Page 1

C

over Page

OPERATING MANUAL

STM-2XM

Rate and Thickness Monitor

PN 074-614-P1A

Page 2

Page 3

www.inficon.com reachus@inficon.com

©2014 INFICON

®

Title P

age

OPERATING MANUAL

STM-2XM

Rate and Thickness Monitor

PN 074-614-P1A

Page 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

Windows® and Microsoft® are registered trademarks of Microsoft Corporation.

Inconel® is a registered trademark of Inco Alloys International, Huntington, WV.

LabVIEWTM is a trademark of National Instruments Corporation.

Sycon Instruments

All other brand and product names are trademarks or registered trademarks of their respective companies.

TM

is a trademark of INFICON,

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2014 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

Page 6

Page 7

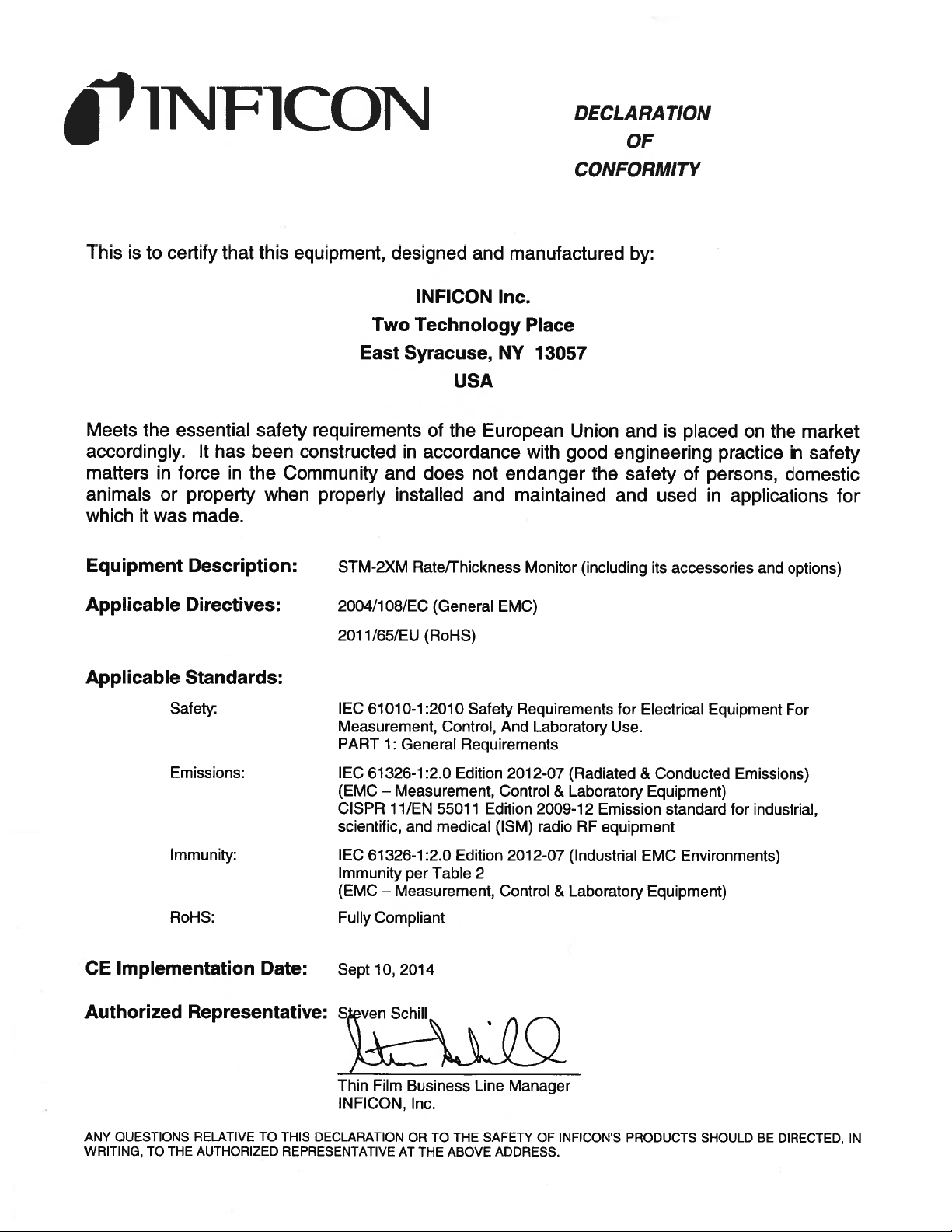

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

two (2) years from the date of shipment thereof by Seller. Seller's liability under

this warranty is limited to such of the above products or parts thereof as are

returned, transportation prepaid, to Seller's plant, not later than thirty (30) days

after the expiration of the period of warranty coverage in respect thereof and are

found by Seller's examination to have failed to function properly because of

defective workmanship or materials and not because of improper installation or

misuse and is limited to, at Seller's election, either (a) repairing and returning the

product or part thereof, or (b) furnishing a replacement product or part thereof,

transportation prepaid by Seller in either case. In the event Buyer discovers or

learns that a product does not conform to warranty, Buyer shall immediately notify

Seller in writing of such non-conformity, specifying in reasonable detail the nature

of such non-conformity. If Seller is not provided with such written notification,

Seller shall not be liable for any further damages which could have been avoided if

Seller had been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

www.inficon.com reachus@inficon.com

Page 8

Page 9

STM-2XM Operating Manual

Table Of Contents

Cover Page

Title Page

Trademarks

Disclaimer

Copyright

Declaration Of Conformity

Warranty

Chapter 1

Introduction and Specifications

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.1 Related Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 Instrument Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.1 Definition of Notes, Cautions and Warnings. . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2.2 General Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2.3 Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.3 How To Contact INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.3.1 Returning STM-2XM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.4.1 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.4.2 Film Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.4.3 System Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.4.4 Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.4.5 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.4.6 Operating Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

PN 074-614-P1A

1.4.7 Size and Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.5 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.6 Parts and Options Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.6.1 Base Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.6.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1.6.3 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

TOC - 1

Page 10

STM-2XM Operating Manual

Chapter 2

Installation

2.1 Installation Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Parts Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2 Ground Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.3 Connection to Earth Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.1 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.2 Relay Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.3 Analog Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2.4 Remote Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

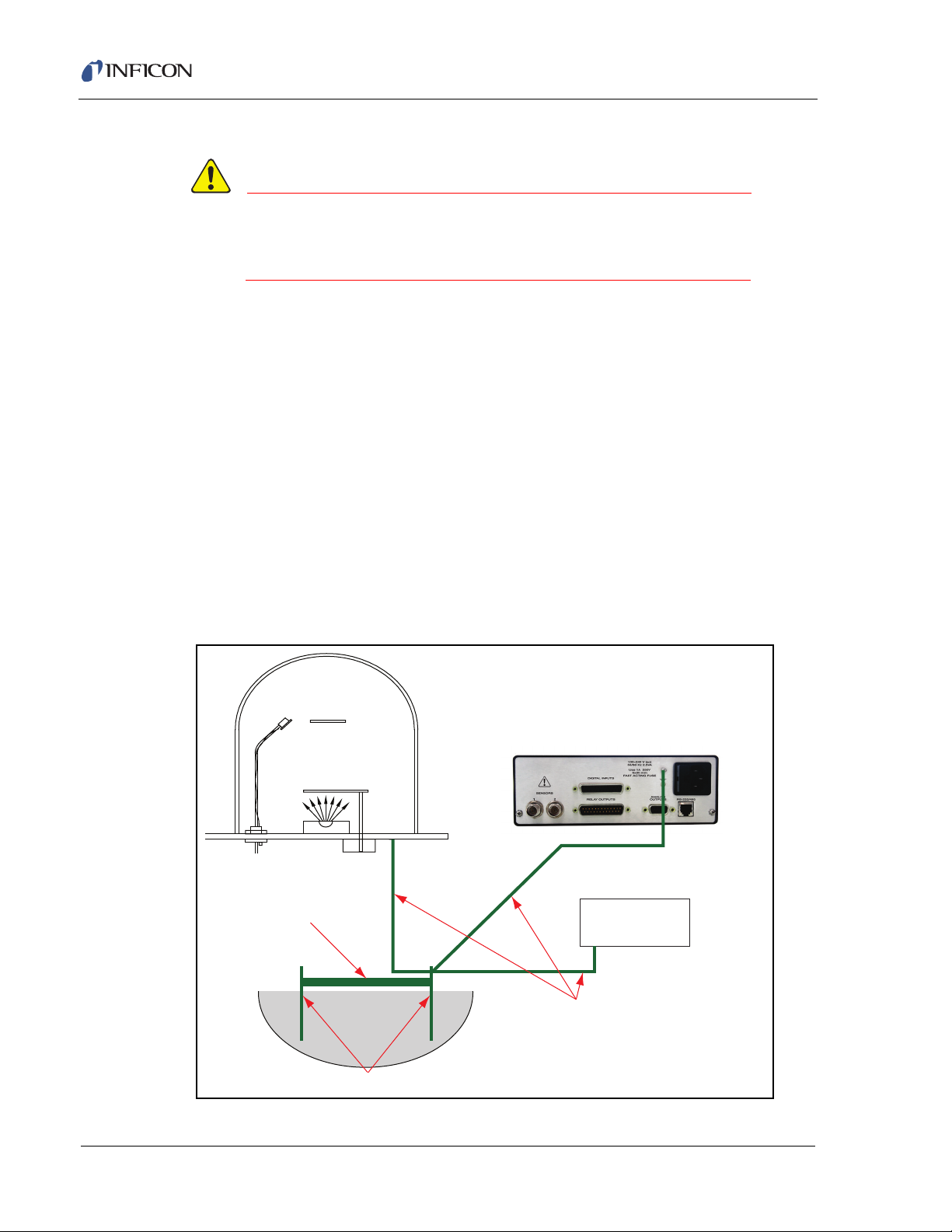

2.3 Basic Vacuum System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.4 Deposition System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.4.1 Sensor Head Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Chapter 3

