Page 1

Contents: Advanced course TNC 4xx

Conventional Programming

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

Title

Drilling

Two rows of holes

Irregular drilling pattern, 3 tools

Linear hole pattern

Linear offset hole pattern

Four double bolt hole circles, 3 tools

Large drilled plate

2D Milling

Loading frame

Free Contour Programming

FK Telephone

FK Dumbbell

FK Hammer basic

FK Mickey Mouse basic

FK Comb, basic, uncorrected

FK Comb first original, then mirrored in Y

PGM-No.

7280

7153

7109

7426

7139

7411

72810

75103

75116

75119

71750

75108

75122

HEIDENHAIN

Advanced course TNC 4xx

D08

IH1

Page 2

Contents: Advanced course TNC 4xx

No.

14

15

16

17

18

19

20

21

22

23

24

25

Title

3D Milling

Toggle joint, 1 tool

Toggle joint, 2 tools

Truncated cone, standing, 2D, external, horizontal

Truncated cone, standing, 3D, external

Truncated cone, internal, 3D, basic

Truncated cone, internal, 3D, from solid block

Hemisphere, internal, 2D, horizontal

Hemisphere, internal, 2D, horiz. with pockets

Hemisphere, external, 2D, horizontal

Hemisphere, external, 3D, vertical, 1 cut

Hemisphere, external, 3D, vertical, 2 cuts

Threadmilling in three steps, 2 settings

PGM-No.

761260

761261

7162

7282

7283

7284

7322

7323

72841

76130

76131

7164

Q-Parameter Programming

No.

Title

Milling

26

27

28

Milling a contour with several Z-settings

Finish milling rectangular pocket

Milling cylindrical pins

Drilling

29

30

31

32

1 Simple bolt hole circle

6 Bolt hole circles, 1 tool

6 Bolt hole circles, 3 tools, 3 cycles

Linear hole pattern

PGM-No.

7285

7286

7288

7416

74160

74161

746910

HEIDENHAIN

Advanced course TNC 4xx

C08

IH2

Page 3

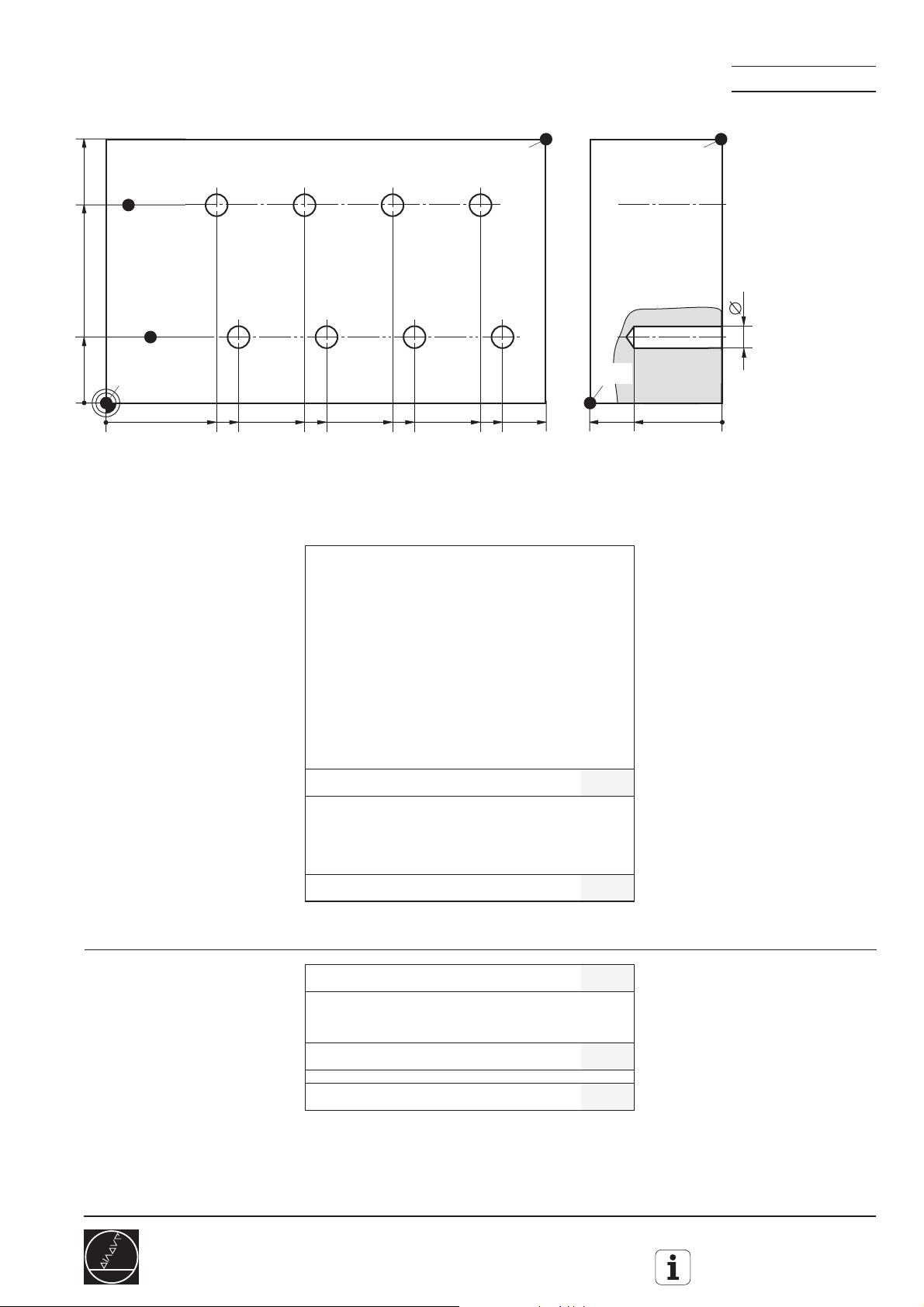

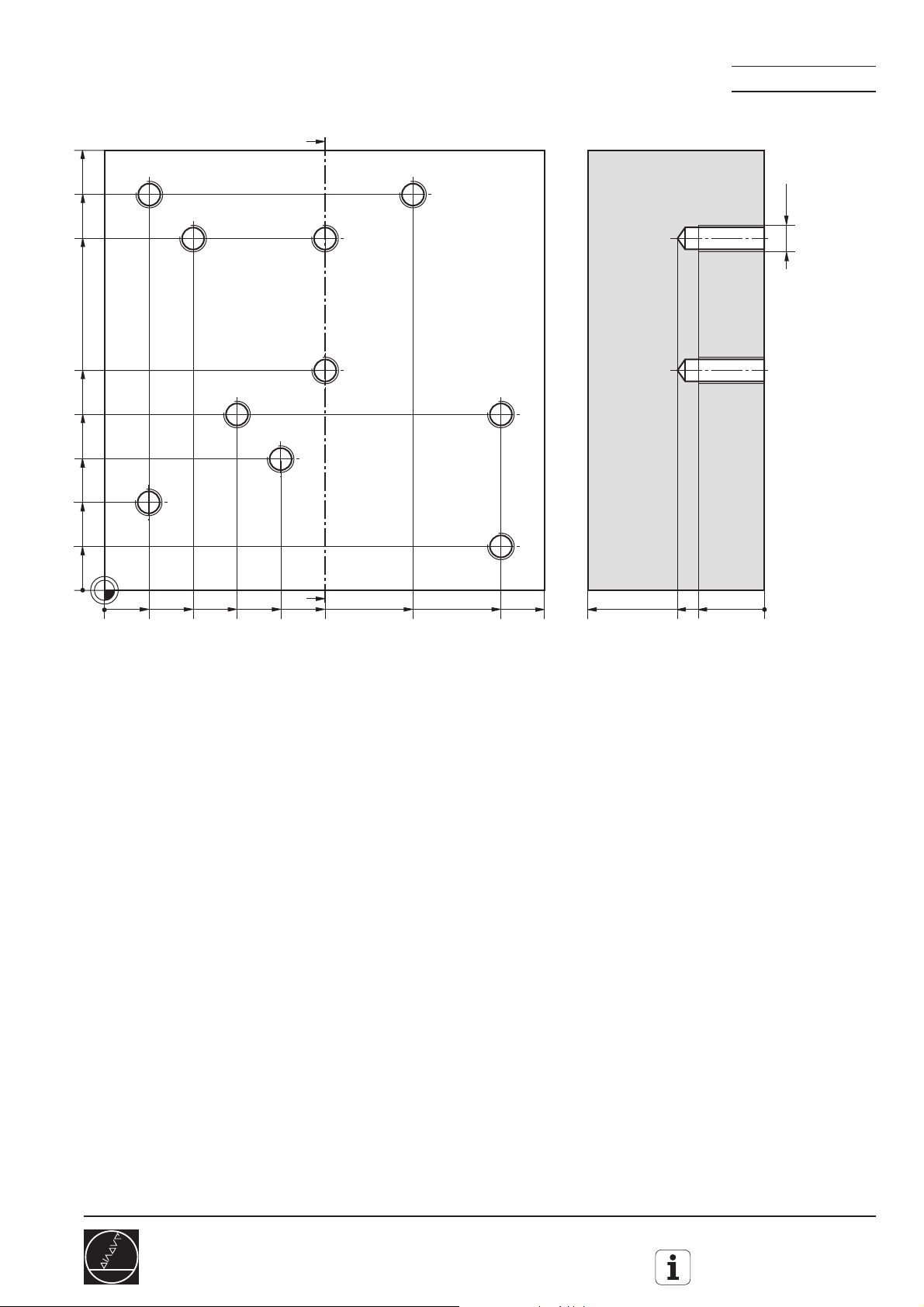

60

45

15

Task:

➀

➁

Two rows of holes

Max

Program(s):

Max

5

Min

0

0

Program layout:

Conventional

preparation

25

30

➀

50

45

658570

90

100

BLK FORM

TOOL DEF

TOOL CALL 1 Z S3000

CYCL DEF 1.0 PECKING

L X . . . Y . . . R0 F9999 M3

L Z . . .

CALL LBL 1

L X . . . Y . . .

L Z . . .

Min

30

20

0

Workpiece blank

First tool call

Pecking cycle

Pre-position

Pre-position

➁

Retract tool, end

SPGM 1

HEIDENHAIN

Advanced course TNC 4xx

CALL LBL 1

L Z . . . M2

LBL 1

L IX+20 M99

CALL LBL 1 REP 3/3

LBL 0

C04

7280/1

Page 4

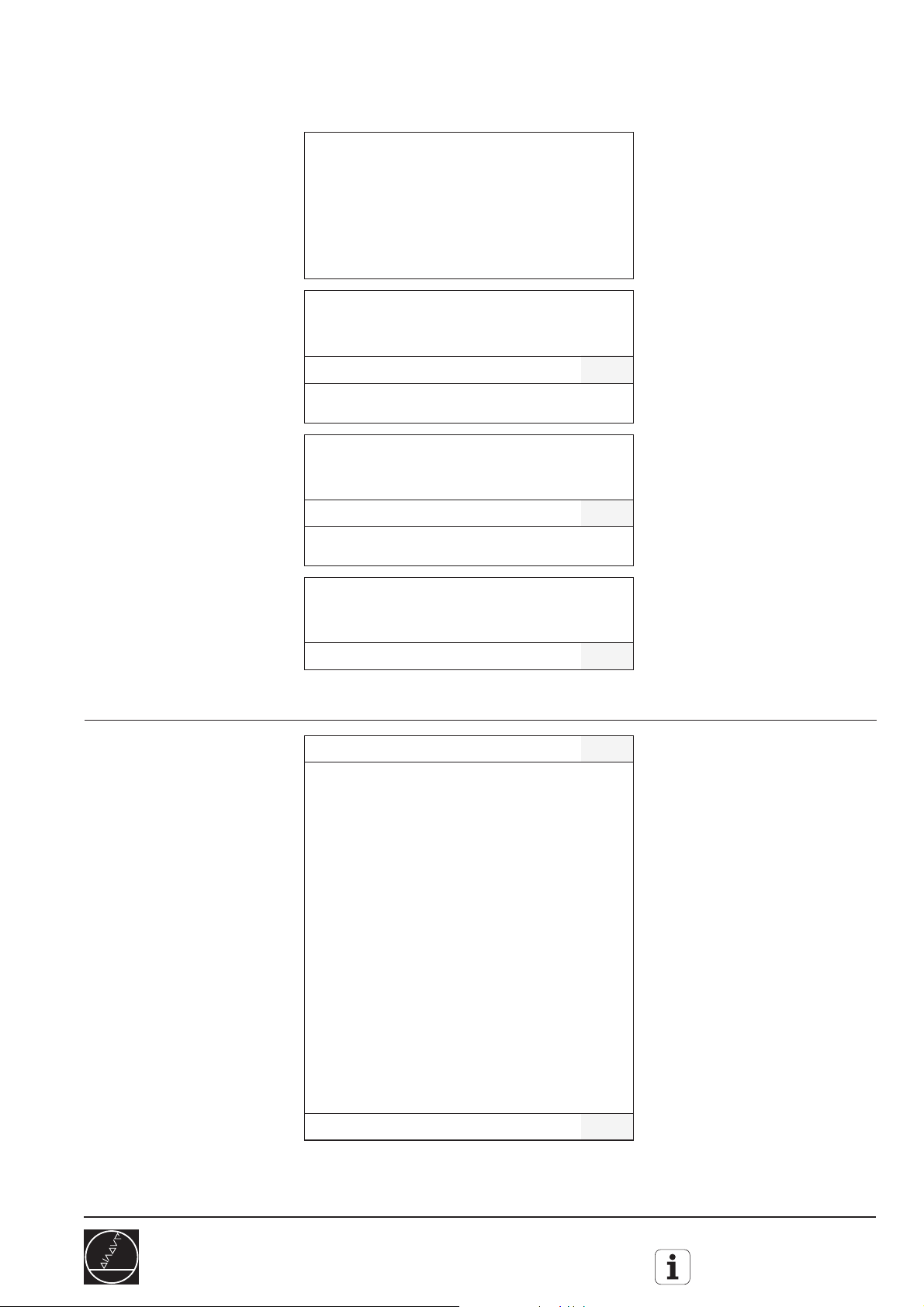

Solution:

Two rows of holes

Main program

60

➀

45

➁

15

Min

0

0

0 BEGIN PGM 7280 MM

1 .................................................................................

2 BLK FORM 0.1 Z X+0 Y+0 Z-30

3 BLK FORM 0.2 X+100 Y+60 Z+0

4 TOOL DEF 1 L+0 R+2,5

5 TOOL CALL 1 Z S3000

6 CYCL DEF 1.0 PECKING

7 CYCL DEF 1.1 SET UP -2

8 CYCL DEF 1.2 DEPTH -22

9 CYCL DEF 1.3 PECKG -10

10 CYCL DEF 1.4 DWELL 0

11 CYCL DEF 1.5 F150

25

30

45

50

658570

Max

90

Max

Min

20

30

100

TWO ROWS OF HOLES

5

0

Retract tool, end

SPGM 1

12 L X+5 Y+45 R0 F9999 M3

13 L Z+2

14 CALL LBL 1

15 L X+10 Y+15

16 CALL LBL 1

17 L Z+20 R0 F9999 M2

18 LBL 1

19 L IX+20 F9999 M99

20 CALL LBL 1 REP 3/3

21 LBL 0

22 END PGM 7280 MM

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

C04

7280/2

Page 5

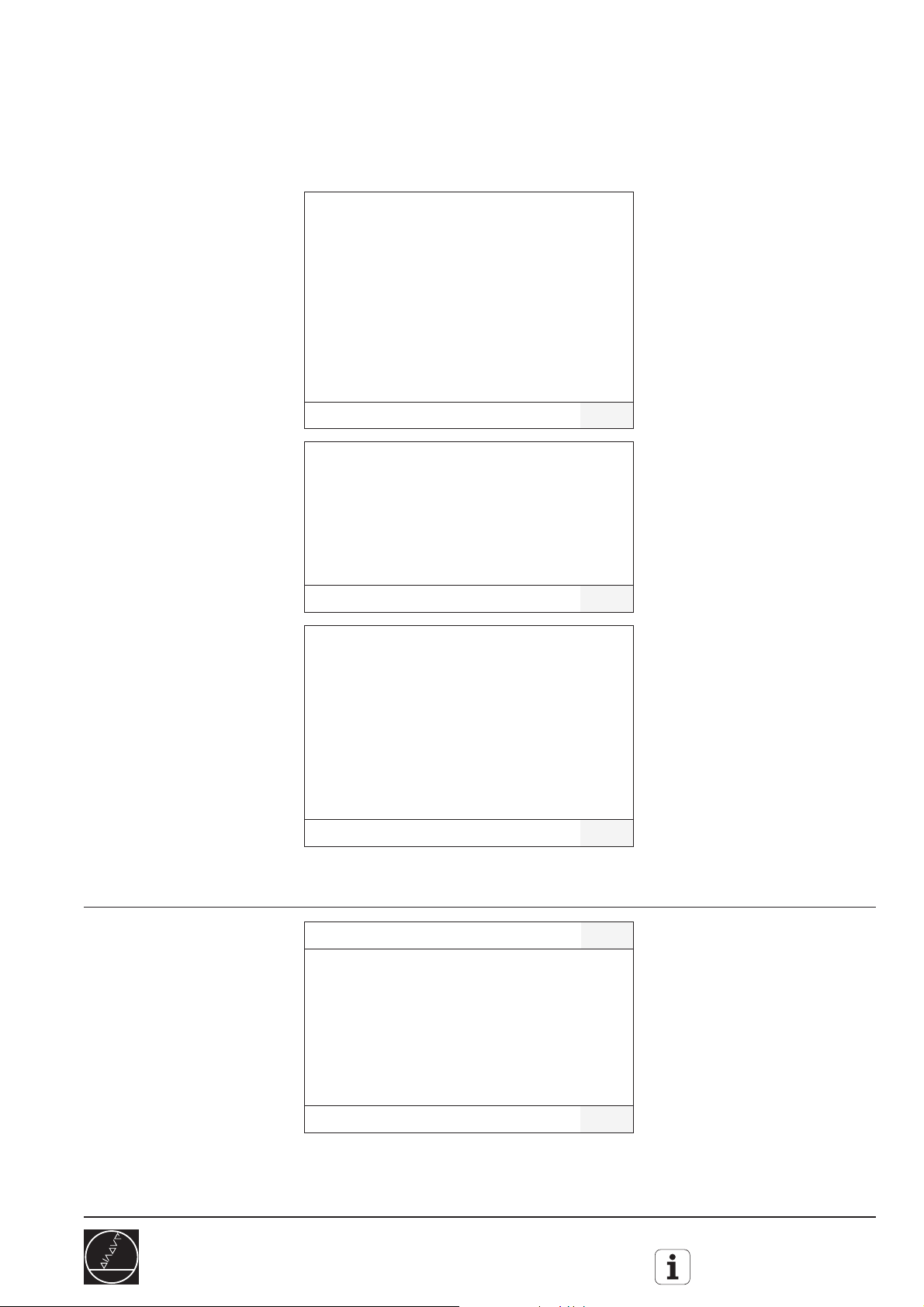

100

Task:

Irregular drilling pattern,

with 3 tools and 3 cycles

Program(s):

90

80

50

40

30

30

20

10

M6

0

0

10

20

30

40

50

70

90

100

40

20

15

0

Tools: • NC-center drill

• Twist drill

•Tap

HEIDENHAIN

Advanced course TNC 4xx

C04 7153/1

Page 6

Program layout: Irregular drilling pattern,

with 3 tools and 3 cycles

Preparation

Process

Center

Pecking

Tapping

BLK FORM

TOOL DEF

TOOL 1 . . .

L Z . . . . . . . . . . M6

CYCL DEF,

DEPTH = PECKG

CALL LBL 1

STOP M6

TOOL 2 . . .

CYCL DEF,

DEPTH ≠ PECKG

CALL LBL 1

STOP M6

TOOL 3 . . .

CYCL DEF

Workpiece blank

Tool list

First tool call

Tool change

Pecking cycle

Call drilling pattern

Tool change

Pecking cycle

Call drilling pattern

Tool change

Tapping cycle

Retract tool, end

Drilling pattern,

SPGM 1

CALL LBL 1

L Z . . . M2

LBL 1

L X . . . Y . . .

L Z . . . M89

L X . . . Y . . .

L X . . . Y . . . M99

L Z . . .

L X . . . Y . . .

