Page 1

OPERATING MANUAL

STM-2

Rate and Thickness Monitor

PN 074-613-P1A

STM-2 Operating ManualPN

074-613-P1ATOC - #1 - #

Page 2

Page 3

www.inficon.com reachus@inficon.com

©2014 INFICON

®

Title P

age

OPERATING MANUAL

STM-2

Rate and Thickness Monitor

PN 074-613-P1A

Page 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

Windows® and Microsoft® are registered trademarks of Microsoft Corporation.

Inconel® is a registered trademark of Inco Alloys International, Huntington, WV.

LabVIEW

Sycon Instruments

TM

is a trademark of National Instruments Corporation.

TM

is a trademark of INFICON, Inc.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2014 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

Page 6

Page 7

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

one (1) year from the date of shipment thereof by Seller. Seller's liability under this

warranty is limited to such of the above products or parts thereof as are returned,

transportation prepaid, to Seller's plant, not later than thirty (30) days after the

expiration of the period of warranty coverage in respect thereof and are found by

Seller's examination to have failed to function properly because of defective

workmanship or materials and not because of improper installation or misuse and

is limited to, at Seller's election, either (a) repairing and returning the product or

part thereof, or (b) furnishing a replacement product or part thereof, transportation

prepaid by Seller in either case. In the event Buyer discovers or learns that a

product does not conform to warranty, Buyer shall immediately notify Seller in

writing of such non-conformity, specifying in reasonable detail the nature of such

non-conformity. If Seller is not provided with such written notification, Seller shall

not be liable for any further damages which could have been avoided if Seller had

been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

www.inficon.com reachus@inficon.com

Page 8

Page 9

STM-2 Operating Manual

Table Of Contents

Title Page

Trademarks

Disclaimer

Copyright

Declaration Of Conformity

Warranty

Chapter 1

Introduction and Specifications

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.1 Related Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Instrument Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.1 Definition of Notes, Cautions and Warnings. . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2.2 General Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3 How To Contact INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.3.1 Returning STM-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4.1 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4.2 Operating Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4.3 Size and Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4.4 Computer Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.5 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.6 Parts and Options Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.6.1 Base Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.6.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

PN 074-613-P1A

1.6.2.1 Oscillator Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.6.2.2 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Chapter 2

2.1 Installation Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Parts Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 System Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2.1 Internal Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2.2 External Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 Switching Between Internal and External Oscillator. . . . . . . . . . . . . . . . . . . 2-4

2.4 STM-2 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Installation

TOC - 1

Page 10

STM-2 Operating Manual

2.4.1 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.4.2 USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Chapter 3

STM-2 Software Operation

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Installing INFICON STM-2 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.1 Installing the Protocol Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.2 Installing the INFICON STM-2 Software and Device Drivers. . . . . . . . . . . . 3-2

3.2.3 Starting INFICON STM-2 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.3.1 Starting the Software in Windows XP or Windows 7 . . . . . . . . . . . . . . . . . . 3-3

3.2.3.2 Starting the Software in Windows 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3 STM-2 Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3.1 File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.3.1.1 Open Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.1.2 Save Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.1.3 Save Configuration As . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.1.4 Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.1.5 Screen Image to File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.2 Edit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.2.1 Graph Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.2.1.1 X Axis & Colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.3.2.1.2 Rate Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.3.2.1.3 Thickness Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.3.2.1.4 Frequency Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.3.2.2 Display Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.3.2.3 Sample Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.3.3 Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.3.3.1 About Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.3.4 STM-2 Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.3.5 Rate Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3.3.6 Thickness Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3.3.7 Frequency Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Chapter 4

STM-2 LabVIEW Operation

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Installing the STM-2 LabVIEW Application. . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2.1 Installing the Protocol Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2.2 Installing the LabVIEW Application and Device Drivers. . . . . . . . . . . . . . . . 4-2

PN 074-613-P1A

TOC - 2

Page 11

STM-2 Operating Manual

4.2.3 Starting the STM-2 LabVIEW Application. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2.3.1 Starting the Software in Windows XP or Windows 7 . . . . . . . . . . . . . . . . . . 4-3

4.2.3.2 Starting the Software in Windows 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.3 STM-x_win32.VI Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3.1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.3.1.1 Manual Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4.3.1.2 Simulate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

4.3.2 Operate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

4.3.3 Films . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.3.4 Rate Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.3.5 Mass/Thick Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.3.6 Frequency Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

4.3.7 Help/About . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Chapter 5

Communication

5.1 Communication Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Sycon Multi-Drop Protocol (SMDP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2.1 Command Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2.1.1 Checksum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.2.1.2 Command Packet Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5.2.1.3 Response Packet Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.2.2 Optional Serial Command Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5.2.2.1 Optional Serial Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.2.2.2 Additional Option to Serial Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.3 Communications Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Chapter 6

Troubleshooting and Maintenance

PN 074-613-P1A

6.1 Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.1.1 Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.1.2 General STM-2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.1.3 Troubleshooting Computer Communications . . . . . . . . . . . . . . . . . . . . . . . .6-7

Chapter 7

Calibration Procedures

7.1 Importance of Density, Tooling and Z-Ratio. . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Determining Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.3 Determining Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.4 Laboratory Determination of Z-Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

TOC - 3

Page 12

Chapter 8

8.1 Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1.1 Monitor Crystals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.1.2 Period Measurement Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.1.3 Z-match Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Appendix A

A.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

STM-2 Operating Manual

Measurement and Theory

Material Table

TOC - 4

PN 074-613-P1A

Page 13

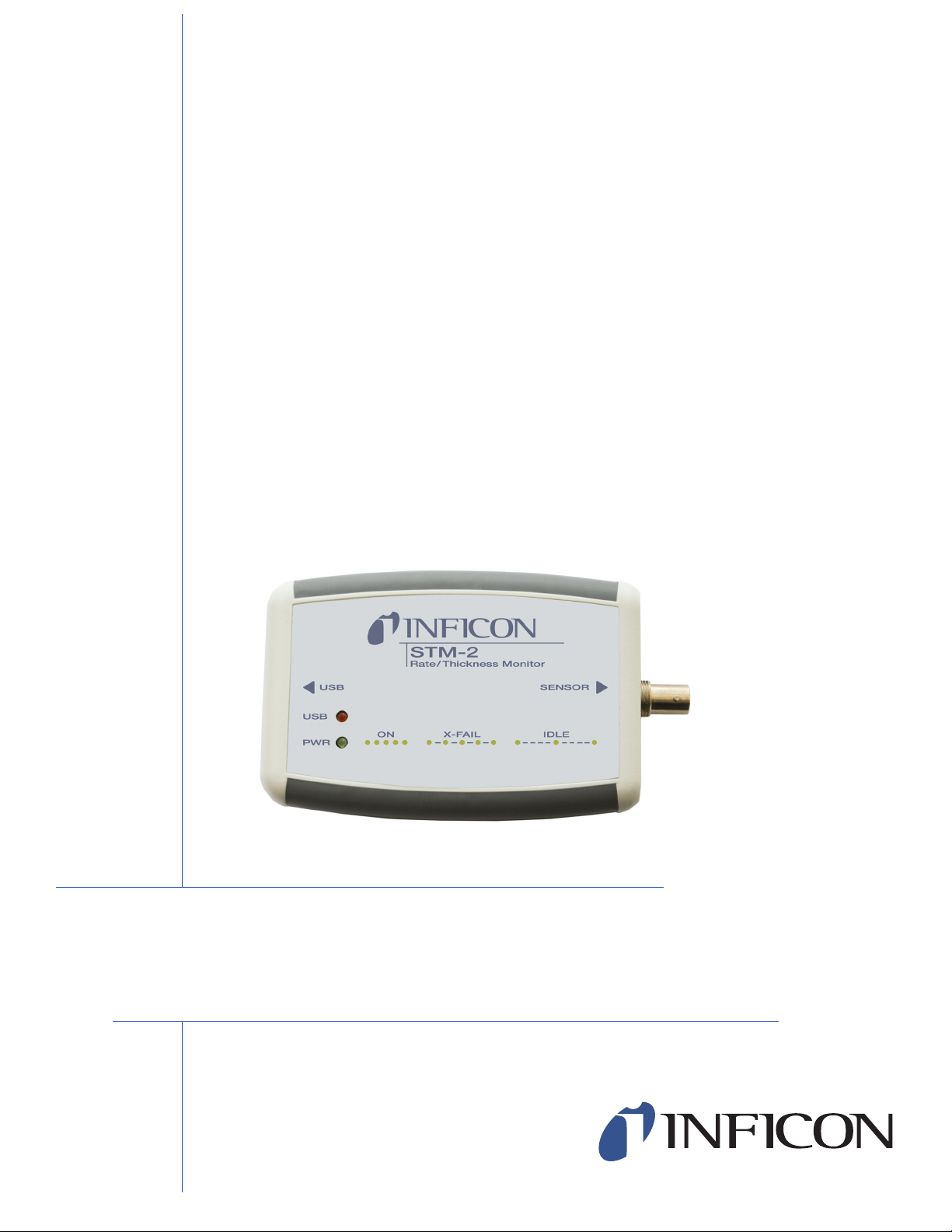

1.1 Introduction

STM-2™ is a USB-powered thin film thickness and rate deposition monitor (see

Figure 1-1). STM-2 provides precise control of thickness or mass deposition

experiments using a USB connection, Windows® or LabVIEW™ software

(provided), and a Windows computer (user supplied).

The STM-2 internal oscillator allows the sensor to be located within 76.2 cm (30 in.)

of STM-2. An external oscillator, PN 783-500-013, can be used when the sensor is

located farther than 101.6 cm (40 in.) from STM-2.

STM-2 can take ten measurements per second. The measurements are shown on

a 0.01Å/s rate display. STM-2 LabVIEW software has an option for multi-layer

mode. This mode enables a Layer Stackup pane, displaying a list of process

layers. It also enables cumulative substrate thickness to be displayed on the

software (see section 4.3.1 on page 4-6).

STM-2 Operating Manual

Chapter 1

Introduction and Specifications

Figure 1-1 STM-2

PN 074-613-P1A

1.1.1 Related Manuals

Sensors are covered in separate manuals. These manuals are contained in the

Thin Film Manuals CD (PN 074-5000-G1), which is part of the ship kit.

PN 074-154—Bakeable Sensor

PN 074-156—Front Load Sensor, Single/Dual

PN 074-157—Sputtering Sensor

PN 074-609—Cool Drawer Sensor, Single/Dual

1 - 1

Page 14

STM-2 Operating Manual

CAUTION

WARNING

WARNING - Risk Of Electric Shock

1.2 Instrument Safety

1.2.1 Definition of Notes, Cautions and Warnings

When using this manual, please pay attention to the notes, cautions and warnings

found throughout. For the purposes of this manual they are defined as follows:

NOTE: Pertinent information that is useful in achieving maximum STM-2 efficiency

when followed.