Operation

3.1 Front Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 System Control Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.2 Data Entry and Programming Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.3 Changing a Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.1.4 Runtime Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.2 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.2.1 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.2.1.1 Edit Film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.2.1.2 System Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.2.1.3 Setup Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

TOC - 2

3.3 STM-2XM Operating Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.3.1 Simple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.3.2 Backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.3.3 Averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.3.4 Alloy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3.3.5 Independent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3.4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.4.1 No Shutter Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.4.2 Shutter Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.4.3 Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.4.4 Rate Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.5 Film States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

PN 074-614-P1A

Page 11

STM-2XM Operating Manual

Chapter 4

Software

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Installing INFICON STM-2XM FilmMaker Software . . . . . . . . . . . . . . . . . . .4-1

4.2.1 Installing the Protocol Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2.2 Installing INFICON STM-2XM FilmMaker Software . . . . . . . . . . . . . . . . . . .4-2

4.2.3 Starting INFICON STM-2XM FilmMaker Software . . . . . . . . . . . . . . . . . . . . 4-3

4.2.3.1 Starting the Software in Windows XP or Windows 7 . . . . . . . . . . . . . . . . . . 4-3

4.2.3.2 Starting the Software in Windows 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.3 STM-2XM Parameter Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3.1 Main Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.3.1.1 Main Setup Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.3.1.2 Utilities Pane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.3.2 Films Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4.3.3 System Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.3.3.1 Setup parameters Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.3.3.2 System parameters Pane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4.3.4 Save/Load file Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

4.3.5 Save/Load instrument Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4.3.6 About Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Chapter 5

Communications

5.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Communications Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2.1 RS-232/RS-485 Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2.2 RS-232 Point-to-Point Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2.3 RS-485 TTL Differential Signaling Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3 Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

PN 074-614-P1A

5.3.1 RS-485 Line Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.3.2 Bit Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.4 Bauds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.5 Message Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.5.1 Sycon Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.5.1.1 Command Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5.5.2 Sycon Multi-Drop Protocol (SMDP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5.5.2.1 Command Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5.5.2.1.1 Checksum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.5.2.1.2 Command Packet Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

5.5.2.1.3 Response Packet Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

TOC - 3

Page 12

STM-2XM Operating Manual

5.5.3 Optional Serial Command Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.5.3.1 Optional Serial Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.5.3.2 Additional Option to Serial Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.6 Communication Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.6.1 Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.6.2 Communication Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.6.3 Other Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.7 Windows/SMDP Server Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.8 Communications Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.8.1 Command: ?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.8.2 Command: @ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.8.3 Command: C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.8.4 Command: E/F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.8.4.1 Analog Output Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.8.4.2 Relay Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

5.8.4.3 Input Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

5.8.5 Command: G/H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.8.6 Command: I/J . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.8.7 Command: K/L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

5.8.8 Command: M/N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

5.8.9 Command: O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

5.8.10 Command: P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

5.8.10.1 Alloy State Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

5.8.11 Command: Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

5.8.11.1 Raw Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

5.8.11.2 Raw Status 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

5.8.11.3 Film State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

5.8.12 Run Screen Lock Codes and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38

5.8.13 Command Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

5.8.13.1 Query Software Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

5.8.13.2 Reboot SMDP Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-40

Chapter 6

Troubleshooting

6.1 Troubleshooting Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.3 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.4 Persistent Crystal Fail Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.5 Diagnostics Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

PN 074-614-P1A

TOC - 4

Page 13

Chapter 7

7.1 Importance of Density, Tooling and Z-Ratio. . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Determining Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.3 Determining Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.4 Laboratory Determination of Z-Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Chapter 8

8.1 Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1.1 Monitor Crystals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

8.1.2 Period Measurement Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.1.3 Z-match Technique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-6

Appendix A

A.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

STM-2XM Operating Manual

Calibration Procedures

Measurement and Theory

Material Table

PN 074-614-P1A

TOC - 5

Page 14

STM-2XM Operating Manual

This page is intentionally blank.

TOC - 6

PN 074-614-P1A

Page 15

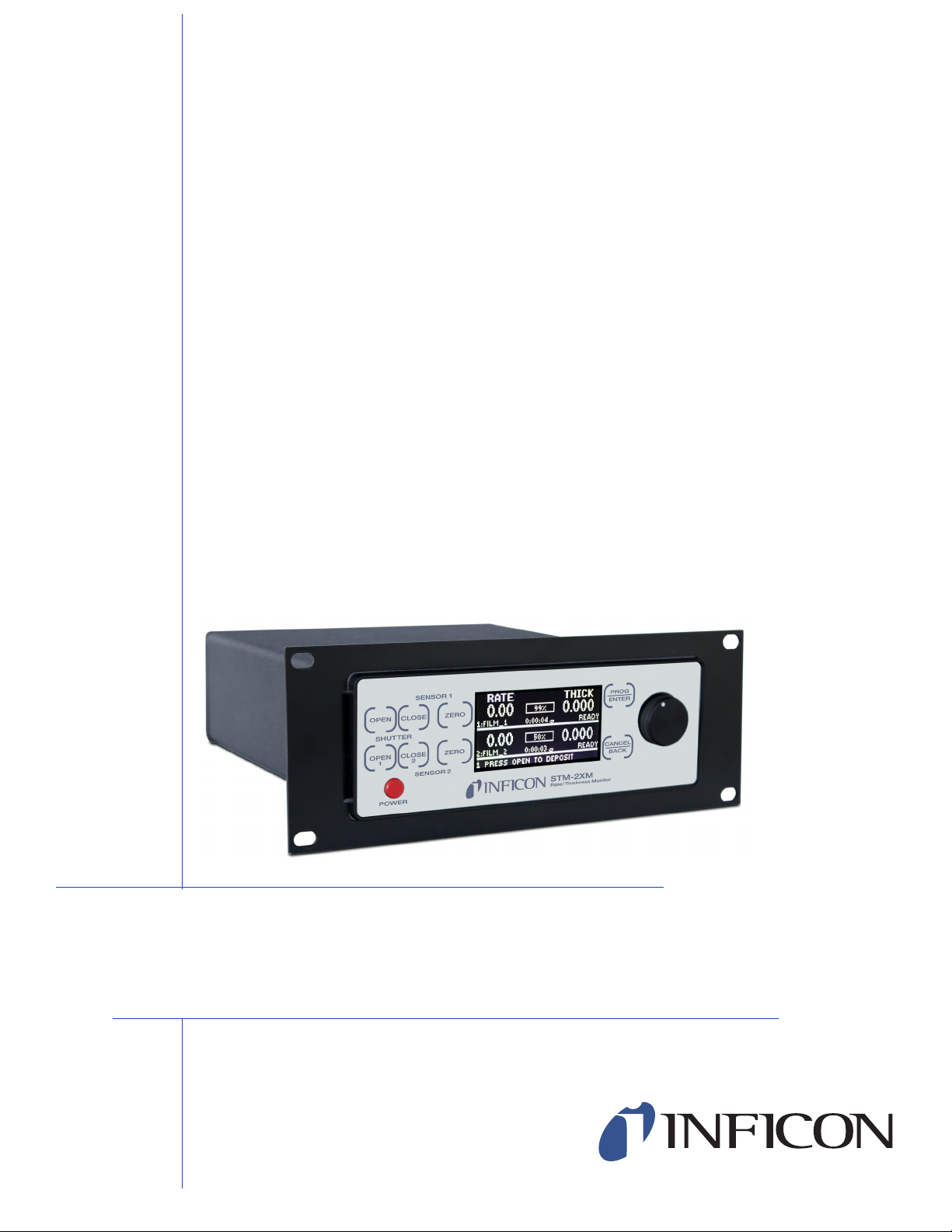

1.1 Introduction

STM-2XM rate and thickness monitor (see Figure 1-1) will manage single sensor

processes as well as codeposition and alloy processes through five modes of

operation:

Simple mode (single film mode)

Backup mode (crystal switching)

Averaging mode

Alloy mode

Independent mode

Independent mode allows STM-2XM to function as two completely separate

monitors with shutter delay. To extend crystal life for thicker films, the Alloy mode

provides a linked shutter delay.

STM-2XM Operating Manual

Chapter 1

Introduction and Specifications

Time/Power allows films to complete even with a crystal failure. STM-2XM displays

accumulated film mass or thickness and can also display a graph of rate, thickness,

or rate deviation.

STM-2XM has eight programmable digital inputs, eight programmable digital

outputs, and four analog outputs.

Figure 1-1 STM-2XM rate/thickness monitor

PN 074-614-P1A

1 - 1

Page 16

STM-2XM Operating Manual

CAUTION

WARNING

WARNING - Risk Of Electric Shock

1.1.1 Related Manuals

Sensors are covered in separate manuals. PDF files of these manuals are

contained in the Thin Film Manuals CD (PN 074-5000-G1), part of the Ship Kit.

