Page 1

SID-242

Thin Film Deposition Controller

SQS-242

Deposition Control Software

Version 3.00

User’s Guide

© Copyright Sigma Instruments, Inc. 1998-2002

Page 2

Sigma

instruments

Page 3

Safety Information

Read this manual before installing, operating, or servicing equipment. Do not install

substitute parts, or perform any unauthorized modification of the product. Return the

product to Sigma Instruments for service and repair to ensure that safety features are

maintained.

Safety Symbols

WARNING: Calls attention to a procedure, practice, or condition that could

possibly cause bodily injury or death.

C

AUTION: Calls attention to a procedure, practice, or condition that could

possibly cause damage to equipment or permanent loss of data.

Refer to all manual Warning or Caution information before using this product

to avoid personal injury or equipment damage.

Hazardous voltages may be present.

Earth ground symbol.

Chassis ground symbol.

Equipotential ground symbol.

Page 4

Warranty Information

This Sigma Instruments product is warranted against defects in material and

workmanship for a period of 2 years from the date of shipment, when used in

accordance with the instructions in this manual. During the warranty period, Sigma

Instruments will, at its option, either repair or replace products that prove to be

defective.

Limitation of Warranty

Defects from, or repairs necessitated by, misuse or alteration of the product, or any

cause other than defective materials or workmanship are not covered by this warranty.

NO OTHER WARRANTIES ARE EXPRESSED OR IMPLIED, INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE. UNDER NO CIRCUMSTANCES SHALL SIGMA

INSTRUMENTS BE LIABLE FOR CONSEQUENTIAL OR OTHER DAMAGES

RESULTING FROM A BREACH OF THIS LIMITED WARRANTY, OR OTHERWISE.

Return Policy

The purchaser may return this product in new condition within 30 days after shipment

for any reason. In case of return, purchaser is liable and responsible for all freight

charges in both directions.

Sigma Instruments

120 Commerce Drive, Unit 1

Fort Collins, CO 80524 USA

970-416-9660

970-416-9330 (fax)

Page 5

Table of Contents

Chapter 1 Introduction

1.0 SID-242 Introduction ........................................................................................1-1

1.1 SRC Series Computer ......................................................................................1-1

1.2 SQM-242 Deposition Control Card ...................................................................1-2

1.3 SQS-242 CoDeposition Control Software ........................................................1-2

1.4 Digital I/O .........................................................................................................1-3

Chapter 2 Quick Start

2.0 Introduction ......................................................................................................2-1

2.1 Installation ........................................................................................................2-1

2.2 Front Panel ......................................................................................................2-2

2.3 Program Startup ...............................................................................................2-3

2.4 Single Layer Process Setup .............................................................................2-4

2.5 Single Layer Process Simulation ......................................................................2-8

2.6 SoftKey Functions ............................................................................................2-10

2.7 Multi-Layer CoDeposition Process ...................................................................2-11

2.8 Conclusion .......................................................................................................2-15

Chapter 3 SQS-242 Software

3.0 Introduction ......................................................................................................3-1

3.1 Installation and Registration .............................................................................3-2

3.2 Operation .........................................................................................................3-2

3.3 File Menu .........................................................................................................3-4

3.4 Edit Menu .........................................................................................................3-5

3.4.1 Processes....................................................................................................3-6

Layers .....................................................................................................3-7

Rate Ramps ............................................................................................3-9

Deposition ...............................................................................................3-10

Conditioning ............................................................................................3-12

Sources and Sensors ..............................................................................3-13

3.4.2 Films ............................................................................................................3-15

3.4.3 Materials ......................................................................................................3-16

Page 6

Chapter 3 SQS-242 Software (continued)

3.4.4 System ........................................................................................................3-17

Sensors ...................................................................................................3-17

Sources ...................................................................................................3-18

Digital I/O .................................................................................................3-19

PLC Setup ...............................................................................................3-22

SQM-242 Setup .......................................................................................3-23

RS232 Setup ...........................................................................................3-24

3.4.5 Security .......................................................................................................3-25

3.5 View Menu .......................................................................................................3-27

3.6 Specifications ...................................................................................................3-28

Chapter 4 SQM-242 PC Card

4.0 Introduction ......................................................................................................4-1

4.1 Installation ........................................................................................................4-2

4.2 Sensor Connections .........................................................................................4-4

4.3 Power Supply Connection ................................................................................4-4

4.4 TroubleShooting ...............................................................................................4-4

4.5 Demo Programs ...............................................................................................4-7

4.6 SQM32C.DLL ...................................................................................................4-7

4.7 Specifications ...................................................................................................4-7

Chapter 5 Digital I/O

5.0 Introduction ......................................................................................................5-1

5.1 PLC Installation ................................................................................................5-2

5.2 PLC Setup and Test .........................................................................................5-3

5.2 PLC Programming ............................................................................................5-4

Chapter 6 Computer Interface

6.0 Introduction ......................................................................................................6-1

6.1 Serial Interface .................................................................................................6-1

6.2 Ethernet Interface .............................................................................................6-1

6.3 SQS-242 Comm Program ................................................................................6-2

6.4 Protocol ............................................................................................................6-3

6.5 Command Summary ........................................................................................6-5

Appendix

A. Material Parameters

B. Loop Tuning

Page 7

Page 8

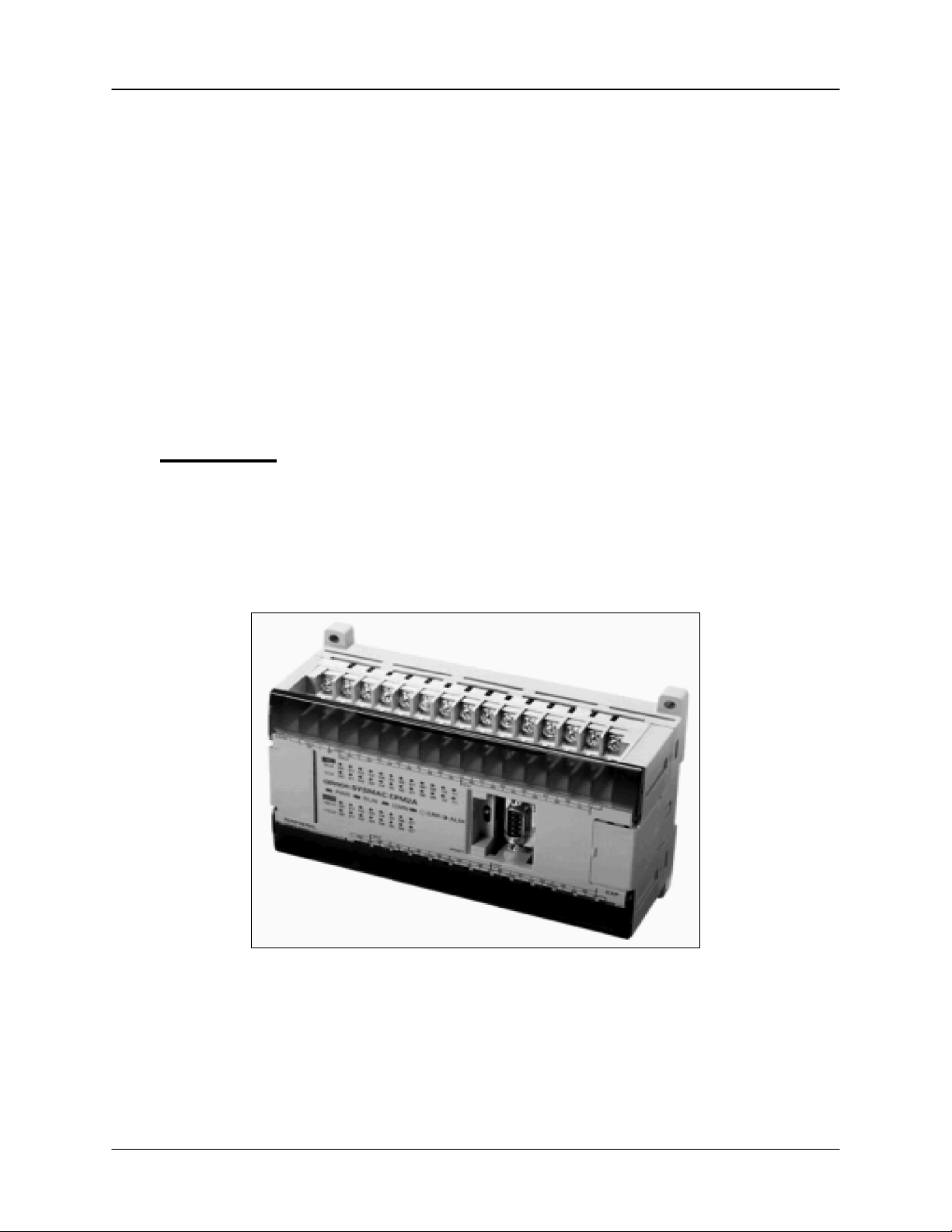

Chapter 1 Introduction

1.0 Introduction

This manual covers both the hardware and software associated with the SID-242 Thin

Film Deposition Controller. The SID-242 consists of four main elements, integrated into

a complete deposition control system:

SRC Series Rack-mount Computer

SQM-242 PC Card(s)

SQS-242 Windows CoDeposition Software

PLC for Digital I/O (option)

While the focus of this manual is on the SID-242 Controller package, it also covers each

of these components separately. If you have purchased only the SQS-242 Software

and/or the SQM-242 Card, we suggest that you also review Chapters 1 and 2 of this

manual for important information.

1.1 SRC Series Computer

Sigma’s SRC Series computers are Celeron (or better) class computers running the

Windows operating system. The SRC computer series uses standard off-the-shelf

components and Sigma’s custom rack-mount chassis to provide a compact, low cost

instrument.

Included in the 5.25” or 7” high rack-mount chassis are an LCD Display, a TouchPad

pointing device, a setting Knob, and six SoftKeys. A keyboard is provided for initial

setup, but is not necessary for normal operation of the SQS-242 deposition control

software. An optional rack-mount keyboard is also available.

1-1

Page 9

Chapter 1 Introduction

1.2 SQM-242 Deposition Control Card

Sigma’s SQM-242 is a PCI expansion card for use in computers running the Windows

operating system. Each card measures up to four quartz sensors via BNC inputs, and

supplies the control signal for two evaporation sources via a dual phone plug output.

Up to two cards can be installed in a computer, creating an eight input, four output,

codeposition controller.

The SQM-242 card is supplied with demonstration software written in Visual Basic and

LabView, including complete source code. The SQM-242 card and a Windows based

computer form a basic deposition control system (without digital I/O capabilities).

1.3 SQS-242 CoDeposition Control Software

Included with the SID-242 is Sigma’s SQS-242 software, a Windows-based program

that provides all of the functions required for an eight sensor, four output, codeposition

controller. It is optimized for use with the Setting Knob and six SoftKeys of our SID-242

controller. However, it will run on any Win98 or later system with our SQM-242 card

installed.

