Page 1

OPERATING MANUAL

SQC-310

Thin Film Deposition Controller

IPN 074-550-P1B

™

Page 2

Page 3

www.inficon.com reachus@inficon.com

©2012 INFICON

®

OPERATING MANUAL

SQC-310

Thin Film Deposition Controller

IPN 074-550-P1B

™

Page 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

SQC-310™ and INFICON® are trademarks of INFICON GmbH.

Visual Basic®, Windows® and Microsoft® are registered trademarks of Microsoft Corporation.

Oracle® and Java® are registered trademarks of Oracle and/or its affiliates.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2012 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

DECLARATION OF CONFORMITY

This is to certify that this equipment, designed and manufactured by:

INFICON Inc.

Two Technology Place

East Syracuse, NY 13057

USA

meets the essential safety requirements of the European Union and is placed on the market

accordingly. It has been constructed in accordance with good engineering practice in safety

matters in force in the Community and does not endanger the safety of persons, domestic

animals or property when properly installed and maintained and used in applications for

which it was made.

Equipment Description:

SQC-310 Rate / Thickness Controller (including all options).

Applicable Directives: 2006/95/EC (LVD)

2004/108/EC (General EMC)

2002/95/EC (RoHS)

Applicable Standards:

Safety: EN 61010-1:2001

Emissions: EN 61326-1:1997/A1: 1998/A2: 2001 (Radiated & Conducted Emissions)

Class A: Emissions per Table 3

(EMC – Measurement, Control & Laboratory Equipment)

Immunity: EN 61326-1:1997/A1: 1998/A2: 2001 (General EMC)

Class A: Immunity per Table A1

(EMC – Measurement, Control & Laboratory Equipment)

RoHS: Fully compliant

CE Implementation Date: May 2001 (Updated February, 2011)

Authorized Representative:

Steve Schill

Thin Film Business Line Manager

INFICON Inc.

ANY QUESTIONS RELATIVE TO THIS DECLARATION OR TO THE SAFETY OF INFICON'S PRODUCTS SHOULD BE DIRECTED, IN

WRITING, TO THE AUTHORIZED REPRESENTATIVE AT THE ABOVE ADDRESS.

Page 6

Page 7

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

two (2) years from the date of shipment thereof by Seller. Seller's liability under

this warranty is limited to such of the above products or parts thereof as are

returned, transportation prepaid, to Seller's plant, not later than thirty (30) days

after the expiration of the period of warranty coverage in respect thereof and are

found by Seller's examination to have failed to function properly because of

defective workmanship or materials and not because of improper installation or

misuse and is limited to, at Seller's election, either (a) repairing and returning the

product or part thereof, or (b) furnishing a replacement product or part thereof,

transportation prepaid by Seller in either case. In the event Buyer discovers or

learns that a product does not conform to warranty, Buyer shall immediately notify

Seller in writing of such non-conformity, specifying in reasonable detail the nature

of such non-conformity. If Seller is not provided with such written notification,

Seller shall not be liable for any further damages which could have been avoided if

Seller had been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

www.inficon.com reachus@inficon.com

Page 8

Page 9

Chapter 1

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.4 System Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.6 Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.7 Thin Film Deposition Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.8 Building a Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.9 Depositing a Film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

SQC-310 Operating Manual

Table Of Contents

Trademarks

Disclaimer

Copyright

Quick Start

Chapter 2

Operation

2.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.3 Defining a Film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.4 Defining a Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.5 Defining a Layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.6 Sensor and Source Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.7 Running a Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

IPN 074-550-P1B

2.8 Loop Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2.9 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

Chapter 3

Menus

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Main Screen, Menu 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 Main Screen, Menu 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.4 Main Screen, Menu 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.5 Quick Edit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.6 Process Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

TOC - 1

Page 10

SQC-310 Operating Manual

3.7 Layer Edit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.8 Layer Copy, Insert and Delete Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.9 Film Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.10 Film Edit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.10.1 Film Conditioning Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.10.2 Film Deposit Controls Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.10.3 Film Configure Sensor Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.11 System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.11.1 Input and Relay Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.11.2 Logic Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3.11.2.1 Entering a Logic Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

3.11.2.2 Logic Statement Conditions ("IF") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

3.11.2.3 Logic Statement Actions ("THEN"). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

3.11.3 Sensors and Sources Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

3.11.3.1 Sensor Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

3.11.3.2 Source Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Chapter 4

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 Software Upgrades. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.4 Clearing the Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.5 Half Rack Adapter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.6 Full Rack Extender Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.7 Handheld Remote Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Chapter 5

5.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 SQC-310 Comm.exe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2.1 Communications Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 SQC-310 Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3.1 Get Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3.2 Get/Set Film Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3.3 Get/Set System Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.3.4 Get/Set Process Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.3.5 Get/Set Layer Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.3.6 Delete All Layers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.3.7 Get/Set Material Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Maintenance & Accessories

Communications

IPN 074-550-P1B

TOC - 2

Page 11

SQC-310 Operating Manual

5.3.8 Get/Set Input & Relay Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.3.9 Get/Set Sensor, Source, Relay Parameters. . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.3.10 Get/Set Logic Statement Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

5.3.11 Get Num Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

5.3.12 Get Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

5.3.13 Get Sensor Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

5.3.14 Get Output Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.3.15 Get Sensor Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.3.16 Get Output Thickness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

5.3.17 Get Sensor Frequency/Crystal Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

5.3.18 Get Output Deviation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

5.3.19 Get/Set Output Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.3.20 Set Active Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.3.21 Set Run State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

5.3.22 Get Run State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

5.3.23 Start Download/Upload Session. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

5.3.24 Stop Download/Upload Session. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.4 CRC Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

®

5.4.1 Visual Basic

5.4.2 Java

®. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-21

5/6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

5.4.3 C++. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Appendix A

Material Table

A.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Appendix B

Specifications

B.1 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

IPN 074-550-P1B

B.2 Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

B.3 Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

B.4 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

B.5 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

B.6 Process Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

B.7 Layer Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

B.8 Film Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

TOC - 3

Page 12

Appendix C

C.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

C.2 Interfacing to a INFICON CI-100 Indexer. . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

C.2.1 BCD I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

C.2.2 Binary I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

C.3 Interfacing to a MDC E-Beam Sweep Controller . . . . . . . . . . . . . . . . . . . . .C-4

C.3.1 BCD I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

SQC-310 Operating Manual

I/O Connections

TOC - 4

IPN 074-550-P1B

Page 13

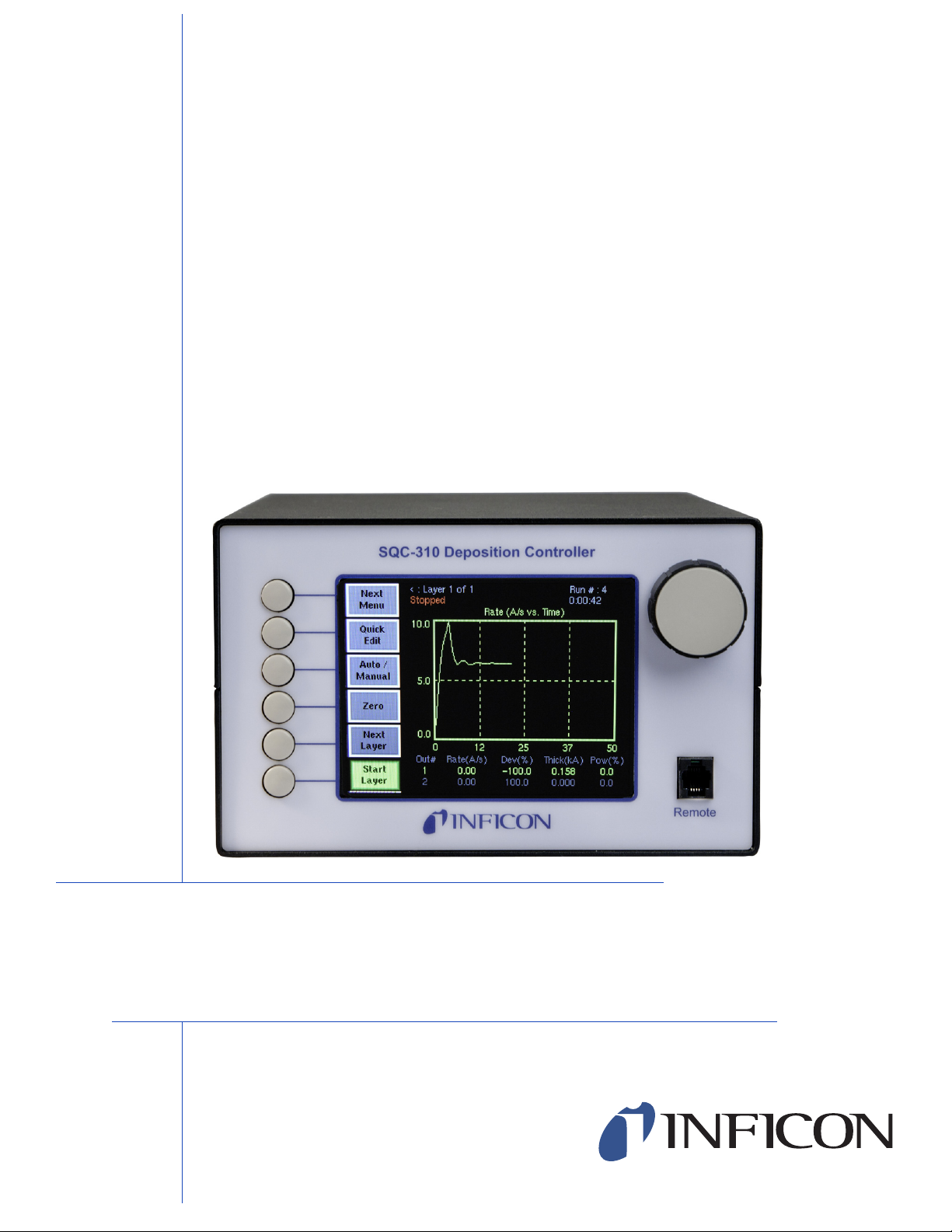

1.1 Introduction

INFICON SQC-310 series instruments are multi-channel QCM-based deposition

controllers. They provide a unique combination of accuracy and powerful features

in a compact, low cost instrument.

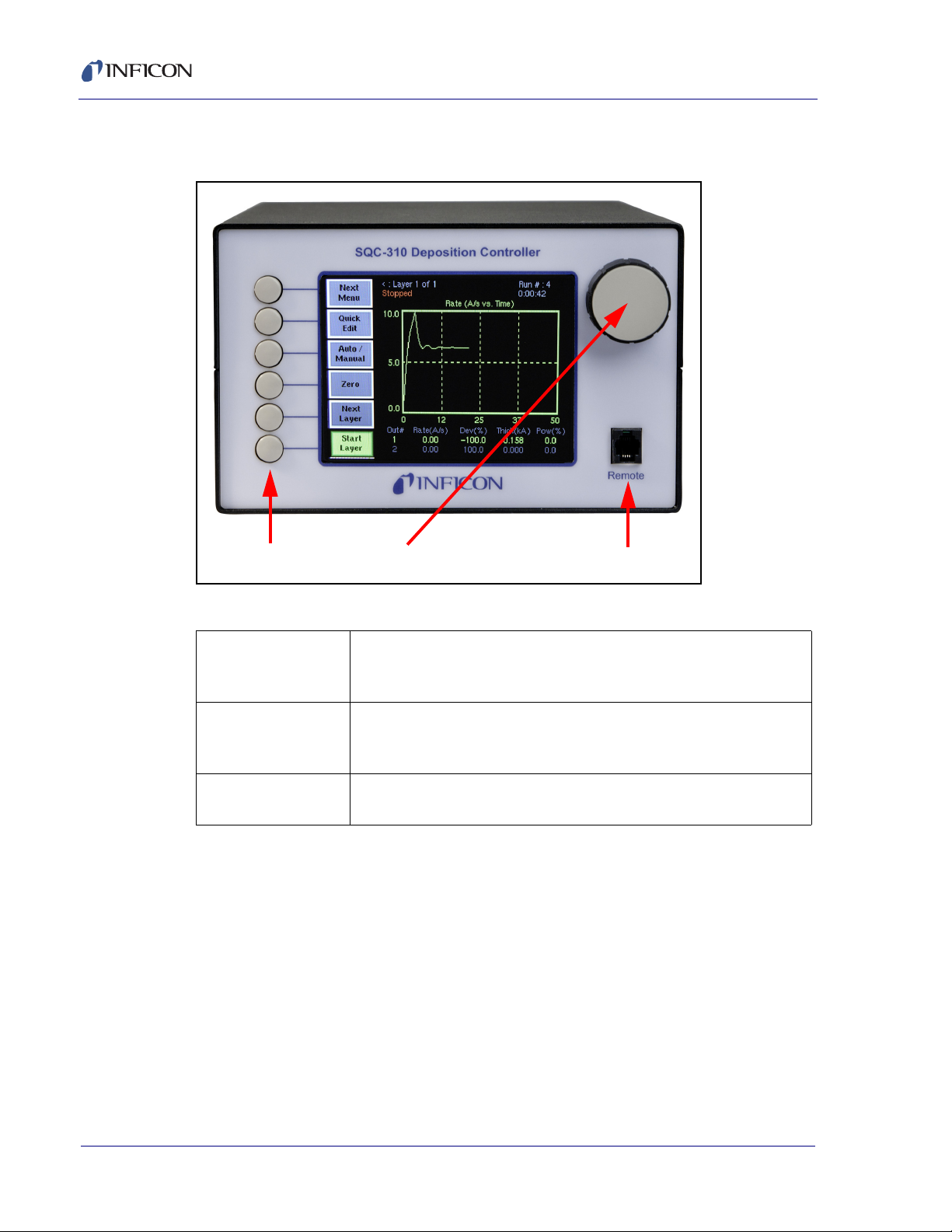

Figure 1-1 SQC-310C

SQC-310 Operating Manual

Chapter 1

Quick Start

The standard SQC-310 measures up to two quartz crystal sensors, and controls up

to two evaporation sources. Eight process control relays and eight digital inputs are

IPN 074-550-P1B

included to support a broad range of external devices. The number of sensors,

outputs, and digital I/O can be doubled with an optional expansion card. The

SQC-310C co-deposition instrument allows simultaneous deposition of up to four

materials. RS-232 and USB communications are standard, with Ethernet optional.

NOTE: Both the SQC-310 and SQC-310C are referred to as the SQC-310 in this

manual. If there is a reason to distinguish between the two models, the

SQC-310 or SQC-310C model number will be called out.

This chapter will aid you in the initial setup and operation of your system. Please

review the entire manual for detailed operational, programming, and safety

information.