Failure to heed these messages could result in damage

to STM-2 or the loss of data.

Failure to heed these messages could result in personal

injury.

Dangerous voltages are present, which could result in

personal injury.

PN 074-613-P1A

1 - 2

Page 15

1.2.2 General Safety Information

CAUTION

CAUTION

WARNING

STM-2 contains delicate circuitry, susceptible to

transient power line voltages. Disconnect the USB cord

whenever making any sensor connections or when the

case is open.

Refer all maintenance to qualified personnel.

STM-2 may not be suitable for use with RF sputtering

systems or other electrically noisy environments.

STM-2 Operating Manual

Failure to operate STM-2 in the manner intended by

INFICON can circumvent the safety protection provided

by the instrument and may result in personal injury.

PN 074-613-P1A

1 - 3

Page 16

STM-2 Operating Manual

1.3 How To Contact INFICON

Worldwide customer support information is available under Support >> Support

Worldwide at www.inficon.com:

Sales and Customer Service

Technical Support

Repair Service

When communicating with INFICON about STM-2, please have the following

information readily available:

the Sales Order or Purchase Order number of the STM-2 purchase.

the version of STM-2 software (see section 3.3.3.1 on page 3-18 or section

4.3.7 on page 4-18).

the version of Windows operating system.

adescription of the problem.

an explanation of any corrective action that may have already been attempted.

the exact wording of any error messages that may have been received.

1.3.1 Returning STM-2

Do not return any component of STM-2 to INFICON before speaking with a

Customer Support Representative and obtaining a Return Material Authorization

(RMA) number. STM-2 will not be serviced without an RMA number.

Packages delivered to INFICON without an RMA number will be held until the

customer is contacted. This will result in delays in servicing STM-2.

If returning STM-2 with a crystal sensor or another component potentially exposed

to process materials, prior to being given an RMA number, a completed Declaration

Of Contamination (DOC) form will be required. DOC forms must be approved by

INFICON before an RMA number is issued. INFICON may require that the

component be sent to a designated decontamination facility, not to the factory.

PN 074-613-P1A

1 - 4

Page 17

1.4 Specifications

Compatible Sensor. . . . . . . . . . . . . . Non-shuttered single QCM sensor

Sensor Inputs . . . . . . . . . . . . . . . . . . 1

Sensor Input . . . . . . . . . . . . . . . . . . . Female BNC

Measurement Frequency Range . . . 6.0 to 5.0 MHz (fixed)

Frequency Resolution . . . . . . . . . . . ± 0.03 Hz @ 6 MHz

Measurement Interval. . . . . . . . . . . . 0.10 s

Reference Frequency Stability . . . . . ± 2 ppm

Thickness and Rate

Resolution/Measurement . . . . . . . . . ± 0.037 Å @ tooling/density = 100/1

Thickness Display Resolution . . . . . 1 Å

Interface . . . . . . . . . . . . . . . . . . . . . . USB, 5 m (16.4 ft.) maximum length

1.4.1 Power

STM-2 Operating Manual

Fundamental frequency = 6 MHz

Rated Supply Voltage. . . . . . . . . . . . 400 mA, 5 V (dc)

USB Isolation Voltage. . . . . . . . . . . . 1000 V

USB Isolation Capacitance. . . . . . . . 300 pF typically

1.4.2 Operating Environment

Usage . . . . . . . . . . . . . . . . . . . . . . . . Indoor use only

Operating Temperature . . . . . . . . . . 0 to 50°C (32 to 122°F)

Storage Temperature . . . . . . . . . . . . -10 to 60°C (14 to 140°F)

Humidity . . . . . . . . . . . . . . . . . . . . . . Up to 85% RH, non-condensing

Altitude . . . . . . . . . . . . . . . . . . . . . . . Up to 2000 meters

PN 074-613-P1A

Pollution Degree. . . . . . . . . . . . . . . . 2

1.4.3 Size and Weight

Size . . . . . . . . . . . . . . . . . . . . . . . . . 11.4 x 7.6 x 2.5 cm (4.5 x 3 x 1 in.)

Weight . . . . . . . . . . . . . . . . . . . . . . . 57 g (2 oz.)

1.4.4 Computer Requirements

Operating system . . . . . . . . . . . . . . . Windows 8, Windows 7, Windows Vista,

Windows XP, or Windows 2000

USB Port(s) . . . . . . . . . . . . . . . . . . . One USB 1.1 (or later) port for each STM-2

1 - 5

Page 18

STM-2 Operating Manual

1.5 Unpacking and Inspection

1 Remove STM-2 from its packaging.

2 Carefully examine STM-2 for damage that may have occurred during shipping.

It is especially important to note obvious rough handling on the outside of the

container. Immediately report any damage to the carrier and to INFICON.

NOTE: Do not discard the packaging material until inventory has been taken and

installation is successful.

3 Refer to the invoice and take inventory.

4 To install STM-2, see Chapter 2, Installation.

For additional information or technical assistance, contact INFICON (refer to

section 1.3 on page 1-4).

1.6 Parts and Options Overview

1.6.1 Base Configuration

STM-2 with software and cables . . . PN STM-2

1.6.2 Accessories

5 m (16.4 ft.) USB cable. . . . . . . . . . PN 068-0506

15.2 cm (6 in.) BNC . . . . . . . . . . . . . PN 755-257-G6

1.6.2.1 Oscillator Kit

STM-2 has an internal oscillator, however, an option exists to use an external

oscillator kit to interface the sensor to the controller (see section 2.3 on page 2-4).

3 m (10 ft.) Oscillator Kit. . . . . . . . . . PN 783-500-109-10

7.6 m (25 ft.) Oscillator Kit . . . . . . . . PN 783-500-109-25

15.2 m (50 ft.) Oscillator Kit . . . . . . . PN 783-500-109-50

22.9 m (75 ft.) Oscillator Kit . . . . . . . PN 783-500-109-75

PN 074-613-P1A

1 - 6

Page 19

Oscillator kits include:

These kits are designed for use with the standard in-vacuum cables ranging in

length from 15.2 cm (6 in.) to 78.1 cm (30.75 in.).

1.6.2.2 Sensors

Front Load Single Sensor. . . . . . . . . . . . PN SL-XXXXX

Cool Drawer Single Sensor . . . . . . . . . . PN CDS-XXFXX

Sputtering Sensor. . . . . . . . . . . . . . . . . . PN 750-618-G1

STM-2 Operating Manual

Oscillator. . . . . . . . . . . . . . . . . . . PN 783-500-013

15.2 cm (6 in.) BNC cable . . . . . PN 782-902-011

One of the following:

3 m (10 ft.) BNC Cable . . . . . PN 782-902-012-10

7.6 m (25 ft.) BNC Cable . . . PN 782-902-012-25

15.2 m (50 ft.) BNC Cable . . PN 782-902-012-50

22.9 m (75 ft.) BNC Cable . . PN 782-902-012-75

UHV Bakeable Sensor . . . . . . . . . . . . . . PN BK-A0F

Low Profile Singe Sensor . . . . . . . . . . . . PN 783-500-042

Low Profile Bakeable Single Sensor . . . PN 783-500-009

NOTE: Low Profile Single Sensors also have options with no cooling lines.

NOTE: "X" in part number indicates customer-selectable option,

see www.inficon.com for Sensor Datasheets.

NOTE: Multi-crystal (rotary) sensors and dual sensors should

not be used with STM-2.

PN 074-613-P1A

1 - 7

Page 20

STM-2 Operating Manual

This page is intentionally blank.

1 - 8

PN 074-613-P1A

Page 21

2.1 Installation Requirements

CAUTION

2.1.1 Parts Requirements

STM-2 Monitor

One crystal sensor with feedthrough

One oscillator kit for the crystal sensor

NOTE: The oscillator kit is not required when using the internal oscillator.

Quartz crystals appropriate for the application

One Windows computer meeting minimum specifications (refer to section 1.4

on page 1-5).

STM-2 Operating Manual

Chapter 2

Installation

To maintain proper STM-2 performance, use only

the provided 15.2 cm (6 in.) BNC cable to connect STM-2

or the oscillator to the crystal sensor.

The length of the in-vacuum cable (Front Load and

Sputtering sensors) or electrical conduit tube

(Cool Drawer and Bakeable sensors) must not exceed

78.1 cm (30.75 in.).

PN 074-613-P1A

2 - 1

Page 22

STM-2 Operating Manual

USB

USB

Cable

BNC Cable

Maximum Length

15.2 cm (6 in.)

Substrate

Source

Sensor

Jumpers set

for internal oscillator

2.2 System Connections

STM-2 can be configured to use either an internal or external oscillator depending

on the internal jumpers. The default jumper setting is to use the internal oscillator.

