Page 1

SRT-422

E-Beam Source Indexer

instruments

MAN

0

AUTO

Ø

ON OFF

0

SRT-422

MULT-POCKET E-BEAM INDEXER

User's Manual

518-034 Revision A, January 2004

Page 2

Page 3

SRT-422

Operators Manual

Page 4

Page 5

Preface

Table of Contents

Preface...........................................................................................................................................3

Table of Contents......................................................................................................................3

List of Figures............................................................................................................................4

List of Table...............................................................................................................................5

Warranty........................................................................................................................................6

SYCON INSTRUMENTS, INC. .................................................................................................6

EQUIPMENT RETURN.............................................................................................................6

EC Declaration of Conformity....................................................................................................8

Section 1......................................................................................................................................11

General Information & Specifications......................................................................................11

Section 1.1: Introduction.................................................................................................................................11

Section 1.2: Unpacking...................................................................................................................................11

Section 1.3: Specifications ..............................................................................................................................12

Section 2......................................................................................................................................17

Operation ................................................................................................................................17

Section 2.1: Automatic Operation....................................................................................................................17

Section 2.2: Stalled Motor Indication on 7-Segment Display .........................................................................17

Section 2.3: Section overview ........................................................................................................................17

Section 2.4: Control/display features...............................................................................................................17

Section 2.5: Clockwise vs. counterclockwise pocket numbering ...................................................................19

Section 2.6: Indexer operation with standard multipocket sources................................................................19

Section 2.7: Indexer operation with 4-pocket UHV sources...........................................................................20

Section 2.8: Indexer operation with three-pocket sources that have one banana shaped pocket.................21

Section 2.9: Indexer operation with continuous trough hearths.....................................................................22

Section 2.10: phase adjustment......................................................................................................................23

Electromechanical Method.........................................................................................................................23

Electronic Method ......................................................................................................................................24

Section 2.11: Rotation speed and torque selection for pocket seeking.........................................................25

Section 3......................................................................................................................................29

Installation...............................................................................................................................29

Section 3.1: Introduction..................................................................................................................................29

Section 3.2: Electrical Connections and Descriptions.....................................................................................29

Line Voltages .............................................................................................................................................29

Section 3.3: Internal Configuration Switches...................................................................................................30

Section 3.4: setting the configuration dip switches..........................................................................................31

Section 3.5: Description of Configuration Switches........................................................................................32

Standard Multi-pocket Sources (Codes 0-5)..............................................................................................34

UHV 4-Pocket Sources (Code 7)...............................................................................................................34

Three-Pocket Hearths with One Banana-Shaped Pocket (Codes 10-13).................................................35

Hearths with Full-Circle Evaporant Troughs (Code 2)...............................................................................36

Section 3.6: configuring the opto-isolator pc board for 24-vdc I/Os................................................................37

Section 3.7: Initial Bench Test........................................................................................................................38

Section 3.8: System Installation .....................................................................................................................39

Section 3.9: Installing the Index-Drive Unit ....................................................................................................40

Section 3.10: Installing the Control Unit.........................................................................................................41

Section 3.11: Indexer and System Grounding................................................................................................42

Section 3.12: initial phase adjustment..............................................................................................................43

Electromechanical Method.........................................................................................................................43

Electronic Method ......................................................................................................................................44

Table of Contents Page 3

Page 6

Section 3.13: making system connections via the rear panel I/O interface ....................................................45

Interlock Connections.................................................................................................................................45

Pins 1, 2, and 7 (Pocket SELect Inputs 0,1, and 2 respectively)...............................................................46

Pin 3 (System Interlock Input)....................................................................................................................46

Pins 4, 8, and 9 (Pocket POSition Outputs 1, 2, and 0, respectively) .......................................................46

Pin 5 (POCKET GOOD Output).................................................................................................................47

Pin 6 (External Supply Ground).................................................................................................................47

Pin 10 (External Supply Positive Input)......................................................................................................47

Pins 11, 12, and 13....................................................................................................................................47

Pin 14 (Internal Supply Ground) ................................................................................................................47

Pin 15 (External Supply Ground)...............................................................................................................47

Section 3.14: making system connections via the rear panel rs232 interface................................................47

Section 3.15: Warranty Repair and Replacement..........................................................................................48

5 Year Service Policy.................................................................................................................................48

Section 4......................................................................................................................................51

Computer Interfacing...............................................................................................................51

RS-232 Interface.....................................................................................................................51

Section 4.1: RS-232 Description .....................................................................................................................51

Section 4.2: Baud Rates And Cabling.............................................................................................................51

Section 4.3: Setting The computer Baud Rate................................................................................................51

Section 4.4: ASCII Protocol.............................................................................................................................52

Section 4.5: Communication Commands........................................................................................................53

Section 4.6: Command Responses.................................................................................................................53

Section 4.7: ‘Illegal’ Responses.......................................................................................................................54

Section 4.8: Command Set..............................................................................................................................54

Query the unit for any operating parameter...............................................................................................54

Version Command @................................................................................................................................54

Lockout Command A.................................................................................................................................54

Pocket Command B..................................................................................................................................56

Power Fail Status Command C.................................................................................................................56

Moving Command D .................................................................................................................................56

Stall Error Command E.............................................................................................................................56

Pocket 1 Offset Command F.....................................................................................................................56

Current Location Command G..................................................................................................................56

Move To Command H...............................................................................................................................56

Read Configuration Command I ...............................................................................................................56

Reset Command J ....................................................................................................................................57

Read AUTO/MAN Switch Command K.....................................................................................................57

RS-232 Source Type Command L............................................................................................................57

Zero Non-Volitile offset and Goto Index Pulse Command ¦......................................................................57

Section 5......................................................................................................................................61

Trouble Shooting.....................................................................................................................61

Section 5.1: SECTION OVERVIEW................................................................................................................61

Section 5.2: ROUTINE TROUBLESHOOTING...............................................................................................62

Appendix A..................................................................................................................................65

Application Notes ....................................................................................................................65

List of Figures

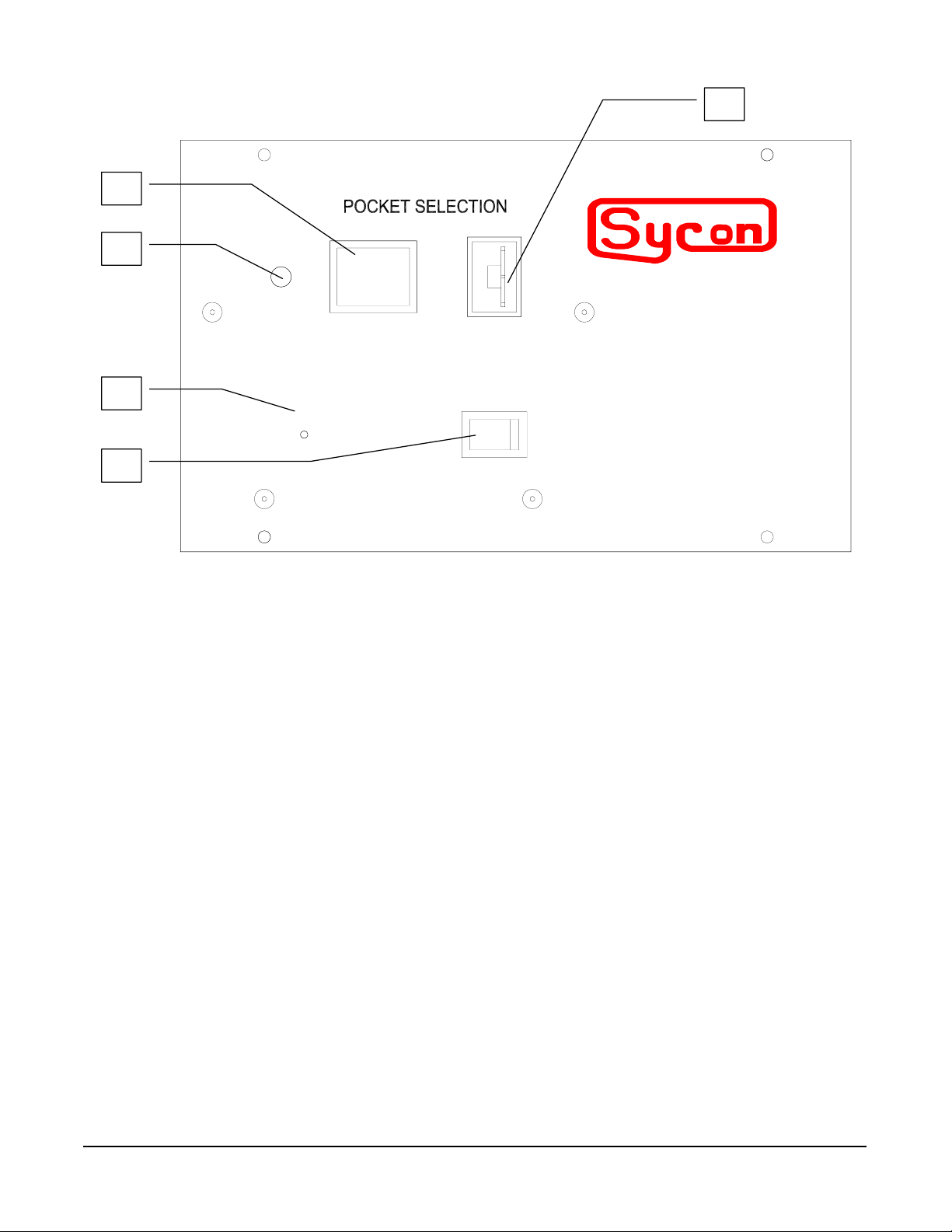

Figure 1.1: SRT-422 Front Panel.....................................................................................................11