PN 074-154—Bakeable Sensor

PN 074-156—Front Load Sensor, Single/Dual

PN 074-157—Sputtering Sensor

PN 074-609—Cool Drawer Sensor, Single/Dual

1.2 Instrument Safety

1.2.1 Definition of Notes, Cautions and Warnings

When using this manual, please pay attention to the NOTES, CAUTIONS, and

WARNINGS found throughout. For the purposes of this manual they are defined as

follows:

NOTE: Pertinent information that is useful in achieving maximum STM-2XM

efficiency when followed.

Failure to heed these messages could result in damage

to STM-2XM.

Failure to heed these messages could result in personal

injury.

Dangerous voltages are present which could result in

personal injury.

PN 074-614-P1A

1 - 2

Page 17

1.2.2 General Safety Information

WARNING - Risk Of Electric Shock

CAUTION

Dangerous voltages may be present whenever the power

cord or external input/relay connectors are present.

Refer all maintenance to qualified personnel.

STM-2XM contains delicate circuitry which is susceptible

to transient power line voltages. Disconnect the line cord

whenever making any interface connections. Refer all

maintenance to qualified personnel.

STM-2XM Operating Manual

PN 074-614-P1A

1 - 3

Page 18

STM-2XM Operating Manual

WARNING - Risk Of Electric Shock

CAUTION

1.2.3 Earth Ground

STM-2XM is connected to earth ground through a sealed three-core

(three-conductor) power cable, which must be plugged into a socket outlet with a

protective earth terminal. Extension cables must always have three conductors

including a protective earth terminal.

Never interrupt the protective earth circuit.

Any interruption of the protective earth circuit inside or

outside STM-2XM, or disconnection of the protective

earth terminal is likely to make STM-2XM dangerous.

This symbol indicates where the protective earth ground

is connected inside STM-2XM. Never unscrew or loosen

this connection.

There are no user serviceable components within the

STM-2XM case.

Refer all maintenance to qualified personnel.

PN 074-614-P1A

1 - 4

Page 19

1.3 How To Contact INFICON

Worldwide customer support information is available under Support >> Support

Worldwide at www.inficon.com:

Sales and Customer Service

Technical Support

Repair Service

If experiencing a problem with STM-2XM, please have the following information

readily available:

The Sales Order or Purchase Order number of the instrument purchase.

The version of STM-2XM firmware.

The version of Windows operating system.

A description of the problem.

An explanation of any corrective action that may have already been attempted.

The exact wording of any error messages that may have been received.

STM-2XM Operating Manual

1.3.1 Returning STM-2XM

Do not return any component of STM-2XM to INFICON before speaking with a

Customer Support Representative and obtaining a Return Material Authorization

(RMA) number. STM-2XM will not be serviced without an RMA number.

Packages delivered to INFICON without an RMA number will be held until the

customer is contacted. This will result in delays in servicing STM-2XM.

If returning STM-2XM with a crystal sensor or another component potentially

exposed to process materials, prior to being given an RMA number, a completed

Declaration Of Contamination (DOC) form will be required. DOC forms must be

approved by INFICON before an RMA number is issued. INFICON may require

PN 074-614-P1A

that the component be sent to a designated decontamination facility, not to the

factory.

1 - 5

Page 20

STM-2XM Operating Manual

1.4 Specifications

1.4.1 Measurement

Sensor Inputs . . . . . . . . . . . . . . . . . . 2

Compatible Sensors. . . . . . . . . . . . . Single/shuttered single or dual QCM sensor

Measurement Frequency Range . . . 6.0 to 5.0 MHz (fixed)

Frequency Resolution . . . . . . . . . . . ± 0.03 Hz @ 6 MHz

Reference Frequency Stability . . . . . ± 2 ppm

Thickness and Rate

Resolution/Measurement . . . . . . . . . ± 0.037 Å @ tooling/density = 100/1

Measurement Interval . . . . . . . . . . . 0.10 s

1.4.2 Film Parameters

Stored Films . . . . . . . . . . . . . . . . . . . 15

Fundamental frequency = 6 MHz

Name . . . . . . . . . . . . . . . . . . . . . . . . 8 characters, 0 to 9, A to Z, _ and [space]

Density . . . . . . . . . . . . . . . . . . . . . . . 0.4 to 99.99 g/cm

3

Z-Ratio . . . . . . . . . . . . . . . . . . . . . . . 0.100 to 9.999

Tooling . . . . . . . . . . . . . . . . . . . . . . . 10 to 999.9%

Setpoint Thickness. . . . . . . . . . . . . . 0.000 to 999.999 kÅ

End Thickness . . . . . . . . . . . . . . . . . 0.000 to 999.999 kÅ

Use Backup Crystal . . . . . . . . . . . . . Yes/No

Setpoint Time . . . . . . . . . . . . . . . . . . 0:00:00 to 9:59:59 h:mm:ss

Deposit Rate . . . . . . . . . . . . . . . . . . 0.0 to 999.9 Å/s

Coast Enable . . . . . . . . . . . . . . . . . . Yes/No

Crystal Life Minimum . . . . . . . . . . . . 0 to 99%

Force Crystal Fail . . . . . . . . . . . . . . . Yes/No

Temporal Average . . . . . . . . . . . . . . 1 to 50

Good Rate Tolerance . . . . . . . . . . . . 0 to 50

PN 074-614-P1A

1 - 6

Page 21

1.4.3 System Parameters

Operation Modes . . . . . . . . . . . . . . . Simple mode (single film mode)

Test Mode. . . . . . . . . . . . . . . . . . . . . On/Off

Active Source . . . . . . . . . . . . . . . . . . Channel 1/Channel 2

Display Mode . . . . . . . . . . . . . . . . . . Thickness/Mass

Plot Type . . . . . . . . . . . . . . . . . . . . . None/Rate Deviation/Rate/Thickness

Plot Time Interval . . . . . . . . . . . . . . . 0:00:00 to 9:59:59 h:mm:ss

LCD Contrast . . . . . . . . . . . . . . . . . . 10 to 85

LCD Brightness . . . . . . . . . . . . . . . . 1 to 99

Beeper . . . . . . . . . . . . . . . . . . . . . . . On/Off

STM-2XM Operating Manual

Backup mode (crystal switching)

Averaging mode

Alloy mode

Independent mode

Communications Protocol . . . . . . . . Sycon 9600 (Sycon Protocol @ 9.6 Kbps)

SMDP L (SMDP Protocol @ 9.6 Kbps)

SMDP M (SMDP Protocol @ 38.4 Kbps)

SMDP H (SMDP Protocol @ 115.2 Kbps)

SMDP Address. . . . . . . . . . . . . . . . . 16 to 254

1.4.4 Digital I/O

Digital Inputs. . . . . . . . . . . . . . . . . . . 8

Digital Input Functions . . . . . . . . . . . Open Shutter

Close Shutter

Zero Thickness

PN 074-614-P1A

Disabled

Select crystal as active (dual mode)

NOTE: To select crystal one, use on a

Channel 1 input (1.x). To select

crystal two, use on a Channel 2 input

(2.x).

Allow sync

Digital Outputs . . . . . . . . . . . . . . . . . 8

NOTE: Allows simultaneous shutter delay of

both films.

1 - 7

Page 22

STM-2XM Operating Manual

Digital Output Functions. . . . . . . . . . Manual (front panel)

Source shutter

Substrate shutter

Sensor shutter

Crystal fail

Setpoint time

Setpoint thick

Forced active

Controlled via serial communications

Rate is steady and within tolerance

Analog Outputs. . . . . . . . . . . . . . . . . 4

Analog Output Functions . . . . . . . . . Rate:

Rate 1000 Å/s, 10.00 µg scale

Rate 10.0 Å/s, 0.10 µg scale

Rate deviation:

Rate deviation 1000 Å/s, 10.00 µg scale

Rate deviation 10.0 Å/s, 0.10 µg scale

1.4.5 Power

Thickness:

Thickness recorder 999 Å scale

Thickness recorder 99.9 Å scale

Disabled

Controlled via serial communications

Fixed positive/negative full scale

Analog Output Rating. . . . . . . . . . . . -10 to +10 V, 10 mA

Relay Rating. . . . . . . . . . . . . . . . . . . up to 48 V (dc)

• V (ac), 2 A

Rated Supply Voltage. . . . . . . . . . . . 100 to 240 V (ac) ± 10%, 50/60 Hz, 2.5 VA

Fuse Rating . . . . . . . . . . . . . . . . . . . 1 A 250 V, 5 x 20 mm, Fast-acting

Mains Power Cable Rating

STM-2XM-G1 . . . . . . . . . . . . . . . 10 A 125 V

STM-2XM-G2 . . . . . . . . . . . . . . . 10 A 250 V

Power Consumption. . . . . . . . . . . . . less than 10 W

PN 074-614-P1A

1 - 8

Overvoltage . . . . . . . . . . . . . . . . . . . Category II

Temporary Overvoltage

Short Term . . . . . . . . . . . . . . . . . 1200 V, < 5 s

Long Term . . . . . . . . . . . . . . . . . 250 V, > 5 s

Page 23

1.4.6 Operating Environment

Usage . . . . . . . . . . . . . . . . . . . . . . . . Indoor use only

Operating Temperature . . . . . . . . . . 0 to 50°C (32 to 122°F)

Storage Temperature . . . . . . . . . . . . -10 to 60°C (14 to 140°F)

Humidity . . . . . . . . . . . . . . . . . . . . . . Up to 85% RH, non-condensing

Altitude . . . . . . . . . . . . . . . . . . . . . . . Up to 2000 meters

Pollution Degree. . . . . . . . . . . . . . . . 2

1.4.7 Size and Weight

Rack Dimensions (HxWxD) . . . . . . . 8.9 x 24.1 x 25.4 cm (3.5 x 9.5 x 10 in.)