Call drilling pattern

1st position lower left

Setup clearance

and modal cycle call

Further hole positions:

automatic

Further hole positions:

Cycle call by block

Tool change position

LBL 0

HEIDENHAIN

Advanced course TNC 4xx

C04

7153/2

Page 7

Program layout: Use of Q-parameter for

irregular drilling pattern

BLK- FORM

Center

Pecking

Tapping

TOOL DEF 1 L0 R3,5

TOOL CALL . . .

Q1 = +2

Q2 = +3

CYCL DEF . . . PECKING

SET UP -Q1

DEPTH -Q2 . . .

CALL LBL 1

TOOL DEF 2 L0 R2,5

TOOL CALL . . .

Q2 = 20

CALL LBL 1

TOOL DEF 3 L0 R3,0

TOOL CALL . . .

Q1 = 6

Q2 = 15

CYCL DEF . . . TAPPING

SET UP -Q1

DEPTH -Q2 . . .

Set up

Depth

Cycle type stays the

same!

Retract tool, end

Drilling pattern,

SPGM

HEIDENHAIN

Advanced course TNC 4xx

CALL LBL 1

L Z100 M2

LBL 1

L X . . . Y . . . R0 F9999 M3

L ZQ1 M89

L X . . . Y . . .

L X . . . Y . . . M99

L Z50

LBL 0

C04

Return jump

G7

Page 8

Solution:

Irregular drilling pattern,

with 3 tools and 3 cycles

100

Main program

90

80

50

40

30

30

20

10

0

0

0 BEGIN PGM 7153 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1 L+0 R+3,5 ...........................................

4 TOOL DEF 2 L+0 R+2,5 ...........................................

5 TOOL DEF 3 L+0 R+3 ..............................................

10

20

30

40

50

70

90

40

100

NC-CENTER DRILL

TWIST DRILL

TAP

20

15

M6

0

Center

Pecking

Tapping

6 TOOL CALL 1 Z S800 ..............................................

7 L Z+100 R0 F9999 M6..............................................

8 CYCL DEF 1.0 PECKING

9 CYCL DEF 1.1 SET UP -2

10 CYCL DEF 1.2 DEPTH -2

11 CYCL DEF 1.3 PECKG -2

12 CYCL DEF 1.4 DWELL 0

13 CYCL DEF 1.5 F200

14 CALL LBL 1 ..............................................................

15 STOP M6 .................................................................

16 TOOL CALL 2 Z S500 ..............................................

17 CYCL DEF 1.0 PECKING

18 CYCL DEF 1.1 SET UP -2

19 CYCL DEF 1.2 DEPTH -20

20 CYCL DEF 1.3 PECKG -10

21 CYCL DEF 1.4 DWELL 0

22 CYCL DEF 1.5 F100

23 CALL LBL 1 ..............................................................

24 STOP M6 .................................................................

25 TOOL CALL 3 Z S500 ..............................................

26 CYCL DEF 2.0 TAPPING

27 CYCL DEF 2.1 SET UP -2

28 CYCL DEF 2.2 DEPTH -15

29 CYCL DEF 2.3 DWELL 0

30 CYCL DEF 2.4 F500

31 CALL LBL 1 ..............................................................

NC-CENTER DRILL

TOOL CHANGE

CALL DRILLING PATTERN

TOOL CHANGE

TWIST DRILL

CALL DRILLING PATTERN

TOOL CHANGE

TAP

CALL DRILLING PATTERN

Retract tool, end

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

32 L Z+100 M2

7153/3C01

Page 9

Solution:

Irregular drilling pattern,

with 3 tools and 3 cycles

SPGM 1,

Drilling pattern

33 LBL 1

34 L X+10 Y+20 R0 F9999 M13

35 L Z+2 M89 ................................................................

36 L X+40 Y+30

37 L X+90 Y+10

38 L Y+40

39 L X+50 Y+80

40 L Y+50

41 L X+30 Y+40

42 L X+20 Y+80

43 L X+10 Y+90

44 L X+70 M99 .............................................................

45 L Z+100 M9 ..............................................................

46 L X-20 Y-20

47 LBL 0

48 END PGM 7153 MM

FIRST MODAL CYCLE CALL

LAST CYCLE CALL BY BLOCK

TOOL CHANGE POSITION

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

C01

7153/4

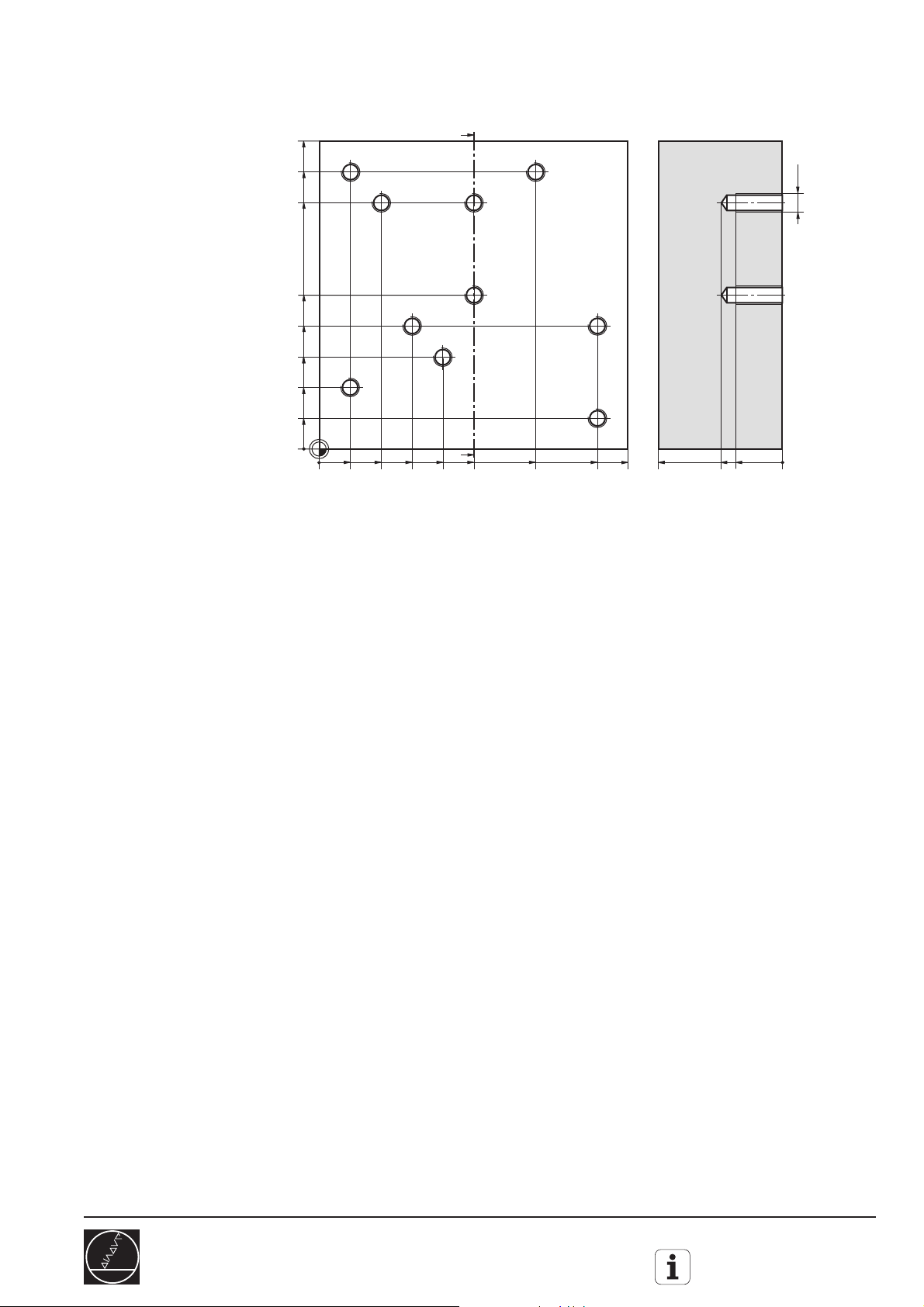

Page 10

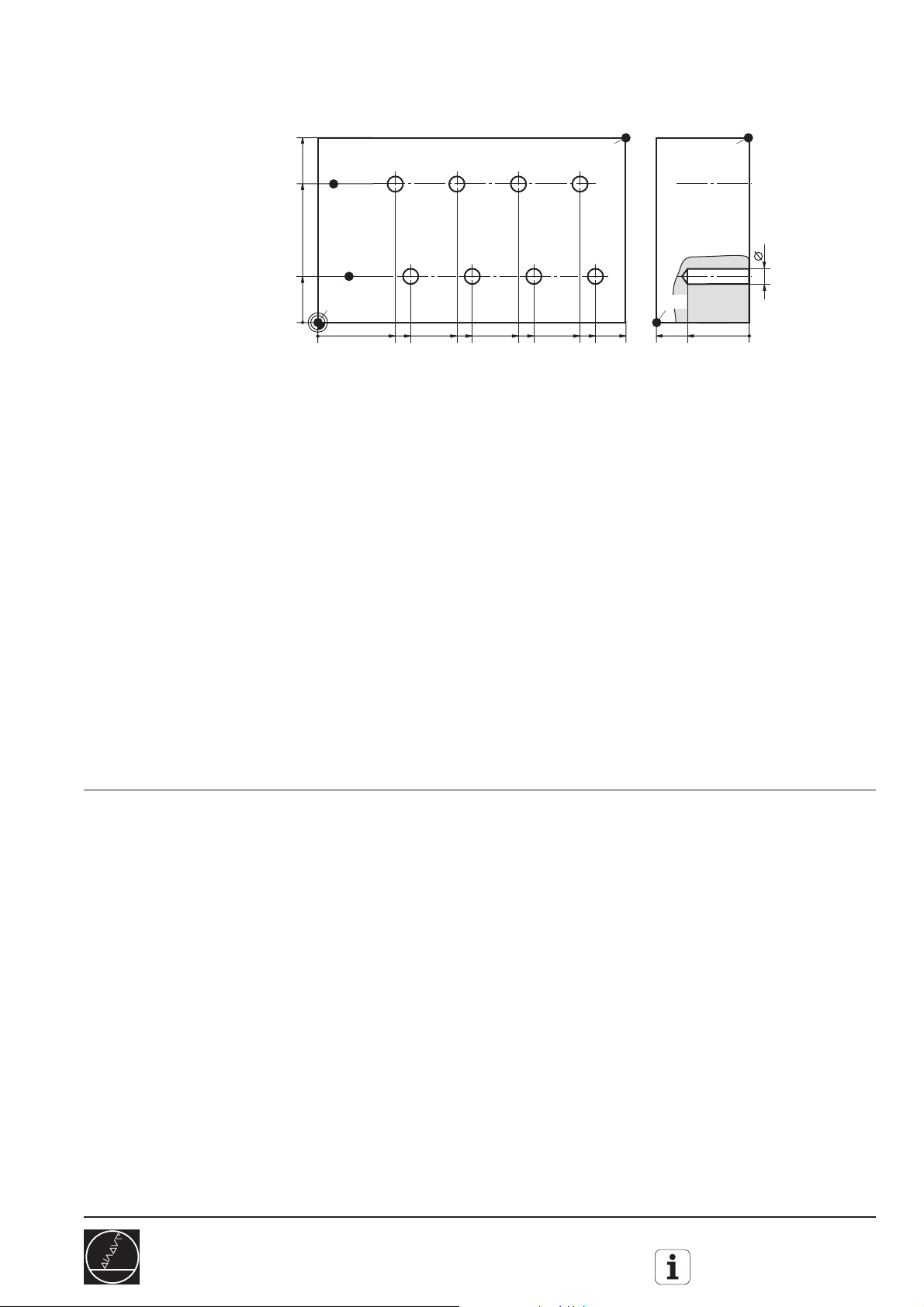

100

84

76

68

60

52

44

36

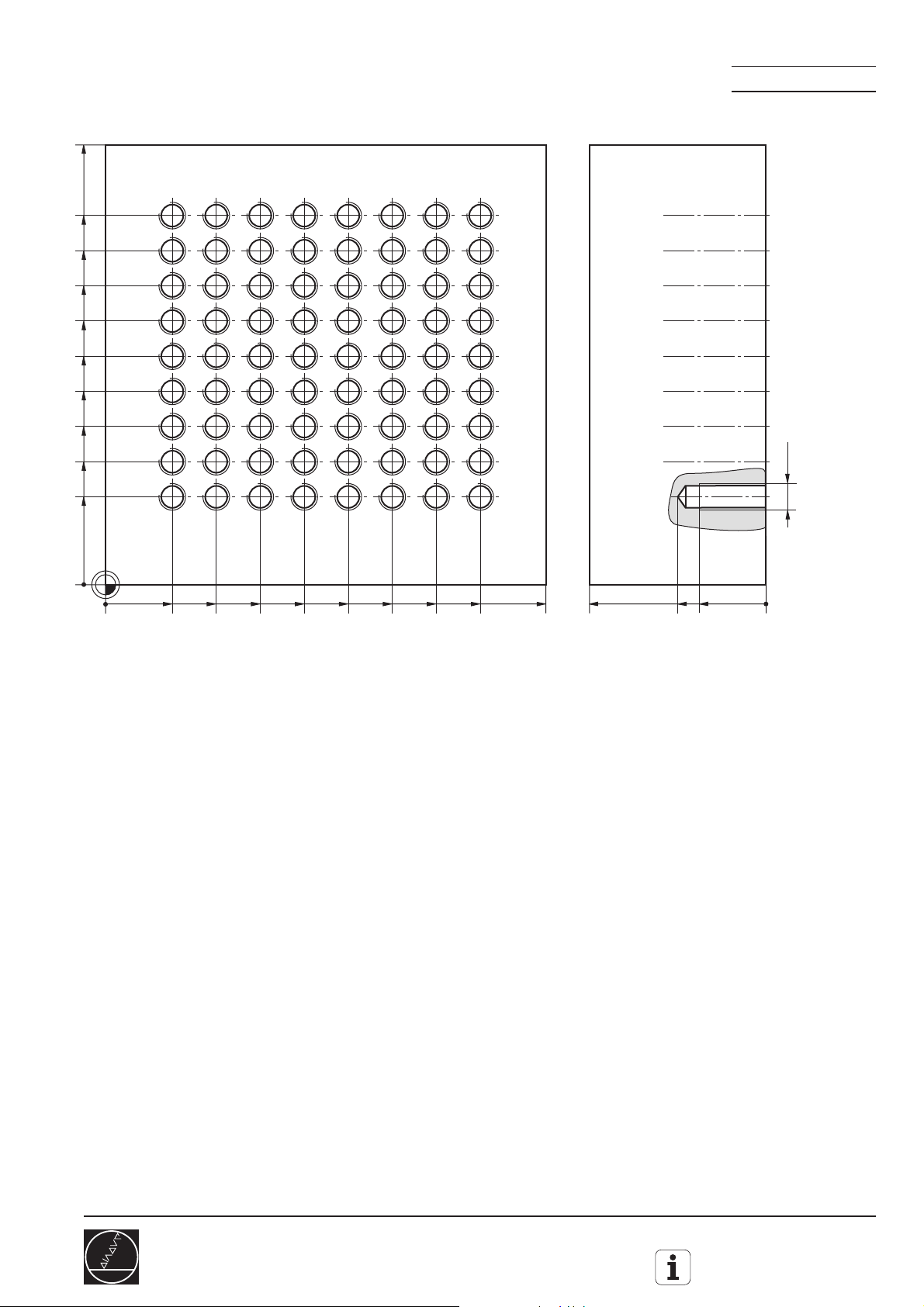

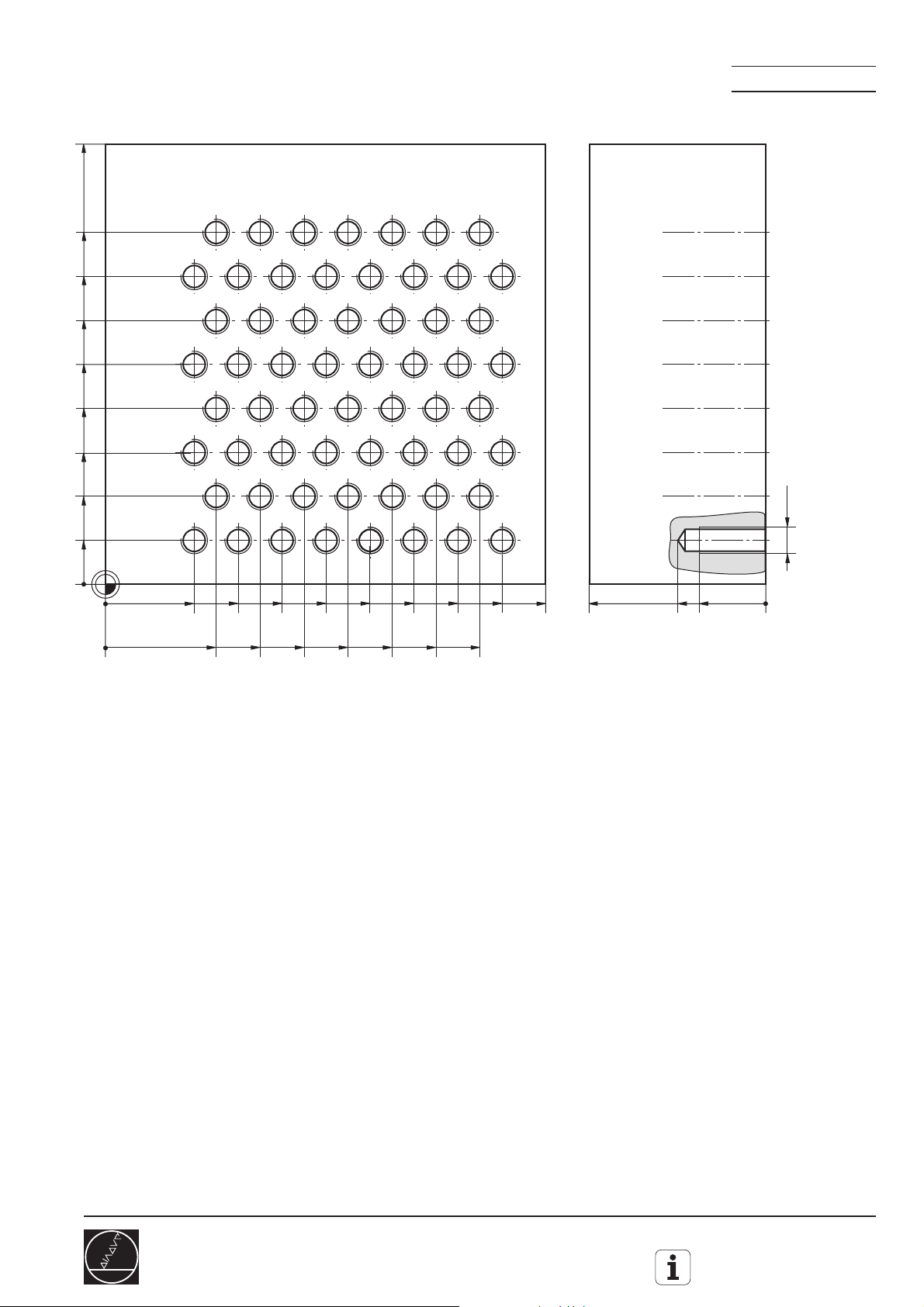

Task:

Linear hole pattern

Program(s):

28

20

0

0

Procedure:

Tools:

15

25

35

45

55

65

75

85

100

40

• Move up and down colums (meandering)

• NC-center drill

• Twist drill

•Tap

20

15

M6

0

HEIDENHAIN

Advanced course TNC 4xx

C04

7109/1

Page 11

Program layout: Linear hole pattern

Preparation

Process

Center

Pecking

Tapping

BLK FORM

TOOL 1 . . . / TOOL 2 . . .

TOOL 1 . . .

CYCL DEF,

DEPTH = PECKG

CALL LBL 1

L Z . . . M6

TOOL 2 . . .

CYCL DEF,

DEPTH ≠ PECKG

CALL LBL 1

L Z . . . M6

TOOL 3 . . .