Figure 1.2: SRT-422 Rear Panel.....................................................................................................12

Figure 2.1: Control / display features on the control unit’s front panel.............................................18

Figure 2.2: How the orientation of pocket numbering depends on the setting of DIP switch 5. .......19

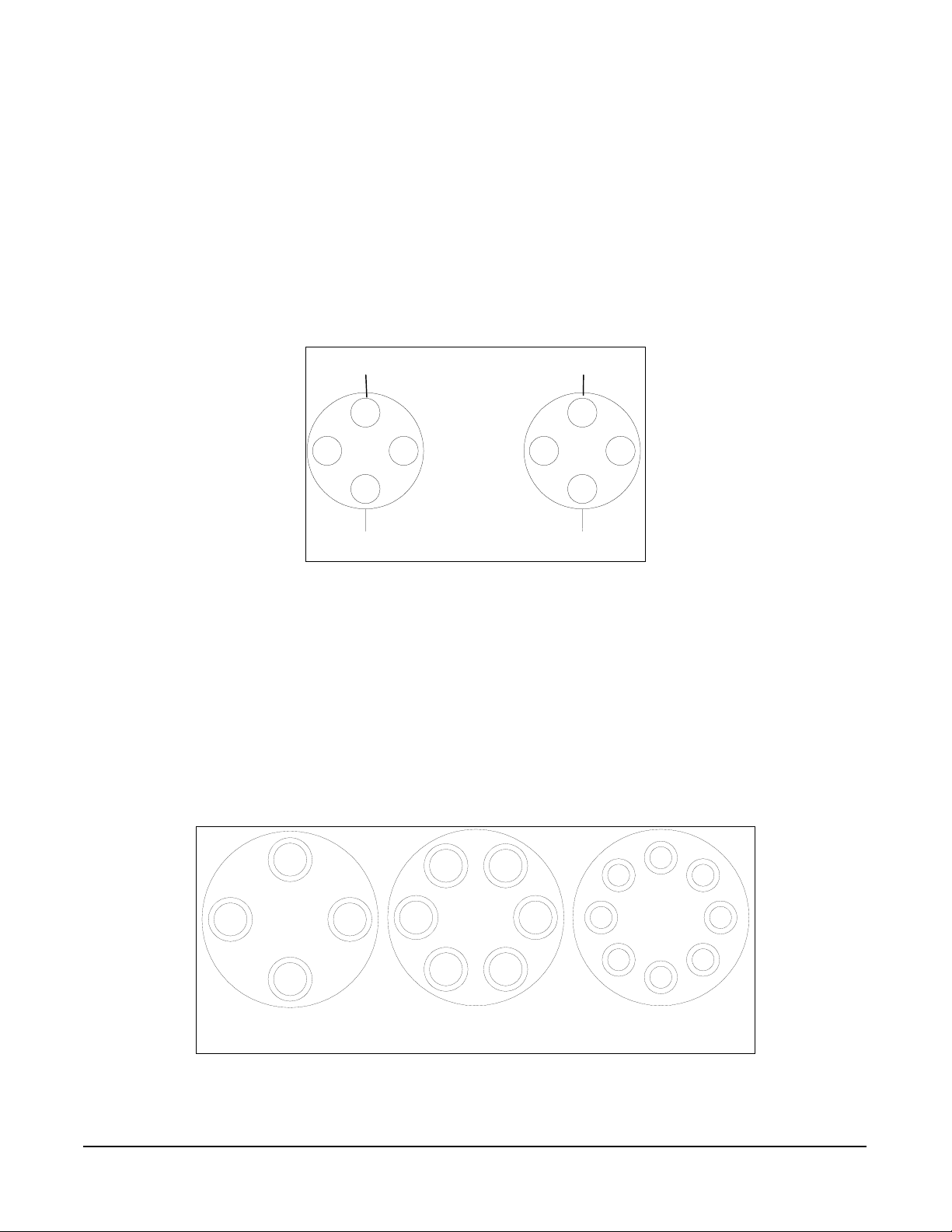

Figure 2.3: Standard 4-, 6-, and 8-pocket hearths...........................................................................19

Page 4 List of Figures

Page 7

Figure 2.4: Illustration of a 4-pocket UHV source, indicating the position of the “software

barrier” implemented in this mode to prevent damage to the bellows attached to

UHV hearths in this area. ................................................................................................21

Figure 2.5: Three-pocket hearths with one banana-shaped pocket.................................................21

Figure 2.6: Illustration of a continuous-trough hearth ......................................................................22

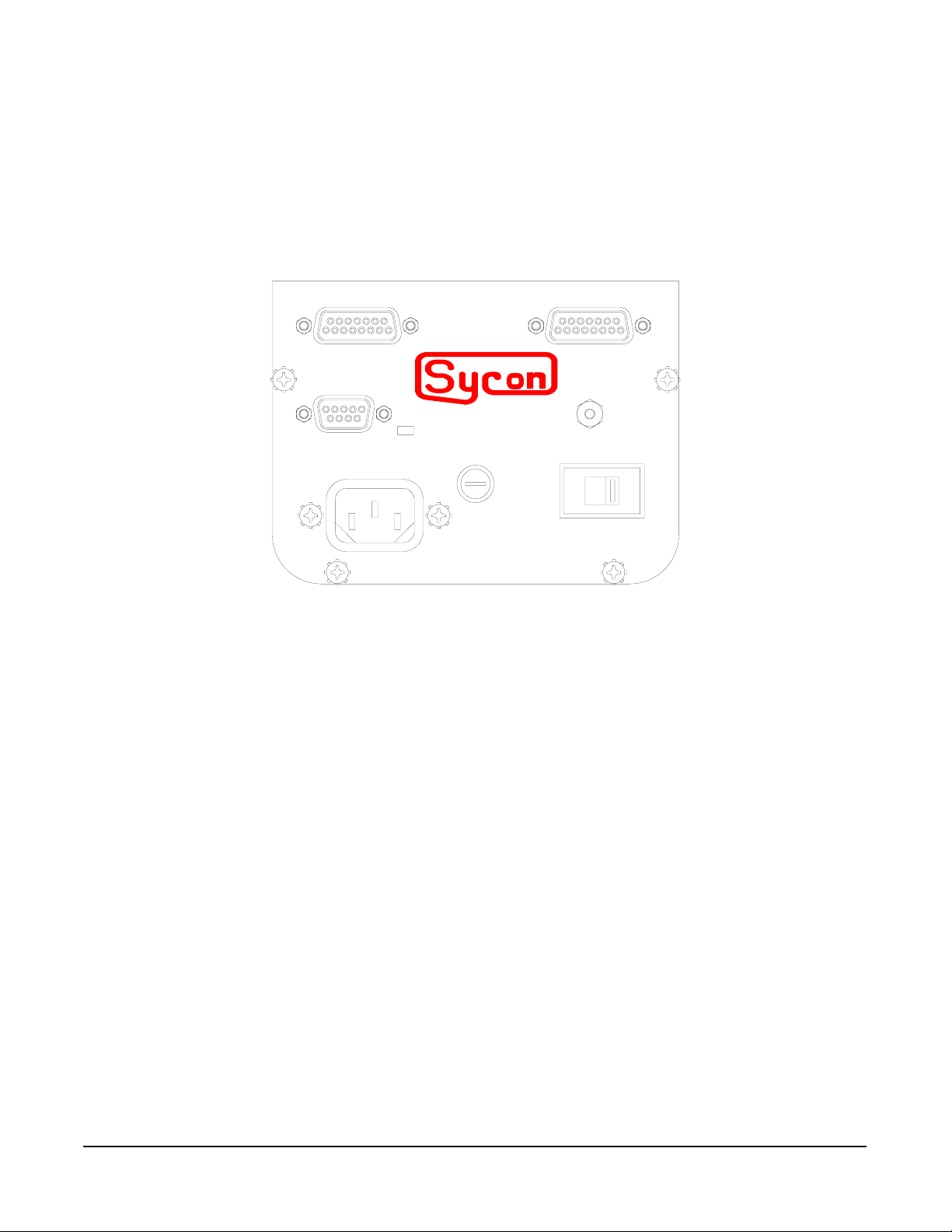

Figure 3.1: SRT-422 Motor Drive unit..............................................................................................29

Figure 3.2: Line Voltage Selection Switch .......................................................................................30

Figure 3.3: SRT-422 Rear Panel.....................................................................................................30

Figure 3.4: Configuration Switch......................................................................................................32

Figure 3.5: Orientation of pocket numbering changes depending on the setting of DIP switch 6....33

Figure 3.6: Source types supported by the SRT-422.......................................................................34

Figure 3.7: Locations of screws that secure the control unit’s rear panel to its body.......................37

Figure 3.8: Motor Drive Unit.............................................................................................................40

Figure 3.9: SRT-422 Grounding ......................................................................................................42

Figure 3.10: Control/display features on the control unit’s front panel.............................................43

