Page 1

OPERATING MANUAL

™

SQM-160

Multi-Film Rate/Thickness Monitor

IPN 074-511-P1C

Page 2

Page 3

www.inficon.com reachus@inficon.com

©2012 INFICON

®

OPERATING MANUAL

™

SQM-160

Multi-Film Rate/Thickness Monitor

IPN 074-511-P1C

Page 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

SQM-160™ and INFICON® is a trademark of INFICON GmbH.

Visual Basic®, Windows® and Microsoft® are registered trademarks of Microsoft Corporation.

Oracle® and Java® are registered trademarks of Oracle and/or its affiliates.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2012 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

Page 6

Page 7

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

one (1) year from the date of shipment thereof by Seller. Seller's liability under this

warranty is limited to such of the above products or parts thereof as are returned,

transportation prepaid, to Seller's plant, not later than thirty (30) days after the

expiration of the period of warranty coverage in respect thereof and are found by

Seller's examination to have failed to function properly because of defective

workmanship or materials and not because of improper installation or misuse and

is limited to, at Seller's election, either (a) repairing and returning the product or

part thereof, or (b) furnishing a replacement product or part thereof, transportation

prepaid by Seller in either case. In the event Buyer discovers or learns that a

product does not conform to warranty, Buyer shall immediately notify Seller in

writing of such non-conformity, specifying in reasonable detail the nature of such

non-conformity. If Seller is not provided with such written notification, Seller shall

not be liable for any further damages which could have been avoided if Seller had

been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

www.inficon.com reachus@inficon.com

Page 8

Page 9

SQM-160 Operating Manual

Table Of Contents

Trademarks

Disclaimer

Copyright

Chapter 1

Introduction

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.1 Related Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 Instrument Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.1 Definition of Notes, Cautions and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.2 General Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.2.3 Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.3 How To Contact INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.3.1 Returning Your SQM-160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4.1 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.4.2 Film Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.4.3 System Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.4.4 Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.4.5 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.5 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.6 Parts and Options Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.6.1 Base Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.6.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

IPN 074-511-P1C

1.6.3 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Chapter 2

2.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.4 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.5 System Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.6 Film Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.7 Depositing a Film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Quick Start

TOC - 1

Page 10

Chapter 3

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Menu Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Film Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.4 System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.5 Sensor Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.6 Sensor Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.7 Sensor Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.8 Display Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.9 Crystal Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.10 Zero Thickness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.11 Shutter Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.12 Dual Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.13 Rate Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.14 Time Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.15 Thickness Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.16 Simulate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.17 Defaulting the Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.18 Relay Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.19 Analog Output Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.20 I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.21 Rack Mounting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

SQM-160 Operating Manual

Operation

Chapter 4

Chapter 5

TOC - 2

SQM-160 Comm Software

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4 Data Log Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.5 Films Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.6 System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.7 Communications Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.8 Graph Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.9 Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Communications

5.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 RS-232C Serial Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.2 USB Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

IPN 074-511-P1C

Page 11

SQM-160 Operating Manual

5.1.3 TCP/IP Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.1.3.1 How to Set Up the Network Protocol on the PC. . . . . . . . . . . . . . . . . . . . . . 5-2

5.1.3.2 How to change the IP address of the SQM-160. . . . . . . . . . . . . . . . . . . . . . 5-5

5.2 SQM-160 Comm Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.3 SQM-160 Communications Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5.4 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

5.4.1 Command: @ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

5.4.2 Command: A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

5.4.3 Command: B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

5.4.4 Command: C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.4.5 Command: D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.4.6 Command: J . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.4.7 Command: L. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.4.8 Command: M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.4.9 Command: N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.4.10 Command: O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.4.11 Command: P. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

5.4.12 Command: R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.4.13 Command: S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

5.4.14 Command: T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .T5-10

5.4.15 Command: U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.4.16 Command: W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

5.4.17 Command: Y. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

5.4.18 Command: Z. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

5.5 CRC Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.5.1 Visual Basic® 5/6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.5.2 Java® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

5.5.3 C++. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

IPN 074-511-P1C

Chapter 6

Troubleshooting and Maintenance

6.1 Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.2.1 Troubleshooting the SQM-160 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2.2 Troubleshooting Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.2.3 Troubleshooting Computer Communications . . . . . . . . . . . . . . . . . . . . . . . .6-8

6.3 Replacing the Crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.3.1 Front Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

6.3.2 Cool Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6.3.3 Bakeable Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

TOC - 3

Page 12

SQM-160 Operating Manual

6.3.4 Sputtering Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6.3.5 Crystal Snatcher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.4 Crystal Sensor Emulator

IPN 760-601-G2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6.4.1 Diagnostic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6.4.1.1 Measurement System Diagnostic Procedure. . . . . . . . . . . . . . . . . . . . . . . 6-16

6.4.1.2 Feedthrough Or In-Vacuum Cable

Diagnostic Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

6.4.1.3 Sensor Head Or Monitor Crystal

Diagnostic Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6.4.1.4 System Diagnostics Pass But

Crystal Fail Message Remains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

6.4.2 Sensor Cover Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

6.4.2.1 Compatible Sensor Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

6.4.2.2 Incompatible Sensor Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

6.4.3 Emulator Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Chapter 7

7.1 Importance of Density, Tooling and Z-Ratio. . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Determining Density. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.3 Determining Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.4 Laboratory Determination of Z-Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Chapter 8

8.1 Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1.1 Monitor Crystals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.1.2 Period Measurement Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.1.3 Z-match Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.1.4 Active Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Appendix A

A.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Calibration Procedures

Measurement and Theory

IPN 074-511-P1C

Material Table

TOC - 4

Page 13

1.1 Introduction

Figure 1-1 SQM-160 Multi-Film Rate/Thickness Monitor

SQM-160 Operating Manual

Chapter 1

Introduction

The SQM-160™ uses proven INFICON® quartz crystal sensor technology to

measure rate and thickness in a thin film deposition process. Two sensor inputs are

standard and four additional sensor inputs are optional. Two recorder outputs

provide analog rate and thickness signals.

Sensor inputs can be assigned to different materials, averaged for accurate

deposition control in large systems, or configured for a dual sensor. The rate

sampling mode allows a shuttered sensor to extend sensor life in high rate

processes. Rate displays of 0.1 Å/s or 0.01 Å/s are user selectable. In addition,

frequency or mass displays can be selected. Four relay outputs allow the SQM-160

to control source or sensor shutters, signal time and thickness setpoints, and signal

IPN 074-511-P1C

crystal failure. Digital inputs allow external signals to start/stop and zero readings.

The SQM-160 comes with an RS-232 port and Windows

®

software that allows

instrument setup from your computer. The software can be used to set and store

all parameters, operate the instrument, and save process data in an .txt file that can

easily be imported into Excel

®

. USB or Ethernet options add to the communications

flexibility.

1 - 1

Page 14

SQM-160 Operating Manual

CAUTION

WARNING

WARNING - Risk Of Electric Shock

1.1.1 Related Manuals

Sensors are covered in separate manuals. PDF files of these manuals are

contained in the 074-5000-G1 CD, part of the Ship Kit.

074-154 - Bakeable Sensor

074-156 - Front Load Sensor, Single/Dual

074-157 - Sputtering Sensor

147-800 - Cool Drawer Sensor, Single/Dual

1.2 Instrument Safety

1.2.1 Definition of Notes, Cautions and Warnings

When using this manual, please pay attention to the NOTES, CAUTIONS and

WARNINGS found throughout. For the purposes of this manual they are defined as

follows:

NOTE: Pertinent information that is useful in achieving maximum SQM-160

efficiency when followed.

Failure to heed these messages could result in damage

to the SQM-160.

Failure to heed these messages could result in personal

injury.

Dangerous voltages are present which could result in

personal injury.

IPN 074-511-P1C

1 - 2

Page 15

1.2.2 General Safety Information

WARNING - Risk Of Electric Shock

CAUTION

Do not open the SQM-160 case! There are no

user-serviceable components within the SQM-160 case.

Dangerous voltages may be present whenever the power

cord or external input/relay connectors are present.

Refer all maintenance to qualified personnel.

This SQM-160 contains delicate circuitry which is

susceptible to transient power line voltages. Disconnect

the line cord whenever making any interface

connections. Refer all maintenance to qualified

personnel.