CYCL DEF

Workpiece blank

Tool list if necessary

Pecking cycle

Call drilling pattern

Tool change

Pecking cycle

Call drilling pattern

Tool change

Tapping cycle

Retract tool, end

CALL LBL 1

L Z . . . M2

Call drilling pattern

HEIDENHAIN

Advanced course TNC 4xx

7109/2C01

Page 12

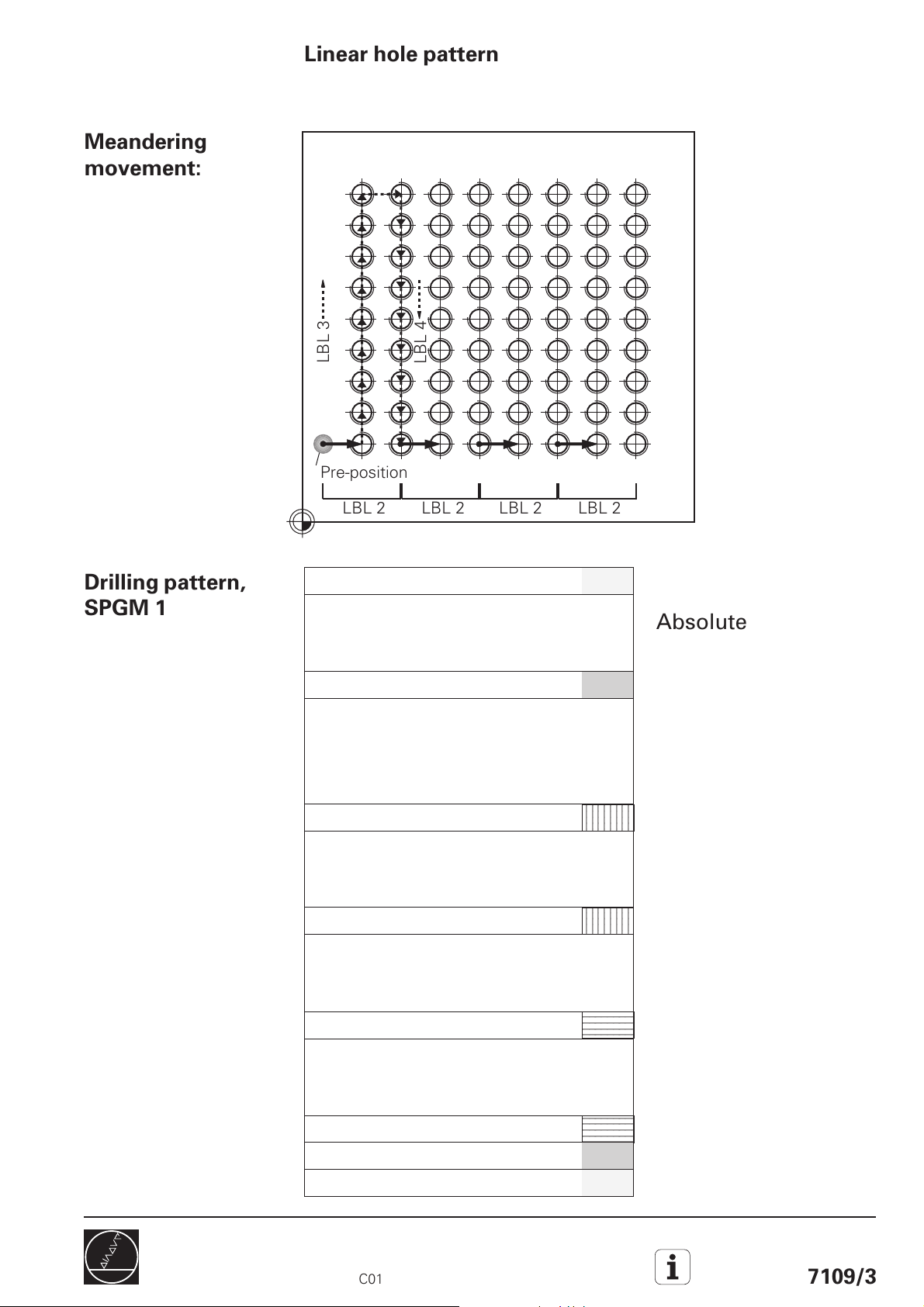

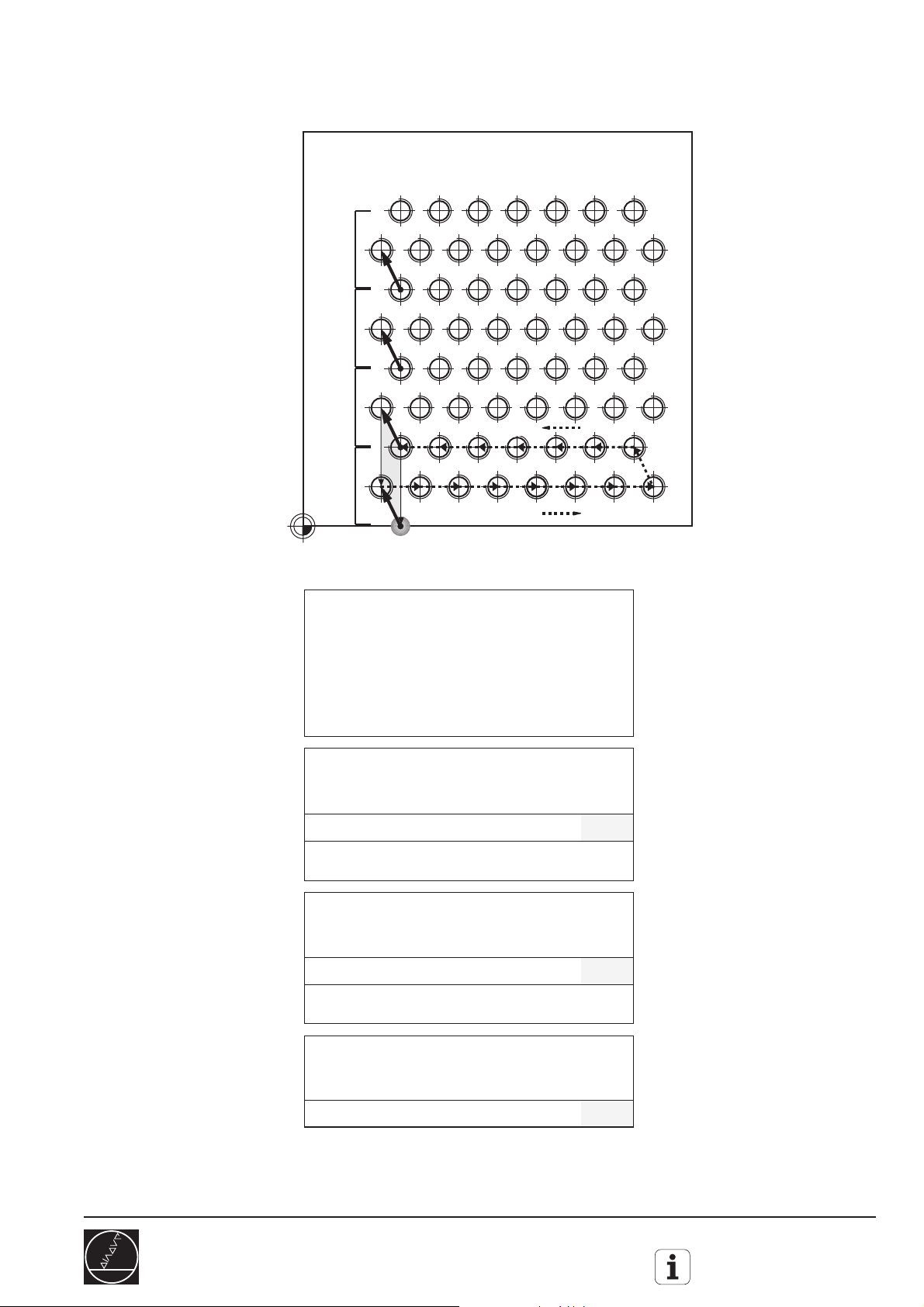

Program layout:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

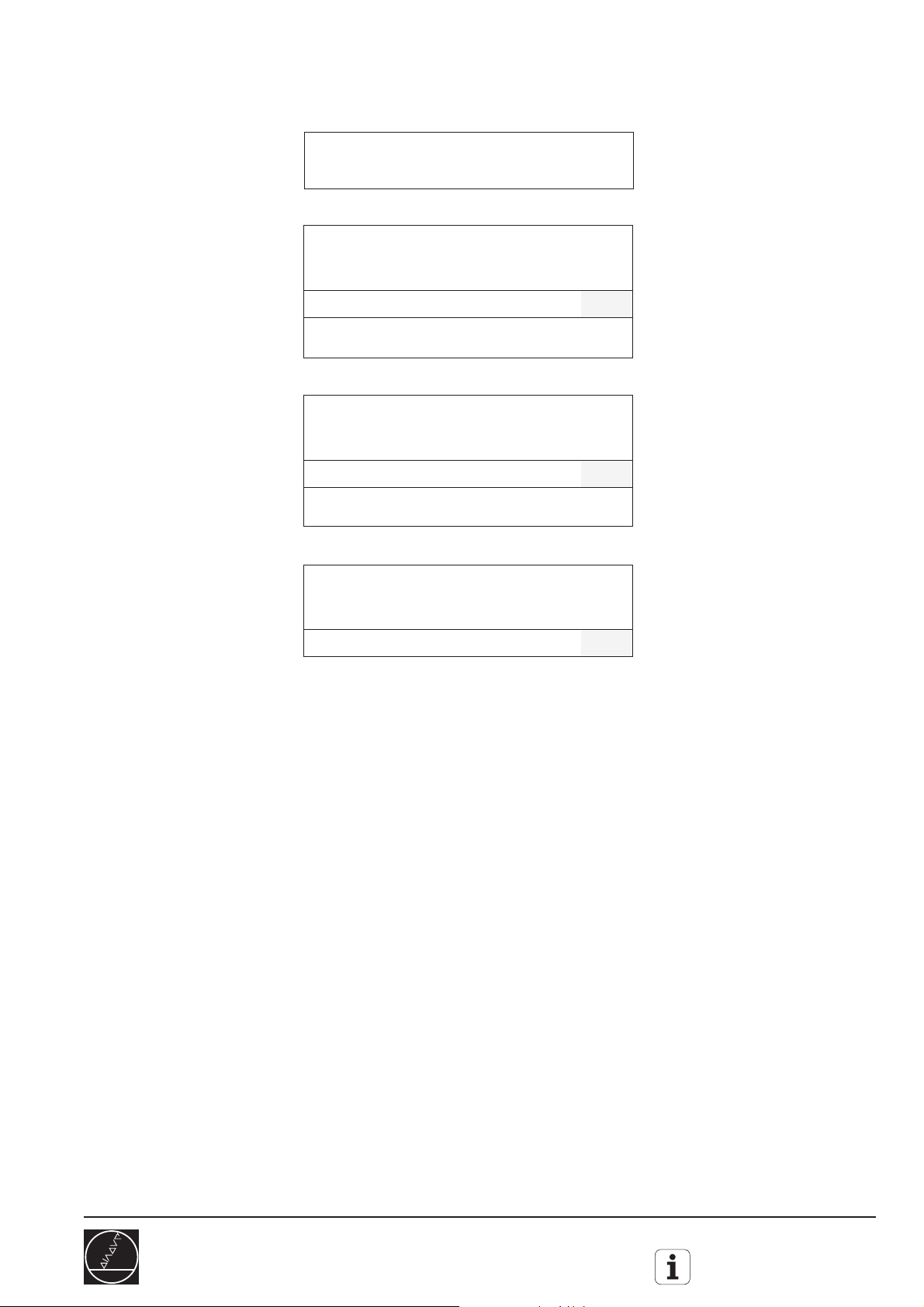

Meandering

movement:

Linear hole pattern

Drilling pattern,

SPGM 1

LBL 3

LBL 4

Pre-position

LBL 2 LBL 2 LBL 2 LBL 2

LBL 1

L X . . . Y . . . R0 F9999 M3

L Z . . . M8

LBL 2

L IX . . . M99

LBL 3

23456789

23456789

23456789

23456789

Absolute Pre-position

Setup clearance

Label

Define increments

Cross over and drill

Label

L IY . . . M99

CALL LBL 3 REP . . .

L IX . . . M99

LBL 4

L IY . . . M99

CALL LBL 4 REP . . .

23456789

23456789

23456789

23456789

23456789

23456789

23456789

23456789

23456789

23456789

23456789

Move up column

Cross over and drill

Label

Move down column

Remaining columns

CALL LBL 2 REP . . .

LBL 0

HEIDENHAIN

Advanced course TNC 4xx

7109/3C01

Page 13

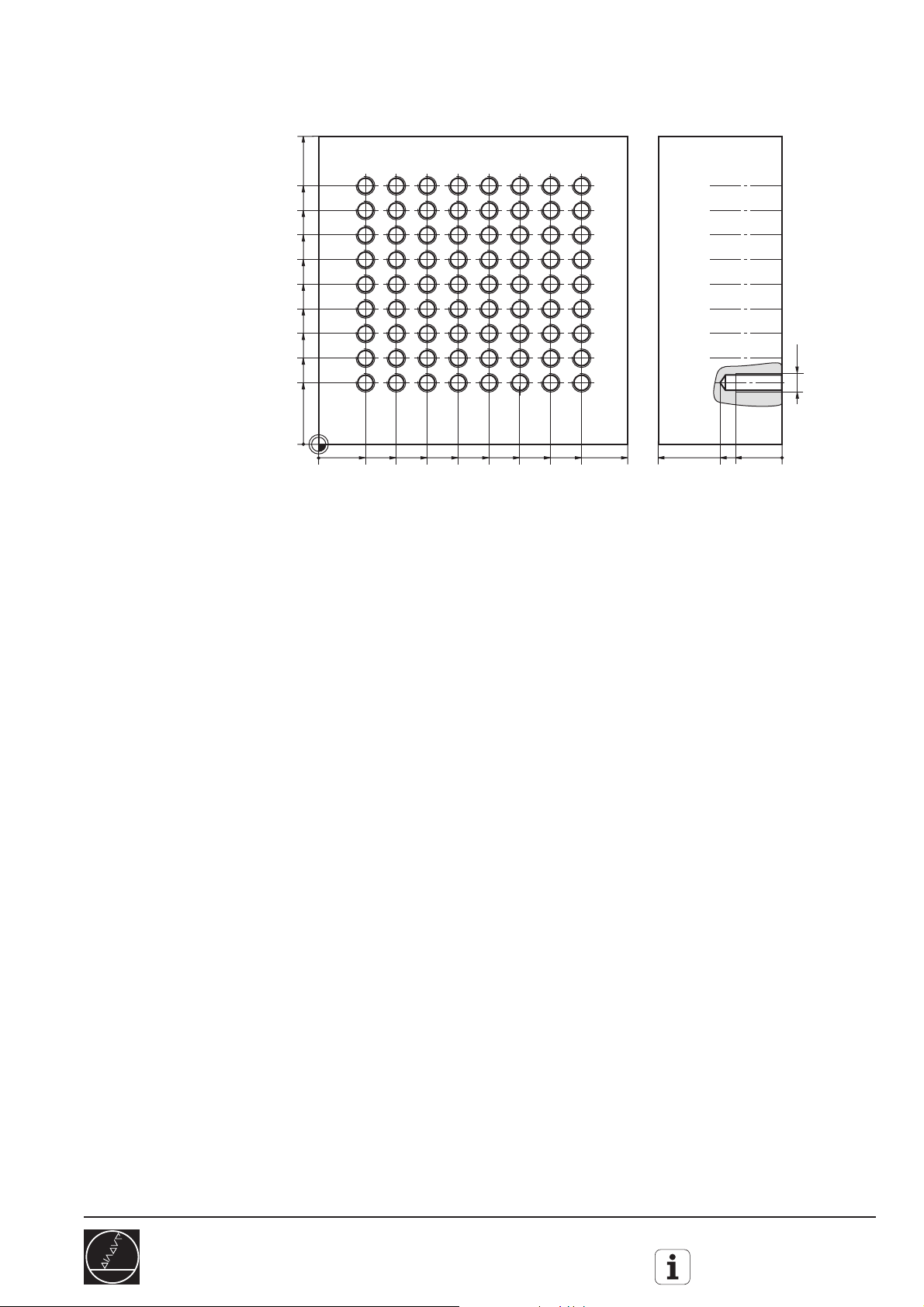

Solution:

Linear hole pattern

100

84

76

68

60

52

44

36

28

20

0

0

15

25

35

45

55

65

75

85

100

40

20

15

M6

0

Main program

Center

Pecking

0 BEGIN PGM 7109 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1 L+0 R+3,5 ...........................................

4 TOOL DEF 2 L+0 R+2,5 ...........................................

5 TOOL DEF 3 L+0 R+3 ..............................................

6 TOOL CALL 1 Z S2500 ............................................

7 L Z+100 R0 F9999 M6..............................................

8 CYCL DEF 1.0 PECKING

9 CYCL DEF 1.1 SET UP -2

10 CYCL DEF 1.2 DEPTH -3

11 CYCL DEF 1.3 PECKG -3

12 CYCL DEF 1.4 DWELL 0

13 CYCL DEF 1.5 F100

14 CALL LBL 1 ..............................................................

15 L Z+100 M6 ..............................................................

16 TOOL CALL 2 Z S1500

17 CYCL DEF 1.0 PECKING

18 CYCL DEF 1.1 SET UP -2

19 CYCL DEF 1.2 DEPTH -20

20 CYCL DEF 1.3 PECKG -20

21 CYCL DEF 1.4 DWELL 0

22 CYCL DEF 1.5 F50

23 CALL LBL 1 ..............................................................

24 L Z+100 M6 ..............................................................

NC-CENTER DRILL

TWIST DRILL

TAP

NC-CENTER DRILL

TOOL CHANGE

CALL DRILLING PATTERN

TOOL CHANGE

CALL DRILLING PATTERN

TOOL CHANGE

Tapping

Retract tool, end

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

25 TOOL CALL 3 Z S500

26 CYCL DEF 2.0 TAPPING

27 CYCL DEF 2.1 SET UP -2

28 CYCL DEF 2.2 DEPTH -15

29 CYCL DEF 2.3 DWELL 0

30 CYCL DEF 2.4 F500

31 CALL LBL 1 ..............................................................

32 L Z+100 M2

C01

CALL DRILLING PATTERN

7109/4

Page 14

Solution:

Linear hole pattern

SPGM 1,

Drilling pattern

33 LBL 1 ........................................................................

34 L X+5 Y+20 R0 F9999 M3 ........................................

35 L Z+2 R0 M8

36 LBL 2

37 L IX+10 M99 ............................................................

38 LBL 3

39 L IY+8 M99...............................................................

40 CALL LBL 3 REP 7/7.................................................

41 L IX+10 M99 ............................................................

42 LBL 4

43 L IY-8 M99 ................................................................

44 CALL LBL 4 REP 7/7.................................................

45 CALL LBL 2 REP 3/3.................................................

46 LBL 0

47 END PGM 7109 MM

DRILLING PATTERN

PRE-POSITION

CROSS OVER

Y-STEP UPWARDS

COLUMN UPWARDS

CROSS OVER

Y-STEP DOWNWARDS

COLUMN DOWNWARDS

REMAINING COUMNS

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

7109/5C01

Page 15

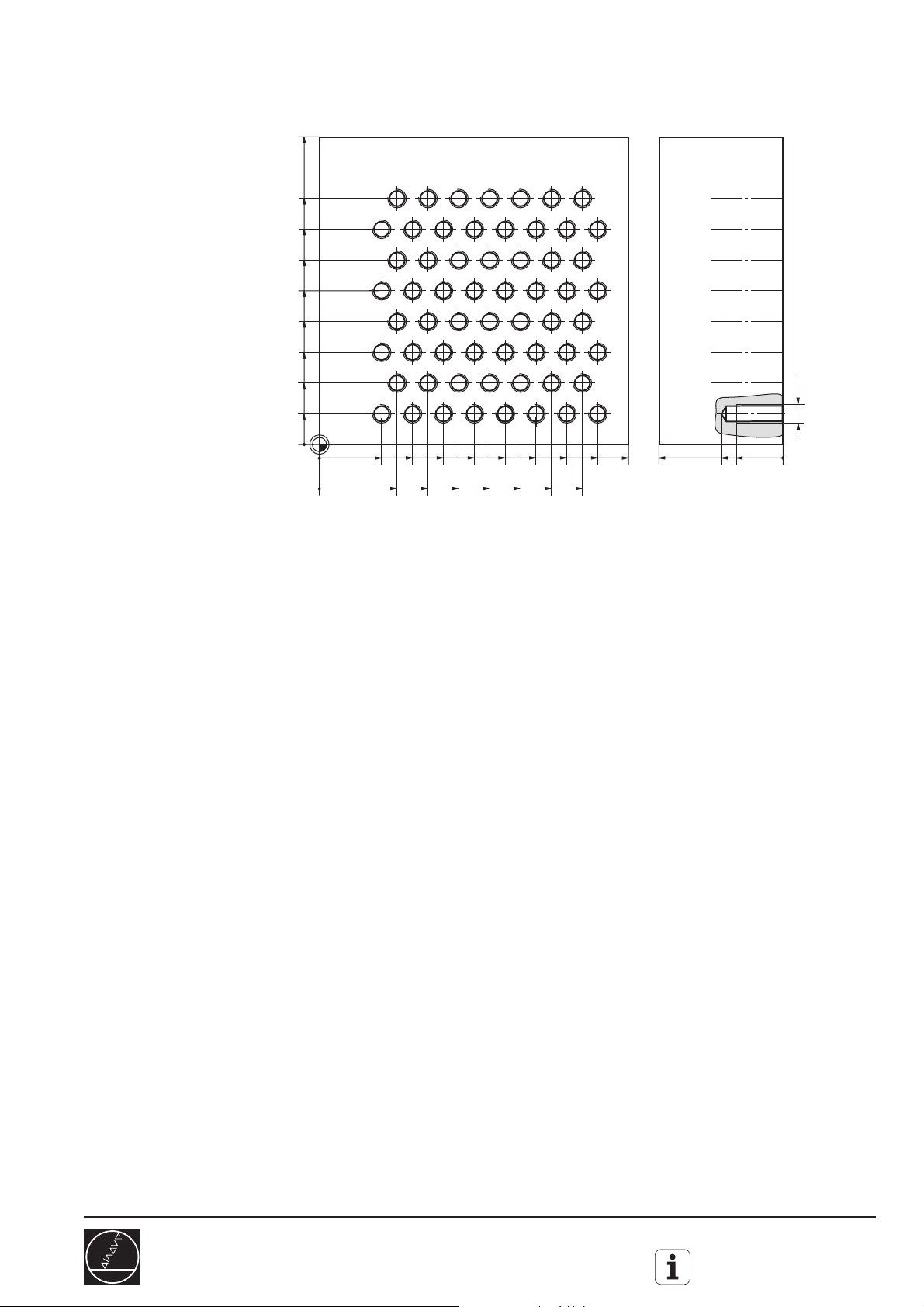

100

80

70

60

50

40

30

30

Task:

Linear offset hole pattern,

including tapping

Program(s):

20

10

0

0

Procedure:

Tools:

20

100

40

25

30

35

40

45

50

55

60

65

70

75

80

90

85

• Move back and forth along rows (meandering)

• NC-center drill

• Twist drill

•Tap

20

15

M6

0

HEIDENHAIN

Advanced course TNC 4xx

C05

7426/1

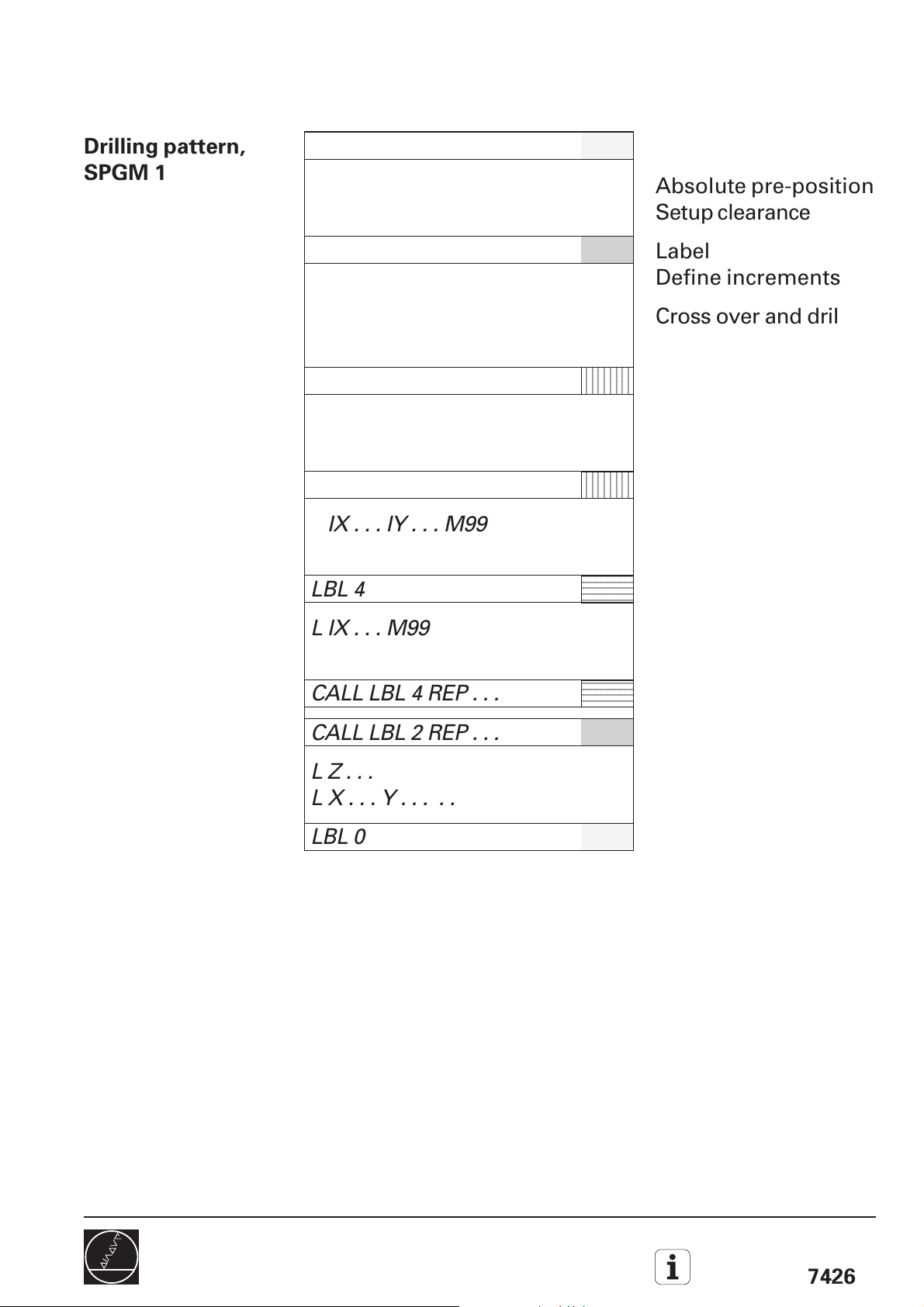

Page 16

Program layout: Linear offset hole pattern,

including tapping

Meandering

movement:

LBL

2

LBL

2

Left end of short

row = Preposition for next

row

Preparation

Process

Center

LBL

2

LBL

2

Pre-position

BLK FORM

TOOL DEF

TOOL 1 . . .

L Z . . . . . . . . . . M6

CYCL DEF,

DEPTH = PECKG

CALL LBL 1

LBL 4

LBL 3

First pre-position

lies under the

first long row

Workpiece blank

Tool list

First tool call

Tool change

Pecking cycle

Call drilling pattern

Pecking

Tapping

Process end

HEIDENHAIN

Advanced course TNC 4xx

STOP M6

TOOL 2 . . .

CYCL DEF,

CALL LBL 1

STOP M6

TOOL 3 . . .

CYCL DEF

CALL LBL 1

STOP M2

DEPTH ≠ PECKG

Tool change

Pecking cycle

Call drilling pattern

Tool change

Tapping cycle

Call drilling pattern

7426/2C05

Page 17

Program layout:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Linear offset hole pattern,

including tapping

Drilling pattern,

SPGM 1

LBL 1

L X . . . Y . . .

L Z . . .

LBL 2

L IX . . . IY . . . M99

LBL 3

L IX . . . M99

CALL LBL 3 REP . . .

L IX . . . IY . . . M99

LBL 4

23456789

23456789

23456789

23456789

23456789

23456789

23456789

23456789

23456789

23456789

Absolute pre-position

Setup clearance

Label

Define increments

Cross over and drill

Label

Move right

Cross over and drill

Label

L IX . . . M99

CALL LBL 4 REP . . .

CALL LBL 2 REP . . .

L Z . . .

L X . . . Y . . . . .

LBL 0

23456789

23456789

23456789

23456789

Move left

Remaining rows

Tool change position

HEIDENHAIN

Advanced course TNC 4xx

7426/3C01

Page 18

Solution:

Linear offset hole pattern,

including tapping

100

80

70

60

50

40

30

30

Main program

Center

20

10

0

30

40

50

60

70

75

80

85

20

0

0 BEGIN PGM 7426 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1 L+0 R+3,5 ...........................................

4 TOOL DEF 2 L+0 R+2,5 ...........................................

5 TOOL DEF 3 L+0 R+3 ..............................................

6 TOOL CALL 1 Z S800 ..............................................

7 L Z+100 R0 F9999 M6..............................................

8 CYCL DEF 1.0 PECKING

9 CYCL DEF 1.1 SET UP -2

10 CYCL DEF 1.2 DEPTH -2

11 CYCL DEF 1.3 PECKG -2

12 CYCL DEF 1.4 DWELL 0

13 CYCL DEF 1.5 F200

14 CALL LBL 1 ..............................................................

15 STOP M6 .................................................................

25

35

45

55

65

90

15

40

100

NC-CENTER DRILL

TWIST DRILL

TAP

NC-CENTER DRILL

TOOL CHANGE

CALL DRILLING PATTERN

TOOL CHANGE

20

M6

0

Pecking

Tapping

Retract tool, end

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

16 TOOL CALL 2 Z S500 ..............................................

17 CYCL DEF 1.0 PECKING

18 CYCL DEF 1.1 SET UP -2

19 CYCL DEF 1.2 DEPTH -20

20 CYCL DEF 1.3 PECKG -10

21 CYCL DEF 1.4 DWELL 0

22 CYCL DEF 1.5 F100

23 CALL LBL 1 ..............................................................

24 STOP M6 .................................................................

25 TOOL CALL 3 Z S500 ..............................................

26 CYCL DEF 2.0 TAPPING

27 CYCL DEF 2.1 SET UP -2

28 CYCL DEF 2.2 DEPTH -15

29 CYCL DEF 2.3 DWELL 0

30 CYCL DEF 2.4 F500

31 CALL LBL 1 ..............................................................

32 STOP M2

C01

TWIST DRILL

CALL DRILLING PATTERN

TOOL CHANGE

TAP

CALL DRILLING PATTERN

7426/4

Page 19

Solution:

Linear offset hole pattern,

including tapping

SPGM 1,

Drilling pattern

33 LBL 1

34 L X+25 Y+0 R0 F9999 M3 ........................................

35 L Z+2 R0 M8

36 LBL 2 ........................................................................

37 L IX-5 IY+10 R0 M99

38 LBL 3 ........................................................................

39 L IX+10 R0 M99

40 CALL LBL 3 REP 6/6

41 L IX-5 IY+10 R0 M99................................................

42 LBL 4 ........................................................................

43 L IX-10 R0 M99

44 CALL LBL 4 REP 5/5

45 CALL LBL 2 REP 3/3.................................................

46 L Z+100 R0 M9.........................................................

47 L X-20 Y-20 R0

48 LBL 0

49 END PGM 7426 MM

PRE-POSITION

CROSS OVER AND DRILL

RIGHT ALONG ROW

CROSS OVER

LEFT ALONG ROW

REMAINING ROWS

TOOL CHANGE POSITION

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

7426/5C01

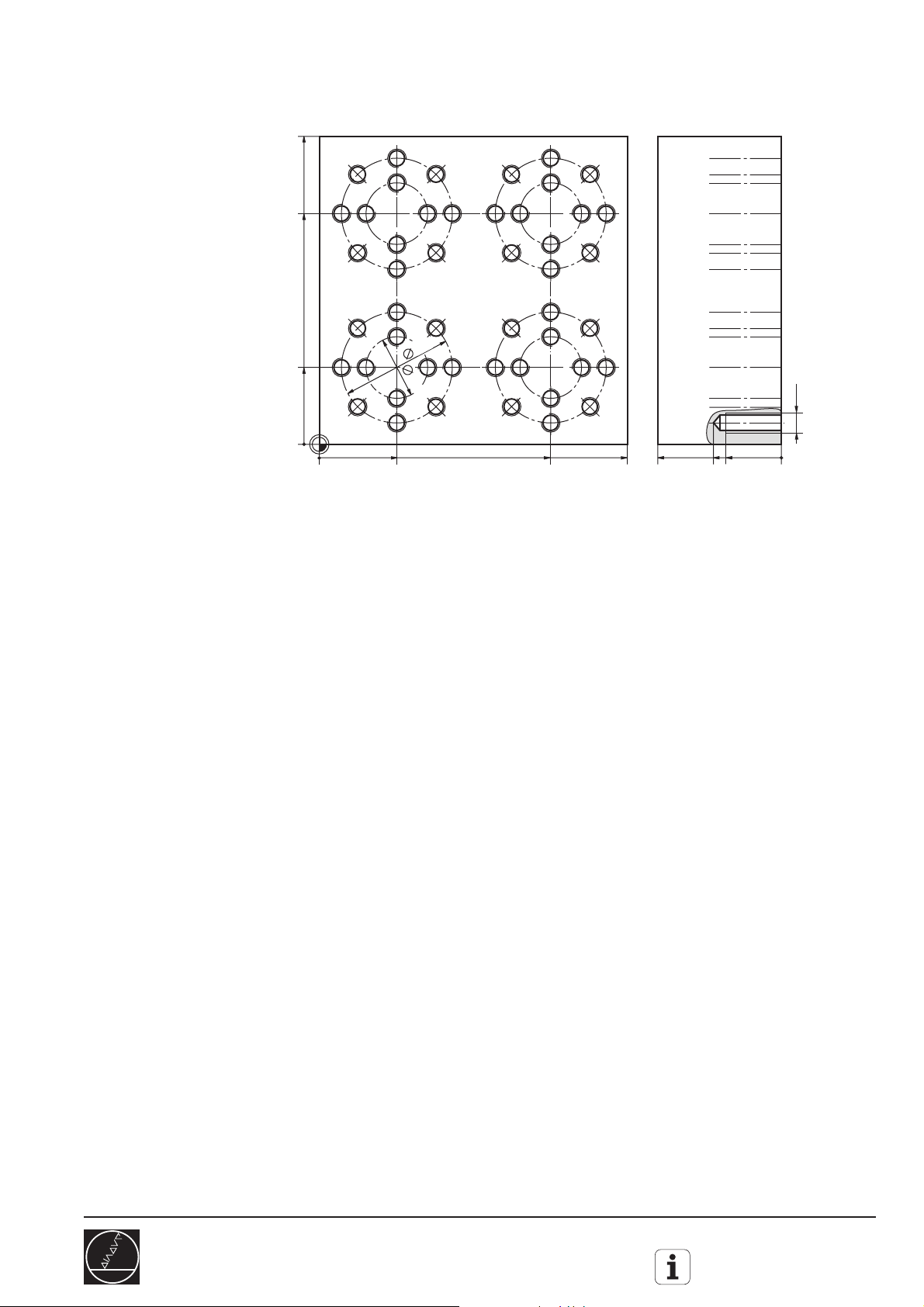

Page 20

100

75

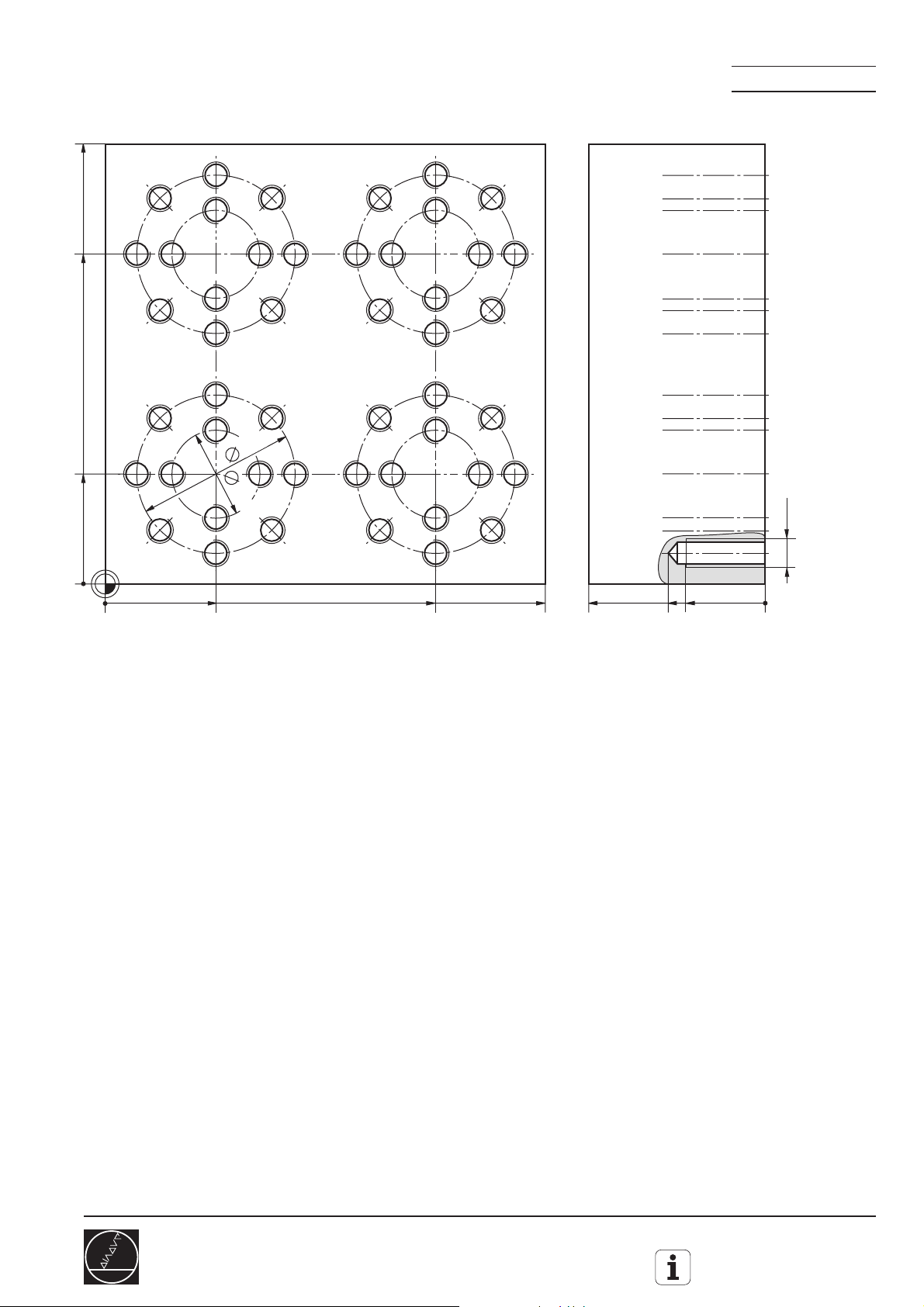

Task:

Four double bolt hole circles,

with 3 tools, 3 cycles,

including tapping

36

Program(s):

25

0

0

20

25

Tools: • NC-center drill

• Twist drill

•Tap

75

100

40

22

18

M6

0

HEIDENHAIN

Advanced course TNC 4xx

C04 7139/1

Page 21

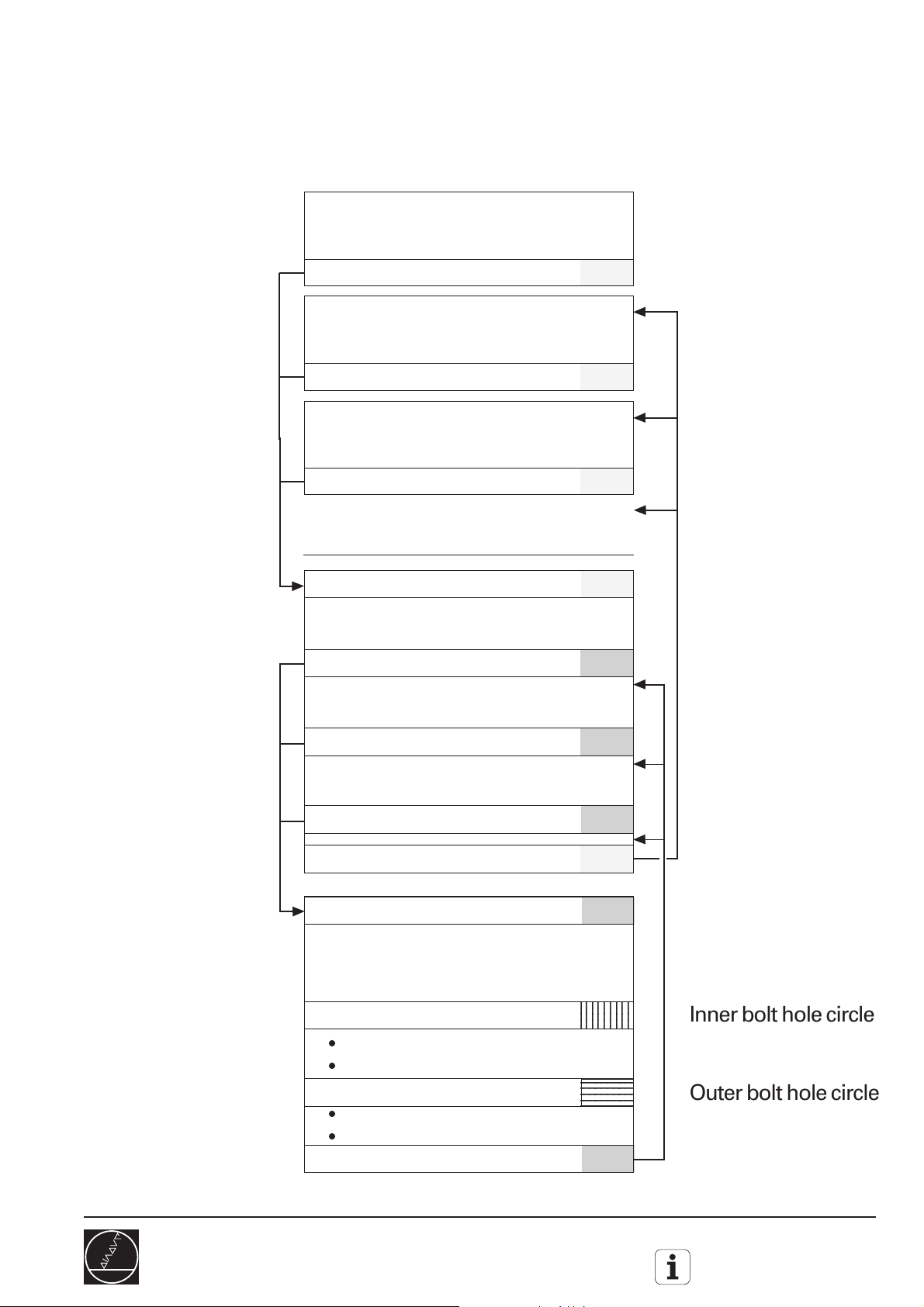

Program layout: Nesting of double bolt hole circles

0

0

0

0

0

0

0

0

BLK- FORM

Center

Pecking

Tapping

Retract tool, end

SPGM 1,

Circle center and

SPGM call

TOOL DEF / TOOL CALL 1 . . .

