INSTRUCTION MANUAL

with Replacement Parts

MODELS 510

MEAT

SLICERS

and

512

THE HOBART MANUFACTURING COMPANY, TROY. OHIO

FORM

11416

(11-73)

45374

510/512 INSTRUCTIONS

Instructions

for

Operation and Care

MODELS 510 AND 512 MEAT SLICERS

1. INSTALLATION:

When the machine is packed for shipment, the

three rubber feet (6, Fig. 1) and the one helper

foot (7, Fig. 1) are removed and sent along in a

cloth bag. The feet can be readily reassembled.

Install the helper foot to the end of its thread at

the comer of the base as shown (7, Fig.

helper foot does not touch the counter or table

and prevents the slicer from tipping.

In ordinary service, it will not be necessary to

fasten the slicer down; the cup-shaped rubber feet

will prevent it from slipping on the table. For

1.

The

Fig.

1

of

mounting on shipboard, discard the feet, and bolt

slicer to the table with 5116"-18 cap screws.

If cord and plug is not used with this machine,

electrical connections should be made by qualified

workmen who will observe all applicable Safety

Codes and the National

Before making electrical connections, CHECK

THE SPECIFICATIONS ON THE NAME

(3,

Fig.

l),

TO MAKE SURE THEY

WITH THOSE OF YOUR ELECTRlCAL

SERVICE.

EIectrical Code.

PLATE

AGREE

INSTRUCTIONS 5101512

2. THICKNESS OF SLICE:

The

knob or dial (4, Fig. 1) adjusts the

thickness of the slices cut. The numbers on the

dial indicate actual measurements in

example when setting dial at

.25, slice would be

.lo". For

114" thick.

3. SAFETY PRECAUTIONS:

When not actually slicing, turn the slice ad-

justment knob clockwise as far as it will go. The

gage plate will cover the edge of the cutting knife

and guard it.

4. SLICING FOOD:

This machine has been designed so a minimum

effort is required to hold and slice, pieces of

various shapes and sizes. The shape of the carriage

and inclined position make it unnecessary to use

holding devices for large items of regular shape,

such as cold boiled ham, loaf meats and picnic

cuts. For holding odd shapes or short end pieces,

use the meat grip (1, Fig. 1). Hold the handle in

your right hand, and press the grip down on the

meat at a convenient location. The carriage can

then be moved back and forth with the same hand

that holds the grip. The left hand is then free to

receive the slices as they come from the knife. The

slices may be stacked on the tray surface which is

easily kept clean. Other trays or platters may be

used if so desired. The slicer is turned

"ON"

and

"OFF" by the switch (5, Fig. 1) (pull to start,

push to stop).

After a few slices have been cut

and the end of the

piece is squared off, the meat will usually feed

without help from the grip. For safety reasons

when cutting a short end piece, ALWAYS place

the grip behind the item being sliced. This method

also allows cutting down to the last slice. The grip,

when not in use, may be stored to its

in-operative

position in the rear and underneath the carriage

tray.

5. CLEANING

&

SANITIZING:

UNPLUG ELECTRICAL POWER CORD and

clean the surface of the machine daily. Make sure

the knife guard is in place and the slice adjusting

knob is turned clockwise as far as it will go when

performing this operation.

WARNING: Observe the same care while working

around the knife that you would use with any

razor sharp-edged tool.

PROCEDURE:

5.1 Materials required:

.I

5.1

Small plastic two compartment pail.

5.1.2 Clean cloths.

5.1.3 Cleaner ("Soilax" All Purpose Cleaner).

5.1.4 Sanitizer ("Mikro-Klene" iodophor

sani-

tizer).

Fig.

5.2 Cleaning (using

5.2.1 Add two ounces of

"Soilax" and "Mikro-Klene"):

"Soilax" All Purpose

Cleaner to a gallon of hot water in wash side

of two compartment pail.