SQM-160 Operating Manual

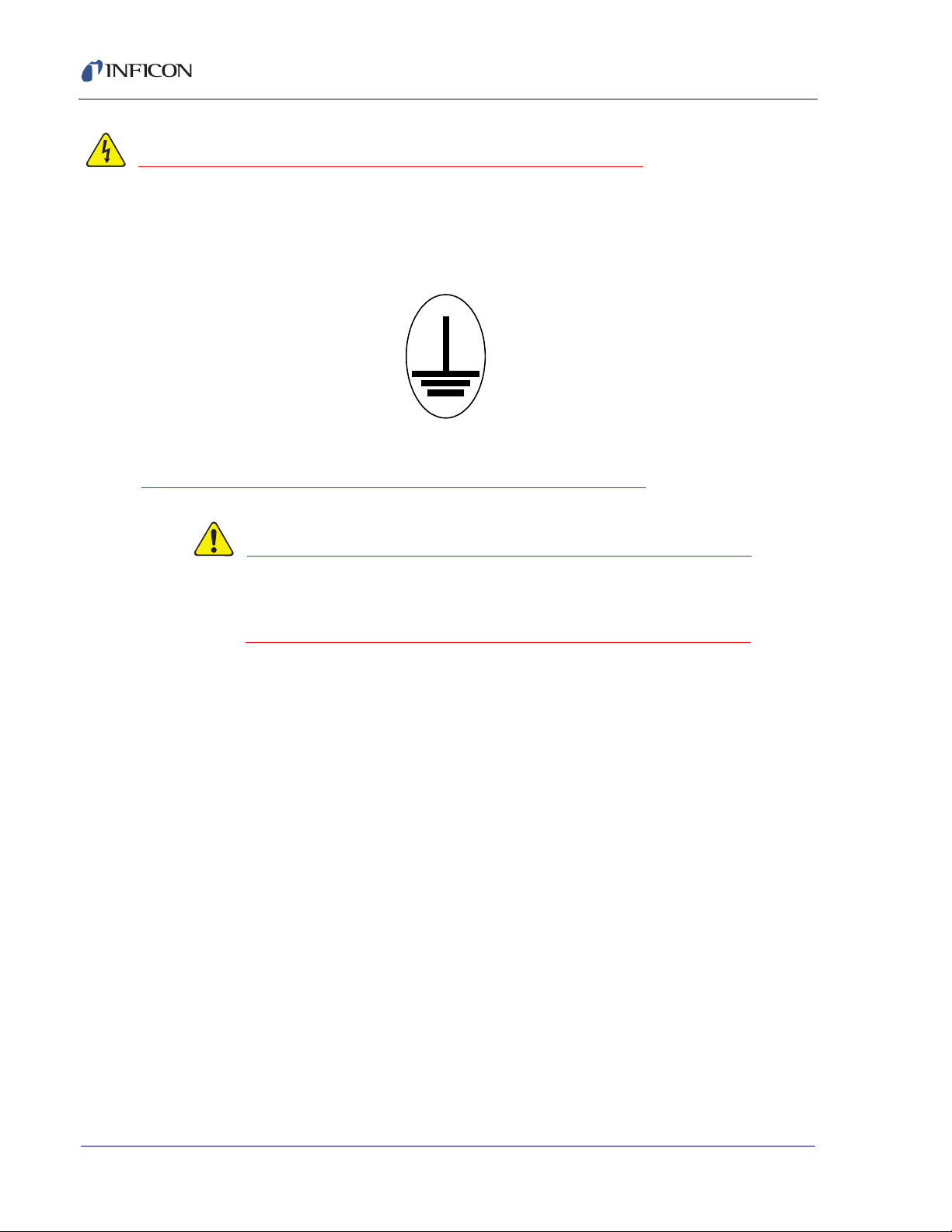

1.2.3 Earth Ground

The SQM-160 is connected to earth ground through a sealed three-core

(three-conductor) power cable, which must be plugged into a socket outlet with a

protective earth terminal. Extension cables must always have three conductors

including a protective earth terminal.

IPN 074-511-P1C

1 - 3

Page 16

SQM-160 Operating Manual

WARNING - Risk Of Electric Shock

WARNING

Never interrupt the protective earth circuit.

Any interruption of the protective earth circuit inside or outside the SQM-160,

or disconnection of the protective earth terminal is likely to make the SQM-160

dangerous.

This symbol indicates where the protective earth ground is connected inside

the SQM-160. Never unscrew or loosen this connection.

There are no adjustments or user-serviceable parts

inside the SQM-160. For maintenance or repair, contact

INFICON.

1.3 How To Contact INFICON

Worldwide support information, to contact a:

Technical Support Engineer with questions regarding applications for and

programming the SQM-160

Service Engineer with questions regarding troubleshooting, diagnosing or

repairing a defective SQM-160

Sales and Customer Service, to contact the INFICON Sales office nearest you

Repair Service, to contact the INFICON Service Center nearest you

is available at the Support tab a www.inficon.com.

If you are experiencing a problem with your SQM-160, please have the following

information readily available:

the serial number and firmware version for your SQM-160,

a description of your problem,

IPN 074-511-P1C

an explanation of any corrective action that you may have already attempted,

and the exact wording of any error messages that you may have received.

To contact Customer Support, see Support at www.inficon.com.

1 - 4

Page 17

1.3.1 Returning Your SQM-160

Do not return any component of your SQM-160 to INFICON without first speaking

with a Customer Support Representative. You must obtain a Return Material

Authorization (RMA) number from the Customer Support Representative.

If you deliver a package to INFICON without an RMA number, your package will be

held and you will be contacted. This will result in delays in servicing your SQM-160.

Prior to being given an RMA number, you may be required to complete a

Declaration Of Contamination (DOC) form if your sensor has been exposed to

process materials. DOC forms must be approved by INFICON before an RMA

number is issued. INFICON may require that the sensor be sent to a designated

decontamination facility, not to the factory.

1.4 Specifications

1.4.1 Measurement

Number of Sensors . . . . . . . . . . . . . 2 standard, 4 additional optional

Sensor Frequency Range . . . . . . . . 4.0 MHz to 6.0 MHz

SQM-160 Operating Manual

Reference Frequency Accuracy . . . . 0.002%

Reference Frequency Stability . . . . . +/- 2ppm (total, 0 to 50°C)

Thickness Display Resolution . . . . . 1 Å

Frequency Resolution* . . . . . . . . . . . +/- 0.12 Hz (Std.), +/- 0.03 Hz (HiRes)

Rate Resolution* . . . . . . . . . . . . . . . 0.60 Å/s (Std.), 0.037 Å/s (HiRes)

Thickness Resolution* . . . . . . . . . . . 0.15 Å (Std.), 0.037 Å (HiRes)

*Density = 1, Period = 4 rdgs/sec (Std.) 10 rdgs/s (HiRes)

1.4.2 Film Parameters

IPN 074-511-P1C

Stored Films . . . . . . . . . . . . . . . . . . . 99

Density . . . . . . . . . . . . . . . . . . . . . . . 0.5 – 99.99 gm/cc

Tooling . . . . . . . . . . . . . . . . . . . . . . . 10 – 399 %

Z-Ratio . . . . . . . . . . . . . . . . . . . . . . . 0.10 – 10.00

Final Thickness . . . . . . . . . . . . . . . . 0.000 – 99.99 kÅ

Thickness Setpoint . . . . . . . . . . . . . . 0.000 – 99.99 kÅ

Time Setpoint . . . . . . . . . . . . . . . . . . 0:00 – 99:59 mm:ss

Sample/Hold. . . . . . . . . . . . . . . . . . . 0-9999 s

Sensor Average . . . . . . . . . . . . . . . . Any combination of installed sensors

1 - 5

Page 18

SQM-160 Operating Manual

1.4.3 System Parameters

Measurement Period . . . . . . . . . . . . 0.15 to 2 s

Simulate Mode . . . . . . . . . . . . . . . . . On/Off

Frequency Mode . . . . . . . . . . . . . . . On/Off

Rate Resolution . . . . . . . . . . . . . . . . 0.01/0.1 Å/s

Measurement Filter . . . . . . . . . . . . . 1 to 20 readings

Dual Crystal 1/2 . . . . . . . . . . . . . . . . On/Off

Rate Sampling . . . . . . . . . . . . . . . . . On/Off

RS-232 Baud Rate . . . . . . . . . . . . . . 2.4/4.8/9.6/19.2 kb/s

Etch Mode . . . . . . . . . . . . . . . . . . . . On/Off

Crystal Tooling 1-6 . . . . . . . . . . . . . . 10-399%

Crystal Fail Min/Max. . . . . . . . . . . . . 4.0 to 6.0 MHz / 4.1 to 6.1 MHz

1.4.4 Digital I/O

Digital Inputs. . . . . . . . . . . . . . . . . . . 4

Functions . . . . . . . . . . . . . . . . . . . . . Open Shutter, Close Shutter, Zero

Thickness, Zero Time

Input Rating . . . . . . . . . . . . . . . . . . . 5 V (dc), non-isolated

Relay Outputs. . . . . . . . . . . . . . . . . . 4

Functions . . . . . . . . . . . . . . . . . . . . . Shutter, Sample/Hold or Thickness Setpoint,

Dual Sensor Shutter or Time Setpoint,

Crystal Fail

Relay Rating. . . . . . . . . . . . . . . . . . . 30 V

or 30 V (dc), 2 A maximum

rms

IPN 074-511-P1C

1 - 6

Page 19

1.4.5 General Specifications

Mains Power Supply. . . . . . . . . . . . . 100-120/200-240~, ±10% nominal, 50/60 Hz

Power Consumption . . . . . . . . . . . . . 20 W

Operating Environment . . . . . . . . . . 0°C to 50°C

Storage Environment . . . . . . . . . . . . -40°C to 70°C

Rack Dimensions (HxWxD) . . . . . . . 88.5 mm x 212.7 mm x 196.9 mm

SQM-160 Operating Manual

0 to 80% RH non-condensing

0 to 2,000 meters

Indoor Use Only

Class 1 Equipment (Grounded Type)

Suitable for Continuous Operation

Ordinary Protection (not protected against

harmful ingress of moisture)

Pollution Degree 2

Installation (Overvoltage) Category II

for transient overvoltages

Weight . . . . . . . . . . . . . . . . . . . . . . . 2.7 kg (6 pounds)

IPN 074-511-P1C

1 - 7

Page 20

SQM-160 Operating Manual

1.5 Unpacking and Inspection

1 If the SQM-160 has not been removed from its packaging, do so now.

2 Carefully examine the unit for damage that may have occurred during shipping.

This is especially important if you notice obvious rough handling on the outside

of the container. Immediately report any damage to the carrier and to INFICON.

3 Do not discard the packing materials until you have taken inventory and have

at least performed a power on verification.

4 Take an inventory of your order by referring to your order invoice and the

information contained in section 1.6.

5 To install and setup, see Chapter 2, Quick Start.

6 For additional information or technical assistance, contact INFICON, refer to

section 1.3 on page 1-4.