CYCL DEF . . .

CALL LBL 1

TOOL DEF / TOOL CALL 2 . . .

CYCL DEF . . .

CALL LBL 1

TOOL DEF / TOOL CALL 3 . . .

CYCL DEF . . .

CALL LBL 1

L Z100 M2

LBL 1

CC X . . . Y . . .

SPGM 2,

Tool movements

and holes

CALL LBL 2

CC X . . . Y . . .

CALL LBL 2

CC X . . . Y . . .

CALL LBL 2

LBL 0

LBL 2

LP PR . . . PA . . . M3

L Z2 M99

LBL 3

○○ ○○

LBL 4

23456789

23456789

23456789

23456789

23456789

23456789

23456789

23456789

Inner bolt hole circle

Outer bolt hole circle

LBL 0

HEIDENHAIN

Advanced course TNC 4xx

G8C04

Page 22

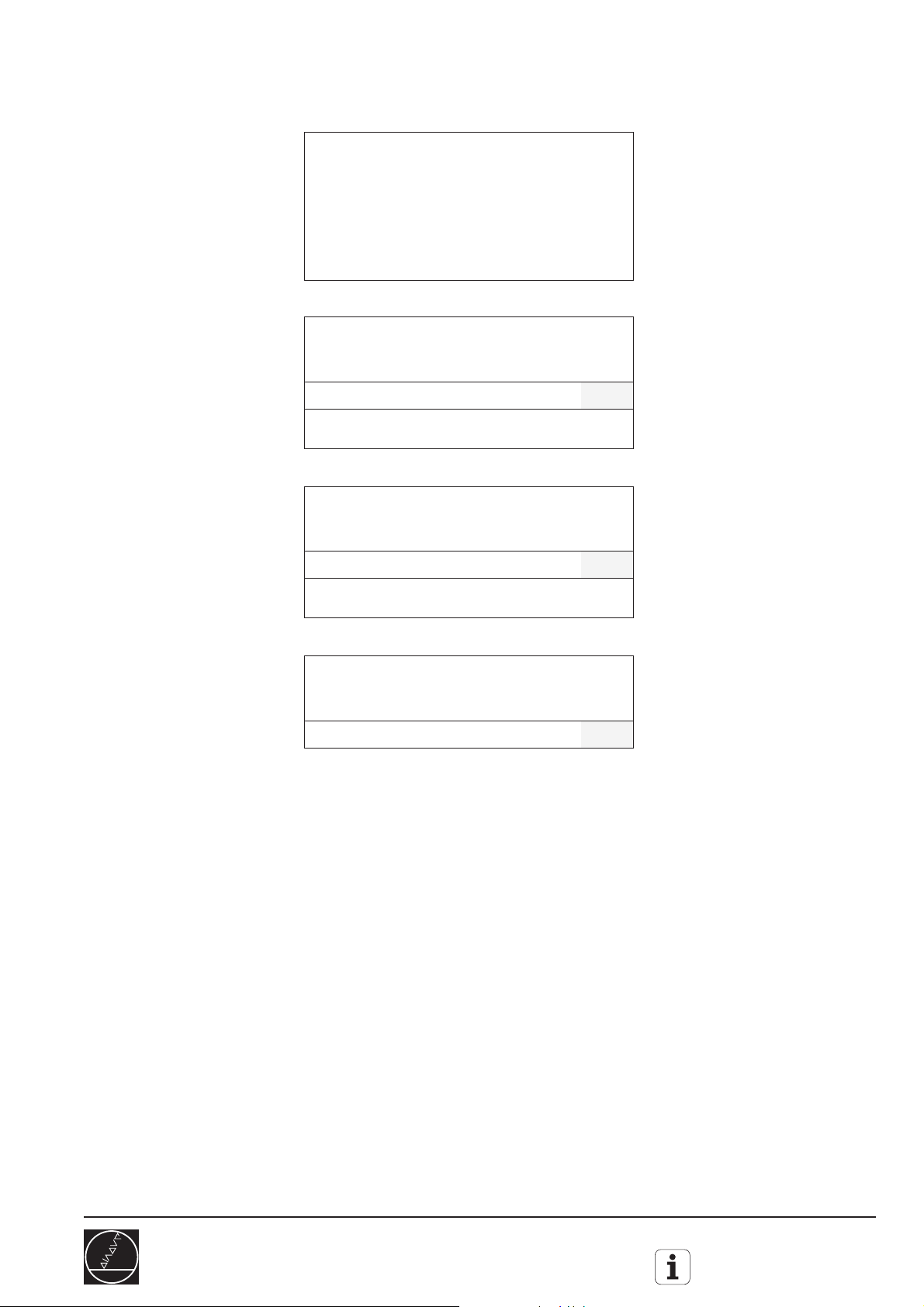

Program layout: Four double bolt hole circles,

with 3 tools, 3 cycles,

including tapping

Preparation

Process

Center

Pecking

BLK FORM

TOOL DEF

TOOL 1 . . .

L Z . . . . . . . . . . M6

CYCL DEF,

DEPTH = PECKG

CALL LBL 1

L Z . . . M6

TOOL 2 . . .

CYCL DEF,

DEPTH ≠ PECKG

CALL LBL 1

Workpiece blank

Tool list

First tool call

Tool change

Pecking cycle

Call drilling pattern

Tool change

Pecking cycle

Call drilling pattern

Tapping

Retract tool, end

L Z . . . M6

TOOL 3 . . .

CYCL DEF

CALL LBL 1

L Z . . . M2

Tool change

Tapping cycle

Call drilling pattern

HEIDENHAIN

Advanced course TNC 4xx

7139/2C05

Page 23

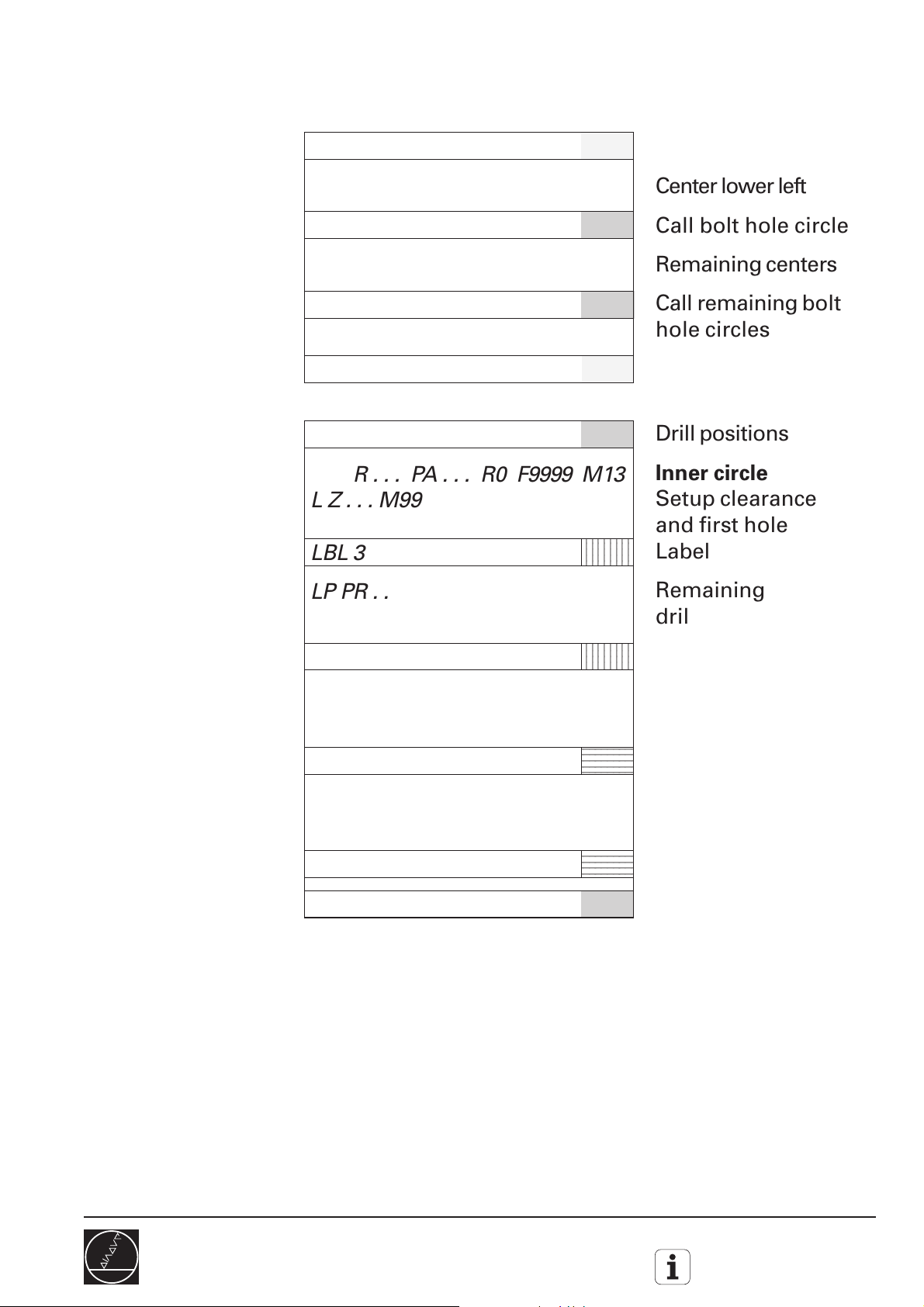

Program layout:

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Four double bolt hole circles,

with 3 tools, 3 cycles,

including tapping

Center of circles,

SPGM 1

End SPGM 1

Drilling pattern,

SPGM 2

Bolt hole circle

LBL 1

CC X . . . Y . . .

CALL LBL 2

CC X . . . Y . . .

CALL LBL 2

. . .

LBL 0

LBL 2

LP PR . . . PA . . . R0 F9999 M13

L Z . . . M99

23456789

23456789

LBL 3

23456789

LP PR . . . IPA . . . M99

23456789

23456789

23456789

CALL LBL 3 REP . . .

23456789

Center lower left

Call bolt hole circle

Remaining centers

Call remaining bolt

hole circles

Drill positions

Inner circle

Setup clearance

and first hole

Label

Remaining

drill positions

End SPGM 2

LP PR . . . M99

LBL 4

LP PR . . . IPA . . . M99

CALL LBL 4 REP . . .

LBL 0

23456789

23456789

23456789

23456789

23456789

23456789

23456789

Outer circle,

first hole

Label

Remaining

drill positions

HEIDENHAIN

Advanced course TNC 4xx

7139/3C01

Page 24

Solution:

Four double bolt hole circles,

with 3 tools, 3 cycles,

including tapping

100

75

36

25

0

0

20

25

75

100

40

22

18

M6

0

Main program

Center

Pecking

0 BEGIN PGM 7139 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1 L+0 R+3,5 ...........................................

4 TOOL DEF 2 L+0 R+2,5 ...........................................

5 TOOL DEF 3 L+0 R+3 ...............................................

6 L Z+100 R0 F9999 M6 ..............................................

7 TOOL CALL 1 Z S2500 .............................................

8 CYCL DEF 1.0 PECKING

9 CYCL DEF 1.1 SET UP -2

10 CYCL DEF 1.2 DEPTH -1,5

11 CYCL DEF 1.3 PECKG -1,5

12 CYCL DEF 1.4 DWELL 0

13 CYCL DEF 1.5 F100

14 CALL LBL 1 ..............................................................

15 L Z+100 M6 ..............................................................

16 TOOL CALL 2 Z S500

17 CYCL DEF 1.0 PECKING

18 CYCL DEF 1.1 SET UP -2

19 CYCL DEF 1.2 DEPTH -22

20 CYCL DEF 1.3 PECKG -10

21 CYCL DEF 1.4 DWELL 0

22 CYCL DEF 1.5 F100

23 CALL LBL 1 ..............................................................

24 L Z+100 M6 ..............................................................

NC-CENTER DRILL

TWIST DRILL

TAP

TOOL CHANGE

NC-CENTER DRILL

CALL DRILLING PATTERN

TOOL CHANGE

CALL DRILLING PATTERN

TOOL CHANGE

Tapping

Retract tool, end

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

25 TOOL CALL 3 Z S250

26 CYCL DEF 2.0 TAPPING

27 CYCL DEF 2.1 SET UP -2

28 CYCL DEF 2.2 DEPTH -18

29 CYCL DEF 2.3 DWELL 0

30 CYCL DEF 2.4 F250

31 CALL LBL 1 ..............................................................

32 L Z+100 M2

CALL DRILLING PATTERN

7139/4D02

Page 25

Solution:

Four double bolt hole circles,

with 3 tools, 3 cycles,

including tapping

SPGM 1, Center of

circles

SPGM 1, end

SPGM 2, Bolt hole

circle itself

SPGM 2, end

33 LBL 1

34 CC X+25 Y+25 .........................................................

35 CALL LBL 2 ..............................................................

36 CC X+75 Y+25 .........................................................

37 CALL LBL 2 ..............................................................

38 CC X+75 Y+75 .........................................................

39 CALL LBL 2 ..............................................................

40 CC X+25 Y+75 .........................................................

41 CALL LBL 2 ..............................................................

42 LBL 0

43 LBL 2 ........................................................................

44 LP PR+10 PA+0 M13 ................................................

45 L Z+2 M99................................................................

46 LBL 3 ........................................................................

47 LP IPA+90 M99

48 CALL LBL 3 REP 2/2

49 LP PR+18 PA+180 M99............................................

50 LBL 4 ........................................................................

51 LP IPA+45 M99

52 CALL LBL 4 REP 6/6

53 LBL 0

54 END PGM 7139 MM

CENTER LOWER LEFT

DRILL POSITIONS

CENTER LOWER RIGHT

DRILL POSITIONS

CENTER UPPER RIGHT

DRILL POSITIONS

CENTER UPPER LEFT

DRILL POSITIONS

DRILL POSITIONS

INNER CIRCLE

1ST HOLE

REMAINING HOLES

OUTER CIRCLE

REMAINING HOLES

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

7139/5C01

Page 26

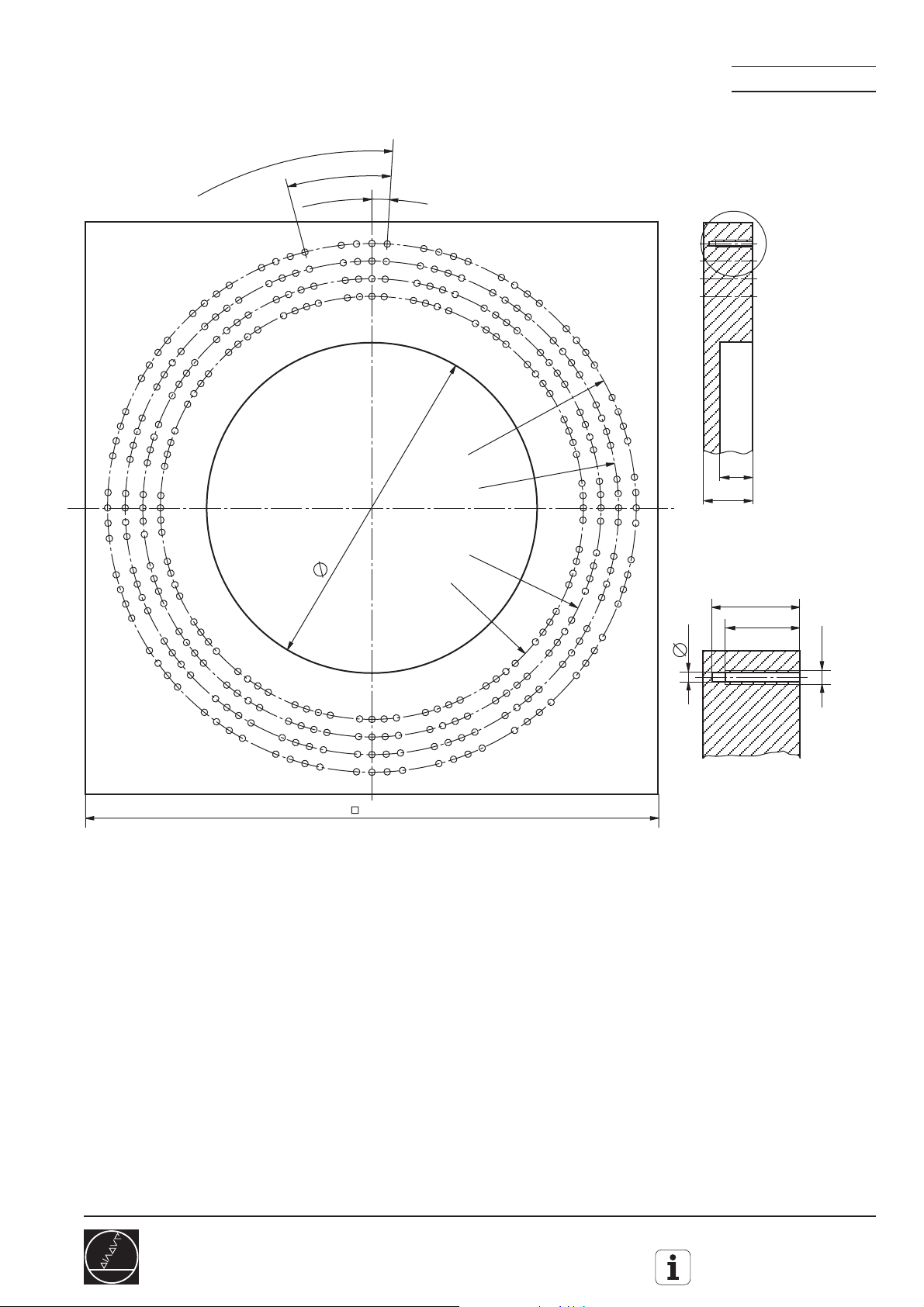

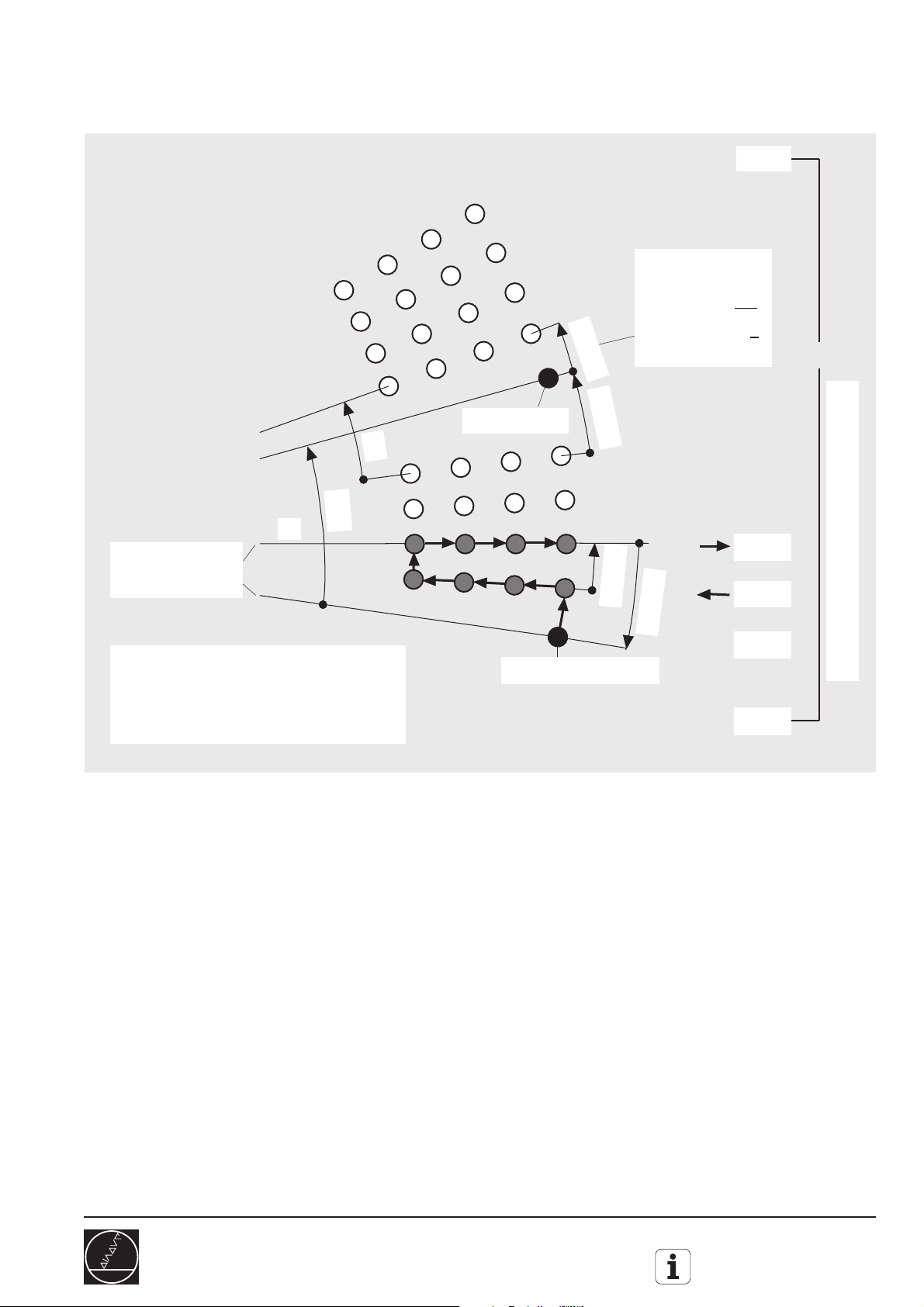

Task:

Large drilled plate

)

0°

6

3

=

(

°

8

1

∗

0

2

°

8

1

0'

2

°

3

R

R

Program(s):

Z

0

2

1

2

1

1

15

22

Procedure:

Tools:

0

5

1

260

R

R

1

9

6

• Center holes, drill, tap

• Mill large hole

• NC-center drill

• Twist drill

•Tap

• Mill R30

04

Detail Z

M 2:1

20

17

2

M3

HEIDENHAIN

Advanced course TNC 4xx

C04

7411/1

Page 27

Program layout: Large drilled plate

Preparation

Process

Center

Pecking

Tapping

BLK FORM

TOOL 1 . . . / TOOL 2 . . .

TOOL 1 . . .

CYCL DEF,

DEPTH = PECKG

(R 2,0)

CALL LBL 1

. . . M6

TOOL 2 . . .

(R 1,0)

CYCL DEF

CALL LBL 1

. . . M6

TOOL 3 . . .

(R 1,5)

CYCL DEF

Workpiece blank

Tool list if necessery

Pecking cycle

Call drilling pattern

Tool change

Pecking cycle

Call drilling pattern

Tool change

Tapping cycle

Mill large holes

Retract tool, end

CALL LBL 1

. . . M6

TOOL 4 . . .

CYCL DEF

L X . . . Y . . .

L Z . . . . . M99

L Z . . . . . M2

Call drilling pattern

Tool change

(R 30)

Circular pocket-cycle

Starting position and

cycle call

HEIDENHAIN

Advanced course TNC 4xx

C01

7411/2

Page 28

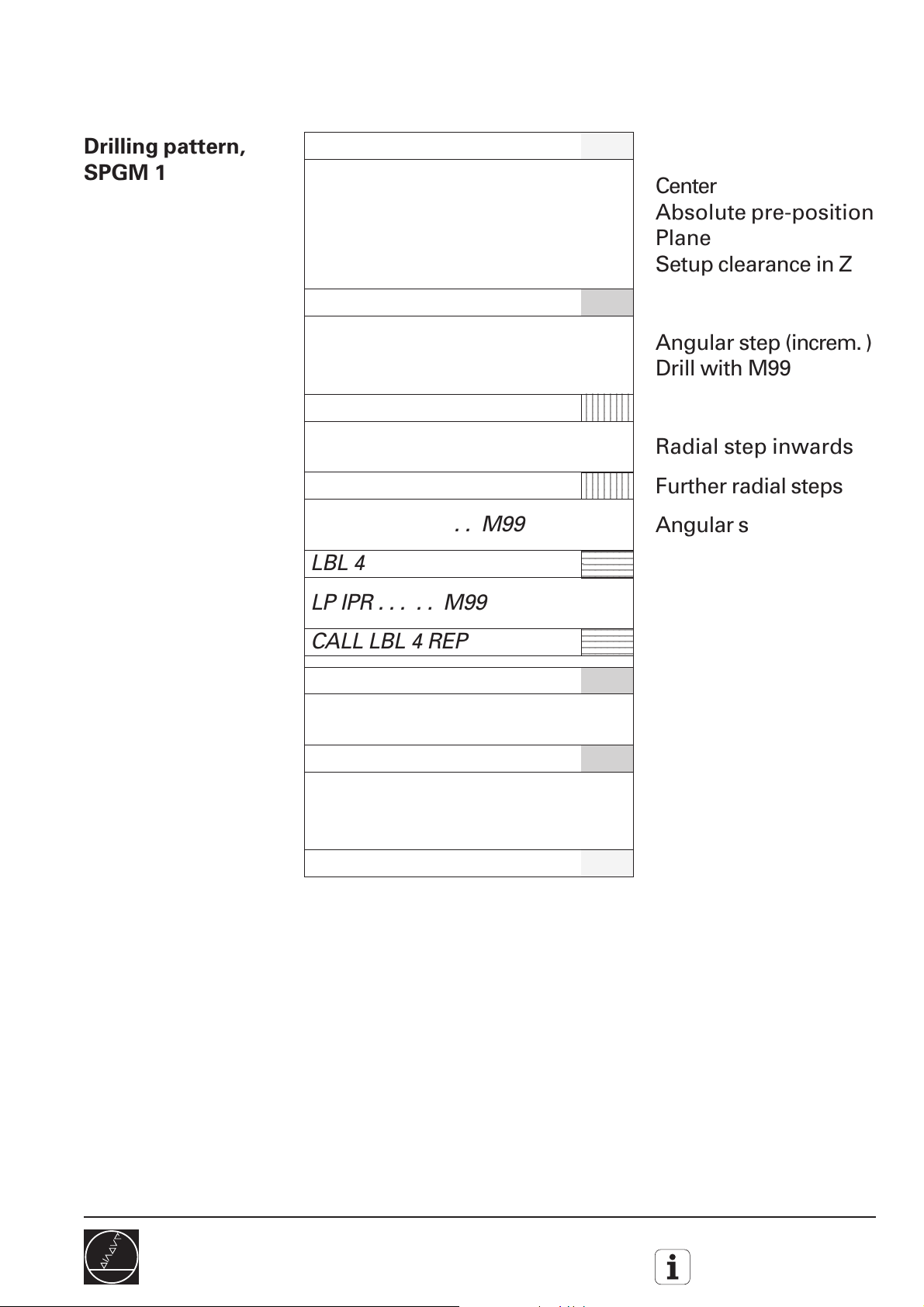

Program layout:

0

0

0

0

0

0

0

0

0

0

0

0

0

Large drilled plate

Drilling pattern,

SPGM 1

LBL 1

CC . . .

LP . . .

L Z . . .

LBL 2

LP IPA . . . . . . . . M99

LBL 3

LP IPR . . . . . M99

CALL LBL 3 REP . . .

LP IPA . . . . . . . . M99

LBL 4

23456789

23456789

23456789

23456789

23456789

23456789

23456789

23456789

23456789

23456789

Center

Absolute pre-position

Plane

Setup clearance in Z

Angular step (increm. )

Drill with M99

Radial step inwards

Further radial steps

Angular step

LP IPR . . . . . M99

CALL LBL 4 REP . . .

CALL LBL 2 REP . . .

LP IPA . . . . . .

CALL LBL 2 REP . . .

L Z . . . . . M99

L X . . . Y . . . . .

LBL 0

23456789

23456789

23456789

Radial step outwards

Further radial steps

Further double rows

To intermediate pos.

Remaining hole gr.

Tool change position

HEIDENHAIN

Advanced course TNC 4xx

7411/3C01

Page 29

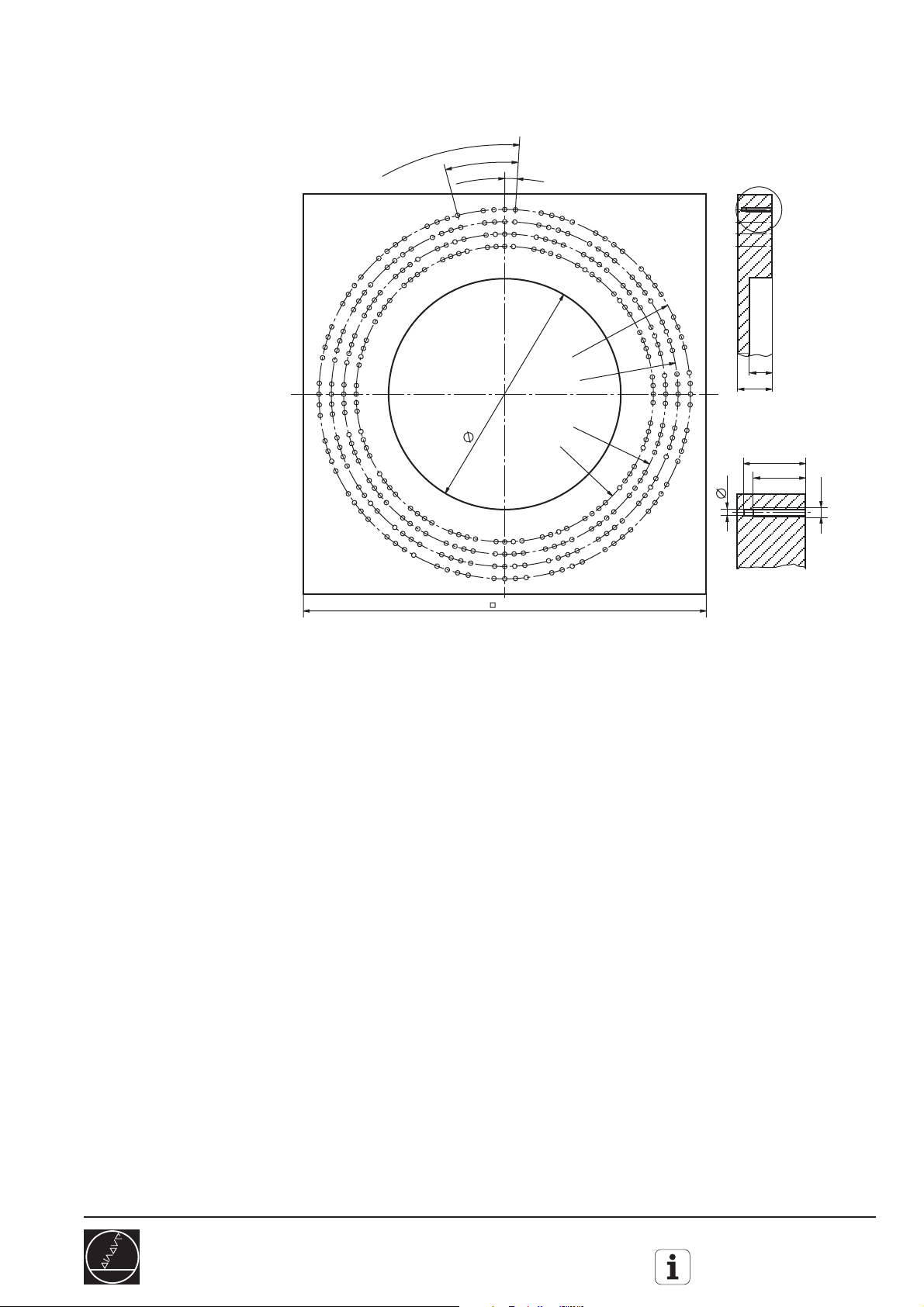

Detail: Large drilled plate

LBL 0

Angular step:

8°

18°

0°

LBL 2

=

1st hole group

LBL 1

= (19 + 1)* drilling pattern +

angle increment 4,667° between

drilling patterns

Pre-position

Start = Pre-position

3,333°

4,667°

3,333°

3° 20' = 3°

= 3,333°

-6,667°

20

60

LBL 4

LBL 3

LBL 2

LBL 1

≈

Overall working direction ➪

➪

HEIDENHAIN

Advanced course TNC 4xx

C04

7411/4

Page 30

Solution:

Large drilled plate

3

=

(

°

8

1

∗

0

2

1

2

°

3

)

0°

6

°

8

0'

Z

0

2

1

R

2

1

1

R

15

22

Main program

Center

0

5

1

260

R

1

04

R

9

6

0 BEGIN PGM 7411 MM

1 BLK FORM 0.1 Z X-125 Y-130 Z-22

2 BLK FORM 0.2 X+125 Y+130 Z+0

3 TOOL DEF 1 L+0 R+2,0 ...........................................

4 TOOL DEF 2 L+0 R+1 ..............................................

5 TOOL DEF 3 L+0 R+1,5 ...........................................

6 TOOL DEF 4 L+0 R+30 ............................................

7 TOOL CALL 1 Z S3000

8 CYCL DEF 1.0 PECKING

9 CYCL DEF 1.1 SET UP -2

10 CYCL DEF 1.2 DEPTH -2

11 CYCL DEF 1.3 PECKG -2

12 CYCL DEF 1.4 DWELL 0

13 CYCL DEF 1.5 F100

14 CALL LBL 1

15 L Z+20 R0 F9999 M6

2

CENTER DRILL

TWIST DRILL

TAP

MILL

Detail Z

M 2:1

20

17

M3

Pecking

16 TOOL CALL 2 Z S3000

17 CYCL DEF 1.0 PECKING

18 CYCL DEF 1.1 SET UP -2

19 CYCL DEF 1.2 DEPTH -20

20 CYCL DEF 1.3 PECKG -20

21 CYCL DEF 1.4 DWELL 0

22 CYCL DEF 1.5 F200

23 CALL LBL 1

24 L Z+20 R0 F9999 M6

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

7411/5C04

Page 31

Solution:

Large drilled plate

Tapping

Circular pocket

Retract tool, end

SPGM 1,

Drilling pattern

25 TOOL CALL 3 Z S500

26 CYCL DEF 2.0 TAPPING

27 CYCL DEF 2.1 SET UP -2

28 CYCL DEF 2.2 DEPTH -17

29 CYCL DEF 2.3 DWELL 0

30 CYCL DEF 2.4 F250

31 CALL LBL 1

32 L Z+20 R0 F9999 M6

33 TOOL CALL 4 Z S400

34 CYCL DEF 5.0 CIRCULAR POCKET

35 CYCL DEF 5.1 SET UP -2

36 CYCL DEF 5.2 DEPTH -15

37 CYCL DEF 5.3 PECKG -5 F100

38 CYCL DEF 5.4 RADIUS 75

39 CYCL DEF 5.5 F500 DR40 L X+0 Y+0 R0 M3

41 L Z+2 M99

42 L Z+20 R0 F9999 M2

43 LBL 1

44 CC X+0 Y+0 .............................................................

45 LP PR+120 PA-6,666 R0 F9999 M3 .........................

46 L Z+2 R0 M8

CENTER

PRE-POSITION BY 1ST HOLE

47 LBL 2

48 LP IPA+3,333 M99 ...................................................

49 LBL 3

50 LP IPR-8 M99

51 CALL LBL 3 REP 2/2 ................................................

52 LP IPA+3,333 M99 ...................................................

53 LBL 4

54 LP IPR+8 M99

55 CALL LBL 4 REP 2/2 ................................................

56 CALL LBL 2 REP 1/1 ................................................

57 LP IPA+4,666 ...........................................................

58 CALL LBL 2 REP 19/19 ............................................

59 LBL 0

60 END PGM 7411 MM

Pre-position

Space

18°

ANGULAR STEP

ROW RADIALLY INWARDS

ANGULAR STEP

ROW RADIALLY OUTWARDS

FURTHER DOUBLE ROWS

SPACE

REPEAT FURTHER GROUPS OF 16

0°

CC

Angular step

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

C04

Row radially outwards

Row radially inwards

Angular step

Pre-position

7411/6

Page 32

110

100

96

Task:

Loading frame for plate

with M97 and M98

Program(s):

90

50

14

10

Undimensioned radii R5

0

0

0

8

10

14

96

100

110

25

10

5

Procedure:

Tools:

• Rough out inside

• Travel one mill radius farther at the corners of the loading

surface

• Small contour step on the side protrusions

• Roughing-finishing mill R5

HEIDENHAIN

Advanced course TNC 4xx

C04 72810/1

Page 33

Program layout: Loading frame for plate with M97 and M98

Preparation

Process

Rough out inside

Loading surface

BLK FORM

TOOL DEF

TOOL 1 . . .

L Z . . . . . . . . . . M6

CYCL DEF

L X . . . Y . . .

L Z . . . . . M99

L X . . . Y . . . R0

L Z . . .

APPR . . . X . . . Y . . .

L X . . . M98

Workpiece blank

Tool list

Call tool data

Tool change

Pocket milling-cycle

Starting position and

cycle call

Pre-position

Depth

Contour approach tang. ,

lower center

In corner one tool

radius farther

Retract tool, end

L X . . . Y . . .

L Y . . . M97

L X . . .

L Y . . .

L X . . . M97

L Y . . . M98

L X . . .

L X . . . M98

L X . . .

DEP . . . X . . . Y . . .

L Z . . . . . . . . . . M2

Small contour step

Protrusion

Protrusion

Reverse contour step

Next corner

Next corner

End of contour

Depart contour tang.

Tool change position

HEIDENHAIN

Advanced course TNC 4xx

72810/2C01

Page 34

Solution:

Loading frame for plate with M97 and M98

110

100

96

90

50

14

10

0

0

Undimensioned radii R5

8

10

14

96

100

110

25

10

0

5

Roughing out

Milling

0 BEGIN PGM 72810 MM

1 .................................................................................

