HP LSG202A, LSG202M, LSGX202M, LSGX202A, LSG203M User Manual

...

Installation Manual |

5647000F |

|

|

|

|

Omnivore Sewage and Grinder Pumps

Models:

LSG202A |

2 hp, 208-230V, 1 phase, Automatic |

LSG202M |

2 hp, 208-230V, 1 phase, Manual |

LSG203M |

2 hp, 208-230V, 3 phase, Manual |

LSG204M |

2 hp, 460V, 3 phase, Manual |

|

|

LSGX202A |

2 hp, 2-Stage, 208-230V, 1 phase, Automatic |

LSGX202M |

2 hp, 2-Stage, 208-230V, 1 phase, Manual |

LSGX203M |

2 hp, 2-Stage, 208-230V, 3 phase, Manual |

LSGX204M |

2 hp, 2-Stage, 460V, 3 phase, Manual |

*Do not throw away or lose this manual. Keep it with the installation and refer to it often.

Contents

•General Information

•Introduction

•Mechanical Installation

•Electrical Connection

•Operation

•Warranty

7000 Apple Tree Avenue Bergen, NY 14416 Phone: (800) 543-2550 Fax: (585) 494-1839 www.libertypumps.com

IMPORTANT:

Prior to installation, record Model, Serial Number, and Code Number from pump nameplate for future reference.

MODEL _____________________

SERIAL _____________________

CODE _____________________

INSTALLATION

DATE _____________________

©Copyright 2008 Liberty Pumps Inc. All rights reserved

Table of Contents

SECTION |

1 |

GENERAL INFORMATION------------------------------------------------------------------------------ |

3 |

SECTION |

2 |

INTRODUCTION-------------------------------------------------------------------------------------------- |

4 |

SECTION |

3 |

MECHANICAL INSTALLATION ----------------------------------------------------------------------- |

4-6 |

SECTION |

4 |

ELECTRICAL CONNECTION-------------------------------------------------------------------------- |

6-8 |

SECTION |

5 |

OPERATION ------------------------------------------------------------------------------------------------ |

8 |

|

|

TROUBLESHOOTING CHART ------------------------------------------------------------------------ |

9 |

|

|

PANEL INSTALLATION SHEET----------------------------------------------------------------------- |

10 |

|

|

TYPICAL INSTALLATION DRAWING----------------------------------------------------------------- |

11 |

|

|

PERFORMANCE CURVE------------------------------------------------------------------------------- |

12 |

SECTION |

6 |

WARRANTY------------------------------------------------------------------------------------------------- |

13 |

©Copyright 2008 Liberty Pumps Inc. All rights reserved |

- 2 - |

1. General Information

Before installation, read the following instructions carefully. Each Liberty pump is individually factory tested to insure proper performance. Closely following these instructions will eliminate potential operating problems, assuring years of trouble-free service.

•Risk of electric shock. Always disconnect the pump from the power source before handling or making adjustments.

•The electrical connections and wiring for a pump installation should only be made by qualified personnel.

•This pump is supplied with a grounding conductor and grounding-type attachment plug. To reduce the risk of electric shock, be certain that it is connected only to a properly grounded, grounding-type receptacle.

•DO NOT bypass grounding wires or remove ground prong from attachment plugs.

•DO NOT use an extension cord.

•This pump requires a separate, properly fused and grounded branch circuit. Make sure the power source is properly sized for the voltage and amperage requirements of the pump, as noted on the nameplate.

•The electrical outlet shall be within the length limitations of the pump power cord, and at least 4 feet above floor level to minimize possible hazards from flood conditions.

•The installation must be in accordance with the National Electric Code, Uniform Plumbing Code, International Plumbing Code, as well as all applicable local codes and ordinances.

•Sump and sewage pumps often handle materials which could cause illness or disease. Wear adequate protective clothing when working on a used pump or piping.

•Never enter a pump basin after it has been used. Sewage and effluent can emit several gases which are poisonous.

•Keep clear of suction and discharge openings. To prevent injury, never insert fingers into pump while it is plugged in.

•DO NOT use this product for flammable or corrosive liquid.

•DO NOT use this product in applications where human contact with the pumped fluid is common (such as swimming pools, fountains, etc.)

•NEVER dispose of materials such as paint thinner or other chemicals down drains, as they can chemically attack and damage pump components, potentially causing product malfunction or failure.

•Do not use these pumps in water over 140° F.