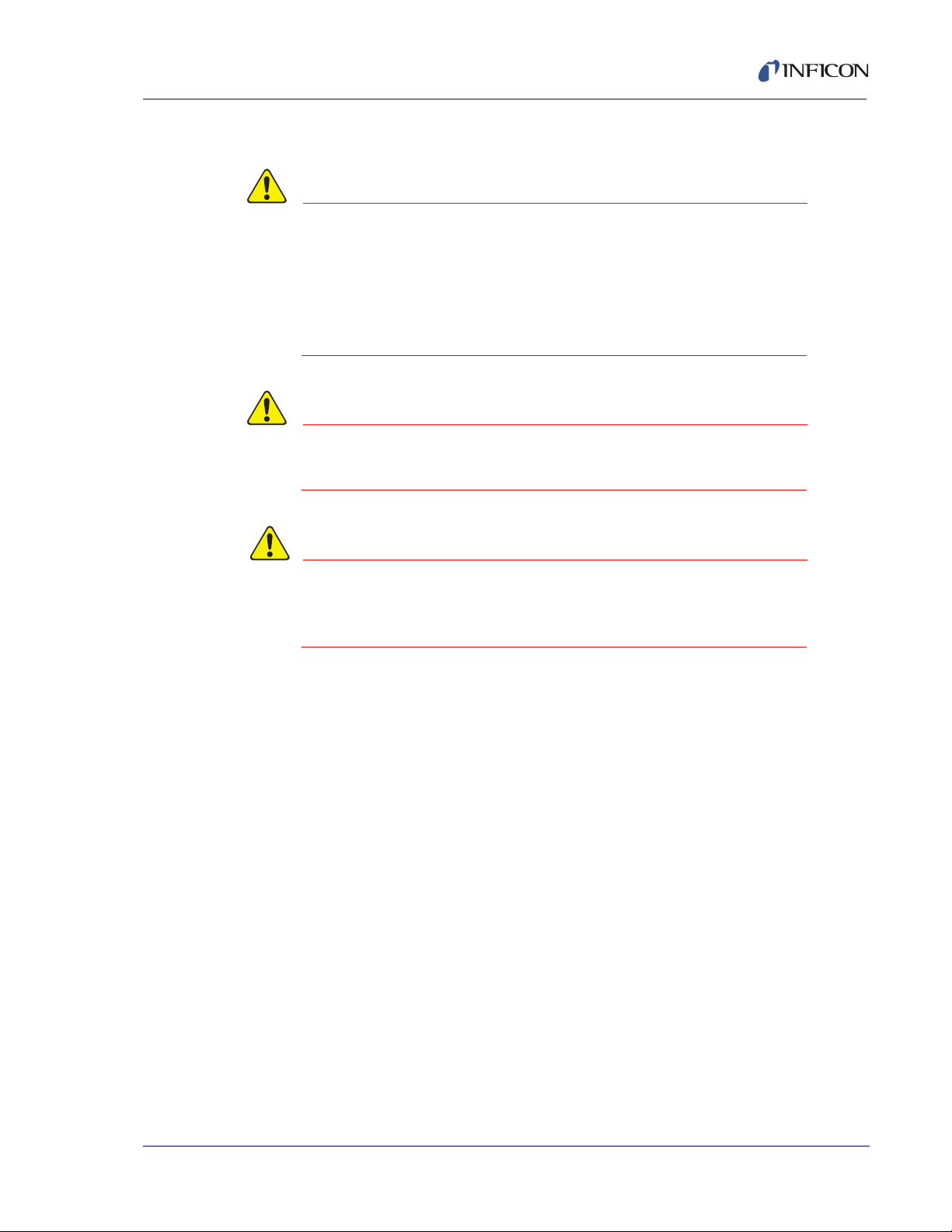

2.2.1 Internal Oscillator

1 Connect the (provided) USB cable to a computer USB port and to STM-2.

2 Use the (provided) 15.2 cm (6 in.) BNC cable to connect STM-2 to the sensor

feedthrough (see Figure 2-1).

Figure 2-1 Internal oscillator

3 Install and run STM-2 Software or STM-2 LabVIEW Application (see Chapter 3

or Chapter 4).

NOTE: STM-2 Software and STM-2 LabVIEW can be installed and run on the

same computer without interference.

4 The PWR indicator on STM-2 illuminates (see section 2.4.1 on page 2-5).

5 The USB indicator on STM-2 illuminates (see section 2.4.2 on page 2-5).

PN 074-613-P1A

2 - 2

Page 23

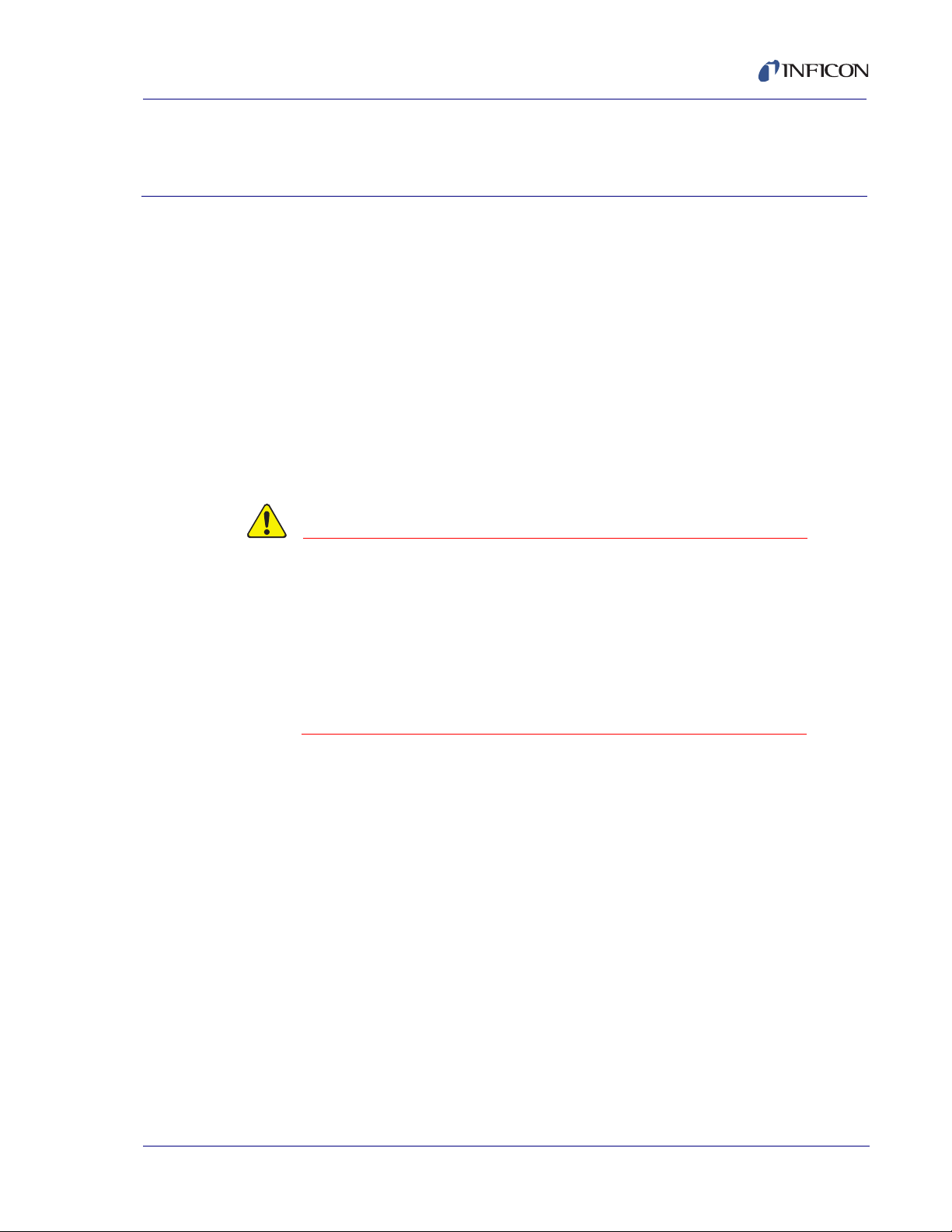

2.2.2 External Oscillator

USB

USB

Cable

BNC Cable

Maximum Length

22.9 m (75 ft.)

Substrate

Source

Sensor

Jumpers set

for external oscillator

Oscillator

783-500-013

15.2 cm (6 in.)

BNC Cable

To use an optional external oscillator, the jumpers inside STM-2 must be

repositioned (see section 2.3). The maximum BNC cable length connecting the

external oscillator and STM-2 is 22.9 m (75 ft.) (see Figure 2-2).

Figure 2-2 External oscillator

STM-2 Operating Manual

PN 074-613-P1A

2 - 3

Page 24

STM-2 Operating Manual

CAUTION

CAUTION - Static Sensitive Device

2.3 Switching Between Internal and External Oscillator

Three jumpers must be repositioned inside the STM-2 case to switch between the

internal oscillator and an external oscillator.

STM-2 contains delicate circuitry, susceptible to

transient power line voltages. Disconnect the USB cord

whenever making any sensor connections or when the

case is open.

Observe proper ESD procedures when the STM-2

case is open.

Remove the two phillips screws which secure the back of the case, and remove the

back of the case.

Near the BNC connector are three jumpers on the circuit board, labeled Internal

and External. Move all three jumpers:

To Internal for internal oscillator operation (see Figure 2-3).

To External for external oscillator operation.

Figure 2-3 Jumpers set for internal oscillator operation

PN 074-613-P1A

2 - 4

Page 25

2.4 STM-2 Indicators

2.4.1 Power

Illuminated . . . . . . . . . . . . . . . . . . . . STM-2 is powered up and is connected to a

Flashing fast . . . . . . . . . . . . . . . . . . . STM-2 is powered up but cannot detect a

Blinking slow

(approximately once per second) . . . STM-2 is powered up and the crystal is good,

Extinguished. . . . . . . . . . . . . . . . . . . STM-2 does not have power. Check the USB

STM-2 Operating Manual

good crystal.

The host computer has initialized STM-2 by

returning a reset status when the software

begins communication.

good crystal.

but the computer application has not

initialized STM-2. Once the computer

initializes STM-2 the indicator will illuminate

continuously (see section 6.1.1 on page 6-1).

connection, and make sure the computer is

turned on.

2.4.2 USB

The USB indicator detects communications signal traffic.

Illuminated . . . . . . . . . . . . . . . . . . . . STM-2 is connected and communicating to a

host computer. Communications

sent/received every 100 ms will cause the

indicator to be steadily illuminated.

Flashing . . . . . . . . . . . . . . . . . . . . . . STM-2 is connected and communicating to a

host computer. A flashing indicator will

correspond to the time elapsed between sent

PN 074-613-P1A

Extinguished. . . . . . . . . . . . . . . . . . . STM-2 is not communicating to the

NOTE: STM-x_win32 LabVIEW application software and INFICON STM-2

software will steadily illuminate the indicator due to communications

queries sent every 100 ms. User-created software may not steadily

illuminate the indicator due a longer time period elapsing between

communications queries being sent.

and received communications. A query sent

once per second will correspond to the

indicator flashing approximately once per

second.

computer.

2 - 5

Page 26

STM-2 Operating Manual

This page is intentionally blank.

2 - 6

PN 074-613-P1A

Page 27

STM-2 Software Operation

3.1 Introduction

INFICON STM-2 Software is capable of interfacing up to eight STM-2 instruments

to display Rate, Thickness, Frequency, and Crystal Life for the connected sensors.

STM-2 Software has independent Density, Z-Ratio, and Tooling parameters for

each STM-2 to allow for codeposition monitoring capabilities.

3.2 Installing INFICON STM-2 Software

3.2.1 Installing the Protocol Server

1 Insert the Thin Film Manuals CD into the CD drive on the computer that will

be connected to STM-2.

2 Click Windows Explorer or

File Explorer >> Computer >> (CD drive letter:) >> Common Software.

STM-2 Operating Manual

Chapter 3

3 Double click setup_smdp_svr_lv.exe. The Zip Self-Extractor window will

display.

4 Click Unzip. The SMDP Serial Protocol Server window will display.

5 On the Destination Directory pane, click Browse to select the location where

all software will be installed.