Weight . . . . . . . . . . . . . . . . . . . . . . . 1.25 kg (2.75 lb.)

1.5 Unpacking and Inspection

1 If STM-2XM has not been removed from its packaging, do so now.

STM-2XM Operating Manual

2 Carefully examine STM-2XM for damage that may have occurred during

shipping. It is especially important to note obvious rough handling on the

outside of the container. Immediately report any damage to the carrier and to

INFICON.

3 Do not discard the packaging material until inventory has been taken and

installation has been successful.

4 Refer to the invoice to take inventory (see section 1.6).

5 To install STM-2XM, see Chapter 2, Installation.

6 For additional information or technical assistance, contact INFICON (refer to

section 1.3 on page 1-5).

PN 074-614-P1A

1.6 Parts and Options Overview

1.6.1 Base Configurations

STM-2XM with US Power Cord . . . . PN STM-2XM-G1

STM-2XM with

European Power Cord . . . . . . . . . . . PN STM-2XM-G2

Thin Film Manuals CD . . . . . . . . . . . PN 074-5000-G1

1 - 9

Page 24

STM-2XM Operating Manual

1.6.2 Accessories

3 m (10 ft.) Oscillator Kit. . . . . . . . . . PN 783-500-109-10

7.6 m (25 ft.) Oscillator Kit . . . . . . . . PN 783-500-109-25

15.2 m (50 ft.) Oscillator Kit . . . . . . . PN 783-500-109-50

22.9 m (75 ft.) Oscillator Kit . . . . . . . PN 783-500-109-75

NOTE: Each sensor requires an oscillator kit to interface to STM-2XM.

Oscillator kits include:

Oscillator . . . . . . . . . . . . . . . . . . PN 783-500-013

15.2 cm (6 in.) BNC cable . . . . . PN 782-902-011

One of the following:

3 m (10 ft.) BNC Cable . . . . . PN 782-902-012-10

7.6 m (25 ft.) BNC Cable . . . PN 782-902-012-25

15.2 m (50 ft.) BNC Cable . . PN 782-902-012-50

22.9 m (75 ft.) BNC Cable . . PN 782-902-012-75

These kits are designed for use with the standard in-vacuum cables ranging in

length from 15.2 cm (6 in.) to 78.1 cm (30.75 in.).

48.3 cm (19 in.) rack mount kits are available in the following configurations:

One STM-2XM . . . . . . . . . . . . . . PN 783-014-008

Two STM-2XM . . . . . . . . . . . . . . PN 783-014-009

PN 074-614-P1A

1 - 10

Page 25

1.6.3 Sensors

Front Load Single Sensor. . . . . . . . . . . . . . . . . . . . . PN SL-XXXXX

Front Load Dual Sensor . . . . . . . . . . . . . . . . . . . . . . PN DL-AXXX

Cool Drawer Single Sensor . . . . . . . . . . . . . . . . . . .PN CDS-XXFXX

Cool Drawer Dual Sensor. . . . . . . . . . . . . . . . . . . . . PN CDD-XFXX

Sputtering Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . PN 750-618-G1

UHV Bakeable Sensor . . . . . . . . . . . . . . . . . . . . . . .PN BK-AXF

Low Profile Single Sensor . . . . . . . . . . . . . . . . . . . . PN 783-500-042

Low Profile Dual Sensor. . . . . . . . . . . . . . . . . . . . . .PN 783-500-093

Low Profile Bakeable Single Sensor . . . . . . . . . . . . PN 783-500-009

Low Profile Bakeable Dual Sensor. . . . . . . . . . . . . . PN 783-500-050

NOTE: Low Profile Sensors also have shuttered options as well as options without

NOTE: "X" in part number indicates customer-selectable option, see

STM-2XM Operating Manual

cooling lines.

www.inficon.com for Sensor Datasheets.

NOTE: Shuttered sensors require a feedthrough with an air line and solenoid valve

PN 750-420-G1.

NOTE: Multi-crystal (rotary) sensors should not be used with STM-2XM.

PN 074-614-P1A

1 - 11

Page 26

STM-2XM Operating Manual

This page is intentionally blank.

1 - 12

PN 074-614-P1A

Page 27

2.1 Installation Requirements

CAUTION

CAUTION

2.1.1 Parts Requirements

STM-2XM Monitor

Use the supplied mains power cable.

If this cable must be replaced, the replacement cable

must meet or exceed the ratings of the supplied cable.

STM-2XM Operating Manual

Chapter 2

Installation

One crystal sensor/feedthrough

One Oscillator Kit for each crystal sensor

Quartz crystals appropriate for the application

To maintain proper STM-2XM performance, use only

the 15.2 cm (6 in.) BNC cable that is included to connect

the oscillator to the crystal sensor.

The length of the in-vacuum cable (Front Load and

Sputtering sensors) or electrical conduit tube

(Cool Drawer and Bakeable sensors) should not exceed

PN 074-614-P1A

78.1 cm (30.75 in.).

2 - 1

Page 28

STM-2XM Operating Manual

CAUTION

Substrate

Source

Sensor

Evaporator

Power Supply

2.4 m (8 ft.) Copper Ground Rods

7.62 cm (3 in.)

Wide Copper

Ground

Strap

12.7 mm (0.5 in.)

Wide Copper

Ground

Straps

Earth

2.1.2 Ground Requirements

A ground post is provided on the rear panel. This point

should be connected to the common ground with a

grounding strap.

Use low impedance cables or straps to connect the chassis of all control

components to a common ground point on the vacuum chamber. The common

ground point must be connected to earth ground (see section 2.1.3, Connection to

Earth Ground, on page 2-3).

Solid copper straps are recommended, where RF is present. Use a strap of the

shortest possible length, minimum width of 12.7 mm (0.5 in.), approximately

0.56 mm (0.22 in.) thick. This is particularly important in high-noise electron beam

(e-beam) systems. See Figure 2-1 for the recommended grounding method.

NOTE: The oscillator is grounded to STM-2XM and crystal sensor through the

BNC cables.

The crystal sensor is typically grounded to the wall of the vacuum system. If the

sensor feedthrough is not properly grounded to earth through the vacuum system,

connect a copper strap between the feedthrough and the common ground point on

the vacuum system.

Figure 2-1 Recommended grounding

PN 074-614-P1A

2 - 2

Page 29

2.1.3 Connection to Earth Ground

CAUTION

If an earth ground is not established:

1 Where soil conditions allow, drive two 2.4 m (8 ft.) copper clad steel rods into

the ground 1.8 m (6 ft.) apart. Follow local regulations and codes.

2 Pour a copper sulfate or a salt solution around each rod to improve the

ground conductivity.

3 Measure the resistance. A near zero resistance between the two rods indicates

that a good earth ground is achieved.

4 After verifying a near zero resistance between the rods, connect the rods

together with a 7.62 cm (3 in.) wide copper strap.

2.2 Rear Panel

Figure 2-2 STM-2XM rear panel

STM-2XM Operating Manual

Connecting cables must be routed away from any

PN 074-614-P1A

potential source of electrical noise.

2.2.1 Sensors

The Sensors input provides the remote sensor oscillator interface to STM-2XM,

providing both the signal and power path to the oscillator.

NOTE: Sensors connection requires coaxial cable type RG58 or RG59.

The maximum BNC cable length connecting the oscillator to

STM-2XM is 30 m (98 ft.).

