure 2.2-4 J-Shaped Bus Bar Connects Two Supply Sections in Series................................................2-7

Figure 2.3-1 Location of Six Mounting Holes on T3000 Side Panels......................................................... 2-8

Figure 2.3-2 Side-By-Side19” Rack Mount Configuration.......................................................................... 2-8

Figure 2.5-1 T3000 Case Outline Drawing............................................................................................... 2-10

Figure 3.1-1 LED and Reset Button Location: Back Panel View ............................................................... 3-3

Figure 3.2-1 Various Methods For Controlling The T3000 Power Supply..................................................3-4

Figure 4.2-2: RS-3000 Front Panel .............................................................................................................4-3

Figure 4.2-2 RS-3000 Back Panel..............................................................................................................4-4

Figure A-1 Full-Wave Rectified SIN[2π60t]..............................................................................................A-1

Figure A-2 Current Transformer Method for Estimating True RMS Value of Io from AC Current

Components Measurement ..........................................................................................................................A-3

Preface

Page v

List of Figures

Page 7

T3000

Thermal Power Supply

instruments

List of Figures

Page vi

Preface

Page 8

instruments

Thermal Power Supply

T3000

Section 1

Introduction – Description of Equipment

1.1 Purpose and Capabilities

The Sycon T3000 is designed specifically to power resistive evaporative sources used in

the deposition of thin film coatings. It has been specified to cover the class of resistive load

devices requiring low voltage and high current at power levels up to 3kW. The two output

sections of the supply can be connected in parallel to provide up to 600 Amperes RMS in

excess of 5 Volts, or in the series connected configuration, 300 Amperes RMS in excess of

10 Volts. This versatile output range covers a broad spectrum of thermal sources. T3000

power supplies can be connected in parallel to meet extremely high power requirements,

(two units connected in parallel would provide up to 6kW load power.)

Several methods for controlling output power are available to the user. In the simplest

arrangement, a user-supplied DC voltage is applied to control the output current to the

load. A current feedback loop in the T3000 serves to stabilize output load current in

proportion to this DC control voltage input.

The next level of sophistication is to use the T3000 in conjunction with the Sycon RS3000

controller. This unit allows the user to input desired current levels with corresponding rate

of rise times to control load thermal stresses and to monitor set points and output power

levels. The controller features automatic shutdown to govern over-temperature and openload failure modes.

The T3000 is also directly compatible for use with industry standard thickness/rate

controllers, such as the Sycon STC-200 or STC-2000 products. This configuration allows

setting of specified deposition rates through automatic control of output power to the

thermal source. STC PID control loop features govern deposition dynamics for these

applications.

The most sophisticated configuration employs the T3000 with the RS3000 and STC-200 or

STC-2000 products. This configuration allows setting of specified deposition rates through

automatic control of output power to the thermal source, control of PID loop dynamics and

provides set points and output power level as well as other monitoring and control

functions.

1.2 Theory of Operation

The T3000 is a switch mode power supply (SMPS), which operates at a switching

frequency of 250kHz. High frequency operation allows significant reduction in the size and

weight of the magnetic components while maintaining high operating efficiency.

The SMPS converts 208/220 VAC single-phase line voltage to a line-isolated full-wave

rectified 120-Hertz output waveform, which provides up to 3kW output power. Please note

that the RMS value of a full-wave rectified sine wave is the same as that of the sine wave,

Section 1

Page 1 - 1

Introduction – Description

of Equipment

Page 9

T3000

Thermal Power Supply

instruments

although it contains both DC and harmonics of line frequency. Therefore, the heating value

in the load (the resistive deposition source) is the same whether the current is sine wave,

rectified sine wave or a DC voltage all of equal RMS value.

The rectified line frequency was chosen as the output format because it offers an inherent

unity power factor characteristic for the power supply. This comes about because power is

being delivered to the resistive load throughout the 60-Hertz cycle of line frequency. Since

conversion from line to output is performed at 250 kHz, there is insignificant phase shift

introduced at the 60-Hertz line frequency. The net result is input line current that is, ideally,

sinusoidal and essentially in-phase with the line voltage. This is the condition for near unity

power factor.

1.3 Technical Characteristics

Table 1-1 Specifications

Output Power 3000 Watts

Parallel Output 5 Volts @ 600 Amps RMS

Series Output 10 Volts @ 300 Amps RMS

Input Voltage Range 180-264 VAC, Single Phase

Input Freq. Range 47 Hz to 63 Hz

Input Current 18 Amps @ 220 VAC

Efficiency 80% Full Load

Power Factor >0.99 @ Full Load (TBD)

Total Harmonics < 5% @ Full Load (TBD)

Input Control 0 to +10VDC Required For Controlling Output Current

Response Time <100ms 250A to 500A Step Parallel Output

1

Current Monitor 1 VDC = 100 Amps RMS For Parallel & 50 Amps For Series

Voltage Monitor 1 VDC = 1.5 Volt RMS Across Output Terminals

Protection Over Temperature Shutdown

Size 11.4 in. H x 5.25 in. W x 12.9 in. D

Power Density 4 Watts per cubic inch

Weight 28 Pounds

Ambient Range 0oC to +50oC at full load

Cooling Forced air, two internal fans

EMI Designed to meet Conducted and Radiated EN55022

Safety Designed to meet EN60950

Output Connectors Flat bus bars with ¼” Bolt Hole for Lug Attachment

AC Input Wiring 2-Wire plus Ground with 8 – 32 lugs

I/O Connector 15-pin Dsub for control, monitoring and status signals

Power ON Indicator Green LED: Flashing=Input Power ON, Steady=Output ON

Over Temperature Red LED: Steady=Over Temp, Flashing=Ready for Reset

Open Load Red LED: Steady=Open Load

Compatibility Sycon Controller RS3000 &/or Rate Deposition Controllers

Footnote1; Response time is load dependent with lower resistance loads exhibiting faster response.

