Page 1

instruments

STM-100 / MF

THICKNESS / RATE MONITOR

Users Manual

September 1997 Rev. G

Sycon Instrument s

STM-100 / MF

Thickness / Rate Monitor

Page 2

Tel (315) 463-5297 Fax (315) 463-5298

Sycon Instruments

6757 Kinne Street

East Syracuse, New York 13057-1215

Page 3

Preface

Sycon Instruments, Inc. reser ves the r ight to change any information contained in this manual

without notice.

©

Copyright Sycon Instruments, Inc. 1989-1993

IBM® is a Registered trademark of I B M Corporation

MICROSOFT® is a Registered trademark of Microsoft Corporation

SWAGELOK® is a Registered trademark owned by Crawford Fitting Company

BITBUSTM is a trademark of Intel Corporation

CONFLAT® is a Registered trademark of Varian Associates, Inc.

AMPHENOL® is a Registered trademark of Allied Corporation

Page i Preface

Page 4

Warranty

SYCON INSTRUMENTS, INC.

Policy

Sycon Instr um ent s , I nc . ( Sycon) warrant s t hat all electronic instrumentation equipment

manufactured by Sycon shall be free fr om defects in materials and workmanship for a per iod

of 2 years from date of shipment. Mechanical vacuum components such as feedthroug hs,

sensors, cables, and shutters shall be warranted for a period of six months from t he dat e of

shipment. For the duration of t he warranty period Sycon will, at its option, either repair or

replace any part which is defective in materials or workmanship without charge t o t he

purchaser. The foregoing shall constitute the exclusive and sole remedy of the purchaser for

any breach by Sycon of this warranty.

This warrant y does not apply to any equipment which has not been used in accordance

with the specifications recommended by Sycon for the proper and normal use of the

equipment. Sycon shall not be liable under any circumstances for consequential or incidental

damages in connection with, or arising out of the sale, performance, or use of, the equipment

covered by this warranty.

This warrant y is in lieu of all ot her warrant ies by Sycon, expressed or implied, including

the implied warranty of merchantability, the implied warranty of fitness for a particular

purpose, and warranty against infringem ent of any patent.

EQUIPMENT RETURN

Bef ore returning any equipment to Sycon contact the Product Service Department in

your area for instructions. Obtain a RA (Return Authorization) number and indicate this

number on all shipping cartons and correspondence. Ship all items in suit able cont ainer s with

adequate protection from outside damage.

Sycon Instruments, Inc.

6757 Kinne Street

East Syracuse, New York

13057-1215

Phone (315) 463-5297

Fax (315) 463-5298

Warranty Page ii

Page 5

EC Declaration of Conf ormity

We,

SYCON Instruments

6757 Kinne Street

East Syracuse, NY 13057

USA

declare under sole responsibility that the

STM-100/MF Thickness/Rate Monitor

meets the intent of Directive 89/336/EEC as am ended by 92/31/ EEC and 93/68/ EEC for

Electromagnetic Compatibility and the 72/23/EEC Low Voltage Directive for Pr oduct Safety.

Compliance was demonstrated to the following specificat ions as list ed in the Official Journal

of the European Communities:

EN 50081-1: 1992 Em issions

EN 50022 Class B Radiated and Conducted Emissions

EN 61000-3-2 AC Power Line Harmonic Current Emissions

EN 50082-1: 1995 I m m unit y

IEC 1000-4-2 Electrostatic Discharge Imm unit y

IEC 1000-4-3 RF Electromagnetic Field Immunity

IEC 1000-4-4 Electrical Fast Transient/Burst Immunity

IEC 1000-4-5 Power Line Surge Immunity

IEC 1000-4-11 Power Line Dips and Interrupts Immunity

EN 61010-1: 1993 Safety Requirements f or Electrical Equipment for Measurement,

Control, and Laboratory Use

Page iii Warranty

Page 6

Table of Contents

REFACE .......................................................................................................................................................... I

P

ARRANTY ....................................................................................................................................................... II

W

SYCON INSTRUMENTS, INC. POLICY ........................................................................................................................ II

EQUIPMENT

TABLE OF CONTENTS ........................................................................................................................................ IV

IST OF FIGURES ............................................................................................................................................... VIII

L

IST OF TABLES ................................................................................................................................................ IX

L

GENERAL

INTRODUCTION ........................................................................................................................................................ 1-1

SECTION

UNPACKING .............................................................................................................................................................. 1-1

SECTION

STM-100 / MF

SECTION

SENSOR

SECTION

FEEDTHROUGH

SENSOR

SECTION

STM-100 / MF

SECTION

OPERATION AND PROGRAMMING ............................................................................................................. 2-1

KEYBOARD DESCRIPTION ...................................................................................................................................... 2-1

SECTION

SYSTEM

SECTION

DATA

SECTION

FILM

PARAMETERS ................................................................................................................................................. 2-3

SECTION

USER

SECTION

SWITCH

TEST

MODE ............................................................................................................................................................... 2-11

SECTION

RETURN ............................................................................................................................................... II

INFORMATION ............................................................................................................................. 1-1

1.1 ....................................................................................................................................................... 1-1

1.2 ....................................................................................................................................................... 1-1

SPECIFICATIONS ............................................................................................................................. 1-2

1.3 ....................................................................................................................................................... 1-2

SPECIFICATIONS ...................................................................................................................................... 1-4

1.4 ....................................................................................................................................................... 1-4

OPERATION ................................................................................................................................................... 1-4

INSTALLATION .............................................................................................................................. 1-4

WATER ........................................................................................................................................................... 1-4

ELECTRICAL .................................................................................................................................................. 1-4

MATERIALS

SPARE PARTS ........................................................................................................................................... 1-5

(IN VAC) ..................................................................................................................................... 1-4

1.5 ....................................................................................................................................................... 1-5

PARTS & ACCESSORIES ................................................................................................................. 1-5

1.6 ....................................................................................................................................................... 1-5

MONITOR ....................................................................................................................................................... 1-5

FEEDTHROUGHS .......................................................................................................................................... 1-5

SENSORS ...................................................................................................................................................... 1-5

OPTIONS ........................................................................................................................................................ 1-5

ACCESSORIES .............................................................................................................................................. 1-5

SENSOR

CONTROL KEY GROUP ............................................................................................................................. 2-1

S

HUTTER KEYS ................................................................................................................................................. 2-2

ZERO

C

RYSTAL LIFE KEY ............................................................................................................................................. 2-2

ENTRY AND PROGRAMMING GROUP ........................................................................................................... 2-2

P

ROGRAM KEY .................................................................................................................................................. 2-2

E

NTER KEY ....................................................................................................................................................... 2-3

A

RROW KEYS .................................................................................................................................................... 2-3

LCD

F

ILM NUMBER PARAMETER ................................................................................................................................. 2-4

D

ENSITY PARAMETER ......................................................................................................................................... 2-5

Z-F

CRYSTALS ..................................................................................................................................... 1-5

2.1 ....................................................................................................................................................... 2-1

2.2 ....................................................................................................................................................... 2-1

KEY ....................................................................................................................................................... 2-2

2.3 ....................................................................................................................................................... 2-2

2.4 ....................................................................................................................................................... 2-3

DATA DISPLAYS ......................................................................................................................................... 2-4

ACTOR PARAMETER ...................................................................................................................................... 2-6

END THICKNESS ................................................................................................................................................ 2-6

S

ETPOINT THICKNESS PARAMETER ...................................................................................................................... 2-7

S

ETPOINT TIMER ................................................................................................................................................ 2-7

T

OOLING FACTOR PARAMETER ............................................................................................................................ 2-8

CONFIGURATION SWITCHES ....................................................................................................................... 2-8

2.5 ....................................................................................................................................................... 2-8

FUNCTION DEFINITIONS........................................................................................................................... 2-9

C

ONFIGURATION ................................................................................................................................................ 2-9

2.6 ....................................................................................................................................................... 2-11

E

NABLING THE TEST MODE ................................................................................................................................. 2-11

Table of Contents Page iv

Page 7

BEEPER ..................................................................................................................................................................... 2-12

SECTION

2.7 ....................................................................................................................................................... 2-12

D

ISABLING THE BEEPER ...................................................................................................................................... 2-12

INSTALLATION .............................................................................................................................................. 3-1

ELECTRICAL CONNECTIONS AND DESCRIPTIONS ............................................................................................................... 3-1

SECTION

SECTION

3.1 ....................................................................................................................................................... 3-1

3.2 ....................................................................................................................................................... 3-1

L

INE POWER WARNING ...................................................................................................................................... 3-1

L

INE VOLTAGES ................................................................................................................................................. 3-1

GROUND ................................................................................................................................................................... 3-2

SECTION

I/O

INTERFACE CONNECTION ................................................................................................................................. 3-3

SECTION

3.3 ....................................................................................................................................................... 3-2

G

ROUNDING ...................................................................................................................................................... 3-2

C

ONNECTOR SHIELDING ..................................................................................................................................... 3-2

3.4 ....................................................................................................................................................... 3-3

I/O

CONNECTOR ................................................................................................................................................ 3-3

RELAYS .......................................................................................................................................................... 3-3

INPUTS ........................................................................................................................................................... 3-3

RELAY

OUTPUTS ...................................................................................................................................................... 3-3

R

ELAY OUTPUTS................................................................................................................................................ 3-3

C

RYSTAL FAIL ................................................................................................................................................... 3-3

E

LAPSED TIMER ................................................................................................................................................. 3-3

S

HUTTER .......................................................................................................................................................... 3-3

T

HICKNESS SETPOINT ........................................................................................................................................ 3-4

REMOTE

INPUTS ...................................................................................................................................................... 3-4

REMOTE INPUTS ................................................................................................................................................ 3-4

S

HUTTER RELAYS .............................................................................................................................................. 3-4

T

HICKNESS ZERO INPUT ..................................................................................................................................... 3-4

T

IMER ZERO INPUT ............................................................................................................................................. 3-4

R

EMOTE INPUT SPECIFICATIONS .......................................................................................................................... 3-4

SENSOR

ANALOG

RS-232

COMMUNICATIONS

DEPOSITION

CONNECTION............................................................................................................................................ 3-4

SECTION

SECTION

SECTION

SECTION

SECTION

3.5 ....................................................................................................................................................... 3-4

O

SCILLATOR CONNECTION .................................................................................................................................. 3-4

RECORDER INTERFACE .......................................................................................................................... 3-5

3.6 ....................................................................................................................................................... 3-5

A

NALOG OUTPUT SPECIFICATIONS ....................................................................................................................... 3-5

RECORDER

R

ECORDER OUTPUTS ......................................................................................................................................... 3-6

SERIAL COMMUNICATIONS INTERFACE ................................................................................................... 3-6

RS-232

RS-232

C

OMMUNICATIONS OPTIONS ................................................................................................................................ 3-7

S

YSTEM INSTALLATION ....................................................................................................................................... 3-8

S

ENSOR INSTALLATION ....................................................................................................................................... 3-8

CALIBRATION ........................................................................................................................... 3-5

3.7 ....................................................................................................................................................... 3-6

CONNECTIONS ...................................................................................................................................... 3-6

CONNECTOR DEFINITIONS ............................................................................................................. 3-7

OPTIONS ................................................................................................................................. 3-7

3.8 ....................................................................................................................................................... 3-7

SYSTEM INSTALLATION .................................................................................................................... 3-8

3.9 ....................................................................................................................................................... 3-8

INSTALLING WATER LINES .............................................................................................................................................. 3-9

W

ATER LINES .................................................................................................................................................... 3-9