1.6 Parts and Options Overview

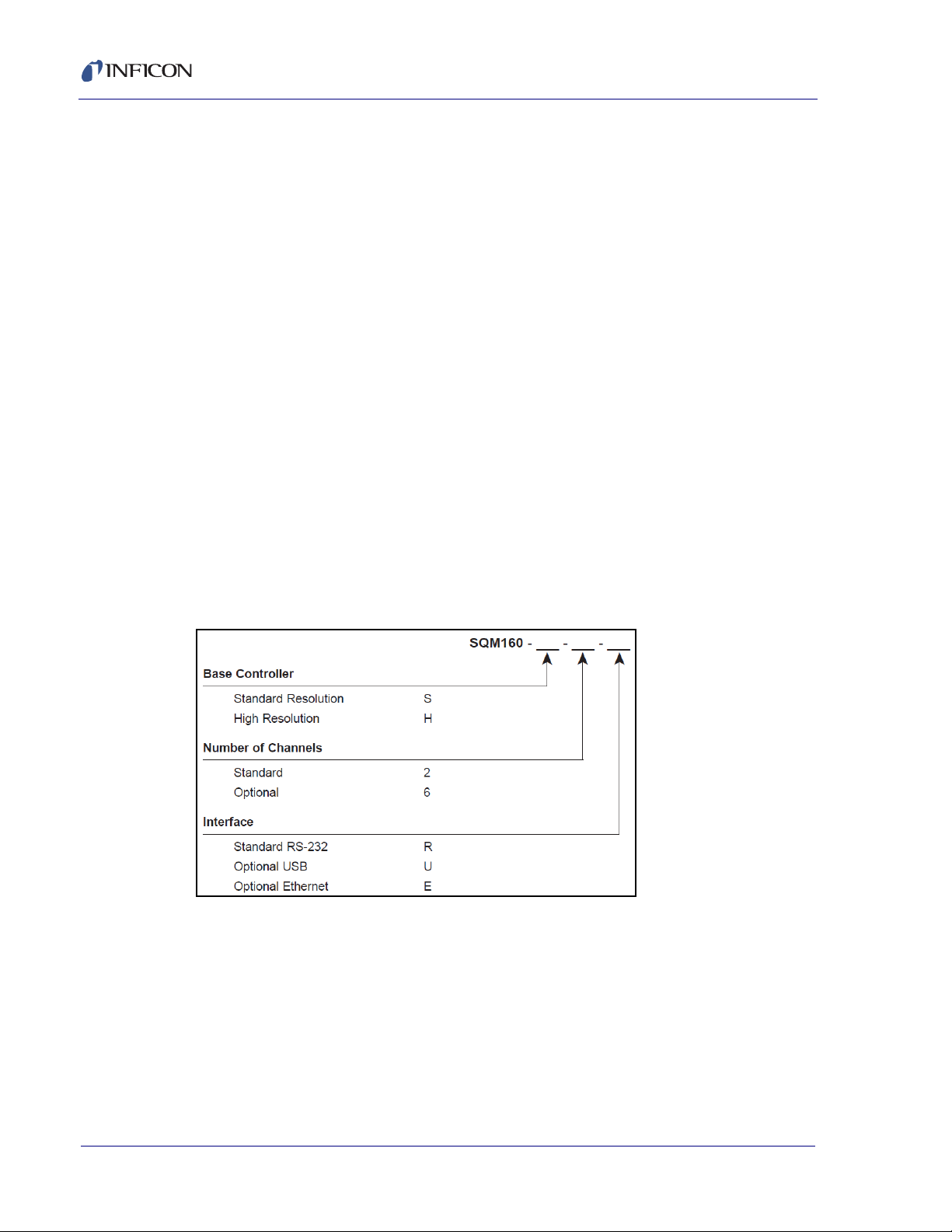

1.6.1 Base Configurations

SQM-160 . . . . . . . . . . . . . . . . . . . . . . . . .SQM160-X-X-X

Consult the figure below for possible configurations.

Figure 1-2 SQM-160 Configurations

Technical Manual . . . . . . . . . . . . . . . . . . .074-511 on 074-5000-G1 CD

IPN 074-511-P1C

1 - 8

Page 21

1.6.2 Accessories

Each sensor requires an oscillator kit to interface to the controller:

SQM-160 10 ft. Oscillator Kit . . . . . . 782-934-003-10

SQM-160 25 ft. Oscillator Kit . . . . . . 782-934-003-25

SQM-160 50 ft. Oscillator Kit . . . . . . 782-934-003-50

SQM-160 100 ft. Oscillator Kit . . . . . 782-934-003-99

Above kits consist of oscillator 782-900-010, 6 inch BNC oscillator to feedthrough

cable 782-902-011 and BNC controller to oscillator cable 782-902-012-10,

782-902-012-25, 782-902-012-50 or 782-902-012-99. These kits are designed for

use with the standard in-vacuum cables ranging in length from 6 in. (15.2 cm) to

36 in. (91.4 cm). The 007-044 standard in-vacuum cable supplied with the front

load style sensors are 30.75 in. (78.1 cm) long.

19 in. Rack mount for 1 SQM-160 . . 782-900-008

19 in. Rack mount for 2 SQM-160 . . 782-900-014

SQM-160 Operating Manual

1.6.3 Sensors

Front Load Single Sensor. . . . . . . . . . . . . . . . . . . . . SL-XXXXX

Front Load Dual Sensor . . . . . . . . . . . . . . . . . . . . . . DL-AXXX

Cool Drawer Single Sensor . . . . . . . . . . . . . . . . . . .CDS-XXFXX

Cool Drawer Dual Sensor. . . . . . . . . . . . . . . . . . . . . CDD-XFXX

Sputtering Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . 750-618-G1

Front Load UHV Bakeable Sensor . . . . . . . . . . . . . .BK-AXF

NOTE: "X" in part number indicates customer-selectable option, see

www.inficon.com for Sensor Datasheets.

NOTE: All shuttered sensors require a feedthrough with an air line and a

IPN 074-511-P1C

Pneumatic Shutter Actuator Control Valve . . . . . . . . 750-420-G1

NOTE: Multi-crystal (rotary) sensor should not be used with the SQM-160

pneumatic shutter actuator control valve.

1 - 9

Page 22

SQM-160 Operating Manual

This page is intentionally blank.

1 - 10

IPN 074-511-P1C

Page 23

2.1 Introduction

WARNING - Risk Of Electric Shock

WARNING - Risk Of Electric Shock

This section assumes you are familiar with thin film monitors. See section 2.3,

Front Panel, on page 2-2 and section 2.4, Rear Panel, on page 2-3 for basic system

use and connection information.

2.2 Installation

SQM-160 Operating Manual

Chapter 2

Quick Start

Maintain adequate insulation and physical separation of

sensor, I/O, and wiring from hazardous voltages.

1 Rack Installation

The SQM-160 occupies a 3.5 in. high, half-rack space. Rack installation

requires an optional half-rack adapter kit or a full rack extender kit. Install the

SQM-160 in a 19 in. rack with the appropriate hardware. See section 3.21,

Rack Mounting Procedure, on page 3-18, for detailed installation instructions.

2 Power Connection

Verify that the power cable provided is connected to a

properly grounded mains receptacle.

IPN 074-511-P1C

3 Sensor Connections

Connect the BNC cables and oscillator from your vacuum chamber

feedthrough to the SQM-160 Sensor Input(s). See section 2.4 on page 2-3.

4 Digital I/O Connections

Refer to section 3.20, I/O Connections, on page 3-16 for details on wiring digital

I/O to the SQM-160 Relay I/O connector.

5 Computer Connection

If you would like to use the supplied Windows Comm software with the

SQM-160, see section Chapter 4, SQM-160 Comm Software, on page 4-1.

2 - 1

Page 24

SQM-160 Operating Manual

Crystal Status

Thickness kA

Next

Clear Program

Open

Closed

Thk SP

1

2

Display 1

Display 2

Crystal

Status

LEDs

Control

Knob

Control

Section

Setpoint

LEDs

Configuration

Section

6 Option Connections

If you have purchased the optional four sensor card, connect the four additional

sensors to these four inputs.

7 Power On

Move the rear panel power switch to the On (|) position. The SQM-160 will

briefly display its software and hardware versions, then go to normal operating

mode.