1-2

Page 10

Chapter 1 Introduction

The six SoftKeys provide easy access to the common operating functions. A single

tabbed dialog box provides all of the settings required for a thin film process. Material

parameters, sensor/source setup, pre/post conditioning, and error conditions are all

visible on a single screen. Process settings, numeric data, and graphical displays are

displayed during all phases of deposition.

The SQS-242 software stores process parameters in a Microsoft Access compatible

database. This provides virtually unlimited access to desktop tools for building and

analyzing thin film processes.

The SQS-242 software can be controlled from another computer using the RS-232 or

Ethernet command protocol.

1.4 Digital I/O

Digital I/O for the SID-242 is provided through an inexpensive, external, programmable

logic controller (PLC). This allows the PLC, and the associated I/O wiring, to be placed

in a convenient location in a wiring cabinet. A single, serial communications cable runs

to the SID-242 computer. The PLC provides electrical isolation, fail-safe operation, and

extensive I/O processing capabilities through its ladder logic programming.

1-3

Page 11

Chapter 1 Introduction

This page left blank for your notes.

1-4

Page 12

Chapter 1 Quick Start

1-1

Page 13

Chapter 2 Quick Start

2.0 Introduction

This section covers the minimum system connections and initial setup required to run

the SID-242 Deposition Controller. Consult later chapters of this manual for more

detailed setup and operational instructions.

2.1 Installation

All electrical connections to the SID-242 are made at the back panel of the instrument.

WARNING: Care should be exercised to route SID-242 cables as far as practical from

other cables that carry high voltages or generate noise. This includes other line voltage

cables, wires to heaters that are SCR-controlled, and cables to source power supplies

that may conduct high transient currents during arc down conditions.

Rack

Installation

Power

Connection

Sensor Input

Connections

Source Output

Connections

Digital I/O

Connections

Keyboard

Connection

The SID-242 occupies a 5.25” high (4U) rack space. Install the

unit in a 19” rack with the supplied hardware.

W

ARNING: Verify that the Voltage Selector Switch, located next

to the power switch, matches your mains supply voltage.

WARNING: Verify that the power cable provided is connected to

a properly grounded mains receptacle.

Connect the BNC cables and oscillators from your vacuum

chamber feedthrough to the desired SQM-242 Card Input(s).

Refer to Chapter 4 for detailed instructions on system hookup

to the SQM-242 card(s).

Connect the dual phone plug from the SQM-242 output jack to

your evaporation supply control input. Refer to Chapter 4 for

detailed instructions on wiring the SQM-242 output phone plug.

Digital I/O is not required for initial operation of the SID-242.

Perform initial setup and checkout of the SID-242 before

connecting your digital I/O. Refer to Chapter 5 for detailed

information on wiring the SID-242 for digital I/O.

A keyboard is supplied for initial user setup of Windows.

Attach the keyboard to the keyboard input jack on the rear of

the SID-242. Once Windows is setup, use of the keyboard is

optional.

2-1

Page 14

Chapter 2 Quick Start

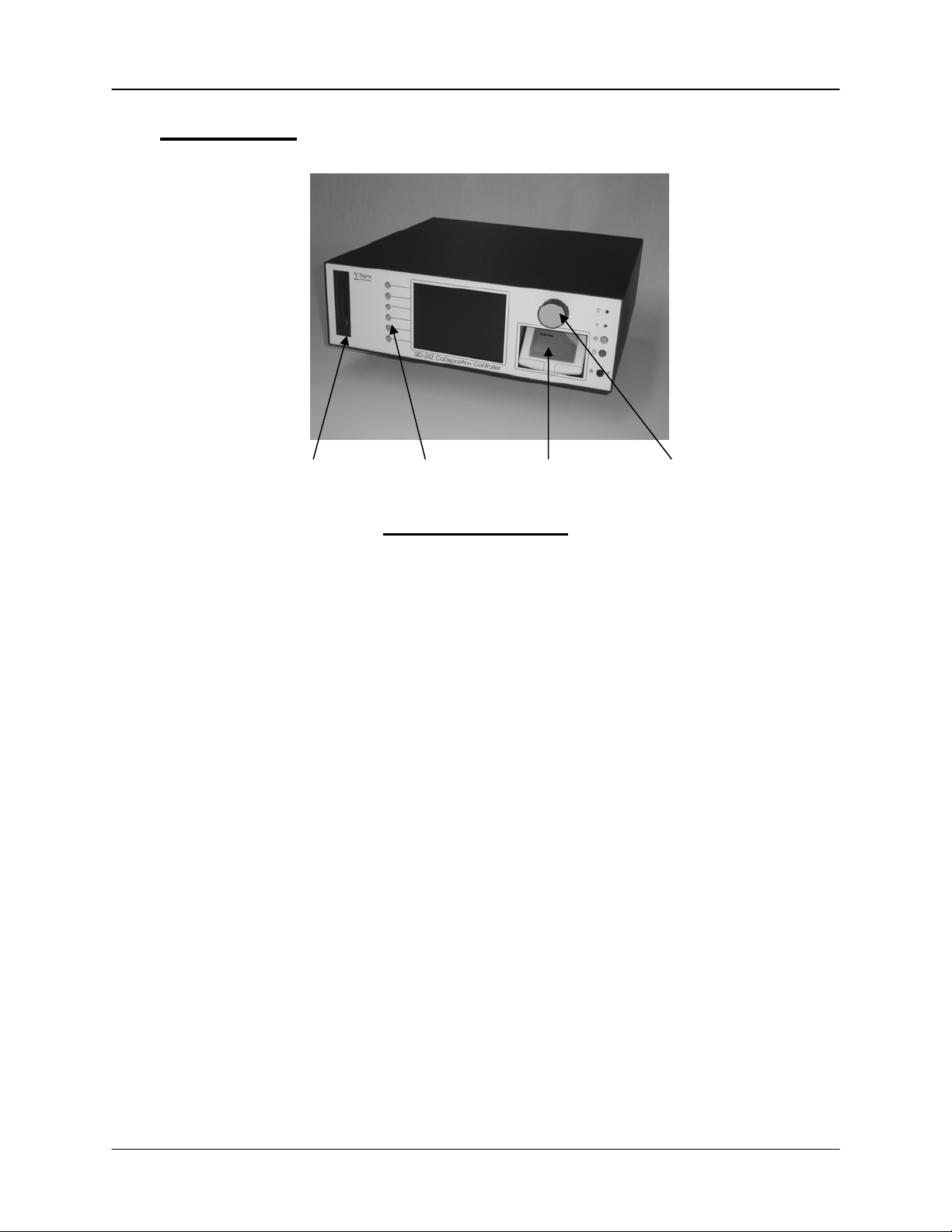

2.2 Front Panel

Floppy Disk SoftKeys TouchPad Control Knob

Front Panel Controls

KeyLock

SoftKeys

TouchPad

Control

Knob

Floppy

Disk

Keyboard

(not shown)

Insert key and turn clockwise to enable the power and reset

buttons. Turn counterclockwise to disable the power and reset.

Provide basic instrument operations within the SQS-242

deposition program. The SoftKeys are functional only in

programs written specifically for the SRC computer.

Provides mouse functions in all Windows programs, including

the SQS-242 software. Move your index finger along the

touchpad surface to move the cursor. Press the left or right

buttons below the touchpad surface to “click.”

Used to adjust values within the SQS-242 software. Pushing

the control knob stores the current setting, and moves to the

next setting. Functional only in programs written specifically for

the SRC computer.

1.44 MB floppy disk for upgrades, backup, and data

storage/transfer.

Required for Windows data entry, and useful during initial SID242 setup. Not required for SQS-242 software operation. The

F1 through F6 keys on the keyboard provide the same

functions as the six SoftKeys on the front panel.

2-2

Page 15

Chapter 2 Quick Start

2.3 Program Startup

This section will start the SID-242 and run the SQS-242 deposition control program.

Power On the

Computer

Start the

Program

User Login

Screen

Process

Database

Main Display

Insert the and turn clockwise to enable the power and reset

buttons. Push the power button to start the computer.

The SID-242 will boot Windows from the internal disk and start

the SQS-242 deposition program. If the SQS-242 program

does not start automatically, use the touchpad to double-click

the desktop icon.

Note: If you are prompted to register the software, just press

Cancel for now.

Note: The SID-242 ships with one pre-assigned user. The

user name is Super, with no Password.

The SID-242 displays a progress bar during program startup,

then a User Login screen. Select a User Name from the drop

down box, enter the Password, then click OK.

See Chapter 3 for more information on users, passwords, and

access levels and registartion.

The SID-242 normally starts with the last active process

database. If that database is not found, a Database Open

dialog will be displayed. Use the touchpad to navigate to the

desired database.

The main display shows a set of labels associated with the

function of the six SoftKeys. As you operate the SID-242,

these labels will change to display appropriate functions.

Along the top of the display is a menu of less commonly used

functions. This menu is available only when the SID-242 is

stopped (i.e. not running a deposition process).

2-3

Page 16

Chapter 2 Quick Start

Simulate Mode

Simulate mode allows you to familiarize yourself with SID-242

operation, and test process recipes. If the first SoftKey is

labeled “START SIMULATE” then the Simulate mode is active.

If the first SoftKey is labeled “START PROCESS" then normal

mode is selected. Use the touchpad to select the Setup menu,

then click System. On the SQM-242 tab, click the Simulate

option button. Click the “Save” SoftKey label, or press the top

SoftKey to activate Simulate mode.