Introduction – Description

of Equipment

Page 1 - 2

Section 1

Page 10

instruments

Thermal Power Supply

T3000

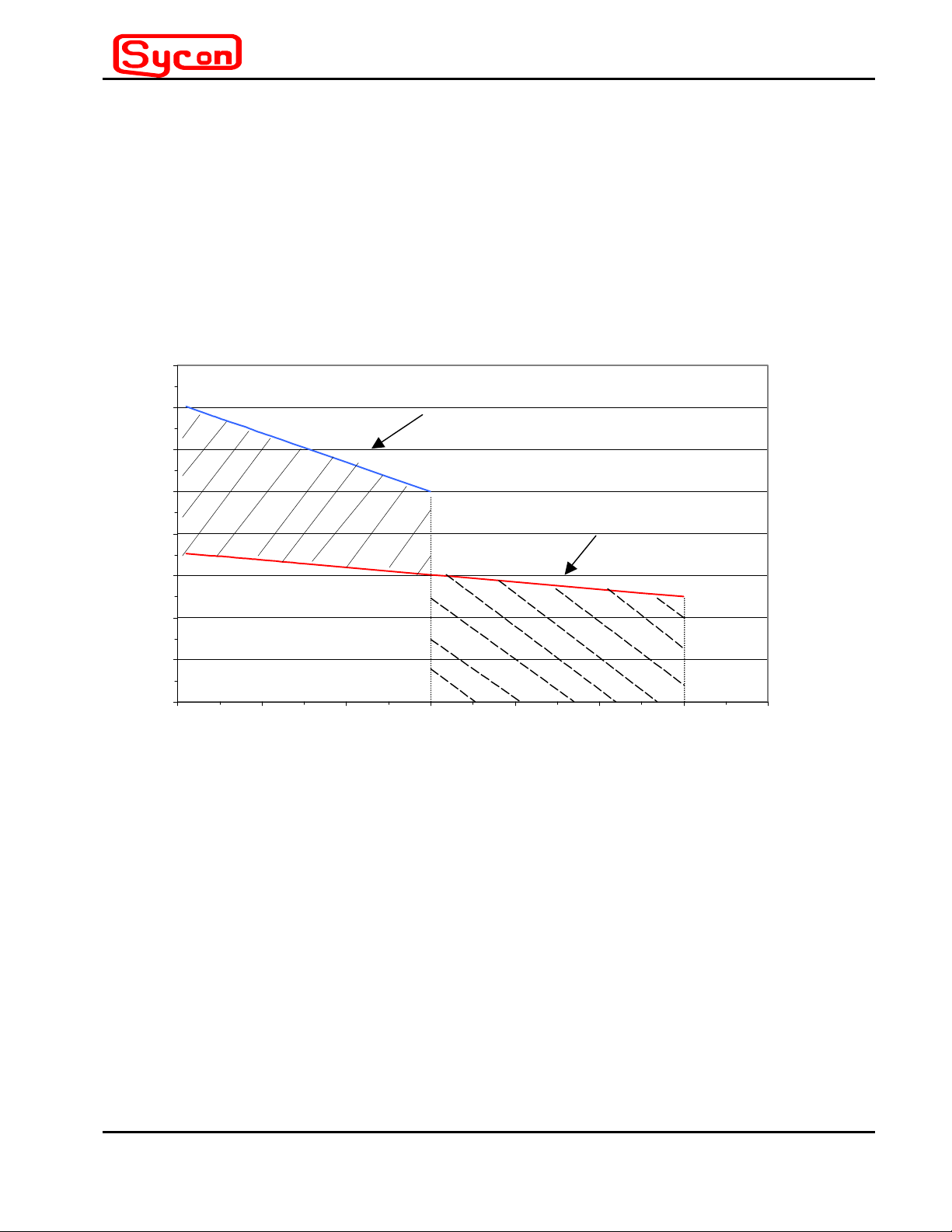

1.4 Output Characteristics

The purpose of this subsection is to provide guidelines for choosing between series or

parallel output connections based on the load requirements of the thermal source being

energized. Output voltage and current profiles vary in proportion to load resistance, up to

maximum limits determined by the output circuit configuration. Figure 1-1 provides a

guideline for choosing the appropriate output hookup configuration, based on the T3000

maximum output profile and the load requirements of the thermal source.

Maximum Load Vol t age- Cur r ent Pr of ile

16

14

12

Series Only Regi on

10

8

6

Load Voltage - Volts RMS

4

2

0

0 100 200 300 400 500 600 700

Max Output: Series Configuration

Vline = 220V rms

Max Output: Parallel Confi gur at ion

Parallel Region OnlyEither Seri es or Pa rallel Regi o n

Load Current - Am ps RMS

Figure 1-1 Maximum Voltage-Current Profile for Series and Parallel Hookup

Figure 1-1 is marked with regions which define when the series or parallel output

configuration is appropriate. The maximum voltage-current rating of any given thermal

source may be located as a point on the graph. The appropriate configuration(s) is

determined by the location of this point.

For example, consider a commercially available thermal source rated at 521 ARMS and a

corresponding voltage drop of 3.89 VRMS. This is a 2kW thermal source and falls in the

area of the graph noted as “Parallel Only”.

By way of contrast, a thermal source rated at 742 Watts, which is specified by a voltage

drop of 8.73 VRMS at 85 ARMS and falls in the “Series Only” region of the graph.

Section 1

Page 1 - 3

Introduction – Description

of Equipment

Page 11

T3000

Thermal Power Supply

instruments

As a third example, consider a thermal source rated at about 365 Watts exhibiting a voltage

drop of 1.34V at a maximum current of 273 Amperes. This falls in the region where either a

series or parallel connection would work.

The above sample calculations assume that the voltage drop in the wires connecting to the

T3000 is small in comparison to the voltage drop across the thermal source load. This

condition is usually satisfied when the output wiring is properly sized for current carrying

capacity.