5.2.2 Mix rinse solution by adding two

teaspoons of "Mikro-Klene" in one gallon of

cool water in rinse side of pail.

5.2.3 Wipe off large scraps of meat soil.

5.2.4 Dip cloth into cleaning solution, then

wring out cloth. Wipe the entire outside of

slicer with cloth. Be sure to CAREFULLY

wipe the gage plate.

5.2.5 Loosen knife guard locking screw

(1, Fig.

2), pull knife guard (2, Fig. 2) straight away

from knife (3, Fig. 2) until center stud clears

mounting hole.

2

5.2.6 CAREFULLY wash the front and rear of

Fig.

3

knife with cloth that has been dipped in

cleaning solution.

5.2.7 Wash the knife guard.

5.2.8 Rinsing and sanitizing can be done by

going over all cleaned surfaces with a cloth

that has been soaked in "Mikro-Klene" rinse

solution and wrung out enough so that the

solution does not run over the machine but

still leaves it wet.

5.2.9 Reassemble knife guard by placing center

stud in the mounting hole and lowering knife

guard down over knife. Lock knife guard into

position with locking knob.

6.2 Remove the camage (section 7) and set the

slice adjusting dial at 50.

6.3 Remove the sharpener from its storage place.

6.4 Unscrew the thumb screw on the sharpener

until the sharpener slips upward into the slot (8,

Fig. 1) at the bottom of the gage plate. Push the

sharpener firmly upward with the right hand to

remove any rocking tendency. Tighten the

thumb screw with the left hand.

6.5 Start the motor.

6.6 Turn the slice adjusting knob (2, Fig. 4)

slowly to the right. This will bring the grinding

wheel in contact with

the beveled side of the

knife.

6.7 Stop knife and check to see if burr has started

to develop on opposite face of knife.

6.8 As soon as burr appears, depress truing wheel

by pressing on plunger (1, Fig. 4) with right

hand as shown. Grind and true simultaneously

for approximately 3 seconds.

6.9 Release truing wheel and back away grinder at

the same time.

6.1 0 Check to make sure that the characteristic

grind marks (1, Fig. 5) are plainly visible on the

ground surface, if not the grinding wheel is not

cutting. (Many operators try to sharpen a knife

with a grease-loaded stone which will not cut).

5.2.10 Allow all surfaces to dry. Do not wipe.

Cover slicer until next use.

5.2.1 1 Cloth used for rinsing should be

laundried or discarded. Wash out pails.

CAUTION: Do NOT wash polished alumi-

num parts in dish or pan washer.