•The Uniform Plumbing Code (UPC) states that sewage systems shall have an audio and visual alarm that signals a malfunction of the system, to reduce the potential for property damage.

|

Model |

|

|

HP |

|

|

Volts |

|

|

Phase |

|

|

Full Load |

|

|

FNPT |

|

|

Automatic or |

|

|

|

|

|

|

|

|

|

|

Amps |

|

|

Discharge |

|

|

Manual* |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LSG202A |

2 |

|

208/230 |

|

1 |

|

15 |

|

|

1.25” |

|

Automatic |

|||||||

|

LSG202M |

2 |

|

208/230 |

|

1 |

|

15 |

|

|

1.25” |

Manual |

||||||||

|

LSG203M |

2 |

|

208/230 |

|

3 |

|

10.6 |

|

|

1.25” |

Manual |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

LSG204M |

2 |

|

440/460 |

|

3 |

|

5.3 |

|

|

1.25” |

Manual |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

LSGX202A |

2 |

|

208-230 |

|

1 |

|

15 |

|

|

1.25” |

|

Automatic |

|||||||

|

LSGX202M |

2 |

|

208-230 |

|

1 |

|

15 |

|

|

1.25” |

Manual |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

LSGX203M |

2 |

|

208/230 |

|

3 |

|

10.6 |

|

|

1.25” |

Manual |

||||||||

|

LSGX204M |

2 |

|

440/460 |

|

3 |

|

5.3 |

|

|

1.25” |

Manual |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: Manual models (“M” suffix), as designated above, require a separate approved pump control device or panel for automatic operation. Operation of these models will be according to the control selected. Make sure the electrical specifications of the control selected properly match the electrical specifications of the pump. Always refer to control panel instructions for proper installation.

©Copyright 2008 Liberty Pumps Inc. All rights reserved |

- 3 - |

2. Introduction

2-1 INTRODUCTION

This manual was prepared to assist you in the correct installation, operation, and maintenance of your Liberty pump. Please read it completely before installing the pump. Make certain that you are familiar with the contents, and the chapters on installation and operation are fully understood before running the pump.

Liberty Pumps are designed for minimal maintenance. However, regular checks will ensure longer life and greater operating reliability.

WARRANTY: No repair work should be carried out during the warranty period without prior factory approval. To do so may render the warranty void.

SERIAL #: In all correspondence and reports, make certain that the pump serial number is given.

2-2.1 DESIGN OF PUMP

The grinder pump contains metal parts that rotate at high speeds. Be careful around pump base while power is connected. Make sure that the pump is either in the tank or clear from people and wires when in operation.

1.Liberty LSG and LSGX-Series grinder pumps are designed for continuous underwater operation. The motor and pump form a close coupled, watertight unit. The induction motor is insulated against heat and moisture in accordance with Class B 265F (130C) regulations.

2.A thermal overload protector is imbedded in the stator windings. This is connected in series and wired to shut down the pump if overheating occurs. The overload switch resets automatically when the motor cools.

3.The motor is protected against damage from water entry by two seals. The lower seal is a viton lip seal. The upper seal is mechanical, consisting of two silicon-carbide faces.

4.The impeller and volute are designed for efficient flow characteristics and clog-free operation. The hardened cutters grind solids and fibrous matter into small particles that can be safely pumped through small diameter piping.

5.For sewage systems, consult local plumbing codes on requirements of venting the tank. The pump shall not be installed in locations classified as hazardous in accordance with the National Electrical Code, ANSI/ NFPA70.

NOTE: The major material of Liberty LSG and LSGX-Series pumps is cast iron. They should not be used to pump corrosive liquids.

3. Mechanical Installation

3-1 INSPECTION UPON RECEIPT

The shipping container should be immediately inspected for damage that may have occurred in shipment. Exercise care in opening the shipping container to avoid damage to the pump. Remove any blocking and cushioning from within the container.

Check all cushioning for spare parts before discarding. Visually check the pump and any spare parts for damage. Check for damaged electrical wires, especially where they exit the motor housing. Contact the Liberty Pumps Customer Service Department to report any damage or shortage of parts. Turn the hex socket head cap screw at the center of the cutter wheel on the bottom of the grinder several rotations clockwise. This will insure that the impeller and cutter are free of any seizure due to prolonged storage. If the impeller is not rotated manually prior to installation, the pump may fail to activate. If the impeller’s rotation is difficult or completely resistant, contact the Liberty Pumps Customer Service Department.