6 Click Next.

7 Read the license agreement.

8 Click I accept License Agreement(s).

9 Click Next.

10 Review the summary of information.

PN 074-613-P1A

11 Click Next. Installation Complete will display.

12 Click Next. The Setup Wizard pane will display.

13 Click Next. The Confirm Installation pane will display.

14 Click Next.

15 Read the license agreement.

16 Click I Agree.

17 Click Next. Installation Complete will display.

18 Click Close.

19 Click Close on the Zip Self-Extractor.

3 - 1

Page 28

STM-2 Operating Manual

3.2.2 Installing the INFICON STM-2 Software and Device Drivers

1 Insert the Thin Film Manuals CD into the CD drive of the computer that will be

connected to STM-2.

2 Click Windows Explorer or File Explorer >> Computer >> (CD drive letter:)

>> STM-2.

3 Double click STM-2 v1.0.0 Setup.exe. The STM-2 - InstallShield Wizard will

display.

4 Click Next.

5 Review the summary of information.

6 Select I accept the terms in the license agreement.

7 Click Next.

8 Click Change to select the location of the software files to be installed.

9 Click Next.

10 Click Install.

11 Click Finish. The USB Installer - InstallShield Wizard window will display.

12 Click Next.

13 Review the summary of information.

14 Select I accept the terms in the license agreement.

15 Click Next.

16 Enter User Name and Organization information.

17 Click Next.

18 Click Install.

19 Click Finish. The CP210x USB to UART Bridge Driver Installer window will

display.

20 Click Next.

21 Review the summary of information.

22 Select I accept this agreement.

23 Click Next.

24 Click Finish.

PN 074-613-P1A

3 - 2

Page 29

STM-2 Operating Manual

3.2.3 Starting INFICON STM-2 Software

3.2.3.1 Starting the Software in Windows XP or Windows 7

1 Click Start >> All Programs >> INFICON >> STM-2.

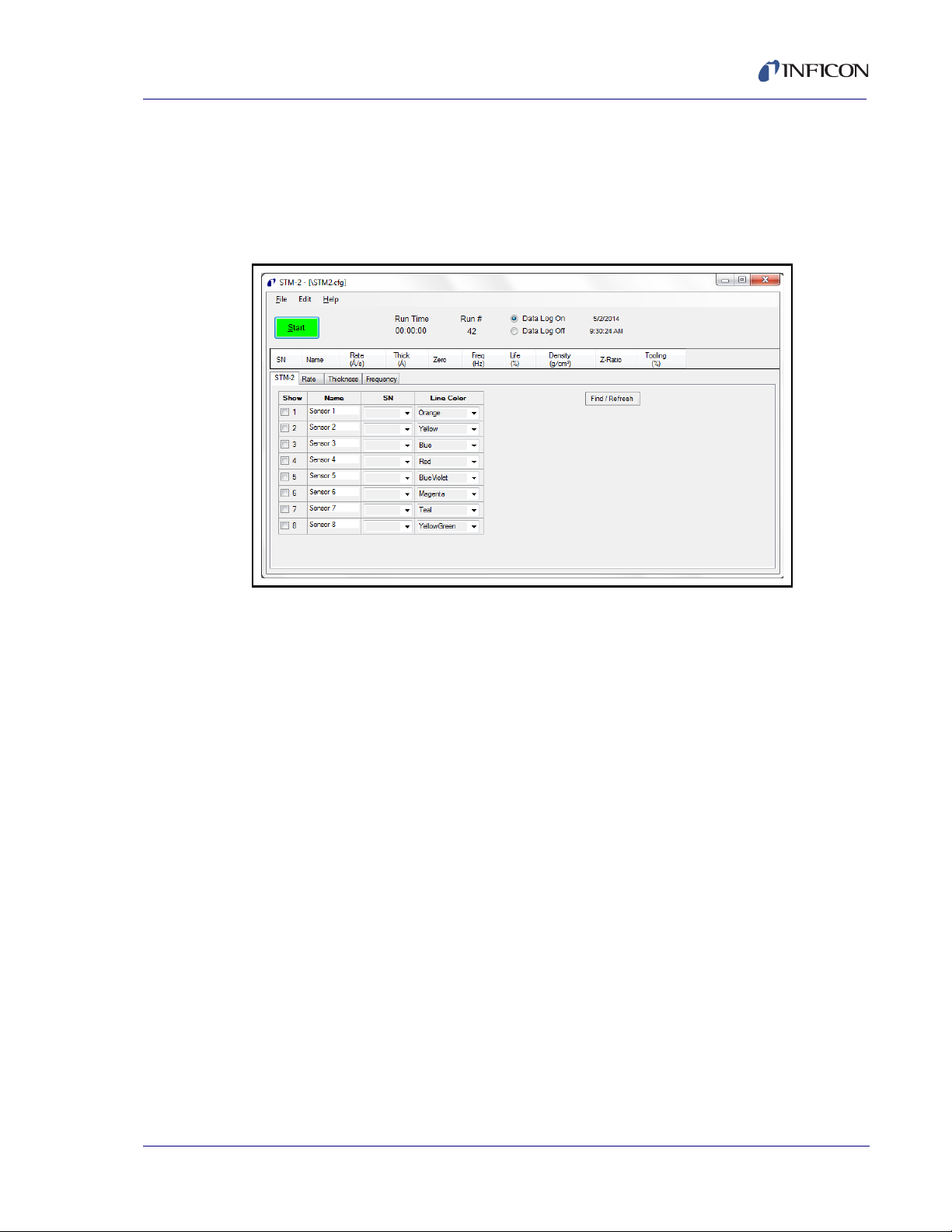

2 The STM-2 window will display (see Figure 3-1).

Figure 3-1 STM-2 window

3.2.3.2 Starting the Software in Windows 8

1 In the Start window, click the STM-2 icon.

2 If the icon cannot be found:

2a Click Search >> Apps.

2b Type STM in the Search text box.

2c Click the STM-2 icon.

PN 074-613-P1A

3 - 3

Page 30

STM-2 Operating Manual

3.3 STM-2 Window

The STM-2 window displays Serial Number (SN), (Sensor) Name, Rate,

Thick(ness) of the film, Zero thickness button, Freq(uency), crystal Life, Density of

the film, Z-Ratio, and Tooling for the connected sensor and process material. This

window also provides a button to Start, Stop, or Pause/Resume monitoring. Also,

the Run Time of the Process, the Run #, a selection for Data Log(ging) to be turned

on and off, and the current date and time are displayed. From this window, there is

also access to STM-2, Rate, Thickness, and Frequency tabs as well as the File,

Edit, and Help menus for customization and configuration (see Figure 3-2).

Figure 3-2 STM-2 window

3 - 4

File menu (see section 3.3.1 on page 3-6)

Edit menu (see section 3.3.2 on page 3-8)

Help menu (see section 3.3.3 on page 3-18)

STM-2 tab (see section 3.3.4 on page 3-19)

Rate tab (see section 3.3.5 on page 3-20)

Thickness tab (see section 3.3.6 on page 3-21)

Frequency tab (see section 3.3.7 on page 3-22)

PN 074-613-P1A

Page 31

STM-2 Operating Manual

STM-2 window

Start/Stop . . . . . . . . . . . . . . . . . . . . Click to Start monitoring. Start changes to

Stop. Stop will halt the process and data log

until Start is clicked.

Pause/Resume . . . . . . . . . . . . . . . . Pause is displayed while monitoring to pause

the monitoring. Pause stops the monitoring

at its current time and changes to Resume

when clicked. Resume will continue

monitoring and increment the Run Time.

Run Time . . . . . . . . . . . . . . . . . . . . . Time that the current run number has been

being monitored; resets when Start is clicked,

stops and continues when Pause/Resume

are clicked.

Run # . . . . . . . . . . . . . . . . . . . . . . . . Incremented when Start is clicked.

Data Log On/Data Log Off . . . . . . . Select Data Log On to enable data logging.

Select Data Log Off to disable data logging.

Date . . . . . . . . . . . . . . . . . . . . . . . . . Current date in month/day/year format.

Time . . . . . . . . . . . . . . . . . . . . . . . . . Current time in hh:mm:ss format.

SN . . . . . . . . . . . . . . . . . . . . . . . . . . Serial Number of STM-2(s) selected to view

(see section 3.3.4 on page 3-19).

Name . . . . . . . . . . . . . . . . . . . . . . . . Name of STM-2(s) selected to view (see

section 3.3.4 on page 3-19).

Rate . . . . . . . . . . . . . . . . . . . . . . . . . Rate, displayed in Å/s or Mass Rate

displayed in ng/cm

2

/s, of STM-2(s) selected

to view (see section 3.3.4 on page 3-19).

Thick . . . . . . . . . . . . . . . . . . . . . . . . Thickness displayed in Å or kÅ, or Mass in

2

µg/cm

, of STM-2(s) selected to view (see

section 3.3.2.2 on page 3-16).

PN 074-613-P1A

Zero . . . . . . . . . . . . . . . . . . . . . . . . . Click to zero thickness.

Freq . . . . . . . . . . . . . . . . . . . . . . . . . Frequency of the crystal connected to

STM-2(s) selected to view (see section 3.3.4

on page 3-19). This changes to !XTAL FAIL!

upon a crystal failure.

Life . . . . . . . . . . . . . . . . . . . . . . . . . . Percentage of crystal life remaining,

decremented from 100%.

NOTE: This is based on a 6 MHz crystal.

3 - 5

Page 32

STM-2 Operating Manual

Density . . . . . . . . . . . . . . . . . . . . . . 0.5 to 99.99

Value in grams per cubic centimeter of

material being deposited. Click in the text box

to edit the density value. For a list of common

material densities, see Appendix A.

Z-Ratio. . . . . . . . . . . . . . . . . . . . . . . 0.1 to 9.999

Z-Ratio of material being deposited. Click in

the text box to edit the Z-Ratio value. For a

list of Z-Ratios for common materials, see

Appendix A.

Tooling . . . . . . . . . . . . . . . . . . . . . . 10 to 399

Tooling of the sensor connected to STM-2.

Click in the text box to edit the Tooling value.

To determine tooling, see section 7.3 on

page 7-2.

3.3.1 File Menu

Click File to open or save a configuration file, to print or capture screen images, or

to exit INFICON STM-2 Software (see Figure 3-3).

Figure 3-3 File menu

PN 074-613-P1A

3 - 6

Page 33

3.3.1.1 Open Configuration

Click to select a file location of a configuration file and load that configuration file

into INFICON STM-2 Software (see Figure 3-4).

Figure 3-4 Open Configuration window

STM-2 Operating Manual

3.3.1.2 Save Configuration

Click to save the current configuration. The default configuration file is STM2.cfg.

3.3.1.3 Save Configuration As

Click to select a name and location to save the configuration file (see Figure 3-5).

Figure 3-5 Save As window

PN 074-613-P1A

3 - 7

Page 34

STM-2 Operating Manual

3.3.1.4 Print

Click to print all of the current views of the STM-2 window (refer to Figure 3-2 on

page 3-4) or, print only the current window displayed.