2.3 Front Panel

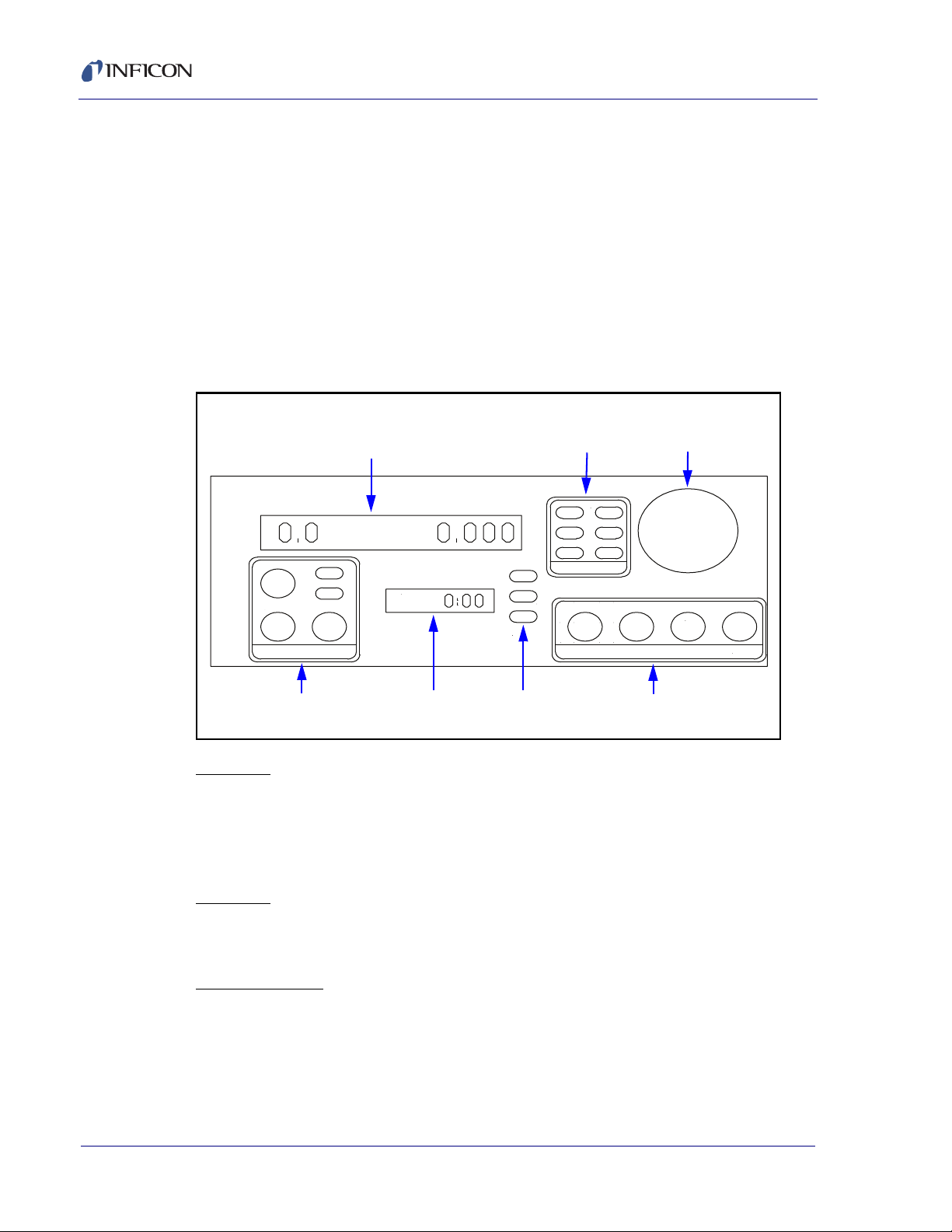

Figure 2-1 SQM-160 Front Panel

Rate A/s

Zero

Xtal Life Shutter

Time

Time SP

Final Thk

3

4

5

6

Prev

Display 1

Displays rate/thickness or frequency in normal operation. If multiple sensors are

being used and Display shows Time, this is the average of those sensors. Turn the

Control Knob right to display each individual sensor's readings. Displays the setup

parameter name in program mode.

Display 2

Displays deposition time, or the sensor # displayed on Display 1 when scrolling

through sensor readings. Displays setup parameter values in program mode.

Control Section

Push-button to zero the thickness reading.

Push-button to toggle display between Crystal Life and Rate/Thickness readings.

Push-button to Open/Close shutter relay.

Control Configuration

IPN 074-511-P1C

2 - 2

Two LED shutter relay status display.

Page 25

SQM-160 Operating Manual

Sensor 1 Sensor 2

Option Card

Relay I/O

100-120/200-240V~

Thick Out

Rate Out

3

456

Fuse T2.5A 250V

USB/Ethernet

Configuration Section

Push-button to enter/exit program mode.

Push-button to cancel a change and return to original value.

Push-buttons to move to Next/Previous parameter.

Setpoint LEDs

Illuminates when the indicated setpoint is reached.

Crystal Status LEDs

Illuminates when the crystal is active and operating properly.

Flashes when an active crystal fails.

Extinguished when that crystal is not being used.

Control Knob

Used to adjust values or scroll though menu selections.

Pushing the control knob stores the current setting.

2.4 Rear Panel

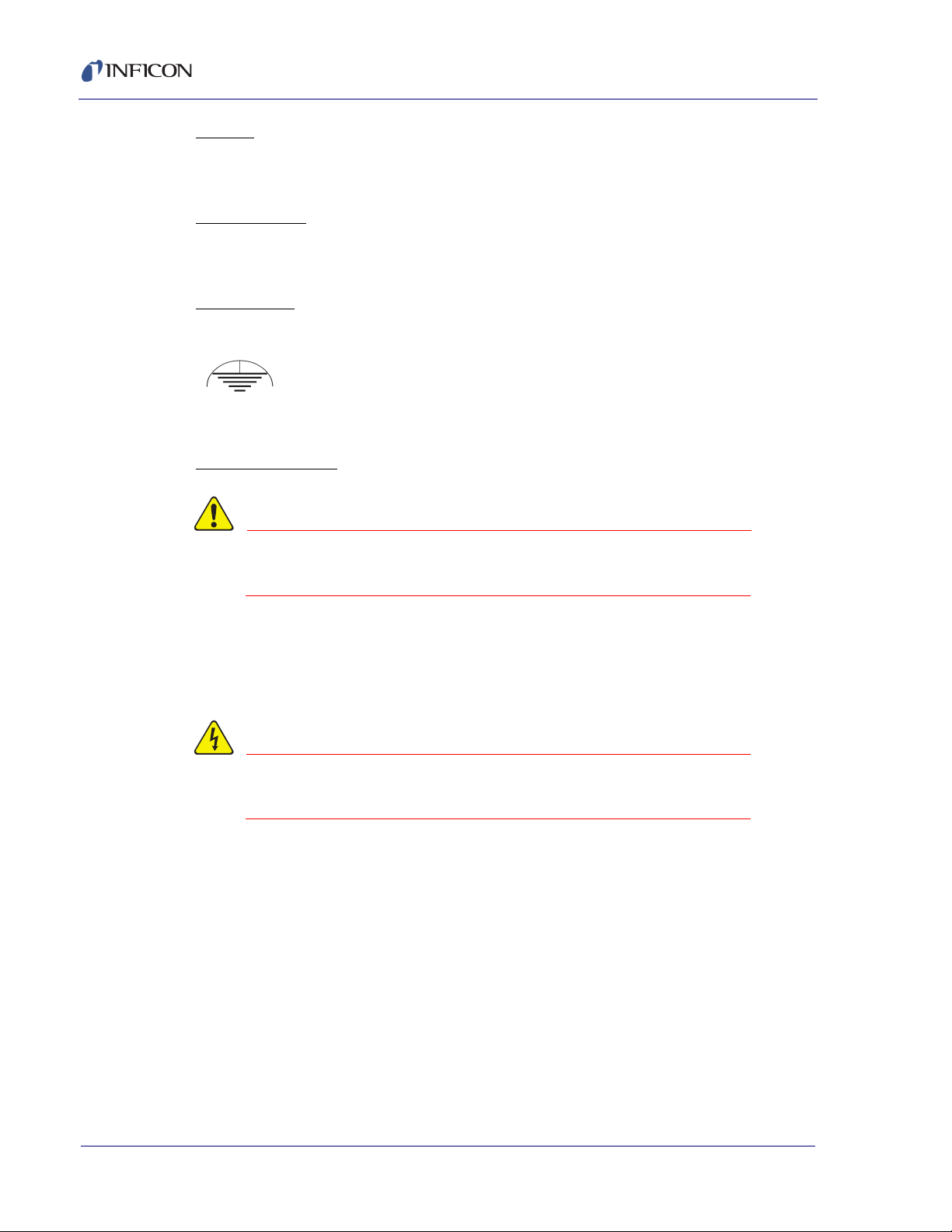

Figure 2-2 Rear Panel

RS-232

IPN 074-511-P1C

Sensor 1 & 2

Connection to quartz crystal sensors. See section 2.5 on page 2-4 for detailed

hookup information.

Rate and Thick Outputs

Provides 0-5 V analog outputs for Sensor 1 & 2 rate and thickness readings. For

connection to strip chart recorders, etc.

Sensor

50/60 Hz

20 W

Relay I/O

Connects 4 relays and 4 digital inputs to external devices. See section 3.20, I/O

Connections, on page 3-16 for connections.

2 - 3

Page 26

SQM-160 Operating Manual

WARNING

WARNING - Risk Of Electric Shock

RS-232

Connection to computer for programming and data acquisition. See Chapter 5,

Communications.

USB/Ethernet

Optional connection to computer USB or Ethernet port for programming and data

acquisition. See Chapter 5, Communications.

Option Card

Provides four additional sensor measurement channels.

Measurement ground terminal useful for common system and cable grounding.

Power Connector

Use removable power cords only of the specified type

and rating, attached to a properly grounded receptacle.