©Copyright 2008 Liberty Pumps Inc. All rights reserved |

- 4 - |

3-2 STORAGE BEFORE USE

Liberty pumps are shipped from the factory ready for installation and use. They should be held in storage if the pump station is not complete. If storage is necessary, the pump should remain in its shipping container. It should be stored in a warehouse or storage shed that has a clean, dry temperature-stable area where the pump and its container should be covered to protect it from water, dirt, dust, etc. The ends of the cables - (plugs) must be protected against moisture.

AT NO TIME SHOULD THE PUMP BE STORED WITHIN AN INCOMPLETE WET PIT. THE PUMP SHOULD NOT BE PLACED INTO THE PIT UNTIL IT CAN BE FULLY OPERATED.

LONG TERM STORAGE

1.If it is necessary to store a pump for a long period of time, it should be stored indoors in a clean, dry temperaturestable environment. The pump should be covered to protect it from dust, dirt and water. The plug end of the cable must be protected against moisture.

2.Do not allow the pump to freeze.

3.Prior to installation, the pump motor should be rotated to ensure the seals and cutters are free spinning.

4.Installed pumps which are idle for long periods of time should be manually operated through the breaker panel once a month to lubricate the seals. Turn off the breaker, unplug the piggyback switch, and plug the pump directly into the wall socket. Turn the breaker on for 30 seconds. Turn the breaker off, and then plug the piggyback switch back in. (refer to Section 4-1)

3-3 PUMP INSTALLATION

THIS PUMP IS NOT TO BE INSTALLED IN LOCATIONS CLASSIFIED AS HAZARDOUS IN ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE,ANSI/NFPA 70.

•Grinder pumps must be installed in a tank that is vented in accordance with local plumbing codes.

Installation should be at a sufficient depth to ensure that all plumbing is below the frost line. If this is not feasible, remove the check valve and size the basin and/or adjust pump differential to accommodate the additional backflow volume. Consult the factory for details on how this should be done.

The Omnivore Grinders may be guide rail mounted using Liberty's GR20 guide rail base, or stand-alone. (See Figure 3, page 11) They may be installed as a completely packaged simplex (single pump) or duplex (two-pump) system. Installation of the pump shall be in accordance with state and local codes and performed only by qualified personnel. Typical installations consist of a guide rail mount in a fiberglass, concrete or polyethylene tank. This section assumes guide rail installation.

NEVER LIFT THE PUMP BY PULLING ON THE POWER CORD.

USE THE LIFTING CHAIN OR CABLE ONLY

1.Liberty GR20 Guide Rail systems feature a self-aligning mounting bracket. Using the lifting chain, slip the pump bracket over the upper guide rail bracket. Lower the pump at an angle down the guide rail into the tank. (See

Figure 3, page 11)

2.As the pump nears its final position, the straightening rib squares the pump bracket with the guide bracket ears. When the pump bracket ears hook the guide bracket ears, the chain will slacken.

3.Grasp the lifting chain and shake the pump to ensure a good seat with the gasket. The pump is suspended by the bracket ears. The weight of the pump compresses the gasket against the mating flange of the guide bracket base.

4.The lifting chain may be removed from the hoist and hooked near the upper guide rail bracket.

©Copyright 2008 Liberty Pumps Inc. All rights reserved |

- 5 - |

IMPORTANT: For 3-phase pumps, check for proper rotation before installing pump into basin. See figure A for proper rotation.

Fig. A – Proper impeller rotation, three phase models

Check three phase pumps for proper rotation prior to installing pump(s) in basin. To change rotation, reverse any two of the three power leads to the pump. Code the wires for reconnection after installation.

Bottom View

4. Electrical Connection

AFTER THE PUMP IS INSTALLED, THE ELECTRICAL CHECKS OF SECTION 4 MUST BE PERFORMED.

4-1 PIGGY BACK SWITCH OPERATION

1.Plug the Piggyback switch into a 6-20R receptacle. The receptacle must be wired to a 30-amp breaker. Be sure to have the breaker turned off before plugging in the switch.

2.Plug the pump power cord into the piggyback switch as shown.

3.The pump is ready to test and your breaker can be turned on.

(Refer to section 5)

ALWAYS TURN OFF BREAKERS BEFORE

WORKING ON ELECTRICAL CORDS.

BE CAREFUL NOT TO DRILL OR SCREW

INTO EXISTING WIRING.