VACUUM

ELECTRICAL

FEEDTHROUGH ........................................................................................................................................ 3-10

V

ACUUM FEEDTHROUGH ..................................................................................................................................... 3-10

IN-VACUUM CABLE ............................................................................................................................ 3-10

V

ACUUM ELECTRICAL CONNECTIONS ................................................................................................................... 3-10

B

AKEABLE SENSOR ............................................................................................................................................ 3-10

CALIBRATION AND THEORY ................................................................................................................................ 4-1

MEASUREMENT THEORY ................................................................................................................................................ 4-1

SECTION

T

HICKNESS READING CALIBRATION ................................................................................................................................. 4-2

SECTION

D

ENSITY DETERMINATION ............................................................................................................................................... 4-2

4.1 ........................................................................................................................................................ 4-1

E

QUATION 1: ..................................................................................................................................................... 4-1

M

EASURING PERIOD ........................................................................................................................................... 4-1

R

ATE COMPUTATION .......................................................................................................................................... 4-1

4.2 ........................................................................................................................................................ 4-2

T

HICKNESS........................................................................................................................................................ 4-2

Page v Table of Contents

Page 8

DENSITY ........................................................................................................................................................... 4-2

Z-F

ACTOR DETERMINATION ............................................................................................................................................ 4-2

Z-F

ACTOR......................................................................................................................................................... 4-2

T

OOLING DETERMINATION .............................................................................................................................................. 4-3

SECTION

M

ATERIAL REFERENCE TABLE ........................................................................................................................................ 4-4

4.3 ........................................................................................................................................................ 4-4

B

ULK DENSITY AND Z-FACTOR VALUES ................................................................................................................ 4-4

A

LUMINUM THROUGH INDIUM ............................................................................................................................... 4-4

I

NDIUM INTIMONIDE THROUGH TANTALUM ............................................................................................................. 4-5

T

ELURIUM THROUGH ZIRCONIUM OXIDE ................................................................................................................ 4-6

COMPUTER INTERFACING .......................................................................................................................... 5-1

RS-232 INTERFACE .................................................................................................................................................. 5-1

SECTION

BAUD

S

YCON PROTOCOL ........................................................................................................................................................ 5-2

SECTION

SECS-II

SECTION 5.3 ....................................................................................................................................................... 5-5

IEEE-488

SECTION

COMMANDS .............................................................................................................................................................. 5-7

SECTION

RESPONSE

DETAILED

SECTION

5.1 ....................................................................................................................................................... 5-1

RS-232

RATES AND CABLING ...................................................................................................................................... 5-1

M

C

S

M

B

SECS-II

SECS-II

D

G

M

SECS-II

M

C

S

S

Z

Z

Z

S

S

DESCRIPTION ....................................................................................................................................... 5-1

AKING AN RS-232 CABLE ................................................................................................................................ 5-2

OMMUNICATION DEMO DISK .............................................................................................................................. 5-2

ETTING BAUD RATES ........................................................................................................................................ 5-2

5.2 ....................................................................................................................................................... 5-2

ESSAGE FORMAT ............................................................................................................................................. 5-3

ASIC DRIVER ROUTINE ..................................................................................................................................... 5-4

PROTOCOL...................................................................................................................................................... 5-5

ADDRESSING ....................................................................................................................................... 5-5

PROTOCOL .......................................................................................................................................... 5-5

OCUMENTATION REQUIREMENTS ....................................................................................................................... 5-5

ENERAL INFORMATION ...................................................................................................................................... 5-5

ESSAGE SUMMARY .......................................................................................................................................... 5-5

MESSAGES .......................................................................................................................................... 5-6

ESSAGE DETAILS ............................................................................................................................................. 5-6

INTERFACE OPTION ................................................................................................................................. 5-6

5.4 ....................................................................................................................................................... 5-6

5.5 ....................................................................................................................................................... 5-7

FORMAT ................................................................................................................................................ 5-7

OMMAND LIST FOR STM-100 / MF ................................................................................................................... 5-8

COMMAND DESCRIPTION ..................................................................................................................... 5-8

5.6 ....................................................................................................................................................... 5-8

OFTWARE VERSION CODE ................................................................................................................................ 5-8

HUTTER RELAY CONTROL ................................................................................................................................. 5-9

ERO THICKNESS AND TIMER .............................................................................................................................. 5-9

ERO THICKNESS ............................................................................................................................................... 5-9

ERO TIMER ...................................................................................................................................................... 5-9

ET THE DENSITY PARAMETER ............................................................................................................................ 5-9

ET THE Z-FACTOR PARAMETER ......................................................................................................................... 5-9

SET THE END THICKNESS ................................................................................................................................... 5-9

S

ET THE SETPOINT RELAY THICKNESS ................................................................................................................. 5-9

S

ET THE TIMER RELAY PARAMETER ..................................................................................................................... 5-10

S

ET THE TOOLING FACTOR PARAMETER ............................................................................................................... 5-10

T

URN THE TEST MODE ON/OFF ........................................................................................................................... 5-10

A

CKNOWLEDGE THE STATUS OF NON-VOLITILE MEMORY ....................................................................................... 5-10

G

ET THE CRYSTAL FAIL STATUS .......................................................................................................................... 5-10

G

ET THE STATUS OF THE SETPOINT TIMER RELAY ................................................................................................. 5-10

G

ET THE STATUS OF THE SETPOINT THICKNESS RELAY ......................................................................................... 5-10

G

ET THE STATUS OF THE END THICKNESS RELAY ................................................................................................. 5-11

G

ET THE REMOTE INPUT STATUS ........................................................................................................................ 5-11

G

ET THE CONFIGURATION SWITCH STATUS .......................................................................................................... 5-11

G

ET THE THICKNESS VALUE ................................................................................................................................ 5-11

G

ET THE RATE VALUE ........................................................................................................................................ 5-11

G

ET THE SENSOR FREQUENCY............................................................................................................................ 5-11

G

ET THE CRYSTAL LIFE VALUE ............................................................................................................................ 5-11

G

ET THE TIMER VALUE ....................................................................................................................................... 5-12

G

ET THE SHUTTER CLOSE EVENT THICKNESS LOG ............................................................................................... 5-12

G

ET THE SHUTTER CLOSE TIME LOG .................................................................................................................... 5-12

G

ET THE LOG EVENT RATE ................................................................................................................................. 5-12

Table of Contents Page vi

Page 9

GET THE POWER ON STATUS .............................................................................................................................. 5-12

F

ORCE PARAMETERS TO THEIR DEFAULT VALUES ................................................................................................. 5-12

T

URN THE KEY BOARD BEEPER ON/OFF .............................................................................................................. 5-13

I

NTERNAL USE COMMANDS ................................................................................................................................. 5-13

M

ULTI-FILM FILM NUMBER SELECTION ................................................................................................................. 5-13

M

ULTI-FILM DENSITY PARAMETER ....................................................................................................................... 5-13

M

ULTI-FILM Z-FACTOR PARAMETER..................................................................................................................... 5-13

M

ULTI-FILM END THICKNESS PARAMETER ............................................................................................................ 5-14

M

ULTI-FILM SET POINT RELAY THICKNESS PARAMETER ......................................................................................... 5-14

M

ULTI-FILM SET POINT TIMER RELAY PARAMETER ................................................................................................ 5-14

M

ULTI-FILM TOOLING FACTOR PARAMETER .......................................................................................................... 5-14

MAINTENANCE .............................................................................................................................................. 6-1

WARNINGS ................................................................................................................................................................... 6-1

SECTION

CONTROL

REPLACING

SECTION

P

ERSISTENT CRYSTAL FAIL INDICATION ........................................................................................................................... 6-3

SECTION

6.1 ....................................................................................................................................................... 6-1

UNIT ......................................................................................................................................................... 6-1

A SENSOR CRYSTAL........................................................................................................................... 6-2

6.2 ....................................................................................................................................................... 6-2

6.3 ....................................................................................................................................................... 6-3

APPENDIX A-COMMUNICATION DEMO DISK ........................................................................................................ A-1

SECTION A-1 .......................................................................................................................................................... A-1

STM-100

/MF SPECIFIC PROGRAMS .............................................................................................................................. A-1

S

ECTION A-2 .......................................................................................................................................................... A-1

APPENDIX B-TECHNICAL DRAWINGS .................................................................................................................. B-1

PPENDIX C-SHMX-4 OPERATION .................................................................................................................... C-1

A

INTRODUCTION ........................................................................................................................................................ C-1

O

PERATION ............................................................................................................................................................. C-2

I

NSTALLATION .......................................................................................................................................................... C-2

Page vii Table of Contents

Page 10

List of Figures

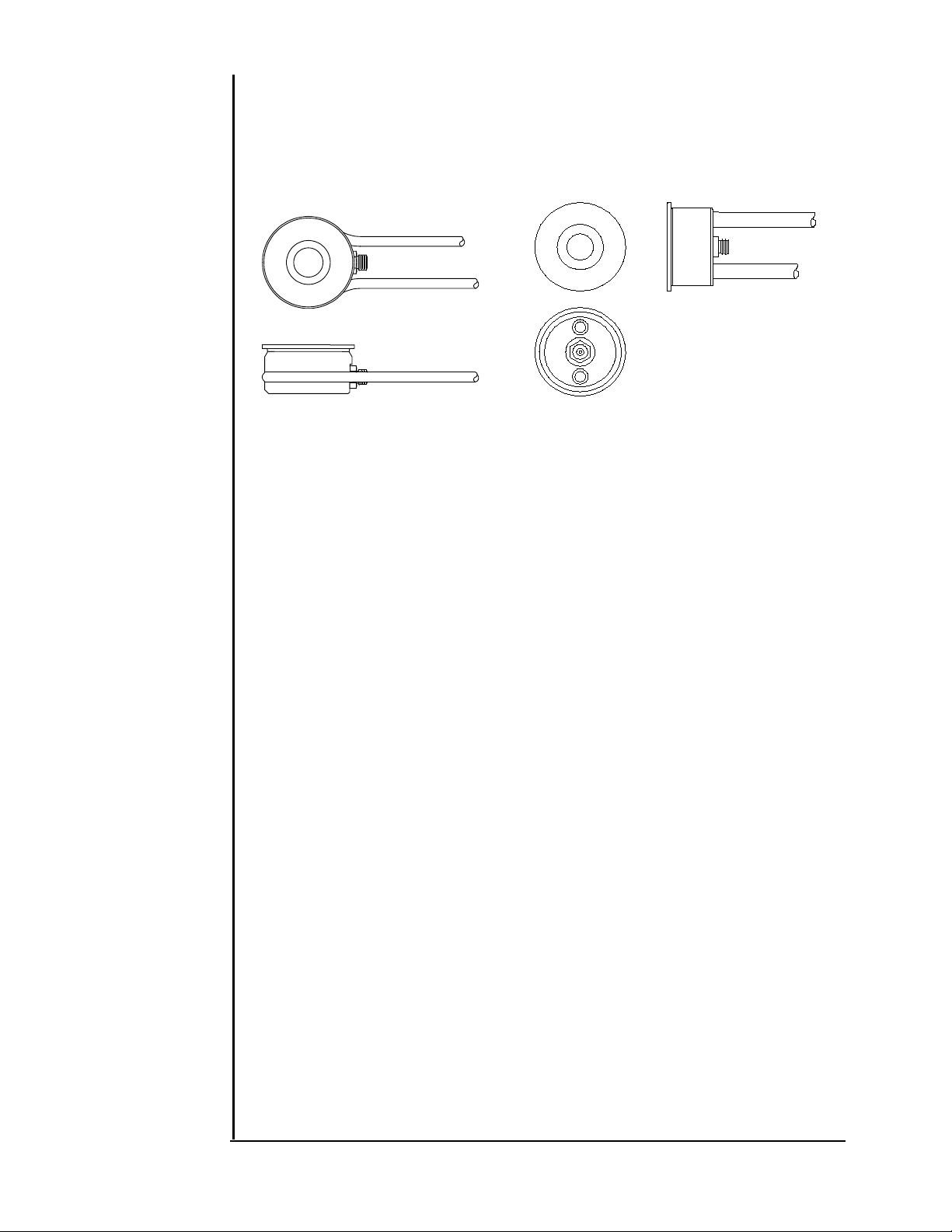

Figure 1.1: Standard Sensors. ................................................................................................. 1-4