2 - 3

Page 30

STM-2XM Operating Manual

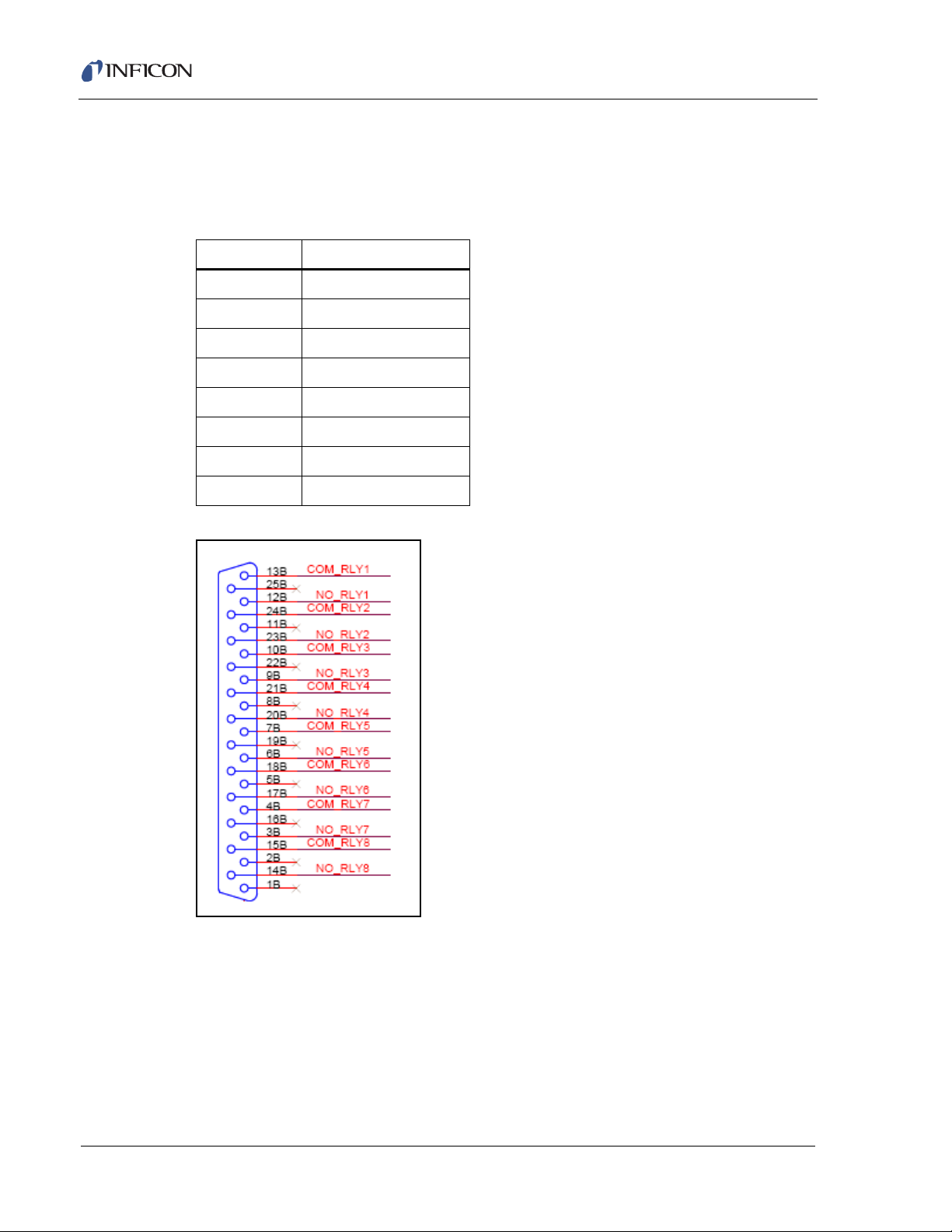

2.2.2 Relay Outputs

STM-2XM has eight normally open (NO) relay contact outputs. These outputs are

intended for low voltage (see section 1.4.4, Digital I/O, on page 1-7).

Table 2-1 Relay output contact pin numbers

Relay Contacts on pins

1 12,13

2 23,24

39,10

4 20,21

56,7

6 17,18

73,4

8 14,15

Figure 2-3 Relay output contact pin numbers

2 - 4

PN 074-614-P1A

Page 31

2.2.3 Analog Outputs

For functions associated with the analog outputs, see section 1.4.4, Digital I/O, on

page 1-7.

Table 2-2 Analog output contact pin numbers

Analog Output Connections

1 9(+), relative to pin 5 or 1

2 4(+), relative to pin 5 or 1

3 2(+), relative to pin 5 or 1

4 6(+), relative to pin 5 or 1

Figure 2-4 Analog output contact pin numbers

STM-2XM Operating Manual

PN 074-614-P1A

2 - 5

Page 32

STM-2XM Operating Manual

2.2.4 Remote Inputs

STM-2XM has eight remote digital inputs that are activated by contact closure to

ground.

For the specific functions associated with the inputs, see section 1.4.4 on page 1-7.

Table 2-3 Remote input pin numbers

Input Contact on pins

Input 1 14,13

Input 2 3,13

Input 3 17,13

Input 4 6,13

Input 5 20,13

Input 6 9,13

Input 7 23,13

Input 8 12,13

Figure 2-5 Remote input pinout

PN 074-614-P1A

2 - 6

Page 33

STM-2XM Operating Manual

Substrate

Substrate Shutter

Source

Shutter

Chamber

Oscillator

Source

Power

Supply

Sensor

Sensor

Shutter

2.3 Basic Vacuum System Components

Figure 2-6 Basic vacuum system components

PN 074-614-P1A

Substrate

The substrate is the object being coated.

Source

The source is the object that emits the evaporant. STM-2XM provides support for

two sources.

Sensor

The sensor is the component that detects the evaporant. The sensor can only

detect evaporant that accumulates on the sensor crystal. To account for differences

in evaporant between the sensor and substrate, tooling adjustments are used (see

section 7.3 on page 7-2). STM-2XM provides support for two sensors.

Source shutter (optional)

The source shutter blocks the evaporant stream from the source. With the source

shutter closed, the evaporant from the source cannot reach the substrate or the

sensors. The front panel shutter buttons and the End Thickness setpoint activate

the source shutter.

2 - 7

Page 34

STM-2XM Operating Manual

Substrate shutter (optional)

The substrate shutter blocks the evaporant stream from reaching the substrate. A

closed substrate shutter will not allow material to reach the substrate but will allow

evaporant to reach the sensor(s). With a substrate shutter installed, it is possible

to have a shutter delay, where the rate can be pre-established before exposing the

substrate to the evaporant stream. STM-2XM automatically accounts for a

substrate shutter (if programmed) and will not display thickness accumulation while

the substrate shutter is closed. The displayed rate is always "live" even if the

substrate shutter is closed.

NOTE: If STM-2XM is programmed to use a substrate shutter, it ignores changes

in substrate thickness when the substrate shutter is closed. Therefore,

program STM-2XM for a substrate shutter only if a substrate shutter

actually exists in the system.

Sensor shutter (optional)

The sensor shutter blocks the evaporant stream from the sensor. Shuttered

sensors are required for rate sampling, where the sensor monitors the source for a

portion of the deposition. Shuttered sensors are also used in multiple-sensor,

multi-layer systems to keep the sensor from being contaminated with incompatible

materials on different layers

In-Vacuum Cable

The in-vacuum cable connects the sensor to the feedthrough.

Feedthrough

A feedthrough provides isolation between vacuum and atmosphere for electrical

and cooling lines.

15.2 cm (6 in.) BNC Cable

A BNC cable provides a flexible connection from the feedthrough to the oscillator.

Oscillator

The oscillator contains the electronics to operate the quartz crystal. The length from

the oscillator to the crystal should be under 1 m (40 in.).

BNC Cable

A BNC cable connects the oscillator to STM-2XM.

Ground Wire

The ground wire is preferably a solid copper ground strap that connects the

earth-grounded vacuum system to the STM-2XM ground terminal (refer to section

2.1.2, Ground Requirements, on page 2-2).

PN 074-614-P1A

2 - 8

Page 35

2.4 Deposition System Installation

Correct

Incorrect

Correct

Incorrect

Incorrect

Obstruction

Source

2.4.1 Sensor Head Installation

Install the sensor as far as possible from the evaporation source (a minimum of

25.4 cm (10 in.)) while still being in a position to accumulate thickness at a rate

proportional to accumulation on the substrate. Figure 2-7 shows proper and

improper methods of installing sensors.

NOTE: For best process reproducibility, rigidly support the sensor so that it cannot

move during maintenance and crystal replacement.

Figure 2-7 Sensor installation guidelines

STM-2XM Operating Manual

PN 074-614-P1A

To guard against spattering, use a source shutter to shield the sensor during initial

soak periods. If the crystal is hit with a particle of molten material, it may be

damaged and stop oscillating. Even in cases when the crystal does not completely

stop oscillating, it may immediately become unstable or instability may occur

shortly after deposition begins.

Plan the installation to ensure that there are no obstructions blocking a direct path

between the sensor and the source. Install sensors in such a manner that the

center axis of the crystal is aimed directly at the source to be monitored. Verify that

the angle of the sensor location (with reference to the source) is well within the

evaporant stream. If the sensor is not perpendicular to the source, the coating on

the crystal will be tapered and diminished crystal life can result.

NOTE: In many cases installing multiple sensors to monitor one source can

improve thickness accuracy for the product. The recommendations for

multiple sensors are the same as for a single sensor installation, and the

locations chosen should be as defined above.

2 - 9

Page 36

STM-2XM Operating Manual

This page is intentionally blank.

2 - 10

PN 074-614-P1A

Page 37

3.1 Front Panel Description

Power

On / Off

System

Control

Display Data

Entry

Control

Knob

Figure 3-1 Front panel

STM-2XM Operating Manual

Chapter 3

Operation

The STM-2XM front panel is divided into two functional groups:

Buttons to the left of the display are for system control.

The control knob and buttons to the right of the display are for data entry and

programming.

An audible beep will accompany each button activation. The beeper may be

disabled if desired (see section 3.2.1.2 on page 3-10).

PN 074-614-P1A

3 - 1

Page 38

STM-2XM Operating Manual

Open for

Channel 1

Close for

Channel 1

Zero for

Sensor 1

Open for

Channel 2

or

Select

Crystal 1

(Backup

Mode)

Crystal 2

Close for

Channel 2

or

Select

(Backup

Mode)

Zero for

Sensor 2

3.1.1 System Control Buttons

NOTE: All button functions can be duplicated with remote inputs.