Generally, where either a series or parallel option is available, the series configuration is

recommended.

Introduction – Description

of Equipment

Page 1 - 4

Section 1

Page 12

instruments

Thermal Power Supply

T3000

Section 2

Installation

2.1 Inspection

Inspect the shipping carton for possible damage before unpacking the unit. Carefully

unpack the equipment. Save all packing materials until inspection is complete. Verify that

all items listed on the packing slips have been received. Visually inspect all exterior

surfaces for damage. External damage may be an indication of internal damage. If any

damage is evident, immediately contact the carrier that delivered the unit and submit a

damage report. Failure to do so could invalidate future claims.

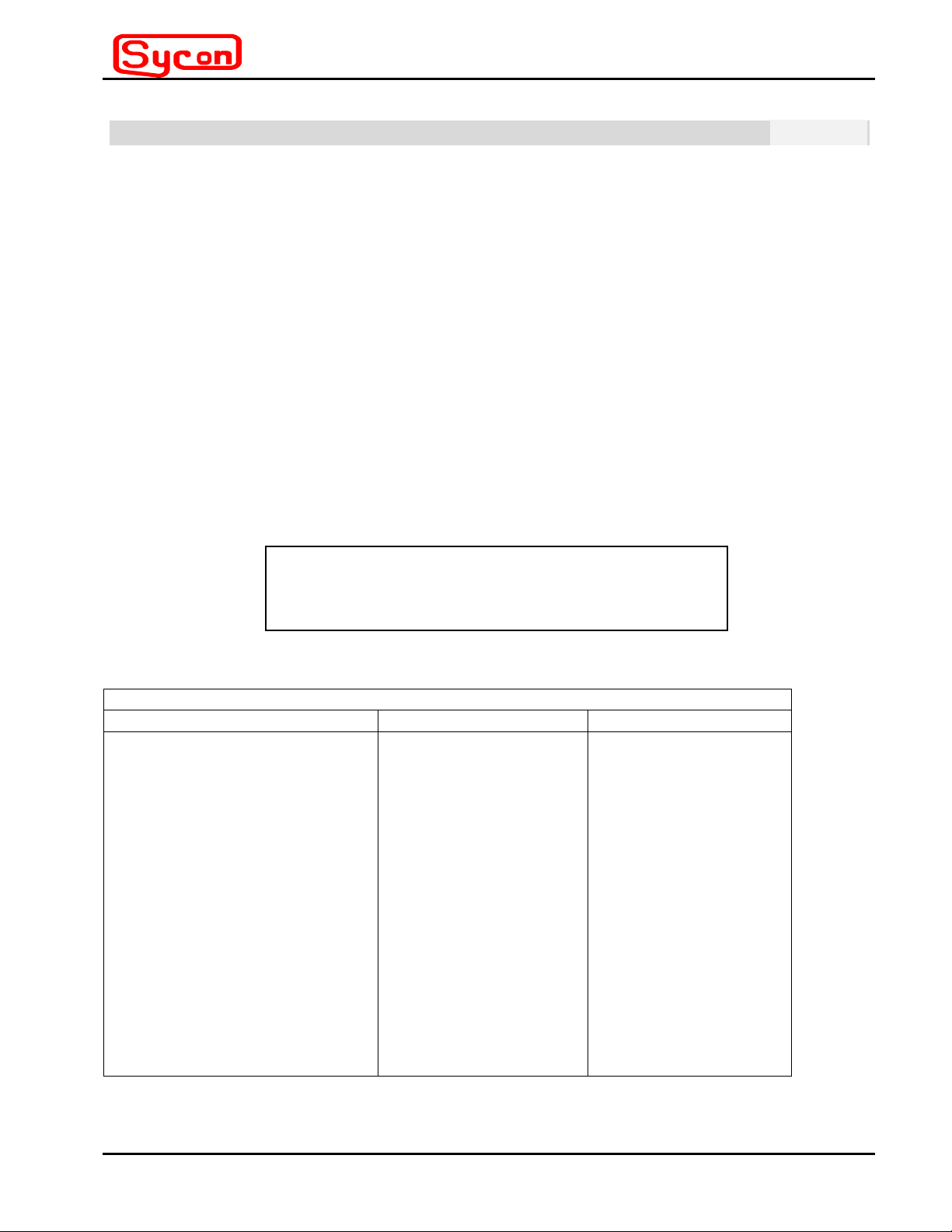

2.2 Input/Output Connectors

Table 2.2-1 lists all external connections for the T3000. An input and output connector

description is provided in Table 2.2-2. For permanently connected equipment, a readily

accessible safety switch shall be incorporated in the fixed AC wiring.

Table 2.2-1 T3000 External Connections

CONNECTOR FUNCTION CONNECTS TO

AC1 (See Figure 2.2-1)

AC2

Frame Ground

Section 1 (See Figure 2.2-2)

Positive Bus Bar

Negative Bus Bar

Section 2 (See Figure 2.2-2)

Positive Bus Bar

Negative Bus Bar

J1

For proper connection to the mains, a 30-Amp circuit

breaker or fuse is required in each AC line.

Prime AC Power Input

Single Phase

Output Power

Output Power

Control Interface

NOTICE

180-264 VAC

47-63 Hertz

Power Source

User Load

(See Figure 2.2-3 for

series or parallel

connections)

User Load

See Table 3.2-1

Section 2

Page 2 - 1

Installation

Page 13

T3000

Table 2.2-2 T3000 Connection Interface

Connector Function Description

AC line connections & frame ground

Output Bus Bars

J1 control interface

Figure 2.2-1 shows the location and connection configuration for the single AC line input

(180-264 VAC). The AC wiring should be terminated with NO. 8 ring terminals and secured

to the 8-32 male terminals on the T3000 with nut and lock-washer. A safety cover, with

strain relief, covers the AC input connections.