NOTE: If the print setup window has been configured once during a session, the

parameters selected will not be able to be changed until the software is

exited and reloaded.

3.3.1.5 Screen Image to File

This list item will display a list of options regarding screen images.

Current View to JPG . . . . . . . . . . . Places a JPEG image of the current window

All Views to JPGs. . . . . . . . . . . . . . Places JPEG images of the current views of

into the default Captures folder located in

Local Disk (C:) >> Program Files >>

INFICON >> STM-2 >> captures.

the STM-2 window into the default Captures

folder located in Local Disk (C:) >>

Program Files >> INFICON >> STM-2 >>

captures.

Select JPG Folder . . . . . . . . . . . . . Displays a window to select the location and

3.3.2 Edit Menu

Provides options to customize graph, display, and sample settings (see Figure

3-6).

Figure 3-6 Edit menu

3.3.2.1 Graph Settings

Click to display a window to configure the settings for Rate, Thickness, and

Frequency graphs. Also provides customization of line colors, axis formatting, and

scrolling.

NOTE: Graph Settings is disabled while monitoring.

name of the folder where the JPEG screen

images will be saved.

PN 074-613-P1A

3 - 8

Page 35

3.3.2.1.1 X Axis & Colors

Figure 3-7 X Axis & Colors tab

X Axis Width . . . . . . . . . . . . . . . . . . 1 minute to 120 minutes, 59 seconds

STM-2 Operating Manual

Use the spin box to enter the minutes and

seconds displayed as a maximum x-axis

value on all of the graphs.

X Text Interval. . . . . . . . . . . . . . . . . 1 to 480 seconds

Displays the time on the x-axis of all graphs

for the selected interval.

X Axis Scrolling . . . . . . . . . . . . . . . Select Step 5%, 25%, 50%, 75%, or 100%, to

determine the percentage of the graph that is

available for new data once the plot reaches

the maximum x-axis value.

Line Colors . . . . . . . . . . . . . . . . . . . Use the drop-down list box to select a color

to correspond with each STM-2 connected.

NOTE: This will also change the Line Color

on the STM-2 tab (see Figure 3-15

PN 074-613-P1A

on page 3-19).

Click Apply to update the display with any changes made. Click OK to save

changes and exit the Configure Graph(s) window. Click Cancel to cancel any

changes and exit the Configure Graph(s) window.

3 - 9

Page 36

STM-2 Operating Manual

3.3.2.1.2 Rate Tab

Figure 3-8 Rate tab

Y Axis Range pane

Min. . . . . . . . . . . . . . . . . . . . . . . . . . -100.00 to 100.00

Minimum y-axis value displayed on the Rate

graph.

NOTE: Minimum value must be less than the

value entered for the maximum.

Max. . . . . . . . . . . . . . . . . . . . . . . . . . -100.00 to 100.00

Maximum y-axis value displayed on the Rate

graph.

NOTE: Maximum value must be greater

than the value entered for the

minimum.

Axis Ticks pane

X Step . . . . . . . . . . . . . . . . . . . . . . . 0 to 100.0

Displays unlabeled x-axis ticks at the interval

selected.

NOTE: Ticks are only visible if Visible has

been selected. Clear to disable ticks.

Y Step . . . . . . . . . . . . . . . . . . . . . . . 0 to 100.0

Displays unlabeled y-axis ticks at the interval

selected.

PN 074-613-P1A

3 - 10

NOTE: Ticks are only visible if Visible has

been selected. Clear to disable ticks.

Page 37

STM-2 Operating Manual

Graph Grid pane

X Spacing . . . . . . . . . . . . . . . . . . . . 0 to 100.0

Displays x-axis grid at the interval selected.

NOTE: Grid is only visible at the selected

interval when Visible has been

selected. Clear to disable grid lines.

Y Spacing . . . . . . . . . . . . . . . . . . . . 0 to 100.0

Displays y-axis grid at the interval selected.

NOTE: Grid is only visible at the selected

interval when Visible has been

selected. Clear to disable grid lines.

Solid Line Y=0. . . . . . . . . . . . . . . . . Select to display a solid line on the Rate

graph at Y=0. Clear to remove the solid line

at Y=0.

Graph Title pane

Edit text box to rename the Rate graph.

NOTE: Click Apply to update the display with any changes made. Click OK to

save changes and exit the Configure Graph(s) window. Click Cancel to

cancel any changes and exit the Configure Graph(s) window.

PN 074-613-P1A

3 - 11

Page 38

STM-2 Operating Manual

3.3.2.1.3 Thickness Tab

Figure 3-9 Thickness tab

Y Axis Range pane

Min. . . . . . . . . . . . . . . . . . . . . . . . . . -100.00 to 100.00

Minimum y-axis value displayed on the

Thickness graph.

NOTE: Minimum value must be less than the

value entered for the maximum.

Max. . . . . . . . . . . . . . . . . . . . . . . . . . -100.00 to 100.00

Maximum y-axis value displayed on the

Thickness graph.

NOTE: Maximum value must be greater

than the value entered for the

minimum.

Axis Ticks pane

X Step . . . . . . . . . . . . . . . . . . . . . . . 0 to 100.0

Displays unlabeled x-axis ticks at the interval

selected.

NOTE: Ticks are only visible if Visible has

been selected. Clear to disable ticks.

Y Step . . . . . . . . . . . . . . . . . . . . . . . 0 to 100.0

Displays unlabeled y-axis ticks at the interval

selected.

PN 074-613-P1A

3 - 12

NOTE: Ticks are only visible if Visible has

been selected. Clear to disable ticks.

Page 39

STM-2 Operating Manual

Graph Grid pane

X Spacing . . . . . . . . . . . . . . . . . . . . 0 to 100.0

Displays x-axis grid at the interval selected.

NOTE: Grid is only visible at the selected

interval when Visible has been

selected. Clear to disable grid lines.

Y Spacing . . . . . . . . . . . . . . . . . . . . 0 to 100.0

Displays y-axis grid at the interval selected.

NOTE: Grid is only visible at the selected

interval when Visible has been

selected. Clear to disable grid lines.

Solid Line Y=0. . . . . . . . . . . . . . . . . Select to display a solid line on the Thickness

graph at Y=0. Clear to remove the solid line

at Y=0.

Graph Title pane

Edit text box to rename the Thickness graph.

NOTE: Click Apply to update the display with any changes made. Click OK to

save changes and exit the Configure Graph(s) window. Click Cancel to

cancel any changes and exit the Configure Graph(s) window.

PN 074-613-P1A

3 - 13

Page 40

STM-2 Operating Manual

3.3.2.1.4 Frequency Tab

Figure 3-10 Frequency tab

Y Axis Range pane

Min. . . . . . . . . . . . . . . . . . . . . . . . . . 4.000000 to 6.100000 MHz

Minimum y-axis value displayed on the

Frequency graph.

NOTE: Minimum value must be less than the

value entered for the maximum.

Max. . . . . . . . . . . . . . . . . . . . . . . . . . 4.000000 to 6.100000 MHz

Maximum y-axis value displayed on the

Frequency graph.

NOTE: Maximum value must be greater

than the value entered for the

minimum.

Axis Ticks pane

X Step . . . . . . . . . . . . . . . . . . . . . . . 0 to 100

Displays unlabeled x-axis ticks at the interval

selected.

NOTE: Ticks are only visible if Visible has

been selected. Clear to disable ticks.

Y Step . . . . . . . . . . . . . . . . . . . . . . . 0.000000 to 100.000000

Displays unlabeled y-axis ticks at the interval

selected.

PN 074-613-P1A

3 - 14

NOTE: Ticks are only visible if Visible has

been selected. Clear to disable ticks.

Page 41

STM-2 Operating Manual

Graph Grid pane

X Spacing . . . . . . . . . . . . . . . . . . . . 0 to 100

Displays x-axis grid at the interval selected.

NOTE: Grid is only visible at the selected

interval when Visible has been

selected. Clear to disable grid lines.

Y Spacing . . . . . . . . . . . . . . . . . . . . 0.000000 to 100.000000

Displays y-axis grid at the interval selected.

NOTE: Grid is only visible at the selected

interval when Visible has been

selected. Clear to disable grid lines.

Graph Title pane

Edit text box to rename the Frequency graph.

NOTE: Click Apply to update the display with any changes made. Click OK to

save changes and exit the Configure Graph(s) window. Click Cancel to

cancel any changes and exit the Configure Graph(s) window.

PN 074-613-P1A

3 - 15

Page 42

STM-2 Operating Manual

3.3.2.2 Display Settings

Click to display a window to configure the settings for Rate Resolution, Filtering,

Format, and View of the STM-2 window (see Figure 3-11).

Figure 3-11 Display Settings window

Rate Resolution . . . . . . . . . . . . . . . Use the drop-down list box to select 0.0 or

Filtering . . . . . . . . . . . . . . . . . . . . . . 1 to 99

0.00 as the rate resolution to be displayed on

the STM-2 window.

Use the spin box to enter the number of

samples to be averaged together for the

STM-2 window Rate display.

NOTE: This value will not affect graphs or

data logs. Use the Samples

Averaged parameter (see section

3.3.2.3) for averaging to affect all

displays and data logs.

Format . . . . . . . . . . . . . . . . . . . . . . . Select Thickness in kÅ, Thickness in Å, or

Mass in µg/cm

2

to be displayed on the

STM-2 window and on the Thickness graph.

NOTE: Mass in µg/cm

a Mass Rate in ng/cm

2

will display Rate as

2

/s.

View/Edit . . . . . . . . . . . . . . . . . . . . . Select Application On Top to display the

STM-2 window in front of all other open

windows. Select Lock Parameters to

disable editing of Density, Z-Ratio, and

Tooling on the STM-2 window.

PN 074-613-P1A

3 - 16

Page 43

3.3.2.3 Sample Settings

Click to display a window to configure the settings for data logging, display, and

graphs (see Figure 3-12).

NOTE: Sample Settings is disabled while monitoring.

Figure 3-12 Sample Settings window

STM-2 Operating Manual

Samples averaged . . . . . . . . . . . . . 1 to 50

Use the spin box to enter the number of

samples averaged for the display, graphs,

and data logging.

Logging Rate . . . . . . . . . . . . . . . . . 1 to 120

Use the spin box to select the logging rate. A

Logging Rate of 1 will log every averaged

measurement.

Logging Interval . . . . . . . . . . . . . . . Displays the data logging period in seconds.

Overwrite. . . . . . . . . . . . . . . . . . . . . Select to overwrite the current data log with

new data.

PN 074-613-P1A

Append . . . . . . . . . . . . . . . . . . . . . . Select to add new data log information to

current data log.

