FOOD

EQUIPMENT

5216-0

DELUXE

Hobart meat saws Models 5216-0 and

5216-0-HS (twice the blade speed

standard 5216) feature incomparable

of

ease

require

without the

access

partments.

The deluxe version

maintained in sanitary condition

environmental conditions conducive to

rust and corrosion. The entire base including legs, column and carriage support, the movable carriage,

table

made

cleaning. All components which

to

and

of

and

cleaning are easily removed

use

smooth, crevice-free com-

their

stainless steel.

5216-D-HS

MEAT

of

tools

of

understructures

SAWS

...

providing

these saws can be

stationary'

even

of

in

are

Interchangeable upper and lower blade

pulleys have double flanges. This as-

jump

or

be

sures the blade will not

dently pulled off. Both pulleys can be

submerged in water for cleaning.

Specifications, Details and Dimensions on Reverse Side

acci-

-

5216-0

MEAT

MOTOR: Model 5216-D equipped with 2

equipped

ball bearings, ventilated, drip-proof type, protected by machine

enclosure. Available in standard electrical specifications as

shown below. Not available in

ELECTRICAL CONTROLS: "Pull

veniently located

magnetic contactor which provides

trical specifications above 250 volts, a control circuit transformer

provides control voltage of

voltages). 5216-D-HS

for single phase, tri·block for three phase) which provide overload

protection (optional

starter enclosures option,

orders, available

DRIVE: Heavy-duty

SAW

BLADE TENSION INDICATOR: Direct reading indicator, mounted

at left front

accurately registers blade tension. Handwheel positive-tension

control, at

mits back-against-the wall installations.

BLADE GUIDES AND CLEANERS: The lower

combines easily adjusted tungsten carbide blade back-up, stainless steel blade guide with tungsten carbide inserts, nylon protector, front blade and lower pulley cleaners. The upper guide and

guard assembly includes adjustable tungsten carbide blade

back-up, stainless steel blade guide with tungsten carbide

serts, and guard. A separate upper pulley cleaner is mounted in

the head. A

cleaners. All cleaner and guide assemblies are easily removed

without the use

PULLEYS: Interchangeable plated cast-iron upper and lower

blade pulleys are identical, both can be easily removed for cleaning. True-running blades are assured by precision machined pulleys with blade-retaining double flanges.

SAW

with 3 H.P.

BLADE:

left

Listed

and

approved

United States Department of Agricultural Approved

'"

motor

(3

phase only).

D.C.

at

front of machine actuates switch controlling the

is

provided with thermal overload relays (one

at

extra cost

at

extra cost. aluminum.Vernier-type adjustment gives quick, positive regulation of

"V"

belt.

o/e"

Wide x 128" Long.

of

the head, easily visible to operator at

of

head beneath the direct-reading indicator, per-

lower

rear assembly provides

of

tools.

to

120

volts (optional

on

5216-0). Special wiring

to

comply with California electrical safety

H.P.,

Model 5216-D-HS

Has

grease-packed

Start-Push

no

voltage protection. For elec-

to

Stop" knob con-

at

extra cost

"lift-out"

auxiliary

assembly

SPECIFICATIONS

by

Underwriters Laboratories

by

National Sanitation Foundation.

CAPACITY: Cutting clearance:

STATIONARY CUTTING TABLE: Extra large,

stainless steel, angle-reinforced, and supported

use, provides extensive stacking space. One quick-acting clamp

locks table securely in place

MOVABLE CARRIAGE TABLE: Stainless steel, reinforced for

rigidity. Measures

movement

on

and

eye

lower

motor

level,

in-

blade

bearings, mounted on underside

on carriage support), assure stability and easy travel, even when

operator leans heavily against carriage. A carriage

vided

as

GAUGE PLATE:

cut thickness with micrometer-fine precision. Easily disengaged for

major adjustment. Adjustable

plate

to

SAFETY FEATURES: All moving parts are enclosed, but readily

accessible. Blade is guarded above and below the cutting zone.

To

eliminate the necessity

pusher

operator. Adjustable legs provide for leveling and secure place-

of

ment

FINISH: Working surface

cover is polished stainless steel. Head, head door, and head cover

are all aluminum. Cabinet and

steel.

OPTIONAL EQUIPMENT: Heavy

carriage, bearings, carriage support, tinned braces and heavy

duty

switch rod and knob. Intermediate speed pulley on high

speed saw provides blade speed

options.

STANDARD EQUIPMENT: One new hardened saw blade and

pusher plate

WEIGHT: Net - 494 Ibs. Shipping - 630 Ibs.

Inc.

18Ve"

high, 15"/16" wide.

21V4"

x

for

or

releases table for cleaning.

of

standard equipment.

original setting.

plate

machine.

17W' x 24". Shaped

carriage by operator's body. Six stainless steel ball

6314"

x 16%" stainless steel face laminated

is

provided.

of

for

short

ends.

of

pin

allows operator

of

handling items close to blade, a

Extended

table, gauge plate, carriage and blade

understructure

duty

front

edge facilitates

carriage (two engage guide

to

gauge

plate

parts are stainless

front

end with stain less steel

of

4700 FPM. Extra cost for

383/4",

heavy

heavy

duty

lock

is pro-

to

cast

return gauge

protects

As

ENLARGED VIEW

SHOWING ADJUSiTNG FOOT

OF

LEG

-

[

,

..!

i

I

0 0

0

I

f--24f----

f--

)

(I

c:;"r-Hf-

1--'--24

'------CARRIAGE

FORM

F·7903

19i'--l-1°s'

Lt'

,

•

REV.

'

I--

TRAVEL

(1280)

continued

1

-

J

b:

9'

,

25

•

product

I.