Figure 3.11: Pinout for the rear panel I/O (ISOLATED connector....................................................46

Figure 3.12: Connections required for RS-232 communications between the SRT-422 and a

remote device with a 9-pin RS-232 port and a 25 pin RS-232 port. ................................48

Figure 5.1: Signal Flow Diagram .....................................................................................................61

List of Table

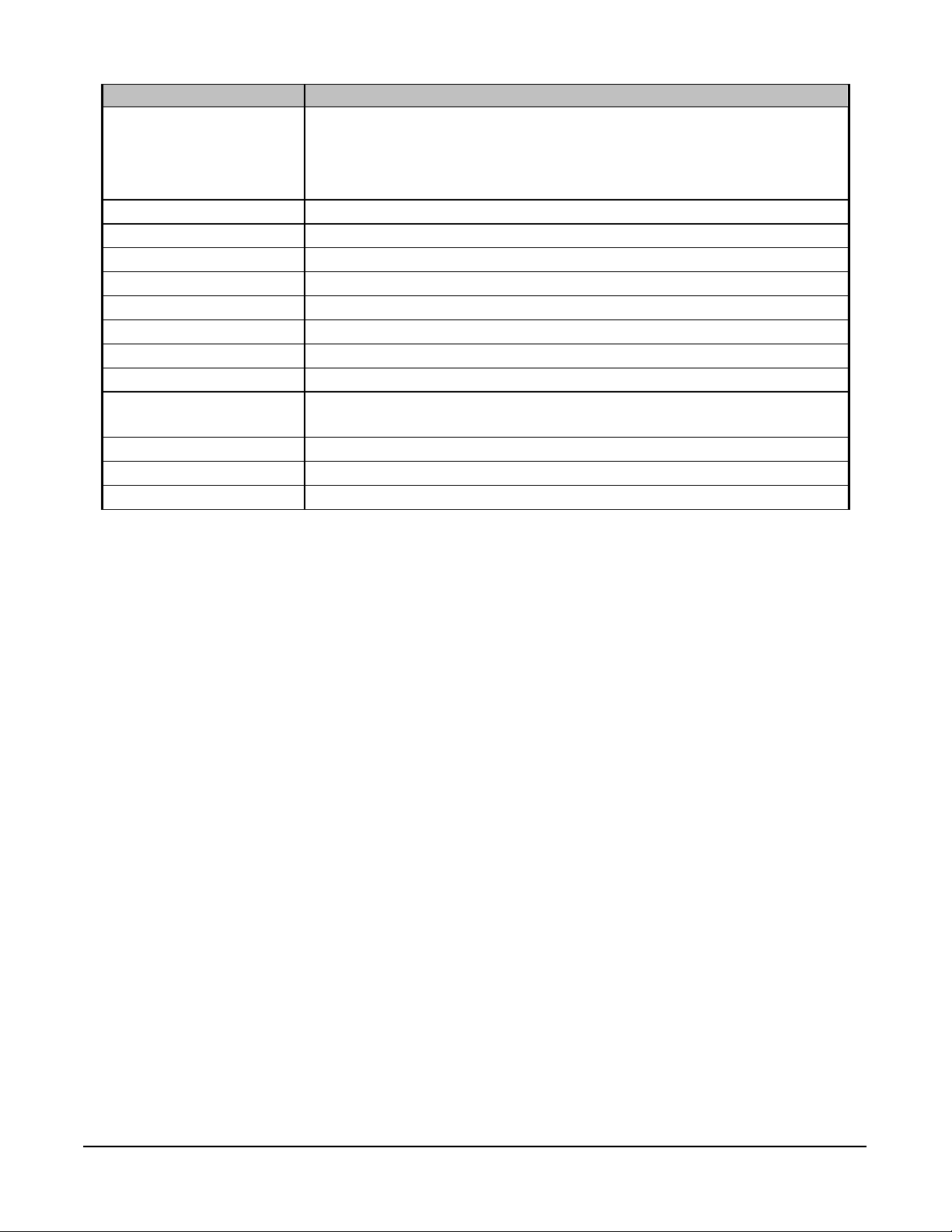

Table 1.1: Specifications..................................................................................................................13

Table 2.1: Speed of Hearth in Banana Mode...................................................................................22

Table 2.2: Hearth rotation speed in continuous mode....................................................................23

Table 2.3: Rotation Speed and Torque............................................................................................25

Table 3.1: Codes 0 – 5 DIP Switches settings.................................................................................34

Table 3.2: Code 7 DIP switch settings.............................................................................................34

Table 3.3: Codes 10 – 13 DIP switch settings.................................................................................35

Table 3.4: Hearth rotation in continuous mode ...............................................................................36

Table 3.5: Pocket-select codes input via pins 1, 2, and 7 **SEL2 not required for four pocket

configurations..................................................................................................................46

Table 3.6: Pocket-position codes output via pins 4, 8, and 9 ...........................................................46

Table 5.1: Trouble Shooting guide...................................................................................................62

List of Table Page 5

Page 8

Warranty

SYCON INSTRUMENTS, INC.

Sycon Instruments, Inc. (Sycon) warrants that all electronic instrumentation equipment

manufactured by Sycon shall be free from defects in materials and workmanship for a period of

1 year from date of shipment. Mechanical vacuum components such as Feedthrough, sensors,

cables, and shutters shall be warranted for a period of six months from the date of shipment.

For the duration of the warranty period Sycon will, at its option, either repair or replace any

part, which is defective in materials or workmanship without charge to the purchaser. The

foregoing shall constitute the exclusive and sole remedy of the purchaser for any breach by

Sycon of this warranty.

This warranty does not apply to any equipment, which has not been used in accordance

with the specifications recommended by Sycon for the proper and normal use of the

equipment. Sycon shall not be liable under any circumstances for consequential or incidental

damages in connection with, or arising out of the sale, performance, or use of, the equipment

covered by this warranty.

This warranty is in lieu of all other warranties by Sycon, expressed or implied, including

the implied warranty of merchantability, the implied warranty of fitness for a particular purpose,

and warranty against infringement of any patent.

EQUIPMENT RETURN

Before returning any equipment to Sycon contact the Product Service Department. You

must obtain a RA (Return Authorization) number from Sycon Instruments and indicate this

number on all shipping cartons and correspondence. Ship all items in suitable containers with

adequate protection from outside damage. Also include a short description of the problem or

condition to facilitate processing.

Sycon Instruments, Inc.

6757 Kinne Street

Syracuse, New York

13057-1215

P (315) 463-5297

F (315) 463-5298

www.sycon.com

Page 6 SYCON INSTRUMENTS, INC.

Page 9

Sycon Instruments, Inc. reserves the right to change any information contained in this manual

without notice.

©

Copyright Sycon Instruments, Inc. 1986 - 2004

IBM® Is a registered trademark of IBM Corporation

Microsoft® is a registered trademark of Microsoft Corporation

SWAGELOK® is a trademark owned by Crawford Fitting Company

BITBUSTM is a trademark of Intel Corporation

ConFlat® is a registered trademark of Varian Associates, Inc.

AMPHENOL® is a registered trademark of Allied Corporation

Microdot

®

is a registered trademark of Microdot Inc.

EQUIPMENT RETURN Page 7

Page 10

EC Declaration of Conformity

We,

Sycon Instruments

6757 Kinne Street

East Syracuse, New York 13057

USA

Declare under sole responsibility that the

SRT-422, E-beam source indexer

Meets the intent of Directive 89/336/EEC as amended by 92/31/EEC and 93/68/EEC for

Electromagnetic Compatibility and the 72/23/EEC Low Voltage Directive for Product Safety.

Compliance was demonstrated to the following specifications as listed in the Official Journal of

the European Communities:

EN 50081-1:1992 Emissions

EN 5022 Class B Radiated and Conducted Emissions

EN 6100-3-2 AC Power Line Harmonic Current Emissions

EN 50082-1: 1995 Immunity

IEC 1000-4-2 Electrostatic Discharge Immunity

IEC 1000-4-3 RF Electromagnetic Field Immunity

IEC 1000-4-4 Electrical Fast Transient/Burst Immunity

IEC 1000-4-5 Power Line Surge Immunity

IEC 1000-4-11 Power Line Dips and Interrupts

EN 61010-1: 1993 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use

Page 8 EC Declaration of Conformity

Page 11

SECTION 1

GENERAL INFORMATION

Page 12

Page 13

Section 1

General Information & Specifications

Section 1.1: Introduction

The Source Rotation Indexer (SRT-422) is a stepping motor driver unit with optical

encoding for the positioning and rotation of multi-pocket electron beam sources. The SRT-422

is unique to other rotation controllers because the motor is small and compact separate from

the driver, and control electronics.. The unit is designed to attach to the input shaft (air side) of

a rotary vacuum feedthrough. For ease of installation, complete installation packages are

available which include either a 1” bolt Rotary Feedthrough or a 2 ¾” Del Seal Rotary

Feedthrough.