Figure 3-2 Button functions

3 - 2

OPEN . . . . . . . . . . . . . . . . . . . . . . . . Press OPEN to open the source/substrate

shutter. When OPEN is pressed, all setpoints

(setpoint time, setpoint thickness, and end

thickness) are cleared and the film will enter

the deposit state.

NOTE: Pressing OPEN while STM-2XM is in

the deposit state has no effect.

CLOSE. . . . . . . . . . . . . . . . . . . . . . . Press CLOSE to close the source/substrate

shutter and terminate the deposition.

STM-2XM will then enter the Ready state.

NOTE: Pressing CLOSE while STM-2XM is

in the Ready state has no effect.

PN 074-614-P1A

Page 39

ZERO . . . . . . . . . . . . . . . . . . . . . . . . Press ZERO to zero the substrate thickness.

Control Knob

When ZERO is pressed, the thickness

displayed is cleared.

NOTE: If ZERO is pressed during the

Mode-Dependent Button Functions

Sensor 2 ZERO is only used in the independent mode.

Channel 2 OPEN is used to select Crystal 1 in the backup mode.

Channel 2 CLOSE is used to select Crystal 2 in the backup mode.

3.1.2 Data Entry and Programming Buttons

Figure 3-3 Data entry and programming buttons

STM-2XM Operating Manual

deposit state, the setpoint thickness

will activate when the film thickness

on the display reaches the

programmed setpoint thickness.

PROG/ENTER . . . . . . . . . . . . . . . . . Provides access to the main menu and

subsequent menus

Saves parameters after edit

Advances to the next list item in a sub-menu

after an edit has been saved

PN 074-614-P1A

CANCEL/BACK . . . . . . . . . . . . . . . . Returns to previous menu or Runtime screen

Control Knob . . . . . . . . . . . . . . . . . Scrolls up/down menu items

Scrolls through fixed choices

Increments value-based parameters

For parameters requiring multiple numeric

placeholders (density, Z-Ratio, thickness,

time, and rate), the control knob will:

increment the selected numeric

placeholder when rotated clockwise

select the next numeric placeholder

when rotated counterclockwise

3 - 3

Page 40

STM-2XM Operating Manual

Counterclockwise

Clockwise

three clicks

two clicks

3.1.3 Changing a Parameter

There are two types of parameters, enumerated and numeric. Enumerated

parameters have a list of fixed choices. Numeric parameters allow a number to be

entered. To change a parameter,

1 Press PROG/ENTER.

2 Rotate the control knob to select Edit Active Film.

3 Press PROG/ENTER to display the Editing Film menu for the active film (see

Figure 3-4).

Figure 3-4 Editing film settings

To edit the density, for example, rotate the control knob clockwise to select

DENSITY, then press PROG/ENTER. The DENSITY numeric parameter editor will

be displayed (see Figure 3-5).

Figure 3-5 Numeric parameter editor

3 - 4

Numeric parameters are changed one digit at a time.

Each digit may only be incremented, and rolls over from 9 to 0.

To select the next digit, rotate the control knob counterclockwise.

To increment the selected digit, rotate the control knob clockwise.

When finished, press the PROG/ENTER button.

To cancel the entry, press the CANCEL/BACK button.

PN 074-614-P1A

Page 41

STM-2XM Operating Manual

WARNING

Clockwise

one click

When changing an enumerated type, rotate the control knob to the appropriate

item, and press PROG/ENTER to save the selection and return to the previous

screen (see Figure 3-6).

Figure 3-6 Enumerated entry

NOTE: The help message changes appropriately with the choice.

Pressing CANCEL/BACK will cancel the entry and set it back to the previous

setting.

Enumerated choices take effect immediately.

PN 074-614-P1A

3 - 5

Page 42

3.1.4 Runtime Screen

Deposition Rate

Substrate Thickness

or Mass

Film State

Set Point

Indicators

Real-Time Chart

Context-Based

Help

Film No.:Film Name

Upper Chart Bound

Chart Type

Lower Chart Bound

Indicates Active Sensor

Sensor Shutter Closed

Sensor Shutter Open

Crystal Life (Frequency-Based)

Deposit Phase Time

Substrate Shutter

Source Shutter

Shutter Closed

Shutter Open

STM-2XM Operating Manual

Figure 3-7 STM-2XM Runtime screen component status

3 - 6

PN 074-614-P1A

Page 43

3.2 Programming

3.2.1 Main Menu

To program STM-2XM, press PROG/ENTER. The MAIN MENU will display.

Figure 3-8 Main menu

Use the control knob to select a menu item, then press PROG/ENTER. Press

CANCEL/BACK to return to the Runtime screen.

Set Active Film . . . . . . . . . . . . . . . . 1 to 15. Sets the active film.

Edit Active Film . . . . . . . . . . . . . . . Lists programmable parameters for the

STM-2XM Operating Manual

currently active film. For a description of the

settings on the film page, see section 3.2.1.1.

System Settings . . . . . . . . . . . . . . . Displays the SYSTEM PARAMS menu. For a

description of the system settings, see

section 3.2.1.2 on page 3-10.

Status/Diagnostics . . . . . . . . . . . . . Displays STM-2XM status and diagnostics.

For example, displays the raw frequency of

the crystal, the status of the inputs and

outputs, and other useful information.

Edit Any Film . . . . . . . . . . . . . . . . . Displays a selection box that allows the

choice of the film to edit, and then displays

the settings menu for the selected film.

Setup . . . . . . . . . . . . . . . . . . . . . . . . Displays the HARDWARE SETUP menu,

where STM-2XM system hardware is

PN 074-614-P1A

programmed, including sensors, shutters,

tooling, and relays. The settings on this menu

must be accurate to allow STM-2XM to

operate properly. For example, if STM-2XM

is programmed for a substrate shutter, and

one does not exist in the system, STM-2XM

will provide false readings because it will not

count any material accumulated on the

substrate during the Ready phase. For a

description of hardware settings, see section

3.2.1.3 on page 3-12.

3 - 7

Page 44

3.2.1.1 Edit Film

All parameters are listed, but during actual operation STM-2XM will show only the

parameters that are relevant to its configuration and mode.

Name . . . . . . . . . . . . . . . . . . . . . . . . Name of the film, displayed on the monitor

Density . . . . . . . . . . . . . . . . . . . . . . Density of the film material. Used to

Z-Ratio. . . . . . . . . . . . . . . . . . . . . . . Z-Ratio of the film material. Used to

Additional Tooling . . . . . . . . . . . . . Tooling applied in addition to the tooling in

STM-2XM Operating Manual

screen.

accurately calculate thickness. The density

of common materials is found in Appendix A,

Material Table.

NOTE: Density is not used in Mass mode.

accurately calculate thickness. The Z-Ratio

of common materials is found in Appendix A,

Material Table.

the setup menu.

NOTE: This only affects the film being edited

and not all films.

Setpoint Thickness . . . . . . . . . . . . Thickness/mass at which the setpoint

thickness relay (if programmed) will close.

NOTE: Each time a film is started, the

setpoint thickness condition is

cleared, and will be activated when

the thickness of the specific film (not

necessarily the total displayed

thickness) reaches the setpoint.

End Thickness . . . . . . . . . . . . . . . . Thickness/mass at which the deposit state

automatically terminates.

NOTE: Each time a film is started, the end

thickness condition is cleared. This

will be activated when the thickness

of the specific film (not necessarily

the total displayed thickness)

reaches the setpoint.

Use Backup Xtal . . . . . . . . . . . . . . . Available in Backup Mode

PN 074-614-P1A

3 - 8

Allows the sensor to switch automatically if

the active crystal fails.

Setpoint Time . . . . . . . . . . . . . . . . . Thickness/mass at which the setpoint time

relay (if programmed) will close.

Page 45

STM-2XM Operating Manual

Deposit Rate . . . . . . . . . . . . . . . . . . Desired rate for the film. Used for the rate

deviation graph (and analog output) and to

ensure the Rate digital output is steady and

within tolerance.

Shutter Delay . . . . . . . . . . . . . . . . . Activates a shutter delay for the film. During

a shutter delay, STM-2XM will monitor the

rate from the source but will keep the

substrate shutter closed. OPEN stops shutter

delay and starts the deposit phase.

NOTE: Available only if the appropriate

shutter setup is present.

Rate Sampling . . . . . . . . . . . . . . . . When using rate sampling, the sensor

shutter opens and closes during deposit to

reduce the exposure of the crystal to the

evaporant stream during deposition. This

feature is intended to extend crystal life for

processes with stable rates.

NOTE: Available only if the appropriate

shutter setup is present.

Rate Sampling Period . . . . . . . . . . Determines how often STM-2XM samples

and holds during Rate Sampling. Rate

Sampling Period minus Rate Sampling Dwell

time yields an approximate hold time (how

long STM-2XM will keep the sensor shutter

closed).

Rate Sampling Dwell . . . . . . . . . . . Determines the amount of time STM-2XM

will keep the sensor shutter open.

Time Power Enable . . . . . . . . . . . . STM-2XM will use the last known steady rate

and continue to accumulate thickness/mass

PN 074-614-P1A

at this rate if a crystal fail occurs. This allows

films to be completed even in the event of a

crystal failure.

Xtal Life Min . . . . . . . . . . . . . . . . . . Adjustable to enter the percent life at which

the crystal will fail. This sets the minimum

acceptable crystal life before a forced failure.