1 - 1

Page 14

SQC-310 Operating Manual

Soft Keys Control Knob Remote Jack

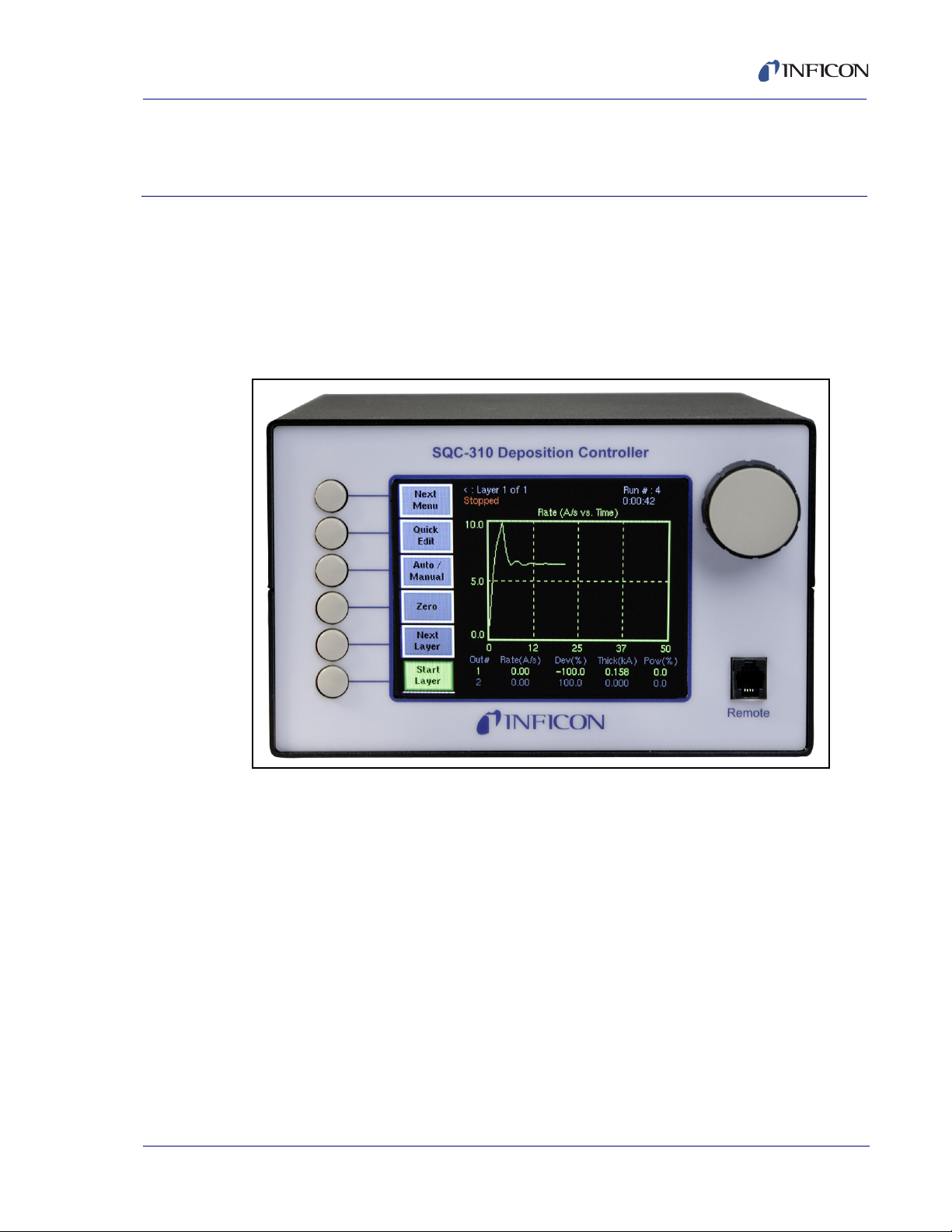

1.2 Front Panel

Figure 1-2 Front Panel Controls

Table 1-1 Front Panel Controls

SoftKeys Provide access to instrument operations and setup menus. The

functions of the SoftKeys change to adapt to different operations

and are displayed on the left of the screen.

Control

Knob

Remote

Jack

Used to adjust values and select menu items. Pushing the control

knob stores the current setting and moves to the next, similar to a

keyboard’s Enter key.

Connection jack for the optional handheld remote controller.

IPN 074-550-P1B

1 - 2

Page 15

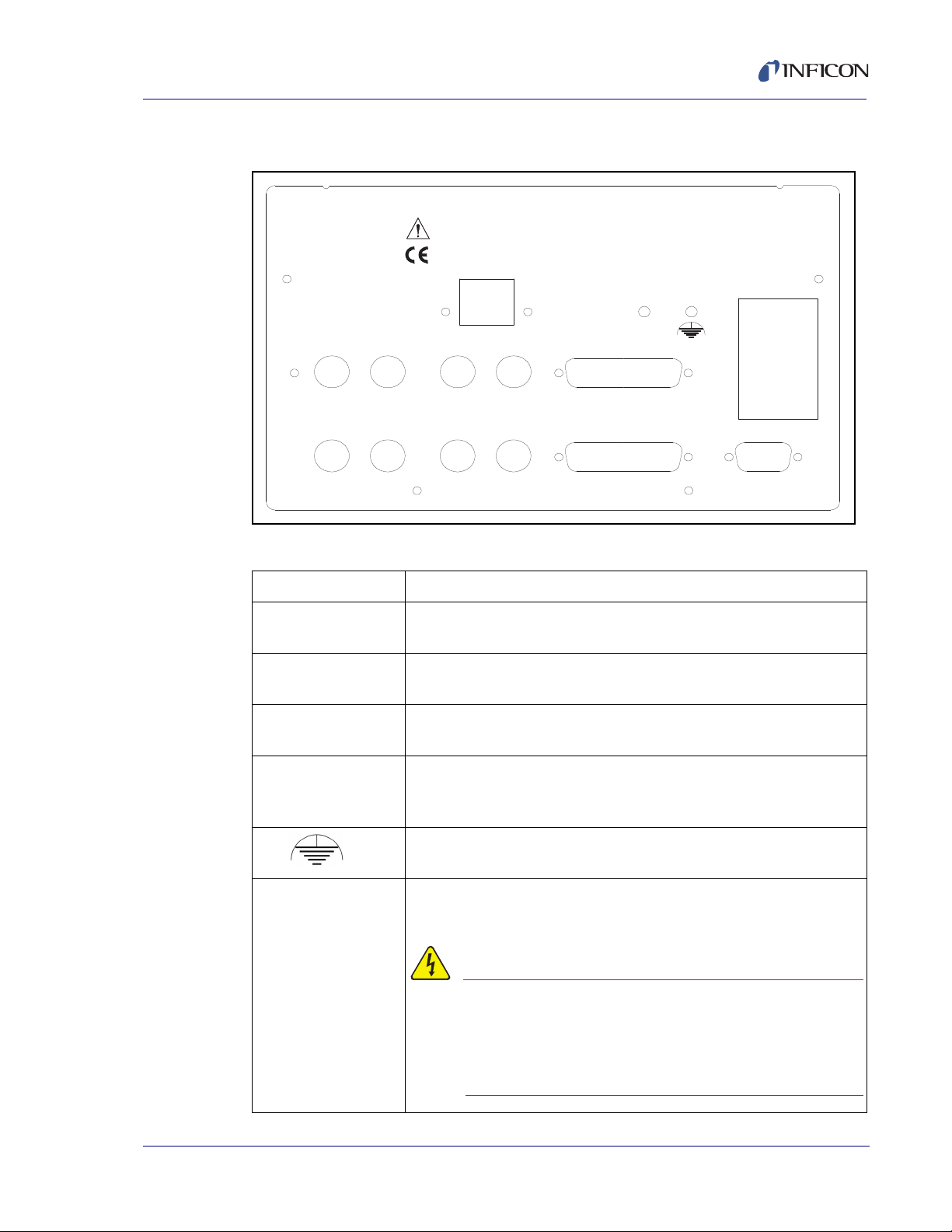

1.3 Rear Panel

WARNING - Risk Of Electric Shock

100-120/200-240 V~

50/60 Hz

25 VA

Sensor 1 Sensor 2 Output 1 Output 2

I/O 1-8

RS-232

Sensor 3 Sensor 4 Output 3 Output 4

I/O 9-16

Fuse T.5A 250V

SQC-310 Deposition Control ler

Serial No.

USB/Ethernet

Figure 1-3 Rear Panel

SQC-310 Operating Manual

Table 1-2 Rear Panel Connections

Sensor 1 & 2 Connects to the oscillator. See section 1.4 on page 1-4.

Output 1 & 2 Connects the SQC-310 output to your evaporation supply control

I/O (1-8) Connects 8 relays and 8 digital inputs to external equipment for

RS-232

USB or Ethernet

Sensor 3 & 4,

Output 3 & 4,

I/O 9-16

IPN 074-550-P1B

Power Input and

Fuse

input (see next section).

process control. See Appendix C.

Connects to a computer for programming and data acquisition.

RS-232 and USB are standard. Ethernet option replaces USB.

Increases the number of input, output, and digital I/O connections

when the optional expansion card is installed.

Measurement ground terminal useful for common system and

cable grounding.

Connects to mains power. The SQC-310 automatically detects

main voltages of 100-120 and 200-240 V (ac), 50/60 Hz

For continued protection, replace fuses

with the proper type and rating. Use

power cords only of the specified type

and rating, attached to a properly

grounded receptacle.

1 - 3

Page 16

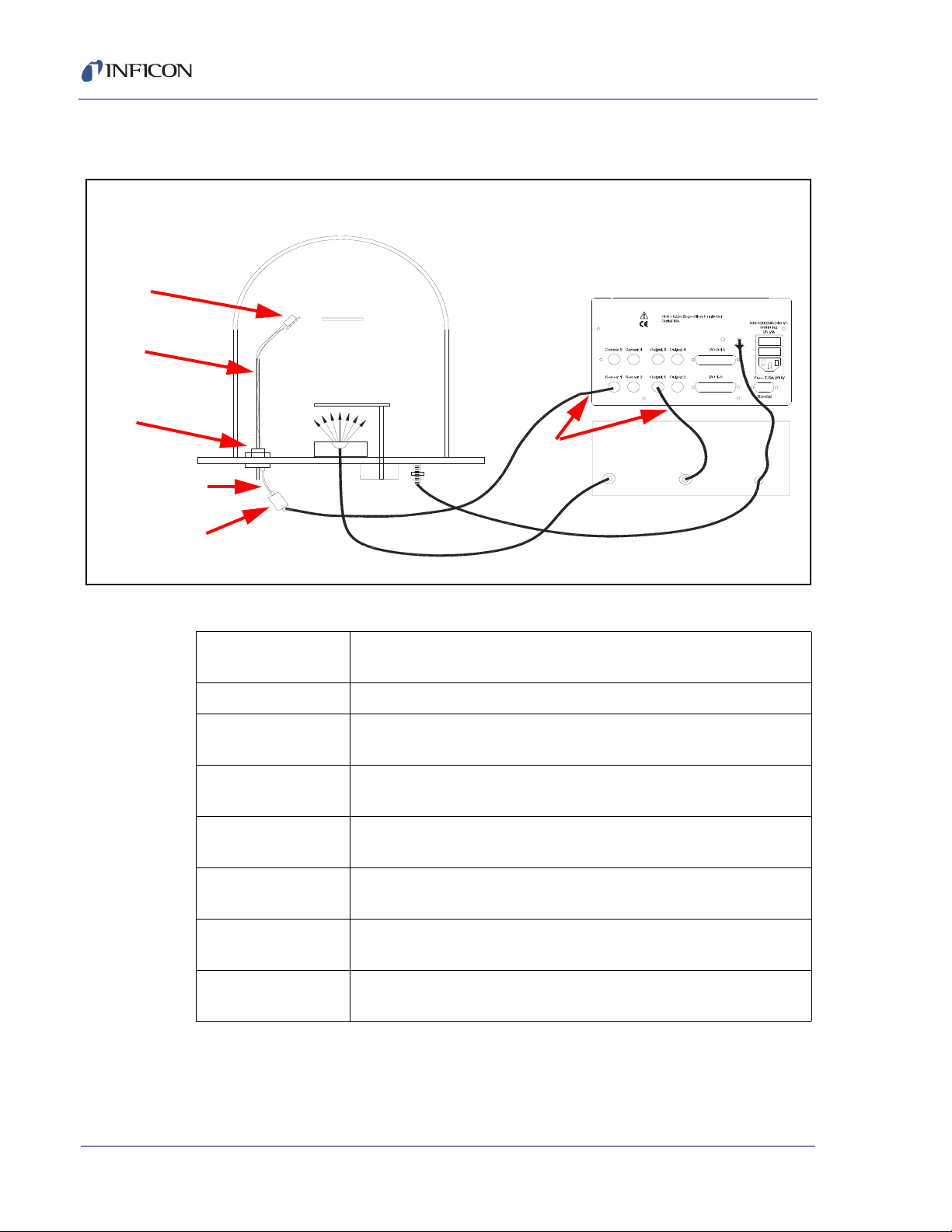

SQC-310 Operating Manual

Sensor

In-Vac

Cable

Feedthrough

6 in. BNC Cable

Oscillator

Source

Shutter

BNC

Cables

Evaporation Supply

Output

Control Input

Ground Wire

1.4 System Connections

Figure 1-4 System Connections

Table 1-3 System Components

Sensor Holds the quartz crystal used to measure rate and thickness.

Crystals must be replaced occasionally.

In-Vac Cable A coaxial cable that connects the sensor to the feedthrough.

Feedthrough Provides isolation between vacuum and atmosphere for electrical

and cooling lines.

6” BNC Cable Provides a flexible connection from the feedthrough to the

oscillator. Keep this cable as short as possible.

Oscillator Contains the electronics to operate the quartz crystal. Total cable

length to the crystal should be under 40 in.

Sensor Input

BNC Cable

Control Output

BNC Cable

Connects the oscillator to the SQC-310 sensor input. Lengths up

to 100 ft. are acceptable.

Connects the SQC-310 output to the evaporation source’s control

voltage input. Keep the length under 10 ft..

Ground Wire A wire, typically braided, that connects the vacuum system to the

SQC-310 ground terminal. Important for noise rejection.