The Indexer can be controlled manually from a remote control panel, or automatically

from STC I/O Input or the RS 232 computer interface. It can control a 3, 4, 6 or 8 pocket

source in either a unidirectional or bi-directional manner. (the bi-directional mode, takes the

shortest path to the next selected pocket). The unit can be used to rotate a continuous trough

source at one of seven selected rotation speeds. For the multi-pocket UHV source, it has the

capability of limiting rotation to 270 degrees (3 pockets) from the pocket 1 position. Three

variations of 3 pocket source rotation control are provided (2 Standard pockets, 1 ‘banana’

pocket) which allow for different retrograde motion of the banana pocket (120°, 135° and 145°

sweep). Five rotational speeds are available for sweeping the ‘banana’ pocket. In addition,

custom firmware can be added to control other variations of sources.

instruments

MAN

0

SRT-422

AUTO

Ø

0

ON OFF

MULT-POCKET E-BEAM INDEXER

Figure 1.1: SRT-422 Front Panel

Section 1.2: Unpacking

When opening the shipping package, you should find the following items:

General Information & Specifications Page 11

Page 14

• SRT-422 Source Rotation Indexer

• 600-004 Power Cord (IEC 110 Volt)

• 514-004 RS232 / I/O Connector Kit

• 518-XXX SRT-422 User’s Manual

The following optional items will be additionally included if they have been purchased:

• 500-074 1” Bolt Rotary Feedthrough and Adapter

• 500-075 2 ¾” Del Seal Rotary Feedthrough and Adapter

MOTOR

instruments

RS-232

I/O (ISOLATED)

Figure 1.2: SRT-422 Rear Panel

Section 1.3: Specifications

Ready

SRT-422

120VAC Fuse 1/4 AMP SB

240VAC Fuse 1/8 AMP SB

Page 12 General Information & Specifications

Page 15

Specifications Description

Rotational Ability

Rotational Speed

Path Finding

Torque

Repeatability

Data Interface

Relay Interface

Manual Control

Safety Interlocks

Pocket Good

Indication

Size

Weight

Power

•4,6 or 8 Pocket Source (Uni or Bi-direction)

•Continuous Trough Source (1 of 8 speeds)

•UHV 4 pocket source (limited rotation)

•3 - 3 pocket ‘banana’ types

•Shaft speeds of up to 12 rpm

•Quickest path (CW, CCW) for multi-pocket source

•120 in-oz. at output shaft

•3° resolution and repeatability

•RS-232

•Allows control from system or deposition

•Inputs/outputs for Remote Manual Control Panel

•Disallows rotation with beam power applied

•Indicated selected pocket is reached or retrograde motion is in

progress.

•5.0w x 5.0h x 4.5d plus 1” shaft extensions

•3.5 lbs.

•Input power 115/230 Volts ac/10 watts

Table 1.1: Specifications

General Information & Specifications Page 13

Page 16

Page 17

SECTION 2

OPERATION

Page 18

Page 19

Section 2

Operation

The SRT-422 can be controlled remotely by the output relays of our STC-2002 and

STC-2000A Thin Film Deposition Controllers, or any other system controller. Additionally, it

can be controlled by a remote panel Manual Pocket Selection Switch or through either of two

standard computer interfaces. An Interlock input is provided to assure that rotation of multipocket sources cannot occur while deposition power is being applied to the source.

Section 2.1: Automatic Operation

With the Auto/Man toggle switch in the Auto position (DOWN), the Indexer will be

controlled through the STC I/O Port or the RS232 Computer Interface. The Binary code

applied to the STC I/O port will direct the Indexer to the proper position. Signals are available

which indicate correct pocket position along with the safety interlock described above.

Section 2.2: Stalled Motor Indication on 7-Segment Display

In addition to indicating the current pocket location the 7-segment LED provides a stall

or jammed source indication. This is done by alternately flashing the 7-segment display

between the current pocket location and zero. (The green LED on the back panel of the

Indexer will also blink if the condition occurs). This flashing indicates the load on the Indexer

has exceeded the torque capacity of the Indexer and it is unable to move to the new desired

position. This usually means that an excess amount of material has accumulated on the

source such that it cannot rotate freely.

Section 2.3: Section overview

This section describes the operation of the SRT-422 with a variety of source hearth types. The specific

sections are

Control/Display Features

Clockwise vs. Counterclockwise Pocket Numbering

Indexer Operation With Standard Multipocket Sources

Indexer Operation with 4-pocket UHV Sources

Indexer Operation With 3-pocket Sources That Have One Banana-Shaped Pocket

Indexer Operation With Continuous-Trough Hearths

Phase Adjustment

Rotation Speed and Torque Selection

Section 2.4: Control/display features

All of the indexer’s control/display features are on the control unit’s front panel, which is

illustrated in Figure below.

Operation Page 17

Page 20

4

instruments

3

2

1

MAN

AUTO

Ø

0

ON OFF

0

SRT-422

MULT-POCKET E-BEAM INDEXER

5

Figure 2.1: Control / display features on the control unit’s front panel

1. ON/OFF switch. This switch controls the input power to the unit.

2. Phase-adjustment switch. This spring-loaded pushbutton is mounted inside a hole

below the Greek letter ph ø. See the instructions on using this switch to recalibrate the

home position of pocket 1.

3. MANual/AUTO mode switch. When this switch is set toward MAN, the position of the

thumbwheel (feature 5) controls the following functions:

• Pocket selection in all multipocket modes.

• Rotation speed in continuous mode and oscillation speed in “banana” mode.

When the switch is set toward AUTO, these functions are controlled by signals from a

host computer, deposition controller, or other remote device. These signals are input via

either the RS-232 port or the I/O (ISOLATED) connector, both of which are on the

control unit’s rear panel.

Note that this switch has a spring-loaded locking feature. You must pull the switch all

the way out and hold it out while changing its position.

4. LED pocket-position indicator. This 7-segment LED displays the numerals 0 through 7

to indicate the current pocket position. The LED also flashes between zero and the

number of the current pocket position to indicate a stalled-motor condition, which

usually results from the buildup of material along the edges of the cutout in the top of

the source.

5. Pocket/speed selection thumbwheel. When the MAN/AUTO switch is set to MANual,

this thumbwheel controls pocket selection and rotation/oscillation speed.

Page 18 Operation

Page 21

Section 2.5: Clockwise vs. counterclockwise pocket numbering

When planning multipocket deposition—with the indexer in either unidirectional or

bidirectional mode, bear in mind that the orientation of pocket numbering is determined by the

setting of internal DIP switch 5. This means that the direction of “forward” rotation (i.e., rotation

“upward” through the pocket numbers) depends on whether DIP switch 5 is set for clockwise or

counterclockwise rotation. The Figure below shows what this means for indexer operation with

a standard 4-pocket source. The pockets of such a source must be thought of as being

numbered 1-4 in a counterclockwise direction when DIP switch 5 is on and 1-4 in a clockwise

direction when switch 5 is off. The same principle applies to all multipocket sources.

HOME

HOME

1

4

3

DIP Switch 5

ON

2

1

4

3

DIP Switch 5

OFF

2

Figure 2.2: How the orientation of pocket numbering depends on the setting of DIP switch 5.

Section 2.6: Indexer operation with standard multipocket sources

The SRT-422 operates any standard 3-, 4-, 5-, 6-, or 8-pocket source that has internal 4:1 gear

reduction. When the internal DIP switches are configured for one of these source types,

operation of the indexer is straightforward. After the pocket selection has been changed either

manually via the front-panel thumbwheel or automatically by a remote device, the indexer

rotates the hearth to that pocket position at a constant rotational speed and then stops.

4-pkt. standard

(code 1)

6-pkt. standard

(code 3)

8-pkt. standard

(code 5)

Figure 2.3: Standard 4-, 6-, and 8-pocket hearths

Operation Page 19

Page 22

Source rotation can be either uni- or bidirectional if you select unidirectional rotation, you can

also select clockwise or counterclockwise rotation. If you select bidirectional rotation, the unit

will index to the selected pocket by the shortest path, whether that means rotating clockwise or

counterclockwise. Bear in mind that both uni- and bidirectional modes, the orientation of pocket

numbering depends on whether clockwise or counterclockwise rotation is selected.

Notes on This Operating Mode

1. When the indexer is configured for a standard 4-pocket source, selecting pocket

positions 1-4 moves the hearth to pockets 1-4, respectively. In addition,

Selecting pocket 5 moves the hearth to pocket 1, as indicated by the LED

Selecting pocket 6 moves the hearth to pocket 2, as indicated by the LED

Selecting pocket 7 moves the hearth to pocket 3, as indicated by the LED

Selecting pocket 8 moves the hearth to pocket 4, as indicated by the LED.

2. When the indexer is configured for a standard 6-pocket source, selecting pocket

positions 1-6 moves the hearth to pockets 1 -6, respectively. In addition, selecting either

pocket 7 or pocket S moves the hearth to pocket 1 , as indicated by the LED.

3. When the indexer is configured for a standard 8-pocket source, selecting pocket

positions 1 -8 moves the hearth to pockets 1-8, respectively. However, note that the

LED displays a zero rather than an 8 when the hearth is at pocket 8.

Section 2.7: Indexer operation with 4-pocket UHV sources

The distinguishing operating characteristic of the indexer in this mode is that it will not move

directly in either direction between pocket 1 and the pocket 90° counterclockwise from pocket

1. (The unit’s software may be thinking of the latter pocket as either pocket 2 or pocket 4.

depending on the primary rotation direction. This ‘software barrier” prevents damage to the

special bellows that is attached in this location to the hearth of a 4-pocket UHV source.

