Hobart 6115 Installation Manual

MODEL 6115 POTATO PEELER

MODEL

ML-137600 6115 (with Timer)

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 37004 (Apr. 2006)

Installation, Operation and Care of

MODEL 6115 PEELER

SAVE THESE INSTRUCTIONS

GENERAL

The model 6115 Peeler is designed to peel 15 to 20 lb (7.0 to 9.0 kg) of product in 1 to 3 minutes using

1

/3 HP electric motor. The 6115 includes a 4-minute, synchronous timer which increments from 1/2 to 4

minutes and is a single-phase electrical service ONLY.

The peelers incorporate a reinforced peeling disc with abrasive permanently bonded to its surface and

a Lexan Liner for the inside of the hopper. The timer is mounted on the right side of discharge chute

as standard but can be ordered on the left or changed in the field. The bottom of peeler unit is cushioned

with a rubber trim molding which also provides a seal.

Optional accessories include a peel trap, a portable stand and a peel trap basket.

INSTALLATION

Immediately after unpacking, the machine should be checked for possible damage. If the machine is

found to be damaged after unpacking, save the packing material and contact the shipper.

This machine MUST be cleaned after installation and before being put into service. Refer to

MAINTENANCE for instructions.

PEELER UNIT (WITHOUT PEEL TRAP)