Check to make sure installation is in accordance with the National Electric Code and all applicable local codes. Installation and servicing is to be conducted by qualified personnel. This pump is supplied with a grounding conductor. To reduce the risk of electrical shock, be certain that it is connected to a properly grounded earth wire.

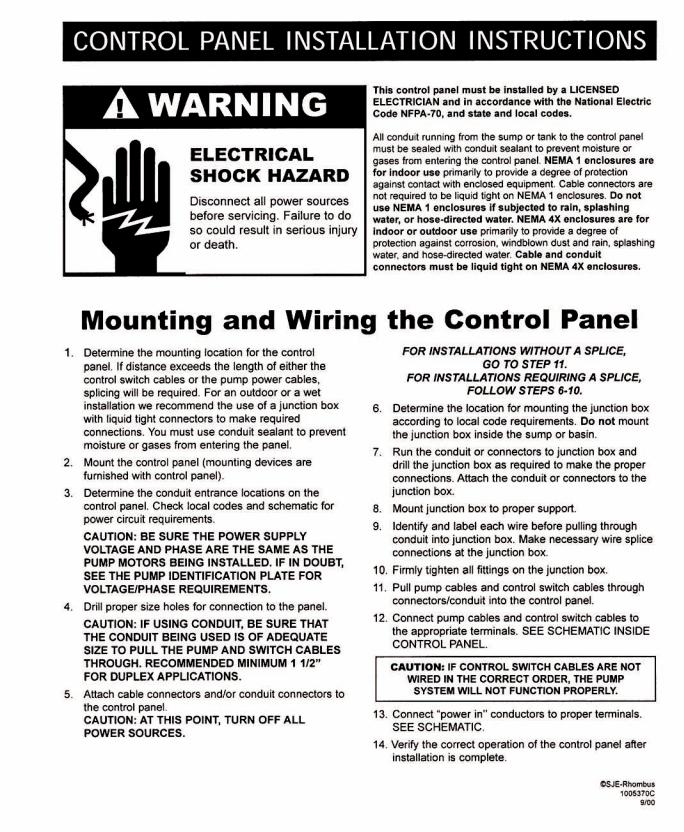

4-2 CONTROL PANEL OPERATION

REFER TO WIRING DIAGRAM INCLUDED WITH CONTROL PANEL. IF THERE IS NO WIRING

DIAGRAM, CONTACT THE MANUFACTURER TO OBTAIN ONE. DO NOT ATTEMPT TO

CONNECT PUMP WITHOUT A WIRING DIAGRAM.

1.The pump can run on a voltage rating of 230V or 208V. Check that it is the same as the supply voltage. The pumps are supplied with 6-20P (20-amp) cord plug ends. Most often the pump will be plugged into a receptacle. If your pump needs to be hard wired into a panel then the plug end will have to be removed and the leads stripped back. The connection of the pump cable leads should be carried out by a licensed electrician in accordance with the identification on the individual leads and the corresponding connections in the control panel. Refer to the wiring diagrams supplied with the panels.

©Copyright 2008 Liberty Pumps Inc. All rights reserved |

- 6 - |

2.The control panel is preferably mounted in a cool, dry environment. Installation and connections are specific to the control panel. Control panels should be installed and serviced only by a qualified electrician (Refer to Figure

2, page 10).

4-3 STEPS TO BE TAKEN BEFORE ENERGIZING

1.Retighten all field-made connections. Retighten all factory-made connections. These may have loosened due to shipping and handling vibrations.

2.Check the security of mounting hardware.

3.Check the enclosure to see that it has not been damaged in such a manner as to reduce electrical spacing.

4.Rotate the cutter wheel with the hex socket head cap screw to verify movement and lubricate the seals.

5.Ensure that no wires or other obstacles are in the way of the pump cutter.

6.Conduct an electrical insulation resistance test to make sure that the control panel is free from short circuits and ground faults. This should be done both phase-to-phase and phase-to-ground.

7.MOTOR OVERLOAD PROTECTION: The pump motor is protected from locked rotor and running overloads by a thermal overload integrally mounted to the motor. No adjustments are required.

Check to determine that all grounding connections are made properly

8.If a panel is used, remove all debris, scrap wire, etc., from the control panel interior before closing the doors. Install covers, close doors making certain that no wires are pinched and that all enclosure parts are properly aligned and tightened.