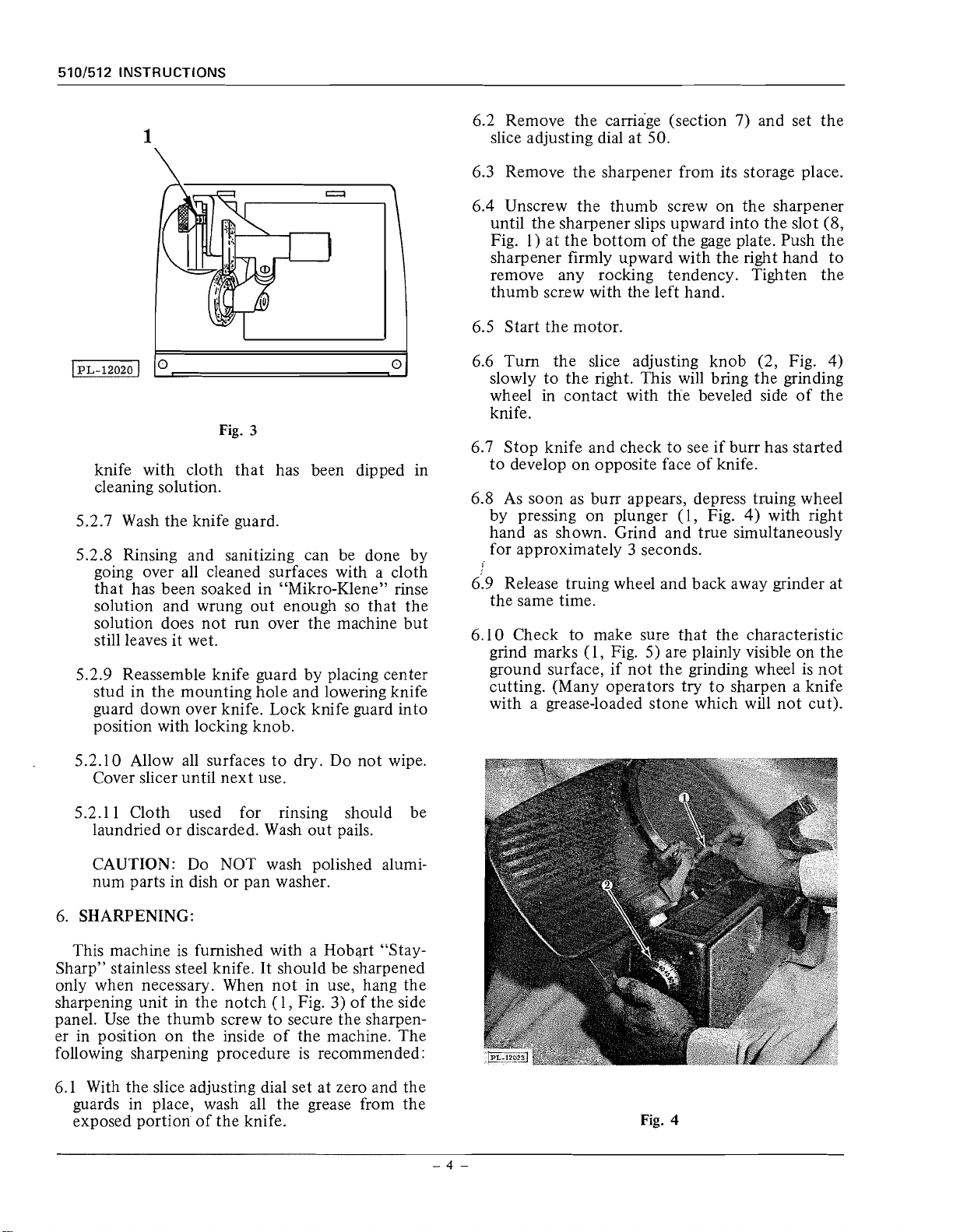

6. SHARPENING:

This machine is furnished with a Hobart

"StaySharp" stainless steel knife. It should be sharpened

only when necessary. When not in use, hang the

sharpening unit in the notch (1, Fig.

3)

of the side

panel. Use the thumb screw to secure the sharpener in position on the inside of the machine. The

following sharpening procedure is recommended:

6.1 With the slice adjusting dial set at zero and the

guards in place, wash all the grease from the

exposed portion of the knife.

Fig.

4

6.1 1 Stop the motor, remove the sharpener, turn

the slice adjusting dial back to zero, and return

the sharpener to its place on the inside of the

side plate.

6.1 2 After sharpening; the slicer should again be

cleaned to remove any dust, or dirt as a direct

result of sharpening.

NOTE: The adjustments on the sharpening unit

are factory-set for best operation on the

machine.

7.

CARRIAGE REMOVAL & ADJUSTMENT:

The carriage tray assembly can be taken off as a

unit by loosening the thumb screw (2; Fig. 6) and

sliding off the assembly out of the

"V" support.

Care should be used in order to prevent the tray

from striking and damaging the knife edge. The

carriage tray knife clearance may be changed by

adjusting the self-locking set screw

(1, Fig. 6) to

suit.

8.

WEAR ADJUSTMENT:

INSTRUCTIONS

Fig.

6

5101512

Fig.