72i

~

.=1'

improvement is a policy

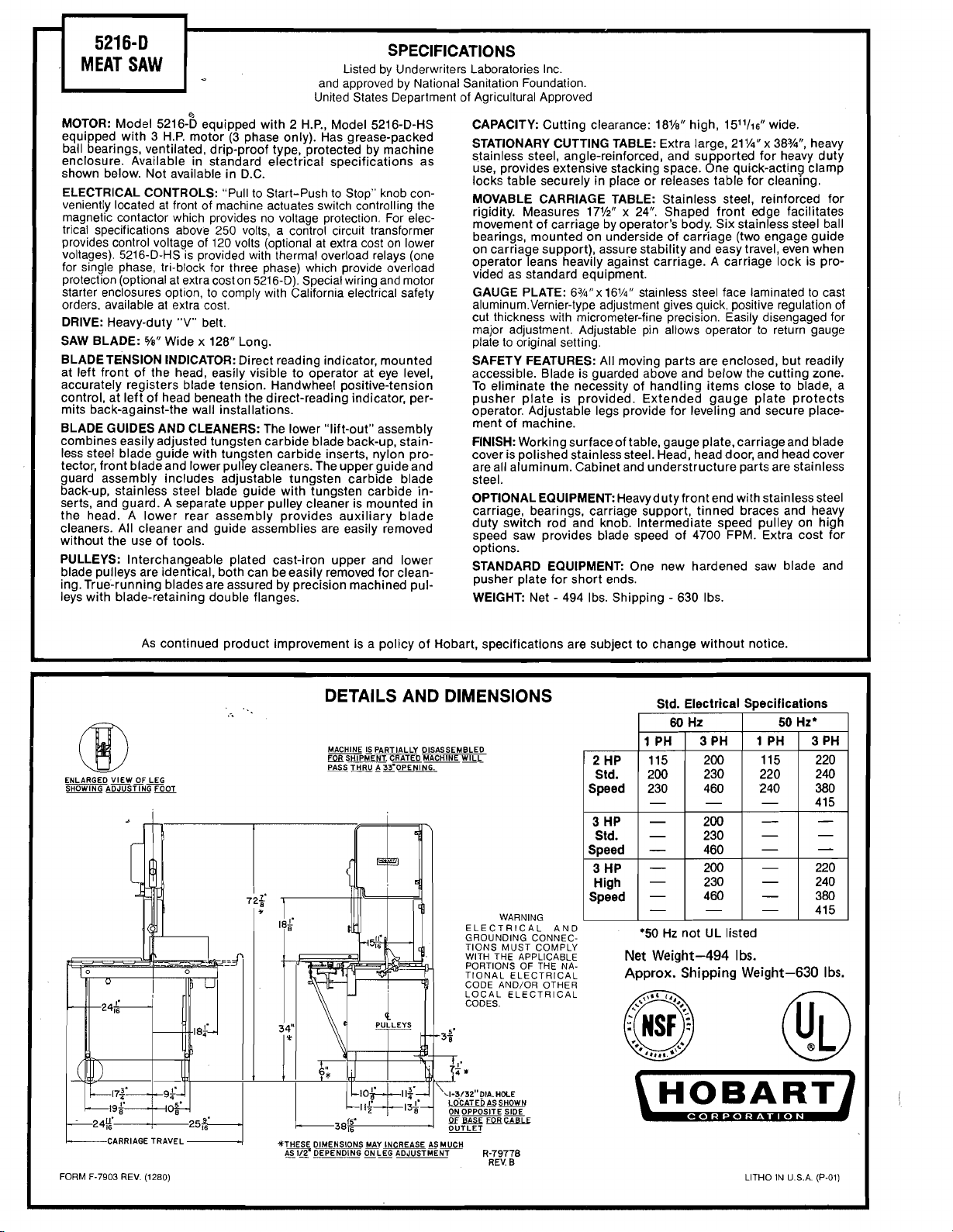

DETAILS AND DIMENSIONS

MACHINE

IS

PARTIALLY DISASSEMBLED

THRU

P,

rrDPENING

r§

!!!1J

{

I

,.,.11-

I.

i\"

'Q

1"

lB.

EQRSHIPMENT. CRATED MACHINE

PASS

u

1

34"

'*

\

~Ili

L

"'THESE DIMENSiONS

~

I~'

DEPENDING

!'1!\obill

tIO~,r-

Ilf

13{-

3B(f

MAY

INCREASE

Q!!LEGADJUsTME~

of

Hobart, specifications are subject to change without notice.

Std. Electrical Specifications

60

Hz

3

PH

200

230

460

200 -

230

460

200

230

460

-

not UL listed

2,!!,~,~

c

.

.

I,

I'

5'

3.

t

f'

\+

~O

Qf~EQRCABLE

0

AS

MUCH

WILL

WARNING

ELECTRICAL

GROUNDING

TIONS

WITH THE APPLICABLE

PORTIONS OF THE NATIONAL

CODE

LOCAL

CODES.

CONNEC·

MUST

COMPLY

ELECTRICAL

AND/OR

ELECTRICAL

OTHER

••

3/32"

DIA.

HOLE

'CATEDASSHOWN

N OPPOSITE SIDE

UTLET

R-79778

REV.B

AND

1

PH

2

HP

Std. 200

Speed

3

Std.

Speed

3 HP

High

Speed

115

230

- - -

HP

-

-

-

-

-

-

-

·50

Hz

Net Weight-494

Approx. Shipping Weight-630

\ H

Ibs.

LITHO

1

115

220

240

-

-

-

-

-

-

PH

50

Hz·

3

PH

220

240

380

415

-

-

~

220

240

380

415

Ibs.

®

T J

IN

U.S.A.

(P-01)

Loading...

Loading...