2.5 System Connections

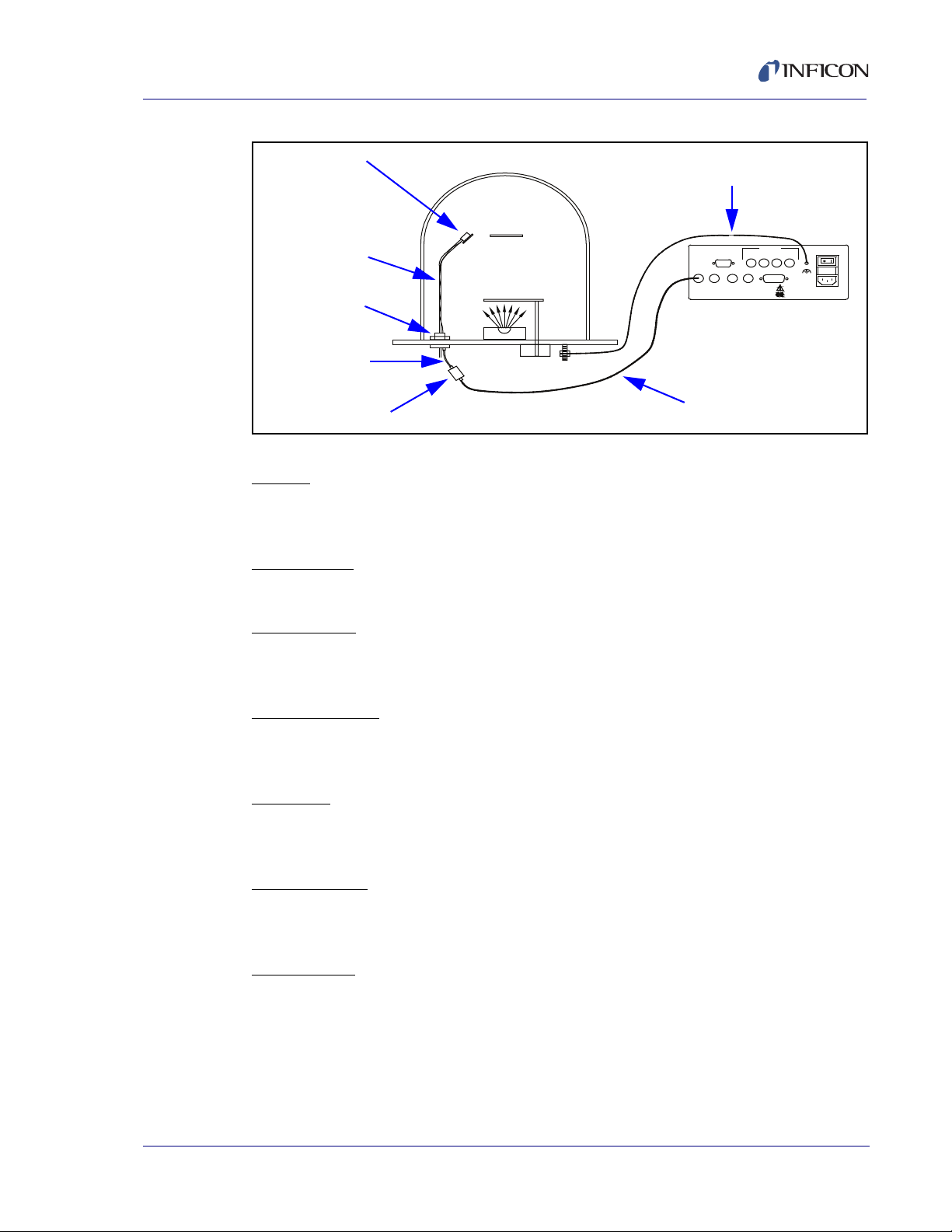

Figure 2-3 shows typical vacuum system wiring.

WARNING: Maintain adequate insulation and physical

separation of sensor wiring from hazardous voltages.

IPN 074-511-P1C

2 - 4

Page 27

SQM-160 Operating Manual

Sensor

Relay I/O

Option Card

Rate OutThick OutSensor 2Sensor 1

RS-232 43

100-120/200-240V~

50/60 Hz

20 W

Fuse T2.5A 250V

65

Sensor

In-Vac Cable

Feedthrough

6 in. BNC Cable

Oscillator

10 ft. BNC Cable

Ground Wire

SQM-160 Monitor

Figure 2-3 Typical Vacuum System Wiring

Sensor

Holds the quartz crystal used to measure rate and thickness. Crystals must be

replaced occasionally.

IPN 074-511-P1C

In-Vac Cable

Microdot cable that connects the sensor to the feedthrough.

Feedthrough

Provides isolation between vacuum and atmosphere for electrical and cooling

lines.

6 in. BNC Cable

Provides a flexible connection from the feedthrough to the oscillator. Keep this

cable as short as possible.

Oscillator

Contains the electronics to operate the quartz crystal. The length from the oscillator

to the crystal should be under 40 in. (1 m).

10' BNC Cable

Connects the oscillator to the SQM-160. Lengths up to 100 ft. (30 m) are

acceptable.

Ground Wire

A wire, preferably braided, that connects the vacuum system to the SQM-160

ground terminal.

2 - 5

Page 28

SQM-160 Operating Manual

2.6 Film Setup

This section will help you set up the SQM-160 to measure a film. See Chapter 3,

Operation, for detailed programming instructions.

1 Enter Program Mode

Press Program to enter the film setup menu. If the Crystal Life display is shown,

press Xtal Life to return to Rate/Thickness mode, then press Program.

2 Select a Film

Turn the Control Knob to select one of the 99 possible films, then press the

Control Knob to enter that Film Menu.

3 Set Film Parameters

Turn the Control Knob to set the first film parameter (Density). The parameter

value is shown in Display 2. Press the Control Knob to save the value and move

to the next parameter. Press Clear to return the film parameter to its original

value. Continue to set each parameter. Be sure to press the Control Knob to

store each parameter. Press Program to exit Program mode and return to

normal mode.

4 Set System Parameters

To Enter the System Menu, press Program, then Prev. Select and set system

parameters by turning and then pressing the Control Knob as described above.

Press Program to return to Normal mode.

If the sensor(s) selected during Film setup are connected properly to the SQM-160,

the Crystal Status LEDs should be illuminated. If not, return to the Film Menu and

set the Sensor Average parameter to the desired sensor(s). See section 3.5 on

page 3-6 for detailed information on assigning sensors to a film.

If the Crystal Status LED is flashing, the sensor is most likely not properly

connected. A small test crystal, supplied with each oscillator module, can be used

to test sensor connections external to the vacuum chamber. To use the test crystal,

disconnect the oscillator from its 6 in. BNC cable. Attach the test crystal to the

oscillator's feedthrough connector. The Crystal Status LED will remain illuminated

if the external sensor connections are correct.

See section 6.2.2, Troubleshooting Sensors, on page 6-3 for assistance in

troubleshooting sensor problems.

IPN 074-511-P1C

2 - 6

Page 29

2.7 Depositing a Film

If you have followed this Quick Start chapter, you are ready to deposit a film. Follow

the procedure below to begin deposition.

1 Verify Sensor Operation

Verify that the Crystal Status LED for the measuring sensor(s) is illuminated,

and not blinking.

2 Display Rate/Thickness

Display 1 should be displaying Rate on the left and Thickness on the right. If

the Crystal Life display mode is active, press the Xtal Life switch to return to

Rate/Thickness mode. If the Program Mode is active, press Program to return

to normal mode.

3 Zero Thickness

If needed, press the Zero switch to zero the thickness reading.

4 Start Deposition

Apply power to the source evaporation supply. If the SQM-160 shutter relay is

connected, press the Shutter switch to open the source shutter and begin

deposition.

SQM-160 Operating Manual

Rate and Thickness displays should begin to move from zero.

If the displays remain at zero, check the system setup to assure that evaporating

is actually taking place. Also check that the deposited material is reaching the

sensor.

If the display is erratic or noisy, first check your sensor connections. See section

6.2.2, Troubleshooting Sensors, on page 6-3 for information that can help in

identifying the cause of noisy readings.

If the rate and thickness readings do not match expectations, see the Film

Parameter (Density, Z-Ratio (Z-Factor), Tooling) and Sensor Tooling sections of

IPN 074-511-P1C

Chapter 3.

Review the remainder of this manual for detailed operational, programming, and

safety information.

2 - 7

Page 30

SQM-160 Operating Manual

This page is intentionally blank.

2 - 8

IPN 074-511-P1C

Page 31

3.1 Introduction

Crystal Status

Thickness kA

Next

Clear Program

Open

Closed

Thk SP

1

2

Press Next to

move through the

Film menu

Press Prev then

Next to move through

the System menu

Press

Program

to access

menus

Display 1

Display 2

This chapter details the operation of the SQM-160 menus and front panel controls.

3.2 Menu Selection

Two menus provide control of the SQM-160 programming. The Film Menu

customizes each stored film. The System Menu sets values that remain constant

for all films.

The Configuration section of the SQM-160 front panel contains four switches used

to access the program menus. Within the program menus, the Control Knob is also

used to adjust values and select menu choices. In program mode, Display 1 shows

the parameter to be changed. Display 2 shows the selected parameter's value.

SQM-160 Operating Manual

Chapter 3

Operation

NOTE: If Crystal Life is shown on the SQM-160 displays, press the Xtal Life

switches to return the displays to normal rate/thickness or frequency

display.

To enter the Film Menu, press Program. The SQM-160 displays the currently

selected film. If desired, turn, then press, the Control Knob to select a different film.

Press Next to display the first parameter for the selected film.

To enter the System Menu, press Program then press Prev.

Figure 3-1 SQM-160 Front Panel

Rate A/s

IPN 074-511-P1C

Zero

Time

Xtal Life Shutter

Control Configuration

Time SP

Final Thk

3

4

5

6

Prev

3 - 1

Page 32

SQM-160 Operating Manual

Program

Film 1

Film 99

- DENSITY

- TOOLING

- Z-FACTOR

- FINL THK

- THK SET *

- TIME SET *

- SAMPLE *

- HOLD *

- SENS AVG *

- 1

- 2

- 3

- 6

Sensors 3 - 6

show only if the

four-sensor

option card is

installed

Film Selection

Film Parameters Menu Sub-Menu

NOTE: Depending on System Menu setup, selections marked with a *

may not be available. See Table 3-1.

3.3 Film Menu

The Film Menu programs the SQM-160 for the materials that will be deposited.

Ninety-nine films can be stored, but only one film is active at any time.

1 Press Program to enter program mode.

2 Use the Control Knob to scroll to the desired Film # (1-99).

3 Press the Control Knob or Next to enter the film parameters for the selected

film.