Thermal Power Supply

8-32 Threaded Stand-off accepts #8

Ring terminal

¼” bolt holes

15 pin DB female (accepts 15 pin male

matching connector on cable)

instruments

CAUTION

Hazardous

Voltages

Present

Figure 2.2-2 shows the location of the bus bars for the two output sections and defines the

polarity relative to each other. Note that the Output-2 positive bus bar is common with the

T3000 signal ground.

TURN OFF THE INPUT AC POWER WITH THE

SAFETY SWITCH BEFORE REMOVING THE

T3000 PROTECTIVE COVER.

Hazardous

Current

Levels

Possible

Figure 2.2-3 shows how the auxiliary C-shaped and flat bus bars are utilized to connect the

two output sections of the T3000 in the parallel configuration. Cables to the thermal

sources (usually the feedthrough terminals of the vacuum chamber) must be terminated in

a suitably current rated solderless connector with a ¼-inch bolt hole for connection to the

bus bars.

Installation

TURN OFF THE INPUT AC POWER

WITH THE SAFETY SWITCH

BEFORE CHANGING

CONNECTIONS TO BUS BARS.

Page 2 - 2

CAUTION

Section 2

Page 14

instruments

Thermal Power Supply

T3000

Figure 2.2-4 shows a similar arrangement for series connection of the two output sections

using the auxiliary Z-shaped bus bar. Cable connection requirements must be consistent

with current load requirements.

Also shown in Figure 2.2-4 is the location of the DB15 connector, which interfaces with the

control cable from the RS3000 or other user specified control hardware.

Section 2

Page 2 - 3

Installation

Page 15

T3000

Thermal Power Supply

instruments

Frame Ground

8-32 Male Standoff

AC line Inputs

8-32 Male

OVER TEMP

POWER MODE

RESET

OPEN

LOAD

SER - PAR

J1

1

Rear Panel

Cutout with

Protective Cover

Removed

OUT 1 NEG

OUT 1 POS

OUT 2 POS

OUT 2 NEG

Figure 2.2-1 AC Line and Frame Ground Connections

(Shown with safety cover removed to expose terminals)

Installation

Page 2 - 4

Section 2

Page 16

instruments

Thermal Power Supply

T3000

Out-1 Pos.

Bus Bar

OVER TEMP

POWER MODE

RESET

OPEN

LOAD

SER - PAR

J1

1

Out-2 Pos.

Bus Bar

(Signal

Ground)

Out-1 Neg.

Bus Bar

OUT 1 NEG

OUT 1 POS

OUT 2 NEG

Out-2 Neg.

Bus Bar

OUT 2 POS

Figure 2.2-2 Bus Bar Identification For The Two Output Sections

Section 2

Page 2 - 5

Installation

Page 17

T3000

Thermal Power Supply

instruments

OVER TEMP

POWER MODE

RESET

OPEN

LOAD

SER - PAR

J1

1

OUT 1 NEG

OUT 1 POS

Figure 2.2-3 Bus Bar Jumpers Connect Two Output Sections In Parallel

Installation

Page 2 - 6

Section 2

Page 18

instruments

Thermal Power Supply

T3000

DB15 Female

Connector For Control

Signal Interface Cable

Neg Cable to Load

Connected By Nut,

Bolt, Washer and

Lock-Washer

Pos. Cable to

Load Connected

By Nut, Bolt,

Washers and

Lock-Washers

Figure 2.2-4 J-Shaped Bus Bar Connects Two Supply Sections in Series

J-Shaped Bus

Bar Connects

Two Output

Sections in

Series

Section 2

Page 2 - 7

Installation

Page 19

T3000

Thermal Power Supply

instruments

2.3 Locations and Mounting

There are six #10-32 threaded mounting holes on each side of the T3000 that can be used

for custom mounting the unit. It is recommended that the unit be located as close as

possible to the vacuum chamber electrical feedthroughs, in order to minimize cable losses

for the high current connections. Locations for these mounting holes are shown in the

outline drawing of Figure 2.3-1.

Figure 2.3-1 Location of Six Mounting Holes on T3000 Side Panels

The T3000 power supply and the RS3000 controller are also designed to mount in a

standard 19.0-inch equipment rack using a custom front panel. The panel contains a power

ON/OFF switch with a built-in circuit breaker. The panel and switch are available from

Sycon Instruments. Four screws, two on each side of the front panel, should be used to

secure the unit in place. Figure 2.3-2 shows the mechanical arrangement for side-by-side

rack mounting of the two units.

Power ON/OFF Switch

T3000 RS3000

Installation

Figure 2.3-2 Side-By-Side19” Rack Mount Configuration

Page 2 - 8

Section 2

Page 20

instruments

Thermal Power Supply

T3000

NOTICE

The front and rear of the unit should be free of obstructions to airflow. Proper ventilation

must be maintained, regardless of mounting or orientation.

2.4 Wire Sizing

Care must be taken to properly size all conductors for the input and output of the power

supply. Table 2.4-1 gives minimum recommended wire size for different current levels and

operating temperatures. This table is derived from the National Electrical Code and is for

reference only. Local laws and conditions may have different requirements. The table is for

copper wire only.