2-4

Page 17

Chapter 2 Quick Start

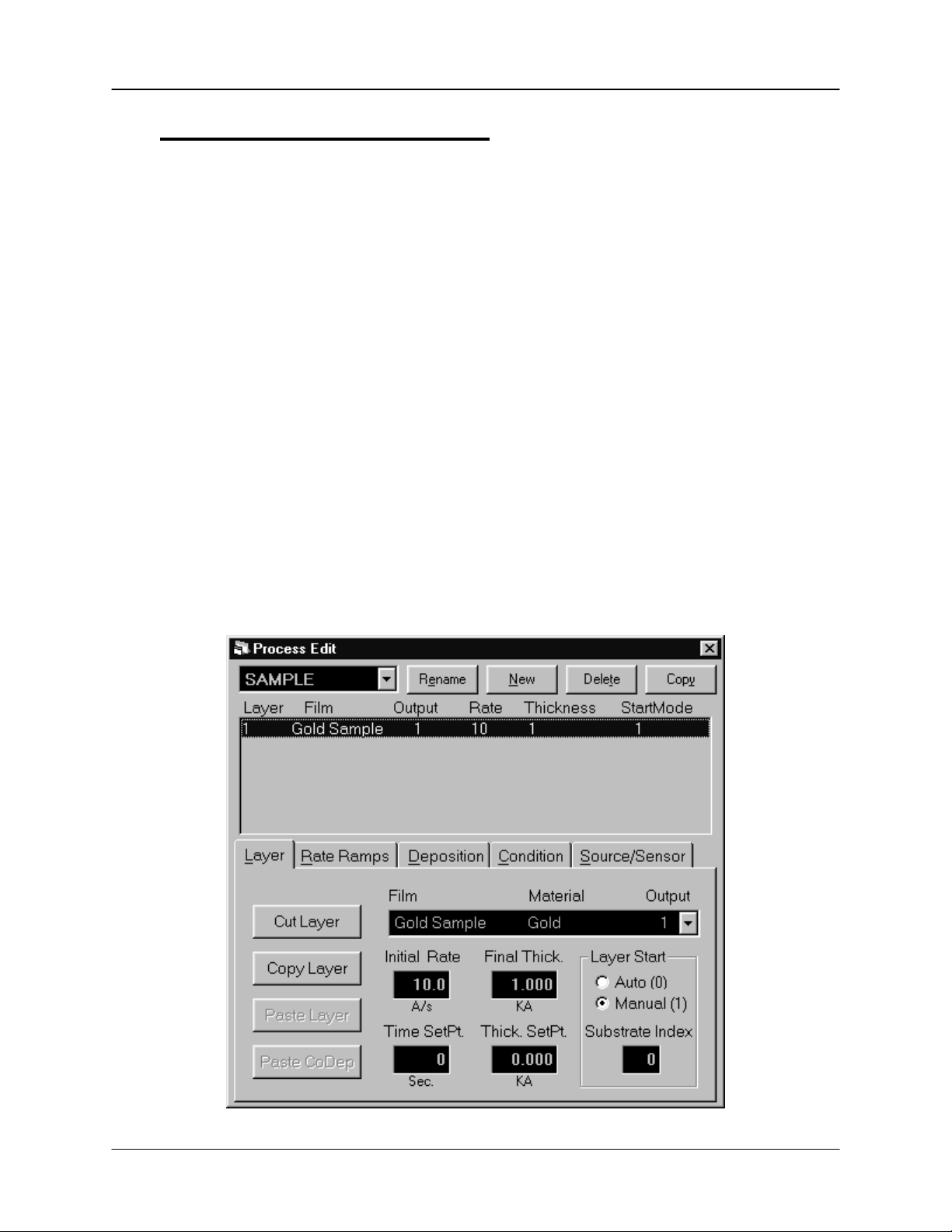

2.4 Single-Layer Process Setup

A thin-film deposition process consists of one or more layers of material evaporated

onto a substrate. Let’s build a simple single-layer process.

Open

Process Edit

Add A New

Process

Edit

Film

Edit Rate and

Thickness

Use the touchpad to click on the “Edit” menu selection along

the top of the display, then click “Process.” The Process Edit

dialog will display the setup for the last process run.

To better understand process setup, see section 3.4.1.

Click the “New” button in the dialog box. An on-screen

keyboard appears, displaying the next numbered Process.

Click “Backspace” several times to delete the name. Now

“type” a new Process name using the touchpad and on-screen

keyboard. Click “Enter” to save the new name.

Click the “Layer” tab to assure the layer parameters are

displayed. Select “Gold Sample” in the Film dropdown box.

Click the “Initial Rate” setting, and then use the Control Knob to

adjust the Initial Rate to 10 Å/s. Adjust the “Final Thickness” to

1.000 kÅ.

2-5

Page 18

Chapter 2 Quick Start

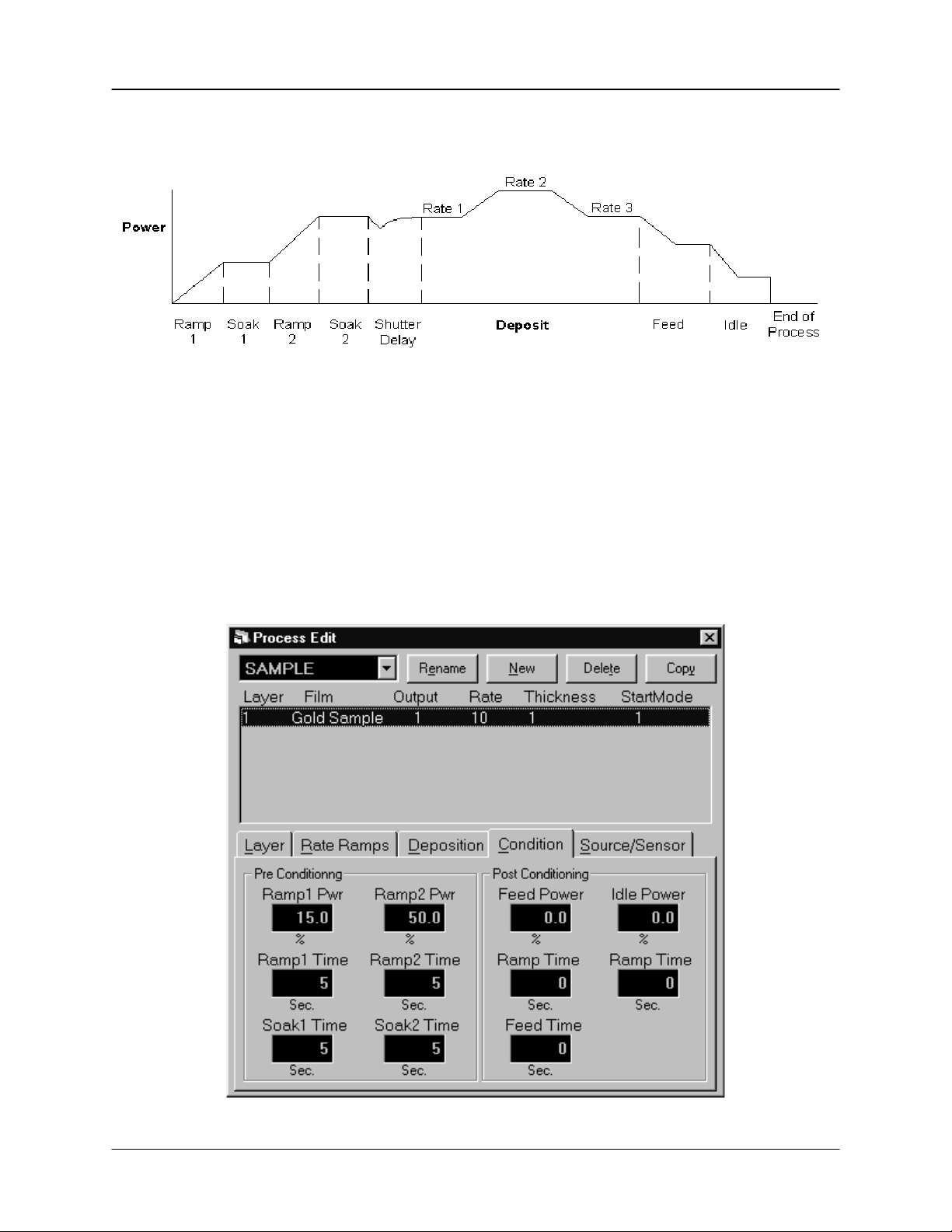

The diagram below illustrates a complete deposition cycle for a single layer. Refer to

this diagram as we set the remaining process setup parameters.

Edit

Rate Ramps

Edit Pre/Post

Conditioning

It may be desirable to vary the deposition rate during a layer.

For example, to deposit slowly at first, then more quickly once

the initial material is deposited. Click the “Rate Ramps” tab,

then click “Insert Ramp.” Adjust the “Start Thickness” to 0.400

kÅ, “Ramp Time” to 5 seconds, and “New Rate” to 15 Å/s.

Before deposition begins, the source material is often brought

to a ready state by raising the evaporation source power.

Select the “Condition” tab and set each parameter to the

values shown below.

2-6

Page 19

Chapter 2 Quick Start

Edit

Deposition

Select the “Deposition” tab. This tab establishes the gain (P

Term), time constant (I Term), and dead time (D Term) for your

process. Set these values to 55, .7, and 0 respectively.

Be sure Shutter Delay Enabled is not selected. Select Ignore

for Control Error, and Continuous for Rate Sampling (see

picture below).

2-7

Page 20

Chapter 2 Quick Start

Edit

Source/Sensor

Select the “Source/Sensor” tab. This tab contains parameters

associated with the physical layout of your evaporation system.

For now, be sure that “Output 1” is selected and “Max Power”

and “Slew Rate” are set to 100. Set the “Tooling” value to 100.

Leave the Source Index as it is.

Save Edits

Your new single-layer process is now the active process in the main window. Notice the

process, layer, and time information above the graph.

Click “Close Form” or press the first SoftKey to save this onelayer process. If you are prompted “Do you want to

change….,” answer Yes to make this the current process.

2-8

Page 21

Chapter 2 Quick Start

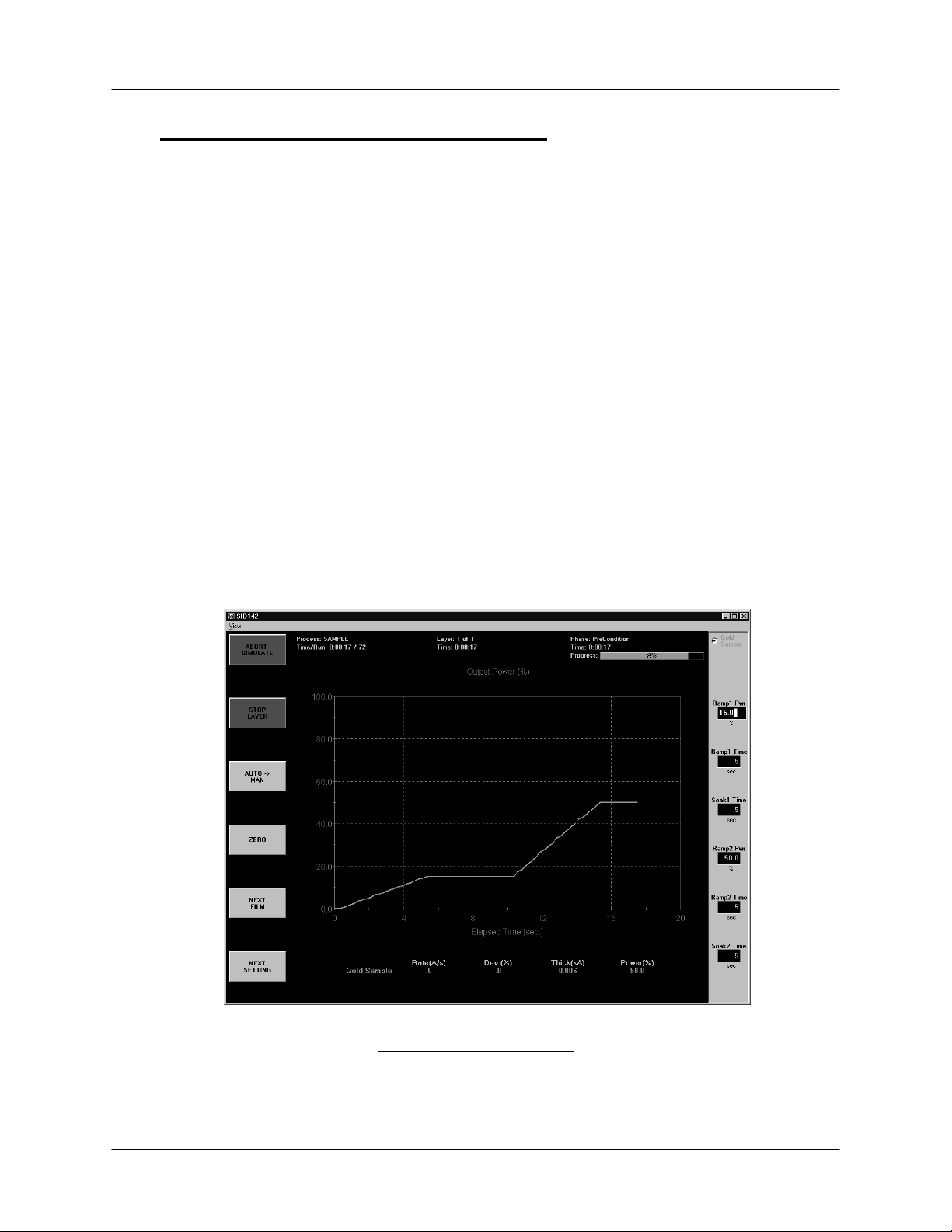

2.5 Single-Layer Process Simulation

If you have followed this chapter, you are ready to simulate a deposition process.