After long service and many sharpenings of the

knife, it may be necessary to adjust the gage plate

closer to the knife. The gage plate may be moved

forward by loosening two screws at the back side

of gage plate, moving gage plate forward to within

1/32" of the knife cutting edge and re-tightening

screws. The bevel on the worn knife also may be

changed. This work should be done by a Hobart

Service Technician.

9.

LUBRICATION:

Very little lubrication is needed. Carriage slide

rod and bar (3

&

4,

Fig. 6) are to be lubricated.

Use a few drops of oil (Texaco "Havoline" or

equiv.) weekly on these parts.

Keep the two gage plate slide rods lubricated with

a drop or two of tasteless oil when required.

Keep the meat grip slide rod (2, Fig. 1) clean but

do NOT lubricate it.

10. MOTOR:

5

No periodic service is required for the motor.

510l512

REPLACEMENT PARTS

BASE

UNIT

REPLACEMENT PARTS

5101512

PART

NO.

B-114297

FE-8-14

A-69375-1

B-114584-1

B-1145 84-3

C-111141

SD14-21

B-76911

M-18682

E-114219

Dl

14452

SD24-1

D-114236

---

M-7 04 12

BASE

NAME

Knob - Locking

Strain Relief (900)

Cord & Plug Assy. (3 Cond. under 150 V.)

Pilot Light (with nut) (115 V.) (Incls. item #5)

Push Nut (Pilot Light)

Panel-Side

Self-Tapping Screw - #8-32 x 112" Pan Hd., Type 1

Base & Logo Plate Ass~.

-

Receiving

Tray

Tray - Receiving (SST)

Self-Tapping Screw - #lo-24 x 318" Pan Hd. "Taptite"

Cover-Bottom---------------------------------------------

Motor (see separate Motor Parts Sheet)

Foot-Helper

............................................

............................................

........................................

------------------------------------------------

--------------

------

..............................................

UNIT

OF

PART

............................

..............................

L

.................................

..............................

........................

AMT.

......................

....................