Figure 2.1: STM-100 / MF Front Panel. .................................................................................. 2-1

Figure 2.2: System Control Keys. ............................................................................................ 2-1

Figure 2.3: Data Entry And Programming Keys. ..................................................................... 2-2

Figure 2.4: LCD Data Areas. .................................................................................................... 2-4

Figure 2.5: LCD Variable Parameter Legends. ........................................................................ 2-4

Figure 2.6: Film Number Parameter. ....................................................................................... 2-4

Figure 2.7: Density Parameter. ................................................................................................ 2-5

Figure 2.8: Z-Factor Parameter. .............................................................................................. 2-5

Figure 2.9: End Thickness Parameter. .................................................................................... 2-6

Figure 2.10: Set Point Thickness Parameter. .......................................................................... 2-7

Figure 2.11: Set Point Timer Parameter. ................................................................................. 2-7

Figure 2.12: Tooling Parameter. .............................................................................................. 2-8

Figure 2.13: Configuration Switch Settings. ............................................................................. 2-9

Figure 3.1: Rear Panel. ............................................................................................................ 3-1

Figure 3.2: Recommended Grounding Procedure. .................................................................. 3-2

Figure 3.3: Recorder Output Plug. ........................................................................................... 3-5

Figure 3.4: Example of Thickness Mode Recorder Output. ..................................................... 3-6

Figure 3.5: Example of Rate Mode Recorder Output. ............................................................. 3-6

Figure 3.6: Cable Connections From STM to MSDos Computers. ......................................... 3-7

Figure 3.7: Typical System. ..................................................................................................... 3-8

Figure 3.8: Head Mounting Dimensions................................................................................... 3-9

Figure 4.1: Typical Tooling Factors. ......................................................................................... 4-3

Figure 5.1: Cable Connection From STM-100 / MF to IBM-AT. .............................................. 5-1

Figure 5.2: Connections for STM-100 / MF to PC Compatible Computers. ........................... 5-2

Figure 5.3: BASIC Driver Routine. ........................................................................................... 5-4

Figure 5.4: HP-85 IEEE-488 BASIC Driver Program. .............................................................. 5-7

Figure 6.1: Sensor and Feed Through Connections. ............................................................... 6-3

Figure 6.2: Test Oscillator OSC-100A. .................................................................................... 6-4

Figure 6.3: SM75, MicroDot

Figure C.1: SHMX-4 Front Panel ............................................................................................. C-1

Figure C.2: Firmware ROM Label ............................................................................................ C-2

Connector. ................................................................................ 6-4

Figure C.3: SHMX-4 Back Panel ............................................................................................. C-2

Figure C.4: SHMX-4 to STM-100 Control Cable ...................................................................... C-3

List of Figures Page viii

Page 11

List of Tables

Table 2.1: Baud Rate Switch Settings .......................................................2-10

Table 2.2: Configuration Switch Address Sett ings ....................................2-11

Table 4.1: Common Material Reference Table ........................................... 4-4

Table 4.1: Common Material Reference Table, Cont inued ......................... 4-5

Table 4.1: Common Material Reference Table, Cont inued ......................... 4-6

Table 5.1: Baud Rate Configuration Table. ................................................ 5-2

Table 5.2: Communication Command Summary........................................ 5-8

Page ix List of Tables

Page 12

SECTION 1

General Information

Page 13

Page 14

GENERAL INFORMATION

SECTION 1.1

SECTION 1.2

INTRODUCTION

The STM-100 / MF from Sycon Instruments, Inc. represents a new class

of thin film monitor. I t uses the time-proven 6 MHz oscillating quartz crystal as

the sensor device. The STM-100 / MF is constructed with advanced LSI and

microprocessor technology. This enables the dir ec t solut ion of the complex

mathematical equation associated with the f r equency shift versus mass

loading characteristics of the quartz crystal sensor. Its computational power

allows the measurement of the material accum ulat ed on t he s ensor c r ystal t o

be accurately converted to film thickness using the exact equation;

inaccuracies due to approximations and limited ranges of m aterial constants

do not contribute to thickness and r at e er r or s . A hig h frequency period

measurement clock (over 70 MHz) enables the STM-100 / MF to make and

display 4 measurements/second with one-tenth Angstr om r ate resolution. The

STM-100 / MF is equipped with 4 setpoint relays, 4 remote inputs, a comput er

interface (RS-232) supporting 2 protocols including SECS-II, and a high

resolution analog recorder output. A r ack mount for half-rac k mounting is also

standard. If desired, t he front panel LCD can be configured, by rear panel

switch setting, to display the freq uency of the sensing crystal instead of

computed rate and thickness. ST M-100 / MF 's manufactured and shipped

after October 1990 have the additional capability of storing film parameter for

nine film or processes. Earlier STM's can be factory upgraded to include this

feature. An extra-cost opt ion is a second com puter interface. This f actory

installed upgrade can be either IEEE-488 or BIT BUS.

UNPACKING

The STM-100 / MF comes with a power cord, and connectors for the RS232 interface, the I/O int er face and analog output. If t he O SC-100 or crystals

were ordered at the same time, they will also be included. The unit is shipped

with the rack mount attached, which may be removed for t able t op oper at ion.

To complete a system installation a sensing head and a vacuum to air

feedthrough are req uir ed. Schematic drawings and a MSDOS Format diskette

of demonstration sof t ware are included with this manual. Refer to Appendix A

for a detailed description of the included software. The unit comes set for the

line voltage as ordered. If you need to change it , r efer to Section 3.2. Make

sure that you install the correct fus es when changing line voltage. If it is ever

necessary to return the unit to Sycon, f or any reason, call and obt ain an Retur n

Authorization (RA) num ber before returning the unit.

Page 1 - 1 GENERAL INFORMATION

Page 15

SECTION 1.3

STM-100 / MF SPECIFICATIONS

DISPLAY TYPE ........................................ 7 DIGIT LCD

THICKNESS DISPLAY RANGE ................ 0 to 999.9 kÅ

RESOLUTION .................................. 1 Å autoranged

# DIGITS .......................................... 4

RATE DISPLAY RANGE........................... 0.0 to 999 Å/S

RESOLUTION .................................. 0.1 Å/S autoranged

# DIGITS .......................................... 3

MEASUREMENT PERIOD........................ 0.25 SEC

SENSOR TYPE ................................ Quartz Crystal Microbalance

FREQUENCY ................................... 6 MHz Plano Convex A/T Cut

MAX. FREQ. SHIFT ......................... 1 MHz

FILM PARAMETER .................................. 9 MATERI AL S

VARIABLES .............................................. 7

FILM # .............................................. 1 t o 9

MATERIAL. DENSITY ...................... 0.500 t o 99. 99 gm/cc

MATERIAL. Z FACTOR.................... 0.100 to 9.999

SYS. TOOLING ................................ 10.0 to 399 %

SHUT TER CLOSURE ...................... 0.000 to 9999 kÅ

T HI CKNESS SETPOINT .................. 0.000 to 9999 kÅ

T I MER SETPOINT ........................... 00:00 to 99:59 M:S

I/O CONNECTION .................................... 15 PIN D MALE

HARDWARE O UTPUTS ........................... 4, SPST 2.5A RELAYS

- Shutter Relay (Pins 5,6)

- Thickness Setpoint (Pins 7,8)

- Sensor Failure (Pins 1,2)

- Timer Setpoint (Pins 3,4)

HARDWARE I NPUTS ............................... 4 TTL COMP., ACTIVE LOW

- Open Shutter (Pin 12)

- Close Shutter (Pin 11)

- Zero Thickness (Pin 10)

- Zero Timer (Pin 9)

Note: Pins 13,14,15 are GND.

ANALOG RECORDER ............................. + 10V F.S. RATE OR THICKNESS

- 2 mA max Load,

- 11 BIT Resolution

CONNECTION ................................. Miniature Stereo Jack

STD. COMMUNICATIONS I/O .................. RS-232, DUAL PROTOCOL

- 4 BAUD RATES

- 300,1200,2400,9600

CONNECTION ................................. - 9 PIN "D" FEMALE

GENERAL INFORMATION Page 1 - 2

Page 16

OPTIONAL COMMUNICATIONS I/O

1) ...................................................... IEEE-488 T/L

CONNECTION ................................. - 24 PIN TYPE 57 FEMALE

2) ...................................................... BITBUS Slave Node

CONNECTION ................................. - 2 TWINAX BNC's

DISPLAY FUNCTIONS

1) ..................................................... DATA/FILM #

2) ..................................................... THICKNESS / RATE

3) ..................................................... CRYSTAL % USAGE / TIMER

4) ..................................................... SENSOR FREQUENCY

DISPLAY ANNUNCIATORS ..................... STATUS

RELAY ............................................. ON/OFF EACH RELAY

PARAMETER ID .............................. EACH VARIABLE

MODE ID .......................................... PROGRAM / OPERATE

ACTIVITY ......................................... COMMUNICATIO NS INTERFACE

KEYBOARD FUNCTIONS ........................ 8 KEYS

TYPE ................................................ Individual Buttons

FUNCTIONS .................................... - Shutter Open

- Shutter Close

- Zero Thickness & Time

- Set Program Mode On / Of f

- Increase Value

- Decrease Value

- Enter Data

- Crystal Status

USER OPTION SWITCHES ..................... Rear Panel

- Baud Rate Selection

- Serial Protocol Selection

- Communications Address

- Parameter Lock

- Negative Limit Operation

- Frequency Meas. Mode

- Analog Recorder Function

POW ER REQUIREMENTS ....................... 120/240V,+5%-

......................................................... 20%,50/60Hz,10VA

CONNECTOR .................................. IEC Standard

POWER SWITCH ............................ Rear Panel Mounted

T EMPERATURE RANG E ................. 0o C to 50oC Operating

-15oC to 65oC Storage

SIZE / WEIGHT ........................................ 2.5"H, 7.25"W, 10"D 4lbs

(RACK MOUNTED) .................................. 3.5"H, 8.0"W, 10"D ;

SHIP WEIGHT .......................................... 8lbs

Page 1 - 3 GENERAL INFORMATION

Page 17

SECTION 1.4

OPERATION

WATER

ELECTRICAL

MATERIALS (IN VAC)

SECTION 1.5

SENSOR SPECIFICATIONS

Low Profile P/N 500-042 RIGHT ANGLE P/N 5 00 -088

Figure 1.1: Standard Sensors.

Low Profile and Right Angle sensors, See Appendix B for dimensions and

more detailed drawings of these and other sensor pac kages.

Maximum Temperature ............................. 175° C

Water Line and Coax Lengt h ................... 30 inches

Sensor Mounting ...................................... Rear of Body, 4-40 Tapped Holes

FEEDTHROUGH INSTALLATION

Connections .................................... Two Required

Type ................................................ 1/8 inch O.D. Stainless Tubing

Flow Rate ......................................... 0.2 to 0.3 gal/min

Water Temp ..................................... 50° C max.