Auto Fail/Force Switch Xtal . . . . . . If the sensor(s) used by this film have a life

lower than Xtal Life Min, and the Auto Fail

parameter is true, then the crystal is failed.

Used to switch to a backup sensor at a given

crystal life.

3 - 9

Page 46

STM-2XM Operating Manual

Temporal Average . . . . . . . . . . . . . Number of measurement samples to

average as the effective rate. More samples

yield a more accurate rate, however, rate and

thickness will not update as quickly at higher

sampling rates.

The effective frequency accuracy is 0.03 Hz

per measurement divided by the square root

of the number of temporal average samples.

Good Rate Tolerance(%) . . . . . . . . Set as a percentage of rate deviation. When

set for good rate, a relay will activate only

within tolerance, when the good rate

condition is true.

For example, if Good Rate Tolerance is set to

10% and the target rate is set to 10 Å/s, when

the rate is between 9 and 11 Å/s (10%), the

good rate relay would be active.

NOTE: A relay must be programmed to use

this feature.

3.2.1.2 System Settings

Operational Mode. . . . . . . . . . . . . . Sets STM-2XM mode of operation (see

Table 3-1 Modes of operation

Mode Description Notes

Simple X1 Single film, single sensor Sensor 1 active only. Analog/shutter outputs

Simple X2 Single film, single sensor Sensor 2 active only. Analog/shutter outputs

Backup Single film, dual sensors Crystal switching mode.

Averaging Single film, two sensors spatially

Alloy Two films codeposited Codeposition of two materials onto a

Independent Two films cluster deposition Allows STM-2XM to be used as two separate

averaged

section 3.3, STM-2XM Operating Modes, on

page 3-17). (See Table 3-1.)

selected by changing active source.

selected by changing active source.

PN 074-614-P1A

Used for large chambers or systems with a

moving substrate.

substrate at the same time.

instruments. Recommended for cluster tools

and research systems.

3 - 10

Page 47

STM-2XM Operating Manual

Test Mode

. . . . . . . . . . . . . . . . . . . . . Test mode provides simulated sensor

Active Source

(Active Channel)

Display Mode

Plot type

Plot time scale

. . . . . . . . . . . . . . . . . . .Displays thickness in kiloangstoms (

. . . . . . . . . . . . . . . . . . . . . . . Available in single film modes.

. . . . . . . . . . . . . . . . . .Sets the horizontal axis size. Defines the

LCD Contrast

LCD Brightness

readings.

NOTE:

If STM-2XM is reset, test mode is

turned off automatically.

. . . . . . . . . . . . . . . .For single film modes, this selects where the

analog and digital outputs and inputs are

connected (refer to

section 2.2 on page 2-3

kÅ)

).

or

mass in micrograms per square centimeter

µg/cm3)

(

.

Displays the graph on the Runtime screen as

None, Rate Deviation, Rate, or Thickness.

amount of time covered by the plot before it is

overwritten.

. . . . . . . . . . . . . . . . .Adjusts the appearance of the screen. Set the

brightness to 100%, and then adjust the

contrast until the display is easily read.

Brightness can be programmed to a desired

level.

NOTE:

The screen dims when STM-2XM is

idle.

Beep [on/off]

Comm Protocol

. . . . . . . . . . . . . . . . . . . Turns the button/control knob beeper on or off.

. . . . . . . . . . . . . . . . .Serial communications mode to STM-2XM,

Sycon 9600 (9.6 Kbps), SMDP L (9.6 Kbps),

SMDP M (38.4 Kbps), and SMDP H (115.2

PN 074-614-P1A

Kbps).

If the protocol selected is Sycon 9600,

STM-2XM performs serial communication with

Sycon protocol at 9600 baud, using RS-232

electrical levels.

If the protocol selected is SMDP, STM-2XM

performs serial communication using SMDP

protocol at 9600, 38400, or 115200 baud.

3 - 11

Page 48

STM-2XM Operating Manual

CAUTION

SMDP address

3.2.1.3 Setup Parameters

Changes in the Setup menu occur immediately. Relays

and analog outputs can activate unexpectedly during

programming.

Sensor setup . . . . . . . . . . . . . . . . . Main parameter that effects the

Table 3-2 Sensor setup parameter

Sensor Setup Available modes Rate sampling

1:Single

unshuttered

. . . . . . . . . . . . . . . . . . Serial communication mode for STM-2XM. If

the SMDP address is 16, STM-2XM uses

RS-232 electrical signaling; otherwise

STM-2XM uses RS-485 signaling.

choices/modes available (see Table 3-2

capable

Simple No No

).

Backup

capable

2:Single

shuttered

3:Dual w/single

shutter

4:Dual

unshuttered

5:Dual w/dual

shutters

Simple, Averaging, Alloy, Independent No If mode is

Simple, Averaging, Alloy, Independent Yes If mode is

Simple Yes No

Simple Yes Yes

Simple

Simple

Tooling, X1:SRC1 . . . . . . . . . . . . . . The ratio between substrate thickness using

Source 1 and Sensor 1 thickness (see

section 7.3, Determining Tooling, on page

7-2).

Tooling, X2:SRC1 . . . . . . . . . . . . . . The ratio between substrate thickness using

Source 1 and Sensor 2 thickness (see

section 7.3, Determining Tooling, on page

7-2).

NOTE: In independent chambers, set this

value to zero.

PN 074-614-P1A

3 - 12

Page 49

STM-2XM Operating Manual

Tooling, X1:SRC2 . . . . . . . . . . . . . . The ratio between substrate thickness using

Source 2 and Sensor 1 thickness (see

section 7.3, Determining Tooling, on page

7-2).

NOTE: In independent chambers. Set this

value to zero.

Tooling, X2:SRC2 . . . . . . . . . . . . . . The ratio between substrate thickness using

Source 2 and Sensor 2 thickness (see

section 7.3, Determining Tooling, on page

7-2).

Weight Ratio . . . . . . . . . . . . . . . . . . Available only in spatial averaging mode.

This parameter describes the percentage of

time the substrate is near Sensor 1. In

moving substrate systems, if the substrate

spends more time near one sensor than the

other, this needs to be accounted for in the

computations. If the substrate spends 90% of

time near Sensor 1, this parameter should be

programmed for 90%. If the substrate is

fixed, the default value is 50%.

Substrate Shutr . . . . . . . . . . . . . . . Configures the substrate shutter delay

operation (see Table 3-3).

Table 3-3 Substrate shutter setup parameters

Substrate shutter

setup

None N

CH1: Substrate3 Only for film on Channel 1

CH2: Substrate Only for film on Channel 2

PN 074-614-P1A

Shared substrate Only allows shutter delay for one film at a time

Dual substrate Allows dual shutter delay (alloy shutter delay)

Shutter Delay

Thick hold

Anal. Scl Mode . . . . . . . . . . . . . . . . Thickness, Mass

3 - 13

Page 50

STM-2XM Operating Manual

Analog Out 1 to 4 . . . . . . . . . . . . . . Determines the function of each of the

analog outputs (refer to section 2.2.3 on

page 2-5 for details on wiring analog

outputs). (See Table 3-4

Table 3-4 Analog output functions

Setting Description

None Output is disabled

Pos Fscl +10 V Fixed

Neg Fscl -10 V Fixed

Remote Output is computer set value

Ch1 Rdev 1k Rate Deviation, Channel 1, 1000 Å/s

Ch1 Rdev 10 Rate Deviation, Channel 1, 10 Å/s

Ch1 Rate 1k Rate, Channel 1, 1000 Å/s

Ch1 Rate 10 Rate, Channel 1, 10 Å/s

Ch1 Thickns Thickness Recorder, Channel 1, 999 Å

.)

Ch1 Mgthick Thickness Recorder, Channel 1, 99.9 Å

Ch2 Rdev 1k Rate Deviation, Channel 2, 1000 Å/s

Ch2 Rdev 10 Rate Deviation, Channel 2, 10 Å/s

Ch2 Rate 1k Rate, Channel 2, 1000 Å/s

Ch2 Rate 10 Rate, Channel 2, 10 Å/s

Ch2 Thickns Thickness Recorder, Channel 2, 999 Å

Ch2 Mgthick Thickness Recorder, Channel 2, 99.9 Å

PN 074-614-P1A

3 - 14

Page 51

STM-2XM Operating Manual

Relay 1 to 8 . . . . . . . . . . . . . . . . . . . Determines the function of each of the digital

(relay) outputs (refer to section 2.2.2 on page

2-4 for details on wiring digital outputs). (See

Table 3-5.)