2 BLK FORM 0.1 Z X+0 Y+0 Z-25

3 BLK FORM 0.2 X+110 Y+110 Z+0

4 TOOL DEF 1 L+0 R+5

5 TOOL CALL 1 Z S2500

6 L Z+100 R0 F9999 M6

7 CYCL DEF 4.0 POCKET MILLING

8 CYCL DEF 4.1 SET UP -2

9 CYCL DEF 4.2 DEPTH -10

10 CYCL DEF 4.3 PECKG -10 F150

11 CYCL DEF 4.4 X+82

12 CYCL DEF 4.5 Y+82

13 CYCL DEF 4.6 F1000 DR14 L X+55 Y+55 R0 M3

15 L Z+2 R0 M99

16 L X+30 Y+30

17 L Z-5 R0 F100

18 APPR LCT X+30 Y+10 R5 RR F250

19 L X+10 M98

20 L X+10 Y+15

21 L Y+50 M97

22 L X+8

23 L Y+90

24 L X+10 M97

25 L Y+100 M98

26 L X+15

27 L X+100 M98

28 L Y+95

29 L Y+10 M98

30 L X+95

31 L X+30

32 DEP LCT X+30 Y+30 R5 R0

LOADING FRAME WITH APPR/DEP

33 L Z+100 R0 F9999 M2

34 END PGM 72810 MM

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

72810/3C01

Page 35

100

Task:

FK Telephone

Program(s):

50

➂

R14

➁

➀

R88

➅

R25

➄

➃

R14

Start (R0)

0

0

50

100

HEIDENHAIN

Advanced course TNC 4xx

C01 75103/1

Page 36

FK Programming: Choice of contour function F L/

C

Element

form

Start

Seg-

mented

LINEAR

„L“

Tangential

CIRCULAR

Seg-

mented

„C“

Tangential

Softkey

HEIDENHAIN

Advanced course TNC 4xx

G26C01

Page 37

Solution:

FK Telephone

100

➂

R14

50

0

0

FK Program

0 BEGIN PGM 75103 MM

1 BLK FORM 0.1 Z X+0 Y+50 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1 L+0 R+10

4 TOOL CALL 1 Z S2800

5 L X+50 Y+50 R0 F9999 M13

6 L Z-5 F100

7 L X+50 Y+75 RL .......................................................

8 RND R5 F100

➁

➀

➃

➀

R88

➅

R25

➄

R14

Start (R0)

50

Converted Program

0 BEGIN PGM BOGEN MM

1 BLK FORM 0.1 Z X+0 Y+0 Z–20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1 L+0 R+3

4 TOOL CALL 1 Z S2800

5 L X+50 Y+50 R0 F9999 M13

6 L Z-5 F100

7 L X+50 Y+75 RL

8 RND R5 F100

100

9 FC DR+ R25 CCX+50 CCY+50 F500 ........................

10 FCT DR- R14 ............................................................

11 FCT DR- R88 CCX+50 CCY+0 ..................................

12 FCT DR- R14 ............................................................

13 FCT X+50 Y+75 DR+ R25 CCX+50 CCY+50 ............

14 FSELECT 2

15 RND R5 F100

16 L X+50 Y+50 R0 M9

17 L Z+10

18 END PGM 75103 MM

➁

➂

➃

➄

➅

9 CC X+50 Y+50

10 C X+26,805 Y+59,3269 DR+

11 CC X+13,8158 Y+64,55

12 C X+6,9701 Y+76,7622 DR–

13 CC X+50 Y+0

14 C X+93,0299 Y+76,7622 DR–

15 CC X+86,1842 Y+64,55

16 C X+73,195 Y+59,3269 DR–

17 CC X+50 Y+50

18 C X+50 Y+75 DR+

19 RND R5 F100

20 L X+50 Y+50 R0 M9

21 L Z+10

22 END PGM BOGEN MM

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

C01

75103/2

Page 38

100

30

Task:

FK Dumbbell

60°

Program(s):

R20

20

55

0

0

40

100

20

10

0

HEIDENHAIN

Advanced course TNC 4xx

C05 75116/1

Page 39

Solution:

FK Dumbbell

100

R20

20

60°

30

0

0

0 BEGIN PGM 75116 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1 L+0 R+4

4 TOOL CALL 1 Z S4000

5 L Z+2 R0 F MAX M3

6 L X+40 Y+30 R0 F2000

7 L Z-10 F100

8 L X+10 Y+30 RR F200

9 FPOL X+40 Y+30

10 FC DR- R30 CCX+40 CCY+30 F500

11 FL AN+60 PDX+40 PDY+30 D10

12 FSELECT 3

13 FC DR- R20 CCPR+55 CCPA+60

14 FSELECT 2

15 FL AN-120 PDX+40 PDY+30 D10

16 FSELECT 3

17 FC X+10 Y+30 DR- R30 CCX+40 CCY+30

18 FSELECT 2

19 L X+40 Y+30 R0

20 L Z+50 R0 F MAX M2

21 END PGM 75116 MM

40

55

100

20

10

0

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

75116/2C01

Page 40

100

65

40

Task:

FK Hammer

55°

R11

R15

37,5

Program(s):

20

30°

R12,5

80°

15

R11

0

0

15

30

100

20

10

0

HEIDENHAIN

Advanced course TNC 4xx

C05

75119/1

Page 41

Solution:

FK Hammer

100

65

40

R11

55°

R15

37,5

20

30°

R12,5

80°

15

0

0

0 BEGIN PGM 75119 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-20

2 BLK FORM 0.2 X+100 Y+85 Z+0

3 TOOL DEF 1 L+0 R+5

4 TOOL CALL 1 Z S4000

5 L Z+50 R0 F MAX M6

6 L X+80 Y+70 F MAX M3

7 L Z-10 F100

8 CC X+30 Y+40

9 LP PR+37,5 PA+30 RL F500

10 FL LEN10 AN-60

11 FL AN-150

12 FCT DR+ R12,5

13 FLT AN-100

14 FCT DR- R11 CCX+30 CCY+15

15 FLT PDX+15 PDY+65 D11

16 FSELECT 1

17 FCT DR- R11 CCX+15 CCY+65

18 FLT AN-55

19 FCT DR+ R15

20 FPOL X+30 Y+40

21 FLT AN+30 PDX+30 PDY+40 D10

22 FSELECT 2

23 FL PR+37,5 PA+30 IAN+90

24 L X+80 Y+70 R0 F500

25 L Z+50 R0 F MAX M2

26 END PGM 75119 MM

15

R11

30

100

20

10

0

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

75119/2C01

Page 42

Task:

0

R22

FK Mickey Mouse

R38

Program(s):

60°

76

80

R9

R9

8

18

-40

-30

30°

-8

R80

0

R10

R8

40

HEIDENHAIN

Advanced course TNC 4xx

C01 71750/1

Page 43

Solution:

FK Mickey Mouse

R38

R22

0

60°

R9

R9

8

18

76

80

0 BEGIN PGM 71750 MM

1 .................................................................................

2 BLK FORM 0.1 Z X-70 Y-90 Z-12

3 BLK FORM 0.2 X+70 Y+30 Z+0

4 TOOL DEF 1 L+0 R+5

5 TOOL CALL 1 Z S2500

6 L Z+10 R0 F9999 M3

7 L X-62 Y+0 RL

8 L Z-10 F150

9 FC DR- R22 CLSD+ CCX-40 CCY+0

10 FCT DR+ R38 CCX+0

11 FSELECT 1

12 FCT DR- R22 CCX+40 CCY+0

13 FCT DR+ R10

14 FLT AN-60 PDX+0 PDY+0 D0

15 FSELECT 3

16 FCT DR- R8

17 FCT X+0 Y-80 DR- R80 CCX+0 CCY+0

18 FLT X-40 AN+180

19 FL AN+90

20 FL AN+30

21 FCT DR+ R9 CCX-17

22 FLT X-30 PAR21 DP18

23 FSELECT 2

24 FL AN+90

25 FL PAR23 DP8

26 FSELECT 2

27 FCT DR+ R9 CCX-17

28 FCT X-62 Y+0 DR- R22 CLSD- CCX-40 CCY+0

29 FSELECT 2

30 L Z+10 F9999 M2

31 END PGM 71750 MM

-40

-30

30°

R80

0

-8

R10

R8

40

MICKEY

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

C05

71750/2

Page 44

72

42

20

0

Task:

16

FK Comb

16

120°

Program(s):

16

60°

16

16

R4

16

-20

-80

-72

-40

0

12

100

HEIDENHAIN

Advanced course TNC 4xx

C05 75108/1

Page 45

Solution:

FK Comb

72

42

20

0

-20

-80

16

-72

16

-40

120°

0

12

60°

16

16

16

R4

16

100

0 BEGIN PGM 75108 MM

1 BLK FORM 0.1 Z X-80 Y-10 Z-20

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL DEF 1 L+0 R+3,5

4 TOOL CALL 1 Z S1000

5 L X-100 Y+0 R0 F MAX M3

6 L Z-20 F MAX

7 L X-80 Y+0 RL F600

8 FPOL X+0 Y+0

9 FC DR- R80 CCX+0 CCY+0

10 FCT DR- R8 CCPR+72 CCPA+120

11 FCT DR+ R64 CCX+0 CCY+0

12 FCT DR+ R8 CCY+8

13 FSELECT 2

14 FCT DR- R48 CCX+0 CCY+0

15 FCT DR- R8 CCPR+40 CCPA+120

16 FCT DR+ R32 CCX+0 CCY+0

17 FCT DR+ R6 CCY+6

18 FSELECT 2

19 FCT X+0 Y+20 DR- R20 CCX+0 CCY+0

20 FLT X+12 Y+20

21 FL AN-60

22 FCT Y+0 DR+ R4

23 FLT AN+0

24 FCT DR+ R4

25 FLT AN+120 PAR21 DP16

26 FCT DR- R8 CCY+34

27 FLT AN-60 PAR25 DP16

28 FCT Y+0 DR+ R4

29 FLT Y+0 AN+0

30 FCT DR+ R4

31 FLT AN+120 PAR27 DP16

32 FCT DR- R8 CCY+64

33 FLT AN-60 PAR31 DP16

34 FCT X+100 Y+0 DR+ R4

35 FSELECT 2

36 FL X+100 Y-20

37 FL X-80 Y-20

38 FL X-80 Y+0

39 END PGM 75108 MM

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

C05

75108/2

Page 46

Program layout: FK Comb first as island and then mirrored in Y

with SL I roughing

Preparation

Listing

Machining cycle

Execution

Retract tool, end

SPGM,

part contours

BLK FORM

TOOL 1 . . .

CYCL DEF 14 LABEL 1/2

CYCL DEF 6 ROUGH OUT

L X . . . Y . . . R0 F9999 M3

L Z . . . M99

CYCL DEF 7 DATUM SHIFT

X0 Y- . . .

CYCL DEF 8 MIRROR IMAGE Y

CYCL CALL

L Z20 F9999 M2

LBL 1

L X . . . Y . . . RL

○○○ ○○○

Part contours

Upper half

Y-values mirrored in

lower half

Original island

LBL 0

LBL 2

L X . . . Y . . . RR

LBL 0

Original pocket

HEIDENHAIN

Advanced course TNC 4xx

C01

75122/2

Page 47

Solution:

FK Comb first as island and then mirrored in Y

Main program

Retract tool, End

0 BEGIN PGM 75122 MM

1 BLK FORM 0.1 Z X-80 Y-95 Z-50

2 BLK FORM 0.2 X+100 Y+75 Z+0

3 TOOL DEF 1 L+0 R+3

4 TOOL CALL 1 Z S200

5 CYCL DEF 14.0 CONTOUR

6 CYCL DEF 14.1 CONTOUR LABEL 1 /2

7 CYCL DEF 6.0 ROUGH OUT

8 CYCL DEF 6.1 SET UP -2 DEPTH -30

9 CYCL DEF 6.2 PECKG -10 F100 ALLOW +0

10 CYCL DEF 6.3 ANGLE +0 F200

11 L X-100 Y+0 R0 F MAX M3

12 L Z+2 F9999 M99

13 CYCL DEF 7.0 DATUM SHIFT

14 CYCL DEF 7.1 X+0

15 CYCL DEF 7.2 Y-20

16 CYCL DEF 8.0 MIRROR IMAGE

17 CYCL DEF 8.1 Y

18 CYCL CALL

19 CYCL DEF 8.0 MIRROR IMAGE

20 CYCL DEF 8.1

21 L Z+20 F MAX M2

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

C01

75122/3

Page 48

Solution:

FK Comb first as island and then mirrored in Y

SPGM

22 LBL 1

23 L X-80 Y+0 RL

24 FPOL X+0 Y+0

25 FC DR- R80 CCX+0 CCY+0

26 FCT DR- R8 CCPR+72 CCPA+120

27 FCT DR+ R64 CCX+0 CCY+0

28 FCT DR+ R8 CCY+8

29 FSELECT 2

30 FCT DR- R48 CCX+0 CCY+0

31 FCT DR- R8 CCPR+40 CCPA+120

32 FCT DR+ R32 CCX+0 CCY+0

33 FCT DR+ R6 CCY+6

34 FSELECT 2

35 FCT X+0 Y+20 DR- R20 CCX+0 CCY+0

36 FLT X+12 Y+20

37 FL AN-60

38 FCT Y+0 DR+ R4

39 FLT AN+0

40 FCT DR+ R4

41 FLT AN+120 PAR37 DP16

42 FCT DR- R8 CCY+34

43 FLT AN-60 PAR41 DP16

44 FCT Y+0 DR+ R4

45 FLT Y+0 AN+0

46 FCT DR+ R4

47 FLT AN+120 PAR43 DP16

48 FCT DR- R8 CCY+64

49 FLT AN-60 PAR47 DP16

50 FCT X+100 Y+0 DR+ R4

51 FSELECT 2

52 FL X+100 Y-20

53 FL X-80 Y-20

54 FL X-80 Y+0

55 LBL 0

56 LBL 2

57 L X-90 Y-20 RR

58 L Y+100

59 L X+120

60 L Y-20

61 L X-90

62 LBL 0

63 END PGM 75122 MM

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

75122/4C05

Page 49

0

Task:

Toggle joint

Program(s):

–20,2

–30

–51

–55

100

–50

–39

–28,354

0

–Z

+Y

R 30

28,354

39

39

50

0

–50

Procedure:

Tools:

0

• 2½ D-cut in Z/X

• Setting in Y

• End mill R10 for roughing-out

• End mill R10 for finishing

HEIDENHAIN

Advanced course TNC 4xx

C05

+X

50

761260/1

761261/1

Page 50

Program layout: Toggle joint with 1 tool,

constant climb-cut

Preparation

Roughing-out

Retract tool, end

Contour Z/X, SPGM

BLK FORM

TOOL DEF . . . R10

TOOL 2 . . .

L Z50 R0 F . . . . M3

CYCL DEF 7.0 DATUM SHIFT

CYCL DEF 7.1 X+Q108 Y0 / Z0

CALL LBL 1

CYCL DEF 7.0 DATUM SHIFT

CYCL DEF 7.1 X-Q108 Y100 / Z0

CYCL DEF 10.0 ROT180

CALL LBL 1

L Z . . . M2

LBL 1

L X+55 Y-4 R0 F . . . . M3

L Z . . .

Right

Left

Starting plane

Starting Z

LBL 2

L IY . . . F100

L X . . . Z . . . F250

L X . . . Z . . .

CT X . . . Z . . .

L Z . . . F9999

L X . . . Z . . .

L Z . . . F . . .

CALL LBL 2 REP . . .

L Z+ . . .

CYCL DEF 7.0 DATUM SHIFT

CYCL DEF . . . X0 Y0 Z0

CYCL DEF 10.0 ROT 0

LBL 0

Y-steps

Tangent

Arc

Retract tool

For further steps

Retract tool

Reset

HEIDENHAIN

Advanced course TNC 4xx

C01

761260/2

Page 51

Solution:

Toggle joint with 1 tool,

constant climb-cut

0

–20,2

–30

–51

–55

100

–50

–39

–28,354

R 30

0

–Z

+Y

28,354

39

39

50

Main program

Retract tool, end

0

0

–50

0 BEGIN PGM 761260 MM

1 BLK FORM 0.1 Z X-50 Y+0 Z-52

2 BLK FORM 0.2 X+50 Y+100 Z+0

3 L Z+50 R0 F9999 M6

4 TOOL DEF 2 L+0 R+10

5 TOOL CALL 2 Z S4000

6 L Z+50 R0 F MAX M3

7 CYCL DEF 7.0 DATUM SHIFT

8 CYCL DEF 7.1 X+Q108

9 CYCL DEF 7.2 Y+0

10 CALL LBL 1 ..............................................................

11 CYCL DEF 7.0 DATUM SHIFT

12 CYCL DEF 7.1 X-Q108

13 CYCL DEF 7.2 Y+100

14 CYCL DEF 10.0 ROTATION

15 CYCL DEF 10.1 ROT+180

16 CALL LBL 1 ..............................................................

17 L Z+50 R0 F MAX M2

+X

50

RIGHT

LEFT

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

C01

761260/3

Page 52

Solution:

Toggle joint with 1 tool,

constant climb-cut

SPGM, Contour Z/X

18 LBL 1

19 L X+55 Y-4 R0 F9999 M3

20 L Z-51 F1000

21 LBL 2

22 L IY+2 F100

23 L X+39 Z-51 F250

24 L X+28,354 Z-20,2

25 CT X+0 Z+0

26 L Z+5 R0 F9999

27 L X+55 Z+5

28 L Z-51 F1000

29 CALL LBL 2 REP 50/50

30 L Z+5 R0 F MAX

31 CYCL DEF 7.0 DATUM SHIFT

32 CYCL DEF 7.1 X+0

33 CYCL DEF 7.2 Y+0

34 CYCL DEF 7.3 Z+0

35 CYCL DEF 10.0 ROTATION

36 CYCL DEF 10.1 ROT+0

37 LBL 0

38 END PGM 761260 MM

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

C01

761260/4

Page 53

Program layout:

Toggle joint with 2 tools, constant climb-cut

expanded roughing

Preparation

Roughing

Completed section

already exists

BLK FORM

TOOL DEF . . . R10

TOOL 1 . . .

FN 1: Q1 = Q108 + 5

L Z50 R0 F . . . . M3

CYCL DEF 7.0 DATUM SHIFT

CYCL DEF . . . X+Q1 Y0 Z+5

CALL LBL 1

CYCL DEF 7.0 DATUM SHIFT

CYCL DEF . . . X-Q1 Y100 Z+5

CYCL DEF 10.0 ROT180

CALL LBL 1

TOOL 2 . . .

○○

X > tool radius

Retract tool, end

Contour Z/X,

SPGM 1

already exists

CALL LBL 1

○○

CALL LBL 1

L Z . . . M2

LBL 1

○○○○○○○○○

LBL 0

HEIDENHAIN

Advanced course TNC 4xx

C01

761261/2

Page 54

Solution:

Toggle joint with 2 tools, constant climb-cut

Main program

Tool 1

Tool 2

0 BEGIN PGM 761261 MM

1 BLK FORM 0.1 Z X-50 Y+0 Z-52

2 BLK FORM 0.2 X+50 Y+100 Z+0

3 TOOL DEF 1 L+0 R+10

4 TOOL CALL 1 Z S2800

5 FN 1: Q1 = +Q108 + +5

6 L Z+50 R0 F9999 M3

7 CYCL DEF 7.0 DATUM SHIFT

8 CYCL DEF 7.1 X+Q1

9 CYCL DEF 7.2 Y+0

10 CYCL DEF 7.3 Z+5

11 CALL LBL 1 ..............................................................

12 CYCL DEF 7.0 DATUM SHIFT

13 CYCL DEF 7.1 X-Q1

14 CYCL DEF 7.2 Y+100

15 CYCL DEF 7.3 Z+5

16 CYCL DEF 10.0 ROTATION

17 CYCL DEF 10.1 ROT+180

18 CALL LBL 1 ..............................................................

19 TOOL DEF 2 L+0 R+10

20 TOOL CALL 2 Z S4000

21 L Z+50 R0 F MAX M6

22 CYCL DEF 7.0 DATUM SHIFT

23 CYCL DEF 7.1 X+Q108

24 CYCL DEF 7.2 Y+0

25 CALL LBL 1 ..............................................................

RIGHT

LEFT

RIGHT

Retract tool, end

SPGM,

Contour Z/X

26 CYCL DEF 7.0 DATUM SHIFT

27 CYCL DEF 7.1 X-Q108

28 CYCL DEF 7.2 Y+100

29 CYCL DEF 10.0 ROTATION

30 CYCL DEF 10.1 ROT+180

31 CALL LBL 1 ..............................................................

32 L Z+50 R0 F MAX M2

33 LBL 1

34 L X+55 Y-4 R0 F9999 M3

35 L Z-51 F1000

36 LBL 2

37 L IY+2 F100

38 L X+39 Z-51 F250

39 L X+28,354 Z-20,2

40 CT X+0 Z+0

41 L Z+5 R0 F9999

42 L X+55 Z+5

43 L X+55 Z-51 F MAX

44 CALL LBL 2 REP 50/50

45 L Z+5 R0 F MAX

46 CYCL DEF 7.0 DATUM SHIFT

47 CYCL DEF 7.1 X+0

48 CYCL DEF 7.2 Y+0

49 CYCL DEF 7.3 Z+0

50 CYCL DEF 10.0 ROTATION

51 CYCL DEF 10.1 ROT+0

52 LBL 0

53 END PGM 761261 MM

LEFT

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

761261/3D02

Page 55

100

50

Task:

Truncated cone, standing, 2½ D,

external

R35

R15

Program(s):

0

0

Procedure:

Tools:

50

• 2½ D cut

• Vertical position in X/Y

• Setting in Z

• End mill

100

40

30

20

0

HEIDENHAIN

Advanced course TNC 4xx

C01

7162/1

Page 56

Truncated cone, standing, 2½ D, horizontal, with full circles

+Z

0

15

35

-20

-30

-40

0

+X

Number of steps = 10

PR

Z

Calculation of step width per revolution:

PR =

End radius – Starting radius

Number of steps

Z=

End height – Starting height

Number of steps

Example: Number of steps = 10

PR =

Z =

35 – 15

10

-20 – 0

10

20

=

= 2

10

-20

=

= -2

10

HEIDENHAIN

Advanced course TNC 4xx

7162/2C01

Page 57

Program layout: Truncated cone, standing, external, 2½ D, horizontal

Preparation

Roughing

Finishing

BLK FORM

TOOL 1 . . . R10

L Z20 R0 F9999 M3

CC X . . . Y . . .