ENERGIZING THE CONTROL PANEL OR BREAKER FOR THE FIRST TIME IS POTENTIALLY DANGEROUS. LICENSED ELECTRICAL PERSONNEL SHOULD BE PRESENT WHEN THE PANEL OR BREAKER IS ENERGIZED FOR THE FIRST TIME. IF FAULTS CAUSED BY DAMAGE OR POOR INSTALLATION PRACTICES HAVE NOT BEEN DETECTED, SERIOUS DAMAGE CAN RESULT WHEN POWER IS APPLIED (REFER TO SECTION 5).

4-4 FLOAT SWITCHES

1.The pump's on and off cycles are normally controlled by a "piggy back" float switch attached to the side of the pump, or by hanging switches in the wet well. Refer to panel or switch instructions for proper electrical connection

4-4.1 FLOAT SEQUENCEPIGGY BACK (AUTOMATIC MODELS LSG202A & LSGX202A)

1.As the liquid level in the wet well rises, the float tilts, closing the switch. This starts the pump.

2.The pump runs until the liquid level falls below the “PUMP OFF” level of the float (Factory set at 7" minimum), emptying the wet well.

4-4.2 FLOAT SEQUENCESIMPLEX (MANUAL MODELS)

1.As the liquid level in the wet well rises, the “PUMP OFF” float tilts, closing the switch (This level must be set at a minimum of 7"). As the liquid level continues to rise, the “PUMP ON” float tilts. This switch closes, starting the pump.

2.The pump runs until the liquid level falls below the “PUMP OFF” float, emptying the wet well.

3.In the event of a malfunctioning float switch, control relay or pump, the liquid level rises and tilts the “HIGH LEVEL ALARM” float. The alarm system will activate.

4-4.3 FLOAT SEQUENCE-DUPLEX (MANUAL MODELS)

1.As the liquid level in the wet well rises, the “PUMP OFF” tilts, closing the switch. As the liquid level continues to rise, the “LEAD PUMP ON” float tilts. This switch closes, starting the lead pump. The pump runs until the liquid level falls below the “PUMP OFF” float, emptying the wet well.

©Copyright 2008 Liberty Pumps Inc. All rights reserved |

- 7 - |

2.On the next rise of the liquid level, the other pump will start on the “LEAD PUMP ON” signal. The pumps will continue to alternate their cycles.

NOTE: No ON/OFF float switch differential should be set that will exceed 12 starts per hour.

3.If the liquid level rises to the “LAG PUMP ON" float, the second pump will start. Both pumps will run until the liquid falls below the “PUMP OFF” float, emptying the wet well.

4.In the event of a malfunctioning float switch, control relay or pump, the liquid level rises and tilts the “HIGH LEVEL ALARM” float. The alarm system will activate.

4-4.4 FLOAT SWITCH INSTALLATION

The engineering drawings will normally specify the levels for pump start and stop and high level alarm. If they are not specified, these guidelines should be used to determine float switch locations.

PIGGY BACK SWITCH |

|

(1-Float System) |

|

Pump Off: |

Factory set. (Float tether 4") |

Pump On: |

Factory set. (Float tether 4") |

SIMPLEX PUMP STATION |

|

(3-Float System) |

|

Pump Off: |

Level to top of motor housing. |

Pump On: |

Minimum 1-1/2 ft. above Pump Off Level. |

High Level Alarm: |

Minimum 1 ft. above pump ON level. Below influent pipe. |

|

DUPLEX PUMP STATION |

||

(4-Float System) |

|

|

Pump Off: |

Level to top of motor housing. |

|

Lead Pump On: Minimum 1-1/2 ft. above Pump Off level. |

||

Lag Pump On: Minimum 1 ft. above Lead Pump On level. |

||

High Level Alarm: |

Minimum 1 ft. above Lag Pump On level. Below influent pipe. |

|

5.

5-1

Operation

OPERATION

After the electrical and mechanical installations have been performed, the pump is ready for operation. No operational procedures are required except to apply rated power to the pump. There are no specific shutdown procedures beyond disconnecting the power supply.