Connections .................................... One Coaxial Line

Type ................................................ Microdot Miniature S-50

Body and Water Lines .................... 304 Stainless

Insulators ........................................ Alumina

Coax Insulator ................................. Teflon

Coax Conductor and Shields ........... Copper/Silver

Braze Material ................................. High Vac Ni/CR/Cu Alloy

Crystal ............................................. Quartz with Gold Electrodes

SENSOR SPARE PARTS

Description SYCON Part Number

Sensor Body (Standar d) .................. 550-219

Snap Spring ..................................... 024-002

Sensor Cap ...................................... 550-218

30 inch In-Vacuum Coax Cable ....... 500-024

10 inch In-Vacuum Coax Cable ....... 500-023

Crystals (box of 10) ......................... 500-117

GENERAL INFORMATION Page 1 - 4

Page 18

STM-100 / MF PARTS & ACCESSORIES

SECTION 1.6

MONITOR

FEEDTHROUGHS

SENSORS

OPTIONS

ACCESSORIES

SENSOR CRYSTALS

ASSEMBLY PART NUMBER

STM-100 / MF (Multi Film) ................ 500-104

POWER CORD (12 0 VAC).............. 600-004

FUSES (1/4 A Slow Blow for 120VAC) ...... 356-005

FUSES (1/8 A Slow Blow for 240VAC) ...... 356-007

RECORDE R PLUG ......................... 404-007

I/O 15 PIN CONNECTOR ................ 404-008

RS-23 2 9 PIN CONNECTOR .......... 404-009

MANUAL ......................................... 518-000

CONNECTOR KIT ............................ 514-001

19" Rack Mount (Single) ................... 014-008

19" Rack Mount (Dual) ..................... 014-009

1" BOLT STANDARD ...................... 500-016

2 3/4" ConFlat STANDARD ............. 500-017

LOW PROFILE ................................. 500-042

RIGHT ANGLE ................................ 500-088

IEEE-488 BUS INTERFACE ............ 500-021

BITBUS INTERFACE ...................... 500-022

30" I N-VACUUM COAX CABLE ...... 500-024

10" I N-VACUUM COAX CABLE ...... 500-023

10' OSC TO STM CABLE ................ 500-026

30' OSC TO STM CABLE ................ 500-027

6" OSC TO FEED THRU COAX ....... 500-025

BOX O F 10 ...................................... 500-117

Page 1 - 5 GENERAL INFORMATION

Page 19

SECTION 2

Operation and Programming

Page 20

Page 21

STM - 100 / MF

THICKNESS / RATE MONITOR

instruments

SHUTTER

SENSOR

OPEN

ZERO

CLOSE

LIFE

DENS

Z-FACT END THK

XTAL FAIL

SHUTTER

SP TIME

SP THICK

SP THK SP TMR TOOL

PGM

COM

DATA ENTRY

PROGRAM

ENTER

DATA

OPEN

CLOSE

SENSORSHUTTER

ZERO

LIFE

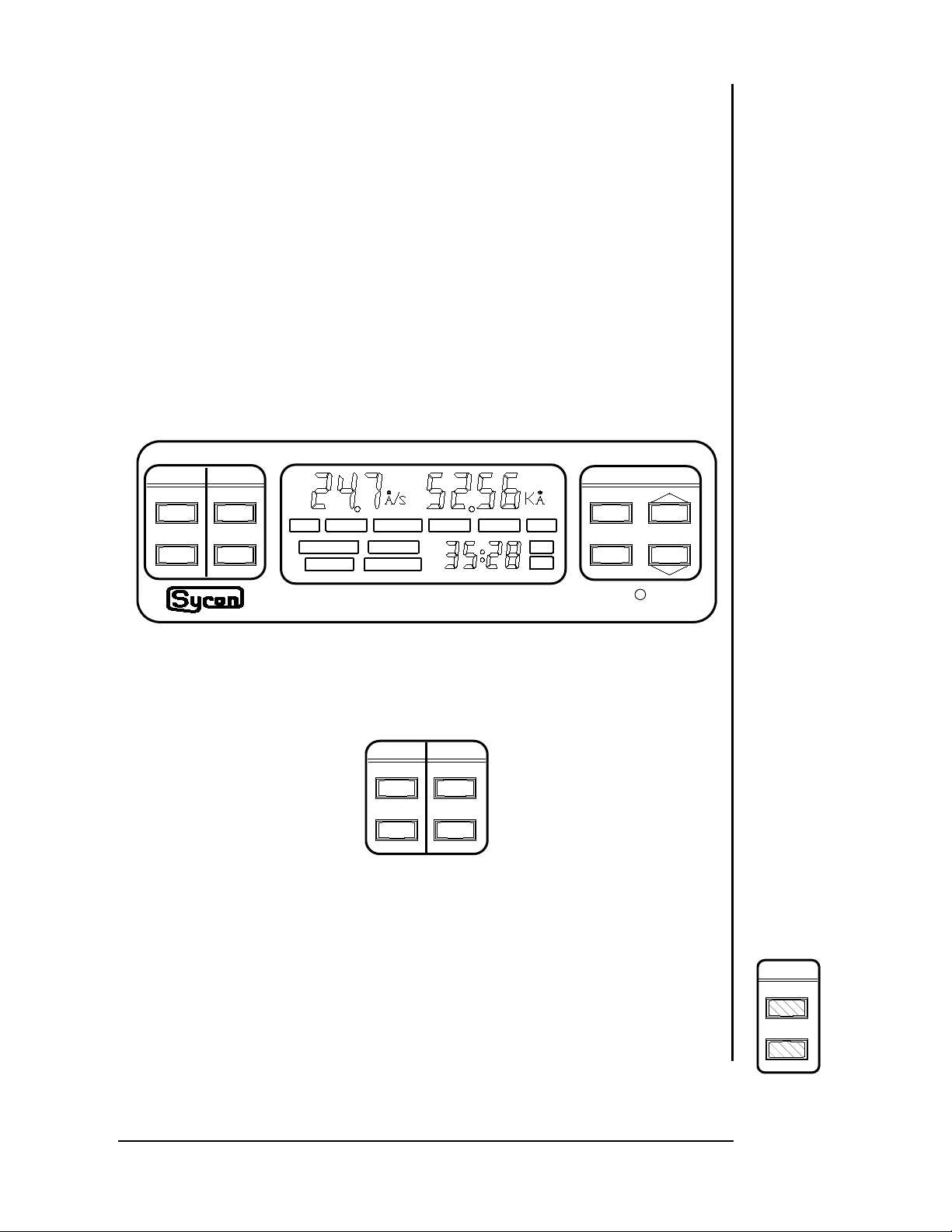

SECTION 2.1

SECTION 2.2

OPEN

CLOSE

SHUTTER

Shutter Keys

OPERATION AND PROGRAMMING

KEYBOARD DESCRIPTION

The STM-100 / MF keyboard is divided into two separate functional

groups. The keys to the left of the LCD display are system control keys and

the keys to the right of the display are data entry and programming keys. All

keys are sensed when depressed and must be released to cause further

action. The exceptions to this rule are the (LI FE) and ( ARROW) keys. T hese

keys will cause continuous action if held depressed. An audible beep will

accompany each key activation. The beeper may be disabled if desired. See

Section 2.7.