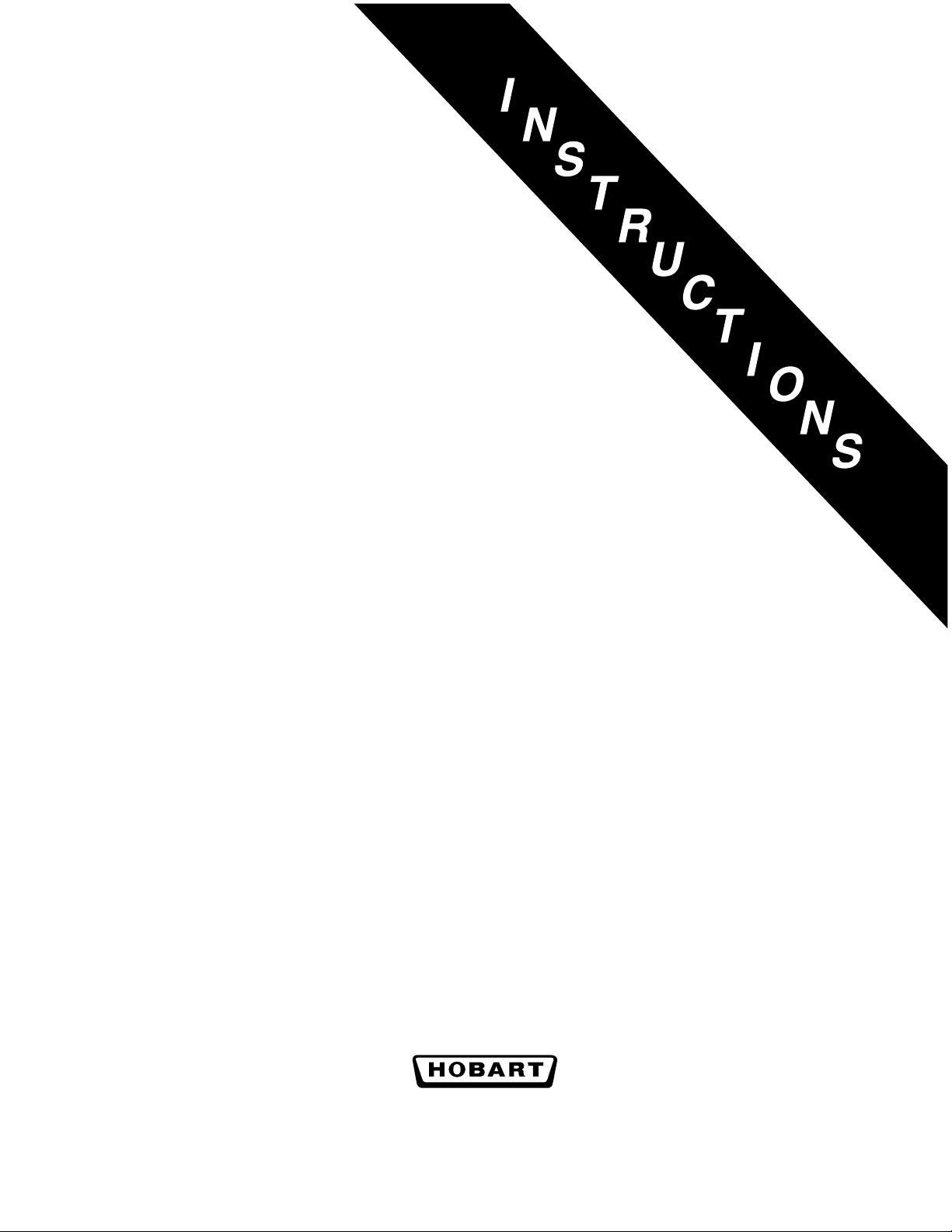

Remove the peeler unit from its shipping carton and remove the hopper top (Fig. 1). Remove the fill tube

and bracket assembly (Fig. 1), as well as the fill hose (Fig. 1) and clamp, from inside the peeler housing.

DO NOT remove the rubber molding on bottom of peeler.

Lay the peeler on its side and remove the bottom cover plate (Fig. 1) by removing the four screws.

Remove the corrugated packing material from between the motor and peeler housing. Replace the

bottom cover and set the machine upright.

The four acorn nuts (Fig. 1), for attaching the fill tube and bracket assembly, are threaded onto their

studs for shipment. Remove the four acorn nuts, leaving the gasket in place, and attach the fill tube and

bracket assembly.

Use pliers to depress the fill hose clamp and slide fill hose up onto the bottom of the fill tube.

If the optional portable stand is to be used, position peeler on top of stand and fasten it with the four

bolts (supplied). This completes installation for units without peel trap.