Consequently, the indexer rotates 270° to go between these two pockets in either direction.

However, because this operating mode requires the indexer to be set for bidirectional rotation,

it follows the shortest path in moving between any other pair of pockets.

CAUTION!

The indexer MUST be configured for bidirectional rotation when it is

controlling a UHV 4-pocket source. Damage to the source and/or its

bellows is likely to occur if the unit is configured for unidirectional motion.

There are no limits programmed for unidirectional motion in UIIV mode, as

there are for bidirectional motion in UHV mode.

Page 20 Operation

Page 23

Rotational range when indexer

is configured for bidirectional

motion in 4-pocket UHV mode

4-pkt. UHV

(code 7)

Figure 2.4: Illustration of a 4-pocket UHV source, indicating the position of the “software

barrier” implemented in this mode to prevent damage to the bellows attached to UHV hearths

in this area.

Section 2.8: Indexer operation with three-pocket sources that have one

banana shaped pocket

The SRT-422 can be configured to operate three-pocket sources that have two conventional

circular pockets 90º apart and one banana-shaped pocket, which can be either 12O°, 135°, or

145° in arc length or a source which has pockets 6O° apart and one 180° banana.

120

135

145

18

0

3-pkt., 120 banana

(code 10)

3-pkt., 135 banana

(code 11)

3-pkt., 145 banana

(code 12)

3-pkt., 180 banana

(code 13)

Figure 2.5: Three-pocket hearths with one banana-shaped pocket

When the indexer is properly configured to operate in this mode, selecting either pocket

1 or pocket 2 causes the indexer to rotate the hearth to one of the conventional circular

pockets. However, in this mode, the pocket-select codes for pockets 3-8 all select the bananashaped pocket. When the indexer receives any of these six pocket-select codes — either from

a remote device or from the front-panel thumbwheel — it first rotates the midpoint of the

“banana” to the home position. If the pocket-select code received by the indexer is one those

for pockets 3 through 7, the indexer then begins to oscillate the hearth in such a way that the

electron beam will sweep from one end of the “banana” to the other end. This oscillation

continues until the pocket selection is changed or until indexer rotation stops. Either because

Operation Page 21

Page 24

of interlock action or because the indexer has been switched off. As Table 3-i shows, the

speed of this oscillating motion depends on which of the pocket-select codes between 3 and 7

is received. The pocket-select code for pocket 8 causes the hearth to rotate the midpoint of the

banana to the home position and then stop. Note that this means that the electron beam will be

focused on the same point continuously until it is switched off or until another pocket is

selected.

How the speed of oscillating hearth motion in “banana” mode varies depending on the pocket

number selected

Pocket Selected Hearth Rotation Speed

3 .630 RPM

4 .515 RPM

5 .405 RPM

6 .295 RPM

7 .187 RPM

8 0 RPM

Table 2.1: Speed of Hearth in Banana Mode.

NOTE

When the indexer is configured for “banana” mode operation, internal DIP switch 5 MUST be

set for bidirectional motion. If unidirectional motion is selected, the indexer will not move the

banana-shaped pocket correctly.

Section 2.9: Indexer operation with continuous trough hearths

The SRT-422 operates in a continuous-rotation mode to support the use of full-circle evaporant

carousels (see Figure 3-6). When the indexer is properly configured for operation in this mode,

the hearth rotates continuously at any of 7 speeds in the direction determined by internal D[P

switch #5. (See section 2.3 for instructions on setting the internal DIP switches.) As the hearth

rotates, the LED displays the numerals 1-4 successively and then begins again with 1. These

numerals indicate motion relative to what would be the home position of pocket 1 on a 4pocket source.

Continuous

(code 9)

Figure 2.6: Illustration of a continuous-trough hearth

Page 22 Operation

Page 25

In this mode, the pocket-select codes whether issued via the front-panel thumbwheel or by a

remote device determine the hearth’s rotation speed. As the table below indicates, the pocketselect codes for pockets 1 through 7 select rotation speeds ranging from .187 RPM to .845

RPM, and the pocket-select code for pocket 8 stops or prevents hearth rotation. Speed

changes can be made while the hearth is rotating.

Pocket Selected Hearth Rotation Speed

0 0 RPM

1 .845 RPM

2 .732 RPM

3 .630 RPM

4 .515 RPM

5 .405 RPM

6 .295 RPM

7 .187 RPM

8 0 RPM

Table 2.2: Hearth rotation speed in continuous mode.

Section 2.10: phase adjustment

A unique front-panel feature of the SRT-422 makes it easy to reset the home position

when hearth rotation is out of phase (i.e., when the home position is no longer centered within

the cutout in the top of the source). This phase adjustment can be accomplished in either of

two ways, both of which are described in detail below. The electromechanical method

necessitates breaking vacuum and lowering and swinging out the source tray. However, this

method allows extremely precise phase adjustment. The electronic method lets you reset the

home position using front panel controls alone. However, it may prove difficult to achieve the

desired accuracy with this method, as it entails judging the accuracy of the phase adjustment

while observing the source at an angle through a view port.

Electromechanical Method

DANGER: HIGH VOLTAGE

Observe all applicable high-voltage precautions in

performing the following procedure. These precautions

include making sure that the high-voltage is OFF and using a

properly connected grounding rod to neutralize any residual

charge on the structures on and around the source tray.

STEP NO. PROCEDURE

1 Make sure that the high-voltage power supply is switched OFF.

2 If the power supply is equipped with a key lock, remove it and keep it in your

pocket while you complete this procedure.

3 Lower the source tray, open the vacuum enclosure ‘ s access doors, and swing

Operation Page 23

Page 26

the source tray away from the enclosure.

4 Using a properly connected grounding hook, touch the source tray and the frame

of the vacuum enclosure in several places to neutralize any residual high-voltage

charge.

5 Make sure the MAN/AUTO switch on the control unit’s front panel is set to MAN.

6 Use the thumbwheel on the control unit’s front panel to select pocket 1

7 Switch on the indexer, if it is not already on. After going through some rotation

involved in its initialization routine, the indexer will rotate the hearth to the factory-

set home position for pocket 1.

8 If pocket 1 is not correctly centered within the cutout in the top of the source,

switch off the indexer.

9 Turn the hearth by hand until pocket 1 is precisely centered within the cutout.

10 Using the end of a paper clip or some other small-diameter probe, push in the

spring-loaded phase adjustment pushbutton and keep it depressed as you switch

on the indexer and as the hearth goes through its initialization routine. (This

routine involves what may appear to be random rotation.) Release the

pushbutton only after the hearth has returned to the new home position for

pocket 1 and stopped. If this is not the correct home position, switch off the

indexer and repeat steps 9 and 10.

11 Use the pocket selection thumbwheel to change pockets several times, checking

to see that each pocket goes to the correct home position. If the hearth does not

remain properly in phase, return to pocket 1 and repeat steps 9 - 11.

Electronic Method

STEP NO. PROCEDURE

1 Make sure the MAN/AUTO switch on the control unit’s front panel is set to MAN.

2 Use the thumbwheel on the control unit’s front panel to select pocket 1.

3 Switch on the indexer, if it is not already on. After going through some rotation

involved in its initialization routine, the indexer will rotate the hearth to the factory-

set home position for pocket 1.

4 If pocket 1 is not correctly centered within the cutout in the top of the source,

switch off the indexer.

5 Switch the indexer on and off rapidly, watching the hearth move a small amount

each time you do so. When pocket 1 is centered in the cutout, leave the indexer

switched off.

6 Using the end of a paper clip or some other small-diameter probe, push in the

spring-loaded phase adjustment pushbutton and keep it depressed as you switch

on the indexer and as the hearth goes through its initialization routine. (This

routine involves what may appear to be random rotation.) Release the

pushbutton only after the hearth has returned to the new home position for

pocket 1 and stopped. If this is not the correct home position, switch off the

indexer and repeat steps 5 and 6.

7 Use the pocket selection thumbwheel to change pockets several times, checking

to see that each pocket goes to the correct home position. If the hearth does not

remain properly in phase, return to pocket 1 and repeat steps 5-7.

Page 24 Operation

Page 27

Section 2.11: Rotation speed and torque selection for pocket seeking

The SRT-422 provides the ability to select between three speed/torque relationships by

configuring the internal DIP switches. There is a four to one gear reduction within the source,

which produces the reduced speed and increased torque at the Hearth.

Rotation Speed Rotation Torque

Setting Indexer Hearth Indexer Hearth*

High Speed 9.25 rpm 2.31 rpm 120 In-oz. 480 In-oz.

Mid Speed 7.0 rpm 1.75 rpm 156 In-oz. 625 In-oz.

Low Speed 5.0 rpm 1.25 rpm 180 In-oz. 720 In-oz.

Table 2.3: Rotation Speed and Torque

The high speed/low torque setting is desired when you want the indexer to get to the

next pocket as soon as possible, or when you want the indexer to stop rotating in the event

that evaporant material build up is starting to causing mechanical interference between the

hearth and the cover. The low speed/high torque setting may be desired when the drive

feedthrough mechanism is producing a lot or resistance to rotation. It is also desirable when

you do not want the indexer to stop rotation (i.e. during a process sequence) in the event that

the evaporant material build up is starting to cause mechanical interference between the

hearth and the cover. In any case, if a significant amount or resistance is created by either

excessive material build-up or improperly aligned drive components, the indexer will stop

rotating and signal a stall. If a stall occurs, the pocket-position LED flashes between zero and

the number of the current pocket position. A stall can occasionally be cleared temporarily by

cycling power to the indexer, however the cause of the stall should be addressed as soon as

possible. Changing the speed torque setting affects the torque and speed when the indexer is

seeking out a new pocket, however it does not affect the speed or torque when oscillating

within a banana pocket or while in the continuous-rotation mode. While using these modes,

the torque will be greater than 180 in-oz (at the indexer) due to the slow rotation speeds.