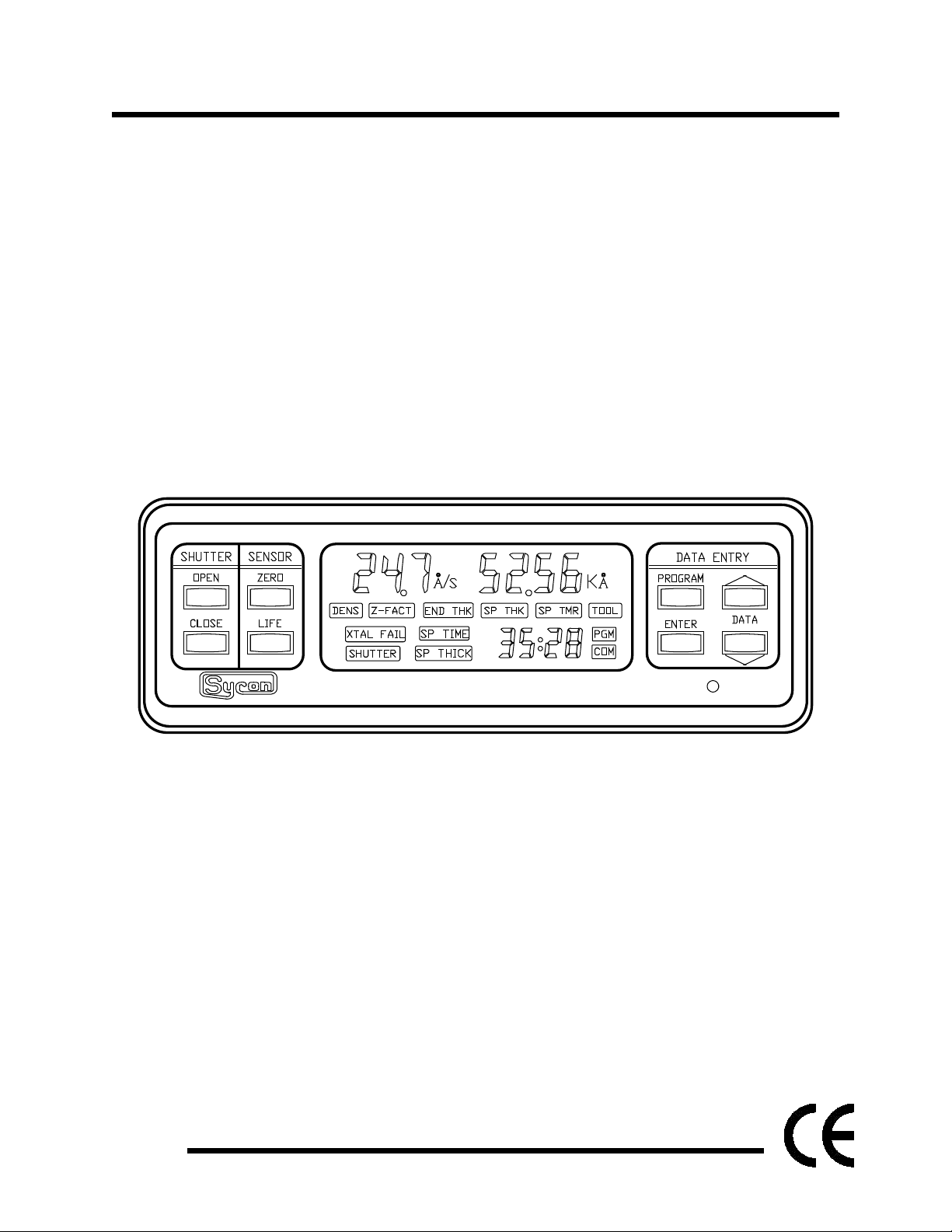

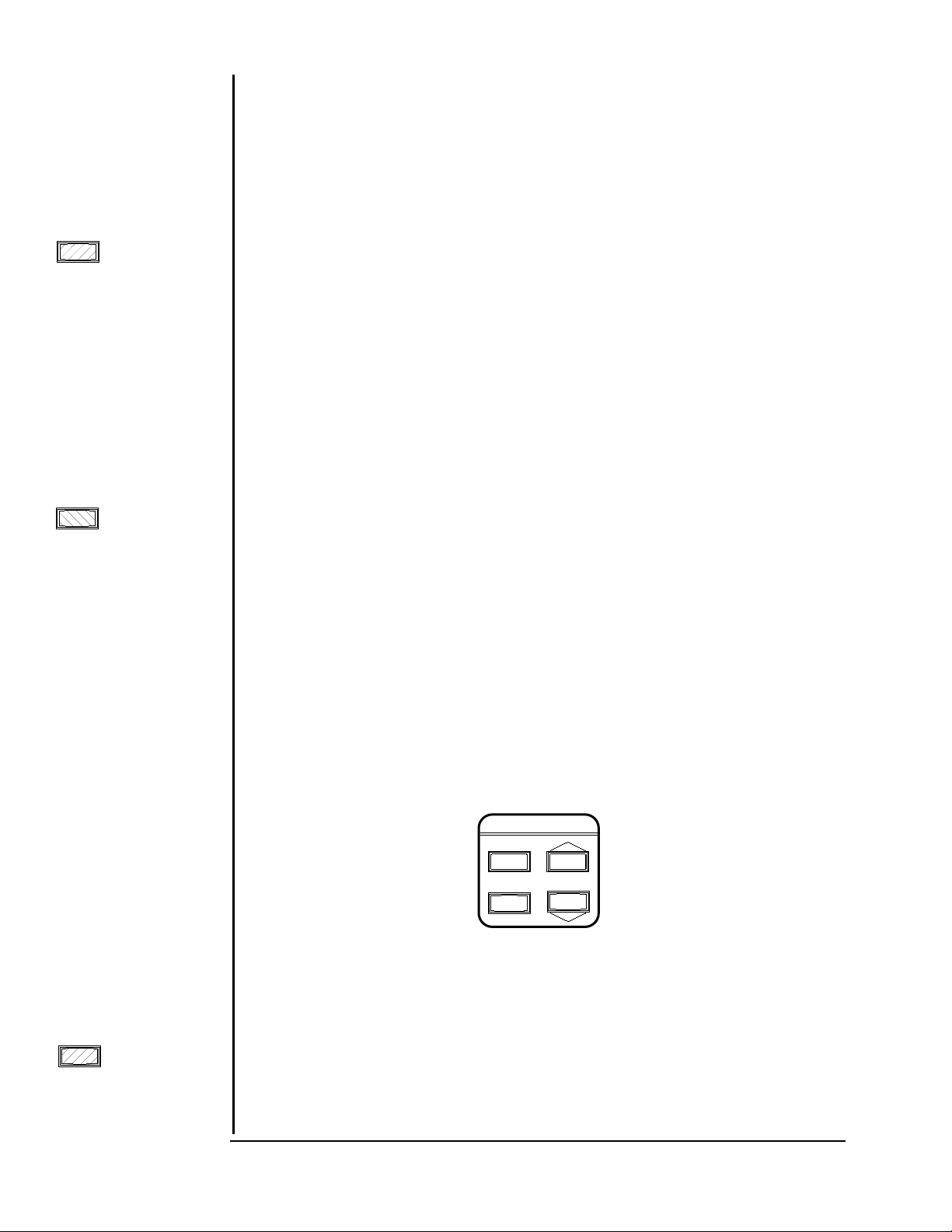

Figure 2.1: STM-100 / MF Front Panel.

SYSTEM CONTROL KEY GROUP

Figure 2.2: System Control Keys.

SHUTTER OPEN

Activating the SHUTTER OPEN key will cause the internal shutter relay

contacts to close. This relay is typically used to control a deposition system

source shutter. The LCD display (SHUTTER) leg end will be visible when the

shutter relay is active. This key is active at all times and states (Program and

Normal) of the STM-100 / MF. A remote input duplicating this key function is

also provided.

Page 2 - 1 OPERATION AND PROG RAMMING

Page 22

SHUTTER CLOSE

DATA

ENTER

PROGRAM

DATA ENTRY

ZERO Key

ZERO

Crystal Life Key

LIFE

SECTION 2.3

Program Key

PROGRAM

The SHUT TER CLOSE key provides the reverse function of the

SHUTTER OPEN key. This key is active at all times and states of the

STM-100 / MF. A remote input duplicating this k ey f unc t ion is also provided.

ZERO

The ZERO key provides two functions, "THICKNESS ZERO" and " TIMER

ZERO". Activating the key will cause any accumulated reading in the

thickness display to be set to zero, thus providing a new accumulation

reference point. It will also reset the elapsed t imer and display to t he set point

value contained in the program m emory. Any setpoint relays that may have

been closed at the time of the "ZERO" key operation will be reset to the open

state. This key is inactive in the PROGRAM mode. Remote inputs providing

separate operation of the THI CKNESS ZERO and T I MER ZERO operations

are also provided. Note that during a Crystal Fail condition, the Zer o key does

not function.

LIFE

Activating the CRYSTAL LIFE key will provide the user with a measure of

remaining possible sensor crystal life. T his information is expressed in percent

with 100% representing a new sensor crystal and 0% indicating a fully loaded

sensor crystal (1MHz frequency shift). This information is presented where

rate information is normally shown. This data should serve as an indicator for

the need to change the sensor crystal. T he frequency of the sensor crystal t o

the nearest kilohertz is also presented. T his information is shown where

accumulated thickness data is normally displayed. A new sensor crystal

should indicate close to 99% life and a freq uency near 5. 950 MHz. This key

function is inactive in the PROGRAM mode. Activating this key during a

CRYSTAL FAIL condition may result in a blank data display. The LIFE display

is active as long as the LIFE key is held depressed.

DATA ENTRY AND PROGRAMMING GROUP

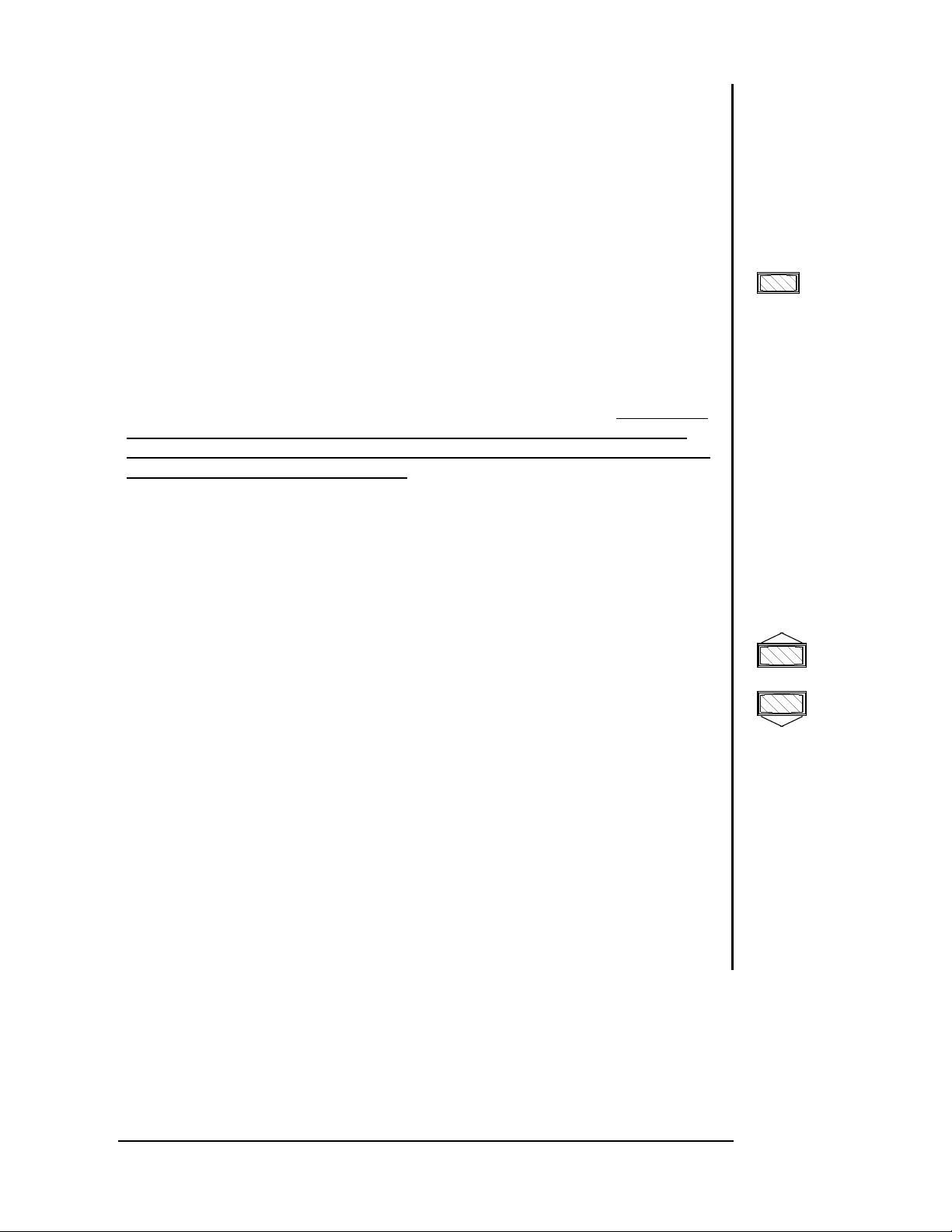

Figure 2.3: Data Entry And Programming Keys.

PROGRAM

Activation of the PROGRAM key places the instrument in a mode wherein

the internal parameter variables may be viewed or modified. Data view

operation is always available whereas, data modification may be inhibited by a

user option switch on the rear panel. If the instrument is in the PROGRAM

mode, depressing the PROGRAM key will return the unit to the norm al display

mode. Six variable parameters, for each of nine films of the STM-100 / MF

OPERATION AND PROG RAMMING Page 2 - 2

Page 23

may be programmed by the user. Two of t hes e m at erial constants are needed

Enter Key

ENTER

Arrow Keys

DATA

SECTION 2.4

LCD Data Displays

to provide correct thickness and rate information for a particular film material

and one is a constant used to correct f or system sensor and substrate

geometry variations. Three setpoint variables ar e pr ovided to act ivate relay

events. Two of these are related to thickness and one to elapsed time. These

variables and their meanings are discussed in detail in Section 2.4.

ENTER

The ENTER key has two functions. It is used (1) to sequence through

the six parameter variables, one parameter f or eac h pr ess of the ENTER key,

and (2) to place modified variable data into the non-volatile storage memory of

the instrument. This data will be retained until modif ied by the user even with

no power to the instrument. A legend on the LCD display will indicate which

variable parameter data is being displayed. Any modifications to parameter

data occur in the display memory only, and will cause the associated

parameter legend to f lash. The flashing legend indicates that a param et er

change has been made but has not yet been saved in memory. To stor e the

data in memory the ENTER key must be pressed. Exiting t he PRO G RAM

mode (via the PROGRAM key) while a parameter legend is flashing does not

cause the modified data to be saved. Previously saved parameter data will be

retained. The ENTER key only functions in the PROGRAM mode.

ARROW KEYS

The ARROW keys are used to select t he ac t ive f ilm and to increment or

decrement the displayed parameter variable data in order to achieve the

desired value. The rate of incremental change will increase as the key is held

depressed. This will speed up parameter changes covering a large dynamic

data range. Letting up on the key and then resuming key depression will reset

the rate of change to t he slowest rat e and it will again increase with time as t he

key remains depressed.

FILM PARAMETERS

The STM-100 / MF utilizes a high contrast liquid crystal display for the

viewing device. All measurement data, instrument status, and pr ogram

variable operations are viewable on the display. A three or four digit parameter

display and a four digit time display (min:sec) are used t o display the dynamic

data.