IPN 074-550-P1B

1 - 4

Page 17

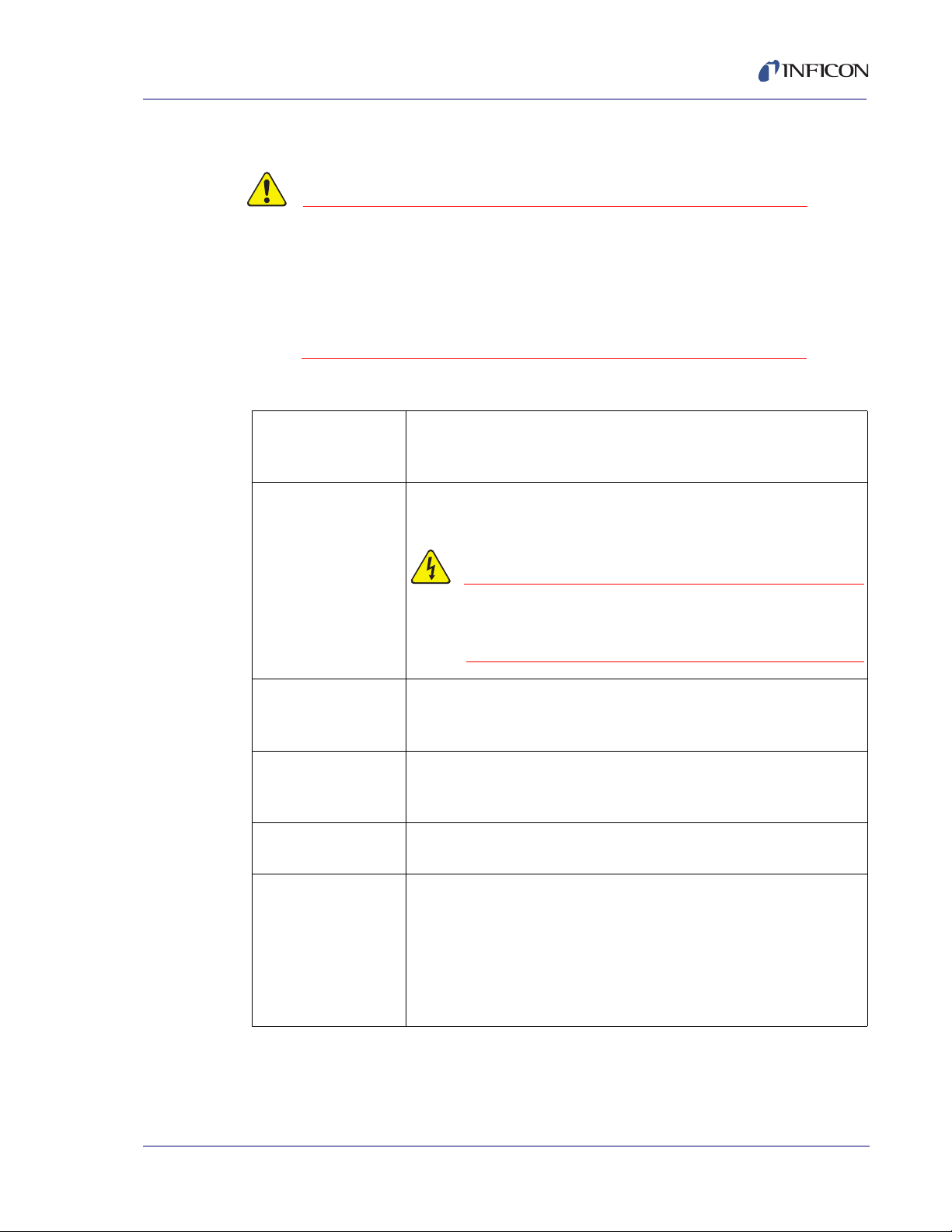

1.5 Installation

CAUTION

WARNING - Risk Of Electric Shock

Table 1-4 Installation

SQC-310 Operating Manual

Care should be exercised to route SQC-310 cables as far

as practical from other cables that carry high voltages or

generate noise. This includes other line voltage cables,

wires to heaters that are SCR-controlled, and cables to

source power supplies that may conduct high transient

currents during arc down conditions.

Rack

Installation

Power

Connection

Sensor Input

Connections

Source Output

Connections

IPN 074-550-P1B

Digital I/O

Connections

The SQC-310 occupies a 5.25 in. high, half-rack space.. An

optional installation kit (P/N 782-900-007) is available to adapt to a

full rack (see section 4.6 on page 4-3 ).

The SQC-310 automatically detects main voltages of 100-120 and

200-240 V (ac), 50/60Hz.

Verify that the power cable provided is

connected to a properly grounded mains

receptacle.

Connect the BNC cables and oscillators from your vacuum

chamber feedthrough to the desired SQC-310 sensor inputs. See

the previous section for cabling details.

Connect the BNC cables from the SQC-310 output connectors to

your evaporation supply control input. Consult your Power Supply

operator’s manual for control input wiring instructions.

Refer to Appendix C for details on wiring digital I/O to the SQC-310

Relay I/O connectors.

Computer

Connection

If you want to collect data or program the SQC-310, attach a

straight-thru RS-232 cable from the RS-232 connector to your

computer’s serial port.

You can also communicate via USB using a standard USB cable. If

you ordered the Ethernet option, the USB connection is replaced

with an RJ-45 Ethernet connector.

1 - 5

Page 18

1.6 Menus

Process 1 : Layer 1 of 1 Run # :0

0.0

50.0

100.0

0.0

6.2

12.5

18.8

25.0

Power ( % vs. Time)

Out#

1

2

3

4

Rate(A/S)

0.00

0.00

0.00

0.00

Dev( %)

00.0

00.0

00.0

00.0

Thick(kA)

0.000

0.000

0.000

0.000

Pow( %)

0.0

0.0

0.0

0.0

Stopped

0:00:00

SQC-310 Operating Manual

At power up the SQC-310 briefly displays the model number (SQC-310 or

SQC-310C) and firmware version information, then the Main screen. See Figure

1-5.

NOTE: If you are prompted for a password, use the switches along the left of the

screen to enter the password. The top switch is “1”, the bottom switch is

“6.” The Control Knob switch is "7." See section 5.3.3, Get/Set System

Parameters, on page 5-5 for password setup information.

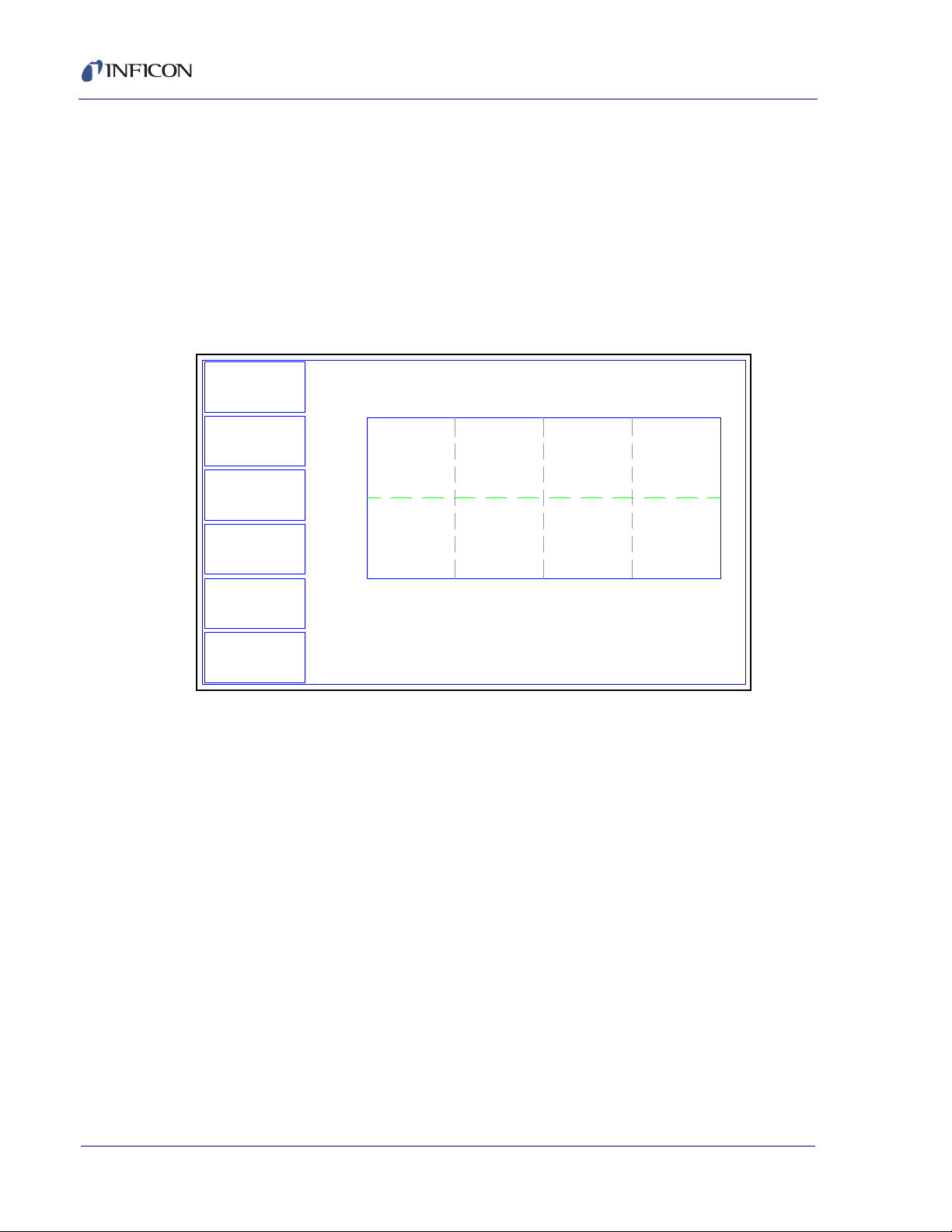

Figure 1-5 Main Screen

Next

Menu

Quick

Edit

Auto /

Manual

Zero

Next

Layer

Start

Layer

The first line of the Main screen shows the name of the currently selected process.

After the process name are the layer that will run when the Start SoftKey is pushed,

and the total number of layers in the process. Further to the right is the number of

times this process has been run.

The second line of the Main screen is a status line. It displays the current phase

of the deposition cycle, and other status or error messages. When the process is

running, the right side of this line shows the process elapsed time.

Three graphs are possible: rate, rate deviation, and output power. The graphs

scale the vertical axis and scroll the horizontal axis based on the data displayed.

Below the graph are two lines that show deposition readings (four lines if the option

card is installed). This section shows current rate, rate deviation, thickness, and

output power as shown above. Alternatively it can show measured rate and

thickness versus rate and thickness setpoints.

IPN 074-550-P1B

1 - 6

The six SoftKey legends along the left side of the screen will change, depending

on the status of the process and the functions you select. Press Next Menu to

display alternate main screen menus. See Figure 1-6.

Page 19

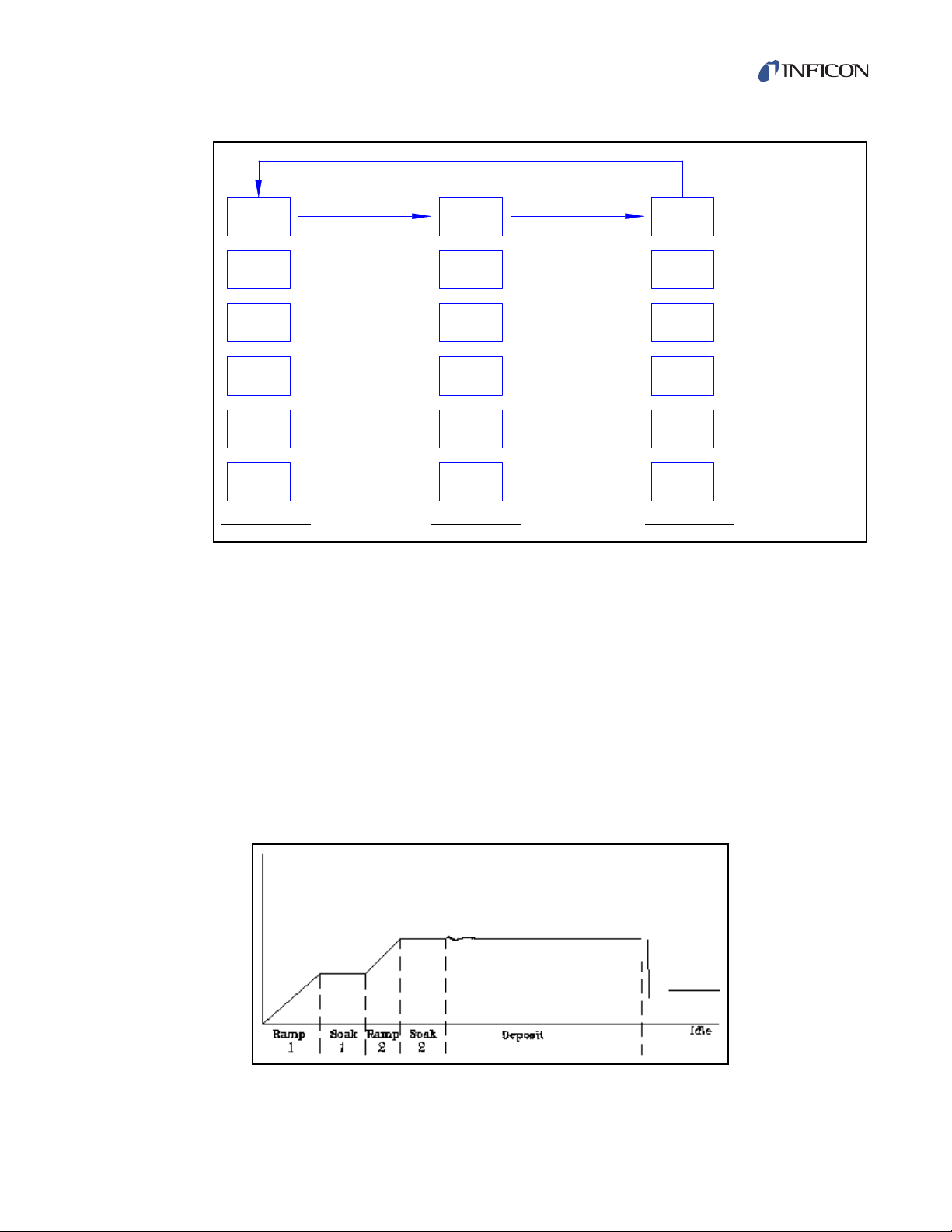

Figure 1-6 Alternate Main Screen Menus

Next

Layer

Start

Zero

Auto /

Manual

Next

Menu

Quick

Edit

Start

Next

Layer

Sensor

Info

Next

Display

Next

Graph

Next

Menu

Start

System

Menu

Film

Menu

Process

Menu

Next

Menu

Zero the thickness

reading on all

channels.

Switch between PID

and Manual power

control.

A

commonly edited

settings.

Select the next layer

in the process.

Start or Stop the

selected layer.

Switch graph between

rate, deviation, and

power.

Switch the readout

below the graph.

Display detailed

sensor information.

Select the next layer

in the process.

Start or Abort the

process.

Start the selected

layer.

Modify instrument

related settings.