LP PR65 PA0 R . . . F . . . M . . .

L Z+2

LBL 1

LP IPR- . . . RL F . . .

L Z-30

CP IPA-360 DR- RL F . . . M98

CALL LBL 1 REP . . .

L Z . . . M6

TOOL 2 . . . R10

L Z+ . . . R0 F . . . M3

LP PR15 PA0 R0 F . . .

LP IPR+Q108

L Z0 F150

Z-Clearance

Compensate tool

radius outside

Contact

Retract tool, end

LBL 2

LP IPR+1

L IZ-1 F200

CP IPA-360 DR- F1000

CALL LBL 2 REP . . .

L Z20 . . . M2

Cone angle 45°

for slope

Full circle in X/Y

HEIDENHAIN

Advanced course TNC 4xx

C09

7162/3

Page 58

Solution:

Truncated cone, standing, 2½ D, horizontal,

external form with end mill

100

R35

50

0

0

0 BEGIN PGM 7162 MM

1 .................................................................................

2 .................................................................................

3 BLK FORM 0.1 Z X+0 Y+10 Z-31

4 BLK FORM 0.2 X+100 Y+100 Z+0

5 TOOL DEF 1 L+0 R+10

6 TOOL CALL 1 Z S2000

7 CC X+50 Y+50

8 L Z+20 R0 F9999 M3

9 LP PR+65 PA+0

10 L Z+2

R15

50

40

30

100

TRUNCATED CONE STANDING

2½ D, HORIZONTAL, END MILL

20

0

11 LBL 1

12 LP IPR-5 RL F200

13 L Z-30

14 CP IPA-360 DR- RL F300 M98

15 CALL LBL 1 REP 5/5

16 L Z+20 R0 F9999 M6

17 TOOL DEF 2 L+0 R+10

18 TOOL CALL 2 Z S2800

19 L Z+20 R0 F9999 M3

20 LP PR+15 PA+0 R0 F9999 M3

21 LP IPR+Q108

22 L Z+2

23 L Z+0 F150

24 LBL 2

25 LP IPR+1

26 L IZ-1 F200

27 CP IPA-360 DR- F1000 M98

28 CALL LBL 2 REP 19/19

29 L Z+20 R0 F9999 M2

30 END PGM 7162 MM

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

7162/4C09

Page 59

100

50

Task:

Truncated cone, standing, 3D,

external form

R35

R15

Program(s):

0

0

Procedure:

Tools:

50

100

40

30

20

0

• 3D-cut from top to buttom

• Rotation about zero point at center of truncated cone

• End mill R6

HEIDENHAIN

Advanced course TNC 4xx

C01

7182/1

Page 60

Detail: Truncated cone, standing, 3D, external form

with end mill, radius compensation

0

-20

-30

-40

100

+Z

0

+Y

R

Tool

=10mm

15

Incorrect

35

Direction

of travel

+X

50

Correct

R35

0

Manually set

0

datum shift

R15

Programmed zero

point in X/Y

Start of rotation

(clearly visible with very

thin tools) if necessary

program graphics

+X

100

HEIDENHAIN

Advanced course TNC 4xx

C01

7282/2

Page 61

Program layout: Truncated cone, standing, 3D, external form

Preparation

1 call

Retract tool, end

1 revolution, SPGM

BLK FORM

TOOL . . .

L Z . . . M3

CYCL DEF 7.0 DATUM SHIFT . . .

Q3 = 15 + Q108

Q4 = 35 + Q108

CALL LBL 1

L Z . . . M2

LBL 1

L XQ3 Y0 R0 F9999 M3

L Z2

L Z0 F100

LBL 2

Dat. sh. in center of part

Tool compensation

Approach compensated

X-value in drawing

Contact

L XQ4 Y0 Z-20

L Z0 F9999

L XQ3 Y0 F2000

CYCL DEF 10.0 ROTATION

CYCL DEF 10.1 IROT-5

L Y0 F500

CALL LBL 2 REP . . .

CYCL DEF 10.0 ROTATION

CYCL DEF 10.1 ROT+0

LBL 0

3D-cut, mill stays free!

Feed rate for first cut

=100

Z return

Feed rate for

following cuts

HEIDENHAIN

Advanced course TNC 4xx

C01

7282/3

Page 62

Solution:

Truncated cone, standing, 3D, vertical,

external form with end mill, repeatable

100

R35

Main program

50

0

0

0 BEGIN PGM 7282 MM

1 .................................................................................

2 .................................................................................

3 .................................................................................

4 BLK FORM 0.1 Z X+10 Y+10 Z-32

5 BLK FORM 0.2 X+90 Y+90 Z+0

6 TOOL DEF 1 L+0 R+10

7 TOOL CALL 1 Z S4000

8 L Z+20 R0 F9999 M3

9 CYCL DEF 7.0 DATUM SHIFT

10 CYCL DEF 7.1 X+50

11 CYCL DEF 7.2 Y+50

12 FN 1: Q3 = +15 + +Q108 ..........................................

13 FN 1: Q4 = +35 + +Q108 ..........................................

14 CALL LBL 1 ..............................................................

R15

50

40

30

100

TRUNCATED CONE, STANDING,

3D, VERTICAL, END MILL

COMPLETED SECTION

X TOP

X BOTTOM

FIRST CUT

20

0

SPGM

15 L Z+50 R0 F9999 M2

16 LBL 1

17 L X+Q3 Y+0 R0 F9999 M3 .......................................

18 L Z+2

19 L Z+0 F100

20 LBL 2

21 L X+Q4 Y+0 Z-20 .....................................................

22 L Z+0 F9999 .............................................................

23 L X+Q3 Y+0 F2000

24 CYCL DEF 10.0 ROTATION

25 CYCL DEF 10.1 IROT-5.............................................

26 L Y+0 F500 ...............................................................

27 L F500

28 CALL LBL 2 REP 71/71 .............................................

29 CYCL DEF 10.0 ROTATION

30 CYCL DEF 10.1 ROT+0

31 LBL 0

32 END PGM 7282 MM

HEIDENHAINHEIDENHAIN

APPROACH TOP

CUT DOWNWARDS

Z FREE

FINENESS OF ROTATION

CROSS OVER ON TOP

NUMBER OF ROTATION STEPS

Advanced course TNC 4xx

C05

7282/4

Page 63

100

50

Task:

Truncated cone, internal, 3D

R35

R15

Program(s):

0

0

Procedure:

Tools:

40

50

100

30

• 3 D-cut from bottom to top

• Pre-machining with 2 circular pockets

• End mill R6

20

0

HEIDENHAIN

Advanced course TNC 4xx

C05

7283/1

7283/1

7284/1

7284/1

Page 64

Solution:

Truncated cone, standing, 3D, vertical,

internal form with end mill, upwards

100

R35

Main program

50

0

0

0 BEGIN PGM 7283 MM

1 .................................................................................

2 .................................................................................

3 .................................................................................

4 BLK FORM 0.1 Z X+0 Y+10 Z-32

5 BLK FORM 0.2 X+100 Y+90 Z+0

6 TOOL DEF 1 L+0 R+10

7 TOOL CALL 1 Z S2800

8 L Z+20 R0 F9999 M3

9 CYCL DEF 7.0 DATUM SHIFT

10 CYCL DEF 7.1 X+50

11 CYCL DEF 7.2 Y+50

12 FN 1: Q3 = +35 + -Q108

13 FN 1: Q4 = +15 + -Q108

14 CALL LBL 1

R15

50

40

30

100

TRUNCATED CONE, STANDING,

3D, VERTICAL, INTERNAL, END

MILL, COMPLETED SECTION, B06

20

0

SPGM

15 L Z+50 R0 F9999 M2

16 LBL 1 ........................................................................

17 L X+10 Y+0

18 L Z-20 R0 F400 M3

19 L X+Q3 Y+0

20 LBL 2 ........................................................................

21 L X+Q3 Y+0 Z-20 F1000

22 L X+Q4 F9999

23 L Z-30 F2000

24 CYCL DEF 10.0 ROTATION

25 CYCL DEF 10.1 IROT-5

26 CALL LBL 2 REP 71/71

27 CYCL DEF 10.0 ROTATION

28 CYCL DEF 10.1 ROT+0

29 LBL 0

30 END PGM 7283 MM

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

C01

VERY FIRST CUT

FOLLOWING CUTS 3D UPWARDS

7283/3

Page 65

Solution:

Truncated cone, standing, 3D, vertical,

internal form with end mill, upwards,

with roughing

Main program

0 BEGIN PGM 7284 MM

1 .................................................................................

2 .................................................................................

3 .................................................................................

4 .................................................................................

5 BLK FORM 0.1 Z X+0 Y+10 Z-32

6 BLK FORM 0.2 X+100 Y+90 Z+0

7 TOOL DEF 1 L+0 R+10

8 TOOL CALL 1 Z S2800

9 L Z+20 R0 F9999 M3

10 FN 0: Q1 = +20.........................................................

11 FN 0: Q2 = +35 ..........................................................

12 CYCL DEF 5.0 CIRCULAR POCKET

13 CYCL DEF 5.1 SET UP-2

14 CYCL DEF 5.2 DEPTH -Q1

15 CYCL DEF 5.3 PECKG -5 F150

16 CYCL DEF 5.4 RADIUS Q2

17 CYCL DEF 5.5 F500 DR+

18 L X+50 Y+50

19 L Z+2 M99 ................................................................

20 FN 0: Q1 = +10

21 FN 0: Q2 = +15

22 L Z-18 M99

23 CYCL DEF 7.0 DATUM SHIFT

24 CYCL DEF 7.1 X+50

25 CYCL DEF 7.2 Y+50

26 FN 1: Q3 = +15 + -Q108 ..........................................

27 FN 1: Q4 = +35 + -Q108 ..........................................

28 FN 0: Q5 = -25 .........................................................

TRUNCATED CONE, STANDING,

VERTICAL, INTERNAL FORM

FROM SOLID BLOCK WITH

END MILL

DEPTH

RADIUS

ROUGHING OUT

XA BOTTOM

XB TOP

Z DEPTH, FIRST CUT

SPGM, Contour

29 CALL LBL 1 ..............................................................

30 FN 0: Q5 = -30 .........................................................

31 CALL LBL 1 ..............................................................

32 L Z+50 R0 F9999 M2

33 LBL 1

34 L X+Q3 Y+0 Z+Q5 R0 F400 M3...............................

35 L X+Q4 Y+0 Z+0 ......................................................

36 LBL 2

37 L X+Q3 Y+0

38 L Z+Q5

39 L X+Q4 Y+0 Z+0 F1000 ...........................................

40 L X+Q3 F9999 ..........................................................

41 L Z+Q5 F2000

42 CYCL DEF 10.0 ROTATION

43 CYCL DEF 10.1 IROT-5

44 CALL LBL 2 REP 71/71

45 CYCL DEF 10.0 ROTATION

46 CYCL DEF 10.1 ROT+0

47 LBL 0

48 END PGM 7284 MM

ROUGHING OUT SLOPE

Z DEPTH, SECOND CUT

FINISHING

A

B

B

A

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

7284/3C09

Page 66

100

50

Task:

Hemisphere, internal machining,

2D, horizontal

R

Sphere

Program(s):

0

0

Procedure:

Tools:

55

50

100

50

• Full circles (vertical positions) in X/Y

• Pre-machine with 2 circular pockets

• Roughing out (circular pockets) with end mill R10

• Machine contour with spherical mill R5

0

HEIDENHAIN

Advanced course TNC 4xx

C05

7322/1

7323/1

Page 67

Program layout: Hemisphere, internal machining with spherical mill

conventional with R0, 2D, horizontal

-50

-55

100

0

CC Z/X

+180°

–Z

+Y

Full circles

in X/Y

+90°

IPA+

in Z/X

+X

50

+90°

CC X/YCC X/Y

0°

R

= Q108 = 5

Tool

0

+X

0

50

PR50

100

HEIDENHAIN

Advanced course TNC 4xx

7322/2C05

Page 68

Program layout: Hemisphere, internal machining with spherical mill

conventional with R0, 2D, horizontal, working

downwards

Preparation

Approach

Full circles

Setting

Angular steps

BLK FORM

TOOL 1 . . . R5

L Z10 R0 F9999 M3

CC X50 Y50

LP PR50 PA0 R0 F9999

LP IPR-Q108

L Z+0 R0 F100

LBL 1

CC X50 Y50

CP DR+

CC X50 Z0

CP IPA2 DR+

CALL LBL 1 REP 44/44

L Z+ . . . M2

Z-clearance

X/Y plane

PR = R

Account for tool radius

Plunge

X/Y plane

Z/X plane

Part

– R

Tool

HEIDENHAIN

Advanced course TNC 4xx

7322/3C05

Page 69

Solution:

Hemisphere, internal machining with spherical mill

conventional with R0, 2D, horizontal

100

R

Sphere

50

0

0

50

100

55

50

0

Set datum

0 BEGIN PGM 7322 MM

1 BLK FORM 0.1 Z X-2 Y-2 Z-55

2 BLK FORM 0.2 X+102 Y+102 Z+0

3 TOOL DEF 1 L+0 R+5

4 TOOL CALL 1 Z S4000

5 L Z+70 R0 F9999 M6 ................................................

6 CC X+50 Y+50 ..........................................................

7 LP PR+50 PA+0 R0 F9999 M3..................................

8 LP IPR-Q108 .............................................................

9 L Z+0 R0 F100

10 LBL 1

11 CC X+50 Y+50 ..........................................................

12 CP DR+ F500 ............................................................

13 CC X+50 Z+0 ............................................................

14 CP IPA+2 DR+ F100 .................................................

15 CALL LBL 1 REP 44/44 .............................................

16 L Z+70 R0 F9999 M2

17 END PGM 7322 MM

Z

Z-CLEARANCE

CENTER IN X/Y

STARTING POINT

ACCOUNT FOR TOOL RADIUS

CENTER IN X/Y

CIRCULAR RING

CENTER IN Z/X

MOVE DEEPER (ARC)

FURTHER REVOLUTIONS

Y

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

C05

CC

Z = R

Tool

X

X = R

CC

Part

+ R

X

Tool

7322/4

Page 70

Solution:

Hemisphere, internal machining with end and

die sink mill

Main program

End mill

Die sink mill

Retract tool, end

SPGM 1, Roughing

out with end mill

0 BEGIN PGM 7323 MM

1 BLK FORM 0.1 Z X-2 Y-2 Z-51

2 BLK FORM 0.2 X+102 Y+102 Z+0

3 TOOL DEF 1 L+0 R+10

4 TOOL CALL 1 Z S4000

5 FN 0: Q1 = +45.........................................................

6 CALL LBL 1 ..............................................................

7 L Z+100 R0 F MAX M6 ............................................

8 TOOL DEF 2 L+0 R+5

9 TOOL CALL 2 Z S4500

10 CALL LBL 2 ..............................................................

11 L Z+100 R0 F MAX M2

12 LBL 1

13 CC X+50 Y+50 ..........................................................

14 LP PR+0 PA+0 R0 F MAX M3

15 CYCL DEF 5.0 CIRCULAR POCKET

16 CYCL DEF 5.1 SET UP -2

17 CYCL DEF 5.2 DEPTH -14

18 CYCL DEF 5.3 PECKG -5 F150

19 CYCL DEF 5.4 RADIUS Q1

20 CYCL DEF 5.5 F500 DR+

21 L Z+2 R0 F MAX M99

22 FN 0: Q1 = +30 .........................................................

23 L Z-12 R0 F MAX M99

24 LBL 0

UPPER POCKET RADIUS

ROUGHING-OUT

TOOL CHANGE

FINISHING

CENTER IN X/Y

LOWER POCKET RADIUS

SPGM 2, Finishing

with die sink mill

(spherical form)

25 LBL 2

26 LP PR+50 PA+0 R0 F500 M3....................................

27 LP IPR-Q108

28 L Z+0 R0 F MAX

29 LBL 20

30 CC X+50 Y+50 ..........................................................

31 C DR+ F500 ..............................................................

32 CC X+50 Z+0 ............................................................

33 CP IPA+2 DR+ F150 .................................................

34 CALL LBL 20 REP 44/44 ...........................................

35 LBL 0

36 END PGM 7323 MM

STARTING POINT

CENTER IN X/Y

CIRCULAR RING

CENTER IN Z/X

MOVE DEEPER

FURTHER CIRCULAR RINGS

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

C01

7323/2

Page 71

100

50

Task:

Hemisphere, external machining

with spherical mill, working

downwards, 2½ D, horizontal

R35

Program(s):

R5

0

0

Procedure:

Tools:

50

100

50

40

35

• Full circles (vertical positions) in X/Y

• Setting with angular steps in Z/X

• Pre-machining e.g. with contour island or

helical interpolation

• (Roughing out with end mill R5)

• Finishing with spherical mill R5

0

HEIDENHAIN

Advanced course TNC 4xx

C05

72841/1

Page 72

Program layout: Hemisphere, external machining with spherical mill,

working downwards, 2½ D, horizontal

Preparation

Finishing

Call

Retract tool, end

SPGM

BLK FORM

TOOL 1 . . . R5

L Z 20 R0 F9999 M3

CALL LBL 1

L Z . . . M2

LBL 1

L X+50 Y+50 R . . . F . . . M . . .

L Z+Q108 F100

LBL 2

CC Z-35 X+50

CP IPA+2 DR+ F100

CC X+50 Y+50

CP DR- F500

Approach center

Account for tool

radius

Setting in Z/X

Full circle in X/Y

CALL LBL 2 REP . . .

LBL 0

Further cuts

HEIDENHAIN

Advanced course TNC 4xx

C05

72841/2

Page 73

Solution:

Hemisphere, external machining with spherical mill,

working downwards, 2½ D, horizontal

100

R35

50

0

0

50

100

40

50R535

0

Main program

Retract tool, end

SPGM

0 BEGIN PGM 72841 MM

1 .................................................................................

2 .................................................................................

3 .................................................................................

4 BLK FORM 0.1 Z X+0 Y+10 Z-36

5 BLK FORM 0.2 X+100 Y+90 Z+5

6 TOOL DEF 1 L+0 R+5

7 TOOL CALL 1 Z S2800

8 L Z+20 R0 F9999 M3

9 CALL LBL 1

10 L Z+100 R0 F9999 M2

11 LBL 1

12 L X+50 Y+50 ............................................................

13 L Z+Q108 F100.........................................................

14 LBL 2

15 CC Z-35 X+50

16 CP IPA+2 DR+ F100 .................................................

17 CC X+50 Y+50

18 CP DR- F500 .............................................................

19 CALL LBL 2 REP 44/44

20 LBL 0

21 END PGM 72841 MM

EXTERNAL HEMISPHERE 2D,

SPHERICAL MILL,

MILLING DOWNWARDS

CENTER IN X/Y

CONTACT WITH TOOL RADIUS

SETTING

FULL CIRCLE

HEIDENHAINHEIDENHAIN

Advanced course TNC 4xx

C05

72841/3