Page 2 - 3 OPERATION AND PROG RAMMING

Page 24

PROGRAM

ENTER

DATA

Film Number Parameter

Figure 2.4: LCD Data Areas.

The STM-100 / MF incorporates six programmable parameter variables

for each of nine films pr ogrammable by the user. Three variables are used by

the thickness equation and are relat ed t o m at erial physical constants and

system geometry (Density, Z-Factor, and Tooling). The three remaining

parameters are used as setpoint values to activate t he internal relays on the

I/O connector.

Each variable has a specif ic LCD legend as soc iated with it. These

legends are only active in the PROGRAM mode and only one will be on at a

time. Each parameter is discussed in more det ail below.

Figure 2.5: LCD Variable Parameter Legends.

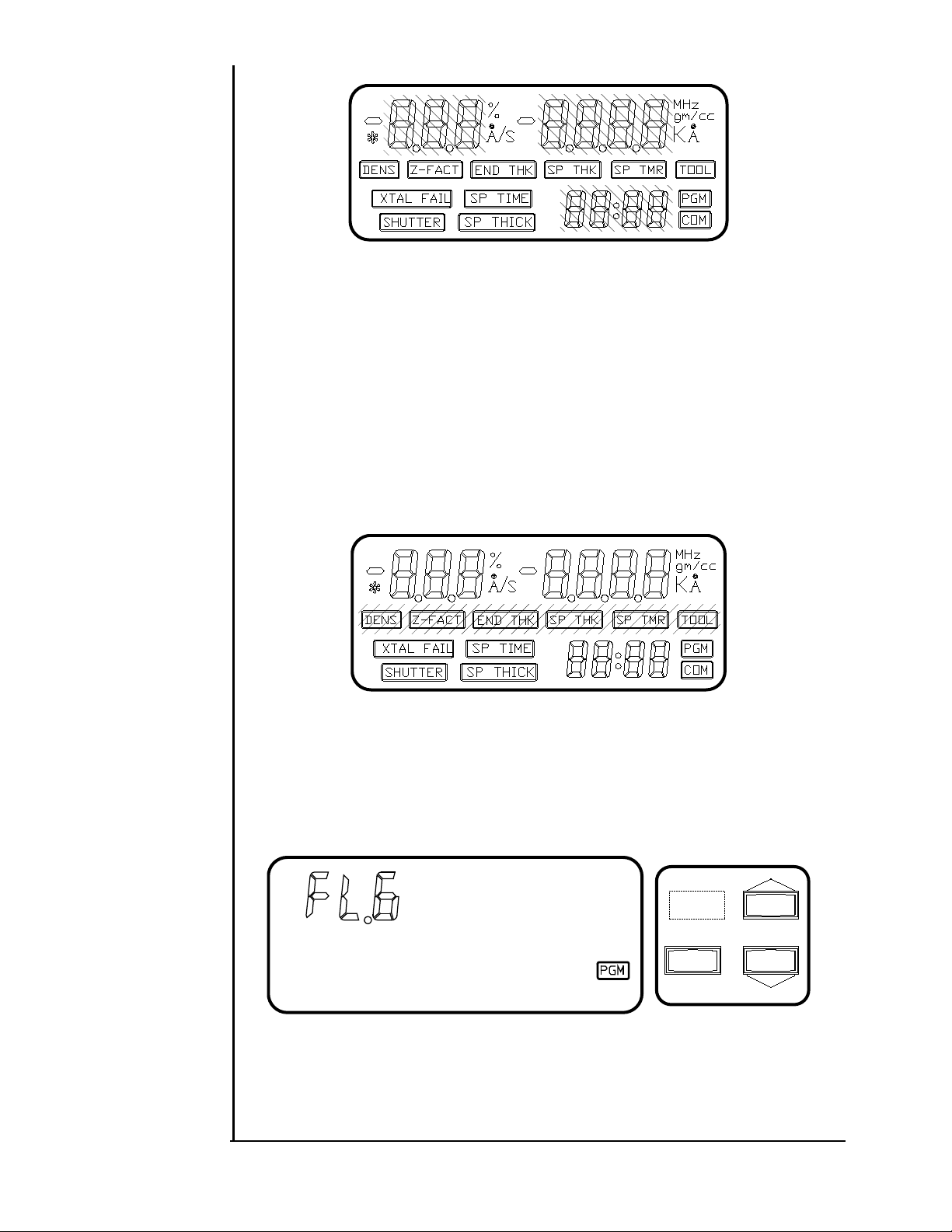

Af ter entering the program m ode by pushing t he Pr ogram Button the

current film number is displayed in the upper lef t hand c or ner of the LCD

display. (FL.n, n is 1 through 9). Ref er to Figure 2.6.

Figure 2.6: Film Number Parameter.

At this point t he c ur r ent film's parameters may be reviewed or changed or

a new current film selected. To select a new current film the film number is

OPERATION AND PROG RAMMING Page 2 - 4

Page 25

increased or decreased by using the up and down arrow keys. Pushing the

Density Parameter

enter button selects the film num ber shown to be the c ur r ent film and displays

the first parameter ( densit y) of that film. Each of t he film parameters can now

be reviewed or changed by using the DATA keys and / or the ENTER key.

WARNING

When leaving the Program Mode, the last Selected

FILM is the current active FILM.

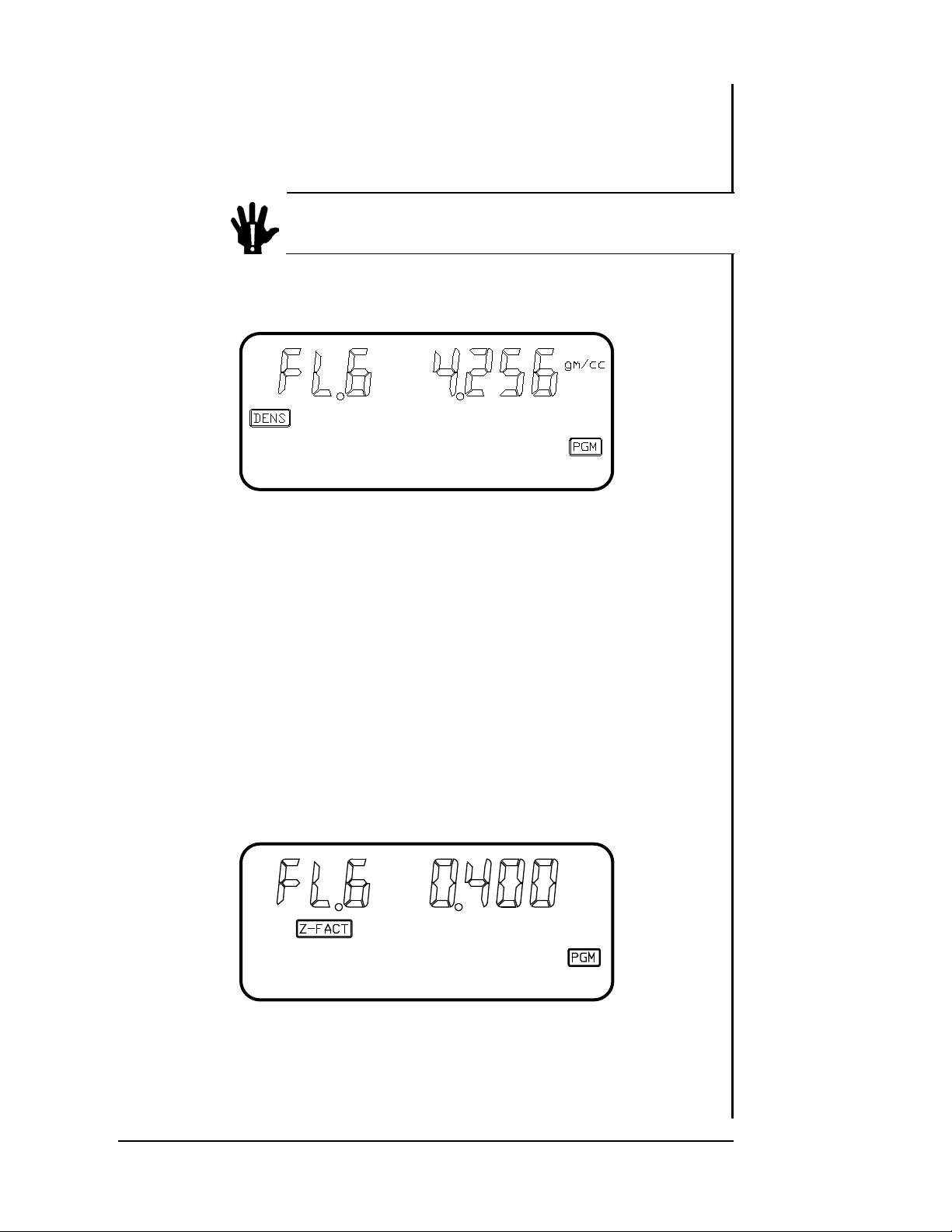

DENSITY

Figure 2.7: Density Parameter.

LEGEND DENS

RANGE 0. 500 to 99.99

UNITS gm/cc

The DENSITY parameter refers to t he m easured material density in

gm/cc. This constant is nor m ally the bulk m at er ial value but is somet im es

different due to deposition and film growth conditions. This value is utilized in

the thickness equation to convert m easured mass to a thickness value. See

Table 4.1 for an extensive value list. See Section 4.2 for calibr at ion

information.

LEGEND Z-FACT

RANGE 0. 100 to 9.999

UNITS NONE

Page 2 - 5 OPERATION AND PROG RAMMING

Z-FACTOR

Figure 2.8: Z-Factor Parameter.

Page 26

Z-Factor Parameter

End Thickness

The Z-Factor parameter refers t o t he elastic properties of the measured

material. This value is utilized in the thickness equation to m at c h t he

acoustical properties of the film being measured to the acoustic properties of

the base quartz material of t he sensor c r ystal. This correction is necessary to

insure accurate measurements when sensor crystal shifts of greater than 15%

are realized. See Table 4.1 for an extensive material value list. See Section

4.2 for calibration inform at ion.