Create or edit films to

be used as layers.

Create or edit process

layers.

Third menu available only

Layer

SQC-310 Operating Manual

Main Menu 1

ccess the most

Main Menu 1

Main Menu 2

Main Menu 2

Main Menu 3

when process is stopped.

Main Menu 3

Because Main Menu 3 provides access to functions that can completely redefine a

process, it is available only when the process is stopped.

IPN 074-550-P1B

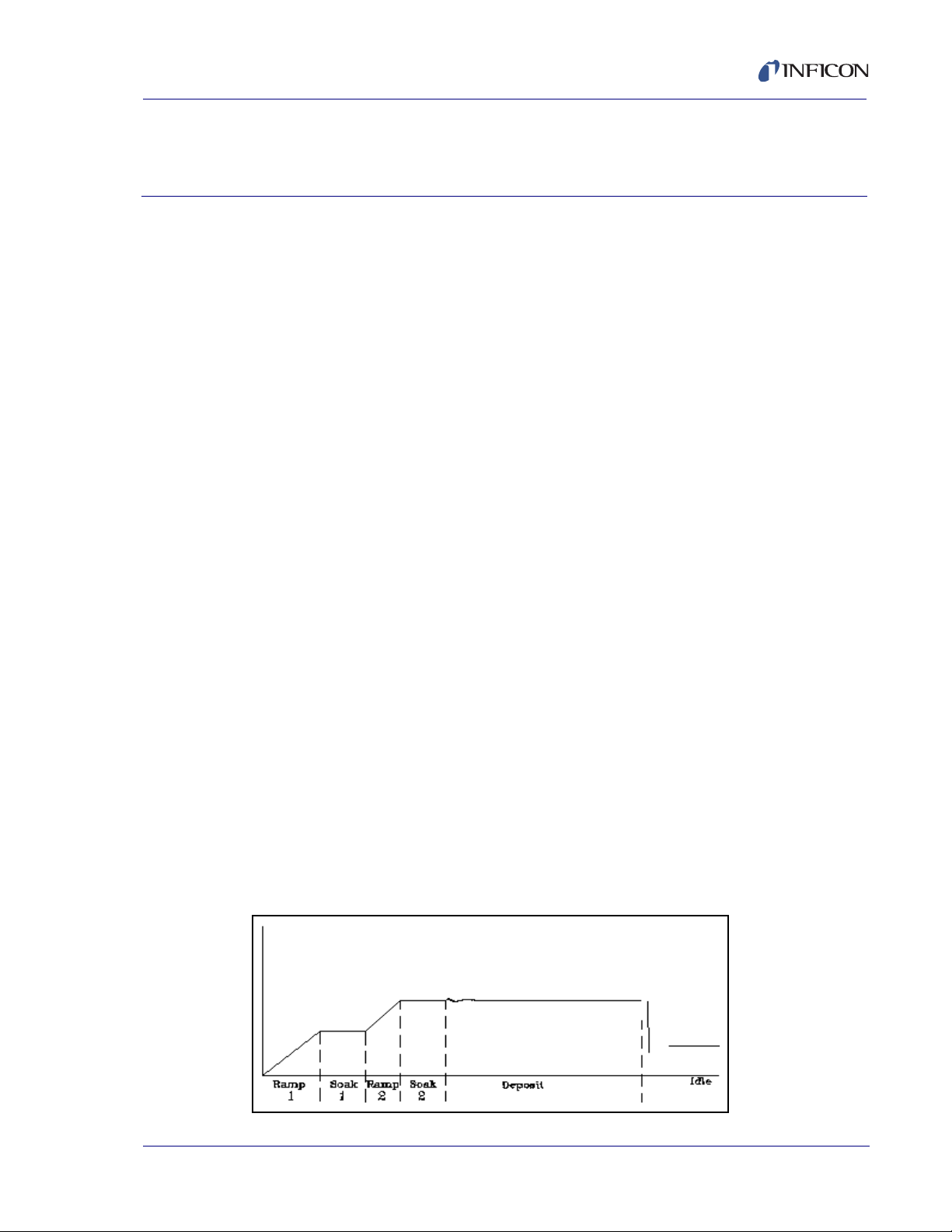

1.7 Thin Film Deposition Overview

Spend some time now moving between the three menus. Pay particular attention

to the effects that the Main Menu 2 selections have on the display. We will cover

the setup parameters of Main Menu 3 in the Building a Process section.

The SQC-310 stores the recipes, and provides the operating functions, required to

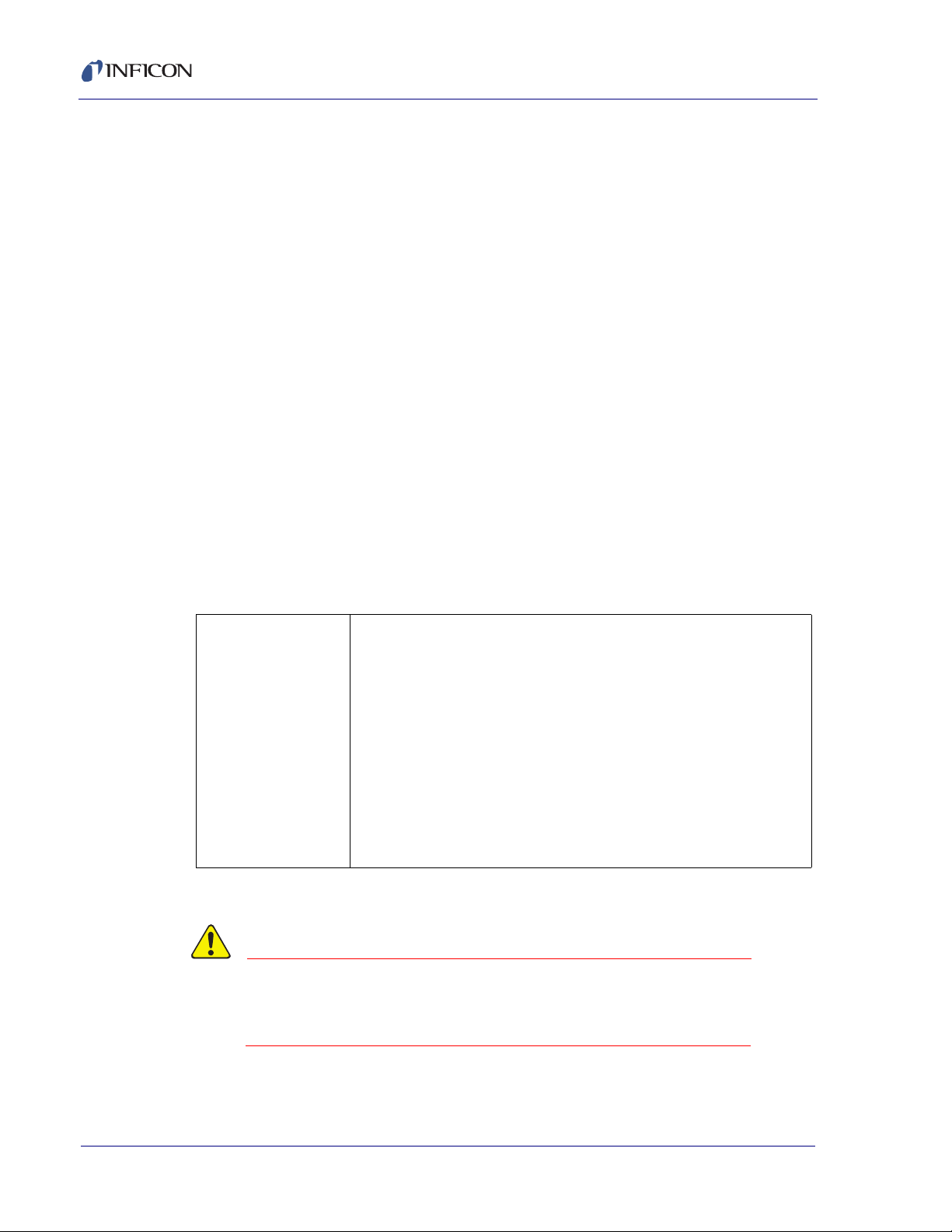

control thin film deposition processes. A typical thin film deposition cycle is shown

in Figure 1-7.

Figure 1-7 Typical Thin Film Deposition Cycle

1 - 7

Page 20

SQC-310 Operating Manual

CAUTION

The cycle can be broken into three distinct phases:

Pre-conditioning (ramp/soak)

Deposition

Post-conditioning (feed/idle)

During pre-conditioning, power is supplied in steps to prepare the evaporation

source for deposition. Once the material is near the desired deposition rate,

material deposition begins.

During deposition, the PID loop adjusts the evaporation source power as required

to maintain the desired rate. In Co-deposition, multiple films can be deposited

simultaneously.

When the desired thickness is reached, the evaporation source is set to idle power.

At this point the process may be complete, or deposition of another layer may

begin.

1.8 Building a Process

This section presents a brief guide to building and running a simple one layer

process. Chapter 2 covers instrument operation in much greater detail.

Table 1-5 Create a Film

Create a

Film

A film is a material to be deposited, and its associated deposition

settings. Initially the list of films may be empty.

Press Next Menu until the Film Menu SoftKey is displayed. Press

Film Menu to view a list of stored films. Turn the control knob to

scroll to an entry in the list that is currently labeled <Empty>.

Press the Create SoftKey to create a default film at that location.

Note the film number that you just created. For now, accept the

default film parameters.

Press Main Screen to return to the main screen.

Be sure to exit to the Main Menu before powering the

instrument down if you have made changes to settings.

Your changes may not be saved otherwise.

IPN 074-550-P1B

1 - 8

Page 21

SQC-310 Operating Manual

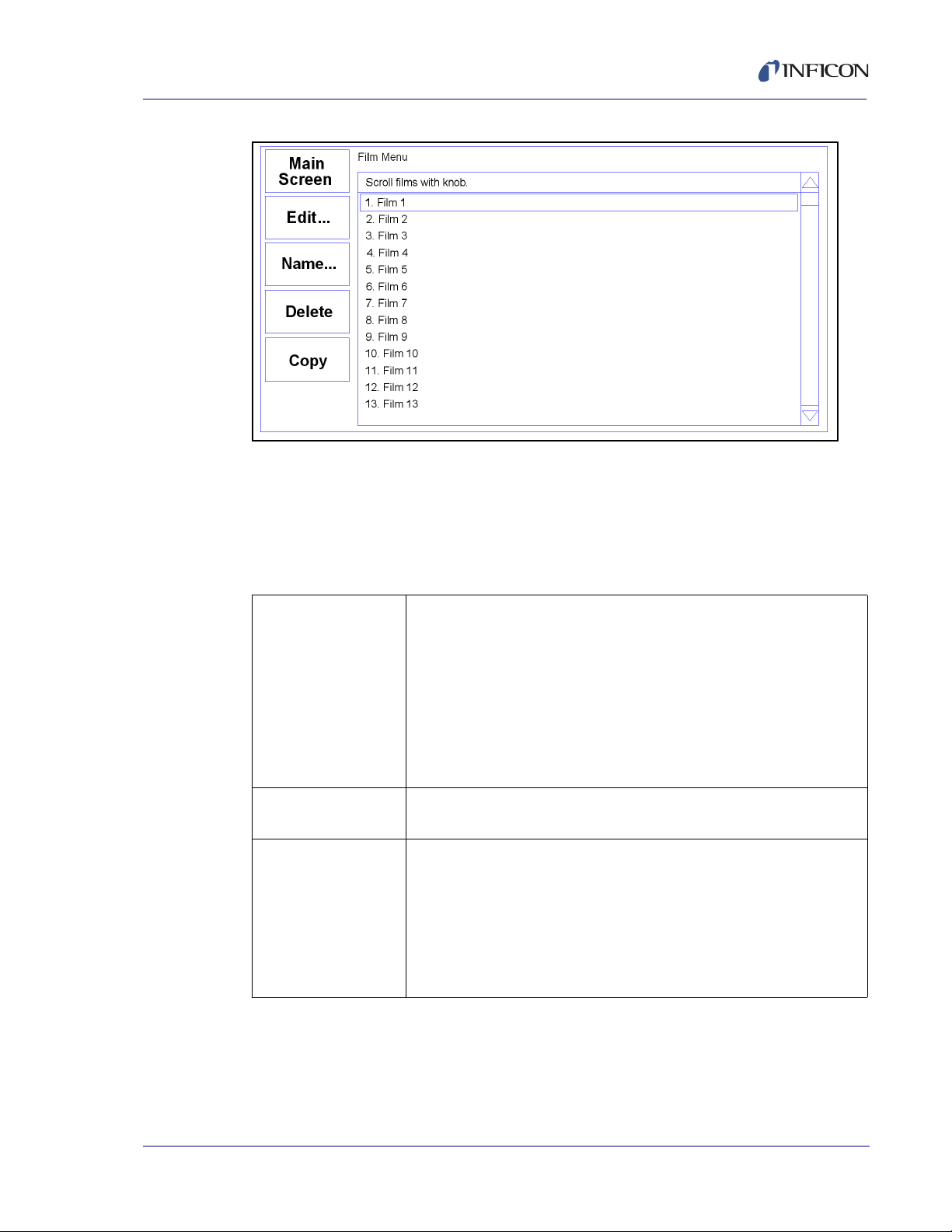

Figure 1-8 Film Select Menu

NOTE: Films are numbered from 1 to 50. Film names and process names can be

changed by pressing the Edit Name SoftKey.

Now that we are sure that at least one film exists, we will build a simple single layer

process using that film.

Table 1-6 Building a Layer

Select

Press the Process Menu SoftKey to view a list of processes.

Process

Turn the control knob to scroll to an entry in the list that is labeled

<Empty>.

Press the Create SoftKey to create a default process at that

location.

Press the Select SoftKey to make the selection the active process.

Edit Press the Edit SoftKey to view a list of layers in the selected

process. The layer list should be blank.

IPN 074-550-P1B

Edit

Layer

Press Insert New..., then scroll down the list of films to the film you

just created.

Press Insert Normal to insert the selected film as Layer 1. The

display returns to the Layer Select menu.

NOTE: On SQC-310C, Insert Codep is also available to create

Co-deposited layers.