5101512

REPLACEMENT PARTS

CARRIAGE

UNIT

REPLACEMENT

PARTS

5101512

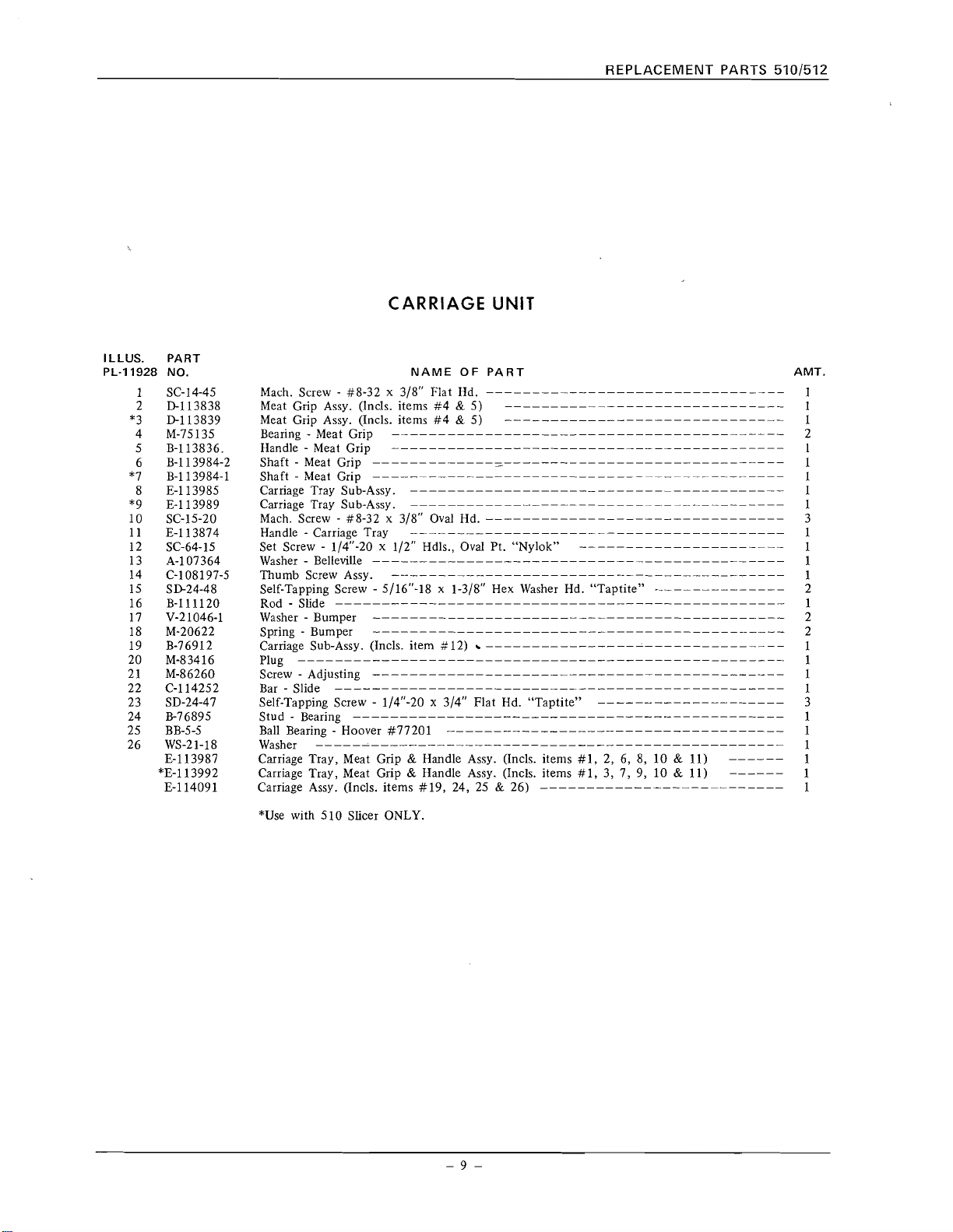

ILLUS. PART

PL-11928 NO.

1 SC-14-45

Dl13838

2

*3 Dl13839

4 M-75135

5 B-113836.

6 B-113984-2

*7 B-113984-1

8 E-113985

*9 E-113989

10 SC-15-20

11 E-113874

12 SC-64-15

13 A-107364

14

C-108197-5

15 SD24-48

16 B-111120

17 V-21046-1

18 M-20622

19 B-76912

20 M-83416

21 M-86260

22 C-114252

23 SD-24-47

24

E-76895

25 BB-5-5

26 WS-21-18

E-113987

*E-113992

E-114091

CARRIAGE

NAME OF PART AMT.

Mach, Screw - #8-32 x 318" Flat Hd

Meat Grip Ass~. (Incls, items

Meat Grip ASS~.

Bearing - Meat Grip

('~CIS.

Handle - Meat Grip

Shaft - Meat Grip

Shaft - Meat Grip

............................................

............................................

Carriage Tray Sub-Ass~.

Carriage Tray Sub-Assy.

Mach, Screw - #8-32 x 3/8" Oval Hd

Handle - Carriage Tray

Set Screw - 114"-20 x 112" Hdls., Oval Pt. "Nylok"

Washer - Belleville

............................

numb Screw Ass~.

Self-Tapping Screw - 5/16"-18 x 1-318'' Hex Washer Hd. "Taptite"

Rod

-

Slide

................................................

.

Bar -Slide

Self-Tapping Screw

Stud - Bearing

Ball Bearine - Hoover #77201

Washer

-

................................................

-

114"-20 x 314" Flat Hd. "Taptite"

..............................................

-

..................................................

Carriage Tray, Meat Grip

Carriage Tray, Meat Grip

Carriage Assy. (Incls. items

#4

items #4 & 5)

------------------------------------------

-

.........................................