IF THE ROTATION OF A SINGLE PHASE PUMP IS INCORRECT, NOTIFY THE LIBERTY PRODUCT SERVICE DEPARTMENT IMMEDIATELY. DO NOT SWITCH THE POWER SUPPLY LEADS. DO NOT OPERATE THE PUMP.

|

ALWAYS ENSURE THAT THE PUMP IS FREE OF WIRES OR OTHER OBSTRUCTIONS THAT MAY CAUSE |

|

|

HARM OR INJURY. |

|

5-2 |

PERIODIC MAINTENANCE & LUBRICATION |

|

|

Liberty pumps are designed for long lasting, efficient and reliable service with a minimum of preventive |

|

|

maintenance checks. These checks are few but will add years of satisfactory service to the life of the pump. |

|

|

Maintenance checks should be performed at the intervals stated. Severe operating environments will require |

|

|

more frequent checks. |

|

5-3 |

LUBRICATION |

|

|

Ball Bearings: None required |

|

|

Mechanical Seal: Lubricated by the motor oil |

|

|

Seal Oil: 32W HIGH Detergent Oil Qty: 1 Gal |

|

|

©Copyright 2008 Liberty Pumps Inc. All rights reserved |

- 8 - |

SYMPTOM

1.PUMP WILL NOT START

2.REPEATED TRIPPING

3.PUMP WILL NOT SHUT OFF

4.LOW FLOW

5.WATER IN OIL CHAMBER

6.WATER INSIDE MOTOR CASING

TROUBLESHOOTING CHART: LSG200

POSSIBLE CAUSE

A.Power supply failure

B.Burned out fuse or tripped circuit breaker

C.Damaged power cable

D.Jammed impeller

E.Water inside motor

A.Circuit protection under-rated

B.Current unbalance

C.Pump connected to incorrect voltage

D.Wet or damaged wiring

E.Obstruction in pump

F.Incorrect motor rotation

G.Foreign matter build-up

A.Control panel failure

B.Switch Failure

A.Incorrect pump rotation

B.Low liquid level

C.Obstruction in pump or piping

D.Partially closed valve(s)

A.Loose or damaged oil plug

A.Damaged lower lip seal or mechanical seal

B.Damaged O-Ring between oil chamber and motor plate

C.Damaged cable

ACTION

A.Check power supply

Check out electrical system for loose connections

Check operating voltage

B.Check circuit protectors

C.Check external cable for damage

– repair

D.Inspect and remove jamming object

E.Refer to Symptom 5 and 6

A.Check rating and replace with proper size

B.Check current draw

C.Verify connections. See wiring diagram

D.Inspect external cable, replace if worn or damaged

E.Remove obstruction

F.Check rotation

A.Clean motor housing

B.Check control panel

C.B. Replace the switch

A.Check rotation

B.Check liquid level

C.Remove obstruction

D.Check and adjust valve

A.Check plug and sealing washer

A.Replace seal

B.Replace O-Ring

C.Replace cable

IF SYMPTOMS CONTINUE, CONSULT THE LIBERTY PUMPS PRODUCT SERVICE DEPT.