1 - 9

Page 22

SQC-310 Operating Manual

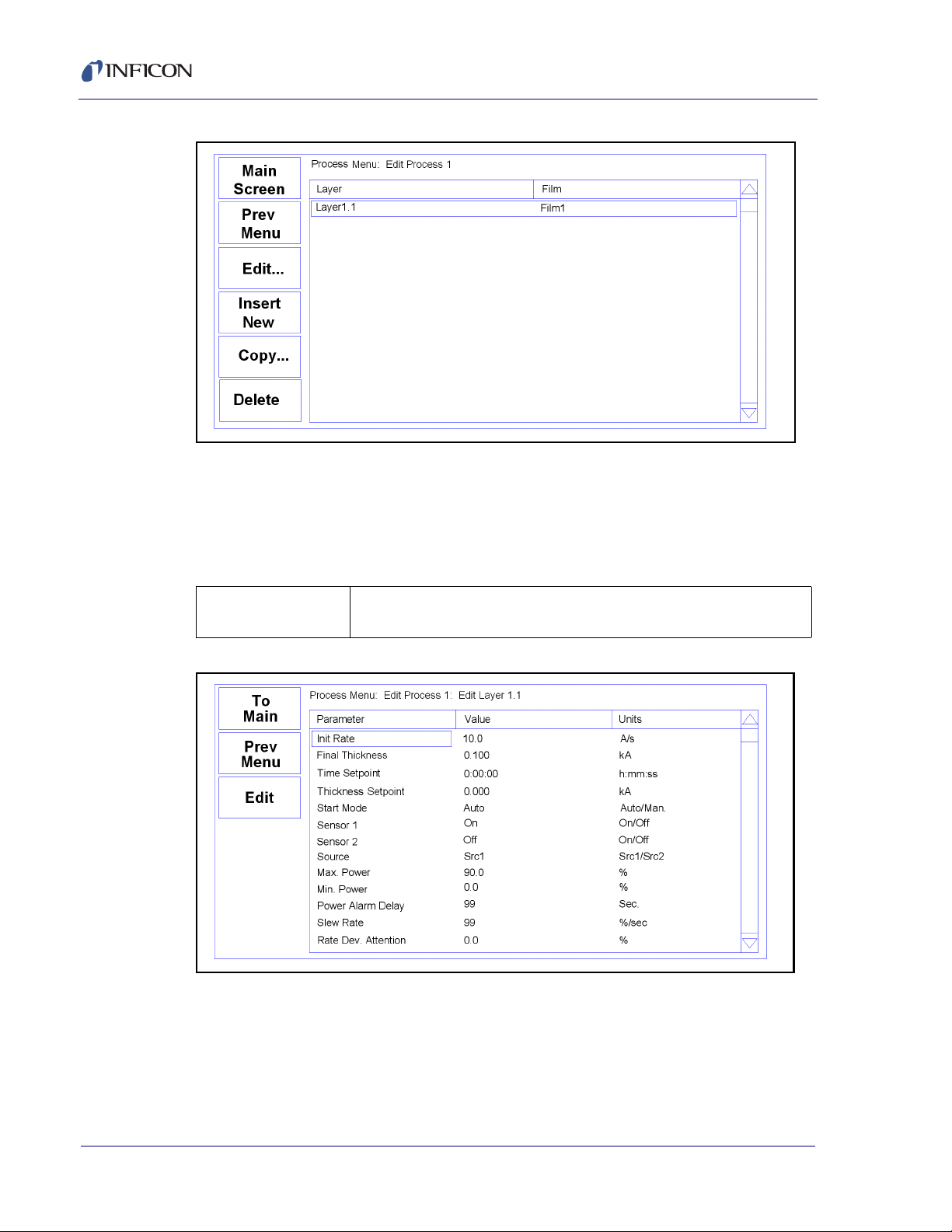

Figure 1-9 Layer Select Menu

A process consists of one or more layers. Each layer can have a different film, or

even multiple films (Co-deposition). For this example, we will stop with only a

single layer. Layers are displayed as "Layer x.y", where x is the layer number and

y is the source number assigned to the layer.

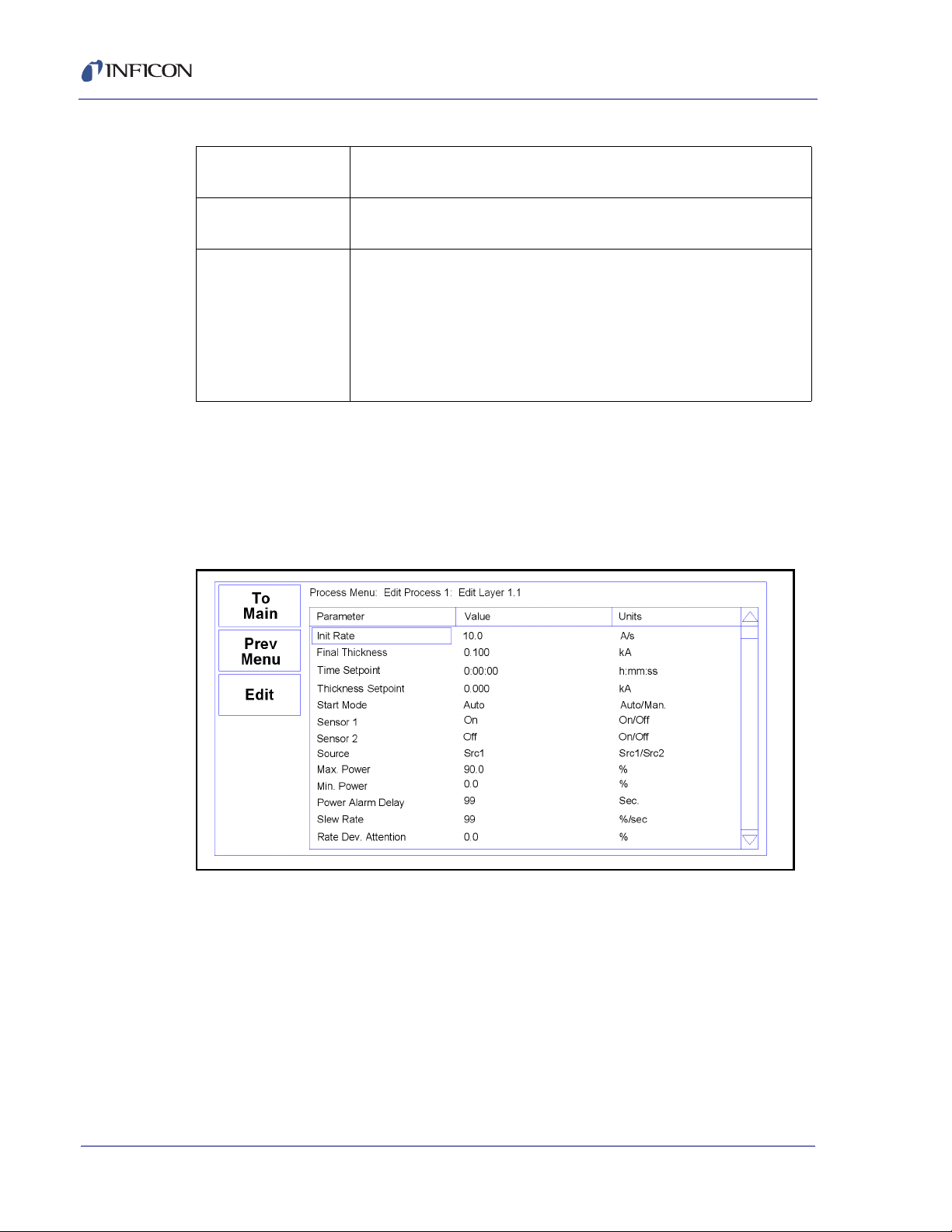

Table 1-7 Edit Layer

Edit

Layer

Figure 1-10 Edit Layer Menu

With Layer 1.1 selected, press Edit to display the Layer Edit menu

for Layer 1.1.

IPN 074-550-P1B

1 - 10

Page 23

Table 1-8 Editing a Setting

SQC-310 Operating Manual

Edit Menu

Operation

To edit a setting in any menu, turn the control knob to scroll to the

desired setting, then press the Edit SoftKey. The cursor moves to

the setting value, and the SoftKey functions change to show:

Next: Store the parameter and move to next parameter for editing.

Cancel: Stop editing and return the selected parameter to its

previous value.

Enter: Stop editing and save values for selected parameter.

In Edit mode, adjust the control knob to set the desired parameter

value.

Edit

Layer 1

Spend some time navigating through the Layer 1 parameters and

editing values. Be sure to enter an Initial Rate and Final Thickness,

and select a Source and Sensor(s).

Press To Mai n to return to the Main Screen.

We have completed the design of a single layer process.

IPN 074-550-P1B

1 - 11

Page 24

SQC-310 Operating Manual

CAUTION

1.9 Depositing a Film

NOTE: You can simulate the steps below, without actually depositing a film, by

going to the System Menu and selecting Simulate Mode ON. Simulate

mode is useful for testing processes before applying power to the

evaporation supply. See section 3.11 on page 3-19 for detailed System

Menu information.

Table 1-9 Depositing a Film

Verify Sensor

Operation

Show

Power Graph

Verify Output

Operation

Press Next Menu until the Sensor Info option is shown.

Press Sensor Info to display the quartz sensor readings. Sensor 1

should be ON and display a % life of over 50%. If not, check your

sensor connections (see section 1.3 - section 1.5), and refer to

Min/Max Frequency (System Menu, see section 3.11).

Press Exit to return to the main screen.

Press the Next Graph SoftKey until the graph shows Power (% vs.

Time).

Press the Next Menu SoftKey until the Auto/Manual SoftKey is

displayed. Now press Auto/Manual until Manual/Auto is displayed.

Press Start Layer to begin deposition in manual mode.

Slowly turn the control knob to increase the control voltage to your

evaporation supply. Verify that the Power(%) reading for Output 1

(lower right, below graph) approximates the actual output of your

evaporation supply. If not, check your hookup (see section 1.3 -

section 1.5), and refer to Scale Voltage (section 3.11.3.2).

1 - 12

Observe the output power versus your

evaporation supply’s actual output. If

there is a problem, press the Stop

SoftKey immediately.

Enter

Auto Mode

Press the Next Menu key until the Manual/Auto SoftKey is shown.

Press Manual/Auto to change the SoftKey display to Auto/Manual.

This places the output under PID deposition control.

Press Stop at any time to halt deposition and set output power to

zero.

Please take time to review the remainder of this manual for detailed operational,

programming, and safety information.

IPN 074-550-P1B

Page 25

2.1 Introduction

This chapter describes common tasks associated with operating the SQC-310. It

assumes that you understand basic operation of the menus and parameter setup

as described in Chapter 1, Quick Start. Detailed definitions of each parameter can

be found under the appropriate menu description in Chapter 3, Menus.

2.2 Definitions

Several terms will be used repeatedly throughout this manual. It is important that

you understand each of these terms.

Material: A physical material to be deposited. A database of 100 materials is stored

in the SQC-310. Three parameters completely define a material: Name, Density,

and Z-Ratio (also called Z-Factor). A table of common materials, their densities,

and Z-Ratios is listed in Appendix A.

Film: A film describes in detail how a material will be deposited. It includes the

material definition and all of the preconditioning, deposition, and post conditioning

variables necessary to accurately deposit the material. Because the film definition

does not include rate and thickness information, a single film can be used in several

different layers and processes. The SQC-310 stores up to 50 films.

SQC-310 Operating Manual

Chapter 2

Operation

Layer: Layers are the basic building blocks of processes. A layer consists of a film

and the thickness and rate setpoints for that stage of the process. Layers also

define which outputs and sensors will be used at that point in the process.

Co-deposition of multiple films occurs when more than one output is active during

a layer.

Process: A process is a sequence of layers to be deposited. The SQC-310 can

store up to 100 processes, consisting of a total of 1000 layers.

Phase: A step in the deposition cycle. Preconditioning phases include Ramp 1,

IPN 074-550-P1B

Soak 1, Ramp 2, and Soak 2. Deposit phases include indexer rotate, shutter delay,

deposition, and deposition rate ramps. Post-conditioning phases include Feed

Ramp, Feed, and Idle Power.

Figure 2-1 Phase

2 - 1

Page 26

SQC-310 Operating Manual

2.3 Defining a Film

A film is a material to be deposited, plus all of its associated setup parameters.

Keep in mind that a film can be used in multiple layers, or even multiple processes.

Editing a film’s parameters will cause changes to every location where the film is

used.

To define a film, press Next Menu until Film Menu is shown (Menu 3). Press Film

Menu. A list of 50 films (or <Empty>) will be displayed. To define a new film, scroll

to <Empty> and press Create. To change the name of a film, scroll to the film and

press Edit Name. Scroll through the character set and Insert each character for

the film name. Press Save to return to the Film Menu. Press Edit to display the

parameters for this film.

Figure 2-2 Film Edit Menu

2 - 2

P Term is the proportional gain, which is the % process rate change divided by the

% input power change. The I Term (integral) sums the rate deviations over time to

more accurately achieve the rate setpoint. The D Term (derivative) speeds

response to sudden changes in rate. Volumes have been written on determining

the proper PID settings. See section 2.8 on Loop Tuning later in this chapter for a

common PID loop tuning procedure. Start with P=25, I=.5, D=0.

Film Tooling adjusts for differences in actual versus measured thickness for this film

(material). This parameter is seldom used, but can adjust for material specific

dispersion patterns. See Xtal Tooling in the System menu for the more commonly

used tooling correction.

Pocket selects the source pocket used for this film. This parameter requires that

the System Menu, Source Setup be configured for an indexer (Sensors and

Sources Menu, see section 3.11.3).

The next chapter will cover Crystal Quality and Stability. For initial operation leave

Quality and Stability disabled.

IPN 074-550-P1B

Page 27

SQC-310 Operating Manual

With Material highlighted, press Edit to scroll through the list of available materials.

Select the desired material and press Enter. You could also change the Density

and Z-Ratio for the selected material, but it is unlikely those values are wrong. You

cannot add materials, but you can edit the Name, Density, and Z-Ratio of one of

the 100 existing materials.

Film conditioning adjusts the output power level to achieve a desired material state

before and after deposition. Press Film Conds to enter the film conditioning menu.