*The value for rotation torque at the hearth in the table above does not include friction losses

or gear efficiency. The actual value would be less, and will depend on the amount of loss

within the drive system.

Operation Page 25

Page 28

Page 29

SECTION 3

INSTALLATION

Page 30

Page 31

0003

Section 3

Installation

Section 3.1: Introduction

The Indexer is shipped from the factory with an assigned home position for pocket #1.

In general, it will be difficult to install the Indexer in such a manner that home position of pocket

#1 of the Indexer correspond exactly to the actual center of pocket 1 of the source. The need

to adjust the phase between the Indexer and the E-Beam Source will generally occur after the

initial mechanical installation. There are two ways to accomplish this phase adjustment

mechanically or electronically.

The SRT-422 Motor drive is packaged in a compact case. A ¼” shaft with flat, provides

the output drive.

Figure 3.1: SRT-422 Motor Drive unit.

Section 3.2: Electrical Connections and Descriptions

Line Voltages

Unit is capable of running on both 230 Volts and 115 Volts. There is a switch located on

the connector panel of the unit to select for the proper voltage requirements.

Installation Page 29

Page 32

Figure 3.2: Line Voltage Selection Switch

The SRT-422 is supplied with an IEC type power cord for 115 Volt operation. If 230 Volt

operation is required, use the proper IEC power cord and change fuse to 1/8 amp SB.

MOTOR

RS-232

instruments

I/O (ISOLATED)

Power Cord

Ready

SRT-422

Fuse Holder

Receptacle

Line Voltage

120VAC Fuse 1/4 AMP SB

240VAC Fuse 1/8 AMP SB

Selection Switch

Figure 3.3: SRT-422 Rear Panel

WARNING! Operating with incorrect line selection will damage unit!

Section 3.3: Internal Configuration Switches

The SRT-422 is capable of controlling several different types of multi-pocket E-Beam

Sources (4 Pocket, 6 Pocket, 4 Pocket UHV, and Continuous Trough). It can also be

configured to rotate in a uni or bi-directional manner. In addition, a RS232 Serial Computer

Line at set baud rate can access it serially. The control unit contains eight internal DIP

switches that enable you to configure the unit to support your application. Four of these DIP

switches configure the indexer for use with a specific source type.

Caution! DIP switches 1-6 MUST be set properly

Internal DIP switches 1-6 MUST be set properly to configure the indexer

for the type of hearth it will be controlling. Failure to set these

switches correctly will lead to improper operation and may

Page 30 Installation

Page 33

result in damage to the source.

Section 3.4: setting the configuration dip switches

The control unit contains eight internal DIP switches that enable you to configure the

unit to support your application. Three of these DIP switches configure the indexer for use with

a specific source type. The other switches allow you to select uni- or bidirectional motion, the

rotation direction, RS -232 communications enabled/disabled, and the baud rate for RS-232

communications.

WARNING!

Procedures involving the controller’s internal circuitry

may be hazardous if attempted with the AC power cord

connected.

Before attempting to change any DIP switch settings, it is essential to ensure that the

AC power is not connected to the controller. If the unit has been in use, first use the front-panel

switch to power down the unit. Then disconnect the unit’s AC power cord.

To gain access to the DIP switches, you must slide back the control unit’s top cover. To

do so, first insert a thin, flat-bladed screwdriver beneath the rear edge of the cover and pry it

up enough so that the retainer dimple in its rear edge clears the top edge of the controller’s

rear panel. Then you can easily slide the cover back by applying thumb pressure to it and

pushing rearward. When you have finished setting the DIP switches, slide the cover forward

until the retainer snaps into place, firmly securing the cover. The switch block containing the

DIP switches is mounted along the front edge of the controller’s main printed circuit board. If

you look at the board from a position above the front panel, you will see the switch block near

the right-hand edge of the board. The DIP switches are on the side of the switch block that

faces the front panel. Note that they are numbered I through 8 from left to right, as viewed from

the front end of the control unit.

The figure below illustrates the eight DIP switches from this point of view and lists the

effects of their settings in tabular form. Note that these switches slide rather than rock up and

down to change position and that the ON position is up.

Installation Page 31

Page 34

1 2 3 4 5 6 7 8

SWITCH 6:

ROTATION DIRECTION

SWITCH 5:

UNI / BI DIRECTIONAL

SWITCHES 1-4:

SOURCE TYPE

= SWITCH IN UP (ON) POSITION

SW7 SW8 Function

OFF OFF High Speed, Low Torque 9.25 120

ON OFF Mid Speed, Mid Torque 7.00 156

OFF ON Low Speed, High Torque 5.00 180

ON ON Not Assigned

SW6

Clockwise ON

CounterClockwise OFF

SW5

BIDIRECTIONAL

UNIDIRECTIONAL

Code Function SW1 SW2 SW3 SW4

0 STD. 3-Pocket, 120 apart OFF OFF OFF OFF

1 STD. 4-Pocket, 90 apart ON OFF OFF OFF

2 STD. 5-Pocket, 72 apart OFF ON OFF OFF

3 STD. 6-Pocket, 60 apart ON ON OFF OFF

4 not assigned OFF OFF ON OFF

5 STD. 8-pocket, 45 apart ON OFF ON OFF

6 not assigned OFF ON ON OFF

7 UHV 4-Pocket ON ON ON OFF

8 not assigned OFF OFF OFF ON

9 Continuous ON OFF OFF ON

10 3-pkt(120 Ban), pkts 90 apart OFF ON OFF ON

11 3-Pkt(135 Ban), pkts 90 apart ON ON OFF ON

12 3-Pkt(145 Ban), pkts 90 apart OFF OFF ON ON

13 3-Pkt(180 Ban), pkts 90 apart ON OFF ON ON

14 not assigned OFF ON ON ON

15 not assigned ON ON ON ON

OFF

ON

Speed RPM torque in-oz

Figure 3.4: Configuration Switch

Internal switches select all the above modes or functions. An eight-position dipswitch is

located at the top end of the main control printed circuit board within the SRT-422. To access

this switch, first disconnect any line power. Remove the six socket head cap screws, which

hold the bottom connector panel to the side extrusions. Slide out the back panel and PC

Boards until this switch is accessible. Make the desired configuration settings and reassemble

the unit.

Section 3.5: Description of Configuration Switches

SW1, SW2, SW3, SW4 -- The first four switches are used to match the Indexer to the type of

source being controlled.

SW5 -- Rotation Type. Controls whether the Indexer moves in a single direction or a bi-

directional path. (Bi-directional should be selected if shortest path operation is desired).

Switch 5 allows you to select uni- directional or bi-directional rotation. If uni-directional

rotation is selected (switch 5 ON), the direction of rotation is determined by the setting of

switch 6. If bidirectional rotation is selected (switch 5 OFF), the indexer will employ

shortest-path indexing in moving between the pockets of rnultipocket sources.

Page 32 Installation

Page 35

SW6 -- This switch defines the relationship between pocket 1 and pocket 2 of the source. It

should be set at the same sense, which the Indexer should rotate to move the source

between pocket 1 and pocket 2, e.g. clockwise or counter clockwise. The setting of

switch 6 determines the direction of hearth rotation in unidirectional mode and the

primary rotation direction in bidirectional mode. For both uni- and bidirectional

operation, the orientation of pocket numbering (i.e., which direction is “forward” or

upward though the pocket numbers) also changes depending on the setting of DIP

switch 6. The figure below illustrates this in the case of a 4-pocket source. When DIP

switch 6 is on, the indexer will operate such a source as if its pockets were numbered 14 counterclockwise (hearth rotates clockwise). When this switch is off, the indexer will

operate the same source as if its pockets are numbered 1-4 clockwise (hearth rotates

counterclockwise). The same principle applies to all other source types.

HOME

4

OFF

CLOCKWISE/COUNTER-CLOCKWISE FROM MOTOR'S POINT OF VIEW

Figure 3.5: Orientation of pocket numbering changes depending on the setting of DIP switch 6

(Note: The output shaft of the index drive unit rotates counterclockwise when D/P switch 5 is

on and clockwise when this switch is off. Because of the effect of the internal gears in the

sources supported by the SRT-422, output shaft rotation is in the opposite direction from

hearth rotation.)

When planning for multipocket deposition, it is critical to bear in mind that

the setting of switch 6 determines the orientation of pocket numbering.

The pockets of a 4-pocket source must be thought of as being numbered

1-4 in a clockwise direction when switch 6 is on and 1-4 in a

counterclockwise direction when switch 6 is off.