Setup

Displays

Start

Process

The process will start with preconditioning (i.e. Ramp1, Soak1, Ramp2, Soak2) as

shown below. Once preconditioning is complete, the process will enter the Deposit

phase. You may want to select “ABORT SIMULATE,” then “START SUMULATE”

several times to familiarize yourself with the on-screen displays during preconditioning.

You may also want to use the settings ribbon to adjust parameters while the process is

running.

Click the “View” menu and assure that these options are

selected: Film Settings, Film Readings, and Automatic. Note

that the settings “ribbon” along the right displays the preconditioning parameters you entered in the previous section.

Verify that the top SoftKey label displays “START SIMULATE.”

If “START PROCESS” is displayed, follow the instructions at

the end of Section 2.2 to enable simulate mode. Press the

“START SIMULATE” SoftKey, or click the label, to start the

process.

Preconditioning Phases

Because we selected “Automatic,” in the View menu, the graph displays Output Power

during preconditioning, then switches to Rate during the deposition phase.

2-9

Page 22

Chapter 2 Quick Start

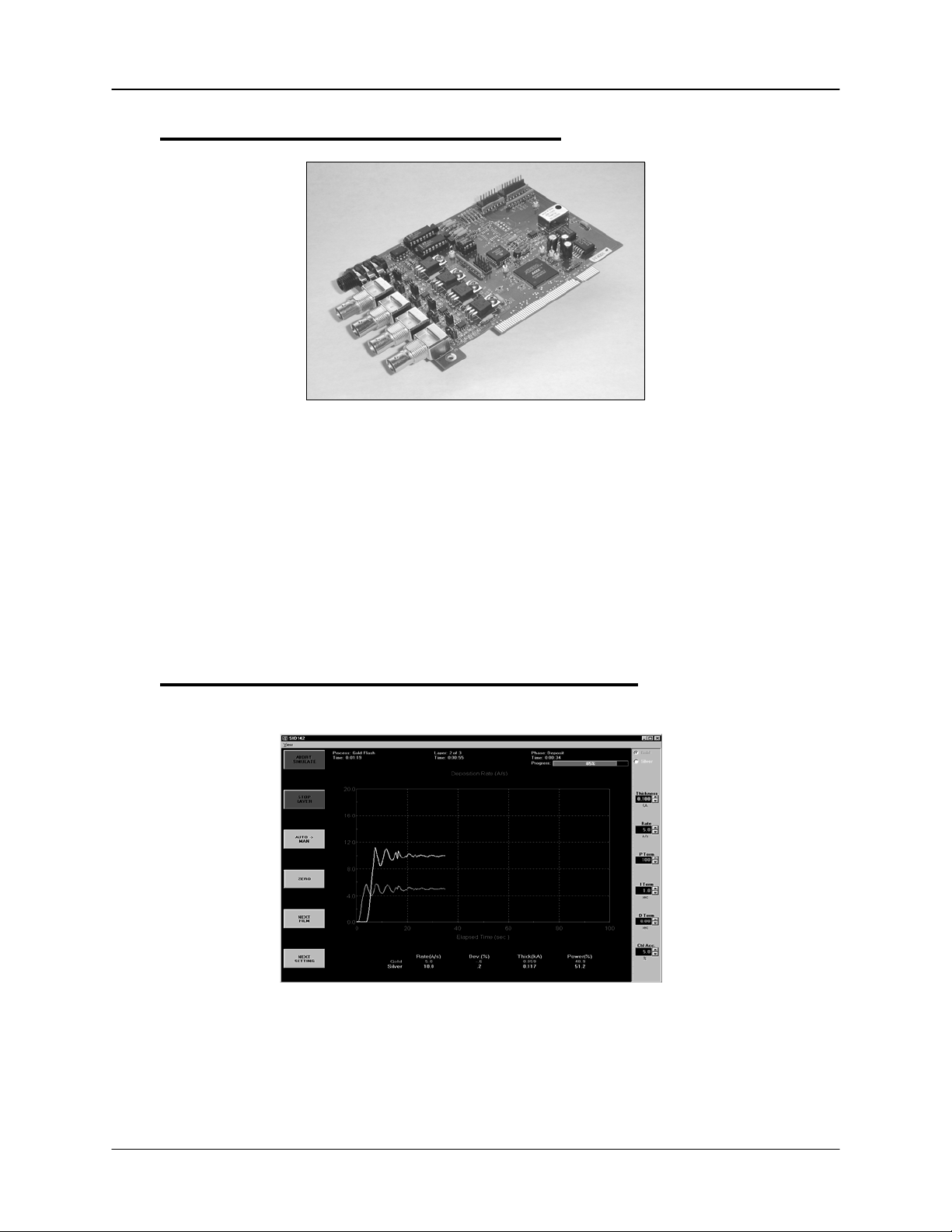

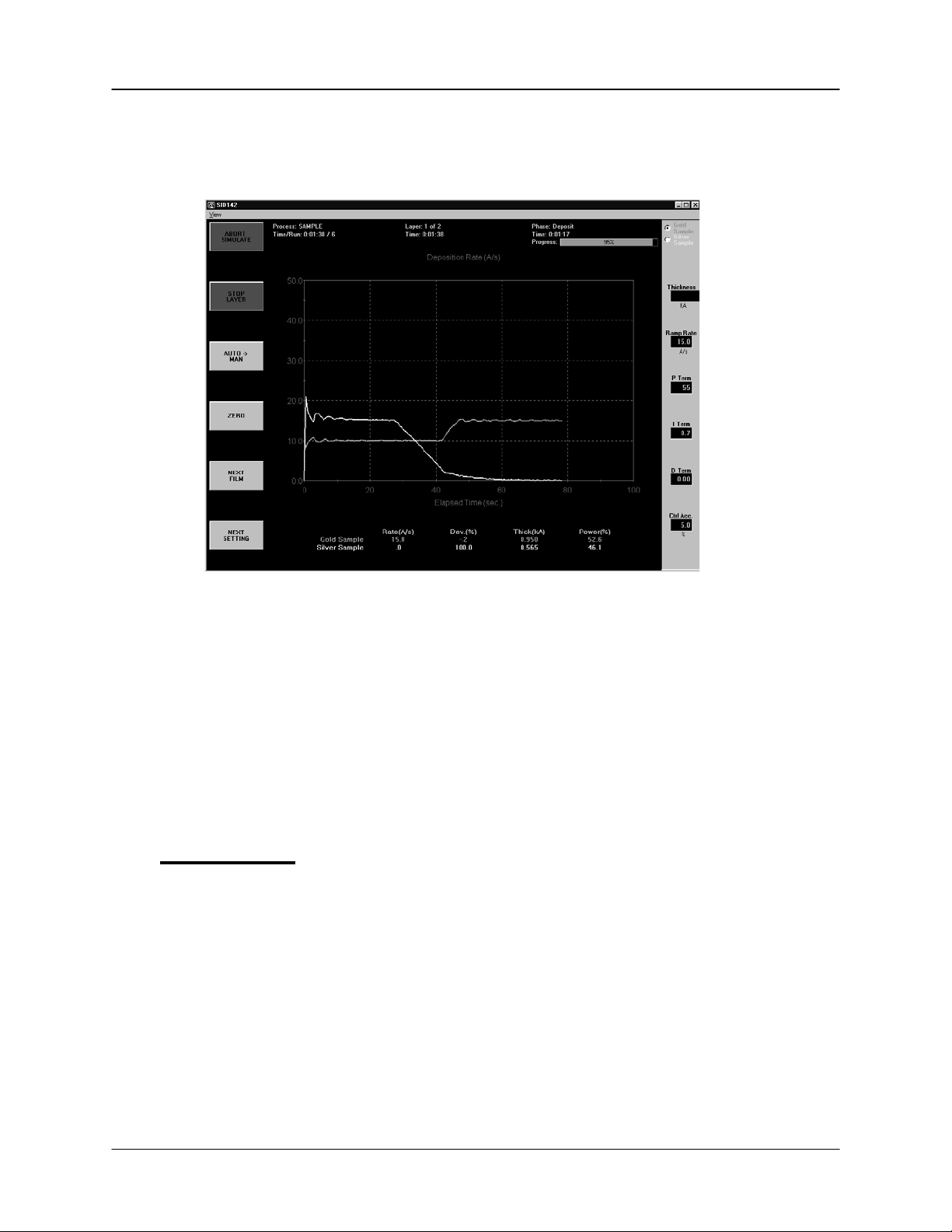

As shown below, the initial deposition rate was 10 Å/s until a thickness of .400 kÅ.

Then the deposition rate was ramped up to 15 Å/s, and held until the desired final

thickness of 1.000 kÅ is achieved. At this point, this single-layer process is finished.

Deposition Phase with one Rate Ramp

You should adjust the PID parameters on the setting ribbon, then Start/Stop the process

several times to become familiar with their effect on control loop response.

2-10

Page 23

Chapter 2 Quick Start

2.6 SoftKey Functions

As you have seen, the SoftKey functions remain constant during deposition. Spend a

few minutes to become familiar with each of these SoftKey functions.

START

PROCESS

ABORT

PROCESS

START

LAYER

STOP

LAYER

NEXT

LAYER

AUTO->MAN

MAN->AUTO

ZERO

NEXT

FILM

NEXT

SETTING

Starts the first layer of a process when START is pushed. If

AUTO->MAN is shown on the third SofKey (AUTO Mode) the

process starts PreConditioning. If MAN->AUTO is shown on

the third Softkey (MANUAL mode) the process immediatly

starts Deposition under PID loop control.

Aborts the process. The process can only restart at the first

layer.

Starts a stopped layer, or a layer that has been designated

“Manual Start” in the process database. Starts the layer based

on the state of the AUTO->MAN SoftKey as described above.

Stops the current layer. Also changes the function of the first

SoftKey to NEXT LAYER.

Abandons the current layer and moves to the next layer in the

process. If it is the last layer of a process, the same as

pushing ABORT PROCESS.