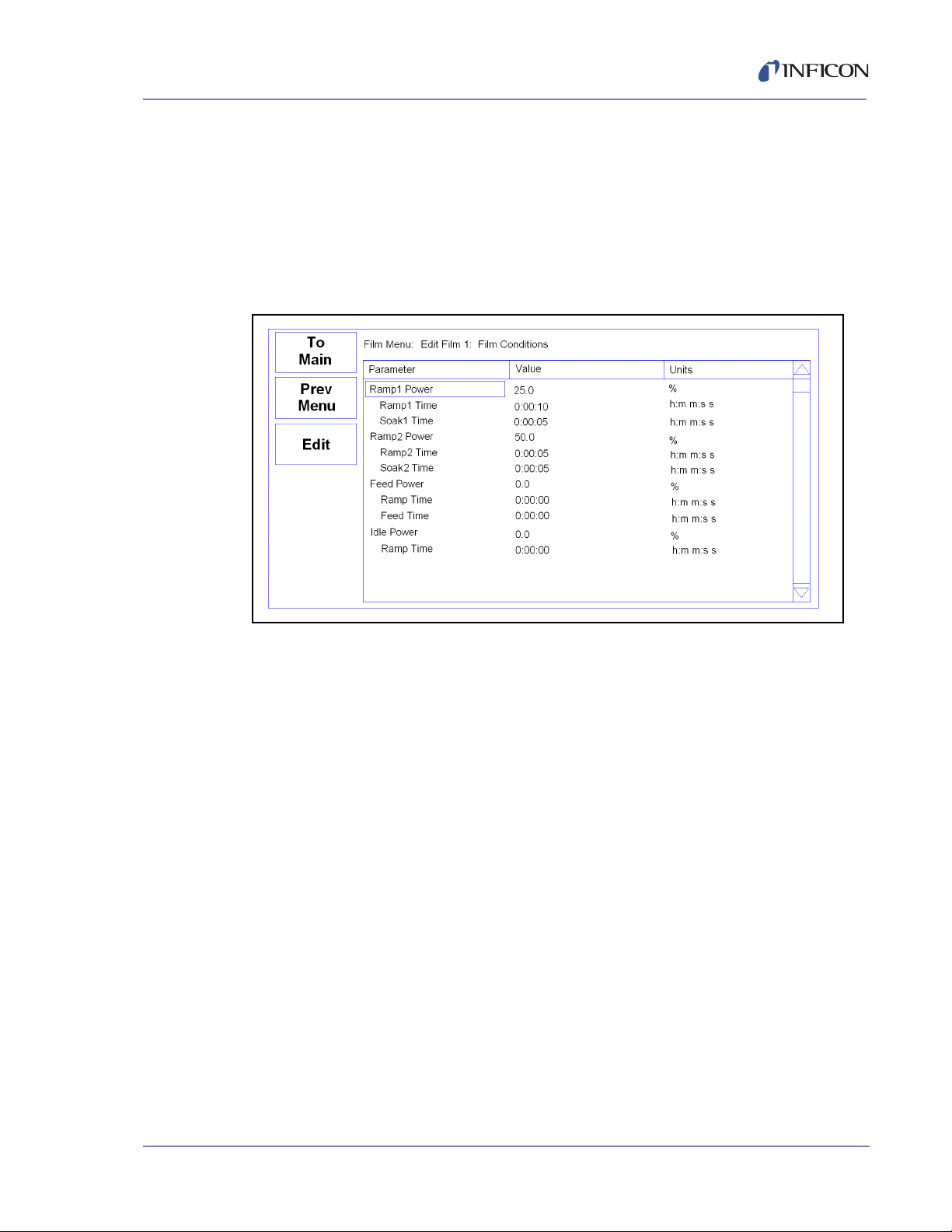

Figure 2-3 Film Conditioning Menu

Ramp1 starts at 0% power and increases the power during Ramp1 Time to the

Ramp 1 power level. Set the Ramp 1 Power and Time to gradually bring the

material to a near molten state. Set the Soak 1 Time to a value that will allow the

material to homogeneously achieve that state. Ramp 2 is used to slowly bring the

material to a power level that nearly matches the desired deposition power. Use

Soak 2 to hold the material at that level until deposition (i.e., rate control) begins.

If you use wire feed to replenish material after deposition, set the Feed Power and

times as required. The idle conditioning phase typically ramps output power back

IPN 074-550-P1B

toward zero at the end of a process.

From the Film Conds menu, press Prev Menu to return to the main Film Menu.

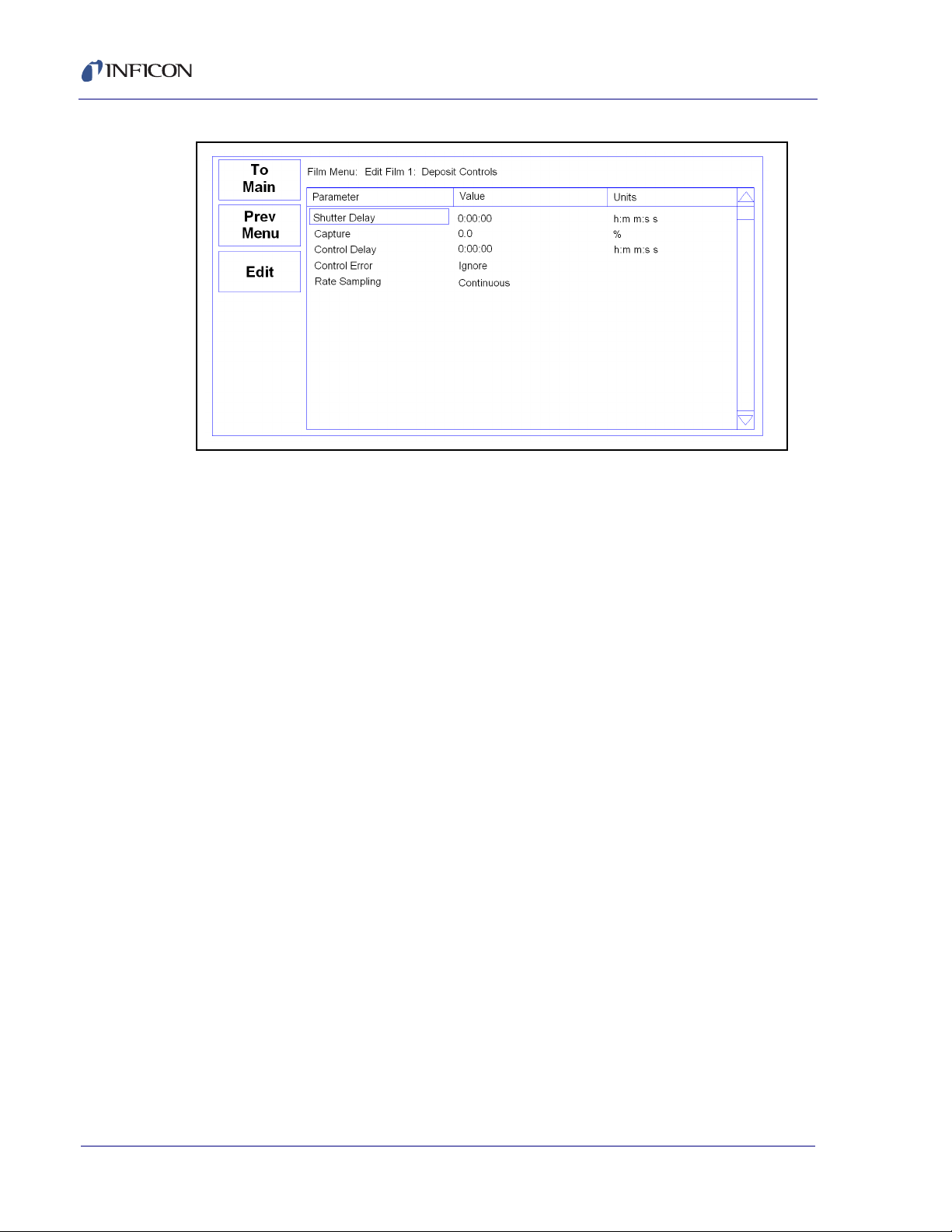

Now press Deposit Controls. The Deposit Controls menu contains parameters

that modify operation during the deposition phase. See Figure 2-4.

2 - 3

Page 28

SQC-310 Operating Manual

Figure 2-4 Deposition Controls Menu

Shutter delay causes the SQC-310 to delay opening the shutter until the process

has stabilized at the desired deposition rate. Capture is the % rate deviation that

must be achieved to open the shutter and go to the Deposit phase. Shutter delay

is the maximum amount of time to wait for capture to be achieved. Set Shutter

Delay and Capture to zero to disable this feature.

NOTE: During co-deposition, the SQC-310 waits for all films to achieve capture

before moving to the deposit phase. If any film fails to achieve rate capture

within its programmed shutter delay time, an error occurs.

When the Control Delay function is used, the control loop will not react to the rate

for a set amount of time at the beginning of the Deposit state. This helps to

eliminate overcompensation by the control loop due to rate spikes when the sensor

or source shutter opens. Control Delay is the amount of time the SQC-310 will wait

before the control loop takes over.

Control Error is a setting that instructs the SQC-310 what to do if it is unable to

maintain the desired deposition rate (for example, out of material or a bad sensor).

One of three actions is possible: Keep trying (Ignore), set power to zero to halt

deposition (Stop), or maintain constant power (Hold) and extrapolate thickness

from the last good rate reading. Until your process is known and stable, it is best to

leave the Control Error setting on Ignore.

Rate sampling can extend sensor life in high rate processes. Select Cont

(continuous) to disable rate sampling. A Time selection closes the shutter for a

fixed time, then opens the shutter for a fixed time to sample the rate. Acc Based

(accuracy based) sampling closes the shutter for a fixed time, then opens the

shutter until the desired rate is achieved. Rate Sampling assumes a very stable

process!

IPN 074-550-P1B

2 - 4

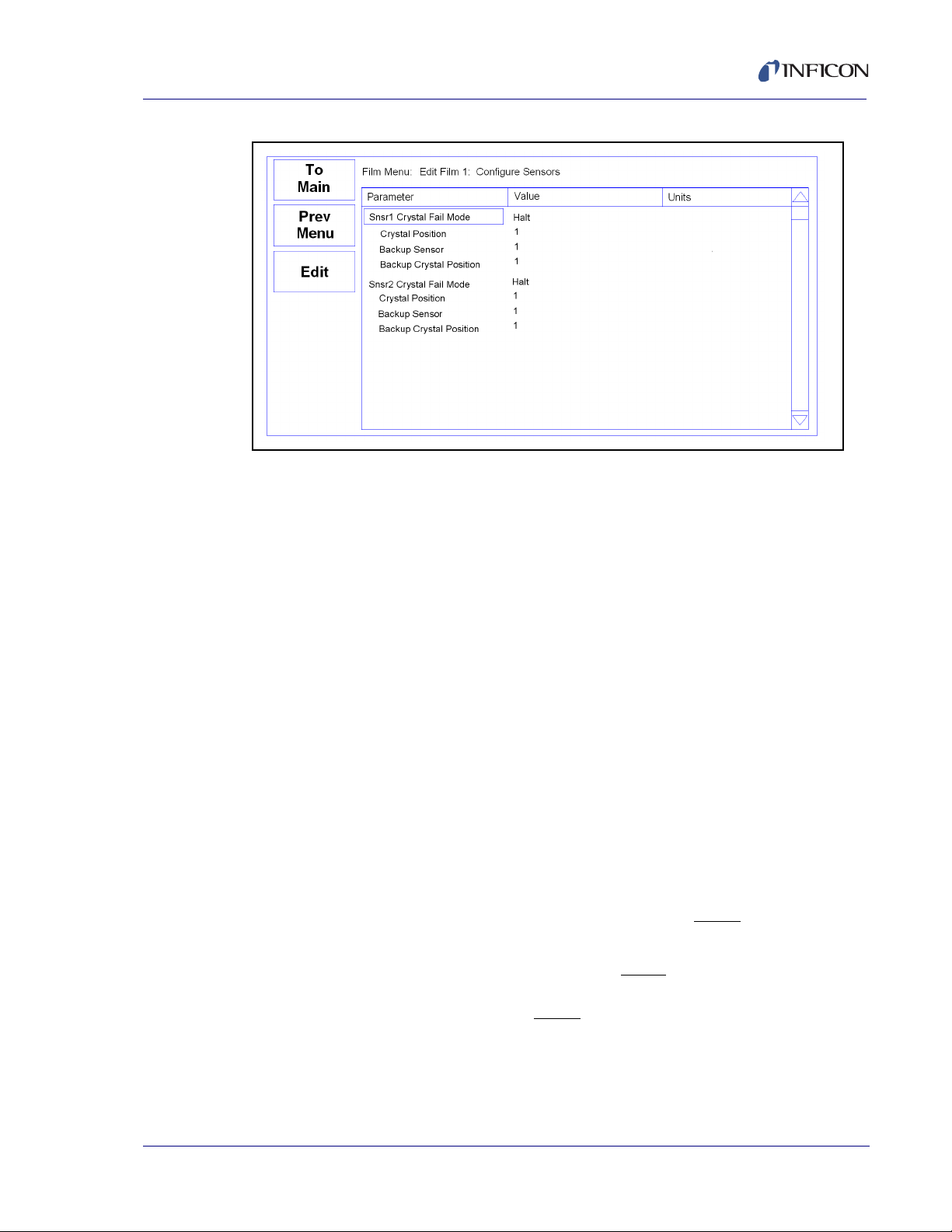

Now, from the main Film Menu, press Configure Sensors. This menu defines

operation of the film when a sensor fails. See Figure 2-5.

Page 29

SQC-310 Operating Manual

Figure 2-5 Configure Sensor Menu

Crystal Fail mode selects the action taken when a sensor crystal fails. Select Halt

to halt the process on failure. Select Halt Last if multiple sensors are used for this

film. Select Timed Power to enter Timed Power mode using the last good

rate/power measurements. Select Switch to Backup to switch to a backup crystal.

The next three parameters define which position of a multi-crystal sensor is used

as the primary, and which is the backup. The number of sensor positions displayed

is determined by the sensor configuration on the Sensors & Sources screen of the

System Menu.