4 Use Next and Prev to move through the film parameters, shown in Display 1

(refer to Figure 3-1).

5 Use the Control Knob to adjust the parameter value, shown in Display 2 (refer

to Figure 3-1), to the desired setting.

6 Press the Control Knob or Next to save the displayed value and move to the

next material parameter. Press Clear to abandon the change and return to the

original setting.

7 Press Program to exit the Film Menu and return to normal mode.

Figure 3-2 and Table 3-1 detail the parameters available in the Film Menu. Refer

to later sections of this chapter for instructions on setting specific film parameters.

Figure 3-2 Film Menu Parameters

IPN 074-511-P1C

3 - 2

Page 33

SQM-160 Operating Manual

Table 3-1 Film Menu

Display Description Range Default Units

DENSITY Density of the material being deposited.

Consult the Appendix A for common material

densities.

TOOLING Overall Tooling Factor for this film. See

section 3.7 on page 3-8.

Z-FACTOR

(Z-Ratio)

Z-Factor of the material being deposited.

See Appendix A for common material

Z-Factors.

FINL THK Desired Final Thickness of deposited

material. Illuminates Final Thk LED when

reached.

THK SET Thickness value that closes the Thickness

Setpoint relay and illuminates Thk SP LED.

Not available when Sampling is ON in

System Menu.

TIME SET Elapsed time that closes the Timer Setpoint

relay and illuminates Time SP LED. Not

available when Relay 2 is set to Dual or

Sensor 2 in the System Menu.

SAMPLE The time for the sensor shutter to remain

open when Rate Sampling is enabled in the

System Menu. Not available when Sampling

is OFF in System Menu.

0.5 – 99.99 1.00 gm/cc

10 – 399 100 %

0.10 – 10.00 1.0

0.000 – 99.99 0.500 kÅ

0.000 – 99.99 0 kÅ

0:00 – 99:59 0 Min:

Sec

0 - 9999 0 Sec

HOLD The time for the sensor shutter to remain

0 - 9999 0 Sec

closed when Rate Sampling is enabled in the

System Menu. Not available when Sampling

is OFF in System Menu.

SENS AVG Enable/disable crystals for this film. See the

IPN 074-511-P1C

Sensor Selection section of this chapter. Not

Enabled/

Disabled

Ch1

Enabled

available when Relay 2 is set to Dual in the

System Menu.

3 - 3

Page 34

SQM-160 Operating Manual

Program Prev

- TIMEBASE

- SIM MODE

- DISPLAY

- RATE RES

- RATEFILT

- RELAY 2

- SAMPLING

- BAUDRATE

- ETCH

- xTOOLING

- RELAYS

- FM IN/MAX

- R/T BNDS

- THCK (A)

- THCK(Nm)

- MASS

- FREQ

- TIME SP

- DUAL

- SENS 2

- FREQ MIN

- FREQ MAX

- xTLTOOL1

- xTLTOOL6

- RELAY 1

- RELAY 4

System Parameters Menu

Sub-Menu

- RATE MIN

- RATE MAX

- THICKMIN

- THICKMAX

3.4 System Menu

The System Menu sets values that pertain to the overall functions of the SQM-160

and to the vacuum system's setup. System Menu parameters apply to all films.

1 Press Program to enter program mode.

2 Press Prev to enter the System Menu.

3 Use Next and Prev to move through the system parameters.

4 Use the Control Knob to adjust the parameter value shown in Display 2 to the

desired setting.

5 Press the Control Knob or Next to save the displayed value and move to the

next material parameter. Press Clear to abandon the change and return to the

original setting.

6 Press Program to exit the System Menu and return to normal mode.

Figure 3-3 System Parameters Menu

Table 3-2 System Menu

Display Description Range Default Units

TIMEBASE Time required for a measurement.

SIM MODE Simulates sensor inputs. On/Off Off

DISPLAY Selects Rate/Thickness in Angstroms,

RATE RES Sets rate resolution to 0.01 or

3 - 4

Longer times yield higher accuracy.

Rate/Thickness in Nanometers, Frequency,

or Mass (ugm/cc) display.

0.1 Å/s. Hi/Low Low

0.15 – 2.00 0.25 Sec.

THCK/nÅnM/FRE

Q/MASS

IPN 074-511-P1C

Rate

Page 35

SQM-160 Operating Manual

Table 3-2 System Menu (continued)

Display Description Range Default Units

RATEFILT Number of rate readings averaged. 1 – 20 8

RELAY 2 Select Timer to cause relay to close when

On/Off Timer

time setpoint is reached. Dual causes relay

to close (to activate dual sensor) when

sensor 1 fails. Sensor 2 causes relay to

activate a sensor shutter when Sensor 2 is

assigned to a film.

SAMPLING When Sampling is ON the sensor shutter

On/Off Off

periodically “samples” the rate. After a

period, the shutter closes and the SQM-160

“holds” the same rate reading until the next

sample period. Sample and Hold times are

set in the Film Menu.

BAUDRATE Serial baud rate to PC. 2.4 – 19.2 19.2 kbps

ETCH Sets rate negative for etching. On/Off Off

xTOOLING Tooling value assigned to each sensor. See

10 – 399 100 %

the Sensor Tooling section of this chapter.

RELAYS Assigns normally open or normally closed

NO/NC NO

operation for each relay. Note: All relays are

open with power off.

FMIN/MAX Sub-menu sets minimum and maximum

4.00 – 6.00

5.00

MHz

crystal frequencies.

4.10-6.10

6.10

R/T BNDS Rate and Thickness Bounds sub-menu for

analog outputs.

RATE MIN Deposition Rate for zero output (zero Volts). 0 – 999 0 Å/s

IPN 074-511-P1C

Volts).

THICKMIN Thickness for zero output

RATE MAX Deposition Rate for full scale output (+5

9.9 – 999 100 Å/s

0 – 99.99 0.00 kÅ

(zero Volts).

THICKMAX Thickness for full scale output

0 – 99.99 1.00 kÅ

(+5 Volts).

3 - 5

Page 36

SQM-160 Operating Manual

3.5 Sensor Selection

The SQM-160 comes standard with two sensor inputs. Four additional sensors are

available by adding a Sensor Option Card. A specific sensor can be assigned to

each film, or multiple sensors can be averaged for a film. The averaging option

provides more uniform coverage of the deposition area and provides a backup

sensor capability. If one of multiple sensors assigned to a film fails, the sensor is

automatically removed from rate/thickness calculations.

NOTE: If Relay 2 Dual is selected in the System Menu, Sensors 1 and 2 are set

up as a primary/secondary sensor pair. In that case, sensor averaging is

disabled. See section 3.12 on page 3-10 for information on dual sensors.

To assign a sensor, or sensors, to a film:

1 Press Program to enter Program mode.

2 Use the Control Knob to scroll to the desired Film # (1-9).

3 Press the Control Knob or Next to enter the film parameters for the selected

film.

4 Press Next until SENS AVG is shown.

5 Use the Control Knob to scroll through the sensors in Display 2.

6 Press the Control Knob to toggle the sensor on/off.

Sensor status can be seen by observing the Crystal Status LEDs:

If the LED is not illuminated, the crystal is disabled.

If the LED is illuminated, the crystal is enabled and receiving valid readings.

If the LED is blinking, the crystal is enabled, but is not receiving valid

readings.

7 Continue selecting sensors until the Crystal Status LEDs indicate the desired

setup.

8 Press Program to exit the Film Menu and return to normal mode.

9 Turn the Control Knob to sequence though each sensor's reading on Display 1.

When a single number is shown in Display 2 it is the sensor number whose

readings are shown in Display 1. When time is shown in Display 2, Display 1

shows the average of all assigned sensors.

IPN 074-511-P1C

3 - 6

Page 37

3.6 Sensor Frequency

Sensor Min/Max frequencies establish the operating range for the sensing quartz

crystals. Both values are used to determine the % life that is displayed in Xtal Life

mode.

When the sensor frequency drops below the minimum (or reads above the

maximum), the SQM-160 indicates a sensor failure by blinking the Crystal Status

display.

To set sensor minimum and maximum frequencies:

1 Press Program to enter Program mode.

2 Press Prev to enter the System Menu.

3 Press Next until FMIN/FMAX is shown.

4 Press the Control Knob to display FREQ MIN.

5 Adjust the Control Knob to the desired minimum operating frequency on

Display 2.

6 Press the Control Knob to accept the minimum value and display FREQ MAX.

SQM-160 Operating Manual

7 Adjust the Control Knob to the desired maximum operating frequency on

Display 2.

8 Press the Control Knob to accept the maximum value.

9 Press Program to exit the System Menu and return to normal mode.

Crystals sometimes fail unexpectedly, or exhibit erratic frequency shifts (mode

hopping) before total failure. Depending on the material, crystals may fail well

before the typical 5 MHz minimum. If you find that crystals fail early consistently,

set FREQ MIN to a value higher than 5 MHz to provide a Crystal Life warning

consistent with actual failure.

A sensor crystal with an initial value that exceeds the maximum will also cause a

blinking Crystal status. The maximum frequency can be set slightly above the

IPN 074-511-P1C

nominal values with no effect on accuracy.

3 - 7

Page 38

SQM-160 Operating Manual

Tooling

Over 100%

Tooling

Under 100%

Substrate

Substrate

3.7 Sensor Tooling

Sensor Tooling adjusts for the difference in deposition rate between the sensor and

the substrate being coated. It is an empirically determined value that matches the

sensor readings to the vacuum system.