........................................

----------------------------------------

........................................

..........................................

....................................

&

Handle Assy. (Incls. items #1, 2, 6, 8, 10 & 11)

&

Handle Assy. (Incls. items #1,

#19, 24, 25 & 26)

UNIT

---

.............................

--

&

5)

............................

---

/

................................

----------

......................

....................

..........................

3,

-----------------

7, 9, 10 & 11)

----------------

------

------

1

3

1

1

1

1

1

1

*Use with 510 Slicer ONLY.

5101512

REPLACEMENT PARTS

KNIFE UNIT

REPLACEMENT PARTS

5101512

ILLUS. PART

PL-11929 NO.

1 RP-2-25

2 C-114190

3 RR-7-22

4 SL-3-6

5 C-114189

6

El11152

7 B-114137

8

SD24-45

9 C-114603-1

10

R-12430-47

11 B-111152

El14141

12

13 El11154

14 E-109749

*15

Dl11108

16 SC-22-18

17 B-114289

18 E-113825

*19 E-113829

20 B-109756

21

(2-114527-2

*22 C-114527-1

23

C-114603-1

24 SD24-46

C-114277

KNIFE

NAME OF PART AMT.

Retaining Ring

Washer - Wavy Spring

Gear-Driven (31T)

Bearing - must

Hub Sub-Assy.

Self-Tapping Screw - 114"-20 x 314" Soc. Flat Hd. "Taptite"

Caplug

Bearing-must

Knife Shaft Ass~.

Ring - Knife Shaft

Knife

....................................................

Knife

....................................................

Mach. Screw - #10-24 x 7/16" Flat Hd.

Spacer

Knife Guard & Shaft Assy. (Incls. items.#17 & 20)

Knife Guard & Shaft Assy. (Incls. items #17 & 20)

Scraper-Knife

Drip Cup Assy

Drip Cup Ass~

caI;lug

-.

Self-Tapping Screw - 114"-20 x 314" Soc. Fil. Hd. "Taptite"

Knife Shaft Assy. Oncls. items #3, 4, 5, 6, 7, 10, 11 & 12)

..............................................

..........................................

..........................................

............................................

..............................................

..................................................

............................................

............................................

............................................

-------------------------------------------------

..............................................

..............................................

..............................................

..................................................

UNIT

..............................

......................

......................

------------------

------------------

------------------

*Use with 510 Slicer ONLY.

5101512 REPLACEMENT PARTS

GAGE PLATE AND INDEXING MECH.

REPLACEMENT PARTS

5101512

ILLUS. PART

PL-11930 NO.

1 B-111117

2 B-113903

3 B-111116

4 B-113906

5 B-114146

6

SC-93-25

7 B-114114

8 B-113994

9 B-114122

10 B-109762

11 B-109767

12 SD24-49

13 C-114238

14 SC-23-49

15 C-114214

16 C-114212

17 B-114213

18 RP-2-40

19 SC-12-49

20 M-88887

21 M-88298

22 SC-63-14

23 B-111144

24 B-114101

25 B-109770

26 RP-2-40

27 B-114107

28

Dl14067

*29 Dl14068

30 B-114112

31 SC-41-10

B-114103

GAGE PLATE AND INDEXING

NAME OF PART AMT.

Rod - Gage Plate Slide

Sleeve - Slide Rod

Rod - Gage Plate Slide (Jndex)

Spring (Slide Rod)

Plug-Cap

Mach. Screw - 1/4"-20 x 1" Pan Hd.

Roller - Index

Washer - Thrust (.010" mk,)

Sleeve - Index

Index Gear Ass~ (207')

................................................

..............................................

--------------

Washer (-089'' Thk.)

........................................

............................................

....................................

............................................

....................................

........................................

..........................................

................................

---

.............................

MECH.

Self-Tapping Screw - 5/16"-18 x 1-314'' Hex Washer Hd. "Taptite"

Insert - Index Knob

Mach. Screw - #lo-24 x 718" Oval Hd.