Table 2.4-1 Minimum Wire Size Table

COPPER WIRE CURRENT CAPACITY

Single wire in open air, ambient temperature 86

o

F

Ampacities of Wire Types (w/ Temp Rating) @ 0-2000 Volts

USE-2, XHH, XHHW, -2, TA,

TBS, SA, SIS, FEP

Wire

Size

AWG

0000

000

00

0

1

2

3

4

TW

UF

(140oF)

300

260

225

195

165

140

120

105

FEPW, RH, RHW, THW,

THWN, ZW,

THHW, XHHW

(167oF)

360

310

265

230

195

170

145

125

MI, RHW-2, THHN, ZW-2,

THWN-2, FEPB, RHH,

THHW, THW-2

(194oF)

405

350

300

260

220

190

165

140

Section 2

Ambient Ampacity Correction for above Wire types

Temp oF 140

96-104

105-113

114-122

123-131

132-140

141-158

159-176

o

F 167

0.82

0.71

0.58

0.41

- - -

- - -

- - -

Page 2 - 9

0.88

0.82

0.75

0.67

0.58

0.35

o

F 194

- - -

0.91

0.87

0.82

0.76

0.71

0.58

0.41

o

F

Installation

Page 21

T3000

Thermal Power Supply

2.5 Outline Drawings

Figure 2.5-1 shows the outline drawing for the T3000 power supply.

instruments

Installation

Figure 2.5-1 T3000 Case Outline Drawing

Page 2 - 10

Section 2

Page 22

instruments

Thermal Power Supply

T3000

Section 3

Operating Instructions

3.1 Controls and Indicators

The T3000 has been designed with few user interface requirements, since primary usage

will be in conjunction with the Sycon RS3000 controller and/or rate deposition controllers,

such as the Sycon STC200 or STC2000. Stand-alone usage is also permissible and only

requires a user supplied control voltage, 0 to +10 Volts, on J1 pin 7 with ground return on

pins 3 and 11 and a external on/off switch between pins 13 and 11 on J1. The power

supply has three LEDs which monitor operation, and a user accessible reset button to

reestablish output power after fault removal. These items are beneficial for monitoring

power supply operation in any usage configuration. The T3000 also has a Series/Parallel

Mode Switch which is intended for use only in conjunction with the RS3000. These

functions are delineated in Table 3.1-1.

Table 3.1-1 T3000 Indicator and Control Description

Indicator or Control Item Usage Description

Green LED: Power Indicator

Red LED: Over-Temperature Fault

Blinks at a regular rate to indicate AC line power is

ON and the supply is in a standby mode. When load

power is enabled, by shorting J1-pin 13 to pin 3 or

11, the supply is in the active state and the LED

emits a constant glow, provided no faults exist.

This LED will glow steadily when power supply

internal temperatures are excessive, causing a

safety shutdown of output power. (A primary cause

could be airflow blockage due to improper installation

of the power supply in the user environment). The

LEDs will blink at a constant rate when the internal

temperature has cooled to a safe operating point.

The reset button can then restore T3000 operation.

Red LED: Open load condition This LED will glow steadily when the load connection

is open, a condition that causes the power supply to

automatically shutdown.

Reset Button Switch: Primarily intended to

allow recovery after an internal

temperature fault

Series / Parallel Mode Switch: Intended

for use only in conjunction with the

RS3000

In addition, after AC line voltage is turned on, the green LED and the red over-temperature LED will

blink sequentially once per second for eight seconds. The unique series of red and green blinks

correspond to identify the version of firmware programmed in the unit. For example, a blinking

sequence of R,R,R,R,R,R,G,G defines a particular firmware code. Sycon technical support

Section 3

After cool-down, output power to the load can be

reestablished with the reset button. It can also be

used to verify the open load condition by attempting

to recycle power to the load.

The position of this switch must be manually set to

match the output configuration of the T3000. Switch

position is decoded by the RS3000 Controller to set

correct scale factors for each mode.

Page 3 - 1

Operating Instructions

Page 23

T3000

Thermal Power Supply

instruments

personnel may request this information, when service calls are made to the factory.

Table 3.1-2 summarizes the different modes associated with the three LED’s.

Table 3.1-2 T3000 LED Mode Indication Summary

Start-up

Timing

Seconds

Power ON

Indicator

Green LED

Internal

Over

Temperature

Open Load

Condition

Red LED

Condition

Red LED

0 to 1 Steady Glow Steady Glow Steady Glow LED Checkout

1 to 9 Blink in sequence per

Steady Glow Denotes Firmware Version

version code

After Start

Sequence is

completed

Blink

once/sec

Steady Glow Dark Dark Output Power Enabled -

Dark Dark Ready for output power

Enable

Operational

Blink

once/sec

Blink

once/sec

Blink

once/sec

Figure 3.1-1 shows the location of the three LEDs and push-button reset switch on the rear panel of

the T3000.

Dark Steady Glow Open Load; Output Power

Inhibited

Steady Glow Dark Over Temp; Output Power

Inhibited

Blinks

twice/sec

Dark Cooled down; Ready for

reset

Section 3

Page 3 - 2

Section 3

Page 24

instruments

Thermal Power Supply

T3000

Reset Push

Button

Thermal

Source Status

Red LED

Power Mode

Green LED

OVER TEMP

POWER MODE

RESET

OPEN

LOAD

SER - PAR

J1

1

Internal

Temperature

Status Red LED

Series/Parallel

Slide Switch

OUT 1 NEG

OUT 1 POS

OUT 2 POS

OUT 2 NEG

Figure 3.1-1 LED and Reset Button Location: Back Panel View

Section 3

Page 3 - 3

Operating Instructions

Page 25

T3000

Thermal Power Supply

instruments

3.2 Basic Operation

The T3000 can be used in several control configurations as depicted by the block diagrams of

Figure 3.2-1.

Vcontrol

0 - +10V

OFF/ON

Momentary

RS3000

Pin 7

Pin 13

To Multimeter Imon Pin 15

To Multimeter Vmon Pin 4

Ex ternal Fault Rest Pin 5

Pins 3 & 11

PBS

Cable

J1

J1

T3000

STAND ALONE

CONFIGURATION

T3000

CONTROLLED

STC

RS3000

For External Monitoring

To Multimeter Imon Pin 15

To Multimeter Vmon Pin 4

External Fault Rest Pin 5

Signal Ground Pins 3 & 11

Custom Split Cable

Cable

Cable

BY RS3000

J1

T3000

CONTROLLED

BY STC

J1

T3000

CONTROLLED BY

STC VIA RS3000

Figure 3.2-1 Various Methods For Controlling The T3000 Power Supply

Section 3

STC

Page 3 - 4

Section 3

Page 26

instruments

Thermal Power Supply

T3000

Table 3.2-1 shows the function of each pin for connector J1 where control and monitor

signals interface with the unit.