END THICKNESS

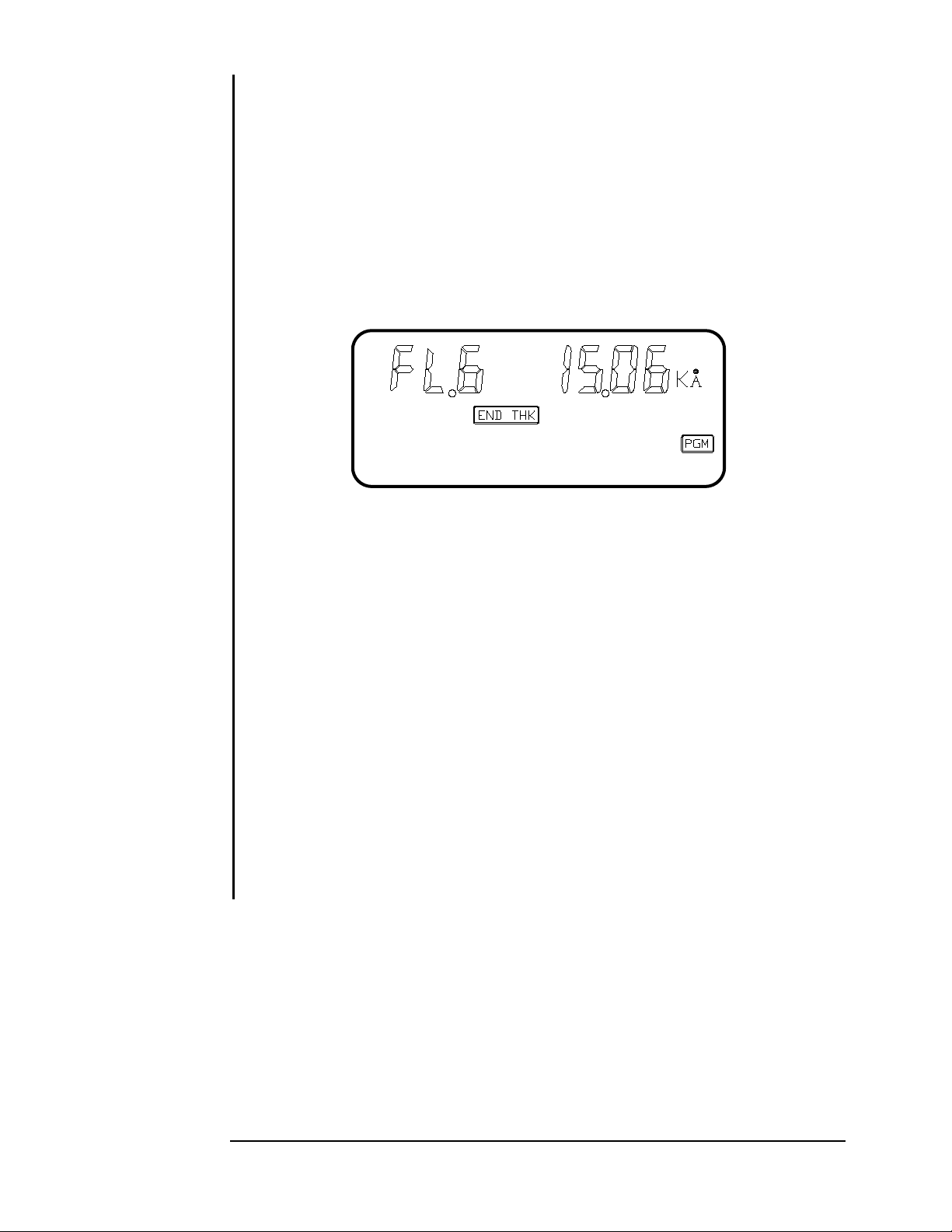

Figure 2.9: End Thickness Param et er .

LEGEND END THK

RANGE 0 to 9999

UNITS KILO ANGSTROMS (1 Angstrom = 10

-10

meters)

The END T HI CKNESS paramet er is used to provide a trigger setpoint for

the STM-100 / MF Shutter Relay contacts. If t he s hut t er relay contacts are

closed by operating the front panel shutt er c losed but t on or by rem ot e input .

These contacts will return to the open state when the thickness display value

becomes equal to or exceeds the END THICKNESS SETPOINT value. T he

STM-100 / MF Shutter Relay contacts are normally used to automatically

control a deposition system source shutter. This is a trigger event and will

only effect shutter st at us at t he time the event occurs. If the shut t er r elay

contacts were already open at the time of the event the event will be ignored.

A setpoint value of 0.000 kÅ causes the setpoint function to be ignored.

OPERATION AND PROG RAMMING Page 2 - 6

Page 27

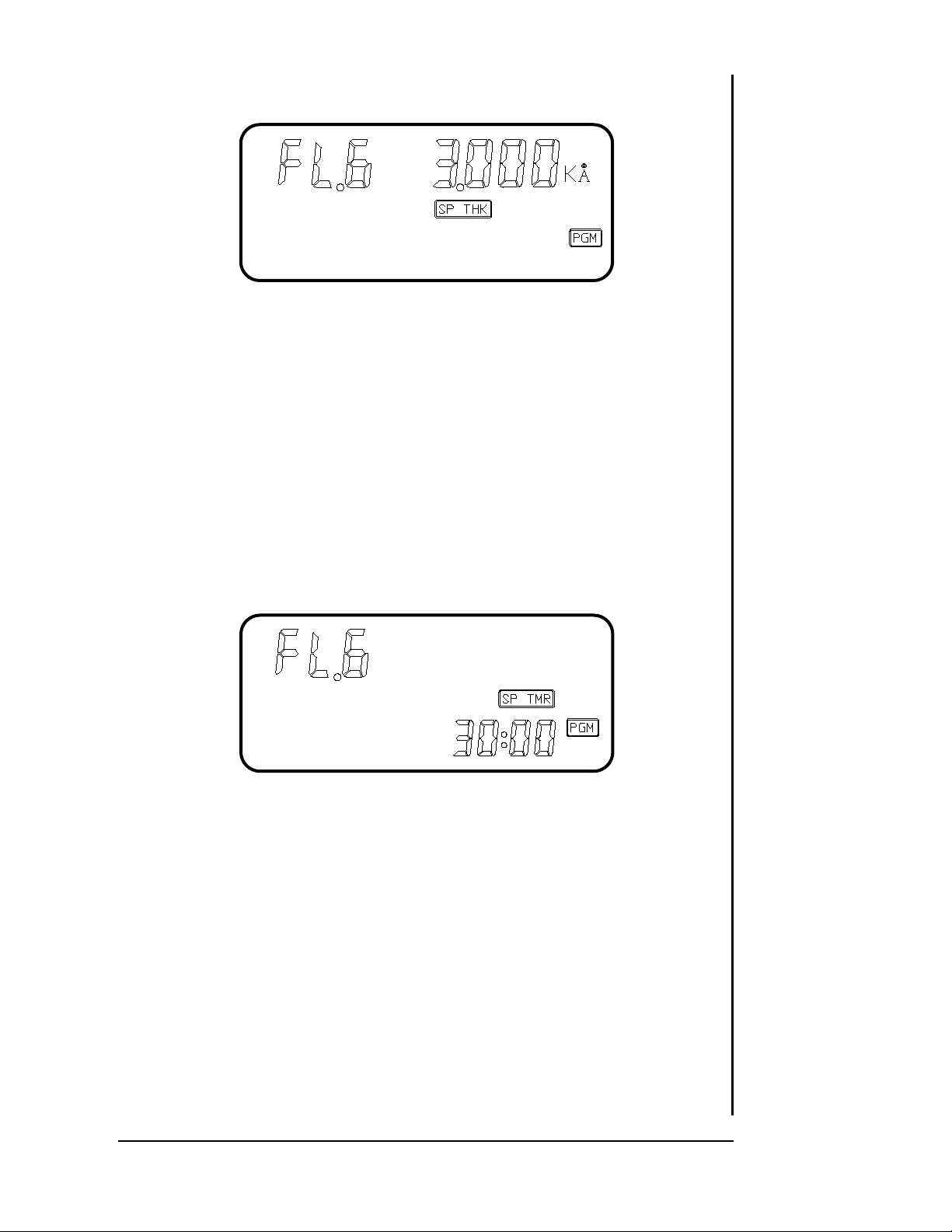

SETPOINT THICKNESS

Setpoint Thickness Parameter

Setpoint Timer

Figure 2.10: Set Point Thicknes s Par am et er.

LEGEND SP THK

RANGE 0 to 9999

UNITS KILO ANGSTROMS

The SETPOINT THICKNESS parameter is used to provide a comparison

point for the STM-100 / MF Thickness Set point Relay. T his set of relay

contacts will be closed whenever the thickness display equals or exceeds the

setpoint value. A setpoint value of 0.000 kÅ causes the t hickness setpoint

function to be ignored.

SETPOINT TIMER

Figure 2.11: Set Point Timer Parameter.

LEGEND SP TMR

RANGE 00:00 to 99:59

UNITS MIN:SEC

The SETPOINT TIMER parameter is used to provide a comparison point

for the STM-100 / MF Timer Setpoint Relay. The int er nal STM-100 / MF timer

is pre-set with the setpoint value whenever the front panel ZERO k ey, or a

remote ZERO TIMER input, is activated. The Tim er Relay contact s ar e

opened at this time and the timer display begins counting downward toward

zero. When the timer display reaches zero the relay contacts are closed and

the display timer begins counting in an upwards fashion. A setpoint value of

00:00 will cause the timer setpoint function to be ig nor ed.

Page 2 - 7 OPERATION AND PROG RAMMING

Page 28

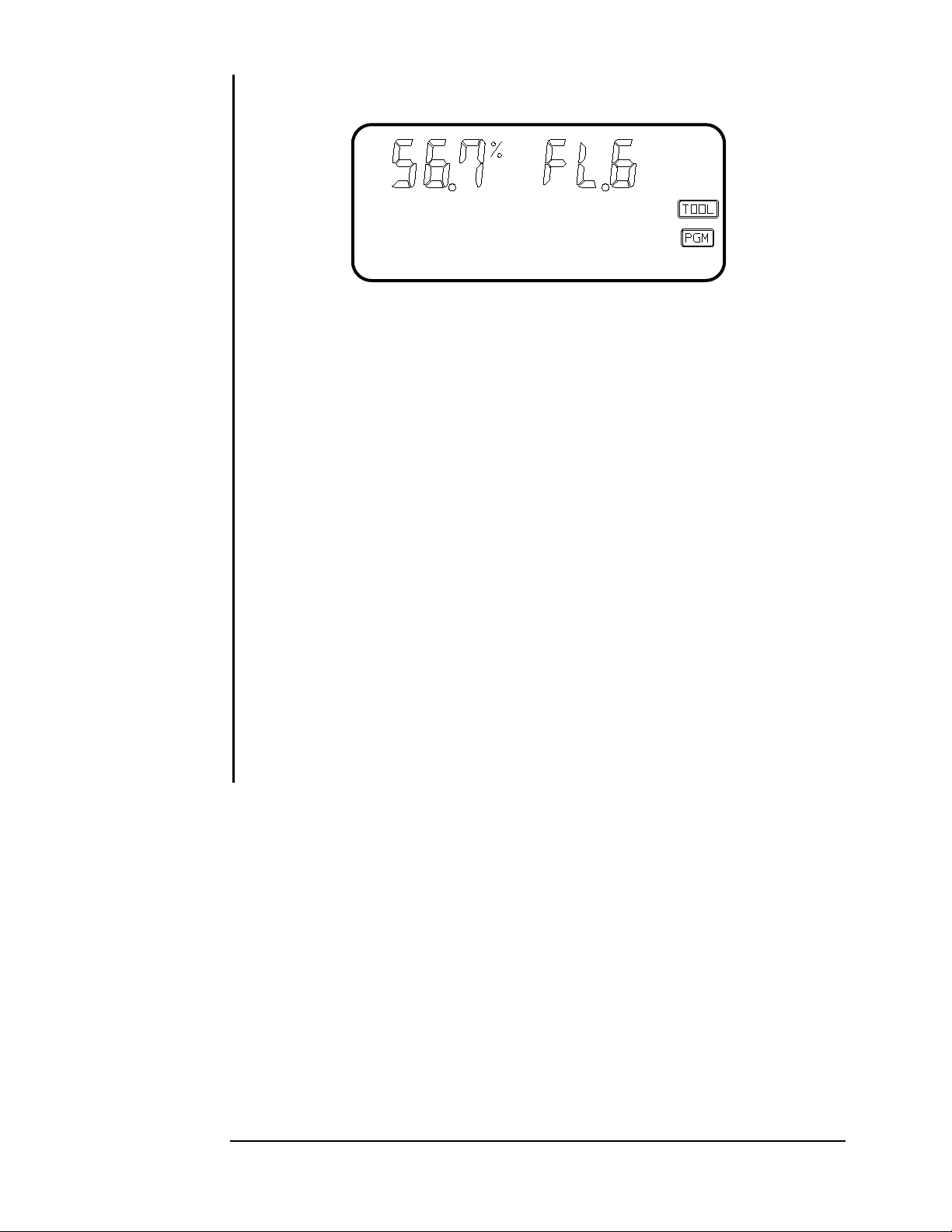

TOOLING

Tooling Factor Parameter

SECTION 2.5

Figure 2.12: Tooling Paramet er .