1

3

2

NOTE

HOME

4

ON

1

3

2

SW7, SW8 -- Rotation Speed and Torque As shown, Switch 7 and 8 allow you to select

between three speed and torque settings. If high speed is selected (switch 7 and

8 OFF) the indexer will seek out the next pocket, when commanded, at the

highest speed rate. If mid-speed is selected (switch 7 OFF and switch 8 ON) the

indexer will seek out the next pocket at an intermediate speed and torque. If

low-speed is selected (switch 7 OFF, switch 8 ON) the indexer will produce the

highest torque while seeking out the next pocket, however it will be at a Lower

speed.

Installation Page 33

Page 36

3-pkt. standard

(code 0)

Continuous

(code 9)

4-pkt. standard

(code 1)

3-pkt., 120 banana

(code 10)

5-pkt. standard

(code 2)

120

6-pkt. standard

135

3-pkt., 135 banana

(code 11)

(code 3)

8-pkt. standard

(code 5)

145

3-pkt., 145 banana

(code 12)

4-pkt. UHV

(code 7)

180

3-pkt., 180 banana

(code 13)

Figure 3.6: Source types supported by the SRT-422

Standard Multi-pocket Sources (Codes 0-5)

When switches 1-4 are set for code 1, the unit is configured to operate a standard 4-pocket

source. When these switches are set for code 3, the unit is configured to operate a standard 6pocket source. When these switches are set for code 5, the unit is configured to operate a

standard 8-pocket source. The switch positions that select these codes are:

Code

Number

DIP

SW1

DIP

SW2

DIP

SW3

DIP

SW4

Code 0 OFF OFF OFF OFF

Code 1 ON OFF OFF OFF

Code 2 OFF ON. OFF OFF

Code 3 ON ON OFF OFF

Code 5 ON OFF ON OFF

Table 3.1: Codes 0 – 5 DIP Switches settings.

UHV 4-Pocket Sources (Code 7)

If the SRT-422 is to be used with a UHV 4-pocket source, switches 1-4 must be set for code 7.

In addition, switch 5 must be set for bidirectional motion. The switch positions that select code

7 are:

Code

Number

DIP

SW1

DIP

SW2

DIP

SW3

DIP

SW4

Code 7 ON ON OFF OFF

Table 3.2: Code 7 DIP switch settings

Page 34 Installation

Page 37

CAUTION!

Switches 1-5 MUST he set as described above when the

SRT-422 is controlling a UHV 4-pocket source. Damage to

the source and / or its bellows are likely to occur if switches

1-4 are set for a UHV source and switch 5 is set for

unidirectional rotation There are no limits programmed for

unidirectional motion in UHV mode, as there are for

bidirectional rotation in that mode.

This mode has a programmed “software barrier” that prevents the hearth from rotating in

either direction between pocket 1 and the pocket next to it in the counterclockwise direction.

This programming serves to prevent damage to the special bellows attached to the hearth in

that location on UHV sources. To move the hearth between these two pockets, the indexer

does not simply rotate the hearth 90° along the shortest path. Instead, the hearth is rotated

270° in the opposite direction. The indexer employs shortest-path rotation when rotating the

hearth between any two other pockets.

Three-Pocket Hearths with One Banana-Shaped Pocket (Codes 10-13)

When switches 1 - 4 are set to codes 10, 11, 12 and 13, the indexer is configured for hearths

with two conventional pockets 90° apart and one banana-shaped pocket. These three codes

configure the indexer to support “bananas” of differing arc lengths.

• Code 10 sets the indexer for a three-pocket hearth with a “banana” covering 120° of arc.

• Code 11 sets the indexer for a three-pocket hearth with a “banana” covering 135° of arc.

• Code 12 sets the indexer for a three-pocket hearth with a “banana” covering 145° of arc.

• Code 13 sets the indexer for a three-pocket hearth with a ‘banana” covering 180° of arc.

The switch positions that select these codes are:

Code

Number

DIP

SW1

DIP

SW2

DIP

SW3

DIP

SW4

Code 10 OFF ON OFF ON

Code 11

Code 12

ON

OFF

ON OFF ON

OFF ON ON

Code 13 ON OFF ON ON

Table 3.3: Codes 10 – 13 DIP switch settings

NOTE

When switches 1-4 are set to any of these FOUR codes, switch 5 MUST

be set for bidirectional motion. If unidirectional motion is

selected, the indexer will not move the “banana” correctly.

In any of these “banana” modes, the indexer moves pockets 1 and 2 to the home

position when it receives the pocket-select codes for those pockets. When the

Installation Page 35

Page 38

indexer receives any of the pocket-select codes for pockets 3 through 7, it moves

the banana-shaped pocket to the home position and then begins oscillating the

hearth in such a way that the e-beam sweeps from one end of the “banana” to the

other. Pocket select codes 3-7 determines the speed of the oscillating motion, as

the Table below indicates. When the indexer receives the pocket-select code for

pocket 8, it moves the midpoint of the “banana” to the home position and stops.

Hearths with Full-Circle Evaporant Troughs (Code 2)

If switches 1-3 are set for this type of hearth (code 2), the hearth will rotate continuously

in the direction set via switch 5. The setting of switch 4 has no effect on rotation in this mode.

The switch settings that select code 2 is in this mode, the pocket-select codes for pockets

through 7 determine the hearth’s rotation speed, as indicated in the table below. The pocketselect code for pocket 8 stops or prevents hearth rotation.

Pocket Selected Hearth Rotation Speed

1 .845 RPM

2 .732 RPM

3 .630 RPM

4 .515 RPM

5 .405 RPM

6 .295 RPM

7 .187 RPM

8 0 RPM

Table 3.4: Hearth rotation in continuous mode .

Page 36 Installation

Page 39

Section 3.6: configuring the opto-isolator pc board for 24-vdc I/Os

The control unit’s opto-isolated I/Os are factory configured to operate on 9 V dc supplied by an

internal power supply. However, the control unit’s opto-isolator board can also be configured to

operate on +24 V dc supplied by an external source. Follow the steps described below to

accomplish this reconfiguration.

STEP NO. PROCEDURE

1 Make sure the power cord is not connected to the control unit.

2 Remove the four screws that secure the control unit’s rear panel (see Figure

Below).

MOTOR

RS-232

Ready

instruments

SRT-422

I/O (ISOLATED)

Remove these Screws to det ach

rea r panel from body.

120VAC Fuse 1/4 AMP SB

240VAC Fuse 1/8 AMP SB

Figure 3.7: Locations of screws that secure the control unit’s rear panel to its body

3 Grasp the rear panel and pull it backwards until it is approximately an inch away

from the body of the controller.

4 The jumper blocks to be reconfigured are mounted on the underside of the opto-

isolator PC board, which is the topmost board in the unit. Turn the control unit

upside down and find the legend JP1 on the underside of this board. You will find

this legend near the rear of the board and along the edge of the board that is

closest to the rear-panel connector labeled I/O (ISOLATED). Jumper block JPI is

just behind the legend JP1 (or just to the right of this legend, if you are looking at it

from the side of the controller).

5 The pins on jumper block JPI are numbered from left to right as you face the side of

the controller that the jumper block is on. From that point of view, pin 1 is on your

left, pin 2 is in the middle, and pin 3 is on your right. The jumper across this jumper

block is factory installed so that it covers pins 1 and 2, leaving pin 3 exposed.

Remove the jumper and replace it so that it covers pins 2 and 3, leaving pin 1

exposed.

7 JP2 is behind and at right angles to JP1 (i.e., behind JP1 with respect to the

controller’s front panel). On this jumper block, pin 1 is the pin nearest the edge of

the board; pin 2 is in the center, and pin 3 is nearest to the center of the board. Like

Installation Page 37

Page 40

JP1 , this jumper block is factory configured so the jumper covers pins 1 and 2,

leaving pin 3 exposed. Remove the jumper and replace it so it covers pins 2 and 3,

leaving pin 1 exposed.

8 Grasp the controller’ s rear panel and slide it forward until it is in contact with the

body of the controller. As you do so, take care that the green ground wire

connected to the inside of the rear panel does not get pinched between the rear

panel and the controller’s body.

9 Replace the four screws that secure the rear panel to the body of the controller.

Section 3.7: Initial Bench Test

After the configuration dipswitch has been set to the desired pocket type and the unit is

reassembled it is useful to confirm the setting by running the unit on the test bench. To do this

first connect the 15-pin Remote Selection Panel cable to the Indexer. Attach the power cord

and plug in to appropriate voltage. (See line voltage selection Refer to Section 3.2). Turn on

power switch on bottom of Indexer. Place remote panel Auto/Man switch the manual mode .

Select the different pocket number using the thumbwheel switch and observe the rotation of

the output shaft of the Indexer. Remember this model of the Indexer is design for 4 to 1

reduction between the Indexer and the rotatable hearth. This means the Indexer will turn 360

degrees for a 90-degree rotation of the hearth.

It is a good idea to bench test the indexer after the control unit is configured for your

application. Follow the steps described below in performing this test.

STEP NO. PROCEDURE

1 Find the motor cable. This is the 25-foot cable supplied to connect the control unit

to the index drive unit.

2 The motor cable has a 1 5-pin ‘D’ connector on each end. Plug the male ‘D’

connector on one end of the cable into the socket labeled MOTOR on the control

unit’s rear panel.

3 Plug the female ‘D’ connector on the other end of the motor cable into the 15-pin

male connector on the end of the index drive unit.

4 Make sure the input power selection switch is set for the correct voltage

WARNING

Operating the SRT-422 with incorrect line voltage

selected will damage the unit.