When AUTO->MAN is pushed, the source output is set to

manual control.. You may adjust the output using the settings

ribbon. Because the PID loop is not running, you can manually

set the output power to different levels and observe the

associated deposition rate.

Returns the output to PID loop control. If the process is

running (ABORT PROCESS and STOP LAYER shown on the

first two SoftKeys) depsoition continues. If the process is

stopped, sets the output to zero and awaits a start command.

Resets the thickness reading to zero.

Sequences the setting ribbon through each Film in a

codeposition layer.

When the settings ribbon is shown, sequences the setting knob

action through each of the displayed parameters.

2-11

Page 24

Chapter 2 Quick Start

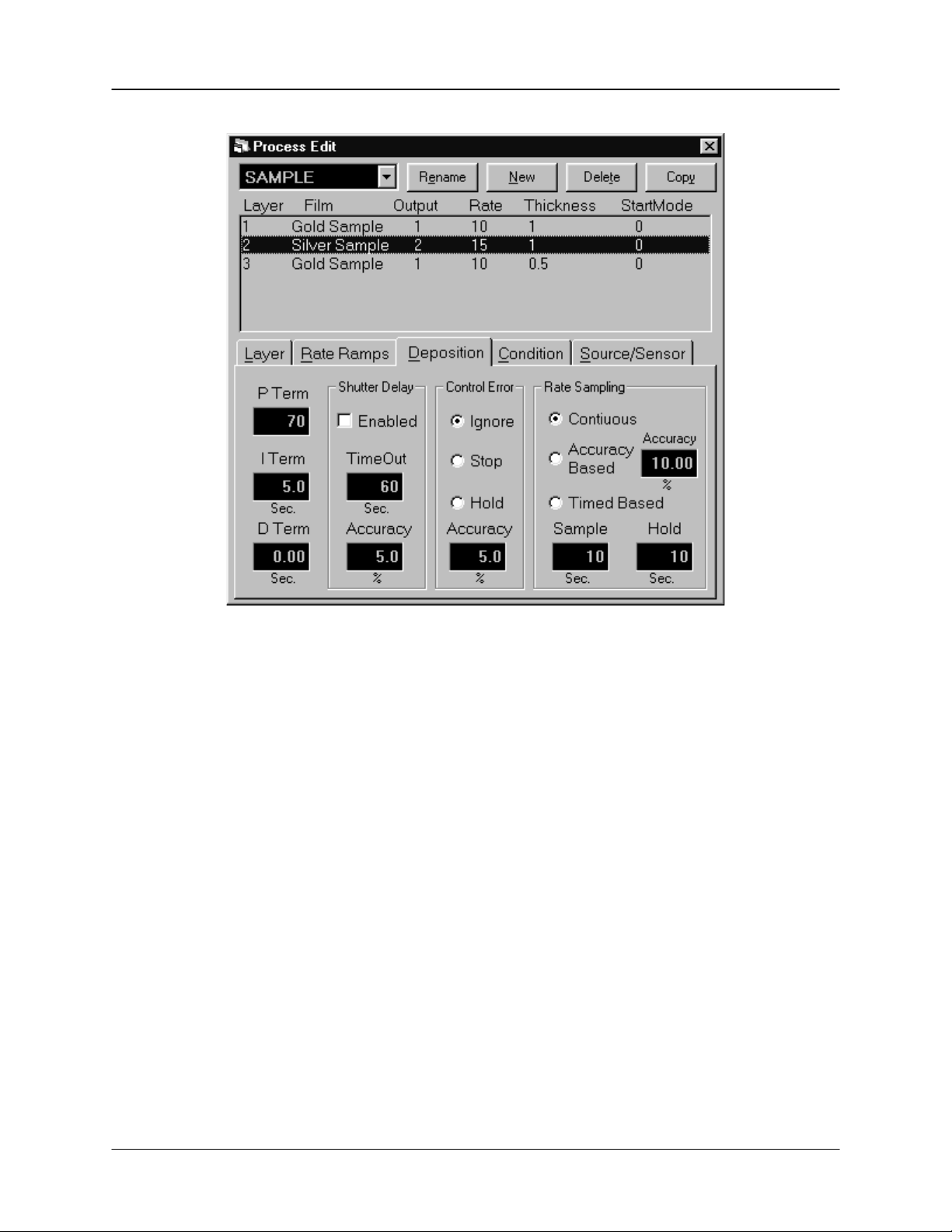

2.7 Multi-Layer CoDeposition Process

Our final example builds on the previous sections. If you have modified the setup of

your process, return to Section 2.4 and adjust the process to those values. When your

single-layer process matches Section 2.4, complete these steps:

Duplicate a

Layer

Select a

CoDep Film

Add a

CoDep Layer

Open the Edit Process dialog. Click on Layer 1, click the

“Layer” tab, then click “Copy Layer.” Now click “Paste Layer.”

A duplicate Gold Sample film will be added as Layer 2. Click

“Paste Layer” again to add a third Gold Sample layer.

Select Layer 3 in the layers list. Now select “Silver Sample” in

the films dropdown. The layers list will update to show the new

Silver Sample film assigned to Layer 3.

Select Layer 3 in the layers list, then click “Cut Layer.” Now

select Layer 1. Click “Paste CoDep.” The Silver Sample film

will be added below Gold Sample as a codeposition layer.

(Your setup should match the picture below.)

We now have two layers in our process. Layer 1 has Gold being deposited from source

Output 1 and Silver is being codeposited on Output 2. Layer 2 is Gold alone.

2-12

Page 25

Chapter 2 Quick Start

Hint: It’s usually best to copy a layer, then paste several temporary layers of that

type. Next, assign the films that you want to each of the pasted layers. When

selecting films for codeposition, remember that each film in a codeposited layer must

be assigned to a different source output! Now use “Cut Layer” on the temporary

layers, and “Paste CoDep” to assign the film to the desired codeposition layers.

Review this example until you are comfortable with these concepts.

Edit Layer 1

Rate & Thickness

Edit Layer 2

Rate & Thickness

Set Layers to

Auto Start

Click Silver Sample in the list of layers. Set “Initial Rate” to 15

Å/s, “Final Thickness” to 1.000 kÅ. Click the Rate Ramps tab

and adjust “Start Thickness” to 0.400 kÅ, “Ramp Time” to 15

seconds, and “New Rate” to 0 Å/s.

Click the Layer Tab, then click Layer 2. Set Final Thickness to

.5000 kÅ.

At the end of deposition, you may choose to have the next

layer wait for a Start Layer command, or to start automatically.

Select each Layer in the layers list, then click Auto to set that

layer to start automatically.

Verify that your process matches the one shown above.

Edit Silver

Deposition

Select the “Deposition” tab and the Silver Sample layer. Set

each parameter to the values shown below.

2-13

Page 26

Chapter 2 Quick Start

2-14

Page 27

Chapter 2 Quick Start

Edit Silver

Conditioning

Select the “Condition” tab and the Silver Sample layer. Set

each parameter to the values shown below.

Save Edits

Start

Process

Preconditioning of the two materials is entirely independent. If the preconditioning of

one layer takes longer than the other, the start times are adjusted so that the end times

coincide.

When preconditioning ends, codeposition of the two materials begins.

Click “Close Form” or press the first SoftKey to save this twolayer codeposition process. Answer Yes if it displays the “Do

you want to change….” message box to make this the current

process.

Press the “START SIMULATE” SoftKey to start the first layer

preconditioning phases. Note that two outputs are displayed

for this codeposition layer.

2-15

Page 28

Chapter 2 Quick Start

Your response should be similar to the graph shown below (your vertical scale may be

slightly different). The slight ringing on the waveforms indicates some further tuning

may be desired. However, this is an example of a reasonably well tuned loop.

At .400kÅ thickness, the Silver Sample deposition rate ramps down from 15Å/s to 0.

Similarly, at .400 kÅ thickness the Gold Sample film ramps to a higher deposition rate of

15Å/s. Because the initial rate for Gold was set lower than the initial rate for Silver,

Gold reached its .400 kÅ thickness rate ramp trigger later in the deposition cycle.

Try a P Term in the 25-30 range (less gain) for both Gold and Silver to decrease the

loop susceptibility to noise. Increasing the I Term a little, say toward 1.0, will lessen

overshoot during rate changes. The D term can be thought of as a “dead band” term.

Most systems require little or no D term.

2.8 Conclusion

Once again, spend some time with this process to become familiar with its setup, and

the effect of changes on deposition performance.

Because we selected Simulate Mode at the beginning of this Quick Start session, the

SQM-242 card is “faking” an actual process. You can use the Simulate feature at any

time to become familiar with SID-242 operation, and the effect of various settings on

process performance. It is also a very useful feature for pre-testing your process

setups. Return to the Setup menu, then select System and set the Mode to Normal to

begin running your process with the SID-242 controller.

2-16

Page 29

Chapter 2 Quick Start

This page left blank for your notes.

2-17

Page 30

Chapter 2 Quick Start

2-1

Page 31

Chapter 3 SQS-242 Software

3.0 Introduction

The SQS-242 Deposition Control Software works with Sigma Instrument’s SQM-242

Card to provide an inexpensive, yet powerful, PC based Thin Film Deposition Controller

that can:

Measure up to eight quartz crystal sensors simultaneously

Control up to four deposition source supplies simultaneously

Codeposit up to four films with preconditioning, multiple rate ramps, and

feed/idle phases

Graph deposition rate, rate deviation, or power output

Store process, film and material parameters in Microsoft Access

Use inexpensive PLCs for flexible and reliable external process controls

A typical deposition cycle for a thin film is shown below. The cycle can be broken into

three distinct phases: pre-conditioning (ramp/soak), deposition, and post-conditioning

(feed/idle). During pre-conditioning, power is supplied to prepare the source material for

deposition. When pre-conditioning ends, material deposition begins. During deposition,

the PID loop adjusts the evaporation source power as required to achieve the desired

deposition rate. When the desired thickness is reached, the evaporation source is set

to feed or idle power. At this point the process may be complete, or deposition of

another film layer may begin. If desired, up to four separate films can be codeposited

within a single layer. There is no limit to the total number of layers.

®

database

The SQS-242 software allows you to build the recipes and perform the operating

functions required to control all aspects of multi-layer thin film deposition. Process

recipes are stored in Microsoft Access format. There is no practical limit to the number

of processes, films, or materials that can be stored in the database.

3-1

Page 32

Chapter 3 SQS-242 Software

3.1 Installation and Registration

The SQS-242 install program is provided on CD-ROM. You can connect an external

USB CDROM to the SID-242 for CDROM program installation. A 3 ½" diskette install is

also possible by using another computer to copy the contents of each of the CD-ROM

“Disk” subdirectories to blank 3 ½” diskettes.

To install the program, start Windows, then insert the disk or CD-ROM into your

computer. Click Start, then Run, then type <d>:Setup (where <d> is the drive letter you

are using). Click OK to begin installation, and follow the on-screen prompts. When

installation is complete, you should restart your computer to load any new Windows DLL

and OCX support files.