© HOBART CORPORATION, 1998

– 2 –

FILL TUBE AND

BRACKET ASSEMBLY

HOPPER TOP

ACORN NUT

FILL HOSE

BOTTOM COVER PLATE

DISCHARGE

CHUTE

DATA PLATE

DRAIN HOSE

PL-56484

Fig. 1

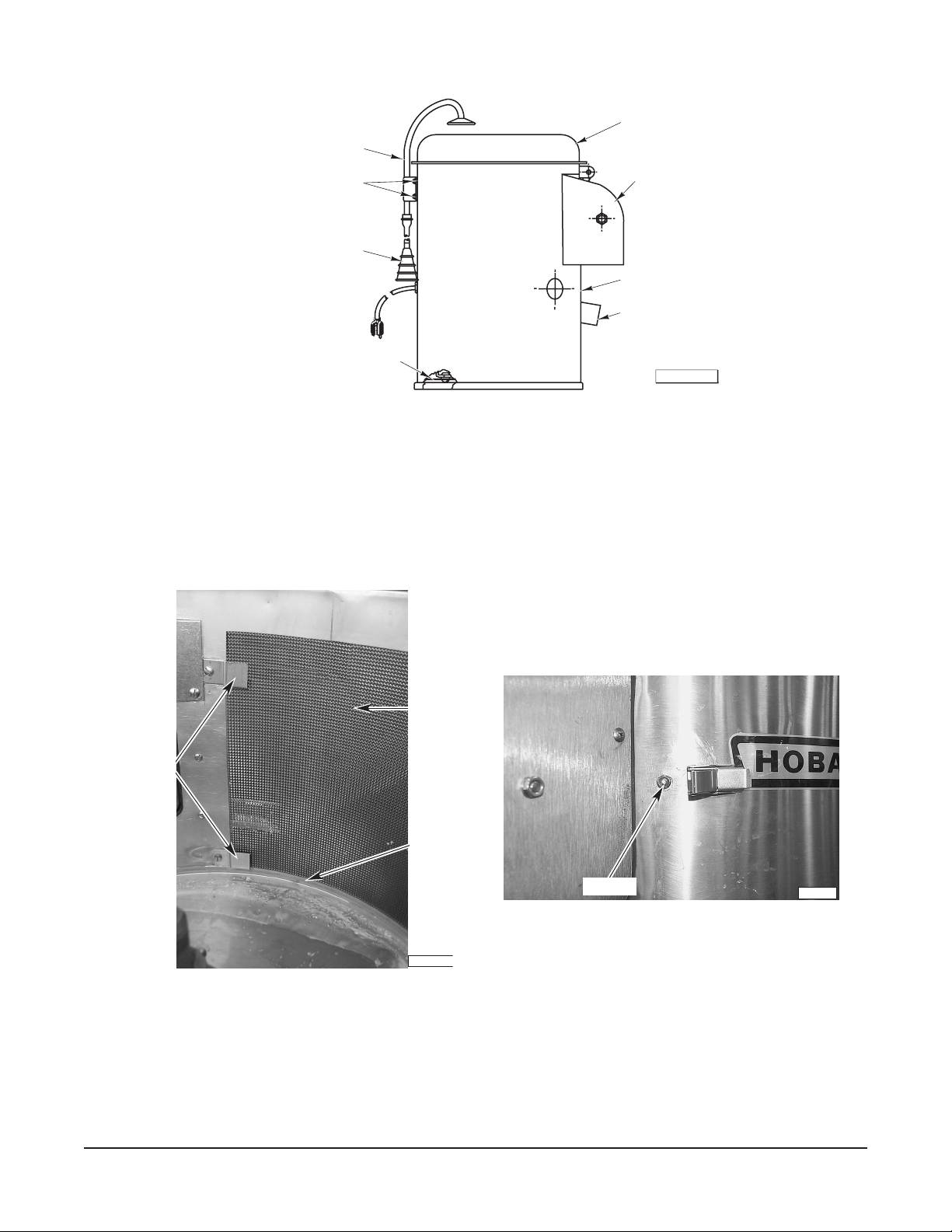

LEXAN LINER

1. Slide the liner (Fig. 2) into the hopper with the keeper to the right side (when viewed from the

discharge chute) of the discharge chute. Ensure the liner is under retaining brackets (Fig. 2) on

the left side of the discharge chute and resting on the top of the lip (Fig. 2) on the bottom of the

hopper chamber.