©Copyright 2008 Liberty Pumps Inc. All rights reserved |

- 9 - |

FIGURE 2 CONTROL PANEL INSTALLATION

©Copyright 2008 Liberty Pumps Inc. All rights reserved |

- 10 - |

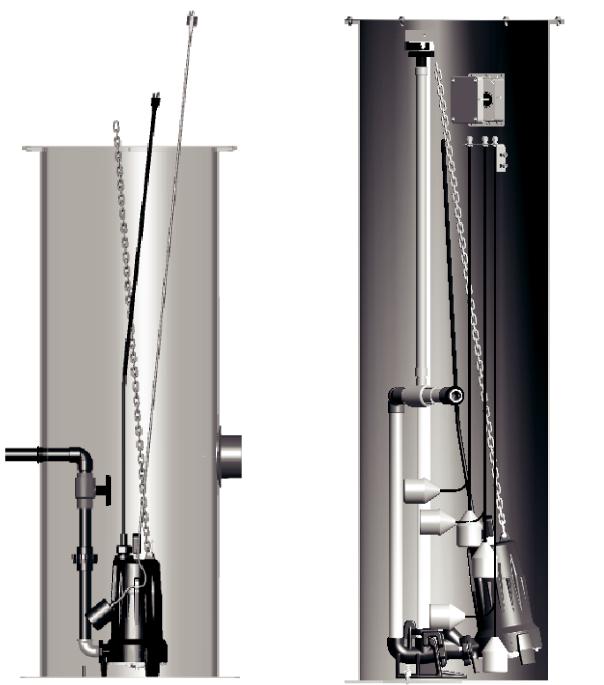

FIGURE 3 TYPICAL INSTALLATION

WITHOUT GUIDE RAIL |

WITH GR20 GUIDE RAIL |

©Copyright 2008 Liberty Pumps Inc. All rights reserved |

- 11 - |

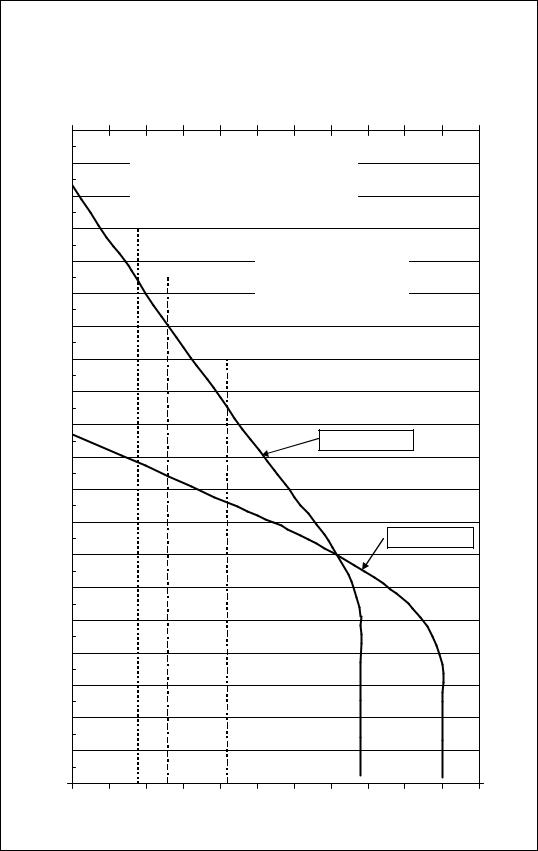

PERFORMANCE CURVE

Omnivore Grinders

HEAD (FEET)

0 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

|

200 |

|

|

|

|

|

|

|

|

|

|

86.6 |

|

190 |

|

In order to ensure sufficient fluid |

|

|

|

82.3 |

|

|||||

180 |

|

velocity to carry solids, (generally |

|

|

|

77.9 |

|

|||||

|

accepted to be 2 feet per second) |

|

|

|

|

|||||||

170 |

|

1-1/4" PIPE |

|

|

|

|

|

|

|

73.6 |

|

|

160 |

|

|

Maximum Total Dynamic Head |

|

69.3 |

|

||||||

|

|

|

|

|

|

|||||||

|

|

|

|

is dependent on friction factors |

|

|

||||||

|

|

|

1-1/2" PIPE of the piping system. Consult |

|

|

|

||||||

150 |

|

|

|

|

factory for proper pump sizing. |

|

64.9 |

|

||||

|

|

|

|

|

1-800-543-2550 |

|

|

|

|

|||

140 |

|

|

|

|

|

|

|

|

|

|

60.6 |

|

130 |

|

|

|

|

2" PIPE |

|

|

|

|

|

56.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120 |

|

|

|

|

|

|

|

|

|

|

51.9 |

|

110 |

|

|

|

|

|

|

LSGX-SERIES |

|

47.6 |

(PSI) |

||

100 |

|

|

|

|

|

|

|

43.3 |

||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

HEAD |

||

90 |

|

|

|

|

|

|

|

|

|

|

39.0 |

|

|

|

|

|

|

|

|

|

|

|

|

||

80 |

|

|

|

|

|

|

|

|

LSG-SERIES |

34.6 |

|

|

70 |

|

|

|

|

|

|

|

|

30.3 |

|

||

|

|

|

|

|

|

|

|

|

|

|

||

60 |

|

|

|

|

|

|

|

|

|

|

26.0 |

|

50 |

|

|

|

|

|

|

|

|

|

|

21.6 |

|

40 |

|

|

|

|

|

|

|

|

|

|

17.3 |

|

30 |

|

|

|

|

|

|

|

|

|

|

13.0 |

|

20 |

|

|

|

|

|

|

|

|

|

|

8.7 |

|

10 |

|

|

|

|

|

|

|

|

|

|

4.3 |

|

0 |

|

|

|

|

|

|

|

|

|

|

0.0 |

|

0 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

|

|

|

|

|

|

FlOW (GPM) |

|

|

|

|

|

|

|

©Copyright 2008 Liberty Pumps Inc. All rights reserved |

- 12 - |

Loading...

Loading...