The SQS-242 software can simulate deposition for demonstration and tutorial purposes.

However, an SQM-242 deposition controller card must be installed to actually read

sensors and control a source supply. The SQM-242 card can be installed before or

after the SQS-242 software. Consult the SQM-242 card User Manual for installation

information.

To start the SQS-242 program, click Start, Programs, Sigma Instruments, then SQS-

242. Until the software is registered, this Registration "nag" screen will appear.

Note: Press Cancel for full acces to the software for up to 30 runs. After 30 runs you

must contact Sigma Instruments to start the program. There is no work-around!

Press OK to show the unlock screen. In some cases your unlock "Name" may actually

be a number. If a valid Name and Unlock Code are entered, the program will start

normally. Otherwise, after three tries the program will start and decrement the

unregistered "run" counter.

3-2

Page 33

Chapter 3 SQS-242 Software

Note: If you enter a name of DEMO and Unlock Code of 5A8CAC8E5586268 the

software will be placed in Demo mode. All features of the software are permanently

available, except that readings from the SQM-242 card are only simulated. The Demo

mode can be disabled by entering a valid Name and Unlock Code later.

3.2 Operation

The SID-242 displays a progress bar during startup, then a User Login screen.

Note: The SQS-242 software ships with one pre-assigned user. The user name is

Super, with no Password. Do not confuse this with the registartion Name and Unlock

Code discussed in the previous section.

Select a User Name from the drop down box, type in the Password, and then click OK

to start the program.

If your software is configured for keyboardless operation, an on-screen keyboard will

appear as shown below. You can use your normal keyboard or mouse/touchpad to

“type” the password, then click Enter. See System Setup, SQM-242 Setup later in this

chapter to enable or disable the on-screen keyboard.

3-3

Page 34

Chapter 3 SQS-242 Software

An Access Level is associated with each User Name. The Access Level controls which

software functions are available to each user. For example, only users with an Access

Level of Supervisor can assign users. See the Security section of this chapter for

information on setting up users.

The remainder of this chapter covers the purpose and operation of each software

function, arranged by menu selections. For a more “operational” approach, consult the

previous Quick Start chapter.

Menus: The menus along the top of the main screen provide access to functions for

building deposition processes, configuring the hardware for your vacuum system, and

other less commonly used functions.

SoftKeys: The six switches to the left of the display are used for the normal operation of

the instrument, and to navigate the setup programs (see below for the individual switch

functions). Normally, you press the button that is adjacent to the labels on the SID-242

screen, but you can also use the mouse. Just move the cursor over the key label on

screen and single click the mouse. You can also use the keyboard F1 to F6 function

keys to simulate the front panel function switches. The SoftKeys change during

operation to address different user input requirements.

Setting Knob: The knob to the right of the display is used by the SID-242 to set

numeric data. A keyboard or the control’s up/down arrows can also be used.

TouchPad: On the SID-242, a touchpad is located below the setting knob. The

touchpad serves the same function as a normal mouse. Use the touchpad or mouse to

access the menus, and for functions not available from the six function keys.

3-4

Page 35

Chapter 3 SQS-242 Software

3.3 File Menu

Note: The current process must be stopped for the File menu to be available.

Process: Used to select a process from a list of all processes in the database. If the

process selected is different than the current process, you are prompted to confirm the

change.

Open Database: Selects a process database to be used for deposition. Remember, a

single process database may contain an unlimited number of processes, films, and

materials.

Save Database As: Saves the current process database to disk under a different name.

This is useful for saving the process database to floppy disk (for backup!), or for making

trial changes without affecting your working database.

Once again, a pop-up keyboard may appear. If you want to browse or type in the

database name, just select Cancel from the pop-up keyboard. Process databases are

saved in Microsoft Access format.

Data Logging: Saves deposition data to a .LOG text file. If an option other than “None”

is selected in the Log File section, data logging is activated. When the Start SoftKey is

pushed, process data is saved in a .LOG file in the SQS-242 installation directory

(typically: \Program Files\Sigma Instruments\SQS-242).

There are three options for file naming and logging. If “Overwrite” is selected, only the

last run of the process is saved as ProcessName.LOG. Subsequent runs overwrite the

log file. If “Append” is selected, each run is appended to ProcessName.LOG. If “Run#”

is selected, each run of the process is saved as a separate file under the format

ProcessName_Run#.LOG.

3-5

Page 36

Chapter 3 SQS-242 Software

A number of “events” can trigger a data entry in the log file. “End Deposit Phase”

records process data (rate, thickness, time, etc.) at the end of each layer’s deposit

phase. Similarly, “End Each Phase” logs data at the end of each phase (conditioning,

depositing, etc.). “I/O Events” logs data each time an external digital input or output

changes. Finally, “Timed Logging” records data at the selected time intervals

throughout the process.

There are two formats for writing data. If “Spreadsheet” is selected, each entry is a

comma-delimited line of data. If “Text” is selected, the data is formatted for easy

reading. The first few lines of the LOG file is a heading that illustrates the file format

and content. Log files can be viewed using a word processor or spreadsheet program.

Print Process: Prints the parameters for the current process to the system printer.

Select “Print to File” in the Printer Setup Menu to print the data to a file.

Print Setup: Selects and modifies the current system printer.

User Login: Displays the User Login screen so that a different user may log in. The

existing user is logged off automatically. The user Access Level changes immediately

to that of the new user.

Exit: Exits the SQS-242 deposition control program.

3-6

Page 37

Chapter 3 SQS-242 Software

3.4 Edit Menu

3.4.1 Edit: Process

A process is a sequence of film layers. Multiple films deposited in the same layer are

known as codeposition. A listing of each film in the selected process appears in the

layers list box. Films in codeposition layers are listed with the same layer number, but a

different output. Select a layer to edit its parameters in the tabbed dialog boxes.

The Edit Process dialog provides all the functions needed to develop a thin film

deposition process from the database of existing films and materials. The Layer and

Rate Ramp tabs specify the sequence of films to be deposited. The Deposition,

Condition, and Source/Sensor tabs provide control over the individual films assigned to

each layer.

Note: Edits to the Deposition, Condition, and Source/Sensor tabs will affect all

processes and layers that use the selected film!

Process: A drop down box that selects the process to be edited. Defaults to the current

process.

Rename: Edits the name of the selected process.

New: Creates a new process. Since every process must have at least one film, the first

film of the currently selected process is used.

Delete: Deletes the currently selected process from the database. There is no

undelete!

Copy: Creates a duplicate of the currently selected process.

3-7

Page 38

Chapter 3 SQS-242 Software

Layer Tab

The layer tab provides the capabilities needed to add and delete process layers, as well

as to edit the film, rate & thickness for each layer. Normally each film in a process is

run sequentially, as layers. Codeposition represents different films that are deposited

concurrently with other films, in the same layer.

Cut Layer: Removes the layer selected in the Layers list box from the process, and

places the layer on the clipboard.

Copy Layer: Places the layer selected in the Layers list box on the clipboard, without

removing it from the process.

Paste Layer: Inserts the clipboard layer above the currently selected layer in the Layers

list box. Existing layers are shifted down.

Paste CoDep: Pastes the clipboard layer as a codeposition layer at the currently

selected layer number. Films that use outputs already assigned to the selected layer

are invalid.

3-8

Page 39

Chapter 3 SQS-242 Software

Hint: To add layers to a process, it is easiest to click an existing layer in the layers

list then click Copy. Click Paste to insert several temporary layers of that type. Next,

assign the proper film to each of the layers, using the Film dropdown box.

When selecting a Film for a codeposition layer, remember that each film must be

assigned to a different source output! To change an existing layer to a CoDep layer,

highlight the existing layer and click “Cut Layer.” Next click the layer desired for

CoDep and click “Paste CoDep” to assign the selected layer. The Multi-Layer

CoDeposition Process section of Chapter 2 illustrates this concept.

Film: Selects the film that is assigned to the selected layer. Changing a layer’s film also

changes the film related parameters for that layer (i.e. preconditioning, PID, material,

etc.)

Initial Rate: Sets the initial deposition rate setpoint for the selected layer. If no rate

ramps are defined for the layer, this is the rate setpoint for the entire layer.

Final Thickness: Sets the endpoint thickness for the selected layer. When final

thickness is reached, deposition is stopped for that layer and the feed/hold phase is

entered.

Time Setpoint: Sets an arbitrary time, after deposition begins, when the time setpoint

relay is activated.

Thickness Limit: Sets an arbitrary thickness when the thickness limit relay is activated.

Auto/Manual Start: Determines whether a layer begins automatically upon completion

of the previous layer. If Manual Start is selected, the previous layer ends at its idle

power and waits for the user to push the Start Layer switch.

Substrate Index: If using a substrate indexer, assigns the substrate to a specific angle

or placement value (0-15). These values are sent to the digital I/O PLC at the beginning

of each layer for interfacing to a specific indexer. See System Setup and Digital I/O for

other settings that pertain to the substrate index.

3-9

Page 40

Chapter 3 SQS-242 Software

Rate Ramps Tab

Rate ramps cause changes to the deposition rate over time under PID control. Each

rate ramp has a starting thickness, an elapsed time to ramp to the new rate, and a new

rate setpoint. Each process layer can have an unlimited number of rate ramps.

Insert Ramp: Inserts a new rate ramp for the selected layer, at the selected position in

the rate ramps list. Existing rate ramps are shifted down.

Delete Ramp: Deletes the selected rate ramp.

Move Up: Shifts the selected rate ramp up one position.

Move Down: Shifts the selected rate ramp down one position.

Start Thickness: The thickness that triggers a timed ramp to a new rate. (Start

thickness should be greater for each subsequent ramp, and less than the final layer

thickness, otherwise the rate ramp is skipped.)

Ramp Time: The time (in seconds) to ramp to the new rate. If the rate ramp is too fast,

a PID control error may be generated.

New Rate: The new deposition rate setpoint for the selected layer.

3-10

Page 41

Chapter 3 SQS-242 Software

Deposition Tab

The deposition tab contains parameters that directly affect the deposition phase of the

process cycle.

P Term: Sets the gain of the control loop. High gains yield more responsive (but

potentially unstable) loops. Try a value of 50, then gradually increase/decrease the

value to respond to step changes in rate setpoint.

I Term: The integral term controls the time constant of the loop response. A small I

term, say .5 to 1 seconds, will smooth the response of most loops.

D Term: The differential term causes the loop to respond quickly to changes. Use 0 or

a very small value to avoid oscillations.

3-11

Page 42

Chapter 3 SQS-242 Software

Shutter Delay: It is often desirable to assure stable process control before the substrate

shutter opens. Enabling shutter delay requires that the system reach the programmed

control accuracy, and maintain that accuracy for 5 seconds, before deposition begins. If

the programmed accuracy is not reached, the process halts. If accuracy is reached, the

substrate shutter opens and deposition begins once the accuracy has been maintained

for 5 seconds. The Thickness reading is zeroed at the end of the shutter delay period.

The time out function sets the length of time the system will wait for control before

aborting.