Run# . . . . . . . . . . . . . . . . . . . . . . . . Select to create a new data log named with

the run number being logged.

Select. . . . . . . . . . . . . . . . . . . . . . . . Click to select the name and location of data

log files.

View . . . . . . . . . . . . . . . . . . . . . . . . . Click to view the current data log.

3 - 17

Page 44

STM-2 Operating Manual

3.3.3 Help Menu

Figure 3-13 Help menu

About. . . . . . . . . . . . . . . . . . . . . . . . Click to view the About window (see section

3.3.3.1 About Window

Displays the version number of INFICON STM-2 Software, copyright information,

and the location of the software files (see Figure 3-14).

Figure 3-14 About window

3.3.3.1).

3 - 18

PN 074-613-P1A

Page 45

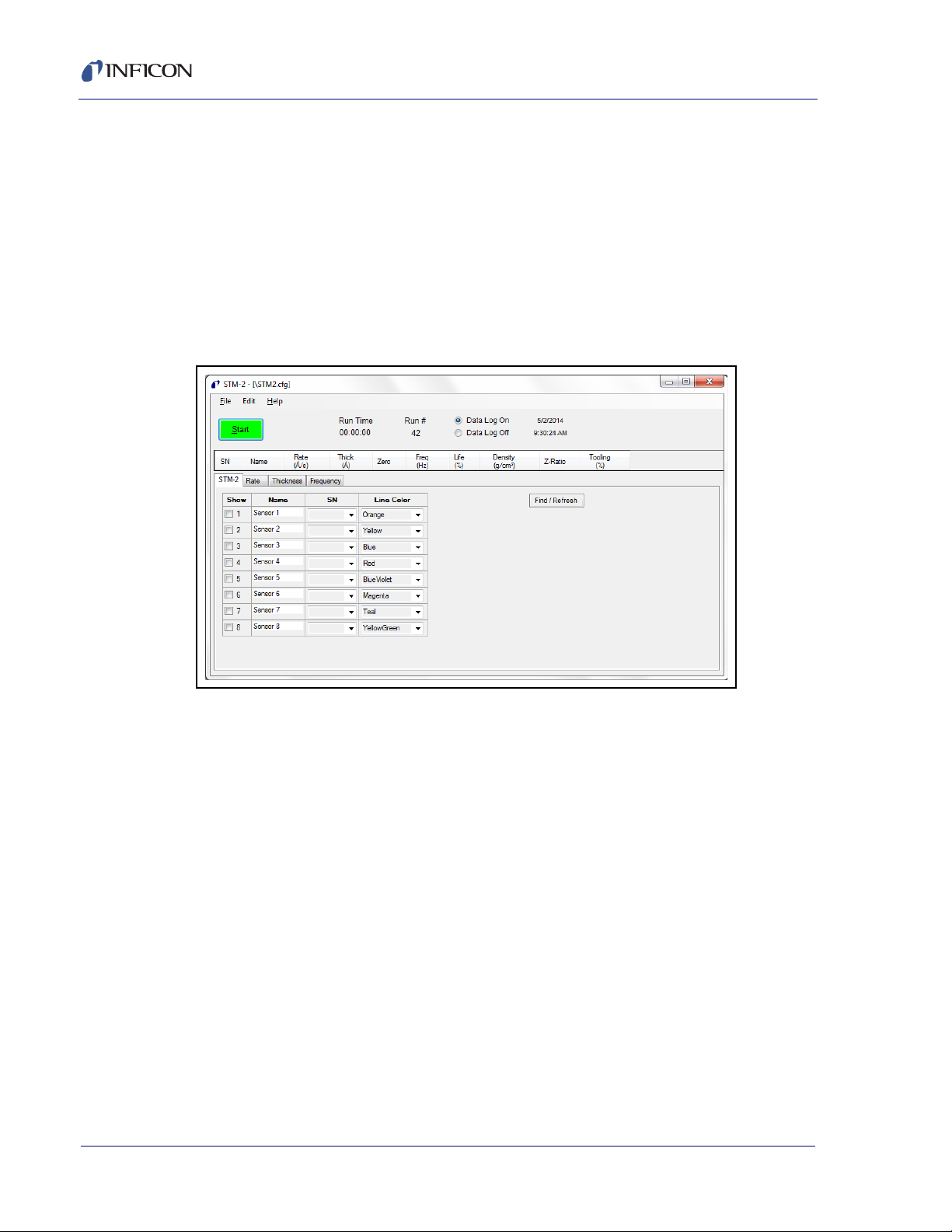

3.3.4 STM-2 Tab

Figure 3-15 STM-2 tab

Show . . . . . . . . . . . . . . . . . . . . . . . . Select the sensors to be displayed on the

STM-2 Operating Manual

STM-2 window.

Name . . . . . . . . . . . . . . . . . . . . . . . . Edit the name of the sensor. This name will

be displayed on the STM-2 window if

selected.

SN . . . . . . . . . . . . . . . . . . . . . . . . . . Use the drop-down list box to select the serial

number of the connected STM-2 associated

with the named sensor.

Line Color . . . . . . . . . . . . . . . . . . . . Use the drop-down list box to select a color

to correspond with each STM-2 connected.

NOTE: This will also change the Line Color

on the X Axis & Colors tab of the

Graph Settings window (refer to

PN 074-613-P1A

Figure 3-7 on page 3-9).

Find/Refresh . . . . . . . . . . . . . . . . . . Click to Find or Refresh connected STM-2(s).

3 - 19

Page 46

3.3.5 Rate Tab

Displays a graph of Rate and Time for the selected STM-2(s) (see Figure 3-16).

Figure 3-16 Rate tab

STM-2 Operating Manual

3 - 20

PN 074-613-P1A

Page 47

3.3.6 Thickness Tab

Displays a graph of Thickness or Mass and Time for the selected STM-2(s) (see

Figure 3-17).

Figure 3-17 Thickness tab

STM-2 Operating Manual

PN 074-613-P1A

3 - 21

Page 48

STM-2 Operating Manual

3.3.7 Frequency Tab

Displays a graph of Frequency and Time for the selected STM-2(s) (see Figure

3-18).

Figure 3-18 Frequency tab

3 - 22

PN 074-613-P1A

Page 49

STM-2 Operating Manual

STM-2 LabVIEW Operation

4.1 Introduction

STM-2 LabVIEW Application is capable of displaying Rate, Thickness, and Crystal

Life for one STM-2 and the connected sensor. STM-2 LabVIEW Application has the

option to use Multi-layer mode to enable a cumulative Substrate Thickness and

independent Density, Z-Ratio, Tooling, and Sample parameters for each film to

allow for multi-layer monitoring capabilities. STM-2 LabVIEW Application can also

operate in Simulate mode without a connected STM-2.

4.2 Installing the STM-2 LabVIEW Application

4.2.1 Installing the Protocol Server

1 Insert the Thin Film Manuals CD into the CD drive on the computer that will

be connected to STM-2.

Chapter 4

2 Click Windows Explorer or

File Explorer >> Computer >> (CD drive letter:) >> Common Software.

3 Double click setup_smdp_svr_lv.exe. The Zip Self-Extractor window will

display.

4 Click Unzip. The SMDP Serial Protocol Server window will display.

5 On the Destination Directory pane, click Browse to select the location where

all software will be installed.

6 Click Next.

7 Read the license agreement.

8 Click I accept License Agreement(s).

9 Click Next.

PN 074-613-P1A

10 Review the summary of information.

11 Click Next. Installation Complete will display.

12 Click Next. The Setup Wizard pane will display.

13 Click Next. The Confirm Installation pane will display.

14 Click Next.

15 Read the license agreement.

16 Click I Agree.

17 Click Next. Installation Complete will display.

18 Click Close.

19 Click Close on the Zip Self-Extractor.

4 - 1

Page 50

STM-2 Operating Manual

4.2.2 Installing the LabVIEW Application and Device Drivers

1 Insert the Thin Film Manuals CD into the CD drive on the computer that will

be connected to STM-2.

2 Click Windows Explorer or

File Explorer >> Computer >> (CD drive letter:) >> STM-2 >> TOOLS >>

main app.

3 Double click setup_stm-x_win32.exe. The Zip Self-Extractor window will

display.

4 Click Unzip. The Sycon STM-x_win32 window will display.

5 On the Destination Directory pane, click Browse to select the location where

all software will be installed.

6 Click Next.

7 Review the summary of information.

8 Click Next. Installation Complete will display.

9 Click Next. The Silicon Laboratories CP210x VCP Drivers for Windows

2000/XP/2003 Server/Vista window will display.

10 Click Next.

11 Read the license agreement.

12 Click I accept the terms of the license agreement.

13 Click Next.

14 On the Choose Destination Location pane, click Browse to select the

location where all drivers will be installed.

15 Click Next.

16 Click Install. The InstallShield Wizard Complete pane will display.

17 Select Launch the CP210x VCP Driver Installer.

18 Click Finish. The Silicon Laboratories CP210x USB to UART Bridge Driver

Installer window will display.

19 Click Change Install Location to select the location where all drivers will be

installed.

20 Click Install. The Success window will display.

21 Click OK.

22 Click Close on the Zip Self-Extractor.

PN 074-613-P1A

4 - 2

Page 51

STM-2 Operating Manual

4.2.3 Starting the STM-2 LabVIEW Application

4.2.3.1 Starting the Software in Windows XP or Windows 7

1 Click Start >> All Programs >> Sycon >> STM-x_win32 >> STM-x_win32.

2 The STM-x_win32.VI window will display (see Figure 4-1).

Figure 4-1 STM-x_win32.VI initial display

4.2.3.2 Starting the Software in Windows 8

1 In the Start window, click the STM-x_win32 icon.

2 If the icon cannot be found:

2a Click Search >> Apps.

PN 074-613-P1A

2b Type STM in the Search text box.

2c Click the STM-x_win32 icon.

4 - 3

Page 52

STM-2 Operating Manual

4.3 STM-x_win32.VI Window

The STM-x_win32.VI window displays Rate, Film Thick(ness), and Substrate

Thick(ness) for the connected sensor. This window also provides an indicator for a

crystal fail (Xtal OK?), Running time, Life percentage, Run number, Logging status,

and Film name as well as customizable display parameters, graphical information,

and access to Setup, Operate, Films, Rate Graph, Mass/Thick Graph, Frequency

Graph, and Help/About tabs (see Figure 4-2).

NOTE: Right-click and select Description and Tip for additional information.