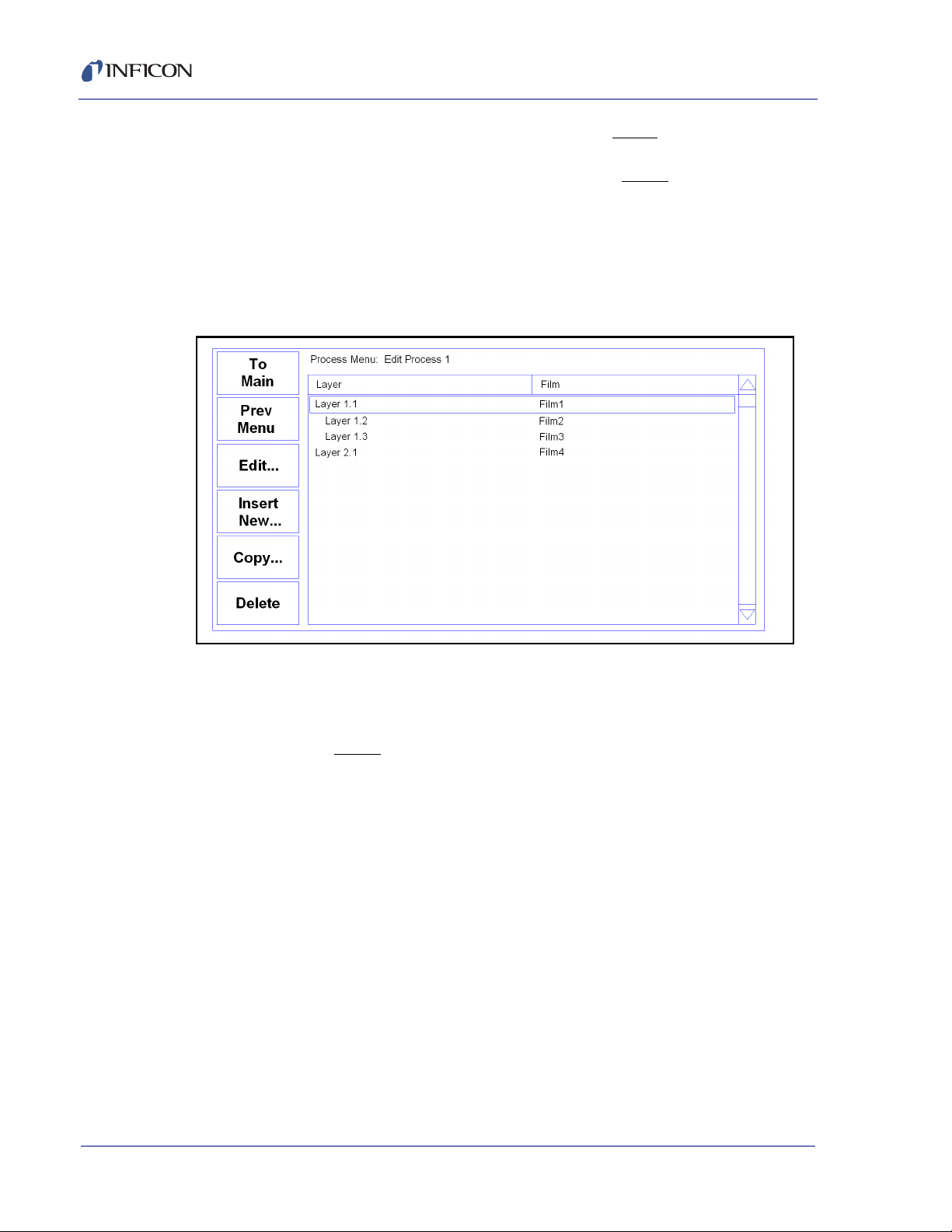

2.4 Defining a Process

To define a process, press Next Menu until the Process Menu SoftKey is shown.

Press Process Menu. A list of 100 processes (or <Empty>) will be displayed. To

define a new process, scroll to <Empty> and press Create. A new Process# is

added to the list of existing processes. Press Edit Name to change the process

name.

IPN 074-550-P1B

Press Select, then Edit to display the sequence of layers and films that comprise

the selected process. To add the first layer, press Insert New. Select a film from

the films screen and press Insert Normal. To add more layers, scroll to below the

last layer and press Insert New. Layers are always added above

the selected

layer.

To insert a layer in a sequence of layers, scroll to below

the desired location in the

layer sequence, and press Insert Normal. Select a film from the list and press

Insert Normal to insert the new layer above

the selected layer. The selected layer

and subsequent layers will be shifted down.

HINT: When building a process it may be easiest to add a “dummy” last layer and

keep inserting above that layer. When the process is complete, delete the

“dummy” layer.

2 - 5

Page 30

SQC-310 Operating Manual

To add a Codeposited film to an existing layer, scroll to below the desired

Co-deposition layer. Press Insert New, select the desired film, then press Insert

CoDep. The Codeposited film will be inserted in the layer above

the selected layer,

and indented to show that it is a Co-deposition film. CoDep is available only on the

SQC-310C.

Figure 2-6 shows two films being Codeposited with Film1, then a fourth film being

deposited as an additional layer. While layers are always numbered sequentially,

the films are sequential only for this example. Any film can be used in any layer.

Figure 2-6 Edit Layer Menu

To delete a layer, highlight it in the Layer Select menu and press Delete.

To move or duplicate a layer, highlight it in the Layer Select menu and press Copy.

On the Paste menu, press Paste to replace a layer. Press Insert Normal or Insert

CoDep to insert it above the highlighted layer. A copy of the layer is saved to the

cut/paste clipboard memory.

NOTE: Once a film is assigned to a process layer, you cannot change the film.

Instead, cut the layer, then insert a new layer and select the desired film.

IPN 074-550-P1B

2 - 6

Page 31

2.5 Defining a Layer

To edit a Process Layer, press Process Menu. Select the desired process,

then press Edit. Finally, select the desired layer and press Edit....

Figure 2-7

SQC-310 Operating Manual

Initial Rate and Final Thickness are the main process setpoints for the film used in

this layer. Time Setpoint and Thickness Limit are secondary values that can

activate a relay when they are reached.

Start Mode controls operation in multi layer processes. In Auto Start the layer starts

immediately on completion of the previous layer. Manual Start waits for a user

signal via the front panel, digital input, or communications port to start the layer.

Don’t confuse this Manual Start mode with the Manual Power SoftKey function.

The SQC-310 can use multiple sensors to measure a film’s deposition rate and

thickness. If multiple sensors are selected, an average of the sensors is used. Set

each sensor that will be used to measure this film to ON.

The Source entry assigns the layer to a specific SQC-310 rear panel source output.

The layer (and associated film parameters) will be applied to the selected output.

IPN 074-550-P1B

Assign the Max, Power, Min. Power, Power Alarm Delay and Slew Rate

appropriate for the material and your power supply. For now, set Max Power & Slew

rate to 100%. Set them to lower values if you find that small power changes cause

excessively large changes in deposition rate. Leave Rate Deviation alarms at 0%

for now.

Rate Ramps allow the PID controlled deposition rate to change over time, under

PID control. Each rate ramp has a starting thickness, an elapsed time to ramp to

the new rate, and a new rate setpoint. Each process layer can have up to two rate

ramps.

2 - 7

Page 32

SQC-310 Operating Manual

Crystal Tooling

Number of Positions

2. Sensor 2

1. Source 1

2. Source 2 Indexer

Single Crystal

1

100%

v

Sensors & Sources Menu

Name

1. Sensor 1

Shutter

No

Substrate

Substrate

Tooling

Over 100%

Tooling

Under 100%

2.6 Sensor and Source Setup

The SQC-310 must be configured to match the type of sensor installed in your

system. We will set up a single sensor without a shutter. Chapter 3 discusses the

other Sensor configuration options.

Select System Menu, Sensors & Sources, scroll to Sensor 1 and press Select to

Display the Sensor 1 menu. See Figure 2-8.

Figure 2-8 Sensor 1 Edit

To

Main

Value

Pre

Menu

Done

Single Source

Edit

Crystal Tooling adjusts for the difference in measured deposition rate between the

sensor and the substrate being coated.

Figure 2-9 Tooling Over/Under

IPN 074-550-P1B

In the left illustration in Figure 2-9, the sensor will measure less rate or thickness

than is actually deposited on the substrate because of its positioning. In the right

illustration, the sensor will measure high. Tooling is the ratio of the actual substrate

deposition rate or thickness, to that measured by the sensor.

A simple rule to remember is: If the rate/thickness reading is low, then increase the

tooling value. If the rate/thickness reading is high, then lower the tooling value.

2 - 8

Page 33

SQC-310 Operating Manual

If your sensor has a shutter, select Dual or Yes. Dual sets the sensor inputs for a

dual sensor (one that uses two sensor inputs). Yes is used for either a shuttered

single or multi-crystal sensor. Either Dual or Yes will automatically assign the first

available relay as the shutter relay. The relay opens immediately when a layer

enters the Deposit, Shutter Delay, or Control Delay states.

For multi-crystal sensors set Number of Positions to the number of crystals.

Several other parameters are required for multi-crystal heads. Set the Control type

and Feedback for the type of Digital I/O used by your sensor. The SQC-310 will

automatically create relays and inputs to control the sensor. Detailed explanations

of multi-crystal setup can be found in section 3.11.3.1, Sensor Setup, on page

3-31.

Source setup is nearly identical to the Sensor Setup described above.

Set the Voltage Scale to the control voltage that corresponds to 100% output on

your source supply. The SQC-310 uses 0 volts as 0% output, and the programmed

value as 100% output. Scale values from –10 volts to 10 volts are possible.

Source shutters will open after pre-conditioning, when deposition begins. In your

system, this may actually be the substrate shutter.

For a multi-position source, select the number of positions. Control and feedback

settings similar to those used for multi-position sensors become available. See

section 3.11.3, Sensors and Sources Menu, on page 3-31 for detailed information

on these settings.

2.7 Running a Process

Once a Process is defined with the desired Layers, and the sensors and source

supply are properly connected, the deposition process is ready to run. This section

describes the steps to select, start, and stop a process.

NOTE: Depending on the Main Menu screen displayed, the last key will be shown

as either Start or Start Layer. For simplicity, this section will use Start to

refer to either.

IPN 074-550-P1B

There are three Main Menu screens while the process is stopped (two when it is

running). Pressing the Next Menu SoftKey accesses the three screens. Next Menu

is the first SoftKey in each of the three menus. Likewise, Start/Stop is the last

SoftKey on each Main Menu. Main Menu 1 displays the SoftKeys used to control

the process.

2 - 9

Page 34

SQC-310 Operating Manual

Figure 2-10 Main Screen

The Quick Edit SoftKey (available while the process is running) provides easy

access to the most commonly set process parameters.

Figure 2-11 Quick Edit Menu

2 - 10

IPN 074-550-P1B

Press Next Layer and Prev Layer on the Quick Edit screen to review each layer.

Press To Main to return to the Main screen.

Page 35

SQC-310 Operating Manual

Figure 2-12 Main Screen

The Auto/Manual key alternates between Automatic (PID) output control and

Manual (user) output control. In Manual mode, the SQC-310 immediately starts the

deposition phase for the current layer, whether the process was stopped or

running. However, the PID loop is disabled and the front panel control knob

controls output power.

In Manual Mode, you will usually display the Rate Graph, and manually adjust the

output power to achieve the desired deposition rate. It is easy to exceed a layer’s

Final Thickness in Manual mode, so watch the Thickness reading carefully. Manual

mode is particularly useful for determining preconditioning power levels, and loop

tuning.

Moving from Manual mode to Auto mode places the SQC-310 into automatic (PID)

control. The PID control loop will try to achieve rate setpoint, so there may be a

rapid change in output power.

NOTE: Don’t confuse the Auto/Manual SoftKey with a layer’s Manual/Auto Start

parameter. Manual/Auto Start is an Edit Layer parameter that tells the

SQC-310 to wait for operator intervention before starting a Layer.

IPN 074-550-P1B

The Zero SoftKey can be used to zero the thickness reading at any time. It is not

normally needed, since the SQC-310 automatically zeroes the thickness at the

beginning of each layer. However, it is useful when simulating a process, and when

operating in Manual mode.

Next Layer moves the starting point for the Start SoftKey to the next layer,

wrapping back layer 1 at the end of the process.

The last SoftKey on this menu is used to Start and Stop the deposition cycle. Press

Start to start the layer shown on the first line of the screen at the preconditioning

phase. Press Stop Layer to halt the current layer. You can restart the current layer

by pressing Start. Press Next Layer, then Start, to start any other process layer.

2 - 11

Page 36

SQC-310 Operating Manual

NOTE: It is best (and safest!) to place the SQC-310 in Simulate mode when a

process is first run. If the bottom SoftKey does not show Start Simulate,

press System Menu and turn Simulate Mode ON.

Enough preliminaries, let’s start the process!

Press Start to start deposition. If the first layer Start mode was programmed as

Manual, you will need to press the Start Layer SoftKey now to start the layer.

Figure 2-13 Preconditioning

The process starts with the first layer preconditioning phase. When preconditioning

is complete, the deposition phase begins. The deposition phase ends when Final

Thickness is reached for the layer, then Feed and Idle phases run (if programmed).

If the second layer is Auto Start, its cycle begins immediately when the first layer is

complete. If the second Layer is Manual Start, or it’s the last layer in the process,

the process halts and waits for operator intervention.

While the process is running, a Stop Layer SoftKey is shown. Pressing Stop Layer

temporarily halts the current Layer.

IPN 074-550-P1B

2 - 12

Page 37

SQC-310 Operating Manual

Figure 2-14 Layer Stopped

Start repeats the stopped layer, beginning with preconditioning. Next Layer allows

you to select another layer to start.

NOTE: Pressing the Reset SoftKey on Main Menu 2 at any time completely aborts

the process.

Spend some time in Simulate mode verifying that the process sequences through

each phase of each layer as expected. If not, use the Quick Edit, Process, and Film

menus to make corrections.

Because the process is being “simulated,” some parameters will not be correct for

your process (particularly PID). However, you can become familiar with the effect

of each parameter in this simulated process. Also practice using the Next Menu

options, especially Auto/Manual modes.

Once you have verified the process in Simulate Mode, you may return to the

System menu and turn Simulate OFF to start testing your process. Use the next

section to finalize the loop PID settings.

IPN 074-550-P1B

2.8 Loop Tuning

This section will help you adjust your SQC-310 to achieve a stable deposition

process. Keep in mind that there is no “best” way to determine tuning parameters,

and no one set of settings that are best.

The first factor to consider is the type of deposition source. Thermal sources are

slow responding and typically free of noise transients. To avoid overshooting and

constantly seeking setpoint, they require PID parameters that anticipate their long

dead time and slow response to changes. Ebeam sources, on the other hand, are

fast responding and often noisy. They are also subject to arcing, which can create

large electrical noise spikes.

2 - 13

Page 38

SQC-310 Operating Manual

NOTE: Control loop tuning is a trial and error process and there is no "best"

procedure to accomplish this task. The procedure described here works

best for fast sources.

Set System Parameters: A Period of 0.25 seconds is a good starting point. Set

Tooling parameters to 100% for now. Initially set the Rate Filter to 1.00 (no filter) to

see the noise of the system. Simulate should be OFF. Keep in mind that Simulate

mode is a tool for testing process layers. It is not likely to match the control

response of your vacuum system.

Create a One-Layer Test Process: Create a new film with all default values and

select the material you will be depositing. Create a process that has the new film

as its only layer, and edit that layer. Set Init Rate to your desired rate and Final

Thickness to a large value to avoid the layer stopping during the tests. Select the

proper Sensor(s) and Source. Leave the other layer and film parameters at their

default values.

Test the Setup: Press Next Menu until the Sensor Info button is displayed, and

press Sensor Info. Verify that the Sensor Status is ON and a stable frequency is

displayed. Exit to the main screen and press Next Menu until the Auto/Manual

button is displayed. Press Auto/Manual to enter Manual mode, then press Start

Layer.

Slowly turn the control knob to a power of 10%, and verify that your power supply

output is about 10% of full scale. Continue to turn the control knob until a Rate near

your desired setpoint is achieved. Again, verify that the power supply output agrees

with the SQC-310 Power (%) reading. If the readings don’t agree, check your wiring

and verify that the System Menu, Source setup Voltage Scale agrees with your

power supply’s input specifications.