LEGEND TOOL

RANGE 10.0 to 399

UNITS PERCENT

The TOOLING parameter is used as a corr ection factor to compensate

for geometric position differences between the location of the sensor and the

target substrate. Cor r ec t ion is r equired both the substrate and sensor see the

material source in an identical manner, unless for this case, the Tooling

Parameter is set to 100%. Generally, if the sensor is farther f r om the source

than the substrate, the tooling will be set to >100%. If the sensor is closer to

the source, the tooling will be set to < 100%. See Section 4. 2 for calibration

information.

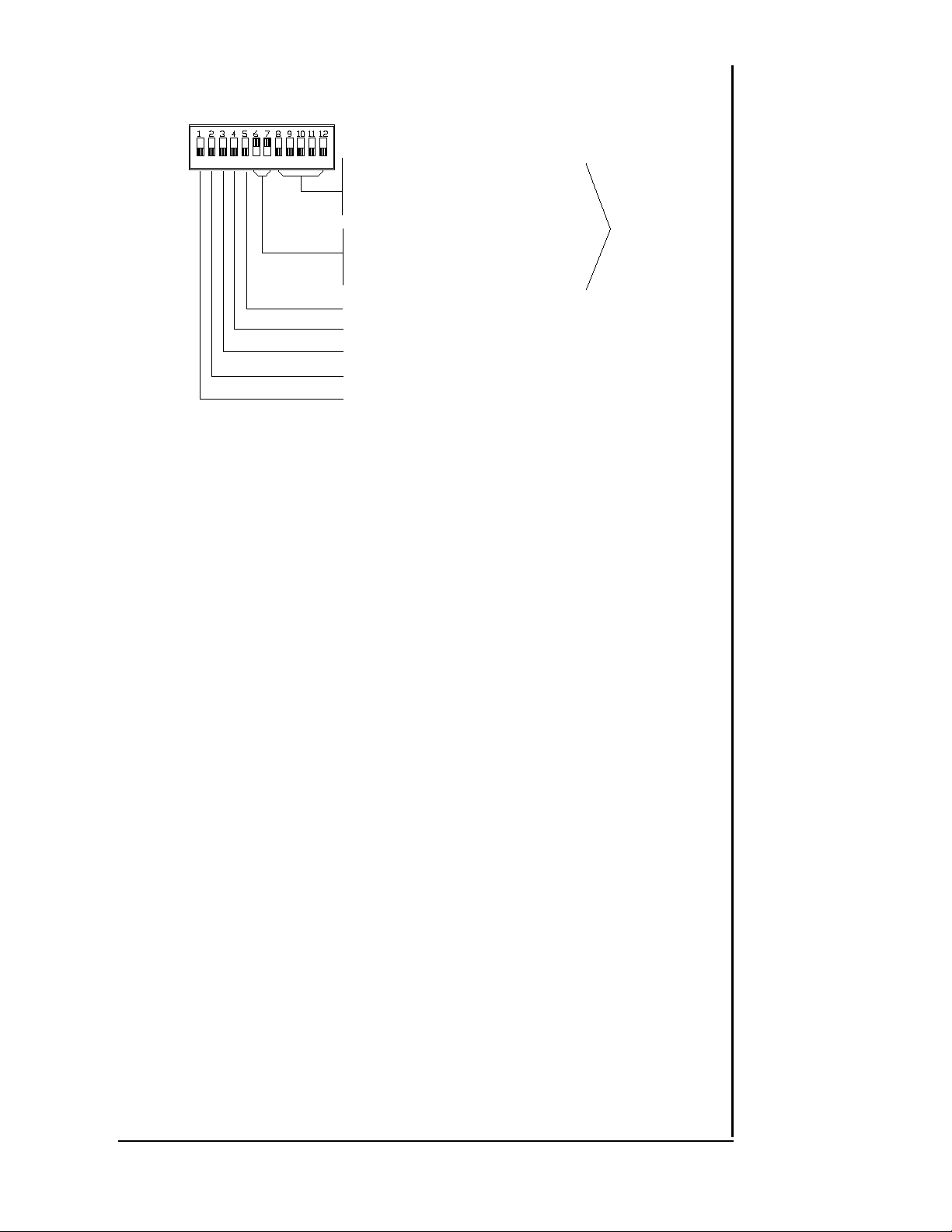

USER CONFIGURATION SWITCHES

On t he r ear panel of the STM-100 / MF a twelve selection configuration

switch is located. The settings of this switch allow the user to select various

system operational modes. All communications related variables are also set

here. Switches 1 thru 4 may be changed at any time and will have immediate

effect. Switches 5 thru 12 ar e only read at t he time of power turn on.

OPERATION AND PROG RAMMING Page 2 - 8

Page 29

CONFIGURATION

SWITCH

BINARY DEVICE ADDRESS

SW8=MS BIT SW12=LS BIT

SW 8 SW9 SW10 SW11 SW12

OFF OFF OFF OFF OFF = 0

OFF OFF OFF ON OFF = 0

ON OFF ON OFF ON = 0

SERIAL BAUD RATE

SW 6 SW7

OFF OFF = 300

OFF ON = 1200

ON OFF = 2400

ON ON = 9600

PROTOCOL ON = SEMI OFF = SYCON

NEGATIVE RATES ON = ENABLE OFF = DISABLE

FREQUENCY MODE ON = ENABLE OFF = DISABLE

ANALOG OUTPUT ON = THICK OFF = RATE

PARAMETER LO CK ON = LOCK OFF = UNLOCK

see Note:

NOTE: Sw itch settings involvi ng c omm unications functions are sensed at power up onl y.

Configuration

Figure 2.13: Configuration Switch Settings.

SWITCH FUNCTION DEFINITIONS

SW1 - PARAMETER LOCK

When on, st or ed par am eter data cannot be modified via the front

panel. This switch is sensed at all times.

SW2 - RECORDER FUNCTION

When on, the analog output will provide thickness information.

Rate information is presented in the off state. This switch is

sensed at all times. See Section 3.6.

SW3 - FREQUENCY MODE

When on, the unit will display seven digits of sensor frequency to

a resolution of one Hertz. All other instrument functions remain

normal. This switch is active at all times.

SW4 - NEGATIVE LIMITS

When on, both thickness setpoints and their associated relays will

activate on negative thickness data only. This switch is sensed at

all times.

SW5 - SERIAL COMMUNICATIONS FORMAT

When on, the RS-232 serial communications channel will respond

SW6 & SW7 - BAUD RATE SELECT ION

These two switch settings in combination select one of four baud

Page 2 - 9 OPERATION AND PROG RAMMING

to SEMI STANDARD SECS-II form at t ed c om m ands. Sycon

formatted commands ar e valid f or the off state. This switch is

sensed only at power-up.

rates for the RS-232 serial comm unicat ions channel. These

switches are sensed only during power-up.

Page 30

SW6 SW7 BAUD

OFF OFF 300

OFF ON 1200

ON OFF 2400

ON ON 9600

Table 2.1: Baud Rate Switch Settings

SW8, SW9, SW10, SW11, SW12 DEVICE ADDRESS SELECTION

These switches in combination select the device address for t he

instrument when operating with the SECS RS-232 protocol or with

either the IEEE-488 or BITBUS communications opt ion car ds.

These options allow multiple devices to operate on a single bus,

and only the individual addressing prevents response conflicts.

Switch coding is in binary 1 of 32 format with SW8 the MSB and

SW12 the LSB. T hes e switches are s ensed only during powerup. See Table 2.2 for a list of addresses.

OPERATION AND PROG RAMMING Page 2 - 10

Page 31

Switch Setting Address

SECTION 2.6

Enabling the Test Mode

SW8 SW9 SW10 SW11 SW12 IEEE BITBUS / SECS II

off off off off off 0 32 / 0

off off off off on 1 1

off off off on off 2 2

off off off on on 3 3

off off on off off 4 4

off off on off on 5 5

off off on on off 6 6

off off on on on 7 7

off on off off off 8 8

off on off off on 9 9

off on off on off 10 10

off on off on on 11 11

off on on off off 12 12

off on on off on 13 13

off on on on off 14 14

off on on on on 15 15

on off off off off 16 16

on off off off on 17 17

on off off on off 18 18

on off off on on 19 19

on off on off off 20 20

on off on off on 21 21

on off on on off 22 22

on off on on on 23 23

on on off off off 24 24

on on off off on 25 25

on on off on on 27 27

on on on off off 28 28

on on on off on 29 29

on on on on off 30 30

on on on on on 0 31

The STM-100 / MF incorporates a test and deposition simulation mode to

aid in trouble shooting and demonstrating t he instrument. This mode simulates

a deposition rate of 16 Angstrom s per second with a Density and Z-Fact or of 1

and Tooling of 100%. The t est mode may be activated only in the nonprogram mode. Holding the UP ARROW key down while activating the

SHUTTER CLOSE key will turn the test mode on. The Å/S and KÅ legends

will blink continuously to indicate the test function. Once in the t es t m ode t he

Page 2 - 11 OPERATION AND PROGRAMMING

Table 2.2: Configuration Switch Address Sett ings

TEST MODE

Page 32

shutter open and close buttons control the sim ulat ed deposit ion. The test

SECTION 2.7

Disabling the Beeper

mode may be turned off by holding the UP ARROW key depressed and then

activating the SHUTTER OPEN key. Turning the unit off and back on also

clears the test mode.

BEEPER

The beeper will give a short audible tone when any key is depressed or

the unit power switch is turned on. The keyboard beeper may be disabled if

desired by holding the DOWN ARROW key and activating the SHUTTER

CLOSE key while not in the PROGRAM mode. The same procedure and

activating the SHUTTER OPEN key will turn the beeper on.

The beeper will always be enabled after power is applied to the unit.

OPERATION AND PROG RAMMING Page 2 - 12

Page 33

SECTION 3

Installation

Page 34

Page 35

INSTALLATION

DAMAGE TO THE UNIT .

DAMAGE TO THE UNIT .

SECTION 3.1

SECTION 3.2

Line Power Warning

Line Voltages

POWER

Electrical Connections and Descriptions

All electrical connections to the STM-100 / MF are made at the rear panel of the

instrument. Care should be exercised in routing all cables as far as practically

possible from any other cables or wires that may be generat ing noise. These may

include other line voltage cables, wires to heaters that are SCR-cont r olled, and

wires or cables that may conduct high transient curr ent s during arc over of an Ebeam type supply.

Figure 3.1: Rear Panel.

WARNING

REPLACE BROKEN OR BLOWN FUSES ONLY W ITH

The STM-100 / MF may be configured to operate on either 110V or 220V

nominal line voltage. Units are factory-shipped conf igured for 110V operation

unless otherwise ordered. The setting may be verif ied by noting t he line voltage

value visible in the small window of the power and fuse module. To change the

configuration firs t r em ove the power cord, then release the latch in the center of

the module and remove the insert holding the f uses . The insert contains two

fuses, the system fus e and a spar e. Remove both fuses, then pull the two-prong

fuse holder out of the latching insert. Rotate the fuse holder and replace it int o t he

latching insert such that the proper line voltage is visible in the window. The

reading will be either 110 or 220. Place the proper fuse into t he m et al clips ( 1/ 4

amp SB for 110V operation and 1/8 amp SB for 220V operation), place the spare

fuse into the spare fuse ar ea and r eplace the latching insert back into the power