Table 3.2-1 T3000 Connector J1 Pin Assignments

PIN NUMBER PIN FUNCTION

1 Open Boat Output High

2 +5 VDC Out

3 Signal Ground

4 Output Voltage Monitor 1VDC = 1.5VRMS

5 External Reset

6 No Connection

7 Current Set Point Control Voltage

8 No Connection

9 Over Temperature Output High

10 +5 VDC

11 Signal Ground

12 + 12 VDC Out

13 Output Load Power On When Low

14 Series / Parallel Select

15 Current Monitor 1VDC =100ARMS Parallel; 50ARMS

Series

Figure 3.2-1 shows the rudiments for controlling the T3000 output current via connections to J1.

Table 3.2-1 shows other signals that are useful in the stand-alone configuration if it is desired to

monitor output levels. For example, the DC voltage between pin 15 and ground (pins 3 and 11) is

proportional to output RMS current in the load. For the parallel output connection the scale factor is

1 VDC equals 100 ARMS, and for the series-connected output, 1VDC equals 50 ARMS in the load.

Similarly, the output voltage can be monitored at pin 4 where the scale factor is set to 1 VDC equals

1.5 VRMS across the output terminals. For example, to set the output current to 300 ARMS for a

parallel load connection, the ON/OFF switch is set to the shorted position and the control voltage

input on pin 7 is slowly adjusted until the pin 15 voltage is equal to 3 VDC, which corresponds to an

output current of 300 ARMS into the load.

Operation of the T3000 with the RS3000 controller is covered in Section 4 of this manual. Use with

a rate deposition controller, such as the STC200 or STC2000, is covered in manuals for those

products. Note that the auxiliary monitor signals are available on connector J1 when used with a

rate controller, but a custom cable would be required to split off the desired signals (see Figure 3.2-

1). For applications requiring rate control, it is recommended that an RS3000 be used in conjunction

with the rate deposition controller as it provides monitoring of set points, output power, temperature

and open load faults, and provides a compatible interface to the T3000.

Section 3

Page 3 - 5

Operating Instructions

Page 27

T3000

Thermal Power Supply

instruments

Section 3

Page 3 - 6

Section 3

Page 28

instruments

Thermal Power Supply

T-3000

Section 4

Use of the T3000 with the RS-3000

4.1 Introduction

This chapter contains information on operating the T3000 power supply using an RS-3000

controller. The RS-3000 functions as a user interface for the T3000, and supplies the

control voltages needed to operate the T3000. The RS-3000 also displays system faults

with a combination of text messages on the displays, and/or indicator LEDs.

The RS-3000 can be controlled from the front panel, with a hand controller (or pendant), or

via the back-panel RS-232 connection.

Programmable parameters include: Maximum current, current ramp time, ramp current, and

beeper control.

For uses requiring PID control loop capability, a remote control unit (such as the STC-2000)

can be connected to the RS-3000.

For operation of the T3000 and RS-3000 using a PC connected to the RS-232 port, see the

RS-3000 manual.

4.2 Description

Dimensions: The RS-3000 is 3

The unit is rack mountable next to the T3000 power supply.

Keys: There are six front panel keys used to program, change modes, and start or stop the

unit.

STOP: Used to abort the current operation (switch the T3000 power output to zero)

from Ramp, Manual or Remote mode.

START: Used to start Ramp mode or to switch from Ramp mode to Manual mode.

PRGM: Used to enter Program mode, step through the programmable parameters,

and exit Program mode.

RMT: Used to toggle between Remote and Manual modes.

INC: Used to increase the value of the maximum current, ramp time (minutes) or

ramp current, toggle the beeper on or off, and select baud rate.

DEC: Used to decrease the value of the maximum current, ramp time (minutes) or

ramp current, toggle the beeper on or off, and select baud rate.

Displays: There are two 3-character displays. The larger display can show mode (such as

“Off” or “Err”), ramp current, and current. The smaller display can show minutes and

kilowatts. Error messages are shown on the smaller display.

7/8

inches wide by 3

3/4

inches high by 5

5/8

inches deep.

Section 4

Page 4 - 1

Use of the T3000 with the

RS-3000

Page 29

T-3000

Thermal Power Supply

instruments

Indicators: There are nine LED-illuminated indicators. Some indicators show the mode

status:

PRGM (for program mode),

RMT (for remote mode), and

MAN (for manual mode).

CUR and MAX illuminated: Large display shows maximum current in Amps.

RAMP and MIN illuminated: Small display shows ramp time in minutes

RAMP and CUR illuminated: Large display shows ramp current in Amps.

Kw illuminated: Small display shows power output in kilowatts

INTERLOCK illuminated: There is a problem with the safety interlock that must be

resolved in order to operate the T3000 power supply.

Hand Controller/Pendant: A pendant may be attached to the RS-3000 front panel. The

pendant comes with a six foot long coiled cord. The pendant provides three keys for control

of the unit: INC, DEC and STOP.

Interconnect Cables: A cable is provided to connect the RS-3000 to the T3000, using the

15-pin D-Sub connectors on the units. Additional cables are available to connect the RS3000 to a Sycon controller or a PC.

Use of the T3000 with the

RS-3000

Page 4 - 2

Section 4

Page 30

instruments

Figure 4.2-2: RS-3000 Front Panel

Large Display

Thermal Power Supply

T-3000

Small Display

LED illuminated

text indicators

(9 places):

Hand Controller /

Pendant Connector

Beeper

Power On Indicator

Pushbutton Keys

(6 places):

Section 4

Page 4 - 3

Use of the T3000 with the

RS-3000

Page 31

T-3000

[15 p

[15 p

]

Figure 4.2-2 RS-3000 Back Panel

To T3000 POWER SUPPLY

in D-SUB MALE]

Thermal Power Supply

instruments

Unit Serial

Number

RS232/485

com port

[RJ-11]

Grounding

Stud

To ext. control (STC-2000)

in D-SUB FEMALE

Use of the T3000 with the

Page 4 - 4

RS-3000

Section 4

Page 32

instruments

Thermal Power Supply

T-3000

4.3 Basic Operation

Program Mode: The Program mode is used to program the parameters of the RS-3000.