Figure 3-4 Sensor Tooling

xTooling is set in the System Menu. It adjusts the tooling for each individual sensor

before it is averaged. xTooling for a sensor applies to all films. If the individual

sensor xToolings are set properly, a sensor failure will not cause a jump in the

average Rate and Thickness reading. See section 7.3, Determining Tooling, on

page 7-2 for more details.

To adjust xTooling:

1 Press Program to enter Program mode.

2 Press Prev to enter the System Menu.

3 Press Next until xTOOLING is shown, then press the Control Knob.

4 Adjust the Control Knob to set the XTLTOOL 1 value. Press the Control Knob

to save the value and move to XTLTOOL 2.

5 Repeat Step 4 for each of the installed sensors.

6 Press Program to exit the System Menu and return to normal mode.

Film Tooling is set in the Film Menu and is applied to the averaged Rate and

Thickness for all sensors assigned to that film. Film Tooling is a film-specific value,

and is seldom required.

IPN 074-511-P1C

3 - 8

Page 39

3.8 Display Units

The SQM-160 can display crystal measurements in several different units. To

select the display units:

1 Press Program to enter Program mode.

2 Press Prev to enter the System Menu.

3 Press Next until DSP..... is shown.

4 Turn the Control Knob left or right to select the desired display mode:

THCK — Rate in Å/s, Thickness in kÅ

nAnM — Rate in nM/s, Thickness in µM

MASS — Rate in ng/cc/s, Mass in µg (micrograms)

FREQ — Frequency in Hz

NOTE: When Nanometers is selected a small "n" appears between the rate

SQM-160 Operating Manual

and thickness displays. When Mass is selected a small "m" appears

between the rate and thickness displays.

5 Press the Control Knob to accept the choice.

6 Press Program to exit the System Menu and return to normal mode.

3.9 Crystal Life

The SQM-160 calculates the remaining crystal life based on the FMin/Max values

set in the System Menu (refer to section 3.4 on page 3-4).

To display the remaining crystal life for the sensors used by the currently active film:

1 Press the Xtal Life switch in the front panel Control section.

2 The sensor is shown in Display 1 and the % remaining life is shown in Display 2.

3 Turn the Control Knob to display the % life of other sensors active for this film.

IPN 074-511-P1C

4 Press Xtal Life again to return to normal rate/thickness, or frequency display.

NOTE: You cannot enter program mode while the crystal life display is active.

3.10 Zero Thickness

Before starting each film deposition, reset the SQM-160 Thickness value to zero.

To zero Thickness, press the Zero switch in the front panel Control section.

In addition to zeroing Thickness, pressing the Zero switch has these effects:

The Time display is reset to its programmed value and starts counting down.

The Thickness Setpoint and Timer relays open.

The Time SP, Thk SP, and Final Thk LEDs extinguish.

3 - 9

Page 40

SQM-160 Operating Manual

3.11 Shutter Operation

The SQM-160 Shutter switch controls a relay that is normally connected to the

source shutter.

To open or close the Shutter relay, press the Shutter switch in the front panel

Control section.

The Open and Closed LEDs illuminate to indicate the shutter status.

NOTE: If Relay 2 is set to Sensor 2 in System Menu, the operation of the Shutter

switch/relay changes slightly. In this case, the shutter relay will activate

only if Sensor 1 is assigned to the active film. If sensor 2 is assigned to the

active film, Relay 2 will close instead.

3.12 Dual Sensors

Dual shuttered sensors provide a backup (secondary) sensor in case of primary

sensor failure. When Relay 2 is programmed for Dual sensors in the System menu,

the SQM-160 will automatically switch to Sensor 2 when Sensor 1 readings stop or

become erratic.

To program the SQM-160 for dual sensors:

1 Press Program to enter Program mode.

2 Press Prev to enter the System Menu.

3 Press Next until RELAY 2 is shown.

4 Turn the Control Knob right to select DUAL sensor function.

5 Press the Control Knob to accept the value.

6 Press Program to exit the System Menu and return to normal mode.

7 In the film menu, assign only Sensor 1 to the film. The backup sensor 2 is

automatically assigned internally.

NOTE: Relay 2 is a multi-function relay. It can be programmed as a dual sensor

shutter, or to close when a programmed time has elapsed, or as a sensor

2 shutter relay. section 3.20, I/O Connections, on page 3-16 discuss the

other Relay 2 functions.

IPN 074-511-P1C

3 - 10

Page 41

3.13 Rate Sampling

In Rate Sampling mode, the SQM-160 opens a sensor shutter for a fixed time to

"sample" the process rate, then closes the shutter and "holds" the last rate reading

for a fixed time. While the shutter is closed (hold mode), the SQM-160 calculates

thickness based on the last sampled rate.

NOTE: Rate sampling can significantly extend crystal life in a high deposition rate

process. However, unless the process is very stable, the thickness

calculation during hold mode may be incorrect. Do not use rate sampling

if your rate varies during deposition.

To program the SQM-160 for Rate Sampling:

1 Press Program to enter Program mode.

2 Press Prev to enter the System Menu.

3 Press Next until SAMPLING is shown.

4 Turn the Control Knob right to turn ON rate sampling. Press the Control Knob

to accept the value.

SQM-160 Operating Manual

5 Press Program to exit the System Menu and return to normal mode.

6 Press Program to re-enter Program mode.

7 Use the Control Knob to scroll to the desired Film # (1-9), then press the Control

Knob or Next to enter the film parameter menu for the selected film.

8 Press Next until SAMPLE is shown.

9 Use the Control Knob to set the sample time period. Press the Control Knob to

accept the sample value and display HOLD.

10 Use the Control Knob to set the hold time period. Press the Control Knob to

accept the Hold value.

11 Press Program to exit the Film Menu and return to normal mode.

IPN 074-511-P1C

NOTE: The rate sampling relay is a dual function relay. It can be programmed

either to sample rate or to close when a programmed thickness is reached.

See section 3.15, Thickness Setpoint, on page 3-13. See 3.20, Operation,

for relay wiring.

3 - 11

Page 42

SQM-160 Operating Manual

3.14 Time Setpoint

The Time Setpoint provides a convenient way to signal a timed event. After a

pre-programmed time period, the Time Setpoint closes a relay when the Zero

switch is pressed.

To program the Time Setpoint:

1 Press Program to enter Program mode.

2 Press Prev to enter the System Menu.

3 Press Next until RELAY 2 is shown.

4 Turn the Control Knob right to select TIME. Press the Control Knob to accept

the value.

5 Press Program to exit the System Menu and return to normal mode.

6 Press Program to re-enter Program mode.

7 Use the Control Knob to scroll to the desired Film # (1-9), then press the Control

Knob or Next to enter the Film Parameter menu for the selected film.

8 Press Next until TIME SET is shown.

9 Use the Control Knob to set the timer setpoint. Press the Control Knob to

accept the value.

10 Press Program to exit the Film Menu and return to normal mode.

11 Press Zero to open the relay and begin counting down the Time Setpoint. When

the time reaches zero, the Time SP LED illuminates and the relay closes.

NOTE: Relay 2 is a multi-function relay. It can be programmed as a dual sensor

shutter, or to close when a programmed time has elapsed, or as a sensor

2 shutter relay. See section 3.11, Shutter Operation, on page 3-10 and

section 3.12, Dual Sensors, on page 3-10 for a discussion of other

Relay 2 functions.

IPN 074-511-P1C

3 - 12

Page 43

3.15 Thickness Setpoint

The Thickness Setpoint closes a relay when a programmed thickness is reached.

This setpoint is independent from Final Thickness, which always closes the source

shutter.

To program the Thickness Setpoint:

1 Press Program to enter Program mode.

2 Press Prev to enter the System Menu.

3 Press Next until SAMPLING is shown.

4 Turn the Control Knob right to turn OFF the Sampling function. Press the

Control Knob to accept the value.

5 Press Program to exit the System Menu and return to normal mode.

6 Press Program to re-enter Program mode.

7 Use the Control Knob to scroll to the desired Film # (1-9), then press the Control

Knob or Next to enter the Film Parameter menu for the selected film.

SQM-160 Operating Manual

8 Press Next until THK SET is shown, not FINL THK.

9 Use the Control Knob to set the thickness setpoint. Press the Control Knob to

accept the value.

10 Press Program to exit the Film Menu and return to normal mode.

When the Thickness Setpoint is reached, the Thk SP LED lights and the relay

closes. Use the Zero switch to open the relay and zero thickness at any time.

NOTE: The Thickness Setpoint relay is a dual function relay. It can be

programmed either to indicate a thickness, or to control a sensor shutter

for rate sampling. See section 3.13, Rate Sampling, on page 3-11. See

Chapter 4 for relay wiring.

IPN 074-511-P1C

3 - 13

Page 44

SQM-160 Operating Manual

CAUTION

3.16 Simulate Mode

In Simulate mode, the SQM-160 simulates attached sensors. It is an easy way to

become familiar with the SQM-160 front panel controls and programming. You can

open/close the shutter to simulate deposition, zero readings, and display crystal

life. You can also test the Time and Thickness setpoint relays and LEDs.

To enter Simulate mode:

1 Press Program to enter Program mode.

2 Press Prev to enter the System Menu.

3 Press Next until SIM MODE is shown.

4 Turn the Control Knob left or right to enable and disable Simulate mode.

5 Press the Control Knob to accept the value.

6 Press Program to exit the System Menu and return to normal mode.

3.17 Defaulting the Memory

Performing this procedure wil default the SQM-160 to its

factory setting. All Parameters set by the user will be

deleted. Do not perform this procedure until you have

created a back up database file using SQM160 Comm.

1 Power cycle the unit while pressing and holding select buttons until an error

message appears.

1a For firmware versions before v4.10 (clears only Film parameters):

Press and hold the ZERO + XTAL LIFE + SHUTTER buttons while powering up

the SQM-160.