With the power set to your desired rate (Init Rate in the Quick Edit menu), push

Next Menu then Next Graph until the Rate Deviation graph is displayed, and

observe the noise. If the system has significant short term noise at fixed power

(maybe >10%), the control loop will be very difficult to adjust, especially at low

rates. It is better to eliminate the source of the noise before attempting to set the

PID values.

Select a Filter Alpha: On the Quick Edit menu, slowly decrease the filter Alpha

from 1 to a lower value until the rate display noise is minimized. If you set Alpha too

low, the display will lag the true system response and may hide significant

problems. A value of 0.5 equally weights the current reading and the previous

filtered readings.

Determine Open Loop Gain: Record the Power reading at the desired rate as

PWR

zero. Record the zero rate Power reading as PWR

. Slowly lower the power until the Rate (Å/s) reading is just at (or near)

DR

.

0R

IPN 074-550-P1B

2 - 14

Determine Open Loop Response Time: Calculate 1/3 of your desired rate

(RATE

), and 2/3 of the desired rate (RATE

1/3

power until Rate (

Å/s) matches RATE

. Get ready to record the loop’s response

1/3

) for this layer. Slowly increase the

2/3

Page 39

SQC-310 Operating Manual

to an input change. Quickly adjust Power (%) to PWRDR. Measure the time for the

Rate (

an average response time. Displaying the Rate graph will also help. Twice

measured time is the step response time, TIME

Å/s) reading to reach RATE

. You may want to do this several times to get

2/3

the

. TIMESR is typically 0.2 to 1

SR

seconds for E-Beam evaporation, 5 to 20 seconds for thermal evaporation.

Set PID Values: Set the power to zero. In the Quick Edit menu set P=25,

I= TIME

, D=0. Set Max. Pwr to ~20% higher than PWRDR. Exit the Quick Edit

SR

menu and press Manual/Auto to move to Auto (PID control) mode and observe the

Power graph. The power should rise from 0%, and stabilize near PWR

with little

DR

ringing or overshoot. If there is more than about 10% overshoot, lower the P Term.

If the time to reach PWR

is very slow, increase the P Term. A lower I Term will

DR

increase response time, a higher value will eliminate ringing and setpoint

deviations. It is unlikely you will need any D Term.

Continue to adjust P & I values, alternating between Manual Power 0% and Auto

mode until steady-state response is smooth and the step response is reasonably

controlled. You don’t need to totally eliminate ringing during the step if the

steady-state response is smooth; preconditioning will minimize step changes.

Typical I values for thermal systems are 4 to 10; Ebeam I values are 0.5 to 2. It’s

impossible to predict P values, but it is best to select the lowest value that provides

adequate rate control.

Ebeam systems may require additional steps to limit the control loop’s response

during arcing. First, be sure Max. & Min. power are set to limit the output to

reasonable values for this material and rate. Slew Rate can further limit

too-aggressive power changes. Remember that slew rate is % of full scale per

second. At rates below 10

Å/s, a slew rate of 1-2% per second is common. Finally,

decreasing the filter Alpha will limit the PID response to occasional large noise

spikes, such as from arcing.

Set Preconditioning: The power level you recorded as PWR

is the power where

0R

deposition just begins. That’s a good value for Ramp 1 power in the Film Conds

menu. PWR

, or slightly less, is a good value for Ramp 2 Power. This will prevent

DR

a large step change when entering the deposition phase.

IPN 074-550-P1B

Once PID terms are established for a material, they will typically be similar for other

materials. Only the P Term and preconditioning power levels may need adjustment.

2.9 Troubleshooting

Most SQC-310 problems are caused by defective crystals or improper film setup,

particularly incorrect PID settings for the control loop. Follow the procedures below

to identify and correct common problems.

No Readings, or Erratic Readings from Sensors

Disconnect the deposition source power supply. This eliminates the possibility that

a noisy source, or poor loop tuning, are causing an unstable PID loop.

2 - 15

Page 40

SQC-310 Operating Manual

Verify that the sensors, oscillator and cabling are connected as shown in section

1.3 - section 1.5. Assure that a good ground connection has been made to the

SQC-310 chassis.

Replace the quartz crystal. Crystals sometimes fail unexpectedly, or exhibit erratic

frequency shifts before total failure. Depending on the material being deposited,

crystals may fail well before the typical 5 MHz value. If you find that crystals

consistently fail early, you may want to set Min Frequency in the System Menu to

a value higher than 5 MHz.

In the System Menu, assure that Simulate Mode is OFF, and Frequency Min/Max

are set properly for your crystals (typically Freq Min=5.0 MHz, Freq Max=6.0 MHz).

Some manufacturer's crystals exceed 6 MHz when new. Setting Frequency Max to

6.1 MHz will correct that problem, with no bearing on instrument accuracy.

Press Sensor Info and assure that the proper sensors are enabled. While not

depositing, observe the % Life display for each active sensor. The value should be

stable, between 20% and 100%.

If the % Life reading is zero or unstable: Recheck the wiring from the sensor to the

SQC-310, and verify that the SQC-310 is properly grounded. Also check that the

crystal is seated properly in the sensor head. You can swap the sensor to the other

SQC-310 input. If both SQC-310 inputs show zero or unstable readings, the

problem is almost certainly a wiring or sensor problem.

If the % Life is less than 50%

: Replace the crystal and assure that % Life is near

100%, very stable. If % Life is not near 100%, check the Frequency Min/Max limits.

If the problem is not corrected

: Referring to section 1.4, disconnect the 6” M/F BNC

cable from the external oscillator module. A 5.5 MHz test crystal and BNC barrel

adapter is supplied with each oscillator kit. Attach the test crystal to the oscillator

Sensor connector. The display should read about 5.5 MHz, very stable. If not,

contact INFICON technical support.

When the frequency reading is stable, reconnect the source supply and sensor.

Start the deposition process in Manual mode with 0% power. The % Life readings

should remain stable.

Slowly raise the % Power until a rate reading is displayed above the graph. As

material is deposited on the crystal, the % Life reading should remain stable, or

drop slowly and consistently. If not, check your source supply for erratic output.

Also assure that the sensor is not too close to the source (particularly in sputtering).

IPN 074-550-P1B

2 - 16

Incorrect Rate or Thickness Measurement

First, complete the procedures in the beginning of section 2.9 to assure reliable

sensor operation.

Set the Xtal Tooling as described in section 3.11, System Menu, on page 3-19.

Incorrect Xtal Tooling values will cause consistently low or high rate/thickness

values for every material.

Page 41

SQC-310 Operating Manual

Once the Xtal Tooling is set, set Film Tooling in the Film Menu to 100% unless you

are certain that another value is needed for a specific film.

Verify that the Density and Z-Factor values match those in the Materials

Parameters Appendix. If the material is not listed, check a materials handbook.

Density has a significant effect on rate/thickness calculations.

Z-Factor corrects for stresses as a crystal is coated. If readings are initially

accurate, but deteriorate as crystal life drops below 60-70%, you need to adjust the

Z-Factor or replace crystals more frequently. The relationship between Z-Factor

and Acoustic Impedance is discussed in Appendix A, Material Table.

Poor Rate Stability

First, be sure that a stable rate can be achieved in Manual mode, as explained in

section 2.8. Once a stable rate is achieved in Manual mode, follow the Loop Tuning

procedures.

IPN 074-550-P1B

2 - 17

Page 42

SQC-310 Operating Manual

This page is intentionally blank.

2 - 18

IPN 074-550-P1B

Page 43

3.1 Introduction

Zero

Next

Layer

Next

Menu

Quick

Edit

Auto /

Manual

Process 1 : Layer 1 of 1 Run # :0

yer

0.0

50.0

100.0

0.0

6.2

12.5

18.8

25.0

Power ( % vs. Time)

Out#

1

2

3

4

Rate(A/S)

0.00

0.00

0.00

0.00

Dev( %)

00.0

00.0

00.0

00.0

Thick(kA)

0.000

0.000

0.000

0.000

Pow( %)

0.0

0.0

0.0

0.0

Stopped

0:00:00

Three menus on the Main Screen control SQC-310 operation. The SoftKeys

associated with each of these menus leads to sub menus. This chapter describes

the function of each setting in each menu. It is arranged by Main Screen menus,

then by major sub menus.

The Main Screen for the SQC-310 is shown in Figure 3-1.

Figure 3-1 Main Screen

SQC-310 Operating Manual

Chapter 3

Menus

IPN 074-550-P1B

Start

La

At the top of the screen you will find information about the current process, layer,

and run status. Immediately below is the current deposition phase and error

conditions.

The central graph displays Rate, Rate Deviation, or Output Power. If multiple

materials are being deposited, the graph shows each material in a different color.

Below the graph is a display of deposition readings. This display always shows the

current rate and thickness readings. The remaining columns can be set to display

either Power and Deviation readings or Rate and Thickness setpoints. For a

standard SQC-310 there will be two lines, corresponding to the two control outputs.

With an expansion card installed there will be four lines, as shown.

The Main Screen SoftKey legends will change based on the Menu selection and

the current process status. The three different menus for the main screen are

accessed by pressing the Next Menu SoftKey.

3 - 1

Page 44

SQC-310 Operating Manual

3.2 Main Screen, Menu 1

Table 3-1 describes the function of each SoftKey on Main Screen, Menu 1.

Table 3-1 Main Screen SoftKeys

Next

Menu

Quick

Edit

Auto /

Manual

Zero Zeros the thickness reading. Useful for resetting or extending the

Next

Layer

Start

Layer

Start/Reset Starts or halts the current process. Sets all outputs to zero.

Sequences through each of the three Main Screen menus.

Displays the Quick Edit Menu of commonly changed process

values. If this key is not visible, the active process has no layers

defined.

Toggles between Auto and Manual power control. When

Auto/Manual is shown, output power is set by the SQC-310 to

achieve the programmed deposition rate. When Manual/Auto is

shown, the control knob sets the output power.

current deposition layer.

Sequences through each process layer. Use this key to start or

restart the process at any layer. Only visible when the process is

stopped.

Each layer in a process can be defined as Auto Start or Manual

Start. Auto Start layers begin immediately on completion of the

previous layer. Manual start layers wait for the operator to press

Start Layer. Only visible when waiting to start a Manual Start layer.

3.3 Main Screen, Menu 2

Table 3-2 describes the function of each SoftKey on Main Screen, Menu 2.

Table 3-2 Main Screen, Menu 2 Softkeys

Next

Menu

Next

Graph

Next

Display

3 - 2

Sequences through each of the three Main Screen menus.

IPN 074-550-P1B

Sequences through the graph options for the Main Screen. Choose

between Rate, Rate Deviation, and Power graphs. The Y-axis of the

Rate Deviation graph can be scaled in the System Parameters

menu. A fourth “graph” screen displays rate, thickness, and power

in large text format for easy viewing.

Toggles between data display options at the bottom of the Main

Screen. The first display option shows Rate, Rate Deviation,

Thickness, and Power readings. The second option shows Rate

measurements in the first column and Rate setpoints in the second

column. Thickness measurements are shown in the third column,

then Thickness setpoints in the fourth.

Page 45

SQC-310 Operating Manual

Table 3-2 Main Screen, Menu 2 Softkeys (continued)

Sensor Info Replaces the Main Screen with the Sensor screen.

Next

Layer

Start

Layer

Start/Reset Starts or halts the current process. Sets all outputs to zero.

Sequences through each process layer. Use this key to start or

restart the process at any layer.

Each layer in a process can be defined as Auto Start or Manual

Start. Auto Start layers begin immediately on completion of the

previous layer. Manual start layers wait for the operator to press

Start Layer. Only visible when waiting to Manual Start.

3.4 Main Screen, Menu 3

Menu 3 can be accessed only while the process is stopped. This menu gives

access to process, film, and system setup parameters that cannot be altered while

a process is running.

To change these parameters when a process is running: Stop the process; modify

the parameters; then restart the process at the desired layer.

IPN 074-550-P1B

Table 3-3 describes the function of each SoftKey on Main Screen Menu 3.

Table 3-3 Main Screen Menu 3 Softkeys

Next

Menu

Sequences through each of the three Main Screen menus.

Process

Menu

Film

Menu

A process is a sequence of layers of deposited film(s). The Process

Menu selection allows you to build and edit the sequence of

process layers.

A film is basically a material plus the setup information necessary

to deposit that material. Settings on the Film Menu include pre/post

conditioning, deposition error controls, and the physical chamber

setup for that material.

3 - 3

Page 46

SQC-310 Operating Manual

Table 3-3 Main Screen Menu 3 Softkeys (continued)

System

Menu

Start/Reset Starts or halts the current process. Sets all outputs to zero.

View Logic View Logic is a read-only screen available while a process is

The remainder of this chapter provides a detailed explanation of each sub menu

and its settings.

3.5 Quick Edit Menu

The Quick Edit Menu provides access to the most commonly adjusted parameters

for the current process and layer. See Figure 3-2.

Figure 3-2 Quick Edit Menu

System parameters control the overall operation of the SQC-310.

Tooling, crystal frequency, and operating modes are examples of

settings found on the System Parameters Menu.

running. This allows you to view whether logic statements are true

or false at any point in the process.

3 - 4

Table 3-4 Quick Edit Menu SoftKeys

To

Main

Returns to the Main Screen Menu 1.

IPN 074-550-P1B

Page 47

SQC-310 Operating Manual

Table 3-4 Quick Edit Menu SoftKeys (continued)

Edit Selects the highlighted parameter for edit. SoftKey functions

change to:

Next: Store parameter and move to next for editing.

Cancel: Stop editing and undo changes to selected parameter.

Enter: Stop editing and save values for selected parameter.

Control Knob: Turn to adjust value. Push to store value and move

to next parameter.

Prev Layer Displays the parameters for the previous layer in the process.

Next Layer Displays the parameters for the next layer in the process.

Quick Edit parameters are described below:

Initial Rate: The beginning rate of deposition for this layer. This is the target rate

that the control loop tries to maintain througough the deposit (assuming no rate

ramps are used).

Final Thickness: The desired final thickness of this layer. The deposition phase of

this layer will end when this thickness is reached.

P Term: The proportional term sets the gain of the control loop. High gains yield

more responsive (but potentially unstable) loops. Try a value of 25, then gradually

increase/decrease the value to respond to step changes in rate setpoint.

I Term: The integral term controls the time constant of the loop response. A small

I term, say 0.5 to 1 seconds, will smooth the response of most loops.

D Term: The differential term causes the loop to respond quickly to changes. Use

0 or a very small value to avoid oscillations.

Max Power: The maximum output power allowed for the selected source. Power