Figure 4-2 STM-x_win32.VI live display

4 - 4

Setup tab (see section 4.3.1 on page 4-6)

Operate tab (see section 4.3.2 on page 4-10)

Films tab (see section 4.3.3 on page 4-12)

Rate Graph tab (see section 4.3.4 on page 4-14)

Mass/Thick Graph tab (see section 4.3.5 on page 4-15)

Frequency Graph tab (see section 4.3.6 on page 4-16)

Help/About tab (see section 4.3.7 on page 4-18)

PN 074-613-P1A

Page 53

STM-2 Operating Manual

Good

Crystal

Crystal

Fail

Sycon STM Instrument Interface pane

Press to Halt . . . . . . . . . . . . . . . . . . Click to exit STM-x_win32.VI application.

Rate . . . . . . . . . . . . . . . . . . . . . . . . . Deposition rate based on the frequency of

the crystal.

Film Thick/Film Mass . . . . . . . . . . . Thickness or Mass of Film being monitored.

Substrate Thick/Substrate Mass. . Accumulated Thickness or Mass of all layers.

Clear Graphs. . . . . . . . . . . . . . . . . . Clears Rate, Mass/Thick, and Frequency

graphs.

Xtal OK? . . . . . . . . . . . . . . . . . . . . . Illuminated light green when a good crystal is

connected; dark green when a crystal fail has

occurred (see Figure 4-3).

Figure 4-3 Xtal OK

RUNNING/PAUSED. . . . . . . . . . . . . Running changes to Paused if the process is

paused on the Operate tab (see section

4.3.2 on page 4-10).

h:mm:ss . . . . . . . . . . . . . . . . . . . . . Time that the current run number has been

running; resets with each new run.

Life/XTAL FAIL . . . . . . . . . . . . . . . . Percentage of crystal life remaining,

decremented from 100%; changes to XTAL

FAIL upon a crystal failure.

PN 074-613-P1A

RUN #. . . . . . . . . . . . . . . . . . . . . . . . Incremented when New run is clicked on the

Operate tab (see section 4.3.2 on page

4-10).

LOGGING OFF/LOGGING ON . . . . Logging off changes to logging on when data

logging is enabled by selecting OFF/ON in

the Datalog pane of the Setup tab (see

section 4.3.1).

Film . . . . . . . . . . . . . . . . . . . . . . . . . Name of film being monitored is displayed.

4 - 5

Page 54

4.3.1 Setup

STM-2 Operating Manual

Figure 4-4 Setup tab

Connection pane

Find Instrument . . . . . . . . . . . . . . . Click to search for instruments (see Figure

4-5).

Figure 4-5 Find instrument window

Search for STM-1s . . . . . . . . . . Automatically detects connected STM-1s.

Search for STM-2s . . . . . . . . . . Automatically detects connected STM-2s.

Manual Connection . . . . . . . . . See section 4.3.1.1 on page 4-8.

Simulate . . . . . . . . . . . . . . . . . . See section 4.3.1.2 on page 4-9

.

Cancel . . . . . . . . . . . . . . . . . . . . Closes Find Instrument window.

PN 074-613-P1A

4 - 6

Text Box . . . . . . . . . . . . . . . . . . . . . Displays the connection information for the

connected STM-2.

Page 55

STM-2 Operating Manual

Display pane

Thickness . . . . . . . . . . . . . . . . . . . . Displays Rate units of Å/s,

Film Thick units of kÅ, and

Substrate Thick units of kÅ on the

STM-x_win32.VI window.

Mass . . . . . . . . . . . . . . . . . . . . . . . . Displays Rate units of µg*s/cm², Film Mass

units of µg/cm², and Substrate Mass units of

µg/cm² on the STM-x_win32.VI window.

Multi-layer mode. . . . . . . . . . . . . . . When enabled, displays Substrate

Thick/Substrate Mass on the

STM-x_win32.VI window and displays the

New Layer button and Layer Stackup pane

on the Operate tab.

Run# . . . . . . . . . . . . . . . . . . . . . . . . Manually increment the Run number on the

Sycon STM Instrument Interface pane.

Datalog pane

OFF/ON . . . . . . . . . . . . . . . . . . . . . . Enables data logging.

Log Period. . . . . . . . . . . . . . . . . . . . hh:mm:ss

Assigns a data log period to record

monitored values. Records:

Date

Time

Running

Life

Run#

Logging on

Film

Rate

Film Thickness/Film Mass

PN 074-613-P1A

Substrate Thickness/Substrate Mass

Frequency

Run# . . . . . . . . . . . . . . . . . . . . . . . . Names the file with the Run number.

STMxlog.txt . . . . . . . . . . . . . . . . . . . Names the file with STMxlog.

Tab delimiter . . . . . . . . . . . . . . . . . . Records values in data logs delimited with

tabs to separate each field.

Comma delimiter . . . . . . . . . . . . . . Records values in data logs with commas to

separate each field.

View Log . . . . . . . . . . . . . . . . . . . . . Click to view current data log.

Logfile folder. . . . . . . . . . . . . . . . . . Click the folder icon ( ) to select the

location to save data log files.

4 - 7

Page 56

STM-2 Operating Manual

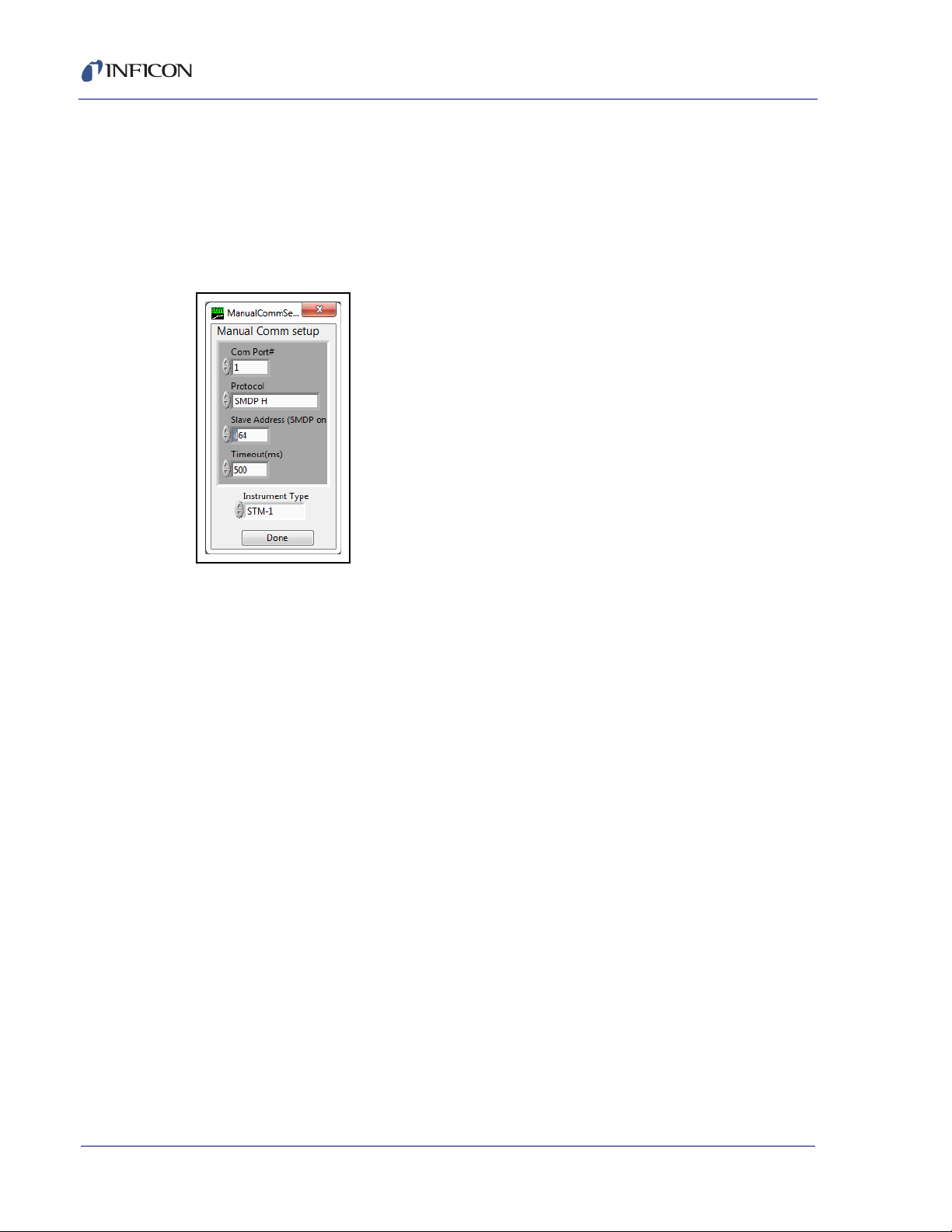

4.3.1.1 Manual Connection

STM-x_win32.VI software allows the creation of a manual connection to STM-1,

STM-2, or Simulate. To enable a manual connection, click Find Instruments on

the Setup tab and click Manual connection. The Manual Comm setup window

will display. Select the correct Com Port#, Protocol, Slave Address,

Timeout(ms), and Instrument Type. Click Done (see Figure 4-6).

Figure 4-6 Manual connection

Comm Ports . . . . . . . . . . . . . . . . . . 1 to 255

Enter the communications port connected to

STM-2.

Protocol. . . . . . . . . . . . . . . . . . . . . . Sycon, SMDP L, SMDP M, SMDP H

Enter the STM-2 communications protocol

and baud rate:

Sycon: Sycon protocol (9.6 kbps)

SMDP L: SMDP protocol (9.6 kbps)

SMDP M: SMDP protocol (38.4 kbps)

SMDP H: SMDP protocol (115.2 kbps)

Slave Address . . . . . . . . . . . . . . . . 1 to 255

Enter the STM-2 communication slave

address.

Timeout . . . . . . . . . . . . . . . . . . . . . . 0 to 4294967295

Communications will timeout when the value

entered in milliseconds has elapsed.

PN 074-613-P1A

4 - 8

Instrument Type . . . . . . . . . . . . . . . STM-1, STM-2, Simulate

Done . . . . . . . . . . . . . . . . . . . . . . . . Close window.

Page 57

4.3.1.2 Simulate Mode

STM-x_win32.VI software allows a simulated deposition without connection to

STM-2. To enable simulate mode, click Find Instruments on the Setup tab and

click Simulate. The Sim Rate hz/sec box will display on the Setup tab. Enter the

rate simulation in hertz per second (see Figure 4-7).

Figure 4-7 Simulate mode

STM-2 Operating Manual

With a rate of hertz per second defined, the software will convert the change in

frequency to Rate in angstroms per second or microgram second per centimeter

squared based on the selection of Thickness or Mass on the Display pane.

PN 074-613-P1A

4 - 9

Page 58

4.3.2 Operate

Figure 4-8 Operate tab

STM-2 Operating Manual

Change Film . . . . . . . . . . . . . . . . . . Changes the active film. Clicking this opens

the FilmPicker.vi window that displays films

to run (see Figure 4-9). Existing thickness is

not zeroed, the thickness is recalculated with

the new Z-Ratio and tooling.