1b For firmware version v4.10 and higher (clears Film and System parameters):

Press and hold the ZERO + XTAL LIFE + SHUTTER + CONTROL KNOB

buttons while powering up the SQM-160.

2 "ERROR 00" message should appear. Power cycle again and no error

messages should appear.

IPN 074-511-P1C

3 - 14

Page 45

3.18 Relay Operation

The four relays of the SQM-160 are physically single-pole, normally-open

(1FormA) relays. However, each can be programmed to act as either

normally-open or normally-closed during SQM-160 operation. It is important to

keep in mind that all relays will open if the SQM-160 is turned off or loses power.

See section 3.20 on page 3-16 for relay wiring.

To set the relay operating mode:

1 Press Program to enter Program mode.

2 Press Prev to enter the System Menu.

3 Press Next until RELAYS is shown and then press the Control Knob to display

Relay 1.

4 Turn the Control Knob left or right to select NO (normally open) or NC (normally

closed). Press the Control Knob to accept the value and display the next relay.

5 Repeat Step 4 for each of the four relays.

6 Press Program to exit the System Menu and return to normal mode.

SQM-160 Operating Manual

IPN 074-511-P1C

3 - 15

Page 46

SQM-160 Operating Manual

1

8

915

3.19 Analog Output Configuration

The SQM-160 analog outputs must be set to match the device that will be attached

to the Rate or Thickness output.

To set up the analog outputs in the System Menu:

1 Press Program to enter Program mode.

2 Press Prev to enter the System Menu.

3 Use Next to move through the system parameters until R/T BNDS is displayed.

4 Press the Control Knob to display RATE MIN.

5 Adjust the Control Knob to the Rate desired for a 0 V output.

6 Press the Control Knob to save the value and display the RATE MAX setting.

7 Adjust the Control Knob to the Rate desired for a 5 V output.

8 Press the Control Knob to save the value and display the THICK MIN setting.

9 Repeat steps 5-8 to adjust the Thickness output values.

10 Press Program to exit the System Menu and return to normal mode.

Refer to section 3.4 on page 3-4 for more information on setting SQM-160 System

parameters.

3.20 I/O Connections

A 15-pin female D-sub connector is included with the instrument to connect digital

I/O to the SQM-160 Relay I/O connector. The figure below shows the solder-side

pin assignments for the supplied connector.

Figure 3-5 Relay I/O Connector Rear View

IPN 074-511-P1C

3 - 16

Page 47

WARNING

WARNING

Table 3-3 Relay I/O Connections

SQM-160 Operating Manual

Pins

1,2

Relay 1

3,4

Relay 2

5,6

Relay 3

7,8

Relay 4

9 Zero Timer

10 Zero Thick

Function Description

Crystal Fail Relay Contacts close when all enabled sensors have failed.

Time Setpoint, Dual

Sensor, or Sensor 2

Relay

Shutter

Relay

Sampling or

Thickness Setpoint

Input

Input

If Relay 2 is set to TIME in the System menu, contacts close when

timer counts down to zero from its programmed Timer Setpoint value.

If DUAL is selected, contacts close when Sensor 1 fails. If SENS2 is

selected, contacts close when shutter is pushed if Sensor 2 is

programmed for the active film.

Controlled by front panel shutter switch. Contacts close when Shutter

Open is selected. If SENS2 is selected for Relay 2 in the System

menu, the shutter relay contacts close only if Sensor 1 is programmed

for the active film.

If Sampling is ON in System Menu, contacts close during Sample,

open during Hold. If Sampling is OFF contacts close when Thickness

Setpoint is reached.

Grounding this pin zeroes the setpoint timer.

Grounding this pin zeroes the thickness display.

11 Close Shutter Input Grounding this pin opens the shutter relay.

12 Open Shutter Input Grounding this pin closes the shutter relay.

13,14,15 Ground

The inputs are not isolated! The voltage level applied

must be limited to between 0 and +5 volts with respect to

IPN 074-511-P1C

Ground.

Output relays are rated for 30 V

or 30 V (dc), at 2 A

rms

maximum. Proper fusing and adequate wiring insulation

and separation should be provided to assure these limits

are not exceeded.

3 - 17

Page 48

SQM-160 Operating Manual

3.21 Rack Mounting Procedure

The Full Rack Extender option mounts a single SQM-160 into a full-width 19 in.

rack space. Follow these steps to assemble the extender and mount the SQM-160:

1 Remove SQM-160 Mounting Ear

Determine on which side of the SQM-160 to attach the rack extender. If a

rack-mount ear is already attached to the SQM160 on that side, remove the two

10-32 flat head screws that mount the ear and remove the rack-mount ear.

2 Assemble the Extender

Assemble the extender "box" using the eight 6-32 flat head screws, two end

panels, and two main panels. Thread two socket head captive panel screws

from the inside of one side of the extender. Continue to thread the captive

screws until their threads are completely exposed on one side.

3 Attach the Extender

Place the extender next to the SQM-160, and thread the captive screws into

the SQM-160 threaded holes that were previously used to mount the rack ear.

Tighten the captive screws to secure the extender to the SQM-160.

4 Attach the Mounting Ears

Attach the mounting ear previously removed from the SQM-160 to the extender

using the same10-32 flat head screws. If a rack-mount ear is not already

attached to the SQM-160, attach it.

5 Mount the SQM-160

Slide the entire assembly into an empty 3 1/2 in. high 19 in. rack-mount space.

Secure the assembly with four rack screws.

The Half Rack Adapter kit mounts one SQM-160 to another 3.5 in. high instrument.

It consists of two rack-mount ears and a small adapter bracket. Mount one rack

mount ear to the SQM-160, and the other to the second instrument. Attach the two

instruments using the adapter bracket.

IPN 074-511-P1C

3 - 18

Page 49

4.1 Introduction

The SQM160 Comm program communicates with INFICON's SQM-160 Thin Film

Monitor to allow remote instrument setup and data logging. With the SQM160

Comm you can:

Select a Film on the SQM-160 Thin Film Monitor, then open the shutter to start

deposition.

View SQM-160 readings in both numerical and graphical format.

Store SQM-160 readings to a text file on a drive.

Create and store an unlimited number of film setups.

Download films to, and upload films from, the SQM-160 monitor.

SQM-160 Operating Manual

Chapter 4

SQM-160 Comm Software

Modify the SQM-160 monitor's system setup parameters.

Consult Chapter 5, Communications for information on connecting a SQM-160 and

establishing communication with this program.

4.2 Installation

To install the SQM-160 program, insert the 074-5000-G1 INFICON CD-ROM. If the

setup program does not start automatically, click Start, then Run, then type

<d>:UtilityDisk (where <d> is the drive you are using). The Program Disk main

menu should appear.

On the program disk menu, see Figure 4-1, click SQM160 Monitor, then click on

SQM160 Software. Follow the directions given there. When installation is

IPN 074-511-P1C

complete, you may be prompted to restart the computer.

To start the SQM160 Comm program, click the SQM160 Comm desktop icon, or

click Start, Programs, INFICON, then SQM160 Comm. The SQM160 Comm

program main window will be displayed.

4 - 1

Page 50

SQM-160 Operating Manual

Figure 4-1 Program Disk Menu

4.3 Main Window

Figure 4-2 SQM-160 Comm Main Window

IPN 074-511-P1C

4 - 2

The main window allows for basic SQM-160 setup and data logging. On program

startup, it may take a few seconds to display the main window and read the

Monitor's setup information.

Page 51

SQM-160 Operating Manual

If the Communications Setup dialog box is displayed, no Monitor was found on the

expected comm port. Follow the instructions in section 4.7, Communications

Menu, on page 4-9 of this manual to establish communications. The top tool bar

is only visible if communications has been established with an SQM-160.

Otherwise, an SQM-160 Offline status message is displayed.

The main window menus allow additional configuration of the program, and the

connected SQM-160 Thin Film Monitor. Some menu selections are not available

during data acquisition, or if SQM-160 communications are not established. The

main window control functions are shown below.

Film . . . . . . . . . . . . . . . . . . . . . . . . . This drop-down list box selects the film on the

SQM-160 that will be used for rate/thickness

measurements. Defaults on startup to the

first SQM-160 film.

Start/Stop . . . . . . . . . . . . . . . . . . . . Causes the program to start/stop SQM-160

data acquisition. Graphing and display of

readings from the SQM-160 start/stop

immediately when this control is toggled.

Open/Close Shutter . . . . . . . . . . . . Toggles the SQM-160 shutter relay. Opening

the shutter automatically starts SQM-160

data acquisition. However, closing the

shutter does not automatically stop data

acquisition.

Zero . . . . . . . . . . . . . . . . . . . . . . . . . Zeros the thickness reading on the

SQM-160.

The remaining main window controls display readings from the SQM-160 Monitor.

Graph. . . . . . . . . . . . . . . . . . . . . . . . Displays rate readings from the SQM-160. A

graph of each sensor assigned to the film, or

an average of all assigned sensors, can be

selected on the View menu.

IPN 074-511-P1C

Elapsed Time . . . . . . . . . . . . . . . . . Displays the elapsed deposition time since

the Start switch was pressed.

Time Remaining . . . . . . . . . . . . . . . Displays the calculated deposition time

remaining based on the current thickness

and current rate, and final thickness setpoint.

Final Thickness . . . . . . . . . . . . . . . The desired deposition thickness for the

selected film. Final thicknesss setpoint can

be set on the Film menu (see section 4.5).

Average Thickness. . . . . . . . . . . . . The current film thickness, based on the

average of all sensors assigned to the

selected film.

4 - 3

Page 52

SQM-160 Operating Manual