Press the PRGM key to enter the programmable parameter sequence. The PRGM LED will

illuminate and flash while the RS-3000 is in Program mode.

Use the INC and DEC keys to adjust values for each parameter. Step through the

parameters by pressing the PRGM key.

Current Maximum

: Use the INC and DEC keys to adjust the maximum current value

within a range of 0-600 Amps for parallel-wired outputs or 0-300 Amps for serieswired outputs.

Ramp Minutes: Use the INC and DEC keys to adjust the ramp time value within a

range of 0.0-99.9 minutes.

Ramp Current

: Use the INC and DEC keys to adjust the ramp current value within a

range of 0-600 Amps for parallel-wired outputs or 0-300 Amps for series-wired

outputs.

Beeper: Use the INC and DEC keys to toggle the beeper on or off.

Host Communication Baud Rate: Adjustments to this parameter are needed only if

the RS-3000 is controlled using a PC. See the RS-3000 manual for further

information.

Ramp Mode: The Ramp mode is used to ramp the power supply current up from zero to a

preset level, and then hold at that level. Ramp mode is selected by entering a non-zero

time in the “Ramp Minutes” parameter.

When the RS-3000 is running in Ramp mode, the small display shows time remaining,

which counts down to zero, alternately with power supply output (in kilowatts.) The Kw

indicator illuminates while the power value is displayed, and the MIN indicator illuminates

while the time-remaining value is displayed. The large display shows ramp current.

When the RS-3000 finishes ramping it will automatically switch to Manual mode and

maintain the current level until the STOP key is pressed. When Manual mode begins, the

small display will switch to show time elapsed (counting up from zero).

The process may be stopped during Ramp or Manual mode by pressing the STOP key.

Manual Mode: The Manual mode allows manual control of the current level via the INC

and DEC keys. Manual mode will be entered and the MAN LED indicator will illuminate

when the Start key is pressed, if the value of the Ramp Minutes parameter is zero.

When the RS-3000 is running in Manual mode, the large display shows current in Amps.

The small display shows time elapsed since the Start key was pressed alternately with

Section 4

Page 4 - 5

Use of the T3000 with the

RS-3000

Page 33

T-3000

Thermal Power Supply

instruments

power supply output (in kilowatts.) The Kw indicator illuminates while the power value is

displayed, and the MIN indicator illuminates while the elapsed-time value is displayed.

The process may be stopped during Manual mode by pressing the STOP key.

Remote Mode: The Remote mode allows control of the power supply output via a remote

controller such as the Sycon Instruments STC-2000. See the RS-3000 manual for further

information.

4.4 Error Conditions

The following messages and error indications may appear on the front panel of the RS3000:

“Interlock” LED illuminated on front panel: This indicates that a problem exists with

the interlock system which must be resolved before the T3000 cam be operated.

“Err” and “Opn” present on front panel displays: This indicates that an open boat

condition exists which must be resolved before the T3000 can be operated.

“Err” and “Hot” present on front panel displays: This indicates that the T3000 power

supply has overheated, and must cool before it can be operated.

“Err” and “PrG” present on front panel displays: This indicates a memory error,

which can be cleared by pressing the “PGRM” key.

“MAX” LED indicator illuminated: This indicates that the output current has reached

the maximum value.

Use of the T3000 with the

RS-3000

Page 4 - 6

Section 4

Page 34

instruments

Thermal Power Supply

T3000

Section 5

Calibration

5.1 Instructions

The T3000 power supply and companion RS3000 controller come factory-adjusted, and there is no

user calibration required. If the unit fails to perform to specification, it must be returned to the factory

for repair and/or adjustment.

NOTICE

Unauthorized adjustment of

internal circuits will invalidate

product warranty.

Section 5

Page 5 - 1

Calibration

Page 35

T3000

Thermal Power Supply

instruments

Calibration

Page 5 - 2

Section 5

Page 36

instruments

A

r

f

Thermal Power Supply

T3000

Section 6

Maintenance

6.1 Introduction

This chapter contains preventive maintenance information for the T3000.

6.2 Preventive Maintenance

Preventive maintenance for the T3000 consists of scheduled inspection and cleaning.

1. Schedule: Table 6-1 lists the preventive maintenance routines and the

recommended performance intervals.

2. Inspection: Table 6-2 lists the visual inspection checks to be performed. It also

indicates the corrective action to be taken.

Table 6-1 Preventive Maintenance Schedule

PREVENTIVE MAINTENANCE

WARNING

ll maintenance that requires removal of the

cover of the unit should only be done by

properly trained and qualified personnel.

Hazardous voltages exist inside the unit.

Disconnect the supply from the input powe

before performing any maintenance.

Service, fuse verification, and connection o

wiring to the chassis must be accomplished

at least five minutes after power has been

removed via external means. All circuits

and/or terminals to be touched must be

safety grounded to the chassis.

RECOMMENDED PERFORMANCE

ROUTINE

Inspection

Cleaning

INTERVAL

Annual

As required

Section 6

Page 6 - 1

Maintenance

Page 37

T3000

Thermal Power Supply

instruments

Table 6-2 Inspection and Corrective Action

ITEM INSPECT FOR CORRECTIVE ACTION

Connector plugs and buss

bars

Loose, bent or corroded

contacts and buss bars.

Damage or improper seating

in mating connector.

Clean contacts and buss

bars with solvent moistened

cloth, soft bristle brush, small

vacuum or low compressed

air.

Chassis, fans & extruded

heatsinks

External electrical wiring Broken, burned or pinched

Dirt and corrosion Replace damaged or

corroded connectors.