Figure 4-9 FilmPicker.vi window

NOTE: If a film is not displayed in this

window, the film will need to be

added by clicking Edit Films on the

Films tab (see section 4.3.3).

PN 074-613-P1A

4 - 10

Page 59

STM-2 Operating Manual

New Layer . . . . . . . . . . . . . . . . . . . . Opens the FilmPicker.vi window and adds

the selection as a new layer to the Layer

Stackup.

New run . . . . . . . . . . . . . . . . . . . . . . Clears the Layer Stackup, opens the

FilmPicker.vi window, adds the selection as

a new layer to the Layer Stackup, and

increments the Run number.

Pause/Resume . . . . . . . . . . . . . . . . Changes the Pause button to Resume and

changes the background of the Sycon STM

Instrument Interface pane to red. Pauses

data logging and graphing until Resume is

clicked.

ZERO TIMER . . . . . . . . . . . . . . . . . . Resets the timer on the Sycon STM

Instrument Interface pane.

ZERO FILM THK . . . . . . . . . . . . . . . Resets Film Thickness or Film Mass.

Layer Stackup. . . . . . . . . . . . . . . . . Lists Film Name and current Thickness or

Mass for each layer in the process.

PN 074-613-P1A

4 - 11

Page 60

4.3.3 Films

STM-2 Operating Manual

Displays a list of films set up for the process in the Films Database. The film

outlined in blue is the active film.

Figure 4-10 Films tab

Edit films . . . . . . . . . . . . . . . . . . . . . Displays FilmEditor.vi window to add or

remove films to the Films Database (see

Figure 4-11). Each of the following

parameters can be manually edited or input

using the Materials button:

Name

Density

Z-Ratio

Too lin g

# samples

Notes

NOTE: User defined films can be input by

typing over existing values or by

entering data into empty cells.

PN 074-613-P1A

4 - 12

Page 61

STM-2 Operating Manual

Figure 4-11 FilmEditor.vi window

Materials . . . . . . . . . . . . . . . . . . List of materials to be added to the Films

Database on the FilmEditor.vi window.

Cancel . . . . . . . . . . . . . . . . . . . . Exits the FilmEditor.vi window without

saving changes.

Save . . . . . . . . . . . . . . . . . . . . . . Saves changes to Films Database on Films

tab.

NOTE: Right-click on the FilmEditor.vi window to Cut, Copy, Insert, or Delete

rows.

PN 074-613-P1A

4 - 13

Page 62

STM-2 Operating Manual

4.3.4 Rate Graph

Displays a graph of the monitored Rate (see Figure 4-12).

Figure 4-12 Rate Graph tab

Right-click anywhere on the graph to Copy Data, Export Simplified Image,

Clear Chart, Auto Scale X, Auto Scale Y, or Update Mode.

Click the magnifying glass icon to zoom in or out of the graph (see Figure 4-13).

NOTE: Zoom in and out are not available if Auto Scale X or Auto Scale Y are

selected.

Figure 4-13 Zoom in and out

Click the upper-left icon, then press and drag in the graph pane to select and

zoom in on a defined area

Click the upper-middle icon, then press and drag in the graph pane to select

and zoom in on a defined x-range

Click the upper-right icon, then press and drag in the graph pane to select and

zoom in on a defined y-range

PN 074-613-P1A

4 - 14

Page 63

Click the lower-left icon to return to the previous graph

Click the lower-middle icon, then click anywhere in the graph pane to zoom in

on a defined location on the graph

Click the hand icon ( ) and then press and drag in the graph pane to move the

graph.

4.3.5 Mass/Thick Graph

Displays a graph of Film Thickness or Film Mass being monitored (see Figure

4-14).

Figure 4-14 Mass/Thick Graph tab

STM-2 Operating Manual

PN 074-613-P1A

Right-click anywhere on the graph to Copy Data, Export Simplified Image,

Clear Chart, Auto Scale X, Auto Scale Y, or Update Mode.

Click the magnifying glass icon to zoom in or out of the graph (see Figure 4-15).

NOTE: Zoom in and out are not available if Auto Scale X or Auto Scale Y are

selected.

Figure 4-15 Zoom in and out

4 - 15

Page 64

STM-2 Operating Manual

Click the upper-left icon, then press and drag in the graph pane to select and

zoom in on a defined area

Click the upper-middle icon, then press and drag in the graph pane to select

and zoom in on a defined x-range

Click the upper-right icon, then press and drag in the graph pane to select and

zoom in on a defined y-range

Click the lower-left icon to return to the previous graph

Click the lower-middle icon, then click anywhere in the graph pane to zoom in

on a defined location on the graph

Click the hand icon ( ) and then press and drag in the graph pane to move the

graph.

4.3.6 Frequency Graph

Displays a graph of Frequency of the crystal used to monitor. Also displays a live

value in the Current Freq pane (see Figure 4-16).

Figure 4-16 Frequency Graph tab

4 - 16

PN 074-613-P1A

Right-click anywhere on the graph to Copy Data, Export Simplified Image,

Clear Chart, Auto Scale X, Auto Scale Y, or Update Mode.

Click the magnifying glass icon to zoom in or out of the graph (see Figure 4-17).

NOTE: Zoom in and out are not available if Auto Scale X or Auto Scale Y are

selected.

Page 65

STM-2 Operating Manual

Figure 4-17 Zoom in and out

Click the upper-left icon, then press and drag in the graph pane to select and

zoom in on a defined area

Click the upper-middle icon, then press and drag in the graph pane to select

and zoom in on a defined x-range

Click the upper-right icon, then press and drag in the graph pane to select and

zoom in on a defined y-range

Click the lower-left icon to return to the previous graph

Click the lower-middle icon, then click anywhere in the graph pane to zoom in

on a defined location on the graph

Click the hand icon ( ) and then press and drag in the graph pane to move the

graph.

PN 074-613-P1A

4 - 17

Page 66

STM-2 Operating Manual

Software Version

Capabilities

4.3.7 Help/About

Displays information for troubleshooting and help (see Figure 4-18).

Figure 4-18 Help/About tab

Software Version . . . . . . . . . . . . . . Displays the software version.

Capabilities . . . . . . . . . . . . . . . . . . . Displays the instruments compatible with

STM-x_win32.VI Application software.

Tip . . . . . . . . . . . . . . . . . . . . . . . . . . Displays directions on how to access

Descriptions and Tips throughout the

STM-x_win32.VI Application.

Firmware Version . . . . . . . . . . . . . . Queries STM-2 and displays the firmware

version of the connected STM-2.

Location of current logfile. . . . . . . Displays the location of the log file that was

set up on the Setup tab.

(Advanced) Location of config file . . . . . . Displays the location of the

configuration file.

PN 074-613-P1A

4 - 18

Page 67

STM-2 Operating Manual

Communication Status and Statistics pane

Com Success . . . . . . . . . . . . . . . . . Counter which displays the number of

successful communication attempts to

STM-2.

Com Error . . . . . . . . . . . . . . . . . . . . Counter which displays the number of failed

communications (communication errors).

SVR Build . . . . . . . . . . . . . . . . . . . . Build or version of the communication server.

#Instances. . . . . . . . . . . . . . . . . . . . Displays the number of instruments using the

communication server. It is possible to have

multiple instances of STM-x_win32.VI

running.

NOTE: It is possible to have other programs

running that access the same

instrument without conflict.

Last Comm (ms) . . . . . . . . . . . . . . . The last communication time in milliseconds.

Last Error . . . . . . . . . . . . . . . . . . . . Report of errors in communication.

Status. . . . . . . . . . . . . . . . . . . . . indicates successful communication

indicates failed communication.

Code. . . . . . . . . . . . . . . . . . . . . . Displays the Error Code for the Failed

Communication.

Source . . . . . . . . . . . . . . . . . . . . Describes the Error Code.

PN 074-613-P1A

4 - 19

Page 68

STM-2 Operating Manual

This page is intentionally blank.

4 - 20

PN 074-613-P1A

Page 69

5.1 Communication Protocol

Although STM-2 connects via USB, it integrates as a virtual serial port. Therefore,

STM-2 may be opened, read from, and written to just like any serial port. STM-2

follows the SMDP (Sycon Multi Drop Protocol), which makes it possible to

communicate with STM-2 without following USB protocol (see section 5.2).

If custom software will be developed on Windows, INFICON provides an ActiveX

control that implements the SMDP protocol and manages the serial ports, allowing

multiple programs to access the same STM-2. For more information concerning

ActiveX and SMDP, contact INFICON (refer to section 1.3 on page 1-4).

5.2 Sycon Multi-Drop Protocol (SMDP)

STM-2 Operating Manual

Chapter 5

Communication

SMDP is a byte-packet, binary protocol. All eight bits of the data of a byte/character

are used. Standard asynchronous serial conventions apply. A packet begins with

STX (ASCII 0x02) and ends with CR (carriage return, 0x0D).

The SMDP specification provides several common, mandated command codes.

STM-2 responds to these common messages. For example, the reset command

will cause STM-2 to reboot, as though power was cycled. This will set STM-2 into

a known state. Another common command queries the product type or ID. This

command (0x30) will return an ASCII integer code that identifies the product type

(see section 5.2.1.2 on page 5-5). This allows a master computer to poll a network

and locate devices by their types and ensure that the proper connection and

commands are used for the appropriate product.

NOTE: Each field in angle brackets (< >) is a byte, and is not optional. Fields in

regular brackets ([ ]) are optional. Ellipses (...) mean one or more of the

PN 074-613-P1A

previous.

5.2.1 Command Format

<STX><ADDR><CMD_RSP>[<DATA>...]<CKSUM1><CKSUM2><CR>

STX . . . . . . . . . . . . . . . . . . . . . . . . . Start of text character (hexadecimal 02)

Multiple STX characters in a row are allowed.

Data between STX characters is ignored. A

single STX character initializes the receiver

to receive a new message, purging any data

collected since the last STX character or

carriage return received.

5 - 1

Page 70

STM-2 Operating Manual

ADDR. . . . . . . . . . . . . . . . . . . . . . . . One byte address field

The address (ADDR) byte identifies the

SMDP address in order to select which

device the command/query is sent to.

NOTE: Slave address is defaulted to 16.

Each connected instrument must be

assigned a unique address. The

slave reply repeats the address

when it replies to the master,

verifying the address of the

instrument receiving the command.

The range of values are 10 hexadecimal to

FE hexadecimal (16 to 254 decimal).

Address FF hexadecimal is reserved. It is

used as an extension to indicate another byte