LINER

RETAINING

BRACKETS

LIP

PL-41652-1

Fig. 2 Fig. 3

2. Push the liner keeper into the hole (Fig. 3) provided.

3. Secure the keeper using the exterior latch.

KEEPER

PL-41653

– 3 –

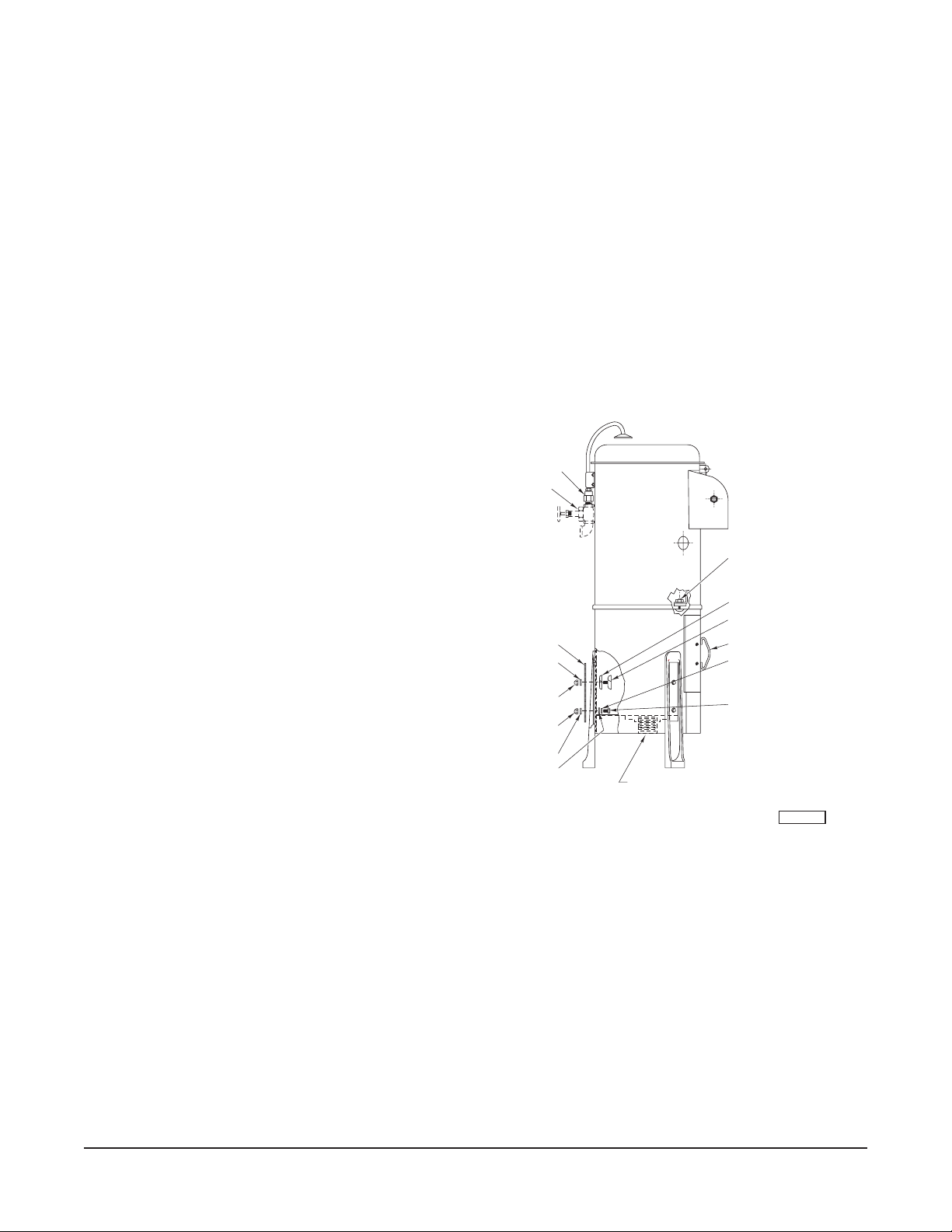

PEELER UNIT (WITH PEEL TRAP)

If the unit is equipped with a peel trap basket, assemble basket per instructions on tag attached to the

basket.

Remove the peeler unit from its shipping carton and remove the hopper top (Fig. 1). Remove the fill tube

and bracket assembly (Fig. 1), as well as the fill hose (Fig. 1) and clamp, from inside the peeler housing.

DO NOT remove the rubber molding on bottom of peeler.

Lay the peeler on its side and remove the bottom cover (Fig. 1) by removing the four screws. Remove

the corrugated packing material from between the motor and peeler housing. Do not replace the bottom

cover.

Unpack the peel trap from its shipping carton. Remove the legs and the cloth bag from inside the peel

trap. The cloth bag contains hardware for attaching the legs.

It will be necessary to remove the peel trap drawer (Fig. 4) to allow enough room for attaching the legs.

Assemble as follows (Fig. 4):

• Assemble one of the rubber gaskets to

one of the curved leg clamp bolts.

• Assemble bolt and gasket through one of

the upper leg bolt holes in peeler housing.

COUPLING

GLOBE VALVE

• Assemble a leg and a leg slot cover on the

leg clamp bolt.

• Place a stainless steel washer and acorn

nut onto the leg clamp bolt and partially

tighten nut.

• Assemble cap screw, washer and lead

washer.

• Place cap screw and washer through lower

leg bolt holes and slot cover.

• Place a stainless steel washer and acorn

nut onto cap screw and partially tighten.

SLOT COVER

WASHER

ACORN NUT

ACORN NUT

WASHER

LEAD WASHER

DRAIN CONNECTION

CAP SCREW

LOCKWASHER

WASHER

RUBBER GASKET

CLAMP BOLTS

PEEL TRAP DRAWER

WASHER

CAP SCREW

• Assemble each leg in this manner. When

all are assembled, set the unit upright.

Adjust each leg to a suitable height so the unit is

level, and tighten the acorn nuts.

Fig. 4

PL-56483

Set the peeler upside-down and, using a pair of pliers, squeeze the hose clip and remove the peeler

drain hose (Fig. 1). Replace this hose with the drain hose packed inside the peel trap.

The peeler may be positioned on the peel trap in one of four positions. Each of the positions will cause

the peel trap drawer to be located in a different position relative to the discharge chute.

The peel trap drawer may be directly beneath the discharge chute, to the right, left or rear (see Fig. 5).

After selecting the most convenient position for the peel trap drawer, remove the cover disc from the

appropriate hole in peel trap and position the peeler on top of the peel trap, with the peeler drain hose

extending through selected hole (Fig. 5).

– 4 –

Loading...

Loading...