Clean with cloth moistened

wire. Frayed, worn or

with soapy water.

missing insulation

External solder connections Corrosion, loose, cracked, or

dirty connections

Dirt and moisture buildup Short circuits, arcing,

corrosion, overheating

Repair or replace defective

wires.

Clean and resolder

connections.

T3000 enclosure Dirt and corrosion Clean as required with cloth

moistened with soapy water.

Page 6 - 2

Section 6

Page 38

instruments

G

Thermal Power Supply

T3000

6.3 Fuses

Only properly trained and qualified personnel

should remove the cover from the power supply.

Service, fuse verification, and connection of wiring

to the chassis must be accomplished at least five

minutes after power has been removed via external

means; all circuits and/or terminals to be touched

must be safety grounded to the chassis.

WARNIN

The T3000 contain two time-delay ceramic ferrule fuses, F1 and F2, which have a current

rating of 25 Amps and a voltage rating of 250 Volts. Use Cooper Bussmann type MDA-25AR or equivalent.

Section 6

Page 6 - 3

Page 39

T3000

Thermal Power Supply

instruments

Page 6 - 4

Section 6

Page 40

instruments

Thermal Power Supply

T3000

Section 7

T3000 Configurations

This section provides a procedure for operation of the T3000 in various configurations.

Please refer to the system diagram in Section 2.1-1.

7.1 T3000 Stand-Alone Configuration

1) Verify that the AC input power is disabled.

2) Connect the AC-In power cable to the T3000 as shown in Figure 2.2-1.

3) Connect the output buss bars for the desired configuration, series or parallel, as per

Figures 2.2-3 or 2.2-4.

4) Connect the control cable to J1 as shown in Figure 3.2-1. (Note: Voltages measured on

pins 5 and 14 are used as monitor points.)

5) Apply the AC power. The green LED should now “blink” indicating that AC power is

applied to the T3000.

6) With 0 V applied to pin 7 of J1, close the Off/On switch. The green LED should now be

on in a steady state which indicates that the T3000 is ready to supply current to the load.

7) Gradually apply the desired input voltage, 0 to +10 V, to pin 7 of J1. (Note: For the

series mode, 1 volt in = 50 ARMS out while 1 volt in = 100 ARMS out for the parallel mode.)

8) When the operation is complete, turn off current to the load by opening the “On/Off”

switch and apply 0 volts to pin 7 of J1. (Note: The operation can also be terminated by

applying 0 volts to pin 7 and then opening the “On/Off” switch.

Section 7

Page 7 - 1

T3000 Configurations

Page 41

T3000

Thermal Power Supply

instruments

7.2 T3000 Controlled by RS3000

1) Verify that the AC input power is disabled.

2) Connect the AC-In power cable to the T3000 as shown in Figure 2.2-1.

3) Connect the output buss bars for the desired configuration, series or parallel, as per

Figures 2.2-3 or 2.2-4.

4) Position the SER-PAR slide switch to coincide with the output buss bar configuration.

(Note: Switch positioned to the left is for the Series configuration while switch positioned to

the right is for the Parallel configuration,)

5) Connect the control cable to J1 as shown in Figure 3.2-1.

6) Verify that all of the interlocks to the RS300 are satisfied.

7) Apply the AC power. The green LED should now “blink” indicating that AC power is

applied to the T3000.

8) Apply appropriate input parameters to the RS3000 as described in Section 7 and

depress the Start control of the RS300. The green LED should now be on in a steady state

mode that indicates that the T3000 is ready to supply current to the load. (Note: The

RS3000 can be operated in the programmed or manual mode.) Refer to Section 7.X for

description of RS3000 displays.

T3000 Configurations

Page 7 - 2

Section 7

Page 42

instruments

Thermal Power Supply

T3000

7.3 T3000 Controlled by STC

1) Verify that the AC input power is disabled.

2) Connect the AC-In power cable to the T3000 as shown in Figure 2.2-1.

3) Connect the output buss bars for the desired configuration, series or parallel, as per

Figures 2.2-3 or 2.2-4.

4) Connect the control cable to J1 as shown in Figure 3.2-1. (Note: A custom split cable is

required if voltages measured on pins 5 and 14 are used as monitor points.)

5) Apply the AC power. The green LED should now “blink” indicating that AC power is

applied to the T3000.

6) Apply appropriate input parameters to the STC200 or STC2000, as described in their

respective manuals, and start the process. The green LED should now be on in a steady

state mode, indicating that the T3000 is ready to supply current to the load. (Note: Set STC

output for the 0 to +10 V range).

Section 7

Page 7 - 3

T3000 Configurations

Page 43

T3000

Thermal Power Supply

instruments

7.4 T3000 Controlled by STC via RS3000

1) Verify that the AC input power is disabled.

2) Connect the AC-In power cable to the T3000 as shown in Figure 2.2-1.

3) Connect the output buss bars for the desired configuration (Series or Parallel), per

Figures 2.2-3 or 2.2-4.

4) Position the SER-PAR slide switch to coincide with the output buss bar configuration.

(Note: Switch positioned to the left is for the Series configuration while switch positioned to

the right is for the Parallel configuration,)

5) Connect the control cable from the RS3000 to J1 as shown in Figure 3.2-1.

6) Connect the cable from the STC output to JX of the RS3000.

7) Apply the AC power. The green LED should now “blink” indicating that AC power is

applied to the T3000.

8) Apply appropriate input parameters to the STC200 or STC2000, as described in their

respective manuals, and start the process. The green LED should now be on in a steady

state mode, indicating that the T3000 is ready to supply current to the load. (Note: Set STC

output for the 0 to +10 V range).

T3000 Configurations

Page 7 - 4

Section 7

Page 44

instruments

Made in the U.S.A

Sycon Instruments

6757 Kinne Street

East Syracuse, New York 13057-1215

V (315) 463-5297 F (315) 463-5298 info@sycon.com

Loading...

Loading...