Cap -Index

................................................

..........................................

..............................

Disc-Index-----------------------------------------------Rollpin - 3/32" Dia x 314" Lg.

Mach. Screw - #8-32 x 318" Fil. Hd.

Retaining Nut & Screw Assy. (Incls. item #19)

Washer - Belleville

Set Screw - #8-32 x 114" Soc. Hdls., Flat Pt.

Bushing - Eccentric

Shaft-Index

Worm-Index

---------

--------------

..............................................

..............................................

Rollpin - 3/32" Dia. x 314" Lg.

Spacer - Slide Rod

Gage Plate Ass~.

Gage Plate ASS~,

Spacer - Gage Plate

----------------

............................................

--------

..........................................

Fin. Bolt - 5/16"-18 x 518" Hex Hd.

Index Assy. (Incls. items #24, 25 & 26)

--

-----

--------

----

-

............................

----

............................

..........................

---------------

..........................

----

------

................................

............................

....................................

................................

..............................

----

--------------

----------

--

--

------

--

----

*Use with 510 Slicer ONLY.

510/512

REPLACEMENT PARTS

PART

NO.

B-76893

B-877 11 -1 29-1

B-76913

C-114243

B-114267

RP-4-26

B-114261

NS-17-3

C-114580

WL-7-12

SD-24-1

SD-24-1

B-76914

ELECTRICAL UNIT

NAME OF PART AMT.

Knob Assy.

Lock Washer - #lo

Self-Tapping Screw - #lo-24 x 318" Pan

Self-Tapping Screw

Clip - Cable

.................................................

Ext.

Shakeproof

-

........................................

#lo-24 x 318" Pan

.................................

Hd.

Hd.

"Taptite"

'"Taptite"

.....................

.....................

1

1

1

3

5

REPLACEMENT PARTS 5101512

ILLUS. PART

PL-11932 NO.

1 M-74833

2 M-73851

3 M-74900

4 P-22670

5 WS-2-18

6 sc-8-10

7 WS-3-40

8 BA-2-1

9 V-13199

10 PG3-7

11 M-72801

12 M-69585-1

13 M-83089

14 M-73974

15 WS-2-18

16 BA-2-1

17 WS-4-39

18 M-70313

19 SC-8-10

20 WS-2-18

21 M-73975

22 M-83092

23 M-13201

24

hI-3404-7

25 B-109702

R-74023

M-73979

M-74007

.

KNIFE SHARPENER UNIT

NAME OF PART AMT.

Screw - Retaining

Wheel -Grinding

Shaft - Grinding Wheel

Carrier - Grinding Wheel

Washer

Mach. Screw - #lo-24 x 112" Rd. Hd.

Washer

Ball - 1/8" Dia

Collar - Thrust

Groov-Pin - Type #1, 3/32" x 7/16"

Sharpener Support & Slice Indicator Plate Sub-Assy.

plug Button

Retaining Ring

Cap - Truing Wheel

Carrier - Truing Wheel

Shaft - Truing Wheel

Wheel - Truing

Screw - Retaining

Thumb Screw - Sharpener Attaching

Knife Sharpener Assy. (Incls. items #1 thru 25)

Truing Wheel Sub-Assy. (Incls. items #12, 13, 14, 15, 16, 17, 18, 21, 22, 23 & 24)

Grinding Wheel Sub-Assy. (Incls. items

..................................................

..................................................

............................................

............................................

........................................

........................................

..............................................

..............................................

................................

................................................

..............................................

..........................................

........................................

..........................................

..............................................

............................................

................................

#l,

--

............................

........................

2,

3,

4, 7, 8, 9 & 10)

......................

--------------

--

5101512

INSTALLATION

FORM

11416

INSTALLA'TION

NOV.

1973

DIAGRAM

PRINTED IN

U.S.A.

Loading...

Loading...