Table 3-5 Relay functions

Setting Decription

None Relay is inactive

Forced ON Relay is always active

Remote Relay is controlled with remote communications

Ch 1 FP Keys Relay is toggled using Sensor 1 OPEN/CLOSE

buttons

Ch 2 FP Keys Relay is toggled using Sensor 2 OPEN/CLOSE

buttons

Srce 1 Shtr Relay activates Channel 1 source shutter

Srce 2 Shtr Relay activates Channel 2 source shutter

Subs 1 Shtr Relay activates Channel 1 substrate shutter

Subs 2 Shtr Relay activates Channel 2 substrate shutter

Sens 1 Shtr Relay activates Sensor 1 shutter

Sens 2 Shtr Relay activates Sensor 2 shutter

Xtal 1 Fail Relay activates when Sensor 1 fails

Xtal 2 Fail Relay activates when Sensor 2 fails

Stpt 1 Time Relay activates when Channel 1 setpoint time has

elapsed

Stpt 2 Time Relay activates when Channel 2 setpoint time has

elapsed

Stpt 1 Thik Relay activates when Channel 1 setpoint thickness

has been reached

PN 074-614-P1A

Stpt 2 Thik Relay activates when Channel 2 setpoint thickness

has been reached

Ch1 Rate OK Relay activates when Channel 1 rate is steady and

within tolerance

Ch2 Rate OK Relay activates when Channel 2 rate is steady and

within tolerance

Xtl 1 N.C. Relay is Normally Closed and opens to use Sensor

1

Xtl 2 N.C. Relay is Normally Closed and opens to use Sensor

2

3 - 15

Page 52

STM-2XM Operating Manual

Input 1.1 to 1.4

Input 2.1 to 2.4 . . . . . . . . . . . . . . . . Determines the function of each of the digital

(relay) outputs for Sensor 1 (1.X) and Sensor

2 (2.X) (refer to section 2.2.4 on page 2-6 for

details on wiring remote inputs). (See Table

3-6

.)

Table 3-6 Input functions

Setting Description

None Input is ignored

Zero Thick Zero accumulated thickness

Open Source Open source shutter and in deposit mode

Close Source Closed source shutter and in monitor mode

Select Xtal Switch active crystal

Terminal Thk Source final thickness

2 Chnl Fnltk All channels final thickness (alloy mode)

Alloy Syncup Open substrate shutter and sync start channels

(alloy mode)

3 - 16

PN 074-614-P1A

Page 53

3.3 STM-2XM Operating Modes

Source Shutter

Sensor

Chamber

Sensor Shutter

Source

Substrate Shutter

Substrate

Notice that one sensor

is off.

3.3.1 Simple

In simple mode, STM-2XM can read one sensor and can control a shutter for one

source. The deposition process is a single material per layer.

Figure 3-9 Simple mode

STM-2XM Operating Manual

PN 074-614-P1A

3 - 17

Page 54

3.3.2 Backup

Source Shutter

Source

Sensor Shutter

Dual Sensor

Chamber

Substrate Shutter

Substrate

Notice that both

sensors are on. The

arrow indicates the

active sensor

Select

Select

In backup mode, STM-2XM is a single layer, single source monitor using two

sensors; one sensor is a backup for the other sensor. If the active sensor fails,

STM-2XM automatically switches to the backup sensor. The active sensor can be

switched manually by pressing the lower OPEN and CLOSE buttons on the front

panel (refer to section 3.1.1 on page 3-2).

NOTE: The 1 and 2 on these buttons indicate which sensor will be selected (see

Figure 3-10 Backup mode

STM-2XM Operating Manual

Figure 3-10).

PN 074-614-P1A

3 - 18

Crystal 1 Crystal 2

Page 55

3.3.3 Averaging

Source

Source

Substrate

Substrate Shutter

Sensor Shutter

Sensor

Chamber

Shutter

Notice that both sensors are on

and their shutters are open.

The averaging mode is spatial averaging for two sensors. STM-2XM calculates

weighted averages of two sensors to determine the film rate and thickness. Both

sensors must be active and monitored at the same time. The effective

rate/ thickness is the average of the readings between Sensor 1 and Sensor 2.

NOTE: Averaging mode requires two operational sensors.

Figure 3-11 Averaging mode

STM-2XM Operating Manual

PN 074-614-P1A

3 - 19

Page 56

3.3.4 Alloy

Sensor Shutter

Source

Sensor

Source

Substrate

Chamber

Substrate Shutter

Source

Shutters

Total Substrate

Thickness

Film No.:Film Name

Film No.:Film Name

Deposit Rate for

Source 1

Deposit Rate for

Source 2

Ratio Indicator

(Based on

current rate)

STM-2XM Operating Manual

In alloy mode, two different materials are deposited onto the substrate at the same

time. STM-2XM associates a material with a sensor. Make sure to shield the

sensors so that each sensor monitors only one source.

In alloy mode, Sensor 1 (X1) is associated with Channel/Source 1 (top line on the

Runtime screen) and Sensor 2 (X2) is associated with Channel 2/Source 2 (bottom

line on the Runtime screen) (see Figure 3-12).

In alloy mode, STM-2XM links the source or substrate shutters together, so that the

evaporants are properly codeposited on the substrate. Each channel (or both) may

still have a shutter delay phase. In this case, when the channel(s) are programmed

with shutter delay, they both enter the deposit phase at the same time by pressing

either of the two OPEN buttons. Also, each channel may independently be

programmed for rate sampling.

In alloy mode, the setpoint thickness of each source channel is independent.

The Ratio Indicator displays the ratio as measured at the instant, not an overall

ratio.

NOTE: The chart is not available in Alloy Mode.

Figure 3-12 Alloy mode

PN 074-614-P1A

3 - 20

Page 57

3.3.5 Independent

Source Shutter

Sensor

Chamber

Sensor Shutter

Source

Substrate Shutter

Substrate

Source Shutter

Sensor

Chamber

Sensor Shutter

Source

Substratre Shutter

Substrate

Source 1 Related

Source 2 Related

In independent mode, STM-2XM acts like two separate simple monitors. The

source shutters are operated independently, and the films can be deposited

independently. The two channels are completely independent. Sensor 1 (X1) is

associated with Channel/Source 1 (top line on the screen) and Sensor 2 (X2) is

associated with Channel 2/Source 2 (bottom line on the screen)

NOTE: The chart is not available in Independent Mode. The setpoint indicators on

Figure 3-13 Independent mode

STM-2XM Operating Manual

the Runtime screen (refer to Figure 3-7 on page 3-6) are also not available

in Independent mode.

PN 074-614-P1A

3 - 21

Page 58

STM-2XM Operating Manual

CAUTION

3.4 Operation

3.4.1 No Shutter Delay

Press OPEN. STM-2XM transitions from Ready to Deposit. The setpoint time,

setpoint thickness, and end thickness indicators are cleared. When the

accumulated thickness reaches the End Thickness value for the active film (refer

to section 3.2.1.1 on page 3-8), STM-2XM automatically closes the source shutter

and transitions back to the Ready phase.

NOTE: The substrate thickness is not zeroed when the deposit phase is entered.

This allows multiple layers to be deposited and the accumulated total

substrate thickness to be displayed (also known as thickness summing).

Zero the thickness by pressing ZERO before pressing OPEN to display the

thickness of a single layer.

3.4.2 Shutter Delay

From the Ready phase, press OPEN. STM-2XM will enter the shutter delay phase

(SHUT_DLY). The substrate shutter remains closed but the source shutter

(if installed) opens. This allows for preconditioning of the source and establishing

a steady rate prior to opening the substrate shutter.

While in shutter delay the Open indicator blinks. When ready to start depositing,

press OPEN again. STM-2XM will open the substrate shutter and enter the deposit

phase.

NOTE: Setpoint time, setpoint thickness, and end thickness indicators are cleared

3.4.3 Test Mode

Test mode allows STM-2XM settings and operation to be tested without performing

an actual deposition. Setting Test mode On provides a simulated rate, to simulate

the effects of a real deposition.

In Test mode, STM-2XM simulates attached sensors, and provides a simplified way

to become familiar with the STM-2XM front panel indicators and programming.

It is possible to open or close the shutter to simulate deposition and zero readings.

It is also possible to test the Time and Thickness Setpoint relays and indicators.

at the beginning of the shutter delay phase.

PN 074-614-P1A

In Test mode, all setpoints, inputs, and outputs are active.

3 - 22

Page 59

3.4.4 Rate Sampling

STM-2XM rate sampling allows for long depositions by limiting the time the sensor

is exposed to the evaporant. STM-2XM samples rate for a period of time, then

closes the sensor shutter and assumes the rate is constant. STM-2XM

continuously opens and closes the sensor shutter according to the times

programmed. While depositing, when STM-2XM closes the sensor shutter,

STM-2XM enters a HOLD phase, and the locked-in rate blinks. STM-2XM will not

enter the HOLD phase unless the measured rate is at least 50% of the

programmed deposit rate for the film or 0.5 Å/s (whichever is greater). This

prevents STM-2XM from jumping into the HOLD phase before the rate has been

established.

3.5 Film States

FAIL TPW . . . . . . . . . . . . . . . . . . . . Crystal failed; completed time power

STM-2XM Operating Manual

(thickness was incremented at last known

rate and shutter was held open until End

Thickness was reached).

X FAIL . . . . . . . . . . . . . . . . . . . . . . . Crystal failed; film was aborted; all shutters

are closed. If the crystal recovers while in the

X FAIL phase, STM-2XM will transition to the

Ready phase.

READY. . . . . . . . . . . . . . . . . . . . . . . Sensor shutters are open, but all other

shutters are closed. Monitor is ready; press

OPEN to open source/substrate shutters.

SHUT DLY . . . . . . . . . . . . . . . . . . . . Sensor and source shutters are open but

substrate shutter is closed. This allows a rate

to be established. Pressing OPEN will

transition the film to Deposit (opening the

substrate shutter).

PN 074-614-P1A

COAST. . . . . . . . . . . . . . . . . . . . . . . Crystal failed, but STM-2XM is incrementing