5 Make sure the power switch on the control unit’s front panel is OFF.

6 Plug the correct power cable for the local AC power into the three-pronged plug on

the control unit’s rear panel. Plug the other end of this cable into an AC power

socket.

7 Make sure the MAN/AUTO toggle switch on the control unit’s front panel is set to

Page 38 Installation

Page 41

MAN. Note that this switch has a locking feature. To change its position, you must

first pull the locking collar out toward you.

8 Set the front-panel thumbwheel to position 1, if it is not already at that position.

9 Using the ON/OFF switch on the control unit’s front panel, switch on the indexer. If

the internal DIP switches are set for a full circle evaporant carousel, the drive unit’s

output shaft will begin rotating continuously at its highest speed. If the DIP switches

are set for any other type of source, the indexer will stop at the factory-set home

position for pocket 1 after proceeding through various rotations involved in its

initialization routine.

10 Change thumbwheel setting to select pocket 2. The indexer rotates to the pocket -2

position after going through rotations that vary depending on the settings of DIP

switches 1-5.

11 Use the thumbwheel to select other pockets and observe the rotation of the output

shaft.

12 When you have completed the bench-test, switch off the control unit, disconnect the

AC power cable from the rear panel, and disconnect the motor cable from both the

control unit and the index drive unit.

Section 3.8: System Installation

The standard unit is designed to be used with the E-Beam source, which has a 4 to 1

reduction within the source or a 4 to 1 reduction between the Indexer output shaft and the

source. Thus 360 degrees of rotation of the Indexer shaft will cause a 4 pocket source to

rotate 90°.

The most cost effective system installation is accomplished by the purchase of either

the 1” or 2 ¾” Rotary Feedthrough Indexer and Adapter Kits from Sycon. If system

configuration of space does not allow the use of these standard items, the Indexer should be

rigidly mounted and the Indexer drive shaft be appropriately attached (minimum slop and

backlash) to the airside of the Rotary Feedthrough.

A one-to-one directed connector is needed between the output shaft of the Indexer and

the airside of the Rotary Vacuum Feedthrough. Sycon stocks the following items to assist in

making the Mechanical connection from the output shaft of the Indexer to the air side of the

Rotary Vacuum Feedthrough:

Installation Page 39

Page 42

Figure 3.8: Motor Drive Unit

Section 3.9: Installing the Index-Drive Unit

The Figure above shows the index-drive unit properly installed on the underside of the source

tray. The drive unit is held in place by the large nut on the underside of the 1 -inch-dia. rotary

feedthrough.

DANGER: HIGH VOLTAGE

If a high-voltage power supply is installed in the vacuum

system in which the SRT-422 is to be installed, observe all

applicable high-voltage precautions in performing the

following procedure. These precautions include making sure

that the high-voltage is OFF and using a properly connected

grounding rod to neutralize any residual charge on the

structures on and around the source tray.

Follow the procedure described below in installing the drive unit.

STEP NO. PROCEDURE

1 Perform the following sub steps only if a high-voltage power supply is connected to

the vacuum system in which the SRT-422 is being installed. Otherwise, proceed to

step 2.

Page 40 Installation

Page 43

(a) Make sure that the high-voltage power supply is switched OFF.

(b) If the power supply is equipped with a keylock, remove it and keef, it in

your pocket while you complete this procedure.

2 Lower the source tray, open the vacuum enclosure’s access doors, and swing the

source tray out from the enclosure.

3 (This step may be skipped if a high-voltage power supply has not been connected

to the vacuum system in which you are installing the SRT-422.) Using a properly

connected grounding hook, touch the source tray and the frame of the vacuum

enclosure in several places to neutralize any residual high-voltage charge.

4 Remove the attachment nut and flat washer (see Fig. 2-7) from the rotary

feedthrough.

5 Put coupling PN 9015-0121-01 in place over the feedthrough input shaft and secure

the coupling to that shaft with the coupling’s upper set screw.

WARNING

To prevent binding during source rotation and to minimize

alignment problems, it is essential to use the same type of

flexible coupling to connect the feedthrough output shaft to

the source’s drive shaft.

6 Place the index-drive unit against the underside of the source tray so that the

feedthrough threaded shaft extends through the hole in the yoke that spans the top

of the drive unit. Make sure that the drive unit’s output shaft fits up into the coupling.

7 Lower the index drive unit enough to put the flat washer and attachment nut back in

place around the threaded portion of the feedthrough. Then restore the drive unit to

the position described in step 6.

8 Screw the attachment nut all the way on, tightening it to approximately 10 ft-lbs.

9 Secure the coupling to the drive unit by tightening the coupling’s lower set screw

against the drive unit's output shaft.

10 Connect the female 'D' connector on one end of the motor cable to the ‘D’

connector on the index-drive unit, securing the connection with the screws on the

‘D’ connector.

Section 3.10: Installing the Control Unit

Follow the procedure described below in mounting the control unit in a standard 1 9-inch

electronics rack.

STEP NO. PROCEDURE

1 Disconnect any cables that have been connected to the control unit’s rear panel.

Installation Page 41

Page 44

2 Put the half-with control unit in place a 5-1/4-in-high space in the electronics rack.

3 Secure the front panel to the rack with the four screws and cup washers provided.

4 Connect the input power cable to the plug on the control unit’s rear panel.

5 Plug the other end of the power cable into a wall socket.

6 Make sure that the line voltage selection switch is set correctly (see Fig. 2-2)..

WARNING

Operating the SRT-422 with incorrect line voltage selected will

damage the unit.

7 Connect the male ‘D’ connector on one end of the motor cable to the MOTOR

connector on the control unit’s rear panel. Use the screws provided on the ‘D’

connector to secure it to the MOTOR connector.

Section 3.11: Indexer and System Grounding

A grounding stud is provided on the control unit’s rear panel. Use a 16-gauge or larger wire

to ground this stud to the electronics rack. Because the rack as a whole is likely to be subject

to RF interference, it is strongly recommended that a low-impedance ground be provided for

the system. The figure below shows a method of setting up such a ground.

CHAMBER

Crystal Sensor

I/O (ISOLATED)

MOTOR

instruments

RS-232

SRT-422

SHUTTER

Chamber ground

To Control Unit

Ready

120VAC Fuse 1/4 AMP SB

240VAC Fuse 1/8 AMP SB

Indexer

Figure 3.9: SRT-422 Grounding

Page 42 Installation

Page 45

A

Section 3.12: initial phase adjustment

The home position will almost certainly have to be reset after the indexer is installed. This

initial phase adjustment can be accomplished in either of two ways, both described in detail

below. The electromechanical method necessitates breaking vacuum and lowering and

swinging out the source tray. However, this method allows extremely precise phase

adjustment. The electronic method lets you reset the home position using front panel controls

alone. However, it may prove difficult to achieve the desired accuracy with this method, as it

entails judging the accuracy of the phase adjustment while observing the source at an angle

through a view port.

Manual / Auto Mode

Switch

ON / OFF Switch

Phase Adjustment

Pushbutton

Figure 3.10: Control/display features on the control unit’s front panel

Pocket

Position

LED

Pocket Selection Thumbwheel

MAN

0

ON OFF

SRT-422

UTO

Ø

0

MULT-POCKET E-BEAM INDEXER

instrument

Electromechanical Method

DANGER: HIGH VOLTAGE

If a high-voltage power supply is installed in the vacuum system in which the SRT-422 has

been installed, observe all applicable high-voltage precautions in performing the following

procedure. These precautions include making sure that the high-voltage is OFF and using a

properly connected grounding rod to neutralize any residual charge on the structures on and

around the source tray.

STEP NO. PROCEDURE

1 Perform the following sub steps only if a high-voltage power supply is

connected to the vacuum system in which the SRT-422 is being installed.

Otherwise, proceed to step 2.

(a)Make sure that the high-voltage power supply is switched OFF.

Installation Page 43

Page 46

(b)If the power supply is equipped with a key lock, remove it arid keep it in your

pocket while you complete this procedure.

2 Lower the source tray, open the vacuum enclosure’s access doors, and swing

the source tray away from the enclosure.

3 (This step may be skipped if a high-voltage power supply has not been

connected to the vacuum system in which you are installing the SRT-422.)

Using a properly connected grounding hook, touch the source tray and the

frame of the vacuum enclosure in several places to neutralize any residual

high-voltage charge.

4 Make sure the MAN/AUTO switch on the control unit’s front panel is set to

MAN.

5 Use the thumbwheel on the control unit’s front panel to select pocket 1.

6 Switch on the indexer, if it is not already on. After going through some rotation

involved in its initialization routine, the indexer will rotate the hearth to the

factory-set home position for pocket 1.

7 If pocket 1 is not correctly centered within the cutout in the top of the source,

switch off the indexer.

8 Turn the hearth by hand until pocket 1 is precisely centered within the cutout.

9 Using the end of a paper clip or some other small-diameter probe, push in the

spring-loaded phase adjustment pushbutton and keep it depressed as you

switch on the indexer and as the hearth goes through its initialization routine.

(This routine involves what may appear to be random rotation.) Release the

pushbutton only after the hearth has returned to the new home position for

pocket 1 and stopped. If this is not the correct home position switch off the

indexer and repeat steps 8 and 9.

10 Use the pocket selection thumbwheel to change pockets several times,