Control Error: If the control loop cannot maintain the desired deposition rate, due to

loss of source material, excess rate ramps, or equipment malfunction, a control error

occurs. The error condition can be ignored, the process stopped (output power to 0%),

or the output power held at the same level as when the error occurred. If hold is

selected, PID control is abandoned, but the process will continue to be monitored for

thickness setpoint. The control error accuracy is the value that must be exceeded for 5

seconds to trigger a control error. Use shutter delay accuracy to assure adequate

process control before entering the deposition phase.

Rate Sampling: Rate sampling can extend the life of crystals. With rate sampling, the

deposition rate is sampled for a period of time, then the sensor shutter is closed. Power

is then held at the same level as the final power setting during the sample period.

Continuous selects no sampling; the sensor shutter remains open during deposition.

Accuracy Based sampling opens and closes the shutter at the rate required to maintain

the desired accuracy during the hold phase. Time Based sampling opens the shutter

for a fixed period of time then closes it for a fixed time.

3-12

Page 43

Chapter 3 SQS-242 Software

Condition Tab

Before deposition begins, it is often necessary to precondition the source material.

This places the system at the proper power level to achieve rapid PID control when

deposition begins.

Ramp 1: Ramp power sets the power level that is desired at the end of the ramp phase,

in % of full scale. Ramp time sets the time to ramp with a linear rate from the initial

power to the Ramp power. Soak time sets the time the output remains at the ramp

power level.

Ramp 2: Ramp 2 functions are the same as Ramp 1. Typically, Ramp 2 power is set

near the power level required to match the desired initial deposition rate.

Feed: The feed phase holds output power at the level and time required to wire feed

new material.

Idle: The Idle phase ramps the material to a state that is ready for deposition, typically

the same as Ramp 2 power.

3-13

Page 44

Chapter 3 SQS-242 Software

Source/Sensor Tab

The Source/Sensor tab controls the physical setup of the deposition system.

Material: Selects the physical deposition material

Max Power: The maximum output power allowed for the selected output. The full scale

output voltage is a function of the deposition power supply input specifications, and is

set in the SQM-242 setup. Max Power controls the maximum % of the full scale power

that can be used by this process layer.

Slew Rate: The maximum power change allowed on an output, per second. If rate

ramps or PID power requirements exceed this value, an error will occur.

Source Index: If using a source index, assigns each film to a specific pocket (one of 16

values). These values are sent to the PLC at the beginning of each layer. See the

System Setup for other settings that pertain to the source index.

Output: Assigns the selected material to one of the source control outputs. When an

output is selected, the Sensor Tooling panel changes to show only those sensors that

are assigned to that output in the Edit, System dialog. The combination of a source

output and its sensor inputs defines the deposition “control loop” for the selected

material.

3-14

Page 45

Chapter 3 SQS-242 Software

In codeposition, a layer may have multiple films, with each material using a different

output and sensor(s) for control. However, no layer can have the same output assigned

to more than one film. If you try to assign the same output to multiple films in a layer, an

error message will be displayed. Reassigning a film to a different output to eliminate

this error may impact other stored processes. If the change would create an output

conflict in another process, an error message is displayed.

Sensor Tooling: Adjusts for sensor measured deposition rates that differ from the

substrate deposition rate. A higher tooling value yields higher rates. For example, if the

sensor sees only 50% of the substrate rate, set the value to 200%. Setting Tooling to

0% causes a sensor to be ignored for this film.

3-15

Page 46

Chapter 3 SQS-242 Software

3.4.2 Edit: Films

The Edit Films dialog provides a subset of the functions of the Edit Processes dialog.

The functions are those that pertain only to a specific film.

NOTE: Edits to a Film will affect all processes and layers that use that film!

Film: A drop down box that selects the film parameters displayed in the edit film dialog

box. Defaults to the current process film.

Rename: Edits the name of the selected film.

New: Creates a new film.

Delete: Deletes the currently selected film from the database. A film cannot be deleted

if it is used in ANY database process!

Copy: Creates a duplicate of the currently selected film.

The function of each Edit Films tab, and its associated controls, are identical to those

detailed in the Edit Processes section. Please consult 3.4.1 for that information.

3-16

Page 47

Chapter 3 SQS-242 Software

3.4.3 Edit: Materials

The Edit Material dialog provides the functions needed to build a materials database. In

addition to the functions listed below, the main screen function keys provide capabilities

to add/edit/delete materials.

Material: Selects a material to edit.

Density: Sets the density for this material. Material density has a significant impact on

deposition calculations.

Z-Factor: Sets the Z-factor, an empirically determined measure of a material’s effect on

quartz crystal frequency change. Z factor has no effect on measurements when using a

new crystal. If the Z Factor for your material is not known, using crystals with >80% life

will eliminate the Z Factor term.

See the Appendix for a list of standard Material Parameters (Density and Z-Factor).

3-17

Page 48

Chapter 3 SQS-242 Software

3.4.4 Edit: System

Sets the operation of system Sensors, Sources, Digital I/O, and SQM-242 measurement

card(s).

Sensors Tab

Sensor Name: A meaningful name assigned to sensors 1 to 4 in single card systems; 1

to 8 in two card systems. For clear display, keep the name to less than 8 characters.

Sensor Output: The source output that a sensor is positioned to measure. Typically

each sensor measures deposition from a particular source. If multiple sensors are

assigned to a single output, the sensor readings are averaged when calculating rate

and thickness. Setting a sensor’s Tooling to 0% in Film setup can override this

assignment and disable a sensor - see the Sensor Tooling section.

Sensor Dual: Indicates that a pair of sensors is setup as primary/secondary duals.

When the primary sensor fails, the SQS-242 switches to the secondary sensor.

Max/Min/Initial Frequency: The frequency values for the quartz crystal sensors used

as inputs to the SQM-242. Sensor readings outside the min/max values cause an error.

Completion Timer: If Complete Signal is checked, the process will halt if a move

complete signal is not received within this timeout period. If Complete Signal is not

checked, the process waits for this fixed time period before starting a layer.

Complete Signal: Check this box if your substrate index sends a signal designating

that the move is complete and preconditioning can begin.

3-18

Page 49

Chapter 3 SQS-242 Software

Sources Tab

Output Name: A meaningful name assigned to SQM-242 outputs 1 and 2 in single card

systems; 1 to 4 in two card systems. For clear display, keep the name to less than 8

characters.

Full Scale: The input voltage required by the deposition source power supply to

produce 100% output power. Positive or negative full scale values are possible.

Completion Timer: If Complete Signal is checked, the process will halt if a move

complete signal is not received within this timeout period. If Complete Signal is not

checked, the process waits for this fixed time period before starting a layer.

Complete Signal: Check this box if your source index sends a signal designating that

the move is complete and preconditioning can begin.

Test Output: Useful for testing source wiring and Full Scale voltage settings. Select an

output, then click Send to set the SQM-242 card output to its Full Scale voltage. Click

Clear to return the selected output to 0 volts.

3-19

Page 50

Chapter 3 SQS-242 Software

Digital IO Tab

The SID-242 uses an inexpensive PLC to provide digital I/O capabilities. The Digital I/O

tab assigns deposition events (i.e. open shutter, start deposit, final thickness, etc.) to

the available relays and inputs on the PLC.

Note: Omron CPM series PLCs number relays from 10.00 to 10.07, then 11.00 to

11.07. These correspond to Relays 1 to 16 on the Digital I/O tab. Similarly, inputs 0.00

to 0.11 on the Omron PLC correspond to inputs 1 to 12 on this screen.

Relay Events: The relay events dropdown box lists the deposition events that can

cause a relay output to be activated. To assign a deposition event to a relay, click the

Relay #, then select the desired event from the dropdown box. As you click each

Relay#, the dropdown will change to show its currently assigned event. A description of

each relay (output) event follows:

Source Shutter 1 and 2 (and 3-4 for a Dual Card System)

These 2 relays are used to control the Shutter that covers your deposition source.

When you enter the deposit phase, the appropriate relay will close its contacts, which

causes the shutter to swing out of the way. When the deposit phase finishes the shutter

relay contacts open.

Sensor Relays 1 through 4 (and 5-8 for a Dual Card System)

These 4 relays are used to control sensor shutters. Their function depends on whether

you have single or dual sensors.

3-20

Page 51

Chapter 3 SQS-242 Software

If Dual Sensor is not selected (i.e. a single sensor), the relay contacts are closed when

you are in a layer with the sensor enabled. As an example, let’s say you have sensors

1 and 3 enabled for Film 1 and sensors 2 and 4 enabled for Film 2. When you start Film

1, the contacts for Sensor Relays 1 and 3 will close. When you start Film 2, these

contacts open and the contacts for Sensor Relays 2 and 4 will close.

If you have the SQS-242 software configured for dual sensors, the operation of these

relays is considerably different. Dual sensors use either Sensor Inputs 1 and 2, or

Inputs 3 and 4. In this case, only Sensor Shutter Relays 1 and 3 have meaning, Relays

2 and 4 are always open. With the relay contacts open, Sensors 1 and 3 are selected.

If a Crystal Fail is detected during the running of a film, the Sensor Shutter Relay’s

contacts will close for the duration of that film. This selects the second sensor in the

Dual Sensor assembly for the remainder of the film.

Xtal All Good and Xtal All Fail Relays

These two relays provide an indication of the general health of your sensors. If the Xtal

All Good Relay is closed, then all enabled sensors are returning a valid reading. If the

Xtal All Fail Relay is closed, none of the enabled sensors are returning a valid reading.

Process Stopped and Running Relays

These relays indicate the overall status of the process. The Process Running relay

closes as soon as Start Process is selected (by front panel or digital input), and opens

when Abort Process is selected. Even if a layer is stopped within a process, the

Process Running relay remains closed until the last film of a process has finished. The

Process Stopped relay contacts behave in the inverse manner.

Process Active

This relay action is similar to the Process Running relay, except it will open if the

process is temporarily halted for any reason, e.g. a Manual Start layer.

Layer Stopped and Running Relays

The Layer Running relay closes as soon as Start Layer is selected (by front panel or

digital input), and opens when Stop Process is selected. The Layer Stopped relay

contacts behave in the inverse manner.

Deposit Phase Relay

This relay indicates that you are in the deposit phase of a film. It is like having the two

Source Shutter Relays connected in parallel. If you have shutter delay enabled, this

relay will wait until the end of the shutter delay before going active.

Pre-Cond Phase Relay

This relay closes for the preconditioning phases (Ramp1, Soak1, Ramp2, Soak2) of a

film.

3-21

Page 52

Chapter 3 SQS-242 Software

Soak Hold Phase Relay

This relay closes for the Soak and Hold phases after deposition.

Manual Mode Relay

Closes when the program is placed in Manual mode.

Max Power Relay

Closes when any control voltage output is at the programmed maximum power level.

Thickness Setpoint Relay

This relay will become active when the Thickness Setpoint is reached. This is a

programmable process parameter.

Time Setpoint Relay

This relay will become active when the Time Setpoint has been reached. This is

measured from the beginning of the deposit phase, and is a programmable parameter.

Input Events: The input events dropdown box lists the deposition events that can be

caused by an external digital input. To assign a deposition event to an input, click the

Input #, then select the desired event from the dropdown box. As you click each Input#,

the dropdown will change to show its currently assigned event. A brief description of

each input event follows:

Start Process Input

Triggering this input is the same as pushing the Start Process button.

Abort Process Input

Triggering this input will abort the process.

Start Layer Input

Triggering this input will start or restart the current layer.

Stop Layer Input

Triggering this input will stop the current layer.

Start Next Layer Input

Triggering this input will skip the current layer and start the next layer.

Zero Thickness Input

This will zero the thickness. It is identical to pressing the Zero Button.

Force Final Thickness Input

Triggering this input has the same as effect reaching Final Thickness setpoint.

3-22

Page 53

Chapter 3 SQS-242 Software

PLC Tab

Comm Port: Selects the serial port used to communicate with the PLC. The Comm

Port drop down lists the available ports. However, some of the ports may be used by

other devices (modem, mouse, etc.). Select Disabled to prevent I/O from using the

PLC.

Address: Several PLCs can be controlled from a single computer Comm Port by

connecting their expansion ports. The slave address of each such PLC is usually set by

a rotary or dip switch, and must be unique. Single PLC systems usually use Address 0.

Consult your PLC User Manual.

Test: The Test section provides a simple means of testing your PLC communications

and digital I/O wiring. To set a relay on the PLC, go to the Digital I/O tab and find which

I/O event is assigned to that relay. On the PLC tab, select the same event in the Test

Relay dropdown, then click Set. The assigned Relay# should close. Click Clear to

open the relay. Use the Source and Substrate Move sections to test indexers.

To test a digital input, find the Input# that is assigned to an event on the PLC tab.

Select the input event in the dropdown, then click Read Input to verify the state of the

PLC input.

Registers: The PLC used for I/O runs a small monitor program that transfers relay and

input states from the PLC connecting block to internal registers. The SQS-242 software

reads/writes to those registers though the PLC’s Comm port. The registers shown are

those that have been programmed for your PLC. Because their redefinition is not a

trivial task, these values cannot be changed in the SQS-242 program. Contact Sigma

Instruments if you need to change the internal PLC register definitions.

3-23

Page 54

Chapter 3 SQS-242 Software

SQM-242 Tab

Normal/Simulate: In Normal mode, the SQS-242 gets readings from the SQM-242

card(s). In Simulate mode, the SQS-242 generates simulated readings even if a card is

not installed. Useful for testing new processes and learning the software.

Note: In Simulate Mode, a deposition rate is not “measured” until the output power

exceeds 50%.

Period: Sets the measurement period between .2 seconds (5 readings per second) and

2 seconds. A longer period gives higher reading accuracy, especially at low rates.

Filter: Sets the number of readings used in the reading filter. A low setting gives rapid

response to process changes, high settings give smoother graphs.

Address: Sets the address of the SQM-242 ISA card in the computer’s address space.

See the SQM-242 Chapter of this manual for detailed setup instructions.

Interrupt: Sets the interrupt used by the SQM-242 ISA card. See the SQM-242

Chapter of this manual for detailed setup instructions.

Slave Enabled: When a second SQM-242 card is present, it enables/disables sensors

5-8 and outputs 3 and 4.

Front Panel Enabled: When used with the SRC series computer, enables/disables the

SQS-242 software to read the SoftKeys and setting knob.

SQM-242 Revision: Firmware revision of the SQM-242 card.

3-24

Page 55

Chapter 3 SQS-242 Software

Comm Tab

RS-232 Port: Selects the comm port used for serial communications with another

computer. This is NOT the same port used by the PLC for I/O. The Comm Port drop

down lists available ports. However, some of the ports may be used by other devices

(PLC, modem, mouse, etc.).

Baud Rate: Sets the baud rate used for serial communications.

Ethernet Port: Sets the TCP/IP port used by the SQS-242 software for Ethernet

communications, 1001 is a typical value.

Ethernet Name: Sets the name of the external computer the software will be

communicating with. The name is either an IP address (xxx.xxx.xxx.xxx) or the Name

assigned in the Windows Network setup. It is NOT the name or IP address of the

computer the SQS-242 software is installed on.

Receive Data: Displays the Query and Update requests received from the Comm and

Ethernet port. See Appendix B for a description of the serial communications protocol.

Transmit Data: Displays the response to Query and Update requests received from the

Comm and Ethernet port.

Note: The Monitor section does not show communications with the PLC.

3-25

Page 56

Chapter 3 SQS-242 Software

3.4.5 Edit: Security

The Security menu assigns Users, their Password, and their Access Level. It also

provides a flexible way to assign program functions to different Access Levels.

Note: The Security dialog is available only to users with Supervisor Access.

Users Tab

User: Drop down used to select an existing user, to edit their Access or Password. It is

not possible to edit or add a user name in the User drop down. Use the New SoftKey to

create a new User. Use the Delete SoftKey to delete the selected user.

Access: Assigns a program access level to the selected user. Generally speaking,

Supervisor (SUPV) provides access to all program functions. Technicians (TECH) have

access to a subset of functions. While User level access (USER) has access to only

those functions needed to run deposition processes. See the Access Tab section to

assign SUPV, TECH, and USER program capabilities.

Password: Each user will typically have their own password. When a password is

entered, a second box will appear for password confirmation. If the Password box is left

blank, no Password is needed for that user to login.

3-26

Page 57

Chapter 3 SQS-242 Software

Access Tab

The Access tab allows Supervisors to assign which menu selections are available to

each of the three Access Levels. When a program menu is assigned to a particular

access level, it is automatically available to higher access levels.

In the example below, every user has access to the File Process menu and the File Exit

menu. Only Supervisors have access to the Edit System and Edit Security menus. The

remaining menus are assigned TECH access. They will be available to TECH and

SUPV users, but not to USER access users.

Those who login with USER access can select and run processes, but they cannot edit

process parameters. TECH’s can also select and run processes (because those

functions are assigned to a lower level access). However, TECH’s can also edit

process parameters. Only Supervisors can change System Setup or Security

assignments.

3-27

Page 58

Chapter 3 SQS-242 Software

3.5 View Menu

The view menu controls the appearance of the main display.

Film Settings: Displays/hides a ribbon of commonly accessed process settings along

the right of the screen. Additional process parameters are available in the Edit menu.

When displayed, the settings ribbon allows the user to easily modify process settings

during deposition without leaving the main screen. Changes are made to the current

process and the process database immediately. In codeposition, first click on the

desired film to display its parameters.

Film Readings: Displays/hides film deposition readings along the bottom of the screen.

Readouts of Film, Rate, Deviation, Thickness, and Power are displayed simultaneously

for each of the active outputs. The rate, deviation, and thickness readings displayed

represent an average of the quartz sensors assigned to each film.

Sensor Readings: Displays/hides a pop up window of sensor rate, thickness,

remaining life, and frequency readings. Unlike the main screen’s Film Readings, this

display is the raw data coming from each sensor. In addition, the output (i.e. PID

control loop) that each sensor is assigned to is displayed. Sensor assignments are

established in the SQM-242 Setup menu.

Rate Graph: Fixes the main graph to deposition rate. Deposition rate is useful during

the shutter delay, rate ramp, and deposition phases. During other phases, the power

output graph is usually more useful.

Deviation Graph: Fixes the main graph to display percent deviation from the rate

setpoint. Rate deviation is useful for fine tuning the PID control loop.

Power Graph: Fixes the main graph at output power. Output power is directly adjusted

during the preconditioning, feed, and hold phases. Output power is also useful during

the deposition phases to detect error conditions, which cause oscillations. Be sure the

Full Scale voltage is set properly in the SQM-242 Setup menu.

Automatic: Changes the main graph to display the most pertinent information for each

deposition phase. During preconditioning, output power is displayed. During shutter

delay, rate ramps, and deposition, the main graph displays deposition rate. During feed

and hold phases, the graph reverts to output power.

3-28

Page 59

Chapter 3 SQS-242 Software

3.6 Software Specifications

Display

Graphs ................................................................................. Rate, Deviation, Power

Readouts .............................................................................. Rate,Dev,Thick,Power

Process Parameters

Name .................................................................................... 12 characters

# Processes ......................................................................... Unlimited

# Layers ............................................................................... Unlimited

# Sensors (Dual) .................................................................. 1 to 8 (4 Dual)

# Sources ............................................................................. 1 to 4

Layer Parameters

Start Mode ............................................................................ Auto/Manual

Rate ...................................................................................... 0.0 to 999.9 /sec.

Thickness ............................................................................. 0.0 to 999.9

Thickness Limit .................................................................... 0.0 to 999.9

Time Setpoint ....................................................................... 0 to 30000 sec.

# Rate Ramps ...................................................................... Unlimited

Rate Ramp Start................................................................... 0.0 to 999.9

Rate Ramp Time .................................................................. 0 to 1000 sec.

New Rate ............................................................................. 0.0 to 999.9 /sec.

Substrate Index .................................................................... 0 to 15

Film Parameters

Name .................................................................................... 12 characters

Ramp Time (1,2) .................................................................. 0 to 30000 sec.

Soak Power (1,2) ................................................................. 0.0 to 100.0 %

Soak Time (1,2) .................................................................... 0 to 30000 sec.

Shutter Delay Time ............................................................... 0 to 200 sec.

Shutter Delay Error ............................................................... 0.0 to 30.0 %

P Term ................................................................................. 1 to 9999

I Term ................................................................................... 0 to 99.9 sec.

D Term ................................................................................. 0 to 99.9 sec.

Control Error ......................................................................... Ignore/Stop/Hold

Control Error Set .................................................................. 0 to 30.0 %

Feed Ramp Time.................................................................. 0 to 30000 sec.

Feed Power .......................................................................... 0.0 to 100.0 %

Feed Time ............................................................................ 0 to 30000 sec.

Idle Ramp Time .................................................................... 0 to 30000 sec.

Idle Power ............................................................................ 0.0 to 100.0 %

Tooling (Sensor 1 to 8) ......................................................... 10.0 to 999.0

Max Power ........................................................................... 0.0 to 100.0 %

Slew Rate ............................................................................. 0.0 to 100.0 %/sec.

Source Index (Pocket) .......................................................... 0 to 15

3-29

Page 60

Chapter 3 SQS-242 Software

Material Parameters

Name .................................................................................... 12 characters

Density ................................................................................. .0.40 to 99.99 gm/cm

Z-Factor ................................................................................ 0.100 to 9.900

Computer Interface

Type ..................................................................................... RS-232

Protocol ................................................................................ Text string with checksum

Digital Inputs (available only with PLC option)

Start Process ........................................................................

Stop Process ........................................................................

Start Layer ............................................................................

Stop Layer ............................................................................

Start Next Layer ...................................................................

Zero Thickness .....................................................................

Force Final Thickness .........................................................

Substrate Index Complete

Source Index Complete

Relay Outputs (available only with PLC option)

Source Shutter ..................................................................... 1 to 4

Sensor Shutter ..................................................................... 1 to 8